Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

292 results about "Arsenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The arsenate ion is AsO³⁻₄. An arsenate (compound) is any compound that contains this ion. Arsenates are salts or esters of arsenic acid. The arsenic atom in arsenate has a valency of 5 and is also known as pentavalent arsenic or As(V). Arsenate resembles phosphate in many respects, since arsenic and phosphorus occur in the same group (column) of the periodic table. Arsenates are moderate oxidizers, with an electrode potential of +0.56 V for reduction to arsenites.

Functionalized nanoparticles and method

ActiveUS20100283014A1Material nanotechnologyPolycrystalline material growthSemiconductor materialsChemical reaction

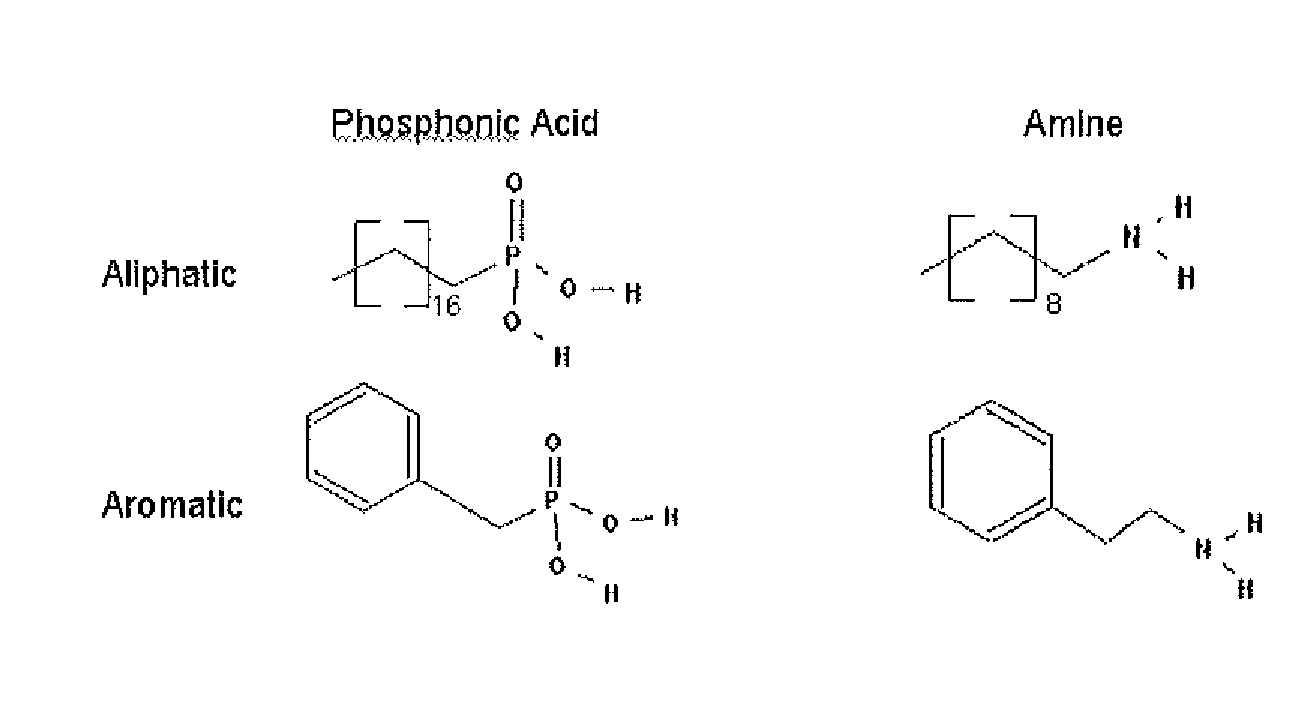

A nanoparticle including an inorganic core comprising at least one metal and / or at least one semi-conductor compound comprising at least one metal includes a coating or shell disposed over at least a portion of a surface of the core. The coating can include one or more layers. Each layer of the coating can comprise a metal and / or at least one semiconductor compound. The nanoparticle further includes a ligand attached to a surface of the coating. The ligand is represented by the formula: X-Sp-Z, wherein X represents, e.g., a primary amine group, a secondary amine group, a urea, a thiourea, an imidizole group, an amide group, a phosphonic or arsonic acid group, a phosphinic or arsinic acid group, a phosphate or arsenate group, a phosphine or arsine oxide group; Sp represents a spacer group, such as a group capable of allowing a transfer of charge or an insulating group; and Z represents: (i) reactive group capable of communicating specific chemical properties to the nanocrystal as well as provide specific chemical reactivity to the surface of the nanocrystal, and / or (ii) a group that is cyclic, halogenated, or polar a-protic. In certain embodiments, at least two chemically distinct ligands are attached to an surface of the coating, wherein the at least two ligands (I and II) are represented by the formula: X-Sp-Z. In ligand (I) X represents a phosphonic, phosphinic, or phosphategroup and in ligand (II) X represents a primary or secondary amine, or an imidizole, or an amide; In both ligands (I) and (II) Sp, which can be the same or different in the two compounds, represents a spacer group, such as a group capable of allowing a transfer of charge or an insulating group; Z, which can be the same or different in the two compounds, is a group chosen from among groups capable of communicating specific chemical properties to the nanoparticle as well as provide specific chemical reactivity to the surface of the nanoparticle. In preferred embodiments, the nanoparticle includes a core comprising a semiconductor material.

Owner:SAMSUNG ELECTRONICS CO LTD

In Situ Remediation of Inorganic Contaminants Using Stabilized Zero-Valent Iron Nanoparticles

InactiveUS20070256985A1Low costProcess environmental protectionMaterial nanotechnologyWater treatment compoundsCelluloseMaterials science

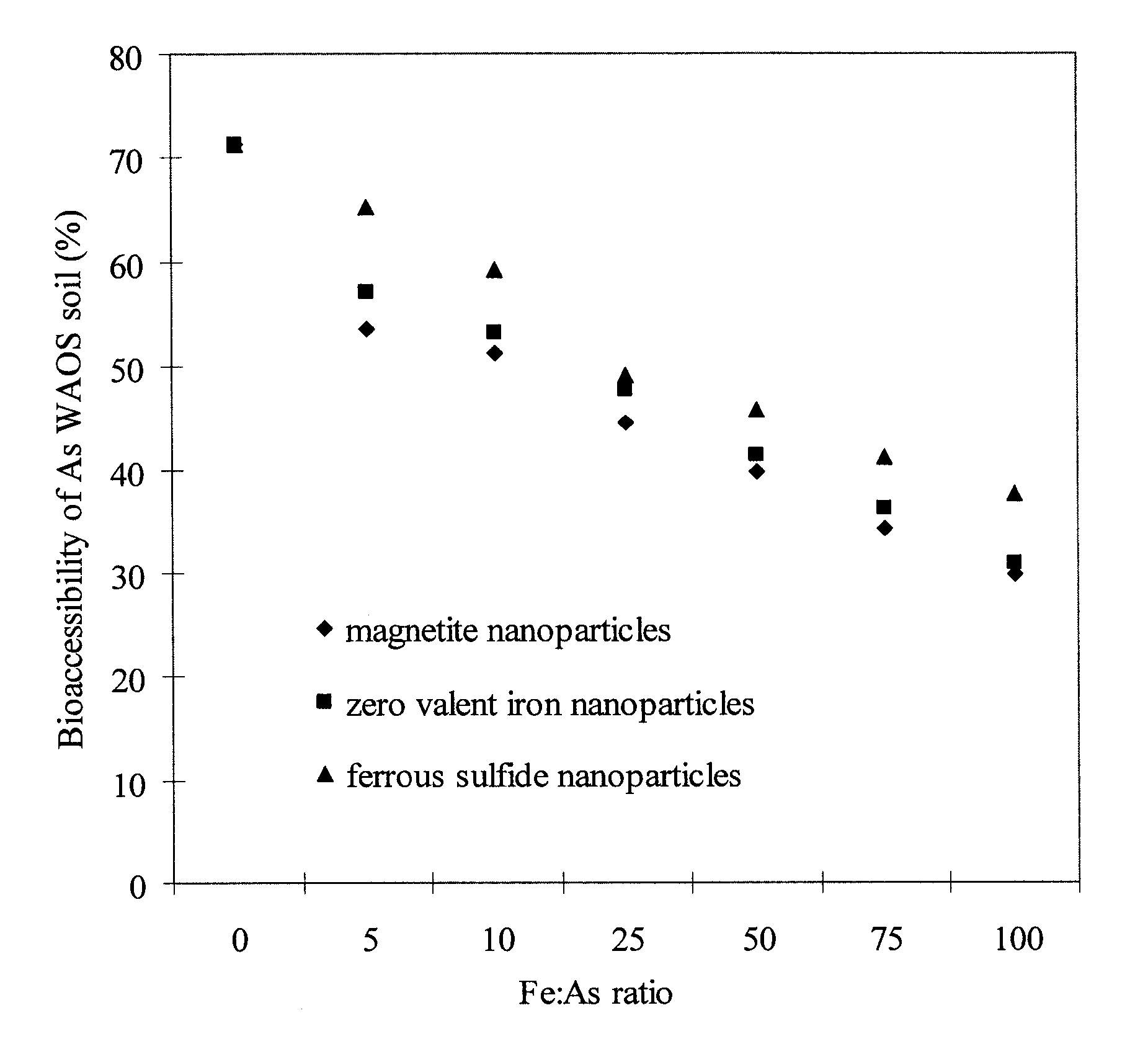

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

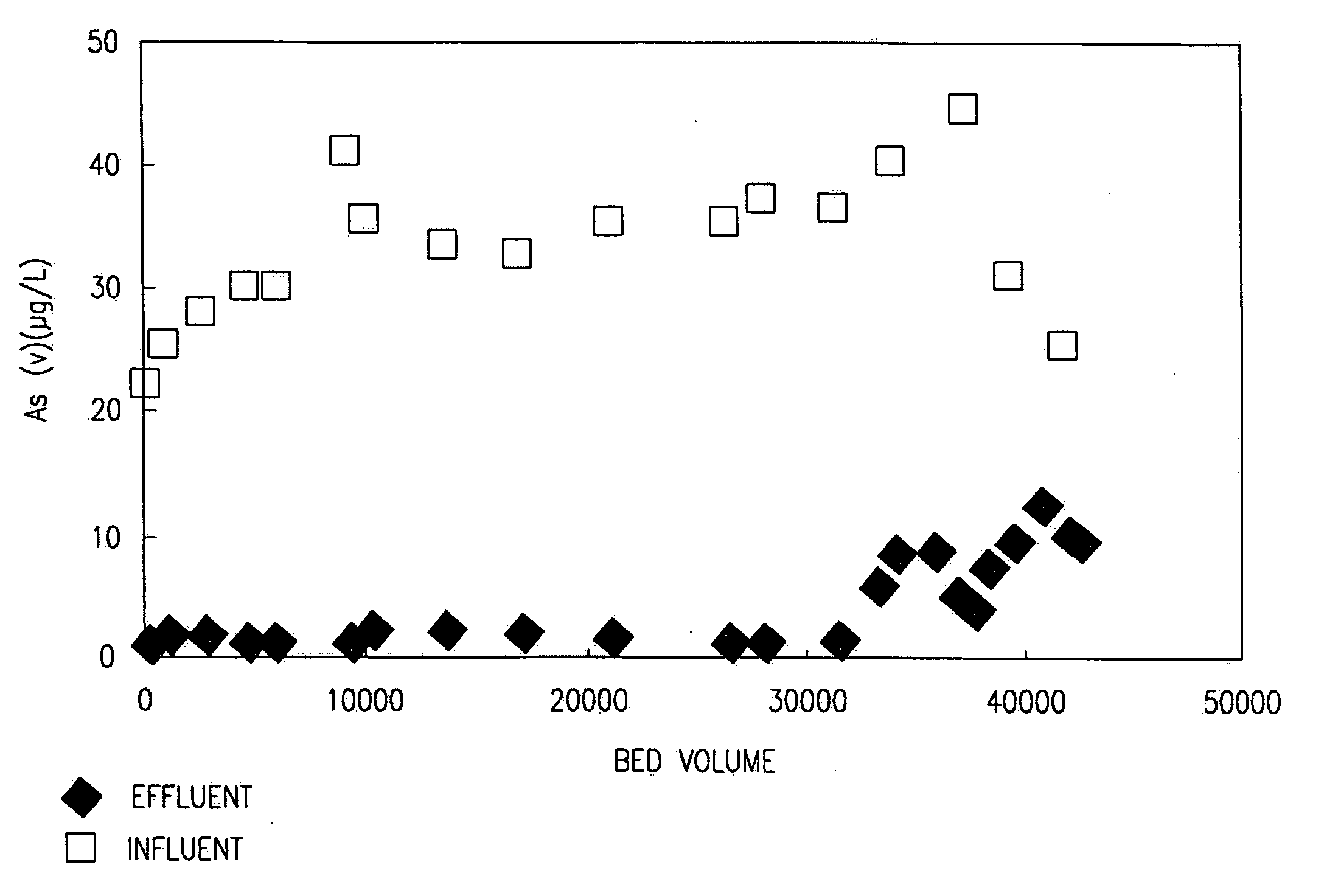

Method of removing arsenic species from an aqueous medium using modified zeolite minerals

InactiveUS6042731AComprehensive understandingHigh affinityOther chemical processesWater contaminantsArsenateMaceral

A method for removing arsenic species from an aqueous medium with modified zeolite minerals comprising providing an aqueous medium containing arsenic species in the form of both arsenate and arsenite, contacting the aqueous medium with an iron (II) laden zeolite mineral so that arsenic in the form of at least one of arsenate and arsenite contained in the aqueous medium can be adsorbed onto the iron (II) laden zeolite mineral forming an arsenic adsorbed iron (II) laden zeolite mineral, and separating the arsenic adsorbed iron (II) laden zeolite mineral from the aqueous medium.

Owner:SOUTH FLORIDA UNIV OF ACTING FOR & ON BEHALF OF THE BOARD OF REGENTS A PUBLIC OF THE STATE OF FLORIDA

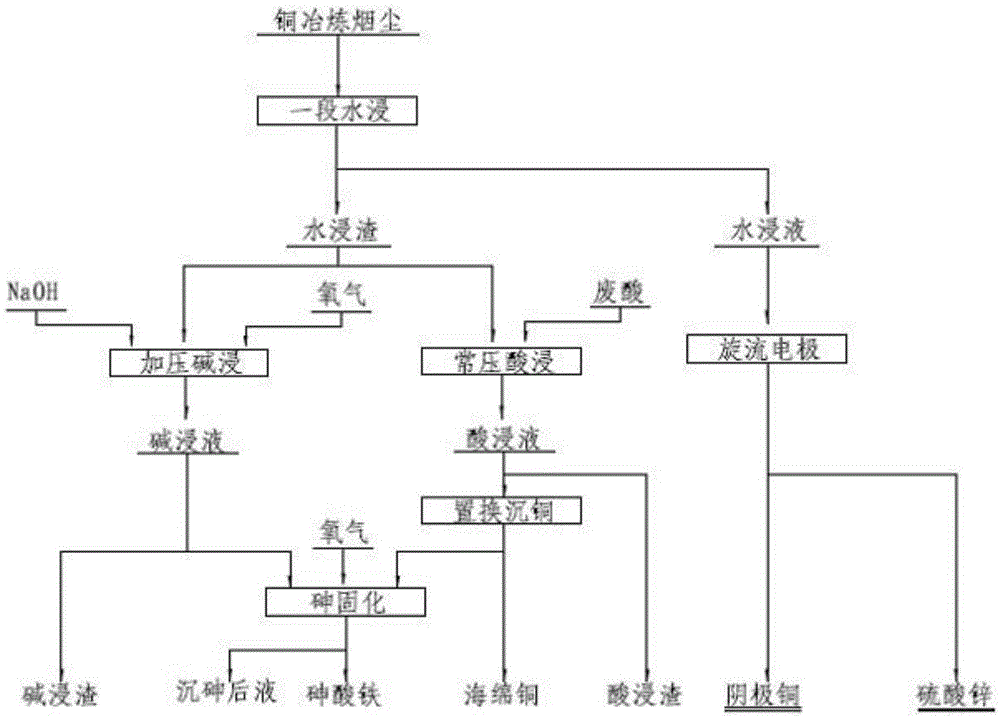

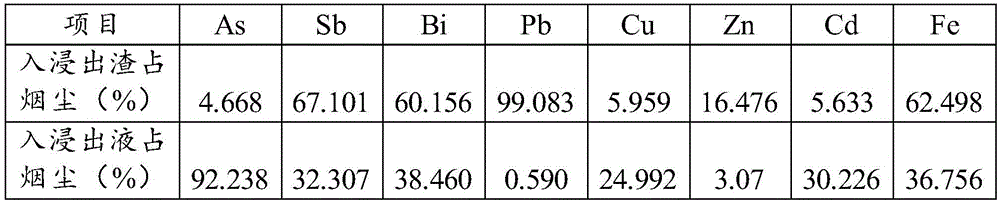

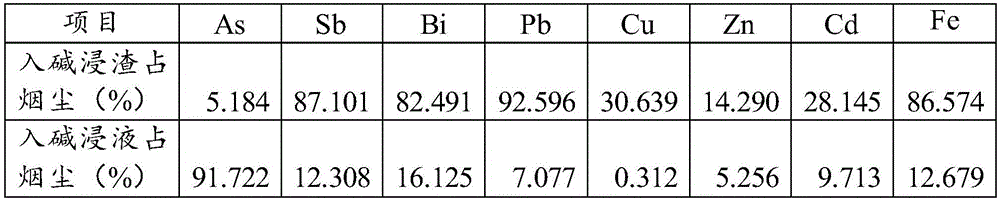

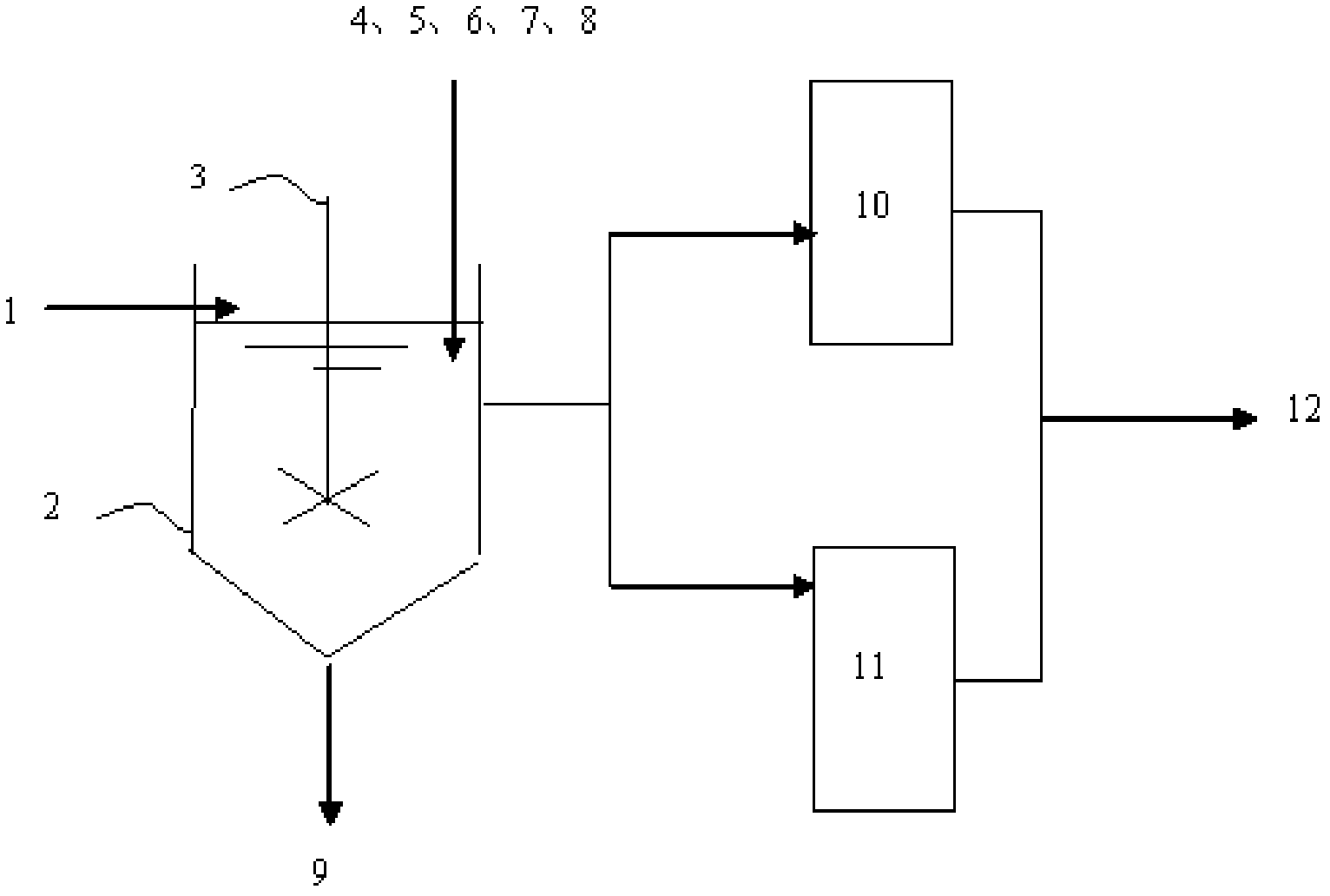

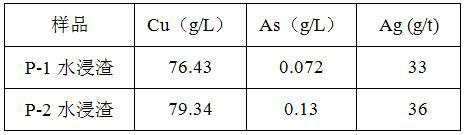

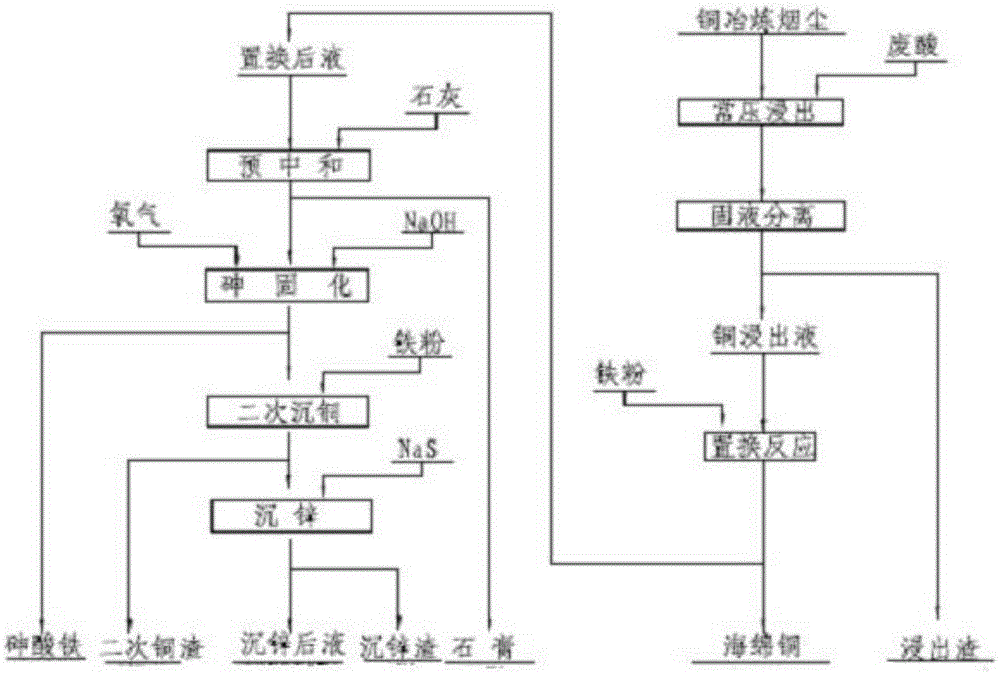

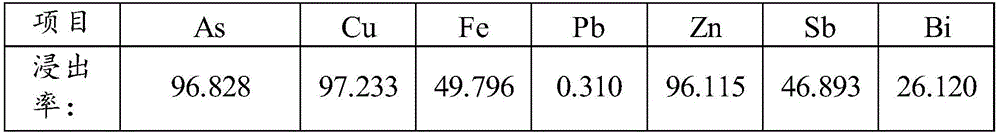

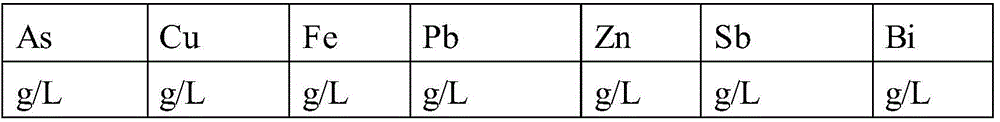

Soot treatment process in copper smelting process

ActiveCN105567983ARealize comprehensive utilizationLow arsenicProcess efficiency improvementArsenateSmelting process

The invention provides a soot treatment process in a copper smelting process. The soot treatment process comprises the following steps: firstly carrying out water leaching on copper smelting soot to obtain a water leaching fluid and water leaching residues; then, carrying out acid leaching on one part of the water leaching residues obtained in the last step to obtain an acid leaching fluid, and carrying out alkali leaching on the other part of the water leaching residues to obtain an alkali leaching fluid; carrying out metal replacement on the acid leaching fluid obtained in the last step to precipitate copper to obtain copper-precipitated filtrate; and finally, neutralizing and oxidizing the copper-precipitated filtrate obtained in the last step and the alkali leaching fluid obtained in the last step to obtain ferric arsenate precipitates and arsenic-precipitated filtrate. The soot treatment process provided by the invention, especially the treatment process for high-arsenic high-copper soot realizes the hazard-free treatment effect of arsenic in the high-arsenic high-copper soot, and comprehensively recycles valuable metal copper, zinc and the like in the high-arsenic high-copper soot, so that gradient recycling and comprehensive utilization of soot impurities are realized.

