Preparation method of organic-inorganic hybrid perovskite thin film

A perovskite and thin film technology, which is applied in the field of preparation of organic-inorganic hybrid perovskite thin films, can solve the problems of difficult condition control, low utilization rate of raw materials, high requirements for gas phase method equipment, etc., and achieve uniform film layer and good compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

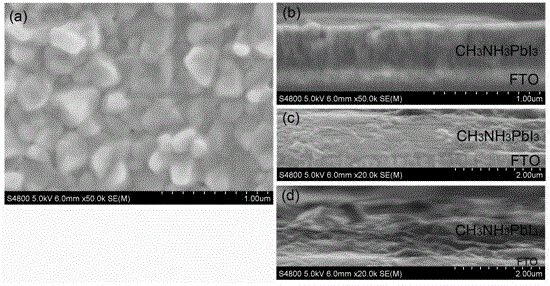

[0019] (1) Use conductive glass as the substrate, use zinc powder and hydrochloric acid with a mass percentage concentration of 2% to corrode the parts that do not need to be deposited on the conductive surface of the FTO conductive glass, leave the area that needs to be deposited, and then use ethanol, acetone and Ultrasonic cleaning with deionized water for 10 minutes respectively, and drying in a constant temperature oven at 50° C. to prepare the treated substrate.

[0020] (2) Weigh 0.033g of lead nitrate and 0.039g of sodium thiosulfate pentahydrate, dissolve them in 100ml of distilled water to prepare a mixed solution, and adjust the pH of the mixed solution to 2.8 with acetic acid, which is the electrolyte.

[0021] (3) Use the substrate treated in step (1) as the cathode, and the graphite sheet as the anode, and insert them into the electrolyte prepared in step (2) in parallel, keep the constant temperature at 80°C and stir slowly with magnetic force, and adjust the cur...

Embodiment 2

[0026] Step (1) and step (2) are the same as embodiment 1.

[0027] (3) Use the substrate treated in step (1) as the cathode, and the graphite sheet as the anode, and insert them into the electrolyte prepared in step (2) in parallel, keep the constant temperature at 80°C and stir slowly with magnetic force, and adjust the current The density is 1.0mA / cm 2 , the electrodeposition time is 20 minutes, the substrate is taken out after the deposition is completed, cleaned with distilled water and then dried with nitrogen gas, and a lead sulfide film is deposited on the substrate.

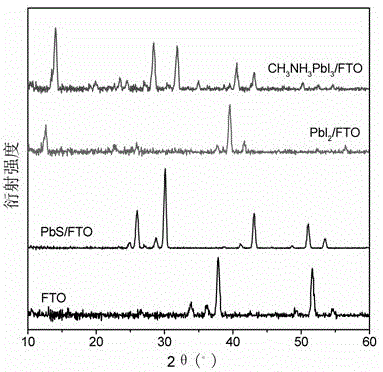

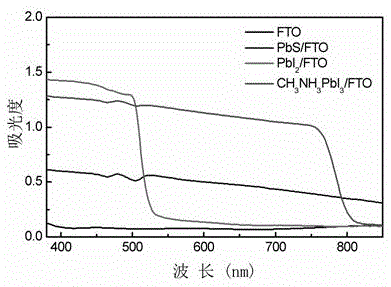

[0028] (4) Use the lead sulfide film deposited in step (3) as a precursor, place it in a vacuum atmosphere furnace together with excess elemental iodine, and keep it warm at 120°C for 30 minutes. The iodine evaporates into iodine vapor, and the lead sulfide film is iodized. , to obtain a yellow lead iodide film.

[0029] (5) dissolving methylammonium iodide in isopropanol and preparing a solution with ...

Embodiment 3

[0031] Step (1) and step (2) are the same as embodiment 1.

[0032] (3) Use the substrate treated in step (1) as the cathode, and the graphite sheet as the anode, and insert them into the electrolyte prepared in step (2) in parallel, keep the constant temperature at 80°C and stir slowly with magnetic force, and adjust the current The density is 1.0mA / cm 2 , the electrodeposition time is 30 minutes, after the deposition, the substrate is taken out, cleaned with distilled water and then dried with nitrogen gas, and a lead sulfide film is deposited on the substrate.

[0033] (4) Use the lead sulfide film deposited in step (3) as a precursor, place it in a vacuum atmosphere furnace together with excess elemental iodine, and keep it warm at 120°C for 30 minutes. The iodine evaporates into iodine vapor, and the lead sulfide film is iodized. , to obtain a yellow lead iodide film.

[0034] (5) dissolving methylammonium iodide in isopropanol and preparing a solution with a concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com