Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309results about How to "Improve leaching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously extracting alkaloids, flavone and polysaccharide active components from mulberry leaves

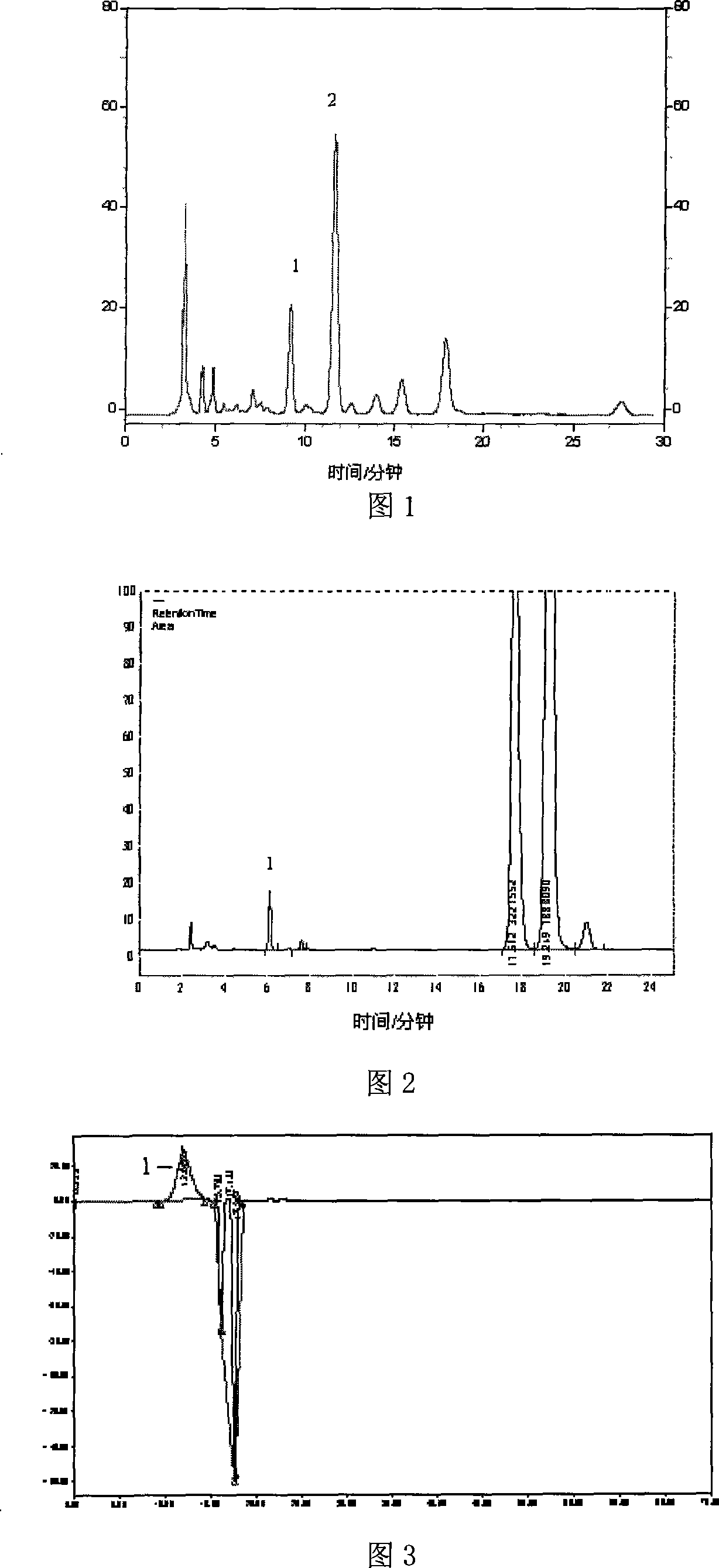

InactiveCN101209284AFast separation rateHigh content of ingredientsAlkaloids chemistrySugar derivativesSolventChemistry

The invention relates to a method of taking mulberry leaves as the raw materials to continuously extract the active ingredients of alkaloids, flavonoids and polysaccharides. The invention includes the following steps: the solvents of 20 percent to 90 percent ethanol or 10 percent to 90 percent acetone are selected for reflux extraction to obtain the filtrate and filter residue; the filtrate is concentrated and dissolved by adding water, the flavonoid compounds with the content of 30 percent to 50 percent are obtained by macroporous resin separation; the solution is treated by ion exchange resin separation to get the alkaloid compounds with the content of 40 percent to 60 percent after passes through the macroporous resin; the filter residue of the mulberry leaves is boiled and decolored by using the water, and the acid polysaccharide compounds with the content of 55 percent to 85 percent are obtained by 10 percent to 60 percent alcohol sedimentation. The invention continuously and efficiently separates three active ingredients of alkaloids, flavonoids and polysaccharides of the mulberry leaves by one-time feeding, all the steps are not disturbed mutually, the extraction rate is high, the process operation is simple, the cost is low, and the invention is conductive to industrial popularization and application.

Owner:TIANJIN UNIV

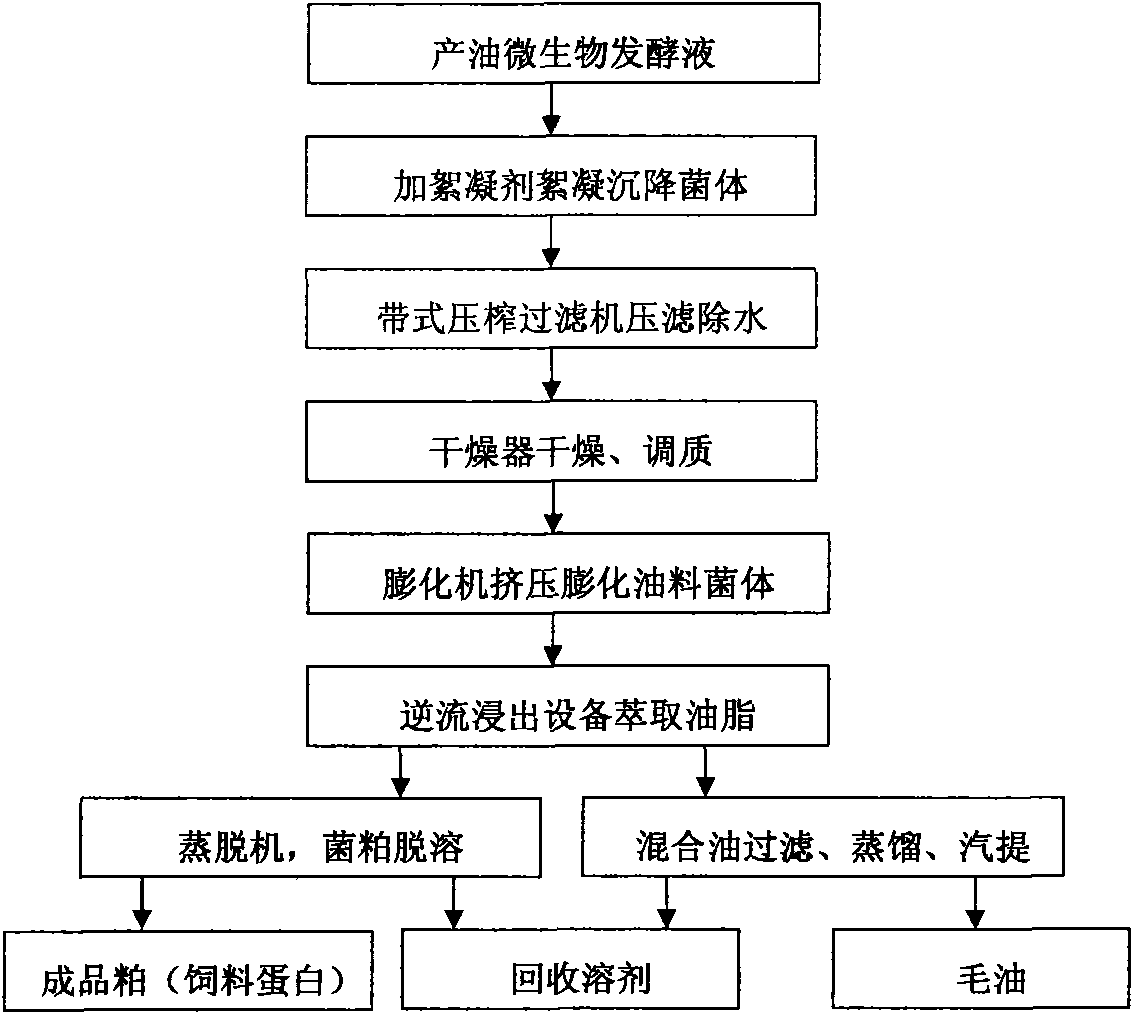

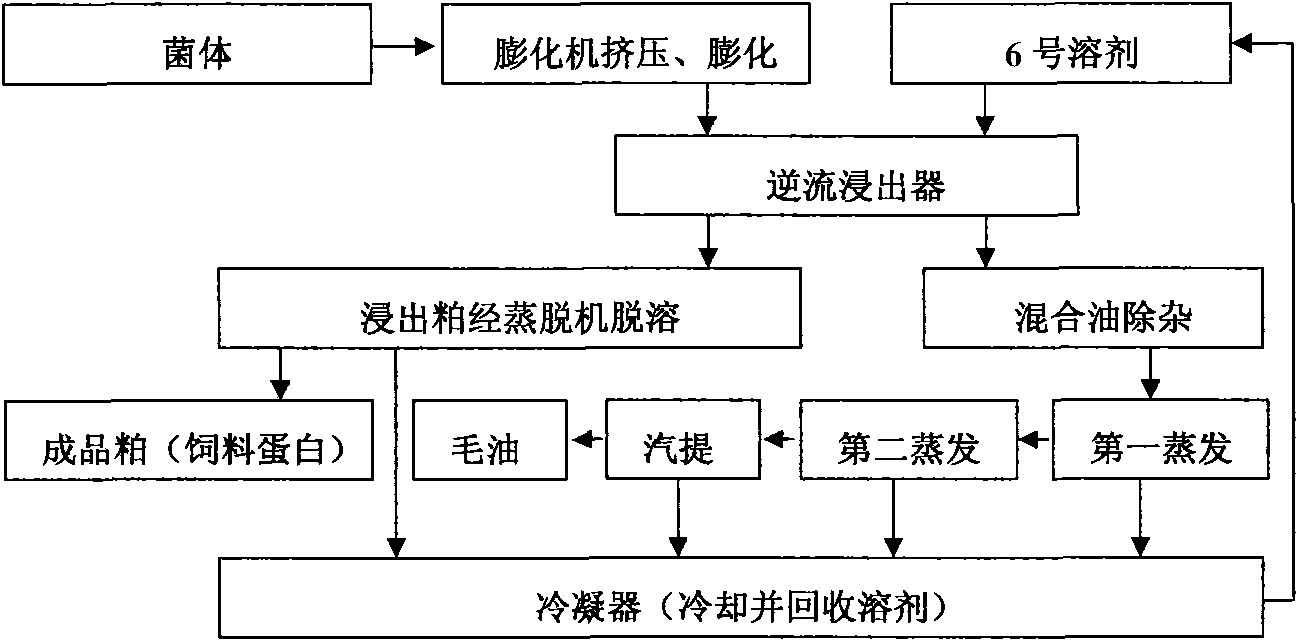

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

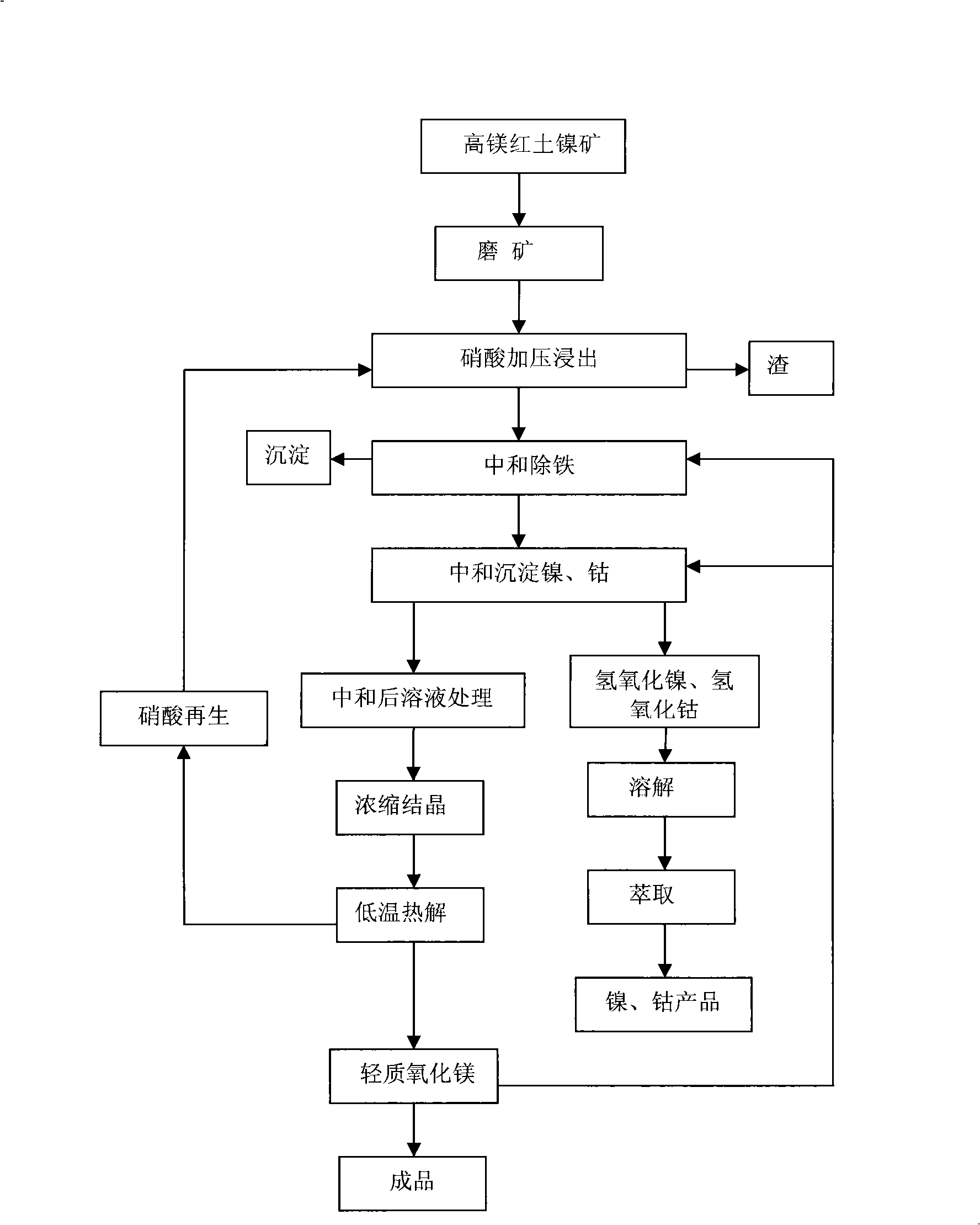

Treating method for high magnesium laterite nickel mine

InactiveCN101289704AEfficient extractionEfficient leachingProcess efficiency improvementPregnant leach solutionHigh magnesium

The invention discloses a method for treating high magnesium laterite-nickel ores. The method comprises the following steps of preliminary treatment of ore, pressurized leaching, iron purification of leach solution, deposition of nickel and cobalt, condensation and crystallization, production of light magnesium oxide by low-temperature thermal decomposition of crystals and regeneration of nitric acid. Under mild conditions of low temperature and pressure, leaching ratios of nickel and cobalt both reach 95 percent, the leaching ratio of magnesium reaches 98 percent, the iron content in the leach solution is less than 1g / L, and no silicon dioxide is leached out. The method can fully recover nickel, cobalt and magnesium, and the magnesium is generated in the form of light magnesium oxide, and the leaching agent-nitric acid can be recovered and regenerated for n, thereby better resolving the problems of highly efficient leaching-out of nickel and cobalt and reasonable utilization of magnesium; moreover, the technical flow is simple and has low requirements on equipment, and in the process of leaching out, the scab phenomenon does not occur in a high-pressure pan, so that the method is applied to the large-scale industrial production.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