Owner:YANGGU XIANGGUANG COPPER

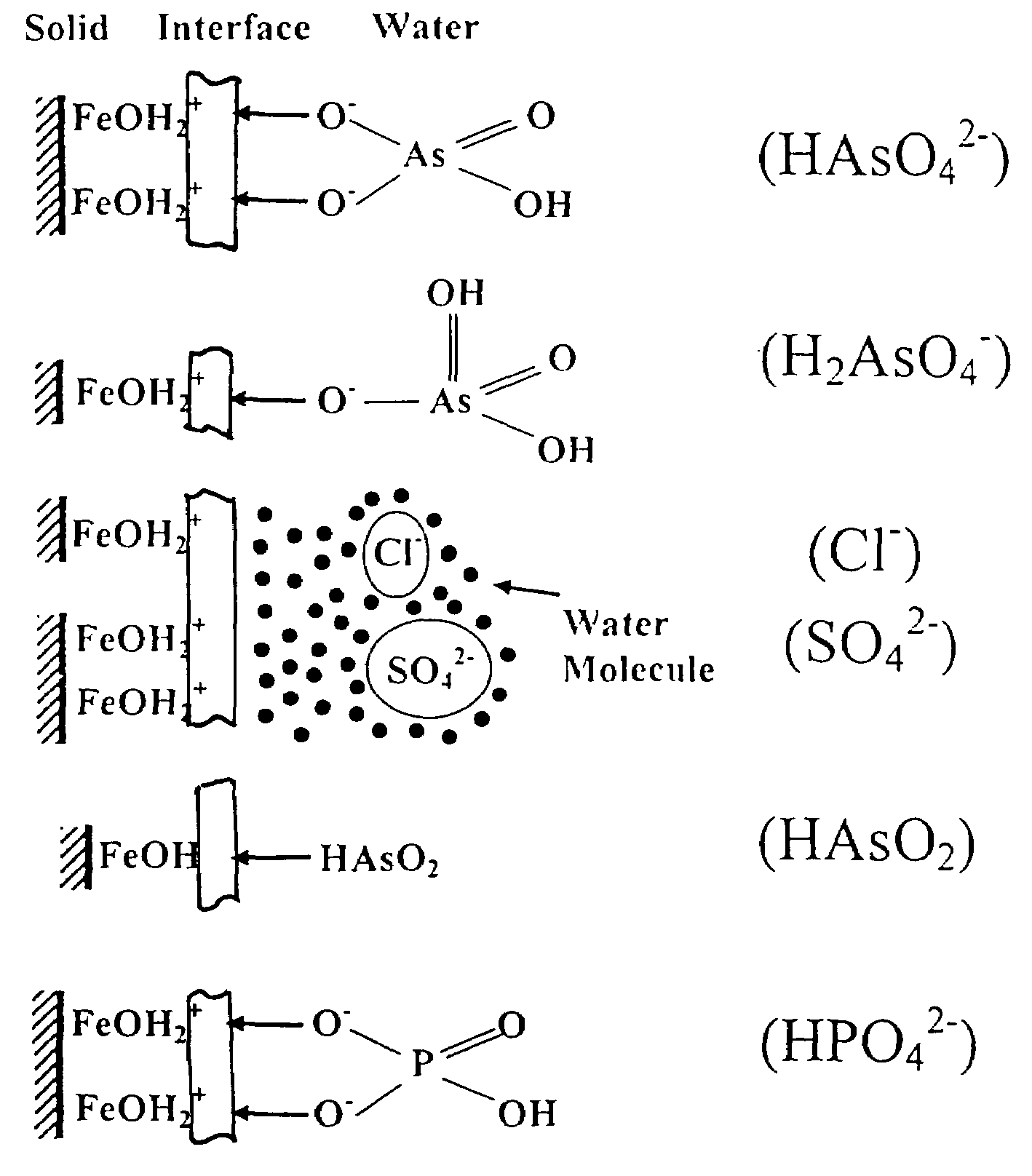

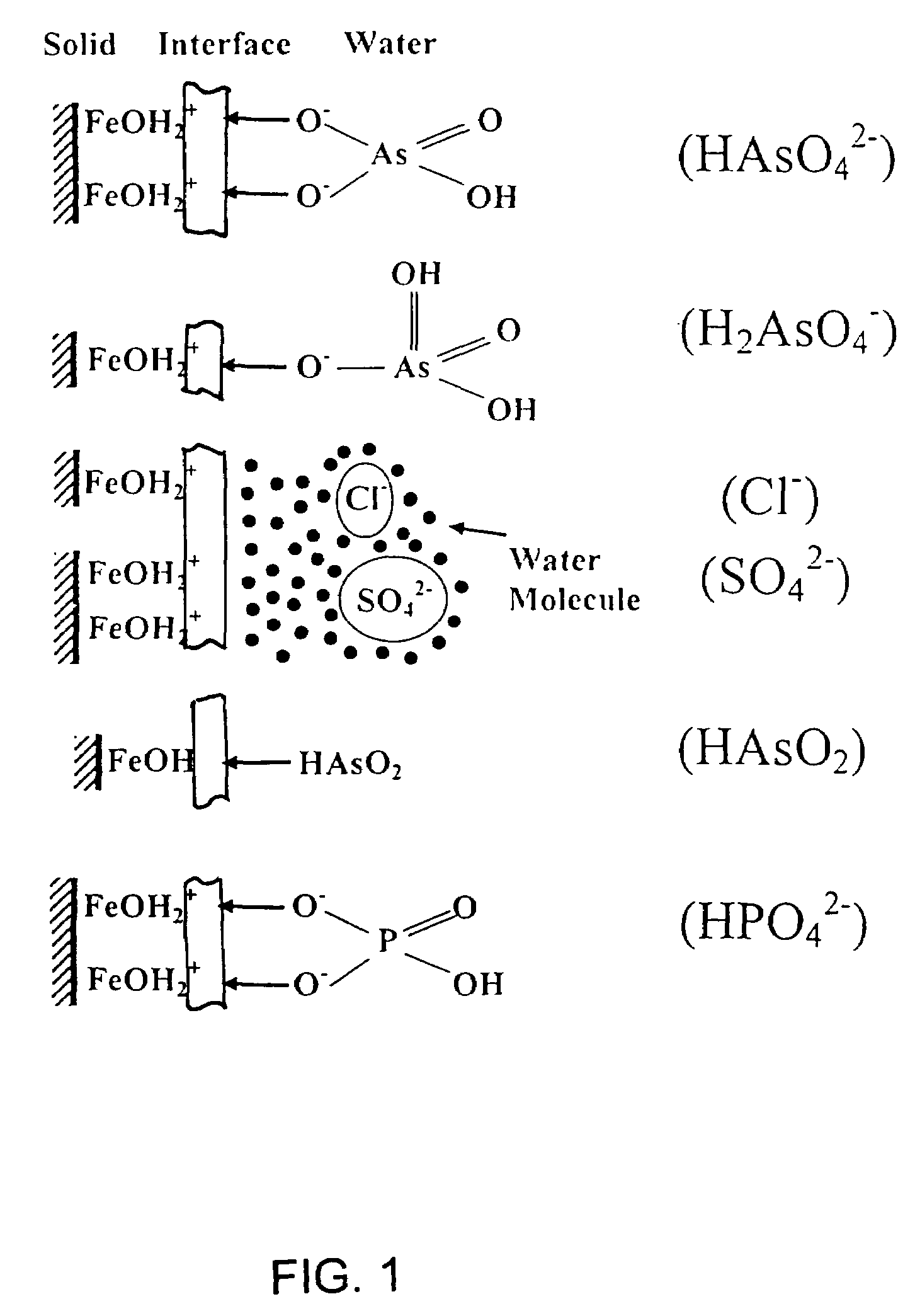

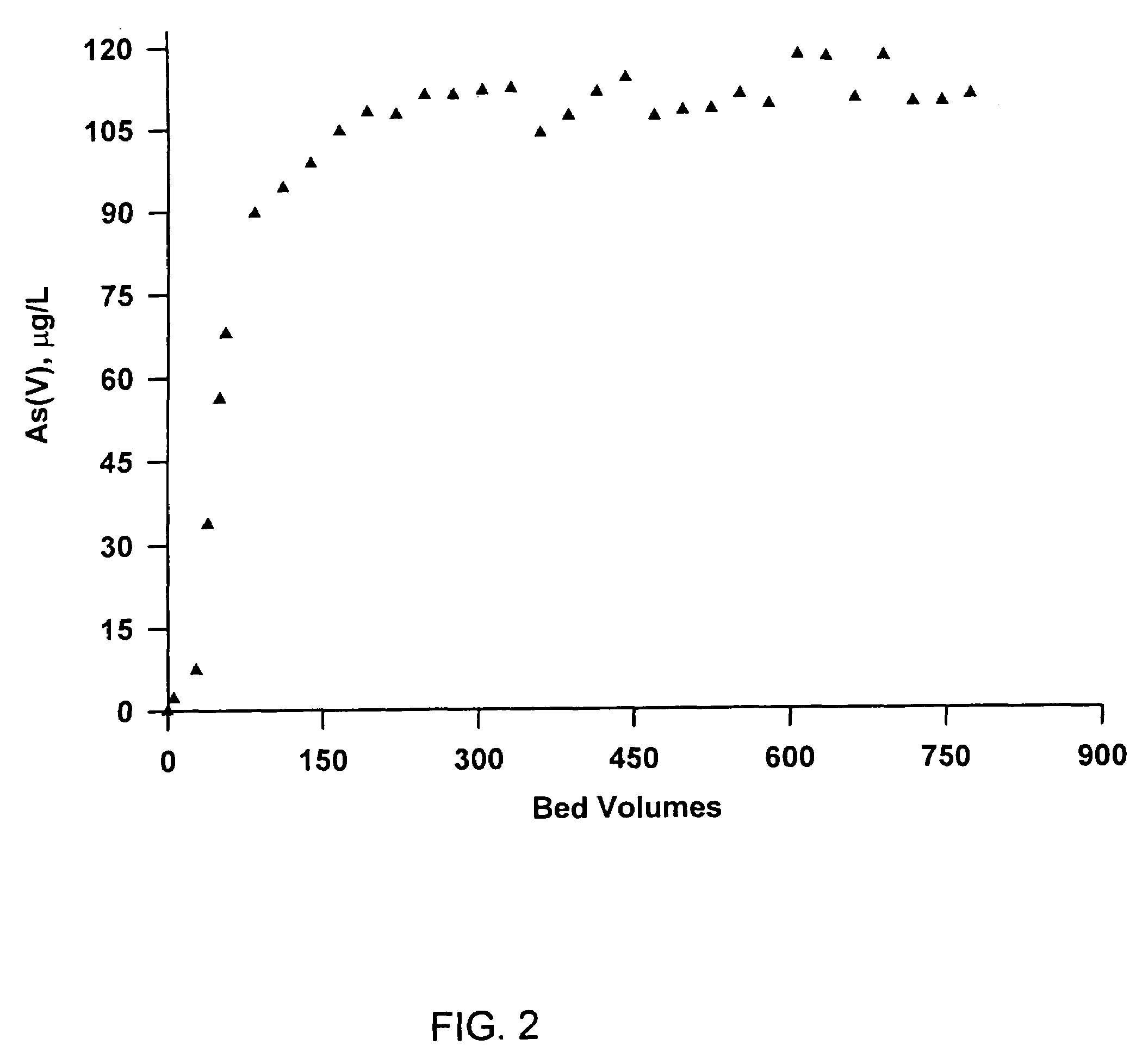

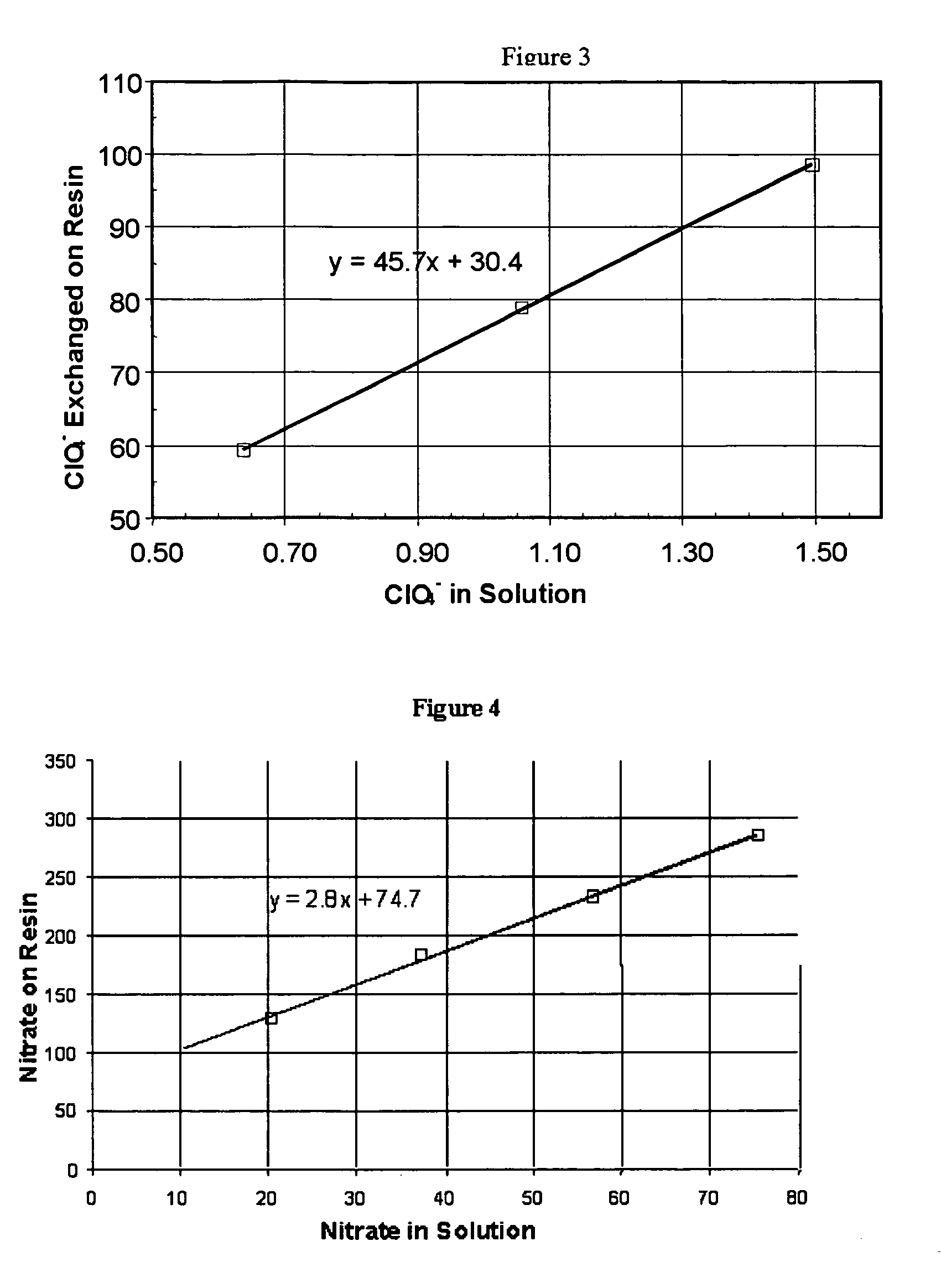

Hybrid anion exchanger for selective removal of contaminating ligands from fluids and method of manufacture thereof

ActiveUS7291578B2Improve material performanceImprove physical strengthOther chemical processesWater contaminantsPhosphateIon-exchange resin

Owner:ARUP K SENGUPTA

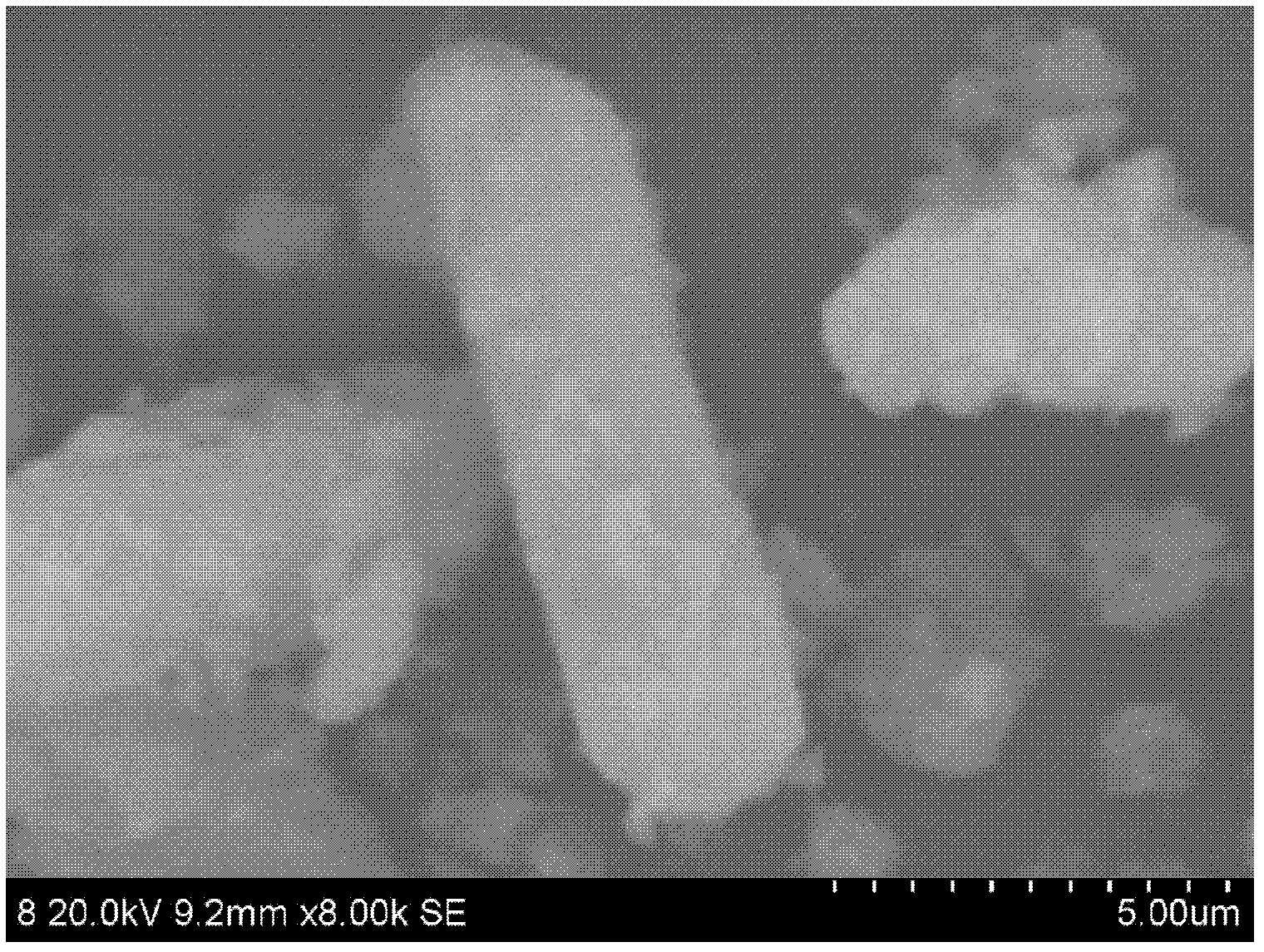

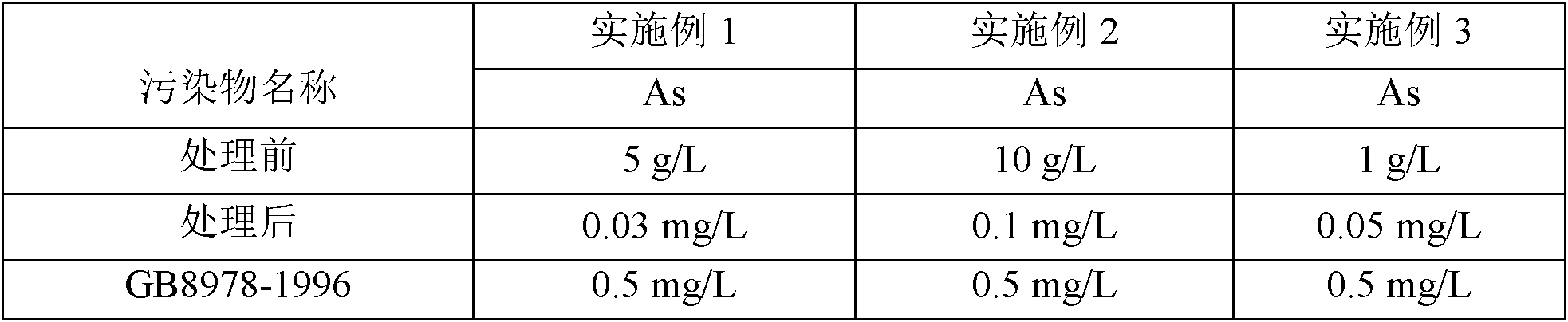

Remediation agent for treating arsenic contaminated soil and usage of remediation agent

ActiveCN102764759AWide range of raw materialsEasy to obtainContaminated soil reclamationArsenateArsenic pollution

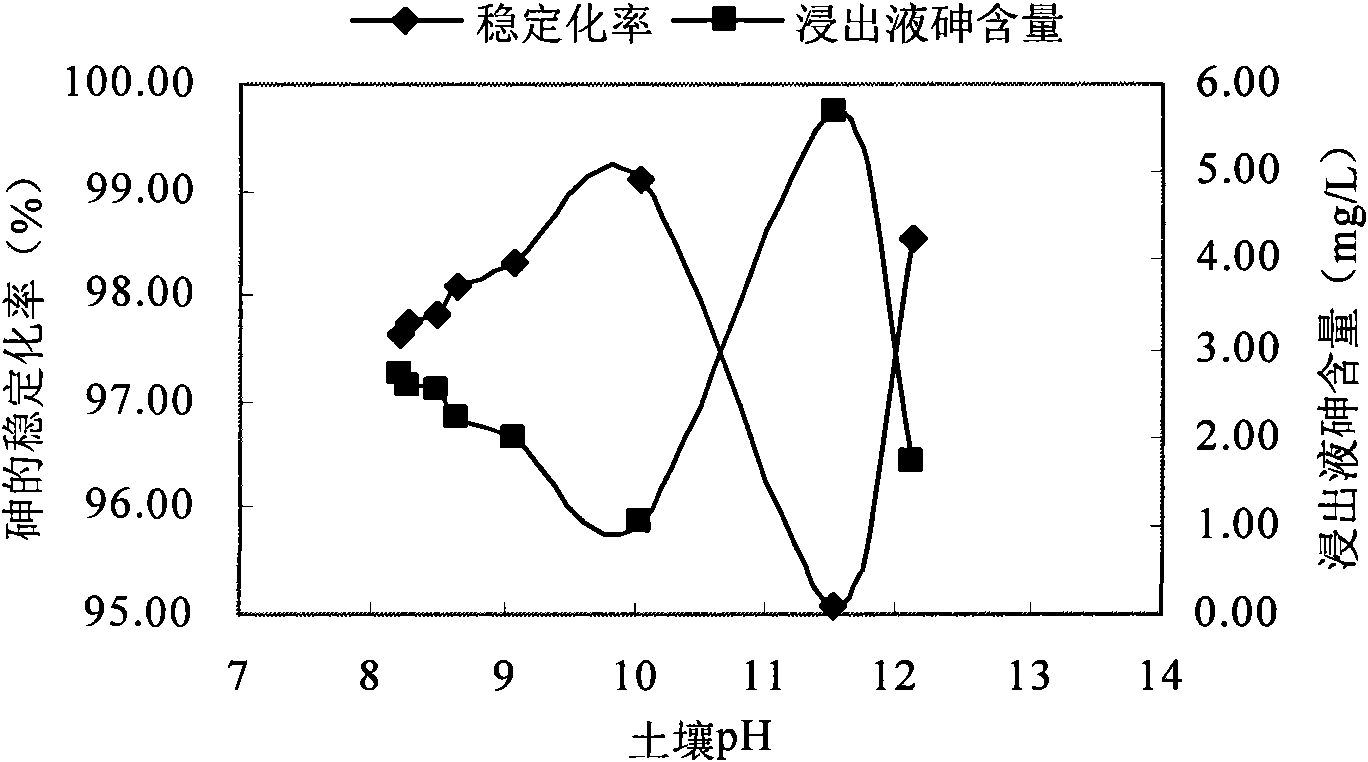

The invention discloses a remediation agent for treating arsenic contaminated soil and a usage of the remediation agent. The remediation agent comprises the following raw materials by mass: 5-30% of oxidant, 30-70% of iron-based compound and 10-60% of mineral material. The raw materials are respectively ground into materials with particle size not smaller than 200 meshes and are mixed uniformly according to the proportion. The usage of the remediation agent for treating the arsenic contaminated soil comprises the following steps that: the arsenic content and the leaching toxicity of the to-be-treated contaminated soil are detected; the remediation agent with different ratios according to the degree of contamination is paved on the surface of the to-be-treated soil; the soil is turned over and uniformly mixed to form the mixed soil; the water content in the mixed soil is kept not to be less than 25% by adding water; a moisturizing material is covered on the mixed soil; and the mixed soil is cured for at least 5 days in order to allow the remediation agent in the mixed soil to be reacted with unstable arsenic in the heavy metal contaminated soil; and the generated insoluble arsenate sediment is stabilized, so that the cured soil can meet the environment protection requirements.

