Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186 results about "Crystalline oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric Oxide, Crystalline (Fe2O3) Description. A purified, naturally occurring mineral called specular hematite (Fe2O3). It a blocky, heavy iron-based crystal and the most stable form of ferric oxide in a fully crystalline state.

Method for manufacturing semiconductor device

ActiveUS20120064664A1Stable electrical characteristicsReduce the amount of variationSemiconductor/solid-state device detailsElectroluminescent light sourcesCrystalline oxidePower semiconductor device

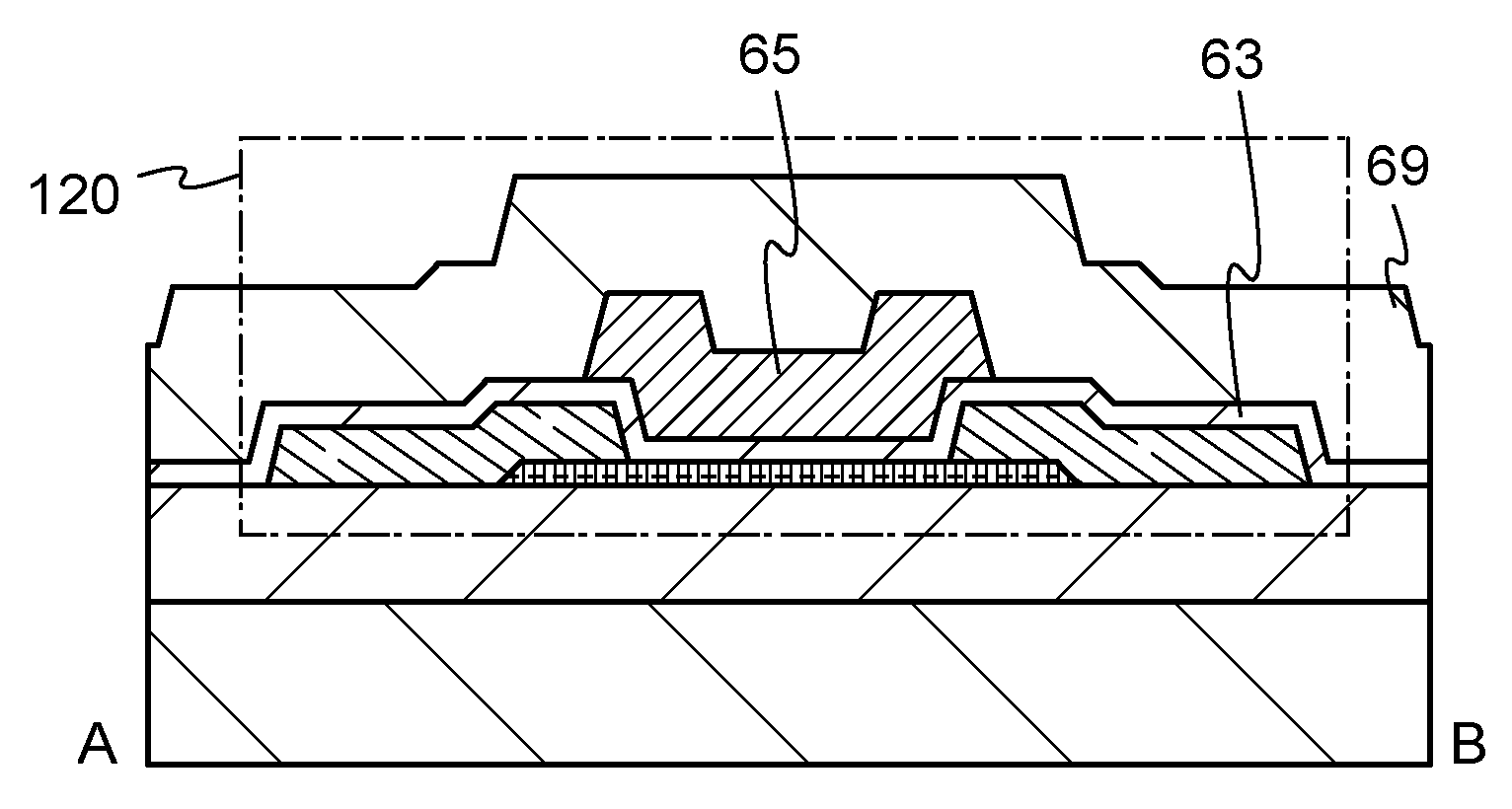

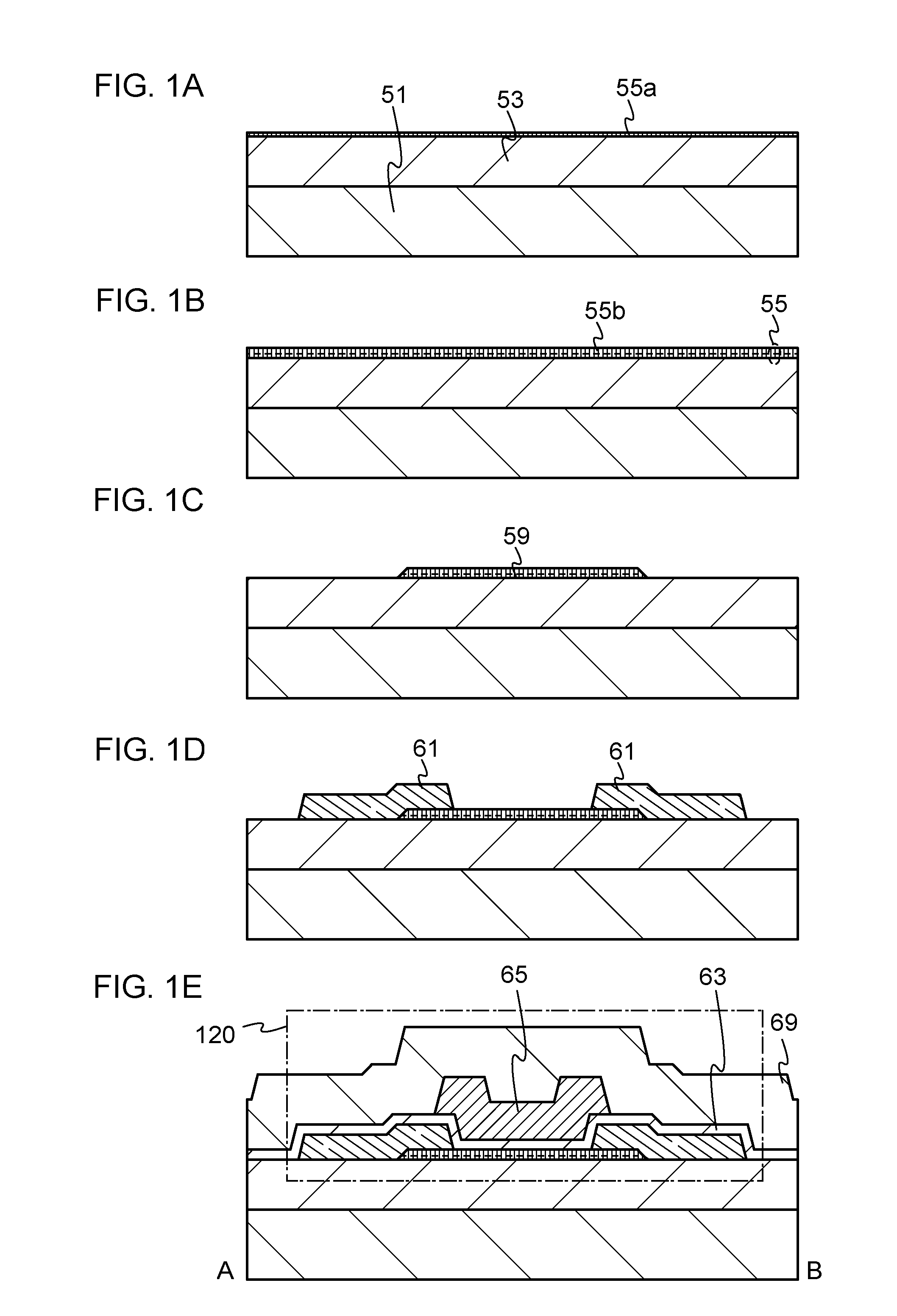

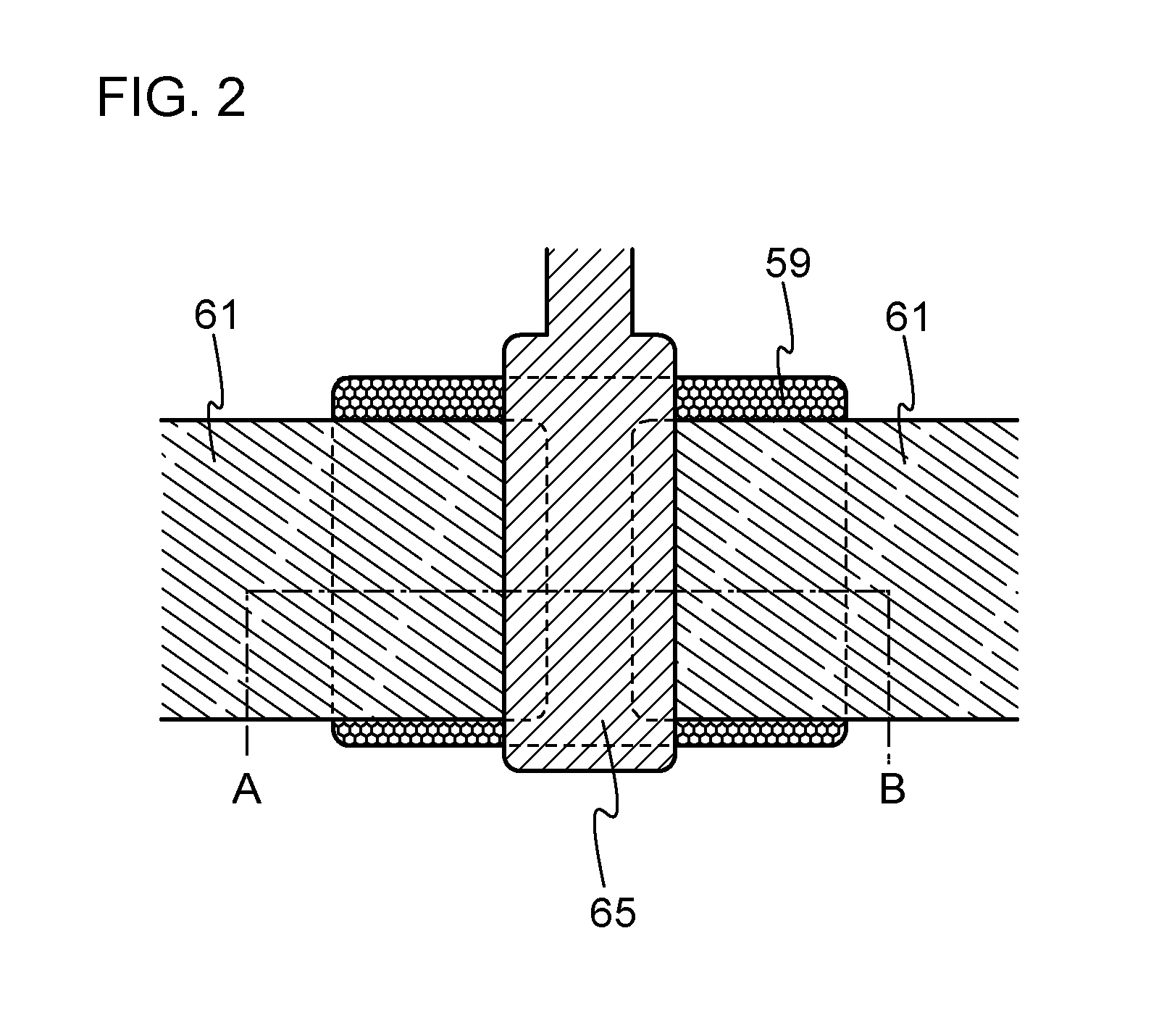

An object is to manufacture a semiconductor device including an oxide semiconductor film, which has stable electric characteristics and high reliability. A crystalline oxide semiconductor film is formed, without performing a plurality of steps, as follows: by utilizing a difference in atomic weight of plural kinds of atoms included in an oxide semiconductor target, zinc with low atomic weight is preferentially deposited on an oxide insulating film to form a seed crystal including zinc; and tin, indium, or the like with high atomic weight is deposited on the seed crystal while causing crystal growth. Further, a crystalline oxide semiconductor film is formed by causing crystal growth using a seed crystal with a hexagonal crystal structure including zinc as a nucleus, whereby a single crystal oxide semiconductor film or a substantially single crystal oxide semiconductor film is formed.

Owner:SEMICON ENERGY LAB CO LTD

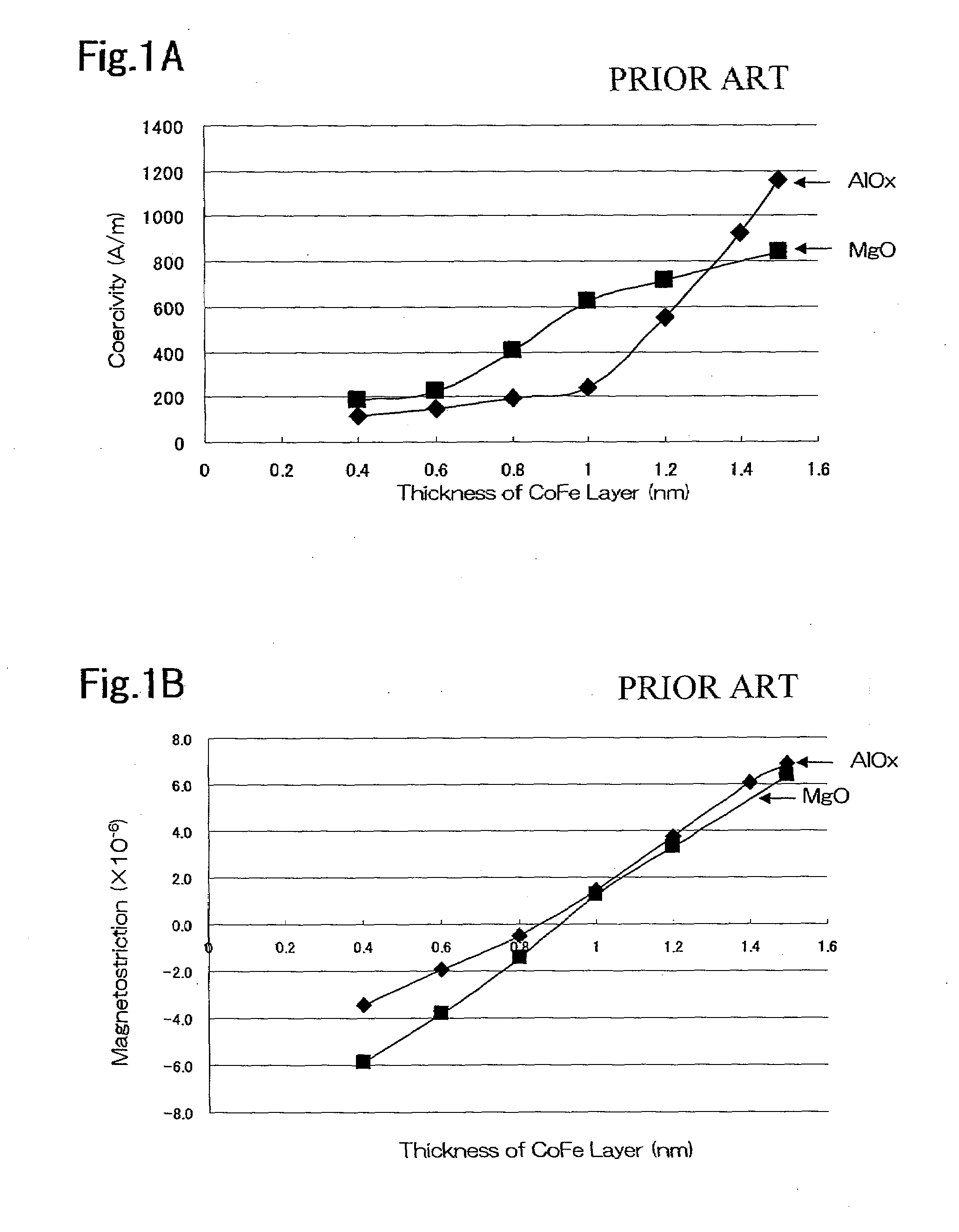

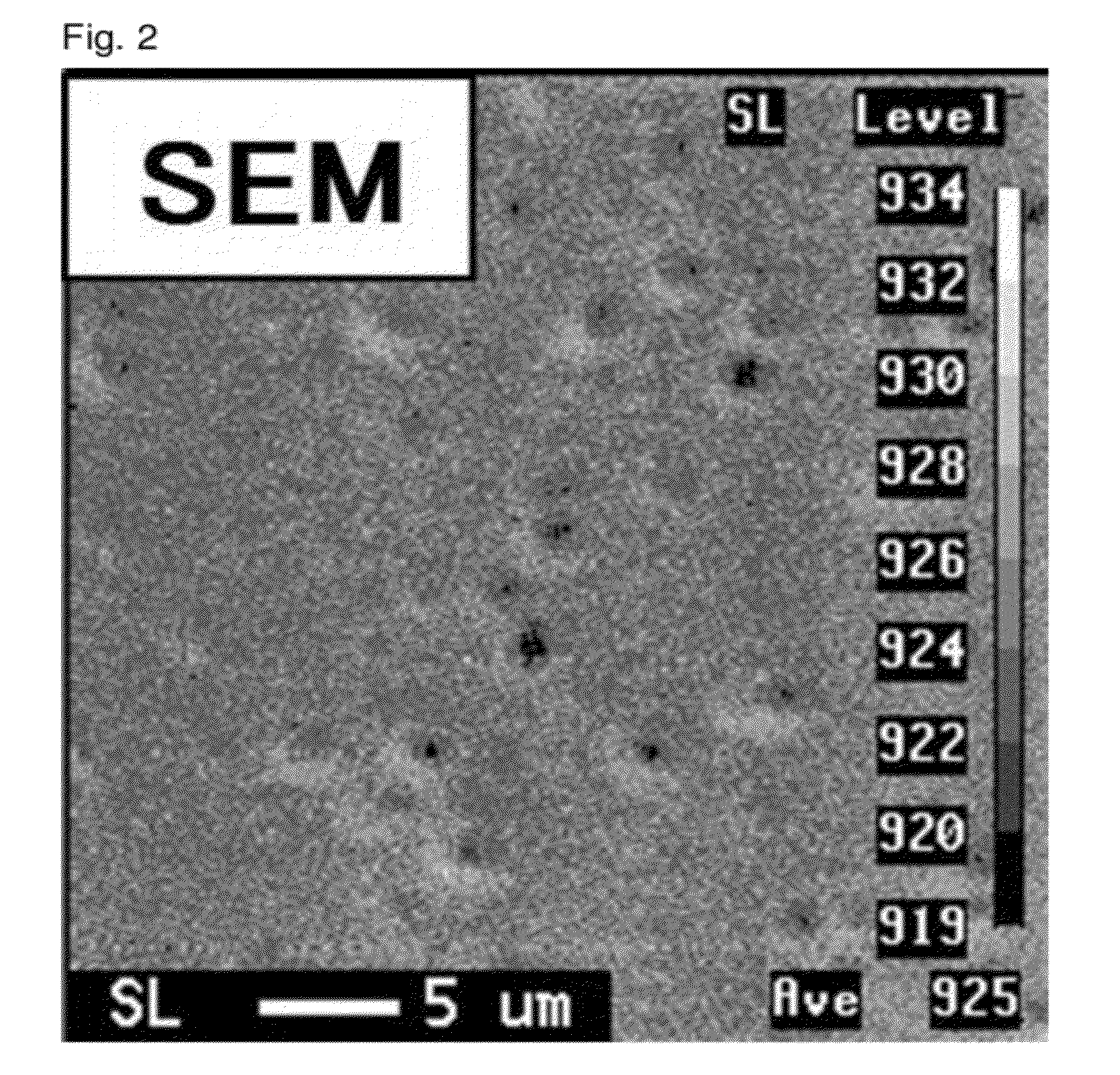

Ferromagnetic Tunnel Junction Structure and Magnetoresistive Effect Device and Spintronics Device Utilizing Same

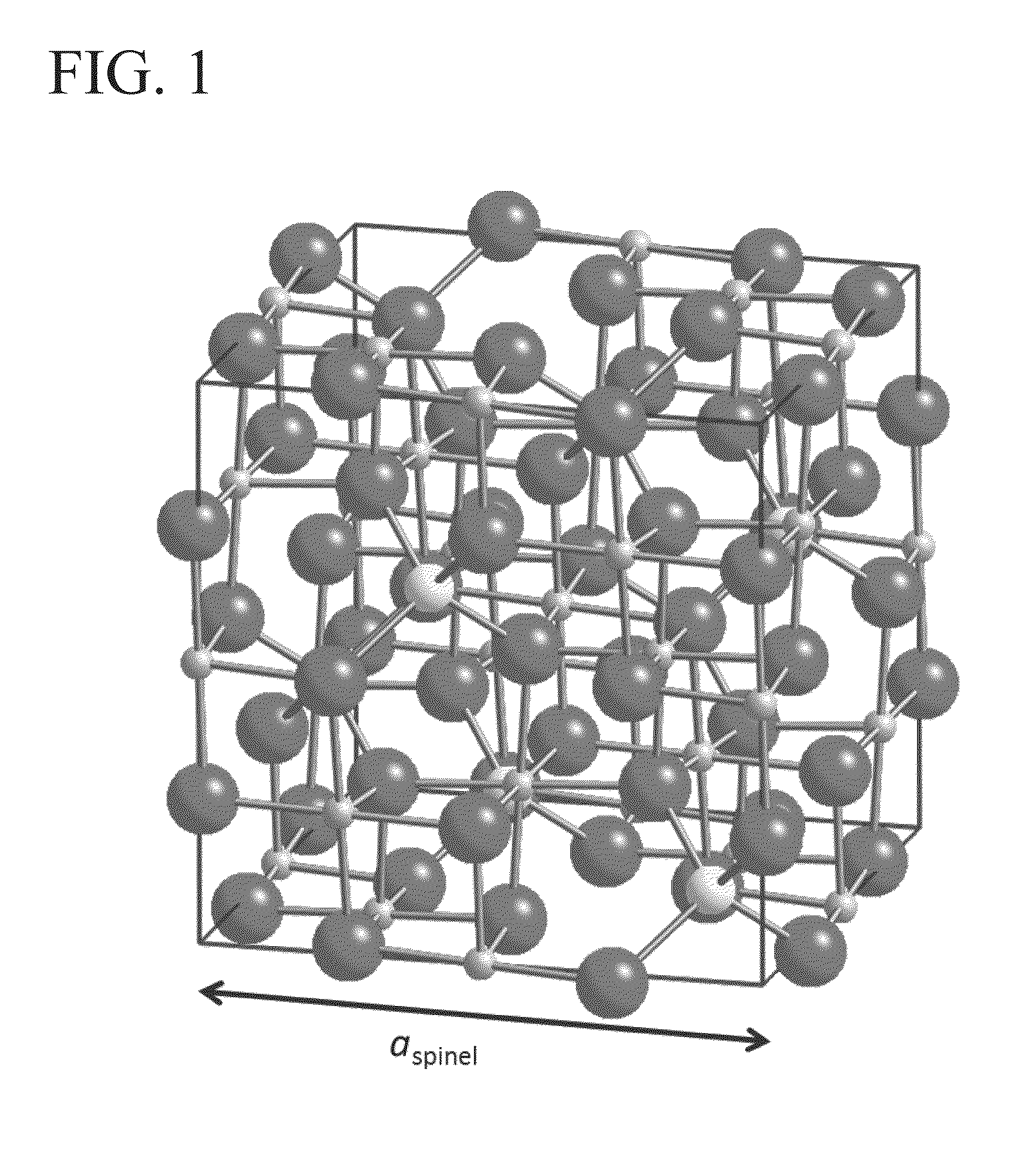

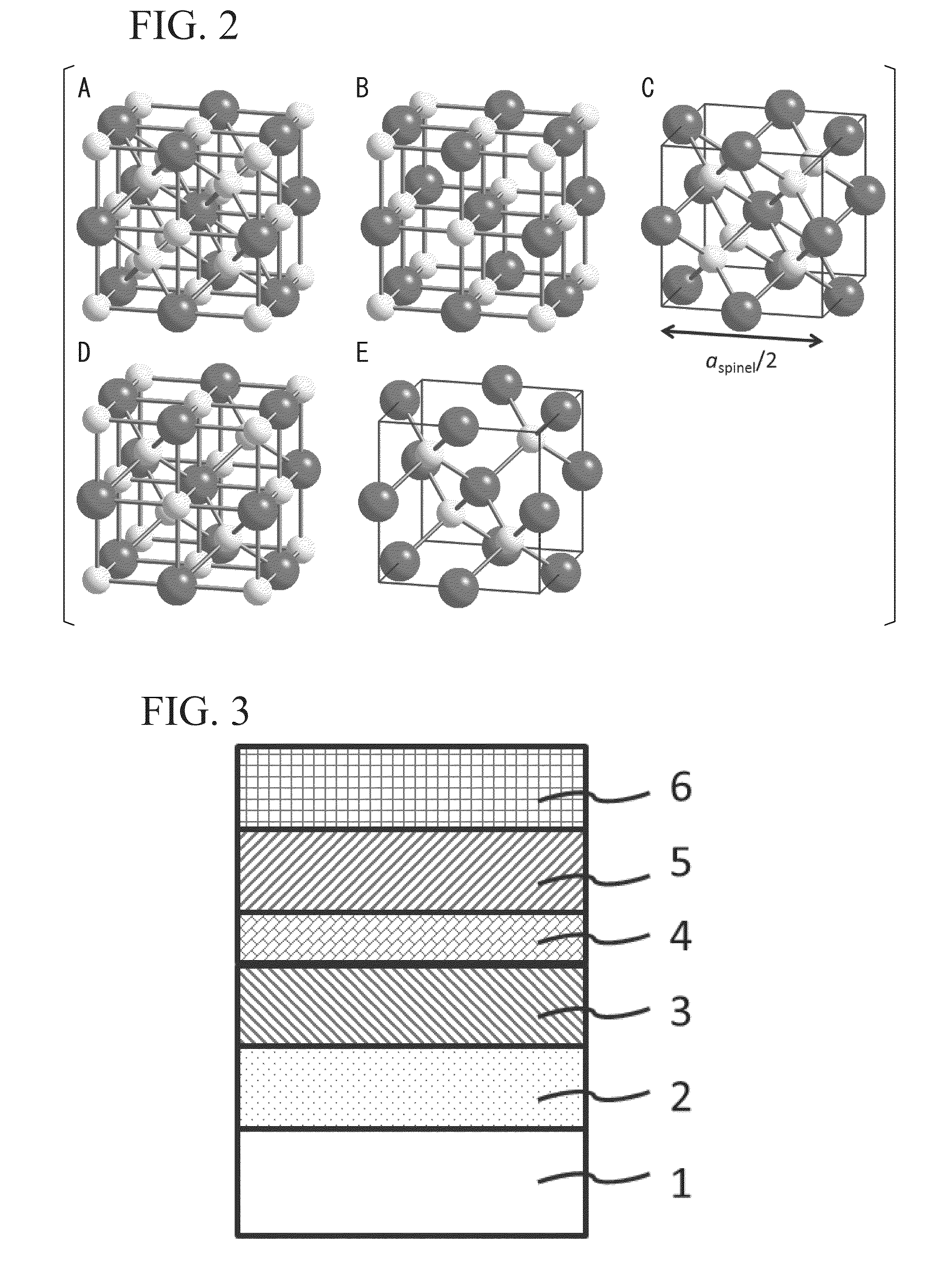

ActiveUS20130221461A1High TMR valueQuality improvementMagnetic-field-controlled resistorsSolid-state devicesCrystalline oxideSpace group

A ferromagnetic tunnel junction structure comprising a first ferromagnetic layer, a second ferromagnetic layer, and a tunnel barrier layer that is interposed between the first ferromagnetic layer and the second ferromagnetic layer, wherein the tunnel barrier layer includes a crystalline non-magnetic material having constituent elements that are similar to those of an crystalline oxide that has spinel structure as a stable phase structure; the non-magnetic material has a cubic structure having a symmetry of space group Fm-3m or F-43m in which atomic arrangement in the spinel structure is disordered; and an effective lattice constant of the cubic structure is substantially half of the lattice constant of the oxide of the spinel structure.

