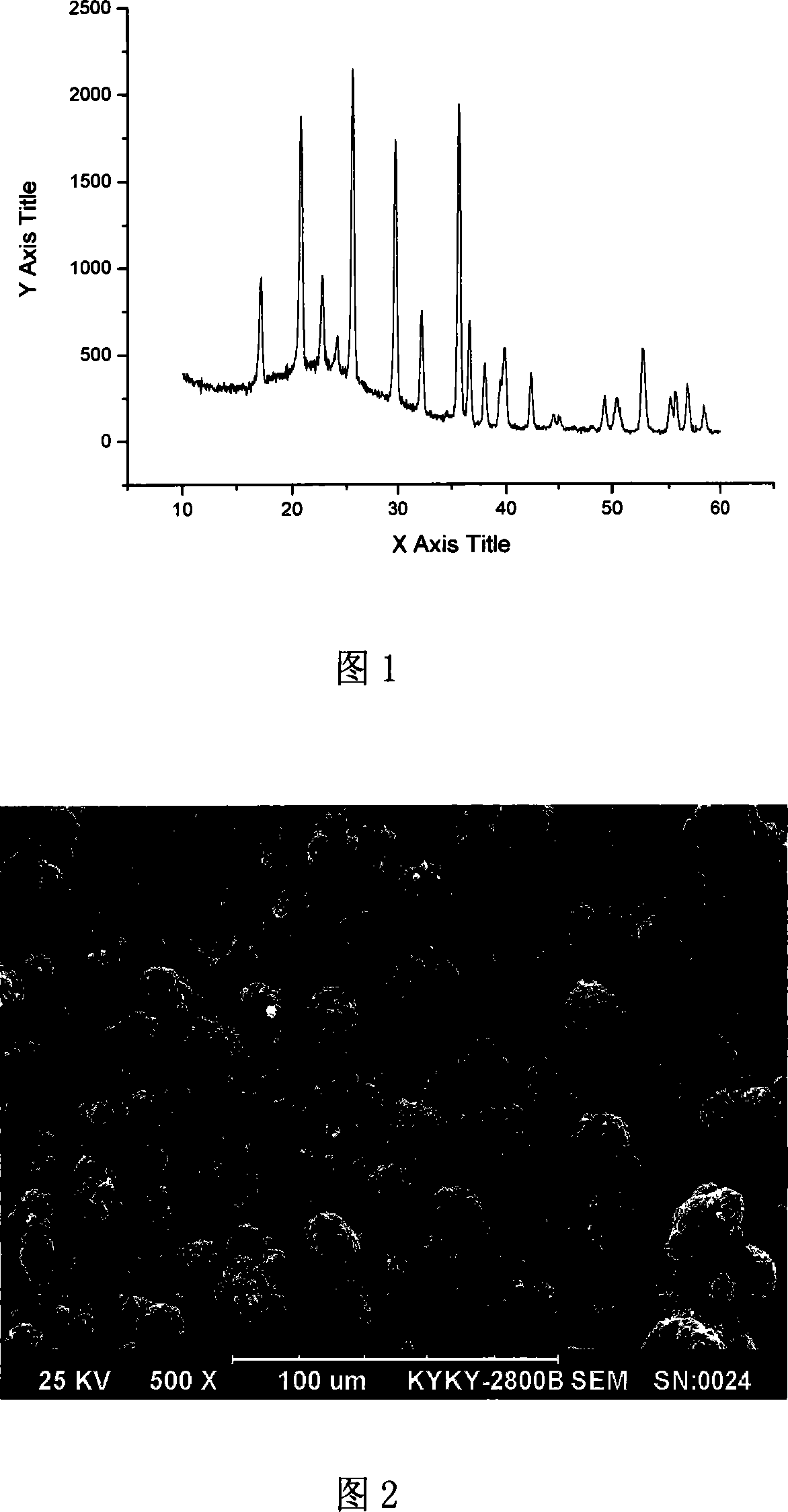

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

A lithium iron phosphate and power battery technology, applied in the field of positive electrode materials and their preparation, can solve the problems of difficult industrialized large-scale production, wide particle size distribution range, poor high-rate charge-discharge performance, etc., and achieves high-rate discharge and safety performance. Industrial production, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