Owner:YONKER ENVIRONMENTAL PROTECTION

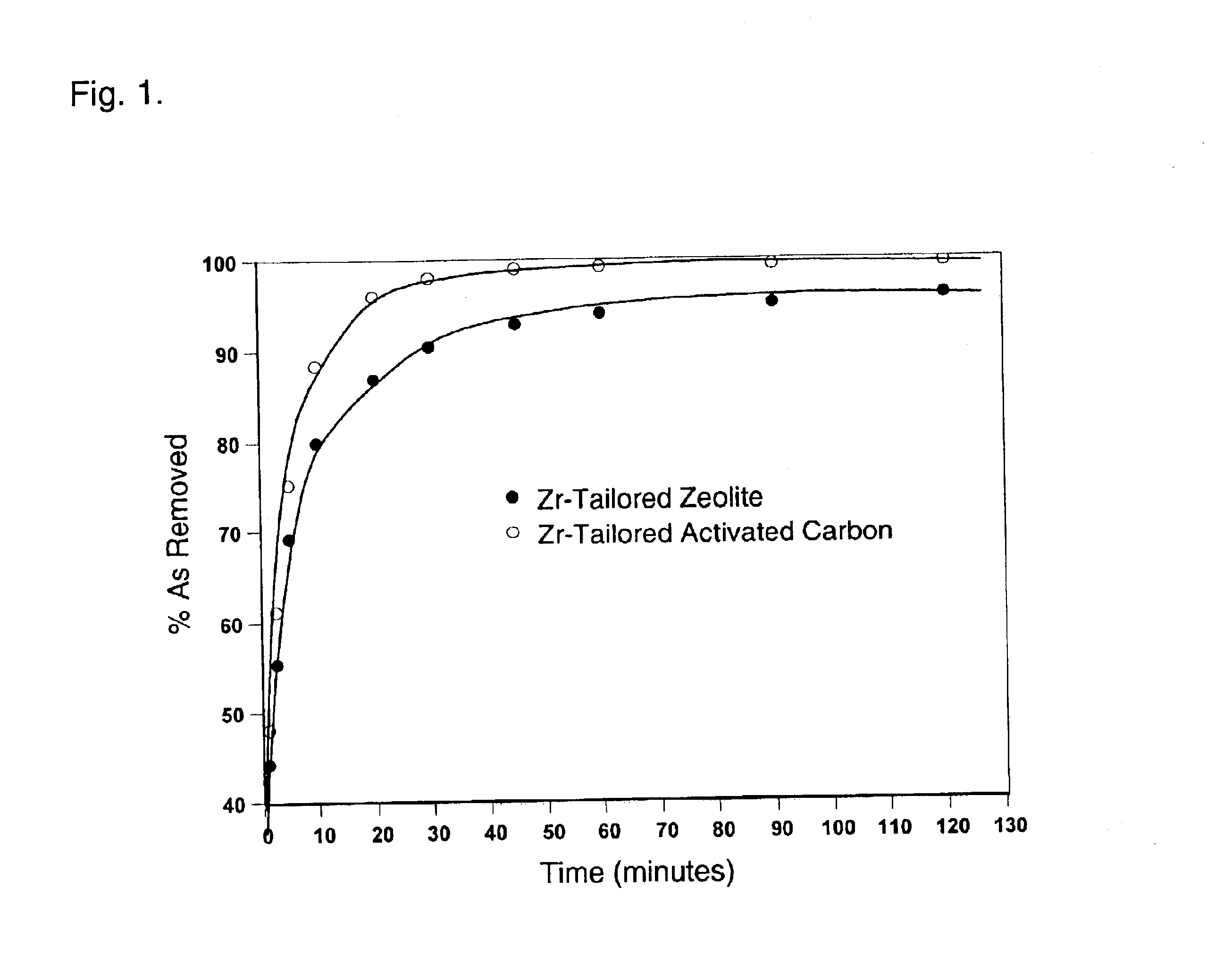

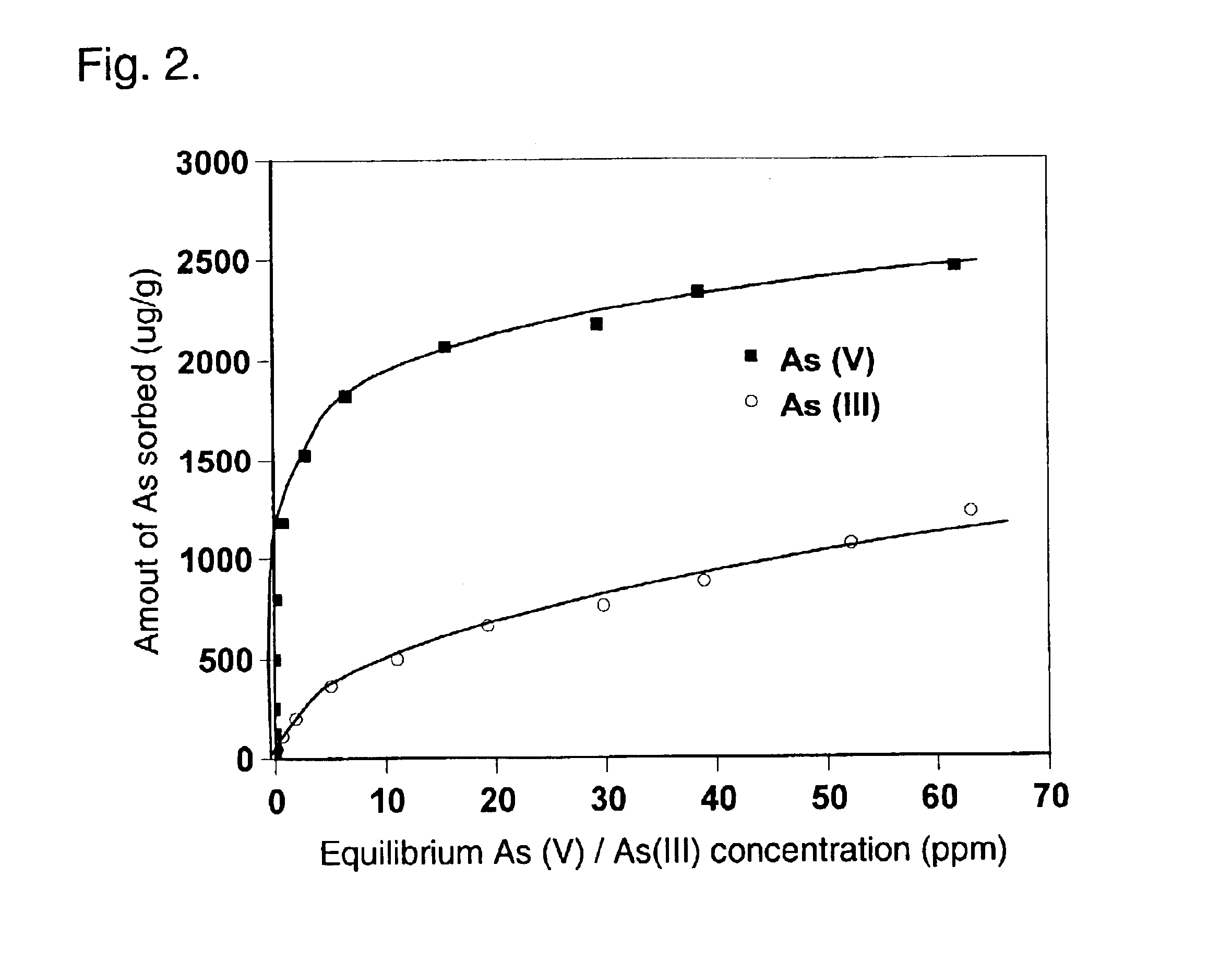

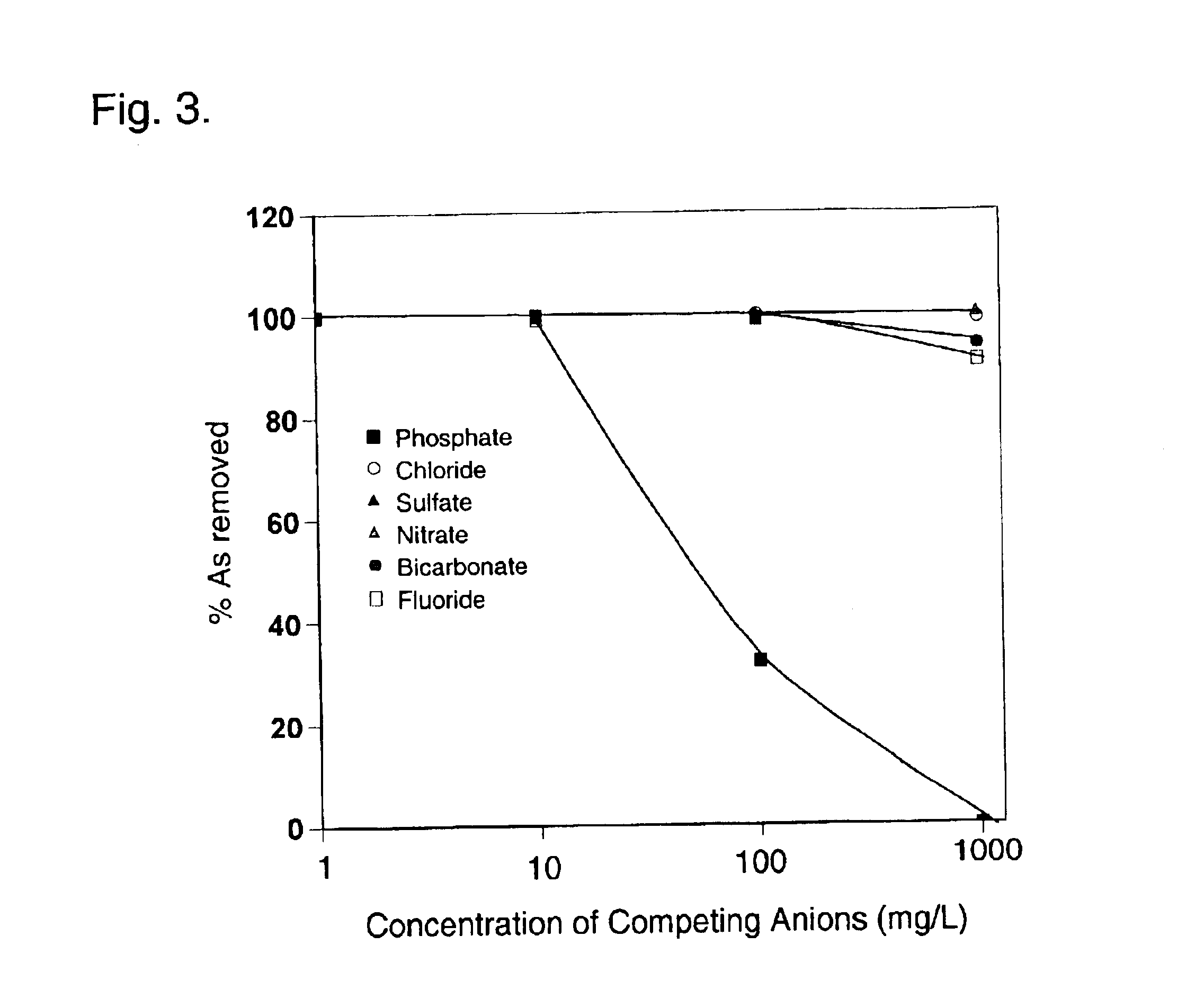

Zirconium-modified materials for selective adsorption and removal of aqueous arsenic

InactiveUS6824690B1Easy to manufactureLow costLiquid surface applicatorsLoose filtering material filtersFiberClay minerals

A method, composition, and apparatus for removing contaminant species from an aqueous medium comprising: providing a material to which zirconium has been added, the material selected from one or more of zeolites, cation-exchangeable clay minerals, fly ash, mesostructured materials, activated carbons, cellulose acetate, and like porous and / or fibrous materials; and contacting the aqueous medium with the material to which zirconium has been added. The invention operates on all arsenic species in the form of arsenate, arsenite and organometallic arsenic, with no pretreatment necessary (e.g., oxidative conversion of arsenite to arsenate).

