Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2104results about "Galvano-magnetic material selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

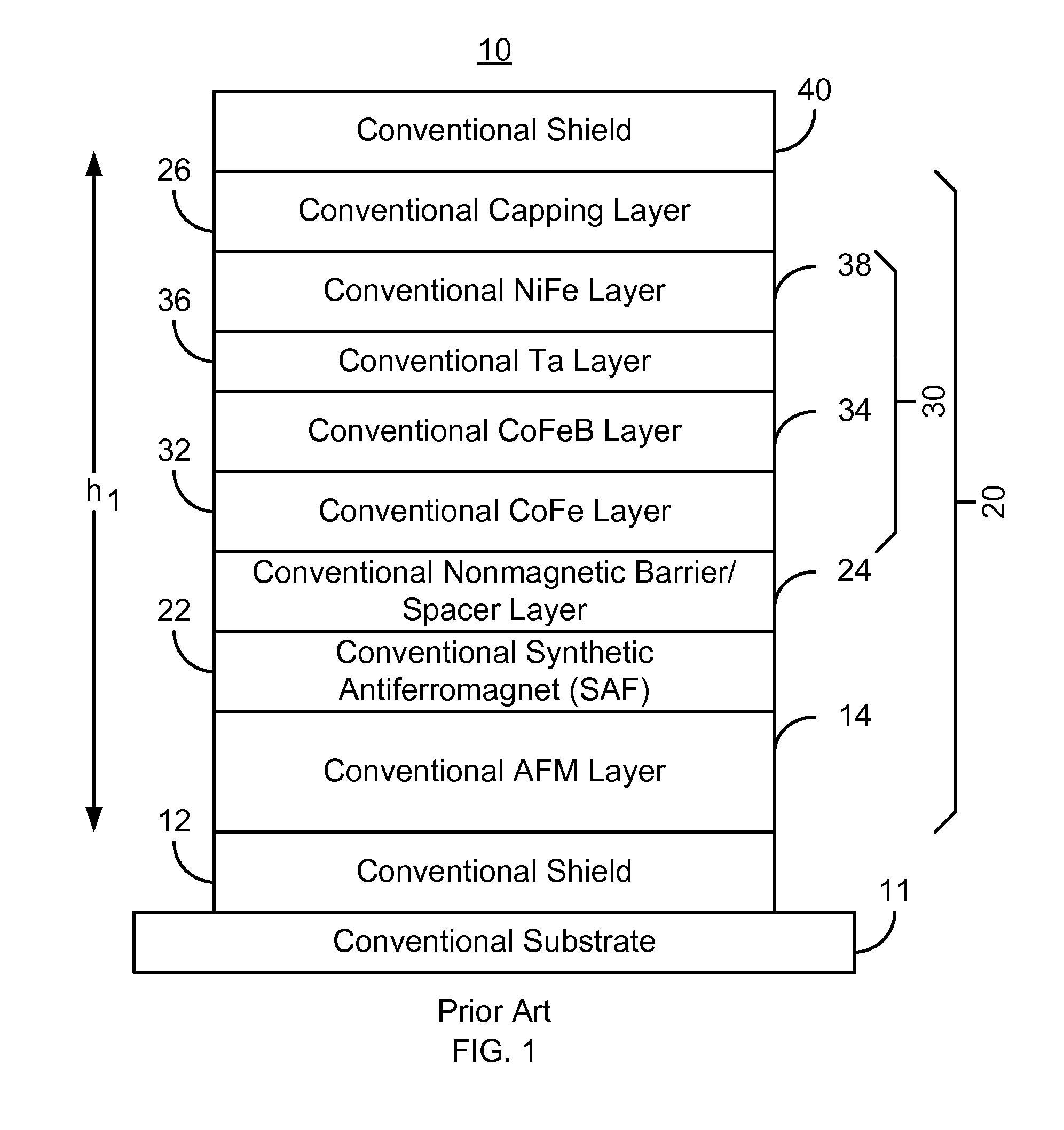

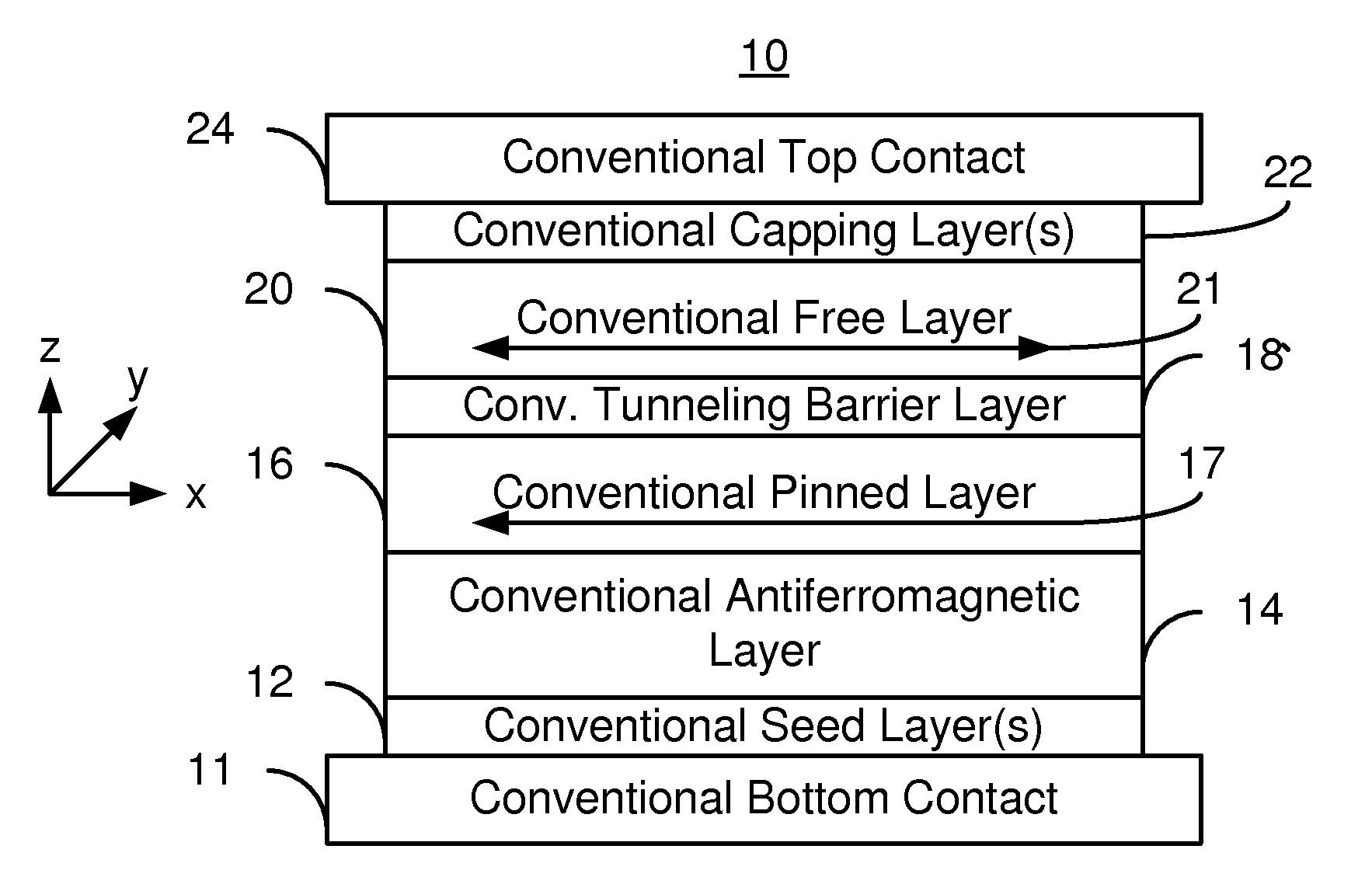

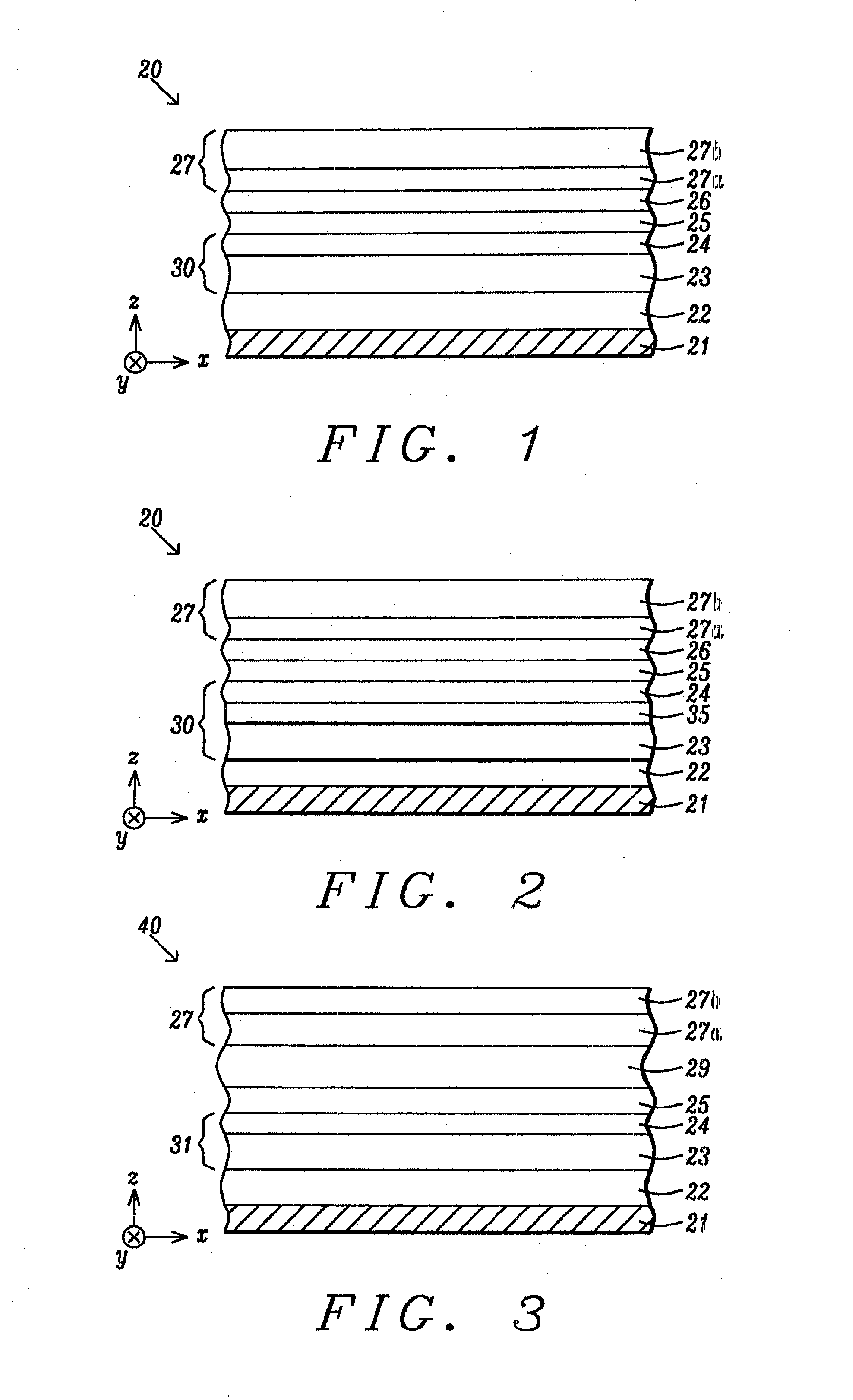

Magnetoresistive element

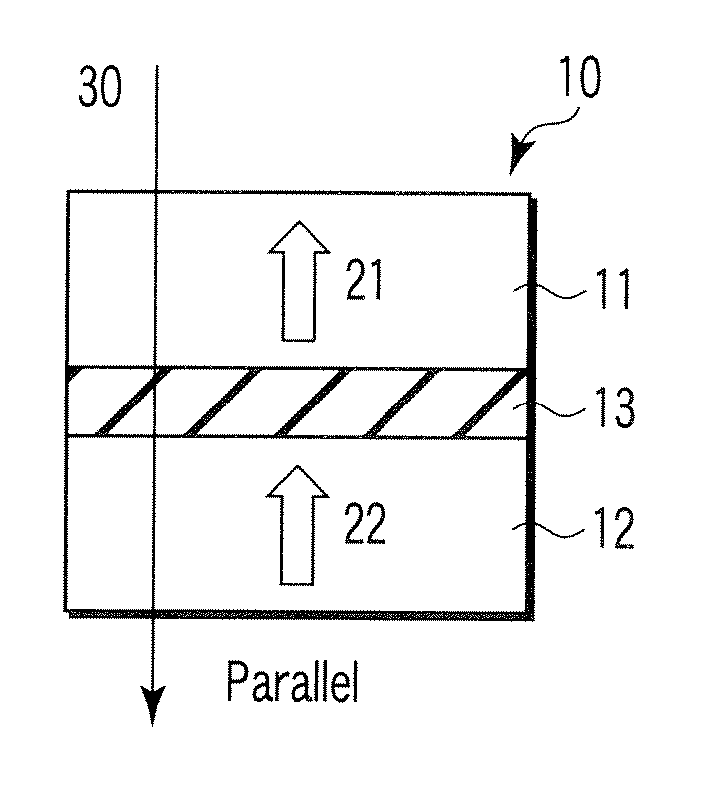

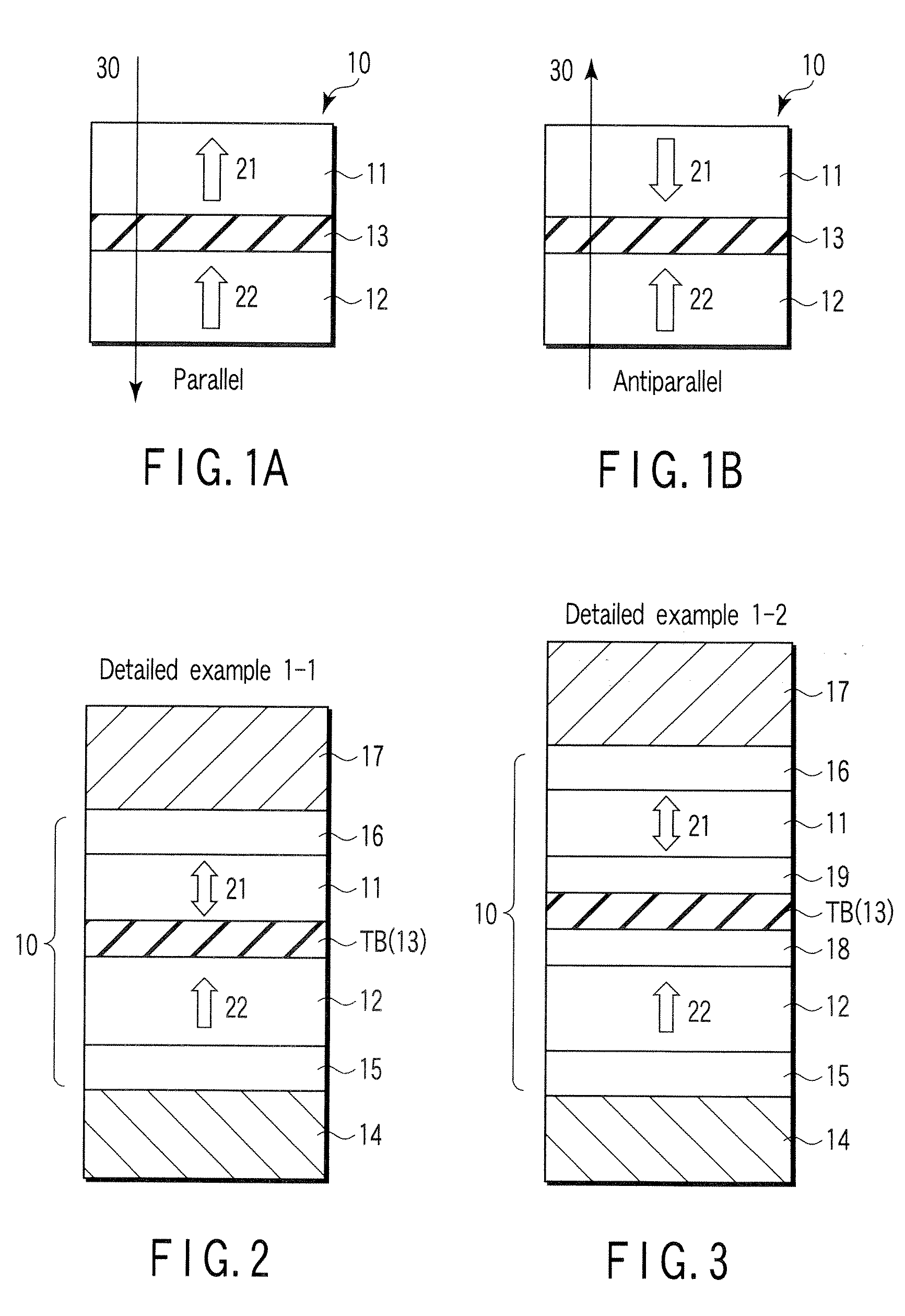

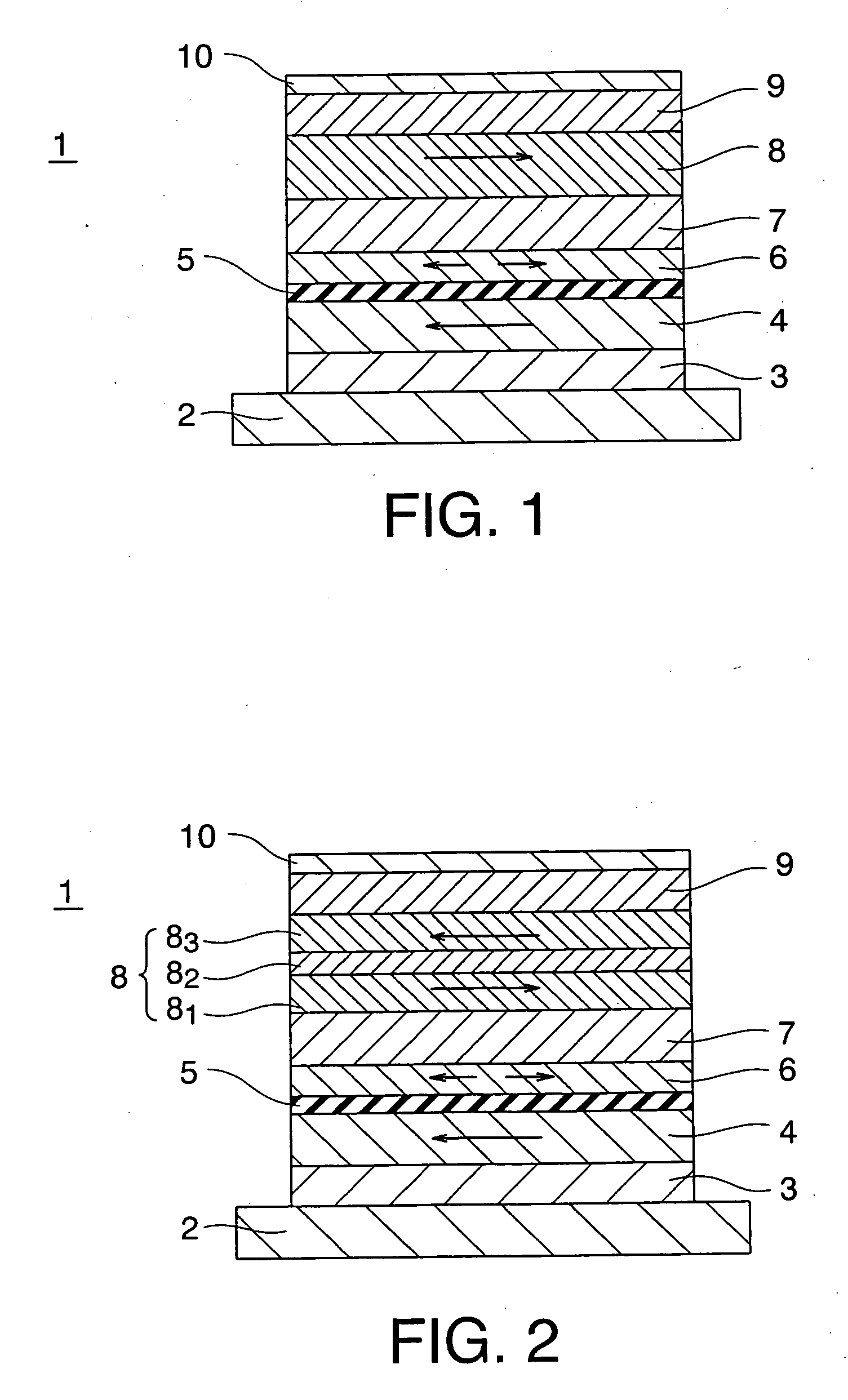

A magnetoresistive element which records information by supplying spin-polarized electrons to a magnetic material, includes a first pinned layer which is made of a magnetic material and has a first magnetization directed in a direction perpendicular to a film surface, a free layer which is made of a magnetic material and has a second magnetization directed in the direction perpendicular to the film surface, the direction of the second magnetization reversing by the spin-polarized electrons, and a first nonmagnetic layer which is provided between the first pinned layer and the free layer. A saturation magnetization Ms of the free layer satisfies a relationship 0≧Ms<√{square root over ( )}{Jw / (6nAt)}. Jw is a write current density, t is a thickness of the free layer, A is a constant.

