Contactor coil

A technology of contactors and coils, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of irregular shape of the wire package, prone to noise, open circuit or short circuit of the coil, etc., and achieve good waterproof performance and not easy to leak , good isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

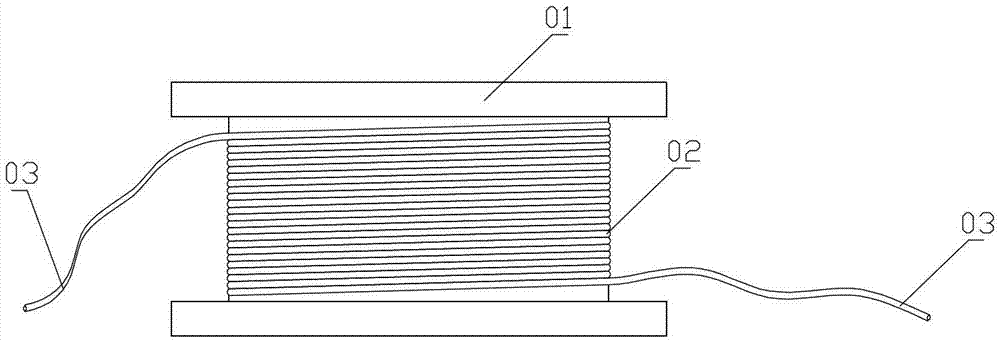

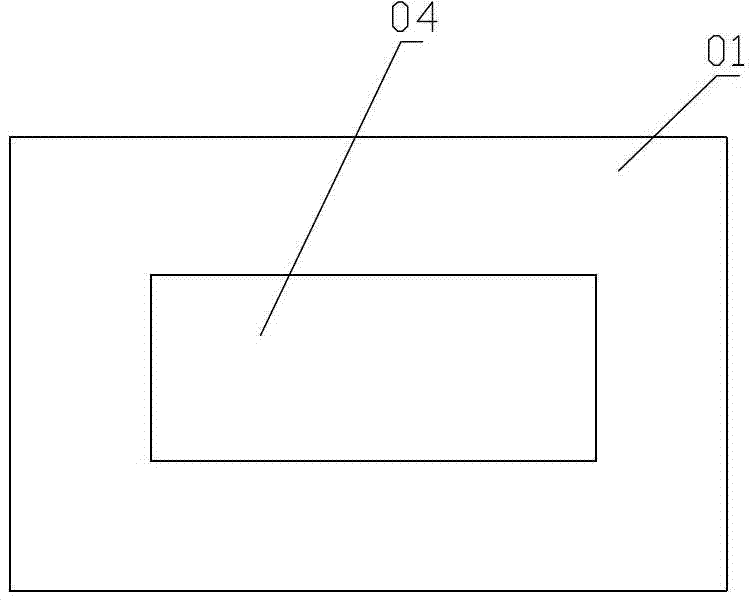

[0021] combined with image 3 to attach Figure 5 , a contactor coil, which includes at least one winding unit, the winding unit includes a skeleton 1 and an enameled wire 2, and the enameled wire 2 is wound on the skeleton 1; it is characterized in that: the enameled wire 2 is covered There is an insulating layer 3 that seals the enameled wire 2, and the starting and ending wire ends of the enameled wire 2 are provided with wiring structures protruding from the insulating layer. . The thickness of the insulating layer 3 is not less than 0.7 mm. The thickness of the insulating layer 3 stated as a best practice value is 1 mm. The insulating layer 3 is integrally formed by die casting of polyethylene terephthalate insulating material. The polyethylene terephthalate insulation material is obtained by condensation polymerization of terephthalic acid and ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com