Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Control chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

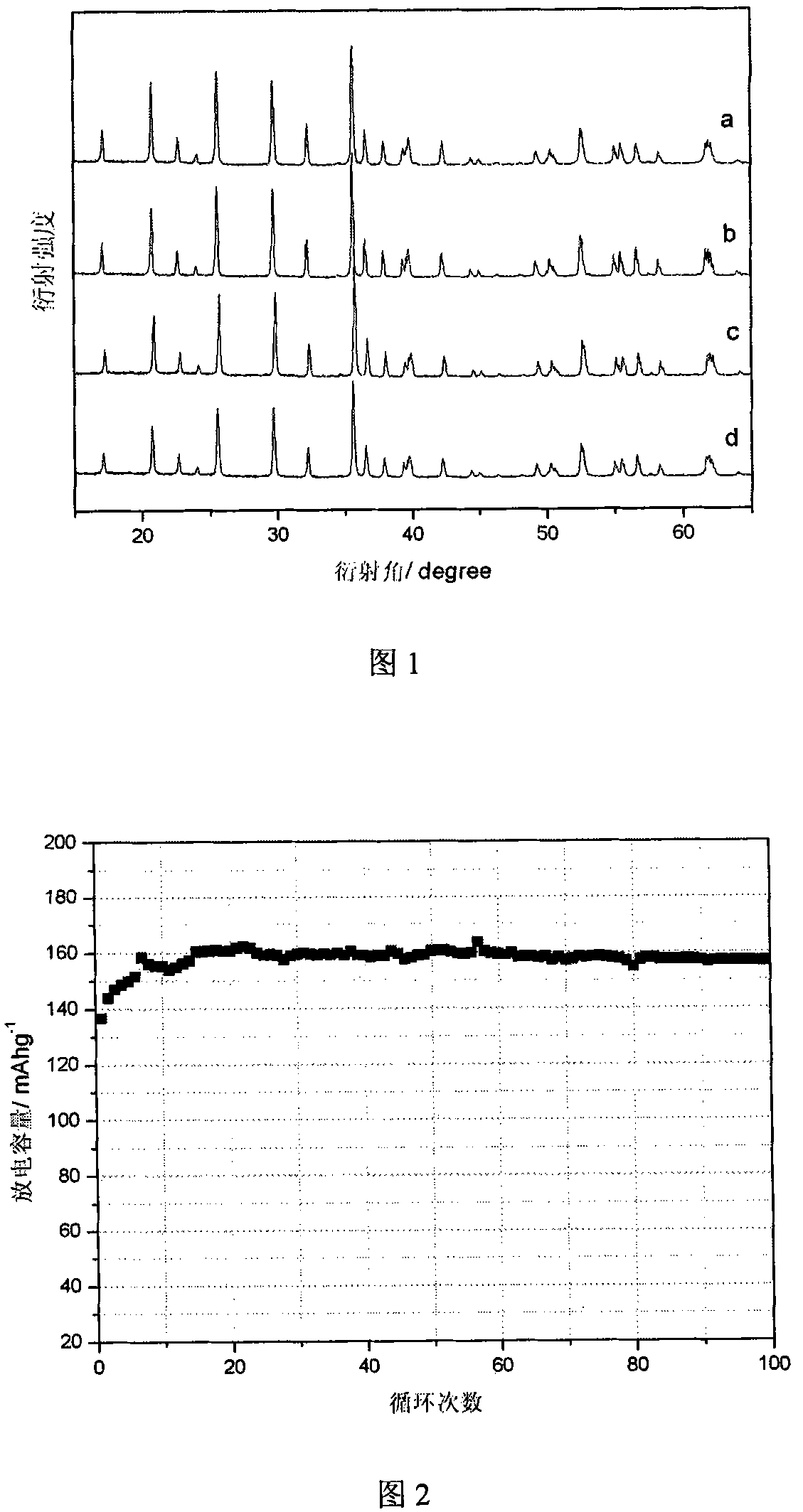

LiFePO4/C nano composite positive pole material and preparation method thereof

InactiveCN101159328AAchieve hybridControl chemical compositionElectrode manufacturing processesChemical industryPhosphateLithium-ion battery

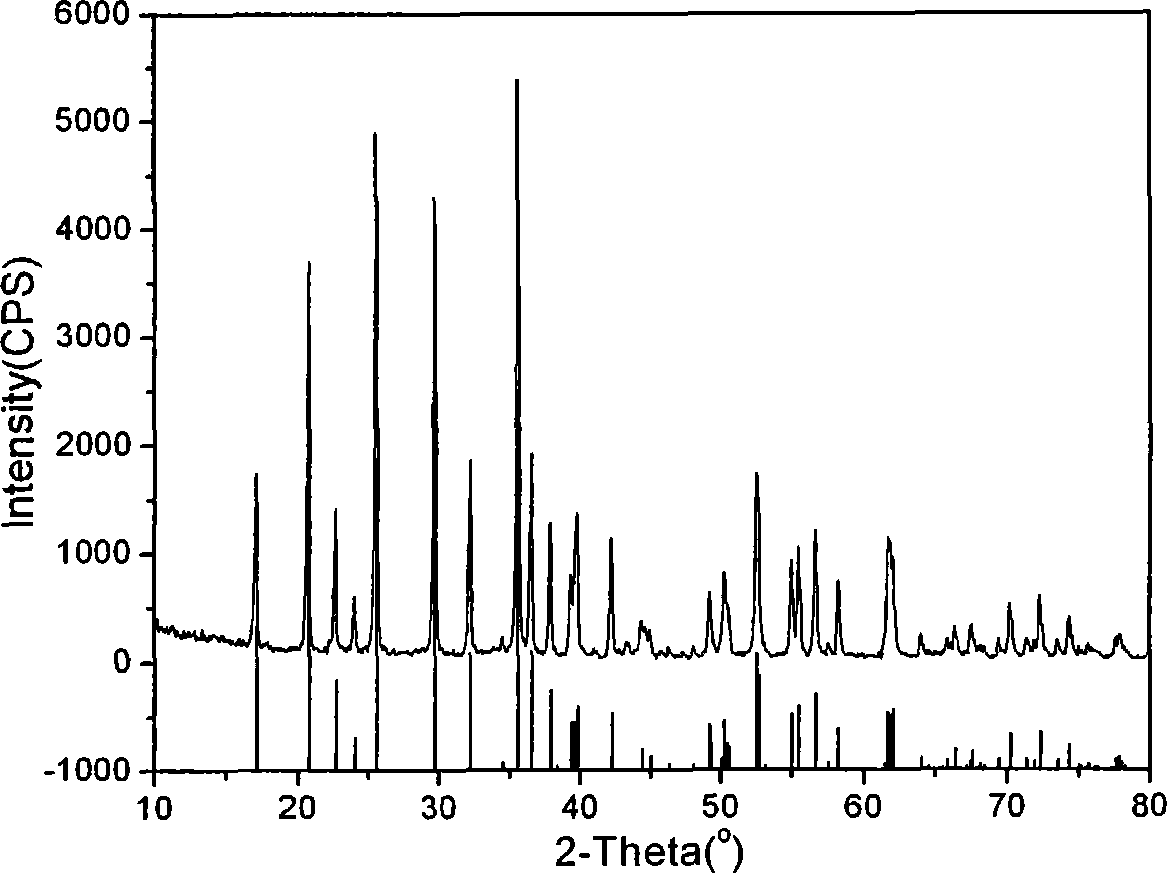

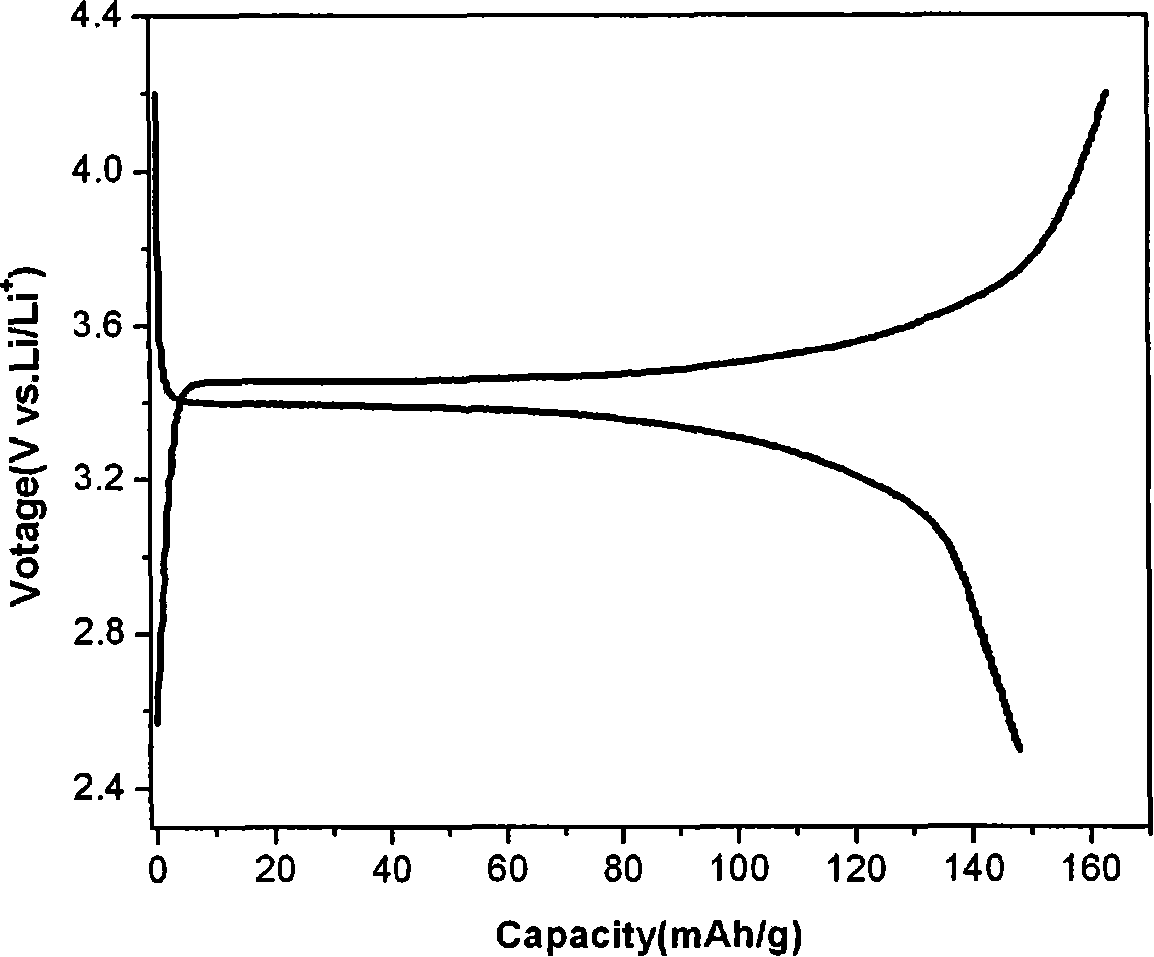

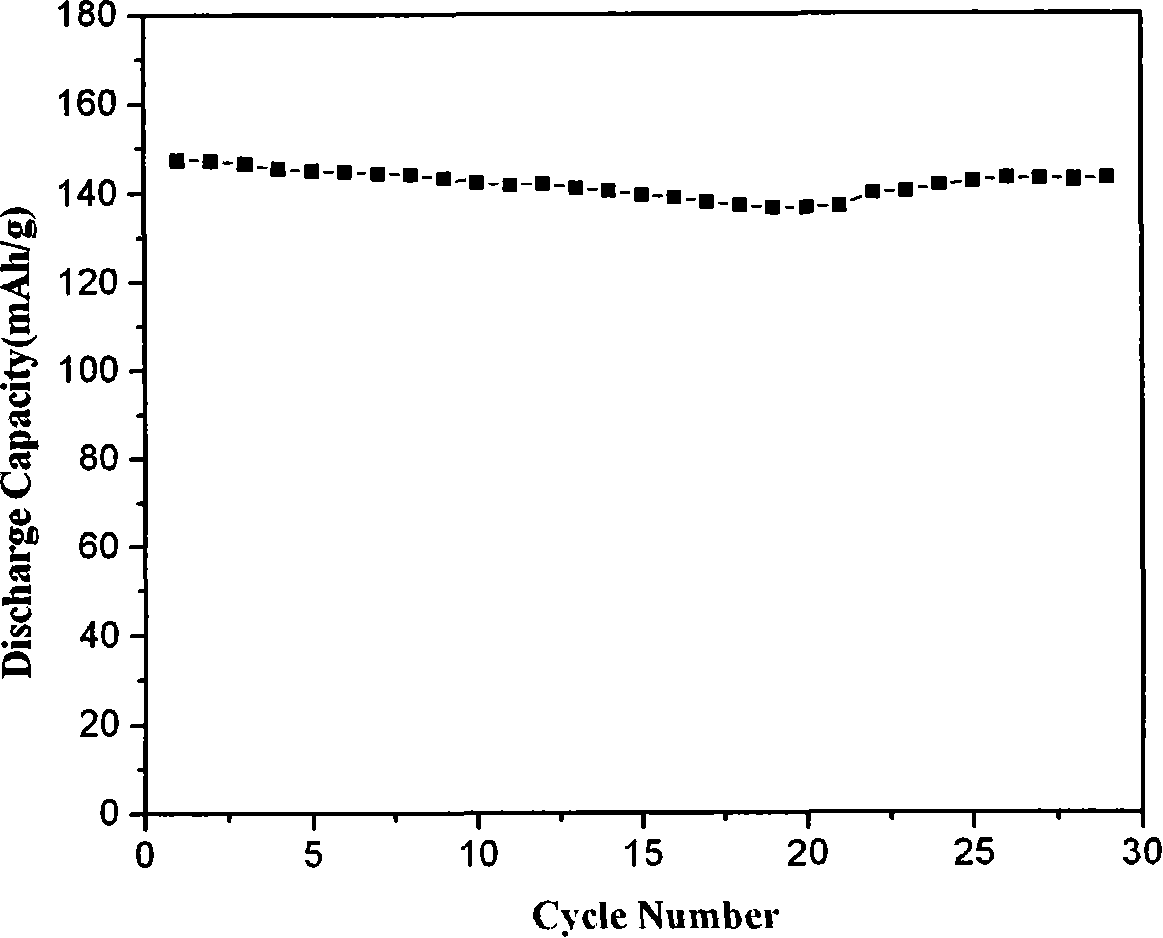

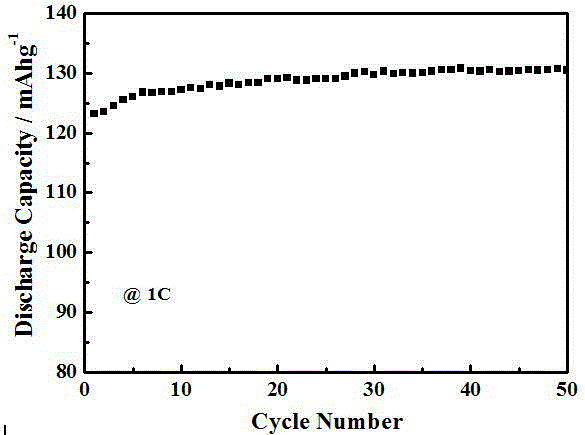

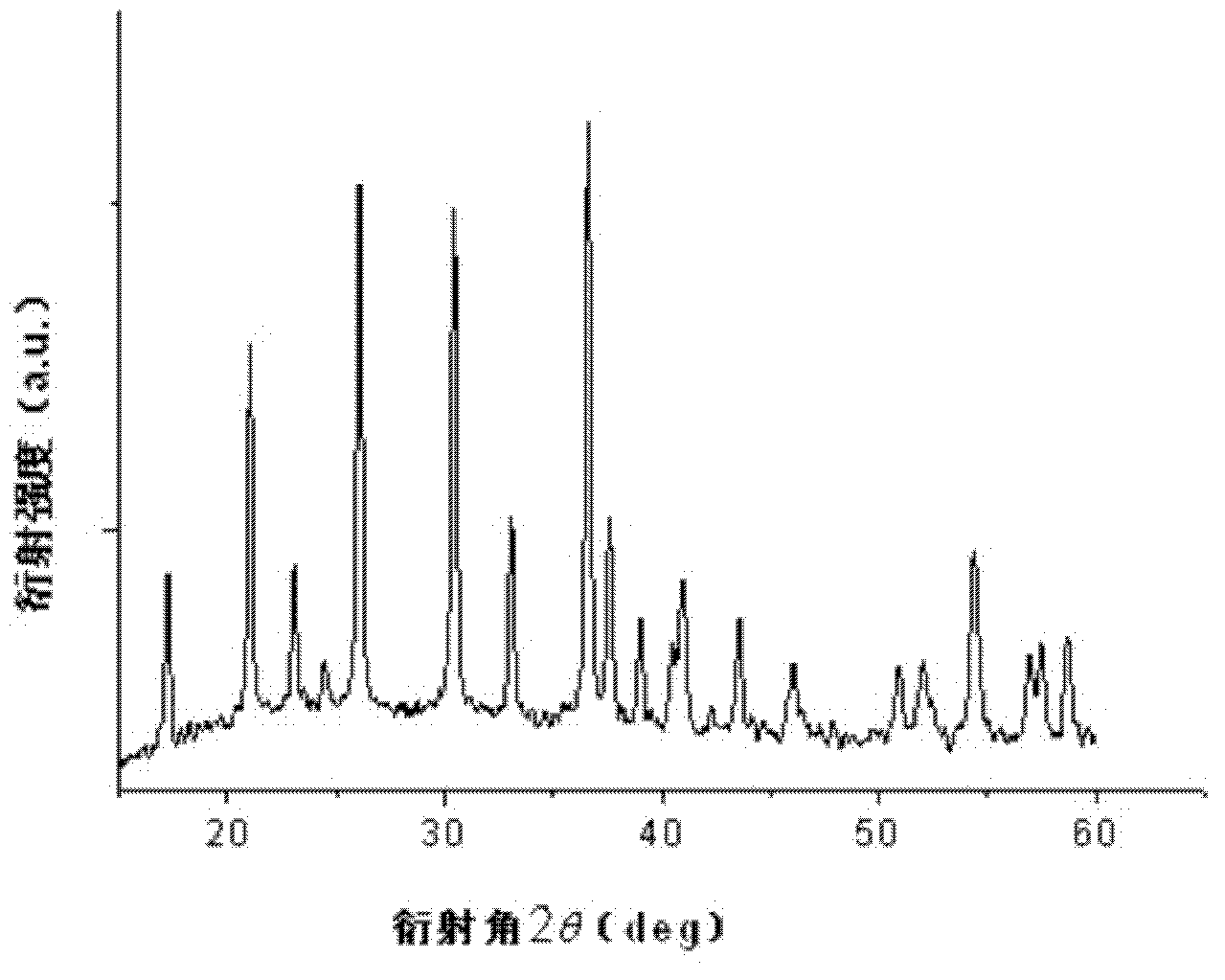

The invention discloses a nano-composite positive material LiFePO4 / C and a fabrication method, relating to a fabrication method of positive material of a lithium-ion battery. The invention uses the method of liquid-phase coprecipitation, the certain amount of lithium resource, iron resource and phosphate resource is weighted as the quality mol ratio of Li:Fe:P = (3.0-3.3):(1.0-1.1):(1.0-1.1), and the appropriate amount of carbon-doped material and organic surfactant is added in the reaction vessel; by controlling the reaction conditions like concentration, temperature etc. of the reaction solution, precursor gels are fabricated, and the precursor gels are separated, cleaned, filtered and dried to obtain precursor powder; the precursor powder is tableted and put into the crucible with microwave absorbent, and then the crucible is placed in the microwave oven, with the microwave power controlled between 100 to 600W and heated for 30 min, to obtain nano-sized composite positive material LiFePO4 / C. The technique method in the invention has the advantages of short periods, saved energy consumption, ease to control the process, suitability for industrialization and so on. The composite positive material LiFePO4 / C fabricated in the invention is characterized by high purity, small particle size lower than 100 nm, and good electrochemical properties.

