Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3351 results about "Resin coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

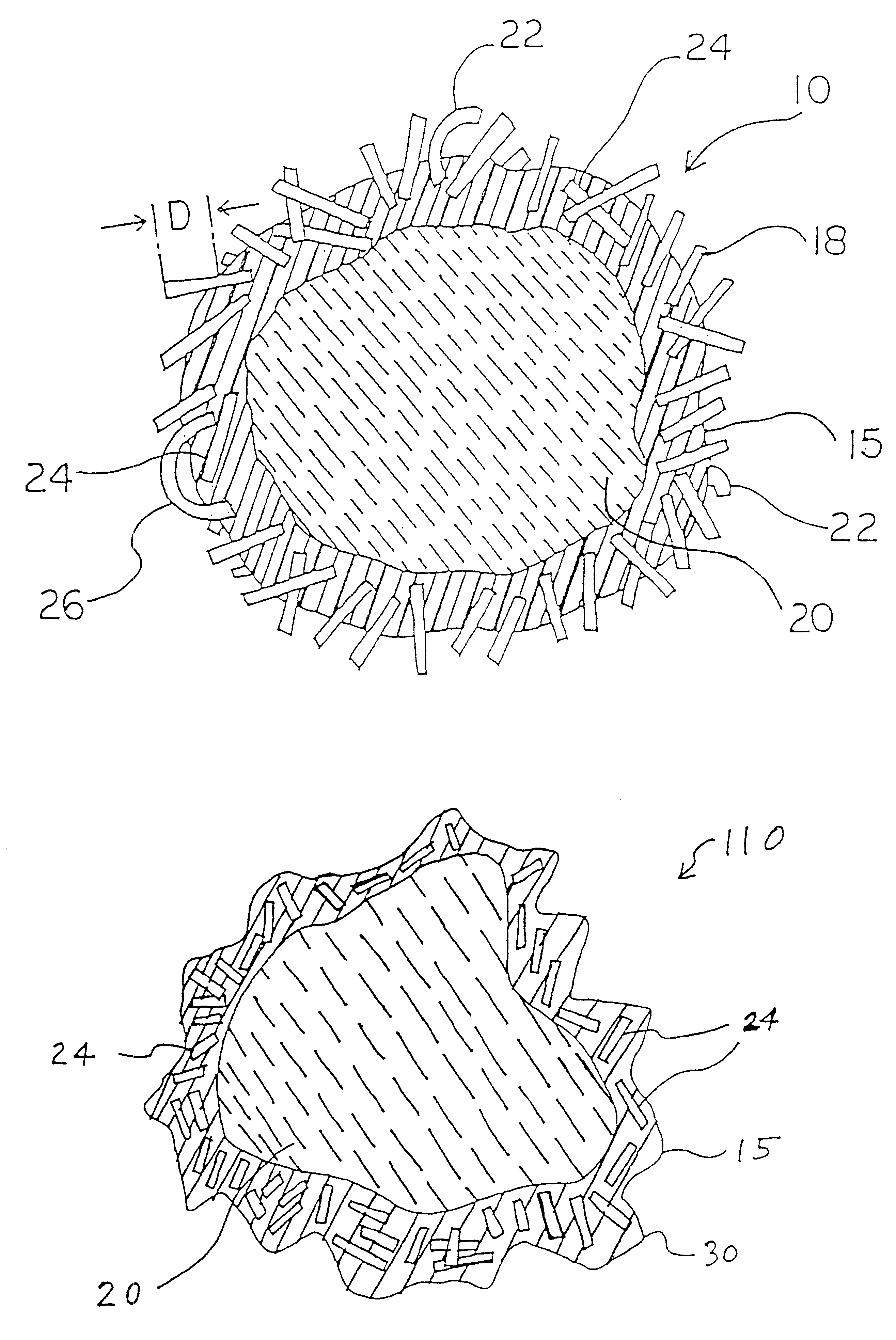

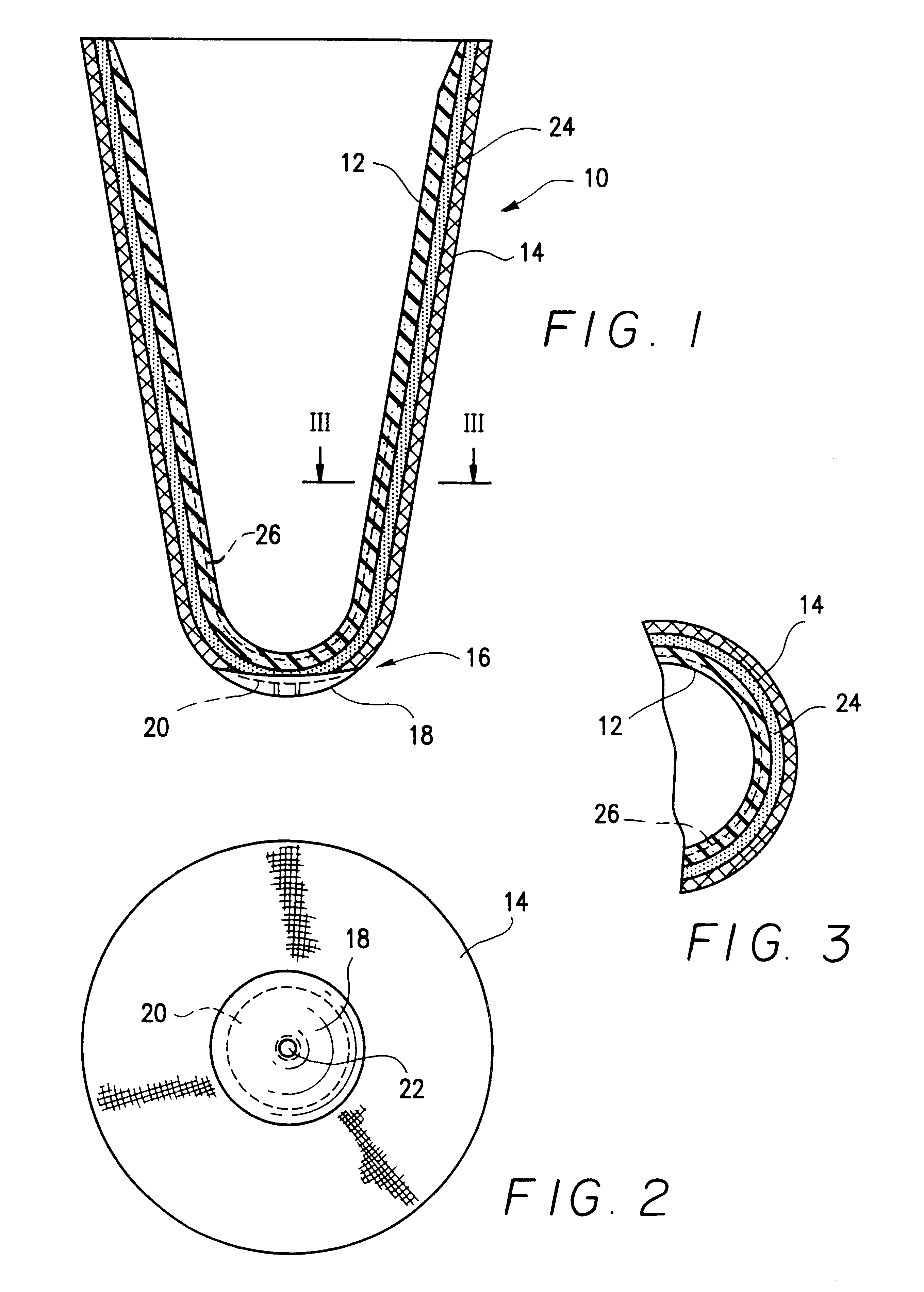

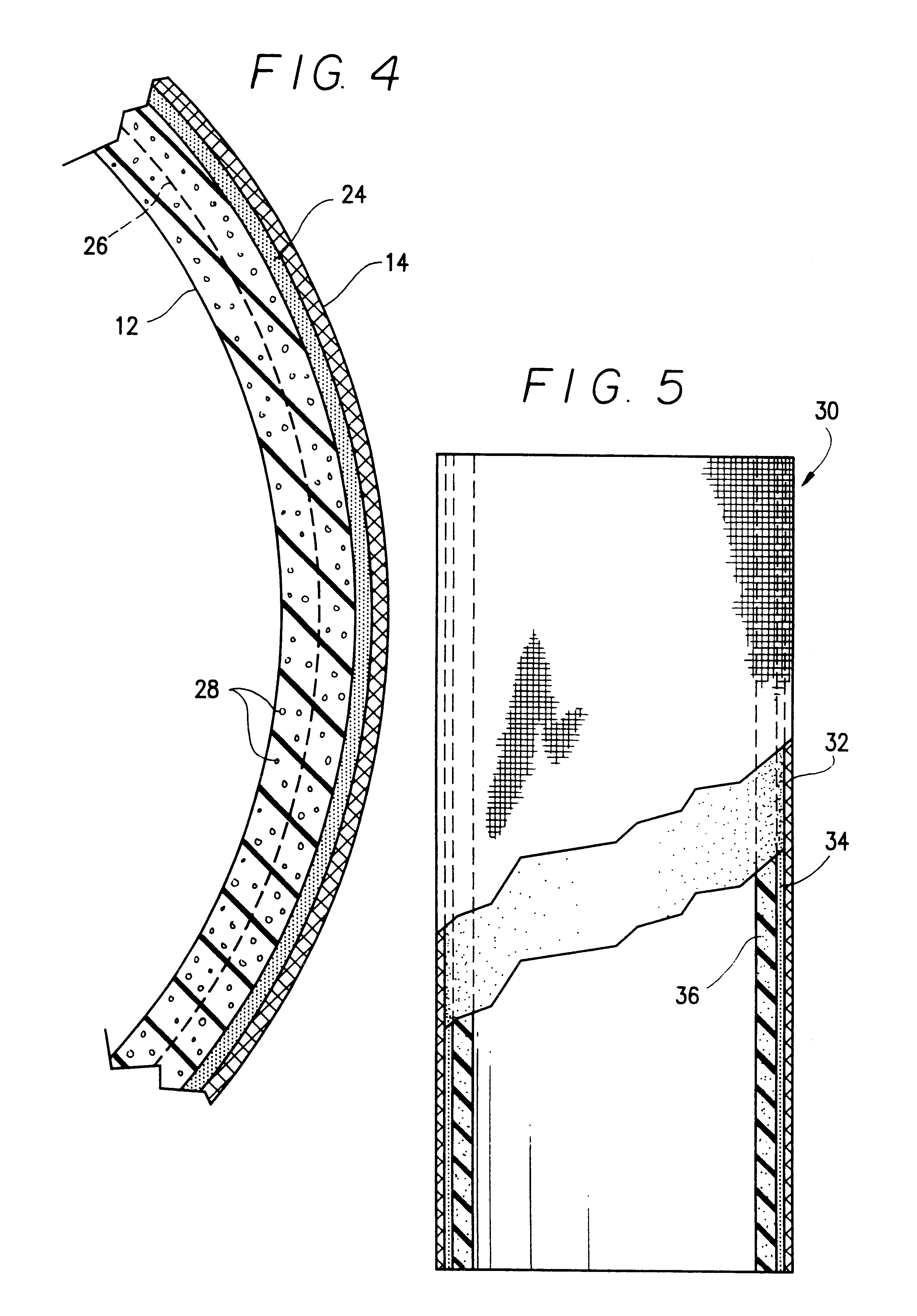

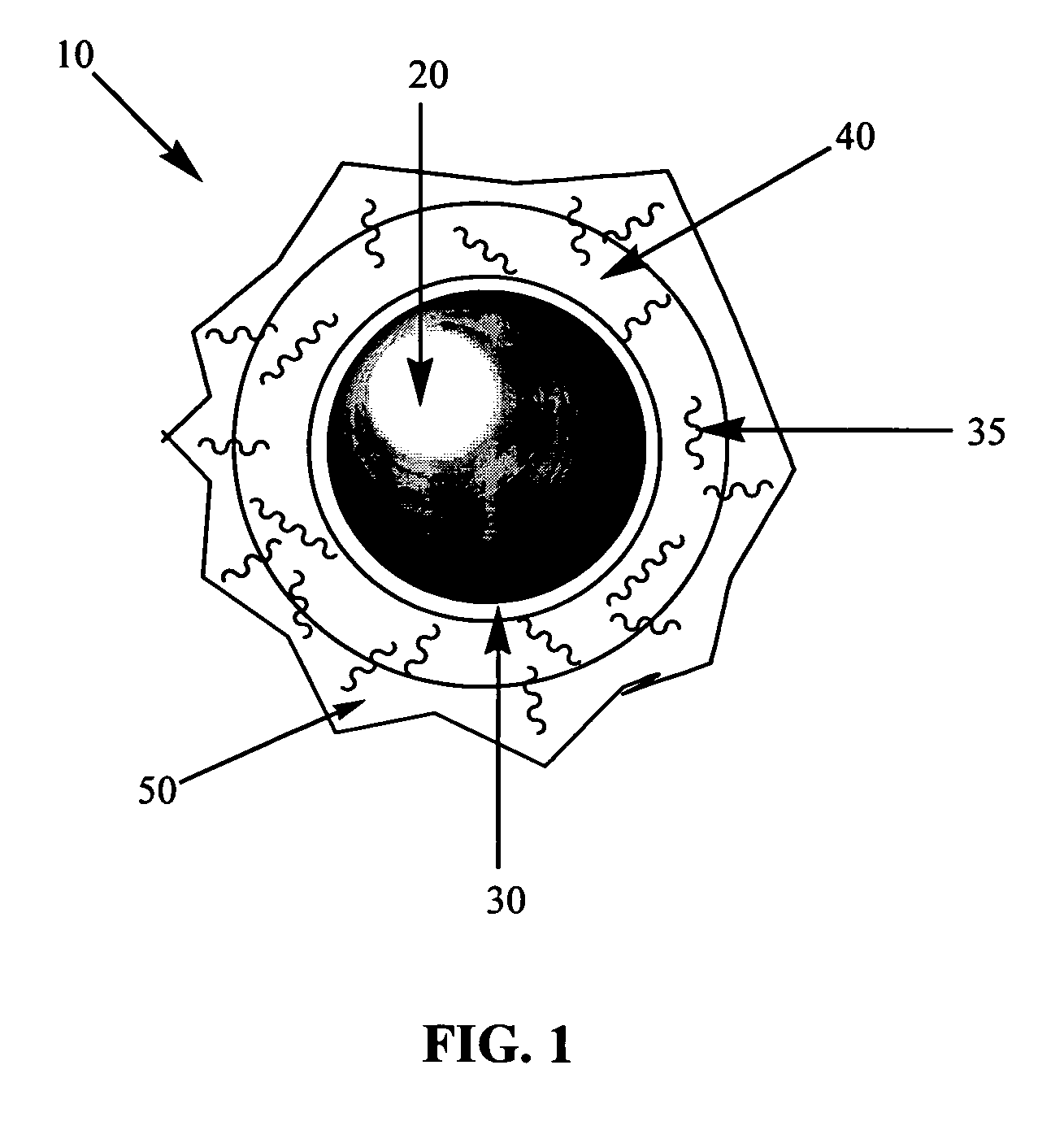

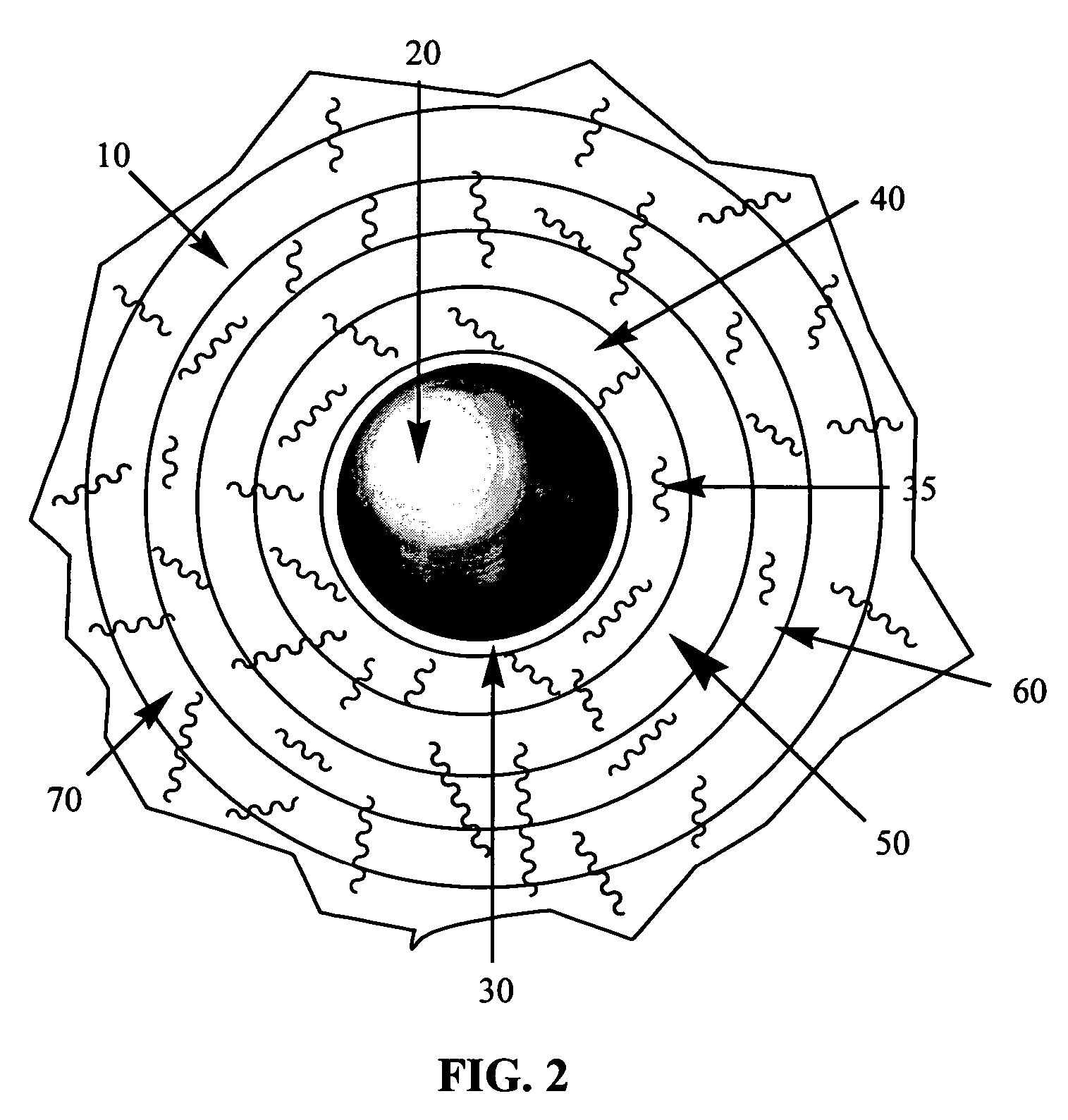

Proppants with fiber reinforced resin coatings

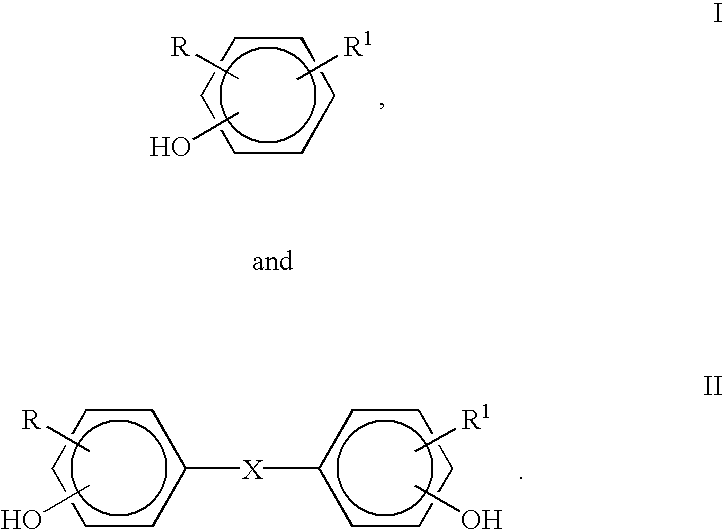

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

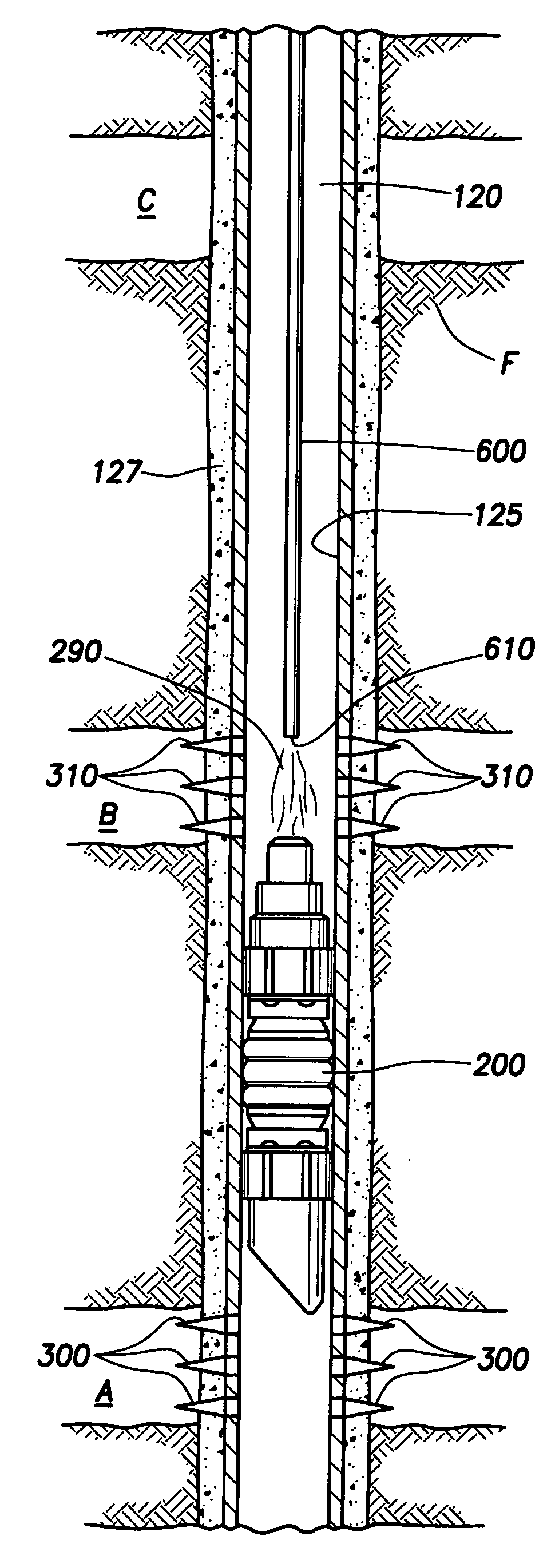

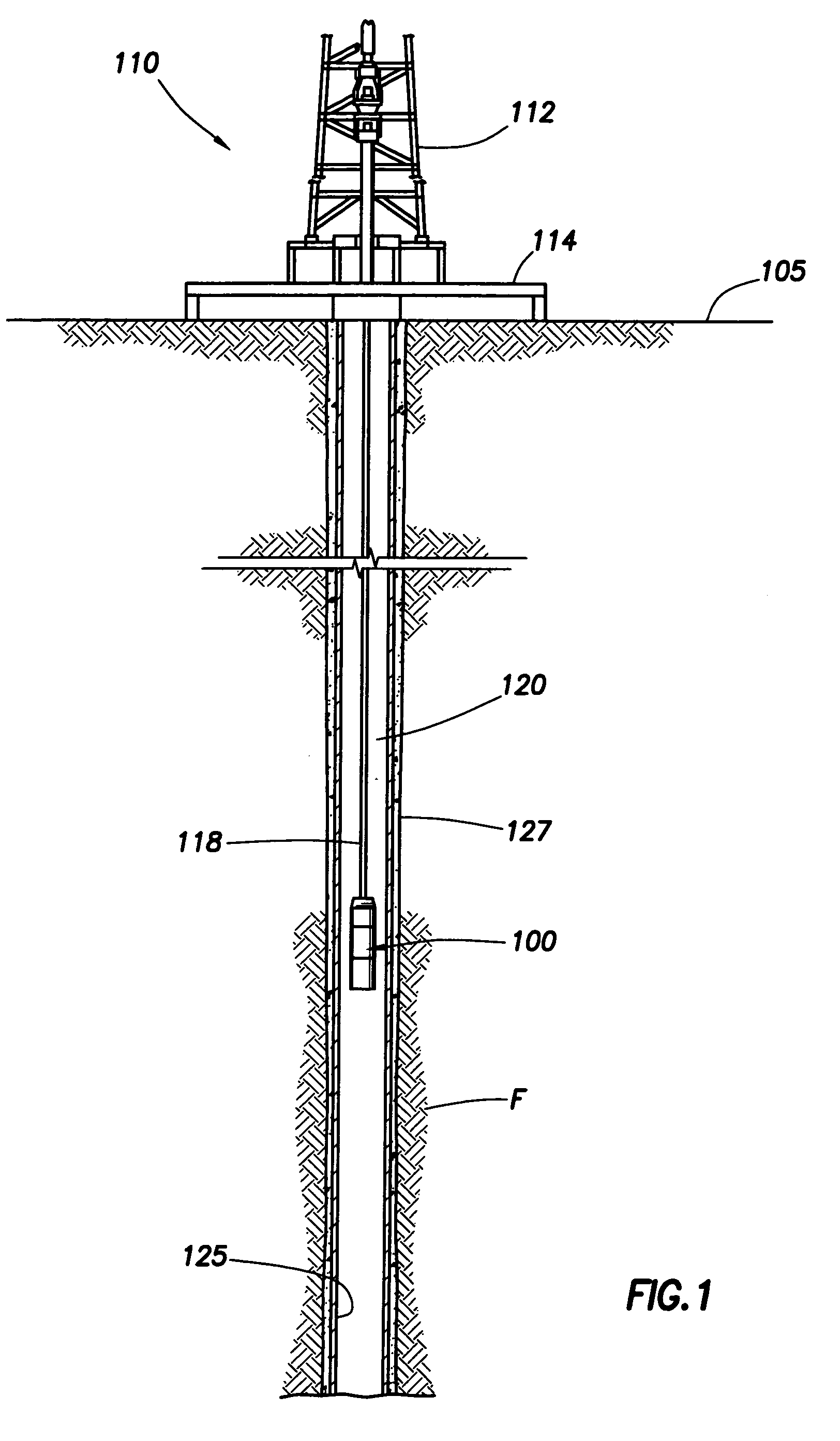

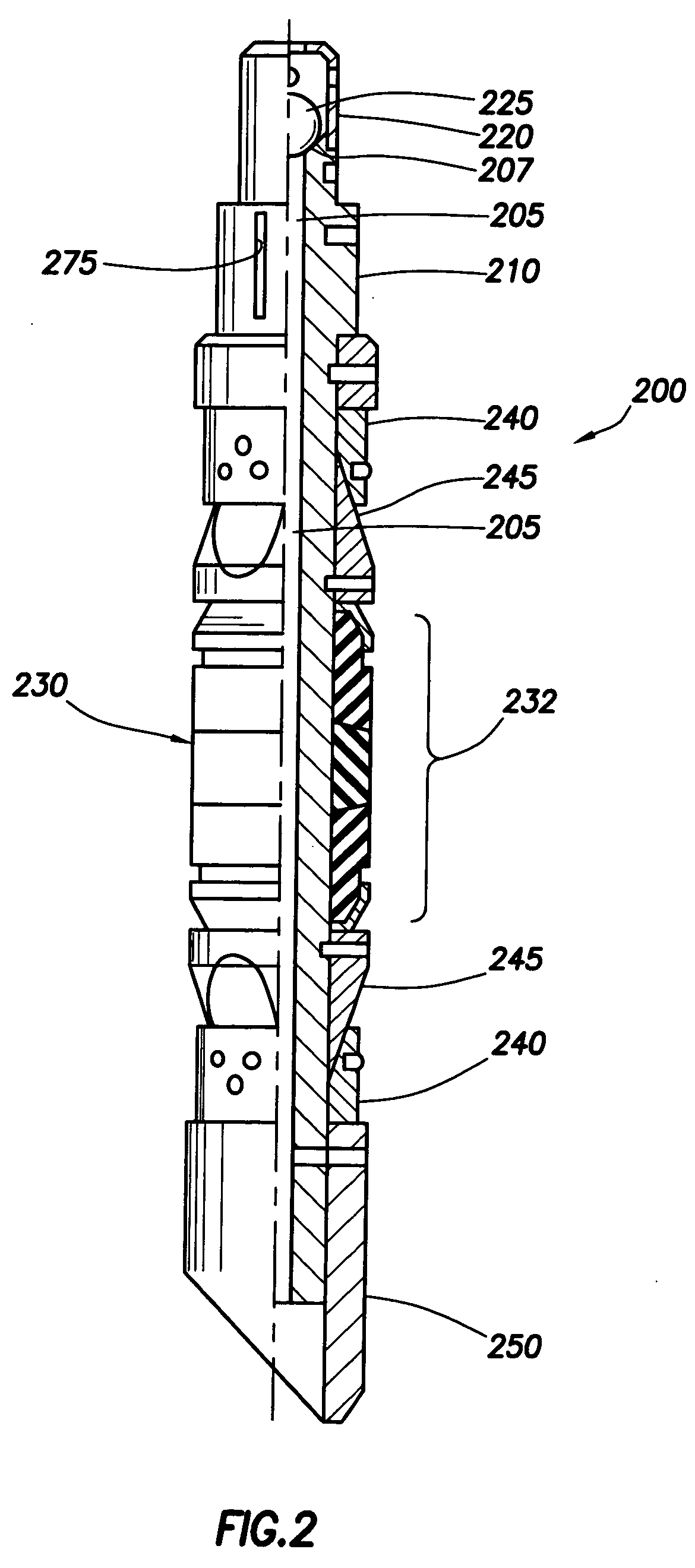

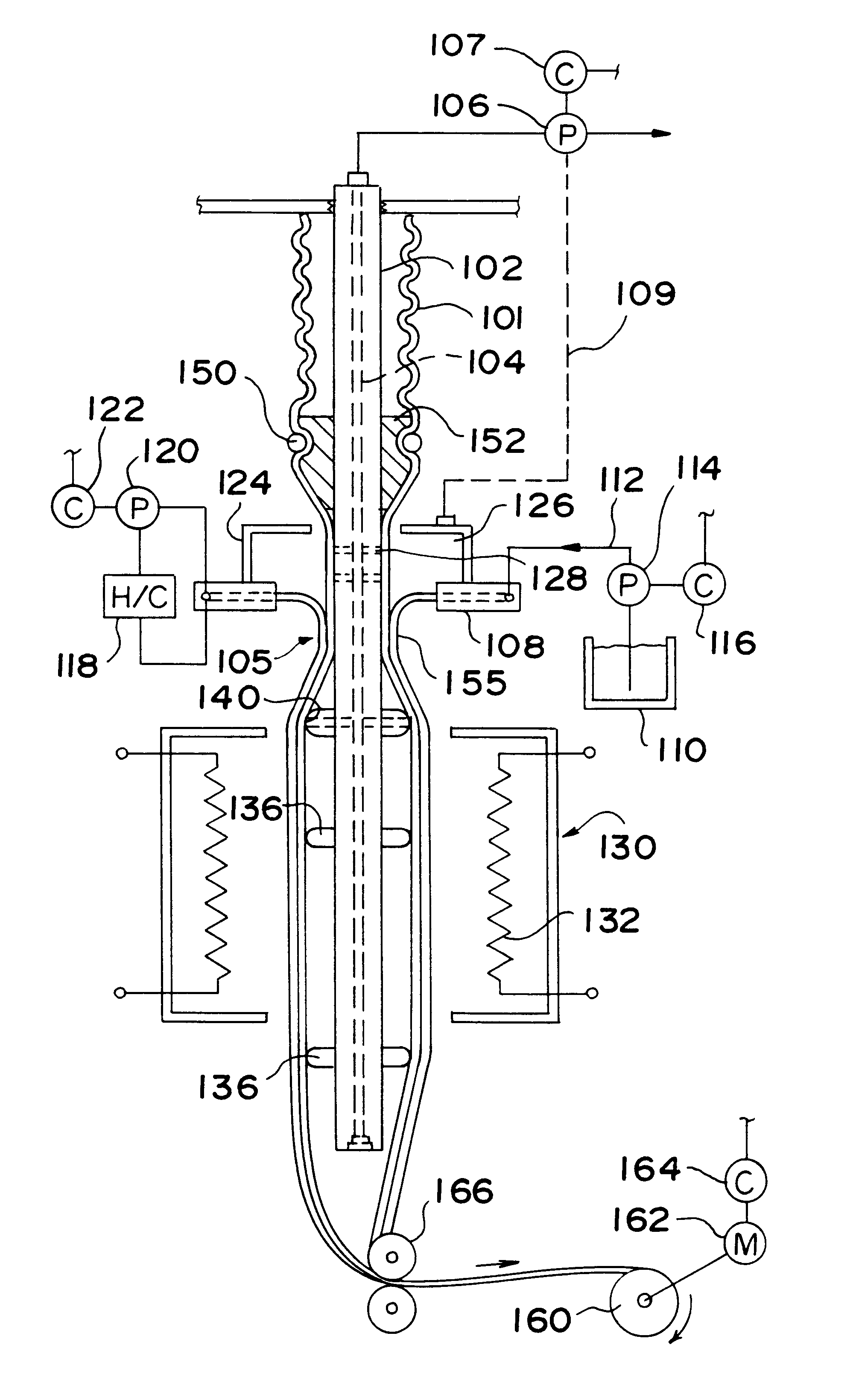

One-time use composite tool formed of fibers and a biodegradable resin

ActiveUS20050205265A1Eliminates and at least minimizes drawbackFluid removalWell/borehole valve arrangementsLactideFiber Chemistry

The present invention is directed to disposable composite downhole tool formed of a resin-coated fiber. The fiber is formed of a degradable polymer, such as a poly(lactide) or polyanhydride. The resin is formed of the same degradable polymer as the fiber. It chemically bonds to the fiber, thereby making a strong rigid structure once cured. The fiber may be formed into a fabric before being coated with the resin. Alternatively, the fiber is formed of a non-biodegradable material.

Owner:HALLIBURTON ENERGY SERVICES INC

Apparatus and process for making prosthetic suction sleeve

Owner:KAUPTHING BANK

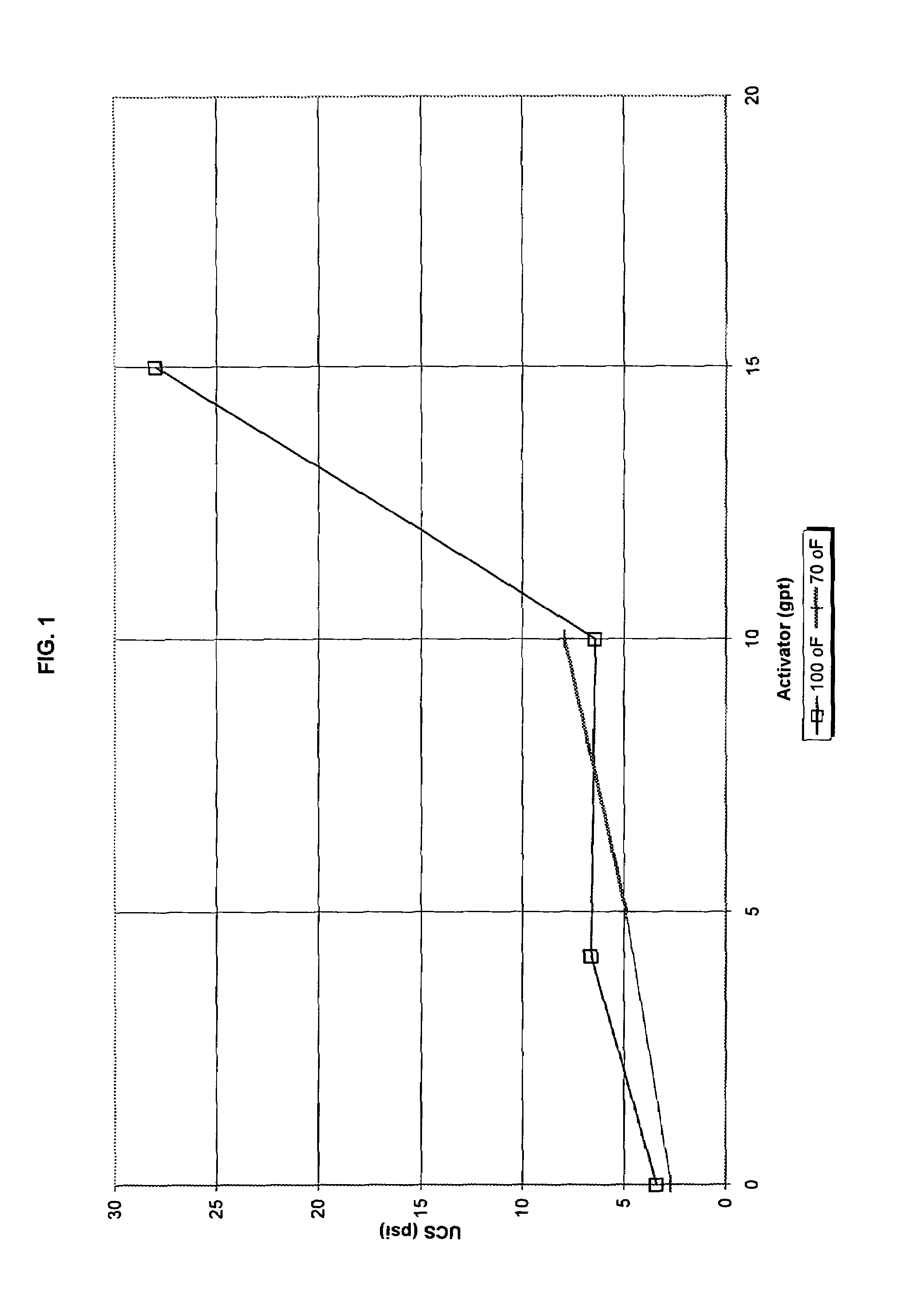

Methods and compositions for enhancing consolidation strength of proppant in subterranean fractures

