Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491results about How to "Improve interface strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

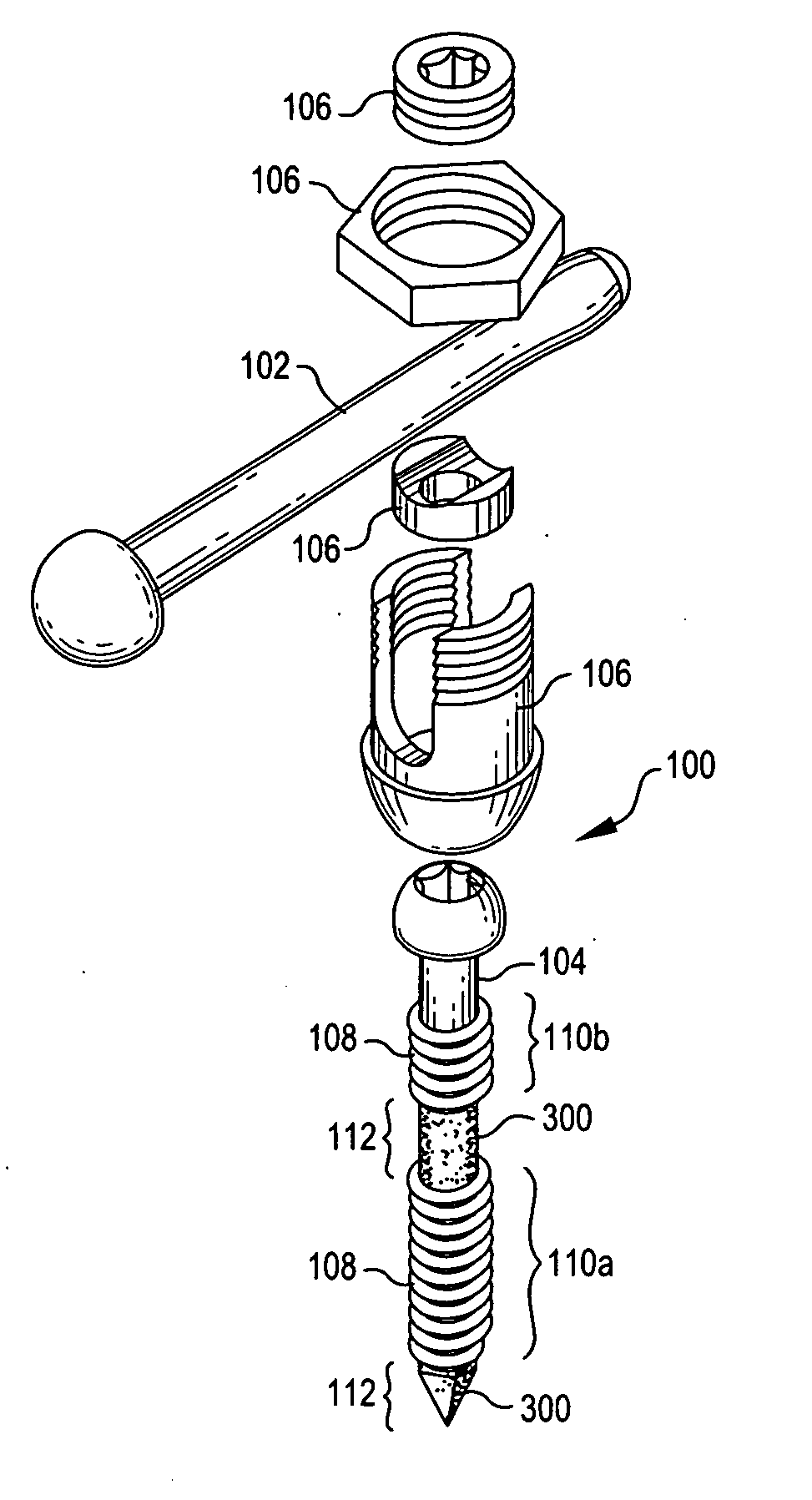

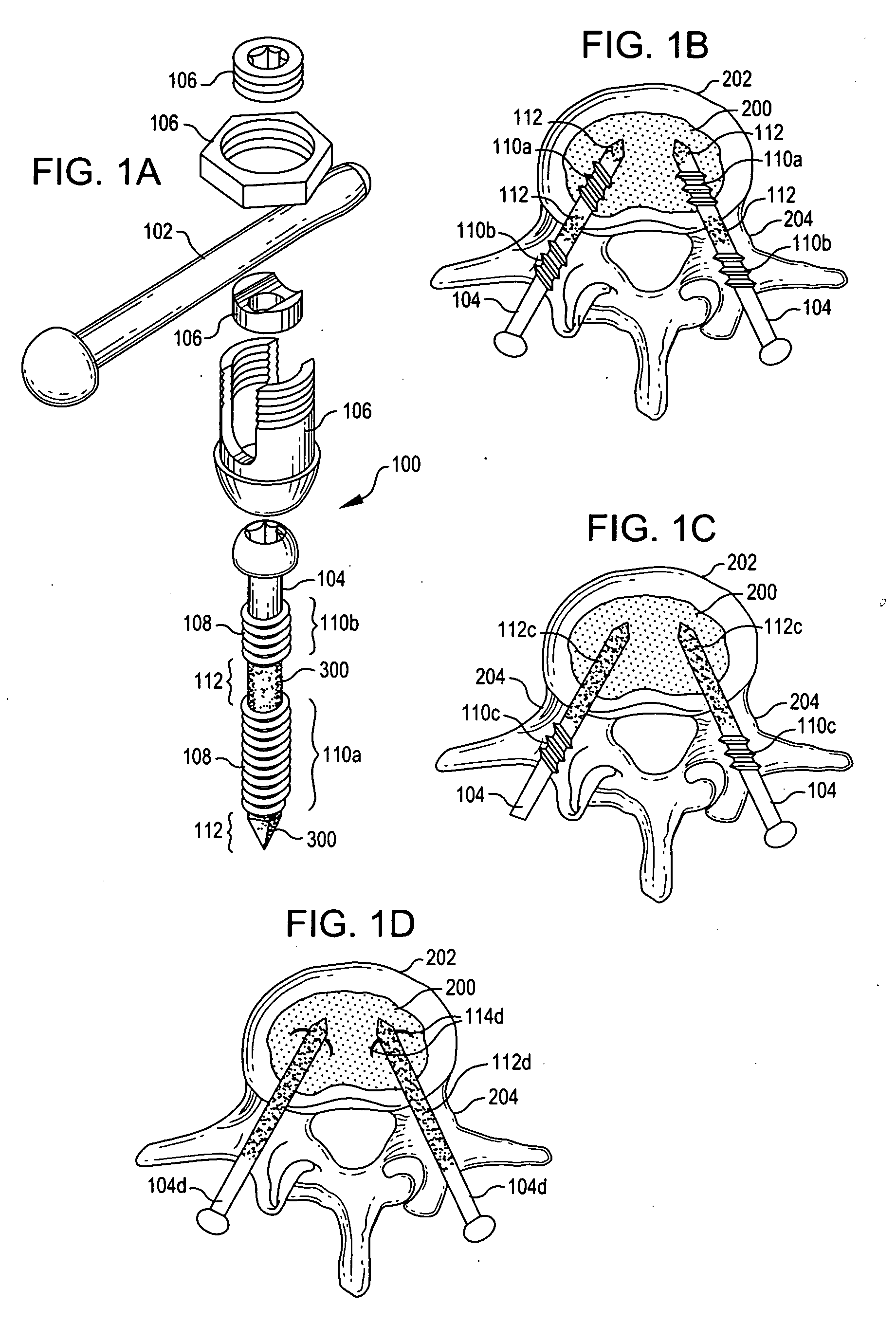

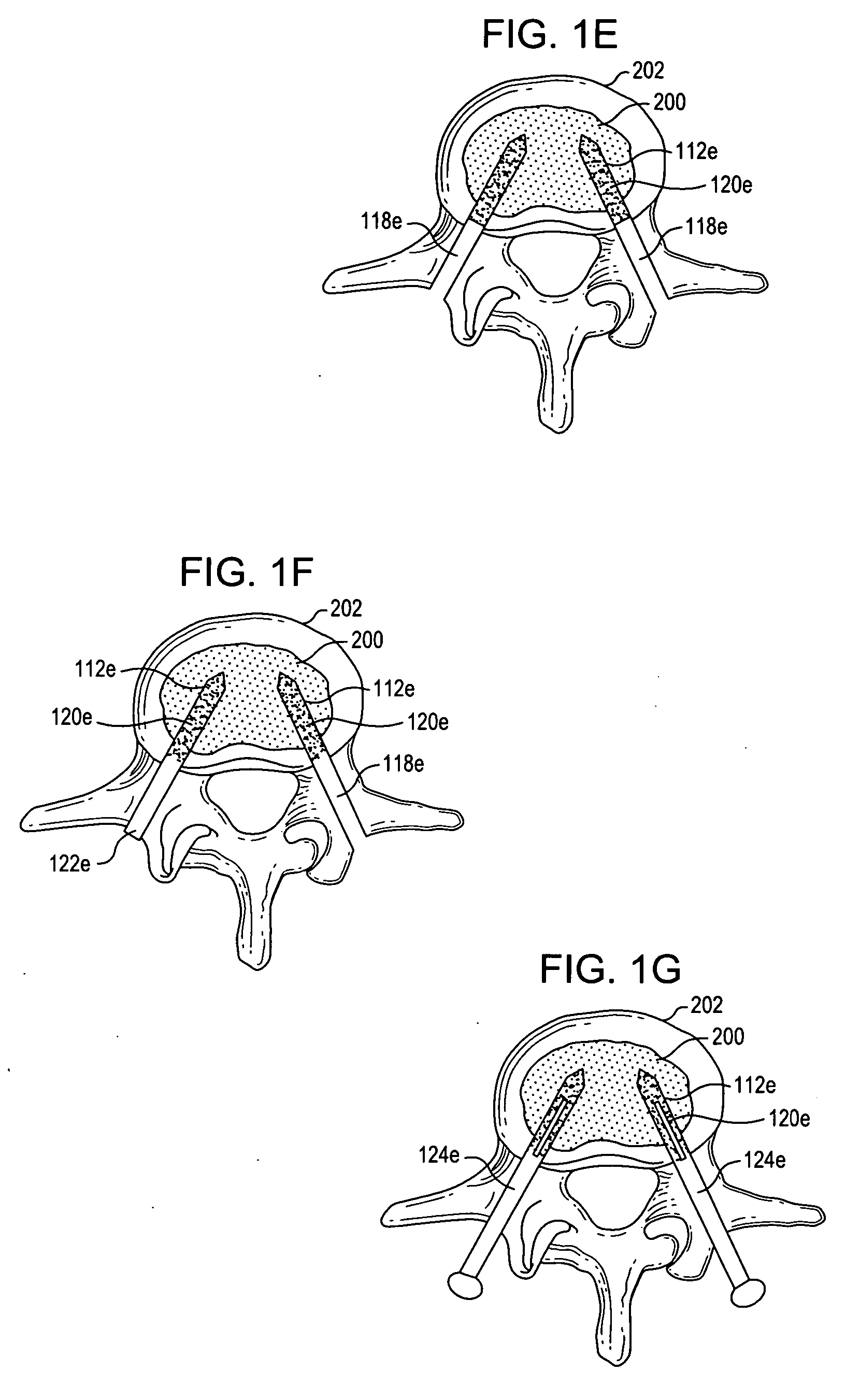

Methods and devices for improved bonding of devices to bone

InactiveUS20060079895A1Improve interface strengthSufficient supportSuture equipmentsInternal osteosythesisImplanted deviceSoft tissue

The present invention is directed to improving bonding between orthopedic devices, particularly vertebral devices, and bone. The present invention provides various methods and devices employing mechanical and bio-fixation modalities for such attachment. As provided herein, the initial mechanical attachment of a device to bone is sufficiently stable to ensure that the implanted device is relatively immobile (or alternatively microscopic motion is promoted), facilitating bone and soft tissue in-growth and the eventual bio-fixation of the device.

Owner:FACET SOLUTIONS

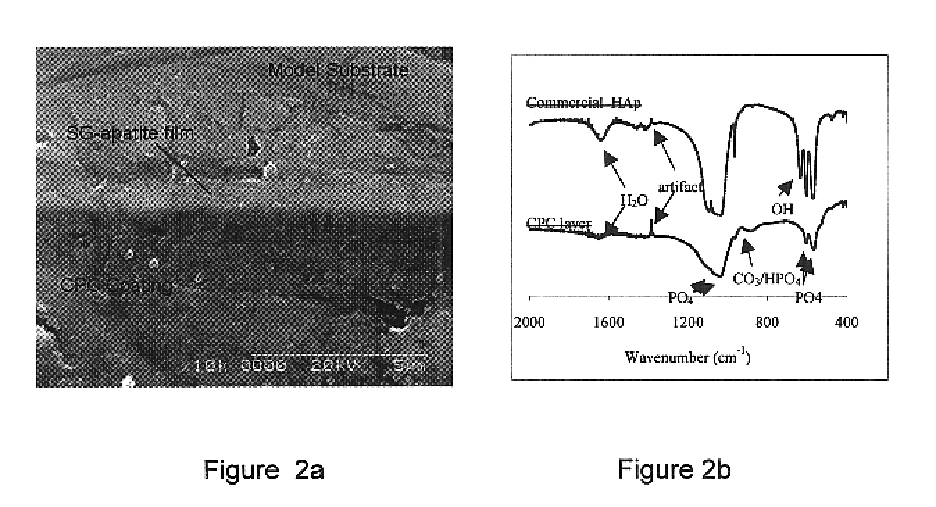

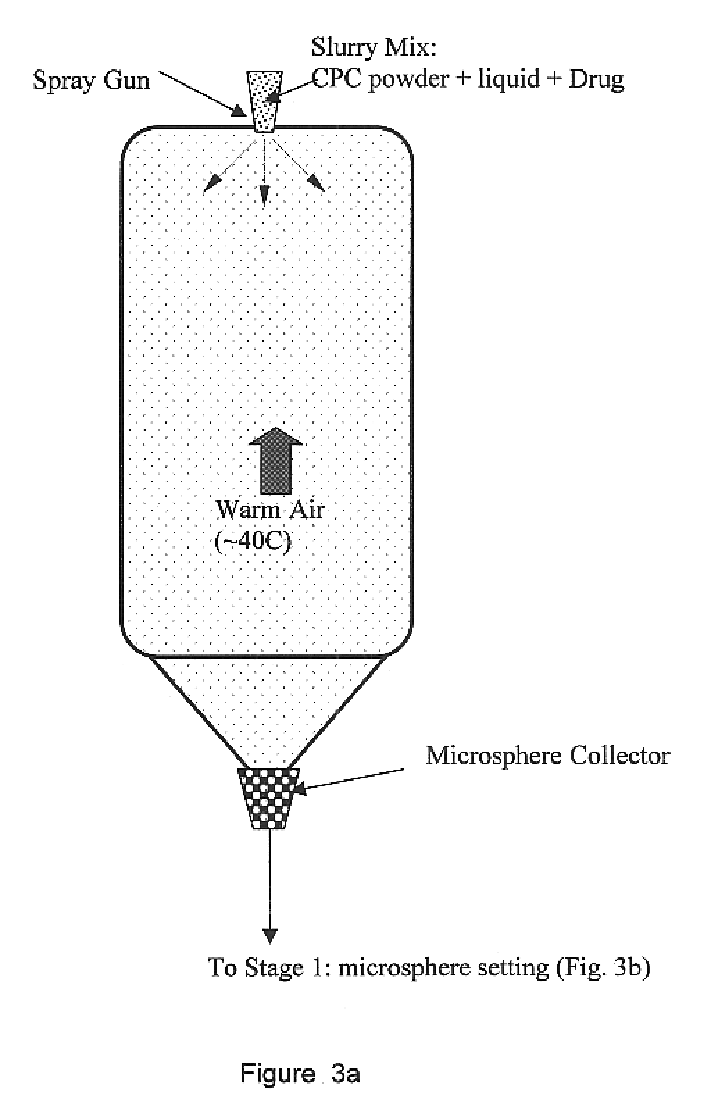

Biofunctional hydroxyapatite coatings and microspheres for in-situ drug encapsulation

InactiveUS6730324B2High strengthEasy to makePowder deliveryOrganic active ingredientsGene deliverySide effect

This invention relates to novel room-temperature process for obtaining calcium phosphate, in particular hydroxyapatite, coatings and microspheres that encapsulate drugs, proteins, genes, DNA for therapeutical use. The coatings and microspheres are designed to perform a defined biological function related to drug delivery, such as gene therapy through gene delivery. A novel method for encapsulation, and subsequent controlled release of therapeutically active agents from such biofunctional coatings and microspheres is disclosed. Such coatings and microspheres are useful for side-effects free, long-term, targeted, controlled release and delivery of drugs, proteins, DNA, and other therapeutic agents.

