Method for continuously extracting alkaloids, flavone and polysaccharide active components from mulberry leaves

A technology of active ingredients and alkaloids, which is applied in the field of extracting biologically active ingredients, can solve the problems of difficult separation, low extraction rate, unreported structure and category, etc., and achieve the effect of fast separation rate and high content of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

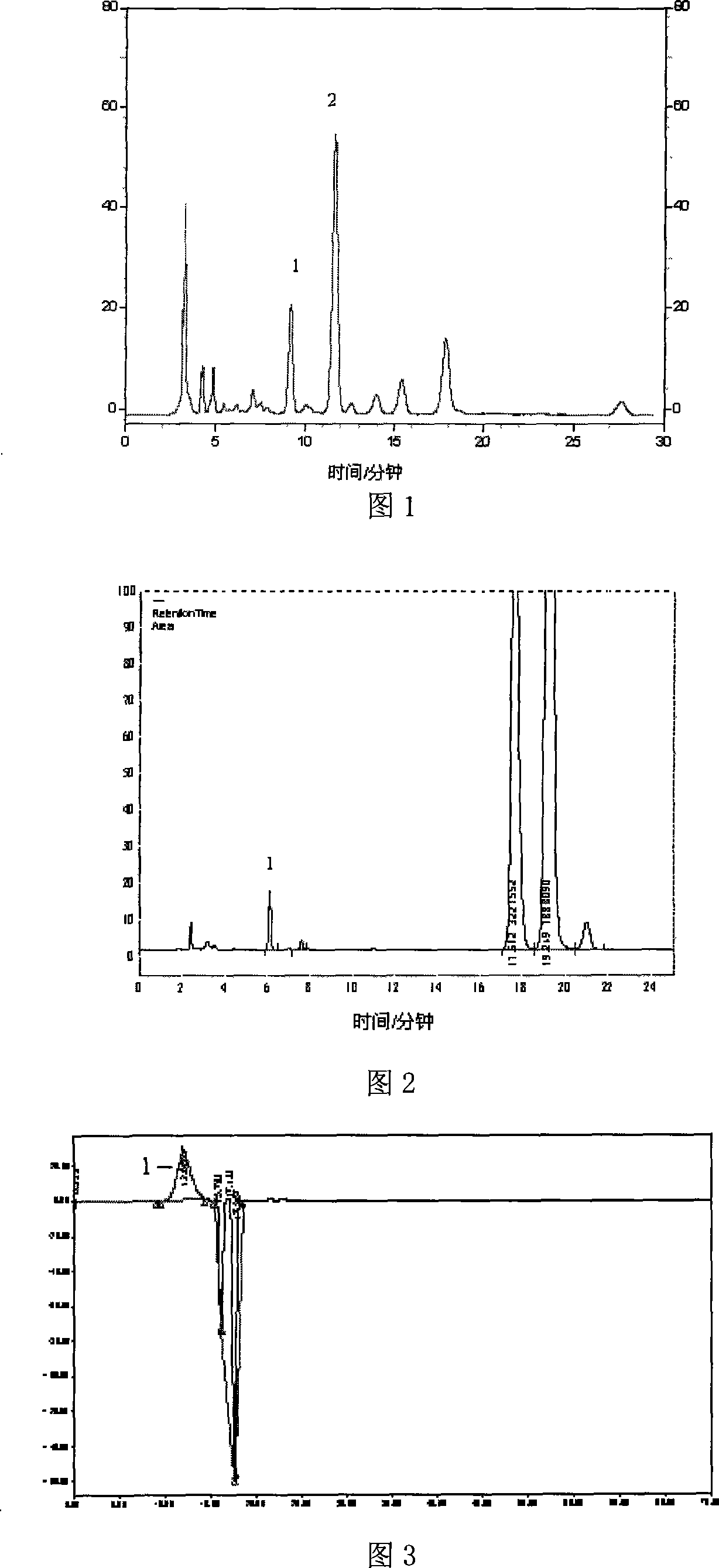

Image

Examples

example 1

[0016] Add 400 g of the pulverized mulberry leaf raw material into 4 L of 30% ethanol aqueous solution, reflux extraction at 95 ° C, repeat the extraction 3 times, each time for 30 min, and the extracts obtained three times are 2.9 L, 3.7 L, and 4.1 L respectively, and combine Extract, filtered. The filter residue was dried in the air for later use, and the ethanol in the resulting filtrate was evaporated to dryness to obtain an extract, and then 2 L of deionized water was added to the extract to dissolve it, and then left to stand for 2 hours, and then centrifuged. The supernatant was passed through 200 g of D4020 macroporous resin and adsorbed at 25° C. for 5 hours. Then first rinse the macroporous resin with 2L deionized water, then elute the macroporous resin with 60% aqueous ethanol solution of 1L, collect the ethanol eluate, and evaporate the eluate to dryness under reduced pressure to obtain 6.3g of extractum, wherein the total flavonoids The mass content is 31%.

[0...

example 2

[0020] Add 400 g of the pulverized mulberry leaf raw material into 4 L of 70% ethanol aqueous solution, reflux extraction at 95 ° C for 3 times, each time for 30 min, and obtain three extracts of 2.8 L, 3.3 L, and 3.8 L respectively, combine the extracts and filter, The filter residue was dried in the air for later use, and the ethanol in the obtained filtrate was evaporated to dryness to obtain an extract, and then 4 L of distilled water was added to the extract, left to stand for 2 hours, and centrifuged. The supernatant was passed through 200 g of H-103 macroporous resin and adsorbed at 30°C. Then first rinse the macroporous resin with 2L of deionized water, then elute the macroporous resin with 60% acetone aqueous solution of 1L, and evaporate the eluent to dryness under reduced pressure to obtain 7.6g of medicinal extract, wherein the mass content of total flavonoids is 36%. .

[0021] The solution after flowing through the macroporous resin was adsorbed by 60g of 001×7 ...

example 3

[0024] Add 400 g of the pulverized mulberry leaf raw material into 4 L of 30% ethanol aqueous solution, reflux extraction at 95 ° C for 3 times, each time for 30 min, and obtain three extracts of 2.8 L, 3.5 L, and 4.2 L respectively. The extracts are combined and filtered, and the residue Dry it for later use, evaporate the ethanol in the resulting filtrate to dryness to obtain an extract, then add 4L of distilled water to the extract, let it stand for 2 hours, and centrifuge. The supernatant was passed through 200 g of D101 macroporous resin and adsorbed at 28°C. Then first rinse the macroporous resin with 2L deionized water, then elute the macroporous resin with 60% acetone aqueous solution of 1L, and evaporate the obtained eluent to dryness under reduced pressure to obtain 6.5g of extractum, wherein the mass content of total flavonoids was 37%.

[0025] The solution after flowing through the macroporous resin was adsorbed by 80g of 001×7×7 cation exchange resin at 25°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com