Owner:SANDIA NAT LAB

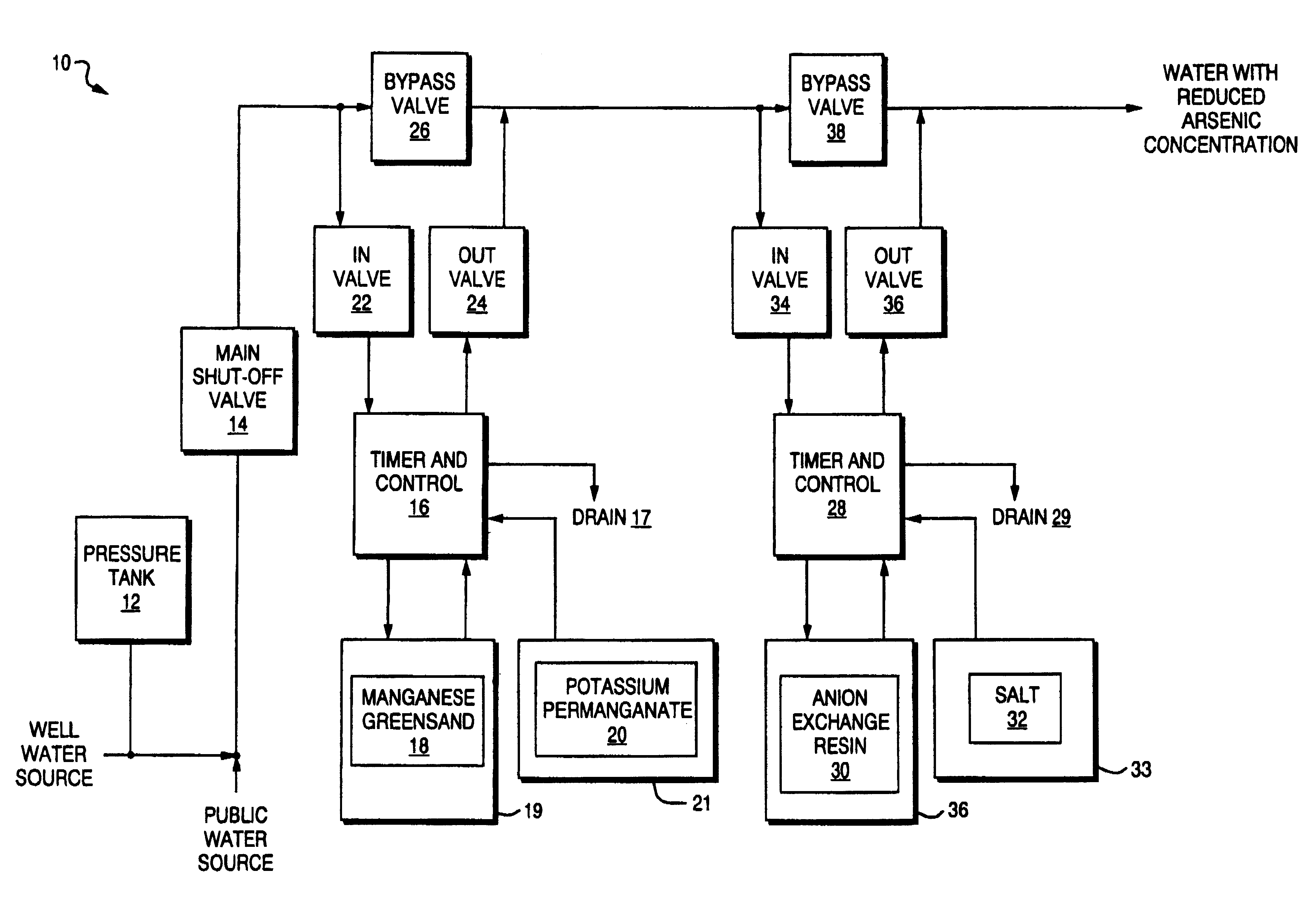

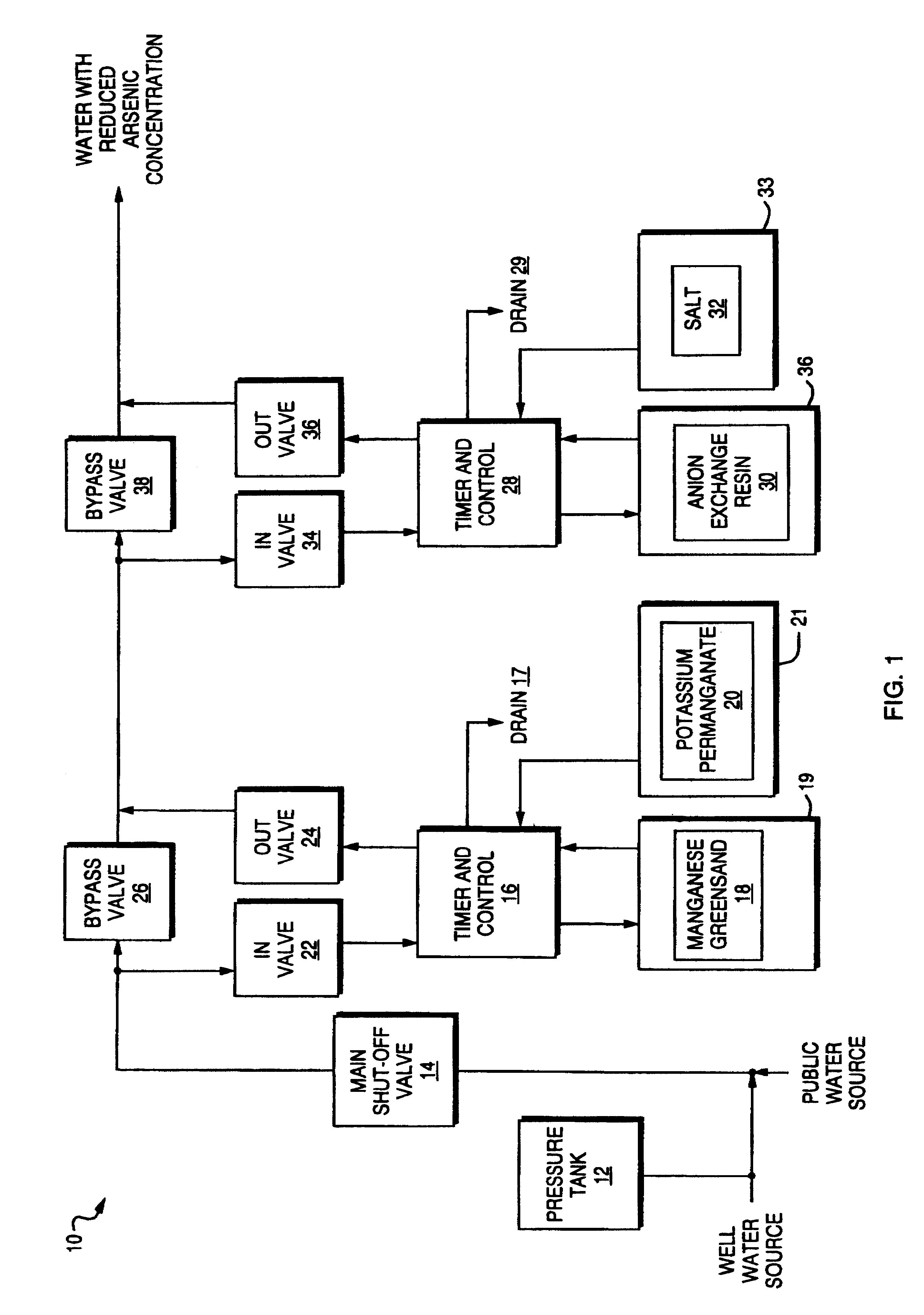

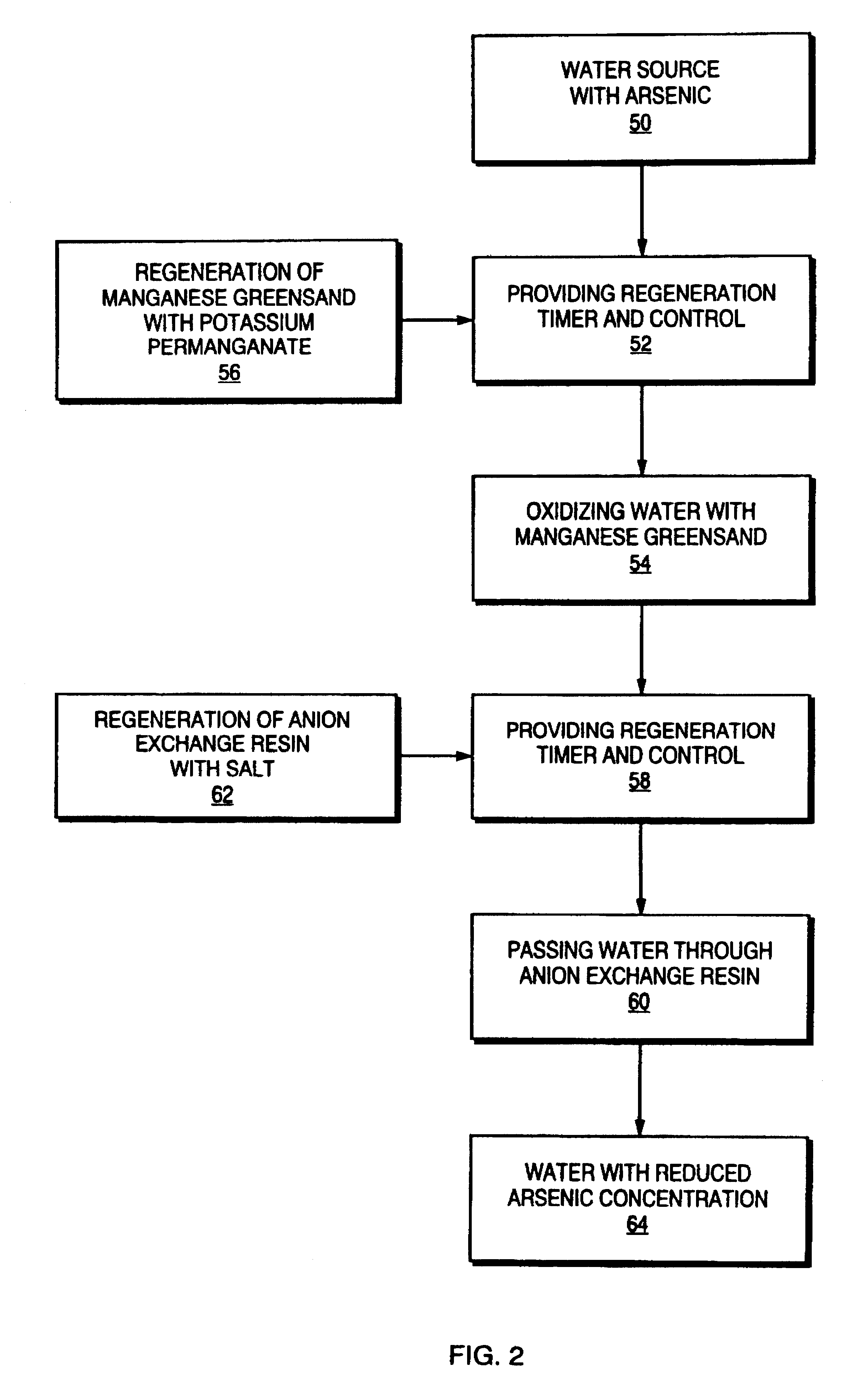

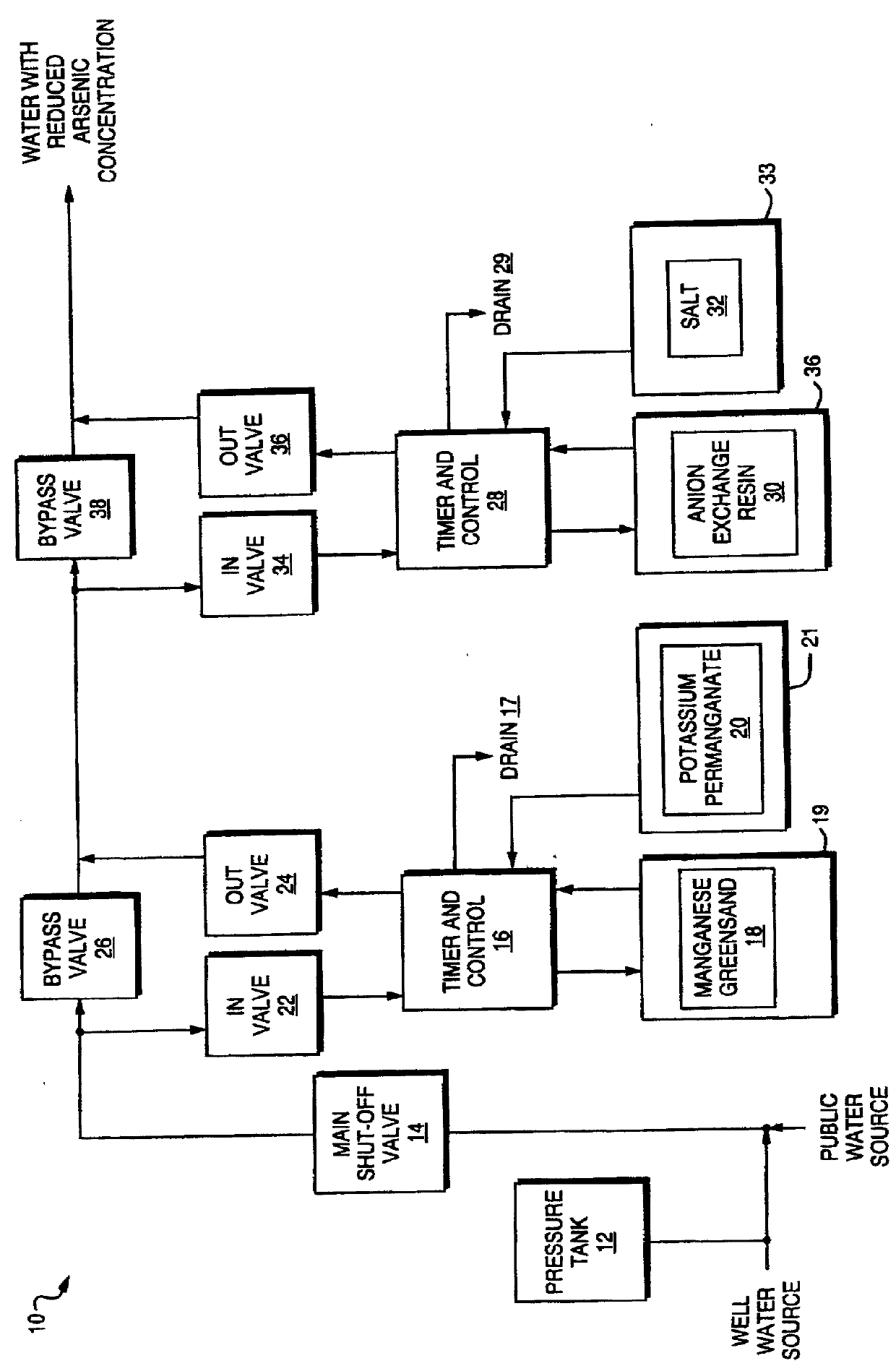

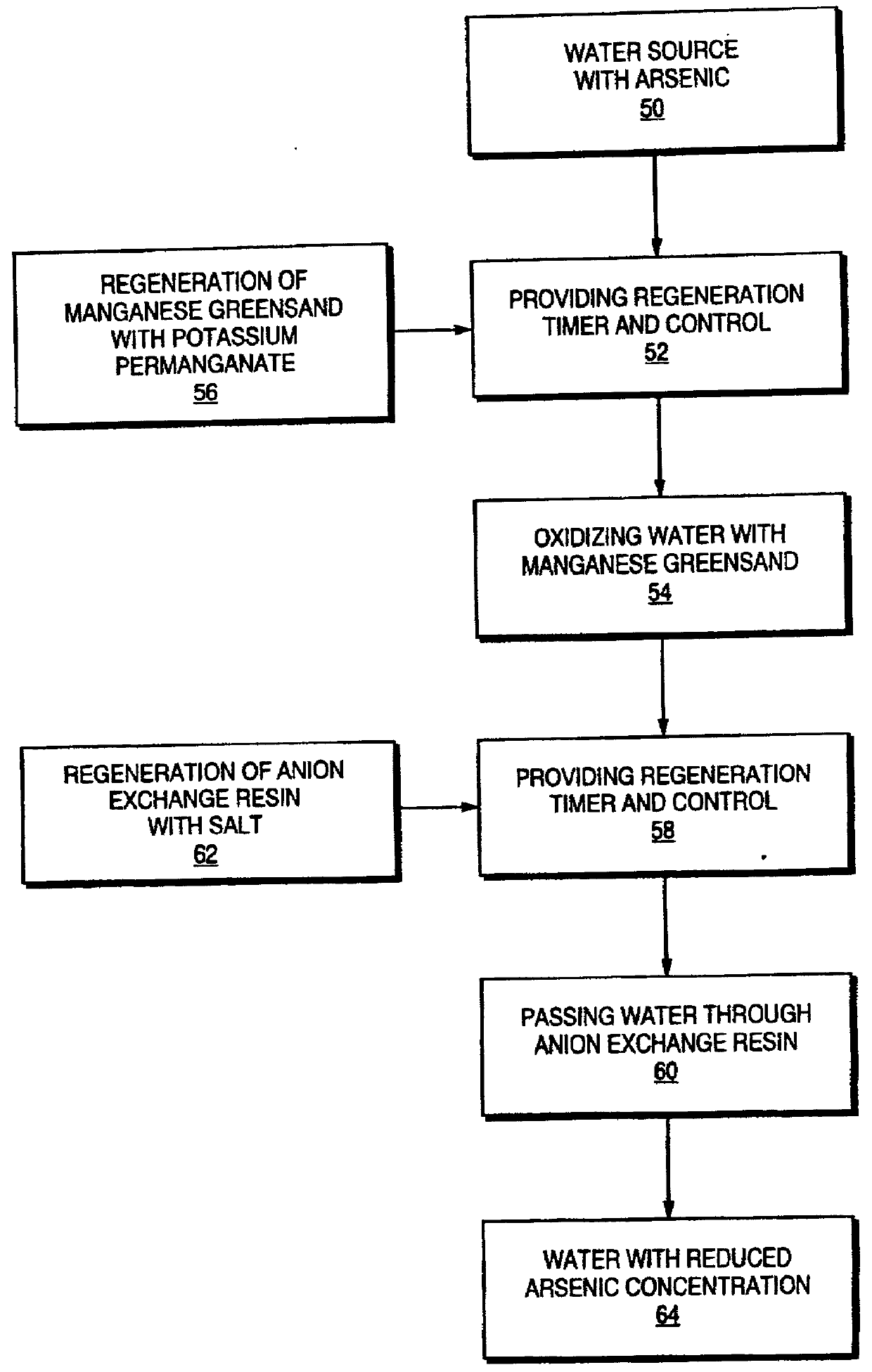

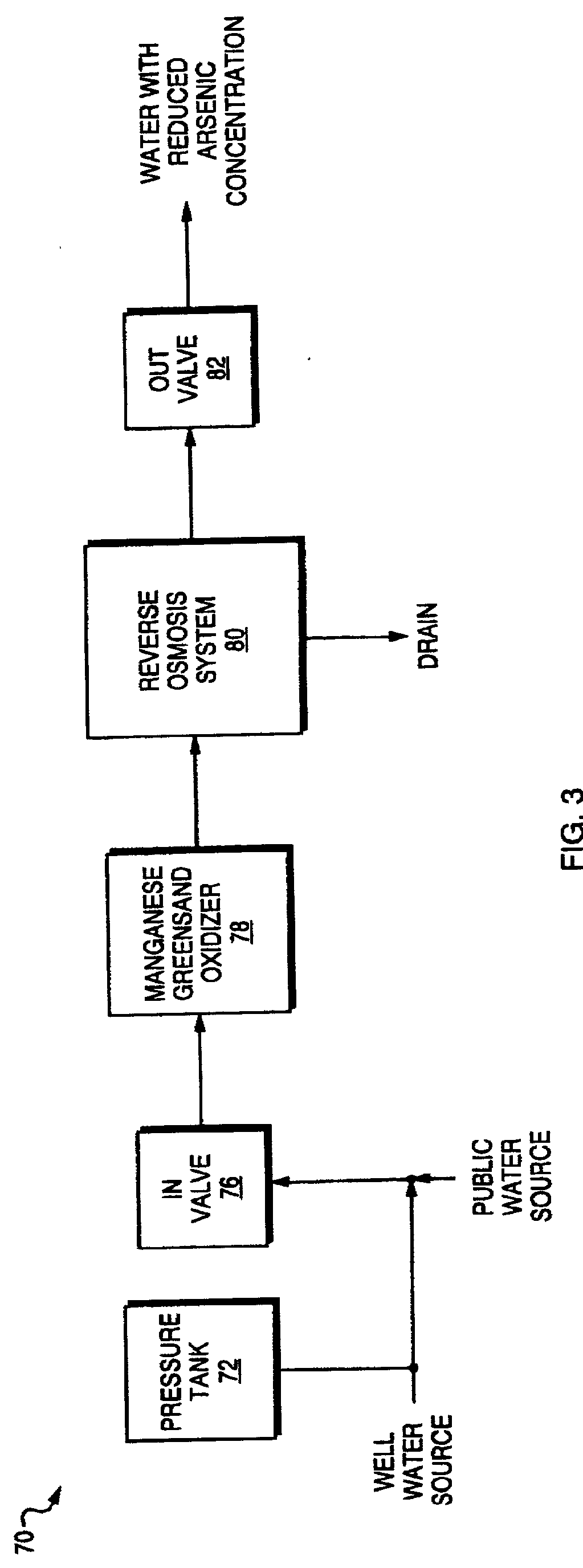

Method and apparatus for the removal of arsenic from water

InactiveUS6368510B2Suitable in cost and space required and efficiencyOrganic anion exchangersIon-exchanger regenerationArsenateManganese

A method and apparatus for removing arsenic from water at point of entry or point of use particularly for residential application. The point of entry system comprises a first stage having a manganese greensand oxidizer to convert arsenite (As+3) present in the water to arsenate (As+5) and a second stage for passing the water through an anion exchange resin. Each stage includes a control head for automatic regeneration at a predetermined frequency. The manganese greensand is regenerated with a solution of potassium permanganate and the anion exchange resin is regenerated with a salt solution. An alternate embodiment for point of use application comprises a manganese greensand oxidizer cartridge to convert arsenite (As+3) to arsenate (As+5) followed by removal of the arsenate (As+5) with a reverse osmosis system.

Owner:THE CLOROX CO +1

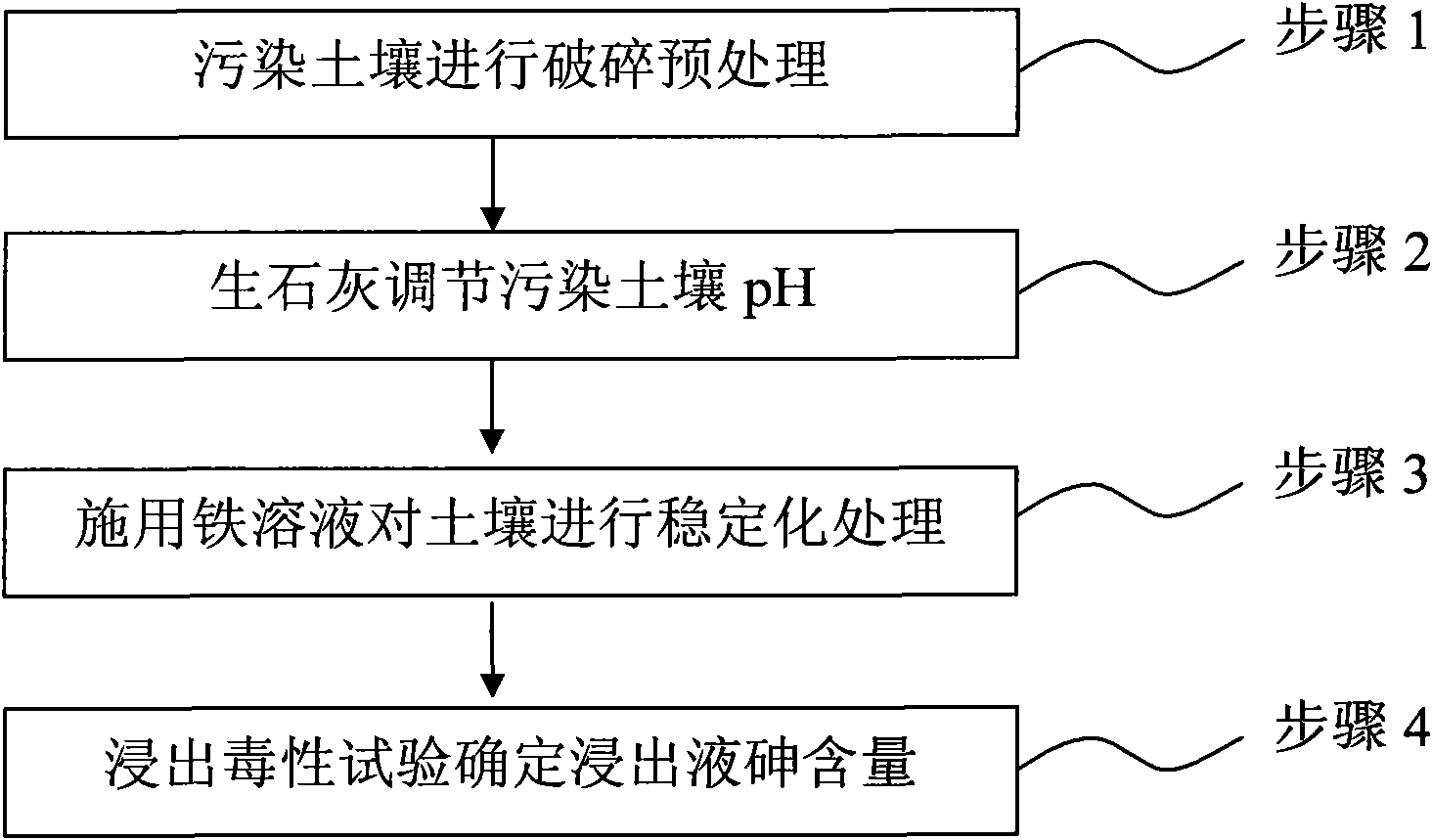

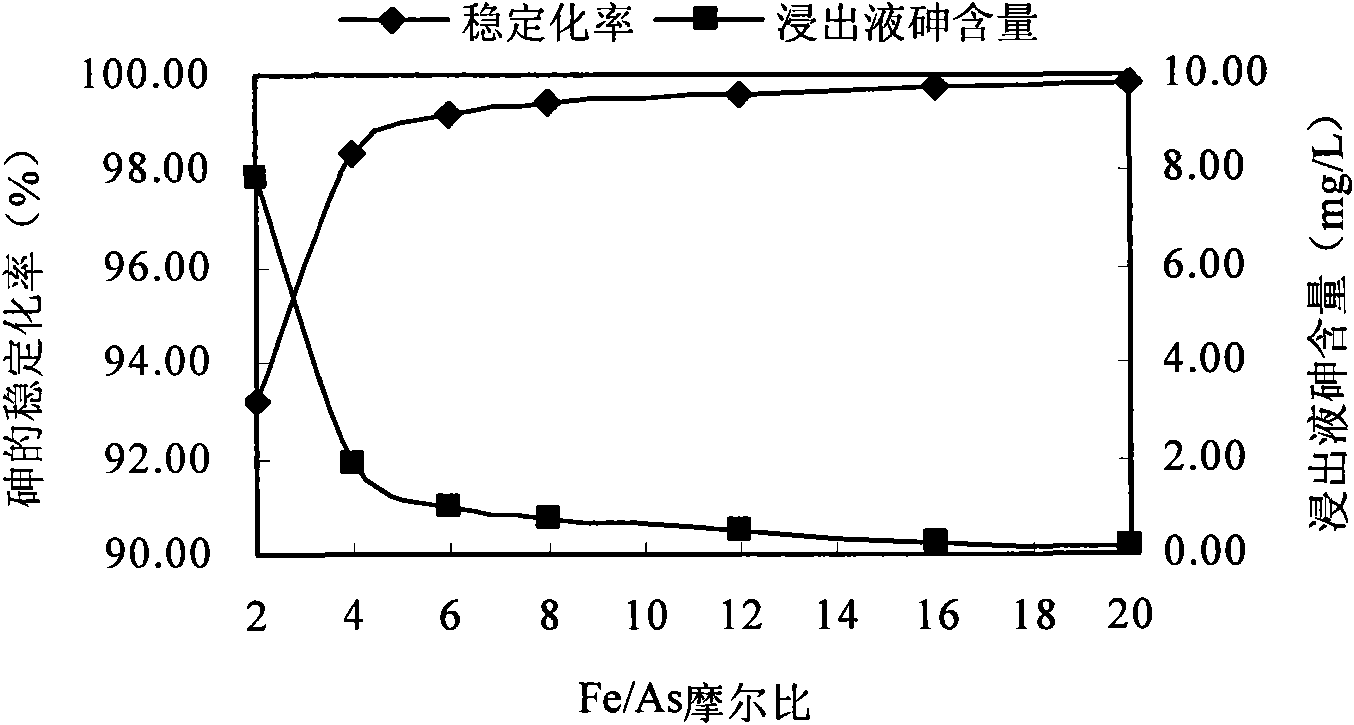

Method for remedying arsenic polluted soil

InactiveCN101879521AEasy to handleSimple operation and managementContaminated soil reclamationArsenateArsenic pollution

The invention discloses a method for remedying arsenic polluted soil. The method comprises a step of adding iron salt solution into the arsenic polluted soil so that the iron salt solution is reacted with arsenic in the soil to form arsenate FeAsO3 or FeAsO4 of iron. Before the iron salt solution is added, the method also comprises a step of crushing the arsenic polluted soil and steps of adjusting the pH of the arsenic polluted soil and measuring the arsenic content of the arsenic polluted soil. The method can quickly and efficiently treat the arsenic polluted soil, has simple operation and management and is suitable for major unexpected arsenic pollution remediation.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Advanced treatment method for arsenic-containing wastewater

InactiveCN103043812AImprove removal efficiencyConducive to aggregation and settlementMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeFerrous salts

The invention relates to a method for treating arsenic-containing wastewater by a process of preoxidation-composite coagulation deposition-filtering, and belongs to the technical field of wastewater treatment. The method comprises the steps of adding a certain amount of an oxidizing agent in a reaction tank for preoxidation in a condition that the wastewater contains trivalent arsenic so as to transform the trivalent arsenic into pentavalent arsenic completely, while for the wastewater only contains the pentavalent arsenic, the preoxidation process is not needed; adding a certain amount of a ferrous salt water solution; controlling a molar ration of Fe to As being 5-50; adding acid or alkali to adjust a pH value being 6-8; stirring for 0.1-1 min rapidly, so that a ferric arsenate precipitate is formed, at the same time, the ferrous salt is hydrolyzed into ferrous carbonyl to promote coagulation deposition of the ferric arsenate; adding a solution of 0.1-10 mg / L organic polymer flocculant; stirring for 0.1-1 min rapidly; stirring for 5-10 min slowly, precipitating for 10-30 min, discharging sludge from the bottom, introducing supernatant into a sand filter tank, a filter film or a filter bag, filtering and discharging the effluent. Arsenic content in water after treatment is lower than that of a drinking water standard (less than 10 [mu]g / L) regulated by the world health organization. The method has low sludge production and low cost, and can be used for advanced treatment of the arsenic-containing industrial wastewater and treatment of arsenic polluted underground water and drinking water.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

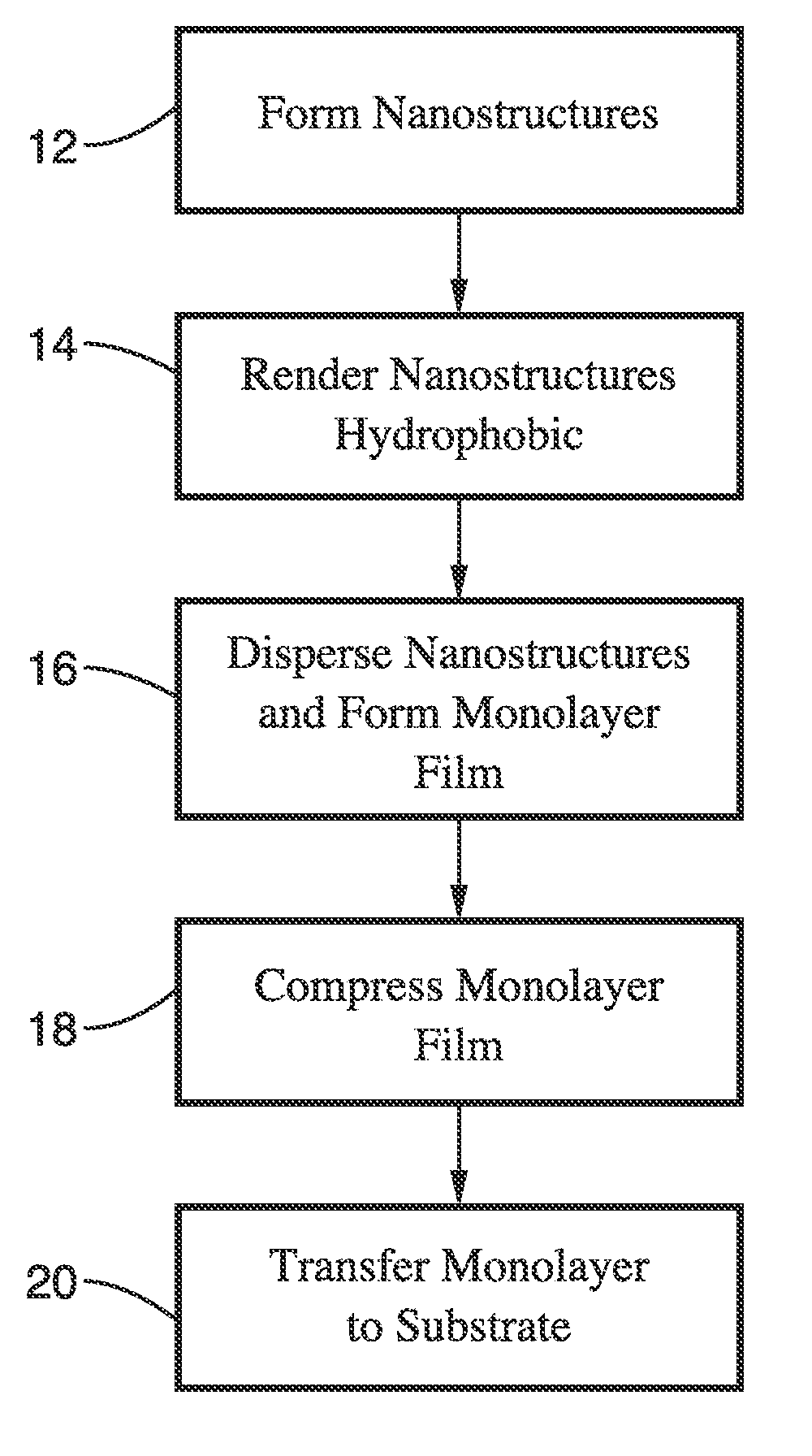

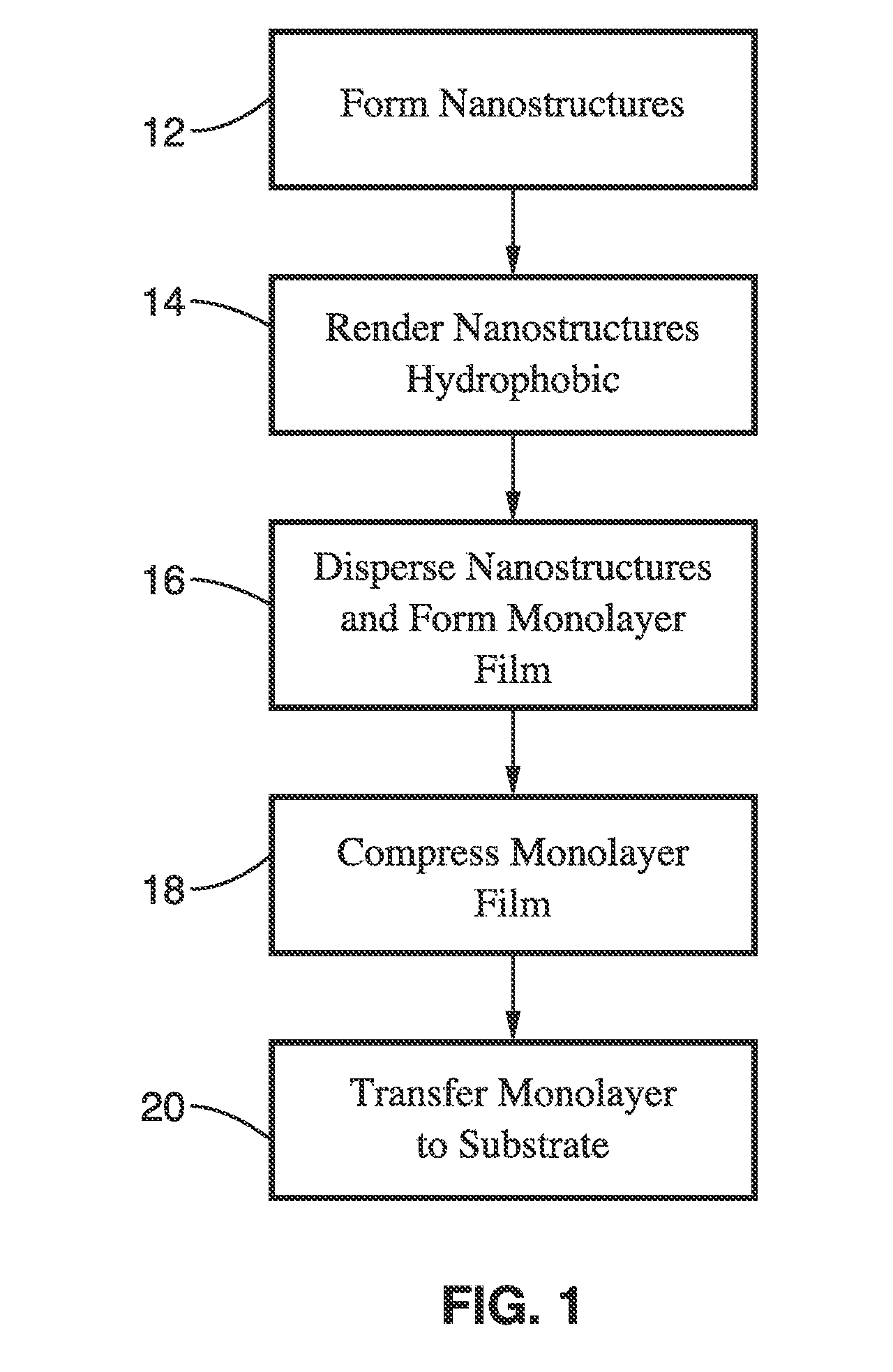

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

ActiveUS20090225310A1Highly accurate and sensitive detectionImprove bindingRadiation pyrometryMaterial analysis by optical meansArsenateHigh density

A surface-enhanced Raman spectroscopy (SERS) substrate formed from a plurality of monolayers of polyhedral silver nanocrystals, wherein at least one of the monolayers has polyvinypyrrolidone (PVP) on its surface, and thereby configured for sensing arsenic is described. Highly active SERS substrates are formed by assembling high density monolayers of differently shaped silver nanocrystals onto a solid support. SERS detection is performed directly on this substrate by placing a droplet of the analyte solution onto the nanocrystal monolayer. Adsorbed polymer, polyvinypyrrolidone (PVP), on the surface of the nanoparticles facilitates the binding of both arsenate and arsenite near the silver surface, allowing for highly accurate and sensitive detection capabilities.

