Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Degree of ionization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The degree of ionization (also known as ionization yield in the literature) refers to the proportion of neutral particles, such as those in a gas or aqueous solution, that are ionized to charged particles. For electrolytes, it could be understood as a capacity of acid/base to ionize itself. A low degree of ionization is sometimes called partially ionized (also weakly ionized), and a high degree of ionization as fully ionized.

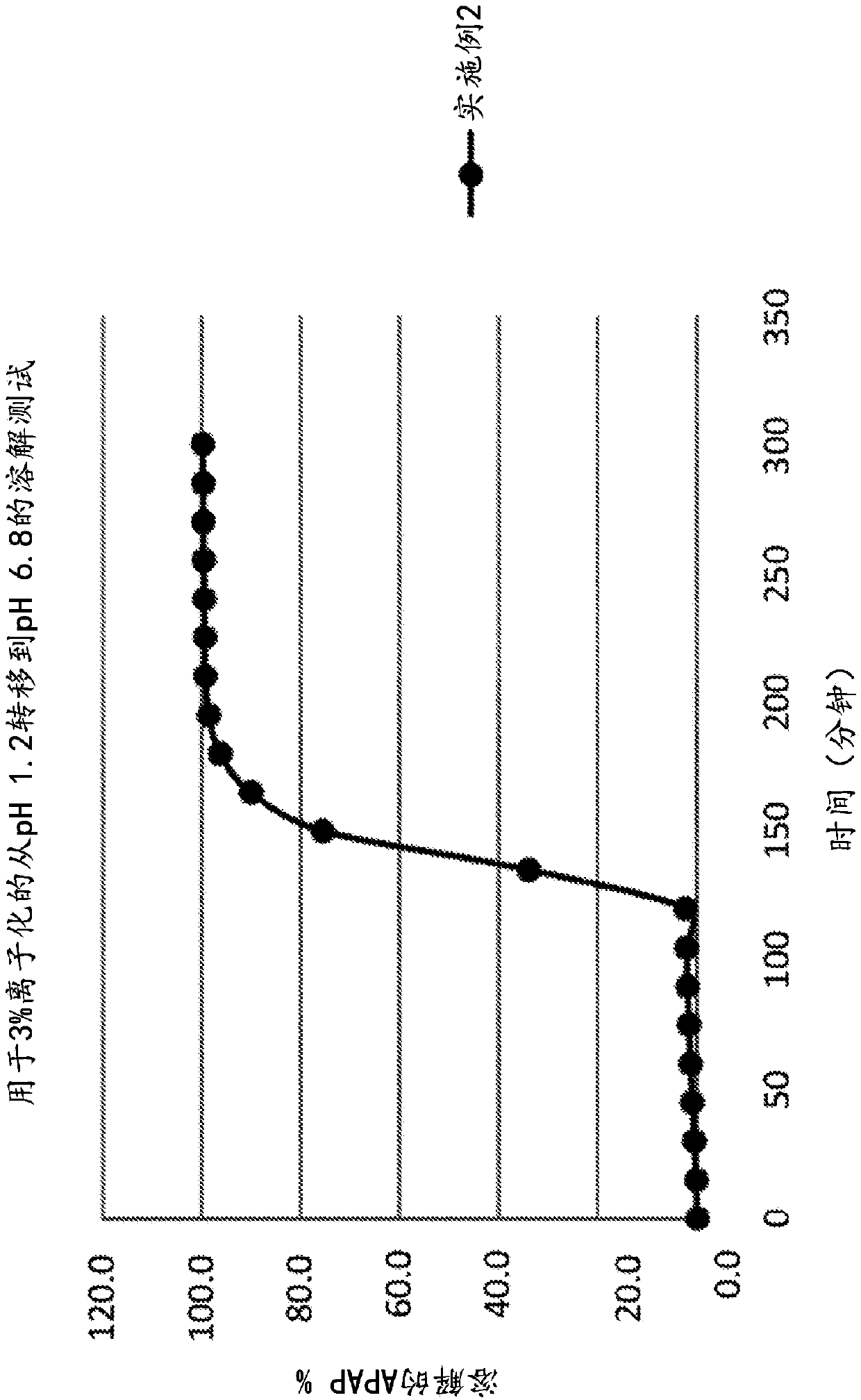

Solvent system of hardly soluble drug with improved dissolution rate

InactiveUS20090318558A1Good disintegrationPromote dissolutionBiocideAntipyreticActive agentDissolution

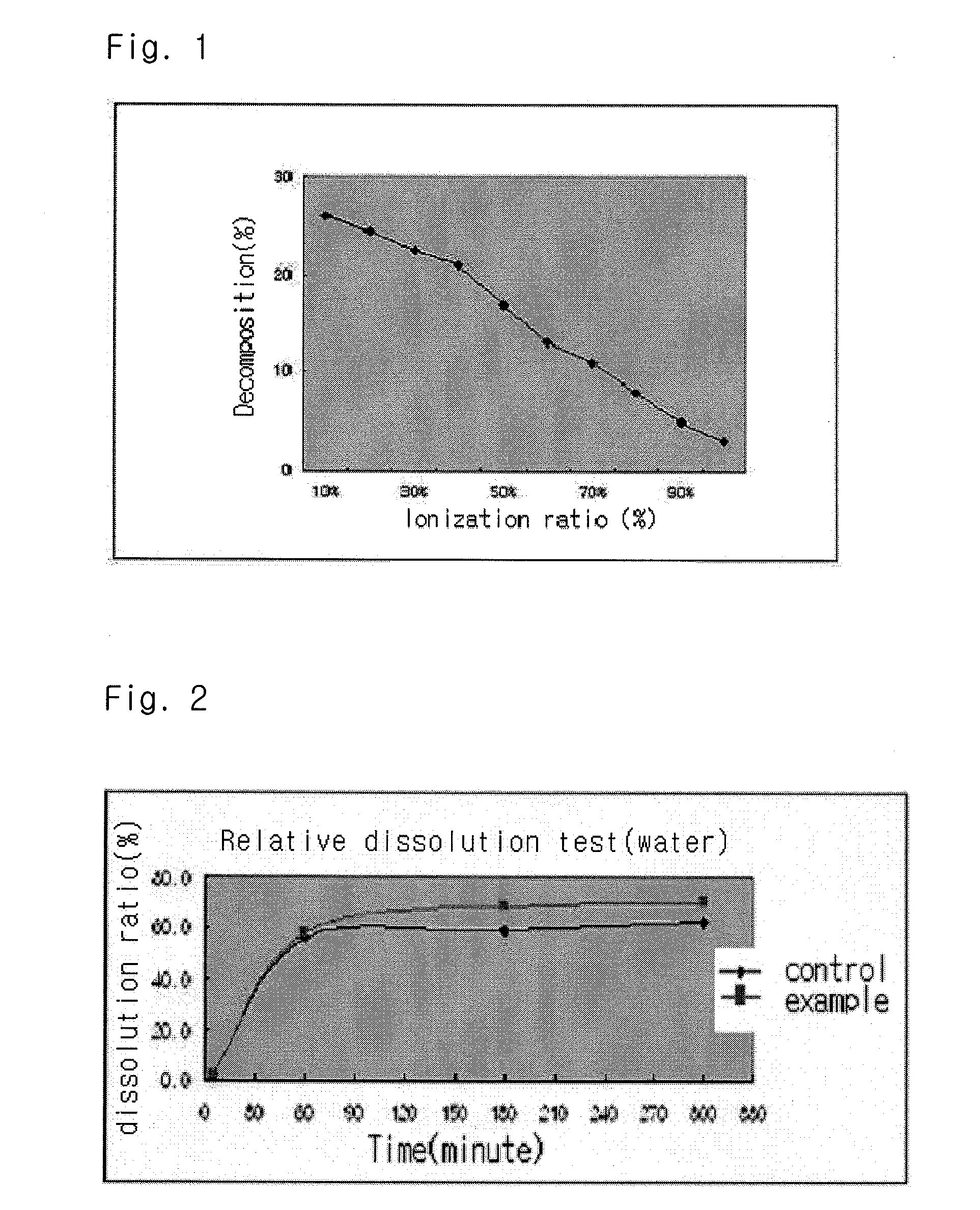

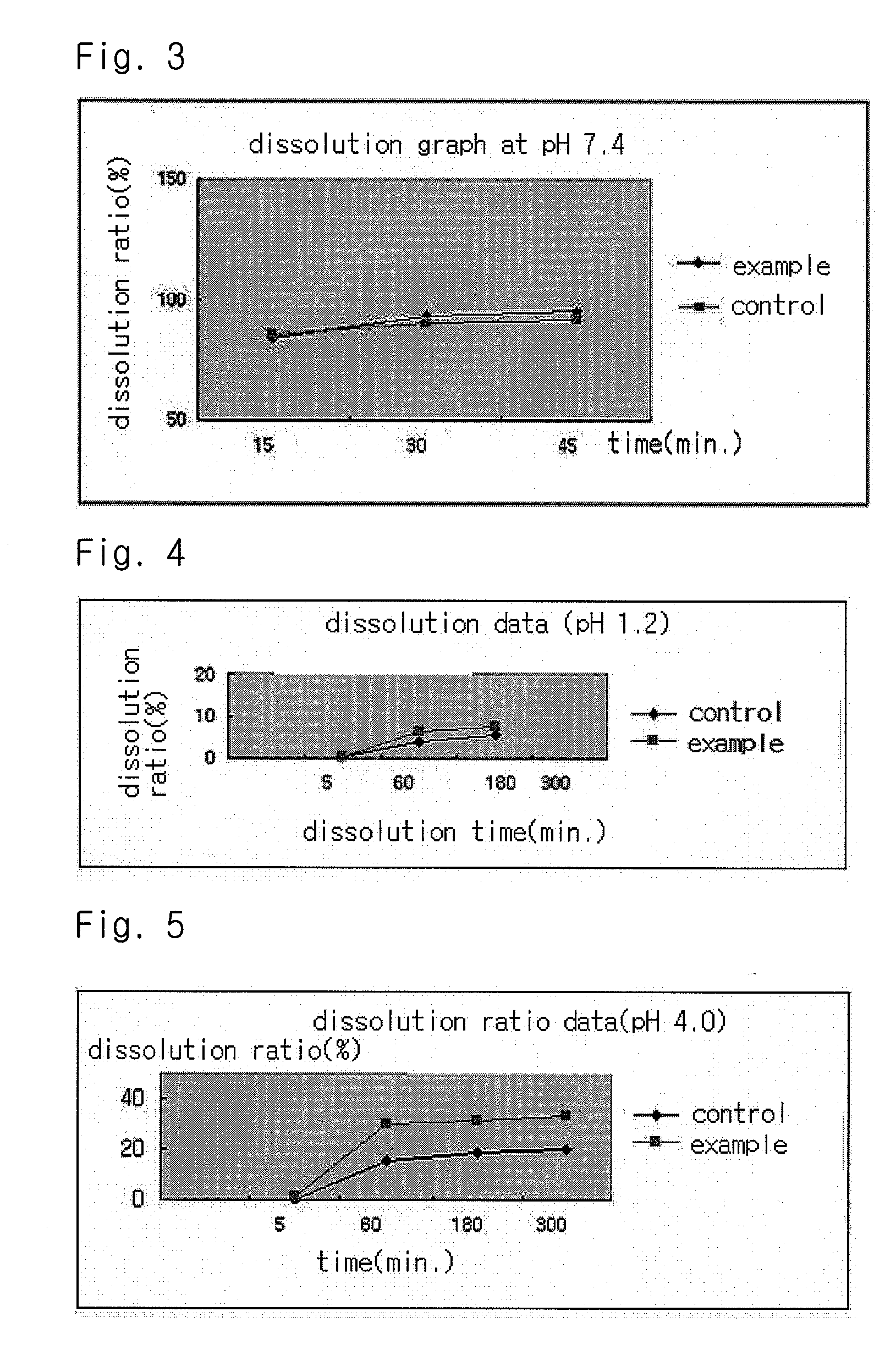

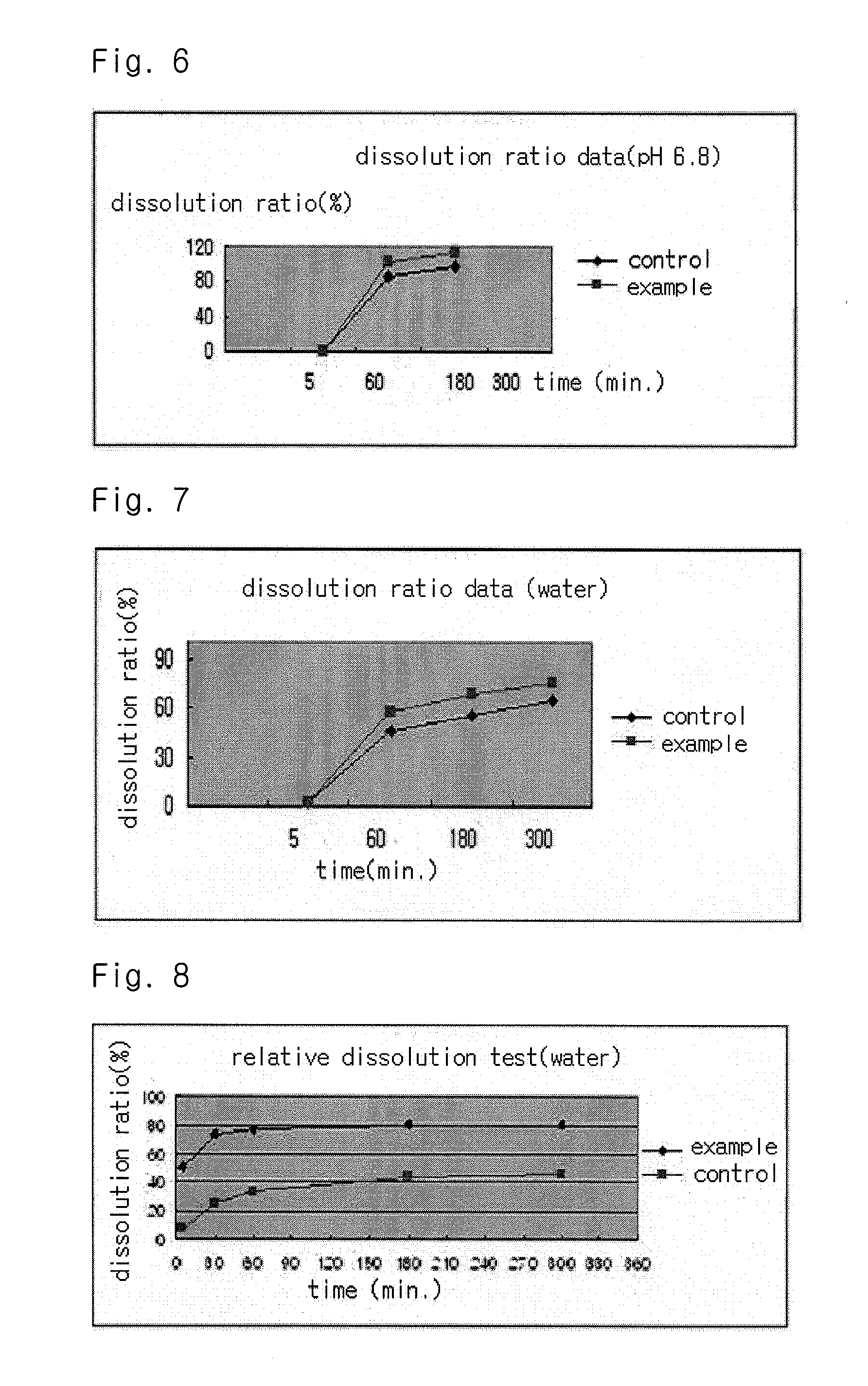

The present invention relates to a solvent system with improved disintegration degree and dissolution ratio of a hardly soluble drug by highly concentrating the drug through partial ionization, and by establishing optimal conditions for enhancing bioavailability of the drug, such as the co-relation between the acid drug and the accompanied components, ionization degree of a solvent system, use of an appropriate cation acceptor, water content, selection of optimal mixing ratio of the respective components and use of specific surfactants, and to a pharmaceutical preparation comprising the same. The solvent system of the invention has advantages in that it can enhance bioavailability by improving the disintegration degree and dissolution ratio of a hardly soluble drug and also provide a capsule with a sufficiently small volume to permit easy swallowing.

Owner:R & P KOREA

Container for retort packaging, resin composition, and gas-barrier film prepared therefrom

InactiveUS6022913AExcellent oxygen barrier propertiesExcellent not in resistanceCosmetic preparationsWrappersCross-linkChemical structure

PCT No. PCT / JP97 / 03131 Sec. 371 Date Mar. 19, 1998 Sec. 102(e) Date Mar. 19, 1998 PCT Filed Sep. 5, 1997 PCT Pub. No. WO98 / 09813 PCT Pub. Date Mar. 12, 1998The present invention provides a container for retort packaging comprising a laminated film having an outermost layer comprising a layer formed of a cross-linked structure containing ester bonds between poly(meth)acrylic acid (A) and polyalcoholic polymer (B); a resin composition having at least the chemical structures (X) [poly(meth)acrylic acid (A) residue], (Y) [poly(meth)acrylic acid (A)-polyalcoholic polymer (B) residue] and (Z) [metal cross-linked ionic residues], wherein the degree of esterification defined by the equation: degree of esterification=c / (b+c+d) is from 0.01 to 0.5 and the degree of ionization defined by the equation: degree of ionization=c / (b+c+d) is from 0.01 to 0.9 (wherein b, c and d represent the molar ratios of the carbon-oxygen double bond in the chemical structure of the resin composition; and a gas barrier film comprising the same.

Owner:TOPPAN PRINTING CO LTD

Container for retort packaging, resin composition, and gas-barrier film prepared therefrom

InactiveUS6143384AExcellent oxygen barrier propertiesExcellent not in resistanceCosmetic preparationsOrganic detergent compounding agentsCross-linkChemical structure

