Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

369 results about "Gold extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold extraction refers to the processes required to extract gold from its ores. This may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.

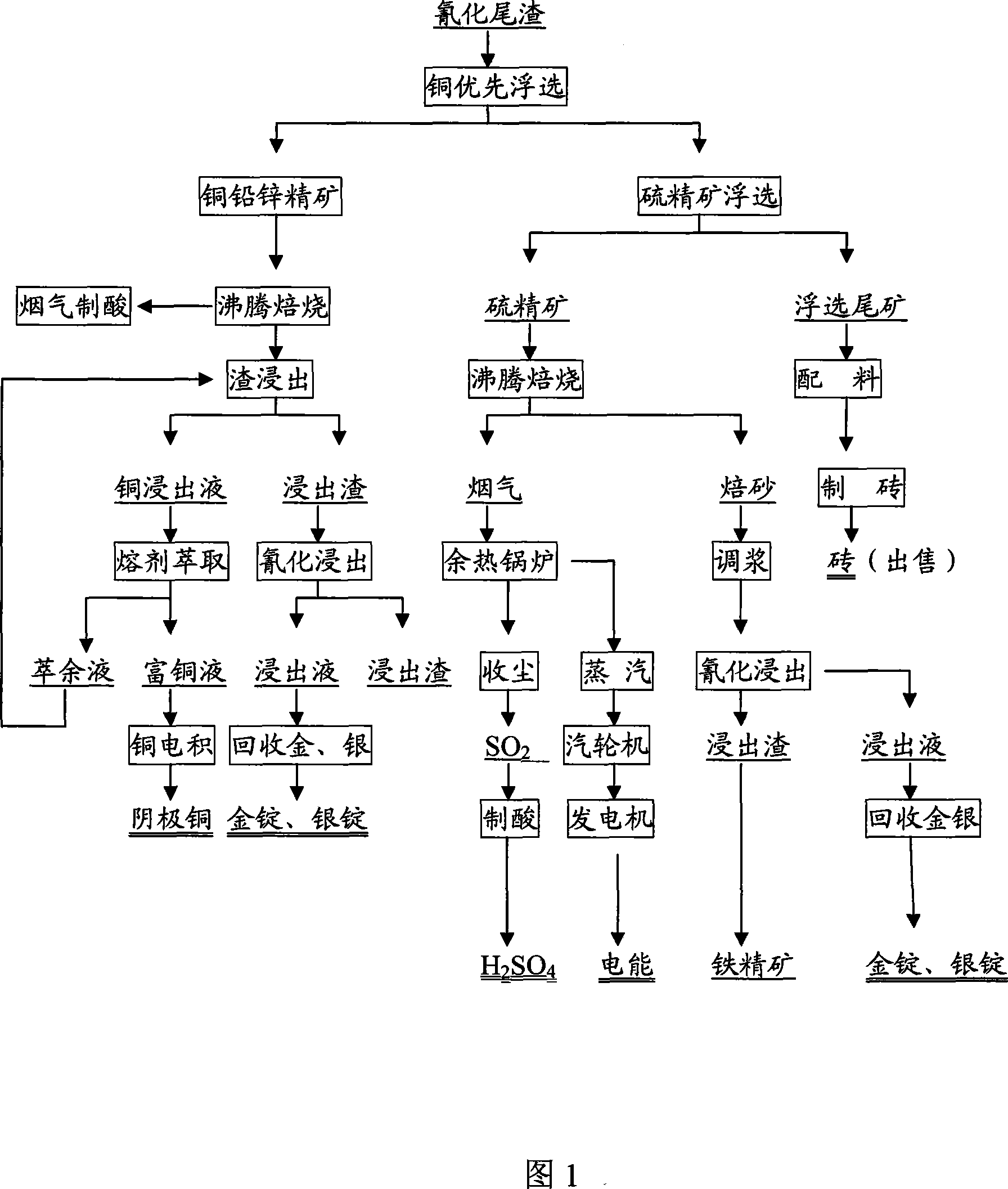

Integrated utilization technique for cyanidation gold-extracted waste slag

InactiveCN101078051AReduce energy consumptionTake advantage ofSolid waste managementSulfur compoundsBrickSlag

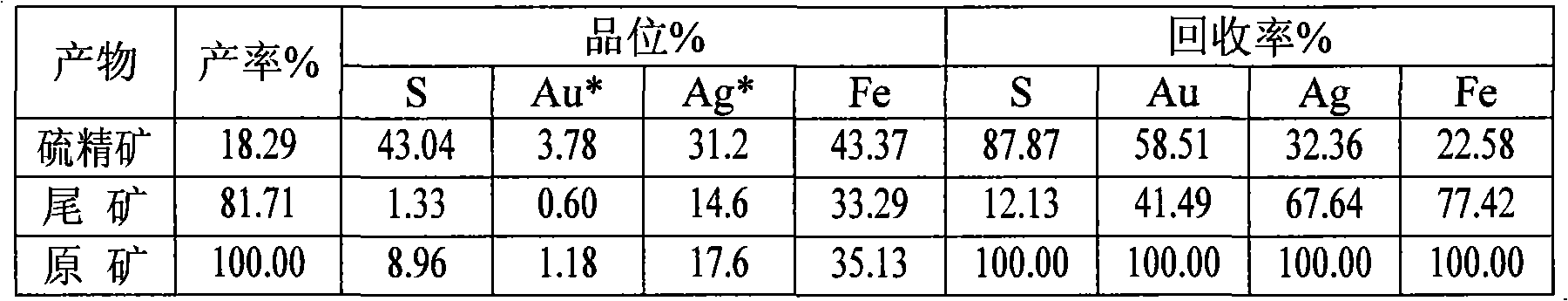

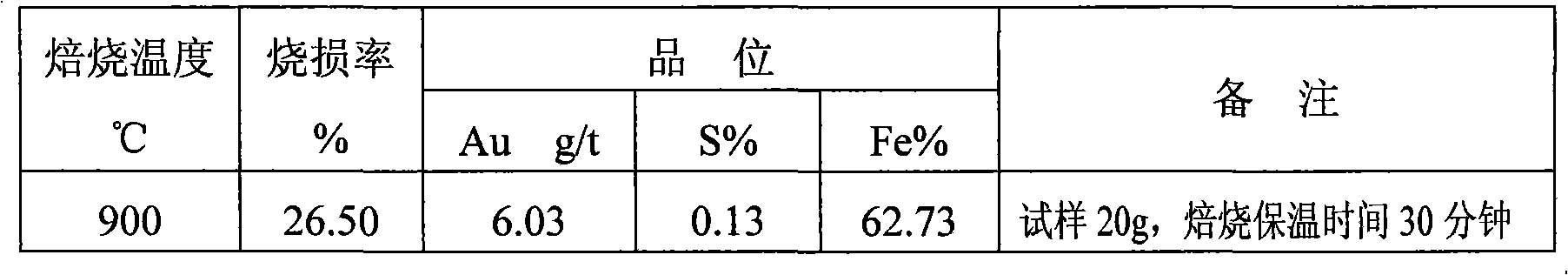

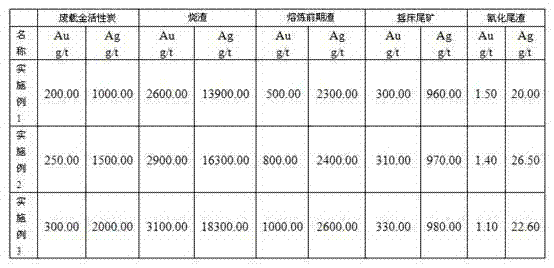

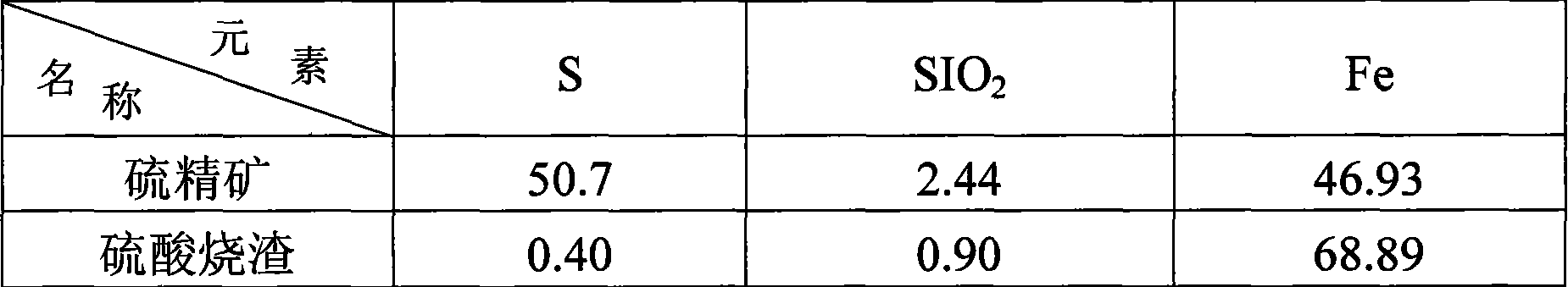

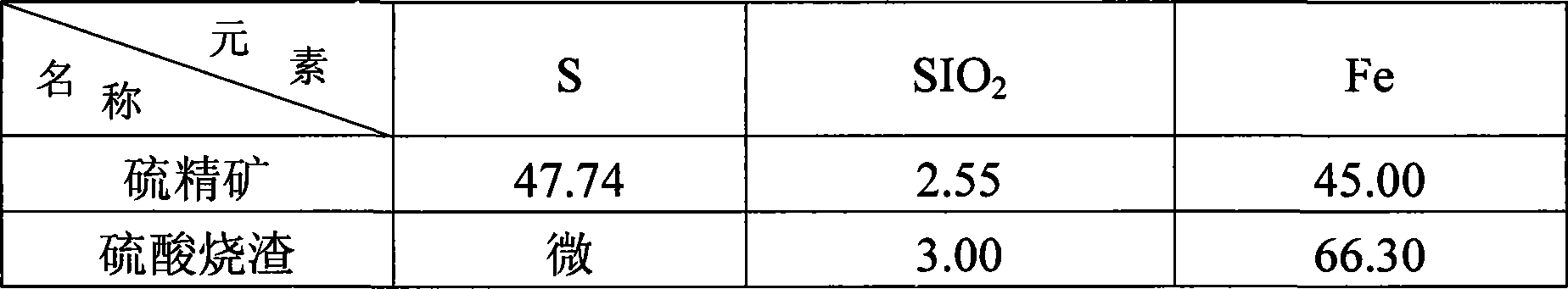

The invention relates to a method of complex utilization of the waste residue that from gold extraction with cyanidation. This invention belongs to the field of metallurgy and chemical technology. Firstly, the waste residue that from gold extraction with cyanidation is pretreated with acid. The floatation process is adopted here. The first step is to concentrate cuprum, plumbum, zincum and argentum; Secondly, collect 47%-52% of the high-grade sulfur and concentrate gold and argentums; Then roast the high-grade sulfur concentrate, the gas is utilized to produce acid, and the waste heat is utilized to produce electricity, and the waste residue is utilized to extract gold with cvanidation. After washing by water, the leavings which contains 62%-68% iron can be used as iron concentrate. Finally, produce slag brick with the refuse. The technology which could reclaim the elements, such as Fe, S, Cu, Pb, Zn, Au, Ag, complex utilizes the waste residue that from gold extraction with cyanidation. The invention takes full advantage of resource. The effect of integrated utilization of resource and the economic benefit are enhanced and the environmental pollution is lessened by this way.

Owner:SHANDONG GUODA GOLD

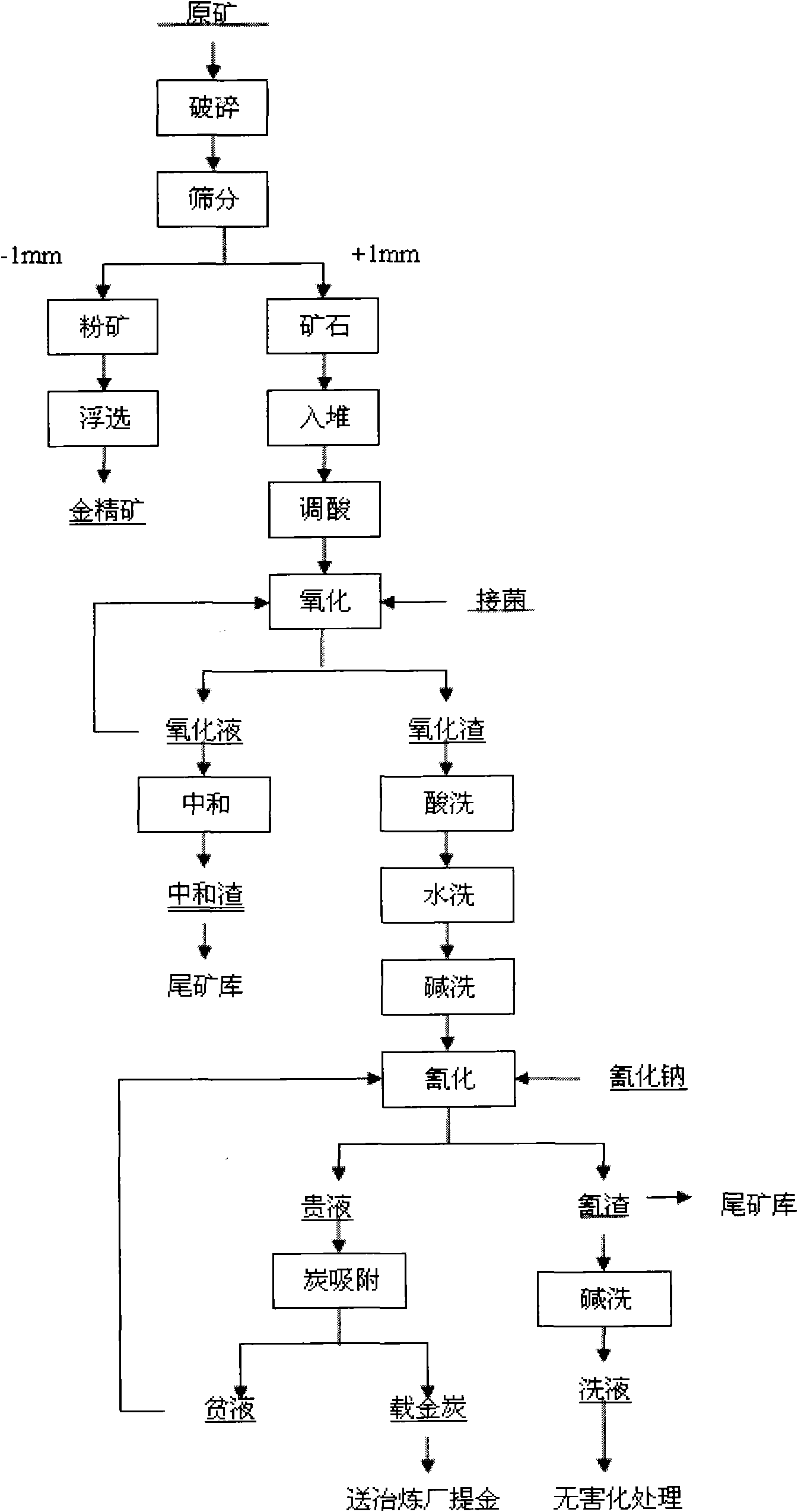

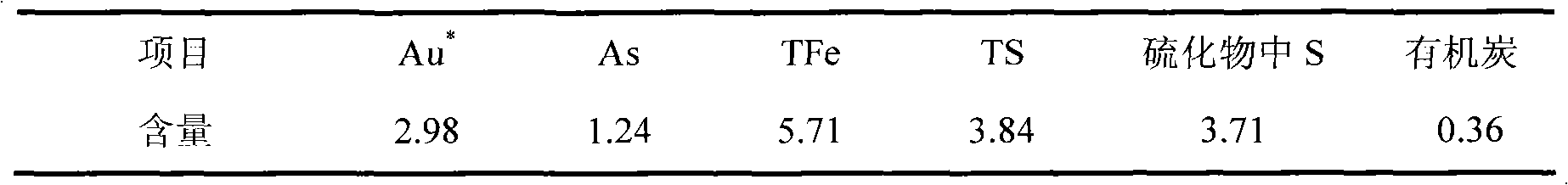

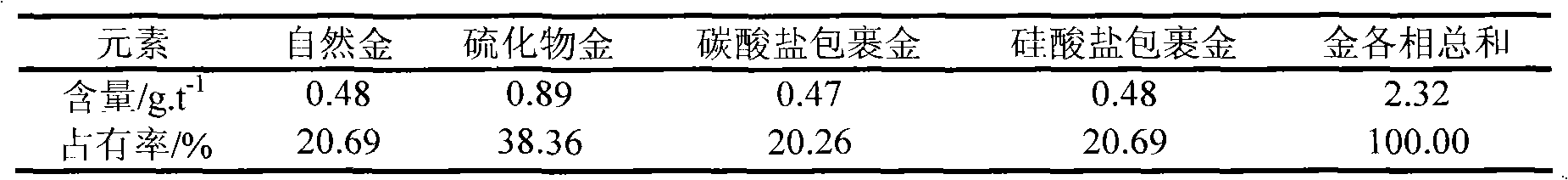

Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

The invention relates to a process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon. The process is characterized in that: the gold ore has the characteristics of high clay mineral content, large fine ore amount after grinding, and the like. The process comprises the following steps of: grinding raw ore to 10 to -30 millimeters; sieving ore through a sample sieve of 1 to -2 millimeters or washing the ore with water so as to separate fine ore from the ore; floating gold concentrate by using the obtained fine ore; performing direct heap leaching on ore of +2 millimeter and performing biological oxidation; performing medium transformation such as acid washing, water washing, alkali washing and the like on the biologically-oxidized ore and cyaniding directly so as to extract gold, wherein gold is extracted from the floated gold concentrate by biological oxidation-cyaniding and carbon soaking-pressure oxidation-cyaniding and gold extraction or baking, oxidation and cyaniding. Due to the adoption of the process, the problem of permeability of gold ore is solved and the gold extracting rate is effectively increased from 2 to 5 percent during direct heap leaching and cyaniding to 55 to 65 percent. The process has the advantages of simple process, high gold extracting rate, low pollution, high benefit and the like.

