Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

361 results about "Oxidizing acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oxidizing acid is a Brønsted acid that is a strong oxidizing agent. All Brønsted acids can act as oxidizing agents, because the acidic proton can be reduced to hydrogen gas. Some acids contain other structures that act as stronger oxidizing agents than hydrogen ion. Generally, they contain oxygen in the anionic structure. These include nitric acid, perchloric acid, chloric acid, chromic acid, and concentrated sulfuric acid, among others.

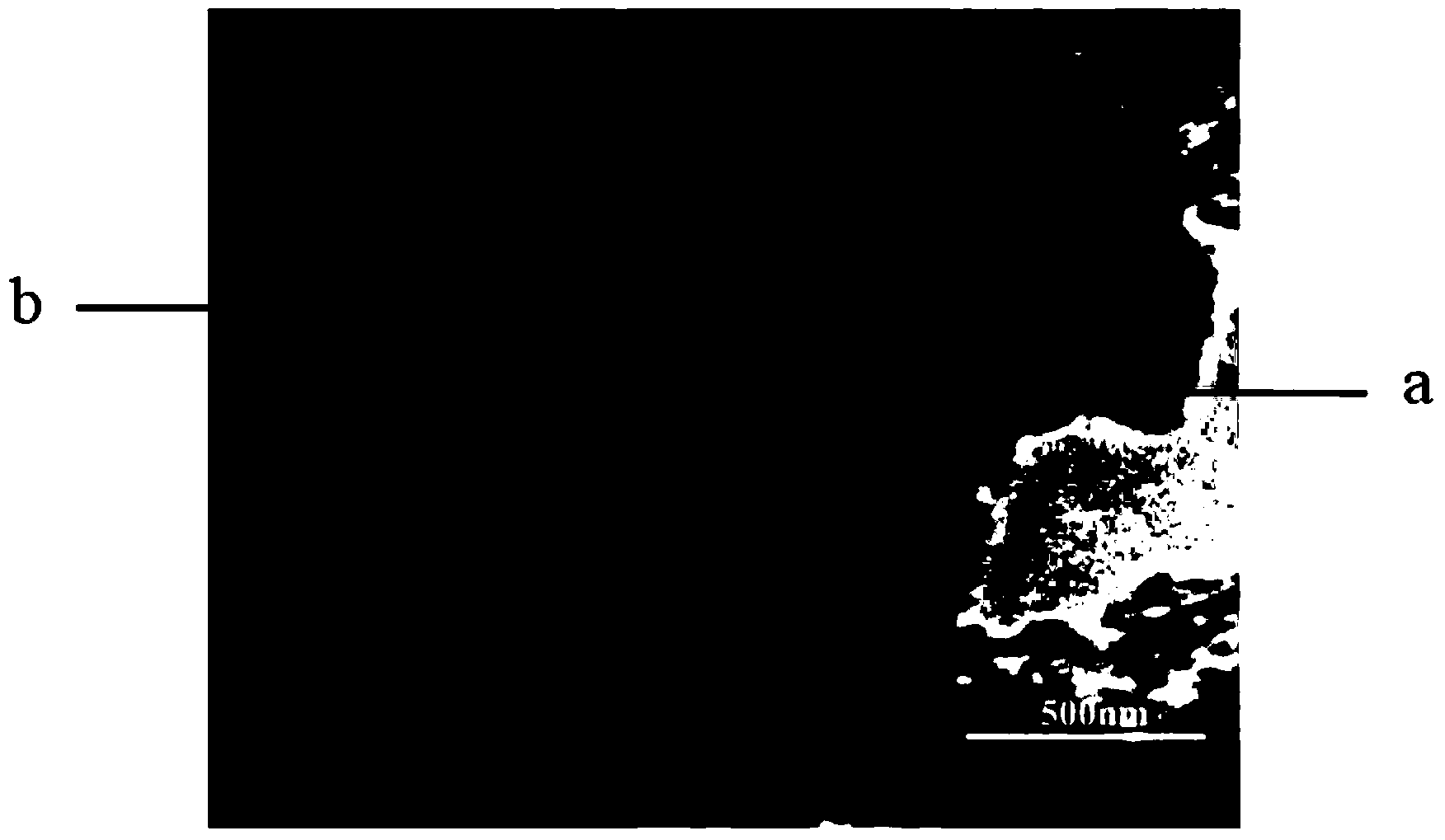

Method of opening and filling carbon nanotubes

PCT No. PCT / GB95 / 02235 Sec. 371 Date Apr. 10, 1997 Sec. 102(e) Date Apr. 10, 1997 PCT Filed Sep. 20, 1995 PCT Pub. No. WO96 / 09246 PCT Pub. Date Mar. 28, 1996Method of making carbon nanotubes open on at least one end wherein capped nanotubes are treated with an oxidizing acid such as nitric acid. The treatment is effective to open at least 50% of the nanotubes on at least one end.

Owner:ISIS INNOVATION LTD

Improved process for preparing porous microsphere active carbon

The improved process for preparing high strength porous microsphere active carbon includes the following steps: oxidizing thermosetting resin ball at 60-400 deg.c in oxygen containing atmosphere or pre-treating thermosetting resin ball at 60-300 deg.c in oxidizing acid, SO2 or SO3; carbonizing at 600-1200 deg.c in helium, nitrogen or their mixture atmosphere; and activating at 600-1200 deg.c in activating water vapor atmosphere to obtain high strength porous microsphere active carbon with grain size of 10 micron to 2 mm, BET specific surface area of 500-4000 sq m / g, and grain strength of 50-200 MPa. The process is simple, low in cost and high in yield, and the prepared microsphere active carbon has high strength and high purity and is one excellent medical active adsorption material.

Owner:EAST CHINA UNIV OF SCI & TECH

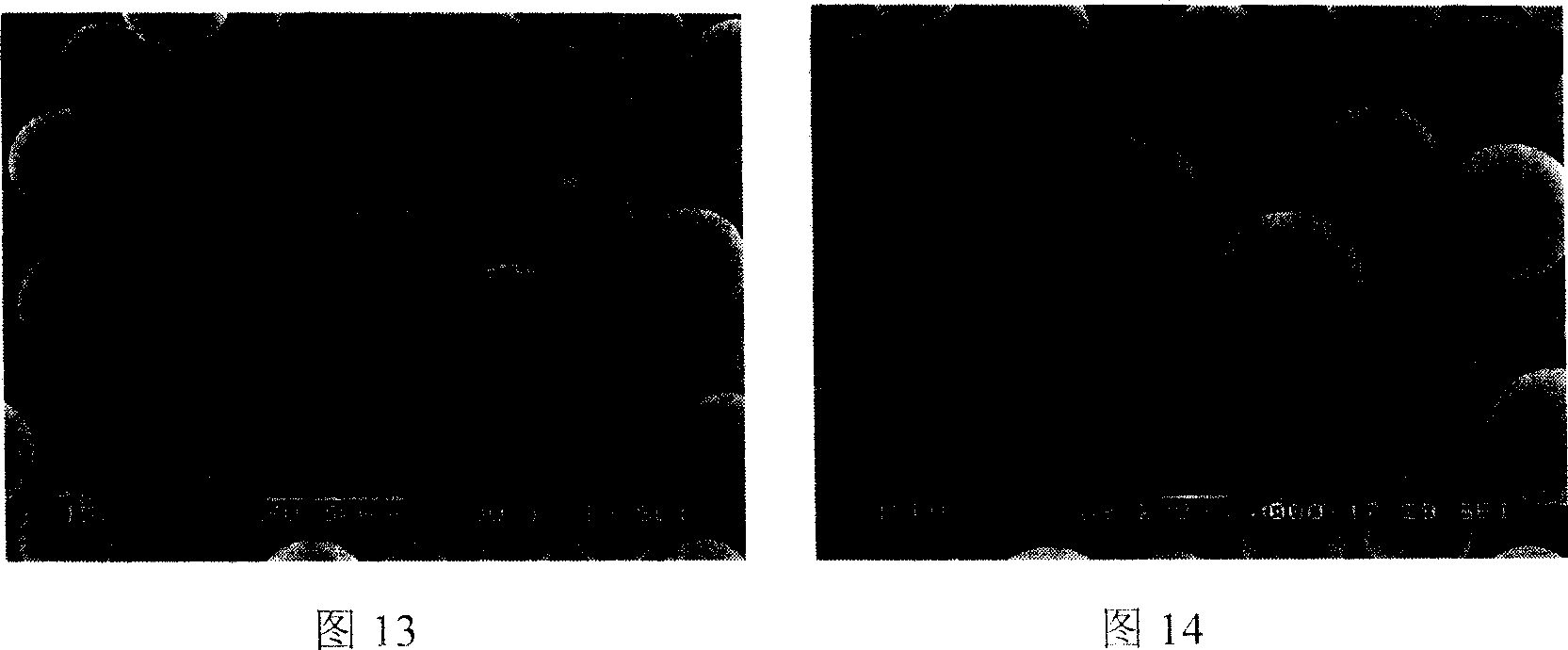

Process for extracting tellurium from copper anode mud

ActiveCN101434385AReduce consumptionEasy to separateProcess efficiency improvementElemental selenium/telluriumTe elementOxygen

The invention discloses a technology for extracting tellurium from copper anode slime, which is characterized by comprising the following steps: (1) the copper anode slime is put into a sulfuric acid solution, oxygen is introduced into the sulfuric acid solution for oxidation sulfuric acid leaching; solid-liquid separation is carried out to obtain leachate containing copper and tellurium; and the leaching process being finished in a closed high-pressure device; (2) copper powder is added into the leachate to remove silver or selenium in the leachate by substitution, and the solid-liquid separation is carried out; (3) sulfur dioxide is introduced into the leachate obtained from the step (2) to precipitate the tellurium by reduction, and the solid-liquid separation is carried out to obtain crude tellurium; and (4) the crude tellurium is processed according to a conventional method to extract pure tellurium. The technology adopts one-section oxidation acid leaching to leach the copper and tellurium out, copper powder to remove the impurities of silver, selenium and the like by substitution, and sulfur dioxide to precipitate the tellurium by reduction (obtaining tellurium dioxide), and the tellurium dioxide precipitation is alkali-dissolved and then electrolyzed to obtain the tellurium, therefore, the flow is simple, the consumption of the copper powder is remarkably reduced, and the simplification of the technology is beneficial to improve the recovery ratio of the tellurium, which can achieve more than 90 percent.

Owner:YANGGU XIANGGUANG COPPER

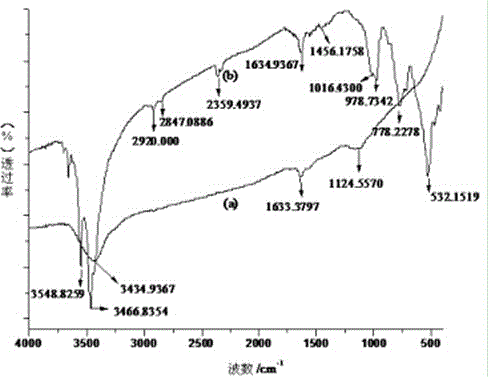

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

Method for recovering gold, silver, tin and copper from industrial wastes

InactiveCN103305698AHigh recovery rateHigh enrichment rateProcess efficiency improvementSlagGoethite

The invention provides a method for recovering gold, silver, tin and copper from industrial wastes. The method comprises the following steps of: (a) adding the industrial wastes in hydrochloric acid solution, adding an oxidant, and performing oxidation acid-leaching treatment to obtain leaching slag, and solution containing tin ions and copper ions; (b) treating the leaching slag to obtain gold and silver; (c) adding iron in the solution containing tin ions and copper ions, and reacting to obtain copper, and a solution containing tin ions and ferrous ions; (d) adding lime in the solution containing tin ions and ferrous ions, and reacting to obtain tin, and solution containing ferrous ions; (e) heating the solution containing ferrous ions, charging air and adding lime, and reacting to obtain goethite and calcium chloride solution; (f) adding concentrated sulphuric acid in the calcium chloride solution to obtain calcium sulphate precipitate and hydrochloric acid solution. The various steps of the method disclosed by the invention are effectively coordinated; zero-discharge in production can be realized; precious metals are efficiently separated, and valent by-products of iron mine and gypsum are obtained; the method has good application prospect.