Owner:上海微纳科技有限公司

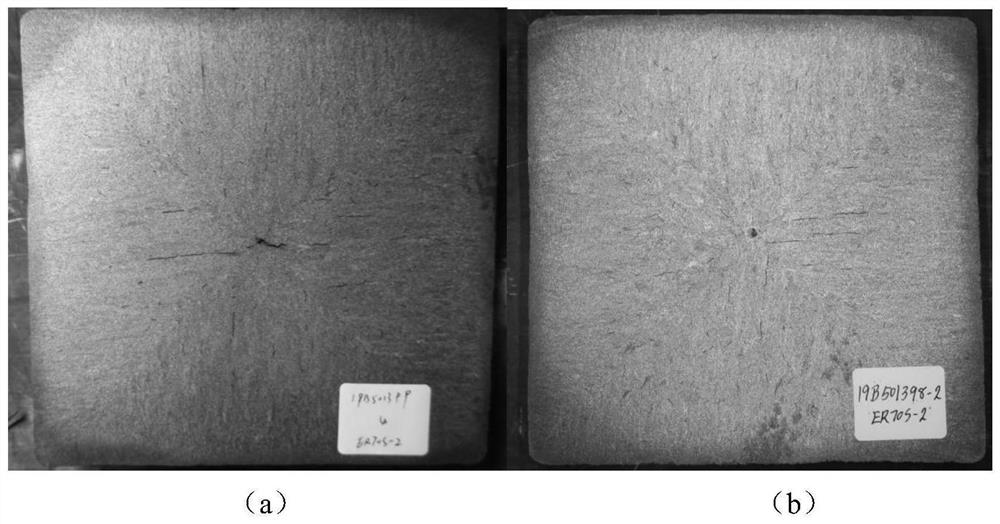

Flux-cored wire used for super duplex stainless steel gas shielded welding and preparation method thereof

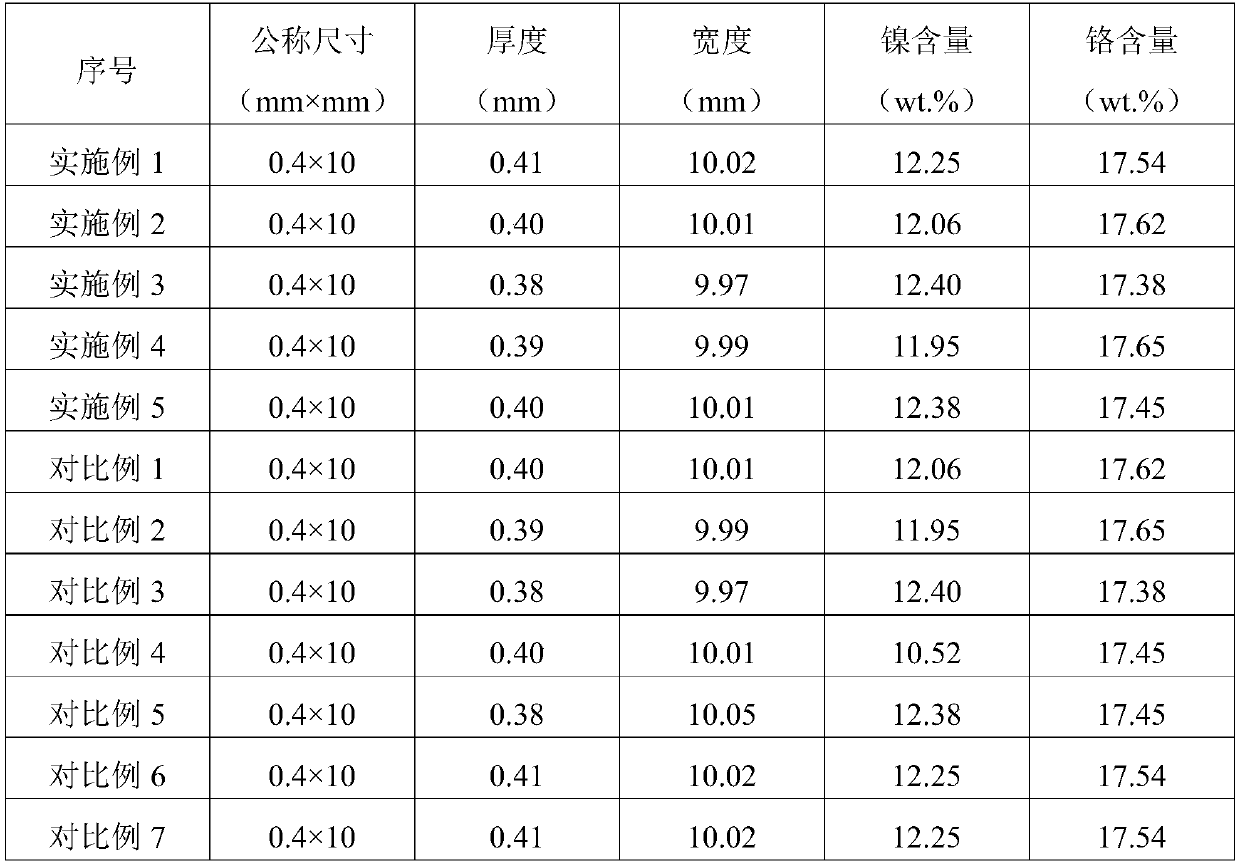

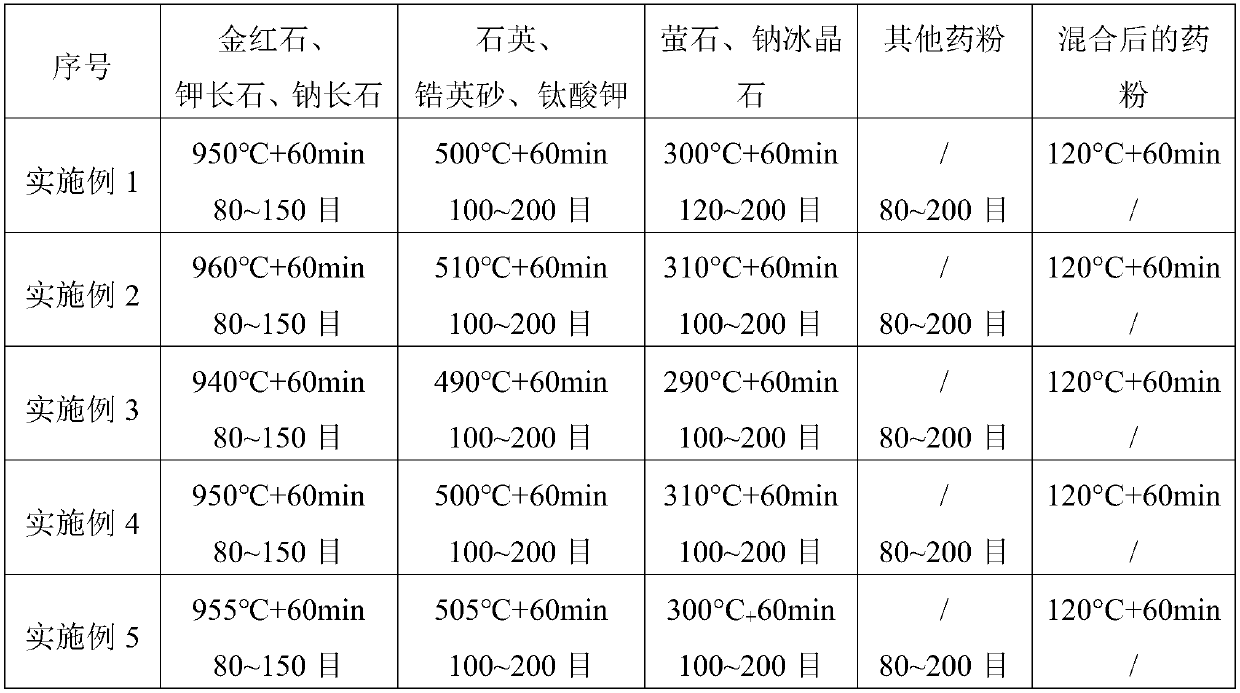

ActiveCN110142529ASimple welding processReduce acidityWelding/cutting media/materialsSoldering mediaAusteniteZircon

The invention discloses a flux-cored wire used for super duplex stainless steel gas shielded welding and a preparation method thereof. The flux-cored wire is composed of an external use steel belt andflux powder, wherein the external use steel belt is made of an austenitic stainless steel belt with 17.0%-18.0% of chromium and 11.0%-12.5% of nickel; and the flux powder comprises the following components of, in percentage by weight, 36.0%-38.0% of chromium powder, 9.0%-13.0% of high-nitrogen chromium iron, 2.5%-3.0% of electrolytic manganese metal, 4.0%-5.0% of molybdenum powder, 0.5%-1.0% of ferrosilicon, 1.0%-1.5% of ferrotitanium, 0.5%-1.0% of aluminum-magnesium alloy, 18.0%-20.0% of rutile, 1.0%-2.0% of quartz, 5.0%-6.0% of zircon sand, 1.0%-1.5% of potassium feldspar, 3.0%-3.5% of albite, 1.0%-1.5% of fluorite, 0.5%-1.0% of sodium cryolite, 1.0%-1.5% of potassium titanate, 0.1%-0.3% of bismuth oxide and the balance iron powder. According to the flux-cored wire used for super duplexstainless steel gas shielded welding and the preparation method thereof, the components and the two-phase proportion of deposited metal can be balanced, thus obtaining a duplex stainless steel welding joint which is good in forming quality and excellent in corrosion resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

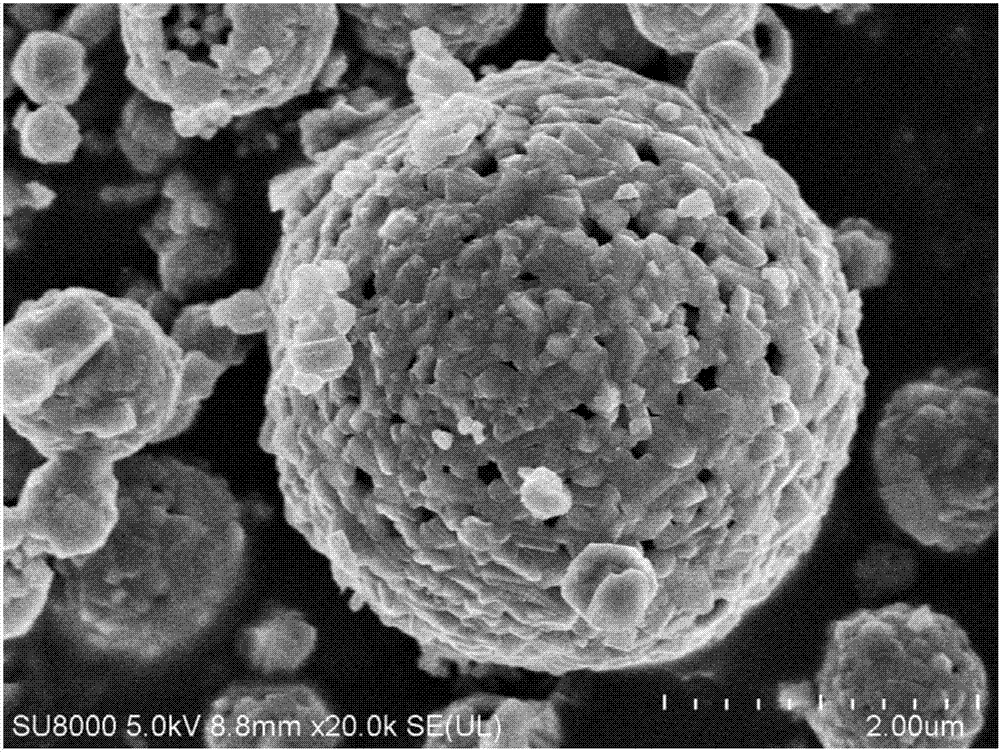

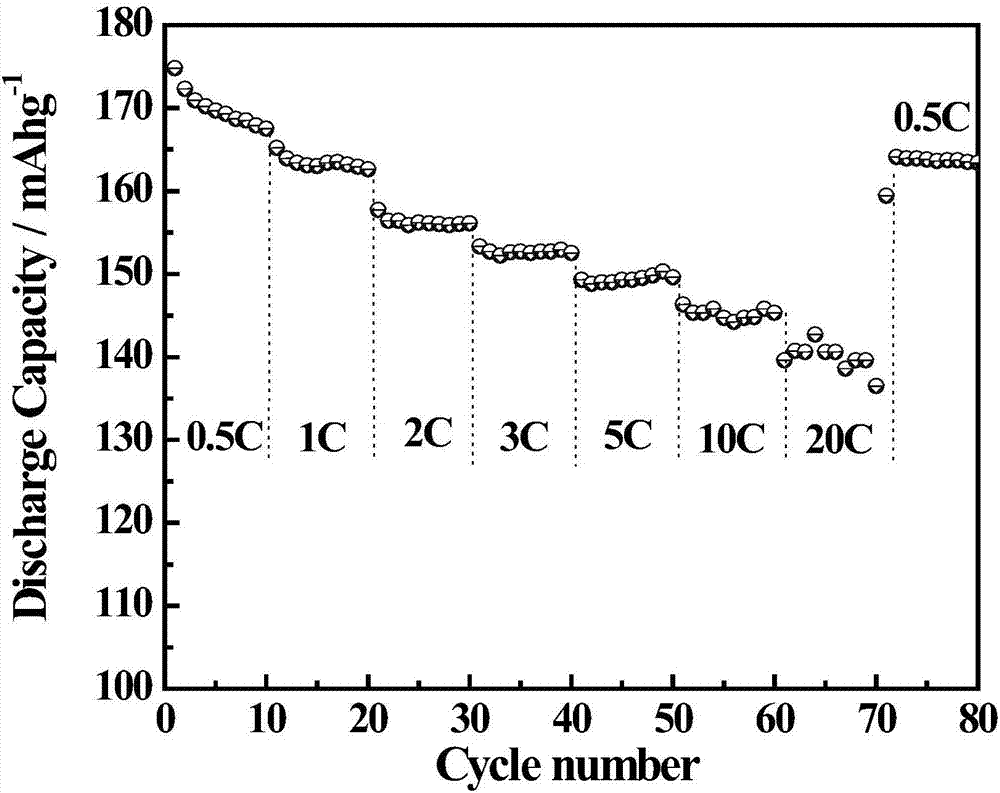

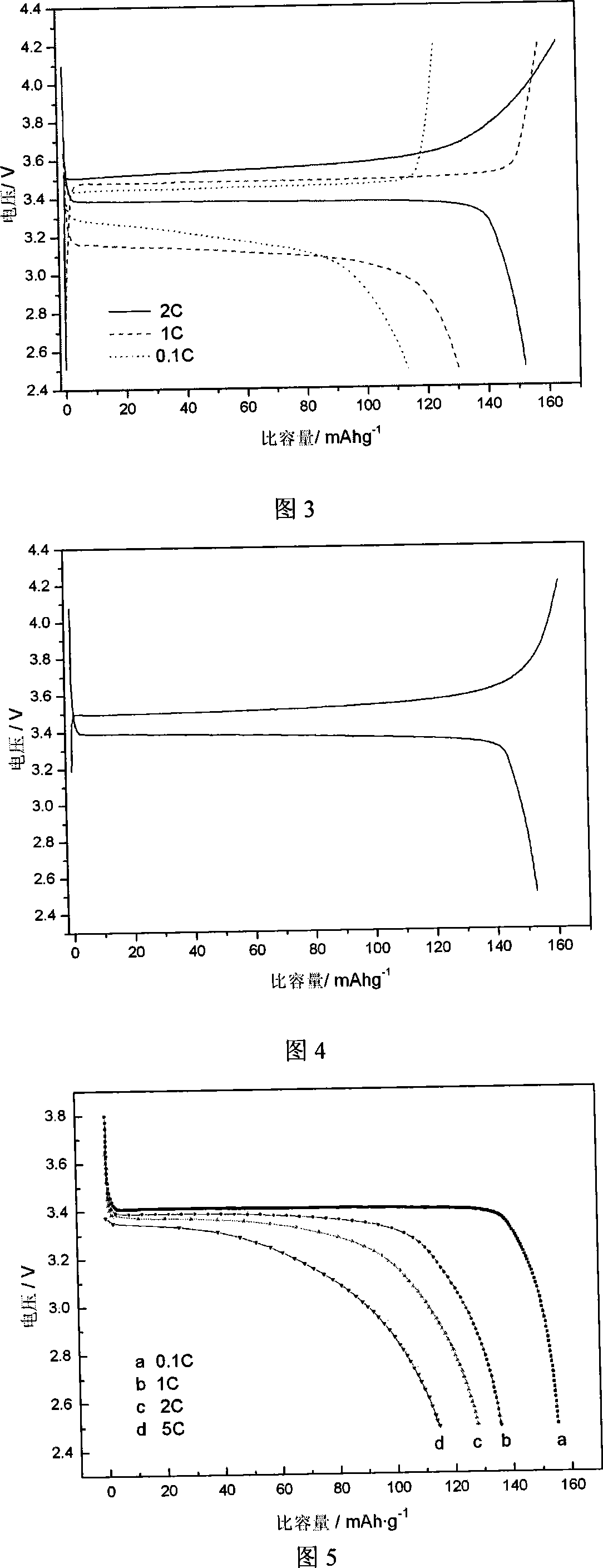

Method for preparing spherical carbon-coated lithium iron phosphate positive electrode material through atomization method