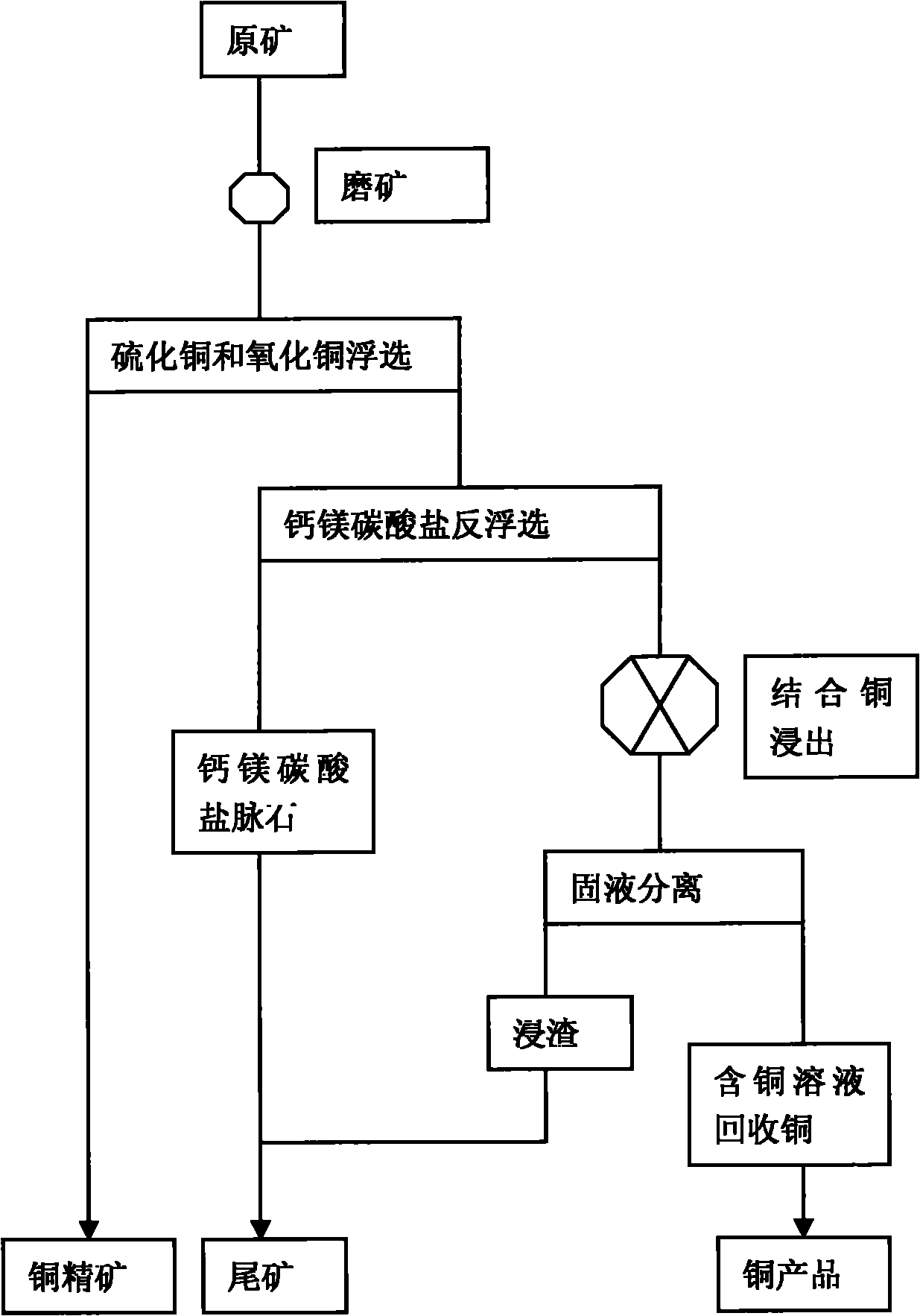

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

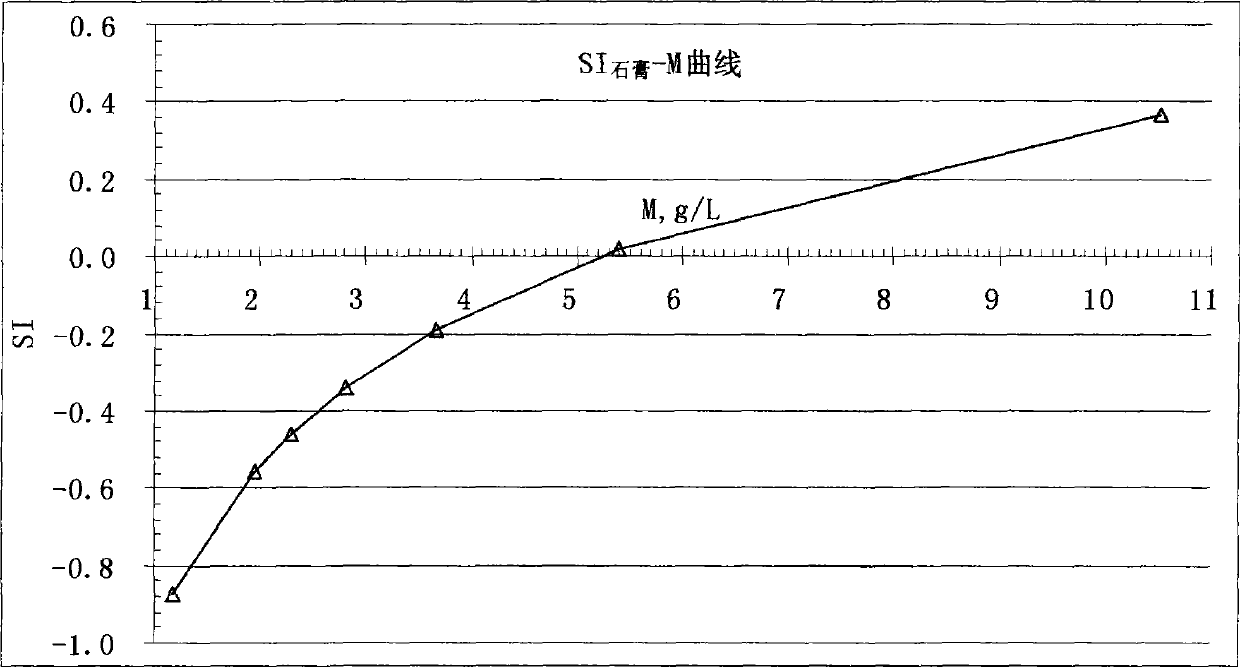

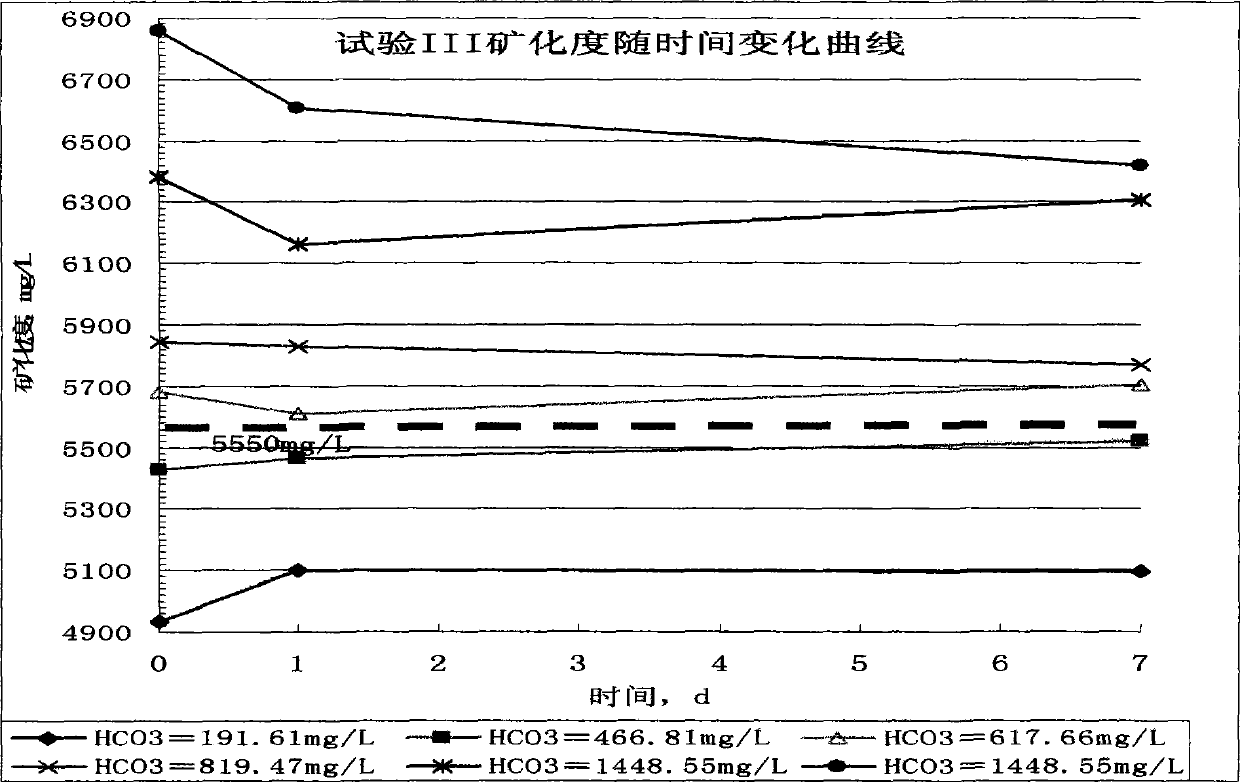

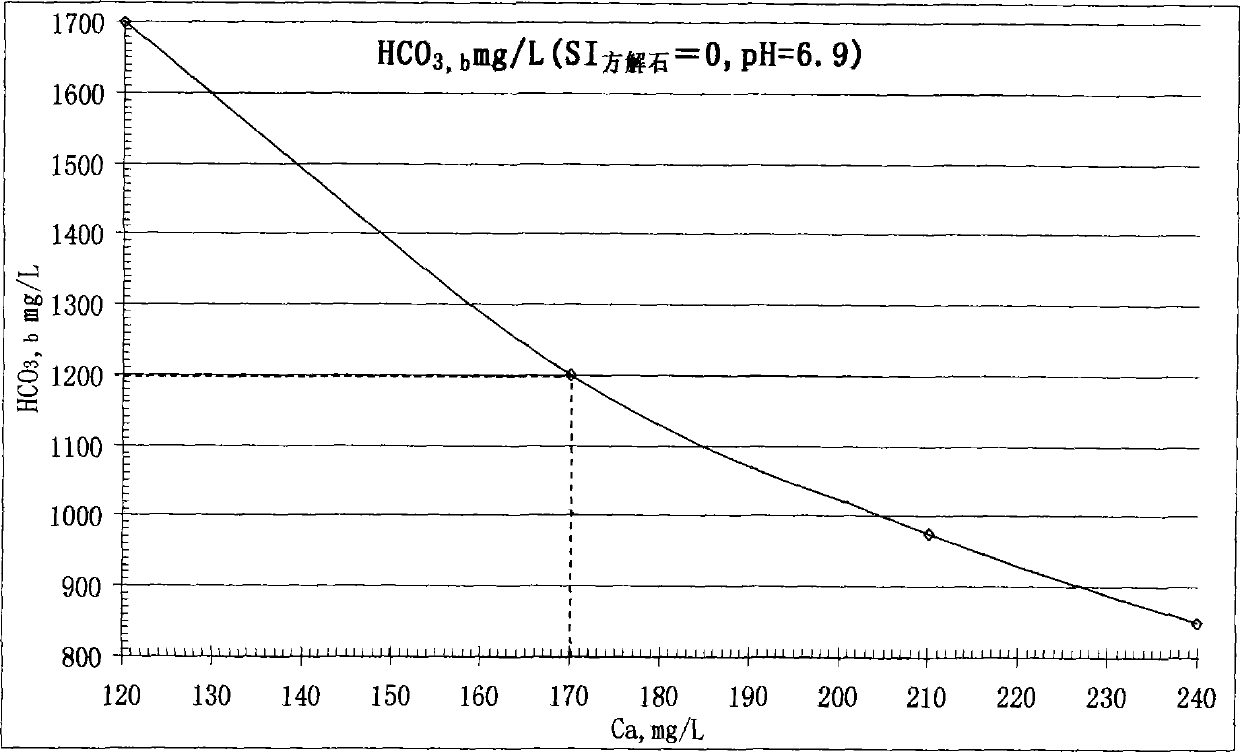

Desalination little-reagent ground-dipping uranium extraction method

The invention relates to a method for extracting uranium by desalting and on-site leaching with less agent, in particular to a technique for extracting uranium from uranium ores with high degree of mineralization of underground water in an ore bed. The technique adopts a desalting plus less agent step, and the concrete steps of the technique include: 1. desalting underground water and reducing the degree of mineralization of the underground water; and 2 extracting uranium by a leaching agent containing a latent solvent HCO3<->, oxygen and a pH adjustment agent. The invention solves problems of blockage caused by calcium sulphate and calcium carbonate in area with underground water of high degree of mineralization during on-site leaching, ensures smooth uranium extraction by on-site leaching and improves the uranium leaching efficiency.