Owner:KIOXIA CORP

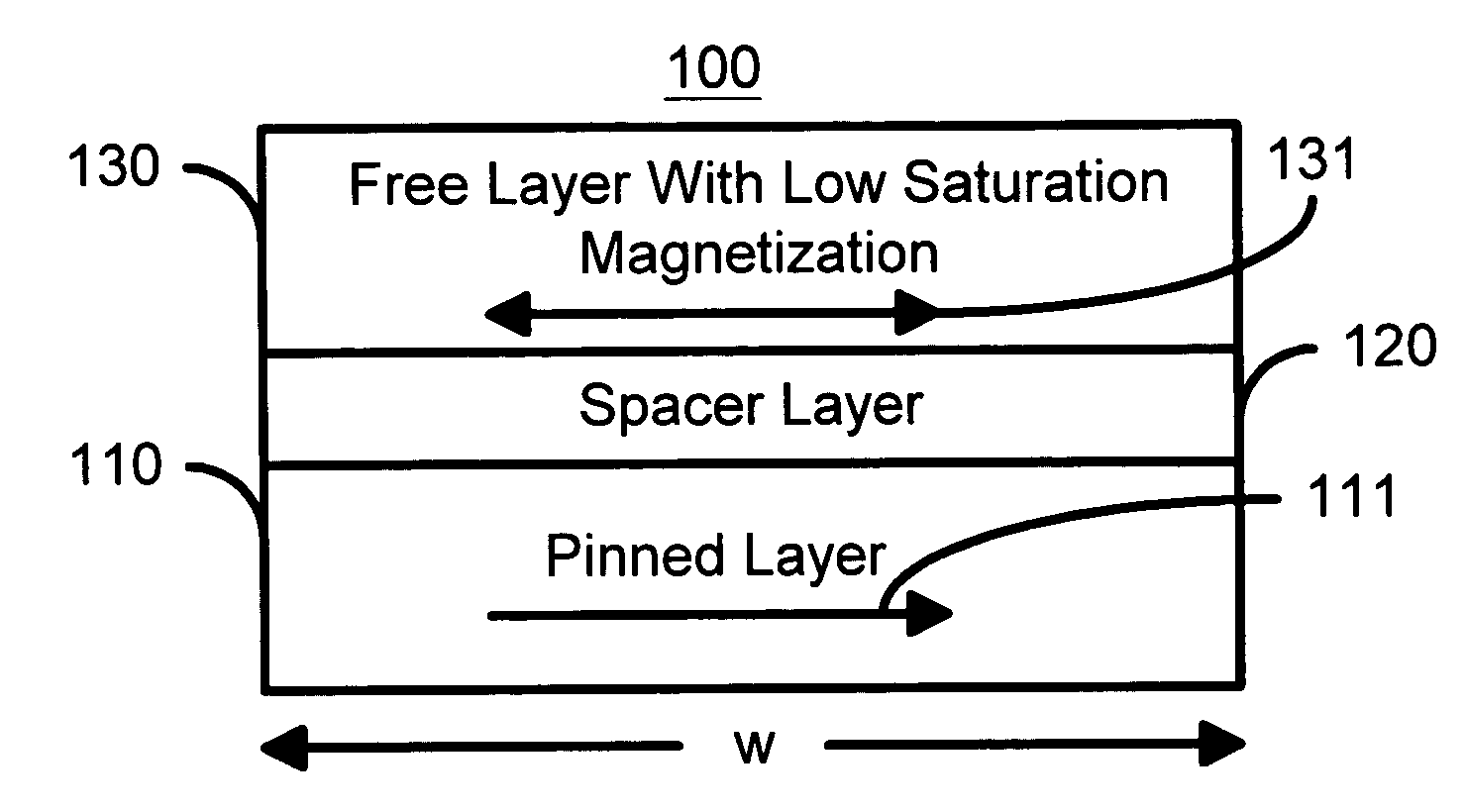

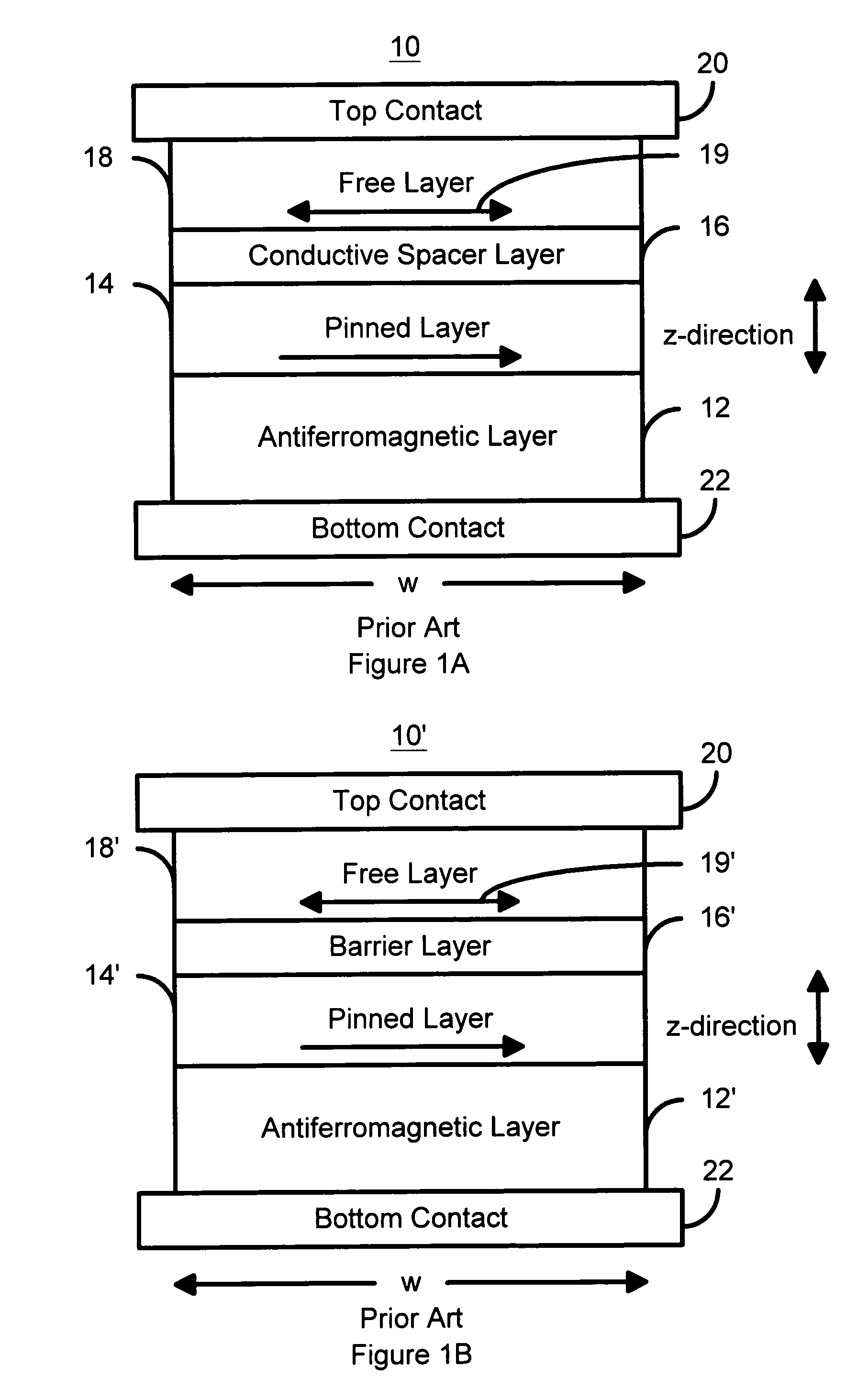

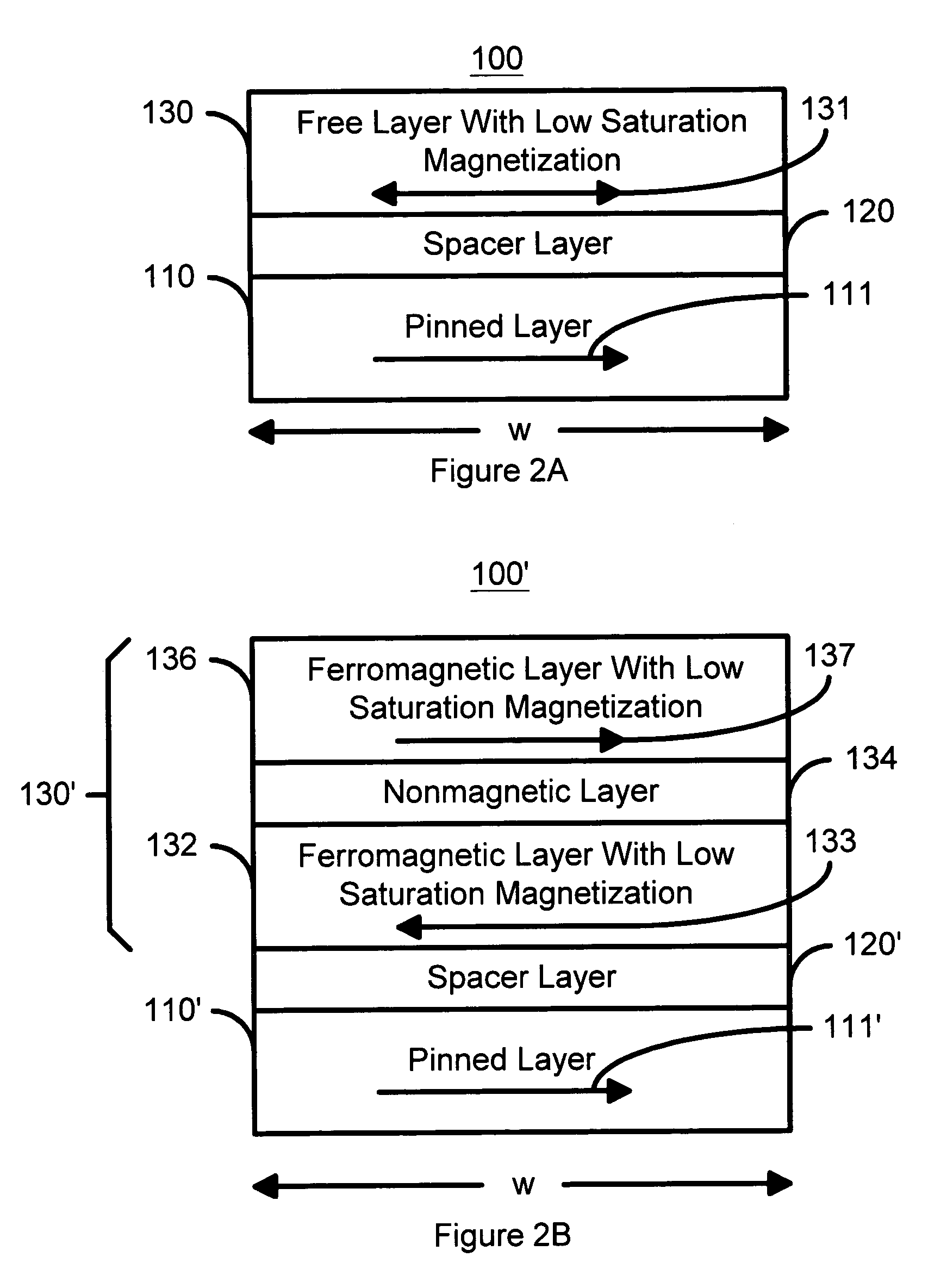

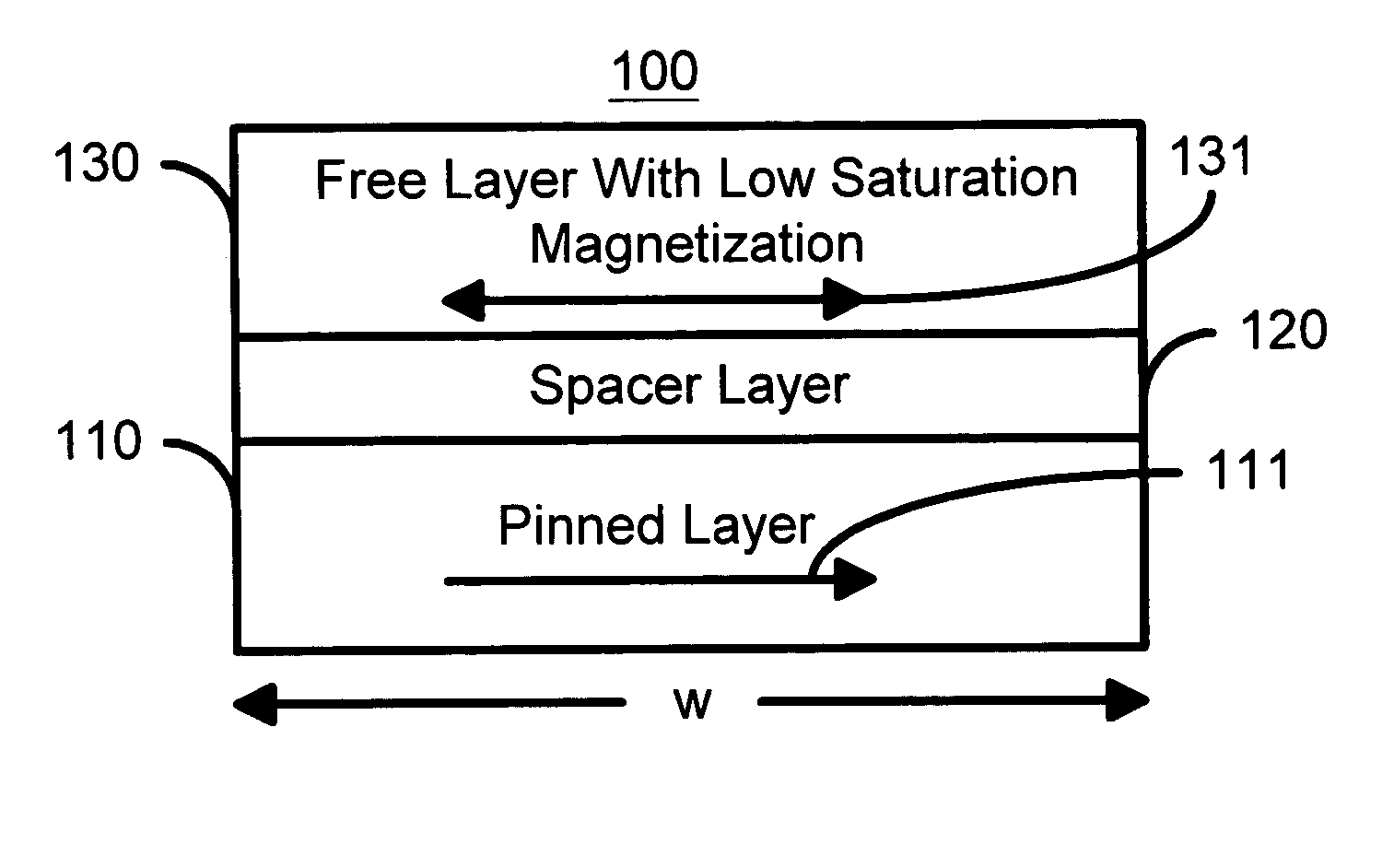

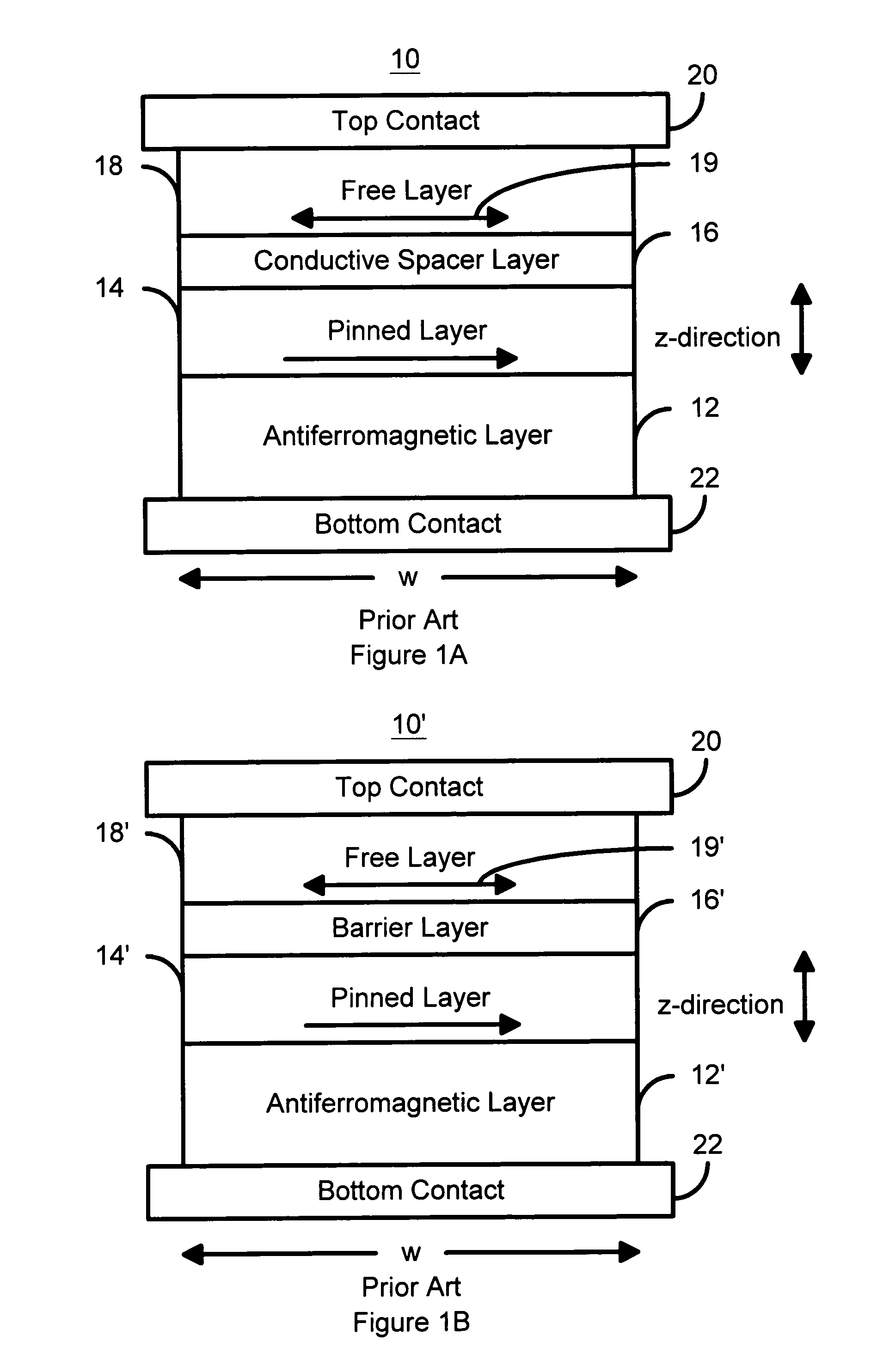

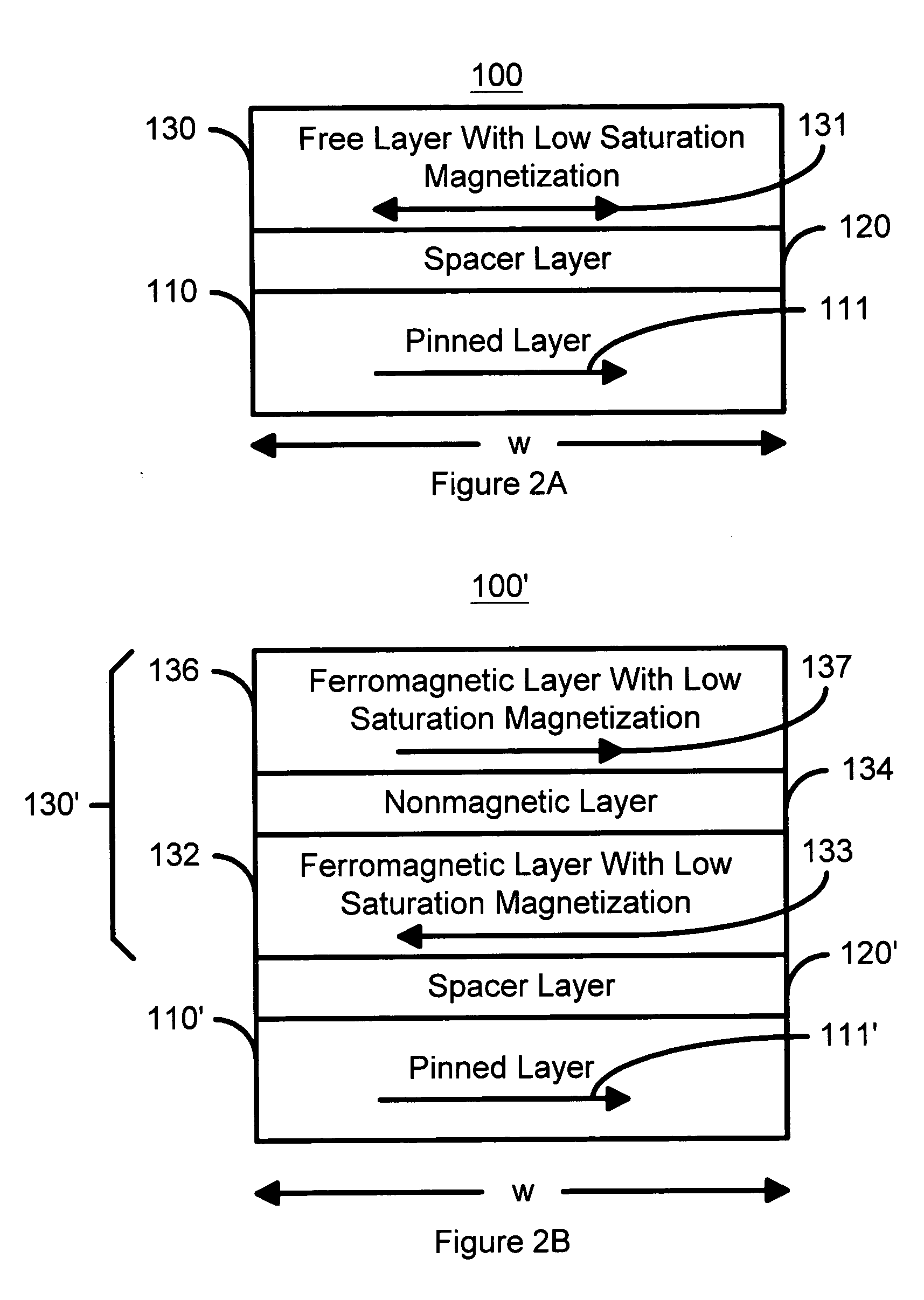

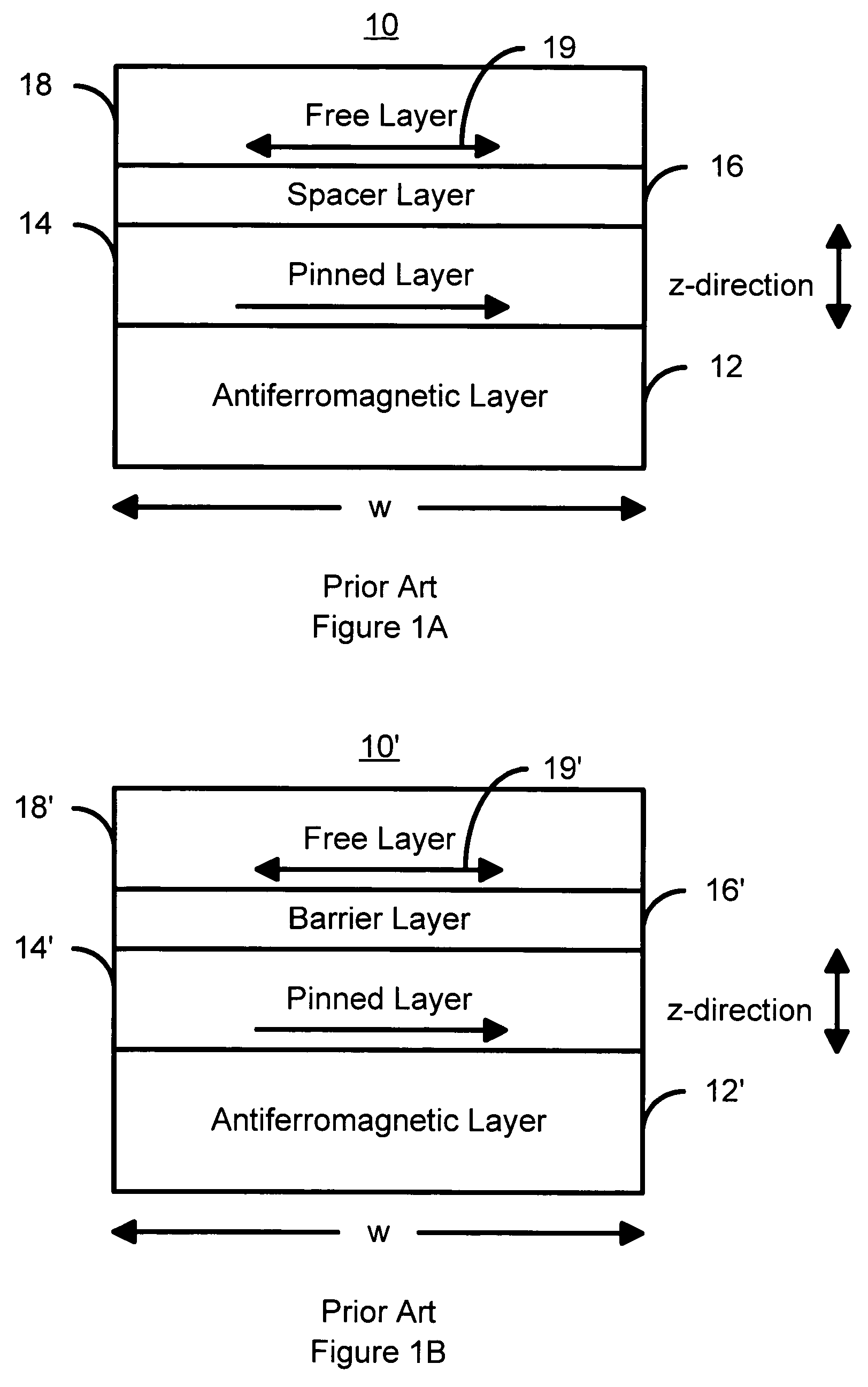

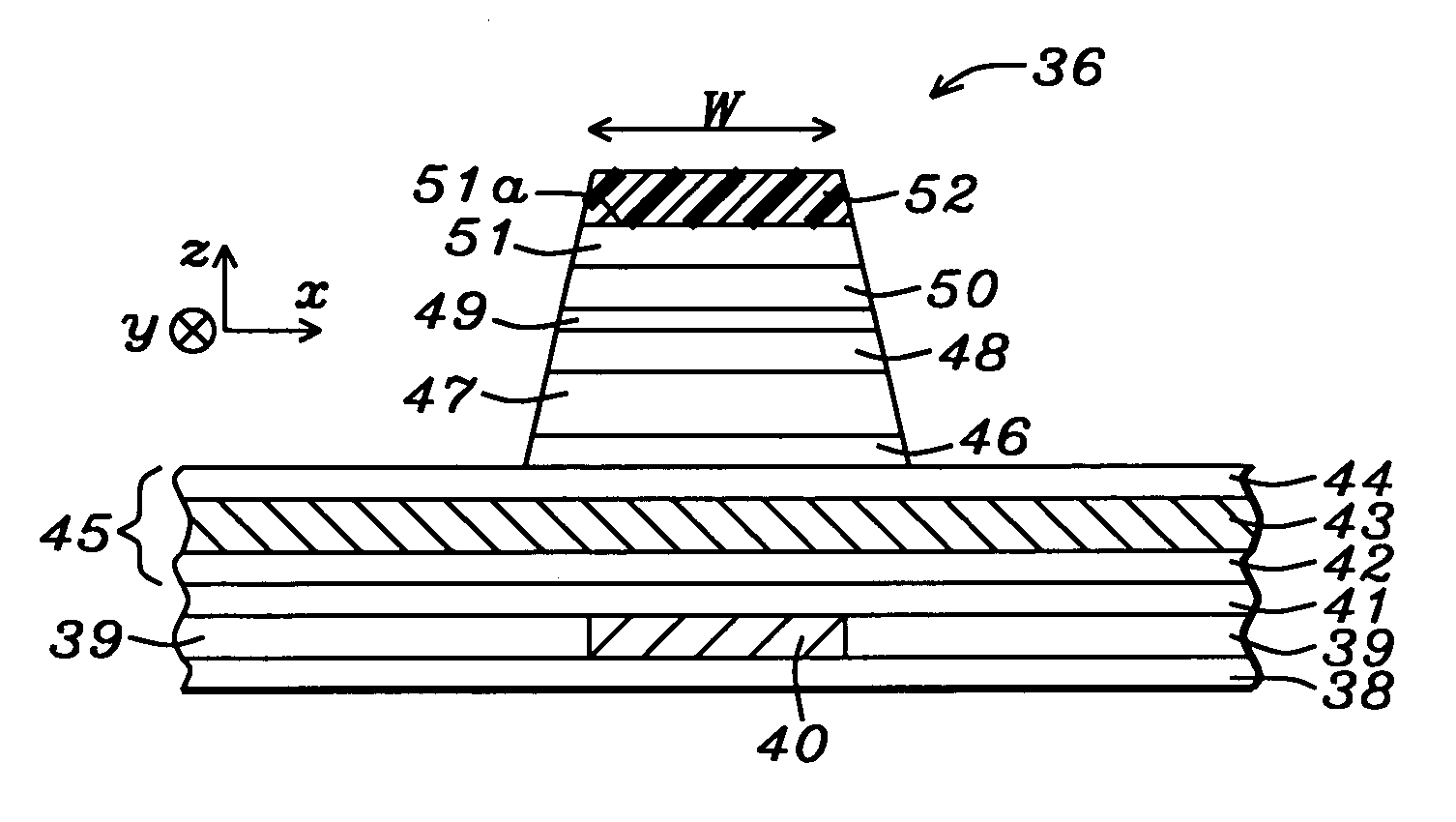

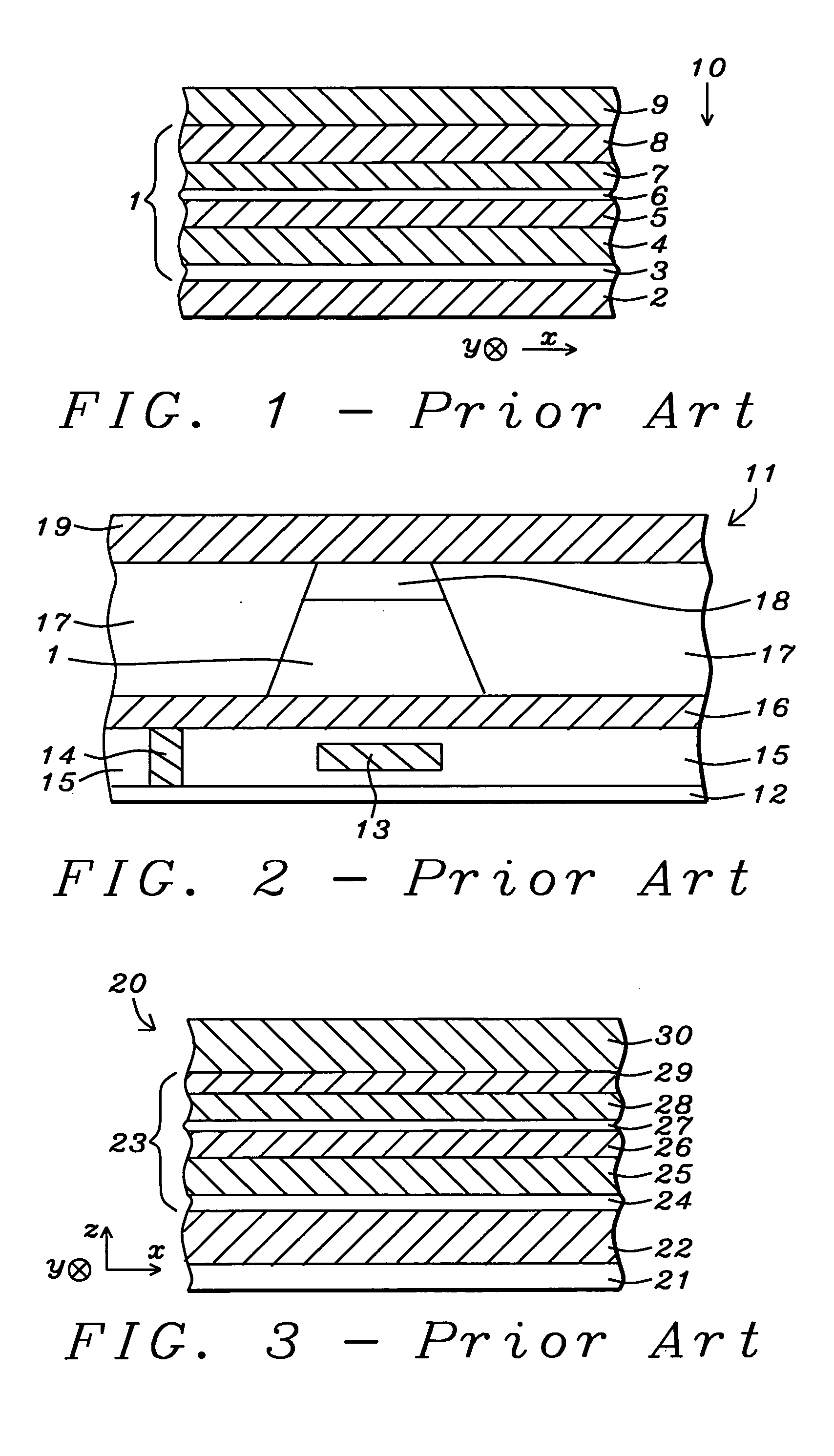

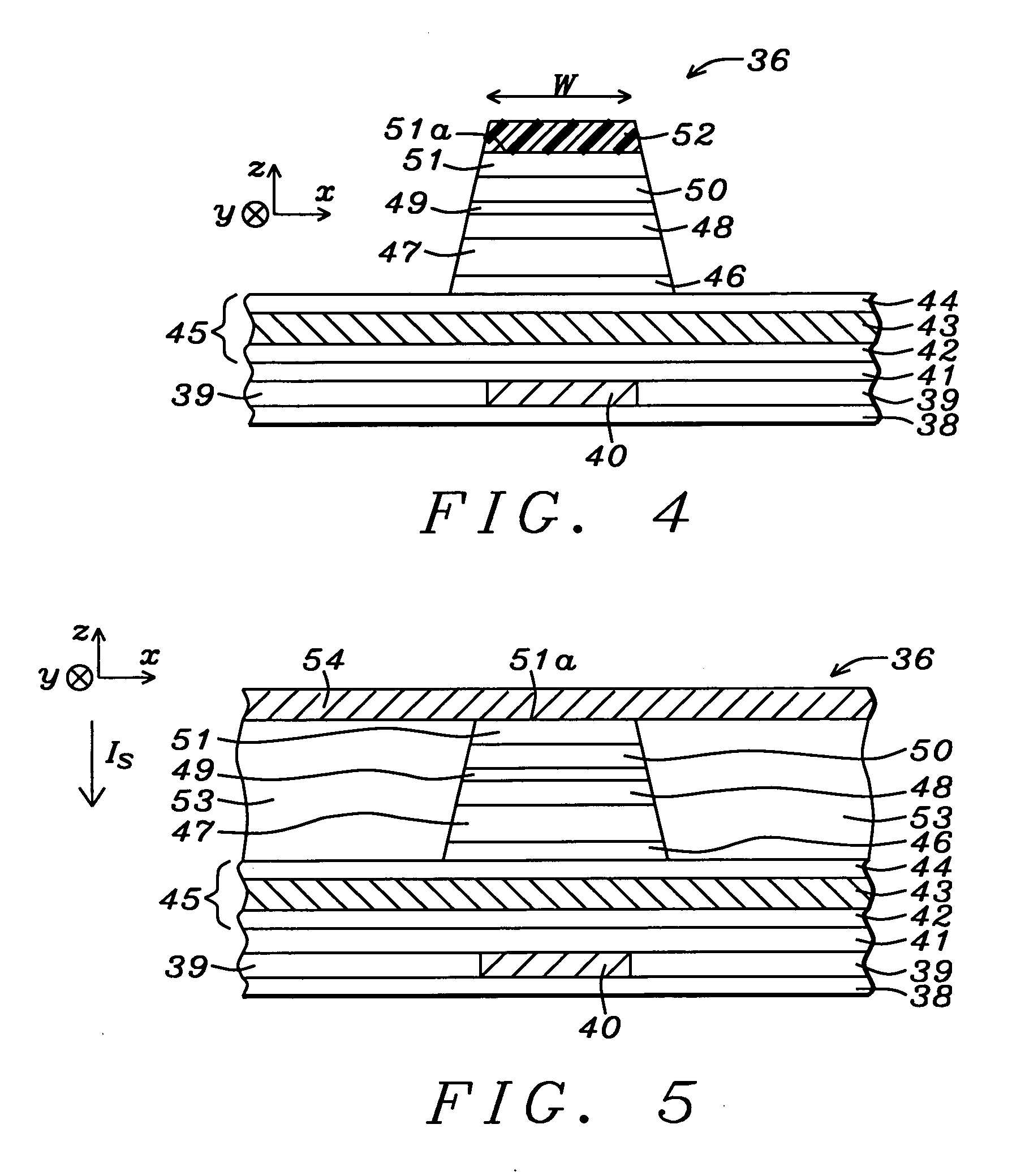

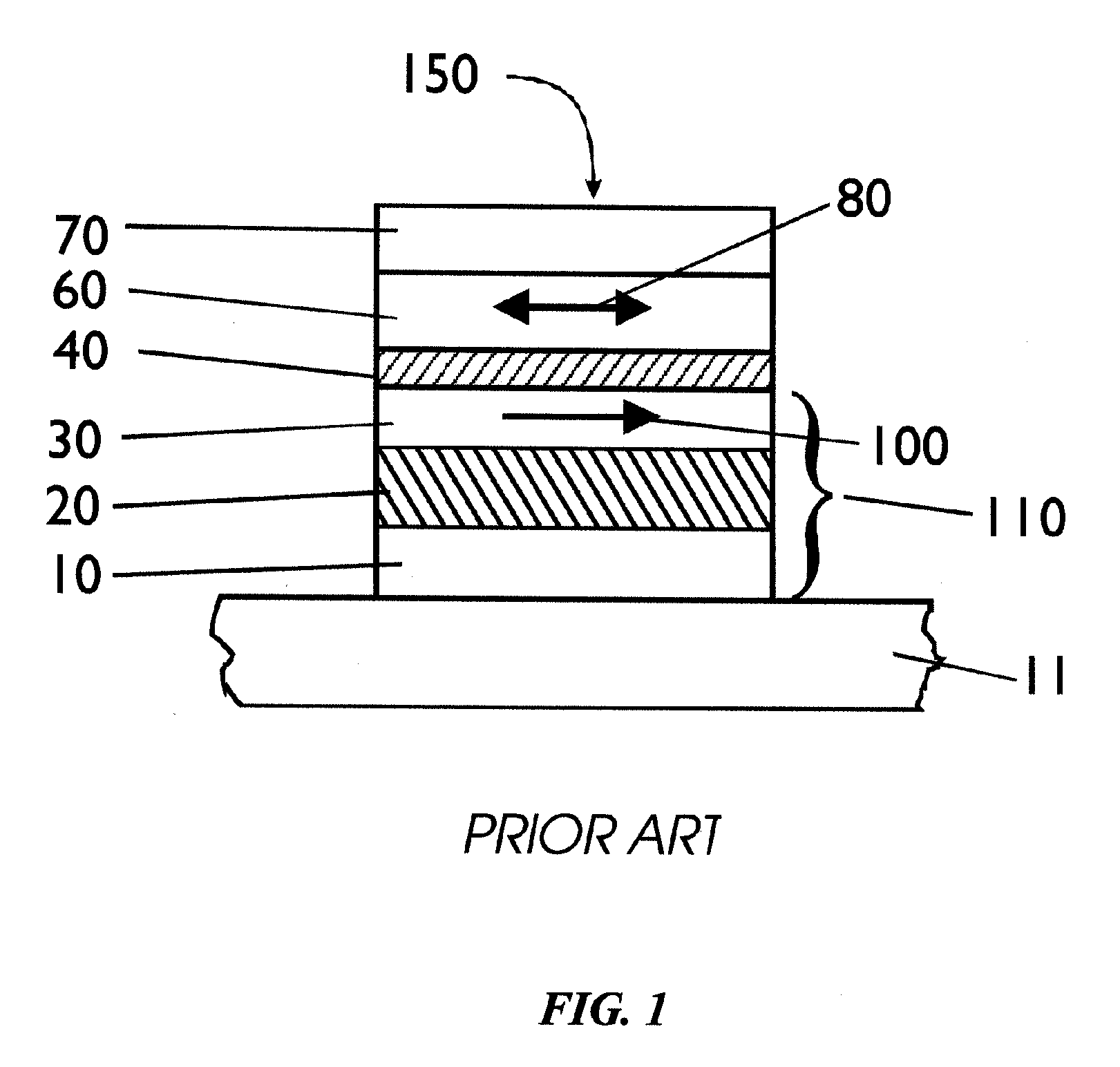

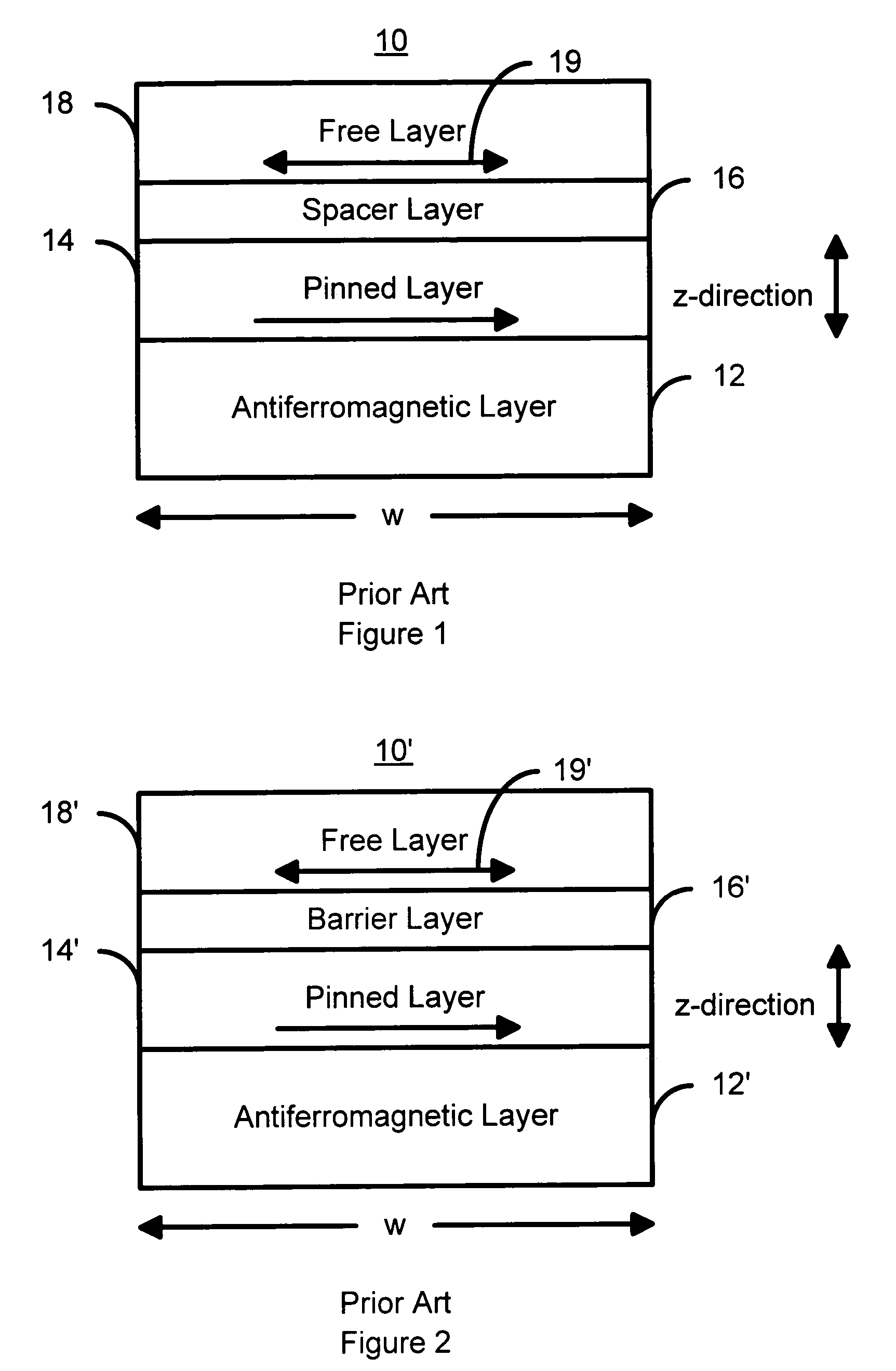

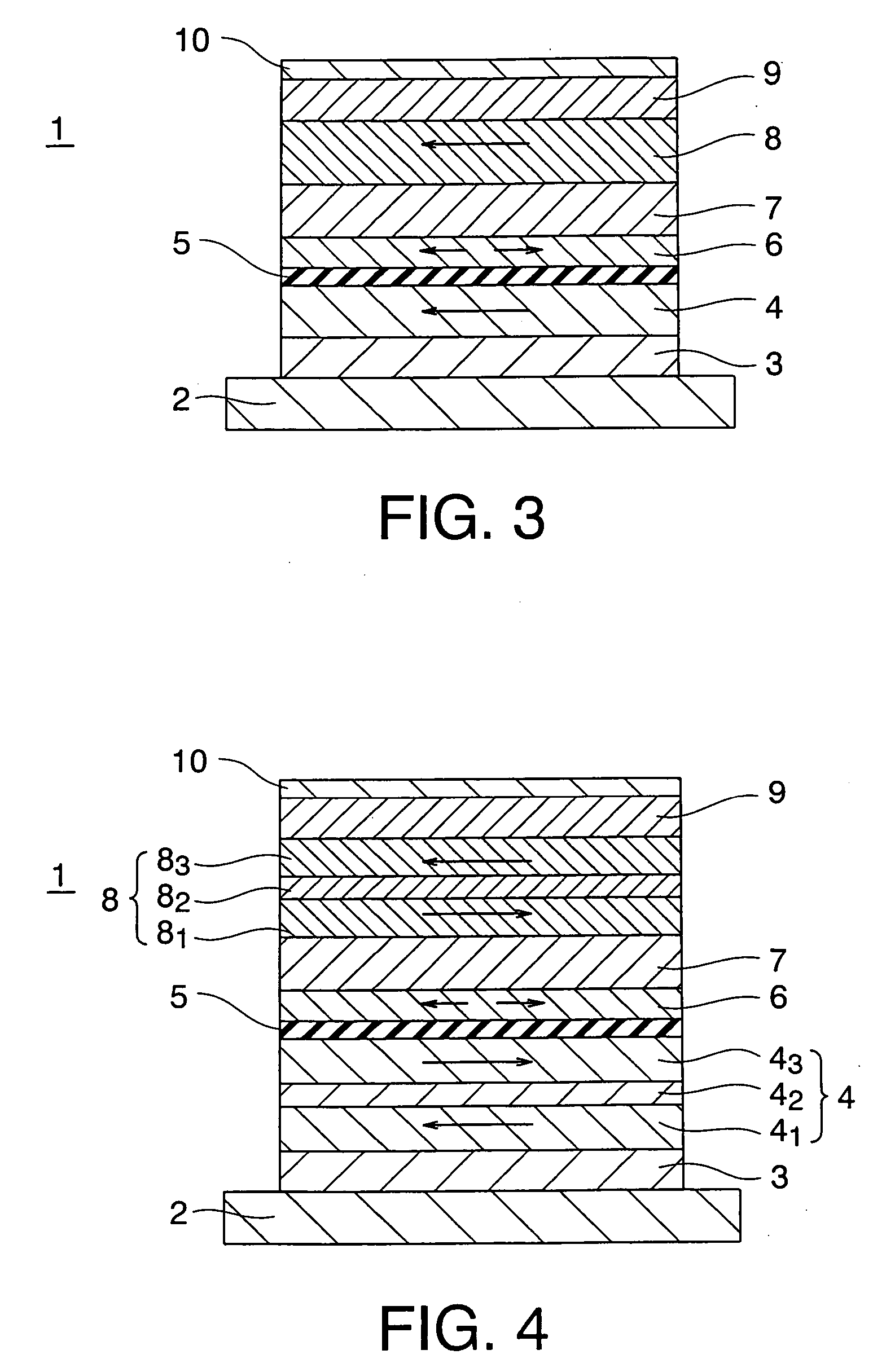

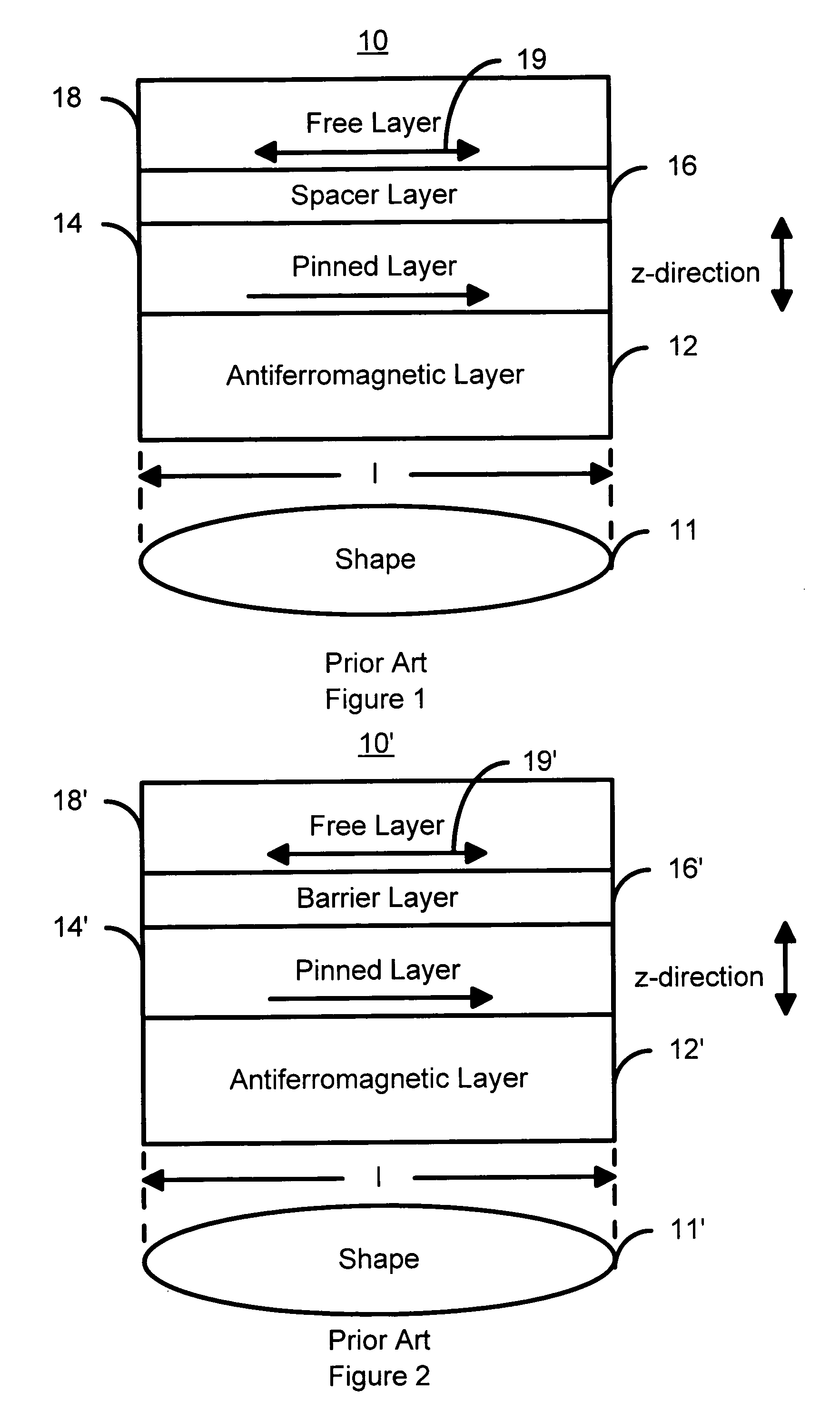

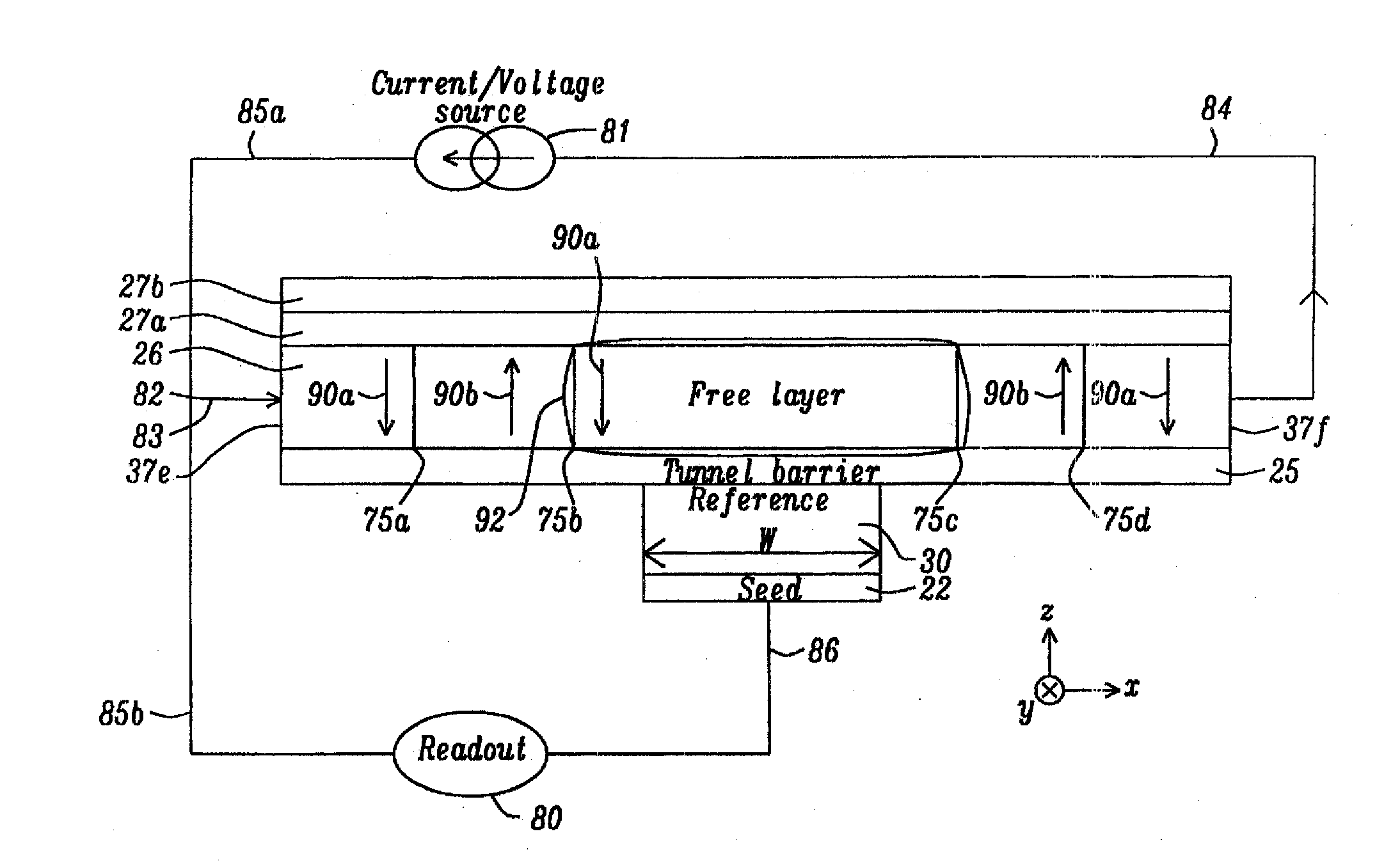

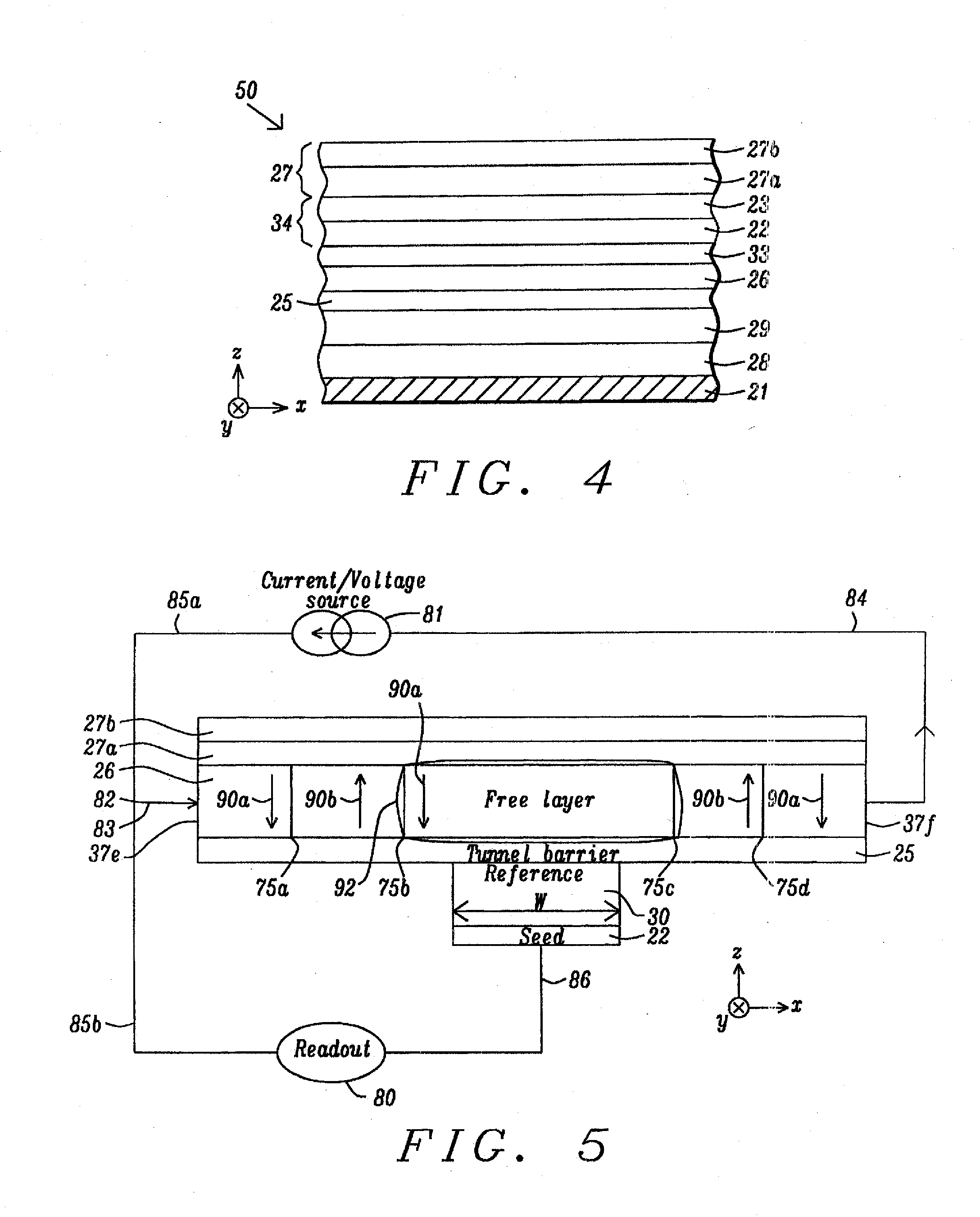

Spin transfer magnetic element having low saturation magnetization free layers

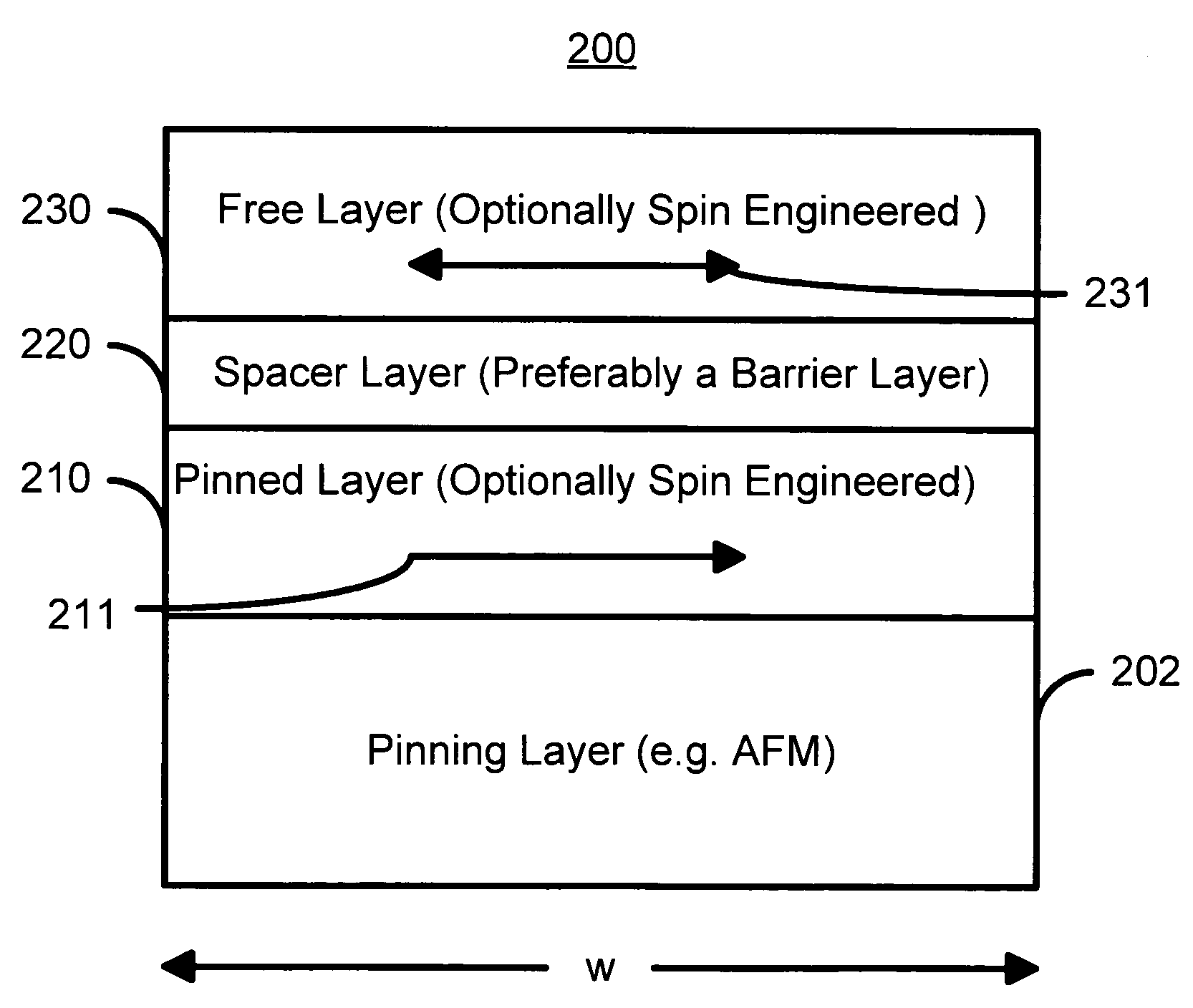

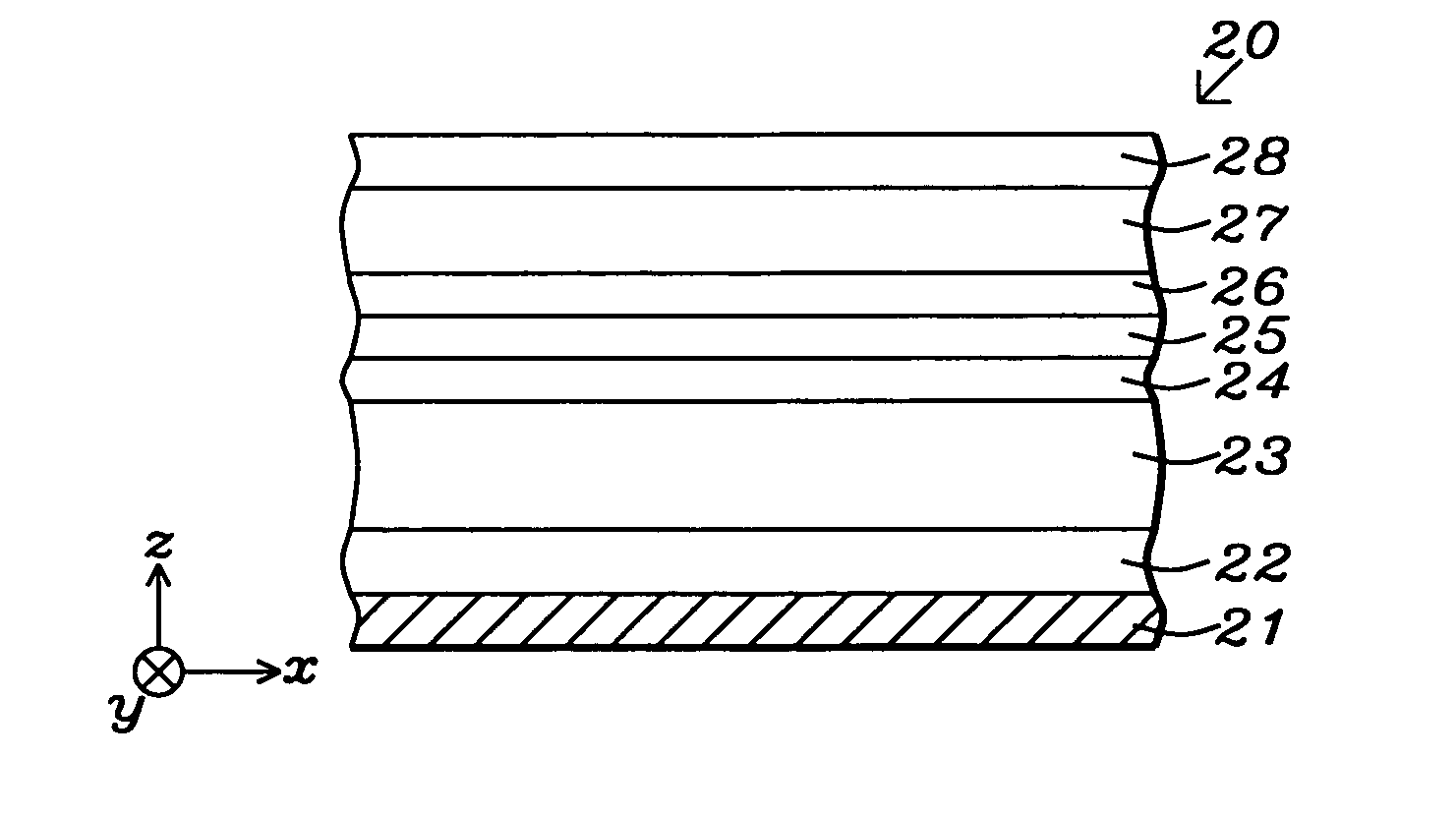

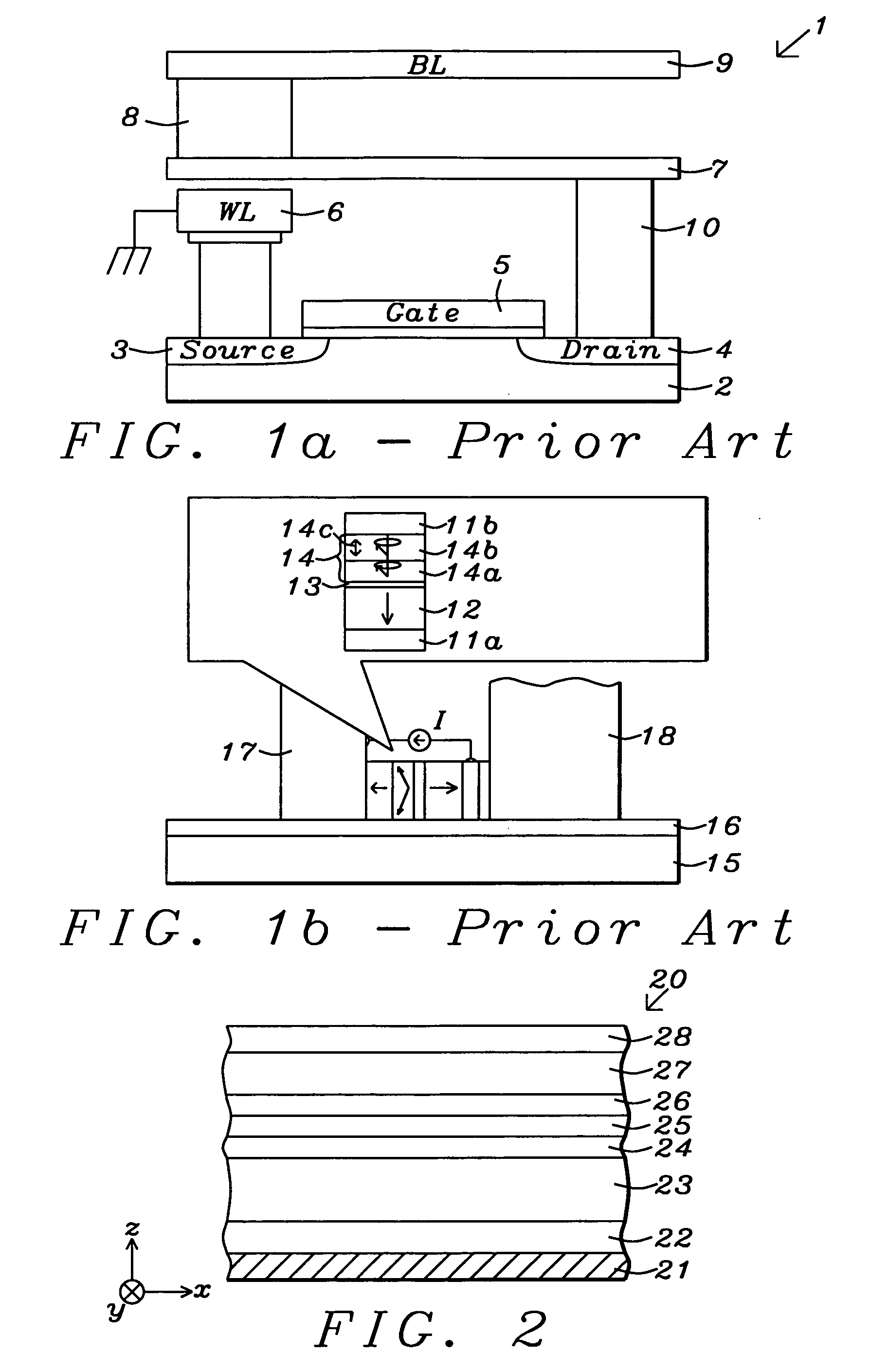

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. In one aspect, the free layer(s) include ferromagnetic material(s) diluted with nonmagnetic material(s) and / or ferrimagnetically doped to provide low saturation magnetization(s).