Owner:THE UNIV OF BRITISH COLUMBIA

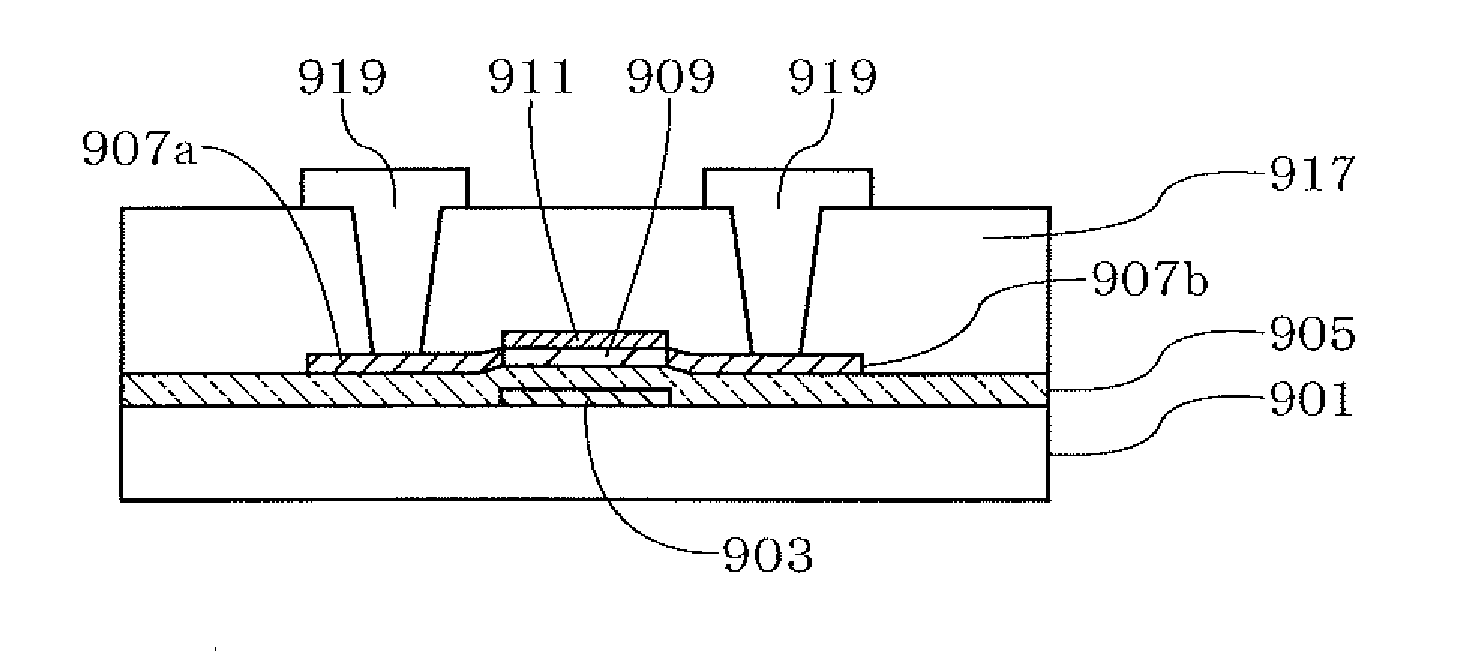

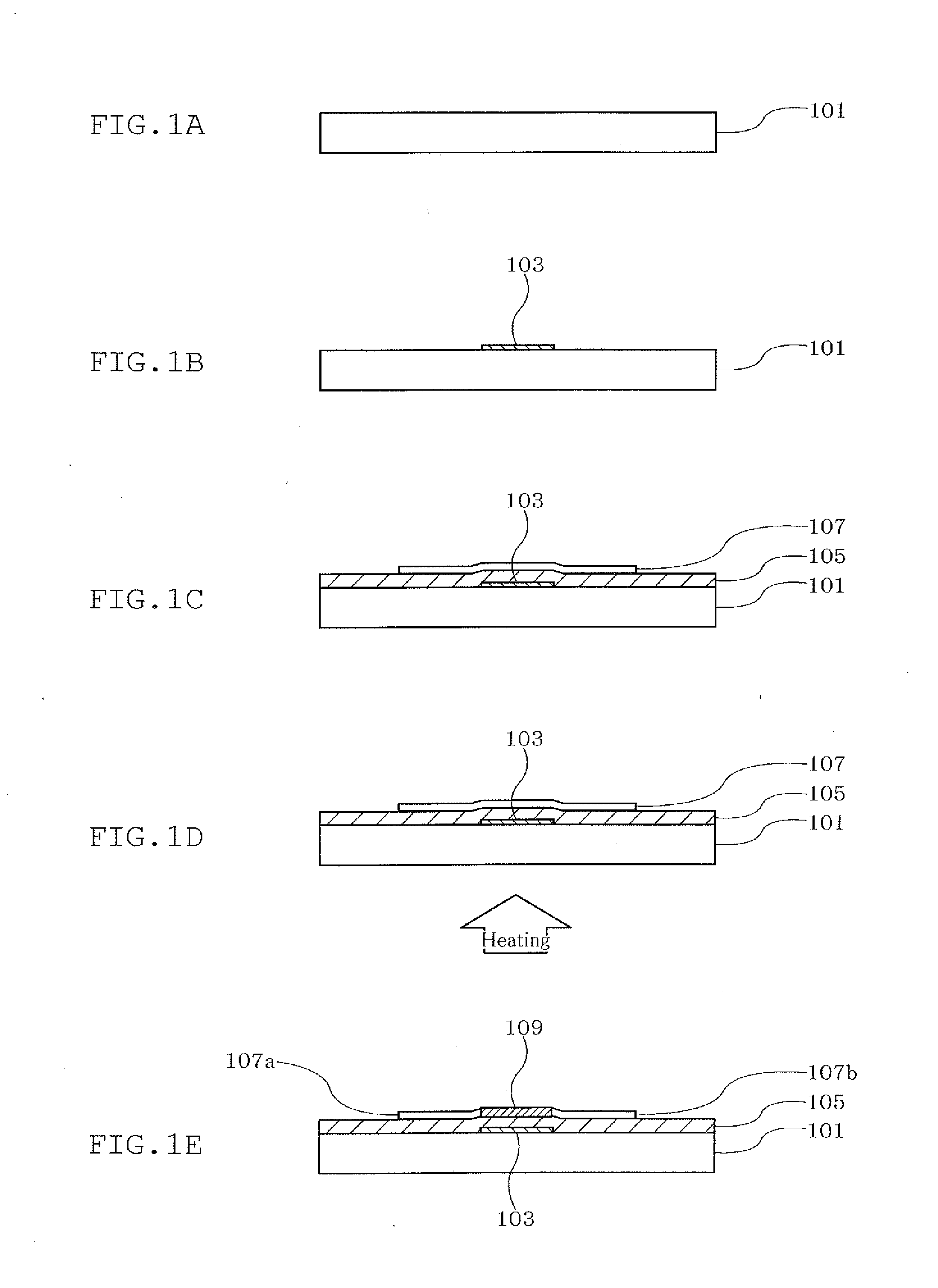

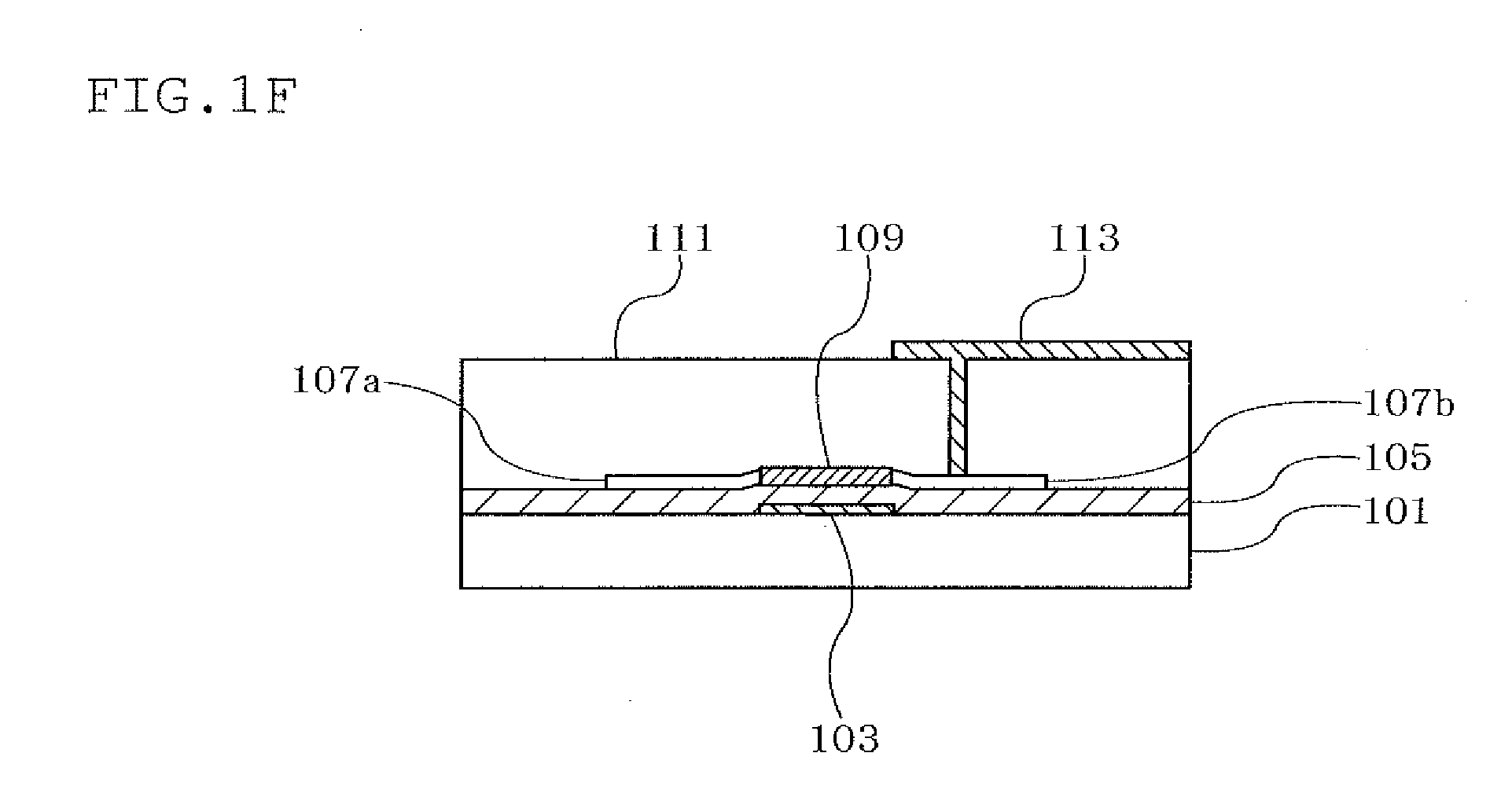

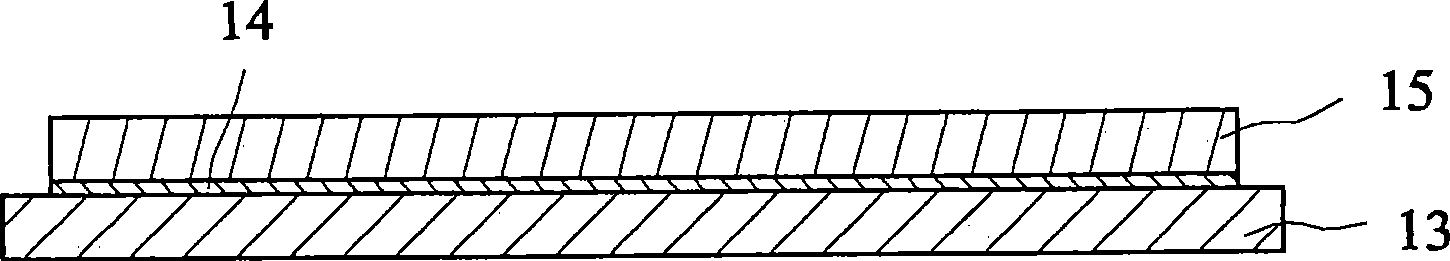

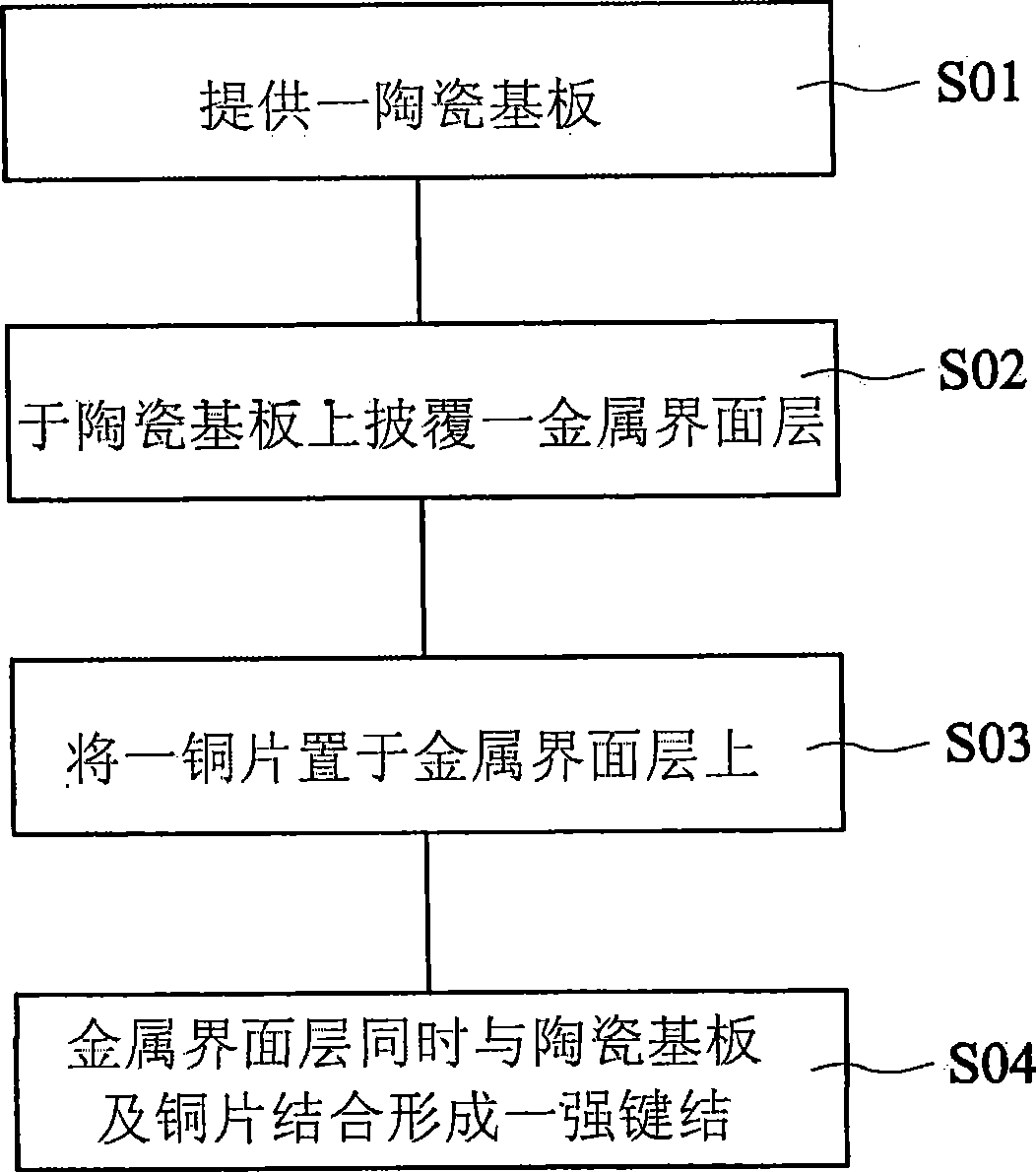

Field effect transistor, semiconductor device and semiconductor device manufacturing method

InactiveUS20110049511A1Reduce contact resistanceImprove interface strengthTransistorSemiconductor/solid-state device manufacturingCrystalline oxideField-effect transistor

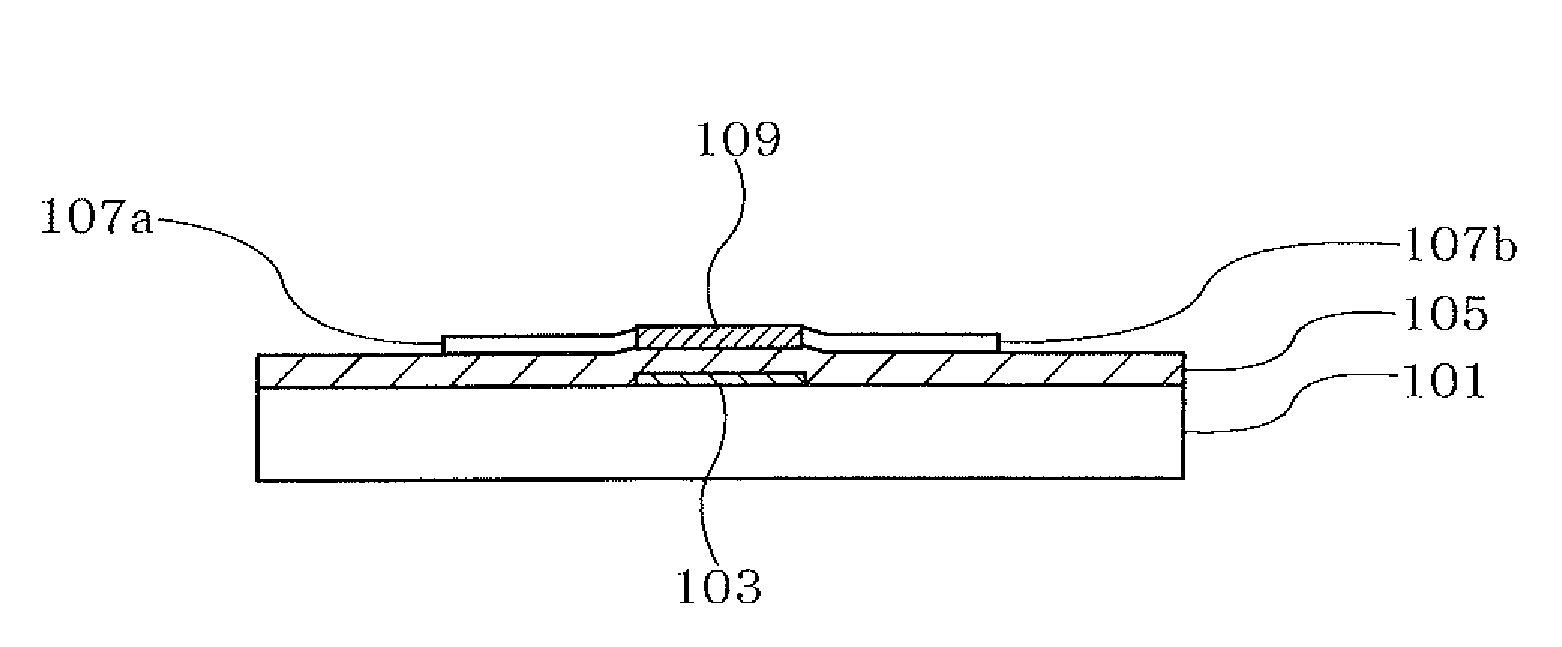

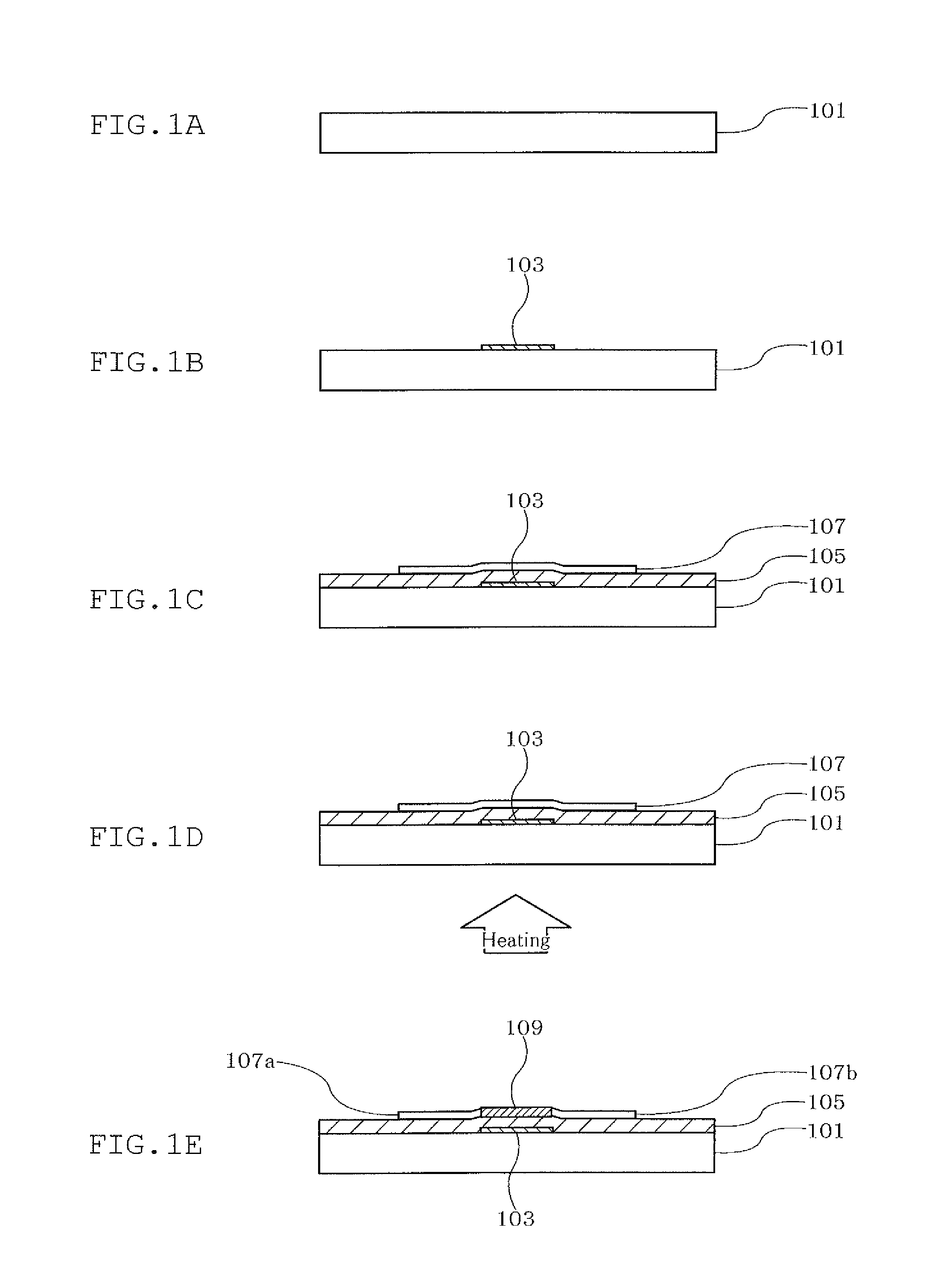

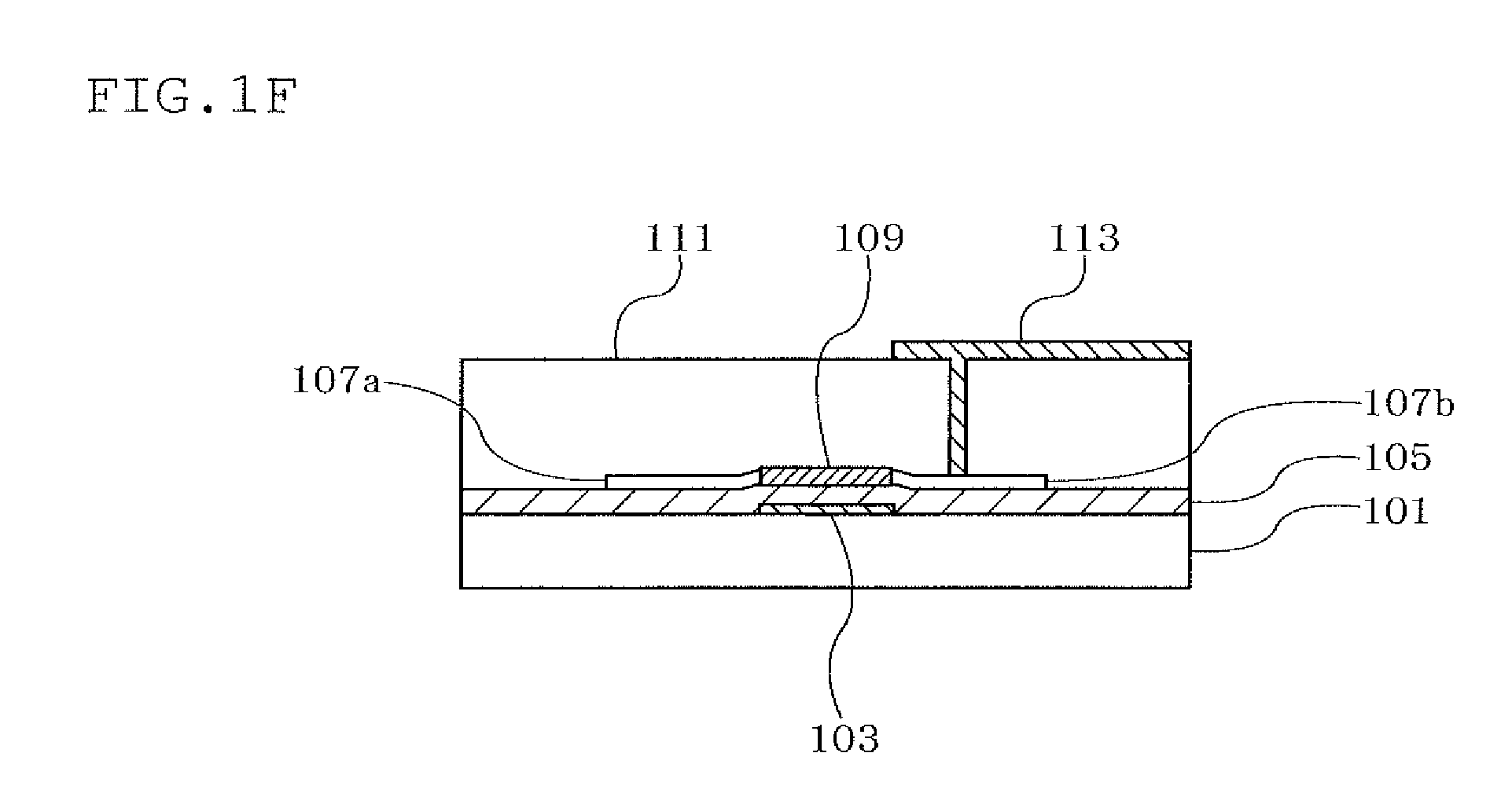

A field effect transistor including a source electrode 107a, a drain electrode 107b, a gate electrode 103, an insulating film 105 and a semiconductor layer 109 containing a crystalline oxide, wherein the source electrode 107a and the drain electrode 107b are self-aligned with the gate electrode 103 with the insulating film 105 therebetween.