Owner:EAST CHINA UNIV OF TECH

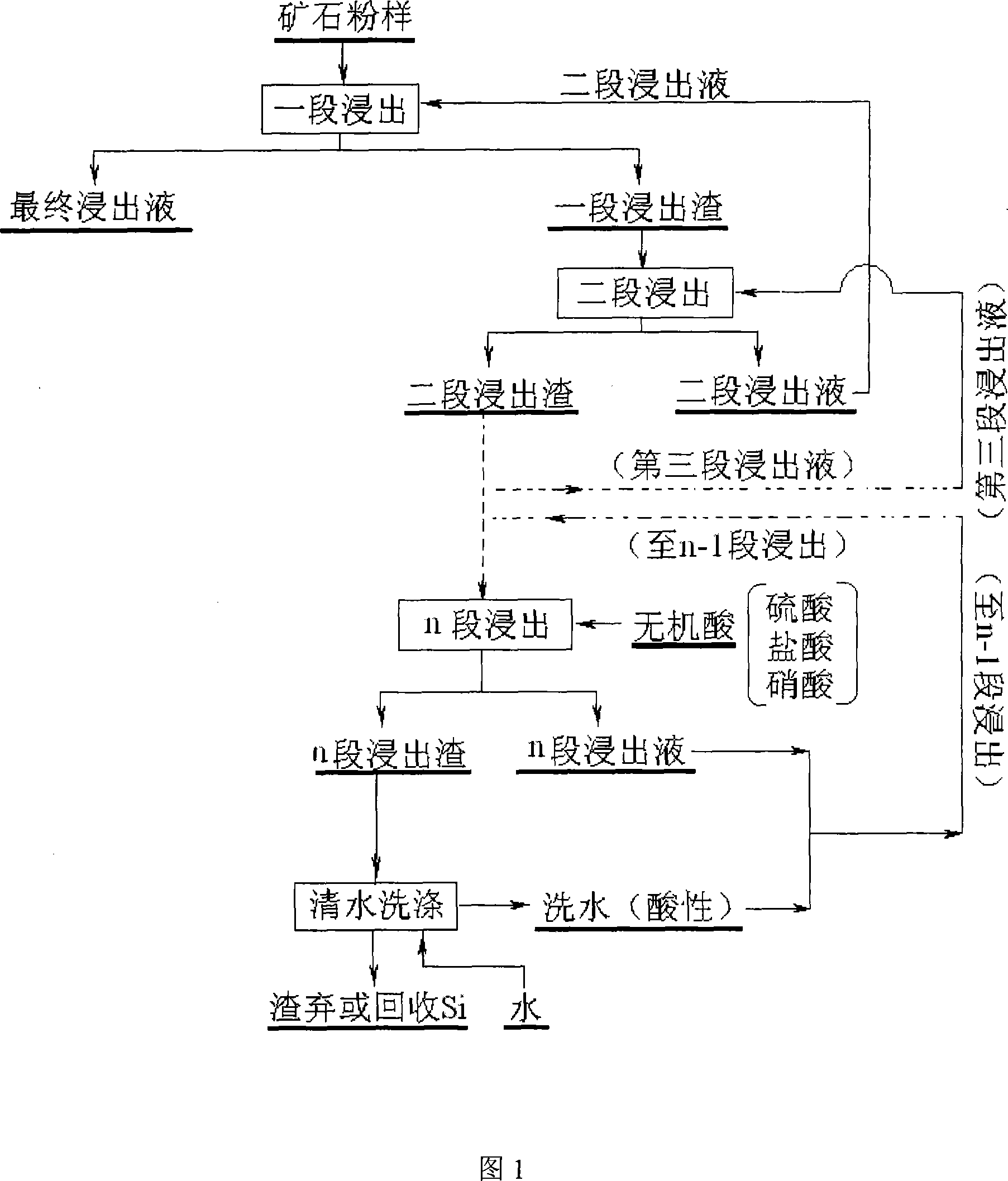

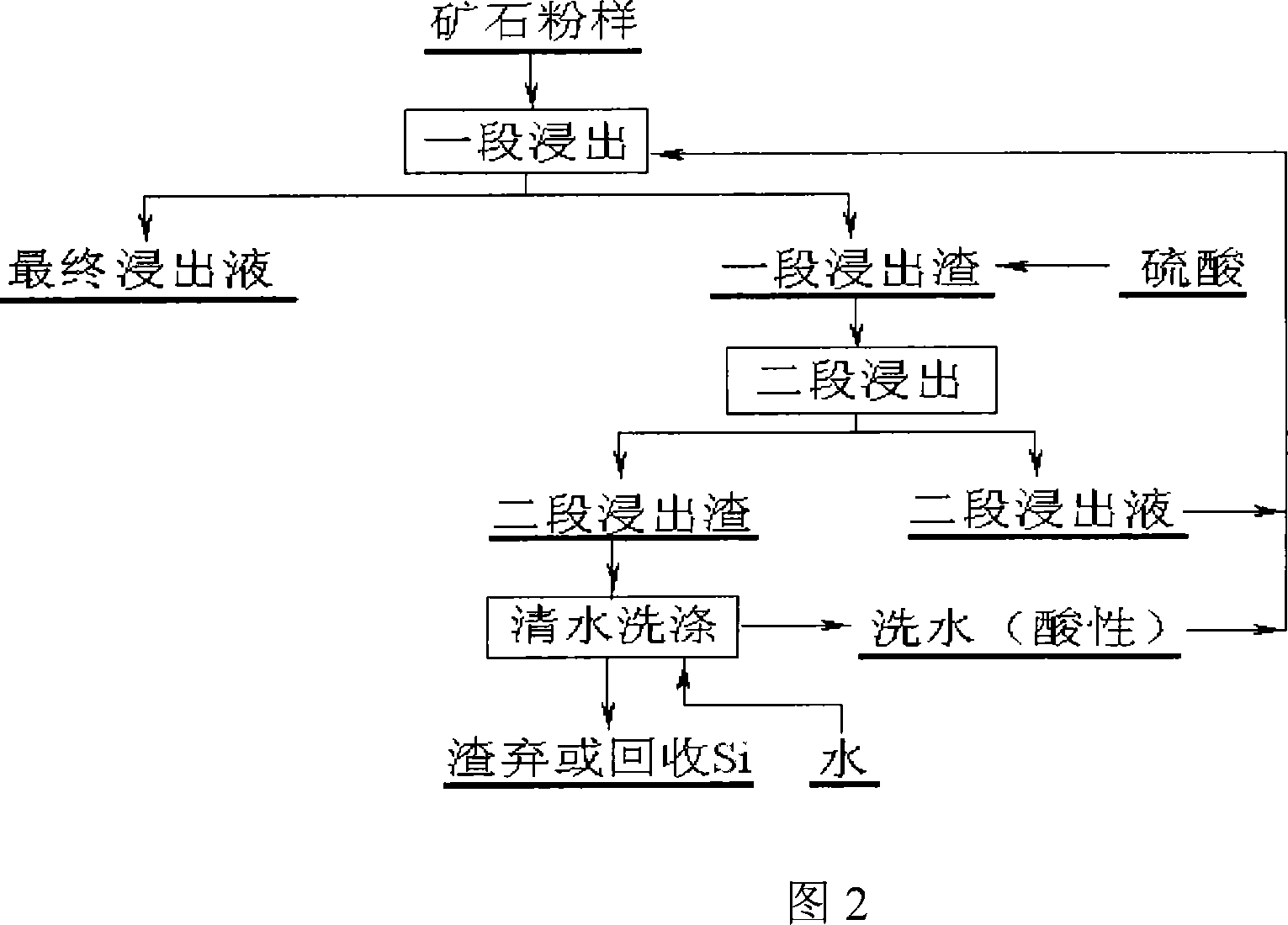

Multistage counter current acid leaching process containing nickel serpentine ore

InactiveCN101058852AReduce leachingReduce consumptionProcess efficiency improvementPregnant leach solutionReverse current

The invention discloses a nepouite with the multi-stage reverse-current acid-dipping technology, which comprises the following steps : grinding the nepouite; reacting with mixing the primary immersion liquid and water; reacting the leach residues a plurality of times endlessly; getting the K extract after finishing filtering the reaction of the k times; making the K extract liquor and the K extract react cyclically the k+1 times; regarding the k extract liquor as the extract liquor of the k-1 leaching reaction; regarding a corrosive acid as the extract liquor of the last leaching reaction; regarding the last extract liquor as a liquor containing Ni and Mg after n times reaction (k is between 1 and n and n is not less than 2). The invention reduces the cost, which recovers the Ni and Mg highly effectively.

Owner:CENT SOUTH UNIV

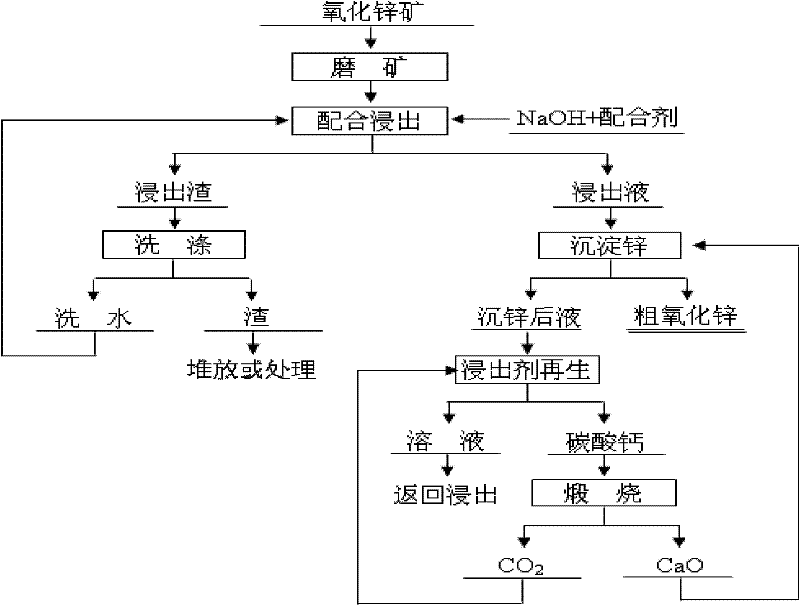

Method for treating low-grade zinc oxide ore by using weakly alkaline amino acid salt system

InactiveCN102242262AImprove leaching effectSmall side effectsProcess efficiency improvementCadmium CationChemistry

The invention discloses a method for treating a low-grade zinc oxide ore by using a weakly alkaline amino acid salt system, which comprises the following steps of: grinding the complex low-grade zinc oxide ore, and performing cooperated leaching in the weakly alkaline amino acid salt system under the certain condition to ensure that zinc, lead, cadmium, copper, nickel and the like are dissolved in leachate and calcium, magnesium, iron, silicon and the like are undissolved and stay in leaching residues; adding CaO or Ca(OH)2 into the leachate to ensure that the zinc is precipitated in the form of zinc oxide and recovered, and valuable metals such as the lead, the cadmium, the copper, the nickel and the like are co-precipitated with the zinc and enriched in crude zinc oxide; and regulating the pH of solution in which the zinc is precipitated to be a certain value by using CO2, regenerating a leaching agent, returning the regenerated leaching agent for recycling, and calcining CaCO3 generated in the process of regenerating the leaching agent for recycling. The method for treating the low-grade zinc oxide ore by using the weakly alkaline amino acid salt system can be used for effectively treating various complex low-grade zinc oxide ores with high calcium, magnesium, iron and silicon content, and the operation system is mild and has small toxic and side effects on human bodies and an environment.

Owner:CENT SOUTH UNIV

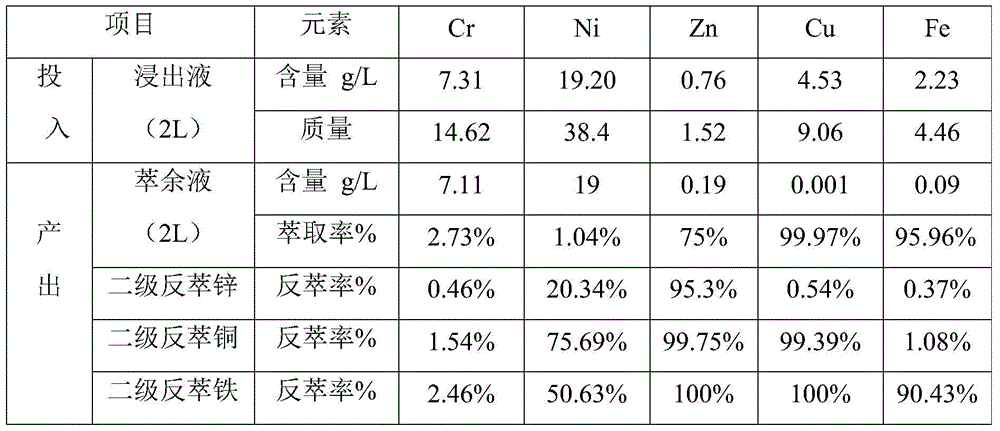

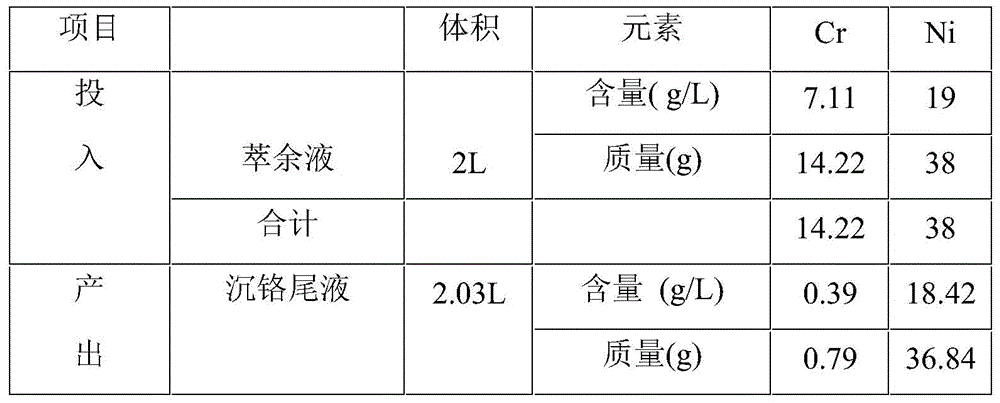

Harmless disposal and resource utilization method for electroplating sludge

InactiveCN105734294ADetoxify thoroughlyAdaptableProcess efficiency improvementResource utilizationSludge

The invention provides a harmless disposal and resource utilization new technology for electroplating sludge and particularly for complex electroplating sludge rich in copper, iron, nickel, zinc and chromium. Selected microorganisms are high in adaptation to the electroplating sludge and good in leaching performance; one-step extraction is adopted to extract copper, iron and zinc, follow-up nickel and chromium separation and purification are facilitated, in the whole technology, the iron cannot form any solid phase, and the problem that according to an existing reported technology, during iron separation, entrainment is serious or iron precipitation is not thorough is solved; a metallurgical method is adopted to carry out separating and recycling on extraction raffinate, the separation effect is good, and an obtained product is high in purity; and according to the technological process, cleaning and efficient high-value recycling of valuable metal in the electroplating sludge are achieved, the method is high in adaptation to various kinds of electroplating sludge, the electroplating sludge meets the harmless requirement, and the method extremely has the industrialized utilization value.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for extracting and recovering copper and selenium from copper anode sludge by microwave treatment

ActiveCN103451438AWith automatic balanceHeating evenlySelenium/tellurium compundsProcess efficiency improvementMicrowave frequencySelenium

The invention belongs to the field of wet metallurgy, and in particular relates to a method for extracting and recovering copper and selenium from copper anode sludge by microwave treatment. The method specifically comprises the following steps of: screening to remove sandy impurities being more than 5mm in particle diameter from the copper anode sludge; adding sulfuric acid at a concentration of 20 to 500g / L to perform size mixing; controlling the weight concentration of the copper anode sludge size to be 1 to 30%; transferring the copper anode sludge size into a microwave oven; filling or adding an oxidizing agent to the copper anode sludge size; adjusting microwave frequency to be 1,500 to 3,500MHz and microwave heating power to be 120 to 700w; and performing leaching reaction for 1 to 30 minutes under normal pressure, wherein the copper is leached out in a form of CuSO4 from the copper anode sludge, and selenium is ledleaded out in the forms of H2SeO3 and SeSO3 and other forms. By adopting the method, the time of treating the copper anode sludge is shortened; the treatment capacity is increased; the removal rate of copper as well as selenium is raised; the rationality and concentricity of other valuable metals in the copper anode sludge are enabled, thus the comprehensive recovery can be performed well, and the energy consumption is reduced; in addition, special high pressure equipment is saved; and the leaching is performed at a faster speed.

Owner:NORTHEASTERN UNIV

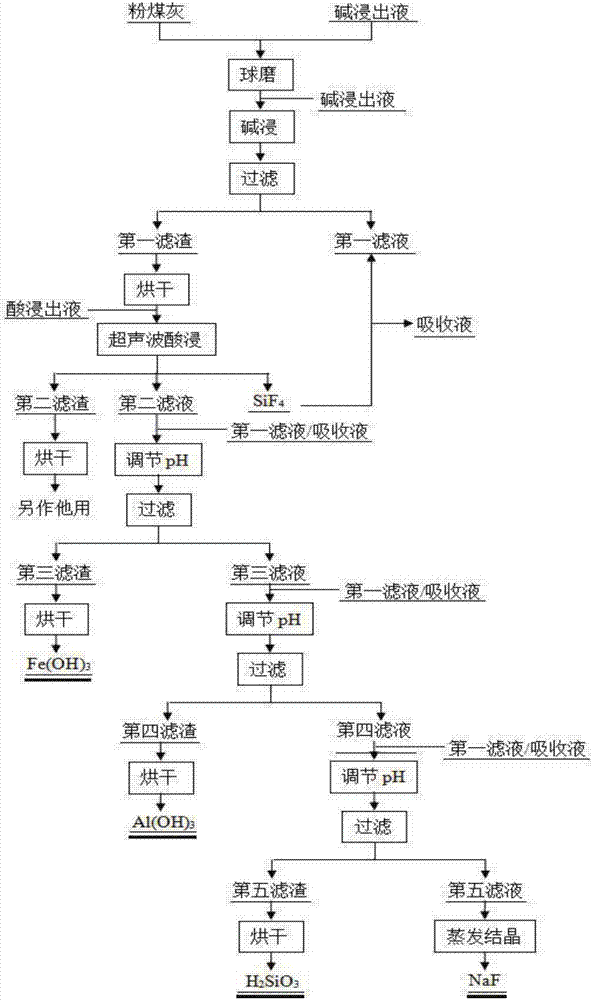

Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

InactiveCN107162061AEliminate hazardsLow costSilicaIron oxides/hydroxidesPregnant leach solutionElectrolysis

The invention discloses a combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of an aluminum electrolysis cell waste cathode carbon block. The pulverized fuel ash and the alkaline leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed and are subjected to ball milling; primary alkaline leaching is performed; then, the alkaline leaching liquid is replenished; secondary alkaline leaching is performed; solid and liquid separation of a secondary alkaline leaching system is separated to obtain first filter liquid and first filter slag; the first filter slag and the acid leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed; acid leaching is performed under the assistance of ultrasound; then, solid-liquid separation is performed to obtain second filter liquid; the pH of second filter liquid is increased in a gradient way; Fe(OH)3, Al(OH)3 and H2SiO3 are obtained from the second filter liquid through sequential separation; finally, the filter liquid subjected to H2SiO3 separation is concentrated to obtain NaF. The whole treatment method achieves the goals of treating wastes by wastes, reducing the energy consumption, reducing the consumption of industrial raw materials and reducing the equipment loss.

Owner:CENT SOUTH UNIV

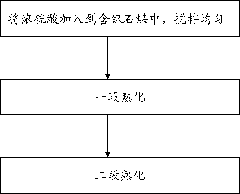

Process for extracting vanadium from stone coal through two-section curing with concentrated acid

InactiveCN102191388AImprove leaching effectImprove conversion rateProcess efficiency improvementMineral SourcesCoal

The invention relates to a process for extracting vanadium from stone coal through two-section curing with concentrated acid. The process flow mainly comprises the following steps of: a), adding concentrated sulfuric acid into the vanadium-containing stone coal, and uniformly stirring; b), performing one-section curing on the mixture of the concentrated sulfuric acid and the vanadium-containing stone coal at the temperature of at least 50 DEG C; and c), performing second-section curing on the mixture subjected to the one-section curing at the temperature of at least 100 DEG C. The process has high conversion rate, saves mineral resources and has high adaptability.

