Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4427 results about "Metal alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Personal fit medical implants and orthopedic surgical instruments and methods for making

InactiveUS20070118243A1Minimizing Ni toxicityImprove visualizationElectrotherapyMechanical/radiation/invasive therapiesPersonalizationManufacturing technology

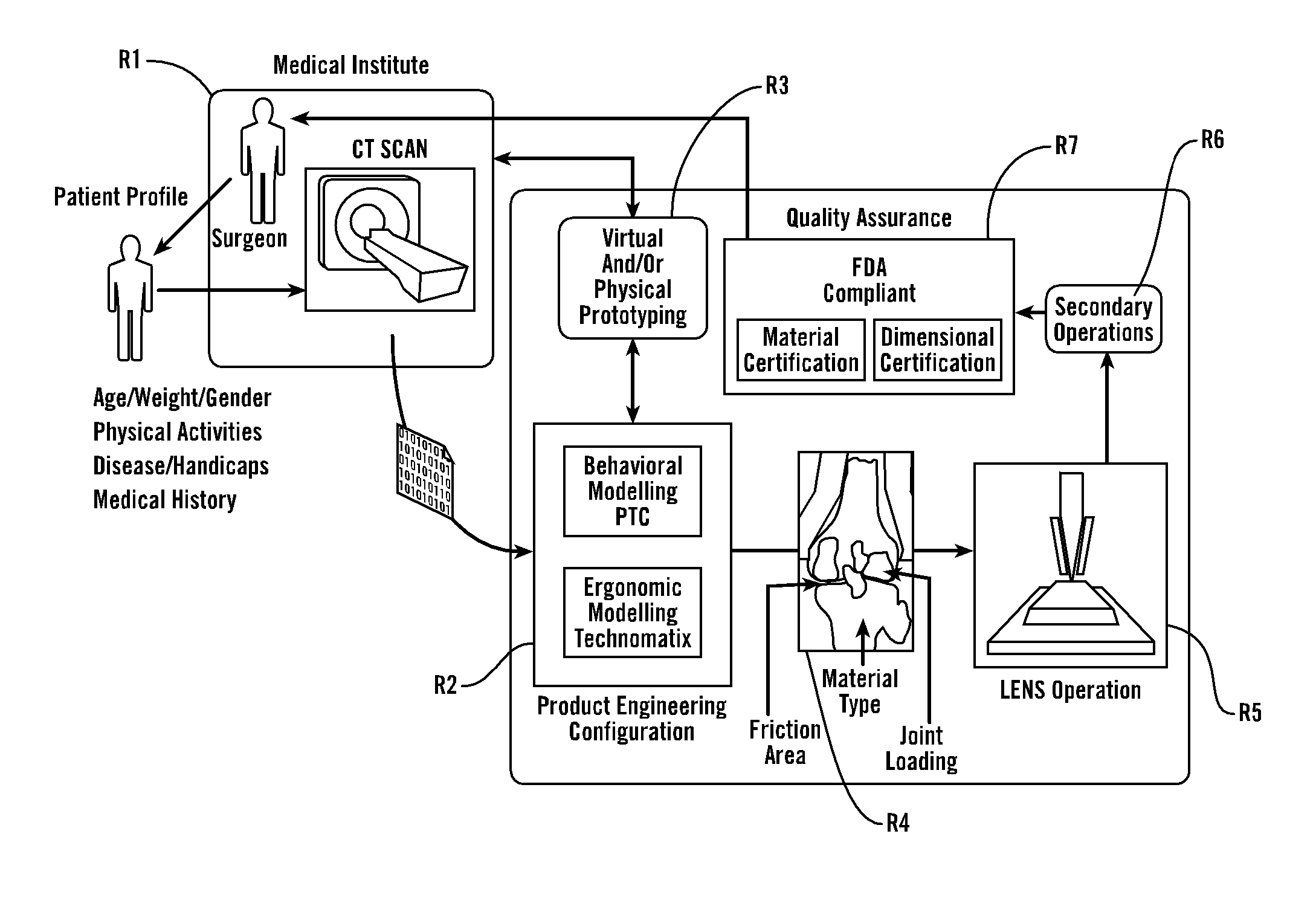

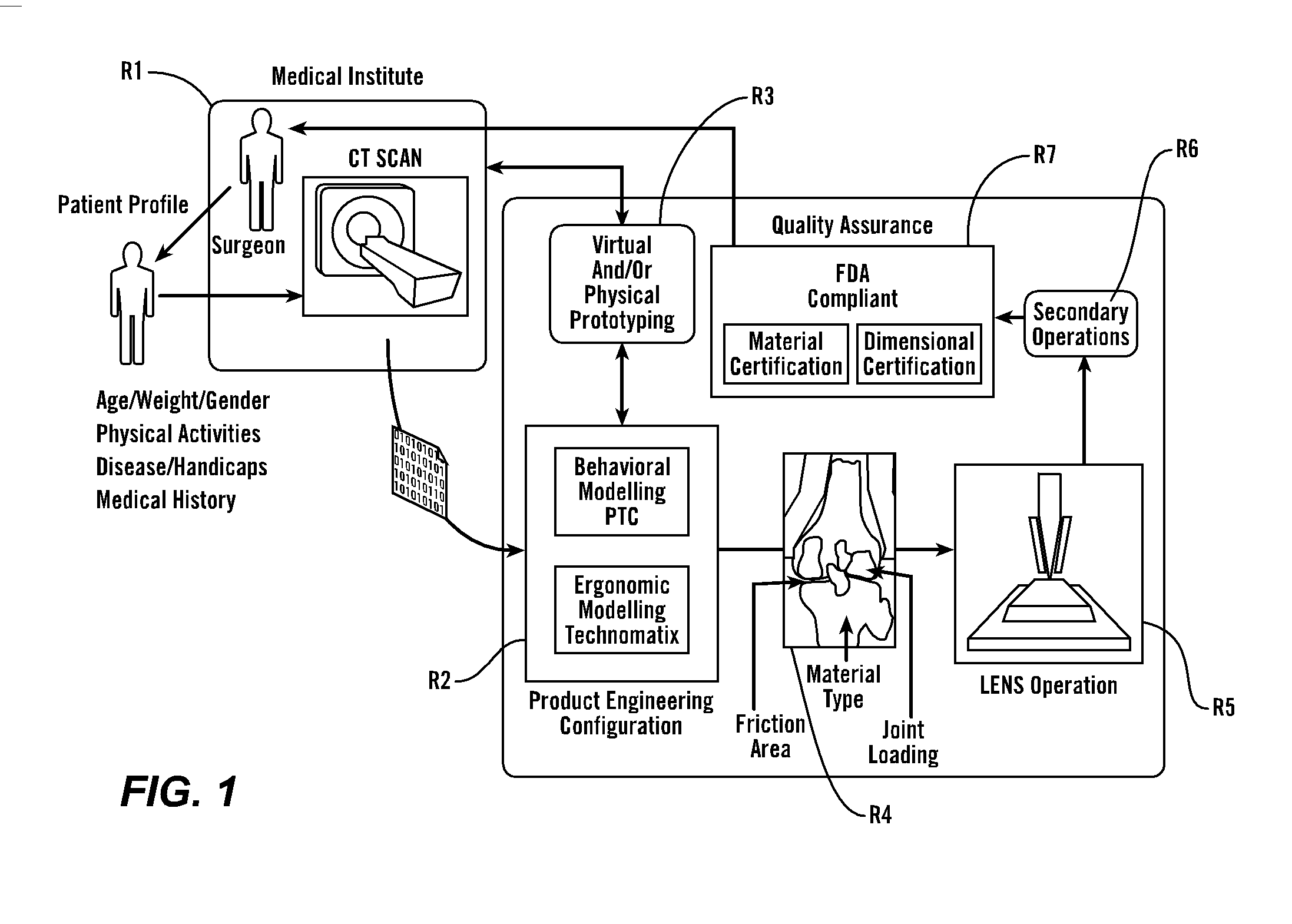

The present invention provides methods, techniques, materials and devices and uses thereof for custom-fitting biocompatible implants, prosthetics and interventional tools for use on medical and veterinary applications. The devices produced according to the invention are created using additive manufacturing techniques based on a computer generated model such that every prosthesis or interventional device is personalized for the user having the appropriate metallic alloy composition and virtual validation of functional design for each use.

Owner:VANTUS TECH CORP

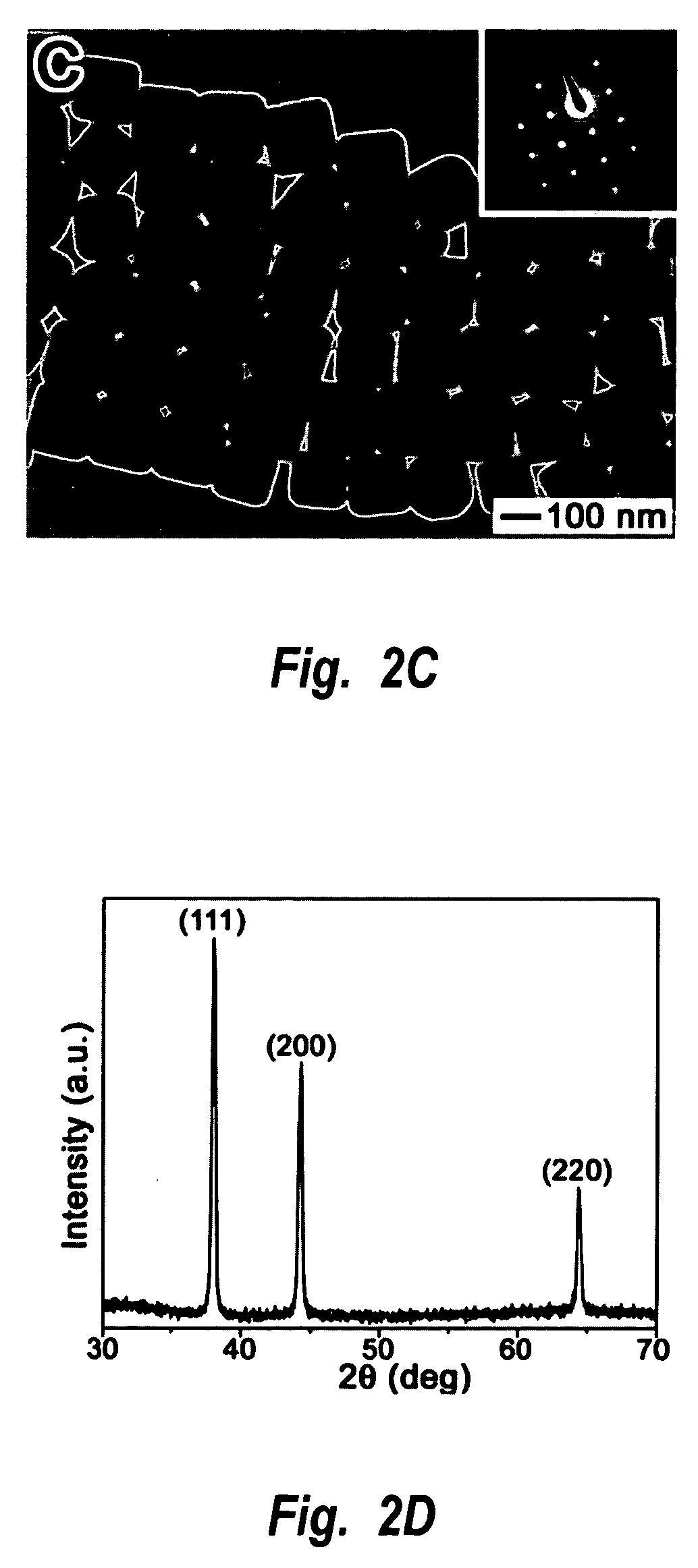

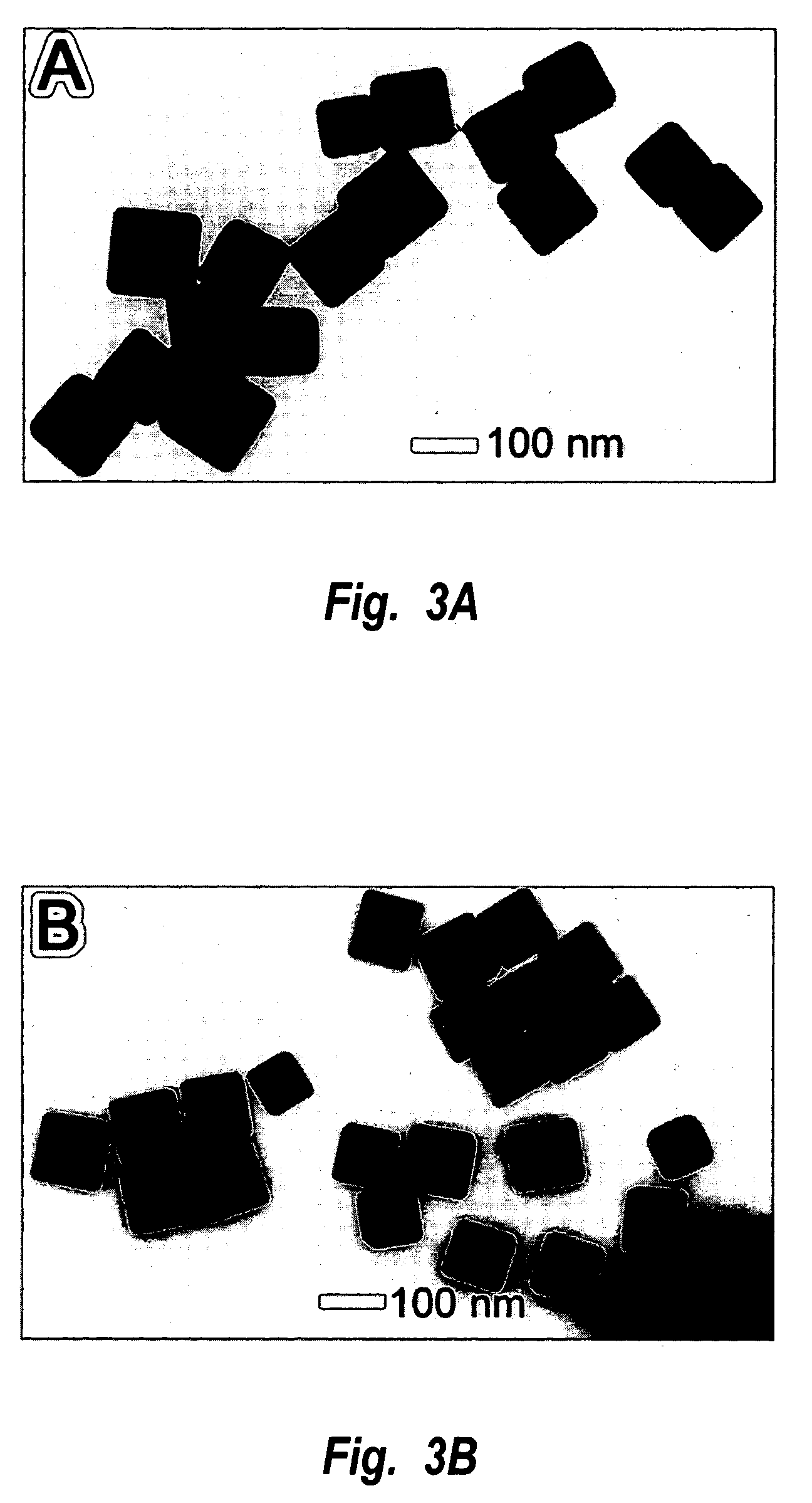

Methods of nanostructure formation and shape selection

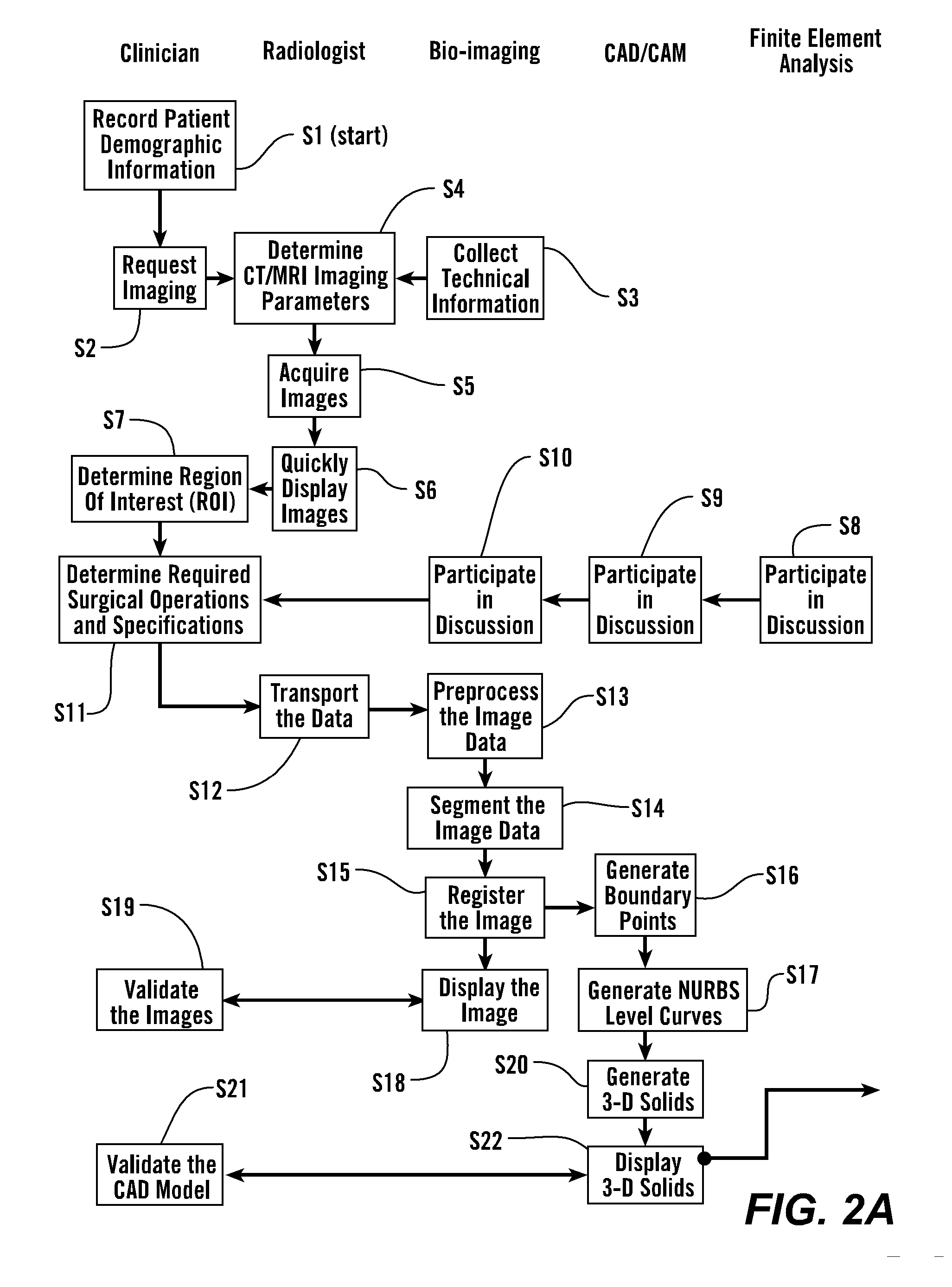

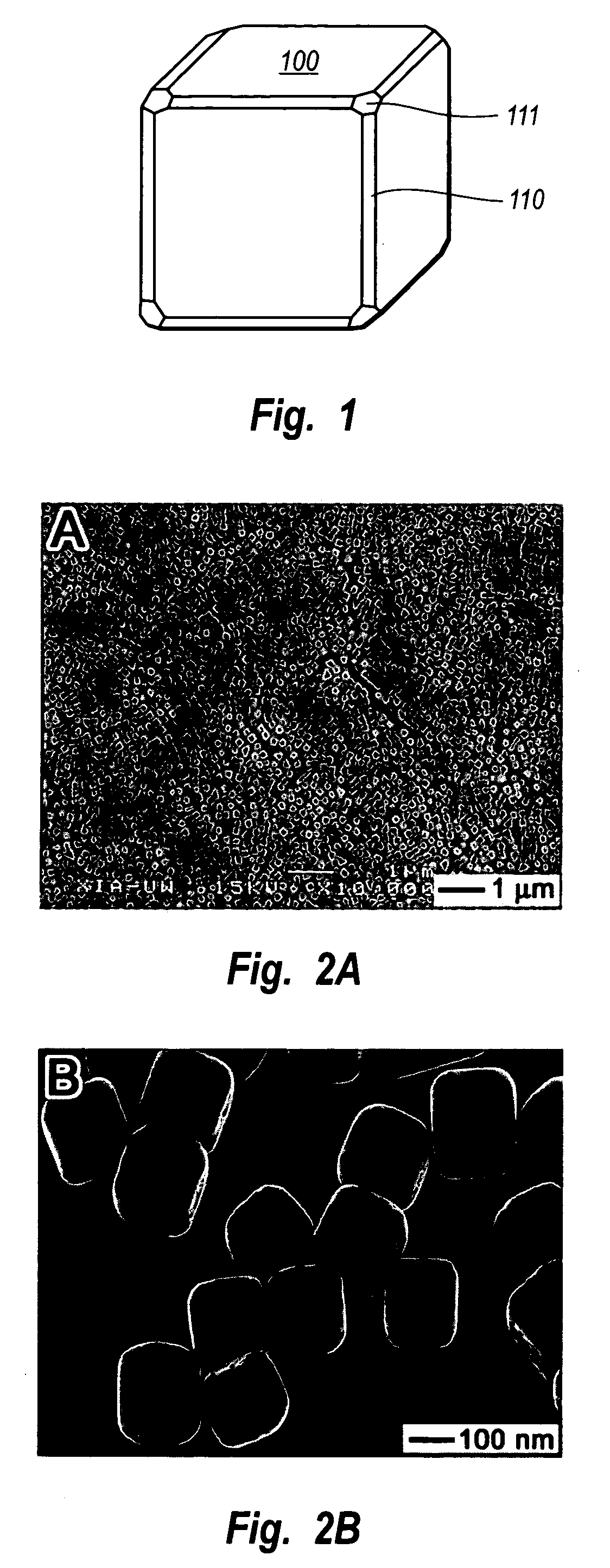

Methods for forming nanostructures of various shapes are disclosed. Nanocubes, nanowires, nanopyramids and multiply twinned particles of silver may by formed by combining a solution of silver nitrate in ethylene glycol with a solution of poly(vinyl pyrrolidone) in ethylene glycol. Hollow nanostructures may be formed by reacting a solution of solid nanostructures comprising one of a first metal and a first metal alloy with a metal salt that can be reduced by the first metal or first metal alloy. Nanostructures comprising a core with at least one nanoshell may be formed by plating a nanostructure and reacting the plating with a metal salt.