Owner:ZIJIN MINING GROUP

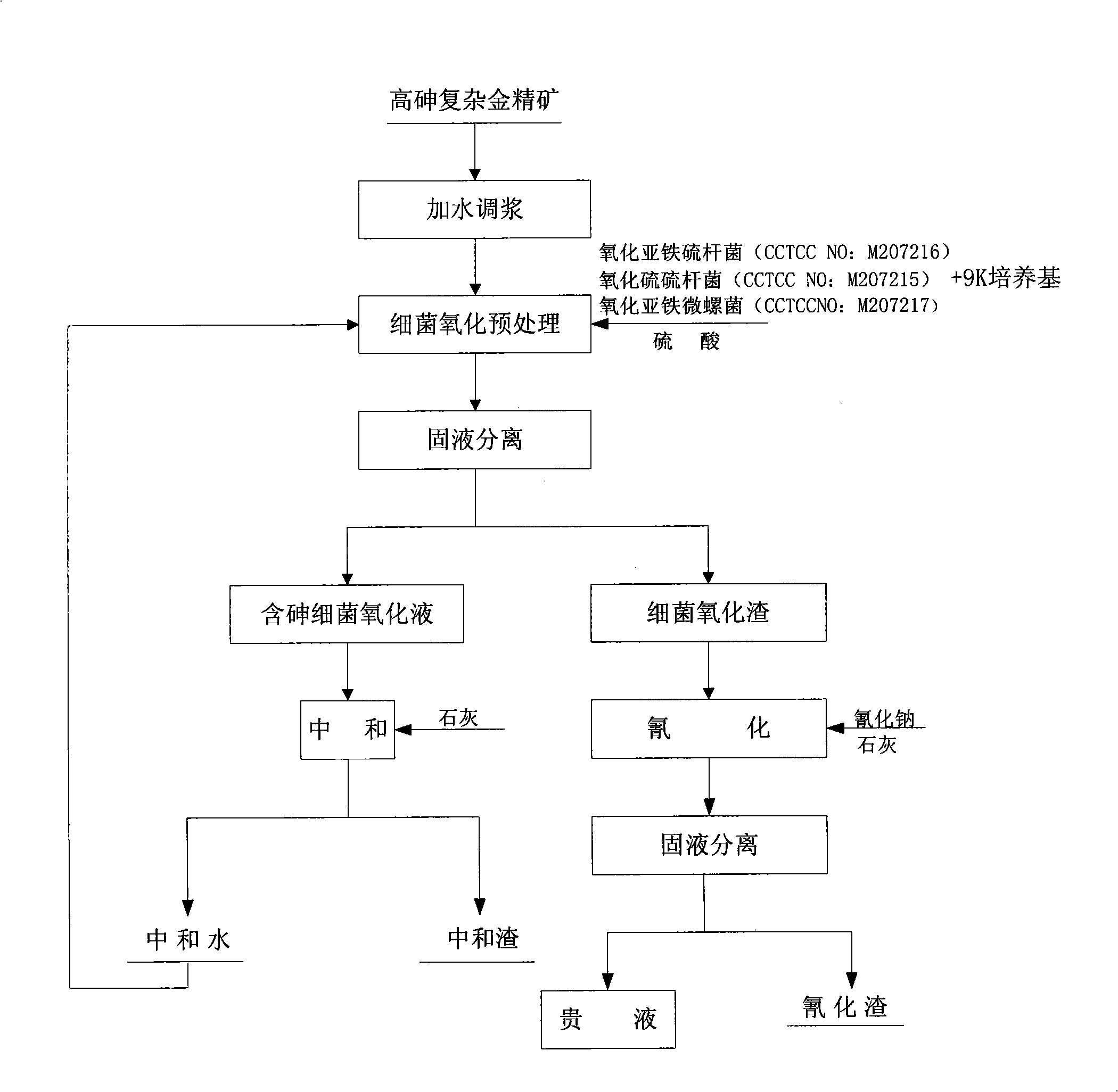

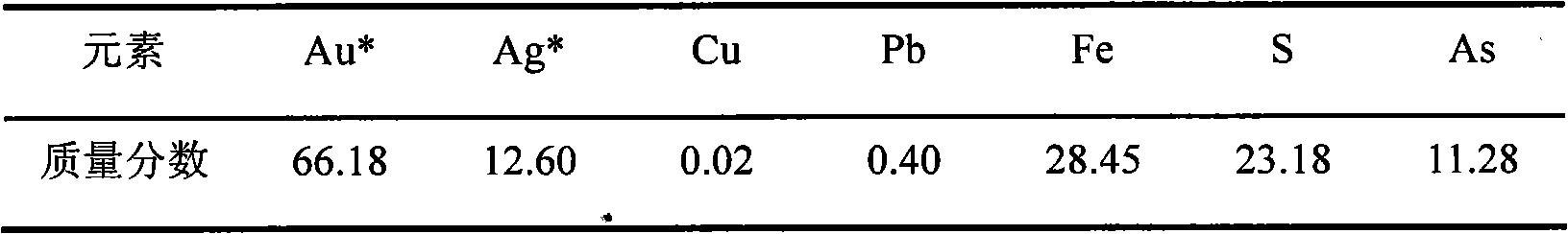

Cyanidation aurum-extracting method for preprocessing high-arsenic complex refractory gold ore by oxidation with arsenic resistant strains

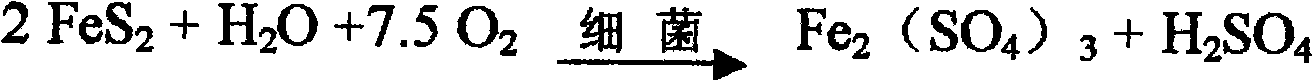

InactiveCN101333599AIncrease growth temperatureStable temperatureProcess efficiency improvementThiobacillus ferrooxidansResistant strain

Disclosed is a cyaniding gold extraction method for pre-treating high-arsenic complex refractory gold ore by arsenic-resistant bacteria oxidation, comprising five steps of arsenic-resistant bacteria culture, flotation concentrate mixing, bacterial oxidation of flotation concentrates, solid-liquid separation and cyaniding gold extraction. The cyaniding gold extraction method adopts specific arsenic-resistant bacteria which are prepared by mixing Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, and conducts oxidation pretreatment of high-arsenic complex refractory gold ore. The high-arsenic complex gold ore containing 8 to 20 percent of arsenic can be pretreated, and the arsenic removal rate is 85 to 98 percent. The leaching rate of gold is up to 90 to 95 percent after cyaniding leaching. The cyaniding gold extraction method adopts unique bacteria for leaching ores, greatly saves cooling cost, conducts direct oxidation of high-arsenic complex gold ore containing 8 to 20 percent of arsenic, and has advantages of being widely adaptable, simple in operation, environmentally friendly and remarkably beneficial.

Owner:NORTHEASTERN UNIV

Method for the floatation of cuprum, plumbi, zincium ore concentrate from tailings for extracting gold

The invention relates to a method for extracting copper, lead and zinc concentrates through flotation from tailings from gold extraction of direct cyanidation, belonging to the technical field of methods for extracting copper, lead and zinc concentrates through flotation in industries of gold smelting and chemical engineering. The invention is applicable to tailings from gold extraction of sulfide ores, which is characterized in that: copper, lead and zinc in the tailings from gold extraction are blended adopting the floatation technology; the mixed concentrates of copper, lead and zinc as well as gangue containing sulfur are obtained, and copper concentrate, lead concentrate and zinc concentrate are obtained after separating the mixed concentrates of copper, lead and zinc through floatation. The invention has the advantages of improved integrated resources utilization, reduced environmental pollution and improved economic benefit of the enterprise.

Owner:SHANDONG GUODA GOLD

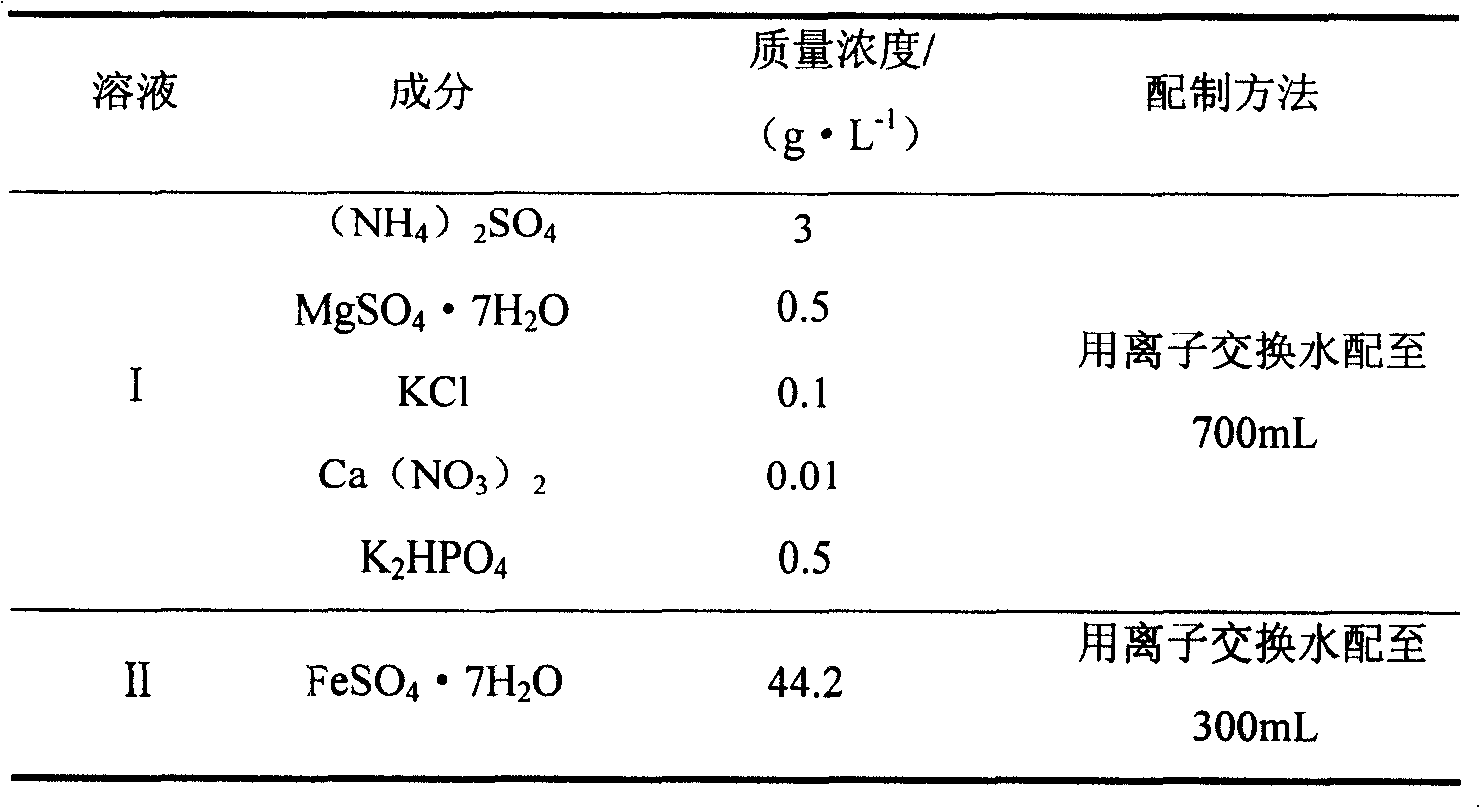

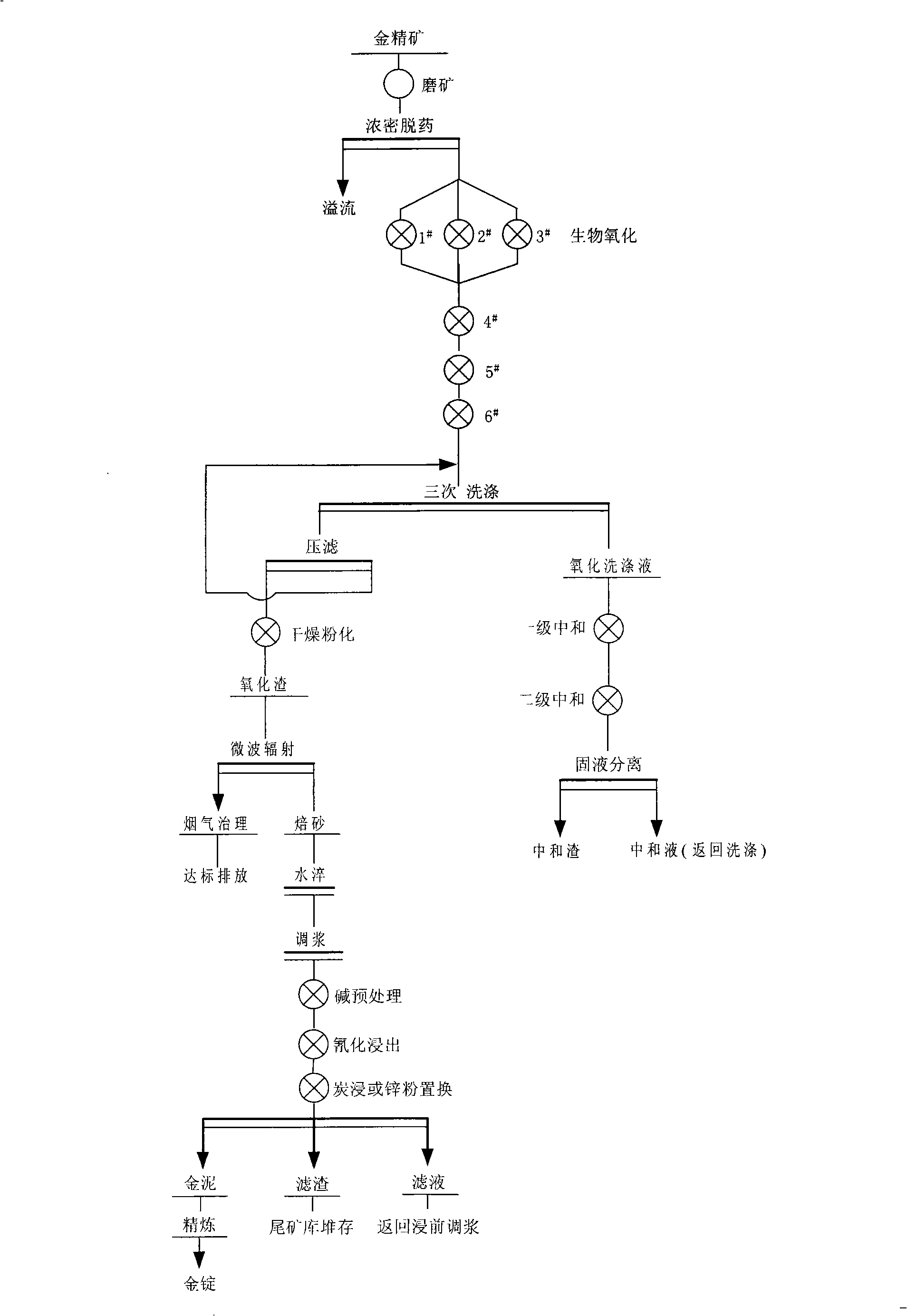

Gold extraction process with low pollution and high recovery for refractory gold concentrate

ActiveCN101285126AReduce pollutionAvoid secondary packagingProcess efficiency improvementSlagSulfide minerals

The invention relates to a process for extracting gold of refractory gold concentrates with low pollution and high recovery rate, belonging to the metallurgical process class. The process proposal which combines organically the bacterial oxidation technology with the microwave irradiation technology comprises the following steps of: oxidizing and decomposing sulfide minerals by means of the bacterial oxidation technology first; exposing and dissociating sufficiently the gold; oxidizing a large part of sulfur and arsenic to enter a liquid-phase; carrying out the neutralization treatment to the oxidizing liquid and returning to use; roasting oxidizing slag with microwave at the low temperature; and removing organic carbon in ore. The process solves completely the problem of absorbing the gold in the subsequent cyaniding gold extraction work. The process has high recovery rate of the gold and less environment pollution, is easy to automatically control and saves energy.

