Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2129 results about "Eggshell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An eggshell is the outer covering of a hard-shelled egg and of some forms of eggs with soft outer coats.

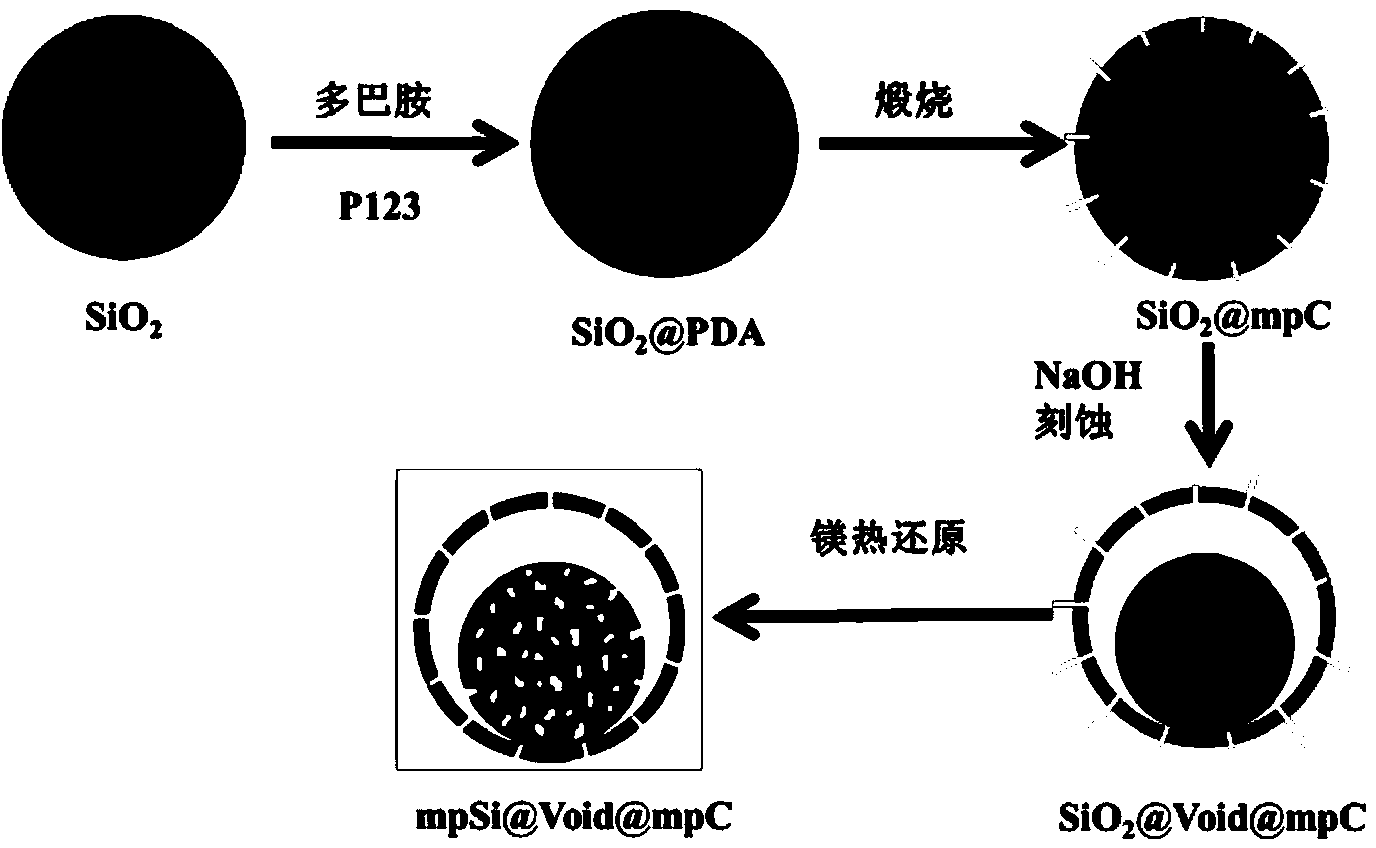

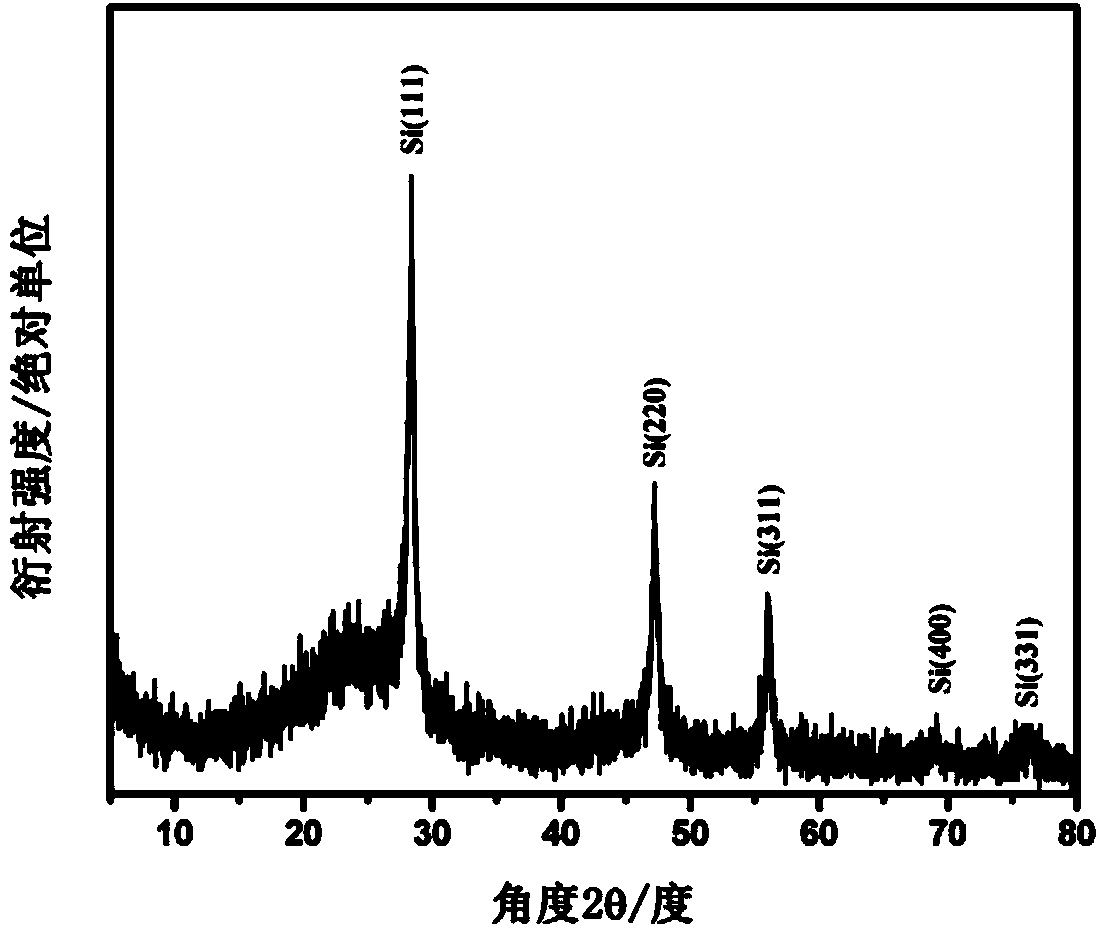

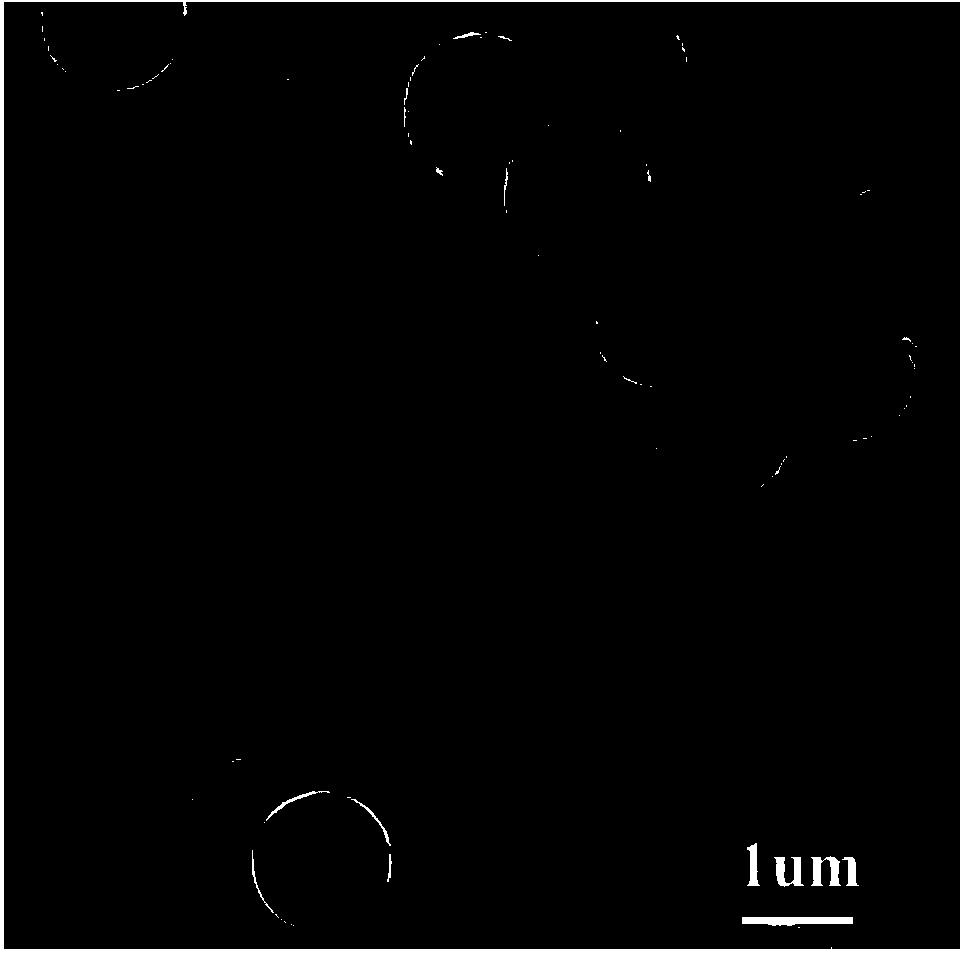

Porous silicon carbon composite microsphere with yolk-eggshell structure and preparation method therefor

InactiveCN103531760AEase of mass productionPromote infiltrationMaterial nanotechnologyCell electrodesCarbon compositesYolk