Owner:UNIV OF WASHINGTON

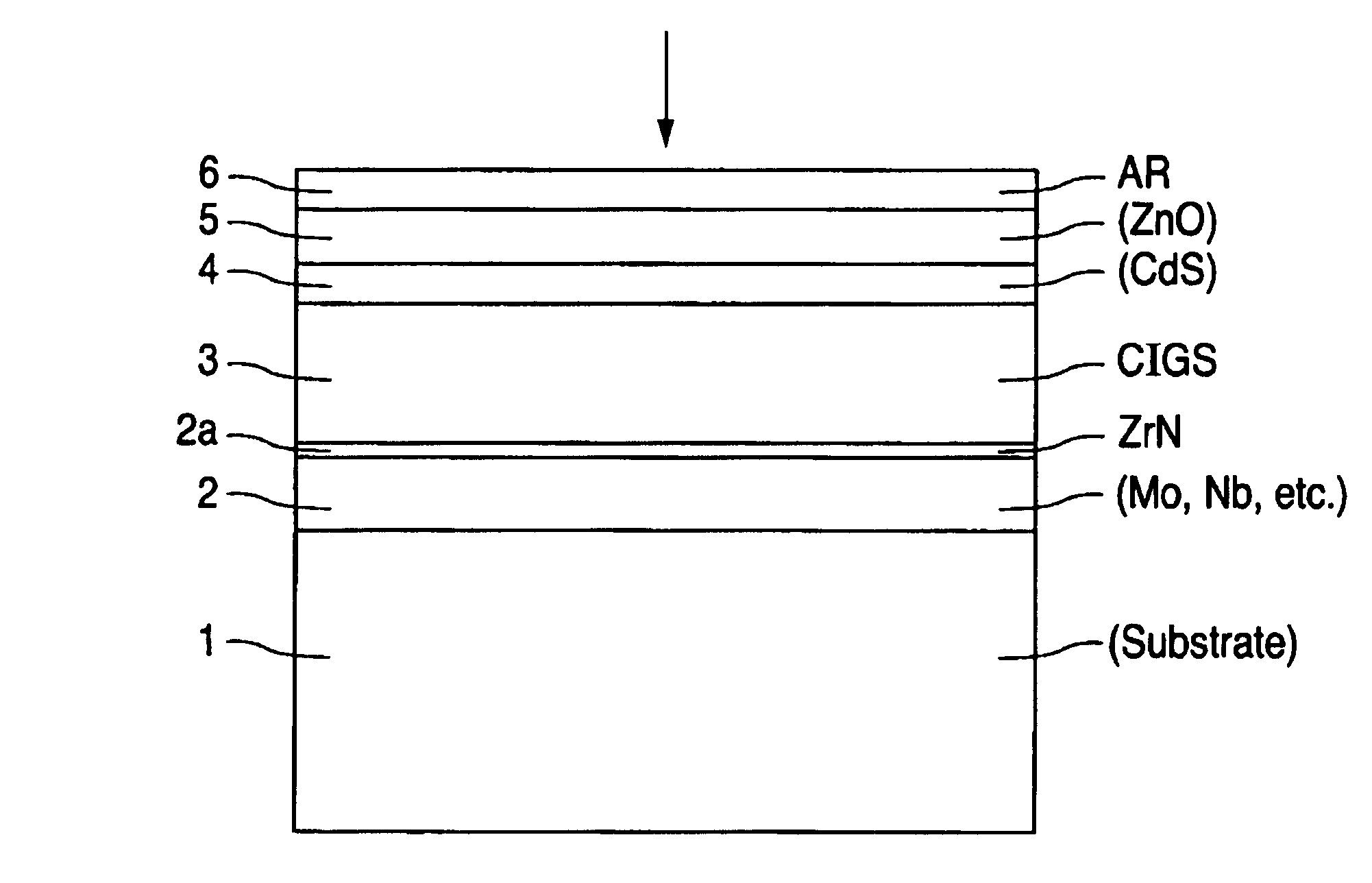

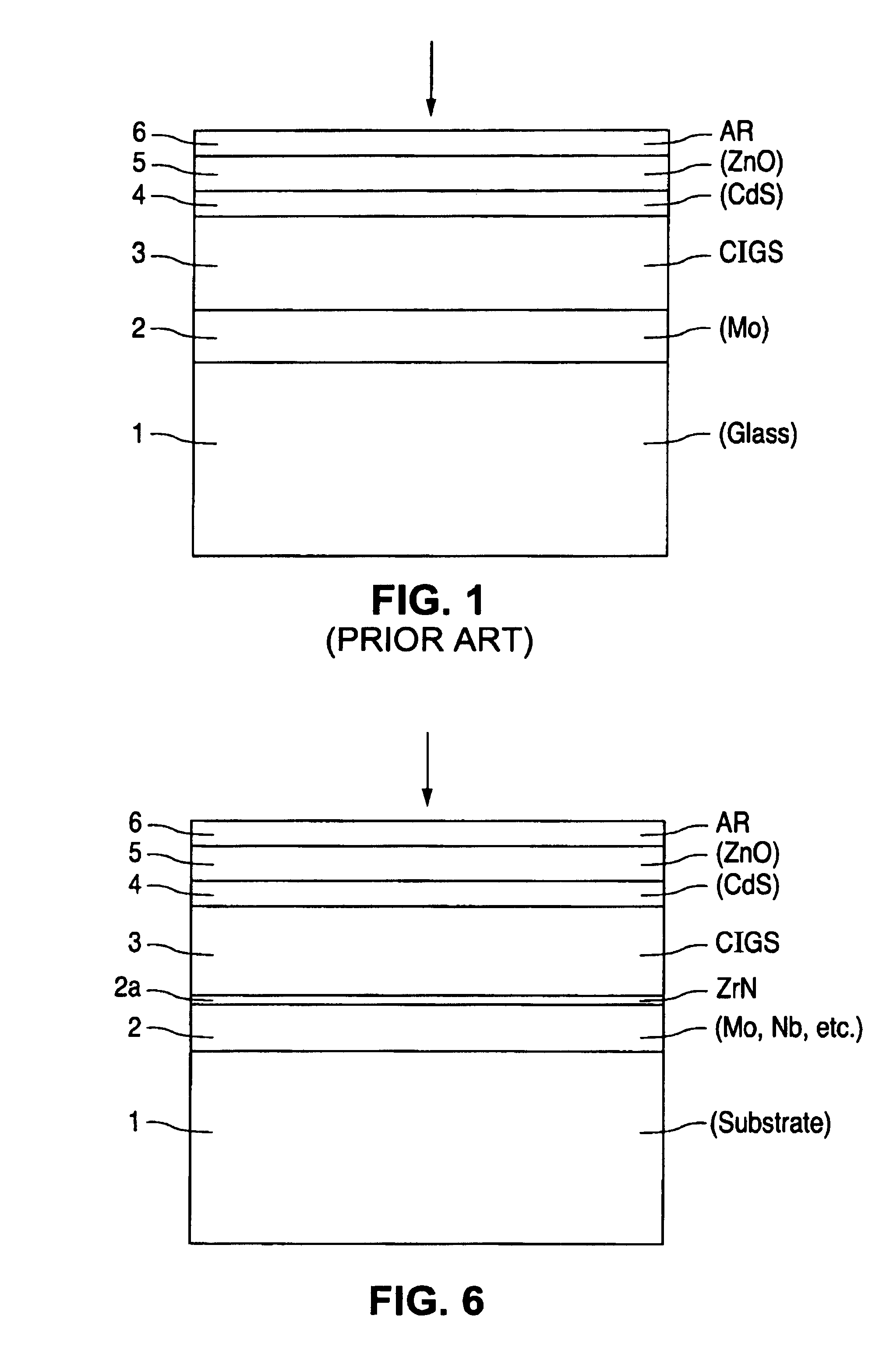

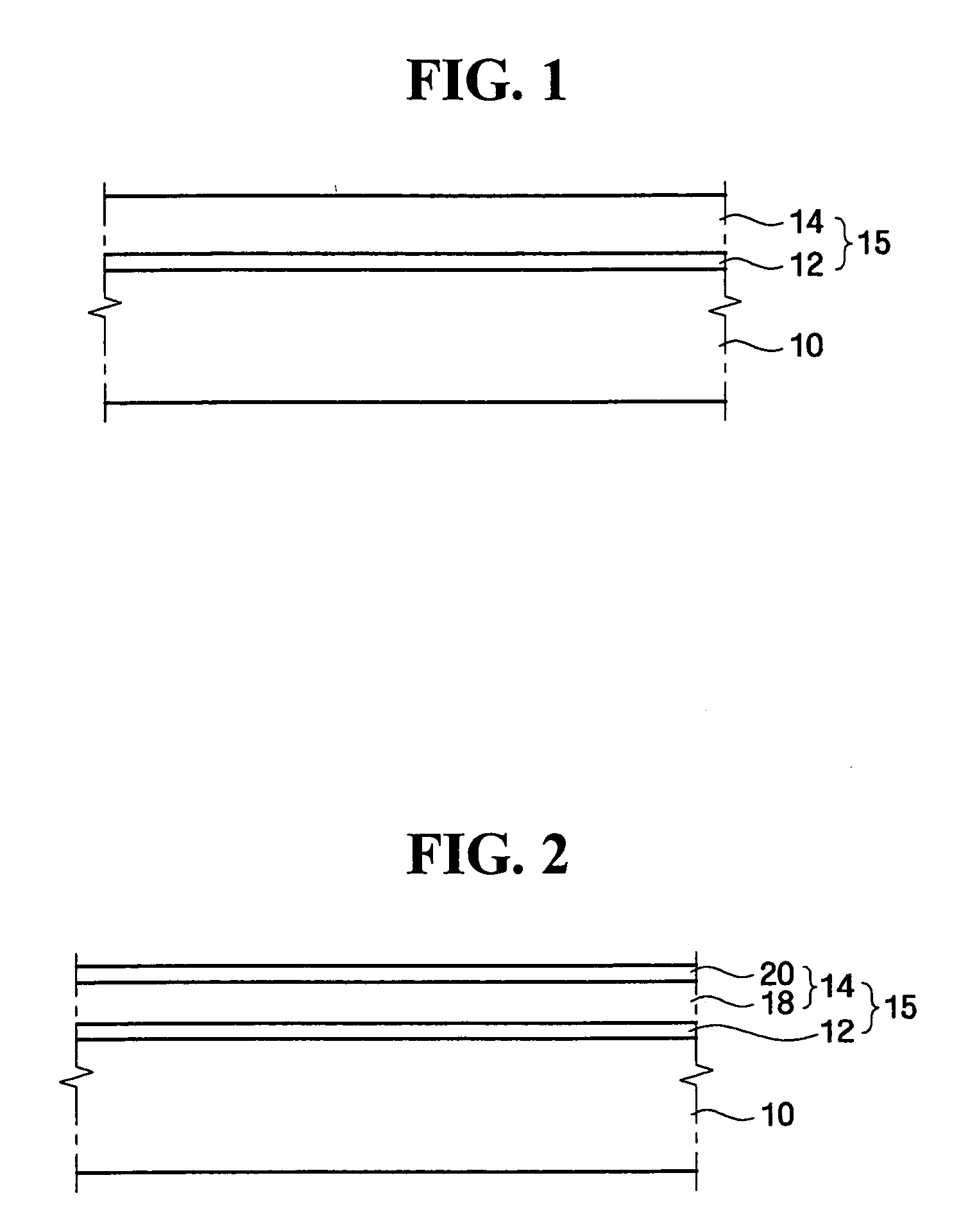

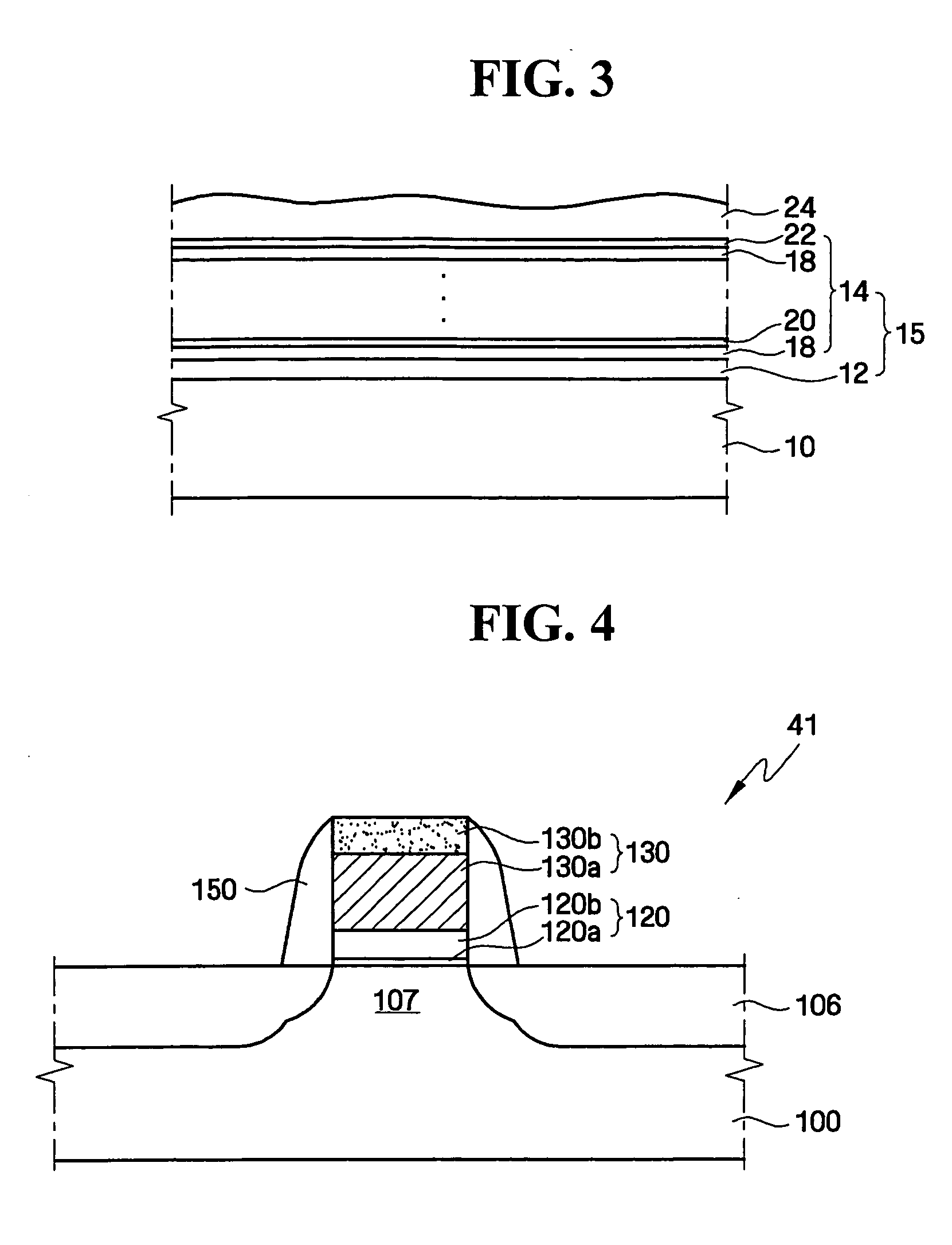

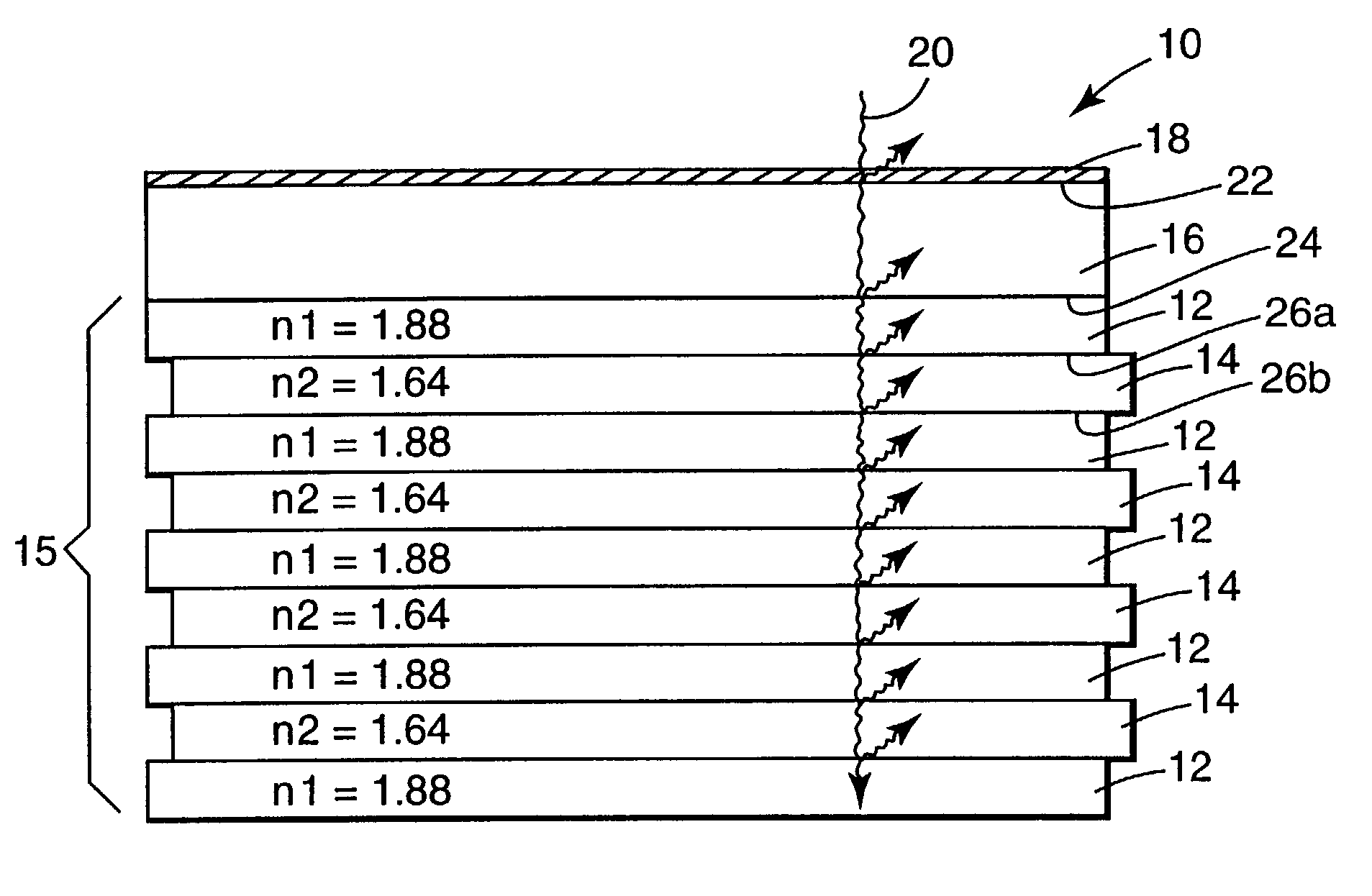

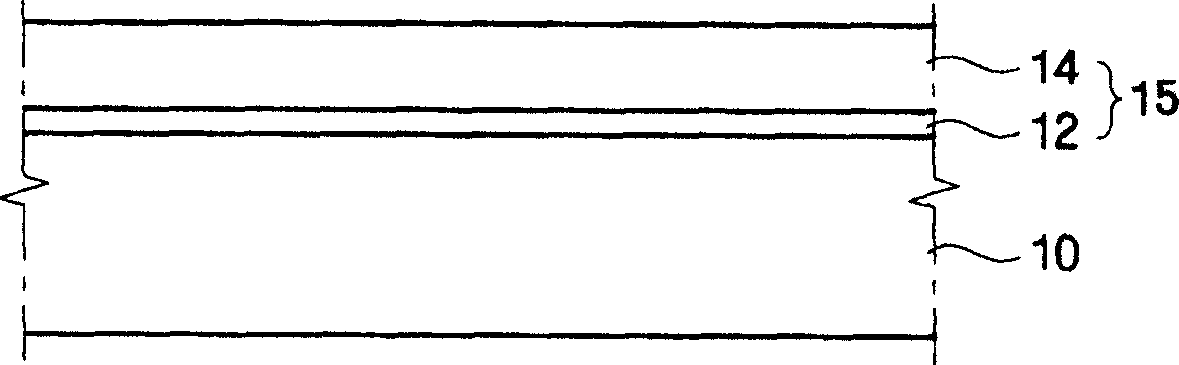

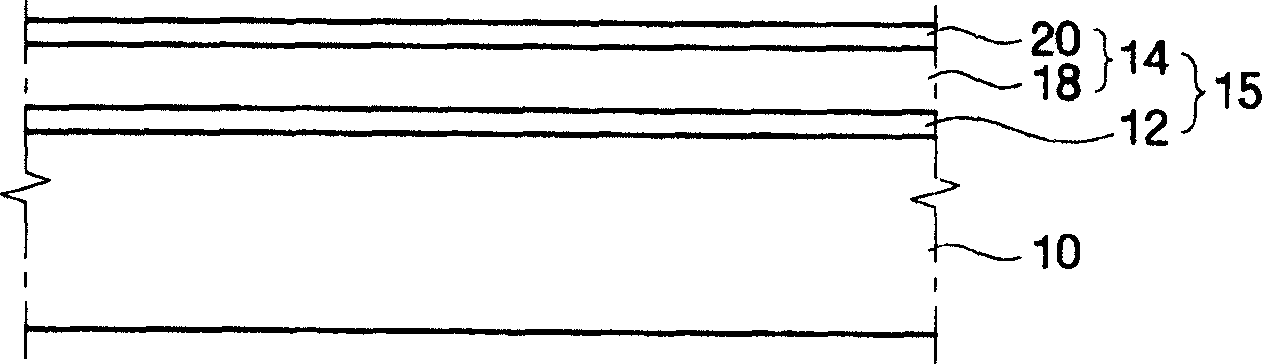

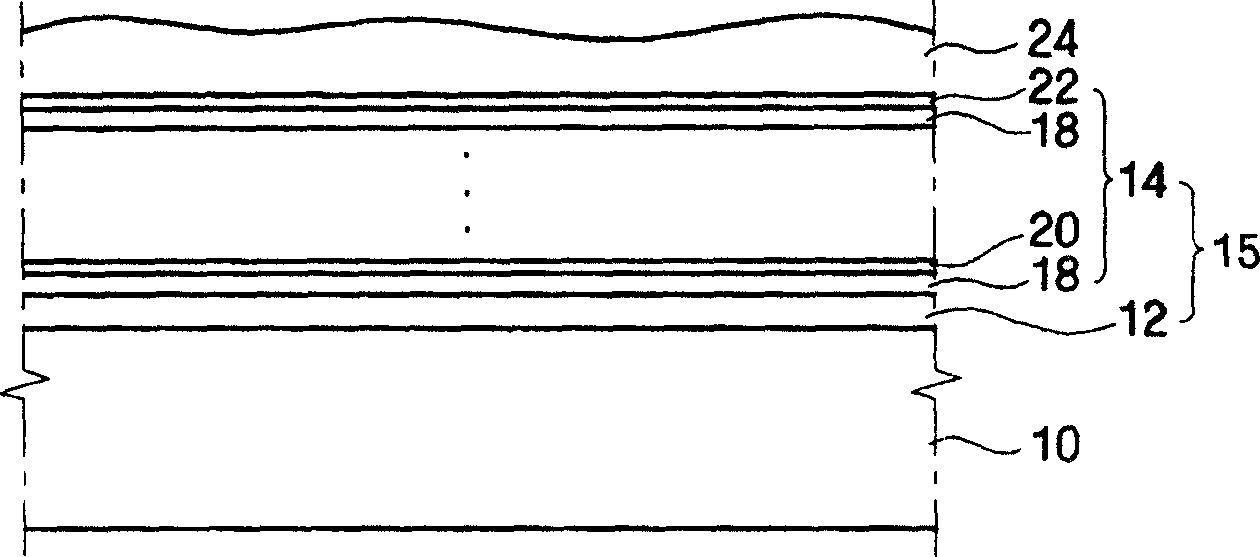

Thin-film solar cells

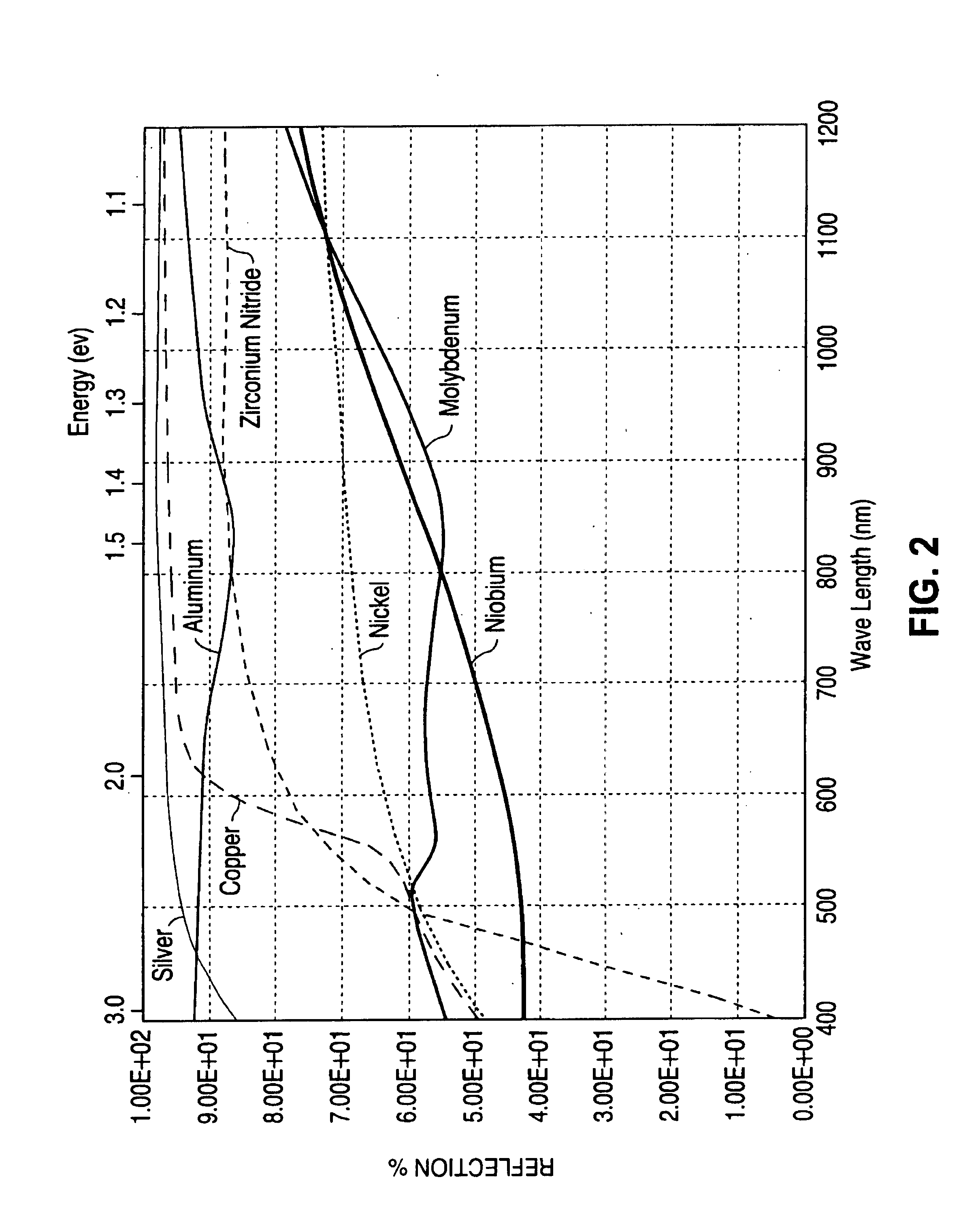

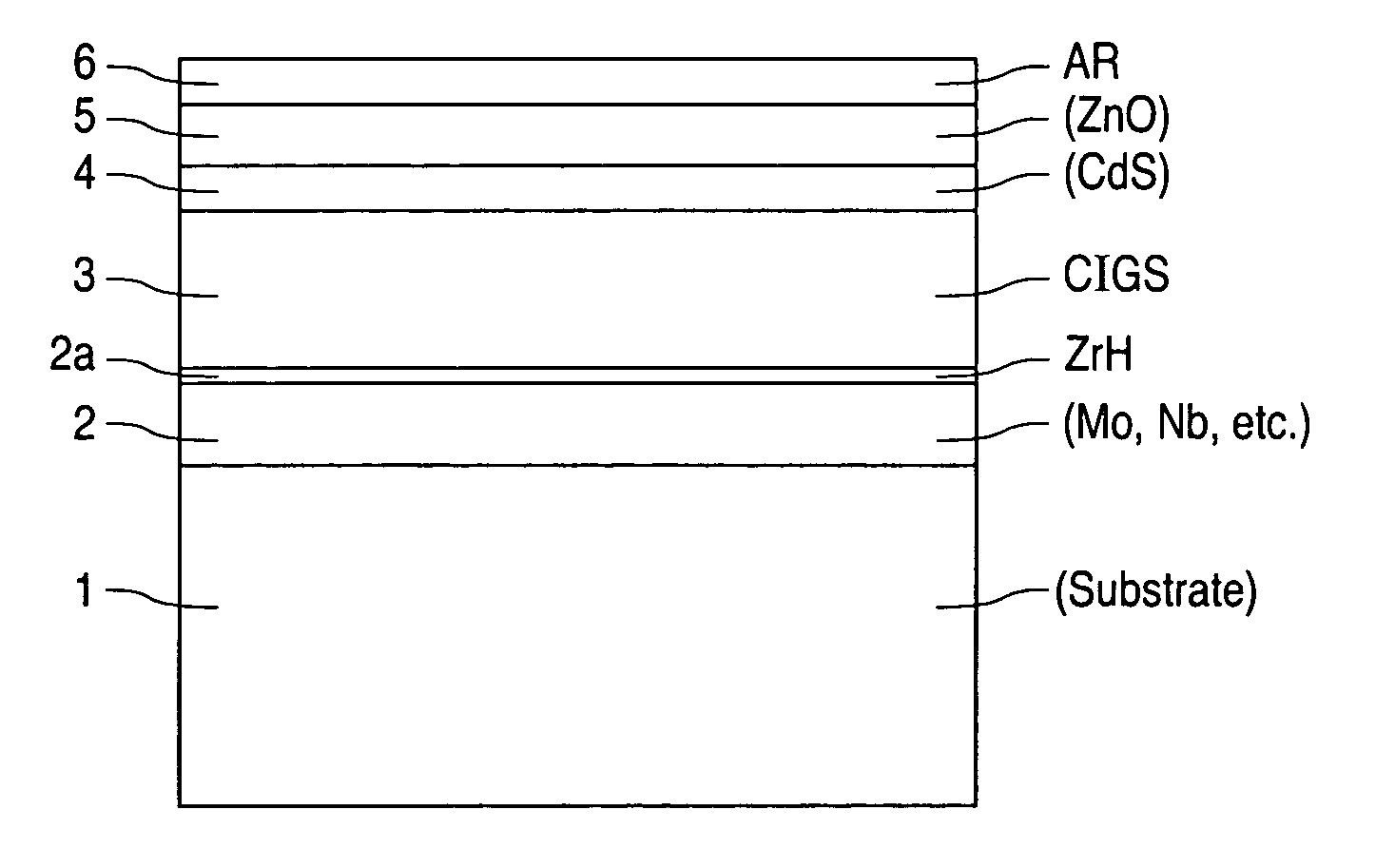

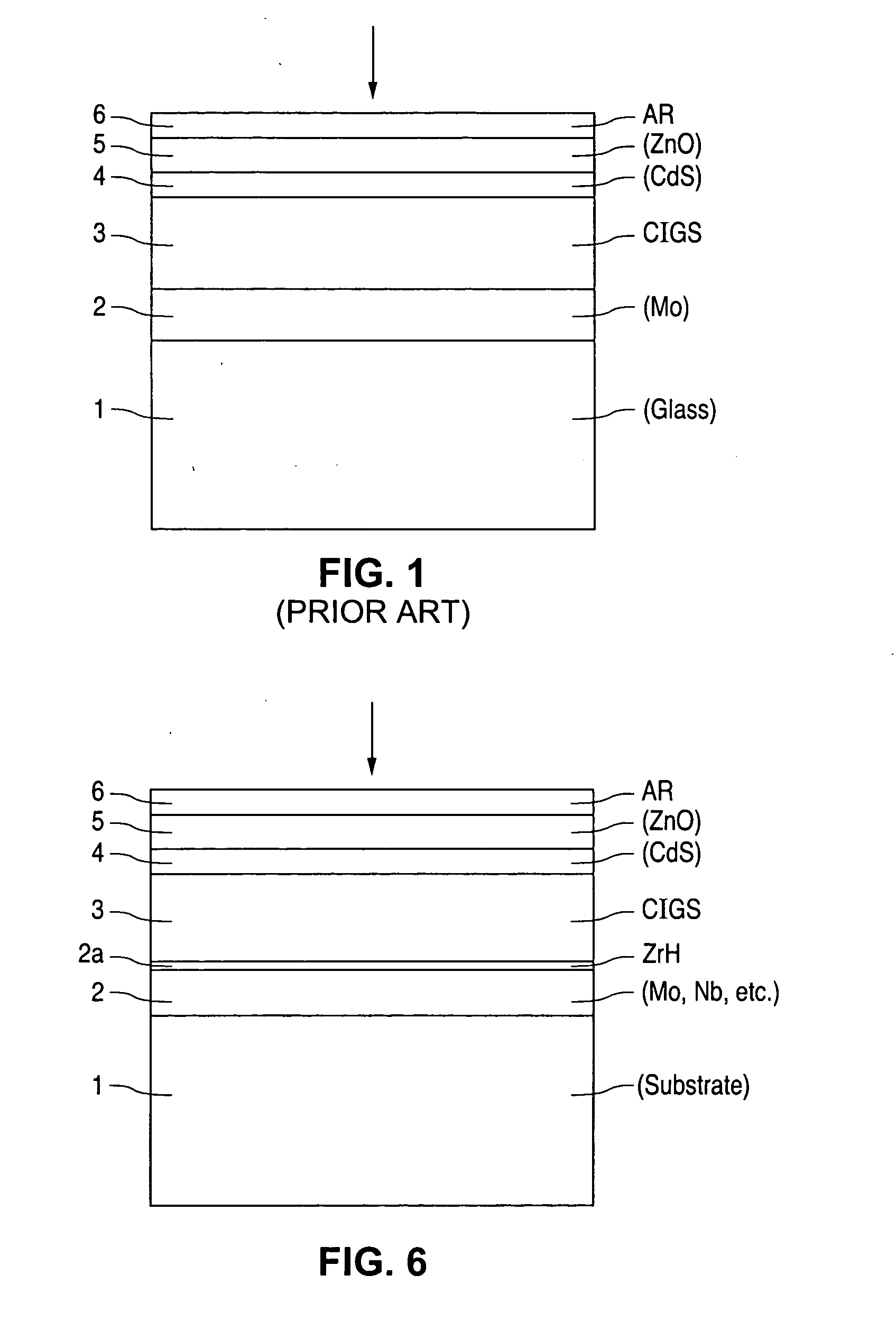

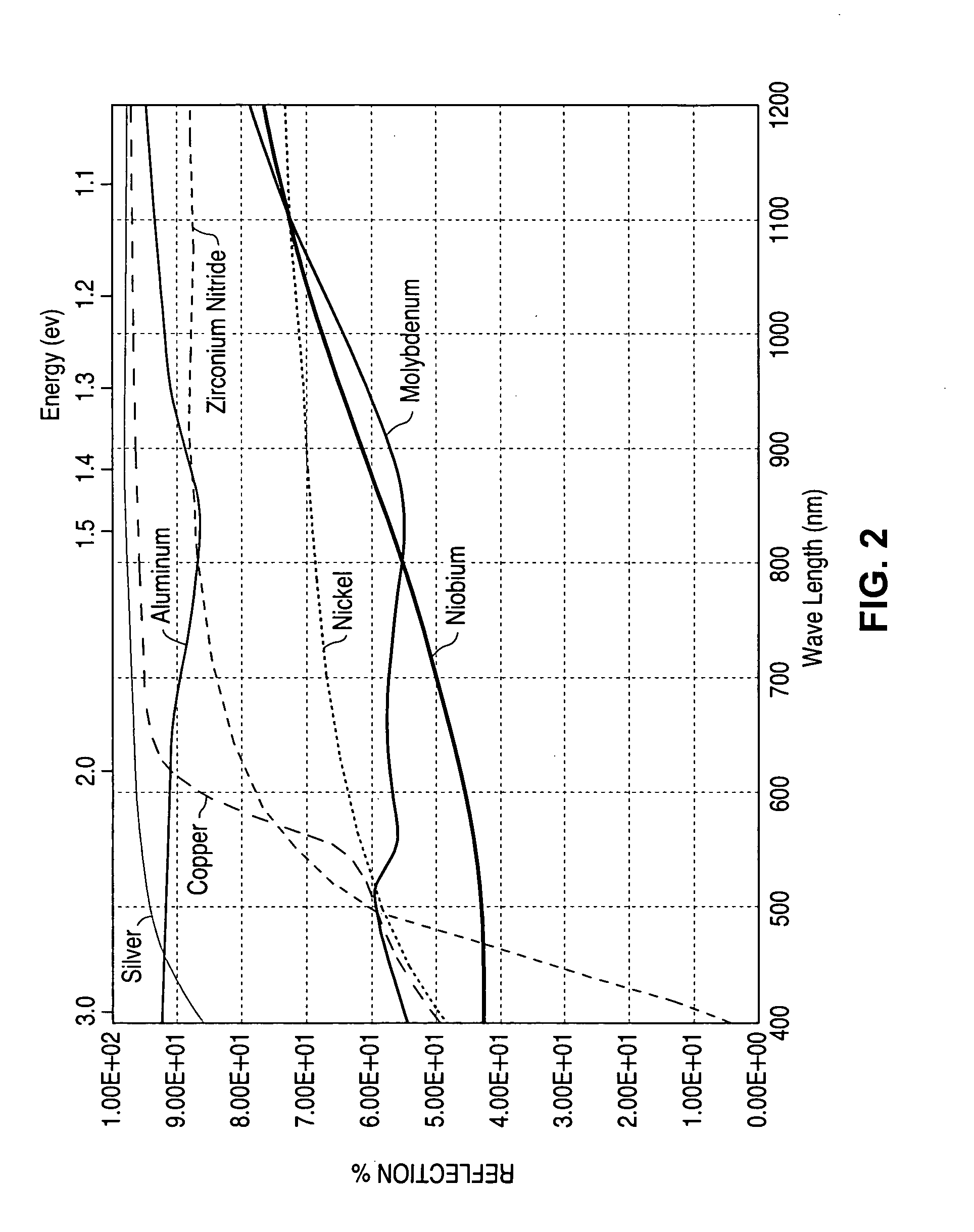

InactiveUS6974976B2Increase reflectionInhibition formationFinal product manufactureVacuum evaporation coatingIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1−X)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

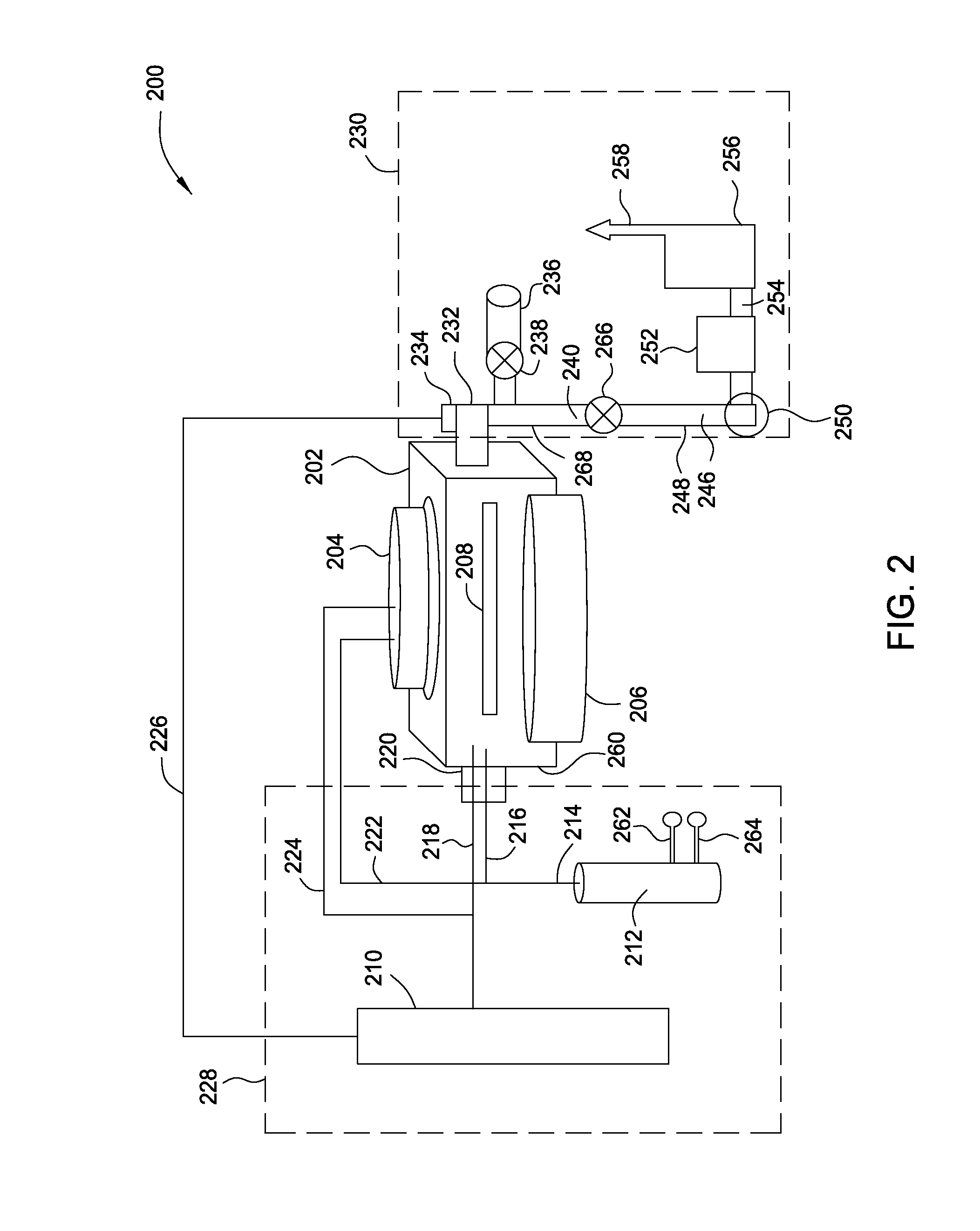

Manufacturing apparatus and method for large-scale production of thin-film solar cells

ActiveUS20050109392A1Cheap productionLow costPV power plantsFinal product manufactureIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

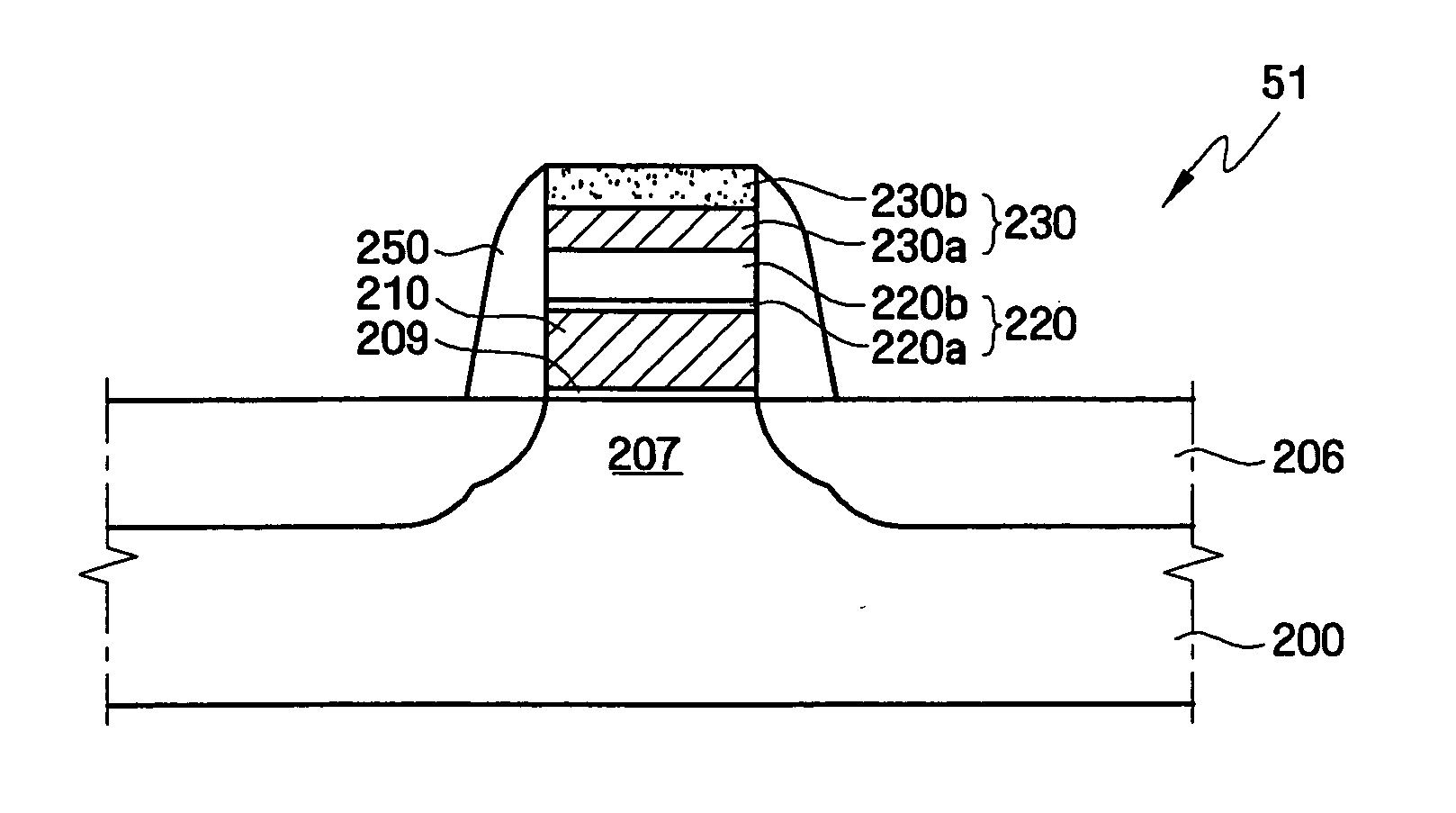

Dielectric layer for semiconductor device and method of manufacturing the same

InactiveUS20050151184A1TransistorSemiconductor/solid-state device manufacturingDevice materialMetal alloy

A semiconductor device comprises a silicate interface layer and a high-k dielectric layer overlying the silicate interface layer. The high-k dielectric layer comprises metal alloy oxides.

Owner:SAMSUNG ELECTRONICS CO LTD

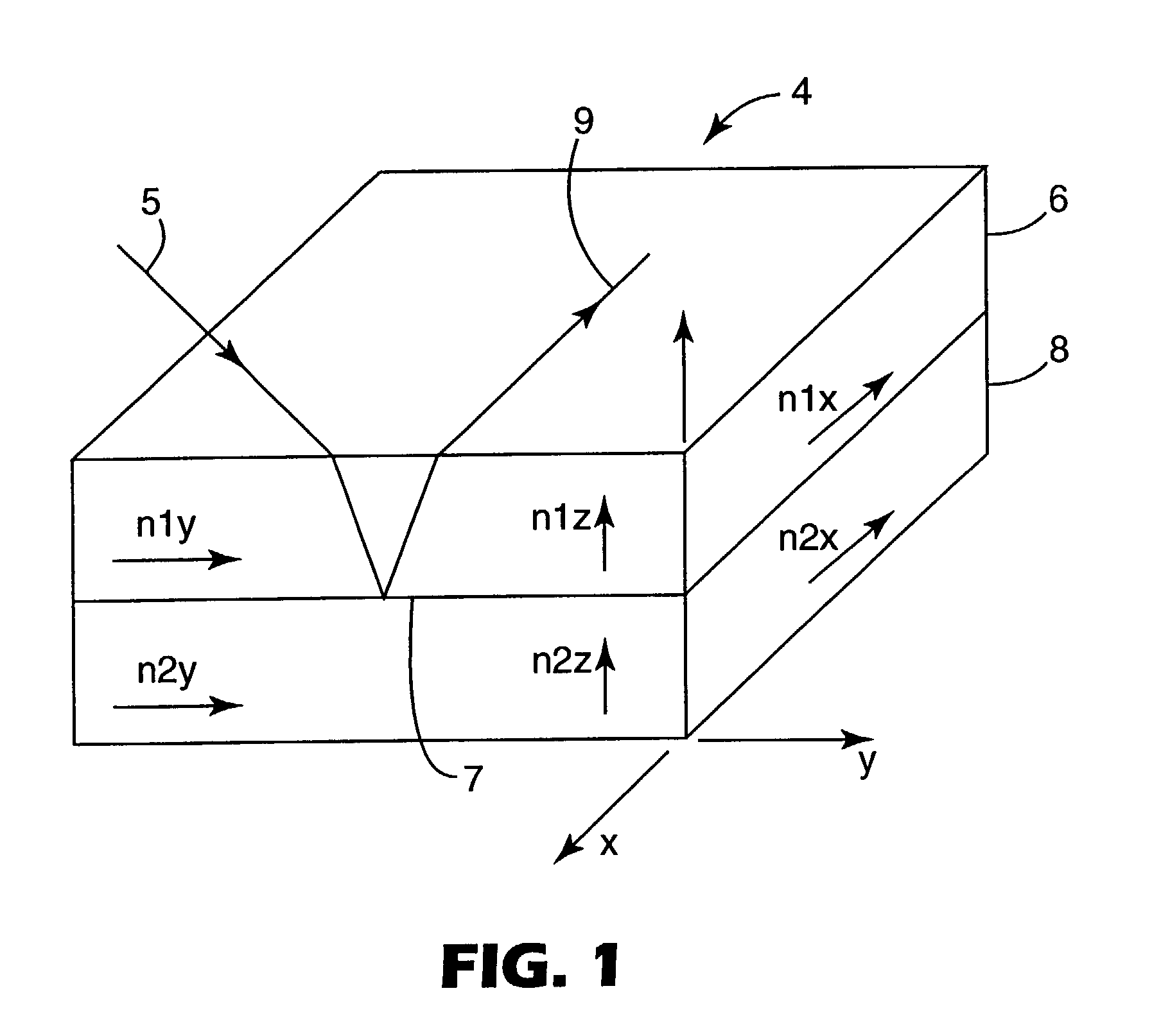

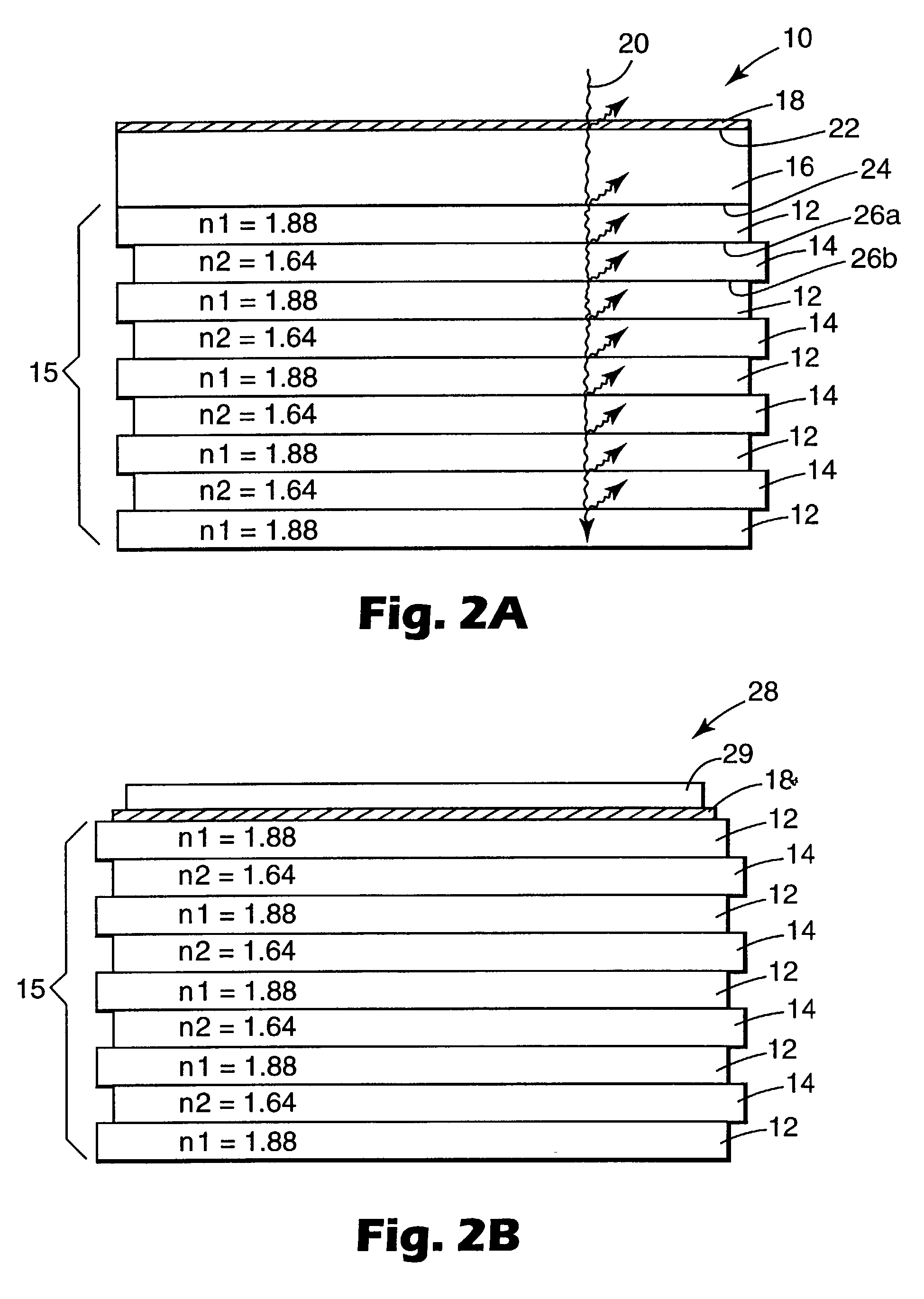

Enhanced heat mirror films

ActiveUS7215473B2Function increaseImprove interlayer adhesionMirrorsSynthetic resin layered productsMetal alloyHot mirror

A heat mirror film containing visible light-transmissive and infrared reflective film comprising a birefringent dielectric multilayer support that reflects at least 50% of light in a band at least 100 nm wide in a wavelength region of interest, a metal or metal alloy layer whose thickness is such that the film is visible light-transmissive and its reflection band is broadened, and a crosslinked polymeric layer has improved infrared reflecting properties. The film can be joined or laminated into glazing (especially non-planar vehicular safety glazing) with reduced likelihood that the metal or metal alloy layer will be damaged or distorted.

