Energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery

An ammonia desulfurization and ammonium sulfate technology, which is applied in the field of ammonia desulfurization process and air pollution control desulfurization, can solve the problems of consuming large steam energy, hindering the oxidation of ammonium sulfite, flue gas temperature loss, etc., and achieves low comprehensive operation cost of recovery. , considerable economic value, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

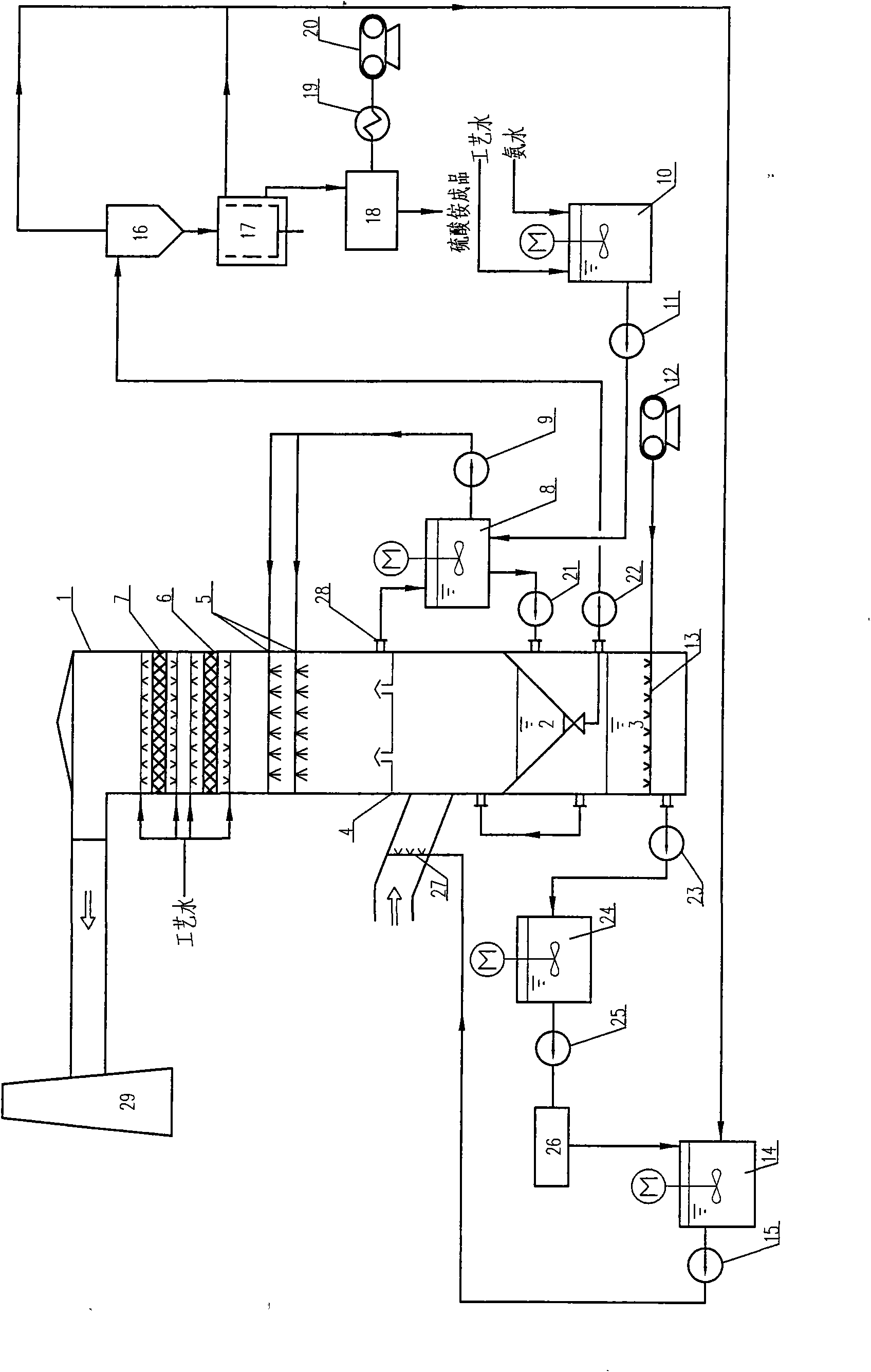

[0041] A 220T / h coal-fired thermoelectric boiler with a flue gas volume of 270,000Nm 3 / h,SO 2 Content 1500mg / Nm 3 , the dust content of flue gas is 80mg / Nm 3 , the flue gas temperature is 140°C. The desulfurization tower (1) has a diameter of 6m and a height of 28m. Such as figure 1 Shown is an energy-saving and high-quality ammonium sulfate recovery ammonia desulfurization process. About 4% ammonia water is configured in the ammonia water storage tank (10), and the prepared ammonia water is sent to the regeneration tank (8) through the ammonia supply pump (11). ); the ammoniacal liquor in the regeneration tank (8) is sent into the desulfurization tower (1) through the ammonium sulfite circulation pump (9) and the spray layer (5); the ammonium sulfate solution of about 4% in the ammonium sulfate storage tank (14) simultaneously It is sent to the cooling spray layer (27) through the ammonium sulfate circulating pump (15). After atomization, it contacts the flue gas inlet ...

Embodiment 2

[0043] A 670T / h thermal power generation unit, namely 200MW, with a flue gas volume of 800,000Nm 3 / h,SO 2 Content 4200mg / Nm 3 , the dust content of flue gas is 200mg / Nm 3 , the flue gas temperature is 145°C. The desulfurization tower (1) has a diameter of 10m and a height of 30m. Such as figure 1 In the shown energy-saving and high-quality ammonium sulfate desulfurization recovery ammonia desulfurization process, about 5% ammonia water is configured in the ammonia water storage tank (10), and the prepared ammonia water is sent to the regeneration tank ( 8); the ammoniacal liquor in the regeneration tank (8) is sent into the desulfurization tower (1) through the circulating pump (9) and the spray layer (5); at the same time, about 5% of the ammonium sulfate solution in the ammonium sulfate storage tank (14) is circulated The pump (15) sends it into the cooling spray layer (27), and the atomized ammonium sulfate solution contacts the high-temperature flue gas at the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com