Owner:RGT UNIV OF CALIFORNIA

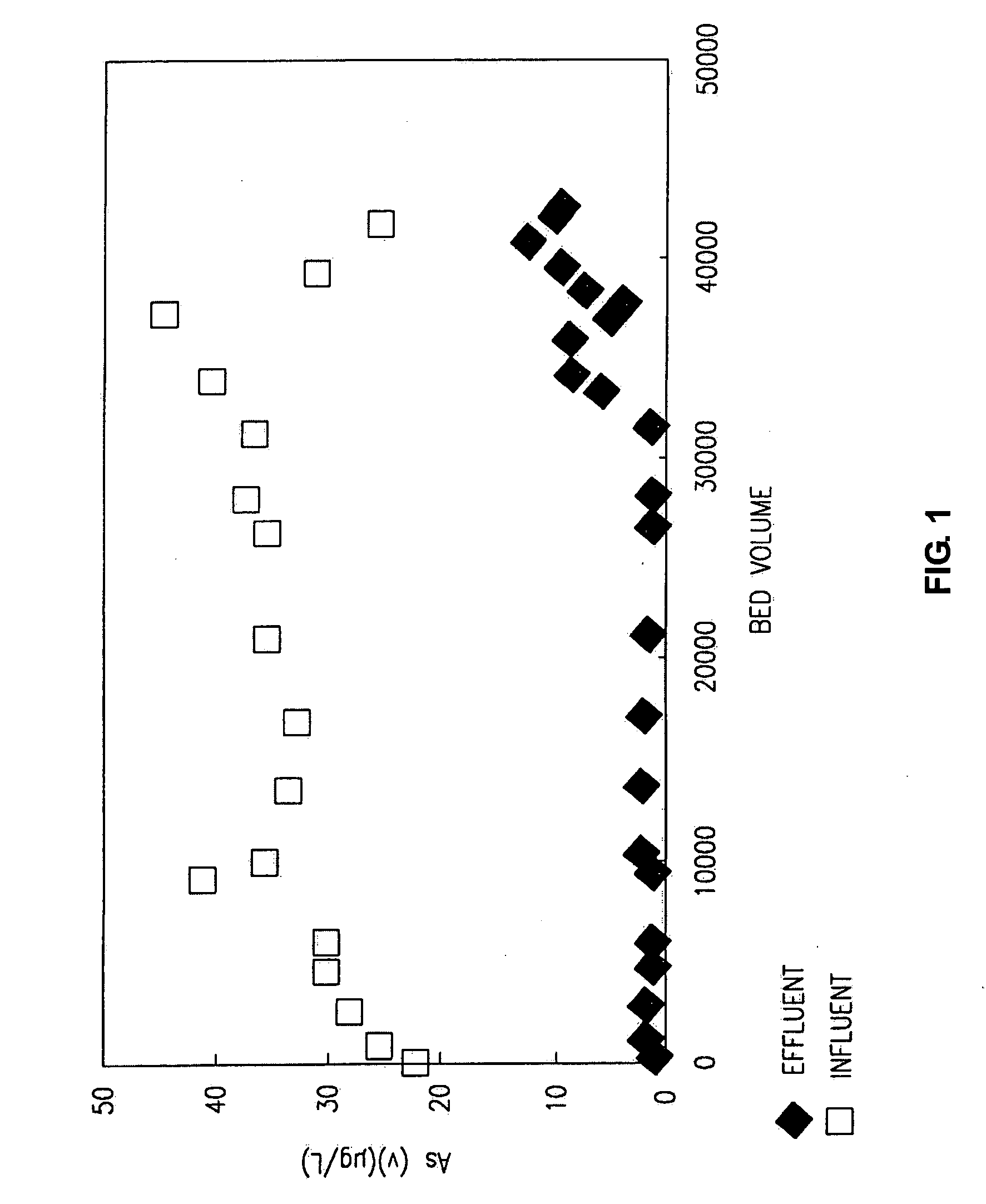

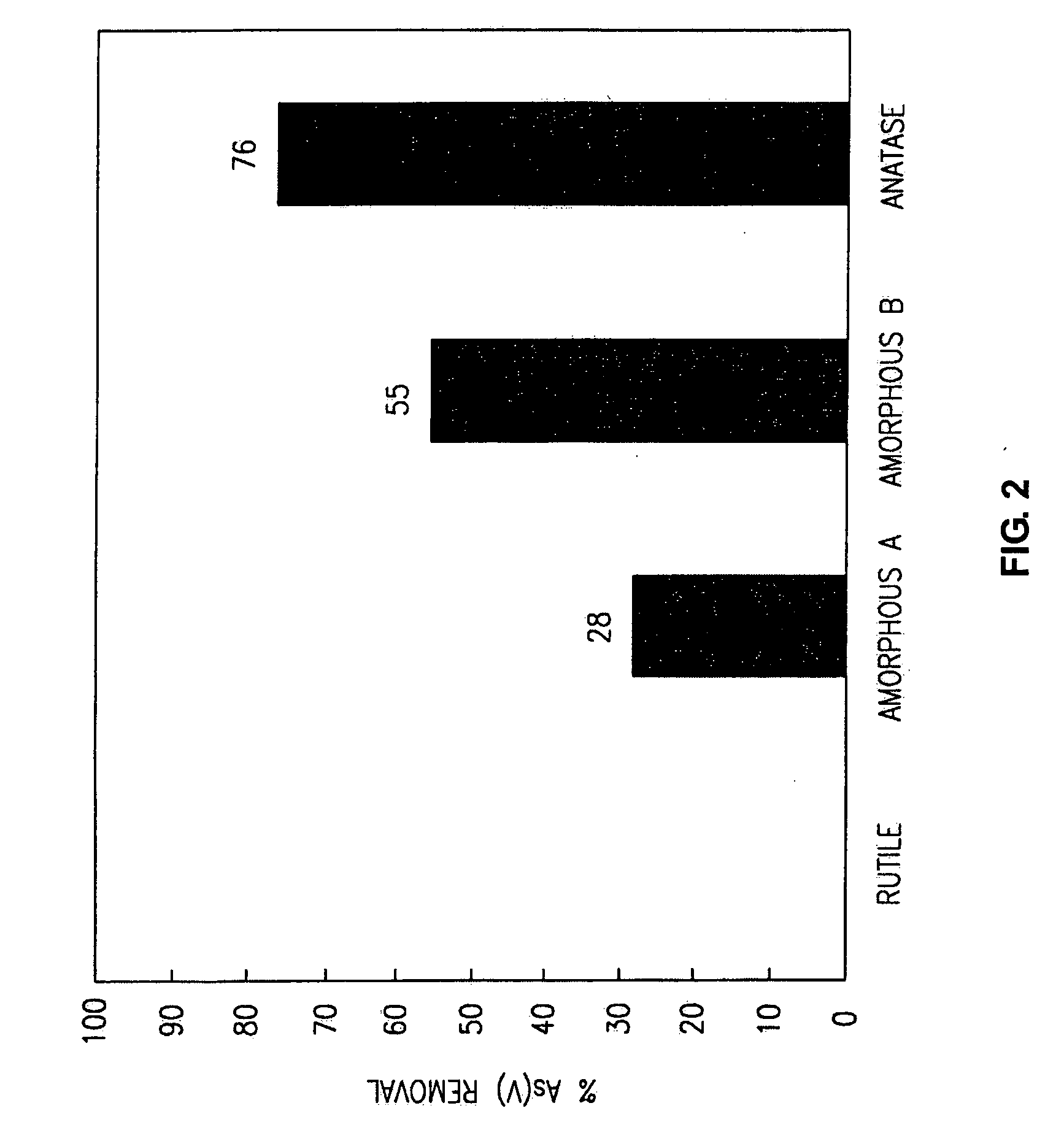

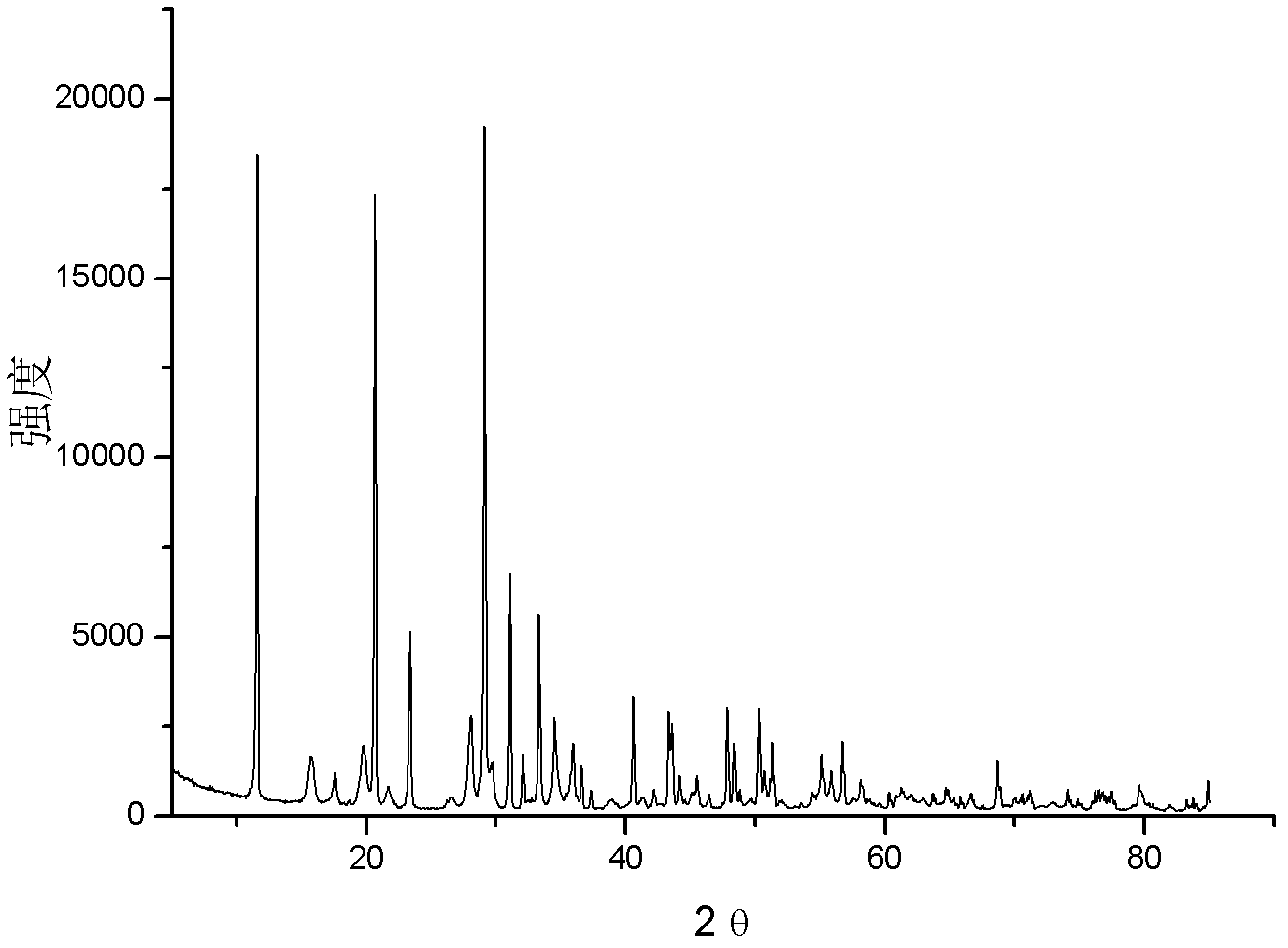

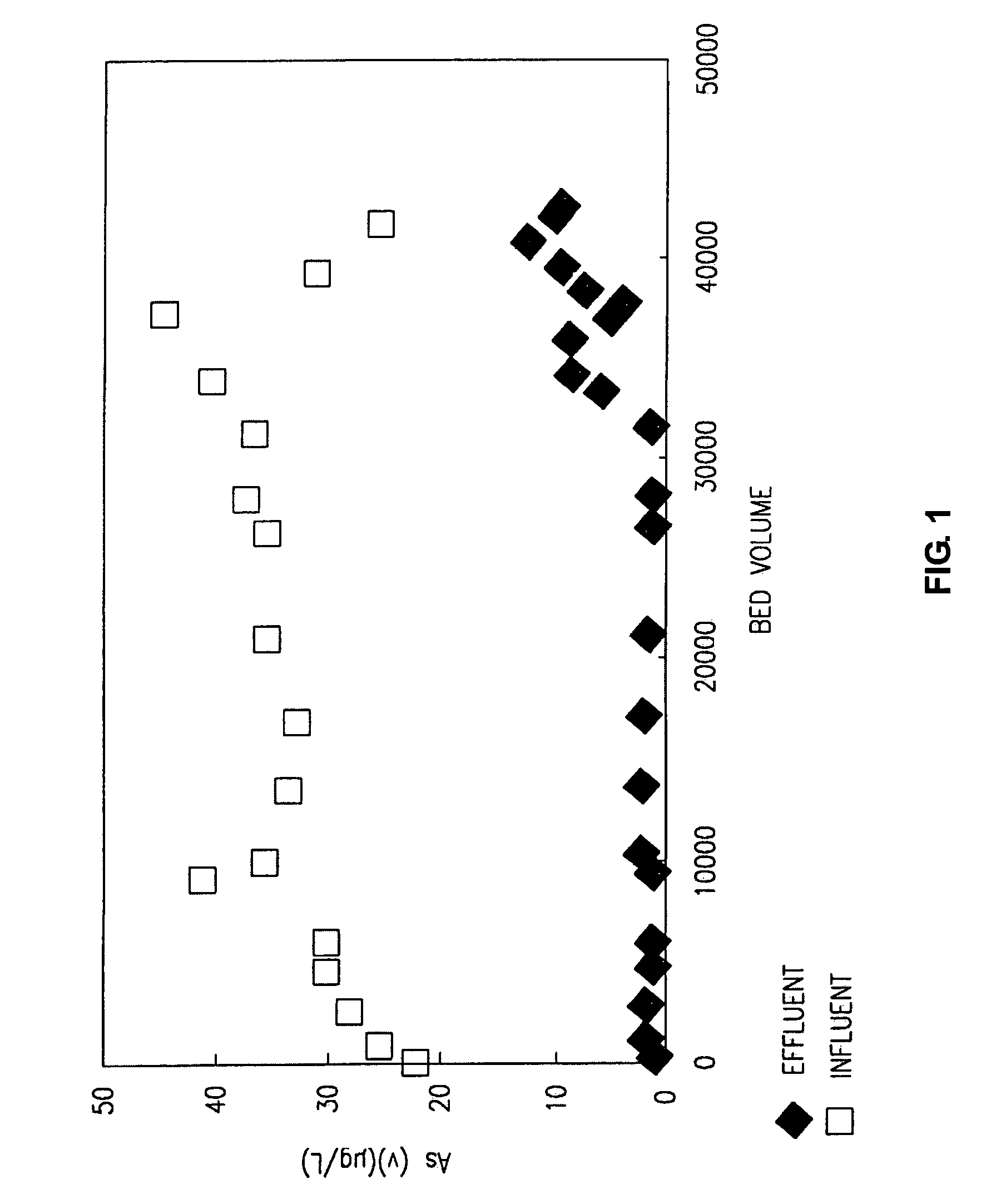

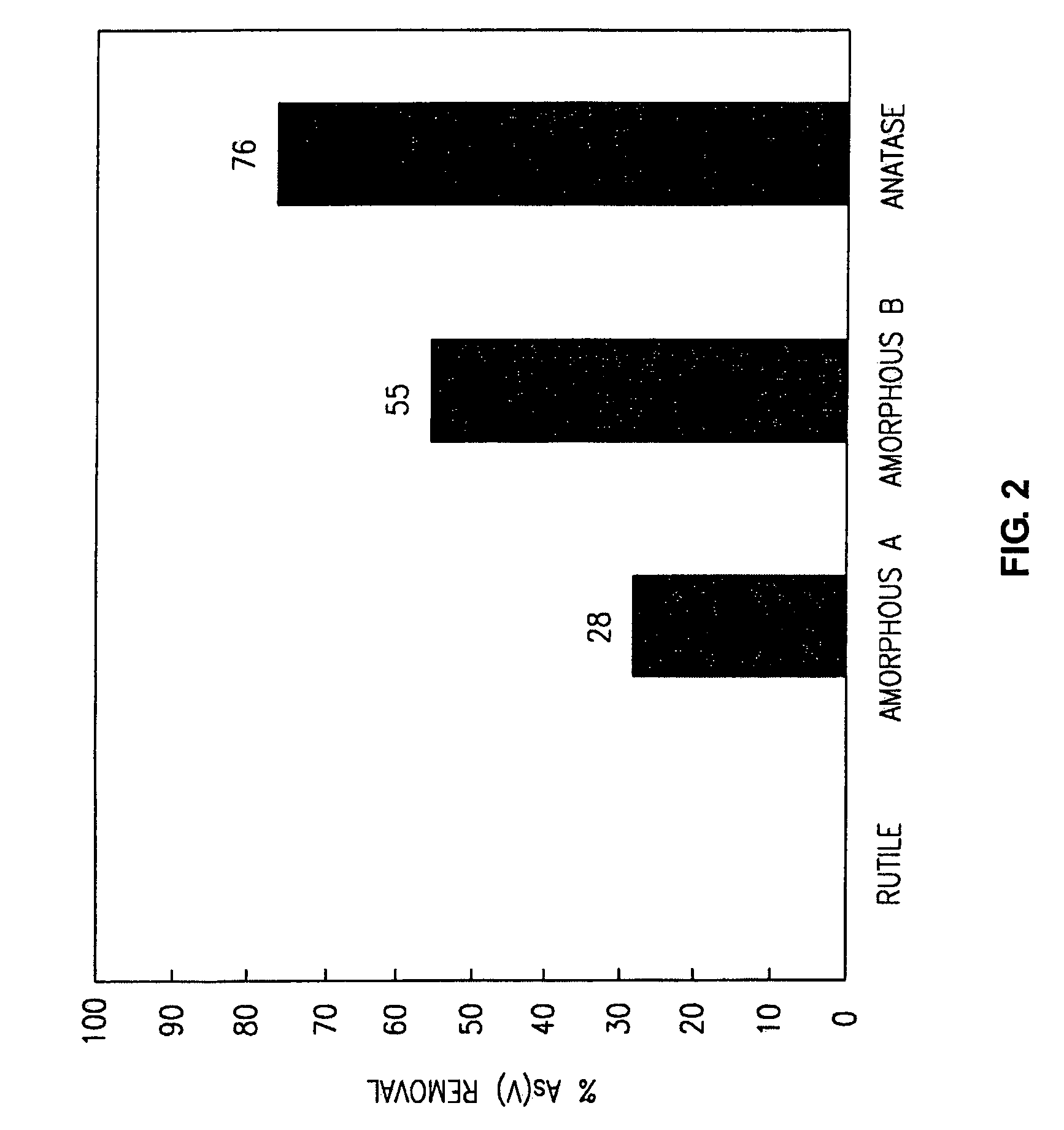

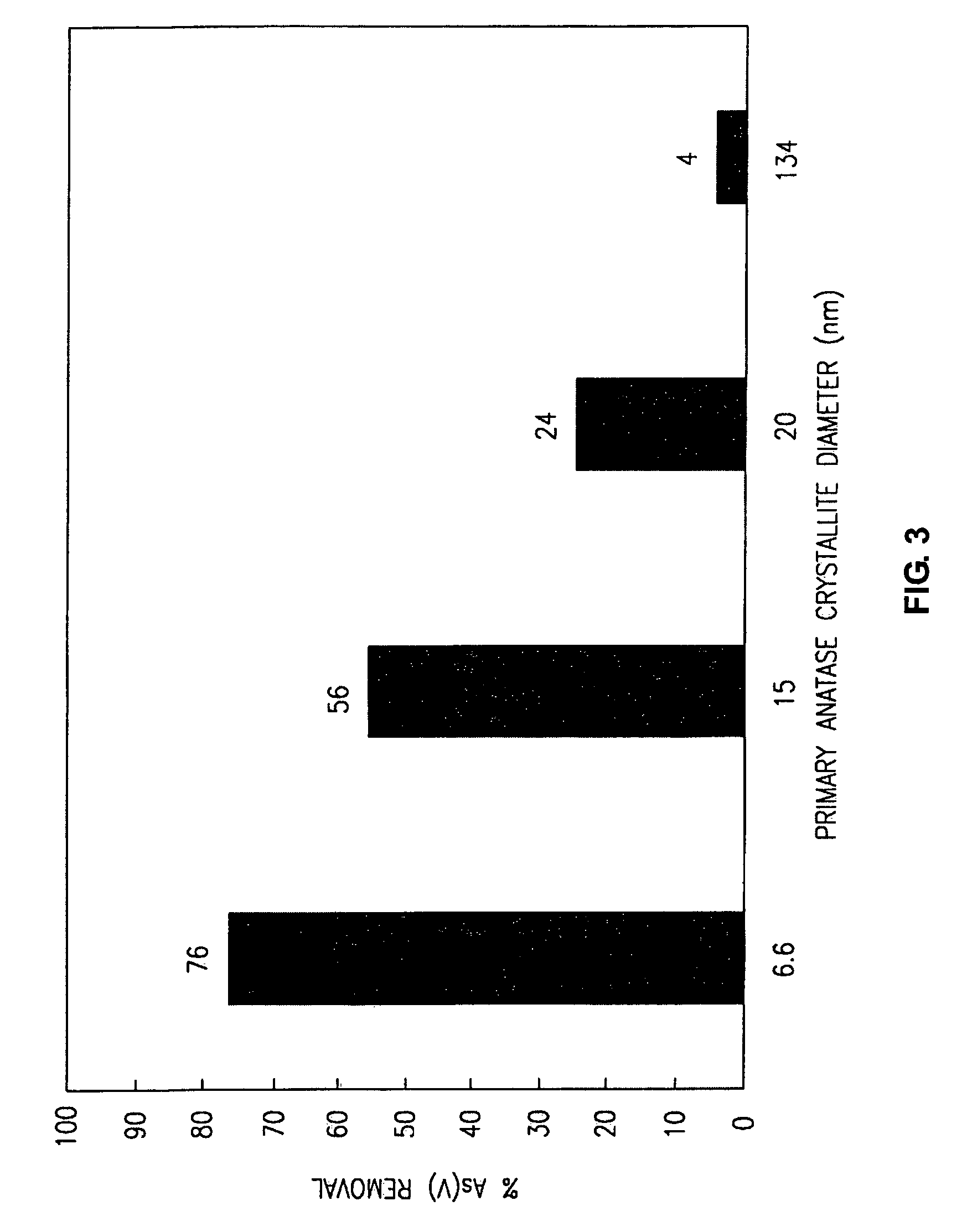

Methods of preparing a surface-activated titanium oxide product and of using same in water treatment processes

InactiveUS20060091079A1Rate of removalMaterial nanotechnologyOther chemical processesArsenateHigh rate

A method for removing dissolved contaminants from solution using a surface-activated crystalline titanium oxide product having a high adsorptive capacity and a high rate of adsorption with respect to dissolved contaminants, in particular, arsenate and arsenite. Preferably, the titanium oxide product includes crystalline anatase having primary crystallite diameters in the range of 1-30 nm. The surface-activated titanium oxide is combined with other filter media to further improve the removal of dissolved contaminants.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

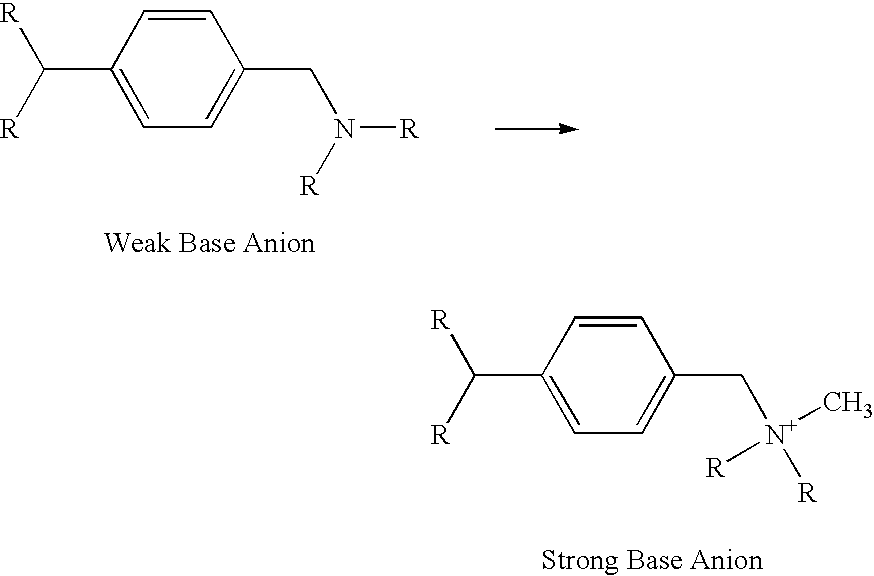

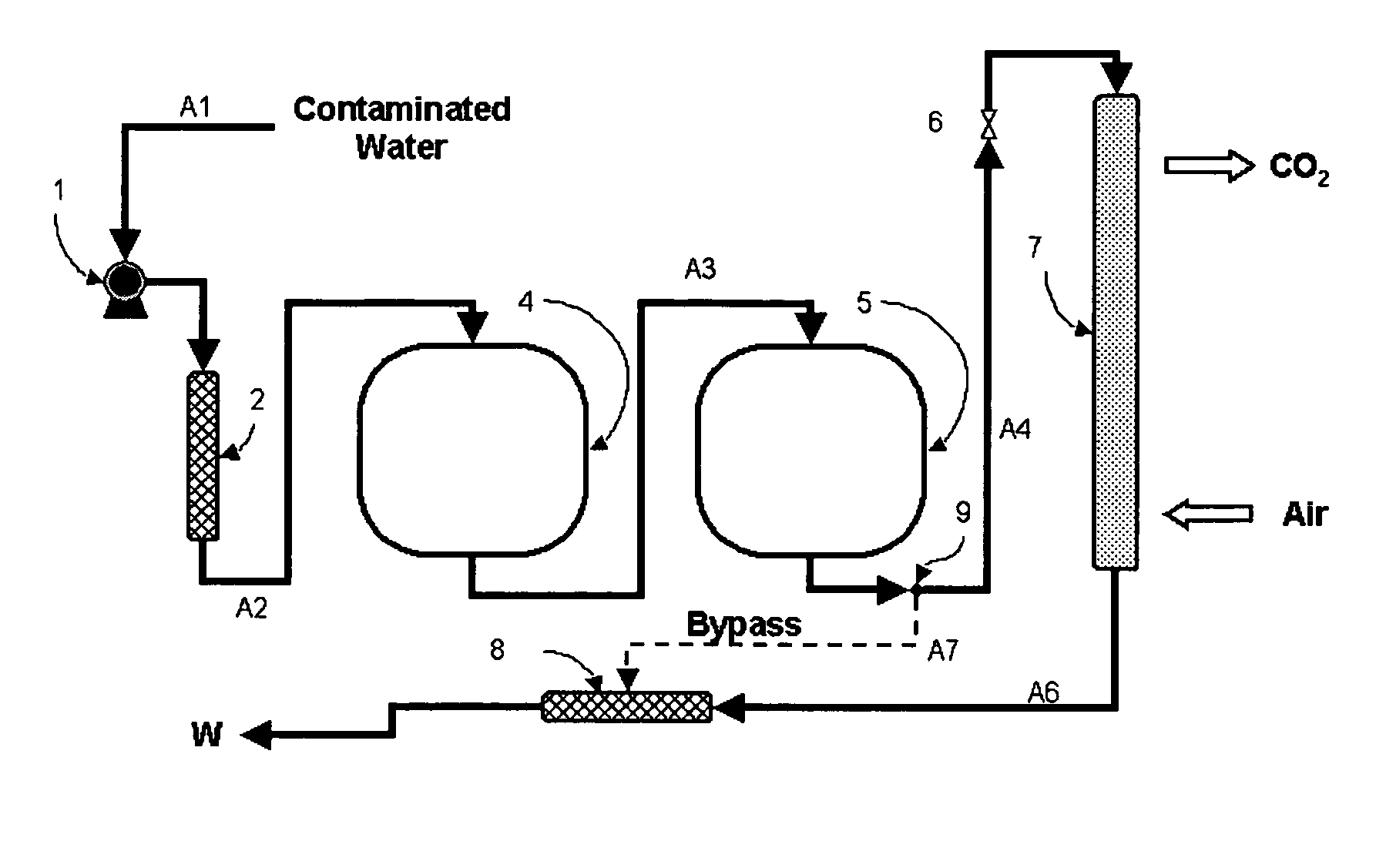

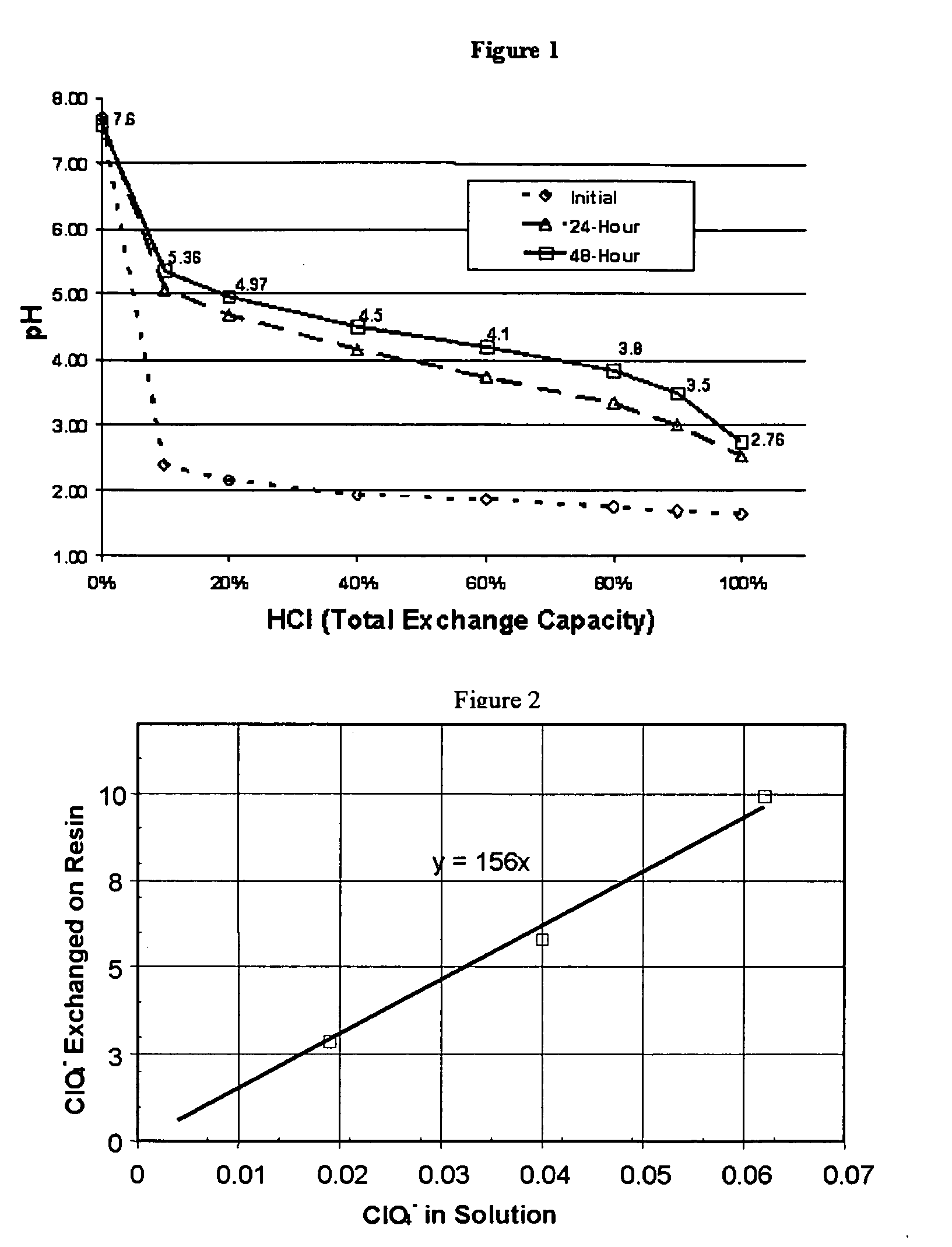

Water treatment process for perchlorate, nitrate, chromate, arsenate and other oxyanions for using weak-base anion exchange resins