Owner:NANKANG HENGYUAN CYCLE TECH CO LTD

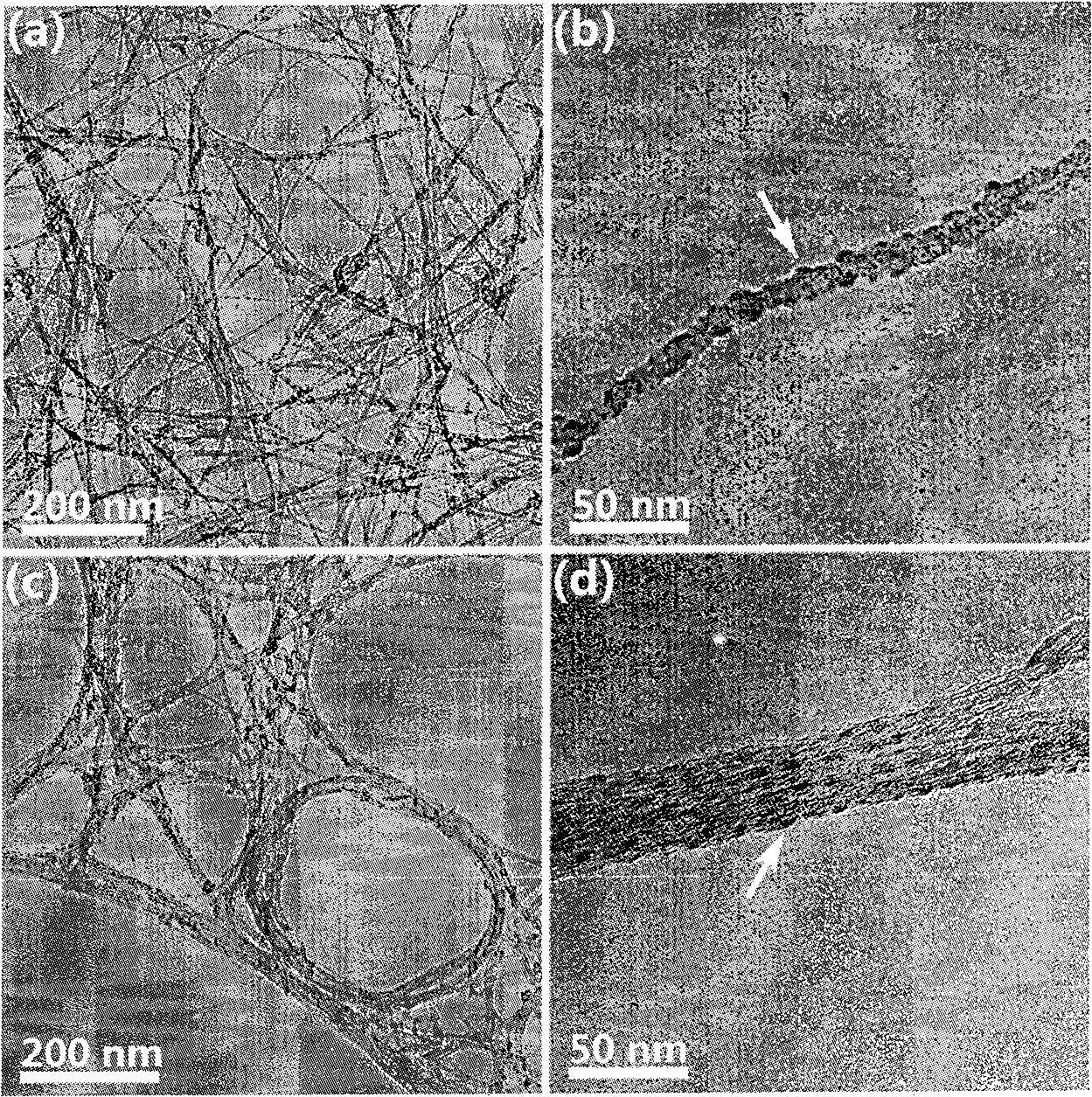

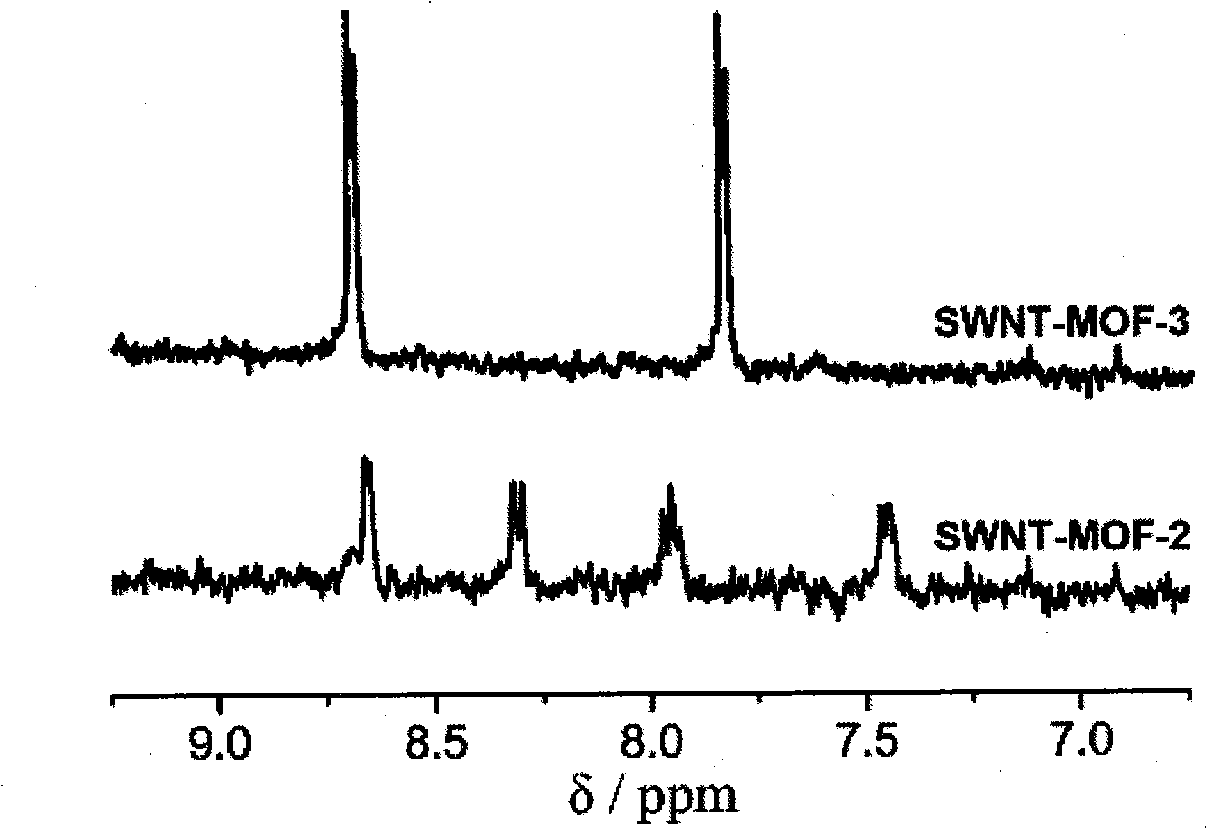

Method for preparing single-wall carbon nanotube metal organic frame

InactiveCN101357760ASimple manufacturing methodImprove controllabilityOrganic solventMetal framework

The invention relates to a preparation method of a single-walled carbon nanotube metal-organic framework in the nanotechnology field, which comprises the following steps: a. mixing 1 weight proportion of dried single-walled carbon nanotube with 50-5000 weight proportions of strong oxidizing acid to be processed by ultrasonic treatment, stirring to react, sucking filtration and washing until the solution is neutral, and obtaining acidulated carbon nanotube after drying; b. adding zinc acetate aqueous solution drop by drop, stirring to react, sucking filtration and washing, dispersing the product in an organic solvent again, sucking filtration once again, and obtaining the product SWNT-MOF-1 after drying; c. mixing the SWNT-MOF-1 and the organic solution to be processed by the ultrasonic treatment, adding the organic solvent solution of an organic ligand, stirring to react, cooling, adding the organic solvent to leach, sucking filtration, dispersing the black products in de-ionized water again, sucking filtration once again, dialyzing the black products, and obtaining the final products after drying. The method is simple and the material with both the perfect structure of the single-walled carbon nanotube and the structure of the metal-organic framework can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

Method for comprehensively recycling silver, selenium, tellurium and copper from telluride copper slag

The invention discloses a method for comprehensively recycling silver, selenium, tellurium and copper from telluride copper slag. The method comprises the following steps of (1), oxidizing acid leaching, wherein the telluride copper slag is added into a sulfuric acid solution containing an oxidizing agent to be heated and stirred so as to be leached, after filtering, copper sulfate leaching liquid and acidic leaching residues are obtained, and the leaching liquid is conveyed to a furnace for copper recycling; and (2) alkali leaching separation, wherein the acidic leaching residues are added into sodium hydroxide solutions to be leached, sodium tellurite solutions and basic leached residues are obtained, the basic leached residues are sent to the KALDO furnace for smelting, so that the silver and the selenium are recycled, and after purification, tellurium deposition, forging and electrolysis of the alkali leaching liquid, refined tellurium is obtained. According to the method, the recycling rate of the silver, the selenium, the tellurium and the copper is high, the silver, the selenium, the tellurium and the copper are not lost, the concentration ratio is high, the silver, the selenium, the tellurium and the copper can be separated from other impurities well, the pollution to the environment is small, the technology is simple, and needed equipment cost is low.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

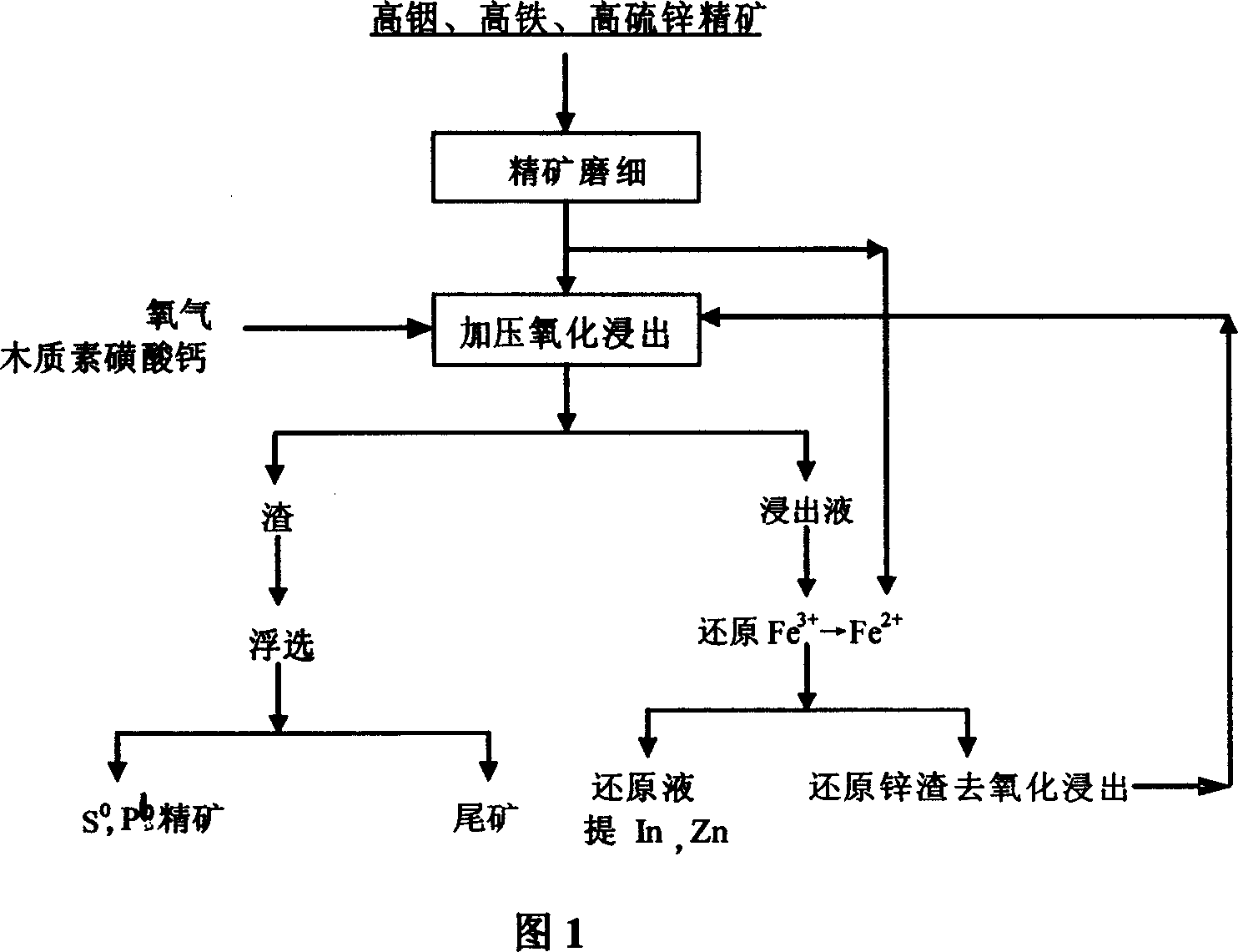

New method for soaking out enriched ores of high indium, high iron, and high sulfur zinc

This invention discloses a wet method for treating high In-Fe-S Zn concentrate by oxidative acid leaching. Compared with traditional high-pressure leaching technique, the method obviously reduces the operation temperature and pressure. Ore slurry composed of Zn concentrate, surfactant and sulfuric acid aqueous solution is operated at 95-105 deg.C under 0.2-0.4 MPa. The surfactant is sodium or calcium lignosulfonate, which can change the hydrophobicity of sulfide and sulfur, raise the leachin speed, and improve the suspension fluidity of the ore slurry. Since the operation temperature is lower than the normal pressure boiling point of the solution system, normal rubber pipe pump can be used to replace oil diaphragm high-pressure slurry pump, and Ti heat exchanger and vacuum flash evaporator are not needed. The leaching rate of Zn and In is up to 95-99%, and the yield of S is higher than 80%. The leaching solution can be treated according to normal method to recover valuable components, with total recovery rate of In up to 90-95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

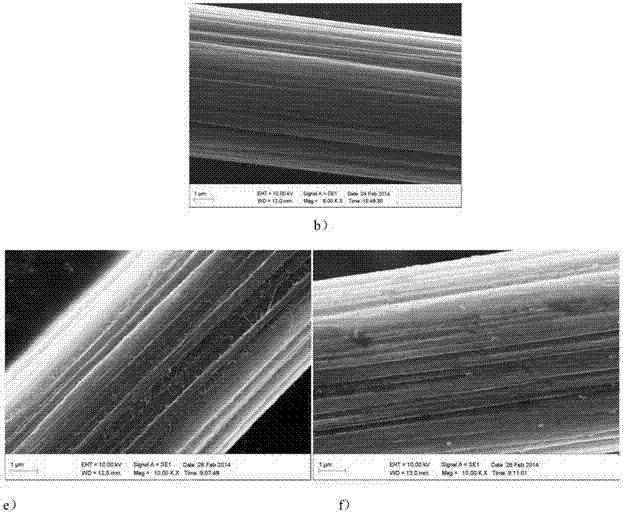

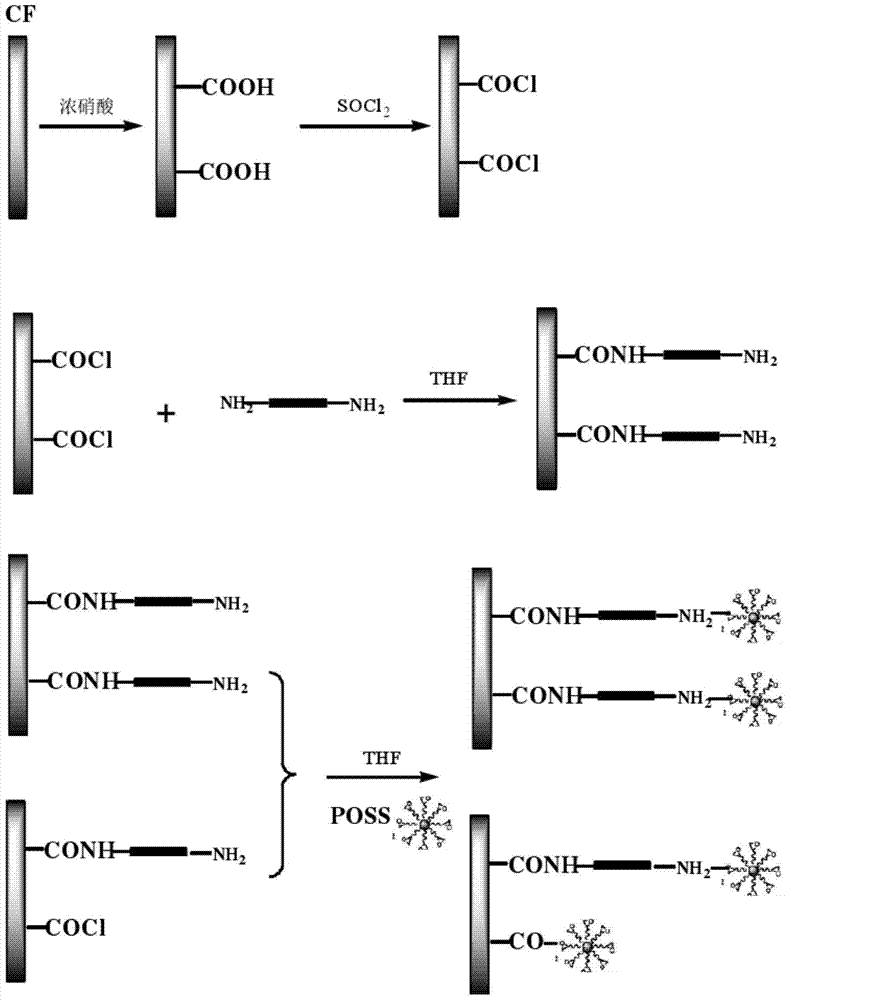

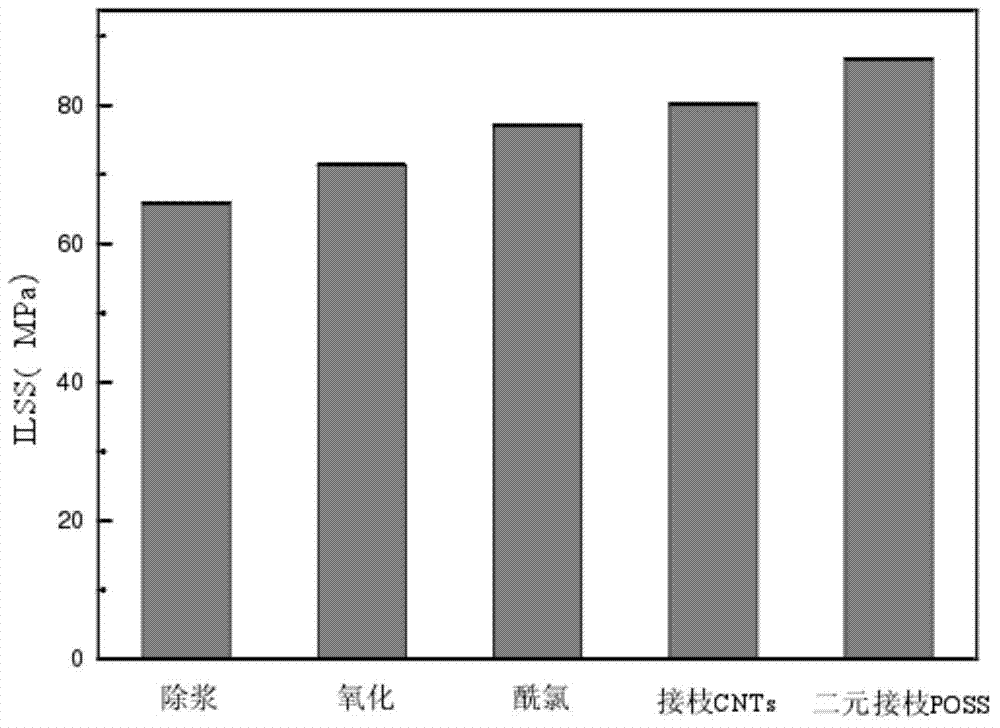

Preparation method of multicomponent-modified carbon-fiber-reinforced epoxy resin composite material

InactiveCN104277421ALow priceEasy to customizePigment treatment with organosilicon compoundsFiberEpoxy

The invention relates to a preparation method of a multicomponent-modified carbon-fiber-reinforced epoxy resin composite material, which comprises the following steps: oxidizing carbon nanotubes (CNTs) with strong acid; carrying out acyl-chlorination and amination on the oxidized CNTs sequentially with thionyl chloride and diamine to introduce amino functional group; oxidizing carbon fiber with strong oxidizing acid, and carrying out acyl-chlorination treatment with thionyl chloride to introduce acyl chloro group; mixing the prepared modifying CNTs and modifying carbon fiber to perform graft reaction, thereby obtaining the CNTs-grafted carbon fiber; mixing the CNTs-grafted carbon fiber with polyhedral oligomeric silsesquioxane (POSS) to perform graft reaction, thereby obtaining the binary POSS-grafted carbon fiber; and sufficiently infiltrating the binary POSS-grafted carbon fiber in the base resin, and carrying out hot pressing to perform curing formation. The CNTs and POSS cografted on the carbon fiber surface can improve the surface topography of the carbon fiber, increase the contact area with the resin base and penetrate into the resin base under the anchoring action, so that the interfacial mechanical mesh action is higher.