Owner:NAT INST FOR MATERIALS SCI

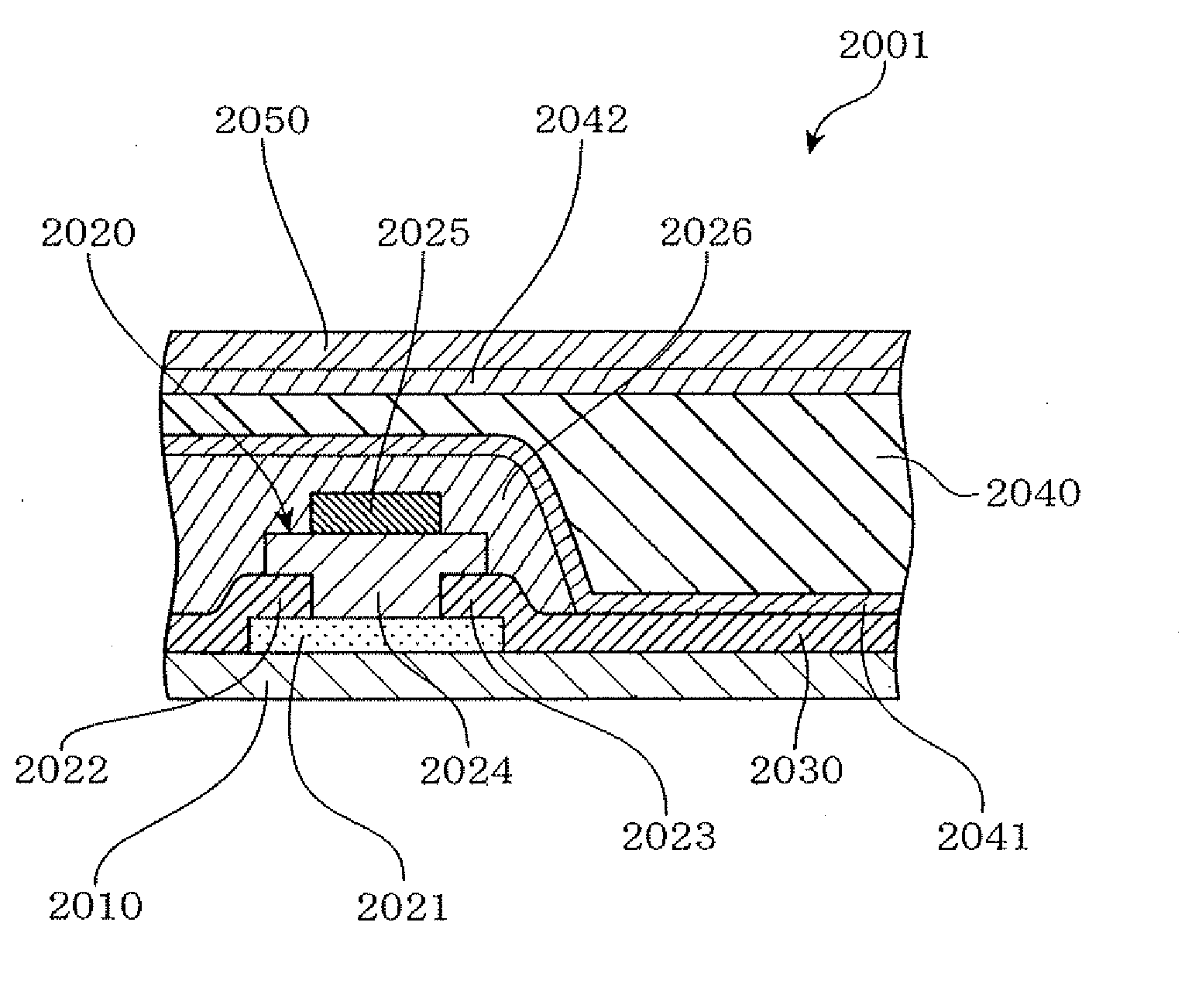

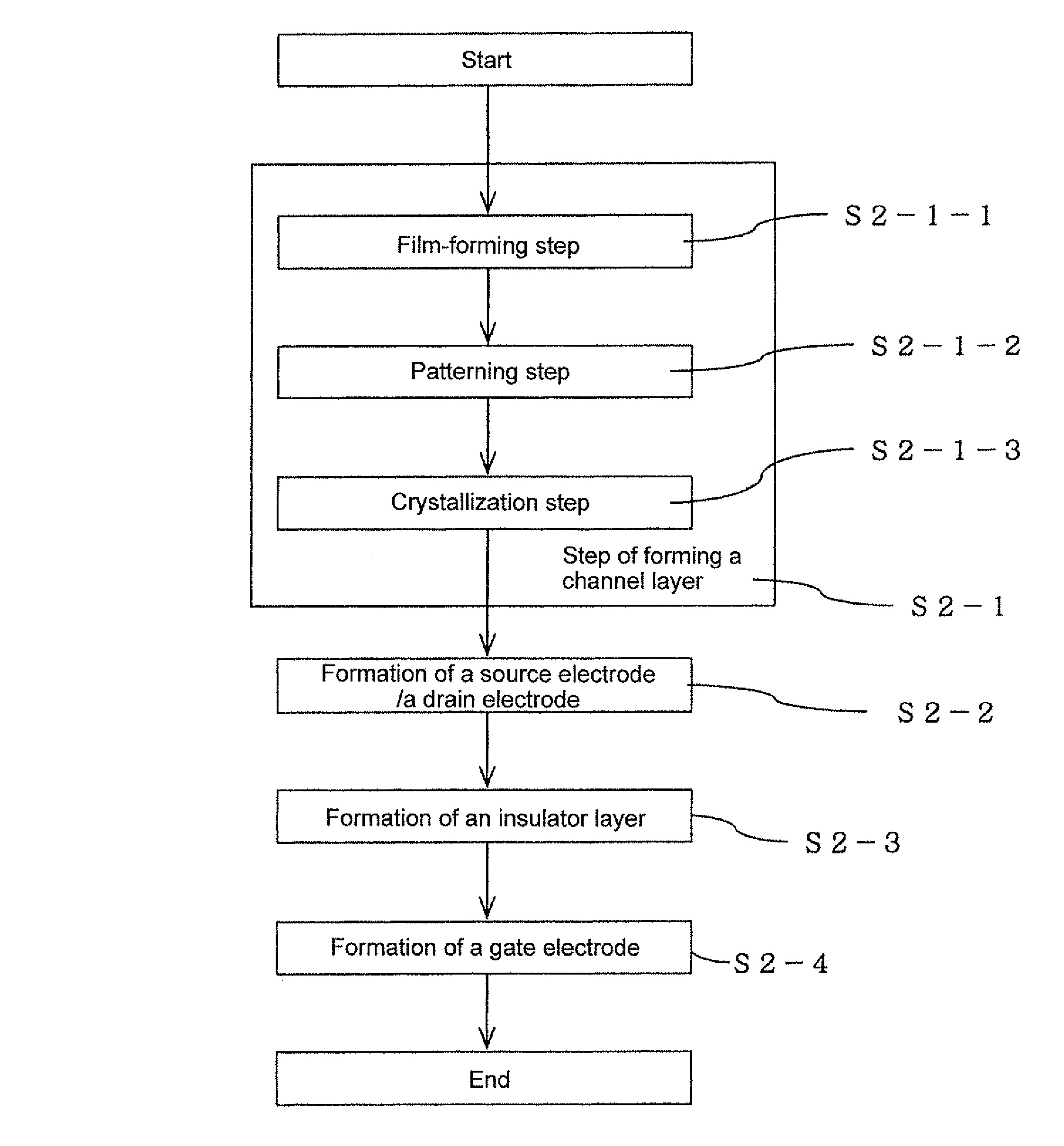

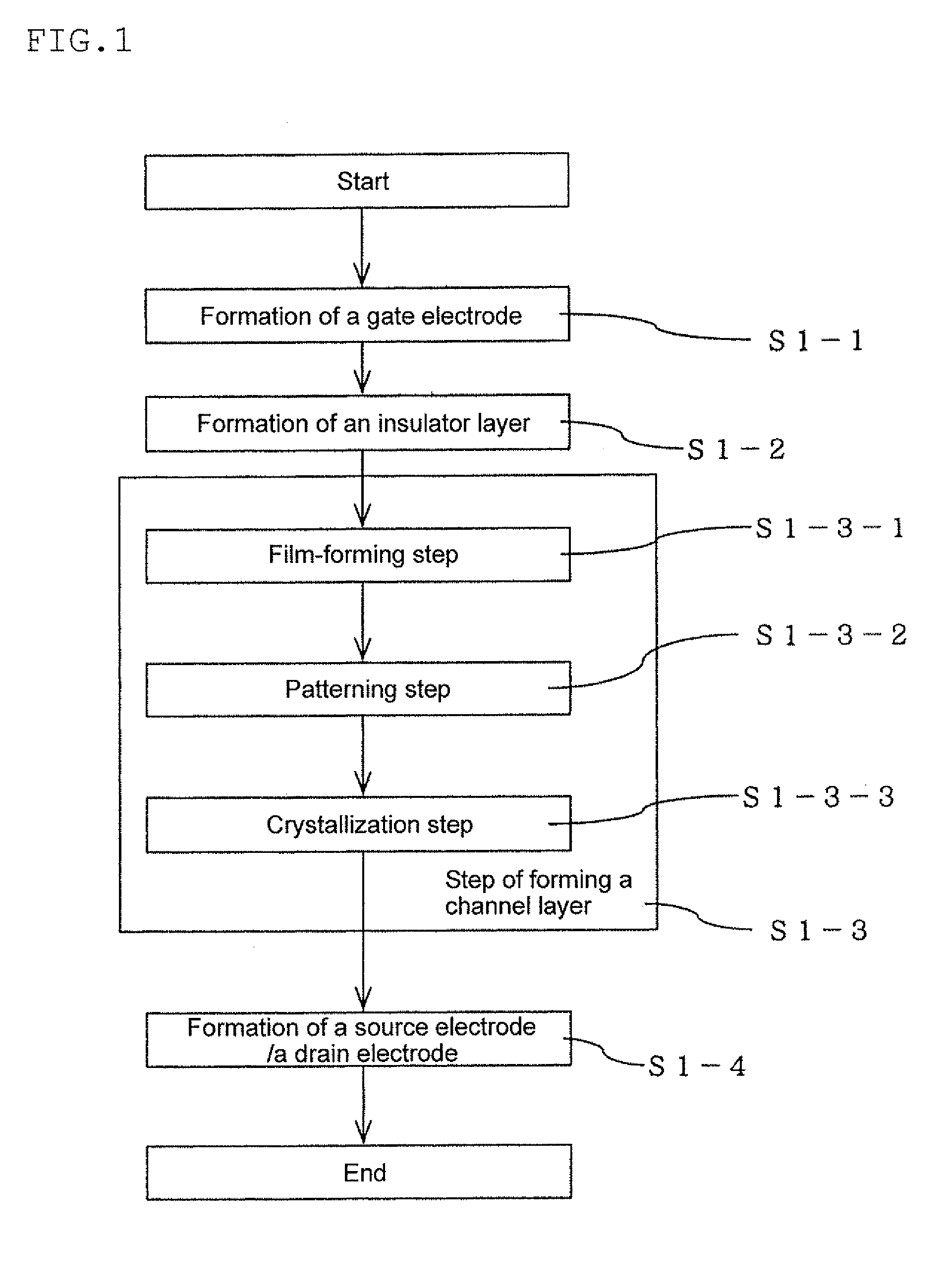

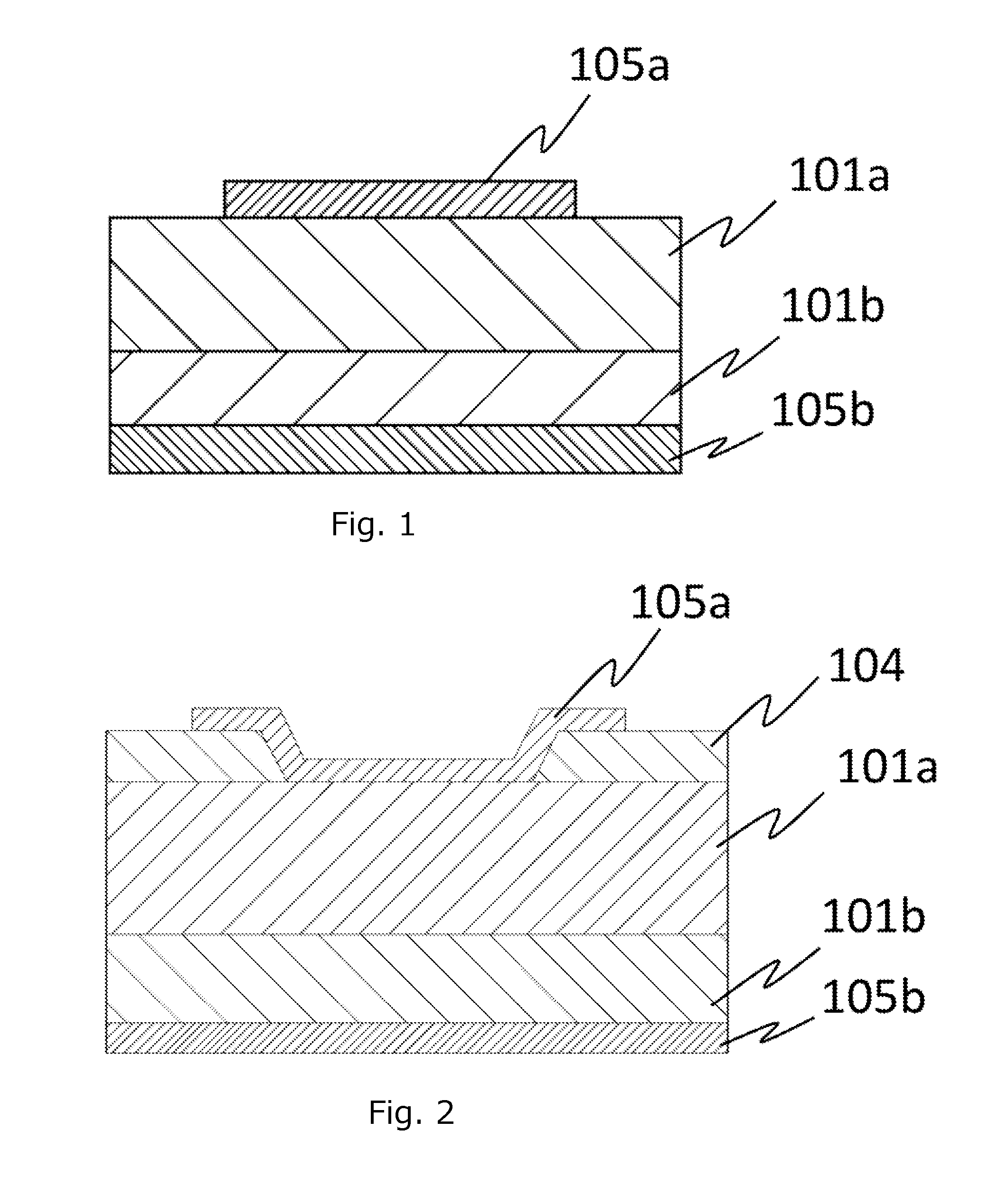

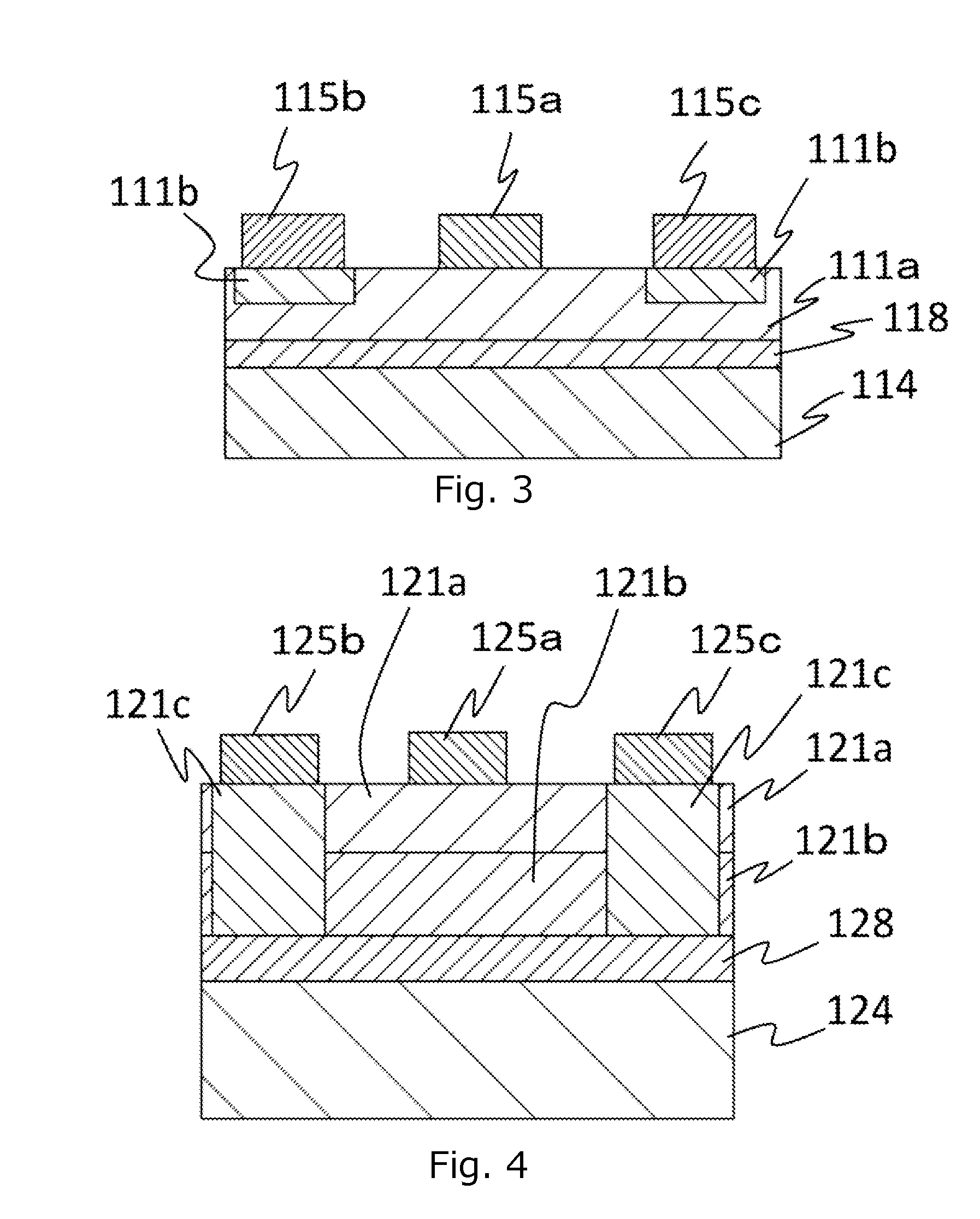

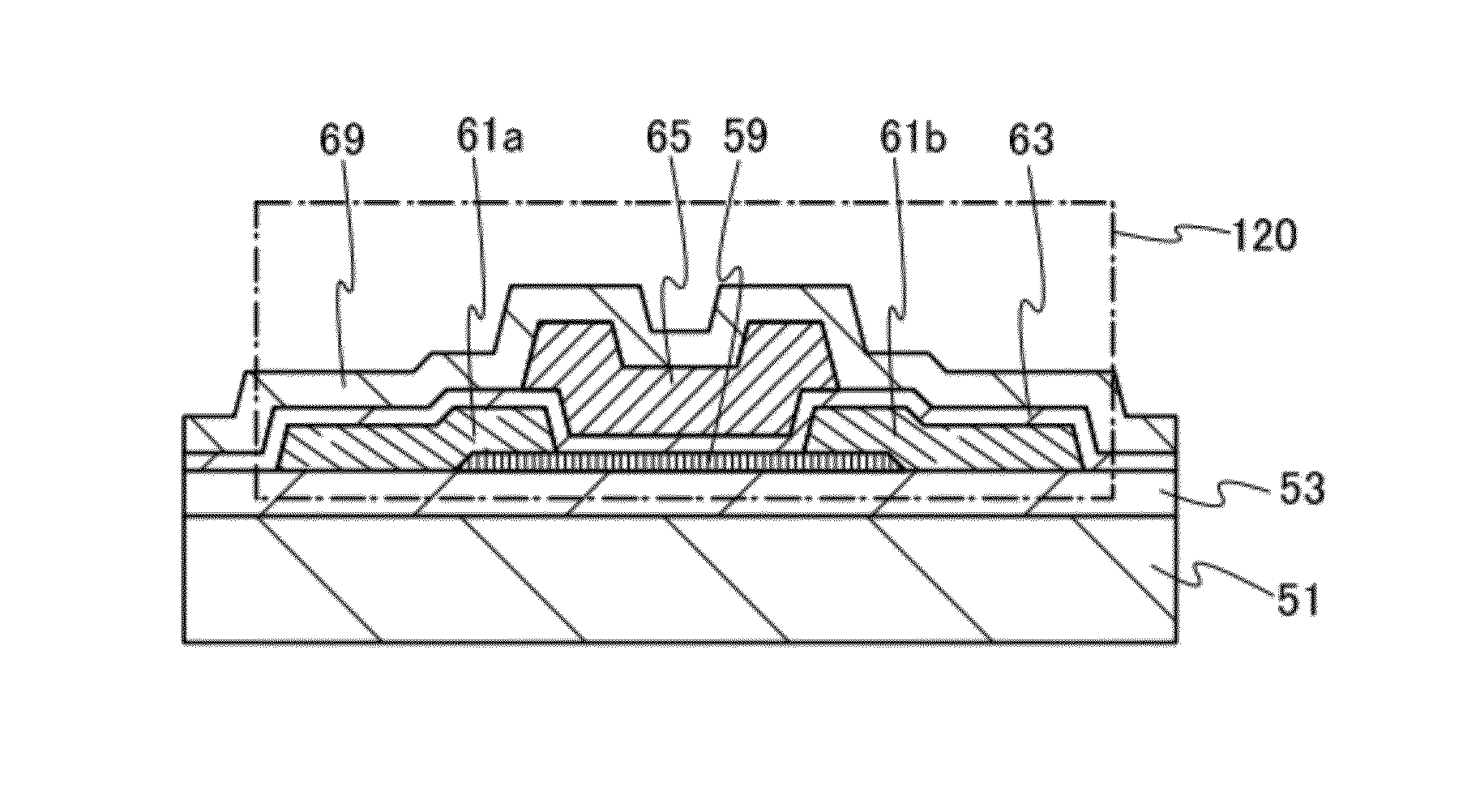

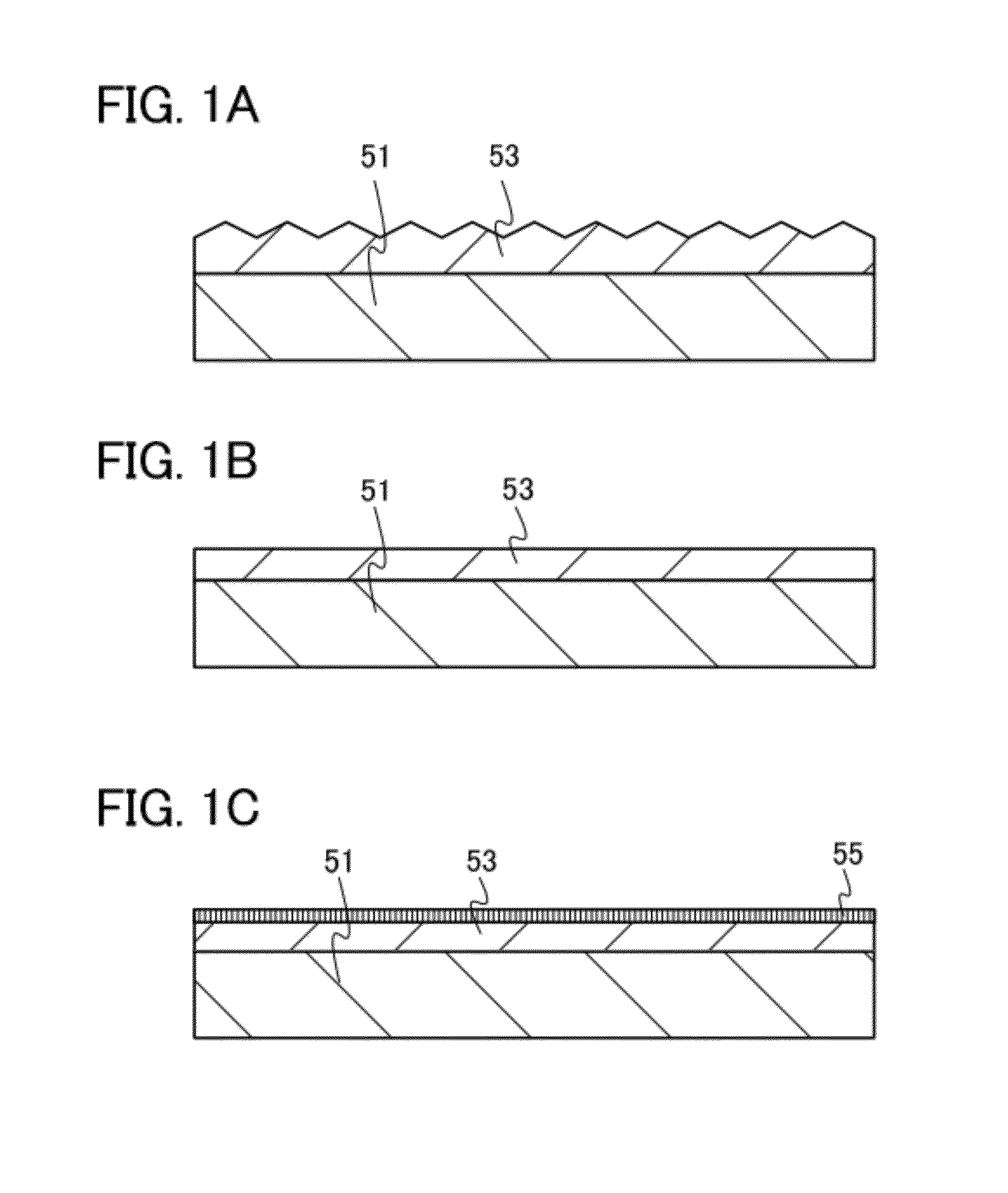

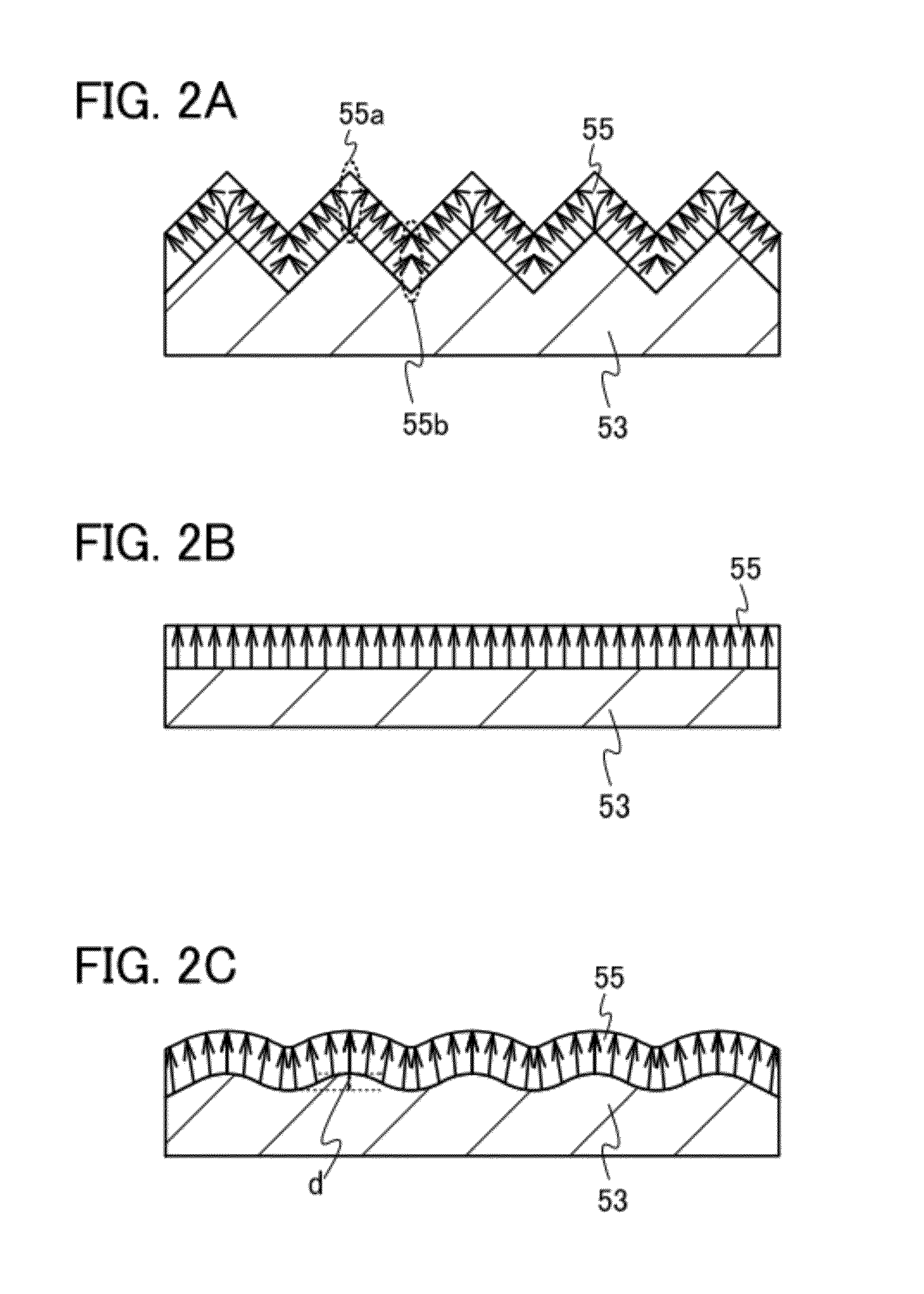

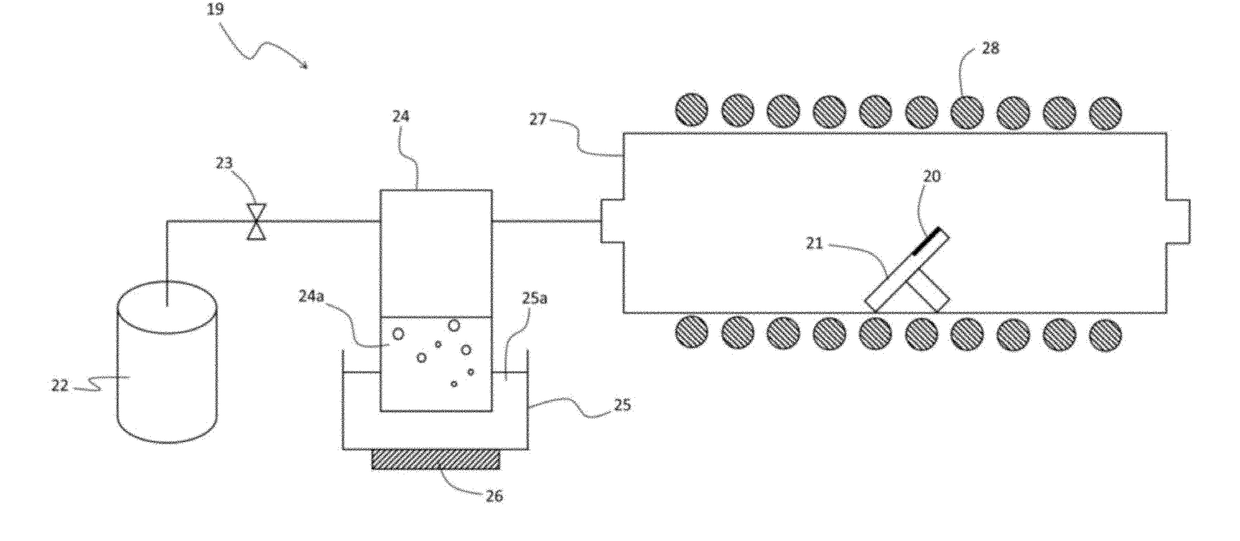

Thin film transistor manufacturing method, thin film transistor, thin film transistor substrate and image display apparatus, image display apparatus and semiconductor device

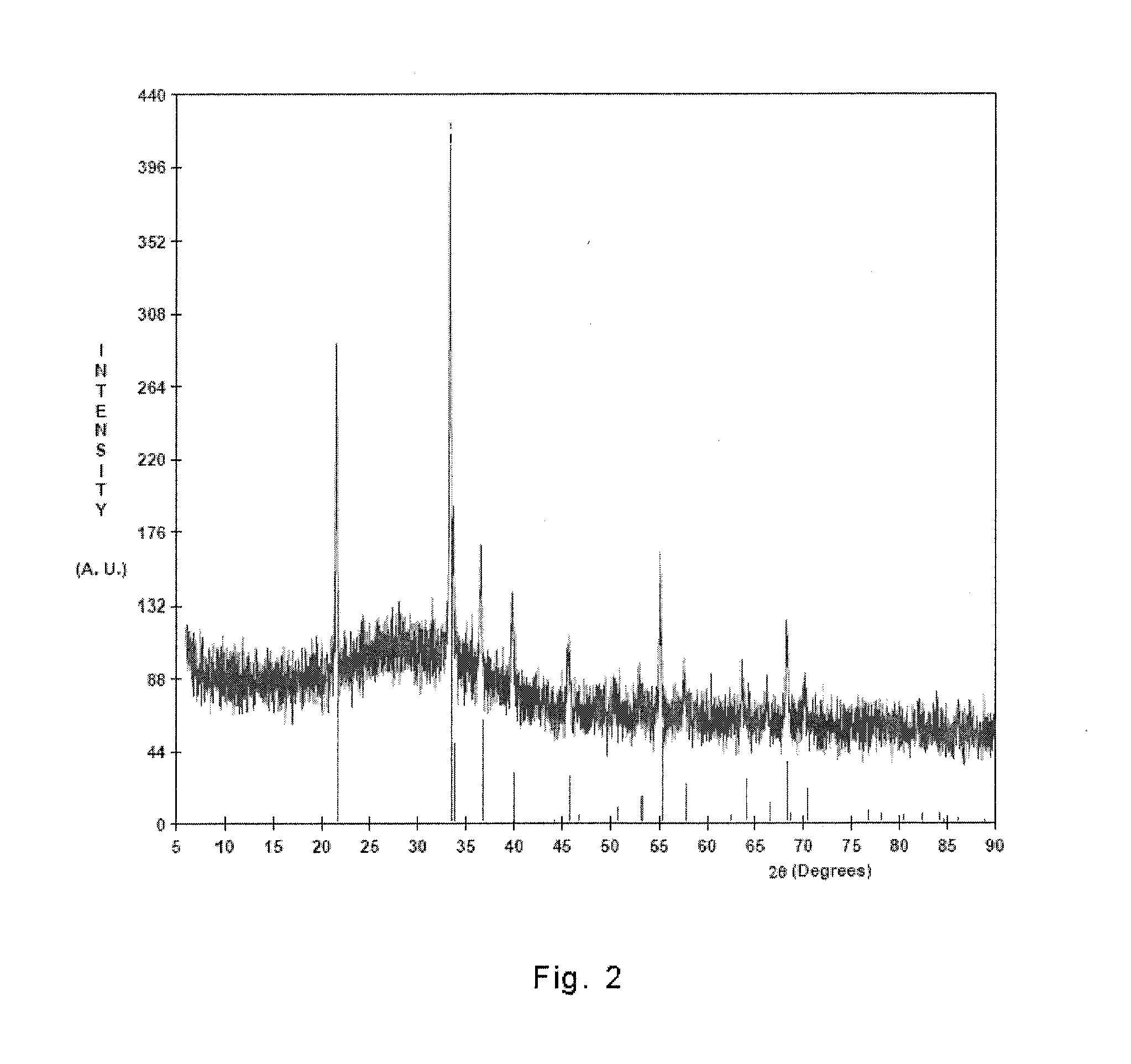

InactiveUS20110050733A1Time requiredEasy to implementVacuum evaporation coatingSputtering coatingCrystalline oxideHeat resistance

To provide a method for producing a thin film transistor improved in stability, uniformity, reproducibility, heat resistance, durability or the like, a thin film transistor, a thin film transistor substrate, an image display apparatus, an image display apparatus and a semiconductor device.In the semiconductor device, a crystalline oxide is used as an N-type transistor and the electron carrier concentration of the crystalline oxide is less than 2×1017 / cm3. Furthermore, the crystalline oxide is a polycrystalline oxide containing In and one or more positive divalent elements selected from Zn, Mg, Cu, Ni, Co and Ca, and the atomic ratio In [In] and the positive divalent element [X][X] / ([X]+[In]) is 0.0001 to 0.13.

