Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6128results about "Transformers/inductances casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

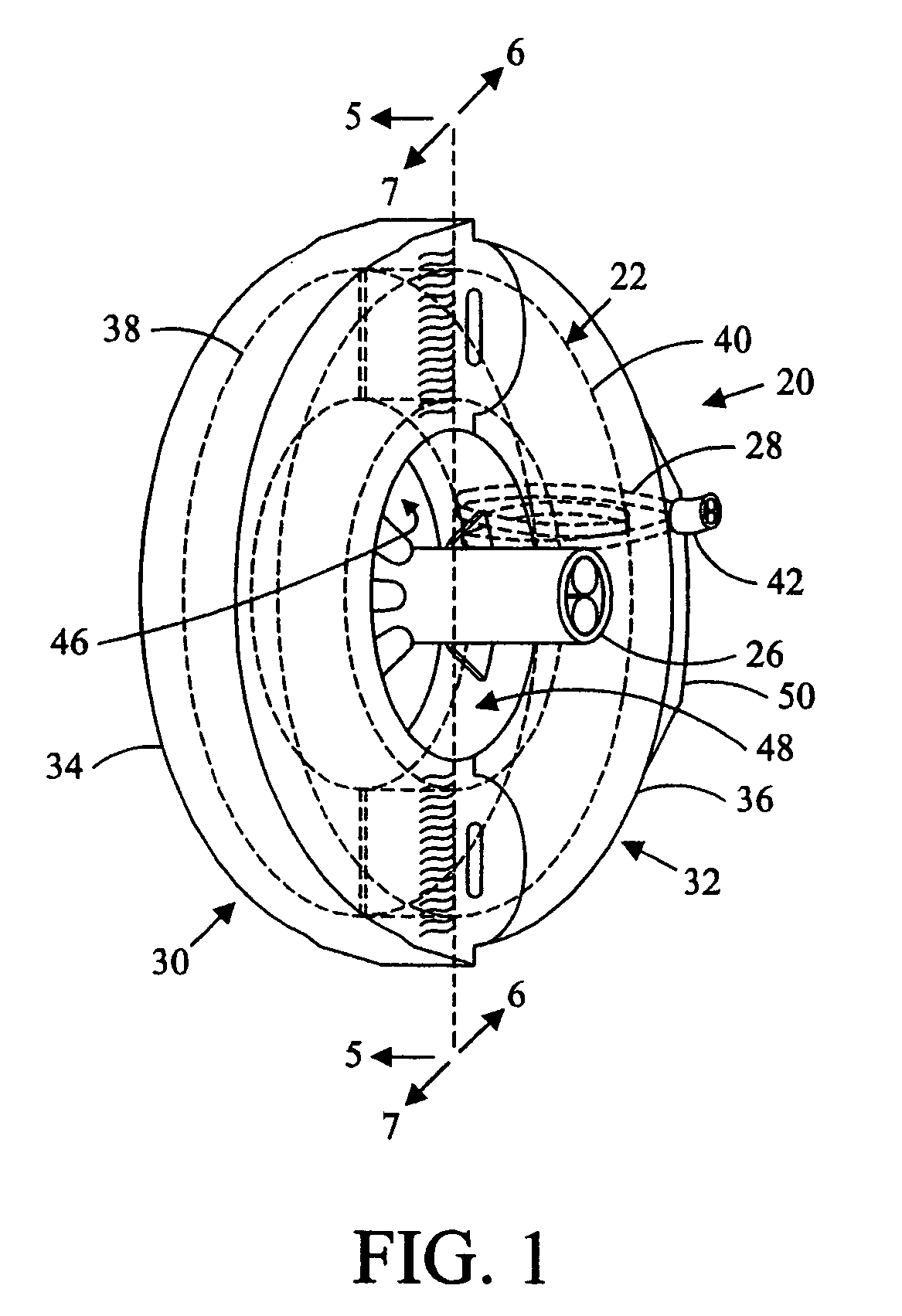

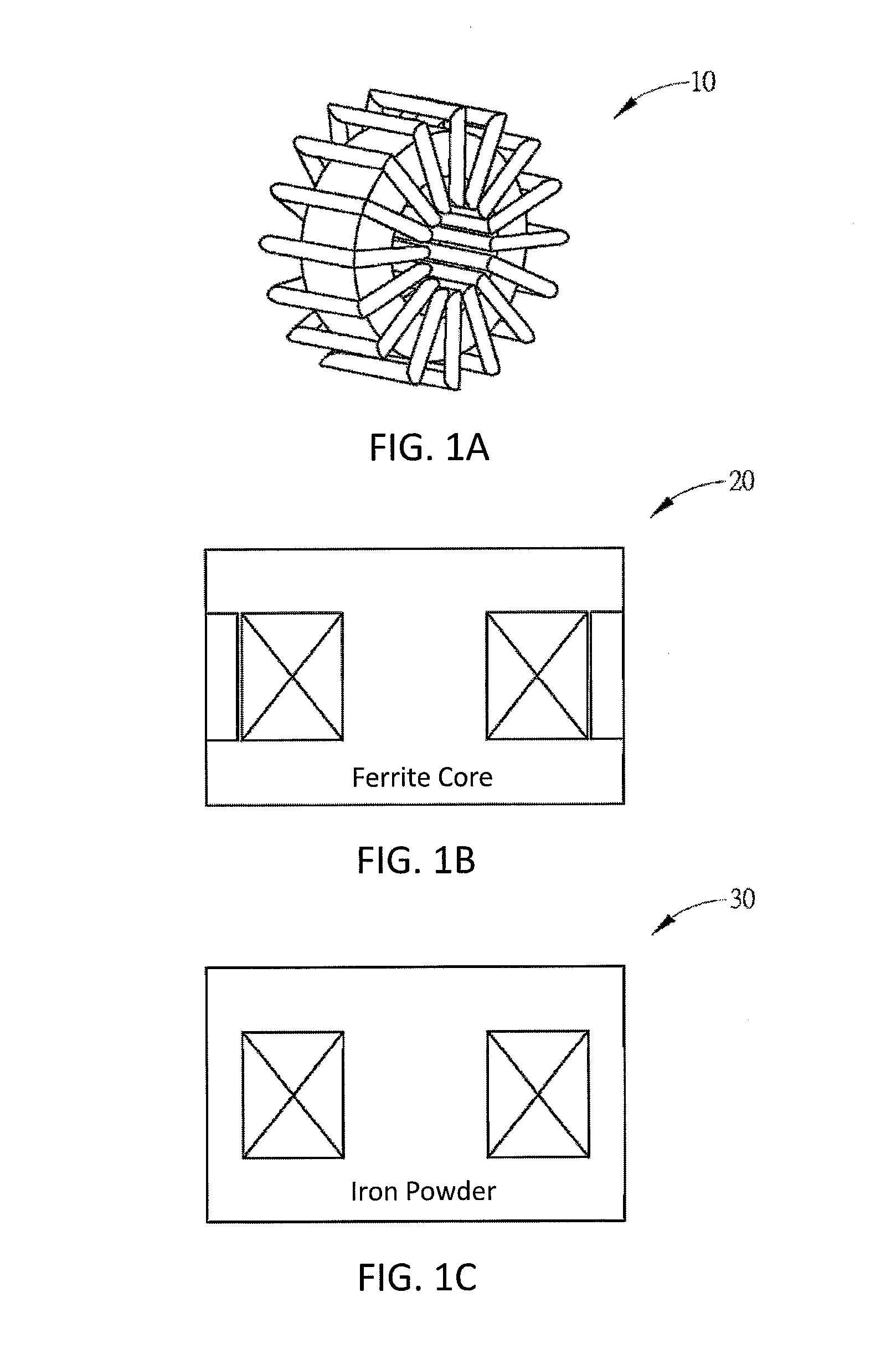

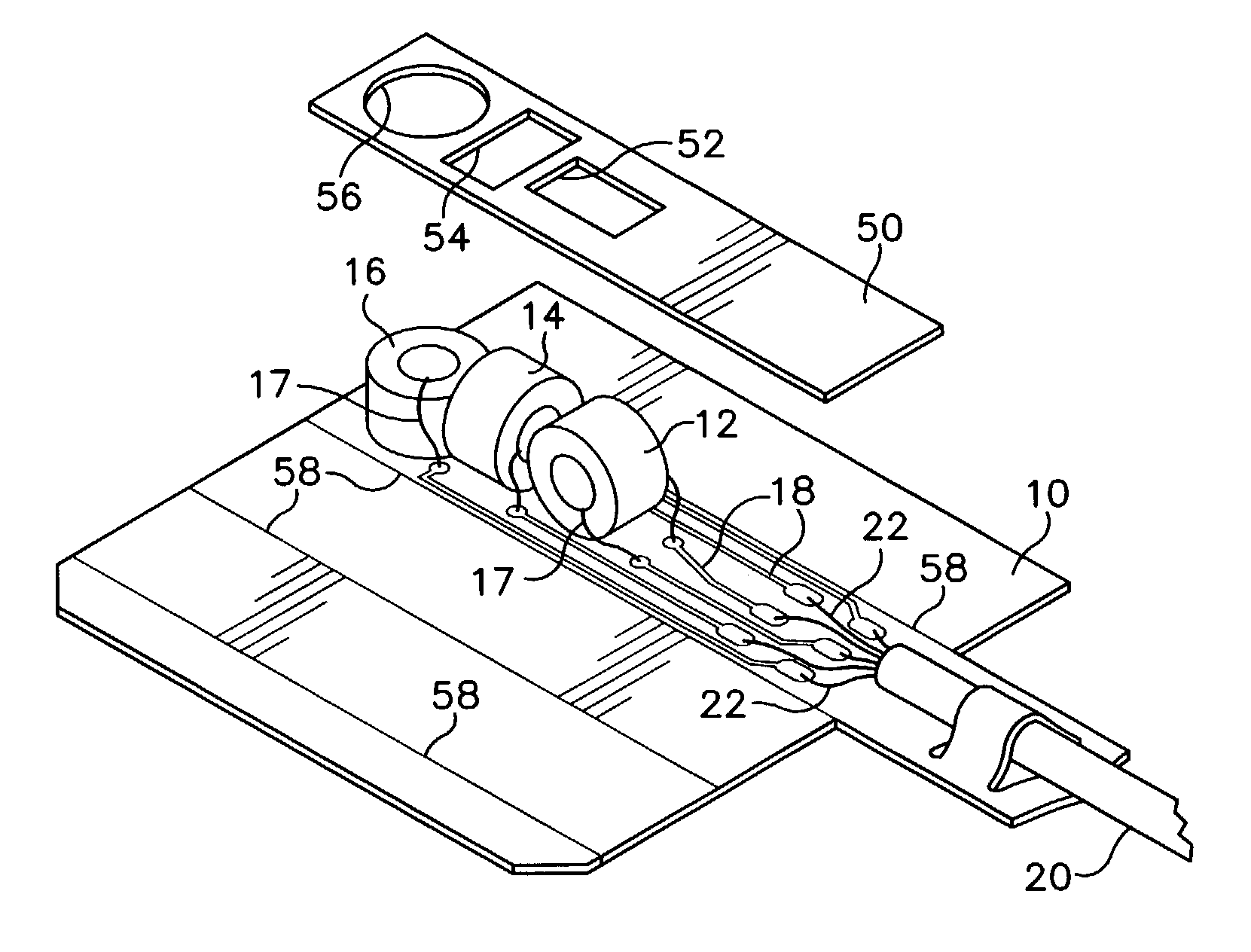

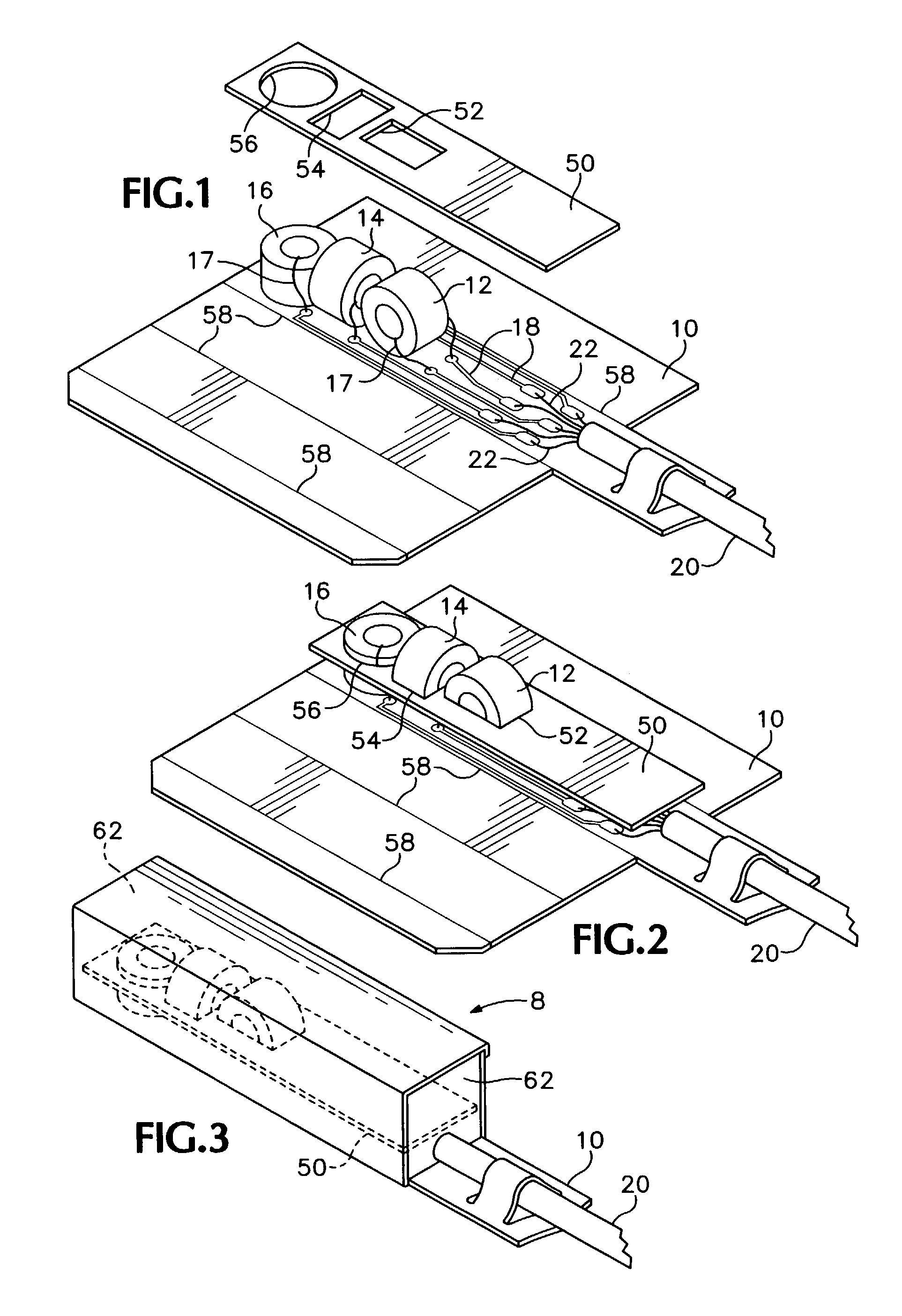

Downhole Coils

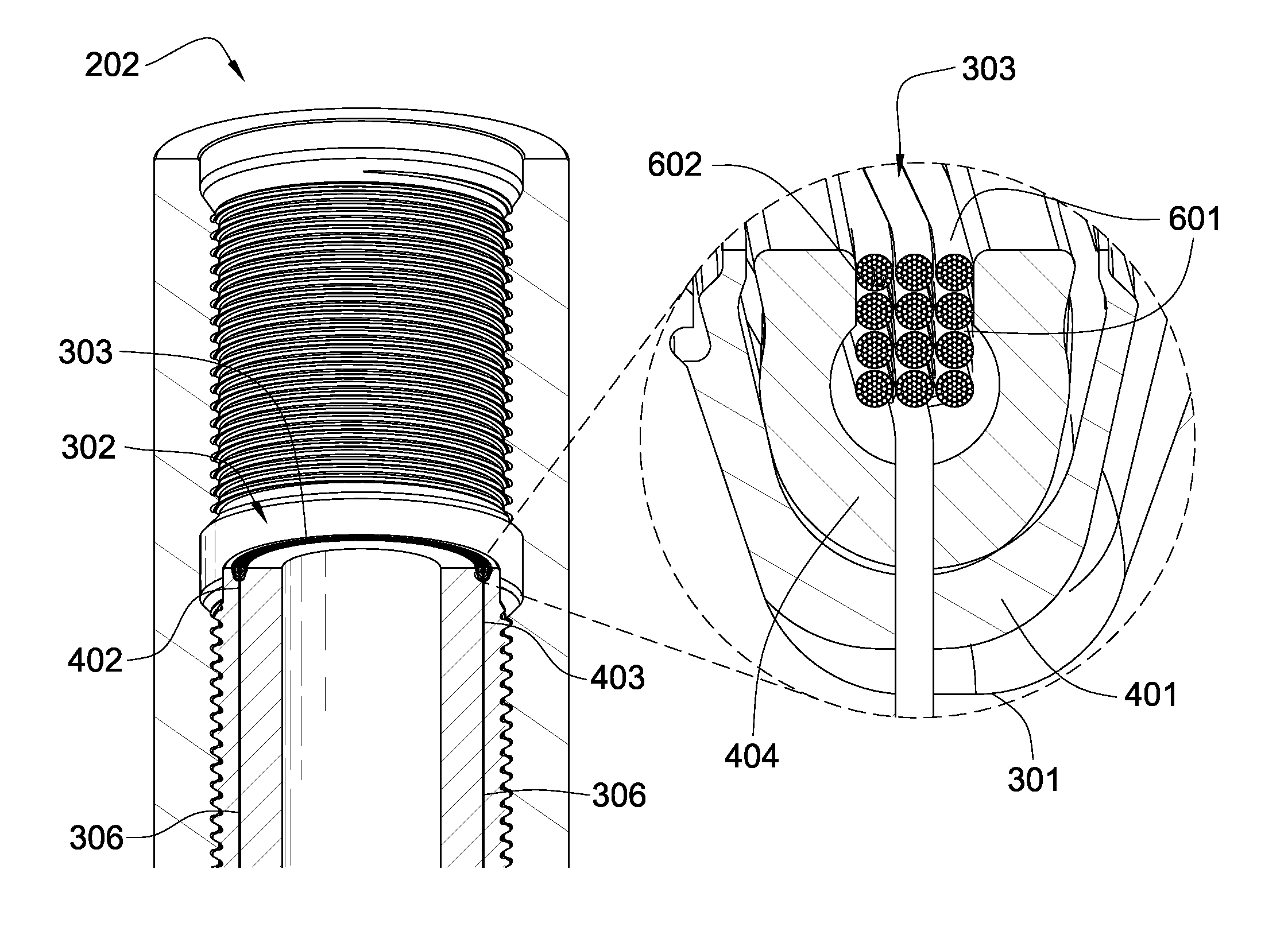

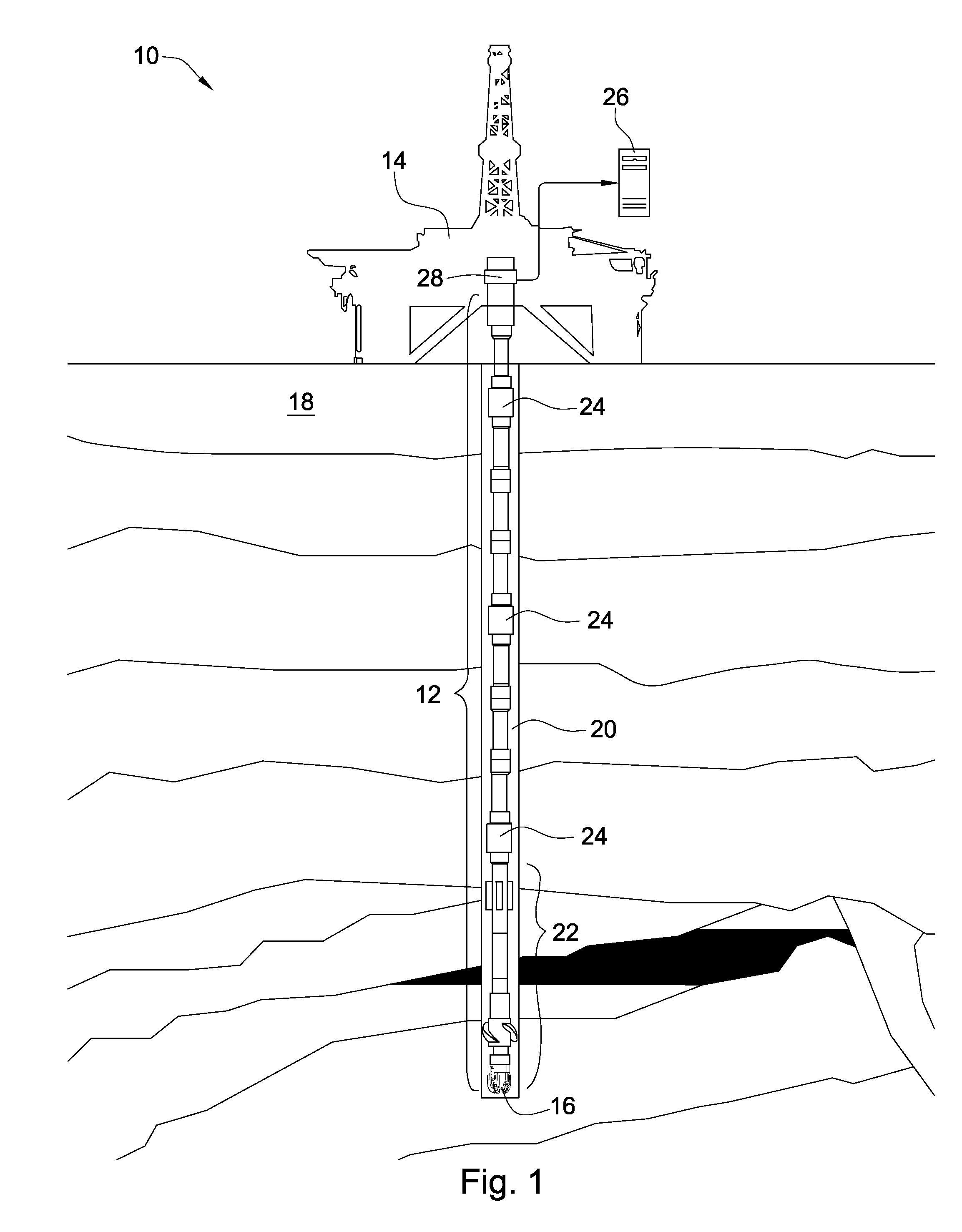

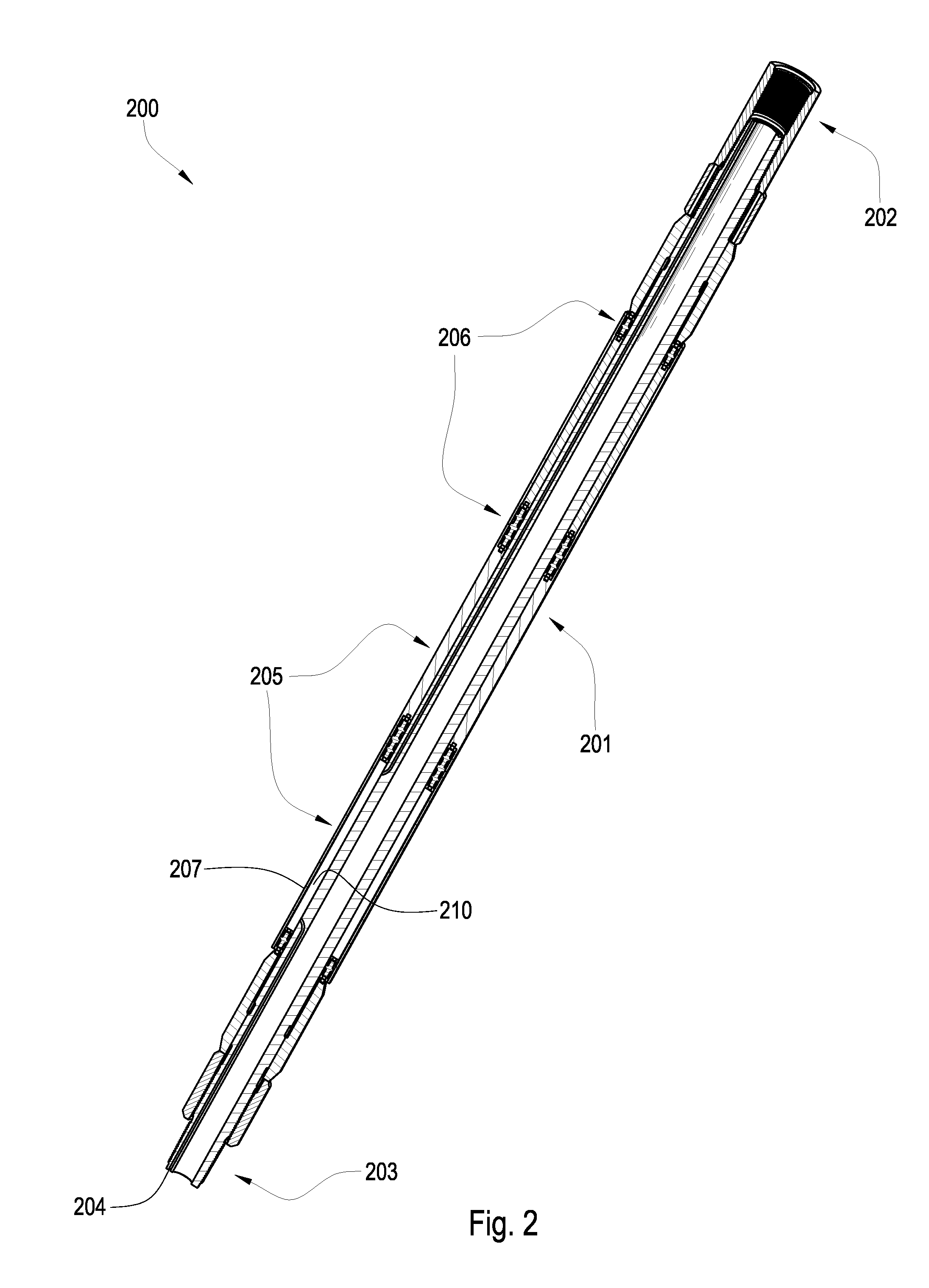

In one aspect of the invention, a downhole tool string component comprises a tubular body with at least one end adapted for threaded connection to an adjacent tool string component. The end comprises at least one shoulder adapted to abut an adjacent shoulder of an adjacent end of the adjacent tool string component. An annular magnetic coupler is disposed within an annular recess formed in the at least one shoulder, and the magnetic coupler comprises a coil in electrical communication with an electrical conductor that is in electrical communication with an electronic device secured to the tubular body. The coil comprises a plurality of windings of wire strands that are electrically isolated from one another and which are disposed in an annular trough of magnetic material secured within the annular recess.

Owner:SCHLUMBERGER TECH CORP

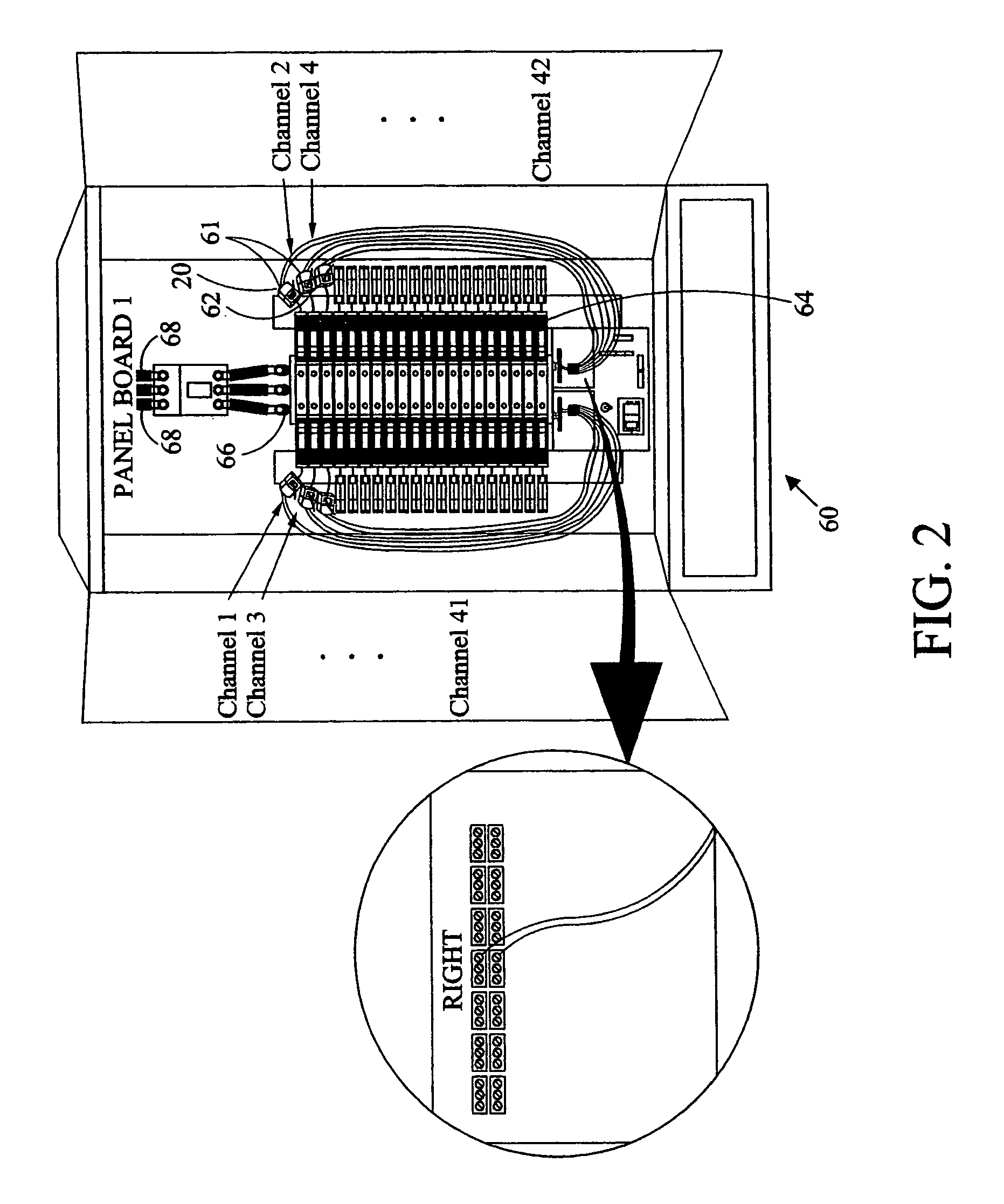

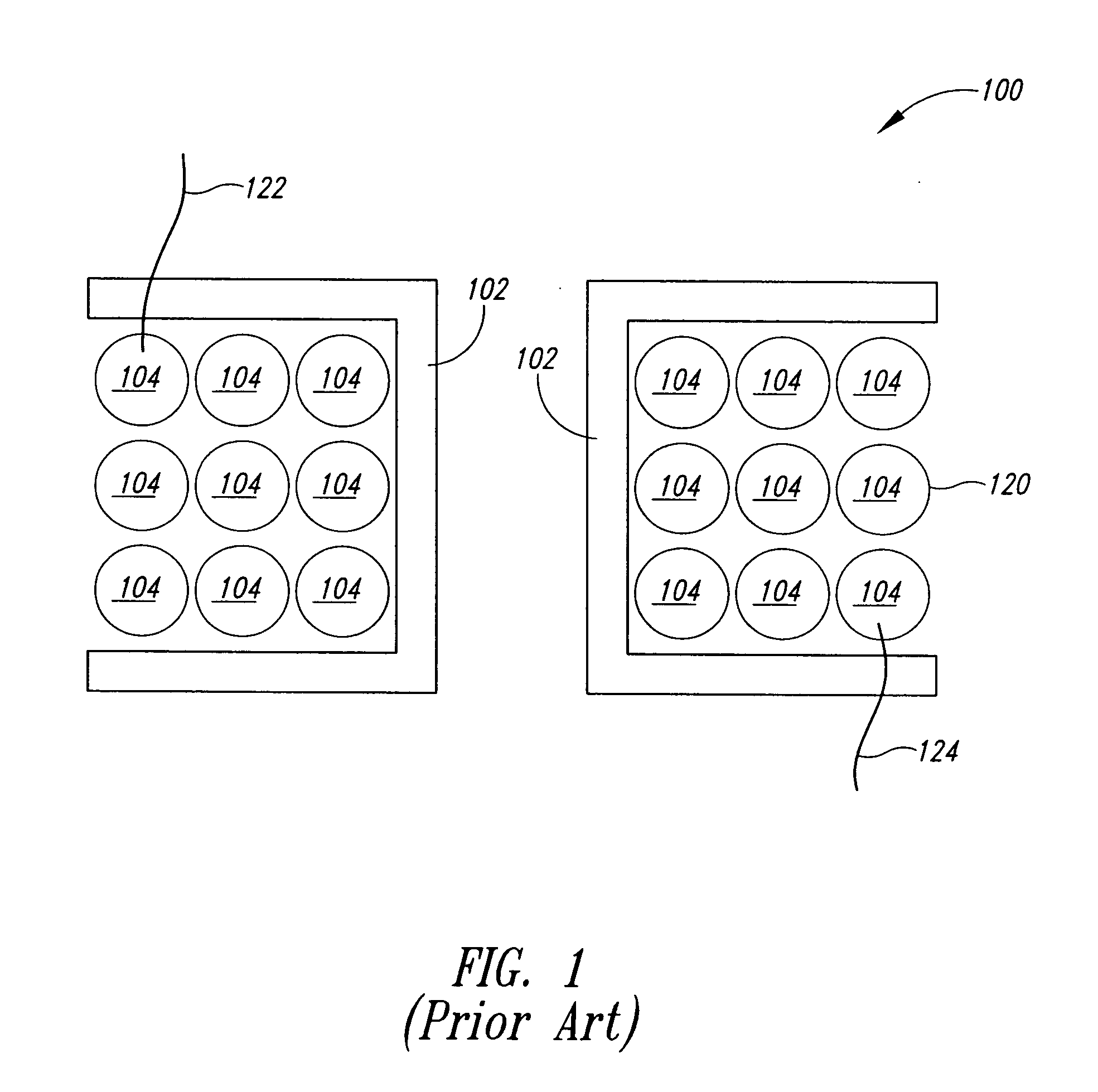

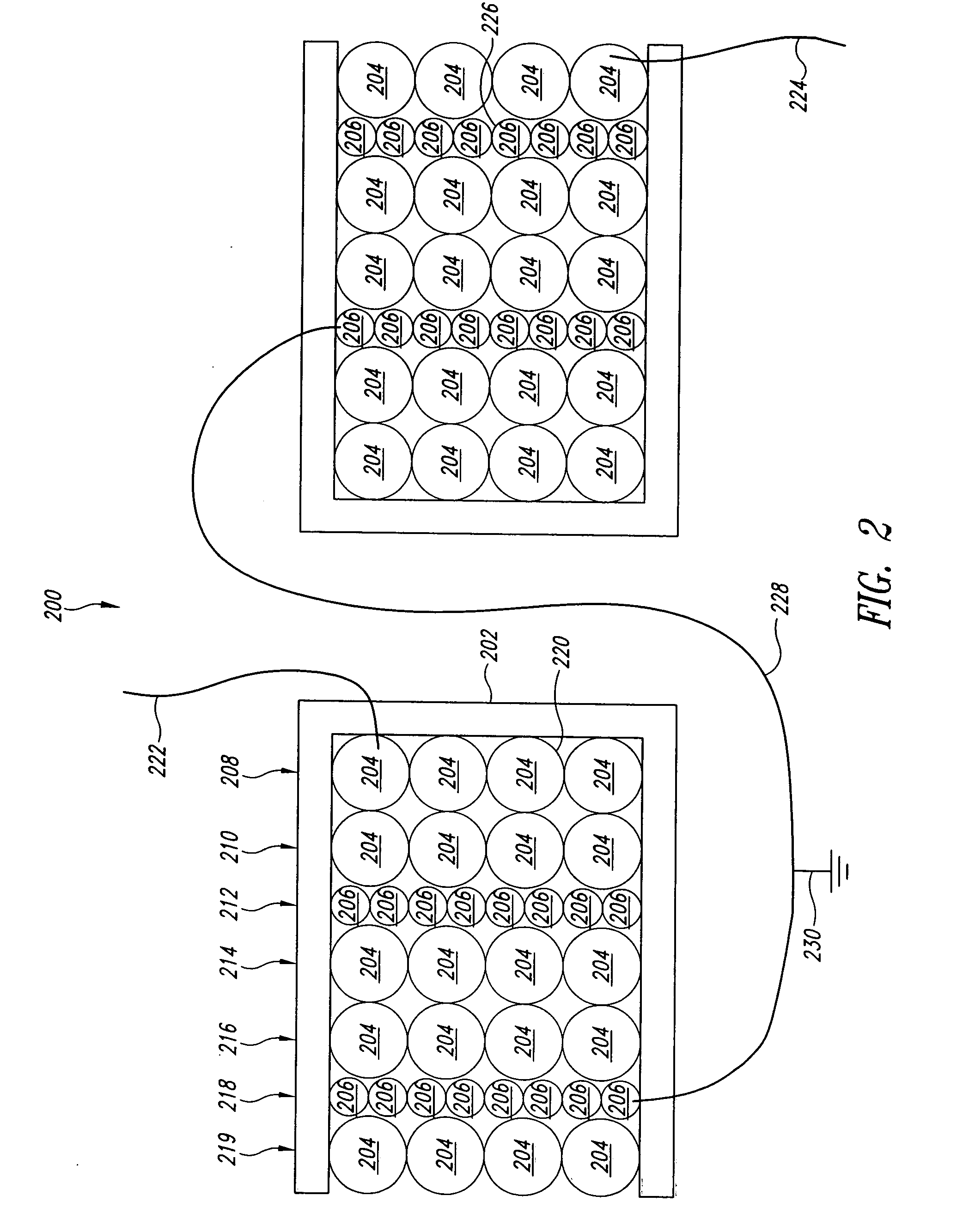

Split core sensing transformer

ActiveUS7312686B2Transformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorTransformer

Owner:VERIS INDS

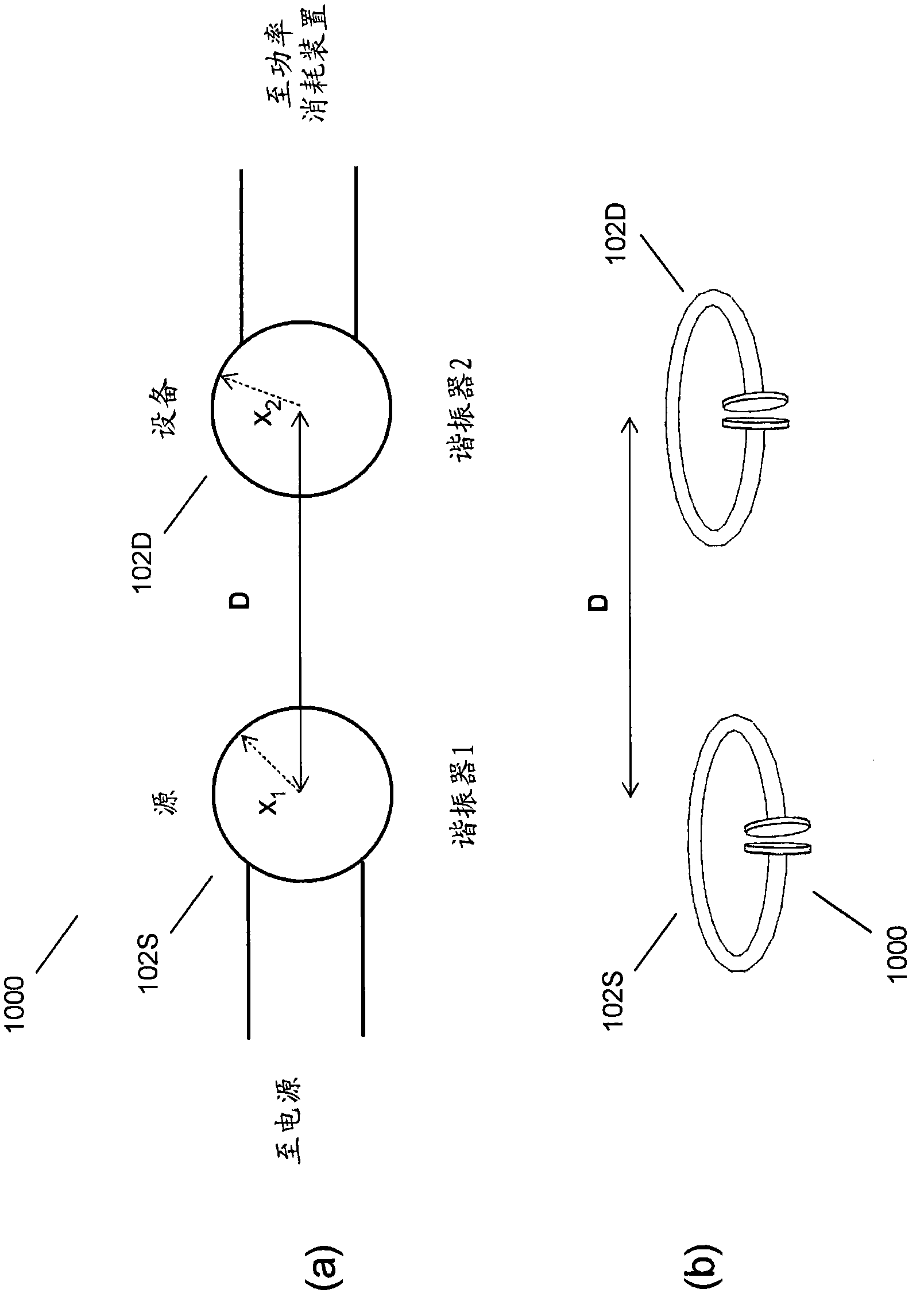

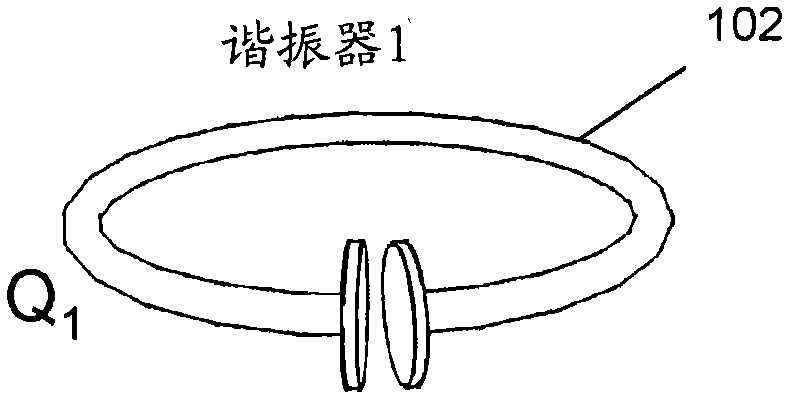

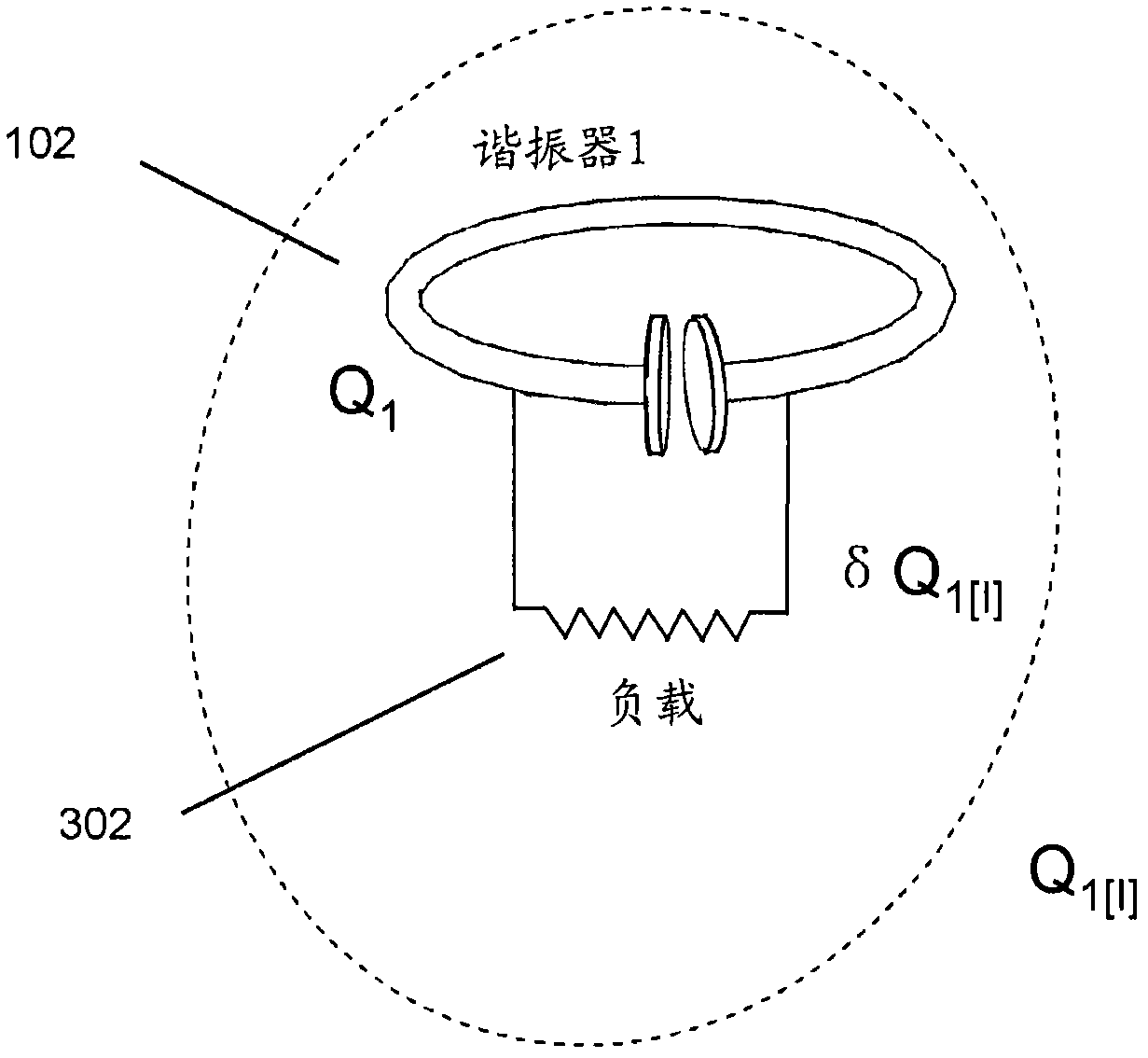

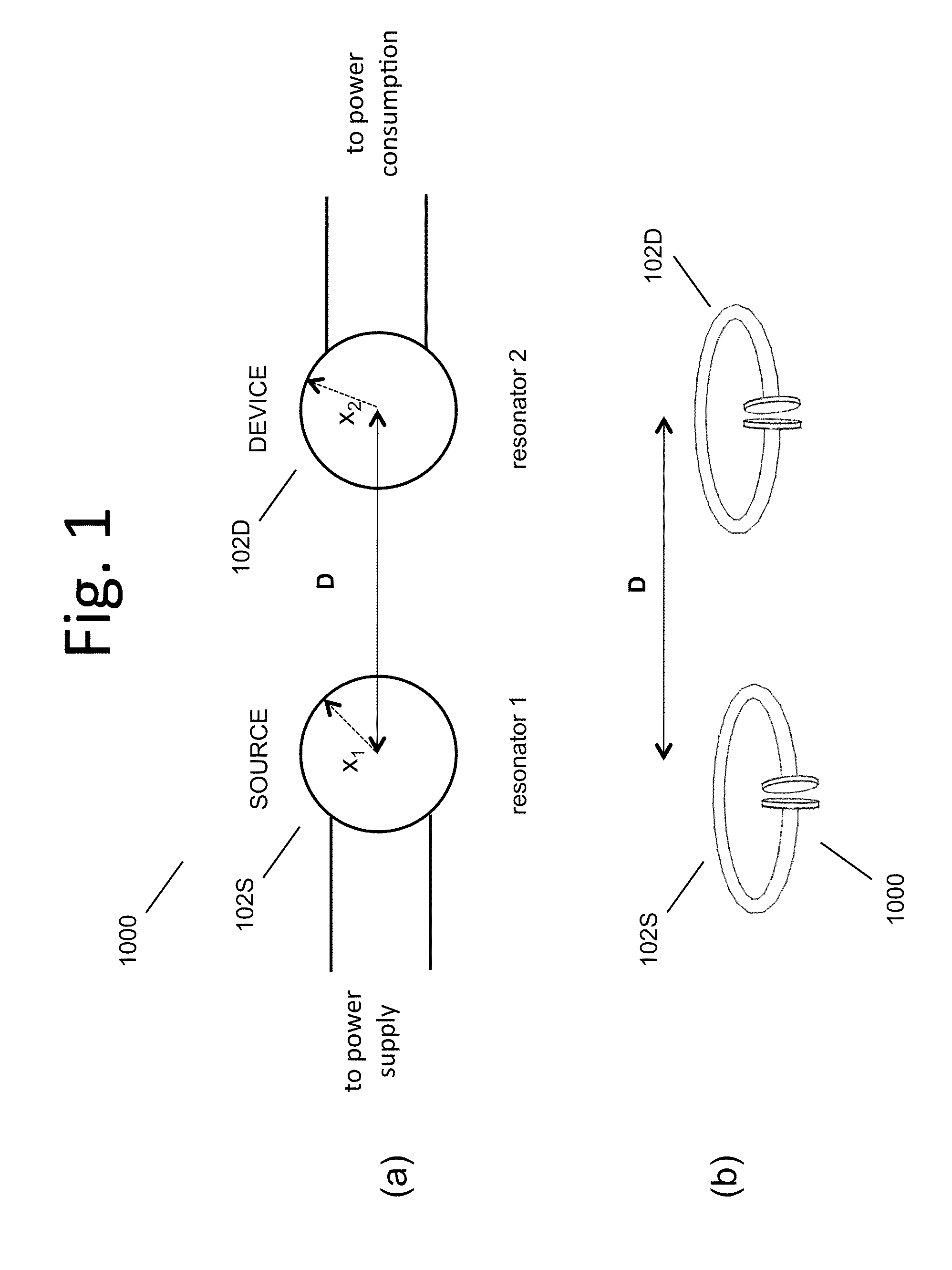

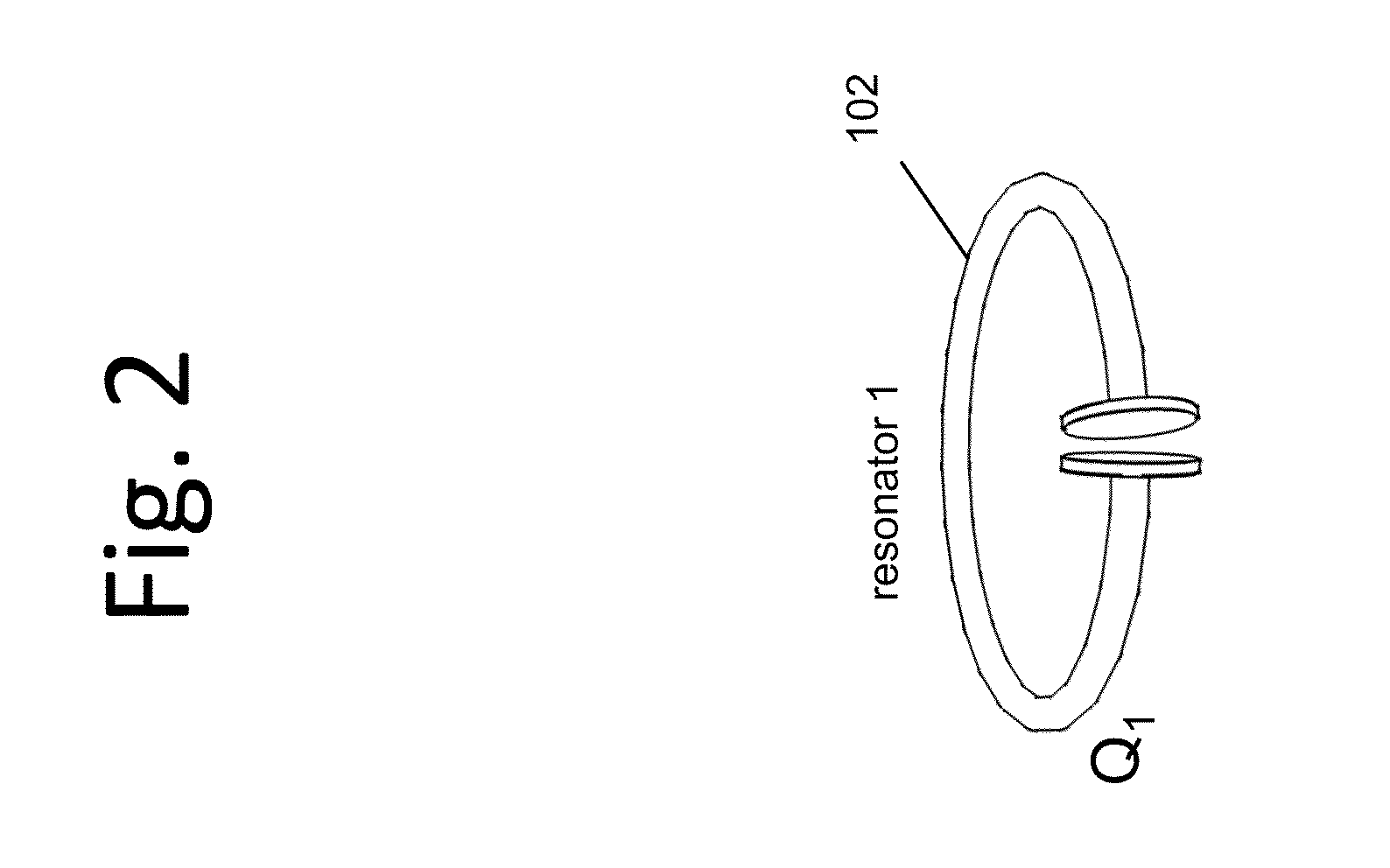

Wireless energy transfer in lossy environments

ActiveCN102439669AShort coupling timeLow intrinsic lossMultiple-port networksBatteries circuit arrangementsEnergy transferCapacitance

Described herein are improved configurations for a wireless power transfer for electronic devices that include at least one source magnetic resonator including a capacitively- loaded conducting loop coupled to a power source and configured to generate an oscillating magnetic field and at least one device magnetic resonator, distal from said source resonators, comprising a capacitively-loaded conducting loop configured to convert said oscillating magnetic fields into electrical energy, wherein at least one said resonator has a keep-out zone around the resonator that surrounds the resonator with a layer of non-lossy material.