Owner:北京天瑞利达投资发展有限公司

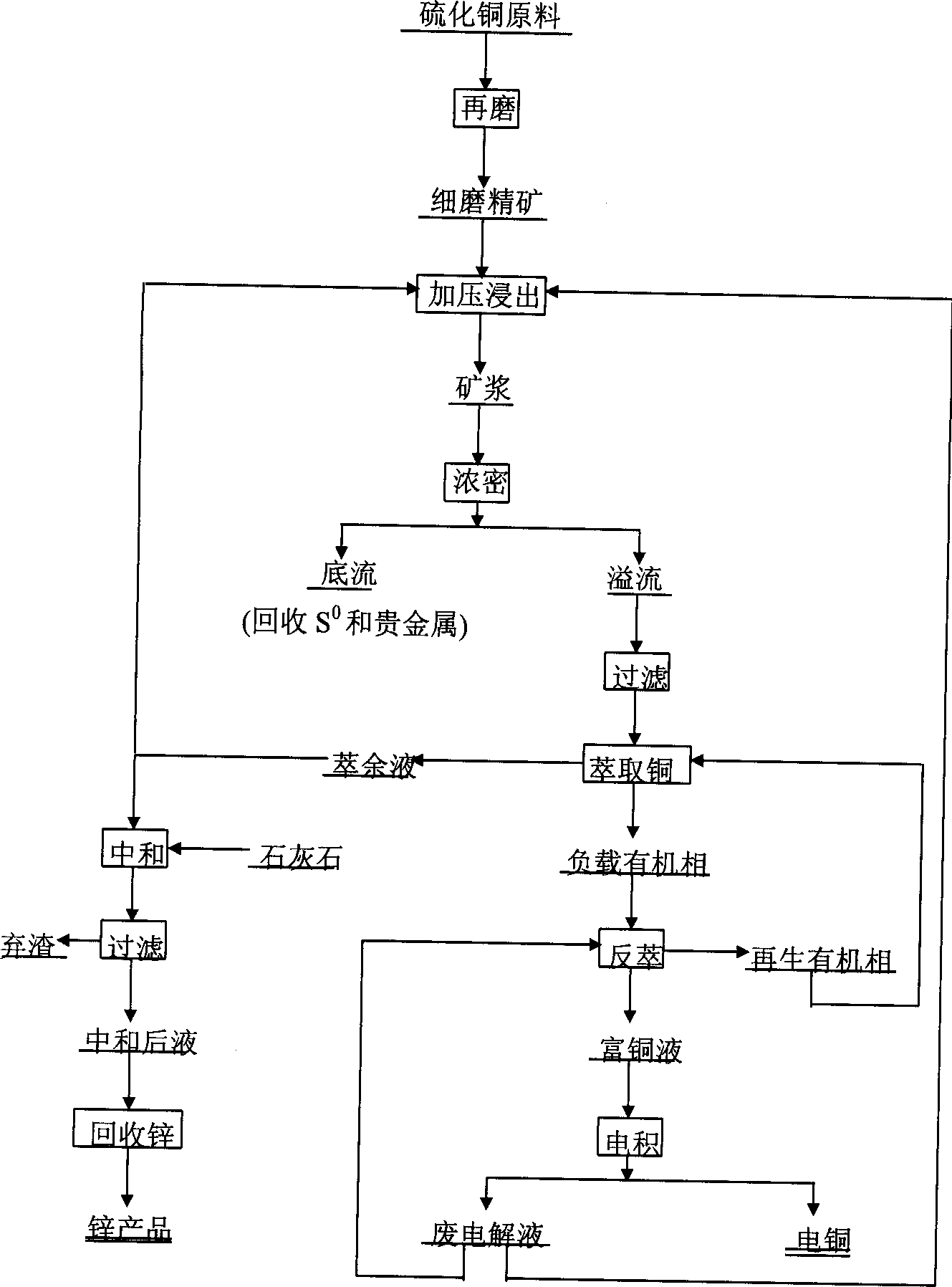

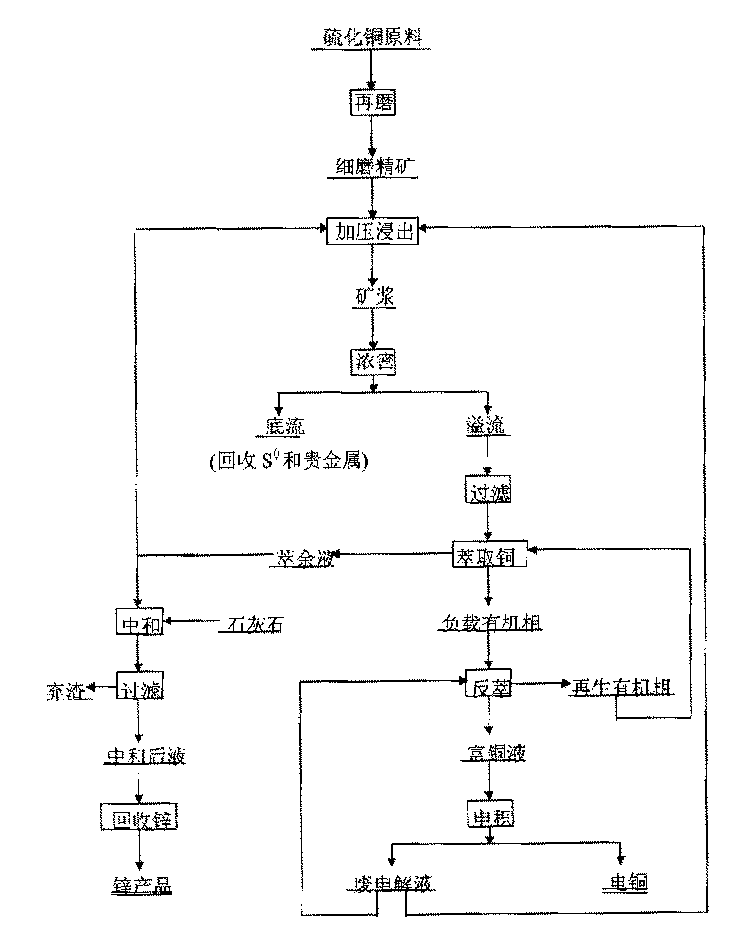

Method for extracting copper for copper containing sulfurized ore

InactiveCN1358871ALow leaching temperatureRelieve pressureProcess efficiency improvementSlagSulfide minerals

The method for extracting copper from copper-bearing sulfide mineral is characterized by leaching copper-bearing mineral under the condition of introduction of oxygen and in the presence of sulfuric acid and chlorine ion, the liquid-solid ratio of leaching-out liquor is 1-8:1, primary concentration of sulfuric acid is 5-70 g / L, leaching total pressure is 200-1000 kPa, partial pressure of oxygen is 100-800 kPa, temp. is 100-130 deg.C and time is 1-4 hr. The leaching temp. and pressure of said method are low, its selectivity is good, the pyrite can not be oxidated, and the harmful impurity, for example arsenic, can be solidifed in arsenic-ion slag, so that it is a process friendly to environment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

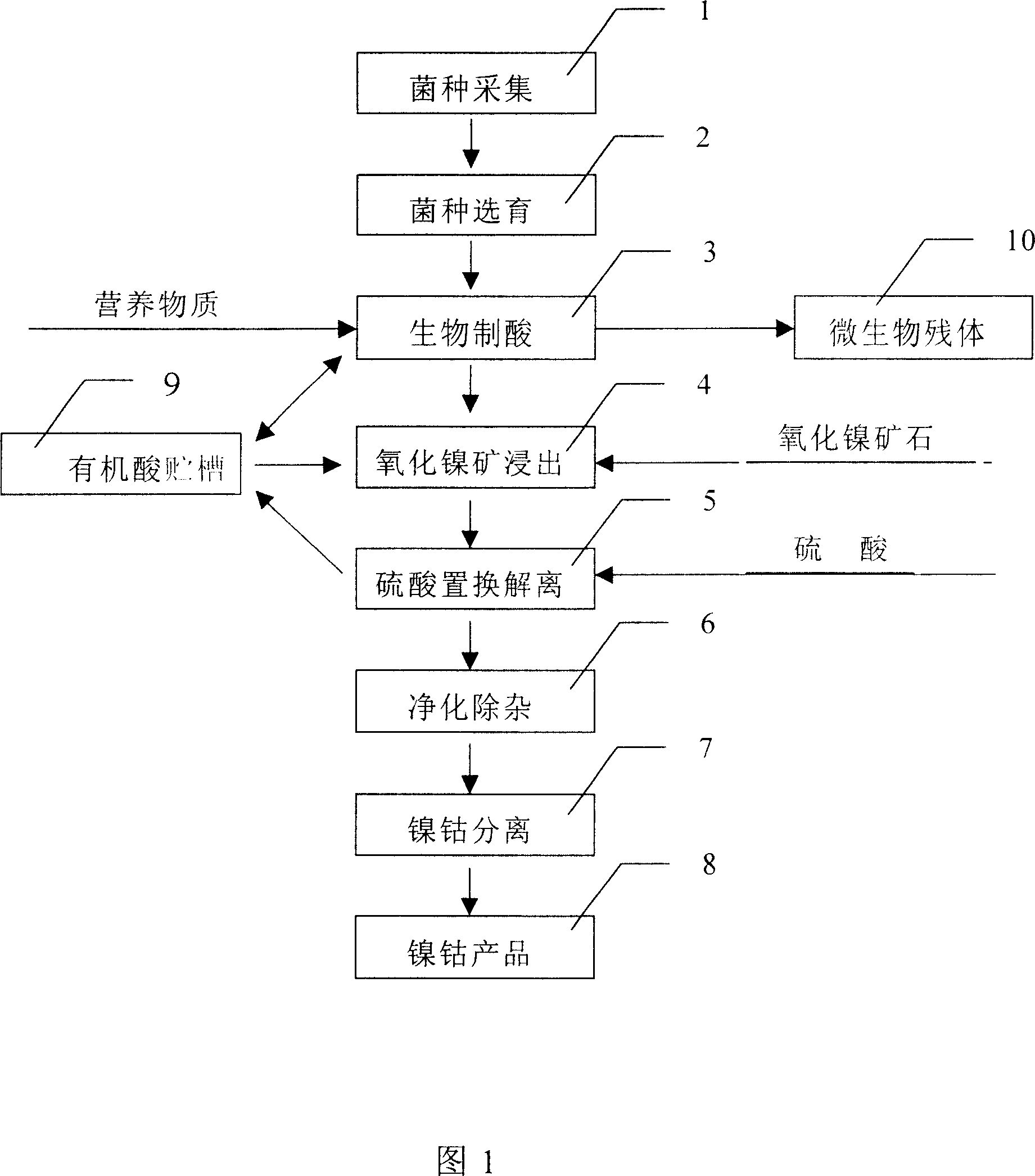

Biological extract technology for ore of cobalt nickel oxide

InactiveCN1958815AImprove leaching effectReduce heavy ironProcess efficiency improvementLower gradeLow graded

This invention relates to a biological method for leaching ores of nickel oxide and cobalt oxide. The method comprises: leaching ores of nickel oxide and cobalt oxide by using leaching organism derived organic acid, dissociating the leaching solution containing nickel and cobalt, passing through a separation resin, and separating nickel and cobalt from the eluate by a resin to obtain nickel sulfate and cobalt sulfate products. The method has such advantages as short process, simple equipment, low investment, low cost, no pollution and high recovery rate. The method can treat low-grade ores of nickel oxide and cobalt oxide that cannot be treated by traditional separation process, thus expanding the utility range of resources and increase the recovery rate of nickel and cobalt.

