High-performance fiber reinforced film composite material

A high-performance fiber and composite material technology, applied in textiles and papermaking, can solve problems such as unsatisfactory, air leakage and water permeability, non-wear-resistant and brittle aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

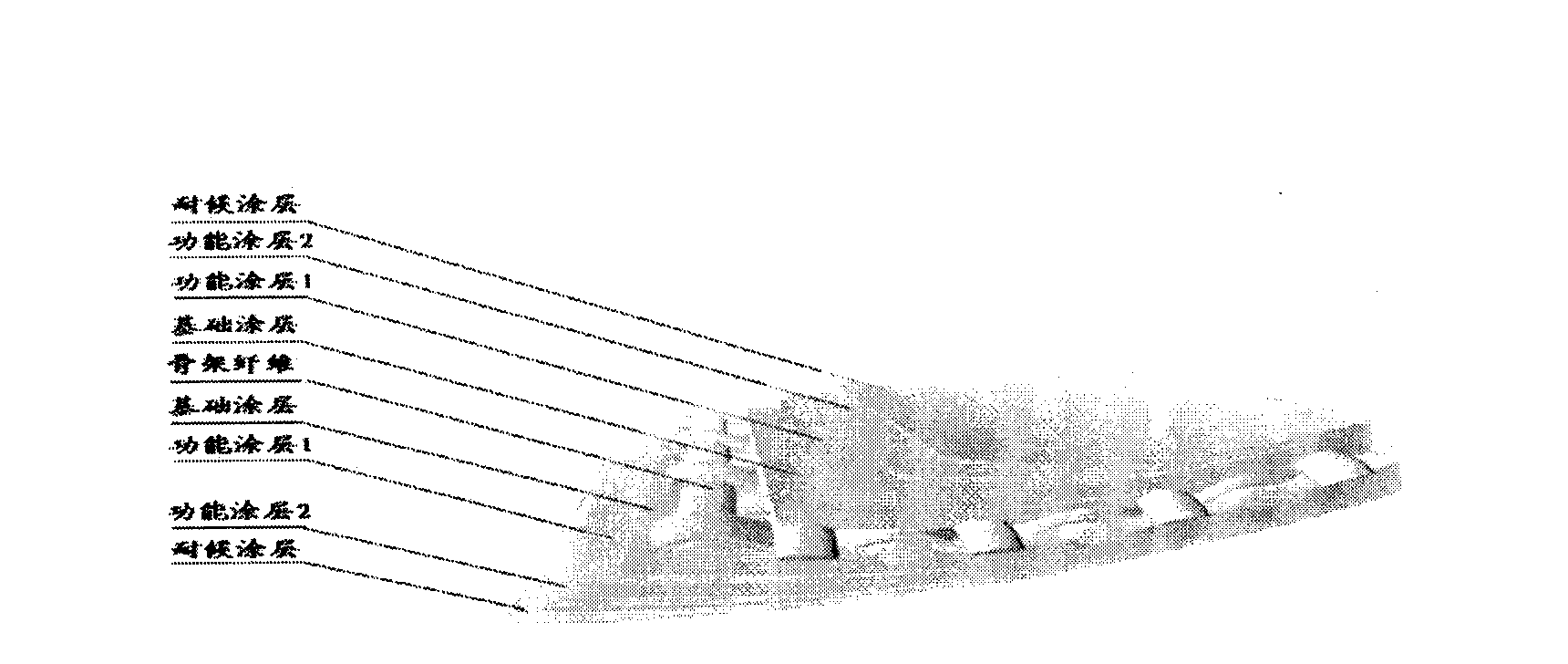

Image

Examples

example 1

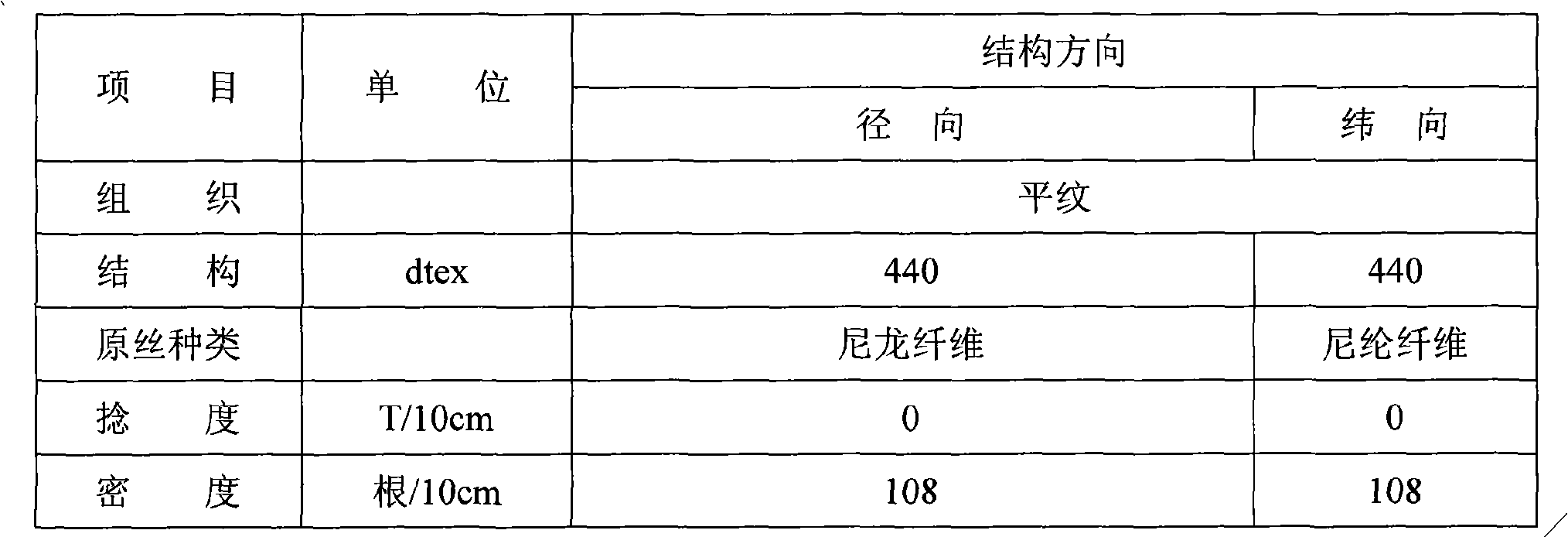

[0033] 1. See the following table for material selection and twist weaving process:

[0034]

[0035] 2. Dipping process: gray cloth pretreatment → drying → padding resin → 1# non-contact drying → shaping tenter → dipping resin → 2# non-contact drying → shaping tenter → cooling → coiling → packaging → Finished product.

[0036] Dipping process conditions: dipping speed 30±3m / min, 1# drying zone temperature 120±5℃, shaping zone temperature 180±5℃, 2# drying zone temperature 120±5℃, shaping zone temperature 180±5℃, The tenter draft rate is 100±1.5%.

[0037] 3. The impregnation adopts thermoplastic PU water-based resin liquid.

[0038] 4. The coating adopts the gap coating process, and the resin content of the single layer coating is 20~30g / m 2 , The drying temperature is 120 ℃, the heating rate is strictly controlled, the coating speed is 15-30m / min, and the white surface coating adopts a thick coating process.

[0039] 5. After the base cloth is coated, apply transparen...