Owner:CHANGCHUN GOLD RES INST +1

Gold-extraction process for tail-one cyanide containing gold wrapped by original sulfides

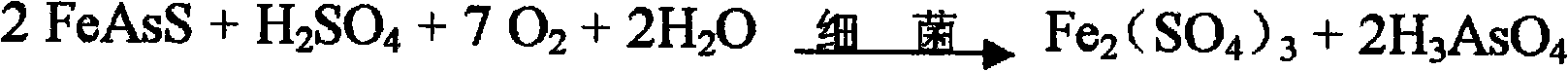

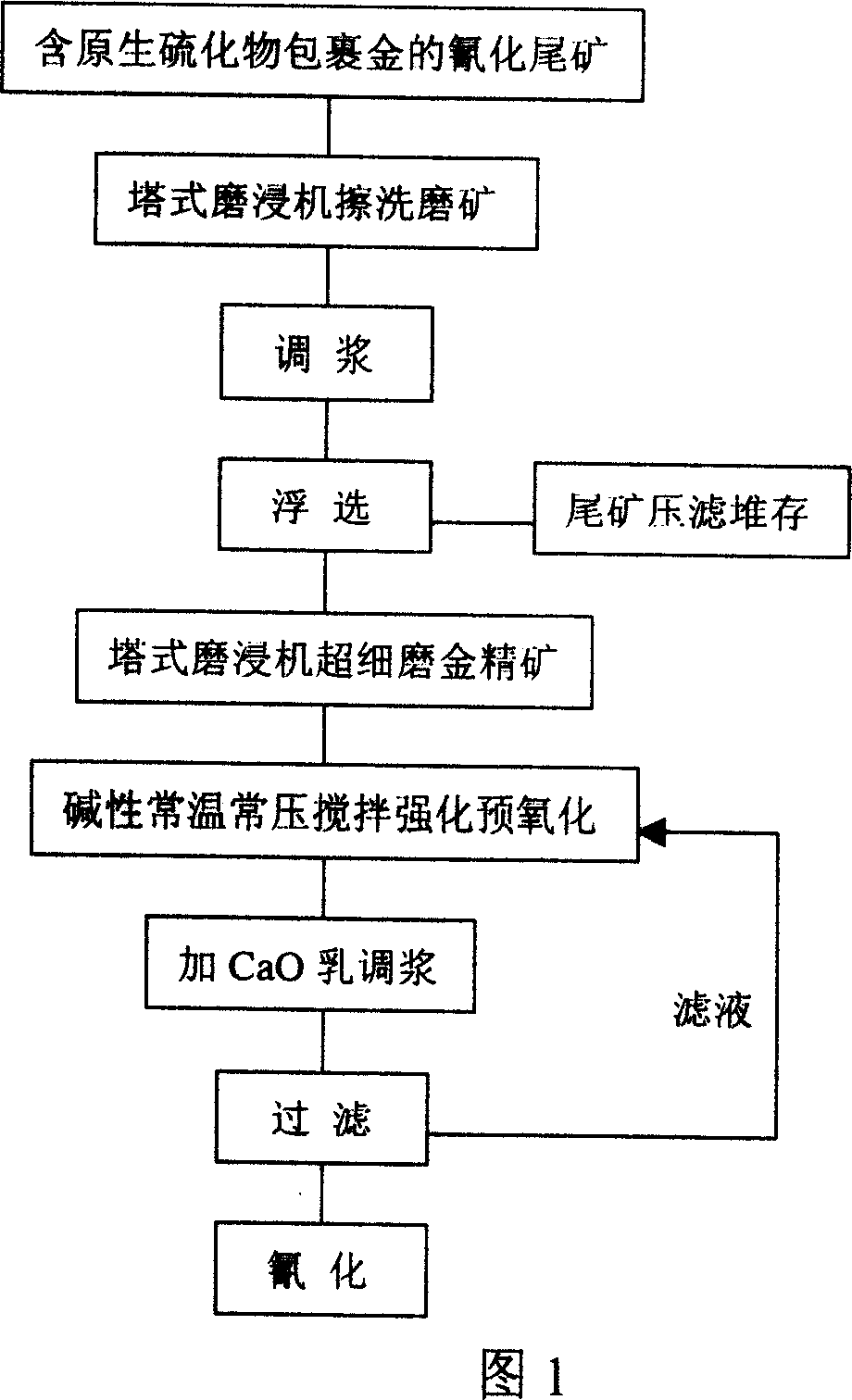

InactiveCN101070566AImprove floatabilityReduce yieldProcess efficiency improvementWet separationAlkalinityEngineering

One kind of cyanidation gangue distilling gold technique method including the primary sulfide wrapped gold, first, separate the primary sulfide wrapped gold from concentrated cyanidation gangue by using flotation process method, then grind fine will contain wrapped gold sulfide ore in tower system dipping machine, after grinding, it enter strengthened alkali agitated vessel to do alkalinity normal temperature atmospheric pressure to strengthen pre-oxidation, after the pre-oxidation, add CaO breast to pulp, after pulp, enter cyaniding leaching work, and distill gold high effectively.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

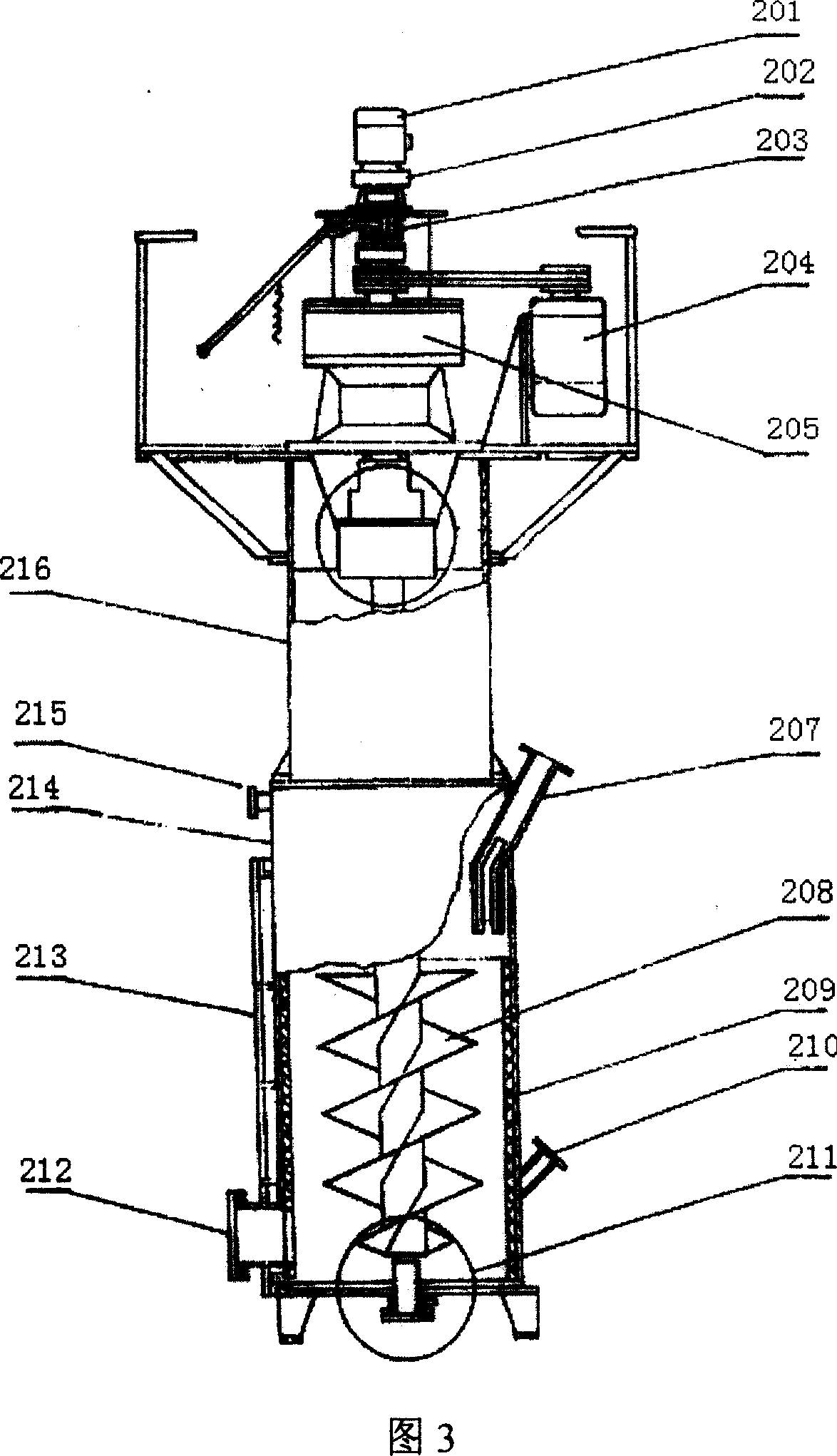

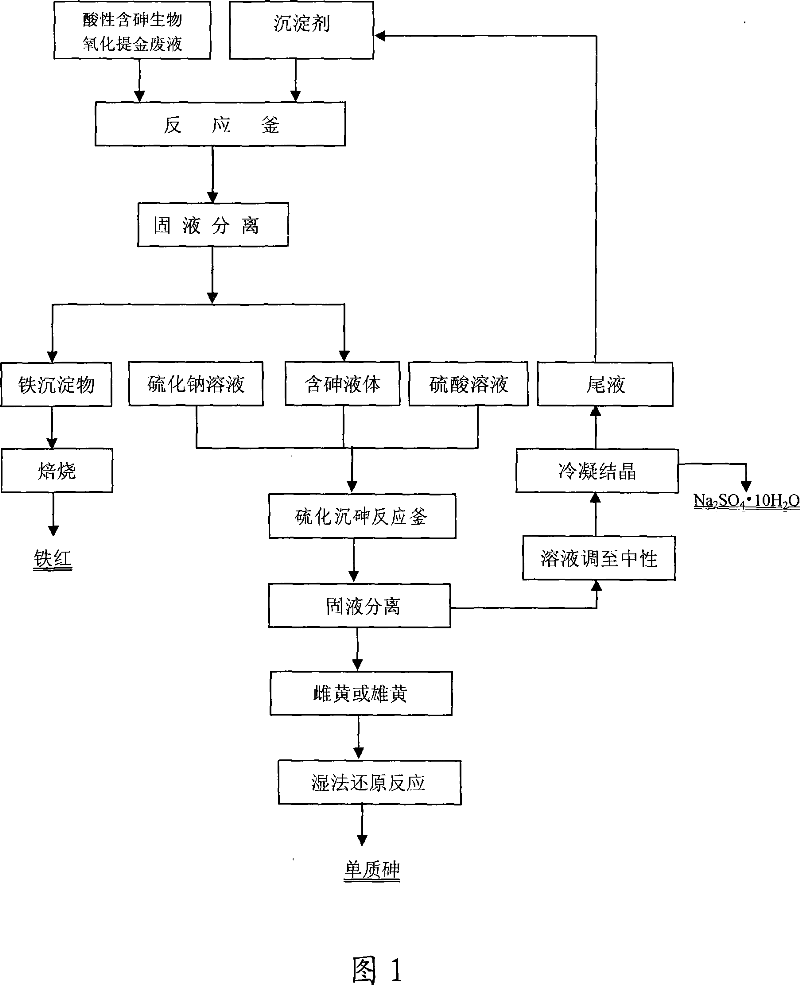

Method for reclaiming valuable element from acidic arsenic-containing biological oxidation gold extraction waste liquor

ActiveCN101041498AEfficient separationNo secondary pollutionWaste water treatment from metallurgical processFerric oxidesBiological oxidationGold extraction

The invention discloses a reclaiming method of valency element from acidic rocan biological oxidation extract gold waste liquid, which comprises the following steps: adding acidic rocan biological oxidation extract gold waste liquid and precipitant into autoclave at the same time; depositing selectively; realizing arsenic iron separation; adopting filtering technology; realizing solid and liquid separation; leading solid phase into iron-oxide red preparing process; leading liquid into process of reclaiming rocan; adjusting the solution to neutral with solid-liquid; condensing at 0-4 deg.c; crystallizing to Na2SO4.10H2O; returning the tail liquid to the first process; using to formulating queous alkali. The good effect of this invention can realize effective segregation of rocan and iron of acidic rocan biological oxidation extract gold waste liquid.

Owner:LIAONING TIANLI GOLD +1

Recovery processing method for cyanogen golden mine tailing

InactiveCN101403042AImprove the level of comprehensive utilizationEmission reductionProcess efficiency improvementSulfurSludge

The invention relates to the recycle of tailings of oxidized ore containing gold with high content of sulfur and iron after cyaniding and gold extraction, in particular to a recycling and processing method of gold-cyaniding tailings. The invention uses the technology of flotation of sulfur, acid preparation with sulphur ore concentrate and gold extraction and iron obtaining by cyaniding acid sludge, magnetizing roasting and magnetic separation for obtaining iron and of selection sulfur tailings after dehydration as additive in cement to realize recycling of the gold-cyaniding tailings, realize single separation and final no-tail of gold mineral and provide the route of proper technique for recycling the gold-cyaniding tailings. The invention has the advantages of low processing cost and wide application range and is a recycling technique of the gold-cyaniding tailings, which is economic, simple and applicable and has good processing effect.

Owner:罗仙平

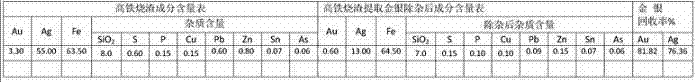

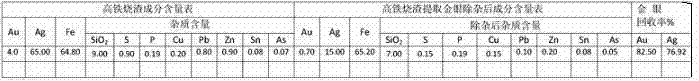

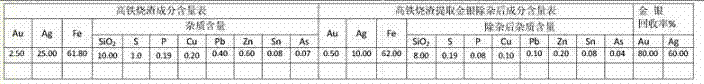

Method for extracting gold and silver from acid making high-iron cinder and removing impurities

ActiveCN104498715AEfficient removalReduce the impactProcess efficiency improvementSocial benefitsSulfur

The invention discloses a method for extracting gold and silver from acid making high-iron cinder and removing impurities. The method comprises the following steps of flotation of enriched high-sulfur ore from cyaniding-based gold extraction tailings, high-sulfur ore roasting acid production for gold-sliver-enriched high-iron cinder production, high-strength grinding impurity removal of the gold-sliver-enriched high-iron cinder, cyaniding on the high-iron cinder without impurities for gold and sliver extraction, and two-step high-efficiency dehydration. The method prolongs a product resource integrated utilization chain, improves a resource integrated recovery value and product grade quality, realizes thorough utilization of value resources, and has large economic, environmental protection and social benefits.