InactiveUS20050006093A1High consolidation strengthFlushingGlass/slag layered productsCarrier fluidImproved method

Improved methods and compositions for consolidating proppant in fractures formed in subterranean zones are provided. An improvement of this invention comprises using proppant particles having a coating of hardenable resin including a gel breaker. The gel breaker facilitates removal of gelled carrier fluid from the surface of the proppant particles.

Owner:HALLIBURTON ENERGY SERVICES INC

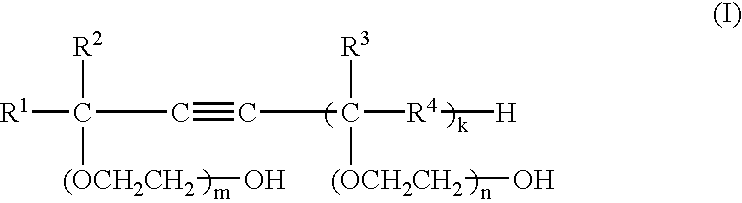

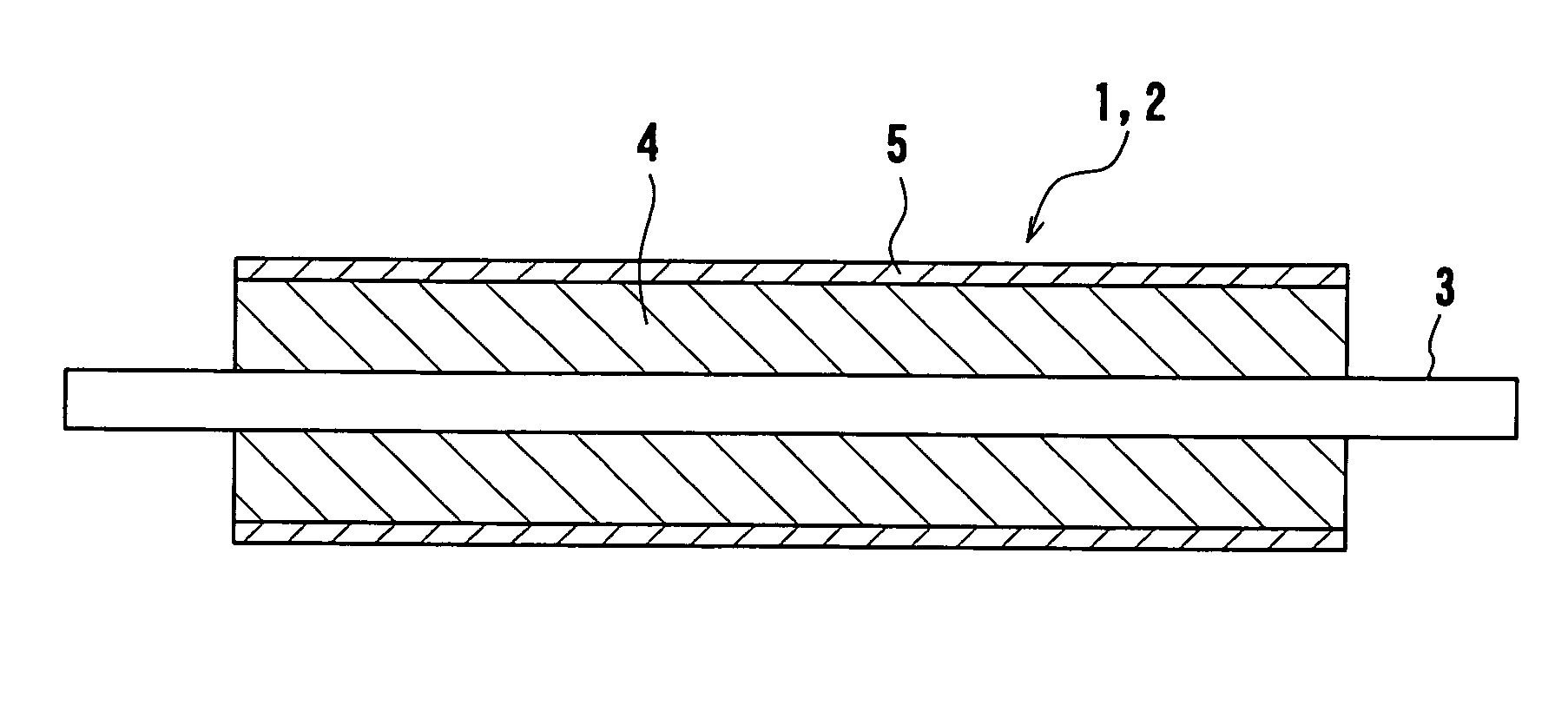

Water-soluble resin composition

InactiveUS6555607B1Improved coating propertiesEasy to diffuseFilm/foil adhesivesSemiconductor/solid-state device manufacturingResistAlcohol

A water-soluble resin composition comprising (1) a water-soluble resin, (2) a water-soluble crosslinking agent, (3) at least one of surface active agents selected from acetylene alcohols, acetylene glycols, polyethoxylates of acetylene alcohols and polyethoxylates of acetylene glycols, and (4) a solvent consisting of water or a mixture of water and a water-soluble solvent. This water-soluble resin composition is applied onto a resist pattern, then heated to crosslink by an acid supplied from the resist, followed by development to remove the non-crosslinked water-soluble resin coating layer. This water-soluble resin composition is excellent in coating characteristics on steps of resist patterns and in dimensional regulation upon fining of patterns so that resist patterns such as trench patterns and hole patterns can effectively be fined.