Owner:TOPPAN PRINTING CO LTD

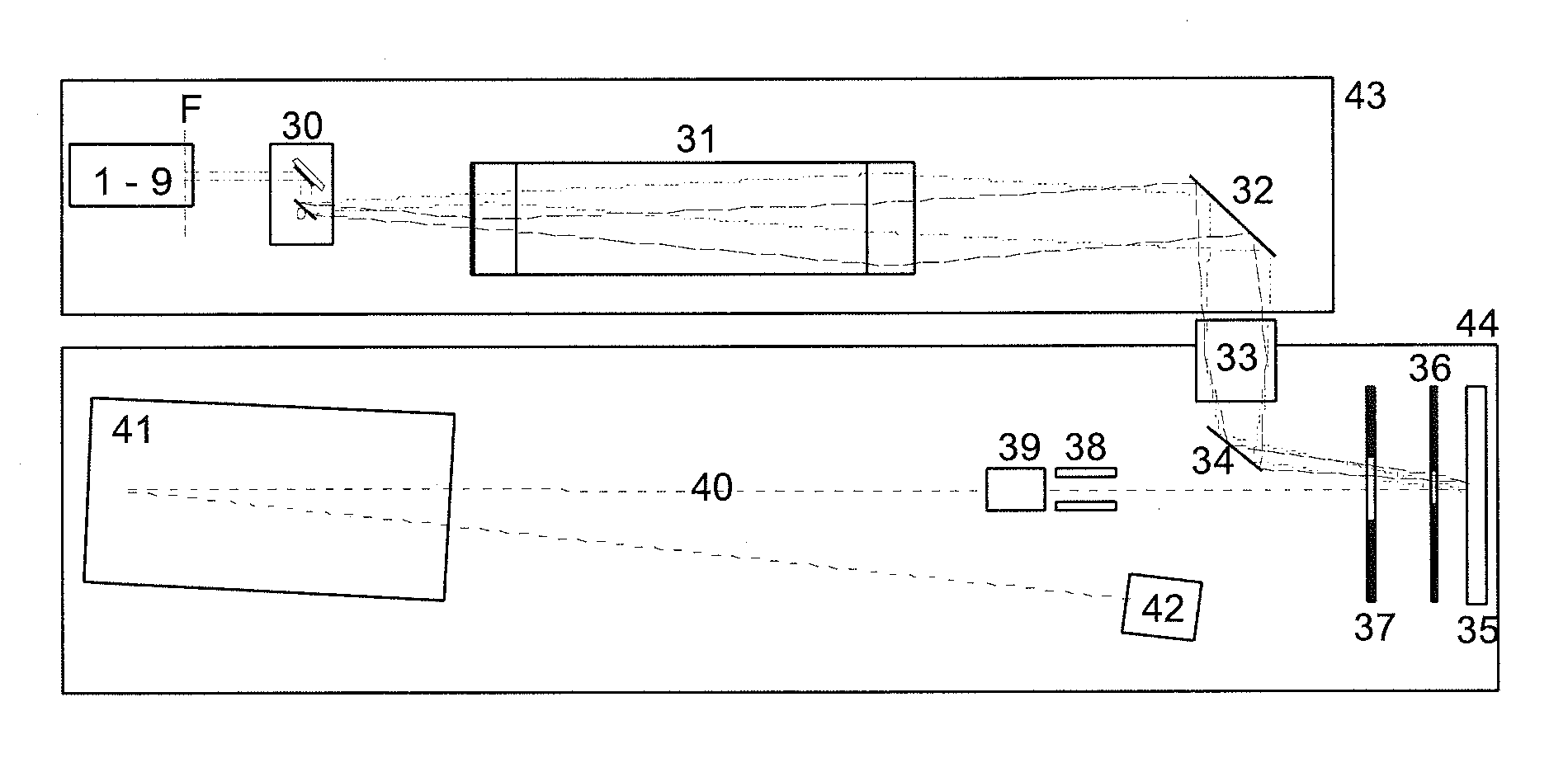

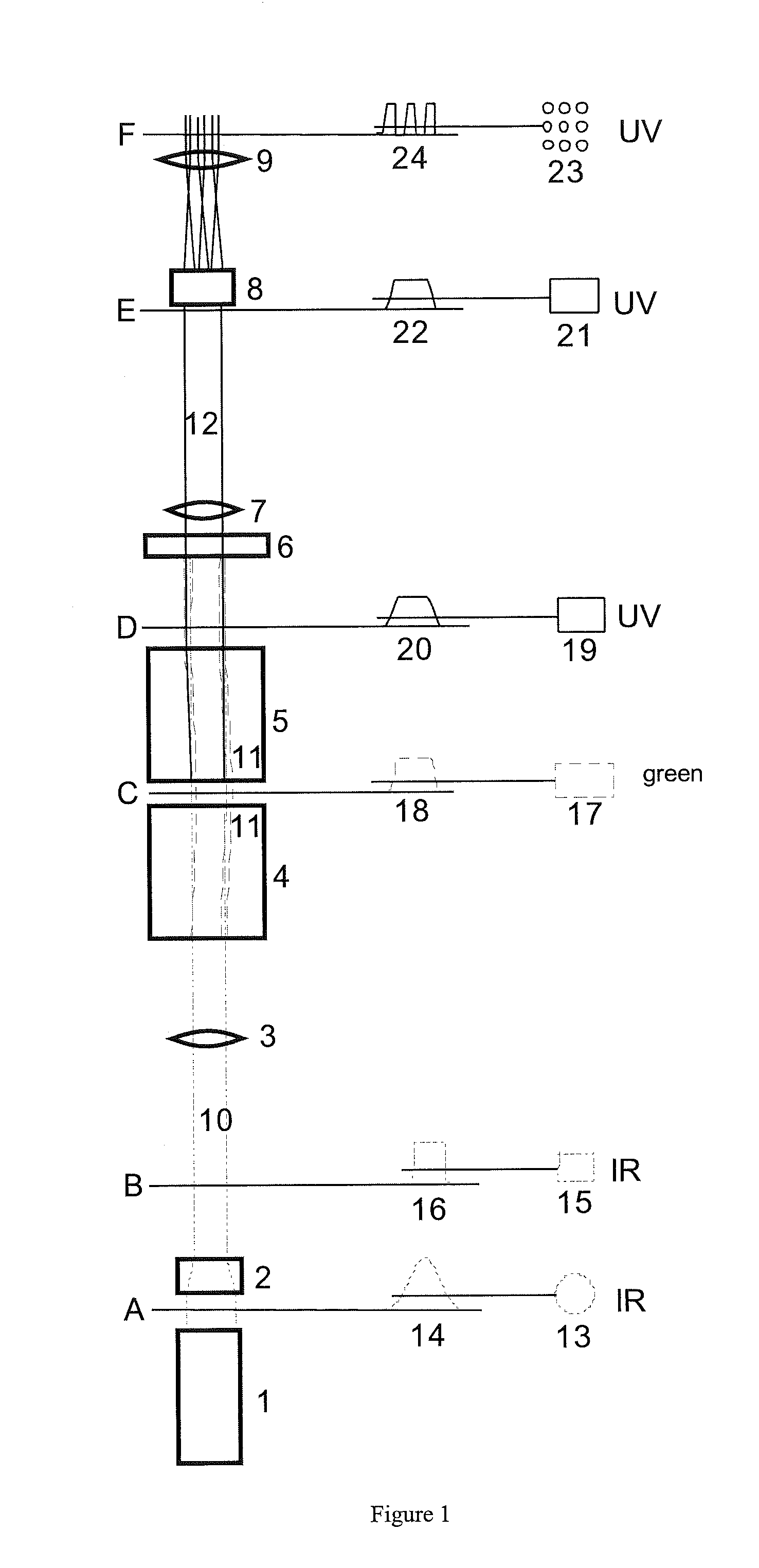

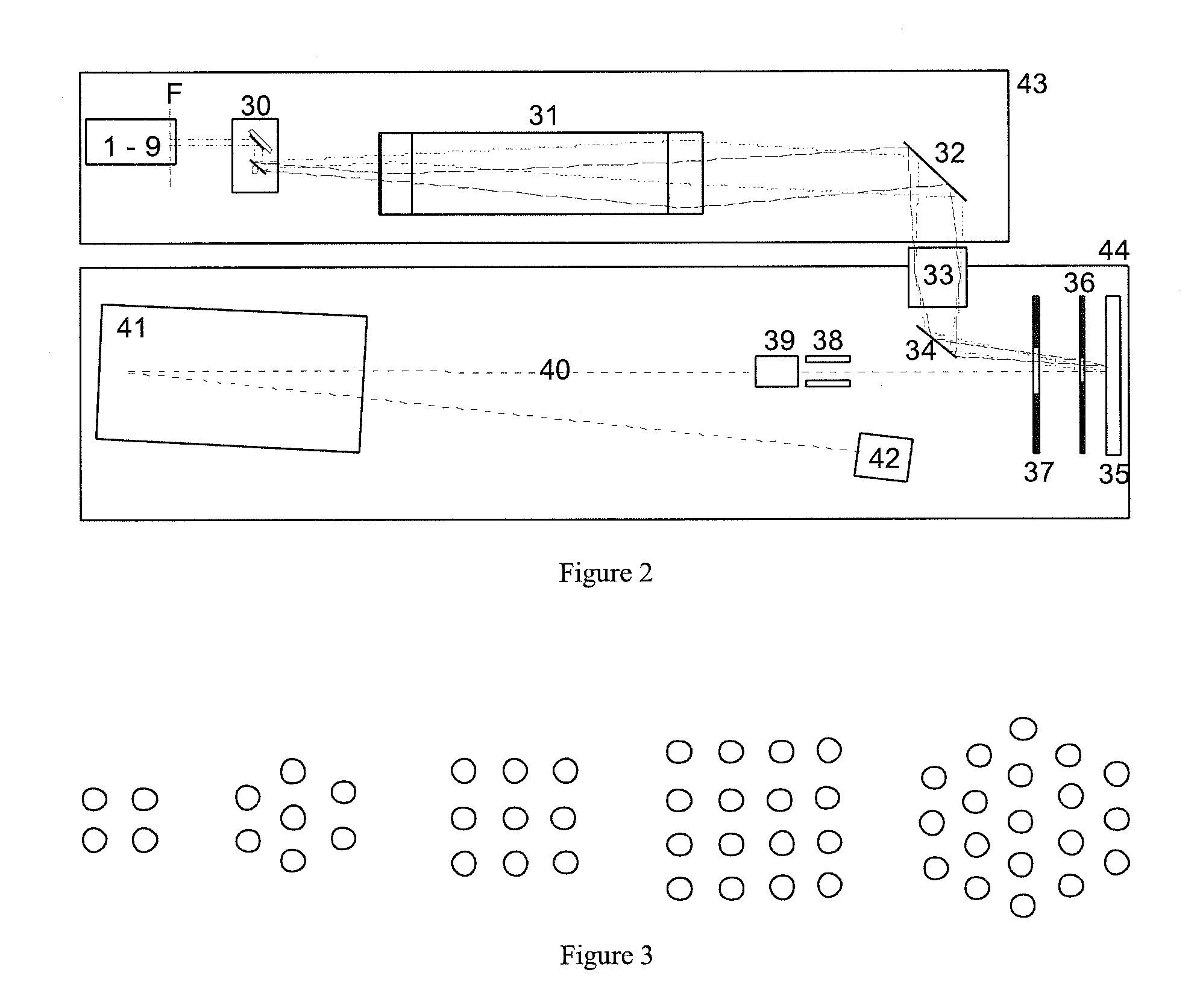

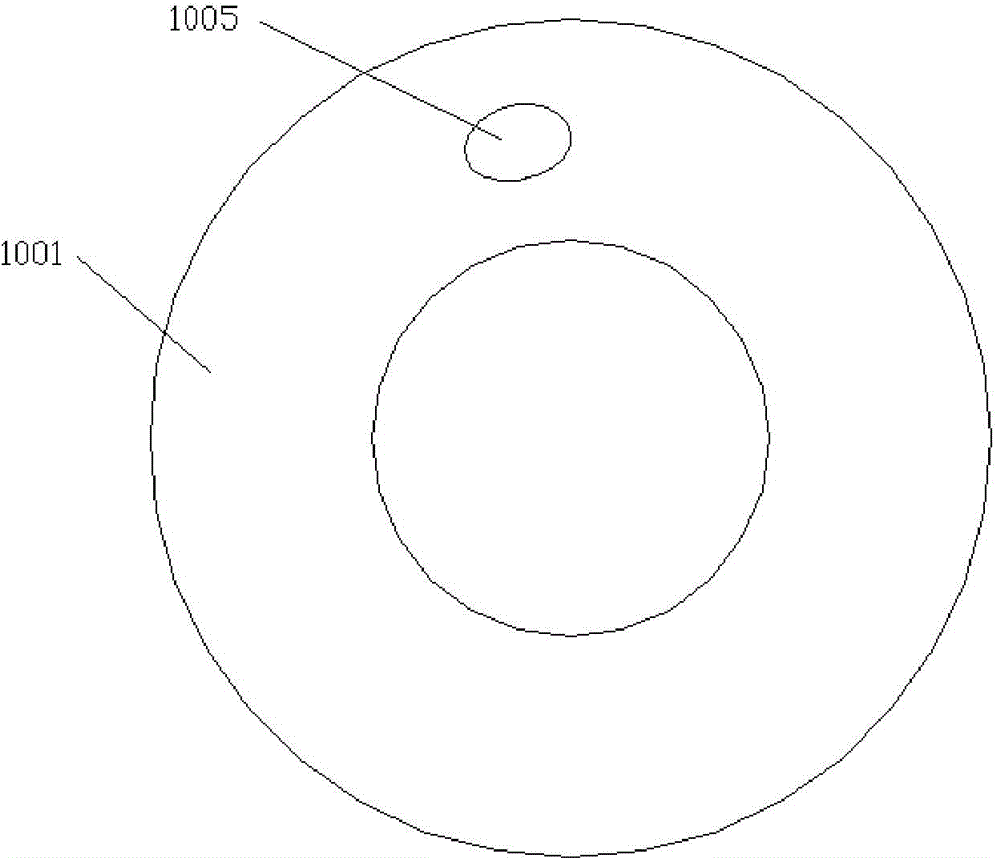

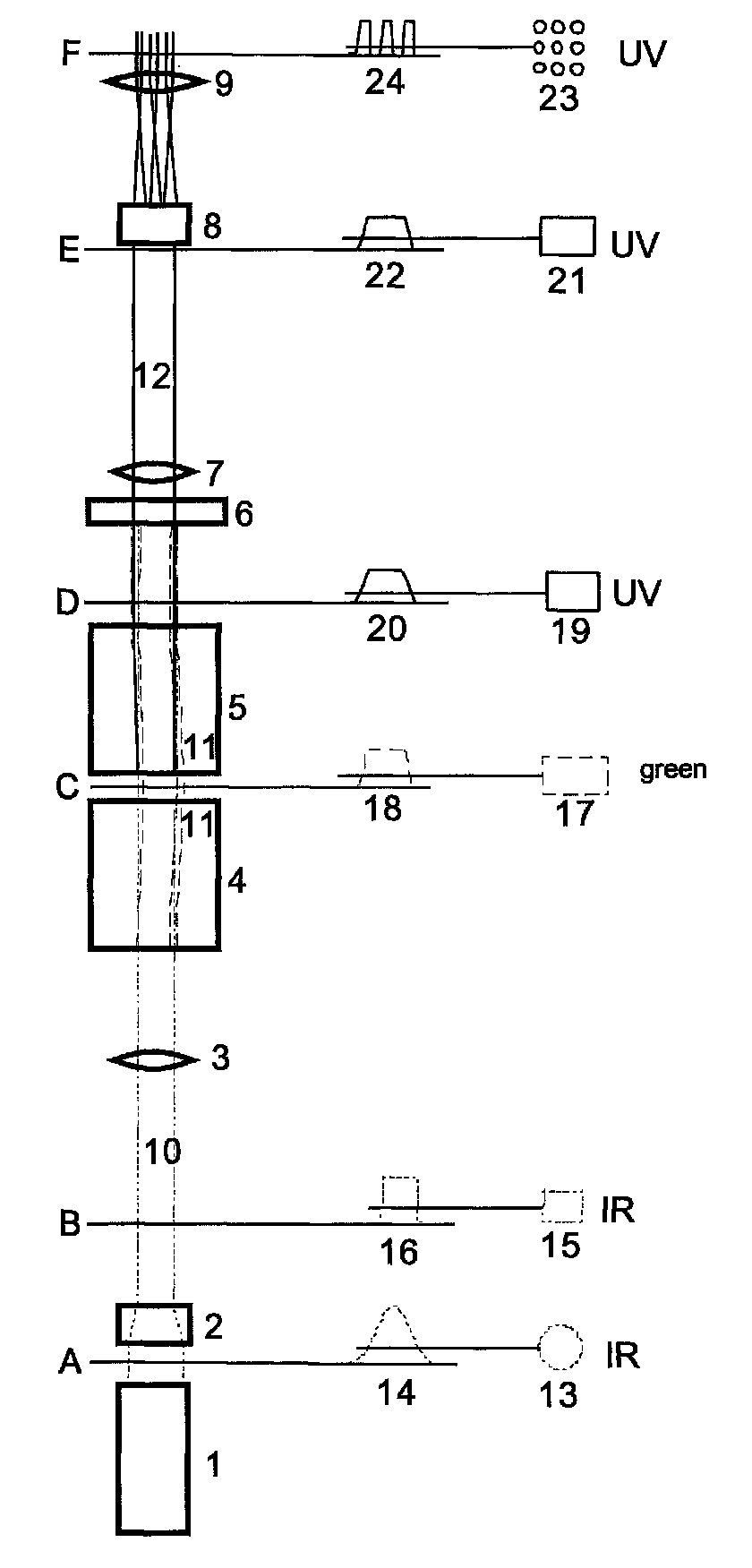

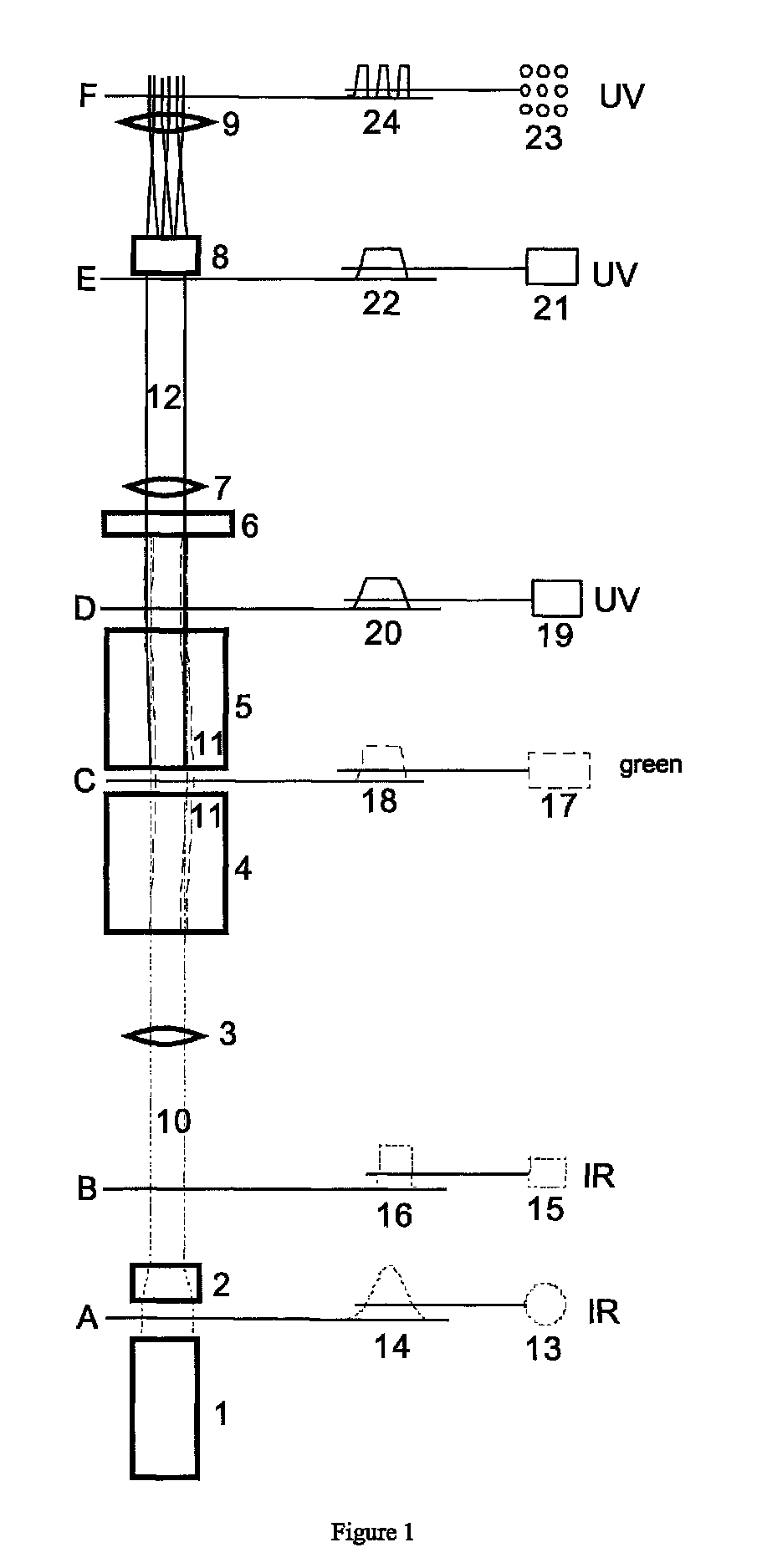

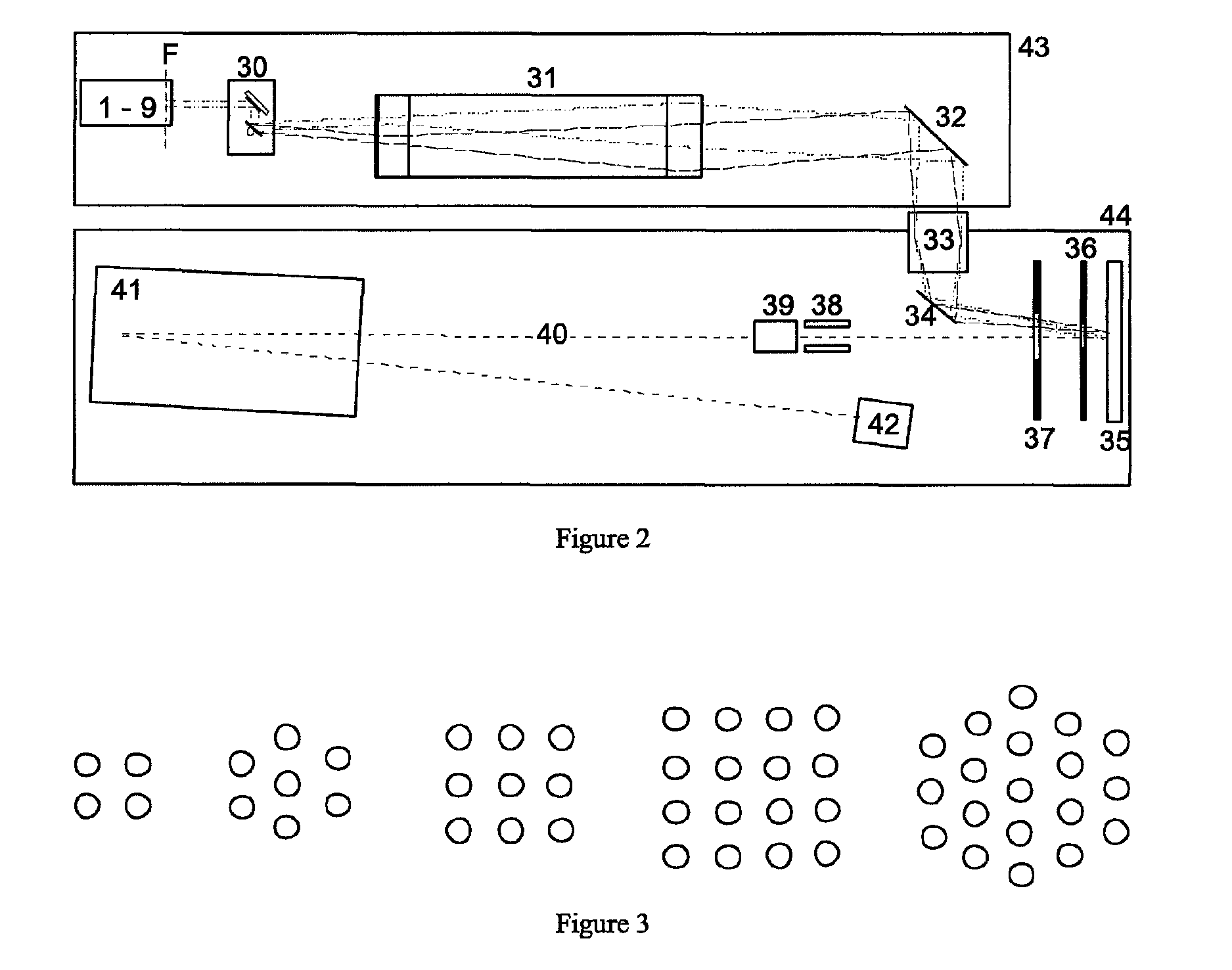

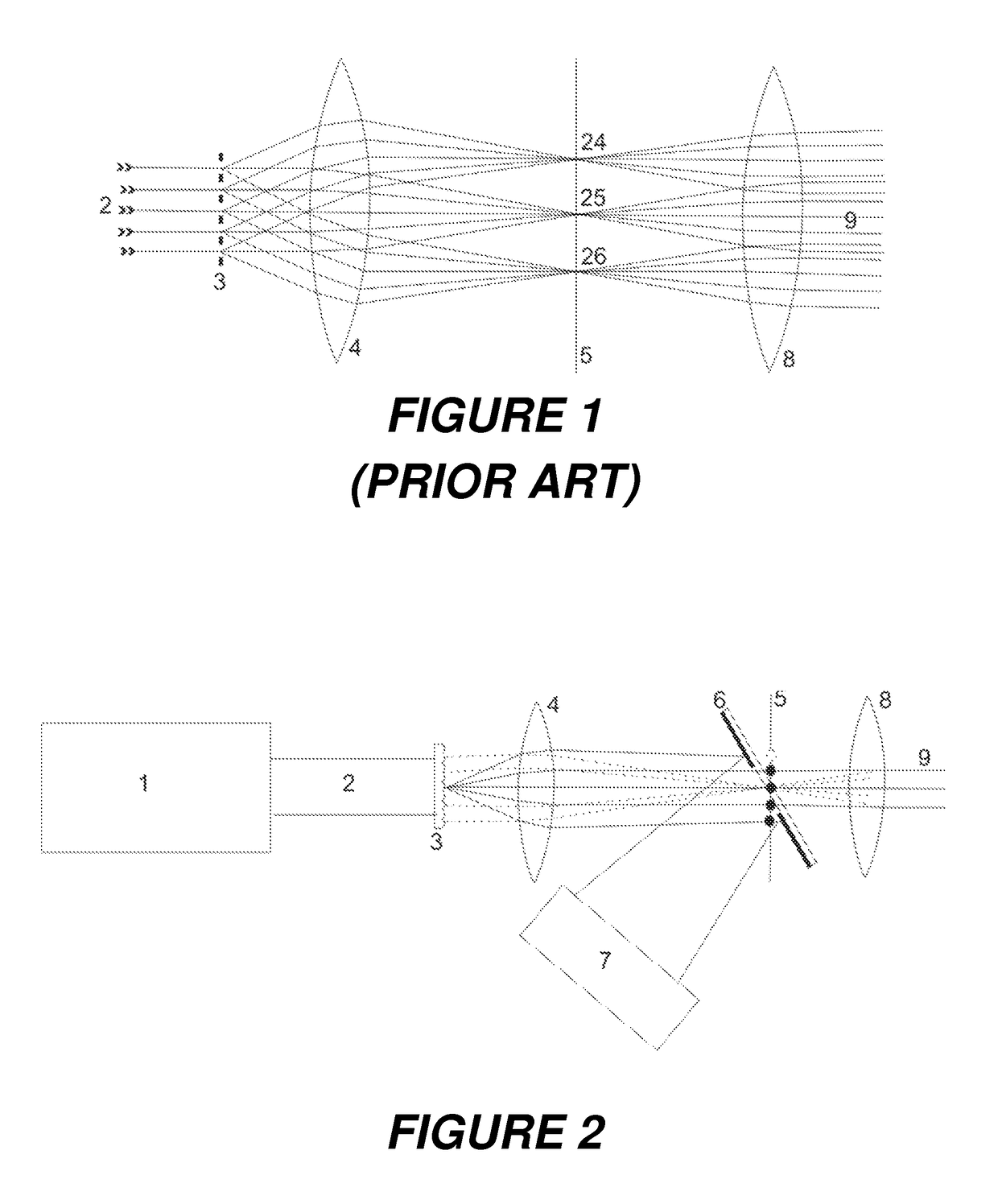

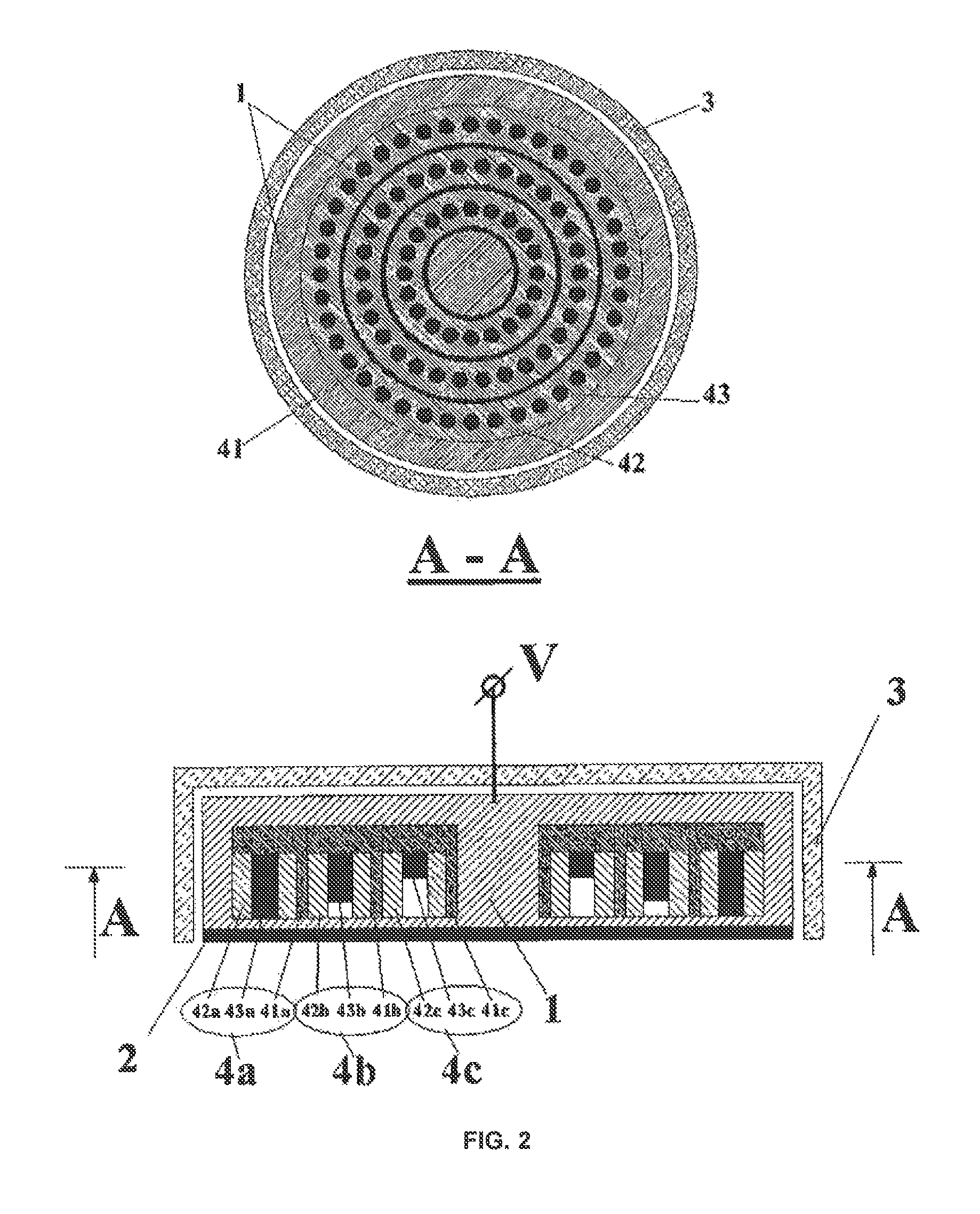

Mass spectrometer with laser spot pattern for maldi

ActiveUS20150122986A1High degree of ionizationReduce energy lossIon sources/gunsIsotope separationDesorptionMass spectrometry

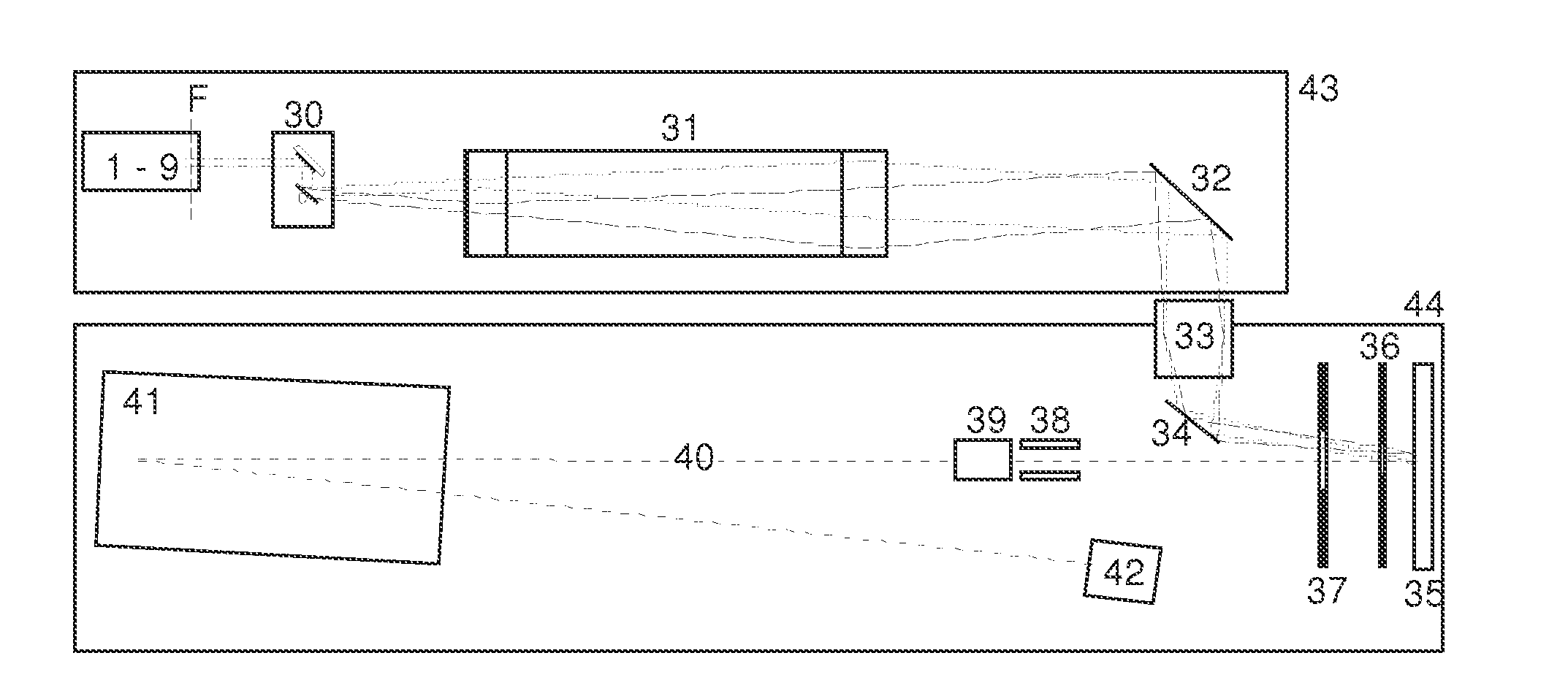

The invention relates to mass spectrometers with an ion source, comprising a UV laser system for mass spectrometric analyses with ionization of analyte molecules in a sample by matrix-assisted laser desorption, which, with very low energy losses, can produce a spatially distributed spot pattern with several intensity peaks of equal height, thus making it possible to achieve an optimum degree of ionization of analyte ions for any task. Such a spot pattern can be generated from the UV beam with high transverse coherence, using a combination of a lens array and a lens, provided that the lens array satisfies a mathematical condition for separation of the micro-lenses from each other (pitch) and their focal length. For example, a lens array with square or round lenses produces a pattern of nine and five spots, respectively. The lens arrays are inexpensive and do not require any lateral adjustment in this arrangement.

Owner:BRUKER DALTONIK GMBH & CO KG

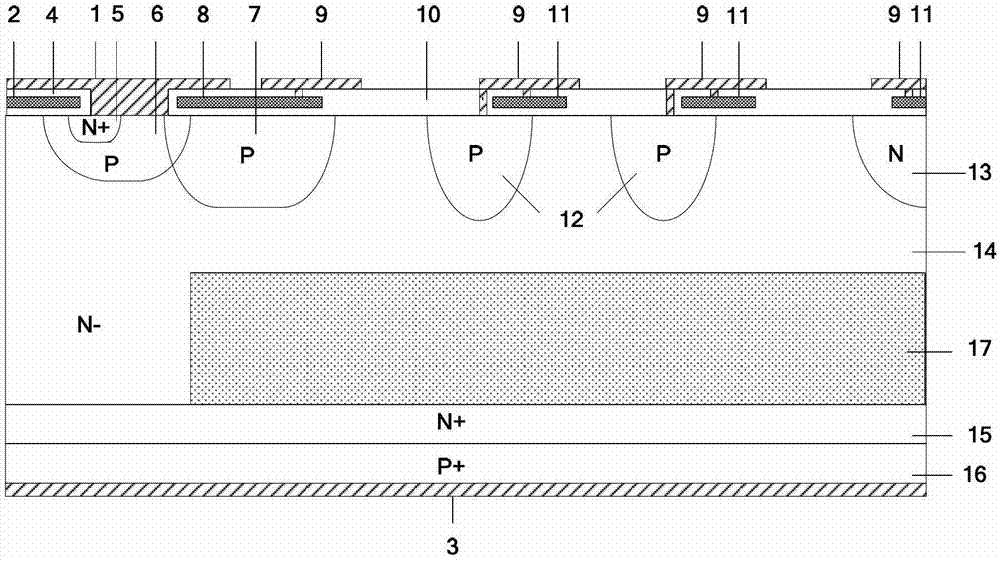

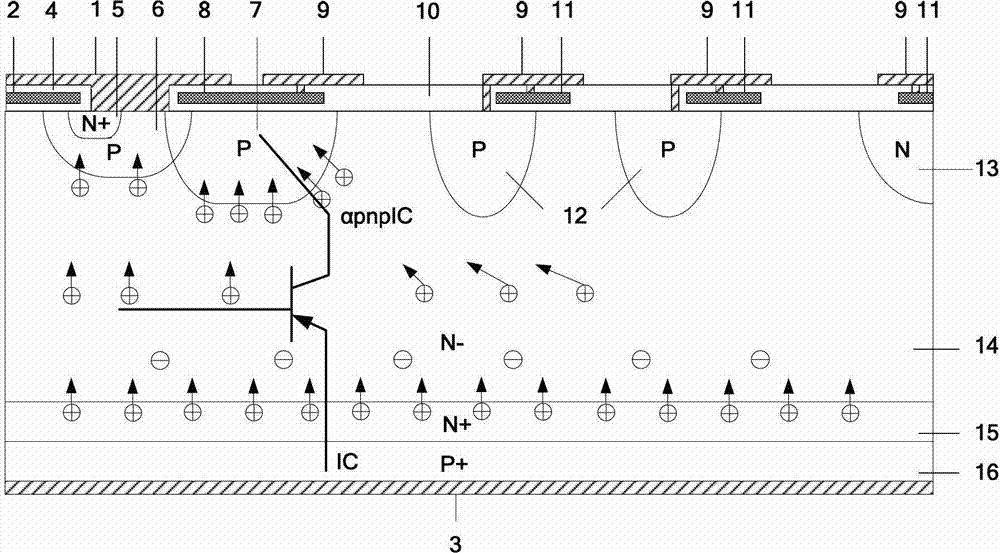