Owner:SAMSUNG SEMICON

Spin transfer magnetic element having low saturation magnetization free layers

ActiveUS20050184839A1Current densityNanostructure applicationNanomagnetismMagnetic memoryNon magnetic

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. In one aspect, the free layer(s) include ferromagnetic material(s) diluted with nonmagnetic material(s) and / or ferrimagnetically doped to provide low saturation magnetization(s).

Owner:SAMSUNG SEMICON

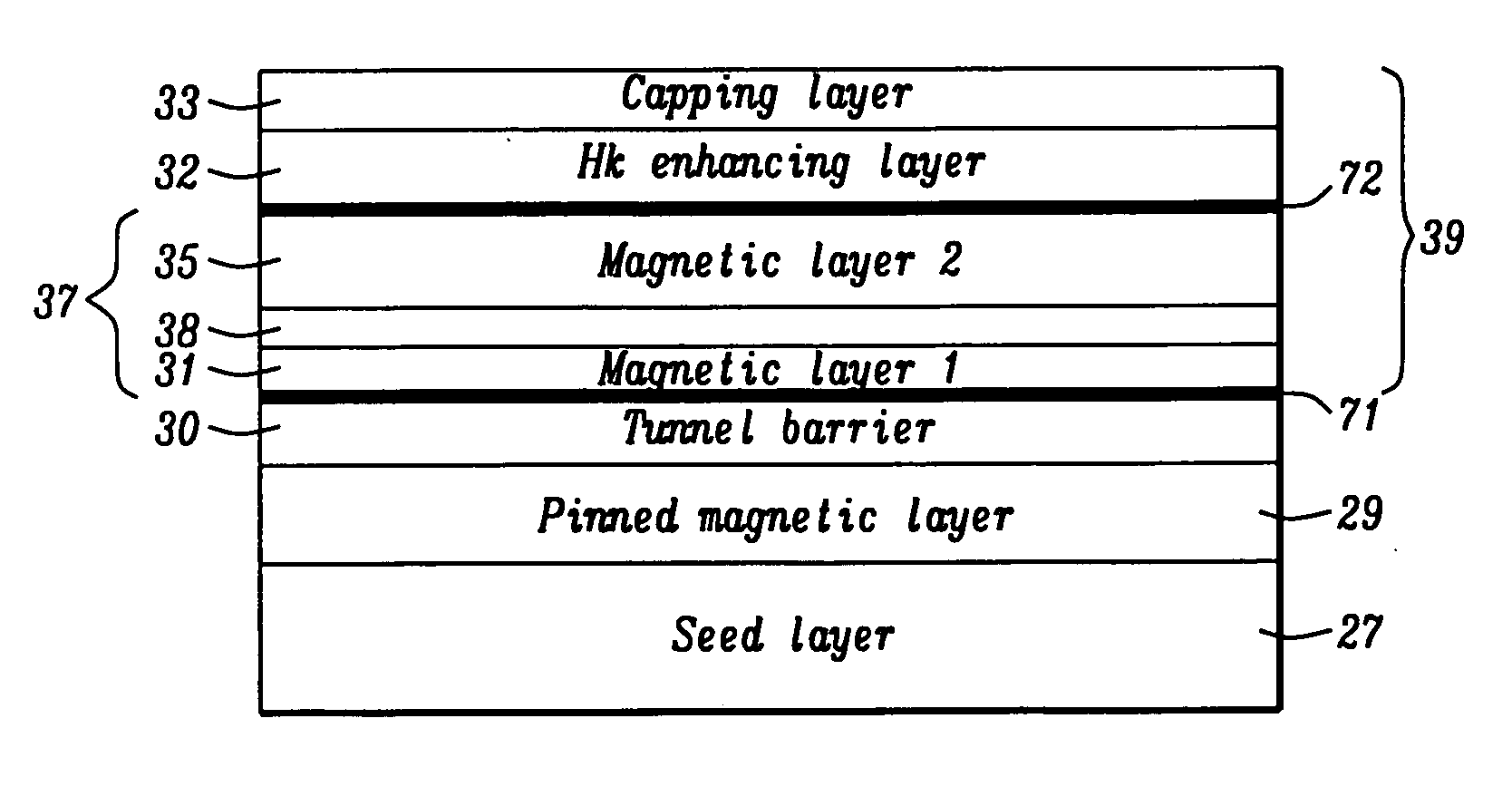

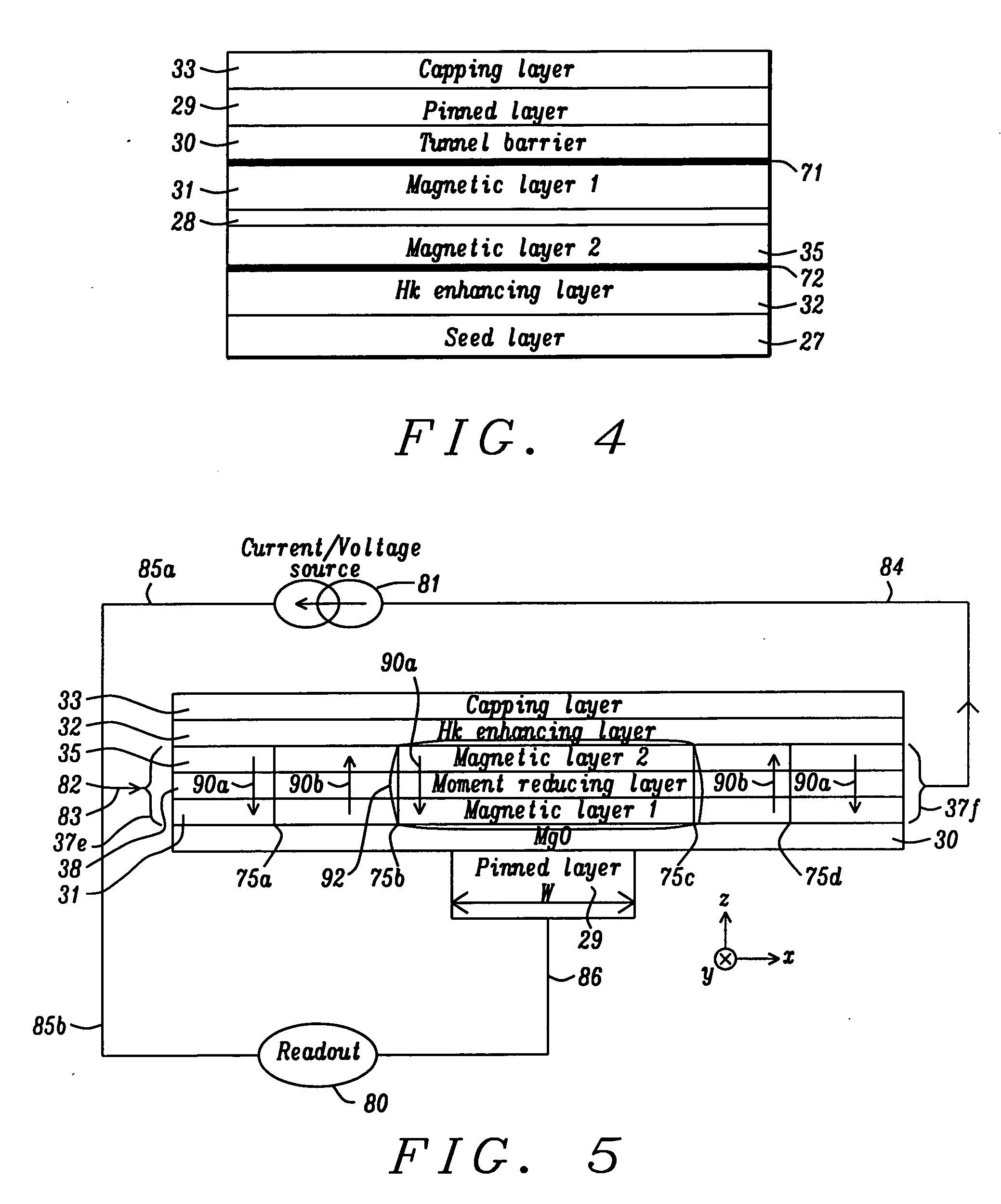

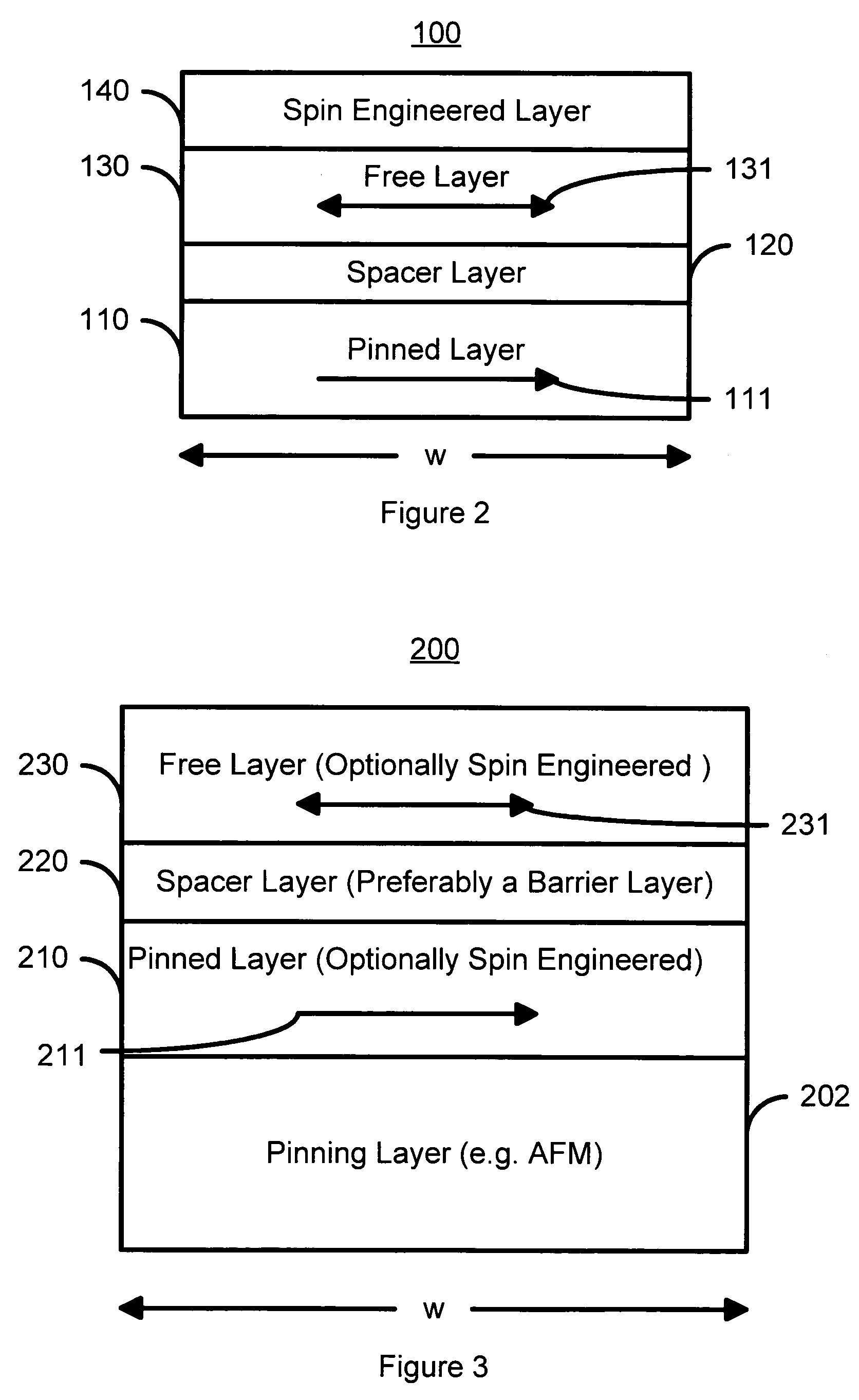

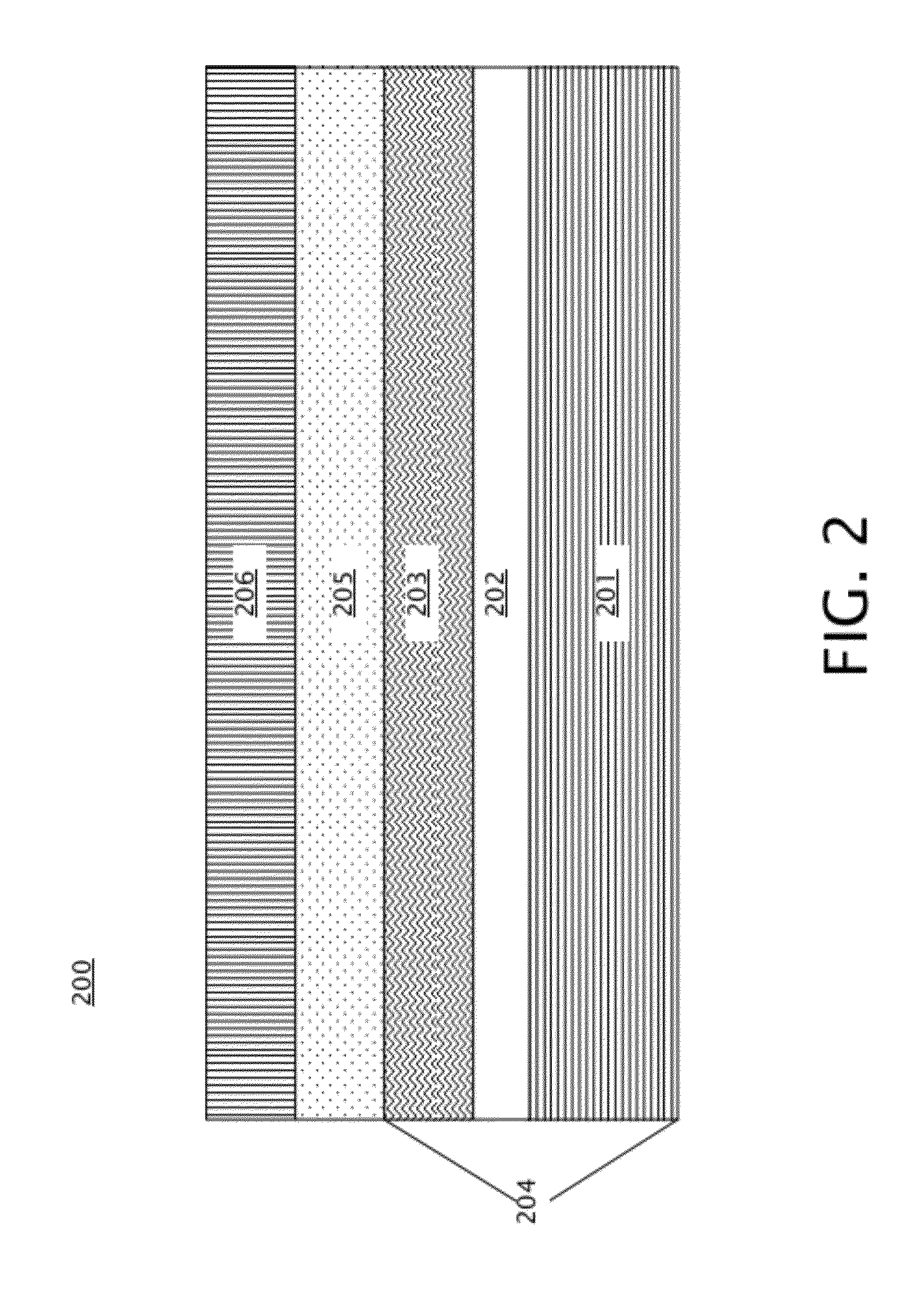

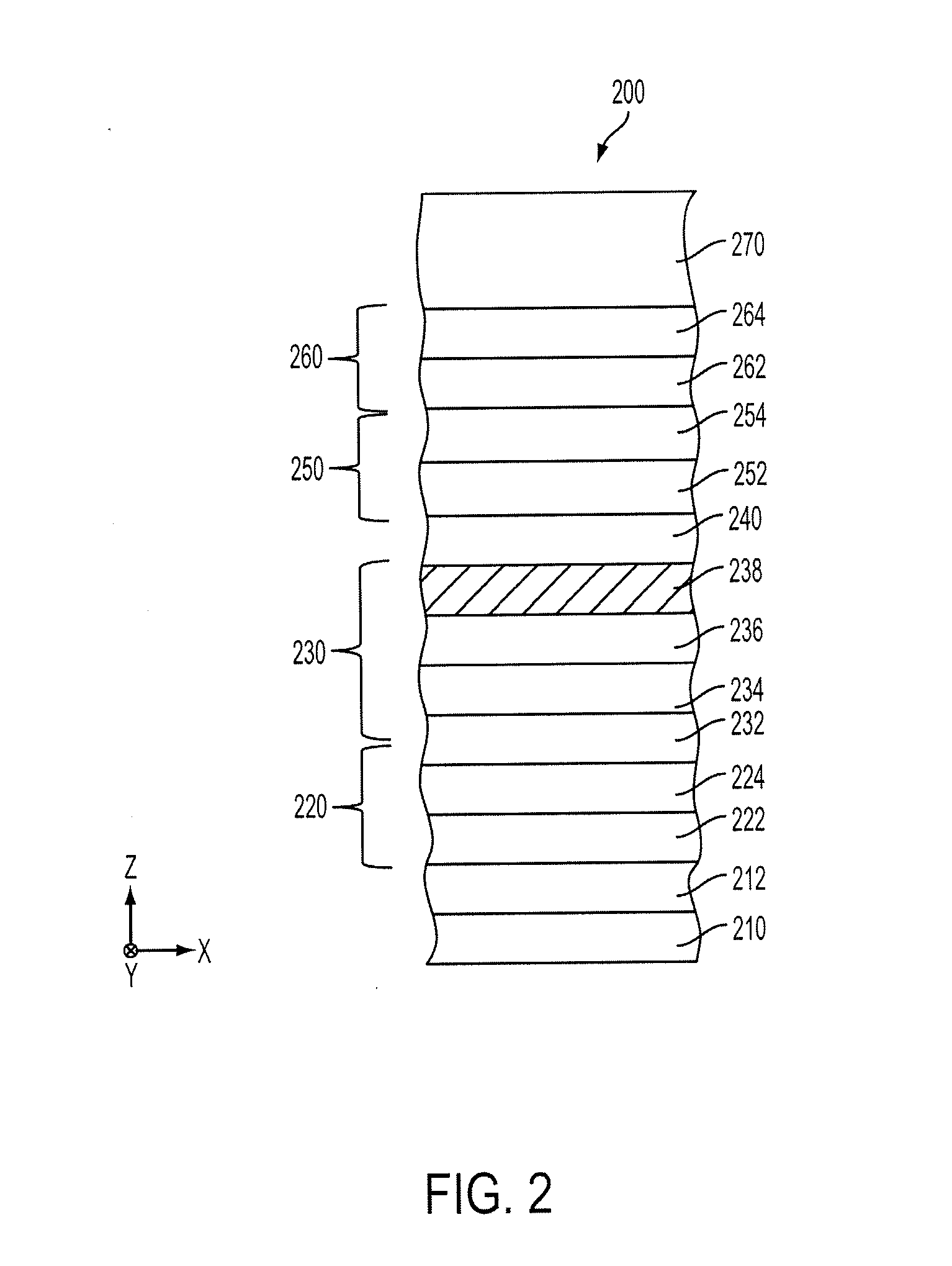

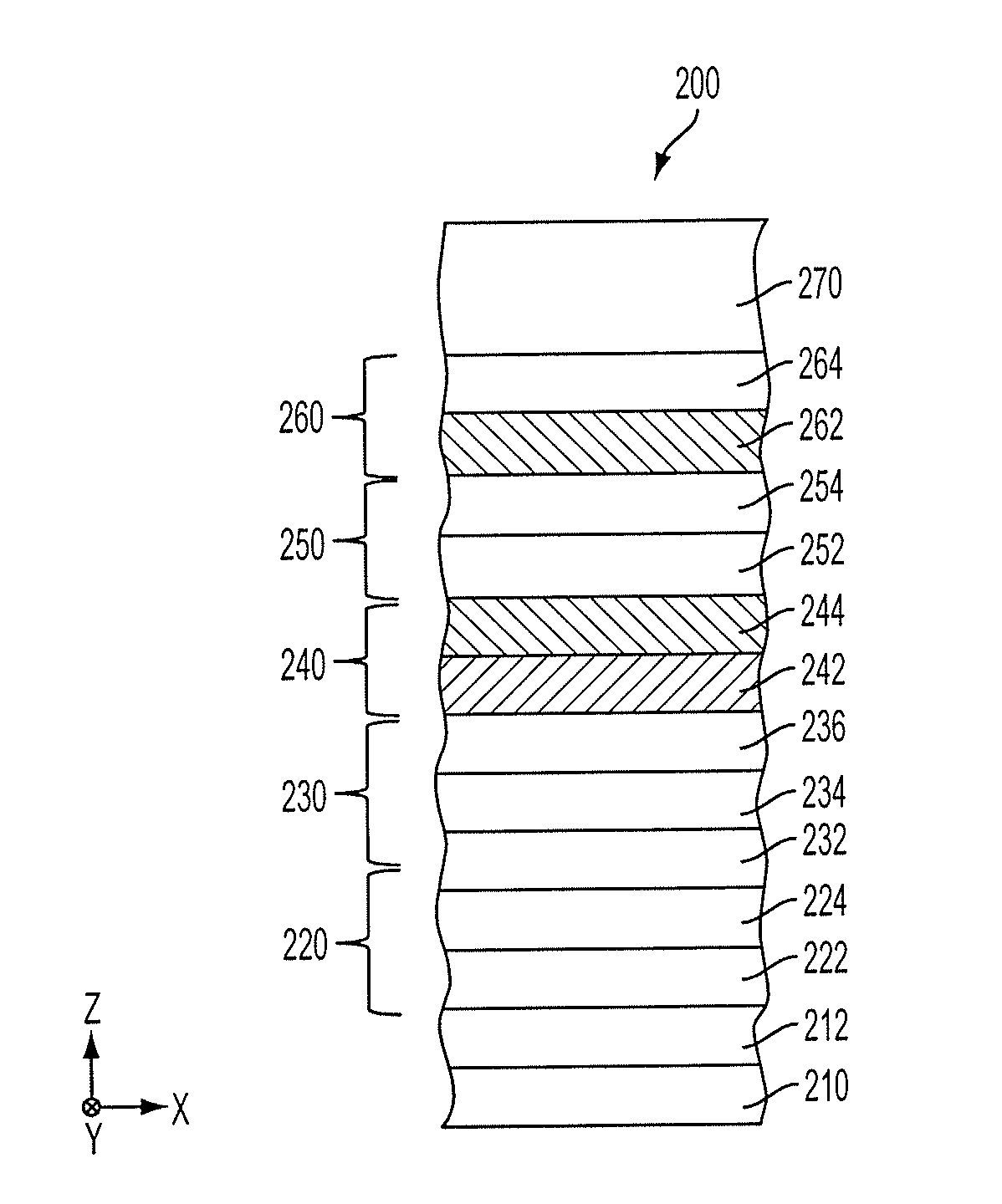

Multilayers having reduced perpendicular demagnetizing field using moment dilution for spintronic applications

ActiveUS20120280336A1Improve thermal stabilityHigh MR ratioMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

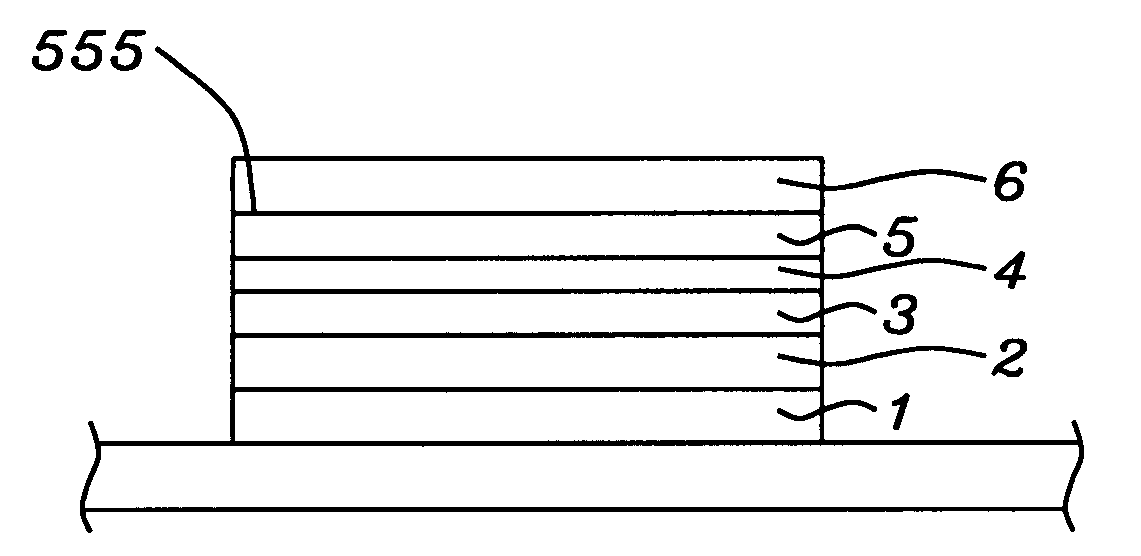

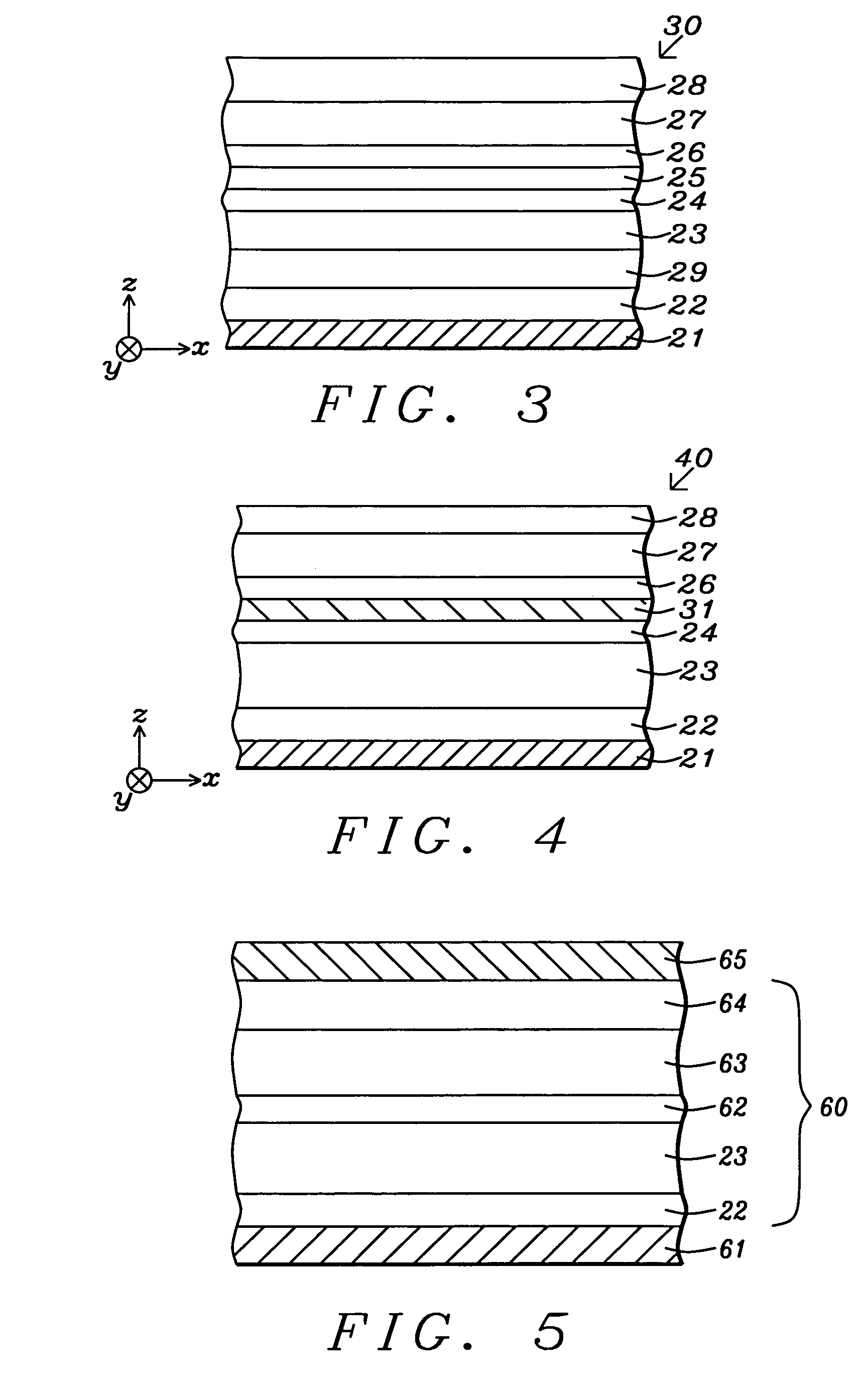

A magnetic element is disclosed that has a composite free layer with a FM1 / moment diluting / FM2 configuration wherein FM1 and FM2 are magnetic layers made of one or more of Co, Fe, Ni, and B and the moment diluting layer is used to reduce the perpendicular demagnetizing field. As a result, lower resistance x area product and higher thermal stability are realized when perpendicular surface anisotropy dominates shape anisotropy to give a magnetization perpendicular to the planes of the FM1, FM2 layers. The moment diluting layer may be a non-magnetic metal like Ta or a CoFe alloy with a doped non-magnetic metal. A perpendicular Hk enhancing layer interfaces with the FM2 layer and may be an oxide to increase the perpendicular anisotropy field in the FM2 layer. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

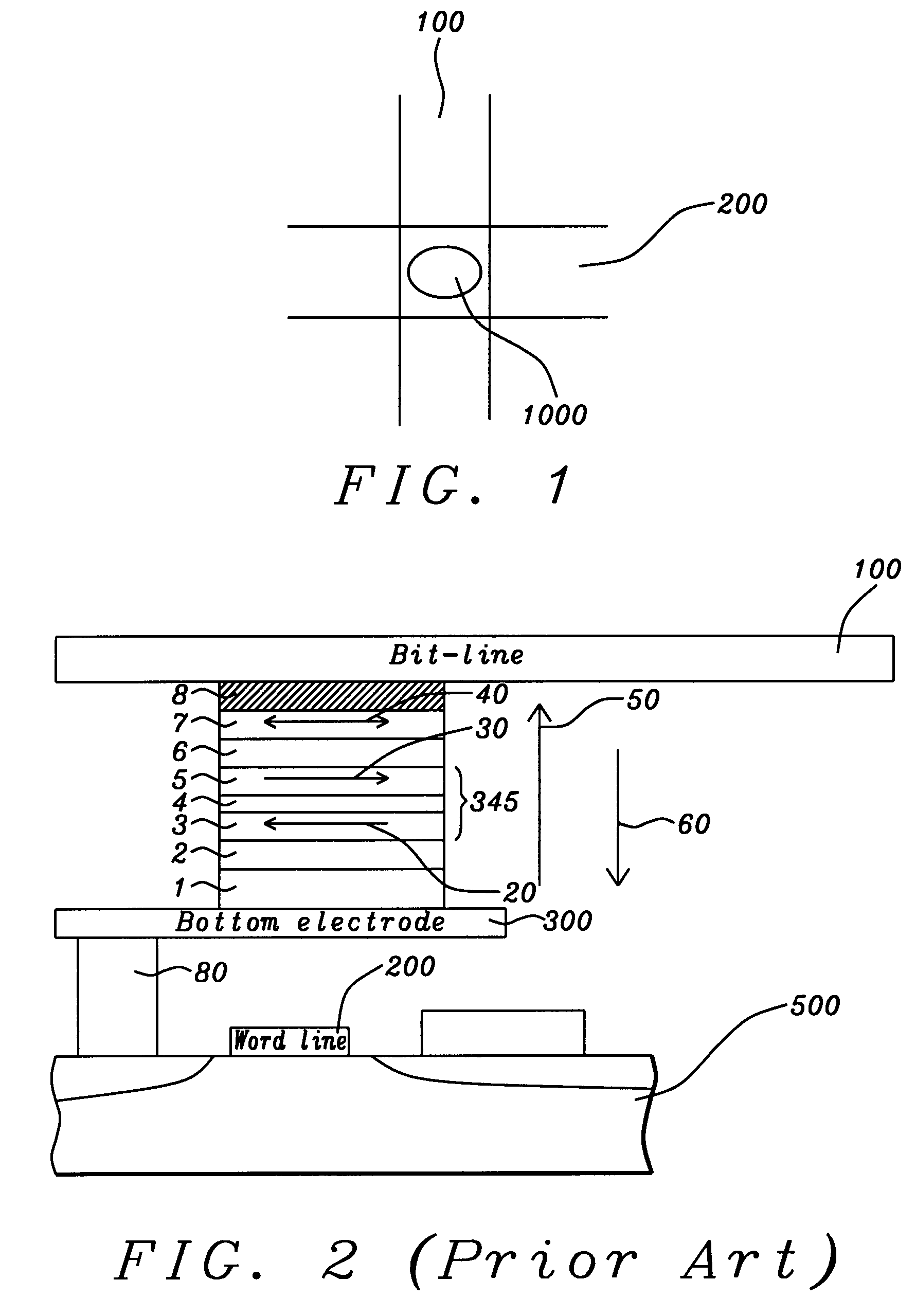

Magnetic tunnel junction magnetic device, memory and writing and reading methods using said device

InactiveUS6950335B2Good reproducibilityEliminate errorsNanomagnetismMagnetic-field-controlled resistorsMagnetizationSemiconductor