Owner:WITRICITY CORP

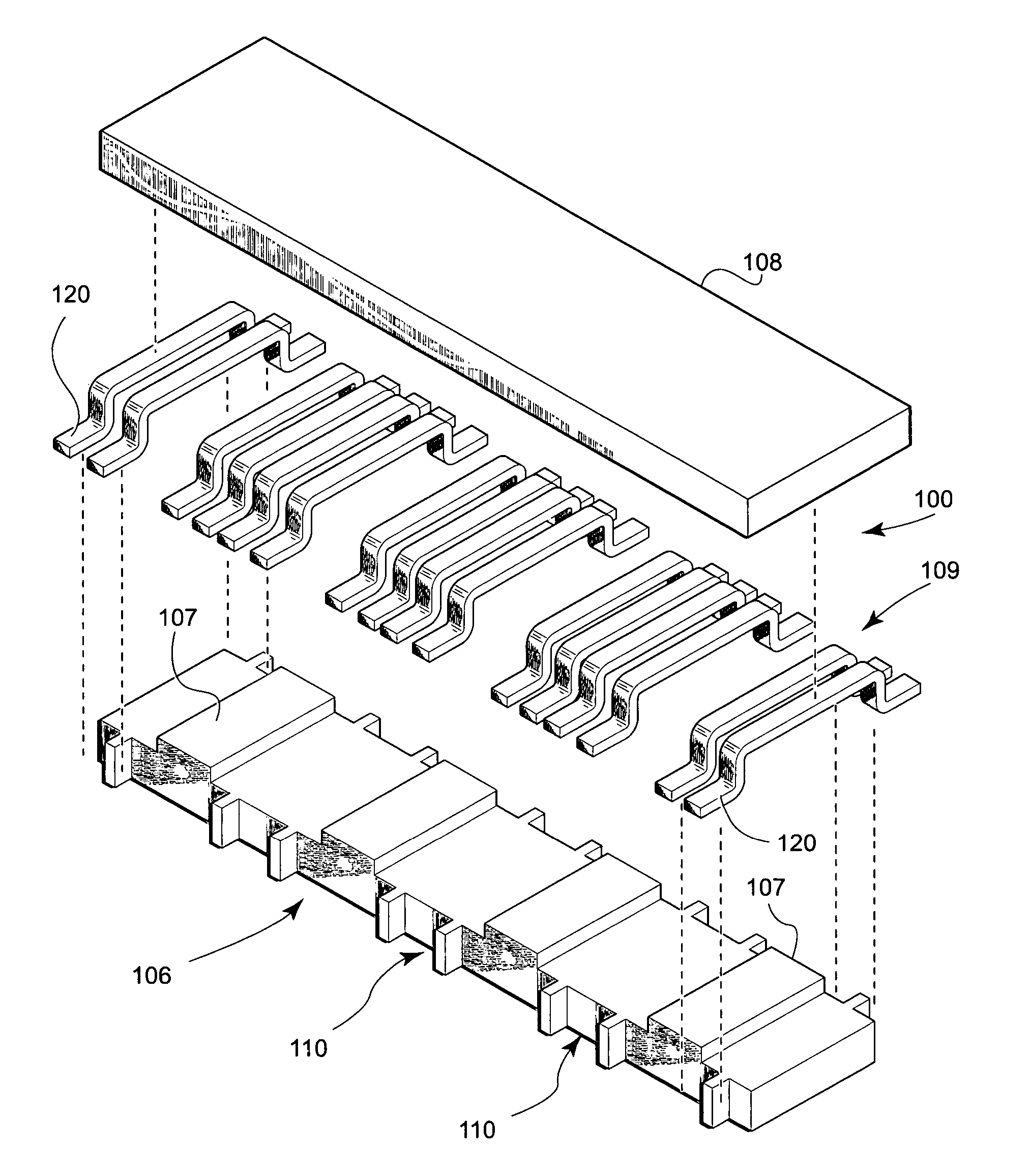

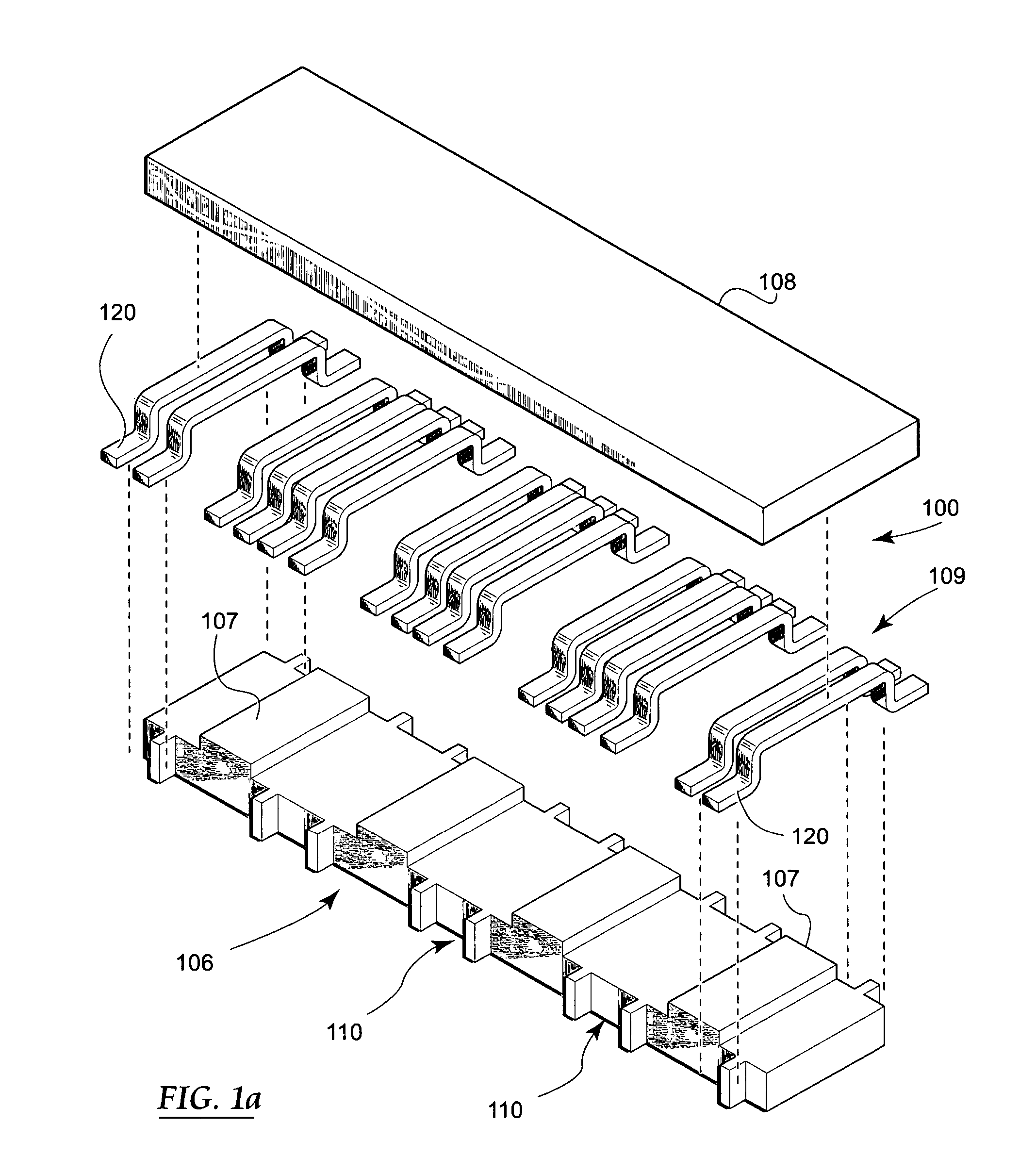

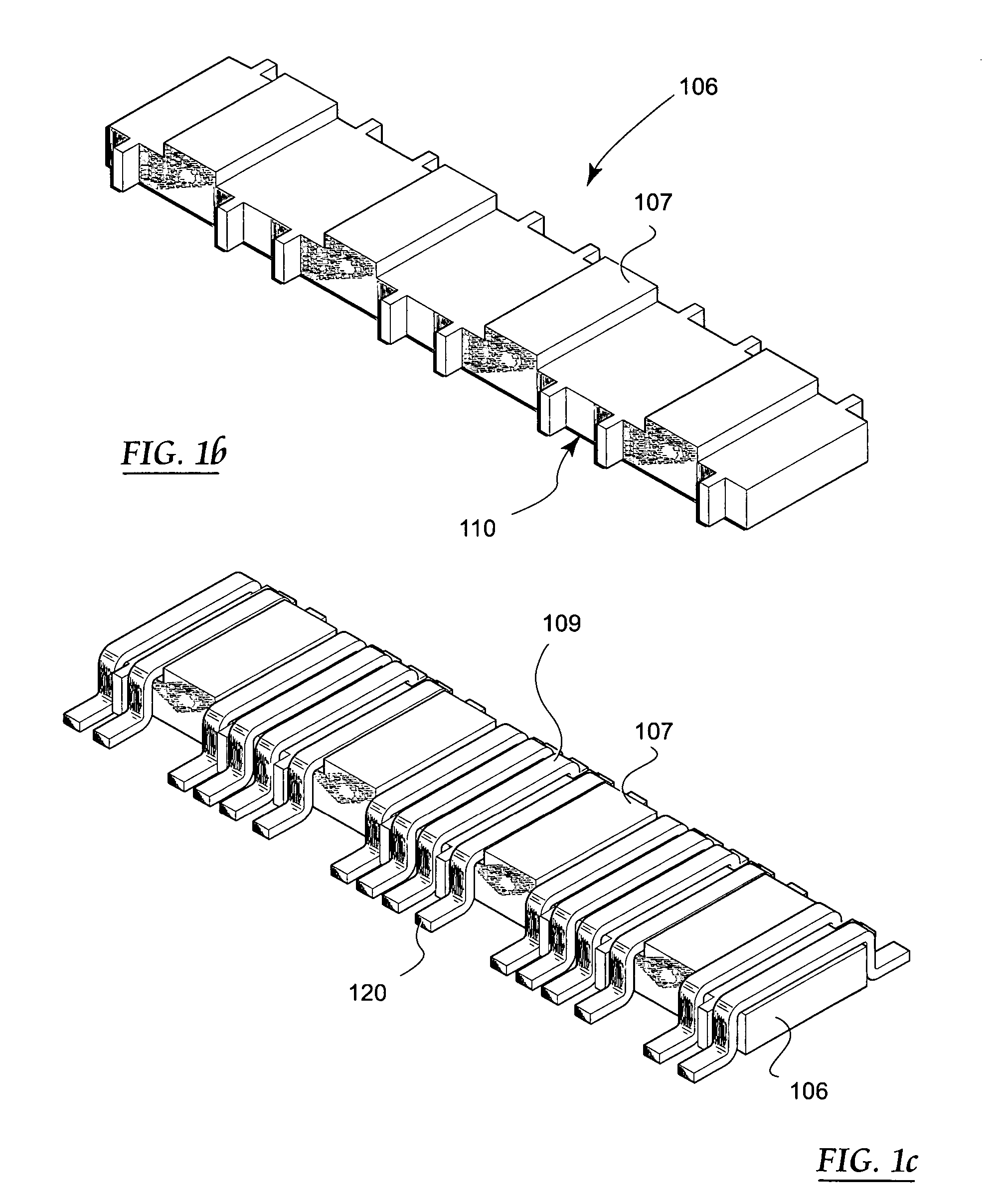

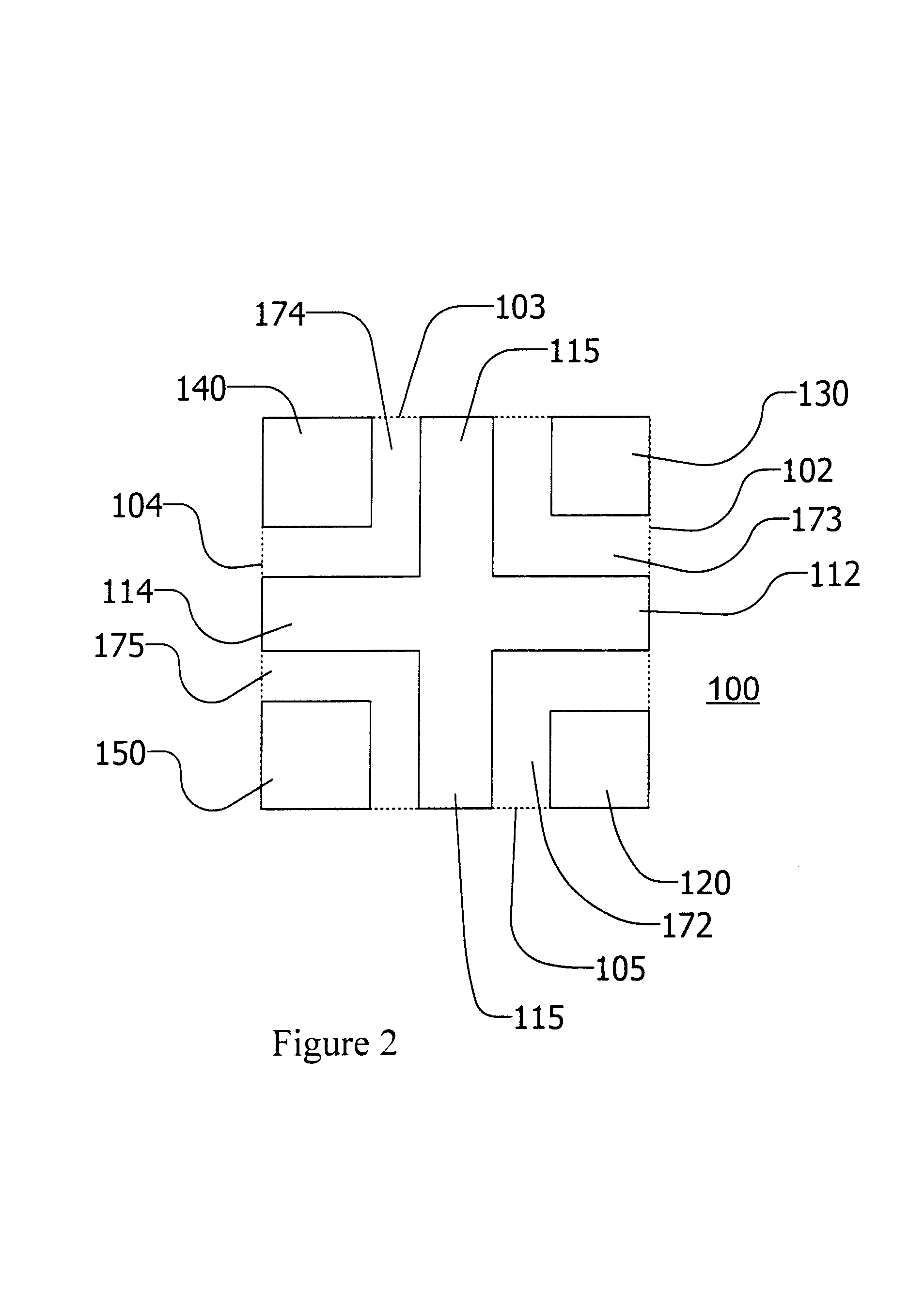

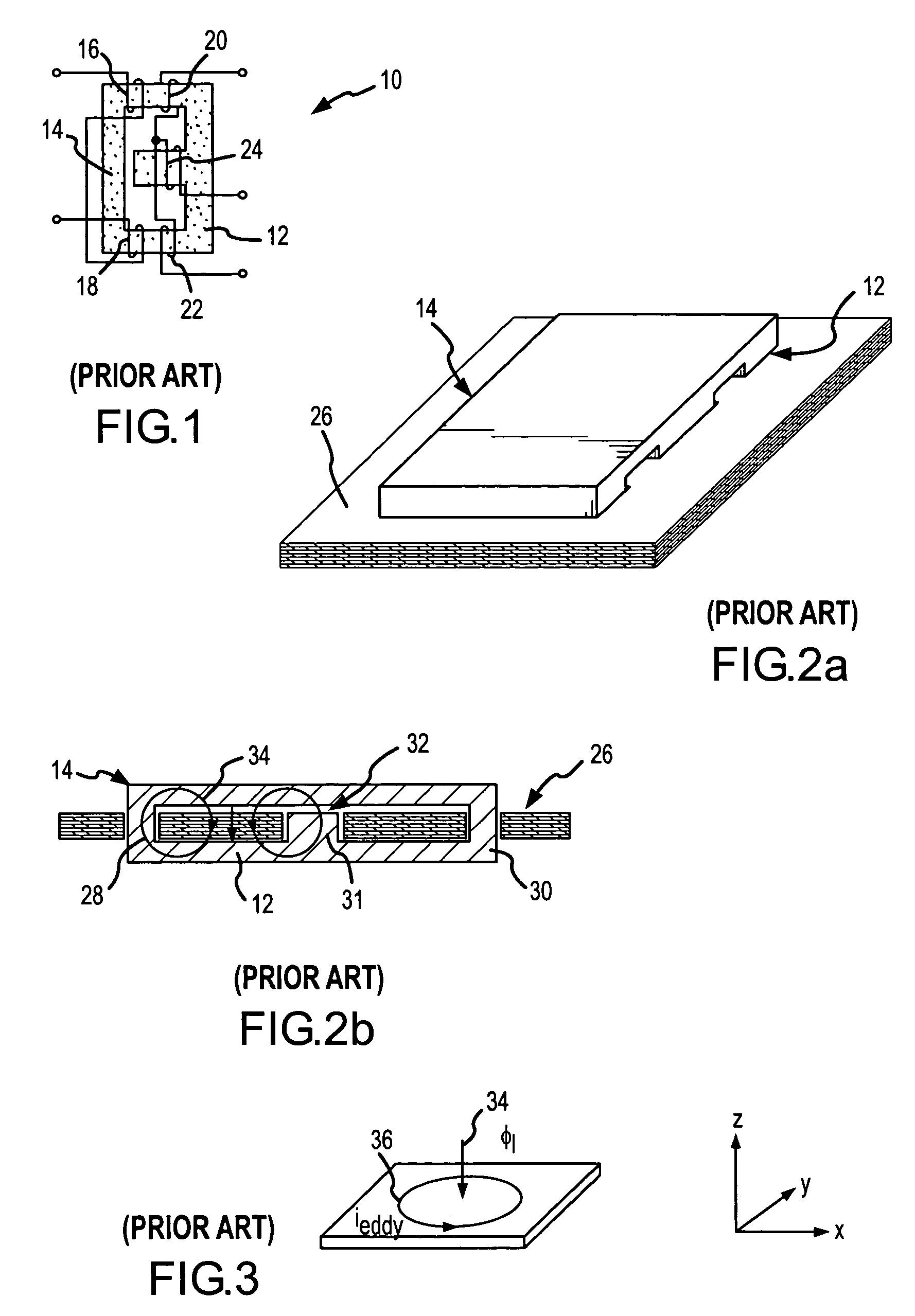

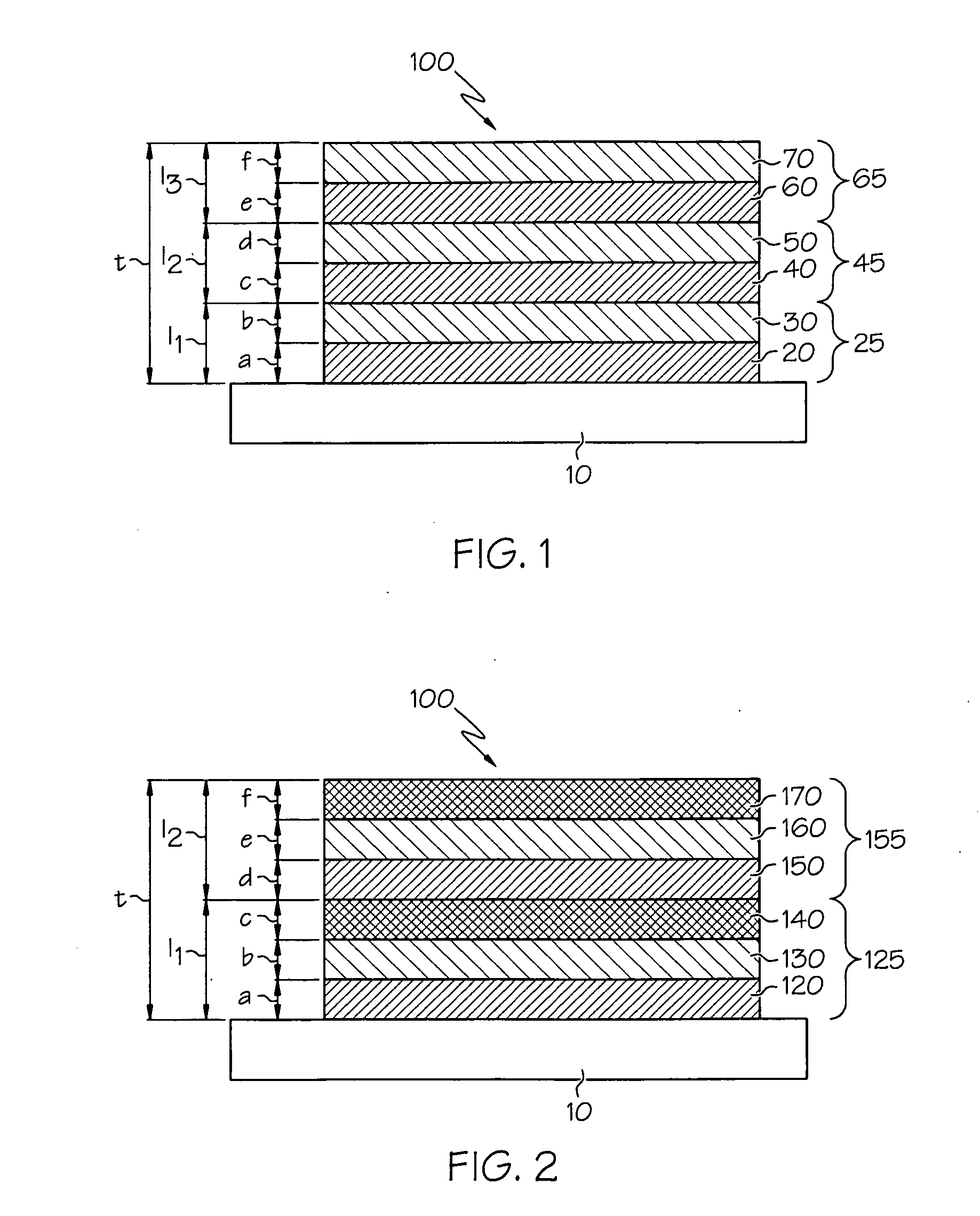

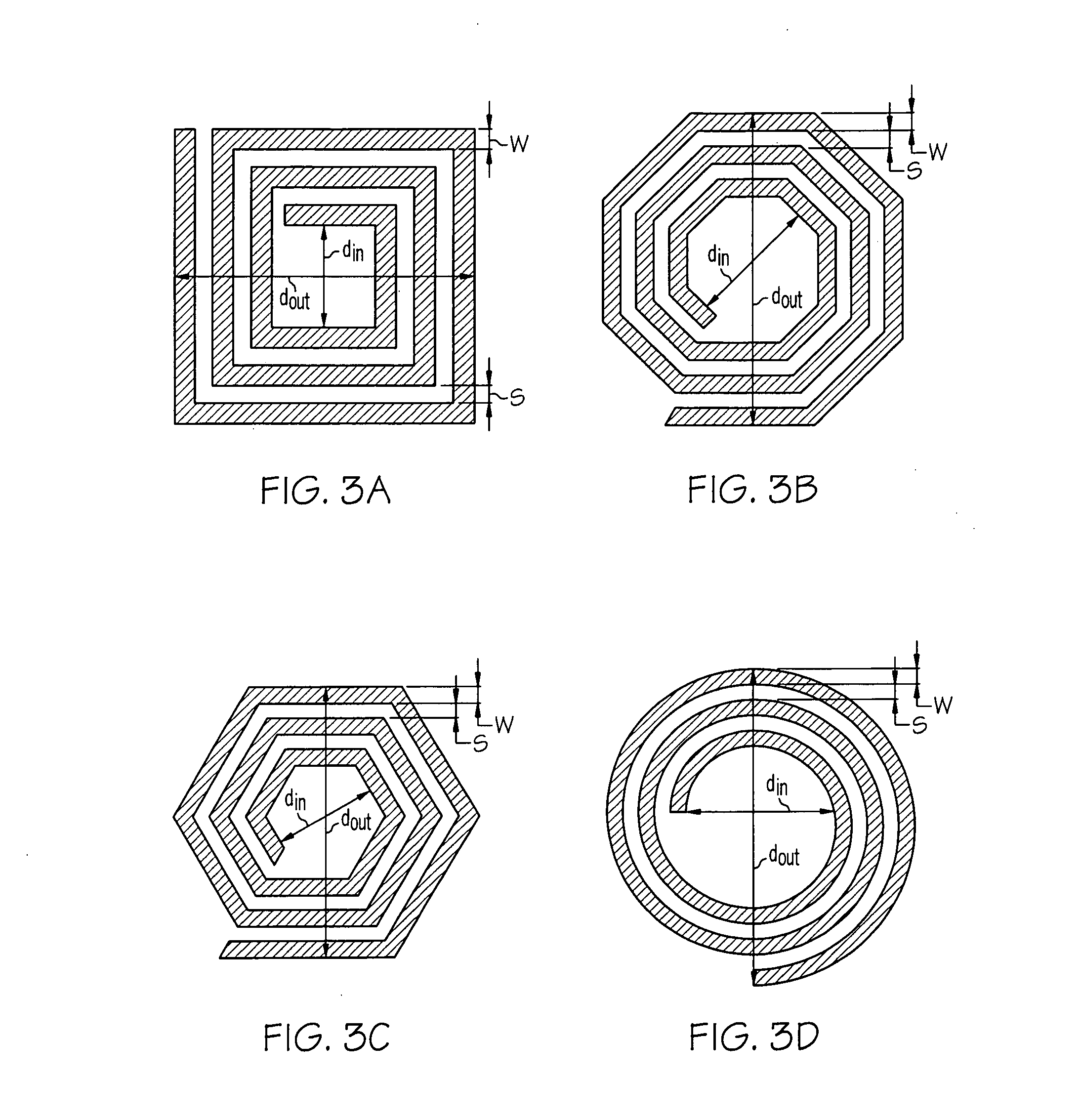

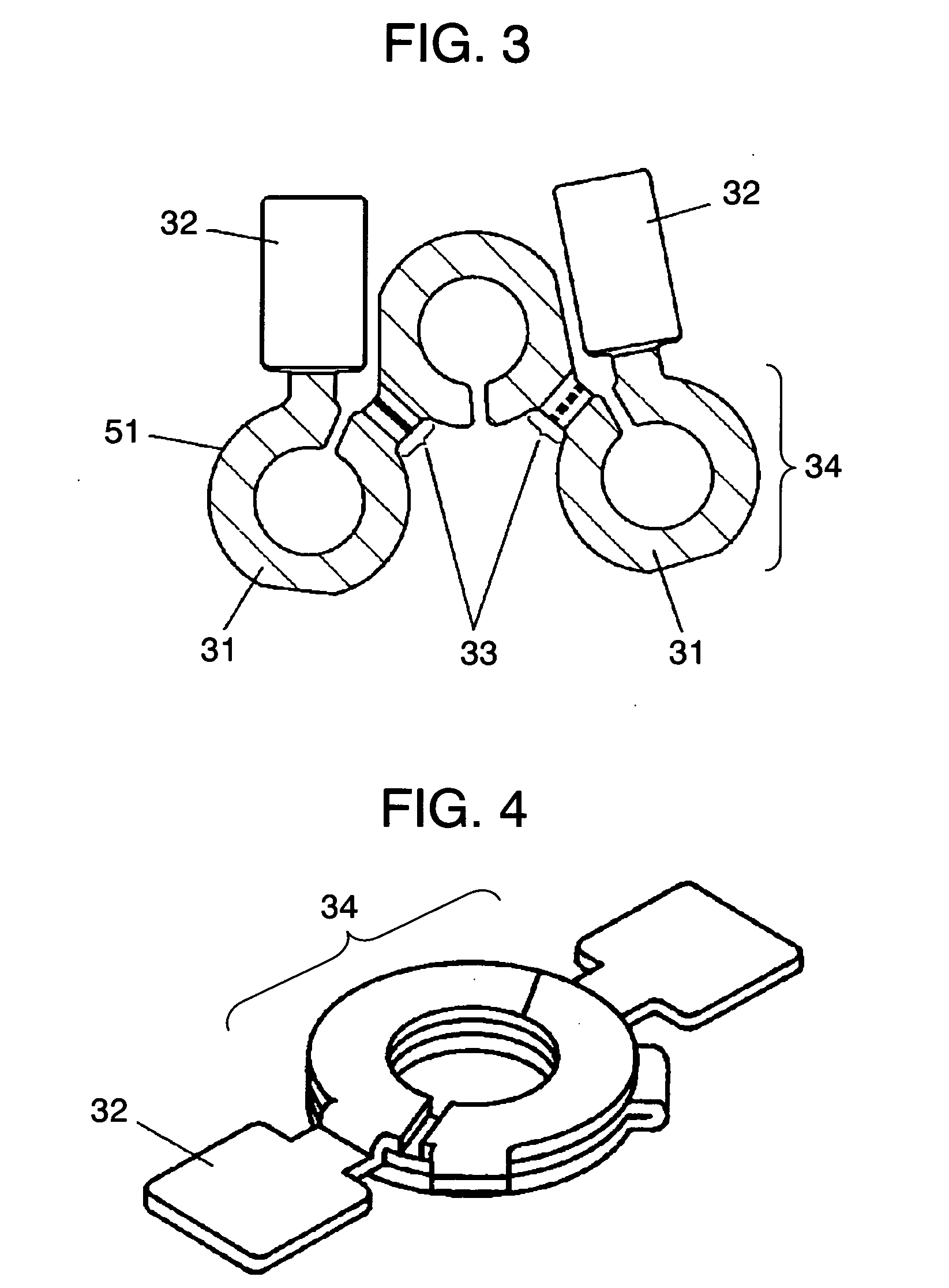

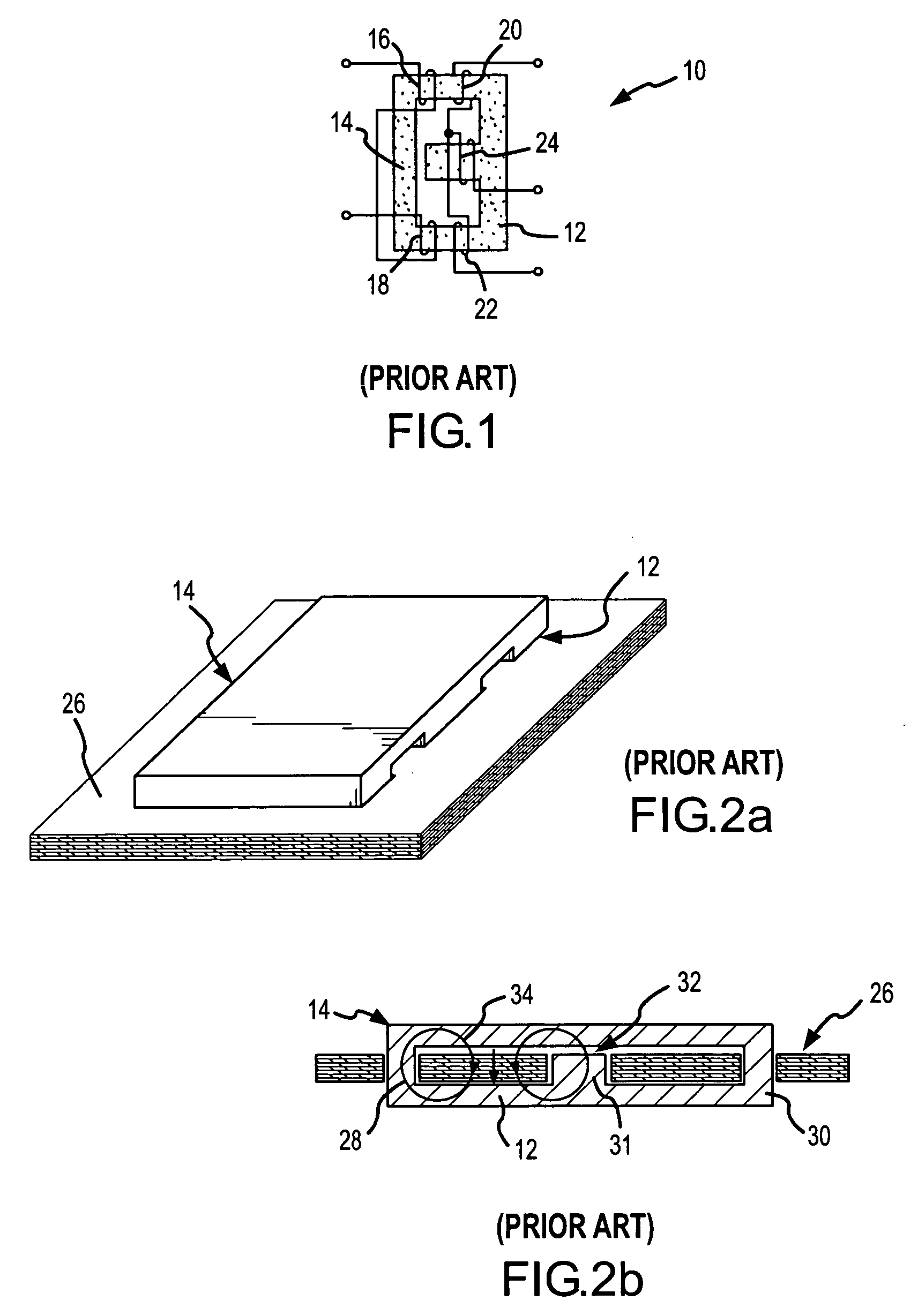

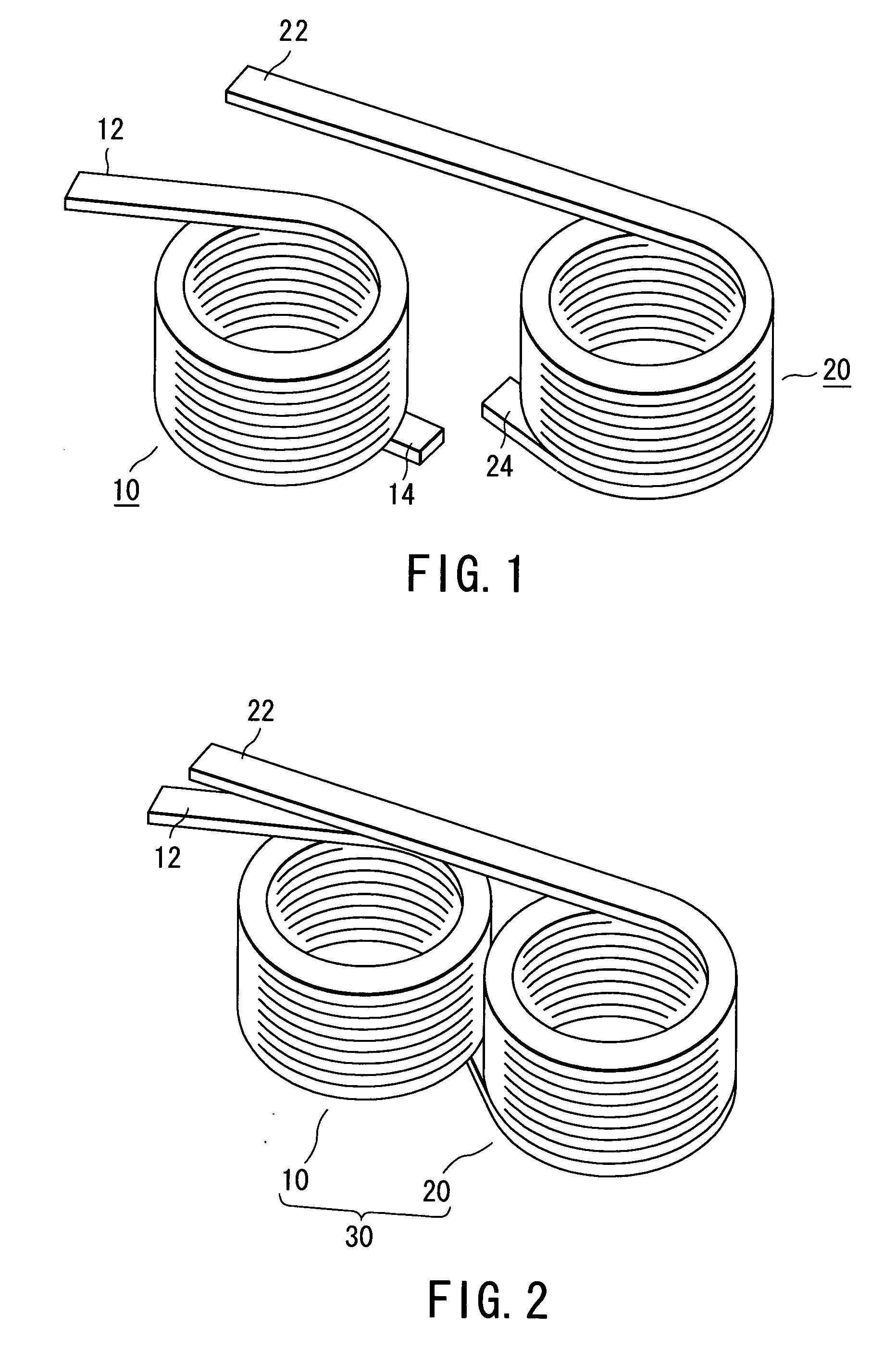

Precision inductive devices and methods

ActiveUS20060145800A1Mitigation of flux leakage effectImprove balanceTransformers/inductances casingsPrinted inductancesEngineeringInductor

A low cost, low profile, small size and high performance inductive device for use in, e.g., electronic circuits. In one exemplary embodiment, the device includes a ferrite core comprising multiple inductors and optimized for electrical and magnetic performance. Improvements in performance are obtained by, inter alia, control of the properties of the gap region(s) as well as placement of the windings relative to the gap. The magnetic path properties of the inductors at the ends of the device are also optionally controllable so as to provide precise matching of inductances. Optionally, the device is also self-leaded, thereby simplifying its installation and mating to a parent device (e.g., PCB). Methods for manufacturing and utilizing the device are also disclosed.

Owner:PULSE ELECTRONICS

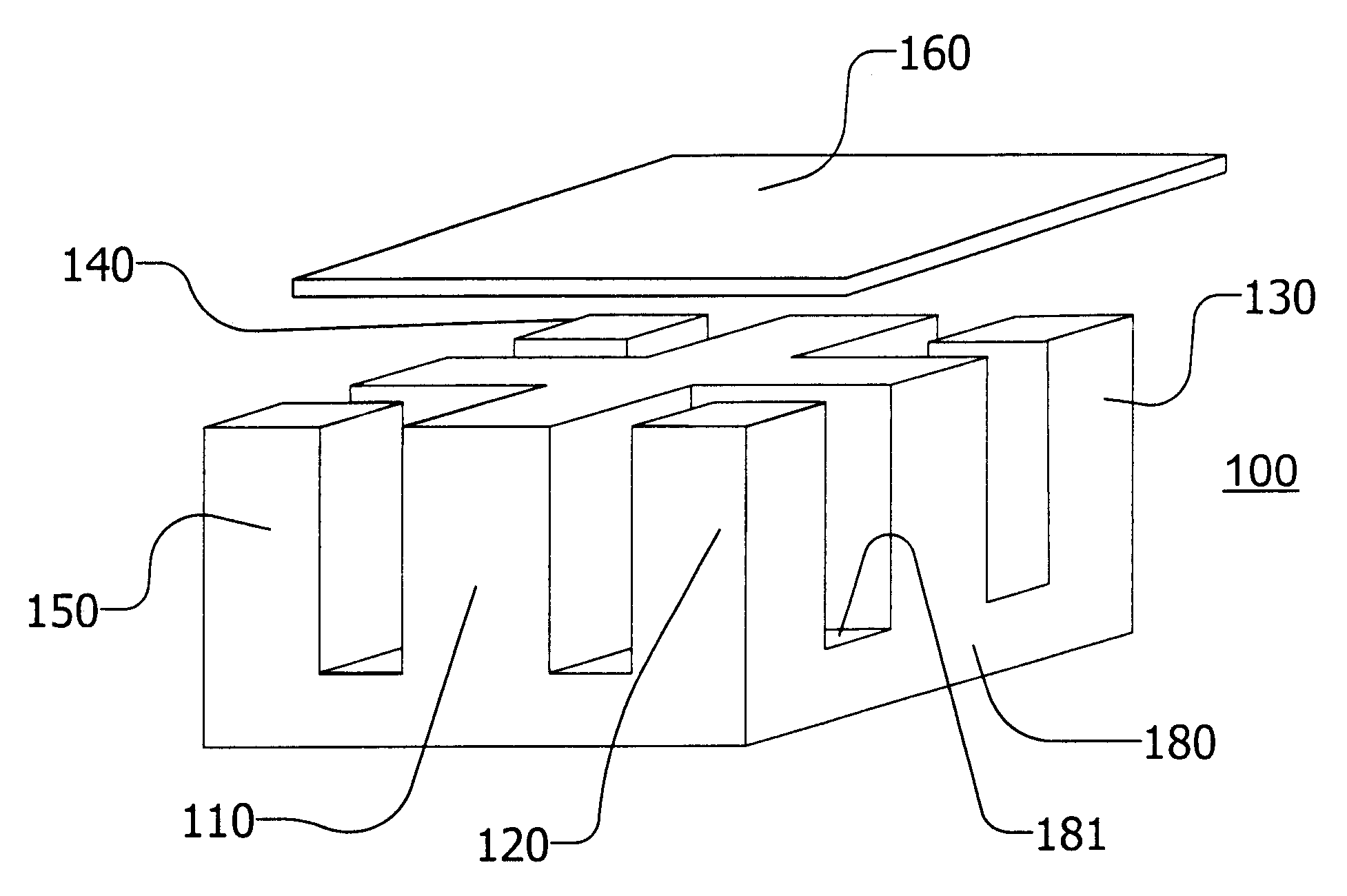

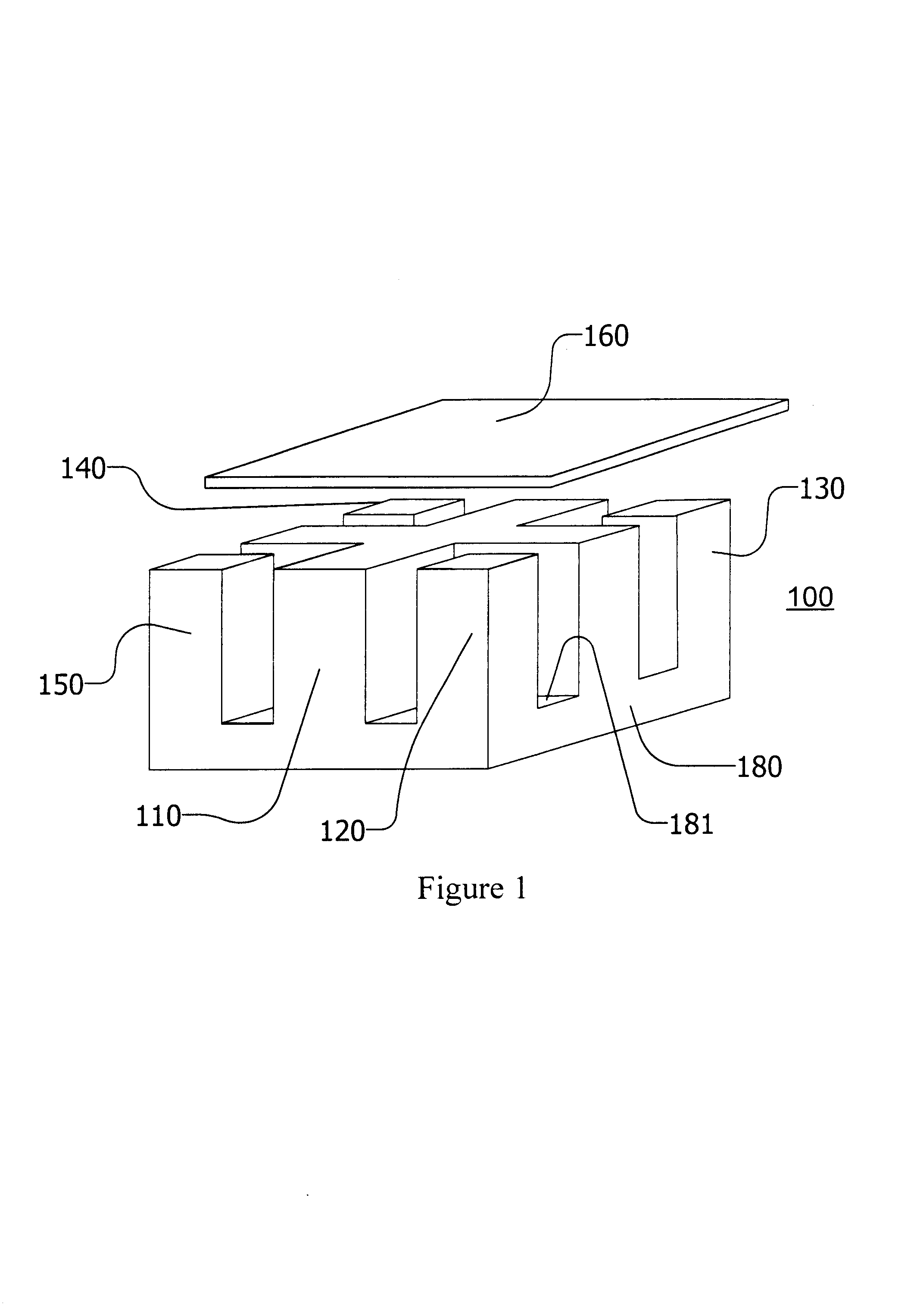

Core structure

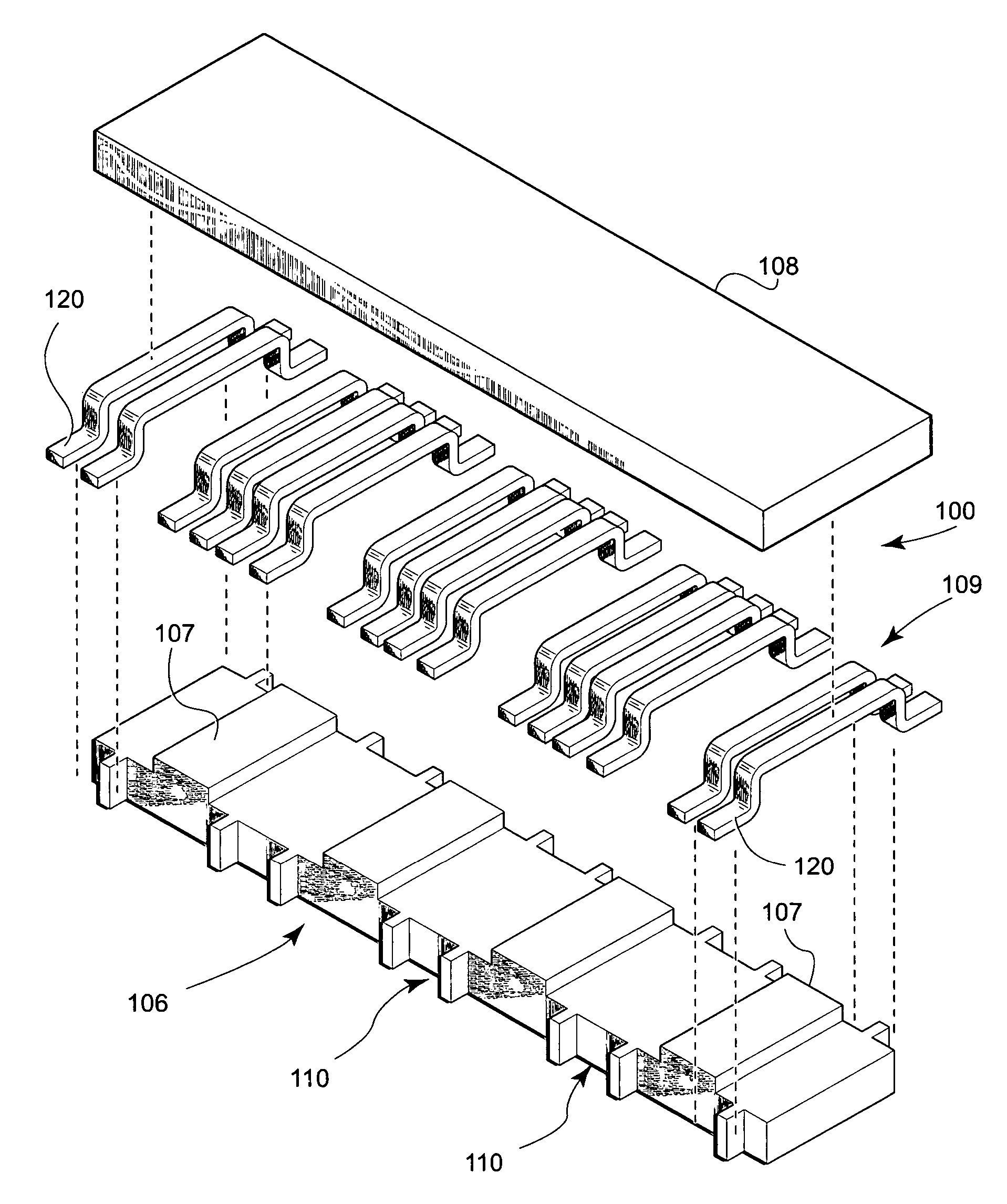

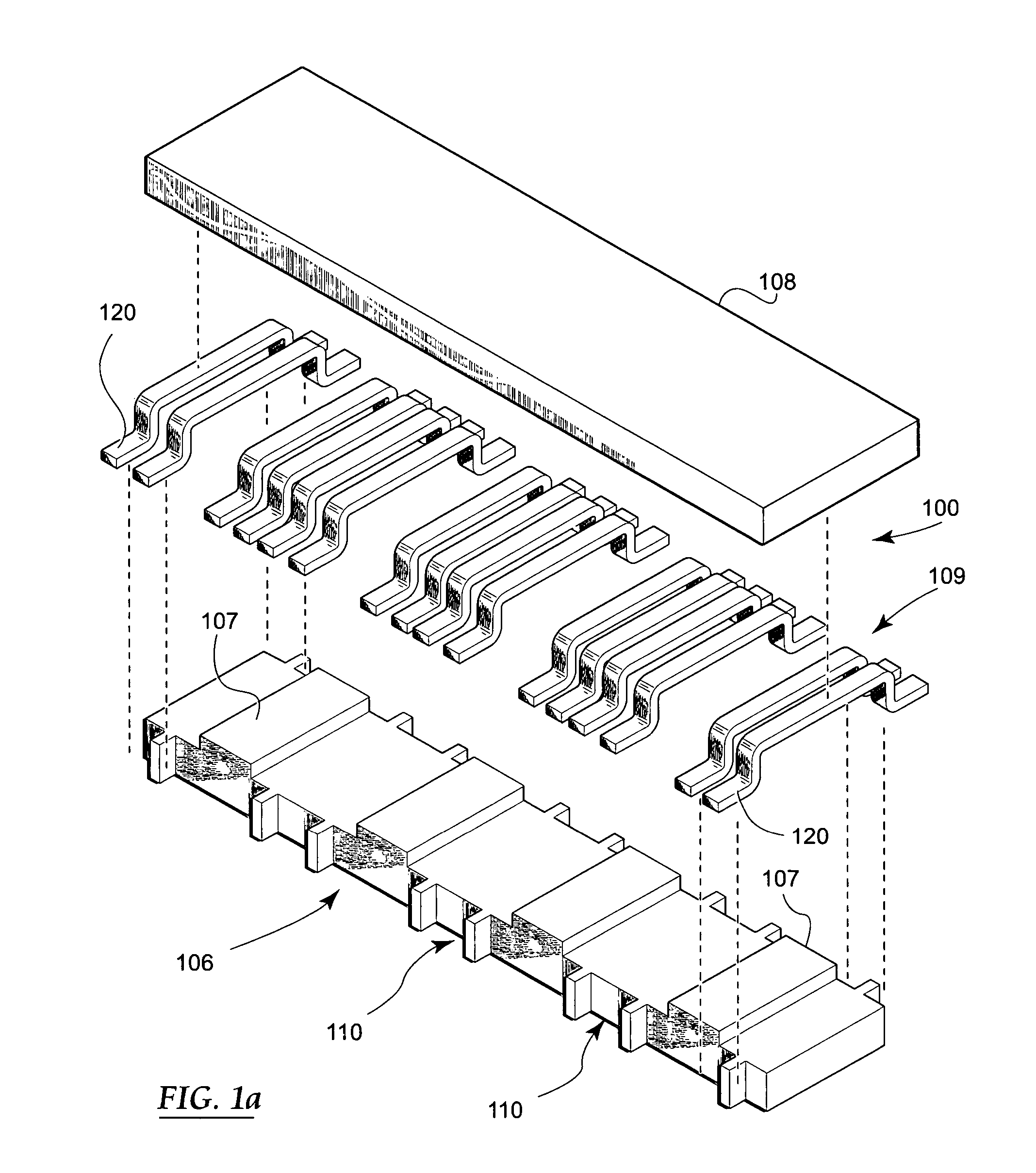

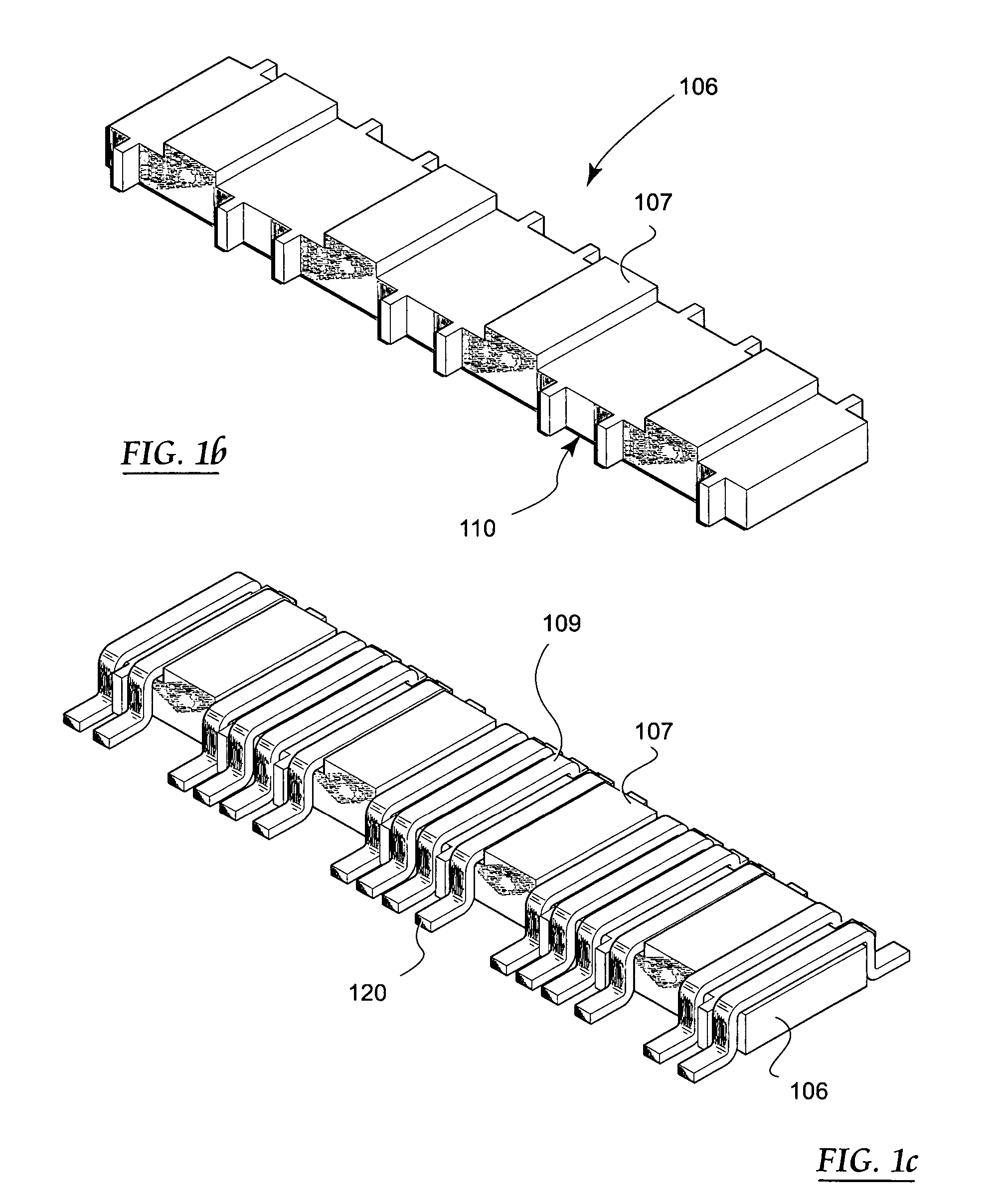

InactiveUS6873237B2Ac-dc conversion without reversalTransformers/inductances casingsHigh power densityLarge core

There is disclosed a core structure with a very low profile, high power density and lower losses. Higher core surface area and improved core utilization in terms of flux density are other desirable feature in the disclosed design. The disclosed design also allowed for a larger core area where the DC fluxes are added, thereby reducing the air-gap requirements in the cores derived from low saturation density materials such as ferrites. The cellular nature of the design can also be effectively employed in vertically packaged power converters and modules.

Owner:MYPAQ HLDG LTD

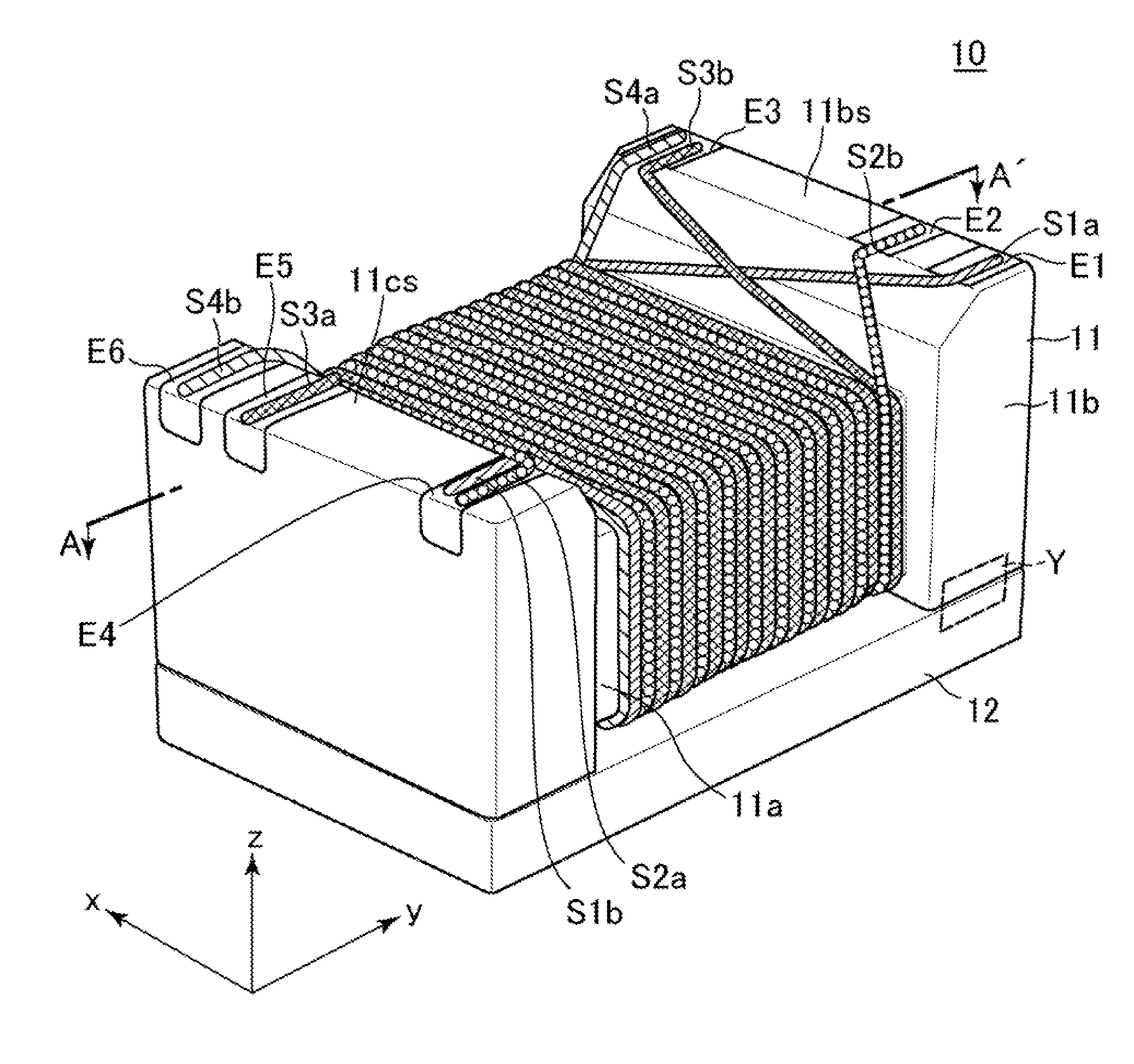

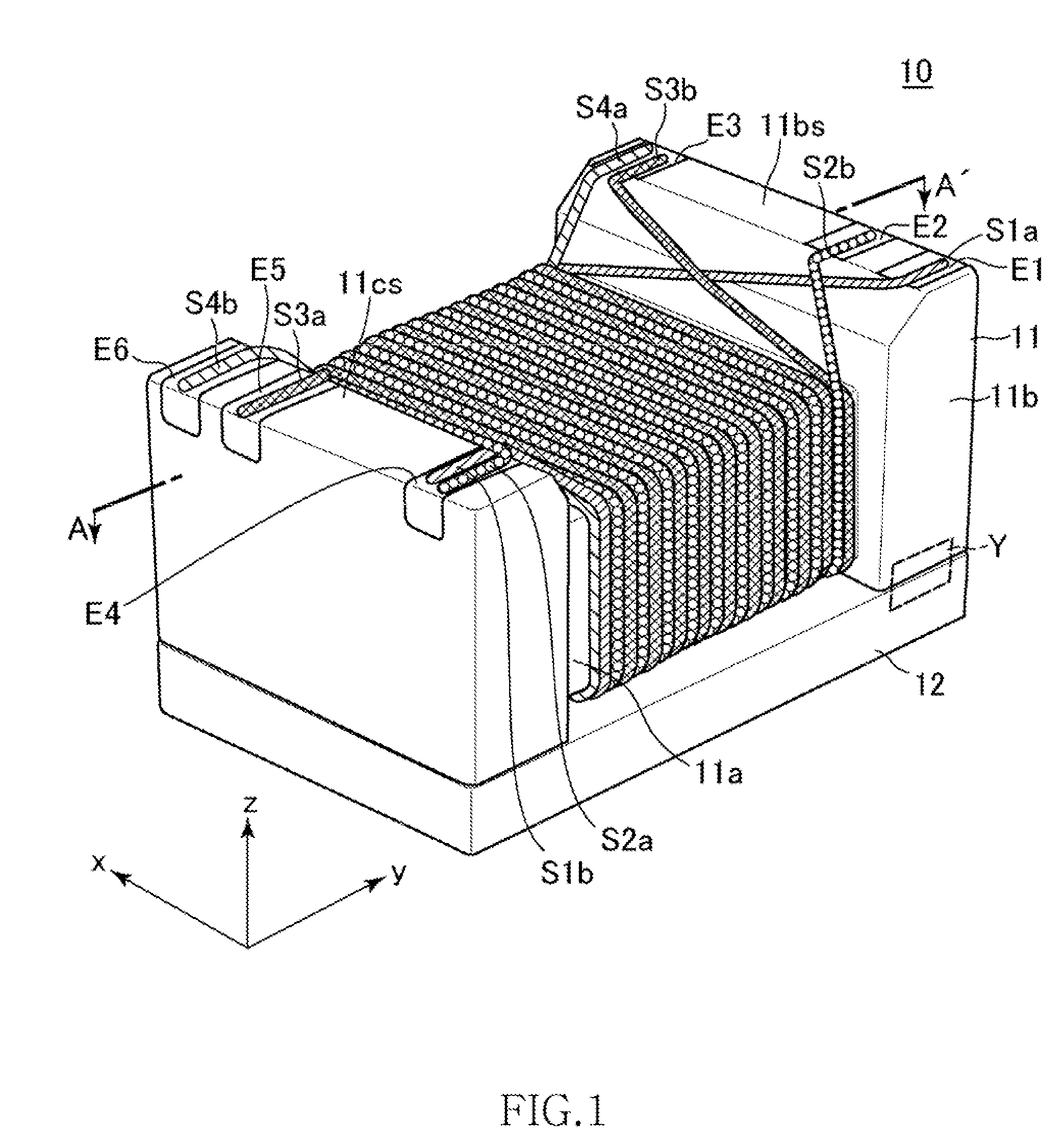

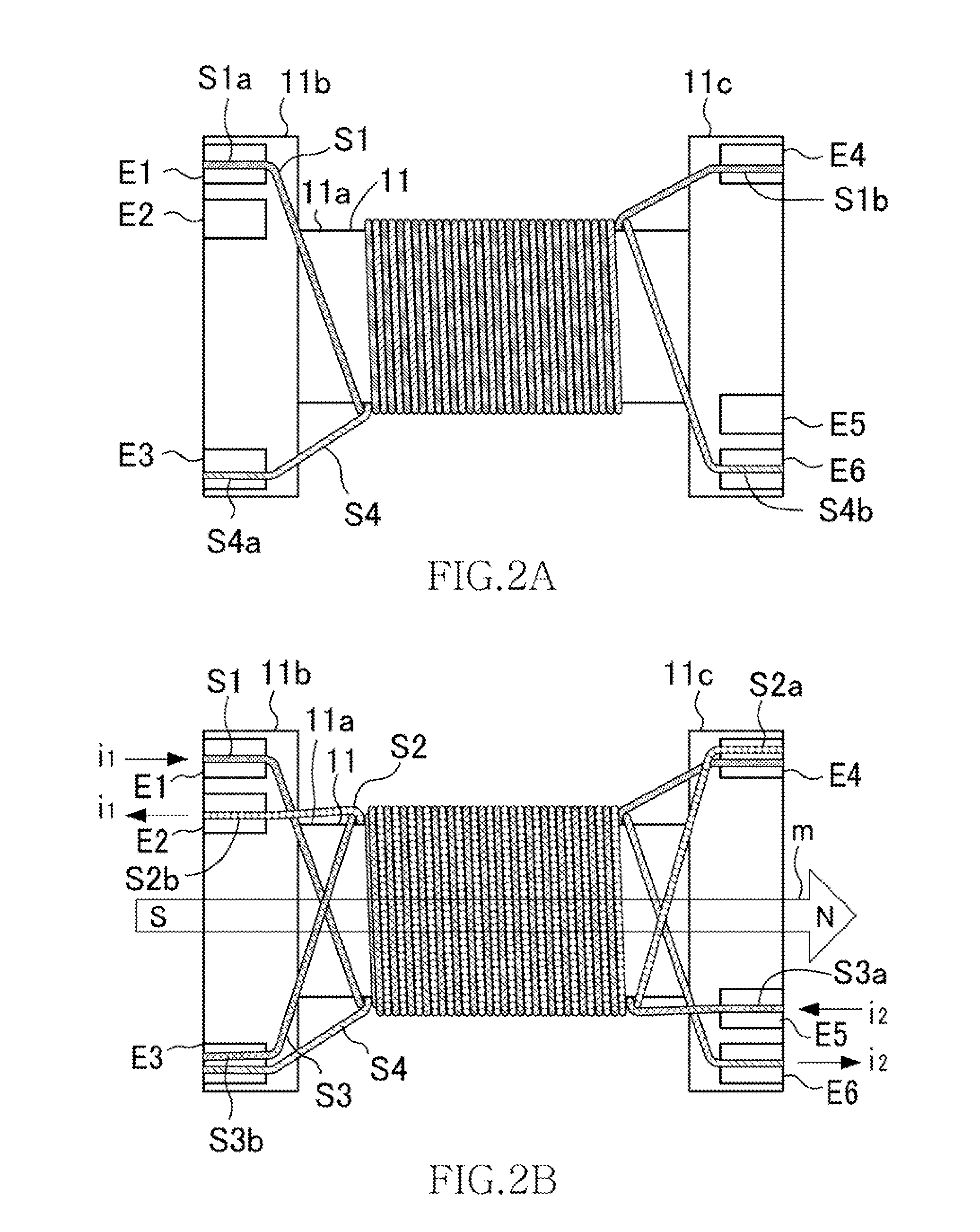

Surface mount pulse transformer and method and apparatus for manufacturing the same

ActiveUS20100109827A1Short working hoursShorten the timeTransformers/inductances casingsTransformers/inductances coils/windings/connectionsSurface mountingEngineering

A surface mount pulse transformer has a drum type core including a core and first and second flanges disposed on both ends of the core and installed on a substrate and a primary winding wire and a secondary winding wire wound around the core and provided with an intermediate tap, respectively, wherein first and second terminal electrodes being connected to each of both ends of the primary winding wire and a third terminal electrode for connecting being connected to the intermediate tap of the secondary winding wire are disposed on the surface of the first flange and a fourth terminal electrode being connected to the intermediate tap of the primary winding wire and fifth and sixth terminal electrodes being connected to each of both ends of the secondary winding wire are disposed on the surface of the second flange.

