Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Poor resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

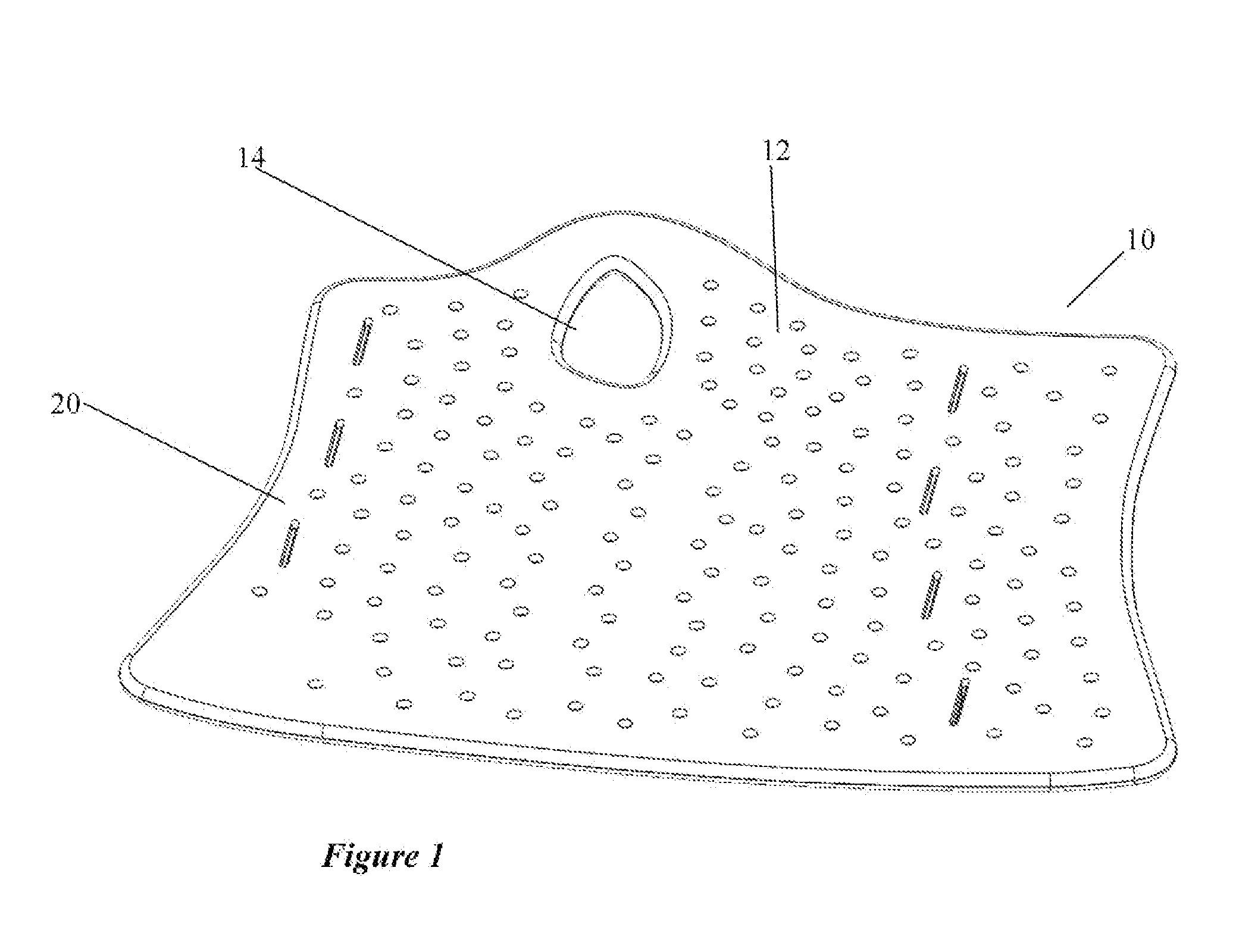

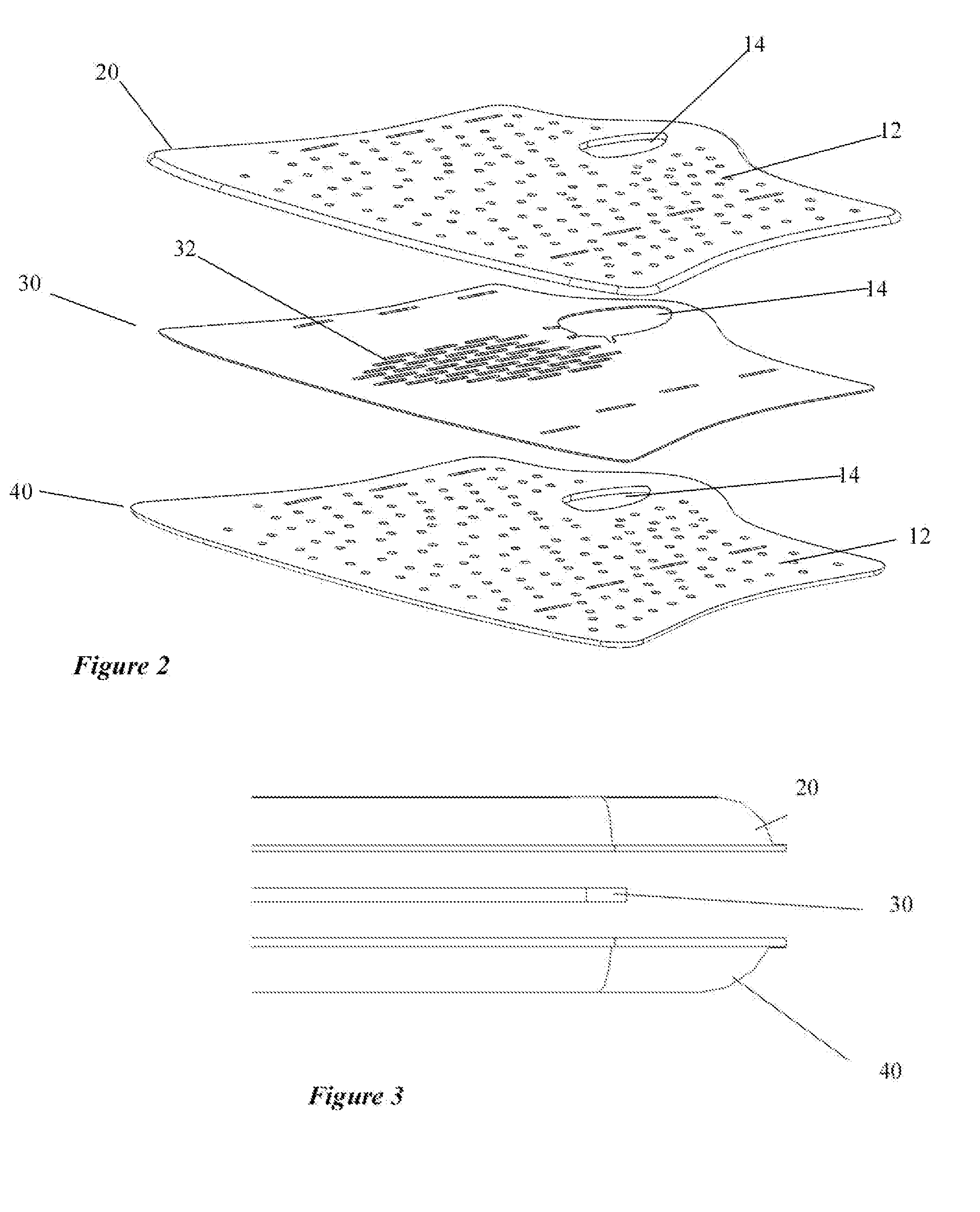

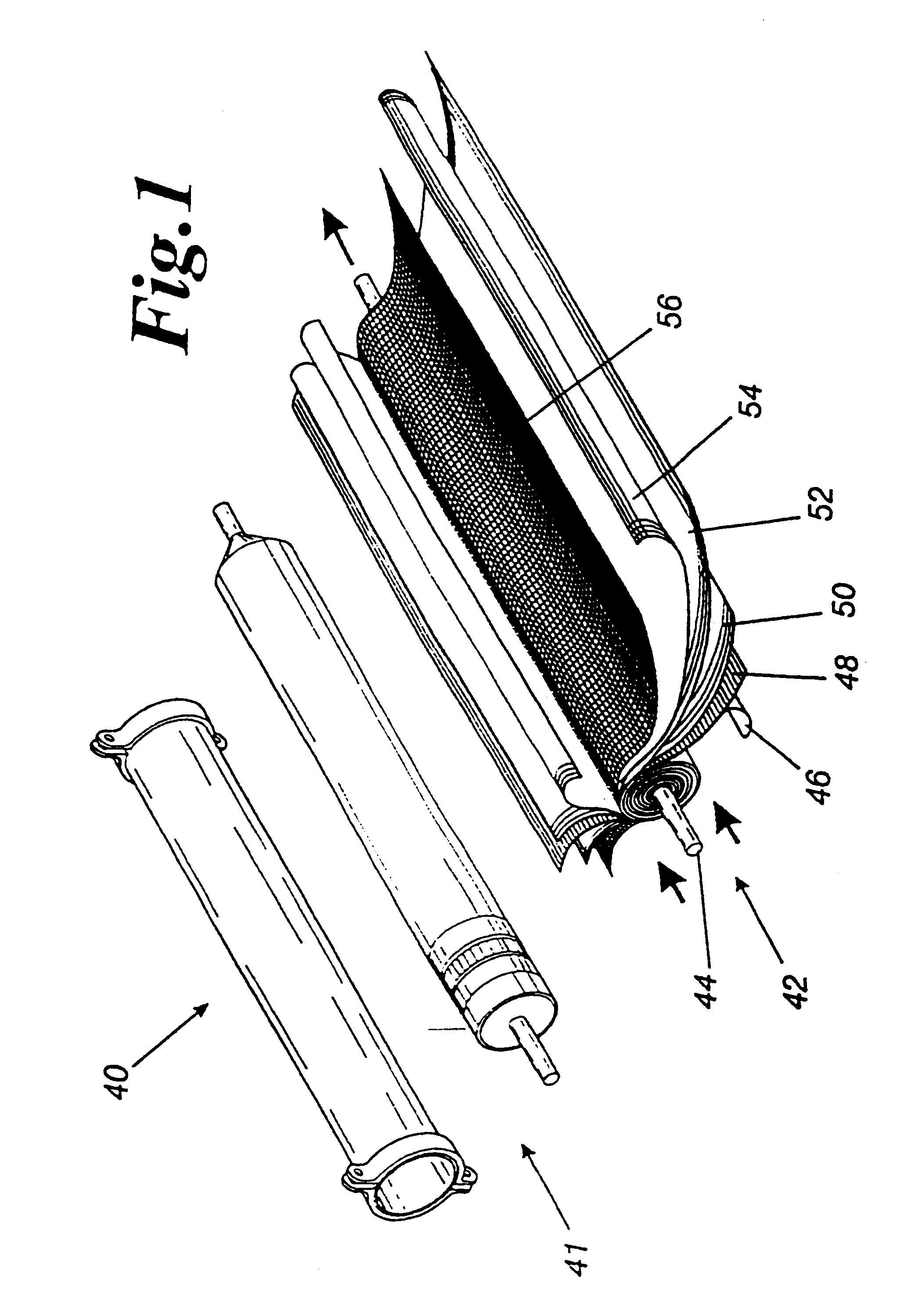

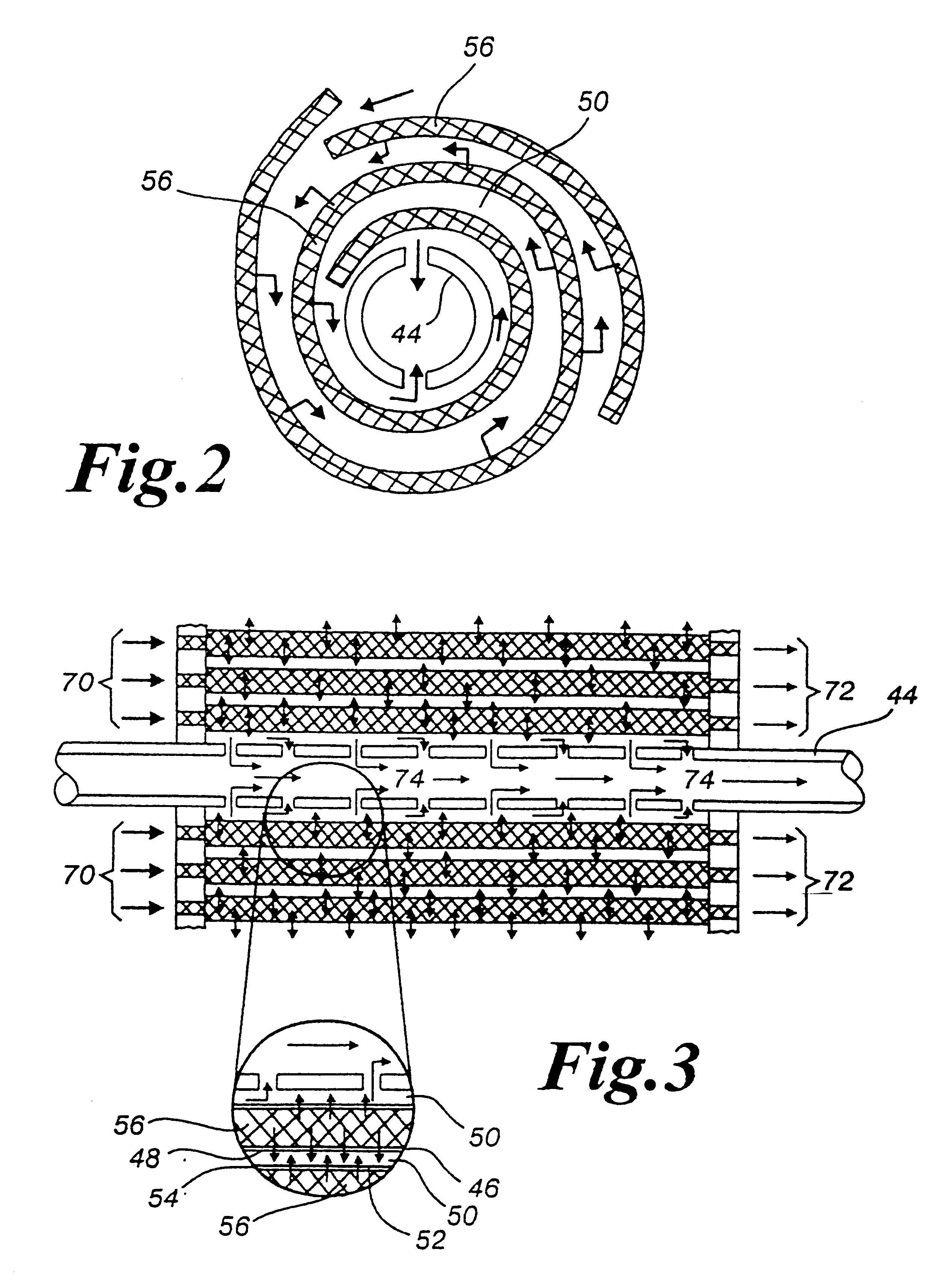

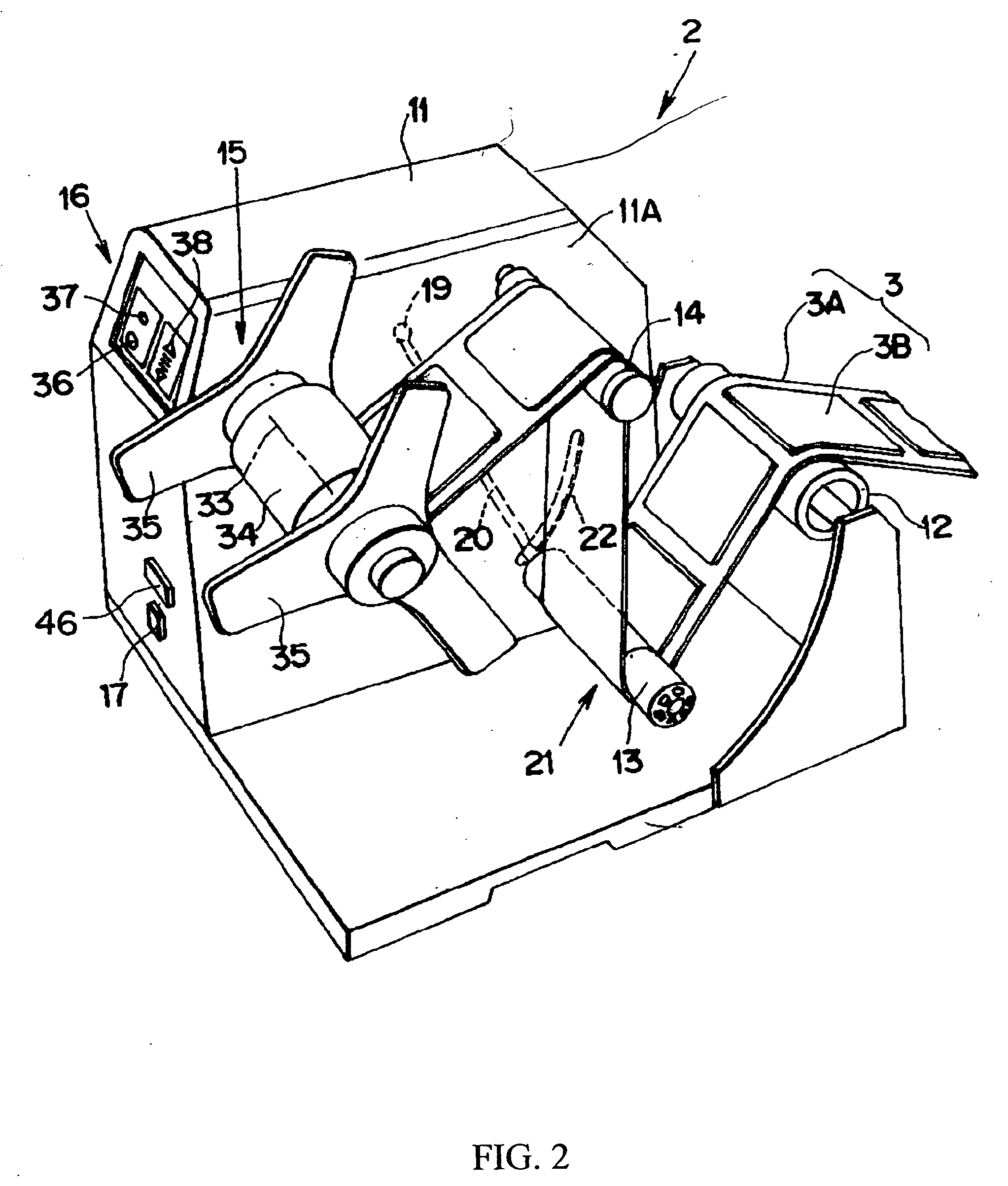

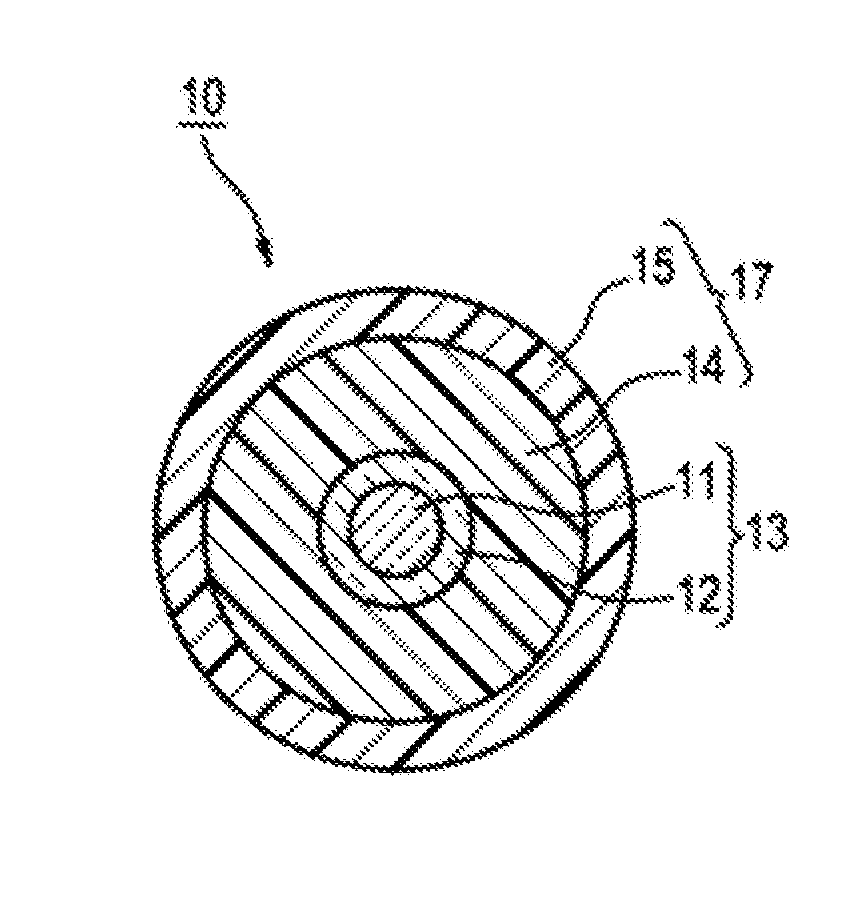

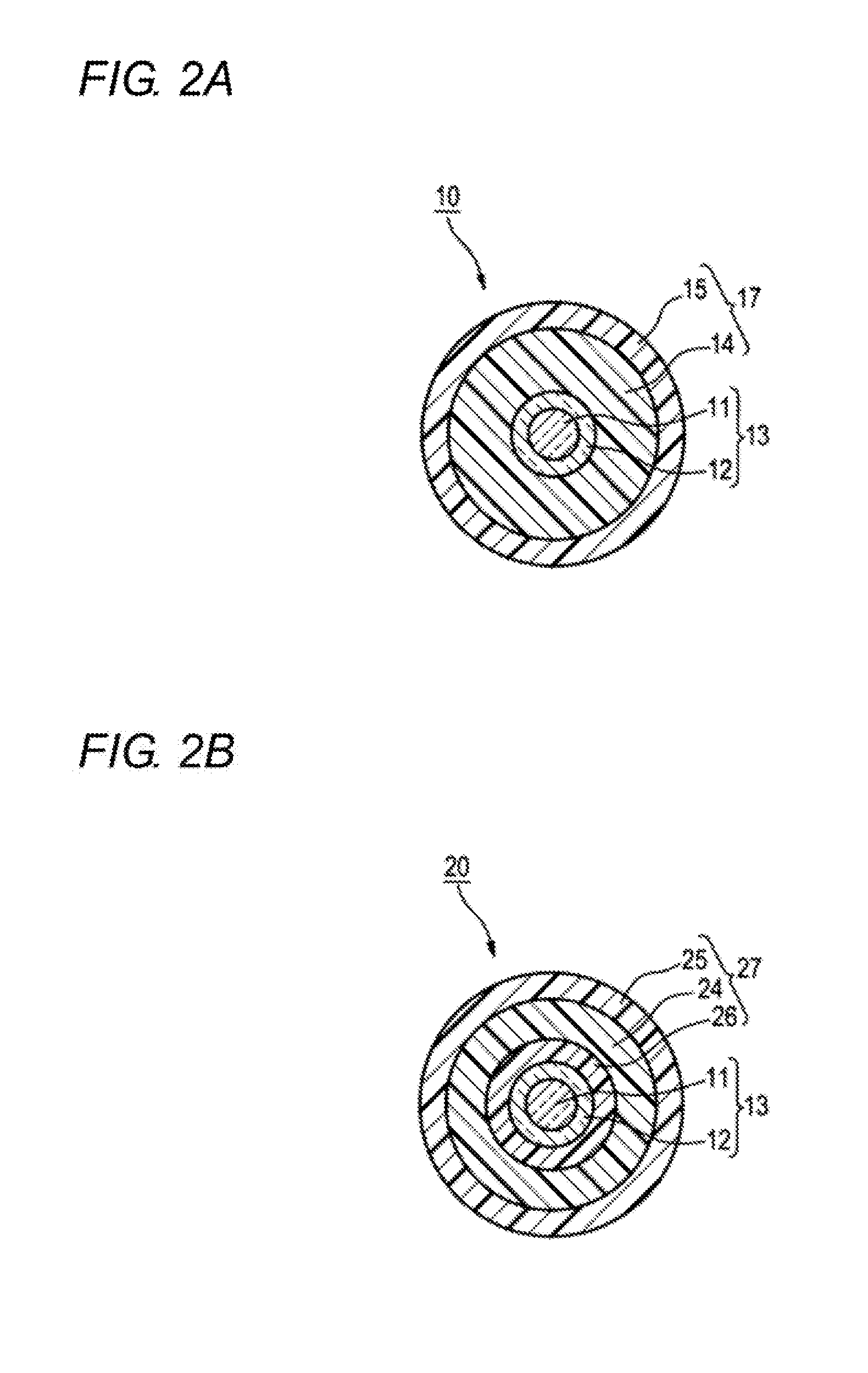

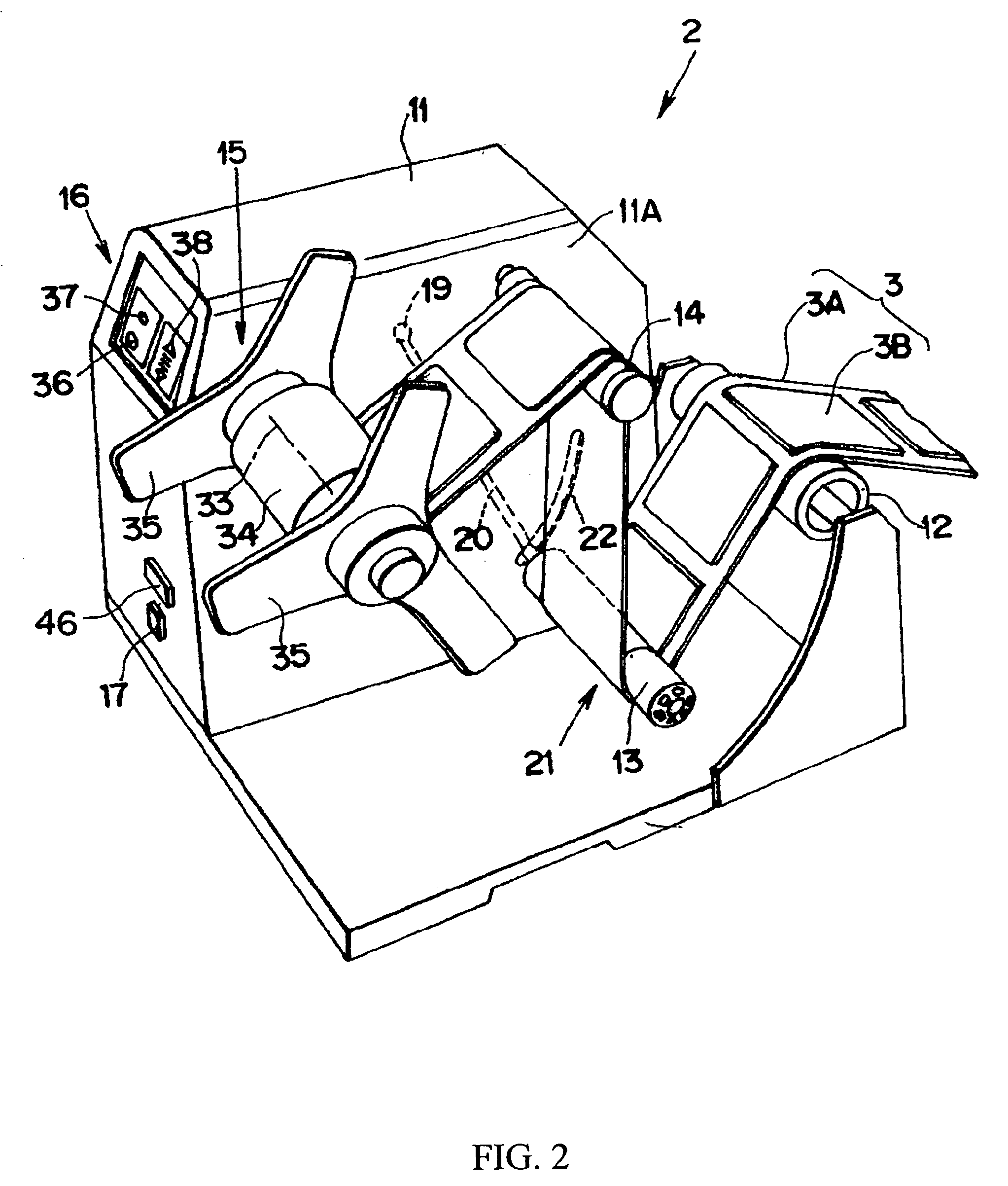

Orthopedic System for Immobilizing and Supporting Body Parts

ActiveUS20080319362A1Little timeLittle manipulationChemical protectionHeat protectionEngineeringStructural material

A unitized cast system for immobilizing and supporting a body part. The unitized casting system includes a first inner layer for padding and dissipating heat against the patient's skin. A second layer is formed from a thermoformable structural material such as perforated plastic. A protective third outer layer is provided to provide insulation for the second layer. These three layers are formed together to form a unitized cast system that is easily formed and applied to the patient.

