New method for soaking out enriched ores of high indium, high iron, and high sulfur zinc

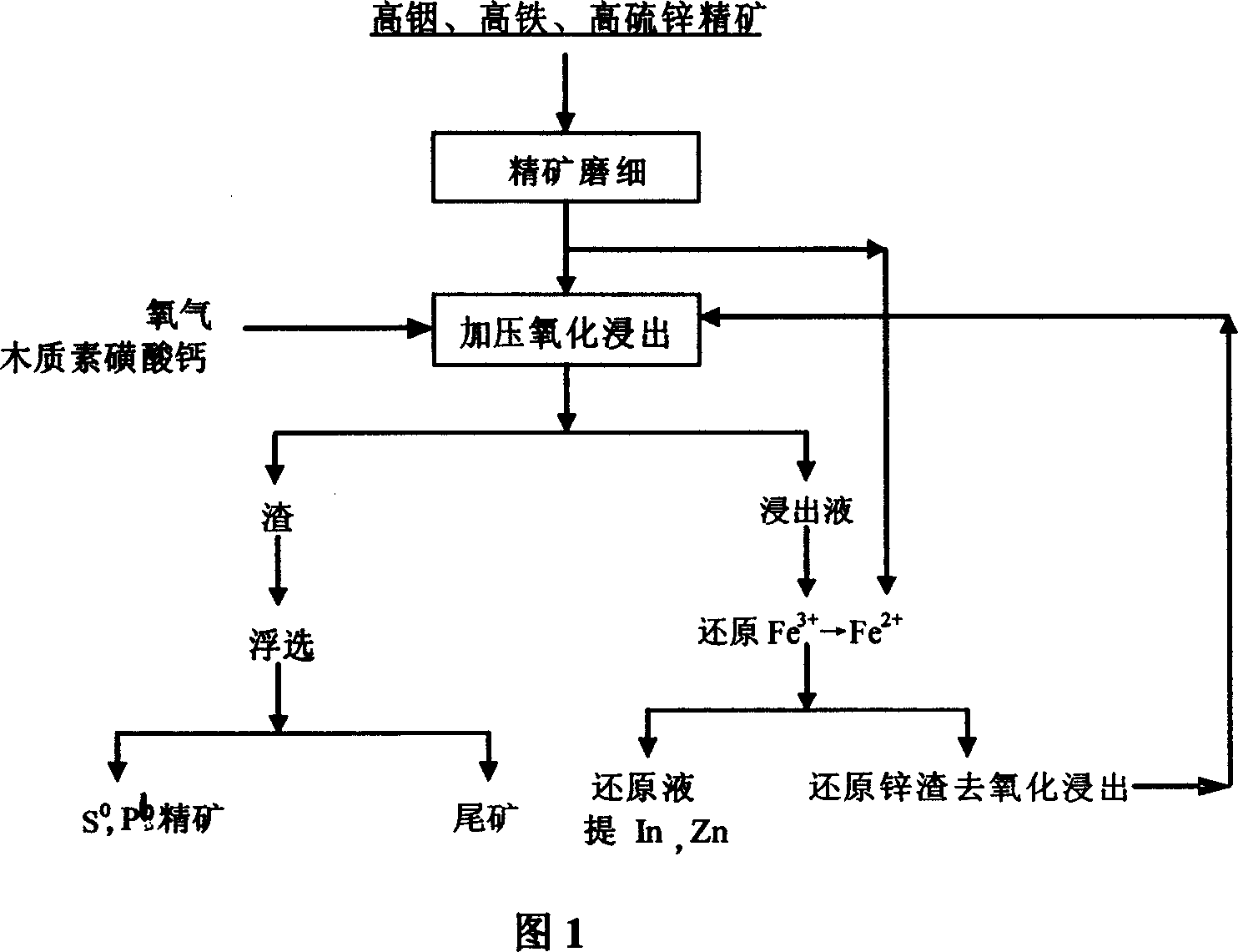

A technology of zinc concentrate and a new method, which is applied in the field of full hydrometallurgical process, can solve the problems of high reaction temperature and high operating pressure, and achieve the effect of reducing equipment investment and being easy to store or transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: The composition (%) of zinc concentrate is: 25Zn, 26Fe, 25S, 0.90In, the concentrate is finely ground, and 90% passes through a 0.043mm sieve.

[0013] Pour 200g of ore, 0.1g of calcium lignosulfonate and one liter of aqueous solution containing 196g of sulfuric acid into a 2000ml titanium autoclave at a temperature of 95°C and an oxygen pressure of 0.2Mpa. Add the corresponding amount of gelatin solution to the standard of 200-800g gelatin per ton of ore. After filtering and washing, the oxidized leachate is obtained, in which effective metals such as zinc, indium, copper, and cadmium are leached efficiently, while sulfur, lead, etc. are left in the leaching residue.

[0014] The result of the operation is: 94m 3 / tO 2 , the yield of leaching residue is 38.8%, and the solution contains H 2 SO 4 It is 48g / L, and the reaction result is: zinc leaching rate 99%, iron leaching rate 81%, indium leaching rate 97.8%, S 0 The yield is 85%. Usually, the recover...

Embodiment 2

[0015] Embodiment 2: Zinc concentrate composition (%): 34Zn, 25Fe, 32S, 0.50In, the concentrate is finely ground, and 92% pass through a 0.043mm sieve.

[0016] Pour 200g of ore, 0.1g of calcium lignosulfonate and one liter of aqueous solution containing 184g of sulfuric acid into a 2000ml titanium autoclave at a temperature of 100°C and an oxygen pressure of 0.4Mpa. Add the corresponding amount of gelatin solution to the standard of 200-800g gelatin ore, and after filtering and washing, the oxidized leachate is obtained, in which effective metals such as zinc, indium, copper, and cadmium are leached efficiently, while sulfur, lead, etc. are left in the leaching residue.

[0017] The result of the operation is: 123m 3 / tO 2 , the yield of leaching residue is 41.0%, and the solution contains H after the reaction 2 SO 4 It is 32g / L, and the reaction result is: zinc leaching rate 97%, iron leaching rate 80%, indium leaching rate 96%, S 0 Yield 86%. During reduction operation...

Embodiment 3

[0018] Embodiment 3: The composition (%) of the zinc concentrate is: 40Zn, 13Fe, 33S, 0.046In, the concentrate is finely ground, and 96% passes through a 0.043mm sieve.

[0019] Pour 300g of ore, 0.06g of calcium lignosulfonate and one liter of aqueous solution containing 240g of sulfuric acid into a 2000ml titanium autoclave at a temperature of 100°C and an oxygen pressure of 0.3Mpa. Add the corresponding amount of gelatin solution to the standard of 200-800g gelatin ore, and after filtering and washing, the oxidized leachate is obtained, in which effective metals such as zinc, indium, copper, and cadmium are leached efficiently, while sulfur, lead, etc. are left in the leaching residue.

[0020] The result of the operation is: Oxygen consumption 94m 3 / t ore, the yield of leaching slag is 41.3%, and the solution contains H after the reaction 2 SO 4 It is 68g / L, and the reaction result is: zinc leaching rate 99%, iron leaching rate 81%, indium leaching rate 97.3%, S 0 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com