Owner:IDEMITSU KOSAN CO LTD

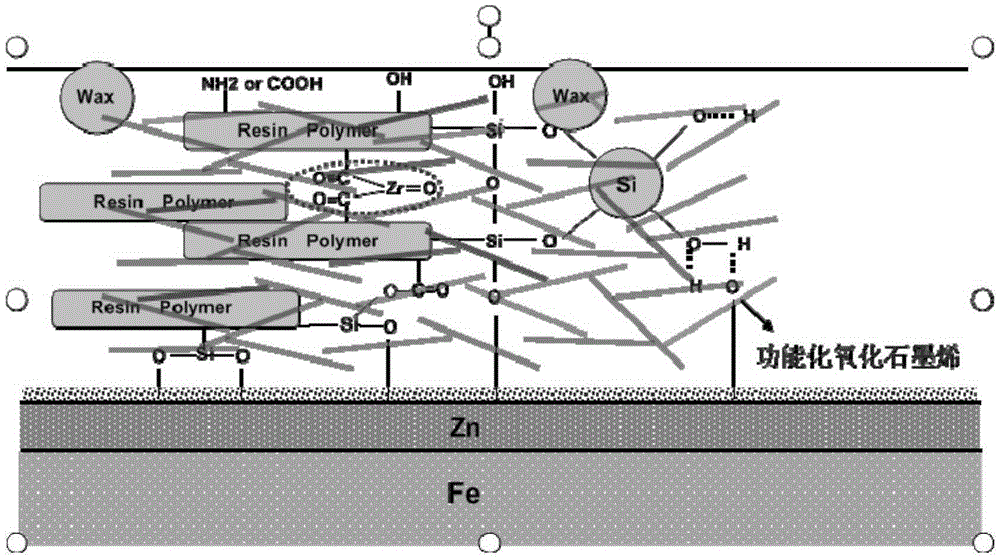

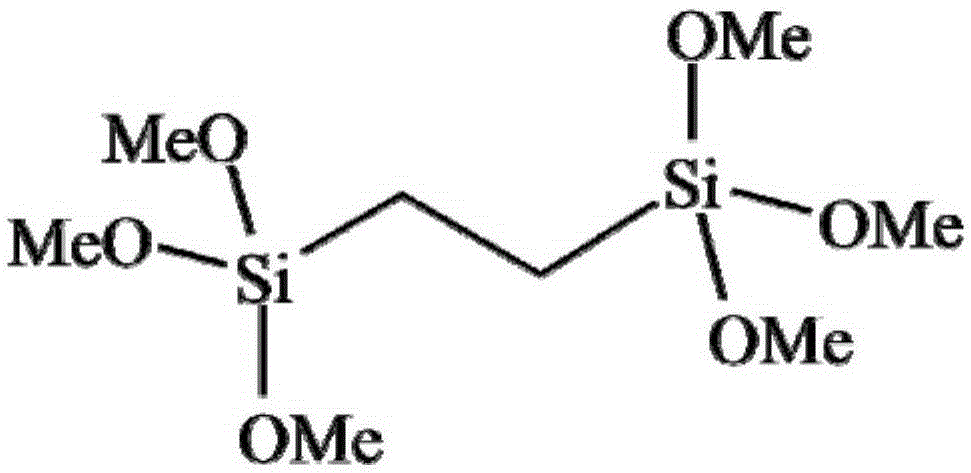

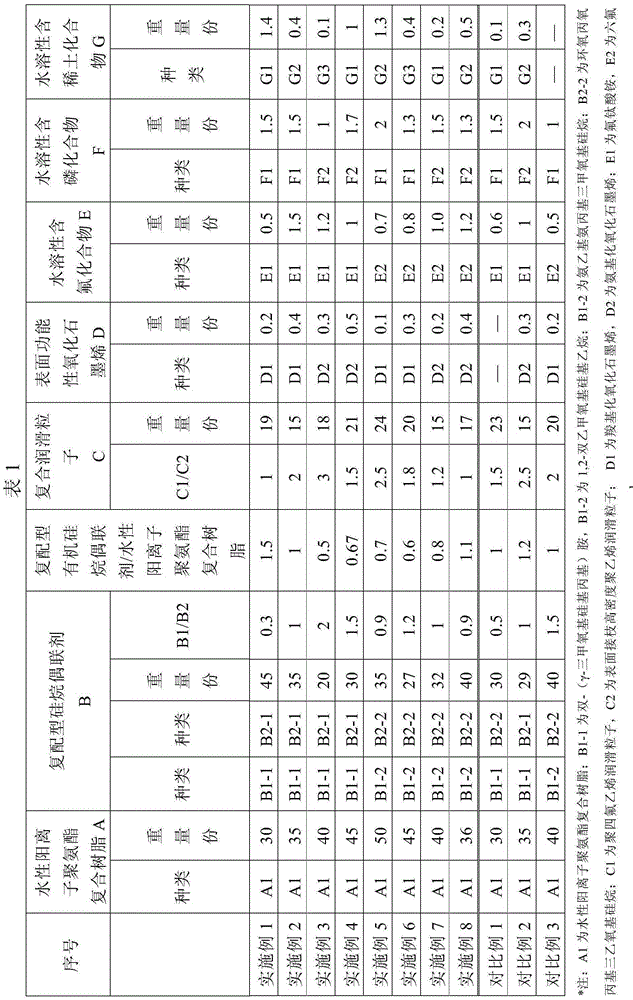

Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

ActiveCN105255338AGood acid and alkali resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCompound organic

The invention relates to a galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and a water-based surface treating agent. The surface of a galvanized steel sheet is coated with the surface treating agent in a solidified mode, wherein the surface treating agent includes water-based positive ion polyurethane composite resin, compound organic silane coupling agents containing bis-organic silane coupling agents and mono-organic silane coupling agents, compound lubrication particles containing teflon-surface modification high-density polyethylene particles, oxidized graphene, water-soluble fluorine-containing compounds, water-soluble phosphorous compounds, water-soluble rare earth salt compounds and other components, and therefore the surface treatment galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance is obtained. Meanwhile, the surface treatment galvanized steel sheet has good resistance, such as solvent resistance, to all kinds of chemical media.

Owner:BAOSHAN IRON & STEEL CO LTD

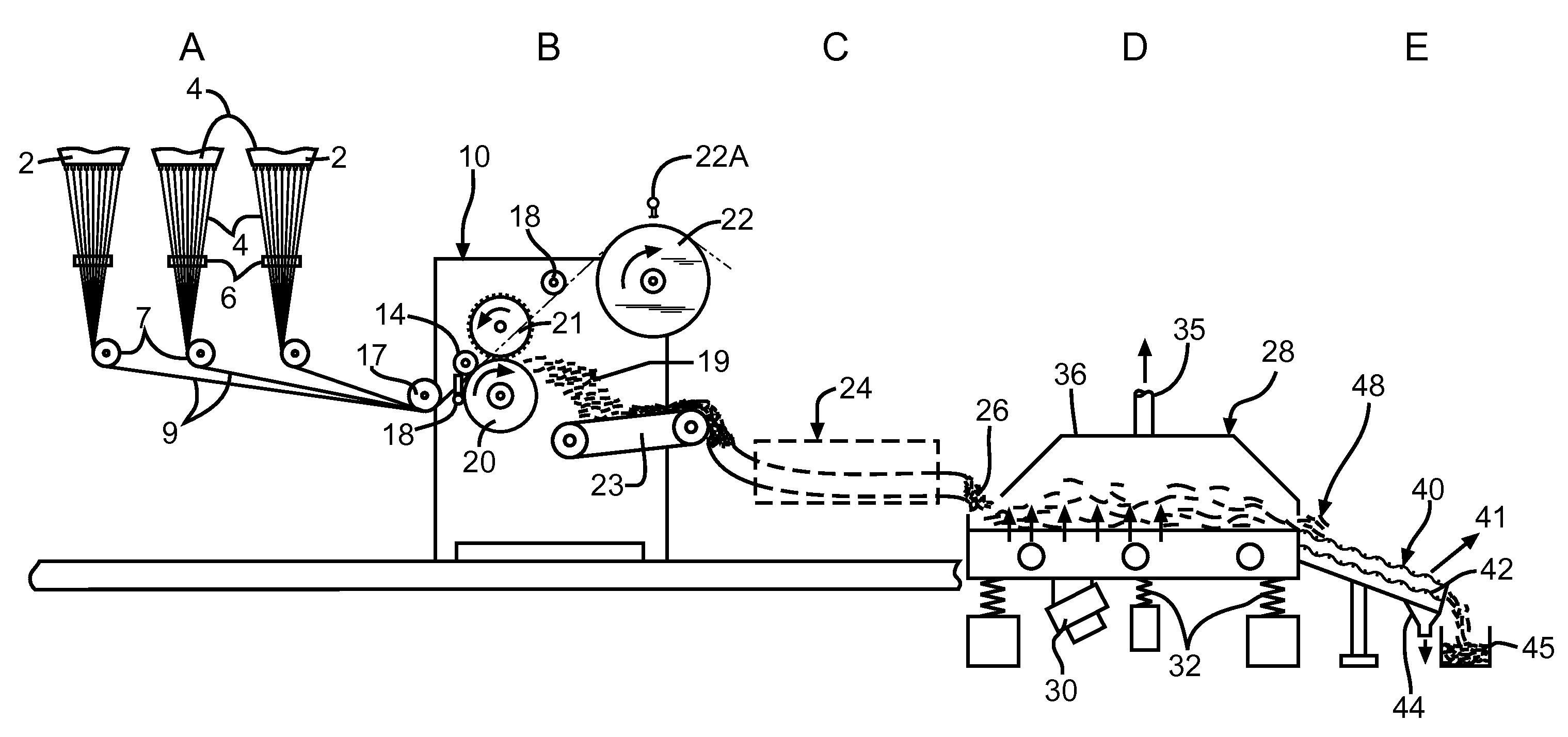

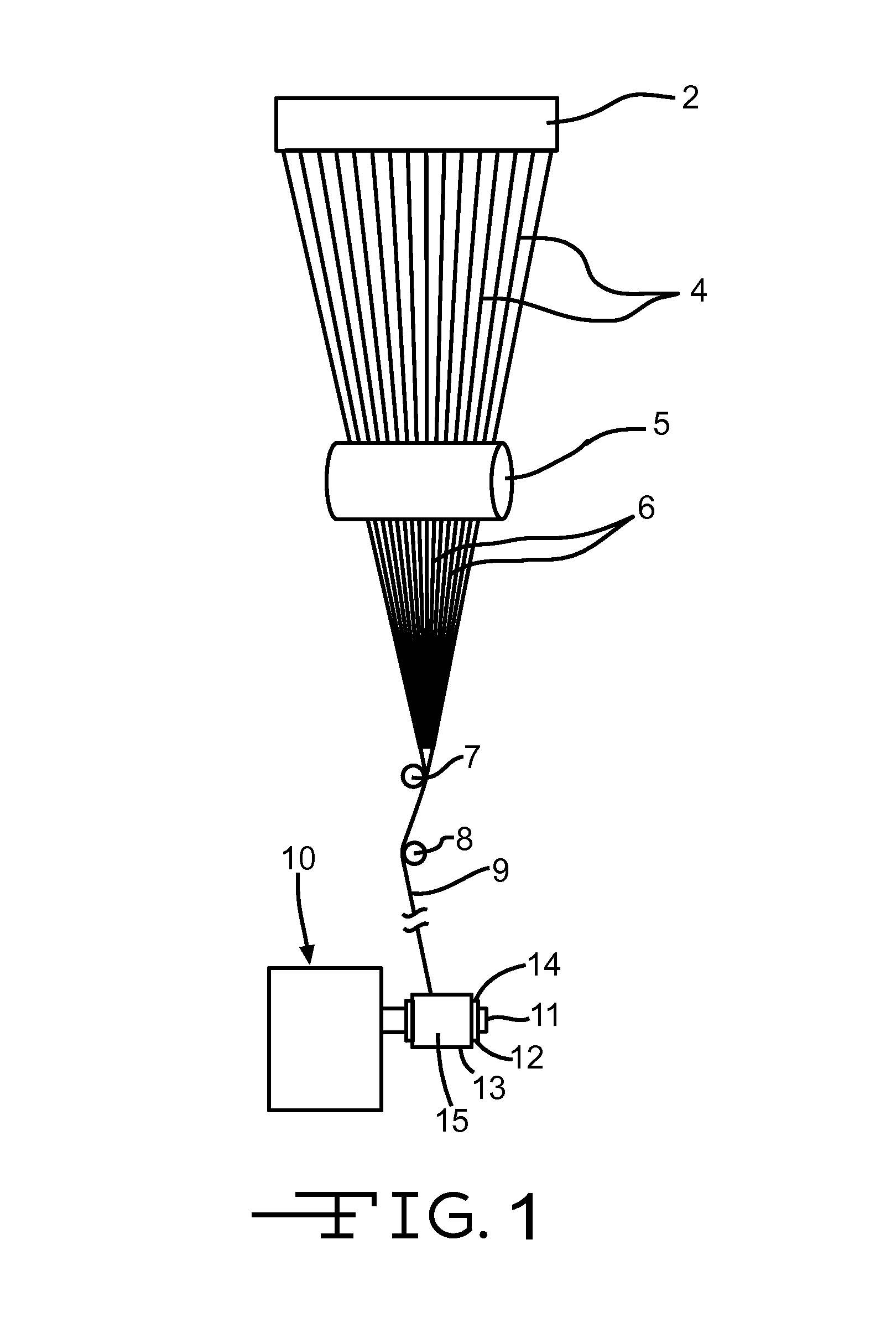

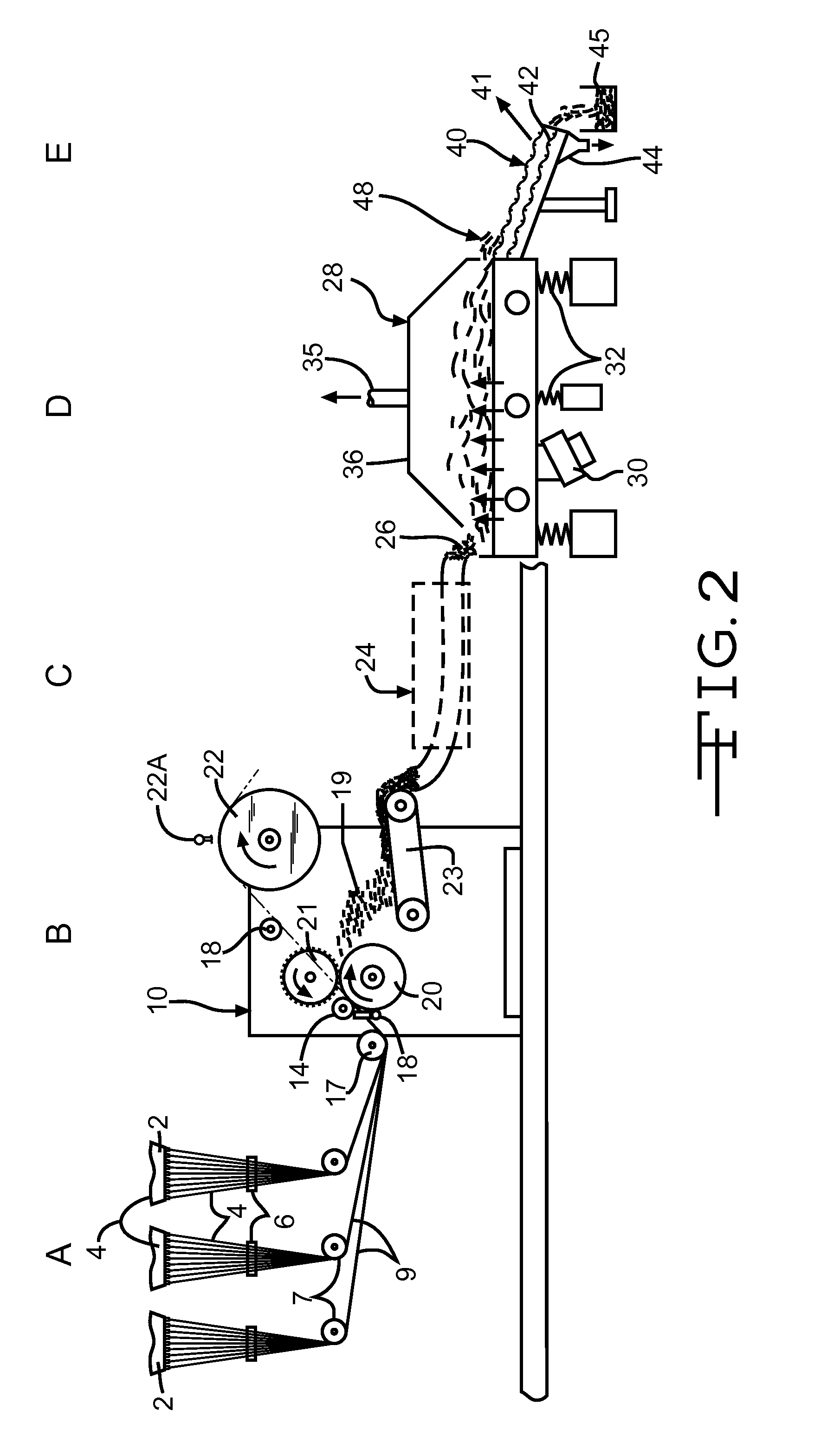

Methods of making reactive fiber/flake prepregs and reactive prepregs

ActiveUS20130165585A1Avoid stickingInhibition of polymerizationWood working apparatusAbsorbent padsOligomerAlternative methods

Prepreg compositions and methods of making them from particles and a binder composition are disclosed. The methods may include placing the particles on a moving conveying belt and applying the binder composition to the particles on the moving conveying belt to form a moving mass. Alternate methods may include first placing the binder composition on the moving conveying belt and then applying the particles to the binding composition to form the moving mass. The methods may further include passing the moving mass through one or more pairs of opposed, compacting rolls, where the particles and the binder composition are pressed into further contact while passing through the compacting rolls to form the prepreg. The binder composition in the prepreg may include monomers and / or oligomers of a polymer that are capable of polymerizing into the polymer under polymerization conditions.