Owner:TDK CORPARATION

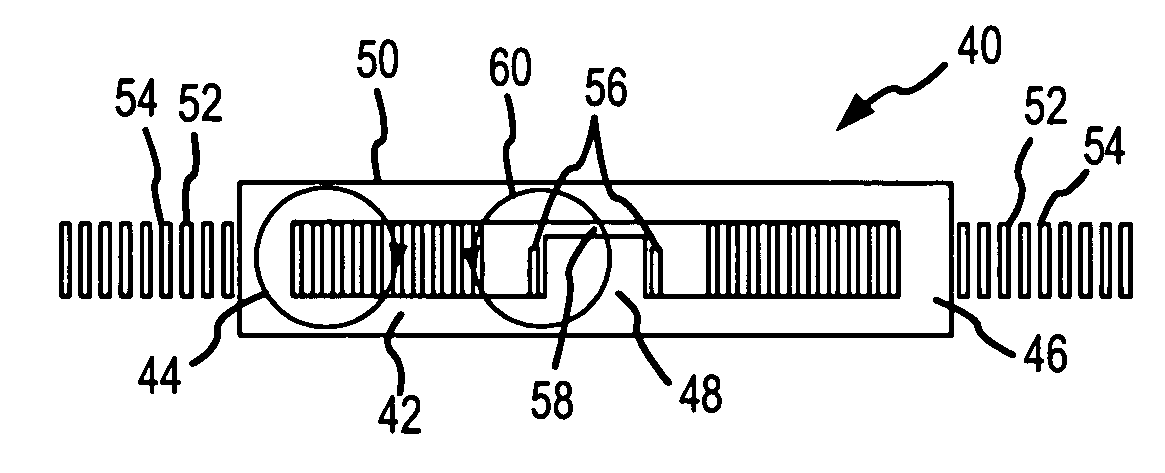

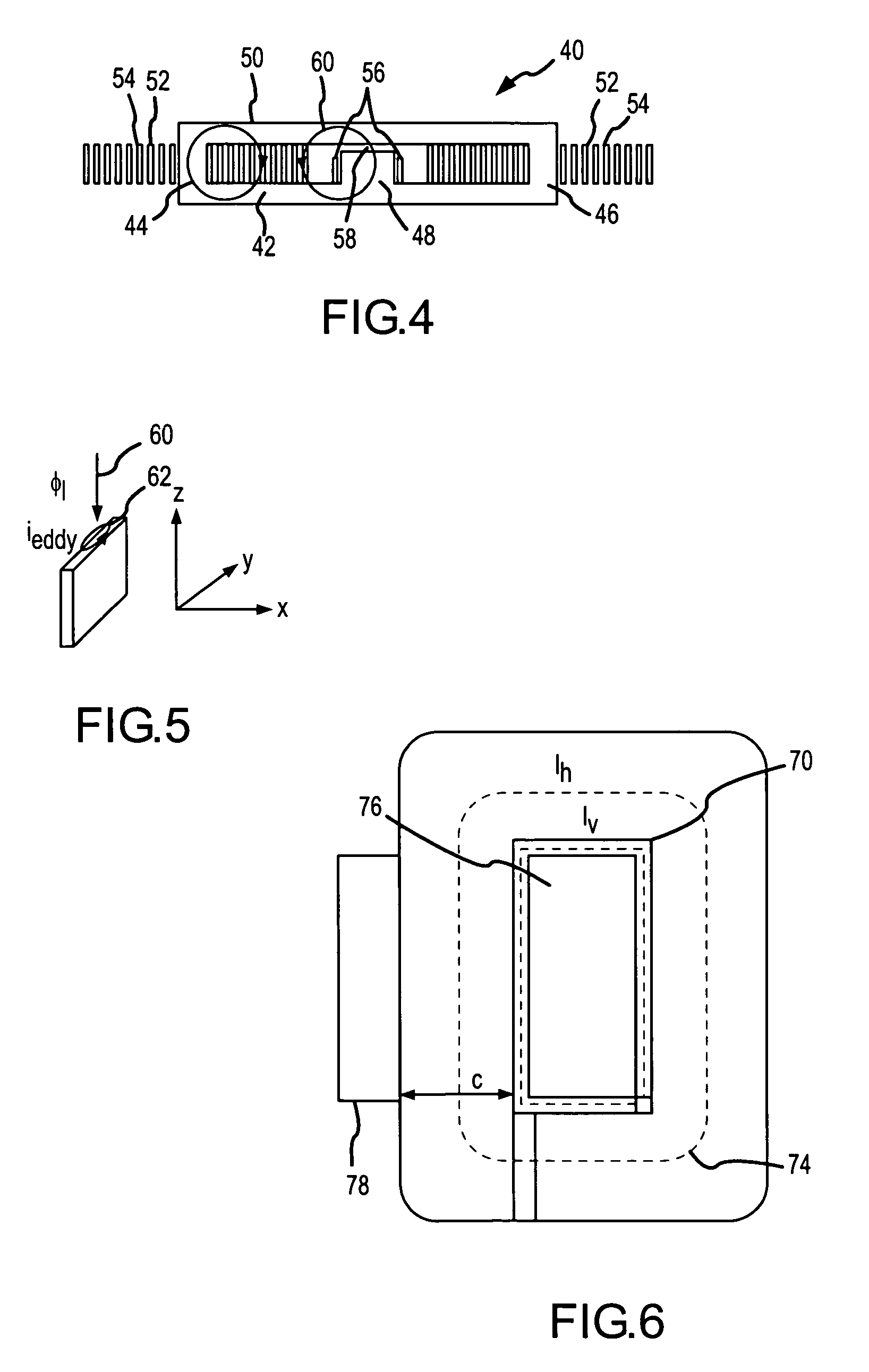

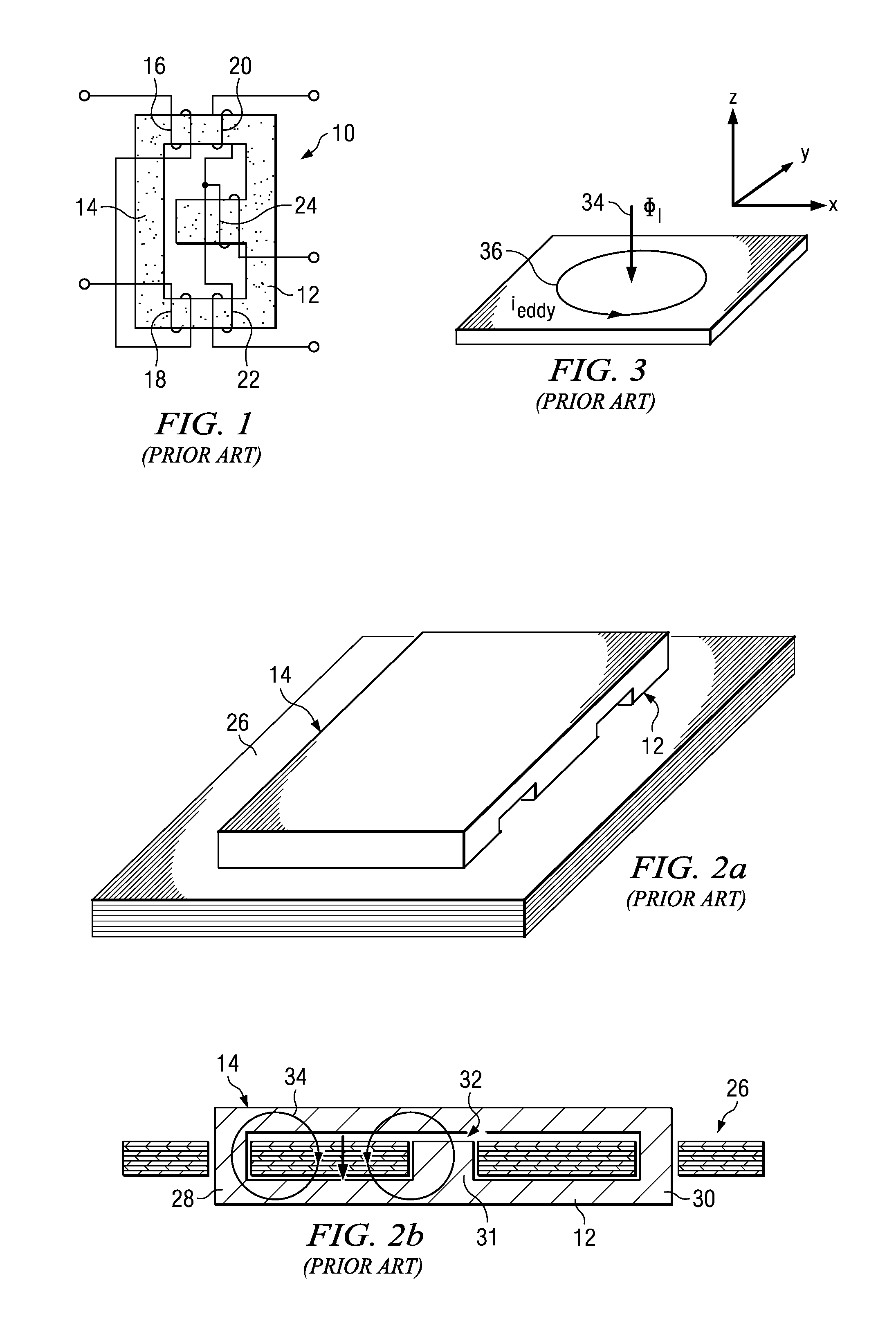

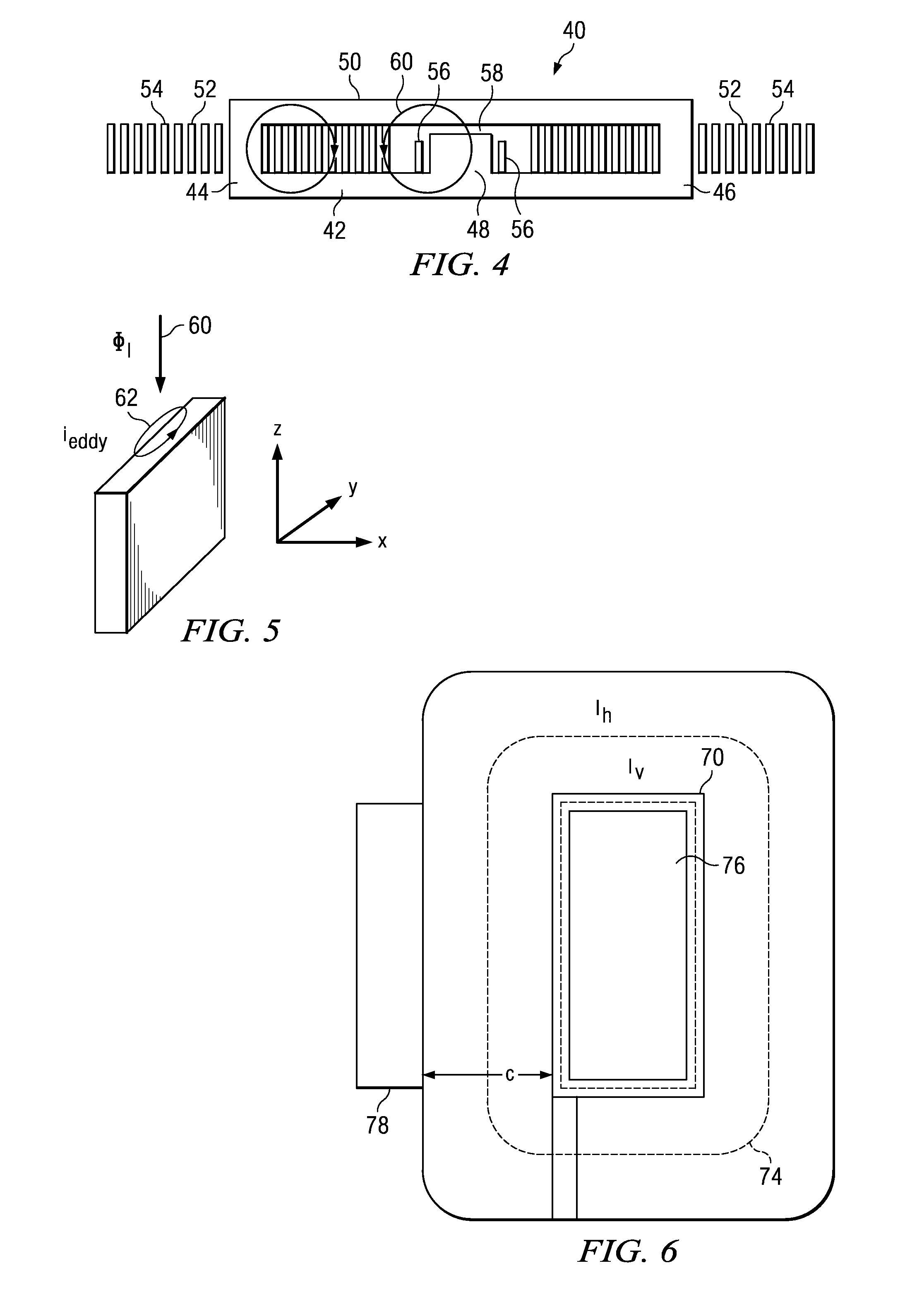

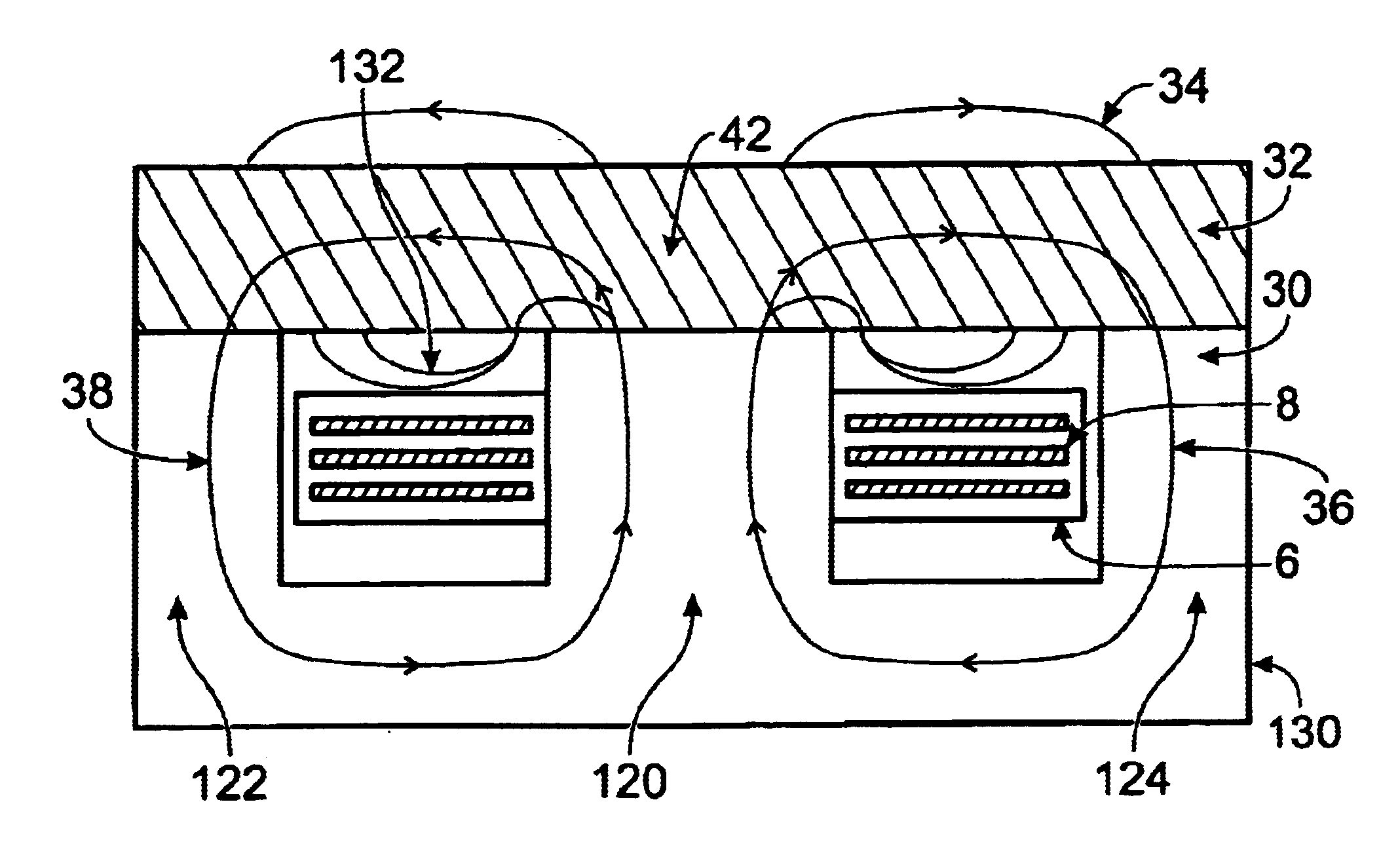

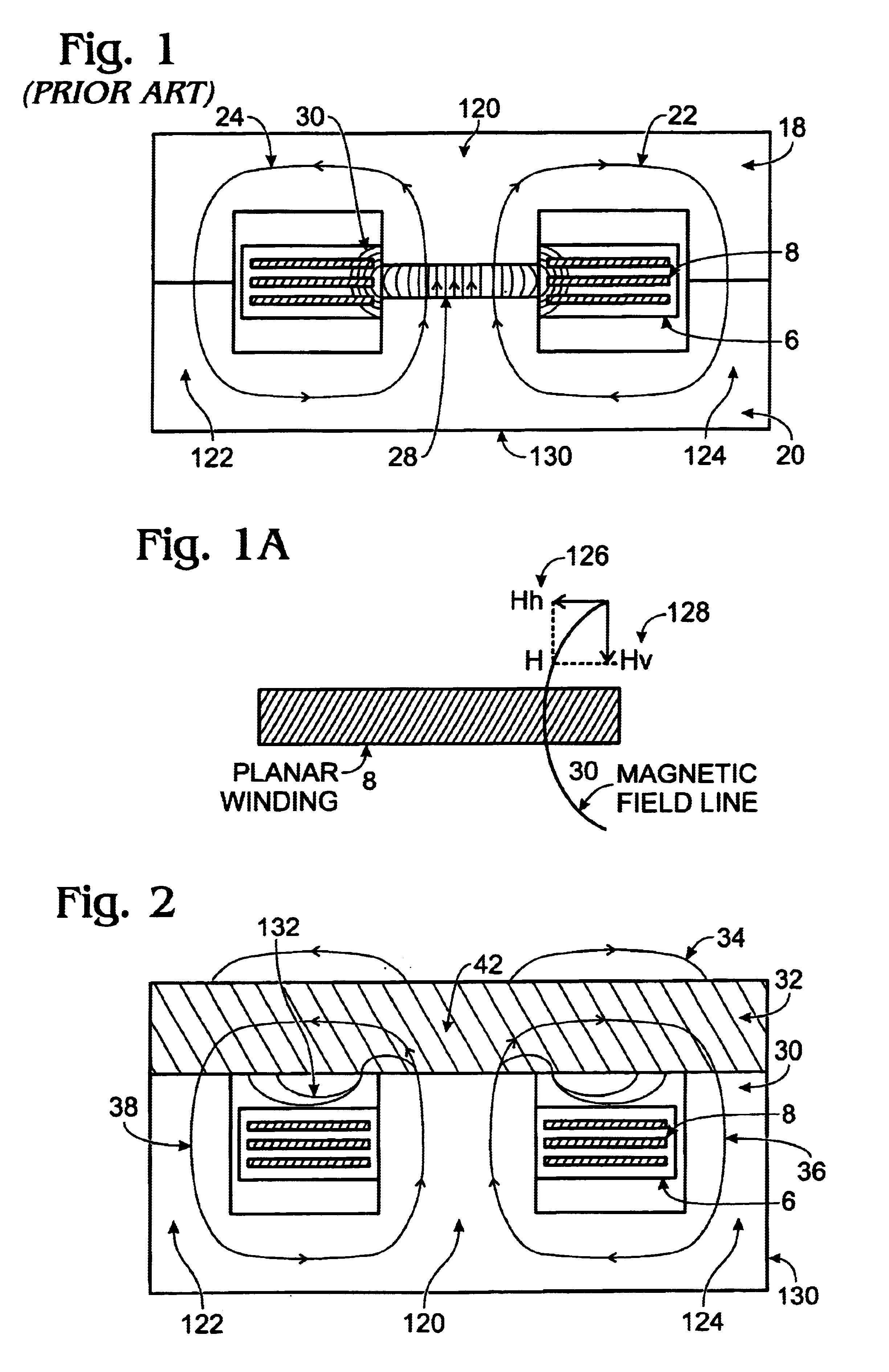

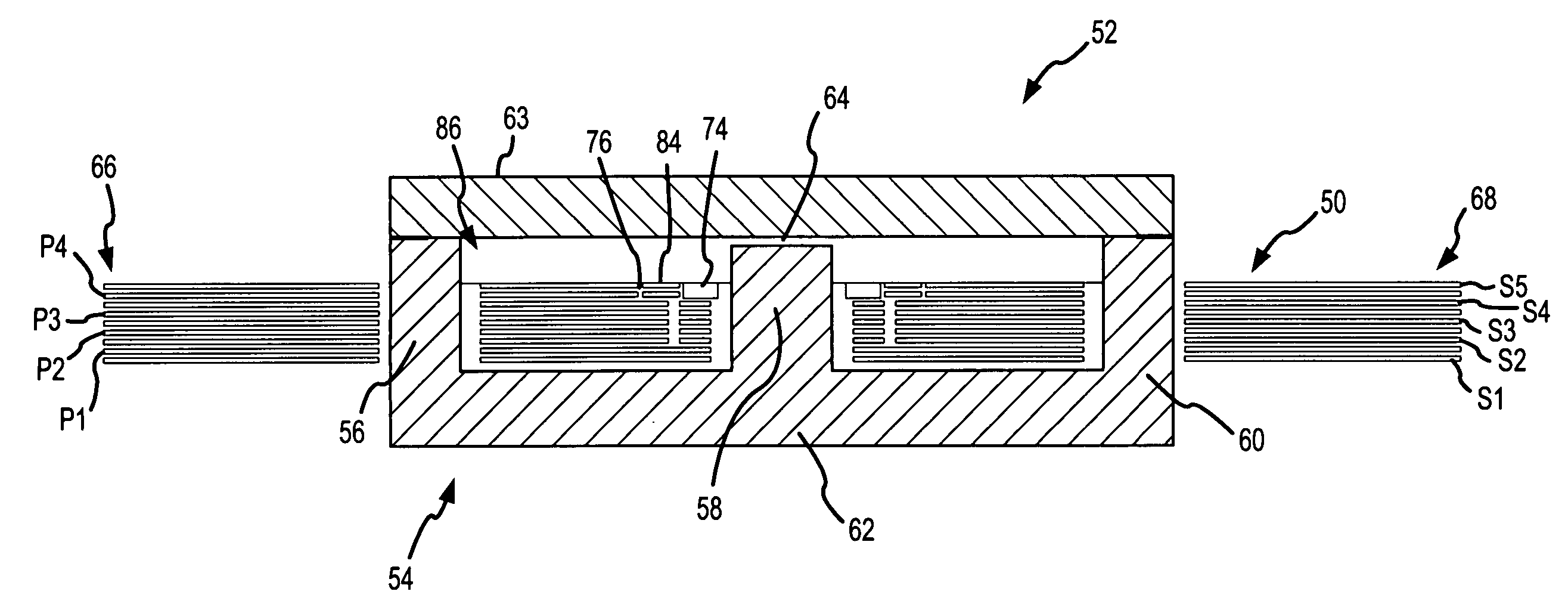

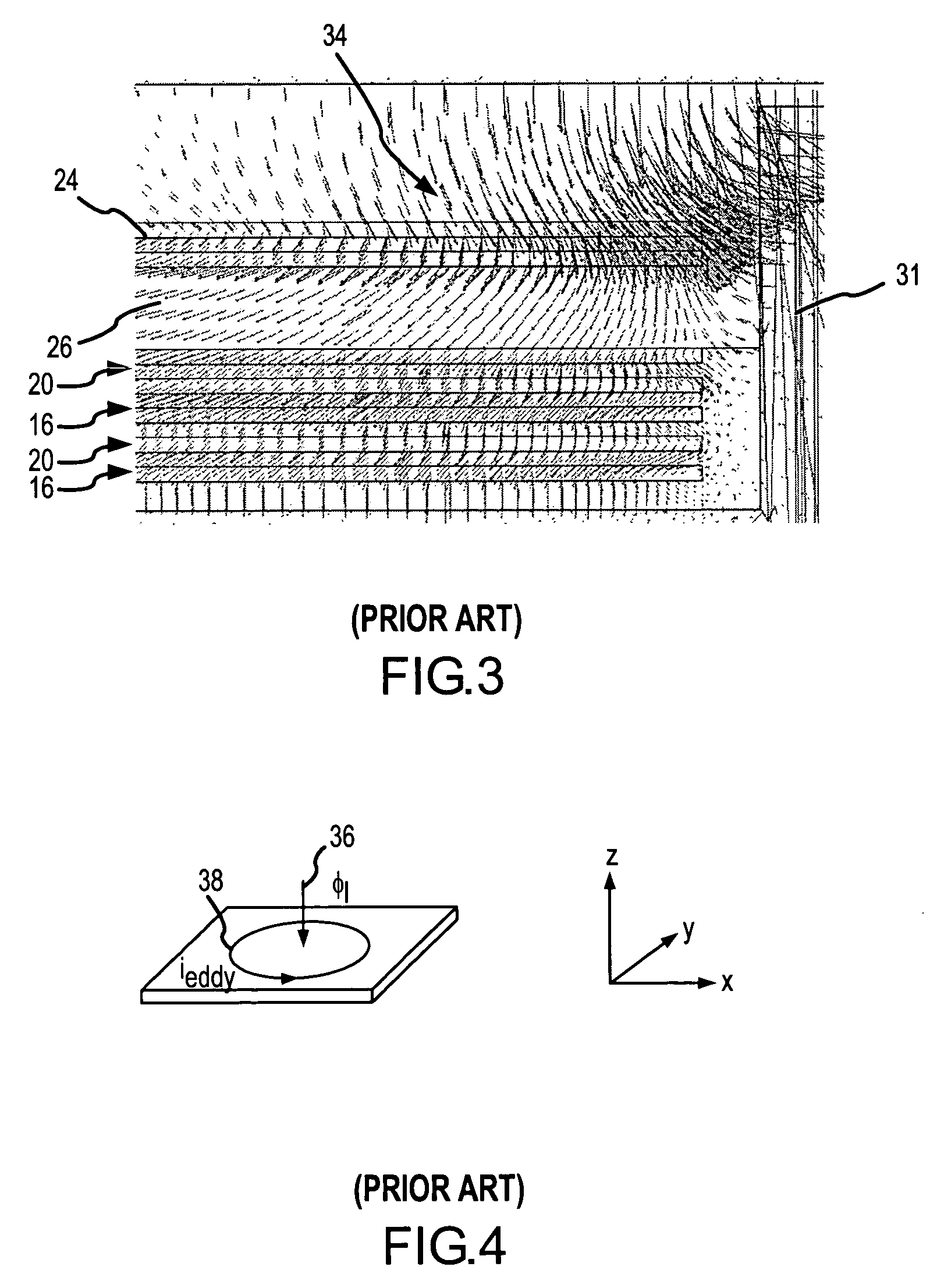

Vertical winding structures for planar magnetic switched-mode power converters

ActiveUS20060038650A1Total current dropLower DC winding resistanceTransformers/inductances casingsApparatus with intermediate ac conversionCapacitive couplingCapacitance

A vertical winding structure for planar integrated magnetics used in switched-mode power converters maintains close coupling between the different windings but reduces the eddy current losses, lowers the DC winding resistance and reduces the number of layers of the PCB. Vertical and horizontal windings can be used together without sacrificing these performance advantages and further minimizing the capacitive coupling between the outer-leg windings and the center-leg winding. This winding structure can be used in a wide range of magnetic structures including isolated and non-isolated CDRs, interleaved CDRs, and buck and boost converters.

Owner:MYPAQ HLDG LTD

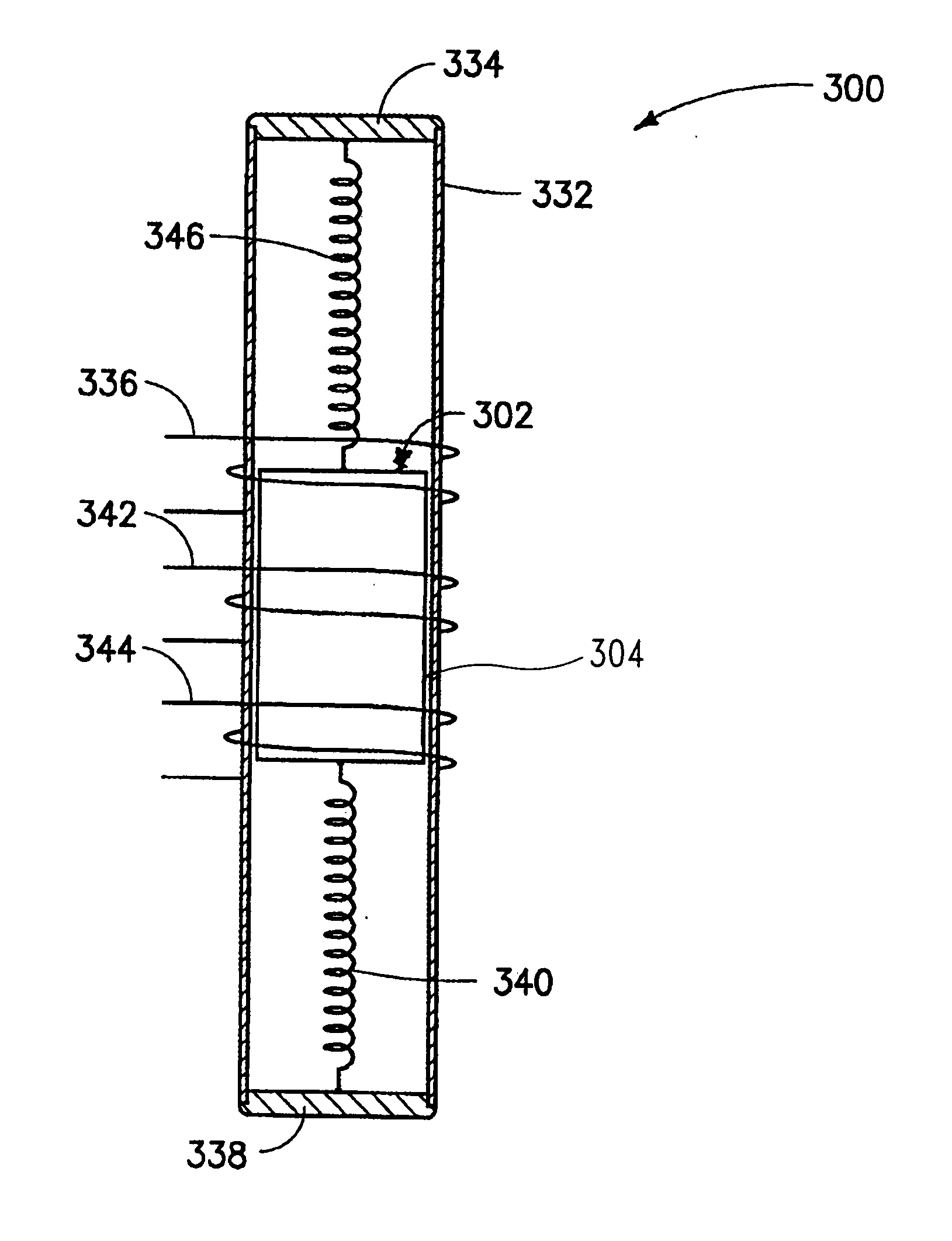

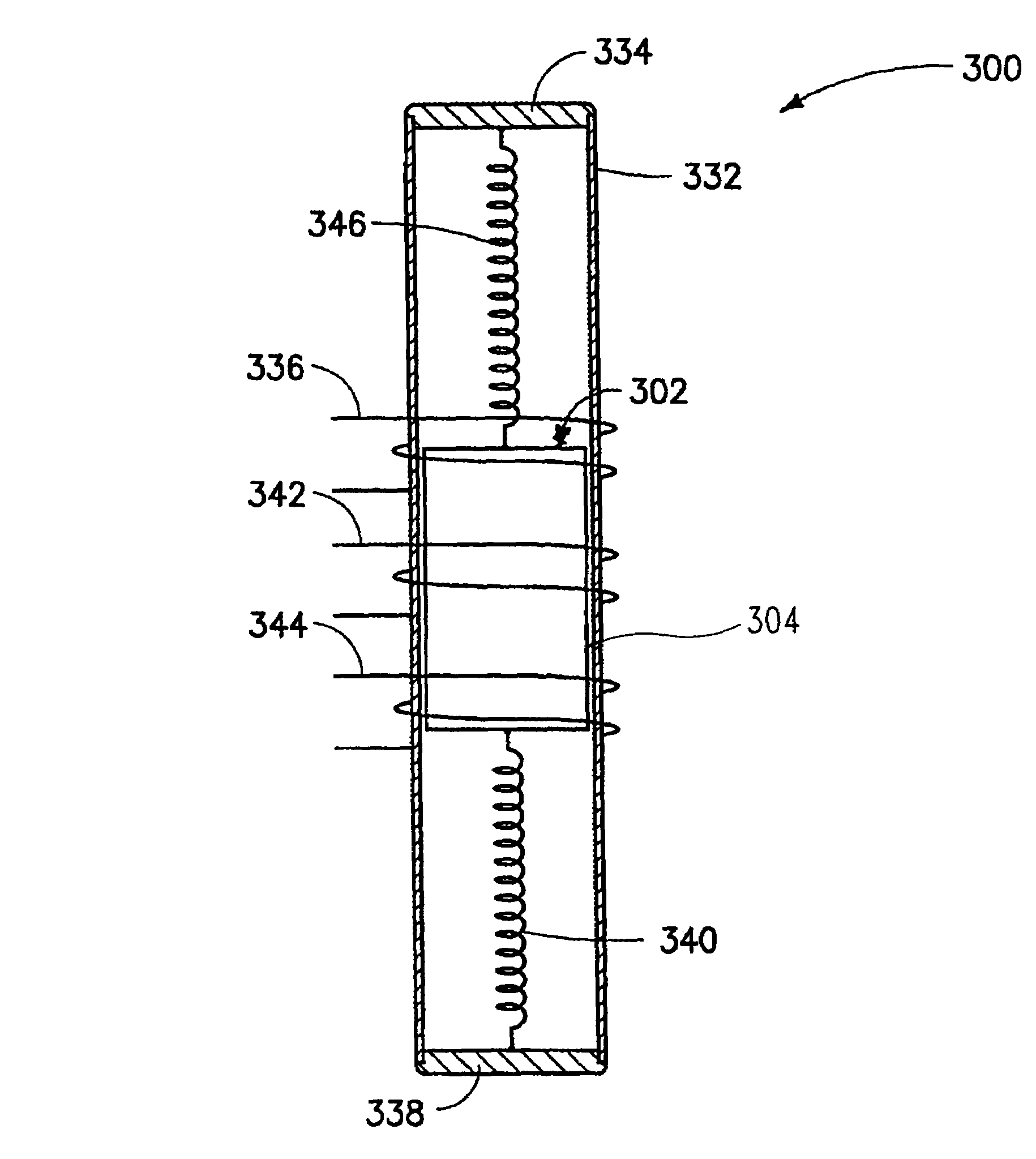

System and method for storing energy

InactiveUS20080074083A1Promote sportsCombination recordingPrimary cell to battery groupingEngineeringEnergy storage

A self-recharging battery comprising a generator and an energy storage device contained within the battery case. The generator comprises a magnetic structure configured to generate a compressed magnetic field and a coil configured to focus the compressed magnetic field in electrical conductive elements of the coil.