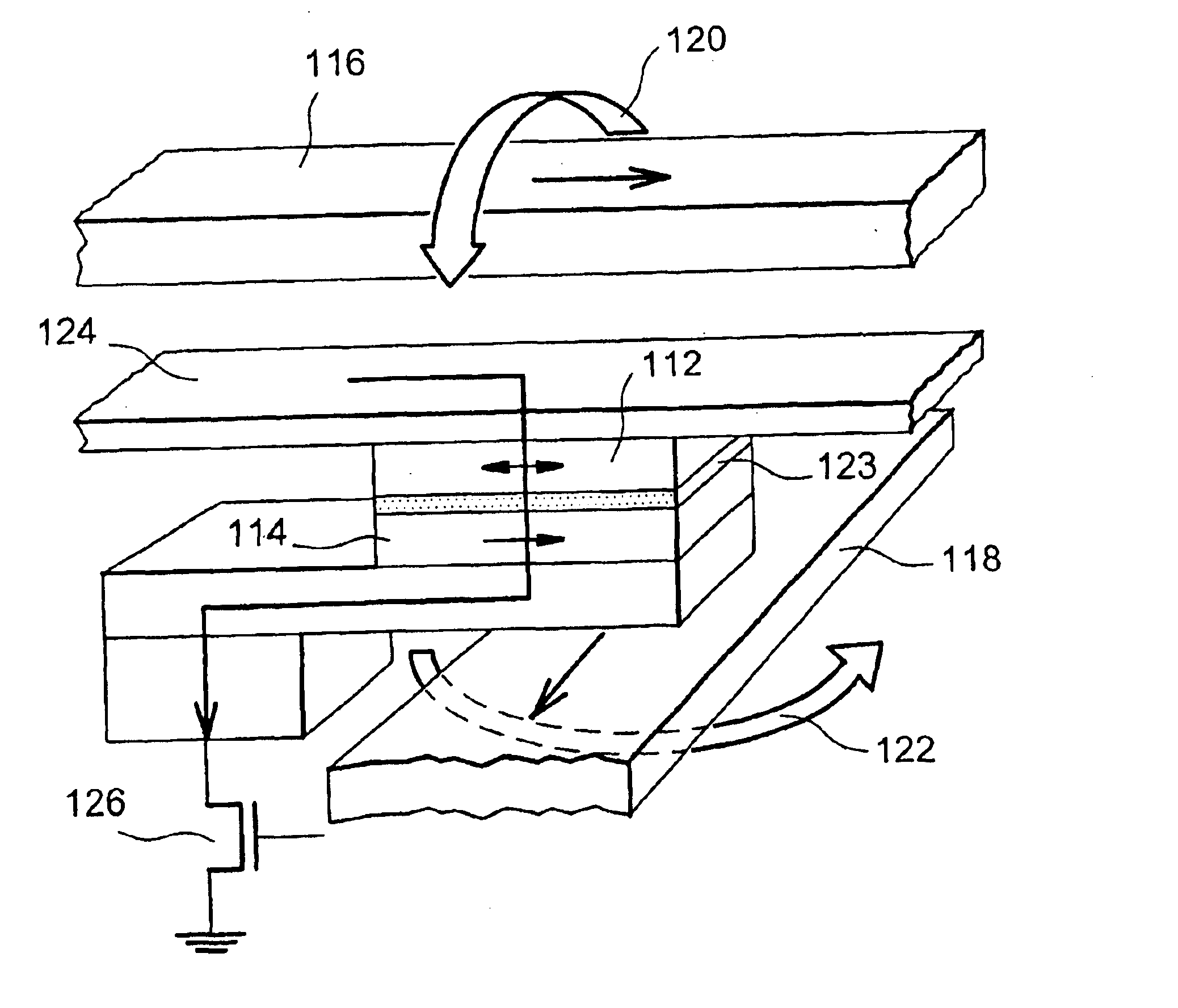

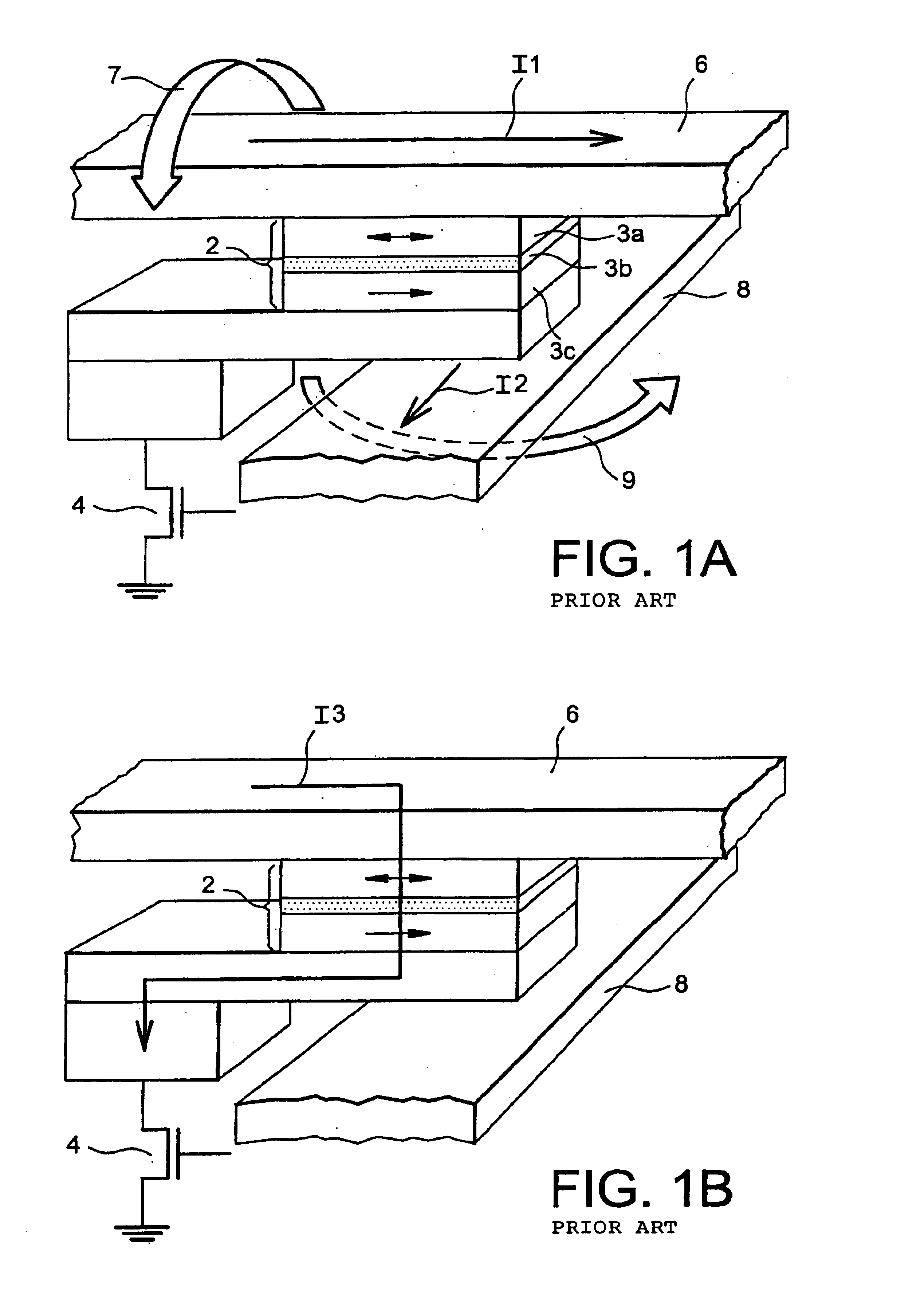

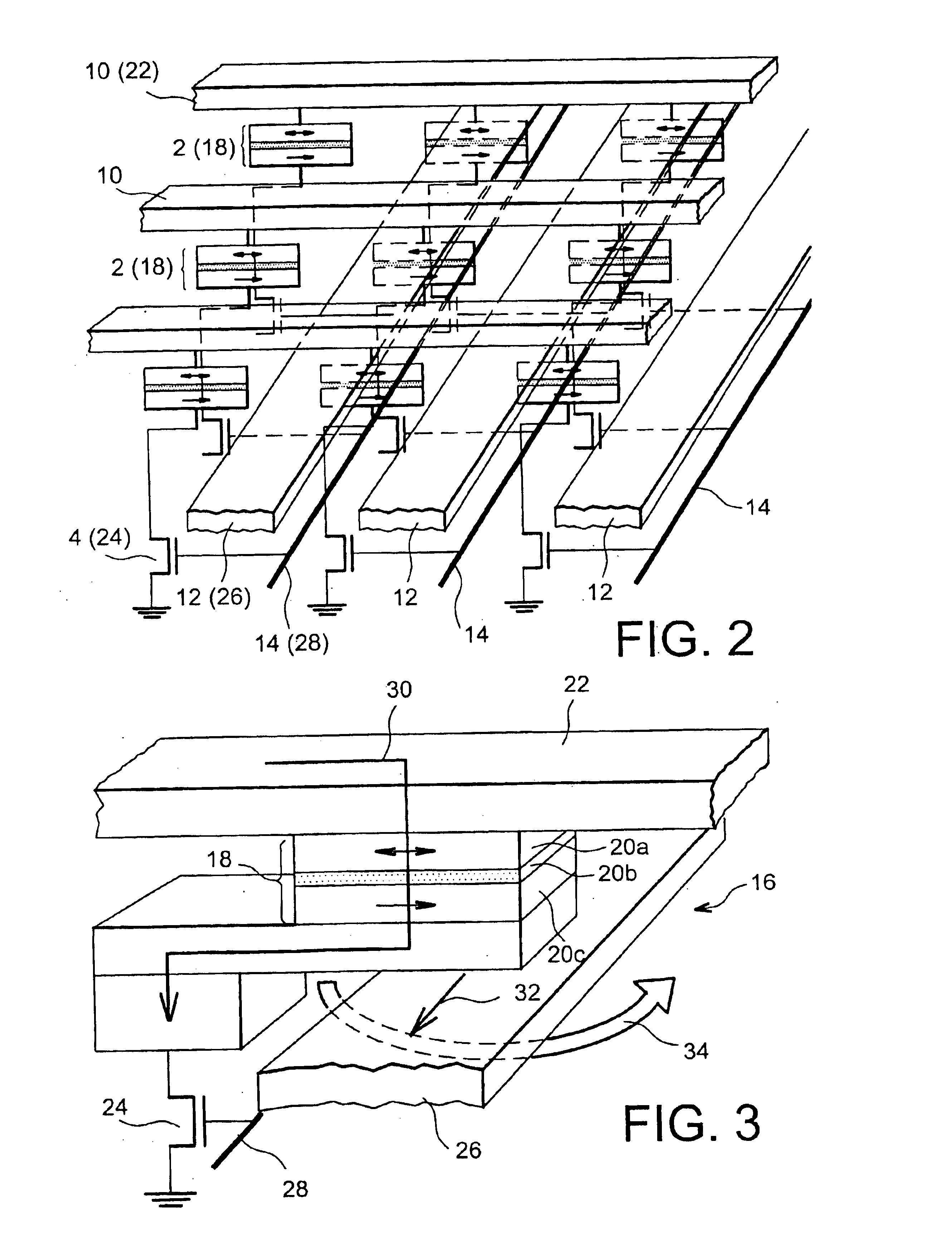

Magnetic tunnel junction magnetic device (16) for writing and reading uses a reference layer (20c) and a storage layer (20a) separated by a semiconductor or insulating layer (20b). The blocking temperature of the magnetisation of the storage layer is less than that of the reference layer. The storage layer is heated (22, 24) above the blocking temperature of its magnetisation. A magnetic field (34) is applied (26) to it orientating its magnetization with respect to that of the reference layer without modifying the orientation of the reference layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

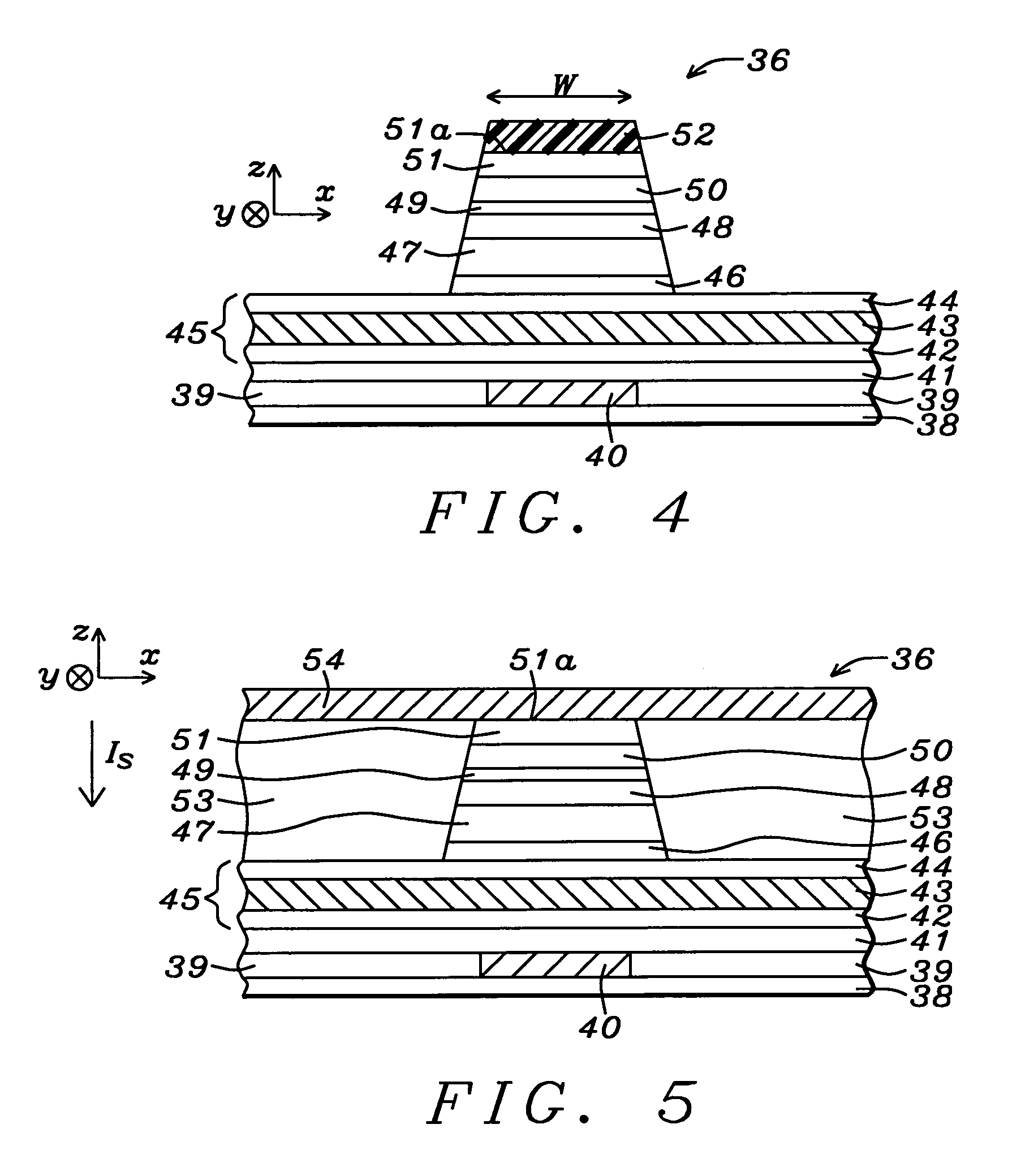

Magnetic elements with spin engineered insertion layers and MRAM devices using the magnetic elements

ActiveUS7369427B2Lower average currentReduce consumptionNanomagnetismGalvano-magnetic material selectionSpinsSpin transfer

A method and system include providing a pinned layer, a free layer, and a spacer layer between the pinned and free layers. The spacer layer is nonmagnetic. The magnetic element is configured to allow the free layer to be switched due to spin transfer when a write current is passed through the magnetic element. In one aspect, the method and system include providing a spin engineered layer adjacent to the free layer. The spin engineered layer is configured to more strongly scatter majority electrons than minority electrons. In another aspect, at least one of the pinned, free, and spacer layers is a spin engineered layer having an internal spin engineered layer configured to more strongly scatter majority electrons than minority electrons. In this aspect, the magnetic element may include another pinned layer and a barrier layer between the free and pinned layers.

Owner:SAMSUNG SEMICON

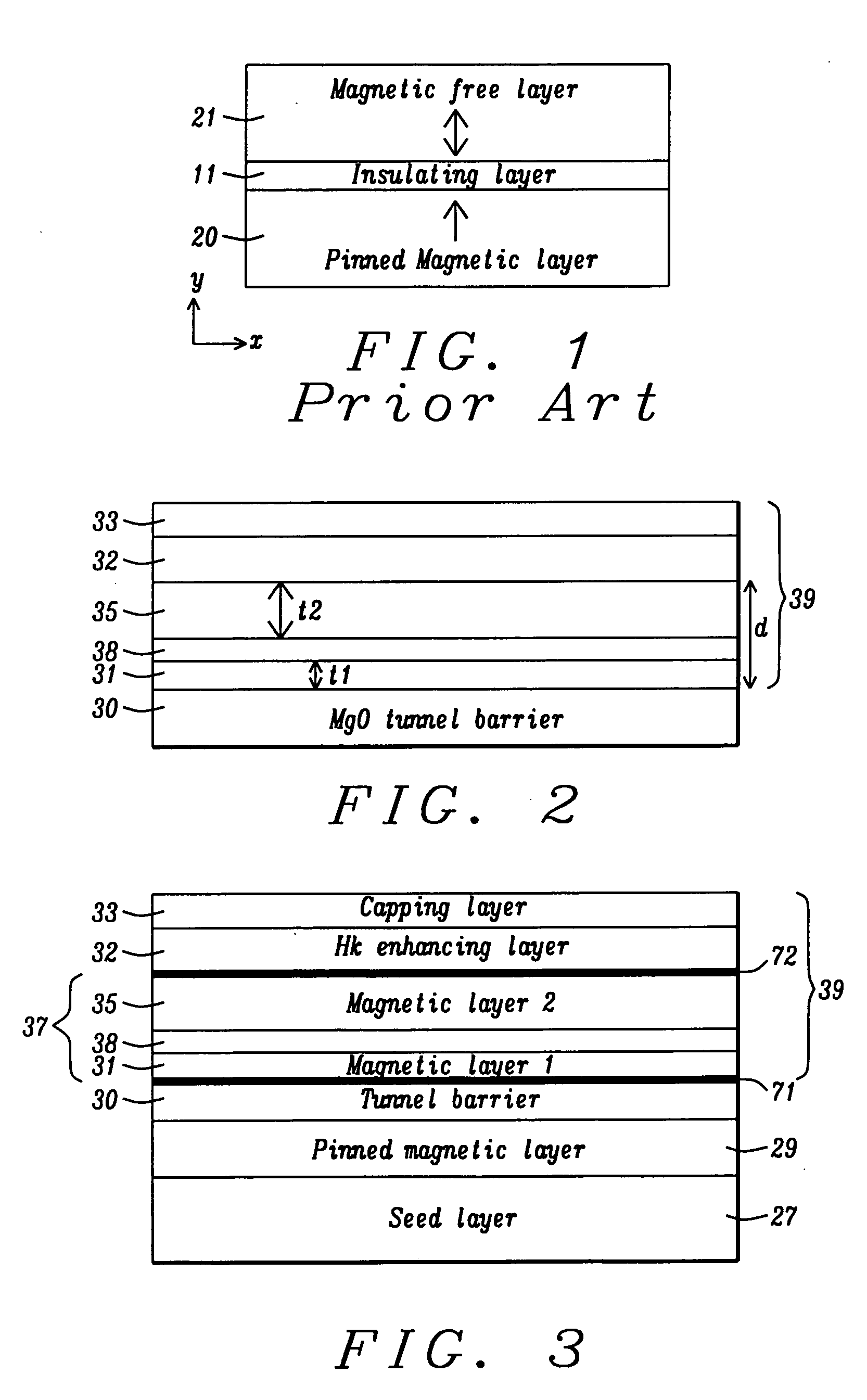

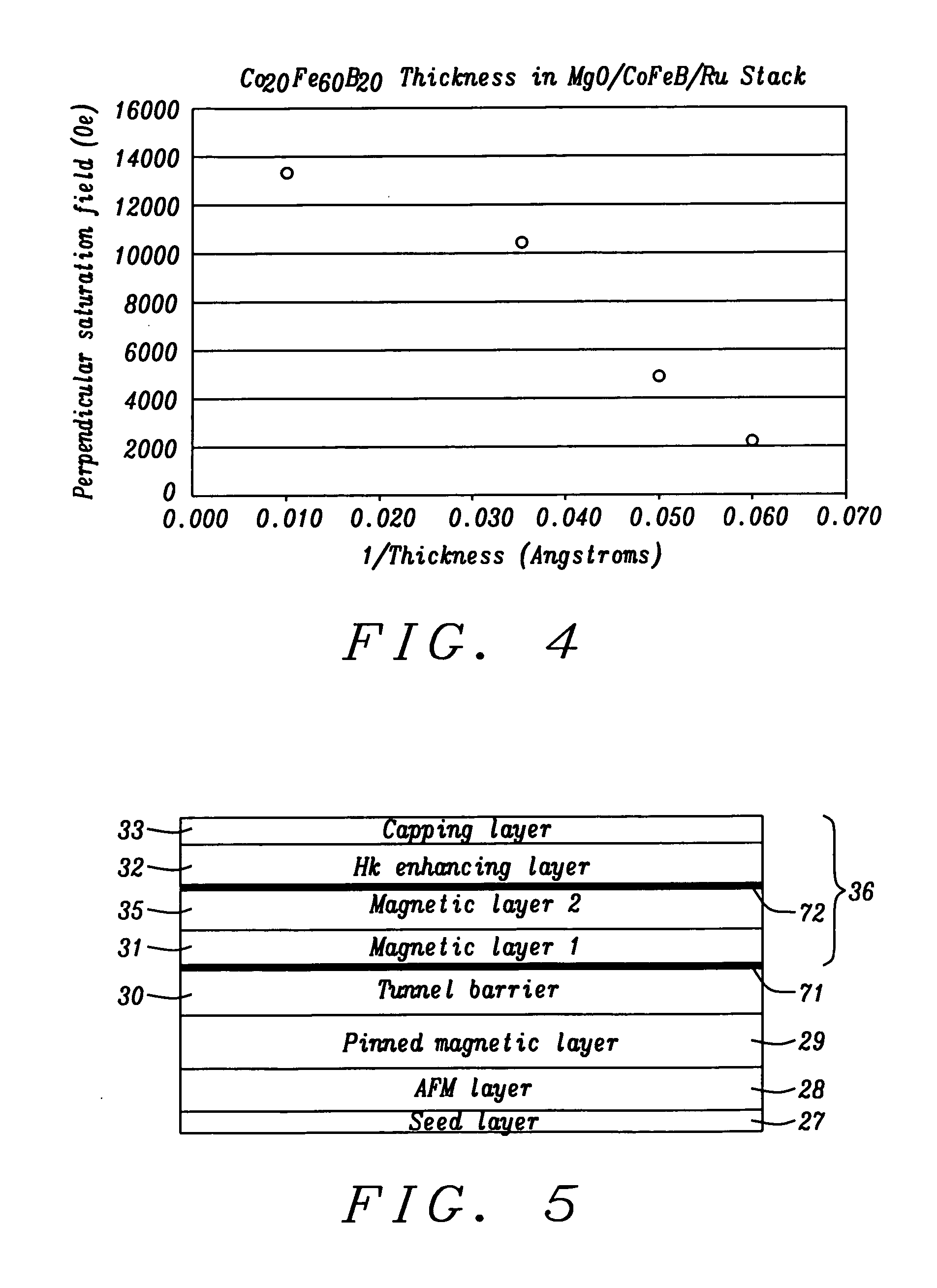

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS20120205758A1Without degrading thermal stability and MR ratioEnhanced interfacial perpendicular anisotropyMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

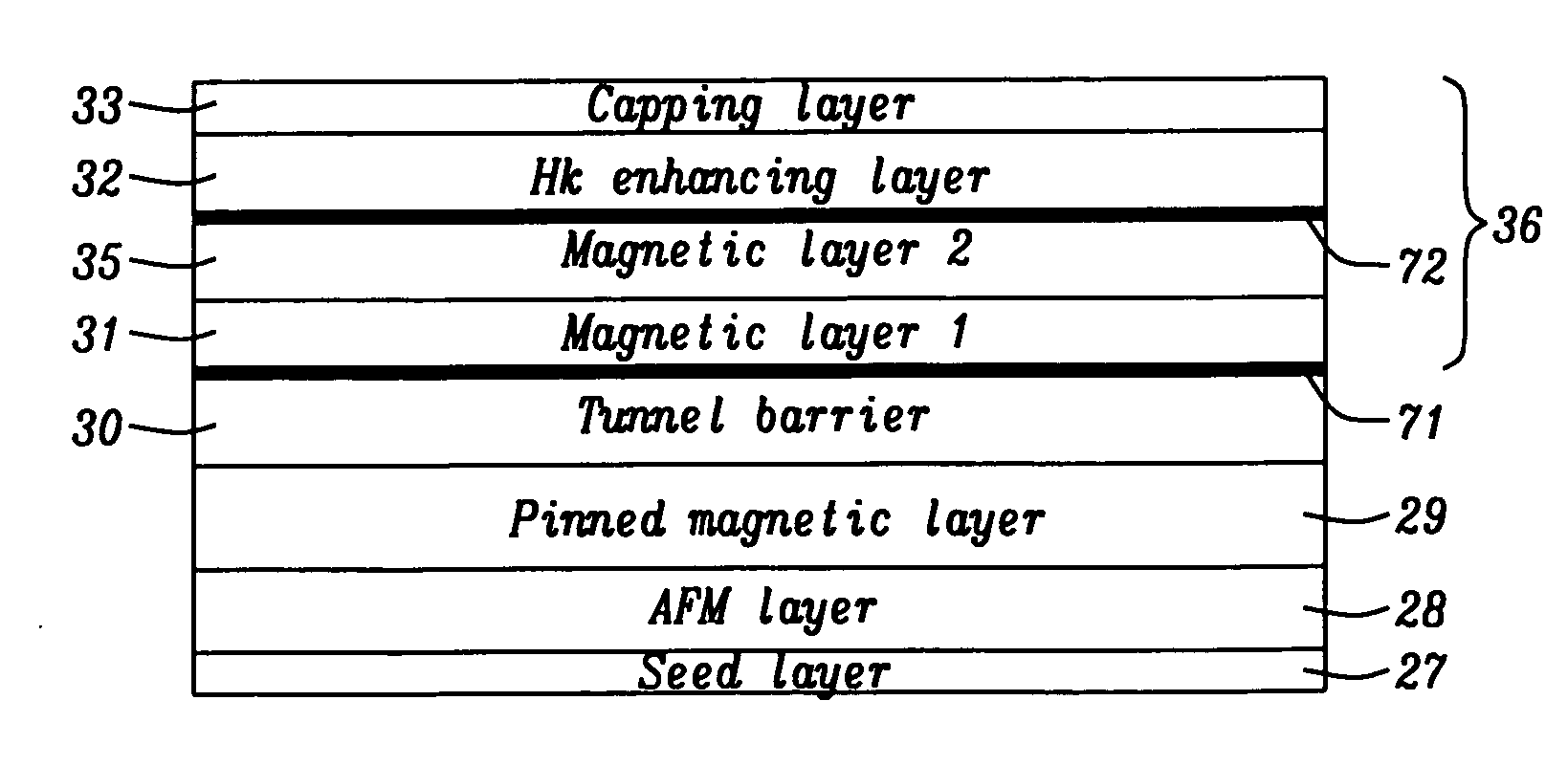

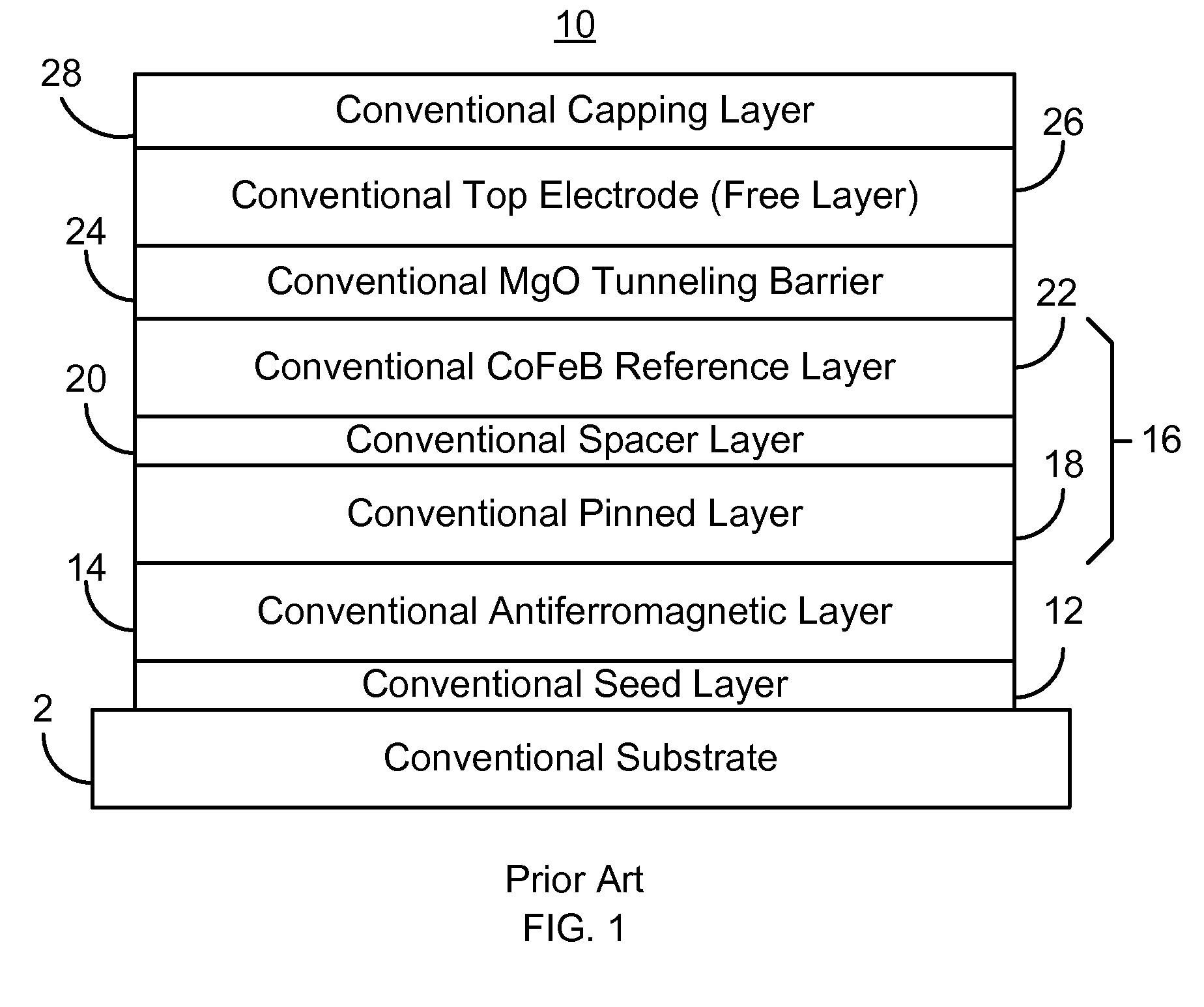

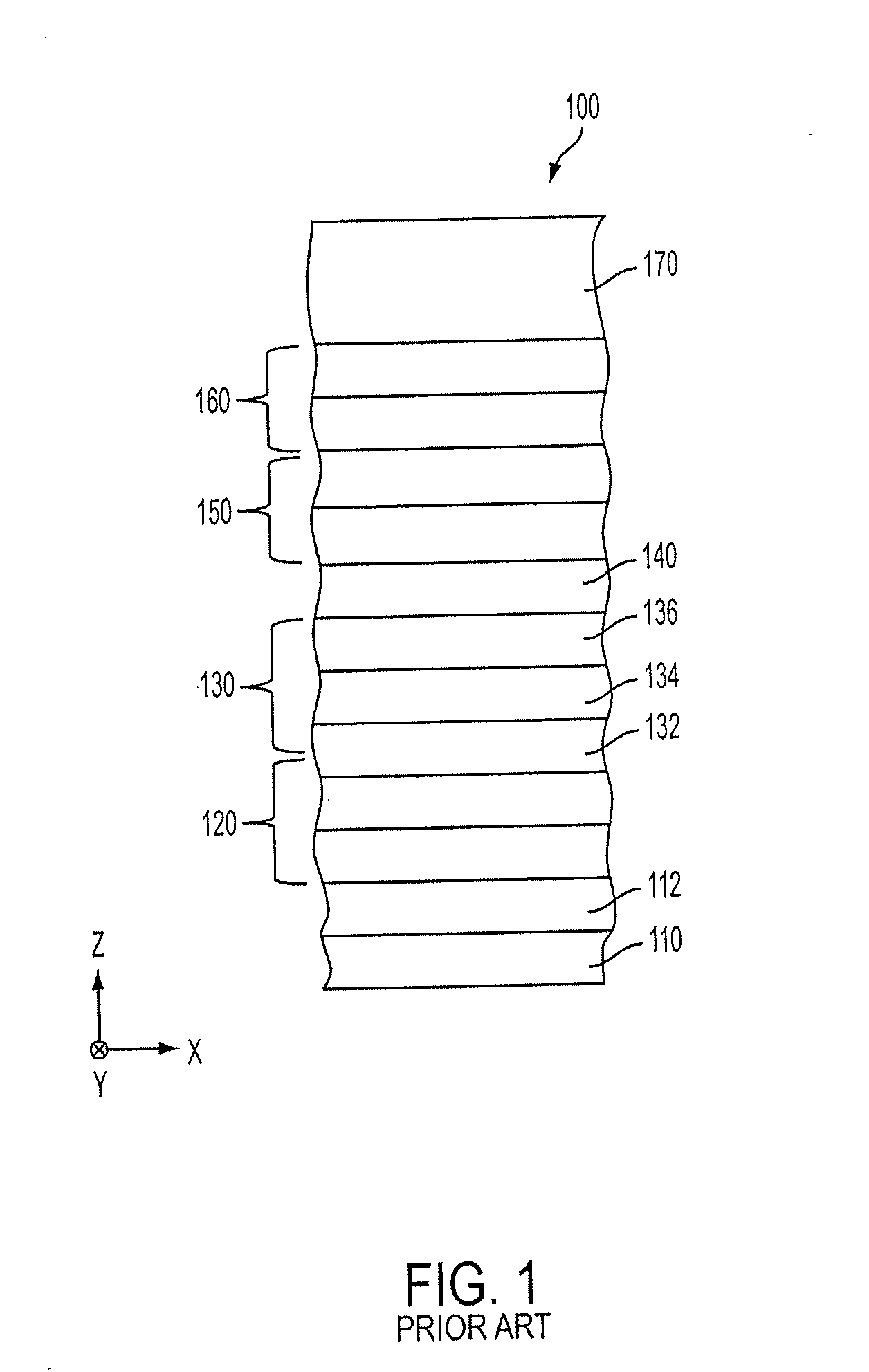

High performance MTJ element for STT-RAM and method for making the same

ActiveUS20090027810A1Low angular dispersionEasy to operateNanomagnetismMagnetic-field-controlled resistorsSpin angular momentum of lightDamping factor

We describe the structure and method of forming a STT-MTJ MRAM cell that utilizes transfer of spin angular momentum as a mechanism for changing the magnetic moment direction of a free layer. The device includes an IrMn pinning layer, a SyAP pinned layer, a naturally oxidized, crystalline MgO tunneling barrier layer that is formed on an Ar-ion plasma smoothed surface of the pinned layer and, in one embodiment, a free layer that comprises an amorphous layer of Co60Fe20B20. of approximately 20 angstroms thickness formed between two crystalline layers of Fe of 3 and 6 angstroms thickness respectively. The free layer is characterized by a low Gilbert damping factor and by very strong polarizing action on conduction electrons. The resulting cell has a low critical current, a high dR / R and a plurality of such cells will exhibit a low variation of both resistance and pinned layer magnetization angular dispersion.

Owner:TAIWAN SEMICON MFG CO LTD

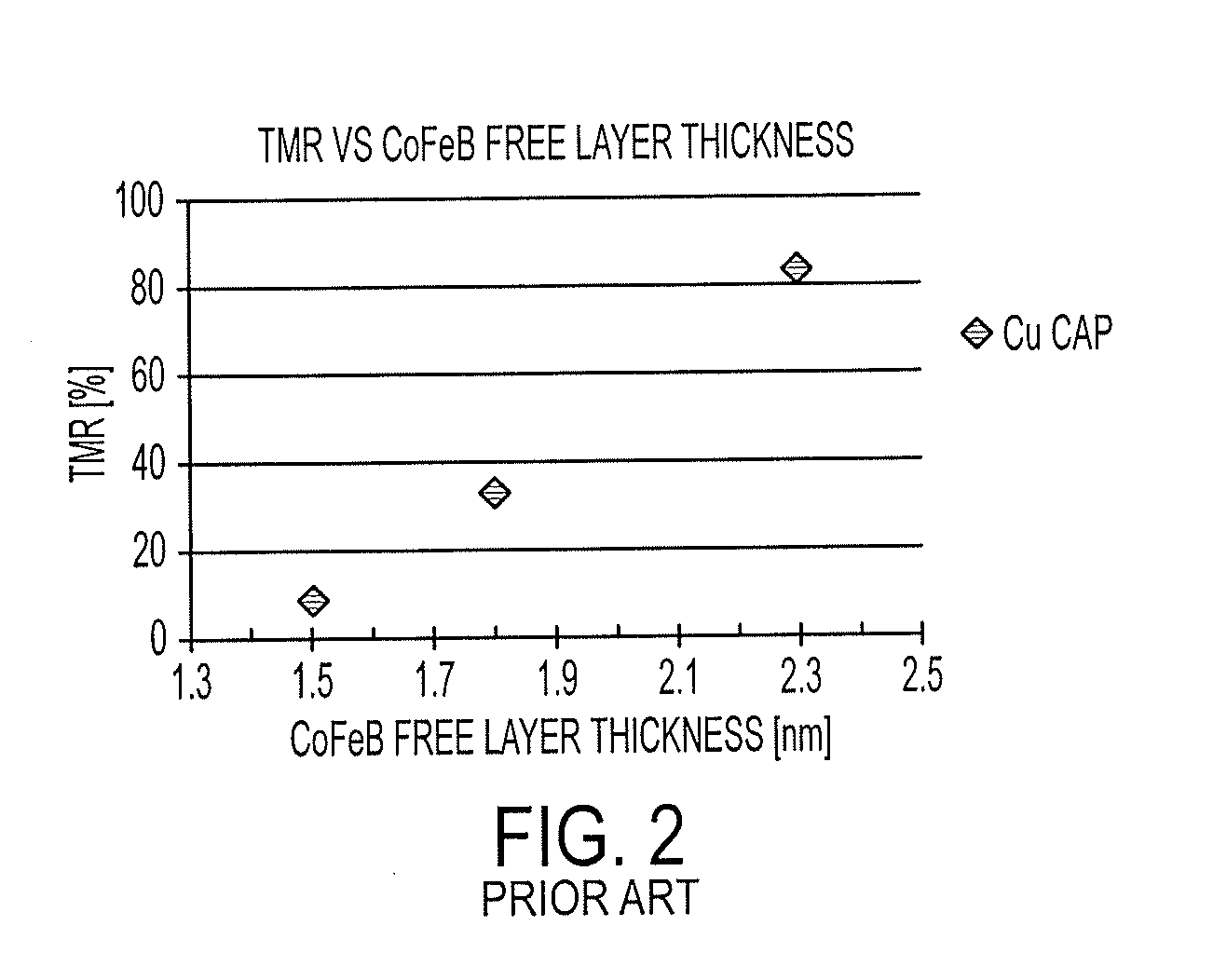

Novel capping structure for enhancing dR/R of the MTJ device

InactiveUS20050276099A1Well controlled magnetizationWell controlled switching characteristicNanomagnetismNanoinformaticsElectrical conductorOxygen

