Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2281 results about "Nuclear fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear fuel is material used in nuclear power stations to produce heat to power turbines. Heat is created when nuclear fuel undergoes nuclear fission. Most nuclear fuels contain heavy fissile actinide elements that are capable of undergoing and sustaining nuclear fission. The three most relevant fissile isotopes are Uranium-233, Uranium-235 and Plutonium-239. When the unstable nuclei of these atoms are hit by a slow-moving neutron, they split, creating two daughter nuclei and two or three more neutrons. These neutrons then go on to split more nuclei. This creates a self-sustaining chain reaction that is controlled in a nuclear reactor, or uncontrolled in a nuclear weapon.

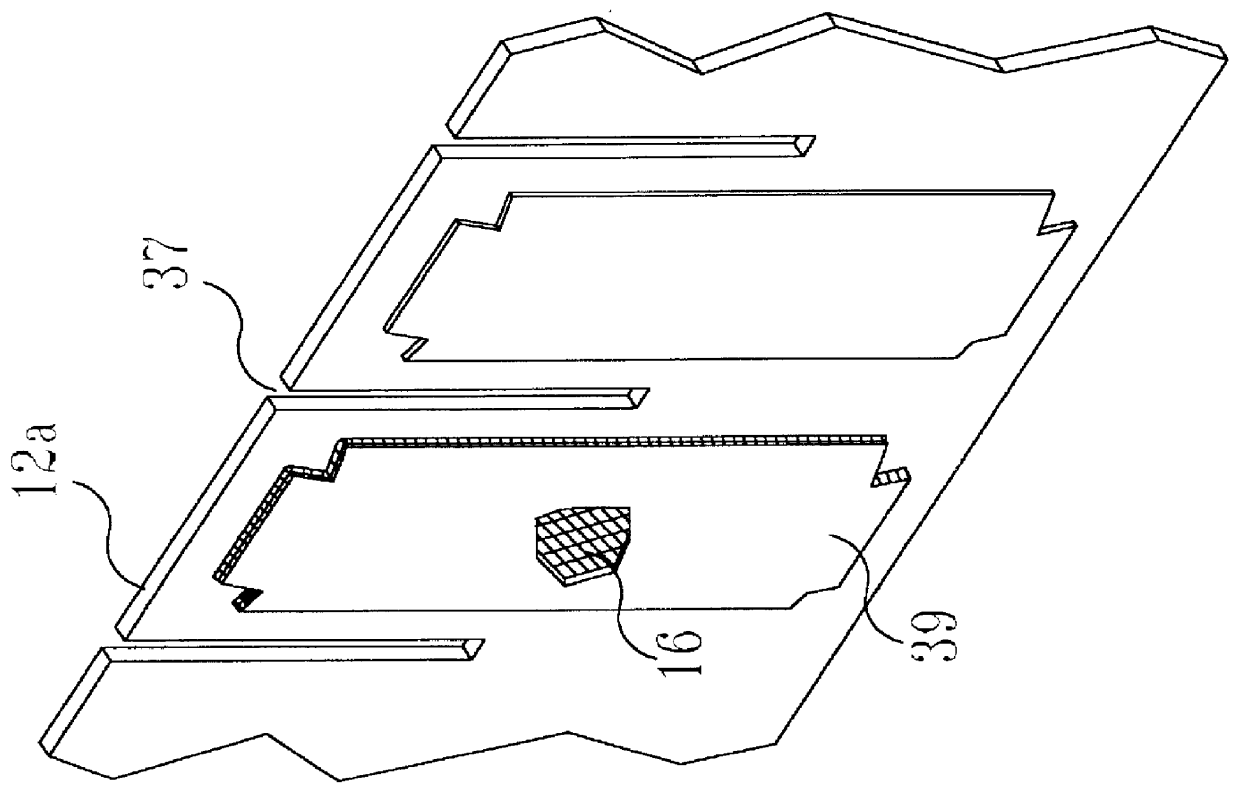

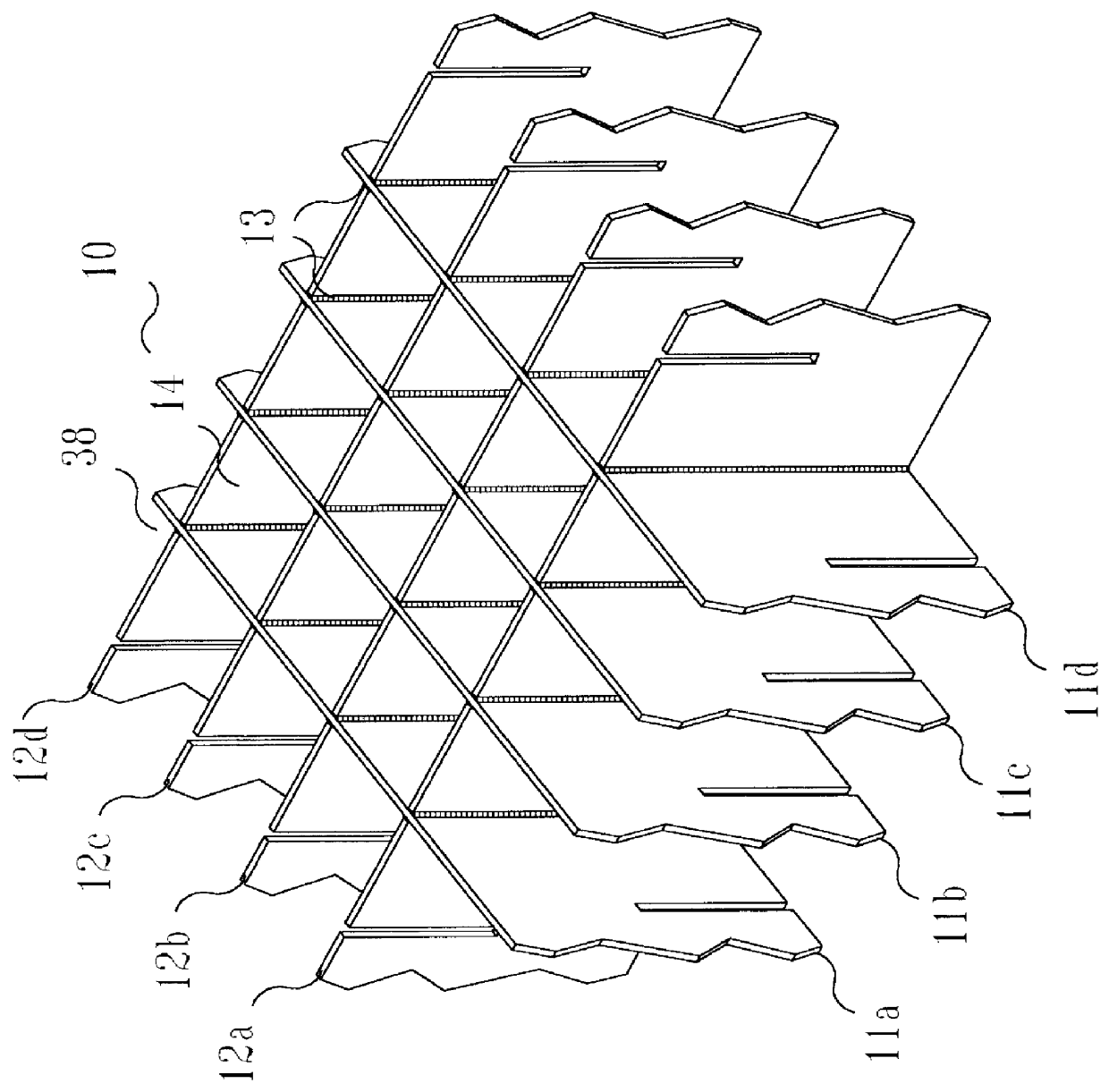

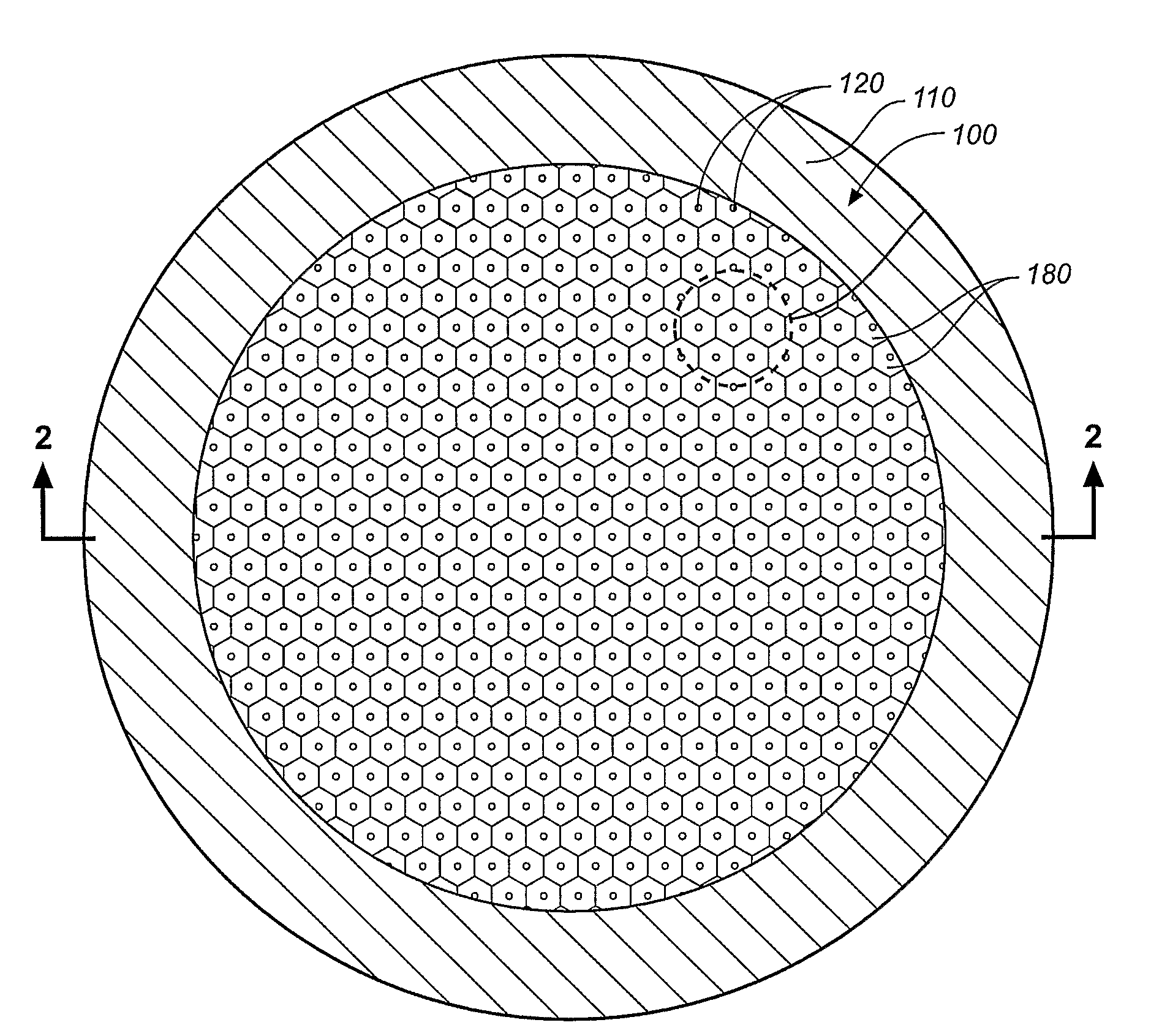

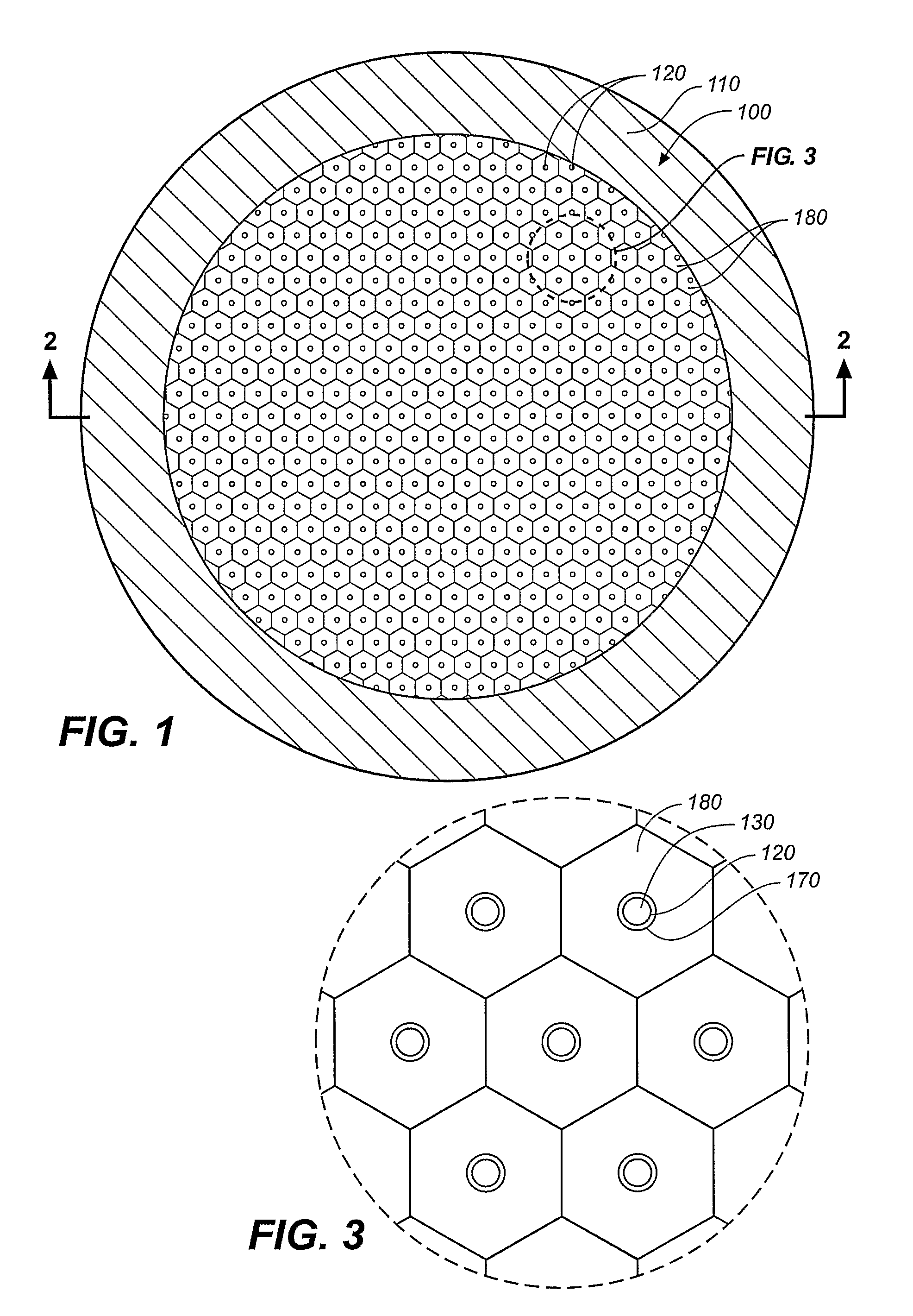

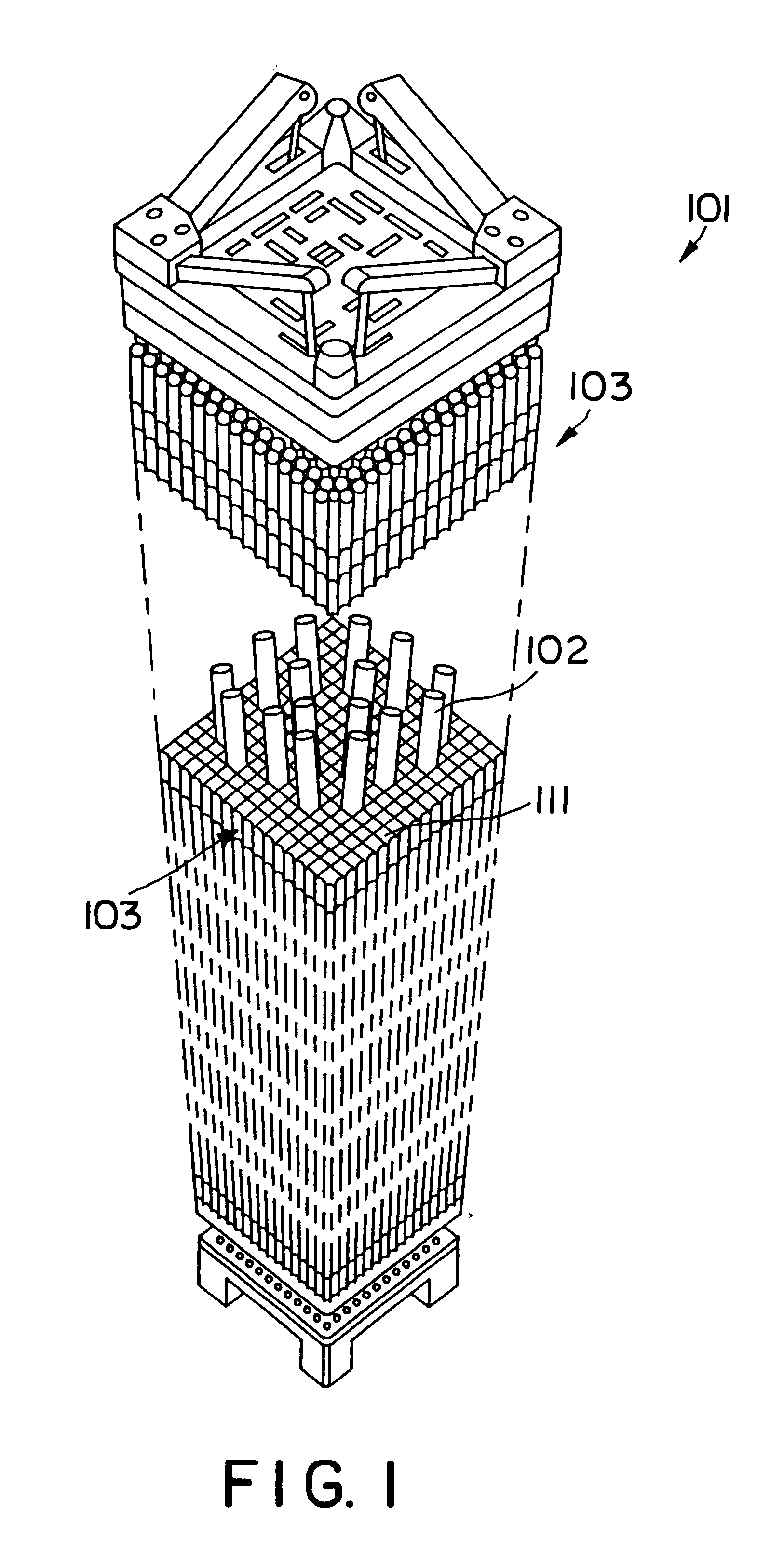

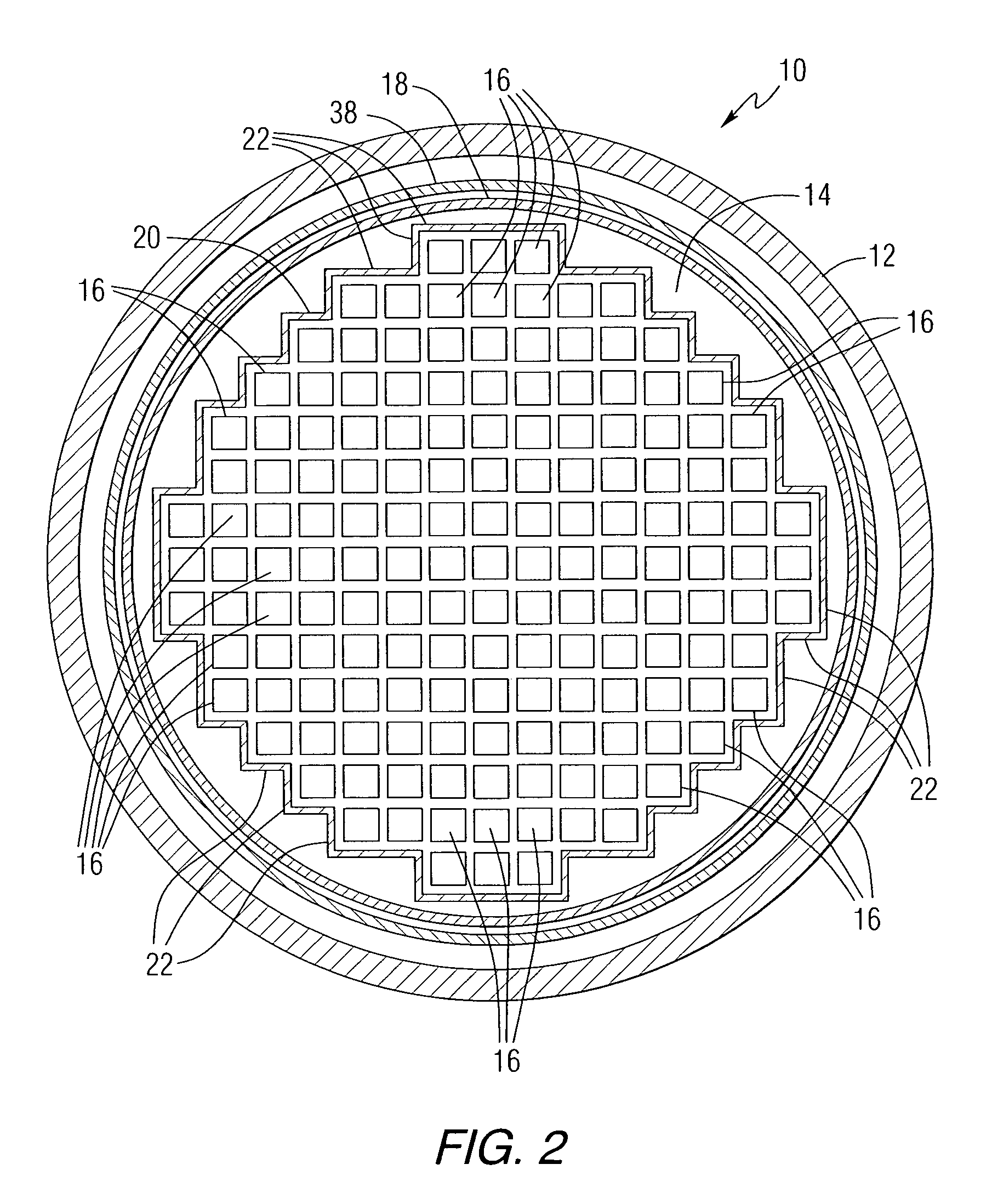

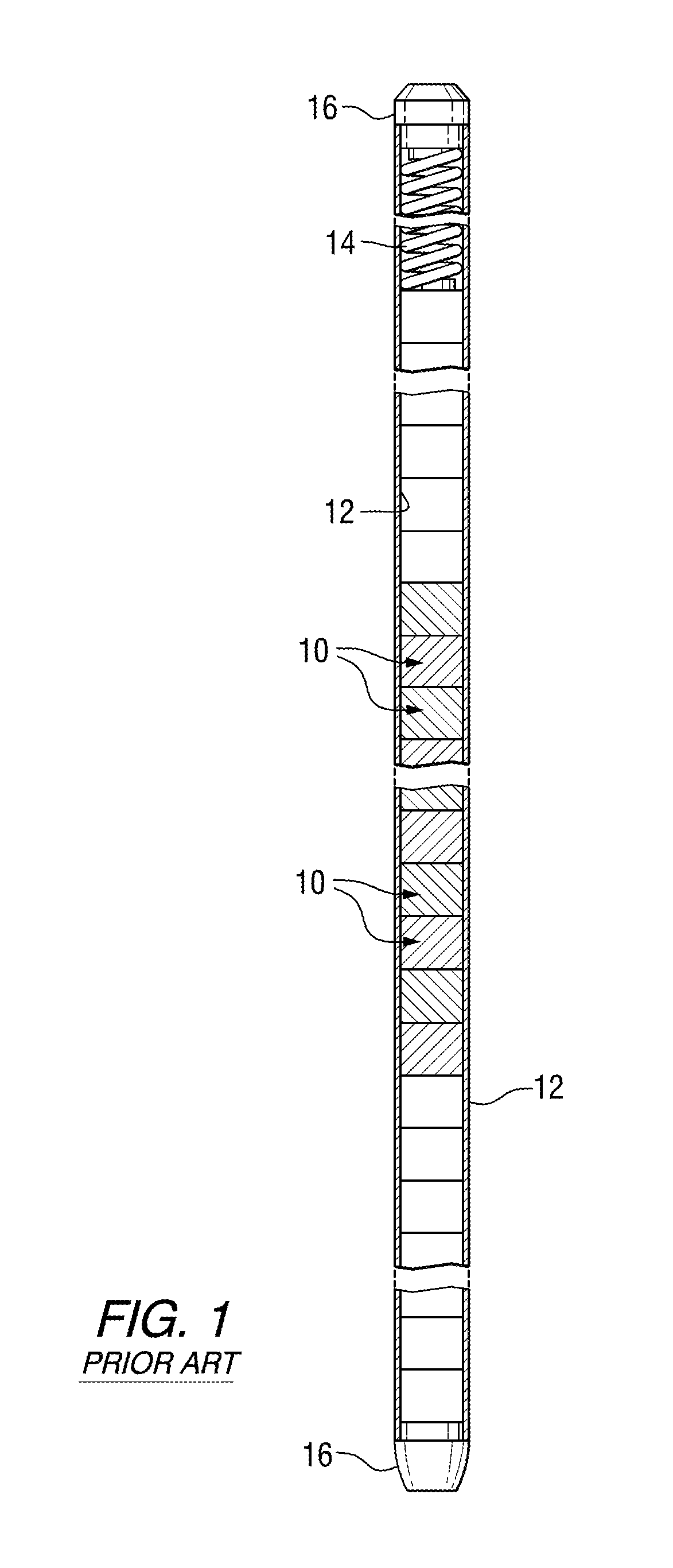

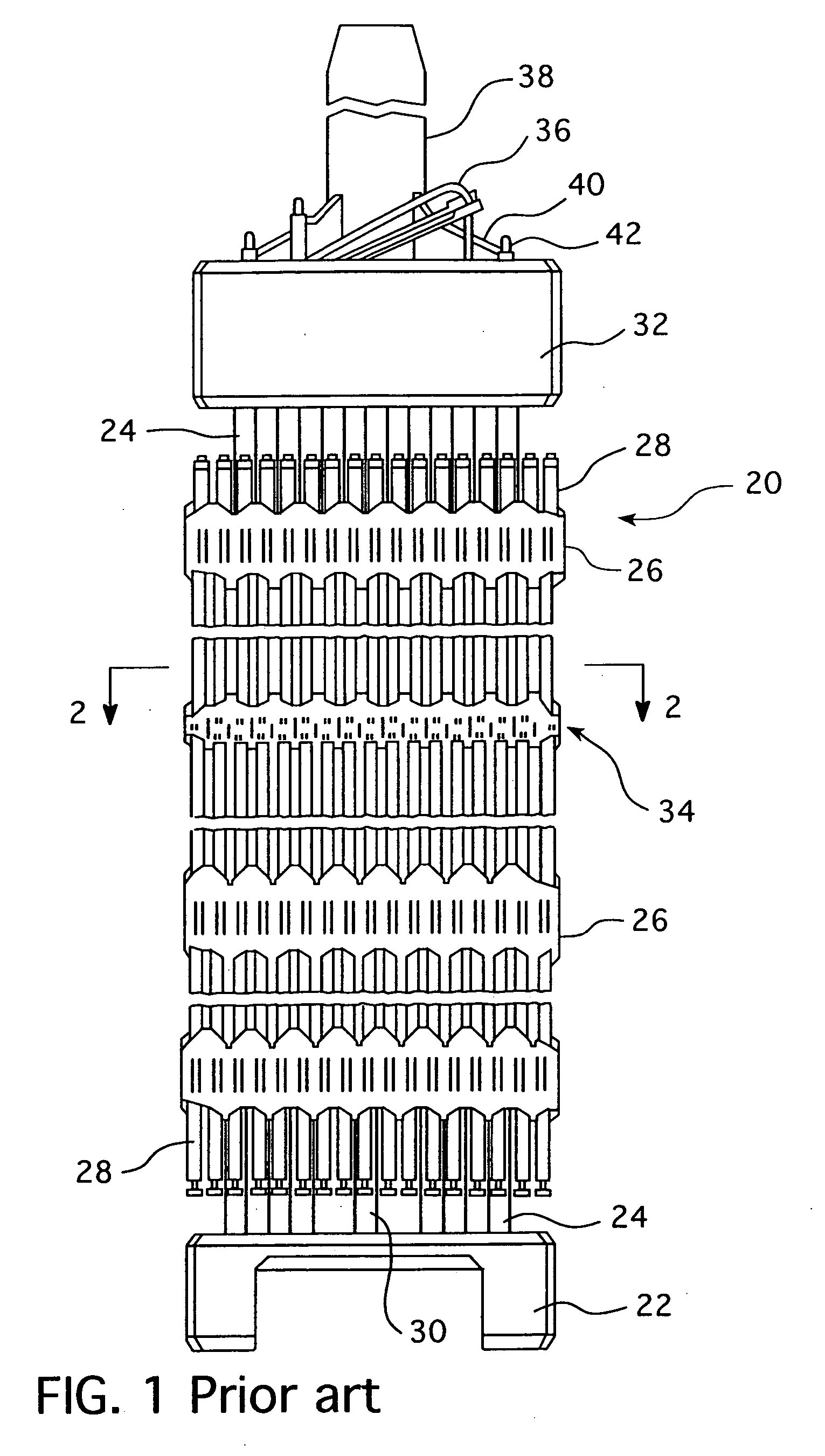

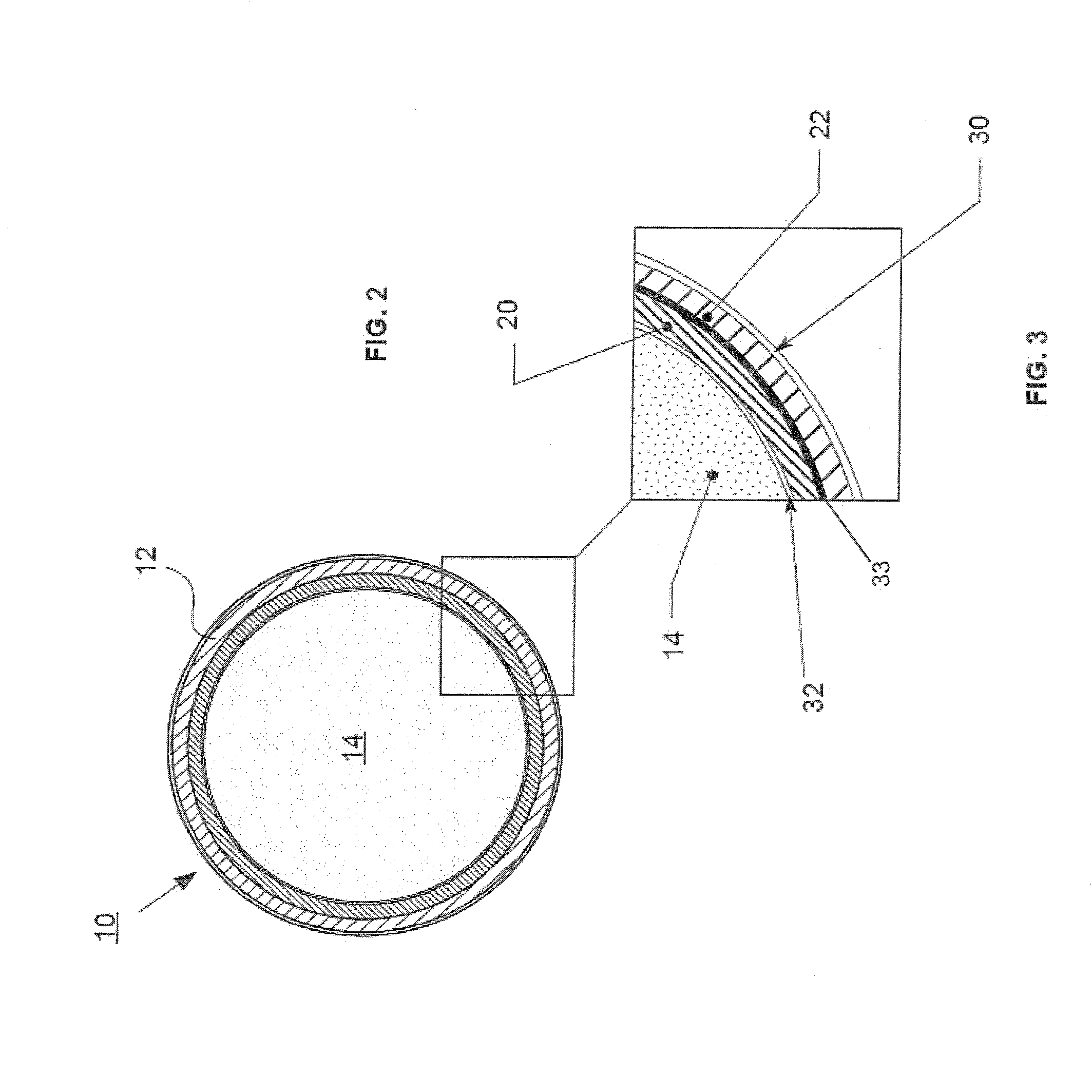

Apparatus suitable for transporting and storing nuclear fuel rods and methods for using the apparatus

InactiveUS6064710ARugged and convenient to handleHighly effectiveReactor fuel elementsPortable shielded containersHoneycombHoneycomb like

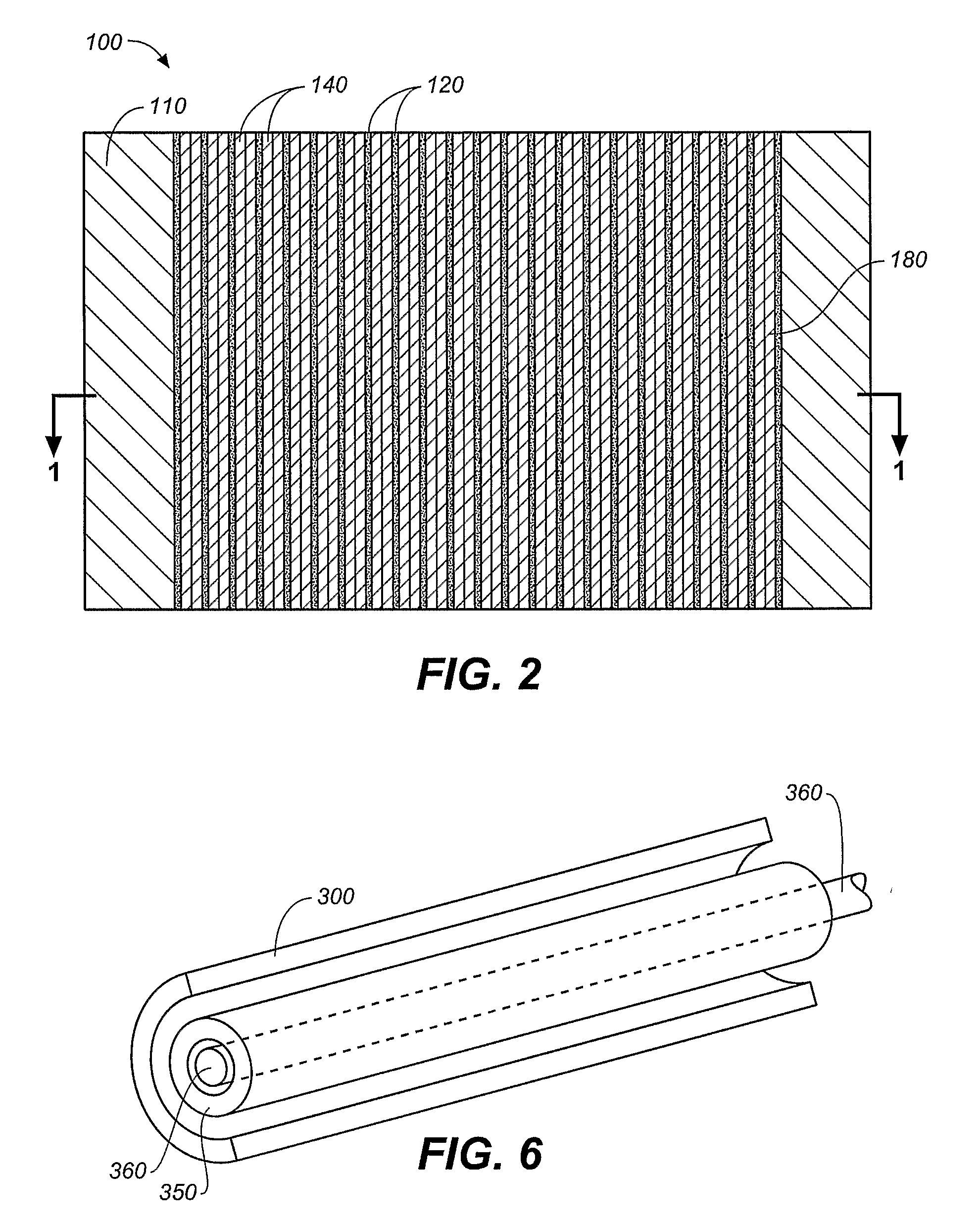

Apparatus suitable for transporting and storing nuclear fuel rods comprising a basket having storage cells formed from a honeycomb gridwork of metal plates in a rectilinear configuration, the plates welded to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer, the metal plates having neutron absorber material positioned in areas which form walls of the storage cells. Method of making an apparatus suitable for transporting and storing nuclear fuel rods comprising a) providing metal plates having slots and having neutron absorber material positioned on sides of the metal plates, b) arranging the plates so that the slots intersect to form a honeycomb gridwork of storage cells having contiguous corners and having the neutron absorbing material on sides of the storage cells, and c) welding the plates to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer and to provide a rigid structure.