InactiveCN105336929AControl chemical compositionSmall particle sizeCell electrodesSecondary cellsIron saltsLithium iron phosphate

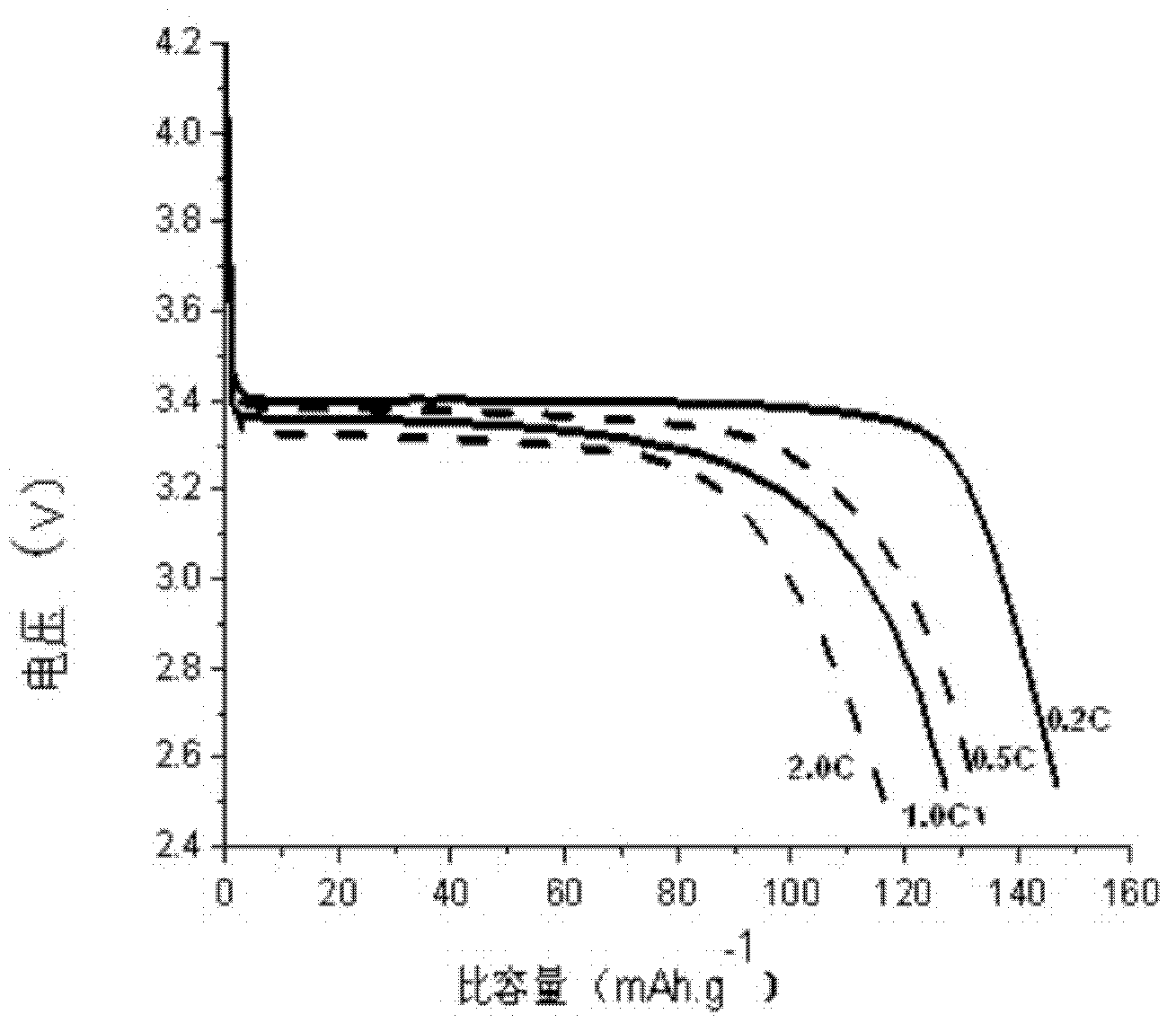

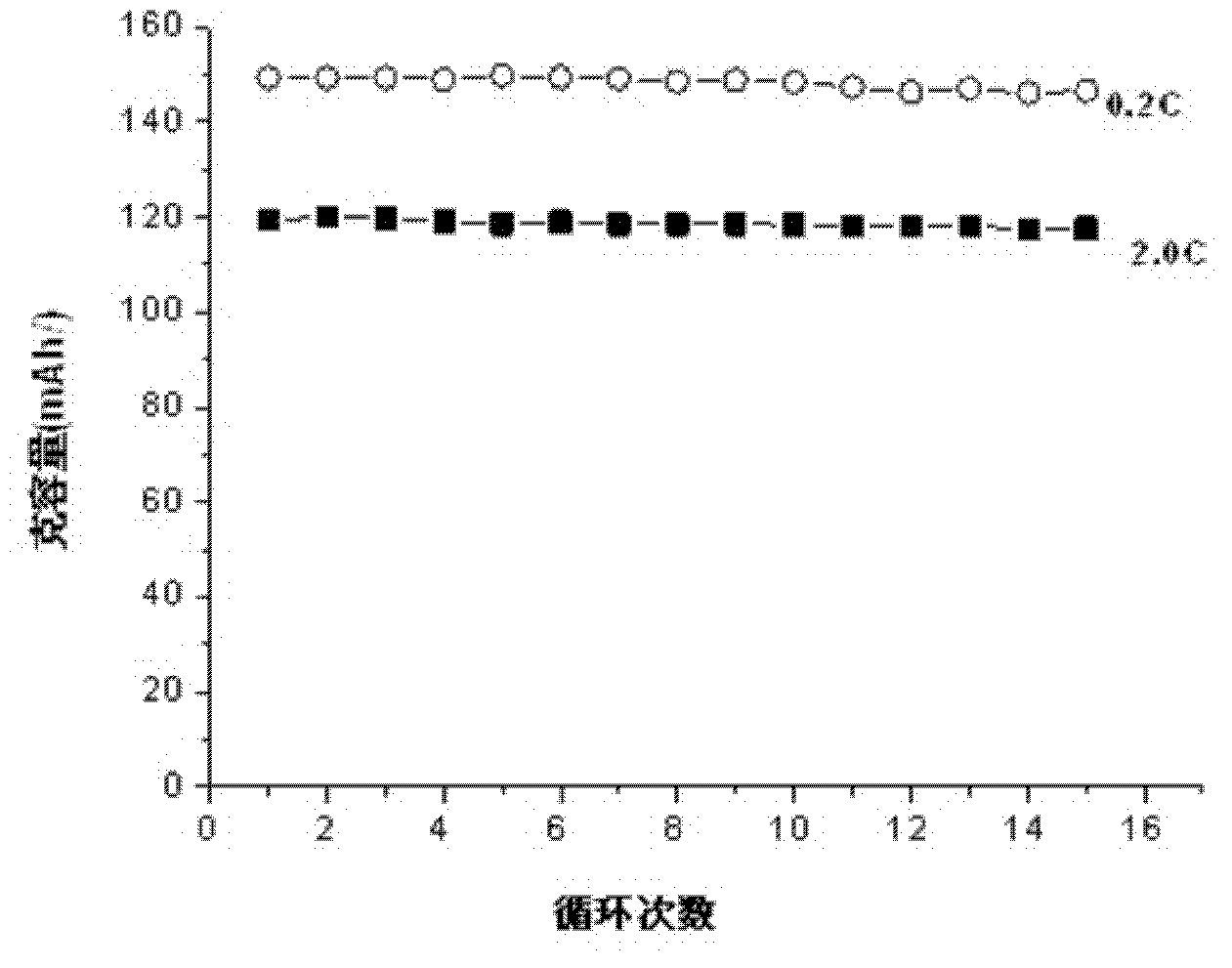

The present invention relates to a method for preparing a spherical carbon-coated lithium iron phosphate positive electrode material through an atomization method. The technical scheme of the present invention comprises: 1, dissolving a lithium salt, an iron salt and a phosphate in water containing a carbon precursor, and uniformly mixing to obtain a clarified solution; 2, adjusting the pH value of the solution; 3, placing the solution in a water bath pot, continuously stirring, and carrying out reflux to obtain a precursor liquid for atomization; 4, atomizing the precursor liquid into small mist droplets, passing through a quartz tube furnace or corundum tube furnace, and collecting the dried spherical lithium iron phosphate precursor by using a powder collector; and 5, placing the spherical lithium iron phosphate precursor into an atmosphere furnace, and carrying out sintering and calcination to obtain the spherical carbon-coated lithium iron phosphate positive electrode material. According to the present invention, the chemical component, the phase component and the particle size of the spherical lithium iron phosphate are effectively controlled, the large current charge-discharge performance and the cycle performance of the lithium iron phosphate are improved, the synthesis process is provided, the production cost is reduced, the product quality is improved, and the method is suitable for industrial implementation application.

Owner:FUJIAN NORMAL UNIV

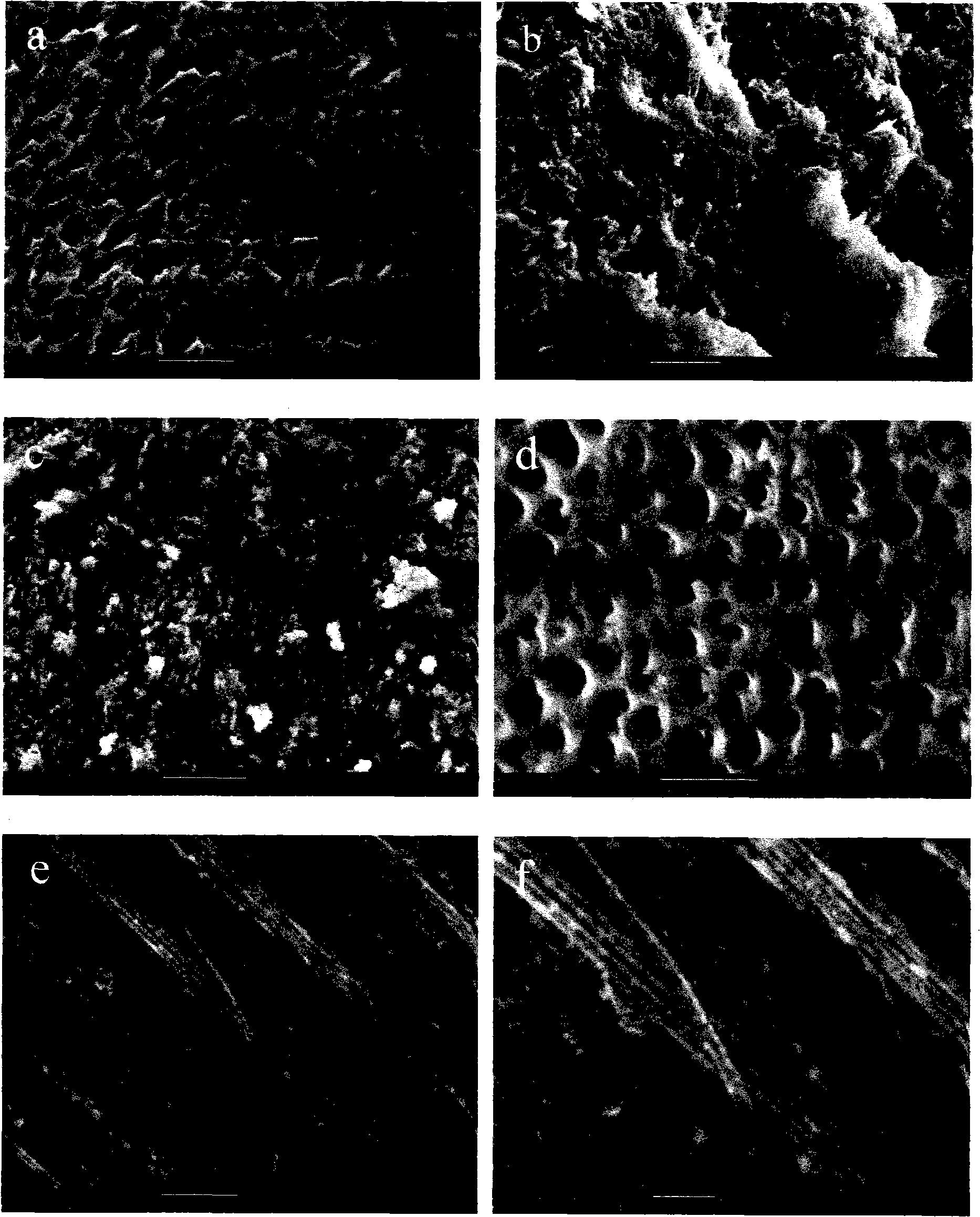

Polysulfone chiral-separation membrane grafted by cyclodextrin through SI-ATRP method, and making method thereof

ActiveCN103585900APerformance is not affectedAggregation is stableSemi-permeable membranesOptically-active compound separationChemical compositionVolumetric Mass Density

The invention belongs to the technical field of polymer membrane materials, and discloses a polysulfone chiral-separation membrane grafted by cyclodextrin through an SI-ATRP method, and a making method and an application thereof. The method includes the following concrete steps: adding a chloromethylpolysulfone membrane, allyl-beta-cyclodextrin and a catalyst into a solvent, sealing, adding a ligand, heating for reacting, washing, and drying to obtain the polysulfone chiral-separation membrane grafted by cyclodextrin through an SI-ATRP method. Chiral recognition sites are introduced into the surface of the membrane and the inner walls of apertures of the membrane through the surface-initiated atom transfer radical polymerization (SI-ATRP) method on the premise that the matrix membrane structure is not destroyed and the use performances of the membrane are not influenced, and the combination between the chiral sites and the membrane matrix are firm; and the grafting density, the length of a graft polymer and the chemical composition of the surface of the membrane can be effectively controlled by adopting a polymerization technology. The Polysulfone chiral-separation membrane grafted by cyclodextrin through the SI-ATRP method can be used in the separation of racemes.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Lithium iron phosphate/PpyPy composite cathode material for boron-doped modification lithium ion battery and preparation method therefor

InactiveCN102569803ASmall particle sizeImprove conductivityCell electrodesChemical compositionComposite cathode

The invention discloses a lithium iron phosphate / PpyPy composite cathode material for a boron-doped modification lithium ion battery and the preparation method therefor. The method comprises the following steps: mixing materials such as lithium source compound, phosphorus source compound, ferric source compound, boron source compound, clad material conductive polymer PpyPy or conductive polymer thermal cracked presoma polyacrylonitrile, heating for 5 to 20 hours under the temperature of 250 to 400 DEG C, and a reaction precursor is obtained through cooling and ball milling; calcining the reaction precursor under 500 to 800 DEG C for 10 to 40 hours, and after cooling, composite cathode material for the boron-doped modification lithium ion battery can be obtained. In the invention, chemical composition, structures and particle size of the material of the modification lithium ion battery can be effectively controlled, the electronic conductivity and the lithium ion diffusion rate of the material are improved, and the electrochemical performance of the material is improved; and meanwhile, the synthesis process of the material is simplified, and the industrialized mass production can be performed conveniently.