Owner:DJO

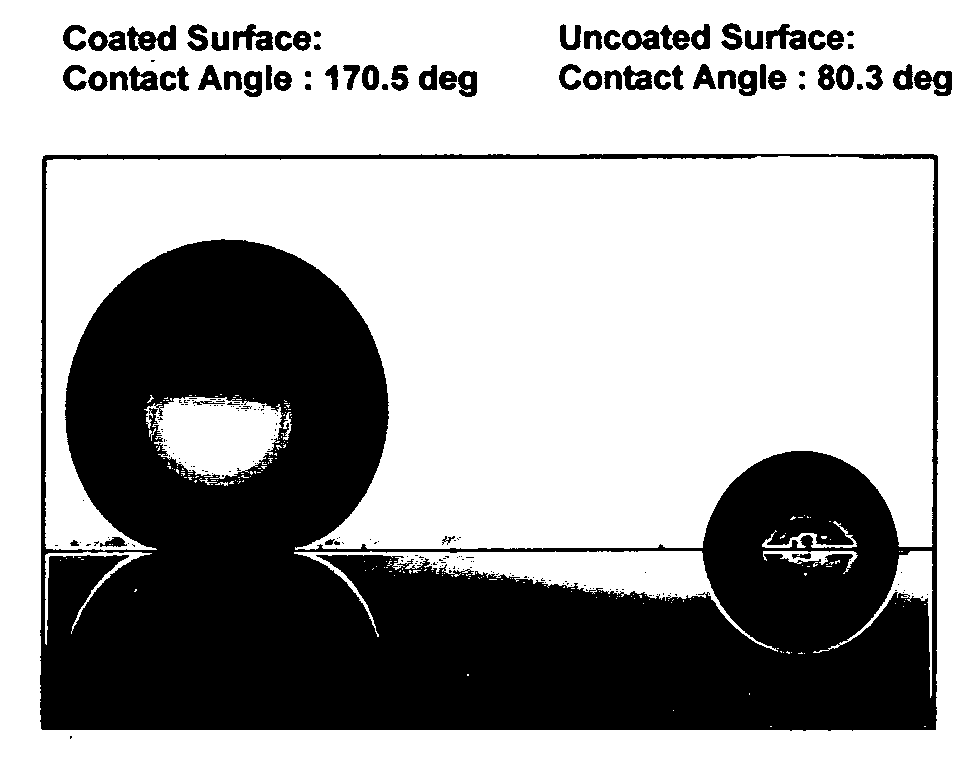

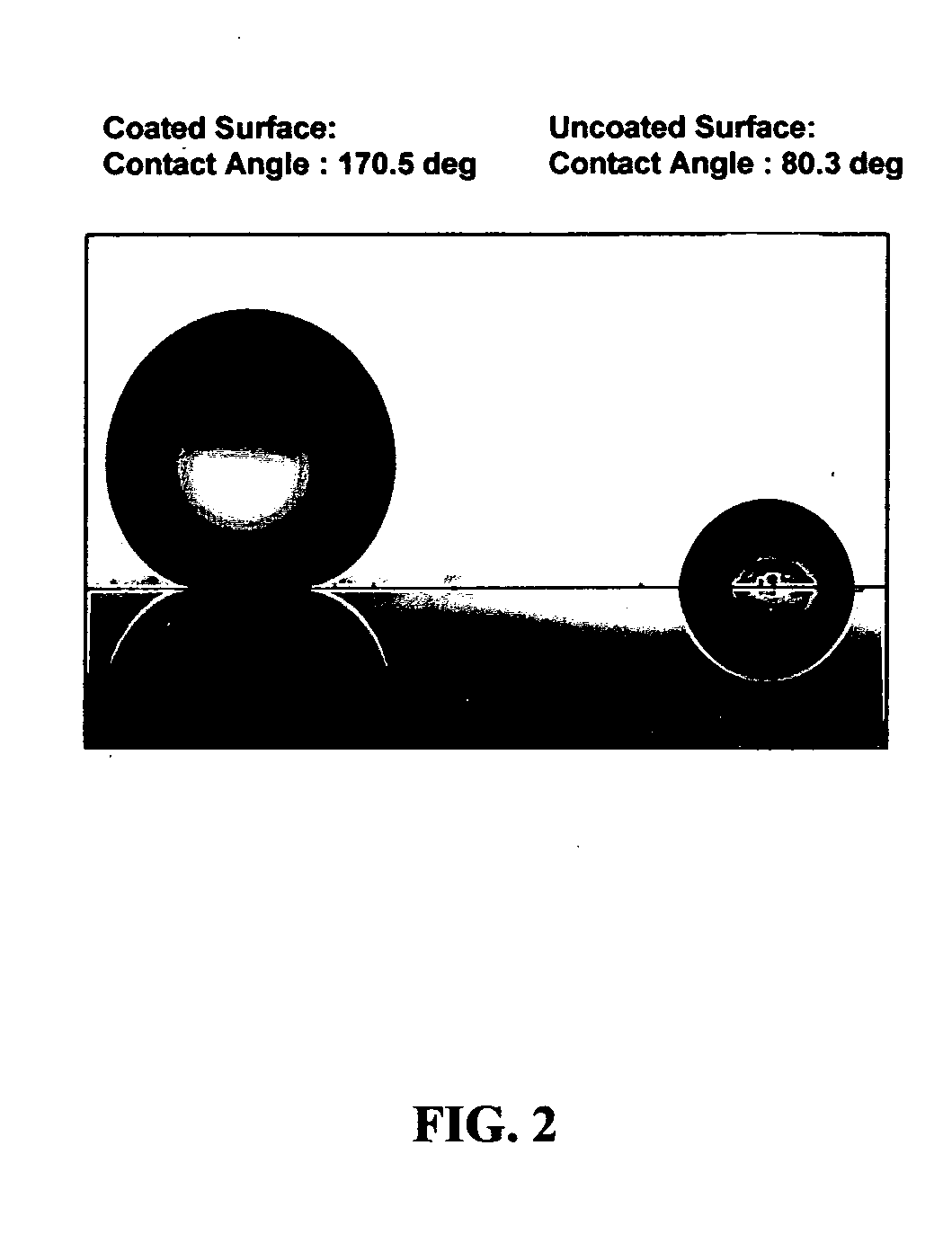

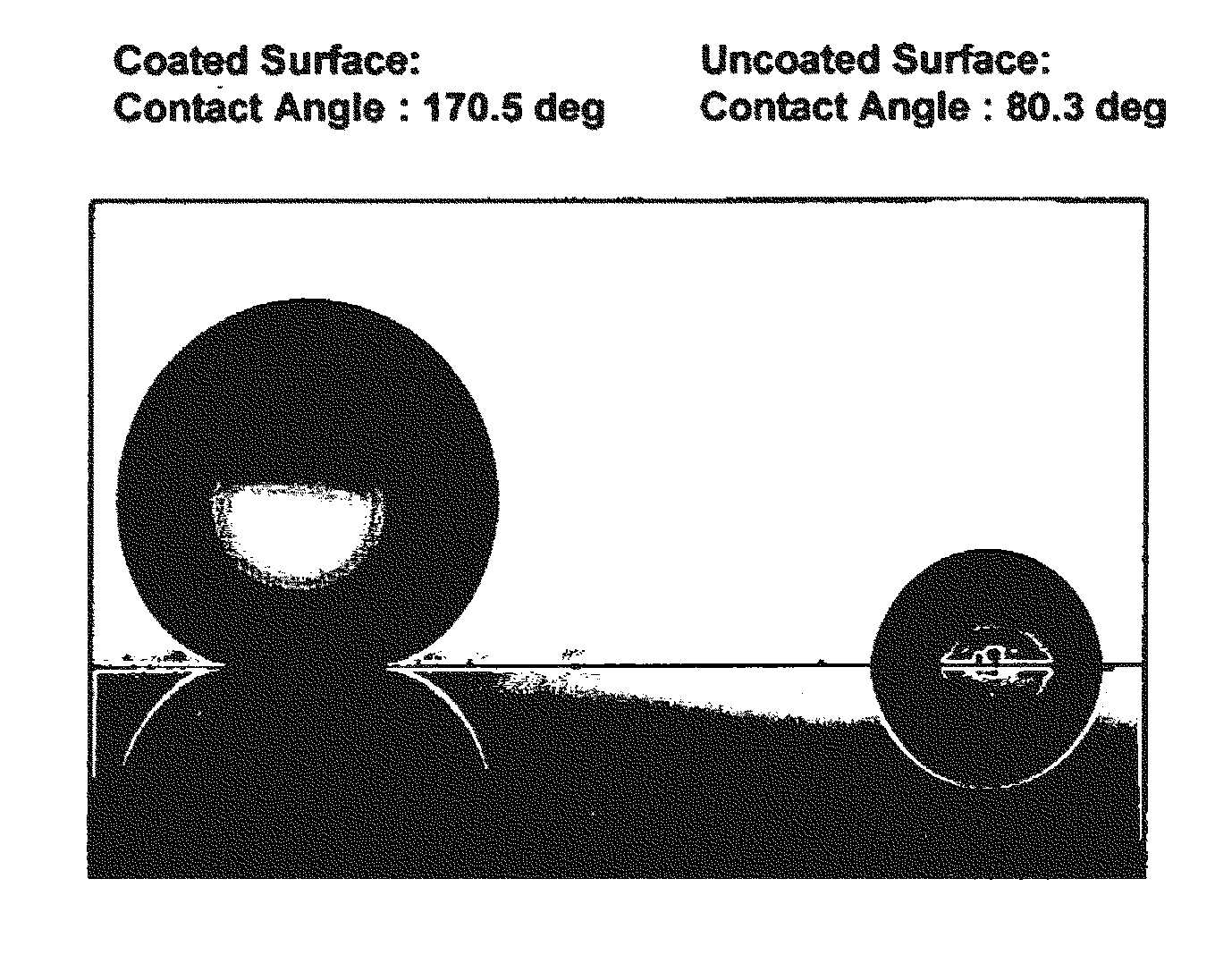

Coating compositions for producing transparent super-hydrophobic surfaces

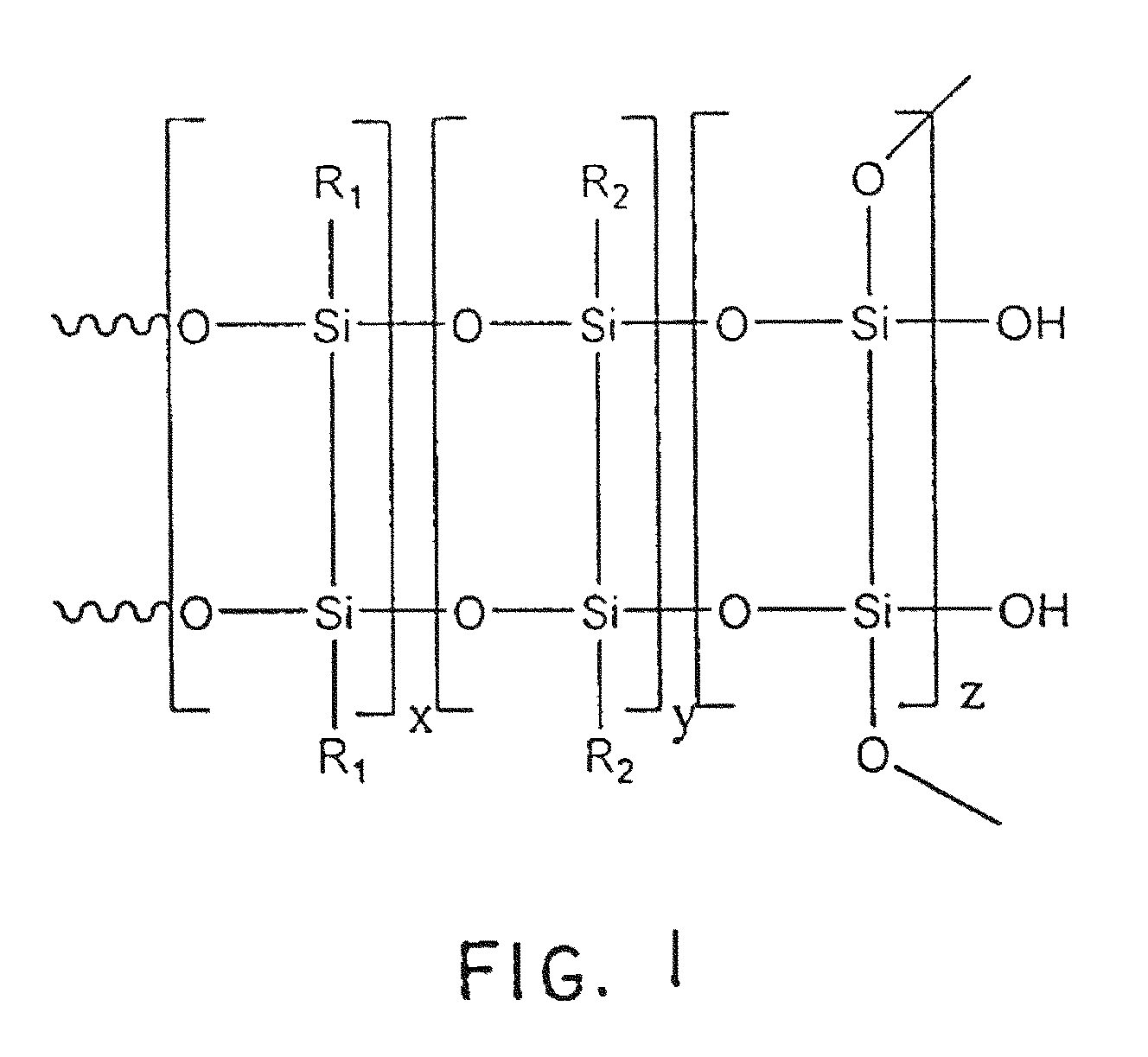

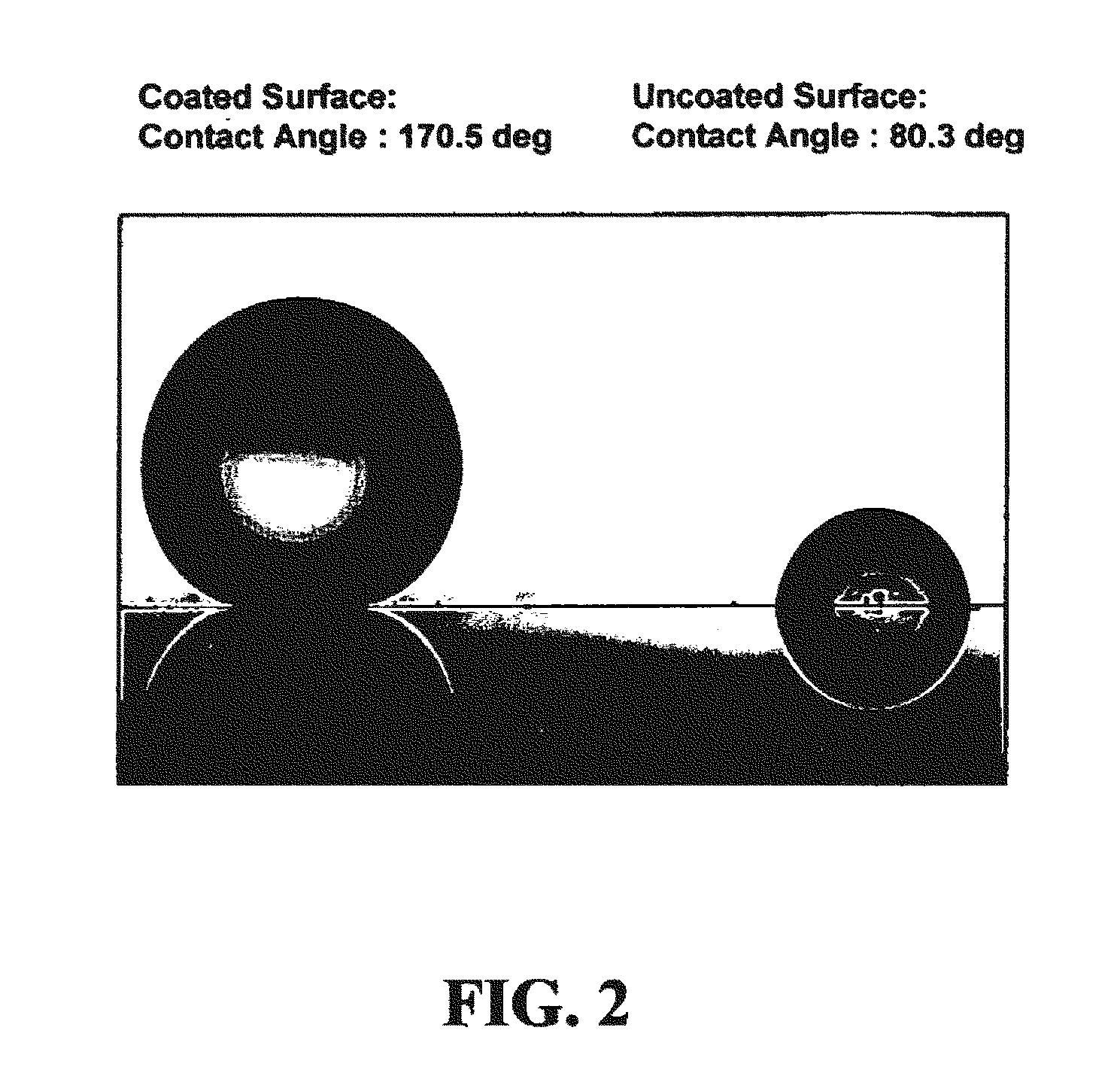

InactiveUS20080221263A1Poor to abrasionImproves UV resistanceCoatingsThin material handlingNanoparticleSilsesquioxane

A coating composition and process for generating transparent, near-transparent, and semi-transparent super-hydrophobic coatings on surfaces having a contact angle of greater than 165 degrees. The composition comprises hydrophobic nanoparticles of silsesquioxanes containing adhesion promoter groups and low surface energy groups.