Owner:SHANDONG UNIV OF SCI & TECH

Production process of alumina template with nano holes

The present invention is the production process of aluminum template with nano holes, and is especially the combined anode oxidation and ion bombardment process of producing aluminum template with nano holes in high density and high order. The technological process includes annealing aluminum foil, cleaning, electrochemical polishing, anode oxidation in water solution of oxidizing acid, such as sulfuric acid, oxalic acid, phosphoric acid, to form alumina film, ion bombardment to form holes in the film physically, water rinsing and stoving. The technological process is simple and low in cost, and the holes are densely distributed in certain order and have controllable shape and size of several nano to 100 nano. The said template may be used widely in direct assembling of nano device except its traditional industrial application.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Corrosion resistant, zinc coated articles

InactiveUS20050181137A1Economical to usePretreated surfacesMetallic material coating processesLithiumHalogen

A zinc or zinc / alloy surface of a metal artifact is protected by passivating or activating the surface with a solution comprising an oxidizing acid or activating acid; applying to the surface an aqueous priming solution of an alkali metal permanganate in the presence of halogen ions, with the solution having a pH of about 1 to 8; and then further applying to the surface an aqueous sealing solution such as a lithium silicate and a sodium or potassium silicate solution. Strong corrosion protection can be achieved. Improvements may also be obtained with the addition of a rare earth salt to the priming solution.

Owner:STRAUS MARTIN L

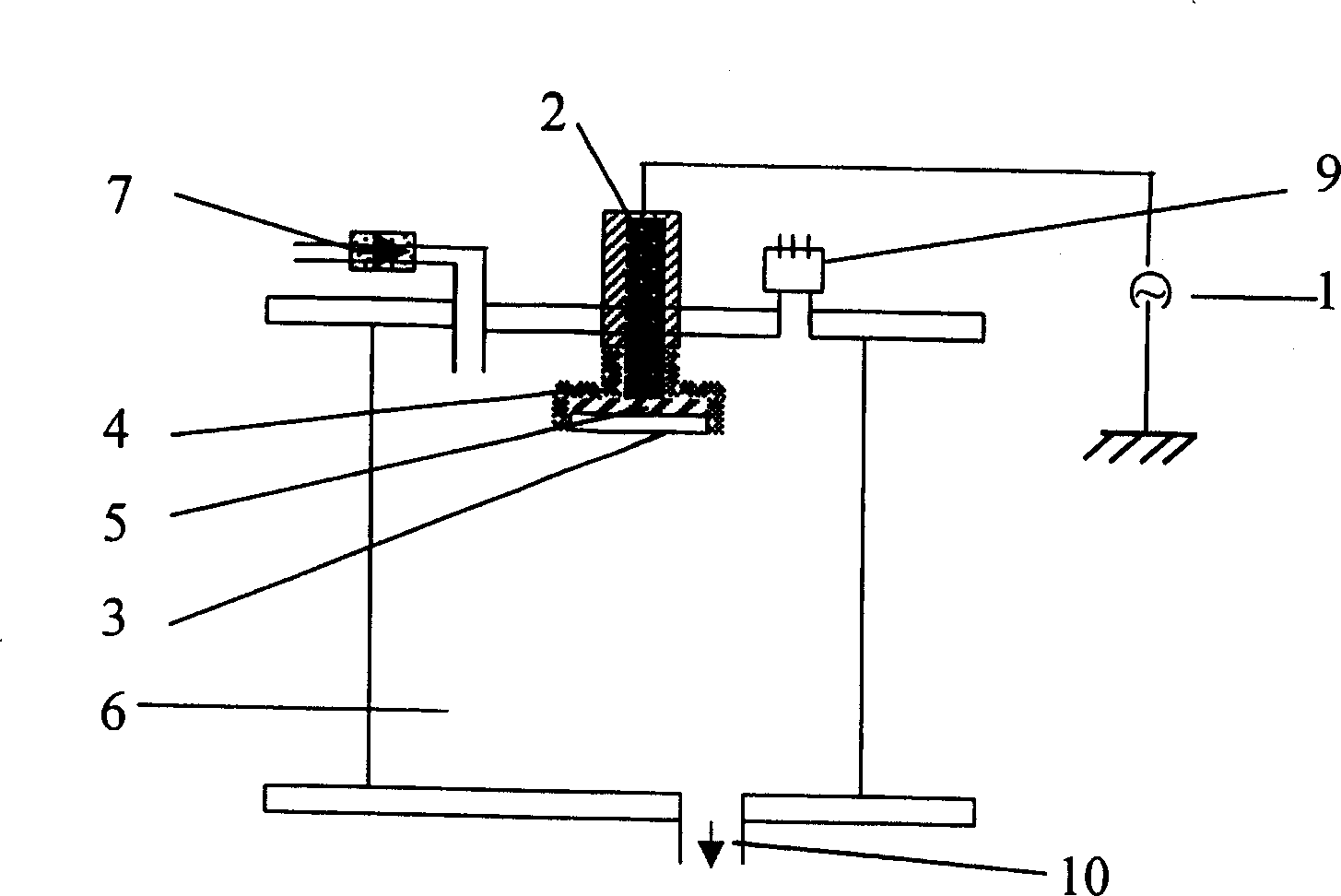

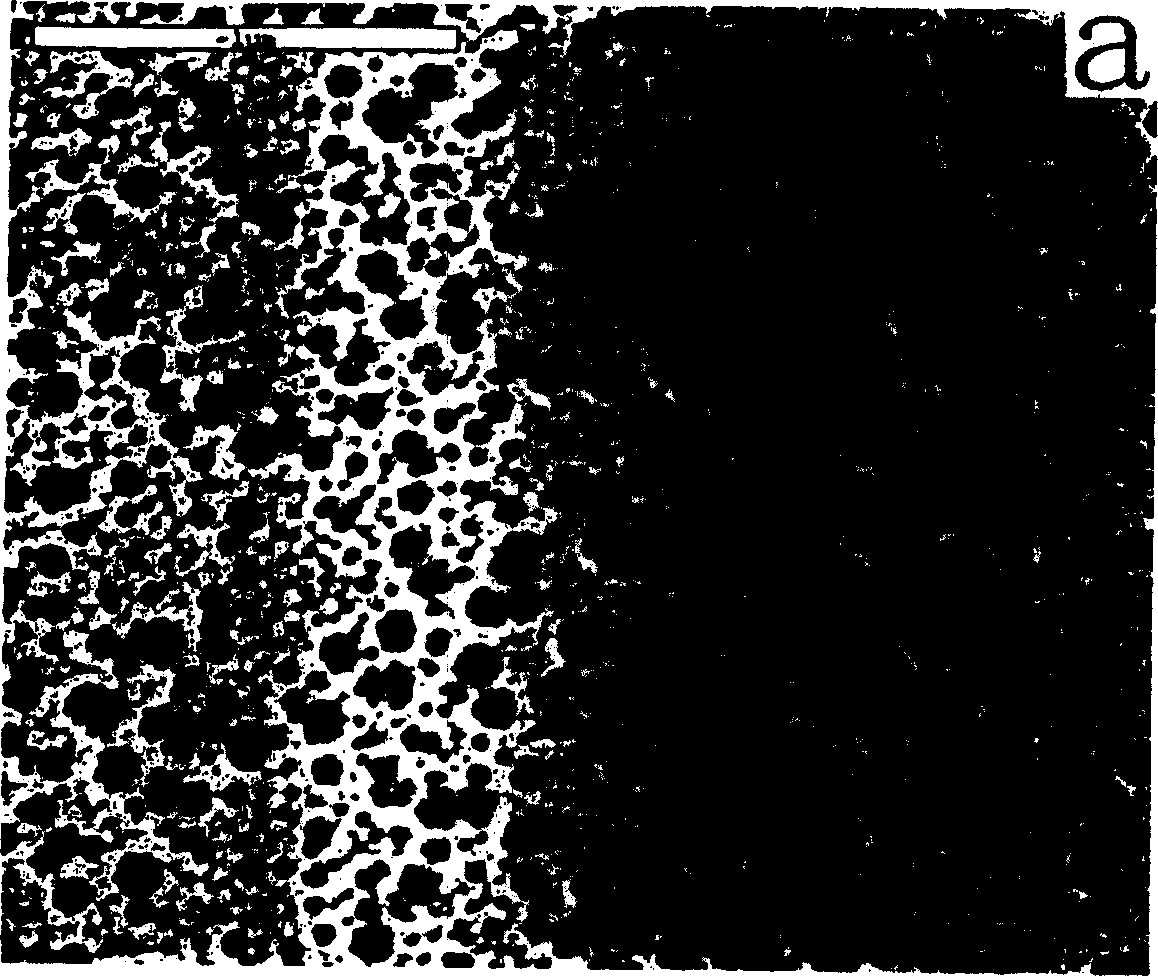

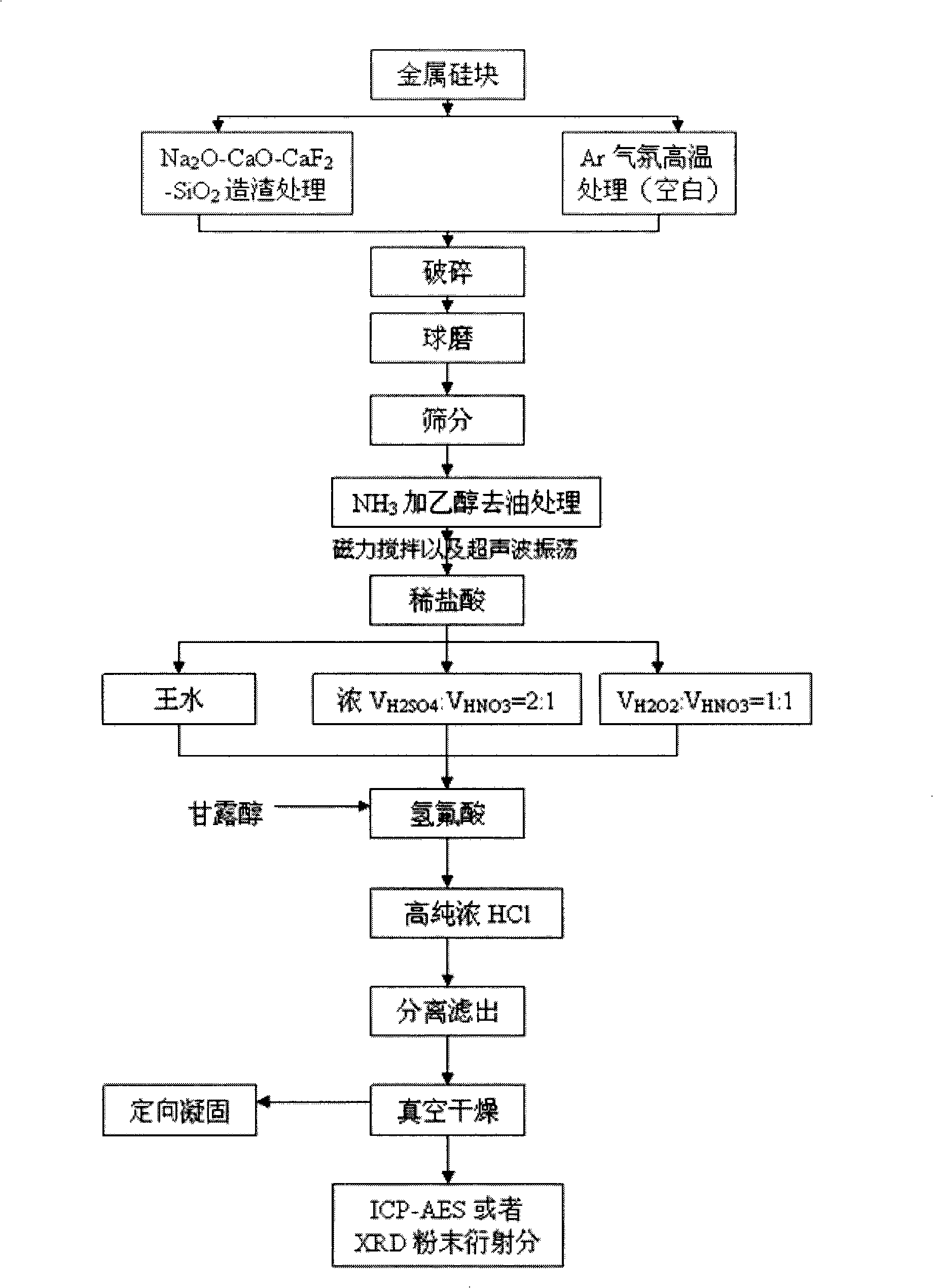

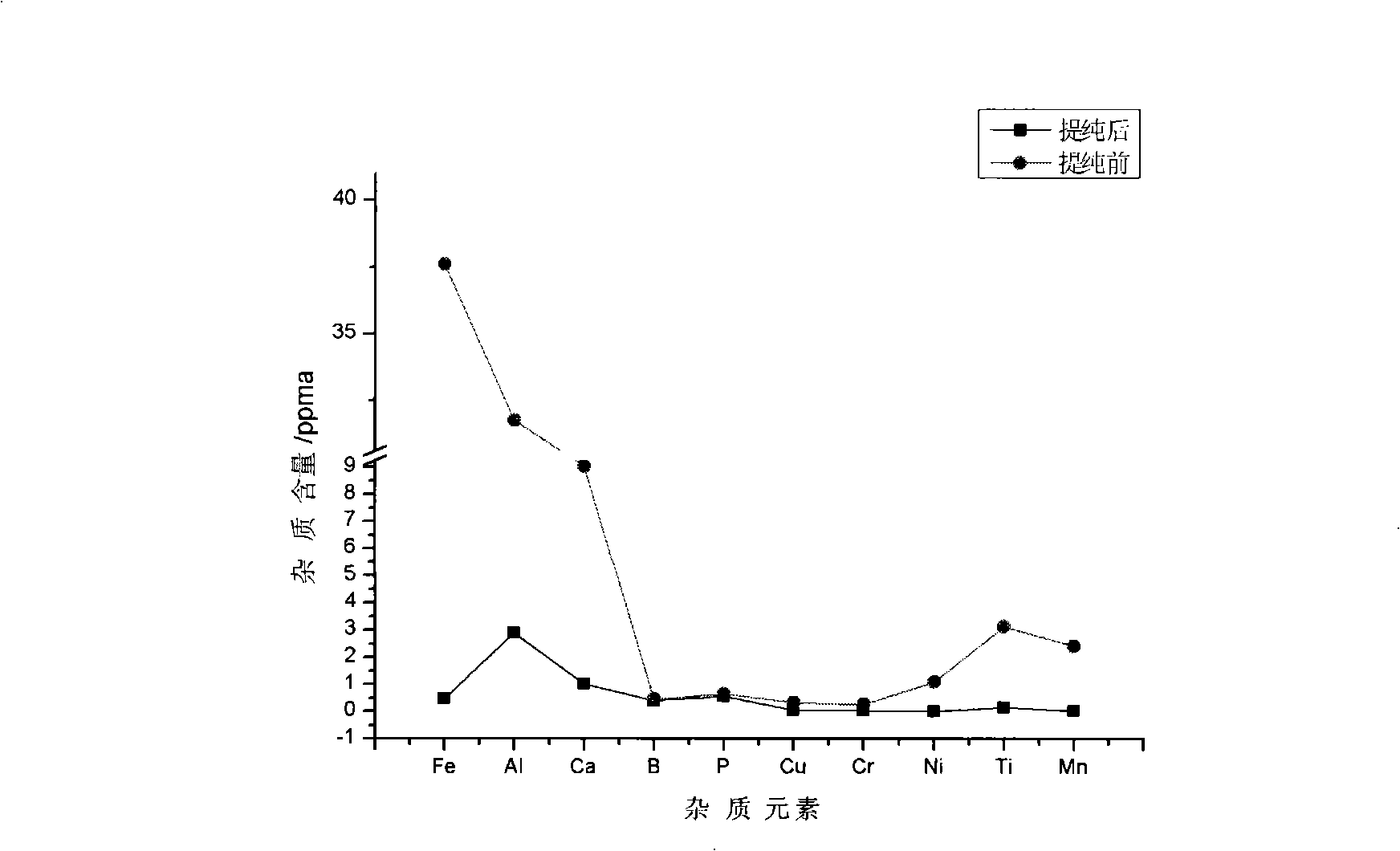

Metallurgy purification method for polysilicon

InactiveCN101318656AHigh purityReduce energy consumptionPolycrystalline material growthSilicon compoundsPurification methodsSlag

The invention discloses a method for metallurgical purification of a polysilicon, which particularly to a purification technology being capable of decreasing the contents of boron and phosphor which influence the battery efficiency. The method comprises the following steps: sodium oxide, lime and fluorite are added during the slagging and oxidation process, boron and phosphor are made into oxide by a displacement reaction, the oxide is dissolved in slag, the melting temperature is reduced by adding with the fluorite, the fluxing medium dissolves in the leaching process of the dilute acid, the oxidizing acid oxidizes and dissolves boride and metallic compounds at the transition zone, and then the complexant for hydrofluoric acid and boron corrodes the surface of silicon, and the boron impurity is extracted from the surface of silicon particles to a solvent under the effect of complexant. The method has low energy consumption and no pollution, and can improve the purity of polysilicon.