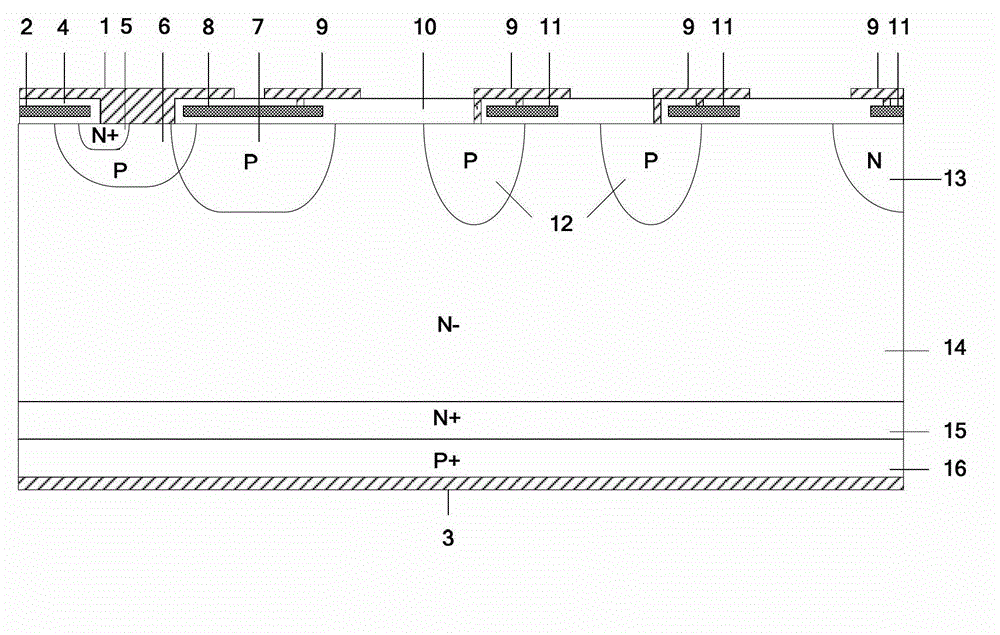

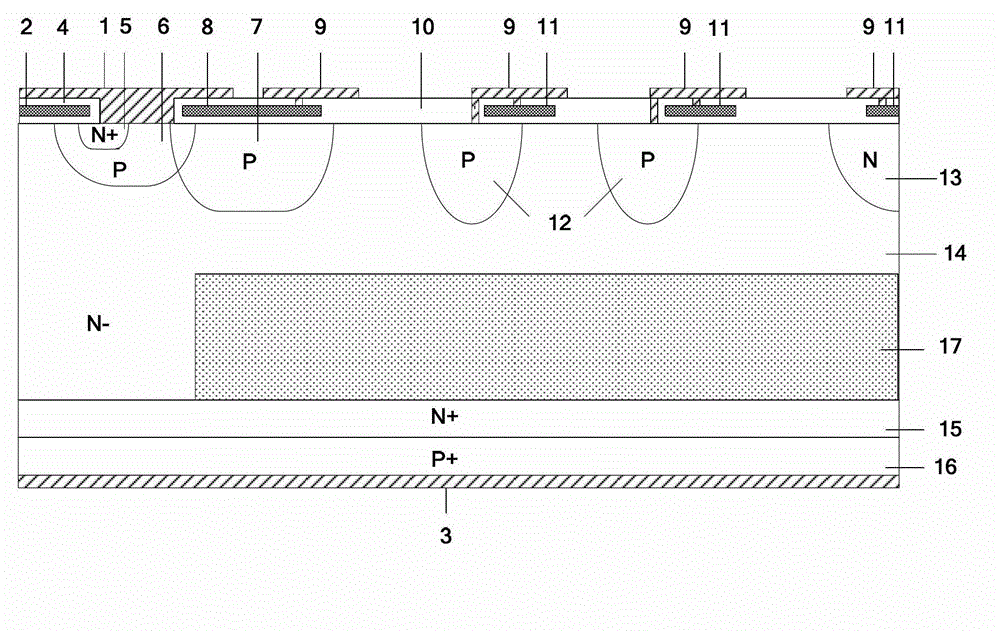

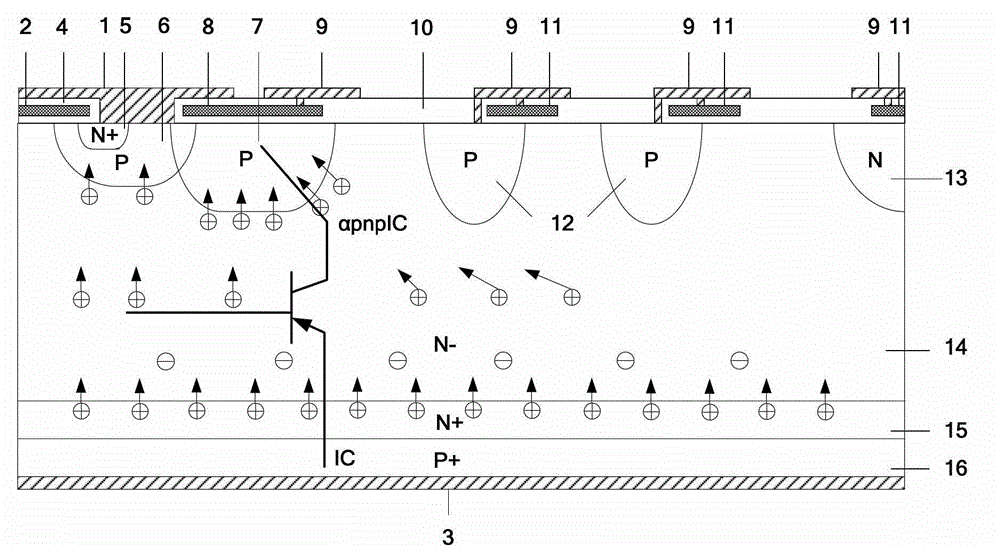

Insulated gate bipolar translator (IGBT) with terminal deep energy level impurity layer

InactiveCN102779840AImprove reliabilityReduce high temperature leakage currentSemiconductor devicesCharge carrierDegree of ionization

The invention discloses an insulated gate bipolar translator (IGBT) with a terminal deep energy level impurity layer, and belongs to the technical field of semiconductor power devices. Based on the conventional Planar field stop-insulated gate bipolar translator (FS-IGBT), a deep energy level impurity layer (15) is injected into a terminal drift area (14); according to the deep energy level impurity layer (15), the degree of ionization of the deep energy level impurities is raised along with the raise of the temperature of the device, and the concentration of the impurities is greatly increased; when the IGBT is turned off, the hole emission efficiency of a P+ current collection area in a terminal area is effectively reduced by carrier concentration added in the terminal drift area is effectively reduced, and alpha PNP (plug-and-play) of a parasitic PNP transistor is reduced, so that high-temperature leakage current of a device is effectively reduced; and electronic concentration added in the drift area and a hole injected into the P+ current collection area are quickly compounded, and the deep energy level impurities serves as a compounding center, so that the compounding of the electronic hole is quickened, the on / off property is effectively improved, and the reliability of the IGBT is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