ActiveUS20070114178A1Reduce pumping costsImprove chemical efficiencyOrganic anion exchangersIon-exchanger regenerationSelenateIon exchange

The invention consists of a water treatment process using selective and regenerable weak base anion exchange resins to remove any number of complex anions, especially oxyanions including perchlorate, nitrate, chlorate, arsenate, selenate, and chromate, from aqueous solutions. The treatment process is comprised of three key processes including 1) pretreatment to lower pH, 2) ion exchange, and 3) post treatment to adjust pH and alkalinity. The invention also includes processes for regenerating weak base anion resins and treatment of the residuals generated. This invention employs pressurized treatment, carbon dioxide management, and reuse of regenerating solution to minimize pumping and treatment costs.

Owner:APPLIED RES ASSOCS INC +1

Treating method of arsenic in waste acid

ActiveCN102531236AReduce usageReduce the risk of secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by neutralisationArsenateSlag

The invention provides a treating method of arsenic in waste acid, which comprises the steps of enabling arsenic in waste acid to form amorphous ferric arsenate precipitation under the conditions of lower Fe / As molar ratio and a certain pH value, adding acid for re-dissolution, heating, carrying on enrichment and concentration on the arsenic in the waste acid, and finally forming stable scoroditecrystals to remove the arsenic in the waste acid, so that the iron usage amount is greatly reduced, the economic cost is reduced, the slag amount is reduced, simultaneously the cost for high temperature transforming heating is reduced, stable solid waste containing arsenic can be obtained, and the secondary pollution to the environment due to the solid waste containing the arsenic can be reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

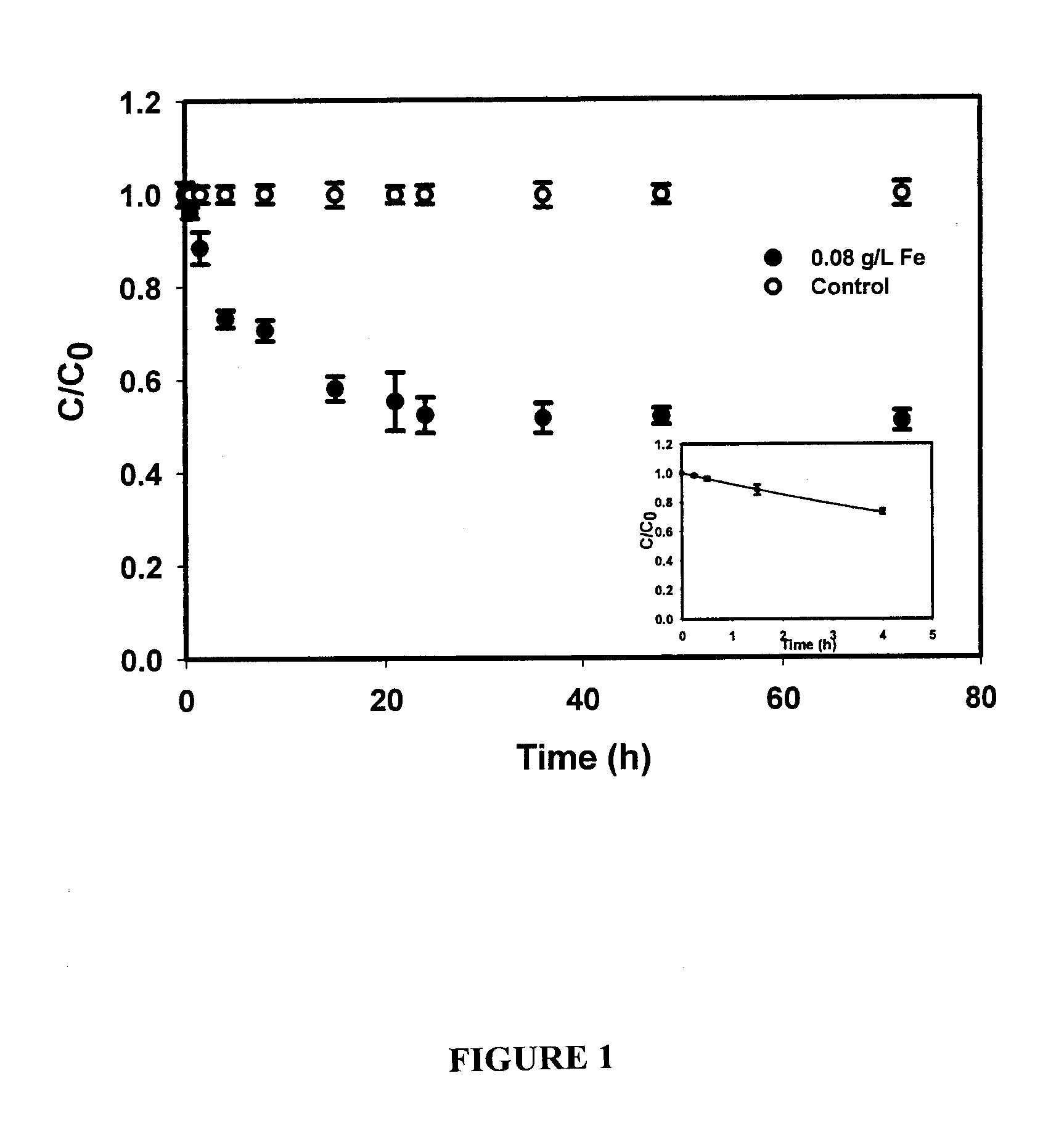

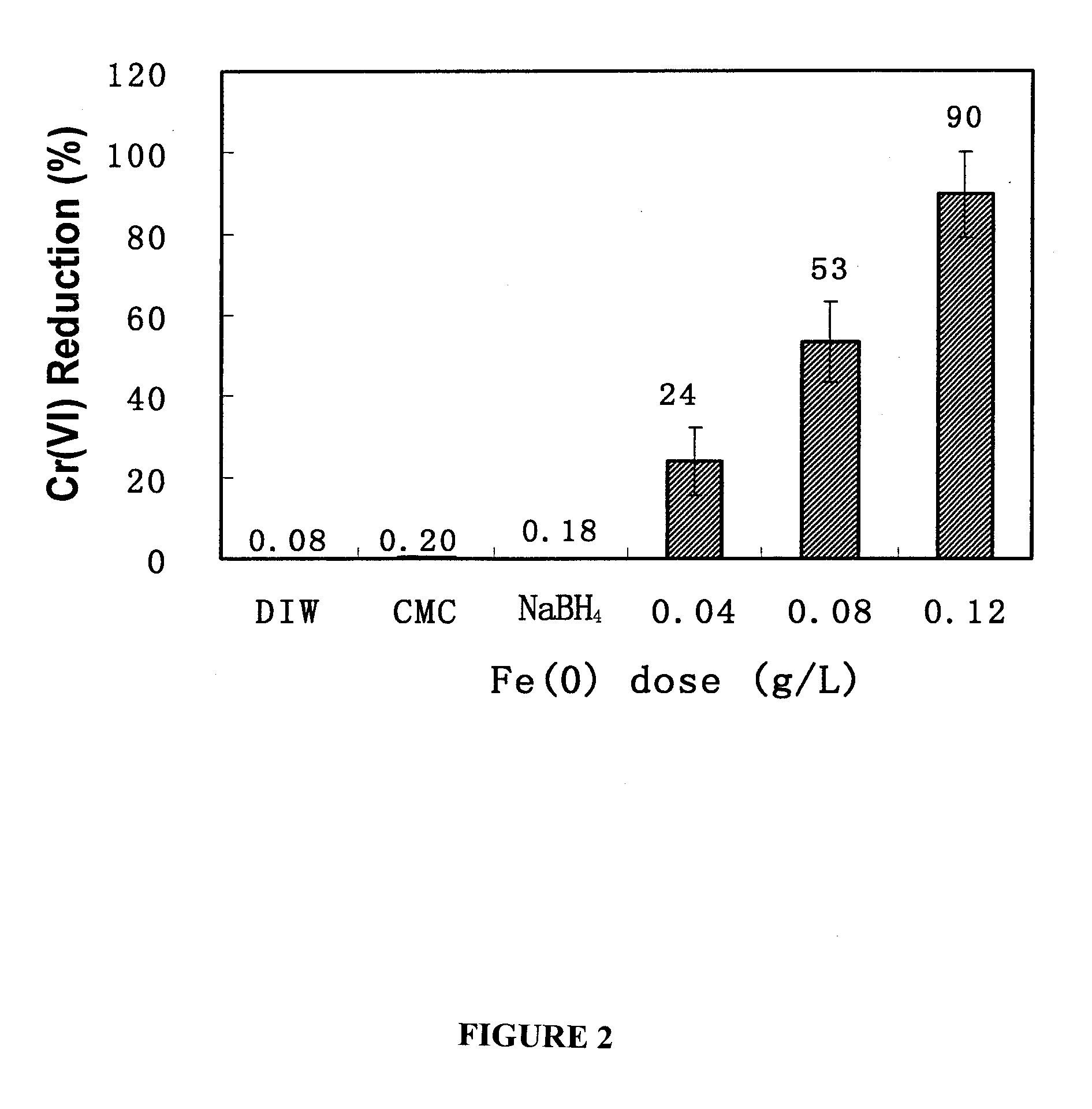

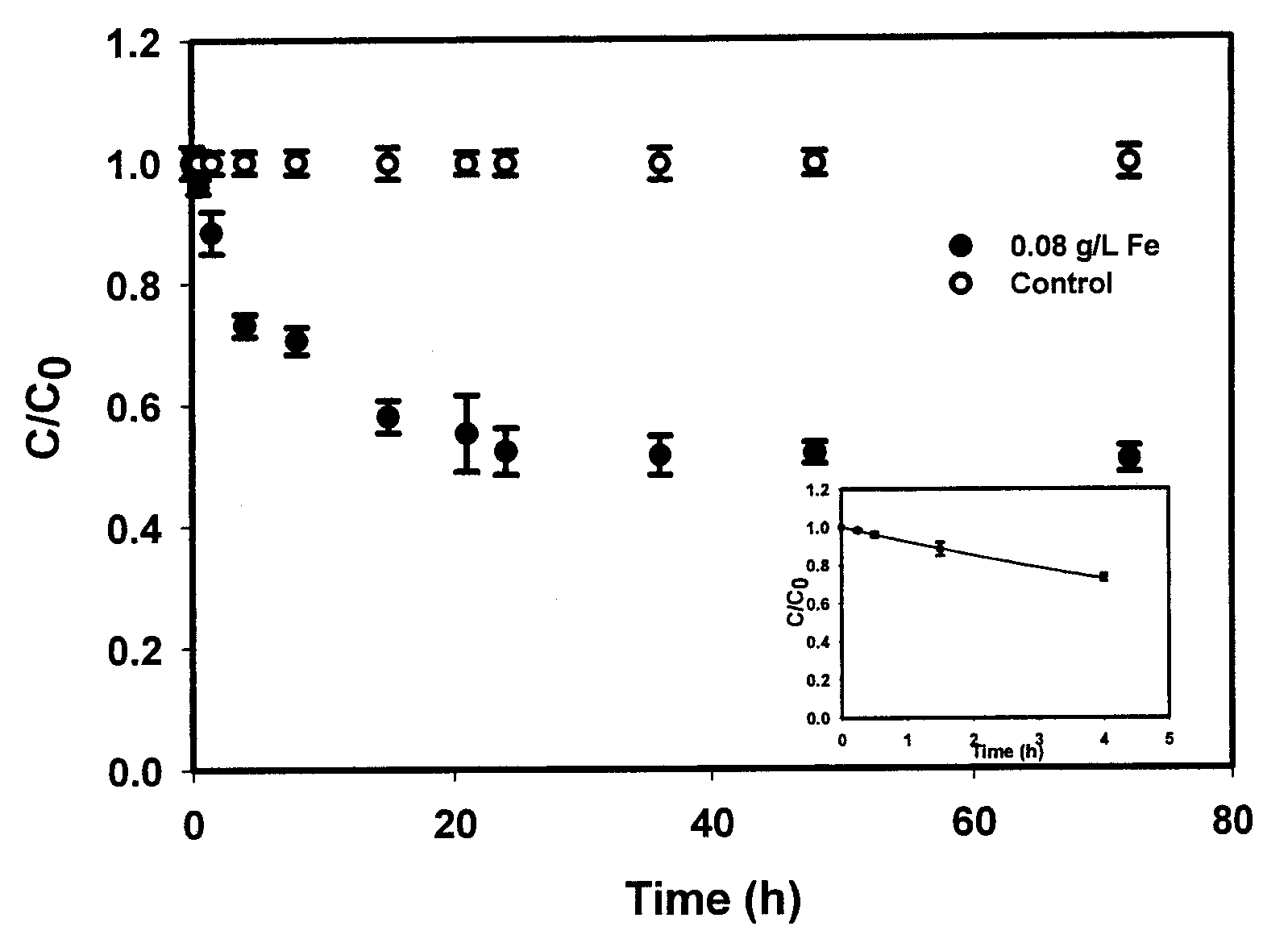

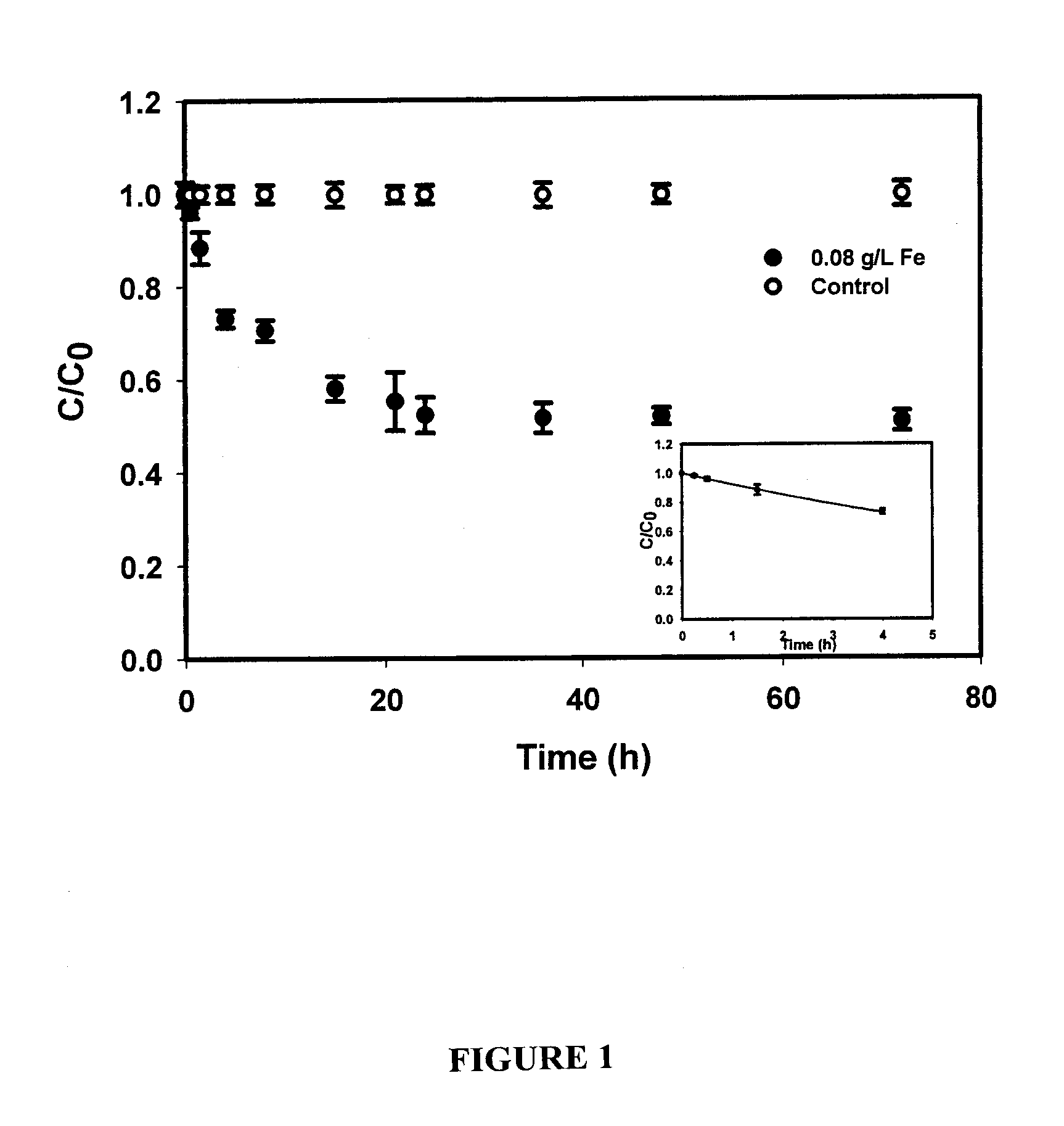

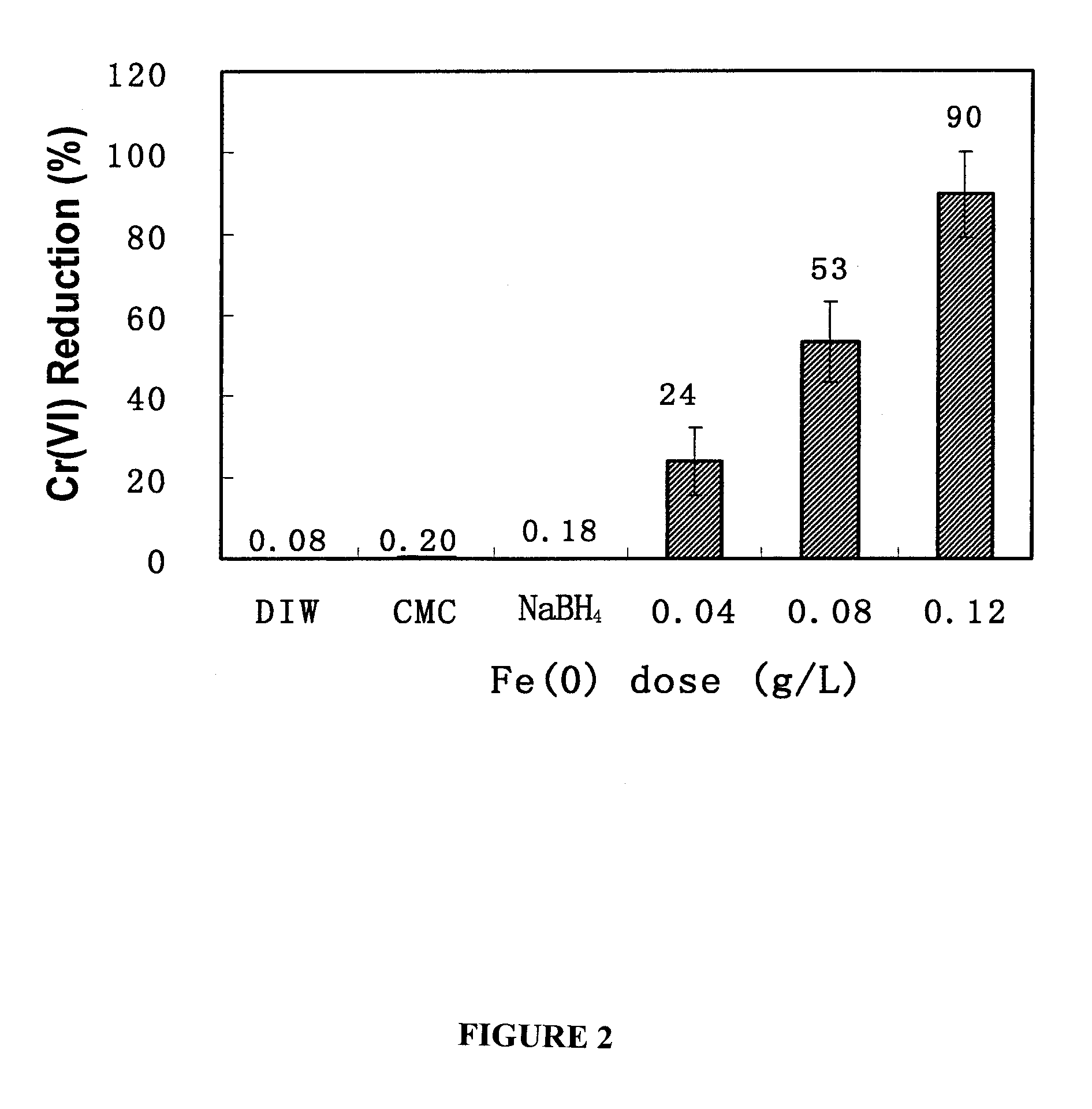

In situ remediation of inorganic contaminants using stabilized zero-valent iron nanoparticles

InactiveUS7635236B2Good dispersionEasy to remedyMaterial nanotechnologyWater treatment compoundsMaterials scienceChromic Ion