Owner:MERCK PATENT GMBH

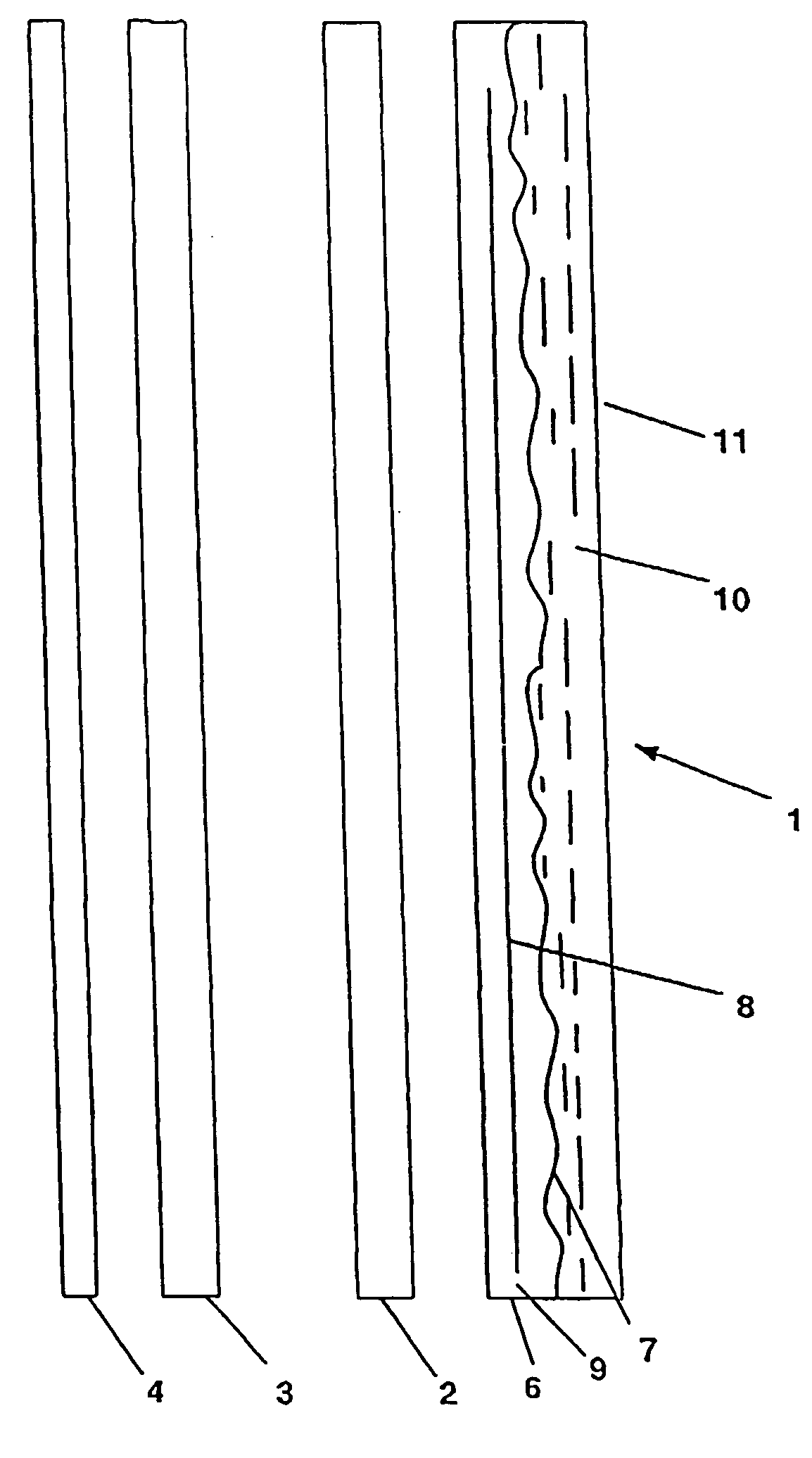

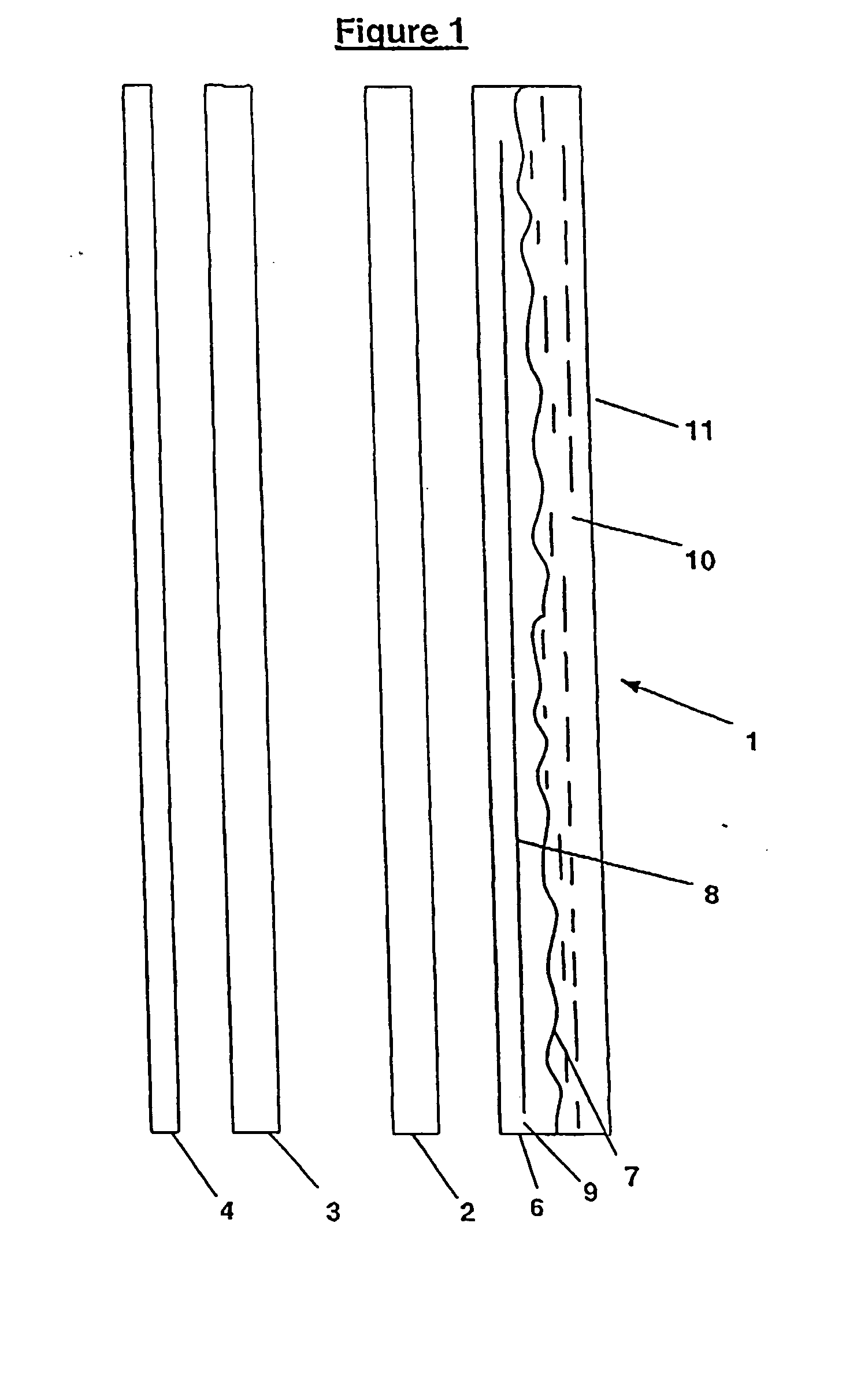

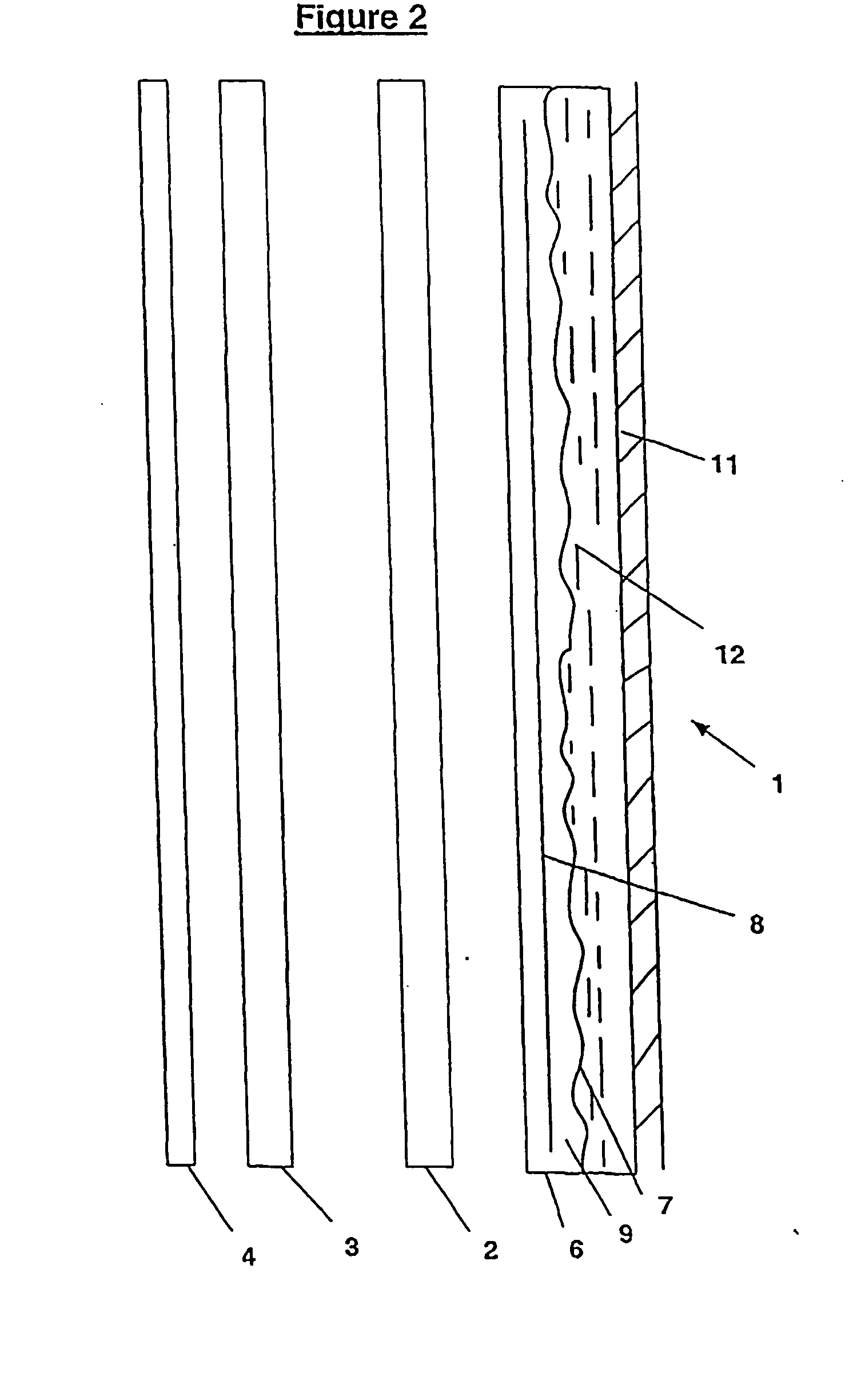

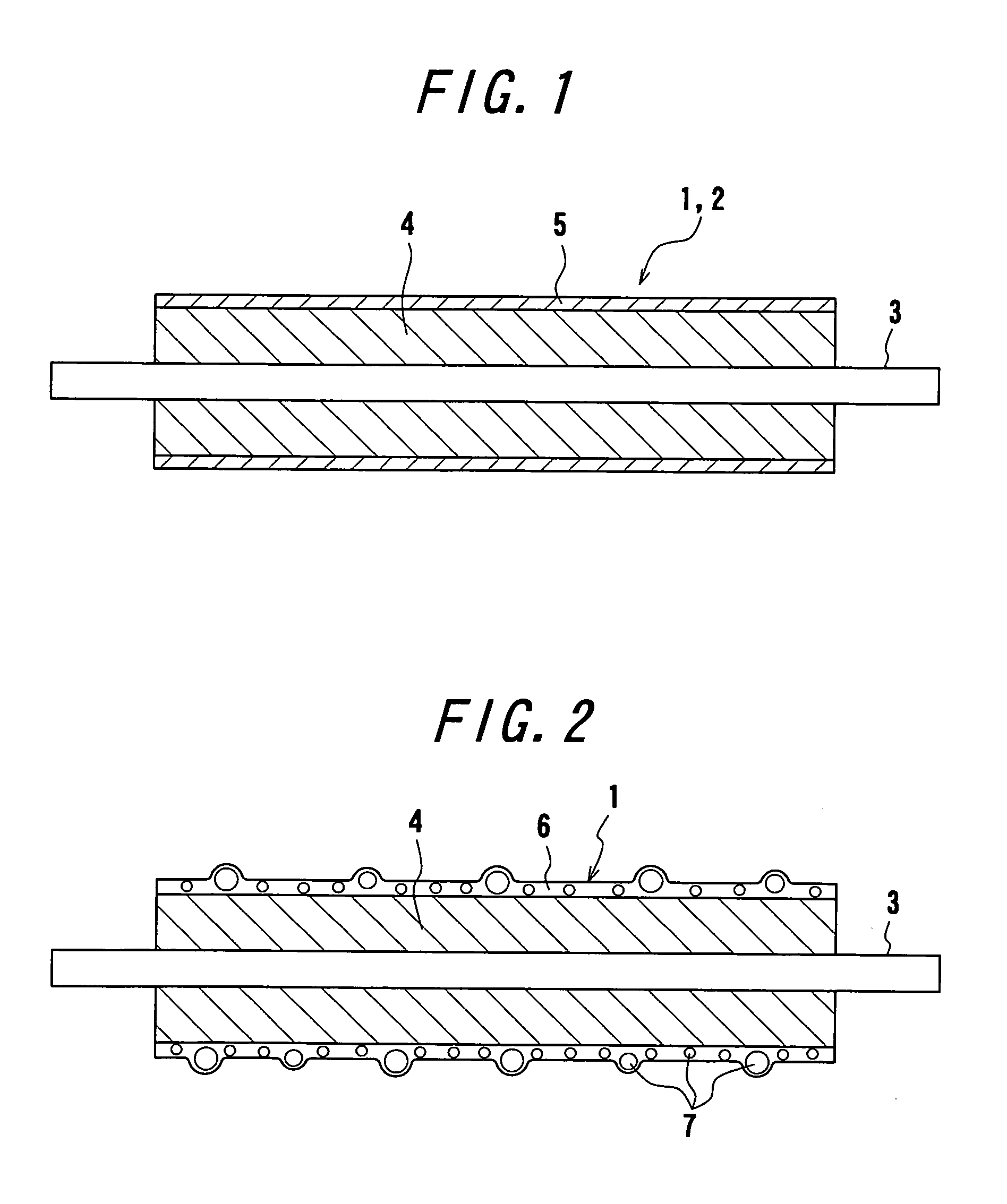

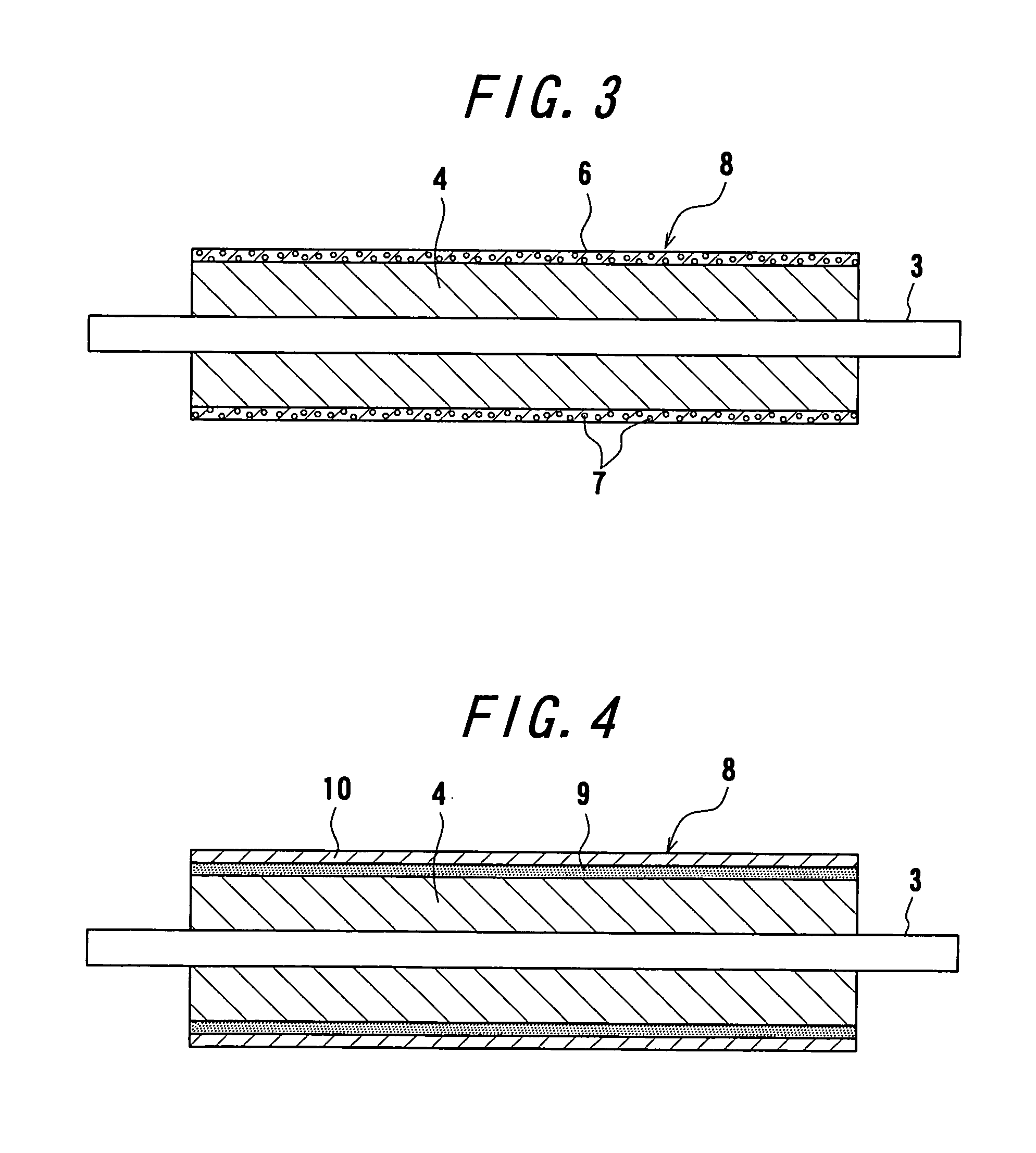

Altering surface of display screen from matt to optically smooth

InactiveUS20040066475A1Improve clarityImprove viewing angleProjectorsAdhesivesRefractive indexResin coating

A matt surface (7) of a display screen (2) is converted to an optically flat surface (11), for example, via an epoxy resin coating (10) or the like which has a refractive index equal to that or the matt surface (7). Alternatively, the matt surface (7) may be removed from the screen (2), and replaced with an optically smooth surface. The matt surface may be a diffusive surface (7) formed on a birefringent film (6) of an LCD screen (2). The display screen (2) is the front screen of a multilevel three-dimensional display comprising layered screens (2, 3), and altering the surface from matt to flat reduces the blurring of displayed images.

Owner:APTIV TECH LTD

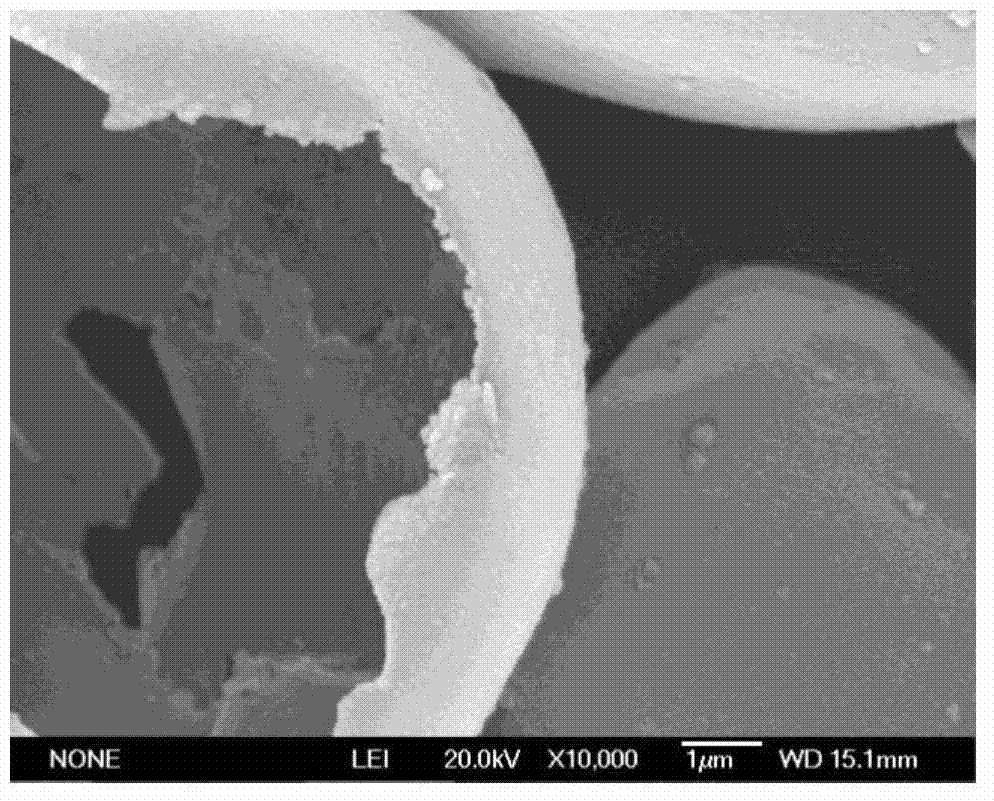

Soluble fibers for use in resin coated proppant

Coated particle substrates having a coating of resin and / or water soluble polymers and soluble, fibrous material are provided for use in subterranean formations. The coated particle substrate particles are typically proppants used to prop open subterranean hydrocarbon formations during recovery processes, such as after a hydraulic fracture, and provide both improved settling characteristics and improved hydrocarbon flow characteristics due to the conductive channels formed by the soluble fibers downhole. Methods of making the coated particles are also described.

Owner:FAIRMOUNT SANTROL

Coated plastic beads and methods of using same to treat a wellbore or subterranean formation

ActiveUS7494711B2Highly desirable resultIncrease resistanceSynthetic resin layered productsCellulosic plastic layered productsPolystyrene beadPolyamide

Plastic beads, including polyamides and polystyrene beads crosslinked with divinylbenzene, having a curable resin coating are highly useful for sand control and / or hydraulic fracturing of subterranean. The curable resin coated plastic beads preferably have an apparent specific gravity less than about 1.5.

Owner:BAKER HUGHES INC

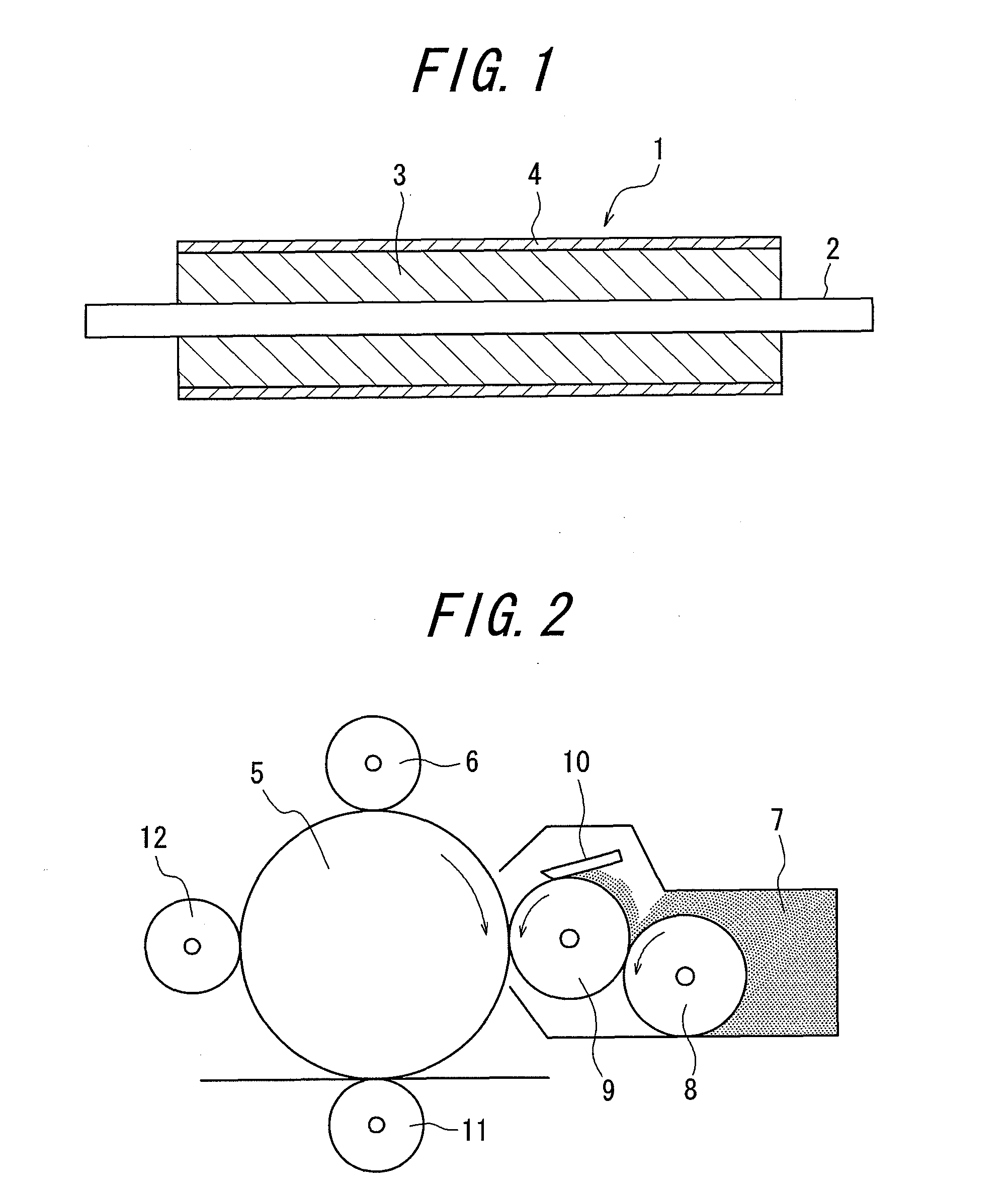

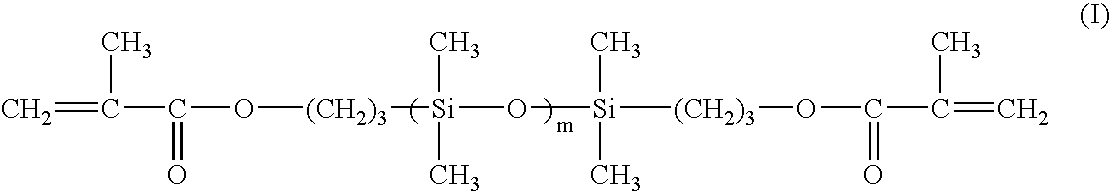

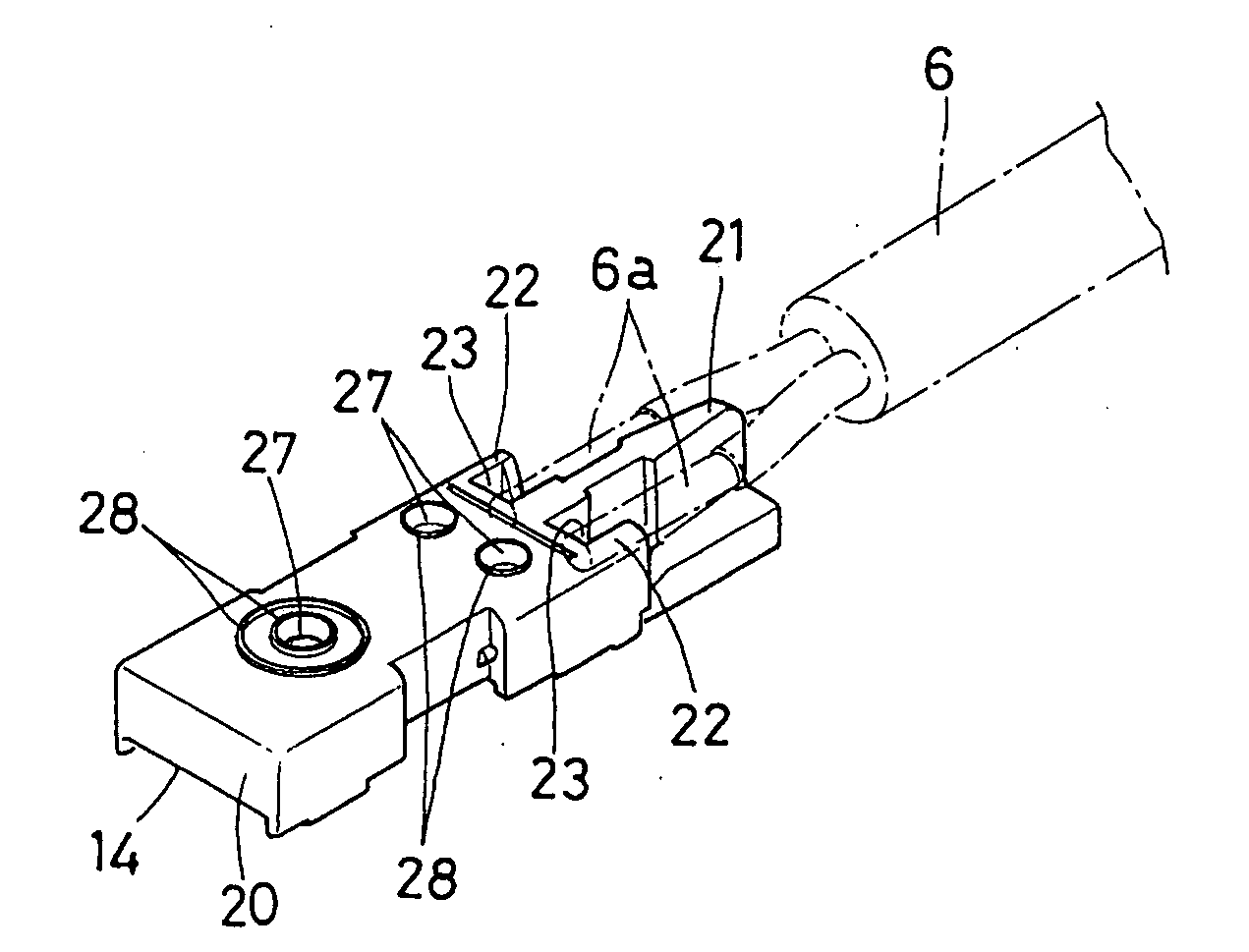

Developing Roller, Charging Roller, Conductive Roller and Method for Producing the Same

ActiveUS20080292366A1Improve propertiesImprove image qualityShaft and bearingsMetal-working apparatusUV curingUltraviolet

This invention relates to a conductive roller such as a developing roller, a charging roller or the like provided with a resin coating calyer on a surface of an elastic layer, and more particularly to a conductive roller having the resin coating layer using an ultraviolet-curing type resin or an electron beam curing type resin and being obtained by contriving a structure of the resin coating layer, rendering the resin coating layer to contain microparticles, controlling the particle size of the microparticles, or forming the resin coating layer after the outer peripheral surface of the elastic layer is subjected to surface treatment.