Owner:ASHLAND LICENSING & INTPROP LLC

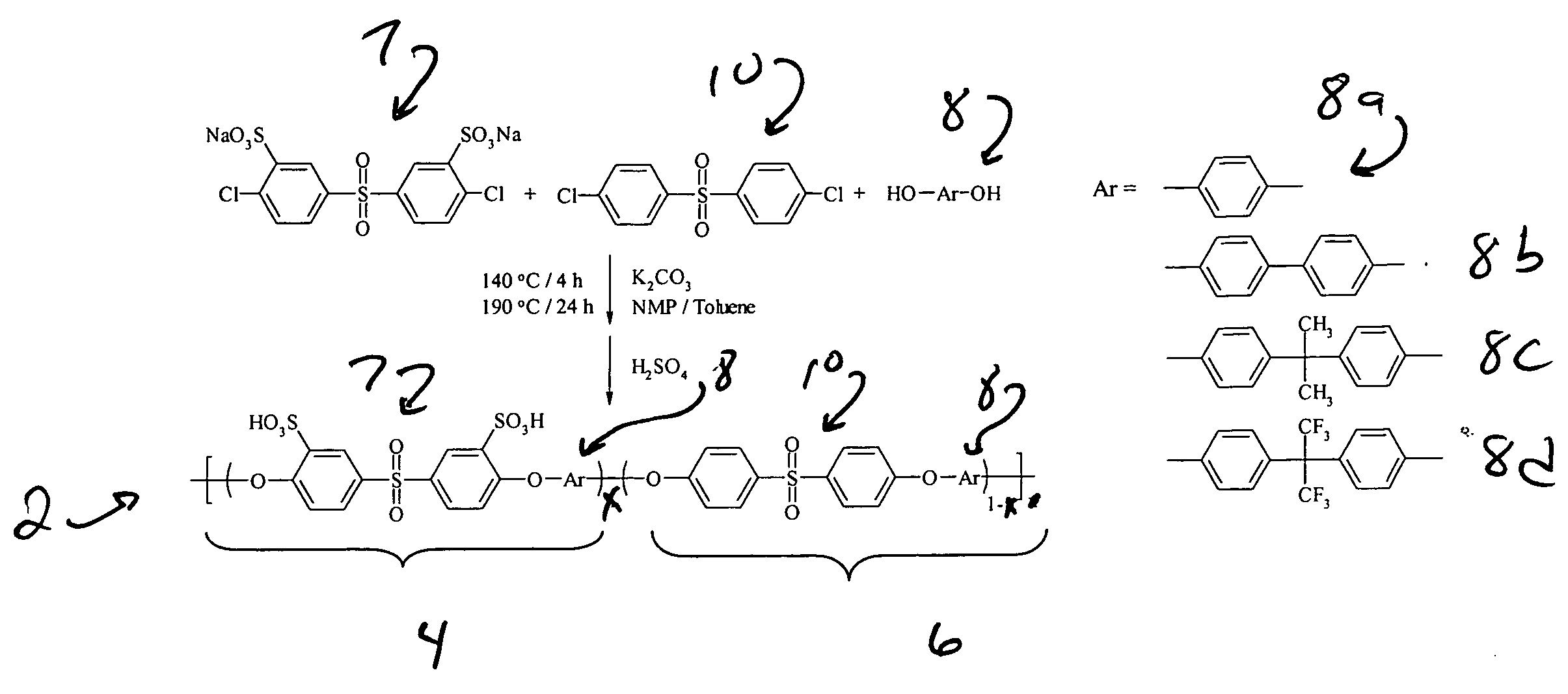

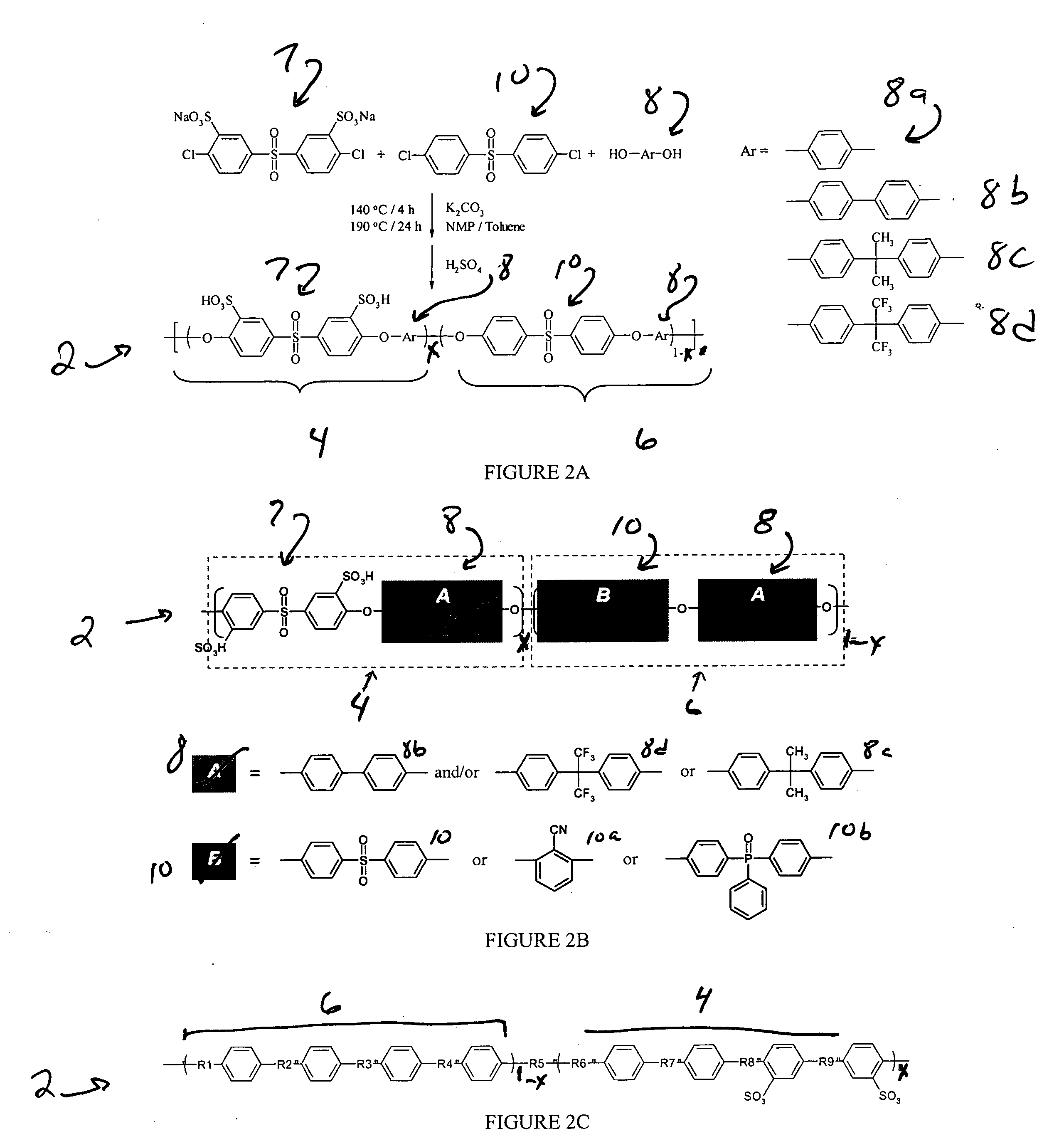

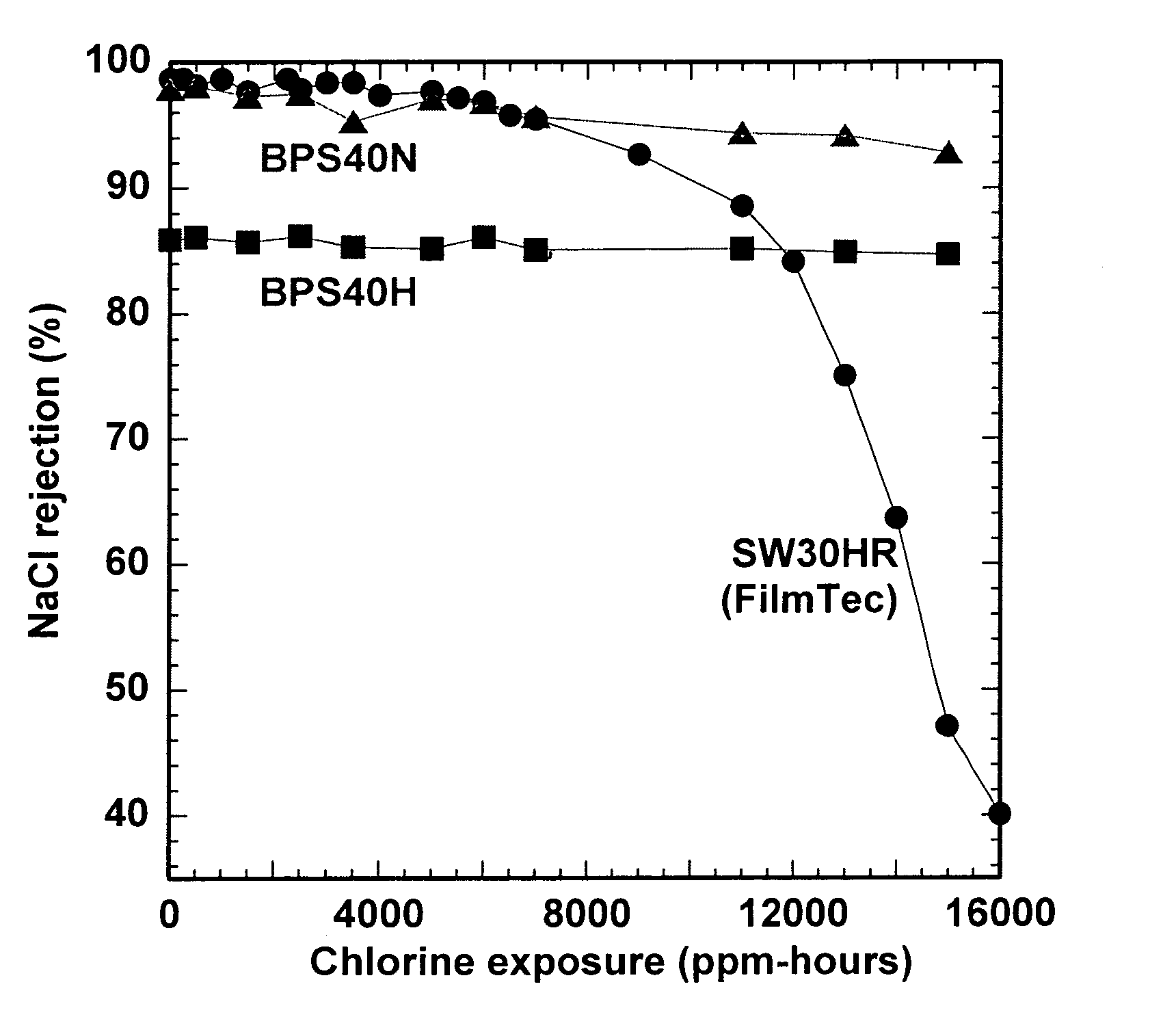

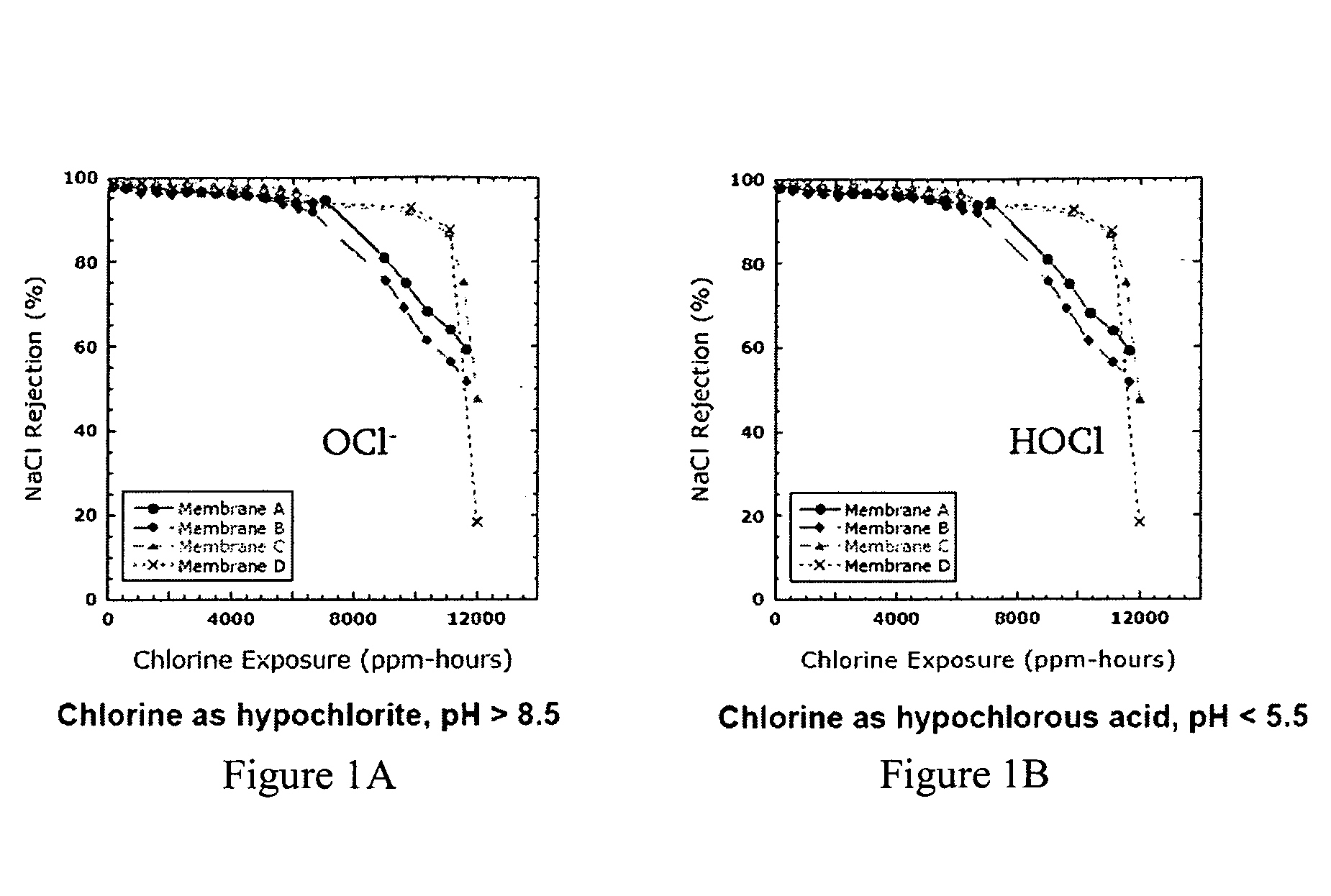

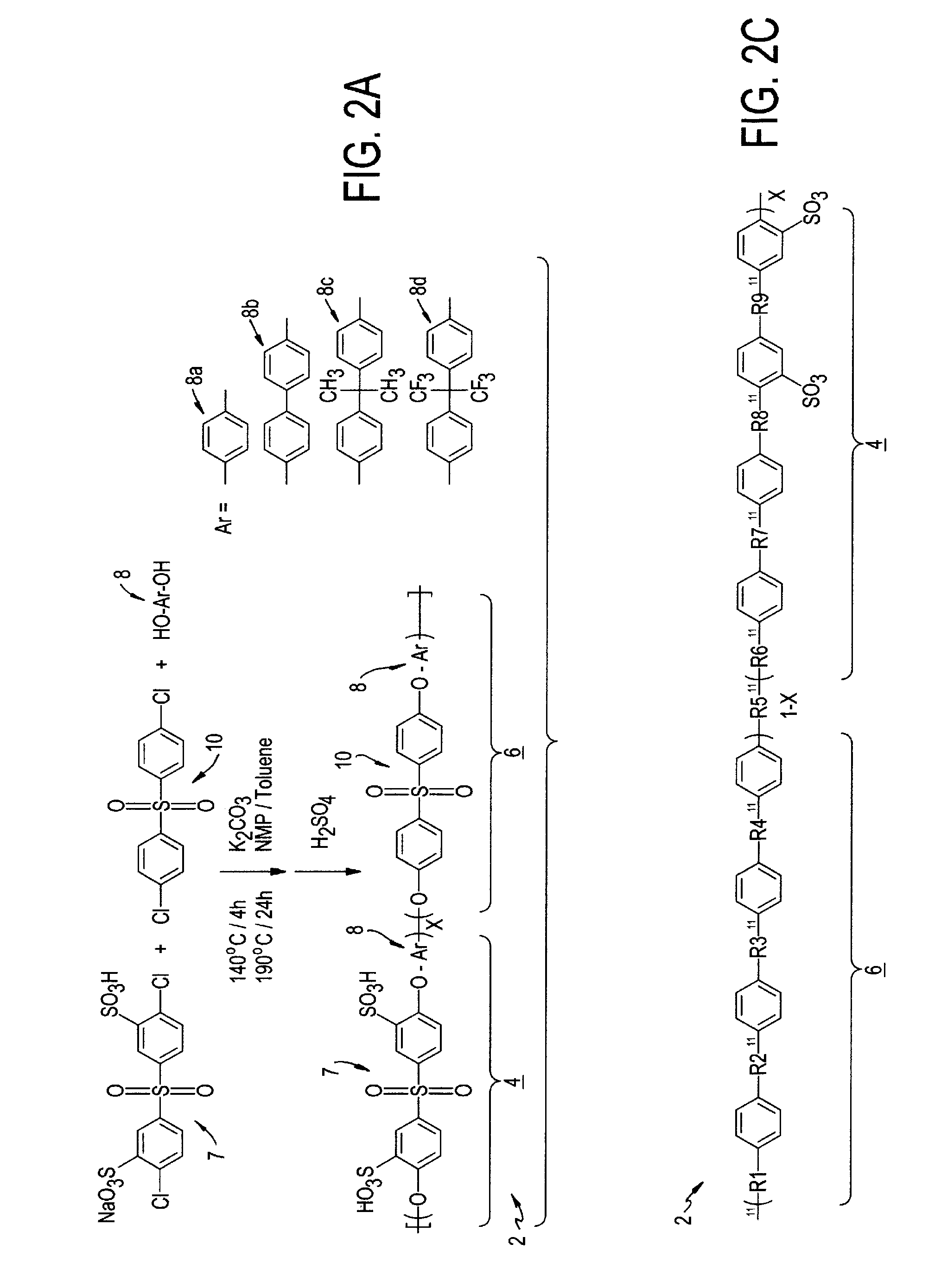

Chlorine resistant desalination membranes based on directly sulfonated poly(Arylene Ether Sulfone) copolymers

ActiveUS20070163951A1Improve pressure resistanceExemption stepsSemi-permeable membranesMembranesHydrophilic monomerSulfonate

The present invention provides a membrane, kit, and method of making a hydrophilic-hydrophobic random copolymer membrane. The hydrophilic-hydrophobic random copolymer membrane includes a hydrophilic-hydrophobic random copolymer. The hydrophilic-hydrophobic random copolymer includes one or more hydrophilic monomers having a sulfonated polyarylsulfone monomer and a second monomer and one or more hydrophobic monomers having a non-sulfonated third monomer and a fourth monomer. The sulfonated polyarylsulfone monomer introduces a sulfonate into the hydrophilic-hydrophobic random copolymer prior to polymerization.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Antimicrobial semi-permeable membranes

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

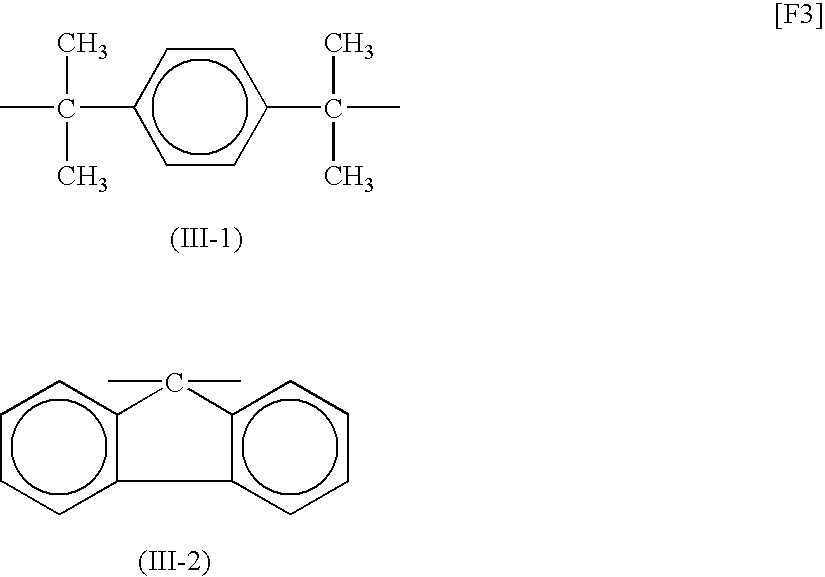

Light diffusive polycarbonate resin composition and light diffusive plate using said resin composition

InactiveUS20090080079A1Improve liquidityEnhanced residence stabilityDiffusing elementsGroup 5/15 element organic compoundsMeth-Liquid-crystal display

The present invention provides a light-diffusive polycarbonate-based resin composition which includes (A) 100 parts by mass of an aromatic polycarbonate resin, (B) 0.01 to parts by mass of a light-diffusing agent, and (C) 0.1 to parts by mass of a styrene-(meth)acrylic ester copolymer, and a light-diffusing plate formed from the composition. The light-diffusive polycarbonate-based resin composition can be injection-molded to form a light-diffusing plate having satisfactory precision in thickness for use in comparatively large liquid crystal displays having a size larger than 20 inches.

Owner:IDEMITSU KOSAN CO LTD

Coating compositions for producing transparent super-hydrophobic surfaces

ActiveUS20110177252A1Improves UV resistanceAbrasion resistanceMaterial nanotechnologyOrganic detergent compounding agentsNanoparticleSilsesquioxane

