Alkali metal negative electrode-electrolyte integrated material, preparation method thereof and application of alkali metal negative electrode-electrolyte integrated material in assembling solid-state battery in air

A solid-state battery and electrolyte technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolyte layer coatings, etc., can solve problems affecting the electrochemical performance of solid-state batteries, large electrode-electrolyte interface impedance, etc. Improve the interface impedance problem and improve the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

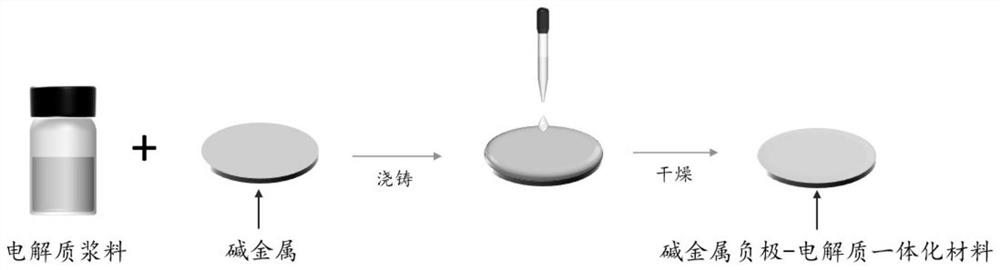

[0043] A method for preparing a lithium metal negative electrode-electrolyte integrated material, comprising the following steps:

[0044] (1) Weigh 0.2g of dried lithium bistrifluoromethanesulfonimide (LiTFSI), dissolve it in 9.5g of tetrahydrofuran and stir at 25°C for 12h, and obtain a uniform electrolyte salt solution after the electrolyte salt is completely dissolved; weigh 0.5 g of dried polyvinylidene chloride (PVDC) powder was added to the prepared homogeneous electrolyte salt solution and stirred at 25° C. for 12 hours to form a PVDC-LiTFSI electrolyte slurry.

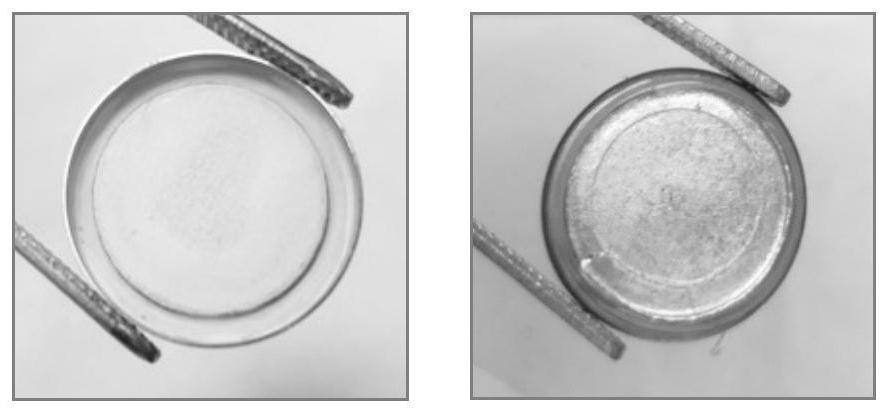

[0045] (2) Transfer the homogeneously dissolved or dispersed electrolyte slurry described in step (1) to an argon atmosphere with a water value and an oxygen value of ≤0.1ppm. in 80 μL cm -2 The coating amount of the electrolyte slurry described in the step (1) is coated on the metal lithium sheet surface, such as figure 1 Coating was carried out according to the coating process shown, and after uniform coat...

Embodiment 2

[0059] A method for preparing a lithium metal negative electrode-electrolyte integrated material, comprising the following steps:

[0060] (1) Weigh 0.4g of dried LiTFSI, dissolve it in 9g of tetrahydrofuran and stir at 25°C for 12h, and obtain a uniform electrolyte salt solution after the electrolyte salt is completely dissolved; weigh 0.9g of dried PVDC powder and 0.10g of dried PEO powder (Mw=600,000) was added to the prepared homogeneous electrolyte salt solution and stirred at 25°C for 12 hours to form PVDC-PEO-LiTFSI electrolyte slurry.

[0061] (2) Transfer the homogeneously dissolved or dispersed electrolyte slurry described in step (1) to an argon atmosphere with a water value and an oxygen value of ≤0.1ppm. in 90 μL cm -2 The coating amount of the electrolyte slurry described in the step (1) is coated on the metal lithium sheet surface, such as figure 1 Coating was carried out according to the coating process shown, and after uniform coating, tetrahydrofuran was vo...

Embodiment 3

[0064] A method for preparing a lithium metal negative electrode-electrolyte integrated material, comprising the following steps:

[0065] (1) Weigh 0.4g of dried LiTFSI, dissolve it in 9g of tetrahydrofuran and stir at 25°C for 12h, and obtain a uniform electrolyte salt solution after the electrolyte salt is completely dissolved; weigh 0.9g of dried PVDC powder and 0.10g of dried PVDF powder was added to the prepared homogeneous electrolyte salt solution and stirred at 25°C for 12 hours to form PVDC-PVDF-LiTFSI electrolyte slurry.

[0066] (2) Transfer the homogeneously dissolved or dispersed electrolyte slurry described in step (1) to an argon atmosphere with a water value and an oxygen value of ≤0.1ppm. in 90 μL cm -2 The coating amount of the electrolyte slurry described in the step (1) is coated on the metal lithium sheet surface, such as figure 1 Coating was carried out according to the coating process shown, and after uniform coating, tetrahydrofuran was volatilized a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com