Owner:BRIDGESTONE CORP

Epoxy resin-oxidized graphene composite coating and application method thereof

InactiveCN104356860AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated surface

The invention provides an epoxy resin-oxidized graphene composite coating. The composite coating is prepared by using oxidized graphene as a packing and adding the packing to epoxy resin coating. A coating layer prepared on the surface of a matrix by utilizing the composite coating is excellent in binding force of the matrix, and further greatly improved in corrosion resistance, so as to effectively obstruct a corrosive medium from penetrating from the surface of the coating layer to the path of the matrix. Therefore, the epoxy resin-oxidized graphene composite coating is good in application prospect, and in particular suitable for the matrix in a highly-corrosive severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

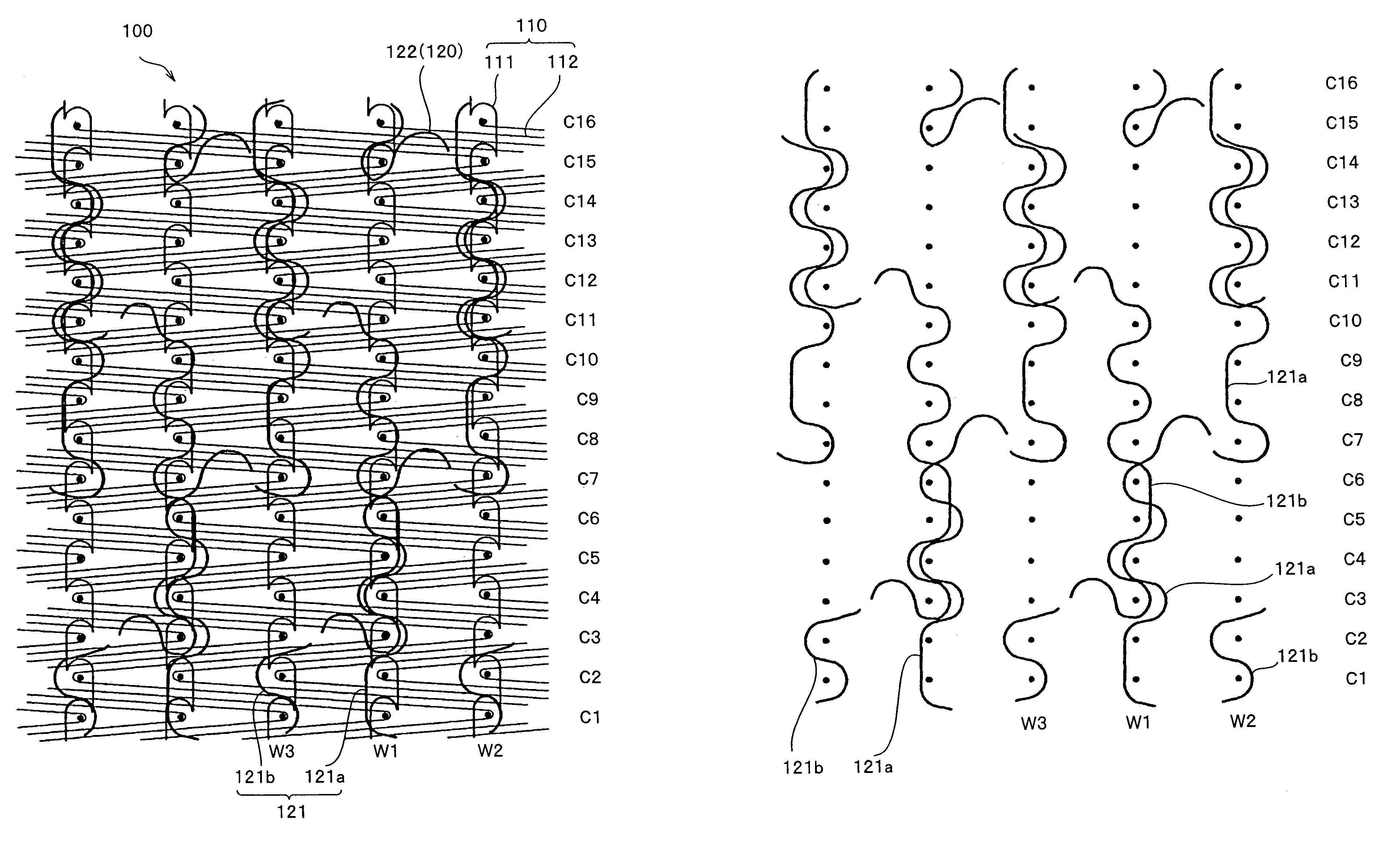

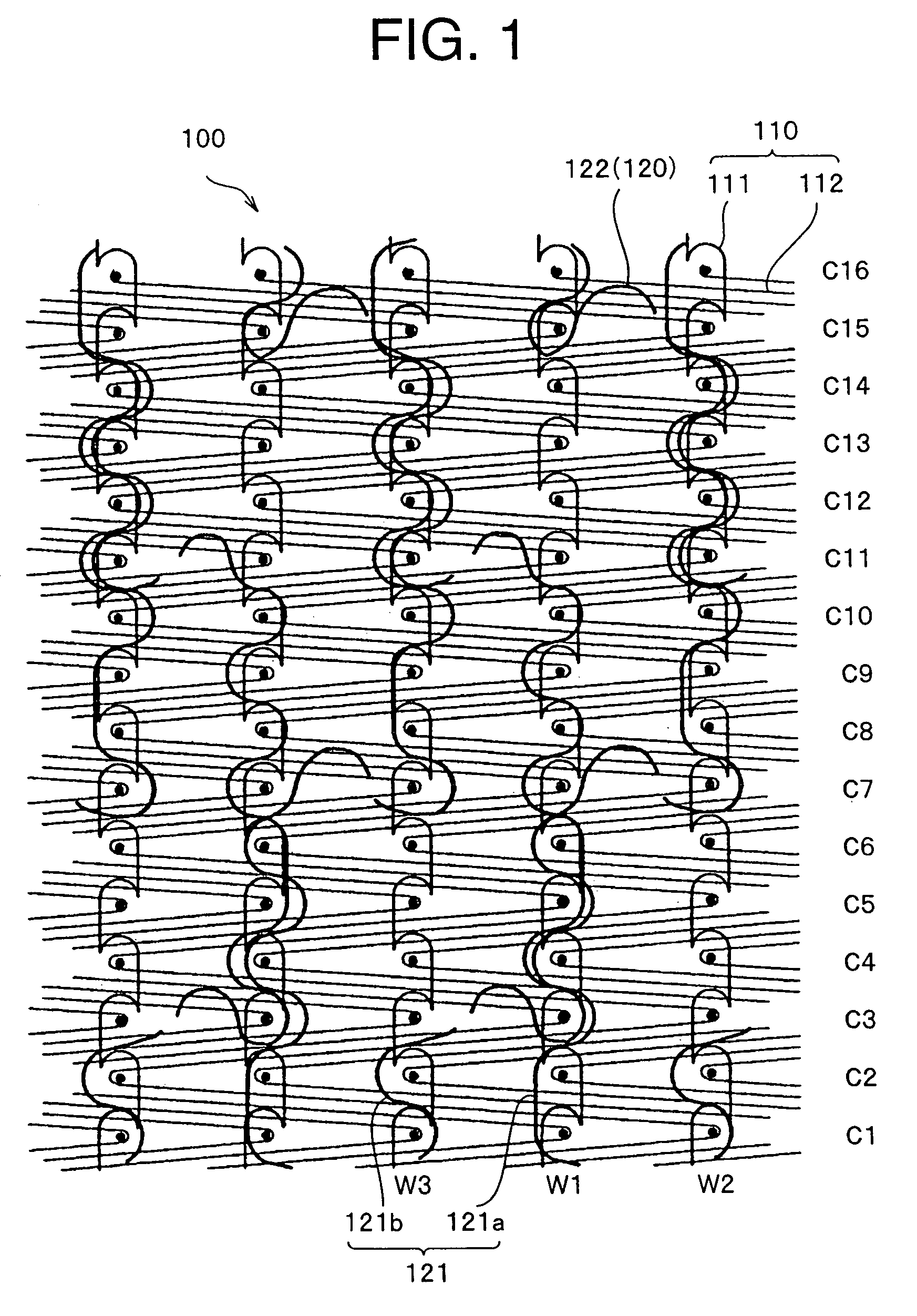

Knitted surface fastener

ActiveUS6988386B1Reduce necessityAvoid problemsWarp knittingTextile/flexible product manufactureYarnResin coating

The invention provides a knitted surface fastener made of warp knitted fabric, which eliminates necessity of resin coating for fixing a base portion of a pile loop and fusion between yarns, securing flexibility and ventilation proper to knitted fabric wherein, in a base fabric of a surface fastener, wales are formed with at least chain knitting yarns and the respective wales are connected including at least weft in-laid yarns, engaging element loops are formed of first and second engaging element forming yarns striding over two or more wales and the respective engaging element forming yarns are knitted into at least three adjoining courses on a same wale in a zigzag shape, at this time, the first and second engaging element forming yarns are knitted into adjoining same stitches of at least two or more courses of the same wale in the zigzag shape.

Owner:YKK CORP

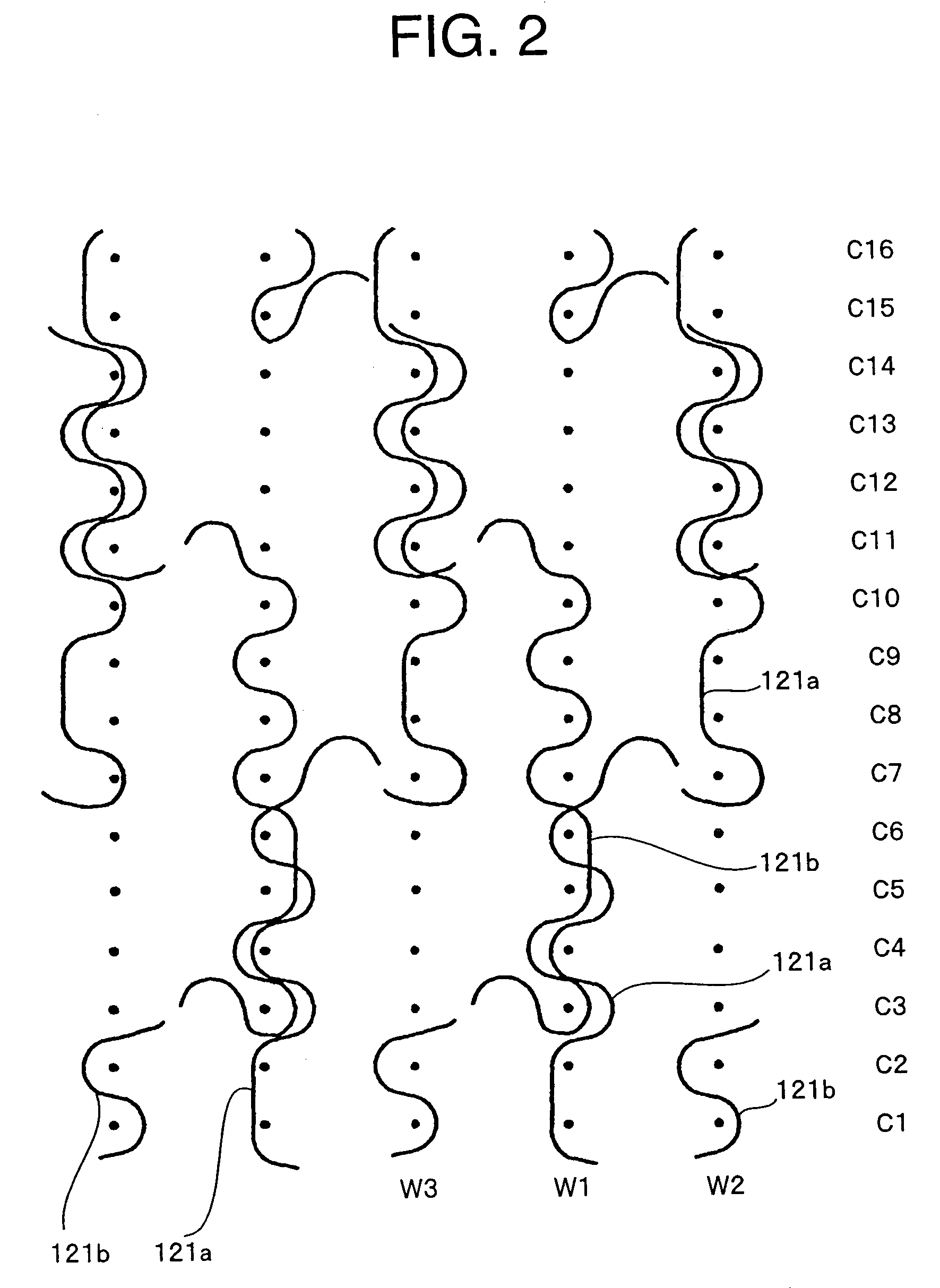

Surface-mounting coil component and method of producing the same

ActiveUS7209022B2Low costReduced durabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsShear modulusSurface mounting

A surface-mounting choke coil has a resin coating material with magnetic powder which is filled a space between the upper flange and the lower flange of a drum-type ferrite core, while covering the circumferential of the winding. The resin coating material with magnetic powder has a glass transition temperature Tg of about −20° C. or lower, more preferably about −50° C. or lower in a course of transferring from a glass state to a rubber state during changing of shear modulus with respect to temperature as a physical property when hardening, and the thickness of the upper flange of the drum-type ferrite core is about 0.35 mm or less, and a value of a ratio L2 / L1 of an outer diameter L2 of the upper flange to a diameter L1 of the winding core of the drum-type ferrite core is about 1.9 or more.

Owner:TAIYO YUDEN KK

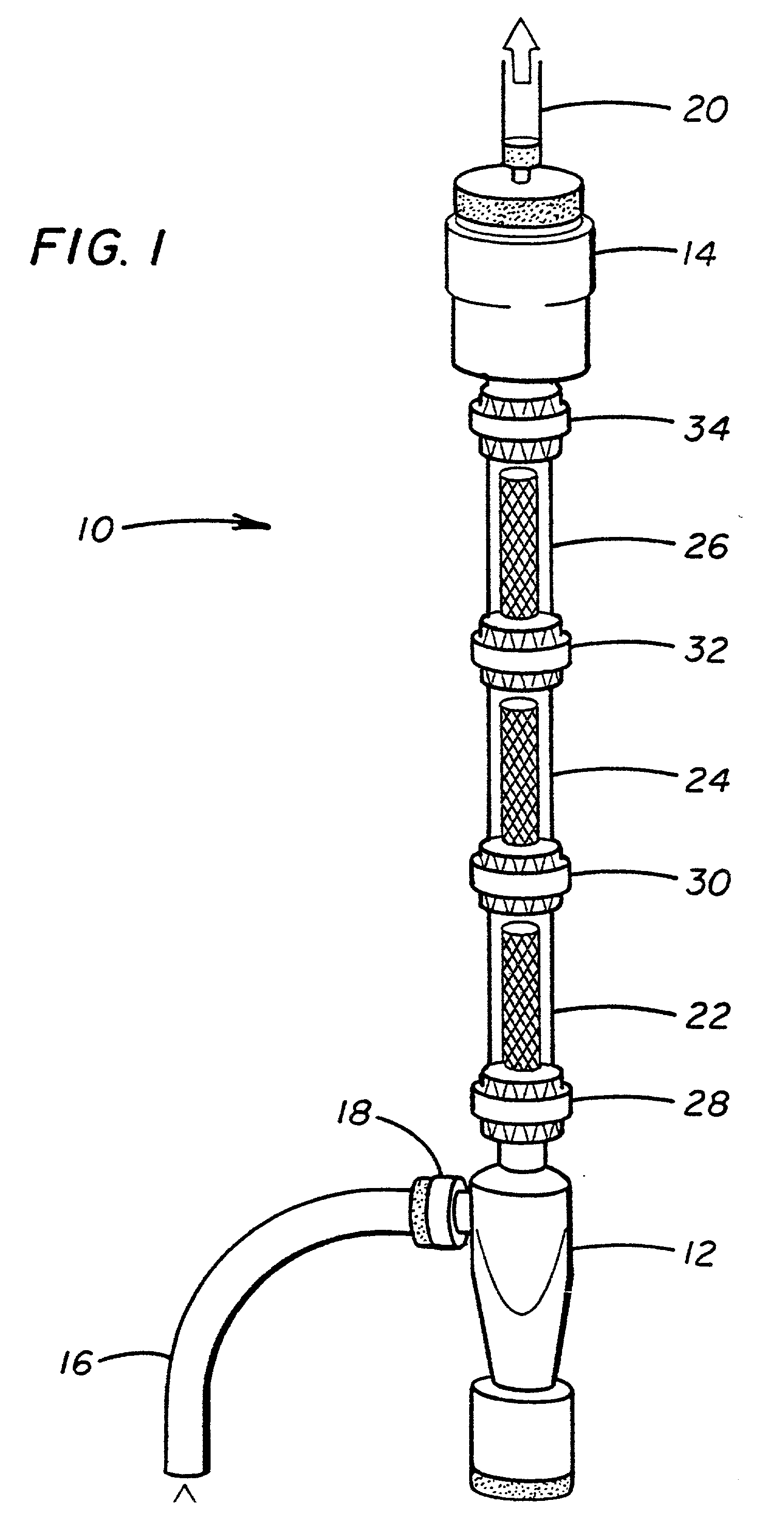

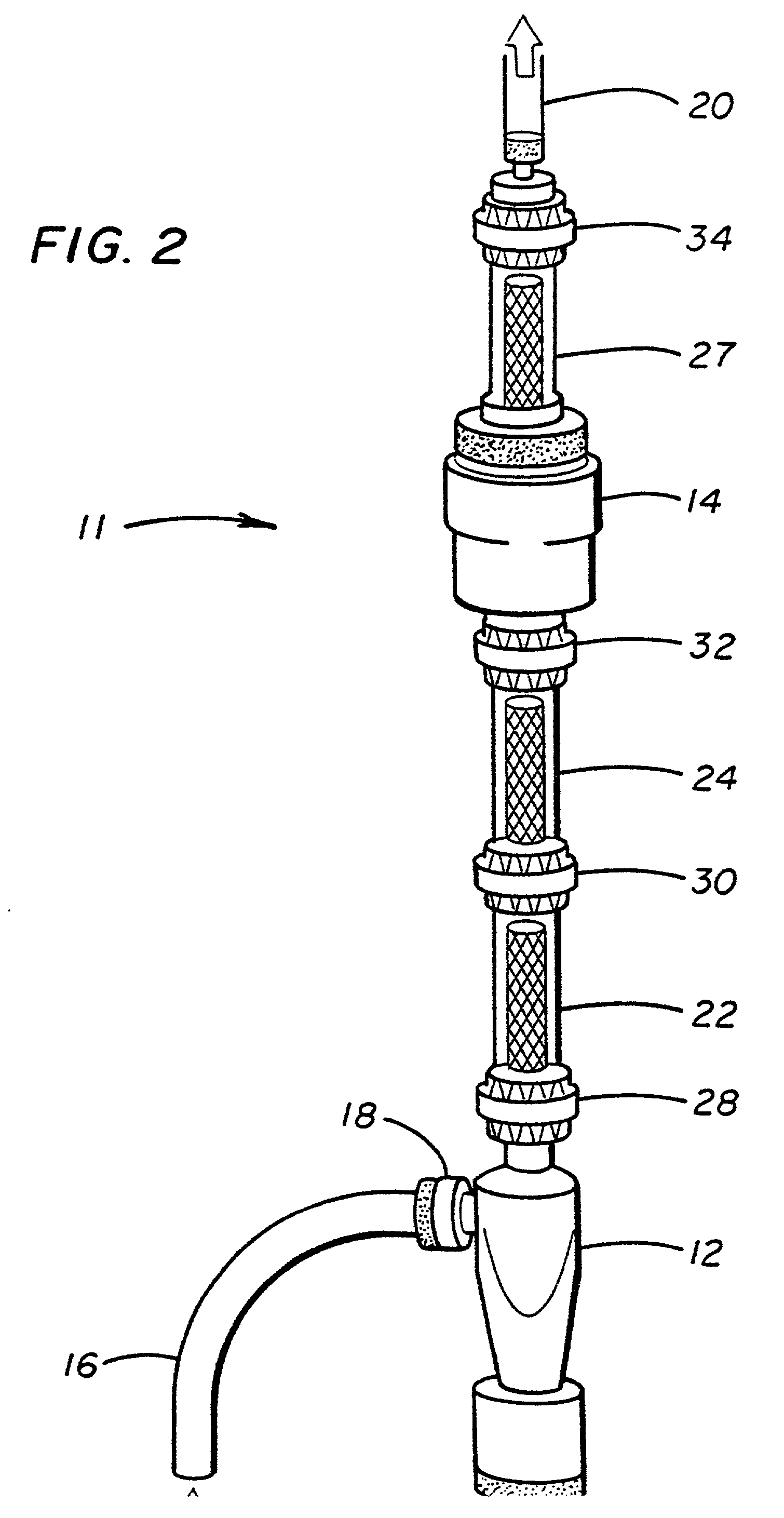

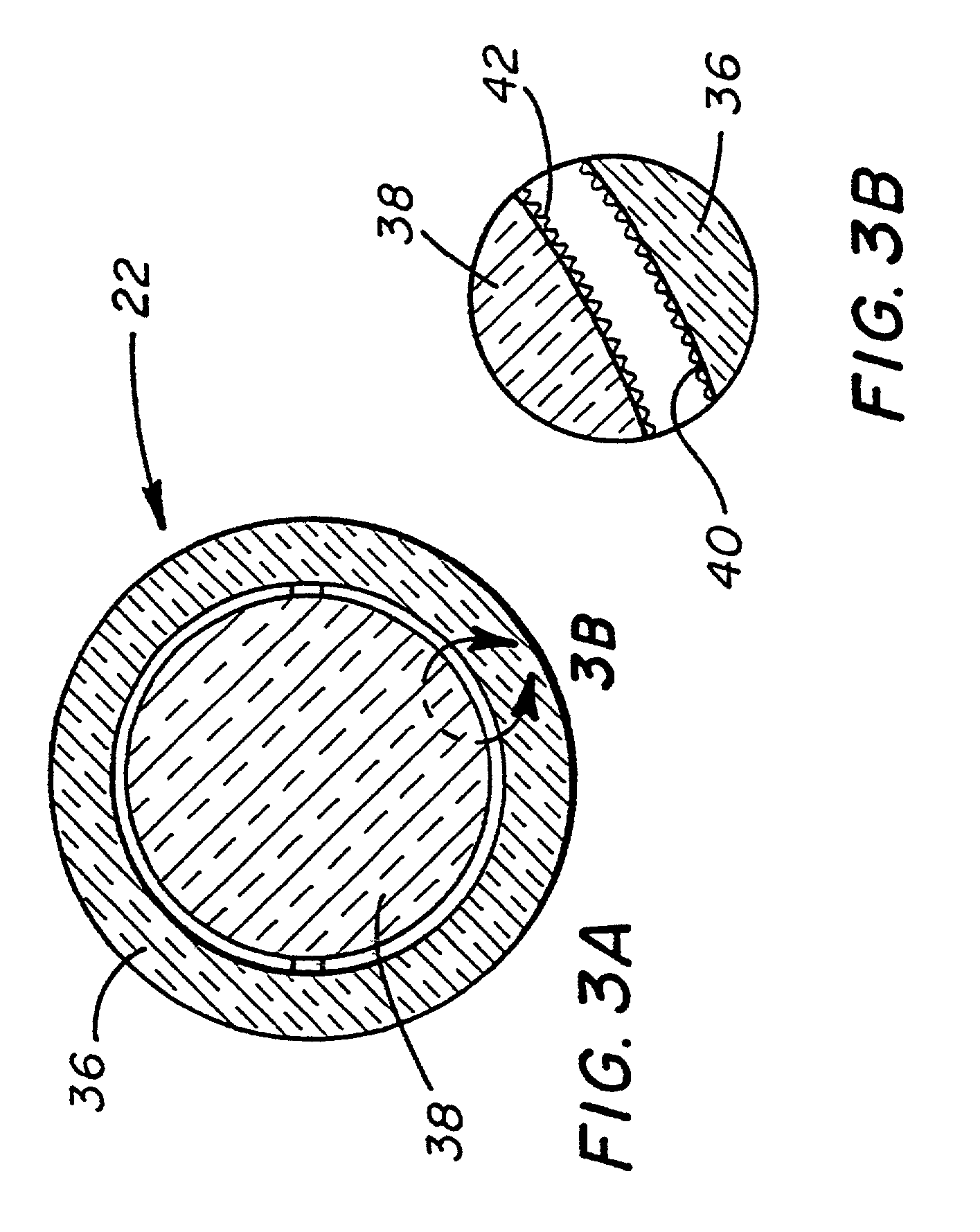

Quantitative organic vapor-particle sampler

InactiveUS20010045000A1Displacement minimizationEliminate artifactsOther chemical processesWithdrawing sample devicesDiffusionMicrosphere

The present invention concerns a quantitative organic vapor-particle sampler which can efficiently sample both semi-volatile organic gases and particulate components through the use of a unique sorbent resin coating and process. The sampler of the present invention comprises in its broadest aspect a tubular device having an inlet at one end through which organic vapor / particles are introduced, an outlet at the other end through which gases exit, at least one annular denuder interposed there between which is coated on the inside surface of the annulus with a specially prepared resin absorbent, which selectively absorbs organic vapors contained in the gases introduced into the inlet, and a filter which traps and collects particles. The invention further concerns a semi-volatile organic reversible gas sorbent for use in an integrated diffusion vapor-particle sampler comprising macroreticular resin agglomerates of randomly packed microspheres with the continuous porous structure of particles ranging in size between 0.05-10 mum.