Owner:BATTELLE ENERGY ALLIANCE LLC

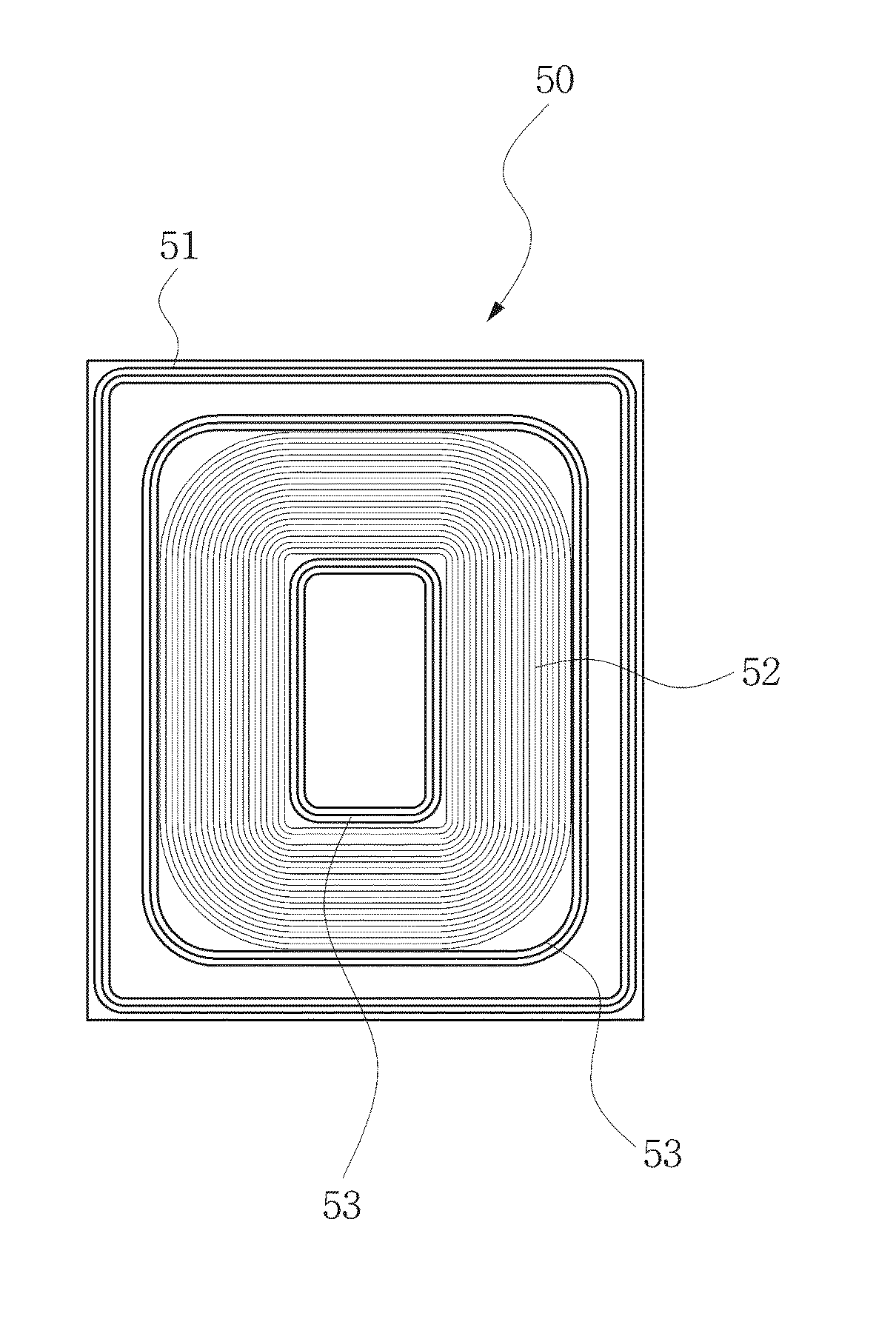

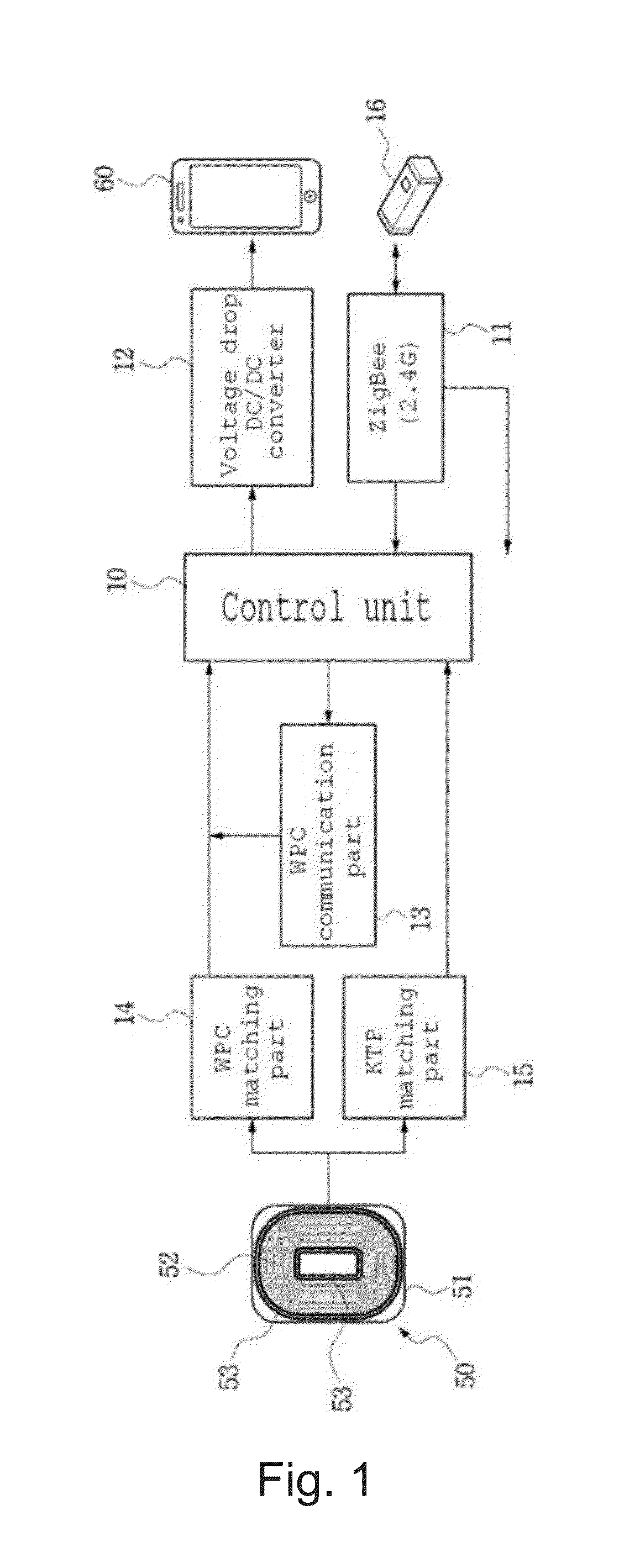

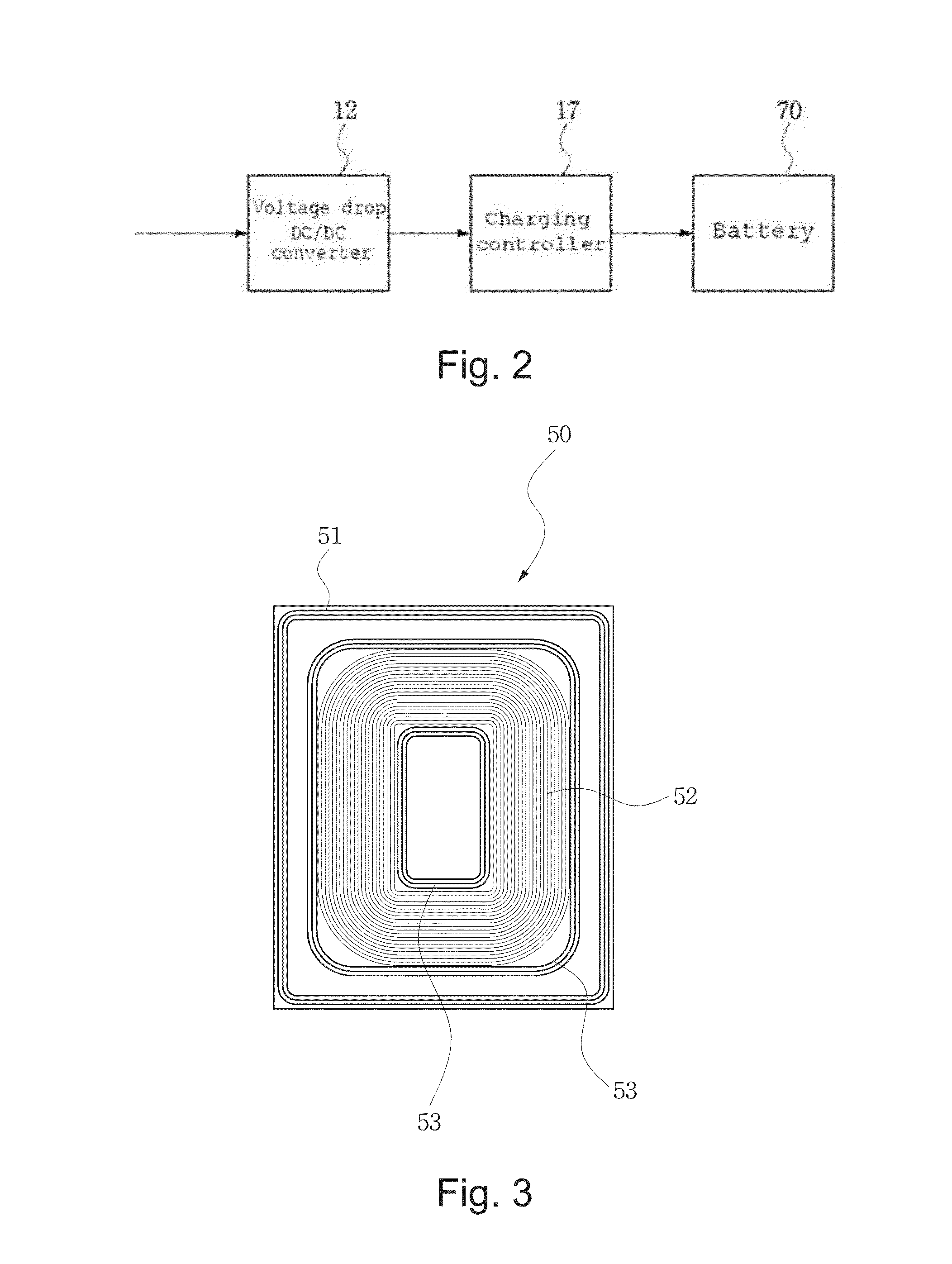

Receiver for wireless charging system

ActiveUS20150054455A1Improve magnetic field efficiencyImprove receiving efficiencyLoop antennas with ferromagnetic coreNear-field transmissionEngineeringInductive charging

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film structures with negative inductance and methods for fabricating inductors comprising the same

ActiveUS20090261936A1Transformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

An inductor structure comprising a substrate and a planar conductor structure on a surface of the substrate, and methods for fabricating an inductor structure. The planar conductor structure may comprise a vertical stack of three or more multilayer films. Each multilayer film may comprise a first layer of a first metal, defining a first vertical thickness, and a second layer of a second metal, defining a second vertical thickness. The metals and thicknesses are chosen such that the inductor exhibits a negative electrical self-inductance when an electrical signal is transmitted from a first contact point to a second contact point.

Owner:UNIV OF DAYTON

System and method for storing energy

InactiveUS7688036B2Promote sportsPrimary cell to battery groupingCombination recordingElectrical batteryEngineering

A self-recharging battery comprising a generator and an energy storage device contained within the battery case. The generator comprises a magnetic structure configured to generate a compressed magnetic field and a coil configured to focus the compressed magnetic field in electrical conductive elements of the coil.

Owner:BATTELLE ENERGY ALLIANCE LLC

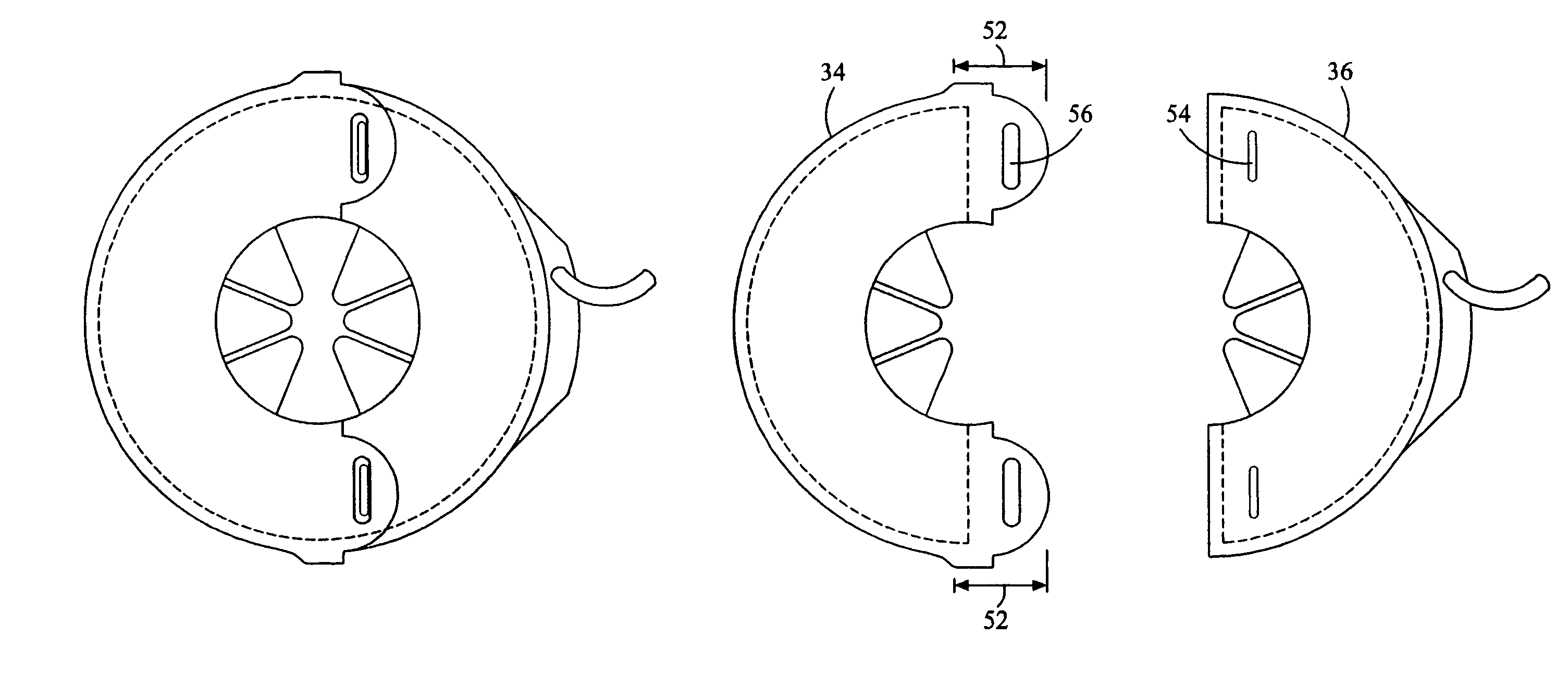

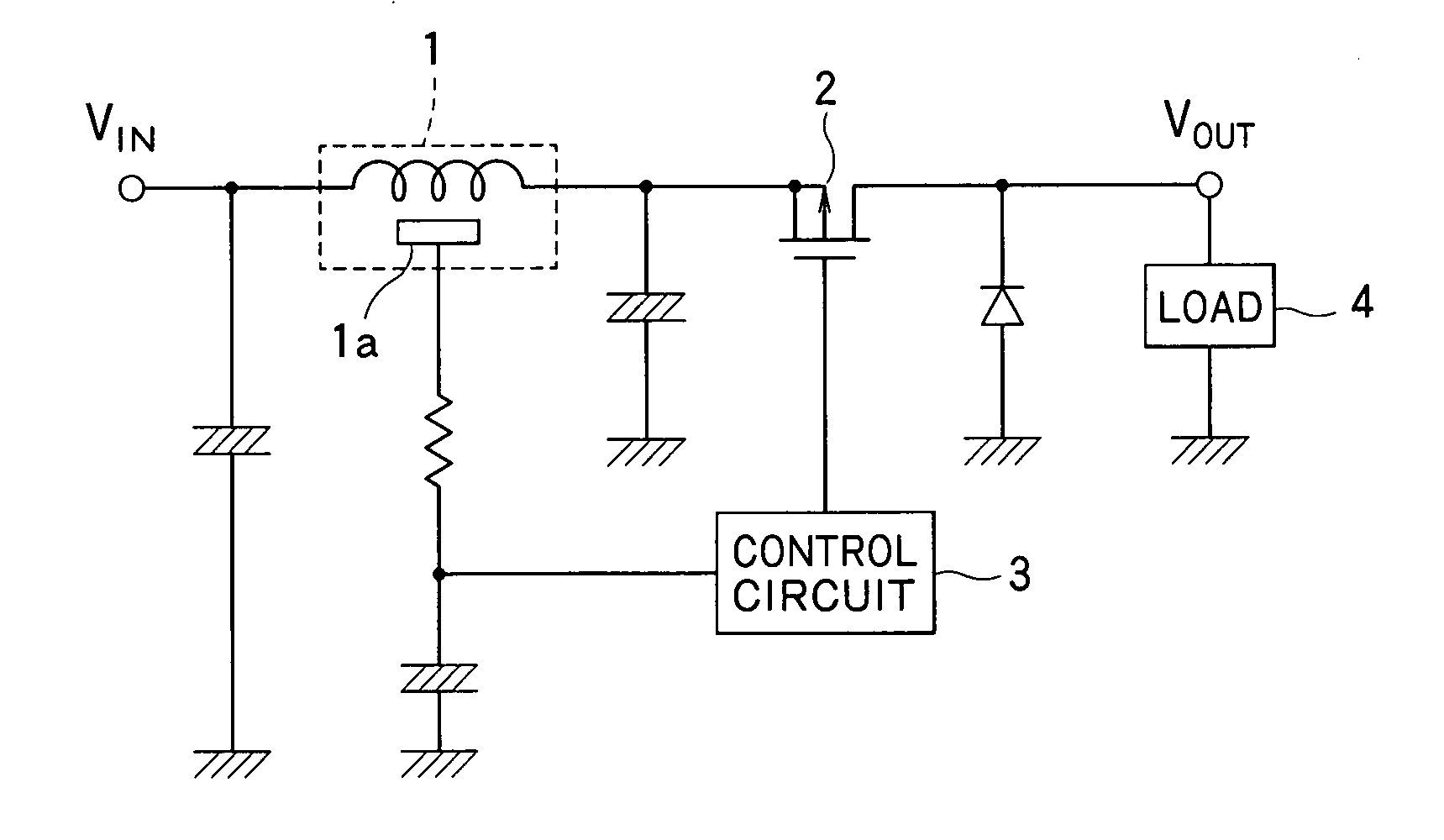

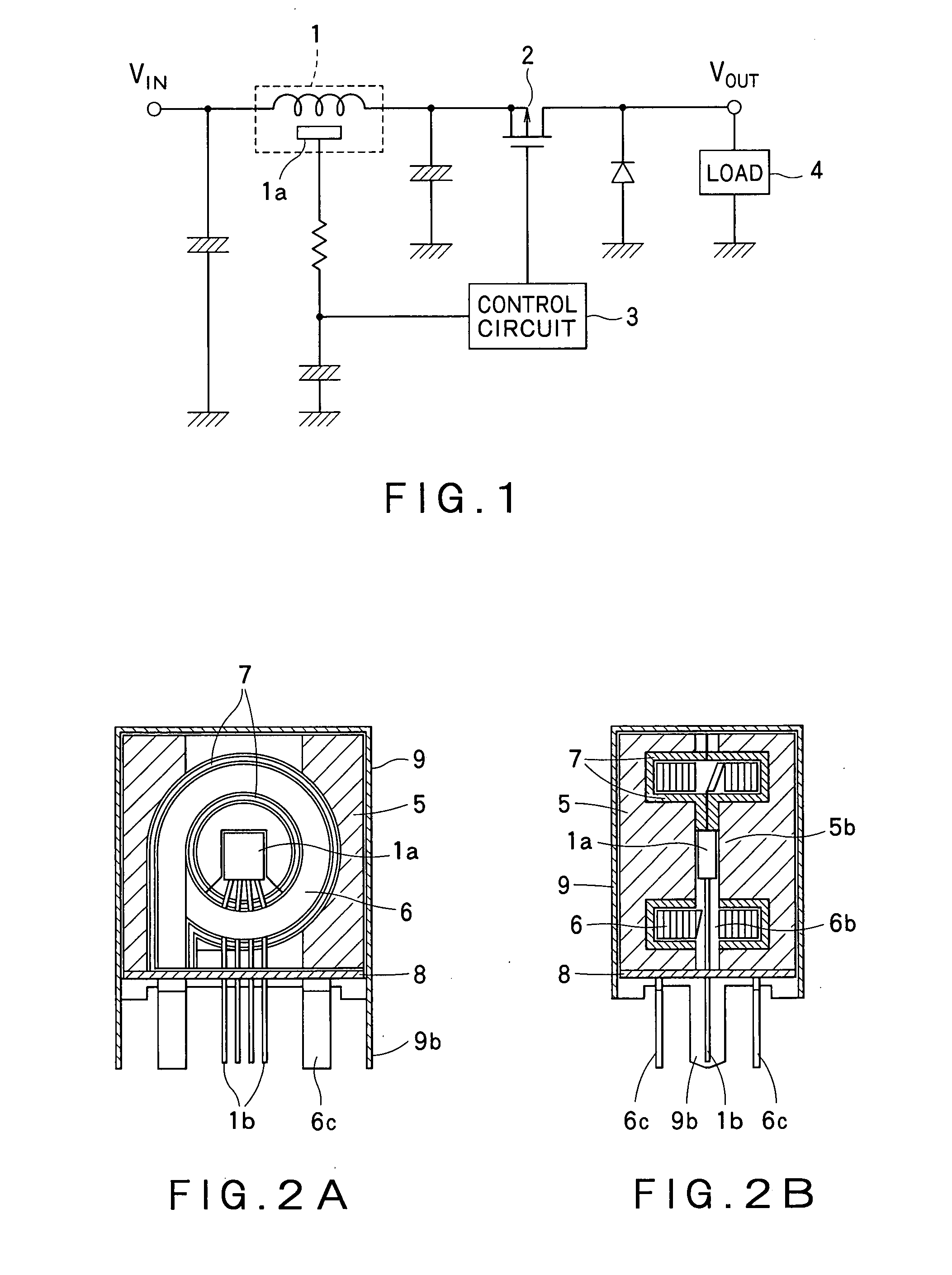

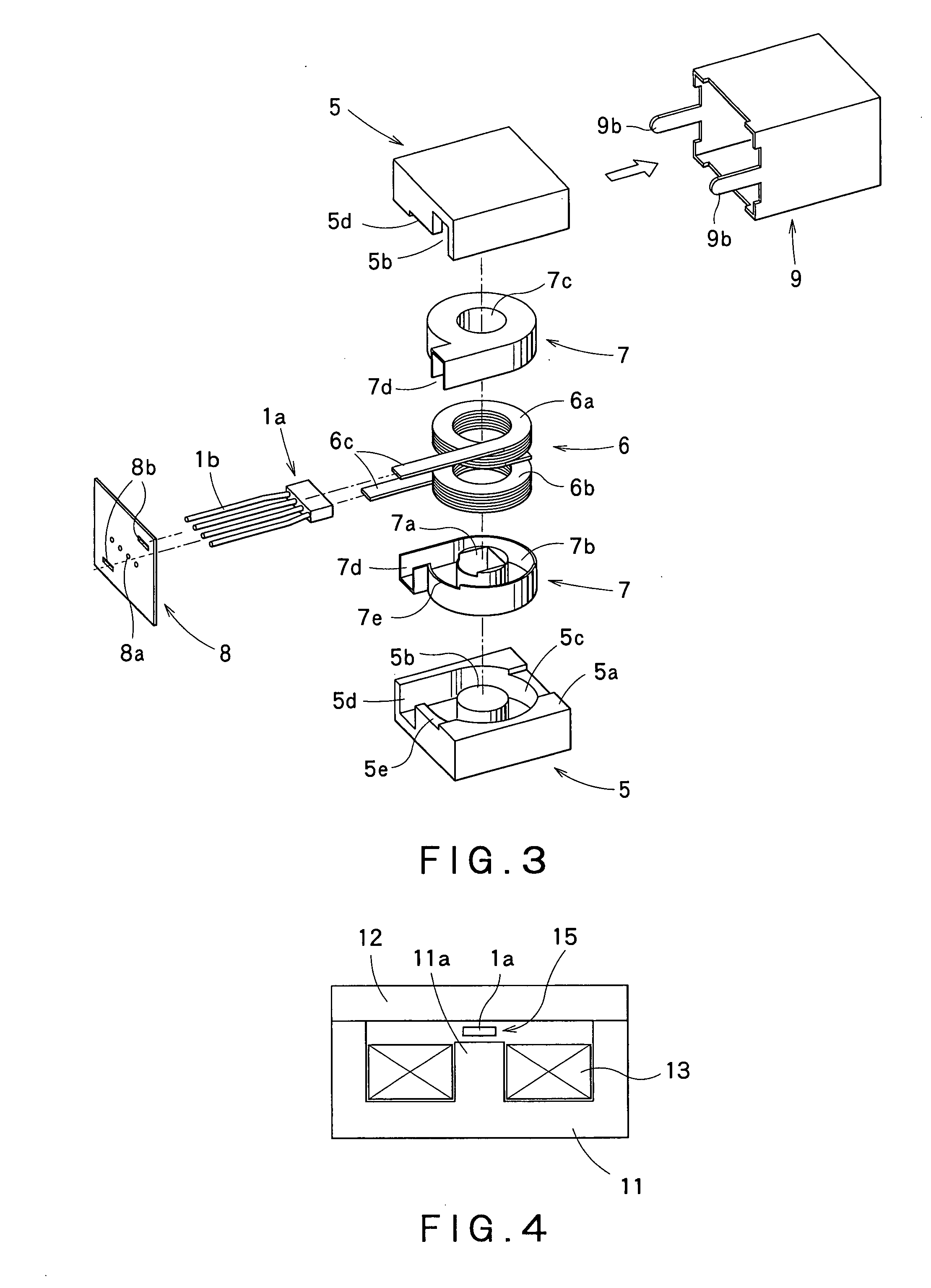

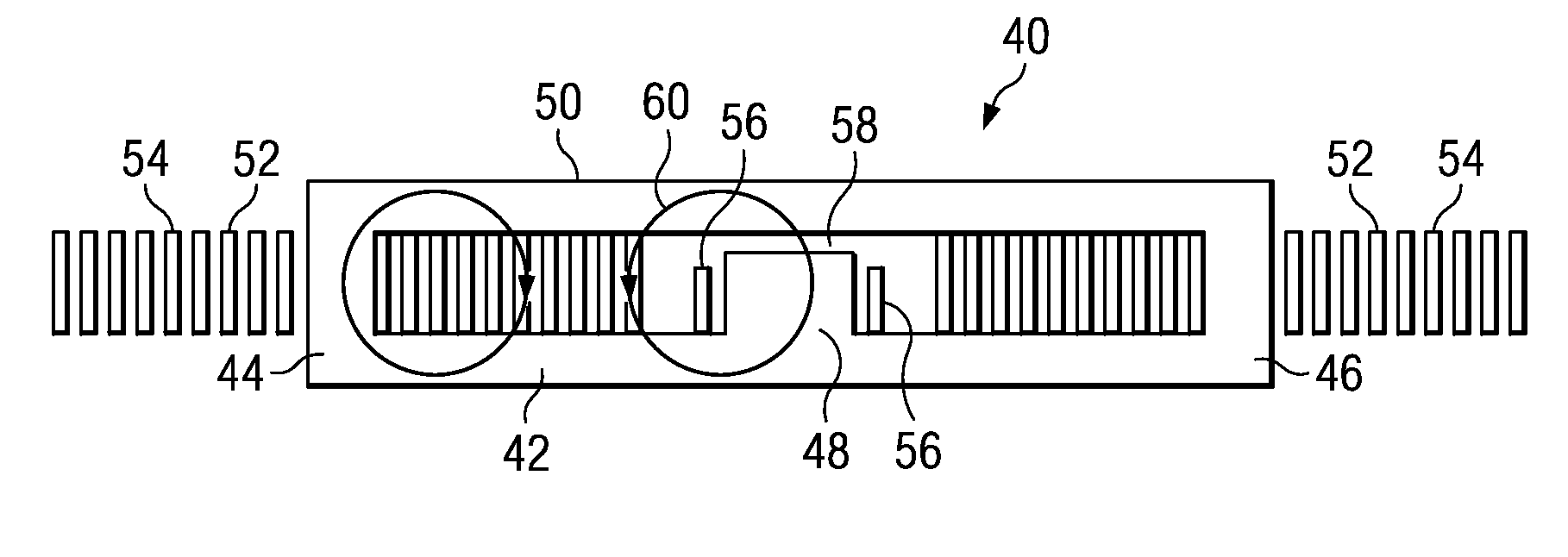

Current detection device

ActiveUS20070247135A1Easy to installLow costDc network circuit arrangementsTransformers/inductances casingsEngineeringAir core

The present invention provides a low-cost current detection device having a magnetic sensor easily placed on a choke coil, wherein assembly and manufacturing costs are reduced and a product is miniaturized. A current detection device including a choke coil for smoothing an input current or an output current and a magnetic sensor 1a built into the choke coil to detect the input current or output current, wherein the choke coil is composed of: a pair of cores 5 provided with an outer magnetic leg 5a constituting a closed magnetic circuit and a center magnetic leg 5b for providing a gap; and an air core coil 6 mounted on the center magnetic leg 5b, and space 6b is provided to a part of winding of the air core coil 6 with the magnetic sensor 1a placed in the gap between the space 6b and the center magnetic leg 5b.

Owner:VICTOR CO OF JAPAN LTD +1

Vertical winding structures for planar magnetic switched-mode power converters

ActiveUS7321283B2Total current dropMinimizes capacitive couplingTransformers/inductances casingsApparatus with intermediate ac conversionClose couplingCapacitance

A vertical winding structure for planar integrated magnetics used in switched-mode power converters maintains close coupling between the different windings but reduces the eddy current losses, lowers the DC winding resistance and reduces the number of layers of the PCB. Vertical and horizontal windings can be used together without sacrificing these performance advantages and further minimizing the capacitive coupling between the outer-leg windings and the center-leg winding. This winding structure can be used in a wide range of magnetic structures including isolated and non-isolated CDRs, interleaved CDRs, and buck and boost converters.

Owner:MYPAQ HLDG LTD

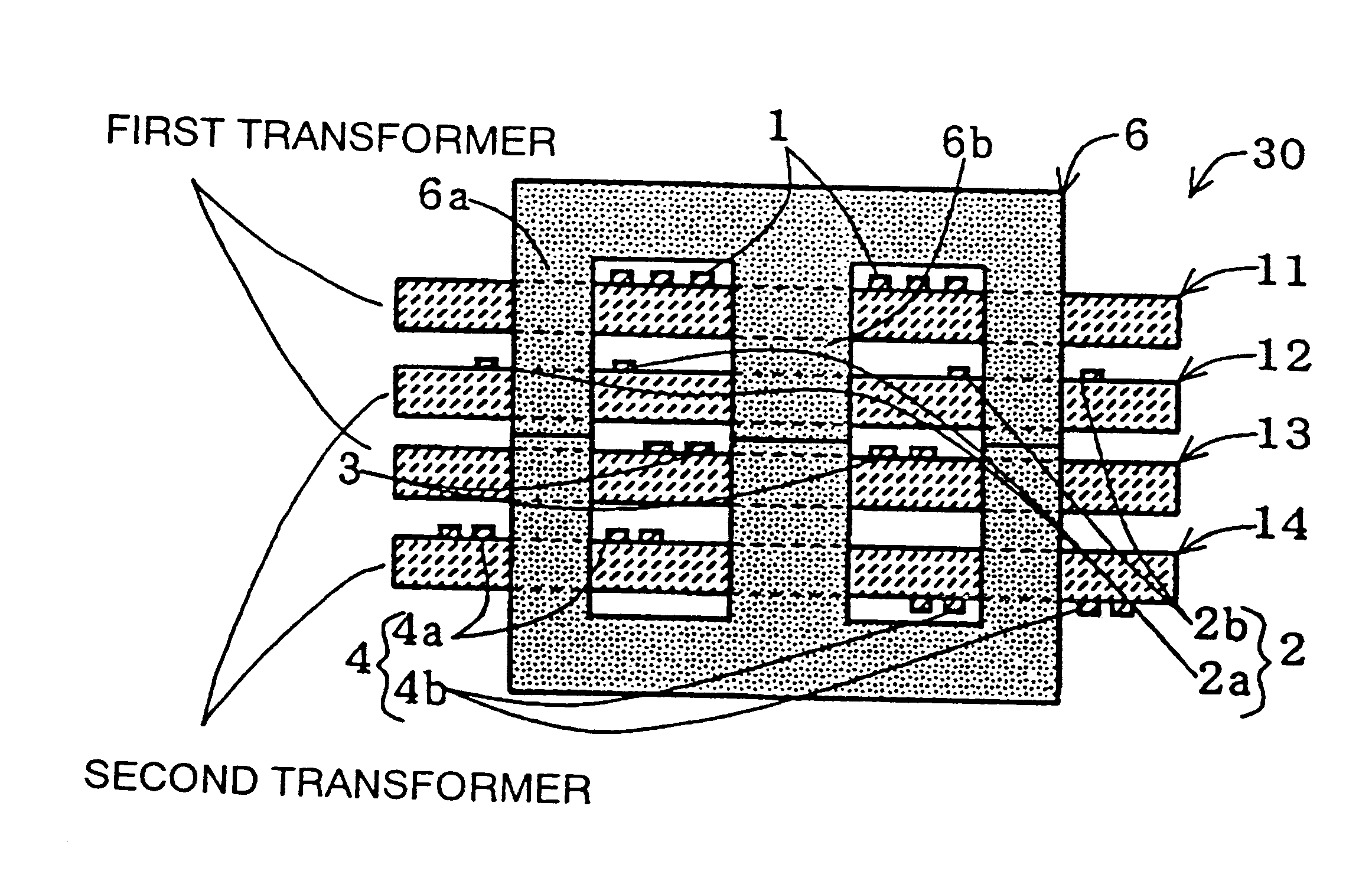

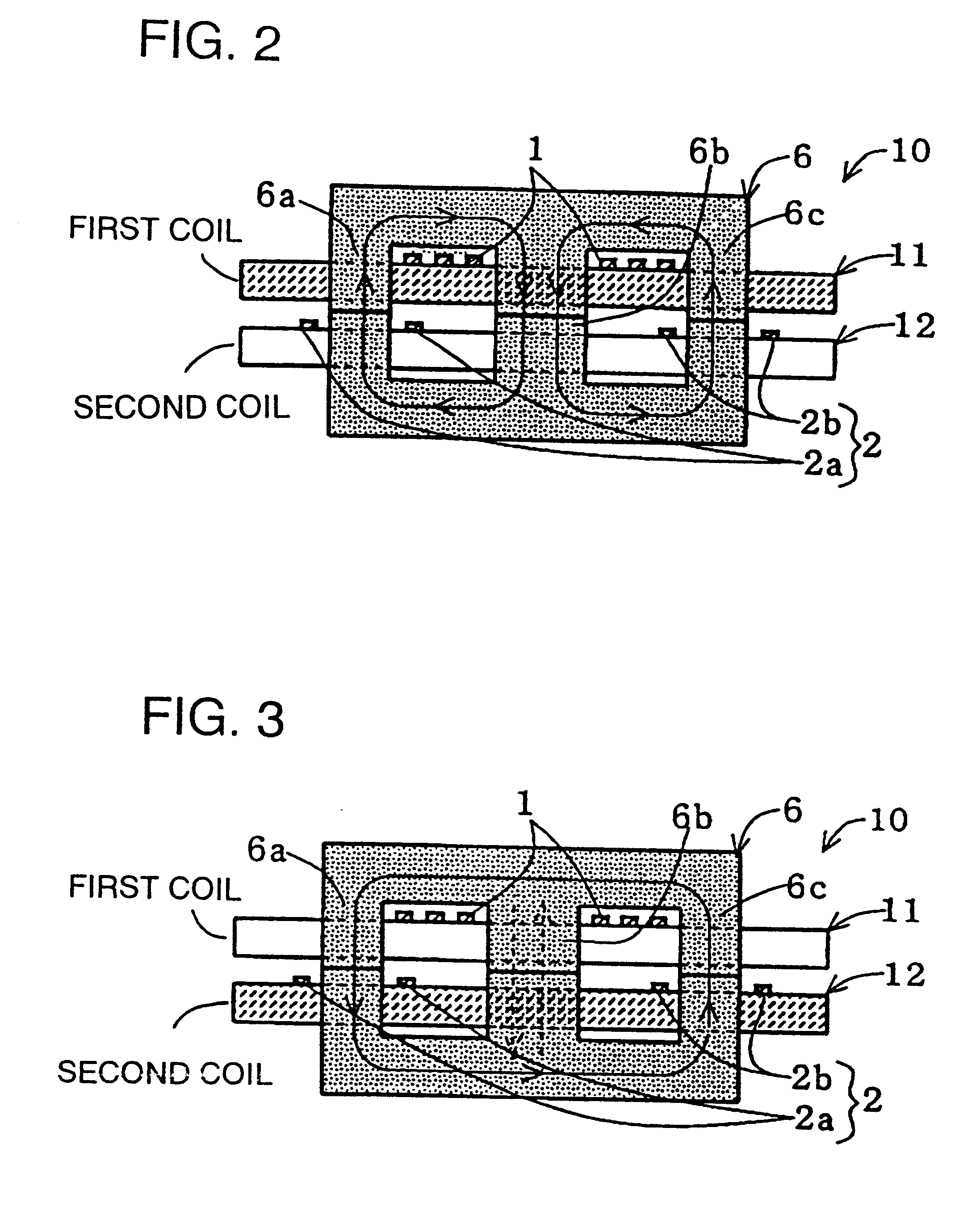

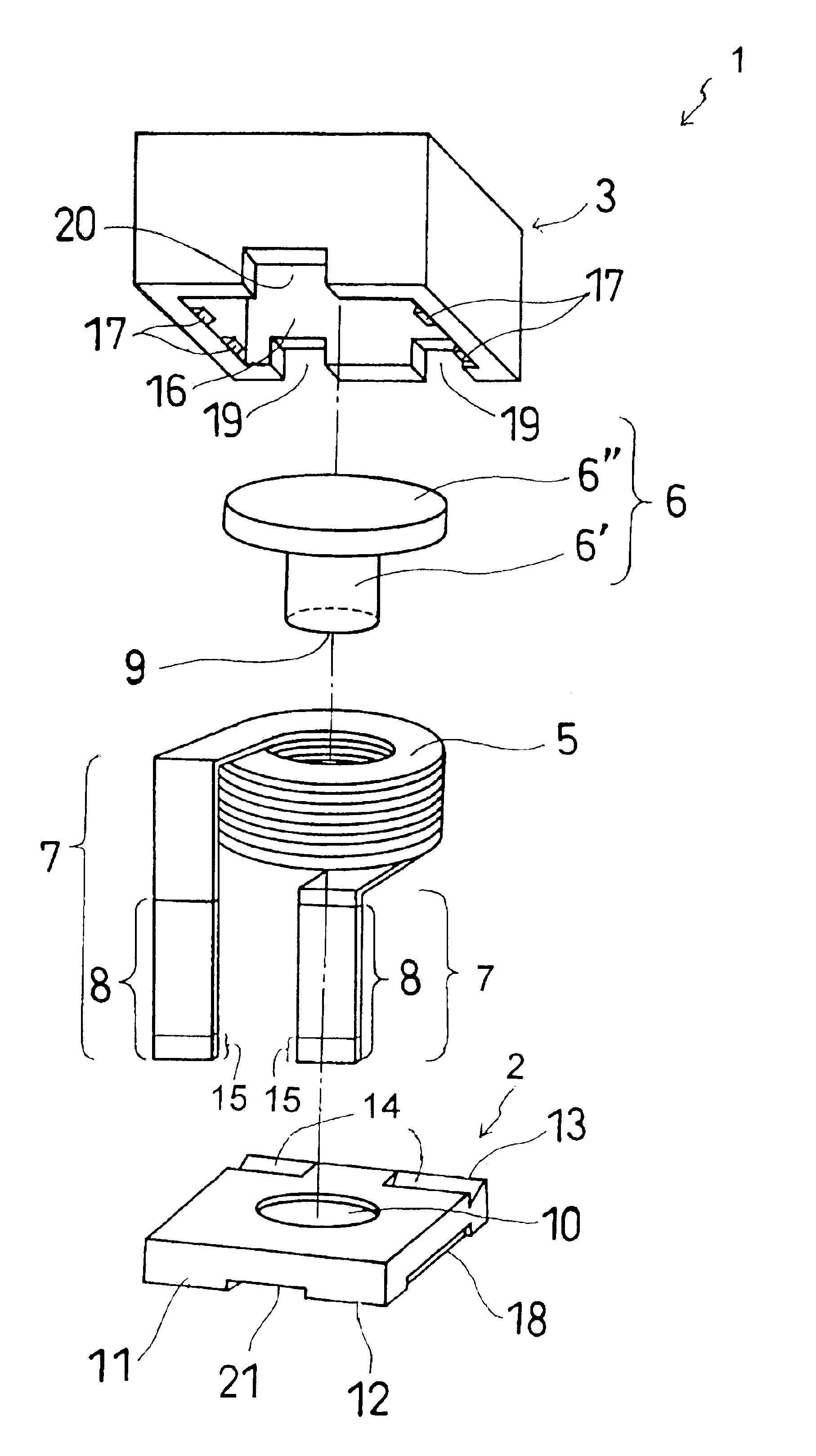

Coil device and switching power supply apparatus using the same

InactiveUS6380836B2Efficient power electronics conversionTransformers/inductances casingsElectric power transmissionTransformer

A switching power supply has a transformer for power transmission. A core is provided having an intermediate leg and at least a pair of external legs arranged at equal intervals from the intermediate leg; a first printed coil is provided on a first substrate which has an intermediate hole and a pair of external holes respectively inserted in the intermediate leg and the pair of external legs of the core, the first printed coil being wound around the intermediate hole; a second printed coil is provided on a second substrate which has an intermediate hole and a pair of external holes respectively inserted in the intermediate leg and the pair of external legs of the core, the second printed coil including a pair of external printed coils which are connected in series and are respectively wound around the pair of the external holes and each having the same number of turns but wound in opposite directions. The pair of external printed coils of the second printed coil generate magnetic fields in opposite directions to each other in the intermediate leg such that the magnetic fields in the intermediate leg cancel each other and induce no induction voltage in the first printed coil, and induction voltages induced in the external printed coils of the second printed coil by magnetic flux generated by the first printed coil are substantially canceled, whereby the first printed coil and the second printed coil form separate inductors which are not magnetically coupled. A third printed coil is provided on a third substrate which has an intermediate hole and a pair of external holes respectively inserted in the intermediate leg and the pair of external legs of the core, the third printed coil being wound around the intermediate hole, whereby the first printed coil is magnetically coupled with the third printed coil to form a first transformer; and further wherein the tranformer for power transmission comprises the first transformer.