Owner:JOHNS MANVILLE CORP

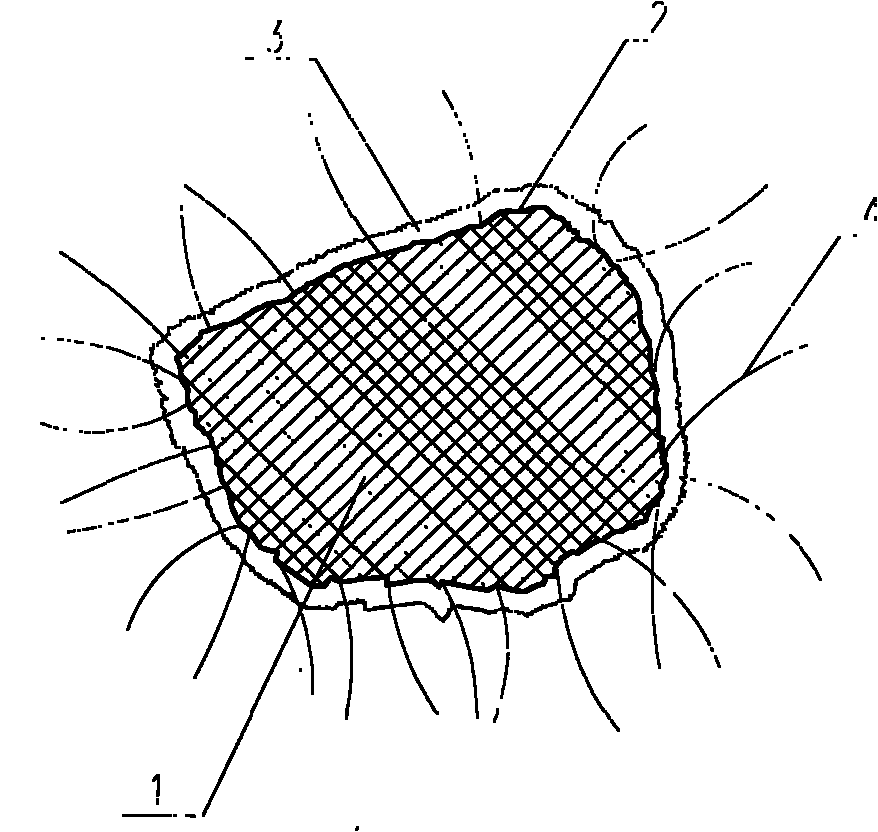

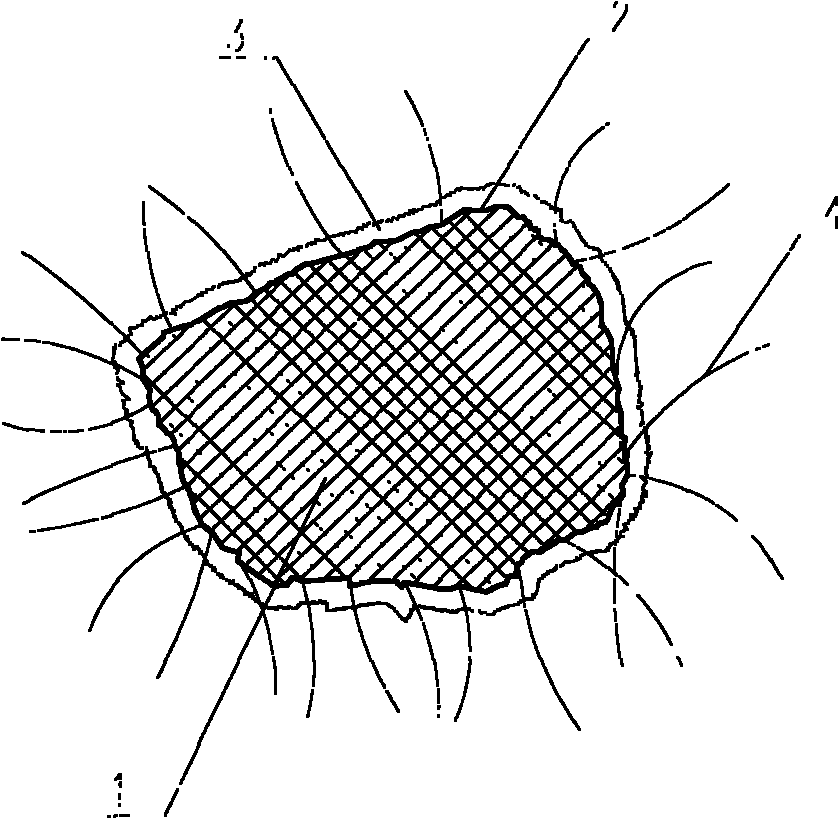

Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

InactiveCN101863631AHigh compressive strengthStrong resistance to deformationSilica fumeVolcanic ash

The invention discloses a stone aggregate wrapped by a microfine fibre polymer mortar thin layer and a preparation method thereof; the stone aggregate is formed by stone aggregate inner cores, an adhesive inner wrapping layer, a polymer cement mortar outer wrapping layer and an adhesive microfine fibre hair layer, wherein the adhesive inner wrapping layer and the stone aggregate are adhered firmly; microfine fibre filaments are anchored and rooted on the adhesive inner wrapping layer; and the polymer cement mortar outer wrapping layer and the adhesive inner wrapping layer are soluble mutually and can effectively form a whole body. Active powder in the polymer cement mortar outer wrapping layer contains silica fume, zeolite powder, finely-ground mineral slag, pulverized coal ash and the like, and can generate volcanic ash reaction with Ca(OH)2 crystal at the interface position of the set cement so as to generate gelled materials, and further carry out improved treatment on the weakest interfaces of set cement and the stone aggregate in concrete. The modified stone aggregate of the invention has good affinity with the set cement, and has higher binding power with the set cement.

Owner:NANTONG ZHONGRUN CONCRETE +1

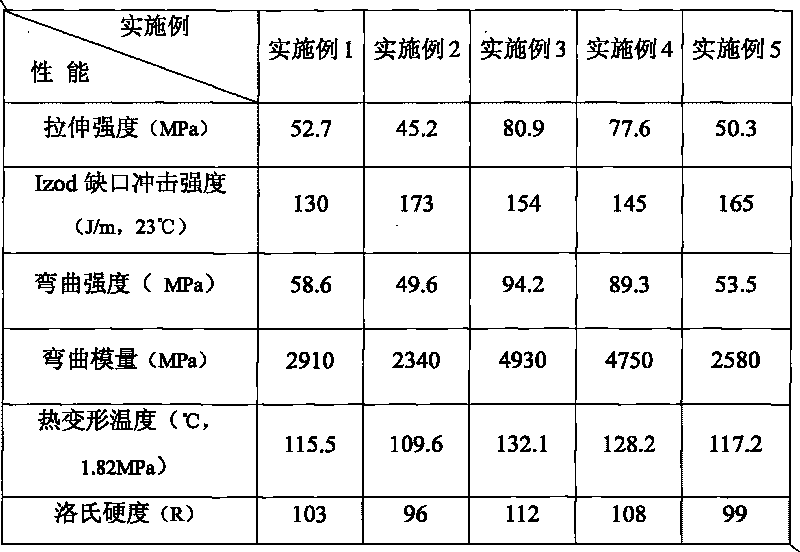

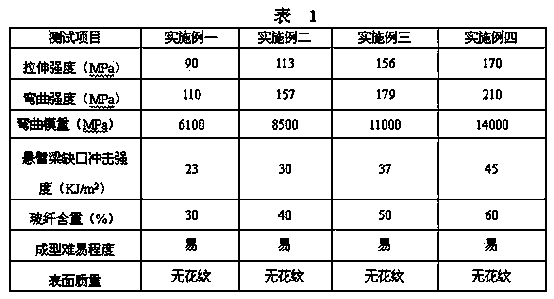

Novel high-intensity high heat-resistance polypropylene modified composite material and preparation method thereof

The invention relates to a novel high-intensity high heat-resistance polypropylene modified composite material and a preparation method thereof. The novel high-intensity high heat-resistance polypropylene modified composite material comprises the following components: 49-69.4 percent of polypropylene, 10-30 percent of calcium sulphate whiskers, 5-25 percent of glass fibers, 5-15 percent of maleic anhydride grafted polypropylene, 0.1-0.2 percent of nucleating agents, 0.3-0.6 percent of antioxygen and 0.2-0.5 percent of lubricating agents. The preparation method comprises the following steps: firstly uniformly mixing all the components except the glass fibers in a mixer according to the proportion; mixing the mixture in a double-screw extruder; adding the glass fibers from a fiberglass intake of the double-screw extruder; and mixing the mixture in the double-screw extruder, extruding, cooling and pelletizing. The calcium sulphate whiskers and the glass fibers are mixed to reinforce the polypropylene; in addition, with the special structure of the calcium suhphate whiskers, not only the intensity and the heat-resistance of the polypropylene modified material can be enhanced, but also the size stability and the surface finish of products can be improved, and the application field of the polypropylene modified material can be enlarged.

Owner:SUZHOU HESHENG NEW MATERIALS

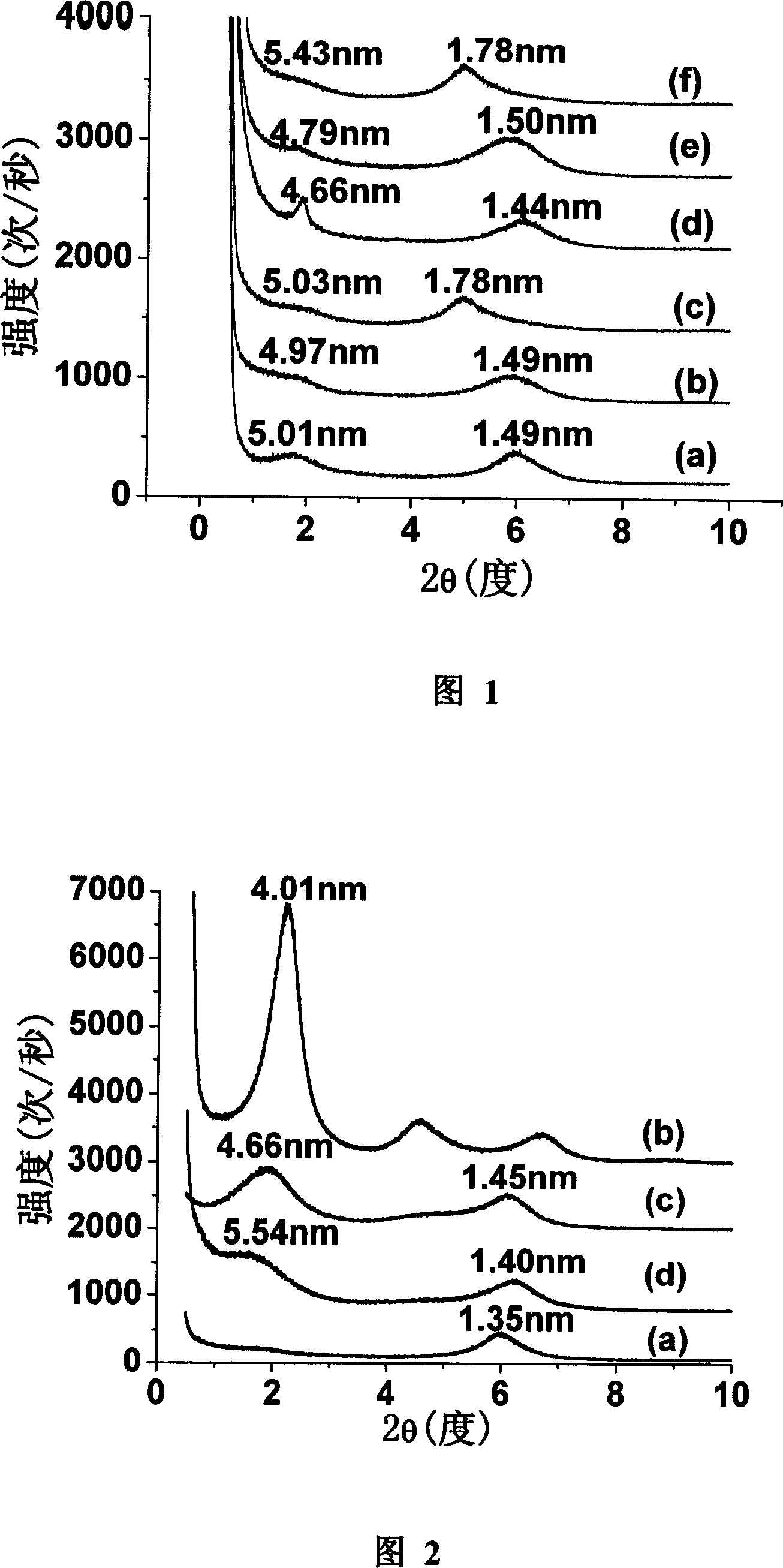

Preparation method of polypropylene nano composite material

ActiveCN102086280AGood modification effectImprove interface strengthHeat deflection temperatureMasterbatch

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Resistive nanocomposite compositions

InactiveUS6617377B2Increased mechanical and wear and electrical and thermal propertyImprove material performanceNanotechPrinted electric component incorporationScreen printingOrganic solvent

A resistive composition for screen printing onto a substrate. The resistive composition, based on total composition has a) 5-30 wt. % of polymer resin, b) greater than 0 up to and including 10 wt. % of thermosetting resin, c) 10-30 wt. % conductive particles selected from the group consisting of carbon black, graphite and mixtures thereof and d) 0.025-20 wt. % carbon nanoparticles, wherein all of (a), (b), (c) and (d) are dispersed in a 60-80 wt. % organic solvent.

Owner:CTS CORP ELKHART

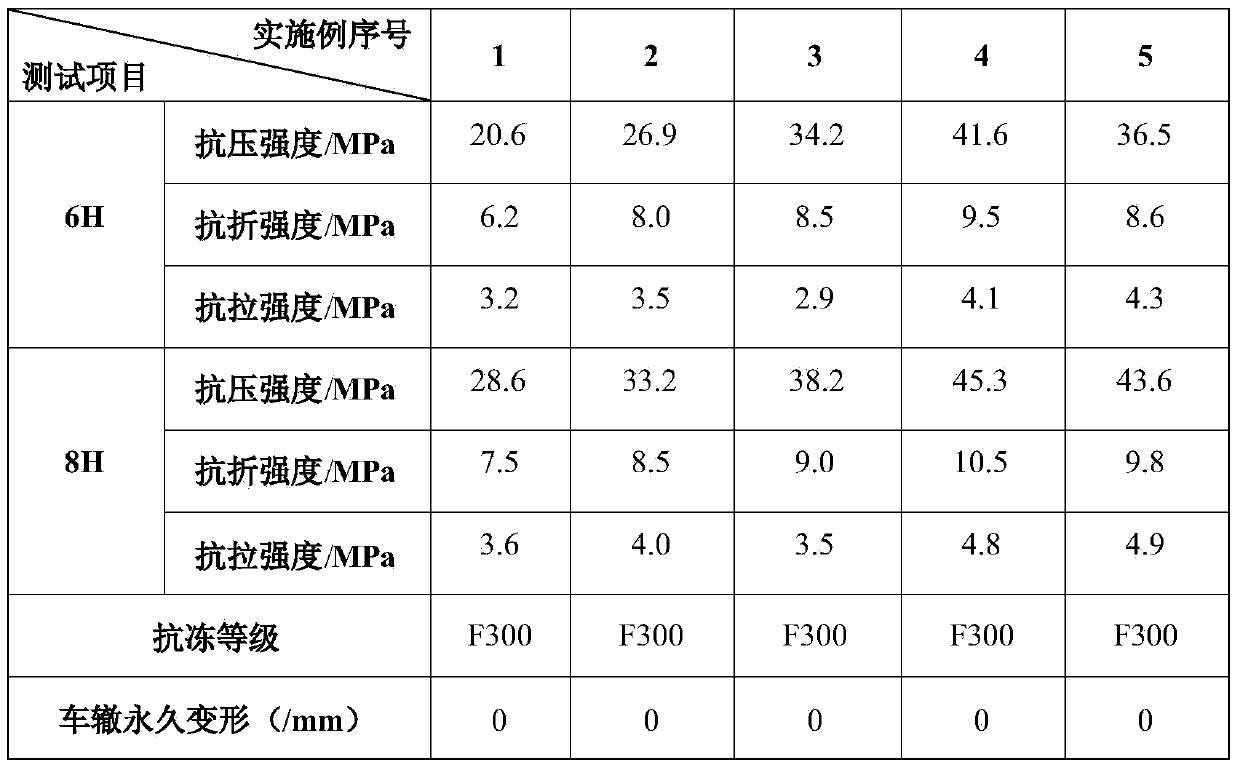

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Processing of biocompatible coating on polymeric implants

ActiveUS20100016985A1Rapid osteointegrationSuperior performanceDental implantsImpression capsPolymer substrateCalcium biphosphate

The present invention provides polymeric substrates comprising a biocompatible coating and methods of preparation thereof. In particular, the coating may be a ceramic material, especially a calcium phosphate material, which may be functionally graded. The invention provides the ability to apply high quality coatings to polymeric substrates without damaging the substrate (e.g., melting the polymeric material). The functionally graded coating can provide crystalline calcium phosphate near the coating interface with the substrate and provide amorphous calcium phosphate at the outer surface of the coating.