Owner:RGT UNIV OF CALIFORNIA

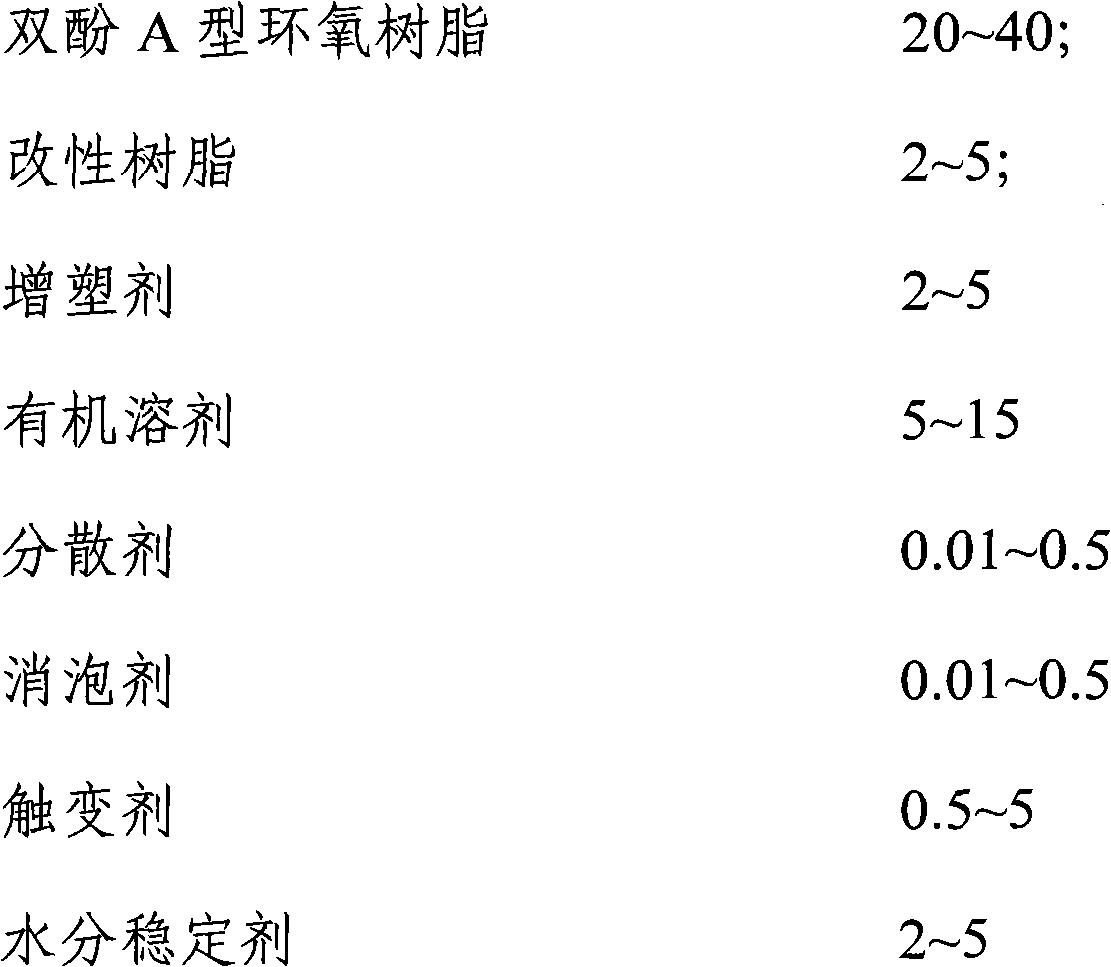

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

High-performance organic-inorganic resin coating material with hybrid acrylic ester and production thereof

InactiveCN1746236AEasy to prepareHigh hardnessLiquid surface applicatorsCoatingsCross-linkResin coating

A high-performance organic-inorganic hybrid acrylate resin coating material and its production are disclosed. The process is carried out by taking inorganic nanometer oxidant collosol containing hydroxyl group and alkoxy as curing agent, reacting with acrylate resin containing functional group, cross-linking and curing to obtain inorganic-organic hybrid coating. It achieves higher hardness, better thermal stability, abrasive and scraping-resistances and ultraviolet shielding characteristic. It can be used for surface protective ornament of car, metal, building, leather and fabric.

Owner:FUDAN UNIV

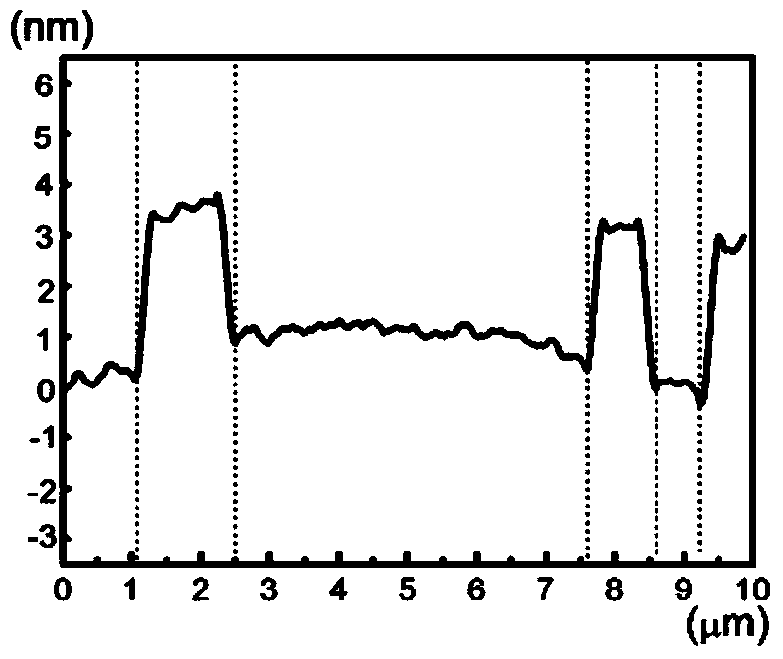

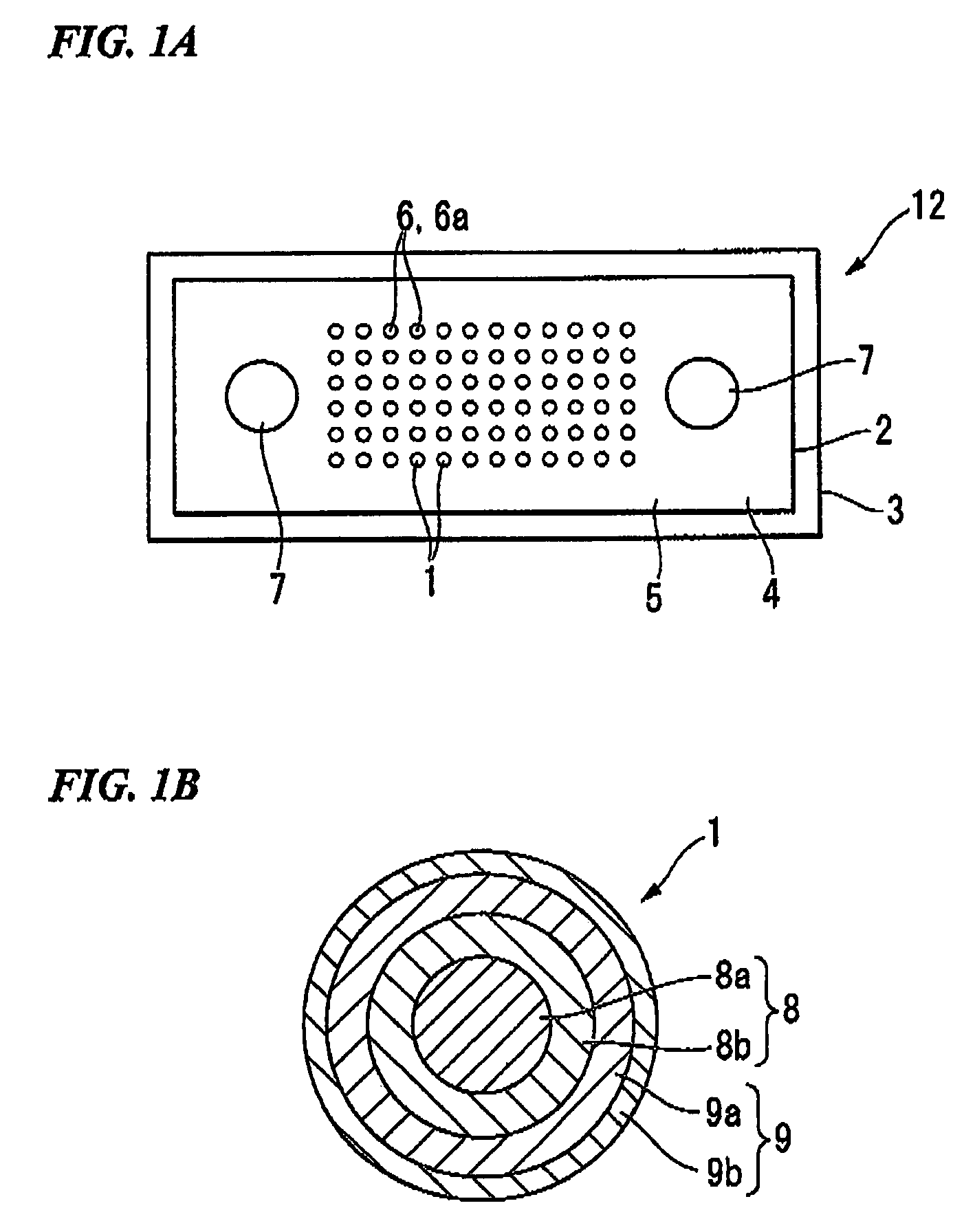

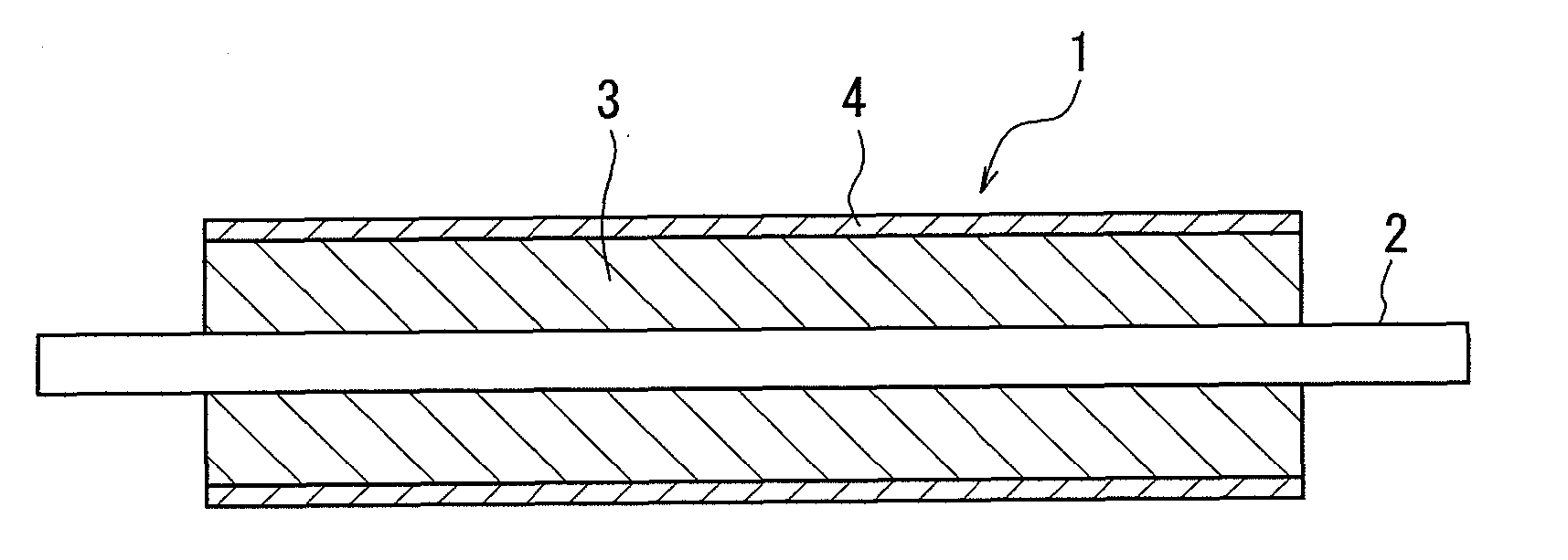

Optical connector with optical fiber

In an optical connector with optical fibers in which silica glass optical fibers with resin coating layers remaining attached are connected in optical fiber openings of a ferrule made from resin, at least a part of the resin coating layer of the optical fiber is glued to an inner face of the optical fiber opening, an outer diameter of the resin coating layer of the optical fiber is less than or equal to 125 μm, and the Young's modulus of the resin coating layer is less than the Young's modulus of the ferrule, and the Young's modulus of the resin coating layer is 1500 to 10000 MPa.

Owner:FUJIKURA LTD

Anti-soiling aging-resisting stainless steel paint and preparation method thereof

ActiveCN101215438AImprove aging resistanceImproves UV resistanceLiquid surface applicatorsAntifouling/underwater paintsEpoxyWater based

The invention relates to anti-pollution anti-aging rustless steel coating material and a process for preparation, and coating material comprises acroleic acid resin, film forming matter, filling material, dissolvent and auxiliary agent which are mixed, the film forming matter comprises fluoro containing resin, water-based polyurethane and epoxide resin, the filling material comprises nanometer silicon oxide. The process comprises dissolving acroleic acid resin in dissolvent, further adding film forming matter, filling material, and auxiliary agent, balling to evenly mix. The rustless steel coating material of the invention adopts nanometer silicon oxide and fluoro containing resin to modify acroleic acid coating material, utilizes the ultraviolet screening performance of nanometer silicon oxide, the particle diameter of nanometer-grade particle and low surface tension of fluoro containing resin to lead the anti-aging capability and anti-ultraviolet performance of acroleic acid resin which is prepared to be greatly enhanced, the invention has longer life span than the existing normal acroleic acid resin coating material, which has better fingerprint resisting effect, and the quality and the level are greatly improved, the scope of application is further enlarged.

Owner:HAIMEN SENDA DECORATION MATERIAL CO LTD +1

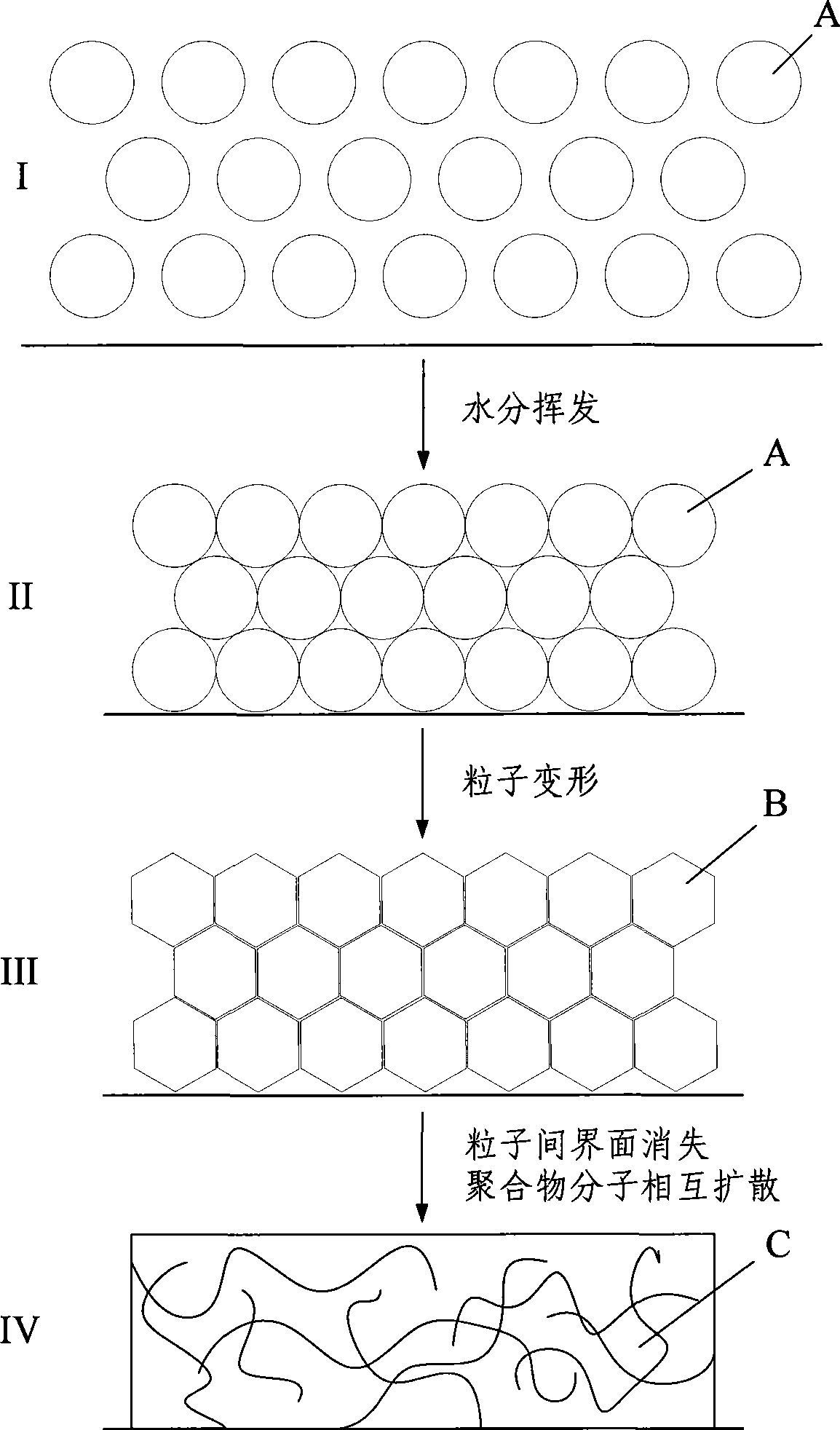

Sealed UV curable aqueous polyurethane resin and preparation method thereof

InactiveCN101381446AGood storage stabilityHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSide chainAdhesive

The invention discloses closed type ultraviolet light solidifying waterborne polyurethane resin and a method for preparing the same. The polyurethane resin and the method are characterized in that the double bond of acrylic ester is introduced to the side chain of the polyurethane by utilizing a chain extender mode, and an end NCO group is sealed and protected by a sealer; and the side chain of a molecular chain of the obtained product has the double bond of an acrylic ester group, wherein the double bond is capable of ultraviolet light solidifying, and the end of a molecular main chain of the product has an unsealable sealer group. The polyurethane resin has the advantages of good storage stability and high hardness after solidification, and further improves the solidifying degree and the adhesive force of a solidifying film and is applied to the coating of workpiece shadow areas, thicker coatings and three-dimensional parts which are hard to penetrate by ultraviolet light. Because the resin coating film is subjected to triple solidification of natural drying solidification, ultraviolet solidification and unsealing-hot solidification, the resin coating film has the advantages of high solidifying degree, high hardness and high adhesive force of base materials. The product of the invention is obviously environmental friendly, and can be widely applied in fields of thick coatings of various base materials and an adhesive.

Owner:UNIV OF SCI & TECH OF CHINA +1

Ultra thin graphics and methods

InactiveUS20060246266A1Reduce shipping costsQuality improvementDecorative surface effectsDuplicating/marking methodsColor effectGraphics

A transferable image for water-slidable application to surfaces is provided comprising a water-absorbing Porous Backing Sheet; a water-soluble Resin Coating coated on the water-absorbing Porous Backing Sheet; a base layer on the water-soluble Resin Coating; and a plurality of ink layers on the base layer, at least one of the ink layers being translucent or transparent and applied in overlapping fashion in a manner to provide a color effect. In preferred embodiments, a transfer premask is provided wherein the transfer premask is substantially no wider than about 0.25 inches than the perimeter of the image shape.

Owner:MODERNISTIC

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Water epoxy resin coating and preparing process thereof

InactiveCN1752163AEvenly dispersedImprove performanceEmulsion paintsEpoxy resin coatingsEpoxyEmulsion

A water epoxy resin paint is prepared from one of low-molecular liquid epoxy resin, the ether solution of epoxy resin and epoxy resin emulsion, and the solidifying agent prepared from polyvinylpolyamine through terminating, addition and salting. Its advantages are high hardness, adhesion and resistance to water and corrosion.