Owner:有研资源环境技术研究院(北京)有限公司

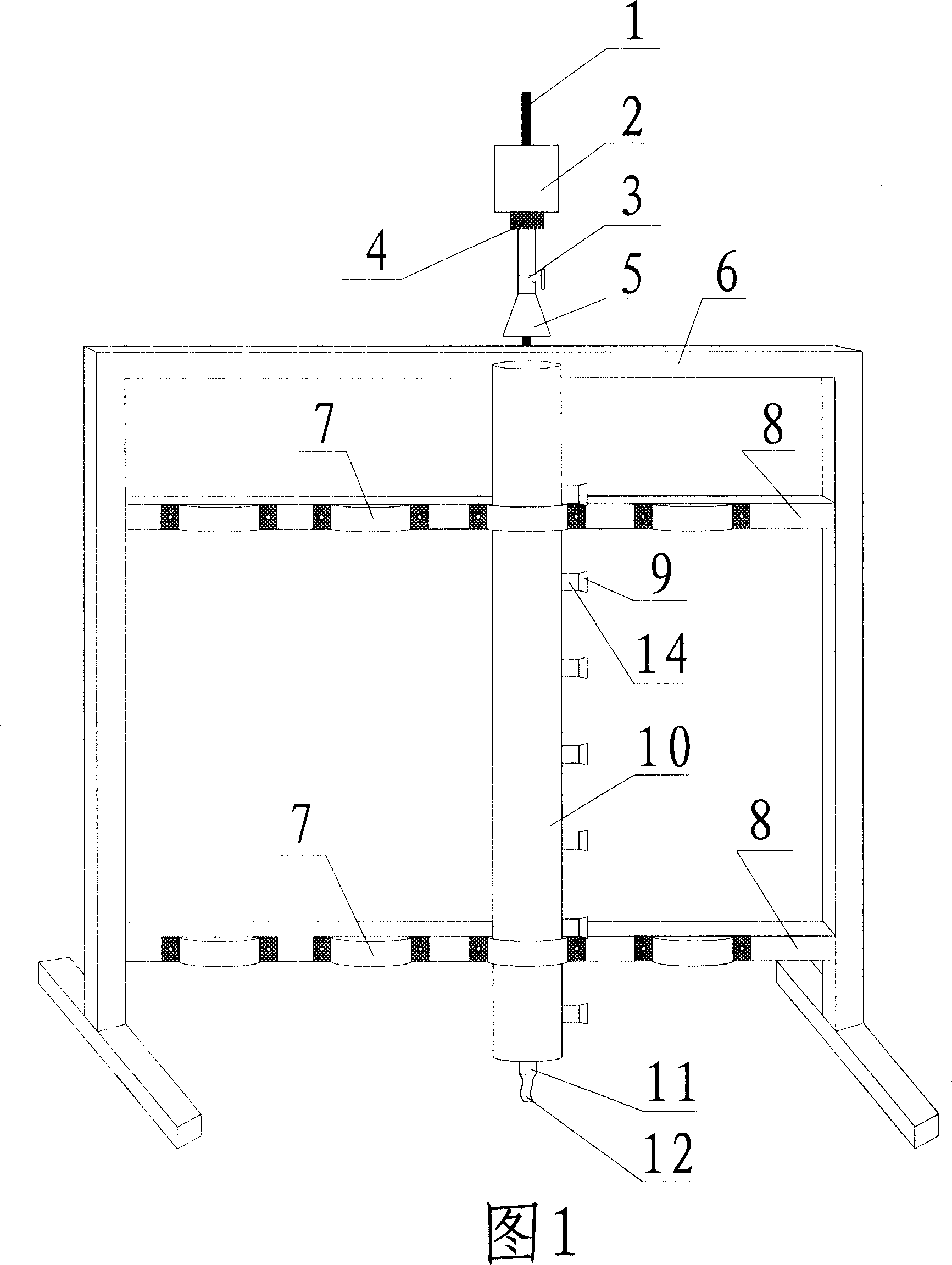

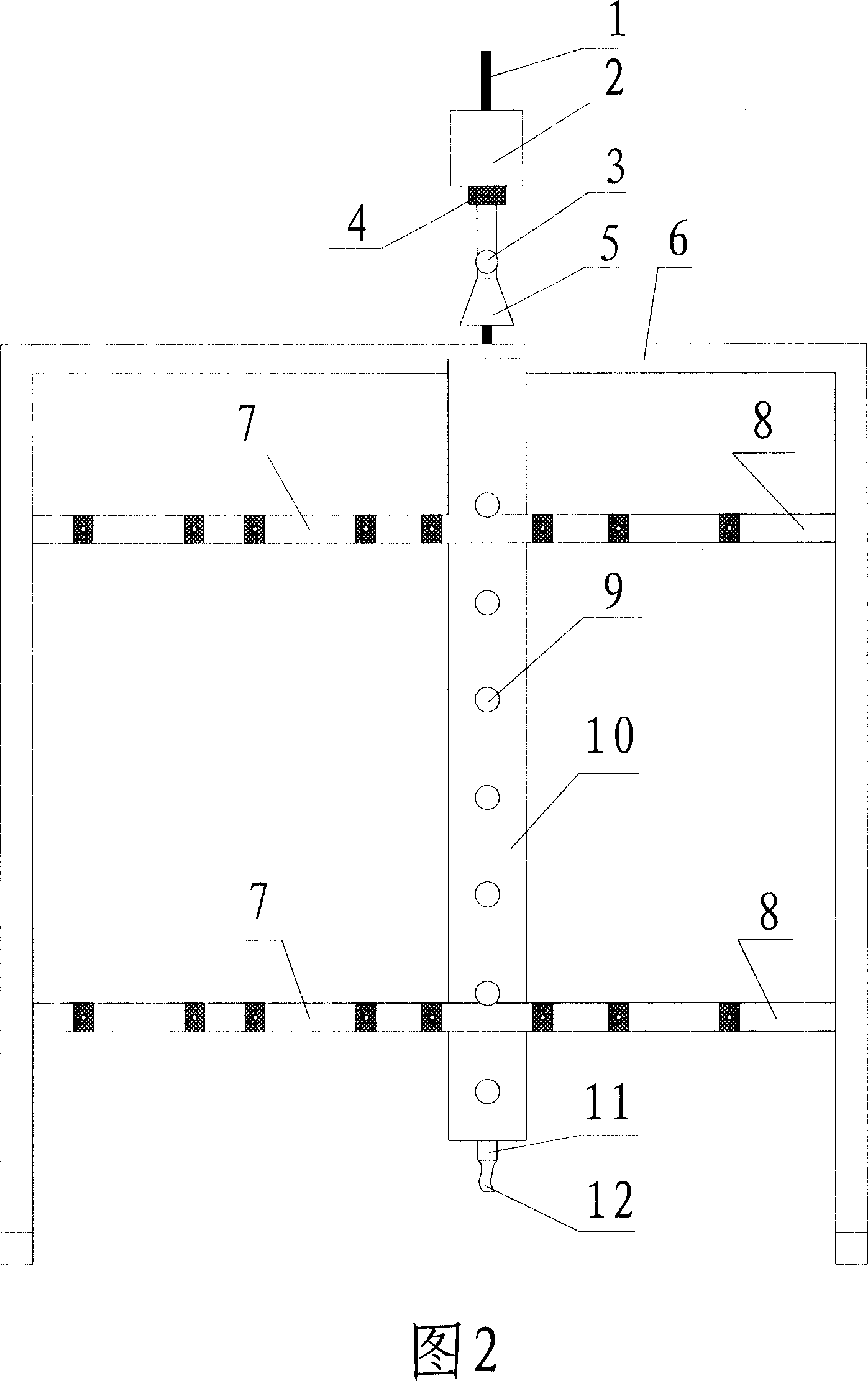

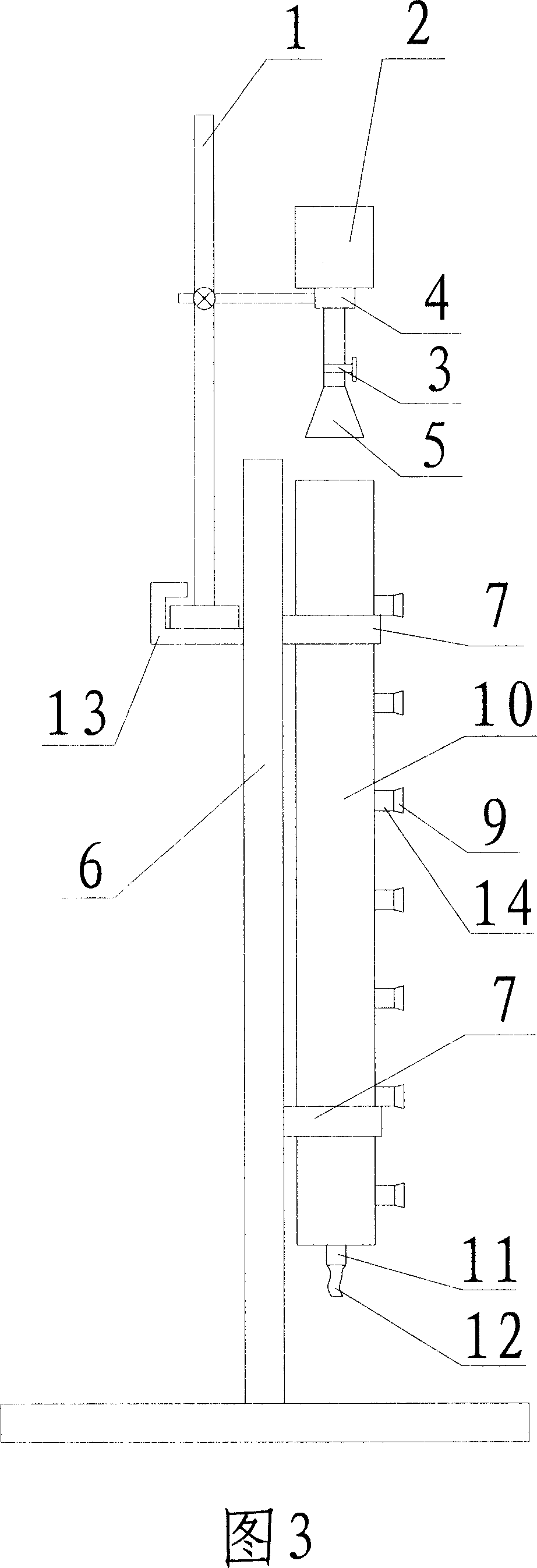

Soil eluviation simulator

InactiveCN101088621AEasy to leachingSimple structurePreparing sample for investigationLaboratory apparatusEngineeringUltimate tensile strength

The present invention relates to soil research equipment, and is especially one kind of soil eluviation simulator for laboratory use. The soil eluviation simulator includes a water feeding support, a water feeder with valve and mounted on the water feeding support, a main frame and an eluviating column fixed on the main frame and below the water feeder. The eluviating column with sampling holes is mounted detachably through a fastener on one side of the main frame, and the water feeding support is set in the slide water on the other side of the main frame. The present invention has simple structure, convenient operation, high eluviating effect, less disturbance on the soil, adjustable water feeding amount and strength, less eluviation simulating error and capacity of recovering the leached liquid.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

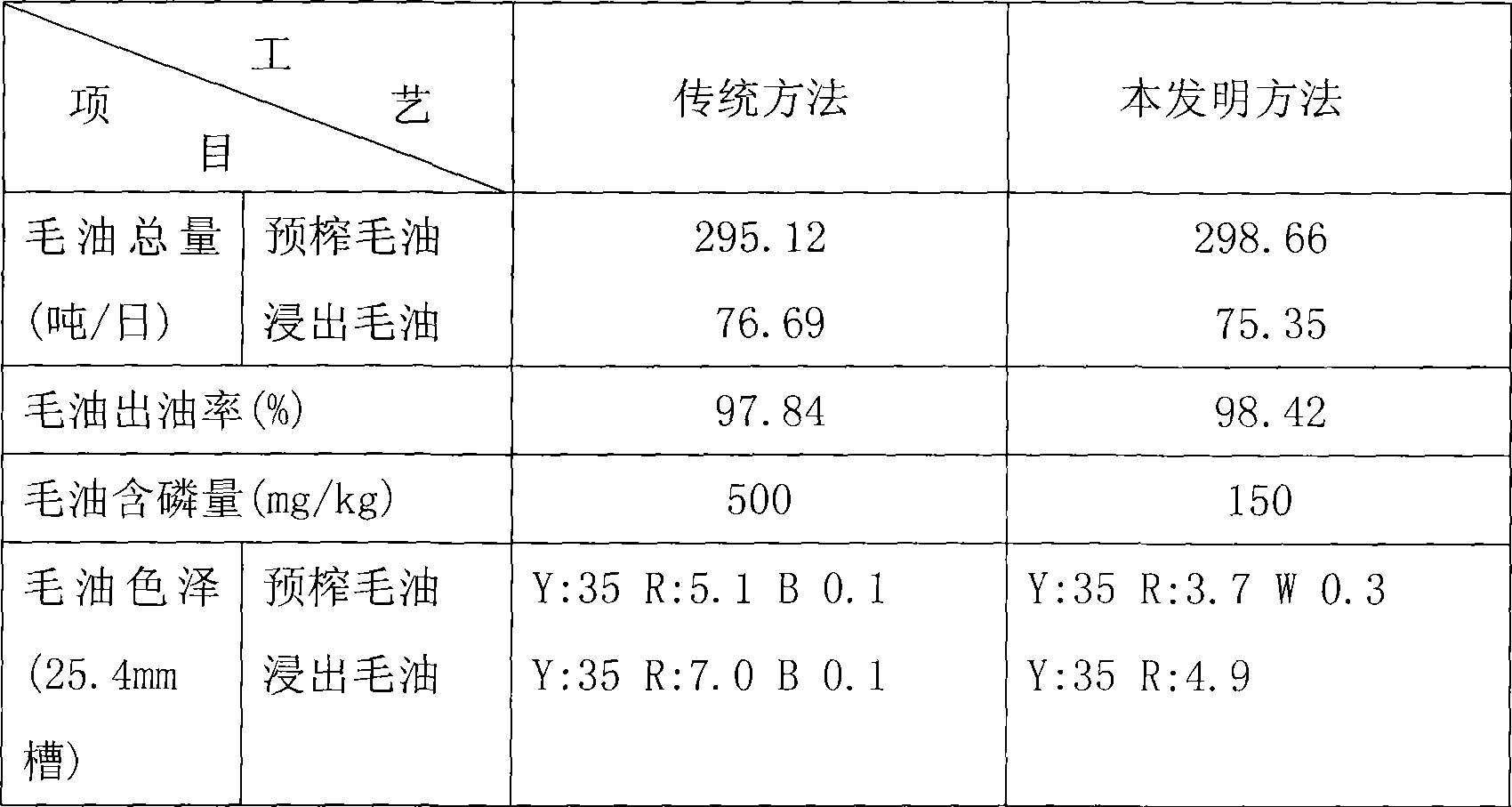

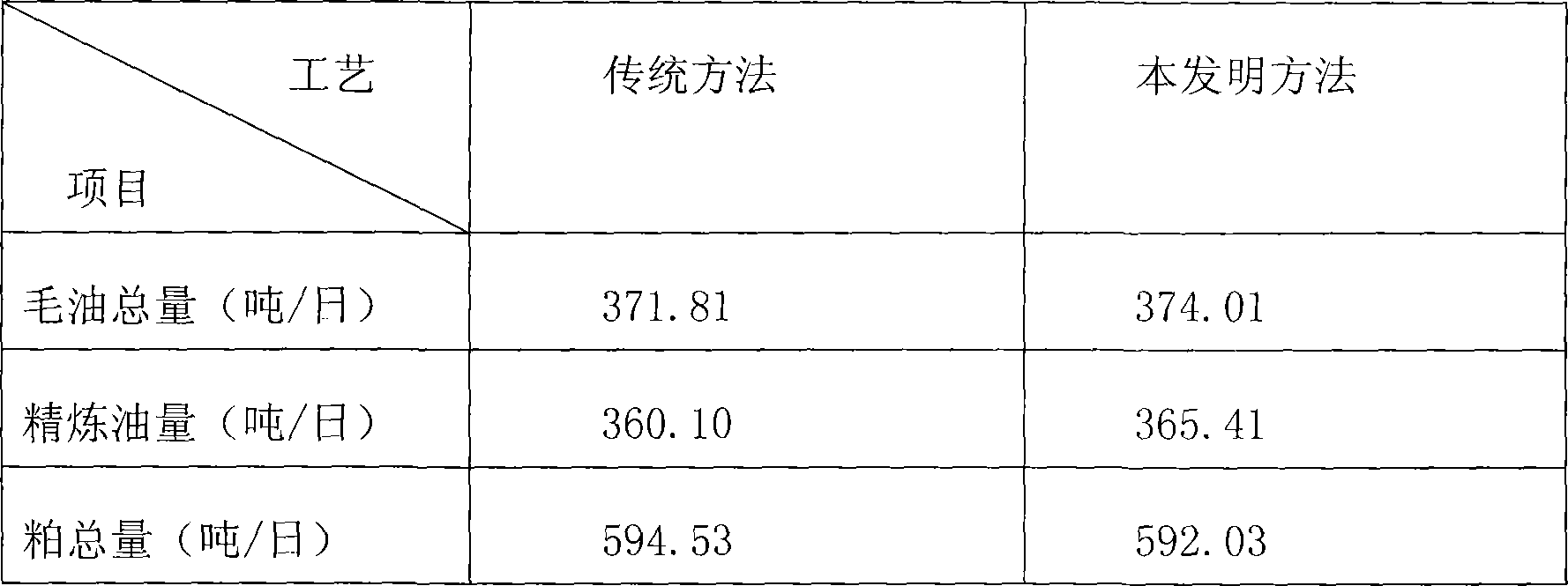

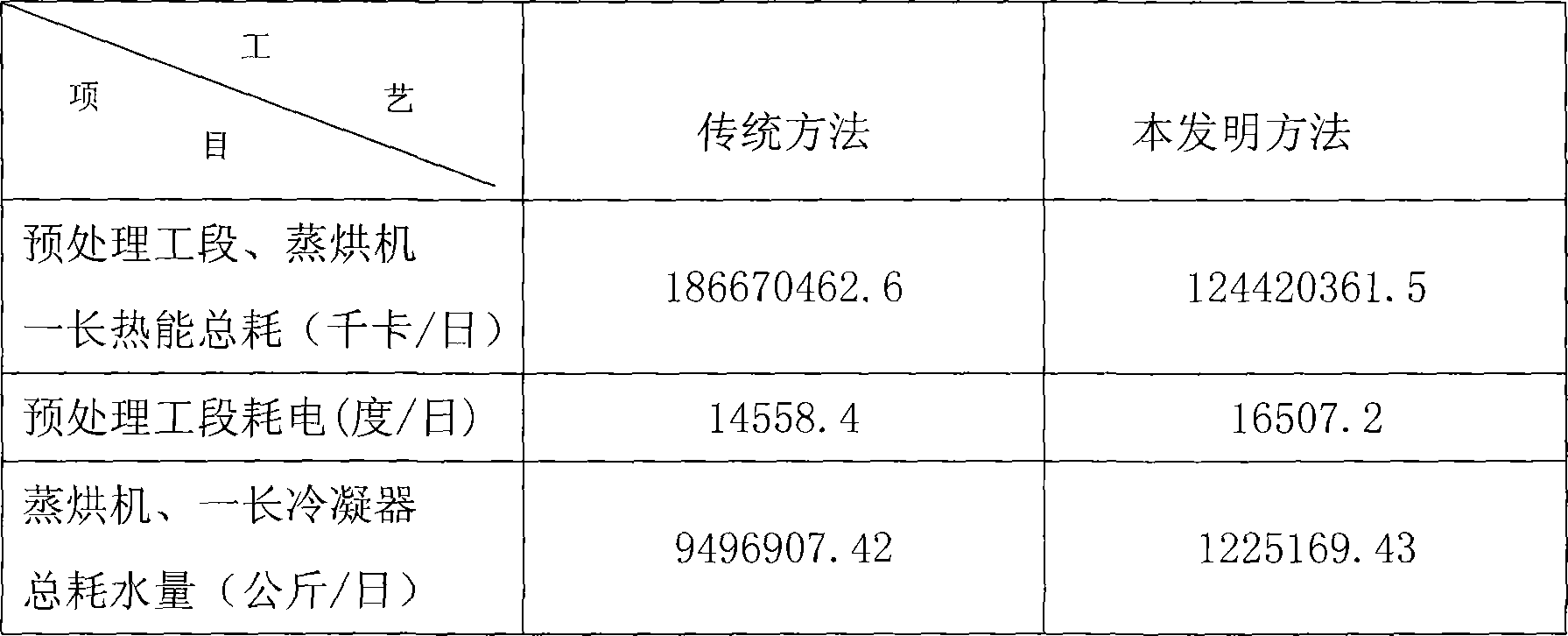

Swelling pre-squeezing leaching preparation method for high oil-containing material

InactiveCN101235340AAvoid excessive denaturationReduces loss of lysineFatty-oils/fats productionWater contentOil content

The invention relates to a high oil-content oil material expanding prepressing leaching oil preparation method, which is characterized in that the method comprises the following steps, firstly, cleaning, cleaning oiling to remove impurities, secondly, tempering, adjusting the water content of oiling whose impurities are removed, thirdly, rolling slab, rolling oiling whose water content is adjusted into material slab, fourthly, squeezing and swelling, squeezing and swelling, the material slab, fifthly, drying, drying the material slab which is squeezed and swelled, sixthly, prepressing, prepressing the material slab which is dried to press one portion of oil, seventhly, leaching, leaching prepressed cake of the oil which is prepressed to get another portion of oil and meal from solvent extraction. A squeezing and swelling step in the invention is utilized to replace a cooking step in the existing method, which improves the quality and amounts of prepressing crude palm oil, increases handling capacity of a prepress expeller, and reduces power consumption and abrasion of a prepress expeller. The method of the invention is mainly applicable for oil preparation enterprises which utilize high oil-content oiling such as rapeseed and the like to be raw material.