Owner:SOUTH CHINA NORMAL UNIVERSITY

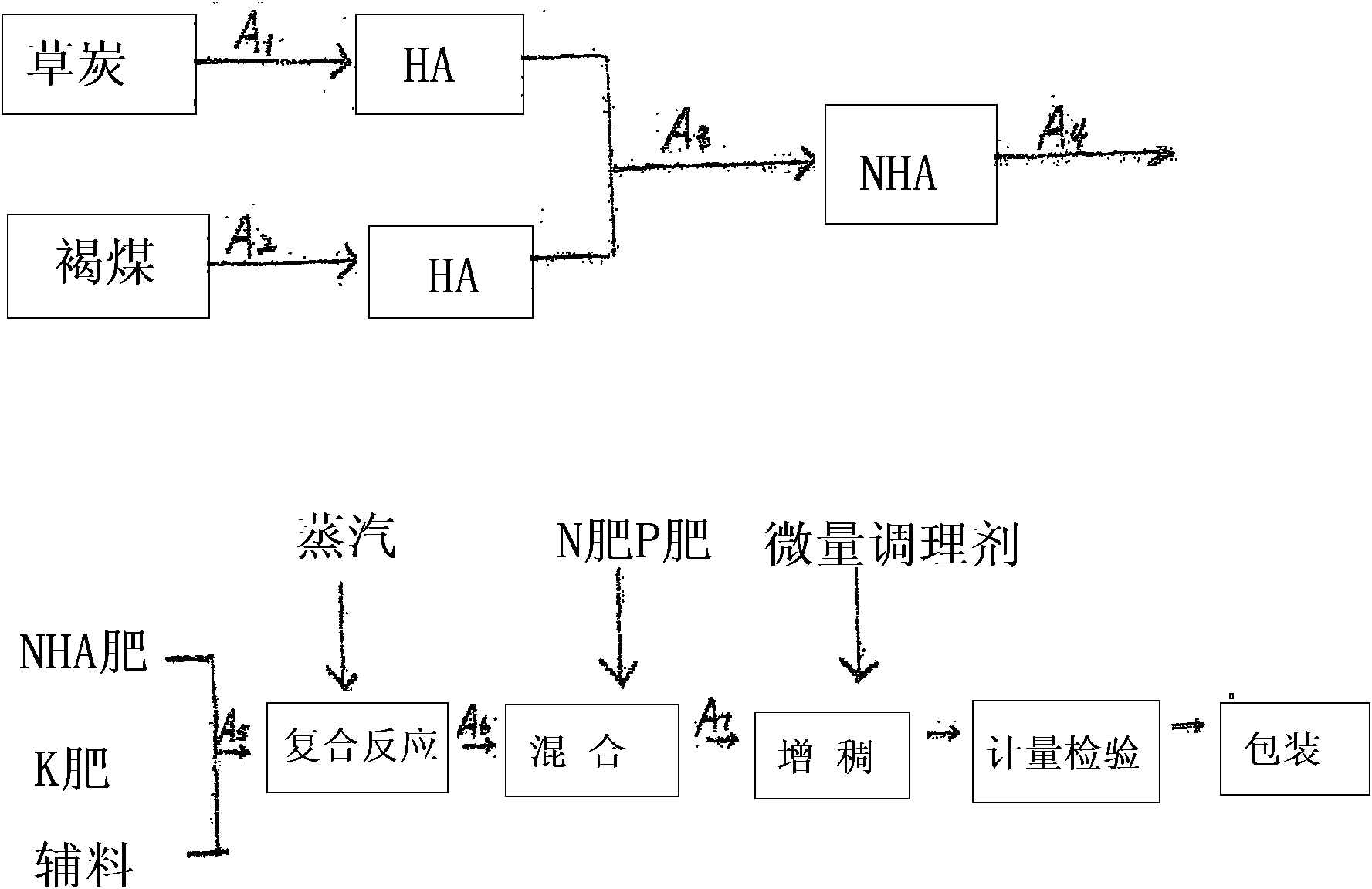

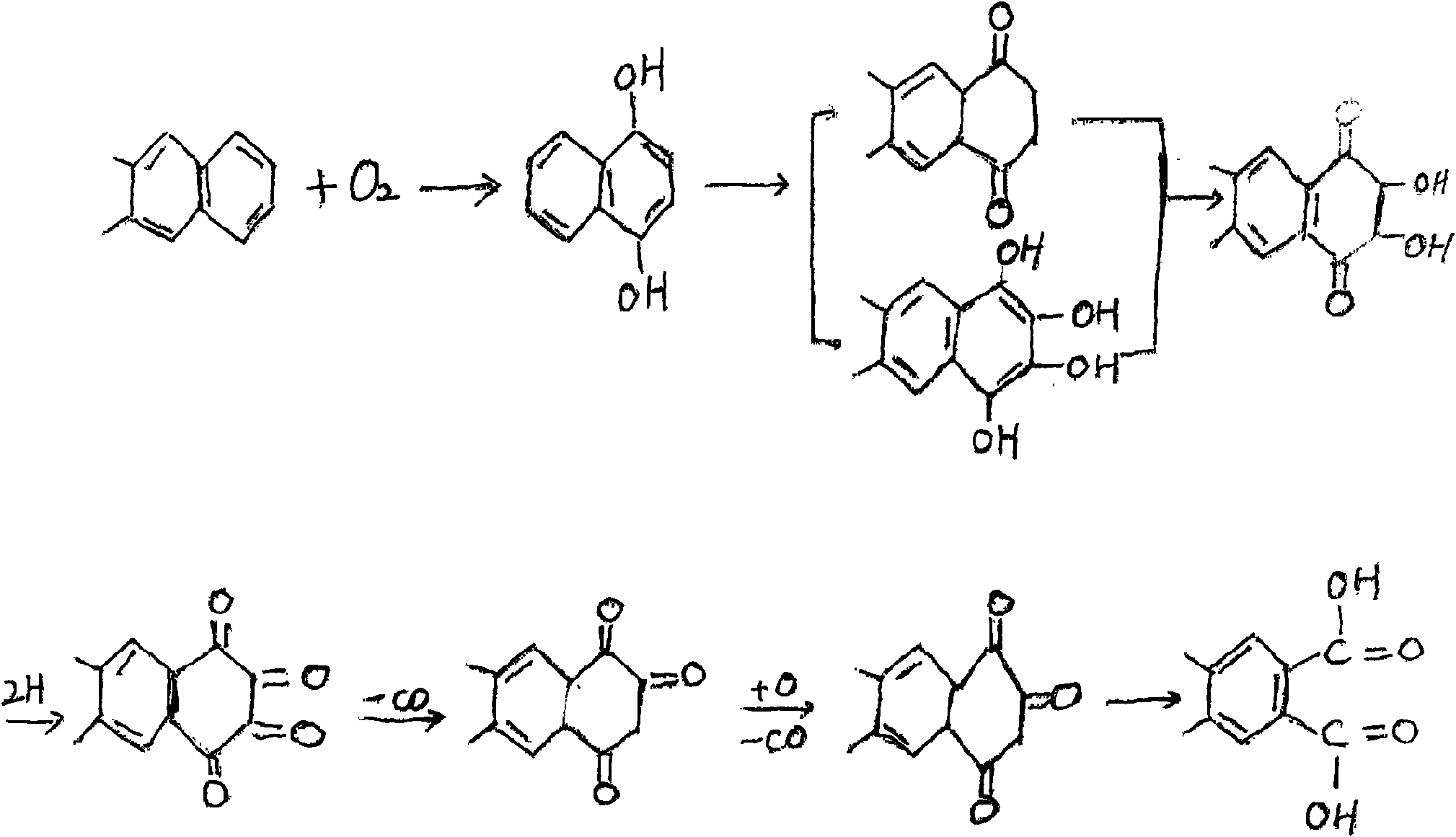

Special fertilizer for Chinese goosebeery and preparation process thereof

InactiveCN101555170AIncrease profitGuaranteed totalOrganic fertilisersFertilizer mixturesActinidiaKiwi

A special fertilizer for Chinese goosebeery is prepared by oxidizing and modifying humic acid into humate and adding nitrogenous fertilizer, phosphorus fertilizer and potash fertilizer. The preparation process comprises the following steps: (1) humic acid modification: oxidizing humic acid material with oxidizing acid and adding sulphite for modification to obtain humate; (2) chelation: adding potash fertilizer and compound fertilizer auxiliary material into the humate, and leading steam into a reaction kettle, heating to more than 80 DEG C and preserving the temperature for chelation for more than 8 h; (3) mixing: after the chelation, adding nitrogenous fertilizer and phosphorus fertilizer and mixing; and (4) thickening: adding micro conditioner for thickening, measuring and packing. In the invention, through adding modified HA salt, the original special fertilizer (M fertilizer) for Chinese goosebeery is further processed, and the pure inorganic fertilizer in the M fertilizer is changed into an organic-inorganic compound fertilizer with different characteristic, so that the operating factor of the fertilizer is improved by 14 percent through the fertilizer modification.

Owner:李涛

Method for preparaing dephosphorized and ferrum-carried activated carbon adsorbent

InactiveCN102614854AImprove adsorption capacityImprove processing efficiencyOther chemical processesPotassium rhodanidePotassium thiocyanate

The invention belongs to the technical field of sewage treatment, in particular to a method for preparaing dephosphorized and ferrum-carried activated carbon adsorbent, which comprises the following steps of: soaking powdered activated carbon through hydrochloric acid, washing through water, and drying at the temperature of 100-150 DEG C; injecting the obtained activated carbon into strong oxidizing acid solution so as to be soaked, rinsing, and drying a rinsed sample; and finally, mixing the obtained activated carbon and inorganic ferric salt solution, stirring, re-drying, cooling to room temperature, removing surface layer coverings, washing unloaded ferric oxide through water until rinsing to be without obvious color and without red color through test by potassium rhodanide solution, and drying continuously to obtain the high-efficient dephosphorized activated carbon adsorbent rich in iron oxide compound. Compared with the prior art, the method has the advantages of simplicity, moderate preparing condition, easiness in implementation, strong operability, high processing efficacy for waste water containing phosphorus, and purification cost reduction.

Owner:FUDAN UNIV

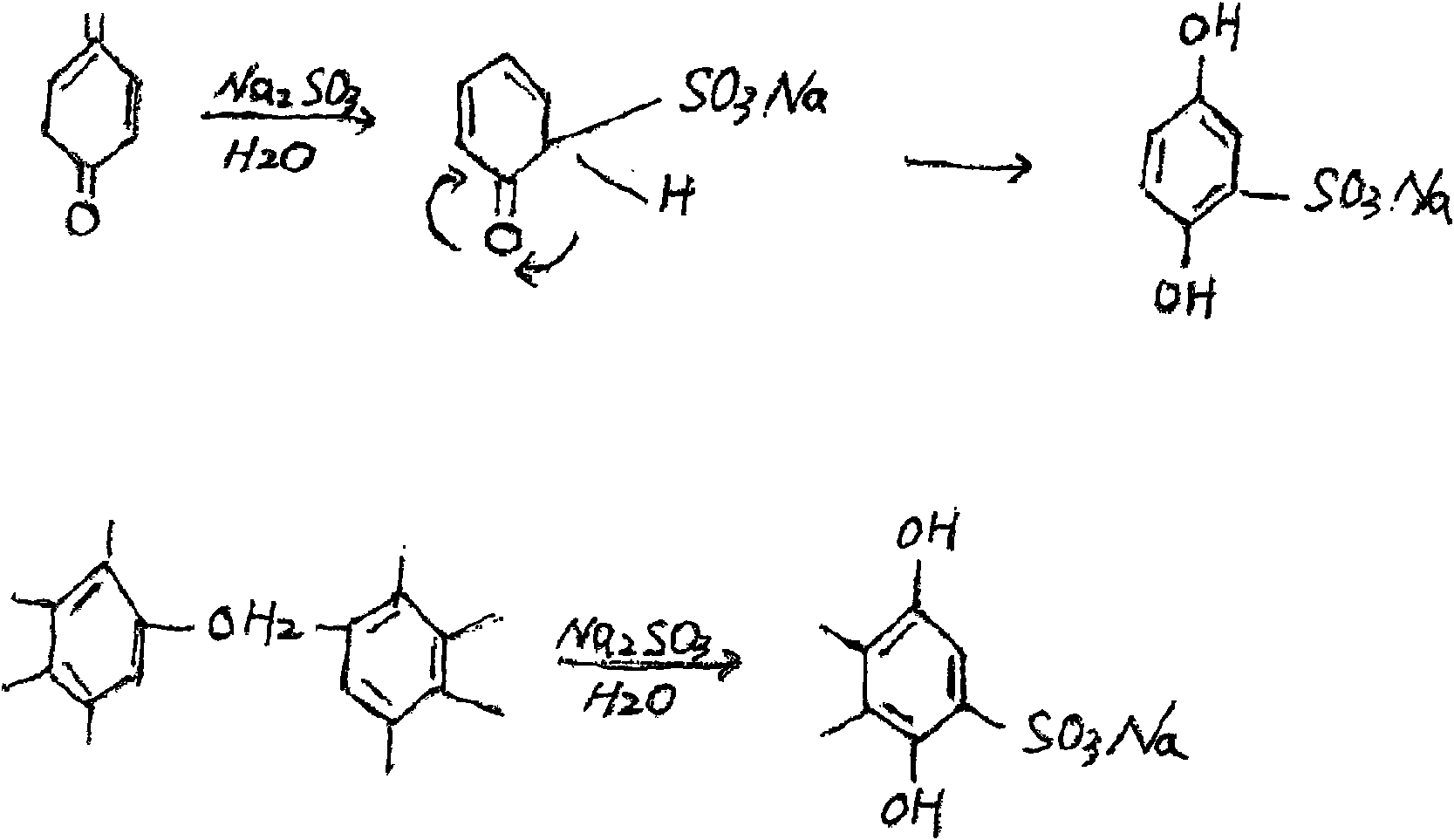

Gradient arsenic removing method for high-arsenic metallurgical wastes

ActiveCN102409165AReduce manufacturing costChoose good dissolutionProcess efficiency improvementPotassiumOxidizing acid

The invention provides a gradient arsenic removing method for high-arsenic metallurgical wastes, which is generally suitable for comprehensive arsenic removing treatments of high-arsenic smoke dust generated in the smelting process of lead, zinc, antimony, copper, tin and the like, high-arsenic anode mud generated in the electrolytic process of wet lead, silver, copper and the like and other metallurgical wastes. The method comprises two stages of water leaching arsenic removal and oxidizing acid leaching arsenic removal and specifically comprises the following steps of: first, selectively dissolving out free arsenic trioxide and water soluble arsenate (like sodium arsenate and potassium arsenate) through water leaching; and then further leaching out indissolvable arsenate and arsenic sulfide in the water leaching residue as well as little incomplete arsenic trioxide dissolved out by water by using a mixed leaching liquor of acid and water soluble oxidizing agent. The method provided by the invention has the advantages of low consumption of acid and alkali, high arsenic removing efficiency, safety, environment friendliness and suitability for arsenic removing treatment of various arsenic contained metallurgical wastes, in particular for arsenic removing treatment of the smoke dust with high content of free arsenic trioxide.