Owner:SOUTH CHINA UNIV OF TECH

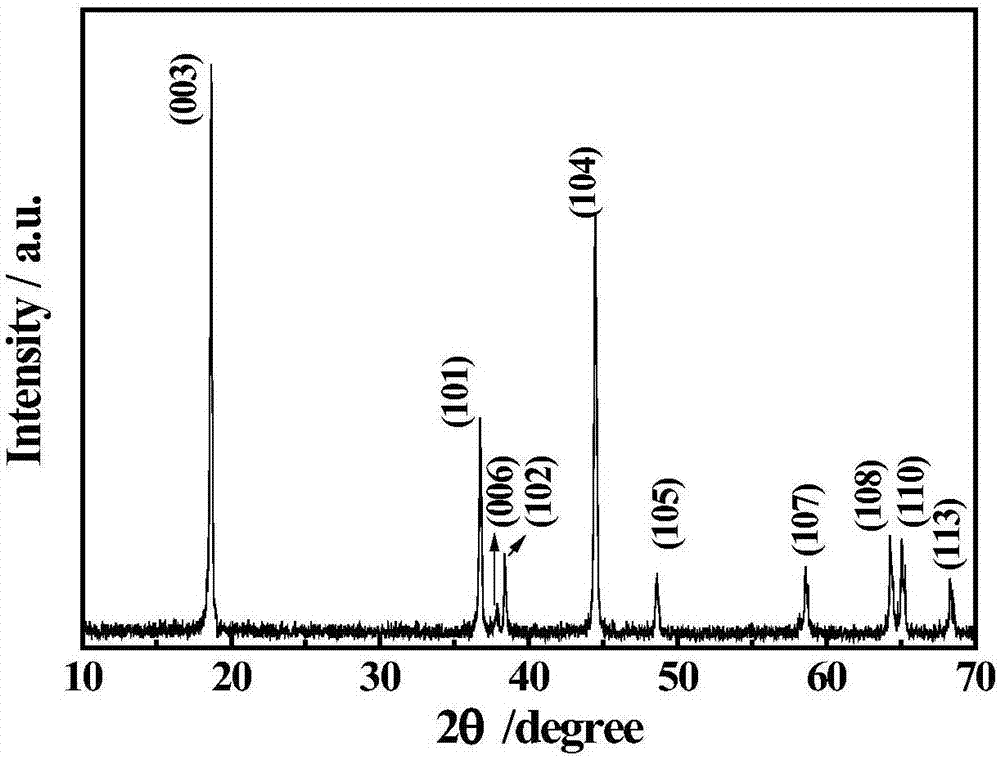

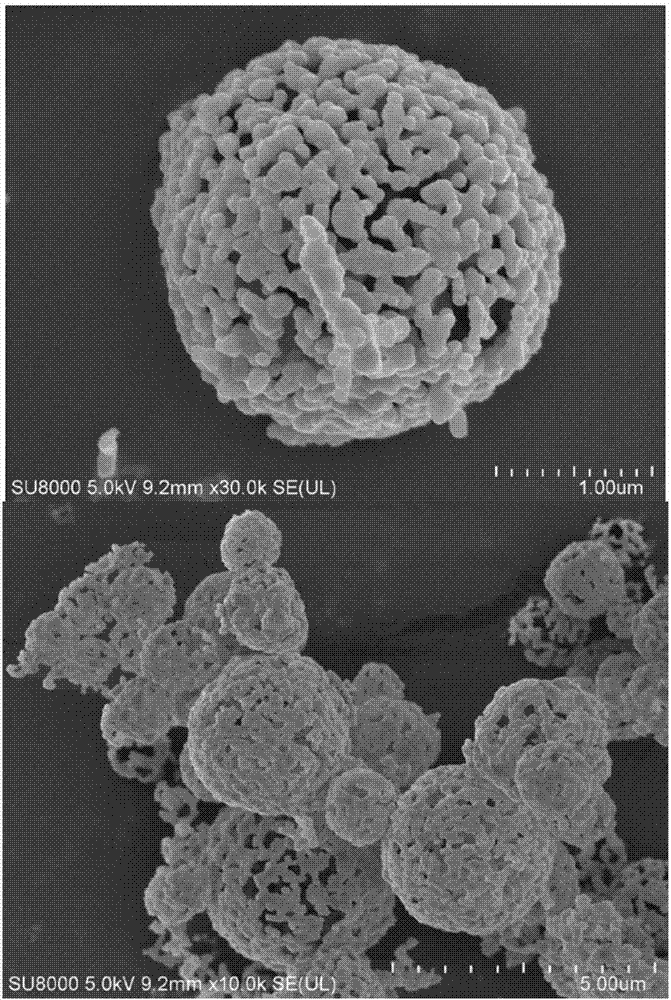

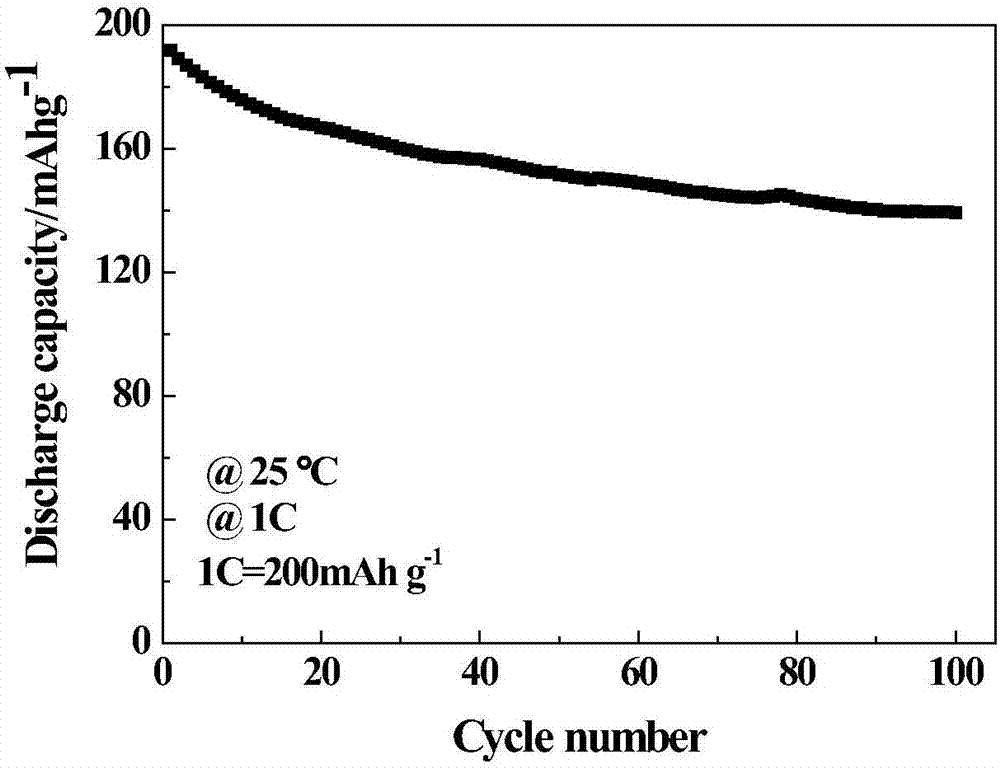

Ultrasonic atomization preparation method of porous hollow spherical ternary positive electrode material

InactiveCN107221643AControl chemical compositionControl phase compositionElectrode thermal treatmentImpregnation manufacturingWater bathsLithium-ion battery

The invention belongs to the technical field of an electrode material of a lithium ion battery, and relates to an ultrasonic atomization preparation method of a porous hollow spherical ternary positive electrode material. The method is as follows: water soluble lithium, nickel, cobalt and manganese sources and a metal chelating agent are dissolved in the molar ratio of 1-1.2: x : y: z into deionized water, and are stirred in a water bath pot to reflux, and after 8 to 20 hours of stirring, a precursor solution for atomization is obtained, then the obtained mixed solution is atomized into droplets by an ultrasonic atomizer, the droplets are loaded into a high temperature furnace with the help of a vacuum pumping system, the droplets become precursor powder, and finally the porous hollow spherical ternary positive electrode material is obtained by calcination in an air or oxygen atmosphere. The method effectively control the chemical composition, phase composition and particle size of the porous hollow spherical ternary positive electrode material, and the prepared porous hollow spherical ternary positive electrode material has high tap density, uniform particle size distribution, and excellent electrochemical performance, and is suitable for industrialized production.

Owner:FUJIAN NORMAL UNIV

Method for preparing high-nitrogen steel from micro-carbon ferrochrome

The invention provides a method for preparing high-nitrogen steel from micro-carbon ferrochrome. First, micro-carbon ferrochrome powder is subjected to nitrogen addition, high-nitrogen ferrochrome intermediates are prepared, and then the high-nitrogen ferrochrome intermediates are employed to prepare high-nitrogen steel. In the method, micro-carbon ferrochrome powder is employed to prepare high-nitrogen ferrochrome intermediates self, the quality is good, the material quality is controllable, which is helpful for smooth and steady smelting of high-nitrogen alloy and high-nitrogen steel melt, chemical components of high-nitrogen steel can be controlled effectively, and high-quality high-nitrogen steel bases and castings can be obtained. Micro-carbon ferrochrome powder is employed as a main raw material for preparing high-nitrogen steel, the source is wide, the quality is reliable, the preparation cost of high-nitrogen steel bases and castings can be lowered when the method is compared with a method employing nitride ferrochrome and high-nitrogen ferrochrome raw materials directly.

Owner:上海相济新材料科技有限公司

Reconstituted tobacco preparation method

ActiveCN108185506AControl chemical compositionImprove qualityTobacco preparationRegulation of chemicalsTotal nitrogen

The invention provides a reconstituted tobacco preparation method. The preparation method includes steps: extracting tobacco raw materials to obtain extraction liquid and solid residues; allowing thetobacco extraction liquid to pass through a horizontal screw centrifuge and a disc separator sequentially and then pass through an activated carbon adsorption device A and an activated carbon adsorption device B to obtain tobacco refined solution B concentrated liquid, and performing concentrating, beating, coating, drying and slitting to obtain a finished product of reconstituted tobacco. Due todifferent activated carbon adsorption effects, macromolecular substances including part of proteins, pectin and the like in the tobacco extraction liquid are adsorbed by coal columnar activated carbonwhile components including nicotine, total nitrogen, total sugar and the like in the tobacco extraction liquid are adsorbed by coconut shell granular activated carbon, and accordingly regulation of chemical components of the reconstituted tobacco is realized, and quality of the reconstituted tobacco is improved.

Owner:HUBEI CHINA TOBACCO IND

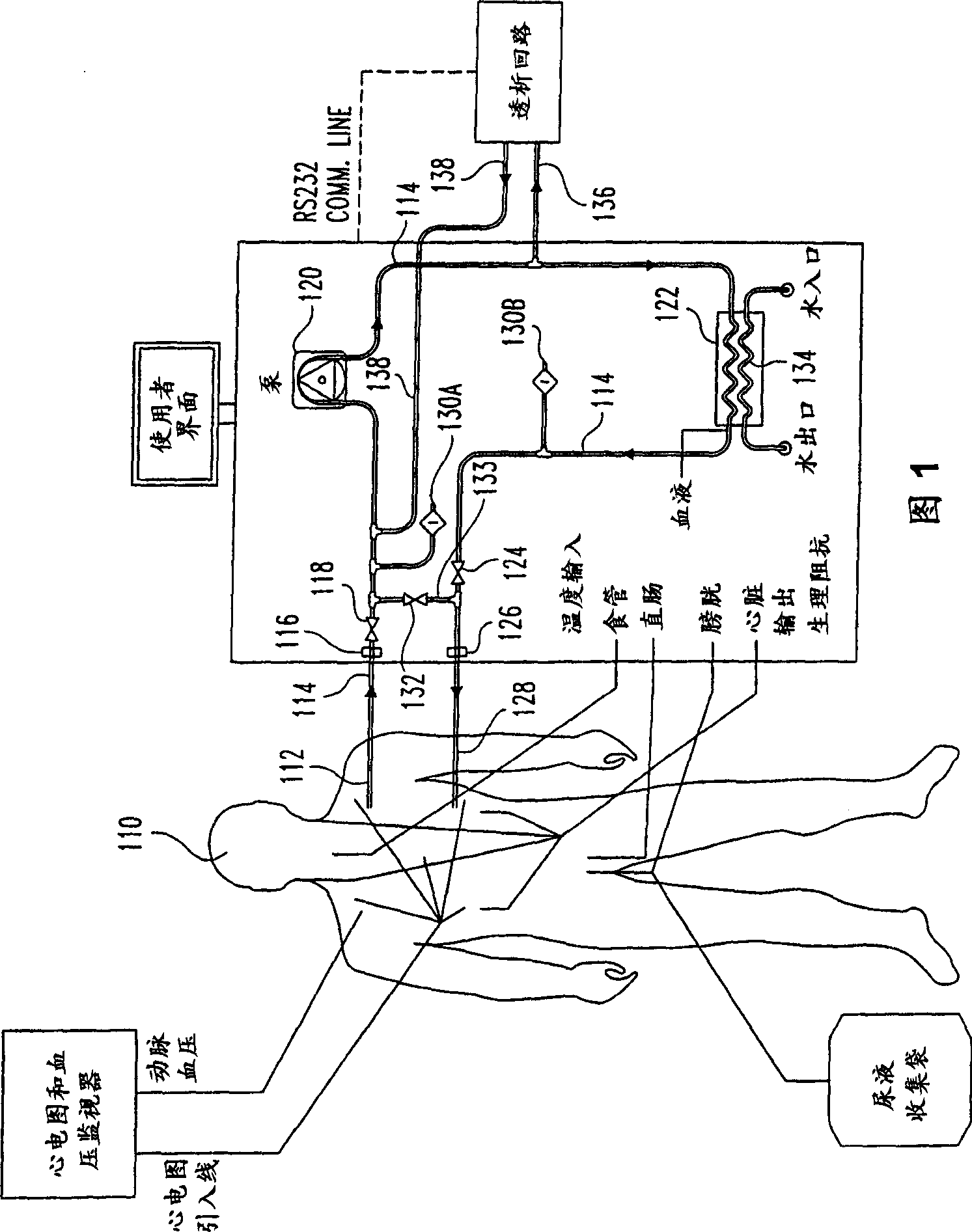

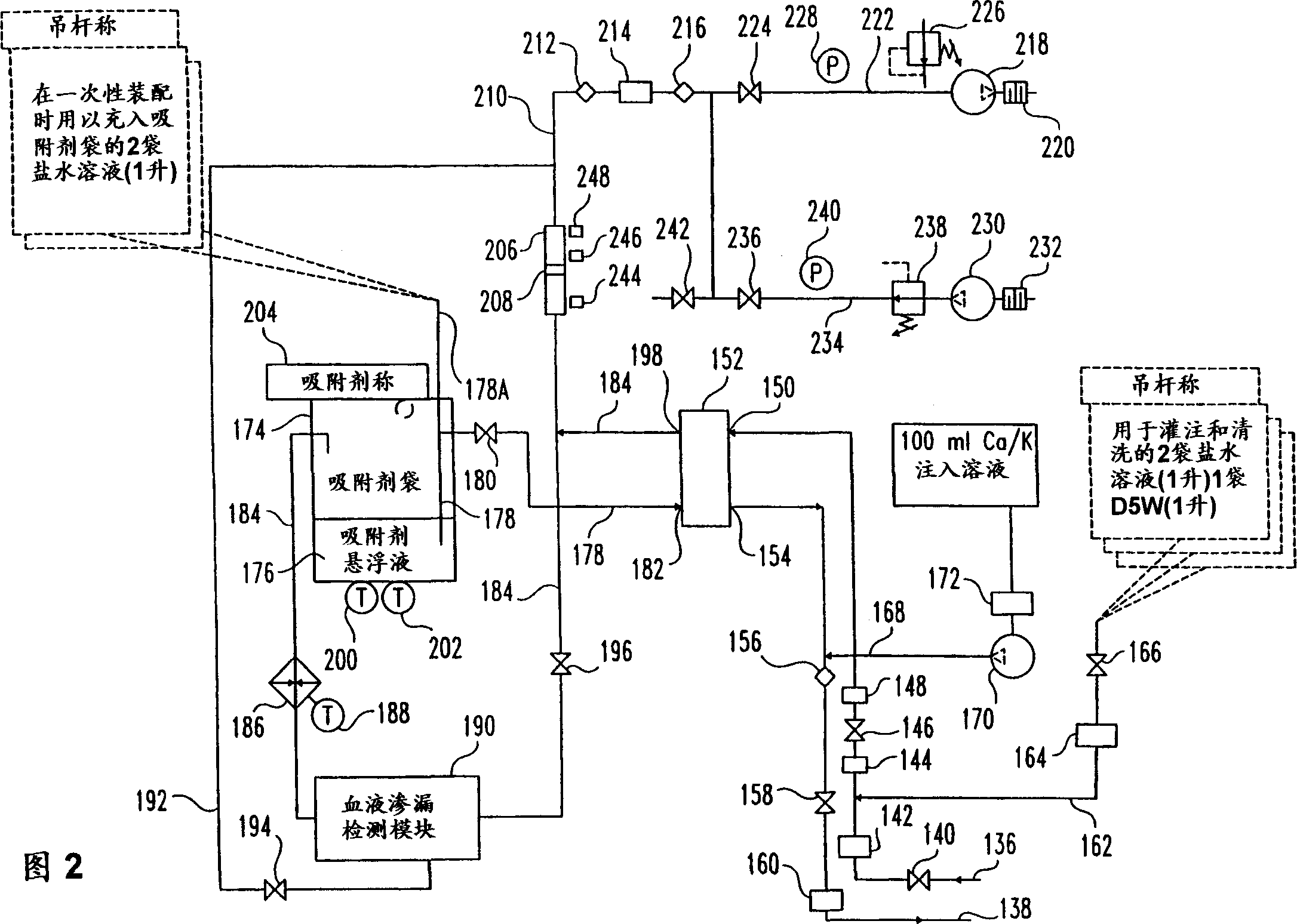

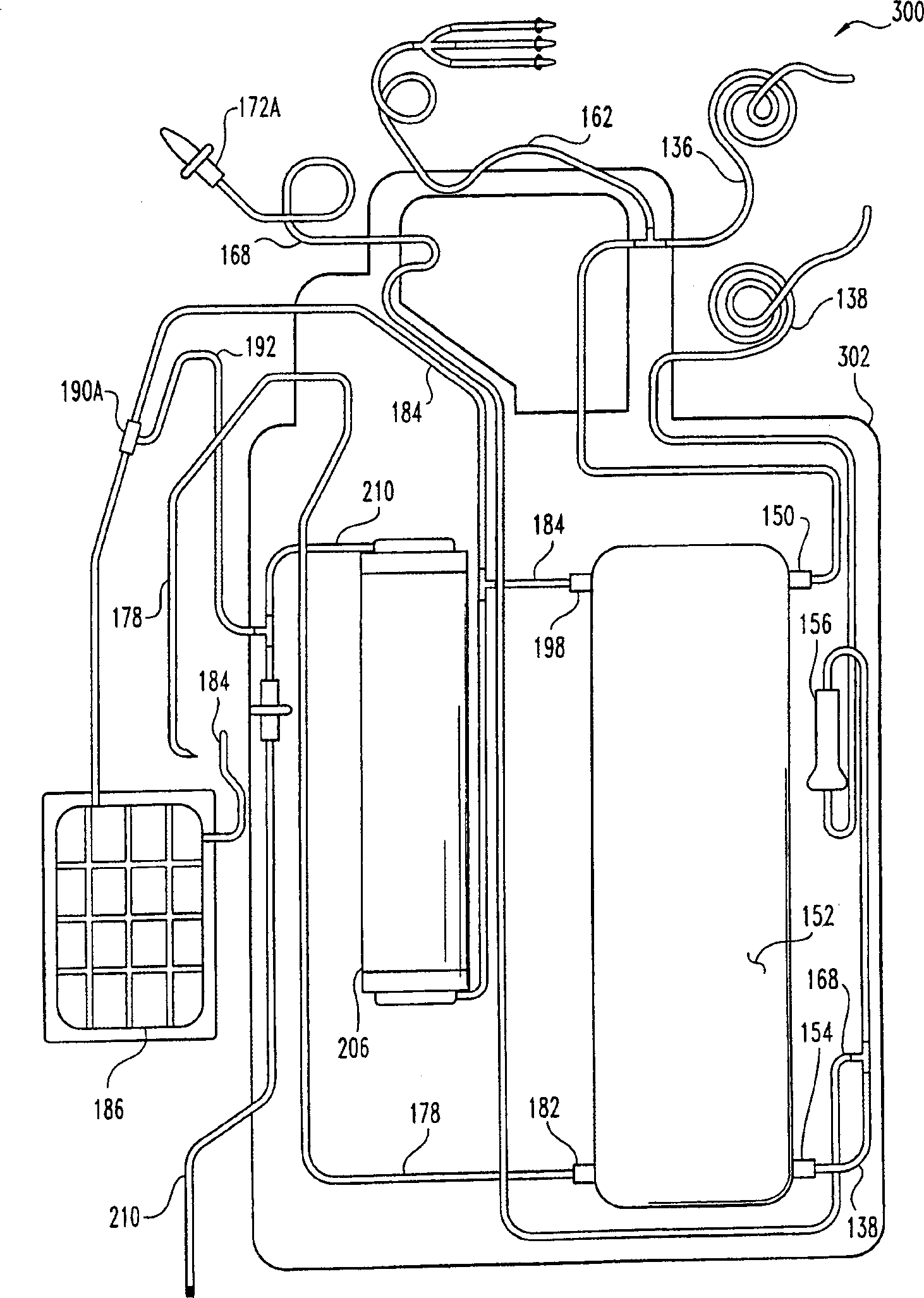

Appts. and processes for whole-body hyperthermia

InactiveCN1294522AControl chemical compositionEffective Whole Body HyperthermiaElectrotherapyOther blood circulation devicesWhole bodyIntensive care medicine

Apparatuses for use in whole-body hypothermia include a high-flow hyperthermia circuit coupled to a low-flow dialysis circuit in a manner which reduces tensioning of membranes in the dialyzer (152) of the dialysis circuit. The arrangement thereby allows proper membrane movement to assist in mixing a sorbent suspension (176) circulated on the sorbent side of the dialyzer. Additional dialysis apparatuses include advantageous disposable packs (300) including the dialyzer (152), sorbent heat exchangers (186) arranged to cooperate with heating elements on base units of the apparatuses, and adaptations for very high flow rates useful in the hyperthermic treatment of cancers.