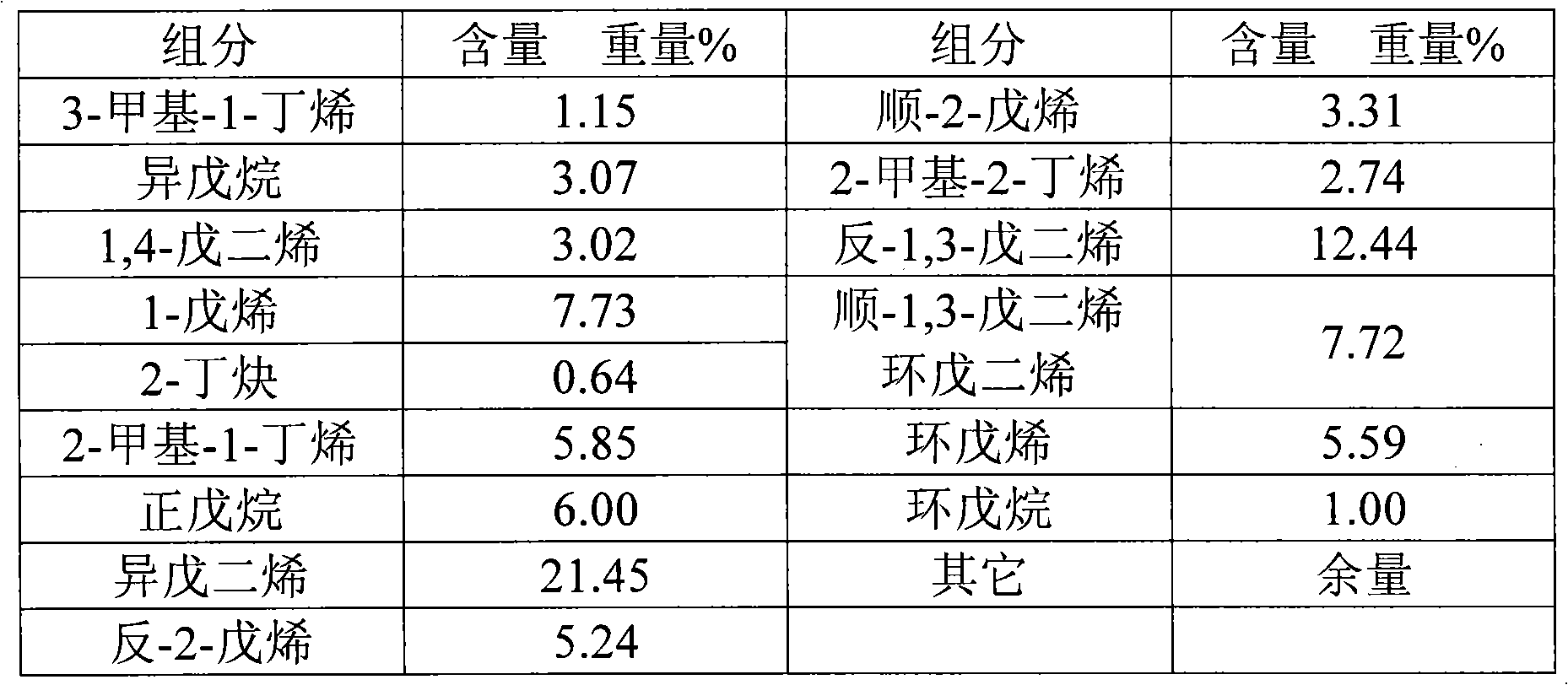

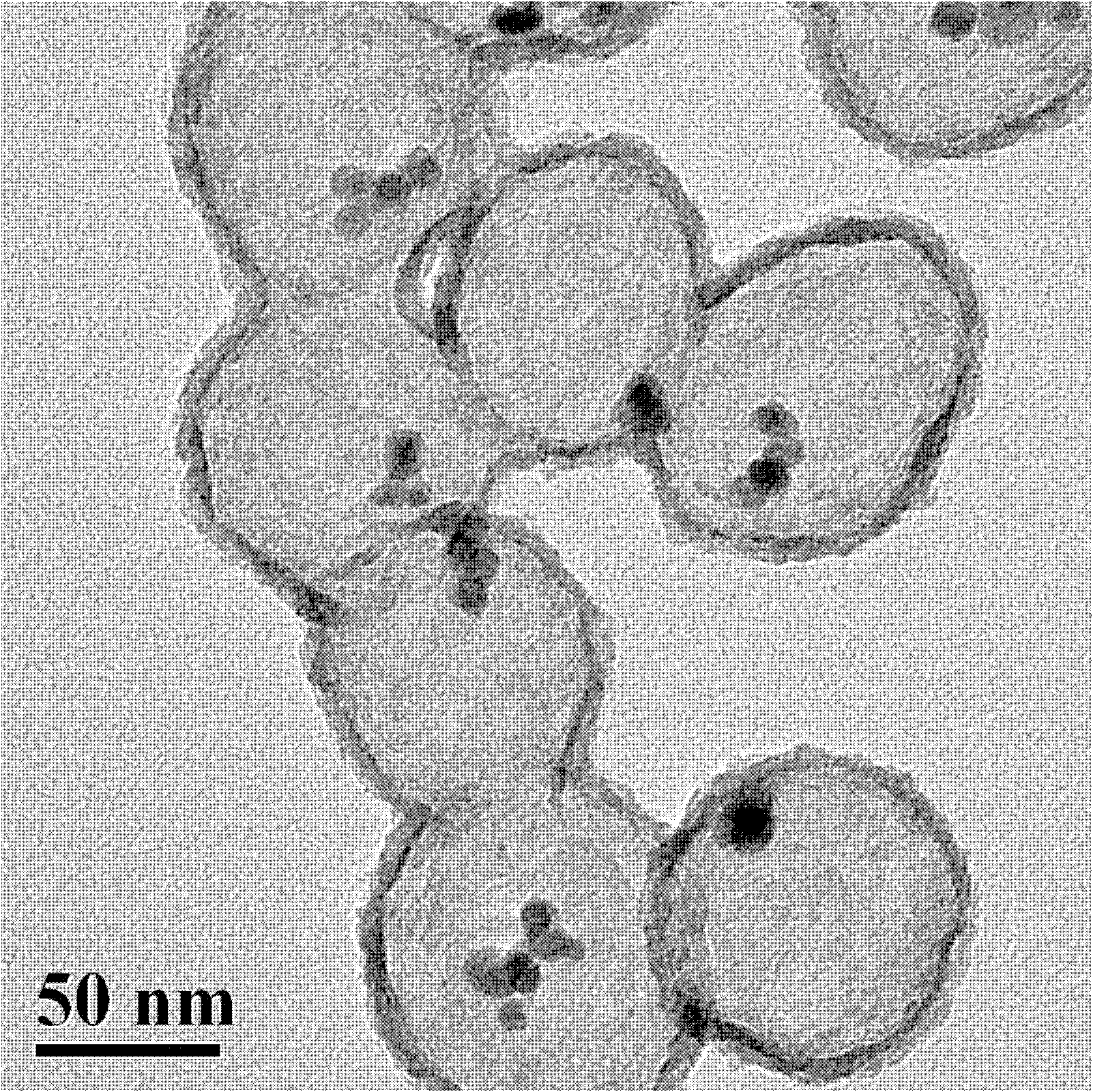

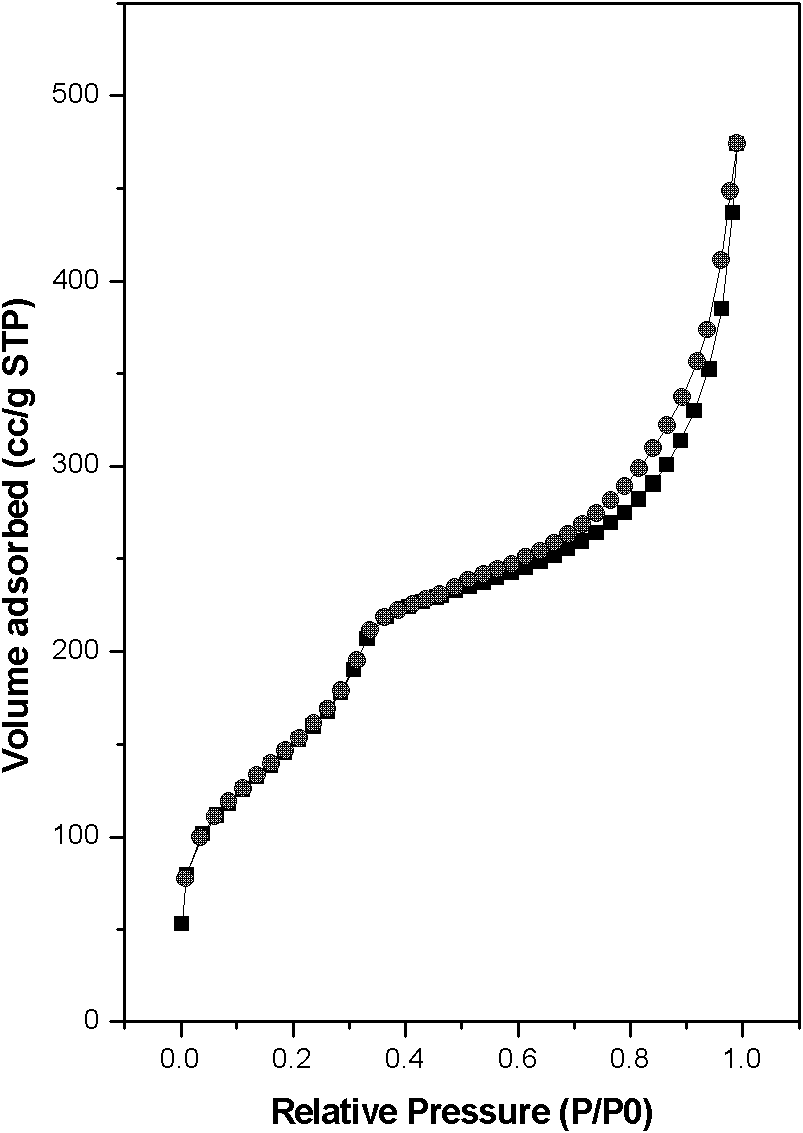

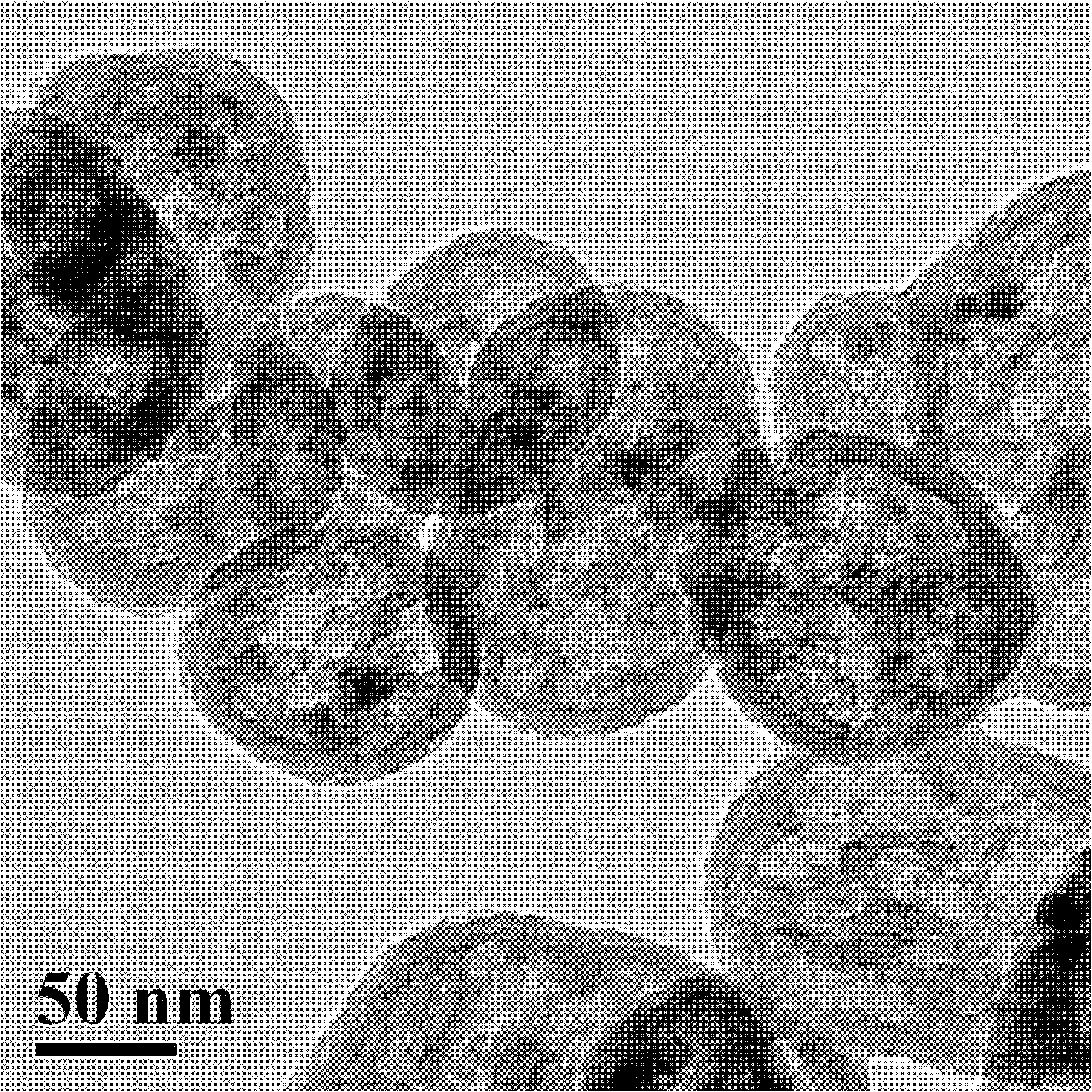

The invention provides a porous silicon carbon composite microsphere with a yolk-eggshell structure and a preparation method therefor, and belongs to the lithium ion battery electrode material technology field. The porous silicon carbon composite microsphere takes a porous submicron silicon sphere mpSi as a core with a diameter of 400-900 nm, and takes porous carbon mpC as a shell with a thickness of 10-60 nm. The inner diameter of a cavity Void is 800-1400 nm. The composition of the silicon carbon composite microsphere can be described as mpSi@Void@mpC. In addition, In the preparation method, cheap silicon dioxide is taken as a silicon source, silicon dioxide is conversed into silicon materials with electrochemical activities through a magnesiothermic reduction method. The size of gaps can be regulated and controlled through control of etching conditions. The preparation method is advantaged in that the material structure can be controlled, the cost is low, the process is simple, and the composite microsphere is convenient for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Hen feedstuff for improving egg-laying performance