Owner:NORTH CAROLINA STATE UNIV

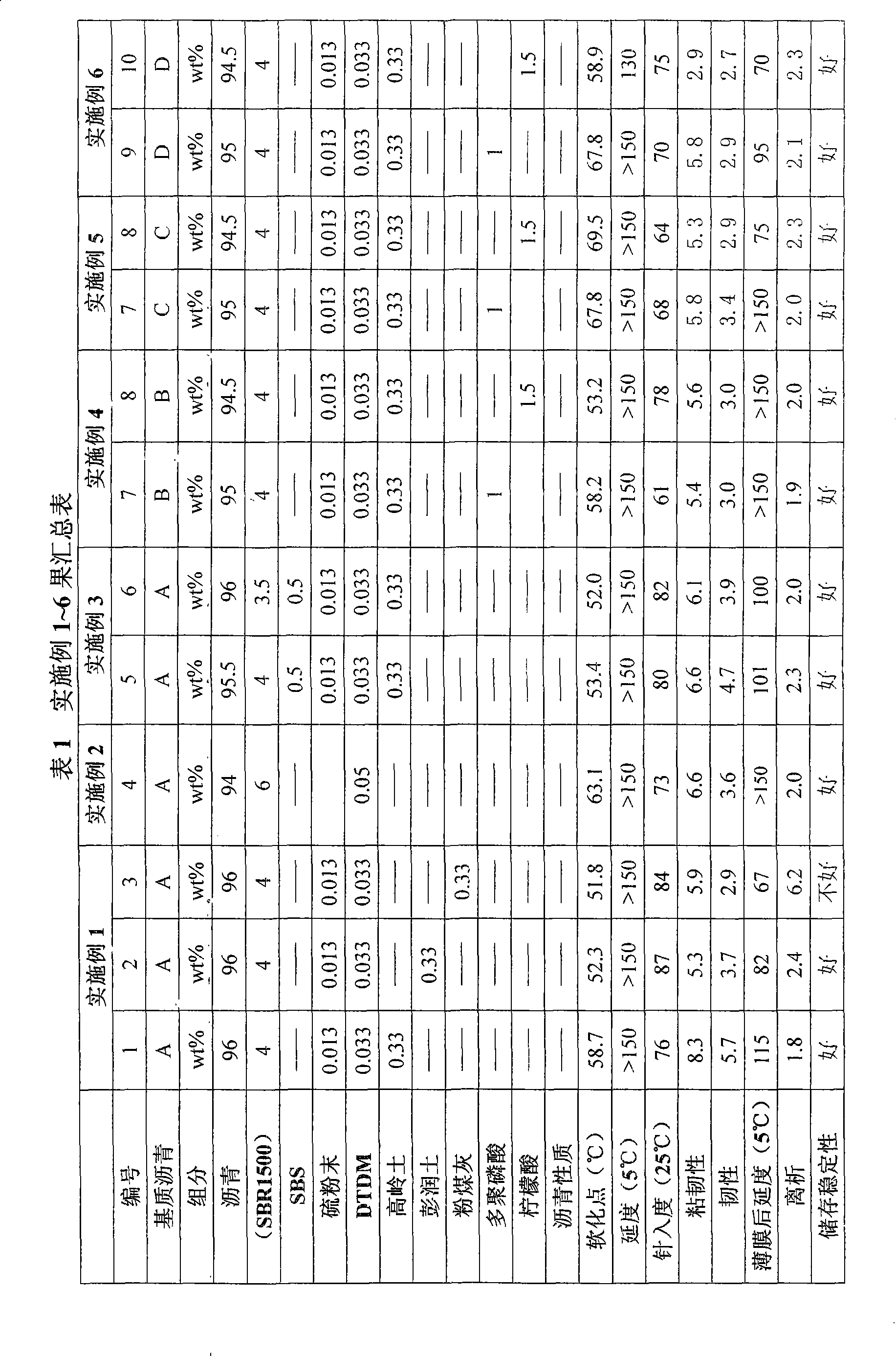

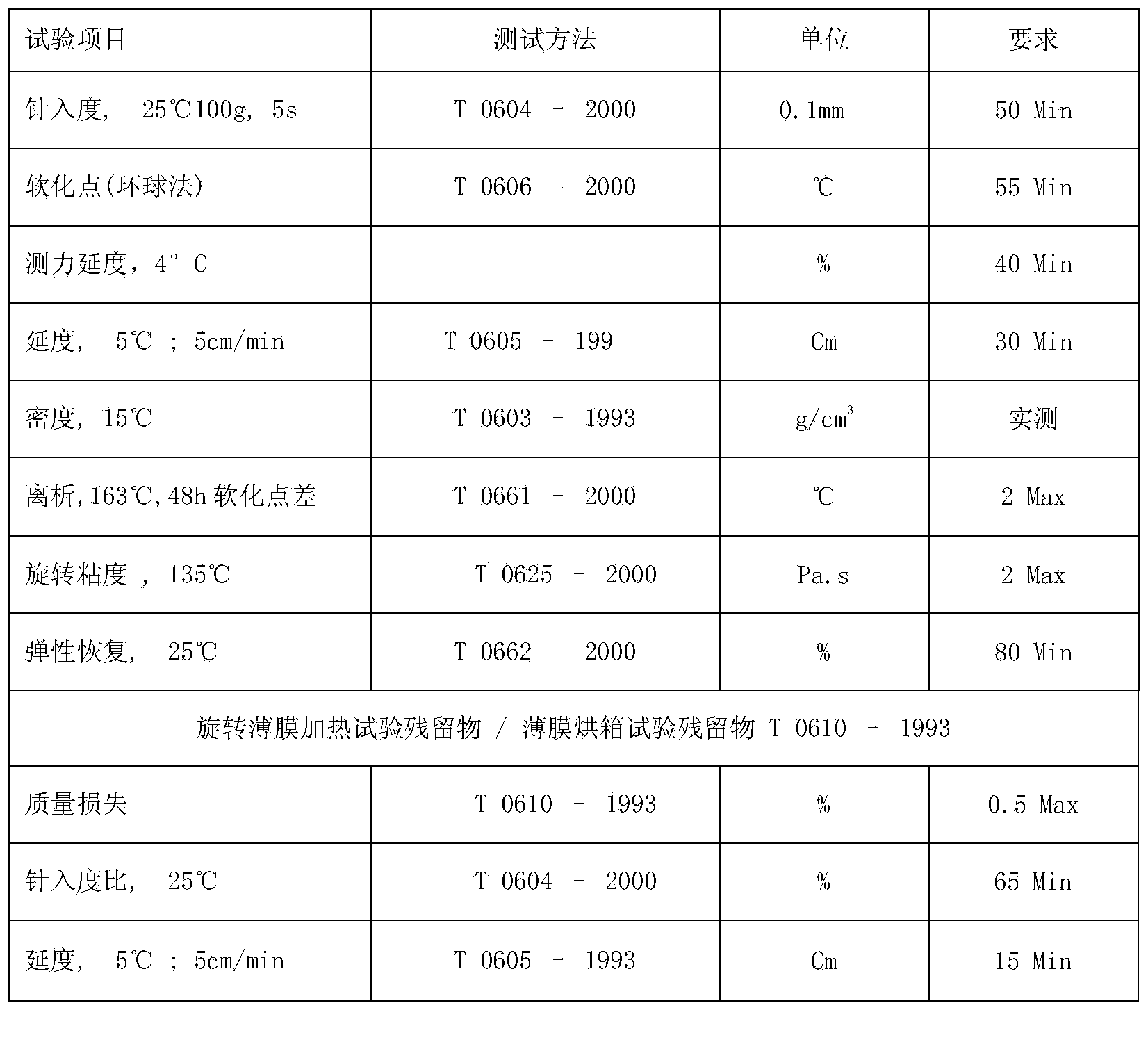

Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

InactiveCN101613533AGood storage stability at high temperatureMeet usable requirementsBuilding insulationsElastomerViscous liquid

The invention relates to a high polymer chemically-modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps: chemically modifying rubber, elastomer and base asphalt, and additionally matching stuffing and processing aids; premixing the materials by high polymer processing equipment to prepare the master batch of the modified asphalt; and fully dispersing the master batch into the asphalt by a high-speed shear mixer or by mechanical stirring. Or the modified asphalt material can be prepared by firstly pre-preparing a viscous liquid mixture of modified asphalt and then stirring and mixing the viscous liquid mixture of modified asphalt with the base asphalt. The modified asphalt material prepared by the invention has stable storage performance at high temperature, good performance at high temperature and low temperature, stable processing and preparation and simple and convenient method, and not only can be directly used in factory production but also can be used for road laying sites and in the construction of waterproofing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

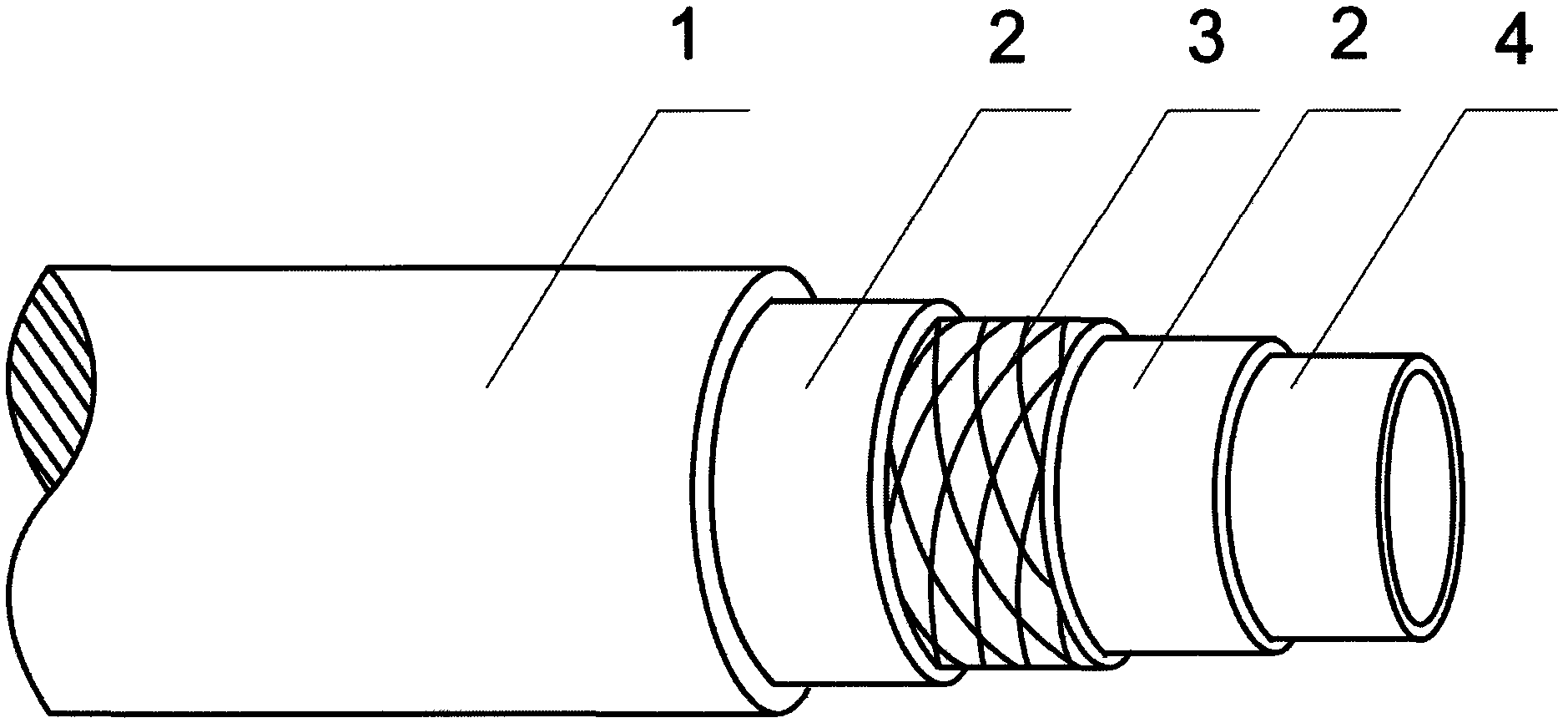

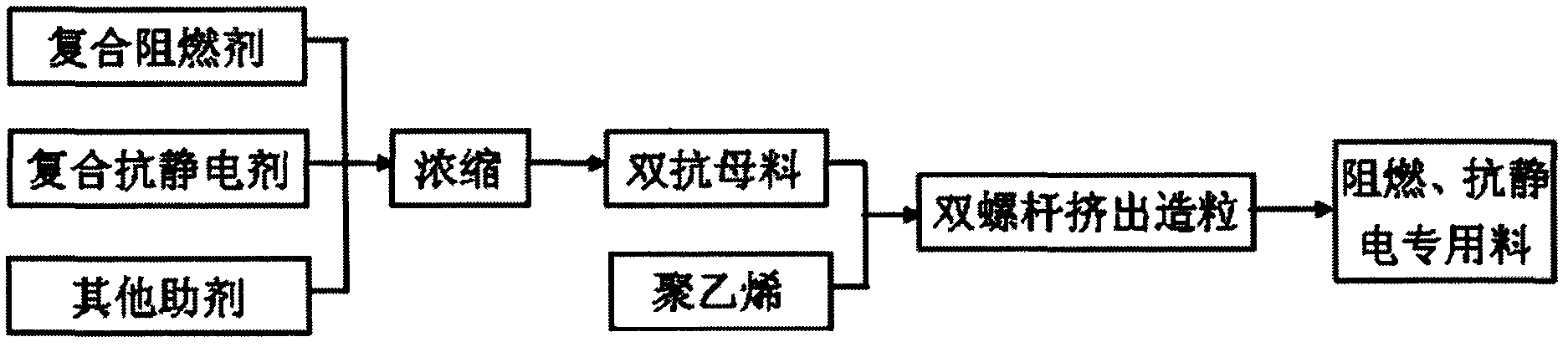

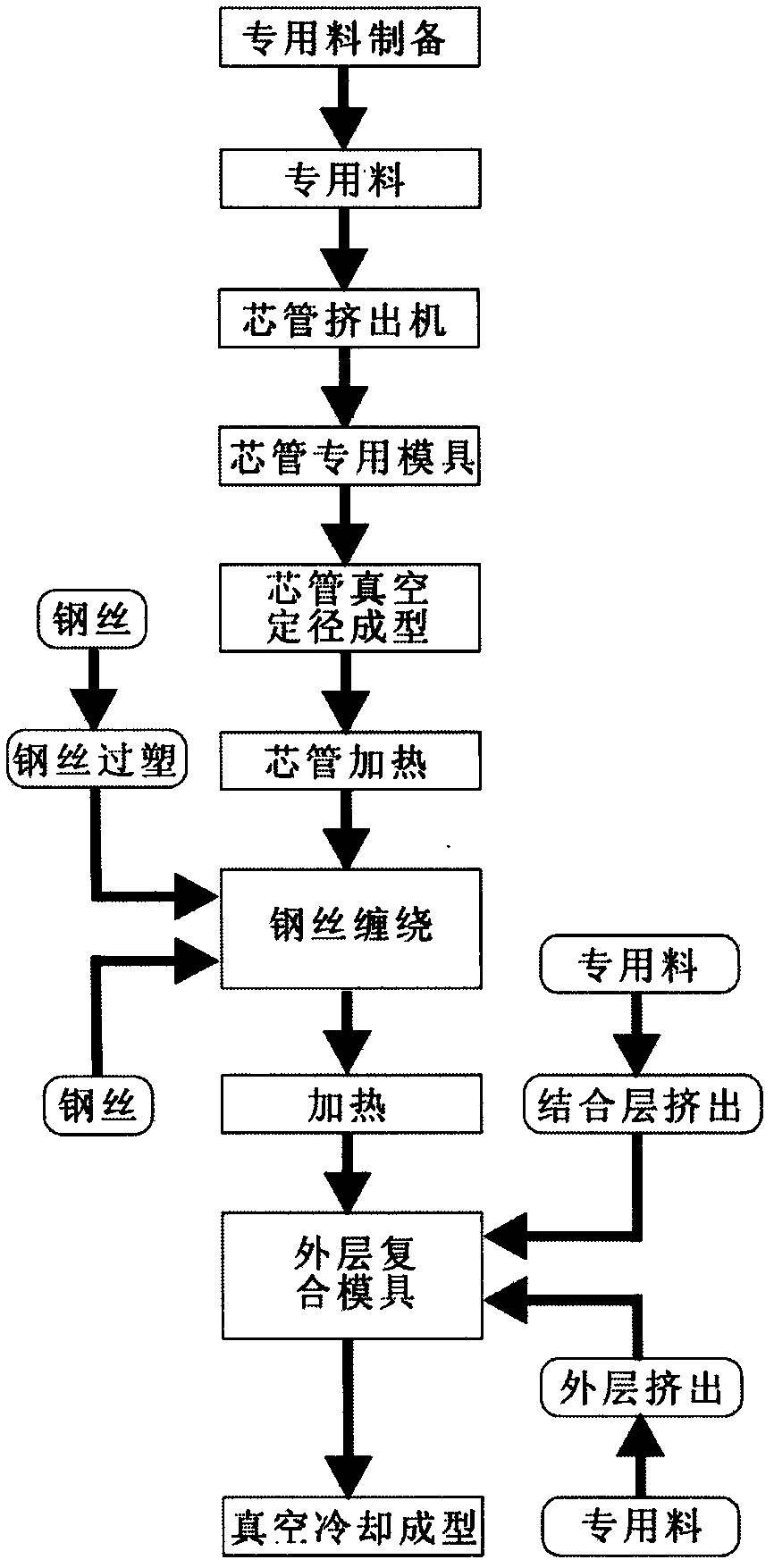

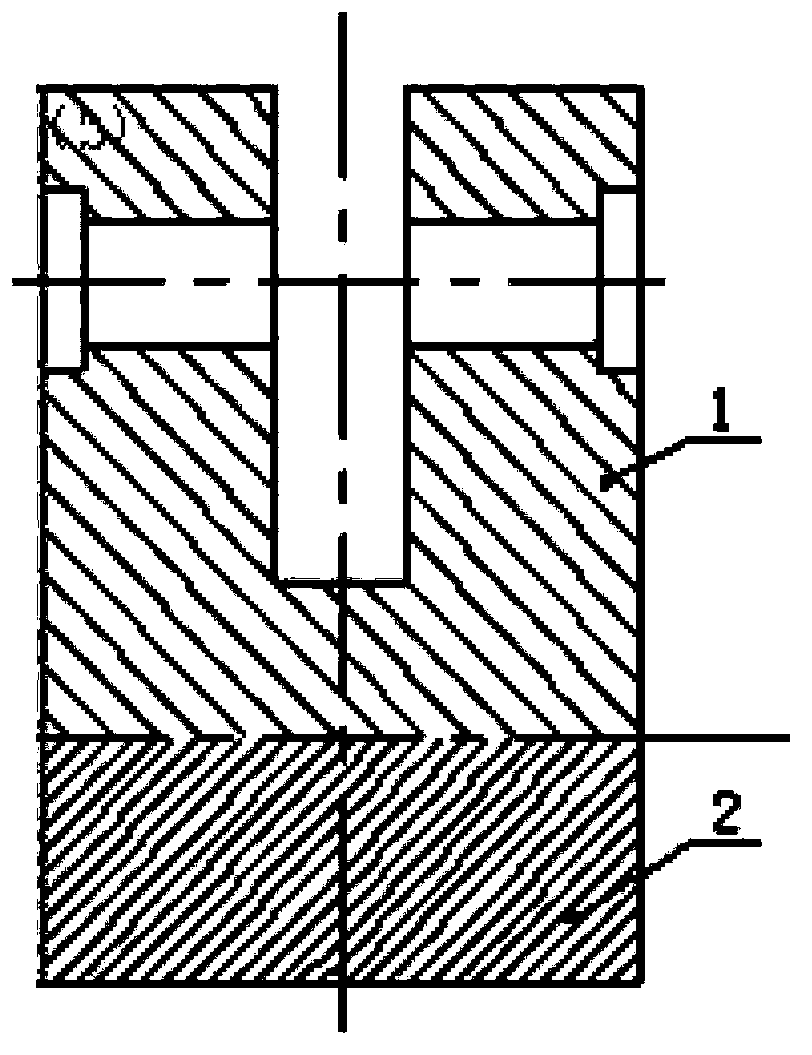

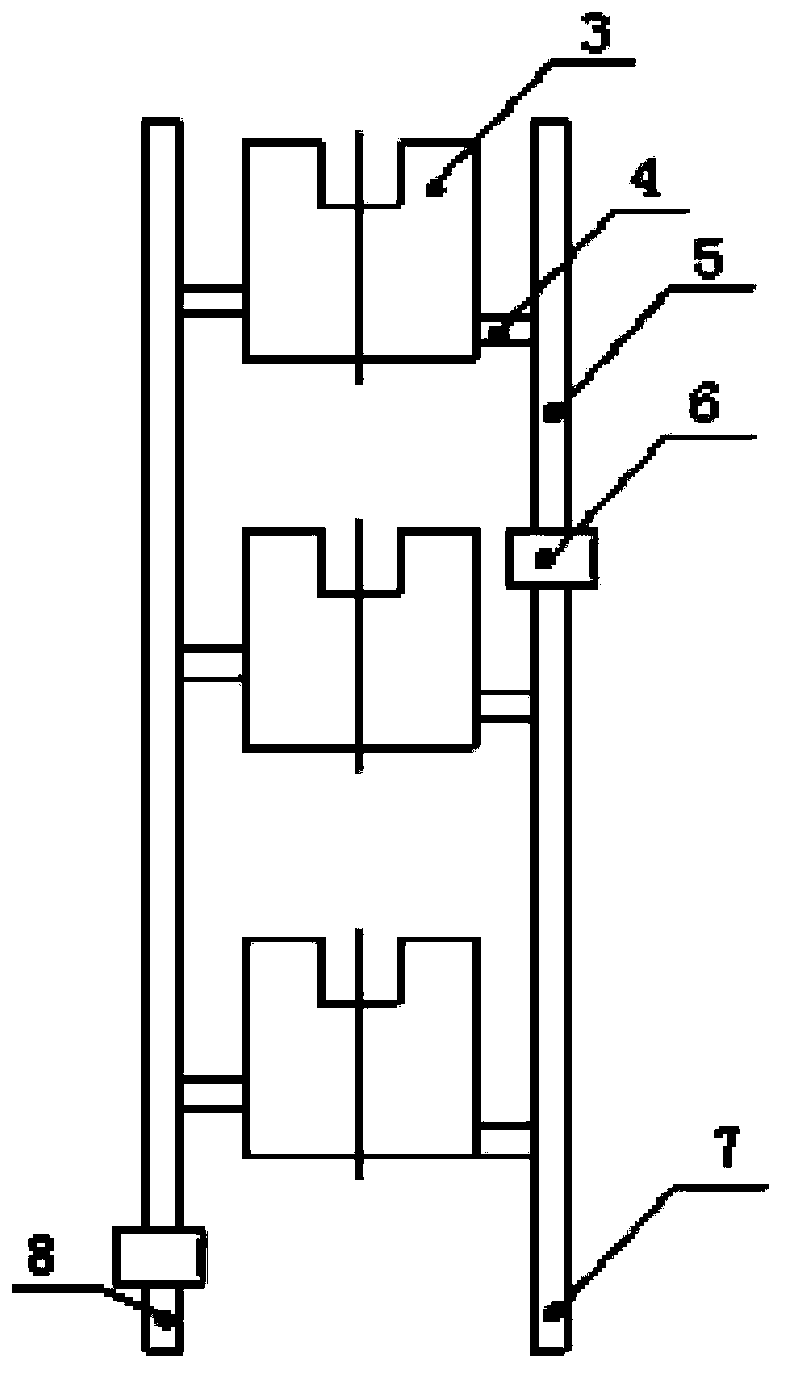

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

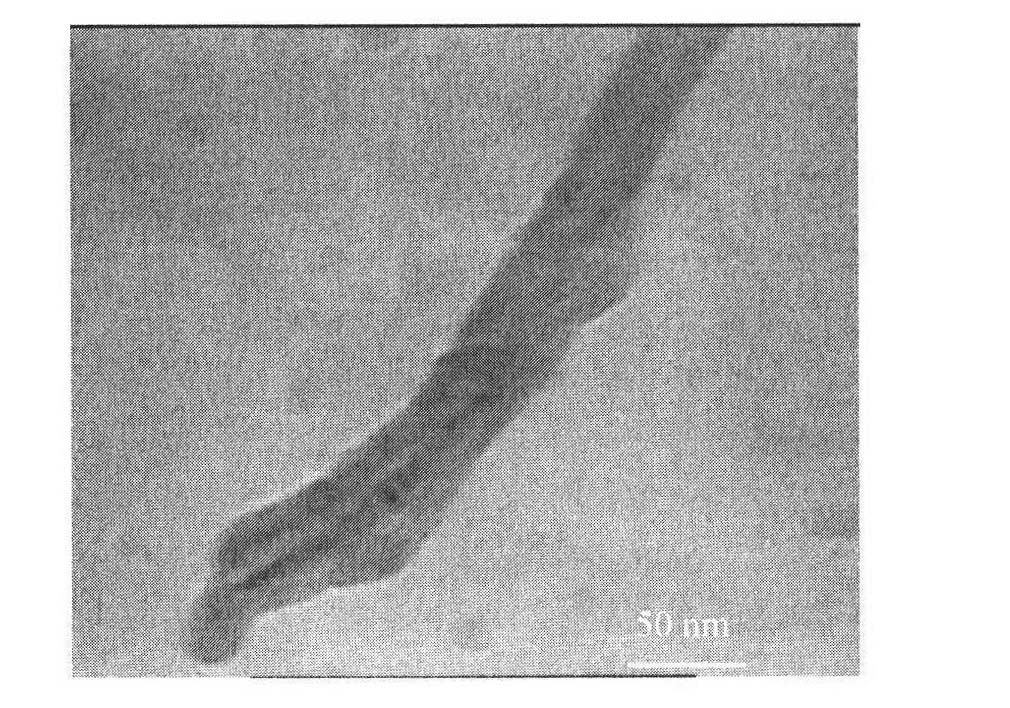

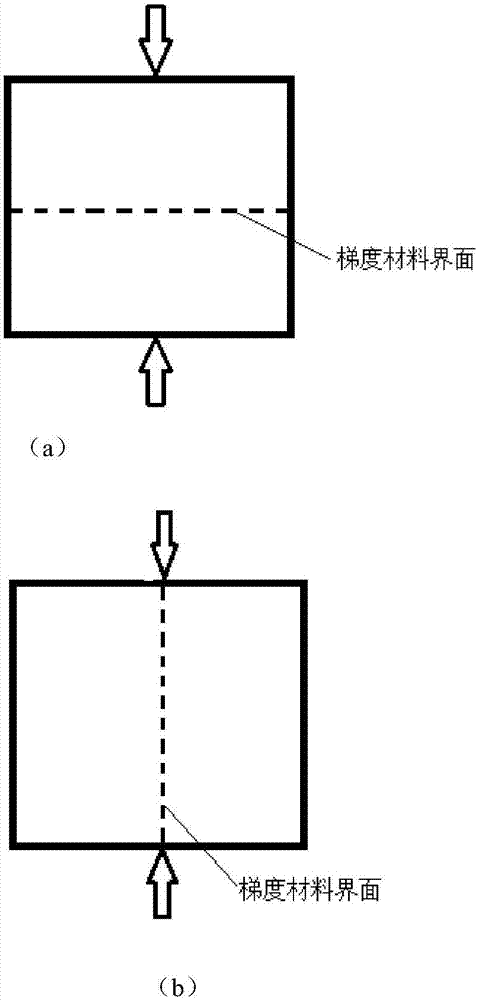

Method for preparing hybrid composite material of carbon fibers/carbon nanotubes/bismaleimide resin

