Method for extracting high arsenic complicated golden ore concentrate multielement

An extraction method and technology for gold concentrate, applied in the field of metallurgy, can solve the problems of equipment requirements for the inability to comprehensively recover harmful elements, low recovery rate of valence elements, etc., and achieve the effects of wide adaptability of raw materials, high comprehensive recovery efficiency, and increased utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

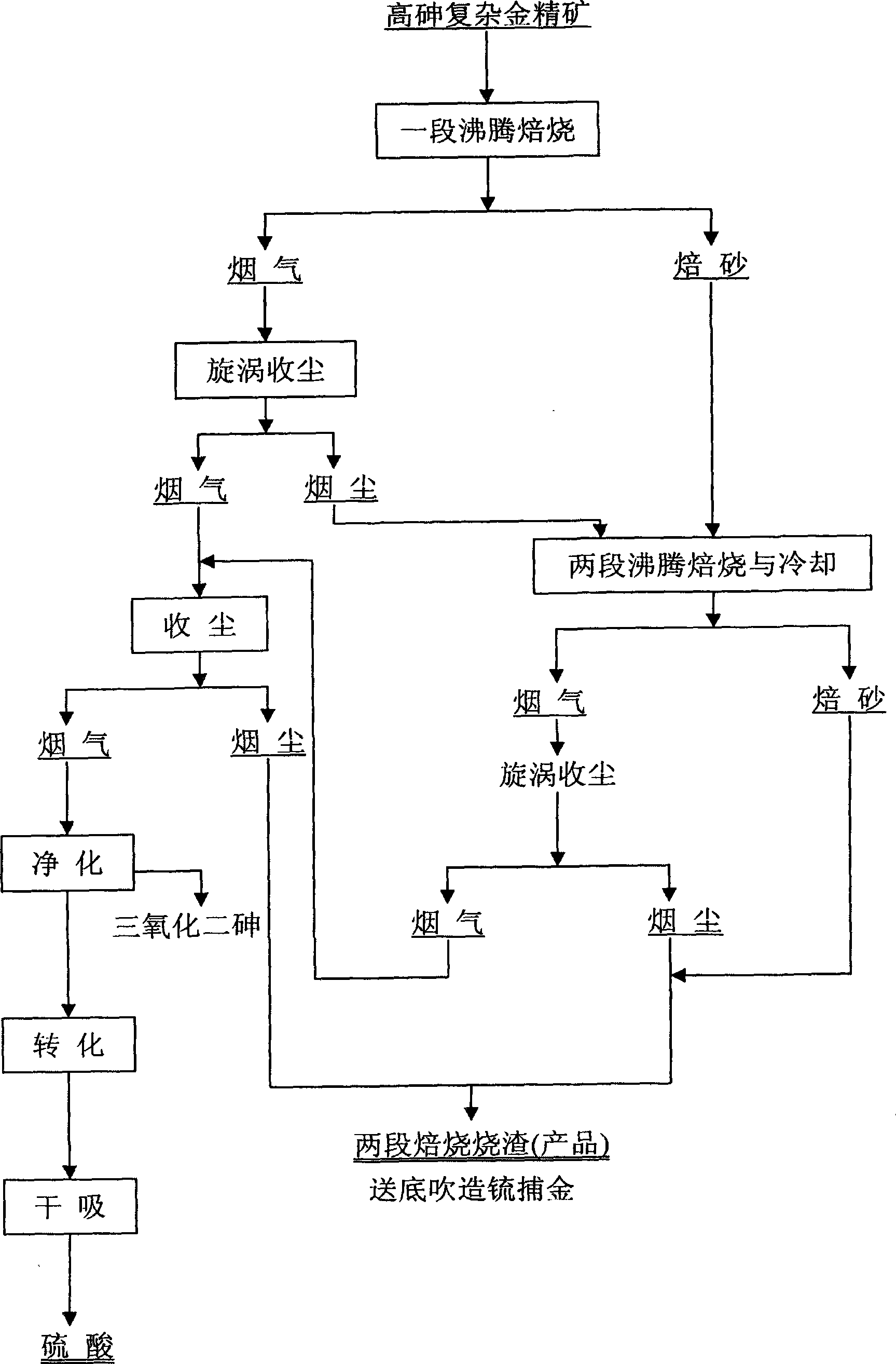

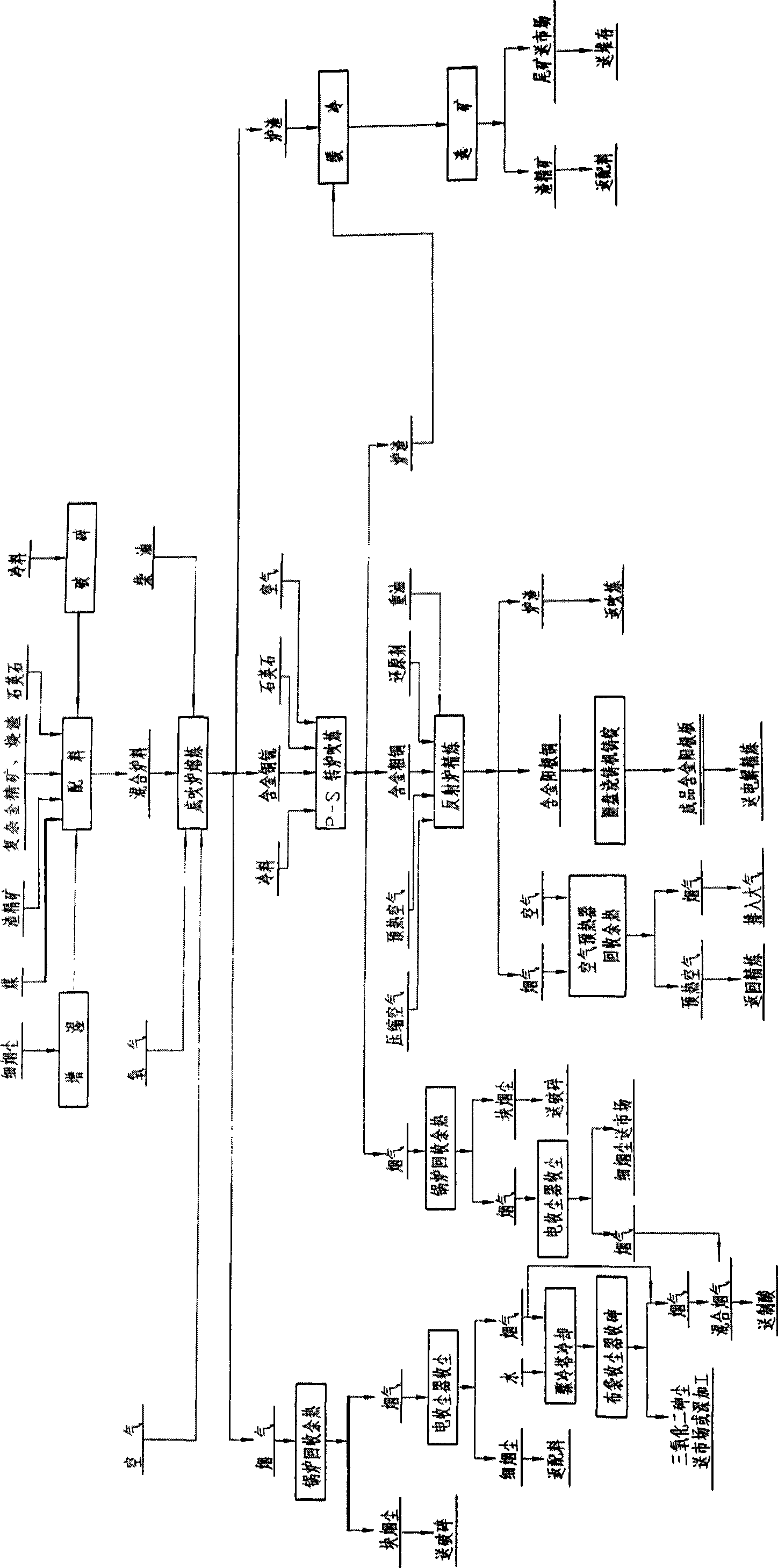

[0025] Example 1, see figure 1 , 2 , select multi-element complex gold concentrate containing gold, silver, arsenic, copper, sulfur, lead, zinc, etc. (see Table 1 for the composition of the gold concentrate), and the process steps are as follows.

[0026] Table 1

[0027] Yuan

white Cu Fe S SiO 2 CaO MgO content

(%) 7.38 27.3

2 32.7

8

8.61

2.25

1.5 Yuan

white Pb al 2 o 3 Zn As Au* Ag* content

(%) 1.12 2.0 1.56 2.20 33.6

3 230.

02

[0028] *The units of Au and Ag are g / t.

[0029] 1. Gold extraction smelting process

[0030] a Two-stage roasting to produce slag concentrate:

[0031] (a) Send the high-arsenic complex gold concentrate into the first-stage roaster, and conduct a first-stage boiling roasting at high temperature under weak oxygen conditions to convert the arsenic in the ore into arsenic trioxide. sent to the second-stage roaster;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com