ActiveCN101181016AIncrease egg productionImprove immunityAnimal feeding stuffAccessory food factorsEggshellVitamin C

The invention relates to a layer foodstuff used for enhancing egg laying performance, which has the components in weight portion as follow: 100 to 160 portions of calcium hydrogen phosphate, 250 to 350 portions of mountain flour, 40 to 70 portions of common salt, 20 to 40 portions of saleratus, 12 to 20 portions of choline, 30 to 40 portions of complex trace elements, 8 to 10 portions of complex vitamins, 1 to 3 portions of vitamin C, 25 to 30 portions of methionine, 50 to 100 portions of fish meal, and 250 to 400 portions of zeolite powder. Such additives as nutritive additive are added into the foodstuff in the invention, which has the advantages of apparently strengthening immunity of the layer, maintaining a long egg laying peak period, good quality of an egg shell, high egg laying rate, low layer culling rate, and obviously improving egg laying performance.

Owner:KUNMING HEMEIHUA FEED

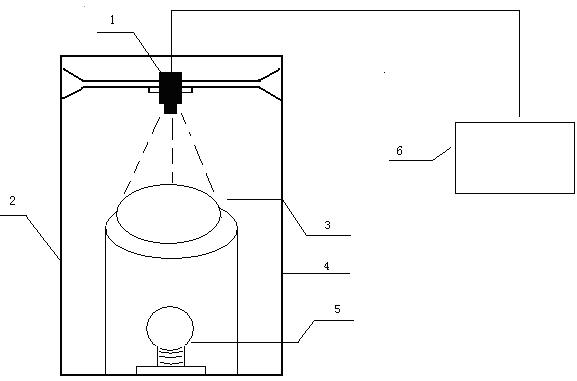

Machine vision technology based method for rapidly detecting egg freshness

InactiveCN102147402AImprove robustnessReduce complexityTesting eggsCharacter and pattern recognitionYolkEggshell

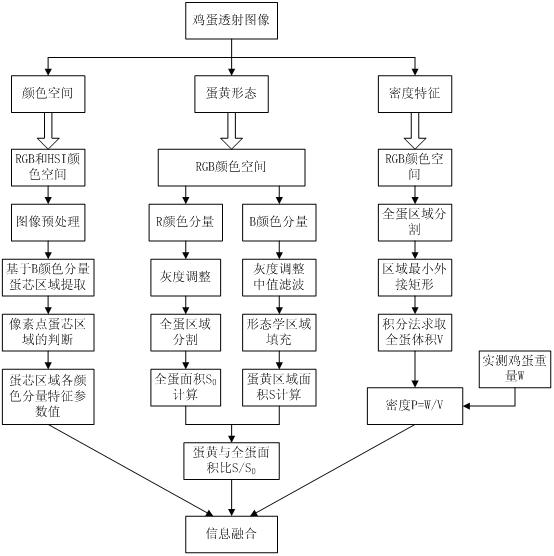

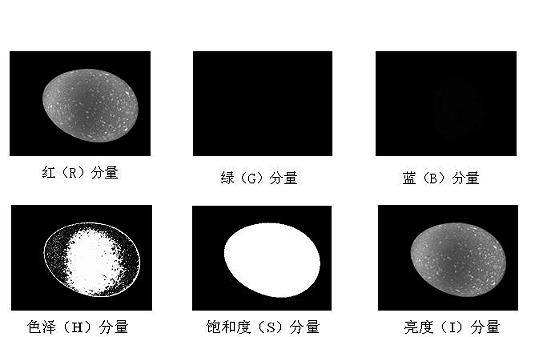

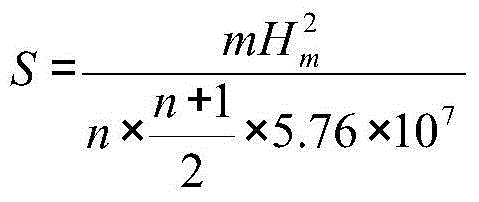

The invention relates to a machine vision technology based method for rapidly detecting egg internal quality, belonging to non-destructive testing technologies for agricultural and animal products. According to the method, a machine vision technology is used for acquiring characteristics on three aspects including a color space, an eggshell shape and an egg density from an egg transmission image so as to comprehensively judge the freshness characteristic of the egg. The machine vision technology based method specifically comprises the steps: acquiring the transmission image of an egg under a certain illumination condition, transmitting the transmission image to a computer through image acquisition equipment, acquiring the information on the three aspects including the color space, an egg yolk area and the egg density from the acquired egg image, fusing and screening the information on the three aspects, and finally obtaining a detection result of the egg freshness by means of a multi-variable analysis model in a standard library, wherein the information on the three aspects including the color space, the egg yolk area and the egg density is in one-to-one correspondence to three phenomena of diluted concentrated egg white, enlarged egg yolk area and raised gas cell height which are expressed under an egg freshness drop condition. In addition, grading can be carried out according to standards so that the egg freshness can be detected more objectively and accurately.

Owner:JIANGSU UNIV

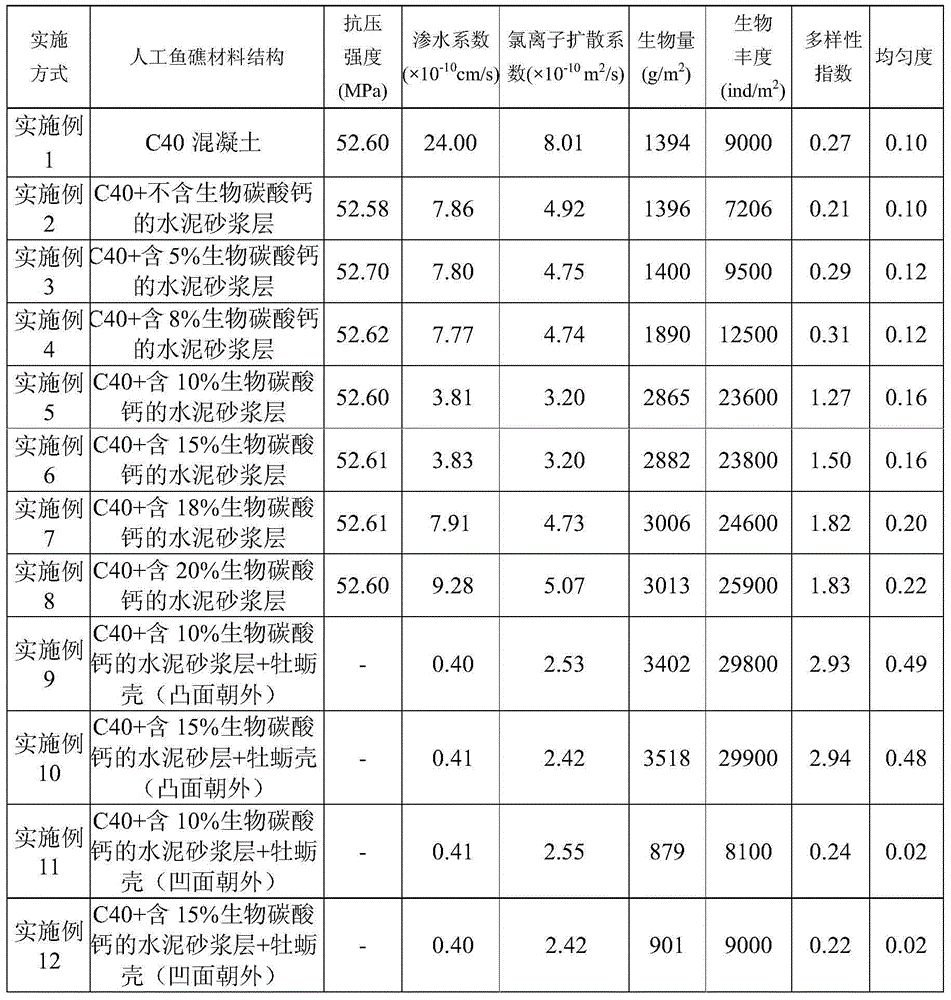

Bionic concrete artificial fish reef and preparation method thereof

InactiveCN104938384AReduce porosityIncreased Durability LifeClimate change adaptationPisciculture and aquariaEggshellOyster shells