Owner:SINGH KRIS

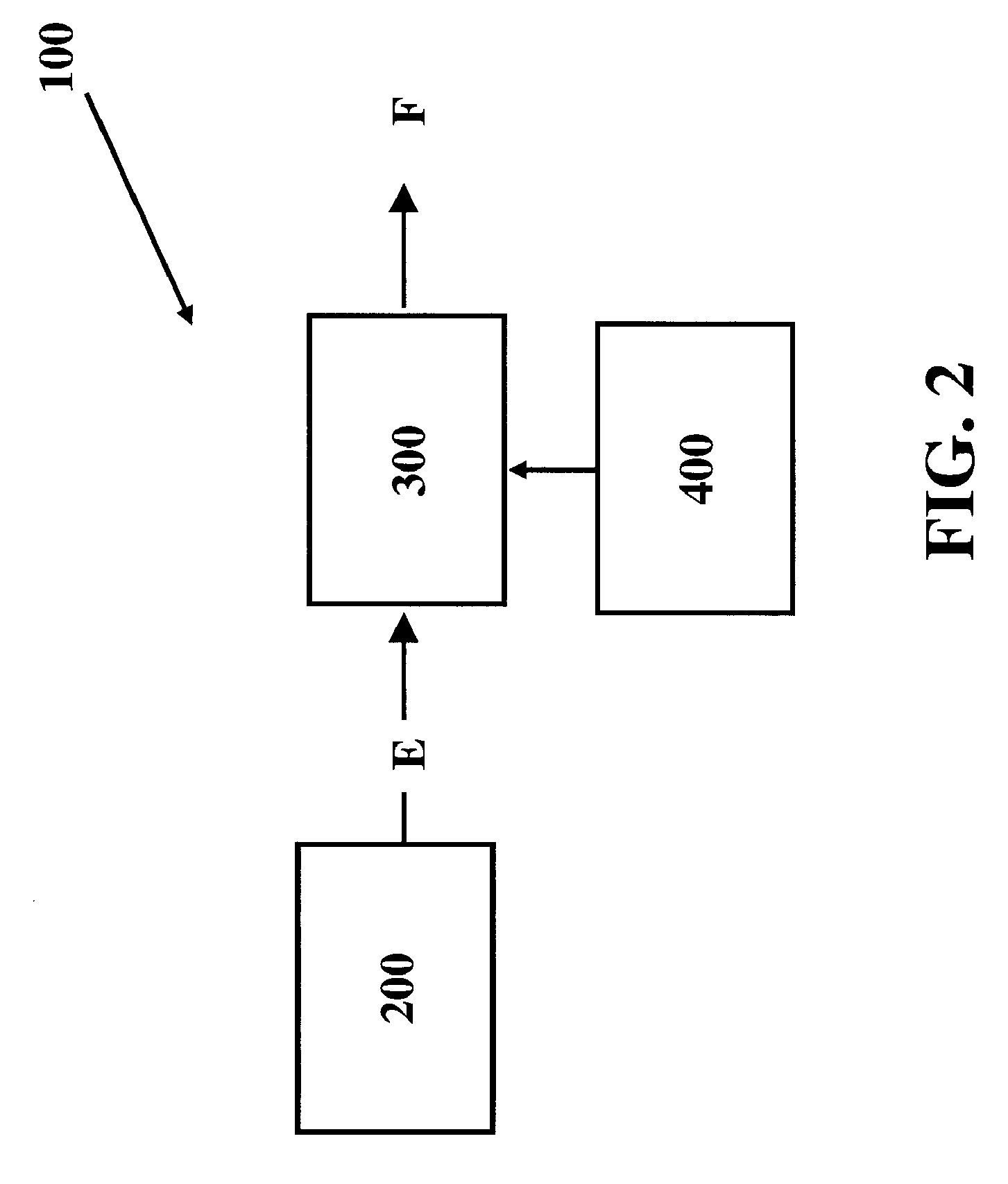

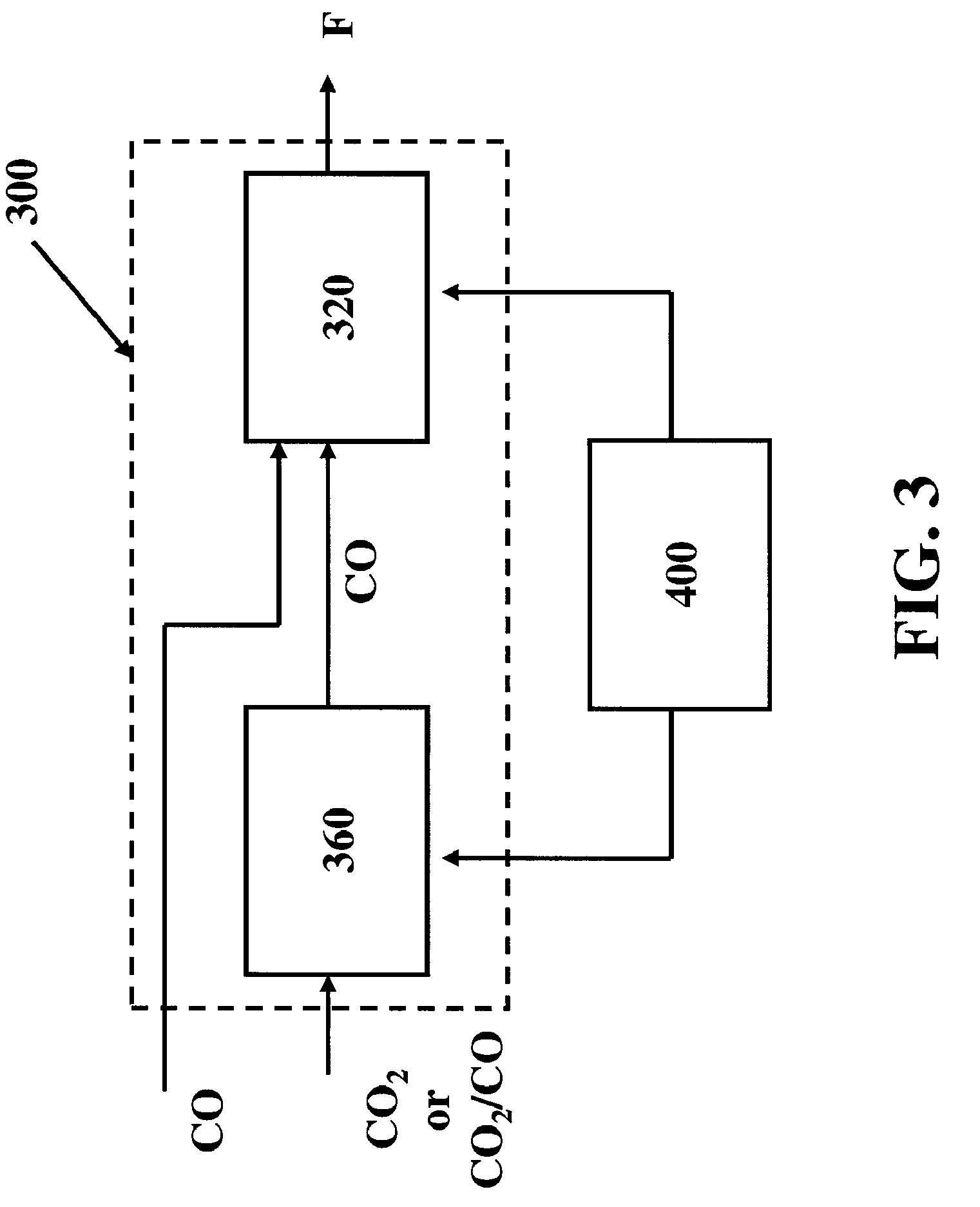

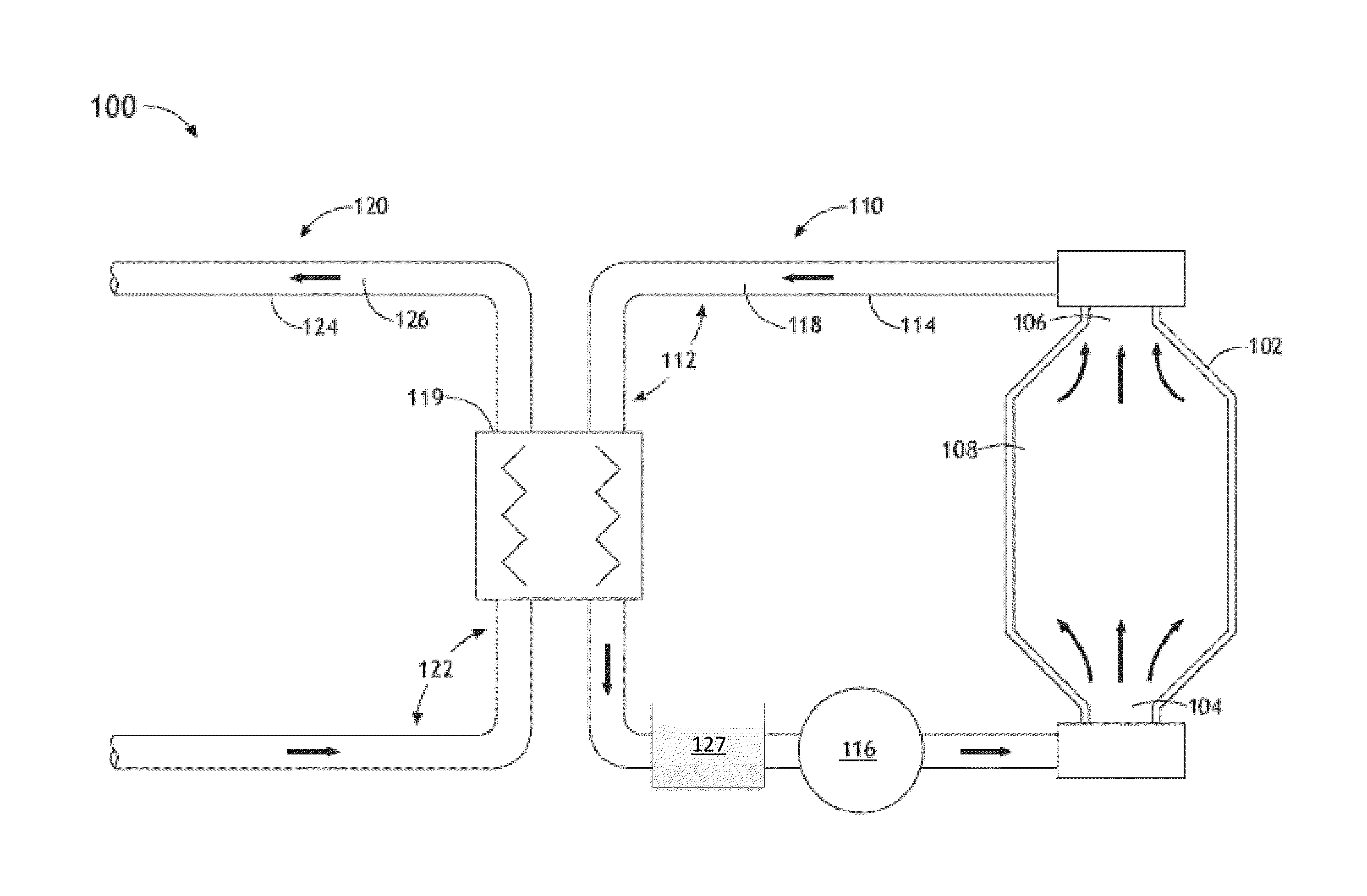

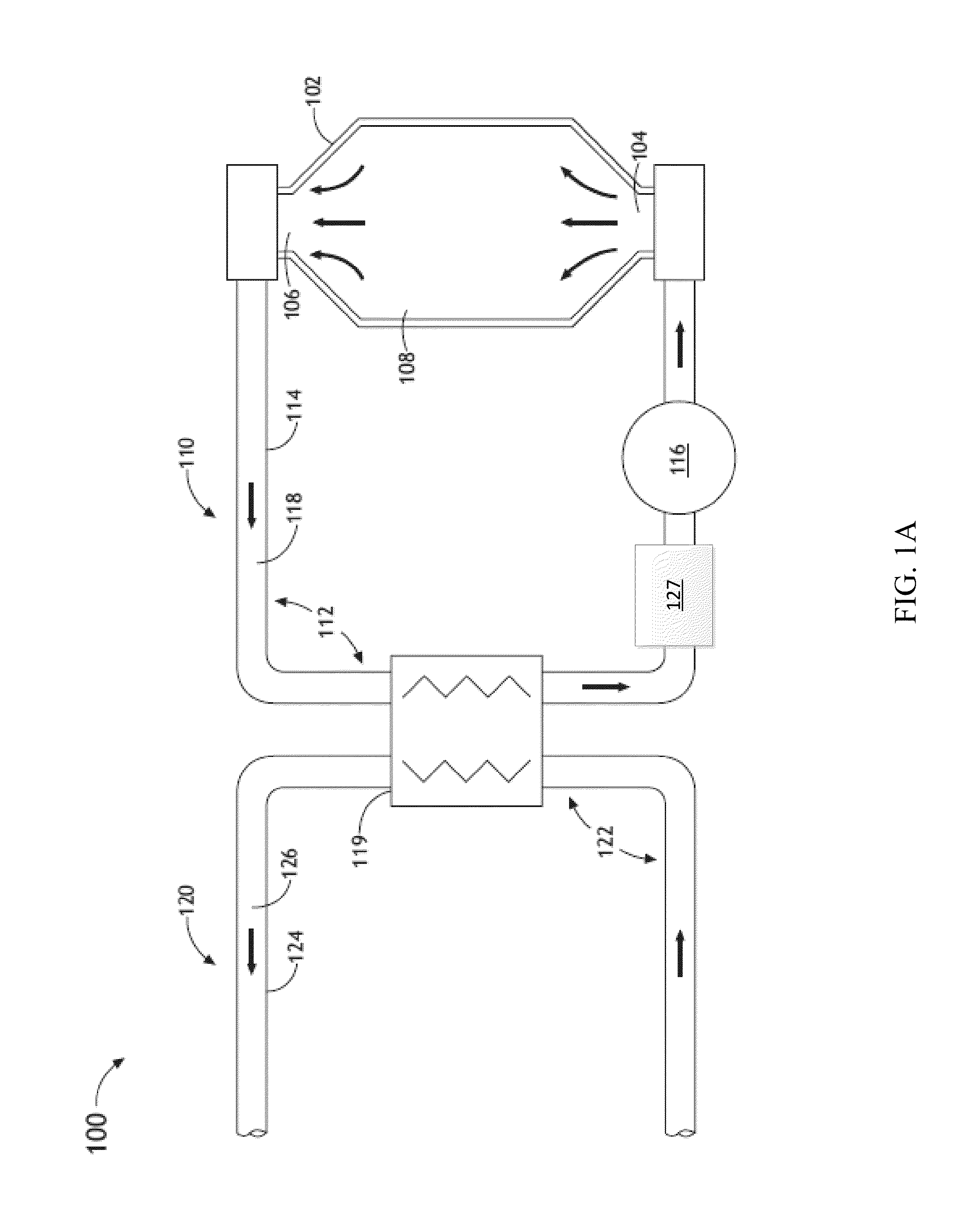

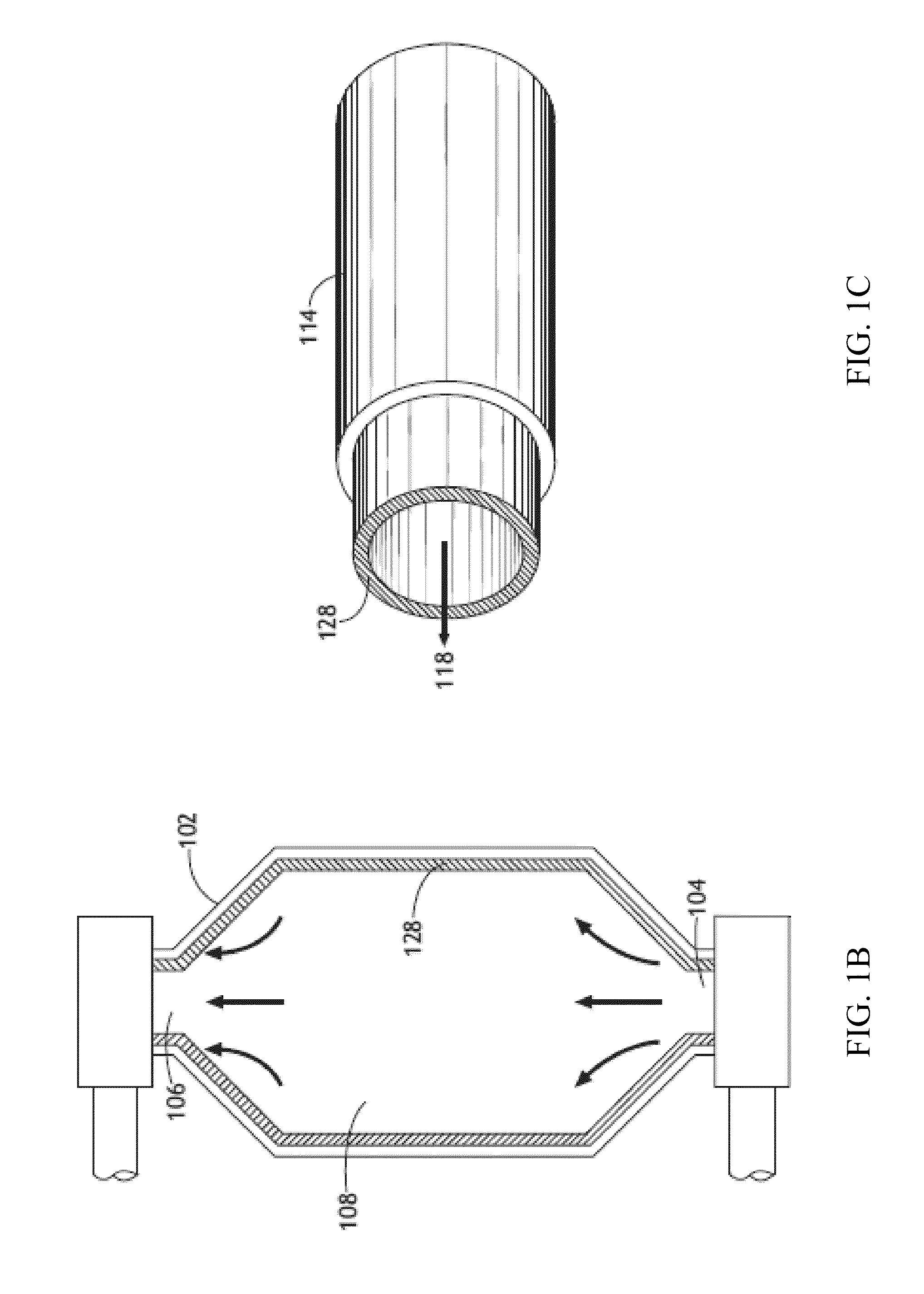

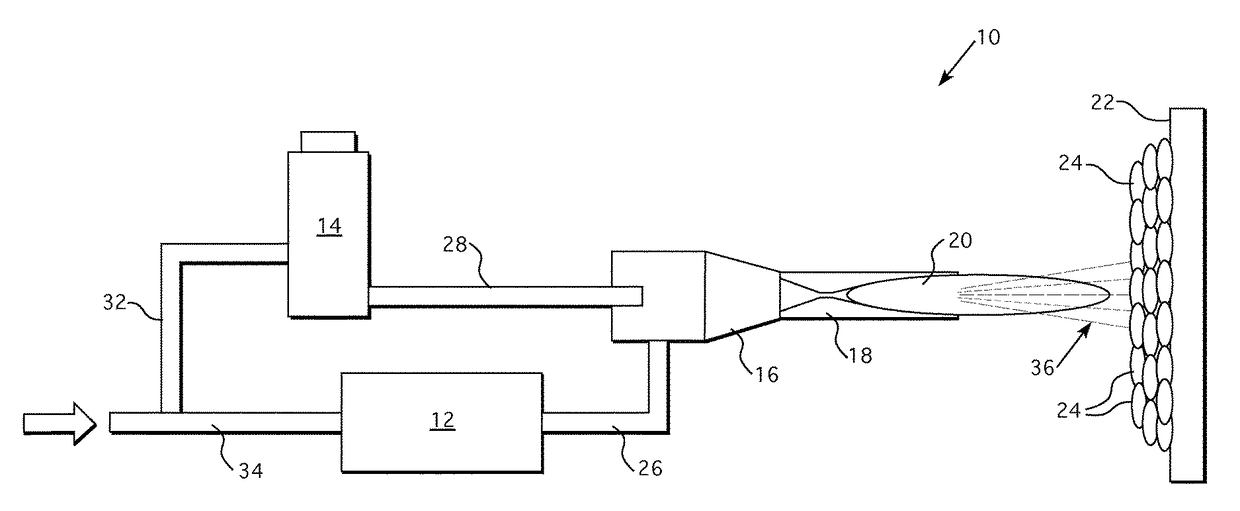

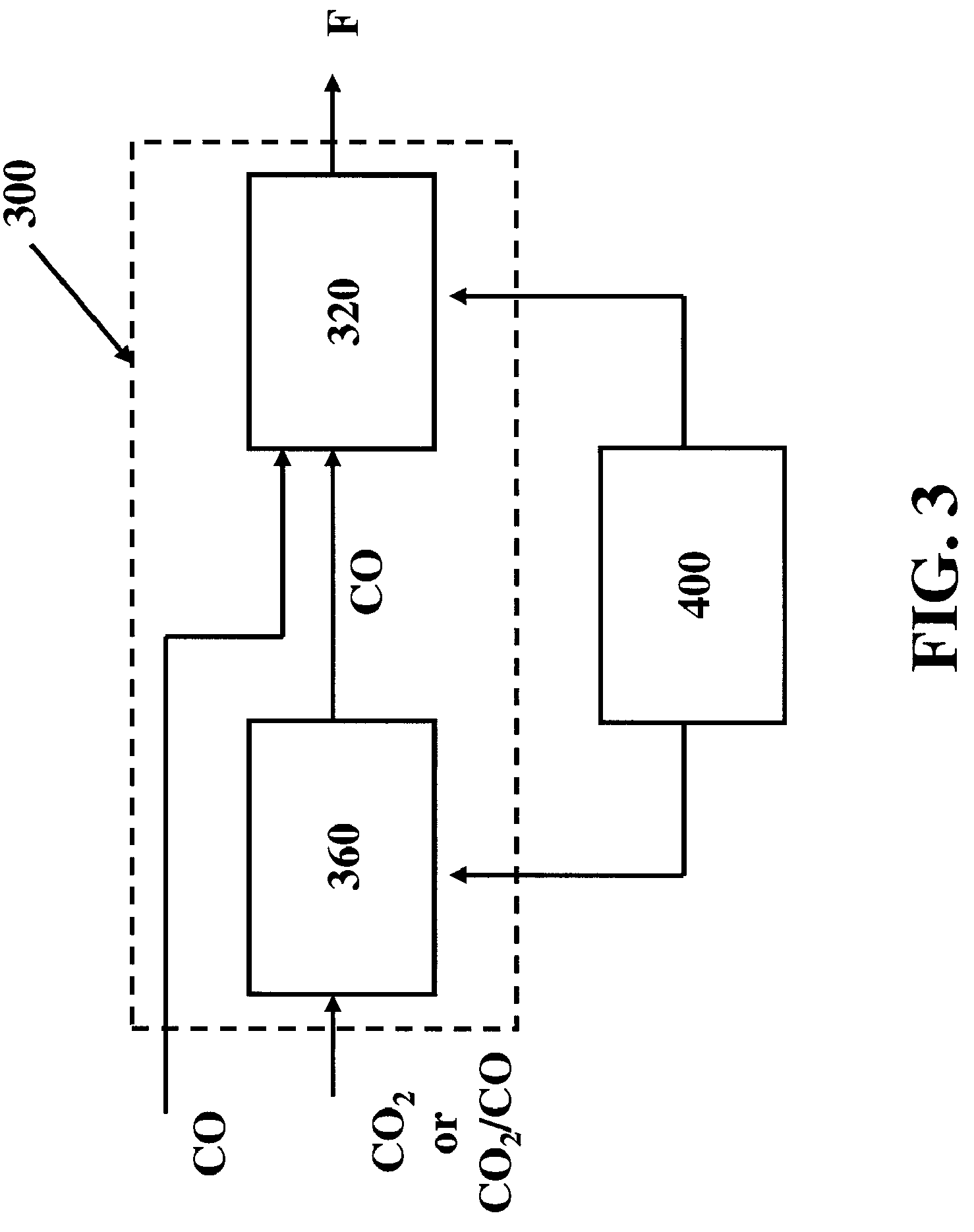

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS20060211777A1Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneHydrocotyle bowlesioides

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolysing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

Non Proliferating Thorium Nuclear Fuel Inert Metal Matrix Alloys for Fast Spectrum and Thermal Spectrum Thorium Converter Reactors

InactiveUS20080144762A1Improve heat transfer performanceRobust assemblyOptical rangefindersNuclear energy generationHigh energyEpithermal neutron

A set of alloy formulations is disclosed to use with thorium based nuclear fuels in a fast spectrum reactor; with thorium based nuclear fuels in existing thermal spectrum power reactors; for medical isotope production in the epithermal, the fast, the fission spectrum and the thermal spectra; and to use as fuel in test and experimental reactors that are non proliferative. The alloys form inert metal matrixes to hold fine particles of dispersed thorium containing fuel. The formulations also are useful for the production of medical and commercial isotopes in the high energy, fast and epithermal neutron spectra.

Owner:RGT UNIV OF CALIFORNIA

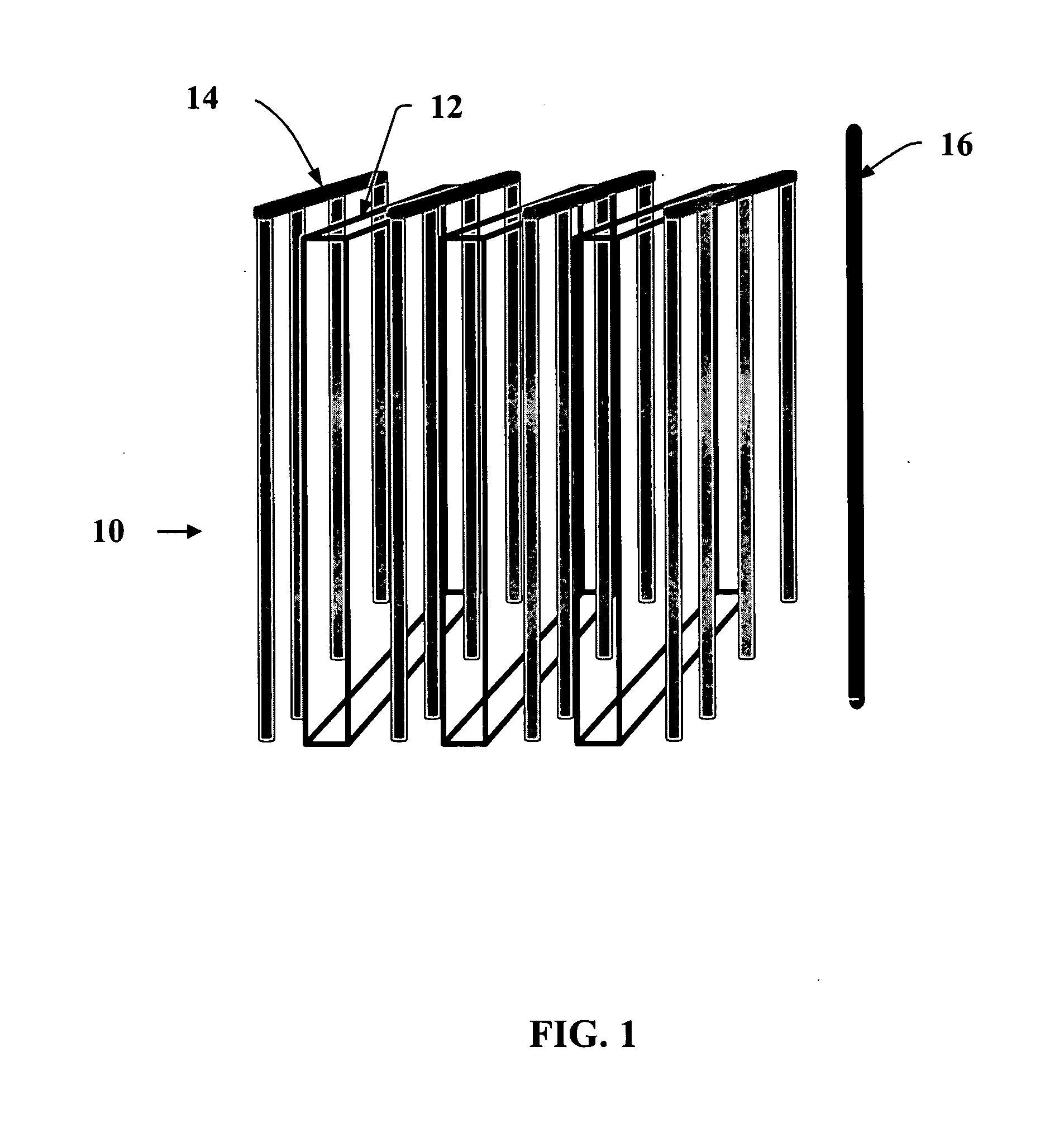

Helically fluted tubular fuel rod support

ActiveUS20060153327A1Minimal pressure dropUniform thicknessNuclear energy generationFuel element assembliesEngineeringCell contact

A support grid for a nuclear fuel assembly, the fuel rod assembly having a generally cylindrical fuel rod with a diameter, wherein the support grid includes a frame assembly having a plurality of generally uniform cells, each the cell having at least one wall and a width and at least one generally cylindrical tubular member having a cell contact portion with a greater diameter and at least one helical fuel rod contact portion with a lesser diameter, the cell contact portion and the fuel rod contact portion joined by a transition portion, the greater diameter being generally equivalent to the cell width, and the lesser diameter being generally equivalent to the fuel rod diameter such that a fuel rod disposed in the tubular member would engage the inner diameter. Wherein the least one tubular member disposed in one cell of the plurality of generally square cells so that the cell contact portion engages the at least one cell sidewall.