example 2

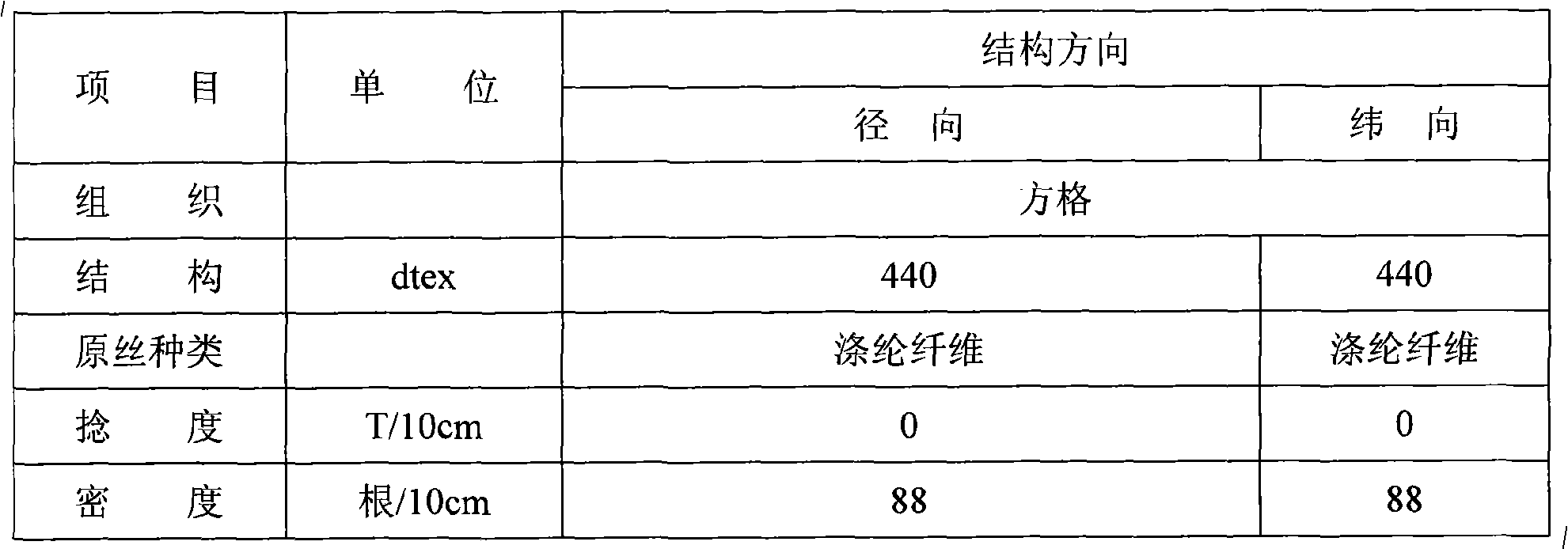

[0041] 1. See the following table for material selection and twist weaving process:

[0042]

[0043] 2. Dipping process: gray cloth pretreatment → drying → padding resin → 1# non-contact drying → shaping tenter → dipping resin → 2# non-contact drying → shaping tenter → cooling → coiling → packaging → Finished product.

[0044]Dipping process conditions: dipping speed 30±3m / min, 1# drying zone temperature 120±5℃, shaping zone temperature 180±5℃, 2# drying zone temperature 120±5℃, shaping zone temperature 180±5℃, The tenter draft rate is 100±1.5%.

[0045] 3. The dipping adopts thermoplastic EVA water-based resin liquid.

[0046] 4. The coating adopts the gap coating process, and the resin content of the single layer coating is 20~30g / m 2 , The drying temperature is 120 ℃, the heating rate is strictly controlled, the coating speed is 15-30m / min, and the white surface coating adopts multiple coating processes.

[0047] 5. After the base cloth is coated, roll-coat transpar...

example 3

[0049] 1. See the following table for material selection and twist weaving process:

[0050]

[0051] 2. Dipping process: gray cloth pretreatment → drying → padding resin → 1# non-contact drying → shaping tenter → dipping resin → 2# non-contact drying → shaping tenter → cooling → coiling → packaging → Finished product.

[0052] Dipping process conditions: dipping speed 30±3m / min, 1# drying zone temperature 120±5℃, shaping zone temperature 180±5℃, 2# drying zone temperature 120±5℃, shaping zone temperature 180±5℃, The tenter draft rate is 100±1.5%.

[0053] 3. The impregnation adopts thermoplastic PA water-based resin solution.

[0054] 4. The coating adopts the gap coating process, and the resin content of the single layer coating is 20~30g / m 2 , The drying temperature is 110 ℃, the heating rate is strictly controlled, the coating speed is 15-30m / min, and the white surface coating adopts the multi-coating process.

[0055] 5. After the base cloth is coated, the inner ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com