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

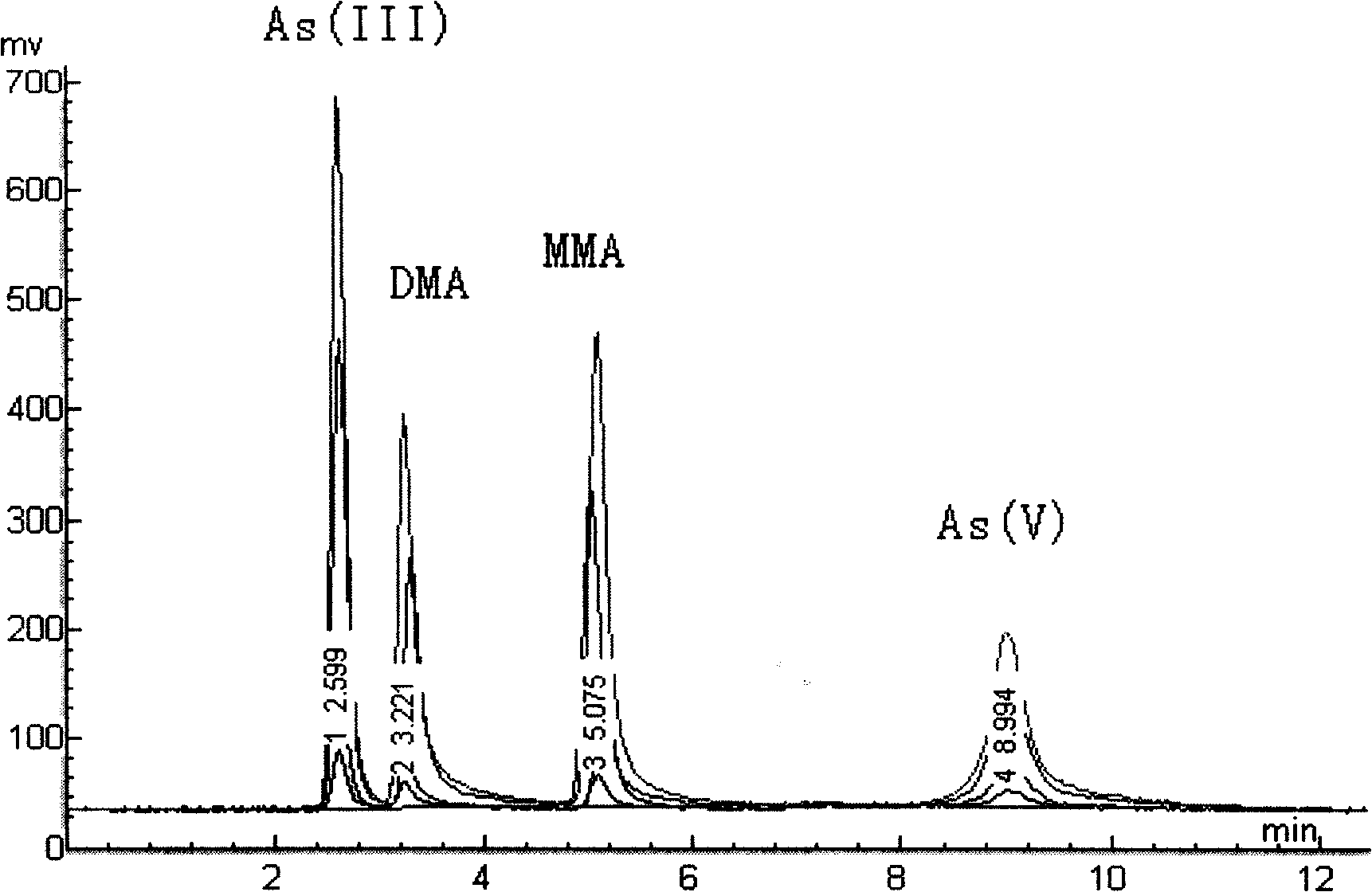

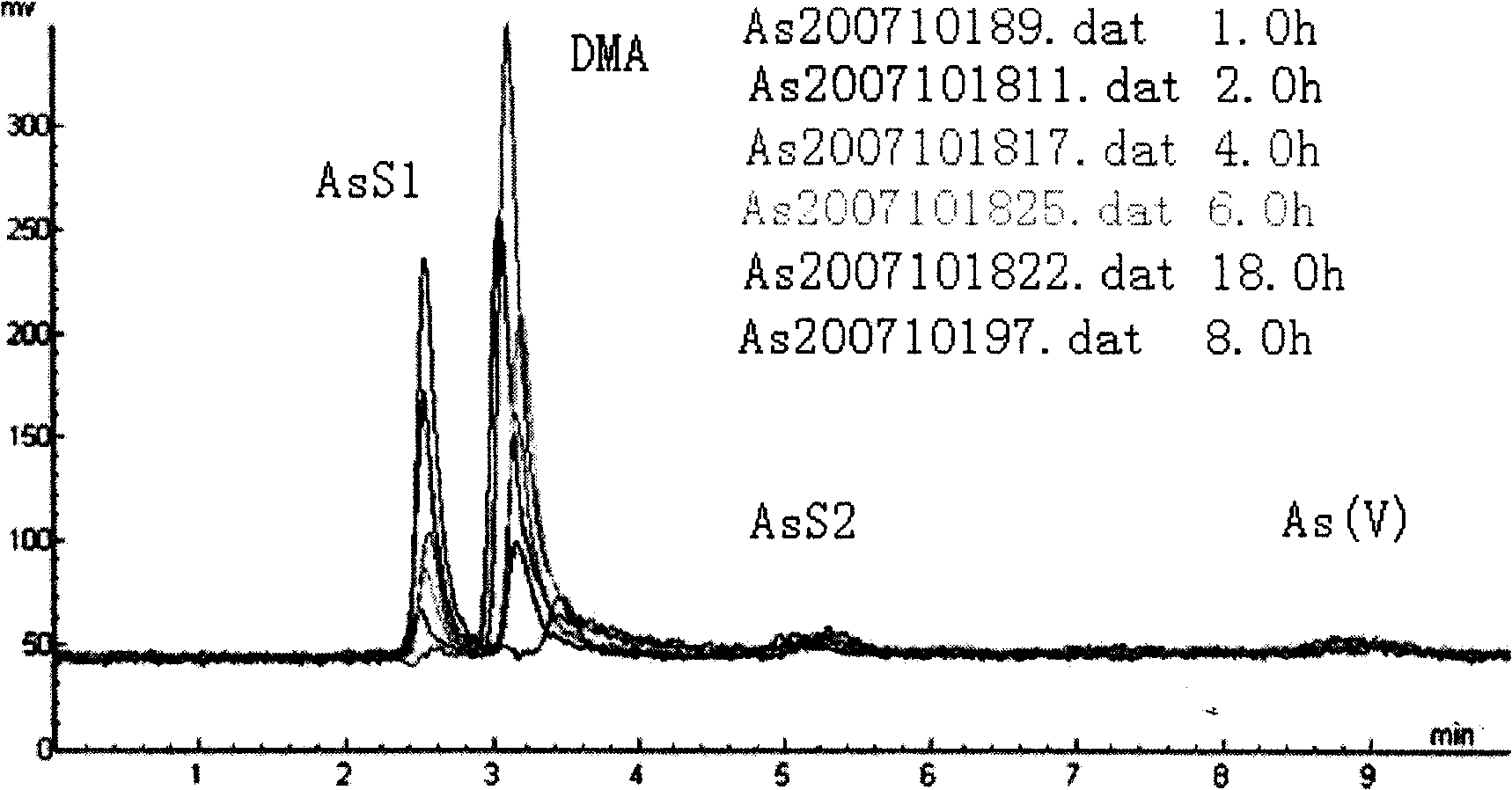

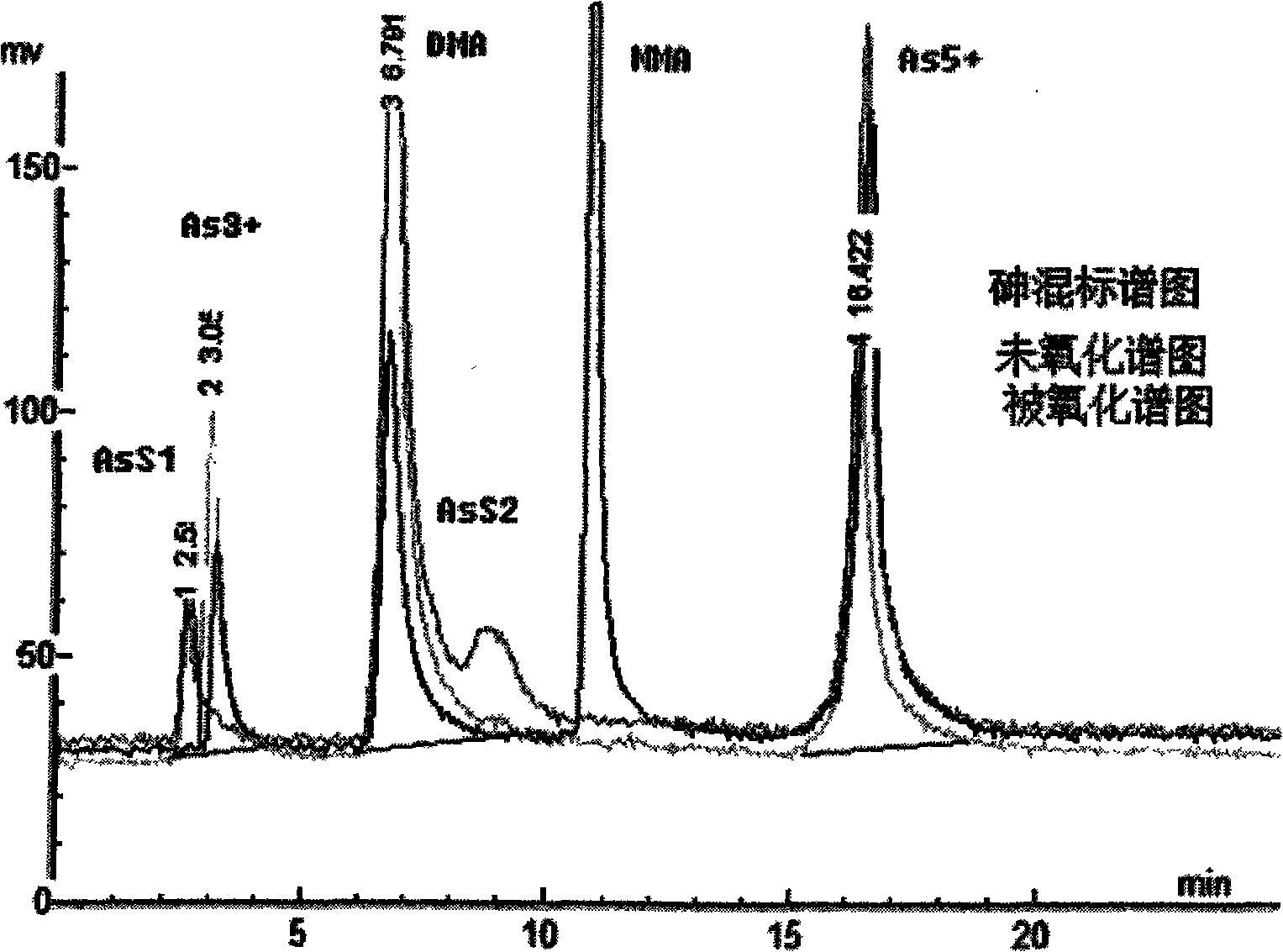

Aquatic product inorganic arsenic determination method

InactiveCN101261258AReasonable selection of experimental conditionsReasonable choiceComponent separationPotassium borohydrideFluorescence

The invention relates to a determination method for inorganic arsenic in aquatic products. After being extracted by hydrochloric acid solution, the inorganic arsenic (1plus1) in the aquatic products passes through an anion-exchange column, and arsenite As (III), dimethyl arsenic compound DMA, methyl arsenic compound MMA and arsenate As (V) are eluted sequentially by mobile phase; owing to different adsorption capacities of the anion-exchange column on the arsenate As (V), the arsenite As (III), the methyl arsenic compound MMA, the dimethyl arsenic compound DMA and arsenic sugar AsS, the eluted solution is hydrogenated by borohydride potassium reducing agent and hydrochloride, and hydride is generated, enters an atomizer, and is subject to analytic determination by being combined with atomic fluorescence. The experimental condition is reasonably selected, and the detecting data is accurate and reliable and can not be influenced by extraction time and temperature. The determination method of inorganic arsenic in aquatic products of the invention not only can detect the inorganic arsenic iAs accurately, but also can determine the methyl arsenic compound MMA and the dimethyl arsenic compound DMA of the organic arsenic, and can be used for the morphometry of the arsenic in the aquatic products.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

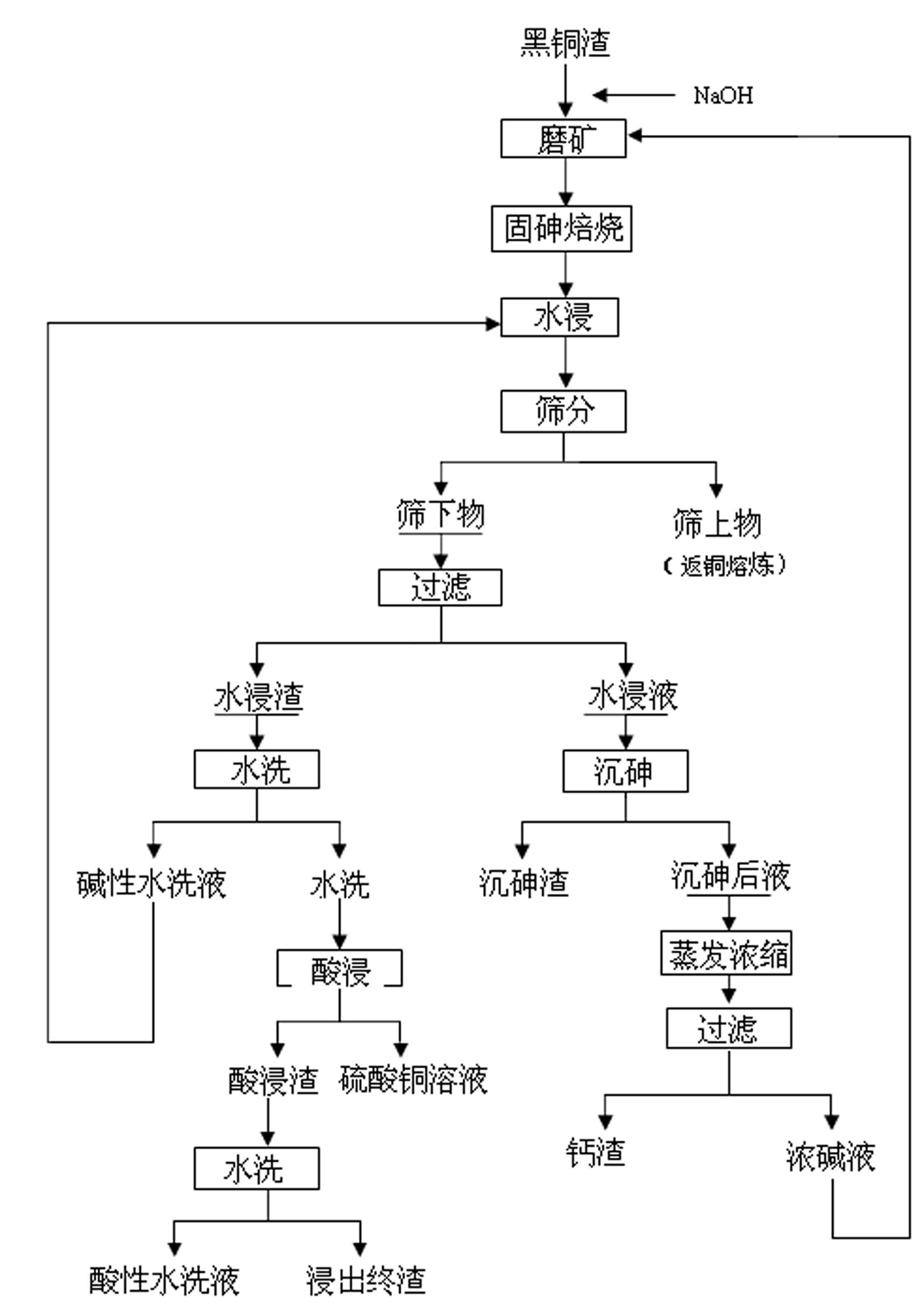

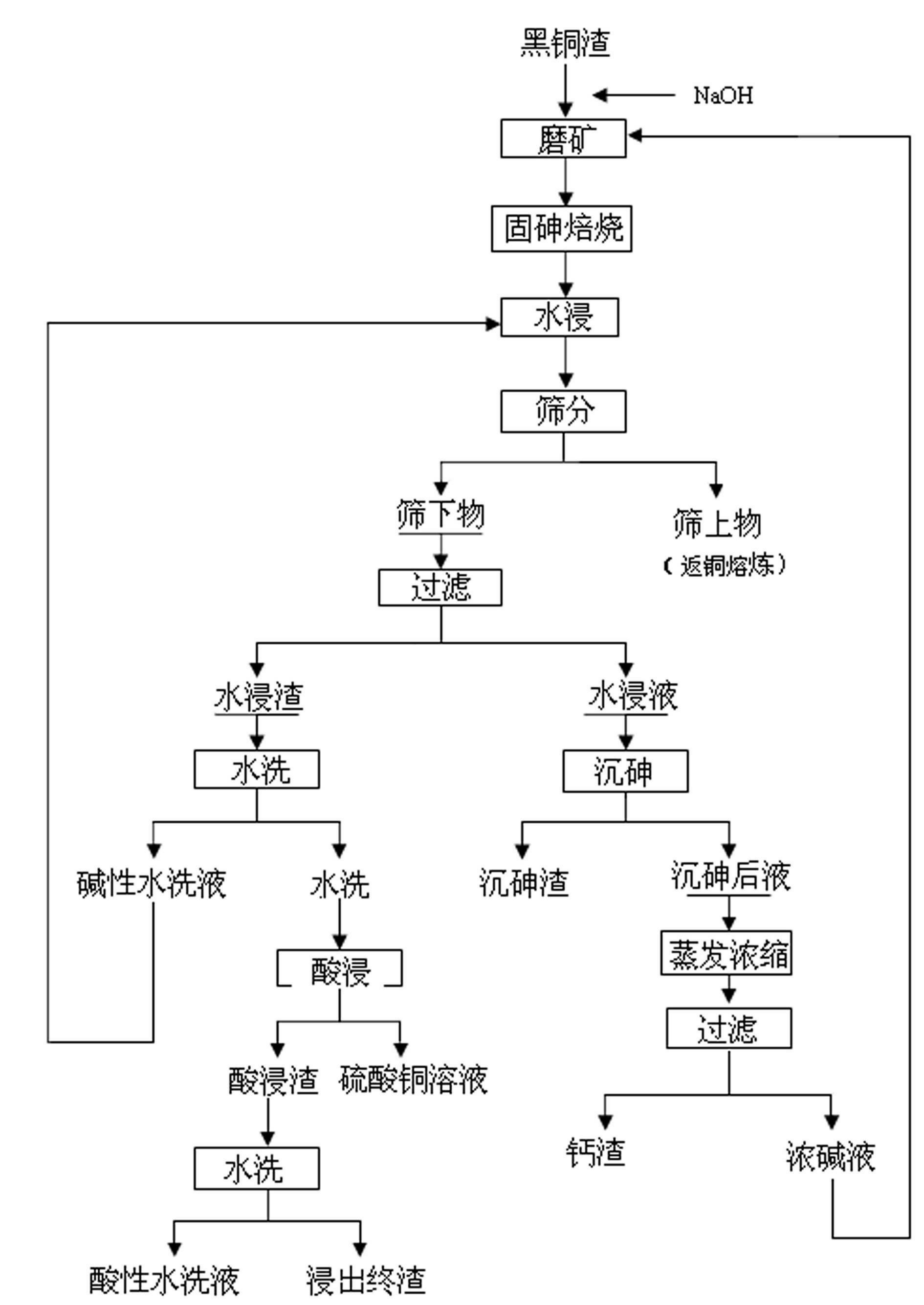

Method for treating arsenic-containing waste copper slag

InactiveCN102634672ASolve the open circuit problemHigh enrichment ratioProcess efficiency improvementArsenateEnvironmental engineering

The invention provides a method for treating arsenic-containing waste copper slag. The method comprises the following steps of: adding alkali and arsenic fixation roasting on the arsenic-containing waste copper slag from a copper electrolysis purification procedure to convert the arsenic into low-toxicity, water-soluble and nonvolatile arsenate, leaching the roasting slag into water to remove the arsenic, recovering copper and enriching antimony bismuth silver by virtue of acid leaching, and embedding calcium arsenate sediment converted from the arsenic in the water leaching solution; and comprehensively recovering valued metals such as copper, silver, antimony and bismuth in the black copper slag. The method is a safe and effective wet smelting method for recovering the valued metals in the black copper slag, and the arsenic and the copper are leached separately; the recovery rate of the copper in the black copper slag reaches 99.6 percent, and the removal rate of the arsenic reaches over 98 percent; over 95 percent of antimony and over 98 percent of bismuth enter the slag, and over 98 percent of silver also enters the acid leaching slag by adding trace chlorine radicals during acid leaching, so that the antimony, the bismuth and the silver are comprehensively recovered; and the method has the advantages of low equipment investment, short flow, low running cost and safe and reliable operating environment.