Owner:HEADWAY TECH INC +1

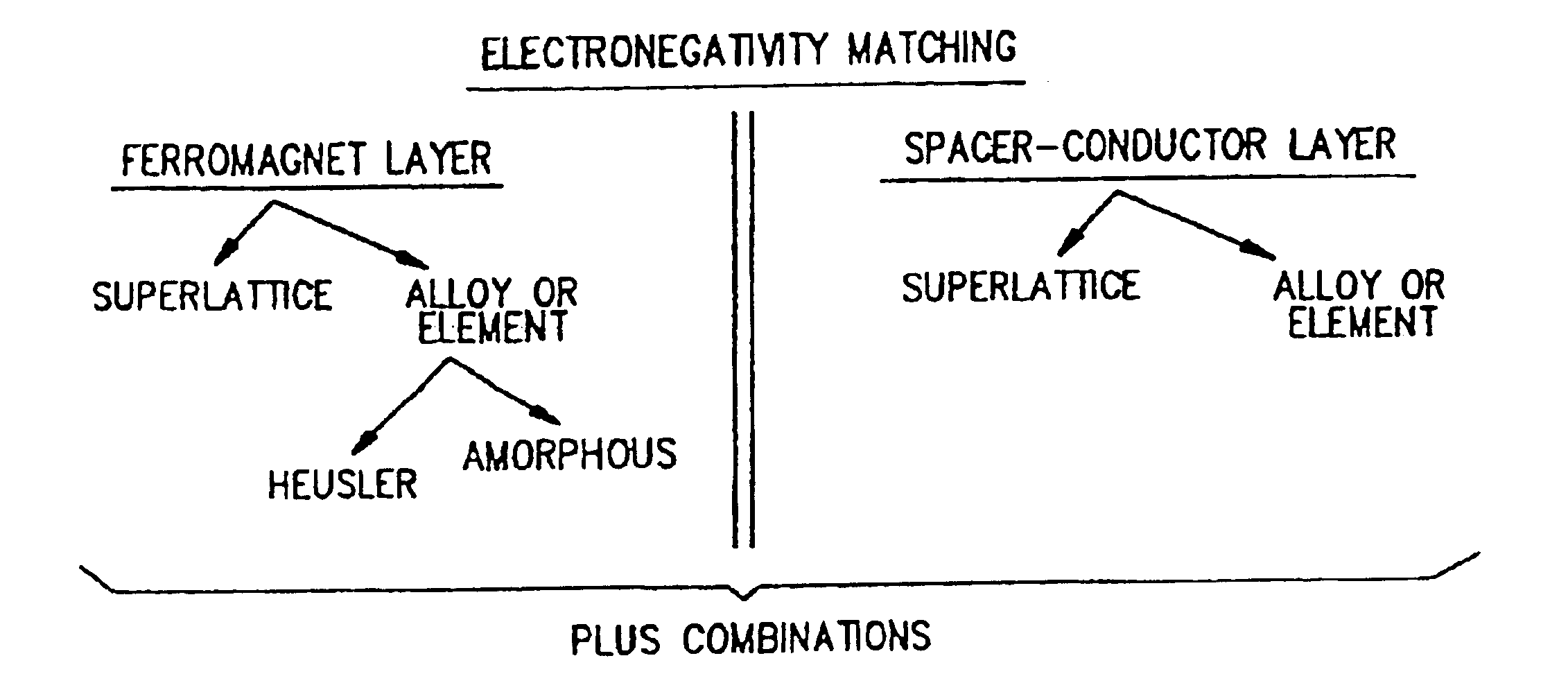

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

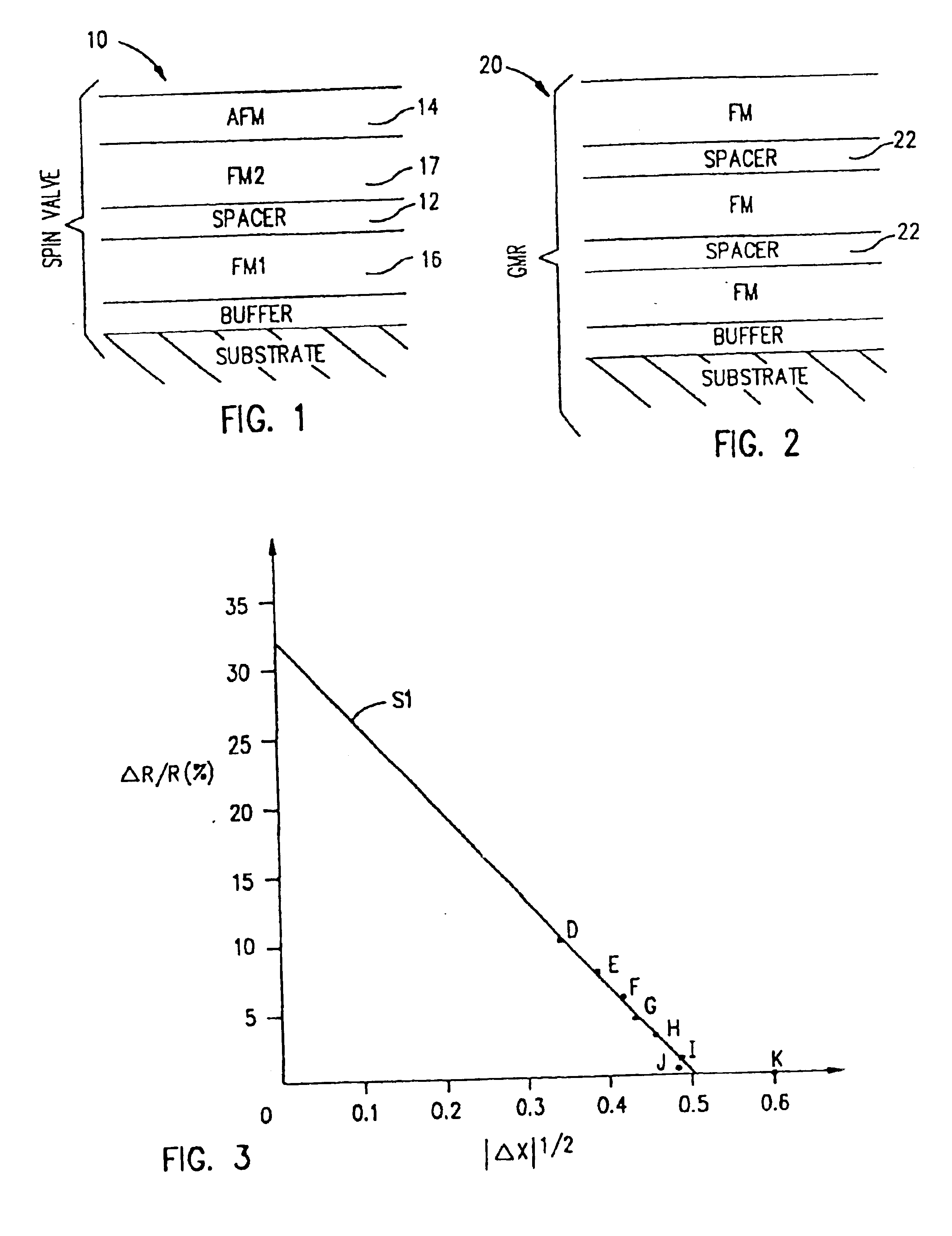

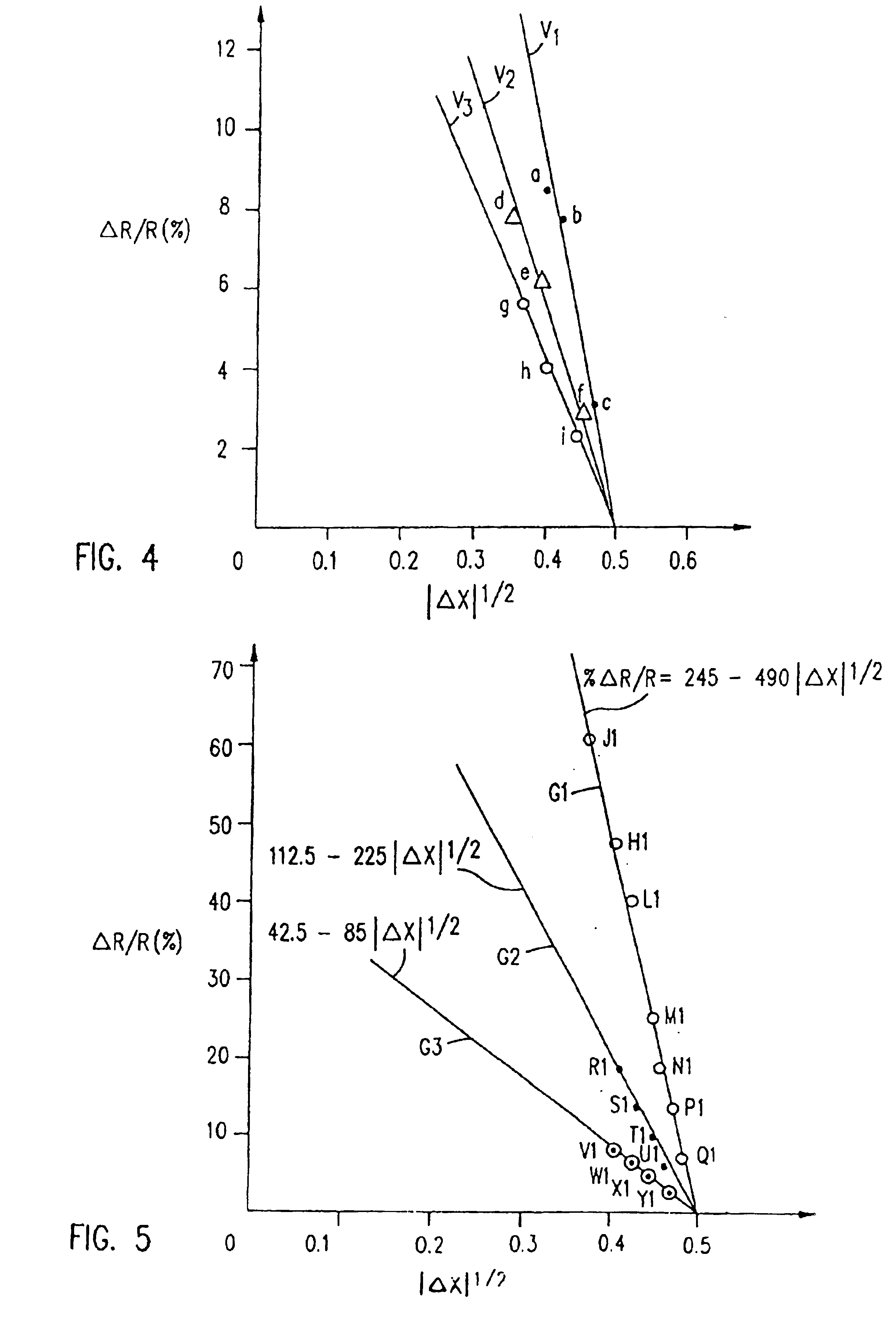

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

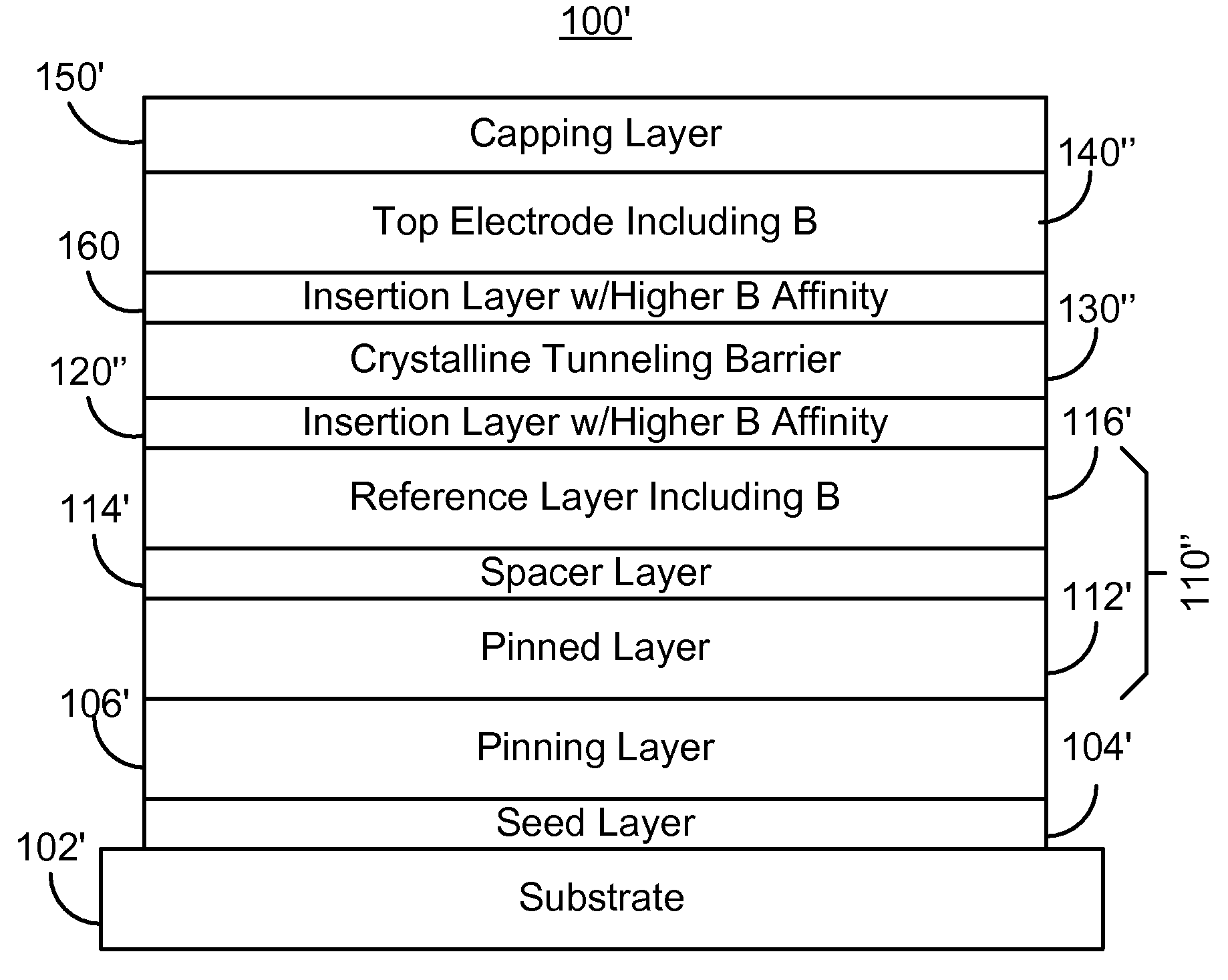

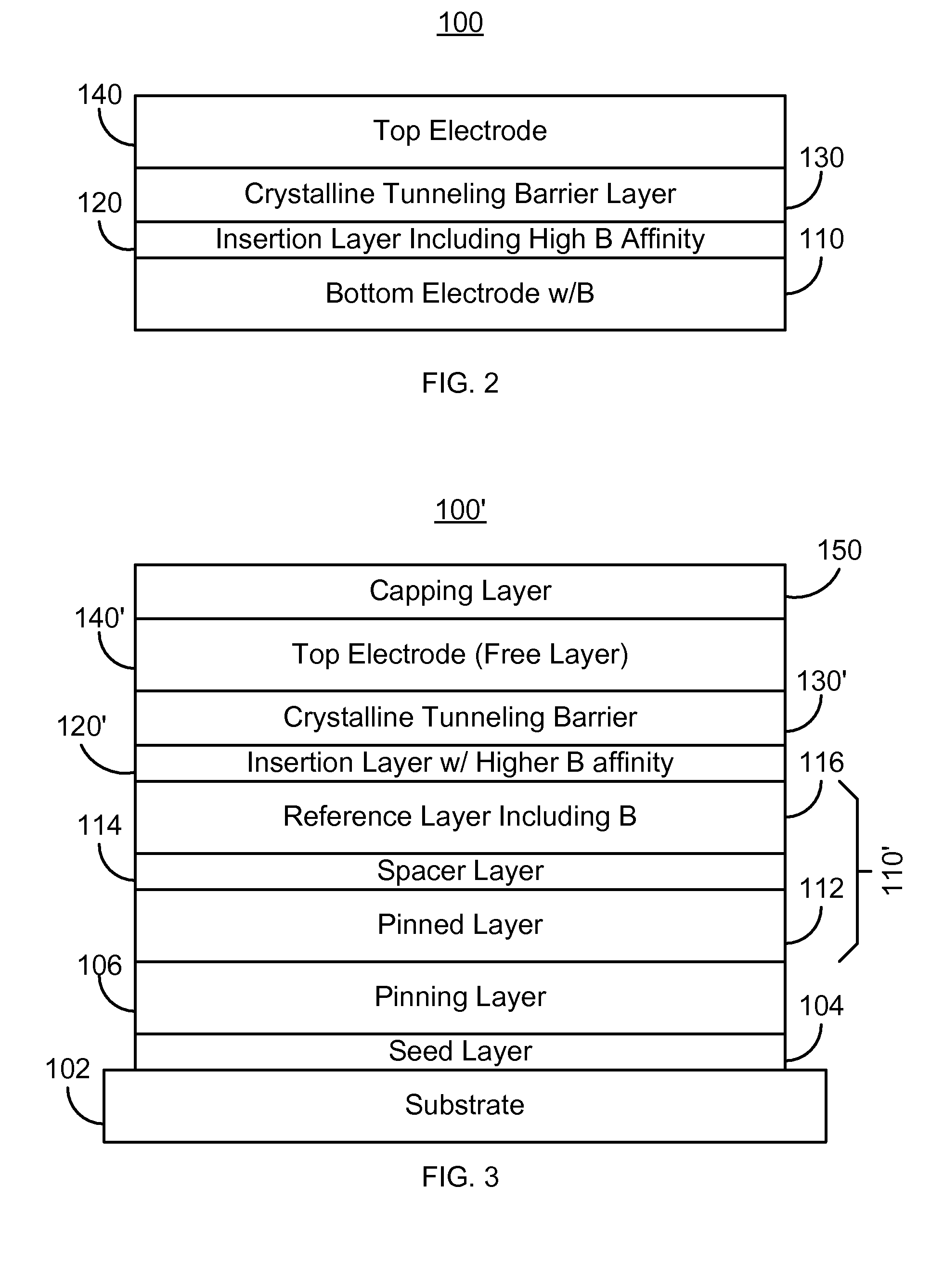

Method and system for providing a magnetoresistive structure

A method and system for providing a magnetoresistive structure are described. The magnetoresistive structure includes a first electrode, an insertion layer, a crystalline tunneling barrier layer, and a second electrode. The first electrode includes at least a first magnetic material and boron. The crystalline tunneling barrier layer includes at least one constituent. The insertion layer has a first boron affinity. The at least one constituent of the crystalline tunneling barrier layer has at least a second boron affinity that is less than the first boron affinity. The second electrode includes at least a second magnetic material.

Owner:WESTERN DIGITAL TECH INC

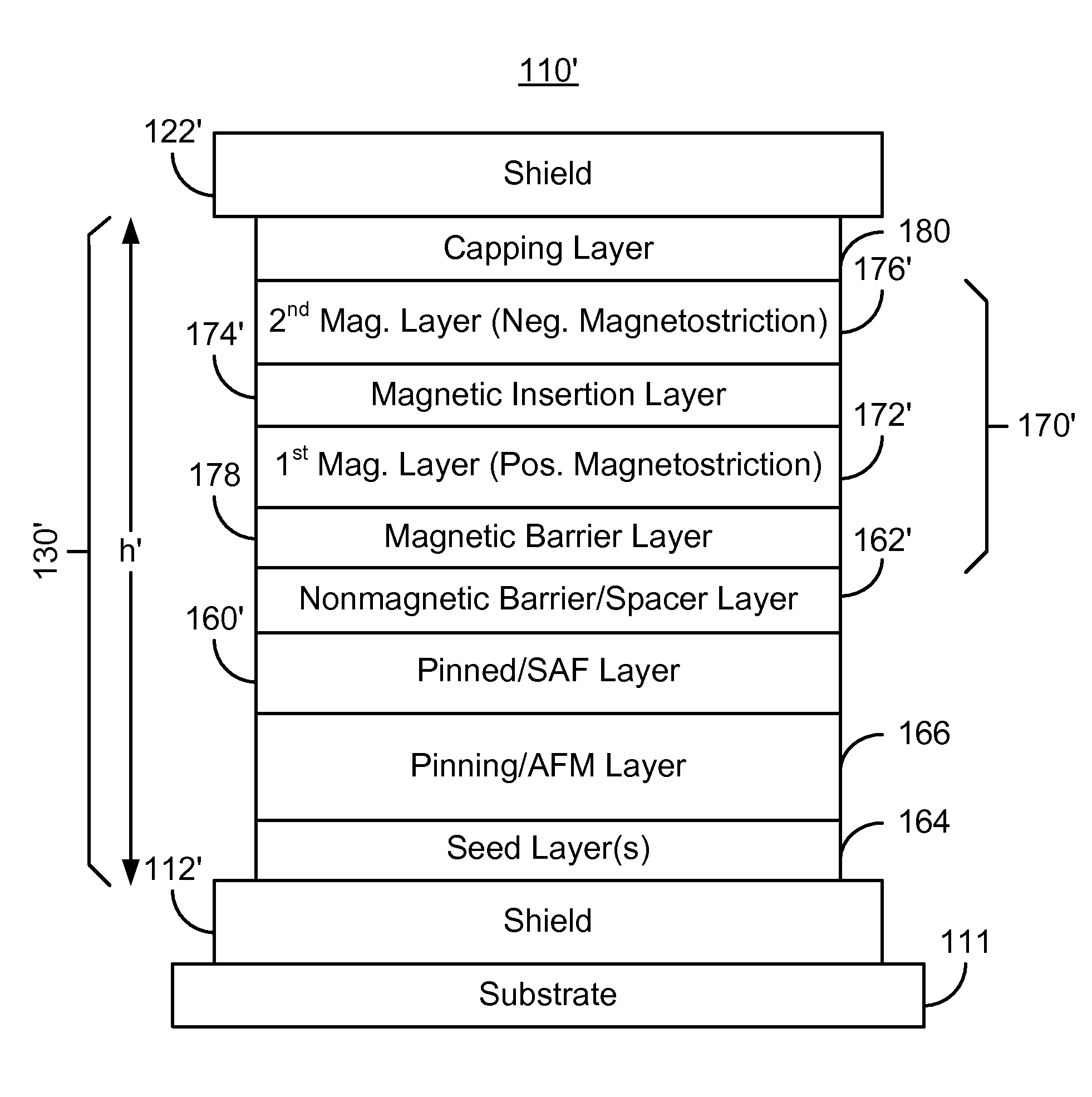

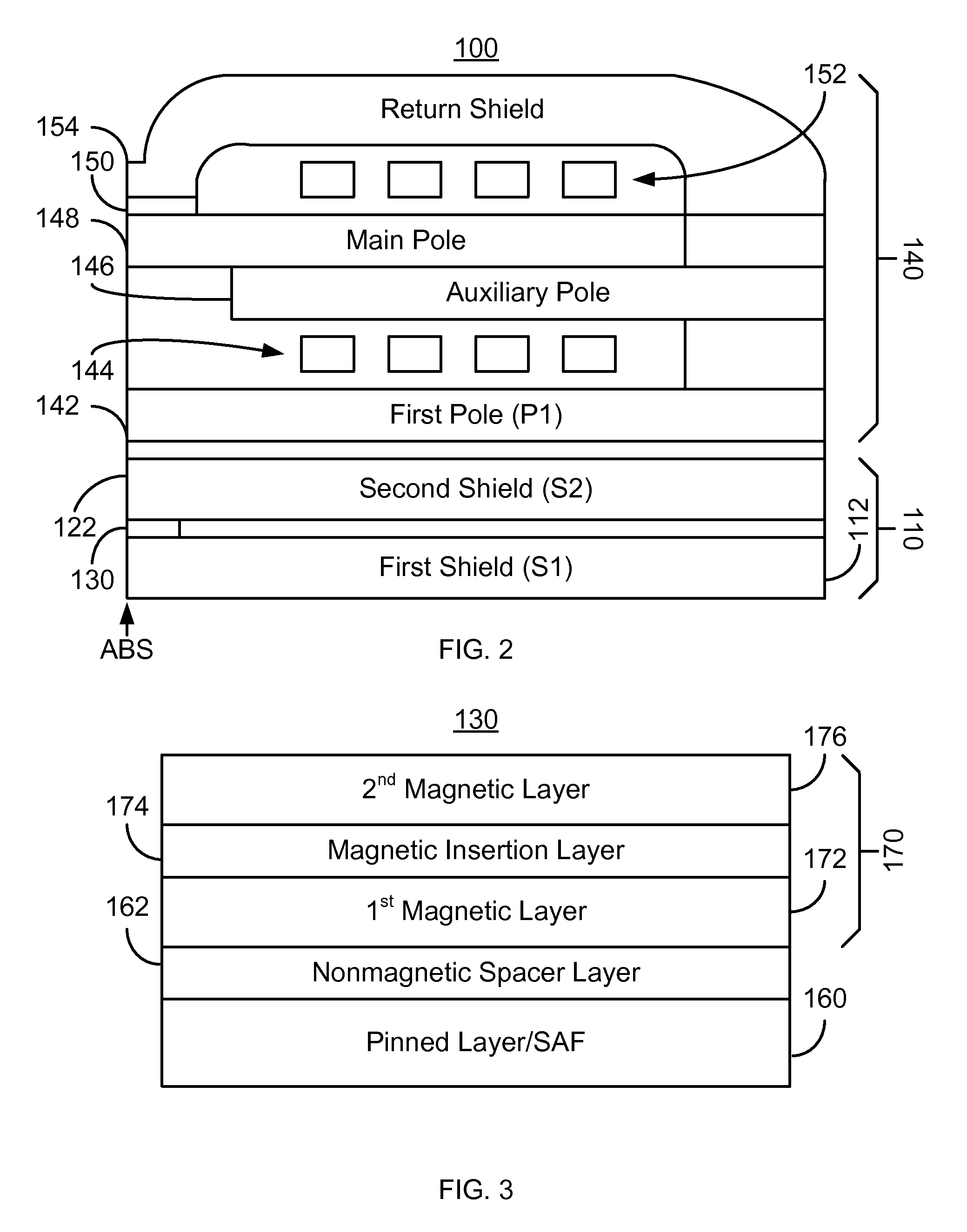

Method and system for providing a read sensor having a low magnetostriction free layer

ActiveUS8194365B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic transducersMagnetic layer

A method and system for providing a magnetic structure in magnetic transducer is described. The magnetic structure includes a pinned layer, a nonmagnetic spacer layer, and a free layer. The nonmagnetic spacer layer is between the pinned layer and the free layer. The free layer includes a first magnetic layer, a second magnetic layer, and a magnetic insertion layer between the first magnetic layer and the second magnetic layer. The first magnetic layer has a first magnetostriction. The second magnetic layer has a second magnetostriction opposite to the first magnetostriction. The magnetic insertion layer provides a growth texture barrier between the first magnetic layer and the second magnetic layer.

Owner:WESTERN DIGITAL TECH INC

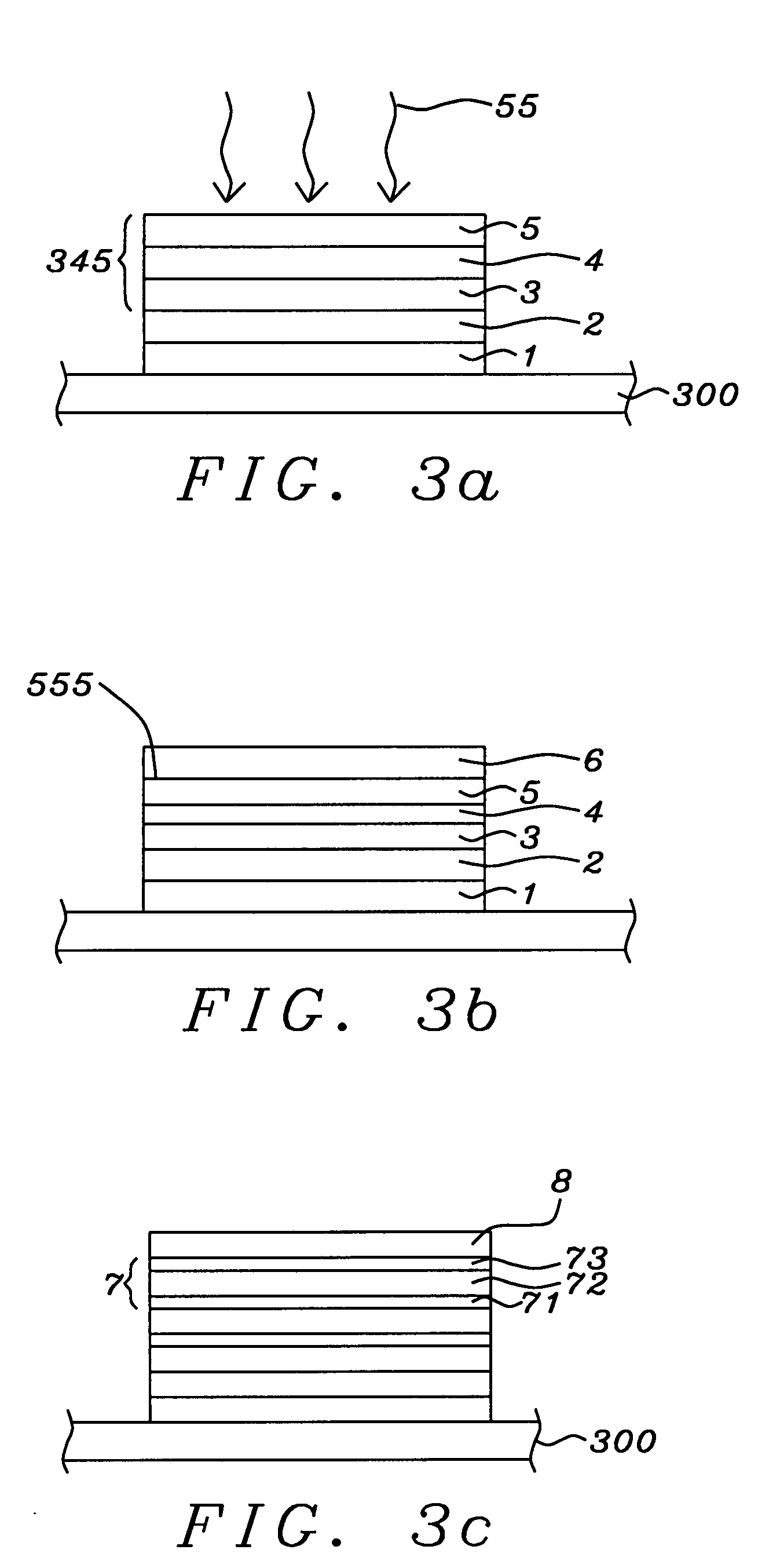

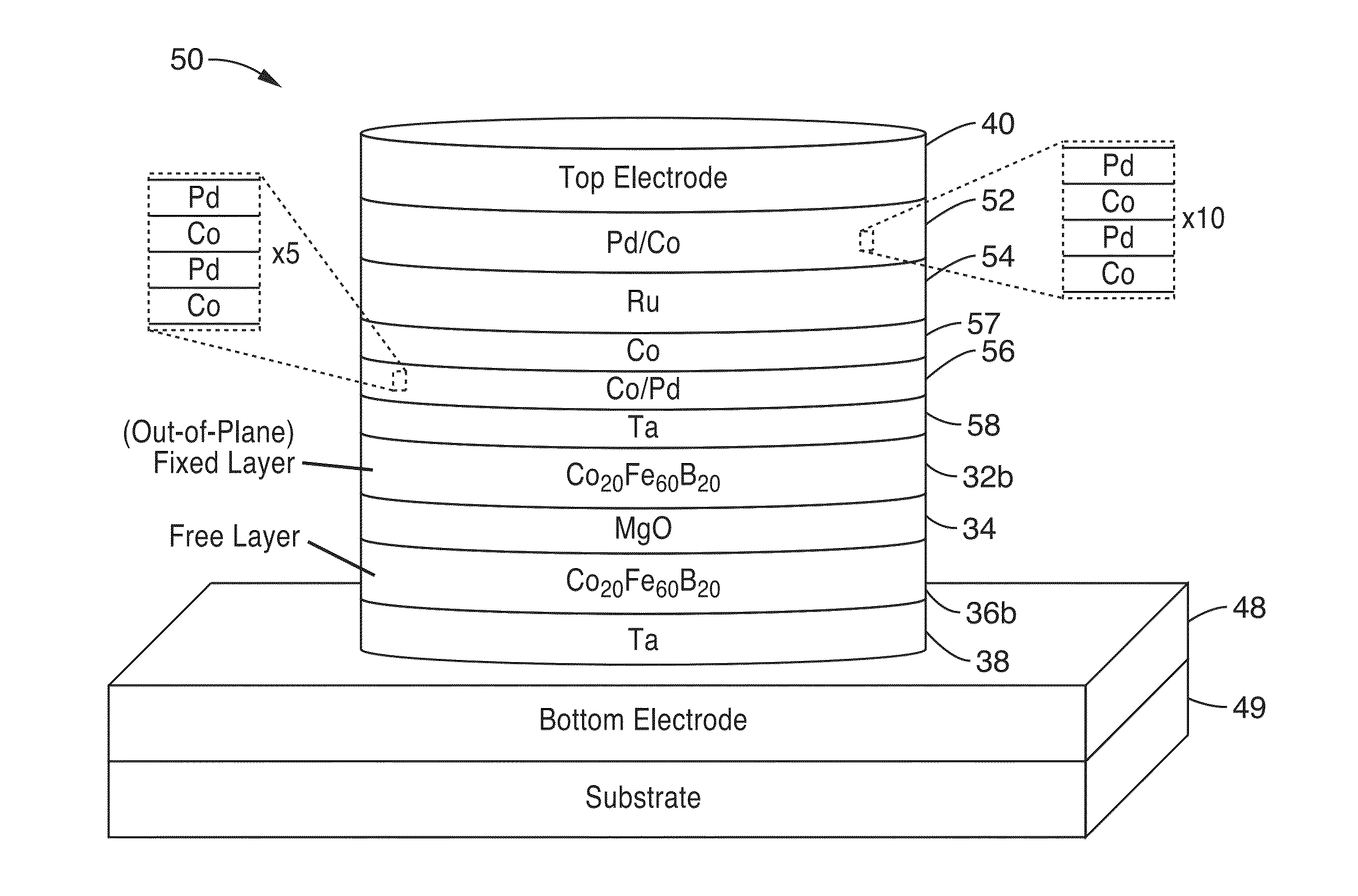

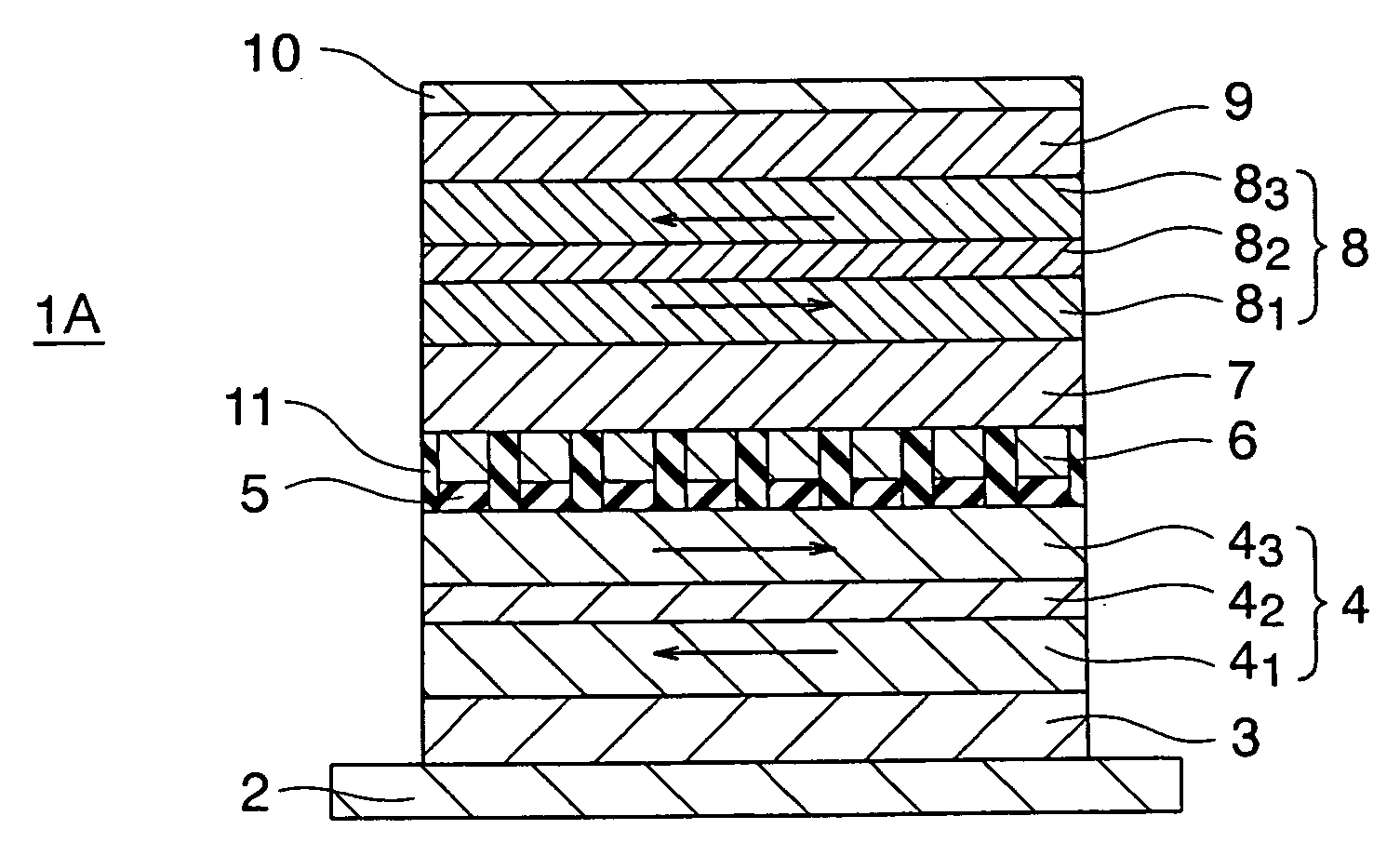

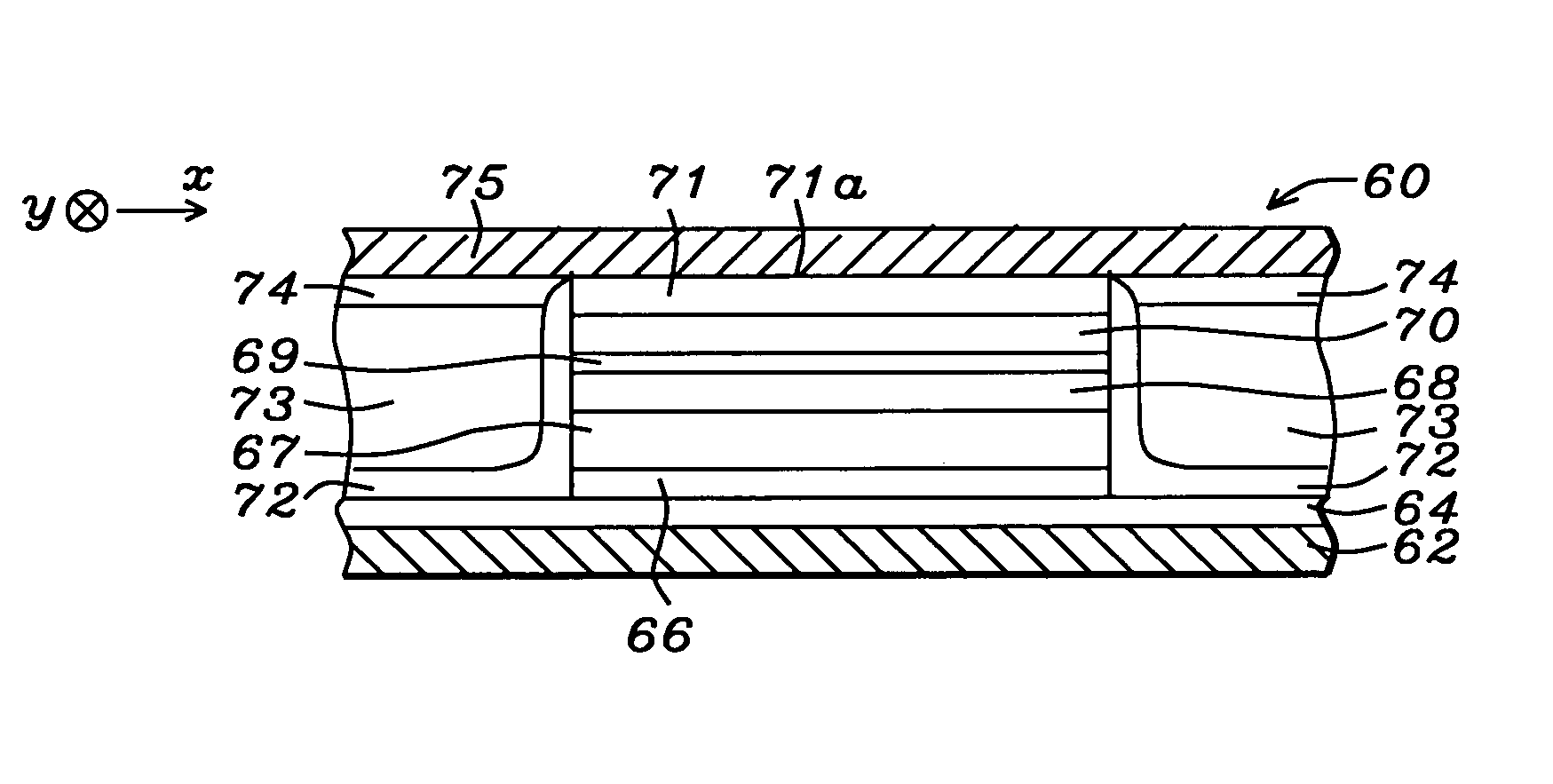

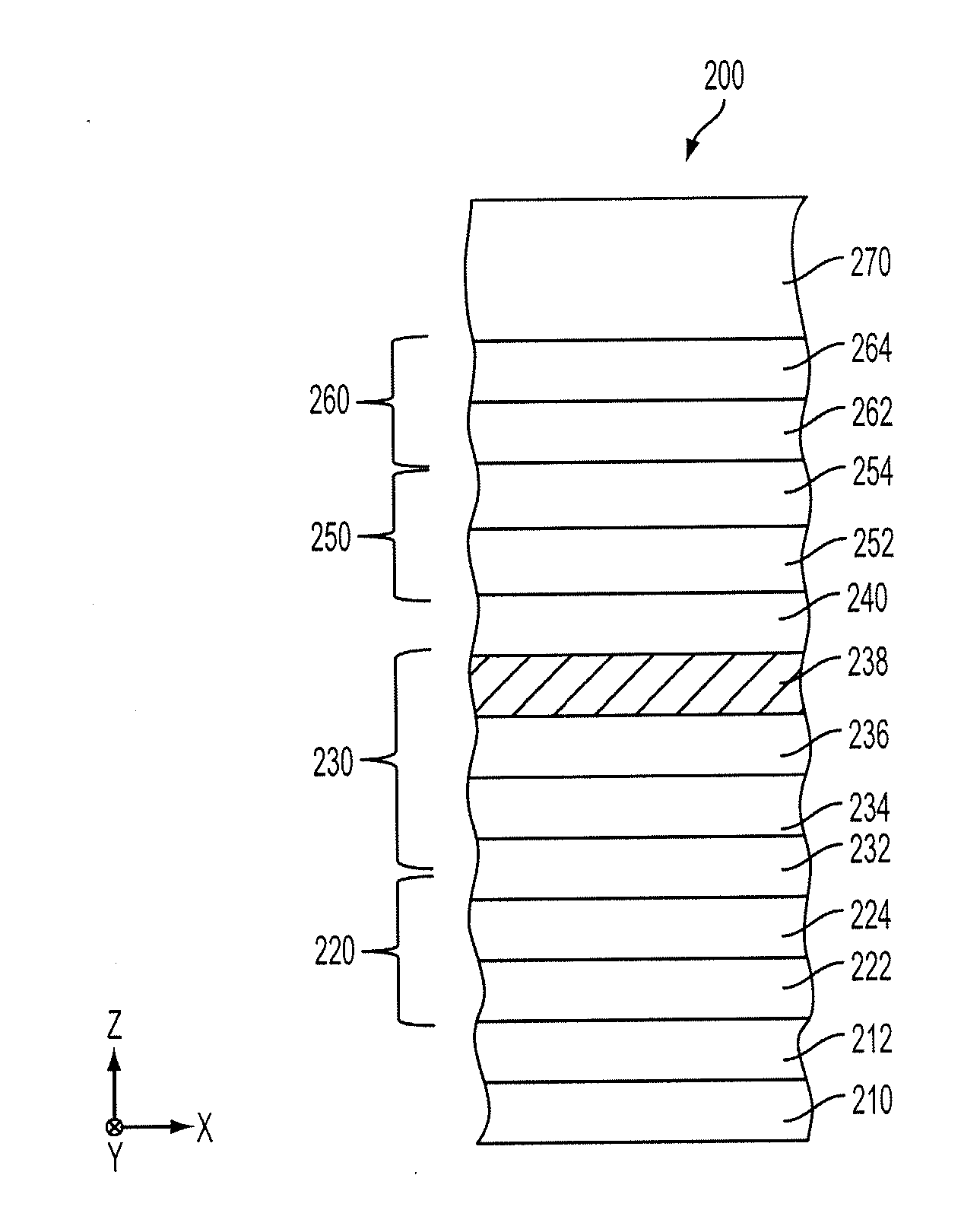

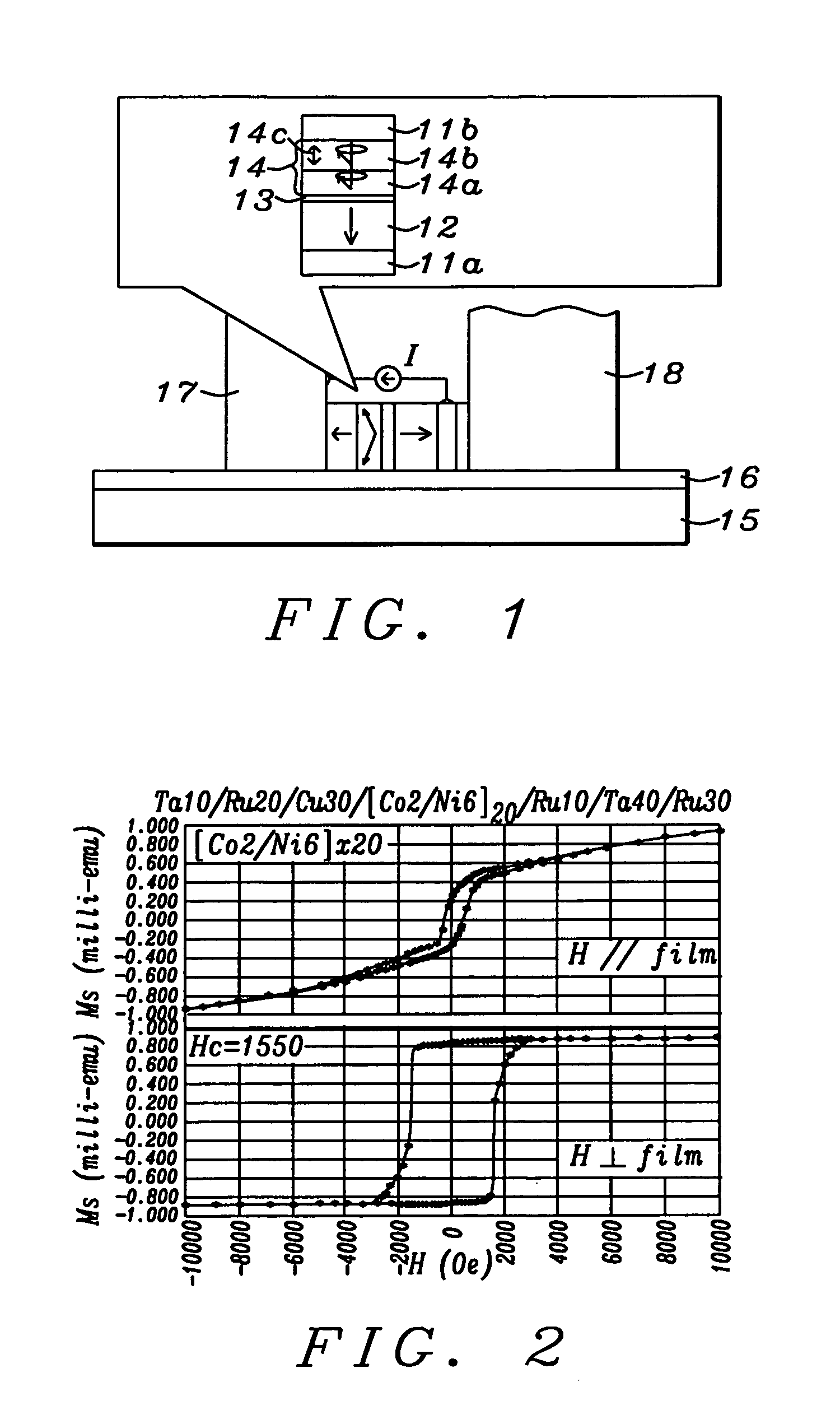

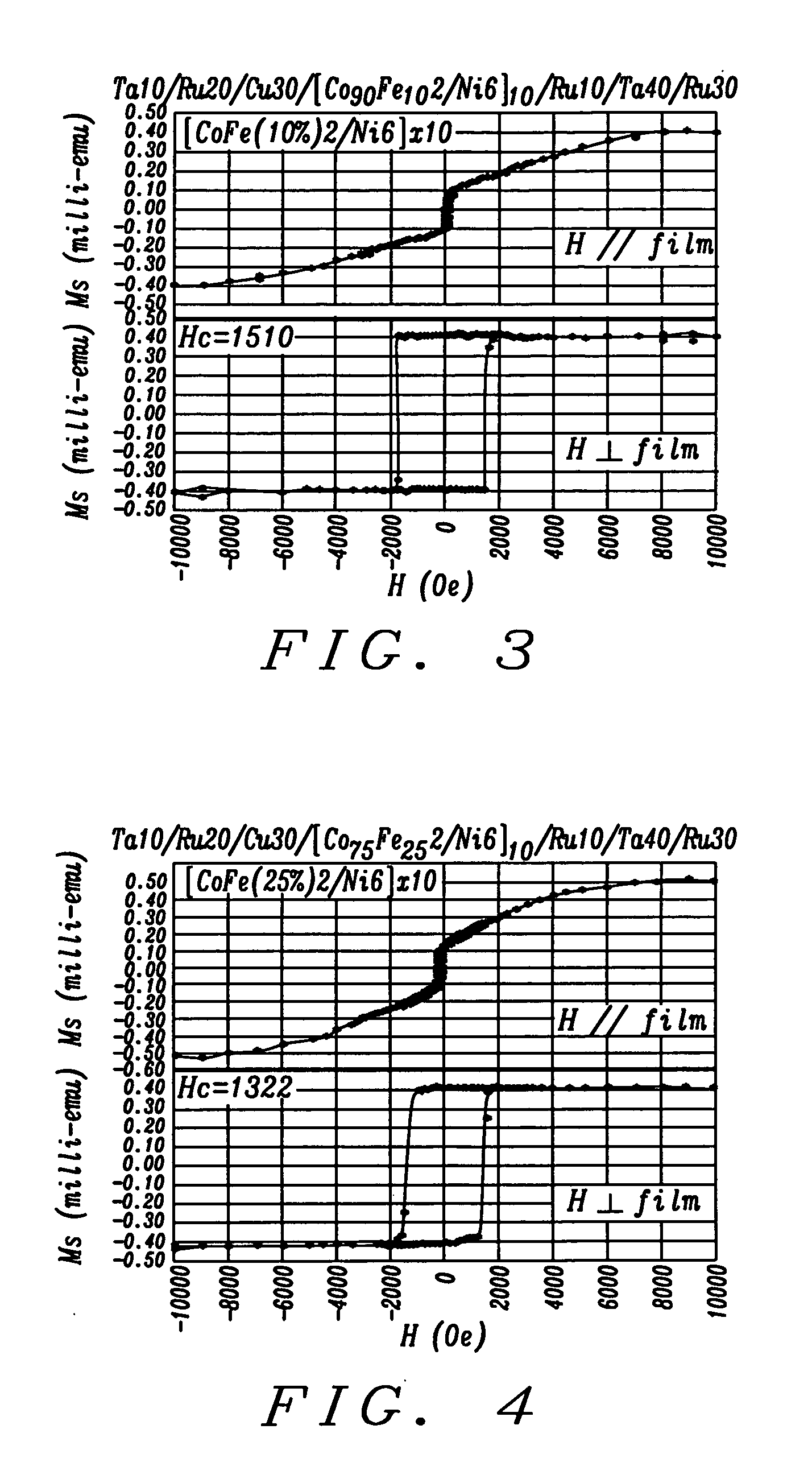

MTJ incorporating CoFe/Ni multilayer film with perpendicular magnetic anisotropy for MRAM application

ActiveUS20110096443A1Minimize impinging ion energyMaximize PMA propertyMagnetic measurementsVacuum evaporation coatingSpin transferSpin valve

A MTJ for a spintronic device is disclosed and includes a thin composite seed layer made of at least Ta and a metal layer having fcc(111) or hcp(001) texture as in Ta / Ti / Cu to enhance perpendicular magnetic anisotropy (PMA) in an overlying laminated layer with a (CoFe / Ni)X, (Co / NiFe)X, (Co / NiCo)X, (CoFe / NiFe)X, or (CoFe / NiCo)X composition where x is from 5 to 30. In one embodiment, a CPP-TMR spin valve has one or both of a laminated free layer and laminated reference layer with the aforementioned compositions. The MTJ includes an interfacial layer made of CoFeB, CoFeB / CoFe, or CoFe / CoFeB between each laminated structure and the tunnel barrier. The laminated layers are deposited by a low power and high Ar pressure process to avoid damaging interfaces between adjoining layers. Annealing occurs at 220° C. to 400° C. A laminated layer with high PMA may also be included in one or more layers of a spin transfer oscillator.