Owner:WESTINGHOUSE ELECTRIC CORP

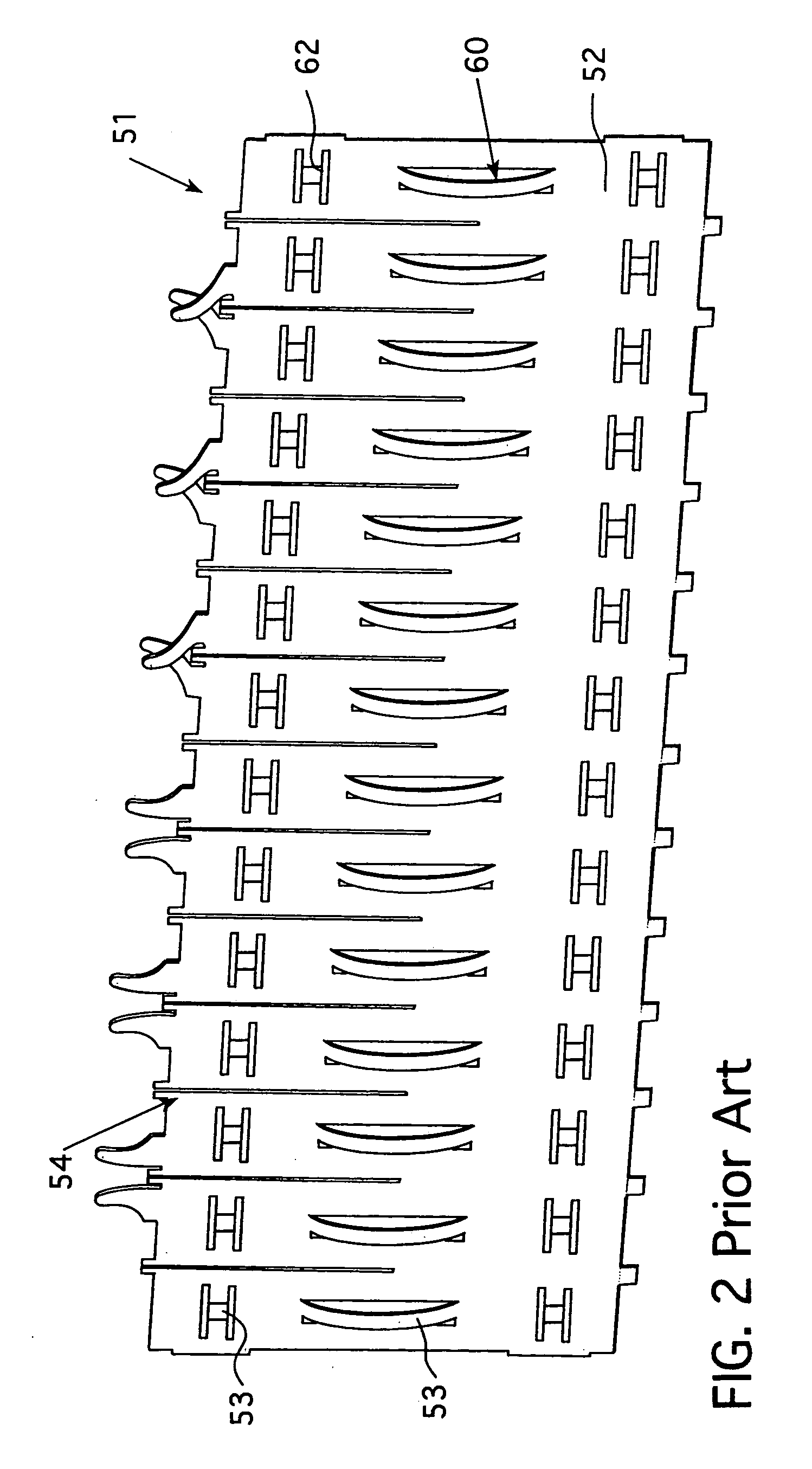

Fuel assembly spacer grid with swirl deflectors and hydraulic pressure springs

InactiveUS6236702B1Minimized pressure lossDecrease in initial mechanical spring forceNuclear energy generationFuel element assembliesSpring forceInterconnection

A fuel assembly spacer grid including swirl deflectors respectively arranged at interconnections between interconnecting longitudinally and laterally-extending straps on upper ends of the interconnecting straps adapted to support fuel elements of a nuclear fuel assembly. Each of the swirl deflectors has four vanes bent to have an air vane shape. By virtue of this configuration, an improvement in the efficiency of the spacer grid cooling the fuel elements. The spacer grid also includes springs each configured to generate not only a main spring force caused by a displacement of the spring occurring when the spring comes into contact with a fuel element placed in a reactor core, but also an additional spring force caused by hydraulic pressure applied to the spring. Each spring, which is in a fixed state at one end thereof, has a free bent portion at the other end. By virtue of such a spring configuration, it is possible to compensate for a reduction in the initial spring force of the spring resulting from a change in the property of the spring material. The spring has a curved contact portion configured in such a manner that it is in conformal surface contact with a circumferential surface of the fuel element, thereby enhancing vibration suppressing and abrasion resistance forces.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

Niobium-containing zirconium alloy for nuclear fuel claddings

InactiveUS6261516B1Improve corrosion resistanceIncrease resistanceOptical rangefindersFuel elementsNiobiumManganese

The invention presented herein relates to a niobium-containing zirconium alloy for use in nuclear fuel cladding. The Zr alloy of this invention with superior corrosion resistance is characterized as comprising an alloy composition as follows:1) niobium (Nb), in a range of 0.8 to 1.2 wt. %; one or more elements selected from the group consisting of iron (Fe), molybdenum (Mo), copper (Cu) and manganese (Mn), in a range of 0.1 to 0.3 wt. %, respectively; oxygen (O), in a range of 600 to 1400 ppm; silicon (Si), in a range of 80 to 120 ppm; and the balance being of Zr,2) Nb, in a range of 1.3 to 1.8 wt. %; tin (Sn), in a range of 0.2 to 0.5 wt. %; one element selected from the group consisting of Fe, Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr,3) Nb, in a range of 1.3 to 1.8 wt. %; Sn, in a range of 0.2 to 0.5 wt. %; Fe, in a range of 0.1 to 0.3 wt. %; one element selected from the group consisting of chromium (Cr), Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr, and4) Nb, in a range of 0.3 to 1.2 wt. %; Sn, in a range of 0.4 to 1.2 wt. %; Fe, in a range of 0.1 to 0.5 wt. %; one element selected from the group consisting of Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

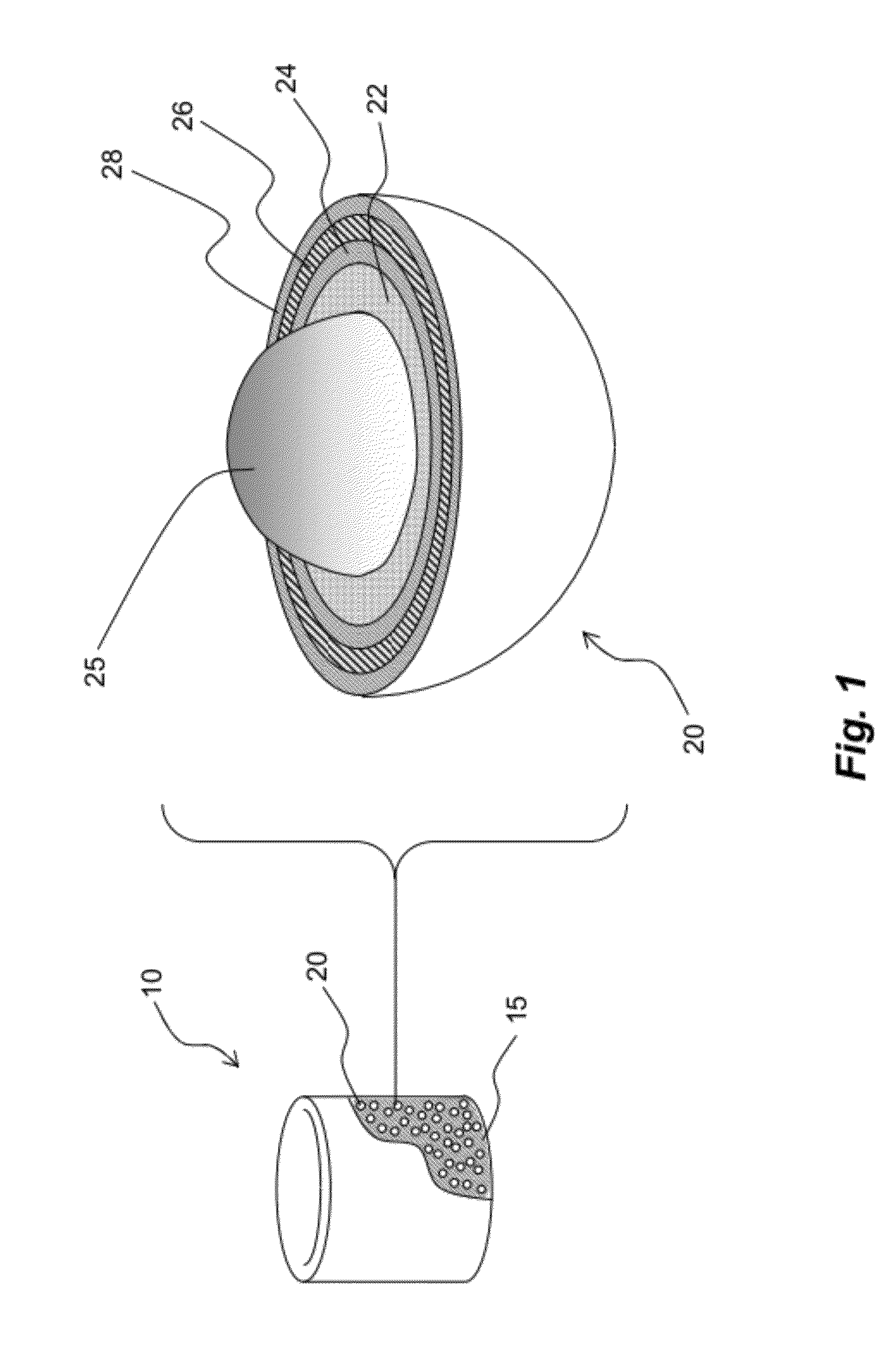

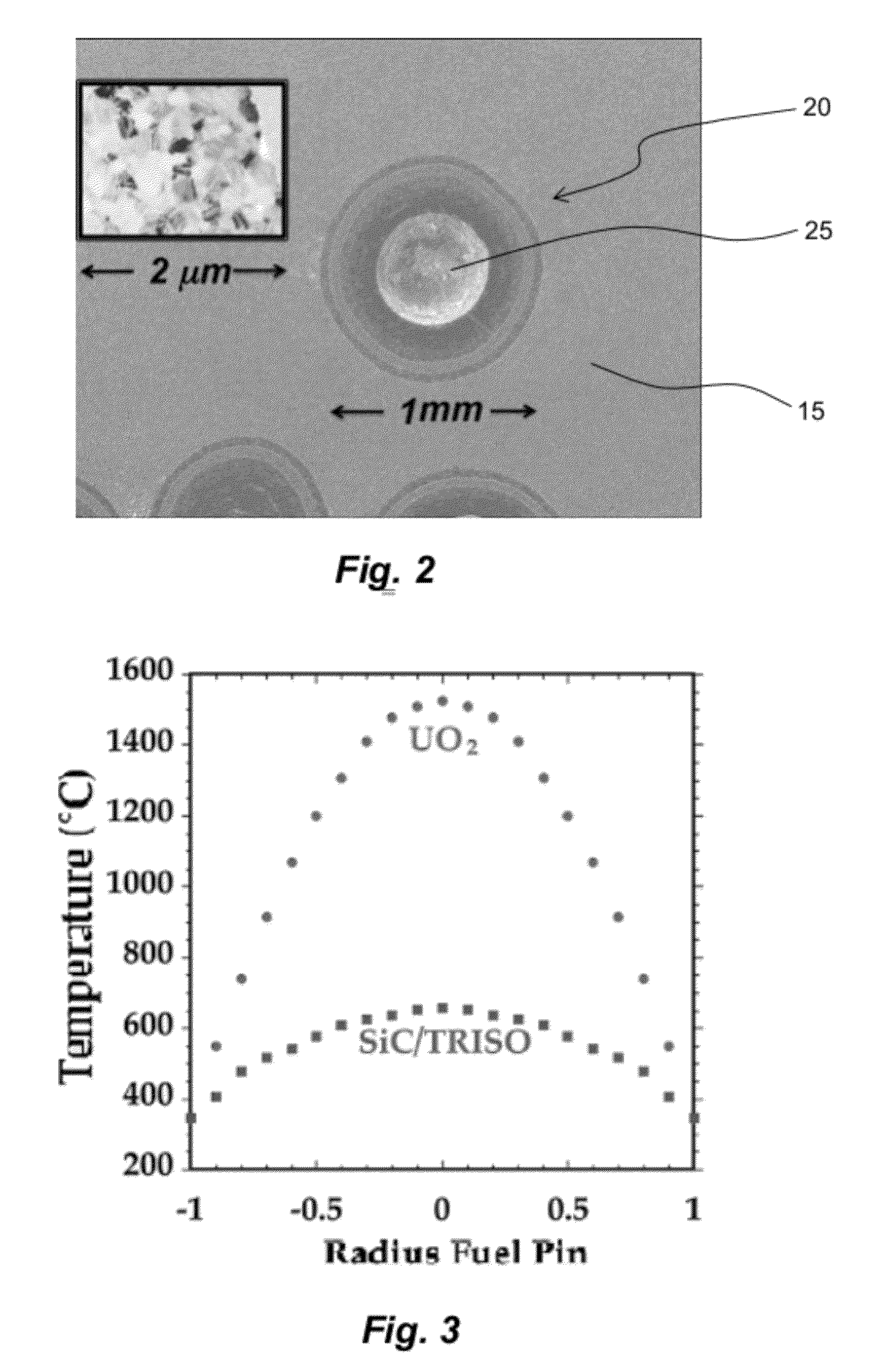

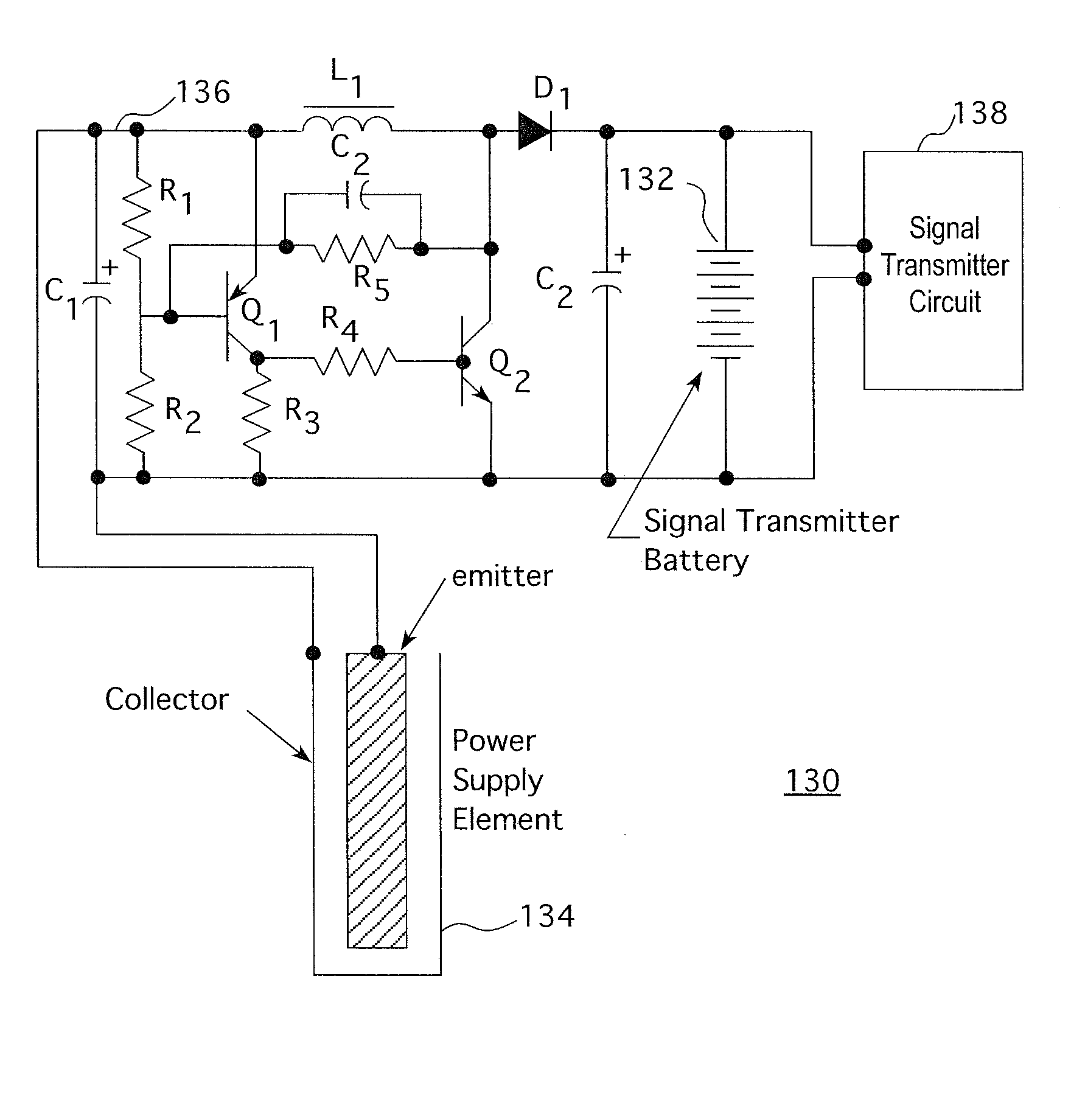

Fully ceramic nuclear fuel and related methods

Various embodiments of a nuclear fuel for use in various types of nuclear reactors and / or waste disposal systems are disclosed. One exemplary embodiment of a nuclear fuel may include a fuel element having a plurality of tristructural-isotropic fuel particles embedded in a silicon carbide matrix. An exemplary method of manufacturing a nuclear fuel is also disclosed. The method may include providing a plurality of tristructural-isotropic fuel particles, mixing the plurality of tristructural-isotropic fuel particles with silicon carbide powder to form a precursor mixture, and compacting the precursor mixture at a predetermined pressure and temperature.

Owner:UT BATTELLE LLC +1

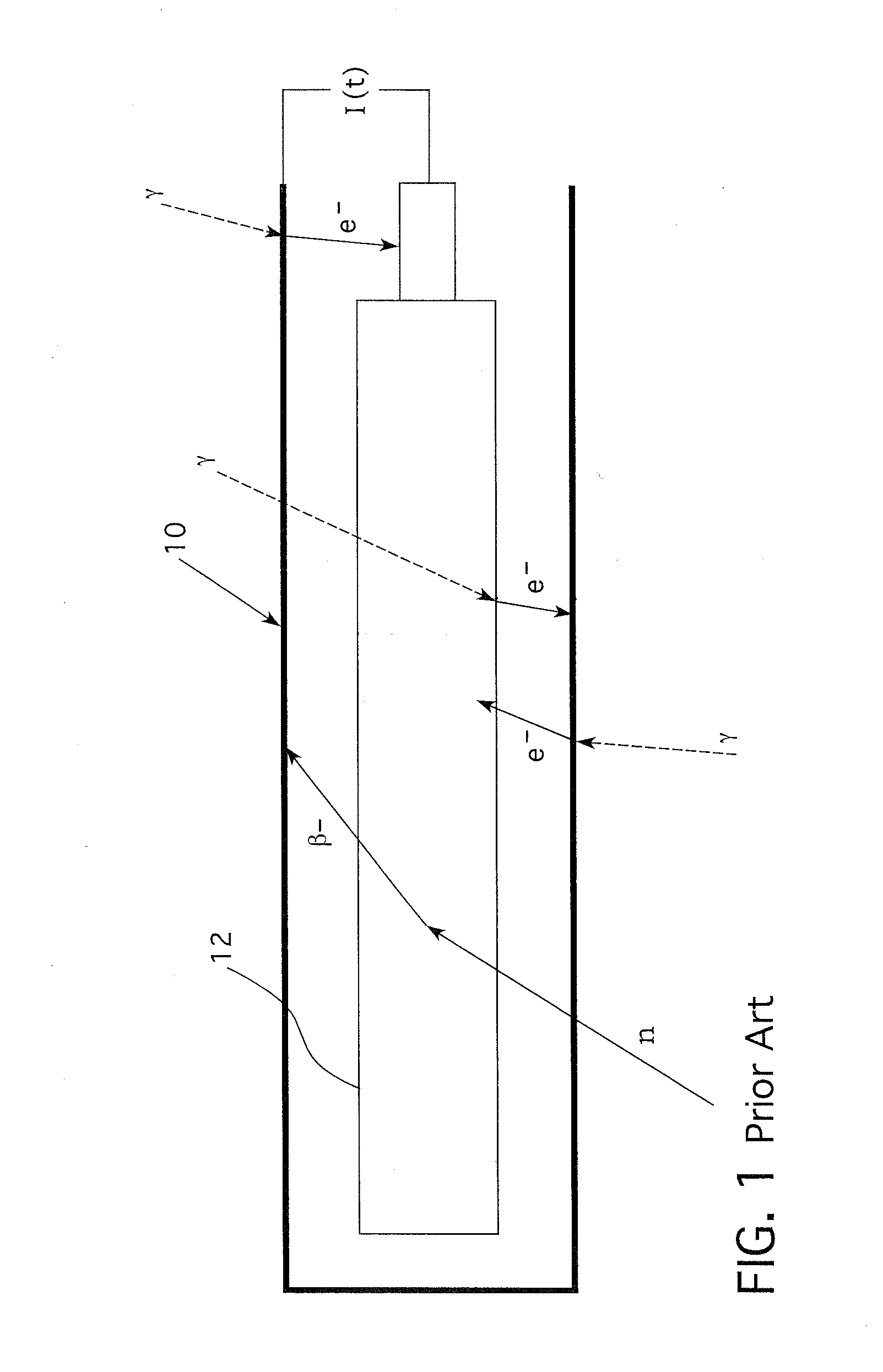

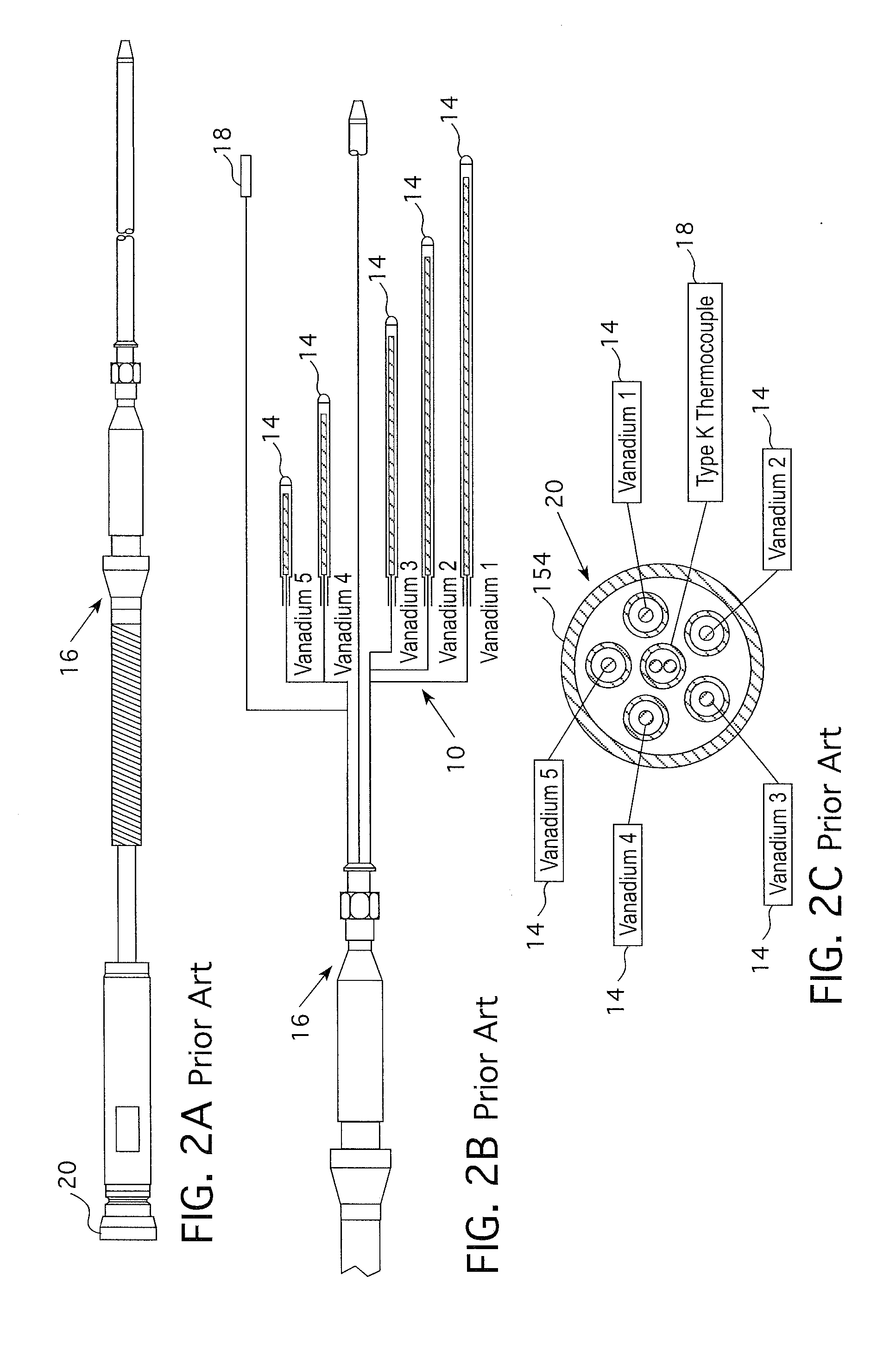

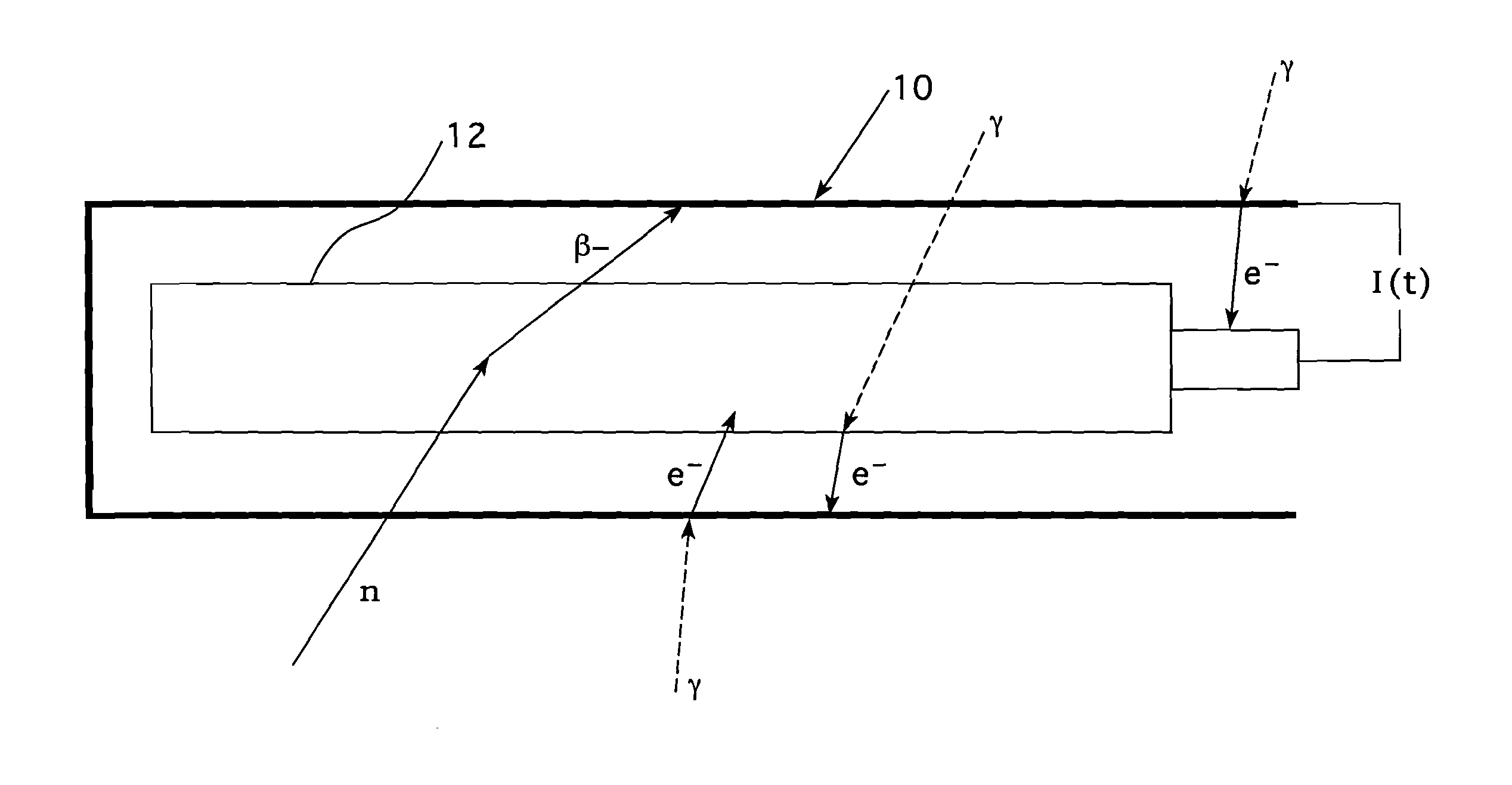

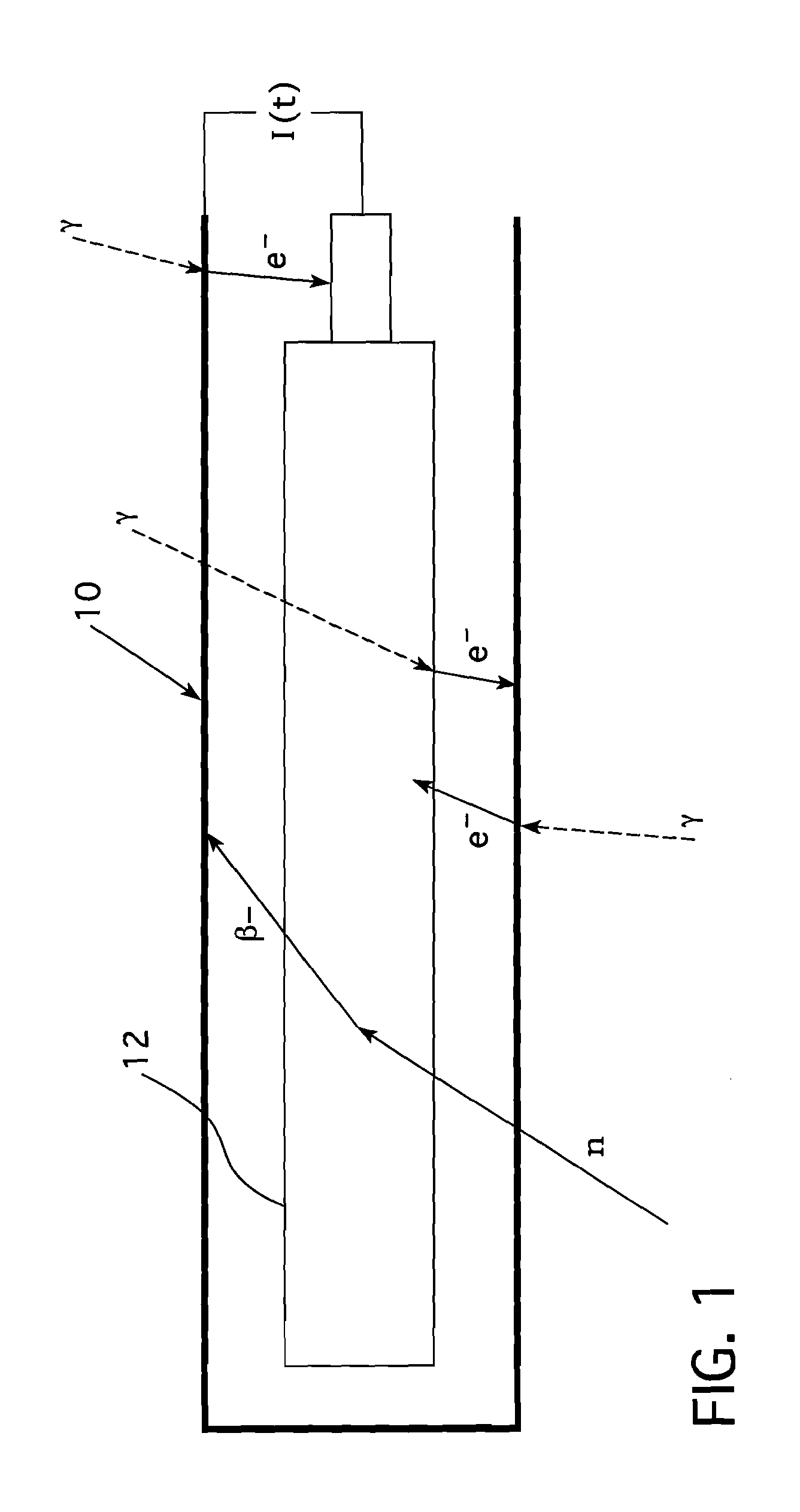

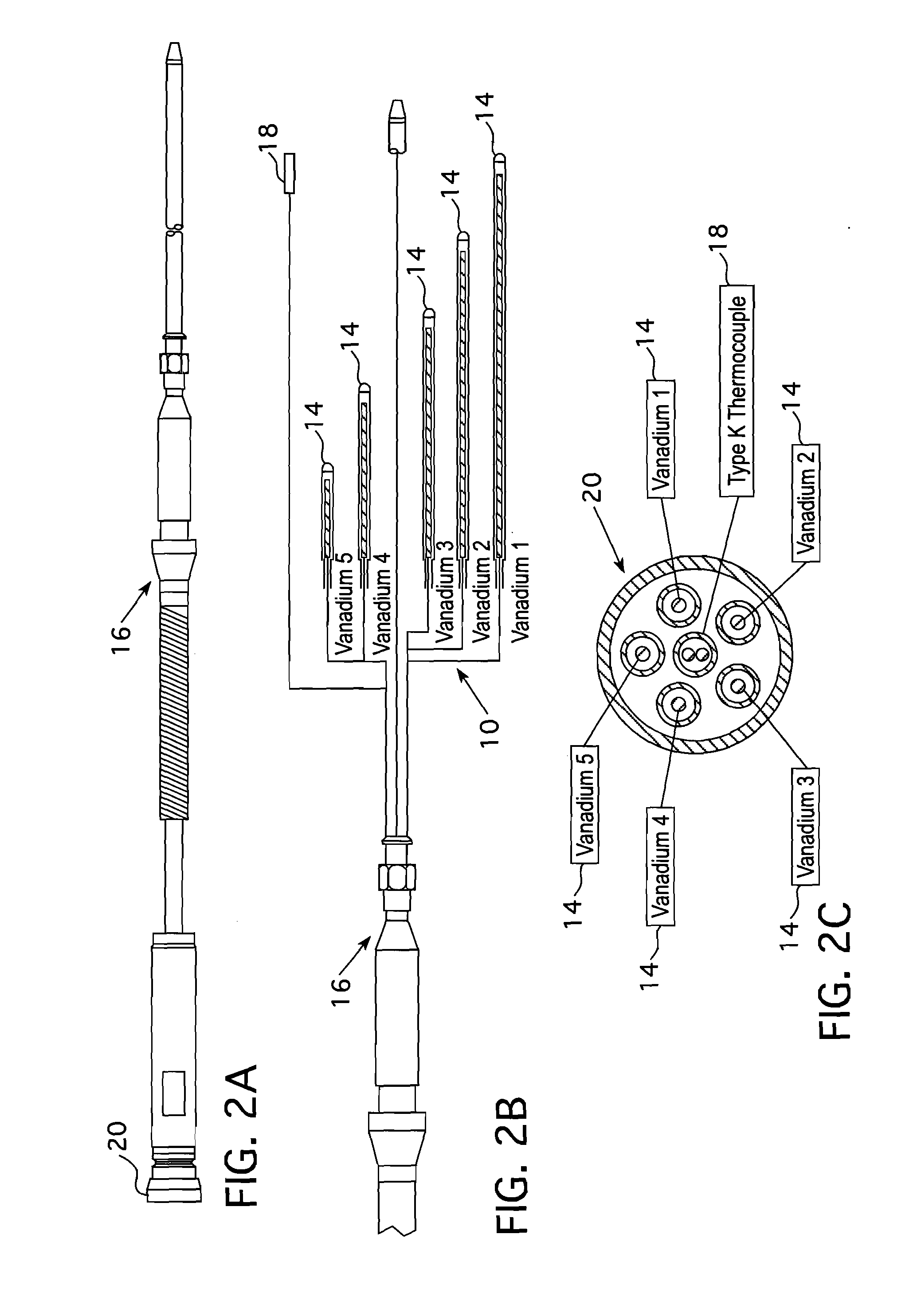

In-core instrument thimble assembly

A self-powered integral in-core instrument thimble assembly for monitoring the temperature and radiation levels surrounding a nuclear fuel assembly, that transmits output signals wirelessly to a remote location. The in-core instrument thimble assembly is activated by a short exposure within a reactor core and remains active after the fuel assembly is removed from the reactor core to continuously provide a remote monitoring capability for the fuel assembly as it is transported or stored at a remote location, without an external power source.

