Process for preparing highly-hydrophilic alumina film material

A technology of hydrated alumina and membrane materials, applied in the field of material chemistry, to achieve the effects of controllable morphology, convenient large-scale promotion and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

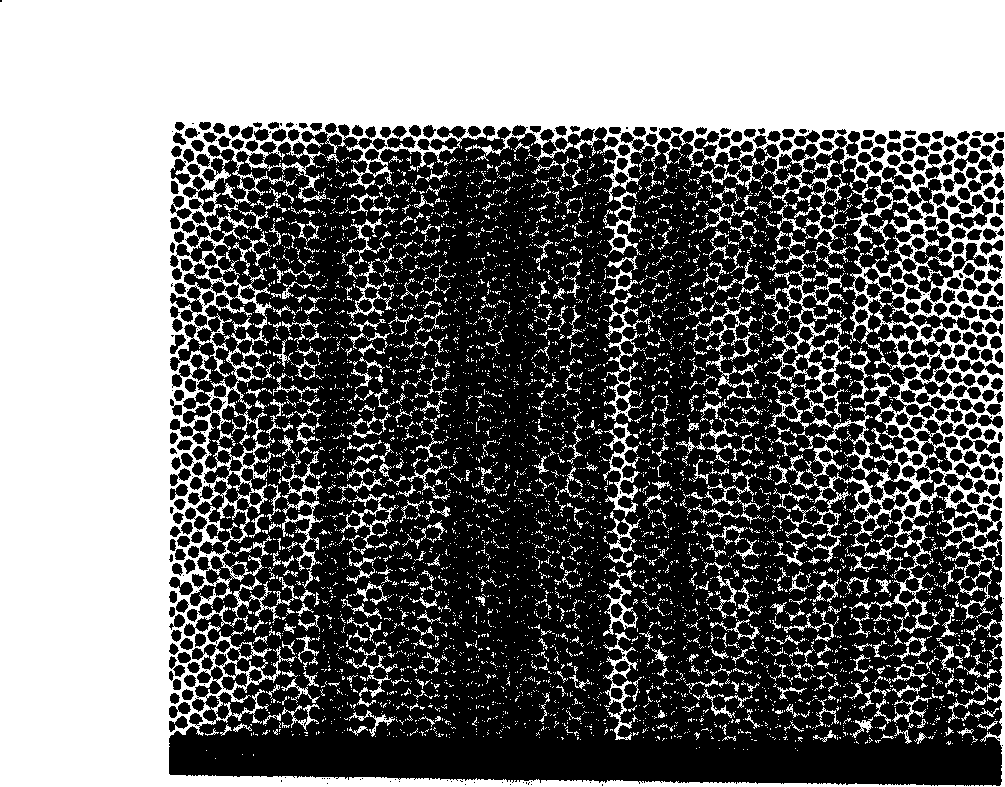

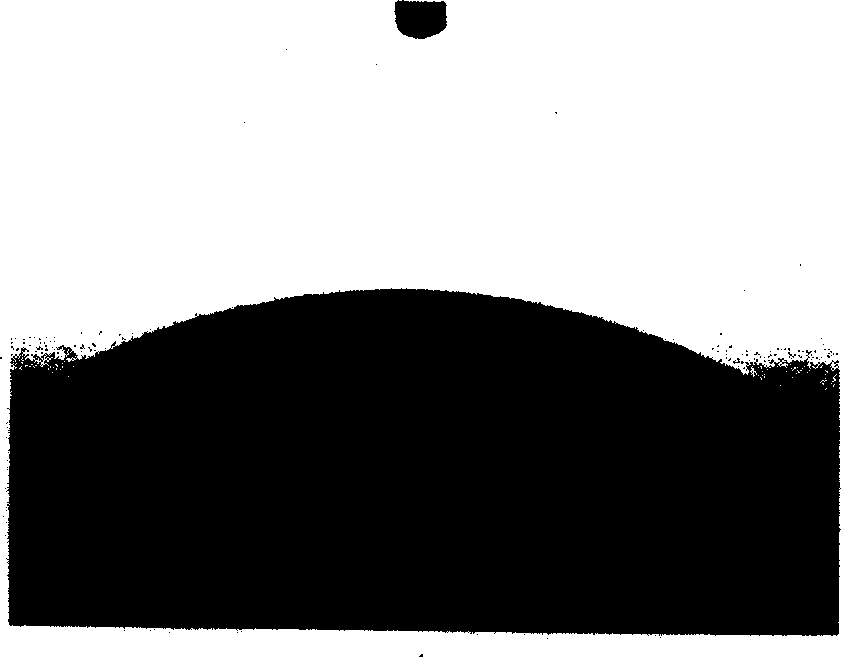

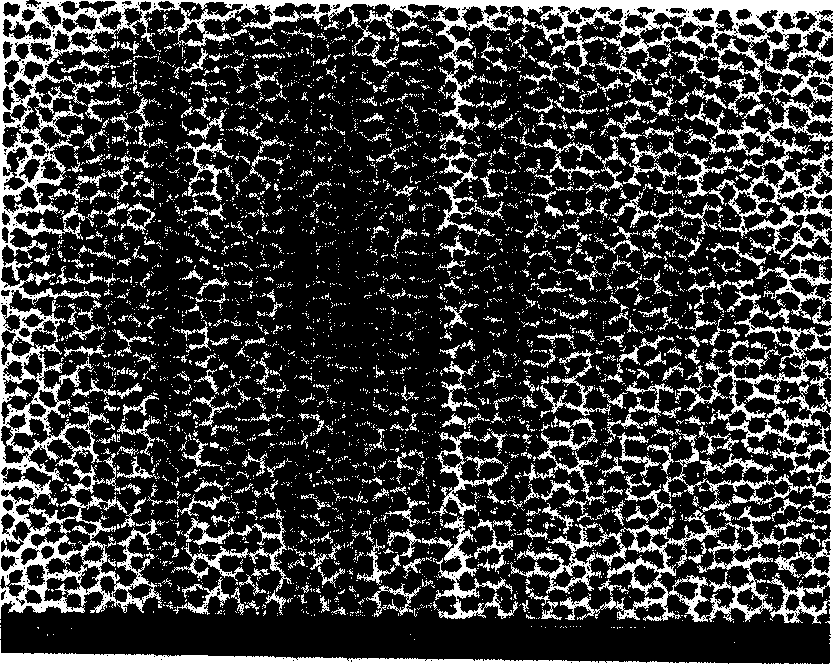

Image

Examples

Embodiment 1

[0039] 1) Pretreatment: Cut out a high-purity aluminum foil with a purity of 99.999% (purchased from the Beijing Institute of Nonferrous Metals) in an appropriate shape and size, ultrasonically clean it with ethanol and acetone for 30 minutes and 10 minutes, respectively, and then wash it in perchloric acid / ethanol ( v / v, 1 / 5) electrochemically polished in the solution until the surface of the aluminum foil is as smooth as a mirror, and then simply rinsed with water for 1-2 times.

[0040] 2) The first step of anodizing: the aluminum foil obtained in step 1) is used as the anode, and the platinum sheet is used as the cathode, in 0.2M oxalic acid, at a voltage of 40V, the first step of anodizing is performed when the ambient temperature is less than 15°C for 12 hours or so.

[0041] 3) Erosion of the one-step oxide film: soak the aluminum foil in step 2) in a mixture of 6wt% phosphoric acid and 1.8wt% chromic acid in a 65°C water bath for 8-10 hours.

[0042] 4) The second ste...

Embodiment 2

[0047] 1) Pretreatment: Cut out a high-purity aluminum foil with a purity of 99.999% in an appropriate shape and size, ultrasonically clean it with ethanol and acetone for 30 minutes and 10 minutes, respectively, and wash it in perchloric acid / ethanol (v / v, 1 / 5) solution Electrochemical polishing until the surface of the aluminum foil is as smooth as a mirror, and then simply rinsed with water for 1 or 2 times.