Owner:TAIWAN SEMICON MFG CO LTD

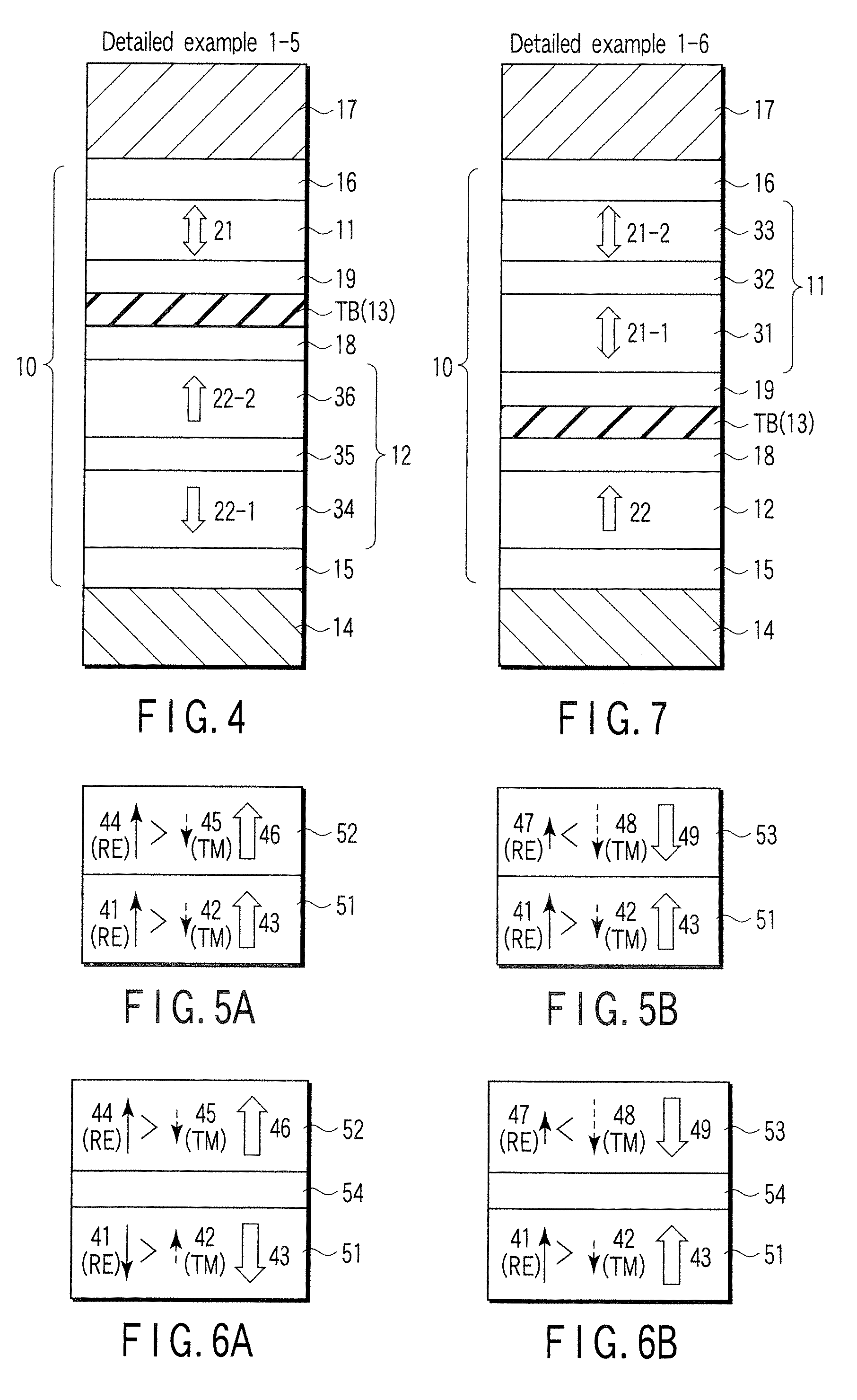

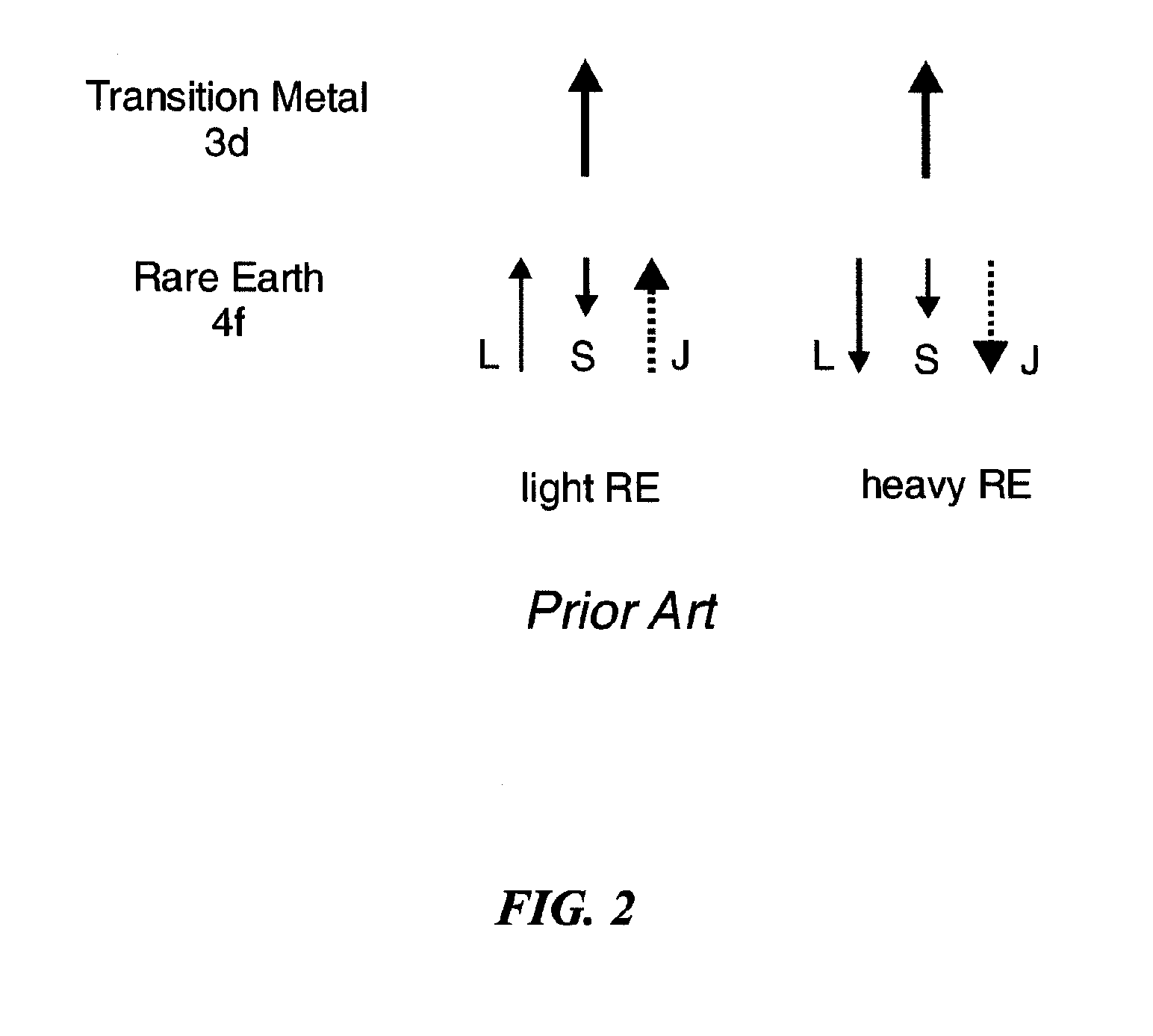

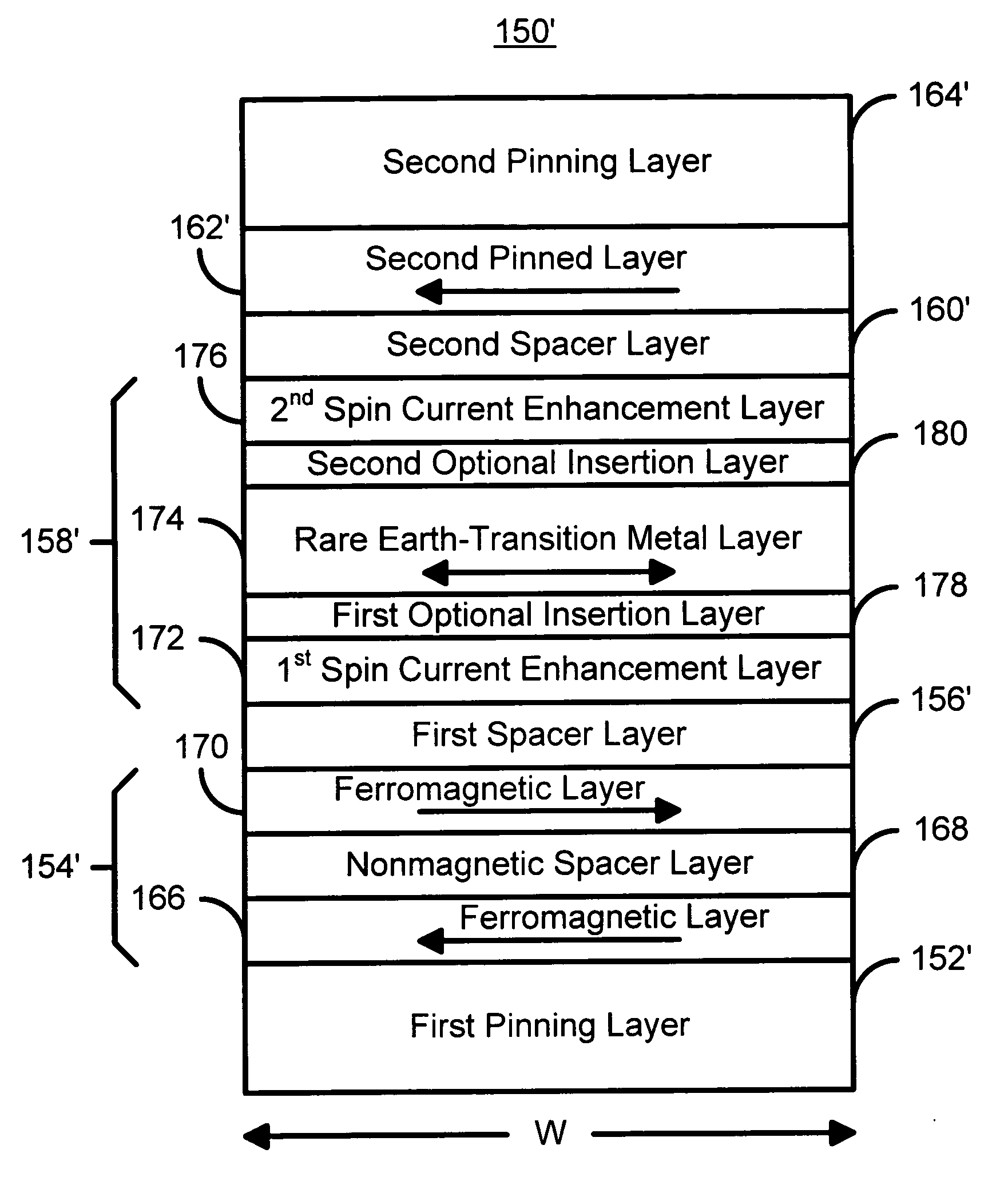

Spin-polarization devices using rare earth-transition metal alloys

ActiveUS7230265B2Magnetic-field-controlled resistorsGalvano-magnetic material selectionRare-earth elementMetal alloy

A tunnel barrier in proximity with a layer of a rare earth element-transition metal (RE—TM) alloy forms a device that passes negatively spin-polarized current. The rare earth element includes at least one element selected from the group consisting of Gd, Tb, Dy, Ho, Er, Tm, and Yb. The RE and TM have respective sub-network moments such that the absolute magnitude of the RE sub-network moment is greater than the absolute magnitude of the TM sub-network moment. An additional layer of magnetic material may be used in combination with the tunnel barrier and the RE—TM alloy layer to form a magnetic tunnel junction. Still other layers of tunnel barrier and magnetic material may be used in combination with the foregoing to form a flux-closed double tunnel junction device.

Owner:IBM CORP

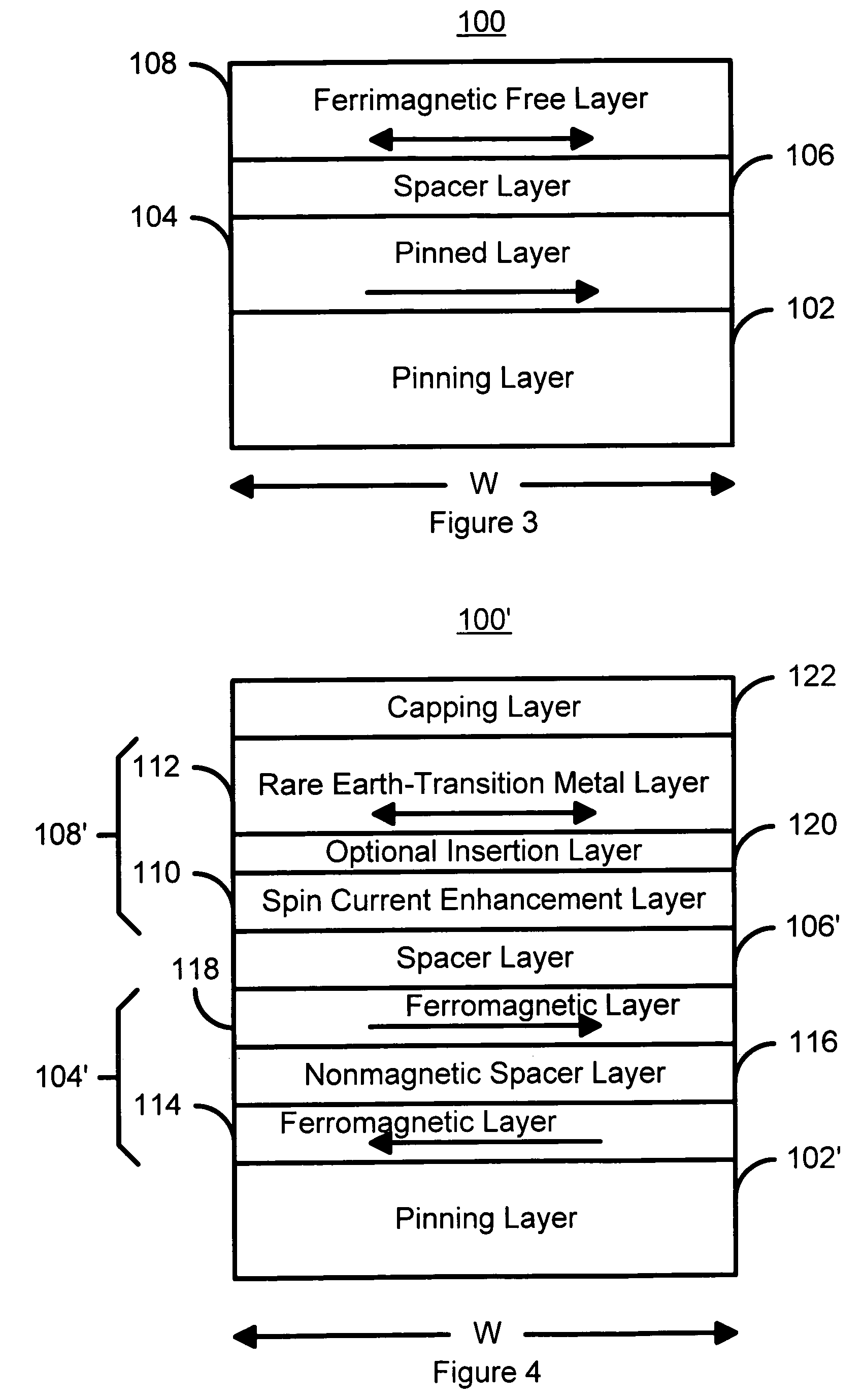

Spin-transfer switching magnetic elements using ferrimagnets and magnetic memories using the magnetic elements

Owner:SAMSUNG SEMICON

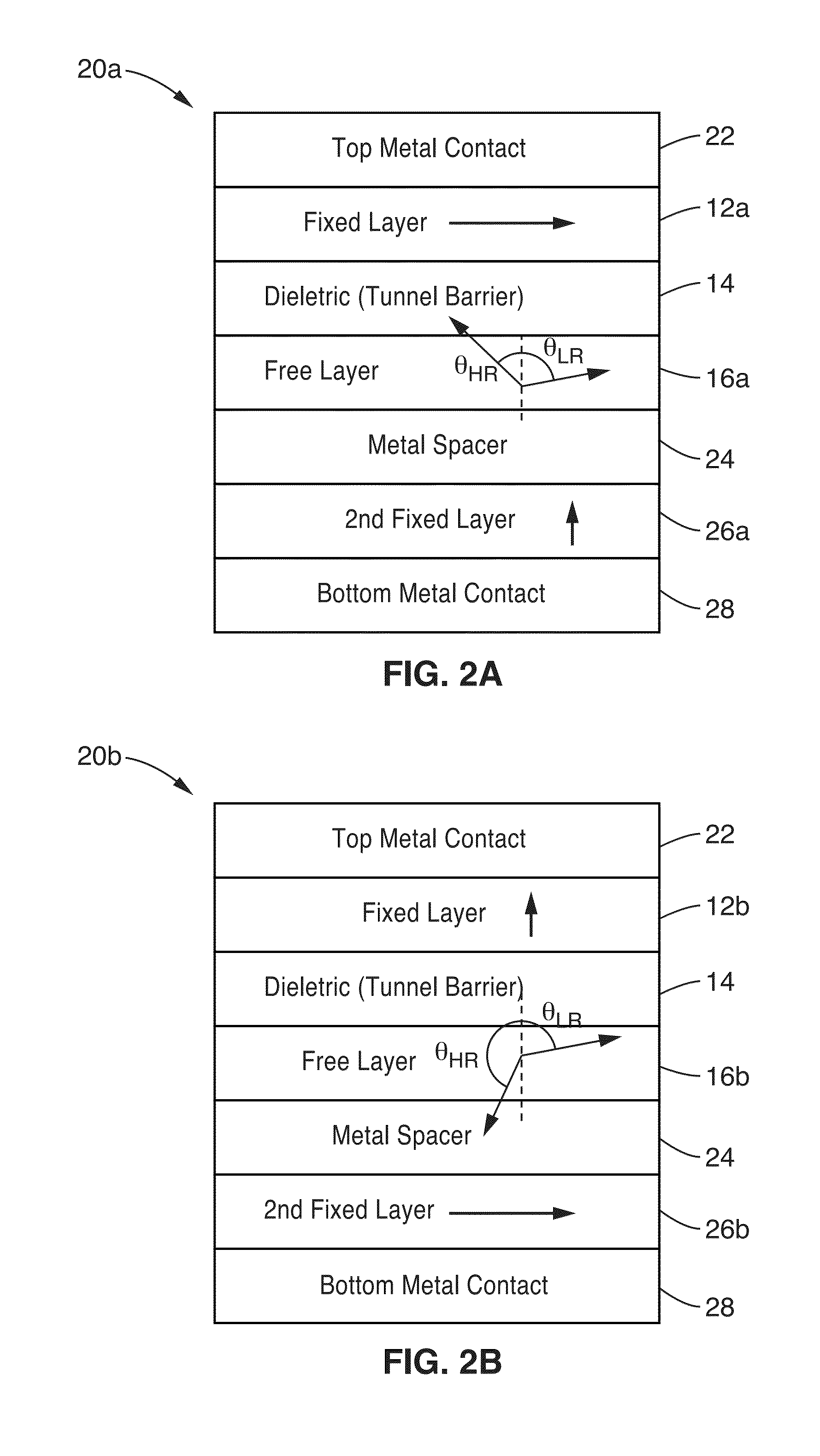

Voltage-controlled magnetic memory element with canted magnetization

ActiveUS20140169085A1High tunneling magnetoresistance (TMRImprove adjustabilitySolid-state devicesGalvano-magnetic material selectionStable stateMagnetic memory

A memory cell including information that is stored in the state of a magnetic bit (i.e. in a free layer, FL), where the FL magnetization has two stable states that may be canted (form an angle) with respect to the horizontal and vertical directions of the device is presented. The FL magnetization may be switched between the two canted states by the application of a voltage (i.e. electric field), which modifies the perpendicular magnetic anisotropy of the free layer.

Owner:RGT UNIV OF CALIFORNIA

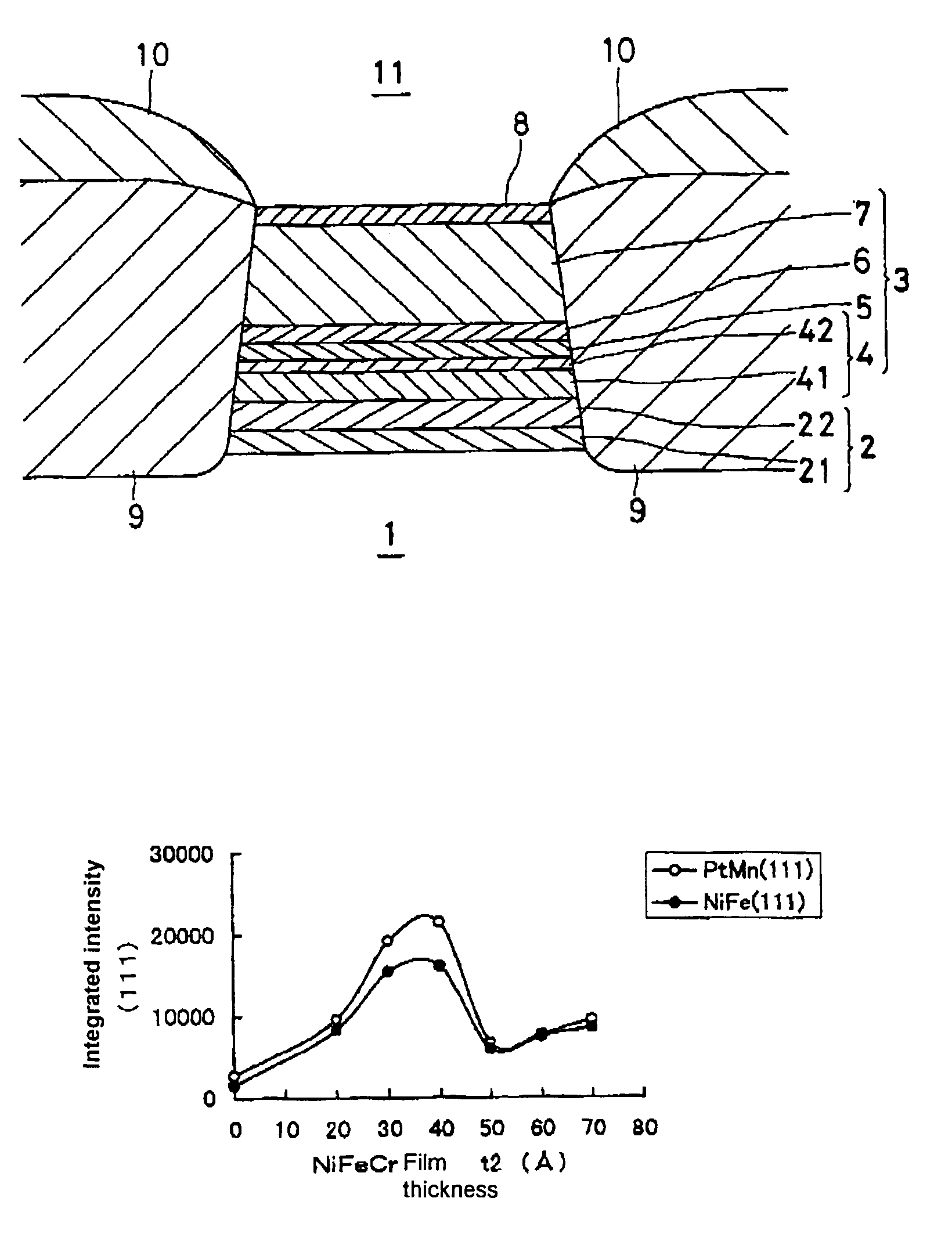

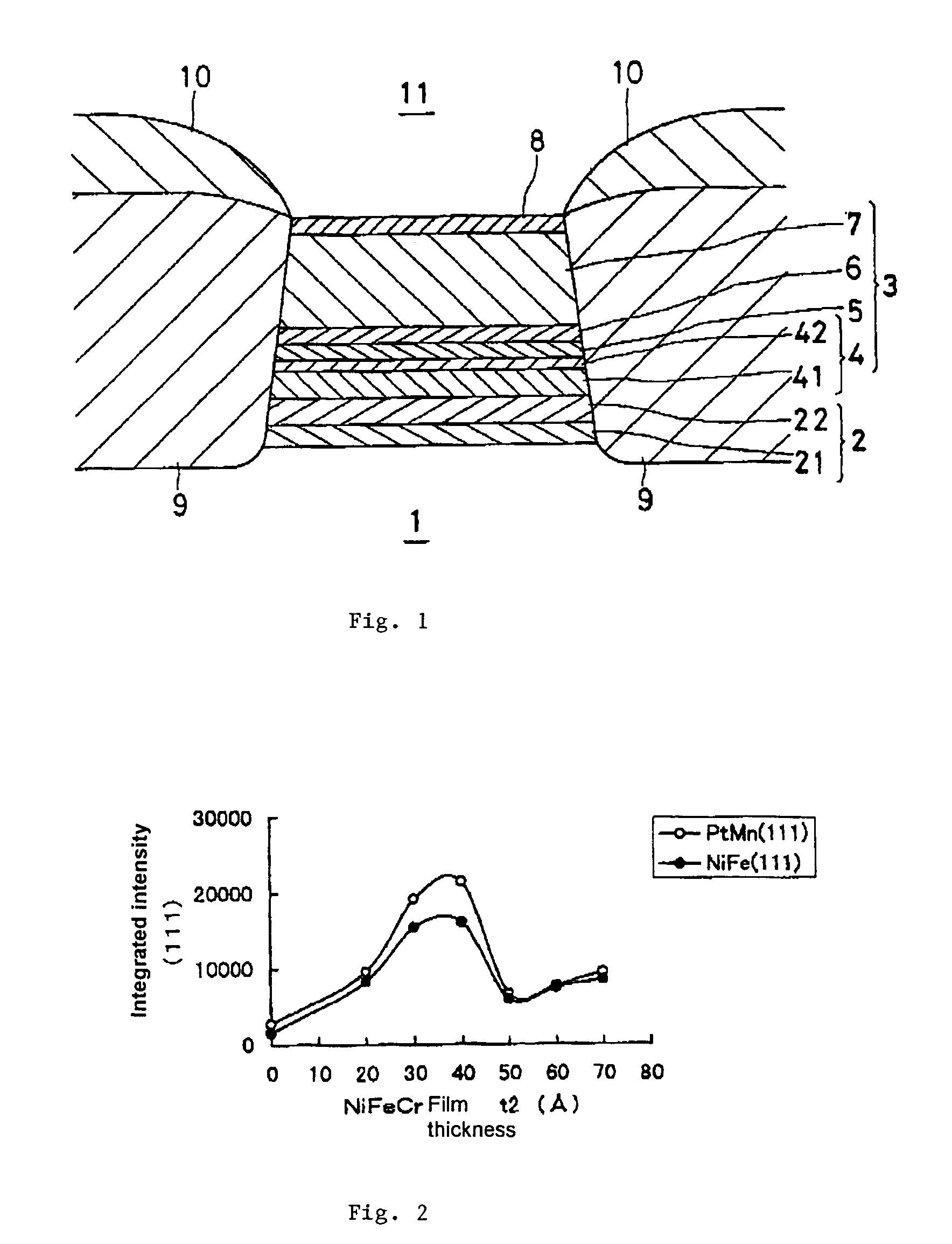

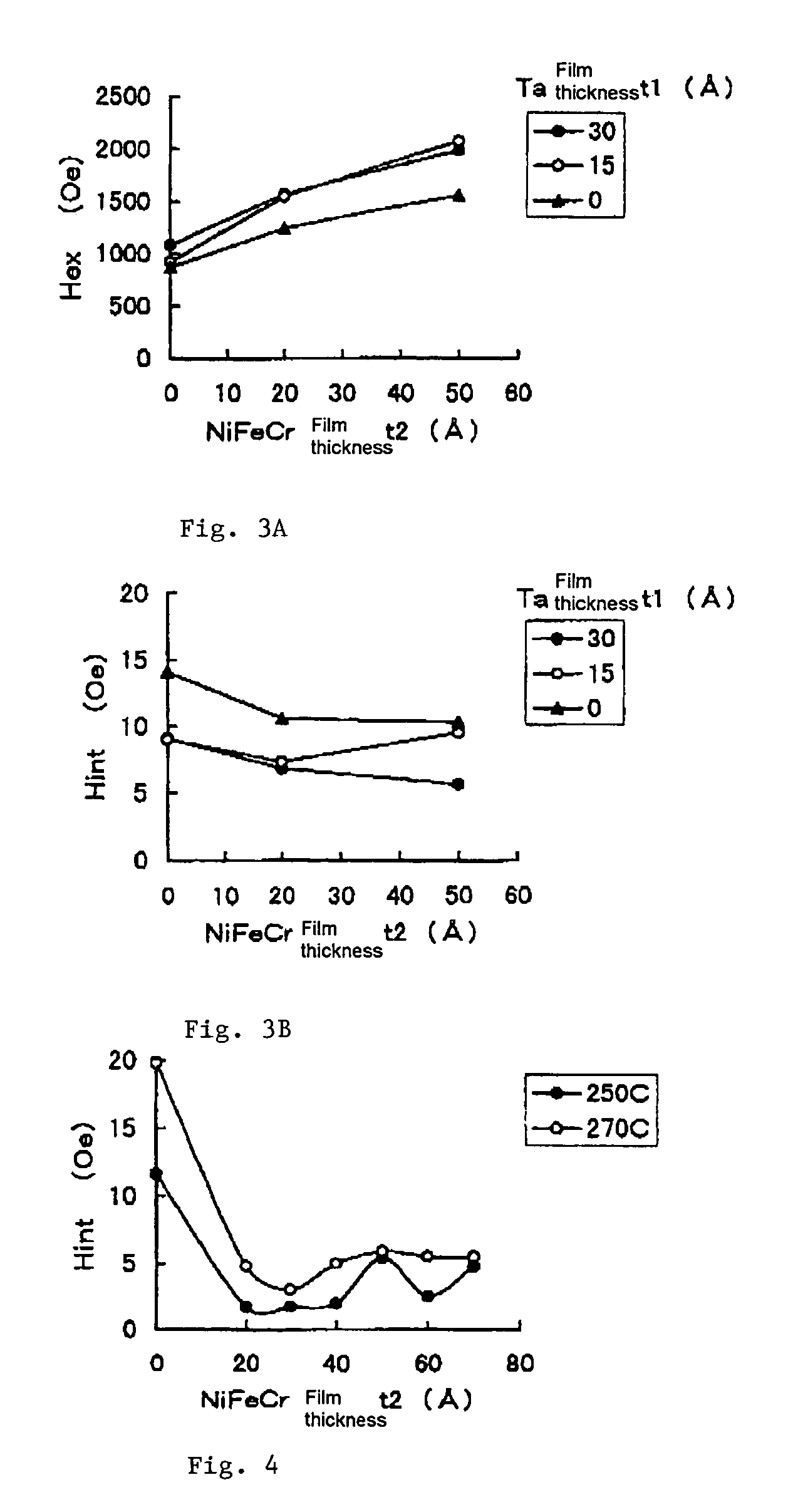

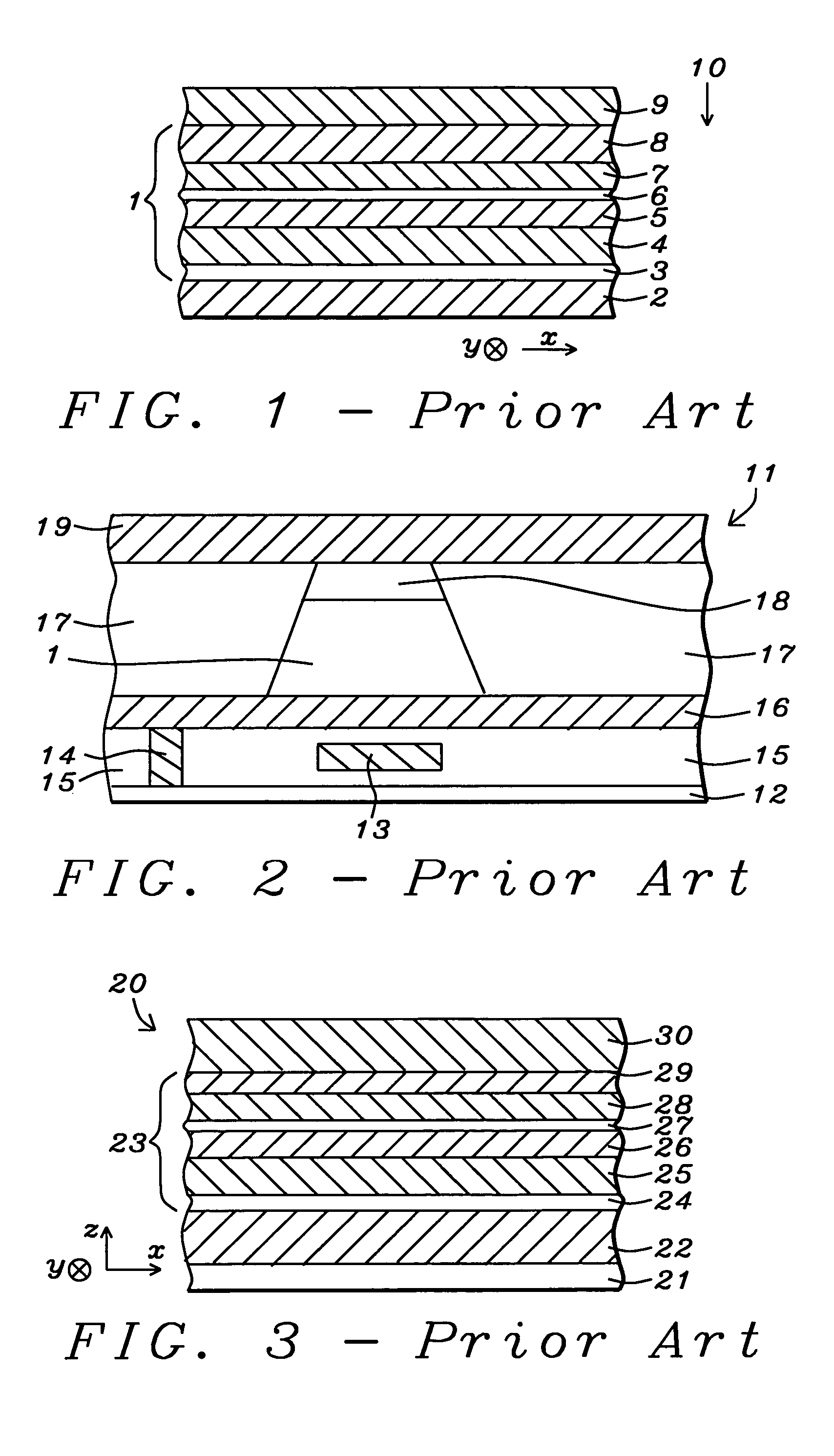

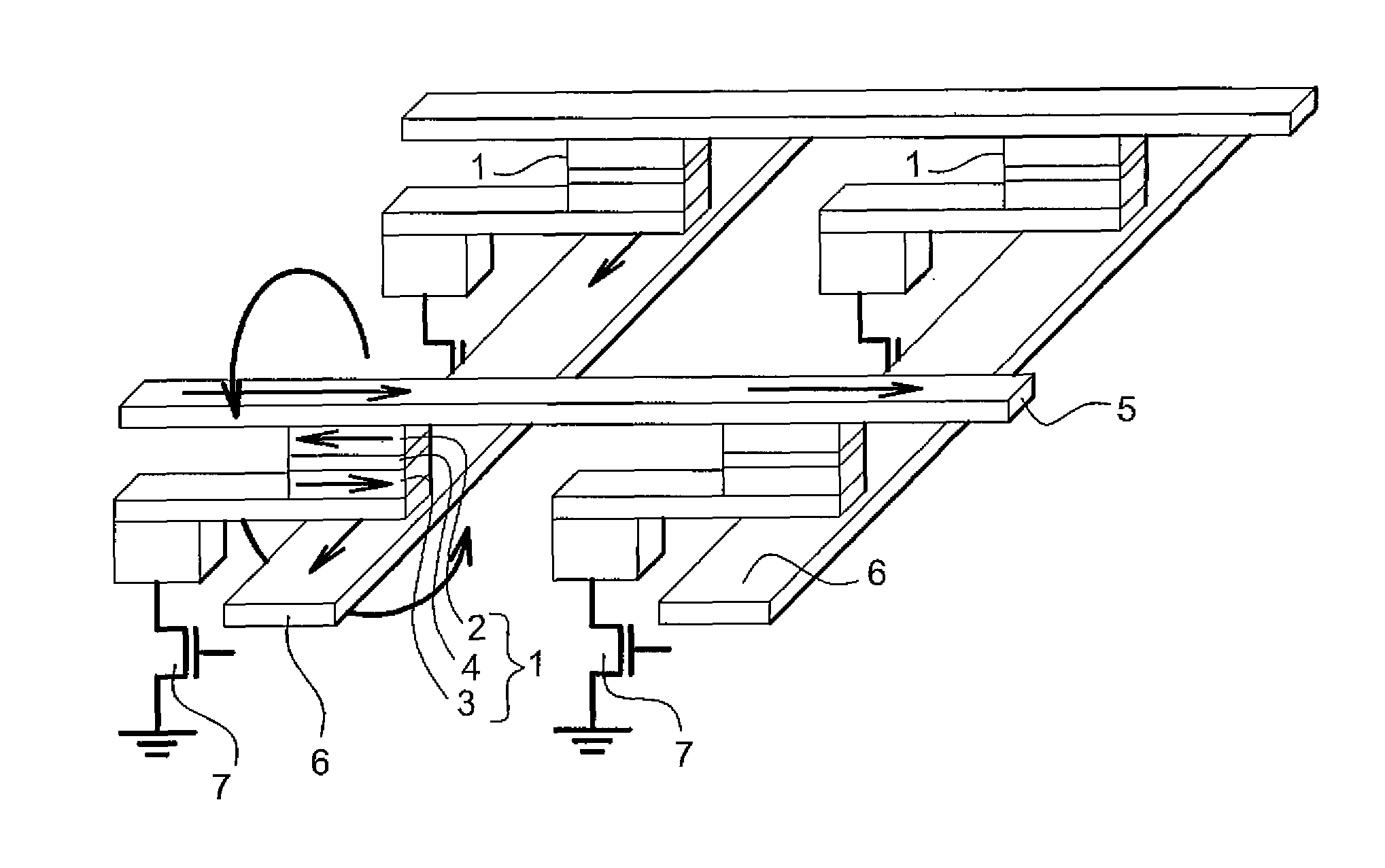

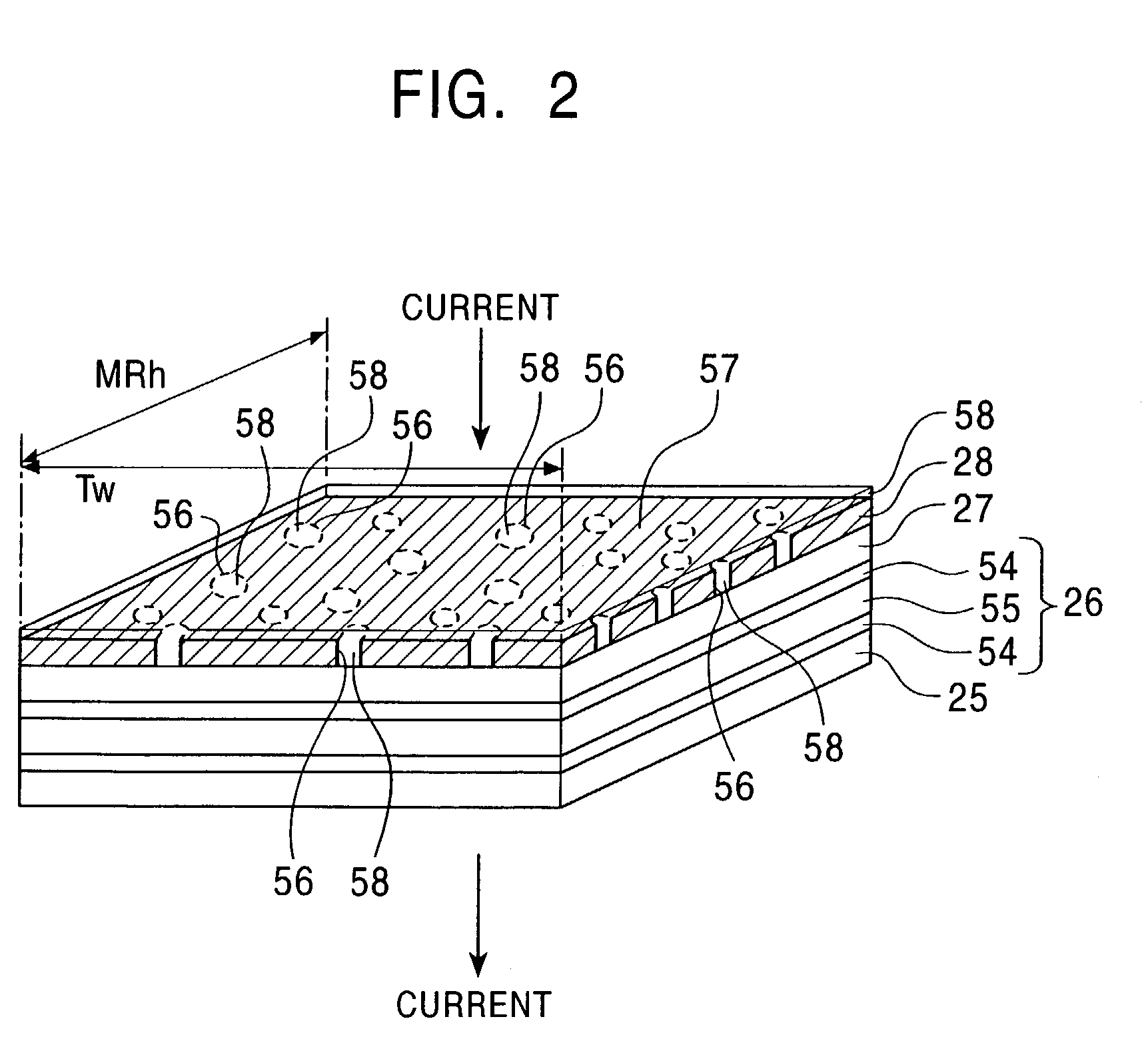

Spin valve magnetoresistance sensor and thin film magnetic head

A spin valve magnetoresistance sensor of a thin film magnetic head. In one embodiment, a spin valve magnetoresistance sensor is provided with a spin valve film, in which a base layer including a first base film of Ta or some other nonmagnetic metal and, on top of this, a second base film of an alloy represented by NiFeX (where X is at least one element selected from among Cr, Nb, Rh) is formed on a substrate, and on top of this are formed by layering a free magnetic layer and pinned magnetic layer arranged to enclose a nonmagnetic conductive layer, as well as an antiferromagnetic layer, the second base film has an fcc (face-centered cubic) structure and also has a (111) orientation.