Owner:TONGJI UNIV

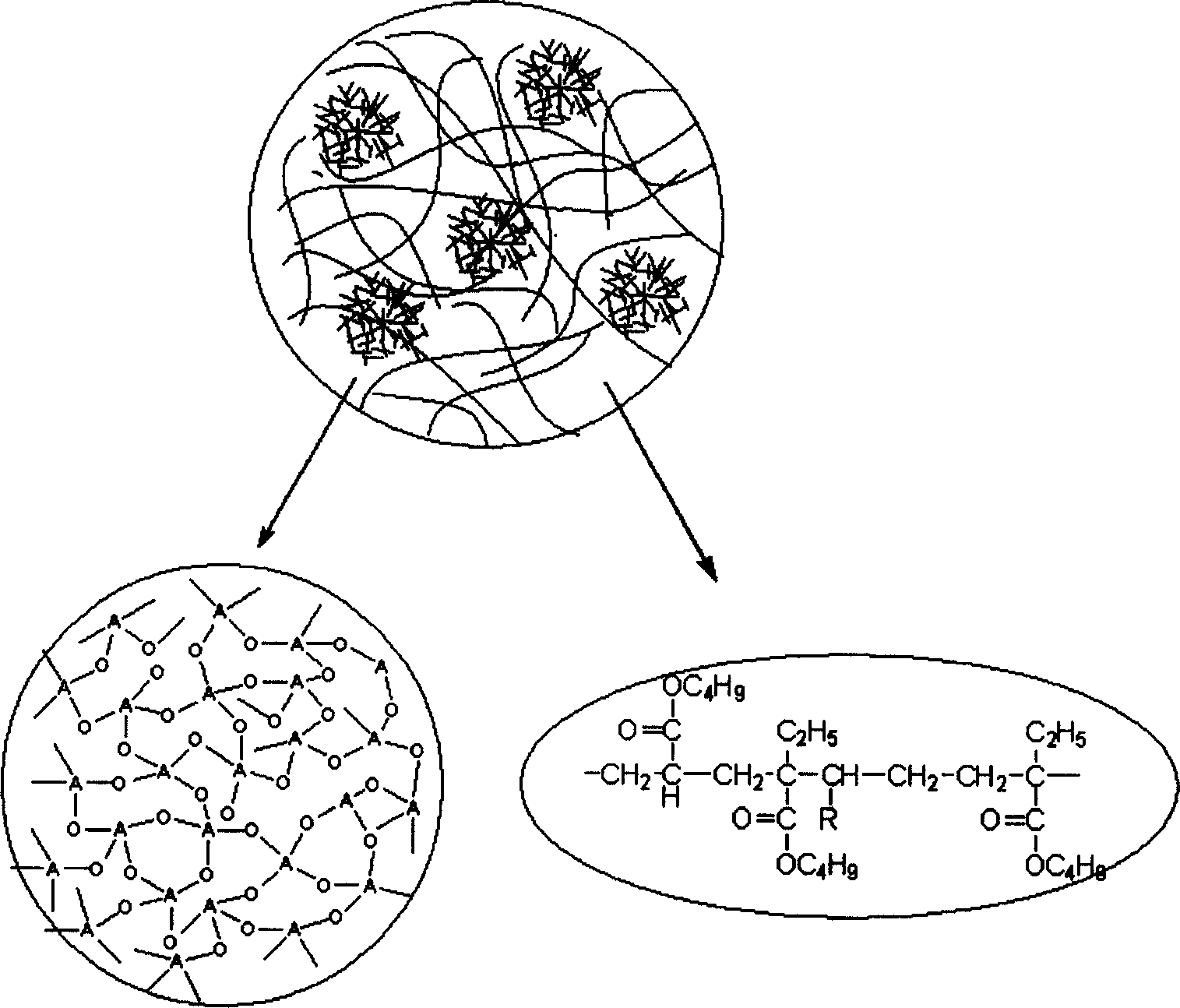

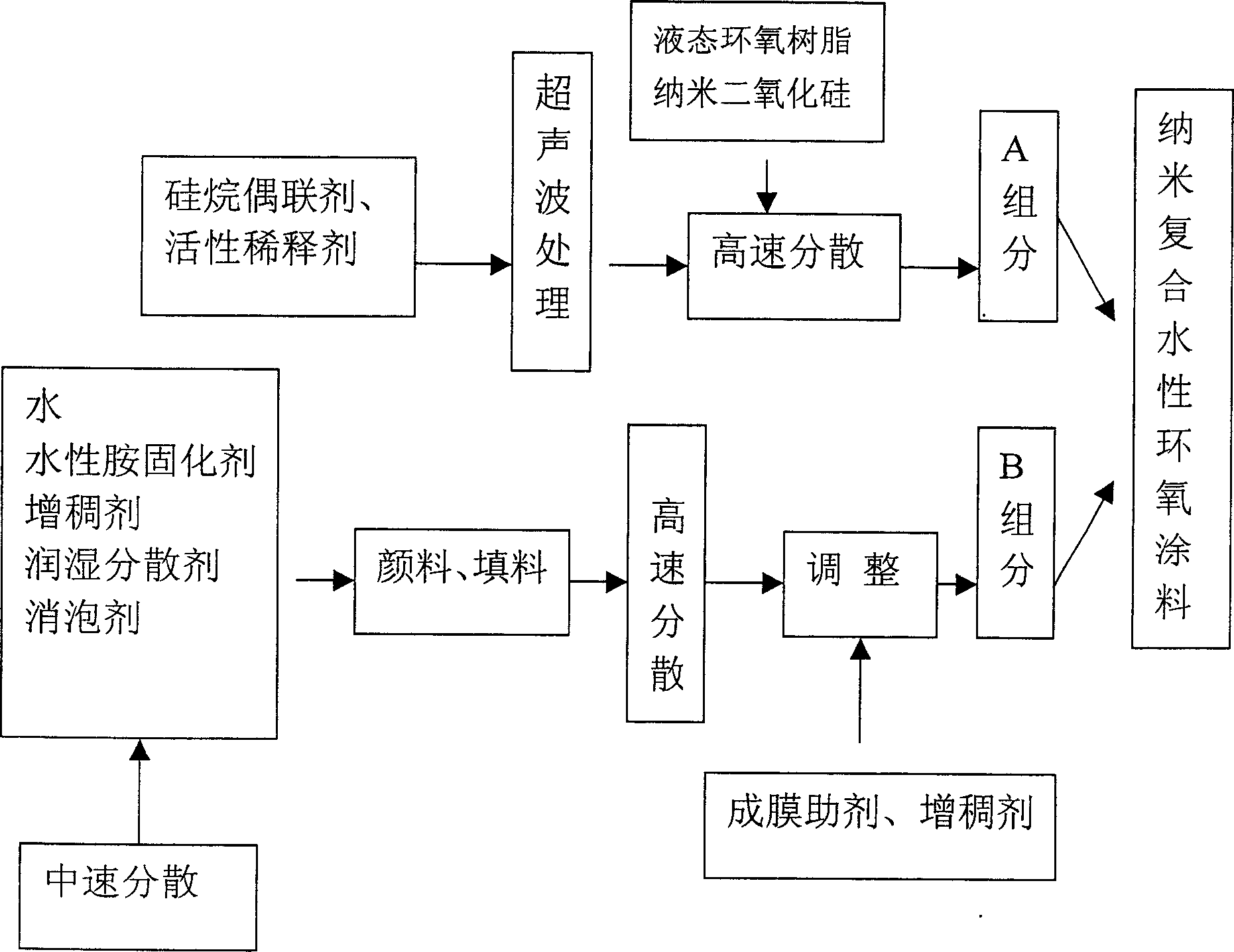

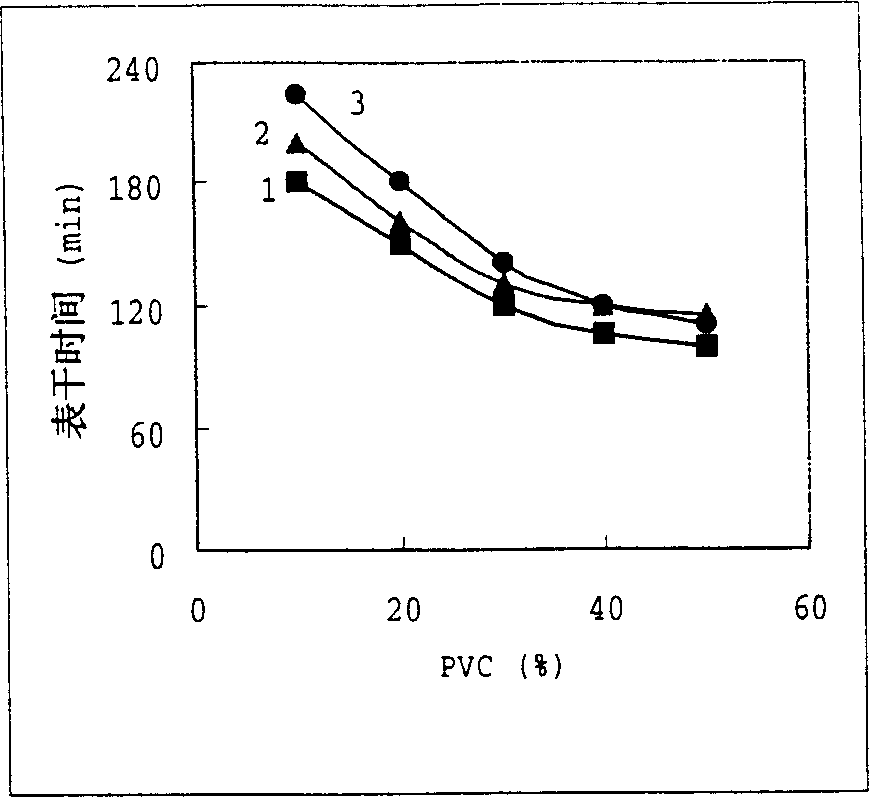

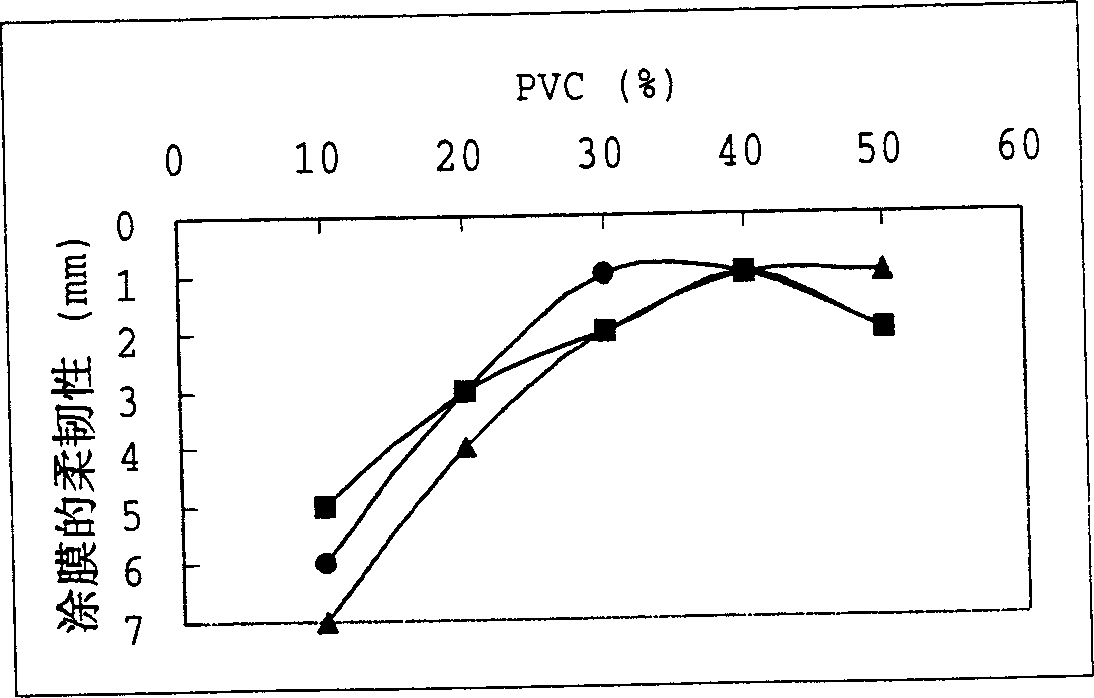

Nano composite aqueous epoxide resin coating material and preparation method

The nano composite water-base epoxy resin coating material comprises: epoxy constituent composed of epoxy resin, active diluent, nano SiO2 particle, and silane coupling agent; and water-base amic curing agent constituent composed of water-base amic curing agent, wet dispersant, defamer, paint, filler, film-forming adjuvant, thickener, and water. This invention also discloses opposite preparation method, improves greatly product properties, and has no pollution.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

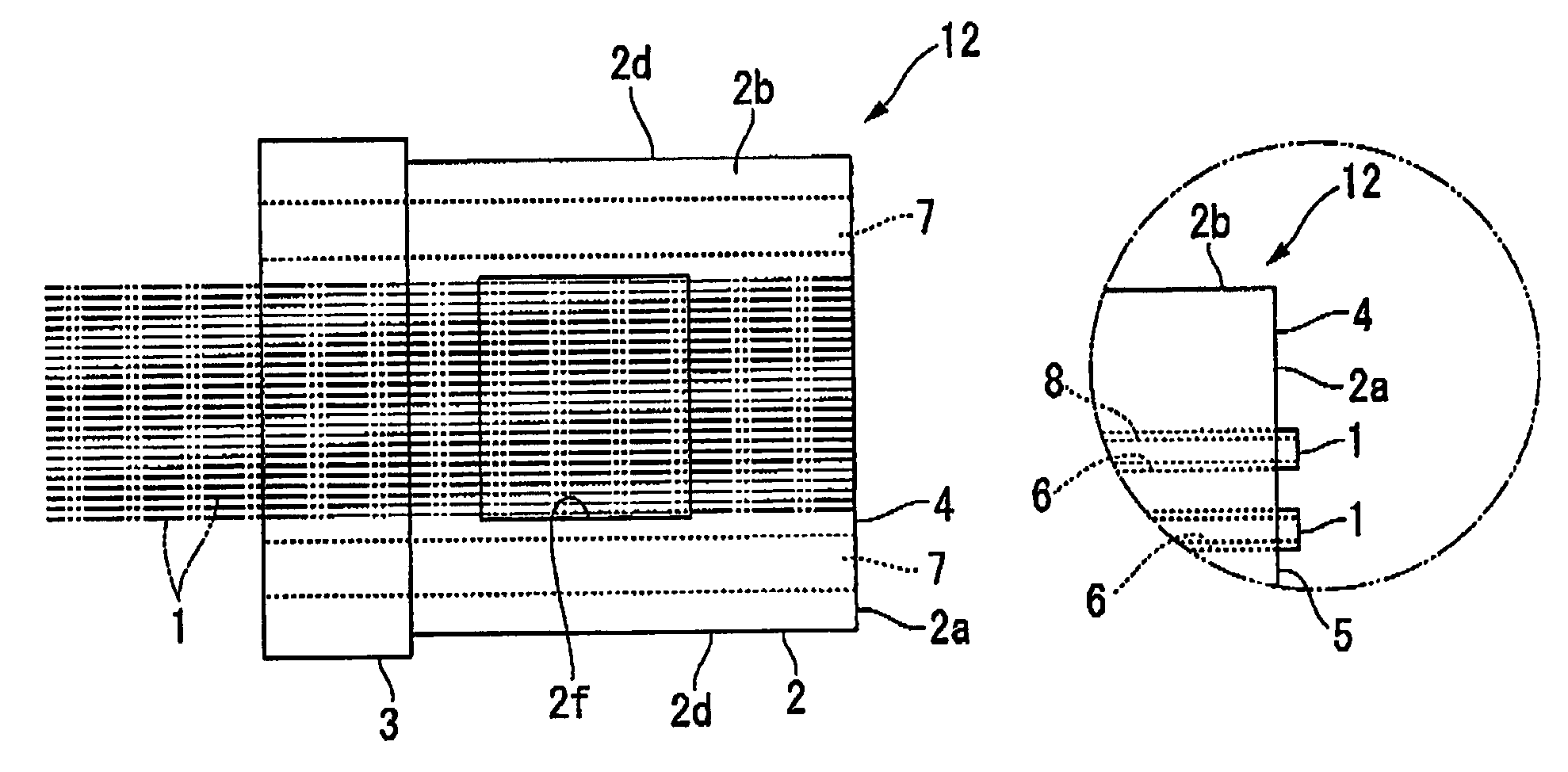

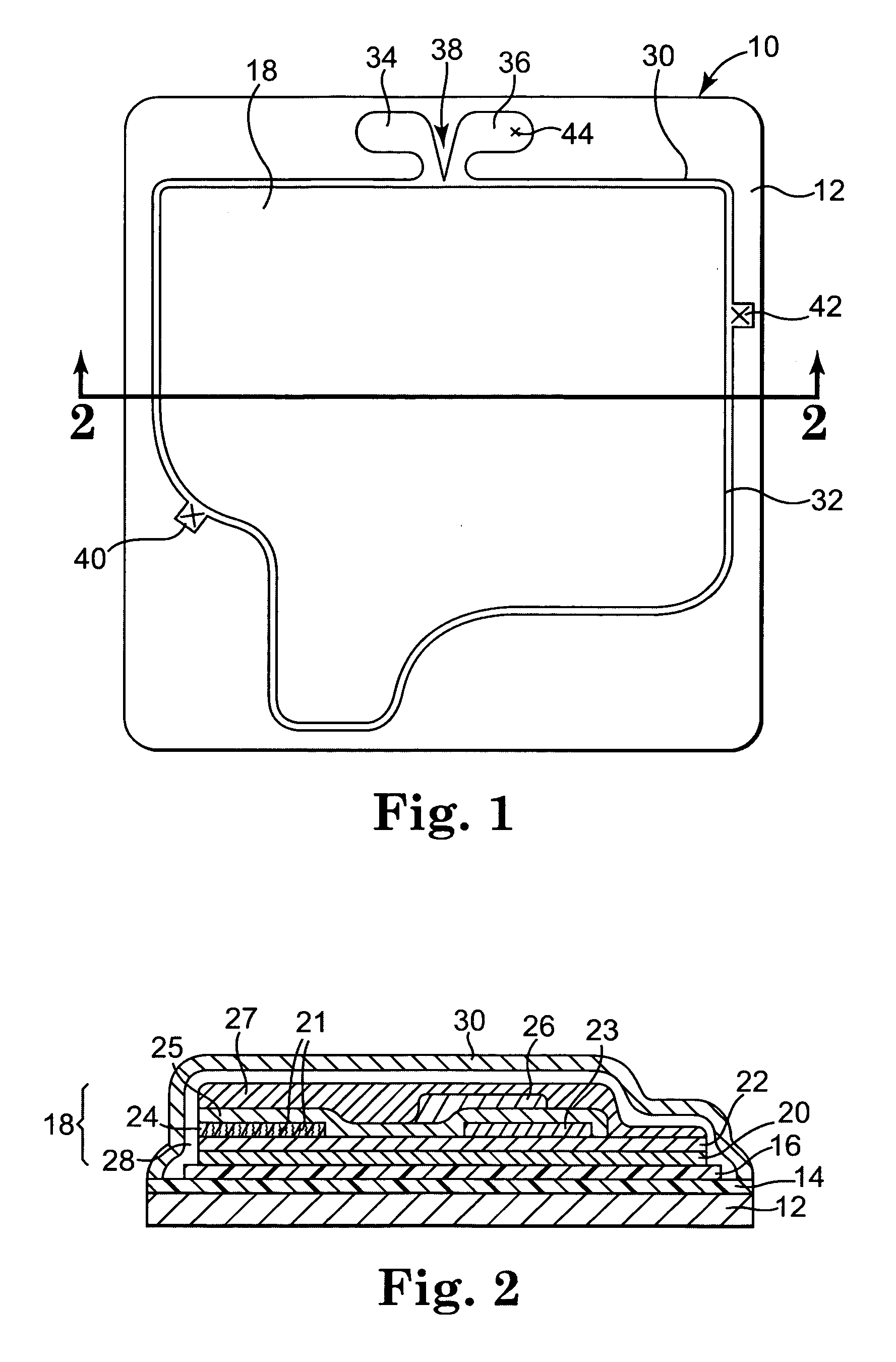

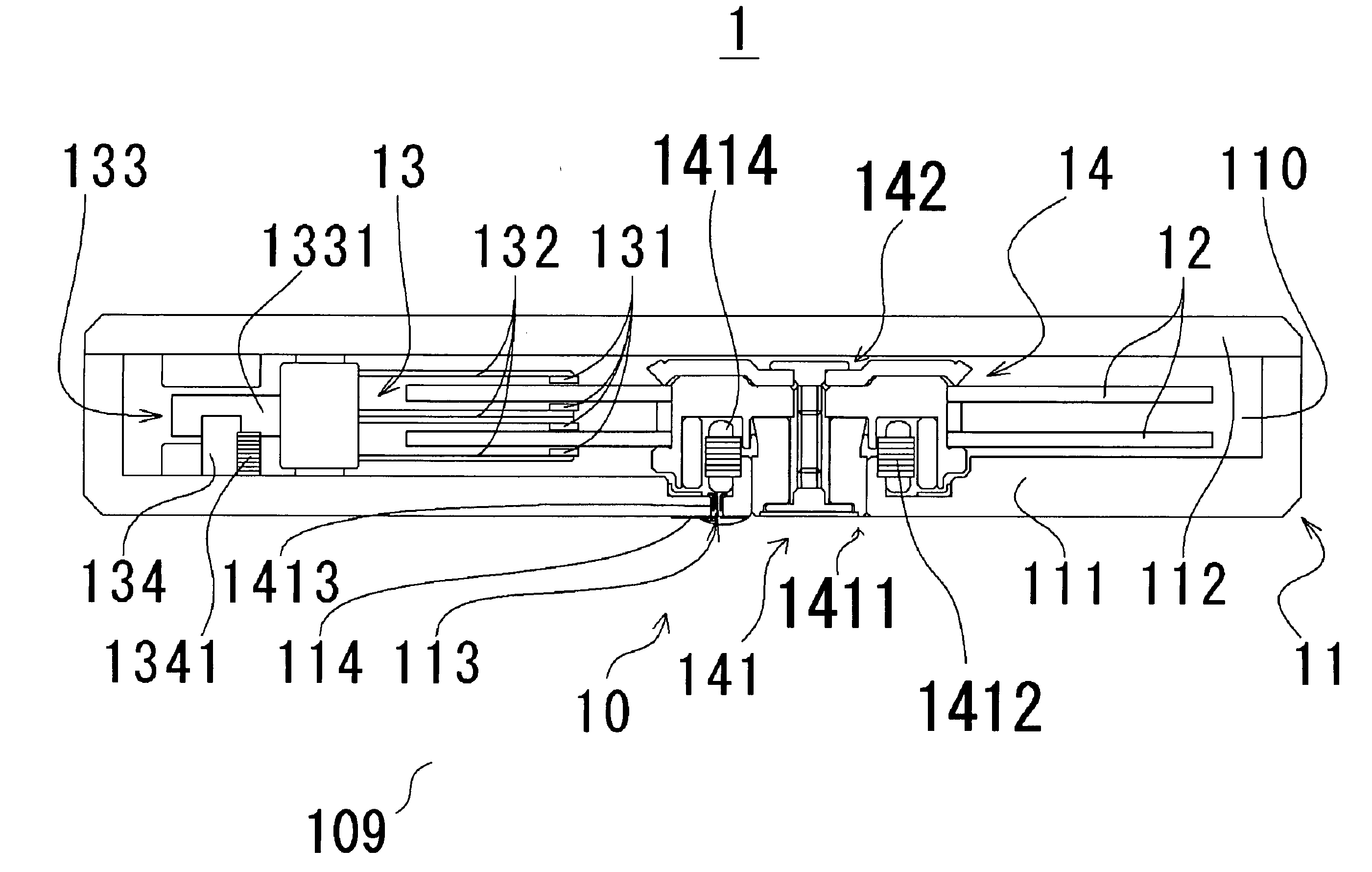

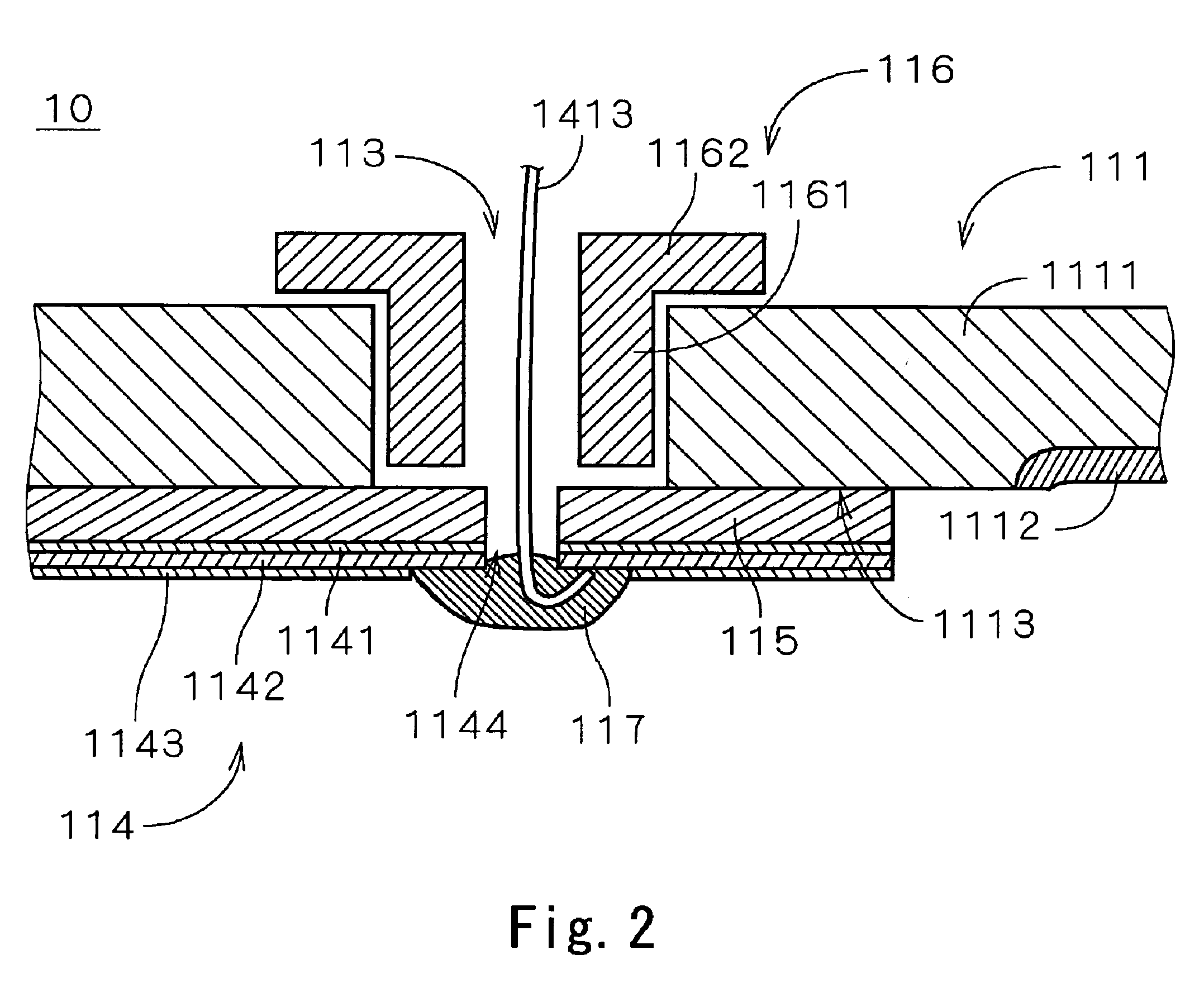

Lead wire sealing device, recording disk drive, and method for sealing housing member

ActiveUS20060138886A1Improve adhesionExcellent reliability and durabilityWindingsApparatus modification to store record carriersEngineeringResin coating

A first metal housing member 111 is provided with a bottom plate part 1111 and a resin coating layer 1112 formed on a lower surface of the bottom plate part 1111. To a board mounted part 1113 which is a metal surface exposed part exposed from the resin coating layer 1112 around a housing through hole 113, an FPC 114 is mounted via an adhesive layer 115. A lead wire 1413 of a stator windings 1414 that is inserted in a board aperture 1144 is connected to the FPC 114 by a sealing material 117 as a solder and the board aperture 1144 is covered with the sealing material 117 to seal the housing through hole 113. A motor unit 10 can securely seal the housing through hole 113 by enhancing adhesiveness between the FPC 114 and the first metal housing member 111.