Owner:JINCHUAN GROUP LIMITED

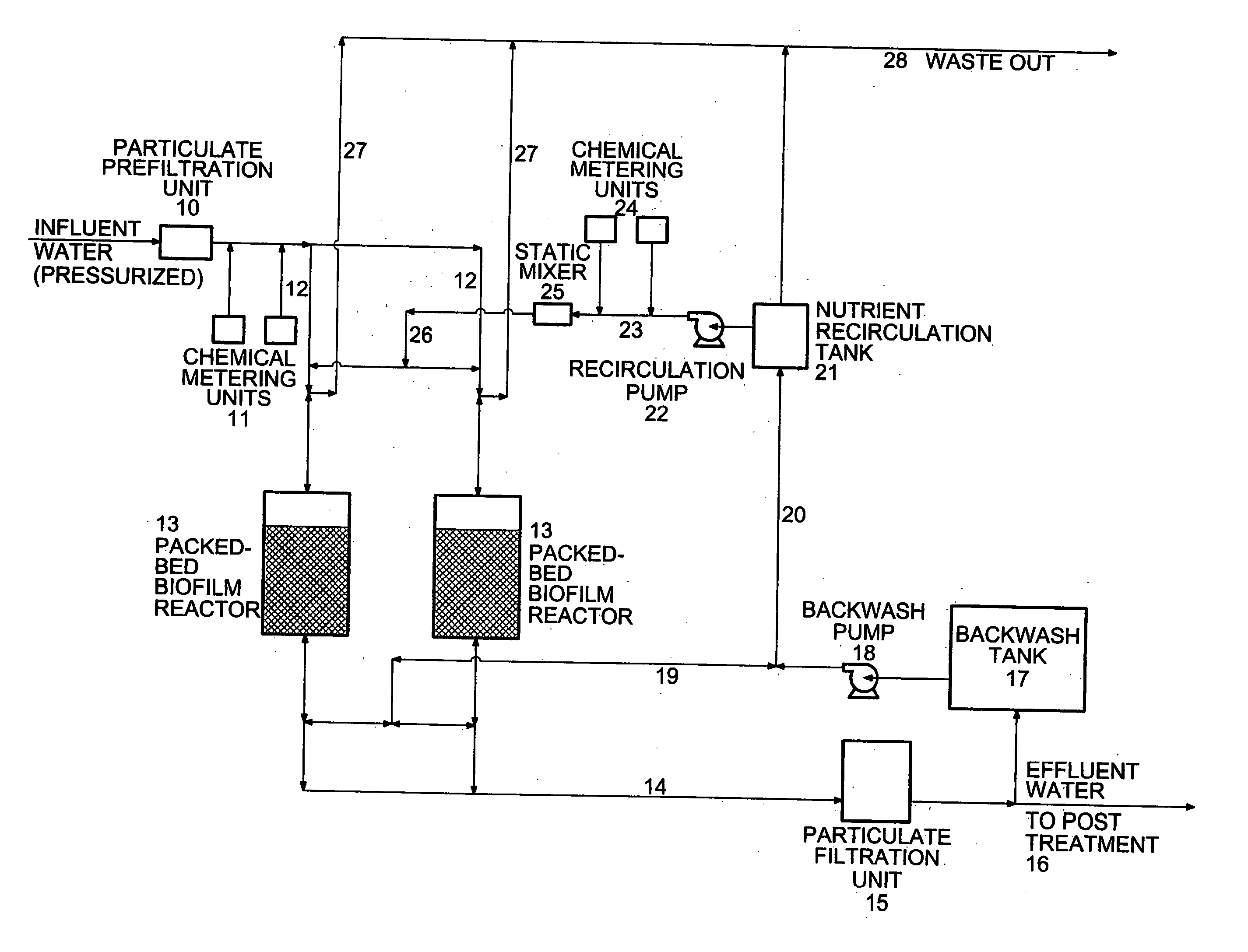

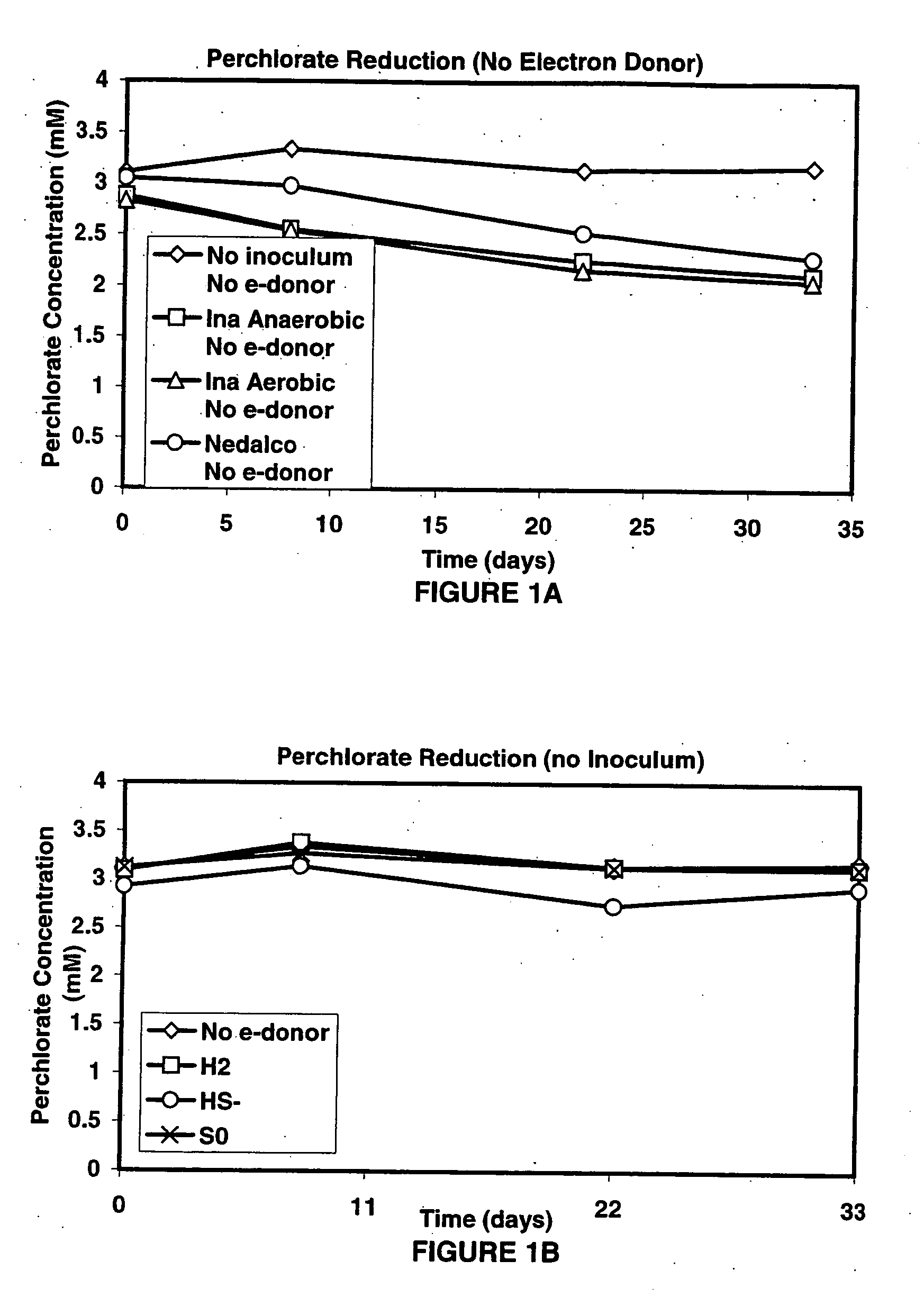

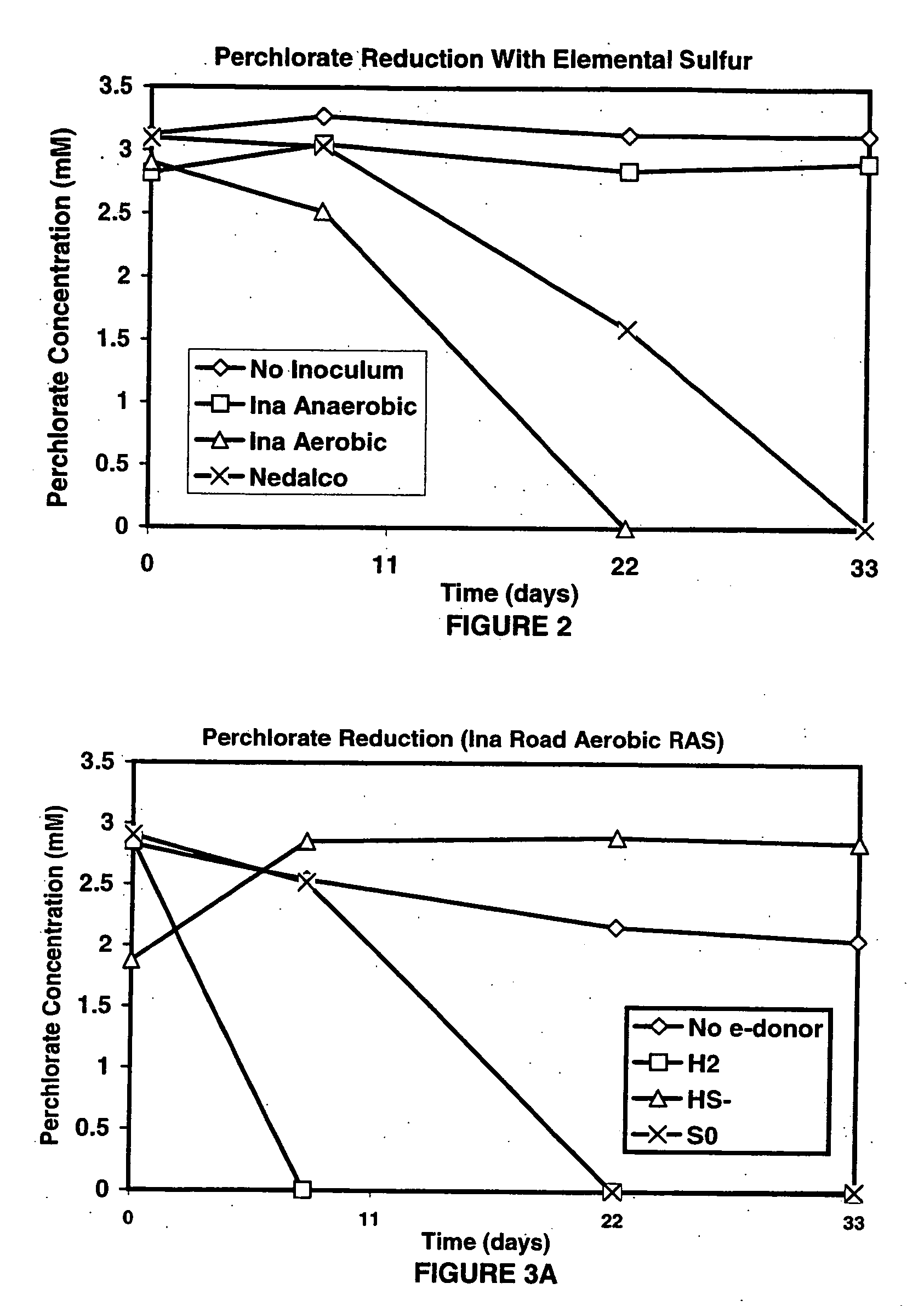

Method and system for treating oxidized contaminant-containing matrix

InactiveUS20060292684A1Reduce maintenanceHigh degreeWater treatment compoundsWater contaminantsSulfurElectron donor

A new and useful way of treating oxidized-contaminant-containing water, soil, rock, other geological or non-geological matrix formation (such as a landfill) is provided. A bioreactor is provided that includes elemental sulfur and a microbial population capable of oxidizing sulfur and reducing pertechnate (TcO4−), arsenate (H2AsO4−), chromate (CrO42−), bromate (BrO3−), chlorite (ClO2−), chlorate (ClO3−), perchlorate (ClO4−), and uranium(VI) oxide, with biological reduction of these oxidized contaminants in the matrix containing the oxidized contaminant performed by the bioreactor, with the elemental sulfur as the electron donor.

Owner:HYDRO GEO CHEM

Method and apparatus for the removal of arsenic from water

InactiveUS20010052495A1Suitable in cost and space required and efficiencyReduce concentrationOrganic anion exchangersIon-exchanger regenerationArsenateManganese

A method and apparatus for removing arsenic from water at point of entry or point of use particularly for residential application. The point of entry system comprises a first stage having a manganese greensand oxidizer to convert arsenite (As+3) present in the water to arsenate (As+5) and a second stage for passing the water through an anion exchange resin. Each stage includes a control head for automatic regeneration at a predetermined frequency. The manganese greensand is regenerated with a solution of potassium permanganate and the anion exchange resin is regenerated with a salt solution. An alternate embodiment for point of use application comprises a manganese greensand oxidizer cartridge to convert arsenite (As+3) to arsenate (As+5) followed by removal of the arsenate (As+5) with a reverse osmosis system.

Owner:THE CLOROX CO +1

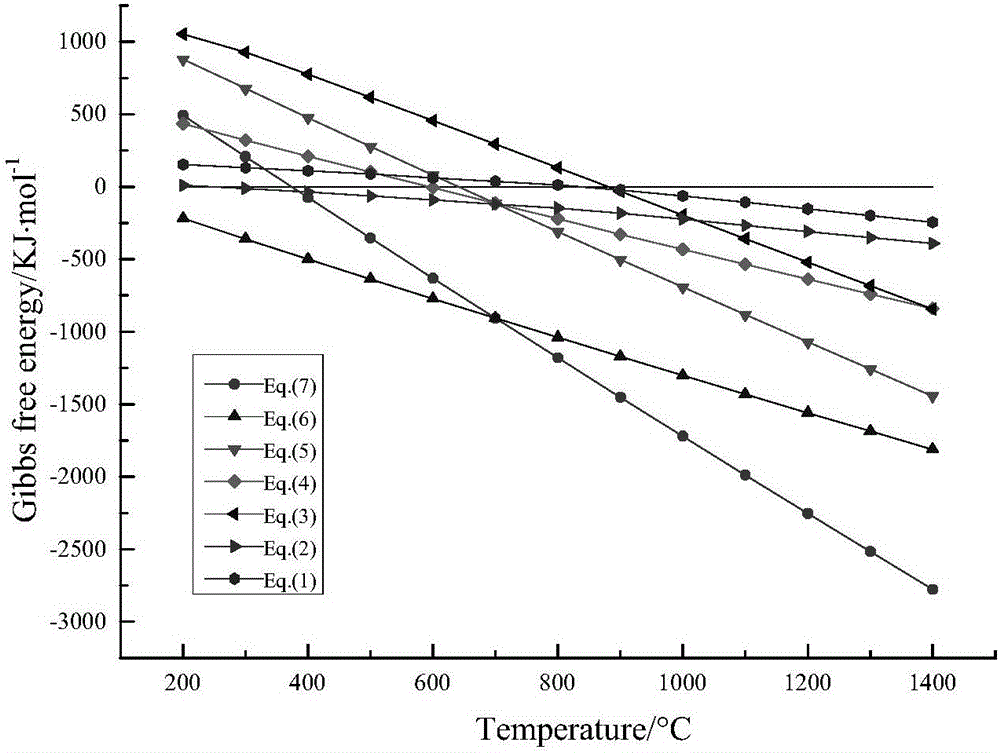

Method for preparing arsenic by direct reduction and roasting of arsenic-containing material

The invention discloses a method for preparing arsenic by direct reduction and roasting of an arsenic-containing material. The method comprises the following steps: taking arsenate as a raw material, uniformly mixing the arsenate material with a carbonaceous reducing agent to obtain a mixture, putting the mixture into an inert or reducing atmosphere, carrying out reduction and roasting under a negative pressure condition, and collecting roasting flue gas to obtain an arsenic product. According to the method, the arsenic-containing material which is commonly used in a metallurgical process and takes the arsenate as a main component is reduced into chemically stable elementary arsenic; the elementary arsenic is nontoxic, can be used as a raw material in the semiconductor and alloy industries, and has a certain market value; weight reduction, harmlessness and recycling of the toxic arsenic-containing material are realized in the reduction process and are the most reasonable development direction of arsenic; and therefore, the method has a large popularization value.

Owner:CENT SOUTH UNIV

Methods of preparing a surface-activated titanium oxide product and of using same in water treatment processes

A method for removing dissolved contaminants from solution using a surface-activated crystalline titanium oxide product having a high adsorptive capacity and a high rate of adsorption with respect to dissolved contaminants, in particular, arsenate and arsenite. Preferably, the titanium oxide product includes crystalline anatase having primary crystallite diameters in the range of 1-30 nm. The surface-activated titanium oxide is combined with other filter media to further improve the removal of dissolved contaminants.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

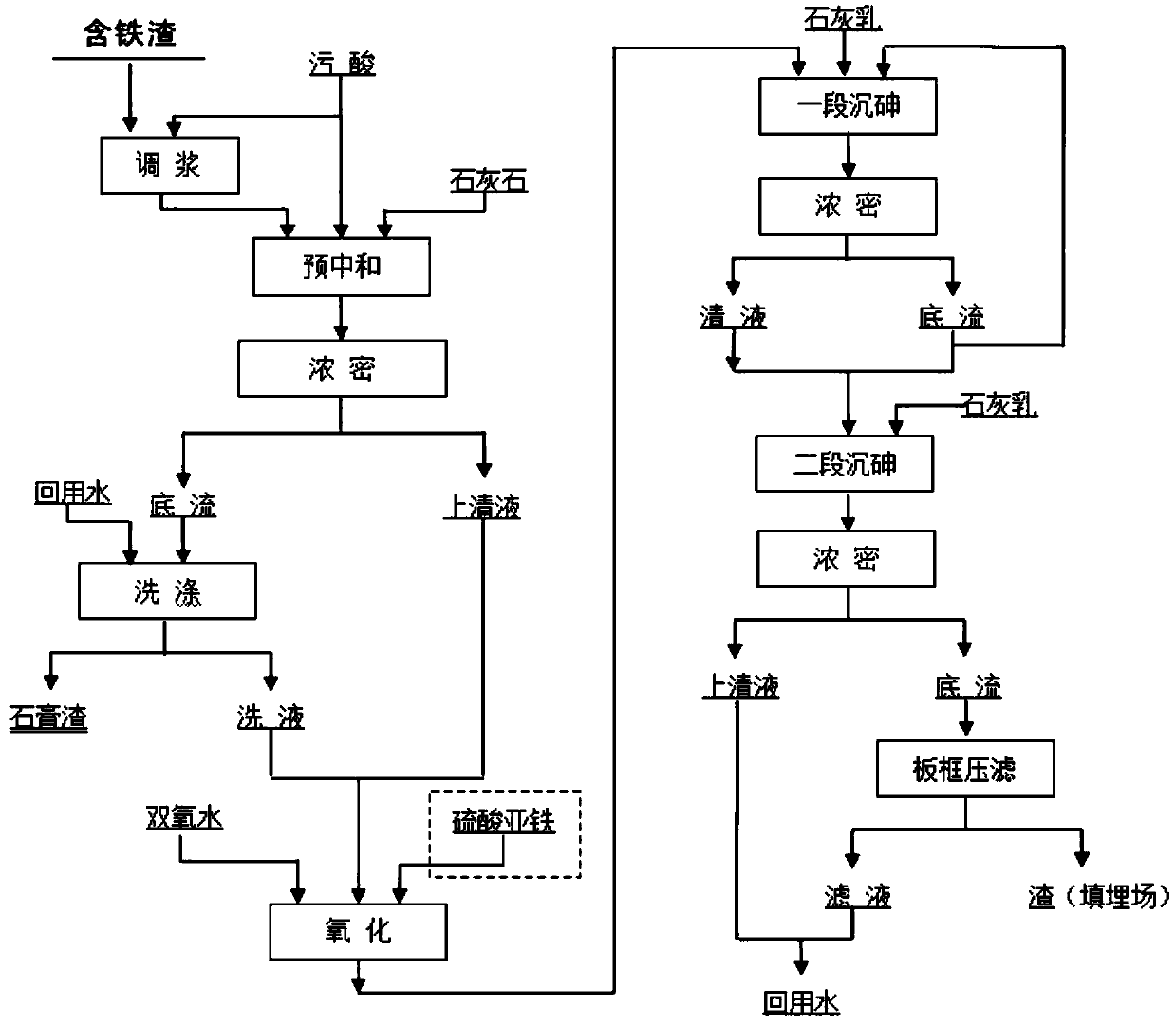

Non-ferrous metal smelting high-arsenic contaminated acid arsenic fixing process

ActiveCN109574319AMild responseSimple processTreatment involving filtrationWaste water treatment from metallurgical processIron sulfateTreatment effect

The invention relates to a non-ferrous metal smelting high-arsenic contaminated acid arsenic fixing process which sequentially includes the steps: pre-neutralization, to be specific, mixing iron-containing slag or iron-containing reagents and smelting contaminated acid, controlling Fe / As molar mole ratio, throwing mixed slurry and the contaminated acid into a pre-neutralization tank, performing reaction, controlling the pH (potential of hydrogen) value of solution, thickening pre-neutralization slag slurry to obtain bottom flow, supernate and gypsum slag, and using the gypsum slag as a cementretarder for sales; oxidation, to be specific, supplementing iron sulfate serving as an iron source reagent as required, heating the pre-neutralized supernate, adding hydrogen peroxide serving as an oxidizing agent for oxidation, controlling oxidation-reduction potential, and completely oxidizing trivalent arsenic into pentavalent arsenic; crystal form iron arsenate precipitation arsenic fixing, to be specific, controlling reaction temperature, adding seed crystals, controlling reaction endpoint pH values by adding lime milk, and conveying bottom flow subjected to two-stage arsenic precipitating reaction to a landfill through filter-pressed crystal form iron arsenate solids. The arsenic fixing process has the advantages of simple process, low cost, good treatment effects, low environmentalpollution risk and the like and is applicable to non-ferrous metal metallurgy industries.

Owner:ZIJIN MINING GROUP +1

Method for cleaning copper electrolyte and removing impurity from it

InactiveCN1400333AIncrease the concentration of AsCopper electrolysis process remains unchangedPhotography auxillary processesProcess efficiency improvementArsenatePurification methods

The copper electrolyte purification method for removing antiomony and bismuth is characterized by that in the copper electrolyte a high-arsenic solution is added to make the As-contained concentration of said electrolyte retain at 10g / L-15g / L, so that most impurities of Sb and Bi in the copper electrolyte can be combined with As to form supersaturated antimony arsenate and bismuth arsenate crystal substances, these crystal substances can be come into anode mud, and can be removed. Said invention possesses obvious effect for removing Sb and Bi, and its removed rate can be up to 100%, and its cost is low.

Owner:江西铜业股份有限公司贵溪冶炼厂

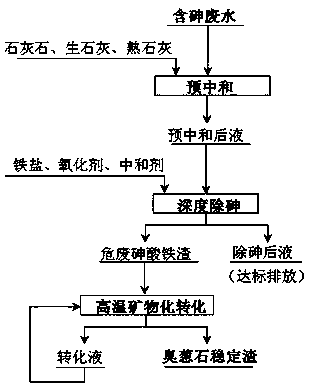

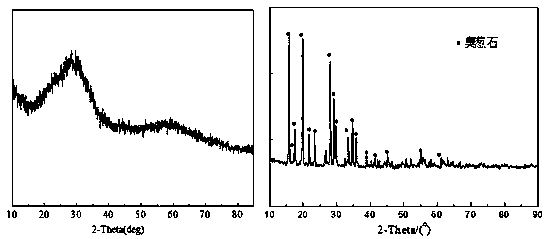

Harmless arsenic solidifying method for industrial wastewater containing arsenic

PendingCN109761390ASimple processHigh arsenic removalWater contaminantsMultistage water/sewage treatmentArsenateArsenic pollution

The invention discloses a harmless arsenic solidifying method for industrial wastewater containing arsenic, and belongs to the field of arsenic pollution control. The harmless arsenic solidifying method includes the steps: the industrial wastewater containing the arsenic is subjected to pre-neutralization treatment; iron salt and an oxidant are added to a solution after pre-neutralization to solidify the arsenic into iron arsenate precipitation arsenic slag, and a neutralizer is used for controlling the process pH; and the iron arsenate precipitation arsenic slag is transformed into scoroditestabilization slag in a high-temperature aqueous solution by high-temperature mineralization. According to the harmless arsenic solidifying method for the industrial wastewater containing arsenic, standardized discharge of the industrial wastewater containing the arsenic can be realized, meanwhile, the arsenic is solidified into the scorodite stabilization slag, the technological process is simple, and the efficiency of arsenic removing and solidifying is high.

Owner:KUNMING UNIV OF SCI & TECH

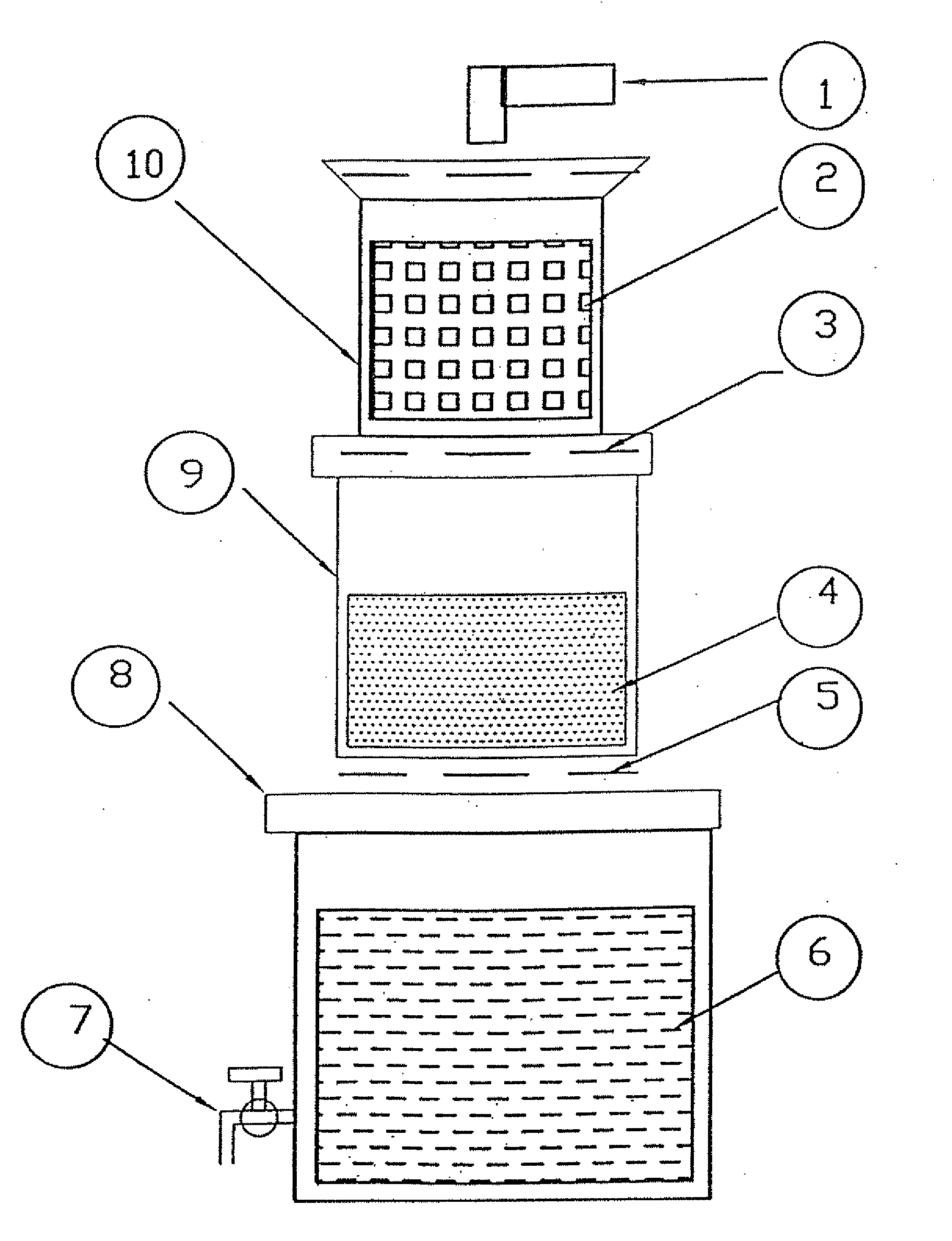

Filtering Device for the Removal of Arsenic from Water

InactiveUS20080308484A1Cheap and affordableLow priceWater cleaningWater contaminantsArsenatePlastic materials

A filtering device for the removal of arsenic from the ground water / surface water. The filtering device of the present invention uses steel wool and sand as the raw material for the removal of arsenic from water and the entire outer body of the device can be made from cheaper material like plastic material or stainless steel. The filtering device works on the simple principle of co-precipitation of arsenic with metals, followed by adsorption and filtration through treated sand. The metal, steel wool, used in the device is a processed waste generated from a steel plant thereby making the device extremely cheaper and versatile. In the filtering device of the present invention, iron arsenate and iron arsenite are co-precipitated by the reaction of steel wool with arsenic in water. The device uses treated river sand simultaneously for the removal of iron leached out during reaction.

Owner:DIRECTOR GENERAL DEFENCE RES & DEV ORG

Synergistic leaching-copper arsenate removing method for leaching residues in high-iron zinc calcine and high-iron zinc sulfide concentrate

InactiveCN103789544AHigh recovery rateEfficient reductionProcess efficiency improvementHydrometallurgyCopper sulfate

The invention belongs to the field of wet metallurgy of zinc, and particularly relates to a synergistic leaching-copper arsenate removing method for leaching residues in high-iron zinc calcine and high-iron zinc sulfide concentrate. The method comprises the following steps: mixing the leaching residues in the high-iron zinc calcine with the high-iron zinc sulfide concentrate; mixing zinc electrowinning waste liquor and a part of sulfuric acid-containing solution prepared from concentrated sulfuric acid and synergistically leaching; adding a reaction dosage of industrial iron powder into a synergistically-leached copper arsenate-removing primary solution; replenishing a proper amount of copper sulfate as required; reacting; performing liquid-solid separation on reaction ore pulp to obtain cuprous arsenide precipitate serving as a copper-leaching raw material and a copper arsenate-removing secondary solution; returning the copper arsenate-removing secondary solution to a zinc hydrometallurgy process to further recover valuable metals therein. The method is clean and efficient, efficient leaching of copper and efficient reduction of Fe<3+> can be realized, the solution treatment amount is small, the comprehensive recovery rate of valuable metals in a zinc hydrometallurgy process is increased comprehensively, and the smelting flow is simplified.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT +1

Treatment method of industrial arsenic wastewater

InactiveCN104787932ARaw materials are easy to getReduce processing costsMultistage water/sewage treatmentArsenateIron sulphate

The invention relates to a treatment method of industrial arsenic wastewater, which comprises the following steps: neutralizing industrial arsenic wastewater with an antalkali to control the end pH value to be greater than or equal to 5.0, and carrying out solid-liquid separation to obtain primary treated water; adding polyferric sulfate and H2O2 into the primary treated water to control the end pH value to be greater than or equal to 5.0, wherein the polyferric sulfate accounts for 0.01-1 wt% of the arsenic wastewater to be treated, and the H2O2 accounts for 0.01-1 wt% of the arsenic wastewater to be treated; and carrying out solid-liquid separation on the product to obtain secondary treated water with the arsenium content of less than 0.5 ppm. The primary treatment adopts lime or any other antalkali, and thus, has the advantages of accessible raw material and low treatment cost. The secondary treatment adopts the H2O2 and polyferric sulfate as reagents, and can convert residual arsenium in the primary treated water into an insoluble ferric arsenate precipitate, thereby achieving the effect of deep dearsenication. The secondary treated water can be further treated by a sewage treatment cyclic utilization system, thereby reducing the subsequent treatment cost for arsenic wastewater.

Owner:TONGLING CHEM IND GRP

Treatment process for copper smelting smoke dust

ActiveCN105543489AImplement gradient recoveryRealize comprehensive utilizationProcess efficiency improvementArsenateVulcanization

The invention discloses a treatment process for copper smelting smoke dust. The treatment process comprises the following steps that 1, after the copper smelting smoke dust is subjected to acid leaching, acid leaching liquor and acid leaching residues are obtained; 2, after the acid leaching liquor obtained in the step 1 is subjected to copper depositing through metal replacement, filter liquor with copper being deposited is obtained; 3, after the filter liquor with the copper being deposited in the step 2 neutralizes and oxidizes with alkali, ferric arsenate and filter liquor with arsenic being deposited are obtained; 4, after the filter liquor with arsenic being deposited in the step 3 is subjected to the secondary copper depositing through metal replacement, filter liquor being subjected to the secondary copper depositing and copper residues are obtained; and 5, after the filter liquor being subjected to the secondary copper depositing in the step 4 is subjected to zinc depositing through vulcanization, filter liquor with zinc being deposited and zinc residues are obtained. According to the treatment process for the copper smelting smoke dust provided by the invention, particularly, a treatment process for high-arsenic low-copper smoke dust, the harmless treatment of arsenic in the high-arsenic low-copper smoke dust is achieved; meanwhile, valuable metal copper, zinc, lead, bismuth and the like in the high-arsenic low-copper smoke dust are recovered comprehensively, and gradient recycle and comprehensive utilization of the impurities of the smoke dust are achieved.

Owner:YANGGU XIANGGUANG COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com