Owner:维亚瑟克公司

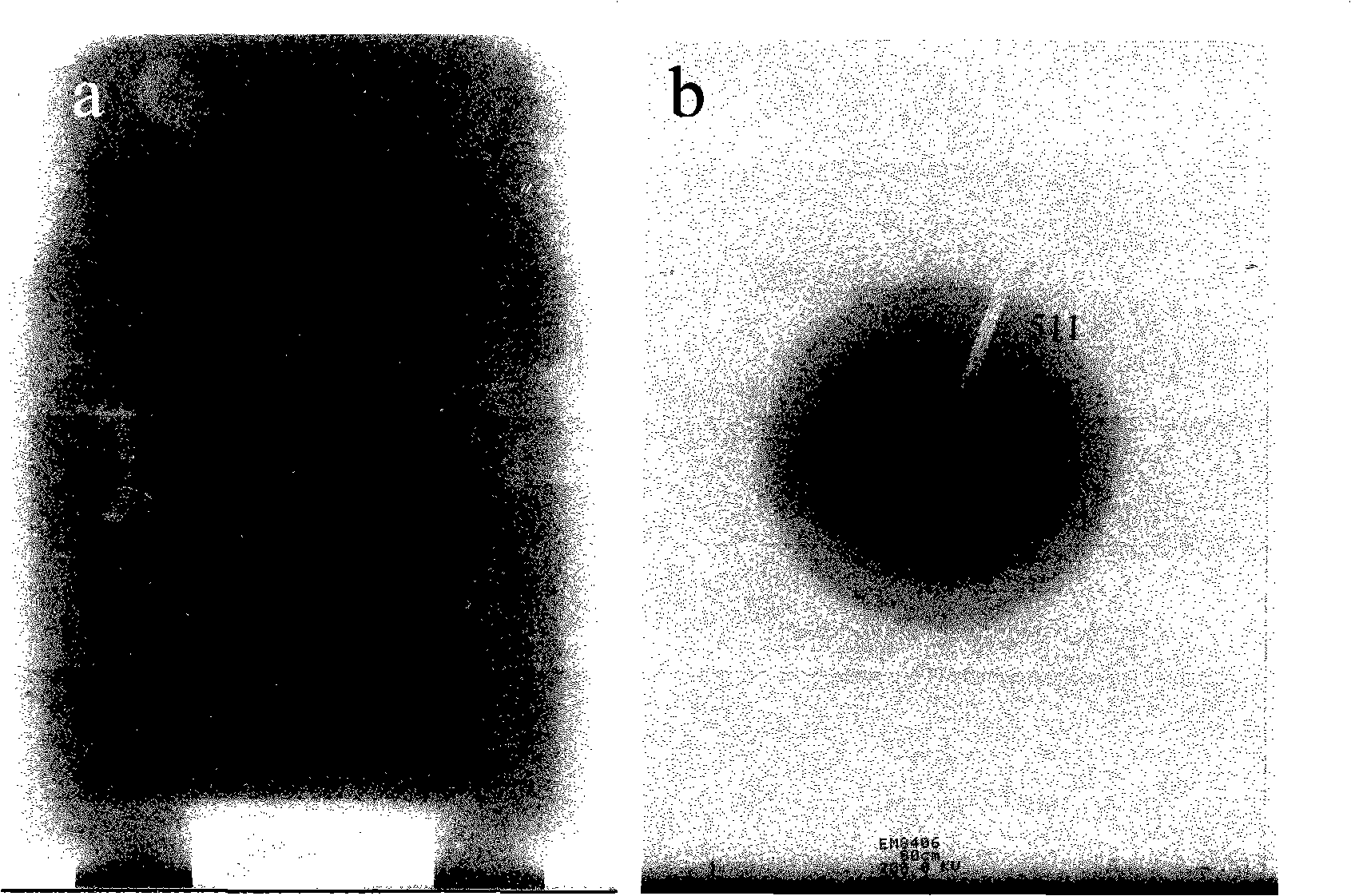

Lanthanum molybdate-based nanotube array and preparation thereof

InactiveCN101376527BImprove ionic conductivityReduce manufacturing costNanostructure manufactureMolybdeum compoundsSolventAluminium

The invention discloses a lanthanum molybdate-based nanotube array and a preparation method thereof. The array comprises lanthanum molybdate-based nanotubes, the nanometer pipe diameter is 40 to 100nm, and the thickness of a tube wall is 3 to 10nm. The preparation method comprises the steps as follows: (a) lanthana, an oxide of a lanthanum-position adulterant, or nitrate or acetate, ammonium molybdate and the oxide of a molybdenum-position adulterant, or nitrate or acetate are weighed according to the constituent ratio of (La(2-x)Ax)(Mo(2-y)By)O(9-Delta) and are respectively added in a solvent to prepare a corresponding solution; a lanthanum nitrate solution, a lanthanum-position adulterant solution, a molybdenum-position adulterant solution and citric acid are added in an ammonium molybdate solution which is stirred; then the mixed solution is put at the temperature ranging from 20 to 100 DEG C and is stirred and vaporized until a sol whose concentration is 0.5 to 2M is obtained; (b)an aluminium flake is produced into an alumina template with a through-hole, the pore diameter of which is 40 to 100nm; (c) the alumina template which is used for instilling the sol is sintered for 10 to 12 hours at the temperature ranging from 550 to 650, and a strong alkalis used for eating off the template to produce the lanthanum molybdate-based nanotube array which is especially used as the material for transforming the oxygen concentration and electricity on an oxygen sensor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

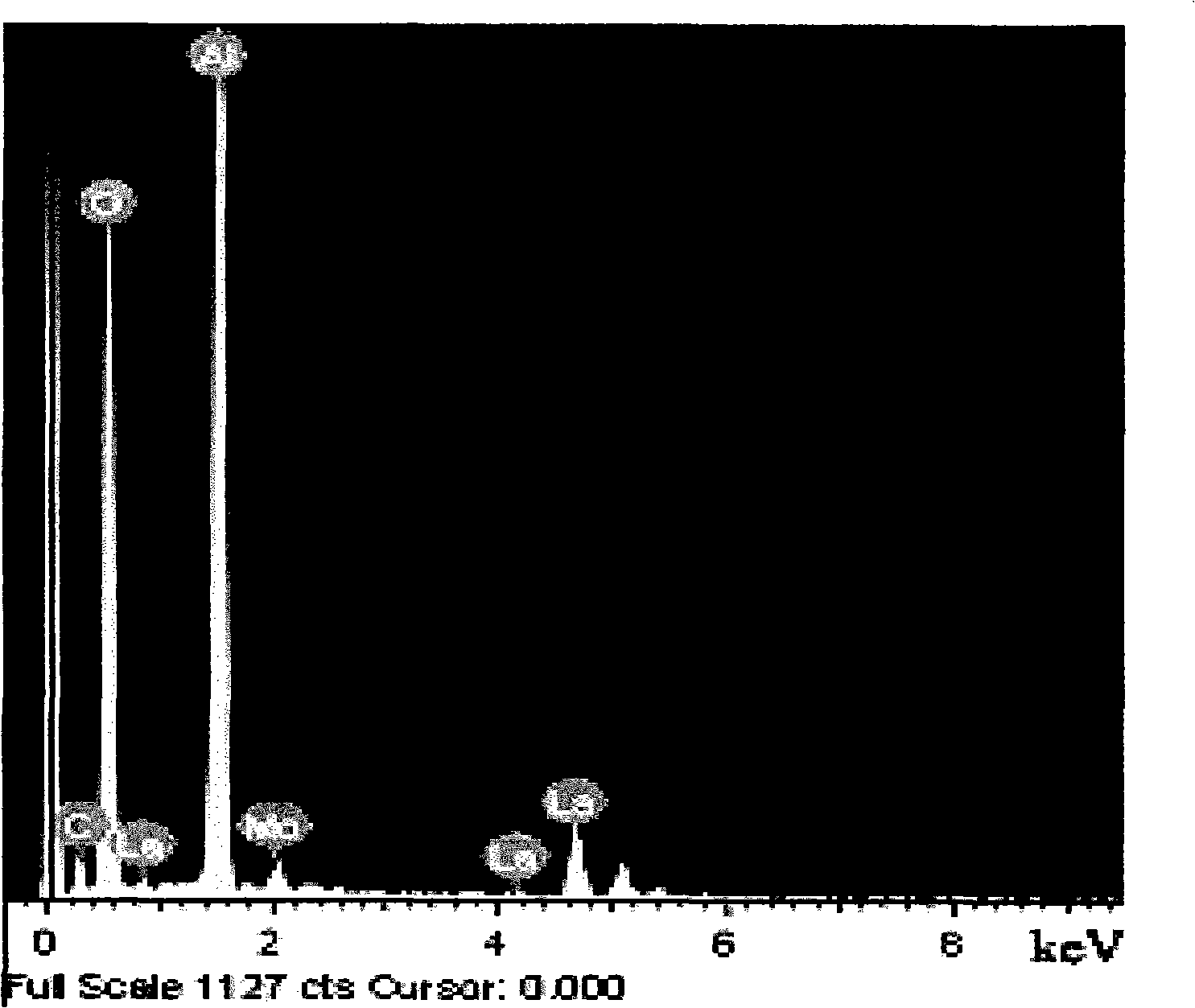

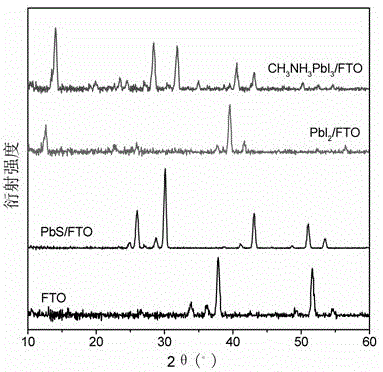

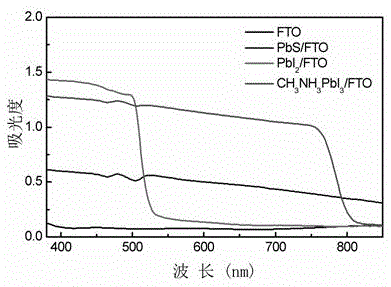

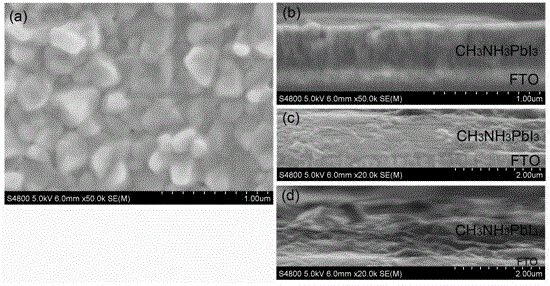

Preparation method of organic-inorganic hybrid perovskite thin film

InactiveCN105552237AControllable areaControllable shapeSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention discloses a preparation method of an organic-inorganic hybrid perovskite thin film. Conductive glass is used as a substrate; a lead sulfide thin film is prepared by adopting an electro-deposition method; the lead sulfide thin film is used as a precursor; an iodine elementary substance is used as an iodizating agent for iodizating lead sulfide into lead iodide; and then the lead iodide reacts with methyl ammonium halide to obtain the perovskite thin film. The method disclosed by the invention can be operated in a large area; a film layer is controllable in area and shape, and an electro-deposition area and shape can be controlled by a method of corroding a conducting plane; a thickness of the film layer is controlled, and the thickness of the film layer can be conveniently controlled by regulating electro-deposition time; chemical components of the film layer are controllable, and the film layers with different components can be obtained by changing a ratio of I to Br in CH3NH3X solution, so that the perovskite thin films with different physical properties are obtained; and the obtained film layer is relatively uniform and has good compactness.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

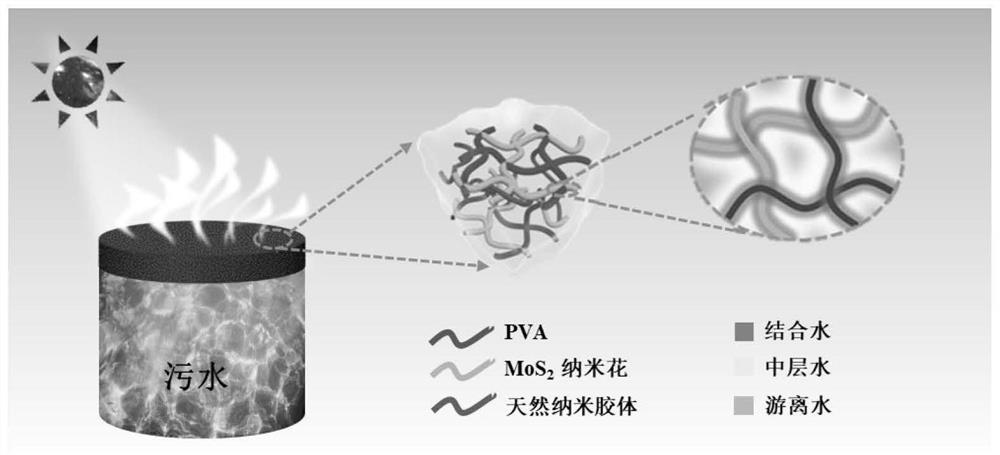

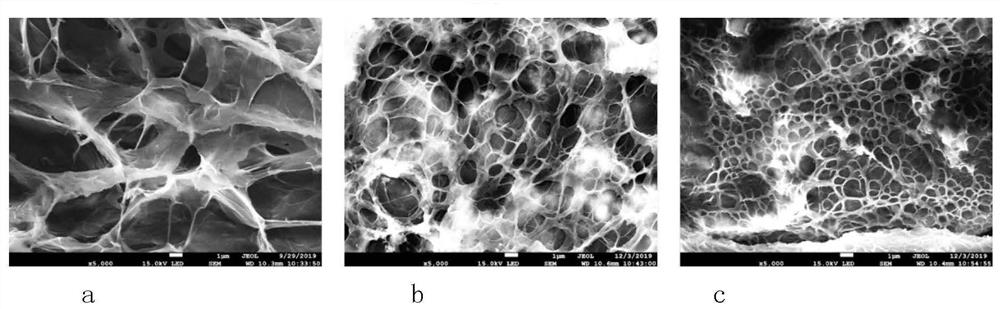

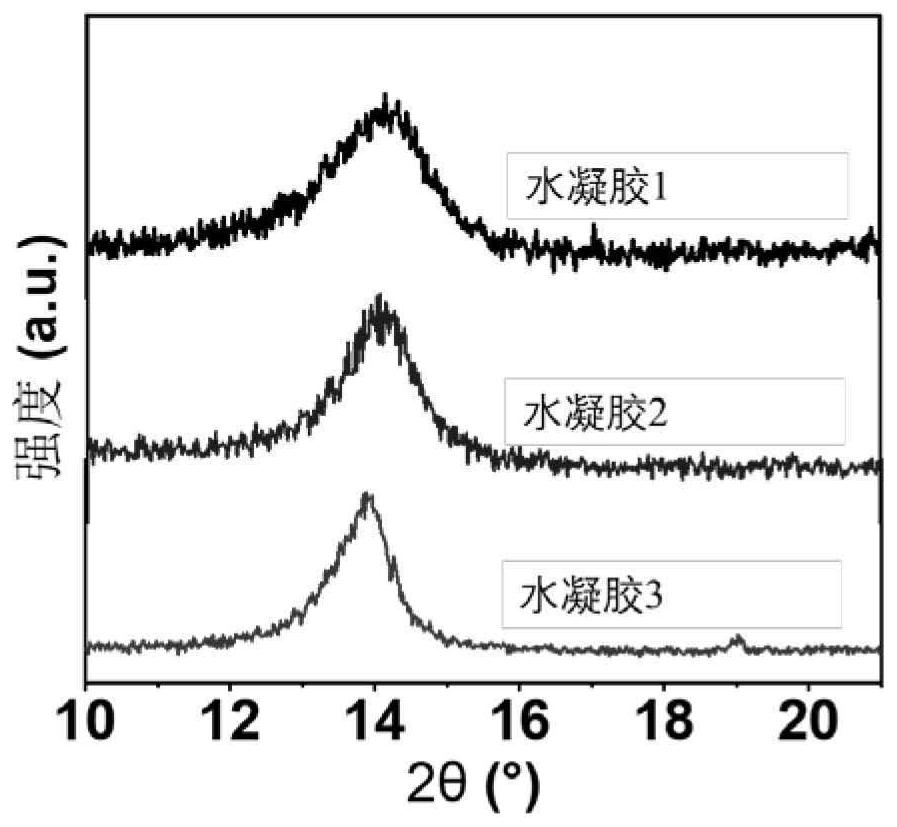

Natural colloid compounded hydrogel and preparation method and application thereof

ActiveCN111635604AEfficient fading effectControl chemical compositionGeneral water supply conservationSeawater treatmentNatural gumPolyvinyl alcohol

The invention relates to natural colloid compounded hydrogel and a preparation method and application thereof. The preparation method comprises the following steps: firstly, taking polyvinyl alcohol and nano colloid concentrated and extracted from seawater, adding water, stirring at 70-75 DEG C to obtain a dispersion initial solution, then adding MoS2 nanoflowers prepared by a hydrothermal synthesis method according to a solid-liquid ratio of 1: 1mg / ml, continuously stirring at 70-75 DEG C to obtain a uniform black dispersion liquid, adding hydrochloric acid, stirring, standing at room temperature, standing in a drying oven for 4 hours, so that the reaction is balanced, finally, freezing the jelly after standing in a refrigerator overnight, taking out the frozen jelly, unfreezing the frozen jelly to normal temperature, freezing the frozen jelly in the refrigerator, repeatedly freezing the frozen jelly for several times, soaking the frozen jelly in deionized water, and washing the frozen jelly to obtain a black opaque gel substance. According to the invention, the hydrogel prepared by graft polymerization by taking polyvinyl alcohol / natural nano colloid / MoS2 as a main raw material is obtained for the first time, and the hydrogel is used as a solar absorber for solar seawater desalination, so that an efficient seawater desalination yield can be obtained.