Owner:MURATA MFG CO LTD

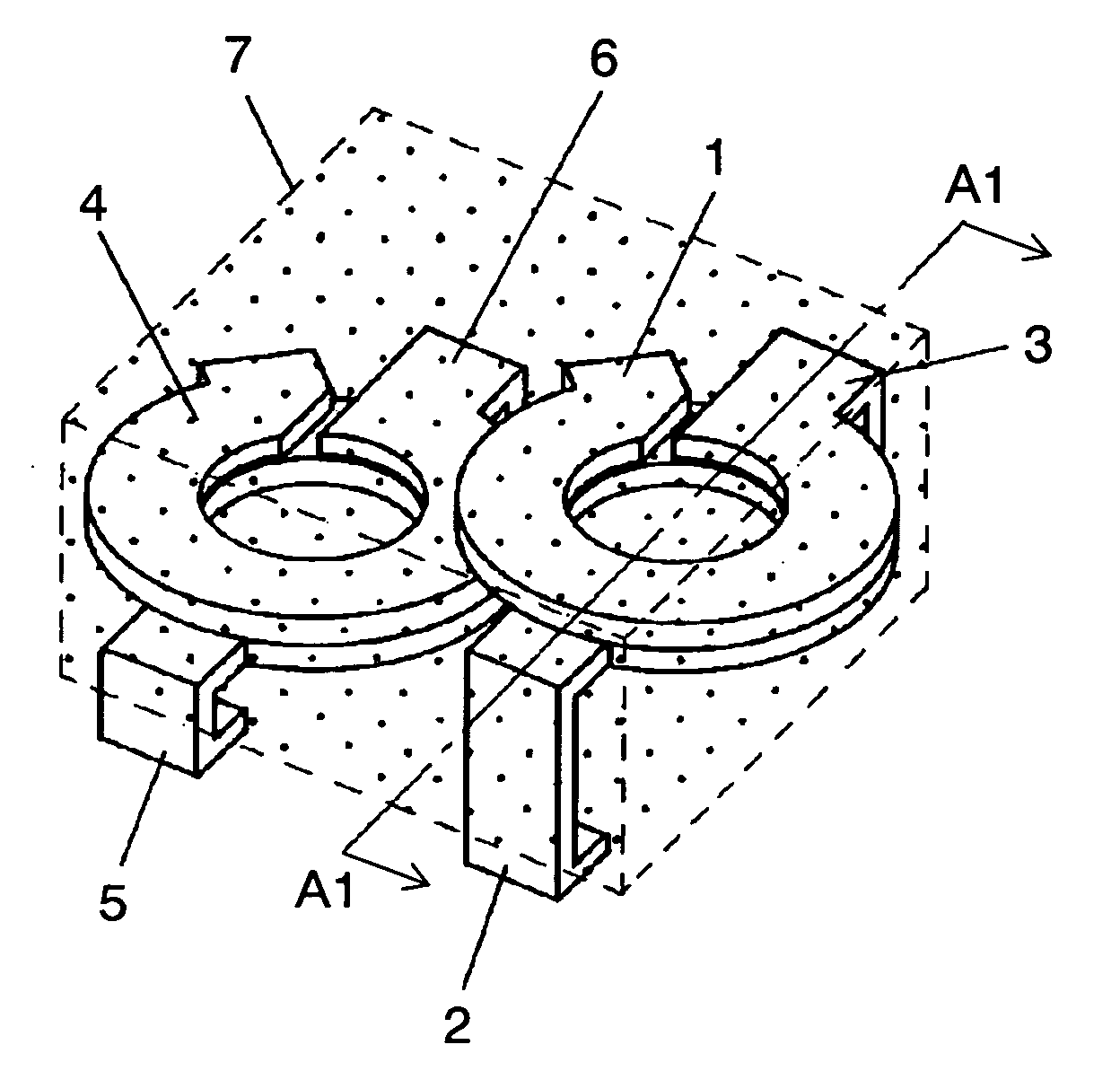

Planar inductive element

InactiveUS6967553B2Reduce the impactReduce impactTransformers/inductances casingsTransformers/inductances magnetic coresEddy currentPlanar inductor

A storage magnetic element, which minimizes the power loss in the planar winding due to the fringe magnetic field associated with a discrete air gap, is presented. The invention describes a construction technique wherein the magnetic core is formed by an E section made of high permeability magnetic material and an I section made by a material capable to store energy due to its distributed gap structure. The I section of the magnetic core in one of the embodiments is covered by an electrically conductive shied to force the magnetic flux into the I section and to minimize the component of the fringe magnetic field perpendicular on the planar winding. In another embodiment of this invention the electrically conductive shield is replaced by a high magnetic permeability material to accomplished the same goal of reducing the magnetic field component perpendicular on the planar winding. In a prefer embodiment of this invention the I section of the magnetic core has a cavity which will accommodate the middle leg of the E section. This construction will force the fringe magnetic field at the edge of the gap to be parallel with the planar winding of the storage magnetic element. In another embodiment of this invention a flat I section is used with the addition of another high permeability magnetic material placed on the I section on top of the winding. This construction will force the fringe magnetic field around the edge of the gap to be parallel with the planar winding. The embodiments of this invention are aimed at reducing the fringe magnetic field perpendicular on the planar winding, lowering the eddy current induced by this field.

Owner:DELTA ENERGY SYST SWITZERLAND

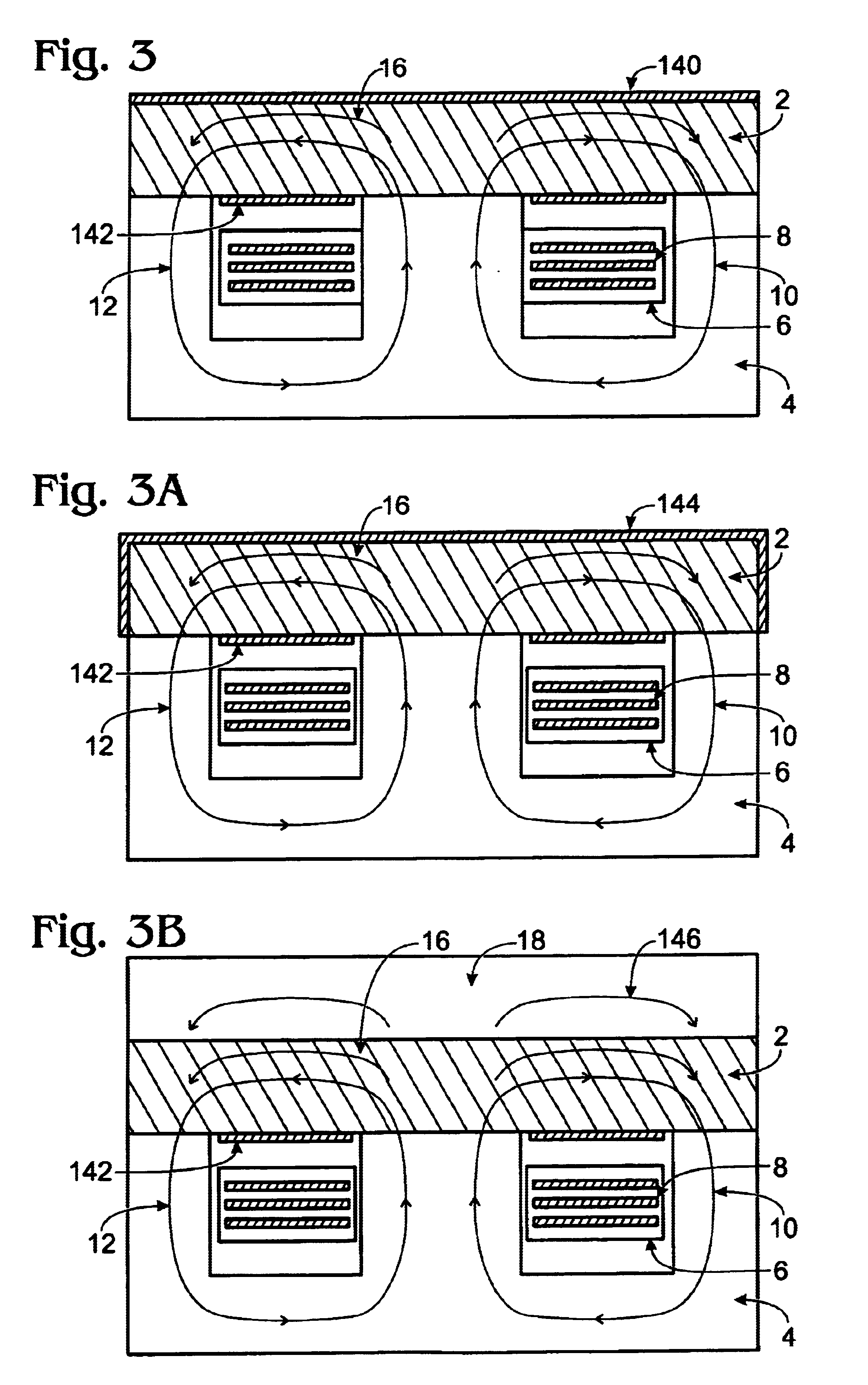

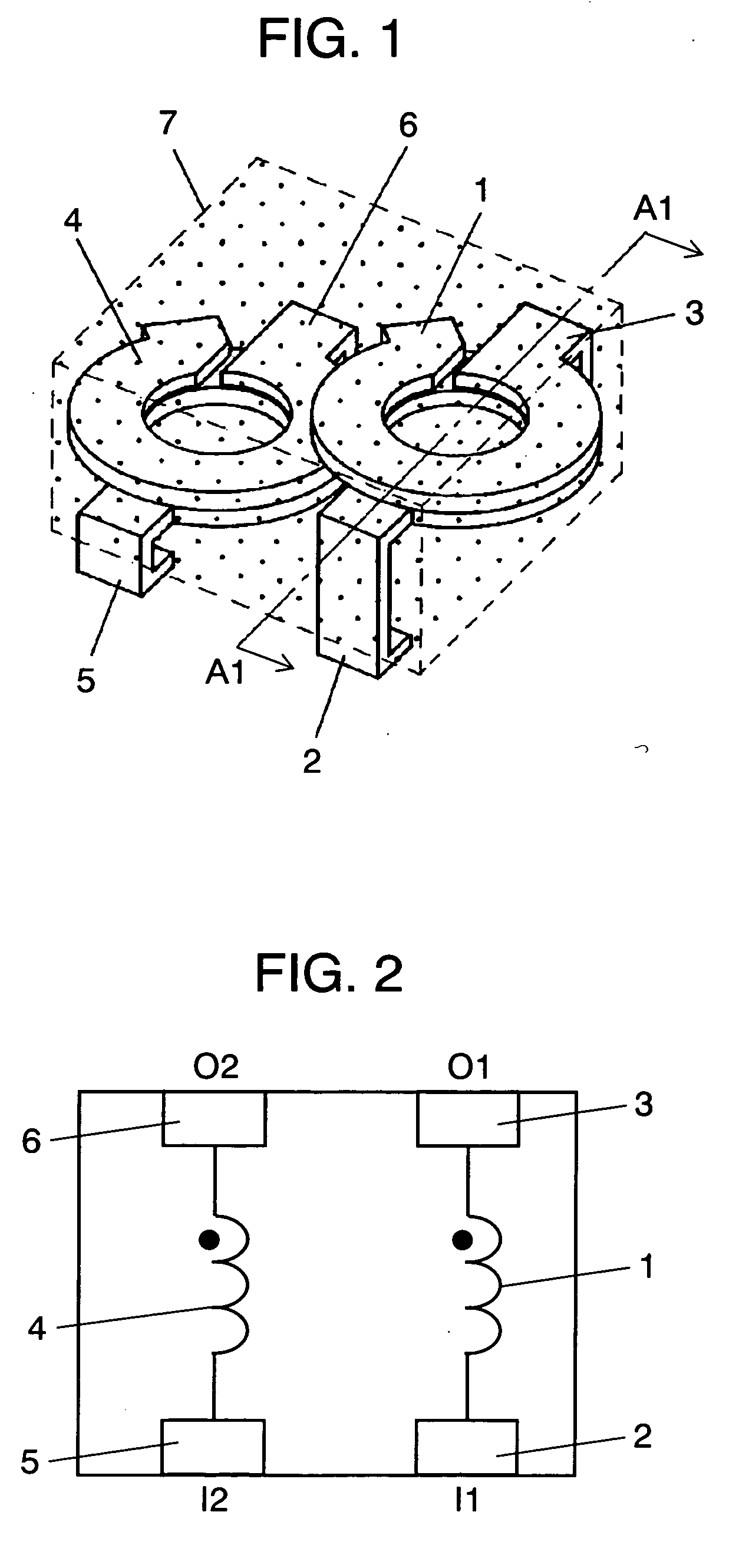

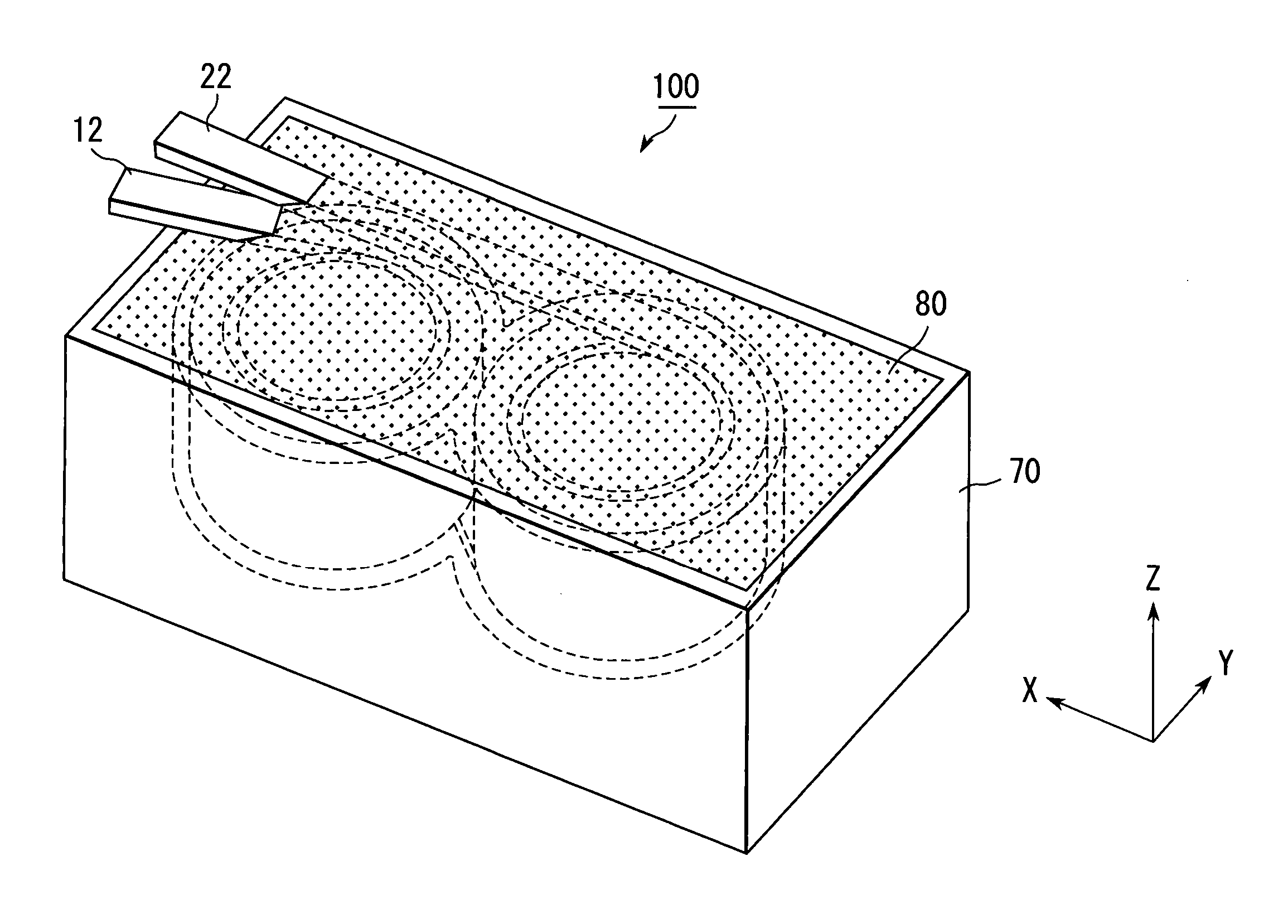

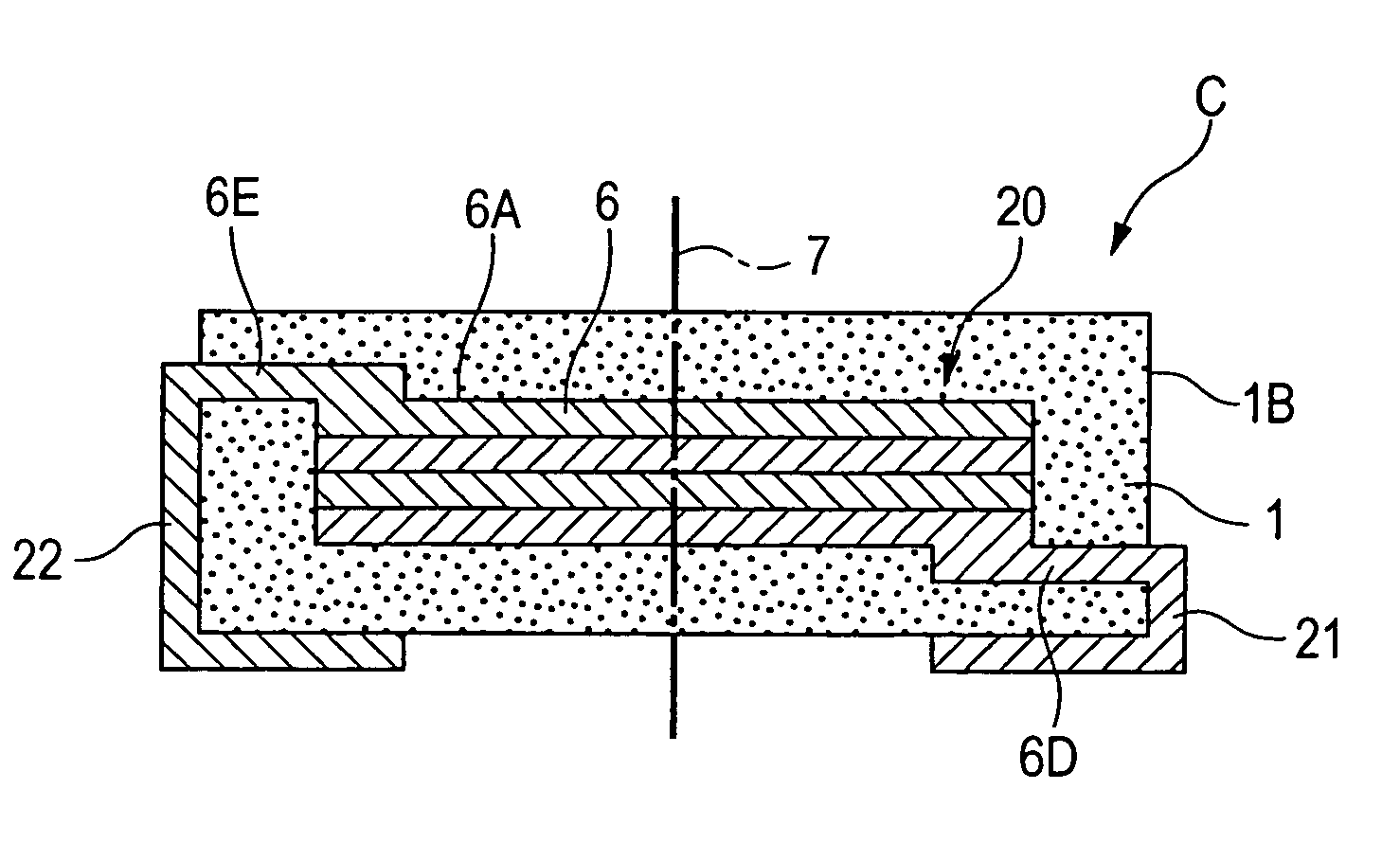

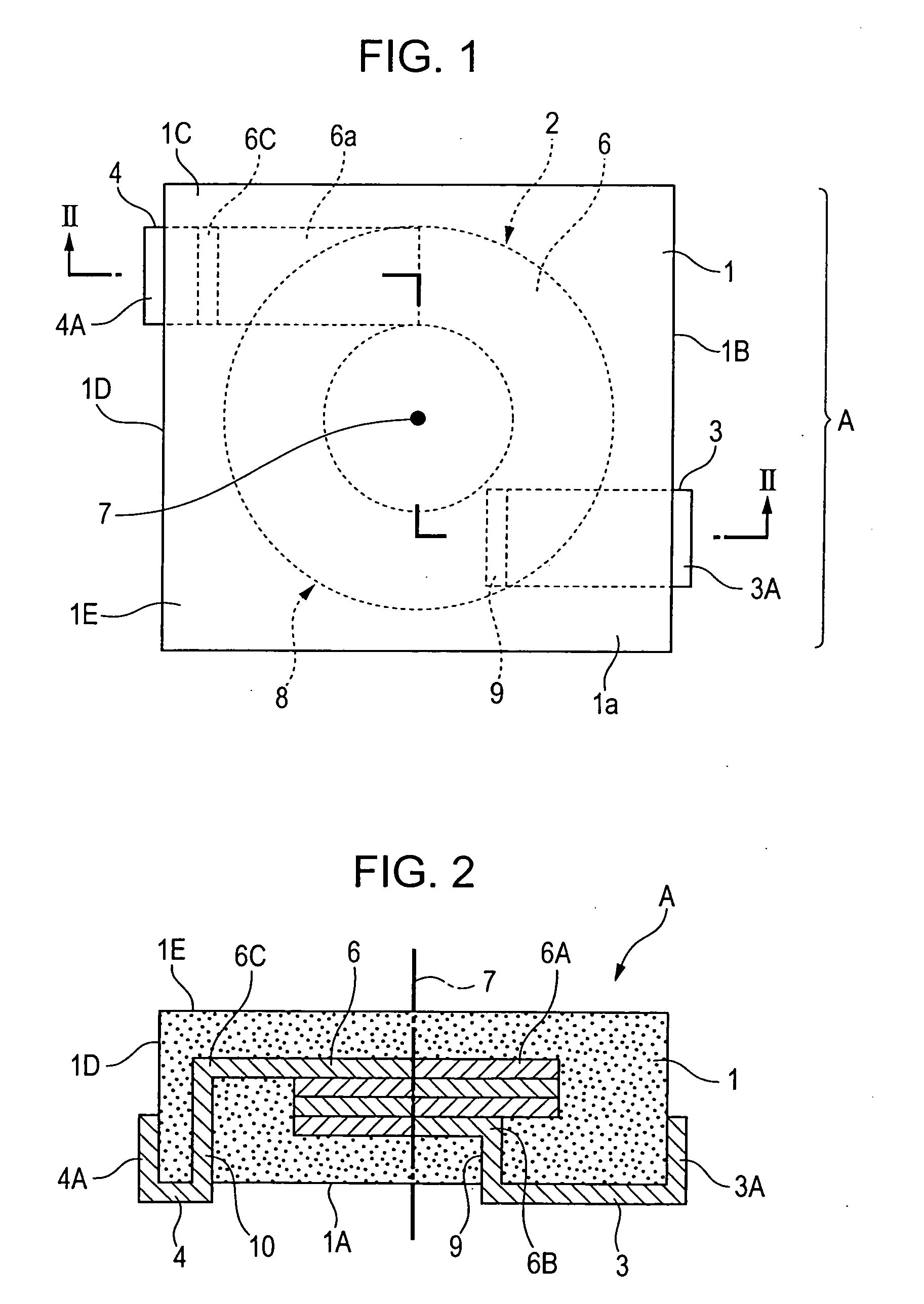

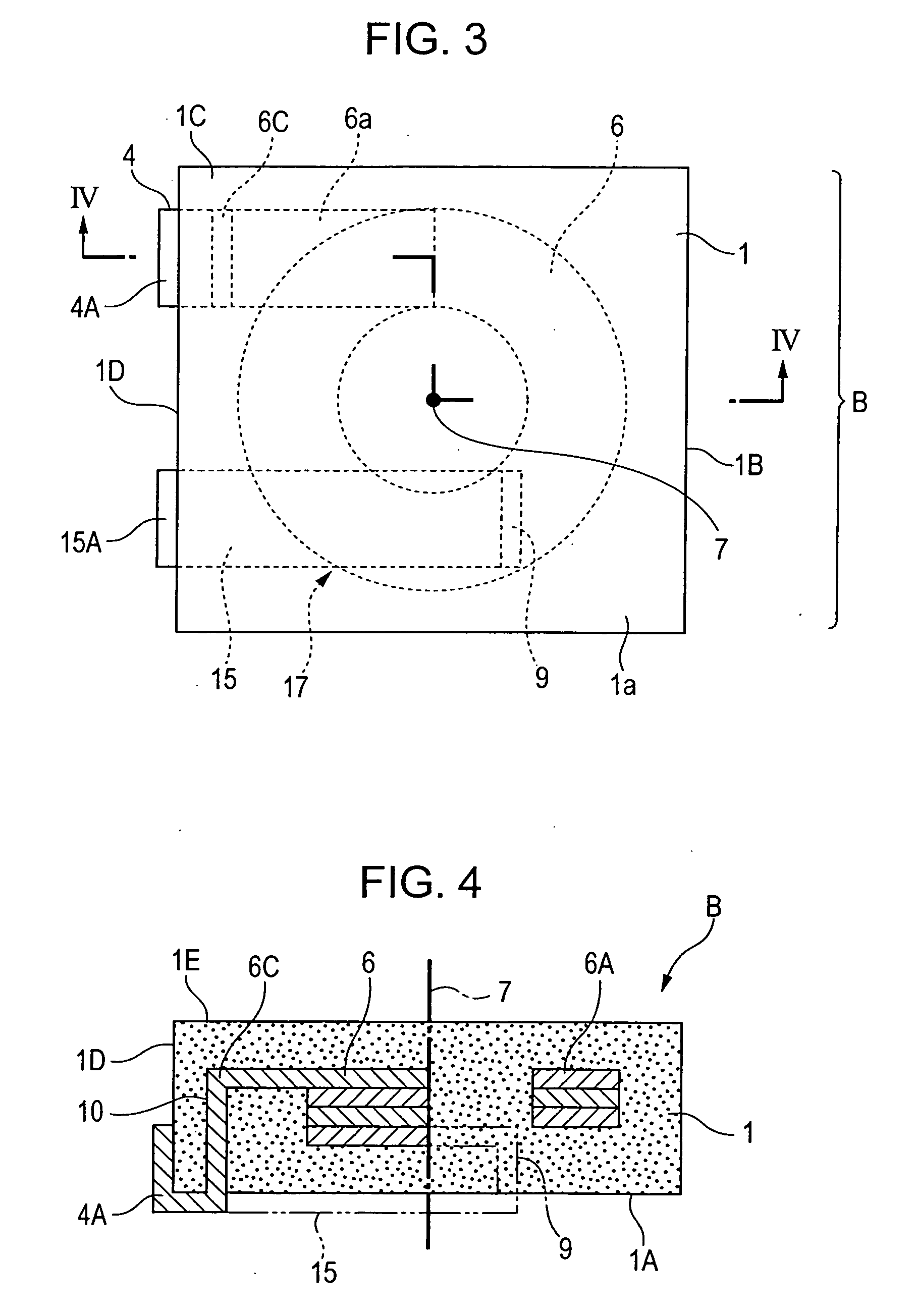

Multiple choke coil and electronic equipment using the same

InactiveUS20060145804A1Small sizeReduce thicknessTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringMetal sheet

The invention is comprised of a coil group arranging a plurality of terminal-integrated type coils (1), (4) formed by bending a metal sheet in a preset development form and having a predetermined positional relationship, and a magnetic material (7) burying therein the coil group. For example, axes of the plurality of coils (1), (4) constituting the coil group, are arranged in parallel wherein the center point of at least one coil selected from the plurality of coils (1), (4) and the center point of a coil other than the selected coil are in an staggered arrangement. Due to this, an array type choke coil can be realized which is thin overall and operable with a large current in a high frequency band.

Owner:PANASONIC CORP

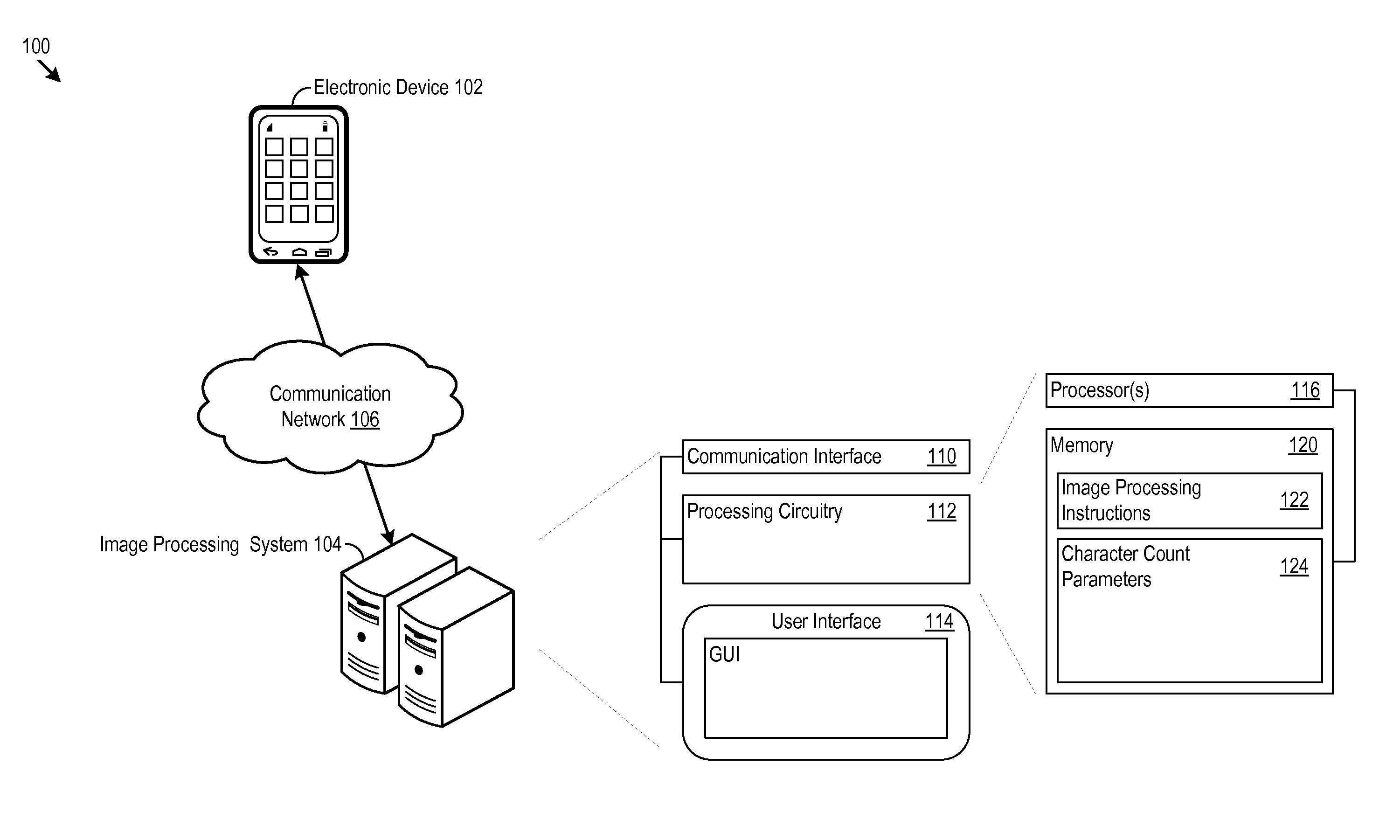

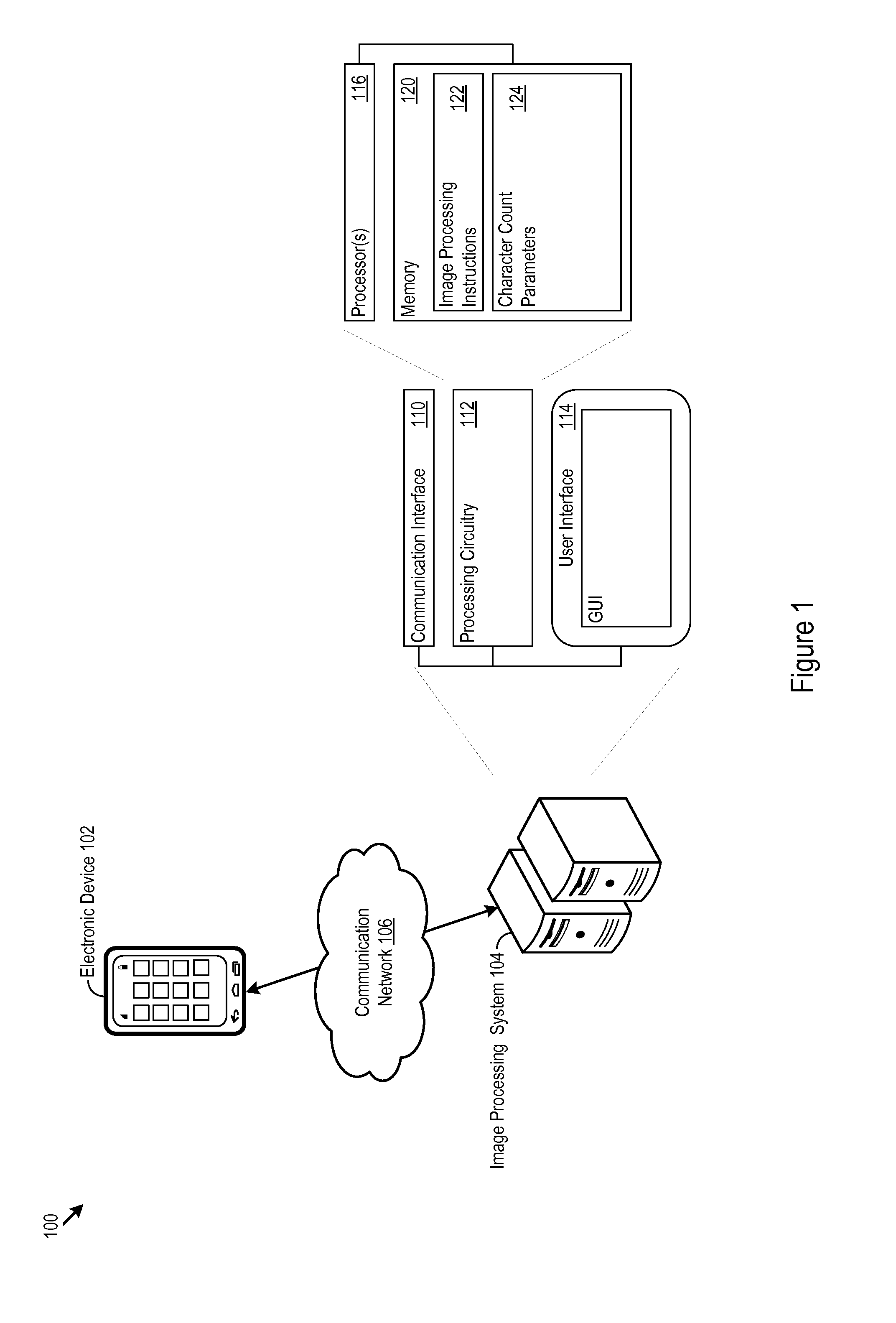

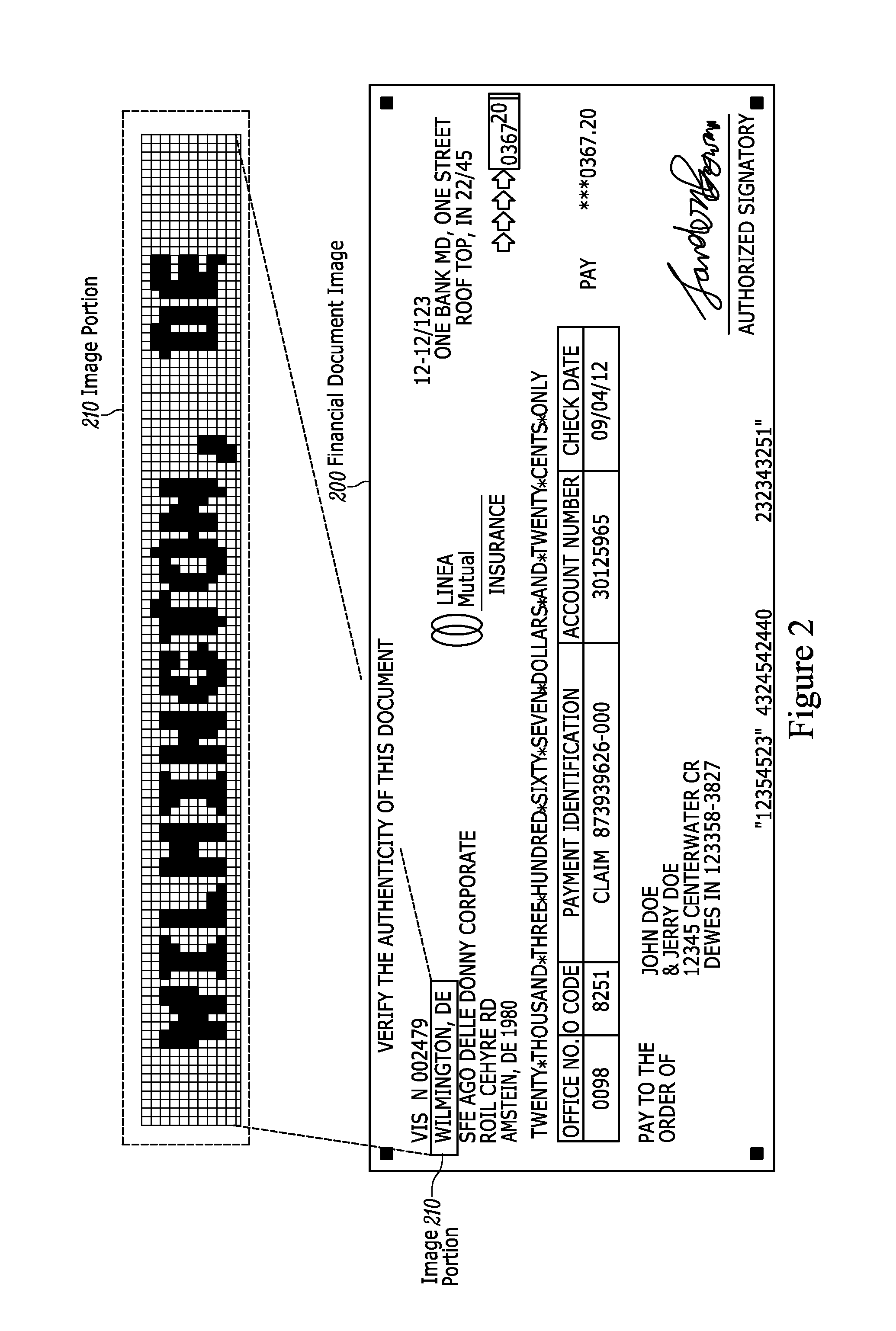

Character count determination for a digital image

ActiveUS9286514B1Transformers/inductances casingsCharacter and pattern recognitionPattern recognitionImaging processing

An image processing system or electronic device may implement processing circuitry. The processing circuitry may receive an image, such as financial document image. The processing circuitry may determine a character count for the financial document image or particular portions of the financial document image without recognizing any particular character in the financial document image. In that regard, the processing circuitry may determine a top left score for pixels in the financial document, the top left score indicating or representing a likelihood that a particular pixel corresponds to a top left corner of a text character. The processing circuitry may also determine top right score for image pixels. Then, the processing circuitry may identify one or more text chunks using the top left and top rights scores for pixels in the financial document image. The processing circuitry may determine a character count for the identified text chunks.