Owner:VGP IPCO LLC

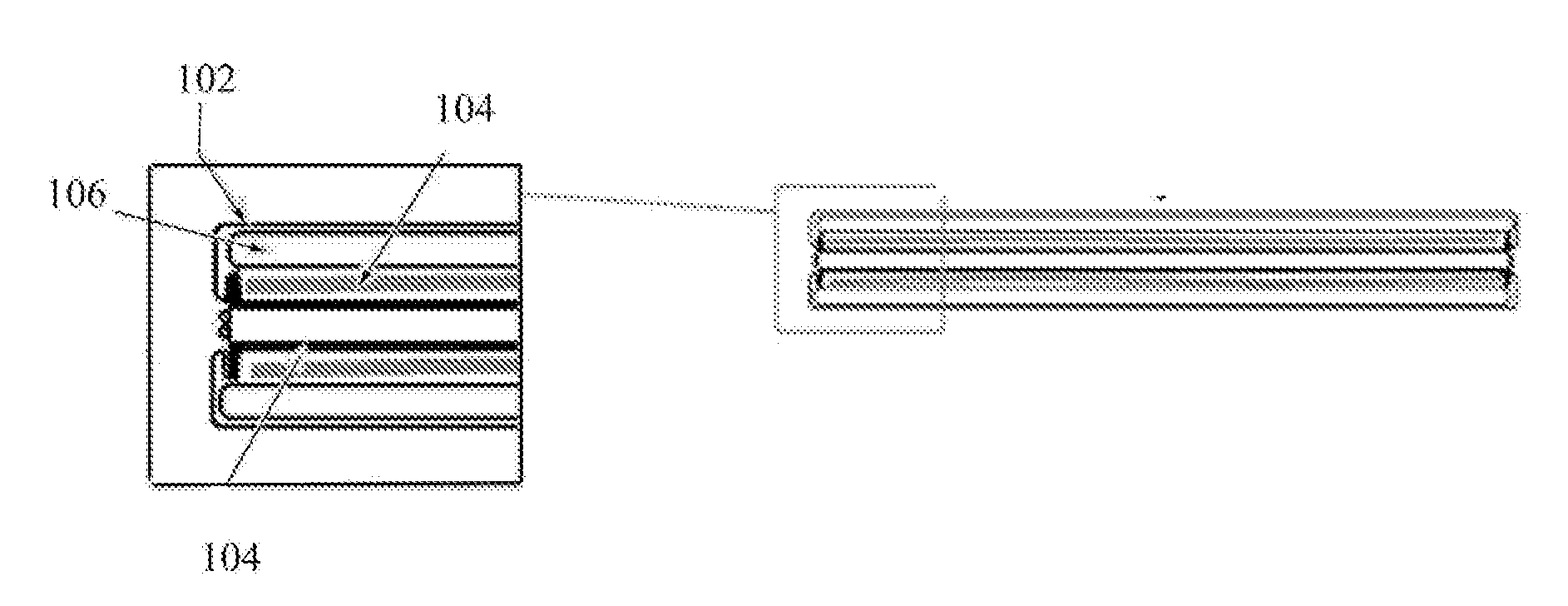

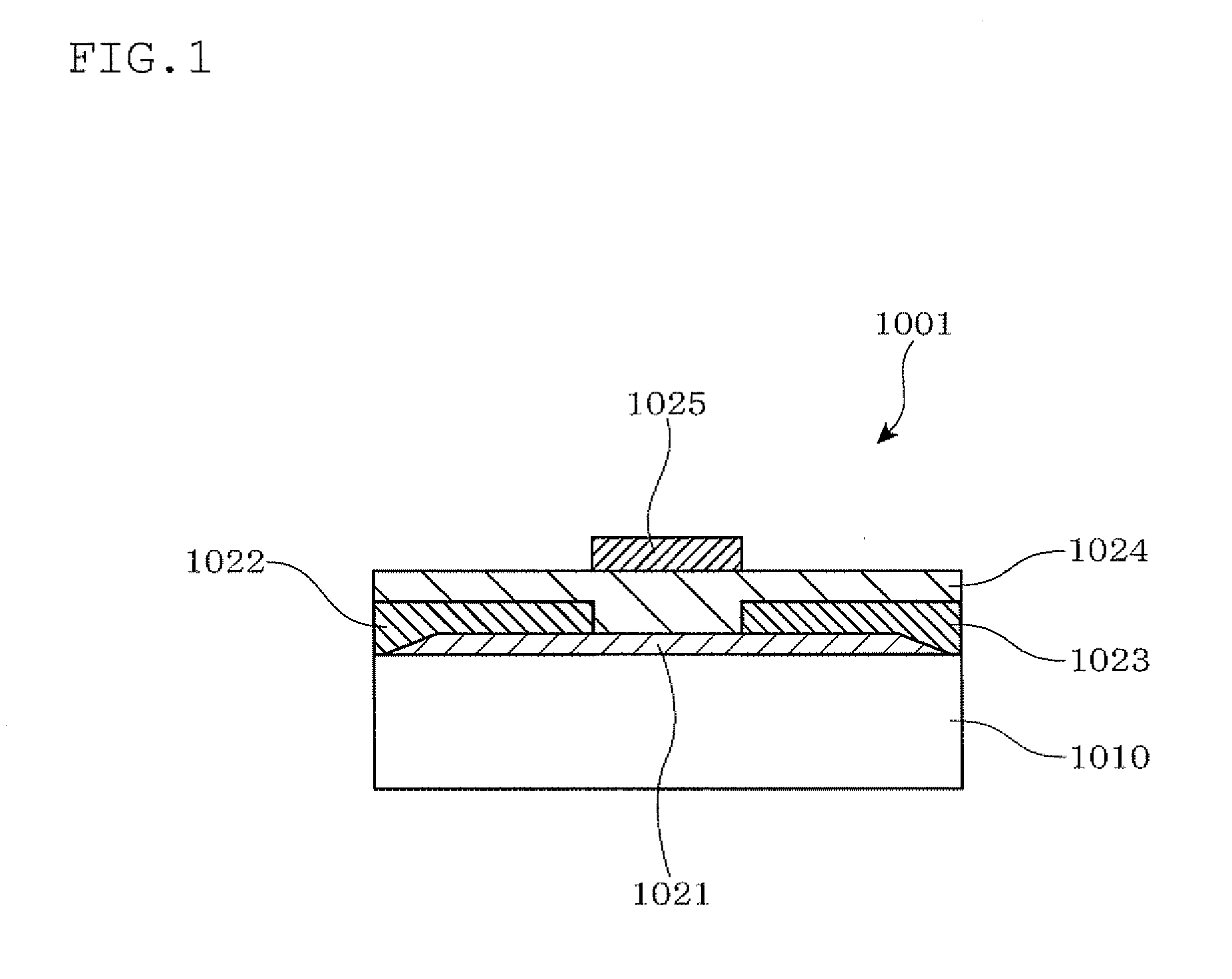

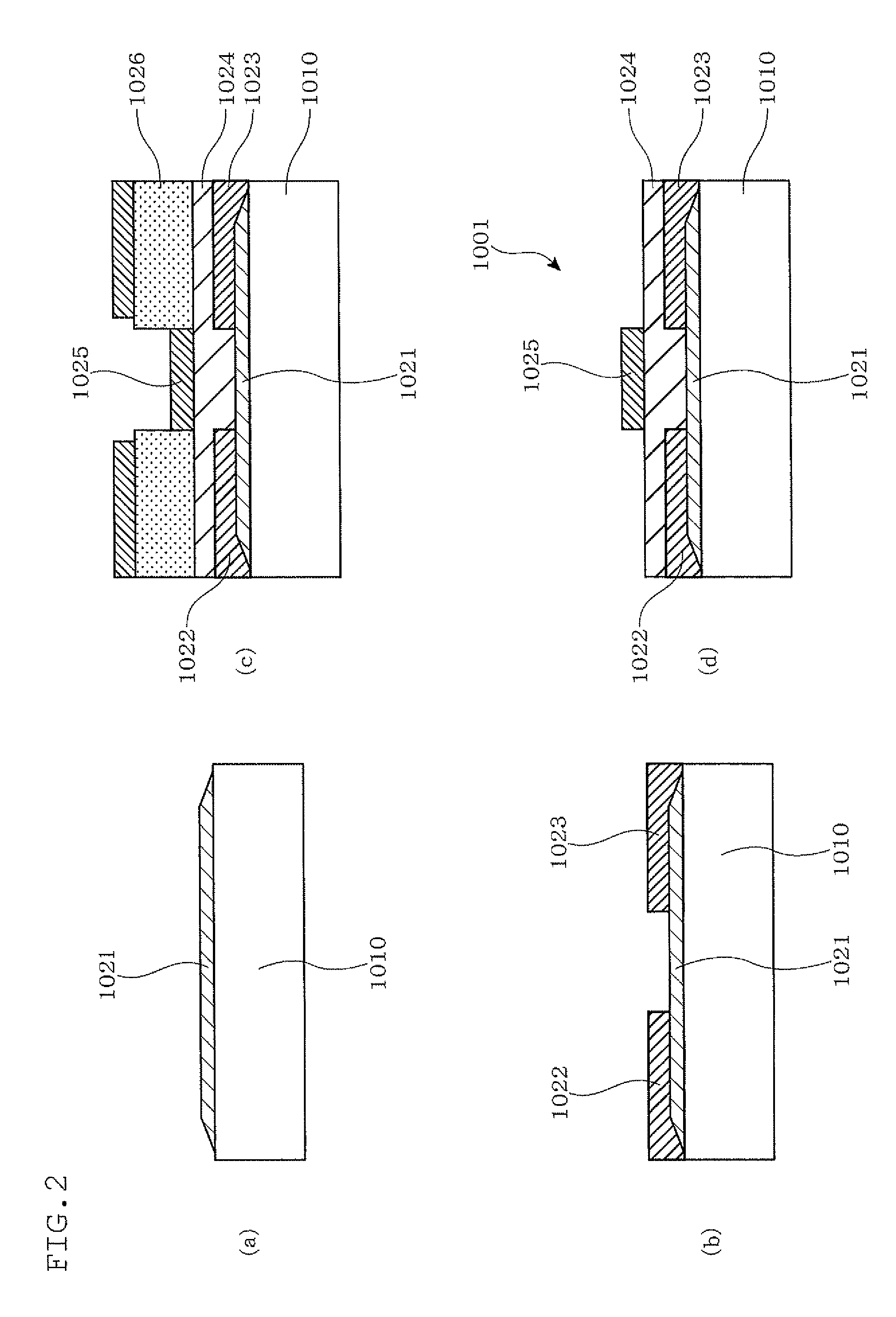

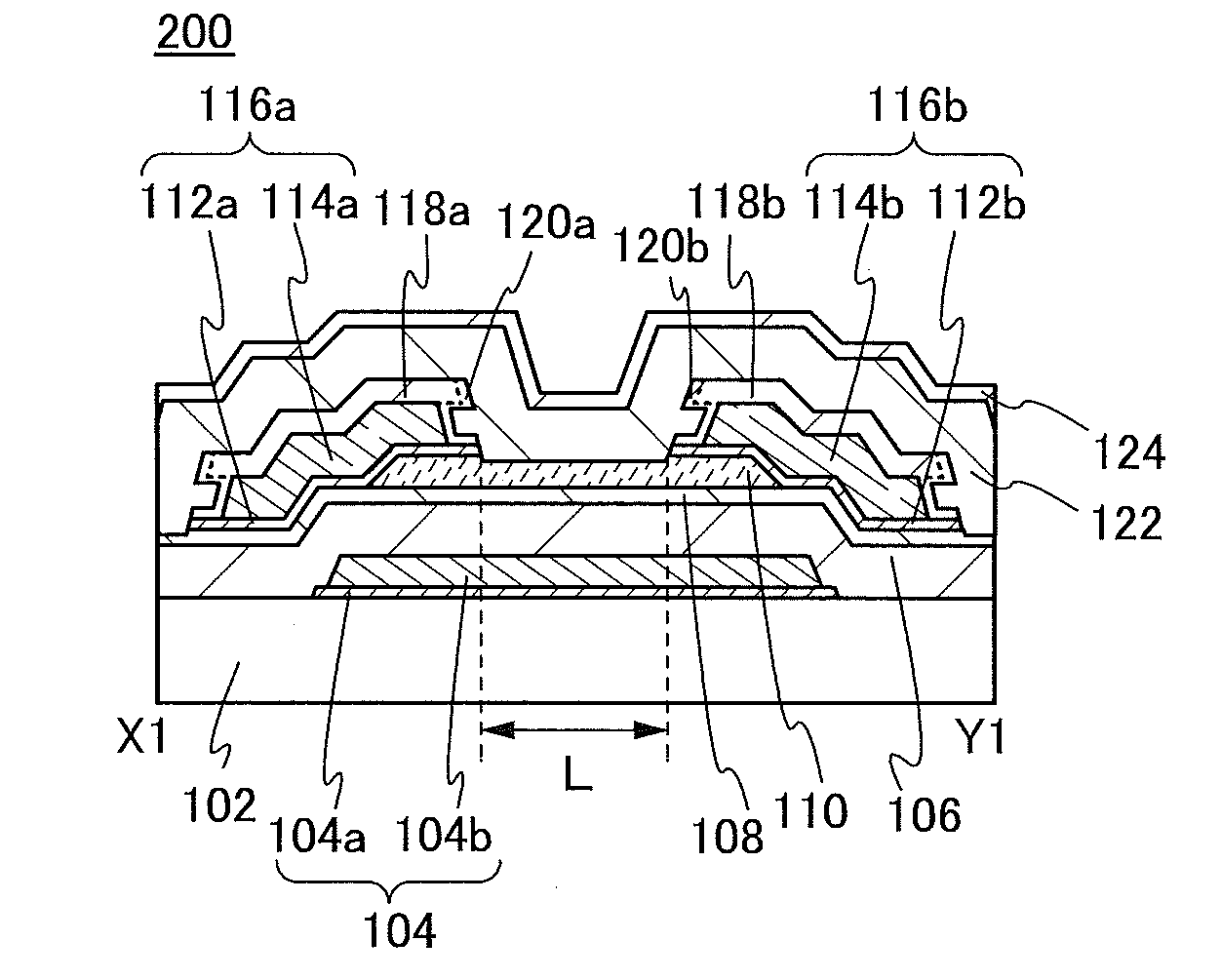

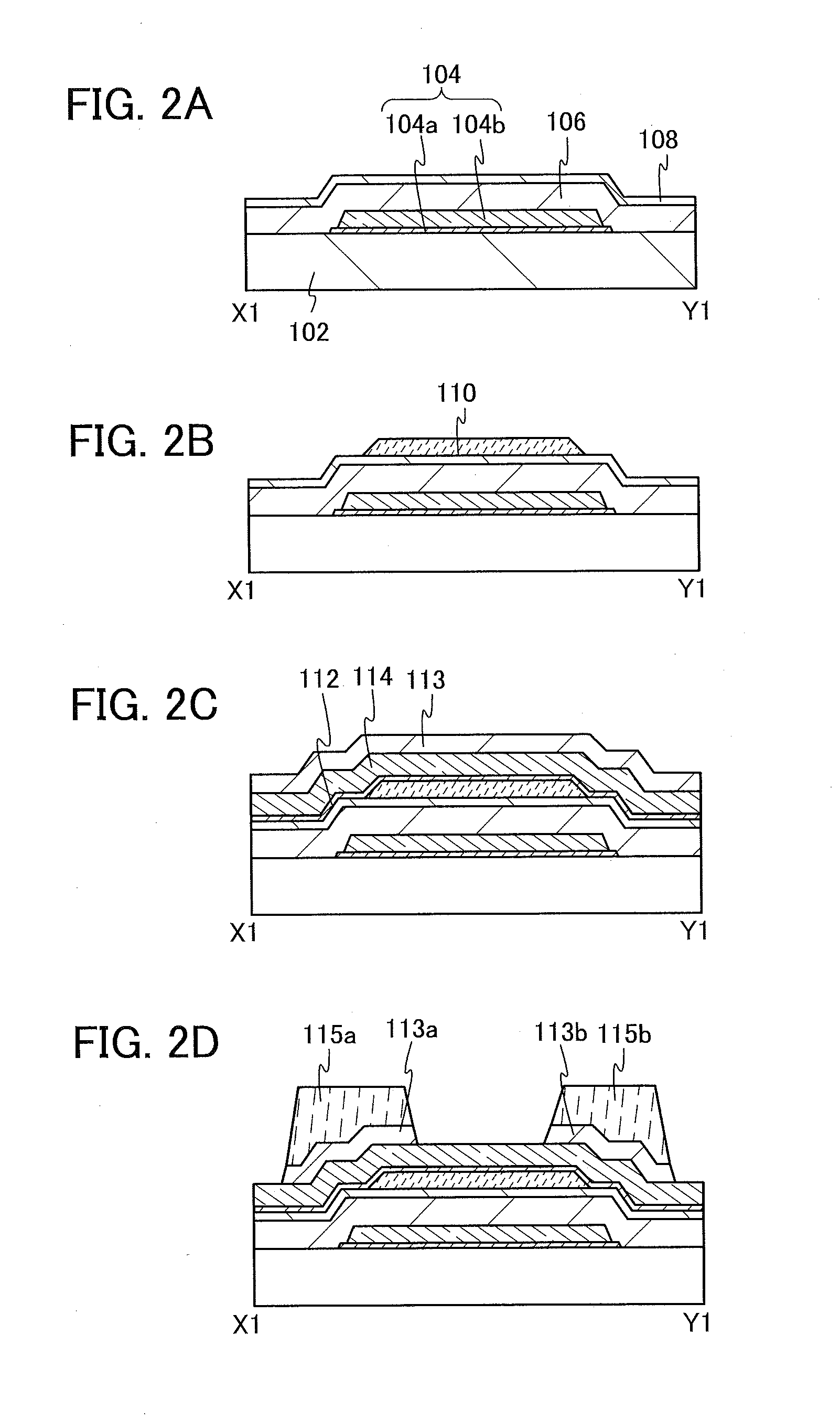

Field-effect transistor, and process for producing field-effect transistor

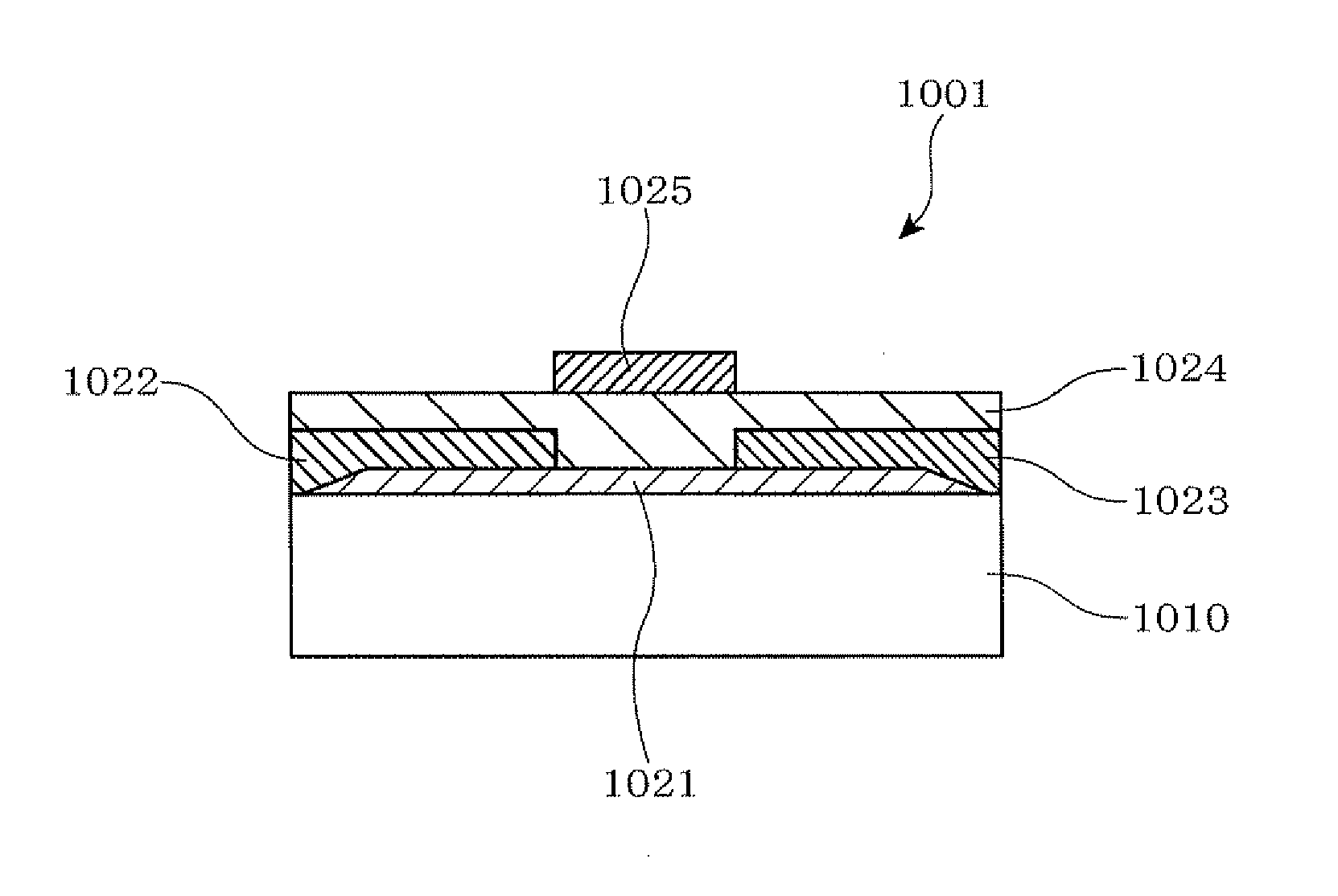

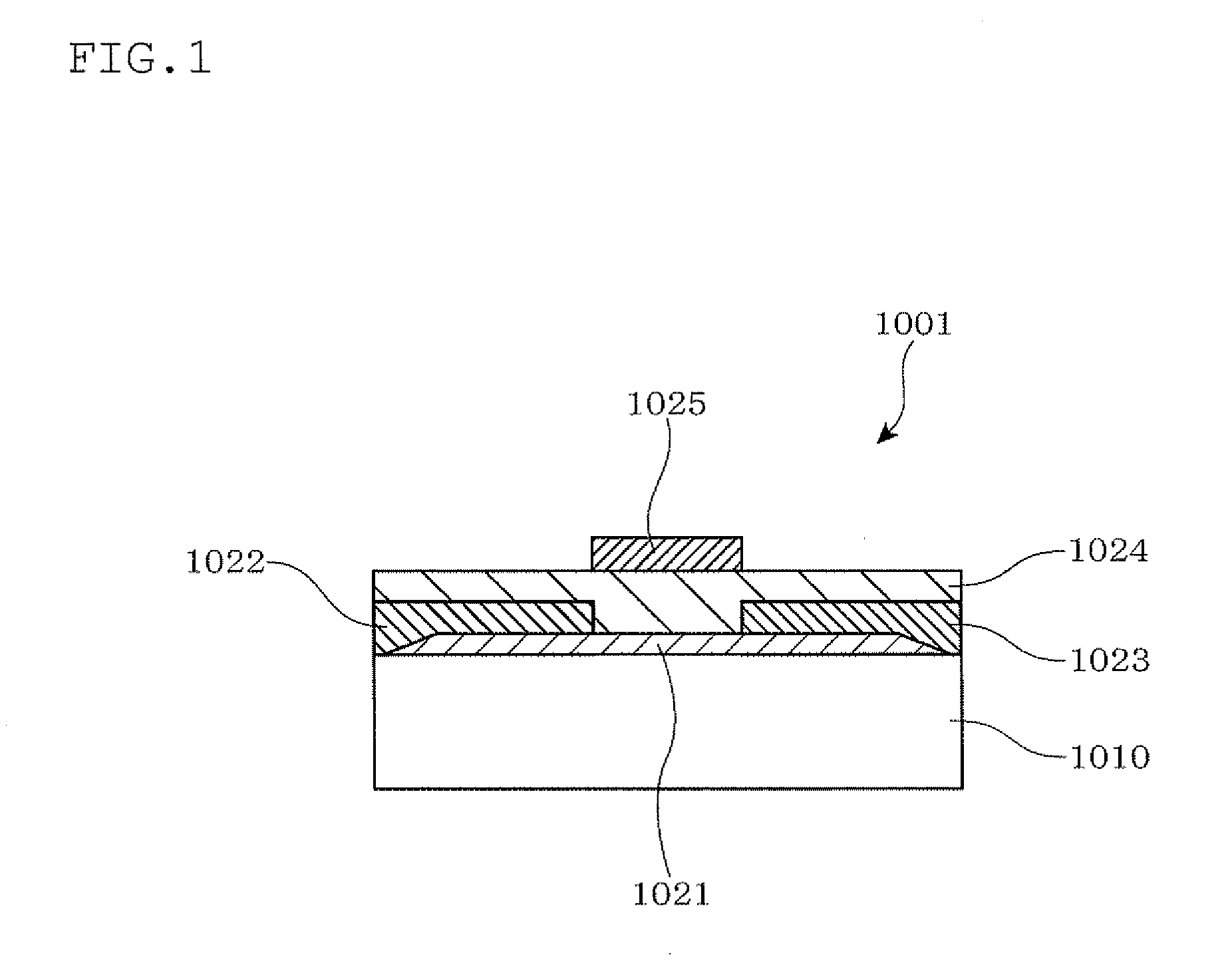

ActiveUS20100117071A1Increase freedomEfficient productionTransistorSemiconductor/solid-state device manufacturingCrystalline oxideIndium

To provide a field-effect transistor improved in transparency, electrical properties, stability, uniformity, reproducibility, heat resistance and durability, and as a reduced overlap capacity between electrodes.A field-effect thin film transistor 1001 includes a gate electrode 1025, an active layer, a source electrode 1022 and a drain electrode 1023, wherein a crystalline oxide 1021 containing indium and having an electron carrier concentration of less than 1018 / cm3 is used as the active layer, and the gate electrode 1025 is in self-alignment with the source electrode 1022 and the drain electrode 1023. The crystalline oxide 1021 contains a positive trivalent element different from a positive divalent element or indium.

Owner:IDEMITSU KOSAN CO LTD

Fouling resistant coating for membrane surfaces