Owner:HUNAN ZHANTAI NON FERROUS METALS

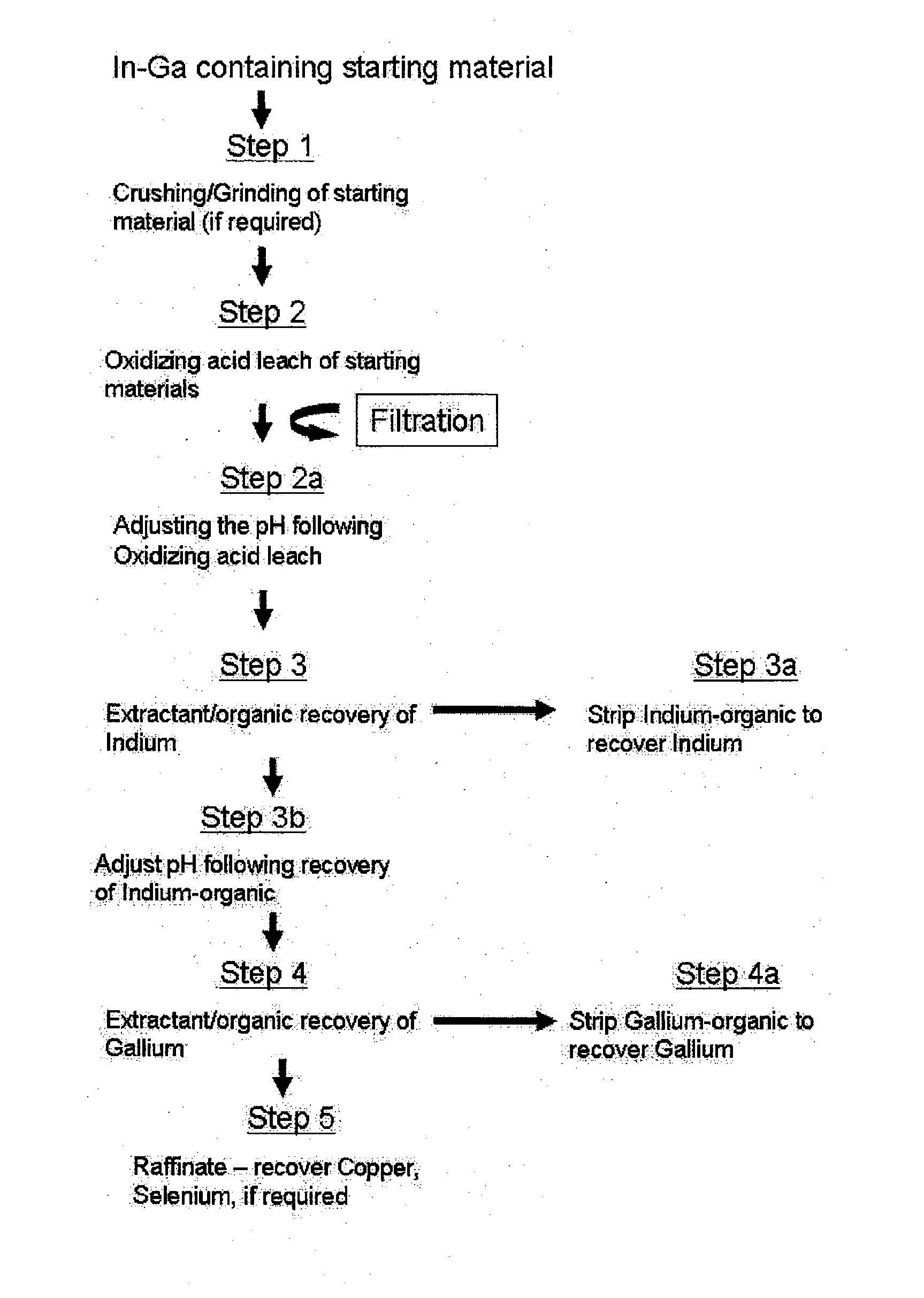

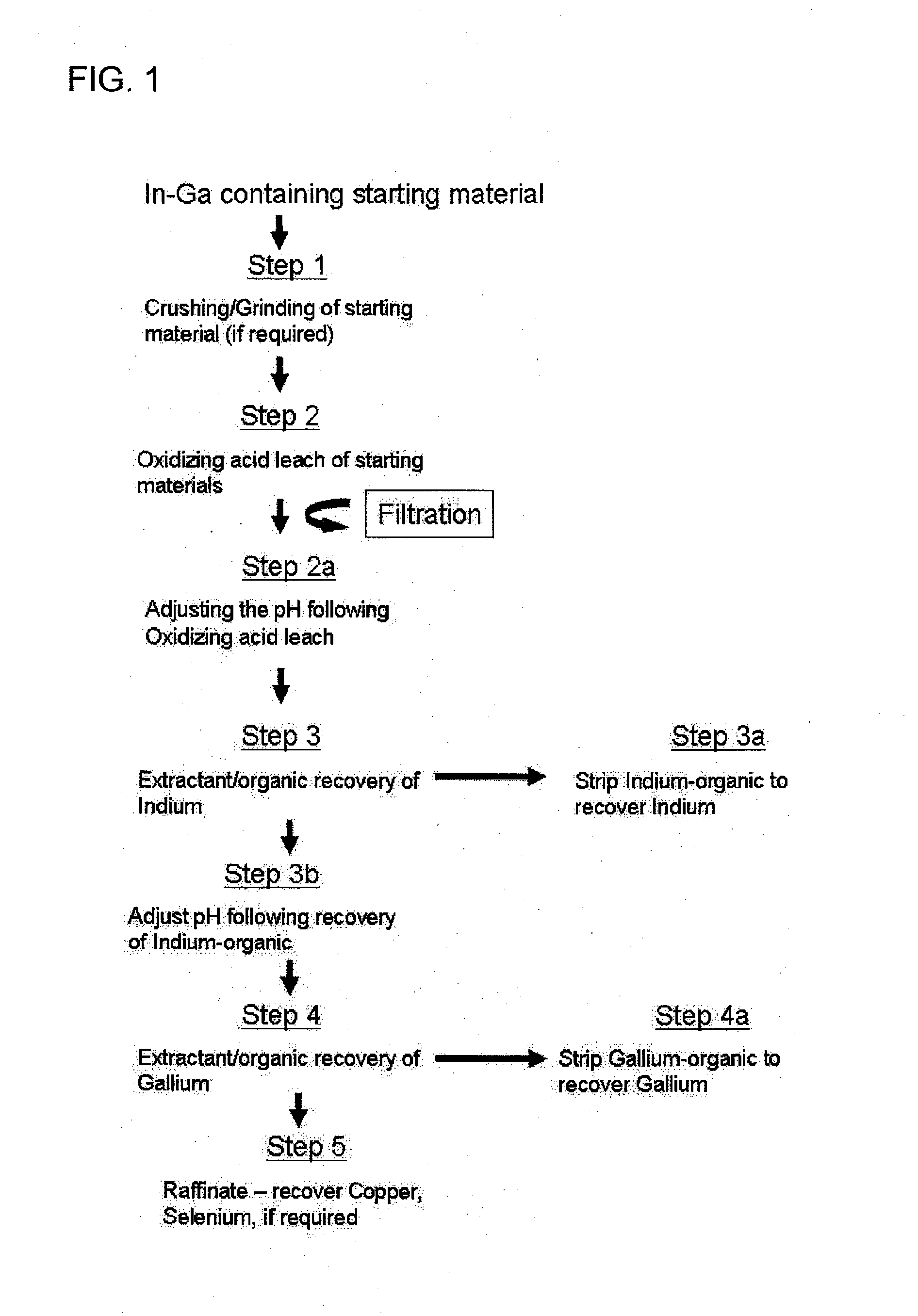

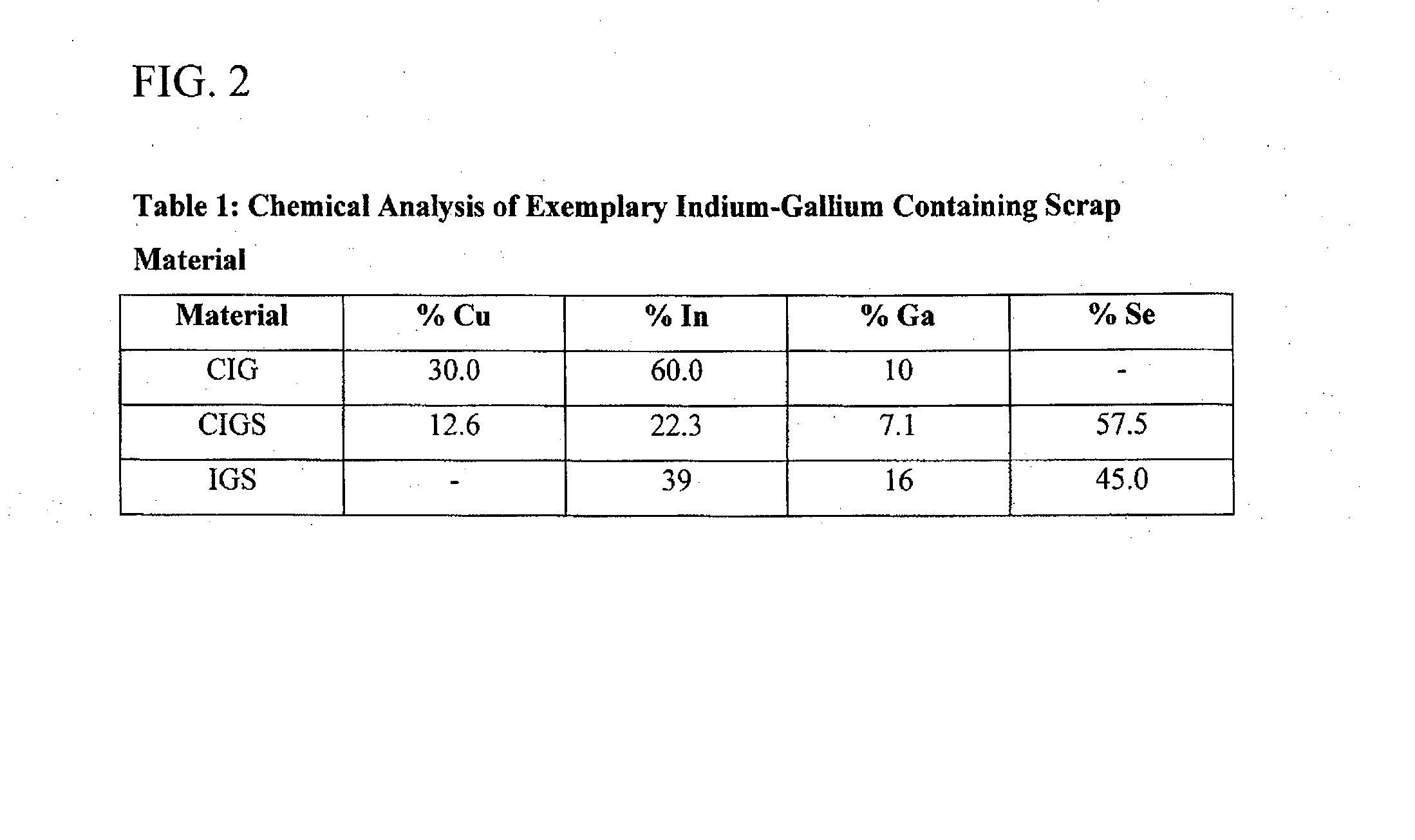

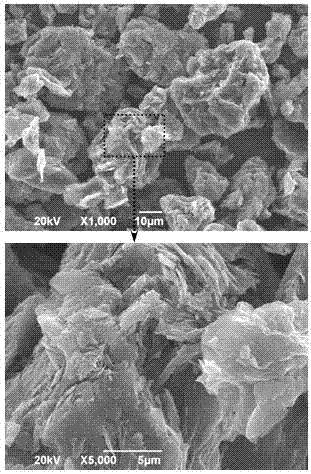

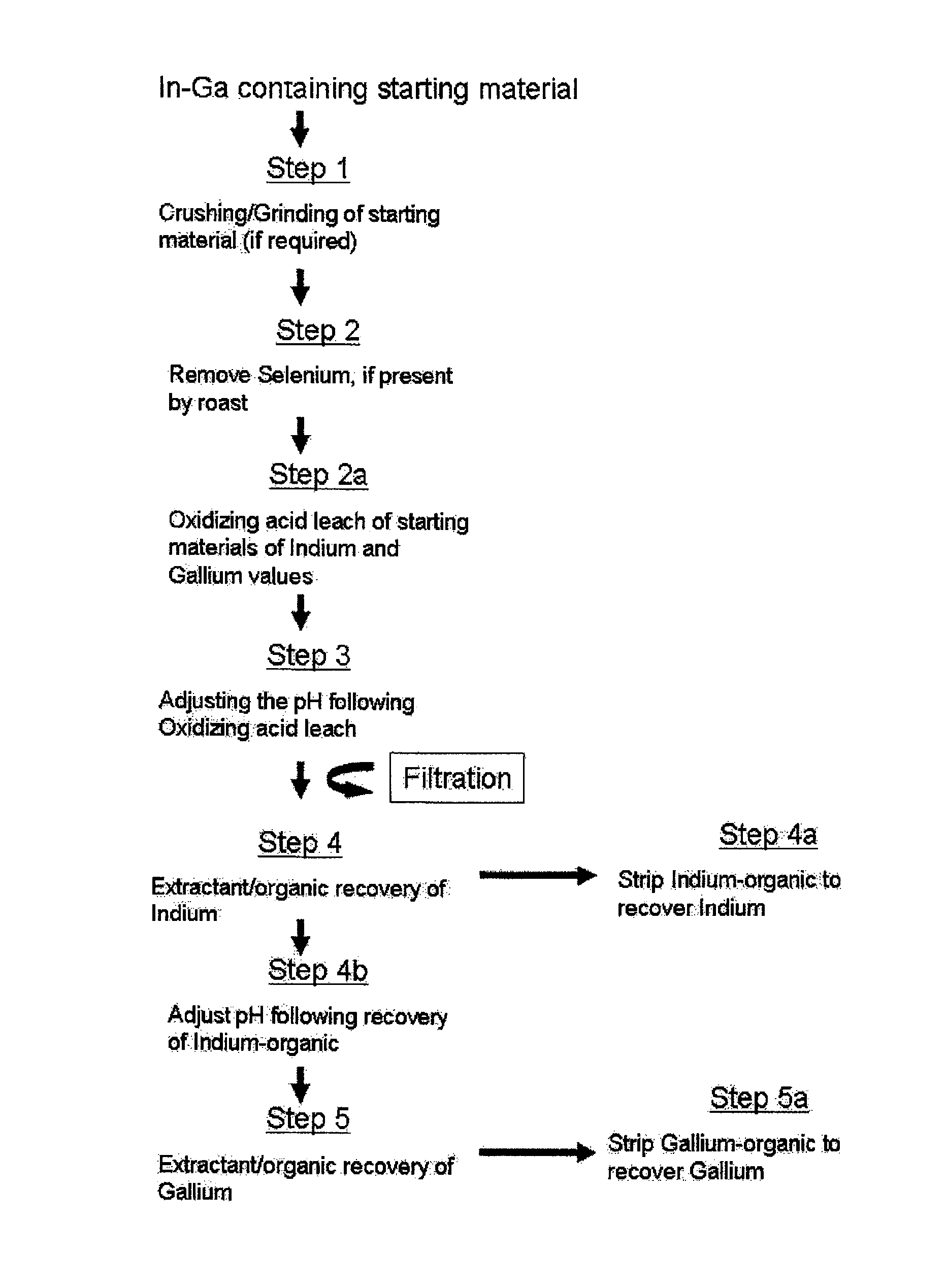

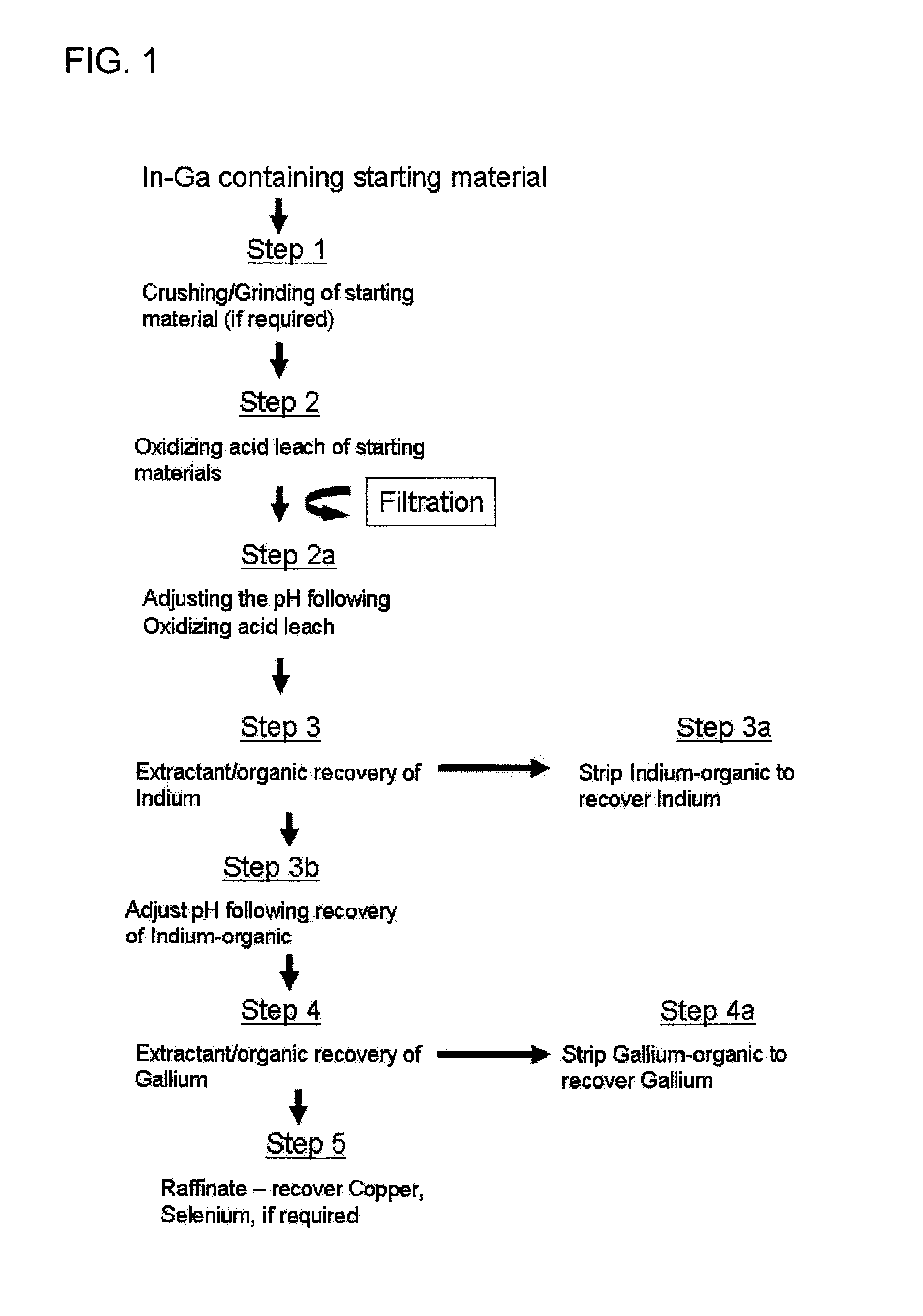

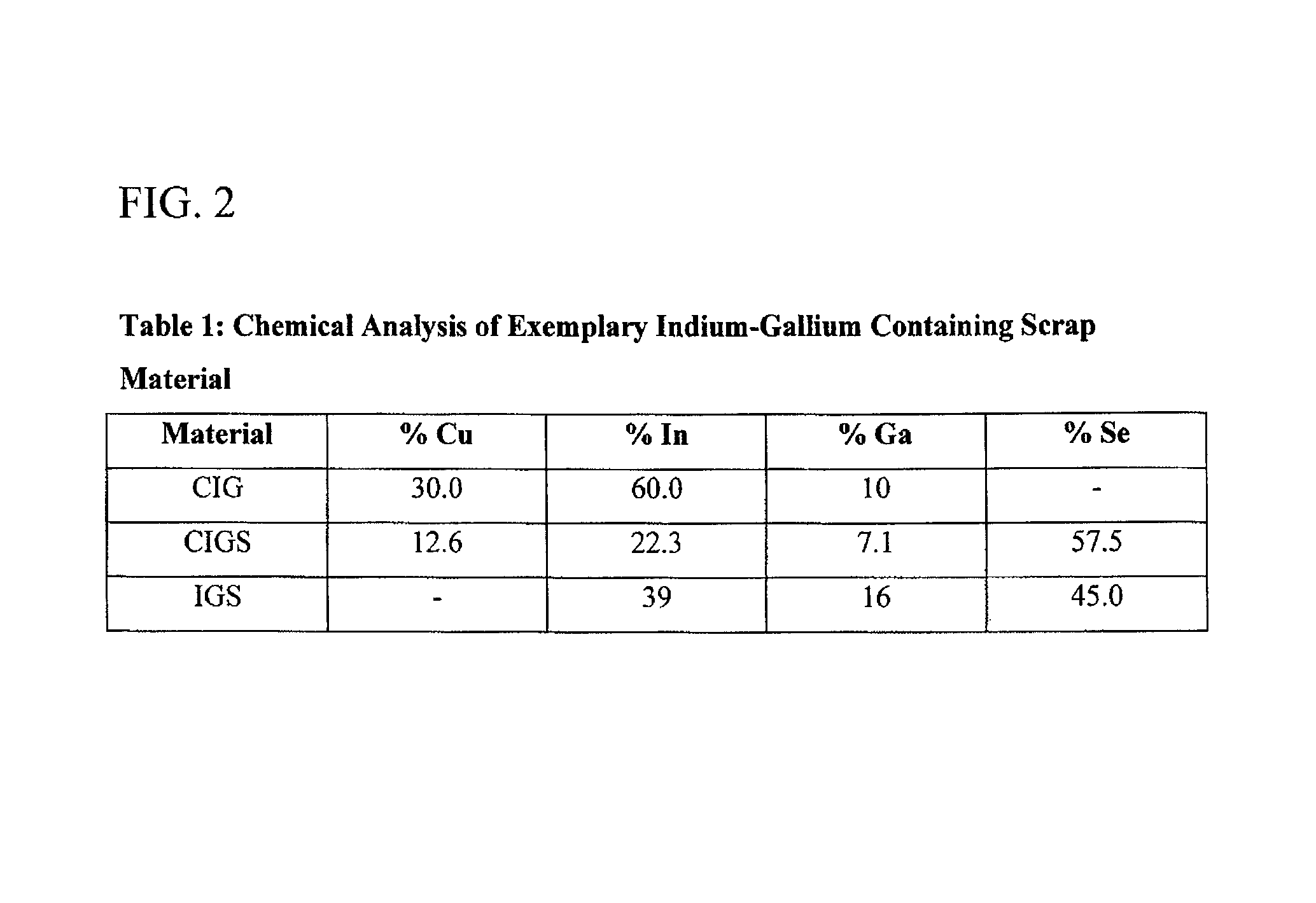

Treatment of indium gallium alloys and recovery of indium and gallium

There is provided a hydrometallurgical process of recovering indium and gallium values from mixtures thereof with other metal values for example recycled and scrap solar panel cells which comprises subjecting the mixture to strongly oxidizing acid conditions, preferably via the simultaneous addition of sulfuric acid and hydrogen peroxide to the leach vessel, so as to form indium and gallium salt species of at least the major proportion of the indium and gallium values in the mixture, extracting the indium and gallium values with an organic extractant by adjusting the pH so as to extract individually the indium and gallium values with the organic extractant, stripping indium and gallium values from the extractant using an acid and an alkaline solution respectively and recovering the indium and gallium values.

Owner:MOLYCORP MINERALS CANADA ULC

Process of preparing chitosan/carbon nano tube composite material by covalence graft

A process for preparing the chitosan-carbon nanotube composition by covalent graft includes such steps as acidifying carbon nanotubes by strong-oxidizing acid to make its surface to carry carboxy radicals, converting them to acylchlorinated carbon nanotubes by sulfoxide chloride, and reaction between said carbon nanotubes and the chitosan in N,N-dimethylformamide and / or N,N-dimethylacetoamino pyridine at 120-140 deg.C.

Owner:TIANJIN UNIV

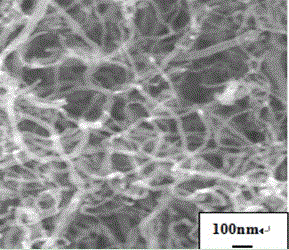

Method for preparing metal nano-particle modified polysaccharide wrapped carbon nano tube

InactiveCN101811665ASmall long diameterHas near-infrared absorption propertiesNanostructure manufactureCancer cellModified carbon

The invention discloses a method for preparing a metal nano-particle modified polysaccharide wrapped carbon nano tube in the technical field of nano composite materials. The method comprises the following steps: placing a carbon nano tube raw material in oxidizing acid and mixed acid in turn, performing ultrasonic truncation treatment on the solution, mixing the treated solution and polysaccharide solution to obtain polysaccharide wrapped carbon nano tube solution, then reducing a metal precursor to obtain a metal crystal seed modified carbon nano tube by using a strong reducing agent, and finally reducing a metal salt precursor to obtain a series of metal nano-particle modified polysaccharide wrapped carbon nano tubes with different growth degree by using a weak reducing agent. The method can improve the dispersion of the carbon nano tube in the water, effectively fix the metal nano-particles and control the modification density and grain size of the metal nano-particles, further cancontrol the plasma resonance absorption performance of the surface metal nano-particles, and is expected to be applied in the fields of targeted detection of cancer cells, photo-thermal treatment, biosensors and the like.