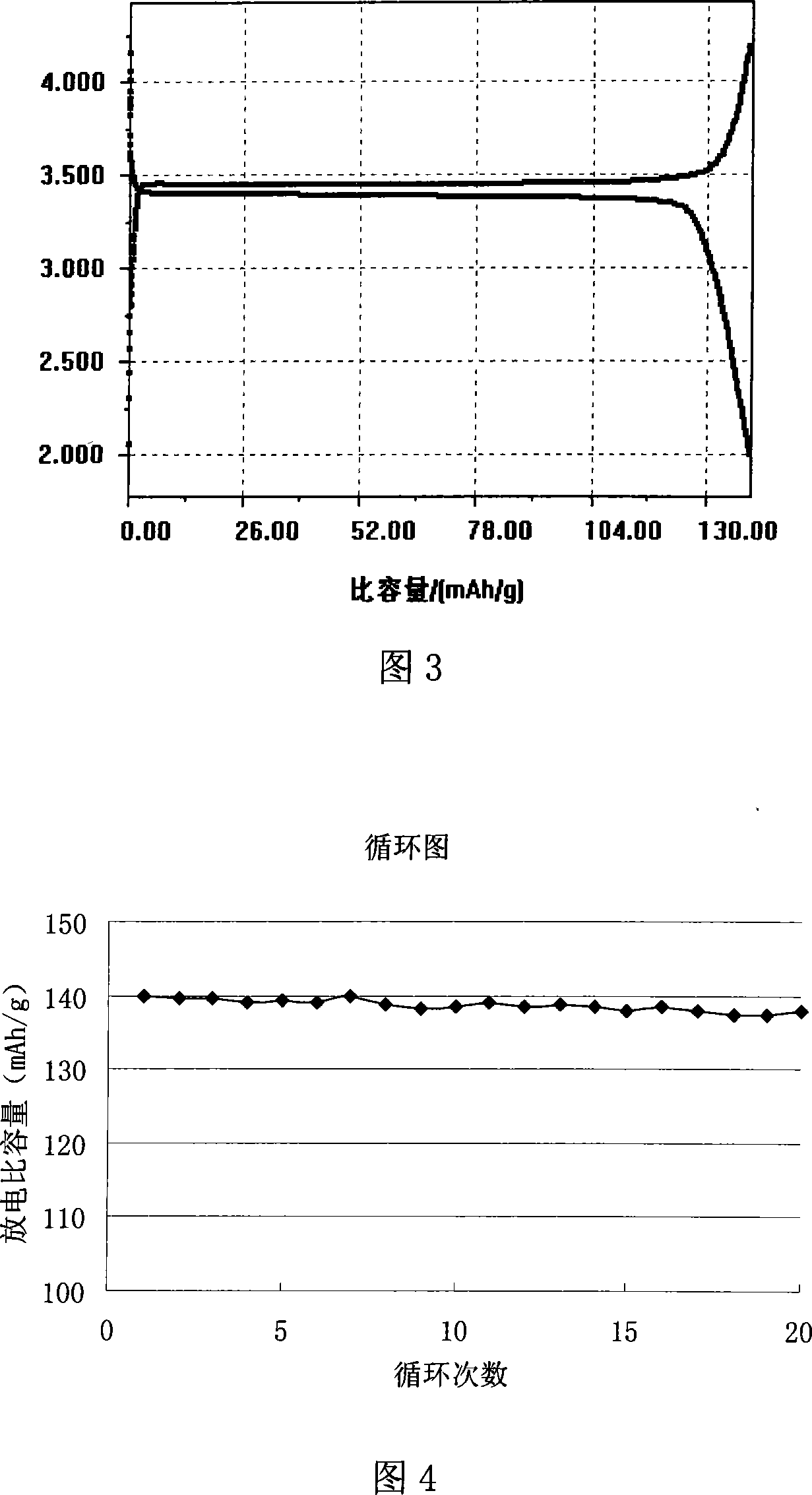

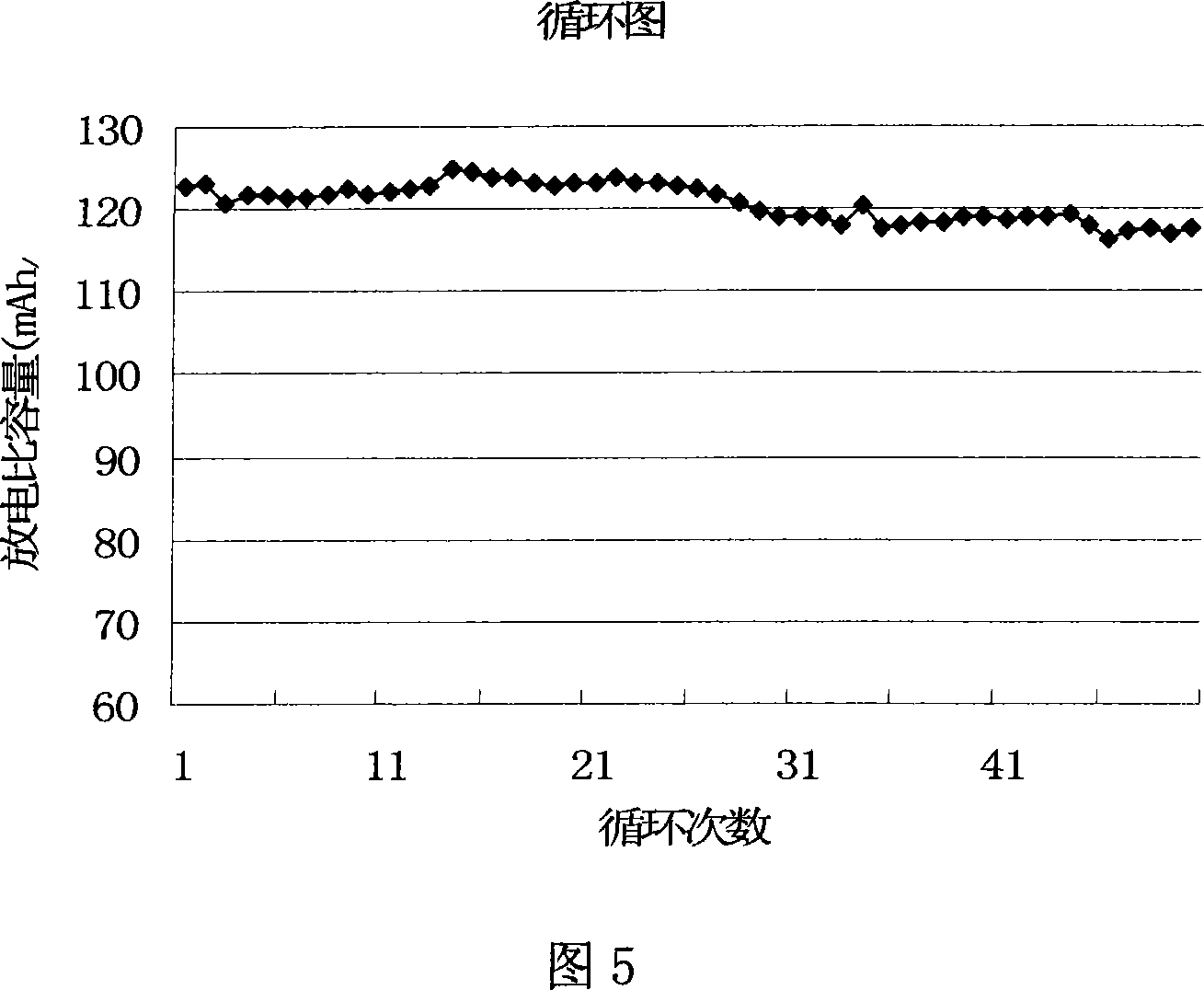

Embodiment 1

[0030] 740g lithium carbonate (Li 2 CO 3 ), 3600g ferrous oxalate (FeC 2 o 4 2H 2 O) and 2300g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), and 50g magnesium hydroxide, add 10kg deionized water, ball mill 24h in the wet stirring ball mill (model SX-30), the medium that uses is the zirconia ball of diameter 1mm, adopts MalvernMS2000 laser particle size analyzer to record the mixture particle The diameter is 200nm. Then add 990g of glucose, continue ball milling for 24 hours, and then use a centrifugal spray granulation dryer to obtain a spherical precursor at an inlet temperature of 250°C and an outlet temperature of 90°C; Inject nitrogen, keep warm at 300°C for 12h, then raise the temperature to 800°C and keep the temperature constant for 24h, and cool down to room temperature naturally; put the above materials into the ultrafine pulverizer, pulverize at 6000rpm for 45min, and then add them to the impact ball mill Inside, the spheroidization process was carried out ...

Embodiment 2

[0034] 840g lithium hydroxide (LiOH·H 2 O), 1600g ferric oxide (Fe 2 o 3 ) and 2300g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), 474g magnesia, add 10kg deionized water, ball mill 48h in the wet stirring ball mill (model SX-30), the medium that uses is the zirconia ball of diameter 1mm, adopts MalvemMS2000 laser particle size analyzer to measure the particle size of mixture is 5nm. Then add 990g of glucose, continue ball milling for 4 hours, and then use a