Owner:SHANDONG GUODA GOLD

Selective heap leaching gold extraction process for gold mine containing copper

ActiveCN101818247AReduce consumptionImprove leaching rateProcess efficiency improvementSelective leachingHydrometallurgy

The invention discloses a selective heap leaching gold extraction process for gold mine containing copper, belonging to the field of hydrometallurgy. The process comprises the steps of: smashing and heaping gold mine containing copper; carrying out alkali treatment on the mine; then adding ammonium salt and sodium cyanide according to a certain proportion to realize the selective leaching of the gold and the restriction to the leaching of the copper; and finally absorbing and extracting the gold from leaching solution by conventional active carbon. The invention has the advantages of simple process method, short procedure, simple equipment, easy implementation, high gold leaching efficiency, low consumption of sodium cyanide, low energy consumption, little investment and low cost, and is the gold extraction method with easy realization of industrialized production and favorable economical benefit.

Owner:ZIJIN MINING GROUP

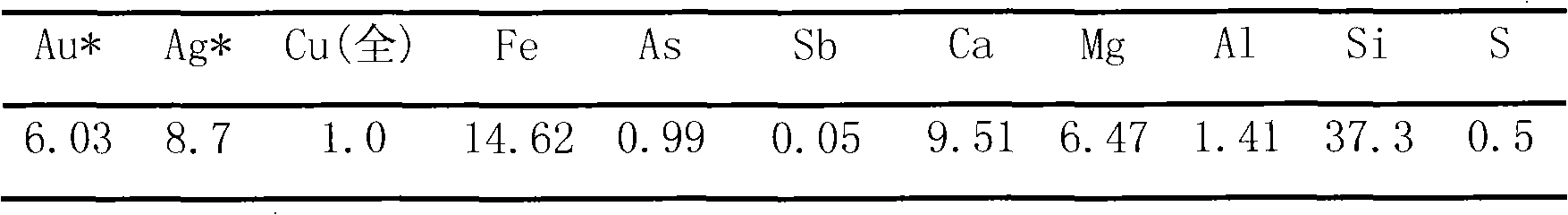

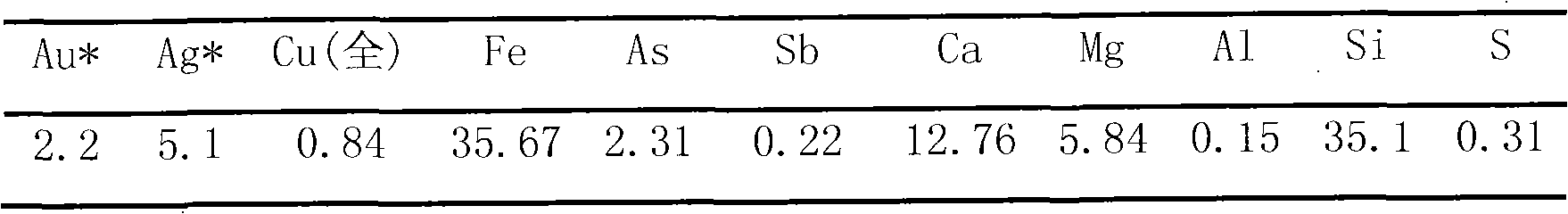

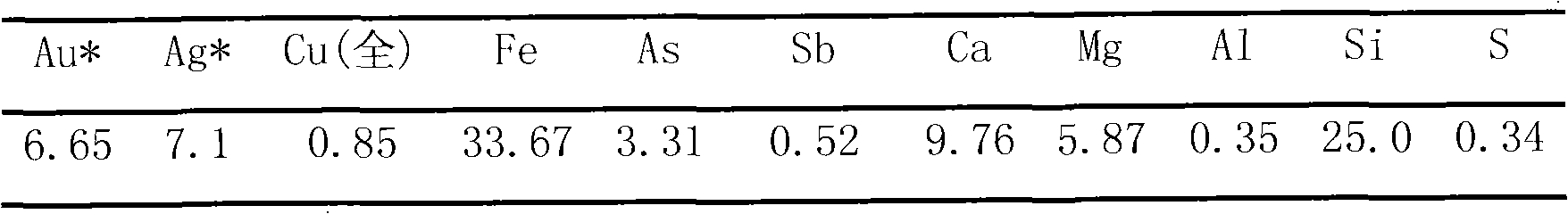

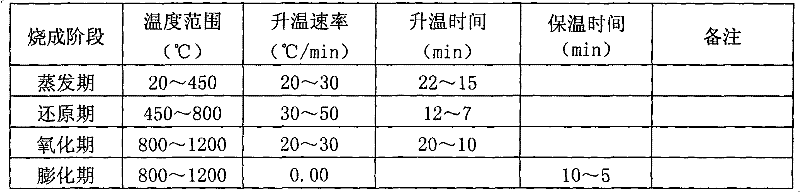

A method of making ceramsite with gold tailing sand

The invention relates to a method for manufacturing haydite from tailings obtained after gold extraction. The haydite comprises the following specific chemical components: 60-65% of SiO2, 10-20% of Al2O3, 4-8% of Fe2O3 and FeO, 3-6% of K2O and Na2O and 3-5% of CaO and MgO, wherein the ignition loss is 3-5%. The method comprises the following specific steps: dewatering and concentrating the tailings obtained after gold extraction until the water content is 20-40%; then introducing 50-80 parts by dry weight of tailings, 20-50 parts by dry weight of clay (or mud) and 3-6 parts of pore-forming agent, and mulling evenly; and then processing the mixed mud to obtain cylindrical or spherical mud particles with a diameter of 5-20 mm, drying, calcining at 800-1200 DEG C, puffing, then cooling, and grading to obtain the haydite with the required size and bulk density.

Owner:河北省地矿局第三地质大队

Gradient separation and comprehensive recovery method for multiple metallic elements in gold concentrate

ActiveCN109351465ATo achieve the purpose of economical and environmental protectionRealize eating dry and squeezing cleanFlotationProcess efficiency improvementRecovery methodBiological activation

The invention relates to a gradient separation and comprehensive recovery method for multiple metallic elements in gold concentrate. According to the process, the first-grade technology is utilizing an efficient mixed activator and a flotation reagent for carrying out pre-flotation on the low-sulfur gold concentrate, the second-grade technology is carrying out alkali leaching cyanide gold extraction on high-sulfur concentrate, the third-grade technology is leaching gold and silver out of low-sulfur tailings through an environment-friendly medicament and a wet method, the fourth-grade technology is giving priority to lead and zinc concentrating for high-sulfur gold concentrate cyanide tailings namely first low-gold high-sulfur concentrate, the fifth-grade technology is selecting copper fromlead and zinc tailings in an activation manner, the sixth-grade technology is roasting acid making and enriching gold, silver and iron to produce iron ore concentrate through copper tailings namely second low-gold high-sulfur concentrate, and the seventh-grade technology is leaching gold and silver out of the iron ore concentrate through an environment-friendly medicament and a wet method. According to the process, the chain for comprehensively utilizing a low-sulfur gold concentrate resource is prolonged, the comprehensive recovery value of the resource and the grade quality of the productsare improved, the complete utilizing of the gold concentrate resource is achieved, and relatively high economic benefits, environment benefits and social benefits are achieved.

Owner:SHANDONG GUODA GOLD

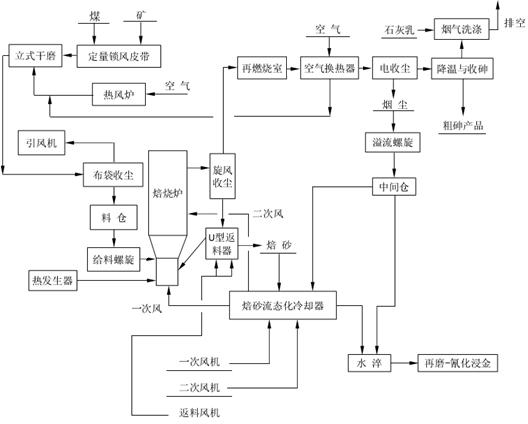

Fluidization roasting method for gold sulfide ore

InactiveCN102127635ASolve the current situation of low recovery rate of gold withdrawalBurn fullyGold oreRoasting

The invention discloses a fluidization roasting method for a gold sulfide ore, and relates to a method for pretreating a refractory and complex primary gold ore (or low-sulfur concentrate), particularly a fine particle-covered refractory gold ore containing arsenic, sulfur and carbon, by calcine external circulation return roasting. The fluidization roasting method for the gold sulfide ore is characterized by comprising the following steps of: (1) adding the gold sulfide ore into coal and drying, finely grinding and mixing the mixture in a vertical milling machine; (2) performing fluidization roasting; and (3) performing water quenching on the calcine which is subjected to the fluidization roasting and then cyaniding and immersing in gold. By the method, the problem of low gold extraction recovery rate in the conventional flow of an arsenic-containing refractory gold ore at present is solved; compared with the conventional process, the method has the advantages that: the gold recovery rate is improved by more than 5 to 15 percent in the calcine external circulation return roasting pretreatment process adopted by the arsenic-containing refractory gold ore; and the method is applicable to the field of gold extraction of primary gold ore roasting and smelting and the field of pretreatment of the low-sulfur concentrate roasting.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

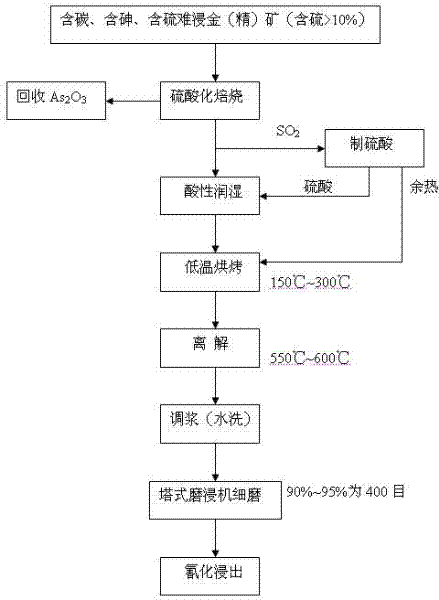

Gold extraction process method for refractory gold ore

A gold extraction process method for refractory gold ore uses continuous operations of sulfation roasting, cinder secondary low-temperature acidic roasting, middle-temperature sulfation decomposition and cyaniding gold extraction. Sulfuric acid produced in a general sulfation roasting process is utilized, cinder is secondarily roasted and oxidized in low temperature and acidic mode, then middle temperature roasting is performed to resolve sulfate, the cinder is finely ground to be cyanided and leached, and refractory gold wrapped in carbon, arsenic and sulphur can be efficiently recycled. The method combines advantages of a roasting oxidation method and an acid hot press oxidation method and enables the advantages to be achieved in normal pressure, thereby being moderate in operation conditions, quick in response speed, low in process investment cost, appropriate in production cost, environmentally-friendly and capable of achieving industrial production easily. The method is also suitable for other roasting-leaching hydrometallurgy systems.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Floating process for enriching Cu, Ag, Au, etc from gold sulfide ore cyanizing gold extraction tailing