InactiveUS20100133172A1Reduce foul potentialIncrease effectivenessSemi-permeable membranesMembranesIonHydrophilic polymers

Owner:SONG QUN +1

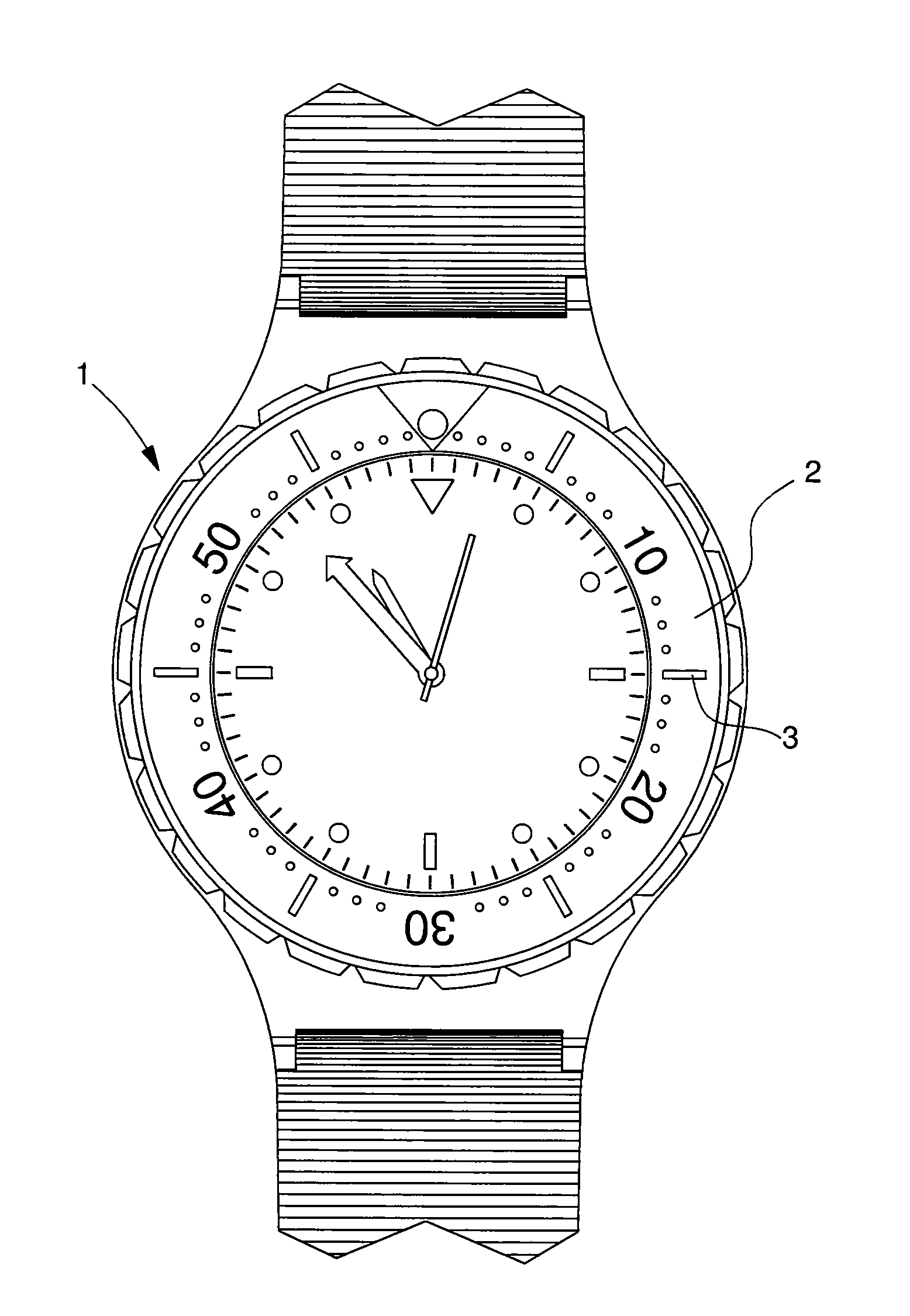

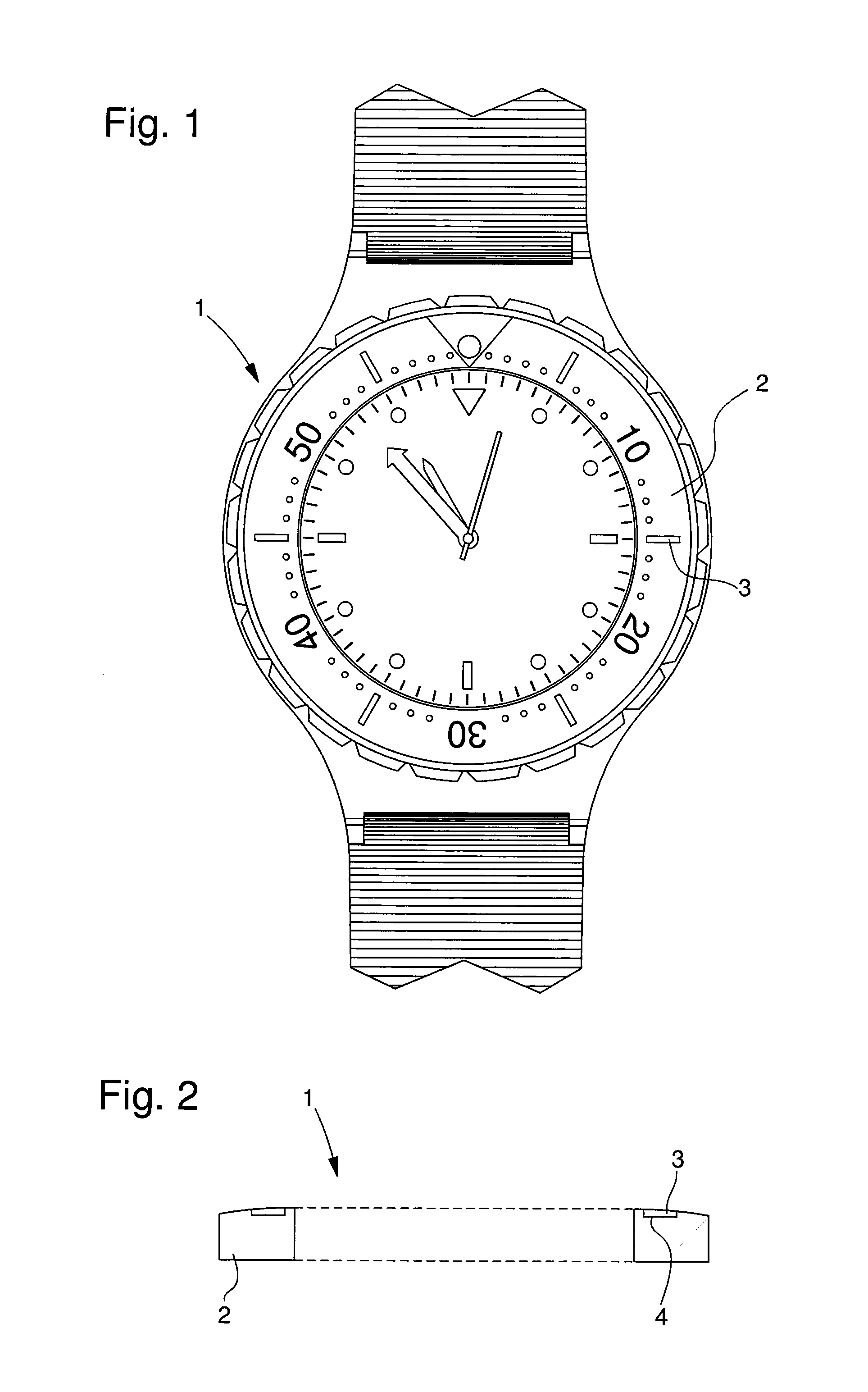

Decorative piece made by inlay

ActiveUS20110103199A1Easy to operateAdd featureVisual indicationDecorative surface effectsEngineering

Owner:OMEGA SA

Field-effect transistor, and process for producing field-effect transistor

ActiveUS8530891B2Poor resistanceEasily deterioratedSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxideIndium

To provide a field-effect transistor improved in transparency, electrical properties, stability, uniformity, reproducibility, heat resistance and durability, and as a reduced overlap capacity between electrodes.A field-effect thin film transistor 1001 includes a gate electrode 1025, an active layer, a source electrode 1022 and a drain electrode 1023, wherein a crystalline oxide 1021 containing indium and having an electron carrier concentration of less than 1018 / cm3 is used as the active layer, and the gate electrode 1025 is in self-alignment with the source electrode 1022 and the drain electrode 1023. The crystalline oxide 1021 contains a positive trivalent element different from a positive divalent element or indium.