Owner:USAA

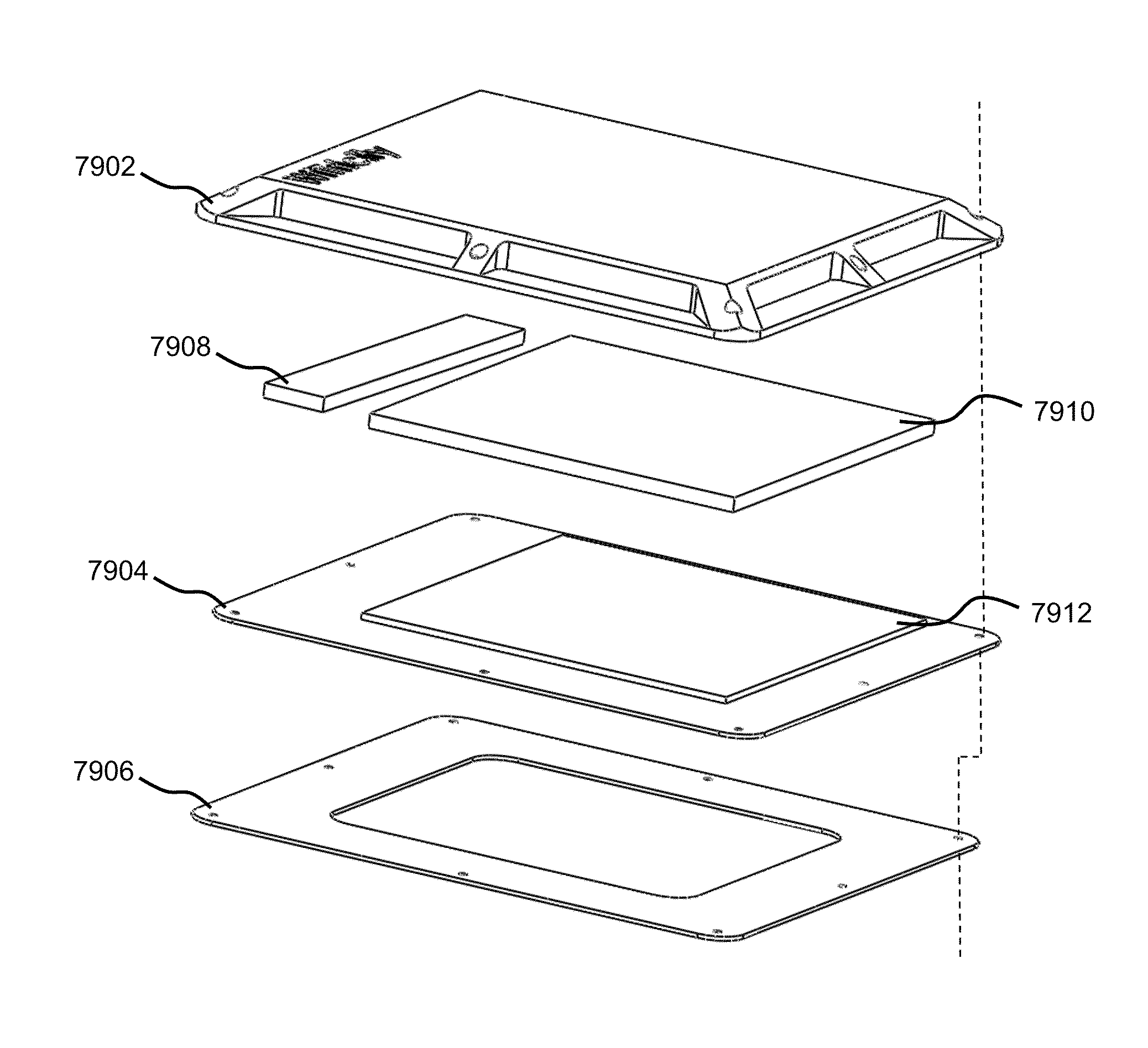

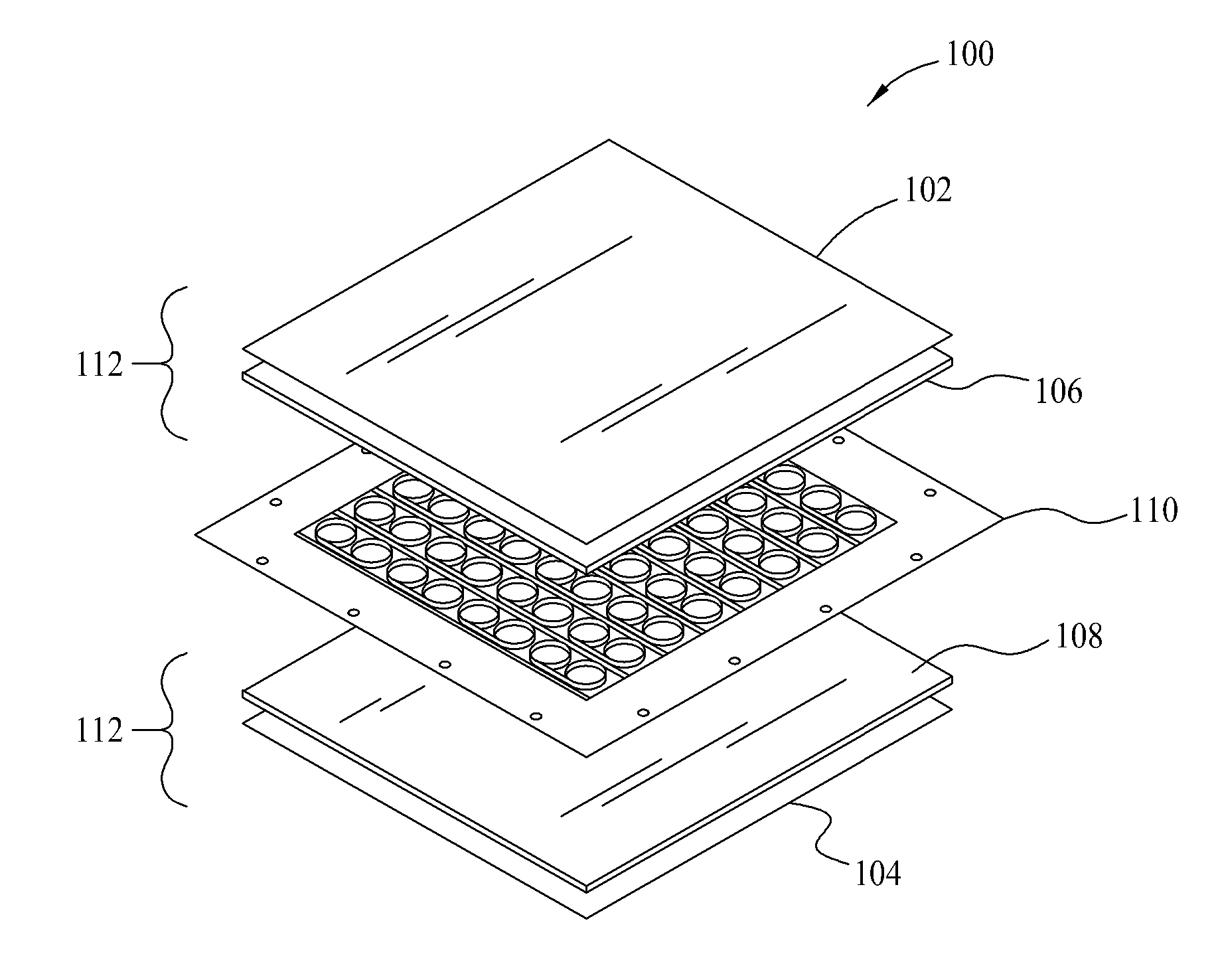

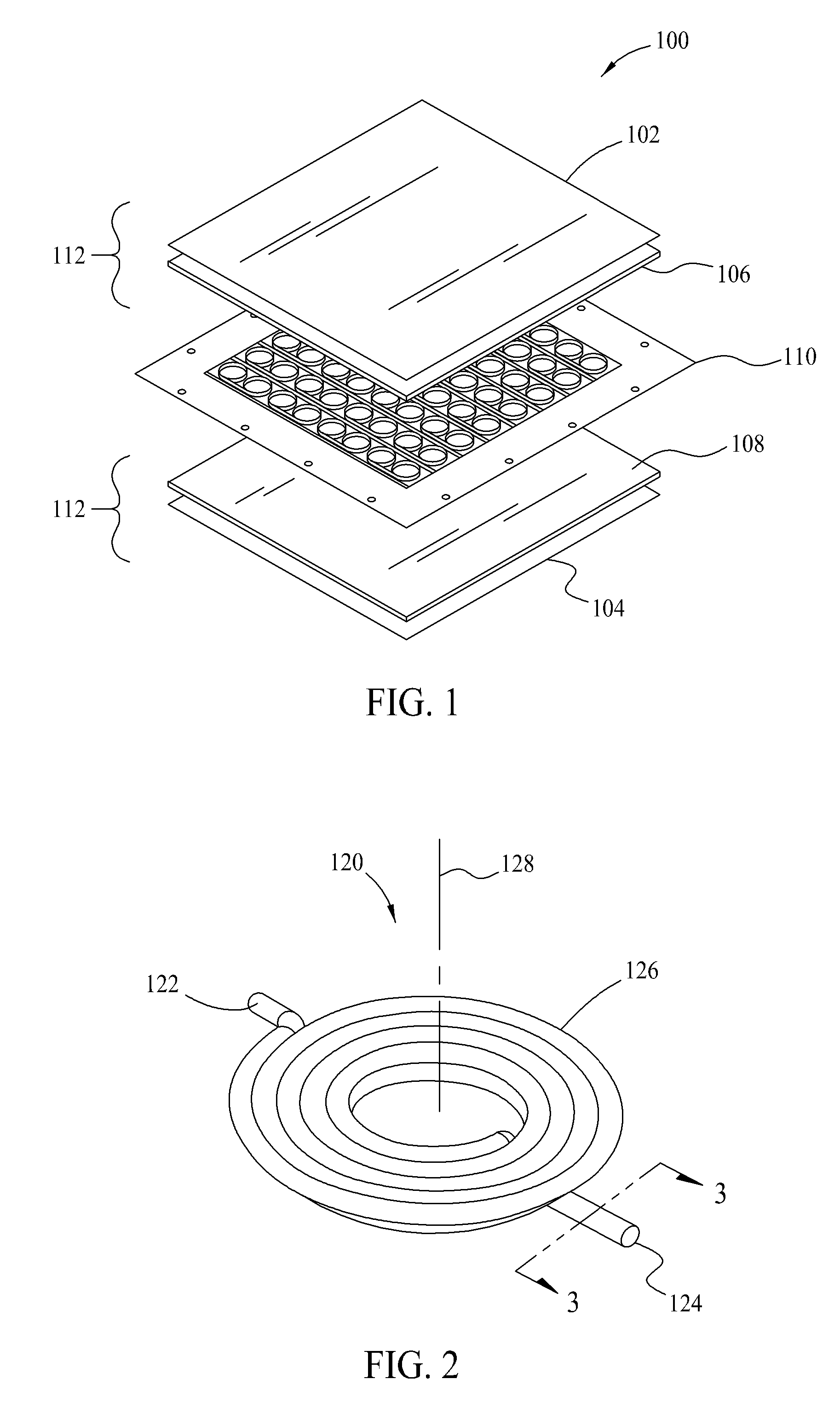

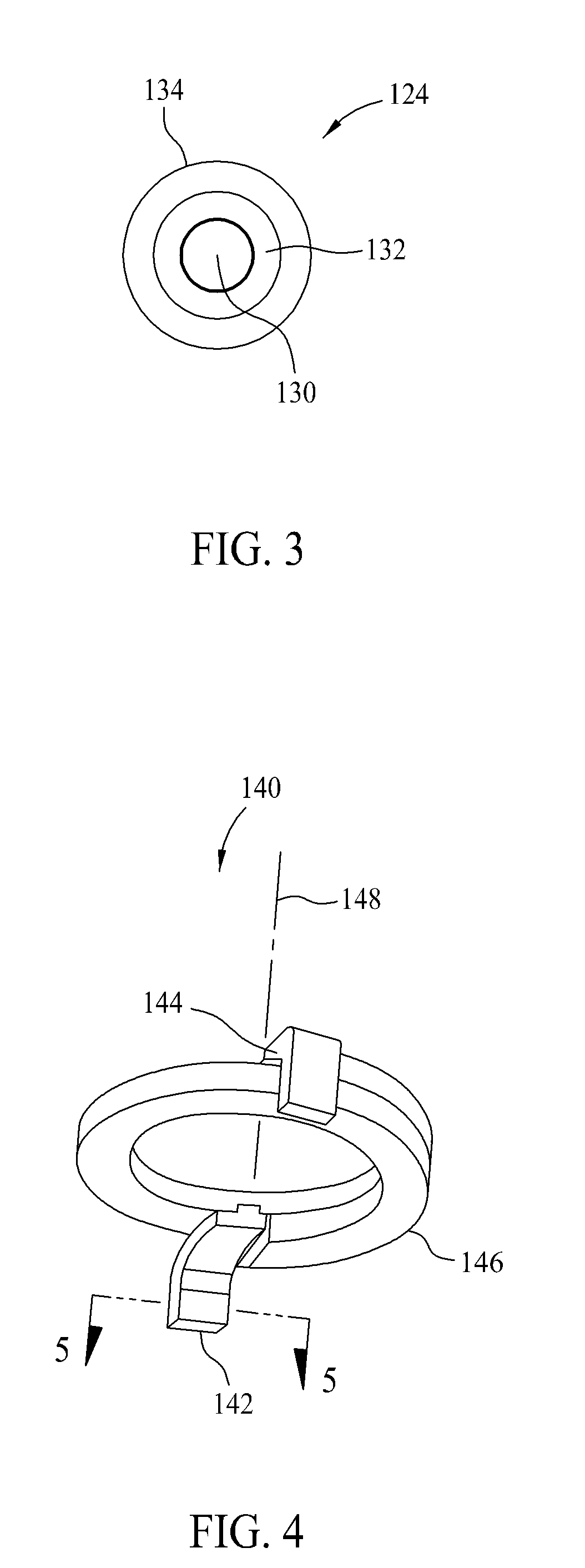

Wireless energy transfer resonator enclosures

ActiveUS8723366B2Efficient deliveryEfficient energy transferMultiple-port networksNear-field transmissionEnergy transferEngineering

Described herein are improved configurations for a resonator enclosure for wireless high power transfer that includes a support plate, a sheet of good conductor positioned on one side of the support plate, a separator piece for maintaining a separation distance between the resonator and the sheet of good conductor, and a cover of a non-lossy material covering the resonator, the separator, the sheet of good conductor and attached to the support plate, wherein the size of the sheet of good conductor is larger than the size of the resonator.

Owner:WITRICITY CORP

Precision inductive devices and methods

ActiveUS7567163B2Reduce interactionImproved high-precision inductive deviceTransformers/inductances casingsPrinted inductancesEngineeringInductor

A low cost, low profile, small size and high performance inductive device for use in, e.g., electronic circuits. In one exemplary embodiment, the device includes a ferrite core comprising multiple inductors and optimized for electrical and magnetic performance. Improvements in performance are obtained by, inter alia, control of the properties of the gap region(s) as well as placement of the windings relative to the gap. The magnetic path properties of the inductors at the ends of the device are also optionally controllable so as to provide precise matching of inductances. Optionally, the device is also self-leaded, thereby simplifying its installation and mating to a parent device (e.g., PCB). Methods for manufacturing and utilizing the device are also disclosed.

Owner:PULSE ELECTRONICS

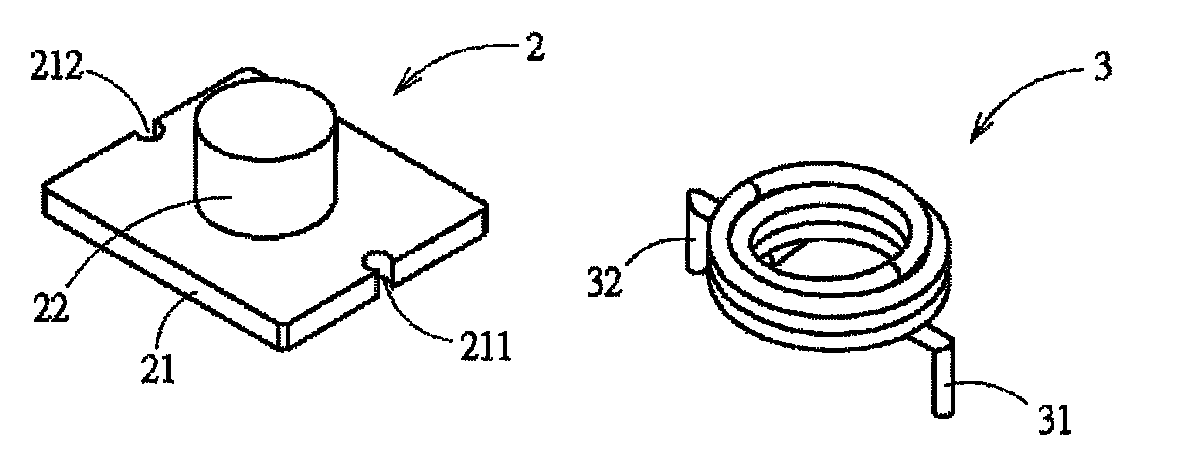

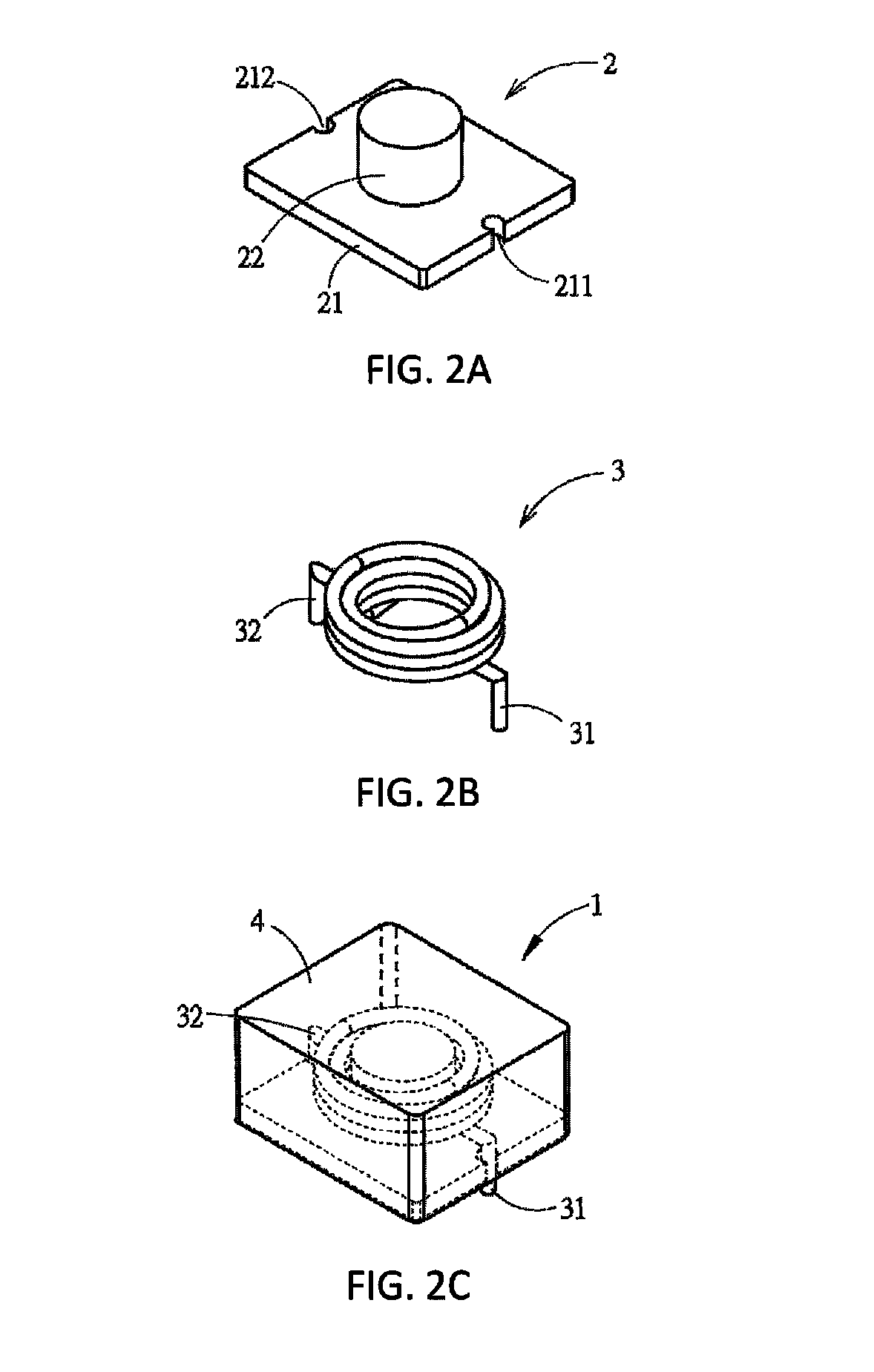

Magnetic device with high saturation current and low core loss

ActiveUS8723629B1Low costHigh saturation currentTransformers/inductances casingsTransformers/inductances coils/windings/connectionsPower flowMagnetic flux

A magnetic device includes a T-shaped magnetic core, a wire coil and a magnetic body. The T-shaped magnetic core includes a base and a pillar, and is made of an annealed soft magnetic metal material, a core loss PCL (mW / cm3) of the T-shaped magnetic core satisfying: 0.64×f0.95×Bm2.20≦PCL≦7.26×f1.41×Bm1.08, where f (kHz) represents a frequency of a magnetic field applied to the T-shaped magnetic core, and Bm (kGauss) represents the operating magnetic flux density of the magnetic field at the frequency. The magnetic body fully covers the pillar, any part of the base that is located above the bottom surface of the base, and any part of the wire coil that is located directly above the top surface of the base.

Owner:CYNTEC

Winding structure for efficient switch-mode power converters

ActiveUS20060038649A1Improves converter efficiencyImprove core utilizationTransformers/inductances casingsApparatus with intermediate ac conversionEngineeringEddy current

Cutout and / or keep away regions are etched in the winding structure near the gapped center leg of a magnetic core. This reduces eddy current losses caused by the leakage field and improves current uniformity and current sharing between windings thereby increasing converter efficiency. Windings closest to the air gap are suitably formed with both keep away regions and cutouts. Windings a little further away are formed with only cutouts and the windings furthest away are unchanged. This approach keeps the net winding losses low in the presence of a fringing field. The precise configuration is determined by the core structure, air gap and winding arrangements.

Owner:MYPAQ HLDG LTD

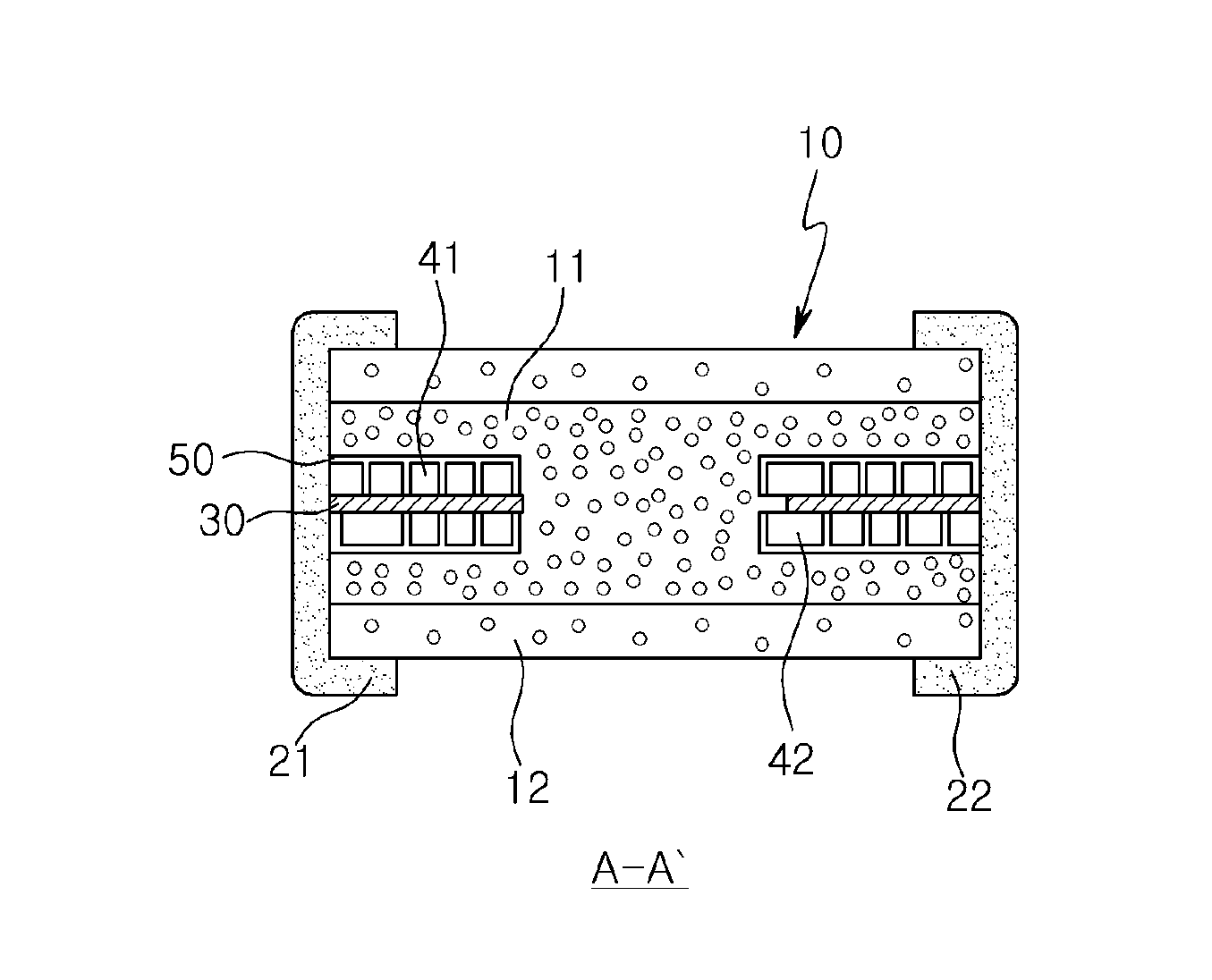

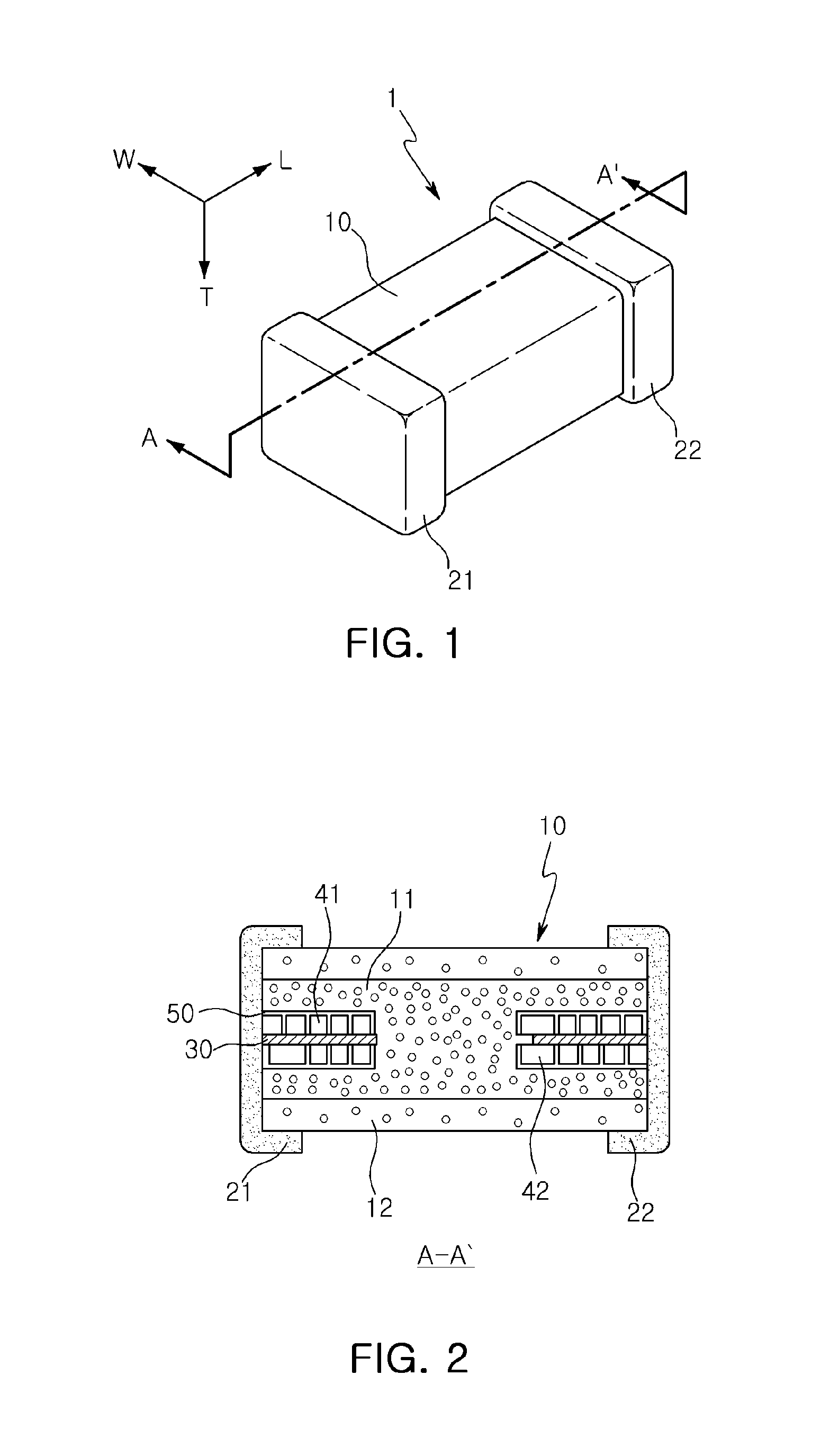

Power inductor and method of manufacturing the same

ActiveUS20140184374A1Good inductanceImprove reliabilityTransformers/inductances casingsInductances/transformers/magnets manufactureInductorEngineering

There is provided a power inductor, including a magnetic body including a substrate having coils formed thereon, a first metal-polymer complex layer formed on upper and lower surfaces of the substrate, and a second metal-polymer complex layer formed on upper and lower surfaces of the first metal-polymer complex layer and including a higher content of a polymer than that included in the first metal-polymer layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

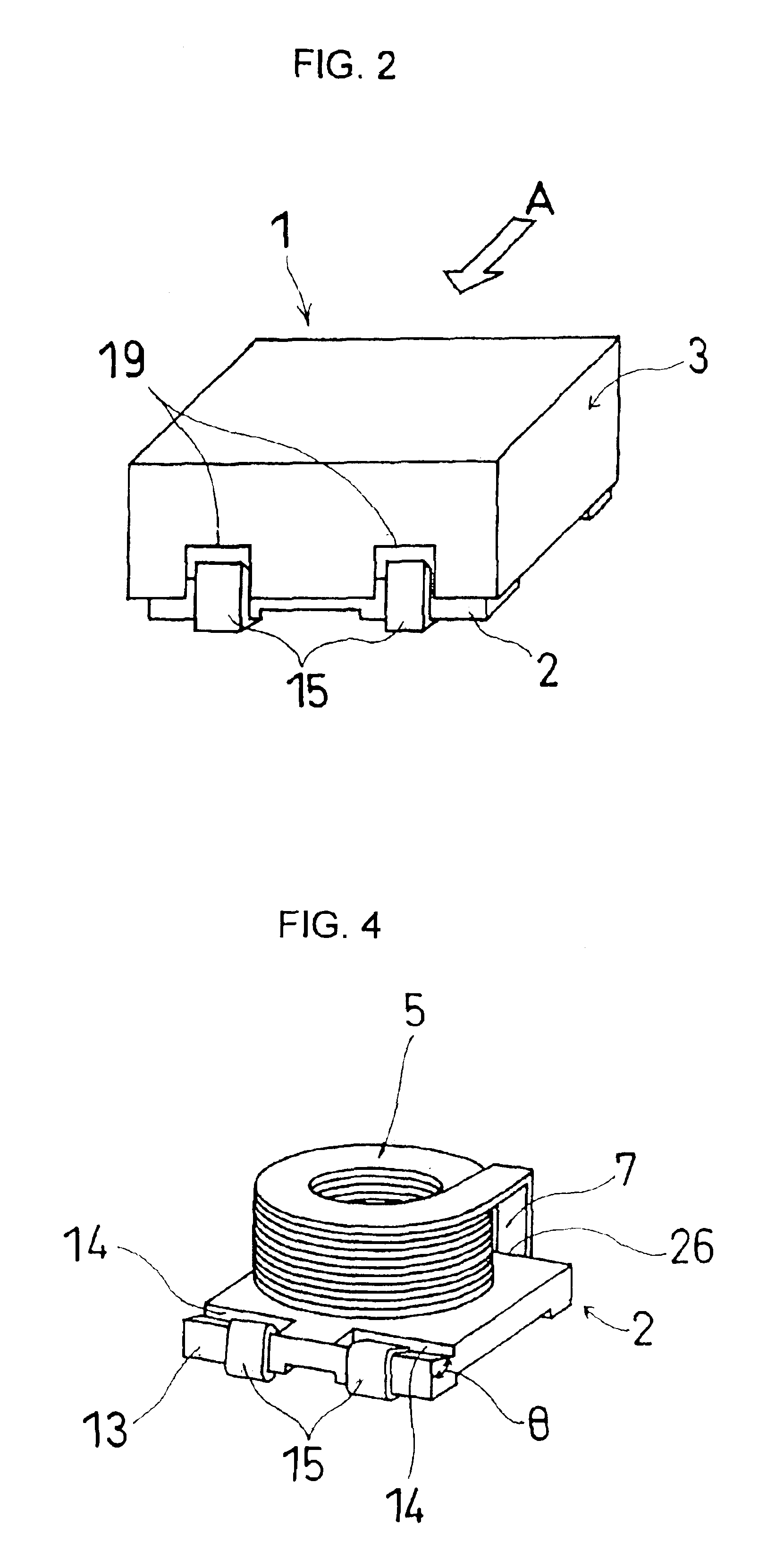

Surface mount coil with edgewise winding

InactiveUS6922130B2Improve reliabilityLow-profileTransformers/inductances casingsTransformers/inductances coils/windings/connectionsSurface mountingEngineering

A surface mount coil comprises: a flanged spool, which includes a spool section and a flange section integrally connected with one end of the spool section; a base flange, which is shaped substantially rectangular and fixedly connected to the other end of the spool section; and an edgewise wound coil, which is made of a rectangular insulated wire, and which is structured such that starting and finishing ends of the rectangular insulated wire lead out in parallel with each other around the base flange in such a manner as to extend along and on one side surface, a bottom surface, and another side surface opposite to the one side surface, and are fixed at an edge of a top surface of the base flange.