Owner:SHANDONG GUODA GOLD

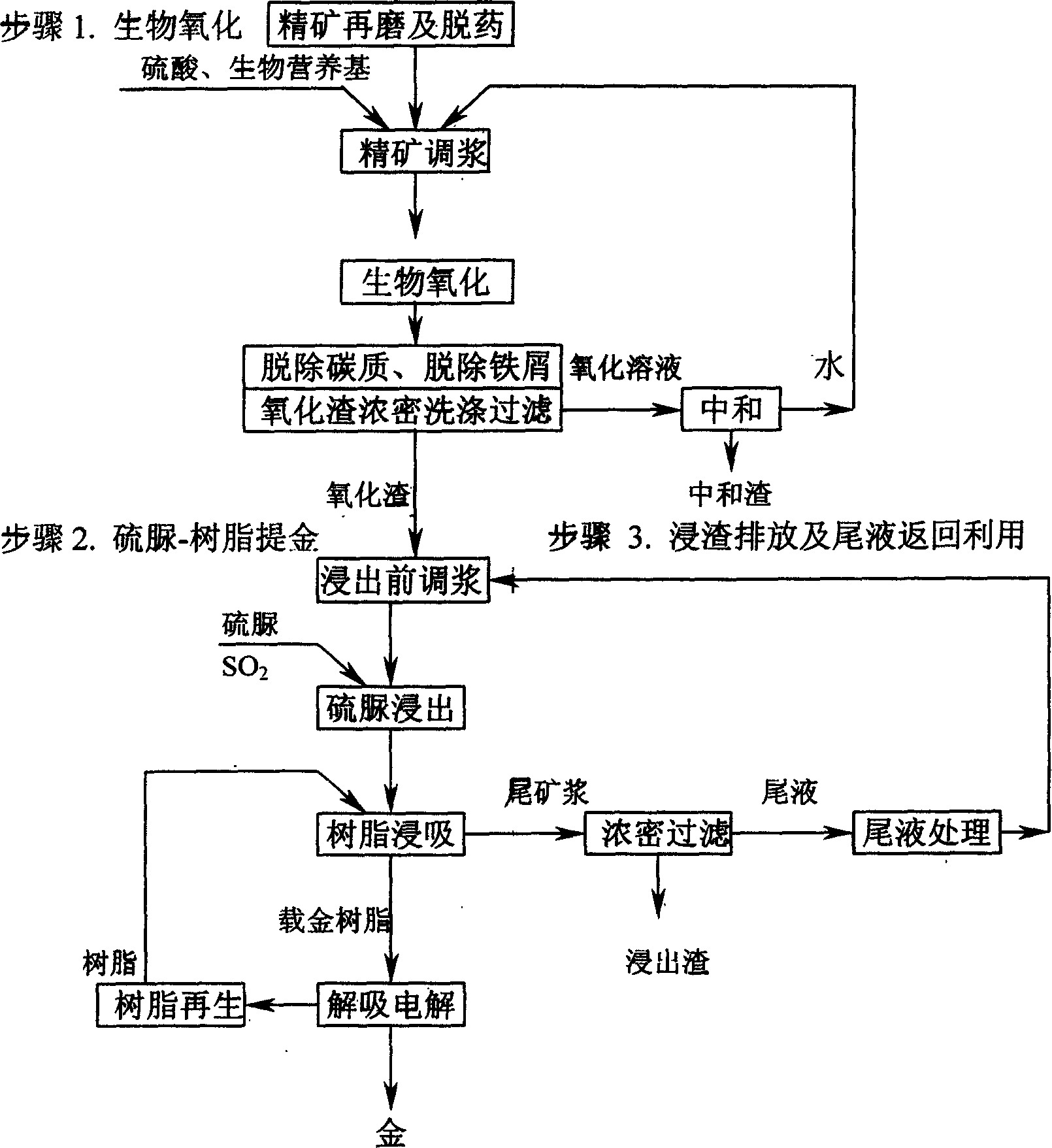

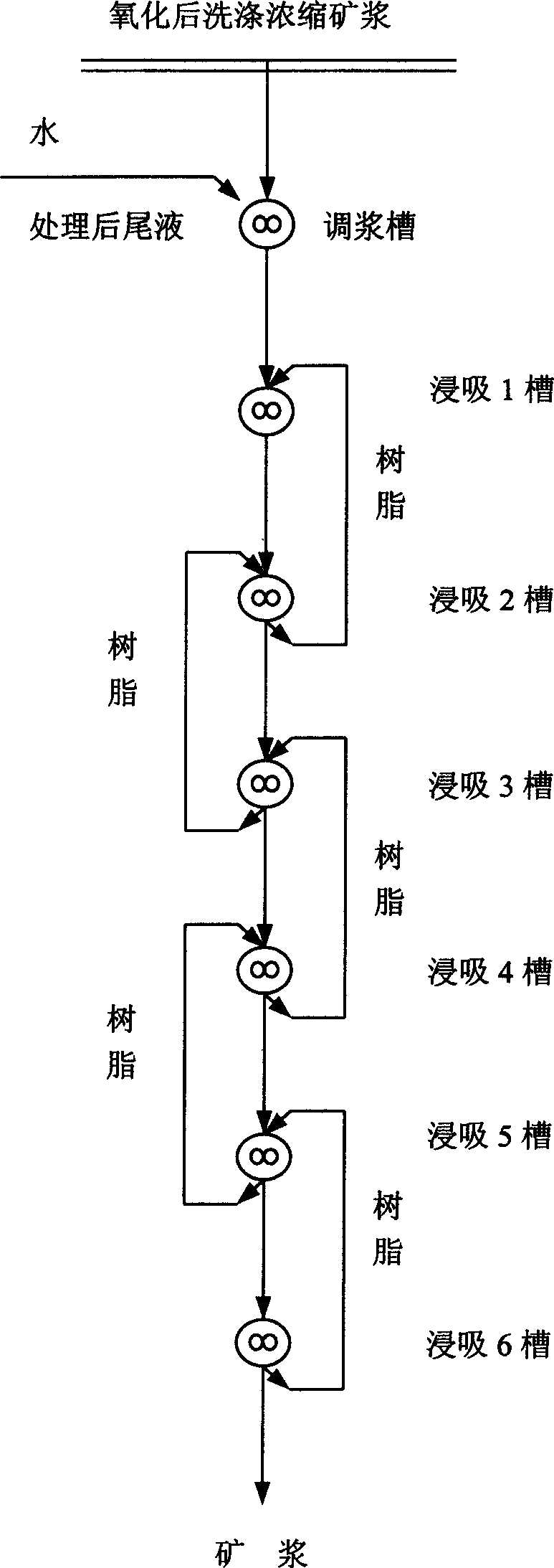

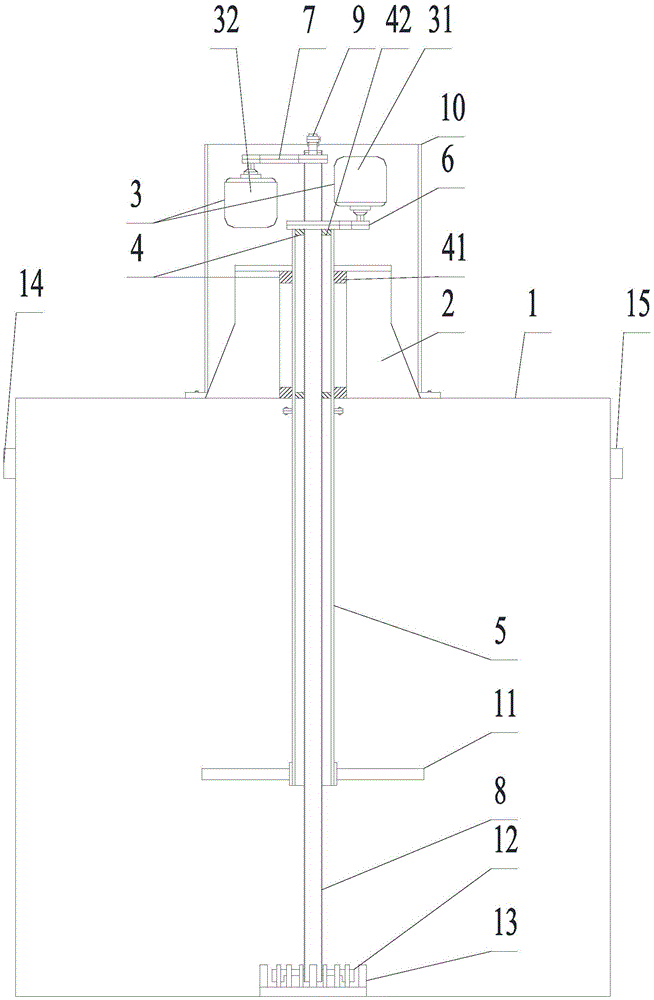

Biological oxidation and thiourea resin slurry method gold extraction technology for difficultly leachable gold concentrate

The invention disclose a refractory gold concentrate's biological oxidation---an gold extracting technique by thionura-resin ore pulp method, including the following steps: making biological oxidation of gold concentrate, using thionura to extract gold and using resin to absorb the gold, processing the tail solution and then returning it to the mixing pulp work before extraction for circular use; the gold extraction can reach above 90%, the tail solution is circularly used so as to be able to reduce consumption of thionura, sulphuric acid and water, thus reducing production cost and beneficial to environmental protection.

Owner:CHANGCHUN GOLD RES INST

Gold extraction technique method for low-grade refractory gold ores

ActiveCN105039737ASolve the problem of resource recyclingLess investmentProcess efficiency improvementActivated carbonSulfide compound

The invention discloses a gold extraction technique method for low-grade refractory gold ores. The method comprises the following steps: raw ores or cyanide tailings containing micro-fine particle sulfide-encapsulated gold are finely grinded; the finely grinded raw ores or cyanide tailings are added into an intense agitation inflation reaction device, and are mixed with water to form pulp; under an ordinary pressure at a temperature of 10 DEG C-100 DEG C, air or oxygen is introduced and mixing is performed so as to perform pre-oxidation; calcium oxide is added into the above mentioned pre-oxidized pulp to perform adequate alkali treatment; NaCN is added into the pulp subjected to alkali treatment for cyanide leaching, and finally, gold extraction is performed by using activated carbon for adsorption. The method disclosed by the invention has the advantages of low investment, low cost, simple equipment, mild conditions, high resource recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

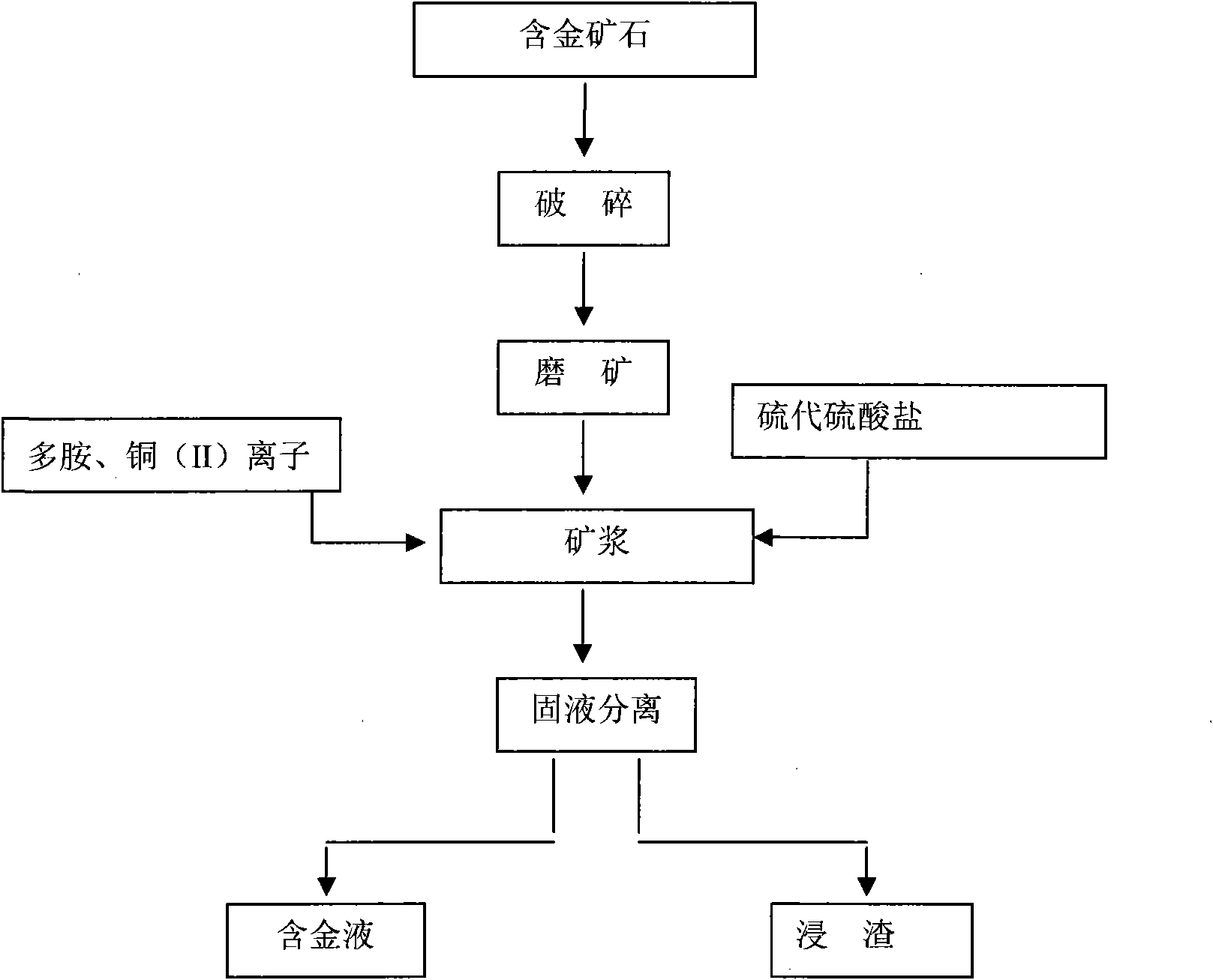

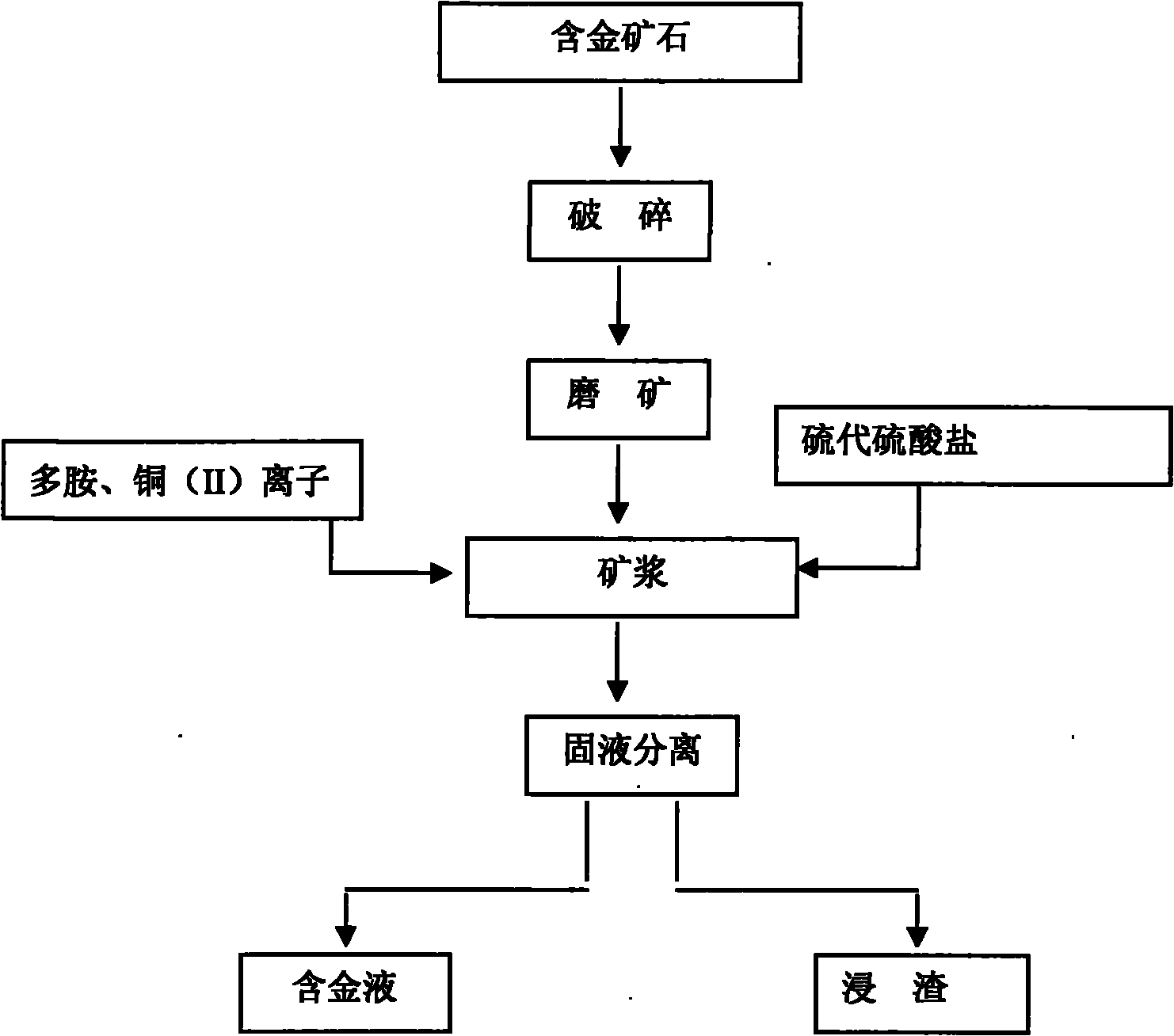

Gold extracting method by thiosulfate using polyamine compoud as additive

InactiveCN101775490AReduce consumptionLittle effect of leachingProcess efficiency improvementToxic materialSodium cyanide

The invention relates to a gold extracting method by thiosulfate using a polyamine compound as an additive, which comprises the steps: after ores are crushed and wet-ground until the fineness is over 90 percent of -200 meshes, 0.03-3mol / dm3 thiosulfate is added to be used as a leaching agent, and then 0.0015-0.09mol / dm3 polyamine compound and 0.0015-0.03mol / dm3 copper (II) ion are added to form a complex ion to be used as an additive to be stirred and leached; and after gold ores are leached, gold from a leaching solution is recovered. The leaching solution is used to extract gold from the ores, so that the gold leaching rate is high, the process operation is simple, the control is easy, the consumption of thiosulfate is extremely low, and the compositions of the gold leaching solution are simple and are favorable for the recovery of the gold; and the application range is wide, the leaching effect is good when the pH value is between 10 and 12, the leaching speed is quick for copper-containing, carbon-containing and other refractory gold ores, quite high gold leaching rate can be maintained, and sodium cyanide and other toxic substances are not used and toxic waste is not discharged in the whole gold extraction process, so the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

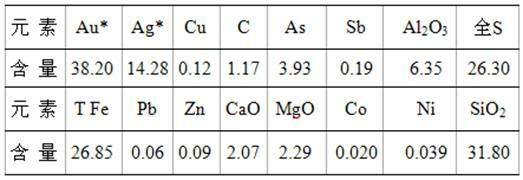

Method for strengthening gold extraction of iron gold concentrate roasted product containing sulphur and arsenic

The invention discloses a method for strengthening gold extraction of an iron gold concentrate roasted product containing sulphur and arsenic. The high-iron gold concentrate containing sulphur and arsenic, especially high sulphur and high arsenic, hinders the subsequent chemical gold leaching process after being subjected to oxidation roasting pretreatment because of the problem that iron oxide is inevitably generated to wrap gold in a high-temperature reaction process. The invention proposes a new method for strengthening gold extraction of the iron gold concentrate roasted product containing sulphur and arsenic by a flow of 'metallized reduction roasting-acid leaching-gold leaching', namely a method for strengthening gold extraction of the iron gold concentrate roasted product containing sulphur and arsenic aiming at the problem. The method comprises the steps of firstly, carrying out metallized reduction roasting on the iron gold concentrate roasted product containing sulphur and arsenic with a reducing agent, carrying out acid leaching on the metalized roasted product, and finally carrying out chemical leaching with an acid slag. By adopting the method disclosed by the invention, the leaching rate of the iron gold concentrate roasted product containing sulphur and arsenic is higher than 95%; and important theory and technical guidance are provided for effective gold extraction of the gold roasted product.