Owner:IDEMITSU KOSAN CO LTD

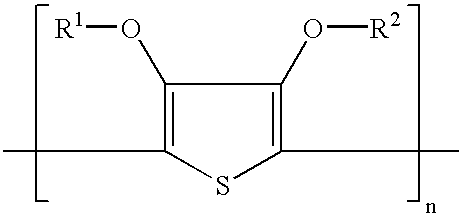

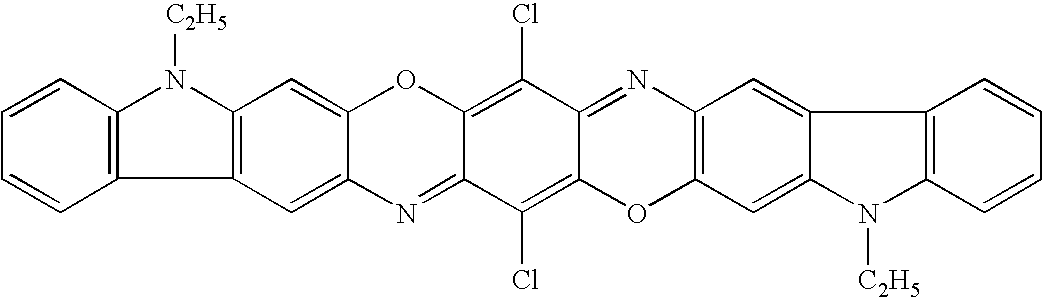

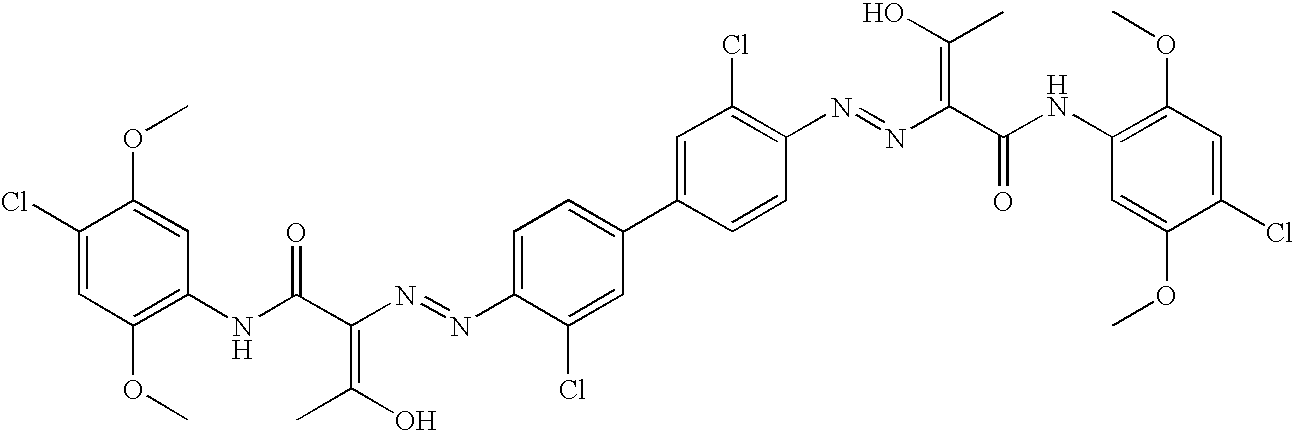

Flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene

InactiveUS6890584B2Improve adhesionPoor resistanceFilm/foil adhesivesConductive materialPolymer scienceAqueous medium

A non-dye containing flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene in which the two alkoxy groups may be the same or different or together represent an optionally substituted oxy-alkylene-oxy bridge, a polyanion and a latex binder in a solvent or aqueous medium, characterized in that the polymer or copolymer of a 3,4-dialkoxythiophene is present in a concentration of at least 0.1% by weight in the ink and that the ink is capable of producing a colorimetrically additive transparent print; a method of preparing the flexographic ink; and a flexographic printing process therewith.

Owner:AGFA GEVAERT AG

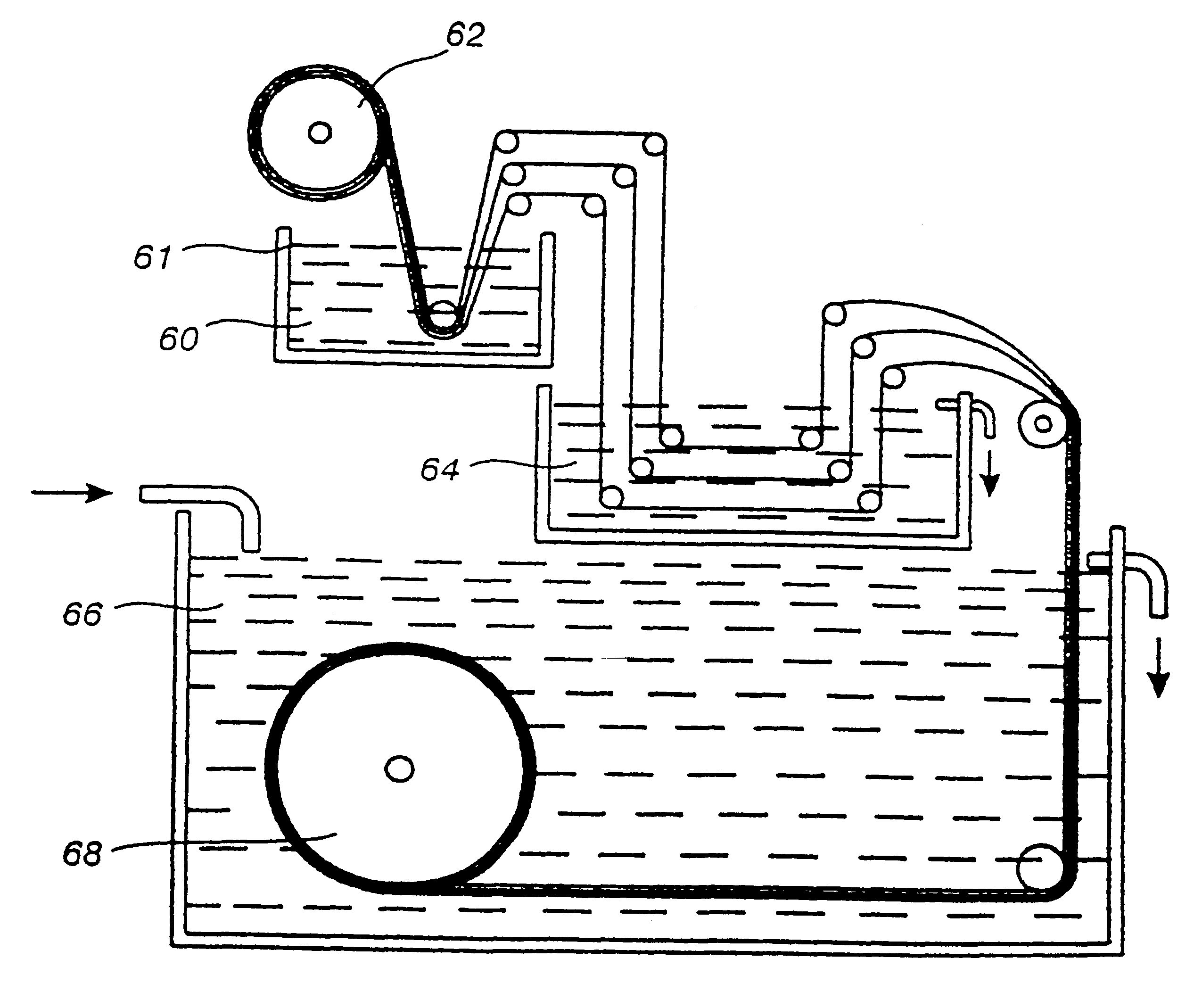

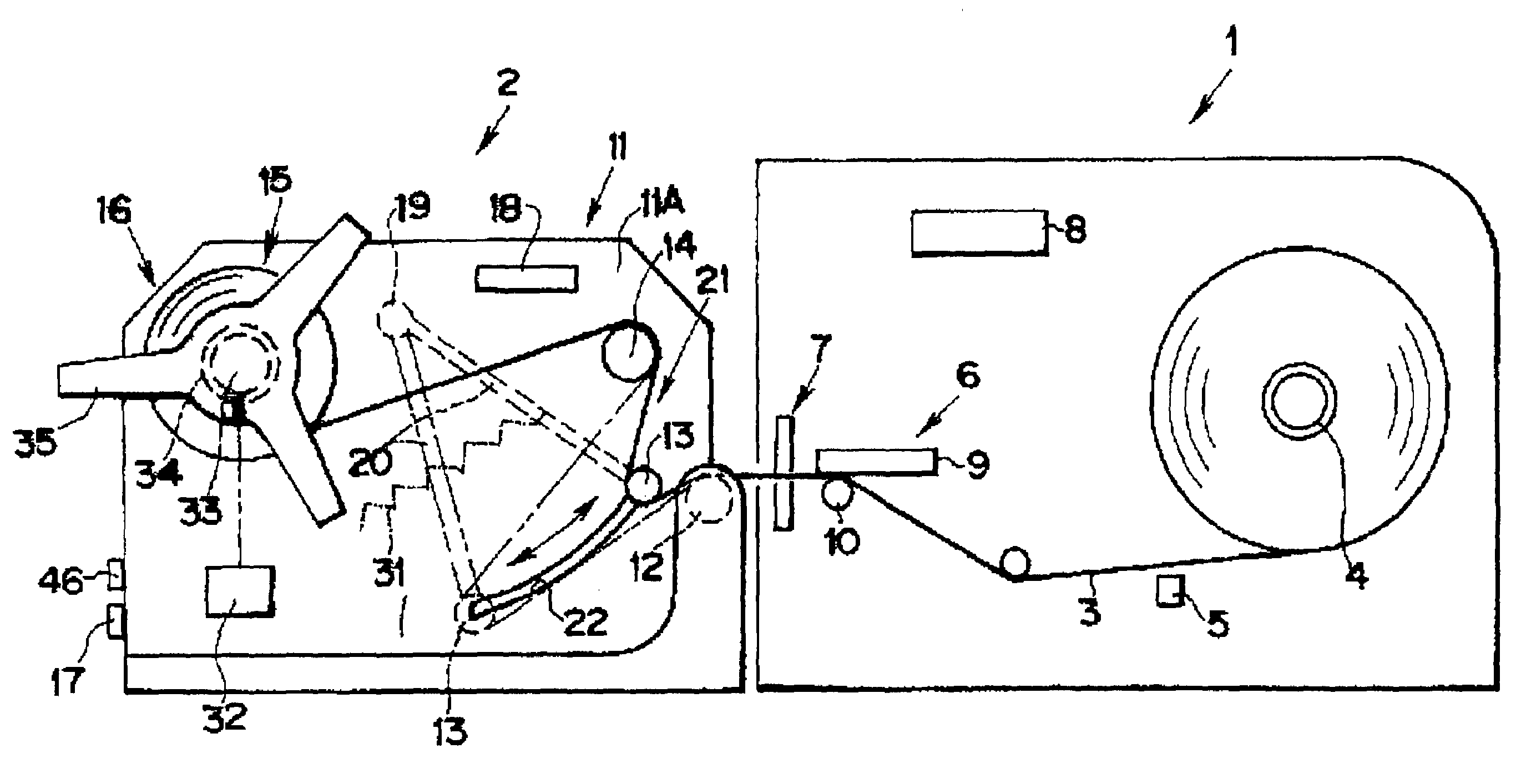

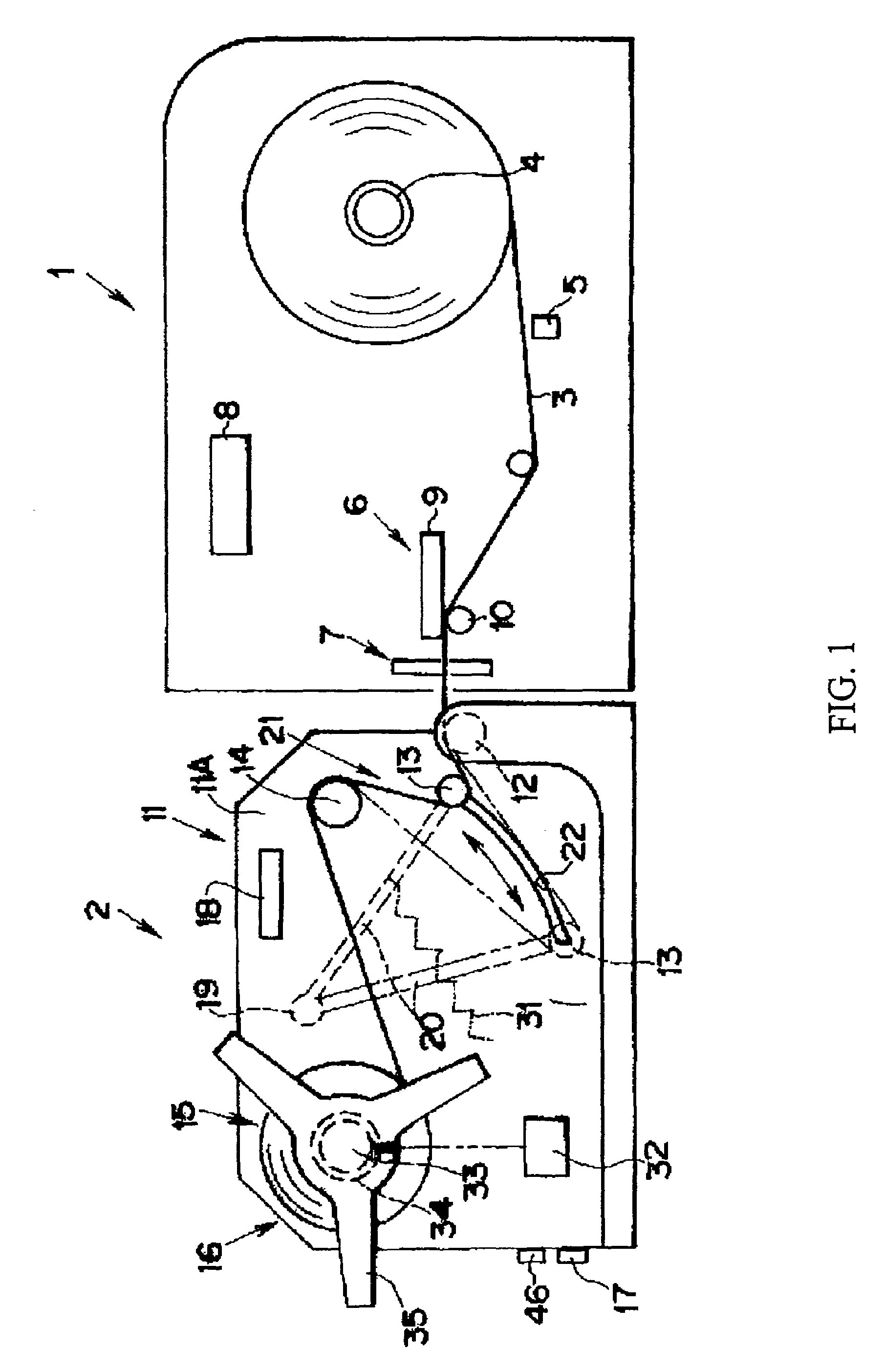

Printing paper winding device

ActiveUS20070079713A1Lower resistancePoor resistanceRotary pressesOther printing apparatusConductor CoilMechanical engineering

A printing paper winding device for enabling winding of printing paper even paper with a base material having a low resistance to bending stresses or printing paper having RFID labels carrying IC chips. Bending stresses are reduced by dividing the movement region of the tension roller into four regions in order to enable the successive detection of the position or posture of the tension roller and by making the bending angle of the printing paper in the winding path close to a more obtuse angle. A winding control unit of the present invention determines whether the tension region where the tension roller is positioned is a first tension region, second tension region, third tension region, or fourth tension region, controls the drive unit to limit the tension roller to a tension region in which winding is possible in the direction such that the bending angle of the printing paper in the winding path, which follows the winding of the printing paper, is close to a more obtuse angle.

Owner:SATO CO LTD

Method of dry etching, dry etching gas and process for producing perfluoro-2-pentyne

InactiveUS20050247670A1Improve etch selectivityImprove stabilityPreparation by hydrogen halide split-offDecorative surface effectsResist2-Pentyne

A dry etching method wherein a resist film is irradiated with radiation having a wavelength of not more than 195 nm to form a resist pattern having a minimum line width of not more than 200 nm, and the substrate having the resist pattern formed thereon is subjected to dry etching using a fluorine-containing compound having 4 to 6 carbon atoms and at least one unsaturated bond as an etching gas. As the fluorine-containing compound, perfuloro-2-pentyne, perfuloro-2-butyne, nonafluoro-2-pentene and perfluoro-2-pentene are preferably used. Perfuloro-2-pentyne is produced by a process wherein a 1,1,1-trihalo-2,2,2-trifluoroethane is allowed to react with pentafluoropropionaldehyde to give a 2-halo-1,1,1,4,4,5,5,5-octafluoro-2-pentene, and the thus-produced halo-octafluoro-2-pentene is dehydrohalogenated.

Owner:ZEON CORP

Semiconductor Device and Manufacturing Method Thereof

ActiveUS20140374908A1Amount of change be reducePoor resistanceTransistorSemiconductor/solid-state device detailsPhysicsSemiconductor device modeling

To improve the reliability of a semiconductor device including a low-resistance material such as copper, aluminum, gold, or silver as a wiring. Provided is a semiconductor device including a pair of electrodes electrically connected to a semiconductor layer which has a stacked-layer structure including a first protective layer in contact with the semiconductor layer and a conductive layer containing the low-resistance material and being over and in contact with the first protective layer. The top surface of the conductive layer is covered with a second protective layer functioning as a mask for processing the conductive layer. The side surface of the conductive layer is covered with a third protective layer. With this structure, entry or diffusion of the constituent element of the pair of conductive layers containing the low-resistance material into the semiconductor layer is suppressed.