Owner:3M INNOVATIVE PROPERTIES CO

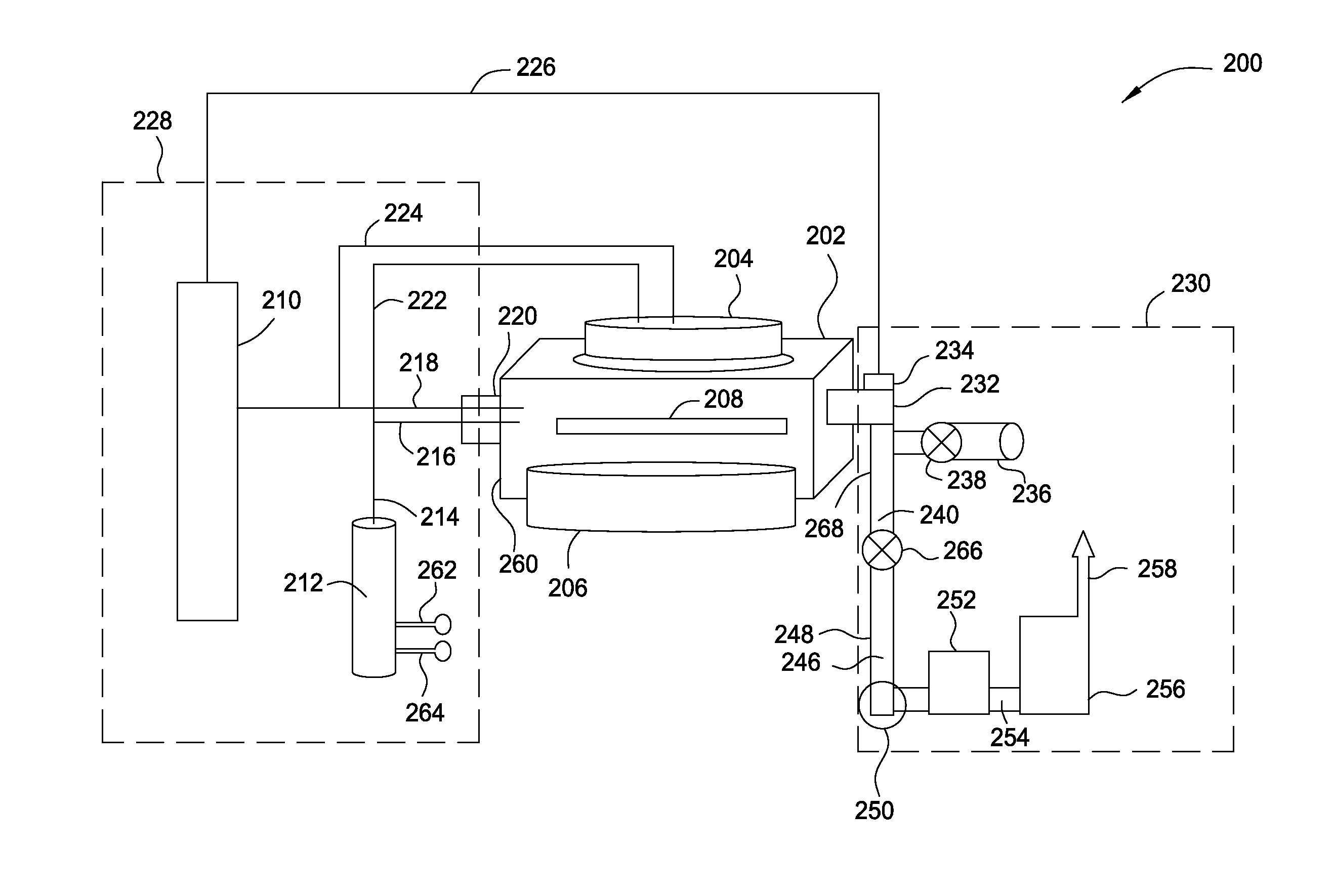

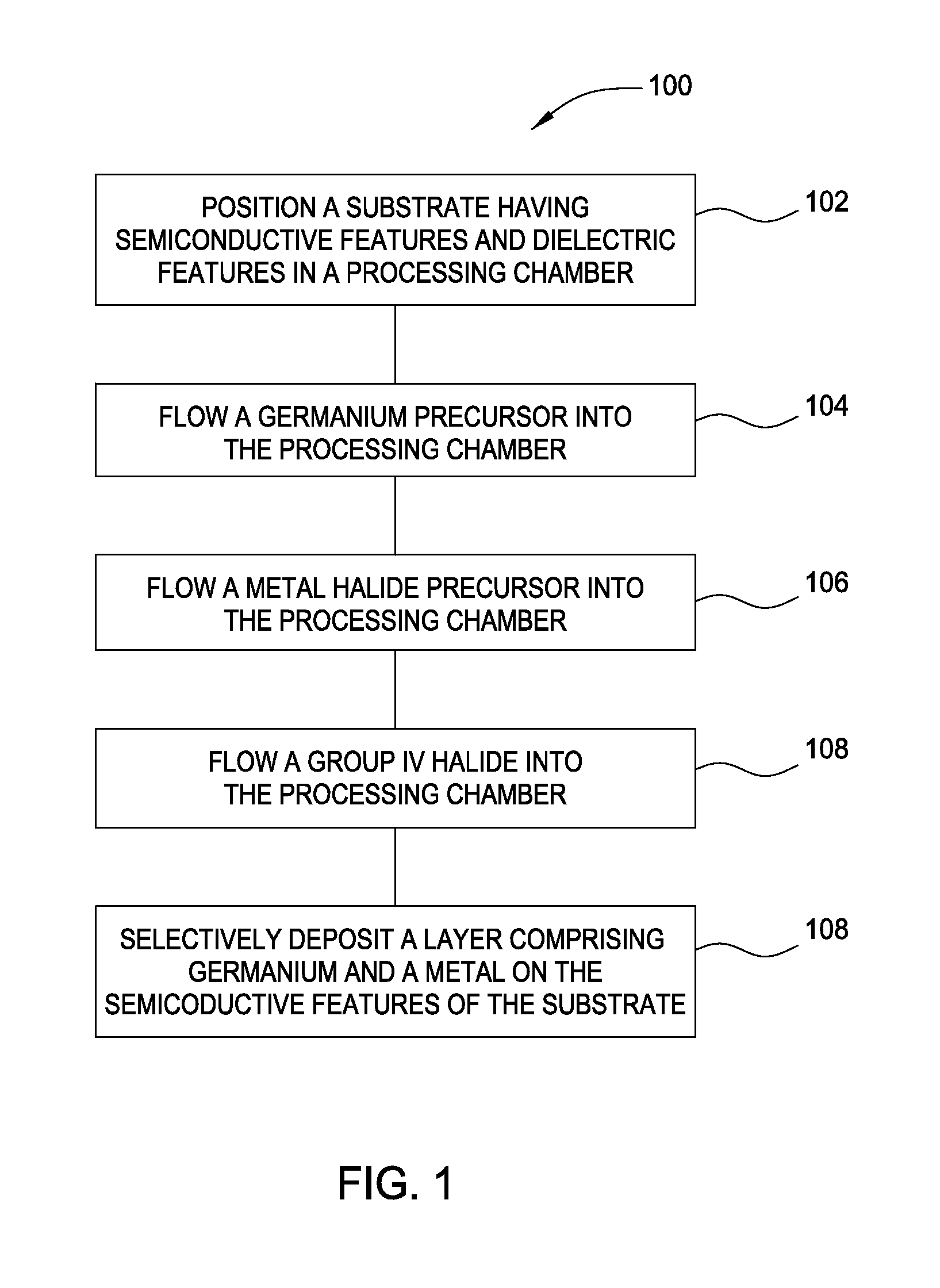

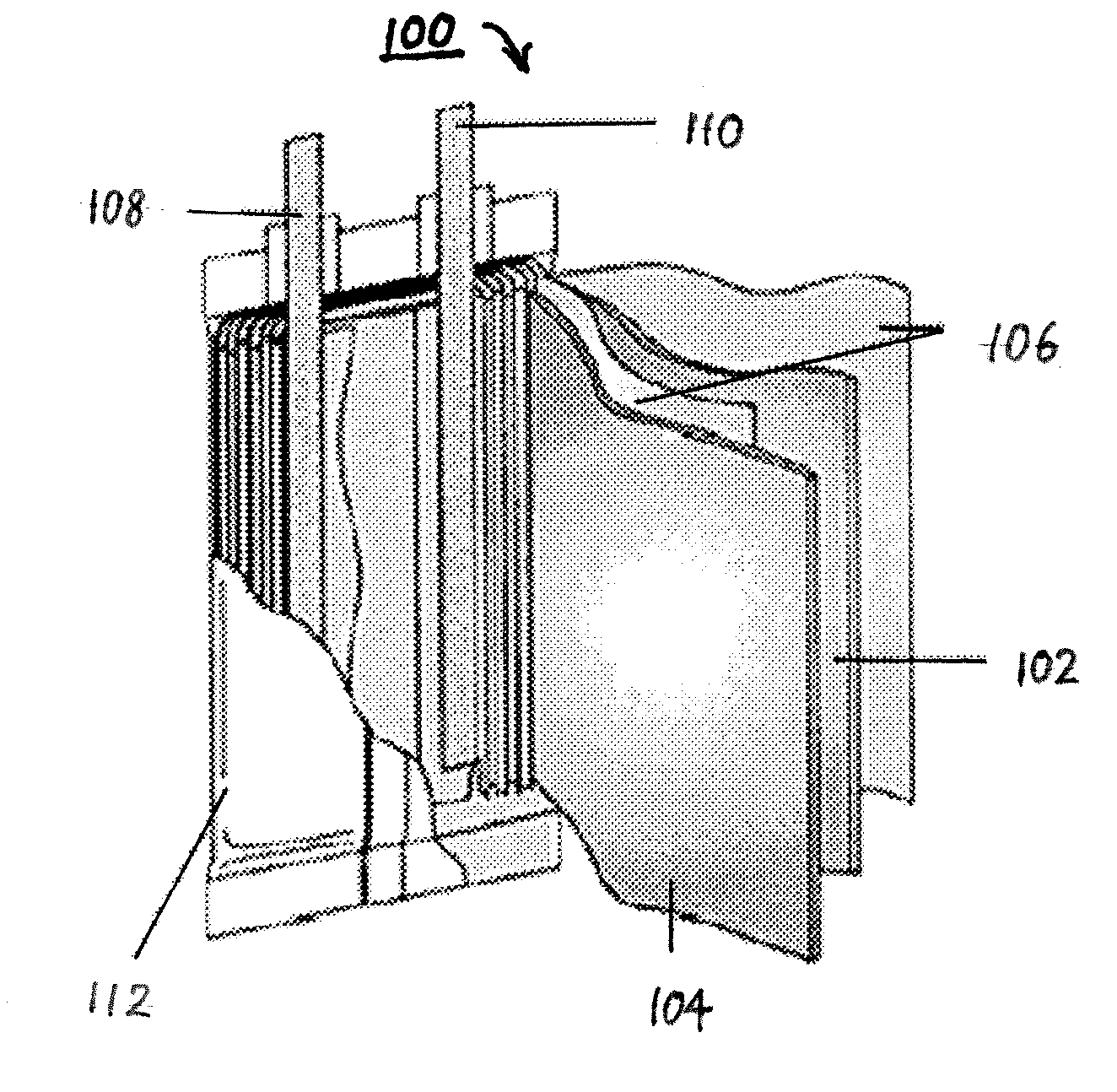

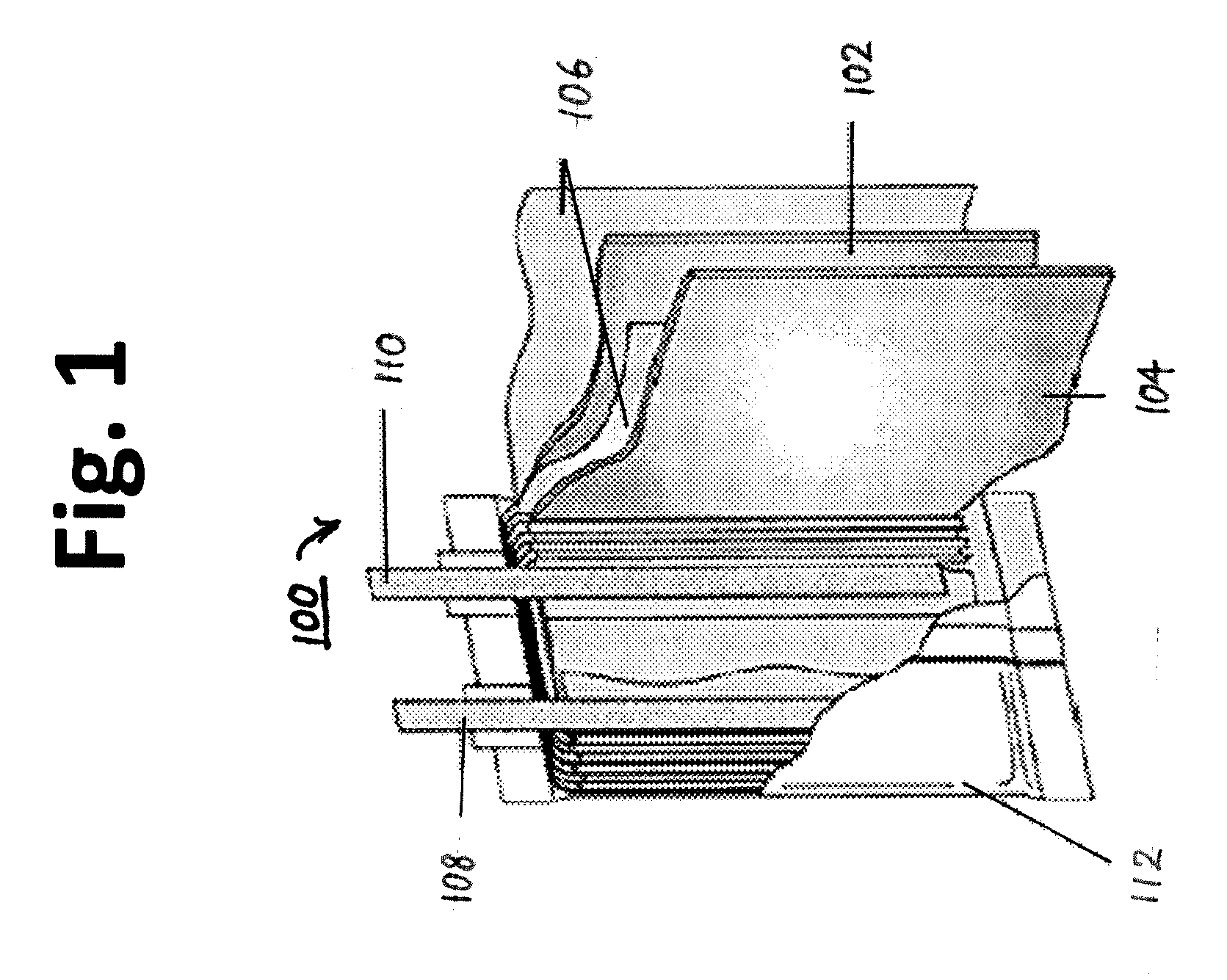

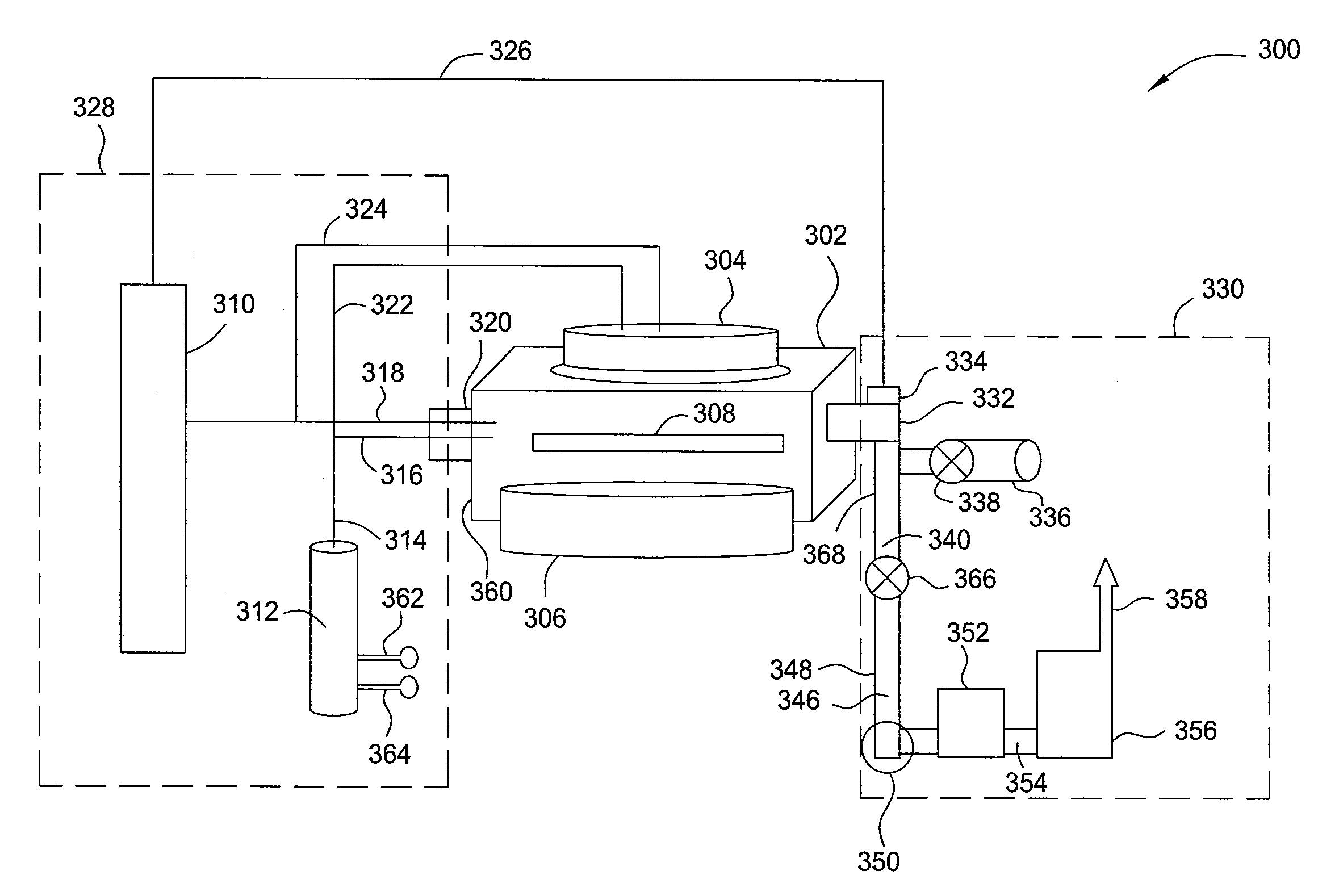

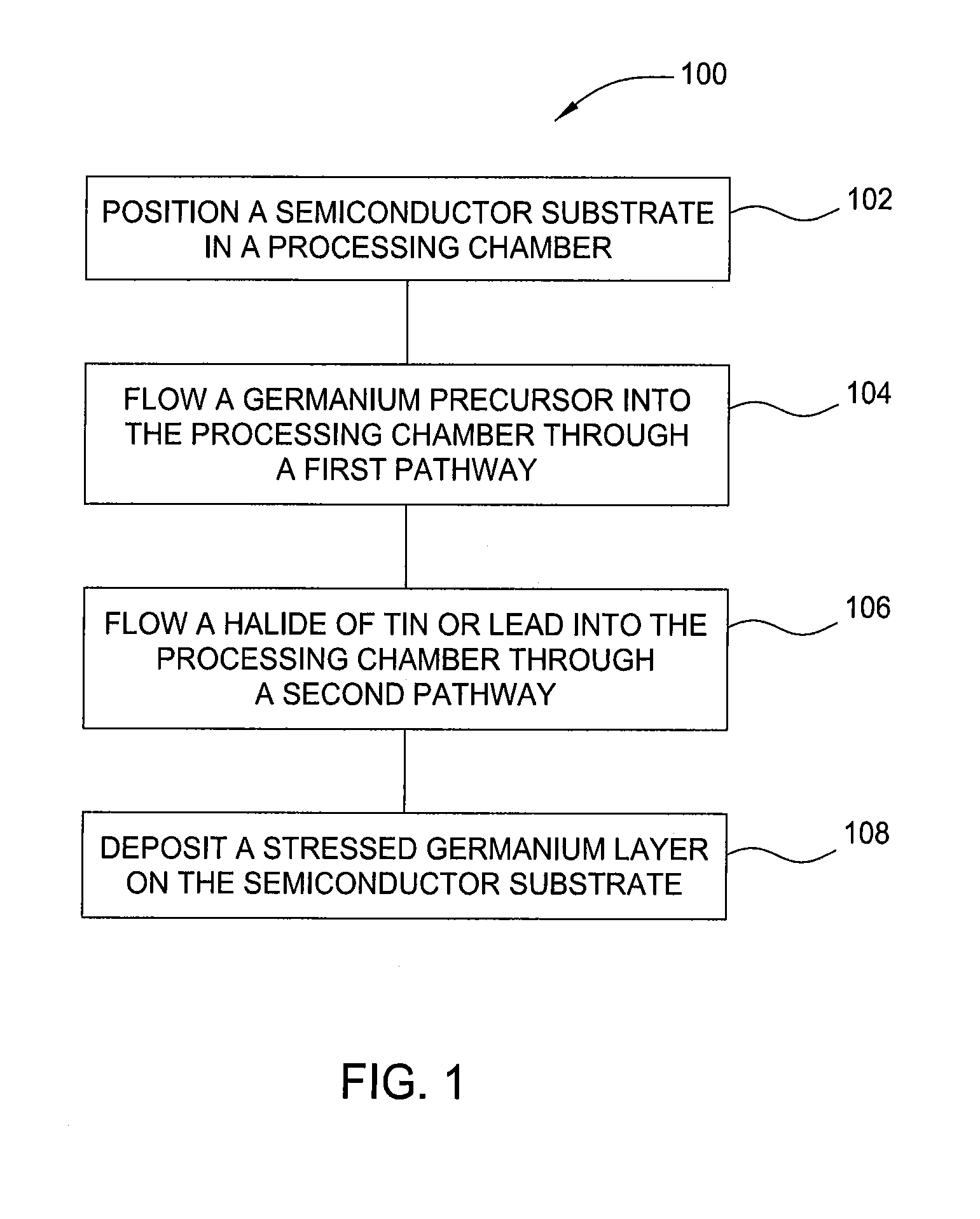

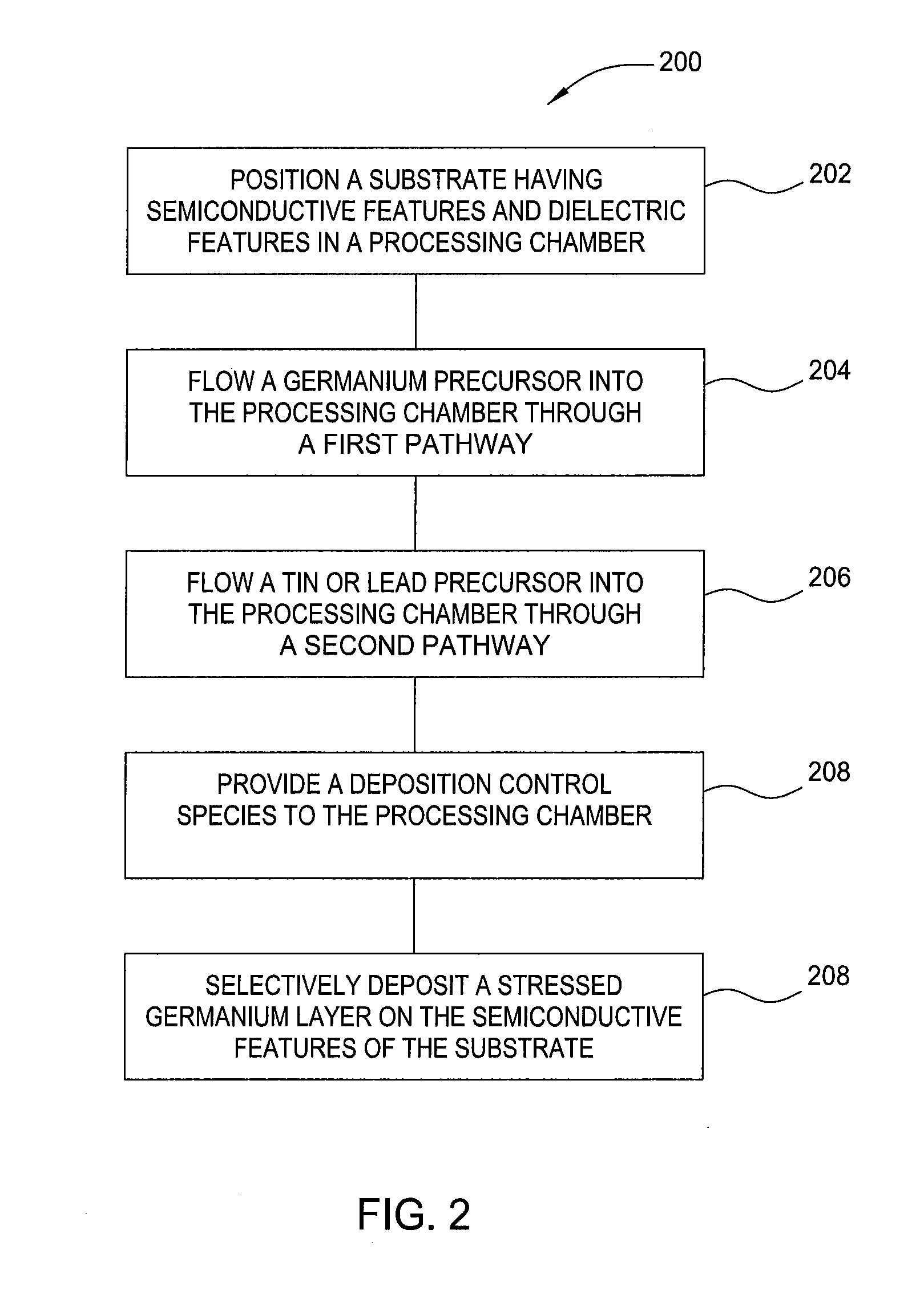

Method and apparatus for germanium tin alloy formation by thermal CVD

InactiveUS20130280891A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSelective depositionLiquid metal

A method and apparatus for forming semiconductive semiconductor-metal alloy layers is described. A germanium precursor and a metal precursor are provided to a chamber, and an epitaxial layer of germanium-metal alloy, optionally including silicon, is formed on the substrate. The metal precursor is typically a metal halide, which may be provided by evaporating a liquid metal halide, subliming a solid metal halide, or by contacting a pure metal with a halogen gas. A group IV halide deposition control agent is used to provide selective deposition on semiconductive regions of the substrate relative to dielectric regions. The semiconductive semiconductor-metal alloy layers may be doped, for example with boron, phosphorus, and / or arsenic. The precursors may be provided through a showerhead or through a side entry point, and an exhaust system coupled to the chamber may be separately heated to manage condensation of exhaust components.

Owner:APPLIED MATERIALS INC

Dielectric layer for semiconductor device and method of manufacturing the same

A semiconductor device comprises a silicate interface layer and a high-k dielectric layer overlying the silicate interface layer. The high-k dielectric layer comprises metal alloy oxides.

Owner:SAMSUNG ELECTRONICS CO LTD

High energy lithium ion batteries with particular negative electrode compositions

ActiveUS20090305131A1Degree of crystallinity of will decreaseAlkaline accumulatorsElectrode manufacturing processesHigh energyMetal alloy

Combinations of materials are described in which high energy density active materials for negative electrodes of lithium ion batteries. In general, metal alloy / intermetallic compositions can provide the high energy density. These materials can have moderate volume changes upon cycling in a lithium ion battery. The volume changes can be accommodated with less degradation upon cycling through the combination with highly porous electrically conductive materials, such as highly porous carbon and / or foamed current collectors. Whether or not combined with a highly porous electrically conductive material, metal alloy / intermetallic compositions with an average particle size of no more than a micron can be advantageously used in the negative electrodes to improve cycling properties.

Owner:IONBLOX INC

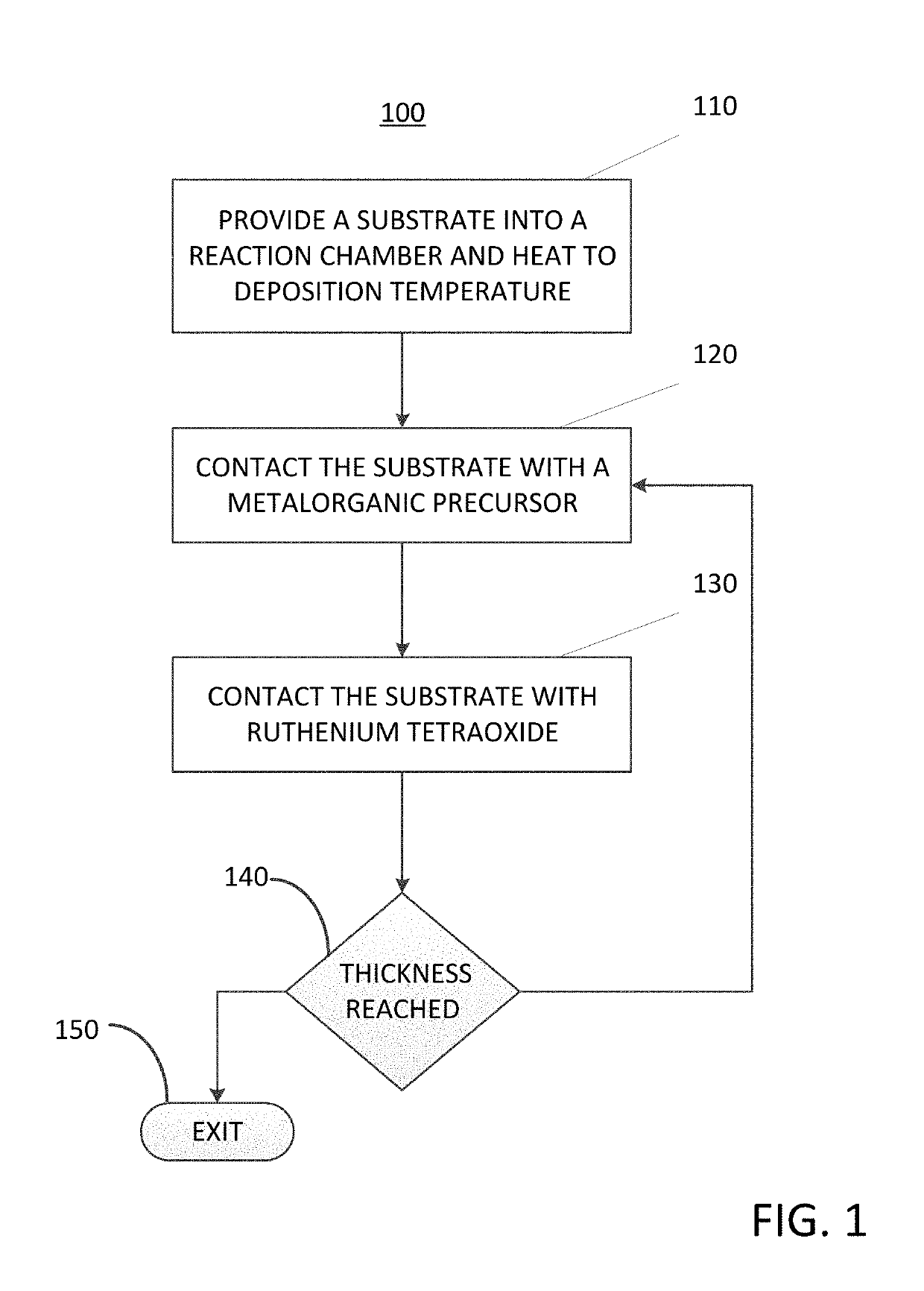

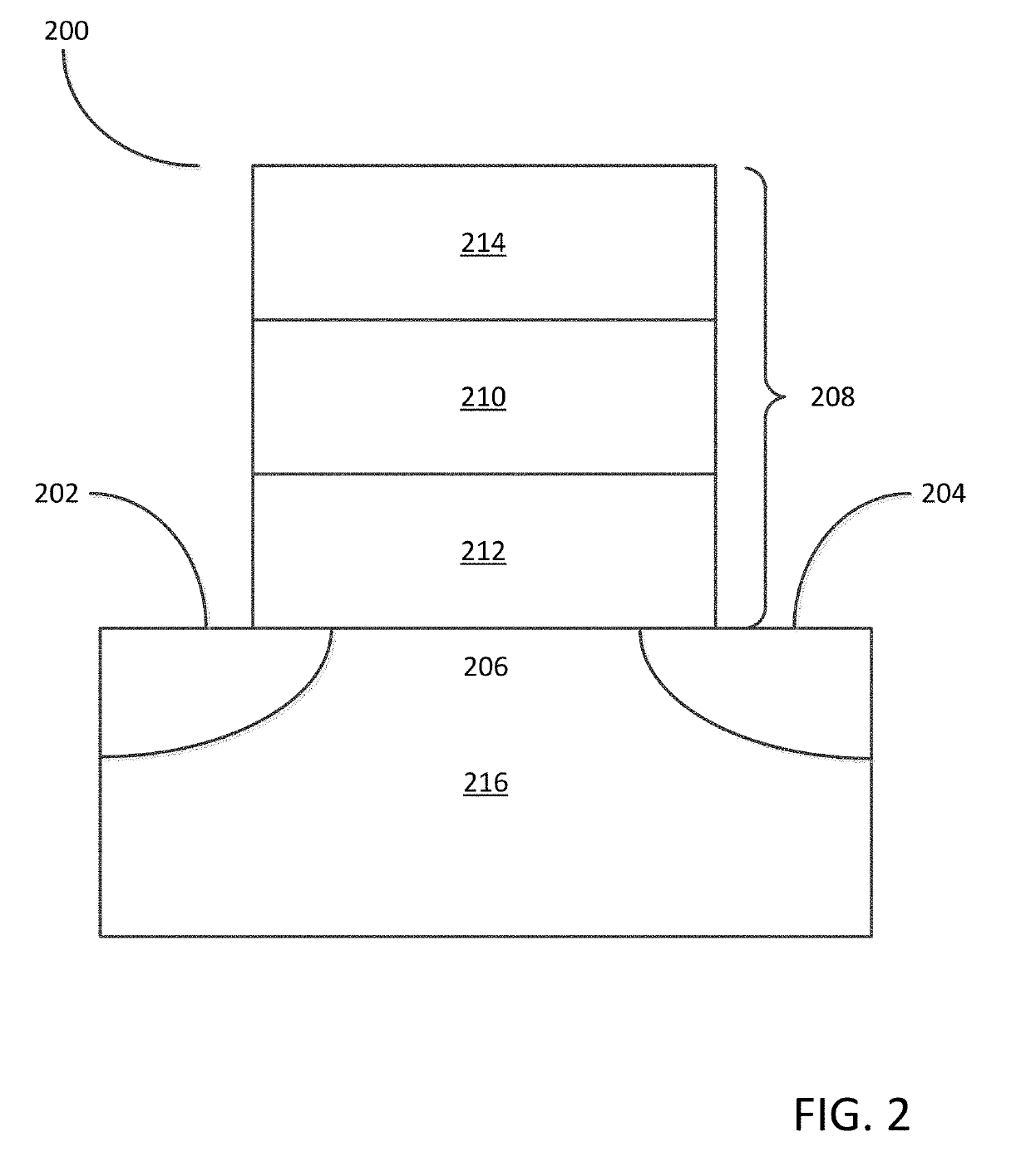

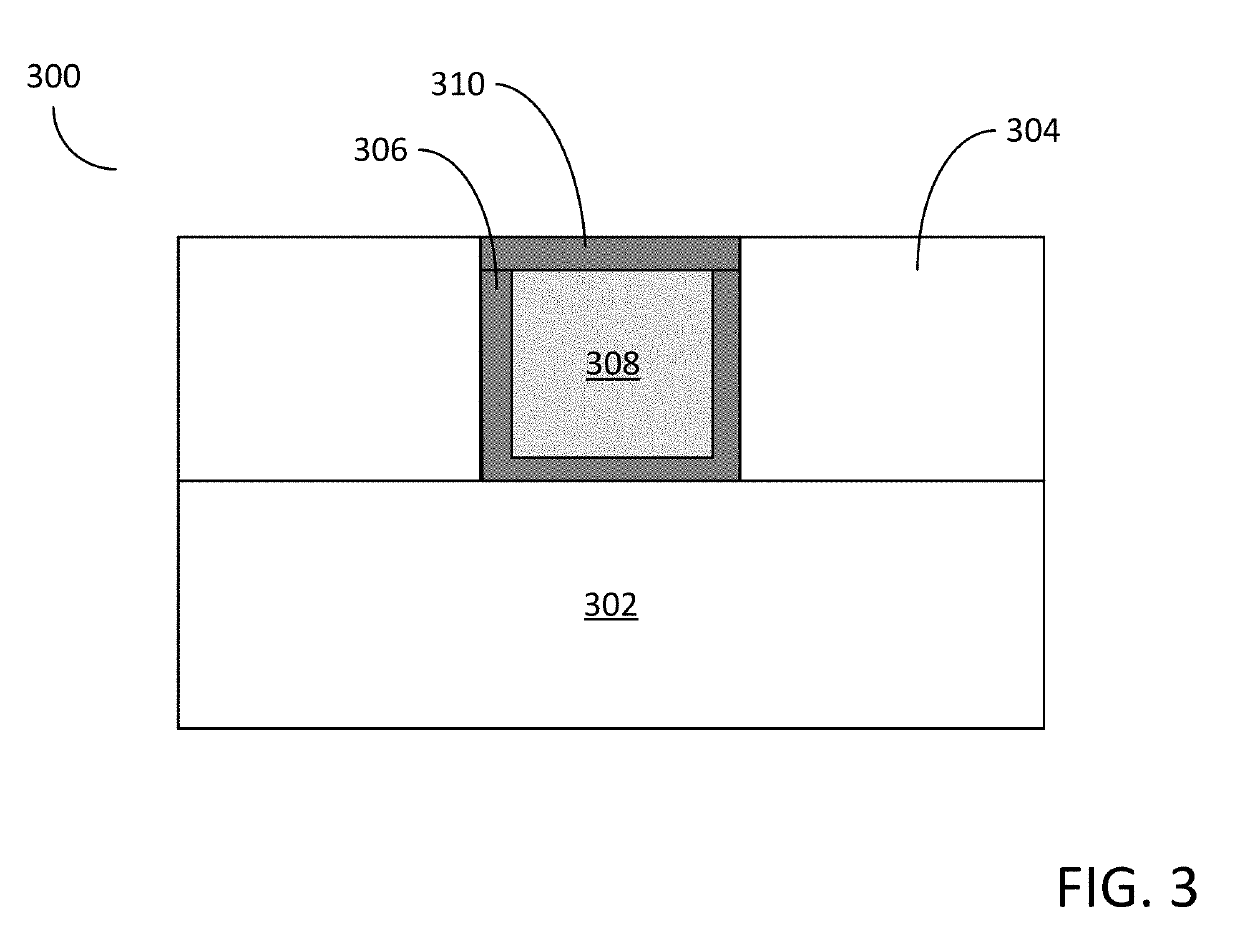

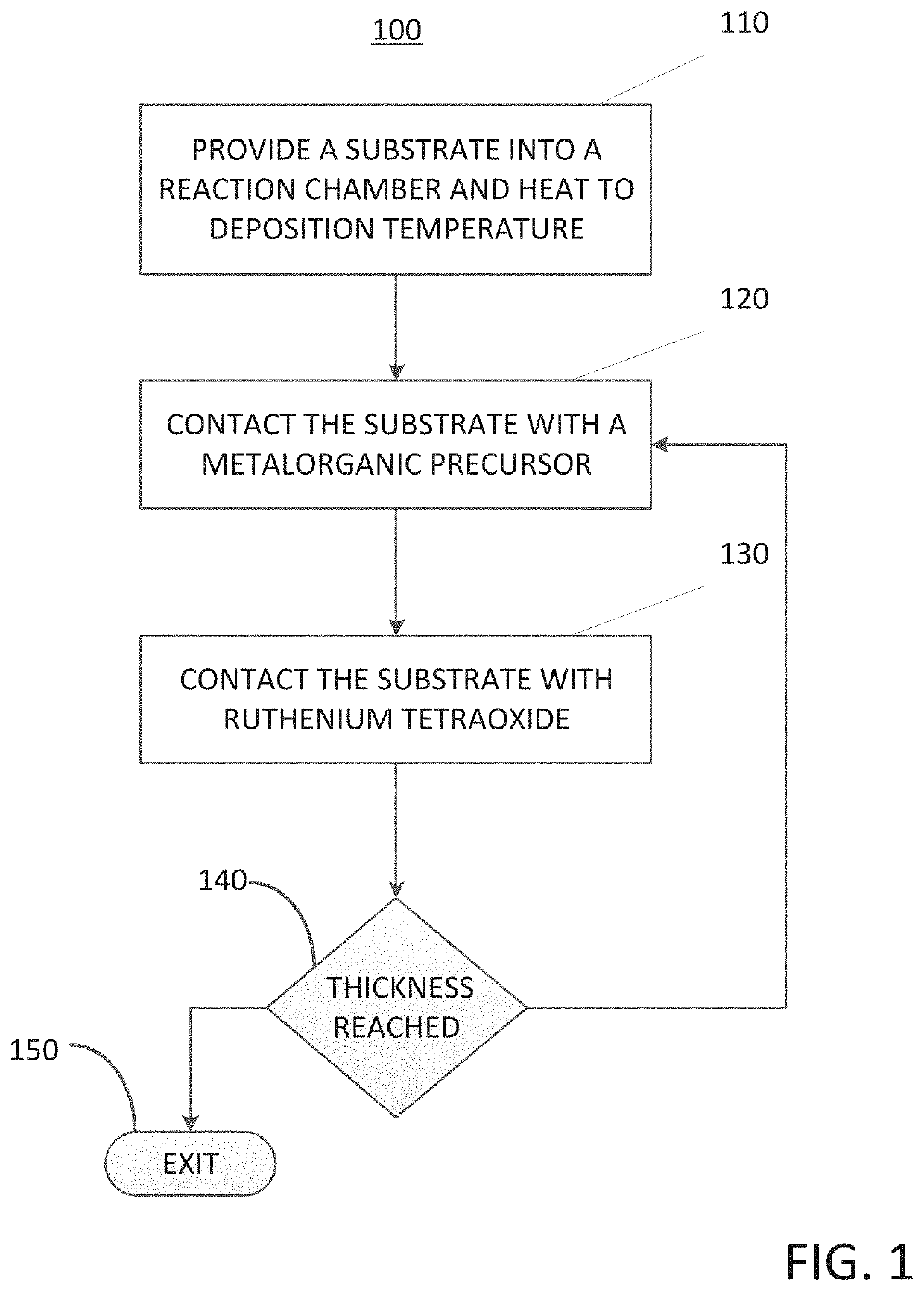

Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process

A method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a metalorganic precursor, the metalorganic precursor comprising a metal selected from the group consisting of a cobalt, nickel, tungsten, molybdenum, manganese, iron, and combinations thereof. The method may also include; contacting the substrate with a second vapor phase reactant comprising ruthenium tetroxide (RuO4); wherein the ruthenium-containing film comprises a ruthenium-metal alloy. Semiconductor device structures including ruthenium-metal alloys deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process

A method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a metalorganic precursor, the metalorganic precursor comprising a metal selected from the group consisting of a cobalt, nickel, tungsten, molybdenum, manganese, iron, and combinations thereof. The method may also include; contacting the substrate with a second vapor phase reactant comprising ruthenium tetroxide (RuO4); wherein the ruthenium-containing film comprises a ruthenium-metal alloy. Semiconductor device structures including ruthenium-metal alloys deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

Method and apparatus for the selective deposition of epitaxial germanium stressor alloys

ActiveUS20120247386A1Reduce adhesionPolycrystalline material growthSemiconductor/solid-state device manufacturingHeterojunctionHalogen

A method and apparatus for forming heterojunction stressor layers is described. A germanium precursor and a metal precursor are provided to a chamber, and an epitaxial layer of germanium-metal alloy formed on the substrate. The metal precursor is typically a metal halide, which may be provided by subliming a solid metal halide or by contacting a pure metal with a halogen gas. The precursors may be provided through a showerhead or through a side entry point, and an exhaust system coupled to the chamber may be separately heated to manage condensation of exhaust components.