Owner:NANKAI UNIV

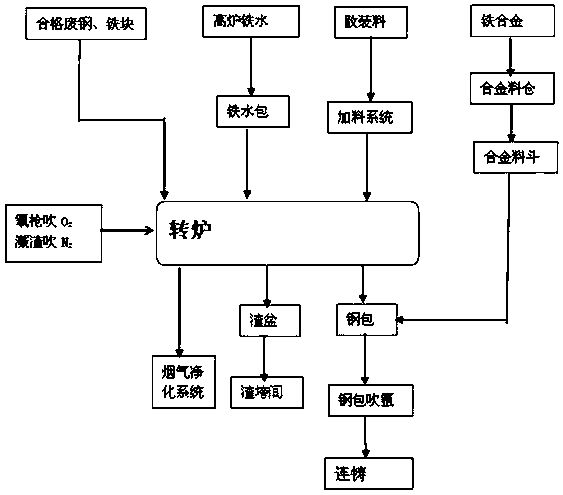

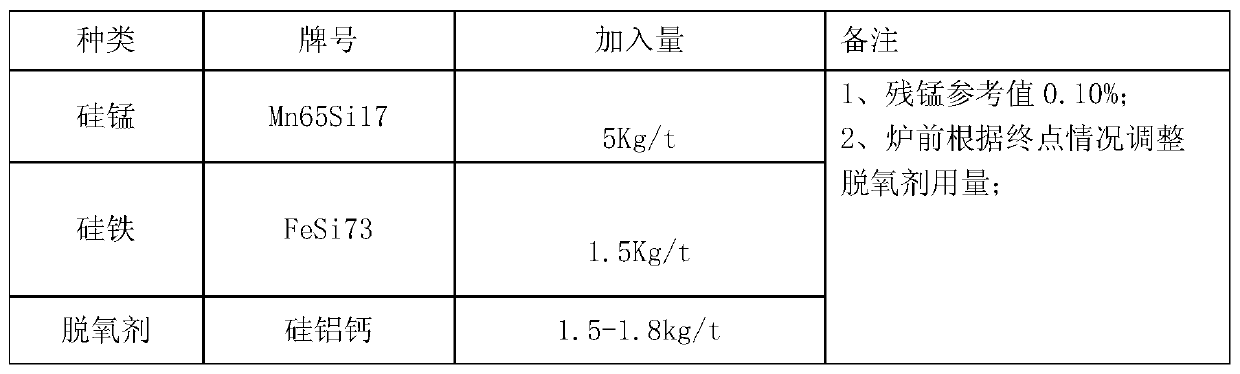

HRB400 alloy steel containing Nb and V and smelting process method thereof

PendingCN110205558AReduce manufacturing costSteelmaking Process ImprovementSmelting processVariable pressure

The invention relates to the technical field of steel production, in particular to HRB400 alloy steel containing Nb and V. The HRB400 alloy steel containing the Nb and the V is prepared from the following components: 0.21 to 0.25 percent of C, 0.40 to 0.55 percent of Si, 1.35 to 1.50 percent of Mn, less than or equal to 0.045 percent of P, less than or equal to 0.045 percent of S, 0.010 to 0.015 percent of V, 0.005 to 0.015 percent of Nb, and the balance Fe. A smelting process of the HRB400 alloy steel containing the Nb and the V comprises the following steps of loading the materials, operating a variable-pressure gun, controlling slagging, controlling a final slag, controlling tapping, adding an alloy and a deoxidizing agent, and soft-blowing a steel ladle. According to the process provided by the invention, the cost is low, the product components meet the requirement, and the quality qualification is realized.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

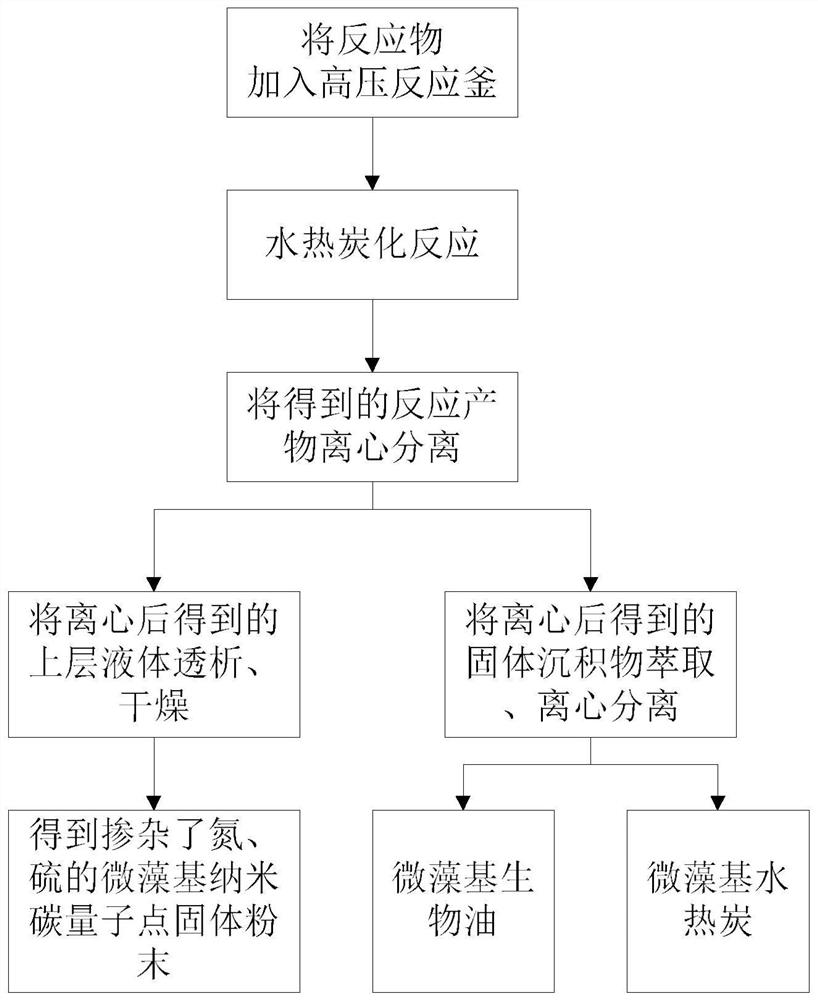

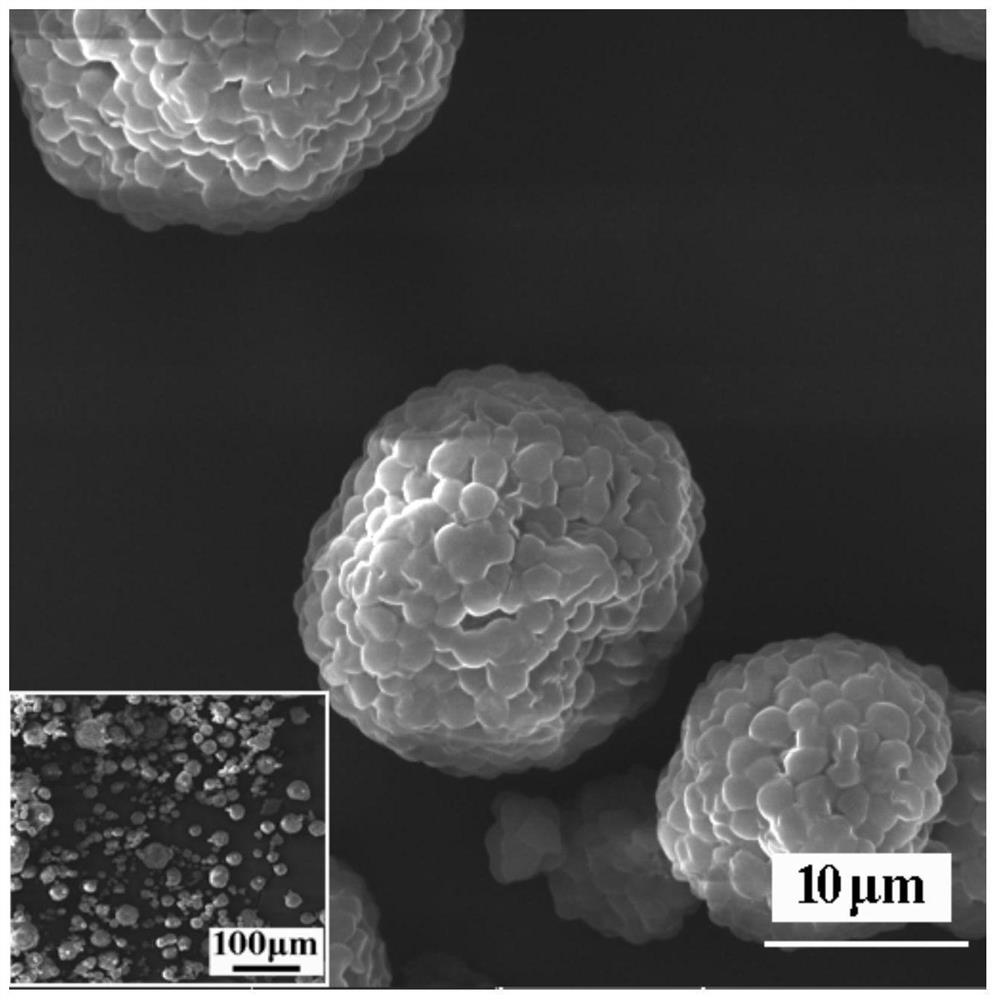

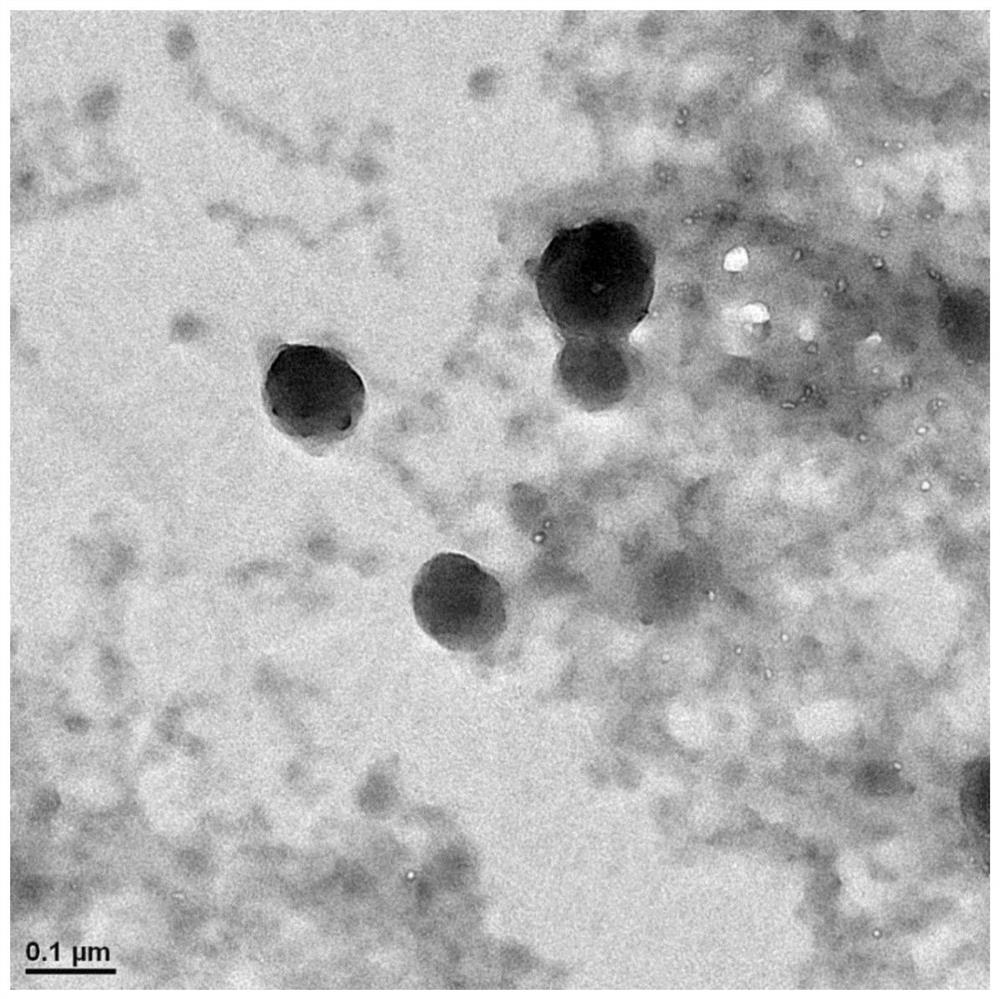

Microalgae-based nano carbon quantum dot solid powder as well as preparation method and application thereof

PendingCN113046073AExpand sourceStrong fluorescenceMaterial nanotechnologyFluorescence/phosphorescencePhysical chemistrySlurry

The invention discloses microalgae-based nano carbon quantum dot solid powder as well as a preparation method and an application thereof. The preparation method of microalgae-based nano carbon quantum dot solid powder is characterized in that chlorella is used as a carbon precursor, a nitrogen and sulfur-doped microalgae-based nano carbon quantum dot material is prepared through hydrothermal reaction, centrifugal separation and dialysis treatment, and the preparation method comprises the following specific steps: step 1, adding deionized water and chlorella into a high-pressure reaction kettle at the same time, or directly adding the microalgae slurry mixture into the high-pressure reaction kettle, replacing air in the reaction kettle with nitrogen, and sealing the reaction kettle; and 2, uniformly mixing the stirred materials, carrying out a hydrothermal carbonization reaction, and combining functional groups such as nitrogen and sulfur contained in chlorella with functional groups on the surfaces of the carbon quantum dots in the hydrothermal carbonization process to form microalgae-based nano carbon quantum dots doped with nitrogen and sulfur. The method can be widely applied to the fields of anti-counterfeiting marks, sensors, energy, semiconductors, medicines and the like.

Owner:CHONGQING UNIV

High-hardness gray cast iron and smelting method thereof

The invention provides high-hardness gray cast iron and a smelting method thereof, and belongs to the field of smelting of molten metal for casting. The quality defect of a thick-wall gray cast iron piece caused by insufficient hardness of a gray cast iron piece is overcome. The gray cast iron is prepared from the chemical components in percentage by mass: 3.0-3.3% of carbon, 1.8-2.1% of silicon,0.7-1.0% of manganese, equal to or less than 0.05% of phosphorus, 0.08-0.12% of sulphur, 0.6-0.9% of copper, 0.5-0.7% of molybdenum, 1.4-1.6% of chrome, and the balance of iron, and of course, a traceamount of other impurities in the gray cast iron is not excluded; and the gray cast iron is smelted through the raw materials in percentage by mass: 3-3.5% of pig iron, 60-64% of steel scrap, 28-32%of organic iron, and 1.5-1.7% of silicon iron. By changing the proportion of the raw materials for smelting of the gray cast iron and adding alloys and through inoculation after smelting, the chemicalcomponents of the gray cast iron are reasonably controlled, thus the produced gray cast iron reaches the surface hardness being not lower than 240 HB, A-type graphite accounts for 99% or above, and no supercooled graphite is generated.

Owner:KOCEL EQUIP

Lithium ion secondary battery negative active material and preparation method thereof, lithium ion secondary battery negative pole piece and lithium ion secondary battery

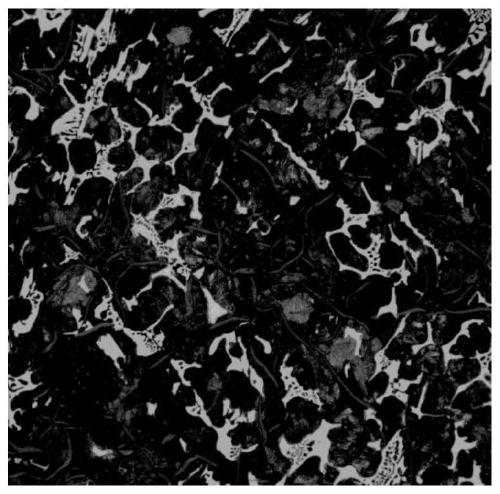

ActiveCN103794766AHigh specific capacityImprove conductivityCell electrodesSecondary cellsLithiumHigh energy

The embodiment of the invention provides a lithium ion secondary battery negative active material, which has a chemical formula of SiaGebAlcMd. Specifically, a, b, c and d respectively represent mole fractions, a is 20%-70%, b is 0.01%-10%, c is 1%-50%, d is 25%-75%, and M is one or more of Sn, Co, Ni, Ti, Fe, Cu, Mn, Mo, V and Cr. The lithium ion secondary battery negative active material has excellent cycling performance and initial efficiency. The embodiment of the invention also provides a preparation method of the lithium ion secondary battery negative active material, a lithium ion secondary battery negative pole piece containing the lithium ion secondary battery negative active material, and a lithium ion secondary battery containing the lithium ion secondary battery negative active material. The lithium ion secondary battery has high energy density and good cycle performance.

Owner:HUAWEI TECH CO LTD

Ultrasonic atomization reparation method of porous Li4Ti5O12 hollow spheres

ActiveCN107215891AControl chemical compositionImprove high current charge and discharge performanceMaterial nanotechnologyAlkali titanatesIonChemistry

The invention relates to an ultrasonic atomization preparation method of porous Li4Ti5O12 hollow spheres. The method is as follows: soluble Li and Ti compounds in the molar ratio of (4-4.3): 5 are dissolved in absolute ethanol to obtain a solution A, a soluble metal ion chelating agent and a carbon-containing compound are dissolved in deionized water to obtain a solution B, the solution A is added to the solution B under stirring condition, stirring is continued for 1 to 3 hours, then the obtained mixed solution is atomized into droplets by an ultrasonic atomizer, the droplets are loaded into a high temperature furnace with the help of a vacuum pumping system, the droplets become precursor powder, and finally the porous hollow spherical lithium titanate material is obtained by calcination in an air or oxygen atmosphere. The method effectively optimizes the space structure and the particle size of the lithium titanate negative electrode material, and effectively improves the high current charge discharge performance and the cycle performance of the Li4Ti5O12 material. At the same time, the method has the advantages of simple operation, high efficiency, low cost and convenient mass production and the like.