Owner:SEMICON ENERGY LAB CO LTD

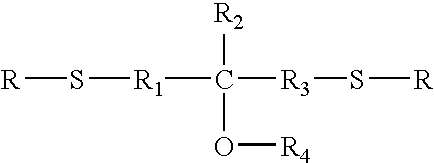

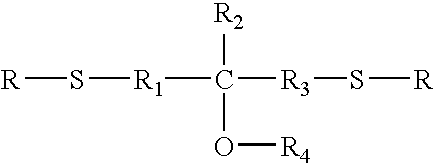

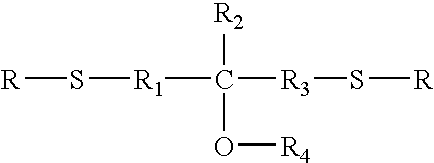

Long-term high temperature and humidity stable holographic optical data storage media compositions with exceptional high dynamic range

ActiveUS20050259303A1High M/ #Low shrinkagePhotosensitive materialsPhotomechanical apparatusBromineAcrylate

A novel photoimageable system for a two-chemistry system containing liquid photoreactive asymmetric acrylate compound containing sulfur, aromatic moieties, and optionally bromine, and an aluminum salt compound is disclosed. The photoimageable system has high dynamic range (M / #) and sensitivity and unexpectedly high temperature and high humidity resistance. The photoimageable system retains its dynamic range when exposed to 60° C. for 4 weeks while a composition without the aluminum salt compound lost 75% of its dynamic range under similar exposure conditions. In one embodiment, 2-10 weight % of a thio-butylacrylate dissolved in a two-component urethane matrix containing 0.002 to 1 weight % of the aluminum salt compound showed a dynamic range of greater than 5 for a 200 microns thick sample and retained more than 80% of the dynamic range after 4 weeks exposure at 60° C.

Owner:AKONIA HOLOGRAPHICS

Multilayer coating systems containing a gel-like base layer and a polyurethane topcoat, and their production and use

InactiveUS20020123562A1Forming accuratelyImprove the immunitySynthetic resin layered productsPretreated surfacesCoating systemSolvent free

The present invention relates to a coating system containing I) anhydrous, gel-like, high molecular weight polyurethane compositions, which may contain active substances, based on (1) 15 to 62 wt. %, based on the weight of 1) and 2), of a high molecular weight covalently crosslinked polyurethane matrix and (2) 38 to 85 wt. %, based on the weight of 1) and 2), of a liquid dispersing agent firmly bound in the matrix by secondary valence bonds, wherein the liquid dispersing agent contains one or more polyhydroxyl compounds having a number average molecular weight of 1000 to 12000 and an OH number of 20 to 112, wherein the dispersing agent is substantially free from hydroxyl compounds having a molecular weight below 800, and II) solvent-containing, solvent-free and / or aqueous polyurethane topcoats.

Owner:COVESTRO DEUTSCHLAND AG +1

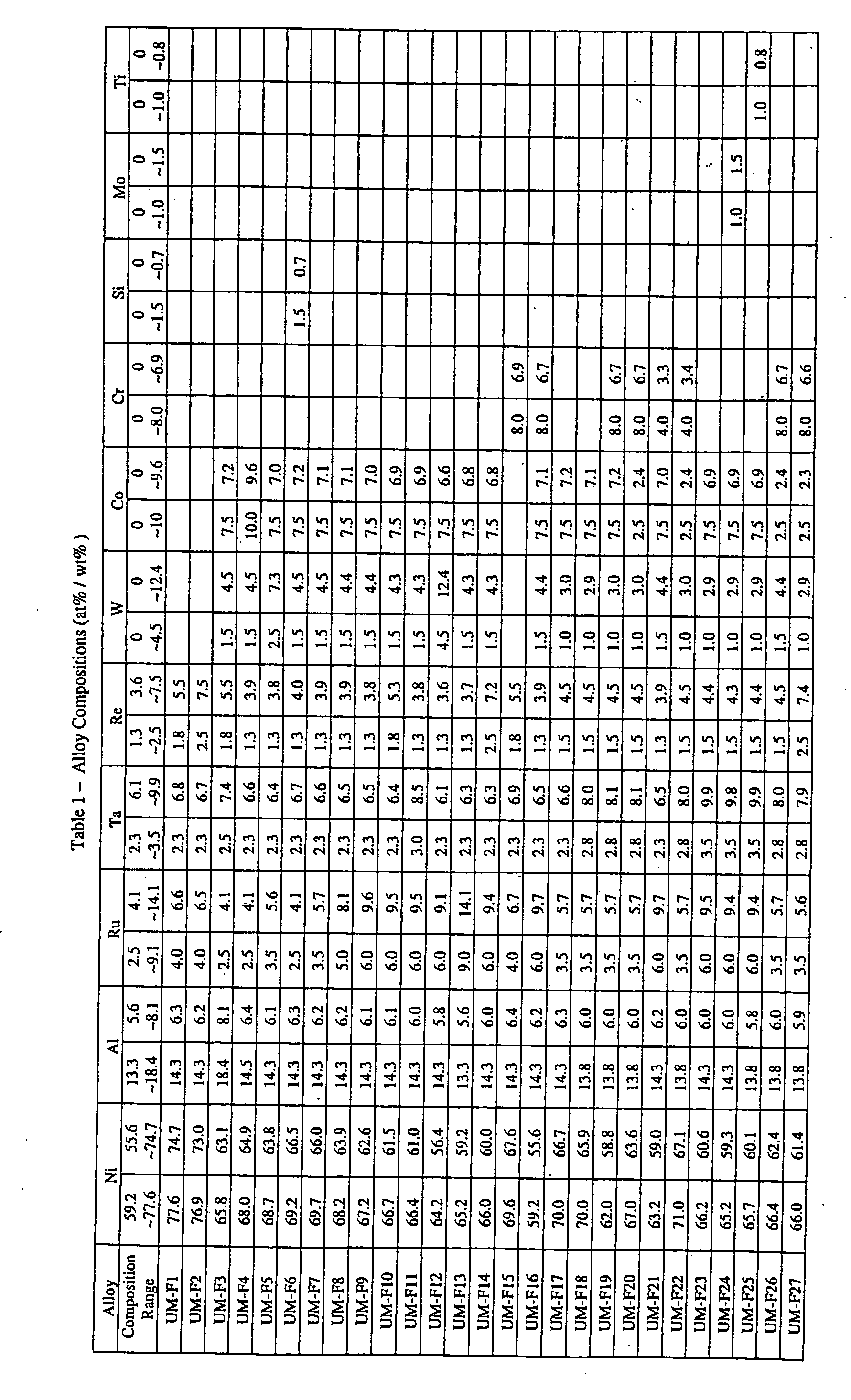

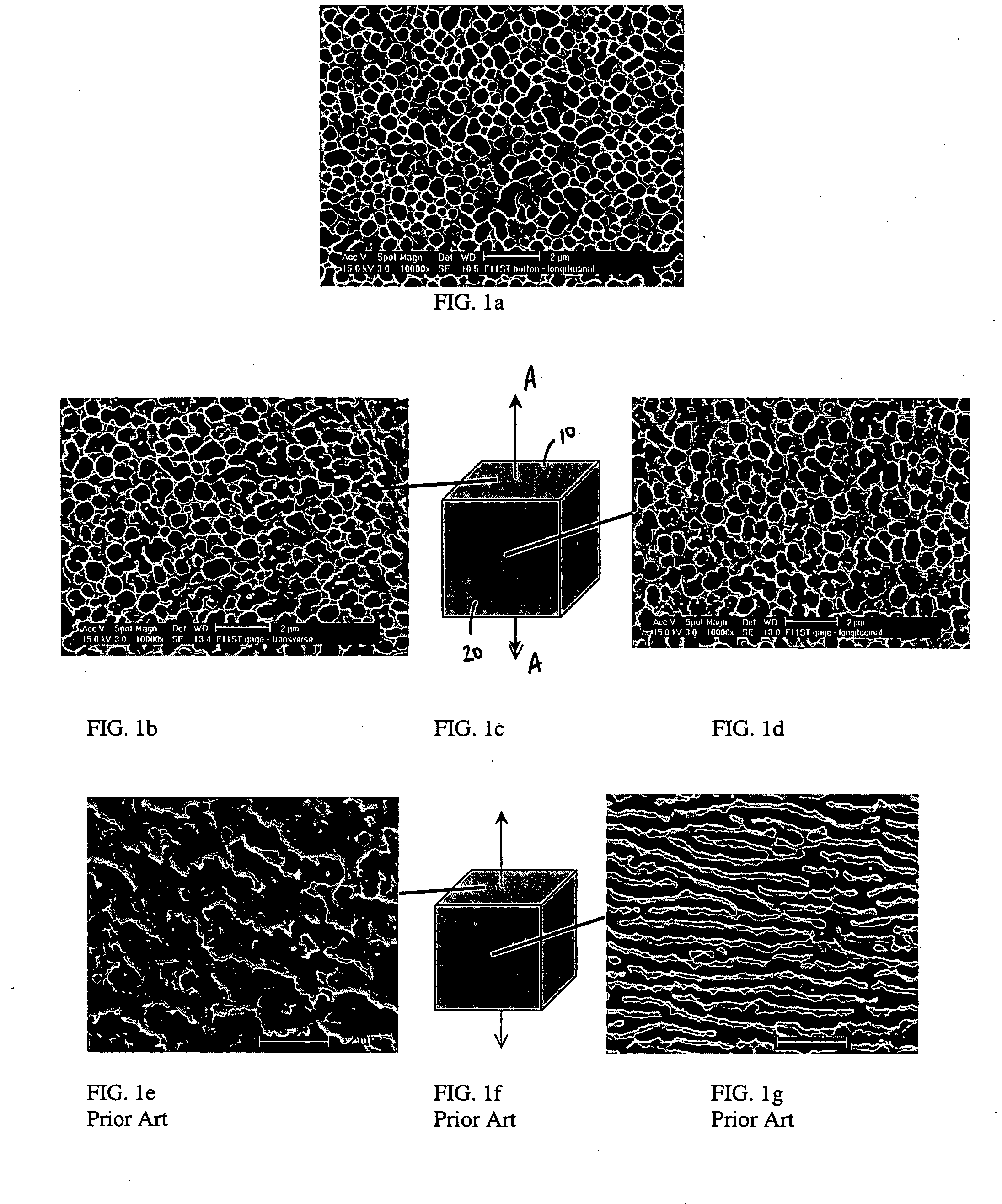

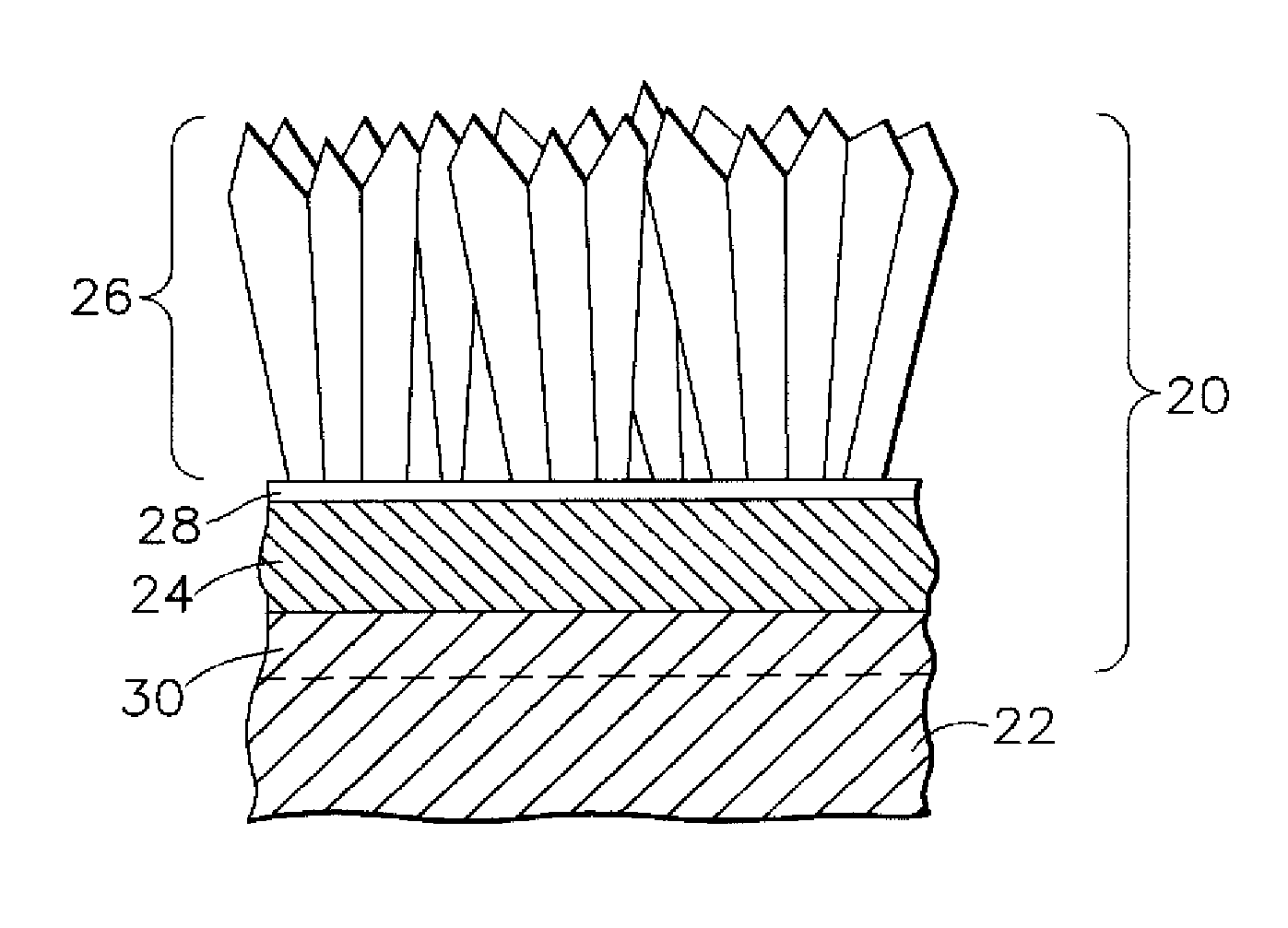

Monocrystalline alloys with controlled partitioning

InactiveUS20050224144A1Maximize useful life and operating propertyMaximize efficiencyBlade accessoriesMachines/enginesSingle crystalTurbine

Nickel-based superalloys, for fabrication of monocrystalline turbine components to be used in industrial and aircraft turbine engines, having the following composition (in wt %): 5.6-8.1% Al, 4.1-14.1% Ru, 6.1-9.9% Ta, 3.6-7.5% Re, and the remaining balance Ni. The partitioning of alloying elements can be controlled to achieve a wide range of precipitate shapes and exceptional resistance to degradation under high temperature exposure conditions.

Owner:RGT UNIV OF MICHIGAN +1

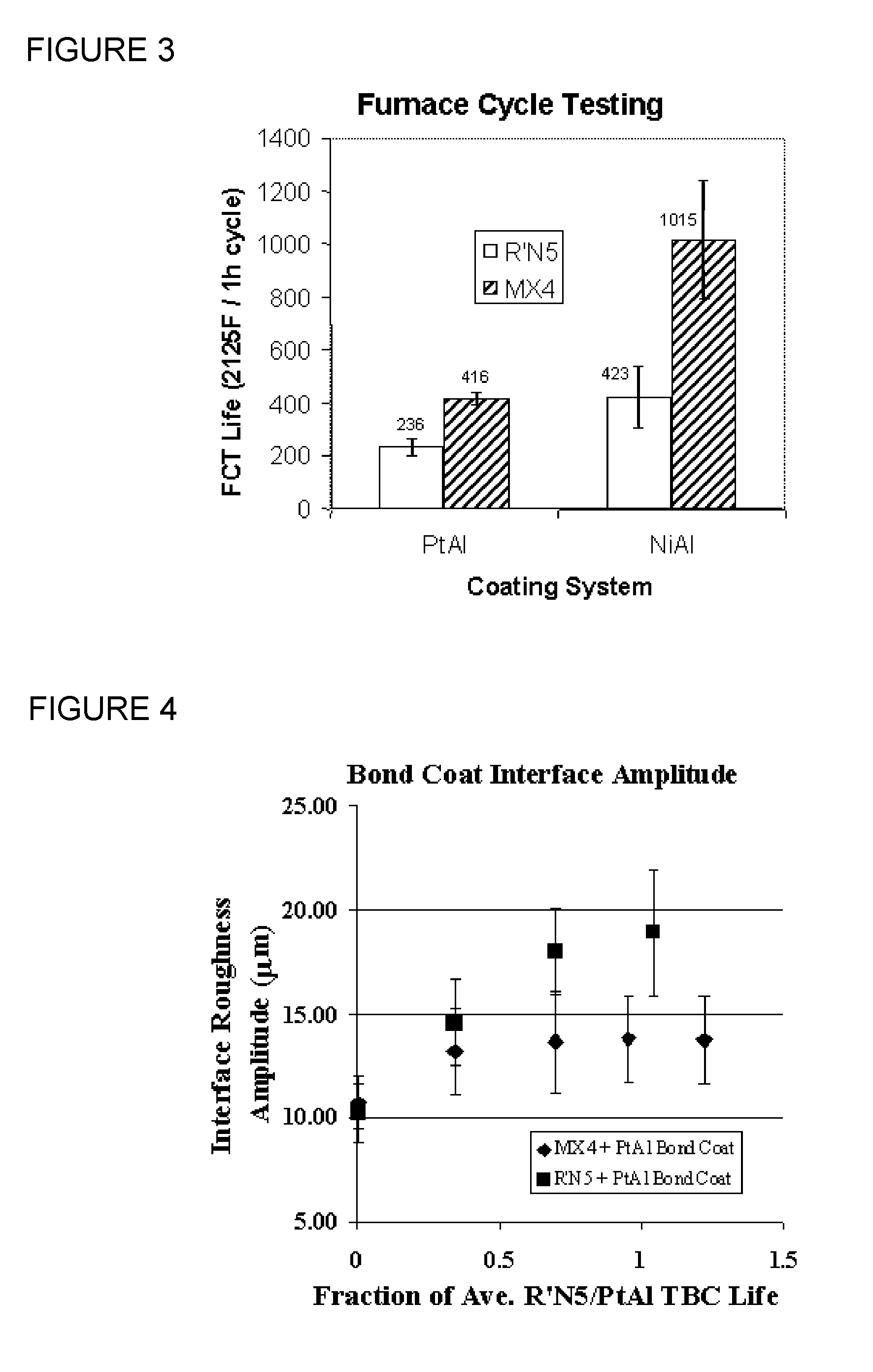

Ni-base superalloy having a thermal barrier coating system

InactiveUS6974637B2Increase resistancePoor resistanceMolten spray coatingBlade accessoriesRheniumCeramic coating

Owner:GENERAL ELECTRIC CO

Method of fabricating microfluidic systems

ActiveUS20120009662A1Low costQuick changeBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMicrofluidic channel

A method of fabricating a microfluidic system having microfluidic channels on a surface of a hydrophilic substrate, the method including the steps of: hydrophobizing the substrate surface; locating a mask defining the substrate surface, the mask having open areas defining the periphery of the microfluidic channels; and applying an irradiation treatment to areas of the substrate surface exposed by the open areas of the mask, said exposed areas becoming hydrophilic to therefore form said microfluidic channels.

Owner:MONASH UNIV

Surface-treated precoated metal sheet, process for producing same, and surface-treating solution

InactiveUS20120040194A1Easy to getMaintain and continue fouling resistanceOrganic-compounds/hydrides/coordination-complexes catalystsPretreated surfacesArylOrganic group

Disclosed is a surface-treated precoated metal sheet of which resistance against contamination with a photocatalyst and a self-cleaning function can be retained for a long period. Also disclosed are a method and a surface-treating solution for producing the surface-treated precoated metal sheet properly. The surface-treated precoated metal sheet is characterized by comprising a precoated metal sheet comprising an under metal sheet and an organic resin coating layer provided on the surface of the under metal sheet and a coating film having at least two layers, having a photocatalytic activity and formed on the precoated metal sheet, wherein the coating film having at least two layers comprises an inorganic-organic composite resin composed of a condensed product of an alkoxysilane selected from a group consisting of an alkoxysilane having an organic group selected from a group consisting of an alkyl group having 1 to 12 carbon atoms, an aryl group, a carboxyl group, a hydroxy group and a combination of two or more of these groups, an alkoxysilane having an epoxy group, an alkoxysilane having an amino group, a tetraalkoxysilane and a combination of two or more of the alkoxysilanes and contains a substance having a photocatalytic activity in such an amount that the content of the substance is highest in the outermost layer of the coating film and is gradually decreased toward an inner layer of the coating film.