The invention discloses a bionic concrete artificial fish reef arranged on the seafloor. According to the fish reef, C40 concrete is used for pouring to form an artificial fish reef base body, the surface of the base body is covered with a protective layer which is composed of cement mortar, biological calcium carbonate and oyster shells, the biological calcium carbonate is made of eggshells, corals, seashells and fishbone and is used as an additive to be added into the cement mortar, the cement mortar mixture is smeared on the surface of the fish reef base body to form cement paste after the biological calcium carbonate and the cement mortar are evenly stirred together, and the oyster shells are inlaid in the cement paste in a convex face outward mode. According to the artificial fish reef, the environment-friendly function, the durable function and the trapping function are integrated, the cement mortar covering layer doped with the biological calcium carbonate and the coating of the oyster shells can attract marine organisms to inhabit, and thus the trapping effect of the artificial fish reef can be better achieved; compared with a traditional concrete fish reef, the artificial fish reef has good waterproof property and chloride ion resistance, surface roughness and alkalinity of the surface of the fish reef are appropriate, bionic performance is achieved, and the fish collecting effect is excellent.

Owner:GUANGDONG UNIV OF TECH +1

Chinese medicinal herb additive for egg chickens and application

InactiveCN101543262AImprove disease resistanceImprove qualityFood processingAnimal feeding stuffDiseasePhytase

The invention discloses a Chinese medicinal herb additive for egg chickens and application. The Chinese medicinal herb additive comprises membranous milkvetch root, eucommia bark, honeysuckle, jiuyue, Weeping Forsythiae Capsule, szechwon tangshen root, sanguisorba, hawthorn, Indian Buead, officinal magnolia bark, Chinese pulsatilla root, giant knotweed rhizome, ricepaperplant pith, largehead atractylodes rhizome, tangerine peel, malt, indigowoad root, swordlike atractylodes rhizome, indigowoad leaf, three immortals, liquorice, cyrtomium fortune, nutgrass galingale rhizome, chatoyancy, calamus and pinellia tuber, and mixture of the compositions is added with calcium bicarbonate, phytase, vitamin E and methionine. The Chinese medicinal herb additive effectively promotes absorption of nutrient, can prevent and control diseases, strengthen quality of eggshells, reduce the broken egg rate and soft-shell eggs, abnormal eggs and sand shell eggs, can effectively prevent bird flu, prevent and control diseases such as laxness, feather pecking, hair shedding, anus pecking, salpingitis, respiratory disease and the like, can achieve good effect with a dosage of about 4 percent, cannot damage physiological functions of the egg chickens, and can prolong egg laying peak season, improve color of the eggshells and the laying rate by 8 to 20 percent, and increase weight of eggs.

Owner:邹振可

Eggshell type nickel-based catalyst

ActiveCN101890351AHigh activityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationSal ammoniacNickel salt

The invention discloses an eggshell type nickel-based catalyst and a preparation method and application thereof, belonging to the technical field of nickel-based catalysts and aiming at developing the eggshell type nickel-based catalyst for meeting the demand. The research shows that the eggshell type nickel-based catalyst can be prepared by dissolving nickel salt into ammonia water solution, loading the mixed solution on a catalyst carrier by adopting a spraying or immersing mode, drying, roasting and reducing. The active component of nickel is mostly centralized in an area from the surface of the carrier to the part of 0.7mm below the surface and can remarkably improve the conversion rate and the selectivity of the catalyst. The invention can be applied to the technical fields of hydrogen addition and trace amount of carbon monoxide removal from hydrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for yolk-eggshell-type organic-inorganic hybrid silicon oxide nanosphere

The invention relates to silicon oxide sphere particles, concretely to a preparation method for organic-inorganic hybrid silicon oxide nanospheres with a structure of yolk-eggshell. The invention provides a yolk-eggshell-type organic-inorganic hybrid silicon oxide or a carbon-silicon composite nano-material with adjustable particle size, adjustable core-shell composition and hierarchical pore structure, and the preparation method thereof. In an alkaline system, nanometer silicon oxide spheres with core-shell structures are composed by taking a cationic surfactant as a structure-directing agent. Organosilicon precursor is added to the system. After being stirred, filtered and dried, the organic-inorganic hybrid silicon oxide nanospheres with freely mobile cores and functionalized mesoporous shells are obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