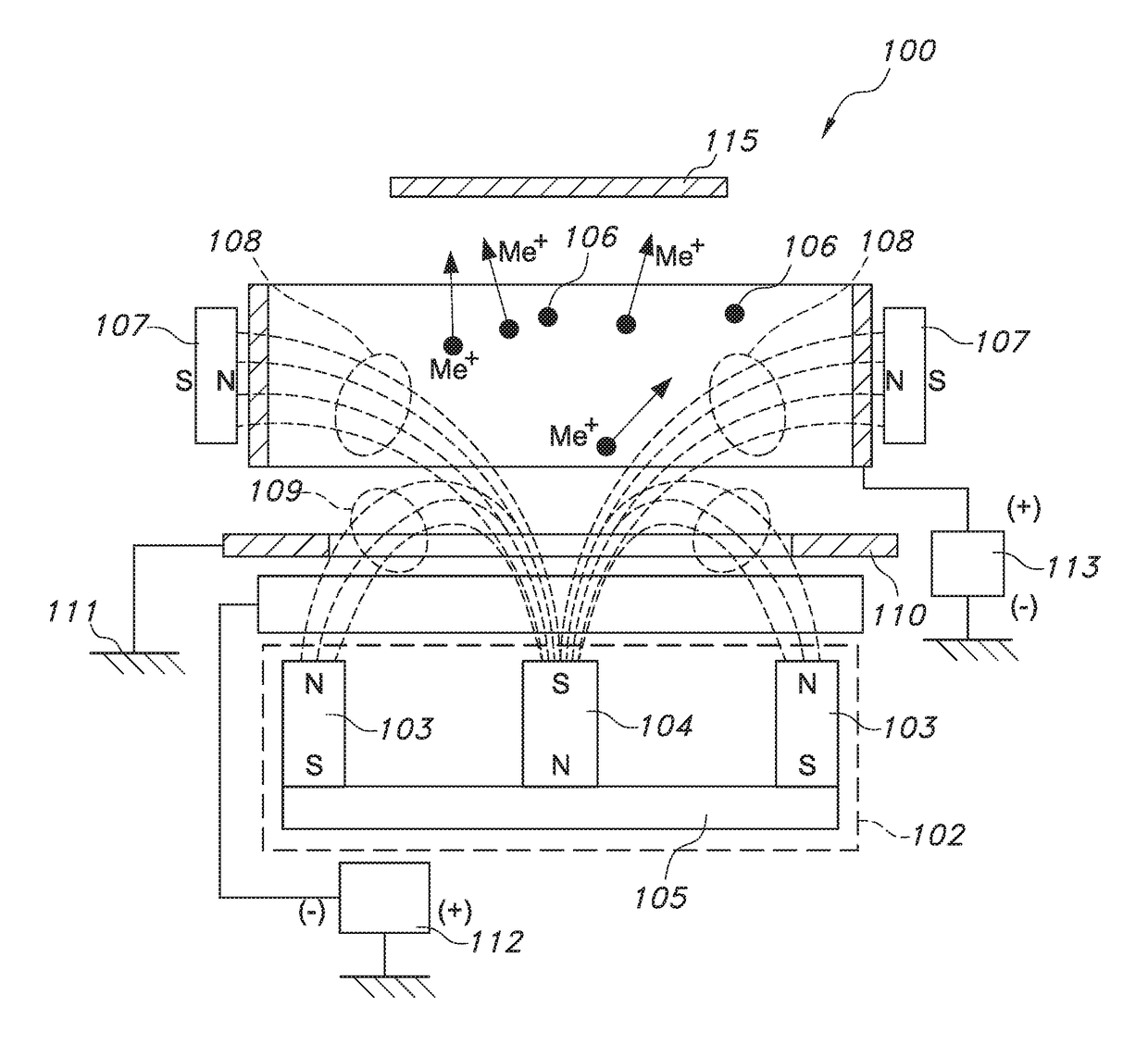

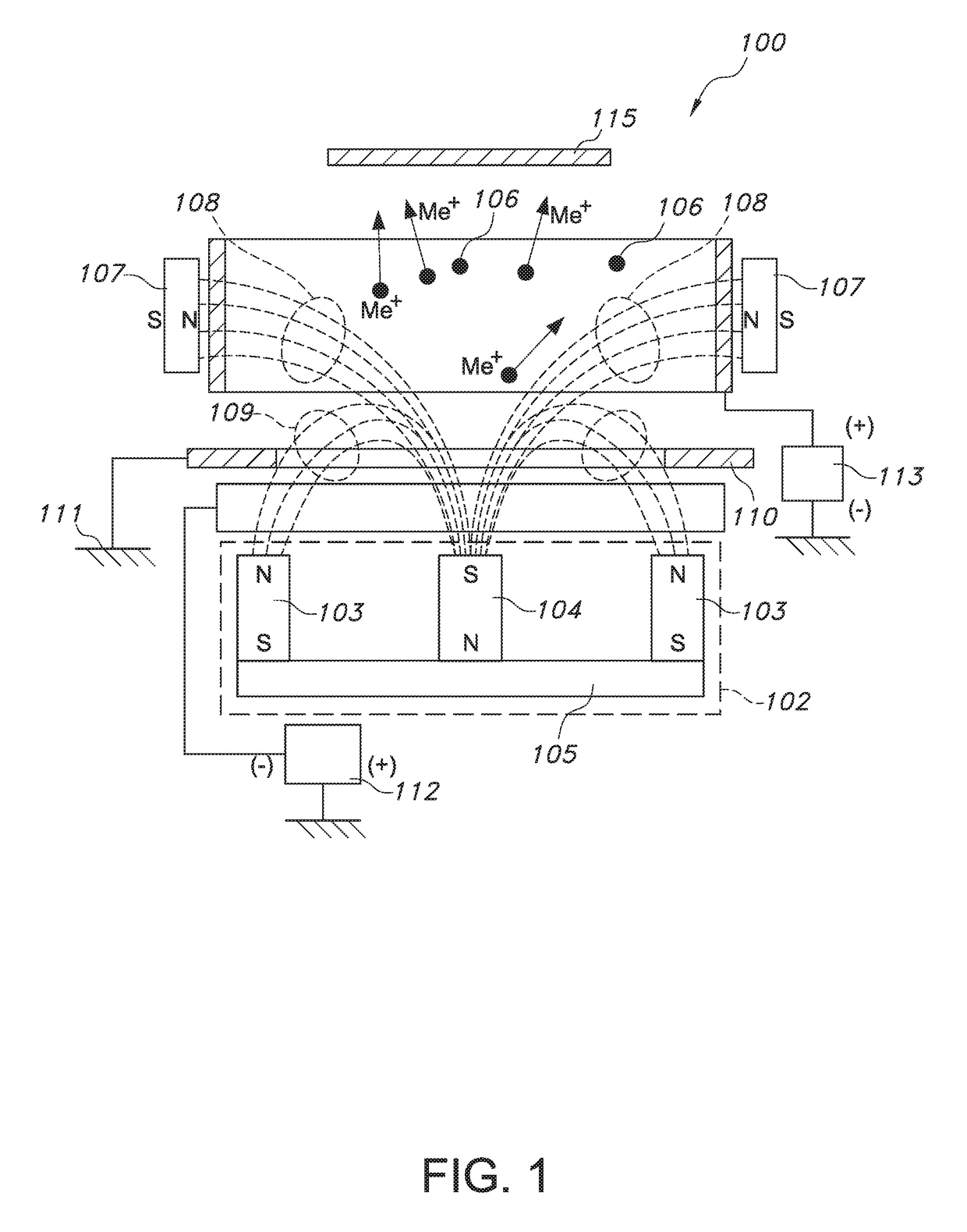

Electrically and Magnetically Enhanced Ionized Physical Vapor Deposition Unbalanced Sputtering Source

InactiveUS20170178878A1Eliminate negative voltage biasElectric discharge tubesSemiconductor/solid-state device detailsPlasma densityGas phase

An electrically and magnetically enhanced ionized physical vapor deposition (I-PVD) magnetron apparatus and method is provided for sputtering material from a cathode target on a substrate, and in particular, for sputtering ceramic and diamond-like coatings. The electrically and magnetically enhanced magnetron sputtering source has unbalanced magnetic fields that couple the cathode target and additional electrode together. The additional electrode is electrically isolated from ground and connected to a power supply that can generate positive, negative, or bipolar high frequency voltages, and is preferably a radio frequency (RF) power supply. RF discharge near the additional electrode increases plasma density and a degree of ionization of sputtered material atoms.

Owner:IONQUEST LLC

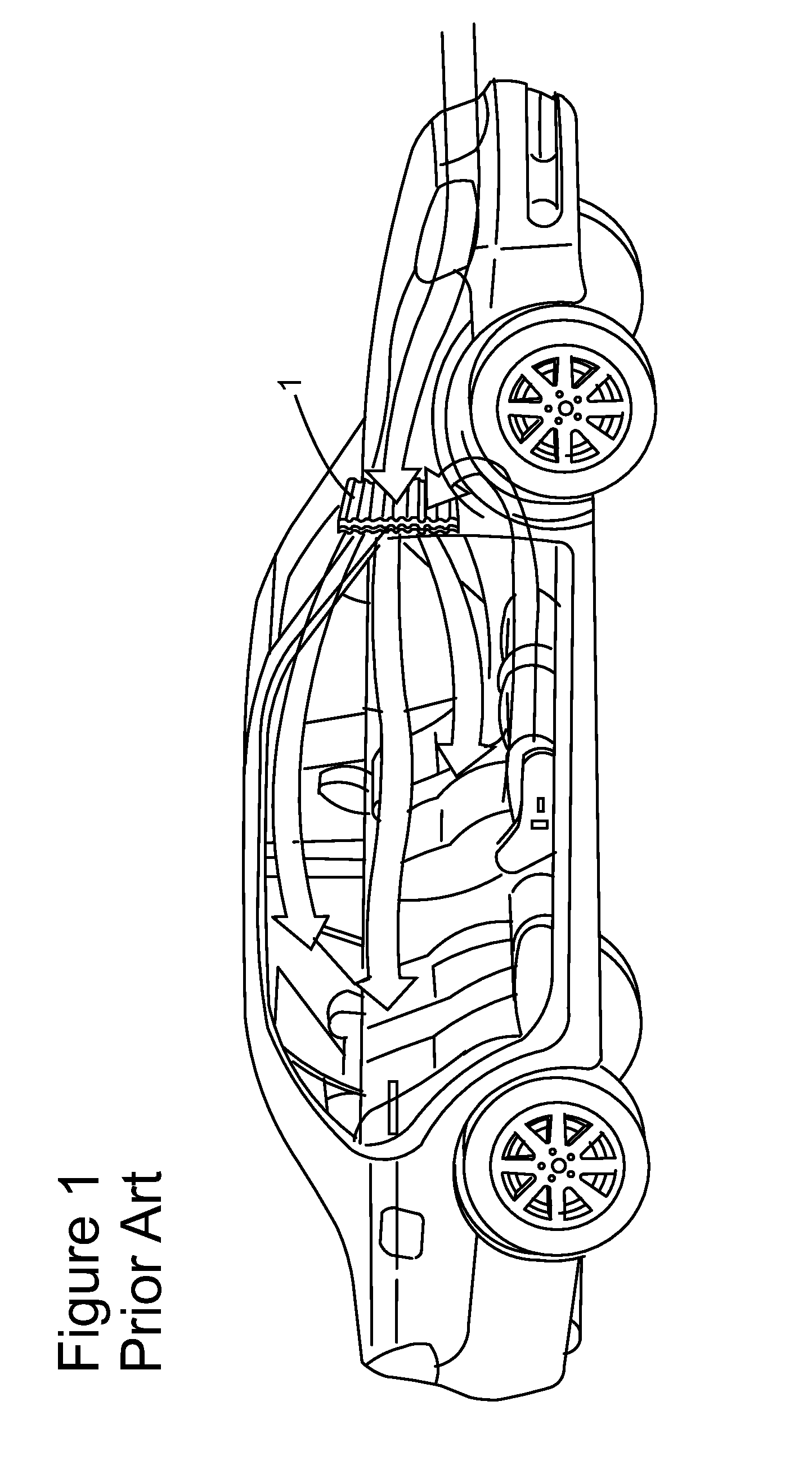

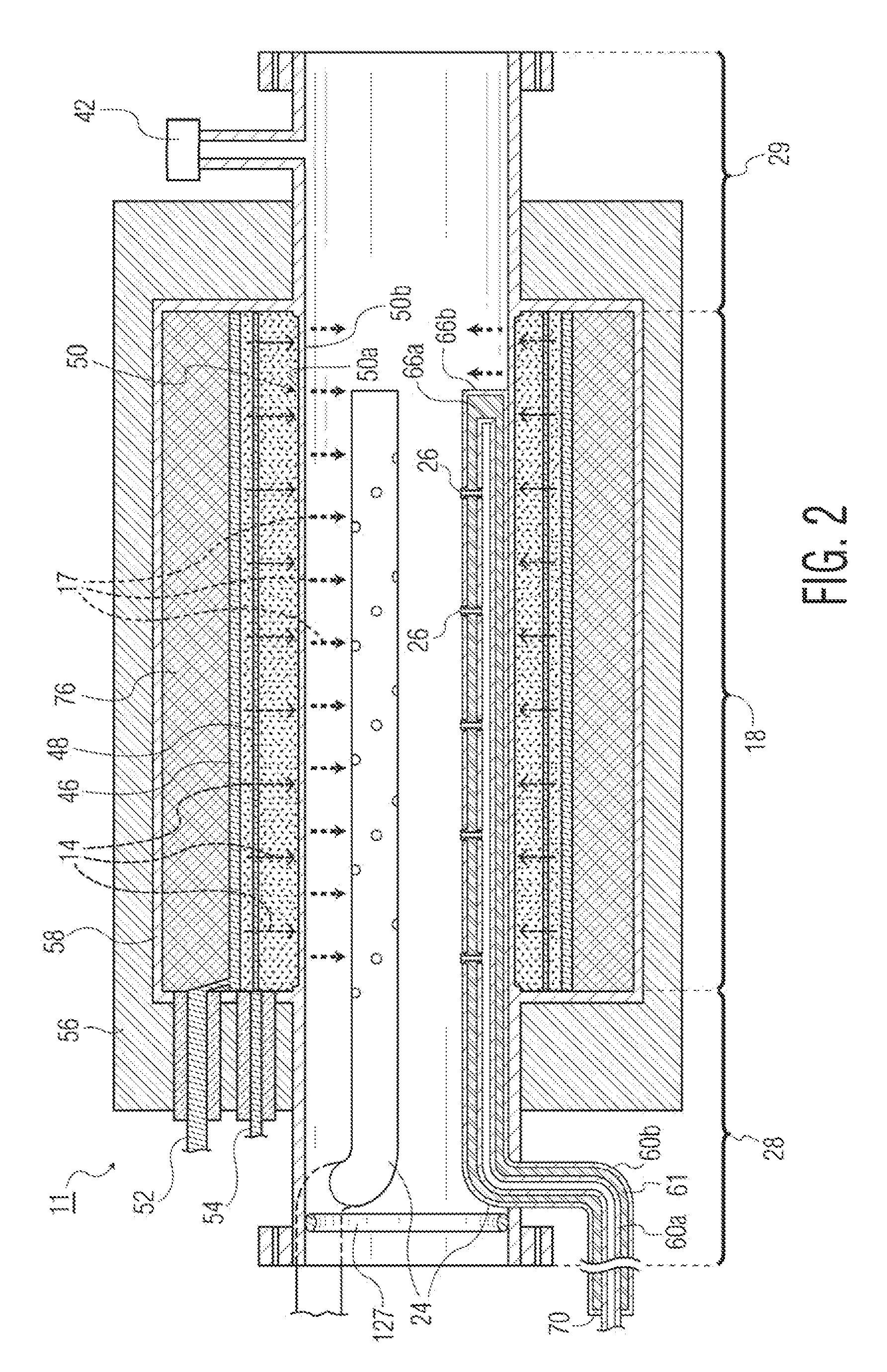

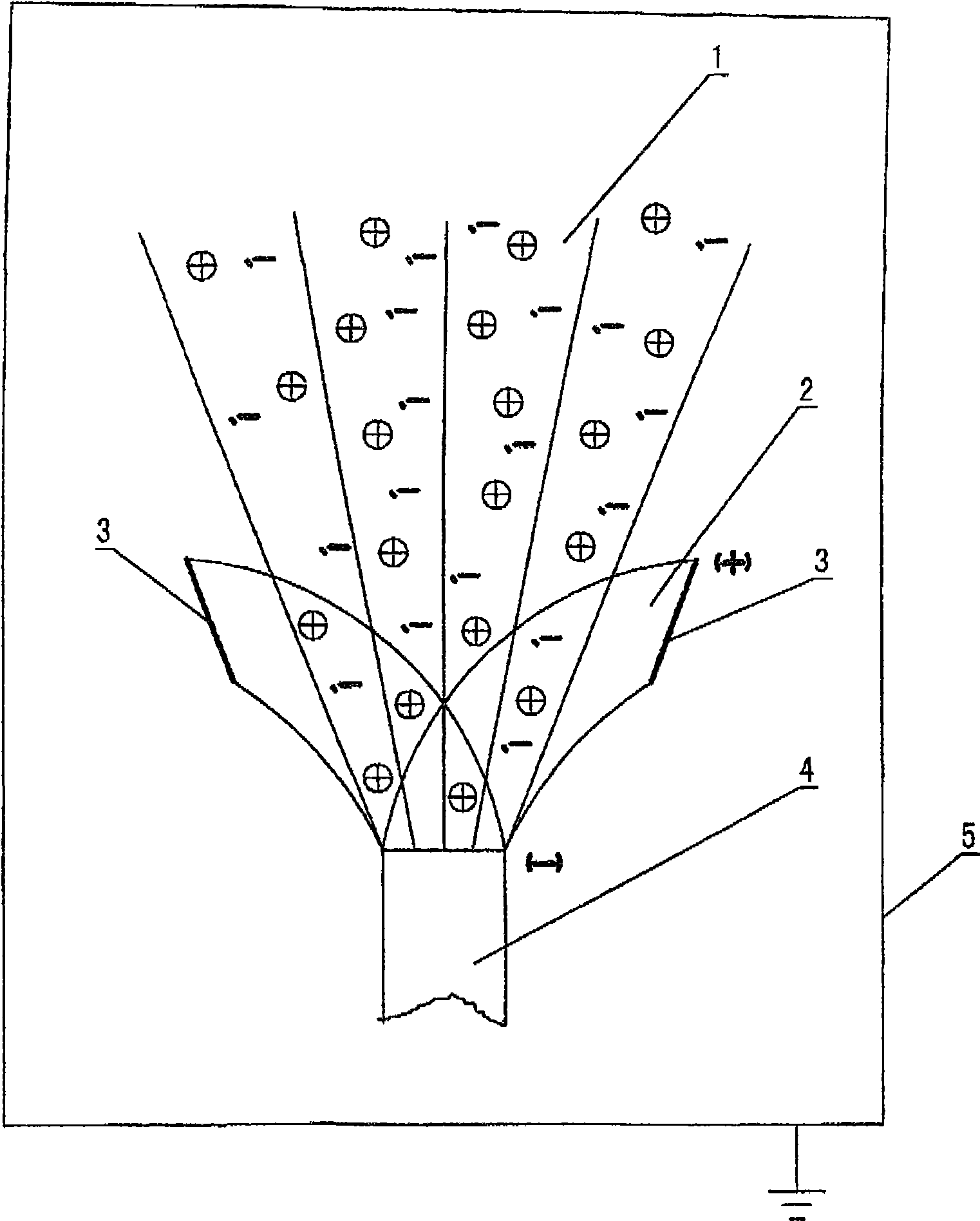

Ionization air purification system for the passenger cabin of a vehicle

ActiveUS20180065126A1Minimizing production of ozoneMinimize abilityAir-treating devicesRailway heating/coolingElectricityDielectric

An ionization air purification system for the passenger cabin of vehicles, which modifies the degree of ionization by modifying the energy levels applied to an air ionization device having a tubular dielectric member or a planar dielectric member or ionization source proportional to the change in air flow dynamics and air quality. In one embodiment, an ionization air purification system for the passenger cabin of a vehicle is disclosed. The system includes an ionization device for purifying the air prior to entering into the passenger cabin of the vehicle while minimizing the production of ozone as a by-product; and means for modifying the degree of ionization by modifying the energy levels applied to the ionization tube or ionization source proportional to the change in air flow dynamics or air quality.

Owner:CLEAN AIR GROUP

Ionization air purification system for the passenger cabin of a vehicle

InactiveUS20150075371A1Unfulfilled needAir-treating devicesRailway heating/coolingDegree of ionizationEngineering

An ionization air purification system for the passenger cabin of vehicles, which modifies the degree of ionization by modifying the energy levels applied to the ionization tube or ionization source proportional to the change in air flow dynamics and air quality. In one embodiment, an ionization air purification system for the passenger cabin of a vehicle is disclosed. The system includes an ionization device for purifying the air prior to entering into the passenger cabin of the vehicle; and means for modifying the degree of ionization by modifying the energy levels applied to the ionization tube or ionization source proportional to the change in air flow dynamics and / or air quality.