Owner:WESTINGHOUSE ELECTRIC CORP

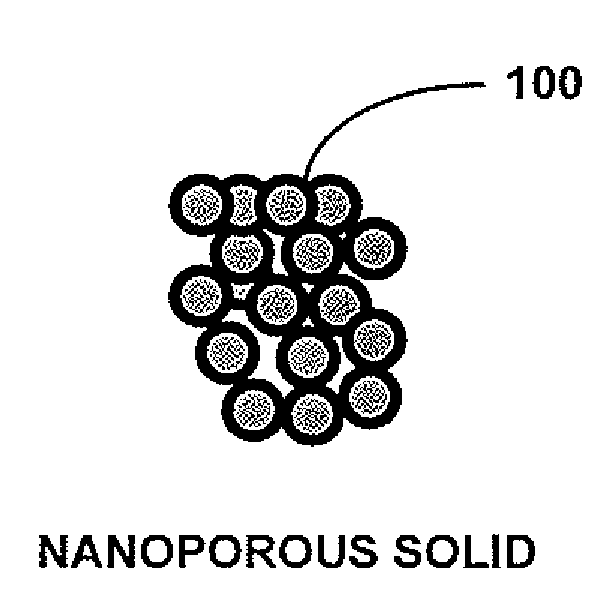

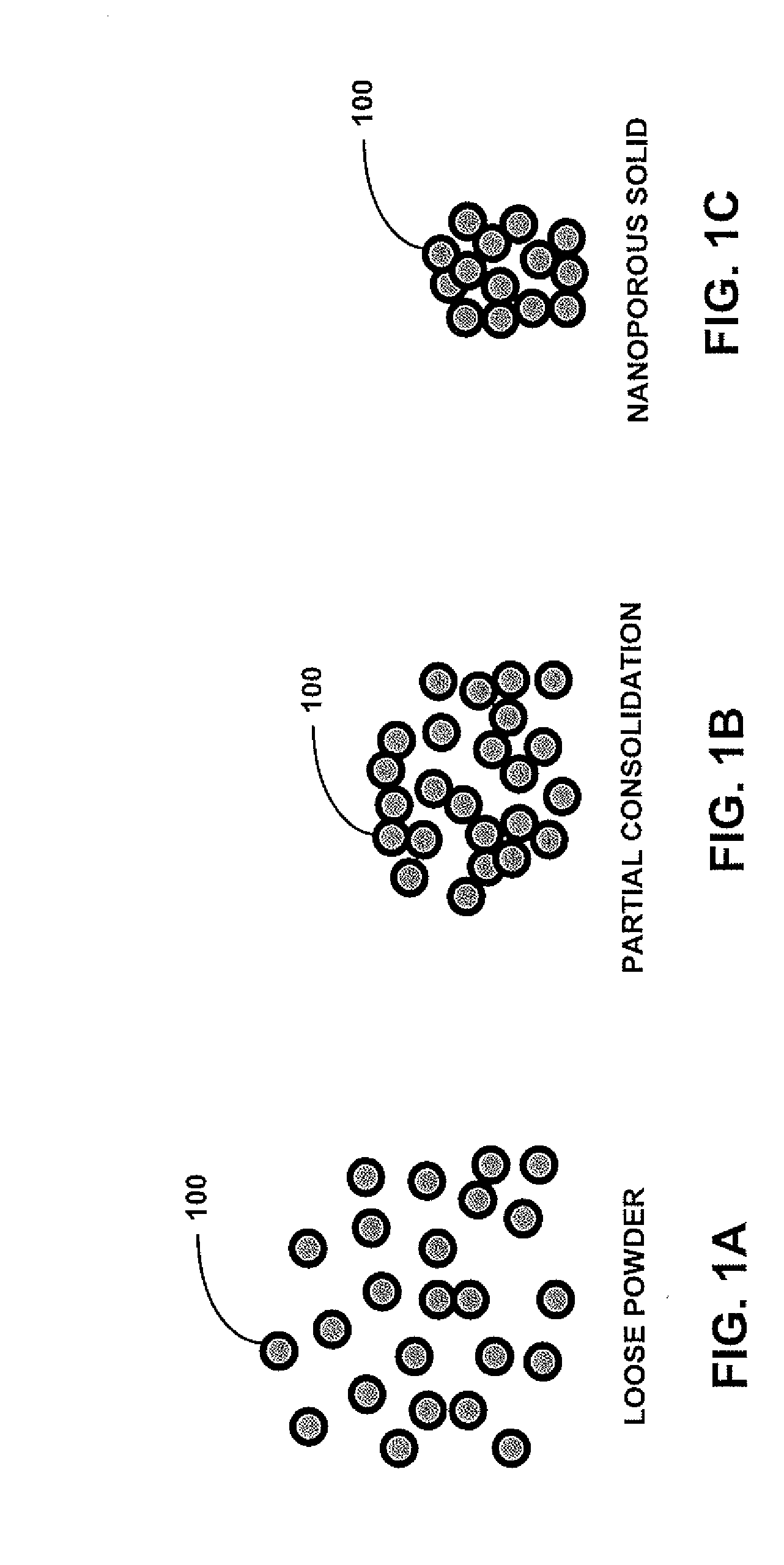

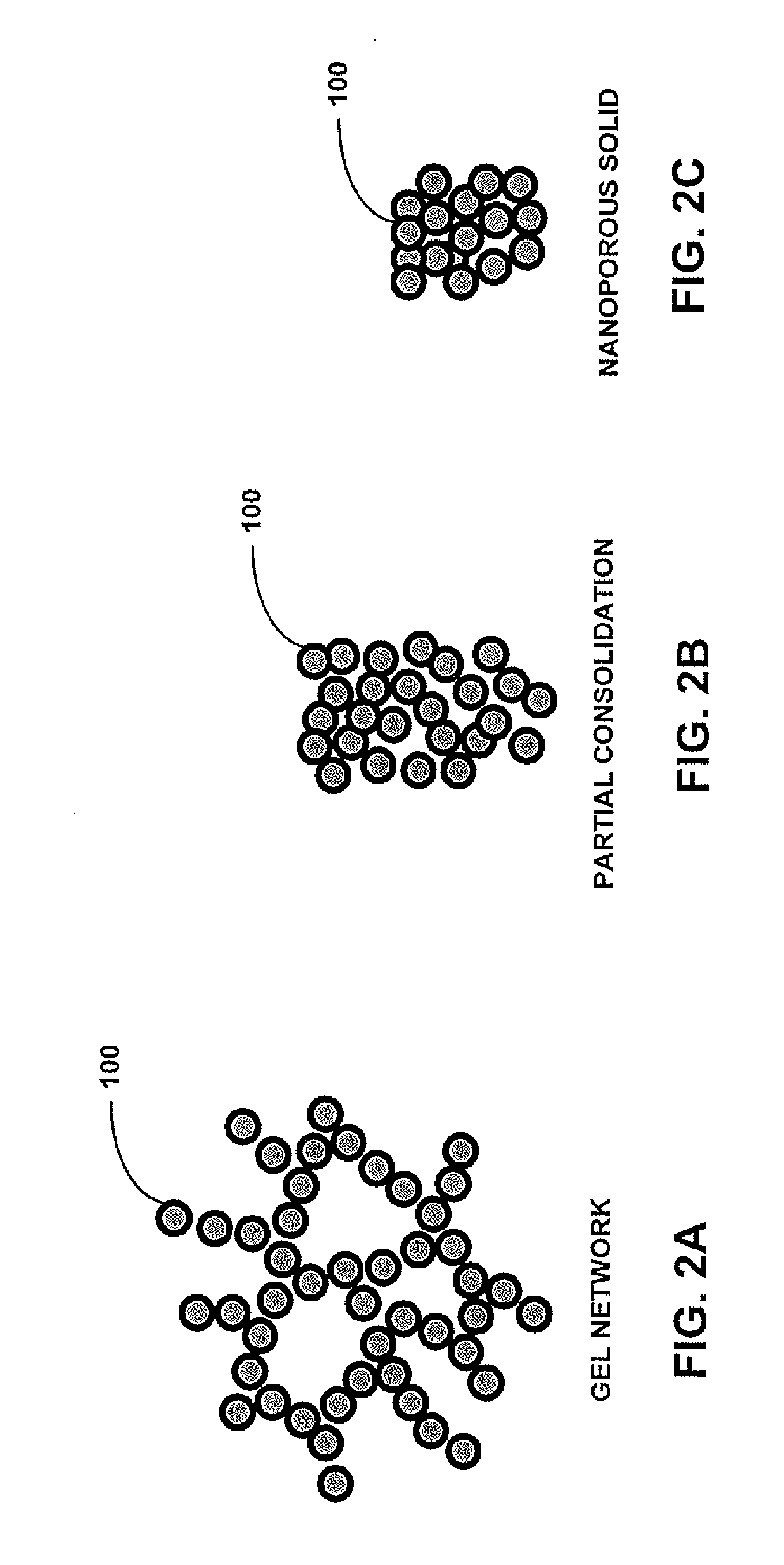

Swelling-resistant nuclear fuel

A nuclear fuel according to one embodiment includes an assembly of nuclear fuel particles; and continuous open channels defined between at least some of the nuclear fuel particles, wherein the channels are characterized as allowing fission gasses produced in an interior of the assembly to escape from the interior of the assembly to an exterior thereof without causing significant swelling of the assembly. Additional embodiments, including methods, are also presented.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

High-density, solid solution nuclear fuel and fuel block utilizing same

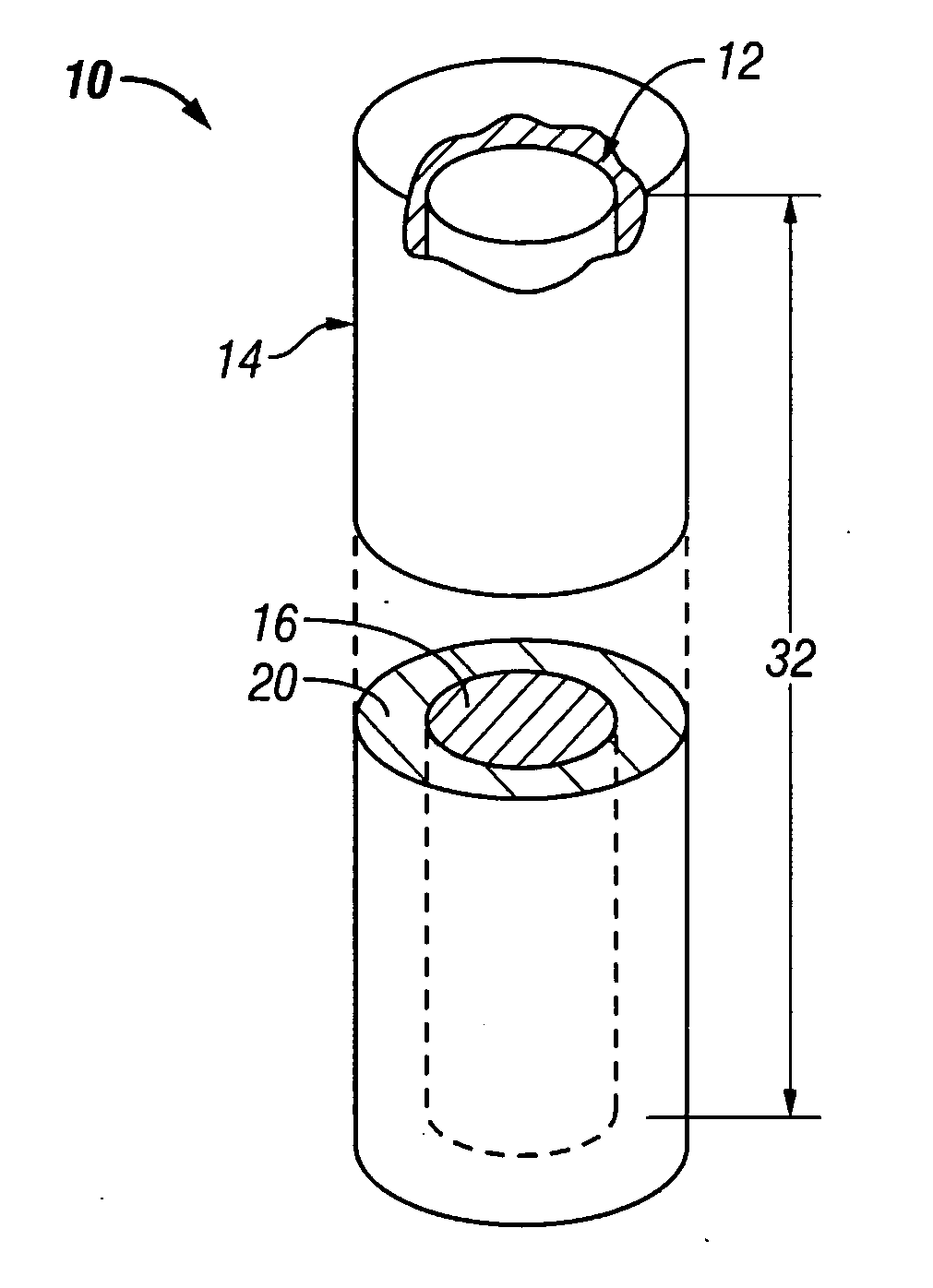

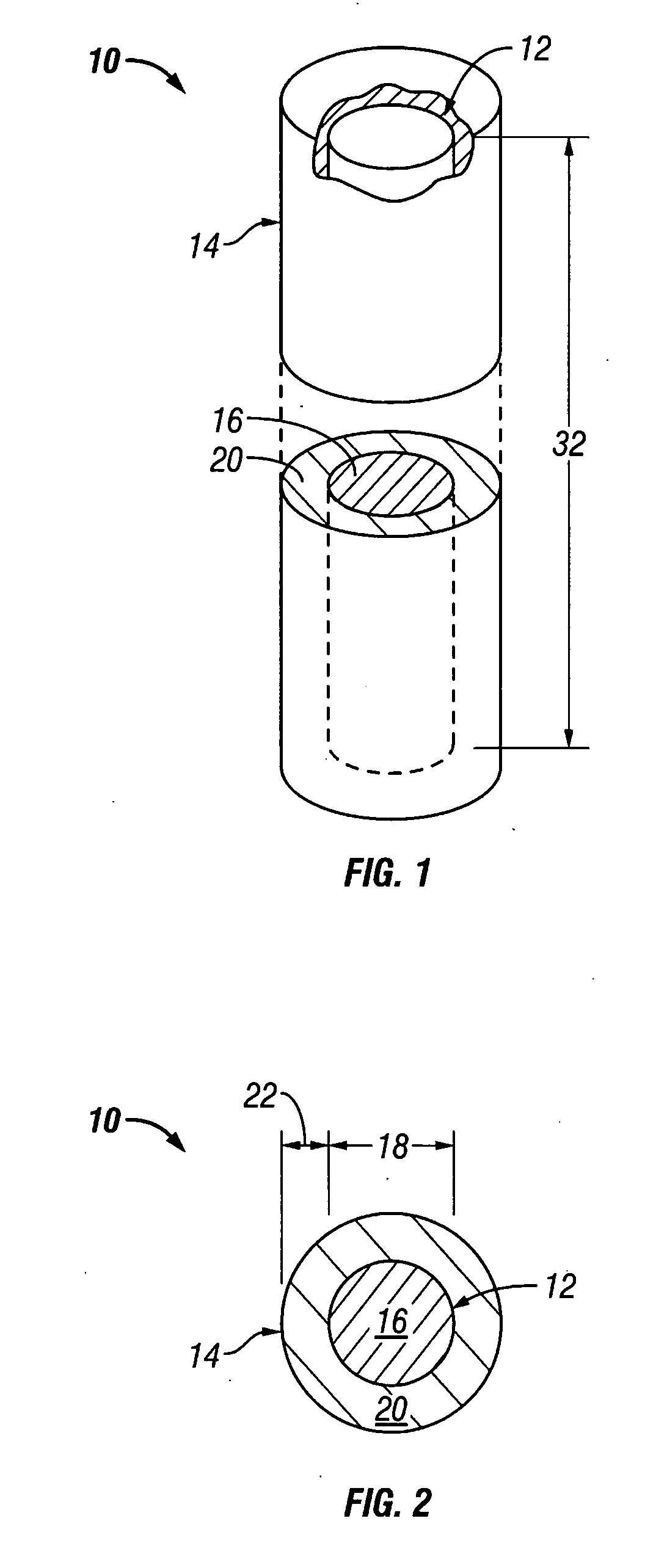

A nuclear fuel element includes a core formed from a high density solid solution fissile material that is substantially free of carbon and void space. A cladding substantially surrounds the core.

Owner:MICRON TECH INC +1

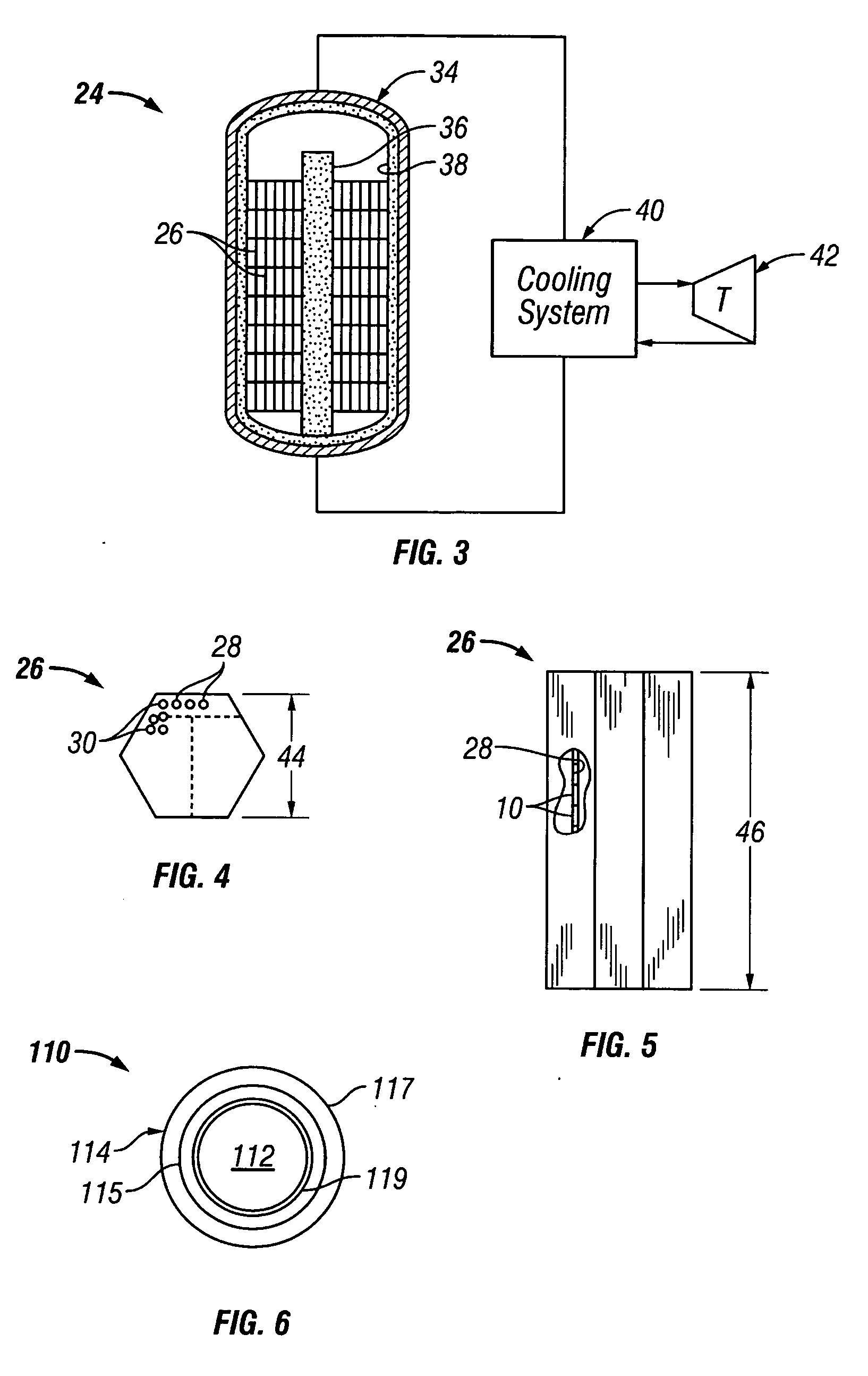

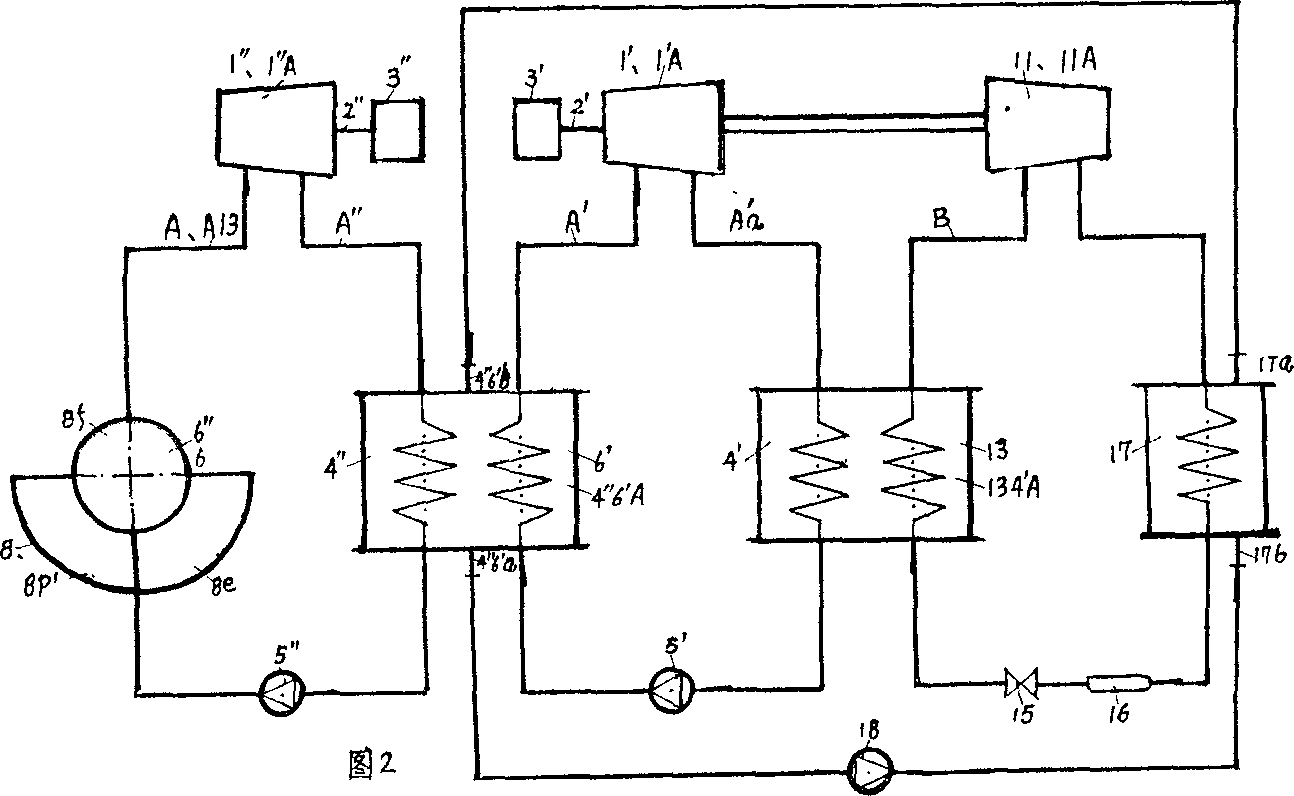

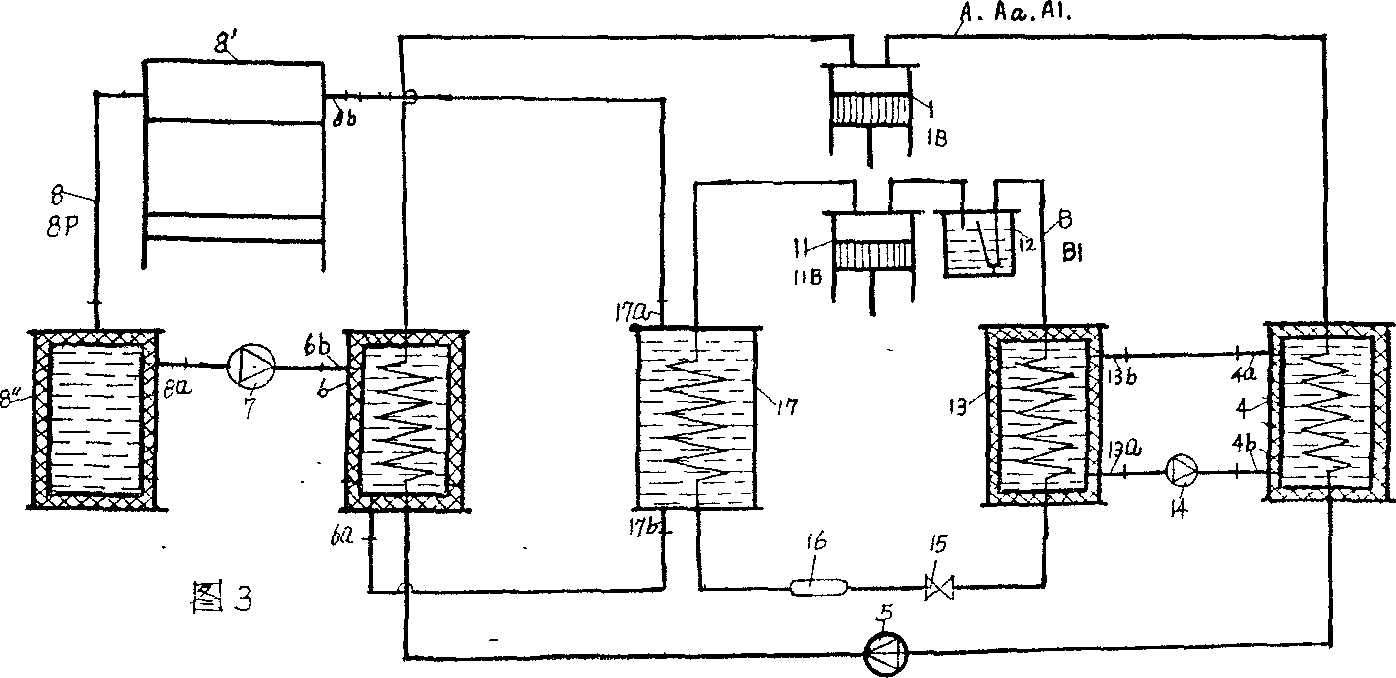

Composite thermodynamic engine of power circulation system and refrigerating circulation system

The inventive compound heat engine consists of a power circulation system and a refrigerating circulation system, in which is mounted a control system. It can provide the fields of power engineerings, refrigerating engineerings, communications and transportations, pumping irrigations and the like with mechanical work or electric energy. It not only can convert the high-grade energy, such as the fossil fuel, the nuclear fuel and soon into mechanical work or electric energy, but also can convert the low-grade heat energy stored in the seawater, the air and the earth crust into mechanical work or electric energy. Is also can convert the new energy like the solar energy and the renewable energy into mechanical work or electric energy.

Owner:罗桂荣 +1

Wireless in-core neutron monitor

ActiveUS20120177166A1Avoid runningNuclear energy generationNuclear monitoringNuclear reactor coreNuclear reactor

An in-core neutron monitor that employs vacuum microelectronic devices to configure an in-core instrument thimble assembly that monitors and wirelessly transmits a number of reactor parameters directly from the core of a nuclear reactor without the use of external cabling. The in-core instrument thimble assembly is substantially wholly contained within an instrument guide tube within a nuclear fuel assembly.

Owner:WESTINGHOUSE ELECTRIC CORP

System for comprehensive utilization of three industrial wastes

InactiveCN101618292AAchieve energy saving and emission reductionReduce manufacturing costDispersed particle separationWater/sewage treatmentElectric powerToxic industrial waste

The invention provides a system for comprehensive utilization of three industrial wastes, mainly relating to the field of energy conservation and emission reduction, in particular to the comprehensive utilization of the three industrial wastes; to realize the objective of energy conservation and emission reduction required by the recycle economy, a system technology targeted at comprehensive utilization of the three industrial wastes of factories is adopted; in the invention, the reactor in the nuclear plant, the boiler in the coal-fired power plant and other types of supercritical boilers are utilized to provide a new cooling and turbine drive mode to solve the issue of industrial discharge of greenhouse gas and other polluting gases; in addition, collected emissions are utilized to produce nuclear fuel, compound chemical fertilizer or feedstuff and other chemical raw materials; moreover, to realize recycling of resources and sustainable utilization of energy, the original three wastes are innovatively applied to nuclear electric power generation. The system is characterized by comprising 10 major links and the beneficial effect thereof lies in utilizing new methods to realize energy conservation and emission reduction and production cost in the late stage of production can be reduced.

Owner:李元胜

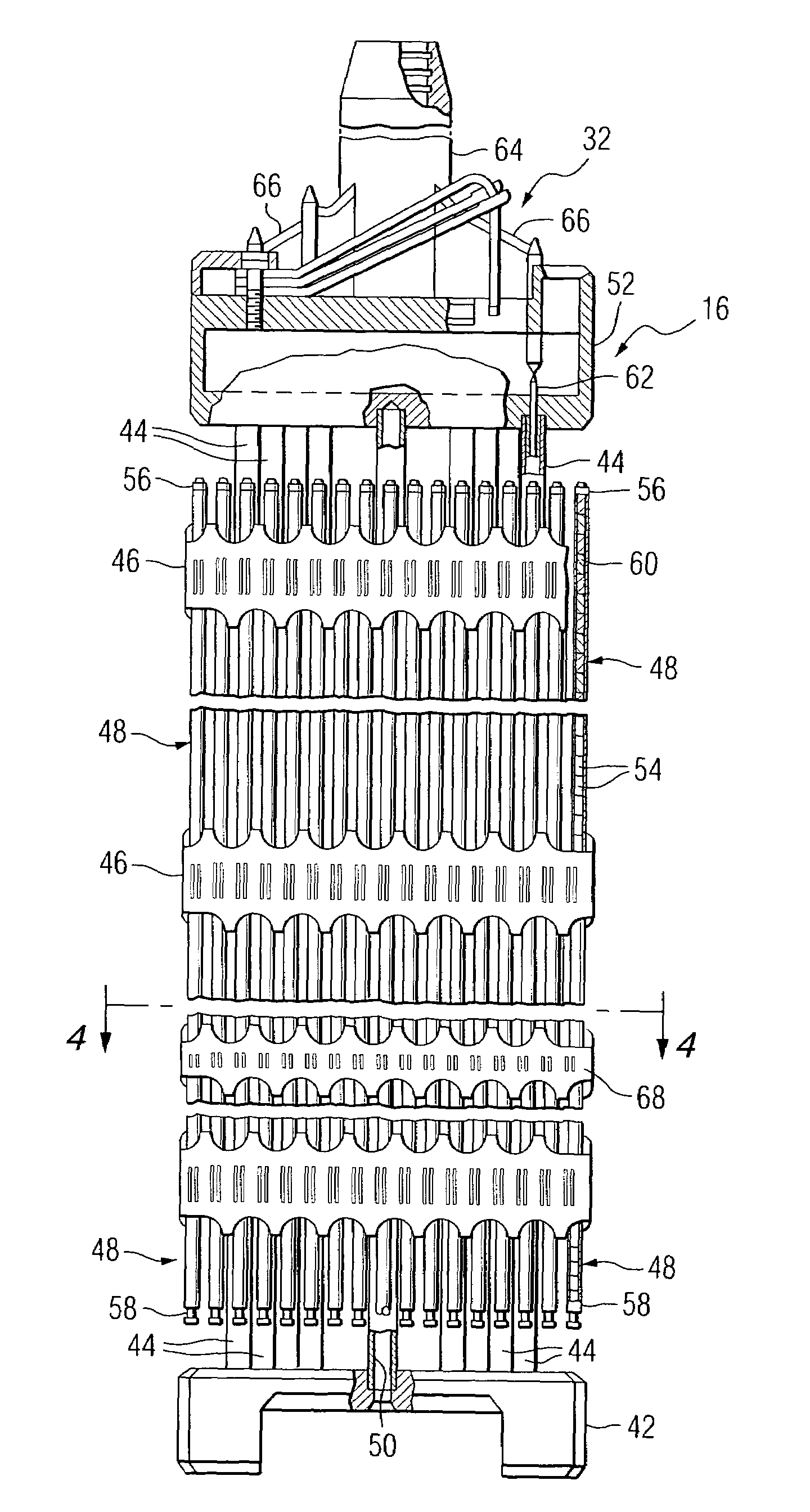

Nuclear reactor fuel assemblies

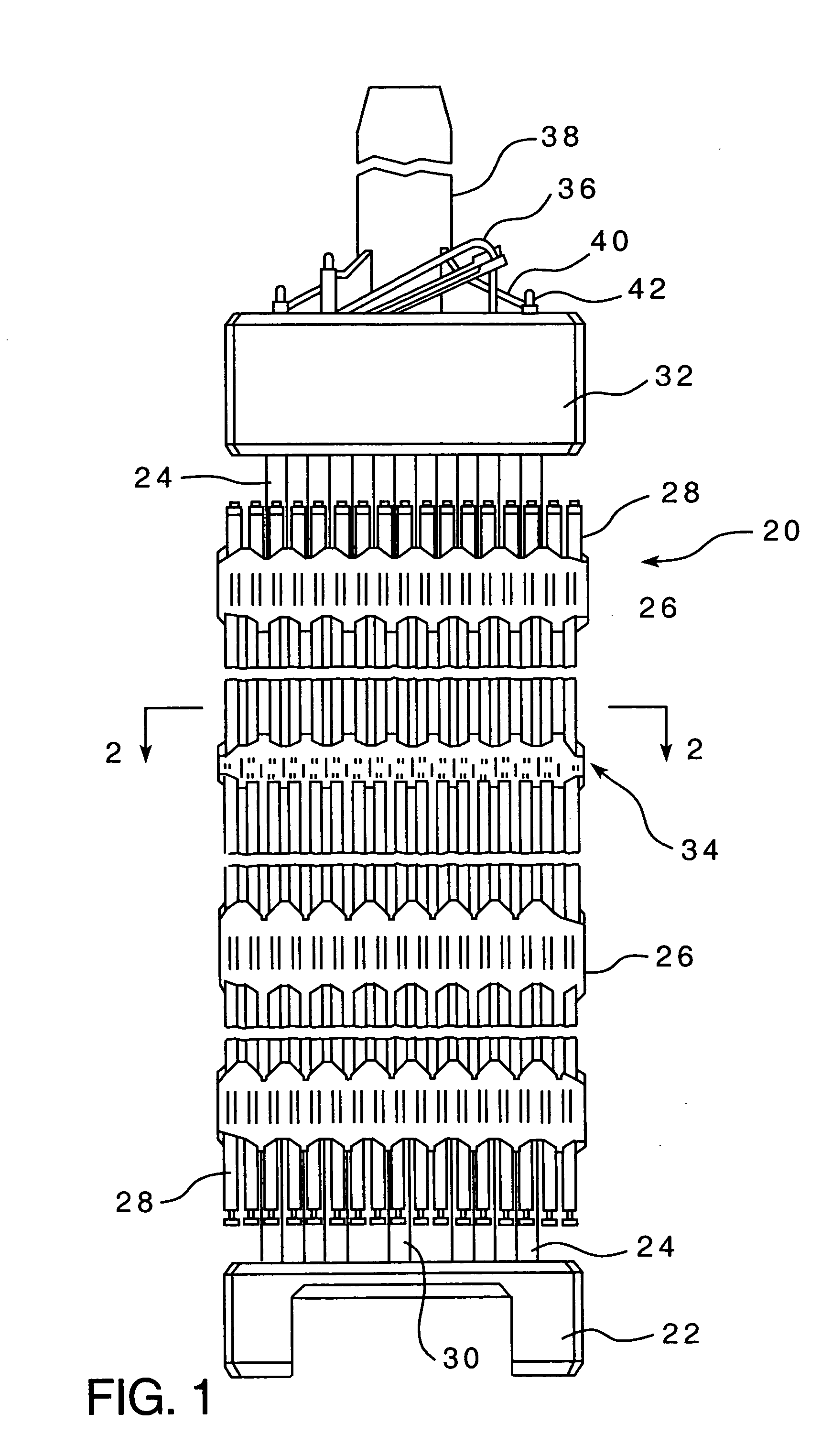

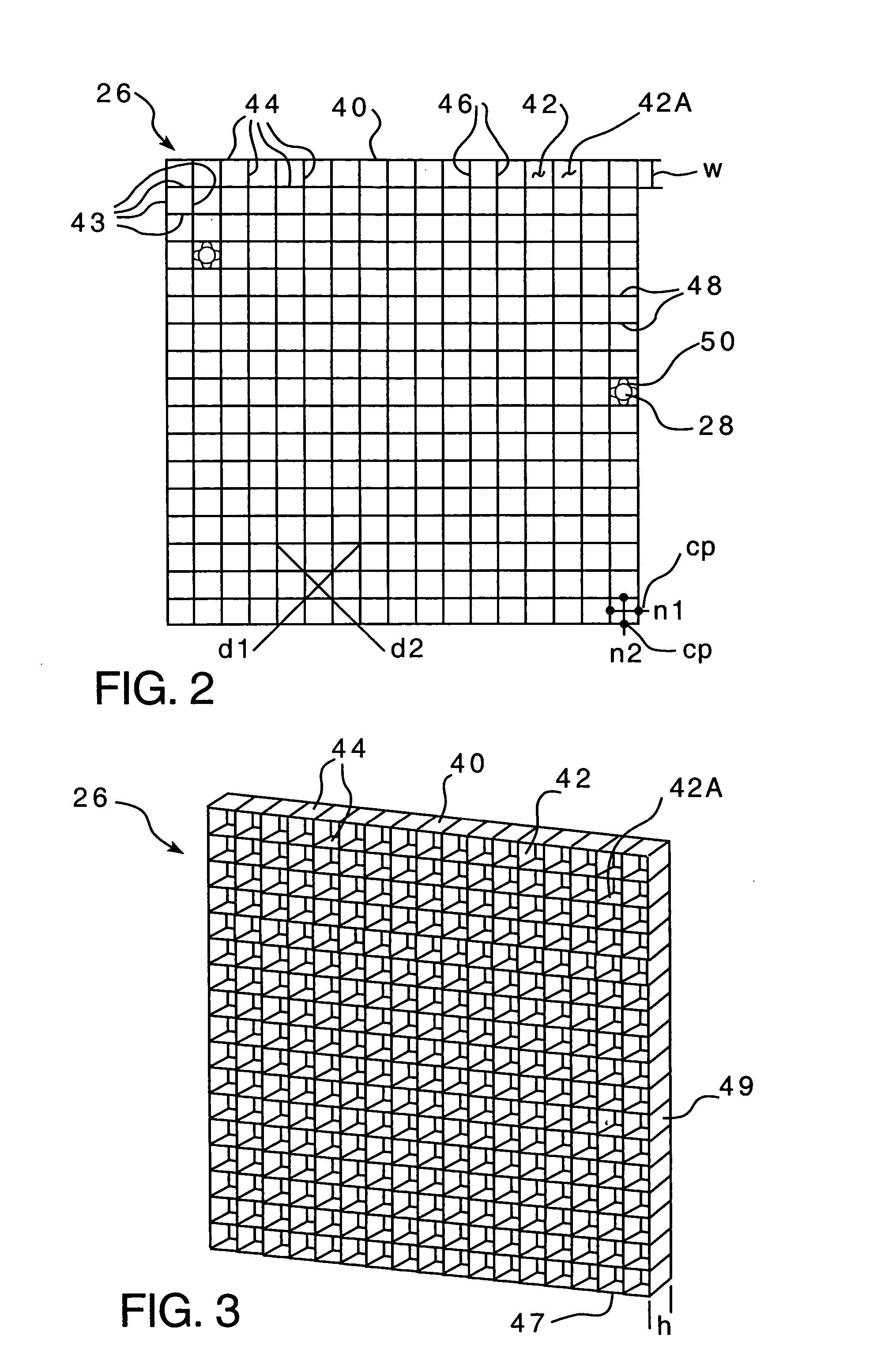

InactiveUS7085340B2Eliminate wearPrevent “hang-upsNuclear energy generationFuel element assembliesNuclear reactorParallel array

A nuclear fuel assembly having a parallel array of elongated fuel elements supported between an upper and lower nozzle. Main support grids are substantially evenly spaced along the elongated dimension of the assembly to maintain the spacing between fuel elements. A plurality of auxiliary vibration-resistant grids respectively positioned between the main support grids in the middle third elongated dimension of the fuel elements, that are smaller in height and provide a larger fuel element contact area than the main support grids.