Owner:NIDEC CORP

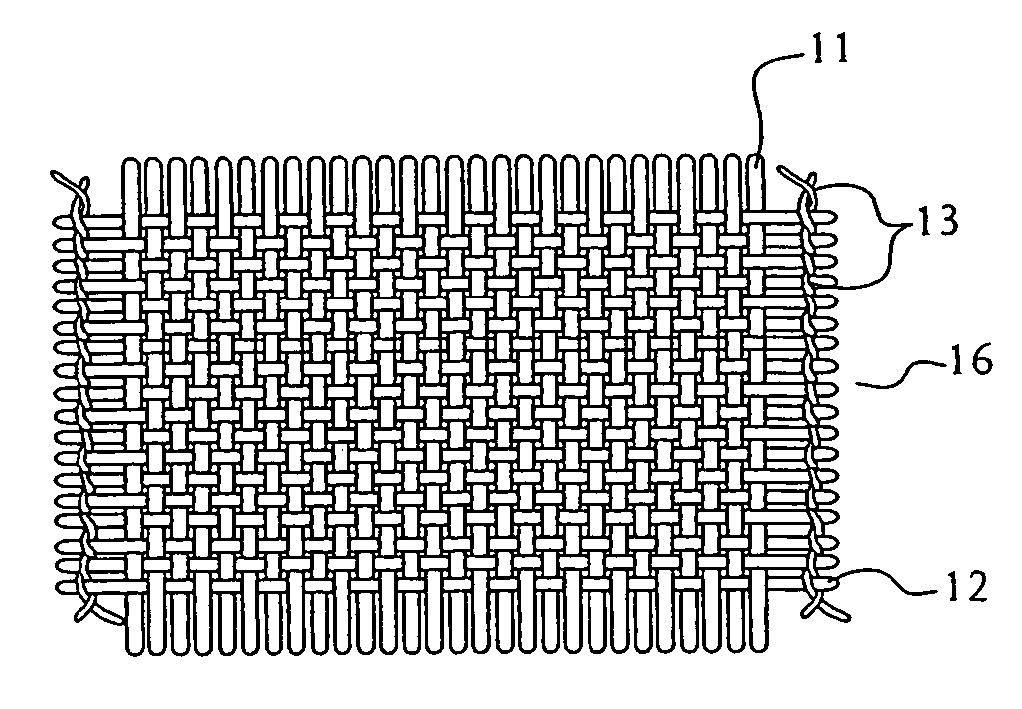

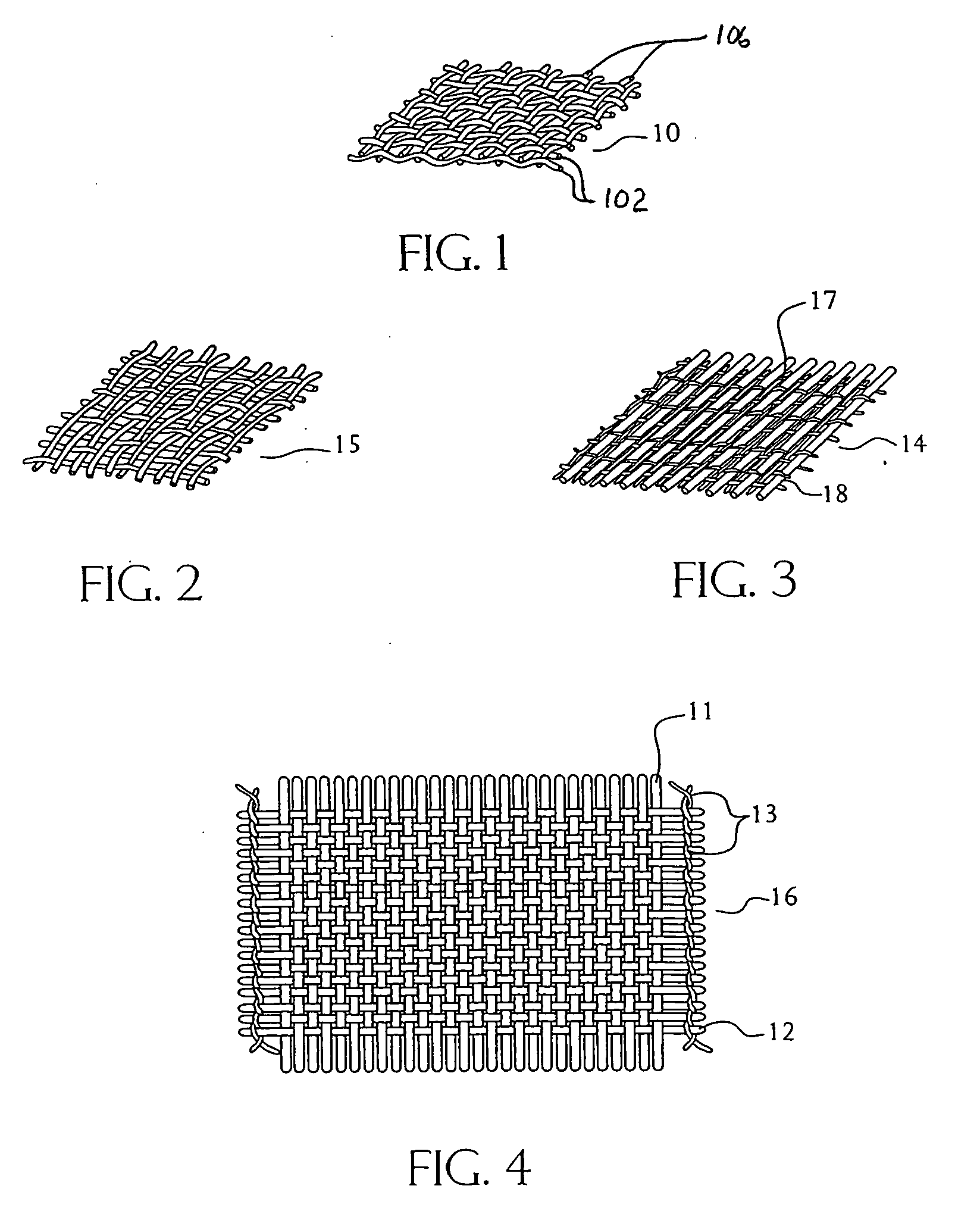

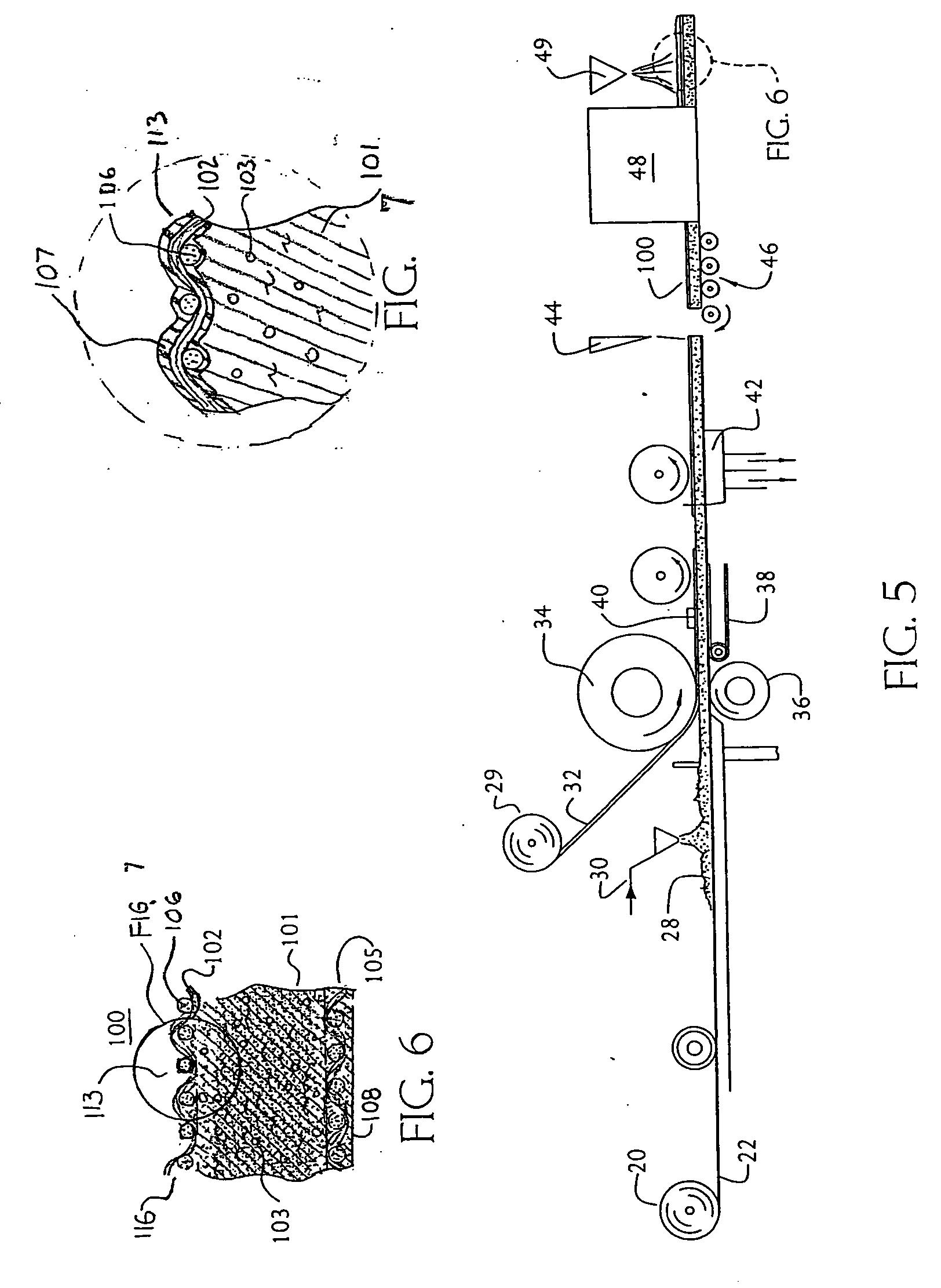

Fabric reinforcement and cementitious boards faced with same

ActiveUS20060013950A1Improve coating uniformityConvenient coatingPretreated surfacesWood working apparatusCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Electrical conductive roller and imaging apparatus comprising the same

InactiveUS20080146427A1Increased durabilityMolding stabilityShaft and bearingsPortable power-driven toolsUV curingOligomer

Owner:BRIDGESTONE CORP

Aqueous agent for treating substrate, method for treating substrated and treated substrate

InactiveUS20050103229A1Improve conductivityExcellent gas barrier propertiesPretreated surfacesAnti-corrosive paintsWater basedCompound (substance)

Water-based, substrate treatment compositions contain (A) at least one chitosan selected from chitosan and a chitosan derivative, and (B) a metal compound containing at least one metal selected from Ti, Zr, Hf, Mo, W, Se, Ce, Fe, Cu, Zn, V and trivalent Cr. In particular, the water-based, substrate treatment compositions can improve the interlayer adhesion between metal materials and resin coating layers such as films or coatings, and can also improve the corrosion resistance and solvent resistance of such metal materials.

Owner:NIHON PARKERIZING +1

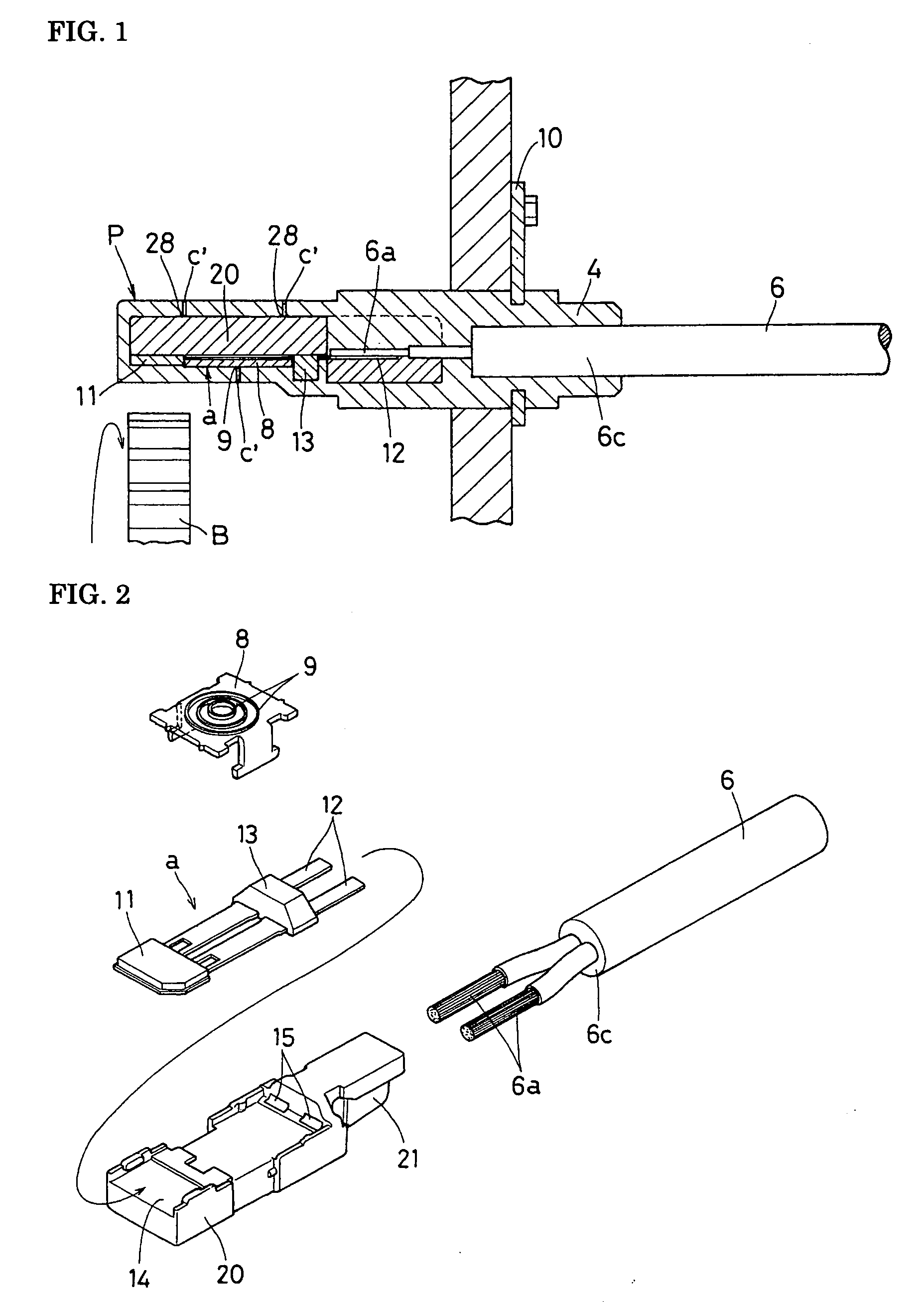

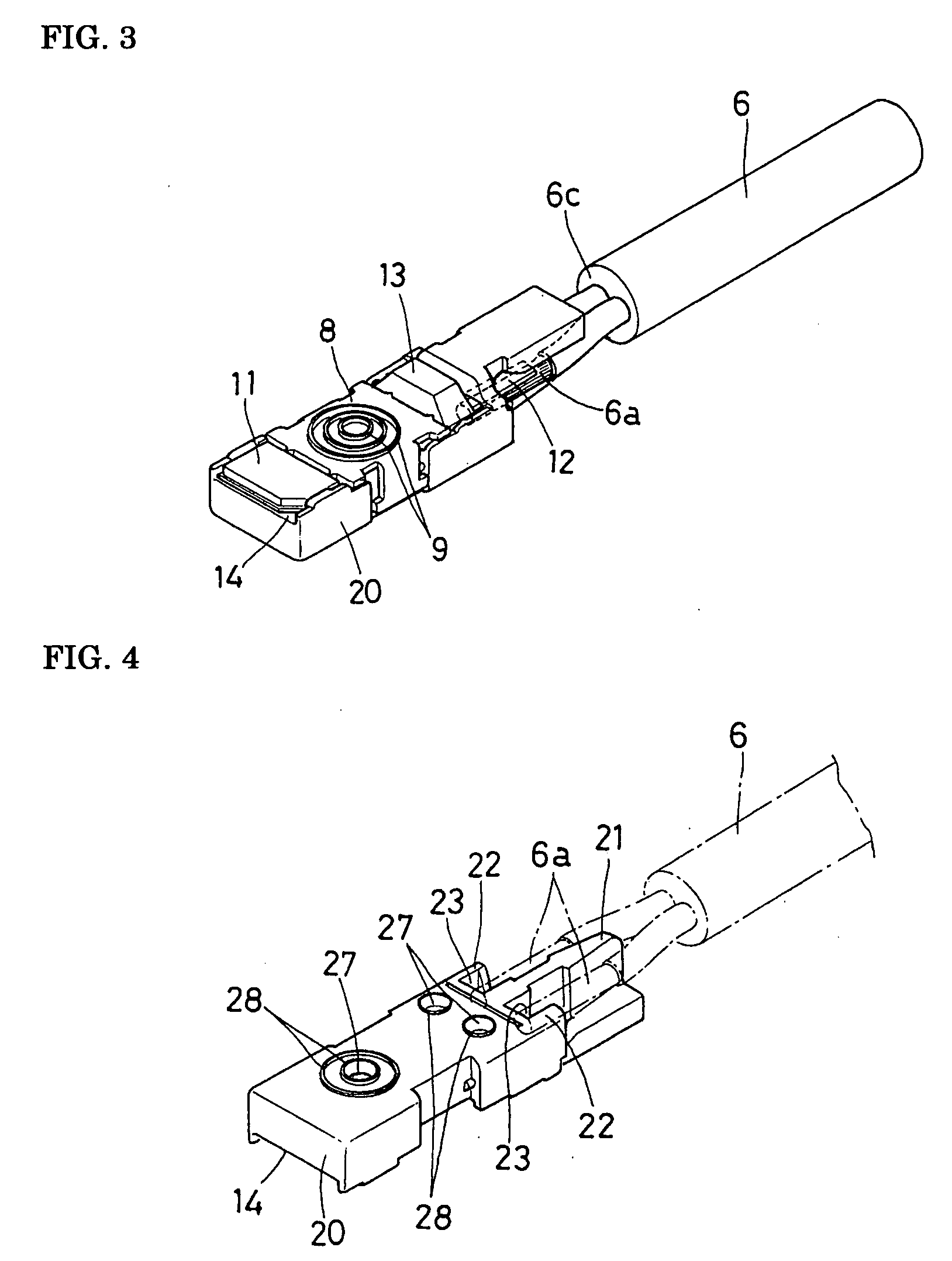

Rotation detecting sensor

InactiveUS20080204007A1Improve sealingSmall sizeMeasurement apparatus componentsUsing electrical meansWheel speed sensorResin coating

A wheel speed sensor includes a hall IC that outputs a signal representing a change of magnetic field generated by rotation of a detection object and that is simply covered with resin coating. In the process of molding the resin coating, a resin injection opening is positioned away from an end face of a sheath of a cable to be coated by a length no less than a minimum adhesion length for ensuring adhesion between the sheath and the resin coating. In addition, the holder and a cover of the detector are provided with waterproof protrusions extending along the entire peripheries of contact areas in which pressing pins are brought into contact with the holder and the cover. Accordingly, immersion of the detector is reliably prevented even when a void or the like occurs in the resin coating at a position near the injection opening.

Owner:SUMIDEN ELECTRONICS

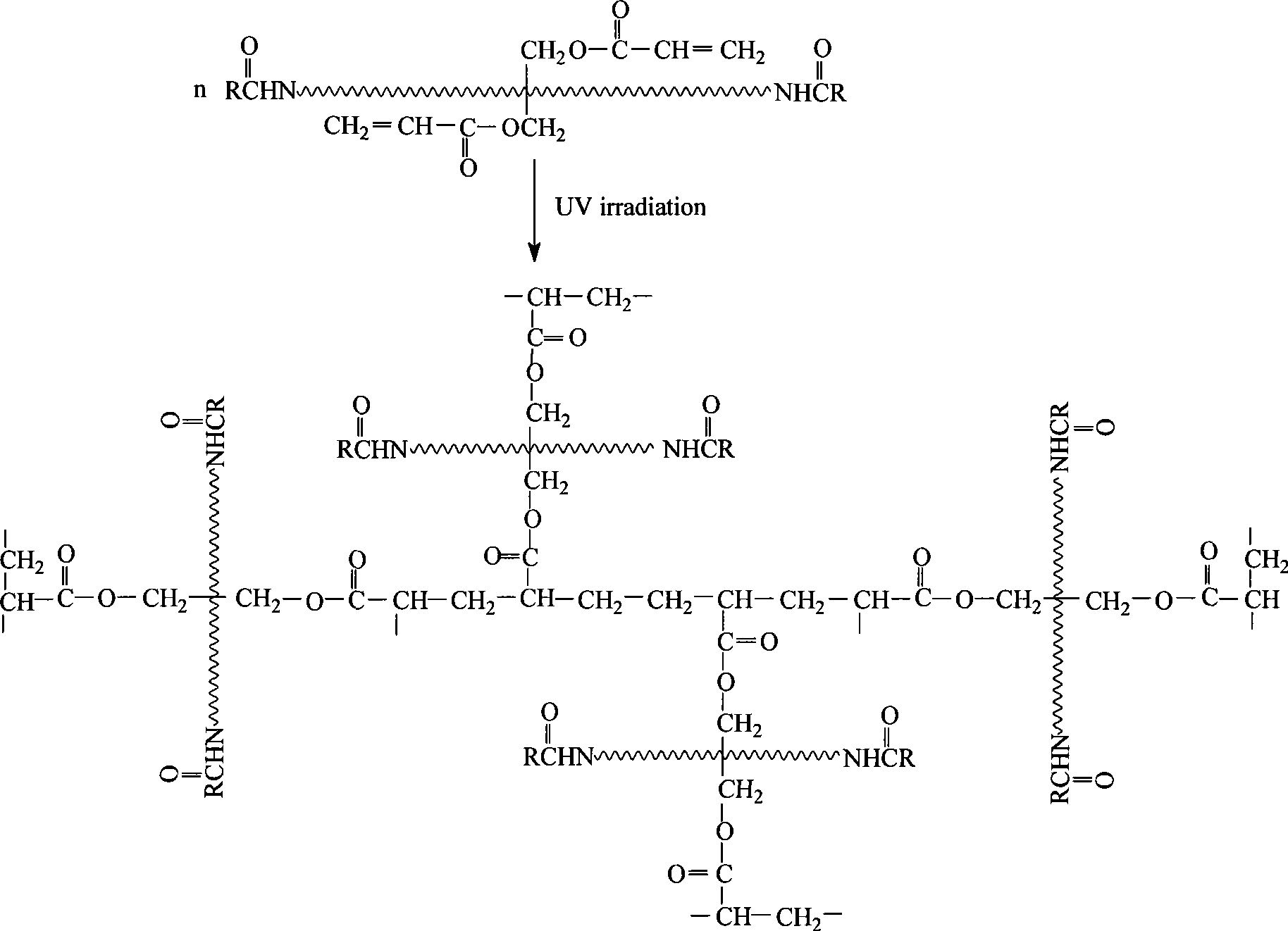

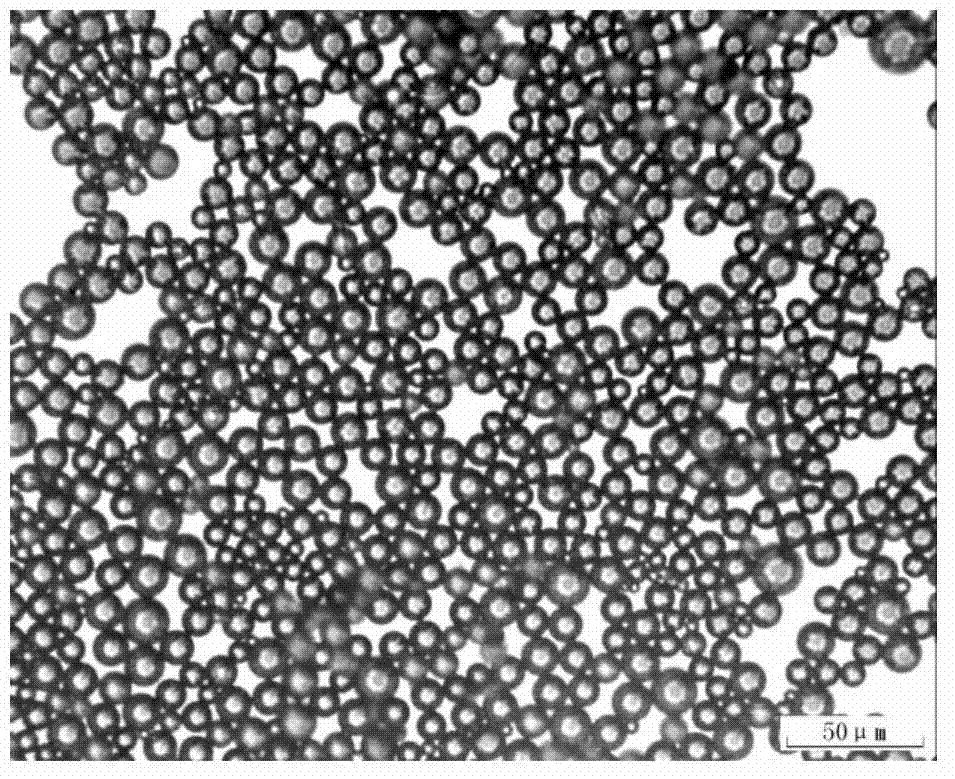

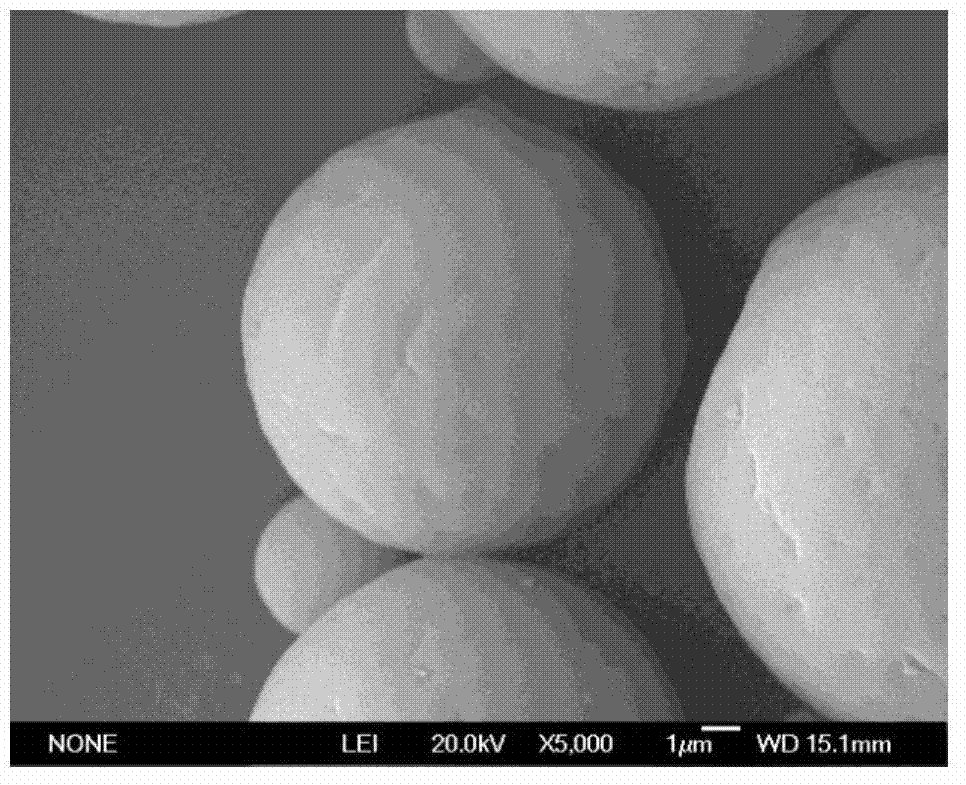

Urea-formaldehyde resin coated epoxy acrylic resin microcapsule for resin-base self-repair coating and preparation method thereof