Owner:MINEBEA CO LTD

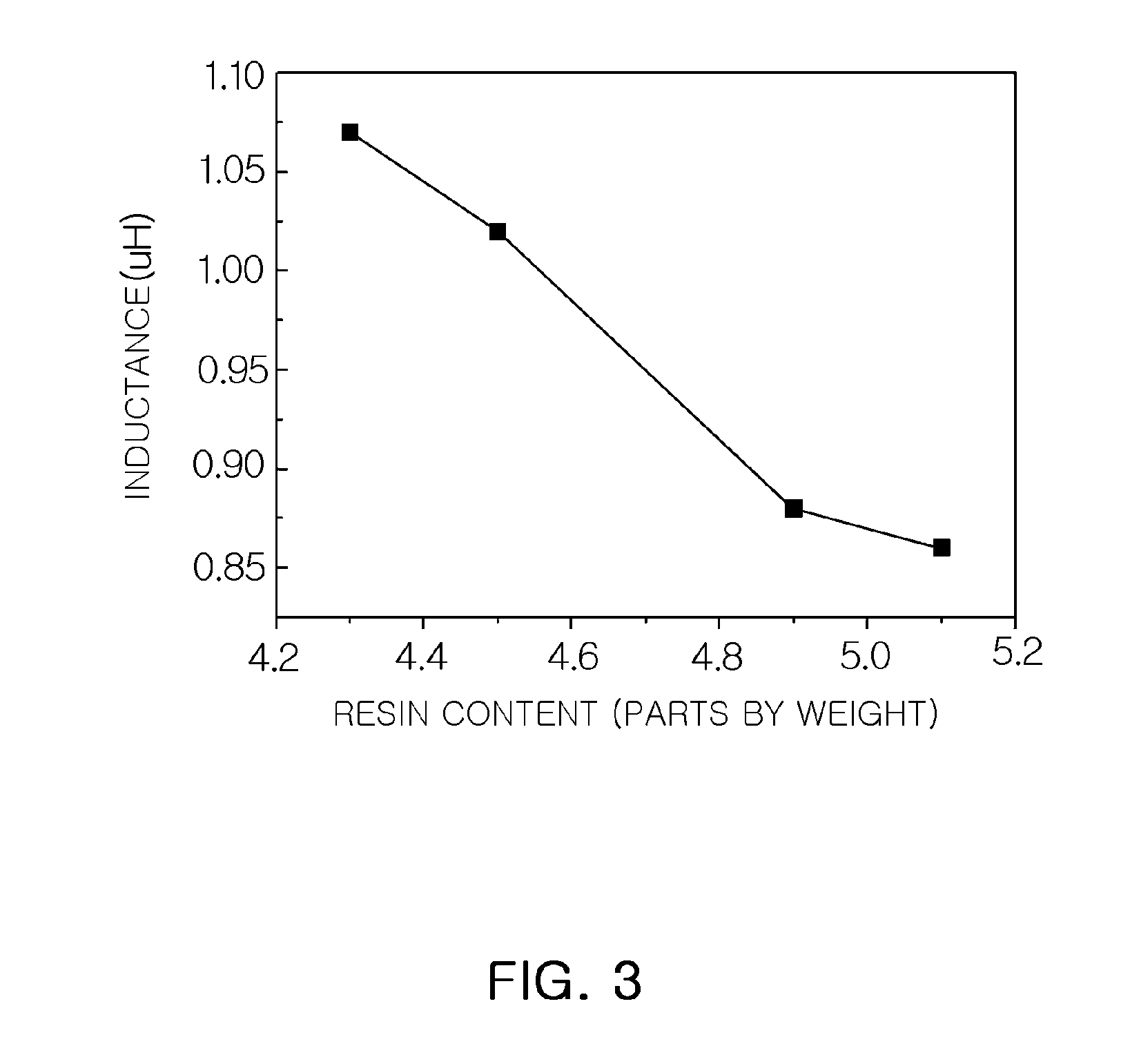

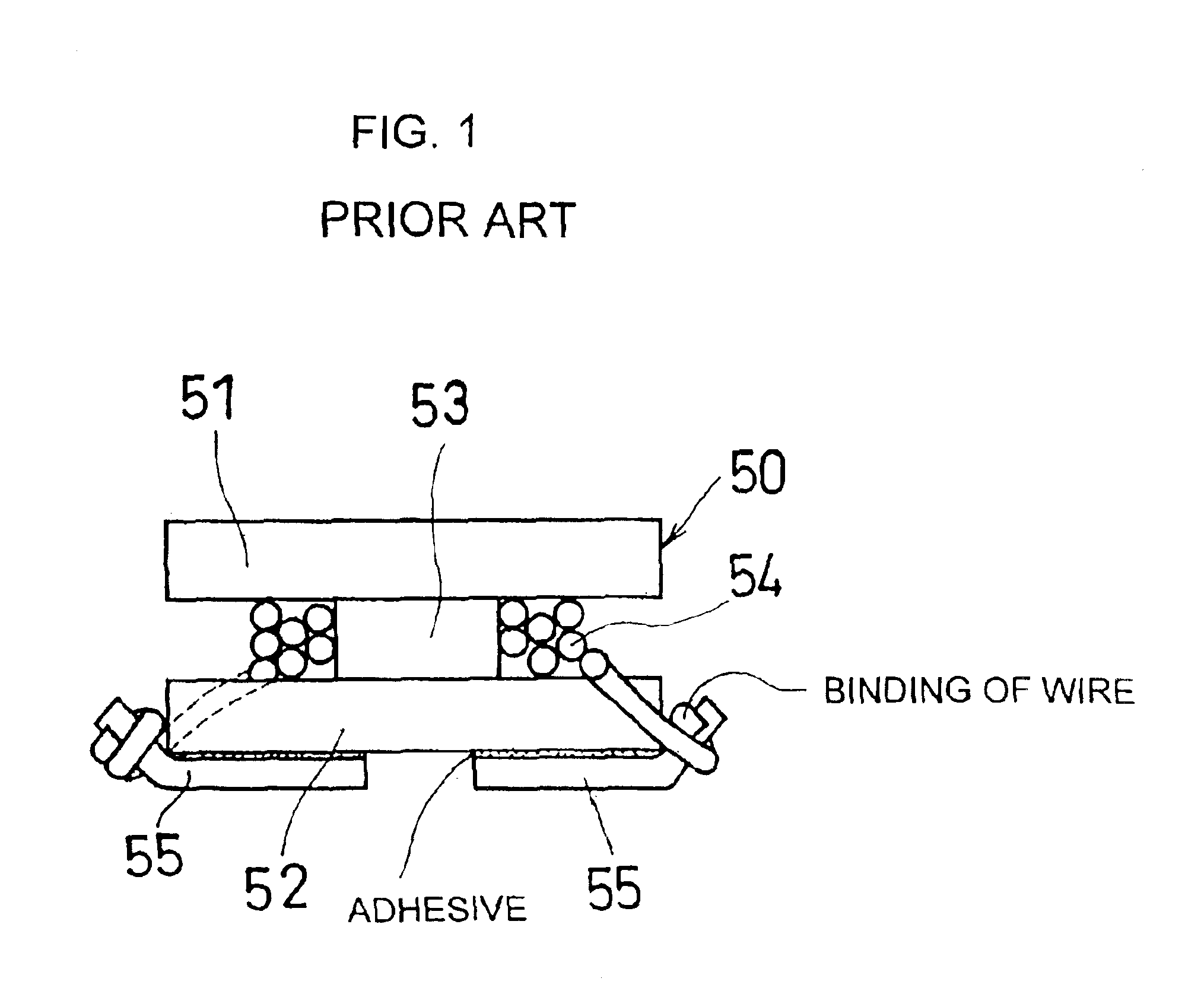

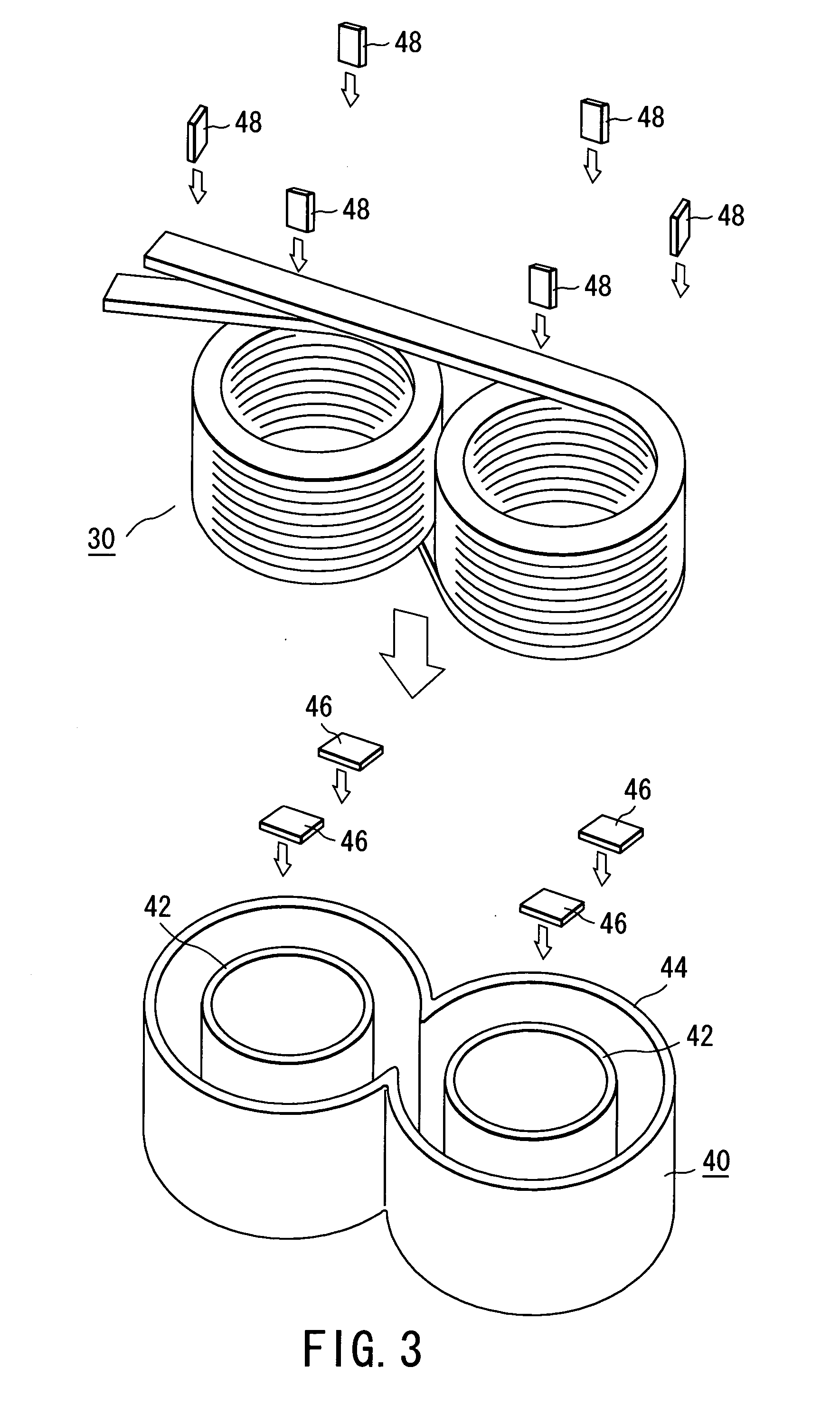

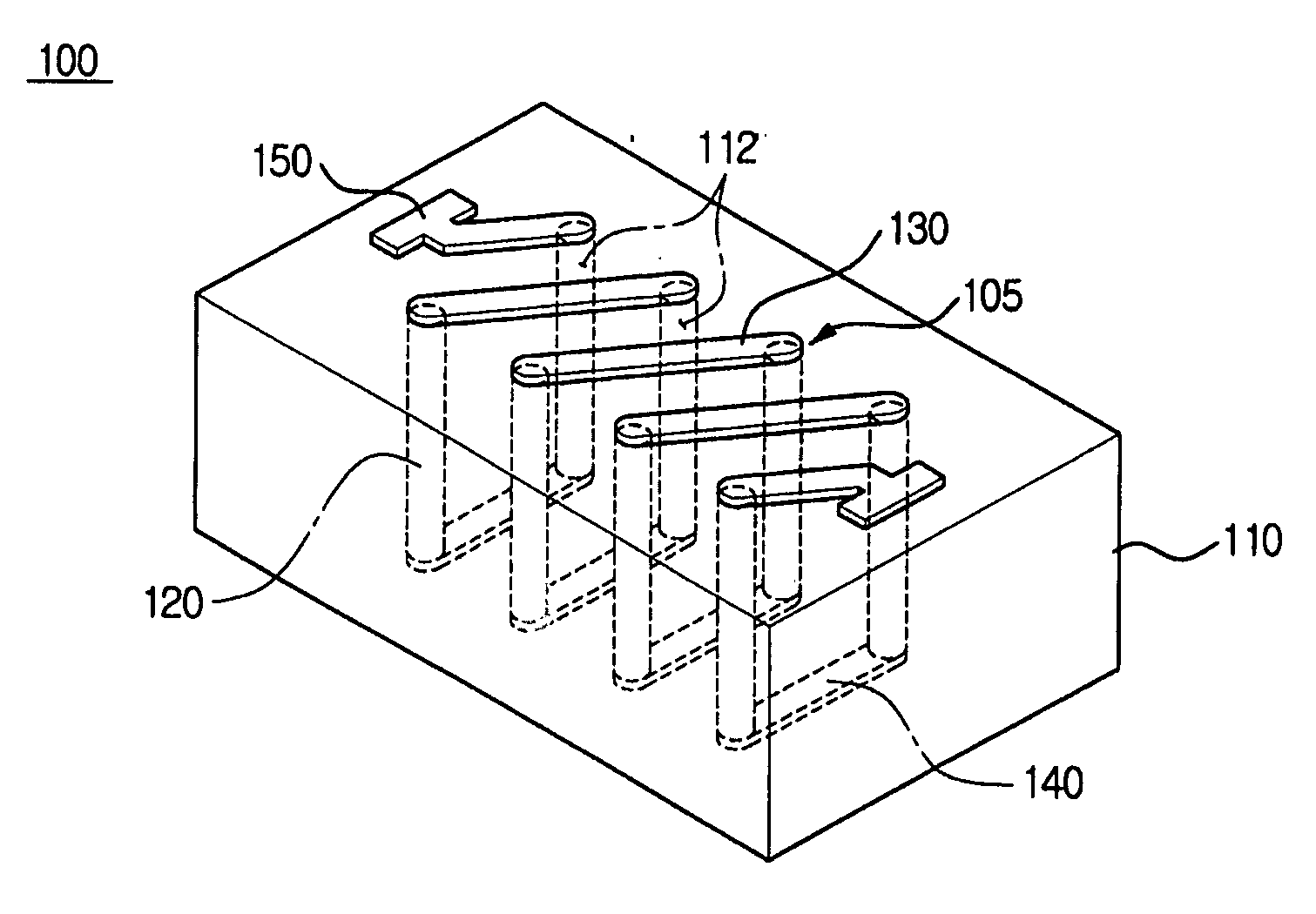

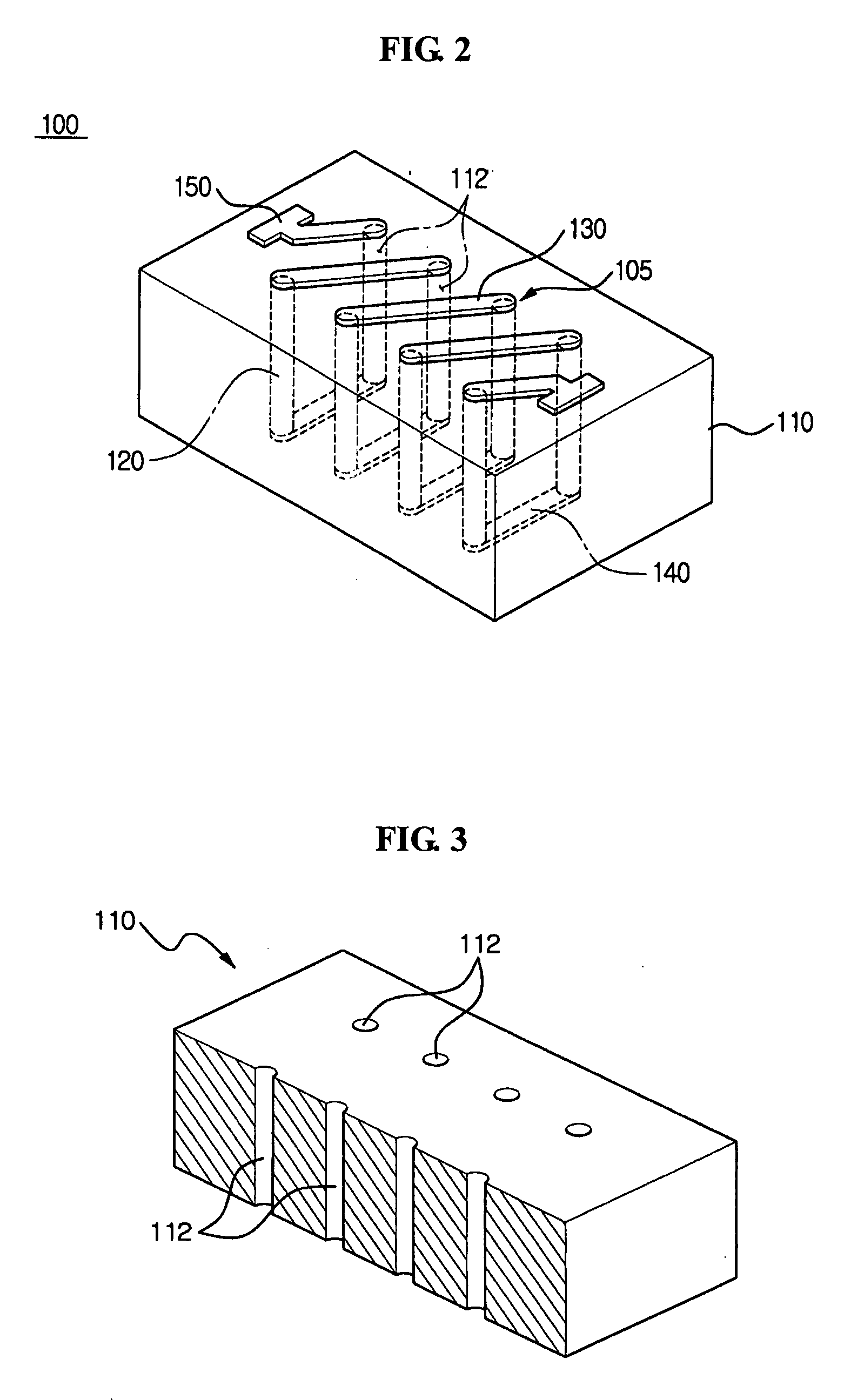

Coil component and fabricaiton method of the same

ActiveUS20050012581A1Suppress whineTransformers/inductances casingsInorganic material magnetismEngineeringElectrical and Electronics engineering

A coil component (100) comprises a coil-containing insulator enclosure and a magnetic core (80). The coil-containing insulator enclosure can be obtained by enclosing a coil (30), except for end portions (12, 22) of the coil (30), with an insulator (50), wherein the insulator (50) comprises at least first resin. The magnetic core (80) is made of a mixture of a second resin (82) and powder, which comprises at least magnetic powder (84). The coil-containing insulator enclosure is embedded in the magnetic core (80).

Owner:DENSO CORP 50 INTEREST +2

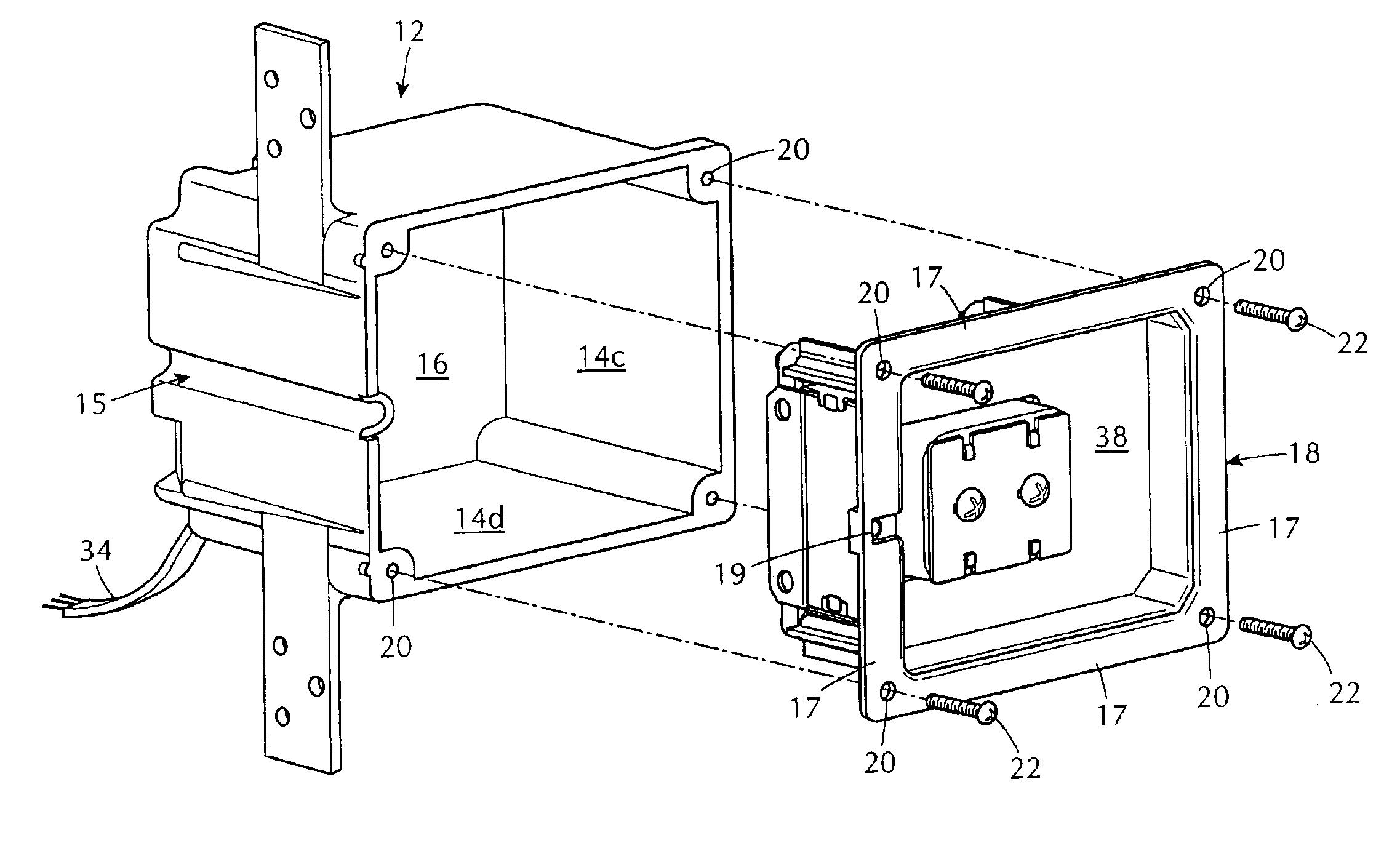

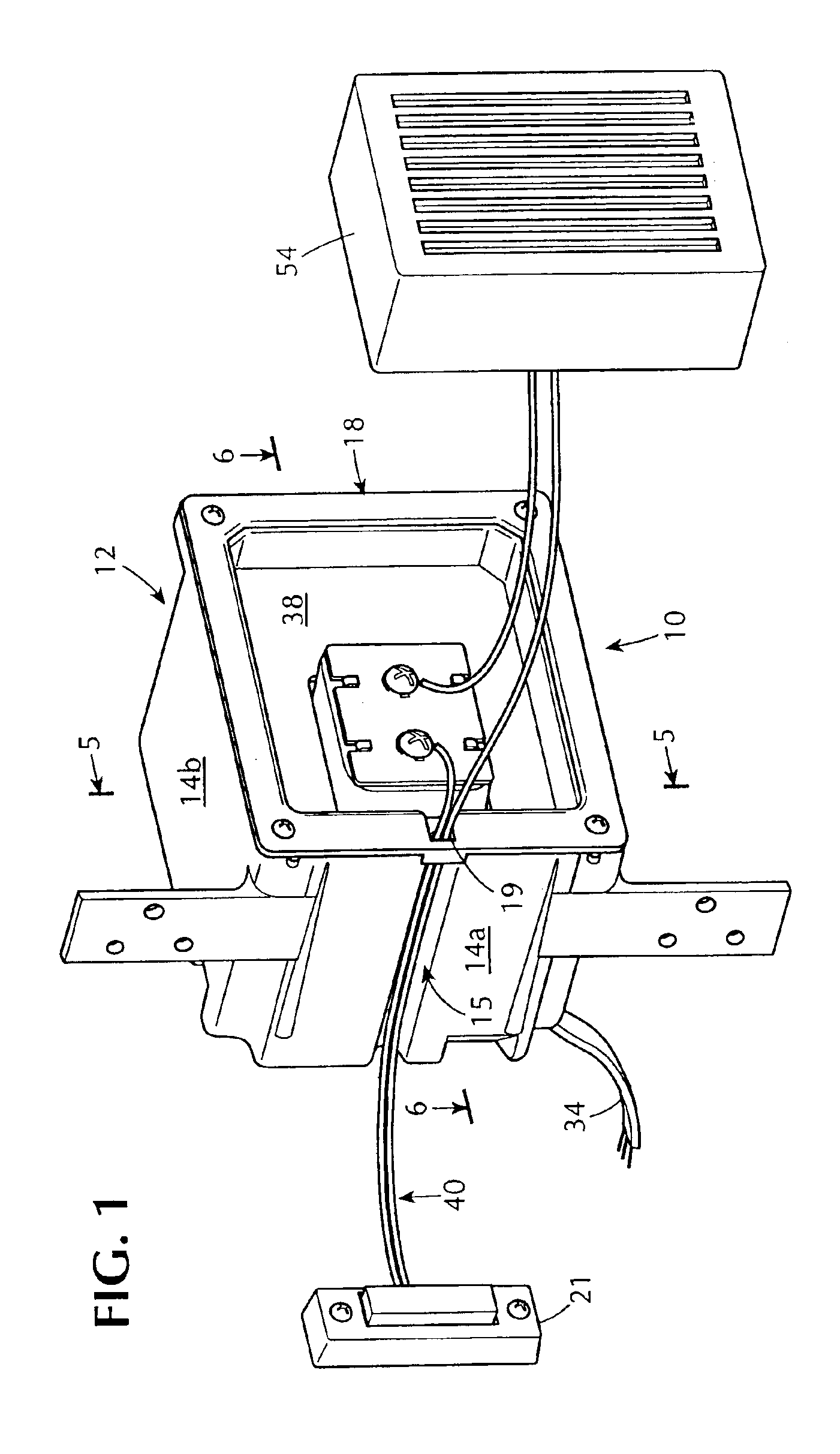

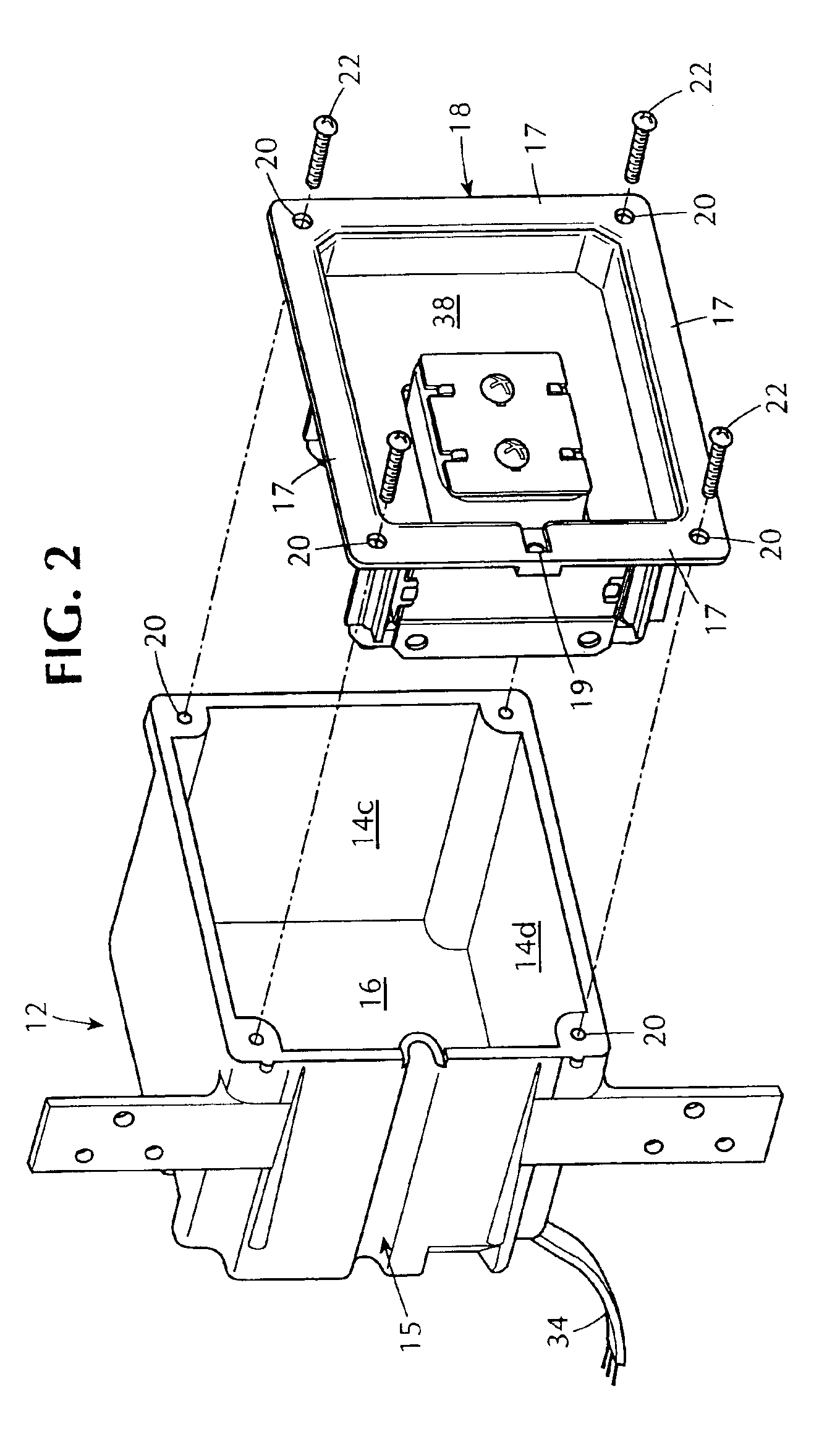

Electrical rough-in box for low voltage transformer

InactiveUS6940016B1Reduce the amount requiredOvercome problemsTransformers/reacts mounting/support/suspensionTransformers/inductances casingsTransformerLow voltage

Owner:HEATH & CO LTD

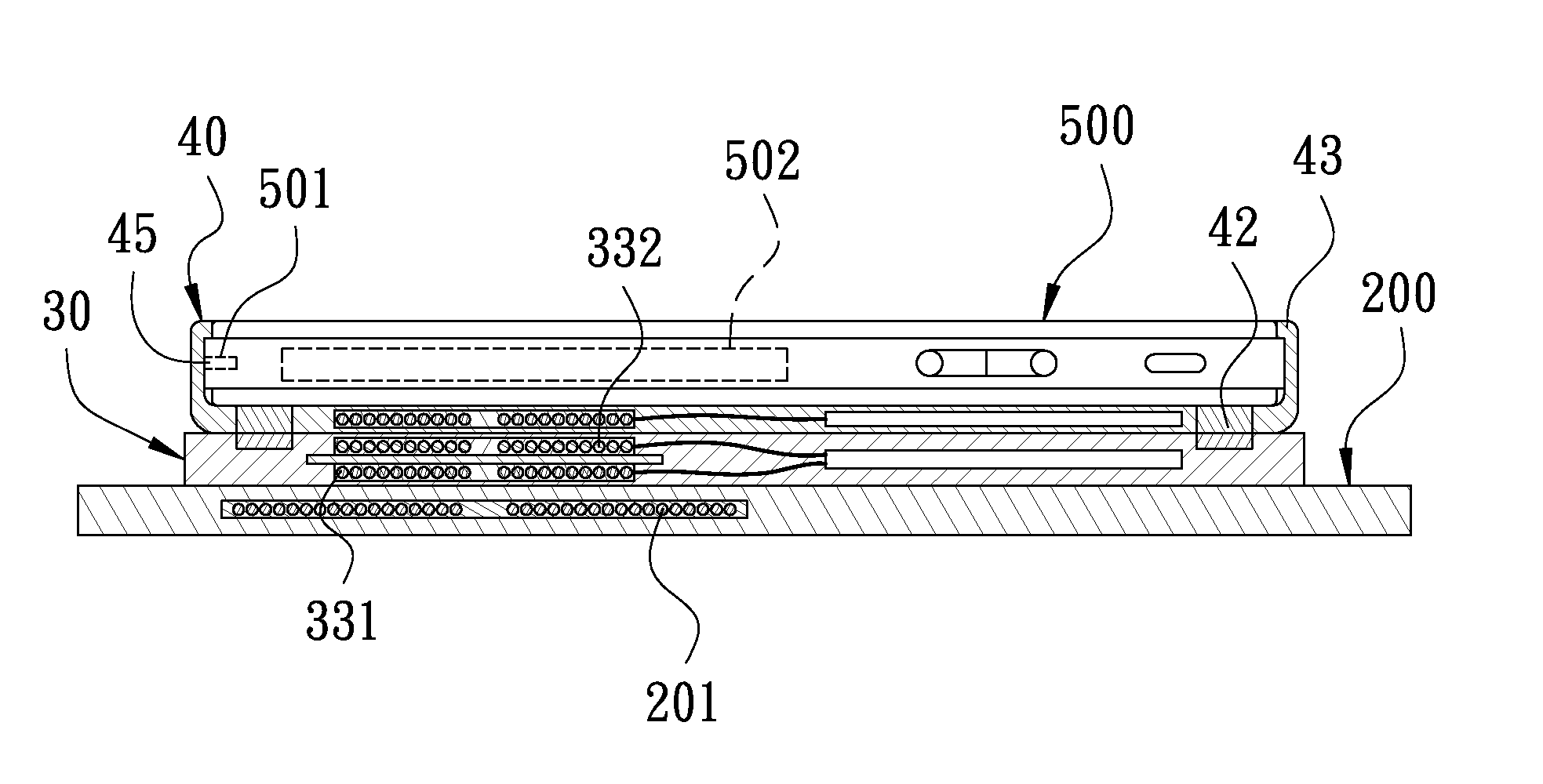

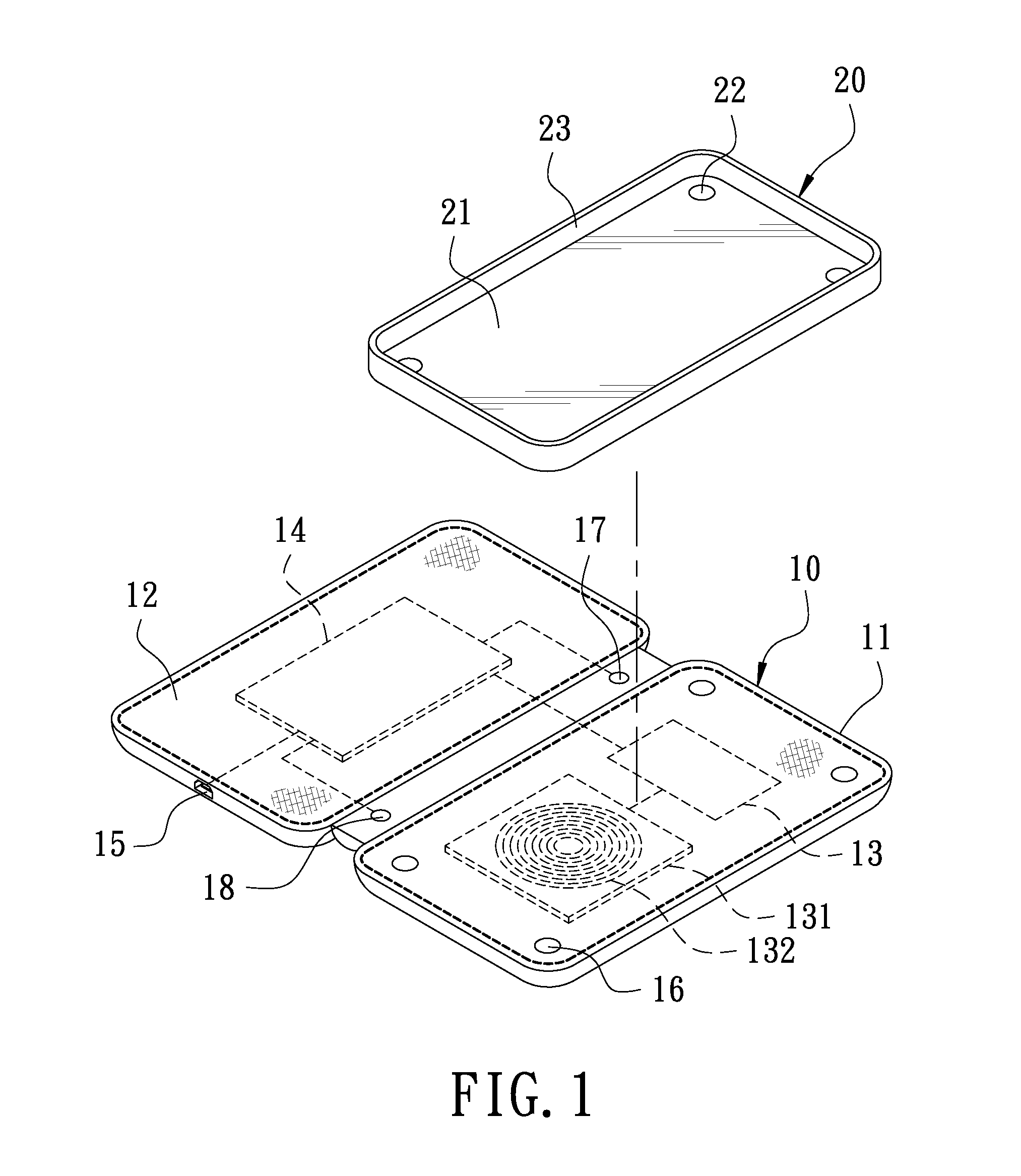

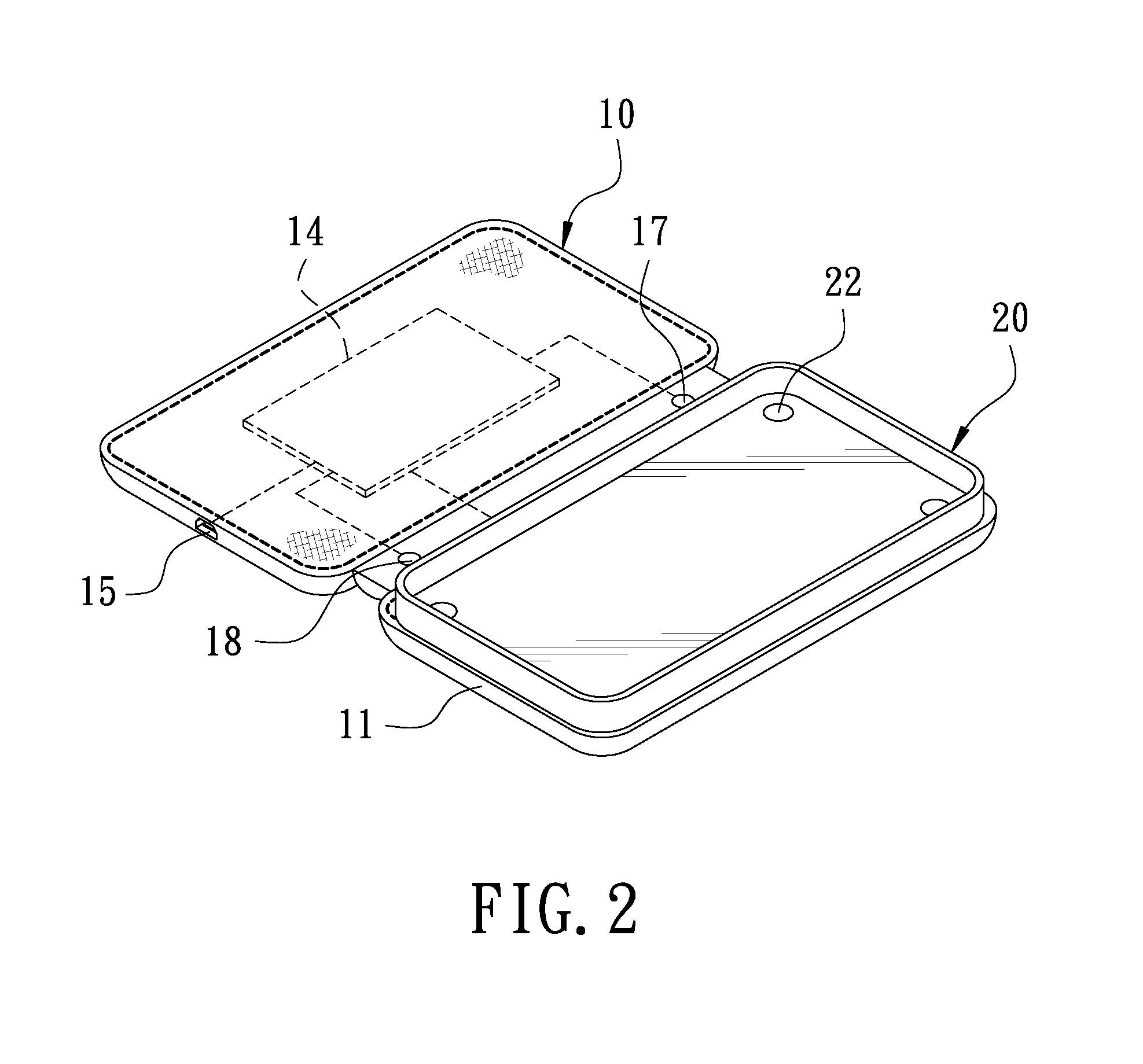

Cell phone protector having wireless charging and discharging function

InactiveUS20160261133A1Easy to useNear-field transmissionBatteries circuit arrangementsElectricityRechargeable cell

A cell phone protector having a wireless charging and discharging function includes a flip cover and a protection case. The protection case is detachably disposed on the flip cover. The flip cover includes a power receiving induction coil and a power output induction coil above the power receiving induction coil. Both the power receiving induction coil and the power output induction coil are electrically connected with a rechargeable battery. The protection case is adapted to accommodate a cell phone. The rechargeable battery can be charged wirelessly through the power receiving induction coil. Through the power output induction coil, the flip cover can be used to charge the cell phone placed in the protection case wirelessly. When the protection case is detached from the flip cover, the flip cover can be used as a wireless power supply board.

Owner:COREMATE TECH CO LTD

High efficiency inductor, method for manufacturing the inductor, and packaging structure using the inductor

ActiveUS20070085648A1Maintain good propertiesHigh quality factorTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringInductor

An inductor is provided which includes a plurality of via holes vertically passing through a substrate, the substrate having insulating properties, vertical conductive portions filling the via holes, and horizontal conductive portions connecting each individual vertical conductive portions at the top and the bottom of the substrate to form a single coil structure with the vertical conductive portions.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of making a miniaturized positional assembly

InactiveUS7028387B1ElectrocardiographyEnvelope/housing resistor manufactureEngineeringMechanical engineering

Owner:ADVANCED NEUROMODULATION SYST INC

Magnetic components and methods of manufacturing the same

InactiveUS20100271161A1Small sizeExpensive manufacturing processTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerSurface mounting

Magnetic component assemblies including moldable magnetic materials formed into magnetic bodies, at least one conductive coil, and termination features are disclosed that are advantageously utilized in providing surface mount magnetic components such as inductors and transformers.

Owner:EATON INTELLIGENT POWER LTD

Coil-embedded dust core

InactiveUS20060038651A1No unevenness in compactionUniform compactionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

A coil-embedded dust core of the present invention is provided with a molded coil component including a coil main body having a structure in which a flat type conductor wire is wound edgewise, one end side terminal portion disposed by being lead in the thickness direction of the coil main body, the other end side terminal portion, one end side leading electrode portion disposed by extending the one end side terminal portion, and the other end side leading electrode portion disposed by extending the other end side terminal portion; and a dust core composed of a soft magnetic alloy powder disposed covering the coil main body, the one end side terminal portion, and the other end side terminal portion of the molded coil component.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com