Owner:APPLIED MATERIALS INC

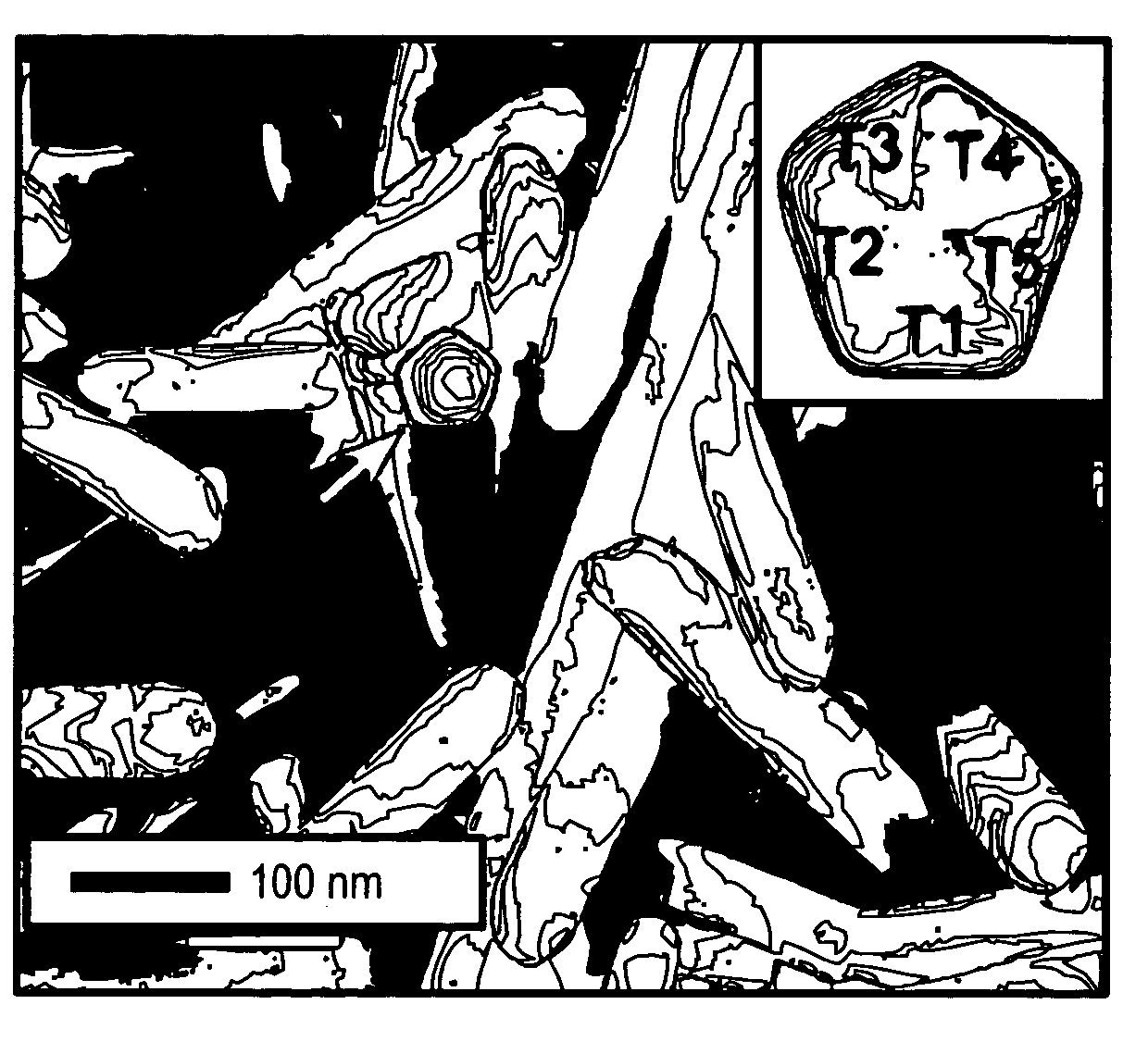

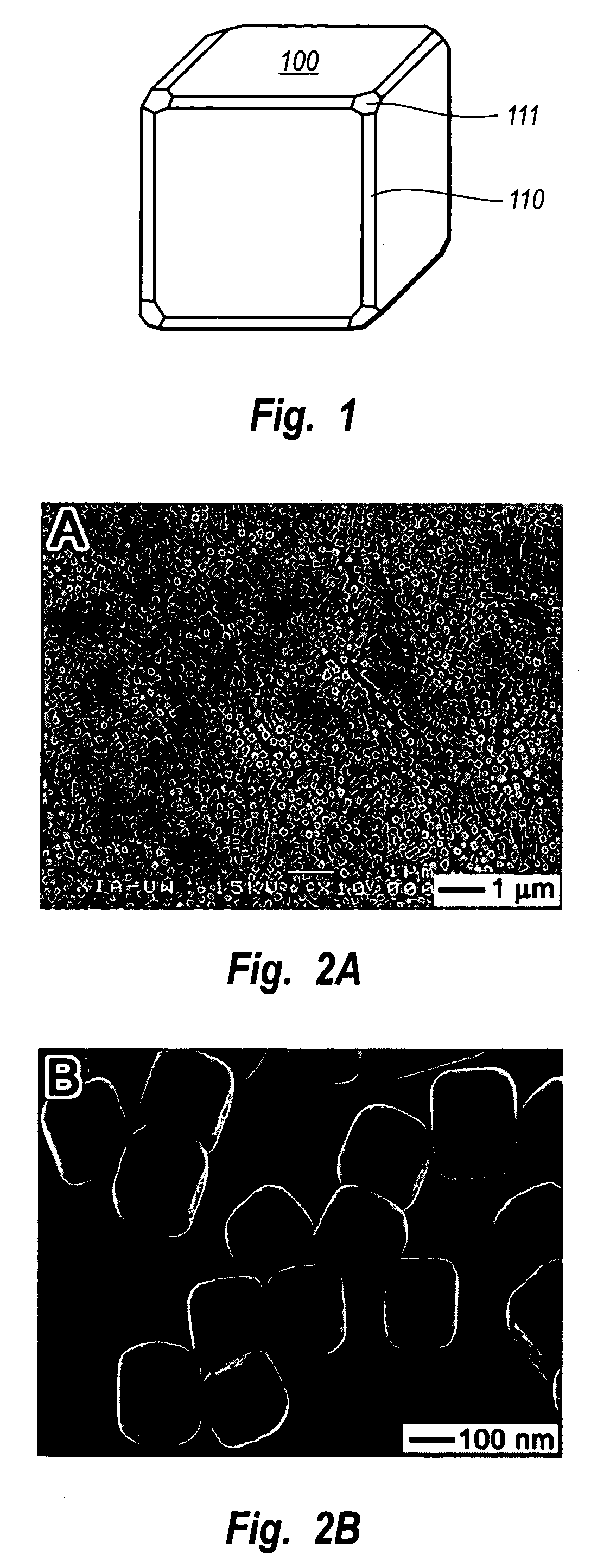

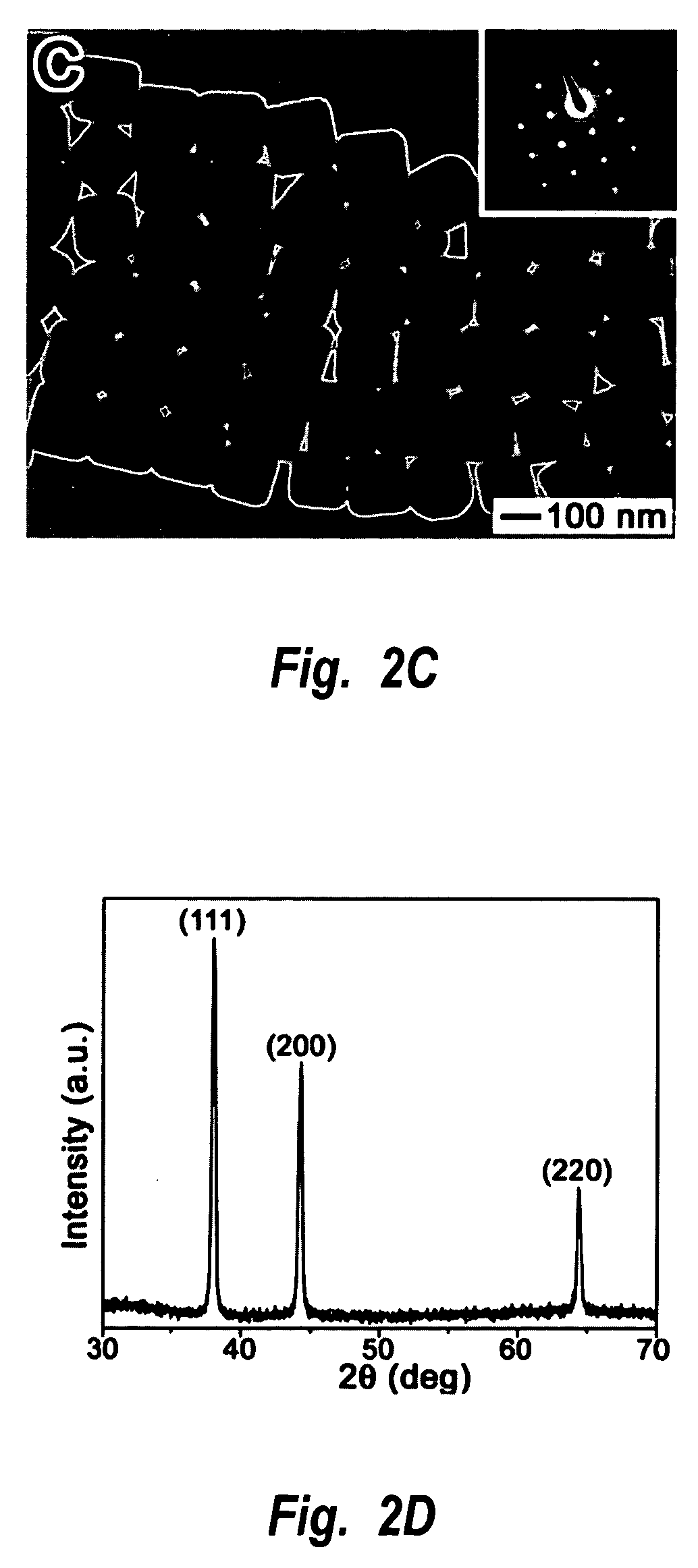

Methods of nanostructure formation and shape selection

Methods for forming nanostructures of various shapes are disclosed. Nanocubes, nanowires, nanopyramids and multiply twinned particles of silver may by formed by combining a solution of silver nitrate in ethylene glycol with a solution of poly(vinyl pyrrolidone) in ethylene glycol. Hollow nanostructures may be formed by reacting a solution of solid nanostructures comprising one of a first metal and a first metal alloy with a metal salt that can be reduced by the first metal or first metal alloy. Nanostructures comprising a core with at least one nanoshell may be formed by plating a nanostructure and reacting the plating with a metal salt.

Owner:UNIV OF WASHINGTON

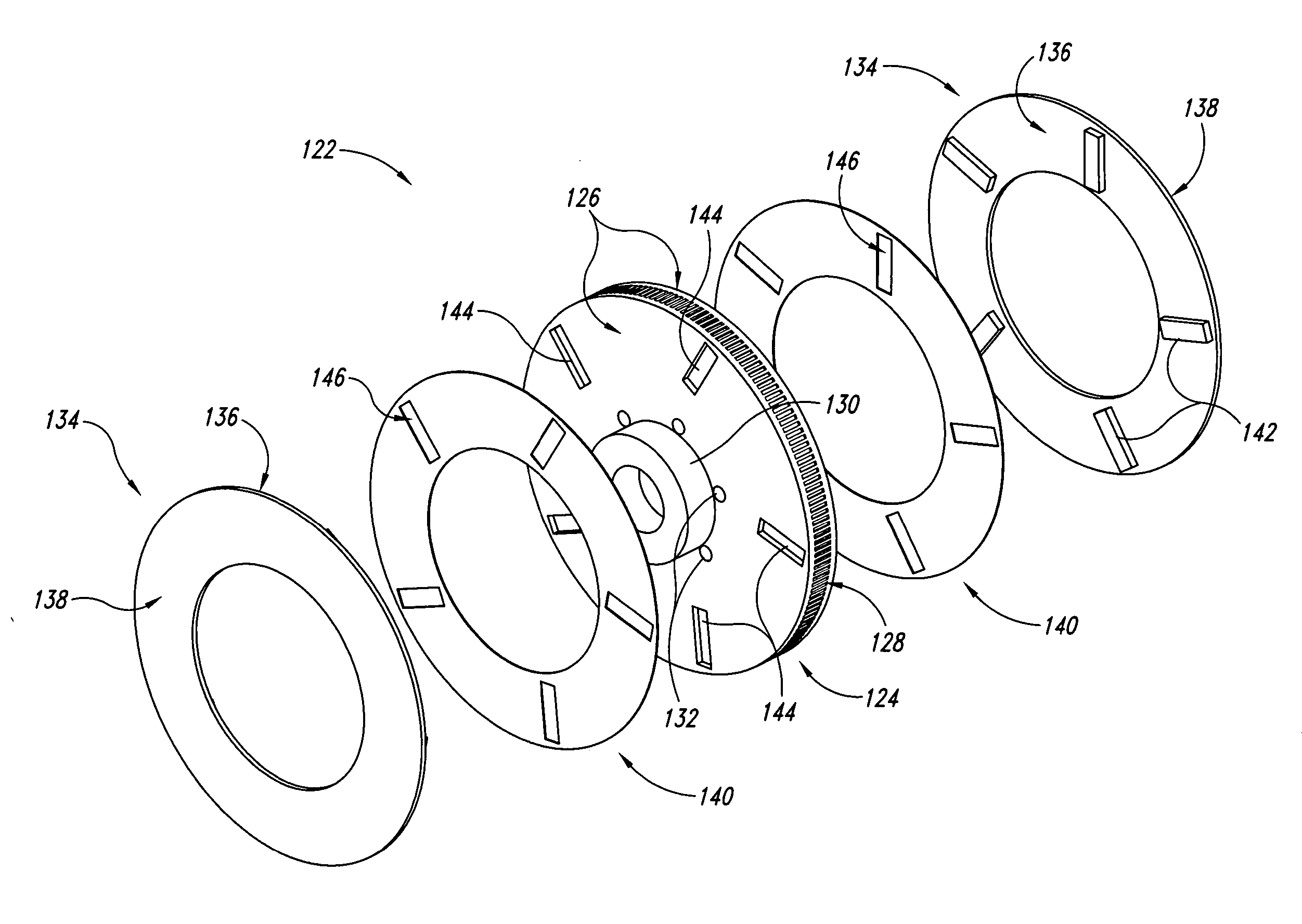

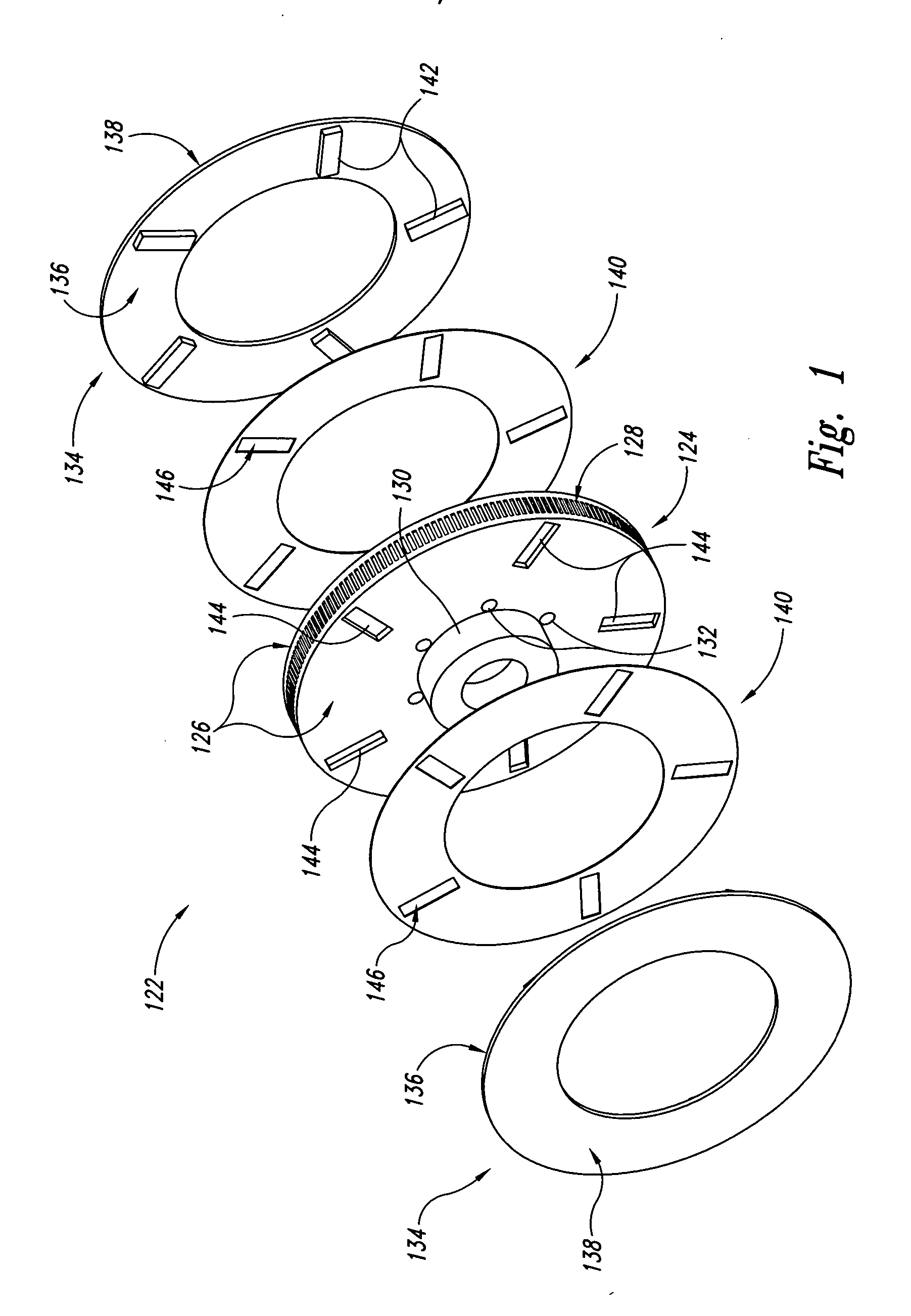

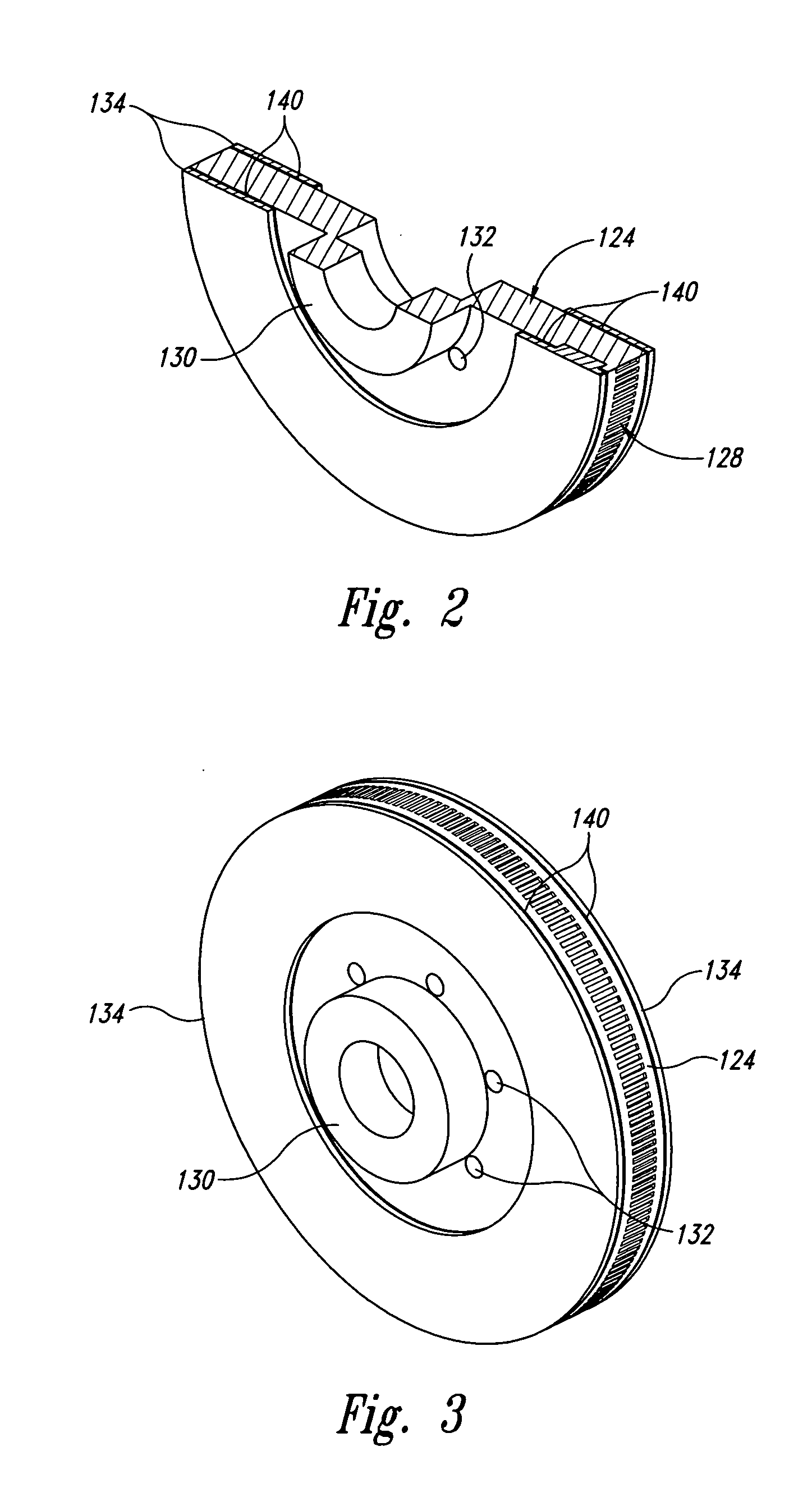

Disc brake rotor assembly and method for producing same

InactiveUS20050183909A1Improve thermal conductivityOptimize acoustic frequency transferBraking element arrangementsNoise/vibration controlAdhesiveMetal alloy

Novel composite disc brake rotor assemblies are provided, along with novel and efficient methods for manufacturing them. Preferably, the rotor assemblies comprise annular wear plates formed of particle reinforced aluminum-based metal matrix composite (MMC), ceramic matrix composite (CMC), or of ‘carbon graphite foam.’ The wear plates, made of a first material, are attached to annular surfaces of a central rotor, made of a second material, by fusing bonding layers between the wear plates and the rotor surfaces. The bonding layers are comprised of at least one of a metal alloy having a melting temperature lower than that of either the first or second materials, and a high-temperature adhesive. Preferably, the wear plates comprise projections that are positioned within adjacent receiving recesses in the center rotor. The bonding layers and projections enhance thermal and acoustical transference between the wear plates and the center rotor section. Carbon graphite foam provides for substantially enhanced heat transference. Use of the fusable binding layer, or adhesive provides for an efficient, low cost method of manufacturing for composite disc brake rotor assemblies.

Owner:BENMAXX

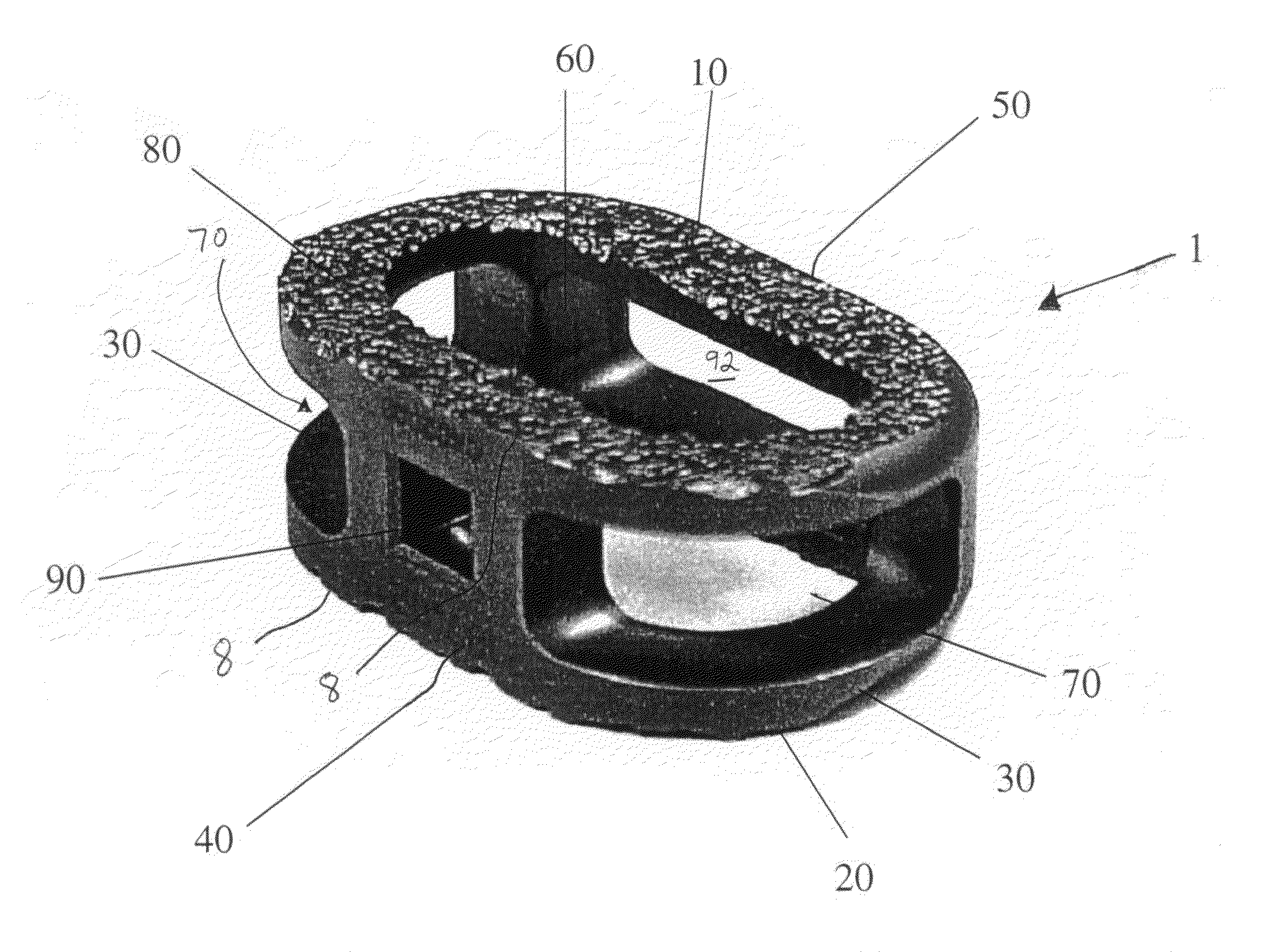

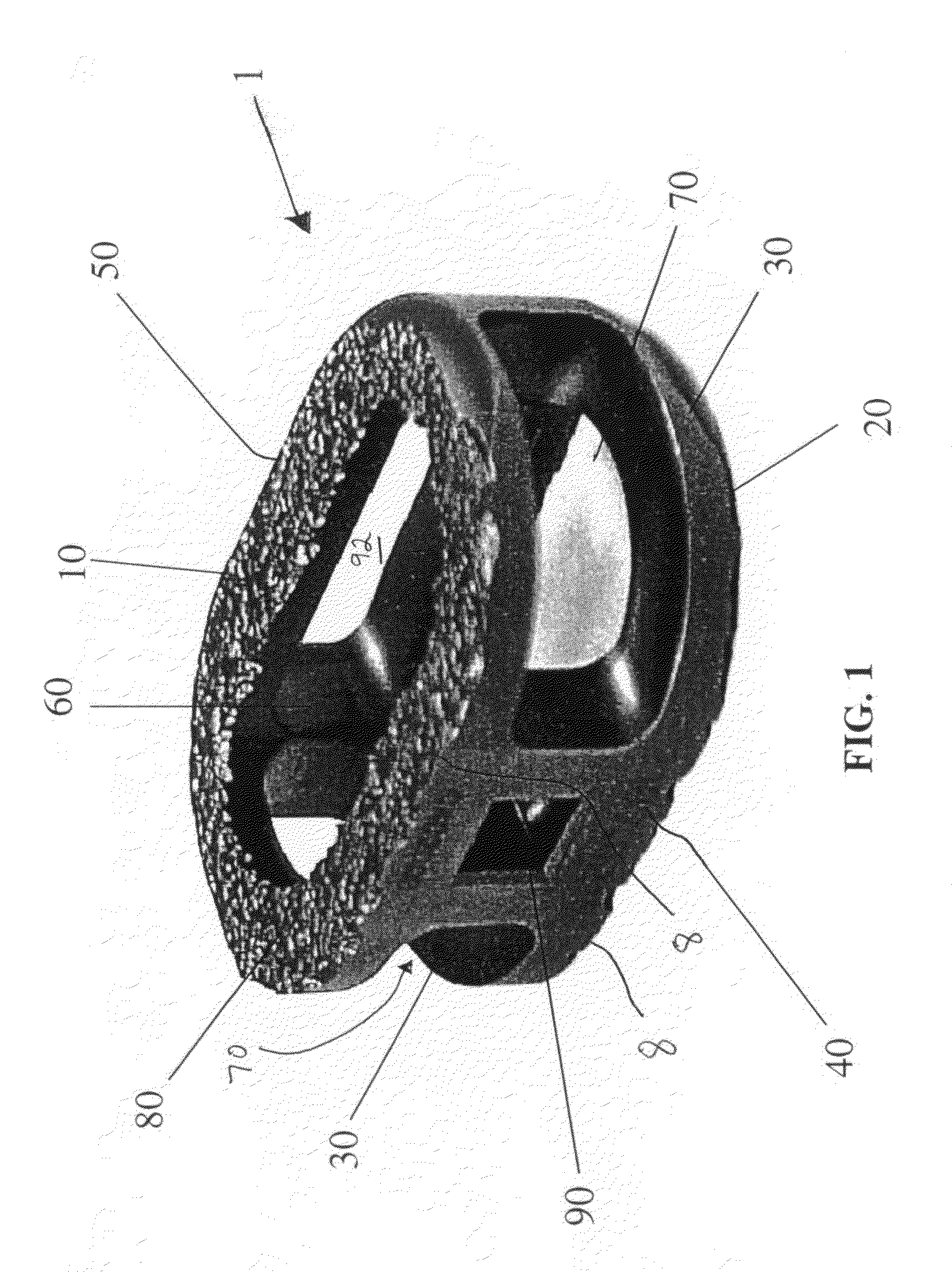

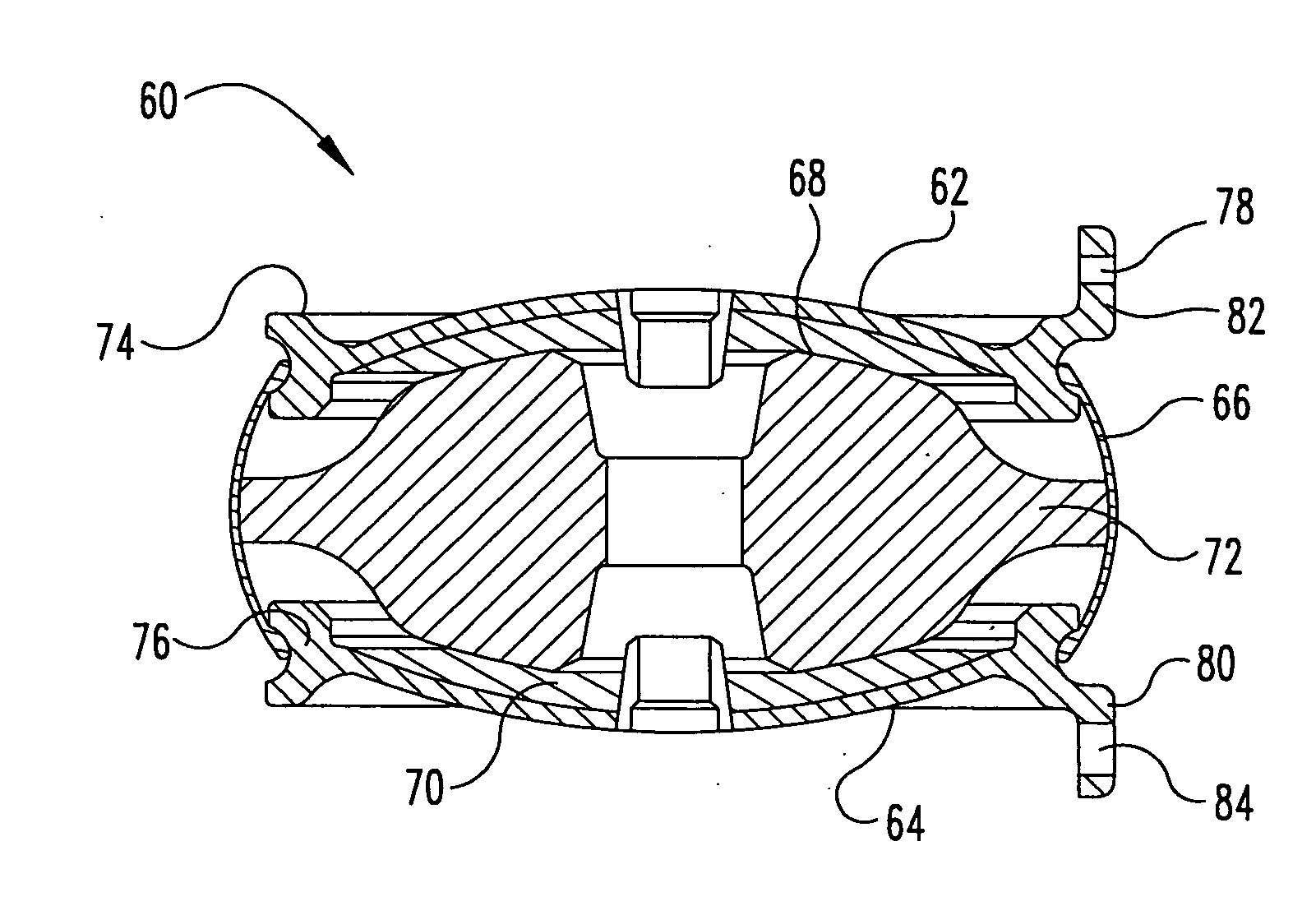

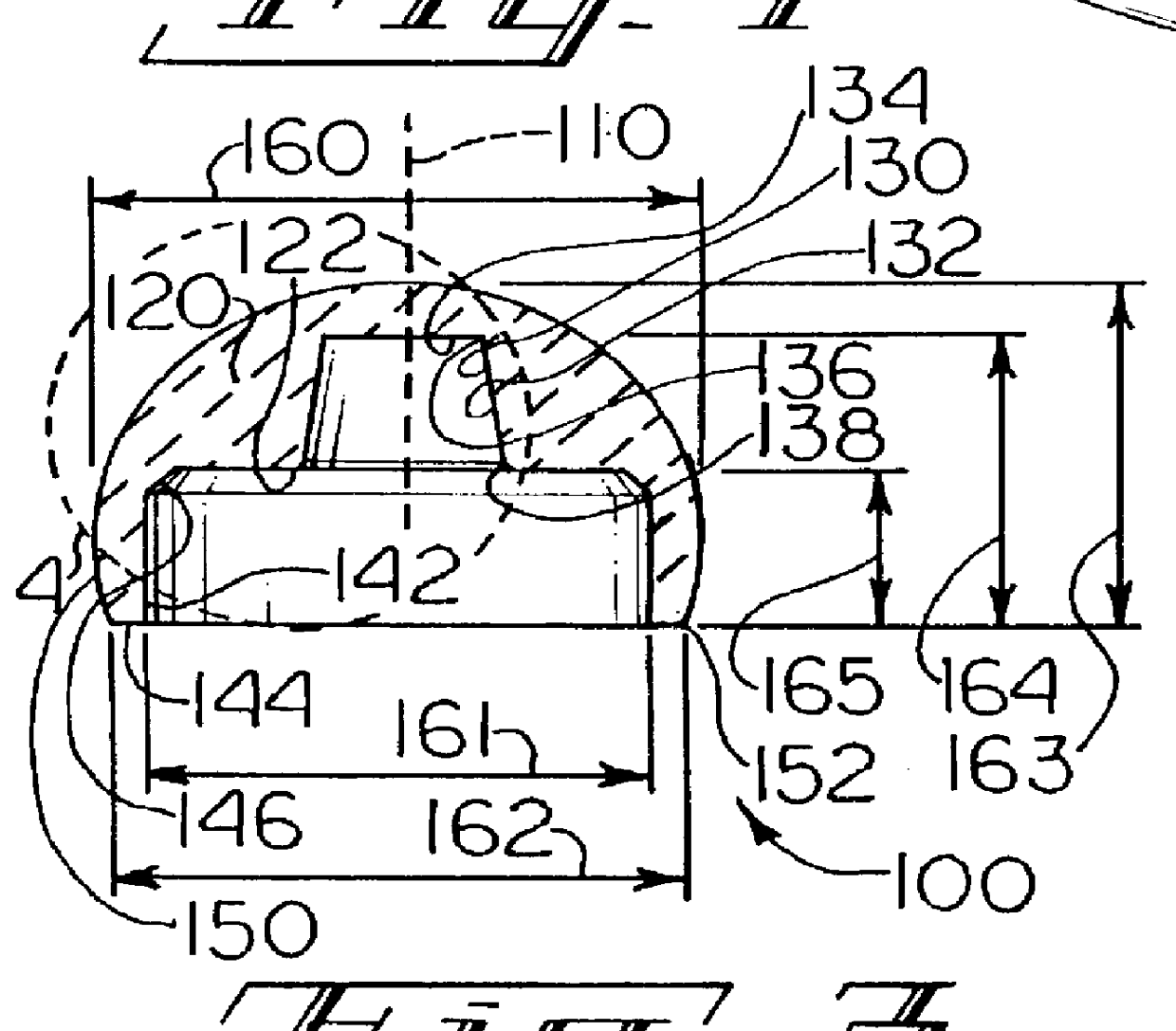

Composite telescoping anterior interbody spinal implant

InactiveUS20100076559A1Add seatsImprove visualizationBone implantSpinal implantsMetal alloySpinal implant

A composite telescoping interbody spinal implant and method of using the implant. The implant includes a cage formed of metal, a metal alloy, or both. The cage is able to change size following manufacture, and has a top plate with a plurality of posts and a bottom plate with a corresponding plurality of columns. The posts telescopically engage the columns upon assembly of the top plate with the bottom plate. The posts extend partially outside the columns when the top plate is in a raised first position with respect to the bottom plate; the posts and columns are fully engaged when the top plate is in a second position closest to the bottom plate. The implant also includes a non-metallic body inserted between the top plate and the bottom plate and defining the adjustable height of the implant.