Owner:WESTINGHOUSE ELECTRIC CORP

Molten nuclear fuel salts and related systems and methods

InactiveUS20160189813A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

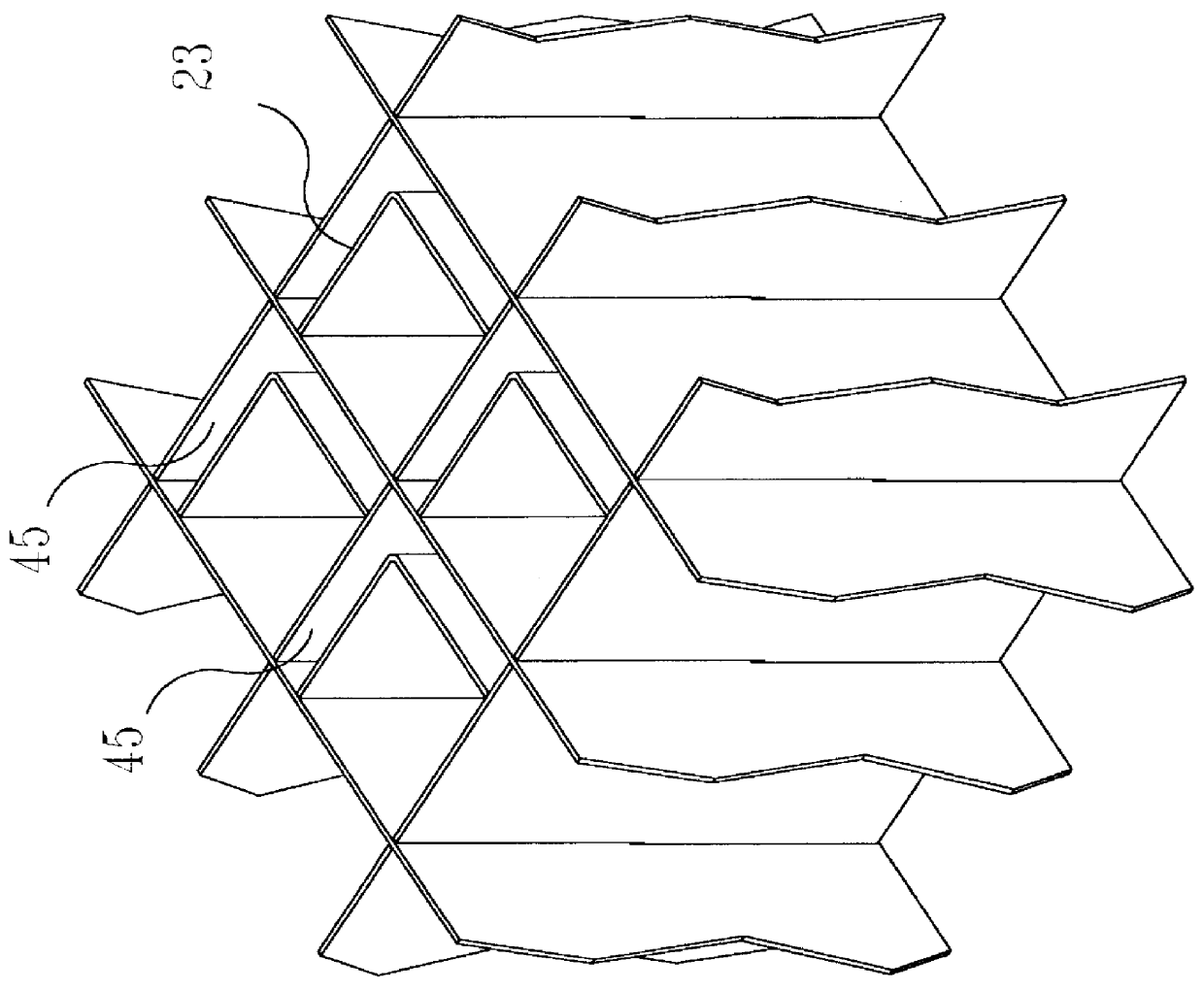

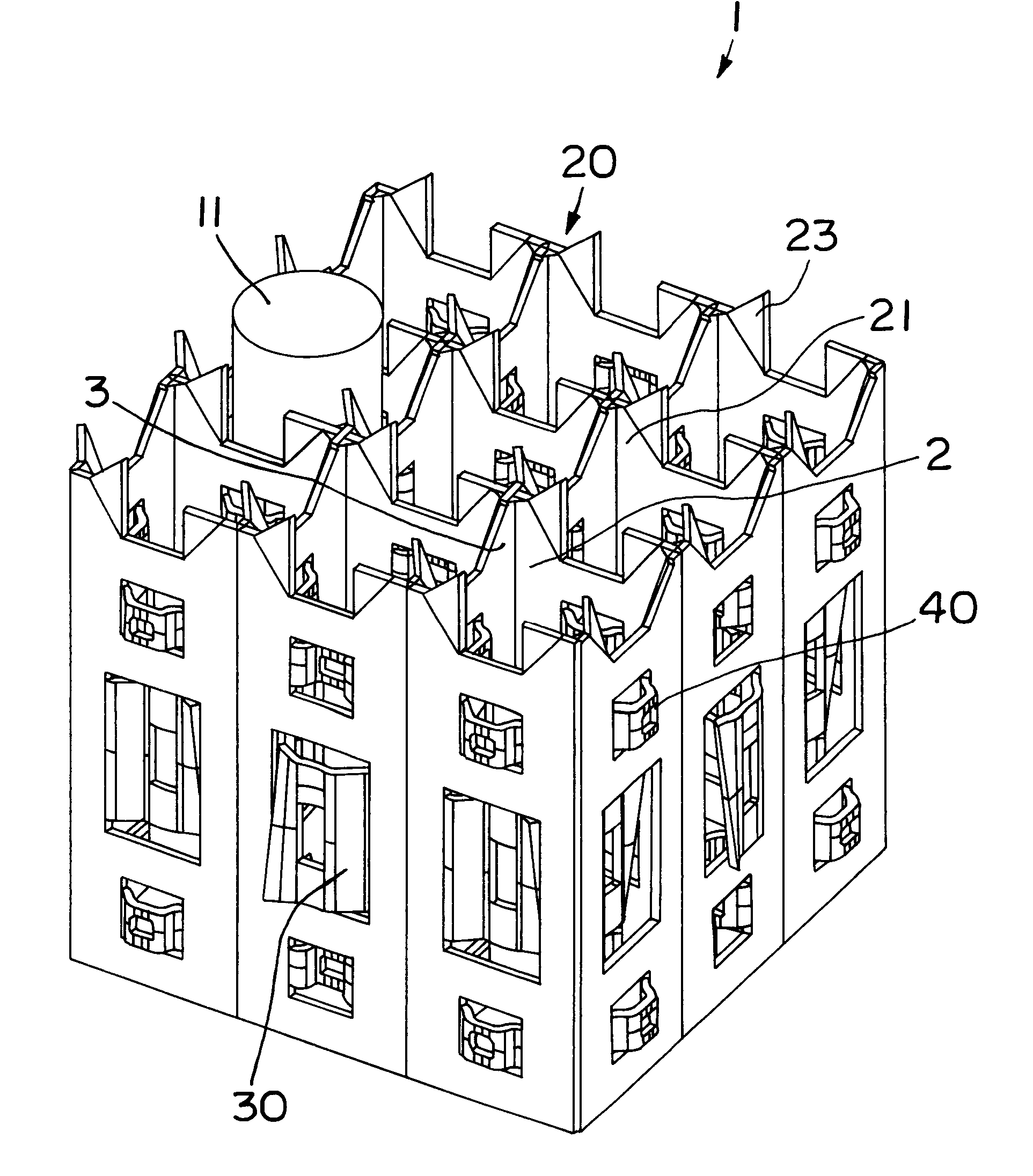

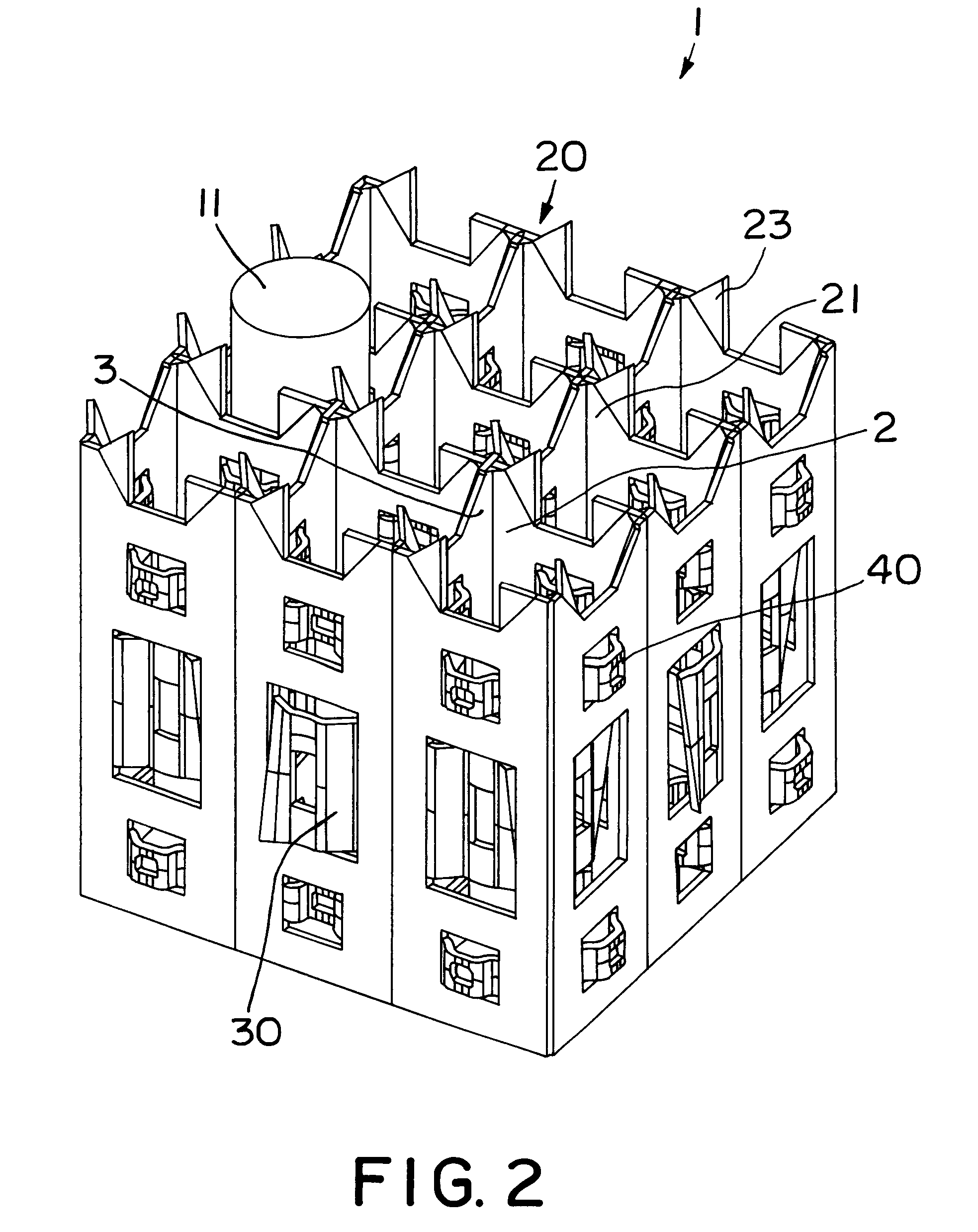

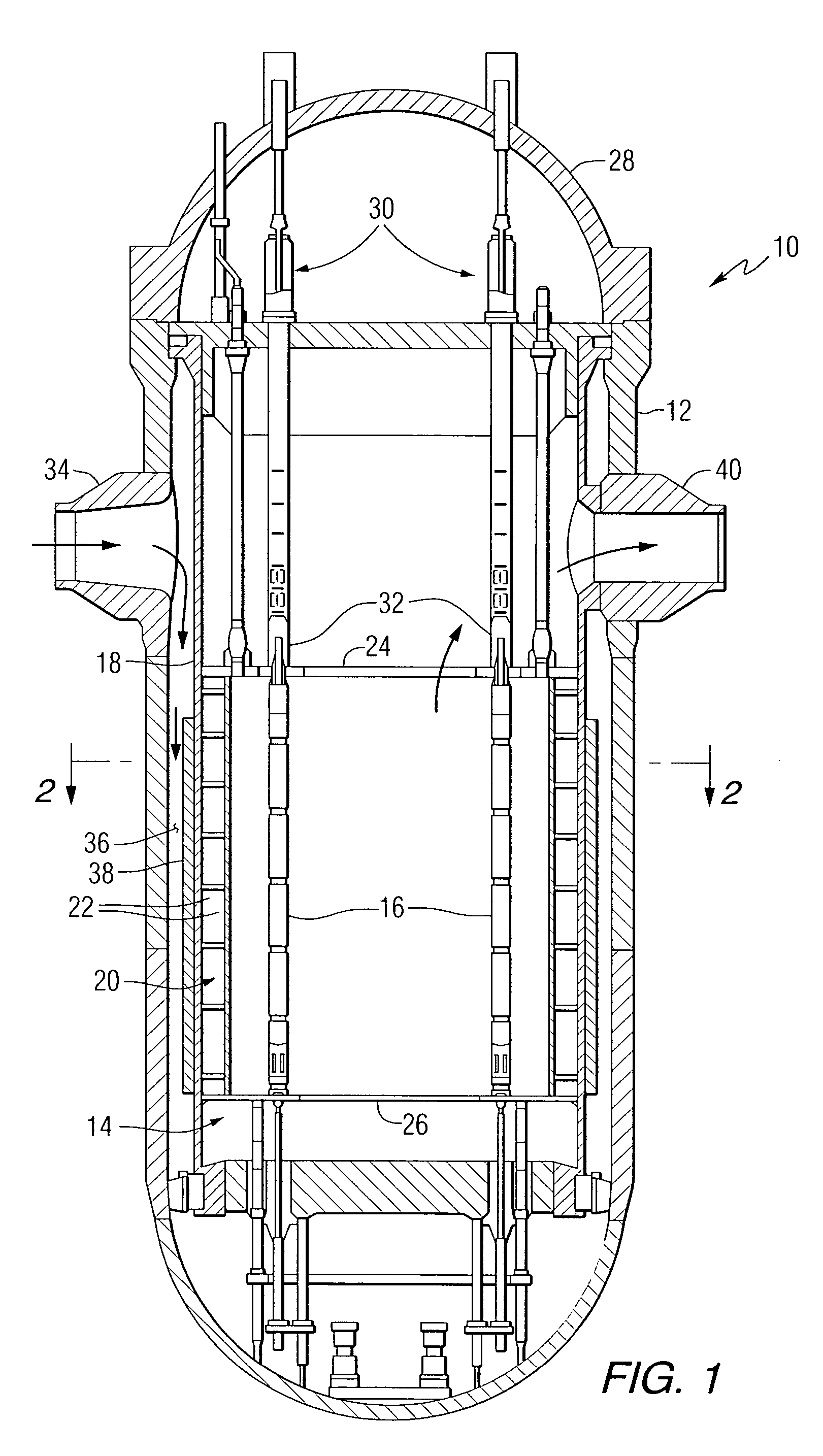

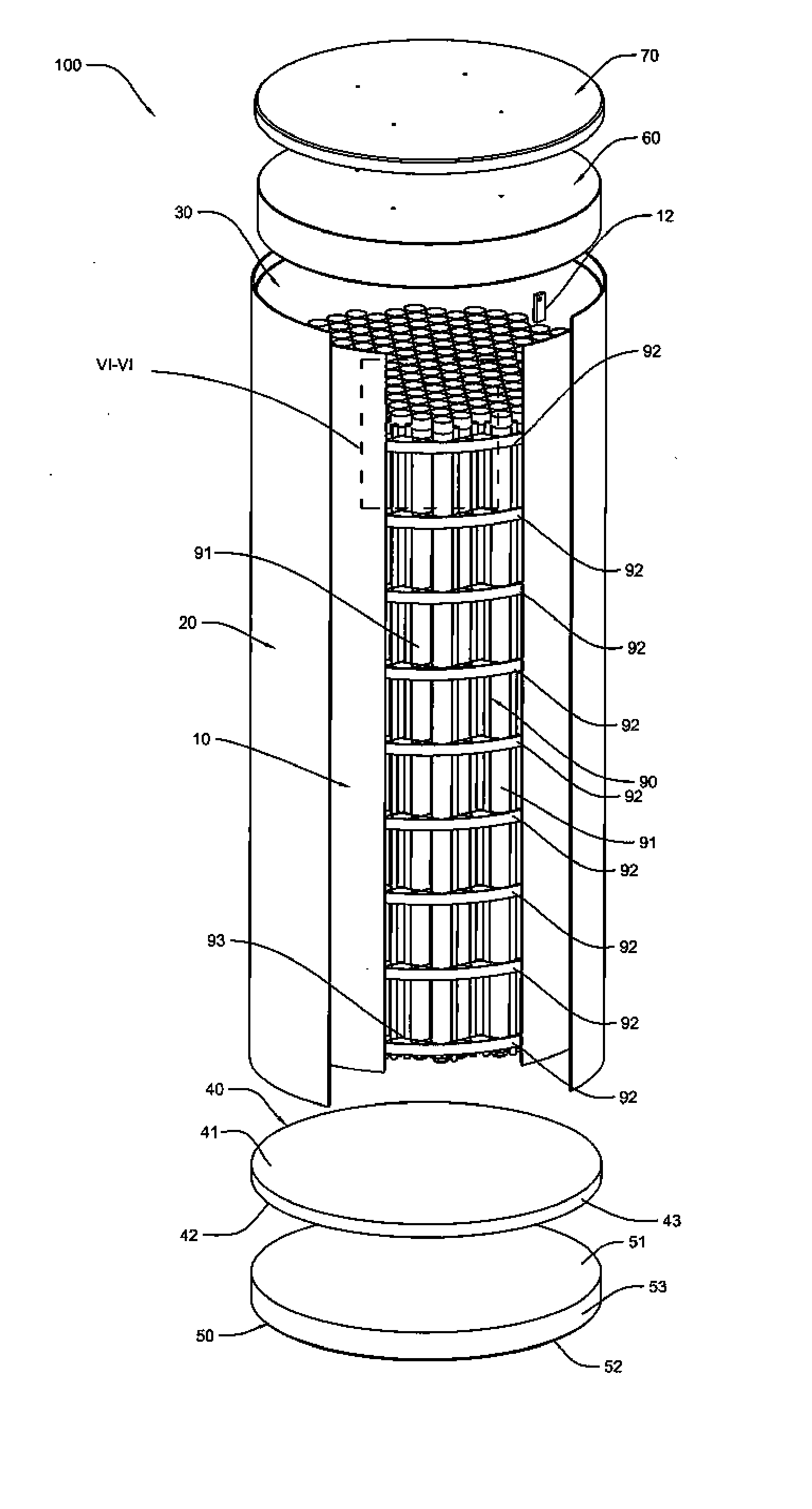

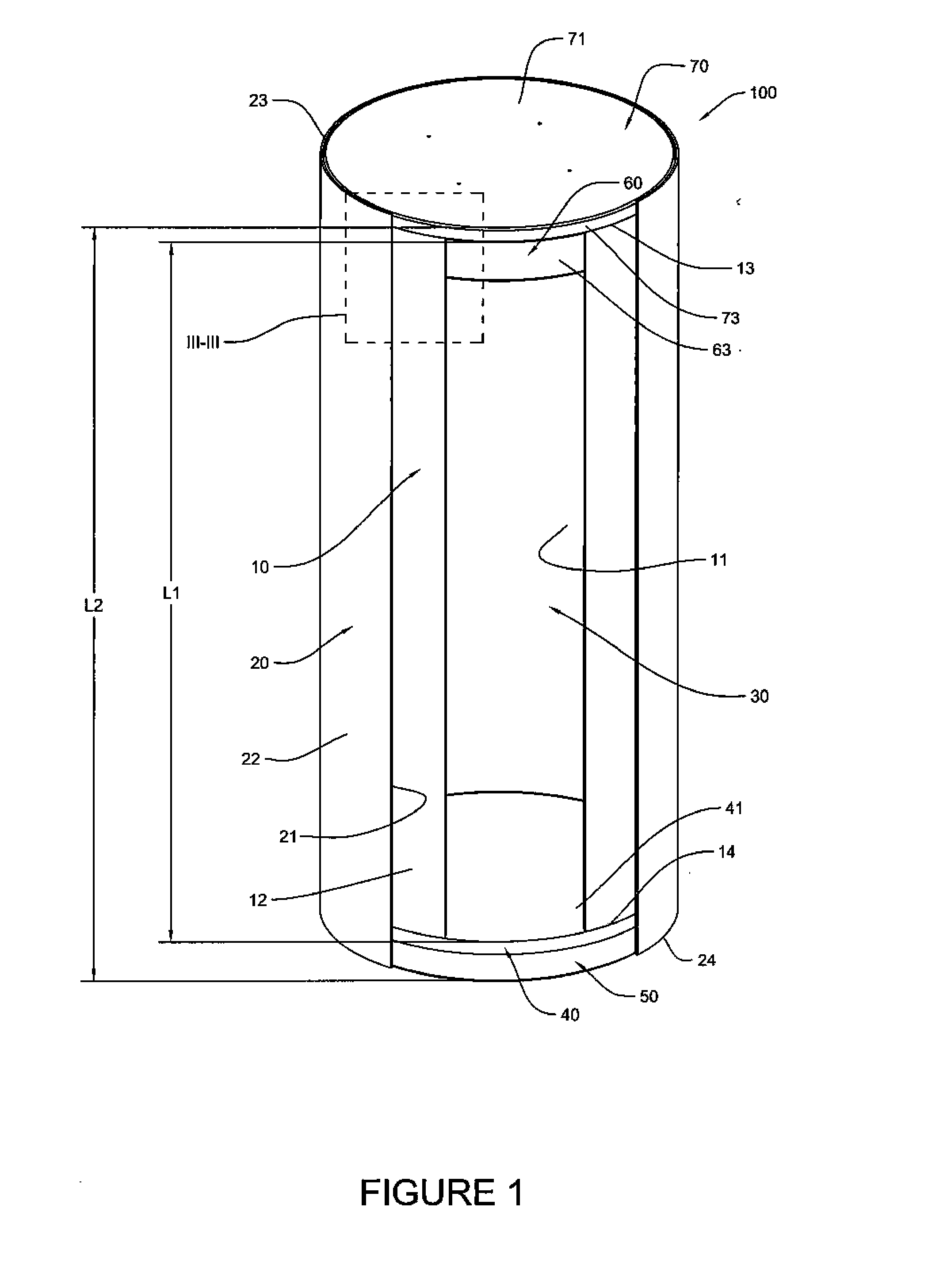

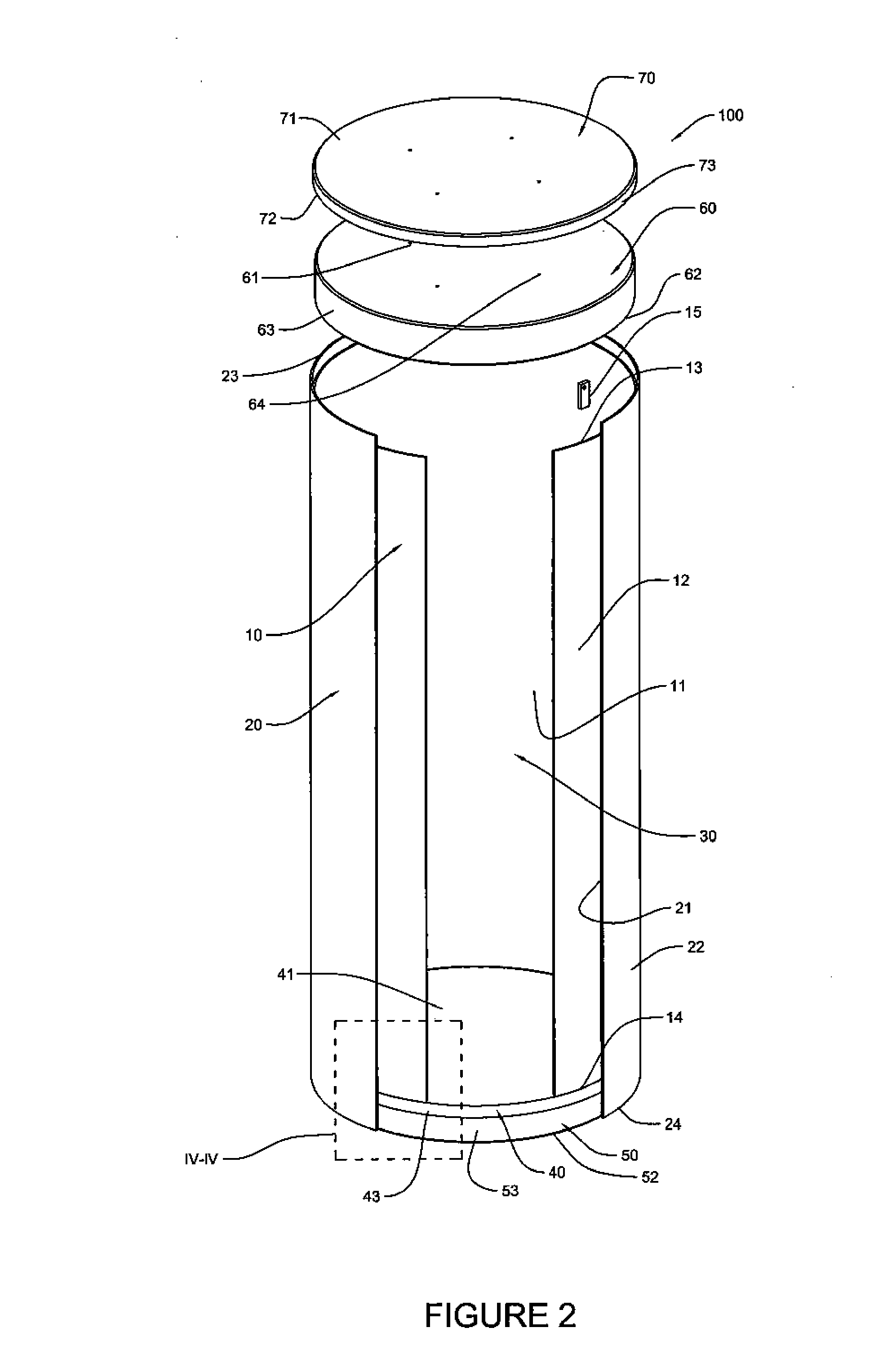

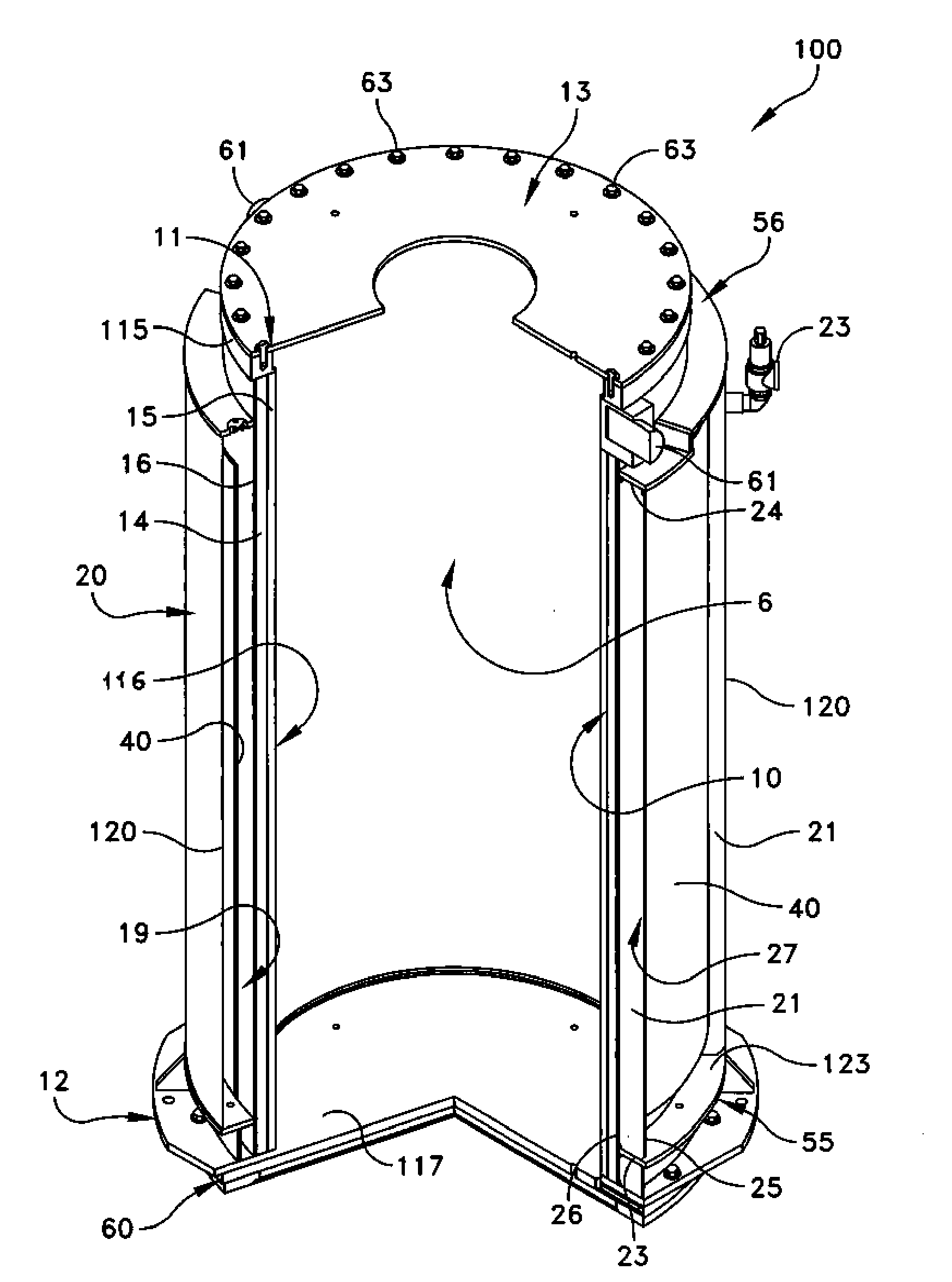

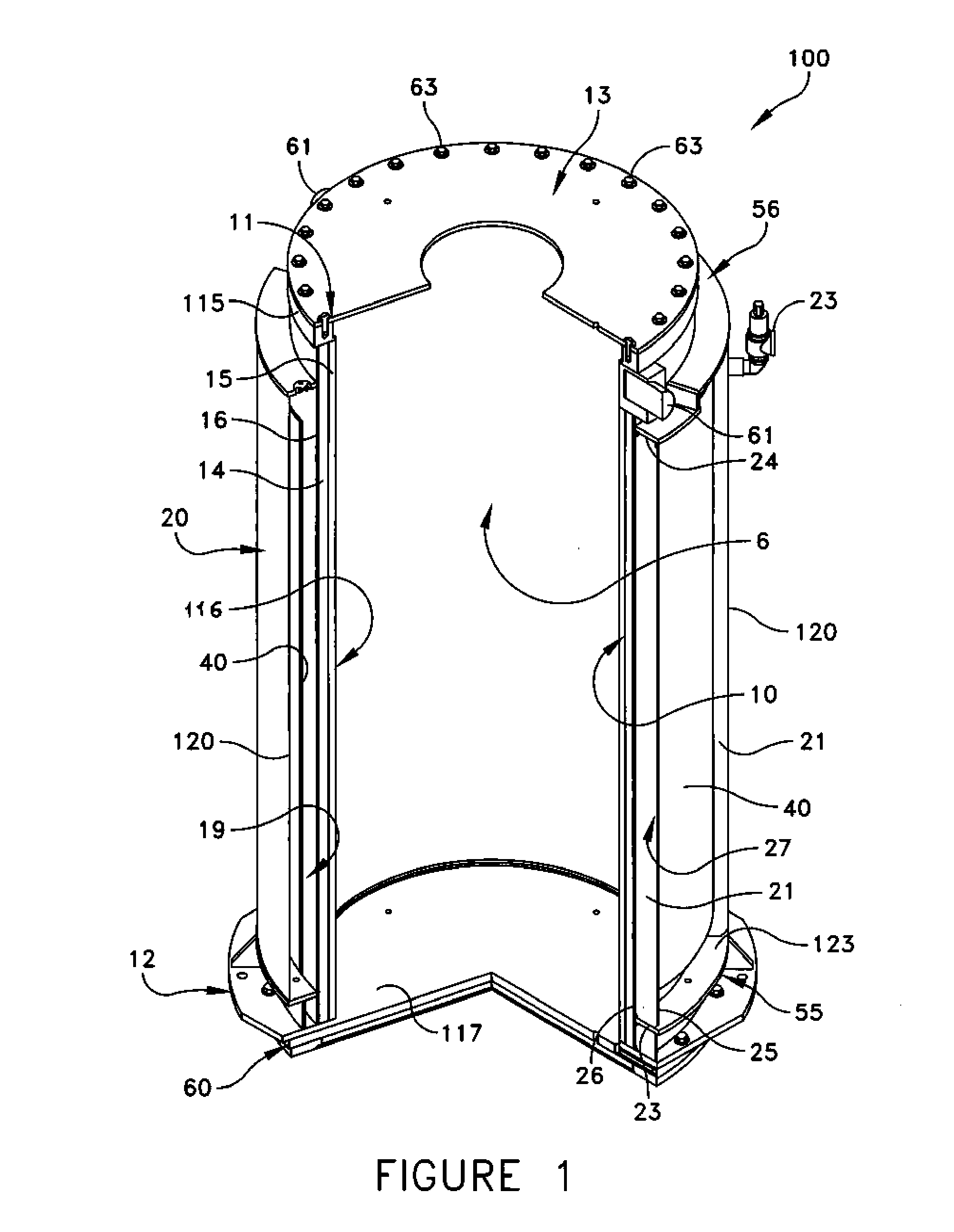

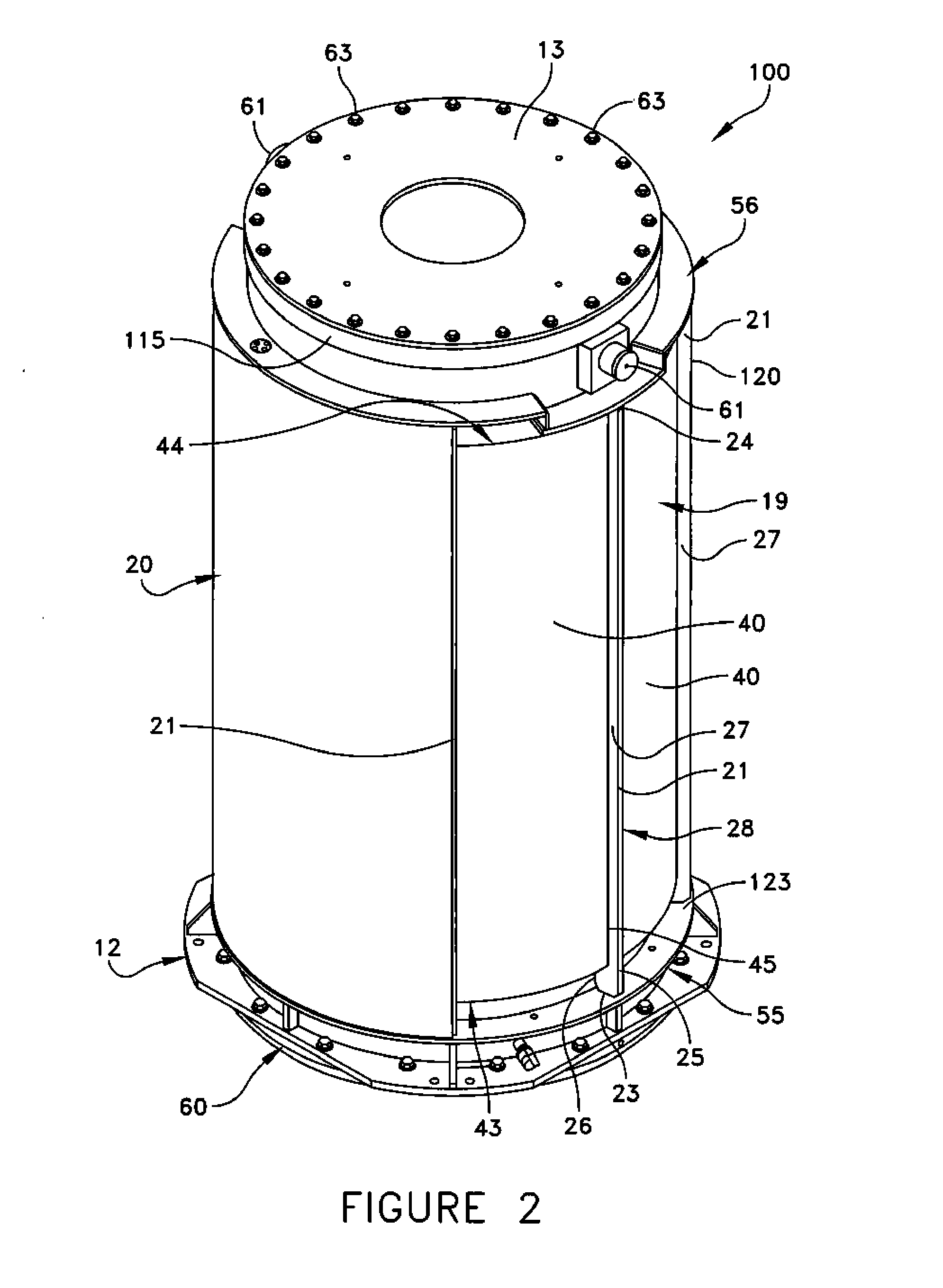

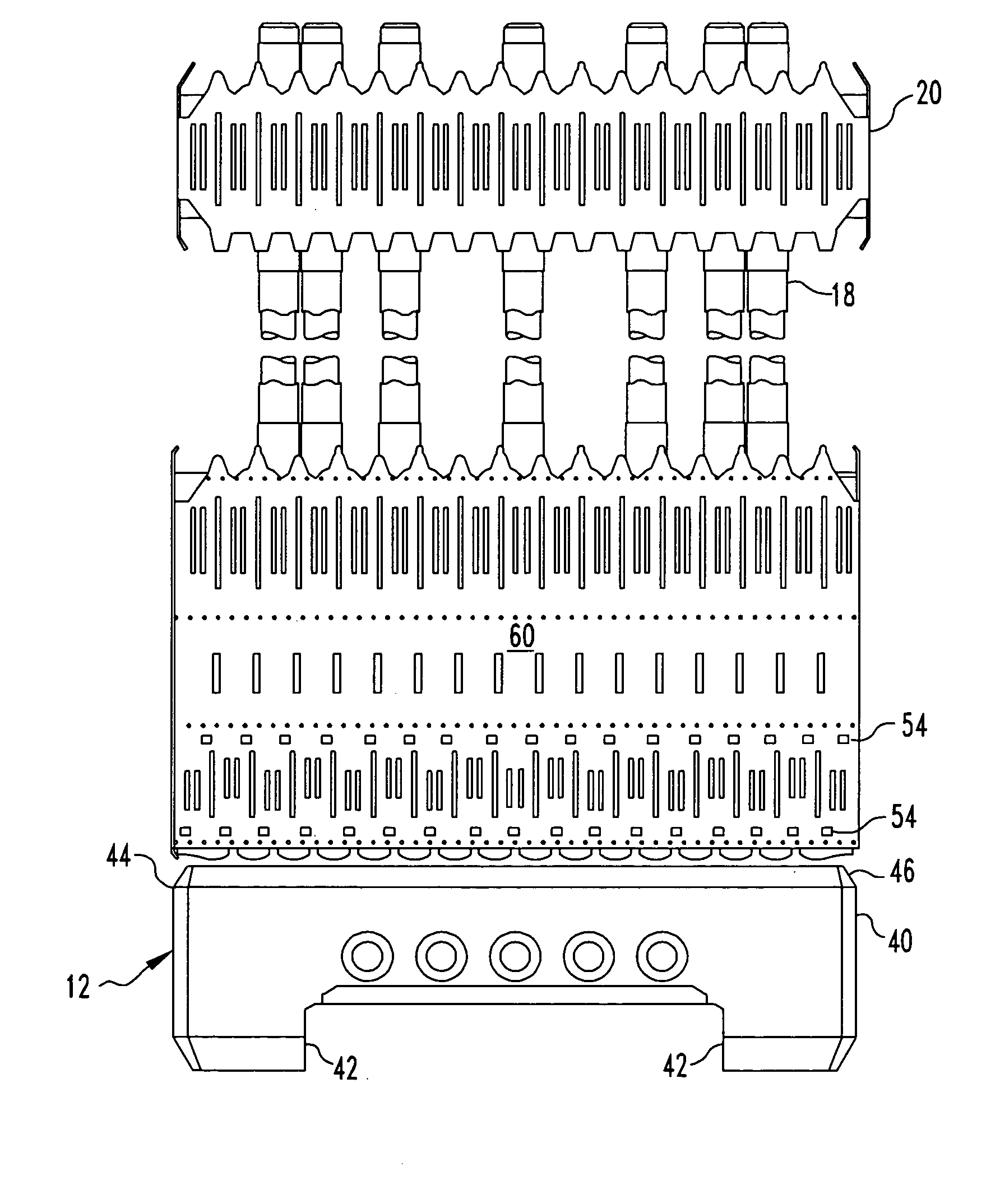

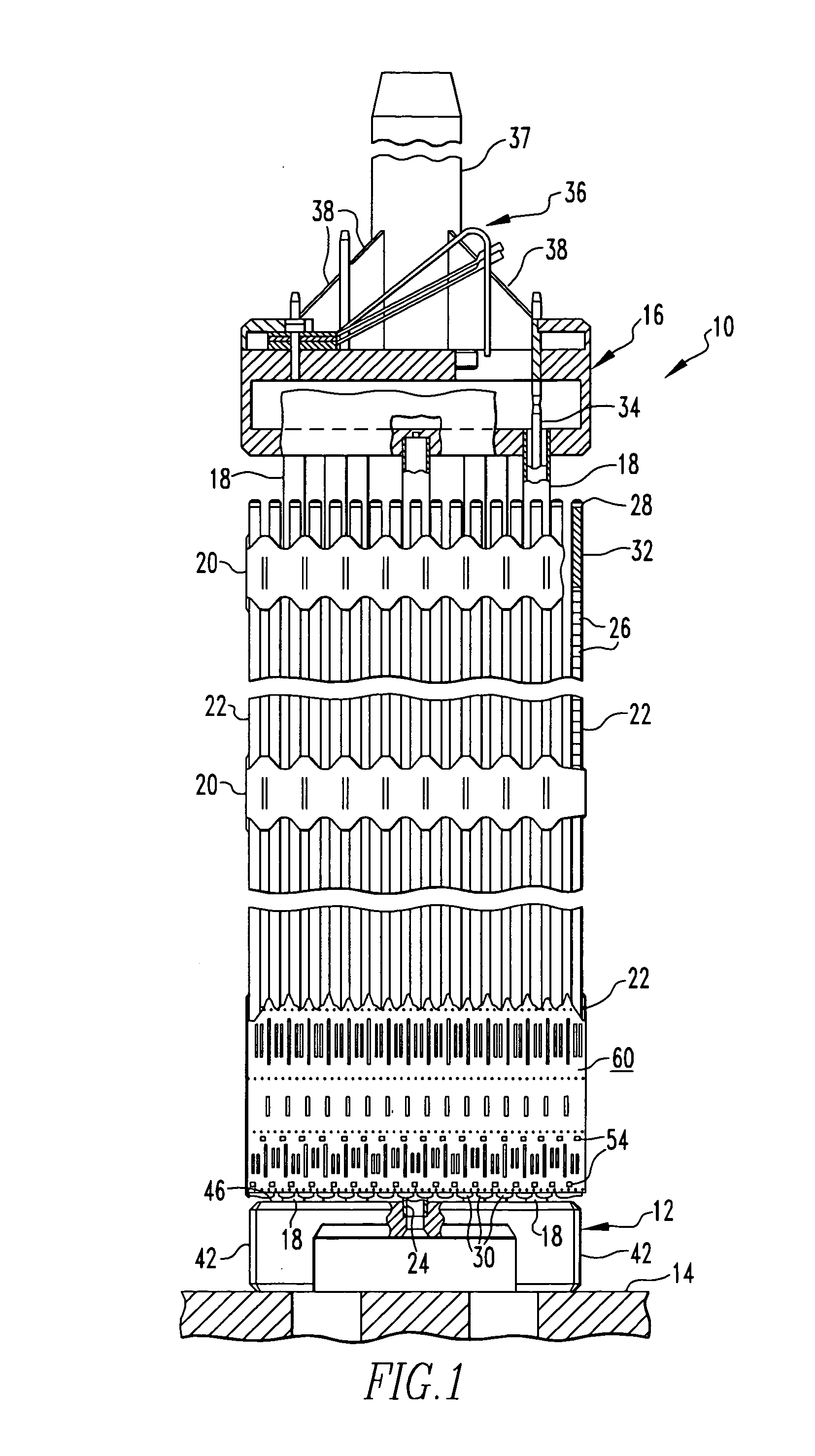

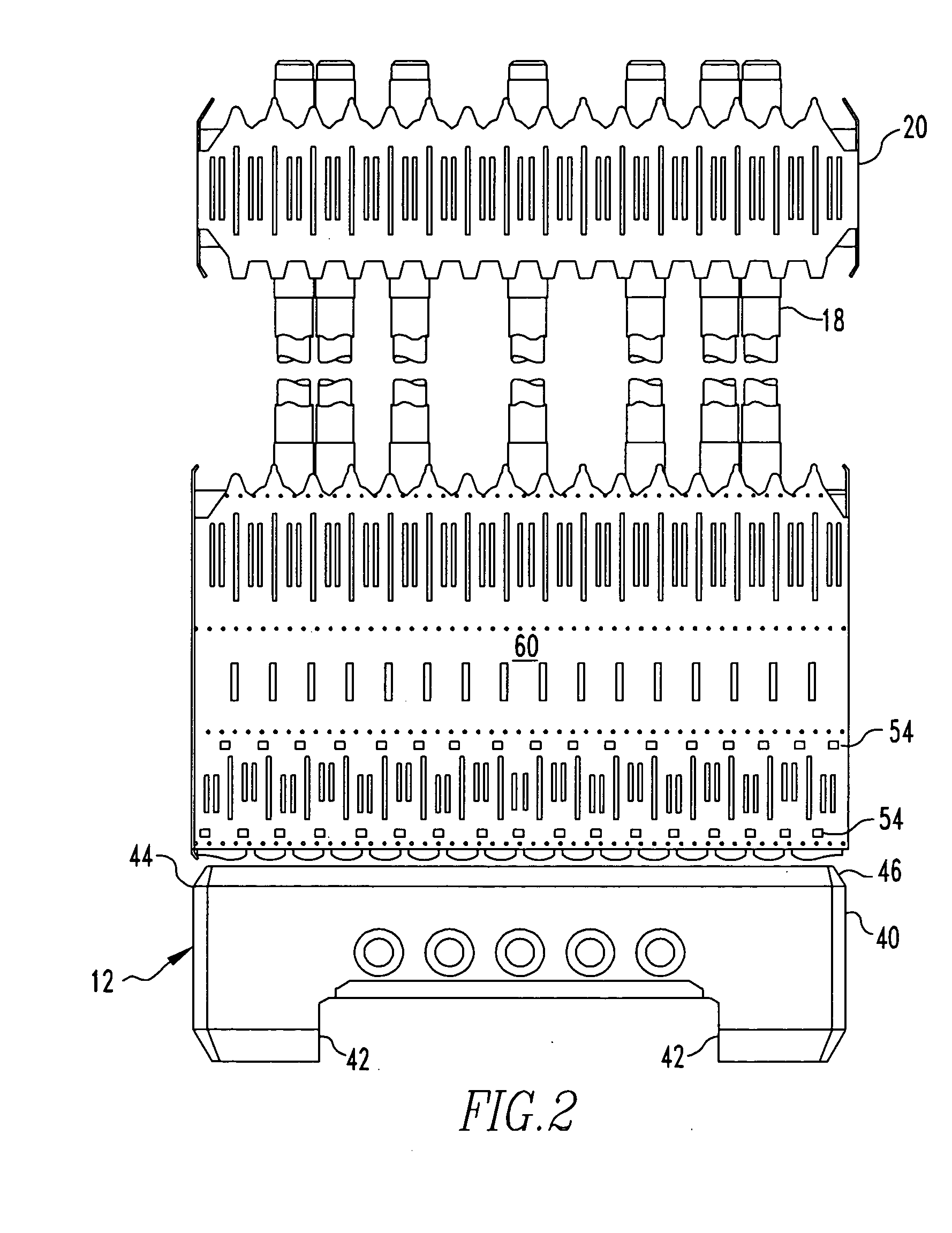

Canister apparatus and basket for transporting, storing and/or supporting spent nuclear fuel

ActiveUS20080069291A1Efficiently accommodate both poison rodEfficiently spent nuclear fuelNuclear engineering problemsNuclear engineering solutionsRadioactive wasteEngineering

A canister apparatus, basket apparatus and combinations thereof for transporting and / or storing high level radioactive waste, such as spent nuclear fuel. The canister apparatus comprises a cavity for receiving the spent nuclear fuel that is surrounded by two independent gas-tight containment boundaries. The structures that form the two independent gas-tight containment boundaries are in substantially continuous surface contact with one another, thereby facilitating sufficient heat removal from the cavity. In another aspect, the invention is a basket apparatus having a plurality of disk-like grates arranged in a stacked and spaced arrangement so that the cells of the disk-like grates are aligned. In still another aspect, the invention can be a basket apparatus having a disk-like grate having a ring-like structure encompassing a gridwork of beams specially arranged to achieve a unique cell configuration.

Owner:HOLTEC INT

Method of removing radioactive materials from a submerged state and/or preparing spent nuclear fuel for dry storage

ActiveUS20090069621A1Quantity maximizationIncreasing transfer procedure cycleNuclear engineering problemsNuclear engineering solutionsRadioactive agentRadioactive waste

A system, apparatus and method of processing and / or removing radioactive materials from a body of water that utilizes the buoyancy of the water itself to minimize the load experienced by a crane and / or other lifting equipment. In one aspect, the invention is a method comprising: a) submerging a container having a top, a bottom, and a cavity in a body of water having a surface level, the cavity filling with water; b) positioning radioactive material within the cavity of the submerged container; c) raising the submerged container until the top of the containment apparatus is above the surface level of the body of water while a major portion of the container remains below the surface level of the body of water; and d) removing bulk water from the cavity while the top of the container remains above the surface level of the body of water and a portion of the container remains submerged. The bulk water can be added back into the cavity to add neutron shielding after the container is placed in a staging area and prior to personnel performing the desired operations to the container. As a result, gamma radiation and neutron shielding of the container can be maximized for any crane capacity.