Owner:FUJIAN NORMAL UNIV

Lithium titanate anode material for lithium ion batteries and preparation method thereof

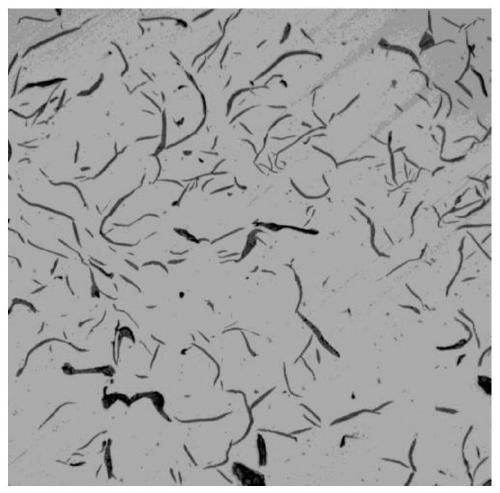

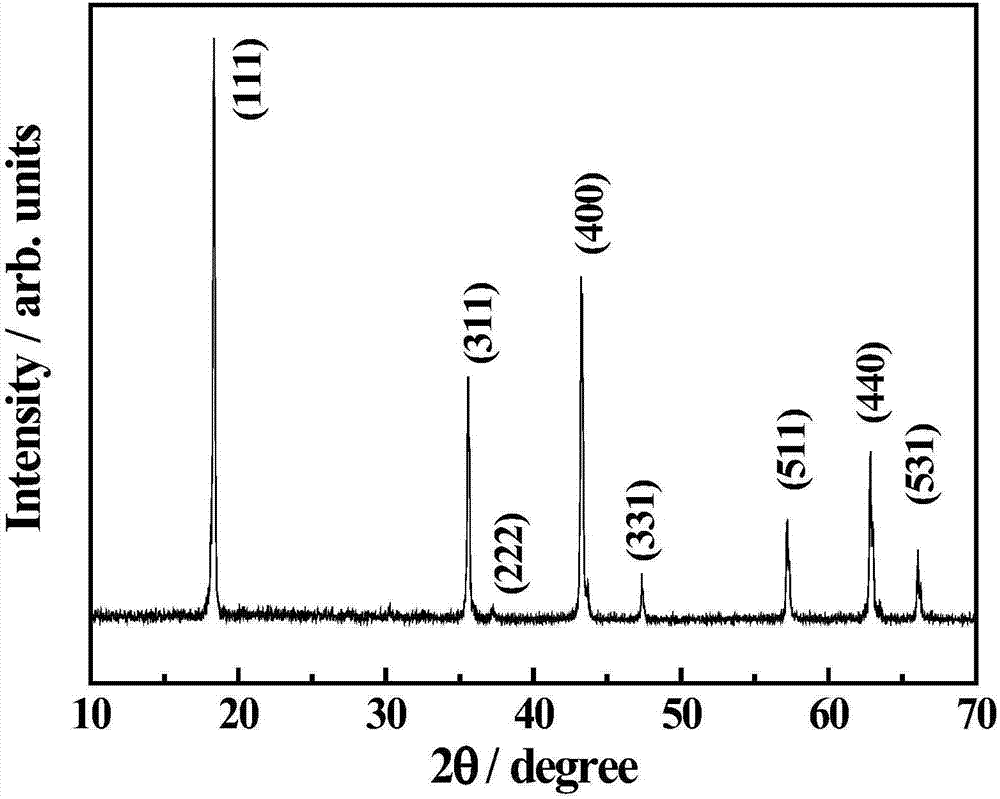

InactiveCN101944591BHigh purityImprove conductivityCell electrodesTitanium compoundsSodium-ion batterySolvent

The invention relates to a lithium titanate anode material for lithium ion batteries and a preparation method thereof. The anode material takes a lithium source, a titanium source and a carbon source as raw materials, wherein the mole ratio of Li to Ti is 4.0-4.3:5; and the doping amount of the carbon source is 1 to 30 percent based on the total mass of the lithium source and the titanium source.The preparation method comprises the following steps of: 1) weighing the lithium source, the titanium source and the carbon source according to the mole ratio and the mass ratio respectively; 2) dissolving the lithium source and the carbon source into a solvent, dissolving the titanium source into the same solvent, adding the solution of titanium source into the solution of lithium source and carbon source, and performing stirring and ultrasonic mixing; 3) adding ammonia water, controlling the pH value of the mixed solution, performing stirring and heating to volatilize the solvent and the ammonia water to form viscous jelly, and performing vacuum heating and oven-drying to obtain a precursor dried gel; 4) under the protection of an inert gas, heating and roasting the precursor dried gel,cooling the precursor dried gel to room temperature, and then crushing and grinding the precursor dried gel; 5) performing mould-pressing to obtain a module; and 6) under the protection of the inert gas, heating and roasting the module again, cooling the module to the room temperature, and then performing crushing, grinding, sieving and oven-drying to obtain the lithium titanate anode material for the lithium ion batteries.

Owner:耿世达

Method for preparing high-nitrogen steel from chromium concentrate powder

The invention provides a method for preparing high-nitrogen steel from chromium concentrate powder. In the method, chromium concentrate is employed to replace carbon reduced chrome oxide as a main raw material for preparing intermediates of high-nitrogen steel and preparing high-nitrogen steel directly. The raw material source is wide and reliable, the operation of calcination of carbon-reduced chrome oxide by utilization of high-carbon ferrochrome is omitted, the production cost is lowered, the production efficiency is raised, smoke pollution is reduced, a low carbon content and a high and controllable nitrogen content can be ensured, melting of high-nitrogen steel with different component requirement can be controlled to ensure a low carbon content and a high and controllable nitrogen content, and high-quality high-nitrogen steel bases and castings can be obtained.

Owner:上海相济新材料科技有限公司

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039BControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingCarbon coatingLithium-ion battery

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

Chemical method for preparing nano iron phosphate lithium as anode material of lithium ion battery

InactiveCN101764206ASimple processParameters are easy to controlElectrode manufacturing processesLithium compoundAmmonium hydroxide

The invention relates to a chemical method for preparing nano iron phosphate lithium as anode material of lithium ion battery, which belongs to the technical field of new energy materials. The chemical method comprises the following technological steps: preparing the solutions of a lithium compound, an iron compound and a phosphorous compound, mixing the three solutions in the mol ratio of Fe:Li:P=(0.8-1.5):1:1, dropwise adding a prepared ammonia solution into the mixed solution, and stirring the solution continuously to form a suspension; pouring the suspension into a reactor, heating to 70-100 DGE C, reacting for 5-10 h, taking out the products to filter and wash, and drying to obtain a precursor product; putting the precursor product into a high temperature furnace, heating to 500-800 DEG C under the protection of inert gas or reducing gas, and maintaining the temperature for 12-24 h; cooling to room temperature, and taking out the product to obtain the nano iron phosphate lithium powder. The preparation method has the advantages of simple synthesis technology and low cost, the particle diameter of the prepared iron phosphate lithium powder is controlled at nano level, and the electric conductivity and the electrochemical performance of the power are improved.

Owner:孙琦

A kind of preparation method of reconstituted tobacco leaf

ActiveCN108185506BControl chemical compositionImprove qualityTobacco preparationBiotechnologyNicotiana tabacum

The invention provides a method for preparing reconstituted tobacco leaves. The preparation method comprises the following steps: extracting tobacco raw materials to obtain extracts and solid slag, passing the tobacco extract through a decanter centrifuge and a disc separator, and then passing Activated carbon adsorption device A and activated carbon adsorption device B obtain the concentrated liquid of tobacco refining liquid B, and then obtain the finished reconstituted tobacco leaves after concentration, beating, coating, drying and cutting. The present invention utilizes the adsorption of different activated carbons, adopts coal-based columnar activated carbon to absorb part of the protein, pectin and other macromolecular substances in the tobacco extract, and adopts coconut shell granular activated carbon to absorb part of the nicotine and total nitrogen in the tobacco extract. , total sugar and other components, so as to achieve the purpose of regulating the chemical components of reconstituted tobacco leaves and improve the quality of reconstituted tobacco leaves.

Owner:HUBEI CHINA TOBACCO IND

Cow repellent compound ointment and preparation method thereof

ActiveCN105726362AMosquito repellent effect is goodPreventing the Spread of Diseases in Dairy CowsCosmetic preparationsToilet preparationsChemistryNepeta

The invention relates to the technical field of livestock health protection articles, in particular to cow repellent compound ointment and a preparation method thereof. The cow repellent compound ointment comprises main materials including N,N-diethyl-m-methyl benzamide DEET, perilla oil, nepeta oil and dichroine, and auxiliary materials including stearic acid, glycerol, glyceryl monostearate, ethylparaben, lauryl sodium sulfate, vaseline and distilled water. DEET and dichroine are adopted as main effective ingredients, plant essential oil serves as a synergist, a good mosquito repelling effect is achieved, and propagation of part of cow diseases can be effectively prevented; due to the fact that cows can take a full rest, the milk yield of the cows is increased; due to the fact that mature repellent DEET and dichroine are adopted, and the plant essential oil is added in a matched mode, the cow repellent compound ointment is safe and reliable; a uniform solid is obtained by means of stirring, the property is stable, quality is controllable, and it is quite beneficial for industrial production. The repellent compound ointment has high clinical application value in veterinary medicine.

Owner:河北美荷药业有限公司

A kind of preparation method of lignin-based high specific surface area carbon material

ActiveCN107628618BLarge specific surface areaLow densityCarbon compoundsFreeze-dryingArgon atmosphere

The invention discloses a method for preparing a lignin-based high specific surface area carbon material. The method comprises the following steps: by taking lignin as a carbon material precursor, preparing a solution from the lignin, performing freeze-drying so as to obtain lignin aerogel, carbonizing the lignin aerogel in a tubular furnace in an argon atmosphere, and cooling, thereby obtaining the lignin-based high specific surface area carbon material. Through freeze-drying and high-temperature carbonization, the carbon aerogel material of a high specific surface area and low density is prepared, the activation process is avoided, and compared with a conventional preparation method of carbonization and activation later, the method has the advantages that the energy consumption is effectively reduced and the environment pollution is avoided.

Owner:YANGTZE NORMAL UNIVERSITY

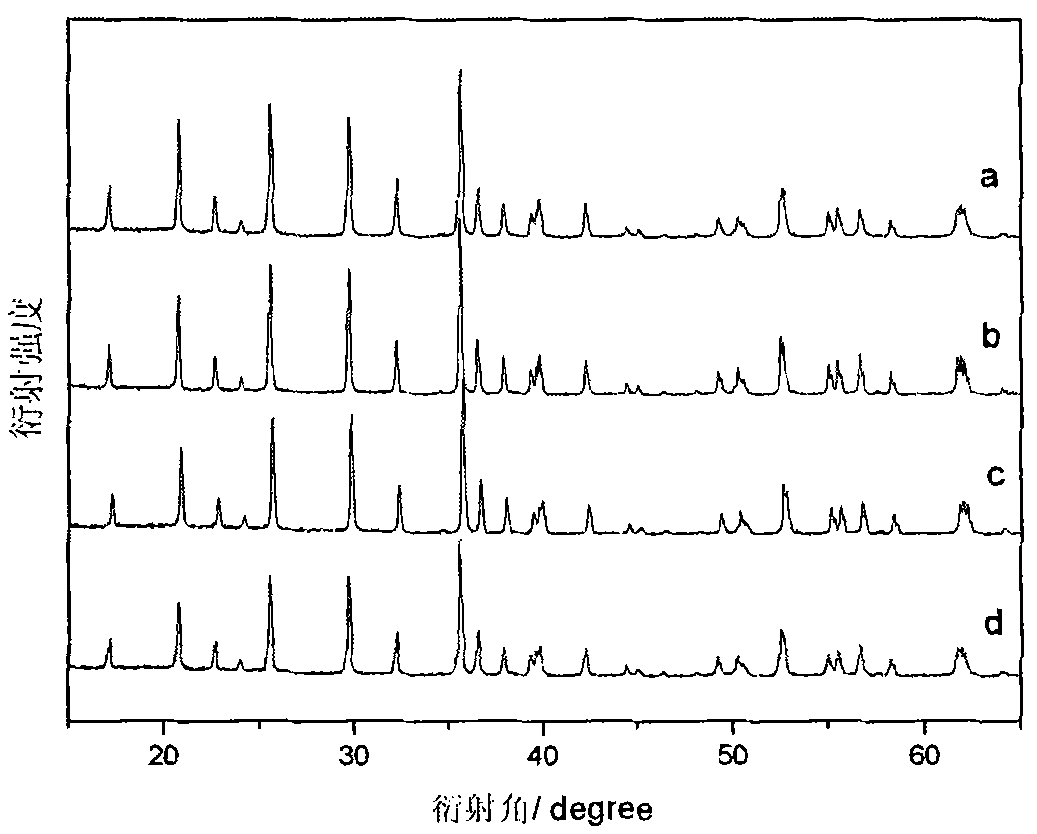

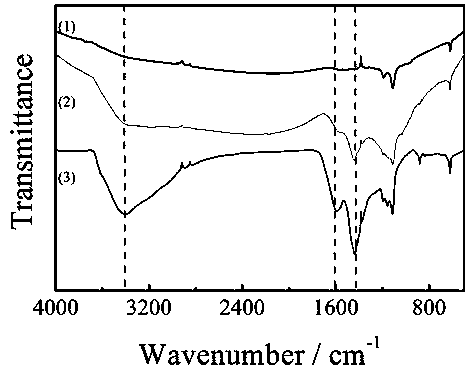

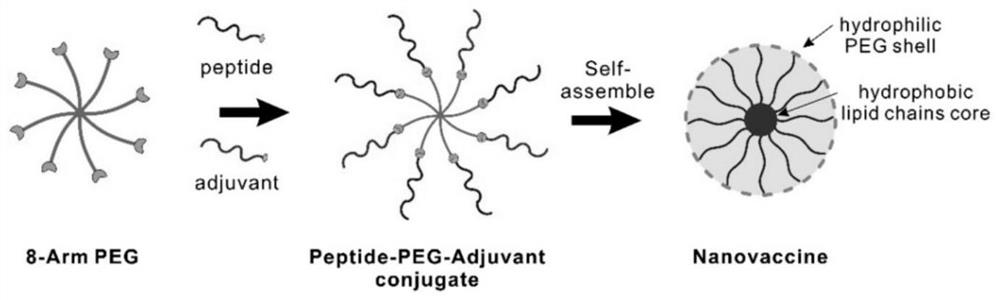

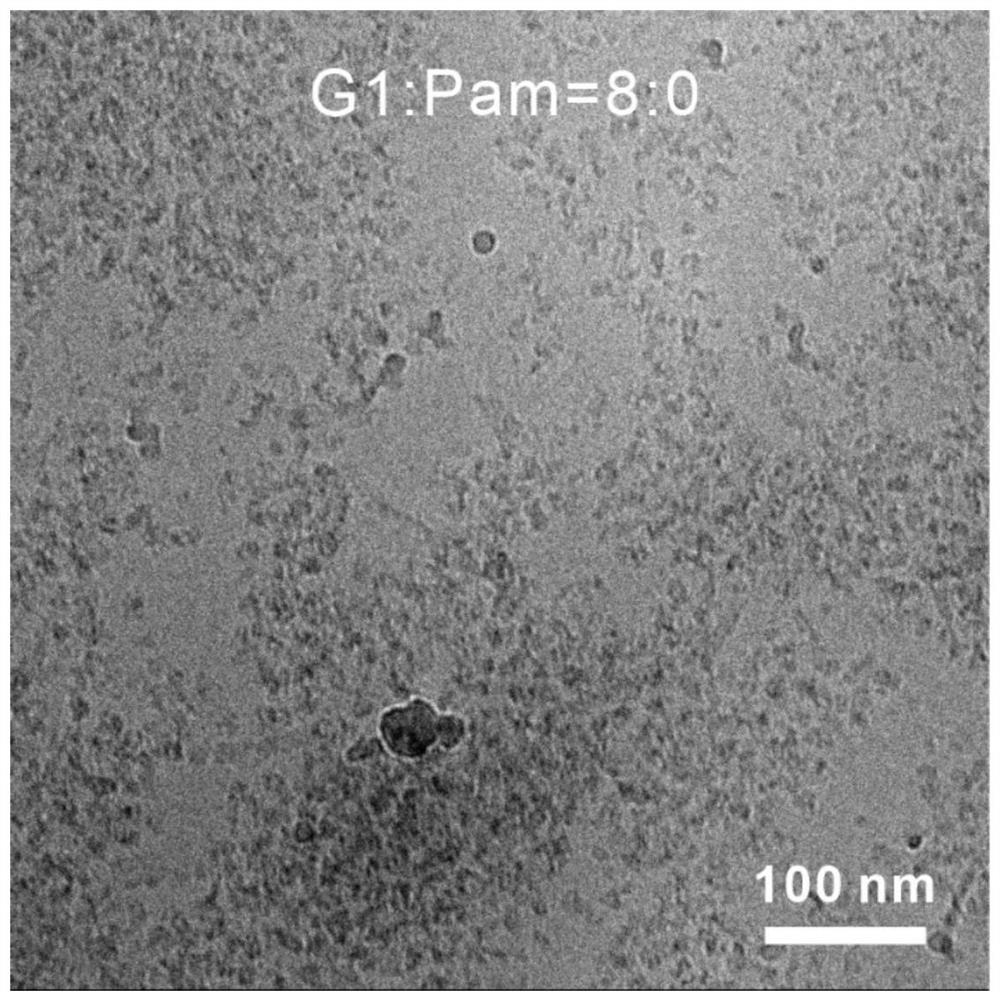

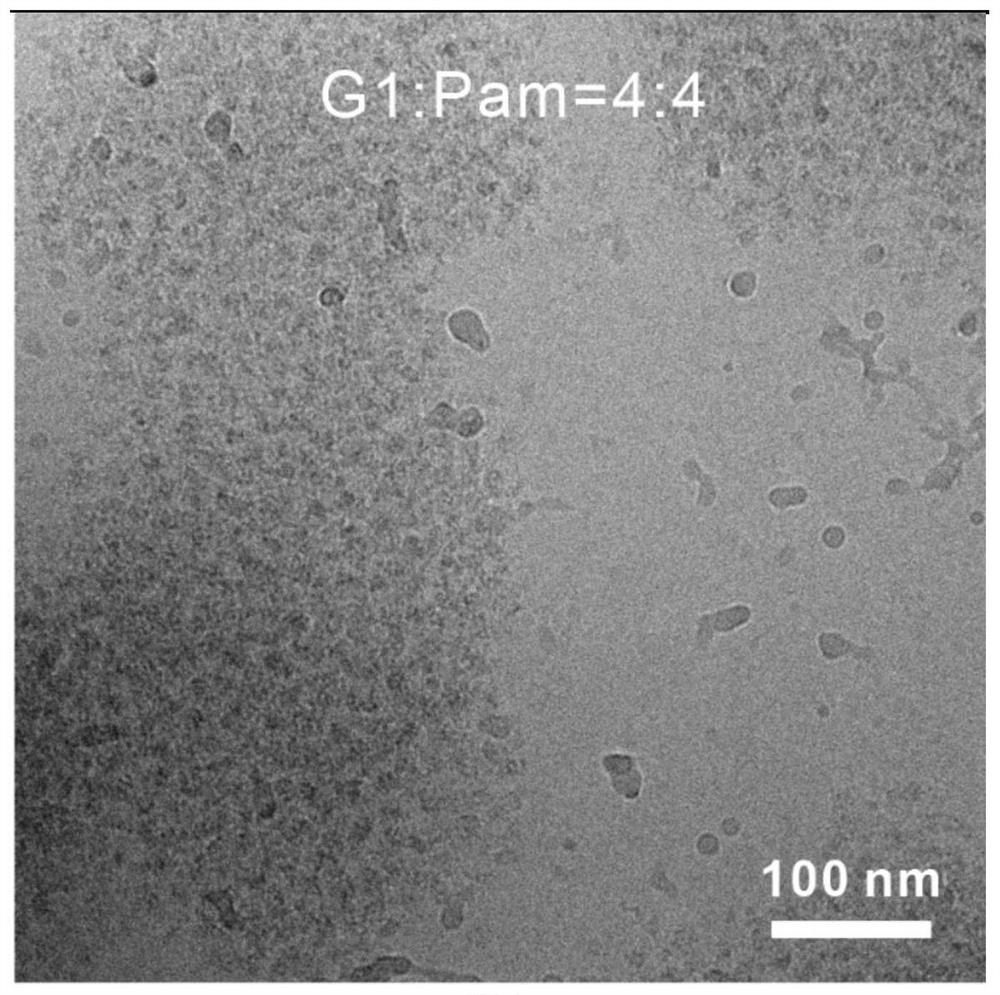

Polymer coupled polypeptide nano vaccine and preparation method thereof

PendingCN114246943AStabilized co-transported adjuvant moleculesControl chemical compositionMaterial nanotechnologyNanomedicineChemistryAdjuvant