Owner:IDEMITSU KOSAN CO LTD

Thin film transistor manufacturing method, thin film transistor, thin film transistor substrate and image display apparatus, image display apparatus and semiconductor device

InactiveUS8642402B2Easy to produceVacuum evaporation coatingSputtering coatingCrystalline oxideHeat resistance

To provide a method for producing a thin film transistor improved in stability, uniformity, reproducibility, heat resistance, durability or the like, a thin film transistor, a thin film transistor substrate, an image display apparatus, an image display apparatus and a semiconductor device.In the semiconductor device, a crystalline oxide is used as an N-type transistor and the electron carrier concentration of the crystalline oxide is less than 2×1017 / cm3. Furthermore, the crystalline oxide is a polycrystalline oxide containing In and one or more positive divalent elements selected from Zn, Mg, Cu, Ni, Co and Ca, and the atomic ratio In [In] and the positive divalent element [X][X] / ([X]+[In]) is 0.0001 to 0.13.

Owner:IDEMITSU KOSAN CO LTD

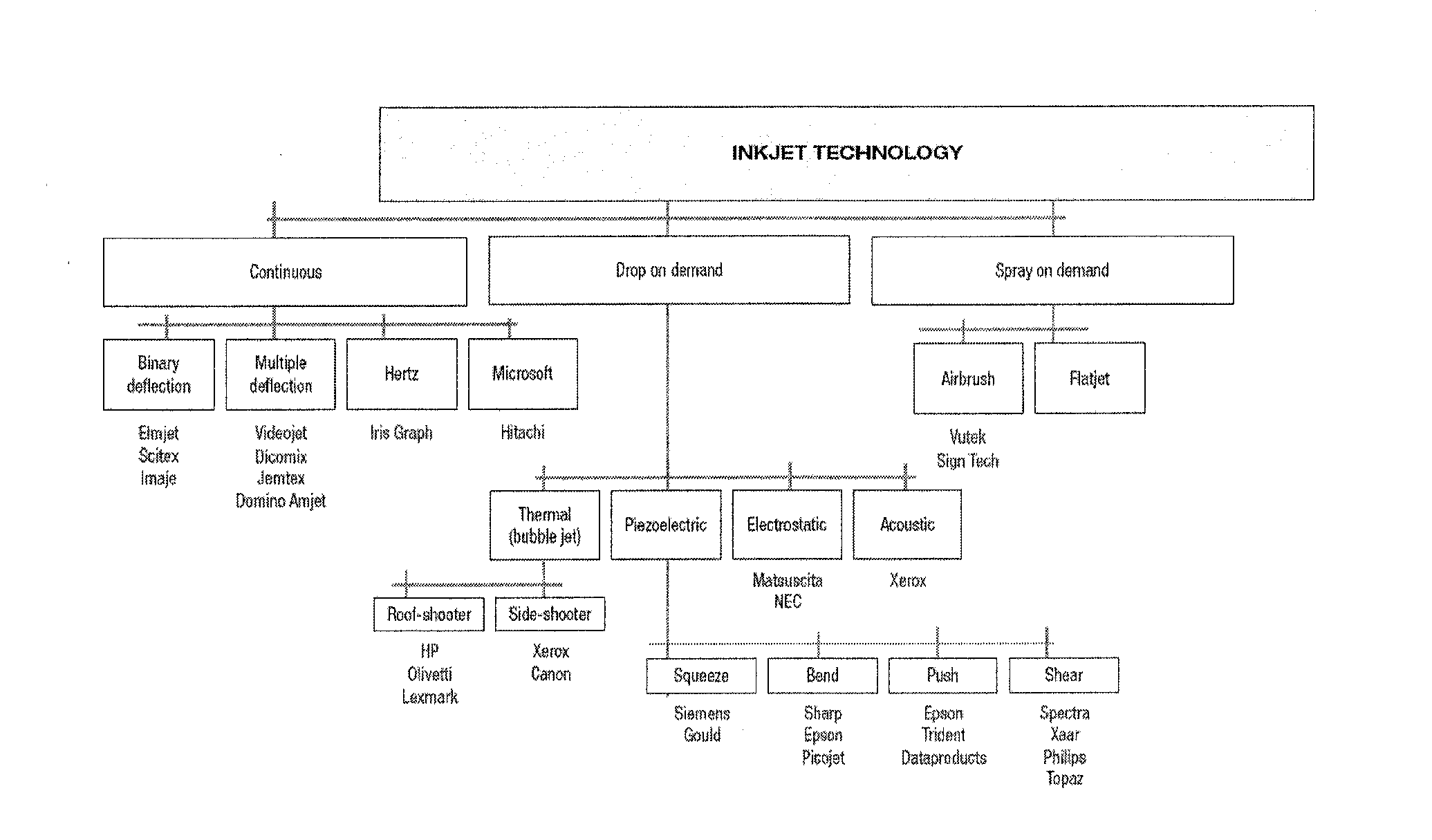

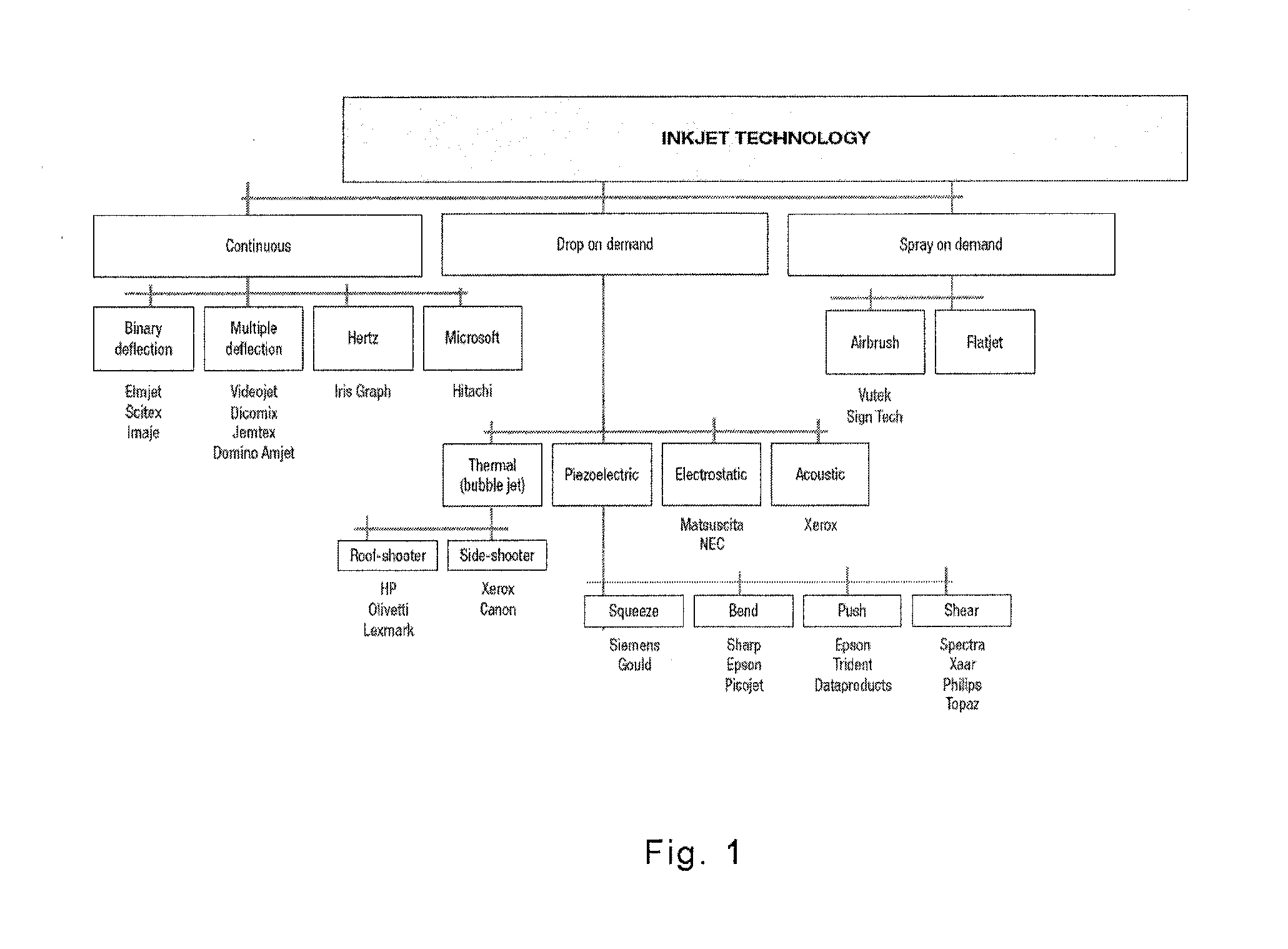

Inkjet Compositions For Forming Functional Glaze Coatings

Inkjet compositions that can be applied to glass and / or ceramic substrates to impart various effect to the substrate after firing, including: gloss, matt, contrast gloss (luster), specular reflection (metallic appearance), relief and slipperiness. The inkjet compositions include solvents, additives for dispersion, and inorganic substances, but preferably do not include any color-producing ceramic pigments. The inorganic substances contained in the inkjet compositions are the responsible for the above mentioned effects on the surface of the ceramic article. Depending on the type of effect desired, the inorganic substance may be a specific frit, a crystalline oxide, or a combination of frits and crystalline oxides.