centrifugal spray granulation dryer to obtain a spherical precursor at an inlet temperature of 280°C and an outlet temperature of 90°C; put the above precursor into an atmosphere-protected tube furnace, pass Inject nitrogen, keep warm at 400°C for 2 hours, then raise the temperature to 750°C and keep the temperature constant for 20 hours, and cool down to room temperature naturally; put the above materials into the ultrafine pulverizer, pulverize at 6000rpm for 10min, and then add them to the impact ball mill , and...

Embodiment 3

[0036] 740g lithium carbonate (Li 2 CO 3 ), 1600g ferric oxide (Fe 2 o 3 ), 2300g ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), and 50g magnesium hydroxide, add 10kg deionized water, ball mill 4h in wet stirring ball mill (model SX-30), the medium that uses is the zirconia ball of diameter 1mm, adopts Malvem MS2000 laser particle size analyzer to measure the mixture The particle size is 300nm. Then add 400g of conductive carbon black, continue ball milling for 48 hours, and then use a centrifugal spray granulation dryer to obtain a spherical precursor at an inlet temperature of 250°C and an outlet temperature of 90°C; put the above precursor into an atmosphere-protected tube furnace , feed nitrogen, keep warm at 350°C for 8h, then raise the temperature to 800°C and keep the temperature constant for 20h, then cool down to room temperature naturally; put the above materials into a superfine pulverizer, pulverize at 5000rpm for 80min, and then add them to impact spheroidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com