Owner:HOLTEC INT

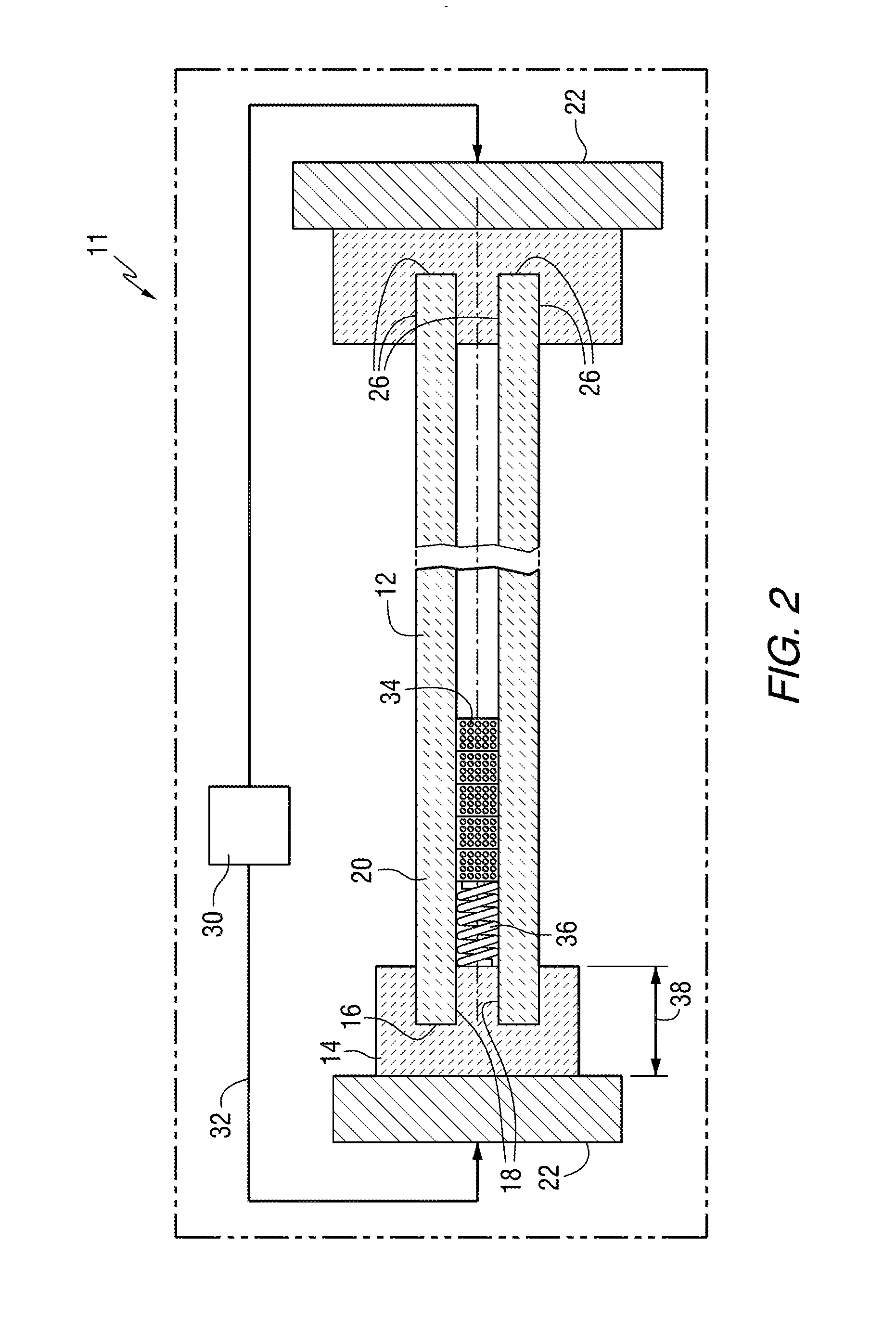

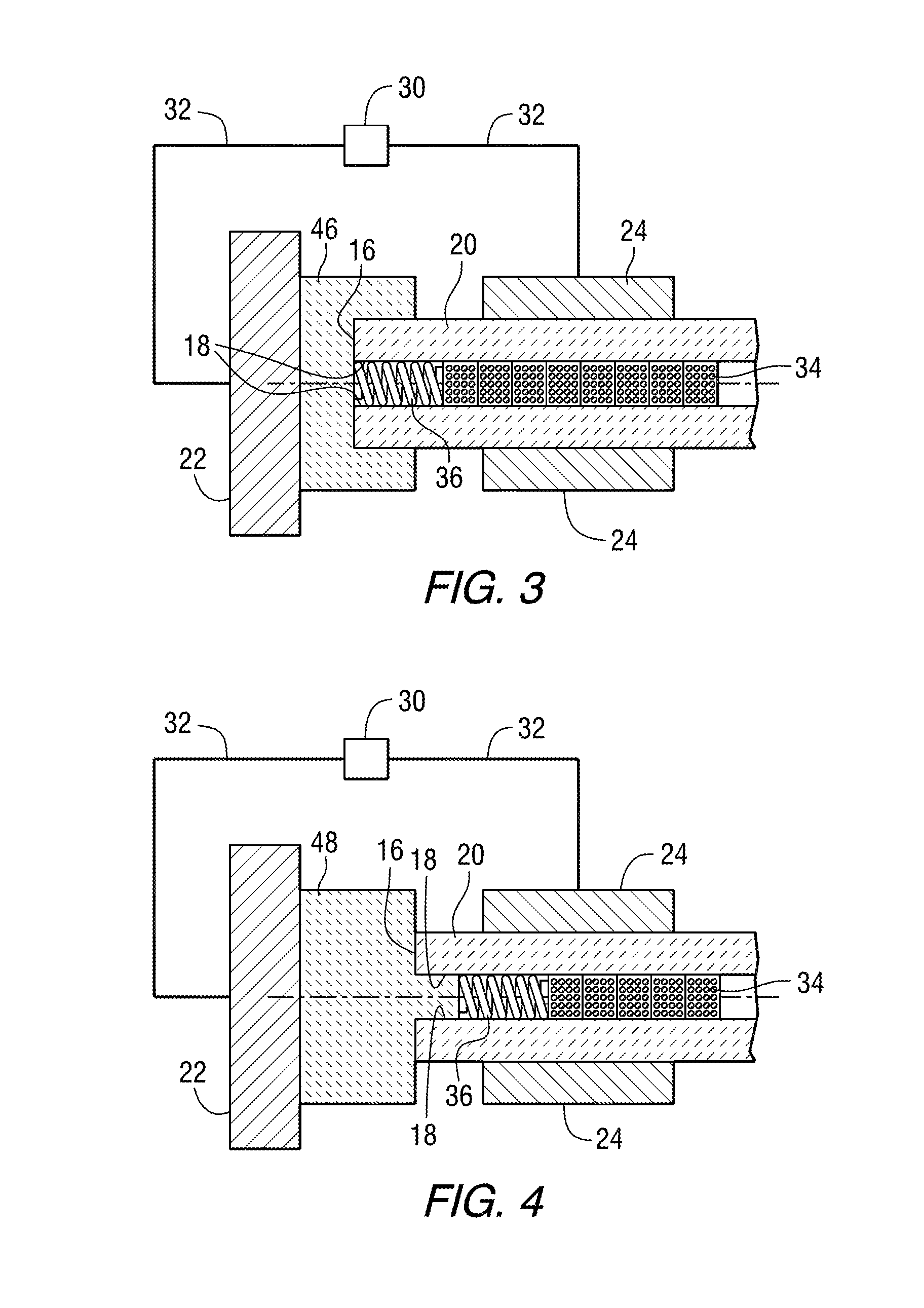

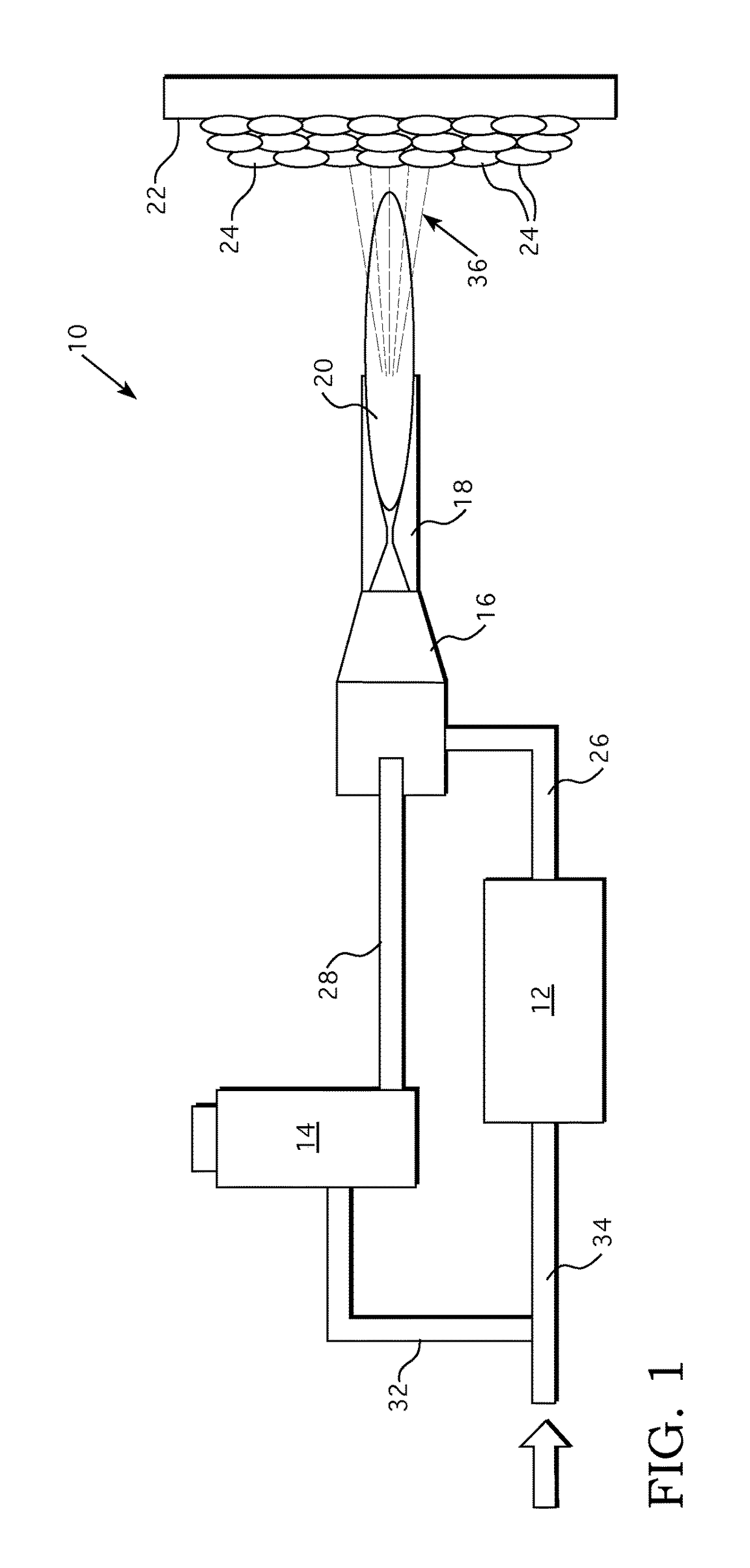

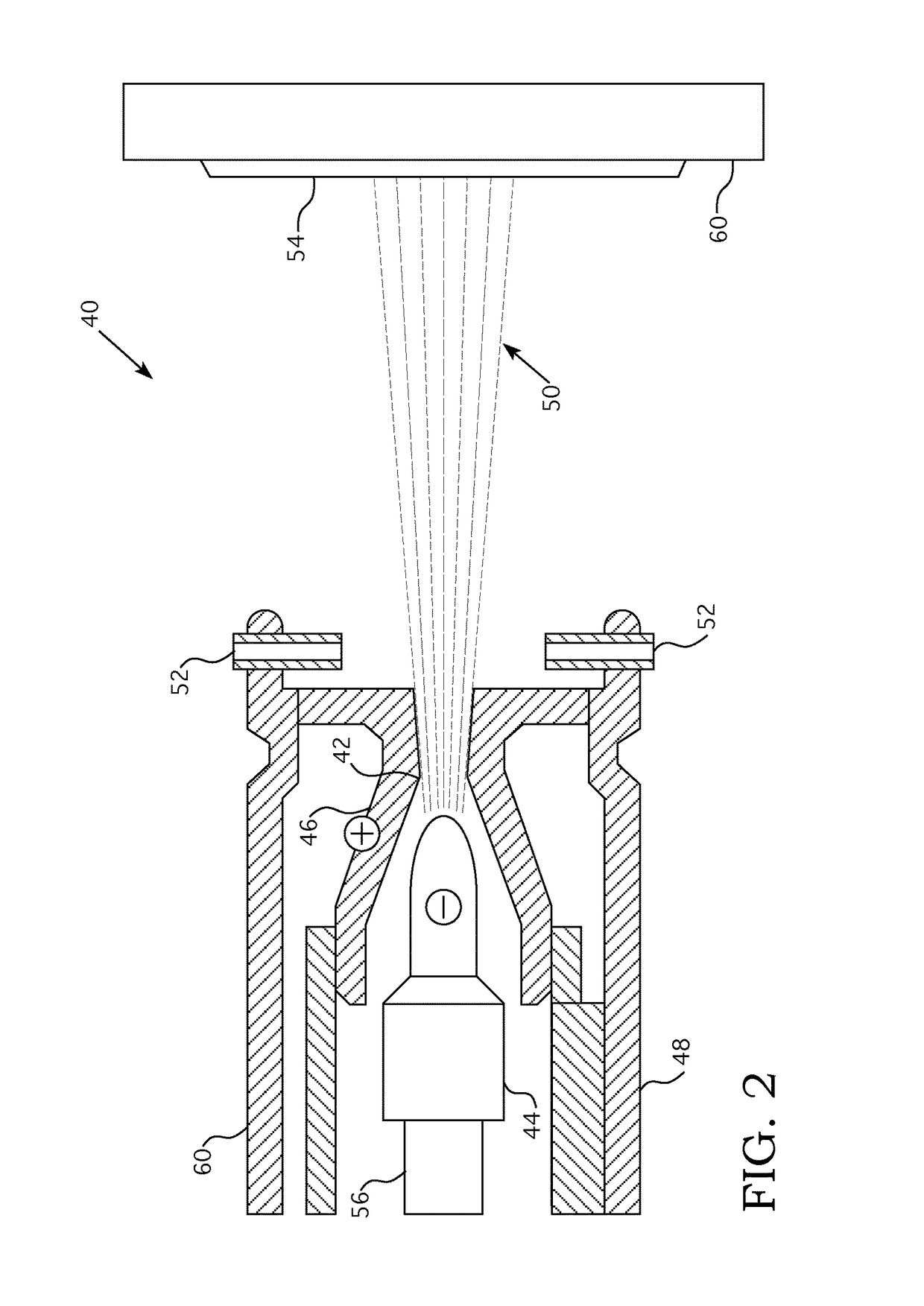

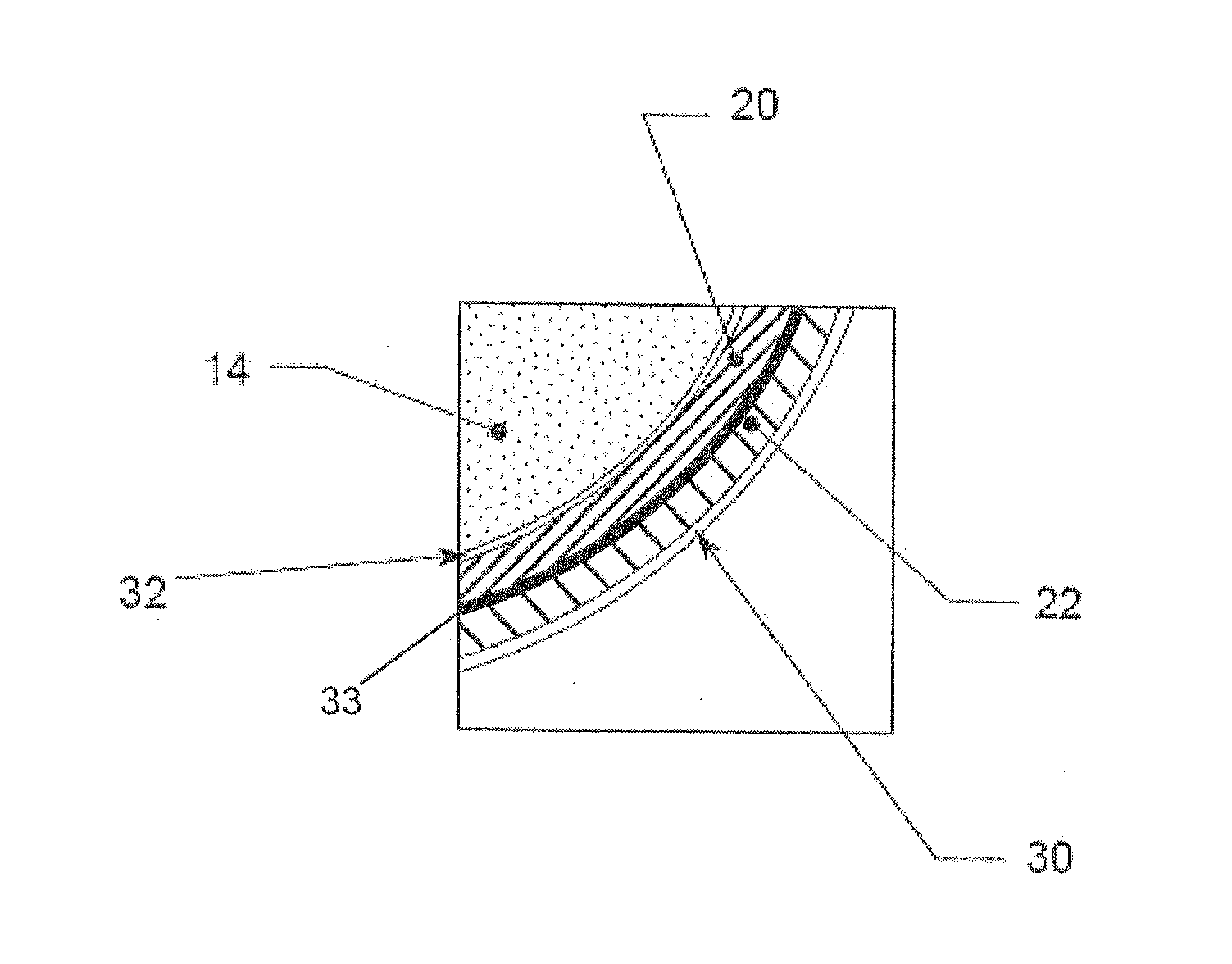

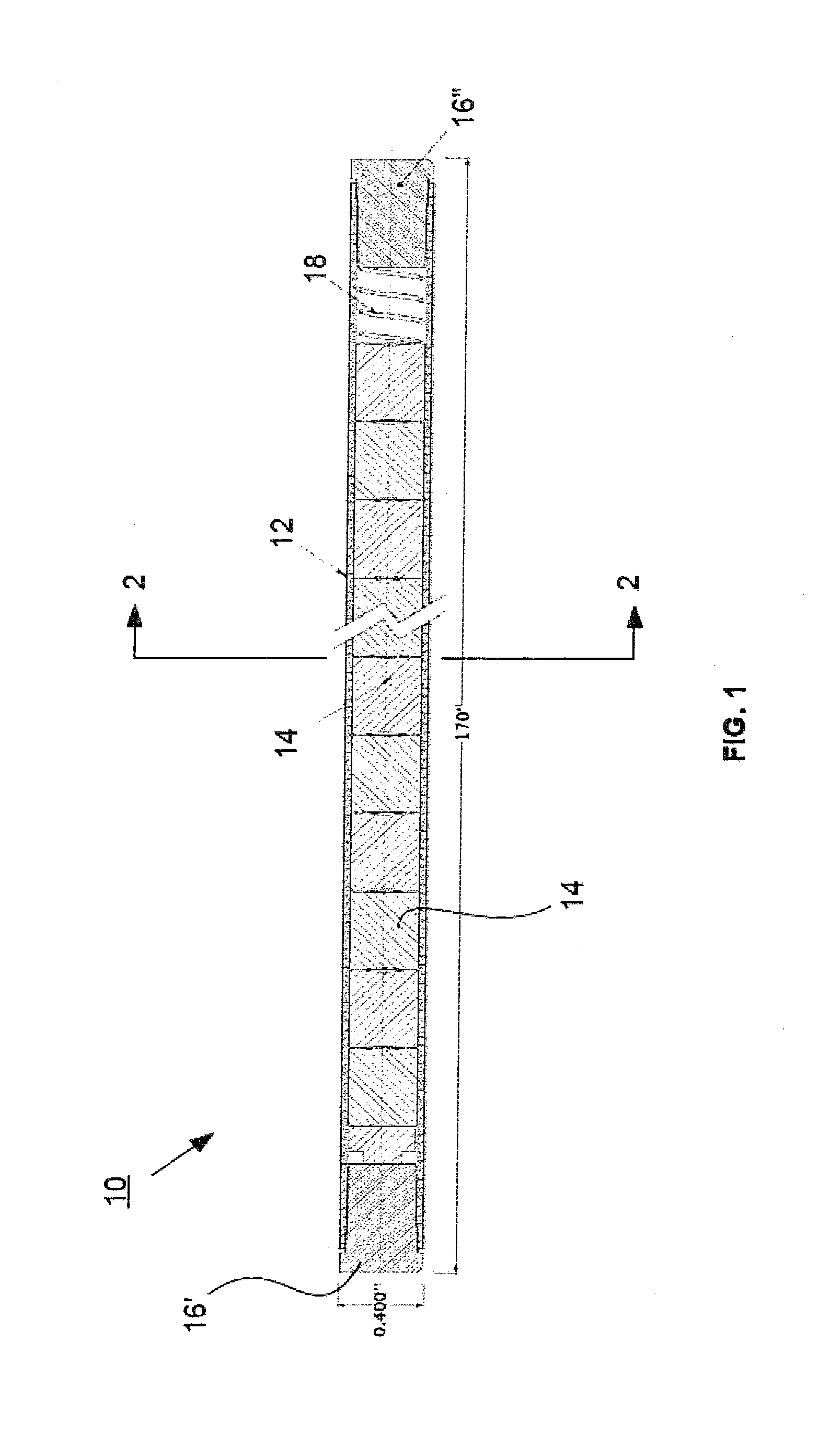

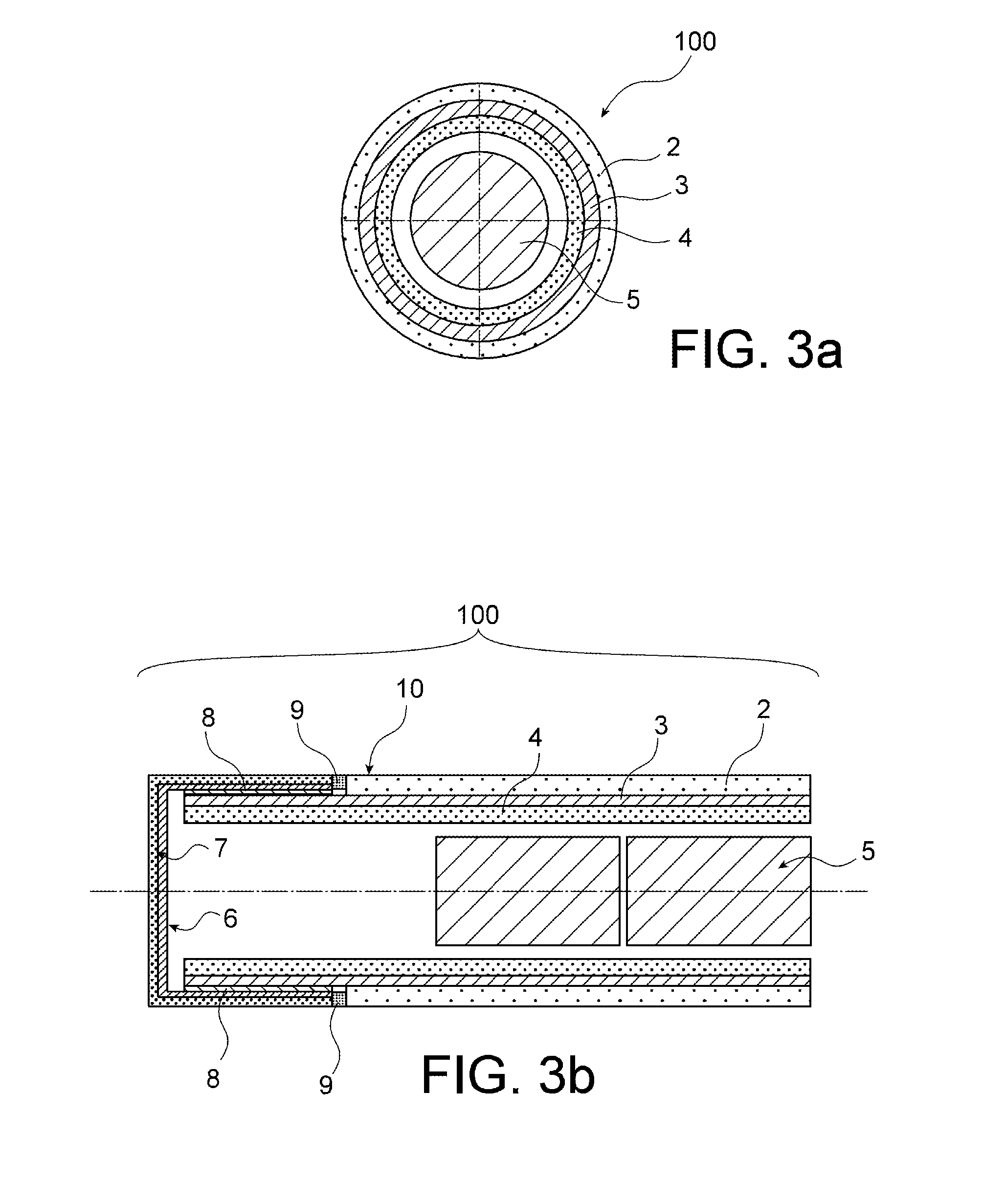

Sic matrix fuel cladding tube with spark plasma sintered end plugs

ActiveUS20150078505A1Increase temperatureResilient to flex and fractureFuel elementsNuclear energy generationCeramic compositeNuclear reactor

A method of providing an end-capped tubular ceramic composite for containing nuclear fuel (34) in a nuclear reactor involves the steps of providing a tubular ceramic composite (40), providing at least one end plug (14, 46, 48), applying (42) the at least one end plug material to the ends of the tubular ceramic composite, applying electrodes to the end plug and tubular ceramic composite and applying current in a plasma sintering means (10, 50) to provide a hermetically sealed tube (52). The invention also provides a sealed tube made by this method.

Owner:WESTINGHOUSE ELECTRIC CORP +1

Spray methods for coating nuclear fuel rods to add corrosion resistant barrier

InactiveUS20180025794A1Increase entropyPrevent and to mitigate diffusionMolten spray coatingOptical rangefindersHigh entropy alloysZirconium alloy

A method is described herein for coating the substrate of a component for use in a water cooled nuclear reactor to provide a barrier against corrosion. The method includes providing a zirconium alloy substrate; and coating the substrate with particles selected from the group consisting of metal oxides, metal nitrides, FeCrAl, FeCrAlY, and high entropy alloys. Depending on the metal alloy chosen for the coating material, a cold spray or a plasma arc spray process may be employed for depositing various particles onto the substrate. An interlayer of a different material, such as a Mo, Nb, Ta, or W transition metal or a high entropy alloy, may be positioned in between the Zr-alloy substrate and corrosion barrier layer.

Owner:WESTINGHOUSE ELECTRIC CORP +1

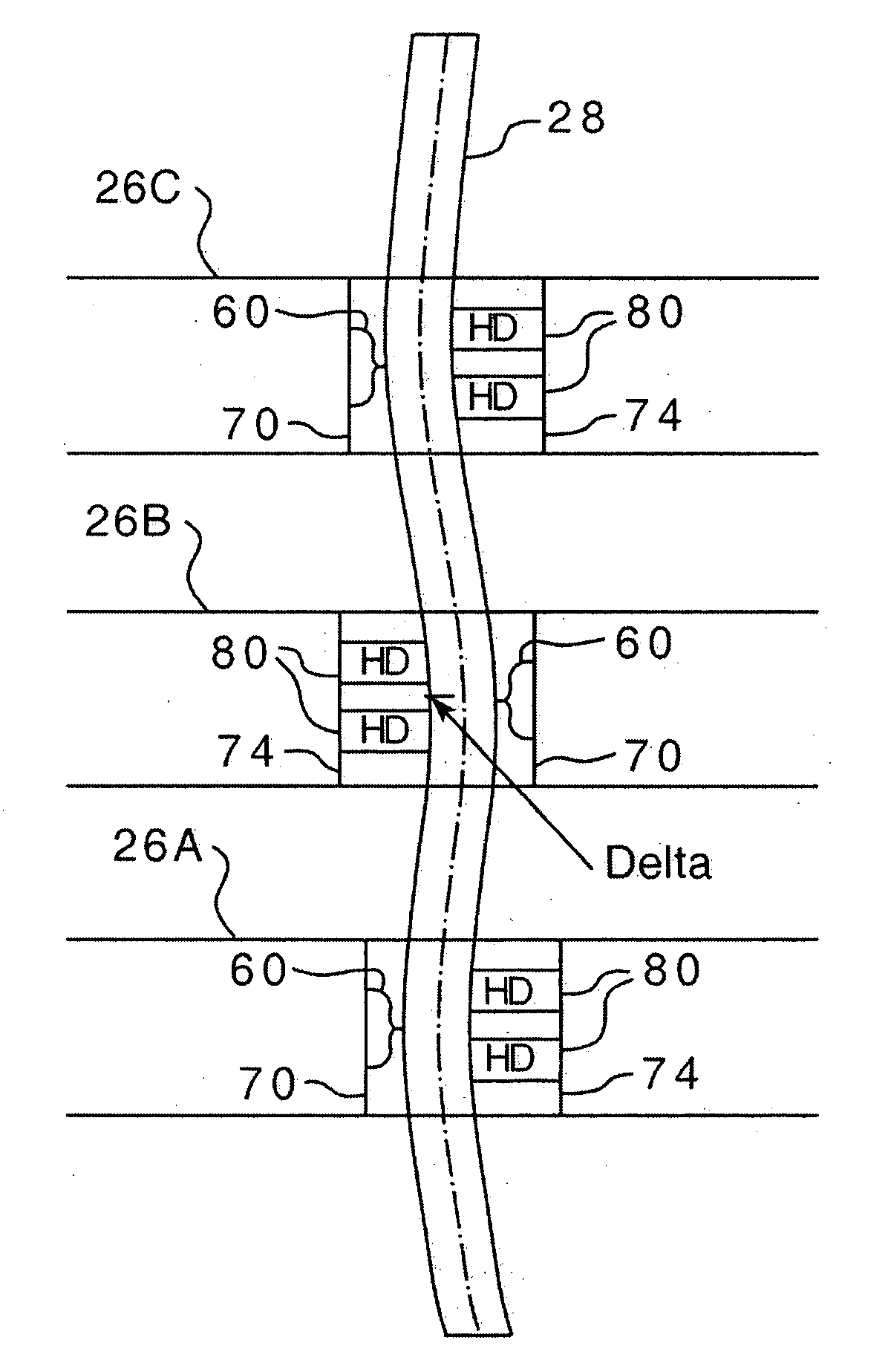

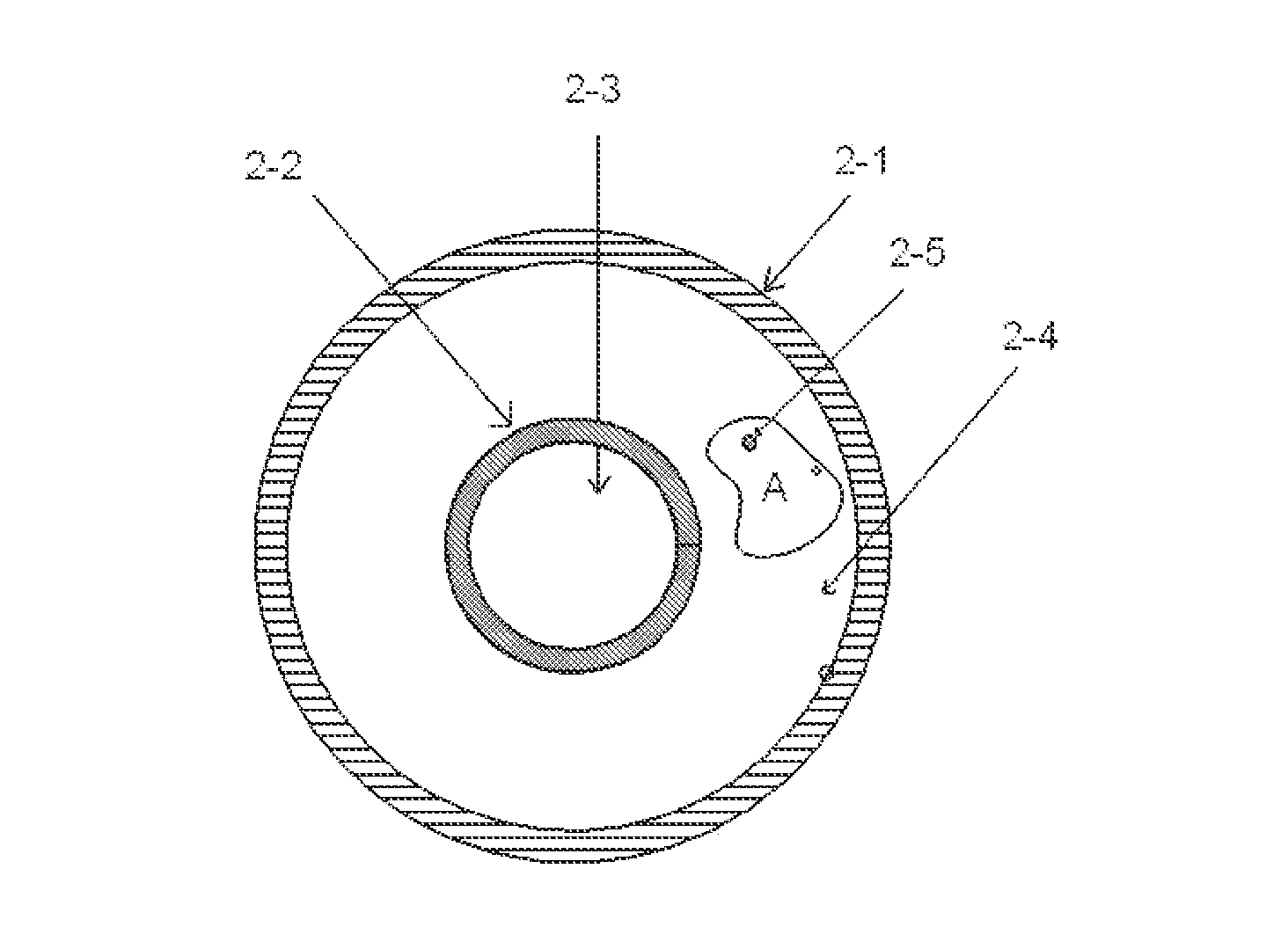

Eccentric support grid for nuclear fuel assembly

InactiveUS20060222140A1Reduce stressReduce stepsNuclear energy generationFuel element assembliesNuclear reactorEngineering

In a nuclear reactor fuel assembly structured to support at least one non-linear fuel rod, the nuclear reactor fuel assembly includes at least two support grids, a first support grid and a second support grid structured to support at least one fuel rod in a non-linear shape. Each support grid has a plurality of generally square cells and wherein the cells on the first support grid and the second support grid are generally vertically aligned. Each cell has a first side, a second side, a third side, and a fourth side. Each cell further has protrusions extending from each the cell sides, wherein the protrusions are selected from the group including a spring, a dimple or an extended dimple. A spring is always disposed opposite of a dimple or an extended dimple. The first support grid includes at least one cell having an extended dimple extending from at least one cell side. The second support grid includes at least one cell aligned with the first support grid at least one cell having an extended dimple, wherein the second support grid cell has an extended dimple extending from a cell side other than cell side having an extended dimple on the first support grid. Thus, the extended dimples cause the fuel rod to be deformed.

Owner:WESTINGHOUSE ELECTRIC CORP

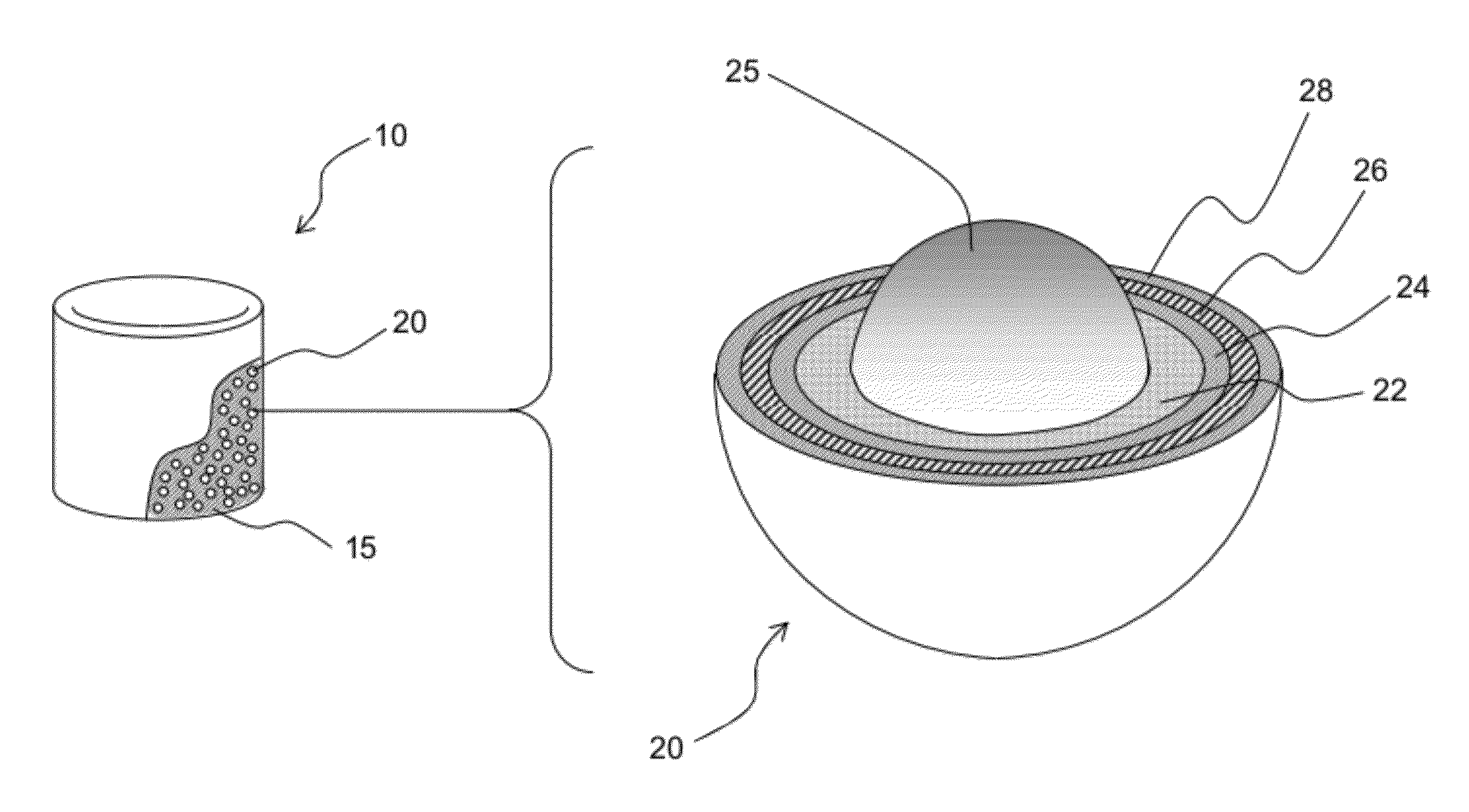

Ceramic encapsulations for nuclear materials and systems and methods of production and use