InactiveCN101787128AIncreased interlaminar shear strengthImprove interface strengthFiberCarbon fibers

The invention belongs to the technical field of nano materials, and in particular relates to a method for preparing a hybrid composite material of carbon fibers / carbon nanotubes / bismaleimide resin. The method comprises the following steps: after carboxylating, acylating and chlorinating the surfaces of purified carbon nanotubes and dried carbon fibers, introducing diamine or polyamine with a feature structure thereon, wherein a large amount of the diamine or the polyamine are jointed on the surfaces of the carbon nanotubes and the carbon fibers; performing an addition reaction on the carbon nanotubes jointed with the amidogen and the bismaleimide resin to obtain a carbon nanotubes-containing bismaleimide resin linear block polymer serving as a substrate; and compositing the substrate and the carbon fibers in a certain mode to form a multi-dimensional hybrid composite material structure linked by covalent bonds finally. The method has the advantages of strengthening and toughening bismaleimide by using the strength and the toughness of the carbon nanotubes, improving the bonding strength between the bismaleimide and the carbon fiber substrate surface, improving overall performance of the multi-dimensional hybrid composite material of the carbon fibers / the carbon nanotubes / the bismaleimide resin, and widening the application of the carbon fibers, the carbon nanotubes and the bismaleimide resin.

Owner:TONGJI UNIV

High-strength lightweight aggregate concrete and preparation method thereof

The invention relates to high-strength lightweight aggregate concrete and a preparation method thereof, and belongs to the technical field of building material concrete. The lightweight aggregate concrete is prepared from the following raw materials in parts by weight: 105-118 parts of cement, 180-185 parts of light coarse aggregate, 120-125 parts of fine aggregate, 65-70 parts of mineral admixtures, 9-24 parts of modified polypropylene fiber, 3.4-3.8 parts of concrete admixtures and 65-70 parts of water. The preparation method comprises the following steps that the raw materials are weighed according to the formula ratio, the light coarse aggregate is added into water accounting for one half of the total water amount for pre-wetting for 45-60 minutes, then the fine aggregate is added, stirring is carried out for 1-2 minutes, the cement, the mineral admixtures and the modified polypropylene fiber are continuously added, uniform stirring is carried out, then the concrete admixtures andthe rest water are added, and uniform stirring is carried out so as to obtain the high-strength lightweight aggregate concrete. The high-strength lightweight aggregate concrete and the preparation method thereof have the advantages that the strength is high, and the quality is stable.

Owner:武汉中阳明建材有限公司

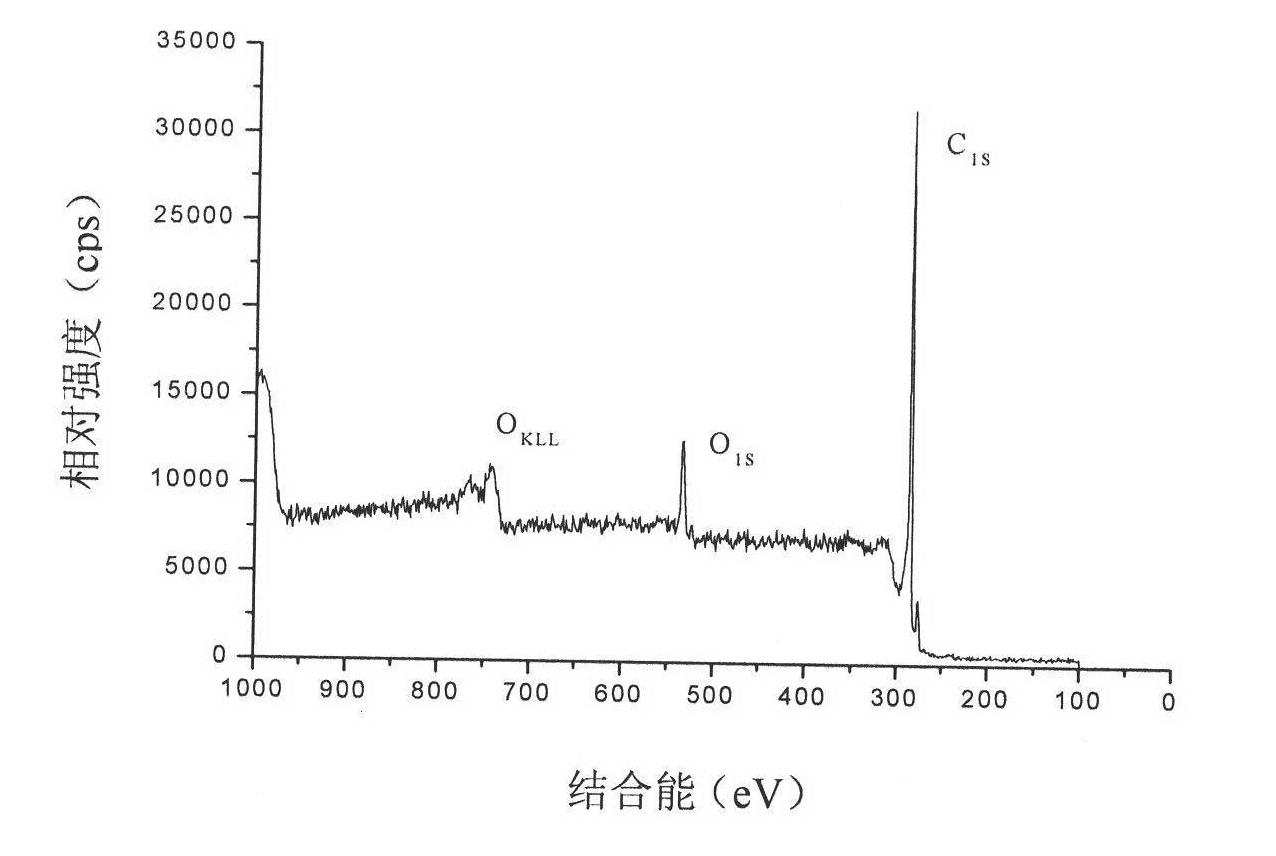

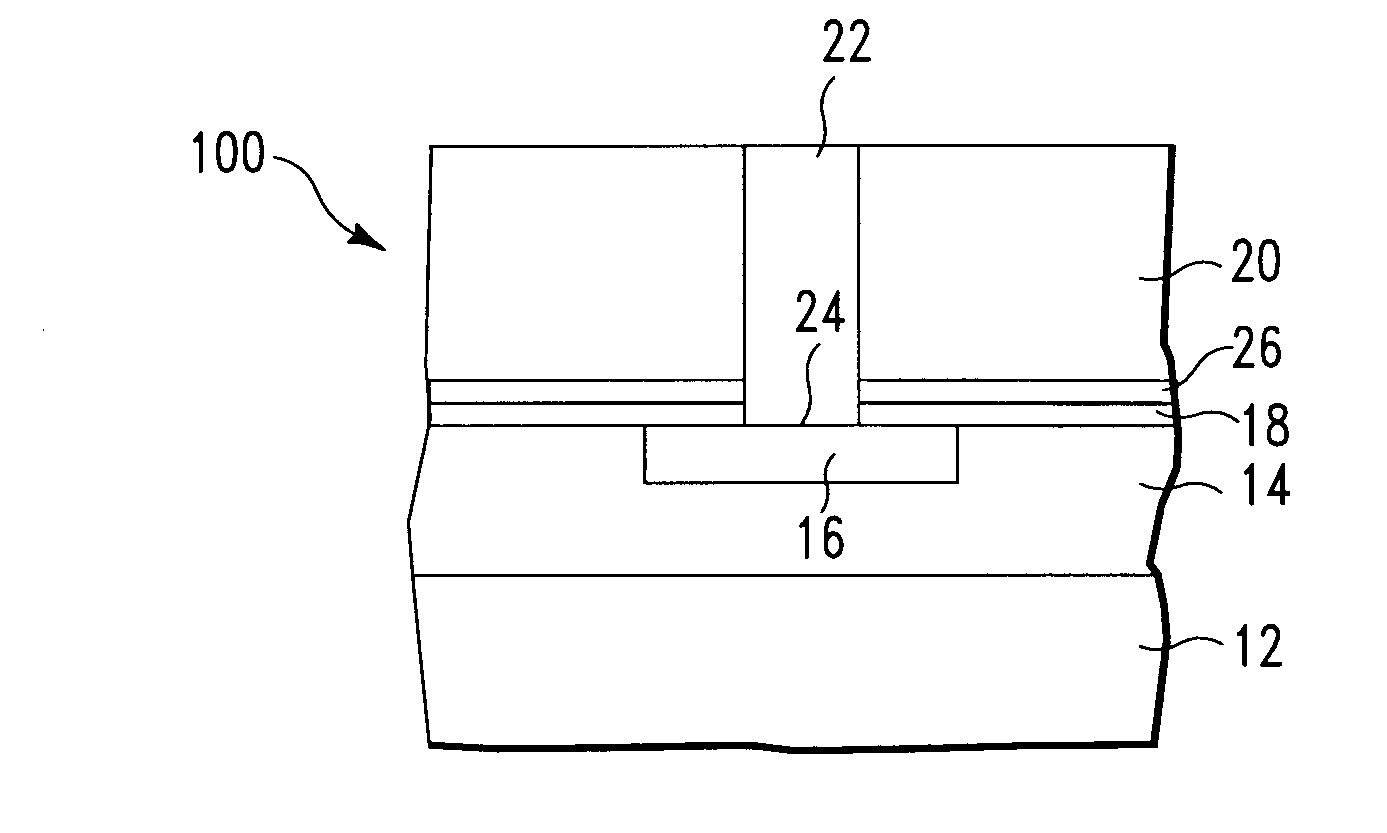

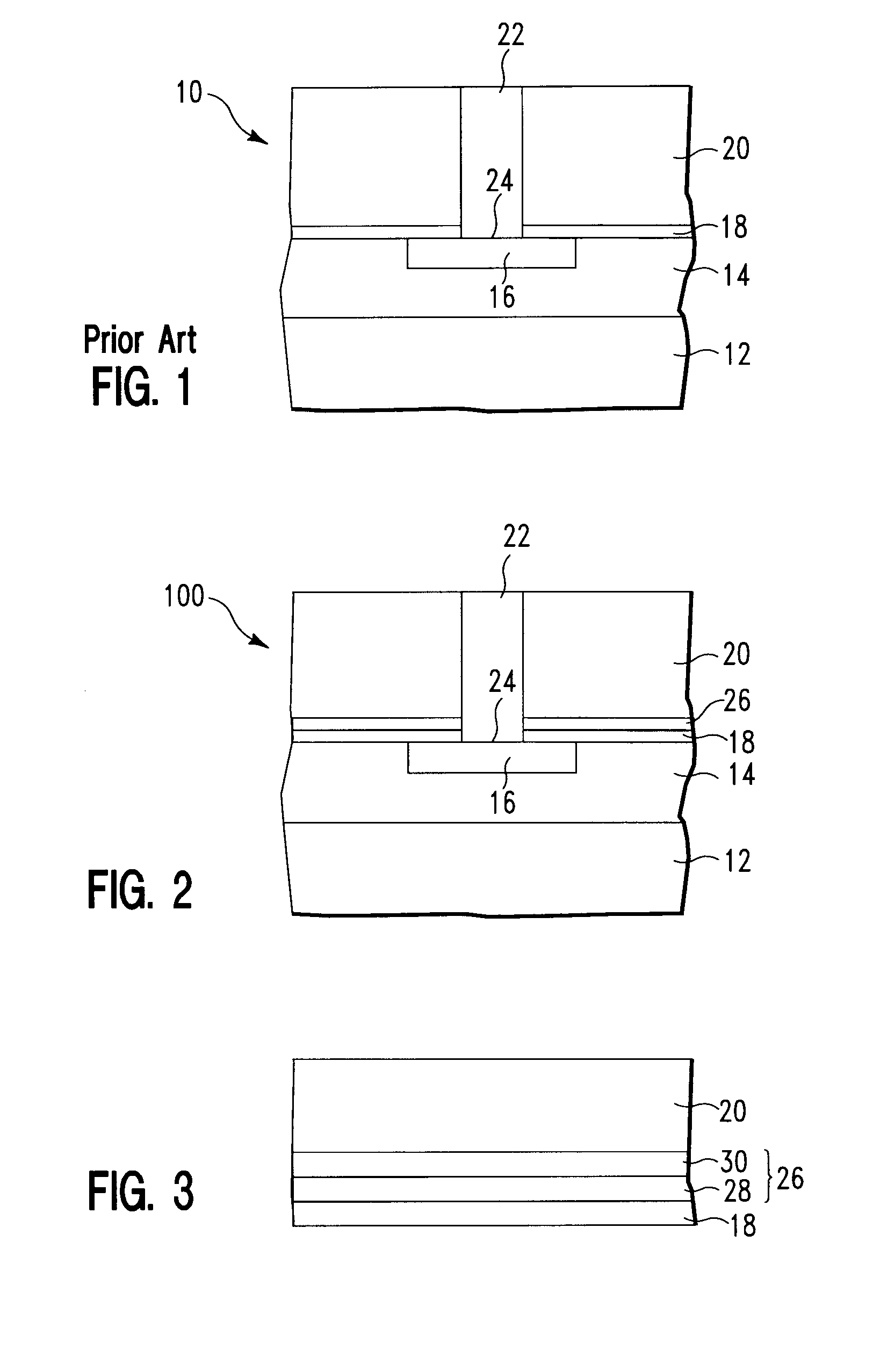

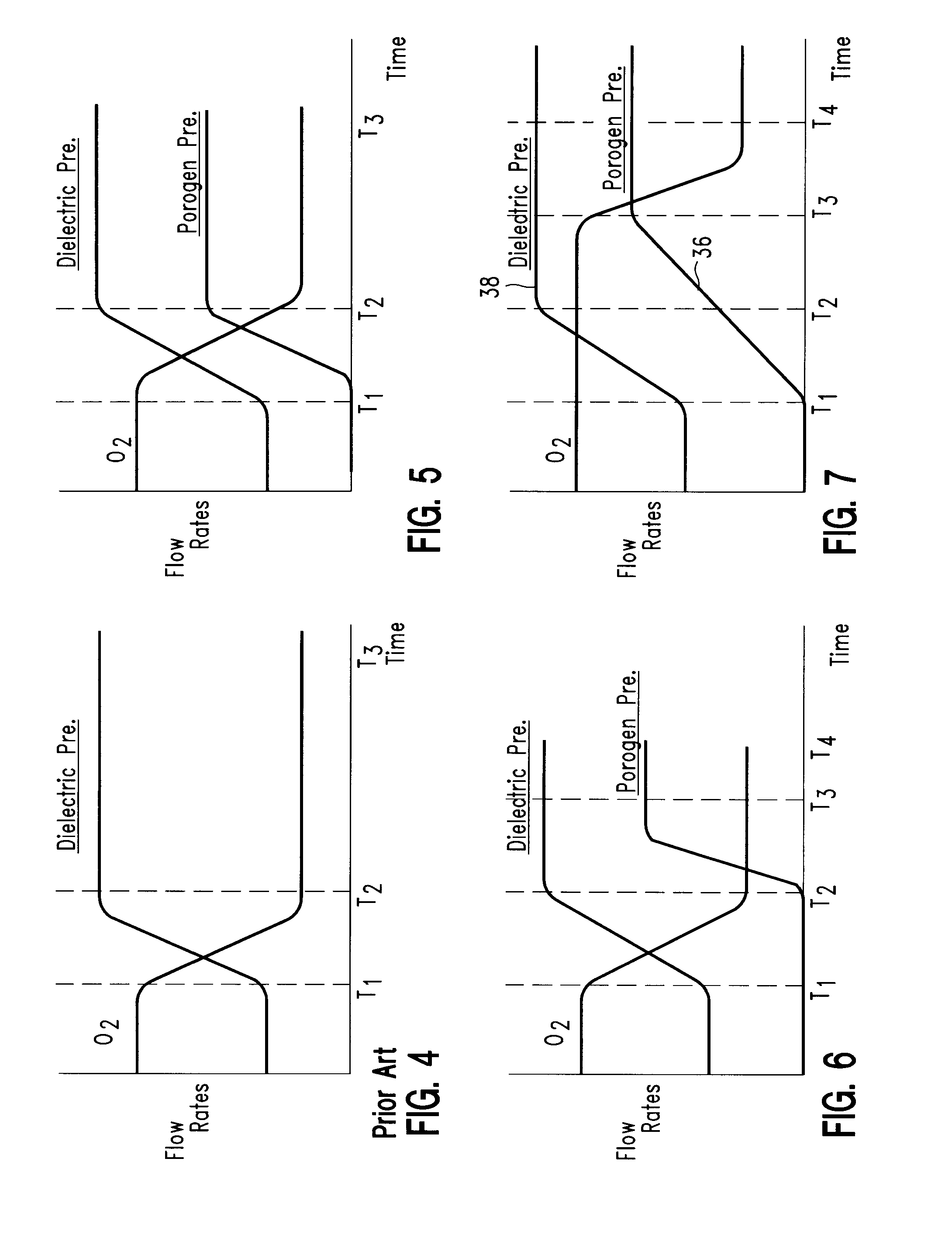

STRUCTURE AND METHOD FOR SiCOH INTERFACES WITH INCREASED MECHANICAL STRENGTH

ActiveUS20080233366A1Improve interface strengthDecorative surface effectsLayered productsConductive materialsOptoelectronics

Disclosed is a structure and method for forming a structure including a SiCOH layer having increased mechanical strength. The structure includes a substrate having a layer of dielectric or conductive material, a layer of oxide on the layer of dielectric or conductive material, the oxide layer having essentially no carbon, a graded transition layer on the oxide layer, the graded transition layer having essentially no carbon at the interface with the oxide layer and gradually increasing carbon towards a porous SiCOH layer, and a porous SiCOH (pSiCOH) layer on the graded transition layer, the porous pSiCOH layer having an homogeneous composition throughout the layer. The method includes a process wherein in the graded transition layer, there are no peaks in the carbon concentration and no dips in the oxygen concentration.