Owner:CLEAN AIR GROUP

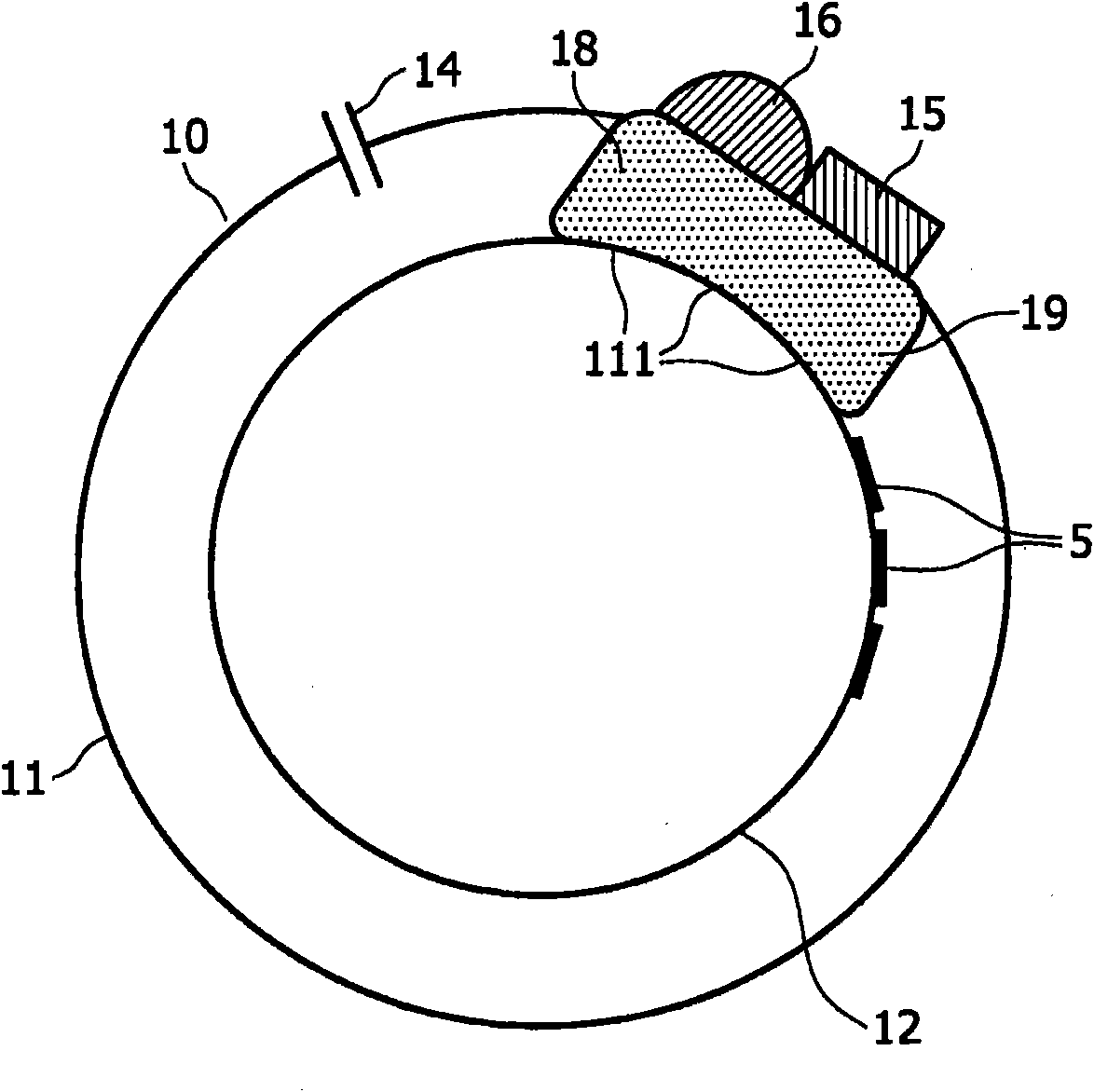

Sputtering system

InactiveCN101796213AHigh densityIncrease reaction rateElectric discharge tubesVacuum evaporation coatingSputteringPlasma density

The invention relates to a device (10) for sputtering at least one selected materialonto a substrate (5) and bringing about a reaction of this material, comprising a vacuum chamber (11), in which a substrate holder (12) is arranged, at least one magnetron sputtering mechanism (15), which is arranged in a workstation close to the substrate holder (12) and which has a target of the selected material which is suitable for producing a first plasma for sputtering at least one material onto the substrate (5), as well as a secondary plasma mechanism (16) for producing a secondary plasma, which is arranged in the workstation close to the magnetron sputtering mechanism (15) and close to the substrate holder (12), the sputtering mechanism (15) and the secondary plasma mechanism (16) forming a sputtering zone and an activation zone. At least two electromagnets (1, 3) and / or radiallymagnetized toric magnets as well as at least one magnetic multipole (2), which is formed from a plurality of permanent magnets, are arranged to produce magnetic fields to include the secondary plasma. The invention also relates to a method for coating a substrate, in which firstly materialis deposited on a substrate by means of a sputtering process and the deposited materialthen reacts in a plasma, which contains the necessary reactive species, to form a compound, wherein the plasma density and the degree of ionization of the plasma are increased with the aid of magnetic fields, which are produced by at least two electromagnets (1, 3) and / or radially magnetized toric magnets as well as at least one magnetic multipole (2), which is formed from a plurality of permanent magnets.

Owner:KONINK PHILIPS ELECTRONICS NV

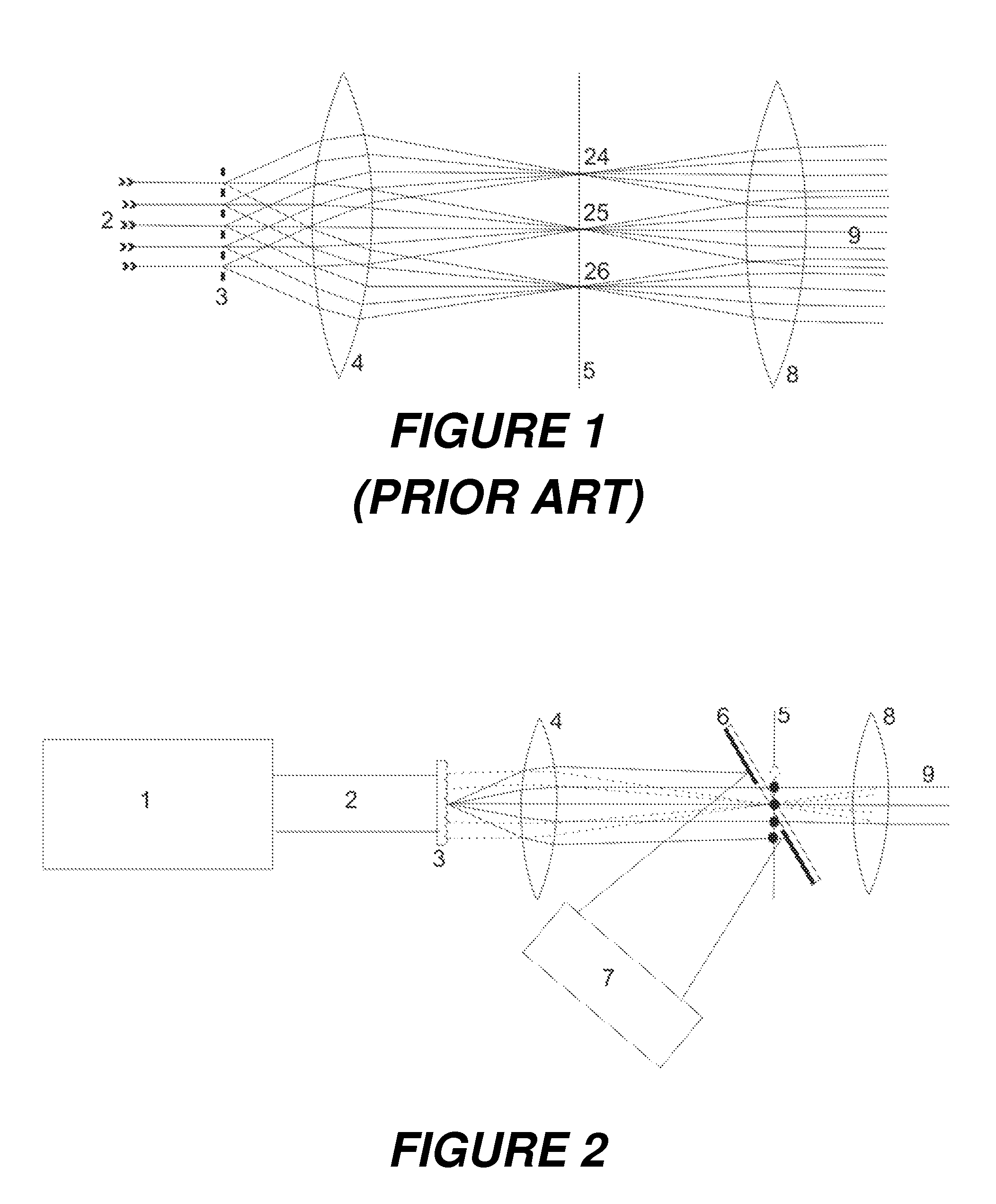

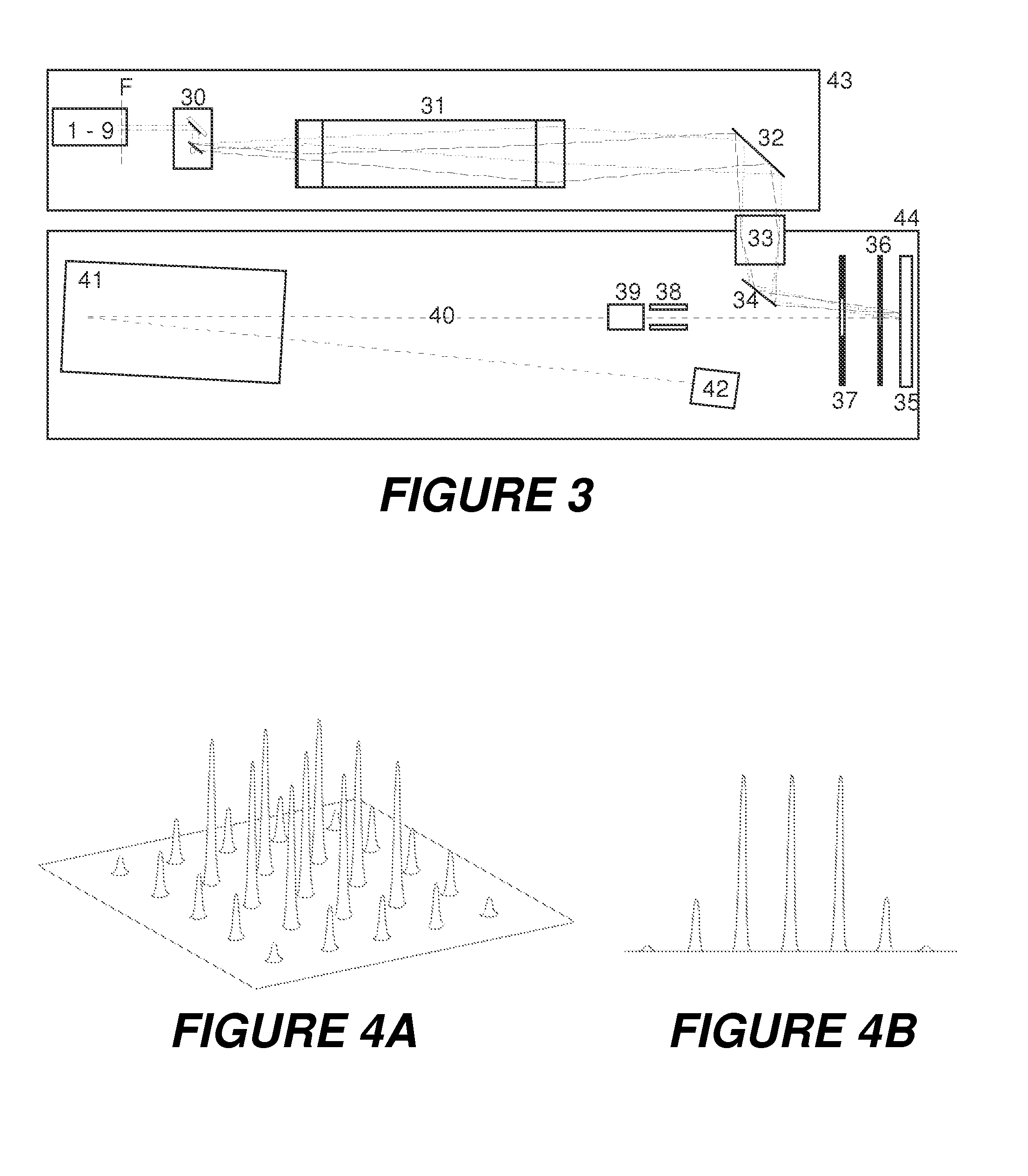

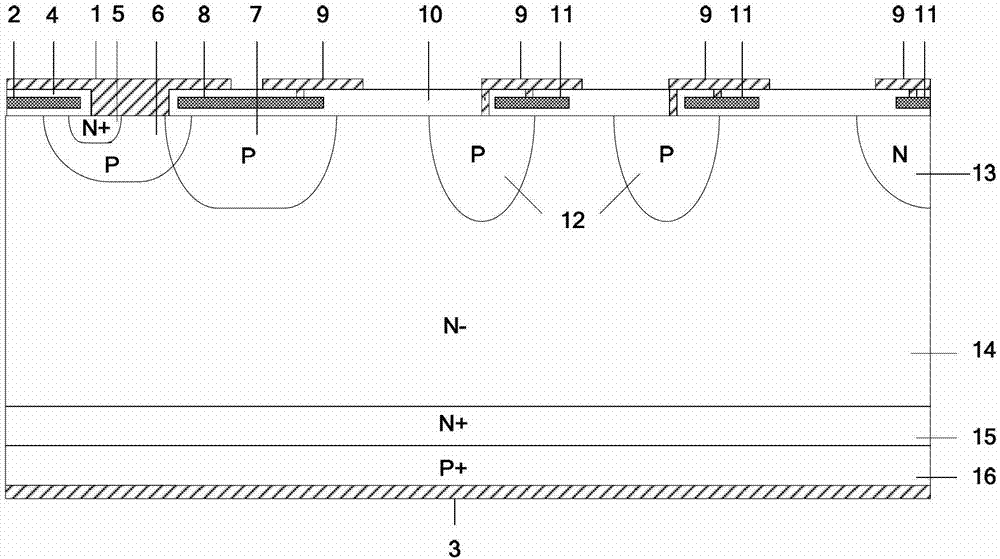

Mass spectrometer with maldi laser system

ActiveUS20130099112A1Low costIncrease conversion rateTime-of-flight spectrometersSamplingDesorptionPeak value

The invention relates to a mass spectrometer comprising a laser system for mass-spectrometric analyses with ionization of analyte molecules in a sample by matrix-assisted laser desorption. A mass spectrometer with a pulsed UV laser system produces a spatially distributed spot pattern with peaks of uniform energy density on the sample, increasing thereby the degree of ionization for analyte ions as compared to conventional spot patterns. The spot pattern with peaks of uniform energy density can be produced by homogeneous illumination of a pattern generator, for example a lens array. The homogeneous illumination can be generated by a low-cost beam-shaping element, which does not act on the UV beam but on the original infrared beam, in conjunction with changes to the beam cross-section and beam profile brought about by the nonlinear conversion crystals. This beam shaping not only produces a beam profile which illuminates the pattern generator homogeneously with low losses, but at the same time increases the efficiency of the frequency multiplication and the lifetime of the conversion crystals so that cost savings are achieved because less laser energy is required and the lifetime is increased.

Owner:BRUKER DALTONIK GMBH & CO KG

Combustible mixed gas heating device for vehicle-mounted microwave reformer

InactiveCN104675582ASimple structureEfficient and reasonable functionMachines/enginesMicrowave heatingThermal energyReaction rate

The invention provides a combustible mixed gas heating device for a vehicle-mounted microwave reformer. The combustible mixed gas heating device comprises a reaction cavity, a microwave power tube, a microwave plasma reaction tube, a discharge ignition device and a microwave power absorber, wherein the microwave power absorber is arranged in the microwave plasma reaction tube and is prepared from a high-temperature-resistant microwave absorption material; the microwave absorption material absorbs most redundant microwave energy which is not absorbed by combustible mixed gas and converts the microwave energy into heat energy; the heat energy generated by the microwave absorption material is used for heating the combustible mixed gas, so that the combustible mixed gas can be preheated to increase the temperature. The reaction temperature of the combustible mixed gas is increased, so that the heat moving speed and the collision frequency of particles are increased, and the breakdown electric field intensity required for ignition can be reduced; furthermore, a reaction chain is additionally arranged, so that the degree of ionization and the rising speed of the degree of ionization are increased, the reaction rate is increased, and the energy is saved.

Owner:JILIN UNIV

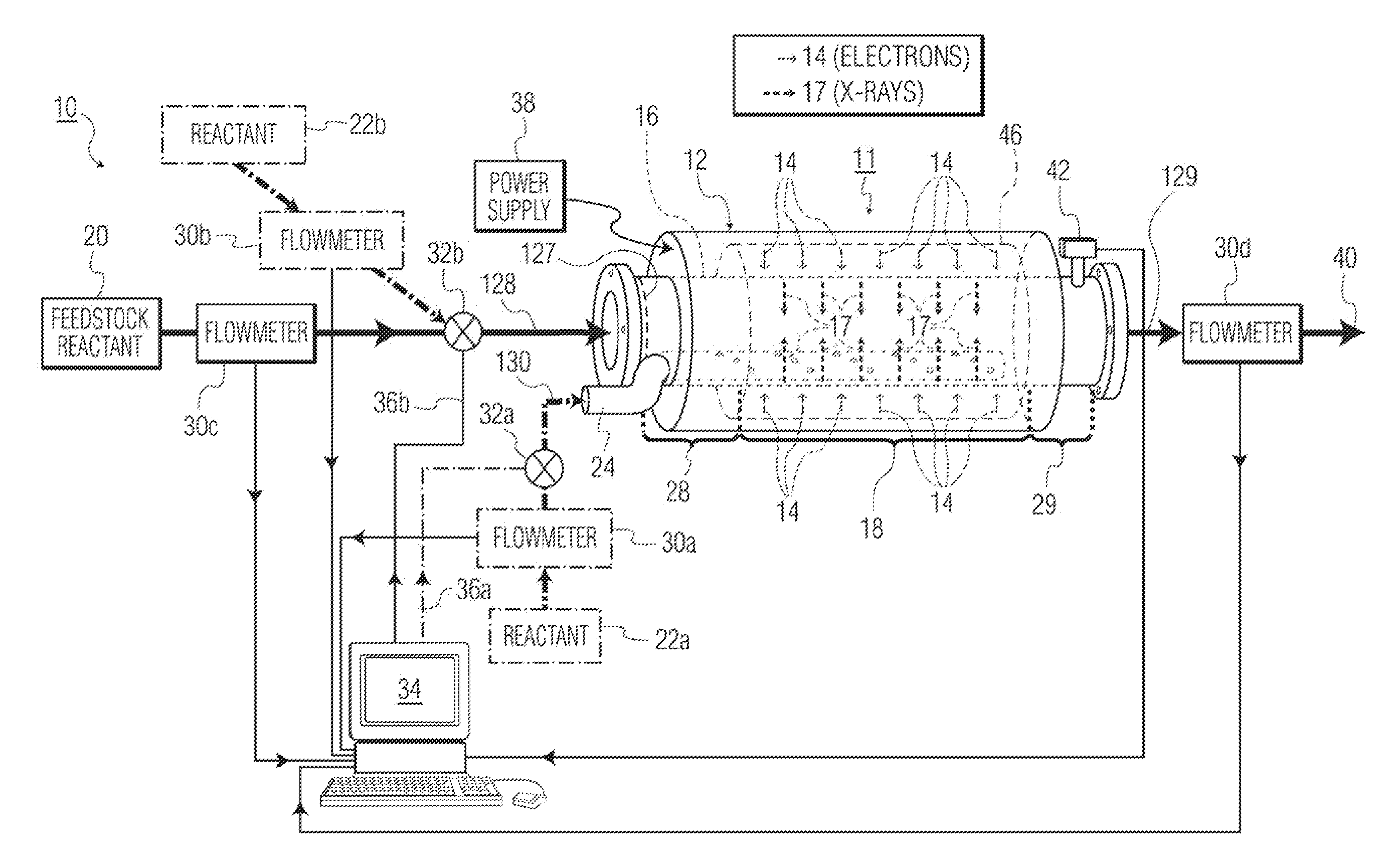

Method and apparatus for inducing chemical reactions by X-ray irradiation

ActiveUS9406478B2Improve efficiencyEliminates and reduces amountX-ray tube electrodesCathode ray concentrating/focusing/directingX-ray shieldSoft x ray

Owner:ADVANCED FUSION SYST LLC

Electrically and Magnetically Enhanced Ionized Physical Vapor Deposition Unbalanced Sputtering Source

ActiveUS20190271070A1Electric discharge tubesSemiconductor/solid-state device detailsPlasma densityGas phase

An electrically and magnetically enhanced ionized physical vapor deposition (I-PVD) magnetron apparatus and method is provided for sputtering material from a cathode target on a substrate, and in particular, for sputtering ceramic and diamond-like coatings. The electrically and magnetically enhanced magnetron sputtering source has unbalanced magnetic fields that couple the cathode target and additional electrode together. The additional electrode is electrically isolated from ground and connected to a power supply that can generate positive, negative, or bipolar high frequency voltages, and is preferably a radio frequency (RF) power supply. RF discharge near the additional electrode increases plasma density and a degree of ionization of sputtered material atoms.

Owner:IONQUEST LLC

Mass spectrometer with MALDI laser system

ActiveUS8431890B1Low costIncrease conversion rateParticle separator tubesSamplingDesorptionMass analyzer

The invention relates to a mass spectrometer comprising a laser system for mass-spectrometric analysis with ionization of analyte molecules in a sample by matrix-assisted laser desorption. A mass spectrometer with a pulsed UV laser system produces a spatially distributed spot pattern with peaks of uniform energy density on the sample, increasing thereby the degree of ionization for analyte ions as compared to conventional spot patterns. The spot pattern with peaks of uniform energy density can be produced by homogeneous illumination of a pattern generator, for example a lens array. The homogeneous illumination can be generated by a low-cost beam-shaping element, which does not act on the UV beam but on the original infrared beam, in conjunction with changes to the beam cross-section and beam profile brought about by the nonlinear conversion crystals. This beam shaping not only produces a beam profile which illuminates the pattern generator homogeneously with low losses, but at the same time increases the efficiency of the frequency multiplication and the lifetime of the conversion crystals so that cost savings are achieved because less laser energy is required and the lifetime is increased.