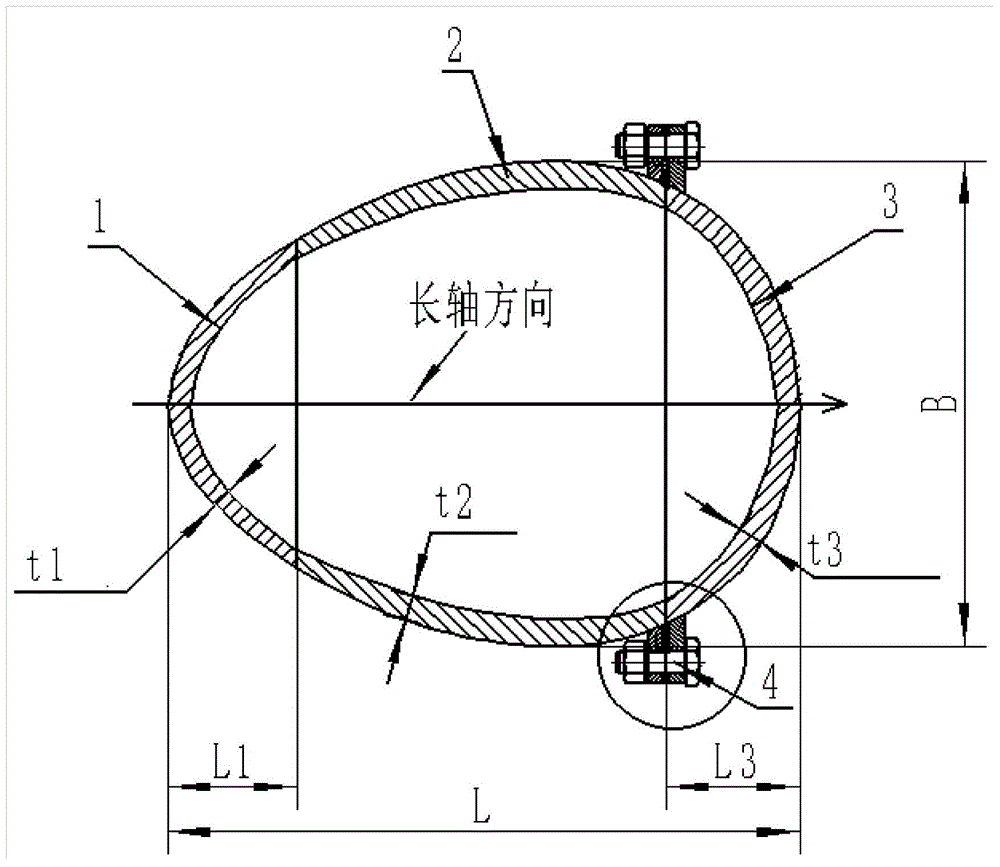

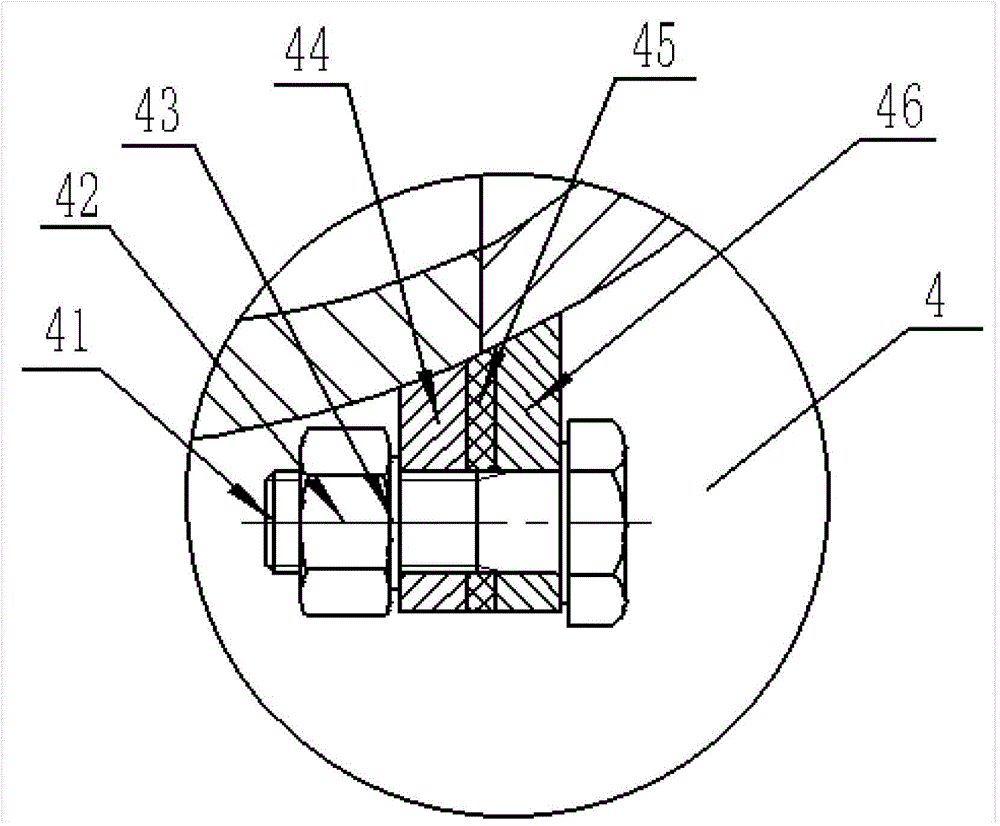

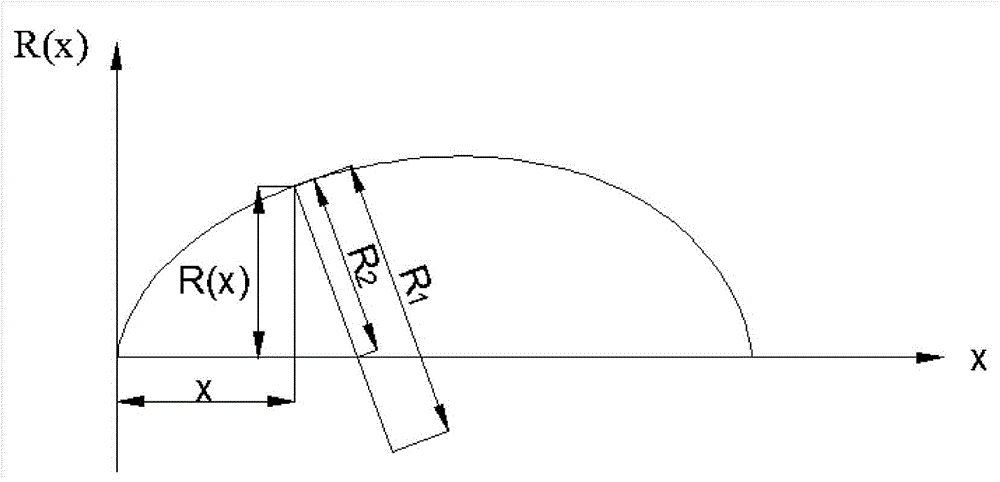

Deep sea bionic pressureproof shell

ActiveCN104648638AGood pressure resistanceStreamlinedUnderwater vesselsUnderwater equipmentVariable thicknessCarrying capacity

The invention discloses a deep sea bionic pressureproof shell. An axial-symmetry eggshell-shaped structure with the length of L, the width of B and the turning radius of R(x) is formed by a left end socket, a right end socket and a middle shell, wherein the thickness t2 of the middle shell is of an equal-strength variable-thickness structure, the thickness t1 of the left end socket and the thickness t3 of the right end socket are respectively of an equal-thickness structure, the left end socket and the middle shell are fixedly connected, and the right end socket and the middle shell are connected by a flange bolt or a movable hatch cover with a seal ring. The deep sea bionic pressureproof shell has good mechanical properties, in-shell space utilization rate, hydrodynamic characteristics and passenger comfort, and comprehensive improvement on safety, carrying capacity, mobility and diving time of a diving device is facilitated; meanwhile, the weight of the pressureproof shell is lightened, the reserve buoyancy of the pressureproof shell is increased, and the processing and manufacturing difficulty and cost are reduced.