Owner:中机康元粮油装备(北京)有限公司 +1

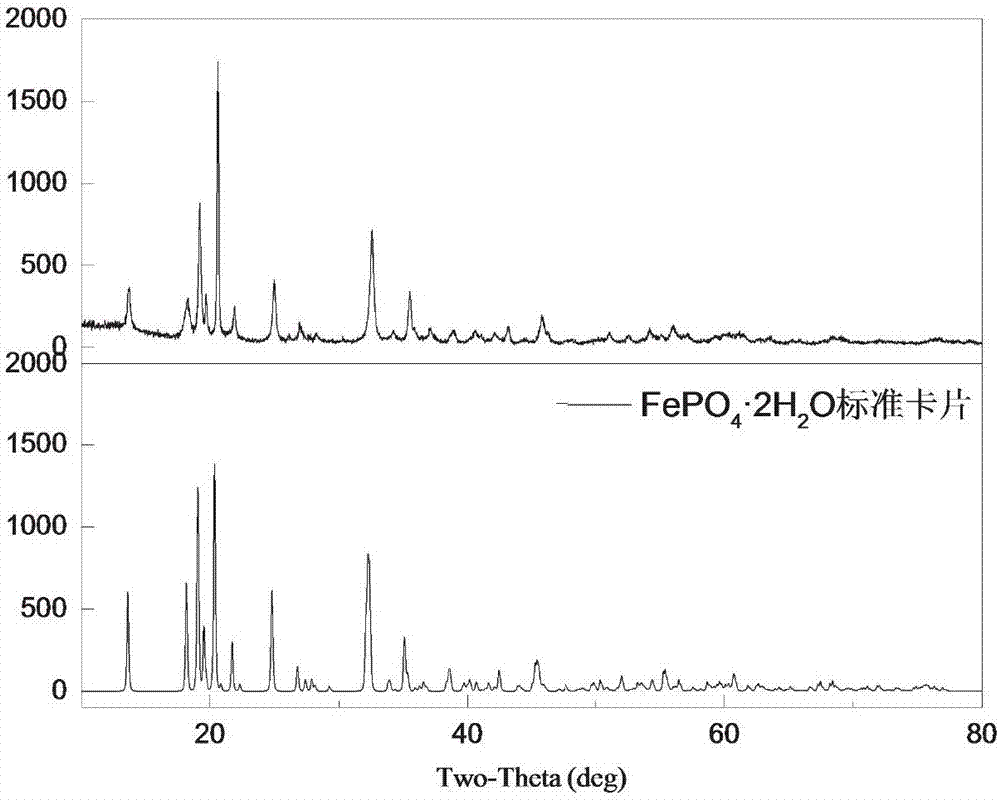

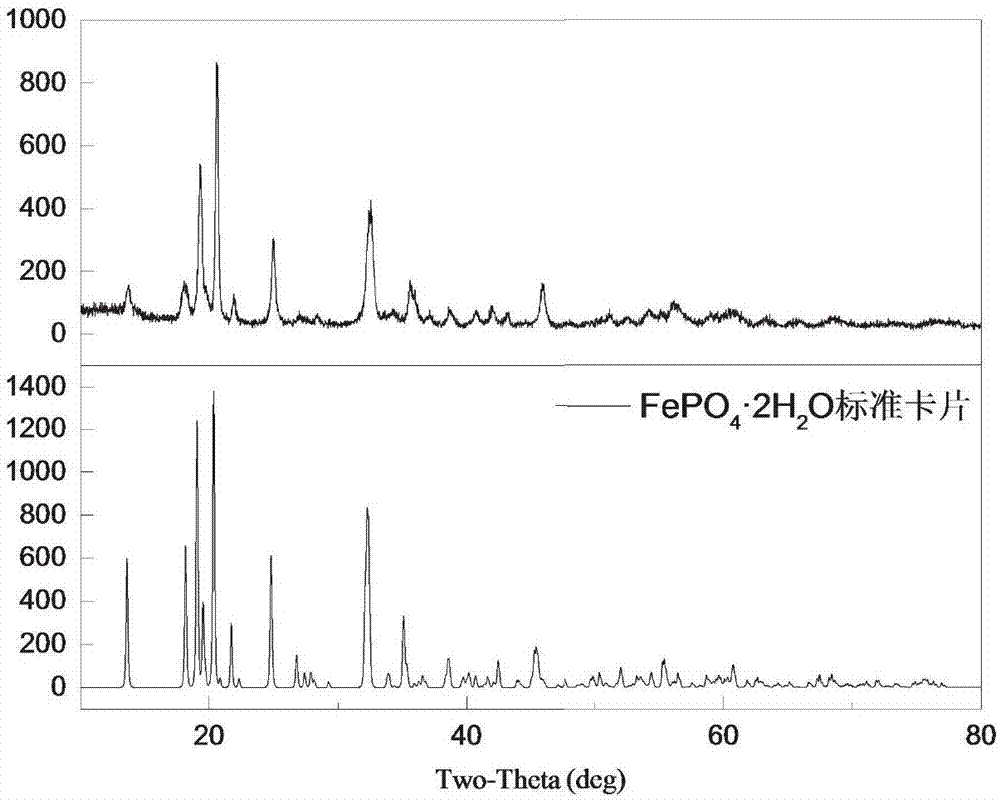

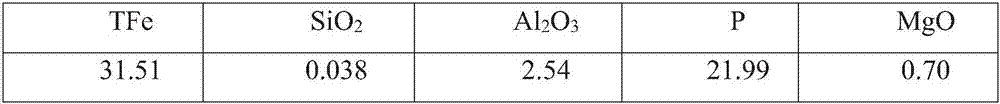

Method for normal-pressure phosphoric-acid leaching of nickel-cobalt and synchronous preparation of iron phosphate

ActiveCN106987728AImprove leaching rateEfficient separationProcess efficiency improvementPhosphorus compoundsPhosphoric acidLaterite

The invention discloses a method for the normal-pressure phosphoric-acid leaching of nickel-cobalt and the synchronous preparation of iron phosphate. The method comprises the following steps: subjecting laterite nickel ore to normal-pressure acid leading treatment, and then carrying out solid-liquid separation to obtain a leaching residue of iron phosphate and a leaching solution of enriched nickel-cobalt, wherein in the leaching process, phosphoric acid with a concentration of 1-3 mol / L is adopted; the adding amount of phosphoric acid is 1-3 times as much as the theoretical molar mass of metal elements in the leached transformed laterite nickel ore; and the laterite nickel ore is subjected to transformation at 300-400 DEG in advance before the acid leading treatment. The method is particularly suitable for the treatment of low-grade limonite-type laterite nickel ore; the nickel-cobalt recovery rate is high; the nickel-iron separation effect is good; and the leaching residue of iron phosphate is not only applicable to the preparation of iron phosphate lithium batteries but also utilized as a raw material for the manufacturing of catalysts and ceramics.

Owner:CENT SOUTH UNIV

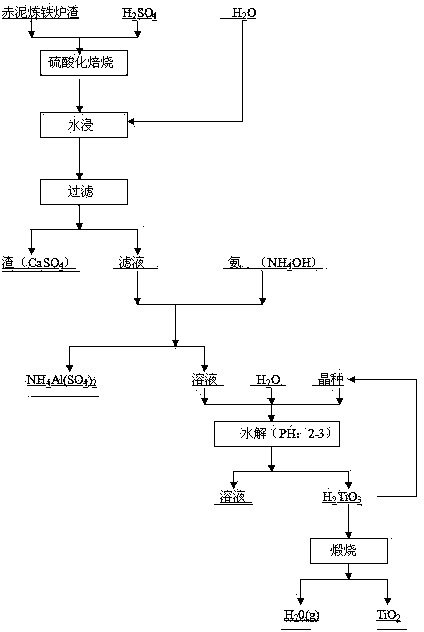

Method for recovering titanium from red mud slag

The invention provides a method for recovering titanium from red mud slag. The method comprises the following steps of recovering iron from red mud, solid waste of aluminum oxide production, mixing the slag after iron recovery and concentrated sulfuric acid for sulfating roasting, draining water to form a mixed solution containing metatitanic acid, adding ammonia water to remove aluminum to purify a titanium solution, hydrolyzing to crystallize and precipitate metatitanic acid, roasting metatitanic acid to form titanium dioxide, and successfully recovering the titanium from the red mud reduced iron slag. The method takes the ironmaking slag of the red mud, the solid waste of the aluminum oxide production, as a raw material, a technology is simple, a recovery rate is high, the comprehensive utilization of red mud is achieved, the cost related to red mud stockpiling is lowered, and the influence on an environment and accident potential caused by the red mud stockpiling are eliminated. The titanium recovery rate can reach above 70%, and the obtained product, titanium dioxide, is high in purity and good in quality.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

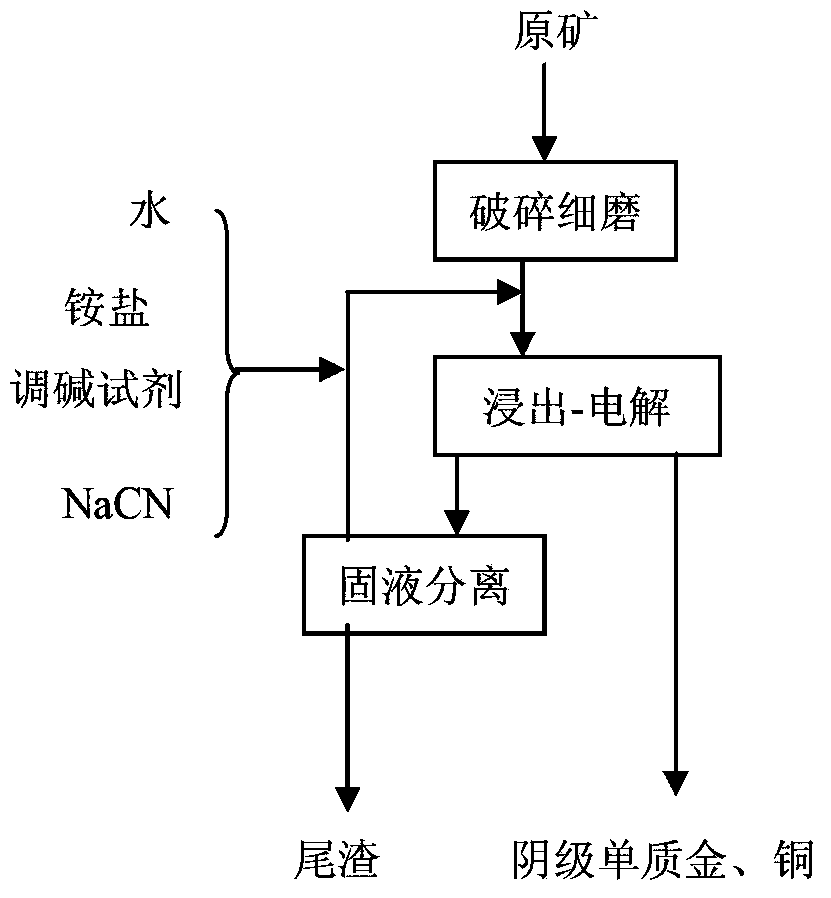

Method for recycling gold and copper from copper-containing oxidization gold ores

ActiveCN103572322AShort processImprove leaching effectPhotography auxillary processesProcess efficiency improvementIridiumGraphite

The invention relates to a method for recycling gold and copper from copper-containing oxidization gold ores, belonging to the technical field of wet-process metallurgy. The method comprises the following steps: firstly, carrying out ore-grinding and pulping onto the copper-containing oxidization gold ores, regulating the pH value by using an alkaline regulating agent in serous fluid and adding a leaching agent; with a titanium-based iridium-coated ruthenium coating electrode, stainless steel or lead alloy as an anode and a graphite plate, a stainless steel plate, a titanium plate or a carbon fiber as a cathode, carrying out leaching-electrodeposition at the current density of 50 A / m<2>-200 A / m<2> under the normal temperature, wherein most of gold and part of copper in the leached-electrodeposited ores are leached out and gathered on the cathode by in-situ electrodeposition reduction; and taking out the cathode plate which is gathered with gold and copper valuable metals as an electrodeposition anode, and carrying out electrodeposition in an electrolytic cell with sulfuric acid, so that anode dissolution-cathode electrodeposition is carried onto the gathered copper, and single-substance gold is collected in the form of anode mud. The method disclosed by the invention has the characteristics of being gentle in reaction condition, simple in process method, short in process flow, low in production cost, energy-saving and synergistic, environment-friendly and the like.

Owner:厦门紫金矿冶技术有限公司

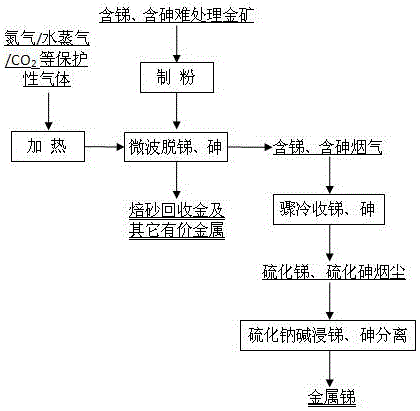

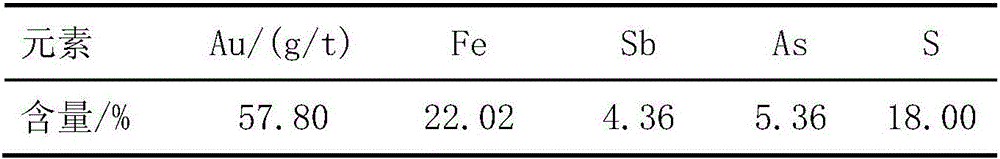

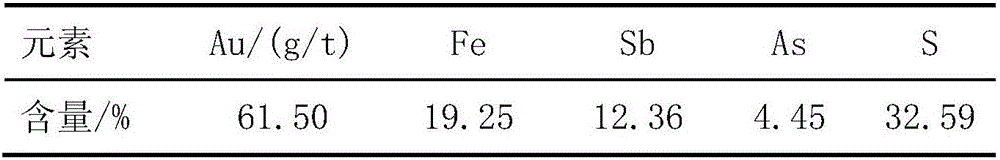

Pretreatment method for refractory gold ore with antimony and arsenic

The invention relates to the technical field of metallurgy, in particular to a pretreatment method for refractory gold ore with antimony and arsenic. The method comprises the steps that 1, the refractory gold ore with antimony and arsenic is broke and subjected to ball milling to form powder; 2, the powder obtained in the step 1 is added into a hermetic vertical pipe type heating furnace, neutral protective gas is introduced in, roasted ore is obtained after roasting and cooling are carried out, produced tail gas enters a tail gas collection device, collected smoke dust is leached through a mixed solution of Na2S with the concentration of 50-200 g / L and NaOH with the concentration of 20-100 g / L, solid-liquid separation is carried out, a filter residue with arsenic and a leaching solution with antimony are obtained, and the leaching solution is electrodeposited to produce metal antimony, wherein leaching time is 30-180 min, and leaching temperature is 20-95 DEG C. The pretreatment method has the advantages that the technological process is simple, operation is flexible, roasting time is short, energy consumption is low, antimony and arsenic can be synchronously removed, smoke gas is low in toxicity and small in amount, and economic and social benefits are good.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