ActiveCN102773053AHigh speedSphericity RulesMicroballoon preparationMicrocapsule preparationAcrylic resinResin coating

The invention relates to a urea-formaldehyde resin coated epoxy acrylic resin microcapsule for a resin-base self-repair coating and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding capsule core raw materials epoxy acrylic resin and acrylate reactive diluent into a water solution containing an emulsifier and a defoaming agent, dispersing the capsule core with a homogenizer or emulsifying machine to form a stable emulsion; regulating the pH value of the stable emulsion system to 2-3, adding capsule wall raw materials urea, formaldehyde and crosslinking agent, stirring until the capsule is formed, and after the reaction finishes, regulating the pH value of the system to neutral; and repeatedly washing with hot water and acetone, centrifuging, and carrying out vacuum drying to obtain the epoxy acrylic resin microcapsule. The capsule provided by the invention has the advantages of favorable sealability, regular sphericity, controllable grain size and controllable capsule wall thickness, and can be widely used for self-repair of a UV-cured acrylic resin coating or epoxy resin coating at low temperature and room temperature, thereby prolonging the service life of the coating material and widening the application range of the resin-base coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

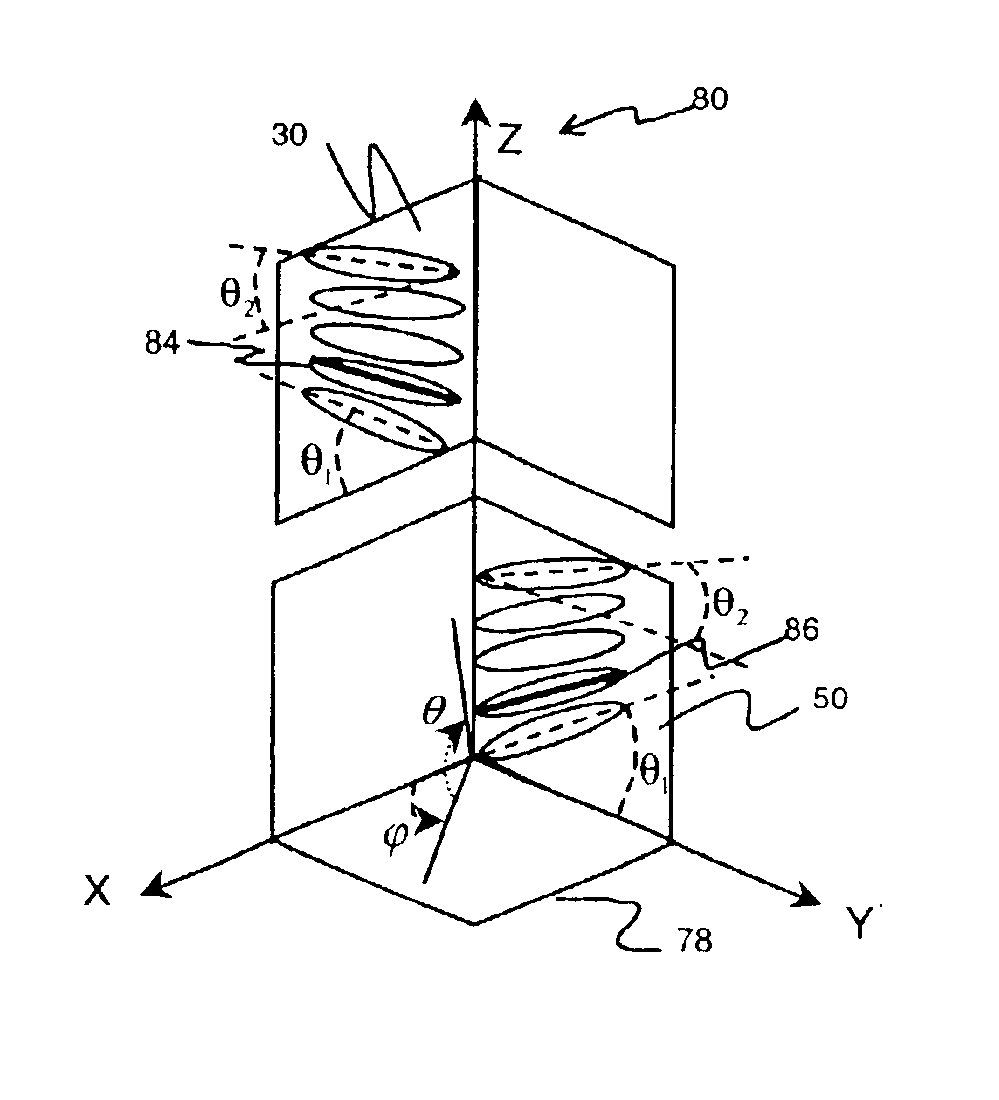

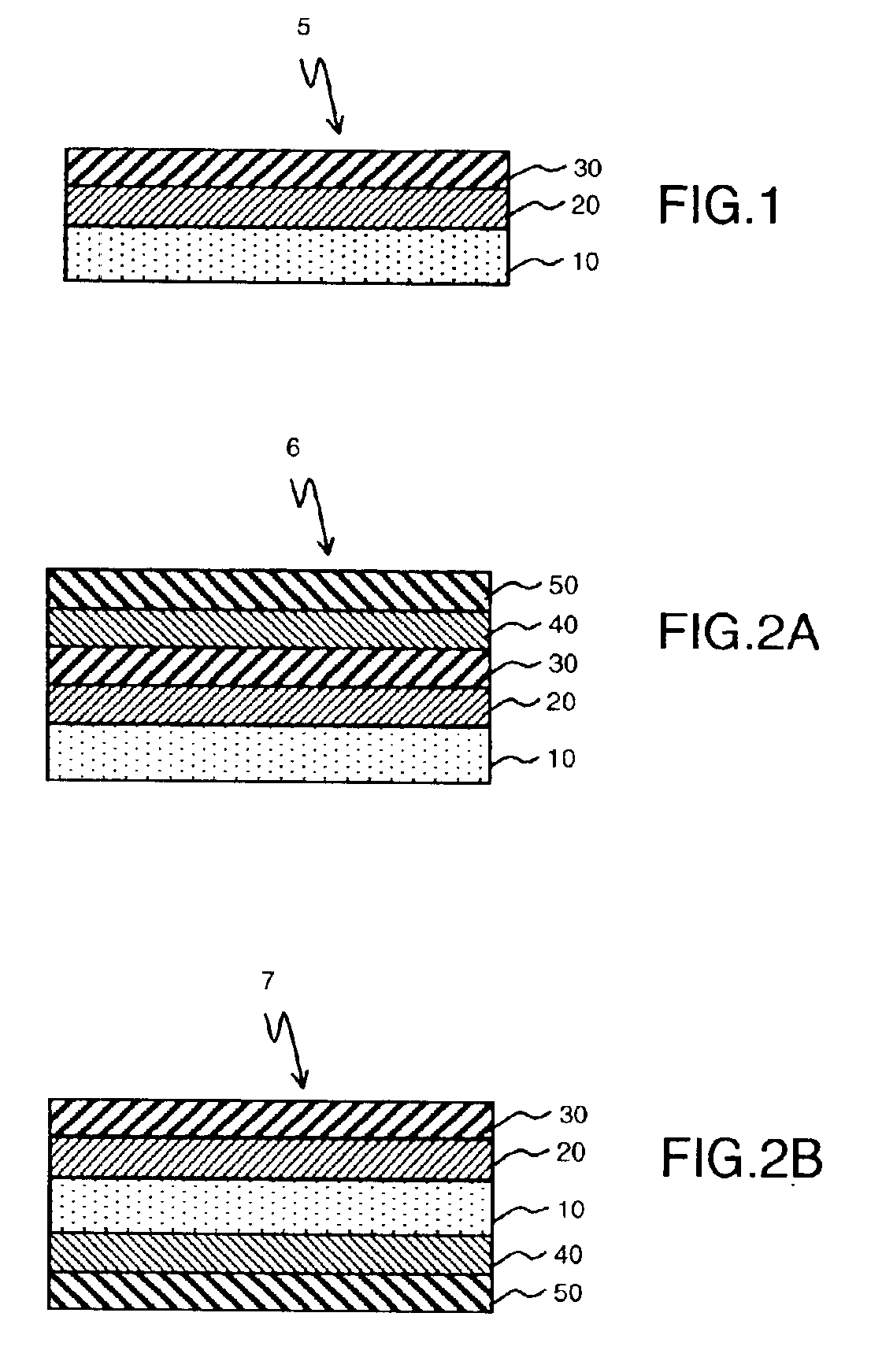

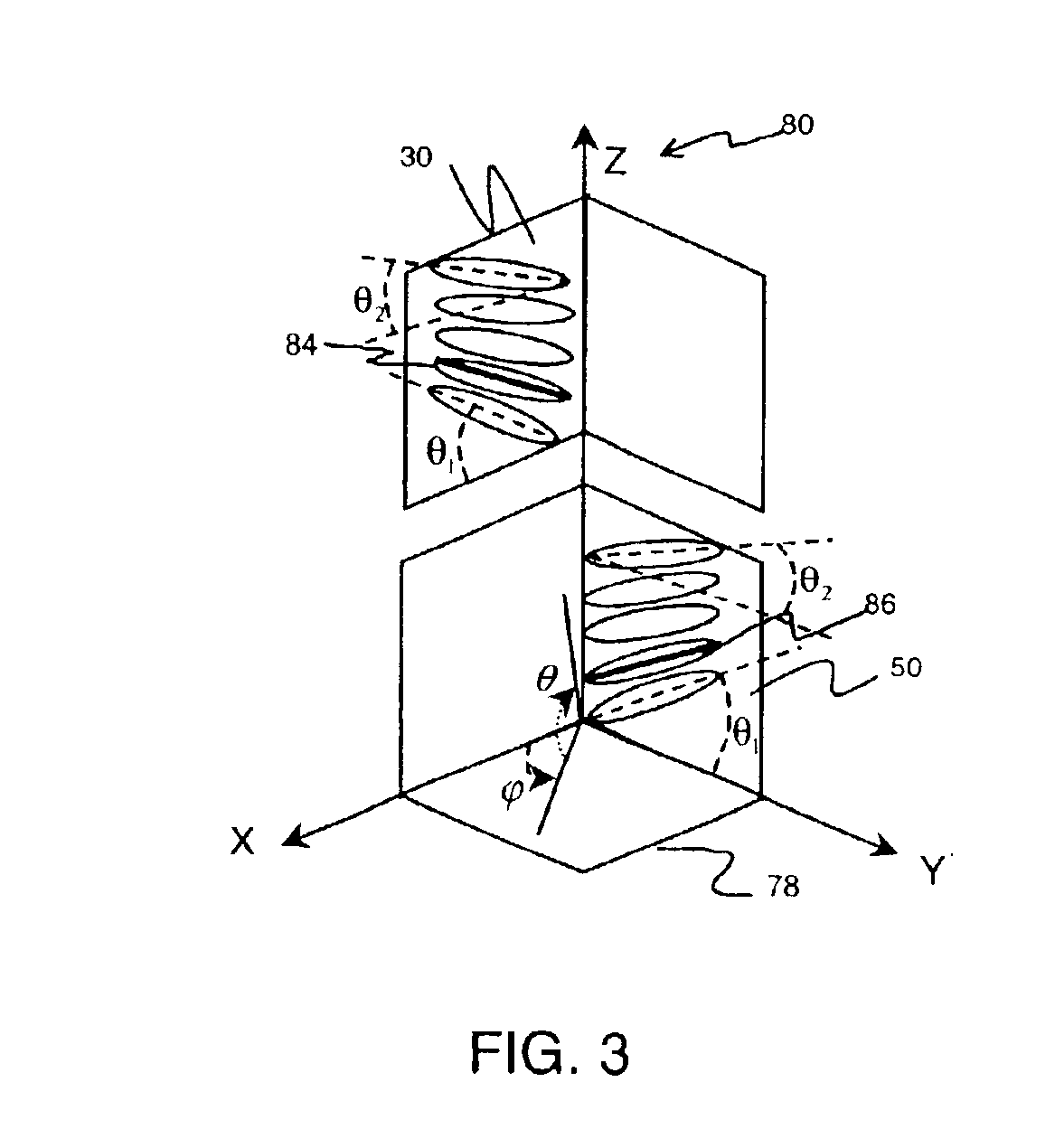

Process for making an optical compensator film comprising an anisotropic nematic liquid crystal

InactiveUS6894751B2Reducing and preventing failureSpeed up the processLiquid crystal compositionsPolarising elementsLiquid crystallineOptical axis

A process for making an optical compensator, comprising the steps of coating a orientable resin in a solvent onto a support; drying the resin-containing coating; orienting the resin-containing layer in a predetermined direction; coating a nematic liquid-crystal compound in a solvent carrier onto the orientation layer; drying the nematic liquid-crystal-containing coating; thermally treating the nematic liquid-crystal compound layer, cooling the nematic liquid-crystal compound layer, polymerizing or curing the anisotropic nematic liquid-crystalline layer to form an integral component; and optionally repeating the above steps on top of the integral component so that the optical axis of the first anisotropic nematic liquid-crystal layer is positioned orthogonally relative to the respective optical axis of the second anisotropic nematic liquid-crystal layer about an axis perpendicular to the plane of the support.

Owner:NITTO DENKO CORP

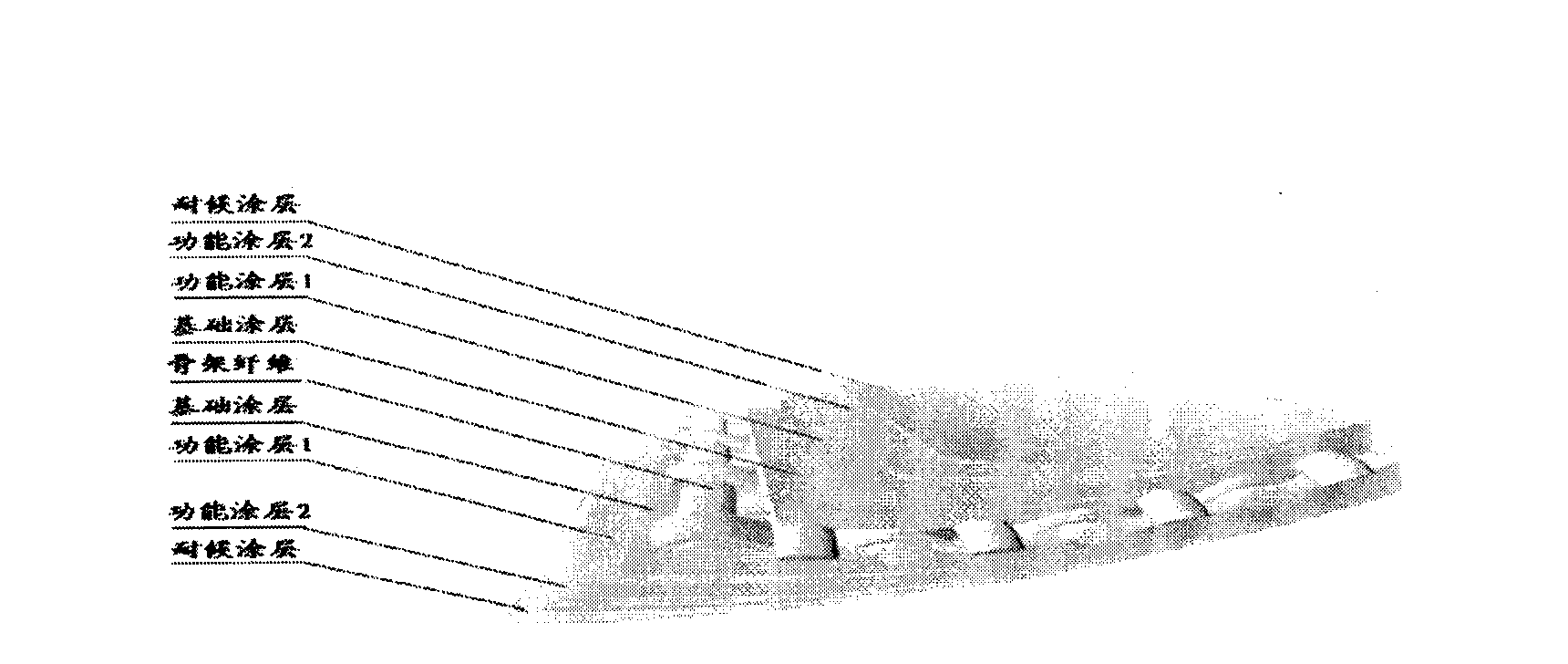

High-performance fiber reinforced film composite material

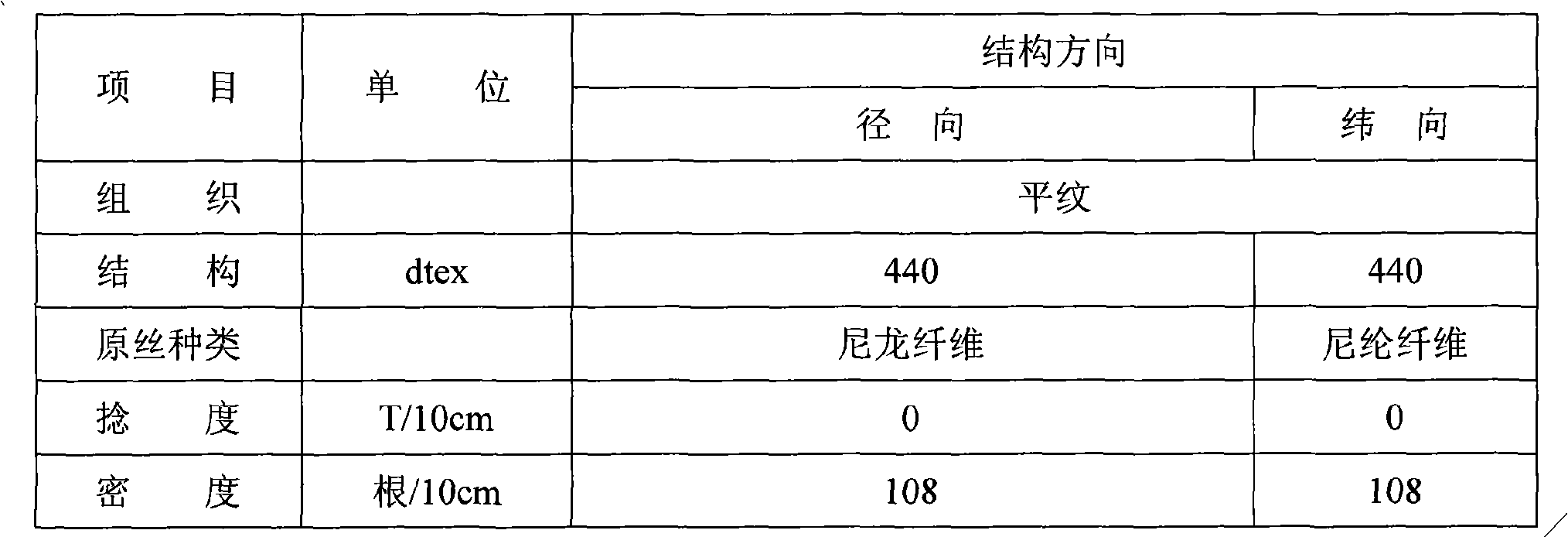

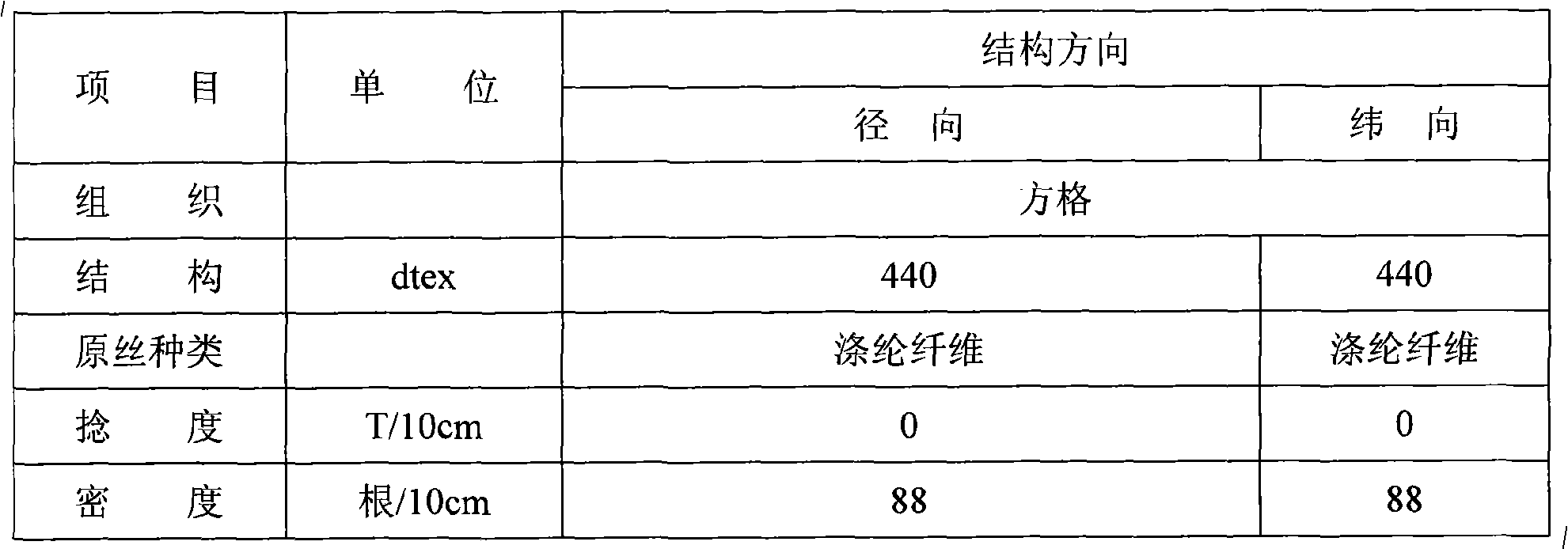

A high-performance fiber reinforced film composite material comprises a bonded fabric and a resin coating layer on the surface of the boned fabric and is characterized in that the boned fabric takes high-strength fiber with the yarn count of 200-600D as warp or weft; the weaved warp and weft density is 22*22-27*27; the boned organization structure is a plain weave or a square grid organization or bi-axial warp-knitting (the warp and weft density is 18*18-18*20) structural fabric; the resin coating layer is characterized in that at least one surface out of two surfaces of the boned fabric is coated by the resin layer with a combination process of clearance coating and transferring coating; the resin layer comprises 85-90 parts of thermoplastic resin, 1-5 parts of nano-inorganic additive and 5-10 parts of organic modifier. The composite material is characterized in that the surface density is less than or equal to 280g / m<2>, the warp and weft elongation breaking strength is 750-1000N / cm, the warp and weft incision tearing strength is 750-850N and the elongation at break is less than or equal to 5%; furthermore, the composite material has the advantages of good weather-resistance and temperature-resistance and self-cleaning performance, strong flexibility and anti-fatigue, and being capable of high-frequency heat sealing; and the peeling strength (fabric / adhesive) is more than or equal to 2500N / m.

Owner:朱守诚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com