Soot treatment process in copper smelting process

A technology for copper smelting soot and processing technology, applied in the field of copper smelting, can solve the problems of polluting the environment, poor working conditions, and deteriorating furnace conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

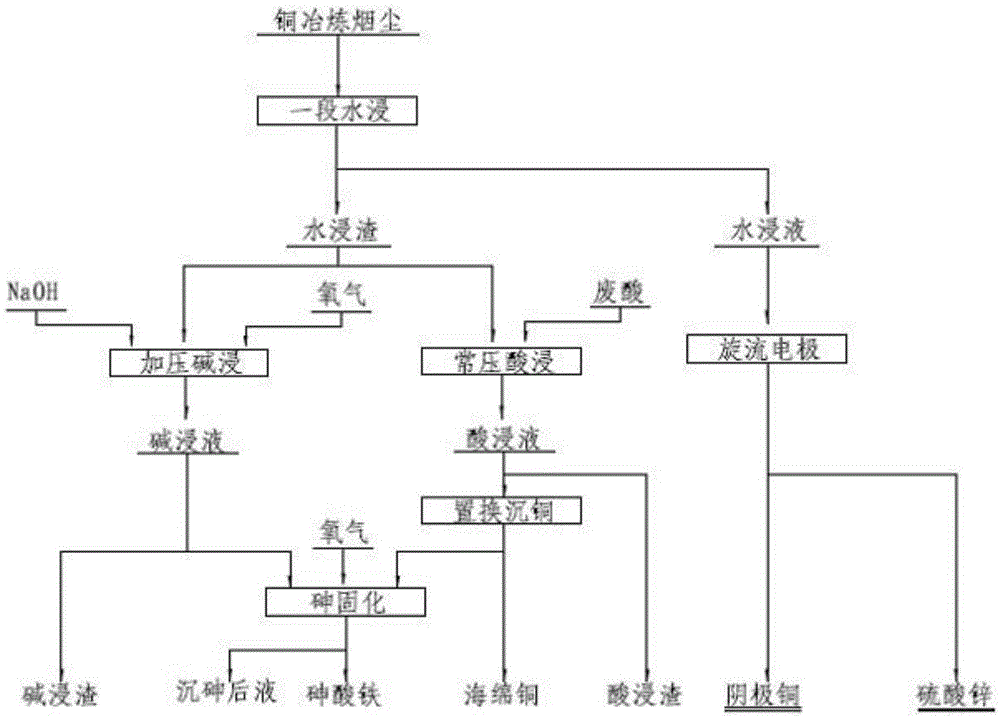

Image

Examples

Embodiment 1

[0080] The composition of high-arsenic and high-copper soot is shown in Table 1-1.

[0081] Table 1-1 Composition of high arsenic and high copper soot

[0082] Element

[0083] 1. Flooding

[0084] Add water and soot into the reaction kettle according to the mass ratio of liquid to solid of 1:2, and react at room temperature for 1 hour under stirring conditions, and the solid and liquid are separated after 1 hour. See Table 1-2 for water immersion results.

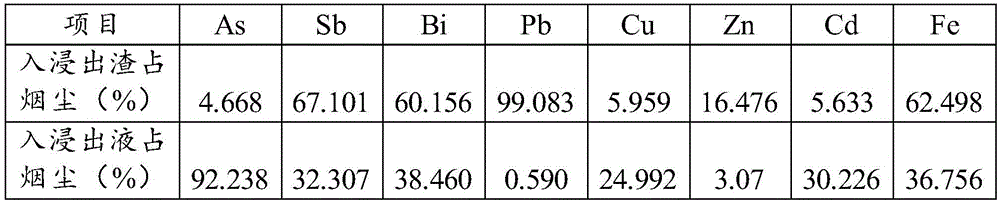

[0085] Table 1-2 Water immersion results

[0086] project

[0087] The water immersion liquid contains high copper and zinc, but not high arsenic. Electrode electrolysis technology is used to produce standard cathode copper. After electrolysis, the liquid is concentrated and crystallized to produce zinc sulfate heptahydrate. After crystallization, the liquid is returned to water immersion for preparation.

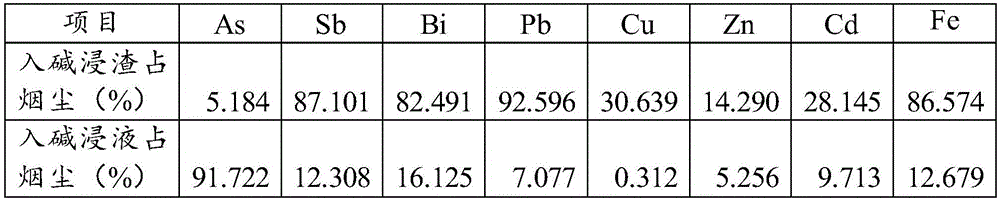

[0088] See Table 1-3 for water leaching slag composition.

[0089] Table 1-3 Composition of...

Embodiment 2

[0127] The composition of high arsenic and high copper soot is shown in Table 2-1.

[0128] Table 2-1 Composition of high arsenic and high copper soot

[0129] Element

As

Sb

Bi

Pb

Cu

Zn

Cd

Fe

unit

%

%

%

%

%

%

%

%

soot

18.324

0.0532

0.894

0.384

20.381

2.854

0.281

14.12

[0130] 1. Flooding

[0131] Put water and soot into the reaction kettle according to the mass ratio of liquid to solid of 1:2.5, and react for 1.5 hours at room temperature under stirring conditions, and the solid and liquid are separated after 1.5 hours. See Table 2-2 for water immersion results.

[0132] Table 2-2 Water immersion results

[0133] project

As

Sb

Bi

Pb

Cu

Zn

Cd

Fe

3.978

0.752

39.664

0.313

75.418

80.238

35.730

15.567

[0134] The water immersion liquid contains high ...

Embodiment 3

[0175] The composition of high arsenic and high copper soot is shown in Table 3-1.

[0176] Table 3-1 Composition of high arsenic and high copper soot

[0177] Element

As

Sb

Bi

Pb

Cu

Zn

Cd

Fe

unit

%

%

%

%

%

%

%

%

soot

24.512

0.0647

0.324

1.024

23.512

3.615

0.314

15.312

[0178] 1. Flooding

[0179] Put water and soot into the reaction kettle according to the mass ratio of liquid to solid of 1:3, and react for 2 hours at room temperature with stirring, and separate the solid and liquid after 2 hours. See Table 3-2 for water immersion results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com