Owner:JIANGSU UNIV OF SCI & TECH

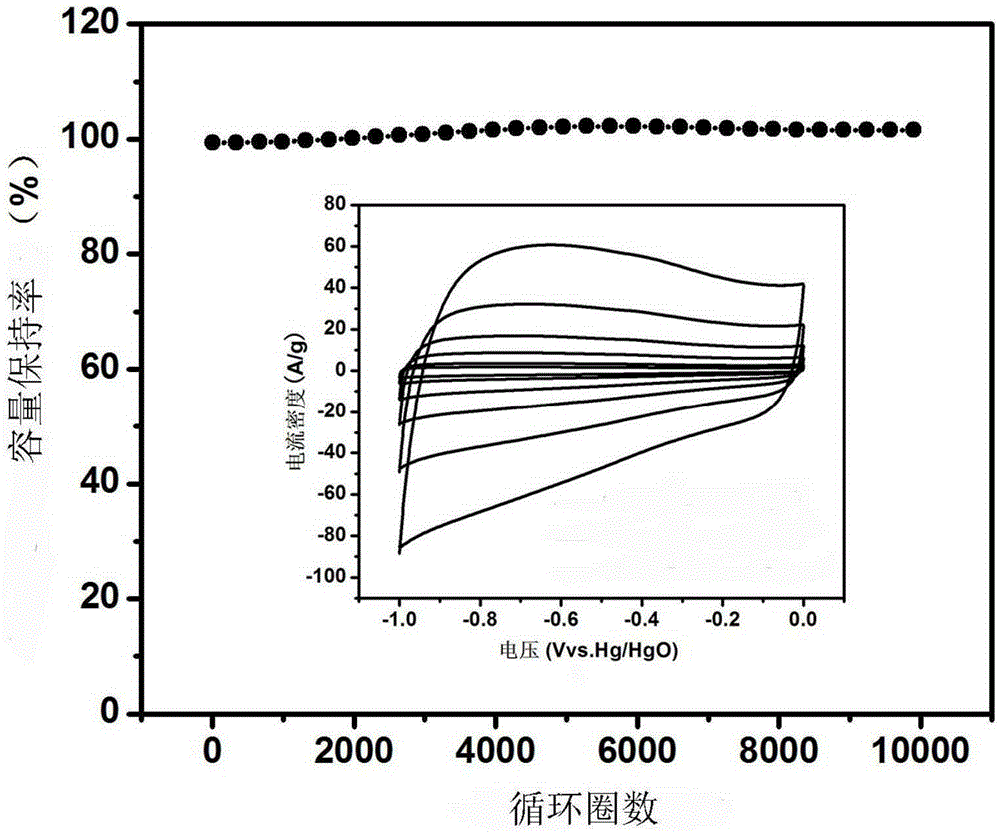

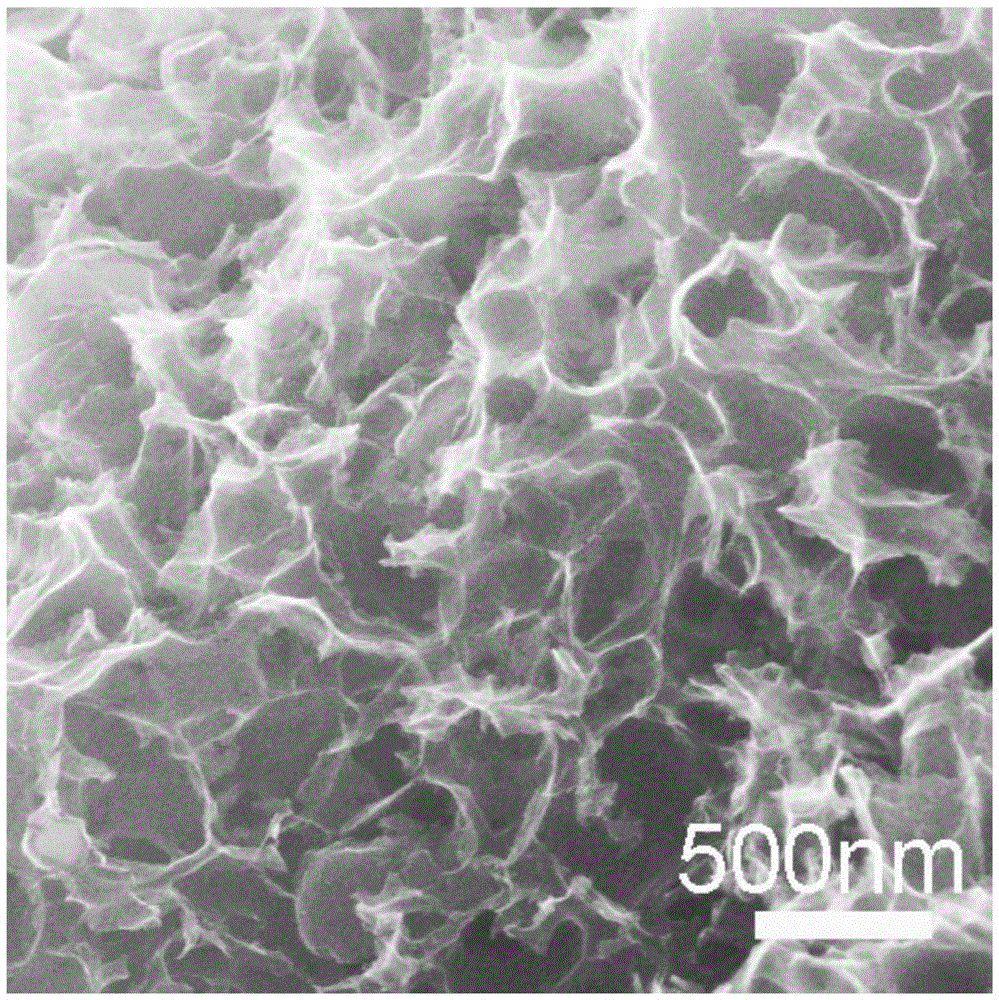

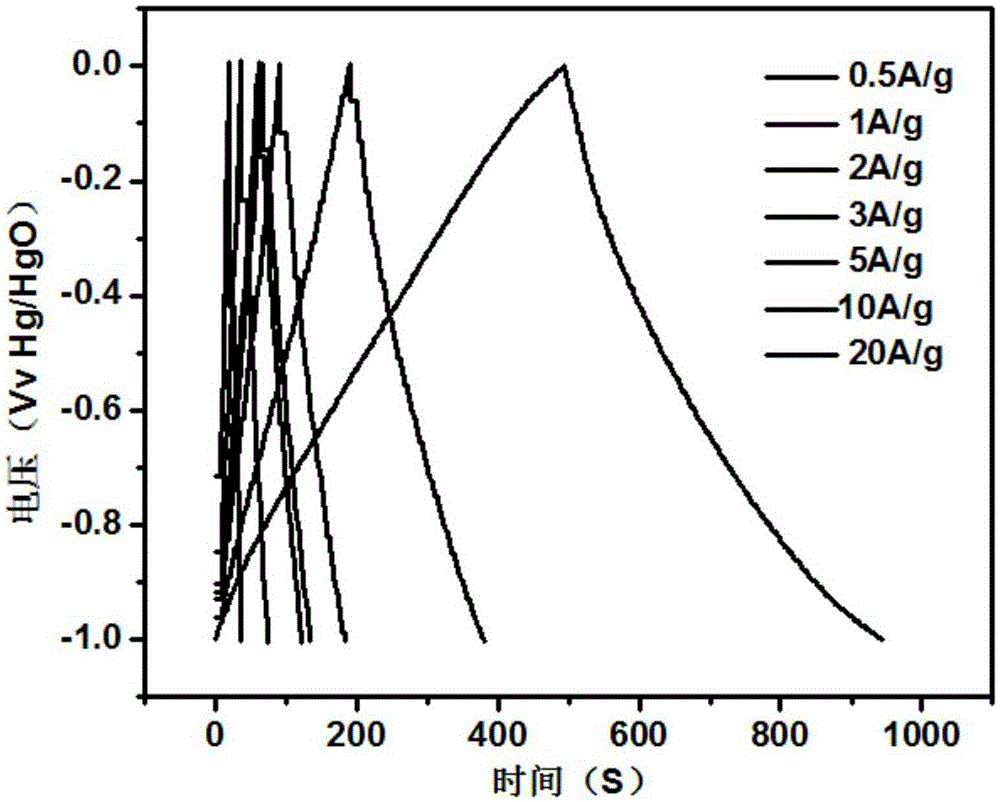

Method for directly preparing co-doping three-dimensional graphene electrode material through biomass carbon sources

The invention discloses a method for directly preparing a co-doping three-dimensional graphene electrode material through biomass carbon sources. The method mainly includes the steps that biomass such as eggshells of artemia cysts, bean pulp and shrimp shells are used as the carbon sources, red phosphorus or boric acid is added to serve as a stripping agent, metal nickel salt is added to serve as a catalyst, and oxygen-nitrogen-phosphor multi-atom co-doping three-dimensional porous graphene is synthesized in a roasted mode at the temperature of 700 DEG C to 900 DEG C under argon atmosphere; the obtained graphene is ground into powder, the graphene, acetylene black and PTFE are ultrasonically dispersed into absolute ethyl alcohol in the mass ratio of 85:10:5, the mixture is dried at the temperature of 80 DEG C to be pasty, 0.5 mg to 5 mg of the mixture is taken and evenly smeared on 1*1-cm foam nickel, vacuum drying is carried out at the temperature of 120 DEG C for 12 h, plate pressing is carried out at the pressure of 12 MPa, and an electrode plate is obtained. According to the method, the source of the required raw materials is wide, the price is low, devices are simple, repeatability is good, and low-cost large-scale industrial production can be achieved easily; the prepared graphene electrode material has the advantages of being good in electrochemical activity, large in specific area, not prone to repeated accumulation and the like; the broad application prospects are achieved in the aspects such as electrode materials and catalyst carriers of supercapacitors and lithium ion batteries.

Owner:YANSHAN UNIV

Five-spice tea low-salt duck eggs and making method thereof

The invention discloses five-spice tea low-salt duck eggs. The five-spice tea low-salt duck eggs are made from, by weight, 70-80 parts of fresh duck eggs, 4-5 parts of fresh ginger, 6-7 parts of pericarpium citri reticulatae, 3-4 parts of cinnamon, 1-2 parts of anise, 2-3 parts of pepper, 5-6 parts of chive, 1-2 parts of garlic, 4-5 parts of liquorice, 1-2 parts of ramulus mori, 18-22 parts of tea leaves, strong baijiu, white vinegar and a proper amount of salt. The fresh eggs are soaked with the white vinegar so that egg shells can generate small holes to facilitate material exchange of salt and the like, and the duck eggs are pickled by a pickling solution and pickling wine with the same salt content as the pickling solution successively; due to the fact that the osmotic pressure of egg white and the osmotic pressure of the exterior of the shells are consistent basically, the salt can permeate into yolks so that the yolks can be dehydrated to achieve looseness and oil permeation, the salt content of the egg white is not increased, depression and pickling are adopted for rapidly completing the first stage, the pickling period is shortened, the strong baijiu is added so that protein can be condensed more quickly, oil can permeate from the yolks rapidly, the finished duck egg white is suitable in taste, the yolks are loose and oily, and the five-spice tea low-salt duck eggs are rich in tea fragrance and have the five-space flavor.

