Flux-cored wire used for super duplex stainless steel gas shielded welding and preparation method thereof

A duplex stainless steel and gas shielding technology, which is applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem that the chemical composition of the weld metal and the ratio of the two phases are difficult to accurately control, the corrosion resistance is reduced, and the impact is relatively large. Large and other problems, to achieve the effect of excellent welding process performance and good weld forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

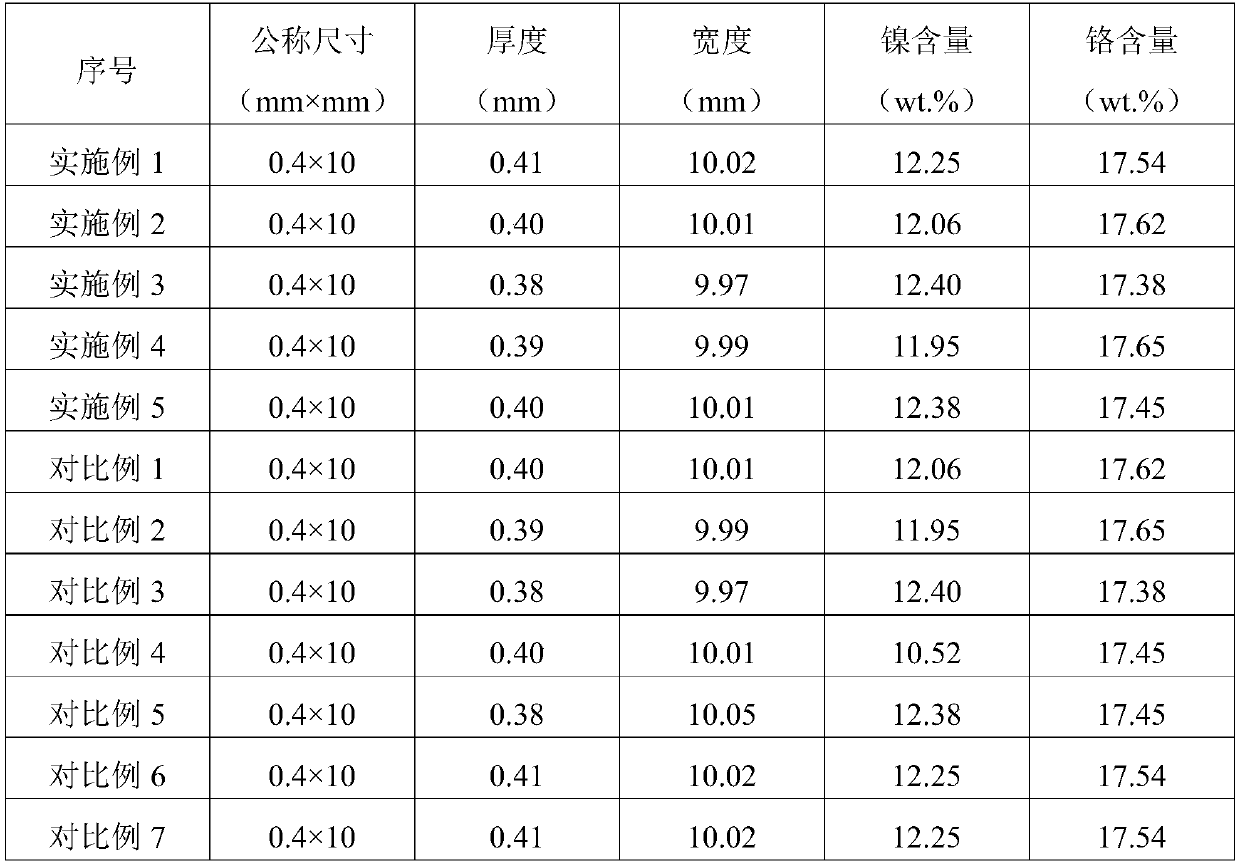

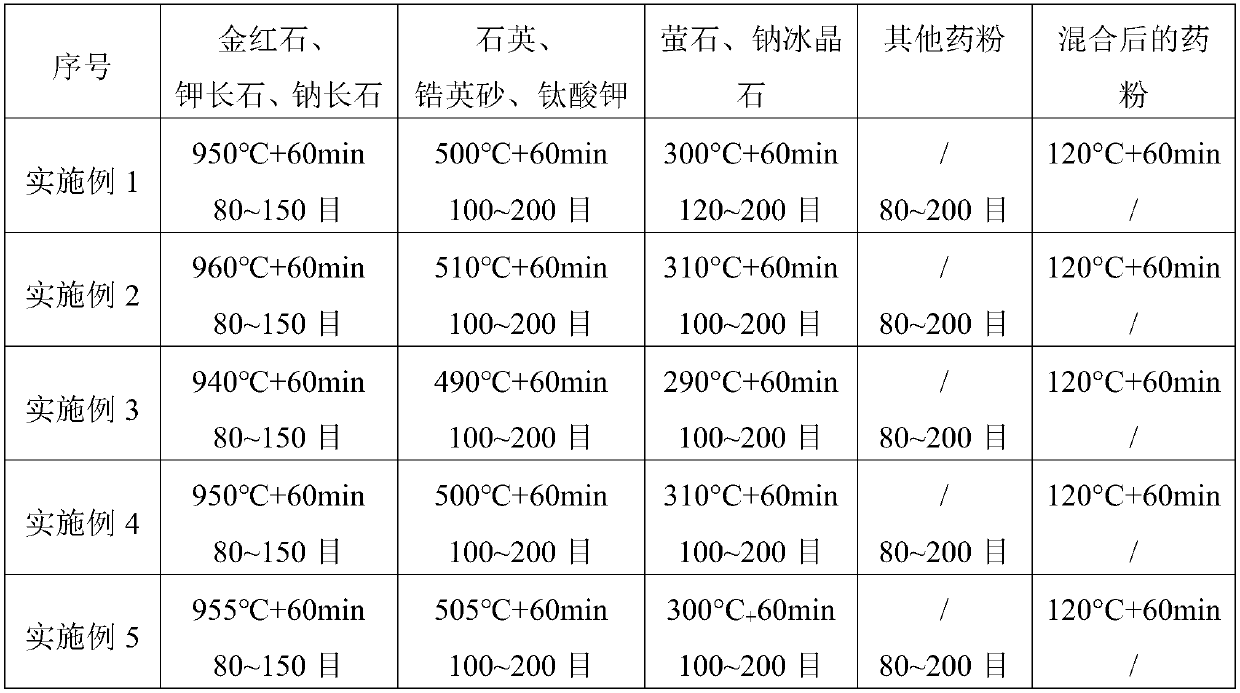

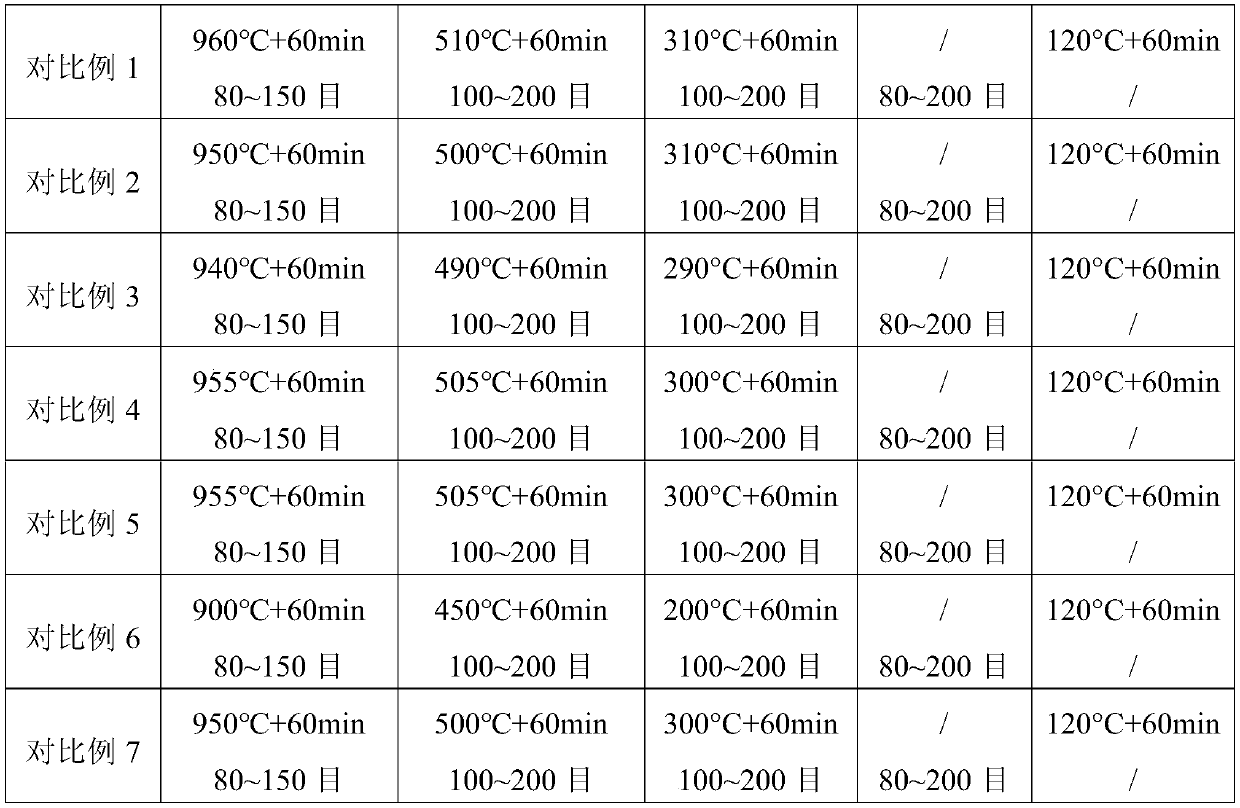

Embodiment 1

[0056] Select austenitic 316L stainless steel strip with a thickness of 0.4mm, a width of 10mm and a weight of 3347g (see Table 1 for the main components and specifications), roll it into a U shape, 380g of chromium powder, 125g of high nitrogen ferrochromium, 30g of electrolytic Metal manganese, 50g molybdenum powder, 10g ferrosilicon, 15g titanium iron, 10g aluminum magnesium alloy, 200g rutile, 