[0048] 2) The first step of anodizing: the aluminum foil obtained in step 1) is used as the anode, and the platinum sheet is used as the cathode. In 0.2M oxalic acid, at a voltage of 45V, the first step of anodizing is performed when the ambient temperature is less than 15°C. 11.5 hours or so.

[0049] 3) Erosion of the one-step oxide film: soak the aluminum foil in step 2) in a mixture of 6wt% phosphoric acid and 1.8wt% chromic acid in a 65°C water bath for 8-10 hours.

[0050] 4) The second step of anodic oxidation: the aluminum foil peeled off in step 3) was subje...

Embodiment 3

[0055] 1) Pretreatment: Cut out a high-purity aluminum foil with a purity of 99.999% in an appropriate shape and size, ultrasonically clean it with ethanol and acetone for 30 minutes and 10 minutes, respectively, and wash it in perchloric acid / ethanol (v / v, 1 / 5) solution Electrochemical polishing until the surface of the aluminum foil is as smooth as a mirror, and then simply rinsed with water for 1 or 2 times.

[0056] 2) The first step of anodizing: the aluminum foil obtained in step 1) is used as the anode, the platinum sheet is used as the cathode, and the first step of anodizing is performed in 0.2M oxalic acid at a voltage of 50V and the ambient temperature is less than 15°C. hours or so.

[0057] 3) Erosion of the one-step oxide film: soak the aluminum foil in step 2) in a mixture of 6wt% phosphoric acid and 1.8wt% chromic acid in a 65°C water bath for 8-10 hours.

[0058] 4) The second step of anodic oxidation: the aluminum foil peeled off in step 3) was subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com