Owner:BRUKER DALTONIK GMBH & CO KG

Acid resistant capsules

An acid resistant capsule comprises at least one hard capsule shell, said shell comprising: an enteric polymer having acid groups; a film-forming aid; and an alkaline material, wherein said alkaline material is present in an amount such that said carboxylic acid groups of said enteric polymer have a degree of ionization of less than 15%.

Owner:CAPSUGEL BELGIUM NV

Carbon nanotube doped ionic liquid modified butyl rubber elastomer and preparation method

The invention provides a carbon nanotube doped ionic liquid modified butyl rubber elastomer. The butyl rubber elastomer is carbon nanotube doped imidazole ionic liquid modified bromobutyl rubber, andis prepared by mixing bromobutyl rubber, an imidazole molecular additive and carbon nanotube powder. The butyl rubber elastomer has high degree of ionization modification and good carbon nanotube dispersion performance; no further vulcanization treatment is needed, and the prepared carbon nanotube doped ionic liquid modified butyl rubber elastomer has tensile strength being more than 15 MPa and elongation at break being close to 10 times that of the traditional butyl rubber elastomer. The prepared carbon nanotube doped ionic liquid modified butyl rubber elastomer has a dielectric constant of 20 or more and a conductivity of 10<-5> S / cm under a frequency of 100 Hz at room temperature, and has high self-healing capacity under a hot pressing state. The invention provides a preparation methodof the butyl rubber elastomer.

Owner:华碳研发(深圳)有限公司

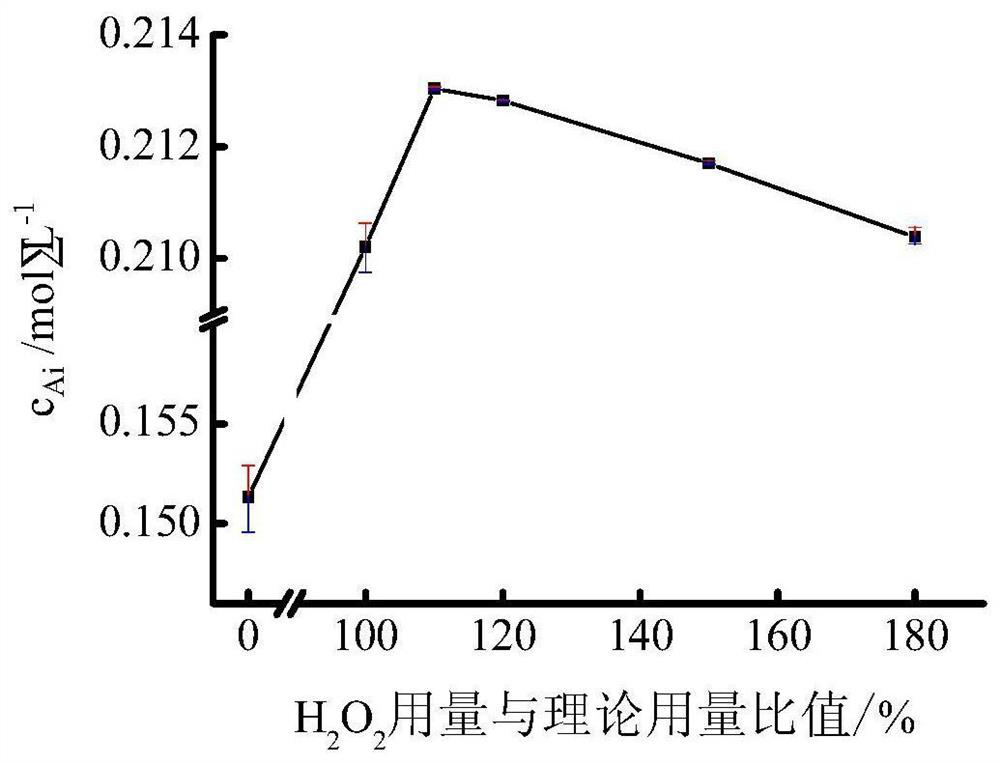

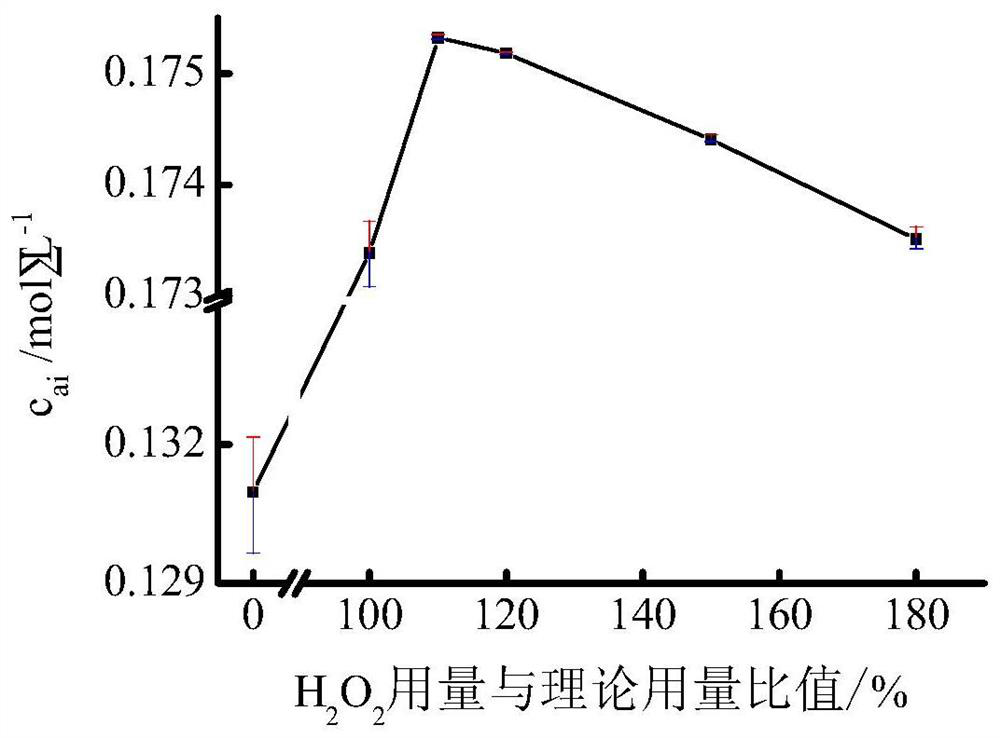

Method for verifying addition amount of hydrogen peroxide for treating nitro-oxidant wastewater

PendingCN112225304AHigh removal rateLarge nitrogen conversion rateWater/sewage treatment by oxidationNitriteNitrate salts

The invention discloses a method for verifying the addition amount of hydrogen peroxide for treating nitro-oxidant wastewater. The method comprises the following steps: preparing a plurality of groupsof nitro-oxidant wastewater solutions; calculating the theoretical volume addition amounts of calibrated H2O2, respectively adding H2O2 with the addition amount increased progressively in a gradientmanner into each group of solution, and setting a blank control group; measuring and calculating the concentration of nitrate nitrogen, the concentration of nitrite nitrogen and the concentration of nitrous acid in the six groups of wastewater before neutralization, and the concentration of nitrate nitrogen and the concentration of nitrite nitrogen in the neutralized wastewater by adopting a spectrophotometric method; drawing a corresponding curve graph according to measured data, and respectively calculating the ionization degree of nitrous acid in the six groups of wastewater before neutralization, the removal rate of nitrite (containing nitrous acid) and the conversion rate of nitrogen in N2O4 after neutralization; and determining the optimal addition amount of H2O2. According to the method, the addition amount of hydrogen peroxide for treating the nitro-oxidant wastewater is determined, and a theoretical basis is provided for realizing a maximum nitrogen element conversion rate anda maximum nitrite removal rate.

Owner:中国人民解放军63605部队

Mass spectrometer with laser spot pattern for MALDI

ActiveUS9741550B2Reduce energy lossFacilitated ionizationIon sources/gunsImaging particle spectrometryDesorptionMass spectrometric

The invention relates to mass spectrometers with an ion source, comprising a UV laser system for mass spectrometric analyses with ionization of analyte molecules in a sample by matrix-assisted laser desorption, which, with very low energy losses, can produce a spatially distributed spot pattern with several intensity peaks of equal height, thus making it possible to achieve an optimum degree of ionization of analyte ions for any task. Such a spot pattern can be generated from the UV beam with high transverse coherence, using a combination of a lens array and a lens, provided that the lens array satisfies a mathematical condition for separation of the micro-lenses from each other (pitch) and their focal length. For example, a lens array with square or round lenses produces a pattern of nine and five spots, respectively. The lens arrays are inexpensive and do not require any lateral adjustment in this arrangement.

Owner:BRUKER DALTONIK GMBH & CO KG

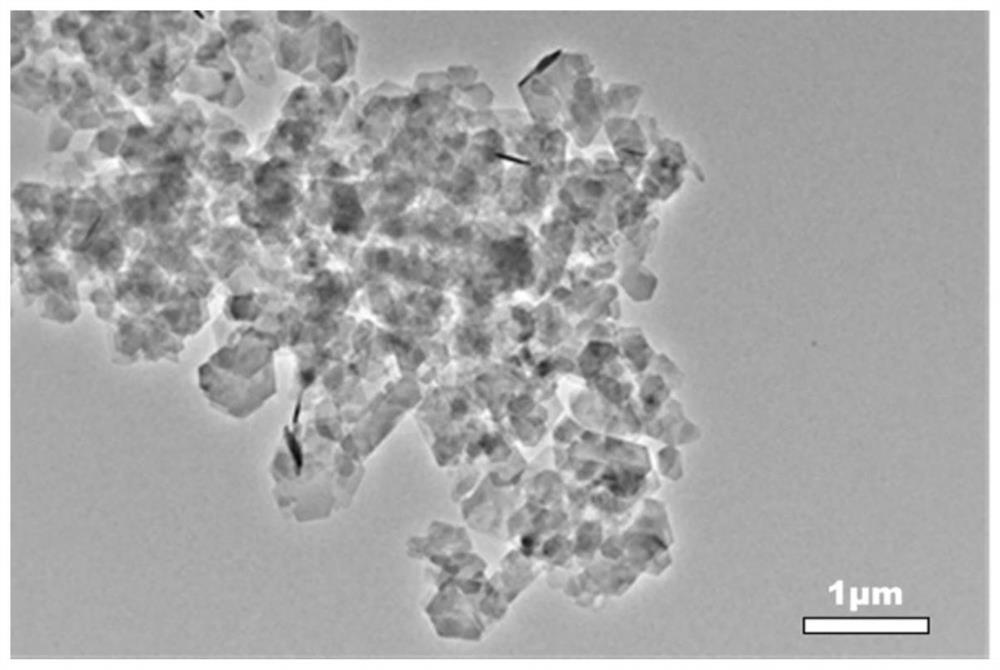

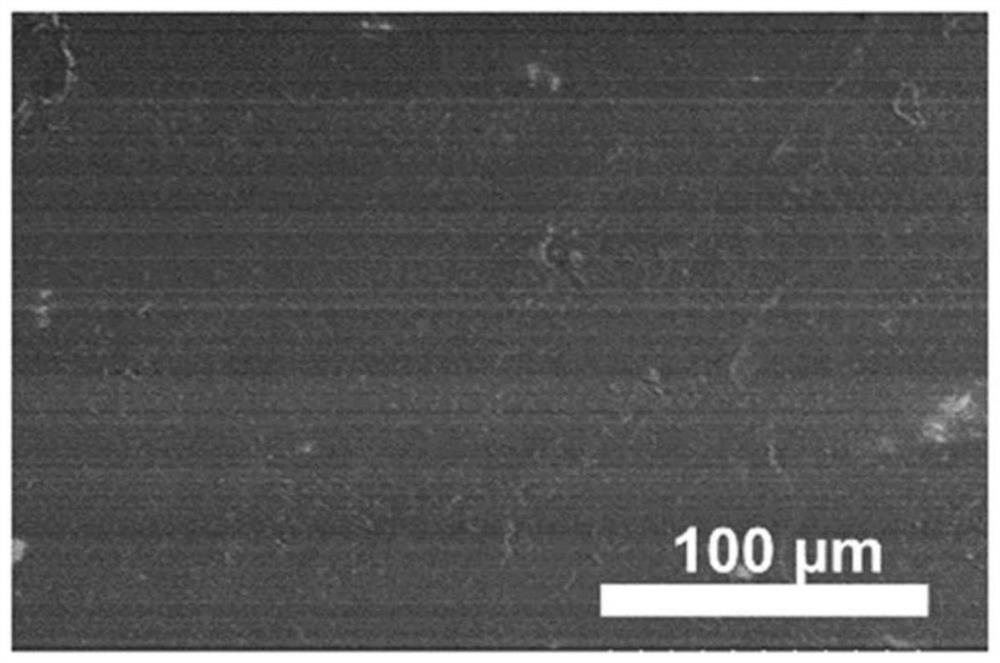

Nano-clay calcium hydroxide composite material for repairing and reinforcing as well as preparation and application of nano-clay calcium hydroxide composite material

ActiveCN114656284AUniform action and effectImprove retentionSolid waste managementCalcium hydroxideDegree of ionization

The invention relates to a nano-clay calcium hydroxide composite material for repairing and reinforcing as well as preparation and application of the nano-clay calcium hydroxide composite material. In-situ growth of nano-calcium hydroxide on a nano-clay sheet is realized by controlling the ionization degree of calcium ions and hydroxyl ions in a nano-clay dispersion liquid and the degree of supersaturation of a solution; further, the nano-clay calcium hydroxide composite material is prepared; after being uniformly dispersed in alcohol or alcohol-water composite liquid, the composite material is applied to functional protection such as repair and reinforcement of rock mass and surface of stone cultural relics. Compared with the prior art, the preparation method of the nano-clay calcium hydroxide repairing and reinforcing material is simple, the composite proportion of the clay and the calcium hydroxide is adjustable and controllable, the size is uniform, and the prepared protection liquid is high in dispersion, good in fluidity, high in permeability, good in compatibility with rock, free of soluble salt, appropriate in rigidity and hardness and appropriate in curing time. The method has high applicability, safety and durability and is free of derivative damage to stone cultural relic protection.

Owner:FUDAN UNIV

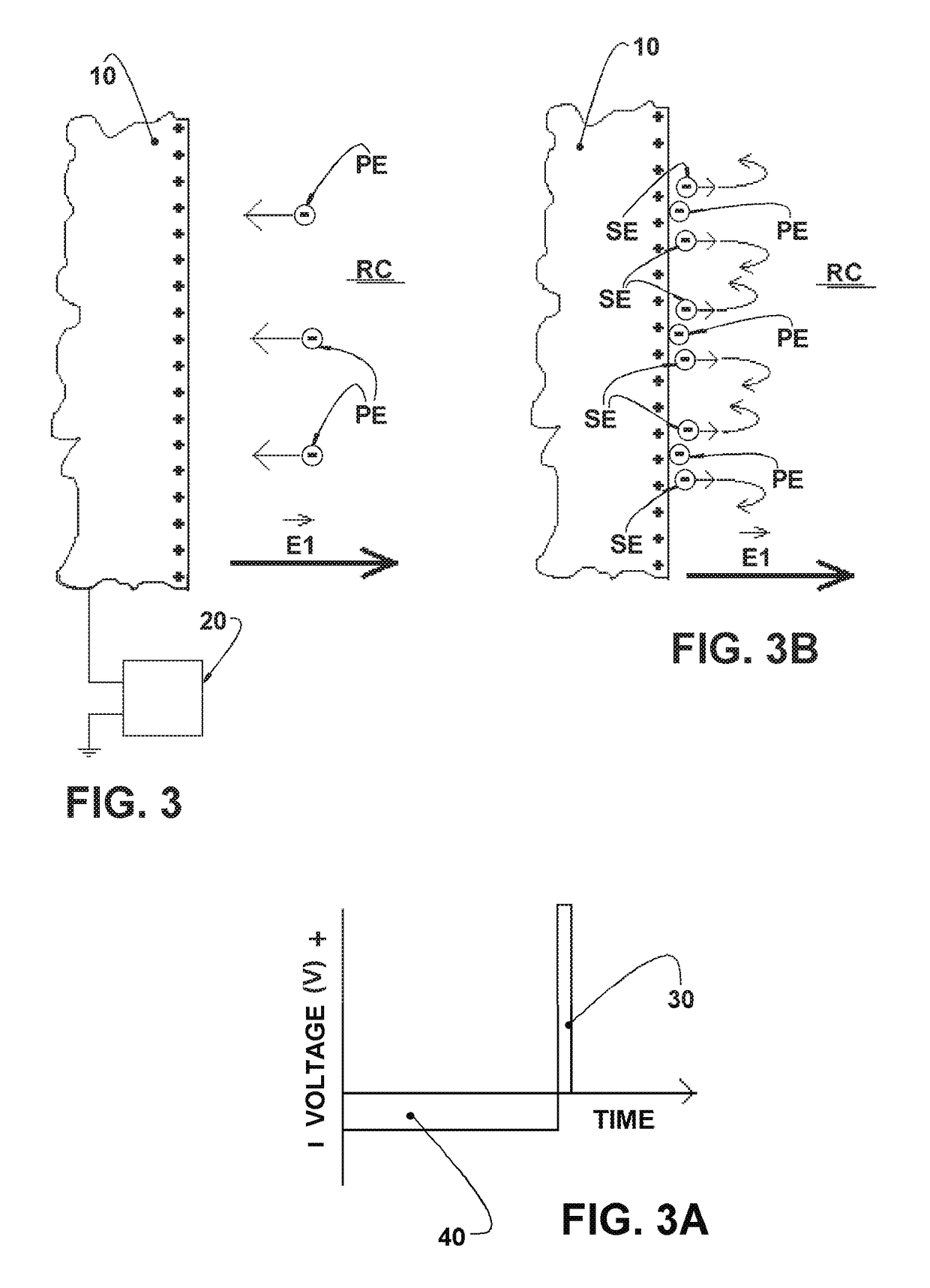

Plasma densification method

InactiveUS20170280548A1Increase temperatureHigh degree of ionizationElectric discharge tubesPlasma techniqueVoltage pulseLow voltage

The plasma is formed between electrodes to be energized from an electric power source, containing a partially ionized mass having a luminescence region including neutral atoms (NA), primary electrons (PE), secondary electrons (SE), and ions.The method comprises the interspersed steps of: accelerating the primary electrons (PE) toward one of said electrodes (10) polarized by a short, positive, high voltage pulse, impacting primary electrons (PE) against said electrode (10) and ejecting secondary electrons (SE) from it; subsequently, accelerating the secondary electrons (SE) toward the luminescence region by polarization of said electrode (10) by a negative voltage with a lower voltage pulse colliding the secondary electrons with neutral atoms (NA) and producing positive ions (PI) and derived electrons (DE); the negative pulse must have a period of time sufficient to accelerate the positive ions (PI) of the luminescent region towards the electrodes 10, striking the surface of said electrodes; repeating the previous steps in order to obtain a steady state plasma with a desired degree of ionization. The control of the intensity and the period of the positive and negative pulses allow the control of the degree of ionization and the volume of the luminescent region of the plasma.

Owner:SCHOLTZ E FONTANA CONSULTORIA LTDA ME

Sputtering sources for high-pressure sputtering with large targets and sputtering method

InactiveUS9481928B2Raise the possibilityImprove sputteringCellsElectric discharge tubesSputteringDegree of ionization

A sputtering head comprises a receiving area for a sputtering target (target receptacle). The sputtering head comprises one or more magnetic field sources so as to generate a stray magnetic field. The magnetic north and the magnetic south of at least one magnetic field source, between which the stray field forms, are located 10 mm or less, preferably 5 mm or less, and particularly preferably approximately 1 mm apart. It was found that, notably when sputtering at a high sputtering gas pressure of 0.5 mbar or more, the degree of ionization of the sputtering plasma, and consequently also the ablation rate of the sputtering target, can be locally adjusted by such a locally effective magnetic field. This allows the thicknesses of the layers that are obtained to be more homogeneous over the surface of the substrate. Advantageously, the sputtering head additionally comprises a solid state insulator, which surrounds the base body comprising the target receptacle and the sputtering target (all connected to potential) and electrically insulates the same from the shield that spatially limits the material ablation to the sputtering target (connected to ground).