Owner:IBM CORP +1

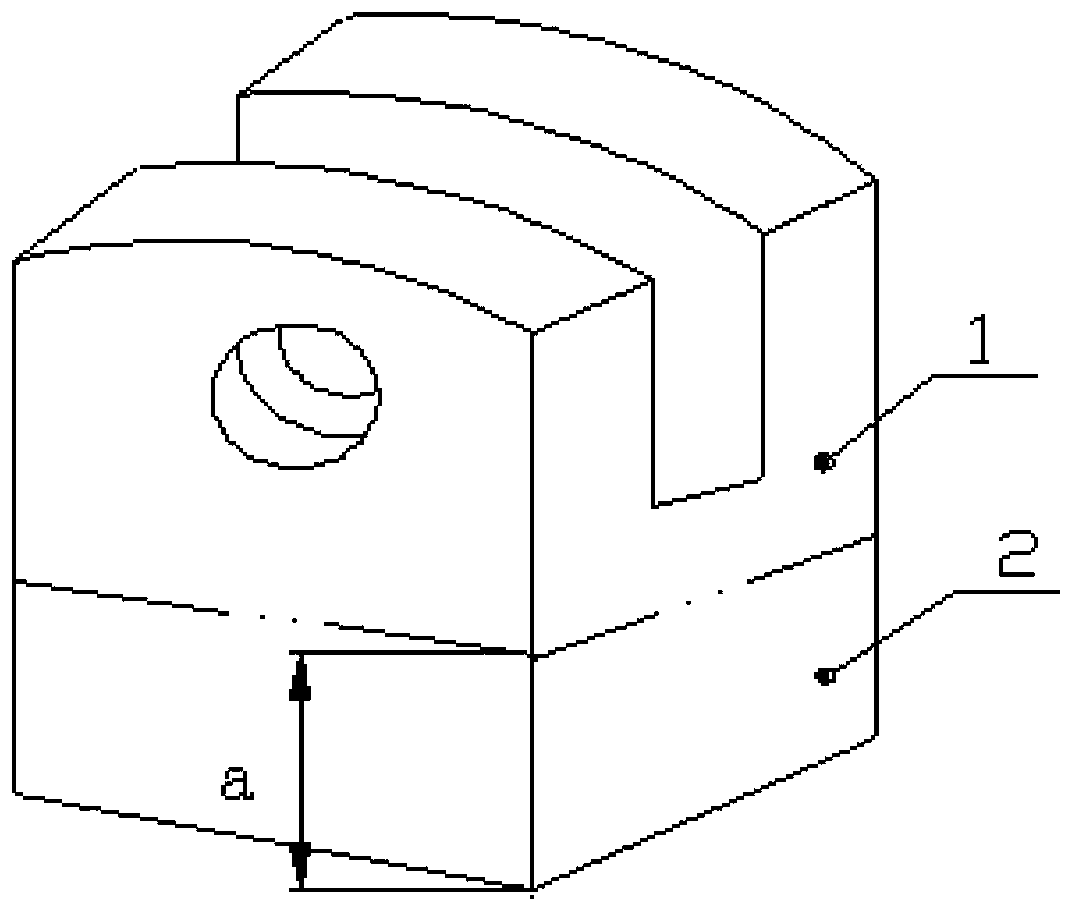

Wear-resistant hammer head of hammer crusher and preparation method thereof

ActiveCN103357470AReduce consumptionAdvanced technologyFoundry mouldsFoundry coresWear resistantInterface bond

The invention discloses a wear-resistant hammer head of a hammer crusher and a preparation method thereof. The wear-resistant hammer head comprises an end part of the hammer head and a handle part of the hammer head, and is characterized in that the end part of the hammer head is made of high-chromium cast iron which comprises the following components in percentage by weight: 2.40-3.20 percent of C, 0.30-1.50 percent of Si, 0.50-2.0 percent of Mn, 12.0-18.0 percent of Cr, less than or equal to 0.10 percent of P, less than or equal to 0.06 percent of S, 0.04 percent of Ce, 0.10-0.20 percent of V and the balance of iron; the handle part of the hammer head is made of medium carbon low-alloy steel which comprises the following components in percentage by weight: 0.30-0.50 percent of C, 0.30-1.0 percent of Si, 0.70-1.5 percent of Mn, 1.0-3.0 percent of Cr, 0.15-0.25 percent of Mo, less than or equal to 0.04 percent of P, less than or equal to 0.04 percent of S and the balance of iron; a liquid-liquid double metal composite wear-resistant hammer head is cast by using a hollow cavity of lost foam, and the casting process is controlled to prepare a double liquid-double metal composite hammer head with interfaces bonded through metallurgical bonding. The handle part of the hammer head is made of the medium carbon low-alloy steel, and the end part of the hammer head is made of the high-chromium cast iron. The service life of the hammer head can be improved by 2-3 times compared with that of a high-manganese steel hammer head without changing the manufacturing cost.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

Silane coupling agent modified clay and butadiene styrene rubber nanometer composite material preparation method

InactiveCN1970607AImprove interface strengthImprove mechanical propertiesMaterials preparationPolymer science

The invention discloses a making method of clay modified by silane coupling agent with butadiene styrene rubber nanometer composite material, wherein the silane coupling agent is gamma-aminotriethylene silane and di-(gamma-triethylene propyl) tetrasulfide, which comprises the following steps: making gamma-aminotriethylene silane modified clay liquid suspension under normal temperature; blending with butylbenzene rubber emulsion completely; flocculating; washing; drying; fusing; sulfurizing to obtain the product; adding di-(gamma-triethylene propyl) tetrasulfide to obtain the modified clay and butadiene styrene rubber nanometer composite material of gamma-aminotriethylene silane and di-(gamma-triethylene propyl) tetrasulfide.

Owner:BEIJING UNIV OF CHEM TECH

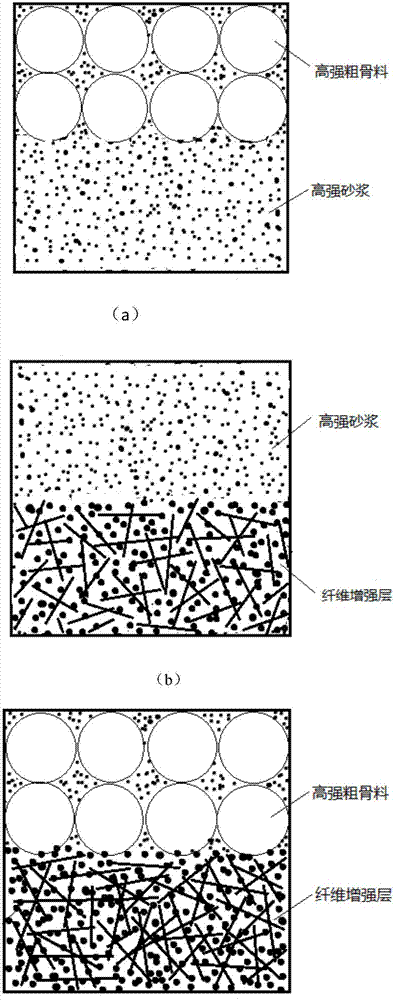

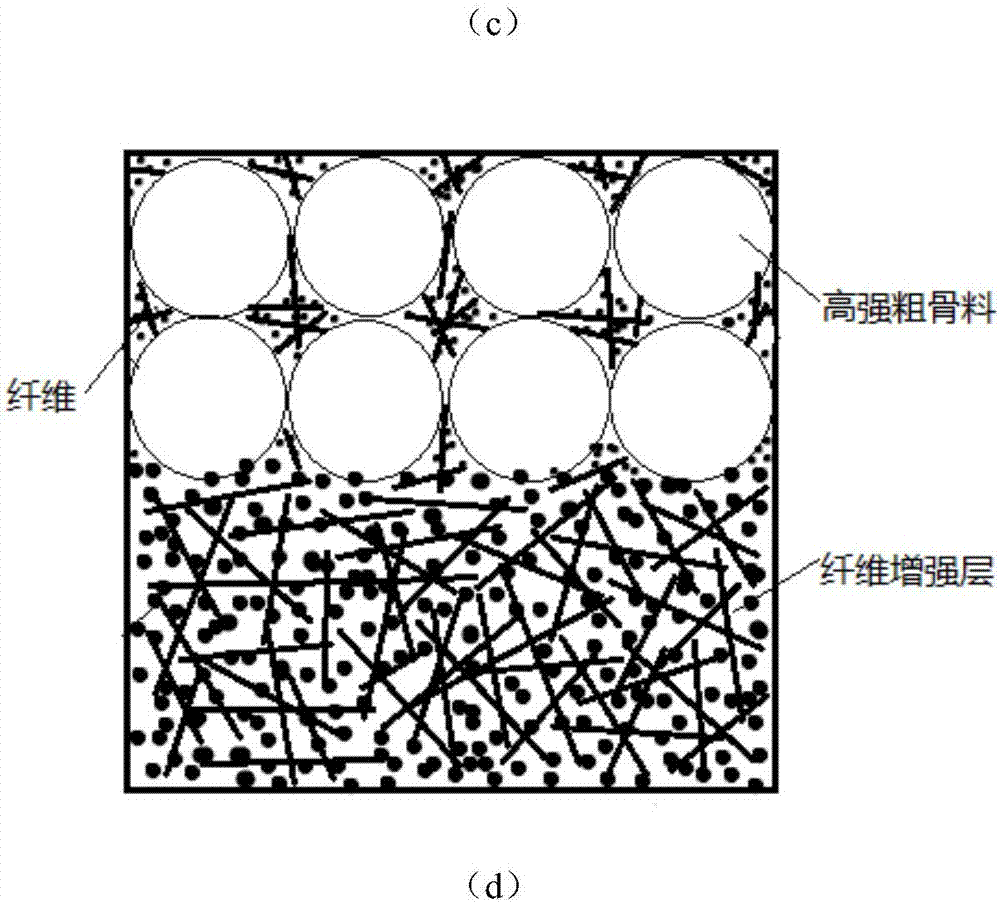

Functional gradient cement-based composite material enhanced by nano material and preparation method thereof

ActiveCN107098657AWide variety of sourcesConducive to ecological sustainable developmentCement pasteUltimate tensile strength

The invention discloses a functional gradient cement-based composite material enhanced by a nano material and a preparation method thereof. The composite material is composed of two or more of high-strength mortar, high-strength crude aggregate concrete, the fiber-enhanced super-high performance concrete, and the fiber-enhanced crude aggregate concrete according to isopyknic ratio. The nano material is doped into the composite material, an aperture and a gap of a gelling system can be filled with the material taken as a micro aggregate, the hydration rate at an early stage of cement paste is increased; at the same time, the gradient design is employed, by aiming at out-phase in the composite material and an interface in a functional zone, the performance of the cement-based composite material is effectively improved, and the functional gradient cement-based composite material is prepared, and the performances of intensity, toughness, impact resistance, penetration resistance, and blast resistance are greatly increased.

Owner:NANJING UNIV OF SCI & TECH

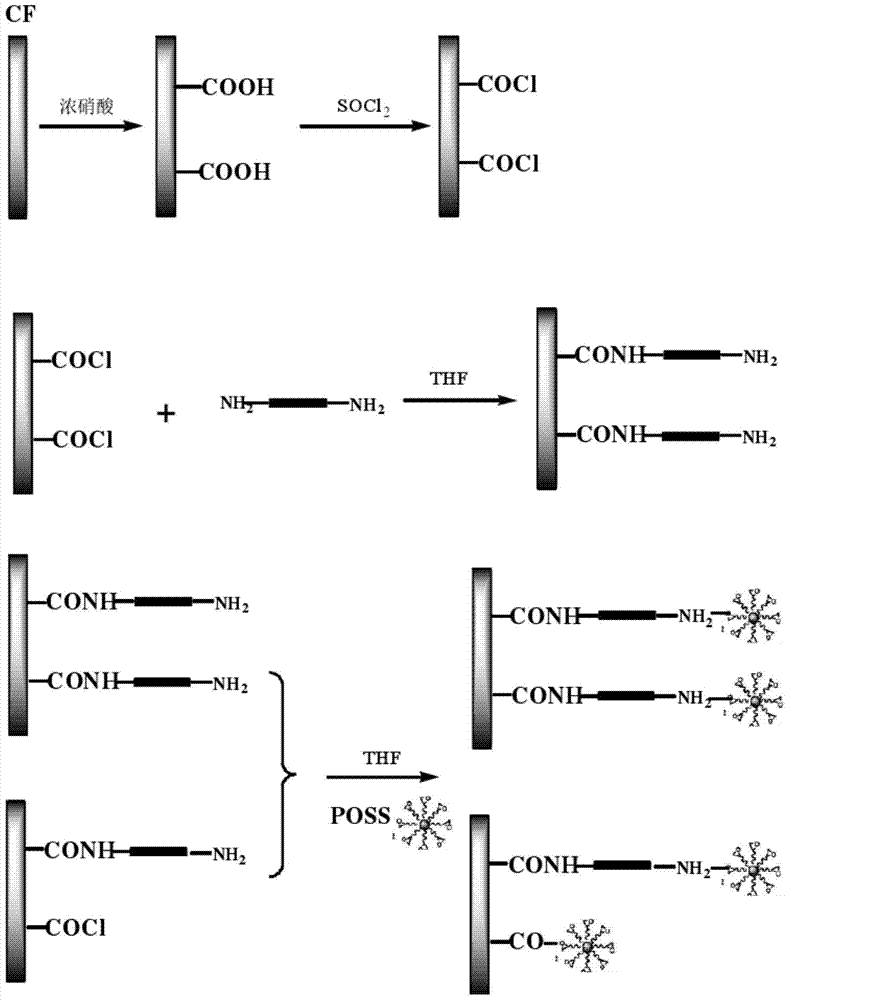

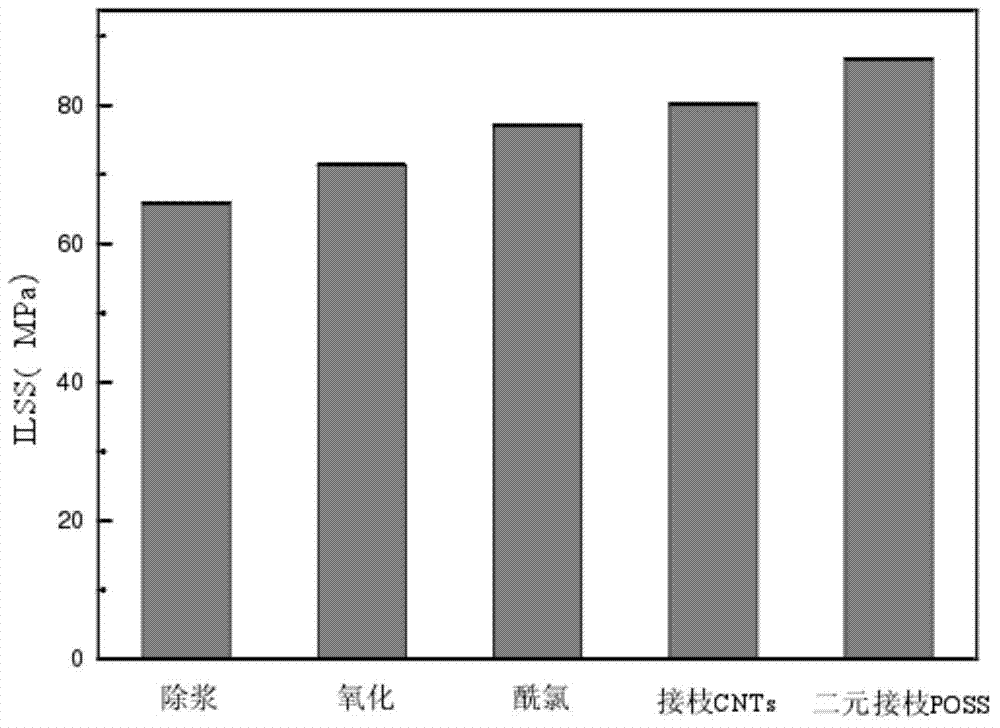

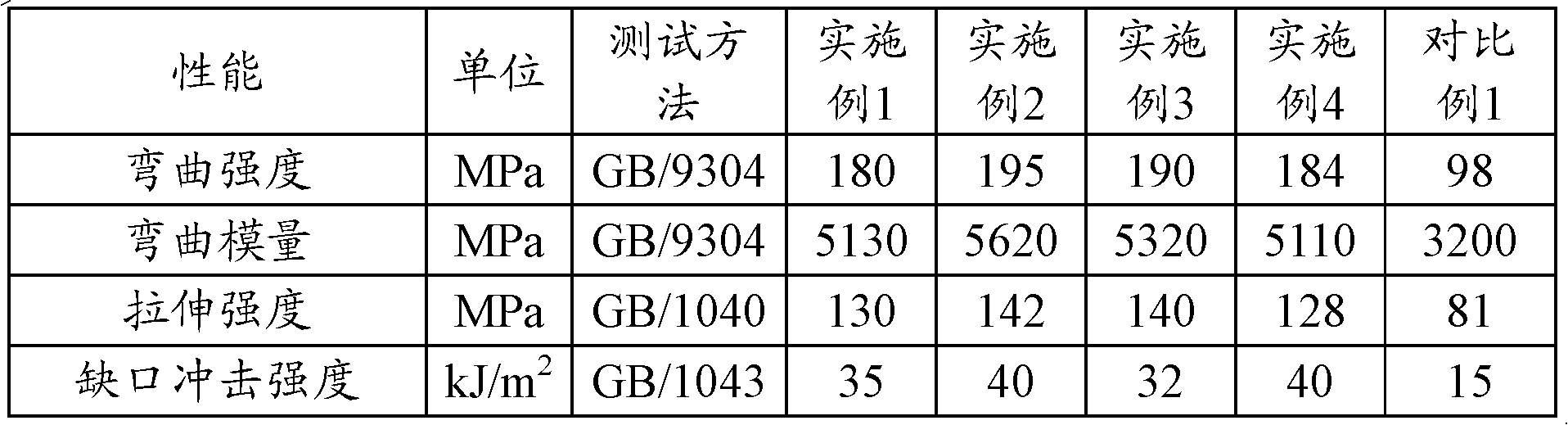

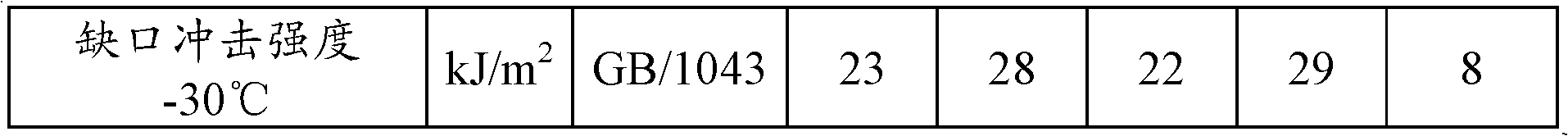

Preparation method of multicomponent-modified carbon-fiber-reinforced epoxy resin composite material

InactiveCN104277421ALow priceEasy to customizePigment treatment with organosilicon compoundsFiberEpoxy

The invention relates to a preparation method of a multicomponent-modified carbon-fiber-reinforced epoxy resin composite material, which comprises the following steps: oxidizing carbon nanotubes (CNTs) with strong acid; carrying out acyl-chlorination and amination on the oxidized CNTs sequentially with thionyl chloride and diamine to introduce amino functional group; oxidizing carbon fiber with strong oxidizing acid, and carrying out acyl-chlorination treatment with thionyl chloride to introduce acyl chloro group; mixing the prepared modifying CNTs and modifying carbon fiber to perform graft reaction, thereby obtaining the CNTs-grafted carbon fiber; mixing the CNTs-grafted carbon fiber with polyhedral oligomeric silsesquioxane (POSS) to perform graft reaction, thereby obtaining the binary POSS-grafted carbon fiber; and sufficiently infiltrating the binary POSS-grafted carbon fiber in the base resin, and carrying out hot pressing to perform curing formation. The CNTs and POSS cografted on the carbon fiber surface can improve the surface topography of the carbon fiber, increase the contact area with the resin base and penetrate into the resin base under the anchoring action, so that the interfacial mechanical mesh action is higher.