Owner:FERRO CORP

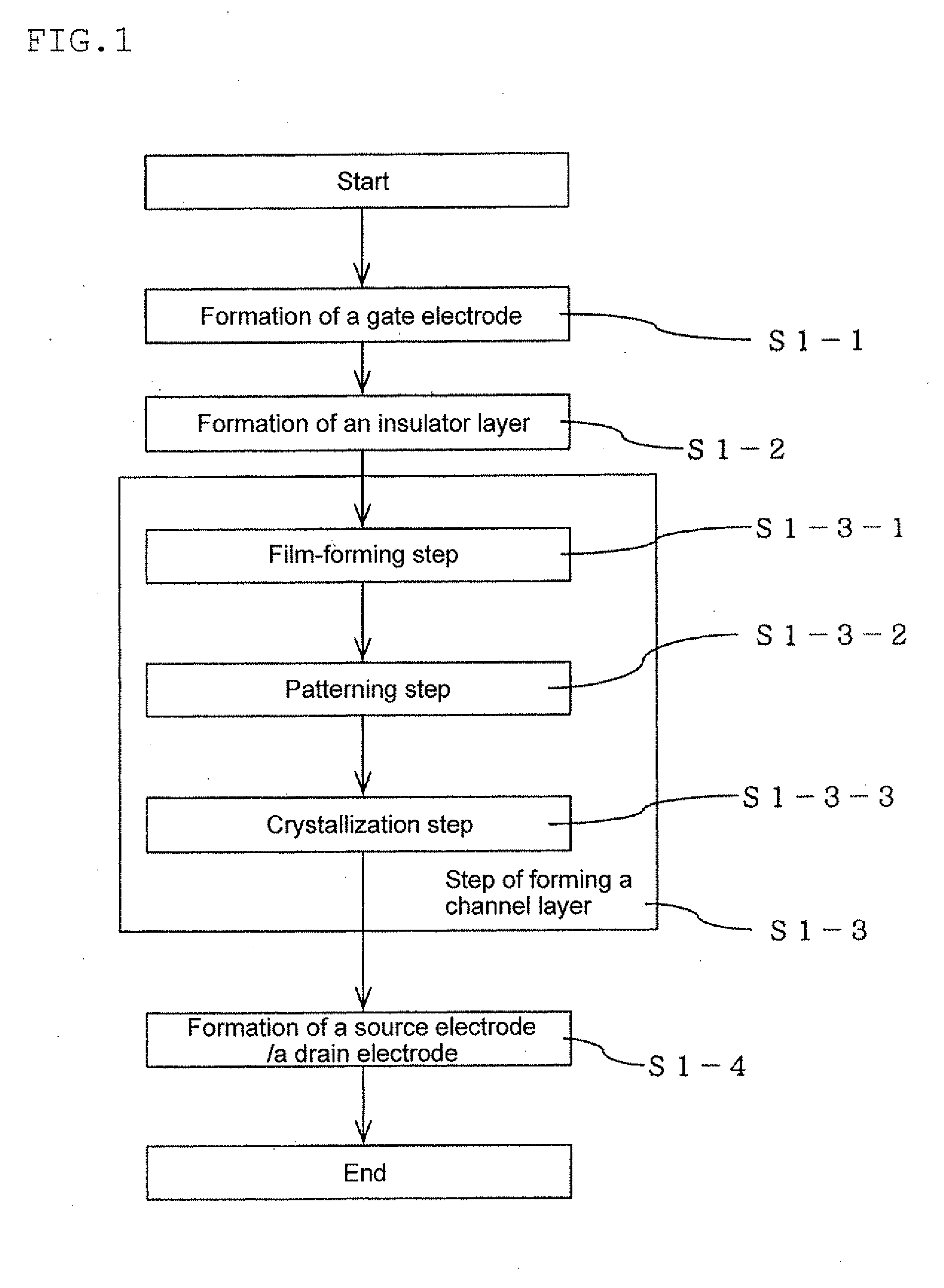

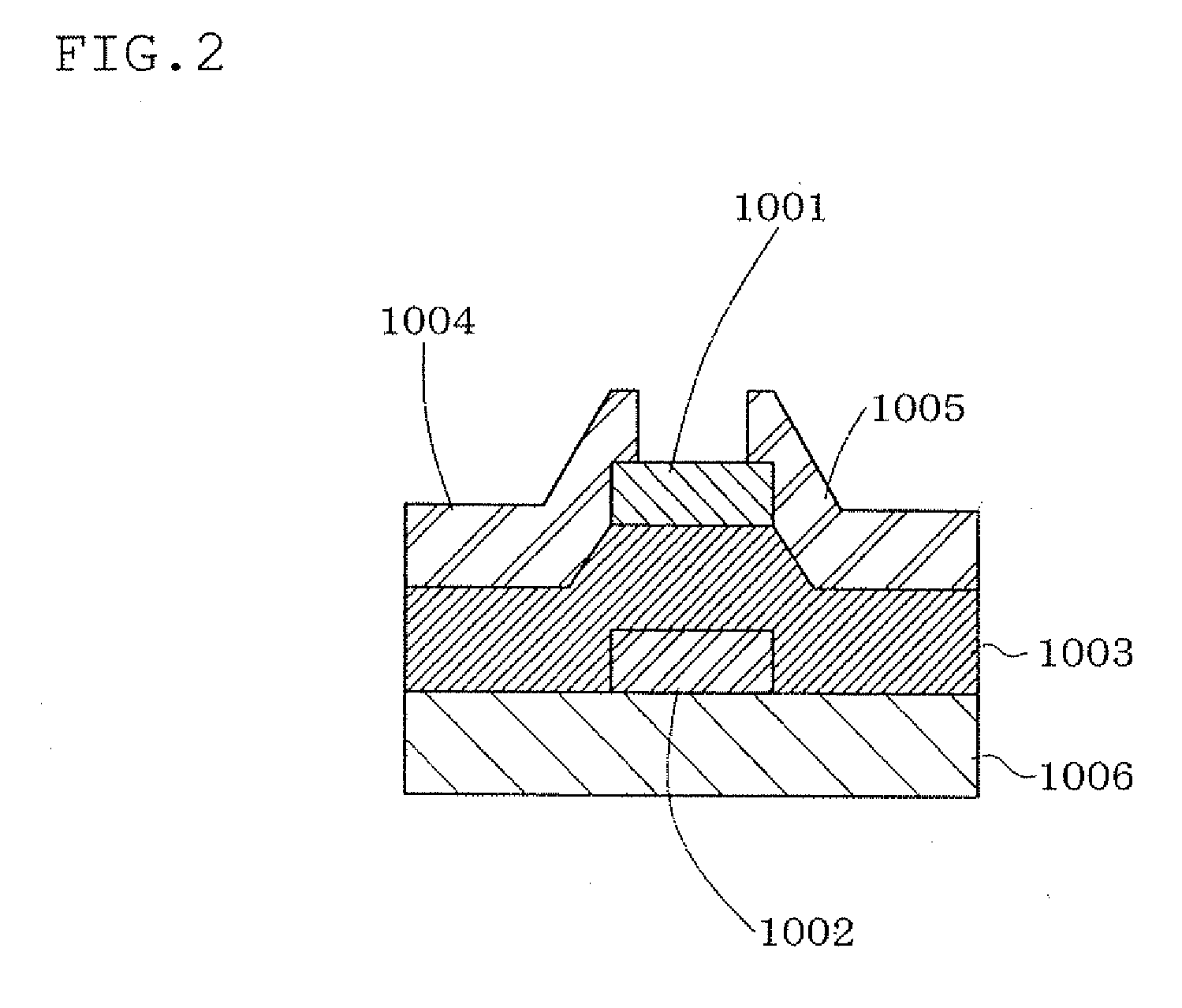

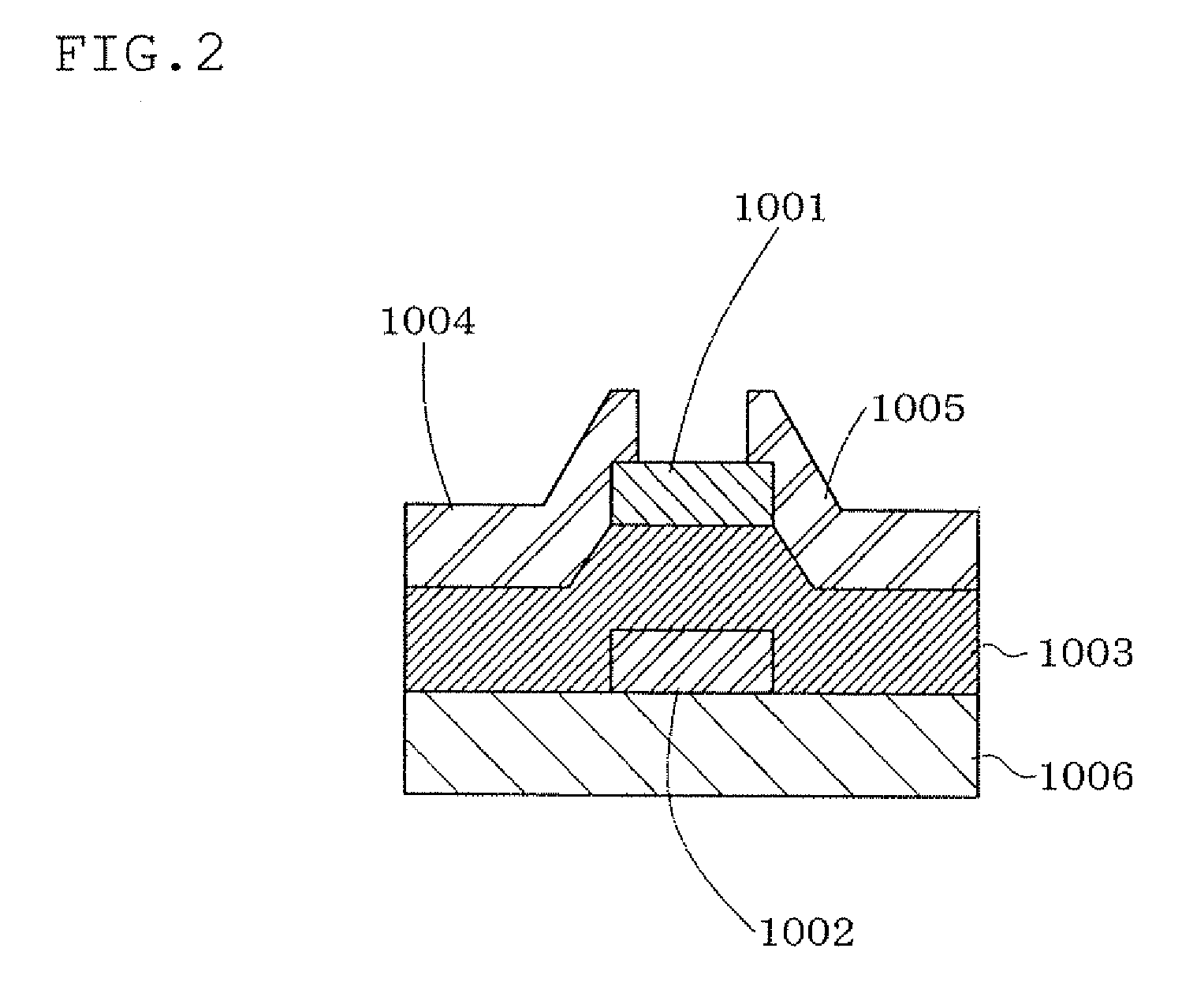

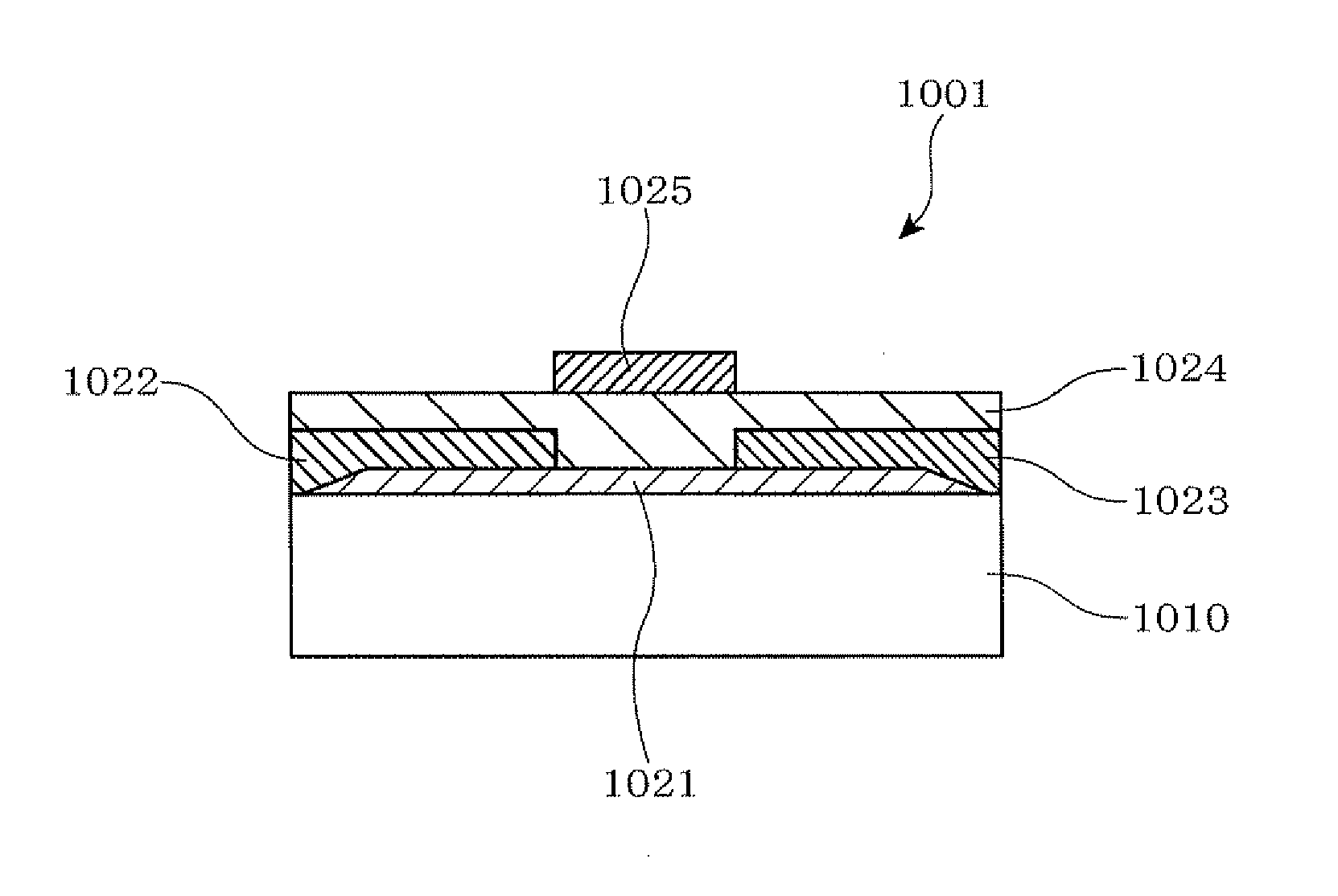

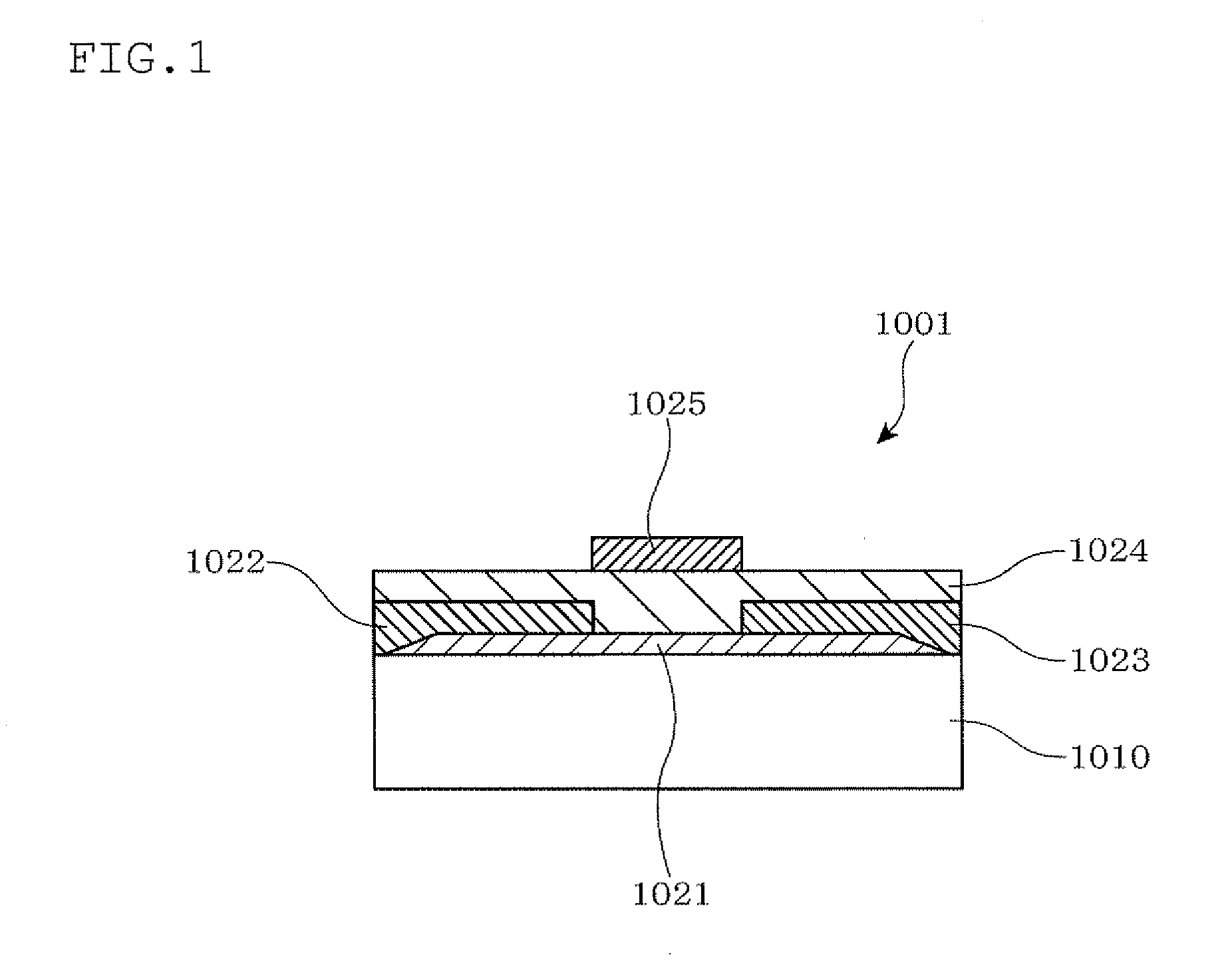

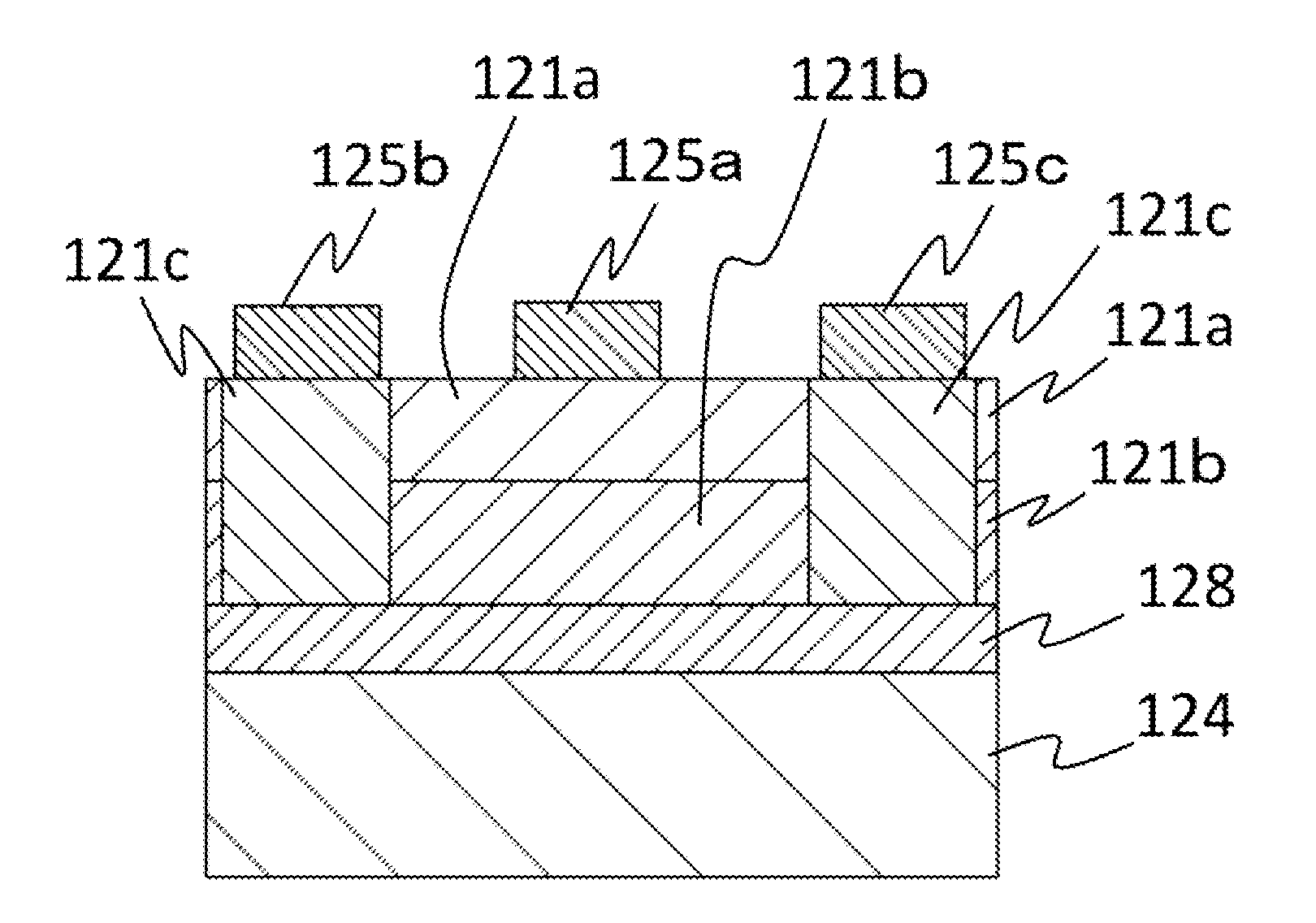

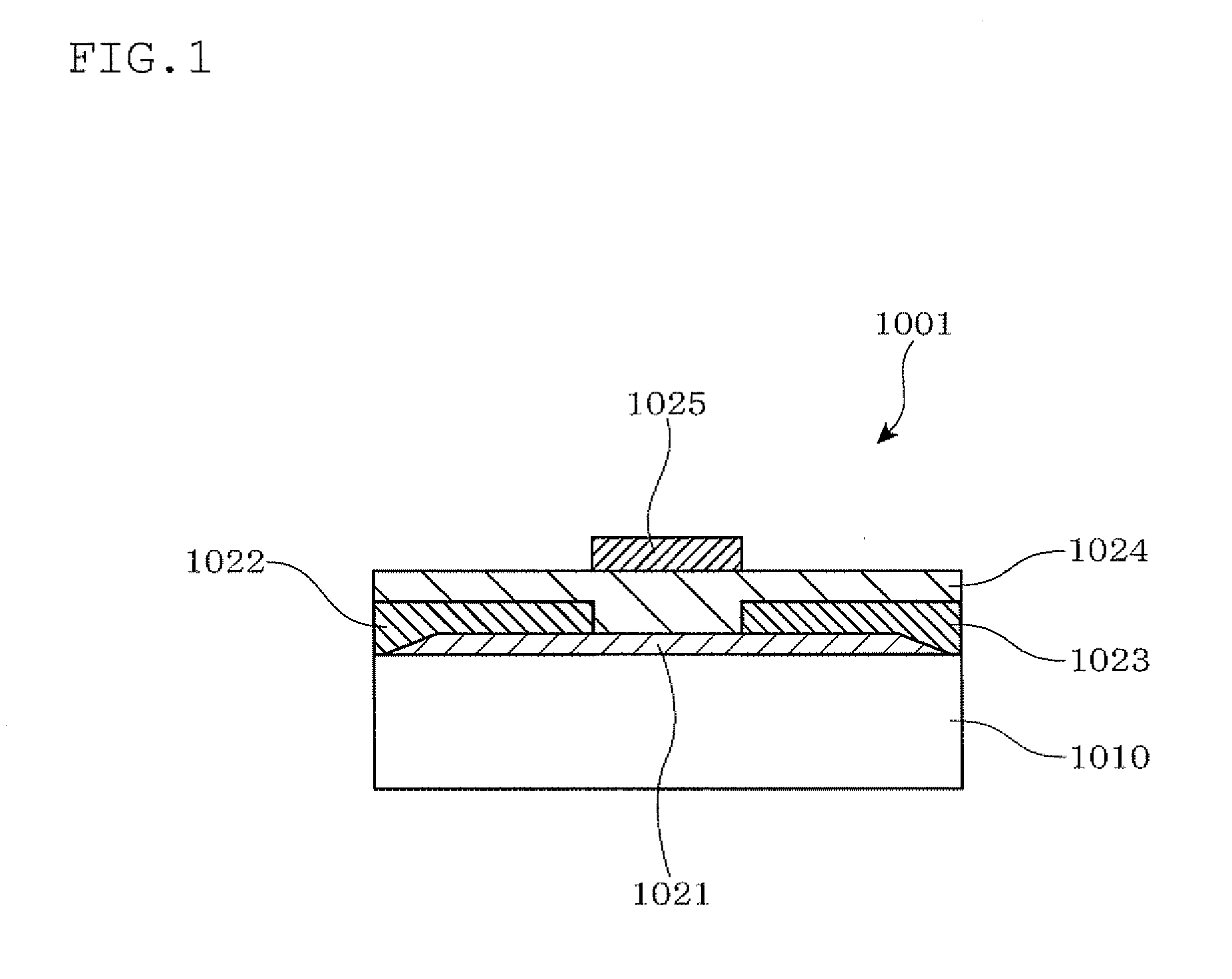

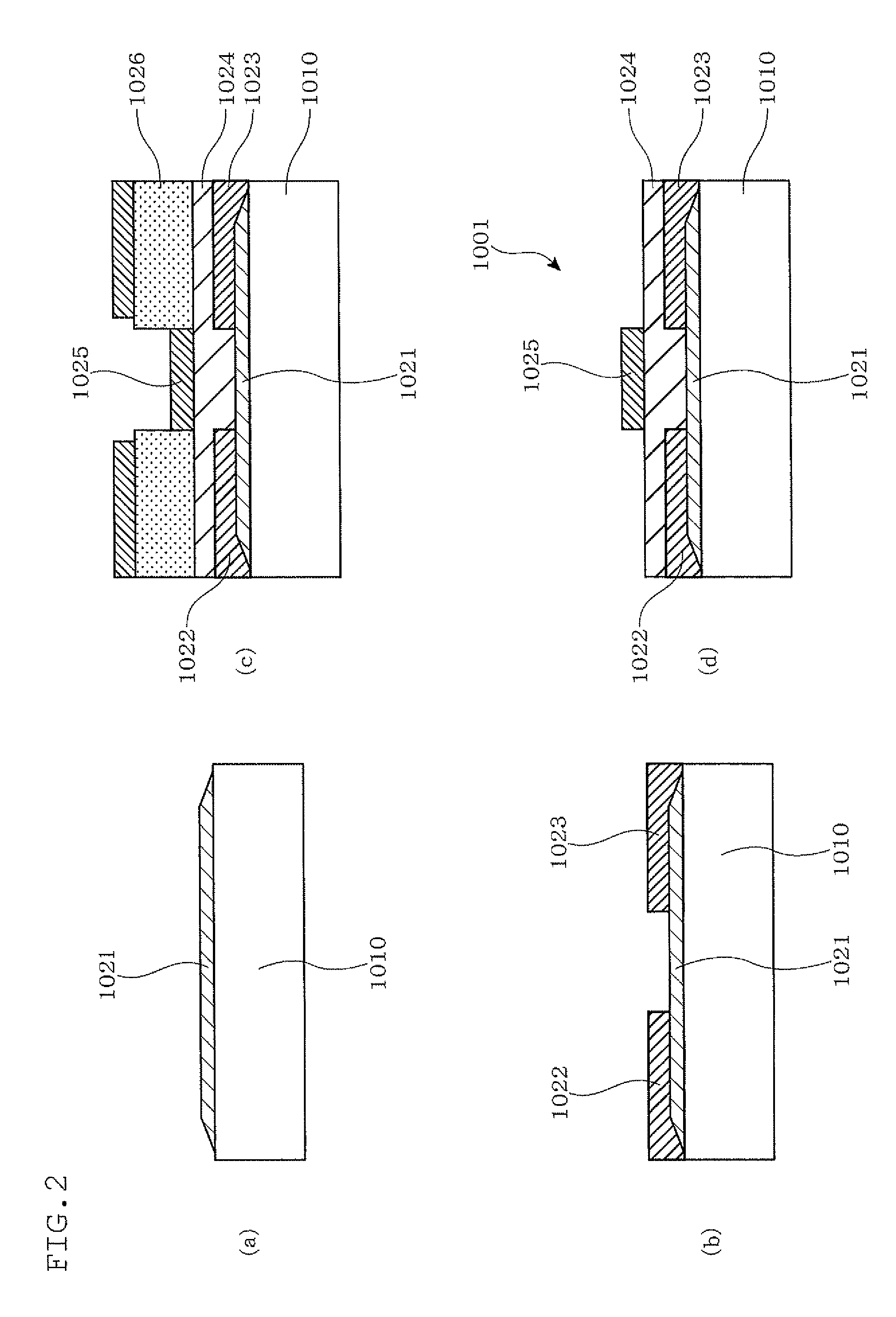

Field-effect transistor, and process for producing field-effect transistor

ActiveUS20100117071A1Increase freedomEfficient productionTransistorSemiconductor/solid-state device manufacturingCrystalline oxideIndium

To provide a field-effect transistor improved in transparency, electrical properties, stability, uniformity, reproducibility, heat resistance and durability, and as a reduced overlap capacity between electrodes.A field-effect thin film transistor 1001 includes a gate electrode 1025, an active layer, a source electrode 1022 and a drain electrode 1023, wherein a crystalline oxide 1021 containing indium and having an electron carrier concentration of less than 1018 / cm3 is used as the active layer, and the gate electrode 1025 is in self-alignment with the source electrode 1022 and the drain electrode 1023. The crystalline oxide 1021 contains a positive trivalent element different from a positive divalent element or indium.