The invention discloses a polymer coupled polypeptide nano vaccine and a preparation method thereof. The vaccine comprises the following components in molar ratio: 1, a polymer skeleton with multiple reaction centers, 8.1, grafted molecules, 49167-213900, an organic solvent and 170-657 of organic alkali, the particle size of the nano vaccine can be controlled by regulating and controlling the stoichiometric ratio of the polypeptide to the Pam adjuvant molecule; the polypeptide nano vaccine obtained by the invention has a stable structure, is hardly influenced by concentration, has no concentration limiting condition, and has the capability of stabilizing co-transport adjuvant molecules.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

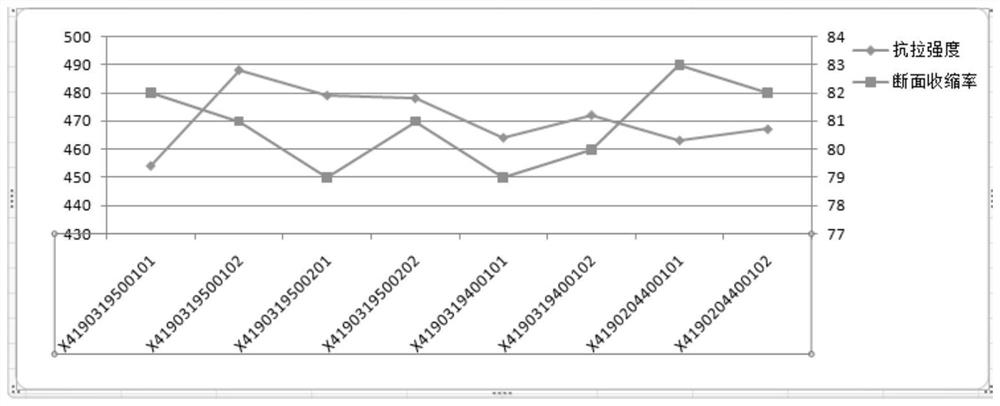

A kind of Zr-containing wire steel hot-rolled wire rod and its production process

The invention provides a Zr-containing welding wire steel hot-rolled wire rod and its production process, the chemical composition of which is calculated according to weight percentage: C≤0.06%, Si: 0.45-0.55%, Mn: 0.95-1.05%, P≤0.020% , S: ≤0.018%, Cr: ≤0.10%, Ni: ≤0.10%, Cu: ≤0.20, Mo: ≤0.10, V: ≤0.02 , Ti: 0.07-0.13%, Al: 0.06-0.12%, Zr: 0.03-0.09%, and the balance is Fe and unavoidable impurities. By adopting reasonable LF slagging and deoxidation process, ferro-zirconium alloy addition method and timing, etc., the Zr content in molten steel can be controlled to meet the standard requirements. By adopting reasonable continuous casting process parameters, tundish mold slag, protective casting measures and other means, nodulation of molten steel in the casting process is avoided, and the normal casting of molten steel is guaranteed. The invention solves the problems of Zr alloying and continuous casting billet pouring process control in the production process of welding wire steel.

Owner:SUZHOU QIJI WELDING MATERIALS CO LTD

A method for preparing high nitrogen steel with micro-carbon ferrochrome

The invention provides a method for preparing high-nitrogen steel from micro-carbon ferrochrome. First, micro-carbon ferrochrome powder is subjected to nitrogen addition, high-nitrogen ferrochrome intermediates are prepared, and then the high-nitrogen ferrochrome intermediates are employed to prepare high-nitrogen steel. In the method, micro-carbon ferrochrome powder is employed to prepare high-nitrogen ferrochrome intermediates self, the quality is good, the material quality is controllable, which is helpful for smooth and steady smelting of high-nitrogen alloy and high-nitrogen steel melt, chemical components of high-nitrogen steel can be controlled effectively, and high-quality high-nitrogen steel bases and castings can be obtained. Micro-carbon ferrochrome powder is employed as a main raw material for preparing high-nitrogen steel, the source is wide, the quality is reliable, the preparation cost of high-nitrogen steel bases and castings can be lowered when the method is compared with a method employing nitride ferrochrome and high-nitrogen ferrochrome raw materials directly.

Owner:上海相济新材料科技有限公司

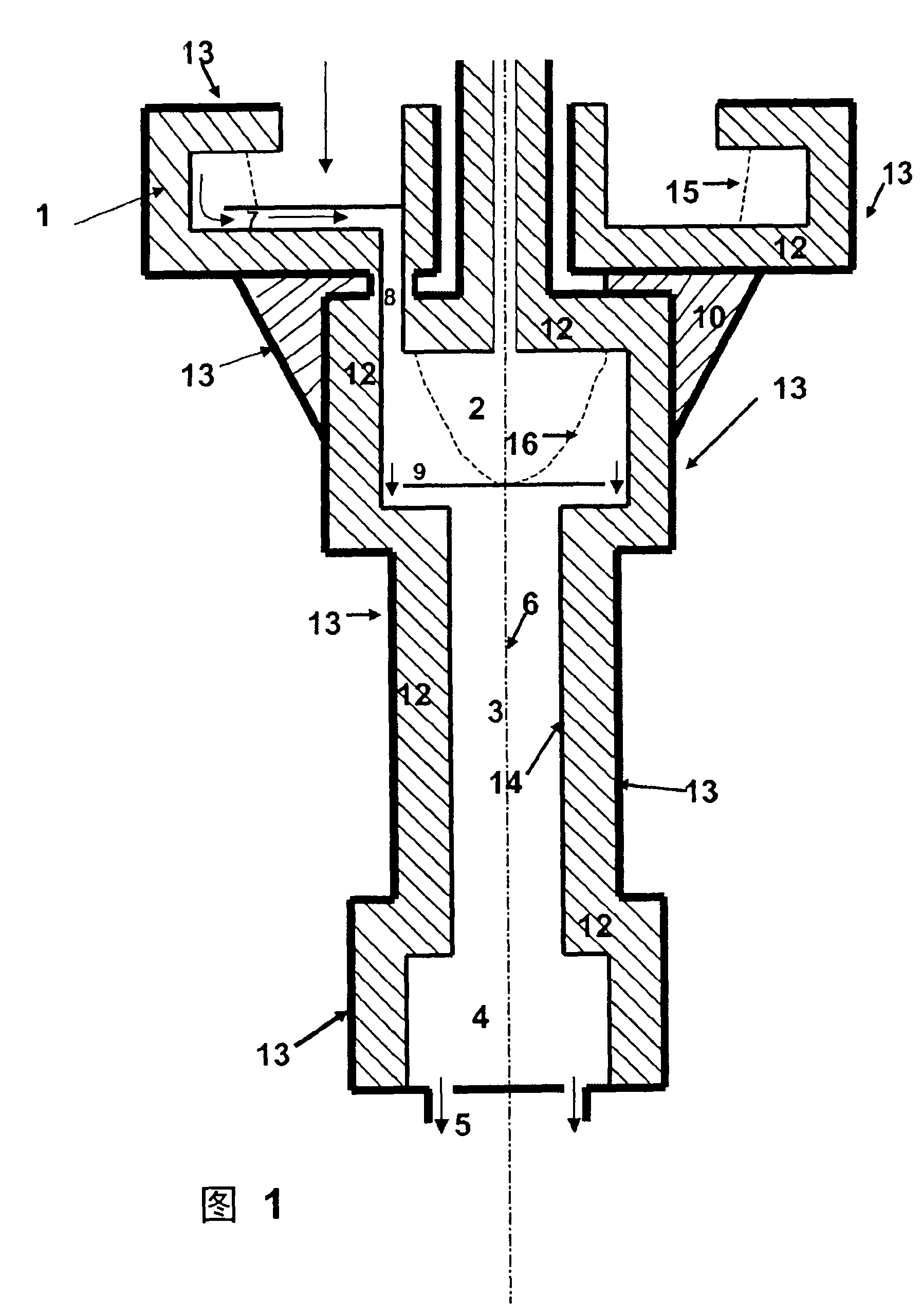

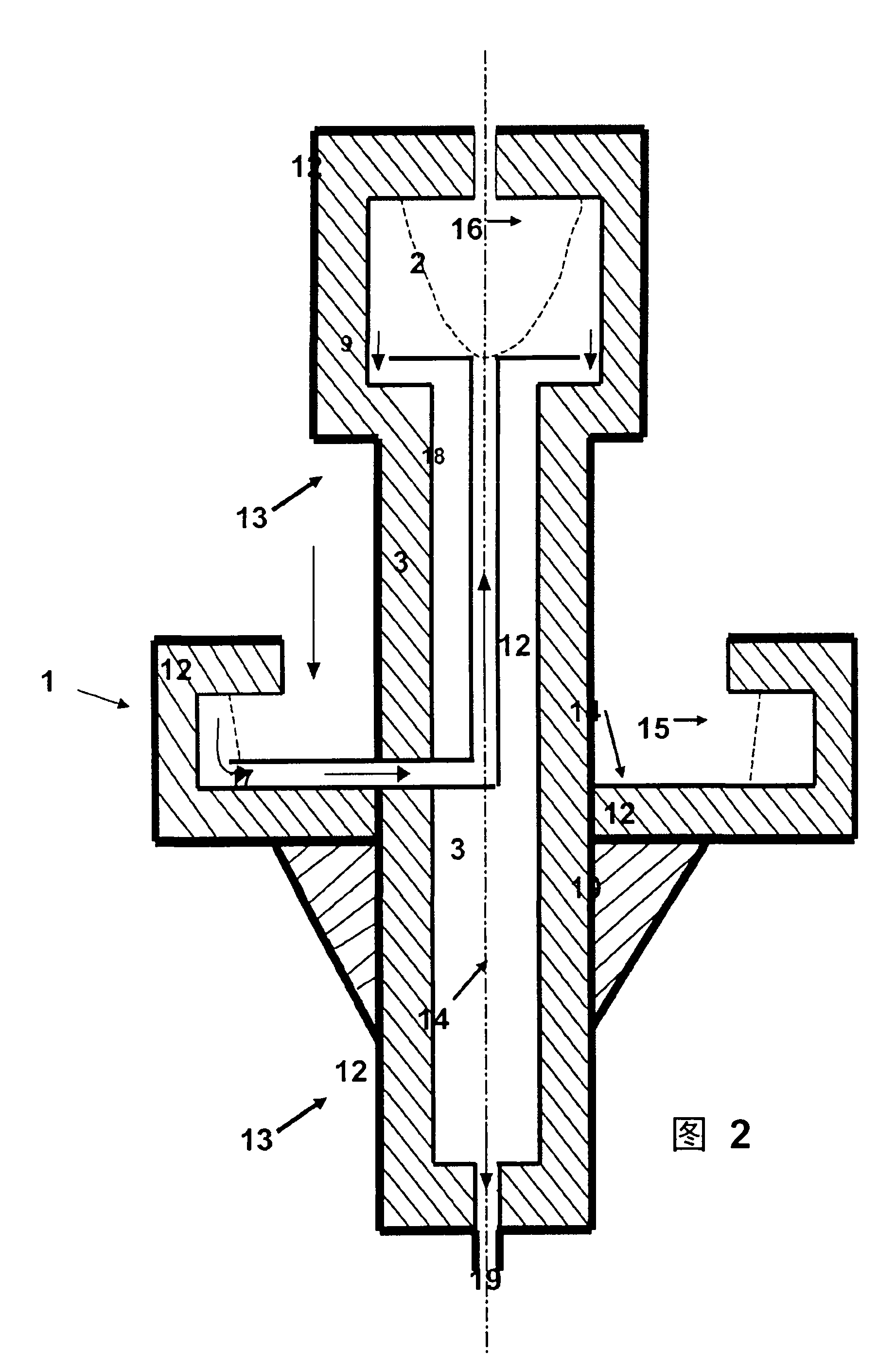

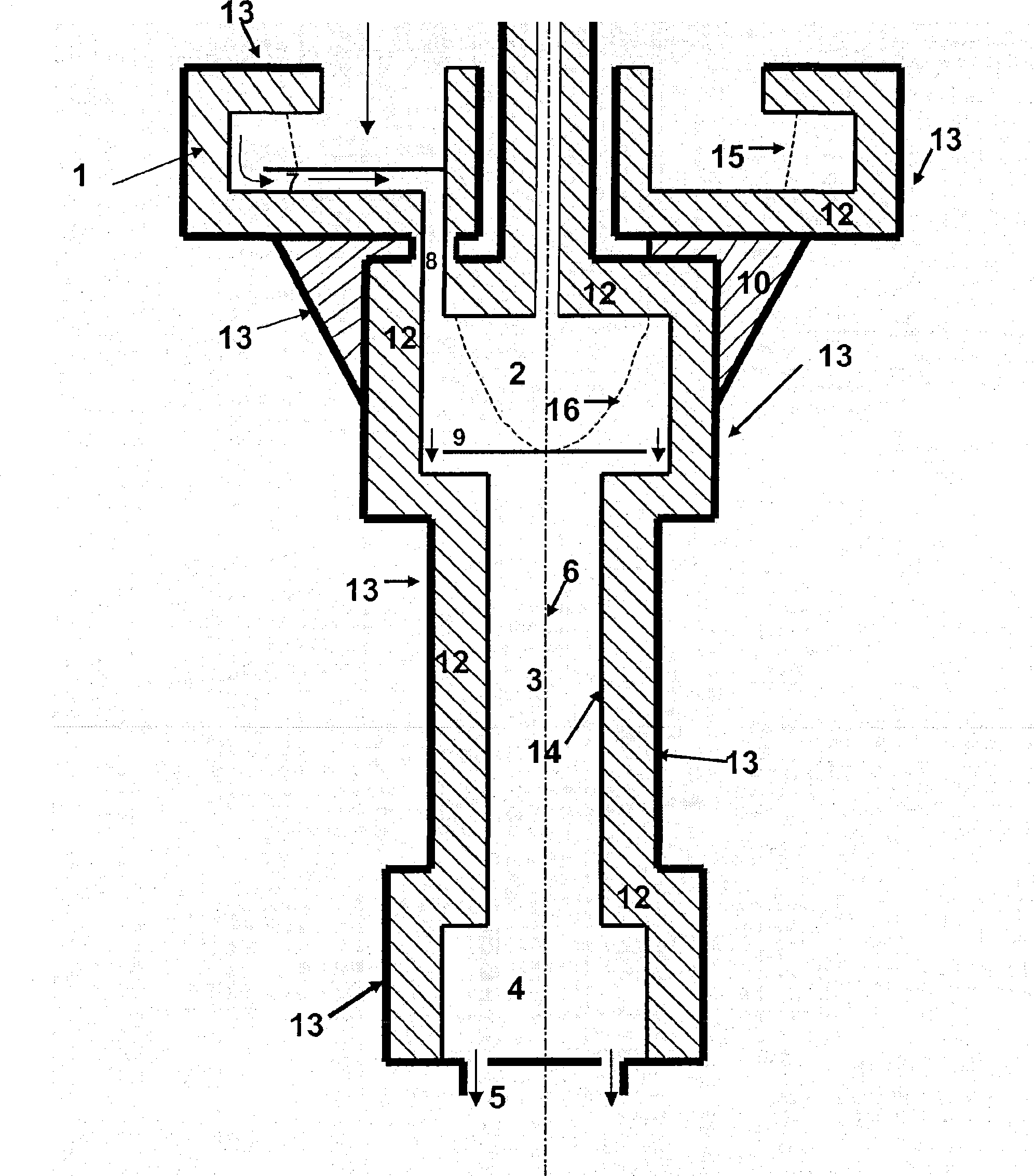

Method and device for manufacturing glass and products obtained with the aid of said method

InactiveCN101023036BSimple designDoes not affect refining performanceGlass furnace apparatusGas discharge vessels/containersMaterials scienceMolten glass

The invention relates to a device which can be rotationally displaced about an axis (6) in order to fine and homogenize glass, comprising a receptacle (1) which is used to receive the molten glass that is to be treated; a depressurizing compartment (2) and at least one opening through which the glass can exit (5, 19); also comprising a means for dispatching (7, 8, 17, 18) the molten glass from the feeder receptacle (1 ) to the depressurizing compartment (2). The invention also relates to a method for the production of substrates, implementing the device according to the invention, and substrates produced therewith.

Owner:SAINT-GOBAIN GLASS FRANCE

Flux-cored wire for gas shielded welding of super duplex stainless steel and preparation method thereof

ActiveCN110142529BControl chemical compositionEasy to solveWelding/cutting media/materialsSoldering mediaFerrochromeAustenite

The invention discloses a flux-cored wire used for super duplex stainless steel gas shielded welding and a preparation method thereof. The flux-cored wire is composed of an external use steel belt andflux powder, wherein the external use steel belt is made of an austenitic stainless steel belt with 17.0%-18.0% of chromium and 11.0%-12.5% of nickel; and the flux powder comprises the following components of, in percentage by weight, 36.0%-38.0% of chromium powder, 9.0%-13.0% of high-nitrogen chromium iron, 2.5%-3.0% of electrolytic manganese metal, 4.0%-5.0% of molybdenum powder, 0.5%-1.0% of ferrosilicon, 1.0%-1.5% of ferrotitanium, 0.5%-1.0% of aluminum-magnesium alloy, 18.0%-20.0% of rutile, 1.0%-2.0% of quartz, 5.0%-6.0% of zircon sand, 1.0%-1.5% of potassium feldspar, 3.0%-3.5% of albite, 1.0%-1.5% of fluorite, 0.5%-1.0% of sodium cryolite, 1.0%-1.5% of potassium titanate, 0.1%-0.3% of bismuth oxide and the balance iron powder. According to the flux-cored wire used for super duplexstainless steel gas shielded welding and the preparation method thereof, the components and the two-phase proportion of deposited metal can be balanced, thus obtaining a duplex stainless steel welding joint which is good in forming quality and excellent in corrosion resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com