Owner:TITAN SPINE

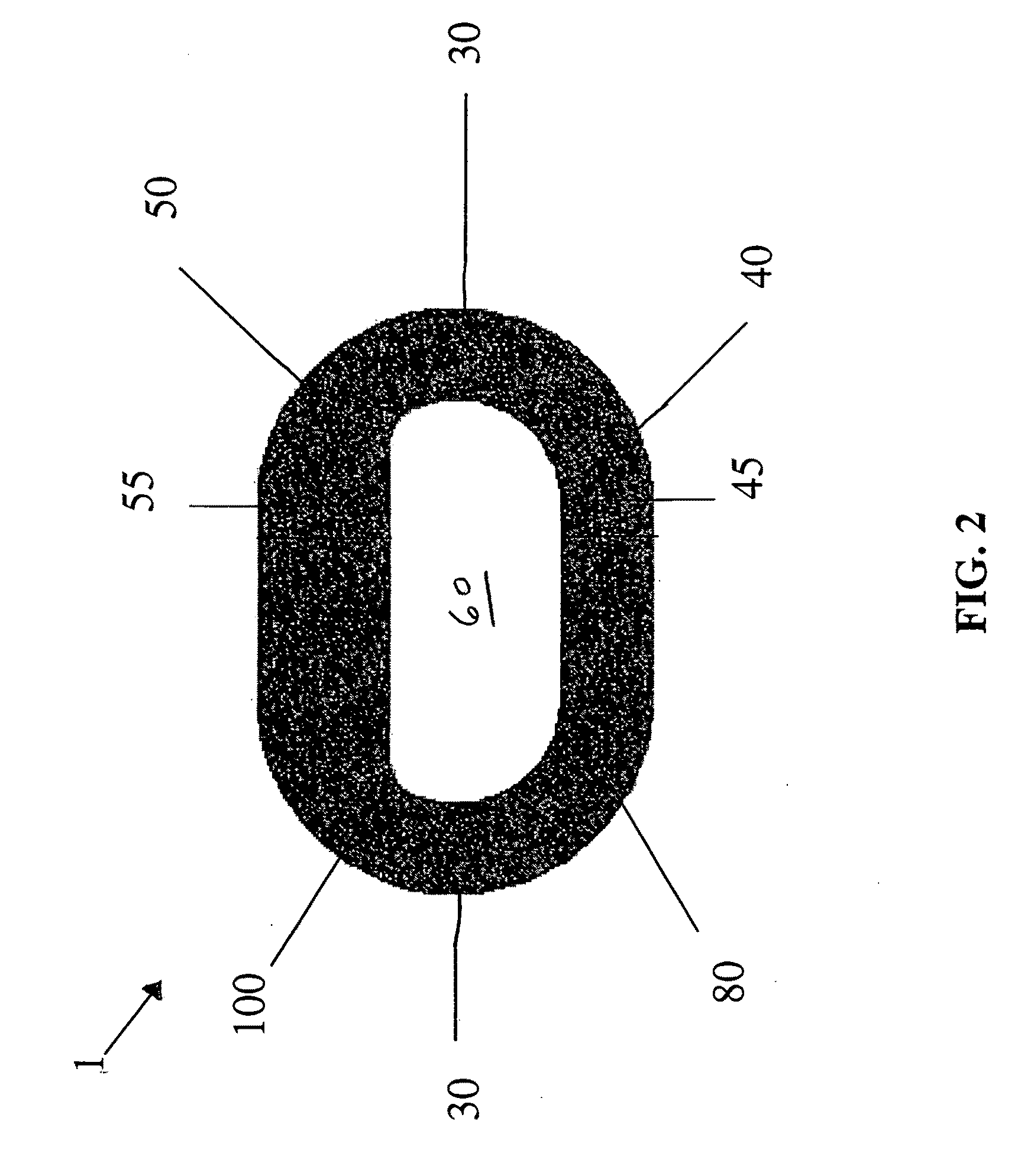

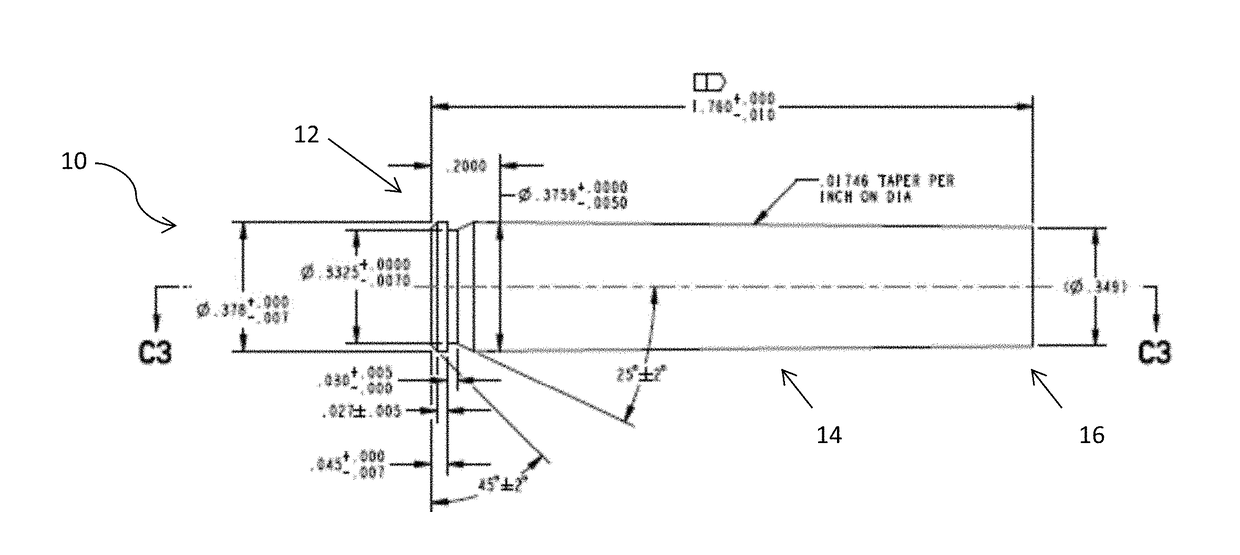

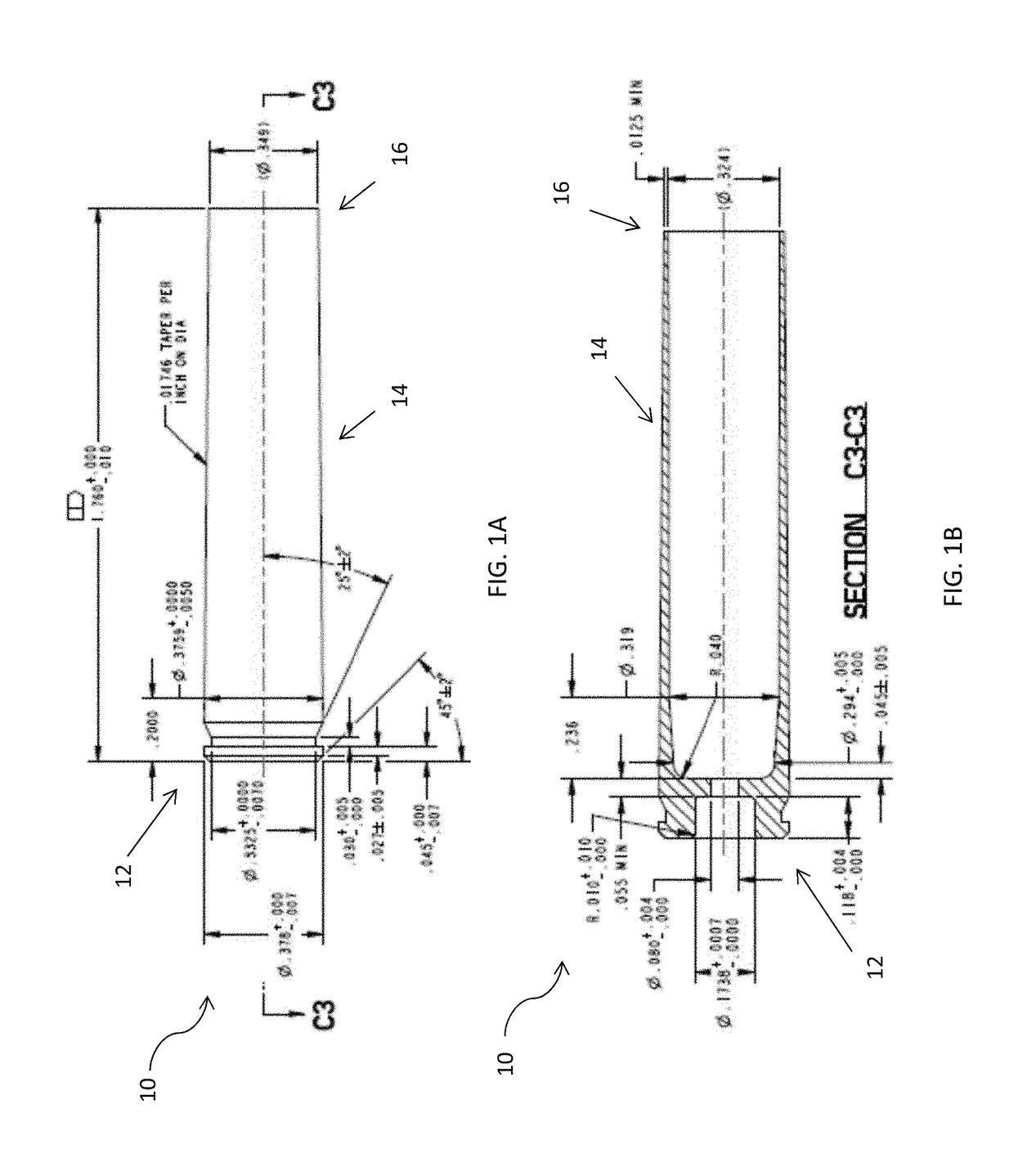

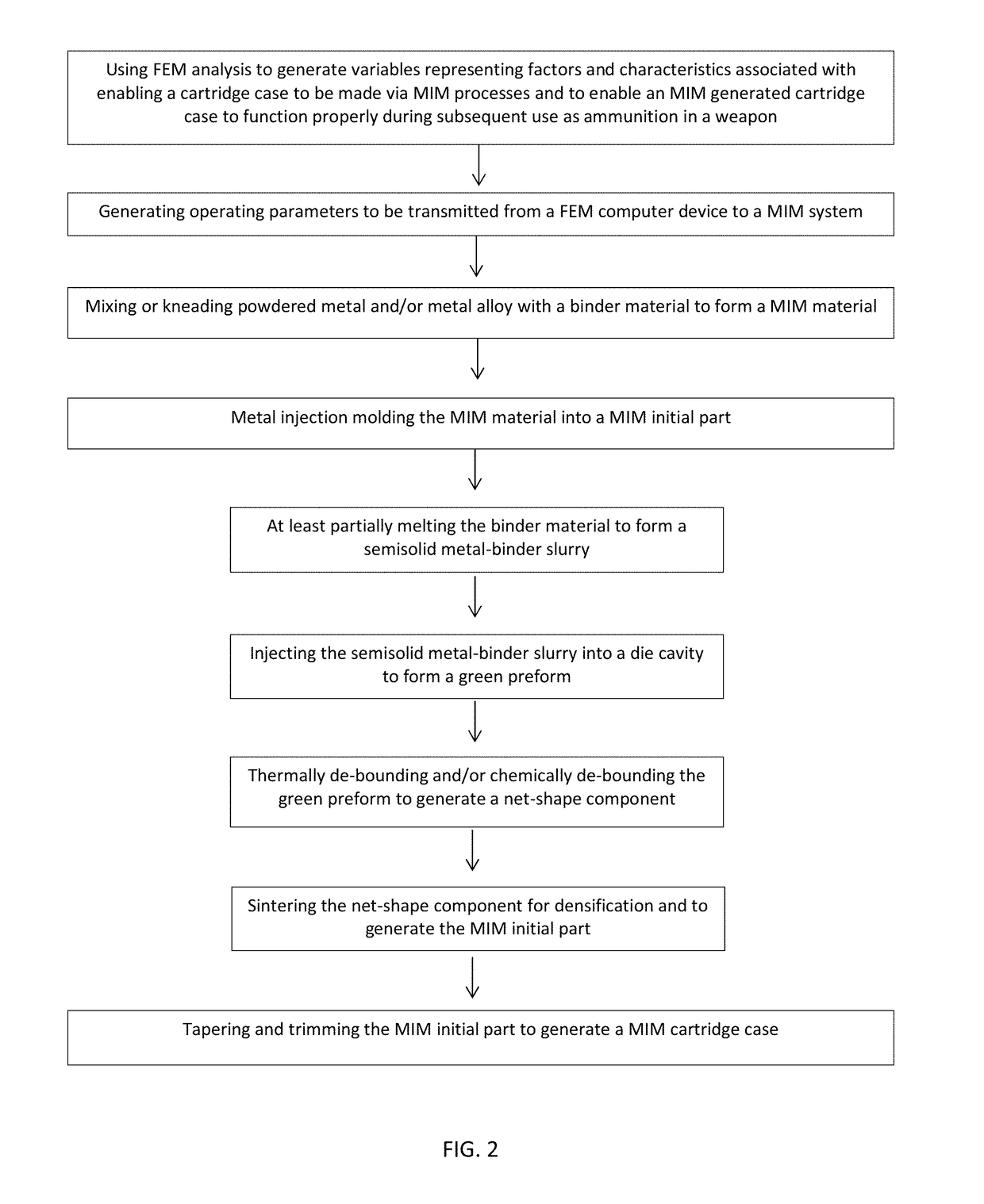

Metal Injection Molded Cased Telescoped Ammunition

ActiveUS20180066925A1Promote generationLight weightTransportation and packagingMetal-working apparatusMetal alloySlug

Disclosed is a cartridge case for various caliber ammunition that can consist essentially of a powdered metal and / or powdered metal alloy(s) that is formed into the cartridge case through an injection mold processing. Also disclosed is a method for forming a cartridge case, which may include use of Metal Injection Molding (“MIM”) processes to produce the cartridge case which retains a primer, propellant, and / or a bullet. Also disclosed are embodiments related to a case telescoped cartridge that may include a cap and a body. The body can consist essentially of or consists entirely of a powdered metal and / or powdered metal alloy(s) that has been formed through MIM. The cap can comprise plastic that has been formed through plastic molding or comprise powdered metal and / or powdered metal alloy(s) that has been formed through MIM.

Owner:CONCURRENT TECH

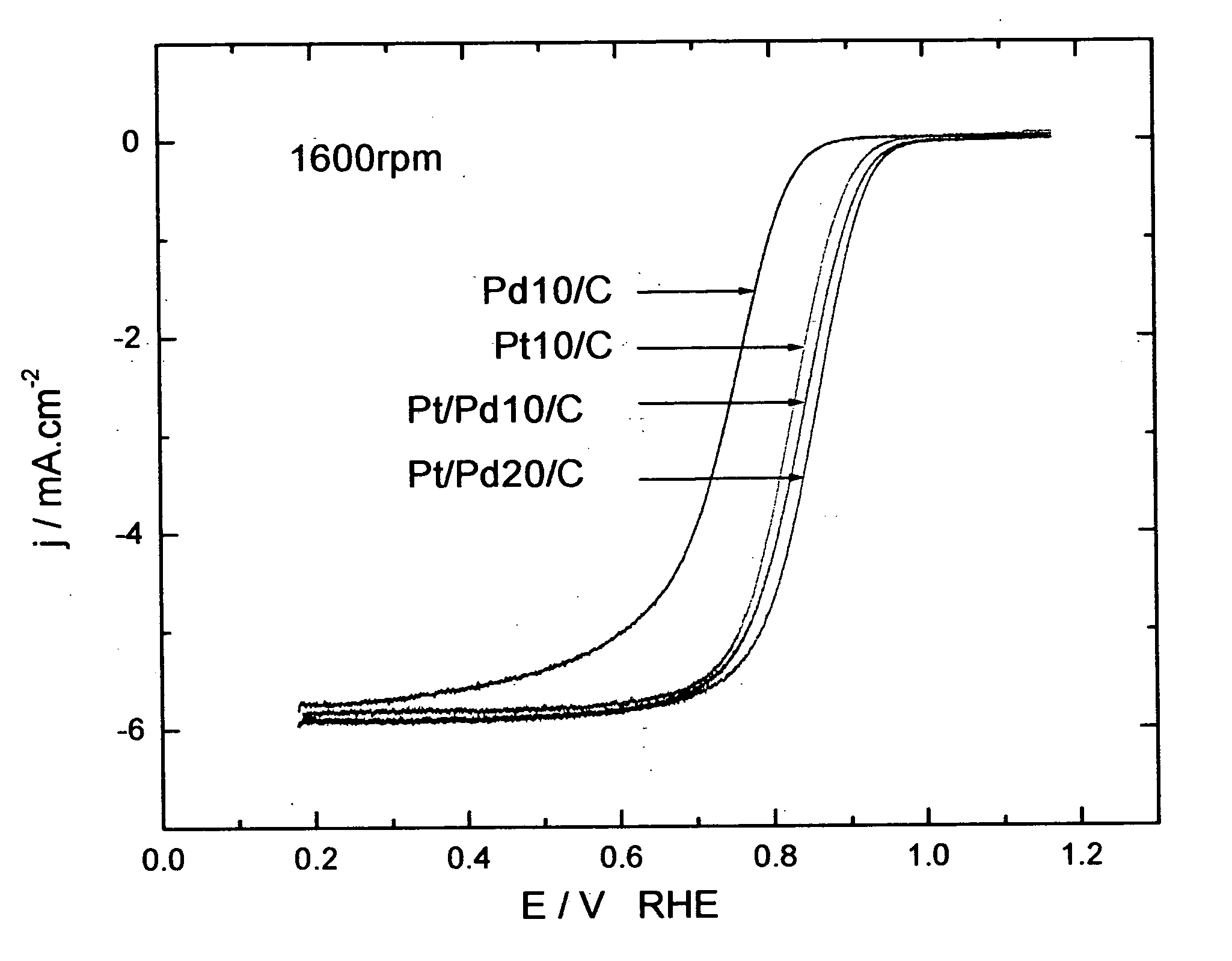

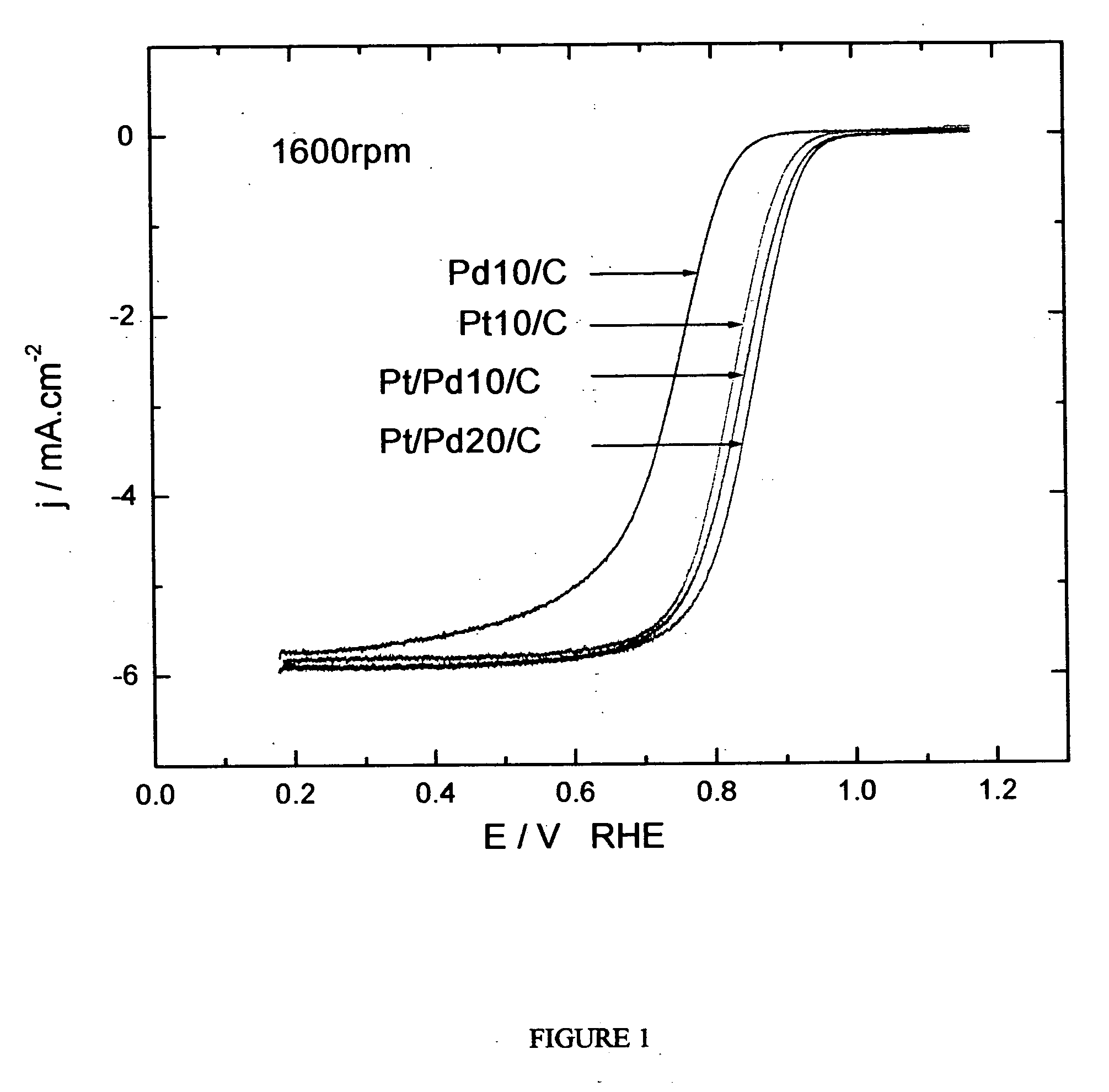

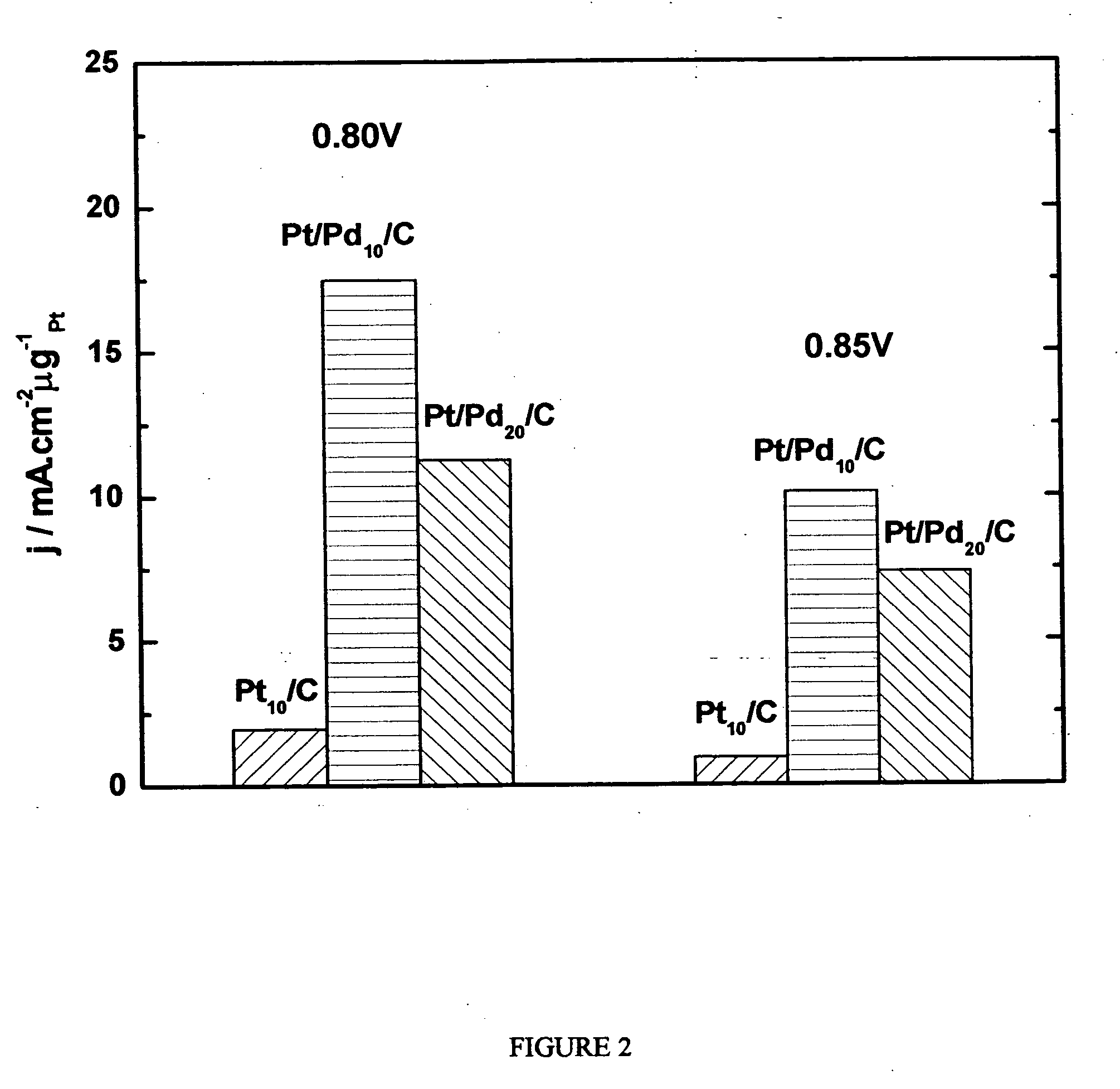

Electrocatalysts having platinum monolayers on palladium, palladium alloy, and gold alloy nanoparticle cores, and uses thereof

ActiveUS20070031722A1Improved oxygen-reducing catalytic activityLow platinum loadingMetal-working apparatusActive material electrodesRheniumGold alloys

The invention relates to platinum-coated particles useful as fuel cell electrocatalysts. The particles are composed of a noble metal or metal alloy core at least partially encapsulated by an atomically thin surface layer of platinum atoms. The invention particularly relates to such particles having a palladium, palladium alloy, gold alloy, or rhenium alloy core encapsulated by an atomic monolayer of platinum. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