Owner:IDEMITSU KOSAN CO LTD

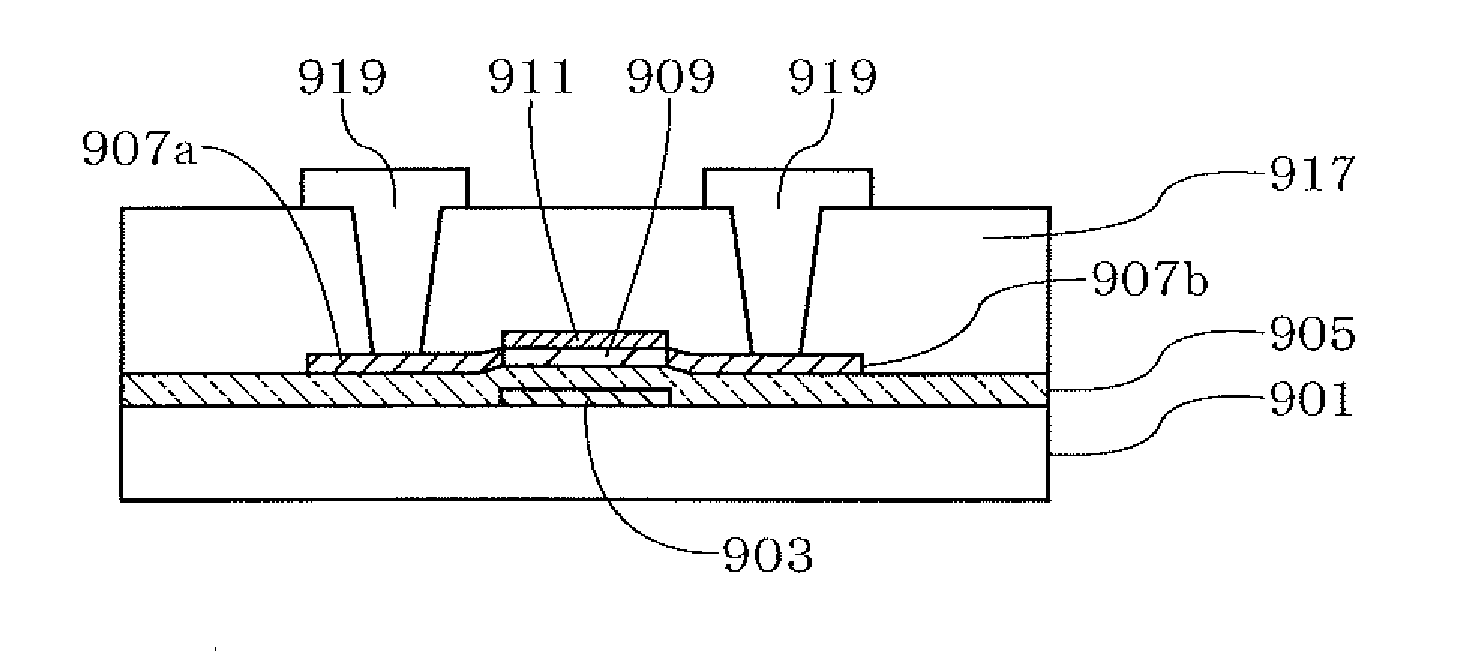

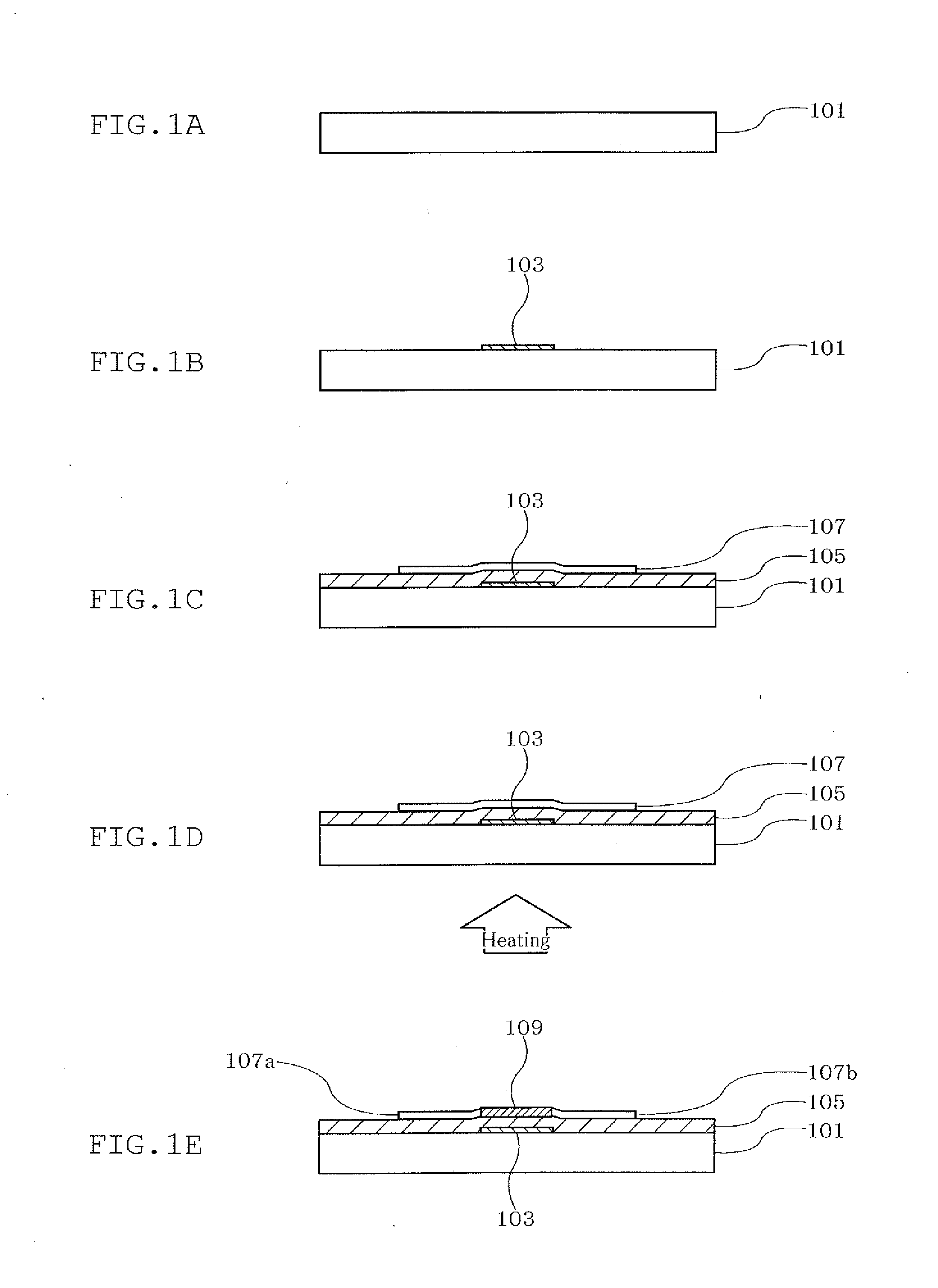

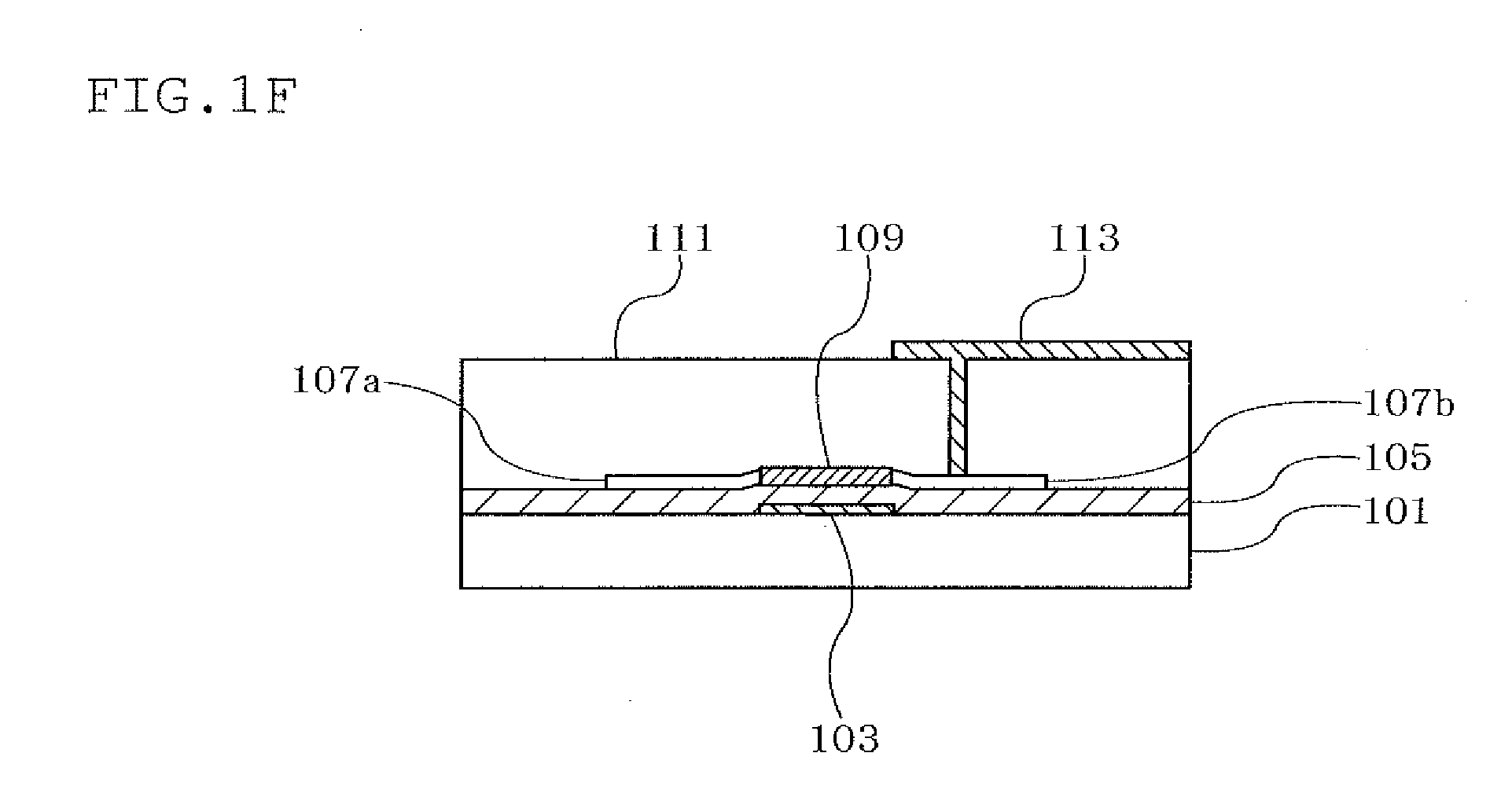

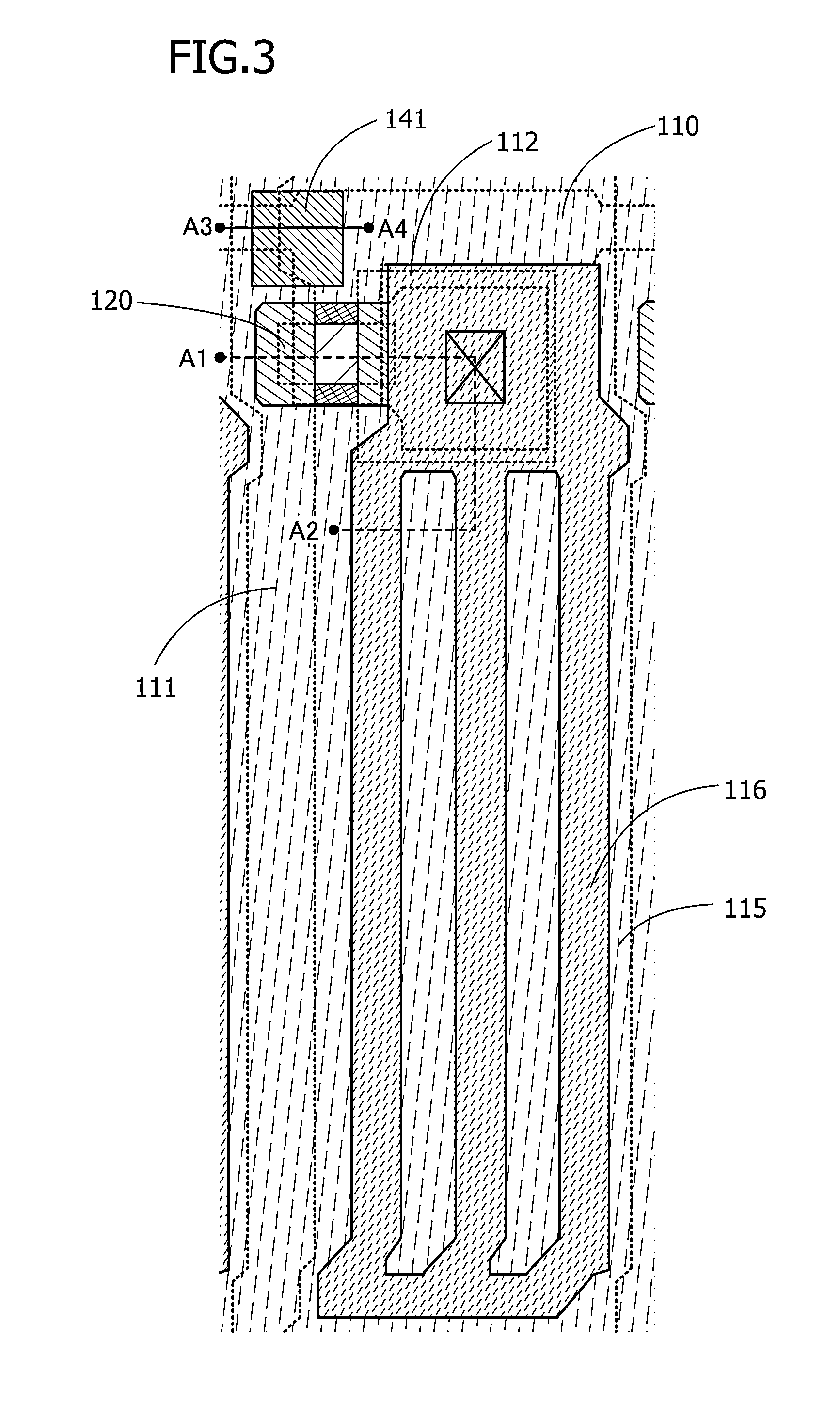

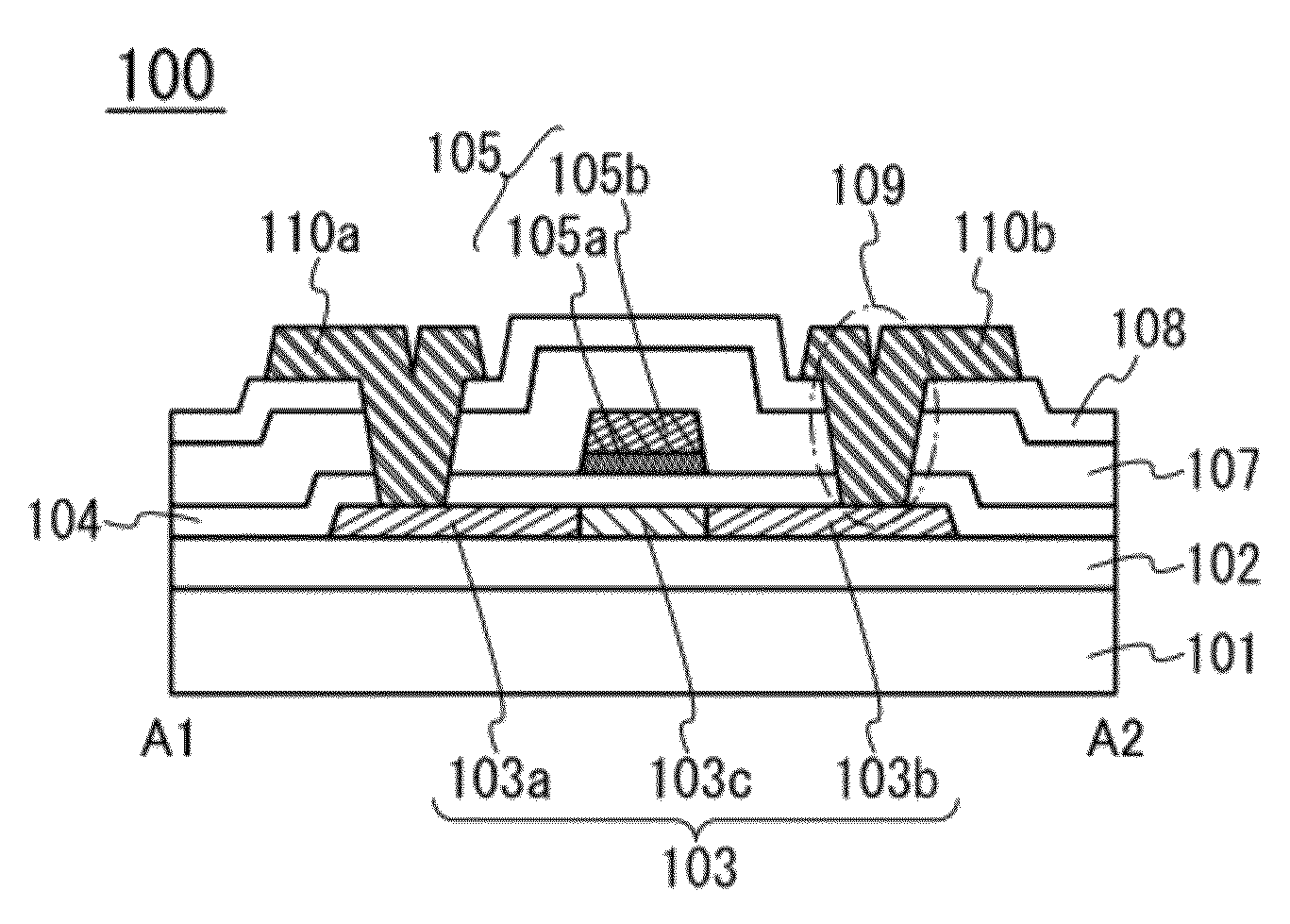

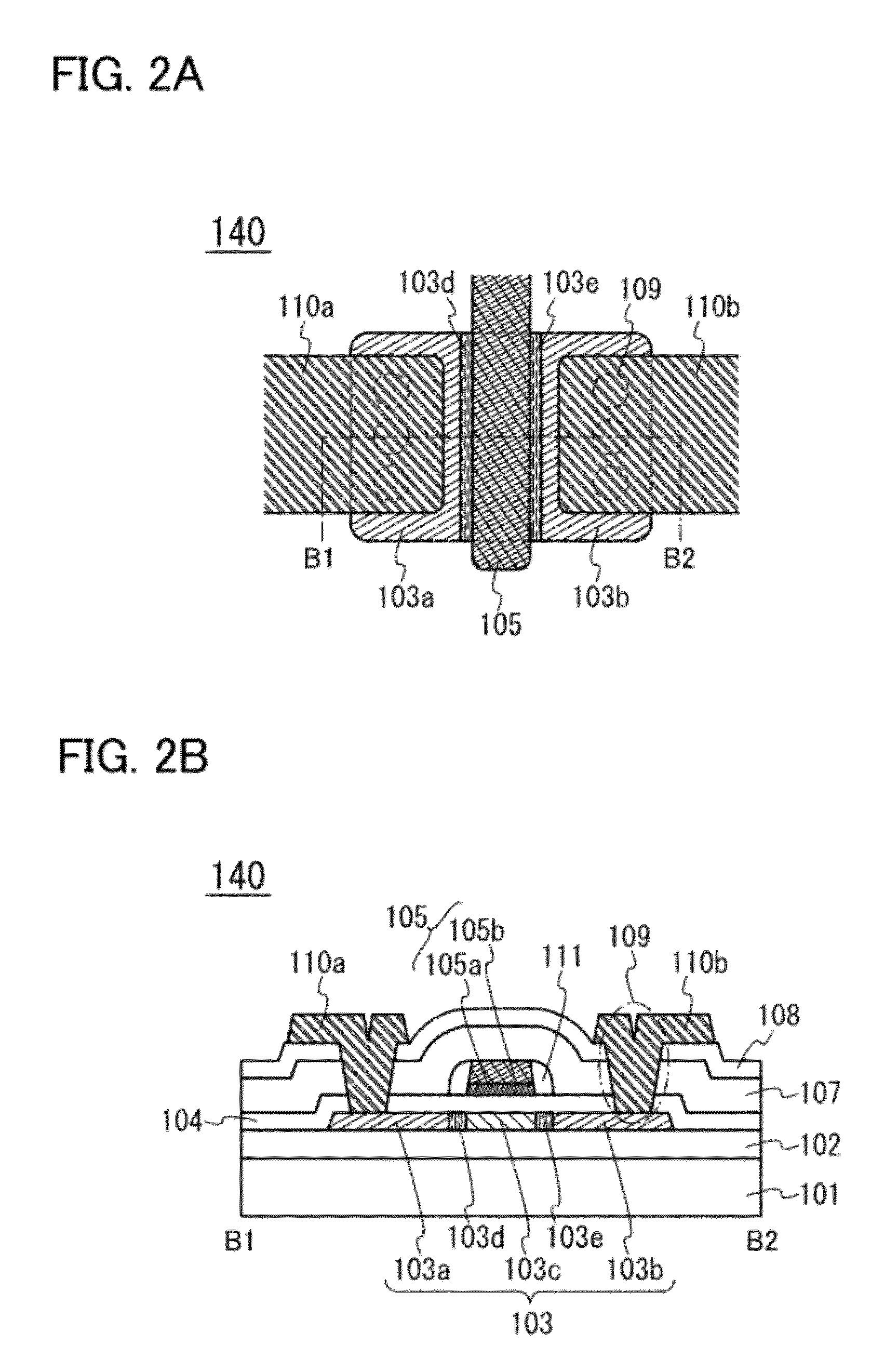

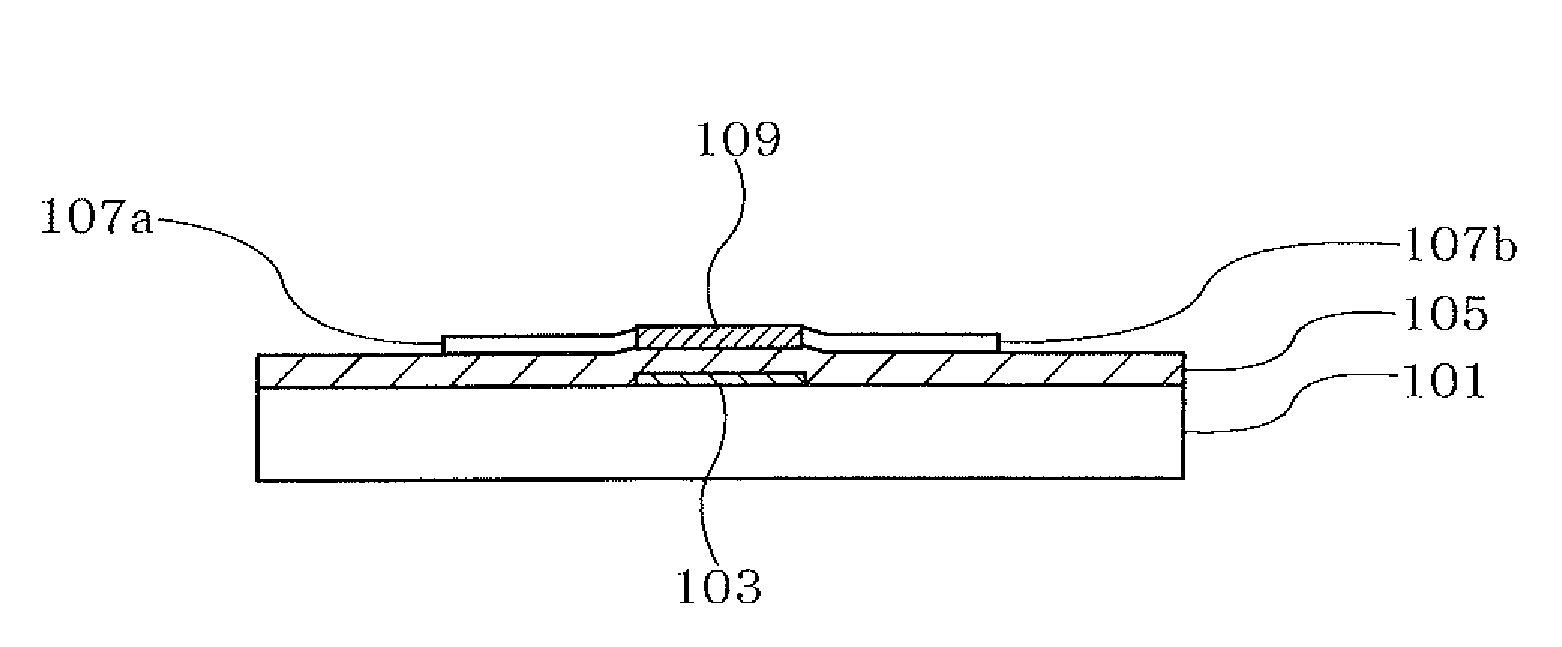

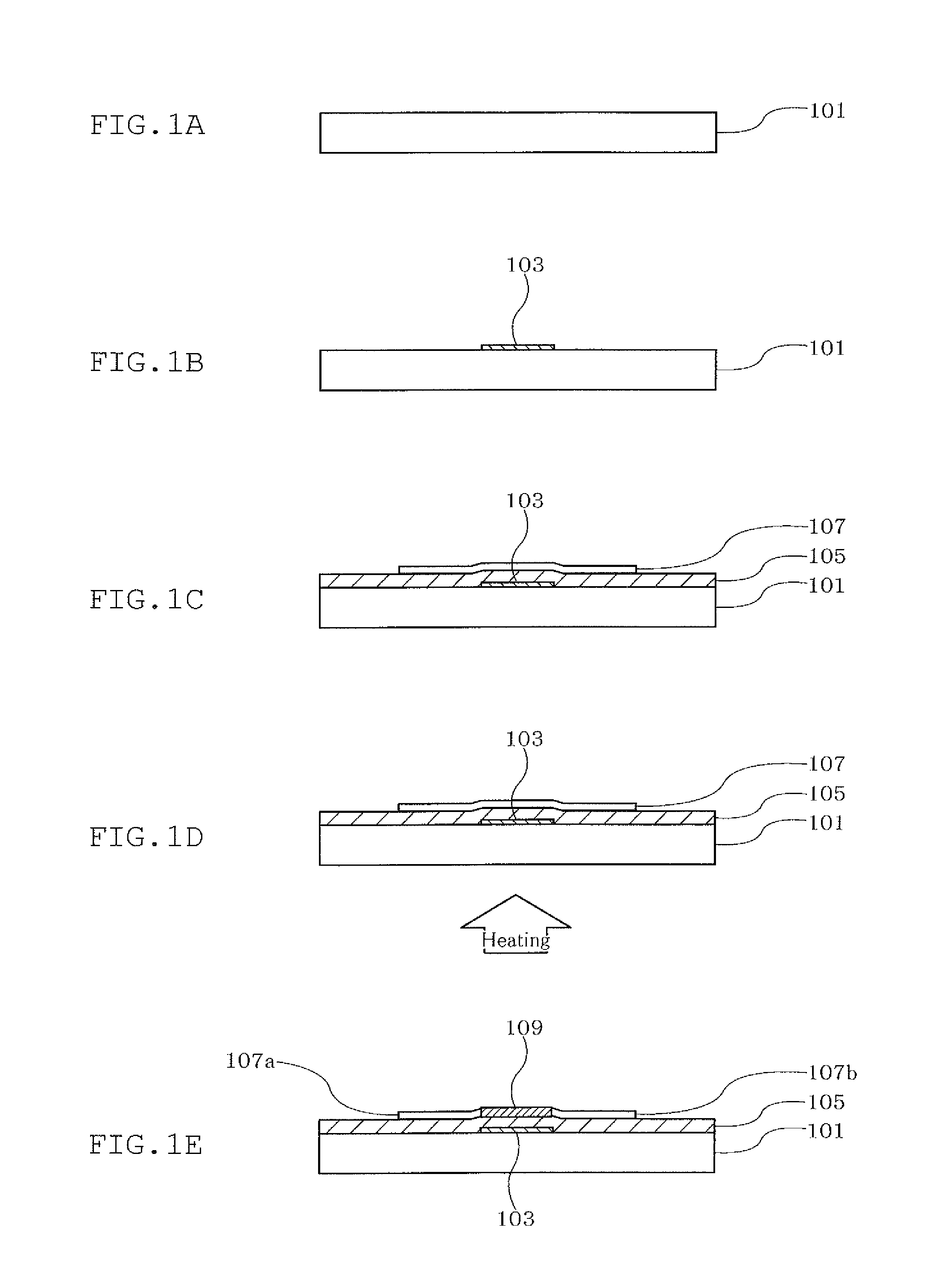

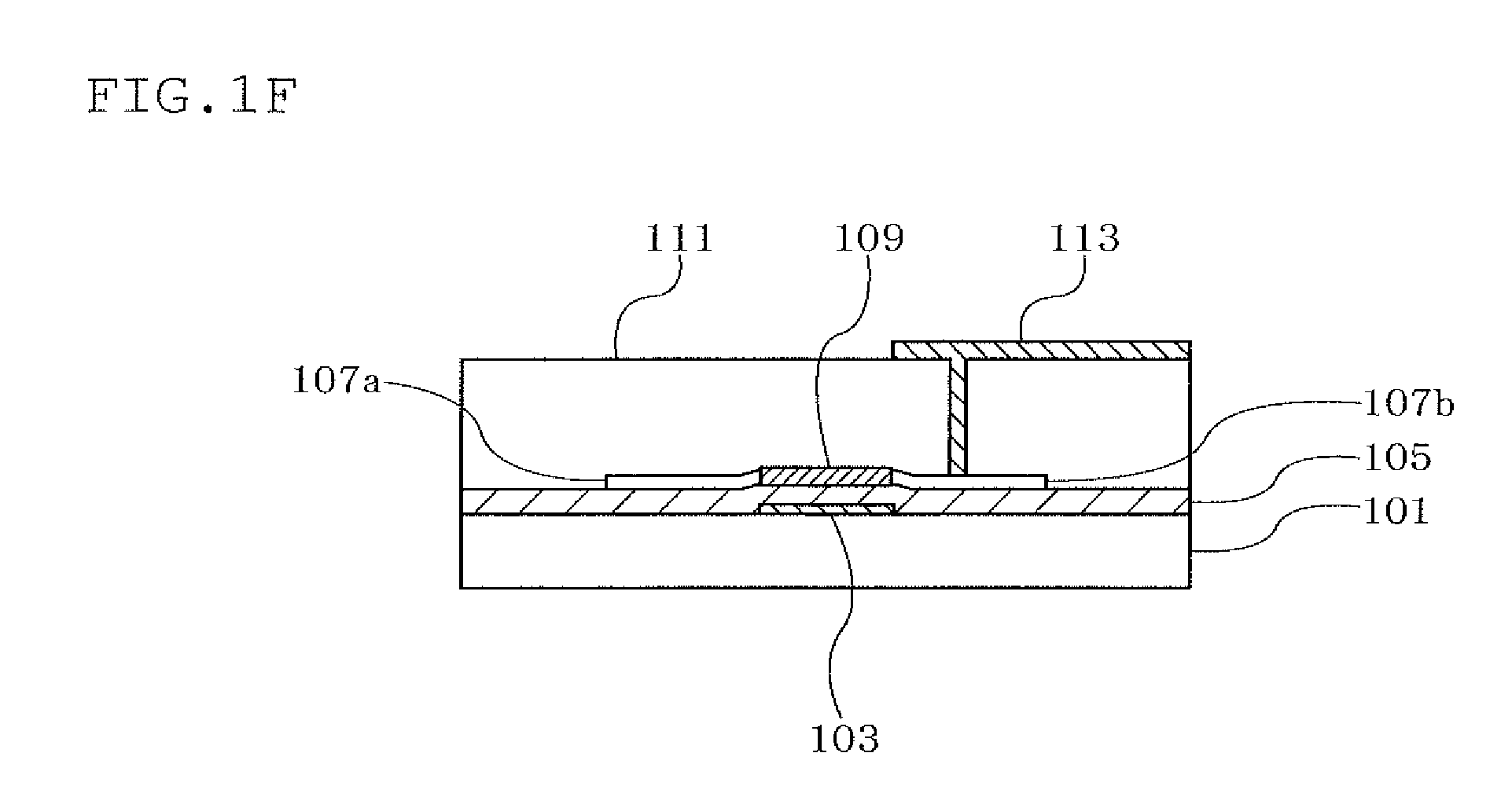

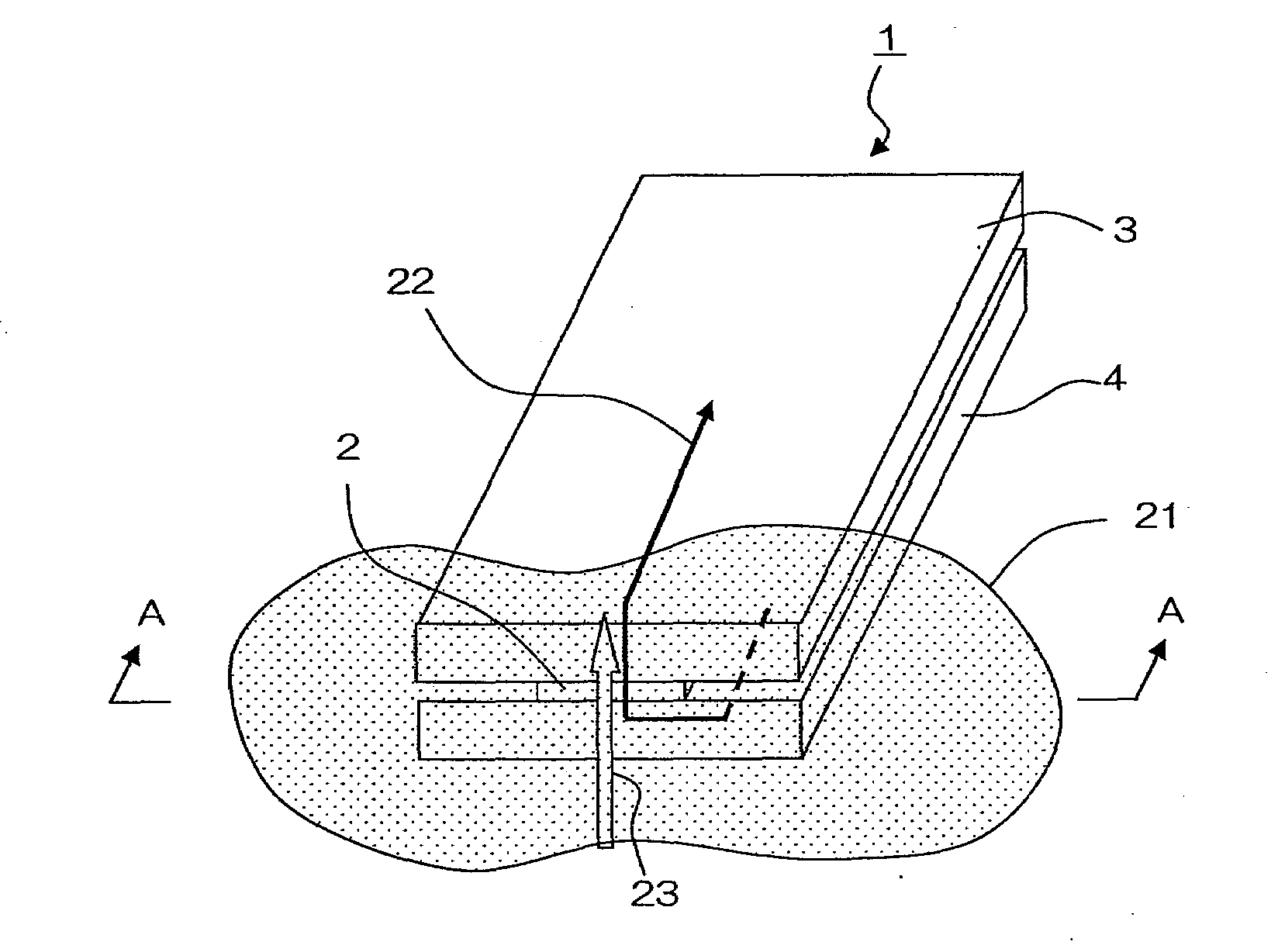

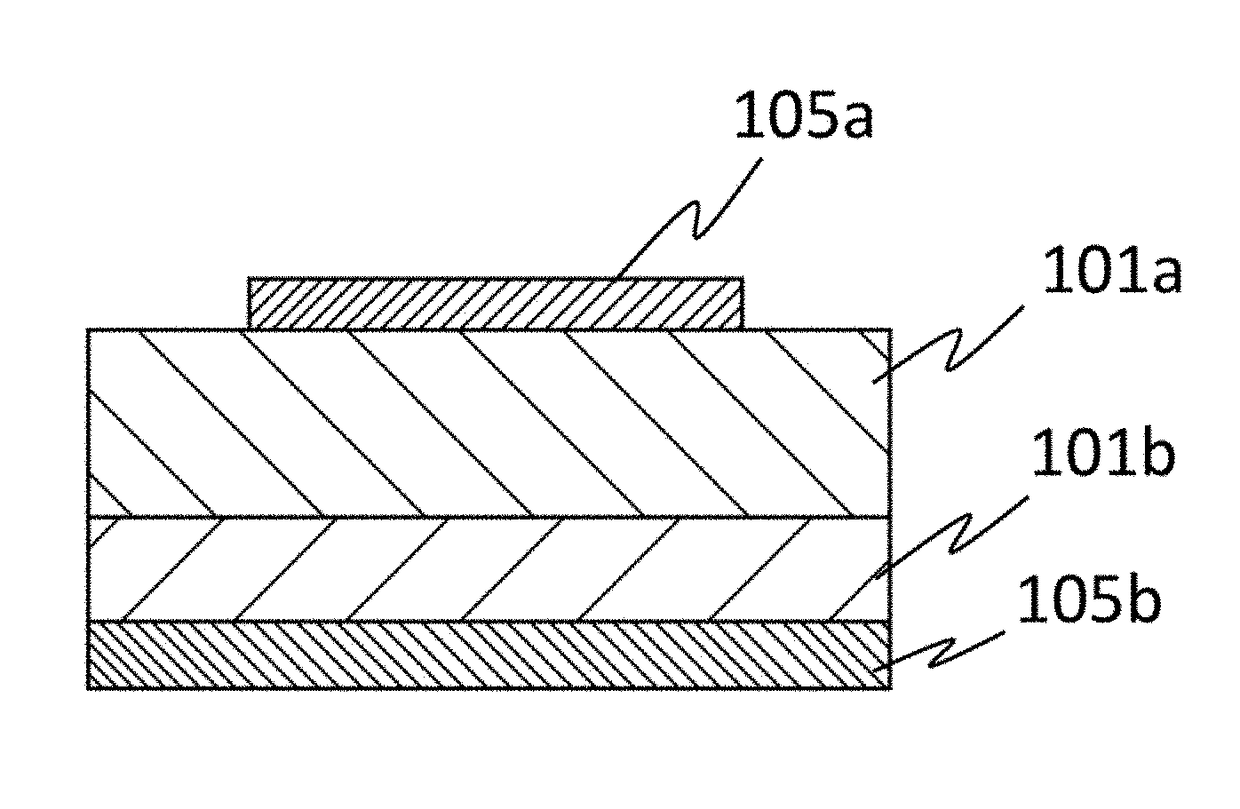

Field effect transistor, semiconductor device and semiconductor device manufacturing method

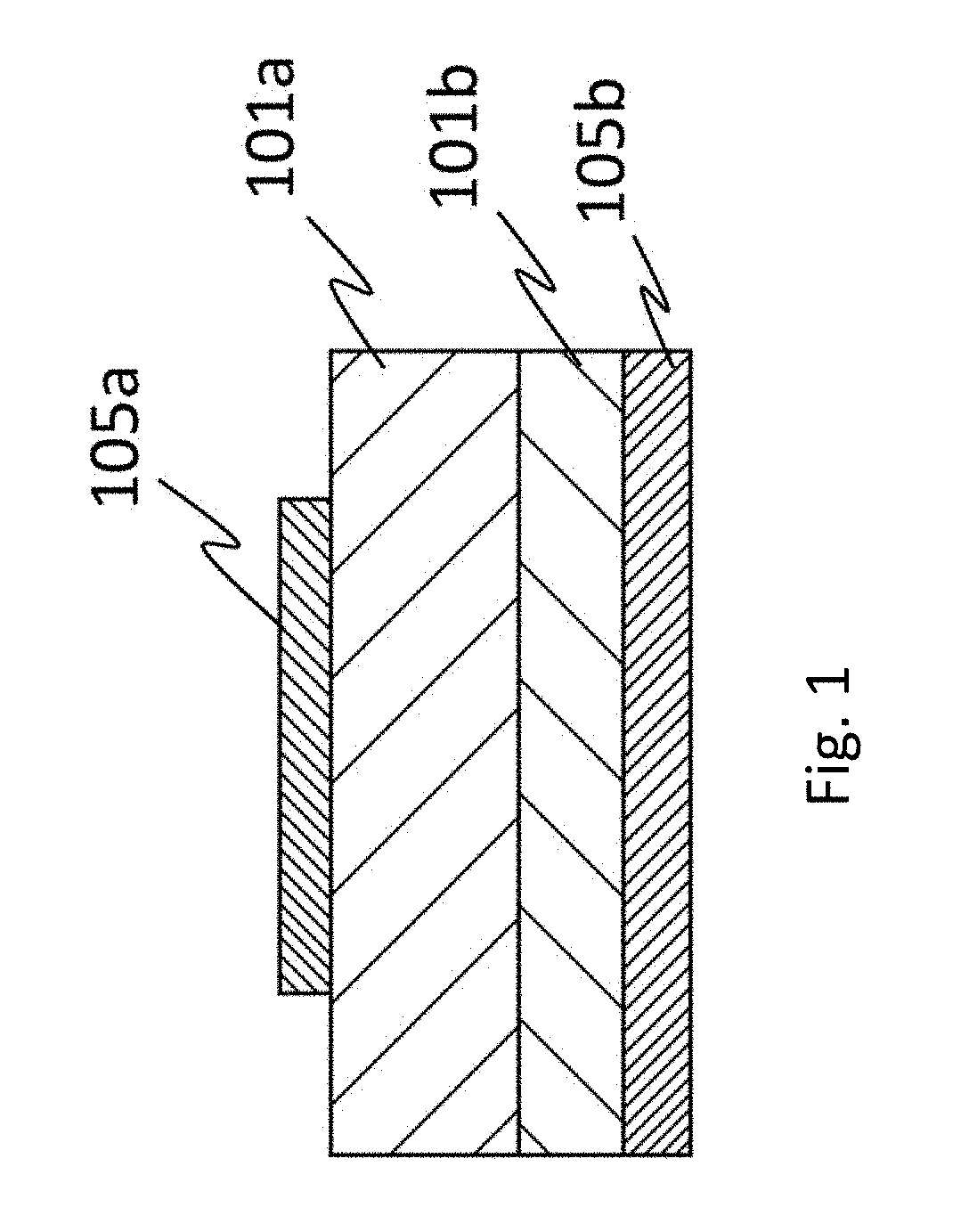

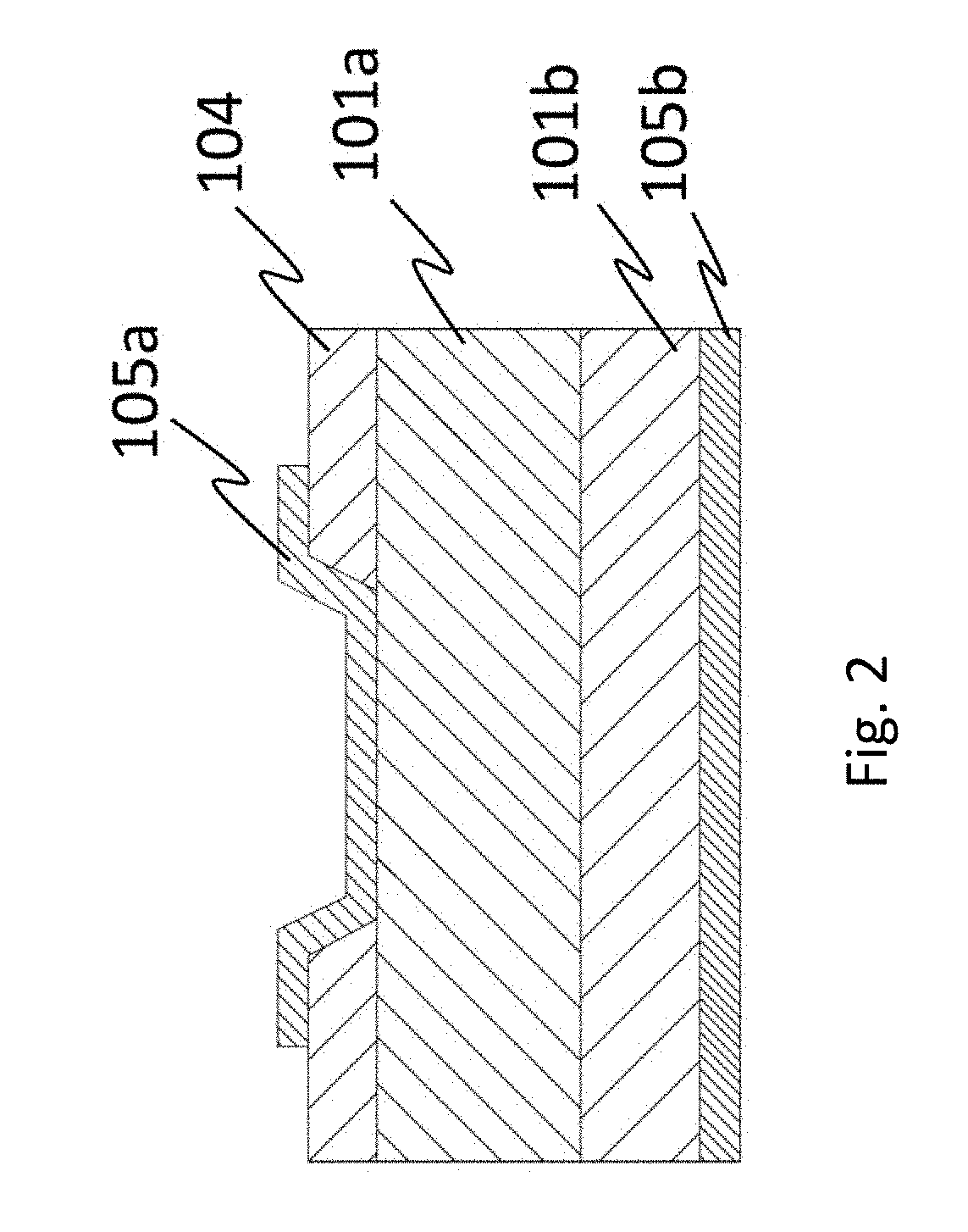

InactiveUS20110049511A1Reduce contact resistanceImprove interface strengthTransistorSemiconductor/solid-state device manufacturingCrystalline oxideField-effect transistor

A field effect transistor including a source electrode 107a, a drain electrode 107b, a gate electrode 103, an insulating film 105 and a semiconductor layer 109 containing a crystalline oxide, wherein the source electrode 107a and the drain electrode 107b are self-aligned with the gate electrode 103 with the insulating film 105 therebetween.

Owner:IDEMITSU KOSAN CO LTD

Novel non-crystalline oxides for use in microelectronic, optical, and other applications

InactiveUS20020024108A1Oxide/hydroxide preparationTantalum compoundsCrystalline oxideField-effect transistor

The invention relates to non-crystalline oxides of formulas (I) and (II), and methods of forming the same, along with field effect transistors, articles of manufacture, and microelectronic devices comprising the non-crystalline oxides.