Owner:WESTERN DIGITAL TECH INC

Magneto-resistance effect element and magnetic memory

InactiveUS20060227465A1Lower average currentNanomagnetismMagnetic-field-controlled resistorsMagnetizationMagnetic memory

It is possible to reduce a current required for spin injection writing. A magneto-resistance effect element includes: a first magnetization pinned layer; a magnetization free layer; a tunnel barrier layer; a second magnetization pinned layer whose direction of magnetization is pinned to be substantially anti-parallel to the direction of magnetization of the first magnetization pinned layer, and; a non-magnetic layer. When the second magnetization pinned layer is made of ferromagnetic material including Co, material for the non-magnetic layer is metal including at least one element selected from the group consisting of Zr, Hf, Rh, Ag, and Au; when the second magnetization pinned layer is made of ferromagnetic material including Fe, material for the non-magnetic layer is metal including at least one element selected from the group consisting of Rh, Pt, Ir, Al, Ag, and Au; and when the second magnetization pinned layer is made of ferromagnetic material including Ni, material for the non-magnetic layer is metal including at least one element selected from the group consisting of Zr, Hf, Au, and Ag.

Owner:KK TOSHIBA

Capping structure for enhancing dR/R of the MTJ device

An MTJ in an MRAM array or in a TMR read head is comprised of a capping layer with a lower inter-diffusion barrier layer, an intermediate oxygen gettering layer, and an upper metal layer that contacts a top conductor. The composite capping layer is especially useful with a moderate spin polarization free layer such as a NiFe layer with a Fe content of about 17.5 to 20 atomic %. The capping layer preferably has a Ru / Ta / Ru configuration in which the lower Ru layer is about 10 to 30 Angstroms thick and the Ta layer is about 30 Angstroms thick. As a result, a high dR / R of about 40% is achieved with low magnetostriction less than about 1.0 E−6 in an MTJ in an MRAM array. Best results are obtained with an AlOx tunnel barrier layer formed by an in-situ ROX process on an 8 to 10 Angstrom thick Al layer.

Owner:HEADWAY TECH INC +1

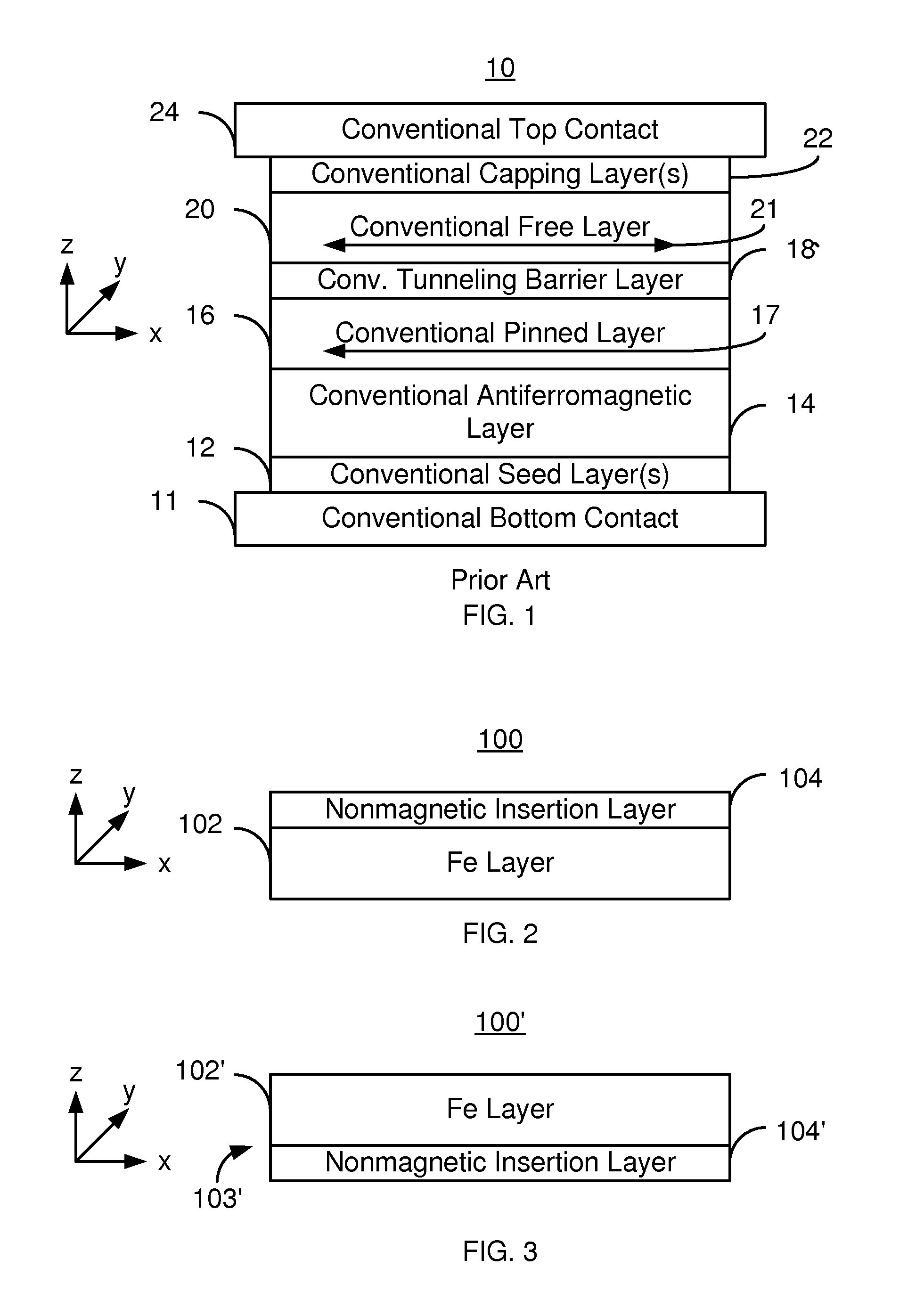

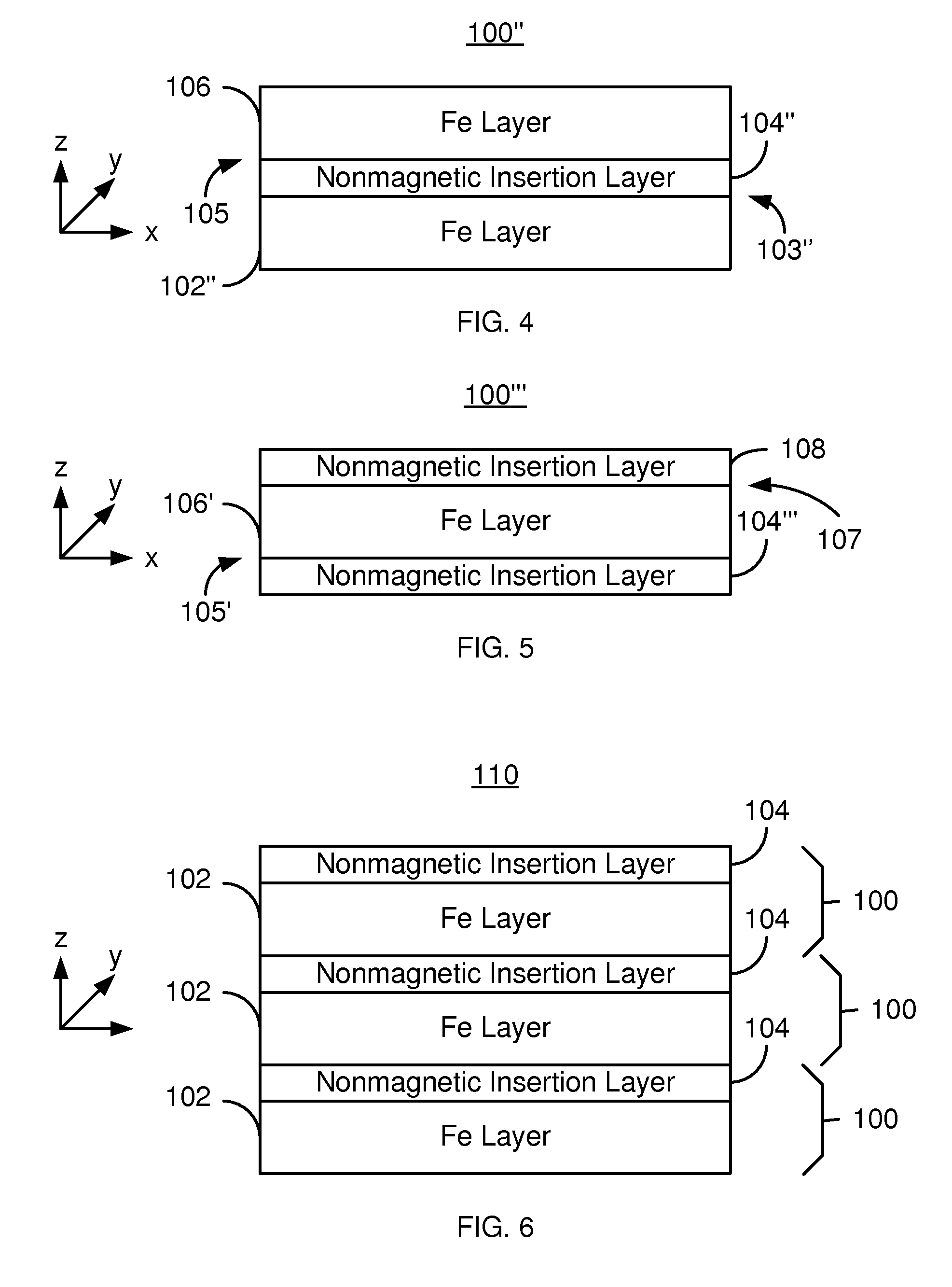

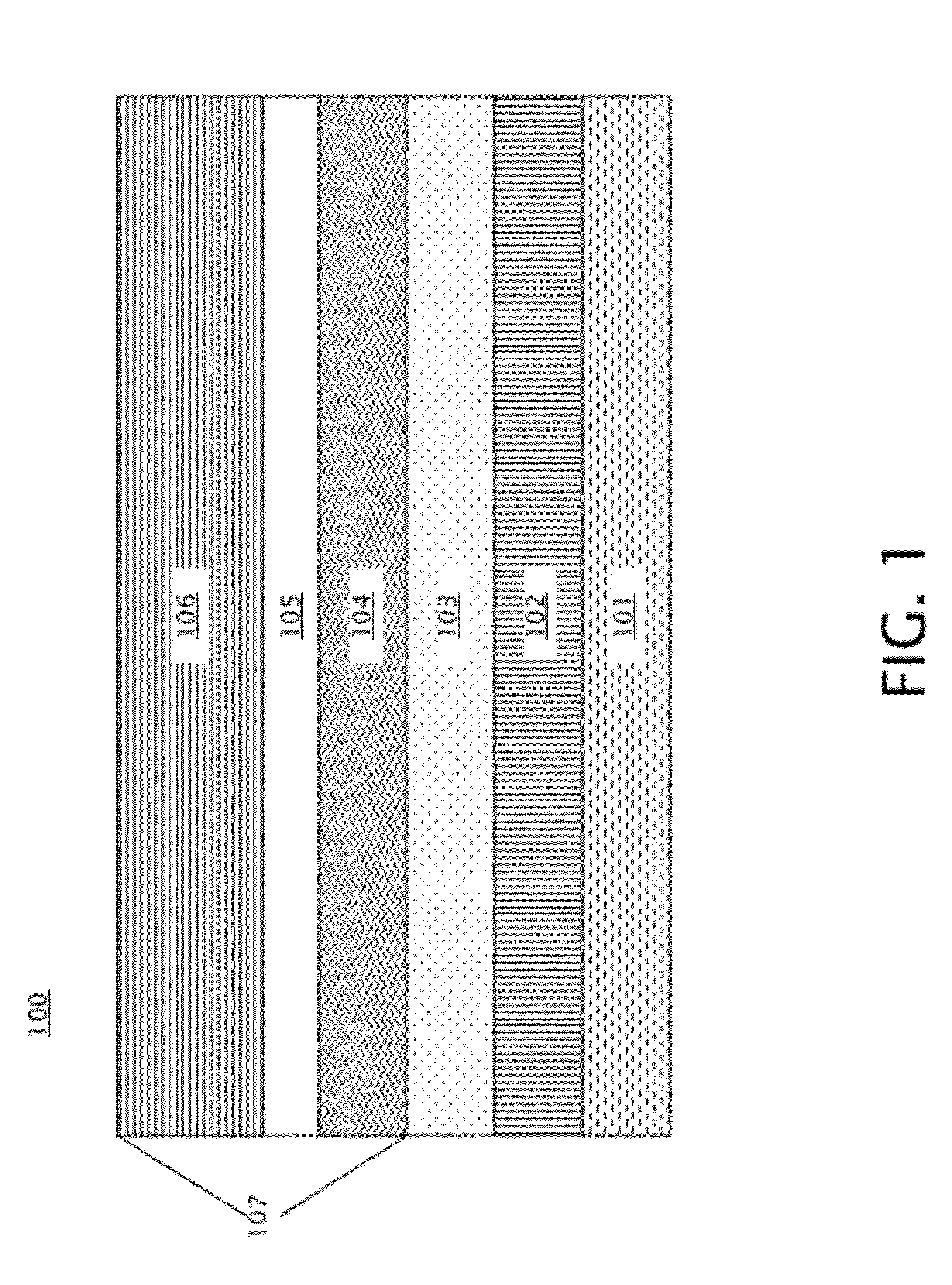

Magnetic junctions having insertion layers and magnetic memories using the magnetic junctions

ActiveUS20140264671A1Galvano-magnetic material selectionSemiconductor/solid-state device manufacturingMagnetic memoryNon magnetic

A method and system for providing a magnetic junction usable in a magnetic device are described. The magnetic junction includes a reference layer, a nonmagnetic spacer layer and a free layer. The nonmagnetic spacer layer is between the reference layer and the free layer. The magnetic junction is configured such that the free layer is switchable between a plurality of stable magnetic states when a write current is passed through the magnetic junction. A portion of the magnetic junction includes at least one magnetic substructure. The magnetic substructure includes at least one Fe layer and at least one nonmagnetic insertion layer. The at least one Fe layer shares at least one interface with the at least one nonmagnetic insertion layer. Each of the at least one nonmagnetic insertion layer consists of at least one of W, I, Hf, Bi, Zn, Mo, Ag, Cd, Os and In.

Owner:SAMSUNG ELECTRONICS CO LTD

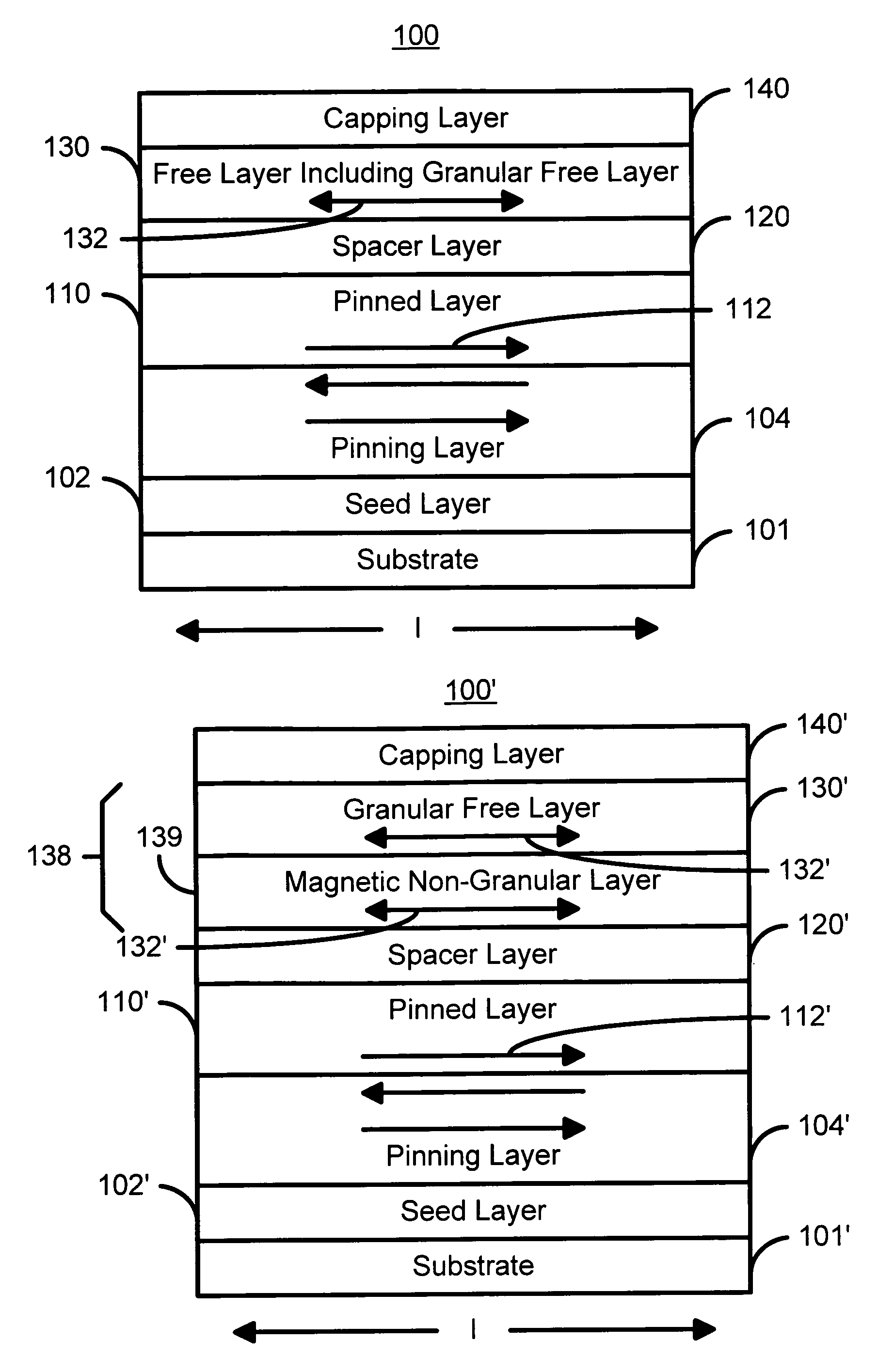

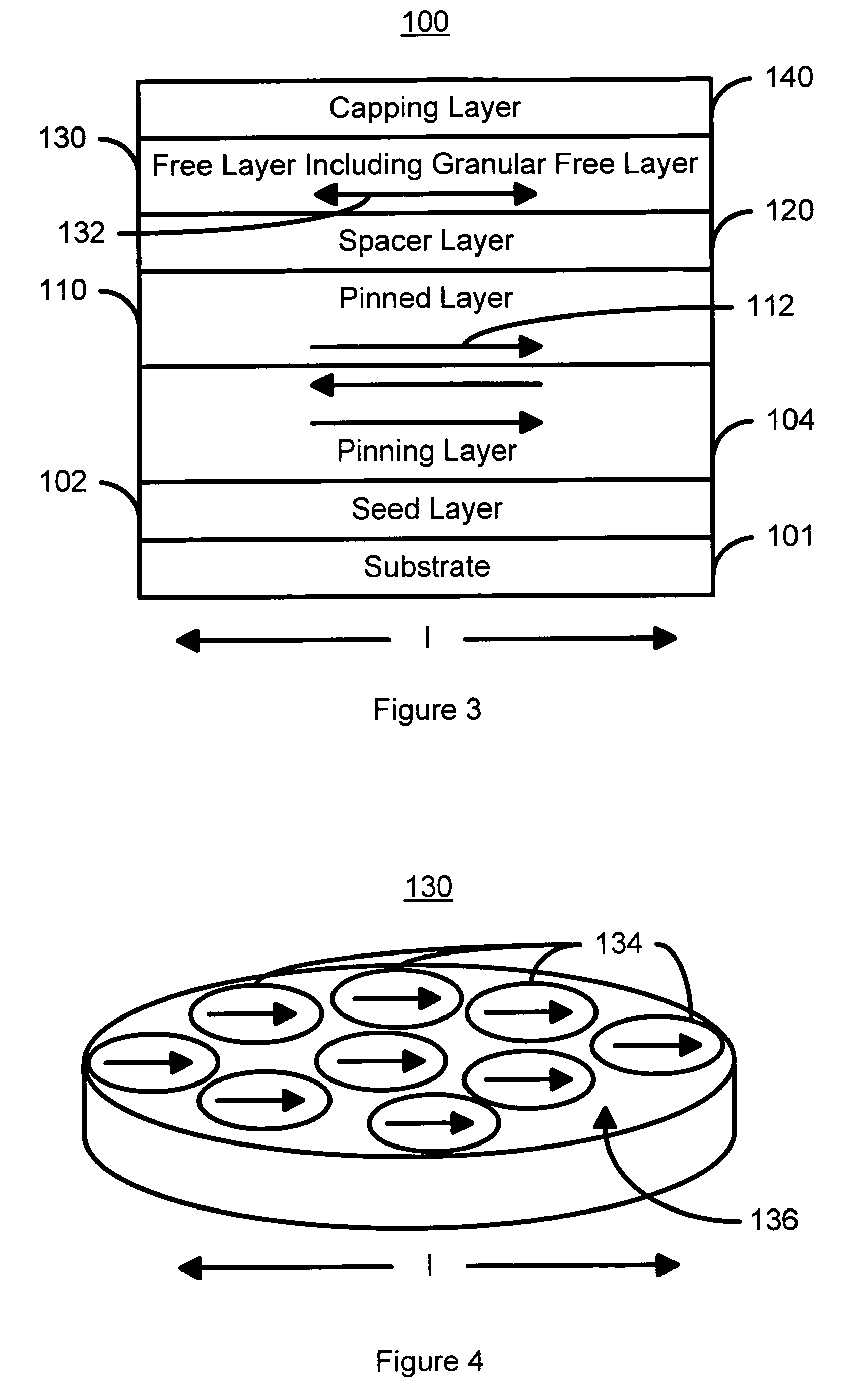

Spin transfer based magnetic storage cells utilizing granular free layers and magnetic memories using such cells

InactiveUS20070085068A1NanomagnetismMagnetic-field-controlled resistorsMagnetic storageSpin transfer

A method and system for providing a magnetic element and a memory incorporating the magnetic element is described. The method and system for providing the magnetic element include providing a pinned layer, a spacer layer, and a free layer. The free layer includes granular free layer having a plurality of grains in a matrix, the spacer layer residing between the pinned layer and the free layer. The magnetic element is configured to allow the granular free layer to be switched due to spin-transfer when a write current is passed through the magnetic element.

Owner:GRANDIS

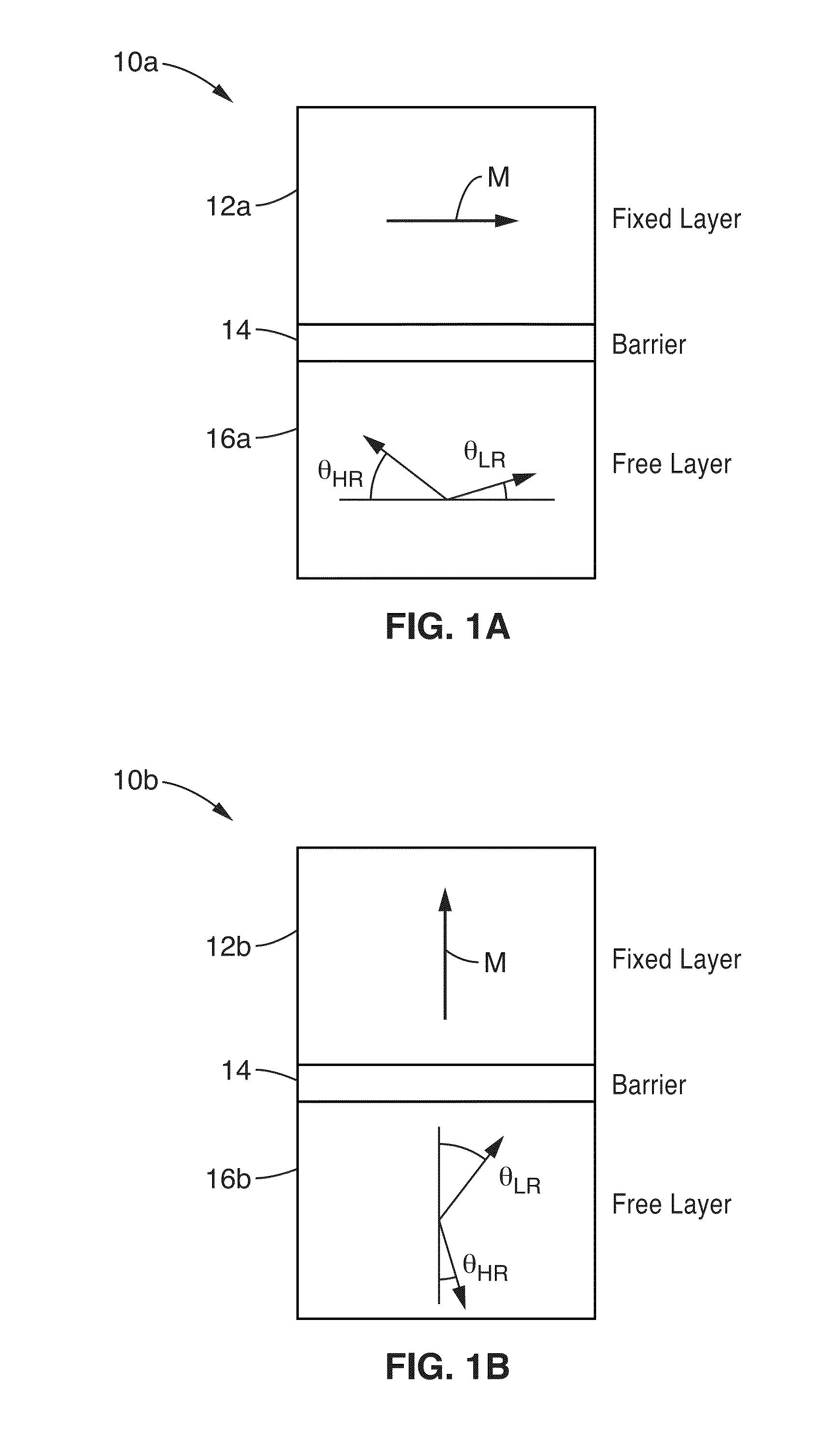

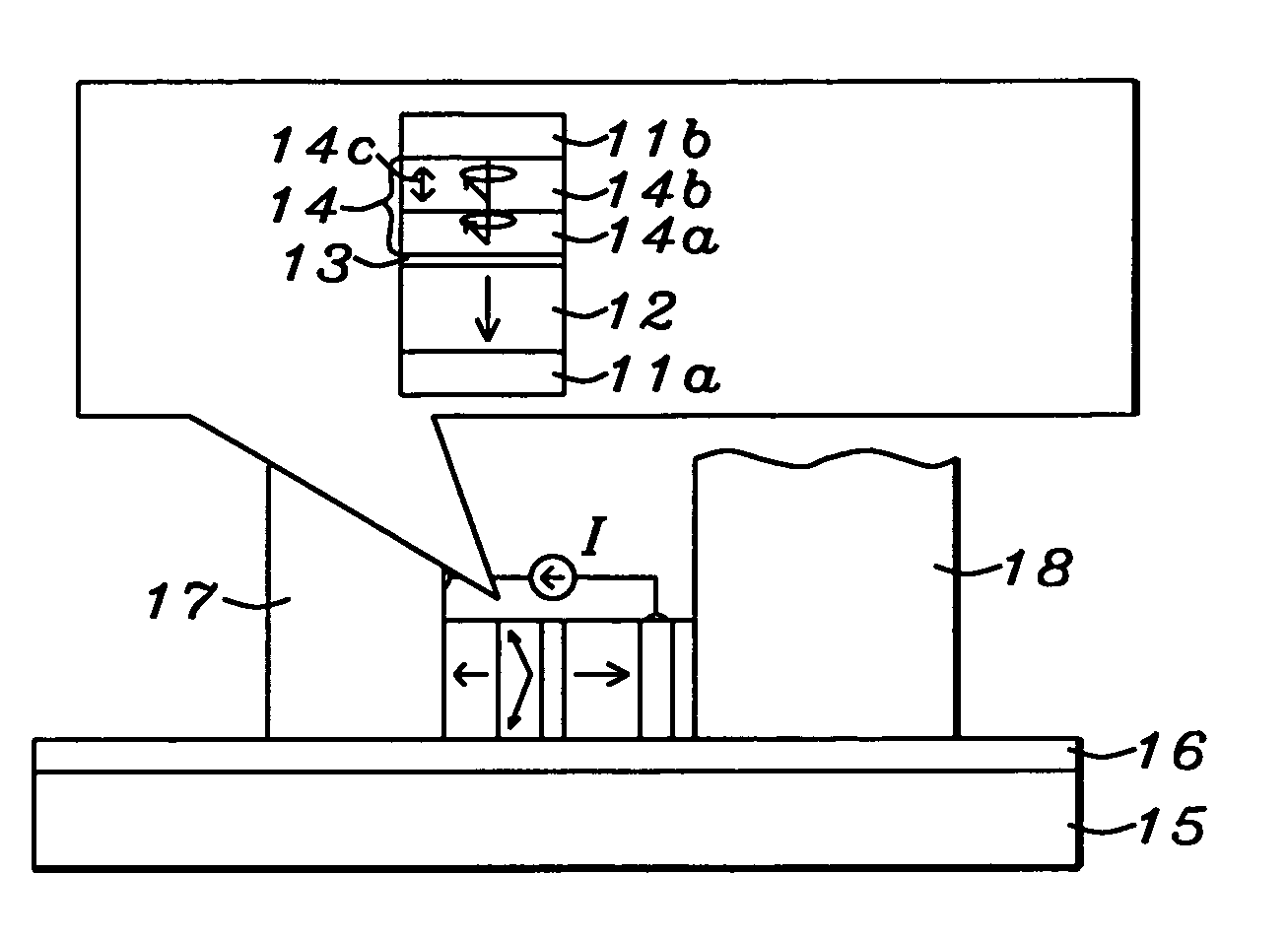

Spin polarised magnetic device

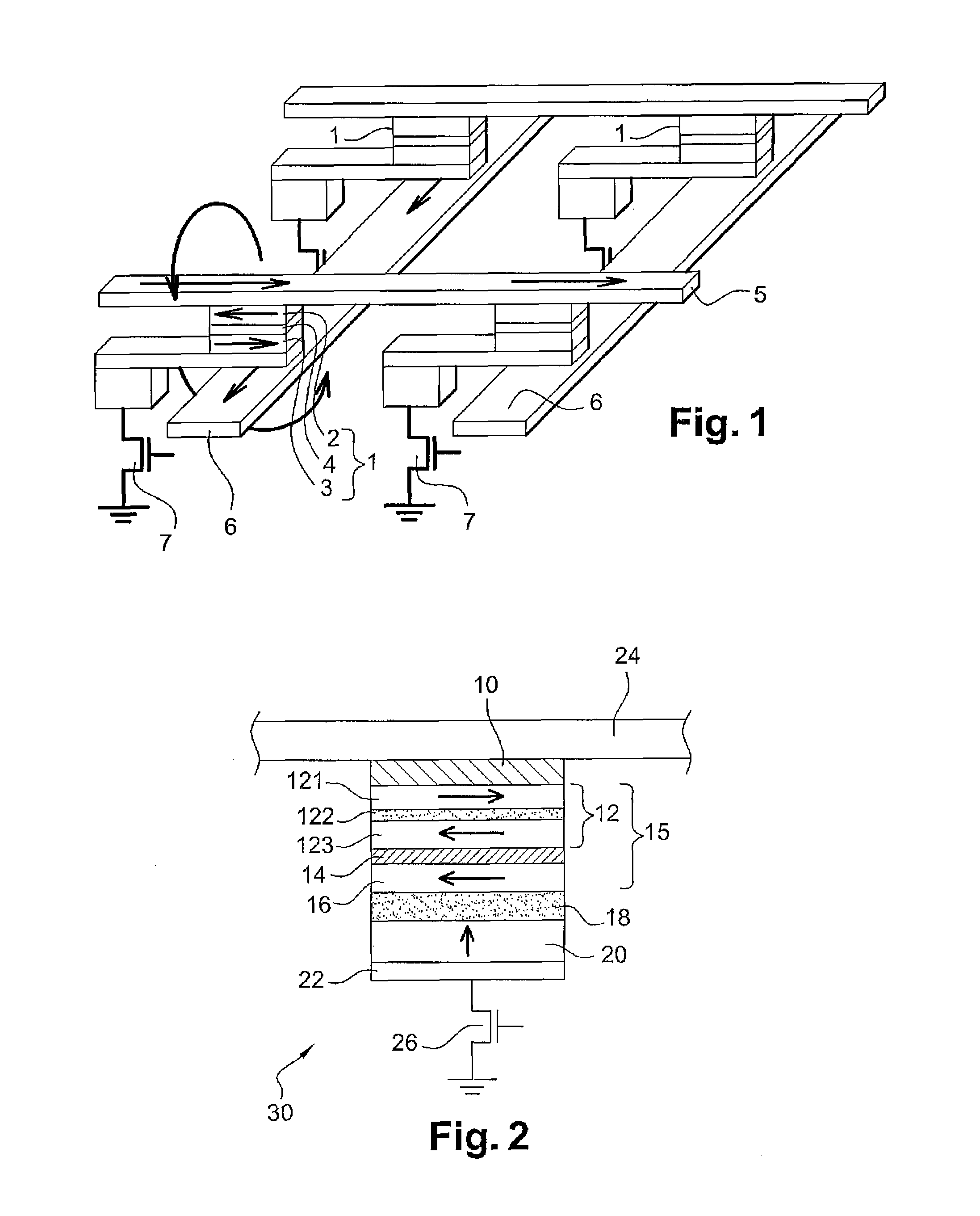

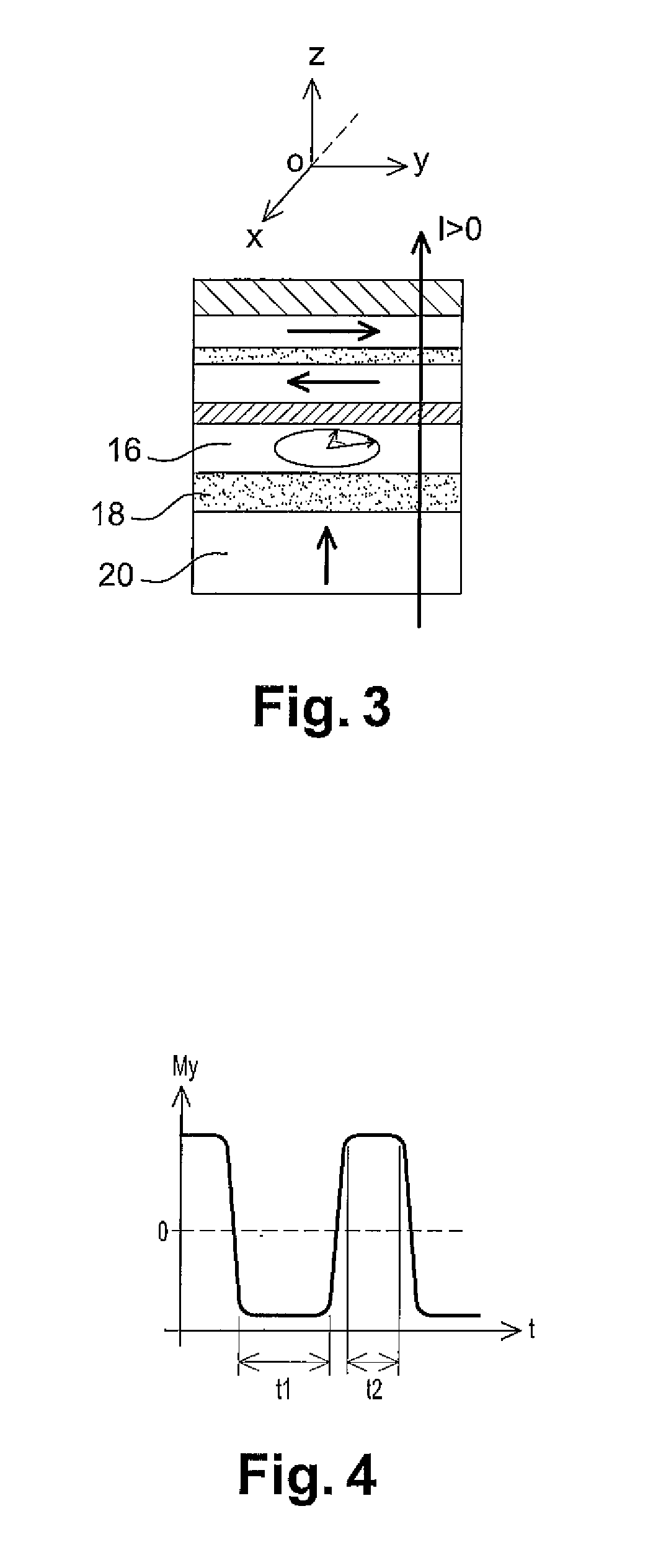

ActiveUS8279666B2Reducing the stochastic fluctuations in the magnetisation reversal timeTotal current dropNanomagnetismMagnetic measurementsMagnetic storageSpins

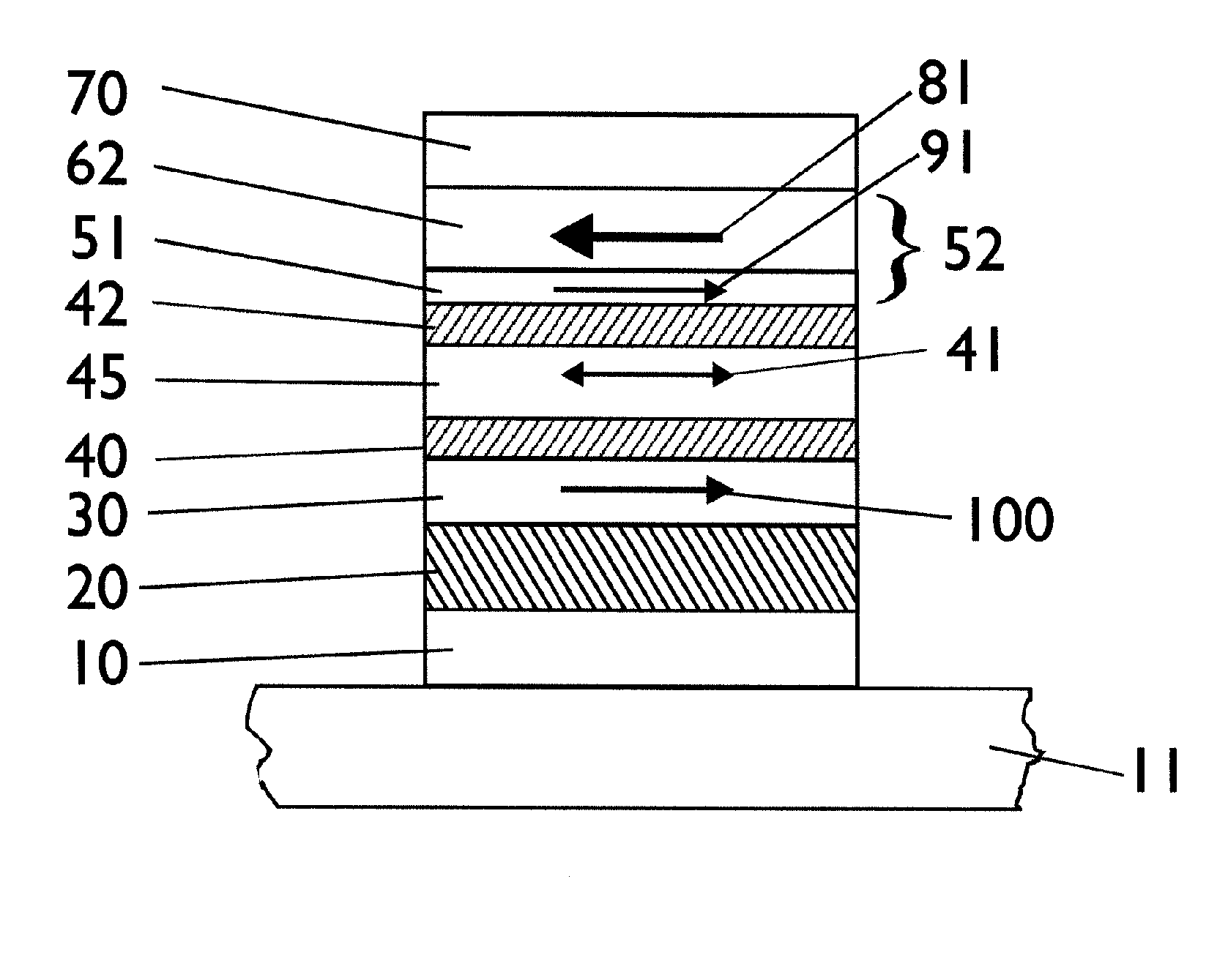

A magnetic device includes a magnetic reference layer with a fixed magnetization direction located either in the plane of the layer or perpendicular to the plane of the layer, a magnetic storage layer with a variable magnetization direction, a non-magnetic spacer separating the reference layer and the storage layer and a magnetic spin polarizing layer with a magnetization perpendicular to that of the reference layer, and located out of the plane of the spin polarizing layer if the magnetization of the reference layer is directed in the plane of the reference layer or in the plane of the spin polarizing layer if the magnetization of the reference layer is directed perpendicular to the plane of the reference layer. The spin transfer coefficient between the reference layer and the storage layer is higher than the spin transfer coefficient between the spin polarizing layer and the storage layer.