Owner:SHANGHAI JIAO TONG UNIV

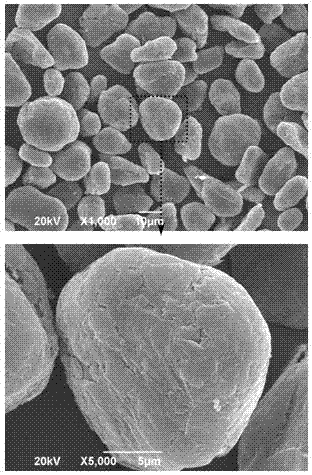

Lithium ion battery negative material structure and preparation method thereof

ActiveCN103904335AImprove electrochemical performanceCell electrodesSecondary cellsCyclic processSilicon oxide

The invention relates to a lithium ion battery negative material structure and a preparation method thereof, which aim at solving the problems that the size of a silicon-based material is rapidly swelled in the lithium intercalation process, and particles are crushed and powdered in the cycling process and dropped off from a current collector. The structure is a one-dimensional linear carbon-cladding empty pomegranate structure. The preparation method comprises the following steps of I, adding silicon oxide SiOx particles, one-dimensional linear carbon, a surface active agent, a pH adjusting agent and polymer monomer into an ethanol aqueous solution to be ultrasonically dispersed; II, preparing a polymerization initiator solution; III, preparing an SiOx carbon precursor / one-dimensional carbon; and IV, preparing SiOxC / one-dimensional carbon, adding the SiOxC / one-dimensional carbon into the ethanol aqueous solution to be dispersed, adding a non-oxidized acid and HF mixed solution, and washing, filtering, crushing and filtering after the reaction. The lithium ion battery negative material structure has good electrochemical performance and is applied to the field of electrochemical power supplies.

Owner:HARBIN INST OF TECH

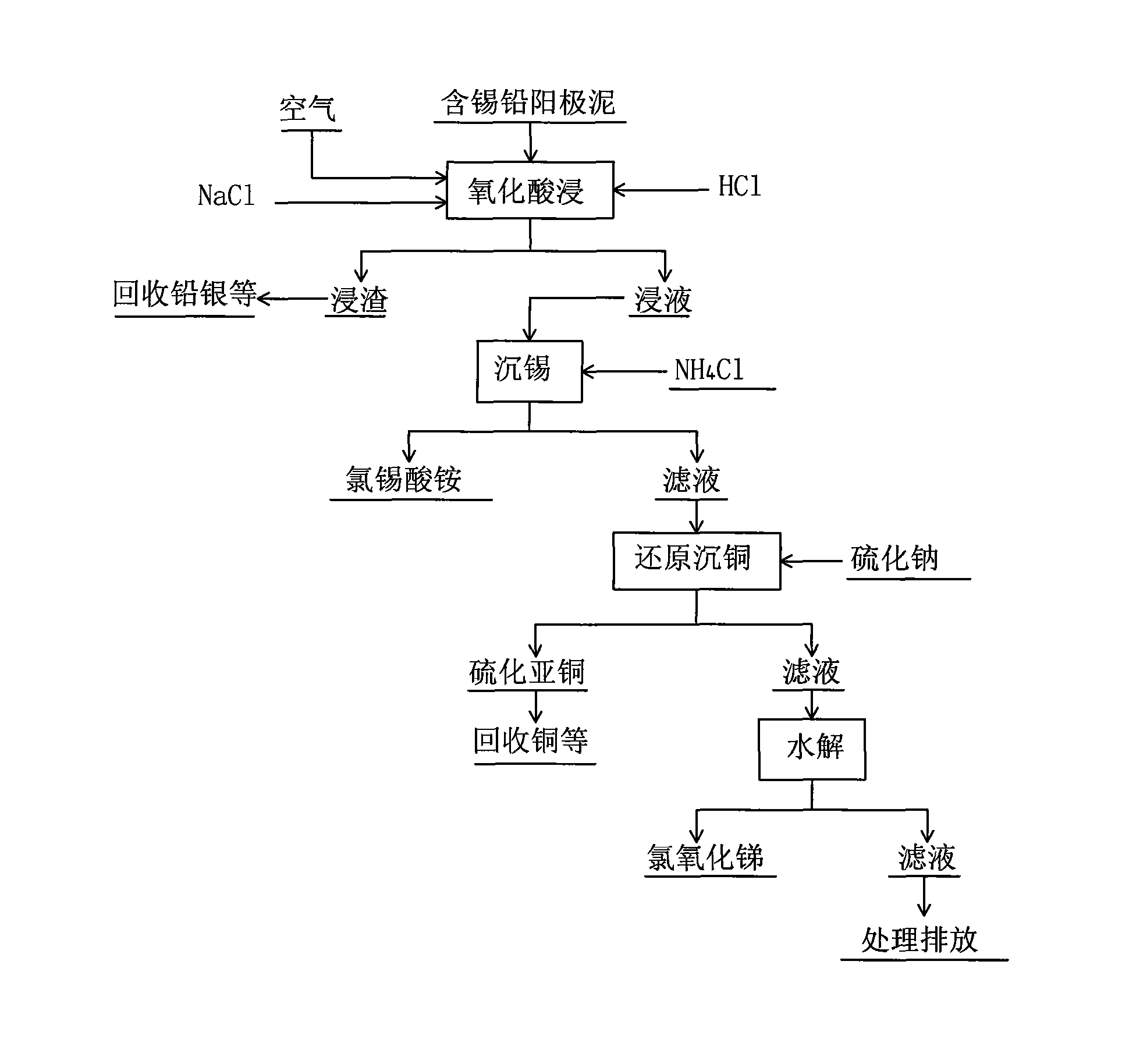

Method for separating tin and stibium from tin-lead anode slime

InactiveCN101514396AAchieve recyclingSolve the separation problemProcess efficiency improvementOxidizing acidBismuth

The invention relates to a method for separating tin and stibium from tin-lead anode slime. The method comprises the following steps: firstly performing oxidizing leaching on the tin-lead anode slime with hydrochloric acid and sodium chloride to cause most the tin, the stibium, bismuth and copper and the like to enter leaching solution and separate from the lead and the silver, then selectively precipitating the tin in the leaching solution in the form of ammonium chlorostannate by ammonium chloride to realize separation of the tin from the stibium, the bismuth and the copper; then depositing copper in filtrate by sodium sulfide, then hydrolyzing the solution after copper deposition to obtain crude antimony oxychloride, and finishing separation of the tin and the stibium. Compared with the prior art, the method helps reduce hydrochloric acid consumption by over 40% and reduce about half of the production cost.