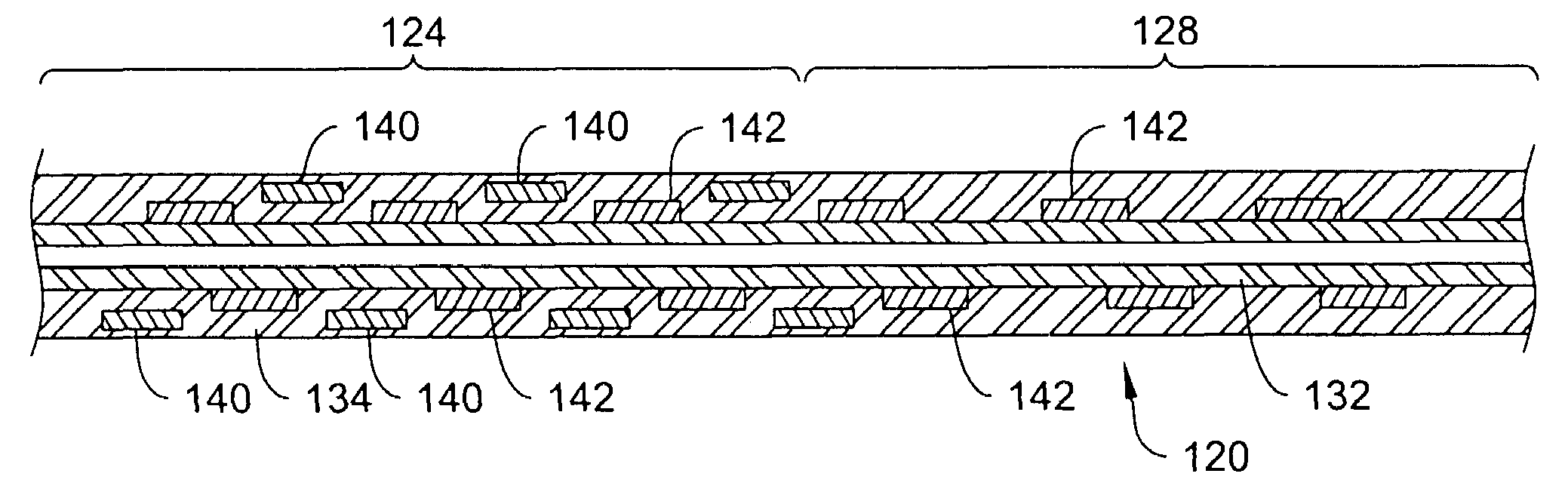

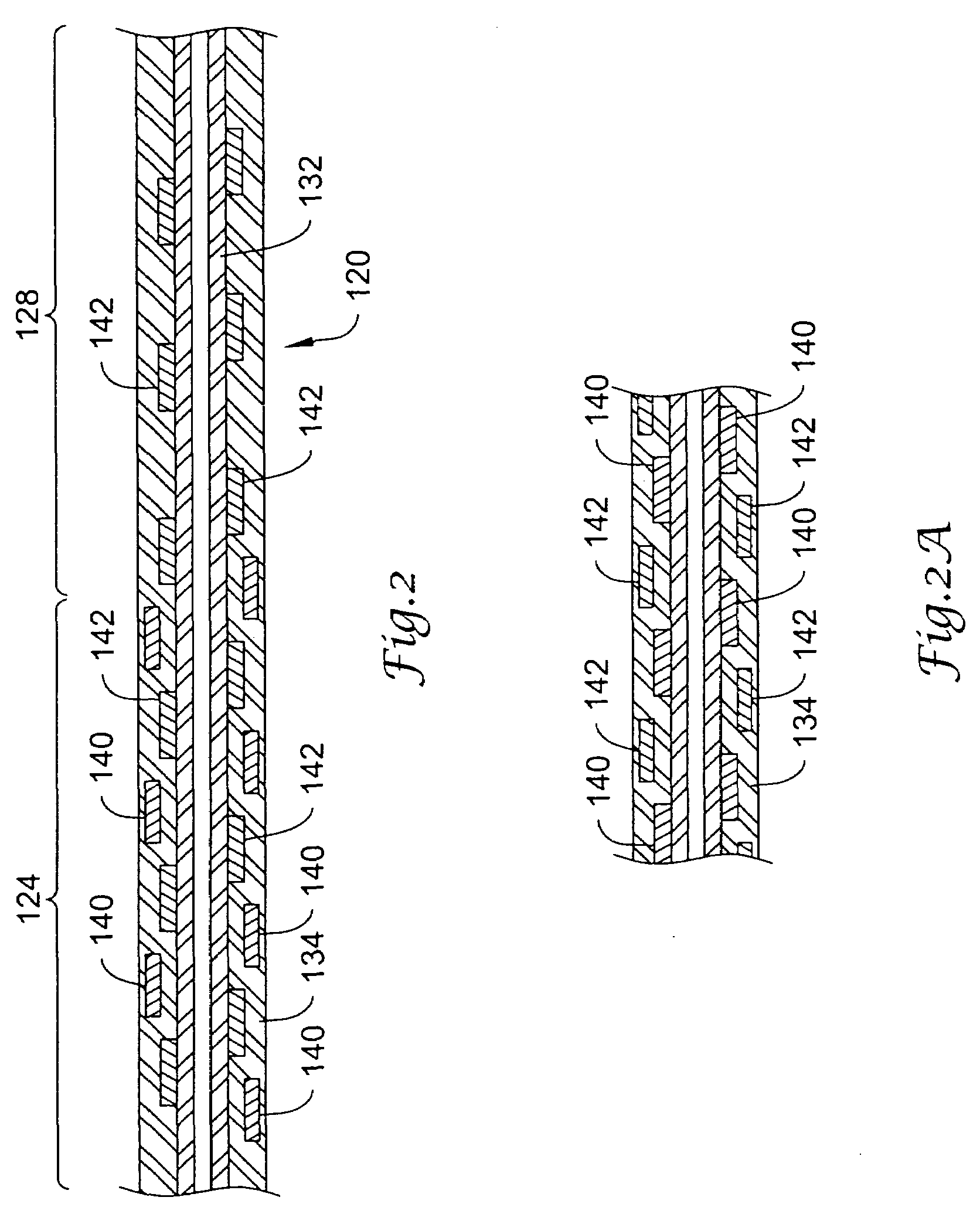

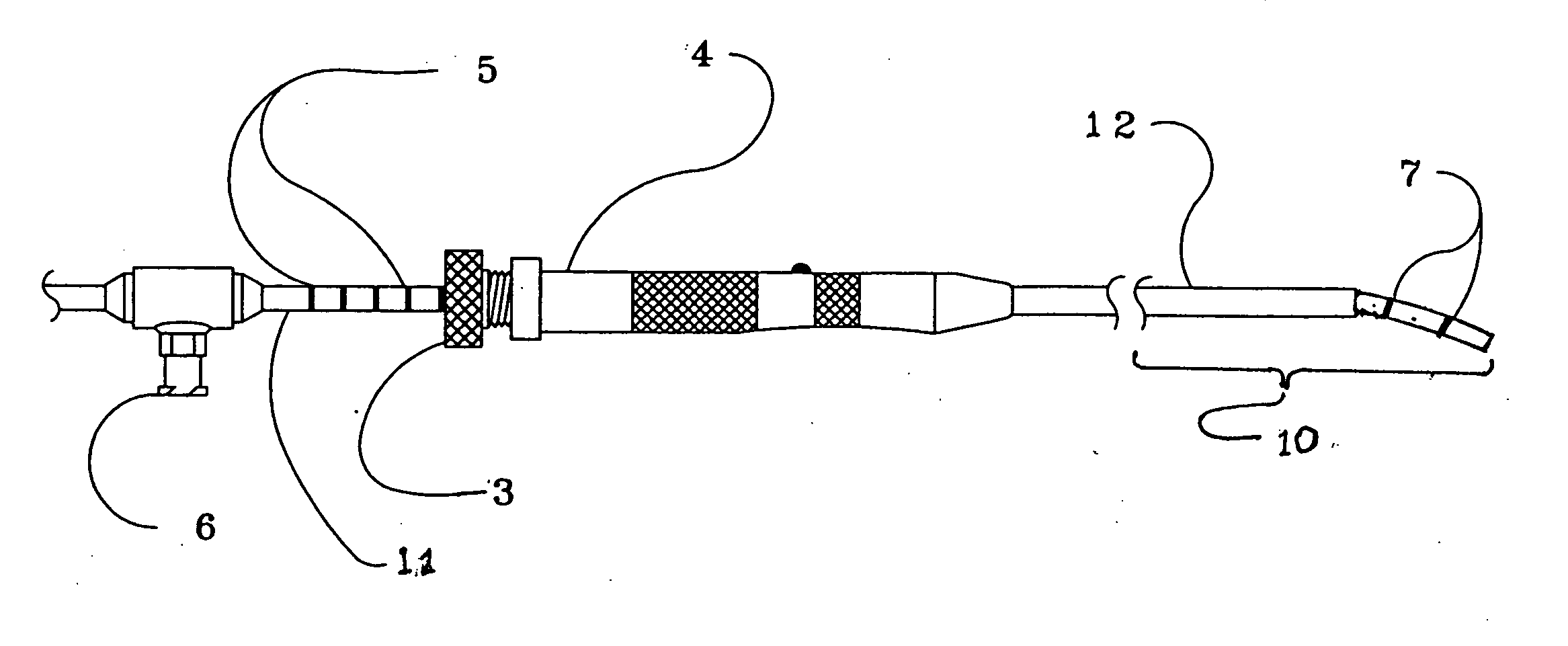

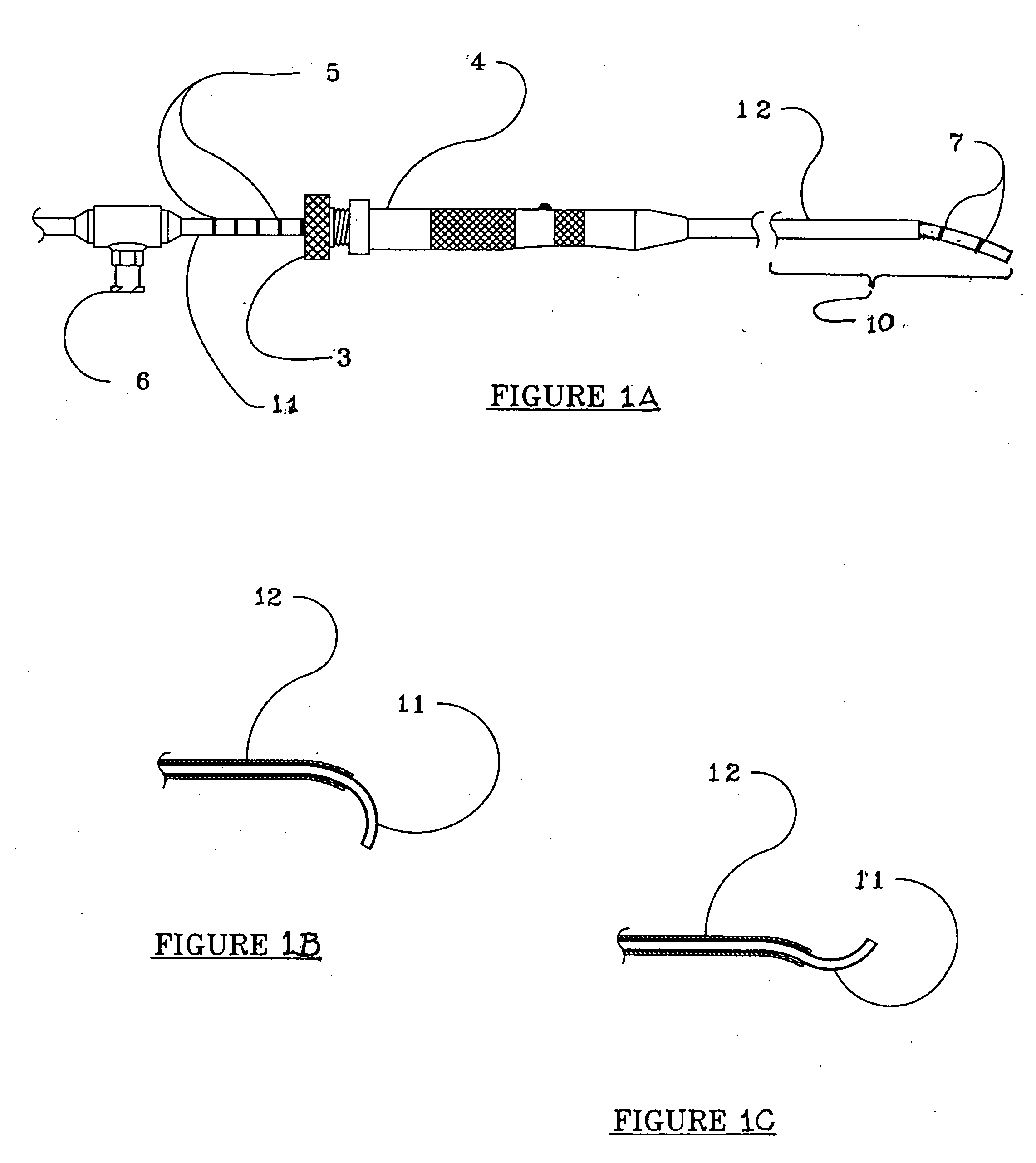

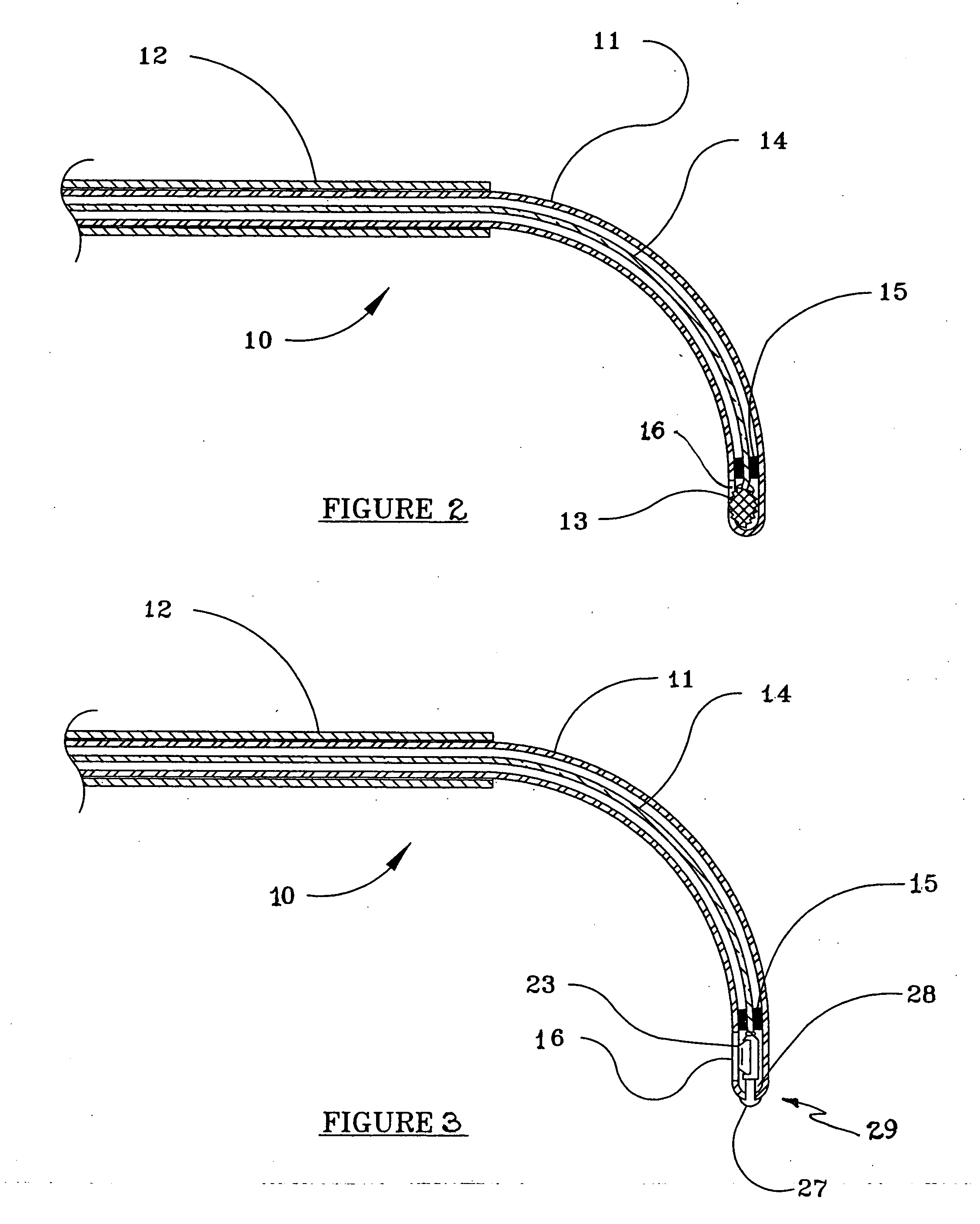

Catheter with composite stiffener

A catheter comprising an elongate tubular member having a proximal end, a distal end, and a passageway defining a lumen extending between the proximal and distal ends. The elongate tubular member comprises a relatively stiff proximal section and a relatively flexible distal section. The proximal section includes an inner tubular liner, a first stiffener comprising a metal alloy, and a second stiffener comprising a non-metal alloy. The first and second stiffeners are coaxially wound exterior to the proximal inner liner. The distal section includes a distal inner tubular liner and the second stiffener coaxially wound exterior to the distal inner liner. The first stiffener terminates before reaching the distal section.

Owner:TARGET THERAPUETICS INC

Implants based on engineered composite materials having enhanced imaging and wear resistance

This invention relates to a metal composite orthopedic device. The device can comprise a metallic substrate cladded or joined to one or more metallic layer(s). The substrate and metallic layer(s) can be selected of different metals and metal alloys to provide desired wear performance, imaging characteristics and optionally to serve as a reservoir for therapeutic agents.

Owner:WARSAW ORTHOPEDIC INC

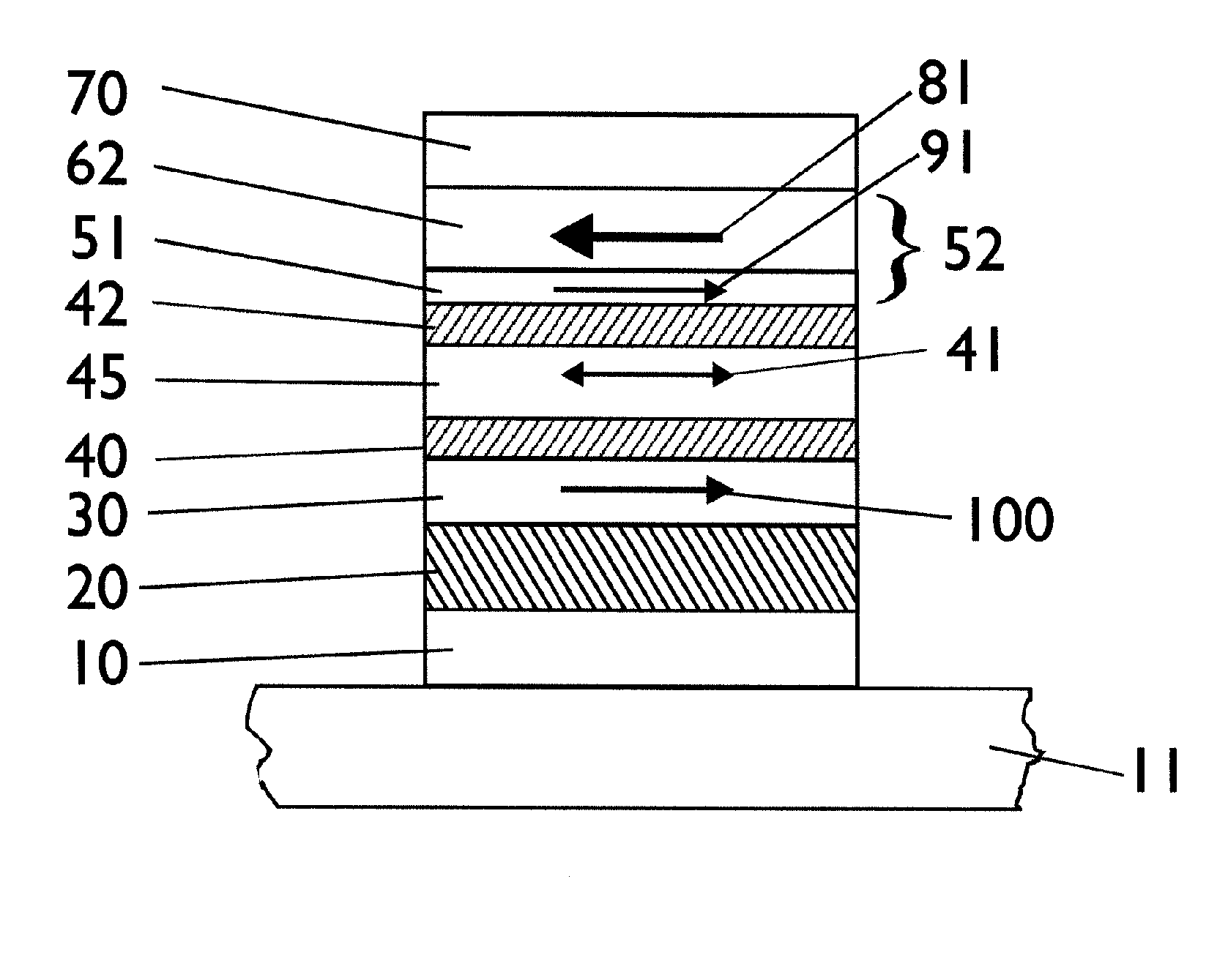

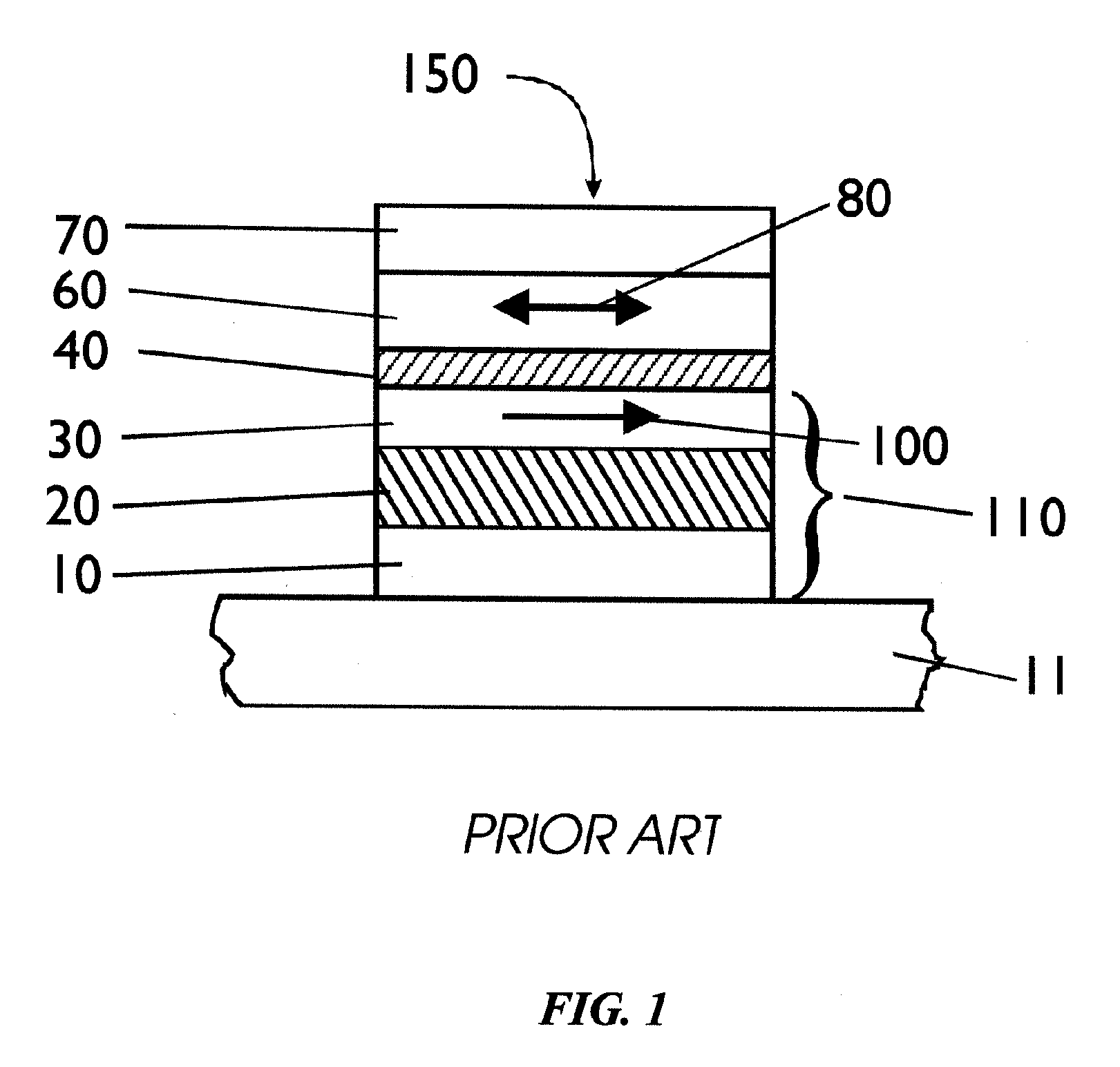

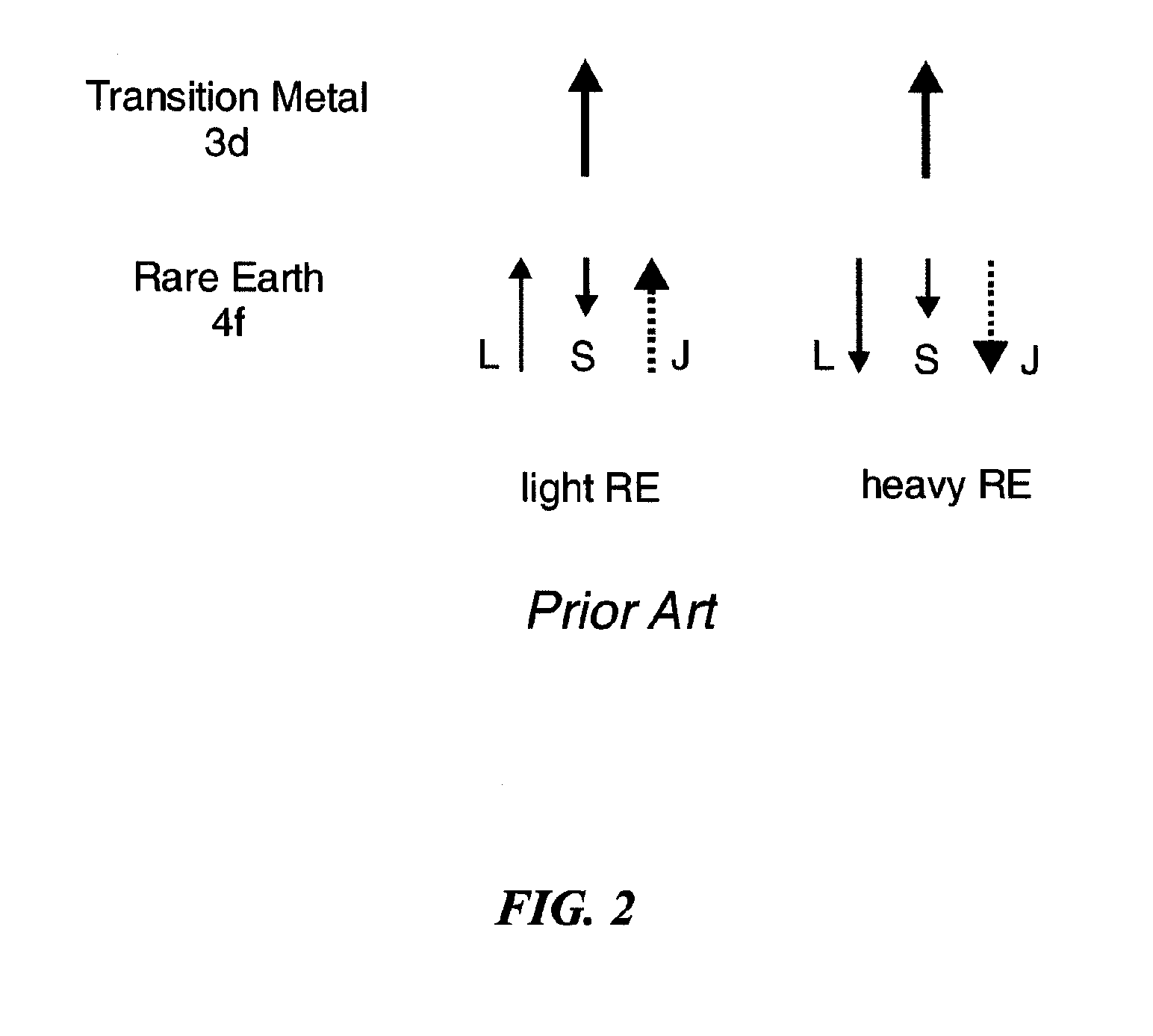

Spin-polarization devices using rare earth-transition metal alloys

ActiveUS7230265B2Magnetic-field-controlled resistorsGalvano-magnetic material selectionRare-earth elementMetal alloy

A tunnel barrier in proximity with a layer of a rare earth element-transition metal (RE—TM) alloy forms a device that passes negatively spin-polarized current. The rare earth element includes at least one element selected from the group consisting of Gd, Tb, Dy, Ho, Er, Tm, and Yb. The RE and TM have respective sub-network moments such that the absolute magnitude of the RE sub-network moment is greater than the absolute magnitude of the TM sub-network moment. An additional layer of magnetic material may be used in combination with the tunnel barrier and the RE—TM alloy layer to form a magnetic tunnel junction. Still other layers of tunnel barrier and magnetic material may be used in combination with the foregoing to form a flux-closed double tunnel junction device.