InactiveUS20130077731A1Improve heat transfer performanceFunctional safetyOptical rangefindersNuclear energy generationPorosityCeramic composite

A novel containment system for encapsulating nuclear fuel particles is disclosed. The containment system has a gas-impervious ceramic composite hollow shell having a spheroidal or ovoidal shape. The shell has a pair of longitudinally aligned round openings that are sealed with a gas-impervious ceramic composite tube to define a cavity between the shell inner surface and the tube outer surface. A ceramic composite matrix containing the nuclear fuel particles is enclosed within the cavity. The ceramic composite matrix has a controlled porosity, and can contain moderators or neutron absorbing material. The tube and shell are composed of a ceramic matrix composite material composed of ceramic reinforcement material that is bound together by a polymer-derived ceramic material.

Owner:TORXX GROUP

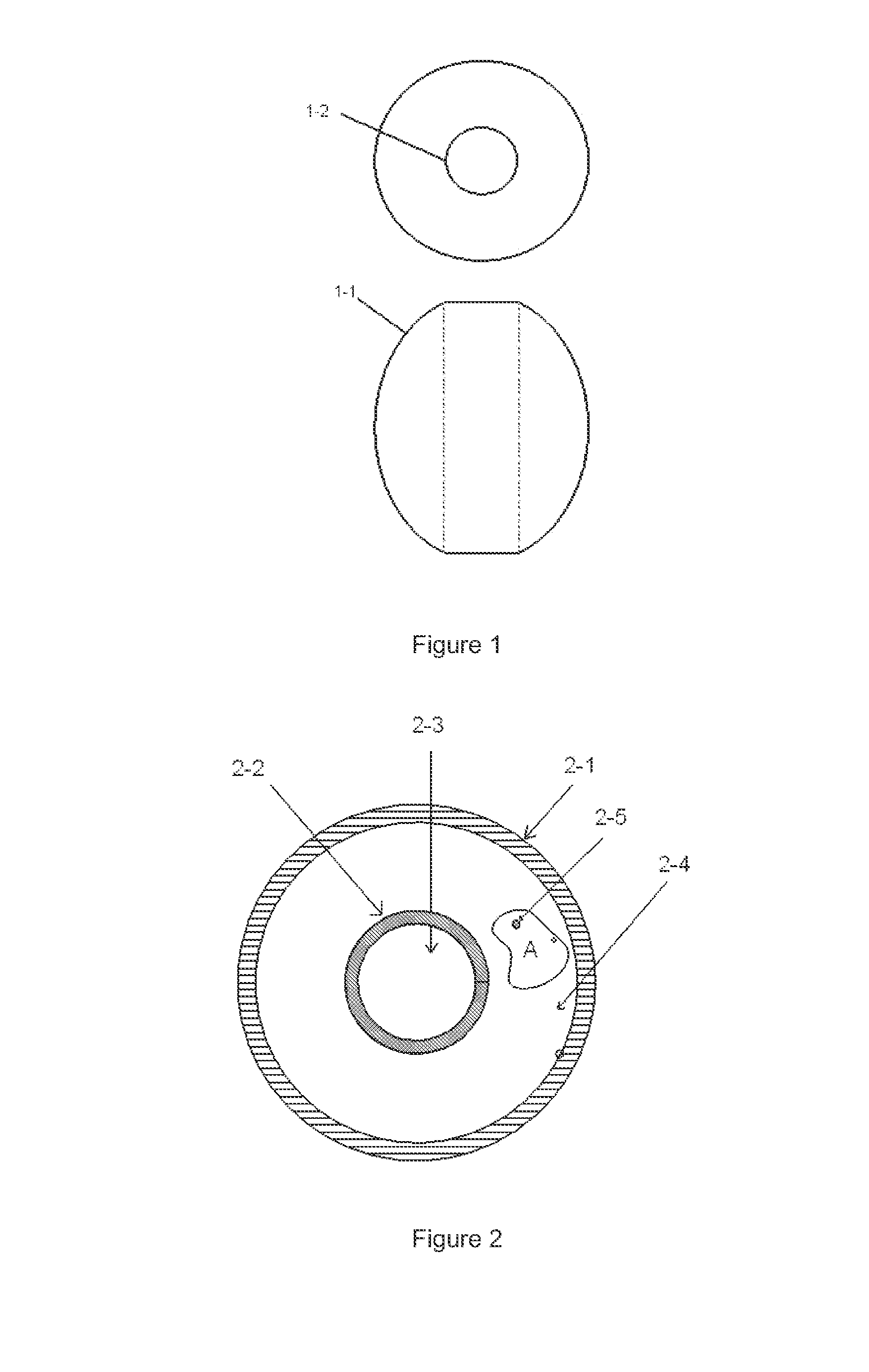

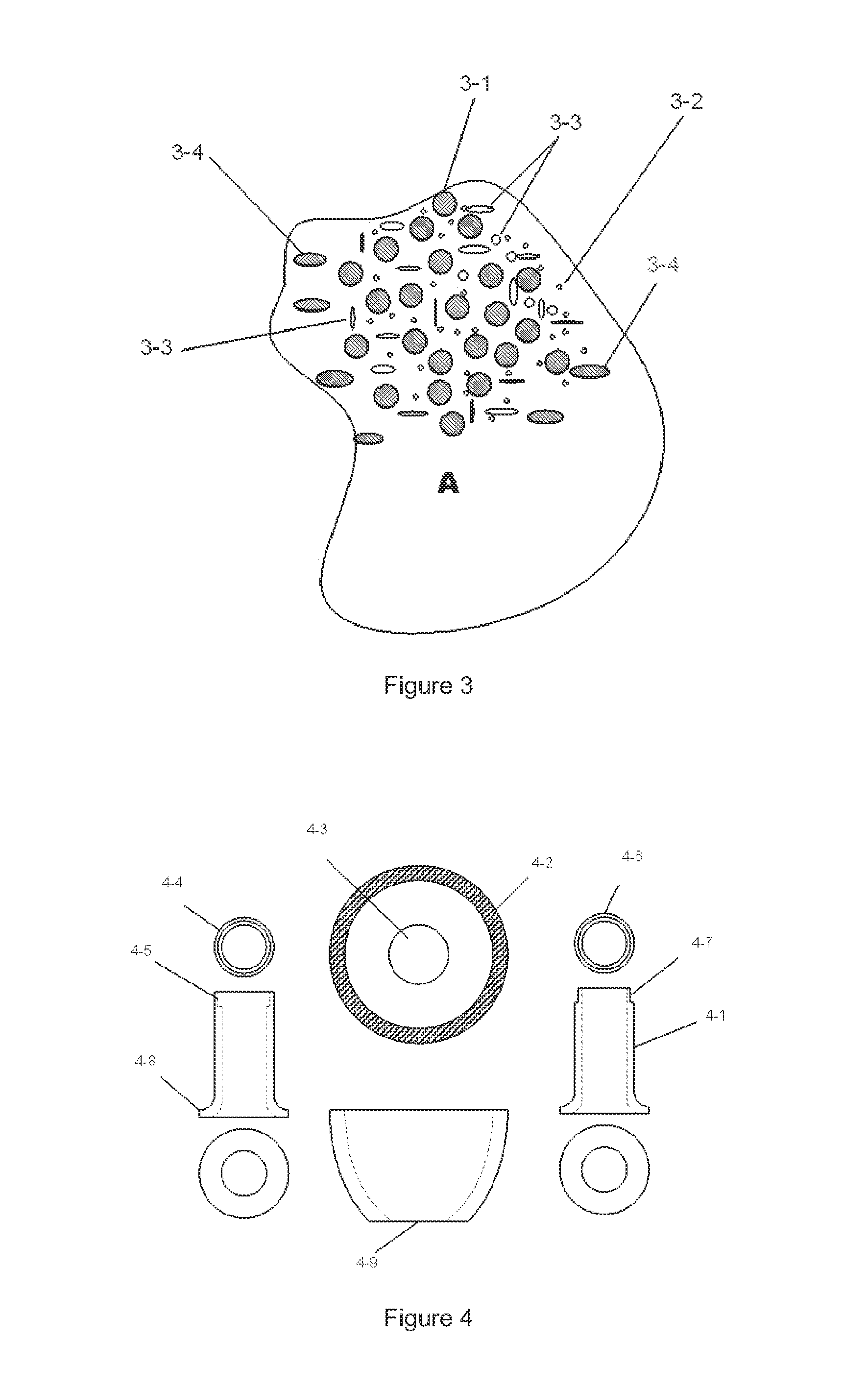

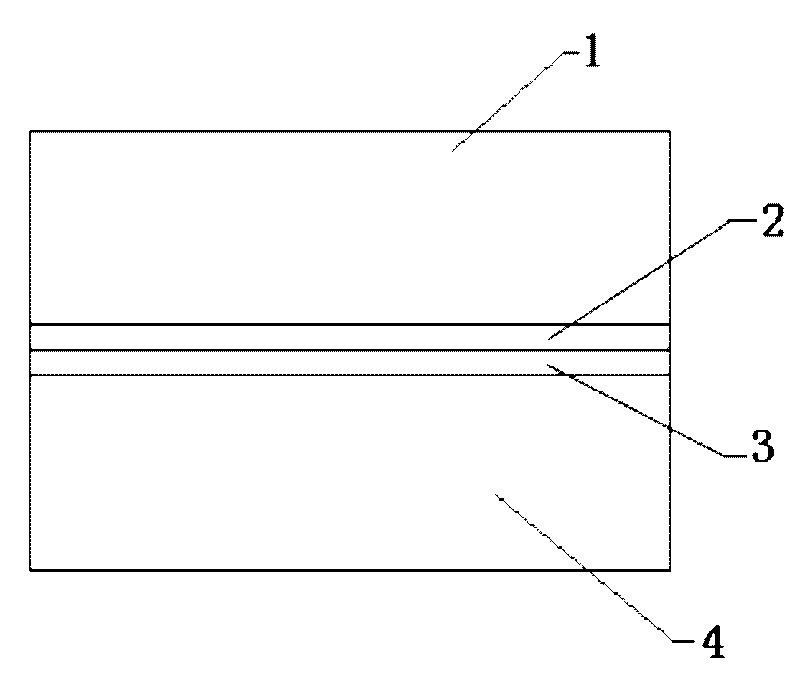

Method for preparing metal reinforced uranium dioxide nuclear fuel pellet

ActiveCN107256726ALow densityHigh strengthNuclear energy generationReactor fuel susbtancesMicro cellTwo step

The invention discloses a method for preparing metal reinforced uranium dioxide nuclear fuel pellets. The method mainly comprises two steps: firstly, preparing core-shell structure granules, namely performing low-temperature rapid pre-sintering on UO2 powder by using a Spark Plasma Sintering SPS technique, pelletizing, balling to obtain UO2 pellets, performing physical mixing on the UO2 pellets with metal (one of Mo, Cr, W and the like) micro powder to coat surfaces of the UO2 pellets by the metal micro powder, thereby obtaining metal coated uranium dioxide core-shell structure granules; secondly, preparing a nuclear fuel pellets, namely performing high-temperature liquidation on the metal powder on the surfaces of the UO2 pellets, thereby forming a micro cell structure continuous phase similar to a cytomembrane structure around the UO2 pellets, and obtaining the special metal reinforced UO2 nuclear fuel pellets with a UO2 substrate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

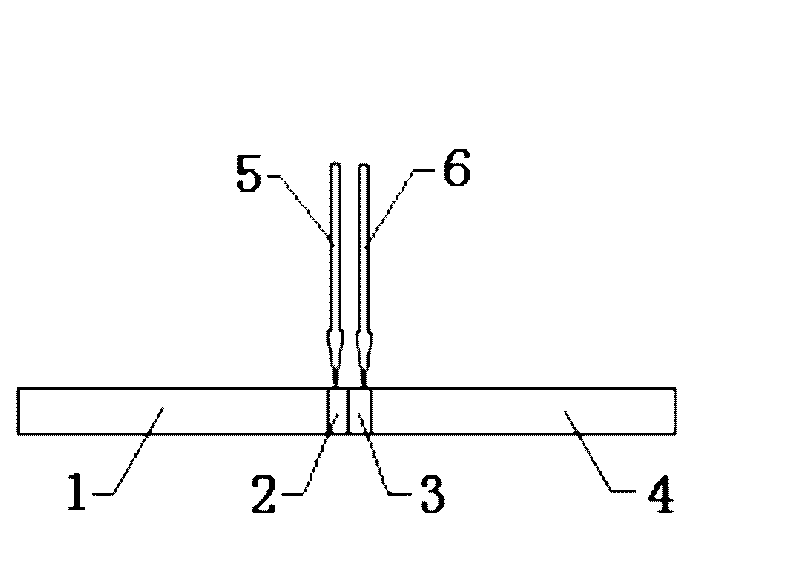

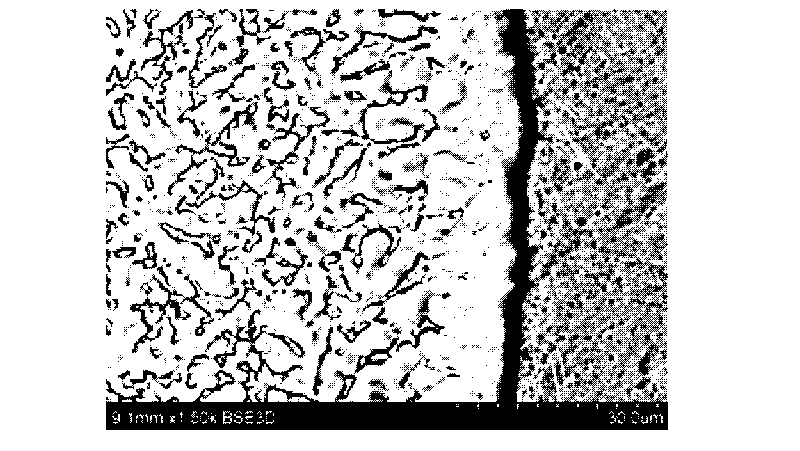

Method for controlling brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers

InactiveCN101722356AElectron beam welding apparatusWelding/soldering/cutting articlesAcid washingTitanium alloy

The invention relates to a method for controlling the brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers, belonging to the welding field of heterogeneous difficult-welding metal. The invention solves the problem that the tradition metal and stainless steel welding method can not avoid the generation of the brittle phases. The method comprises the following steps of: using pure copper and pure vanadium as the intermediate layers to form members to be welded, wherein the members to be welded consist of stainless steel, pure copper, pure vanadium and titanium, ultrasonically cleaning the members to be welded by acetone, drying the members to be welded after acid washing and water washing, and then performing secondary electronic beam welding in vacuum. The joints obtained by the method have no brittle phases, the tensile strength of the joints is greater than 299 MPa, and the yield strength is greater than 260 MPa. The method is suitable for manufacturing thrust chamber bodies of aircraft engines, nuclear fuel processing equipment in nuclear industry, and titanium / steel composite members and titanium alloy / steel composite members in chemical and medical equipment.