Owner:NORTH CAROLINA STATE UNIV

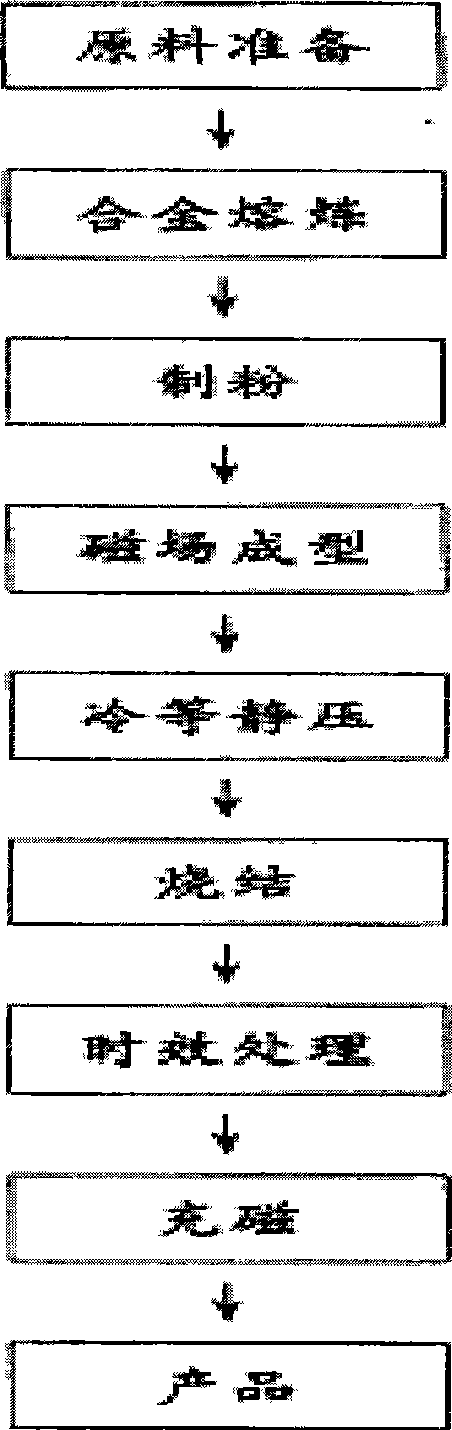

Permanent magnetic RE material and preparation thereof

ActiveCN101364465ASmall temperature coefficientLow coercivityInorganic material magnetismCrystalline oxideSamarium–cobalt magnet

The invention relates to a rare earth permanent magnetic material and a preparation method thereof. The rare earth permanent magnetic material comprises a (Pr, Nd)-Fe-R-Co-Al-Cu-B-M system, and the rare earth as a main phase component has a phase volume ratio of 90%-98%; wherein R is at least two elements selected from Nb, Tb, Dy and Ho; M is at least two nanometer crystalline oxides with particle size of 10-100 nm selected from ZrO2, MgO and ZnO; and the weight of the nanometer crystalline oxides is 0.1%-3% of the total weight. The rare earth permanent magnetic material is a compound nanometer oxidizer enhanced and sintered praseodymium (Pr)-neodymium (Nd)-based permanent magnet with high coercitive force. The inventive product has magnetic features of low temperature coefficient, high coercitive force, low cost and 220 DEG C working temperature, and can overcome the shortcomings of lower coercitive force, high temperature coefficient and high cost of the prior sintered Nd-Fe-B permanent magnet and the sintered samarium-cobalt magnet in application of large motor products. The preparation method provides a powerful guarantee for realizing the positive effects.

Owner:浙江西子富沃德电机有限公司

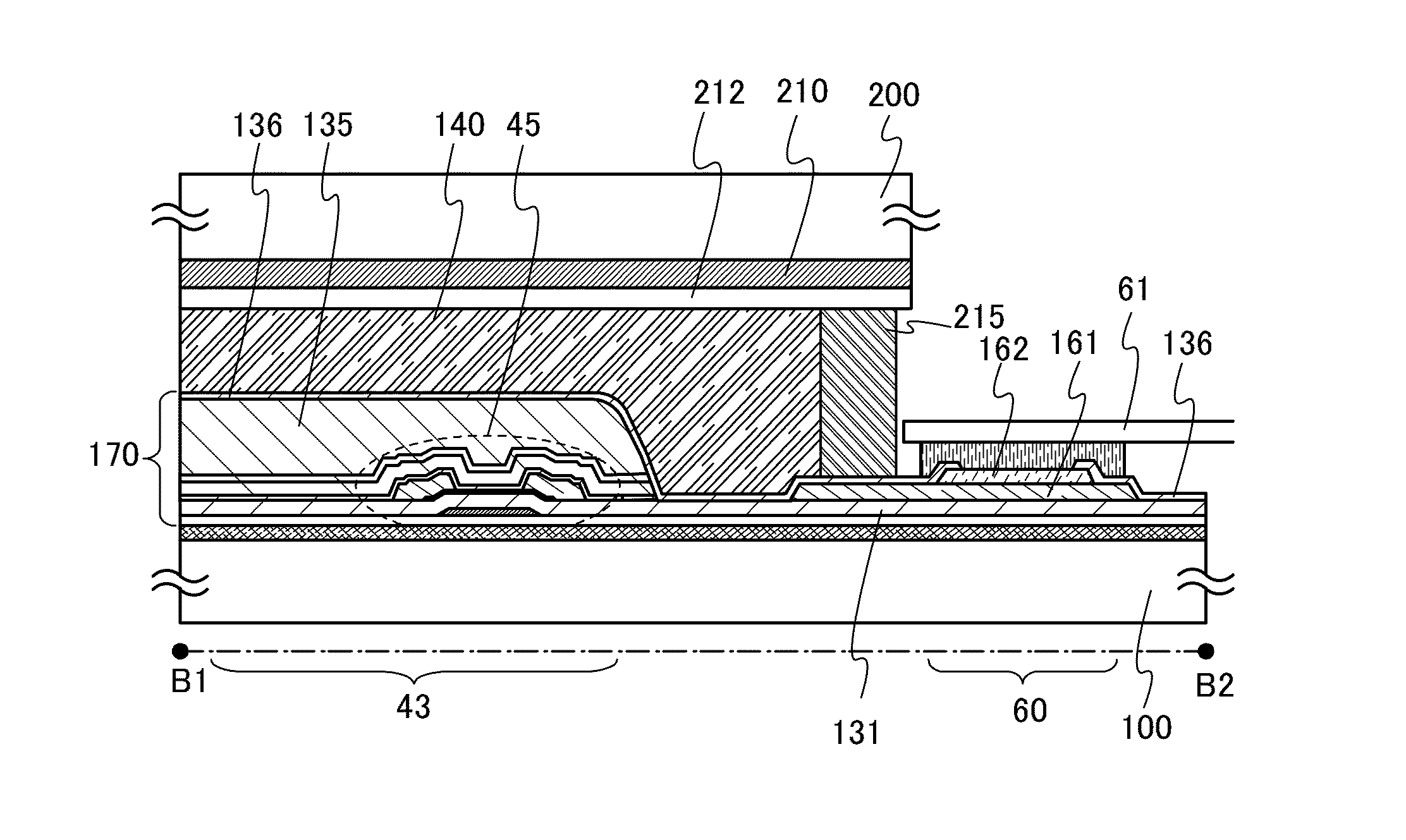

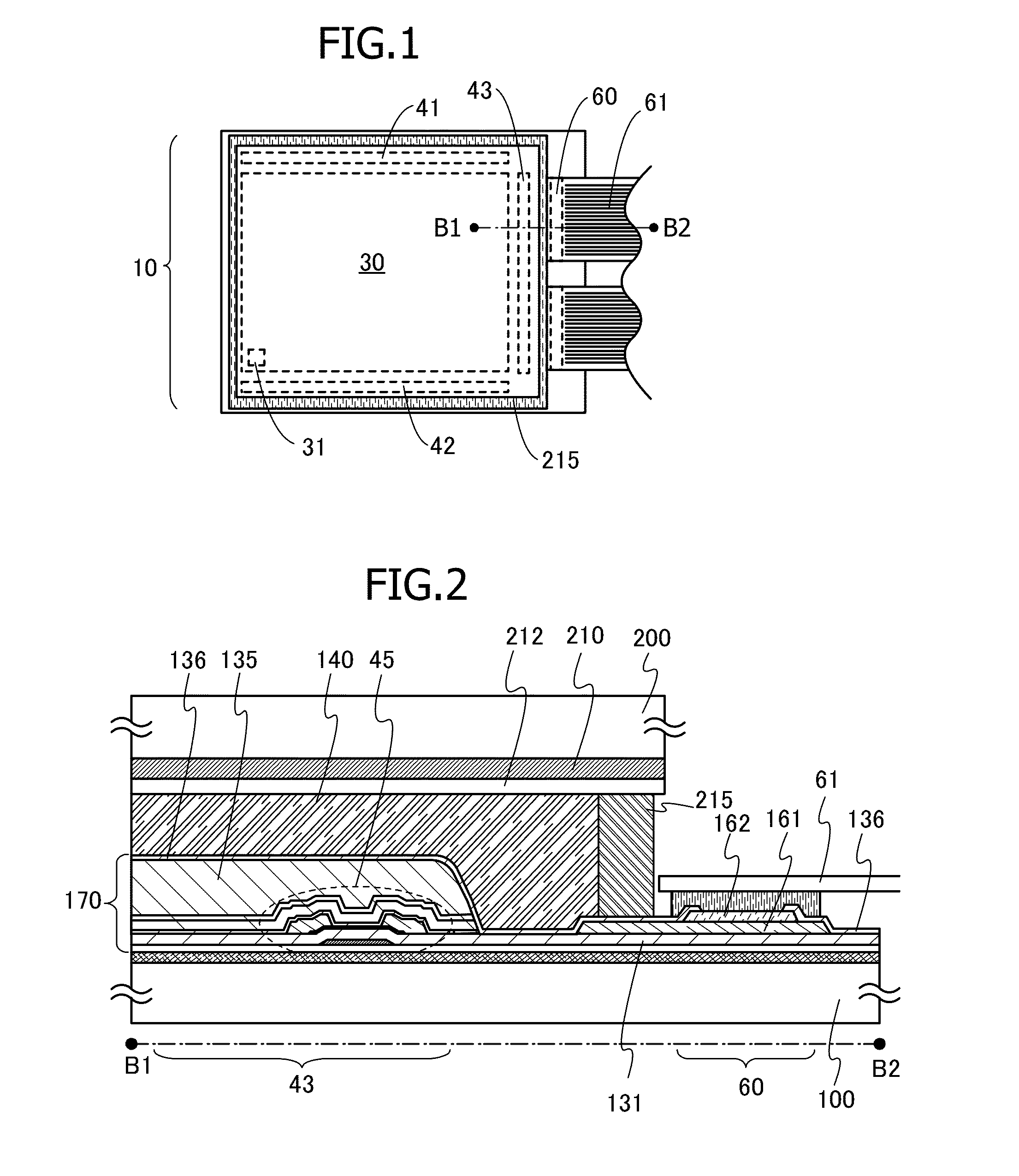

Liquid crystal display device and touch panel

InactiveUS20140104508A1Improve reliabilityReduce power consumptionSolid-state devicesNon-linear opticsCrystalline oxideLiquid-crystal display

To provide a highly reliable liquid crystal display device including flexible substrates and a crystalline oxide semiconductor film for a backplane. The device includes a flexible first substrate, a flexible second substrate facing the first substrate, and a liquid crystal layer sealed between the substrates with a sealing member. The first substrate is provided with a layer including a transistor, an organic resin film over the transistor, a pixel electrode and a common electrode over the organic resin film, which partly overlap with each other with an insulating film provided therebetween, and an alignment film thereover. The transistor includes a crystalline oxide semiconductor film as a semiconductor layer where a channel is formed. Drying treatment is performed on the layer before the liquid crystal layer is sealed between the substrates, and steps from the drying treatment to sealing of the liquid crystal layer are performed without exposure to the air.

Owner:SEMICON ENERGY LAB CO LTD

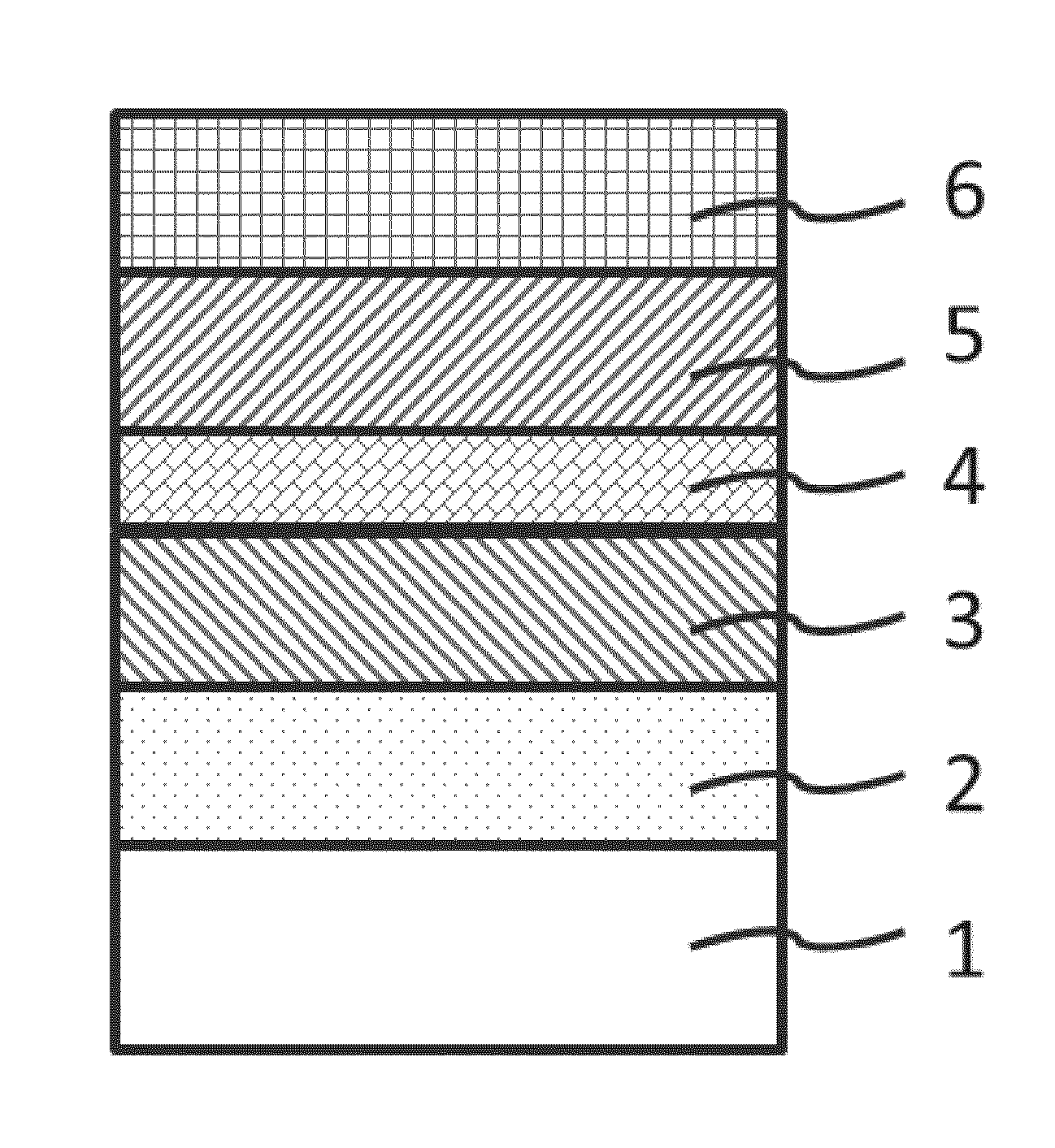

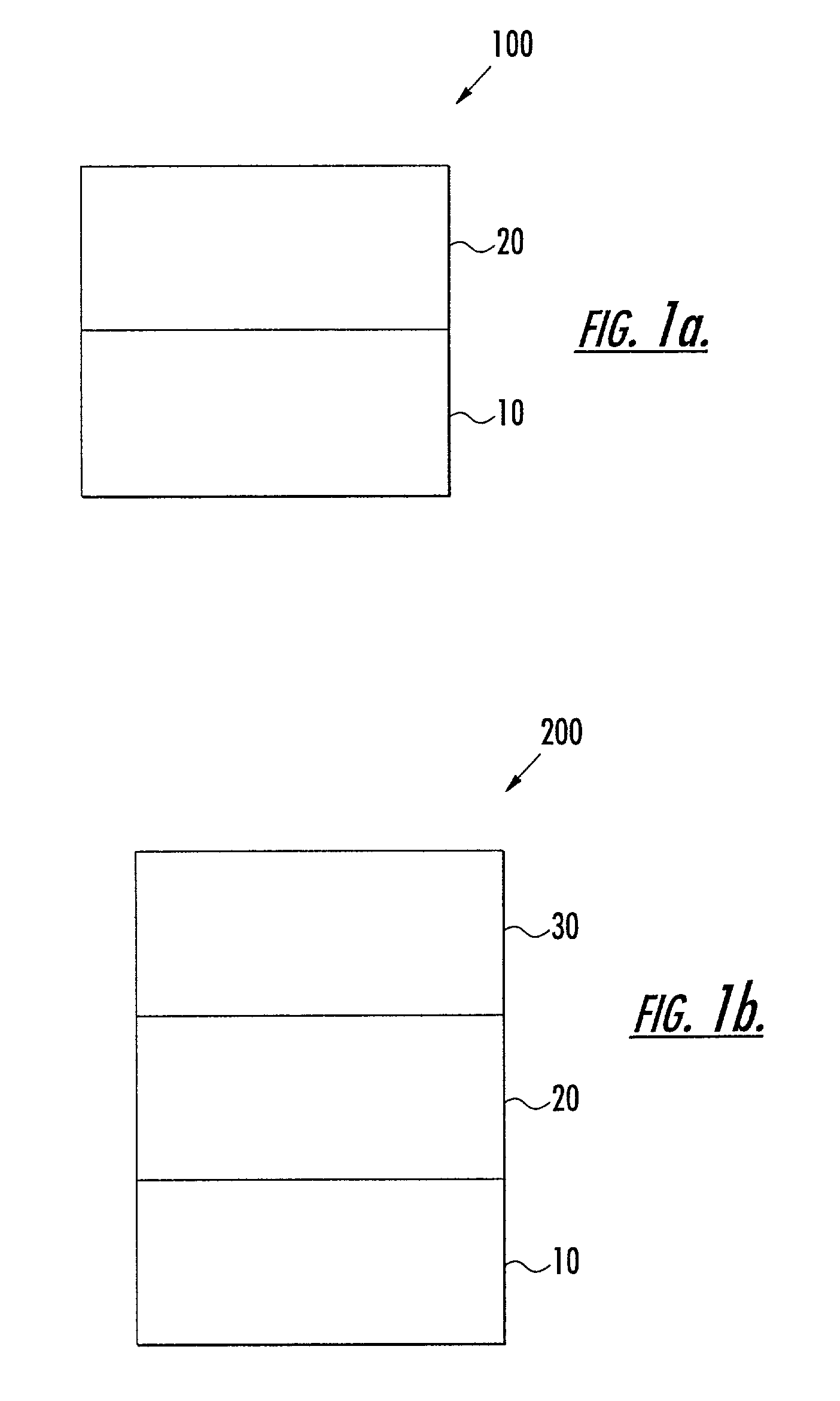

Crystalline multilayer structure and semiconductor device

ActiveUS20150325659A1Improve electrical performanceEfficient use ofSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCrystalline oxideIndium

Provided is a crystalline multilayer structure which has good electrical properties and is useful for semiconductor devices. A crystalline multilayer structure includes a base substrate and a crystalline oxide semiconductor thin film disposed directly on the base substrate or with another layer therebetween and including a corundum-structured oxide semiconductor as a major component. The oxide semiconductor contains indium and / or gallium as a major component. The crystalline oxide semiconductor thin film contains germanium, silicon, titanium, zirconium, vanadium, or niobium.