Owner:INSTITUT NAT POLYTECHN DE GRENOBLE +2

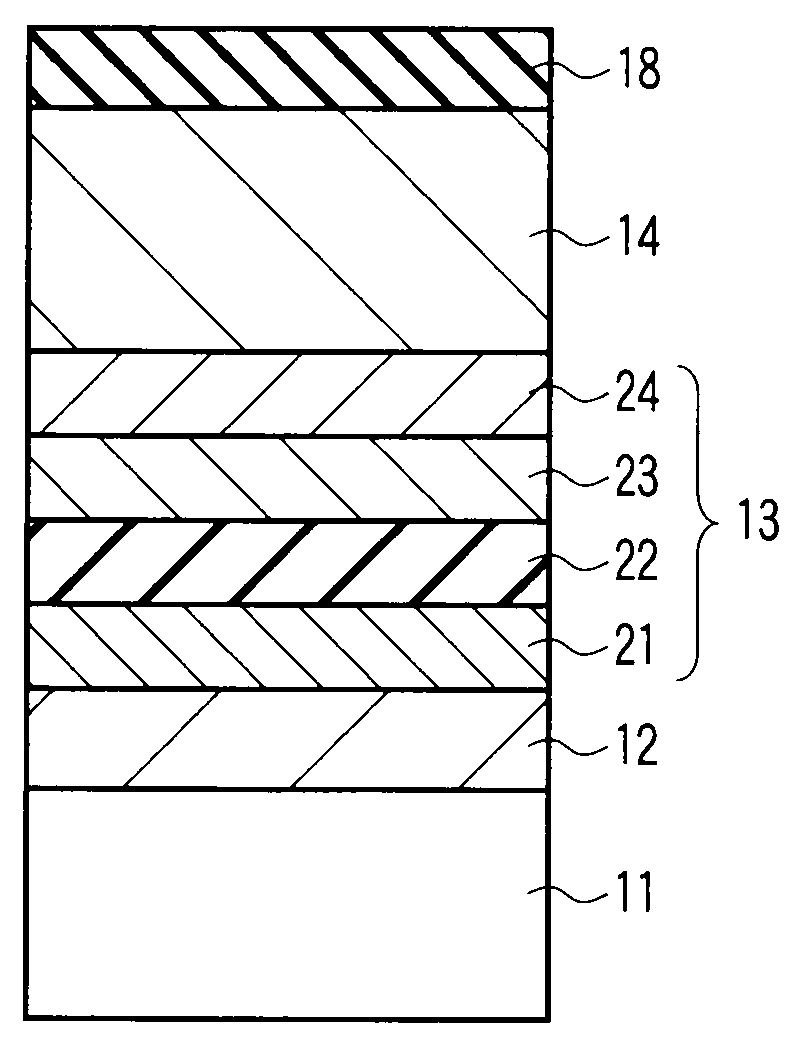

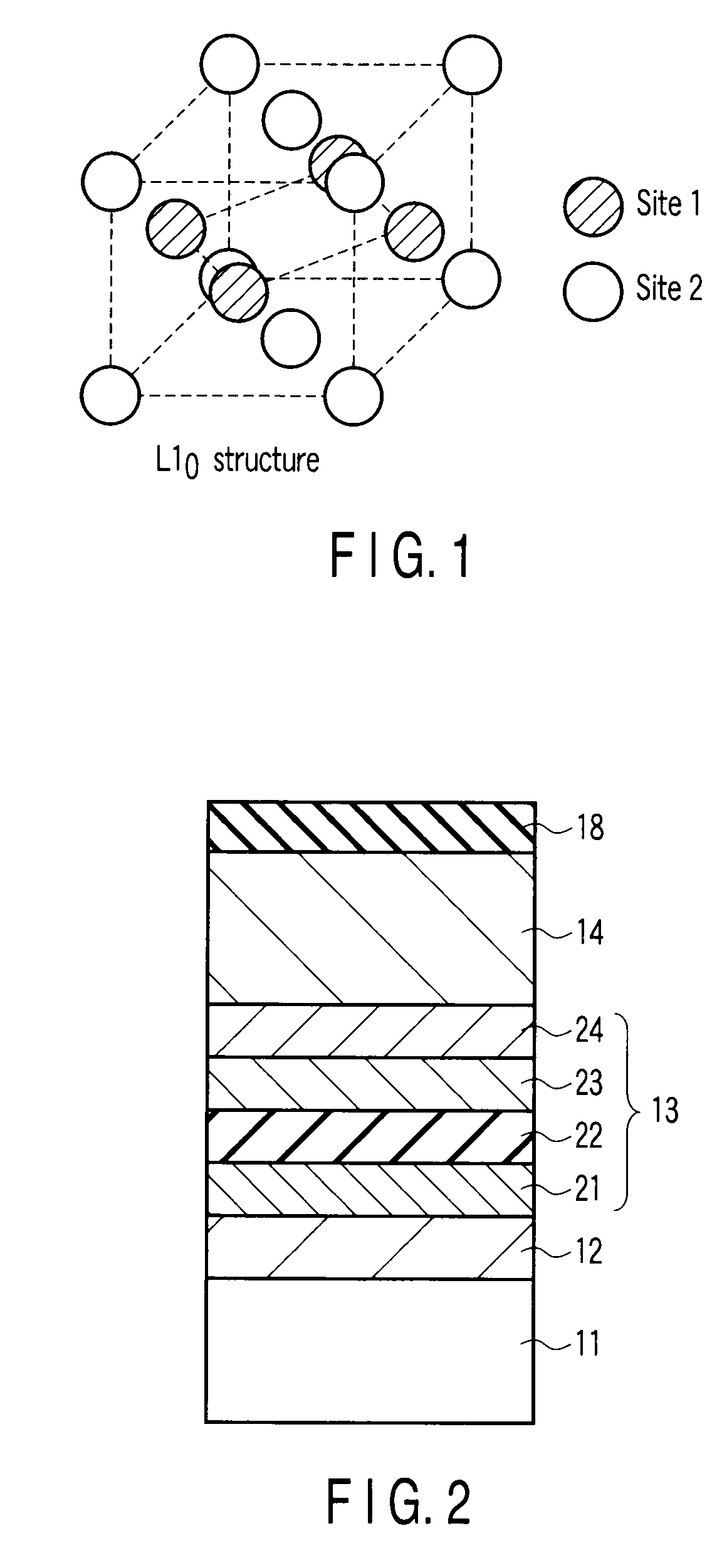

Magnetoresistive element and magnetic memory

ActiveUS20090079018A1NanomagnetismMagnetic materials for record carriersMagnetic anisotropyMagnetic memory

A magnetoresistive element includes a first underlying layer having an NaCl structure and containing a nitride orienting in a (001) plane, a first magnetic layer provided on the first underlying layer, having magnetic anisotropy perpendicular to a film surface, having an L10 structure, and containing a ferromagnetic alloy orienting in a (001) plane, a first nonmagnetic layer provided on the first magnetic layer, and a second magnetic layer provided on the first nonmagnetic layer and having magnetic anisotropy perpendicular to a film surface.

Owner:KIOXIA CORP

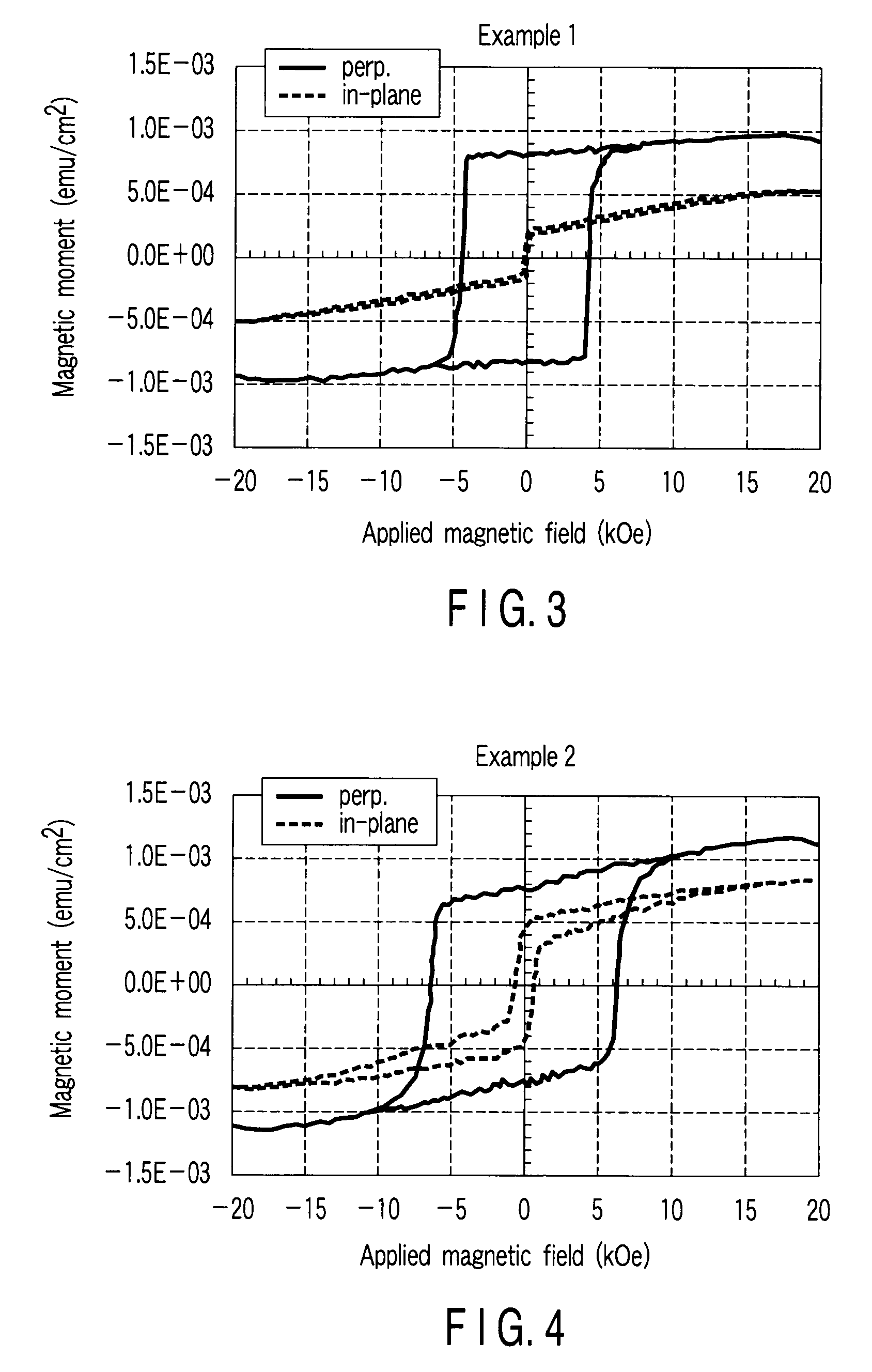

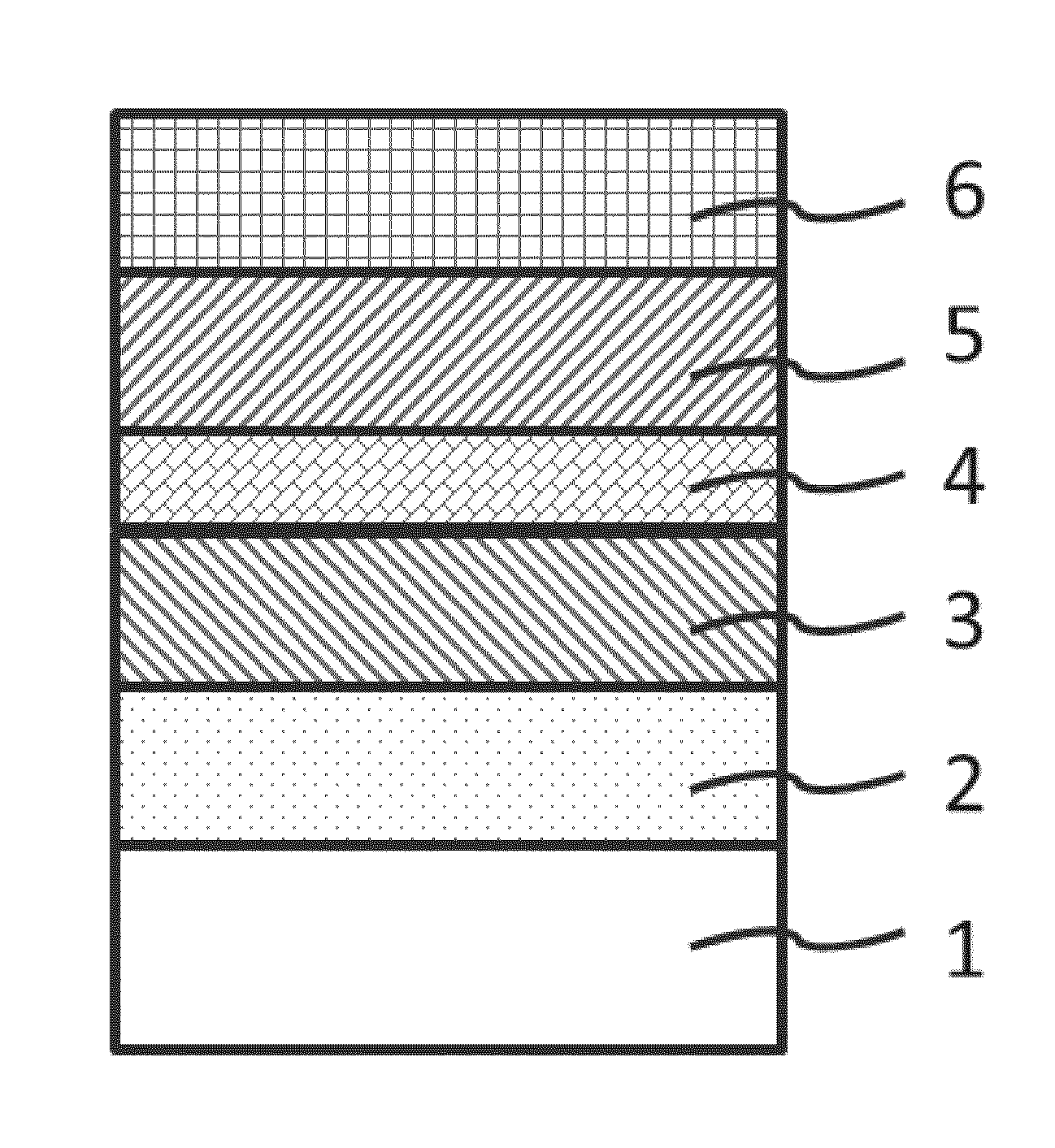

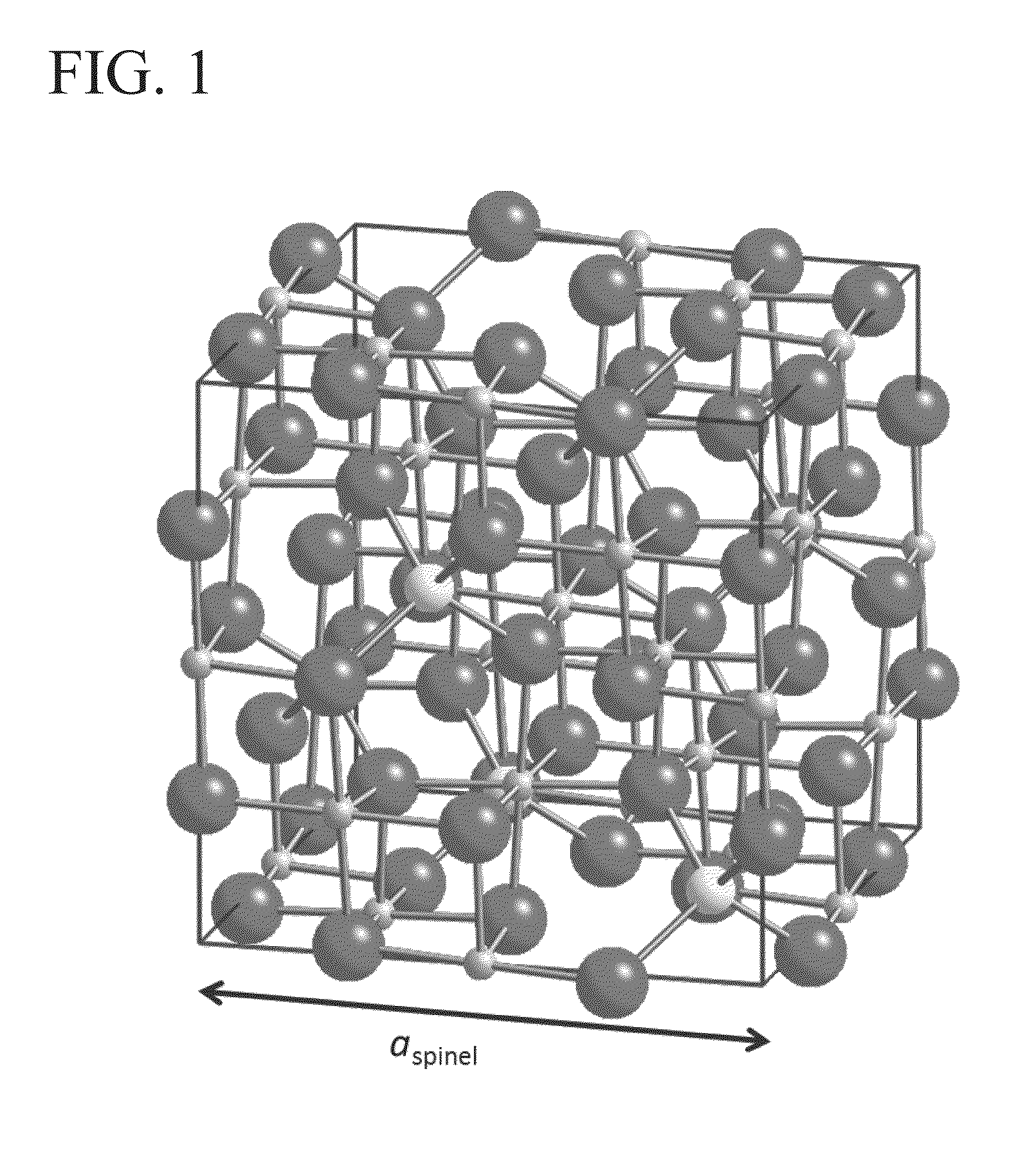

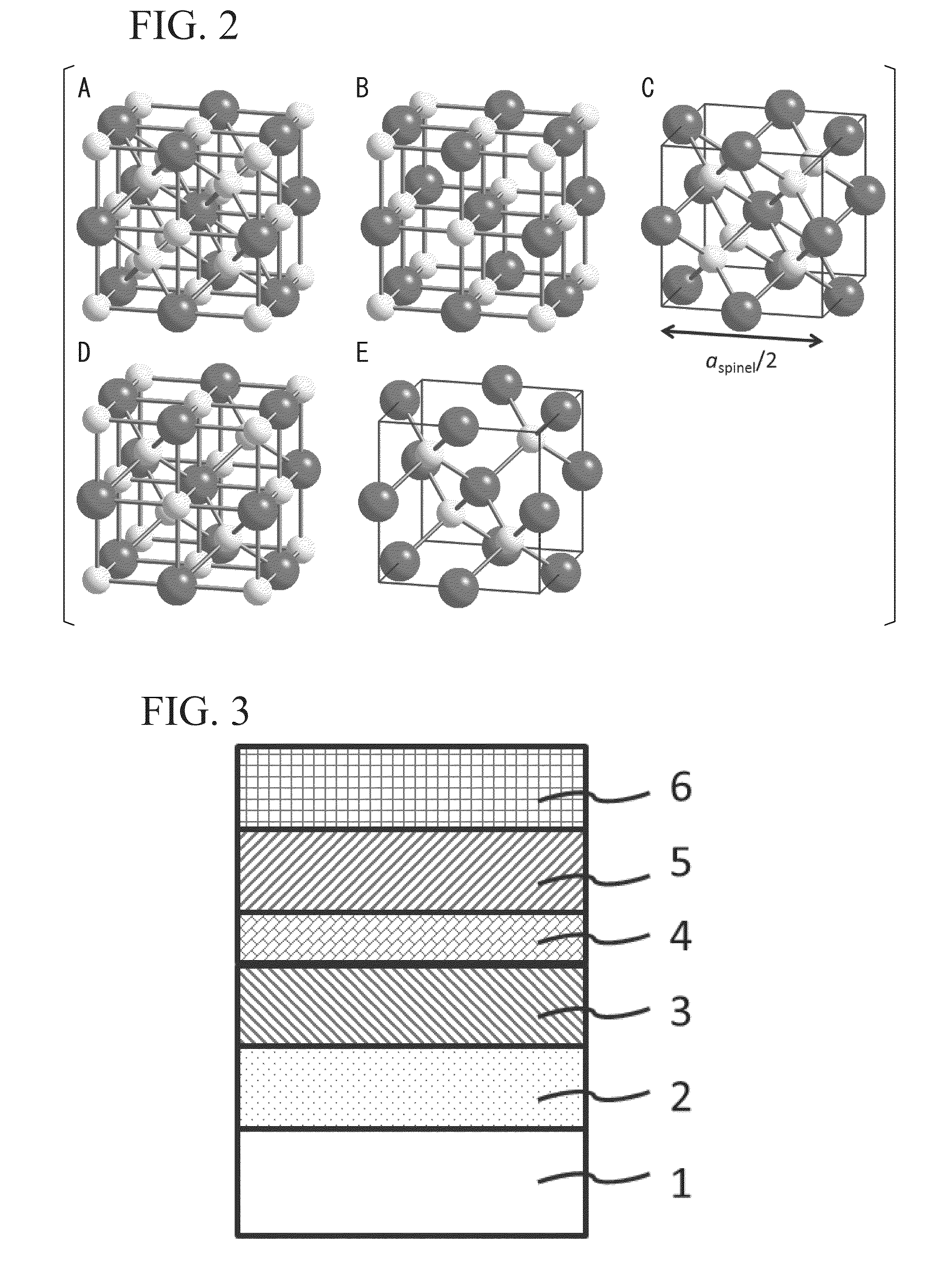

Ferromagnetic Tunnel Junction Structure and Magnetoresistive Effect Device and Spintronics Device Utilizing Same

ActiveUS20130221461A1High TMR valueQuality improvementMagnetic-field-controlled resistorsSolid-state devicesCrystalline oxideSpace group

A ferromagnetic tunnel junction structure comprising a first ferromagnetic layer, a second ferromagnetic layer, and a tunnel barrier layer that is interposed between the first ferromagnetic layer and the second ferromagnetic layer, wherein the tunnel barrier layer includes a crystalline non-magnetic material having constituent elements that are similar to those of an crystalline oxide that has spinel structure as a stable phase structure; the non-magnetic material has a cubic structure having a symmetry of space group Fm-3m or F-43m in which atomic arrangement in the spinel structure is disordered; and an effective lattice constant of the cubic structure is substantially half of the lattice constant of the oxide of the spinel structure.

Owner:NAT INST FOR MATERIALS SCI

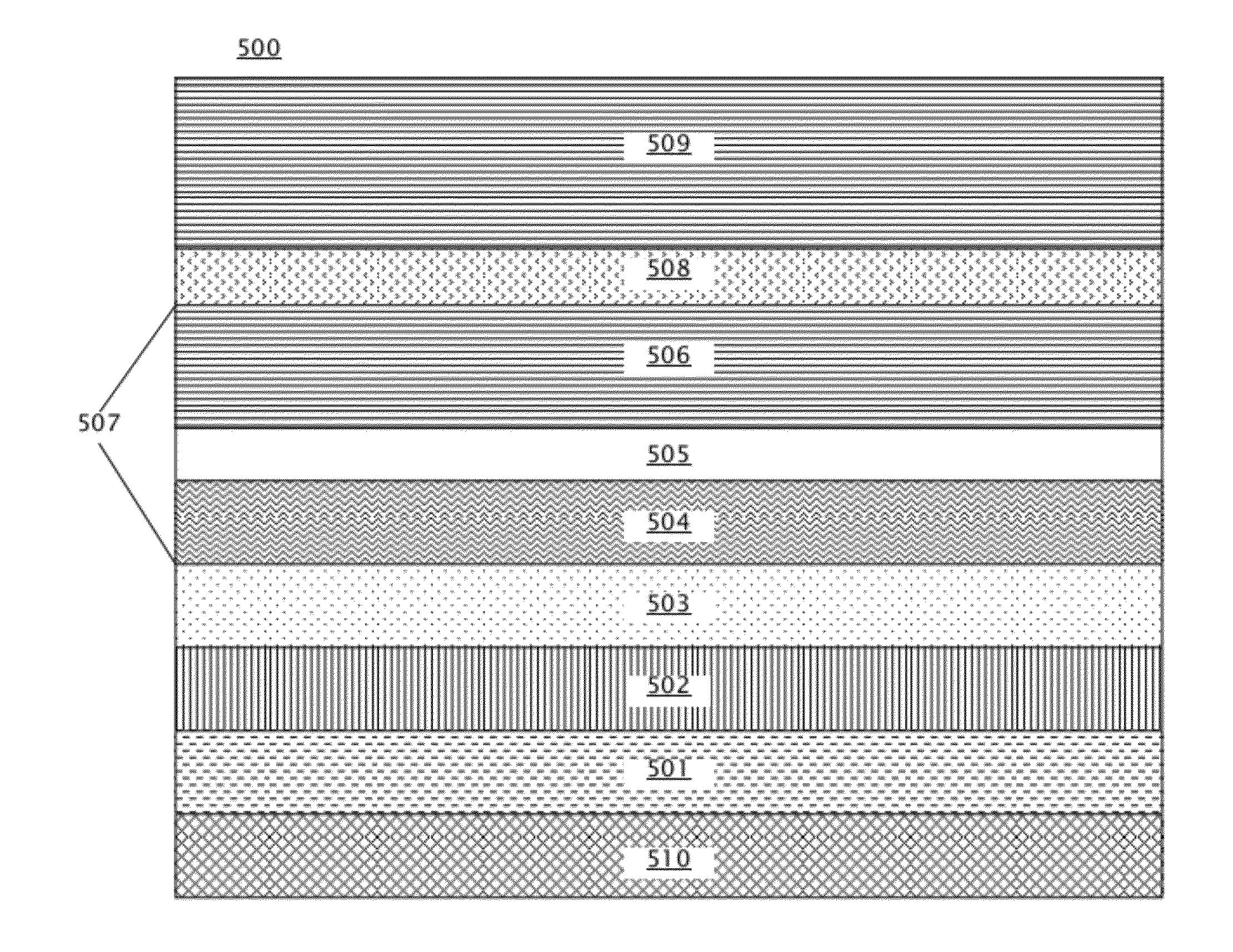

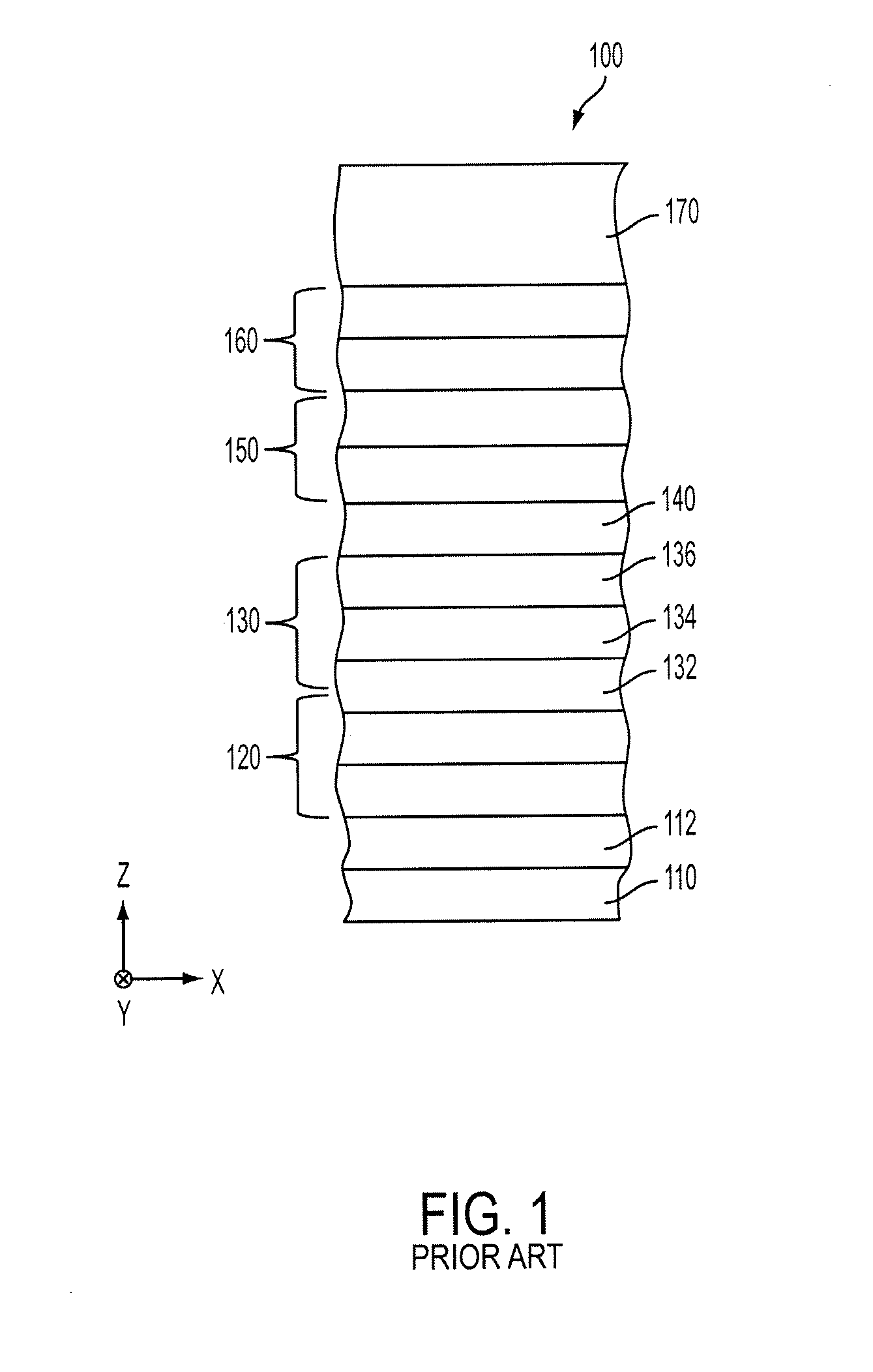

Magnetic stacks with perpendicular magnetic anisotropy for spin momentum transfer magnetoresistive random access memory

InactiveUS20120267733A1Magnetic-field-controlled resistorsGalvano-magnetic material selectionMagnetic reluctanceMagnetization

A magnetic tunnel junction (MTJ) includes a magnetic free layer, having a variable magnetization direction; an insulating tunnel barrier located adjacent to the free layer; a magnetic fixed layer having an invariable magnetization direction, the fixed layer disposed adjacent the tunnel barrier such that the tunnel barrier is located between the free layer and the fixed layer, wherein the free layer and the fixed layer have perpendicular magnetic anisotropy; and one or more of: a composite fixed layer, the composite fixed layer comprising a dusting layer, a spacer layer, and a reference layer; a synthetic antiferromagnetic (SAF) fixed layer structure, the SAF fixed layer structure comprising a SAF spacer located between the fixed layer and a second fixed magnetic layer; and a dipole layer, wherein the free layer is located between the dipole layer and the tunnel barrier.

Owner:IBM CORP

Magnetic tunnel junction for MRAM device

InactiveUS20150279904A1Improve performanceSwitching currentMagnetic-field-controlled resistorsSolid-state devicesTantalum nitrideSoftware engineering

A magnetoresistive random-access memory device with a magnetic tunnel junction stack having a significantly improved performance of the free layer in the magnetic tunnel junction structure. The memory device includes an antiferromagnetic structure and a magnetic tunnel junction structure disposed on the antiferromagnetic structure. The magnetic tunnel junction structure includes a reference layer and a free layer with a barrier layer sandwiched therebetween. Furthermore, a capping layer including a tantalum nitride film is disposed on the free layer of the magnetic tunnel junction structure.

Owner:SPIN MEMORY INC

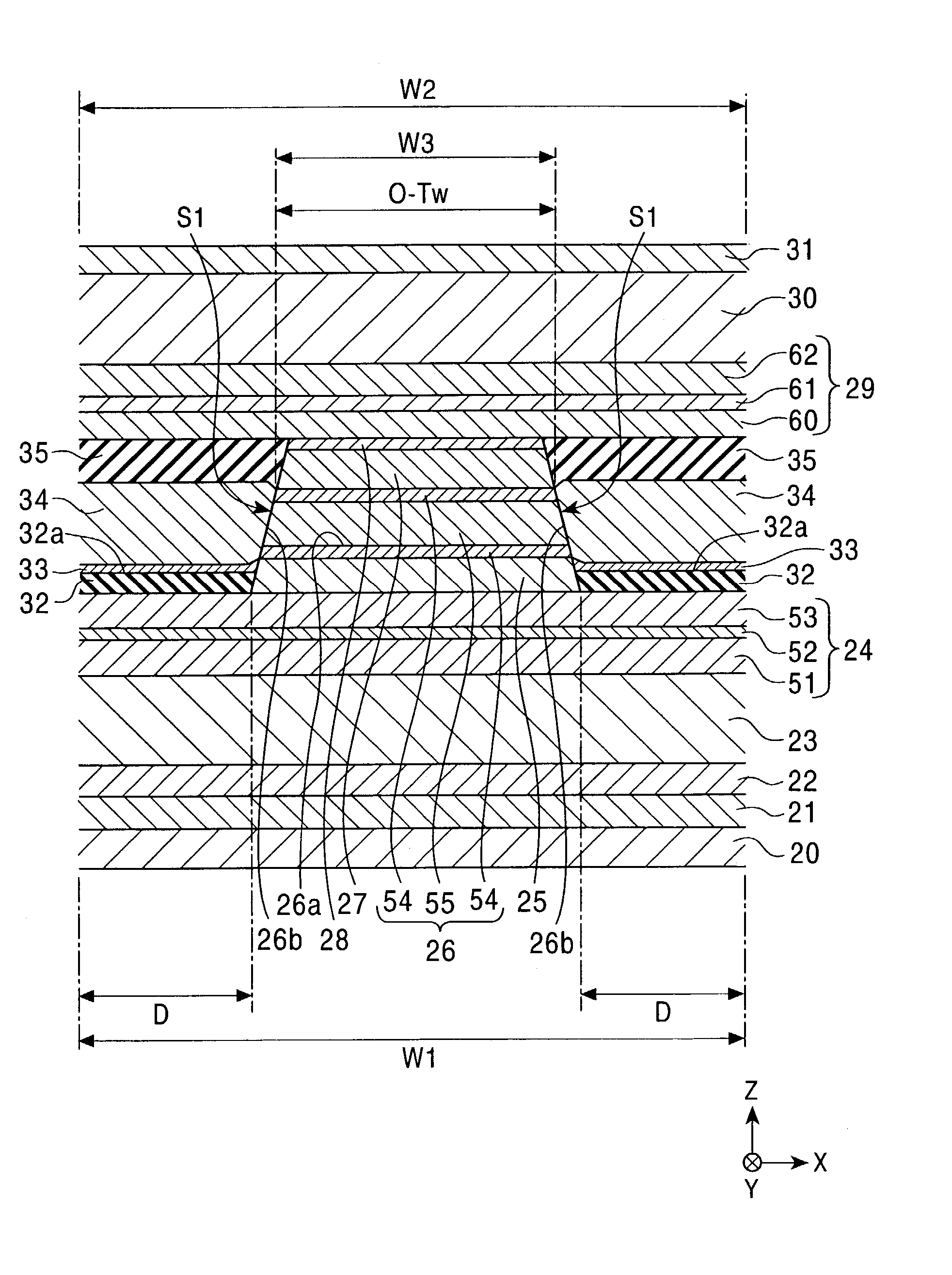

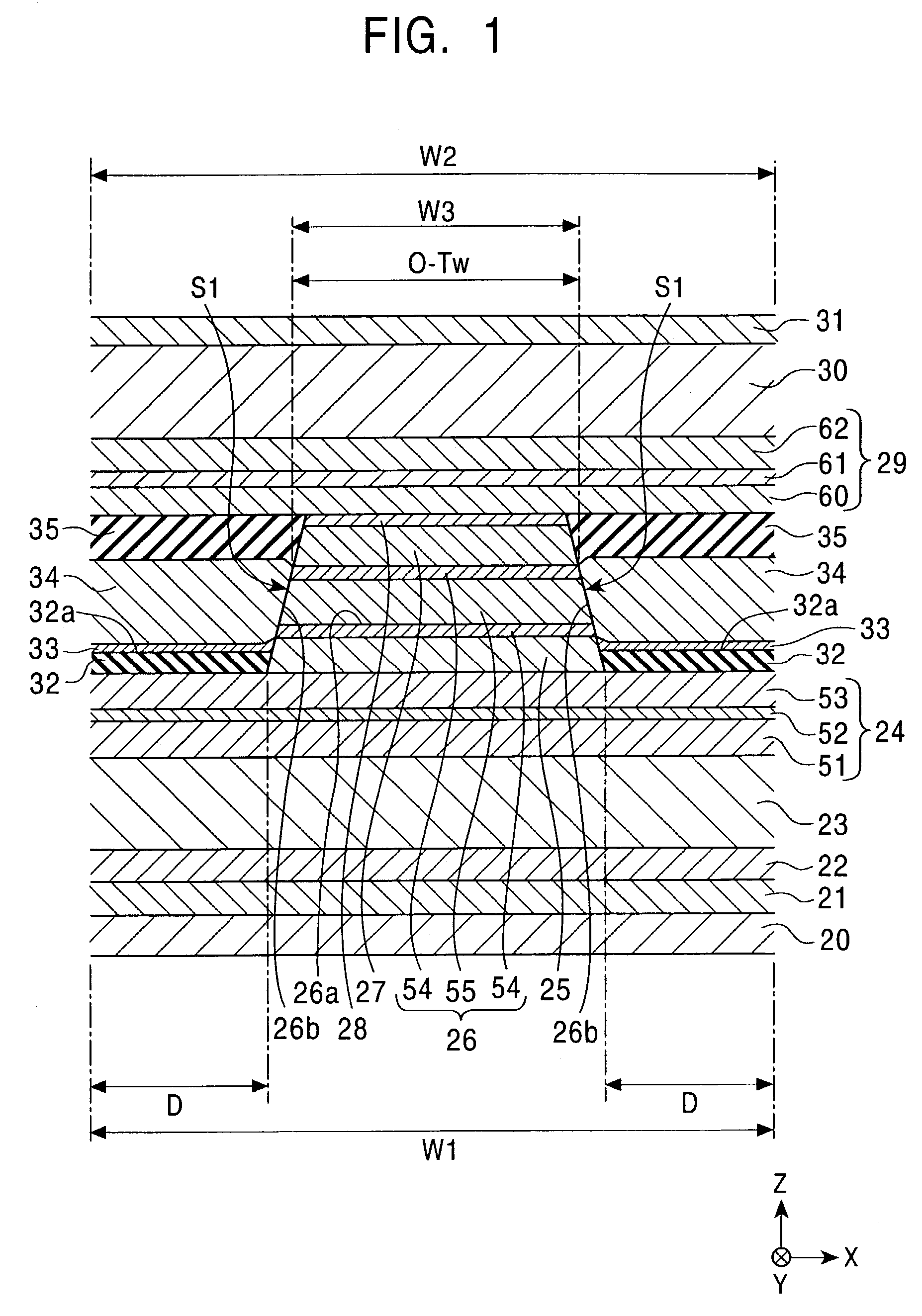

GMR magnetic sensing element having an antiferromagnetic layer extending beyond the track width and method for making the same

InactiveUS7050276B2Easy to disassembleHigh outputNanomagnetismMagnetic measurementsMagnetic layerAntiferromagnetism

A magnetic sensing element with improved magnetic detection output and a method for making the same are provided. In the magnetic sensing element, the length of an upper pinned magnetic layer an upper antiferromagnetic layer in a track width direction is larger than the length of a free magnetic layer in the track width direction. In making the magnetic sensing element, there is no need to remove side portions of the upper pinned magnetic layer and the upper antiferromagnetic layer. The materials of the upper pinned magnetic layer and the upper antiferromagnetic layer are thus prevented from redepositing on two side faces of the free magnetic layer during milling.

Owner:TDK CORPARATION

Co/Ni Multilayers with Improved Out-of-Plane Anisotropy for Magnetic Device Applications

ActiveUS20120299134A1Raise the ratioStrong textureMagnetic-field-controlled resistorsGalvano-magnetic material selectionAlloyElectron

A MTJ for a spintronic device is disclosed and includes a thin seed layer that enhances perpendicular magnetic anisotropy (PMA) in an overlying laminated layer with a (Co / X)n or (CoX)n composition where n is from 2 to 30, X is one of V, Rh, Ir, Os, Ru, Au, Cr, Mo, Cu, Ti, Re, Mg, or Si, and CoX is a disordered alloy. A CoFeB layer may be formed between the laminated layer and a tunnel barrier layer to serve as a transitional layer between a (111) laminate and (100) MgO tunnel barrier. The laminated layer may be used as a reference layer, dipole layer, or free layer in a MTJ. Annealing between 300° C. and 400° C. may be used to further enhance PMA in the laminated layer.

Owner:TAIWAN SEMICON MFG CO LTD

Magnetic tunnel junction structure for MRAM device

ActiveUS20160087193A1Increase TMR valueOptimized free layer magnetic propertiesNanomagnetismSolid-state devicesTantalum nitridePolarizer

A magnetic tunnel junction stack is provided that includes nonmagnetic spacer layers between the free layer and the polarizer layer formed from magnesium oxide and tantalum nitride materials that balance the spin torques acting on the free layer. The design provided enables a deterministic final state for the storage layer and significantly improves the tunneling magnetoresistance value and switching characteristics of the magnetic tunnel junction for MRAM applications.

Owner:INTEGRATED SILICON SOLUTION CAYMAN INC

CoFe/Ni Multilayer film with perpendicular anisotropy for microwave assisted magnetic recording

ActiveUS20110279921A1Improve vibrationImprove robustnessNanomagnetismMagnetic measurementsPerpendicular anisotropySpin transfer

A spin transfer oscillator with a seed / SIL / spacer / FGL / capping configuration is disclosed with a composite seed layer made of Ta and a metal layer having a fcc(111) or hcp(001) texture to enhance perpendicular magnetic anisotropy (PMA) in an overlying (A1 / A2)X laminated spin injection layer (SIL). Field generation layer (FGL) is made of a high Bs material such FeCo. Alternatively, the STO has a seed / FGL / spacer / SIL / capping configuration. The SIL may include a FeCo layer that is exchanged coupled with the (A1 / A2)X laminate (x is 5 to 50) to improve robustness. The FGL may include an (A1 / A2)Y laminate (y=5 to 30) exchange coupled with the high Bs layer to enable easier oscillations. A1 may be one of Co, CoFe, or CoFeR where R is a metal, and A2 is one of Ni, NiCo, or NiFe. The STO may be formed between a main pole and trailing shield in a write head.

Owner:HEADWAY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com