Owner:CENT SOUTH UNIV

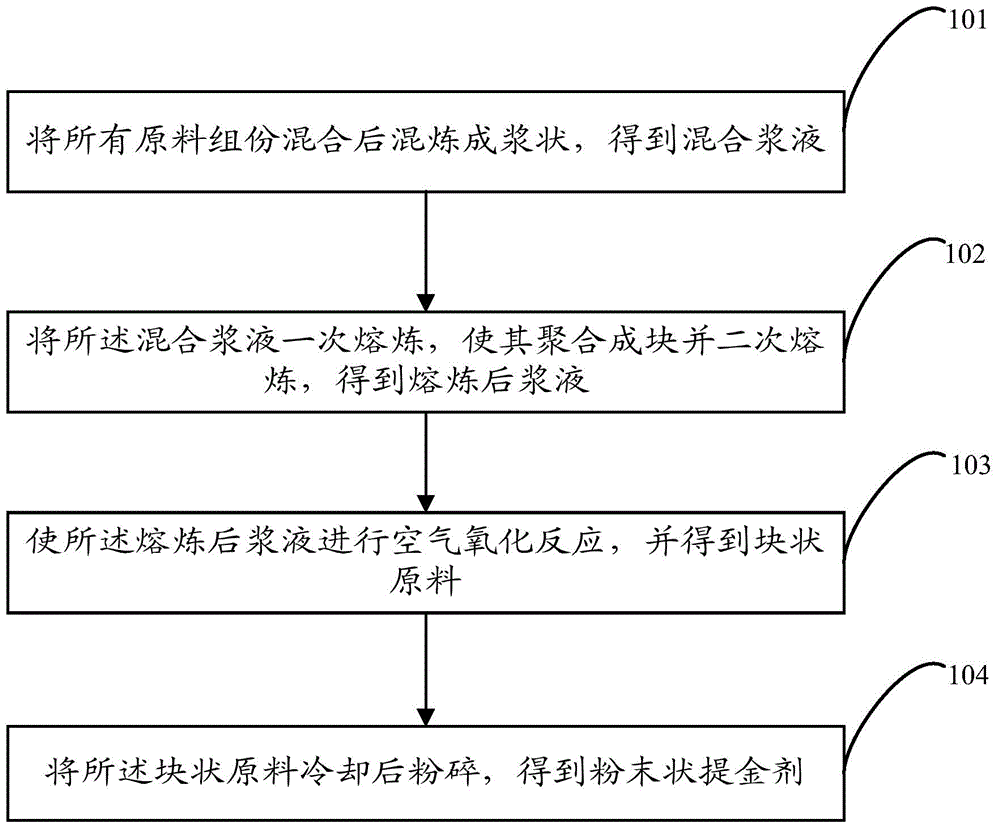

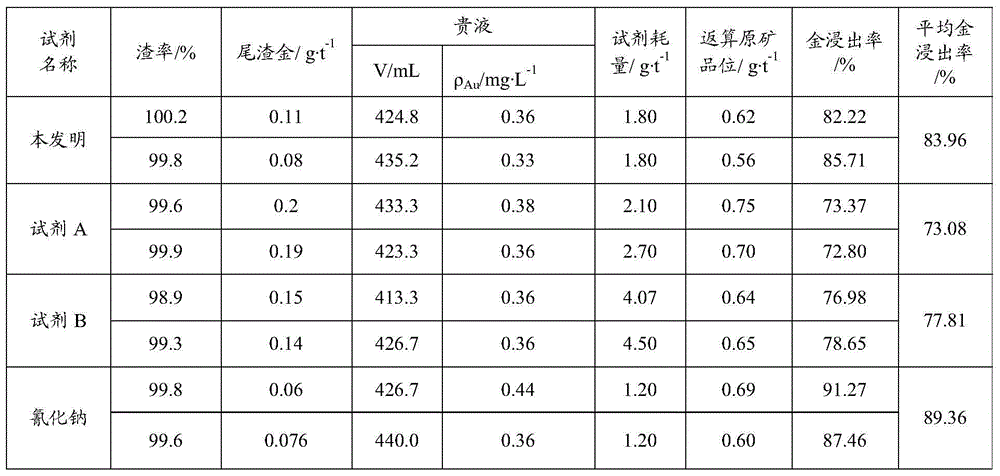

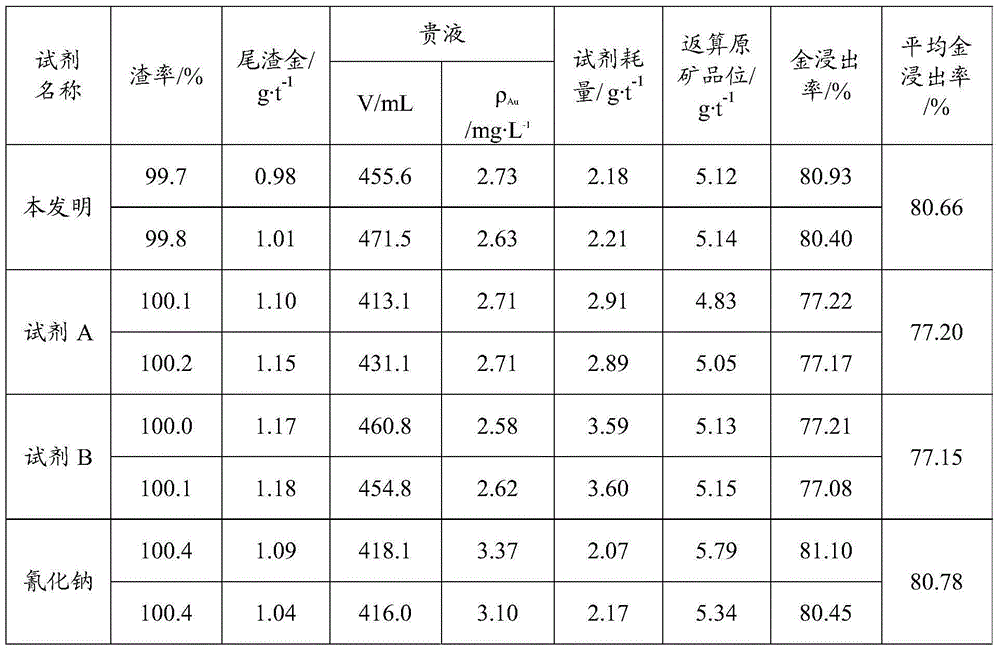

Gold extracting agent and preparation method thereof

The invention provides a gold extracting agent and a preparation method thereof, and belongs to the technical field of gold extraction. The gold extracting agent comprises the raw material components in parts by weight: 12-12.4 parts of sodium hexametaphosphate, 7-7.4 parts of sodium cyanate, 9.4-9.8 parts of sodium ferrocyanide, 10.3-10.7 of sodium sulfide, 13.3-13.7 parts of sulphur, 10.4-10.8 parts of sodium bromide, 6.3-6.7 parts of sodium chloride, 8.2-8.6 parts of manganese dioxide, 11.8-12.2 parts of urea, and 9.3-9.7 parts of industrial sodium carbonate. The gold extracting agent is alkaline, and has the advantages of low toxicity, environmental protection, short leaching time and convenient transportation and keeping and the like; in addition, the gold extracting rate is high; and the gold extracting agent is quite suitable for use as a novel gold extracting agent for heap leaching, pond leaching and carbon paste production processes of micro-fine particle gold-containing oxidized ores.

Owner:圣的新材料(长兴)有限公司

Method for extracting gold from copper-containing gold oxide ore

The invention discloses a method for extracting gold from copper-containing gold oxide ore, belonging to a wet metallurgy technology. The method comprises the steps of: firstly, crushing, grinding and classifying copper-containing gold oxide ore; then carrying out alkali treatment on the copper-containing gold oxide ore; adding a certain proportion of chelant and sodium cyanide for realizing the purposes of inhibiting copper extraction and selective extraction of gold; and finally, extracting gold from the extract solution through adsorption by using conventional active carbon. The method has the advantages of simple process, simple equipment, easy implementation, high gold extraction rate, less chemical consumption, less investment of capital construction, and low cost, easily realizes industrialized production and has better economic benefit.

Owner:ZIJIN MINING GROUP

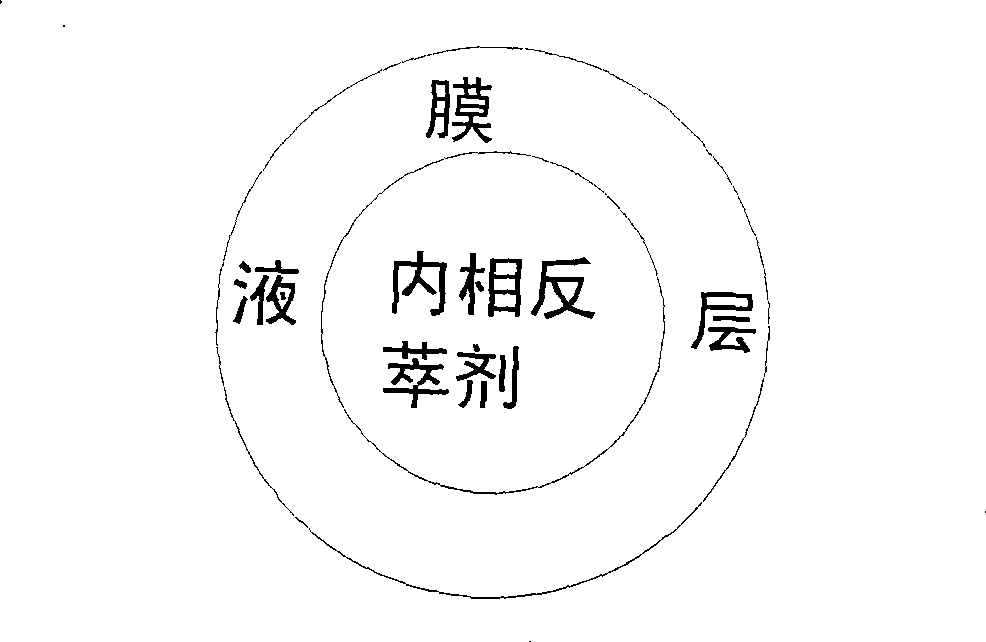

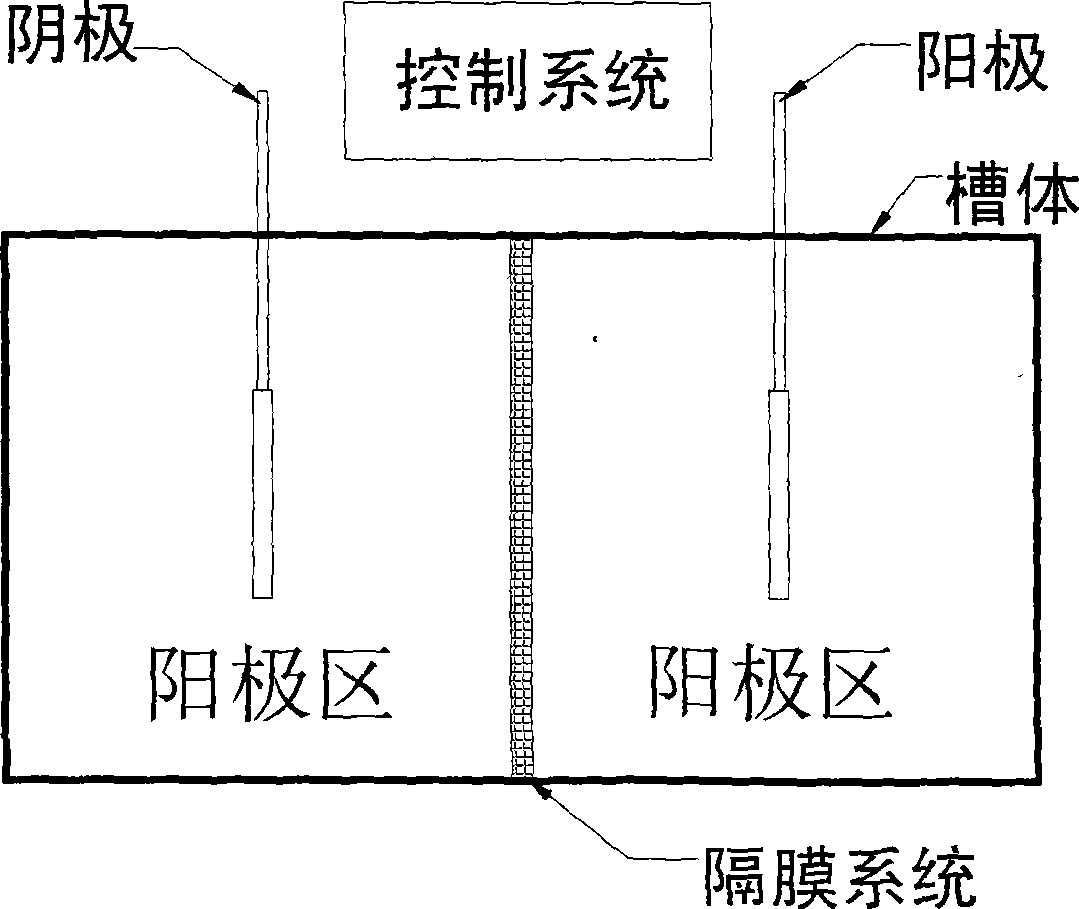

Liquid membrane extraction of gold-diaphragm electrolysis extraction of gold process

InactiveCN101418375AReduce consumptionEfficient use ofPhotography auxillary processesProcess efficiency improvementChemical industryElectrolysis

The invention relates to a liquid membrane gold extraction-diaphragm electrolysis gold extraction process, which belongs to the metallurgy and chemical industry. The process comprises two parts, namely emulsion liquid membrane gold extraction and gold-contained enrichment diaphragm electrolysis gold extraction, wherein the emulsion liquid membrane gold extraction comprises the preparation of an emulsion liquid membrane, the extraction process of the emulsion liquid membrane, and the emulsion breaking process of a gold-contained emulsion liquid membrane. The process has the advantages that the process has a large driving force of mass transfer, few separation stages needed, and little agent consumption; the process improves the production efficiency and greatly simplifies the gold extraction technical flow; useful materials are reclaimed so as to produce no secondary pollution and achieve the more effective energy utilization; and the process is taken as unit operation, and has flexible use, convenient operation and easy realization of automatic control.