Owner:FORSCHUNGSZENTRUM JULICH GMBH

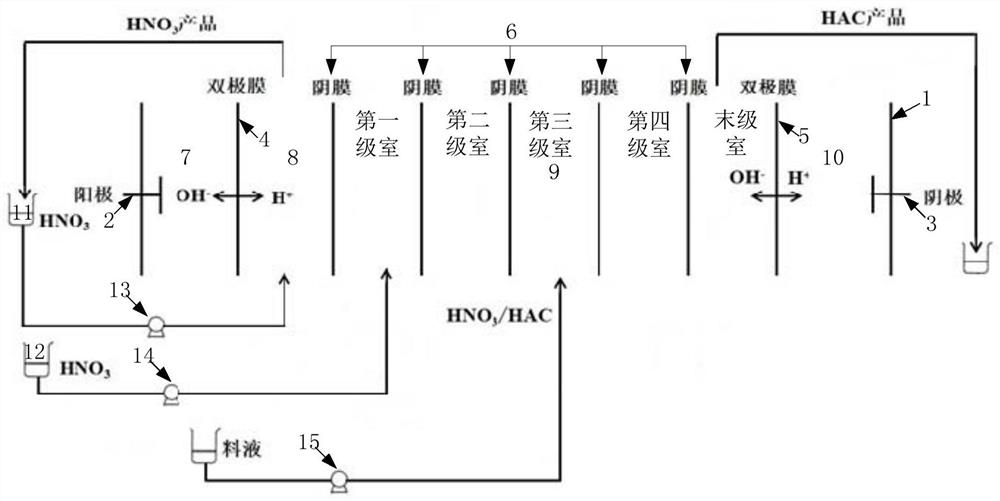

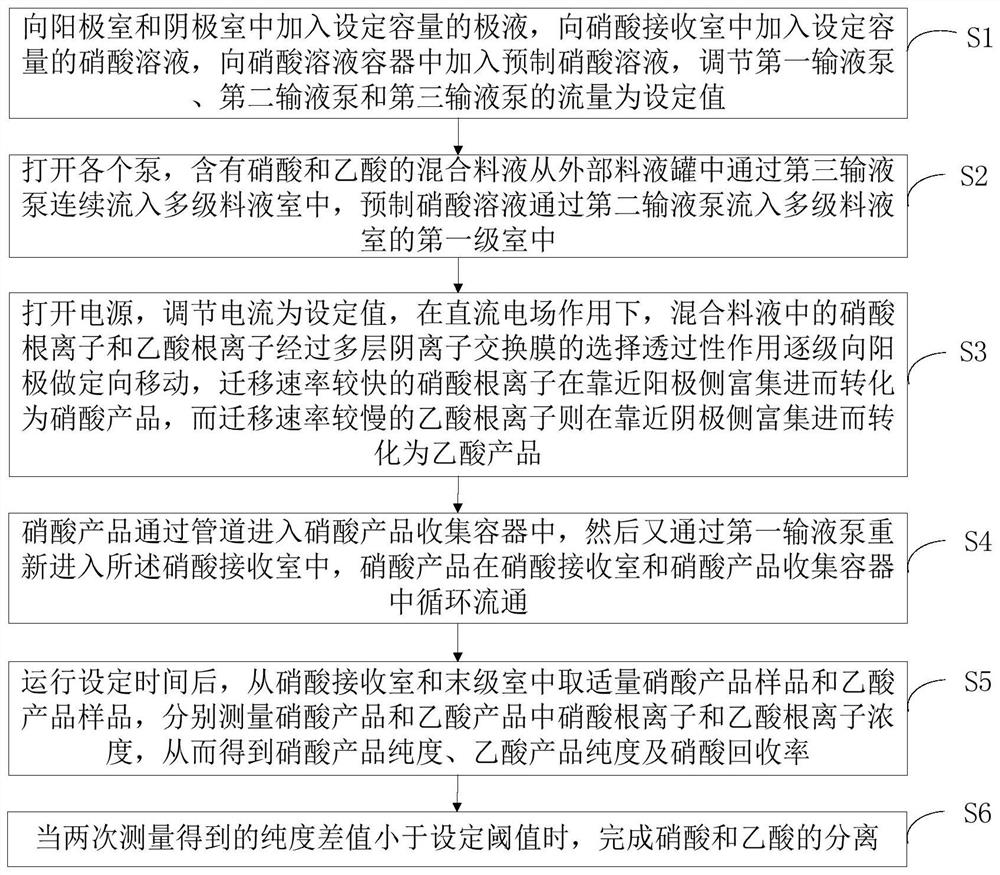

Electrodialysis device and method for separating nitric acid and acetic acid

PendingCN114534501AReduce energy consumptionHigh purityNuclear energy generationElectrodialysisElectrodialysisIon migration

The invention relates to an electrodialysis device and method for separating nitric acid and acetic acid, and belongs to the technical field of nuclear fuel aftertreatment. The method comprises the following steps: under the action of a direct-current electric field, nitrate ions and acetate ions in feed liquid do directional movement towards an anode step by step under the selective permeability action of multiple layers of anion exchange membranes; nitrate ions with higher migration rate are enriched on the side close to the anode, and acetate ions with lower migration rate are enriched on the side close to the cathode. According to the device and the method provided by the invention, nitric acid / acetic acid is separated by utilizing the ionization degree difference of nitric acid and acetic acid in an aqueous solution and the ion migration speed difference under an external electric field, the separation process is simple and safe, the purity of a nitric acid product is high, and no other byproducts are generated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