20g quartz, 60g zircon sand, 15g potassium feldspar, 35g albite, 15g fluorite, 10g sodium cryolite, 15g potassium titanate, 3g bismuth oxide, 7g iron powder, a total of 1000g powder, the particle size, baking temperature and time of each powder are shown in Table 2, after mixing evenly, add it to the U-shaped tank, the filling rate is 23.0%, after a long time The diameter is reduced, and the finished welding wire with a diameter of φ1.2mm is finally obtained.

Embodiment 2

[0058] Select austenitic 316L stainless steel strip with a thickness of 0.4mm, a width of 10mm and a weight of 3545g (the main components and specifications are shown in Table 1), rolled into a U shape, 360g of chromium powder, 110g of high nitrogen ferrochromium, 25g of electrolytic Metal manganese, 40g molybdenum powder, 5g ferrosilicon, 10g titanium iron, 5g aluminum magnesium alloy, 180g rutile, 10g quartz, 50g zircon sand, 10g potassium feldspar, 30g albite, 10g fluorite, 5g sodium cryolite, 10g potassium titanate, 1g bismuth oxide, 139g iron powder, a total of 1000g powder, the particle size, baking temperature and time of each powder are shown in Table 2. After mixing evenly, add it to the U-shaped tank with a filling rate of 22.0%. The diameter is reduced, and the finished welding wire with a diameter of φ1.6mm is finally obtained.

Embodiment 3

[0060] Select austenitic 316L stainless steel strip with a thickness of 0.4mm, a width of 10mm and a weight of 3444g (the main components and specifications are shown in Table 1), rolled into a U shape, 370g of chromium powder, 120g of high nitrogen ferrochromium, 27g of electrolytic Metal manganese, 45g molybdenum powder, 7g ferrosilicon, 12g titanium iron, 8g aluminum-magnesium alloy, 190g rutile, 15g quartz, 55g zircon sand, 12g potassium feldspar, 33g albite, 12g fluorite, 8g sodium cryolite, 13g potassium titanate, 2g bismuth oxide, 71g iron powder, a total of 1000g powder, the particle size, baking temperature and time of each powder are shown in Table 2. After mixing evenly, add it to the U-shaped tank with a filling rate of 22.5%. The diameter is reduced, and the finished welding wire with a diameter of φ1.6mm is finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com