Owner:CHANGCHUN GOLD RES INST +1

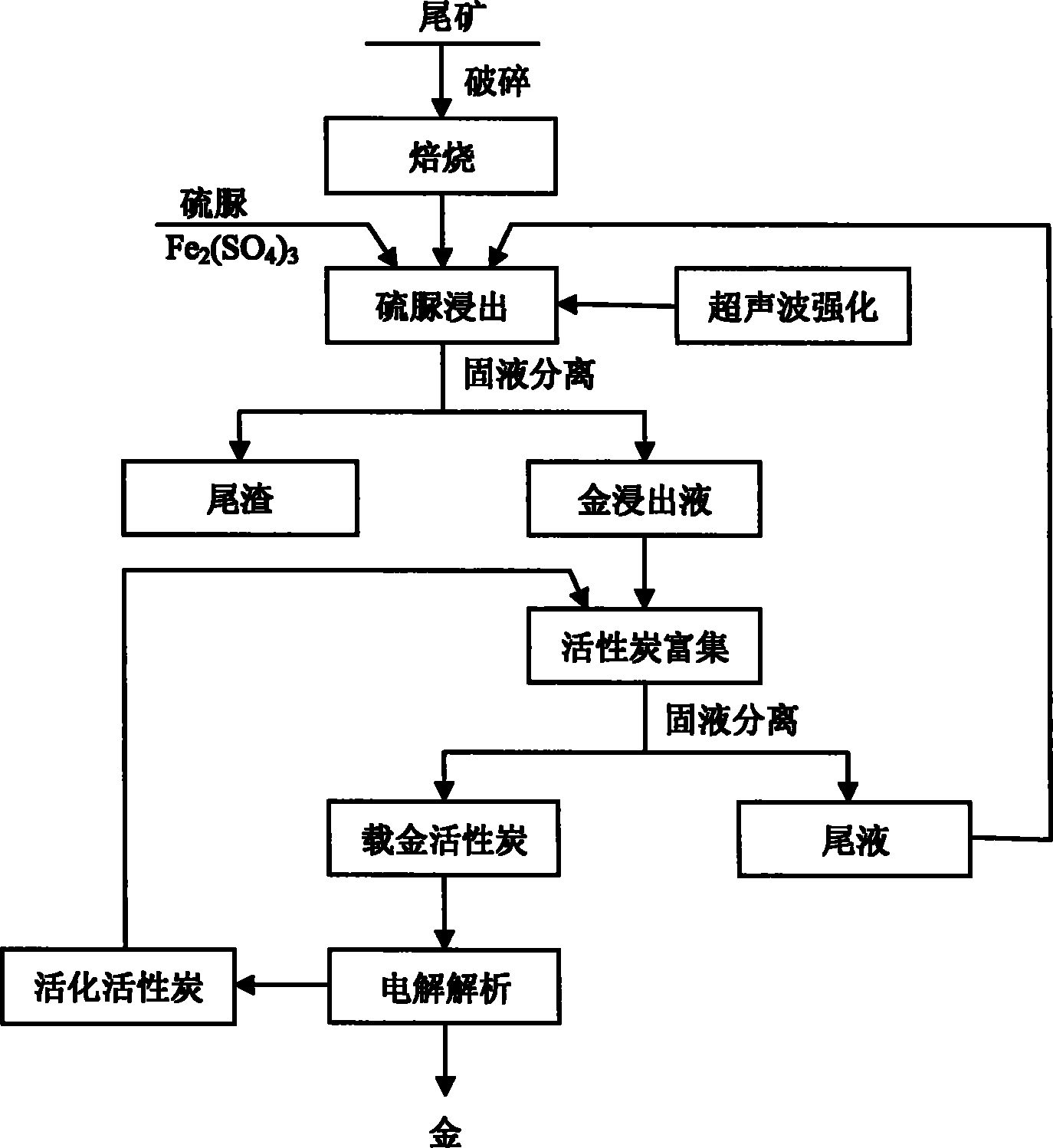

Gold extraction method employing gold cyanided tailing roasting-ultrasonic intensification thiourea gold leaching-activated carbon enrichment

InactiveCN102676838AImprove leaching rateShorten gold immersion timeProcess efficiency improvementActivated carbonThiourea

The invention relates to a gold extraction method employing gold cyanided tailing roasting, ultrasonic intensification thiourea gold leaching and activated carbon enrichment, and belongs to the field of wet method metallurgy. According to the gold extraction method, gold-containing cyanided tailing is subjected to roasting treatment, then thiourea is used for leaching gold, meanwhile the ultrasonic intensification treatment is carried out, solid-liquid separation is performed after the gold leaching, gold contained in the liquid phase is gathered by the activated carbon through enrichment, solid-liquid separation is performed after the enrichment, the activated carbon is used for extracting and resolving gold, after resolving, the activated carbon is activated to be recycled repeatedly, a large quantity of thiourea exits in the tail liquid, and the thiourea can be circularly used for the leaching process after being simply treated. The gold extraction method is used for extracting gold in the cyanided tailing through leaching, the leaching speed is high, the extraction rate can be more than 90%, the cycle is short, and the activated carbon and the tail liquid can be recycled, so the production cost is greatly reduced, the economical benefit on the utilization of gold cyanided tailing is improved, and meanwhile, the environmental protection is facilitated.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

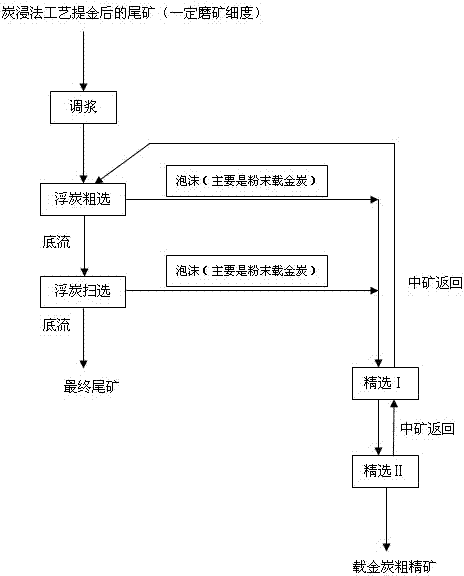

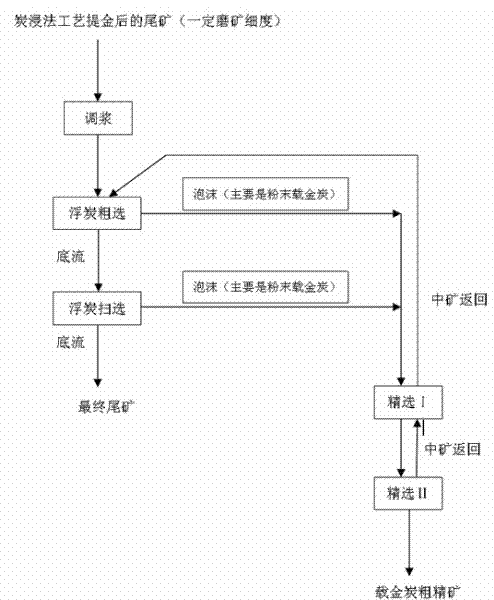

Method for recovering lost gold-loaded carbon from tailings obtained in carbon leaching gold extraction process

InactiveCN102505069AReduce consumptionSimple processFlotationProcess efficiency improvementKeroseneEnvironmental engineering

The invention discloses a method for recovering lost gold-loaded carbon from tailings obtained in a carbon leaching gold extraction process, which is a flotation recovery technology of powder gold-loaded carbon and belongs to the technical field of mineral processing engineering. According to the invention, kerosene is used as a collecting agent to carry out flotation on carbon matter; and after the tailings produced in the carbon leaching gold extraction process is subjected to size mixing, the kerosene is used for carrying out flotation and enrichment on the powder gold-loaded carbon. The method is utilized to recover the gold-loaded carbon lost in the tailings. The method has simple process and high recovery rate and is easy to operate. The loss of gold can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

Comprehensive treatment process of waste gold-bearing activated carbon

InactiveCN102409176AHigh recovery rateImprove utilizationProcess efficiency improvementActivated carbonSlag

The invention relates to a comprehensive treatment process of waste gold-bearing activated carbon, belonging to the technical field of the gold and silver comprehensive recovery of gold smelting wastewater and the gold-bearing carbon retreatment. The comprehensive treatment process comprises the following steps: 1) using a carbon- incinerating furnace to incinerate and remove carbon, enriching gold and silver; 2) burning the obtained slag to perform fine grinding and shaker treatment; 3) smelting the shaker concentrate burden; 4) treating pre-slag; 5) performing acid leaching to the shaker tailings; and 6) cyaniding the acid leaching cake. The comprehensive treatment process of the waste gold-bearing activated carbon fully applies the pyrometallurgical method, the hydrometallurgical process and the cyanide gold extraction process; and by adopting the comprehensive treatment process, the gold and silver in the waste gold-bearing activated carbon can be recycled farthest, the recovery rate of gold and silver can be increased, the comprehensive utilization effect of the resource can be increased and the economic benefit of the enterprise can be increased.

Owner:SHANDONG GUODA GOLD

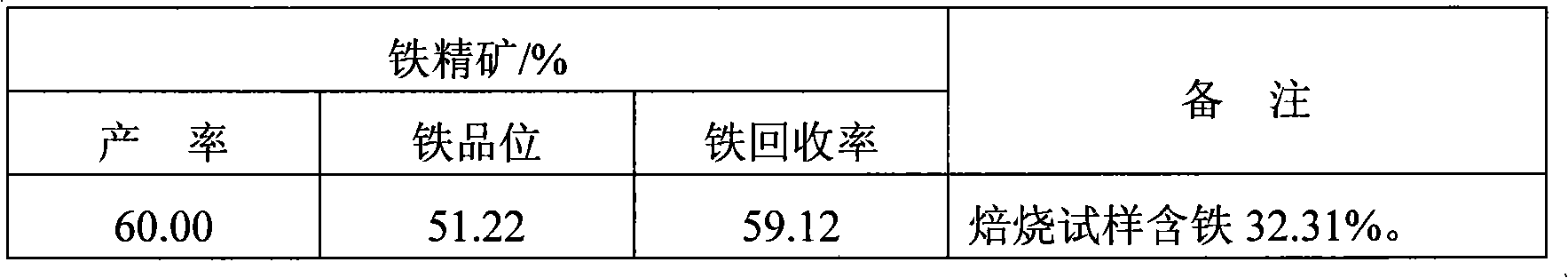

Method of producing iron concentrate from cyanidation gold-extracted waste slag

InactiveCN101078047AImprove utilizationReduce pollutionProcess efficiency improvementWet separationSlagSlurry

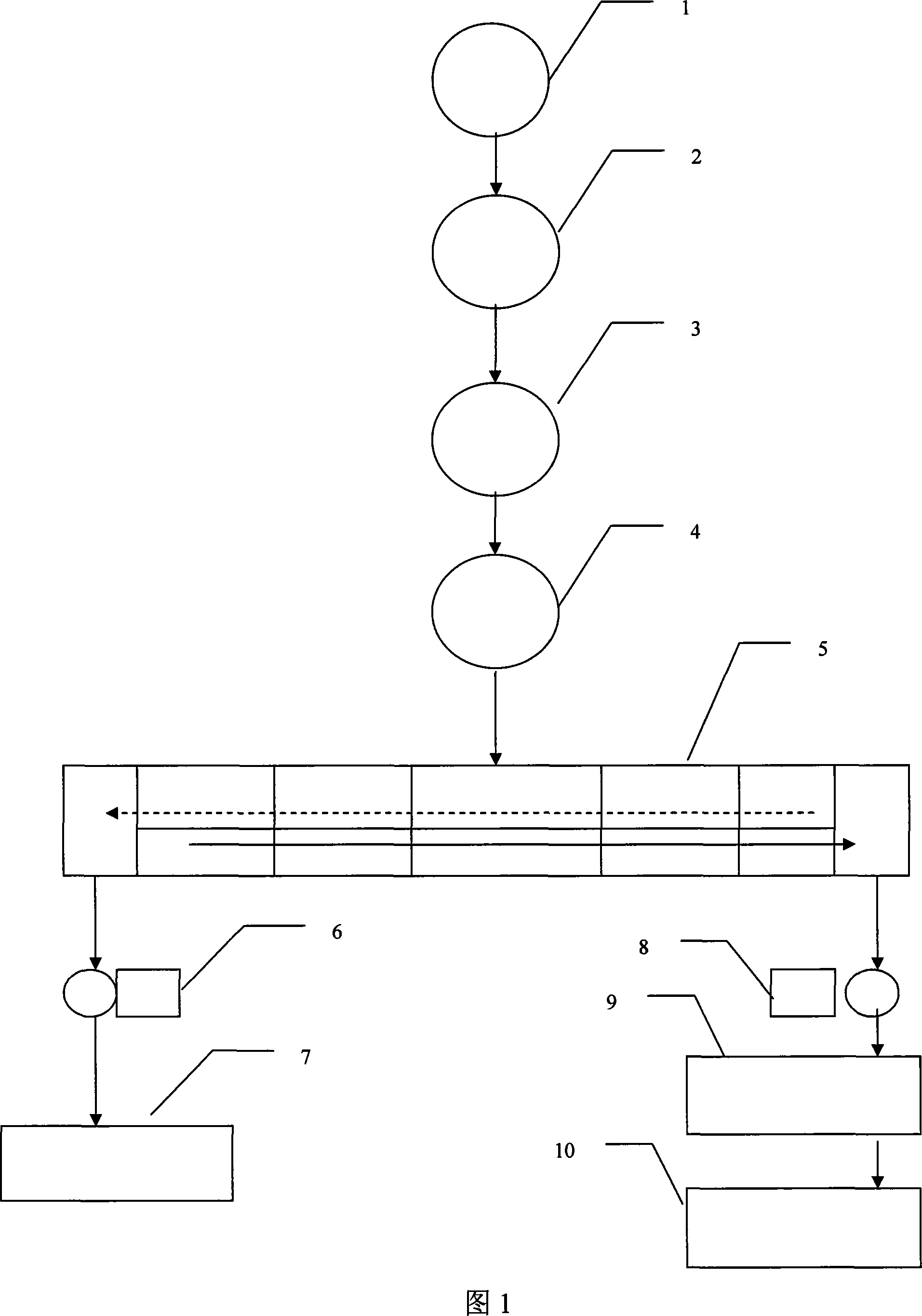

The invention relates to a method of collecting iron concentrate from residue of gold extraction with cvanidation. This invention belongs to the field of metallurgy and chemical technology. It is characterized in that : 1. putting the residue of gold extraction into mix-slurry trough 1, adjusting the concentration of the ore slurry with water, mixing round and then putting it into acidification trough 2; 2. adjusting the acidity of ore slurry with industrial vitriol, mixing round continuously, putting it into mix-slurry trough 3; 3. adjusting the concentration of the ore slurry with water, charging and discharging continuously, putting the mixture into mix-slurry trough 4; 4. adding flotation agent and foaming agent, agitating; 5. carrying out closed circuit flotation process after the ore slurry going into the flotation trough, sulfur is concentrated by one step of rougher flotation, two steps of closed circuit scavenging and four steps of closed circuit picking; 6. lifting the sulfur concentration to filter press 9, dehydrating and separating, high grade sulfur is concentrated; 7. lifting the gangue to filter press 7, dehydrating and separating; 8. feeding the high grade sulfur concentrate to acid producing system 10, roasting, the residue is iron concentrate. The invention makes the content of iron in the residue of roasting to 60%-66%, reach the standard of puddling material.

Owner:SHANDONG GUODA GOLD

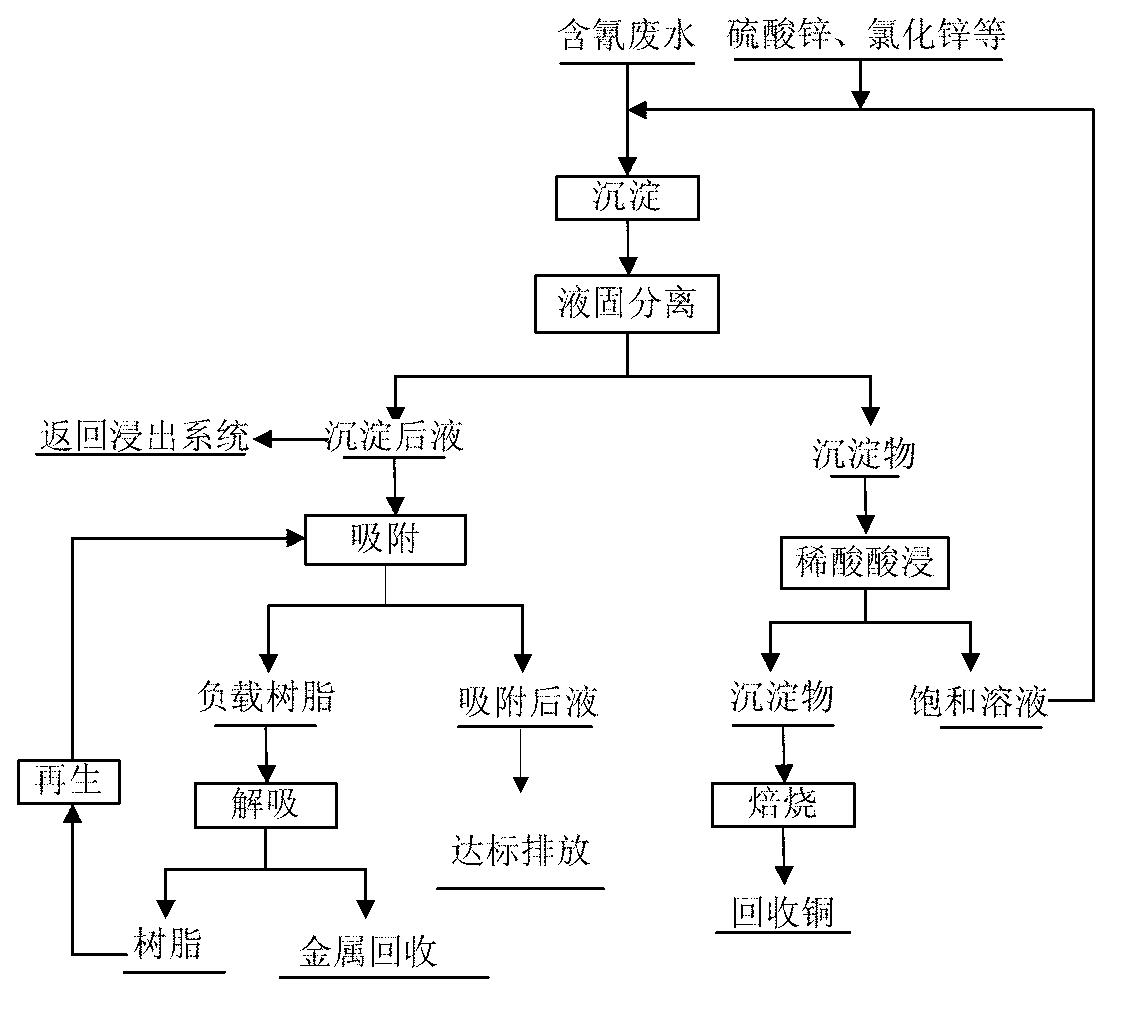

Treatment method of gold extraction cyaniding wastewater containing copper and iron ions with high concentration