Owner:IBM CORP

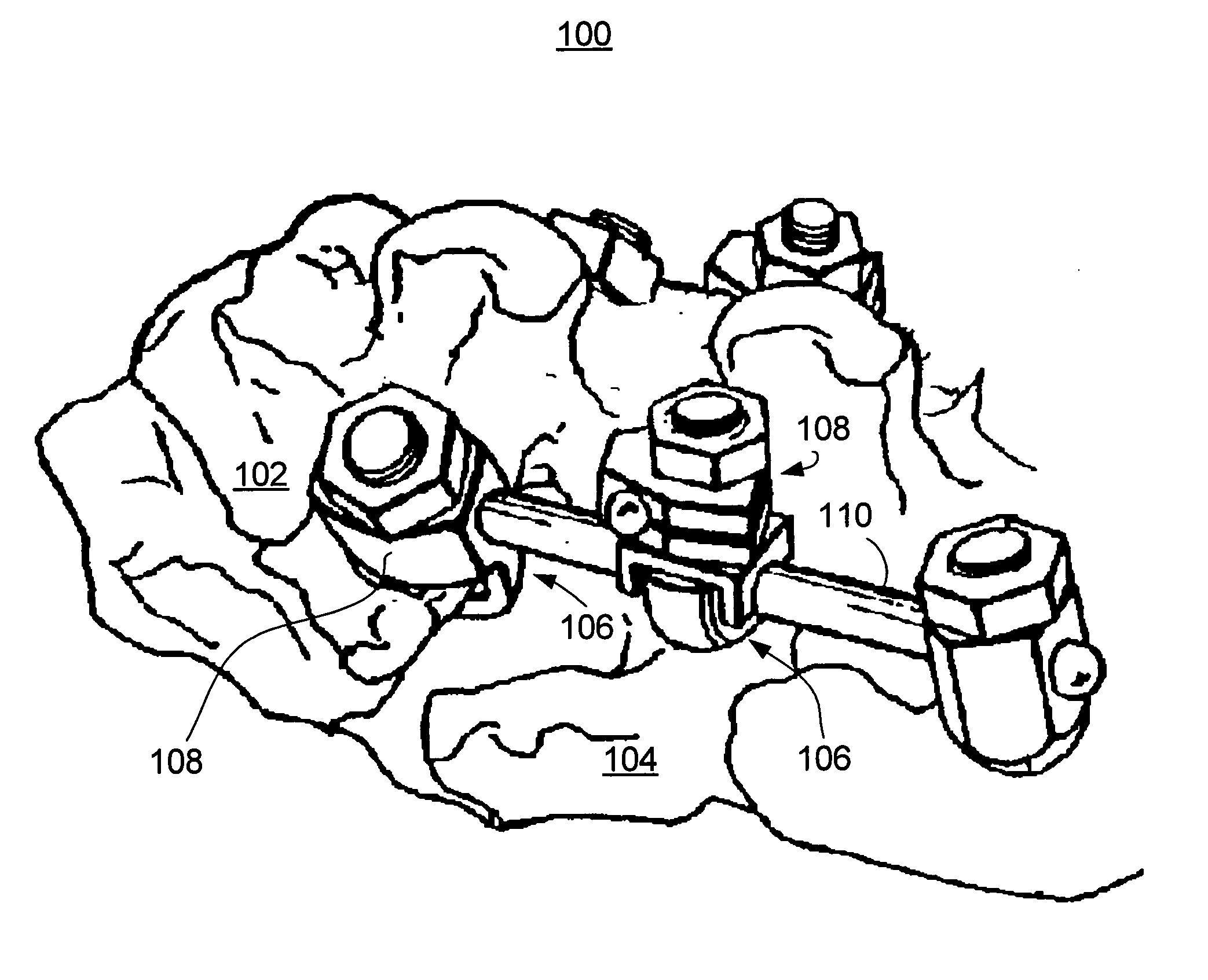

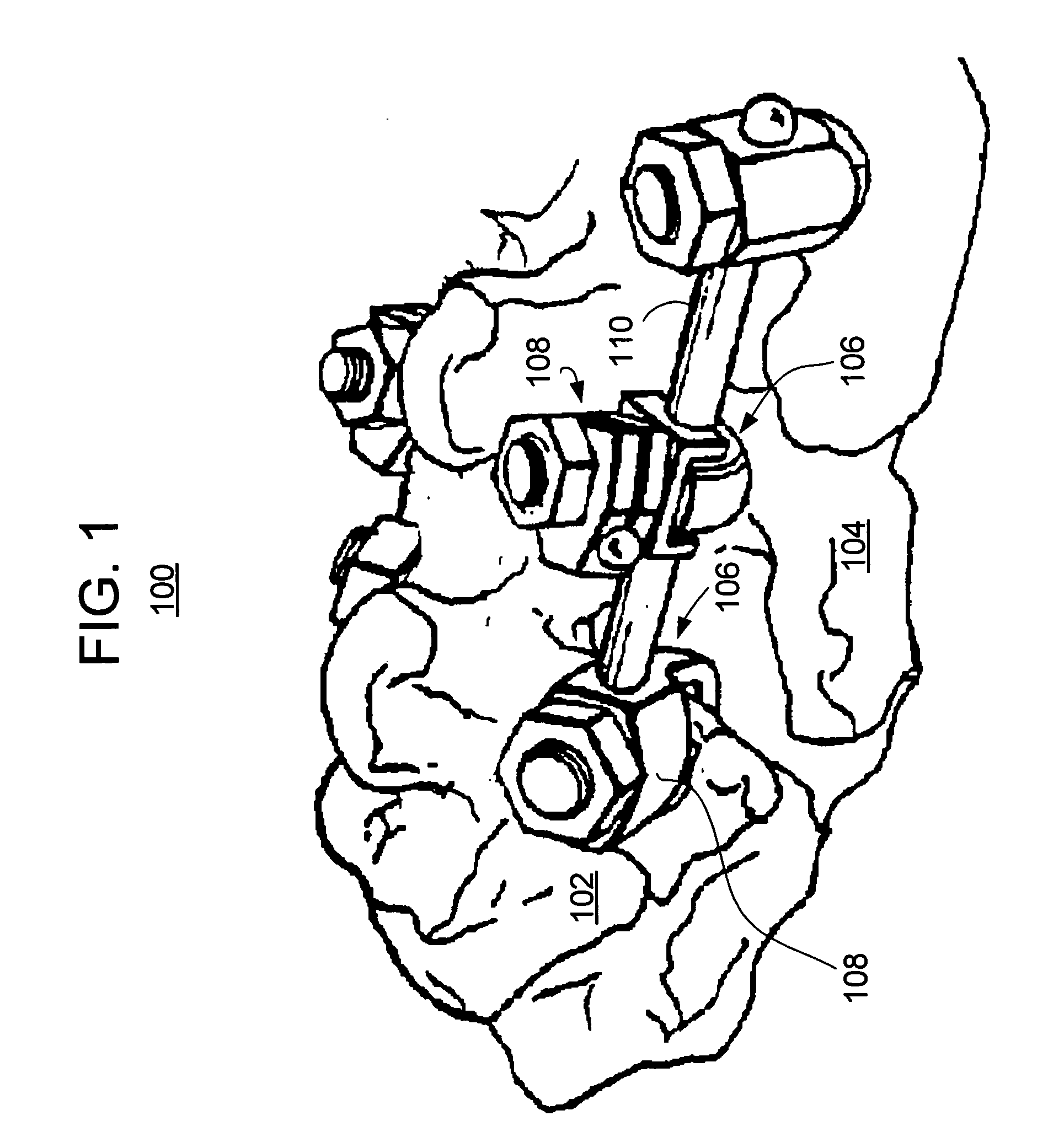

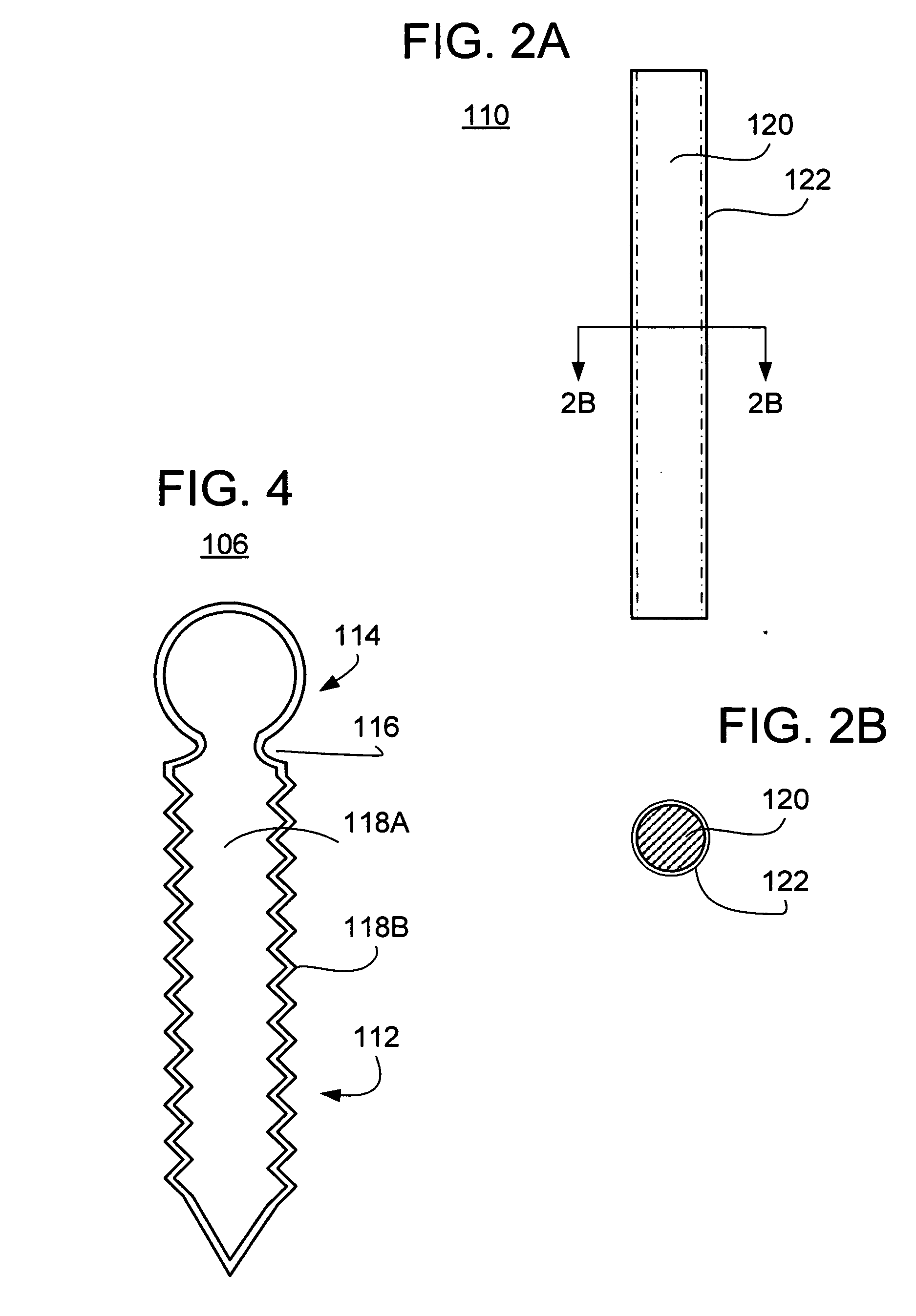

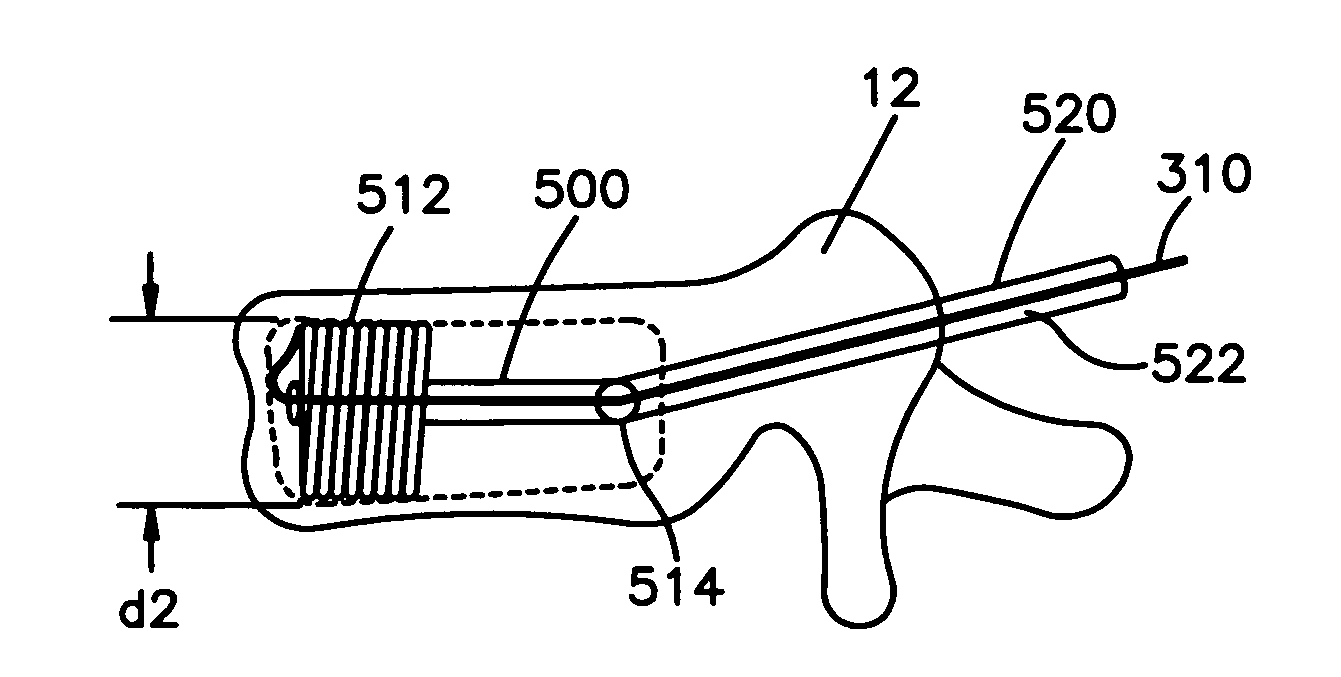

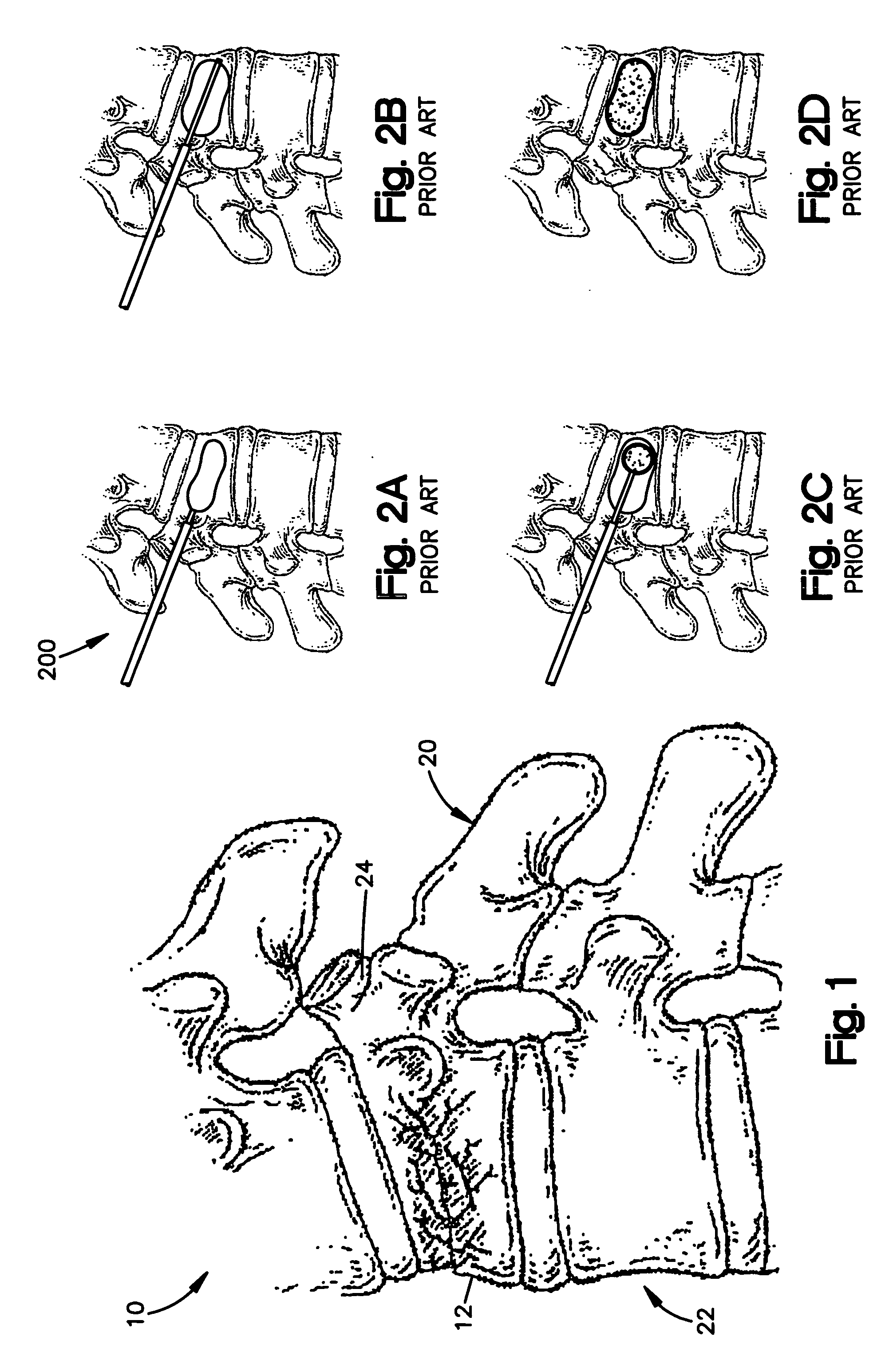

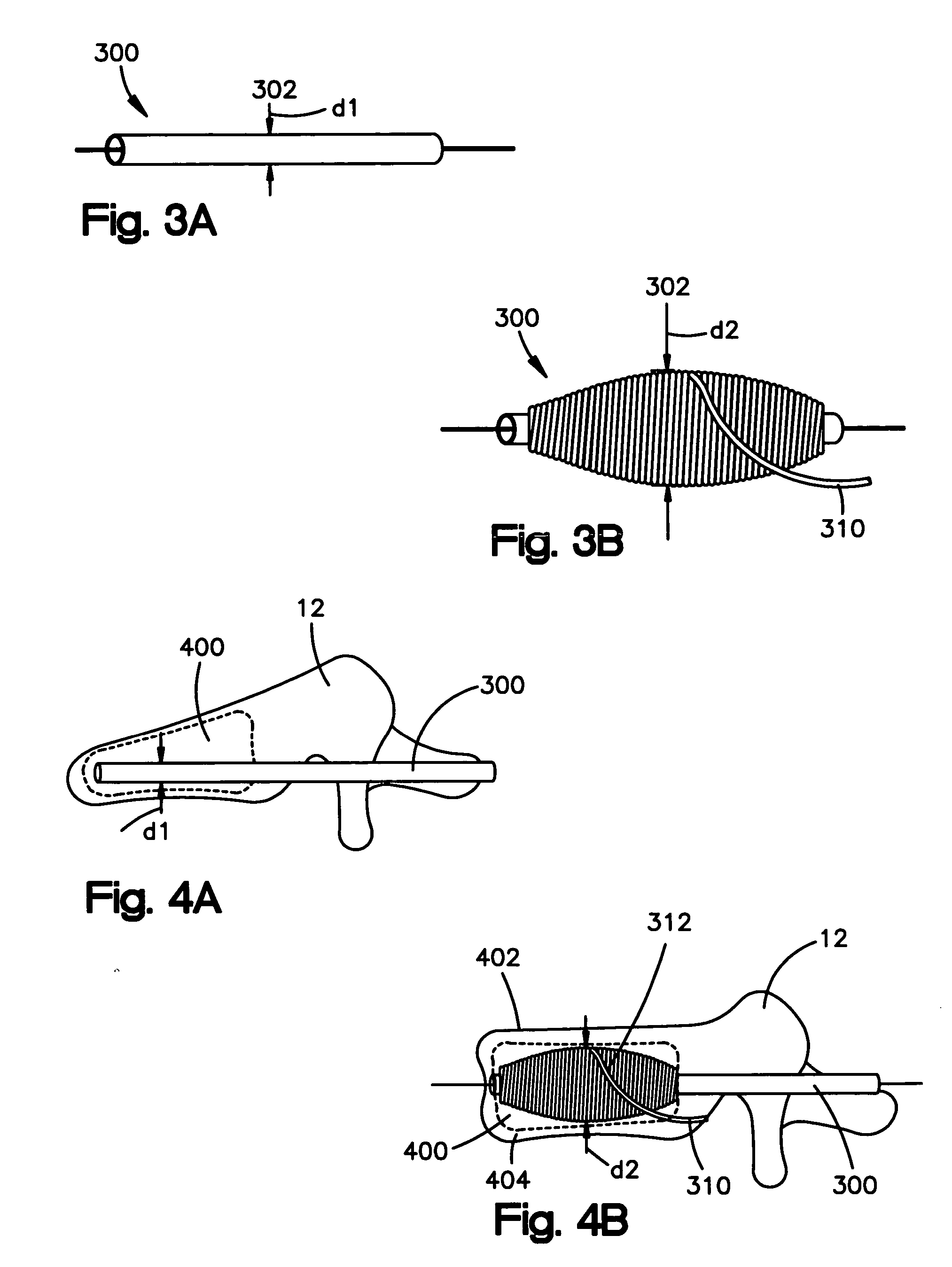

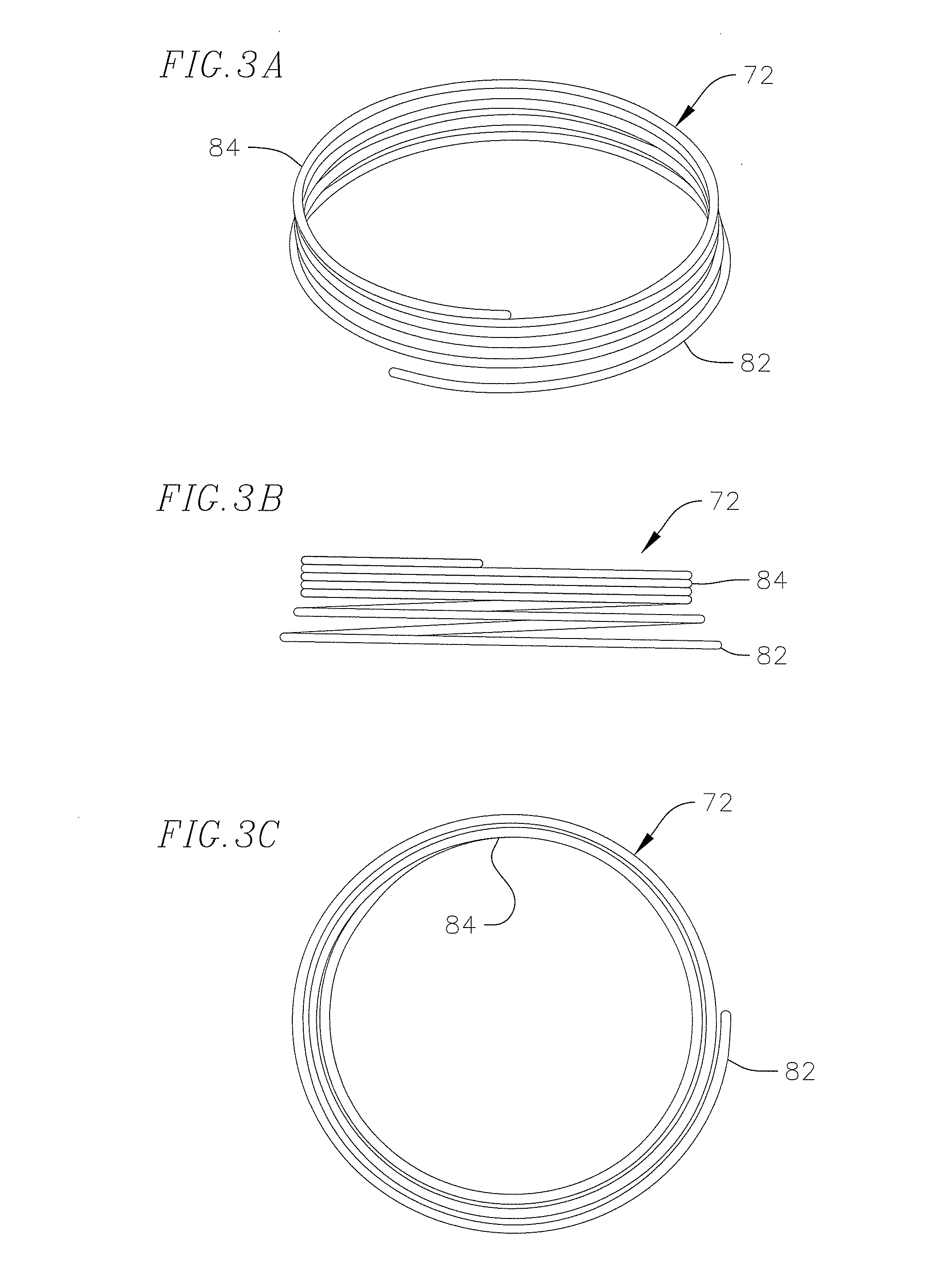

Apparatus and methods for treating bone

ActiveUS20070055274A1Increased radialIncreasing diameter of coilInternal osteosythesisSpinal implantsFiberBobbin

Implants and methods for bone treatment, preferably minimally invasive treatment, including repositioning of vertebrae may comprise insertion of a bobbin having a wire, string, thread or band, coiled around the bobbin. During coiling, the diameter of the bobbing / band complex may increase. Such increase in diameter can push against the inner side of the endplates of the vertebral body, and augment the vertebral body to its original height. The implant may also take the form of a coiled sleeve which when inserted into the vertebral body is uncoiled. The force of the uncoiling sleeve pushes against the inner side o the endplates of the vertebral body, restoring the vertebral body to its original height. The implant may also take the form of fibrous masses comprised of a thread or other relatively thin structure, for example a fiber or strand, of any biocompatible material having desired characteristics, for example a shape memory alloy, titanium, stainless steel, another metal or metal alloy, a ceramic, a composite or any combination thereof. The, strand, thread or other fiber may be coiled, woven, matted, tangled or otherwise formed into a wool-like mass or body having a desired configuration. Expansion of the expandable member within the vertebral body or other bone may reposition the fractured bone to a desired height and augment the bone to maintain the desired height. A bone cement or other filler can be added to further treat and stabilize the vertebral body or other bone.

Owner:SYNTHES USA

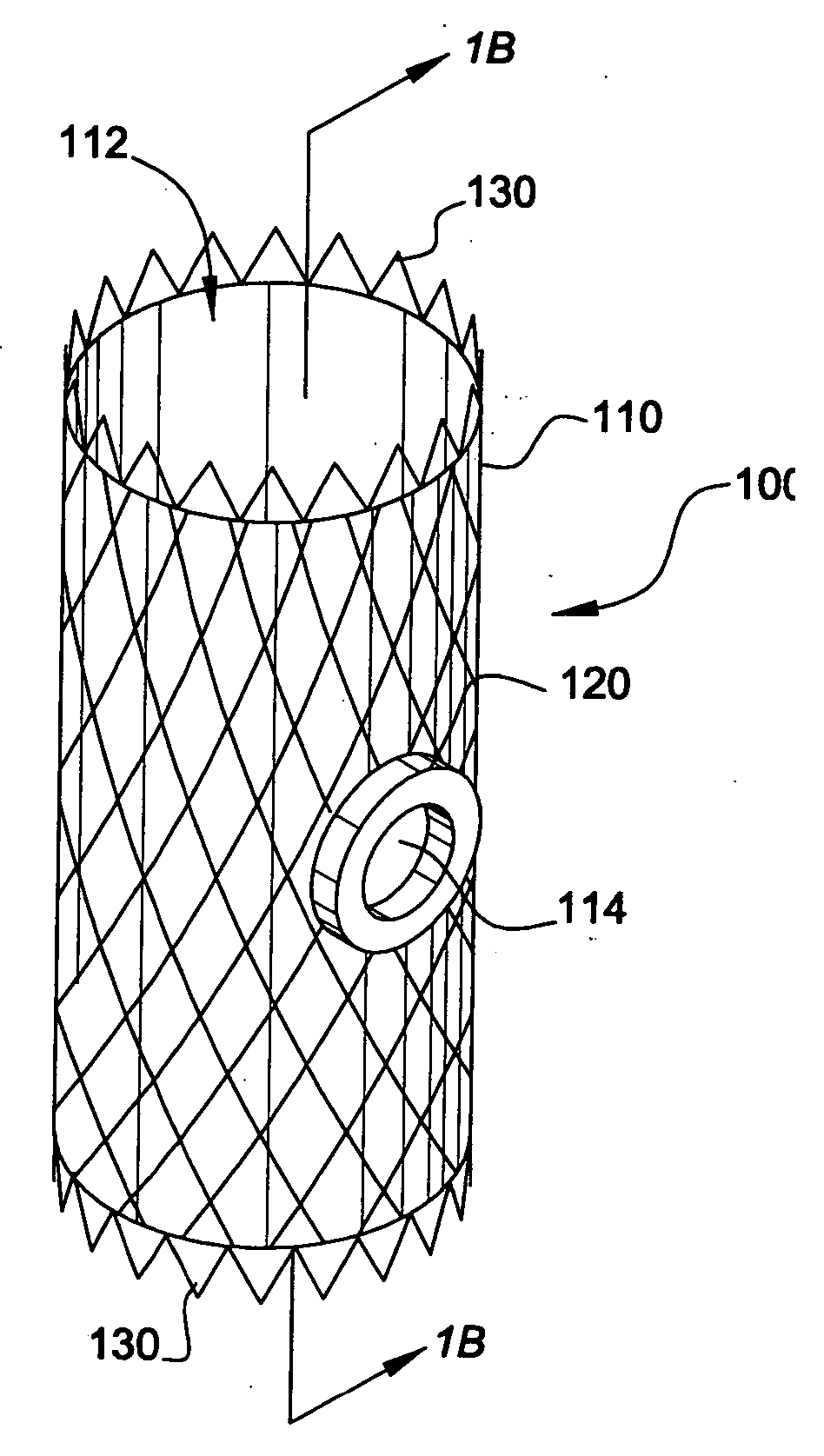

System and method for endoluminal grafting of bifurcated and branched vessels

InactiveUS20050154444A1Improve efficiencyMore aortic aneurysmsStentsBlood vesselsCouplingMetal alloy

A system and method for endoluminal grafting of a main anatomic conduit in its diseased state in which it dilates to pose a life threatening condition and its various conduits that emanate from the main anatomic conduit. The grafting system comprises an endoaortic graft having at least one opening therein and at least one branch graft that is passable through the opening of the endoaortic graft into the branch anatomic conduit(s) such that the junction between the branch graft and the endoaortic graft is substantially fluid tight. A system and method for delivery of the endoaortic graft and also a system and method for efficient alignment and deployment of the branch (e.g., side branch) graft such that the coupling of the branch graft with the endoaortic graft is efficient and exact and fluid-tight; and a system and method for coupling the branch to the endoaortic graft via a coupling mechanism employing a memory metal alloy; a system and method for the proper and exact alignment of the endoaortic graft and the branch using magnetic force of a suitable nature, and which does not use the magnetic force as the coupling mechanism.

Owner:CARDIAQ VALVE TECH

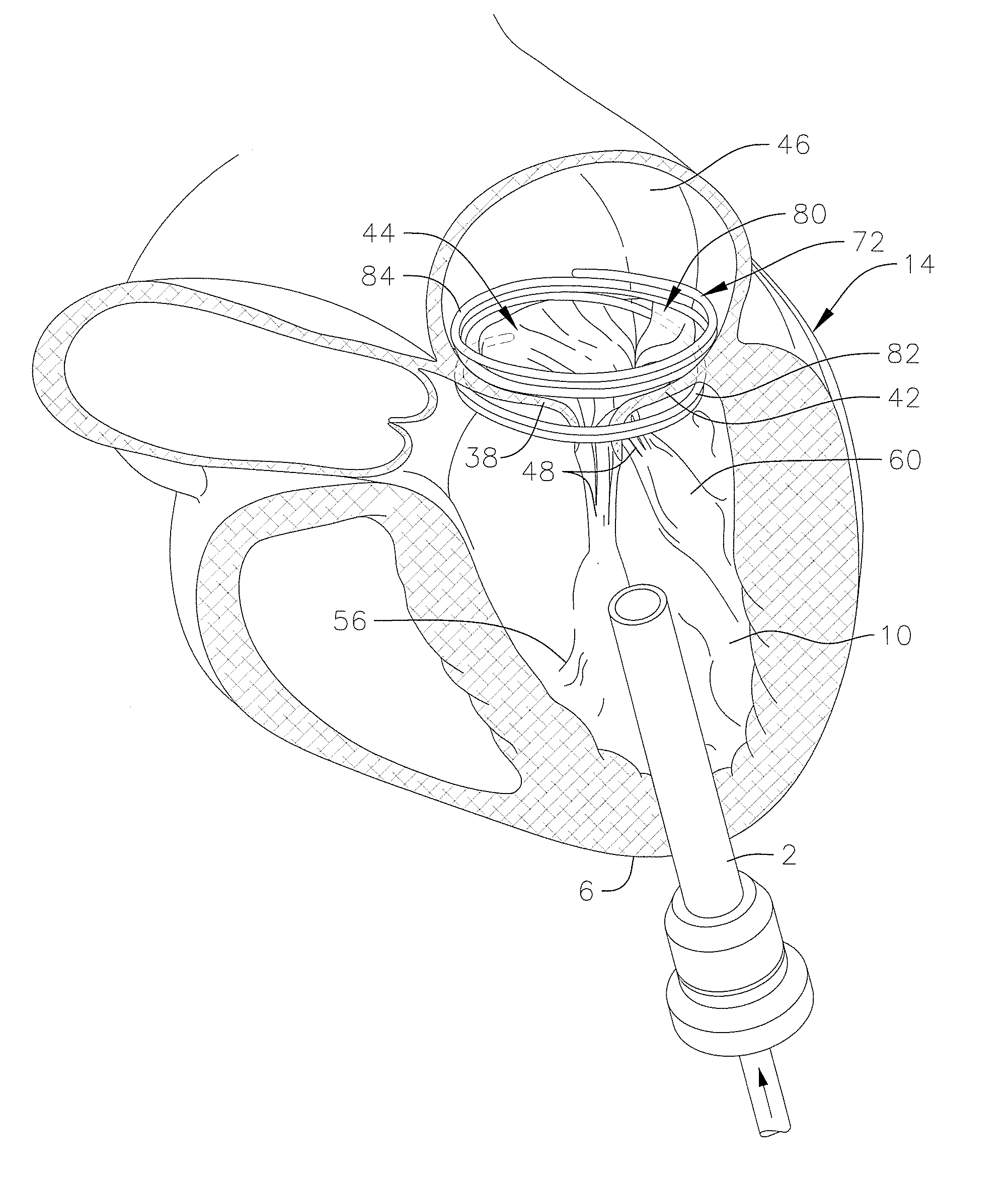

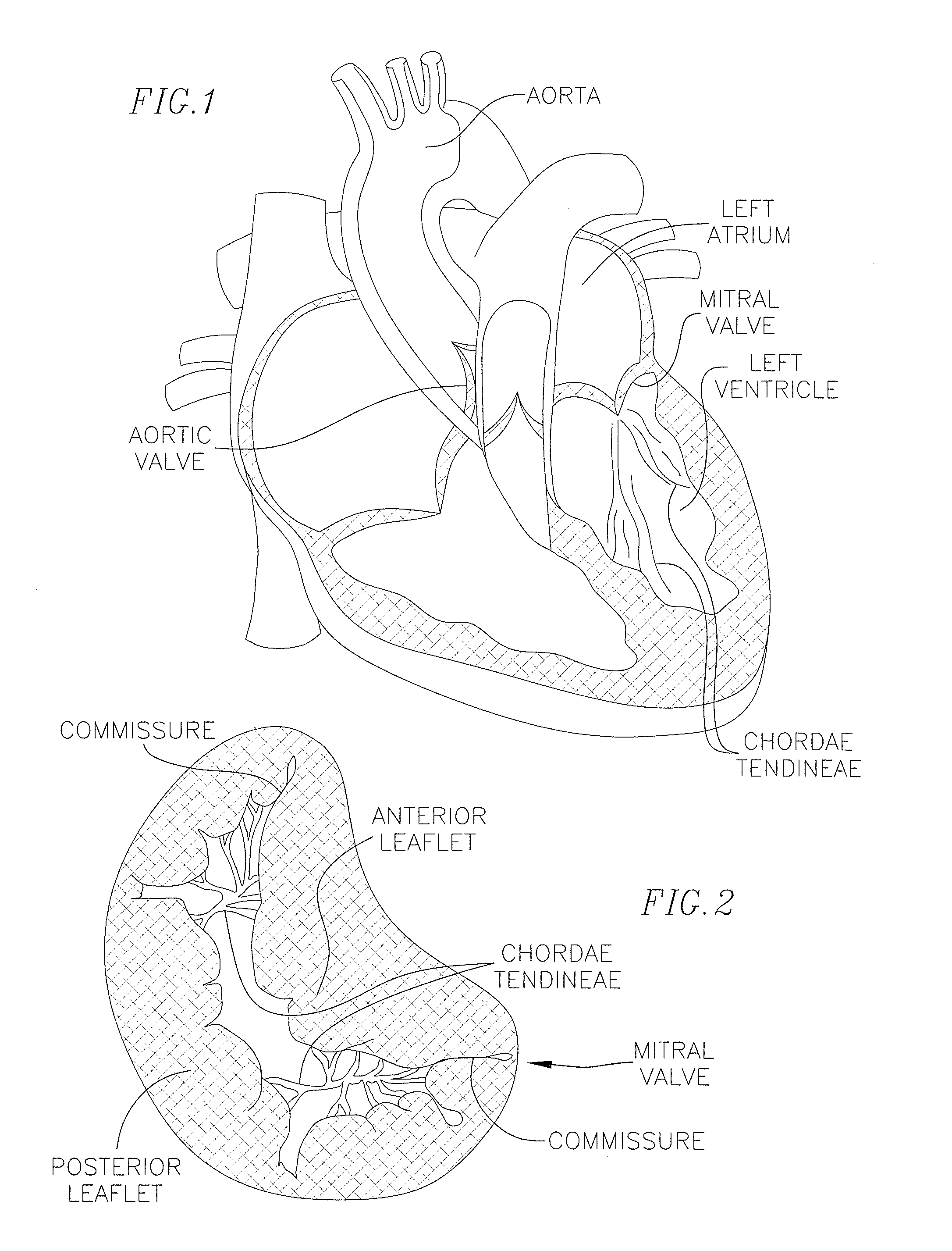

Coiled anchor for supporting prosthetic heart valve, prosthetic heart valve, and deployment device

A coiled anchor for docking a mitral valve prosthesis at a native mitral valve of a heart has a first end, a second end, and a central axis extending between the first and second ends, and defines an inner space coaxial with the central axis. The coiled anchor includes a coiled core including a bio-compatible metal or metal alloy and having a plurality of turns extending around the central axis in a first position, and a cover layer around the core, the cover layer including a bio-compatible material that is less rigid than the metal or metal alloy of the coiled core.

Owner:MITRAL VALVE TECHNOLOGIES SARL

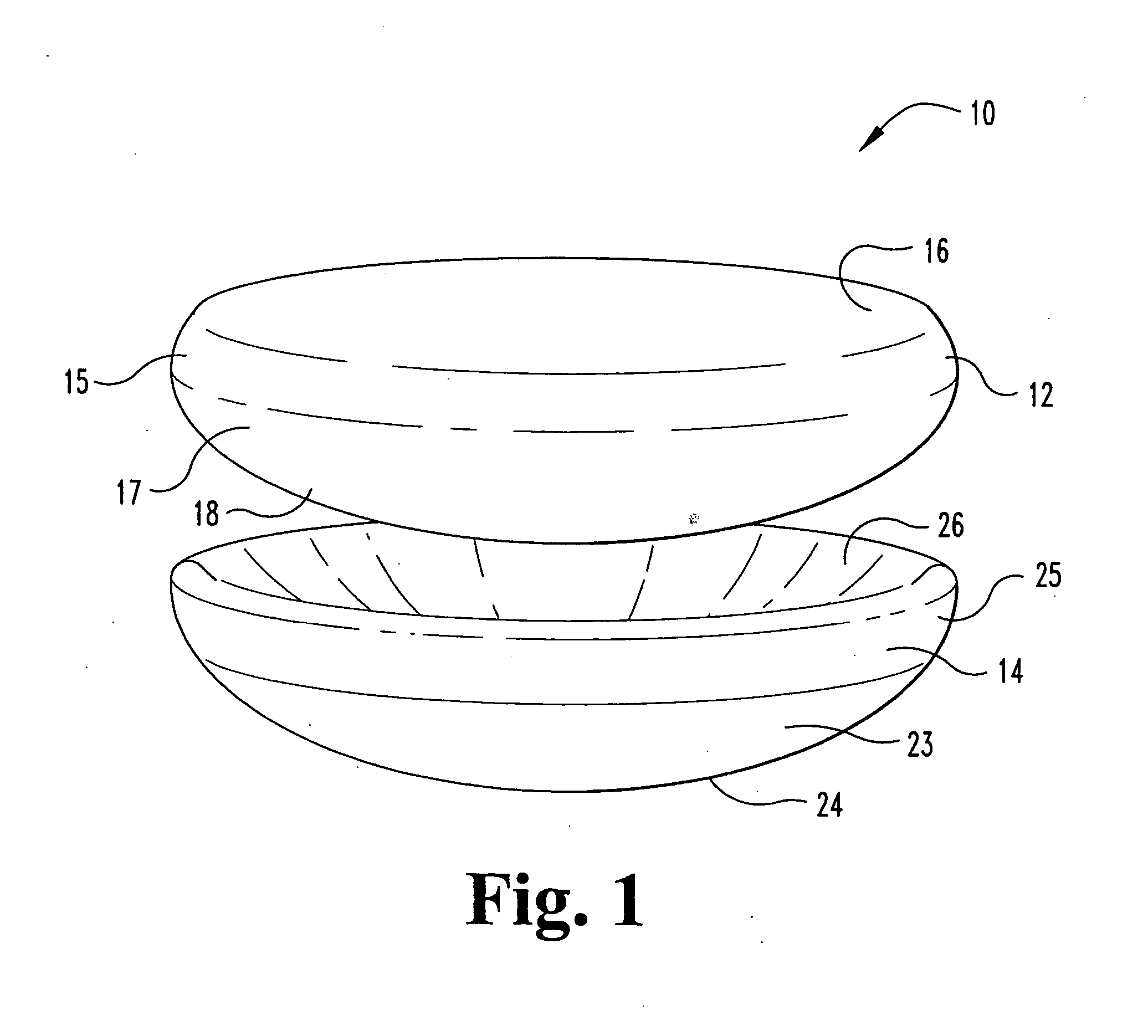

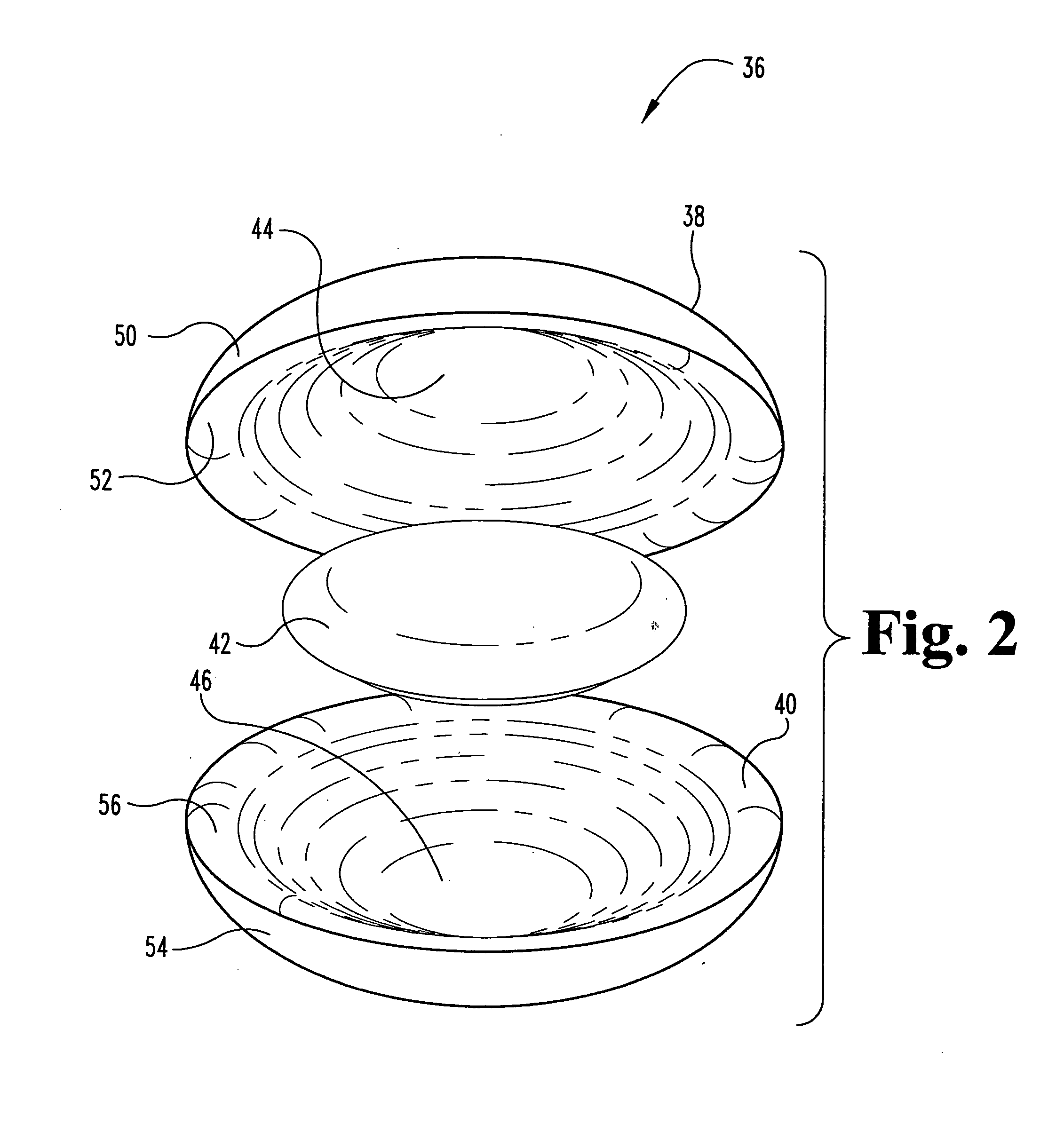

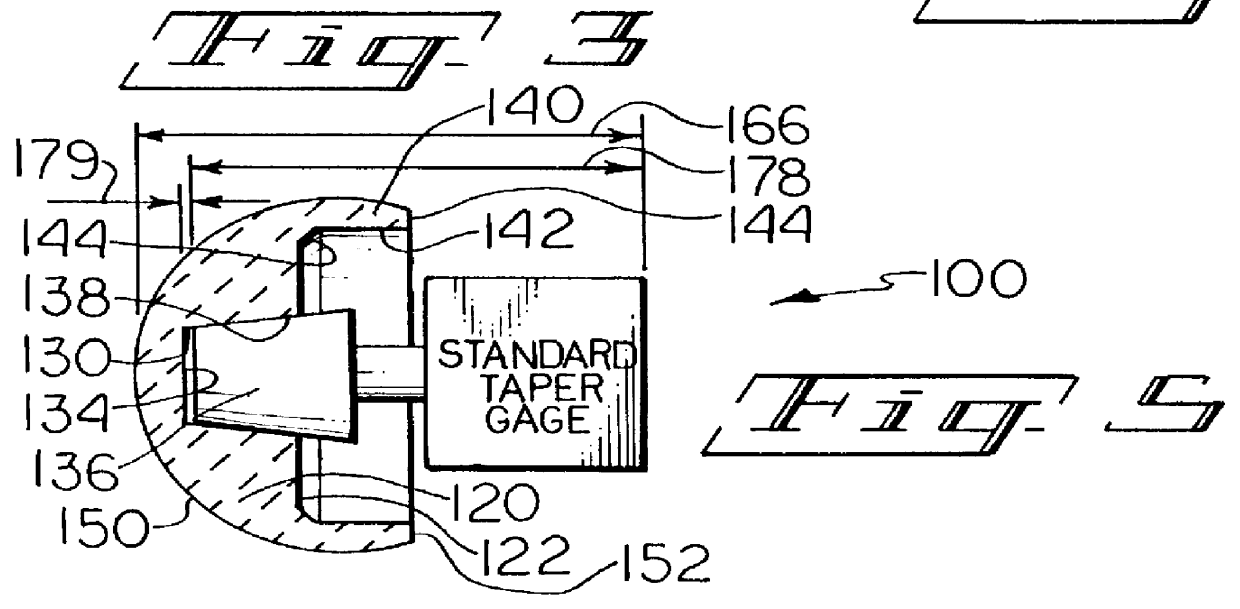

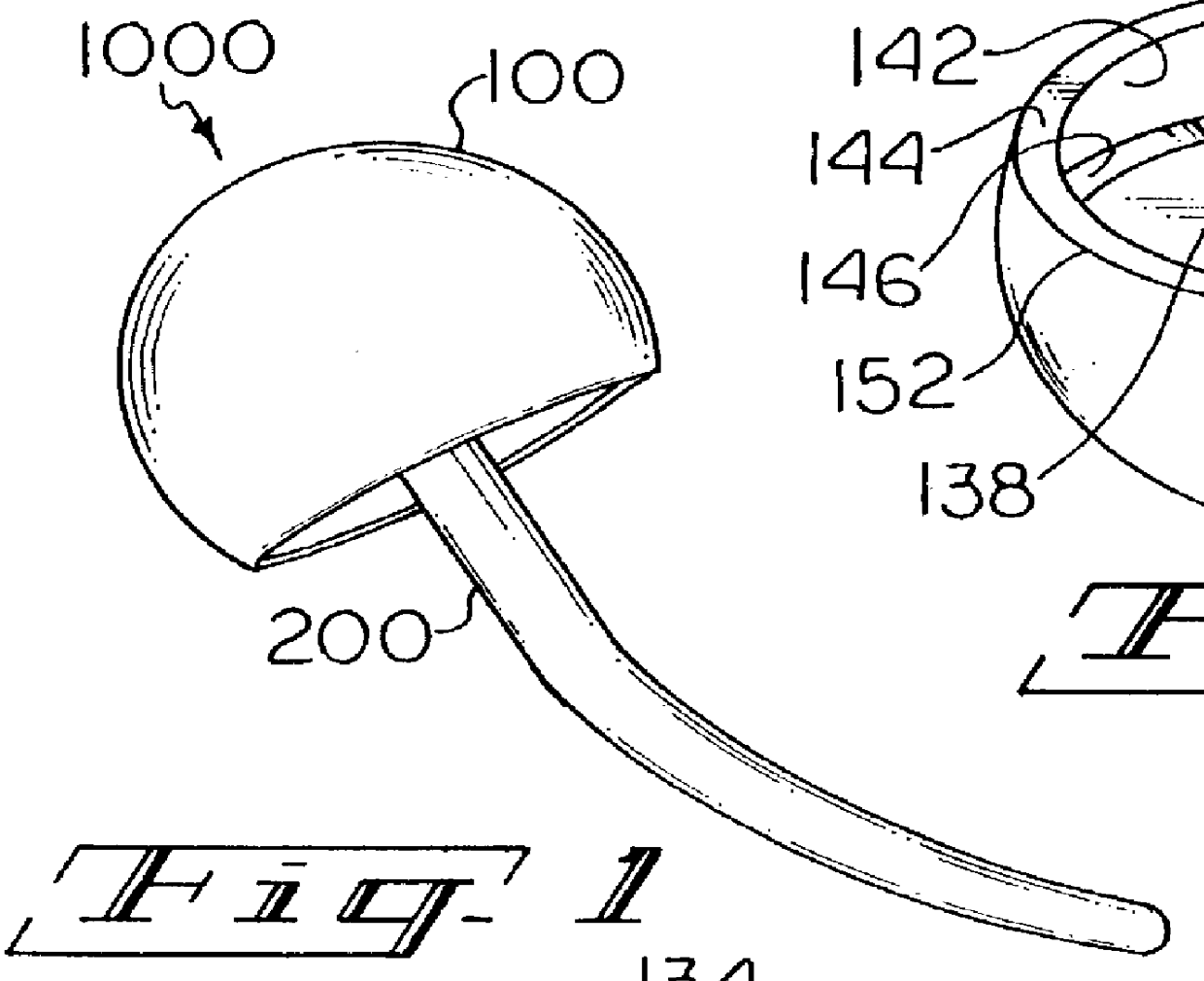

Modular ball and socket joint preferably with a ceramic head ball

InactiveUS6096084AIncrease surgical versatilityImprove proficiencyJoint implantsFemoral headsArticular surfacesArticular surface

Modular ball and socket joint has 1) a cupped ball head, preferably of ceramic, having a support body with an inferior, deep, distally facing, preferably generally planar, surface having a substantially circular outer boundary thereto; a distally opening stem receiving bore preferably centrally located in the support body; a cup wall, extending distally from the support body and having a preferably substantially cylindrical inner surface which extends from said outer boundary of said distally facing surface; and a superficially facing, generally semispherical, smooth external surface, preferably and optimally of a low friction coefficient, encapsulating the support body and cup wall; and 2) an interchangable and modular stem, preferably of metal or metal alloy, having a distally directed spike, and a superior stem cap which is insertable into the bore of the head; optionally with 3) a head-receiving articular cup having an inner articular surface and a mountable back surface, the articular surface of which, when the head-receiving cup is suitably mounted in suitable receiving stock, mates in articulating contact with said smooth external surface of said head when said head and stem are suitably mounted in suitable receiving stock. The head and stem modularity allows for noticeably increased versatility and efficiency in surgical procedures, and the ceramic material is beneficially adapted for employment in the fabrication of femoral resurfacing implants for conservative arthroplasty.

Owner:BIOPRO

Angular deflection apparatus for use in confined spaces and method of use

InactiveUS20050187537A1Avoiding excessive coagulation and edemaElectrotherapyCatheterCurve shapeMetal alloy

A tube having a distal end portion made of a curved, flexible, shape retentive material such as superelastic, nickel-titanium memory metal alloy which has been heat-treated to retain a desired curved shape. The tube translates within and is constrained by a rigid sleeve, which may alternately be an instrument channel of an endoscope. When the distal end portion of the tube is extended from the sleeve, it returns to its original curved shape. Markings about the proximal and, or distal end portions of the tube enable the operator to know to what extent the distal end portion of the tube has been extended from the sleeve even when the distal end portion of the tube is not visible. The tube may be used for supporting and activating a cutting, abrading, coagulating, shrinking, or vaporizing device that is brought near or into contact with a tissue surface.