Owner:FLOSFIA

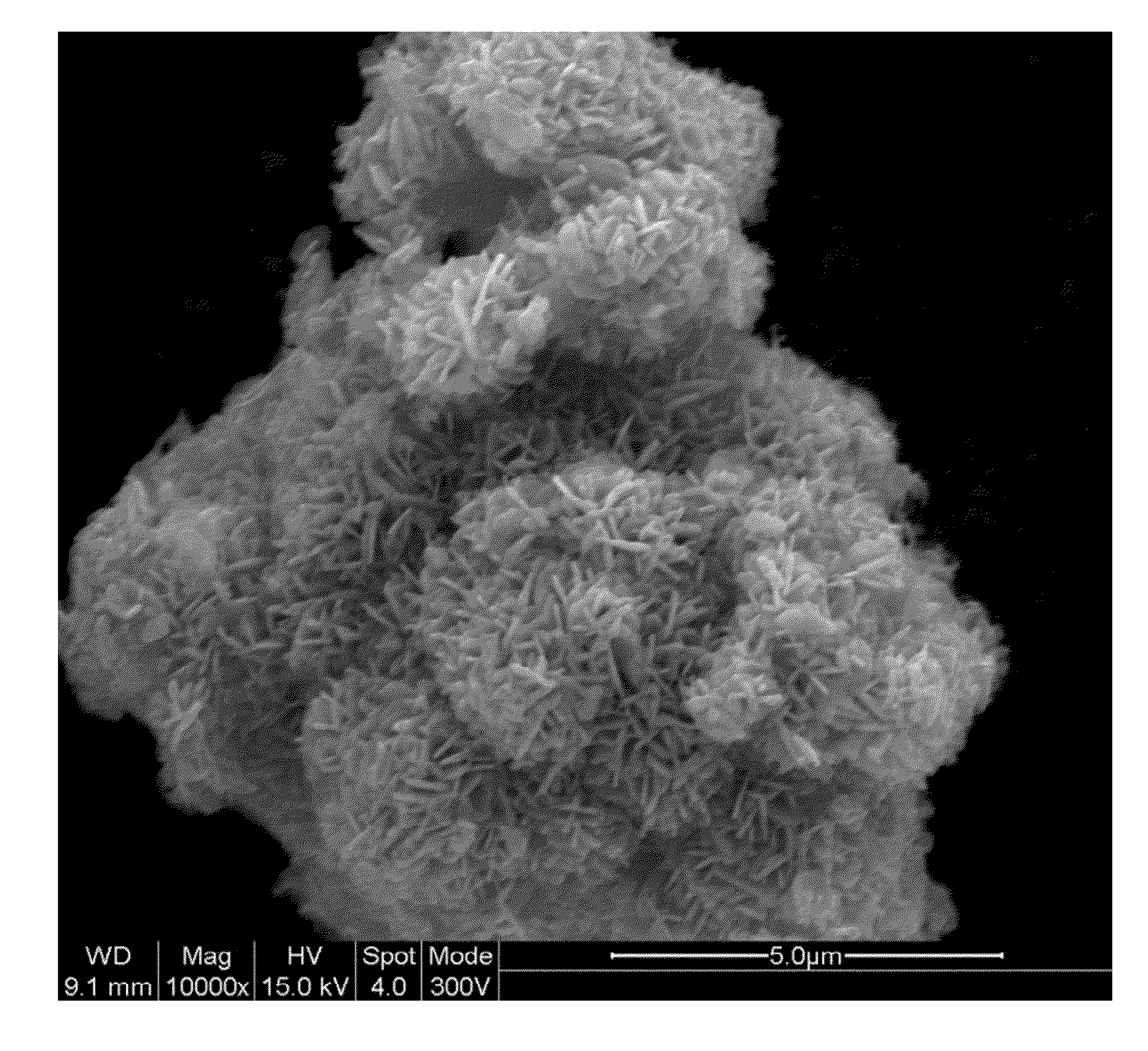

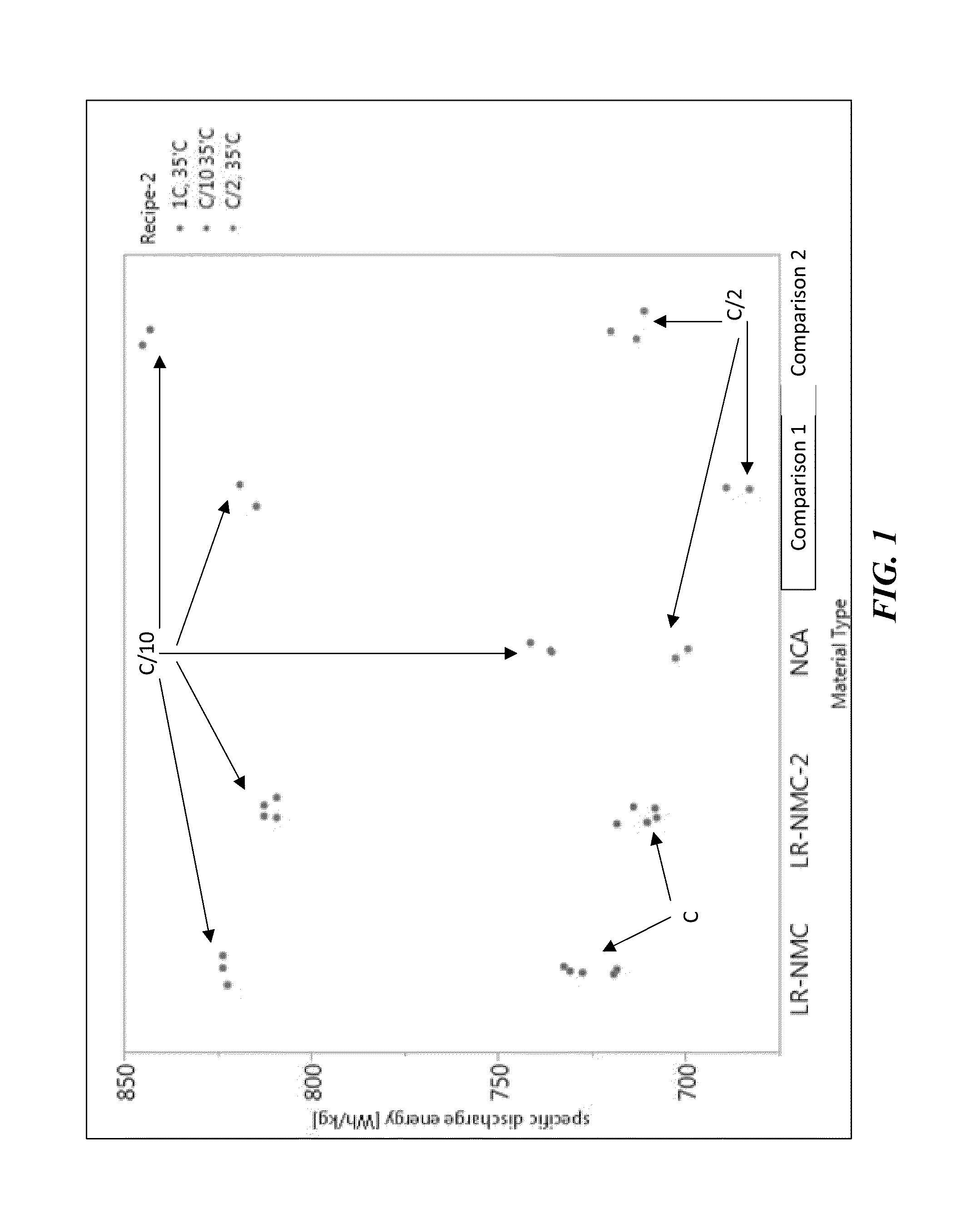

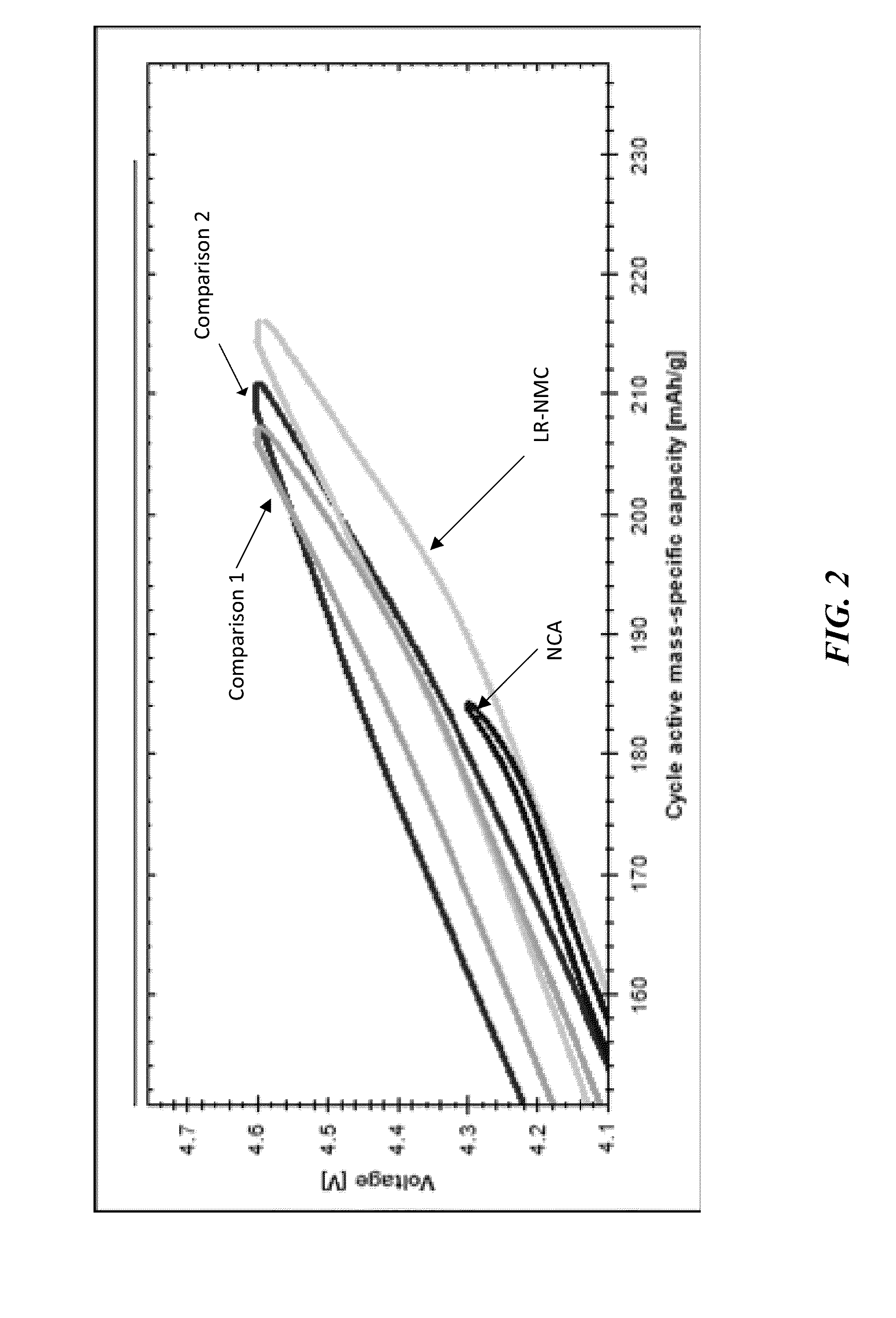

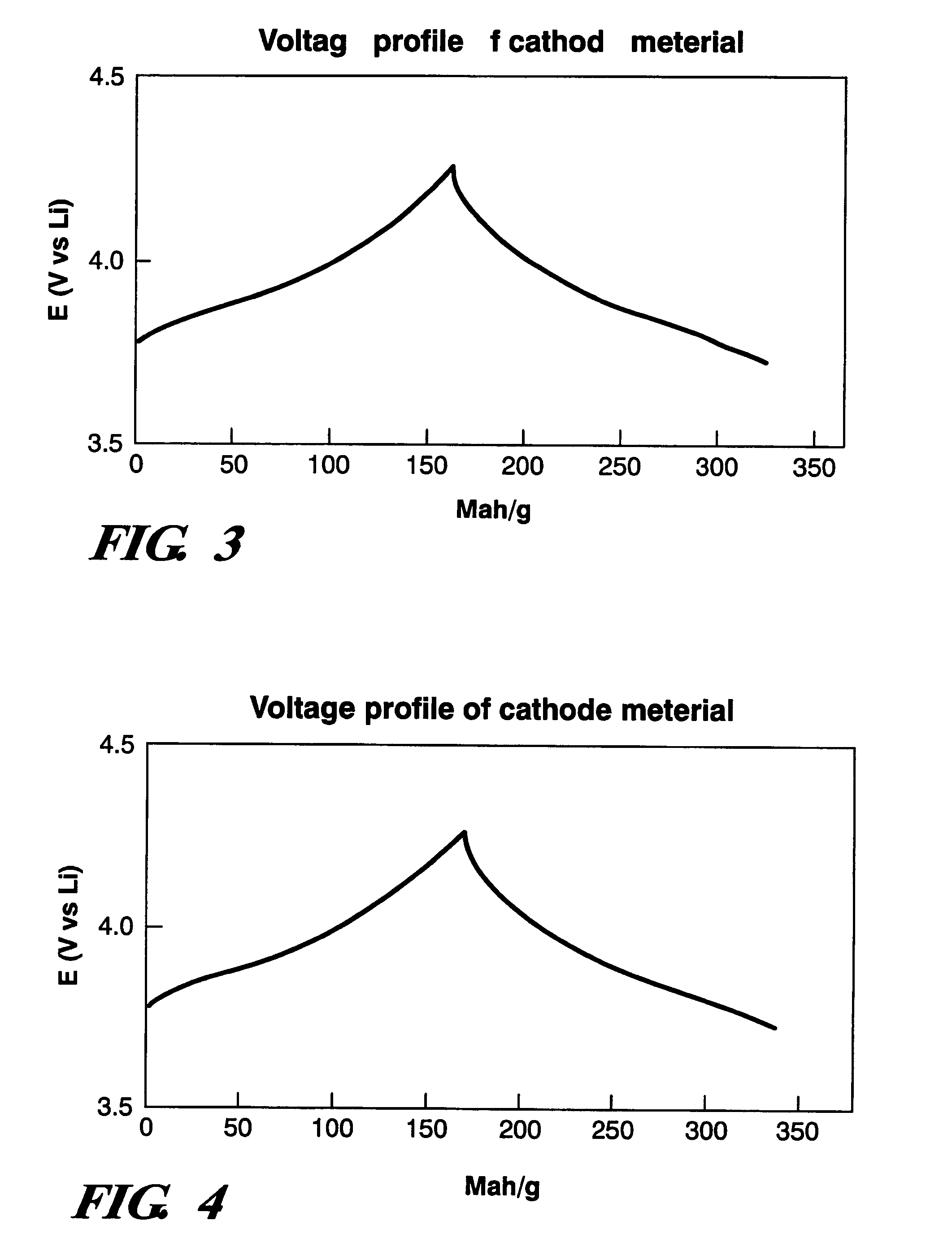

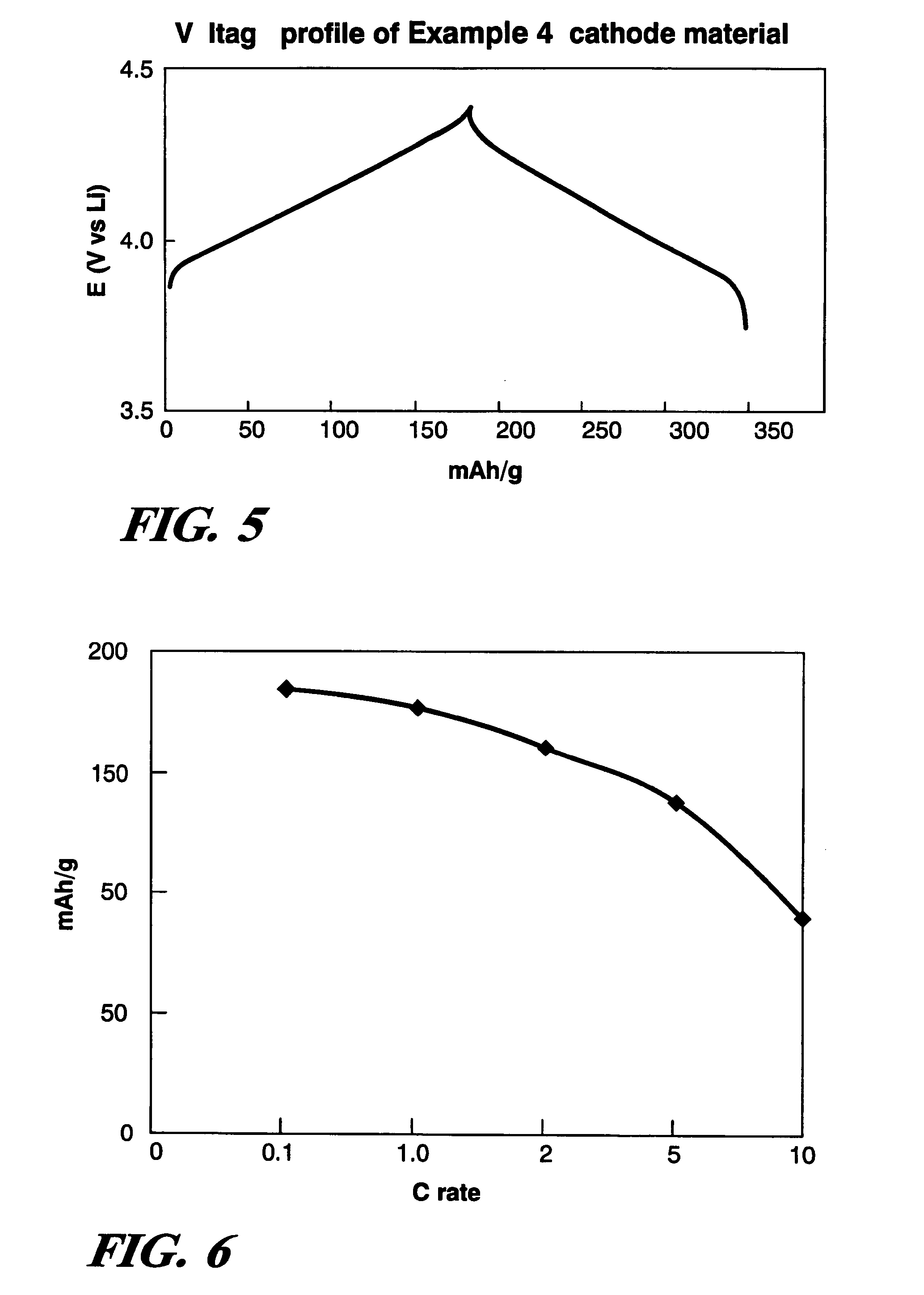

Lithium rich nickel manganese cobalt oxide (lr-nmc)

ActiveUS20160211517A1Increase energy densityStrong power capabilityPositive electrodesCobalt compoundsCrystalline oxideLithium

Set forth herein are positive electrode active material compositions, e.g., lithium-rich nickel manganese cobalt oxides. The lithium-rich nickel manganese cobalt oxides set forth herein are characterized, in some examples, by an expanded unit cell which maximizes the uniform distribution of transition metals in the crystalline oxide. Also set forth herein are positive electrode thin films including lithium-rich nickel manganese cobalt oxide materials. Disclosed herein are novel and inventive methods of making and using lithium-rich nickel manganese cobalt oxide materials for lithium rechargeable batteries. Also disclosed herein are novel electrochemical devices which incorporate these materials.

Owner:QUANTUMSCAPE BATTERY INC

Semiconductor device and manufacturing method thereof

ActiveUS9443984B2Excellent characteristicsImprove reliabilityTransistorSolid-state devicesCrystalline oxideHydrogen

A semiconductor device capable of high speed operation is provided. Further, a highly reliable semiconductor device is provided. An oxide semiconductor having crystallinity is used for a semiconductor layer of a transistor. A channel formation region, a source region, and a drain region are formed in the semiconductor layer. The source region and the drain region are formed in such a manner that one or more of elements selected from rare gases and hydrogen are added to the semiconductor layer by an ion doping method or an ion implantation method with the use of a channel protective layer as a mask.

Owner:SEMICON ENERGY LAB CO LTD

Process for the preparation of 1,1,1,2,2-pentafluoroethane

InactiveUS7074973B2Preparation by halogen halide additionOrganic chemistry methodsCrystalline oxideHydrogen fluoride

A process for the preparation of pentafluoroethane is disclosed which involves contacting a mixture comprising hydrogen fluoride and at least one starting material selected from haloethanes of the formula CX3CHX2 and haloethanes of the formula CX2═CX2, where each X is independently selected from the group consisting of F and Cl (provided that no more than four of X are F), with a fluorination catalyst in a reaction zone to produce a product mixture comprising HF, HCl, pentafluoroethane, underfluorinated halogenated hydrocarbon intermediates and less than 0.2 mole percent chloropentafluoroethane based on the total moles of halogenated hydrocarbons in the product mixture. The process is characterized by the fluorination catalyst comprising (i) a crystalline cobalt-substituted alpha-chromium oxide where from about 0.05 atom % to about 6 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by trivalent cobalt (Co+3) and / or (ii) a fluorinated crystalline oxide of (i).

Owner:EI DU PONT DE NEMOURS & CO

Field-effect transistor, and process for producing field-effect transistor

ActiveUS8530891B2Poor resistanceEasily deterioratedSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxideIndium

To provide a field-effect transistor improved in transparency, electrical properties, stability, uniformity, reproducibility, heat resistance and durability, and as a reduced overlap capacity between electrodes.A field-effect thin film transistor 1001 includes a gate electrode 1025, an active layer, a source electrode 1022 and a drain electrode 1023, wherein a crystalline oxide 1021 containing indium and having an electron carrier concentration of less than 1018 / cm3 is used as the active layer, and the gate electrode 1025 is in self-alignment with the source electrode 1022 and the drain electrode 1023. The crystalline oxide 1021 contains a positive trivalent element different from a positive divalent element or indium.

Owner:IDEMITSU KOSAN CO LTD

Plasma spraying pyrolyzing process of preparing nanometer hollow oxide microsphere powder

The plasma spraying and pyrolyzing process of preparing nanometer hollow microsphere powder of nanometer crystalline oxide includes preparing precursor solution, atomizing, plasma spraying and pyrolyzing in plasma flame to form solid molten drop, and cooling in liquid to solidify form the hollow spherical nanometer crystal structure. The process is simple and suitable for industrial production.

Owner:WUHAN UNIV OF TECH

Cathode material for lithium battery

ActiveUS7018607B2Evenly distributedEfficient dryingAluminium compoundsOxygen/ozone/oxide/hydroxideCrystalline oxideOxygen

A method is disclosed for synthesizing a crystalline metal oxide powder material containing two or more uniformly distributed metal elements. Crystalline, water containing, oxygen containing inorganic acid salts of the metals are heated to liquefy the salts. The apparent solution contains a uniform mixture of the metal elements. The water is removed from the liquid and the resulting powder calcined in air to decompose the acid salts to a mixed metal crystalline oxide. The method is particularly useful to make doped LiNiO2 type crystals using hydrated nitrate or nitrite salts of Li, Ni and the dopant elements. Examples of useful salts are LiNO3.H2O, Ni(NO3)2.6H2O, Co(NO3)2.6H2O, Al(NO3)3.9H2O, and Mg(NO3)2.6H2O.

Owner:GM GLOBAL TECH OPERATIONS LLC

Galvanized steel sheet and method for manufacturing the same

ActiveUS20110217569A1Improve retentionHighly strongHot-dipping/immersion processesThin material handlingCrystalline oxideZinc

A galvanized steel sheet includes a basal steel sheet (BSS) containing C: 0.01-0.15%, Si: 0.001-2.0%, Mn: 0.1-3.0%, Al: 0.001-1.00, P: 0.005-0.060%, and S≦0.01% (all % by mass), balance is Fe and unavoidable impurities; zinc plating layers on both sides of the BSS with 20-120 g / m2 plating / side; one or more oxides selected from Fe, Si, Mn, Al, and P oxides and existing in steel sheet superficial portions in direct contact with zinc plating layers and extending from each surface of the BSS to 100 μm deep, with the total amount of the oxides per side 0.01-0.5 g / m2; and a crystalline oxide in the regions from each surface of the BSS to 10 μm depth, which are also located in direct contact with the zinc plating layers, the crystalline oxide including Fe crystal grains in which Si and Mn atoms are distributed in the regions from grain boundaries to 1 μm deep.

Owner:JFE STEEL CORP

Method for manufacturing semiconductor device

ActiveUS8871565B2Stable electrical characteristicsImprove reliabilityTransistorSemiconductor/solid-state device detailsCrystalline oxideIndium

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method of manufacturing semiconductor device

ActiveUS8987728B2Conductivity easilyDensity is easyTransistorSolid-state devicesCrystalline oxidePower semiconductor device

An object is to provide a highly reliable semiconductor device having stable electric characteristics by using an oxide semiconductor film having stable electric characteristics. Another object is to provide a semiconductor device having higher mobility by using an oxide semiconductor film having high crystallinity. A crystalline oxide semiconductor film is formed over and in contact with an insulating film whose surface roughness is reduced, whereby the oxide semiconductor film can have stable electric characteristics. Accordingly, the highly reliable semiconductor device having stable electric characteristics can be provided. Further, the semiconductor device having higher mobility can be provided.

Owner:SEMICON ENERGY LAB CO LTD

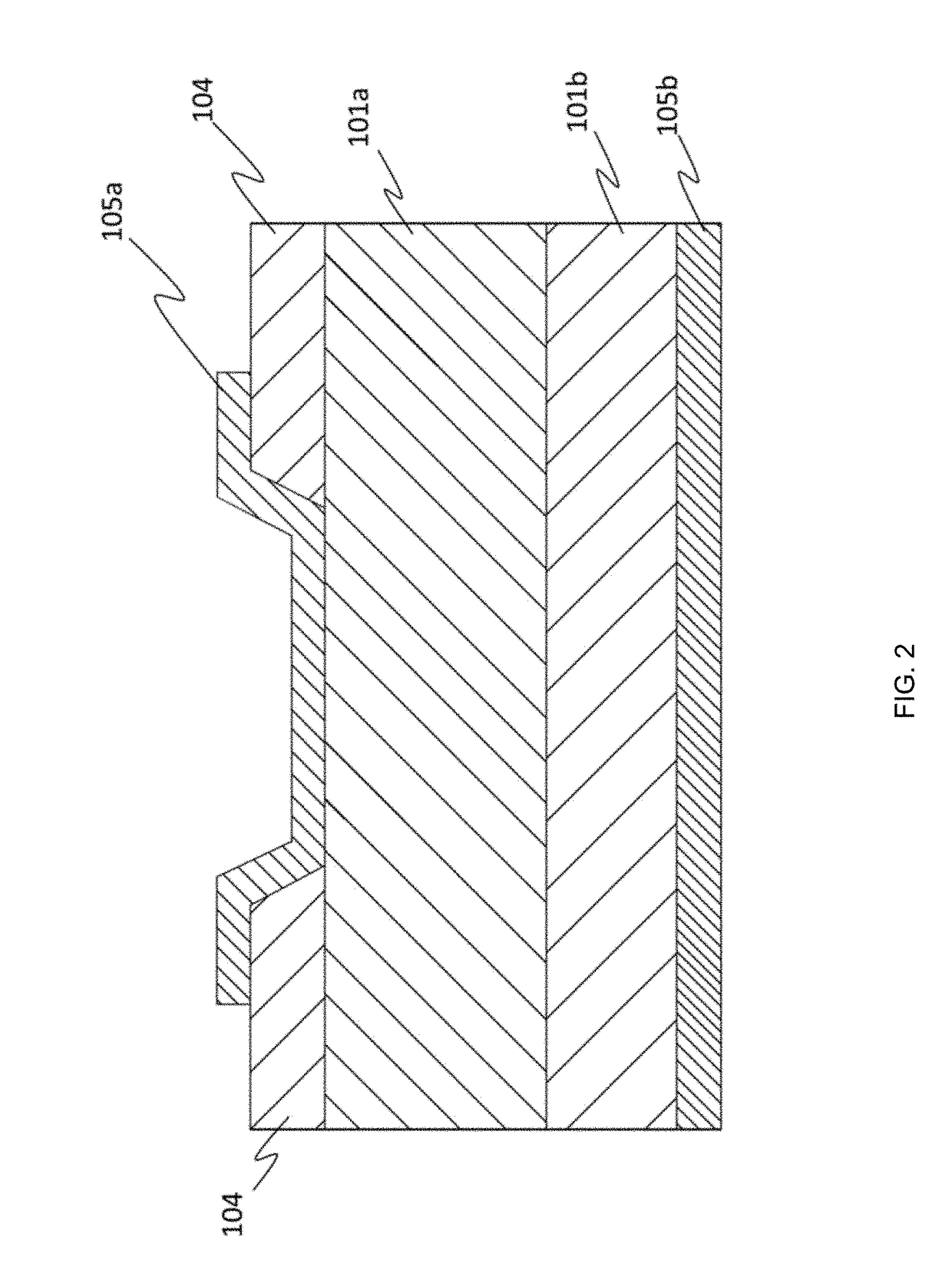

Field effect transistor, semiconductor device and semiconductor device manufacturing method

InactiveUS8704217B2Reduce contact resistanceImprove interface strengthSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxideField-effect transistor

Owner:IDEMITSU KOSAN CO LTD

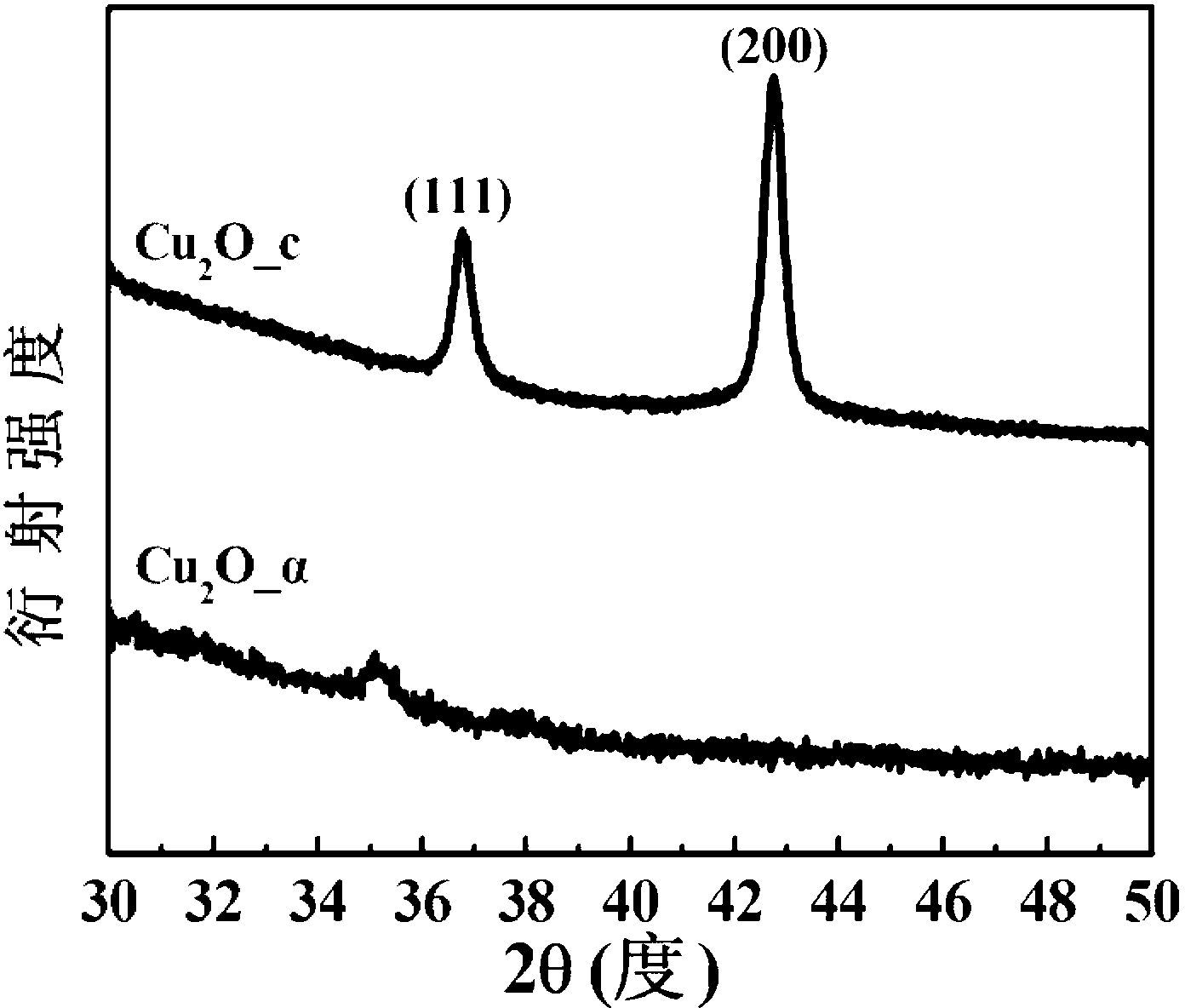

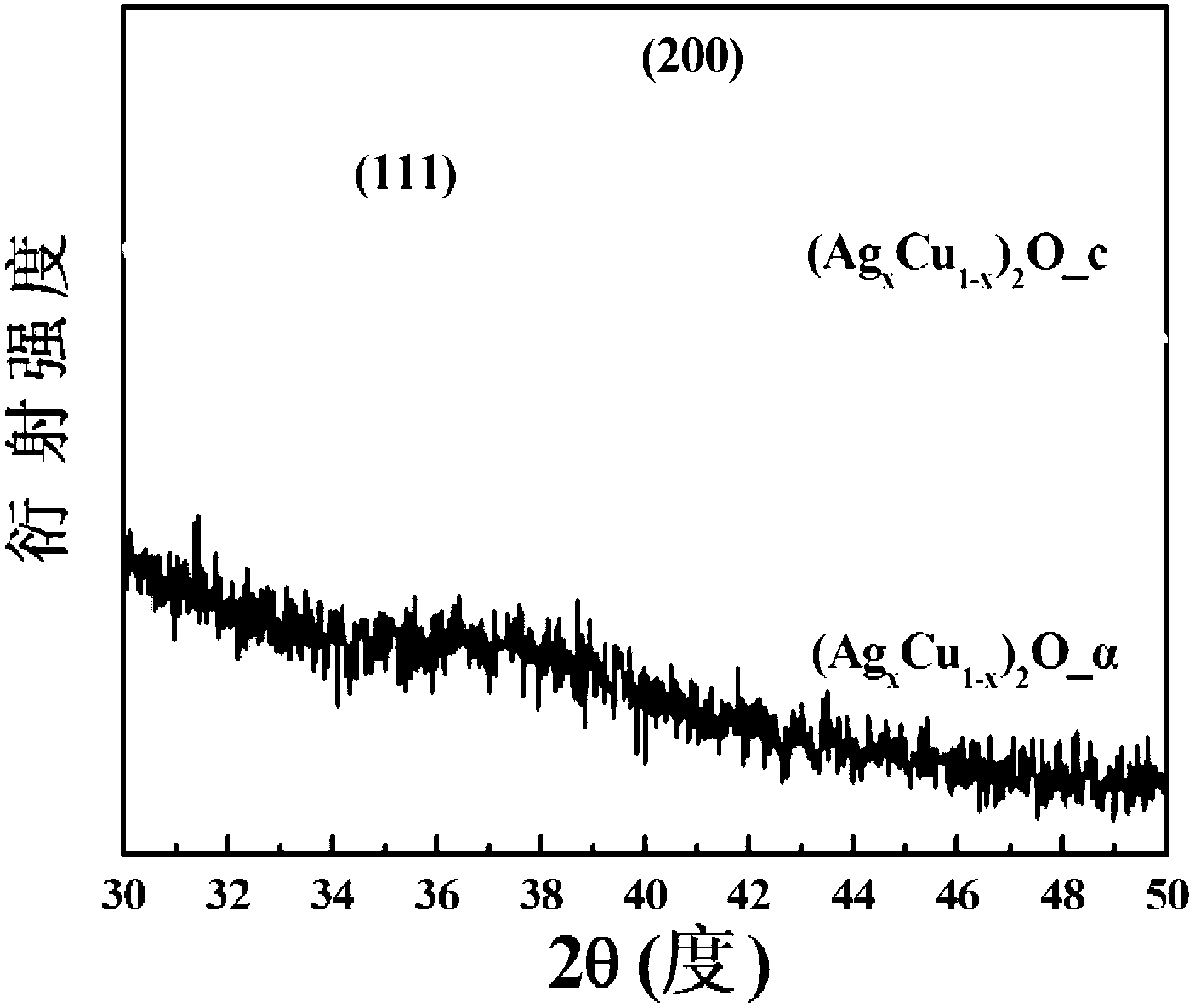

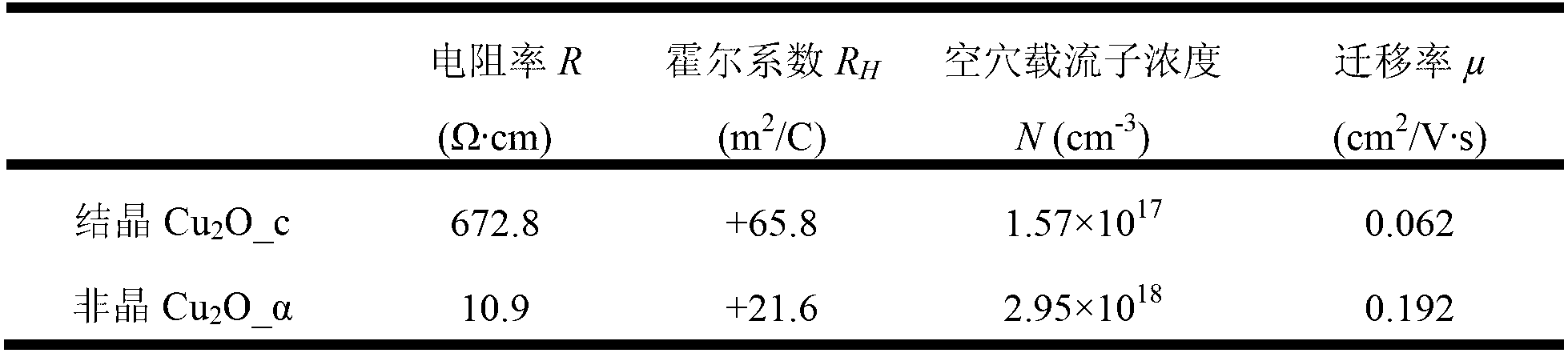

Preparation method of (doped amorphous) p-type transparent conductive oxide films

InactiveCN103173732AThe principle is simpleLow deposition temperatureVacuum evaporation coatingSputtering coatingCrystalline oxideDeposition temperature

The invention discloses a preparation method of films of (doped amorphous) p-type transparent conductive oxide films, and relates to the technical field of semiconductor films. The amorphous films having a higher hole carrier concentration and a higher mobility than crystallized oxide films are prepared through adopting a reaction magnetron sputtering process and controlling technological parameters. The preparation method has the advantages of simple principle, low deposition temperature, strong controllability of the technological parameters, low preparation cost, and huge scale production potential.