InactiveCN103304052AReduce processing costsReduce the amount addedWater contaminantsMultistage water/sewage treatmentHigh concentrationSorbent

The invention discloses a treatment method of gold extraction cyaniding wastewater containing copper and iron ions with a high concentration. The treatment method comprises the steps of with zinc salt as a precipitator, removing a most part of free cyanogens and copper, iron and zinc ions in a solution, and further recovering residual cyanogens ions and other valuable metal ions in the solution after precipitation by using strong basic resin as an adsorbent to enable the wastewater to be discharged up to the standard. Due to the adoption of the treatment method, cyanide and the valuable metal ions in the gold extraction wastewater are furthest recovered by virtue of the two-step process of precipitation and resin adsorption; and moreover, as the treated wastewater can return to a leaching system or be directly discharged according to the needs, the treatment method is very strong in the flexibility, is low in treatment cost for treating the cyaniding wastewater with higher copper and iron contents and has a remarkable economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

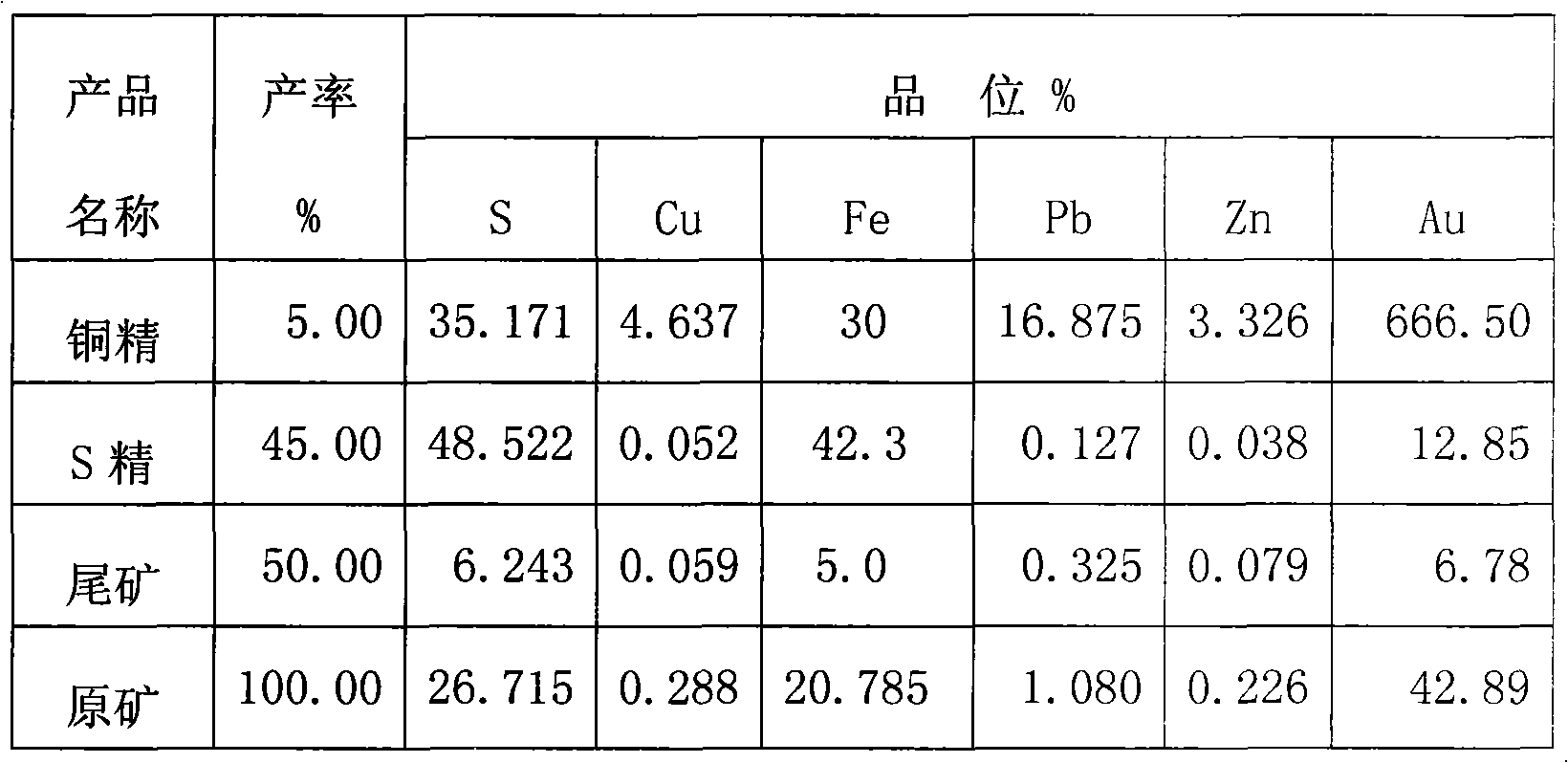

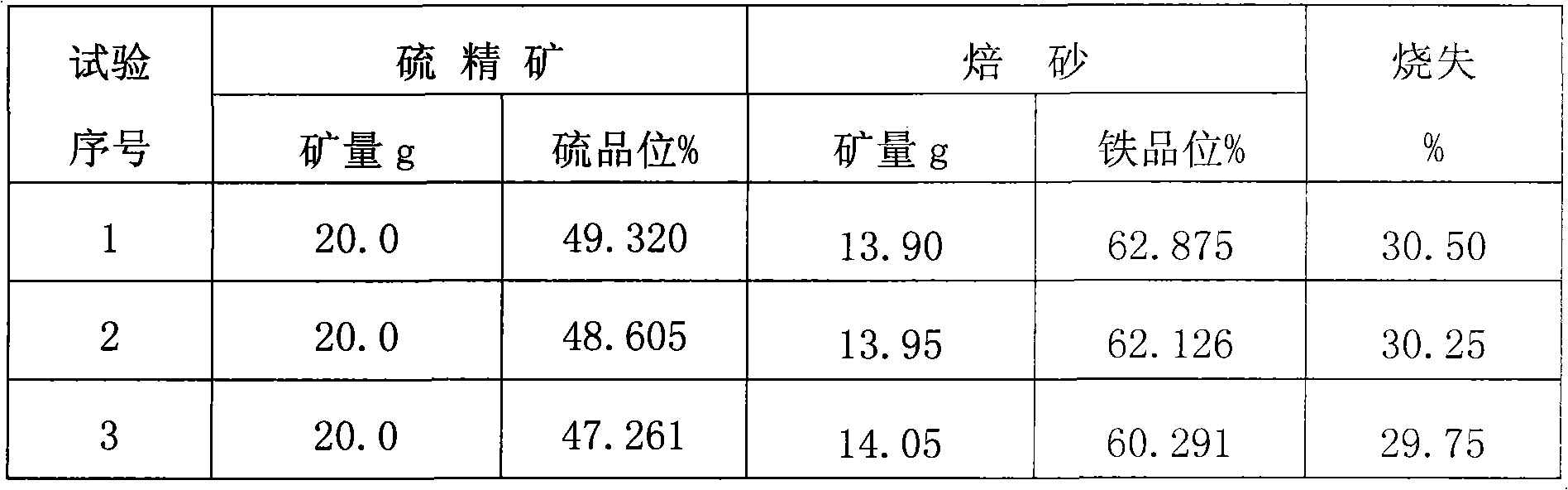

Method for recovering iron from gold concentrate

The invention provides a method for recovering iron from a gold concentrate, comprising the following steps: dividing the gold concentrate into a high sulfur part (the sulfur content is more than 47%) and a low sulfur part (the sulfur content is lower than 7%) by a floatation method, wherein the yield of each part is 50%; through separation and flotation, separating the high sulfur part with 47% of sulfur content to obtain the gold concentrate with high contents of gold, copper, lead and zinc and yield of 5% and obtain the gold concentrate in which the part with more than 48.5% of sulfur content accounts for 45%; and performing gold extraction on the part by cyaniding, calcinating cyanided dreg to obtain above 60% iron powder. By using the technology, more than 80% of iron from the cyanided dreg can be recovered; pyrite in the gold concentrate can be firstly purified to enable the purity of the pyrite to be above 90%, and then the pyrite is calcinated to prepare aid and wast heat is used for generating power; and the calcinated dreg has iron content above 60% so as to be served as a raw material for ironmaking in a steel mill, thus realizing comprehensive reclamation.

Owner:山东黄金冶炼有限公司

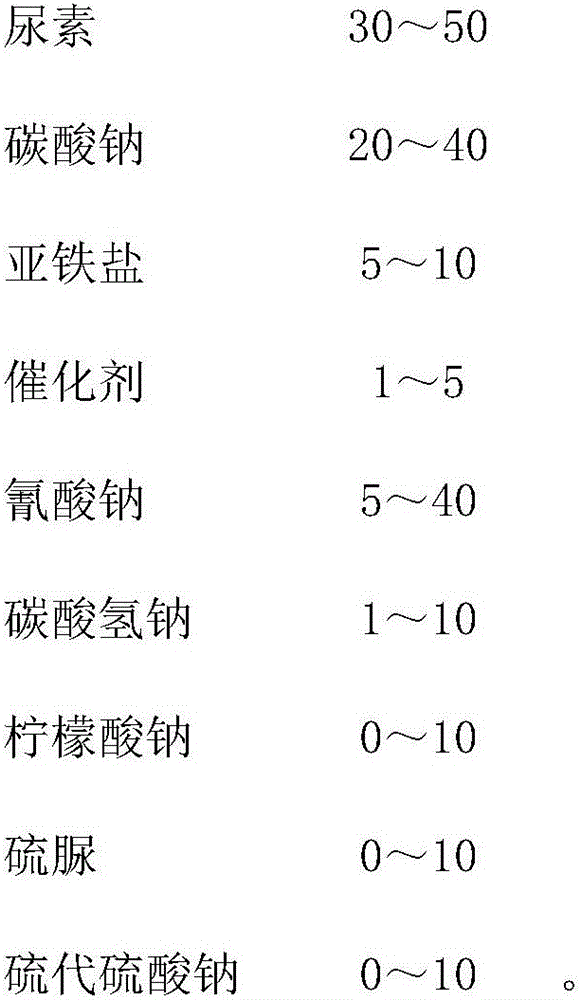

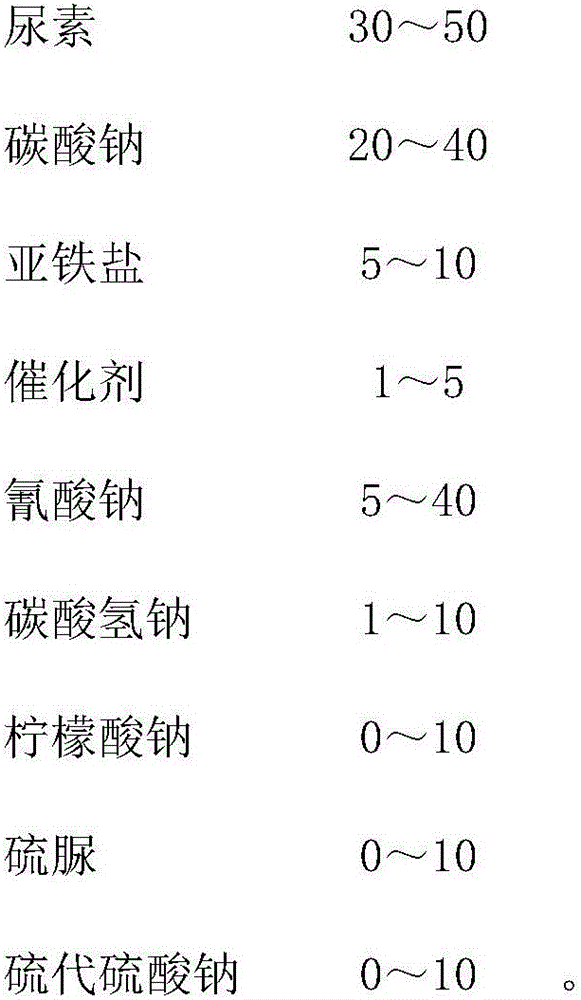

Low-toxicity environment-friendly gold mineral separation agent and preparation method thereof

InactiveCN106399712AExtract impactImprove leaching effectProcess efficiency improvementSodium bicarbonateThiourea

The invention relates to a low-toxicity environment-friendly gold mineral separation agent. Urea, sodium carbonate, ferrite, catalysts, sodium cyanate and sodium bicarbonate are adopted as main raw materials, and sodium citrate, thiourea and sodium thiosulfate are selectively added. After reactions of certain steps, the finished product is obtained. In the low-toxicity environment-friendly gold mineral separation agent, sodium cyanide with highly toxic hazards is not used, iron, nickel and carbon catalysts are used for catalyst reactions in the technology process, and the reaction time is shortened; by means of filtering measures, produced unmelted impurities are removed, and the effects of the impurities on gold extraction are avoided; in a product formula, multiple mineral separation ingredients and inhibitors, decomposing agents and the like for mineral harmful impurities are matched, and an obvious leaching effect is achieved for ores difficult to treat; and by means of a special two-time charging manner, the recovery rate of the product is increased.

Owner:金霖控股(北京)股份有限公司

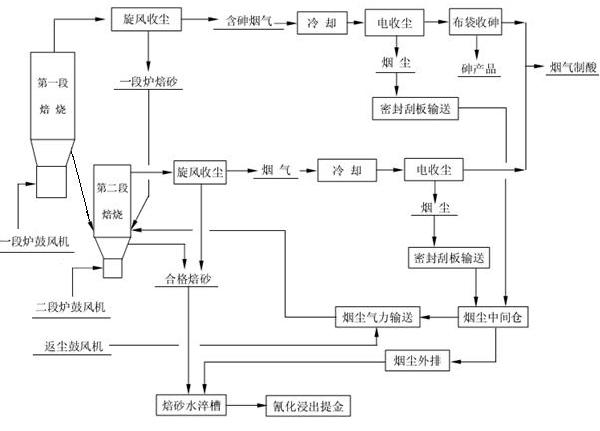

Treatment method of roasting arsenium-containing gold ore concentrate

The invention provides a treatment method of roasting arsenium-containing gold ore concentrate, which relates to gold concentration in a technological process of smelting and extracting gold from gold ore, particularly a treatment method of carrying out pre-oxidizing roasting on arsenium-containing gold ore concentrate. The roasting process adopts a two-stage circulating dust-returning roasting technological process. The method is characterized in that first-stage roasting furnace fume and second-stage roasting furnace fume are respectively and independently subjected to dust collection, and the collected smoke dust is pneumatically delivered back to the second-stage roasting furnace for roasting, and part of the smoke dust is discharged into a water quenching tank to be subjected to water quenching, and is cyanated for gold extraction, wherein the smoke dust, which is pneumatically delivered back for re-roasting, accounts for 90-50% of all the collected smoke dust. The method provided by the invention effectively solves the technical problems of high grade of gold in leaching slag and low recovery rate of gold in the technique for extracting arsenium-containing unmanageable gold ore concentrate, so that the leaching rate of gold in the arsenium-containing gold ore concentrate is increased by 5% or so, and slag gold is reduced from above 4g / t to below 2.5g / t. The invention is widely applicable to the field of gold extraction by roasting and smelting gold ore concentrate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com