Owner:TRIMEDYNE

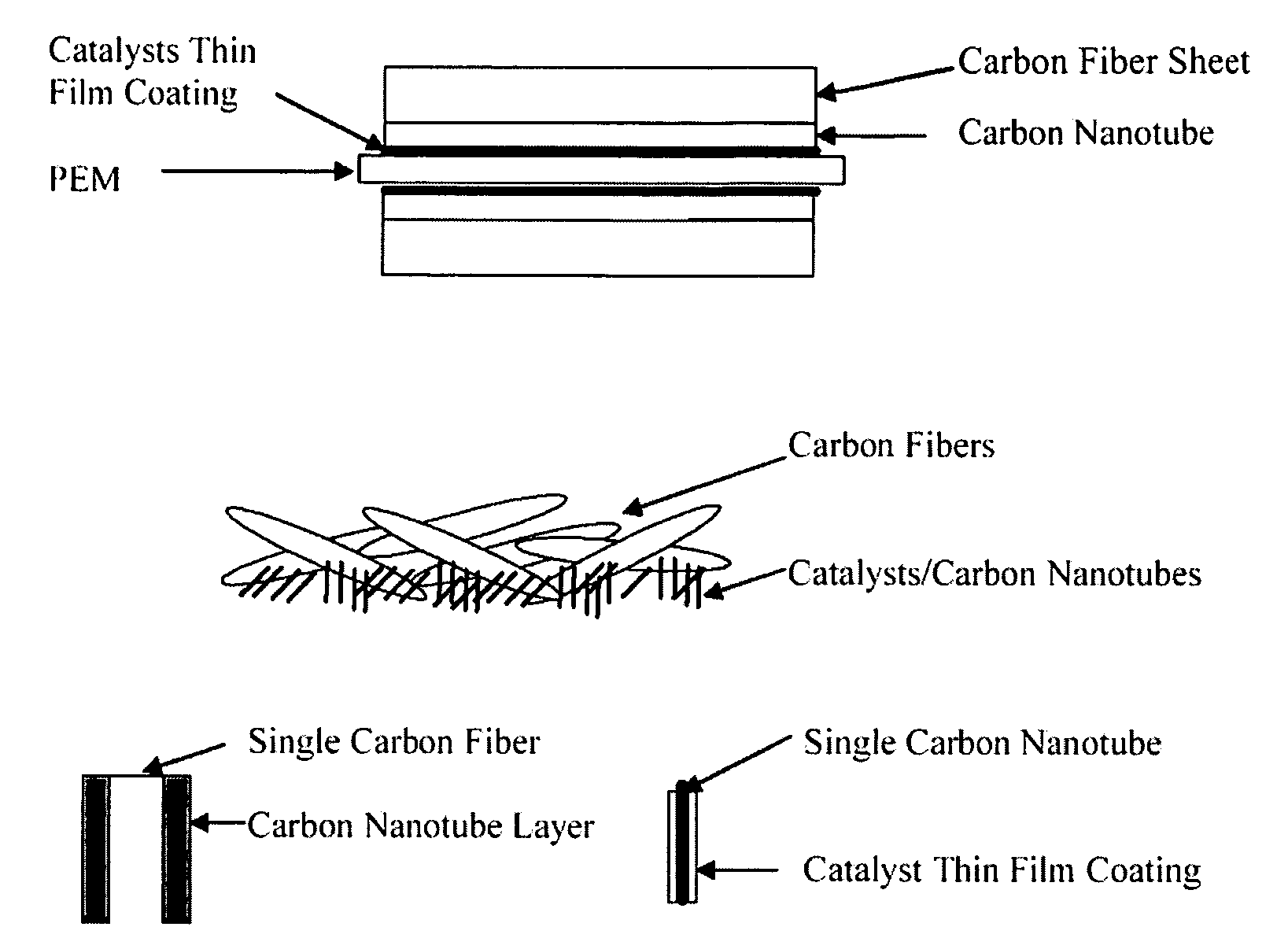

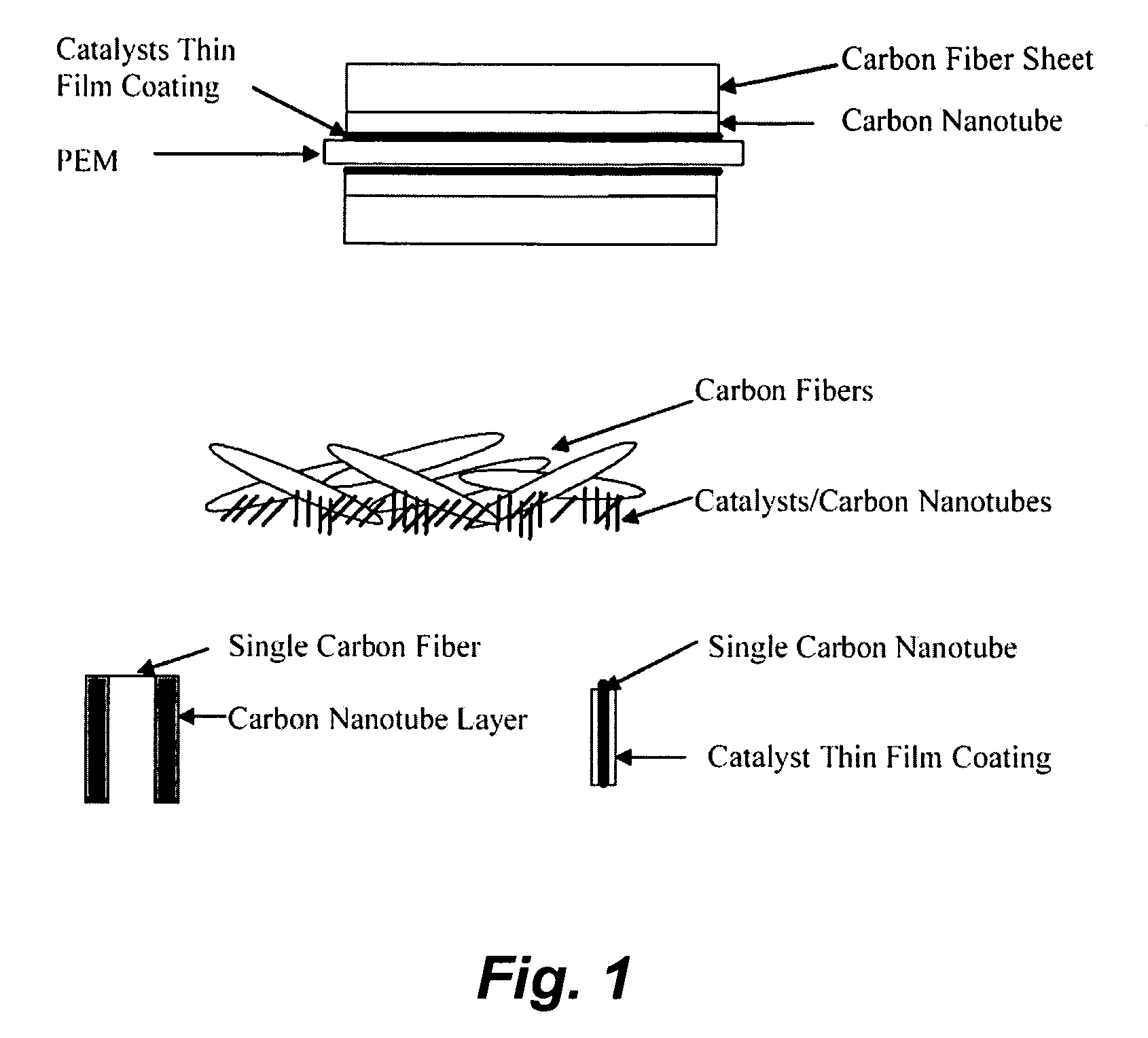

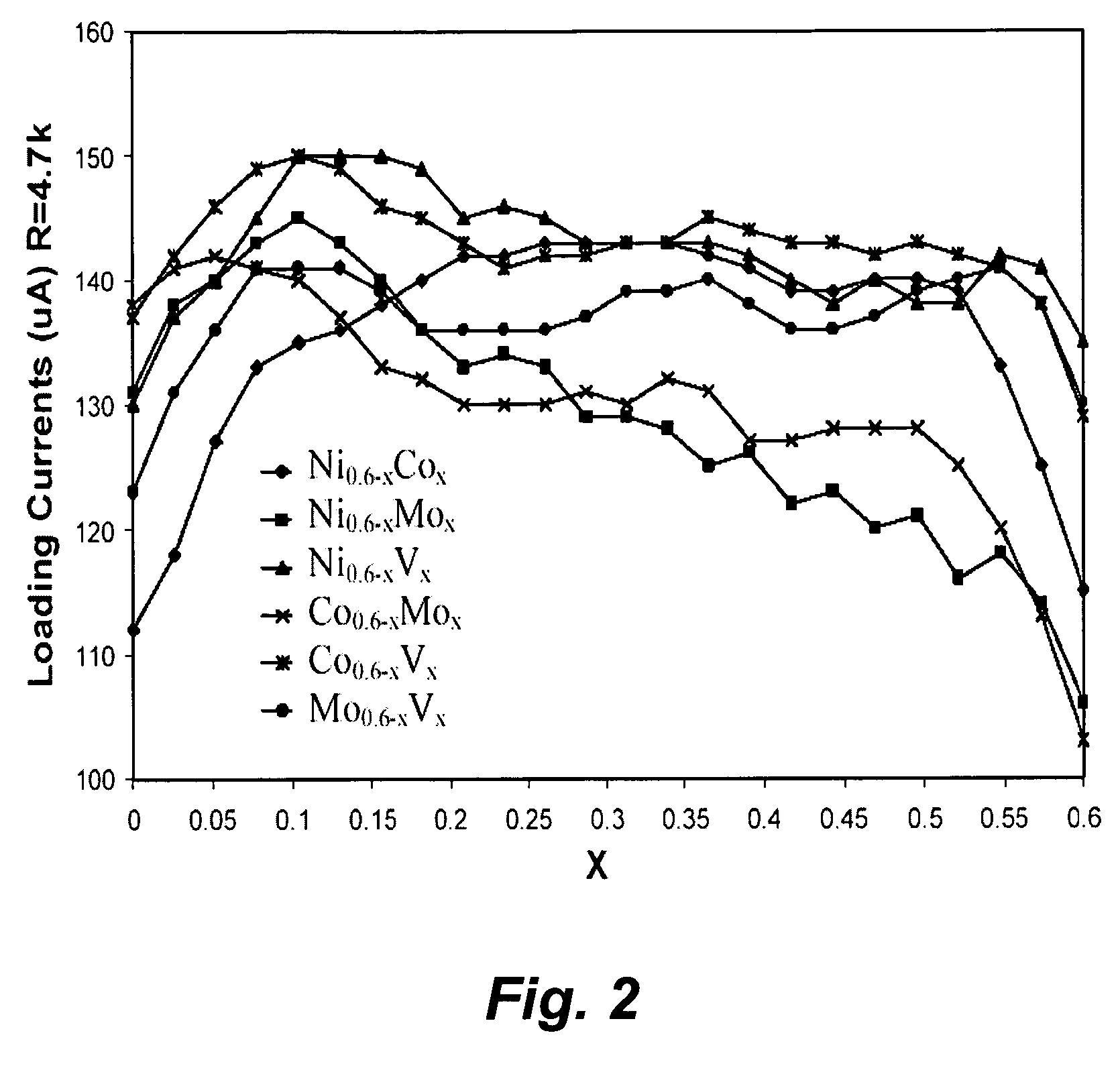

Low platinum fuel cell catalysts and method for preparing the same

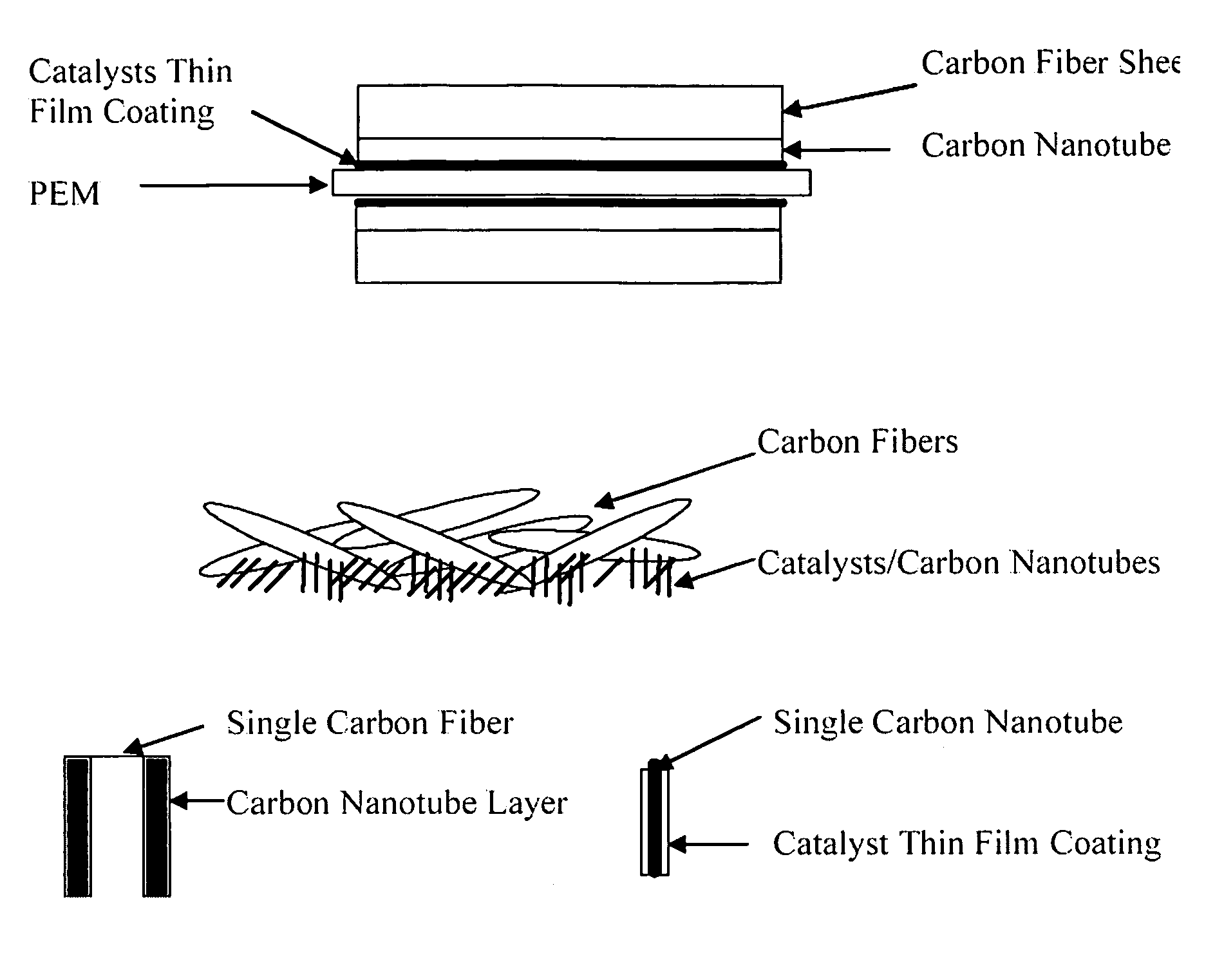

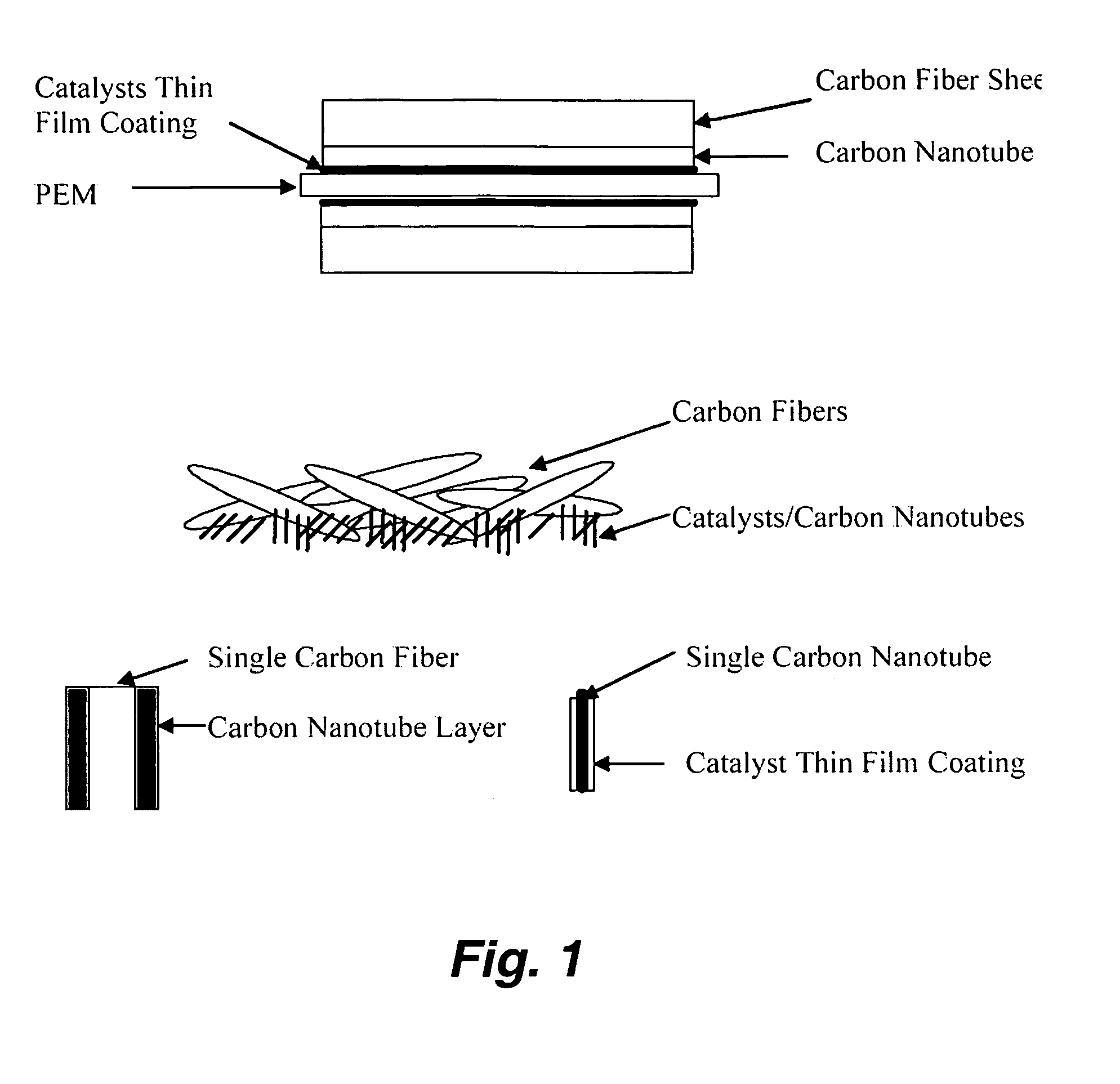

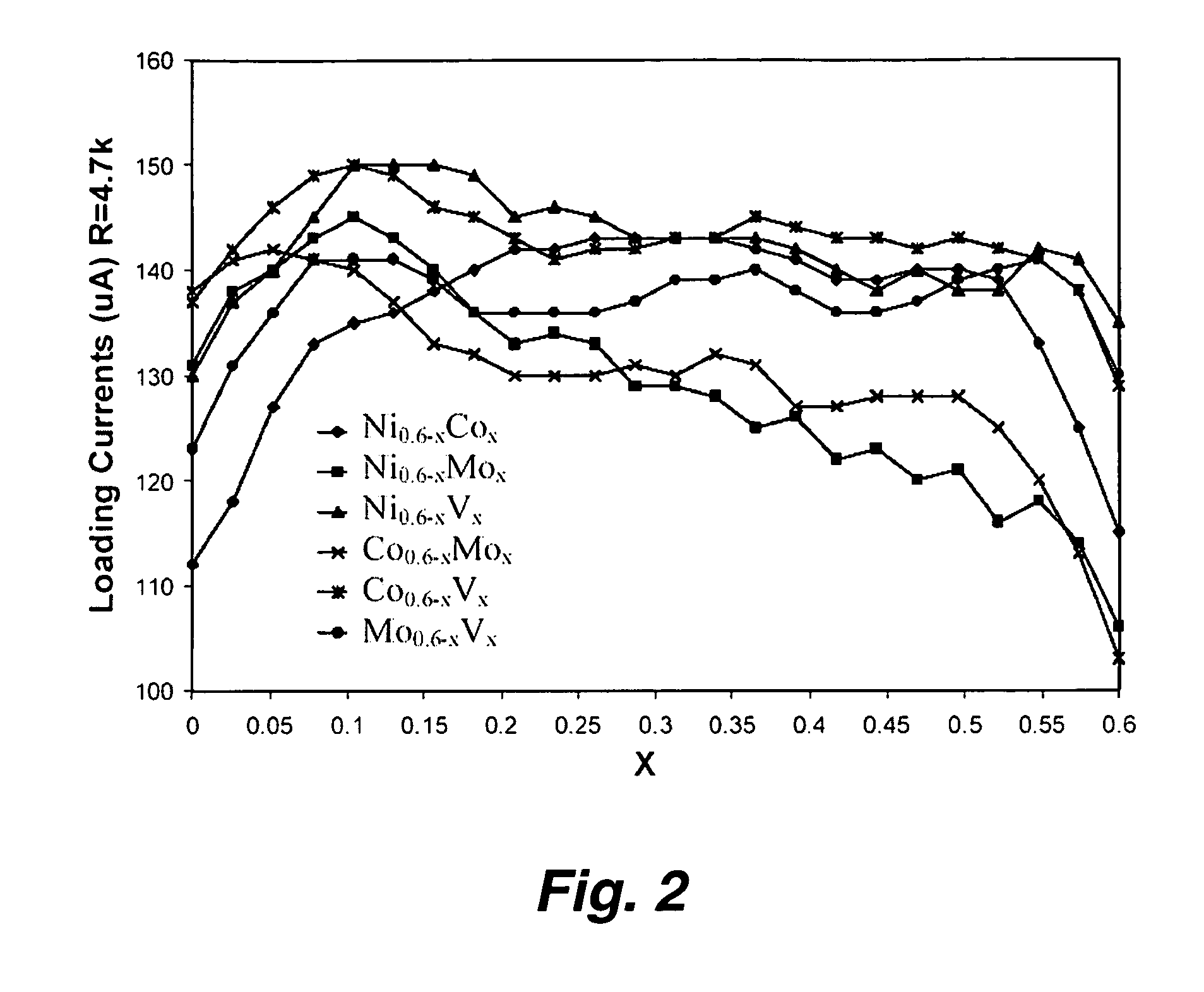

InactiveUS20050053826A1Good dispersionEfficient CatalysisMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell catalysts comprising new series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticales into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

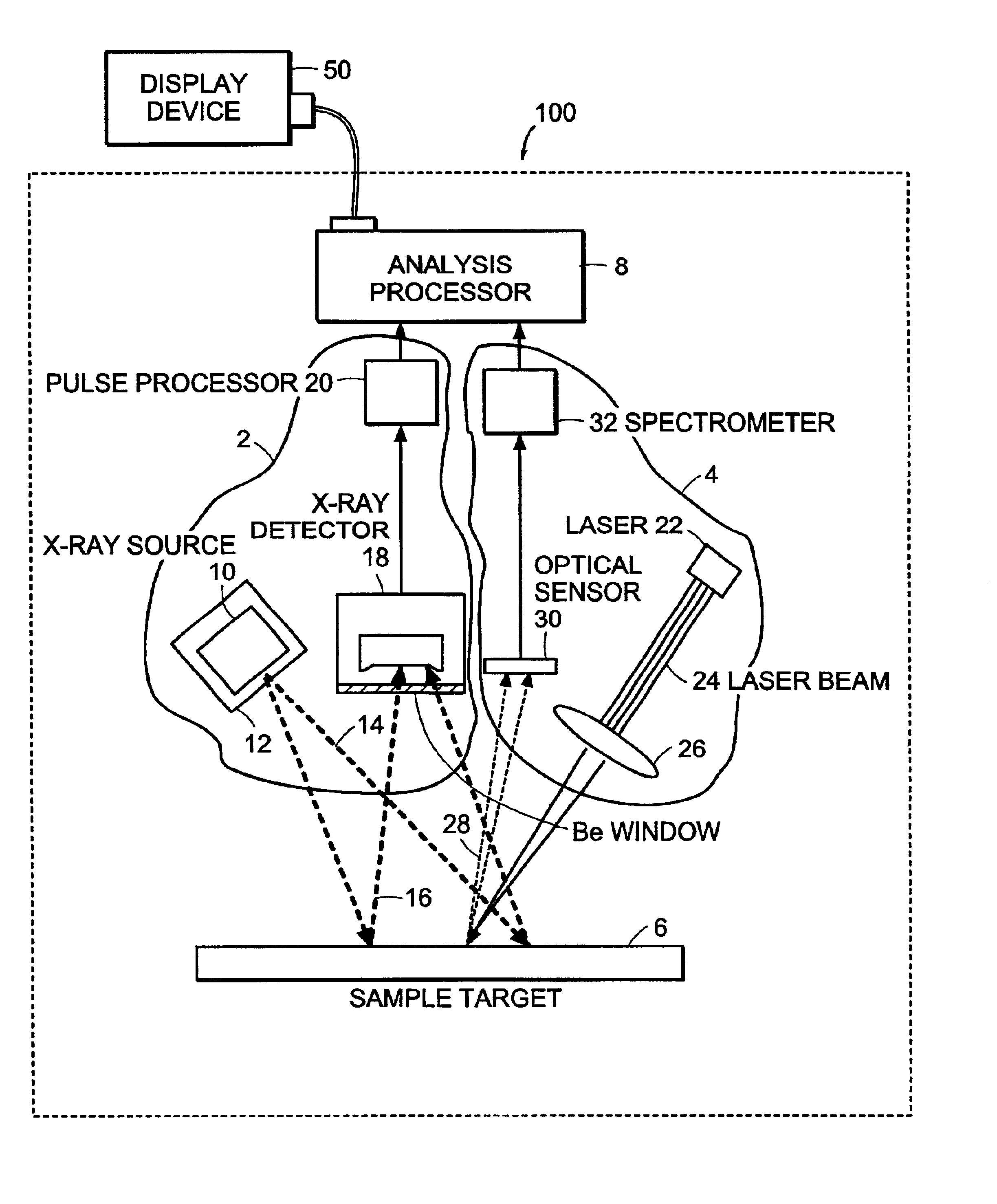

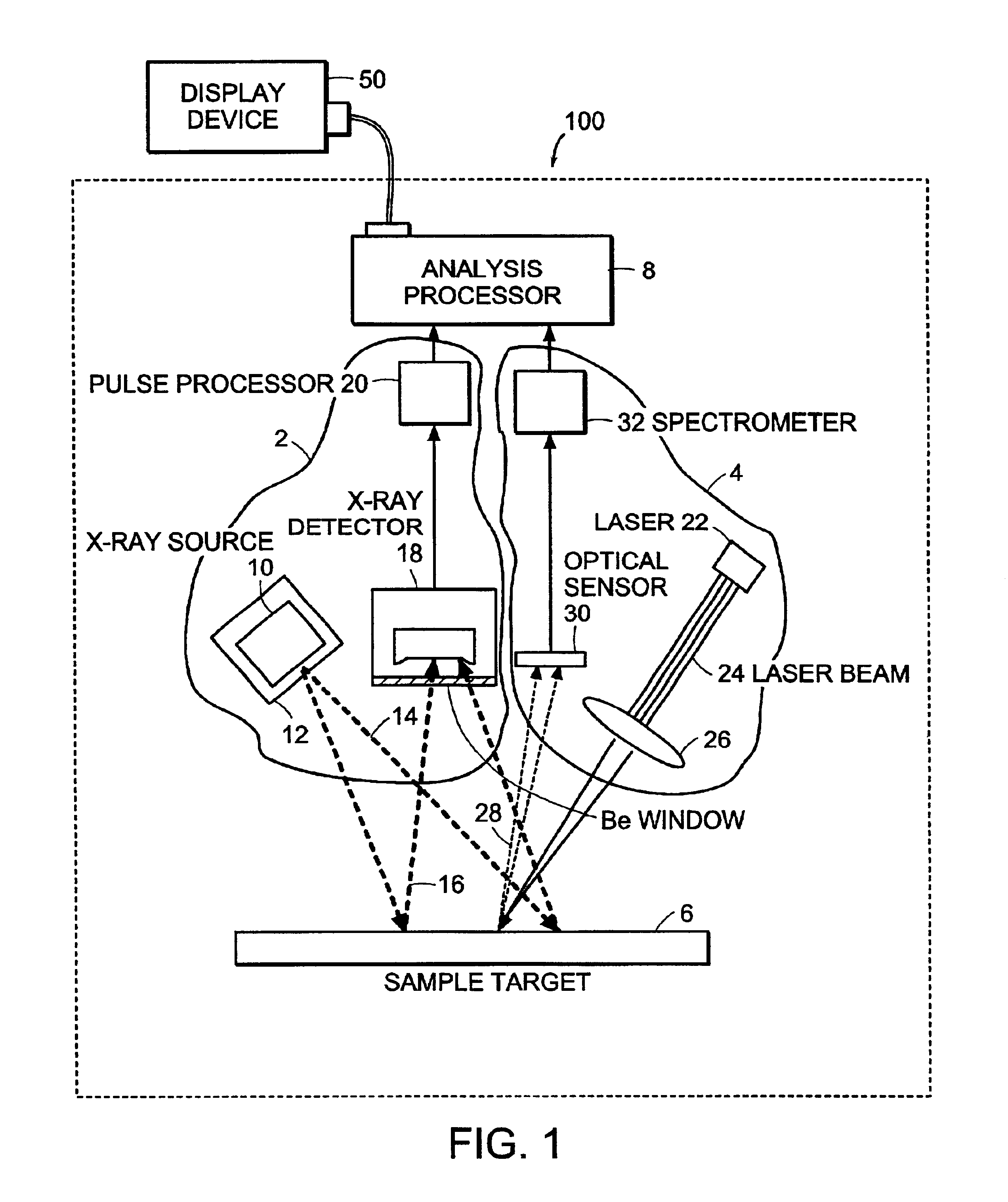

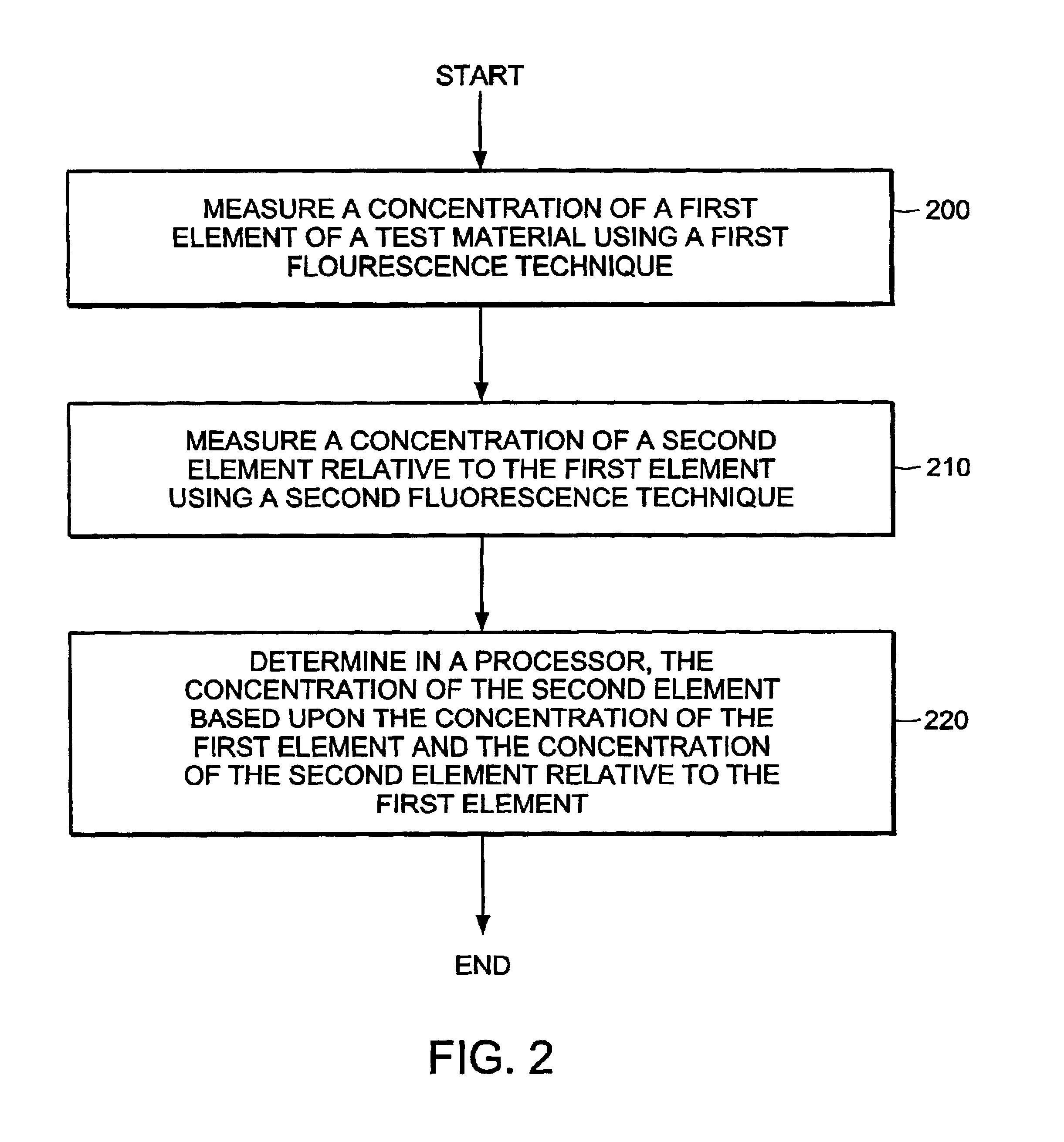

X-ray fluorescence combined with laser induced photon spectroscopy

A device and method for identifying the composition of a target sample. The target sample may be a matrix such as a metal alloy, a soil sample, or a work of art. The device includes an x-ray fluorescence detector that produces an x-ray signal output in response to the target sample. The device also includes an optical spectroscope that produces an optical signal output in response to the target sample. Further, a processor is included that analyzes and combines the x-ray signal output and the optical signal output to determine the composition of the test material. In one embodiment, the optical spectroscope is a laser induced photon fluorescence detector.

Owner:THERMO NITON ANALYZERS

Low platinum fuel cells, catalysts, and method for preparing the same

InactiveUS20060172179A1Efficient processingImprove throughputMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell electrodes and catalysts comprising a series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). Processing of the electrodes and catalysts can include electrodeposition methods, and high-pressure coating techniques. In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticles into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

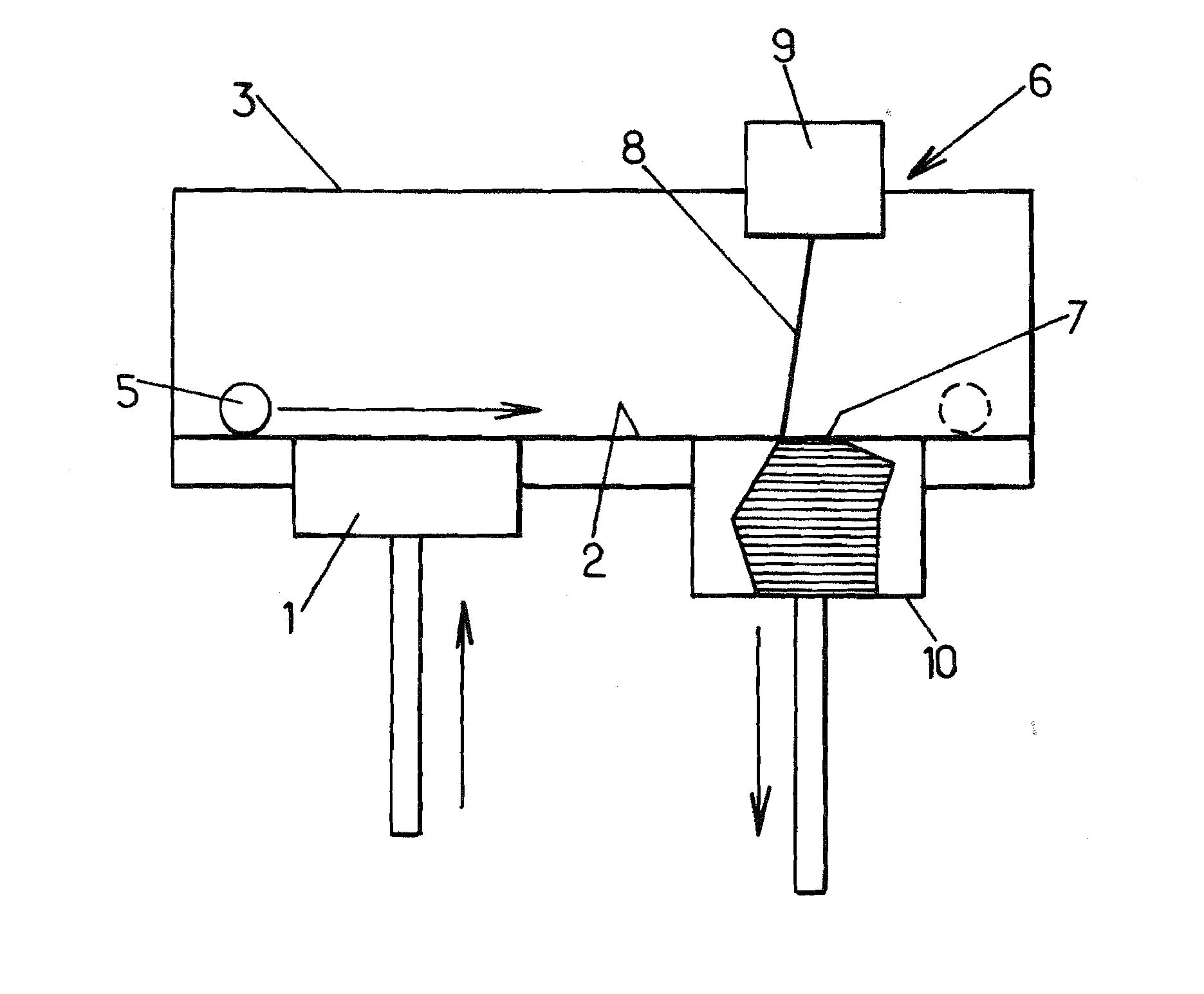

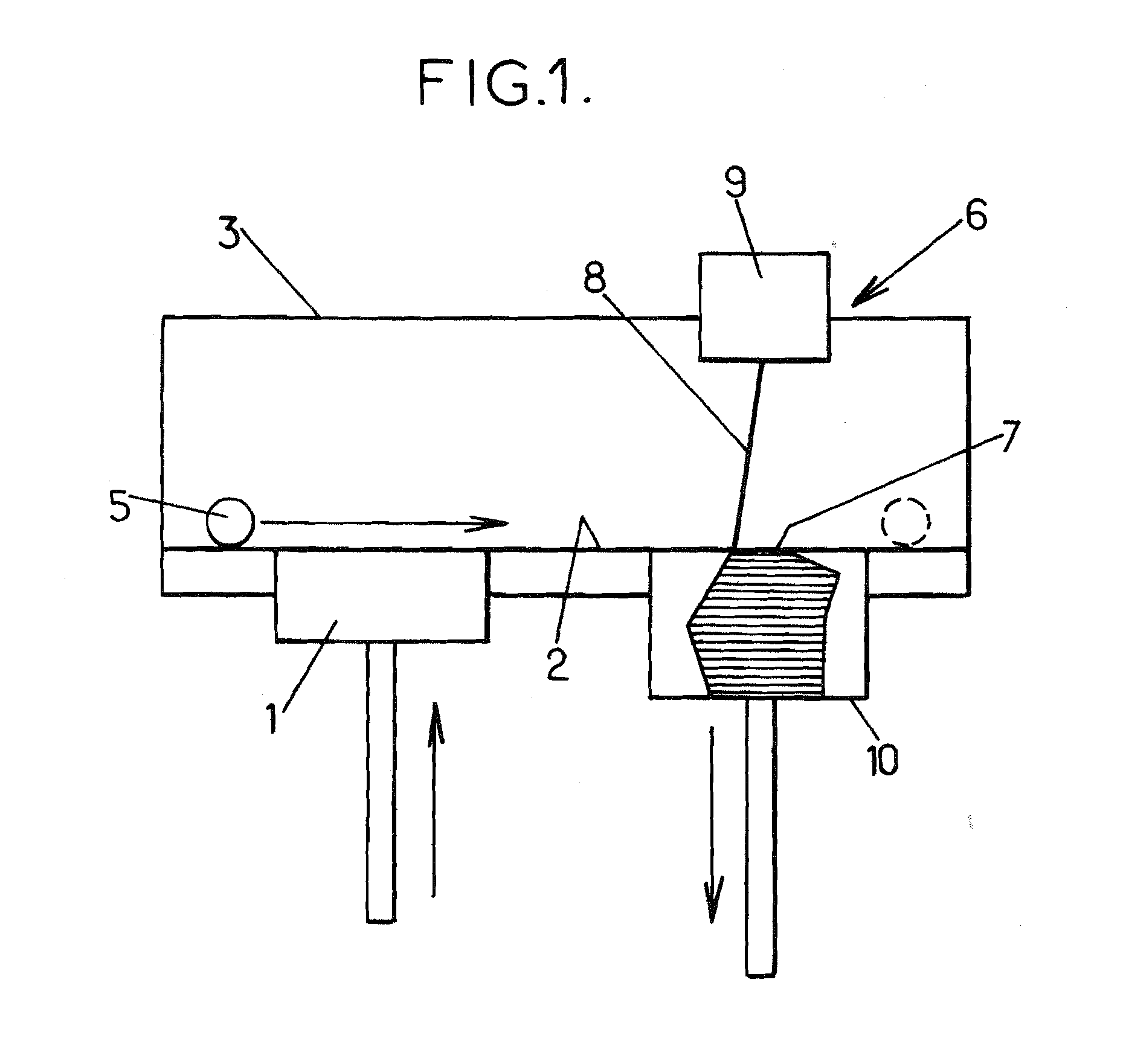

Biomedical device, method for manufacturing the same and use thereof

InactiveUS20120165954A1Reduce usageEasy to processBone implantCeramic shaping apparatusLead zirconate titanatePorosity

A three-dimensional biomedical device having an osteoinductive first area with a controlled porosity and a second area, which is produced by laser technology from a powder including one of ceramics, metals, metal alloys, bioactive glasses, lead zirconate titanate and biocompatible polymers, or mixtures thereof. The ratio of the porosities from the second area to the first area is equal or less than one, preferably from 0.001 to 0.9. A method for manufacturing the device for fitting in a bone defect, wherein a virtual object is designed with a computer-aid designed software, and the device is manufactured by laser technology including layering a powder onto a plate (7) so that a layer of a predetermined thickness is formed; the laser beam (8) selectively processes the powder to produce a processed layer, and, thus, layer after layer, the layers are joined together until the biomedical device is formed.

Owner:NIMAL DIDIER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com