Owner:NIPPON STEEL CORP

Inorganic board and method for manufacturing thereof

ActiveUS20060075931A1Reduce the amount requiredHardening reactionCeilingsCovering/liningsWater solubleSynthetic resin

Owner:NICHIHA CORP

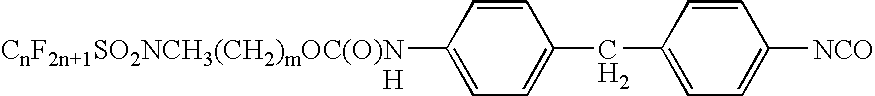

Modified sulfonamide polymers

InactiveUS6987150B2Improve stabilityImproved propertySemi-permeable membranesSolid electrolytesHydrogenProton

The invention provides secondary sulfonamide polymers, wherein some, most, or all of the sulfonamido protons have been replaced with a substituent other than hydrogen. The invention also provides methods for preparing such polymers as well as devices (e.g. composite membranes) incorporating such membranes.

Owner:GE OSMONICS INC

Rewritable thermal label of a non-contact type and method for using the label

A rewritable thermal label of the non-contact type which comprises an anchor coat layer comprising a crosslinked resin, a heat-sensitive color development layer and a light absorption and photo-thermal conversion layer which are laminated on one face of a substrate successively, the anchor coat layer being placed next to the substrate, and an adhesive layer placed on the other face of the substrate and allows recording and erasure of information repeatedly in accordance with the non-contact method; and a method for using a rewritable thermal label of the non-contact type which comprises recording and erasing information repeatedly in accordance with the non-contact method on the rewritable thermal label which remains attached to an adherend. Information can be recorded and erased repeatedly on the label which remains attached to the adherend and the label can be recycled together with the adherend.

Owner:LINTEC CORP

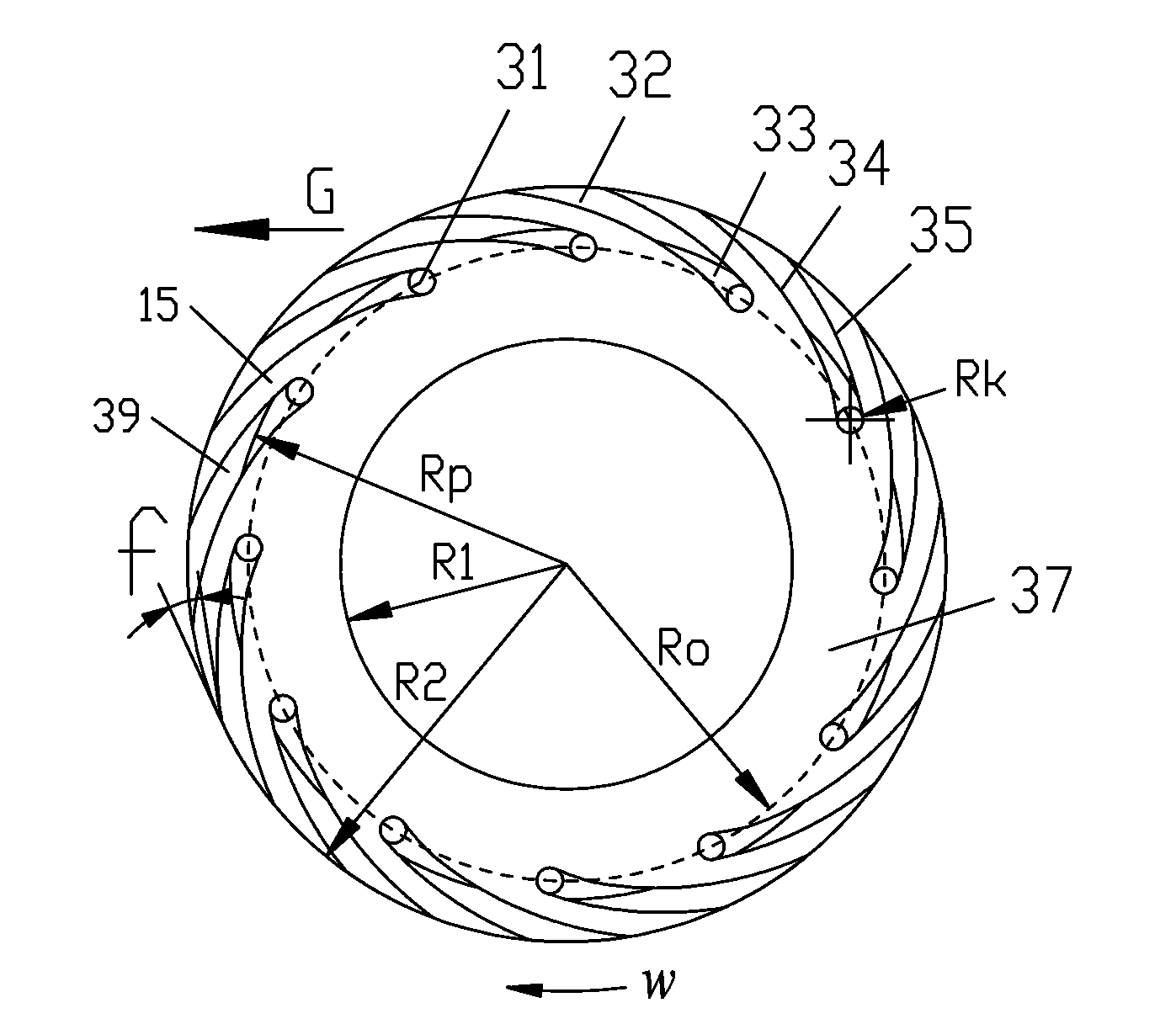

Self-pumping hydrodynamic mechanical seal

InactiveUS20160097457A1Eliminates solid frictionFast formingEngine sealsInterference resistanceSolid particle

A self-pumping hydrodynamic mechanical seal includes a rotating ring (3) and a stationary ring (11). More than three sets of backward curved grooves (39) are provided on a seal face of the rotating ring (3), outlets of the backward curved grooves (39) are provided at an external diameter portion of the seal face of the rotating ring (3), and an inlet (31) connects with a seal chamber (1) through a duct (30) of the rotating ring (3) or the stationary ring (11). When the rotating ring (3) rotates, a medium in the backward curved grooves (39) is accelerated into a high-speed fluid; under a centrifugal force, the high-speed fluid moves to an external diameter side of the rotating ring (3), so as to be pumped into the seal chamber (1) and generates a low-pressure area at the inlets (31) of the backward curved grooves (39); the medium in the seal chamber (1) is driven by a pressure difference, so as to flow into the backward curved grooves (39) through the duct (30), for forming circulation of self-pumping. During pumping the high-speed fluid, a flow speed of the high-speed fluid is slowed and a pressure of the high-speed fluid is increased, as a flow sectional area of the backward curved grooves (39) is increased, so as to generate an opening force which separates the rotating ring (3) from the stationary ring (11). The seal has desirable capabilities of self-lubrication, self-flushing, solid particle interference resistance, and optimal sealing performance.

Owner:NANJING FORESTRY UNIV

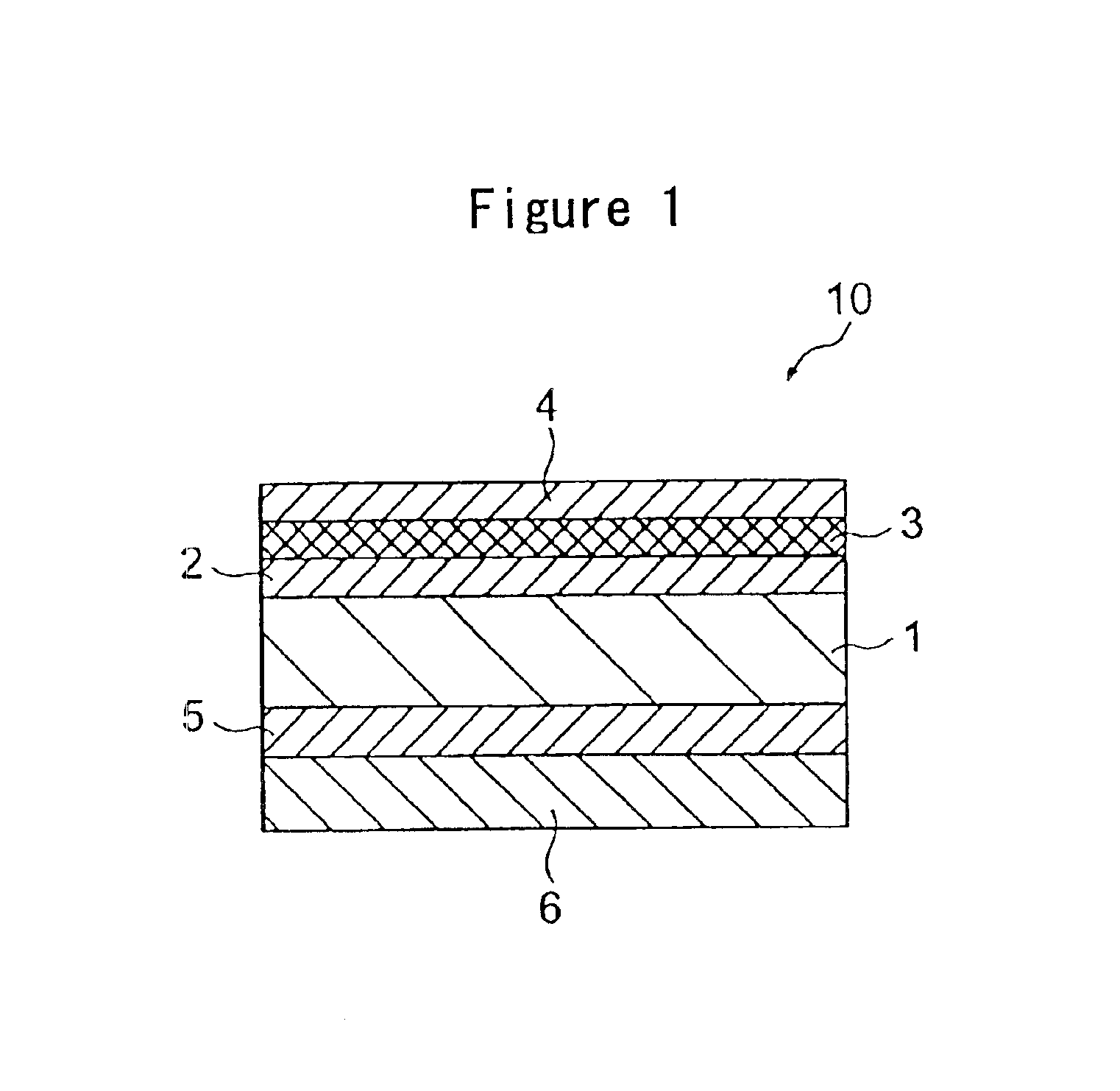

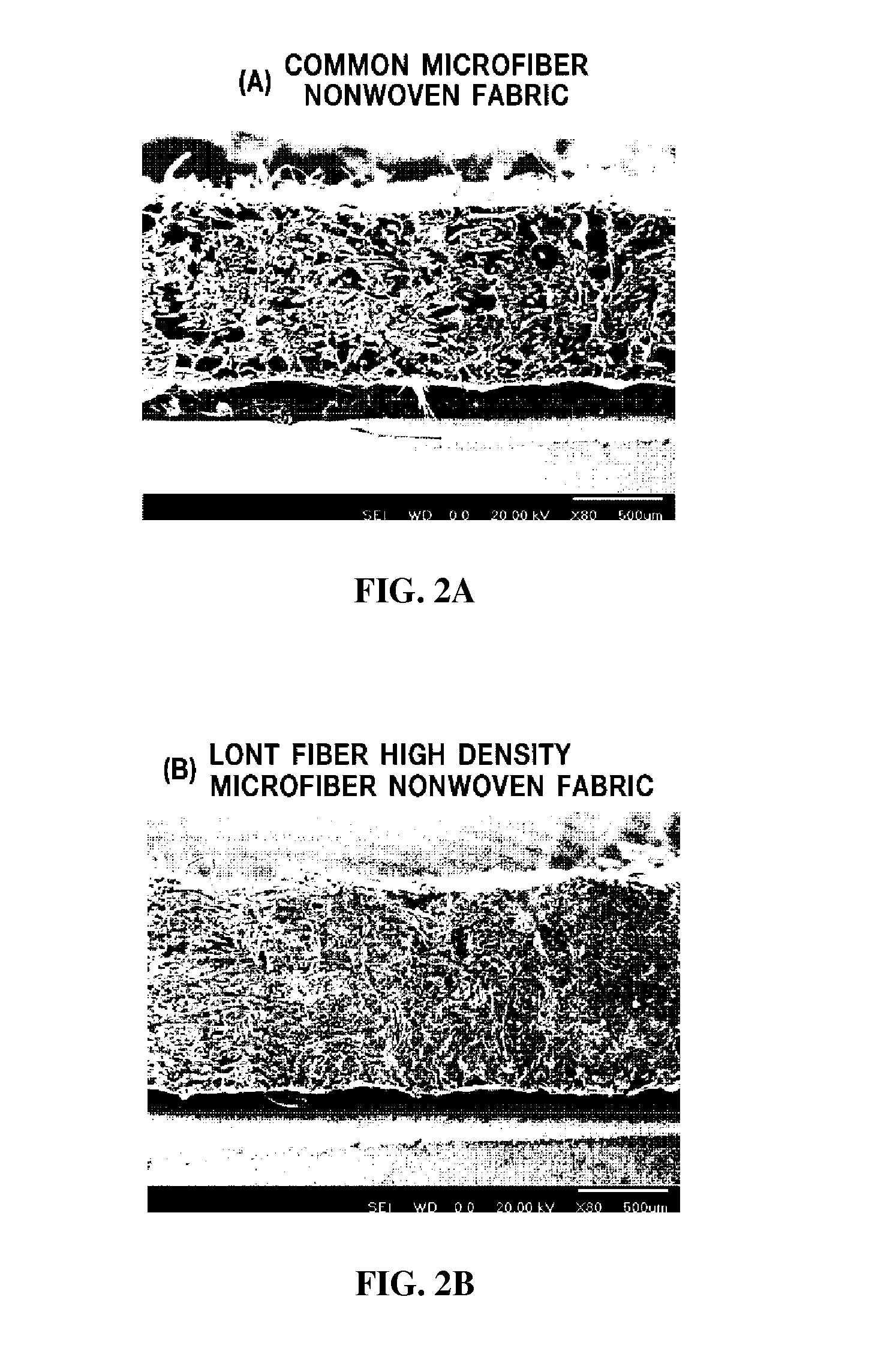

Synthetic leather for steering wheel cover having improved durability and method for preparing the same

ActiveUS20160129665A1Foul resistance be improvePoor resistanceControlling membersSynthetic resin layered productsPolycarbonateMicrofiber

The present invention relates to a synthetic leather for a steering wheel cover of a vehicle, and a method for preparing the same. The synthetic leather including a fiber base layer (101) including a microfiber nonwoven fabric, an urethane porous layer (102) formed on the fiber base layer, a polyurethane resin skin layer (104) formed on the urethane porous layer, and prepared by polymerizing an isocyanate compound and a polyol compound including polycarbonate-based polyol, fluorine-based polyol and ester-based polyol, and an adhesive layer (103) for adhering the urethane porous layer and the skin layer.

Owner:HYUNDAI MOTOR CO LTD +2

Optical fiber

ActiveUS20170003446A1Modulus is reducedResistance to deteriorationGlass optical fibreOptical fibre with graded refractive index core/claddingGlass fiberFiber

An optical fiber comprises a glass fiber which comprises a core and a cladding, a primary resin coating layer which covers the periphery of the glass fiber, and a secondary resin coating layer which covers the periphery of the primary resin coating layer. The glass fiber is a multimode fiber having a core diameter of 40-60 μm and a cladding diameter of 90-110 μm, and the primary resin coating layer is a layer formed by curing a curable resin composition which comprises oligomers, monomers, and a reaction initiator, the curable resin composition containing a one-end-capped oligomer in an amount of 30% by mass or larger based on all the oligomers.

Owner:SUMITOMO ELECTRIC IND LTD

Powerfeed polymers having improved block resistance performance

InactiveUS20130303674A1Increase resistanceLow VOC contentCarboxyl rubber coatingsMonomer compositionEmulsion

The present invention provides emulsion copolymers and coating compositions containing the same having improved room temperature and hot block resistance in coatings wherein the copolymers have a broad measured glass transition temperature and are the copolymerization product of a vinyl monomer composition A and a softer vinyl monomer composition B having a Hansch parameter of at least 3.2, and containing one or more vinyl monomer M, such that each of which vinyl monomer(s) M would when homopolymerized provide a homopolymer having a measured Tg of 20° C. or less, such as, for example, 2-ethylhexyl acrylate. In addition, the present invention provides methods for making the emulsion copolymers by a powerfeed process comprising feeding vinyl monomer composition A into a reactor from a feed vessel while feeding, simultaneously or after a delay, vinyl monomer composition B into the feed vessel while polymerizing the monomers in the reactor.

Owner:ROHM & HAAS CO

Chlorine resistant desalination membranes based on directly sulfonated poly(arylene ether sulfone) copolymers

ActiveUS8028842B2Improve pressure resistanceExemption stepsMembranesSemi-permeable membranesHydrophilic monomerSulfonate

The present invention provides a membrane, kit, and method of making a hydrophilic-hydrophobic random copolymer membrane. The hydrophilic-hydrophobic random copolymer membrane includes a hydrophilic-hydrophobic random copolymer. The hydrophilic-hydrophobic random copolymer includes one or more hydrophilic monomers having a sulfonated polyarylsulfone monomer and a second monomer and one or more hydrophobic monomers having a non-sulfonated third monomer and a fourth monomer. The sulfonated polyarylsulfone monomer introduces a sulfonate into the hydrophilic-hydrophobic random copolymer prior to polymerization.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

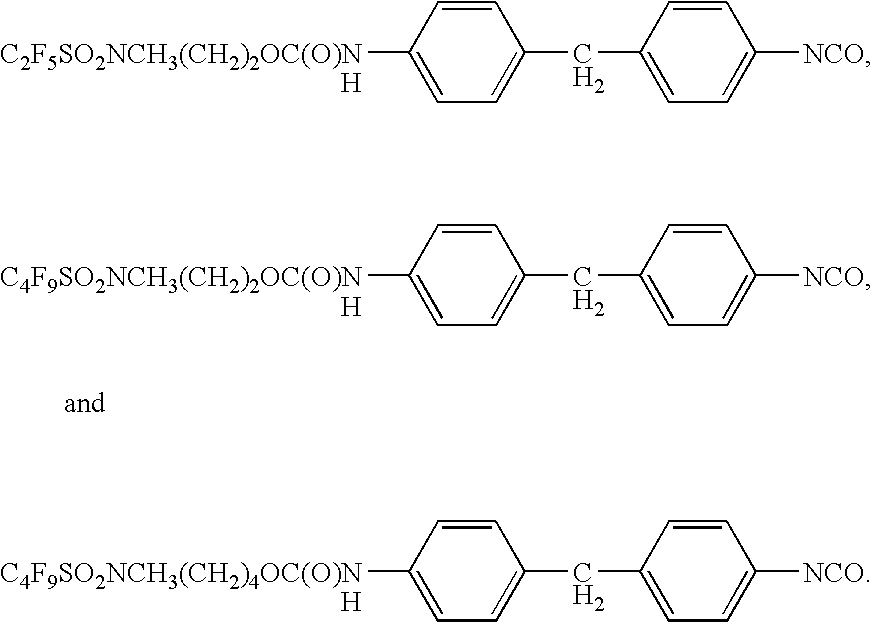

Stain and fouling resistant polyurea and polyurethane coatings

InactiveUS20080229976A1Exceptional physical propertyExcellent abrasion resistanceNon-macromolecular organic additionPaper/cardboardPolyurethane coatingPolyurea

Transporters, e.g., ore carriers, vehicles, materials handling equipment, etc. having fluorinated polyurea and fluorinated polyurethane coatings thereon.

Owner:3M INNOVATIVE PROPERTIES CO

Printing paper winding device

ActiveUS7422385B2Lower resistancePoor resistanceRotary pressesOther printing apparatusEngineeringConductor Coil

A printing paper winding device for enabling winding of printing paper even paper with a base material having a low resistance to bending stresses or printing paper having RFID labels carrying IC chips. Bending stresses are reduced by dividing the movement region of the tension roller into four regions in order to enable the successive detection of the position or posture of the tension roller and by making the bending angle of the printing paper in the winding path close to a more obtuse angle. A winding control unit of the present invention determines whether the tension region where the tension roller is positioned is a first tension region, second tension region, third tension region, or fourth tension region, controls the drive unit to limit the tension roller to a tension region in which winding is possible in the direction such that the bending angle of the printing paper in the winding path, which follows the winding of the printing paper, is close to a more obtuse angle.

Owner:SATO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com