Owner:SHANDONG UNIV OF SCI & TECH

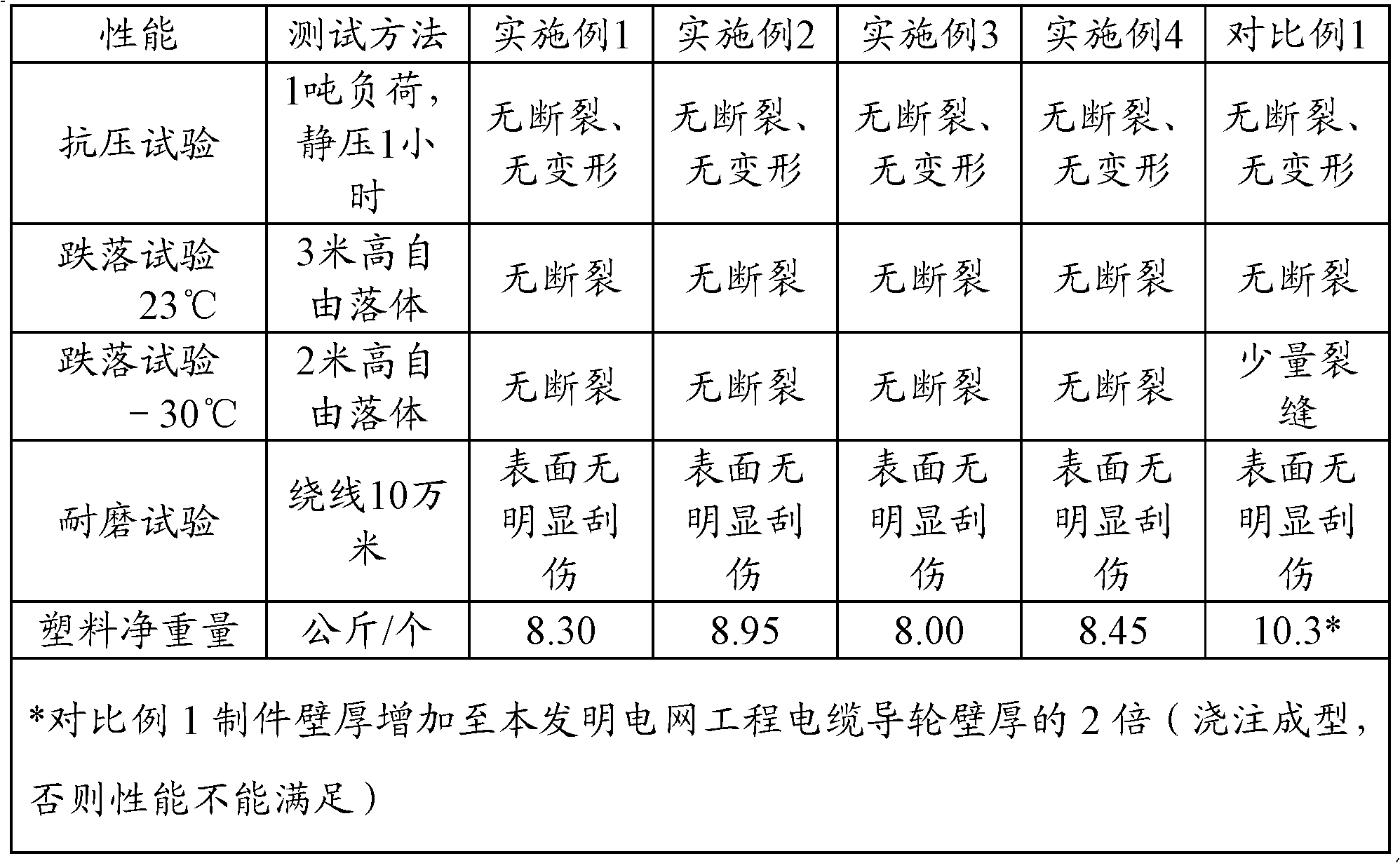

Polyamide composite material and its preparation method and application

The invention discloses a polyamide composite material which comprises, by weight, 20.0% to 40.0% of polyamide 6 with a low viscosity, 10.0% to 30.0% of polyamide 6 with a medium viscosity, 5.0% to 20.0% of a polar low temperature impact modifier, 1.0% to 8.0% of a wear-resisting agent, 0.2% to 5.0% of a heat stabilizer, 0.5% to 5.0% of a lubricant and 20.0% to 45.0% of a reinforcing component. The material has excellent performance and is especially applicable to preparation of cable rollers. The invention also discloses a preparation method for the polyamide composite material. According tothe method, polyamide 6 with a low viscosity, polyamide 6 with a medium viscosity, the low temperature impact modifier, the wear-resisting agent, the heat stabilizer and the lubricant are stirred anduniformly mixed; an obtained mixture is added into a double-screw extruder, and the reinforcing component is added into the double-screw extruder to prepare the polyamide composite material. The method has the advantages of simple operation and suitability to industrial production.

Owner:CGN JUNER NEW MATERIALS +1

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

Field effect transistor, semiconductor device and semiconductor device manufacturing method

InactiveUS8704217B2Reduce contact resistanceImprove interface strengthSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline oxideField-effect transistor

Owner:IDEMITSU KOSAN CO LTD

High modulus cold-mixed asphalt as well as preparation method and mixture thereof

The invention relates to high modulus cold-mixed asphalt as well as a preparation method and a mixture thereof. The asphalt composition comprises the following components in parts by weight: 58-60 parts of petroleum asphalt, 1.5-3.0 parts of a polymer, 1.5-2.5 parts of a compatilizer, 1.0-2.5 parts of an emulgator and 0.3-1.2 parts of an interface repairing agent. The emulgator is in a twin structure with a polar group and a nonpolar group. According to the technology provided by the invention, the modulus of the emulsified asphalt cold-mixed mixture and the cold-recycling mixture is improved, and the mixture can be used as a material of a base layer, a lower surface layer and a middle surface layer of a newly constructed road and a reorganized and expanded road or used for structural repair of high-grade highways, thereby finding a convenient, energy-saving and environment-friendly solution capable adopting 100% reclaimed materials for structural repair of high-grade highways. With the adoption of the scheme of quick setting, the construction time is shortened and the cost is saved.

Owner:BEIJING TONGHUA ROAD MAINTENANCE

Process For Production Of Graphene/Silicon Carbide Ceramic Composites

ActiveUS20150246851A1Reduce complexityLow costMaterial nanotechnologyConductive materialCarbide siliconCeramic composite

We provide a method for the in situ development of graphene containing silicon carbide (SiC) matrix ceramic composites, and more particularly to the in situ graphene growth within the bulk ceramic through a single-step approach during SiC ceramics densification using an electric current activated / assisted sintering (ECAS) technique. This approach allows processing dense, robust, highly electrical conducting and well dispersed nanocomposites having a percolated graphene network, eliminating the handling of potentially hazardous nanostructures. Graphene / SiC components could be used in technological applications under strong demanding conditions where good electrical, thermal, mechanical and / or tribological properties are required, such as micro and nanoelectromechanical systems (MEMS and NEMS), sensors, actuators, heat exchangers, breaks, components for engines, armours, cutting tools, microturbines or microrotors.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Surface modification method for waste rubber powder

ActiveCN107674238AImprove mechanical propertiesIncreased durabilityPlastic recyclingEpoxyPolymer science

The invention belongs to the technical field of high polymer materials and particularly relates to a surface modification method for waste rubber powder. The method comprises the following specific steps: firstly, carrying out clear water treatment on the surface of the waste rubber powder; secondly, carrying out alkaline solution treatment on the surface of the waste rubber powder; thirdly, carrying out coupling agent treatment on the surface of the waste rubber powder; fourthly, carrying out nano-silica coating treatment on the surface of the waste rubber powder; fifthly, carrying out crushing treatment on the modified waste rubber powder aggregate. Compared with the prior art, the surface modification method of the waste rubber powder disclosed by the invention, has the advantages thatthe comprehensive mechanical properties of the waste rubber powder as well as interfacial compatibility and interfacial bonding strength between the waste rubber powder and cementing materials such asepoxy resin and cement paste can be significantly improved.

Owner:SHANXI PROVINCIAL RES INST OF COMM

High-performance long glass fiber-reinforced TPU (thermoplastic polyurethane) composite material and preparation method thereof

ActiveCN103819891AImprove liquidityImprove the defect of molecular weight reductionGlass fiberThermoplastic polyurethane

The invention discloses a high-performance long glass fiber-reinforced TPU (thermoplastic polyurethane) composite material. The composite material comprises the following components in parts by mass: 35-75 parts of thermoplastic polyurethane elastomer, 20-60 parts of long glass fiber, 3-8 parts of compatilizer, 0.4-1.5 parts of flow modifier, 0.2-0.5 part of chain extender, 0.4-0.6 part of heat stabilizer and 0.4-0.6 part of ultraviolet absorber. According to the composite material, TPU with high surface hardness is taken as the base material, the flow modifier is used for improving the fluidity of the matrix, the chain extender is added for improving the molecular weight of TPU so as to prepare the high-performance long glass fiber-reinforced TPU composite material, the strength and rigidity of the TPU material are improved, the toughness of the TPU material is improved, and the cost of the material is lowered. The preparation method is simple, is simple and convenient to operate, has high benefit, and is applicable to industrial production.

Owner:JIANGLIN GUIZHOU HI TECH DEV CO LTD

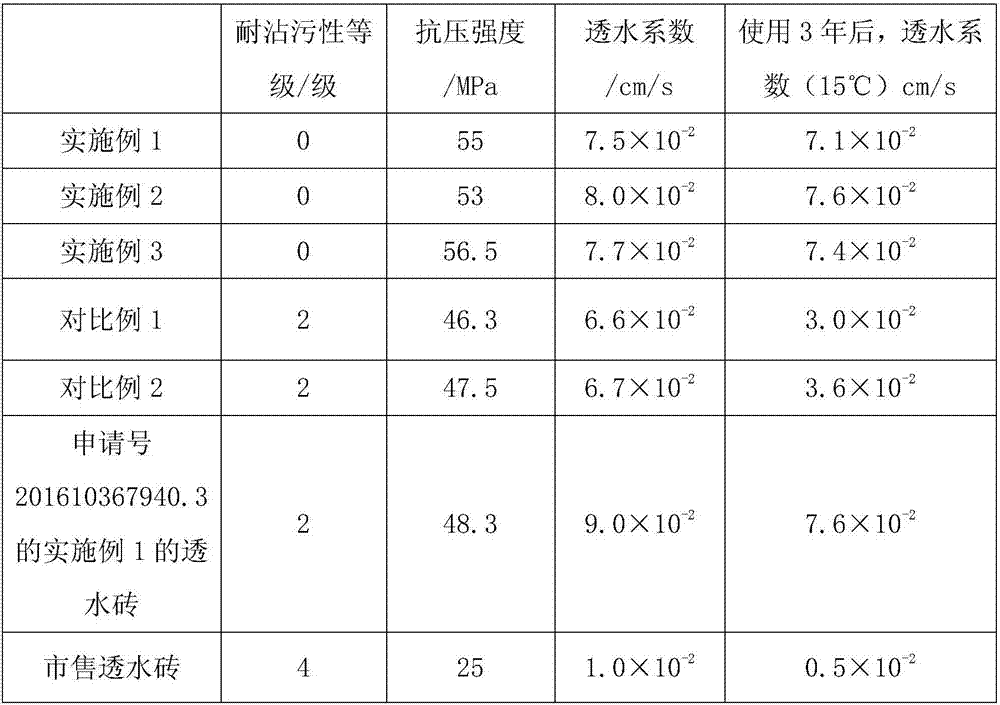

Anti-fouling and water-permeable brick with natural stone imitating effect and preparation method of anti-fouling and water-permeable brick

The invention provides an anti-fouling and water-permeable brick with a natural stone imitating effect and a preparation method of the anti-fouling and water-permeable brick. The anti-fouling and water-permeable brick comprises an anti-fouling and water-permeable surface layer and a water-permeable base layer, wherein the anti-fouling and water-permeable surface layer is prepared from raw materials in parts by mass as follows: 10-15 parts of cement, 0.5-2 parts of an aqueous adhesive, 65-75 parts of modified fine aggregate, 2-4.5 parts of water, 1.5-2 parts of a water-permeable agent and 3-8 parts of pigment; the water-permeable base layer is prepared from raw materials in parts by mass as follows: 15-25 parts of fly ash, 5-10 parts of cement, 10-20 parts of carbide slag, 5-15 parts of slag, 15-20 parts of construction waste, 2-4 parts of the water-permeable agent and 3-8 parts of water. A mass ratio of the anti-fouling and water-permeable surface layer to the water-permeable base layer is 1:(7.5-8.5), and the modified fine aggregate is prepared from one or more fine aggregate of granite debris, marble flakes, quartz sand and silica sand through modification. The anti-fouling and water-permeable brick has the advantages of being high in anti-fouling level, resistant to wear, good in water permeability, high in strength, low in cost and smooth in surface, achieving the attractive natural stone imitating effect and the like.

Owner:山东鑫旺节能建材有限公司

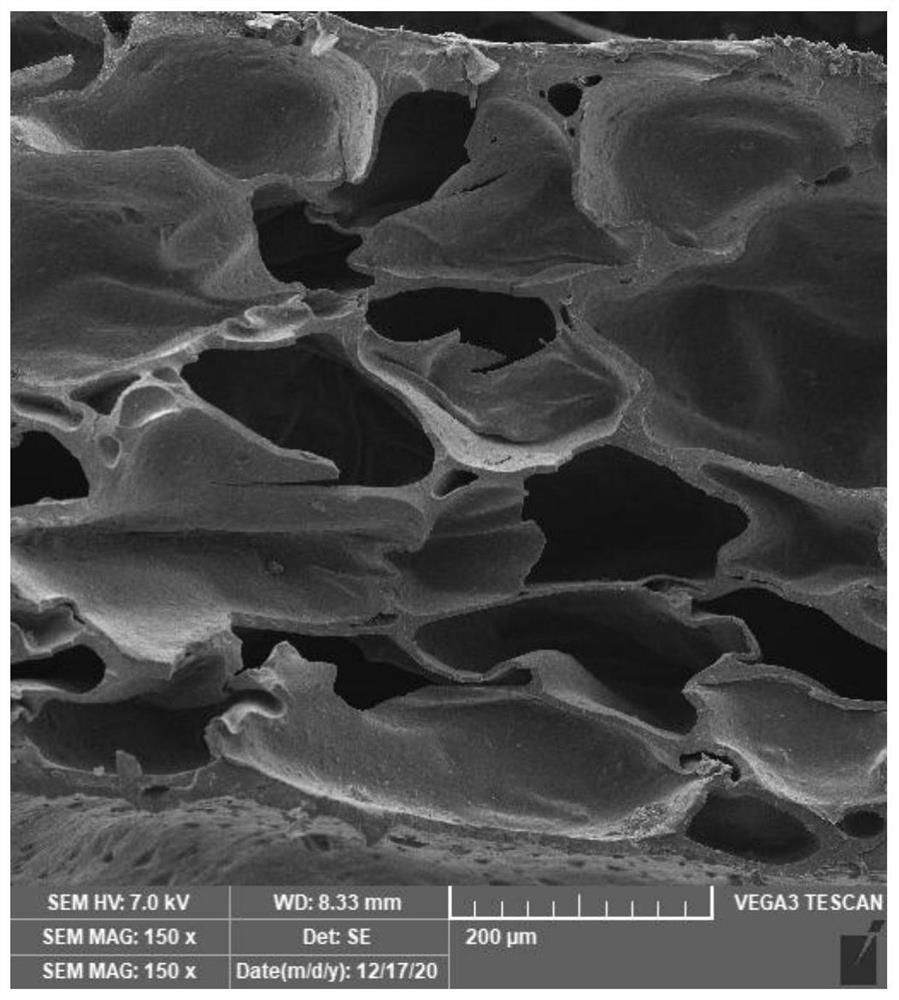

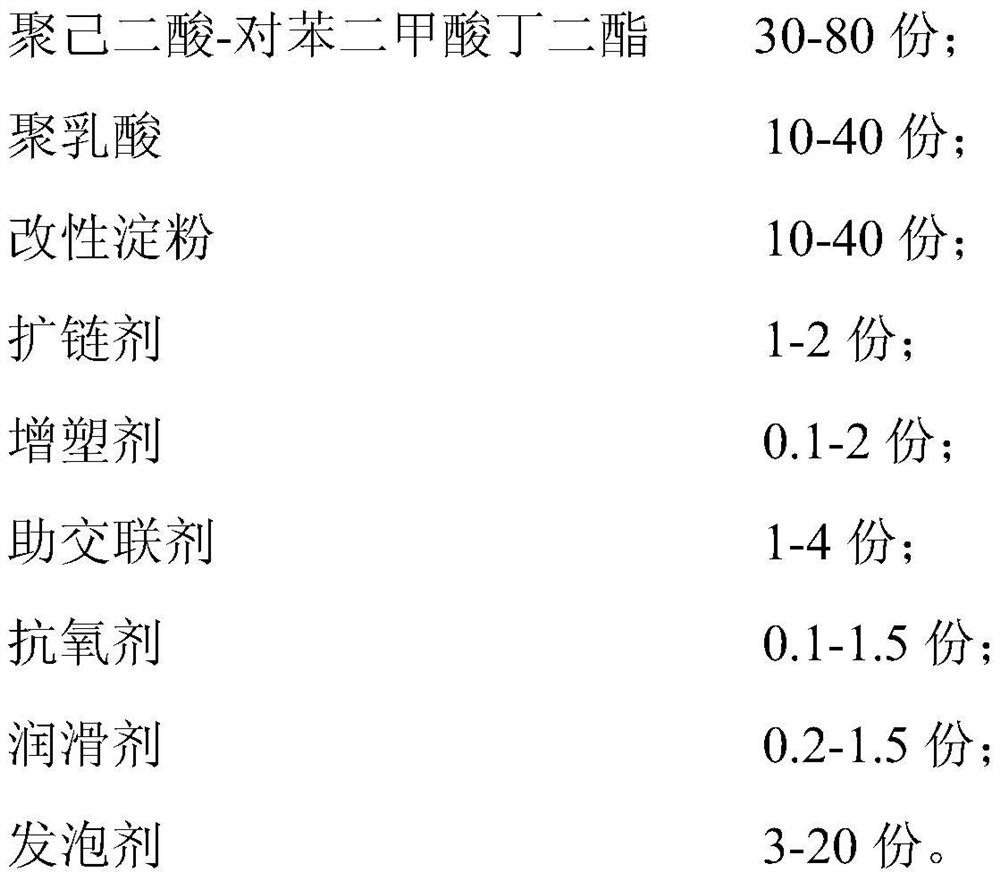

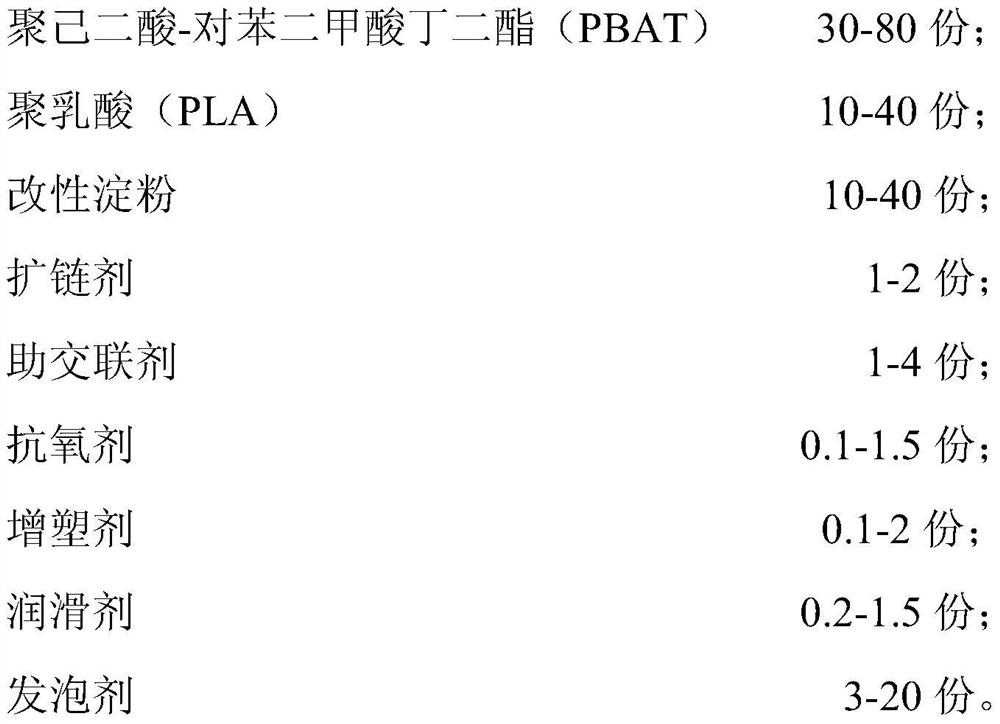

Degradable foaming material and preparation method thereof

The invention relates to the technical field of foaming materials, and discloses a degradable foaming material and a preparation method thereof. The degradable foaming material is prepared from, by mass, 30-80 parts of poly(butylene adipate-co-terephthalate); 10-40 parts of polylactic acid; 10-40 parts of modified starch; 1-2 parts of a chain extender; 0.1-2 parts of a plasticizer; 1-4 parts of an assistant crosslinker; 0.1-1.5 parts of an antioxidant; 0.1-1.5 parts of a lubricant and 3-20 parts of a foaming agent. By blending and modifying PLA through PBAT, on one hand, the melting point of PLA can be remarkably reduced, the melt extrusion temperature during subsequent coiled material extrusion is further reduced, decomposition of a chemical foaming agent is inhibited, and decomposition of the foaming agent is completely controlled in the foaming stage of a high-temperature foaming furnace; and on the other hand, the advantages and disadvantages of PBAT and PLA materials are combined, and the degradable foaming material with excellent ductility, tensile strength and comprehensive performance is obtained.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com