Owner:CHENZHOU YUTENG CHEM IND

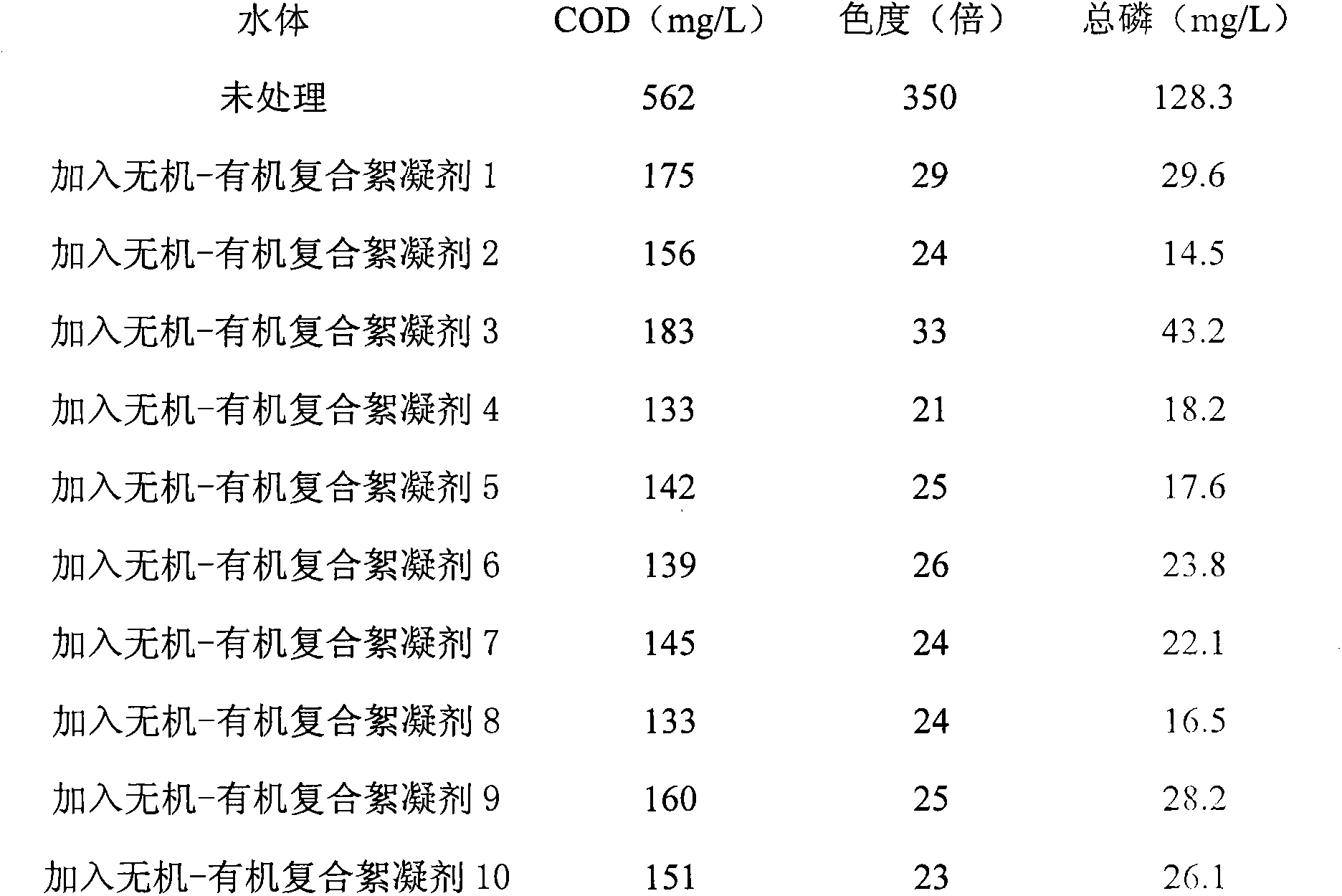

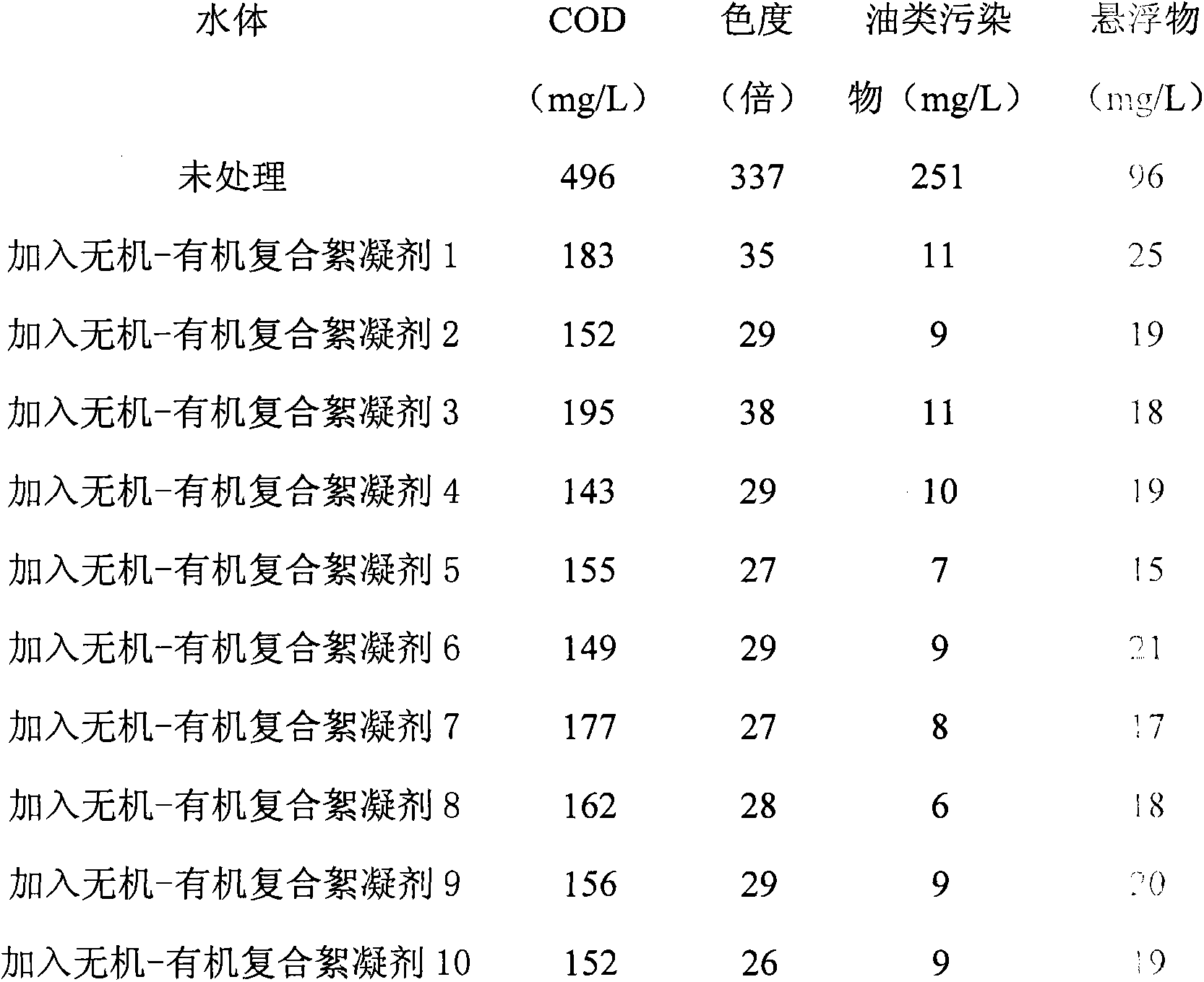

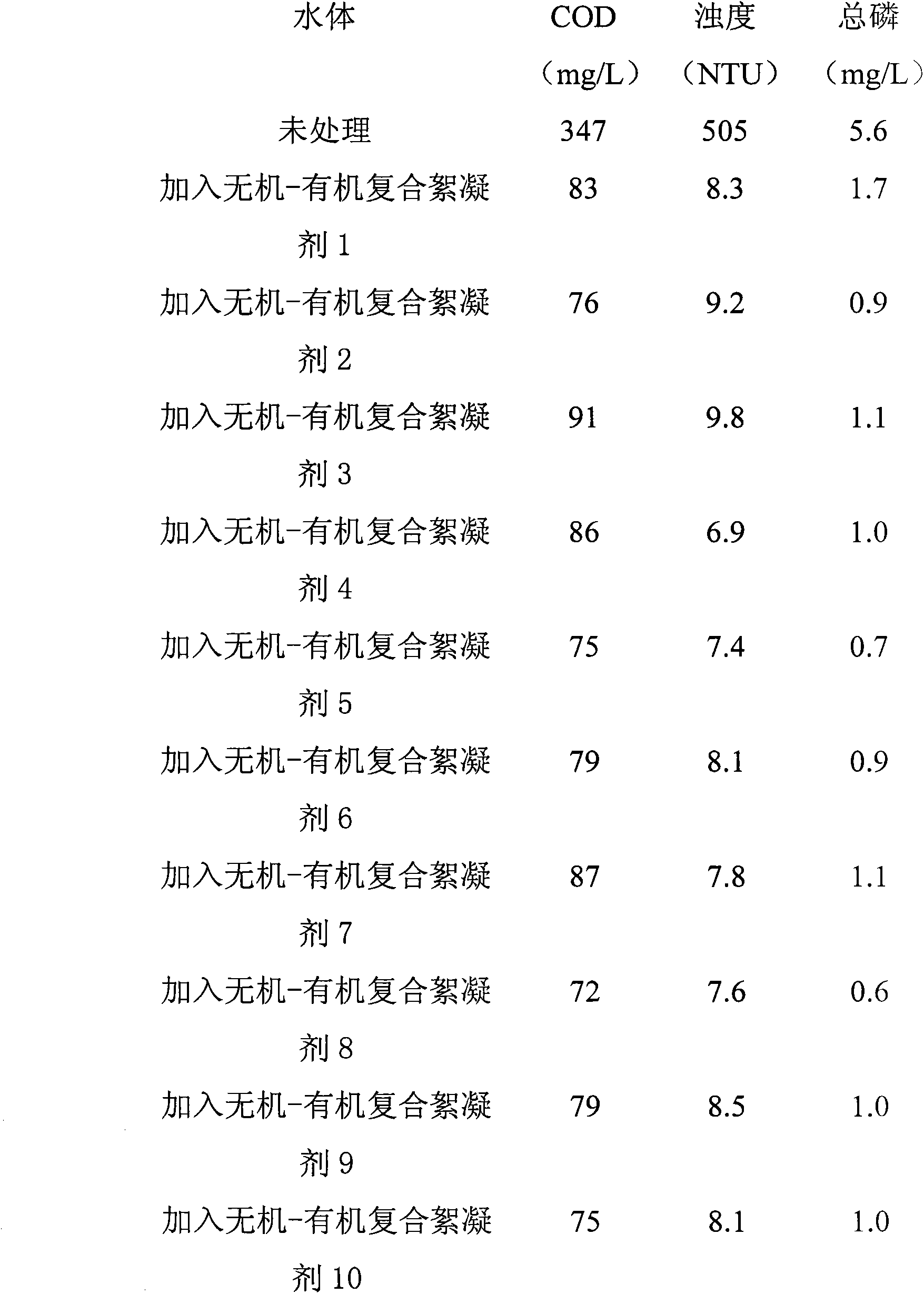

Dephosphorization flocculating agent and preparation method thereof

ActiveCN104261530AGood flocculation effectGood dephosphorization effectWater/sewage treatment by flocculation/precipitationAluminateWater quality

The invention discloses a dephosphorization flocculating agent and a preparation method thereof. The dephosphorization flocculating agent is formed by compounding an inorganic flocculating agent and an organic flocculating agent. The raw materials of the inorganic flocculating agent comprise sodium ferrate, borax, ferrous sulfate, silicate or aluminate; the raw materials of the organic flocculating agent comprise modified chitosan or modified polyacrylamide. The preparation process comprises the following steps: firstly adding a non-oxidizing acid into the silicate or aluminate to obtain a polysilicate colloid or an aluminum hydroxide colloid, then adding a borax solution and a sodium ferrate solution sequentially while stirring, further dropping a ferrous sulfate solution, mixing to form the inorganic flocculating agent, standing, then adding the modified polyacrylamide or modified chitosan into the inorganic flocculating agent, curing and adding the acid till the pH value is less than 7 to obtain the finished dephosphorization flocculating agent. The flocculating agent is suitable for a wide range of water quality, is little affected by co-existing salts, the pH value of sewage and temperature and is particularly effective for dye wastewater, oilfield sewage and the like.

Owner:内蒙古昕晟科贸有限责任公司

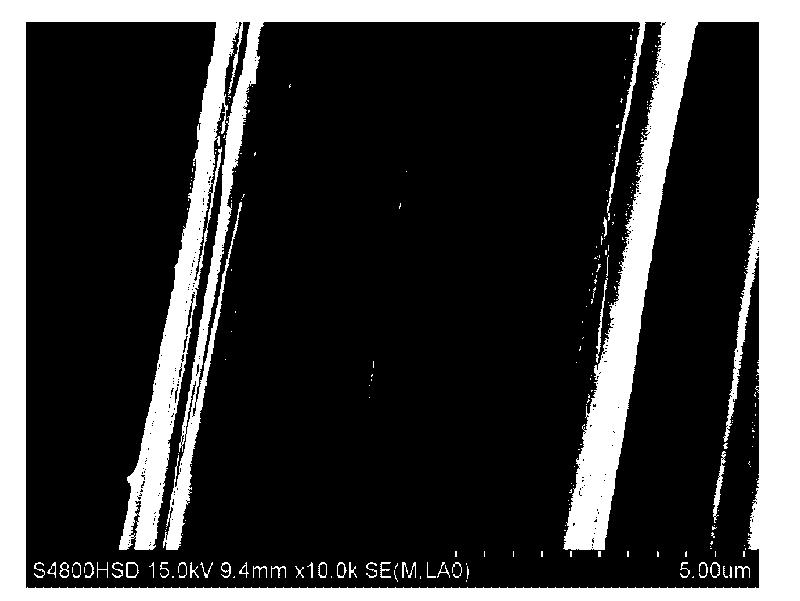

Method for modifying carbon fibers by dendritic macromoleculars

InactiveCN101709542AUnique rheological propertiesGood groomingPhysical treatmentCarbon fibresFiberEpoxy

The invention provides a method for modifying carbon fibers by dendritic macromoleculars, relating to a method for modifying the carbon fibers and aiming at solving the problem of poor stability due to that only one functional group of organic silicon compound can react with the fiber modified surface so as to limit a membrane in a bidimensional surface. The method comprises the following steps: adding carbon fibers in a strong oxidizing acid, utilizing ultrasonic for processing, heating and refluxing, drying, adding into dendritic macromolecular solution for ultrasonic processing once again, reacting under the temperature of 20-100 DEG C, washing and drying to obtain the carbon fibers modified by the dendritic macromoleculars. The dendritic macromoleculars used in the invention have the advantages of tri-dimensional structure, evenly-distributed and thick outer functional groups, lower viscosity, unique flowing deformation property, good film forming property and favorable modified effect. The epoxy resin composite material prepared by using the carbon fibers modified by the dendritic macromoleculars obtained in the invention has 53.2-55.8MPa of interface shearing strength.