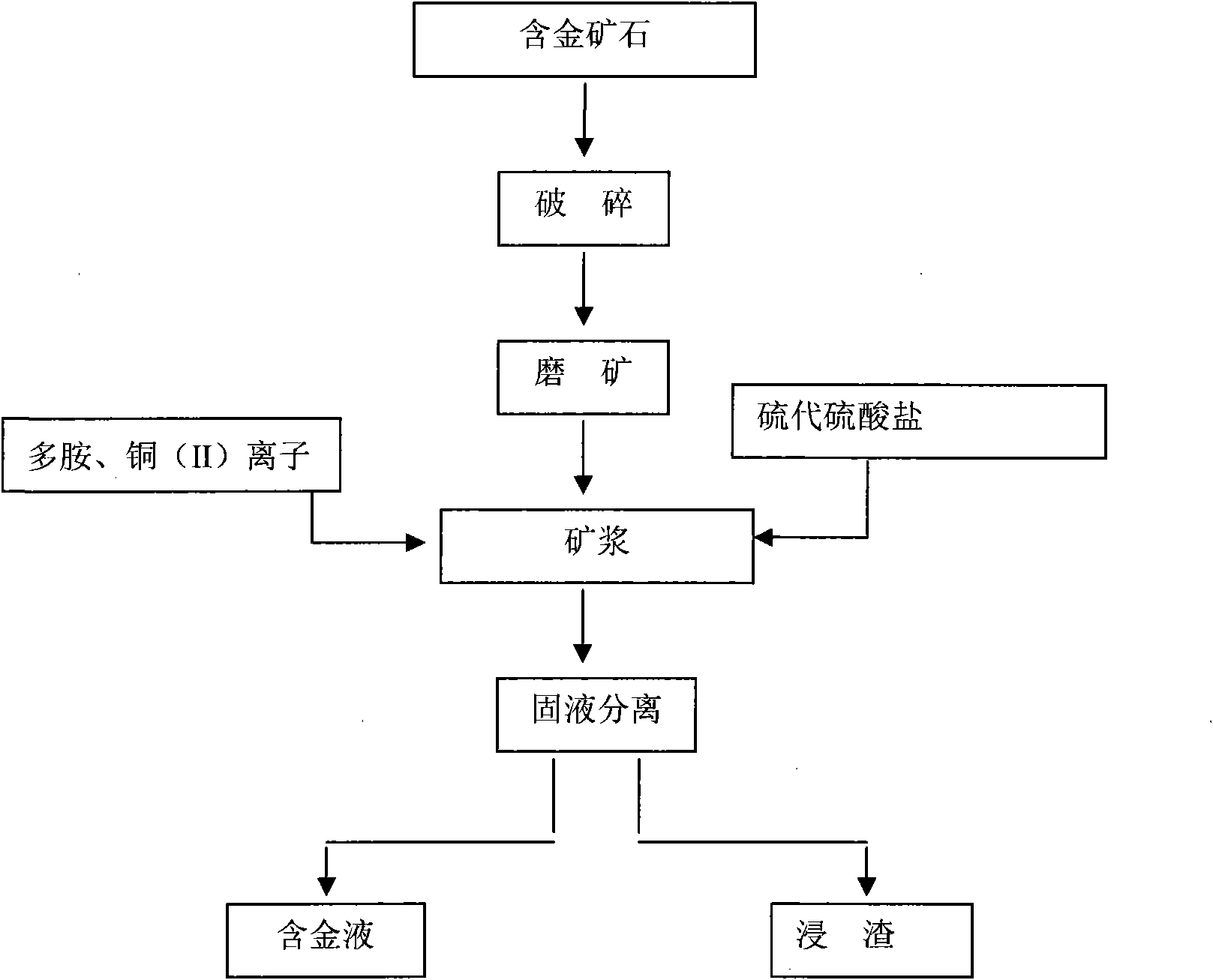

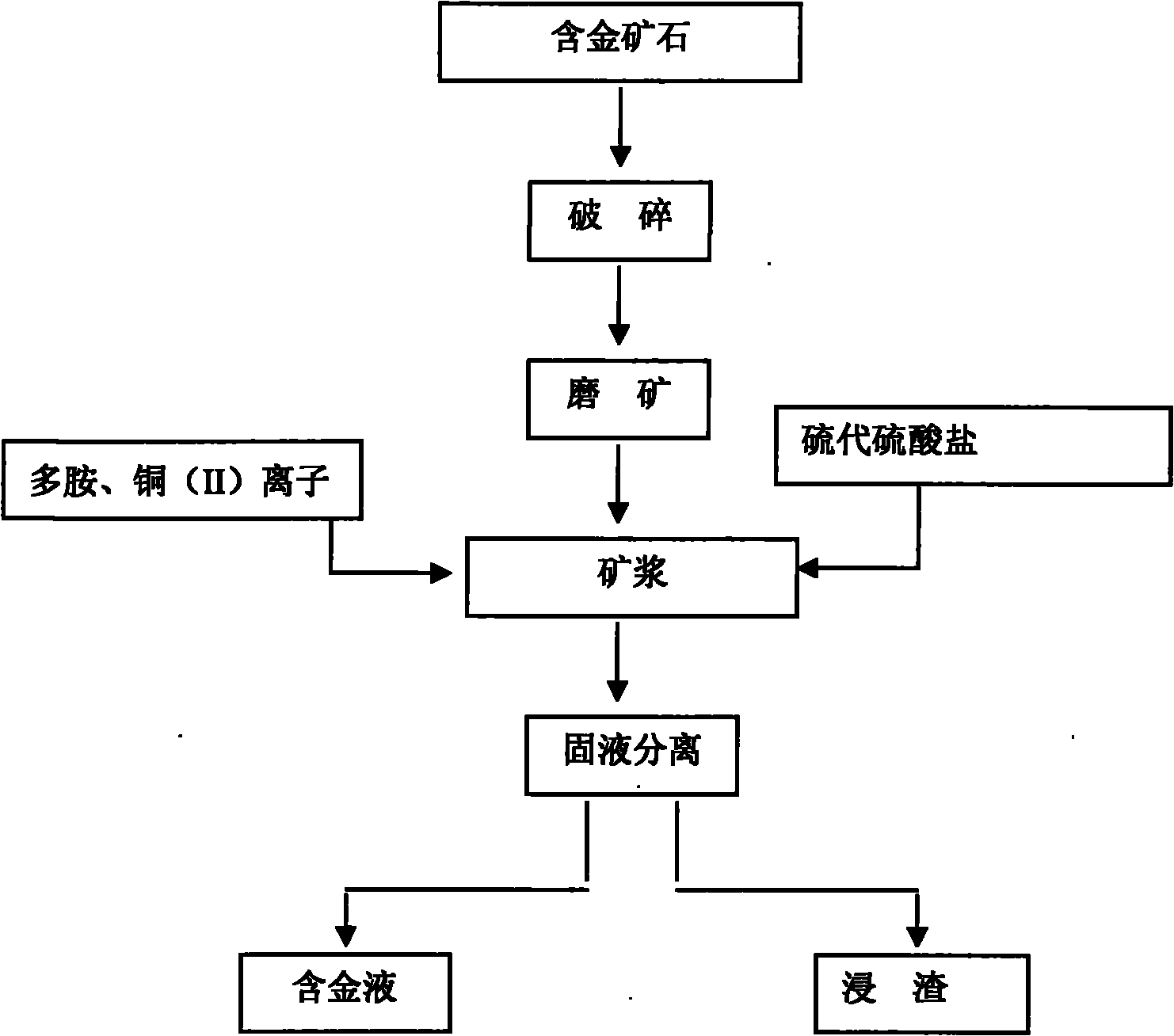

Gold extracting method by thiosulfate using polyamine compoud as additive

InactiveCN101775490AReduce consumptionLittle effect of leachingProcess efficiency improvementToxic materialSodium cyanide

The invention relates to a gold extracting method by thiosulfate using a polyamine compound as an additive, which comprises the steps: after ores are crushed and wet-ground until the fineness is over 90 percent of -200 meshes, 0.03-3mol / dm3 thiosulfate is added to be used as a leaching agent, and then 0.0015-0.09mol / dm3 polyamine compound and 0.0015-0.03mol / dm3 copper (II) ion are added to form a complex ion to be used as an additive to be stirred and leached; and after gold ores are leached, gold from a leaching solution is recovered. The leaching solution is used to extract gold from the ores, so that the gold leaching rate is high, the process operation is simple, the control is easy, the consumption of thiosulfate is extremely low, and the compositions of the gold leaching solution are simple and are favorable for the recovery of the gold; and the application range is wide, the leaching effect is good when the pH value is between 10 and 12, the leaching speed is quick for copper-containing, carbon-containing and other refractory gold ores, quite high gold leaching rate can be maintained, and sodium cyanide and other toxic substances are not used and toxic waste is not discharged in the whole gold extraction process, so the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering germanium from germanium-containing materials

InactiveCN103952575AEfficient leachingImprove solubilityProcess efficiency improvementStrong acidsHydrometallurgy

The invention relates to a method for recovering germanium from germanium-containing materials, particularly relates to a method for recovering germanium from germanium-containing materials of non-ferrous smelting industry, and belongs to the technical field of hydrometallurgy. The method comprises the steps of leaching germanium-containing materials as raw materials of which the particle sizes are 100 meshes with inorganic strong acid as an leaching agent of which the concentration is 50-120g / L and an aid-leaching agent at 35-95 DEG C and filtering to obtain a germanium-containing leaching solution, adjusting the pH value of the germanium-containing leaching solution to be 6-9, stirring and carrying out liquid-solid separation to obtain germanium residues, and calcining the germanium residues at 350-500 DEG C to obtain a crude germanium dioxide product, wherein the aid-leaching agent is one of tartaric acid, water-soluble tartrate, citric acid, water-soluble citrate, oxalic acid and water-soluble oxalate. The method disclosed by the invention has the advantages of simple process, easiness in operation, high recovery ratio of germanium, large enrichment ratio, and convenience in industrial production and application.

Owner:CENT SOUTH UNIV

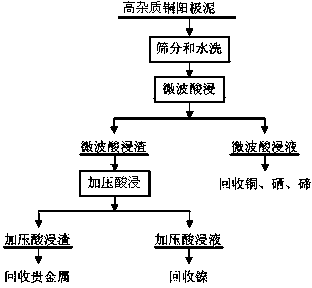

Method for pre-treating high-impurity copper anode slime rich in noble metals

ActiveCN103509953ASimple purification processHigh recovery rateProcess efficiency improvementSeleniumCopper

The invention belongs to the field of hydrometallurgy of non-ferrous metals, and particularly relates to a method for pre-treating high-impurity copper anode slime rich in noble metals. The method comprises the following special steps: adding sulfuric acid in the dried copper anode slime to mix size, placing in a microwave reactor, carrying out the microwave acid leaching for 5-30 min, performing the solid-liquid separation to obtain microwave acid leaching slag and a microwave acid leaching solution, adding dilute sulphuric acid in the microwave acid leaching slag to mix size, placing the microwave acid leaching sizing agent in a high-pressure reaction kettle under the pressure of 0.8-1.2 MPa after oxygen introducing, carrying out pressure acid leaching for 4-6 h to obtain pressure acid leaching slag and a pressure acid leaching solution, recovering gold and silver from the pressure acid leaching slag, and recovering nickel from the pressure acid leaching solution. The method adopting the technical scheme improves the recovery rate of copper, selenium, tellurium and nickel in the impurity copper anode slime, shortens the processing time of the copper anode slime, increases the processing capacity of the copper anode slime, enables the trend of the noble metals to be reasonable and concentrated, and is favorable for comprehensive recovery.

Owner:NORTHEASTERN UNIV

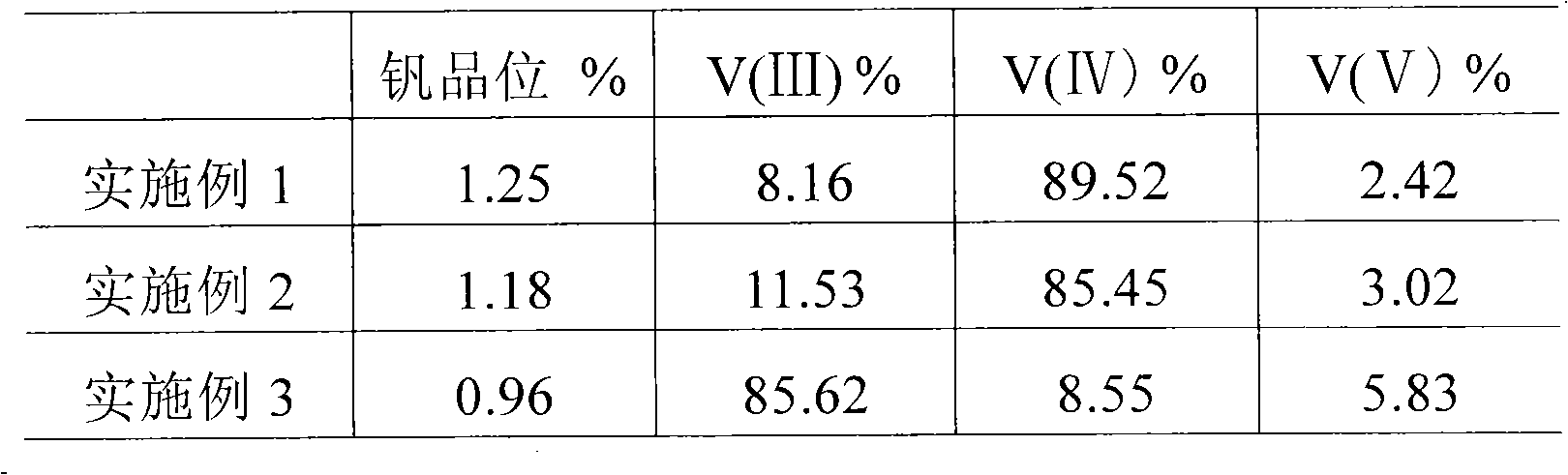

Leaching method of vanadium in vanadium-containing stone coal

InactiveCN101775506AImprove leaching rateImprove leaching effectProcess efficiency improvementKeroseneCoal

The invention relates to a leaching method of vanadium in vanadium-containing stone coal. The leaching method is characterized by comprising the following steps of: adding 98 percent of sulfate and fluorite into the vanadium-containing stone coal, adding water, controlling the liquid-solid weight ratio, leaching and filtering to obtain leachate; regulating the pH value of the leachate by using lime milk, extracting the leachate at room temperature by using 10 percent of P204 and 5 percent of TBP which are diluted by using kerosene, and carrying out back extraction on a load organic phase by using the sulfate; and after adding sodium chlorate into back extraction liquid, adding ammonia water, regulating the pH value, filtering and calcining a precipitate to obtain vanadium pentoxide. The method has simple process, high vanadium leaching rate, little reagent consumption quantity and little pollution and realizes the recycle of wastewater. The method is suitable for leaching the vanadium in the vanadium-containing stone coal.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +2

Method for microorganism-pelleting heap leaching of earthy oxide copper ores

InactiveCN101781705AIncrease throughputReduce ore washingProcess efficiency improvementThiobacillus ferrooxidansHydrometallurgy

The invention relates to a method for leaching earthy oxide copper ores, in particular to a method for microorganism-pelleting heap leaching, and belongs to the technical field of hydrometallurgy. The method is characterized in that: the earthy ores are directly screened, and fine ores with the granularity of 1.5mm are added with strain acid water and cement to prepare ore pellets with the diameter between 10 and 20 mm for heap leaching, wherein the mass concentration of sulphuric acid in the strain acid water is 3 to 10 percent, strains are mixed strains of Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, the mass ratio of the three is 4.0-5.5:2.5-3.5:1.5-2.5, the bacterial load ratio is 105 and 108 / ml, the cement amount is 15 to 30kg / ton of ores; and leachate in the leaching is sprayed for closed cycle production. The method has the advantages of low investment, low energy consumption, good leaching effect, and no discharge of closed cycle, solves the problem of leaching the low-grade earthy oxide copper ores (including sulphide and oxide blend ores) by microorganism heap leaching, and overcomes the defects of long flow and high cost of agitation leaching.

Owner:王宣明

Method for reinforcing microbiological leaching effect of zinc blende

InactiveCN105734285APromote oxidative decompositionImprove leaching rateProcess efficiency improvementChemical factorHigh pressure

The invention discloses a method for reinforcing the microbiological leaching effect of zinc blende. The method comprises the steps of 1, smashing zinc blende sample ore into particles and smashing iron pyrite sample ore and / or copper pyrite sample ore to be added into particles; 2, sterilizing a culture medium, the zinc blende and iron pyrites and / or copper pyrites to be added at high temperature and high pressure; 3, adding the sterilized zinc blende into a shake flask containing the culture medium, then adding the iron pyrites or the copper pyrites into the shake flask and carrying out inoculation of mineral leaching microorganisms; 4, placing the shake flask in the step 3 on a constant-temperature shaker for cultivation; 5, measuring the leaching efficiency of zinc in the leaching process. According to the method, by adding the iron pyrites in a microbiological leaching system of the zinc blende, the pH value in solutions is low, the concentration of iron ions is high, the redox potential is high, oxygenolysis of the zinc blende is reinforced under the synergistic effect of the microorganisms and physical and chemical factors, and the leaching efficiency of the zinc can be improved obviously. The method provides technological guidance for efficient leaching of the zinc blende.