Owner:BEIHANG UNIV

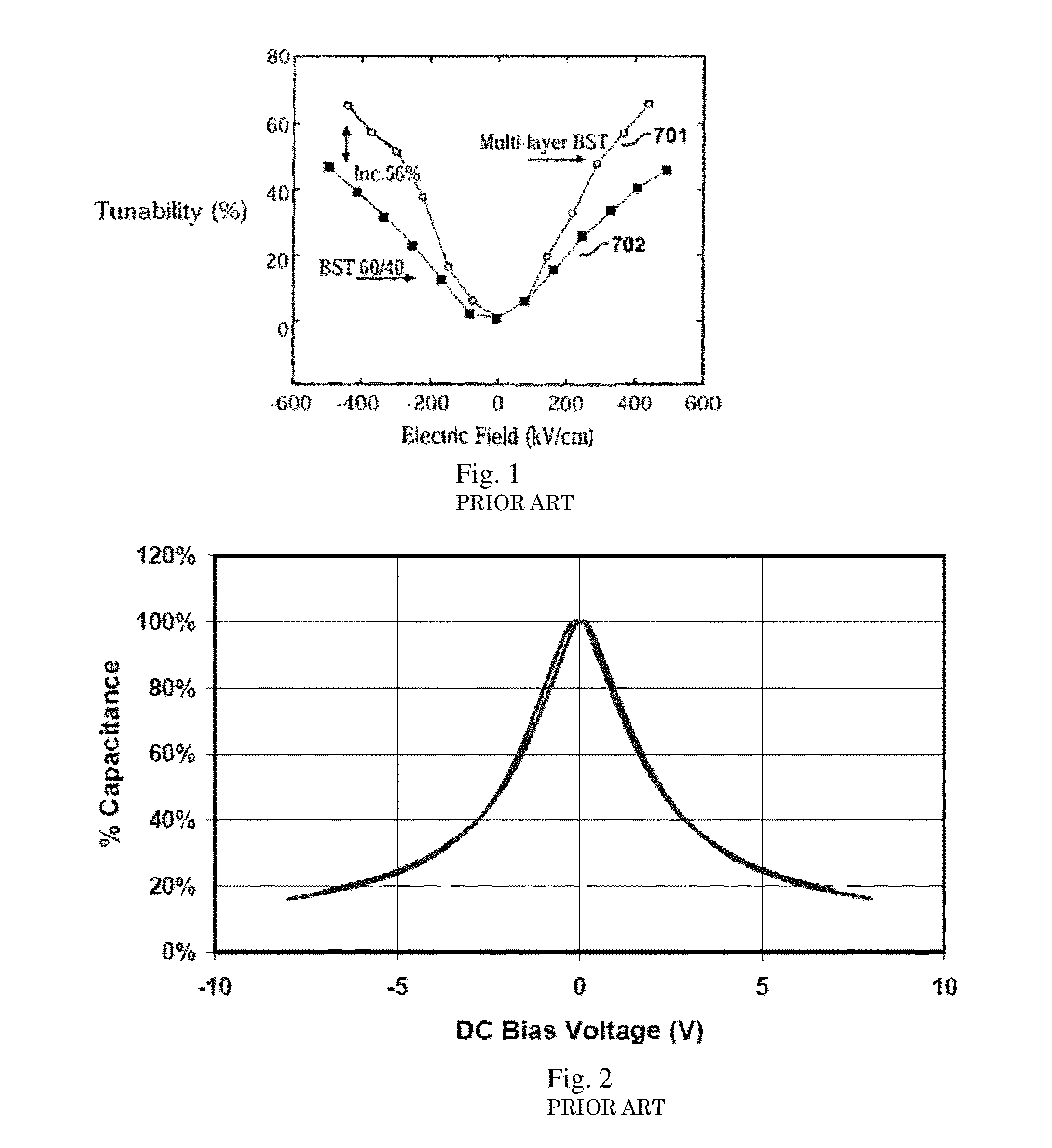

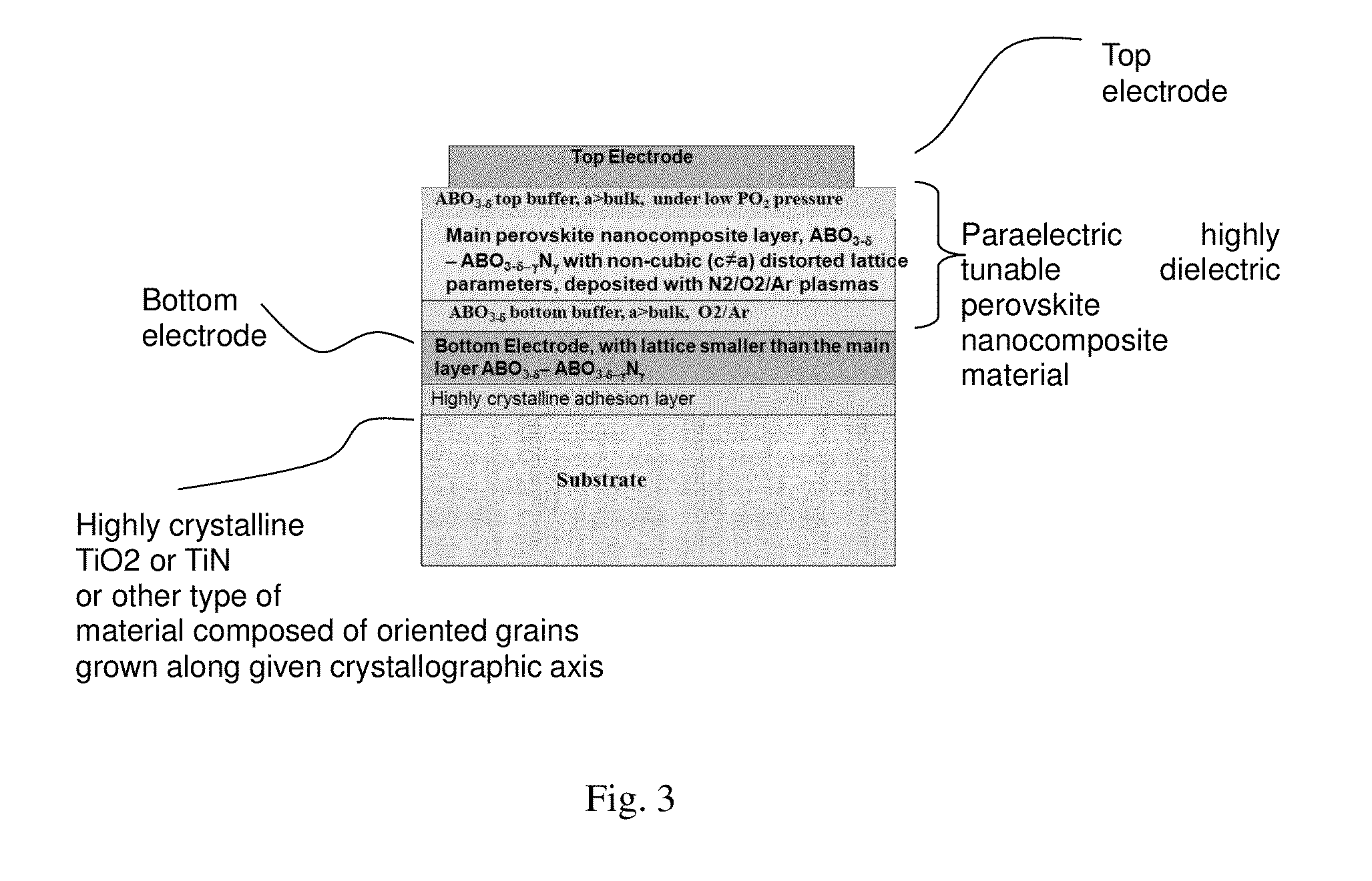

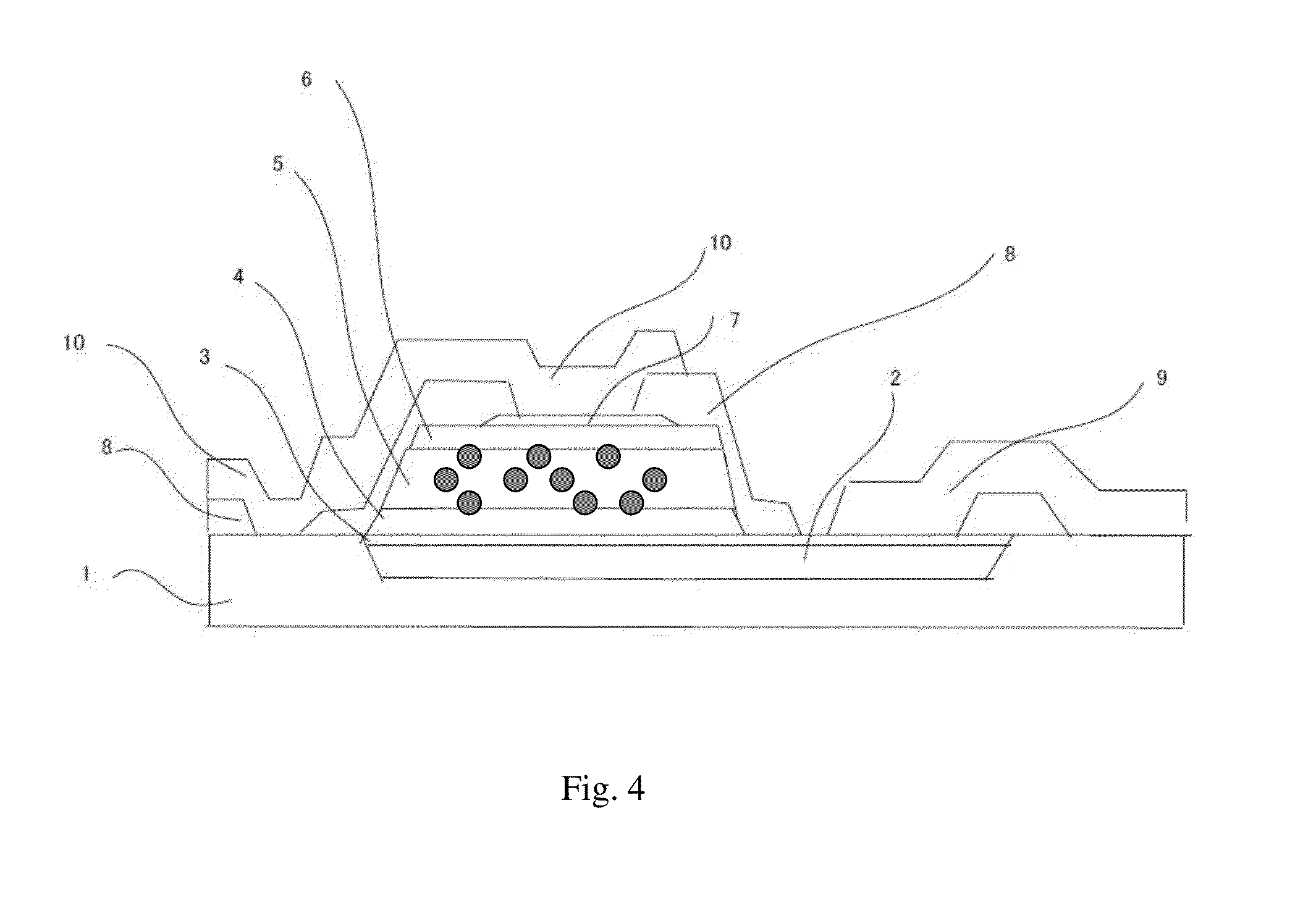

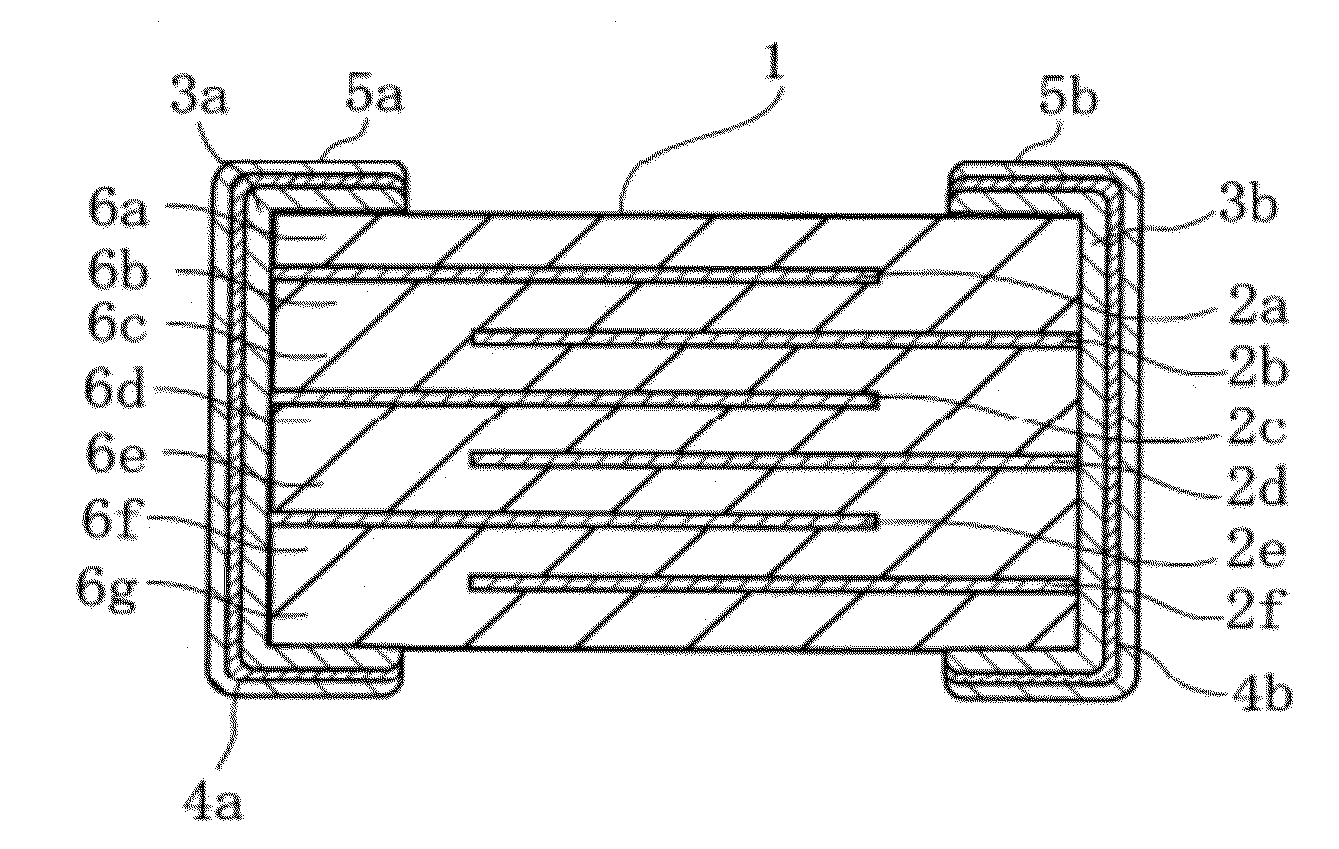

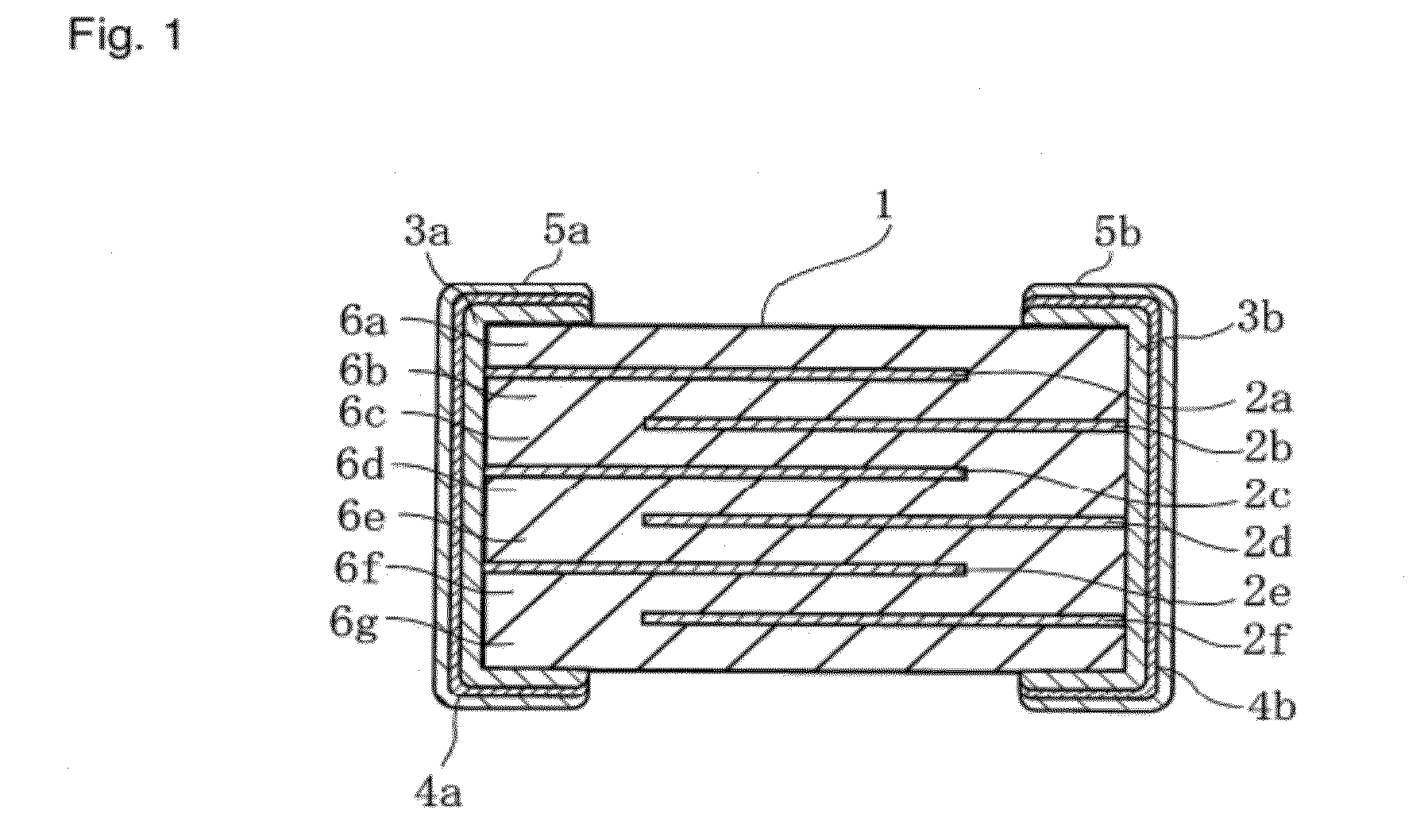

Perovskite material with anion-controlled dielectric properties, thin film capacitor device, and method for manufacturing the same

ActiveUS20130003254A1High voltageHigh dielectric constantMaterial nanotechnologyAlkaline earth titanatesCrystalline oxideFilm capacitor

A crystalline perovskite crystalline composite paraelectric material includes nano-regions containing rich N3− anions dispersed in a nano-grain sized matrix of crystalline oxide perovskite material, wherein (ABO3-δ)α-(ABO3-δ-γNγ)1-α. A represents a divalent element, B represents a tetravalent element, γ satisfies 0.005≦γ≦1.0, 1-α satisfies 0.05≦1-α≦0.9, and 1-α is an area ratio between the regions containing rich N3− anions and the matrix of remaining oxide perovskite material.

Owner:MURATA MFG CO LTD

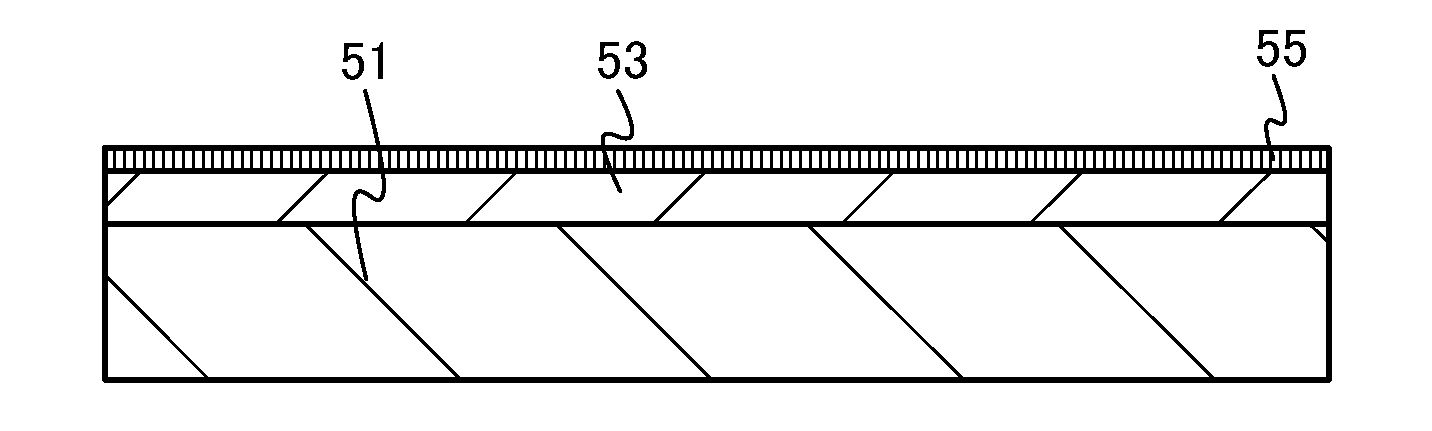

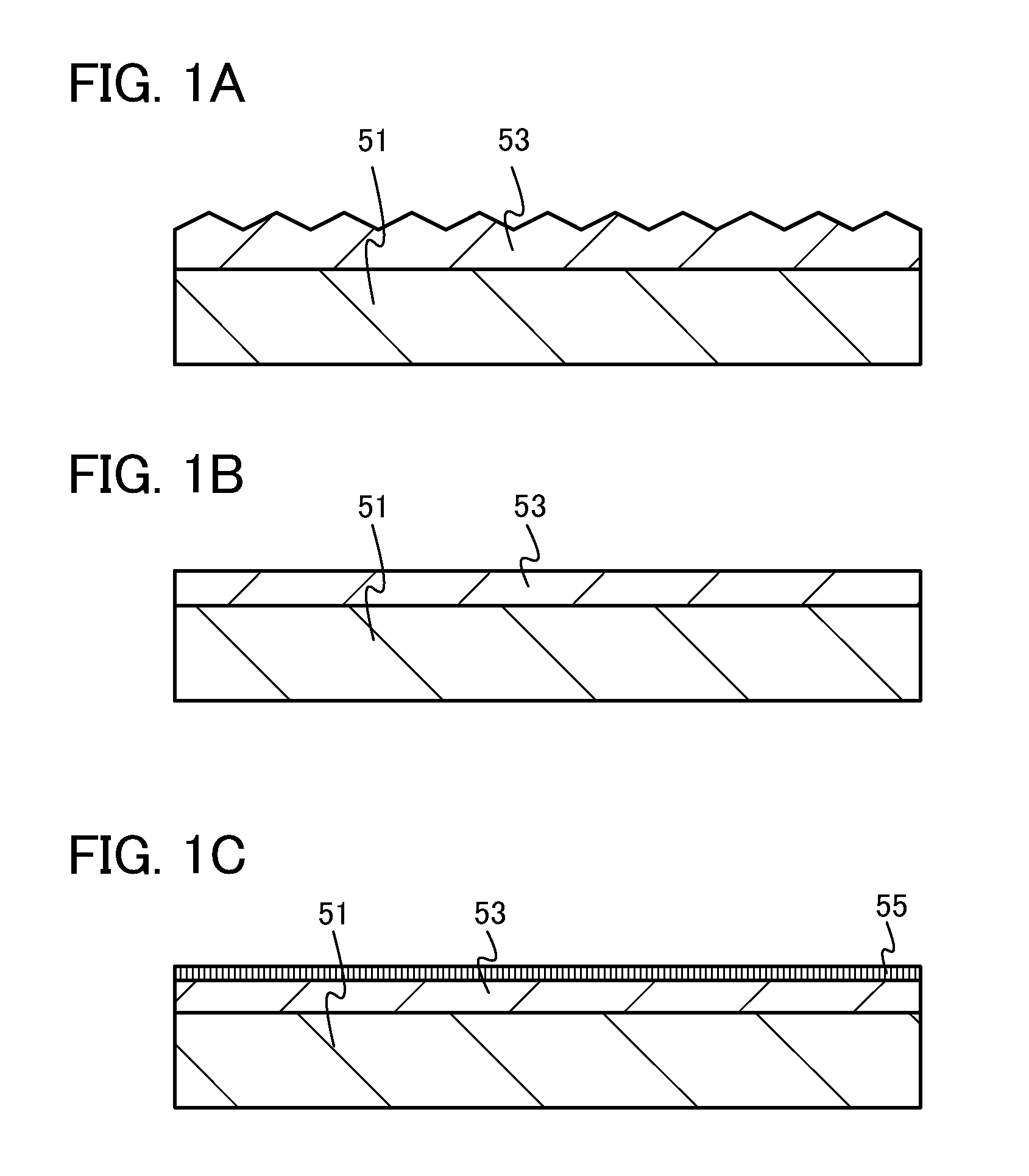

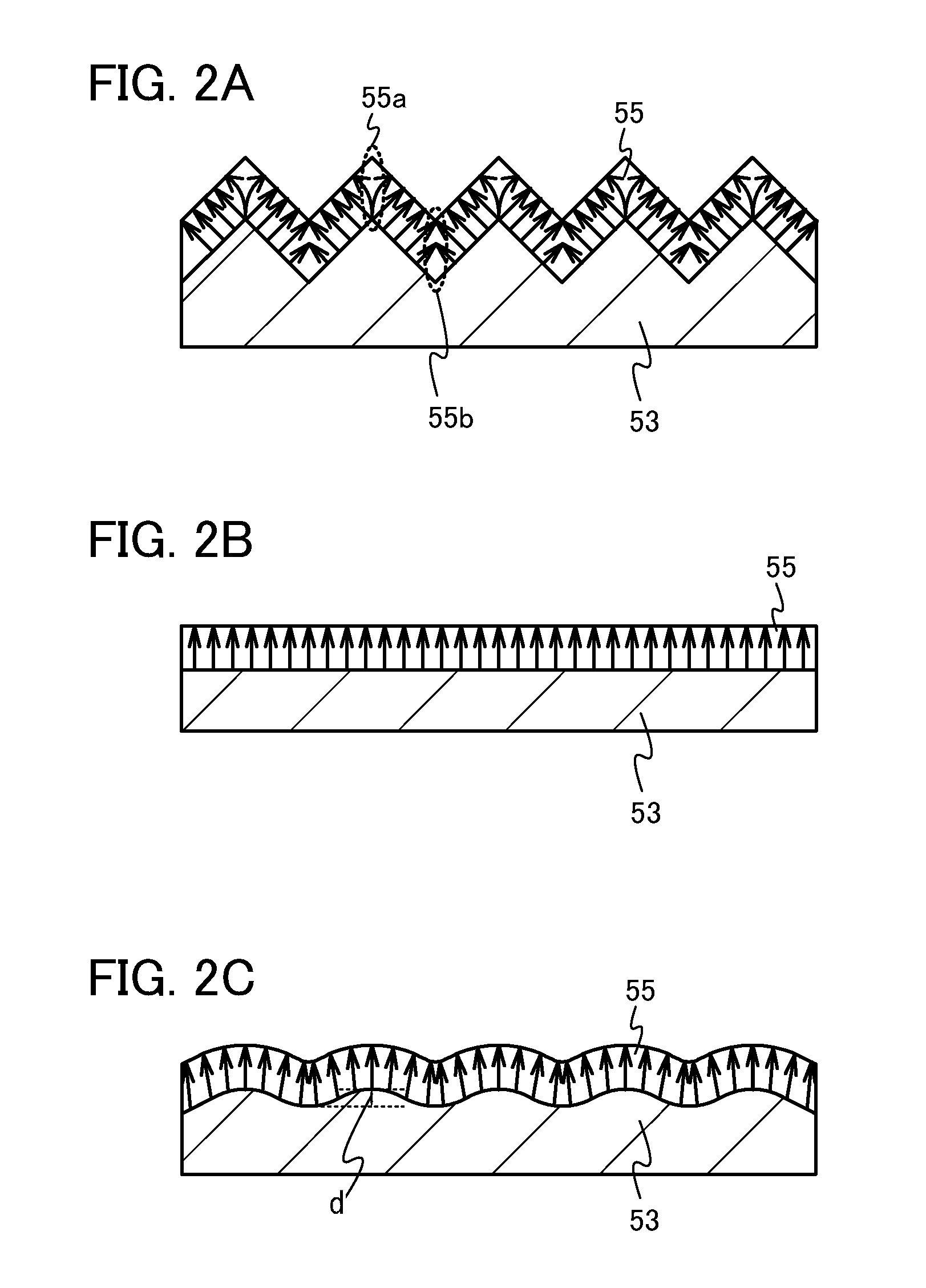

Semiconductor device and method of manufacturing semiconductor device

ActiveUS20120241734A1Reduce defect densityStable electrical characteristicsTransistorSolid-state devicesCrystalline oxidePower semiconductor device

An object is to provide a highly reliable semiconductor device having stable electric characteristics by using an oxide semiconductor film having stable electric characteristics. Another object is to provide a semiconductor device having higher mobility by using an oxide semiconductor film having high crystallinity. A crystalline oxide semiconductor film is formed over and in contact with an insulating film whose surface roughness is reduced, whereby the oxide semiconductor film can have stable electric characteristics. Accordingly, the highly reliable semiconductor device having stable electric characteristics can be provided. Further, the semiconductor device having higher mobility can be provided.

Owner:SEMICON ENERGY LAB CO LTD

Processes for the preparation of 2-chloro-1,1,1,2,3,3,3-heptafluoropropane, hexafluoropropene and 1,1,1,2,3,3,3-heptafluoropropane

InactiveUS7129383B2Preparation by dehalogenationPreparation by hydrogen halide split-offCrystalline oxideHalohydrocarbon

Owner:EI DU PONT DE NEMOURS & CO

Cpp-type magneto resistive effect element having a pair of magnetic layers

InactiveUS20090174971A1High magneto-resistive ratioSoft magnetic characteristicNanomagnetismNanoinformaticsCrystalline oxideFilm plane

A magnetoresistance effect element comprises: a pair of magnetic layers whose magnetization directions form a relative angle therebetween that is variable depending on an external magnetic field; and a crystalline spacer layer sandwiched between the pair of magnetic layers; wherein sense current may flow in a direction that is perpendicular to a film plane of the pair of magnetic layers and the spacer layer. The spacer layer includes a crystalline oxide, and either or both magnetic layers whose magnetization direction is variable depending on the external magnetic field has a layer configuration in which a CoFeB layer is sandwiched between a CoFe layer and a NiFe layer and is positioned between the spacer layer and the NiFe layer.

Owner:TDK CORPARATION

Semiconductor device

ActiveUS20170179249A1Excellent semiconductor propertiesExcellent in semiconductor property and Schottky characteristicSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxidePower semiconductor device

A semiconductor device is provided that is excellent in semiconductor properties and Schottky characteristics. A semiconductor device includes: a semiconductor layer containing a crystalline oxide semiconductor with a corundum structure as a major component; and a Schottky electrode on the semiconductor layer, wherein the Schottky electrode is formed by containing a metal of Groups 4-9 of the periodic table, thereby manufacturing a semiconductor device excellent in semiconductor properties and Schottky characteristics without impairing the semiconductor properties to use the semiconductor device thus obtained for a power device and the like.

Owner:FLOSFIA

Multilayer structure, method for manufacturing same, semiconductor device, and crystalline film

ActiveUS20170278706A1High crystallinityImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxideIndium

A multilayer structure with excellent crystallinity and a semiconductor device of the multilayer structure with good mobility are provided. A multilayer structure includes: a corundum structured crystal substrate; and a crystalline film containing a corundum structured crystalline oxide as a major component, the film formed directly on the substrate or with another layer therebetween, wherein the crystal substrate has an off angle from 0.2° to 12.0°, and the crystalline oxide contains one or more metals selected from indium, aluminum, and gallium.

Owner:FLOSFIA

Dielectric ceramic and laminated ceramic capacitor

ActiveUS20120033344A1Easy to confirmImprove featuresFixed capacitor dielectricCeramicsCrystalline oxideBarium titanate

A dielectric ceramic and a laminated ceramic capacitor using the dielectric ceramic are achieved which provide favorable thermal shock resistance without damaging properties or characteristics such as dielectric properties, insulation properties, temperature characteristics, and characteristics in high temperature loading, even when the dielectric layers are reduced in thickness and the number of stacked layers increased. The dielectric ceramic contains, as its main constituent, a barium titanate based compound represented by the general formula ABO3, and a crystalline oxide containing Al, Mg, and Si is present as secondary phase grains in the dielectric ceramic.

Owner:MURATA MFG CO LTD

Structure and method for controlling band offset and alignment at a crystalline oxide-on-semiconductor interface

InactiveUS6652989B2Polycrystalline material growthSemiconductor/solid-state device manufacturingCrystalline oxideCell layer

A crystalline oxide-on-semiconductor structure and a process for constructing the structure involves a substrate of silicon, germanium or a silicon-germanium alloy and an epitaxial thin film overlying the surface of the substrate wherein the thin film consists of a first epitaxial stratum of single atomic plane layers of an alkaline earth oxide designated generally as (AO)n and a second stratum of single unit cell layers of an oxide material designated as (A'BO3)m so that the multilayer film arranged upon the substrate surface is designated (AO)n(A'BO3)m wherein n is an integer repeat of single atomic plane layers of the alkaline earth oxide AO and m is an integer repeat of single unit cell layers of the A'BO3 oxide material. Within the multilayer film, the values of n and m have been selected to provide the structure with a desired electrical structure at the substrate / thin film interface that can be optimized to control band offset and alignment.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com