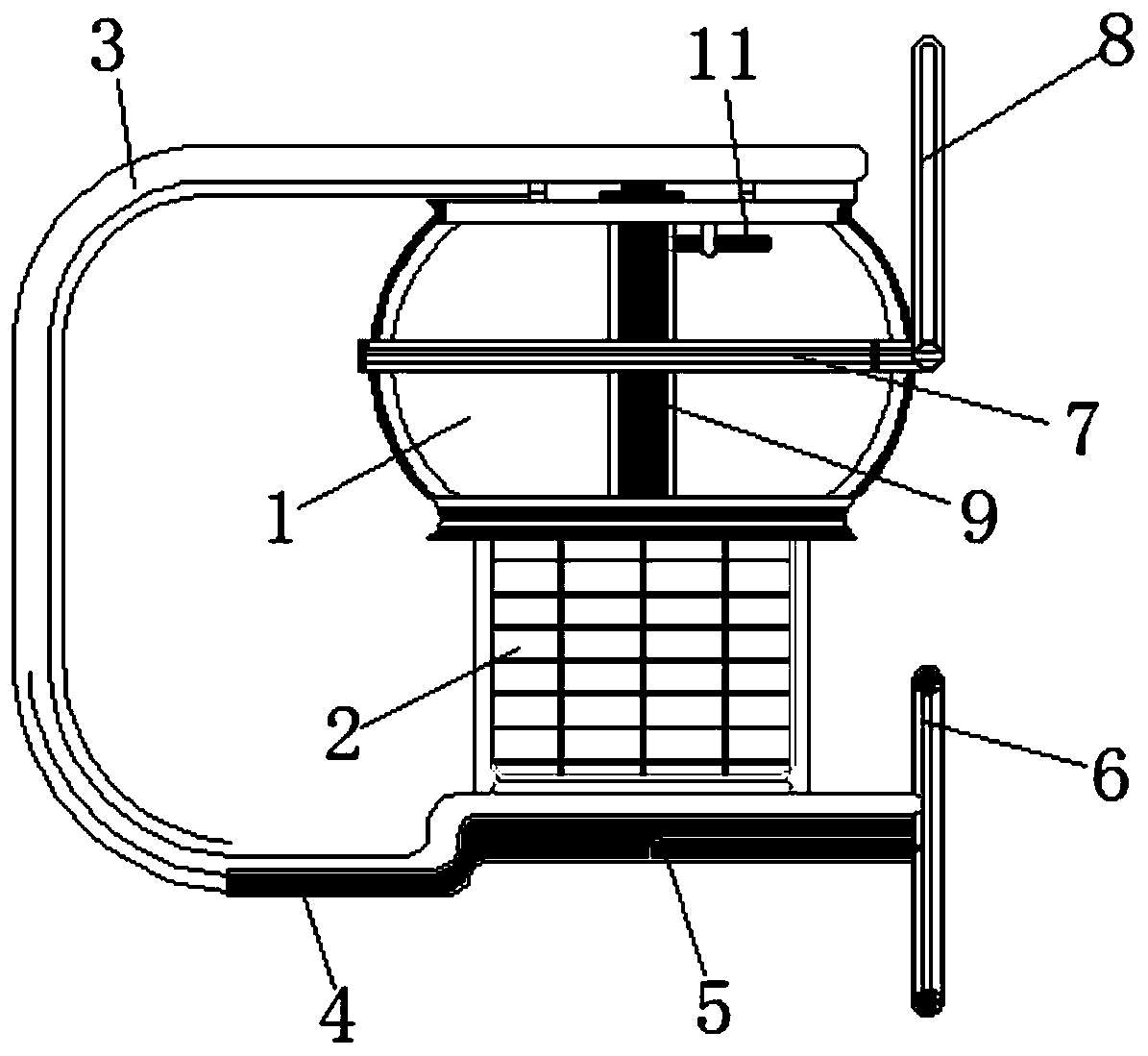

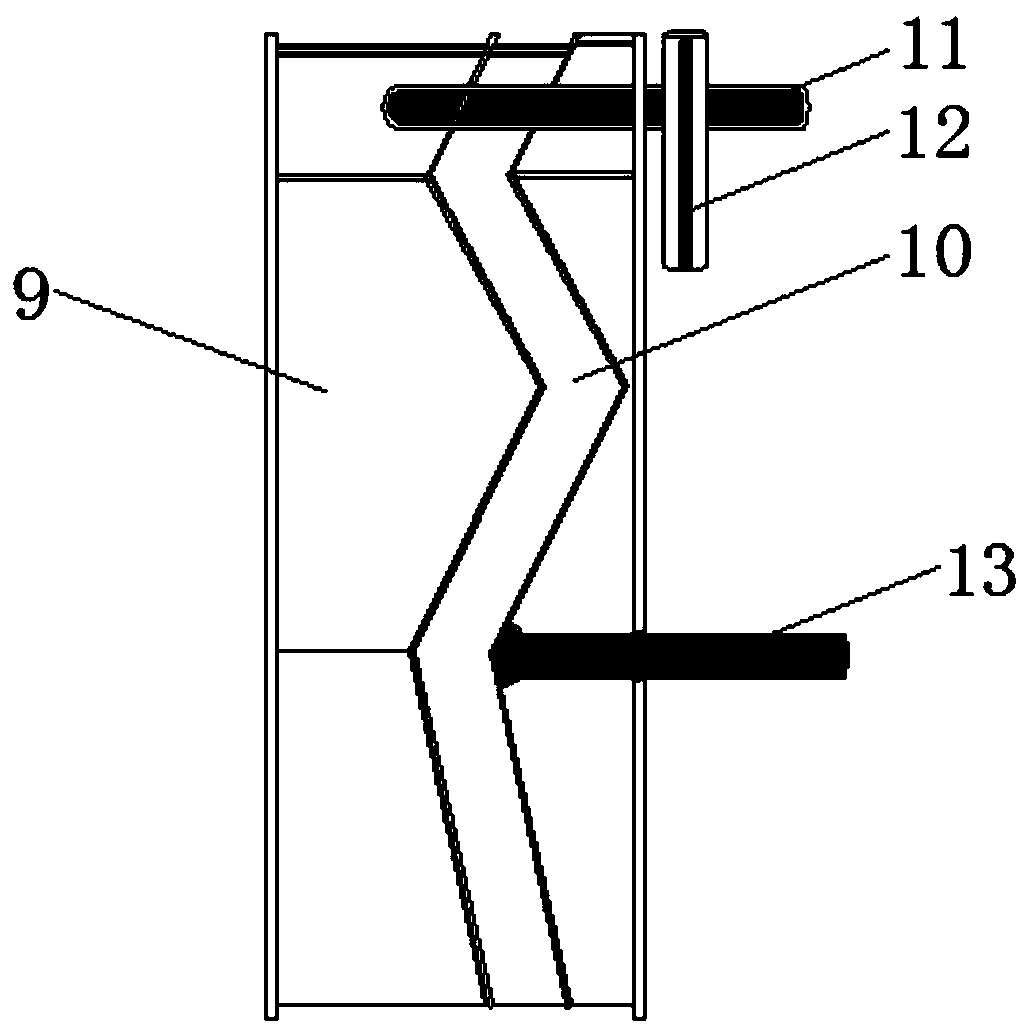

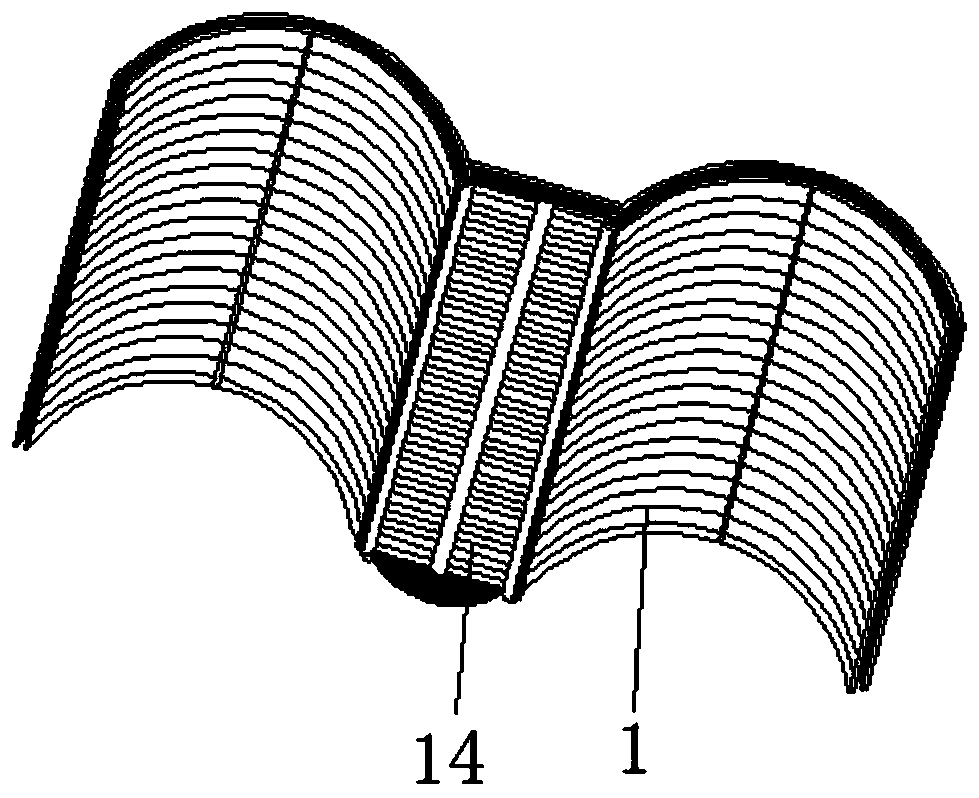

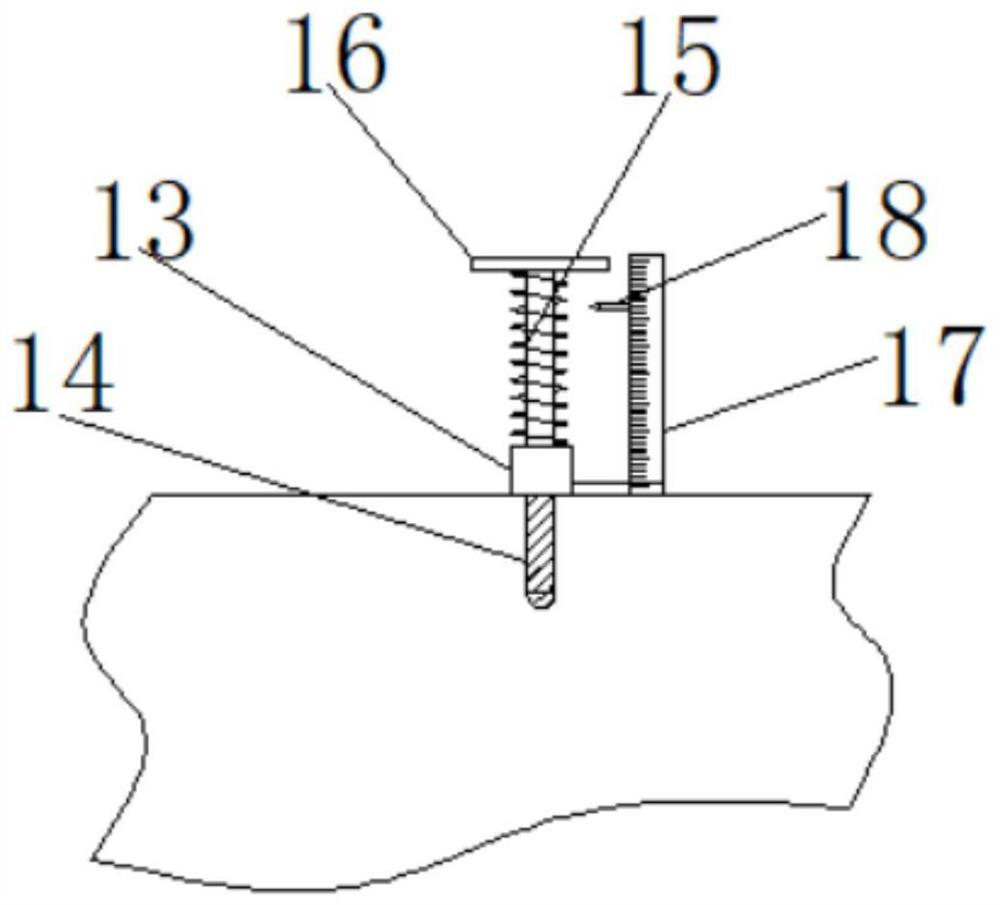

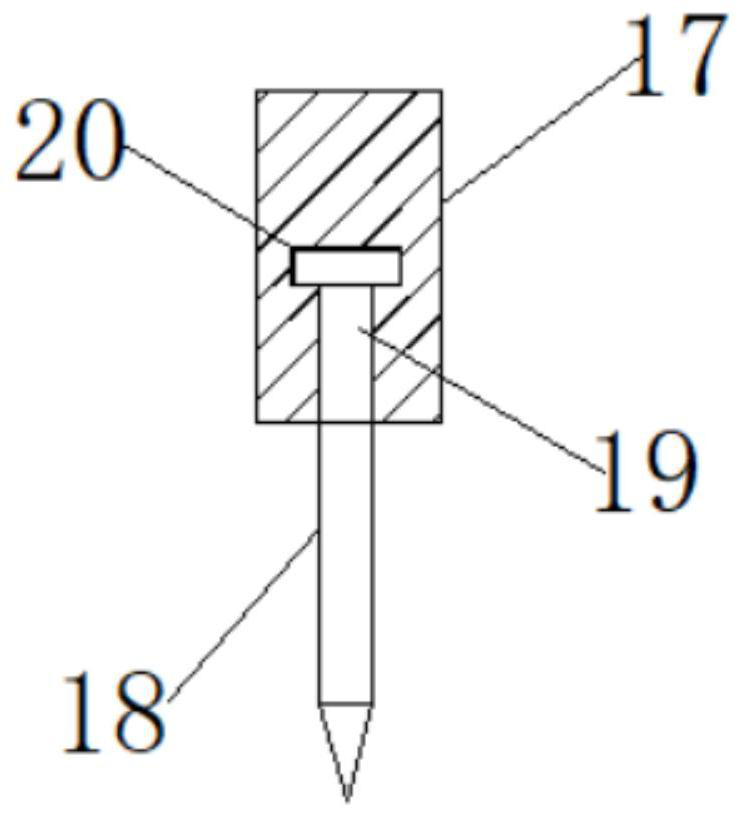

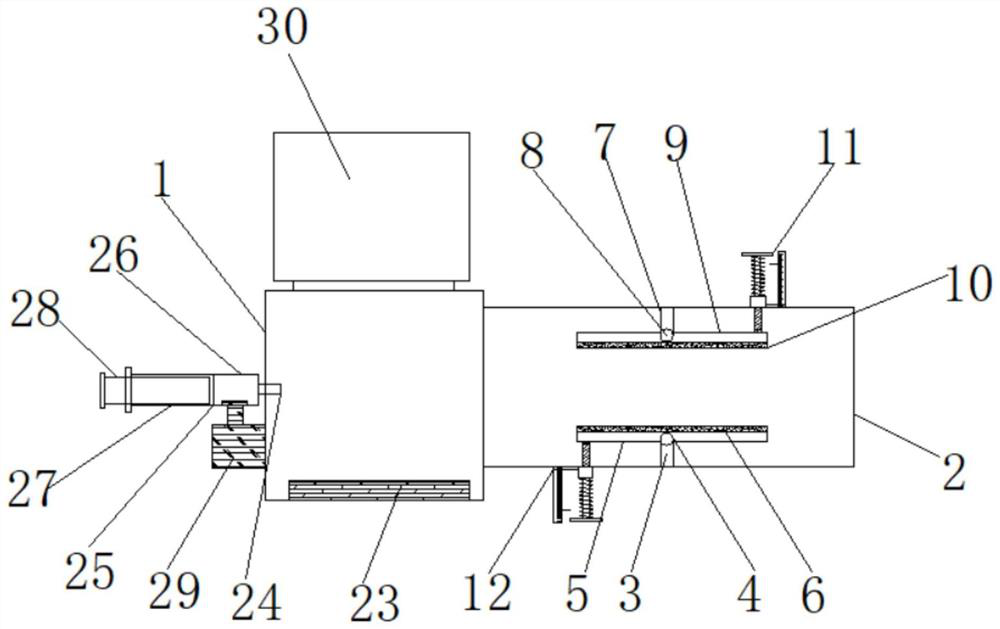

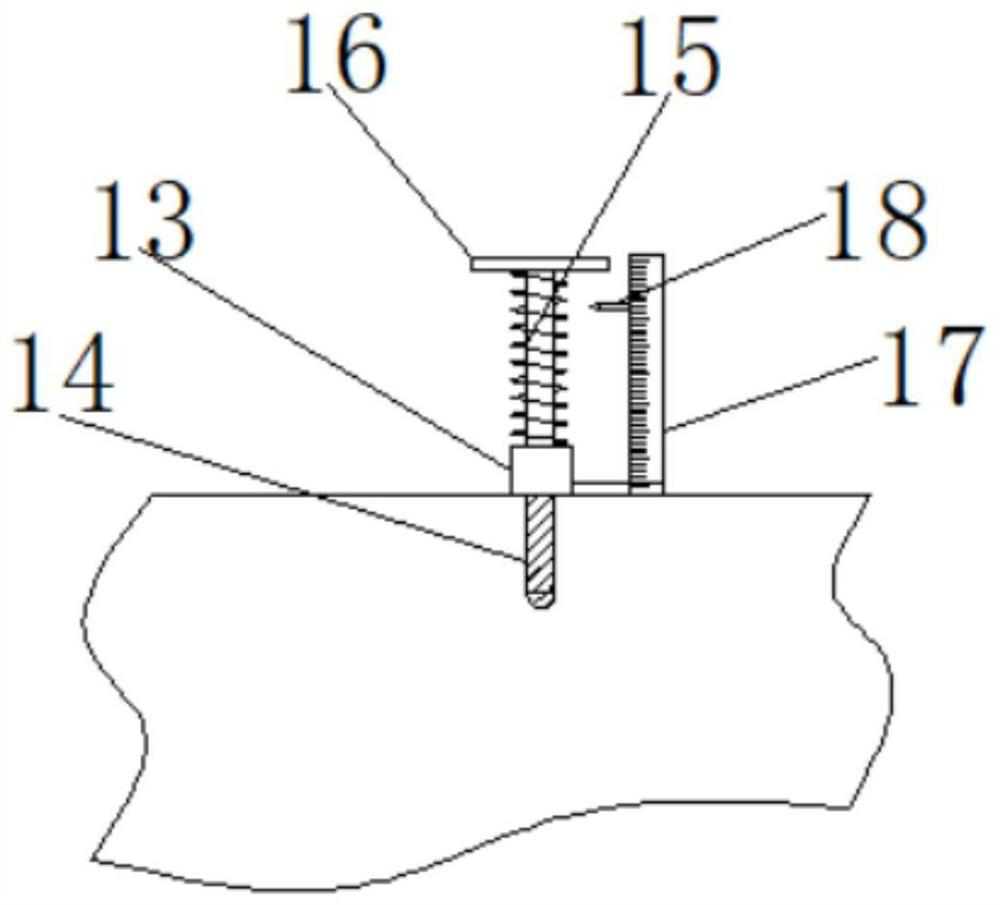

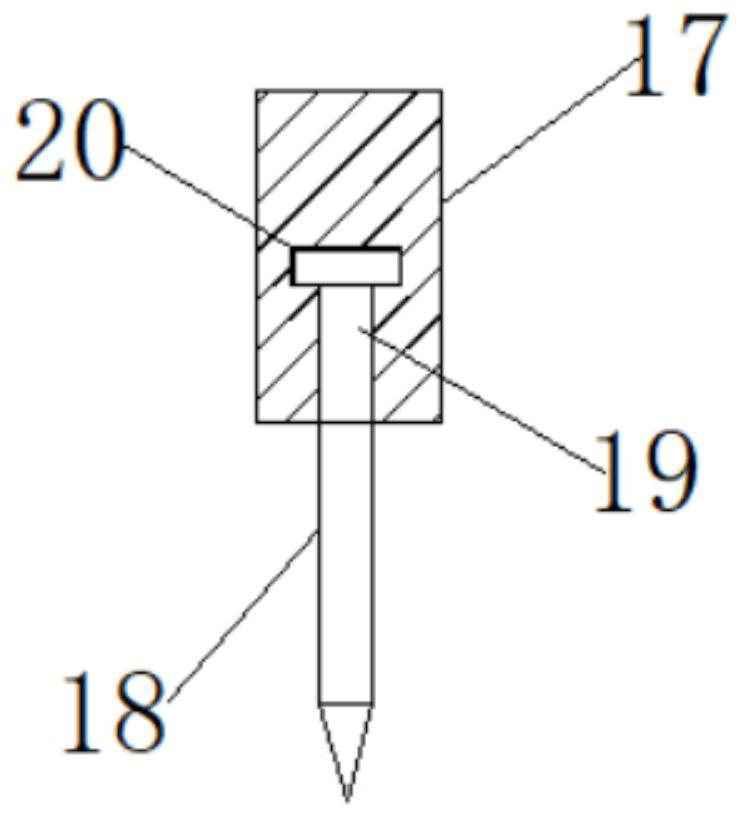

Ionization degree detecting sampling device for electrolyte solution for hemofiltration

The invention provides an ionization degree detecting sampling device for an electrolyte solution for hemofiltration. The device includes a movable cover, the bottom of the movable cover is fixedly installed on the top end of a hollow column, a center column penetrates an inner axis of the movable cover, and the upper end side wall of the center column is movably installed in the middle of a guiderod; and a rotating rod is movably installed at the part, located at the right side of the center column, of the guide rod, the top end of the rotating rod penetrates the top end of the movable coverand is movably connected to the upper end of a flow pipe, and the lower side of the bottom end of the flow pipe is movably connected to the upper side of a through groove. When a center shaft moves towards the right side, a pipe in the center column can be straightened, the pipe is in a straightened state in the center column, so that a period of dialysis time can be reserved for blood in the curved pipe to ensure the filtration effect, the pipe is straightened, the activity of the blood can be accelerated through shaking of the pipe, a dialysate can be promoted to balance impurities in the blood, the efficiency can be improved, and the time of triggering ischemia risk during patient dialysis can be reduced.

Owner:杨光

A kind of igbt with terminal deep level impurity layer

InactiveCN102779840BImprove reliabilityReduce high temperature leakage currentSemiconductor devicesCharge carrierDegree of ionization

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

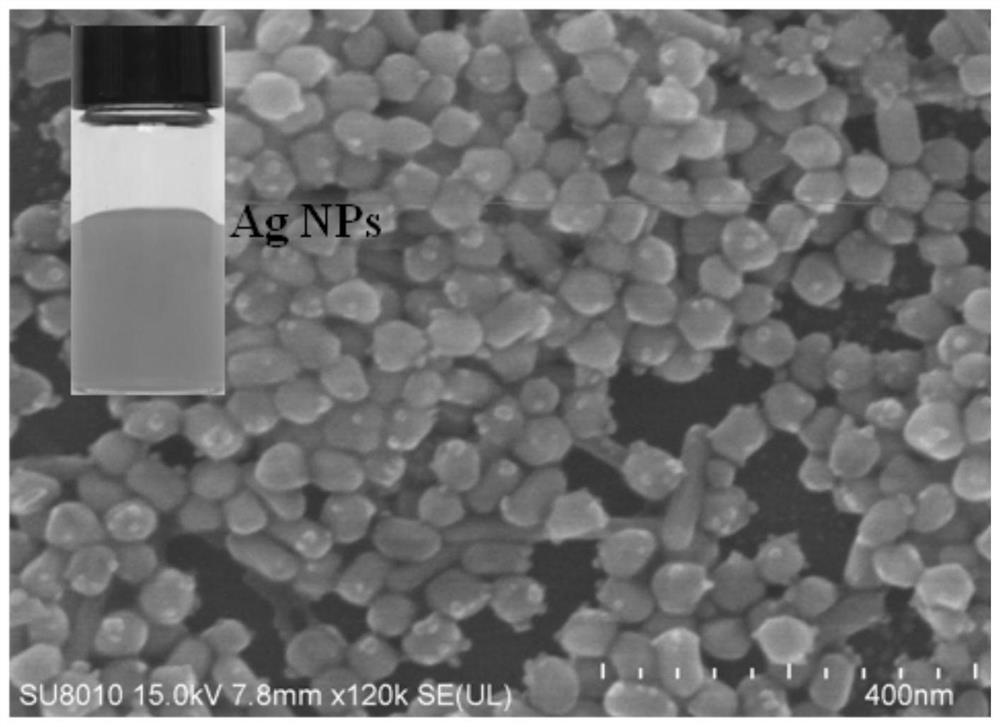

A method based on ag NPs to promote the ionization of benzoic acid derivatives

ActiveCN110698371BIonization reaction promotesIonization reaction promotionThiol preparationMetal/metal-oxides/metal-hydroxide catalystsBenzoic acidPtru catalyst

The invention relates to a method for promoting the ionization of benzoic acid derivatives based on Ag NPs. The adopted technical scheme is: dissolving benzoic acid derivatives in absolute ethanol, then adding Ag NPs catalyst, and ionizing reaction under light. In the present invention, there is no conventional addition of alkali in this system, but it can be clearly seen that the degree of ionization is gradually increasing, so the "racemate of Lewis acid-base"-Ag NPs fully exerts the role of alkali, and the more critical It is that it acts as a boost far beyond that of the base base. Moreover, the present invention introduces surface-enhanced Raman spectroscopy technology, and monitors the system through this simple and efficient means. Moreover, the present invention clarifies the flow direction of electrons. More importantly, the present invention regulates the generation of hot electrons based on the electron-withdrawing effect, prompting the system to generate more hot electrons, and realizing reactions that cannot occur in conventional organic chemistry.

Owner:LIAONING UNIVERSITY

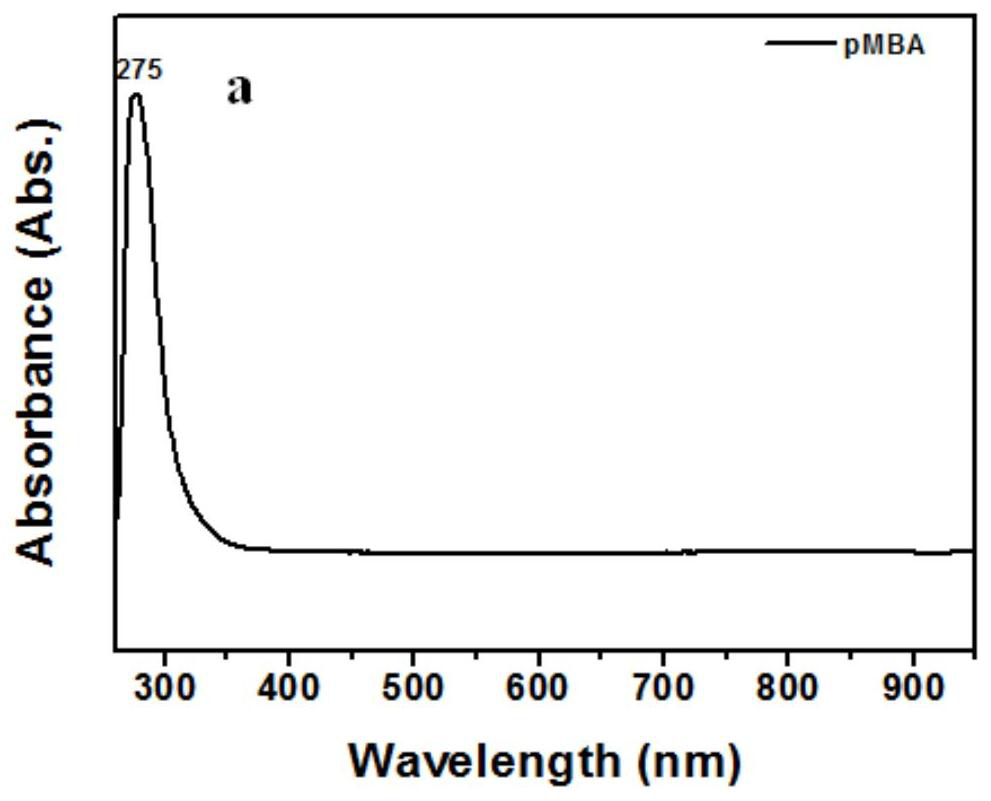

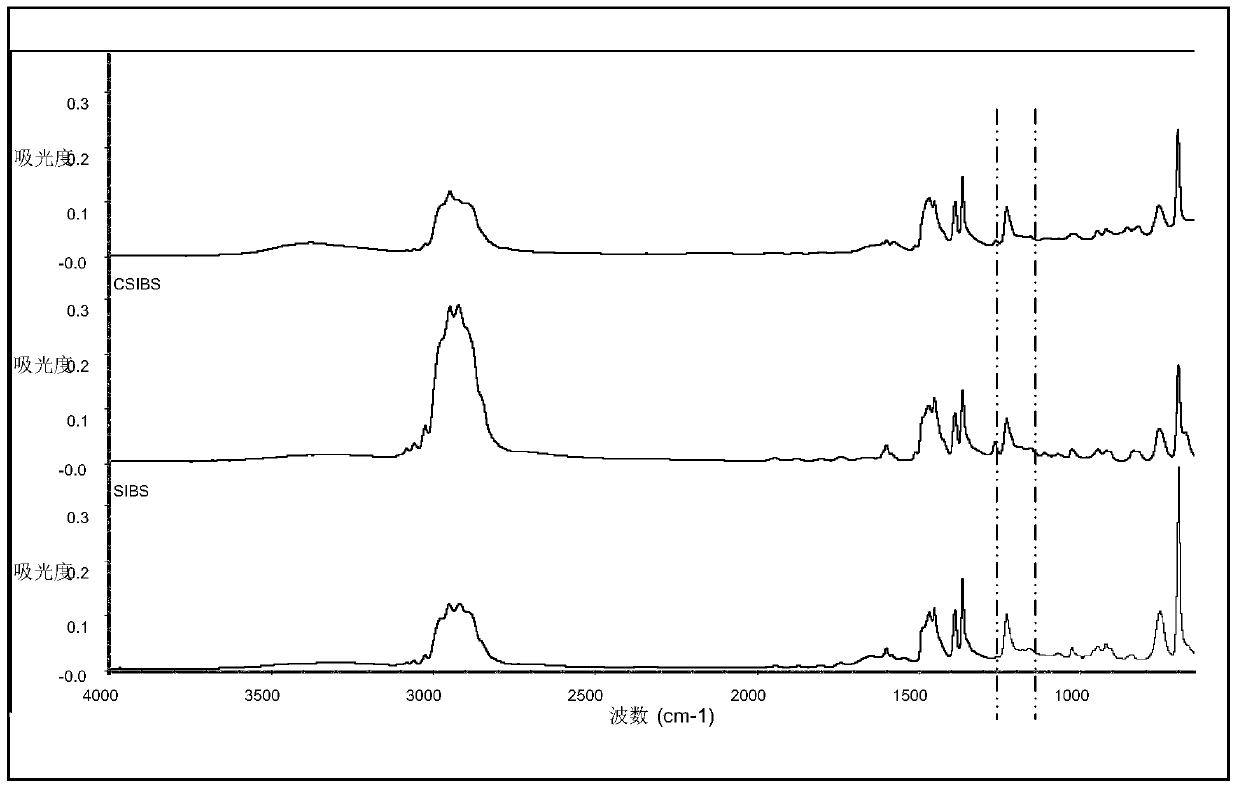

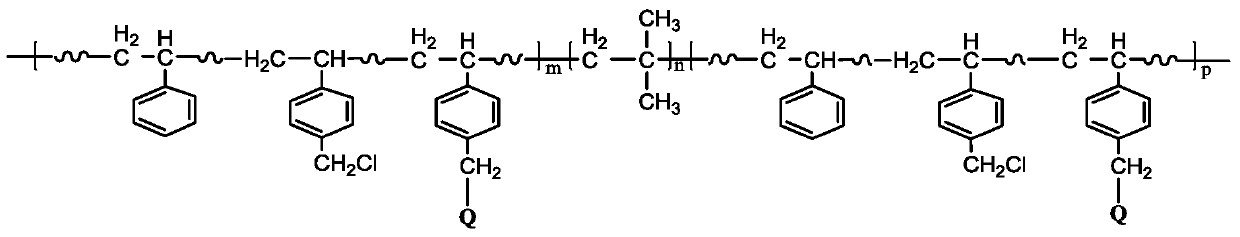

A kind of nitrogen onium ionized poly(styrene-b-isobutylene-b-styrene) triblock copolymer and preparation method thereof

The invention relates to azonium ionized poly(styrene-b-isobutylene-b-styrene) triblock copolymer and a preparation method thereof. Using poly(styrene-b-isobutylene-b-styrene) as the base material, it is prepared through chloromethylation and nitrogenium ionization in sequence. The nitrogen-containing onium ion salt substituted poly(styrene-b-isobutylene-b-styrene) triblock copolymer prepared by the method of the present invention has high ion content, high ionization degree, high ionization reaction efficiency, and the preparation method Simple.

Owner:BEIJING UNIV OF CHEM TECH

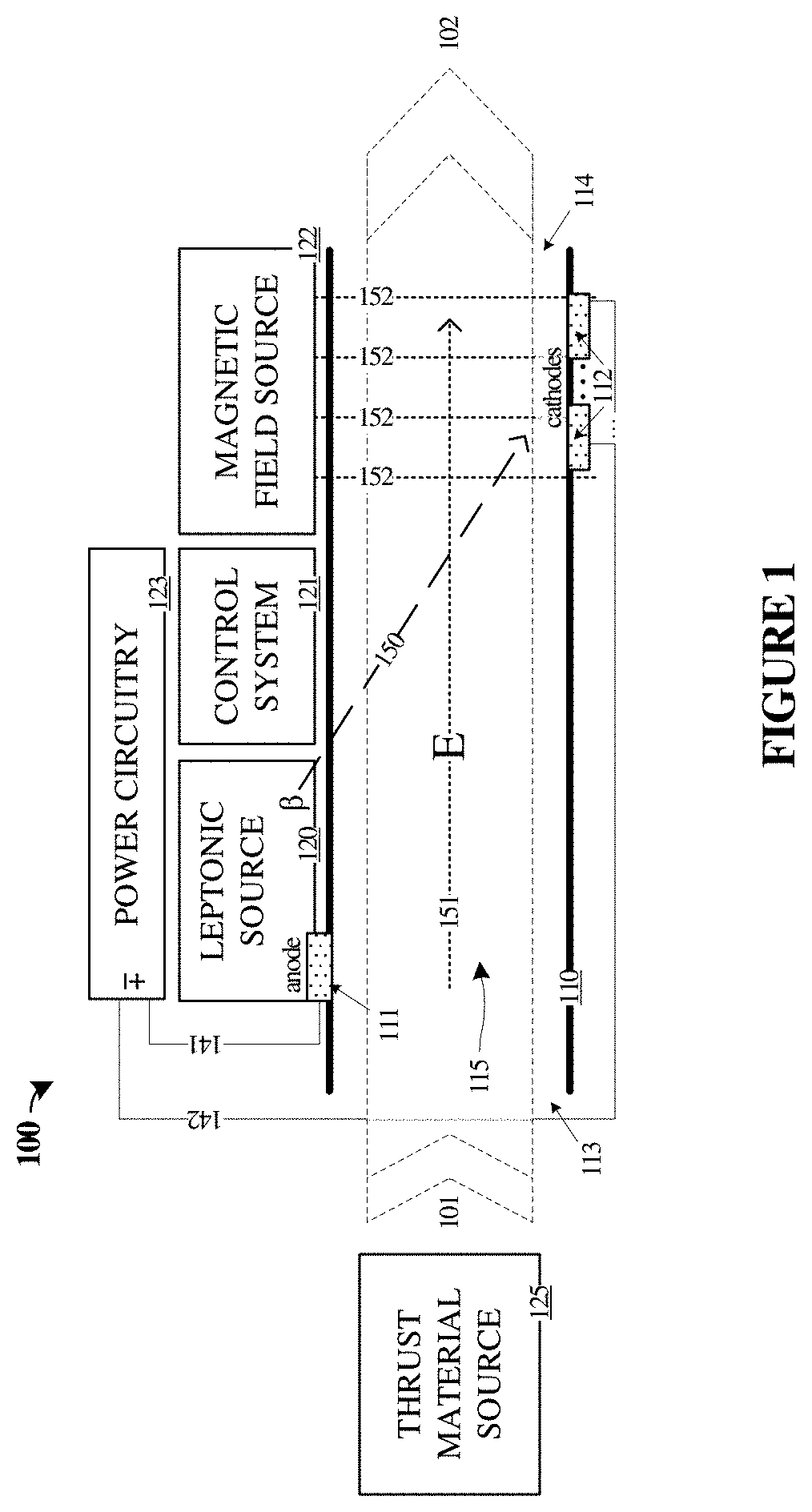

Plasma Engine With Leptonic Energy Source

Provided herein are various leptonic power sources, leptonic control systems, and leptonic-powered engines. In one example, an apparatus includes a housing having apertures through which material can enter and exit, and an anode coupled to the housing upstream from a cathode. A leptonic source emits beam electrons into the housing to ionize the material into a plasma according to a selectable ionization degree and deposit charge onto the cathode to establish an electric field in the plasma. A magnetic field source produces a magnetic field in the plasma at selectable angle to the flow of the plasma to at least partially entrain plasma electrons. Ions of the plasma are accelerated downstream in the housing by the electric field and impart momentum to a portion of the material to produce a thrust proportional to the selectable ionization degree of the plasma and a selectable intensity of the electric field.

Owner:LOCKHEED MARTIN CORP

An ion deflection device and method

ActiveCN112201560BEasy to operateEasy to useElectron/ion optical arrangementsCorona dischargeDegree of ionization

The invention discloses an ion deflection device and method, which belong to the technical field of ion deflection. The ion deflection device and method include an ion generation cabin, a high voltage cabin is installed on the upper end of the ion generation cabin, and a The ion deflection chamber, the outer wall of the upper end of the ion deflection chamber is fixedly connected with a No. 1 position adjustment mechanism. In the present invention, the water molecules absorbed by the silica gel layer are excited by the electrons of the corona discharge and fly out, thereby forming water clusters, so forming longer-lived and heavier cluster ions, the more water cluster molecules formed by surrounding the ions The more stable the multi-ion, the humidity detector detects the humidity of the gas inside the detection chamber, so as to facilitate the control of the degree of ionization in the ion generation cabin according to the humidity; by measuring the proportional relationship between the displacement value of the push rod and the ion deviation angle, the The degree of ion deviation is accurately estimated and controlled, which is suitable for widespread promotion and use.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Ion deflection device and method

ActiveCN112201560ASolution to short lifeEasy to controlElectron/ion optical arrangementsCorona dischargeDegree of ionization

The invention discloses an ion deflection device and method, and belongs to the technical field of ion deflection. The ion deflection device comprises an ion generation cabin, wherein the upper end ofthe ion generation cabin is provided with a high voltage cabin, the right side of the ion generation cabin is provided with an ion deflection cabin, and the outer wall of the upper end of the ion deflection cabin is fixedly connected with a first position adjusting mechanism. Water molecules absorbed by the silica gel layer are excited by corona discharge electrons and the like to fly out, so water clusters can be formed, and cluster ions which are longer in service life and heavier are formed; the more water cluster molecules formed in an ion surrounding mode are, the more ions are, and themore stable the ions are; the humidity detector detects the humidity of gas in the detection chamber, so the ionization degree in the ion generation cabin can be conveniently controlled according to the humidity; by measuring and calculating the proportional relation between the push rod displacement value and the ion deviation angle, the ion deviation degree is accurately estimated and controlled, and the method is suitable for being widely used and popularized.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com