Owner:CENT SOUTH UNIV

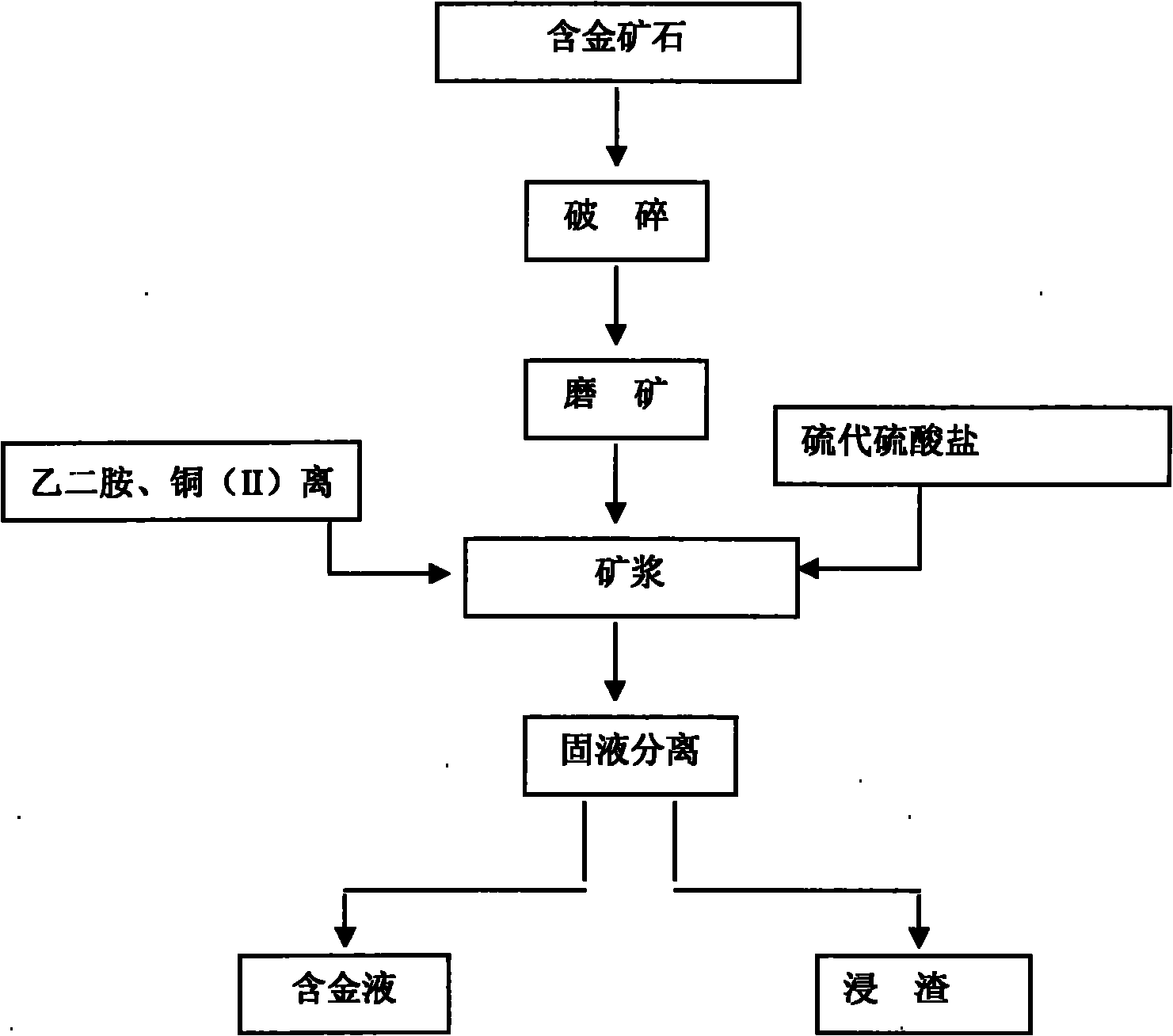

Method for extracting gold from thiosulfate adopting ethanediamine as additive

InactiveCN101824545AReduce consumptionLittle effect of leachingProcess efficiency improvementEthylenediamineToxic material

The invention relates to a method for extracting gold from thiosulfate adopting ethanediamine as an additive. The method comprises the following steps that: the ethanediamineas is adopted as ligand and forms ethanediamine copper (II) complex ion with copper (II) ion, the formed ethanediamine copper (II) complex ion is used as the additive, and the thiosulfate is used as a leaching agent and is used for extracting the gold from ore pulp; and calculated by water amount, the adding amount of the thiosulfate is 0.03-3mol / dm<3>, the adding amount of the ethanediamine is 0.0015-0.09mol / dm<3>, and the adding amount of copper (II) ion is 0.0015-0.03mol / dm<3>. The leachate is used for extracting the gold from the ore, the leaching rate of the gold is high, the technique operation is simple, the control is easy, the consumption amount of the thiosulfate is extremely low, and the ingredients of the gold leachate are simple and are beneficial to recovery of the gold therein. The method has wide application range, has good leaching effect when the pH is between 10 and 12, also has fast leaching speed of gold ores which contain copper, carbon and the like and are difficult to treat, can maintain quite high gold leaching rate, and the whole gold extracting process does not use toxic substances of sodium cyanide and the like, also does not discharge toxic waste, and is environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

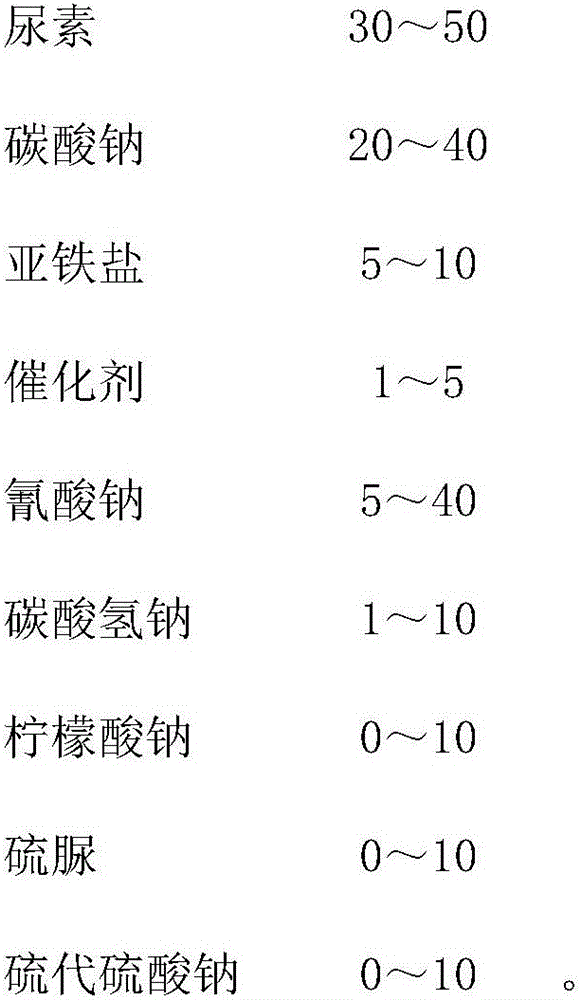

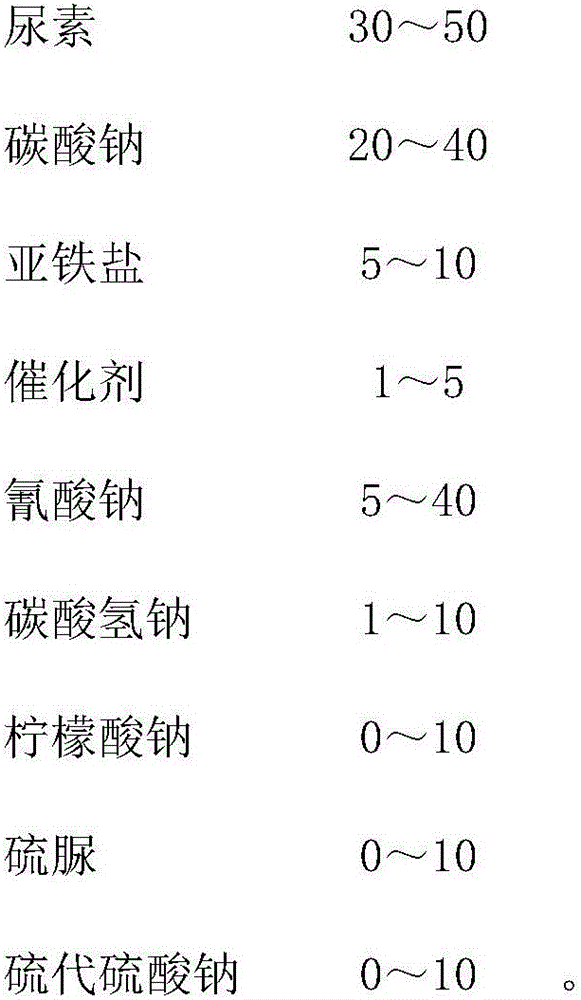

Low-toxicity environment-friendly gold mineral separation agent and preparation method thereof

InactiveCN106399712AExtract impactImprove leaching effectProcess efficiency improvementSodium bicarbonateThiourea

The invention relates to a low-toxicity environment-friendly gold mineral separation agent. Urea, sodium carbonate, ferrite, catalysts, sodium cyanate and sodium bicarbonate are adopted as main raw materials, and sodium citrate, thiourea and sodium thiosulfate are selectively added. After reactions of certain steps, the finished product is obtained. In the low-toxicity environment-friendly gold mineral separation agent, sodium cyanide with highly toxic hazards is not used, iron, nickel and carbon catalysts are used for catalyst reactions in the technology process, and the reaction time is shortened; by means of filtering measures, produced unmelted impurities are removed, and the effects of the impurities on gold extraction are avoided; in a product formula, multiple mineral separation ingredients and inhibitors, decomposing agents and the like for mineral harmful impurities are matched, and an obvious leaching effect is achieved for ores difficult to treat; and by means of a special two-time charging manner, the recovery rate of the product is increased.

Owner:金霖控股(北京)股份有限公司

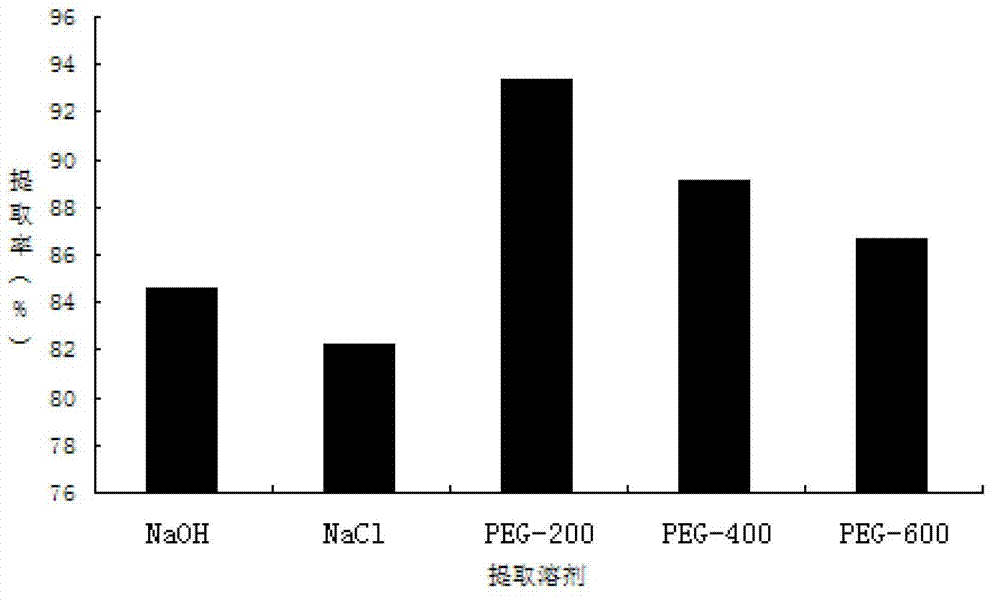

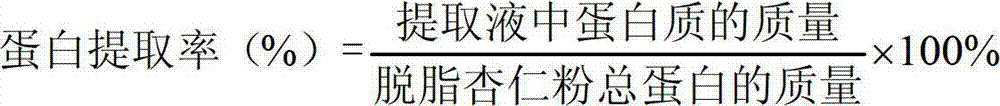

Polyethylene glycol-microwave assisted almond protein extraction method

InactiveCN102845585AHigh purityIncrease sedimentation rateProtein composition from vegetable seedsFreeze-dryingAdditive ingredient

The invention relates to a polyethylene glycol-microwave assisted almond protein extraction method, which adopts degreased almond powder as a raw material, and makes use of polyethylene glycol-microwave assisted extraction, isoelectric point-ethanol co-precipitation and vacuum freeze-drying to extract almond protein. Polyethylene glycol is a novel green solvent, has a solubilization effect on effective ingredients of almond protein, can improve the leaching efficiency and the extraction rate, and has no toxicity. Microwave-assisted extraction has the characteristics of high thermal efficiency, rapid and uniform temperature rising, greatly improved almond protein extraction efficiency, as well as shortened extraction time. Moreover, the almond protein has the advantages of high purity, high precipitation rate, simple extraction method, short extraction time, and environmental friendliness.

Owner:SHAANXI NORMAL UNIV

Method for leaching weathering crust illuviation type rare earth ore by using microorganisms

ActiveCN113293287APromote leachingImprove leaching efficiencyProcess efficiency improvementRare-earth elementEnvironmental chemistry

The invention discloses a method for leaching weathering crust illuviation type rare earth ore by using microorganisms. The method for leaching the weathering crust illuviation type rare earth ore by using the microorganisms comprises the following steps that (1) the microorganisms are activated and cultured to obtain a bacterial suspension; and (2) weathering crust illuviation type rare earth is leached by adopting the bacterial suspension, thalli or metabolites without the thalli as a leaching medium to obtain a leaching solution containing the rare earth. The microorganisms selected in the method for leaching the weathering crust illuviation type rare earth ore are environmentally friendly and safe, generally exist in nature and are wide in source, and some microorganisms are beneficial to environmental pollutant degradation and ecological restoration and improvement; and the metabolites generated in the microbial leaching process generally contain functional groups such as hydroxyl and carboxyl, the surfaces of microbial cell membranes or cell walls can also contain active ingredients acting with the rare earth, rare earth elements can be leached through complexation and chelation, the leaching effect is good, the selectivity is strong, the impurity dissolution is less, the cost is low, and the process is green and environment-friendly.

Owner:CENT SOUTH UNIV

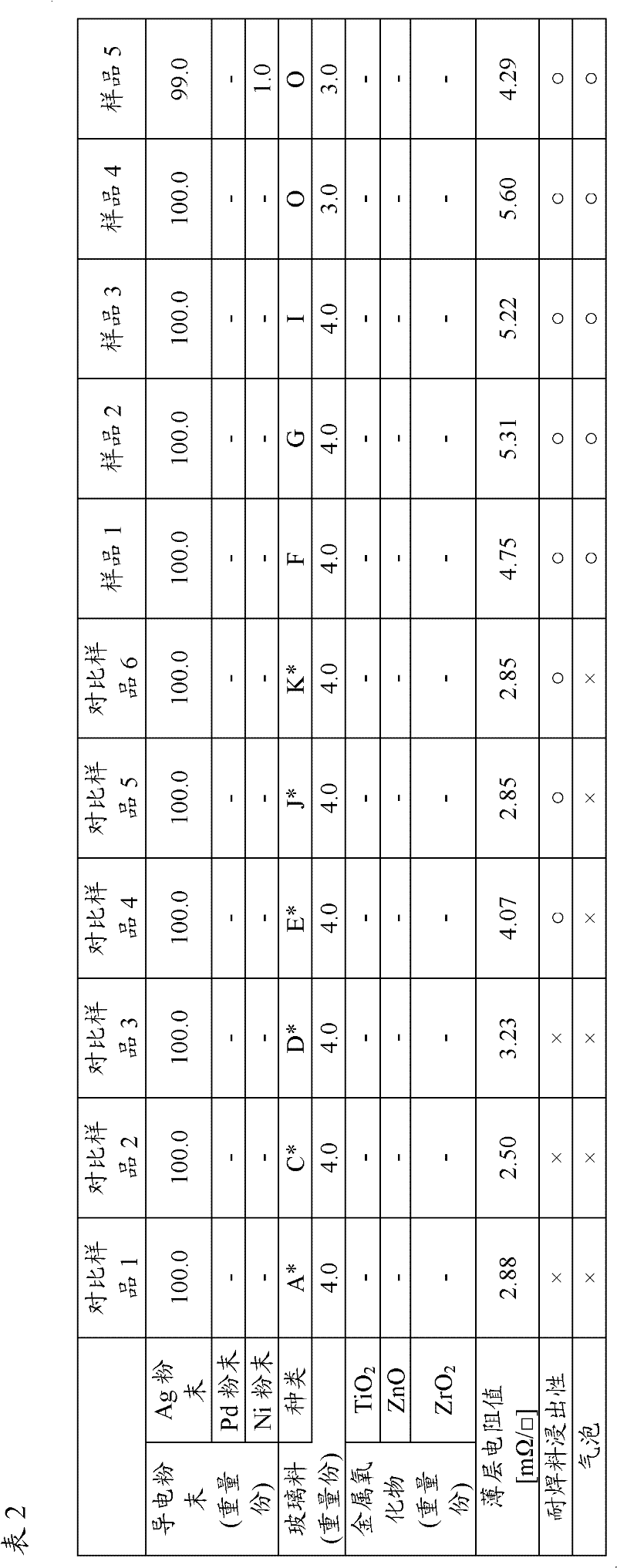

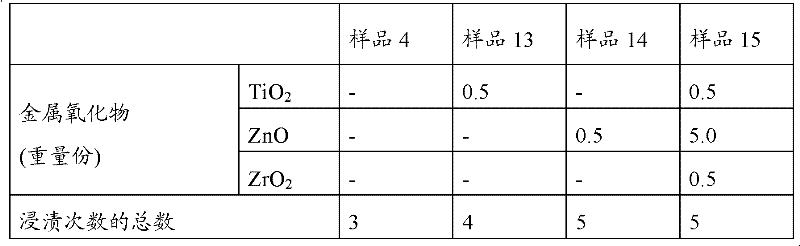

Conductive paste

ActiveCN102332320AImprove leaching effectConductive layers on insulating-supportsStacked capacitorsConductive pasteFrit

The present invention relates to a conductive paste containing: (A) conductive powders; (B) glass frits containing more than 85% the following components by weight converted by oxide and basically no lead, wherein the components comprise 16% to 47% by weight of SiO2, 33% to 52% by weight of Al2O3, 3% to 15% by weight of MgO, 15% to 45% by weight of B2O3, the ratio is the ratio in the glass frits; and (C) organic medium.

Owner:SHOEI CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com