Owner:HARBIN INST OF TECH

Nuclear fuel assembly protective grid

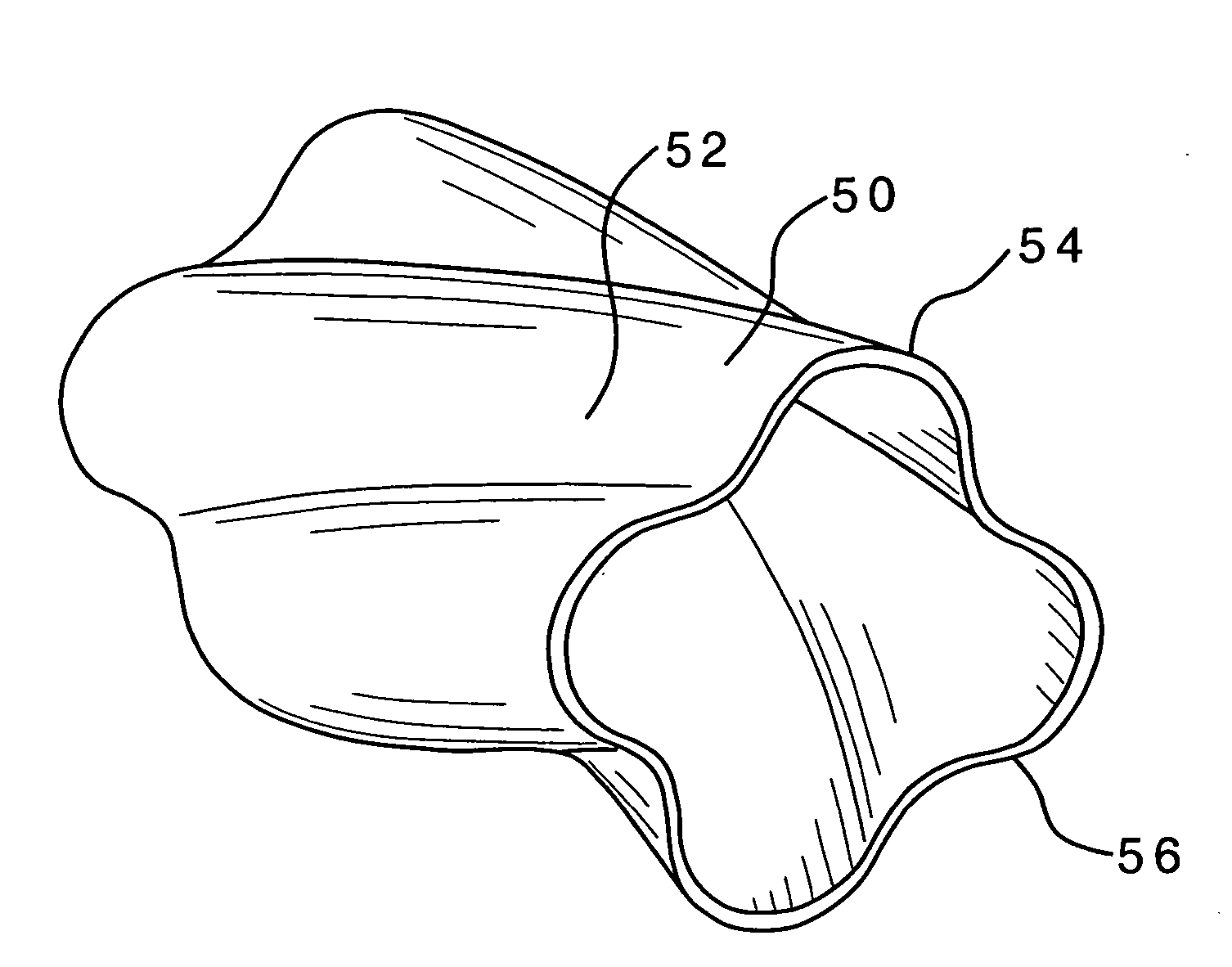

An integral multilevel debris-catching system for a nuclear reactor fuel assembly having a lower protective grid incorporating laterally offset debris-catching arches at several elevations, extended solid fuel rod bottom end plugs and a bottom debris-filtering nozzle. Dimples and opposing opposite springs and the debris-trapping arches, which are spaced from the end plugs, are all located at elevations below the fuel cladding.

Owner:WESTINGHOUSE ELECTRIC CORP

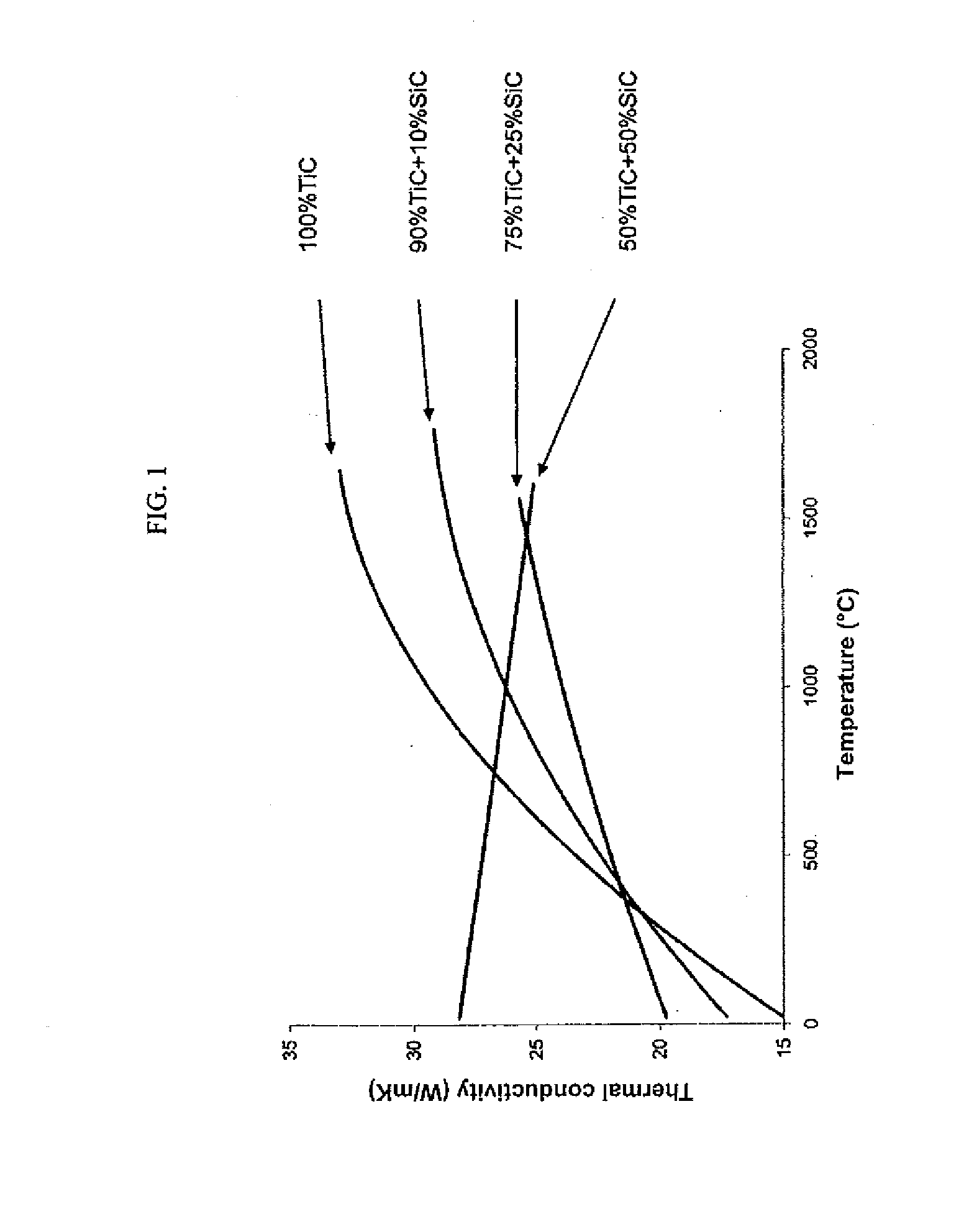

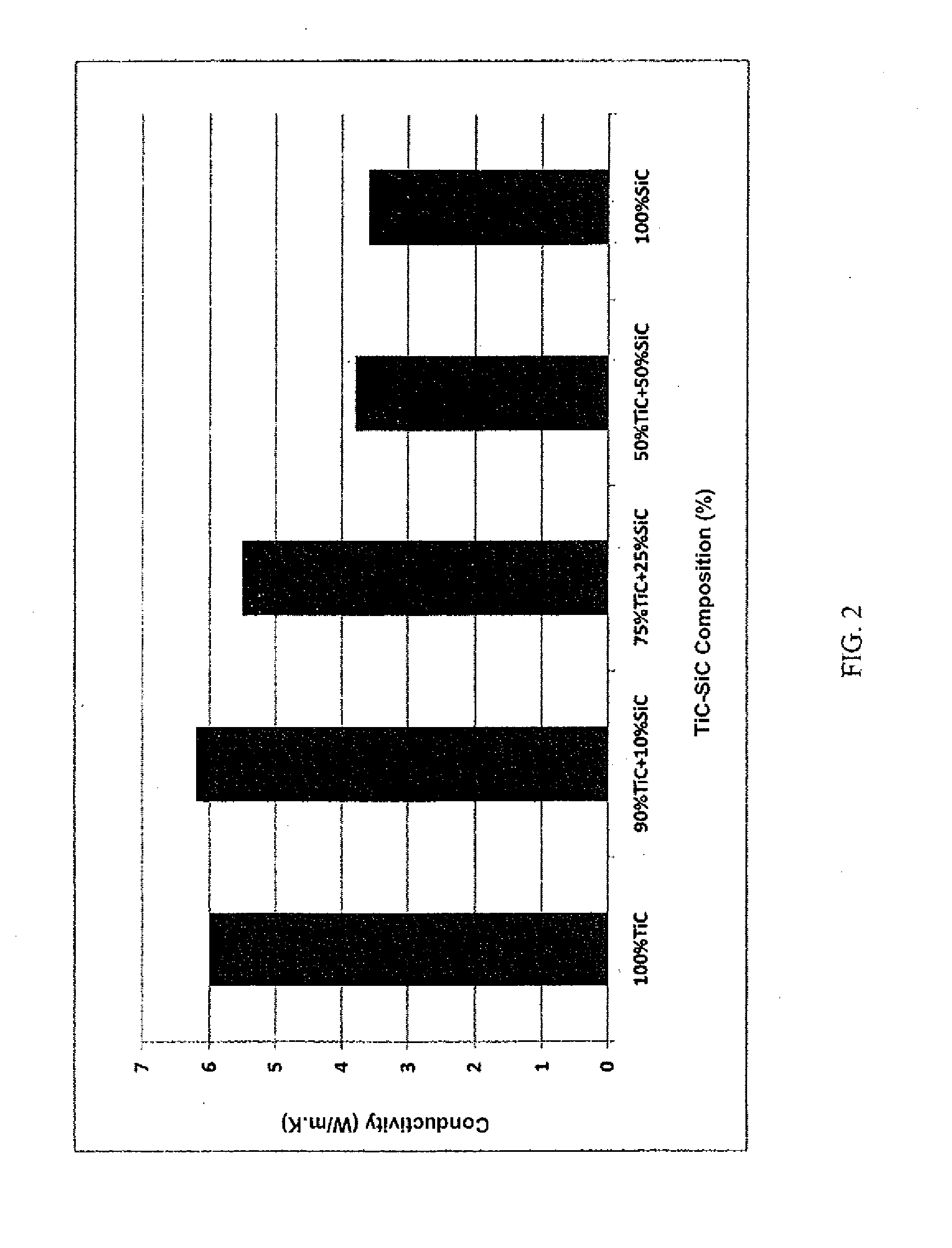

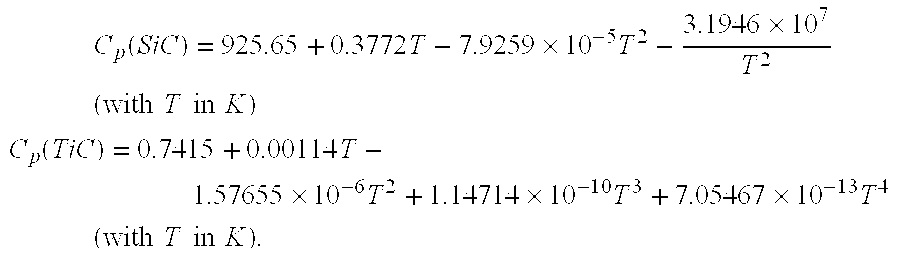

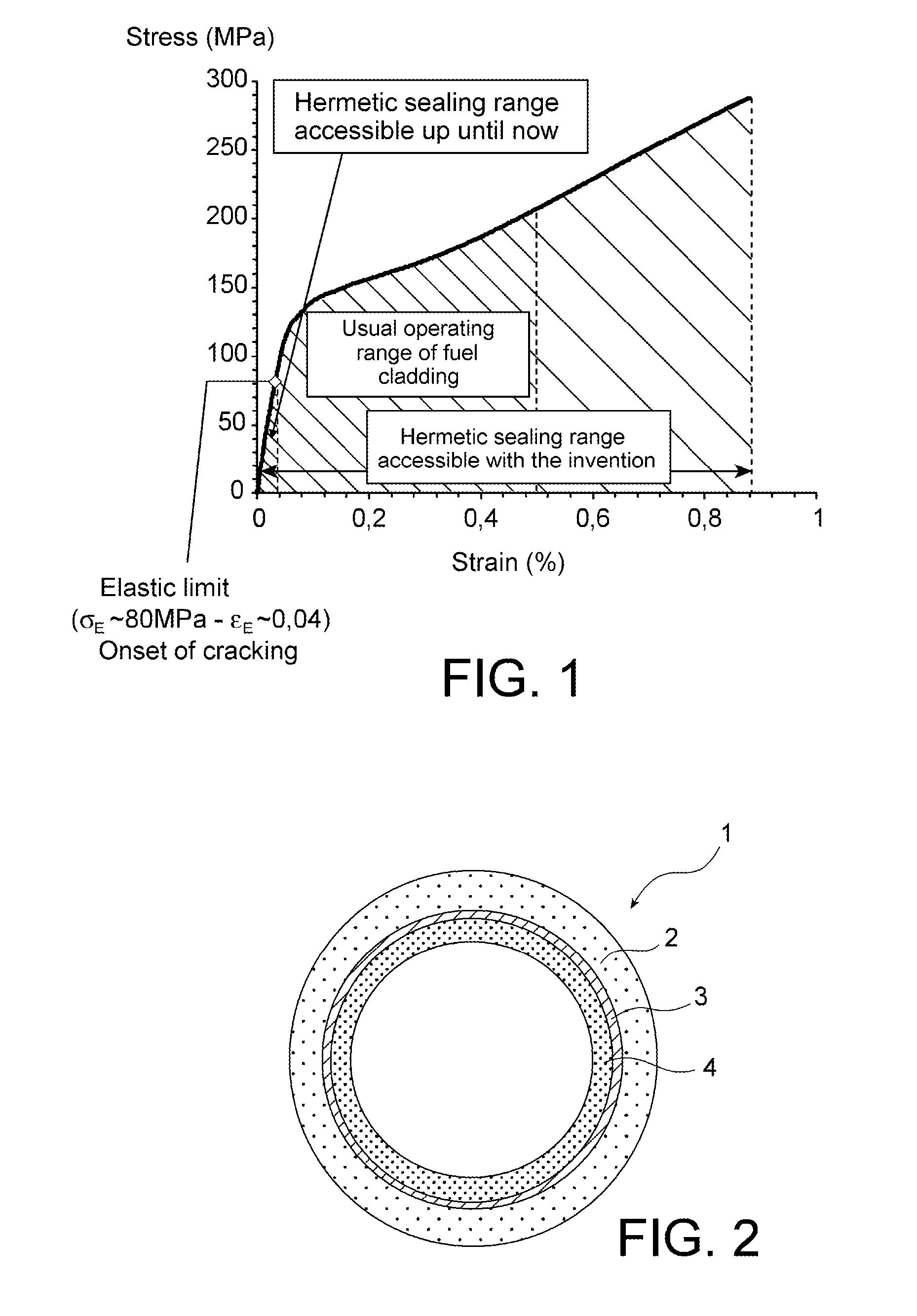

Nuclear fuel cladding with high heat conductivity and method for making same

ActiveUS20110170653A1Optimal transfer of thermal energyEasy transferFuel elementsNuclear energy generationThermal energyFiber

The invention relates to a nuclear fuel cladding totally or partially made of a composite material with a ceramic matrix containing silicon carbide (SiC) fibers as a matrix reinforcement and an interphase layer provided between said matrix and said fibers, the matrix including at least one carbide selected from titanium carbide (TiC), zirconium carbide (ZrC), or ternary titanium silicon carbide (Ti3SiC2).When irradiated and at temperatures of between 800° C. and 1200° C., said cladding can mechanically maintain the nuclear fuel within the cladding while enabling optimal thermal-energy transfer towards the coolant.The invention also relates to a method for making the nuclear fuel cladding.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Silicon carbide multilayered cladding and nuclear reactor fuel element for use in water-cooled nuclear power reactors

InactiveUS20160049211A1Reduce corrosionOptical rangefindersNuclear energy generationCarbide siliconNuclear reactor

A nuclear fuel element for use in water-cooled nuclear power reactors and an improved multilayered silicon carbide tube for use in water-cooled nuclear power reactors and other high temperature, high strength thermal tubing applications including solar energy collectors. The fuel element includes a multilayered silicon carbide cladding tube. The multilayered silicon carbide cladding tube includes (i) an inner layer; (ii) a central layer; and (iii) a crack propagation prevention layer between the inner layer and the central layer. A stack of individual fissionable fuel pellets may be located within the cladding tube. In addition, a thermally conductive layer may be deposited within the cladding tube between the inner layer of the cladding tube and the stack of fuel pellets. The multilayered silicon carbide cladding tube may also be adapted for other high temperature, high strength thermal tubing applications including solar energy collectors.

Owner:CERAMIC TUBULAR PRODS

High -throughput electrorefiner for recovery of u and u/tru product from spent fuel

ActiveUS20110180409A1Improve throughputEliminate useElectrolysis componentsPhotography auxillary processesElectrolysisPotential difference

The present invention provides a method of simultaneously removing uranium and transuranics from metallic nuclear fuel in an electrorefiner. In the method, a potential difference is established between the anode basket and solid cathode of the electrorefiner, thereby creating a diffusion layer of uranium and transuranic ions at the solid cathode, a first current density at the anode basket, and a second current density at the solid cathode. The ratio of anode basket area to solid cathode area that is selected based on the total concentration of uranium and transuranic metals in a molten halide electrolyte in the refiner and the effective thickness of the diffusion layer at the solid cathode, such that the established first and second current densities result in both codeposition of uranium and transuranic metals on the solid cathode and oxidation of the metallic nuclear fuel in the anode basket. Deposited material on the solid cathode is removed, and the first current density at the anode basket is maintained to prevent substantial oxidation of the anode basket during operation of the electrorefiner.

Owner:UCHICAGO ARGONNE LLC

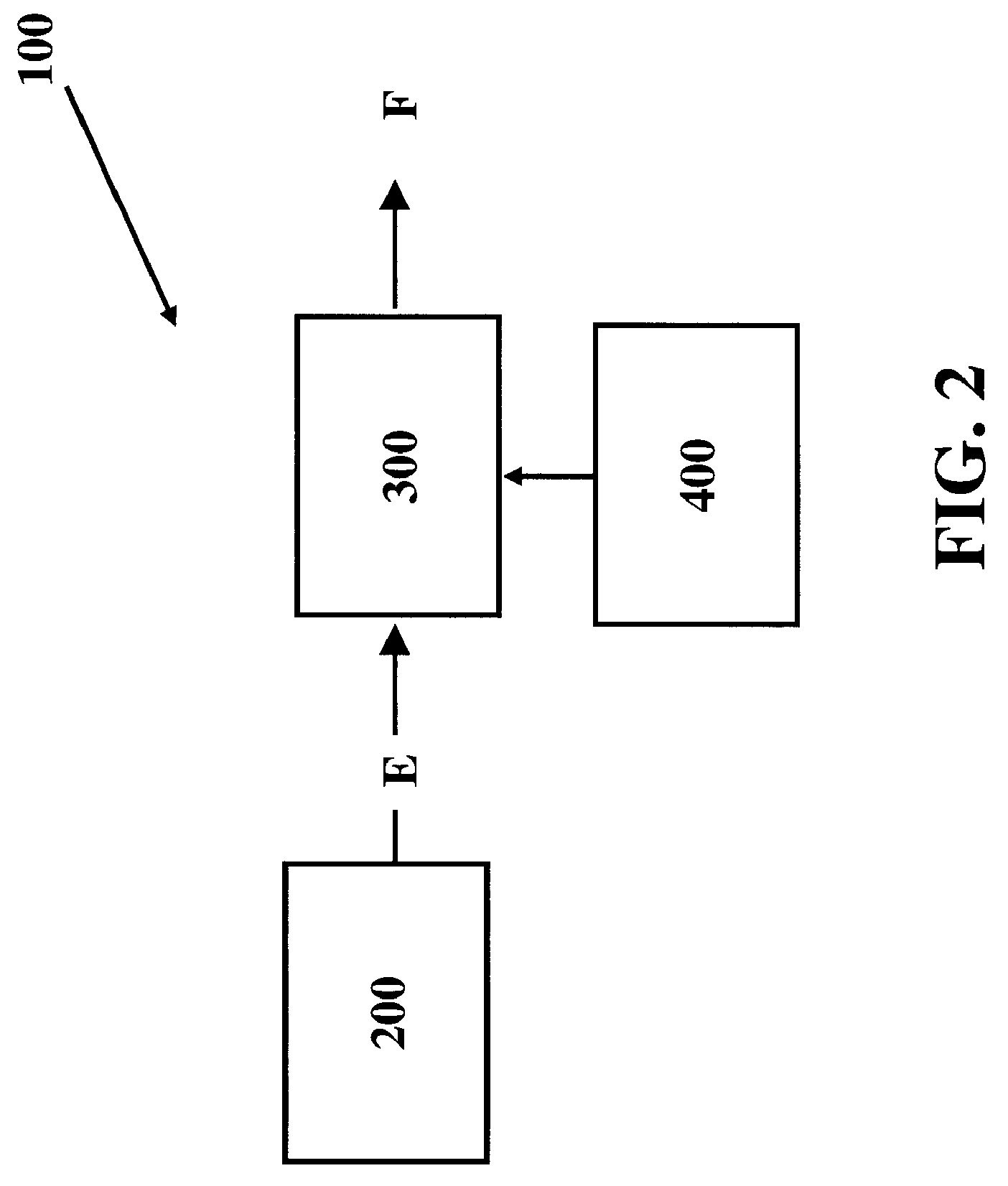

Systems, methods, and compositions for production of synthetic hydrocarbon compounds

InactiveUS7642292B2Efficient processingReduce energy lossElectrolysis componentsLiquid hydrocarbon mixture productionKeroseneJet fuel

A process and system for producing hydrocarbon compounds or fuels that recycle products of hydrocarbon compound combustion—carbon dioxide or carbon monoxide, or both, and water. The energy for recycling is electricity derived from preferably not fossil based fuels, like from nuclear fuels or from renewable energy. The process comprises electrolyzing water, and then using hydrogen to reduce externally supplied carbon dioxide to carbon monoxide, then using so produced carbon monoxide together with any externally supplied carbon monoxide and hydrogen in Fischer-Tropsch reactors, with upstream upgrading to desired specification fuels—for example, gasoline, jet fuel, kerosene, diesel fuel, and others. Energy released in some of these processes is used by other processes. Using adiabatic temperature changes and isothermal pressure changes for gas processing and separation, large amounts of required energy are internally recycled using electric and heat distribution lines. Phase conversion of working fluid is used in heat distribution lines for increased energy efficiency. The resulting use of electric energy is less than 1.4 times the amount of the high heating value of combustion of so produced hydrocarbon compounds when carbon dioxide is converted to carbon monoxide in the invention, and less than 0.84 when carbon monoxide is the source.

Owner:FUELCOR LLC

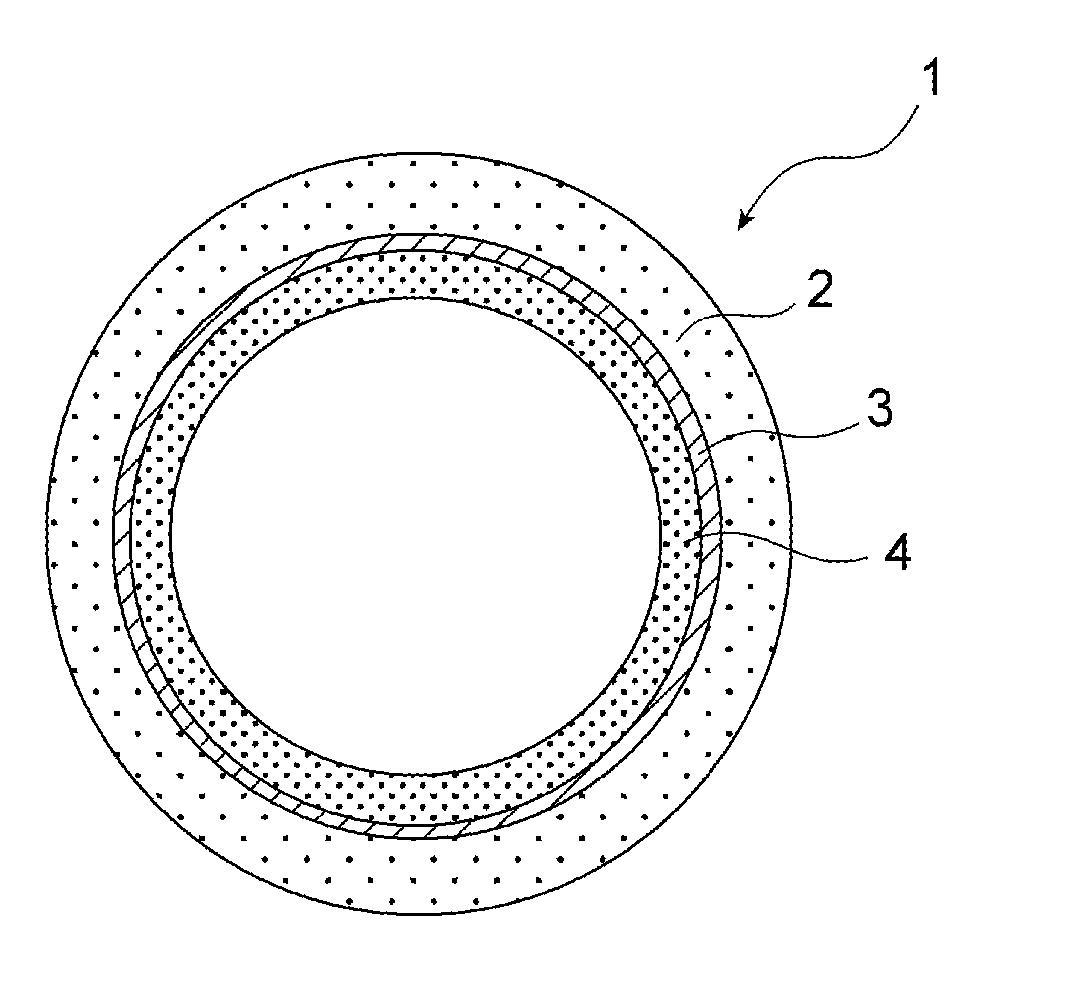

Multilayer tube in ceramic matrix composite material, resulting nuclear fuel cladding and associated manufacturing processes

ActiveUS20140153688A1Improve sealingOptical rangefindersFuel elementsMetal alloyCeramic matrix composite

The invention relates to a multilayer tubular part (1) comprising a metal layer forming a metal tubular body (3) and two layers in ceramic matrix composite material covering the metal tubular body, wherein one of the two layers in ceramic matrix composite material covers the inner surface of the metal tubular body to form an inner tubular body (4), whilst the other of the two layers in ceramic matrix composite material covers the outer surface of the metal tubular body to form an outer tubular body (2), the metal tubular body therefore being sandwiched between the inner and outer tubular bodies. The metal tubular body is in metal or metal alloy. Finally, the metal tubular body has a mean thickness smaller than the mean thicknesses of the inner and outer tubular bodies. A said part is useful in particular for producing nuclear fuel claddings.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

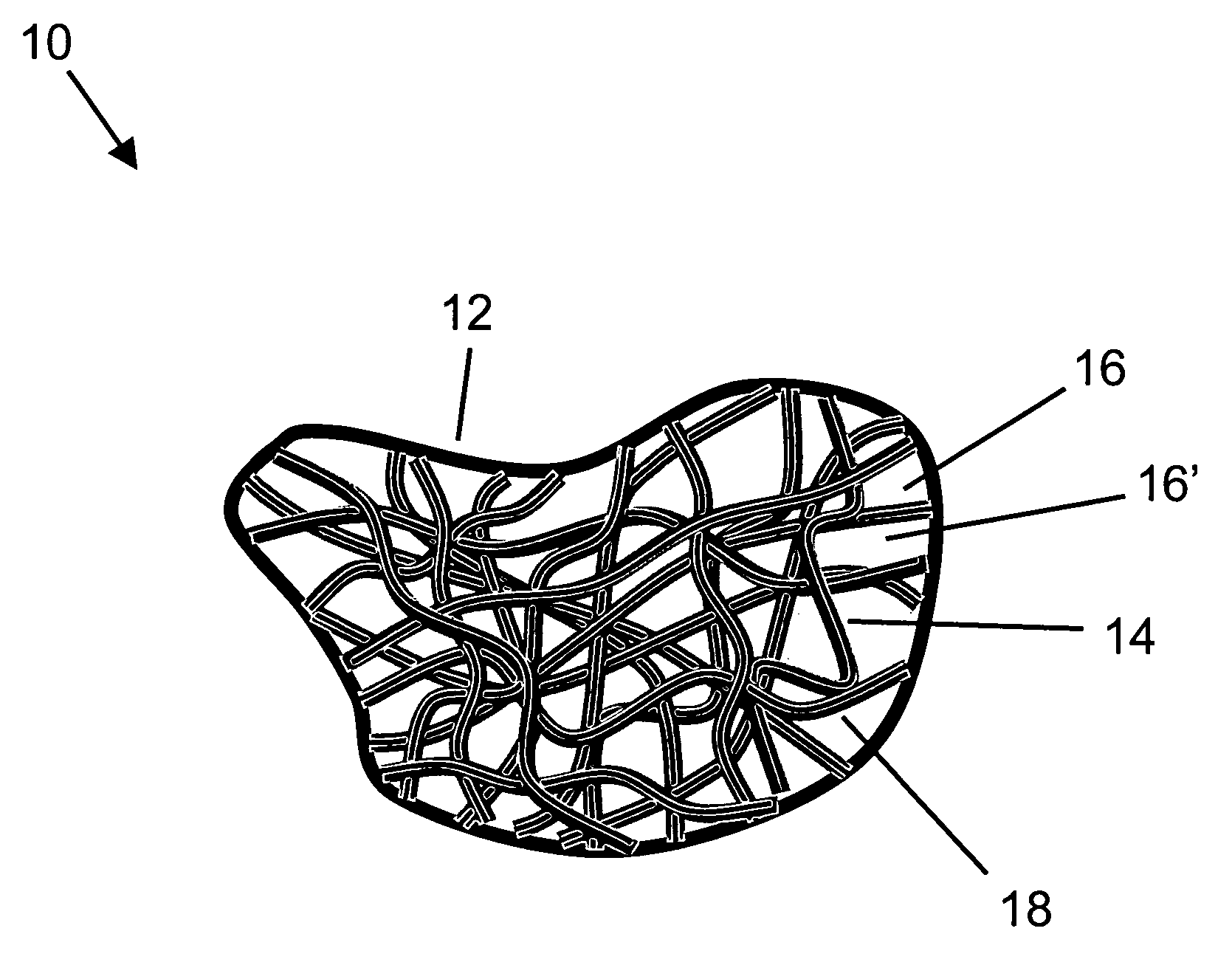

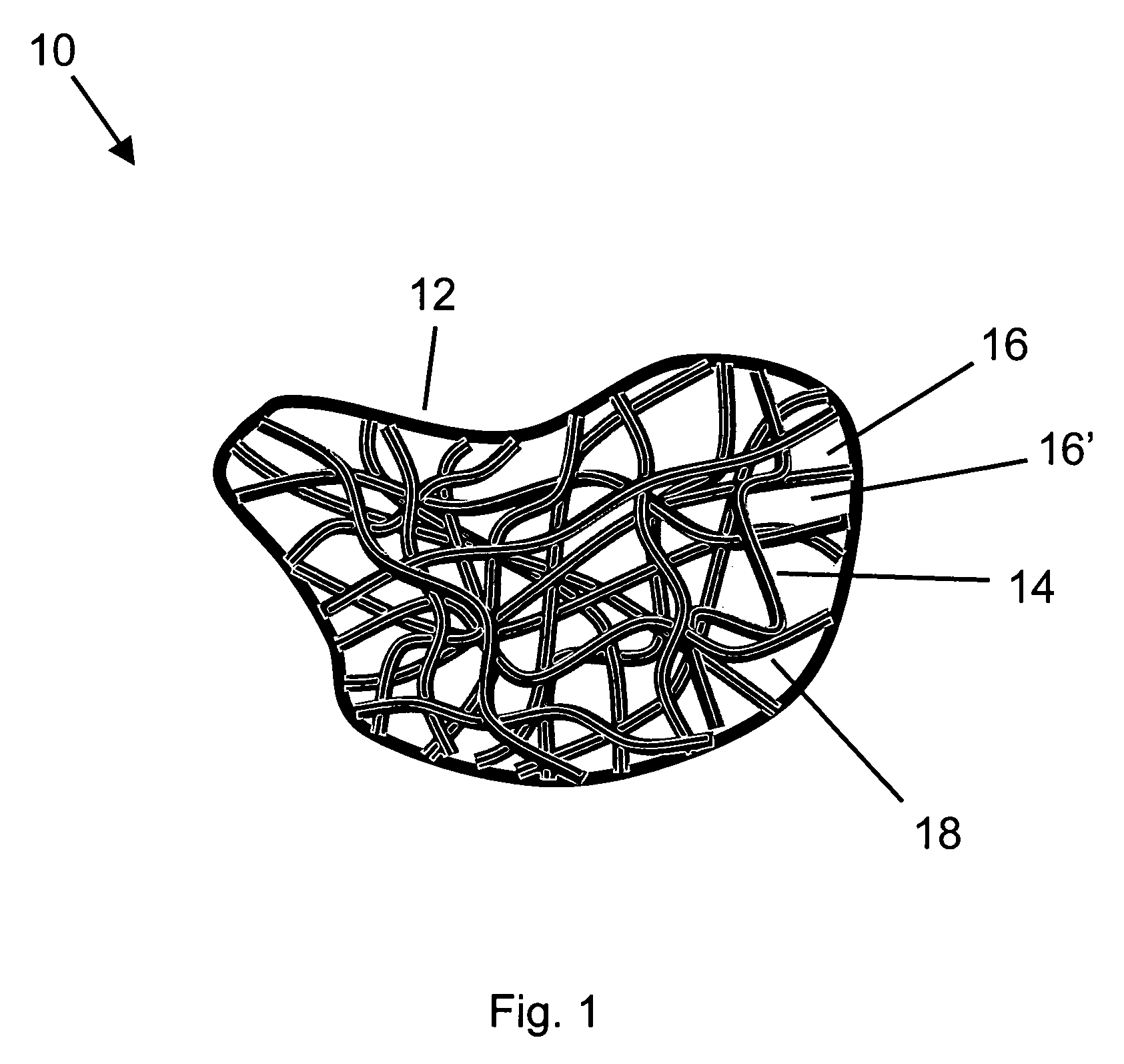

Methods for manufacturing porous nuclear fuel elements for high-temperature gas-cooled nuclear reactors

Methods for manufacturing porous nuclear fuel elements for use in advanced high temperature gas-cooled nuclear reactors (HTGR's). Advanced uranium bi-carbide, uranium tri-carbide and uranium carbonitride nuclear fuels can be used. These fuels have high melting temperatures, high thermal conductivity, and high resistance to erosion by hot hydrogen gas. Tri-carbide fuels, such as (U,Zr,Nb)C, can be fabricated using chemical vapor infiltration (CVI) to simultaneously deposit each of the three separate carbides, e.g., UC, ZrC, and NbC in a single CVI step. By using CVI, a thin coating of nuclear fuel may be deposited inside of a highly porous skeletal structure made, for example, of reticulated vitreous carbon foam.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com