Owner:HARBIN INST OF TECH

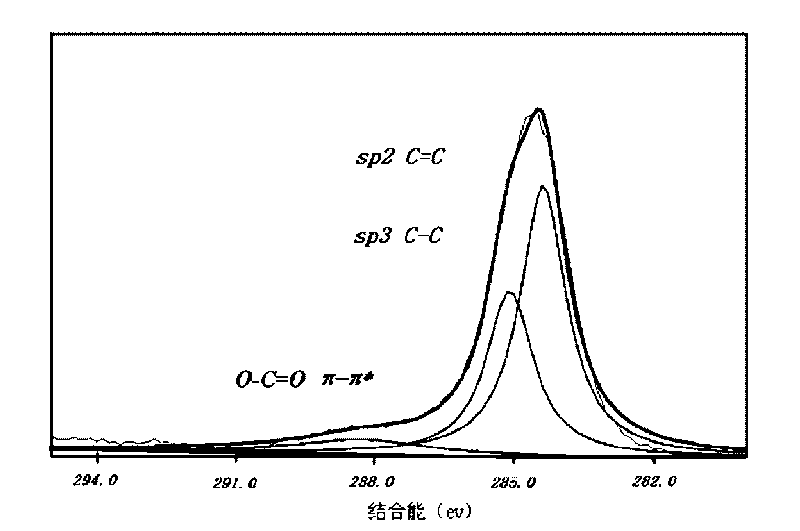

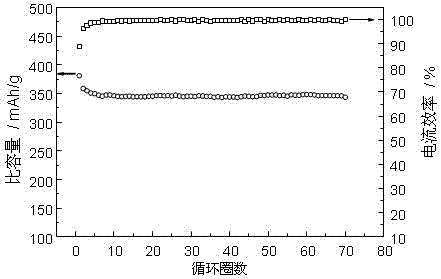

Modified method of natural graphite material for lithium ion battery

InactiveCN101214952AImprove the first charge and discharge efficiencyChange surface chemistryCell electrodesOxidizing acidMaterials science

Disclosed is a modification method for native graphite materials used for lithium ion batteries. The method comprises the following steps that native graphite powders are placed into an autoclave, dense oxidizing acid, oxidizing salt and hydrochloric acid are used for oxidation treatment, wherein the oxidation treatment proceeds at a temperature ranging from 180 to 250 DEC G, the native graphite materials which are washed or not are centrifugalized, then native graphite materials which are centrifugalized are calcined, semi-modified native graphite materials are gained, silanization film forming treatment is completed on the semi-modified native graphite materials, then tetrahydrofuran is used to wash and dry the native graphite materials, thereby obtaining modified native graphite materials. The modified native graphite materials are capable of satisfying the application of the lithium ion batteries, have the advantages of high cost performance, low costs, large specific capacity, perfect circulative property and higher initial charge and discharge efficiency, and simultaneously are adapted to the negative pole application of high-current charge and discharge lithium ion batteries.

Owner:平顶山工学院

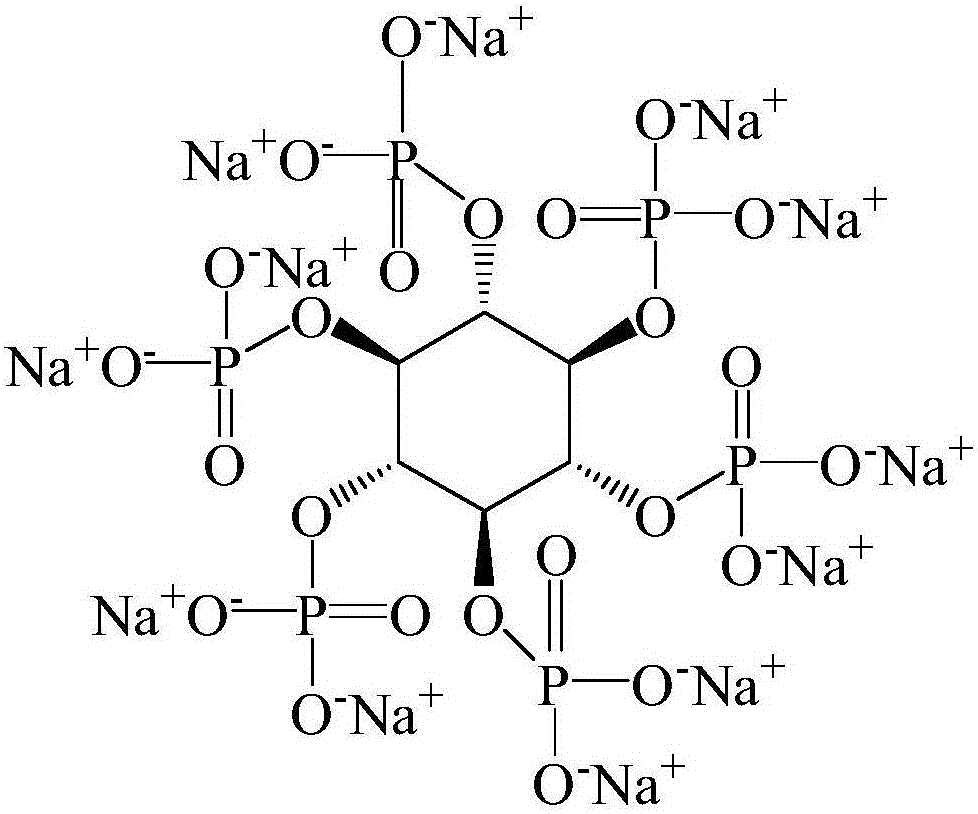

Phosphorus-doped graphene quantum dot and electrochemistry preparing method thereof

ActiveCN105862057AThe operation process is simple and convenientThe preparation process is easy to coordinateElectrolysis componentsElectrochemistryOxygen

The invention provides a phosphorus-doped graphene quantum dot and an electrochemistry preparing method thereof. According to the preparing method, phosphorus-contained macromolecular organic compounds soluble in water are selected to serve as electrolytes, through controlled potential electrolyzing, phosphorus oxygen bonds are broken, phosphorus atoms are separated from the macromolecular organic compounds to enter the interior of the graphene quantum dot, carbon phosphorus bonds and the phosphorus oxygen bonds are formed, doping is completed, and the phosphorus-doped graphene quantum dot with the higher doping concentration content is prepared; the quantum dot has the good cleaning-up effect on hydroxyl radicals, and through ESR energy spectrum test, the clearing-up rate of the hydroxyl radicals can reach 78.49%; the method is easy and convenient in the operation process, the whole preparing process is conveniently planed as a whole, strong oxidizing acid or strong reducing agents are not used, and certain commercial feasibility is achieved; and graphene precursor which is rich in reserving and friendly to environment is adopted to replace expensive materials of graphite oxide, carbon nano-tubes and the like, and the method is hopefully and widely applied in the biomedical field.

Owner:UNIV OF SCI & TECH BEIJING

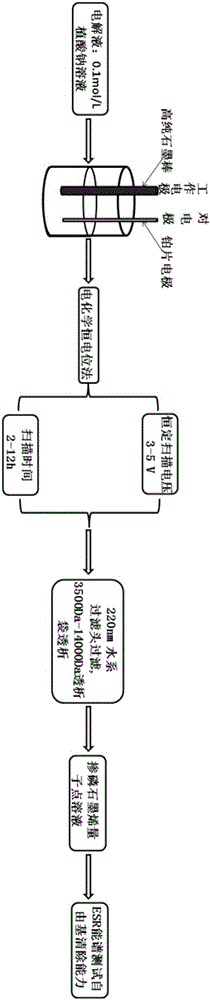

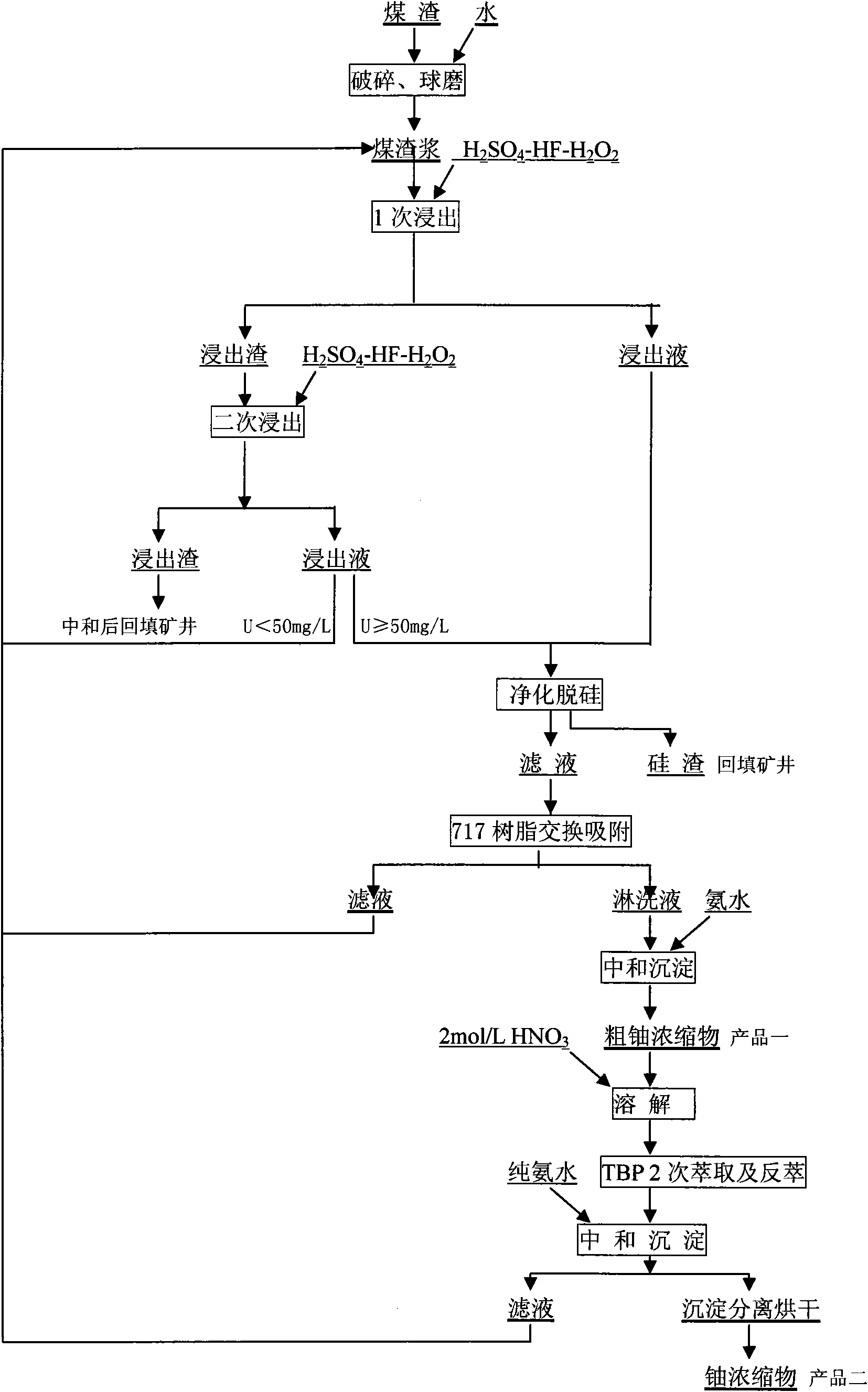

Method for recycling uranium from uranium extraction coal residue with wet method

InactiveCN101619397AHigh recovery rateLow costProcess efficiency improvementEcological environmentSilicic acid

The invention discloses a method for recycling uranium from uranium extraction coal residue with a wet method, which comprising the following steps: (1) particle size requirements: crashing the coal residue below 200 meshes; (2) oxidation and acid leaching: in a dilute sulphuric acid-hydrofluoric acid medium, using peroxide as an oxidizer to carry out reverse oxidation leaching twice; (3) desilicification and purification: using ammonia to adjust the pH value of once leaching filtering liquid of the uranium to 9.8-10.2, enabling the silicon in the solution to become silicic acid sediments, after filtering, carrying out ion exchange on the filtering liquid, desilicificating slag and stockpiling; (4) ion exchange: using a 717 type ion exchange resin to carry out exchange absorption by the filtering liquid, and then using 1 mol / L of NaCl-0.1 mol / LH2SO4 of mixed solution to elute the resin, after using tributyl phosphate to carry out extraction and back-extraction on eluent, obtaining uranium concentrates containing about 65% of the uranium. The invention successfully extracts and separates the uranium from the uranium extraction coal residue to produce the uranium concentrates, has t high recycling rate of uranium as high as 80-85% and low cost, and comprehensively utilizes the uranium extraction waste, thereby eliminating the influence of the radiation wastes on the ecological environment.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

Process for treating waste water containing alkali and oil

ActiveCN101684025AExtended cleaning cycleExtend the life cycleMultistage water/sewage treatmentWater/sewage treatment by neutralisationFlocculationEmulsion

The invention relates to a process for treating waste water containing alkali and oil. The process comprises the following steps: neutralizedly treating the waste water containing alkali and oil; thensequentially carrying out inclined plate precipitation, tapes filtration and ultra-filtration treatment; finally discharging. The neutralization is achieved in a step that the waste water containingalkali and oil is neutralized by adding oxidized acid, and meanwhile, emulsion breaking, delamination as well as oil-water separation are carried out also by same. The process adopts neutralization and flocculation firstly and then carries out ultra-filtration treatment, after which the water quality is good, and less chemical agents are used.

Owner:ANGANG STEEL CO LTD

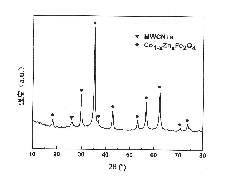

Method for preparing MWCNTs/Co1-xZnxFe2O4 magnetic nanocomposite material

InactiveCN101800105ASimple preparation processProduction equipment requirements are simpleInorganic material magnetismIron compoundsSodium acetatePolyethylene glycol

The invention relates to a method for preparing a multiwall carbon nano-tube (MWCNTs) / cobalt zinc ferrite (Co1-xZnxFe2O4) magnetic nanocomposite material, which comprises the following steps of: (1) mixing a strong oxidizing acid and MWCNTs in a mass ratio of 1:200-1:400 and reflowing the solution in an oil bath after ultrasonic dispersion; and (2) dispersing the acidized MWCNTs into solution of ethylene glycol at room temperature, weighing a ferric salt, a zinc salt and a cobalt salt, dissolving the salts into the solution, adding polyethylene glycol and anhydrous sodium acetate after the added salts are fully dissolved, mechanically stirring the mixture, putting the mixture into a high-pressure reaction kettle for reaction after polyethylene glycol and anhydrous sodium acetate are fully dissolved, cooling the mixture to room temperature, and washing, collecting and drying a product. The magnetic nanocomposite material prepared by the method has the advantages of pure crystalline phase, high dispersibility, difficult agglomeration, high magnetization intensity and high magnetic induction sensitivity; and the method has the advantages of simple preparation process, relatively lower requirements on production equipment and easy industrial production.

Owner:DONGHUA UNIV

Method for modifying natural graphite

InactiveCN102931407AAvoid direct contactInhibition of sheddingCell electrodesPolymer dissolutionOxidizing acid

The invention discloses a method for modifying natural graphite. The method comprises the steps of: (1) using oxidizing acid or salt to carry out oxidation treatment on the natural graphite to obtain an intermediate product graphite A; (2) centrifuging, washing and drying the graphite A to obtain an immediate product graphite B; (3) dissolving a polymer which is used as a shell material into an organic solvent to obtain a polymer solution; (4) adding the graphite B into the polymer solution, stirring the mixture, thus uniformly soaking the graphite B into the polymer solution, stewing the mixture, and evaporating an organic solvent, sieving the mixture to obtain graphite C; (5) curing the graphite C for 0.2-12 hours at 100 DEG C to 600 DEG C under the protective atmosphere to obtain graphite D; (6) carbonizing the graphite D for 1-24 hours at 700 DEG C to 1500 DEG C to finally obtain the modified graphite to be prepared in the invention. According to the method disclosed by the invention, the process is simple, the control is easy, the price is low, and the industrial application is facilitated.

Owner:无锡东恒新能源科技有限公司

Treatment of indium gallium alloys and recovery of indium and gallium

There is provided a hydrometallurgical process of recovering indium and gallium values from mixtures thereof with other metal values for example recycled and scrap solar panel cells which comprises subjecting the mixture to strongly oxidizing acid conditions, preferably via the simultaneous addition of sulfuric acid and hydrogen peroxide to the leach vessel, so as to form indium and gallium salt species of at least the major proportion of the indium and gallium values in the mixture, extracting the indium and gallium values with an organic extractant by adjusting the pH so as to extract individually the indium and gallium values with the organic extractant, stripping indium and gallium values from the extractant using an acid and an alkaline solution respectively and recovering the indium and gallium values.

Owner:MOLYCORP MINERALS CANADA ULC

Preparation method of retarding and water reducing agent

The invention discloses a preparation method of a retarding and water reducing agent. The preparation method comprises the following steps: 1) oxidization: oxidizing the raw material sweet potato starch; 2) acidification: acidifying the oxidized sweet potato starch with hydrochloric acid; and 3) etherification: adding ethylene oxide to the acidified oxidized sweet potato starch in the nitrogen environment to obtain the retarding and water reducing agent. The preparation method of the retarding and water reducing agent provided by the invention has the beneficial effect that the simple and easy-to-get raw material sweet potato starch is taken as the major raw material, and the operation of the preparation method is simple and convenient.

Owner:LIUZHOU ZHENGLING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com