Owner:柳培健

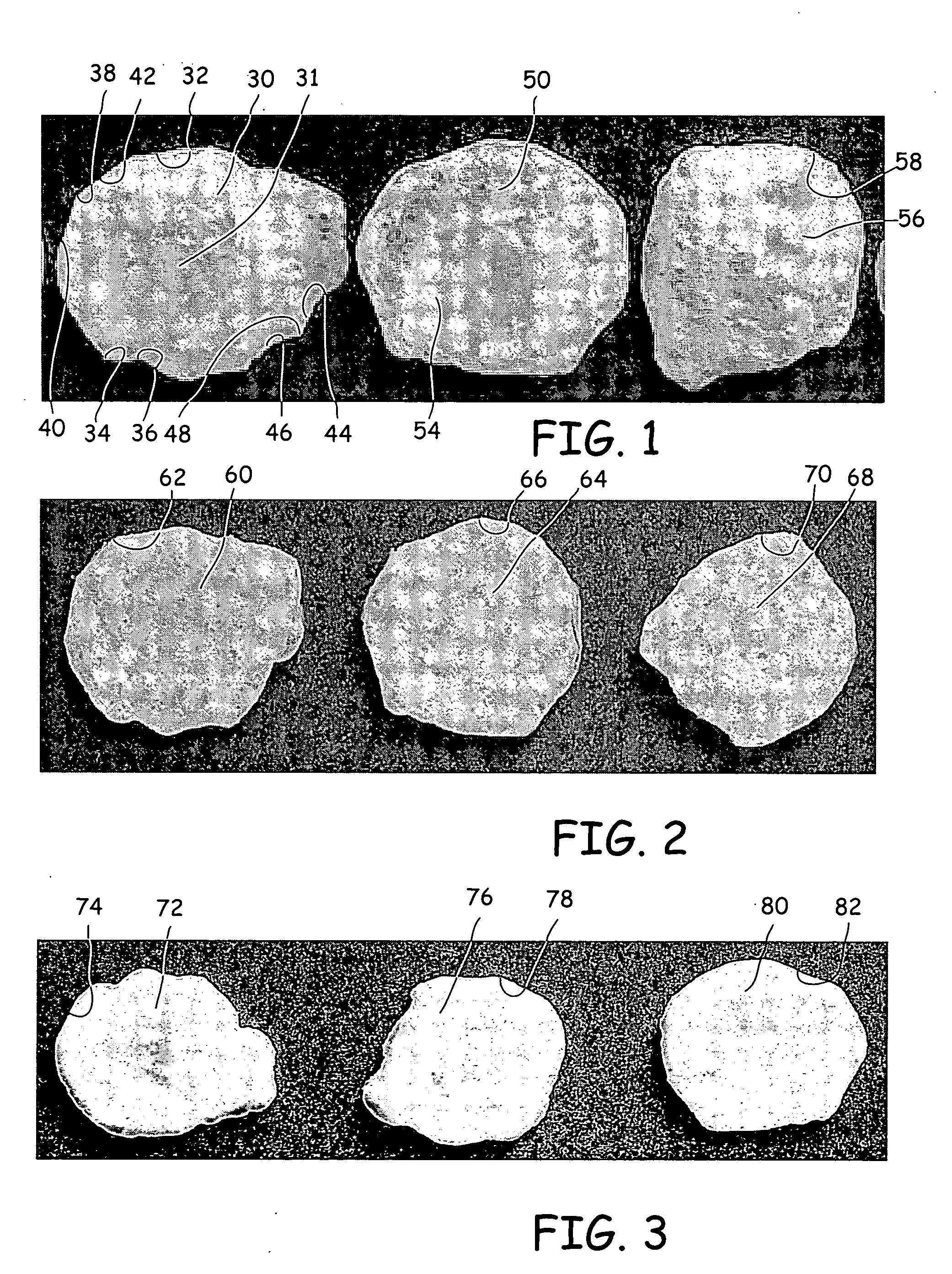

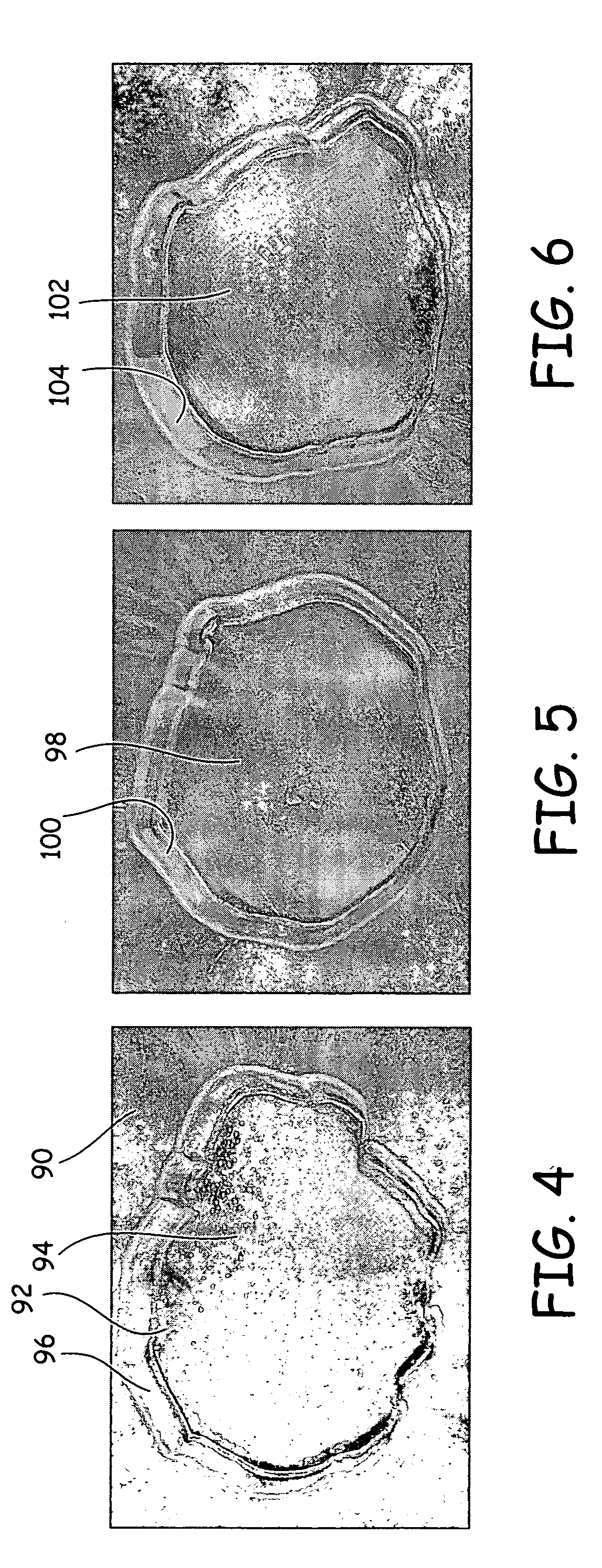

Methods and devices for automatically making large quantities of pre-cooked eggs having a natural appearance

The present invention includes methods and devices for mass producing cooked, cooled egg products having a grill fried egg appearance. One device includes a portion for positioning whole, intact, shelled eggs positioned laterally across and above a cooking mold conveyor, and a portion for cracking the eggshells and depositing the eggs into cooking molds on the conveyor. Some devices and methods include an egg yolk splitter for rupturing the egg yolk sac to deposit a whole egg having a ruptured egg yolk into each mold. Other devices and methods include irregular shaped egg molds for providing a mass produced cooked egg having a natural, irregular shaped outlines and / or surfaces. Devices and methods according to the present invention can be used to produce irregular, outlined shaped cooked egg products including whole eggs, formulated eggs, or eggs made from scrambled egg mixes. The pre-cooked eggs can be delivered pathogen free to fast food establishments and reheated for consumers in less time than required to cook the egg.

Owner:MICHAEL FOODS INC

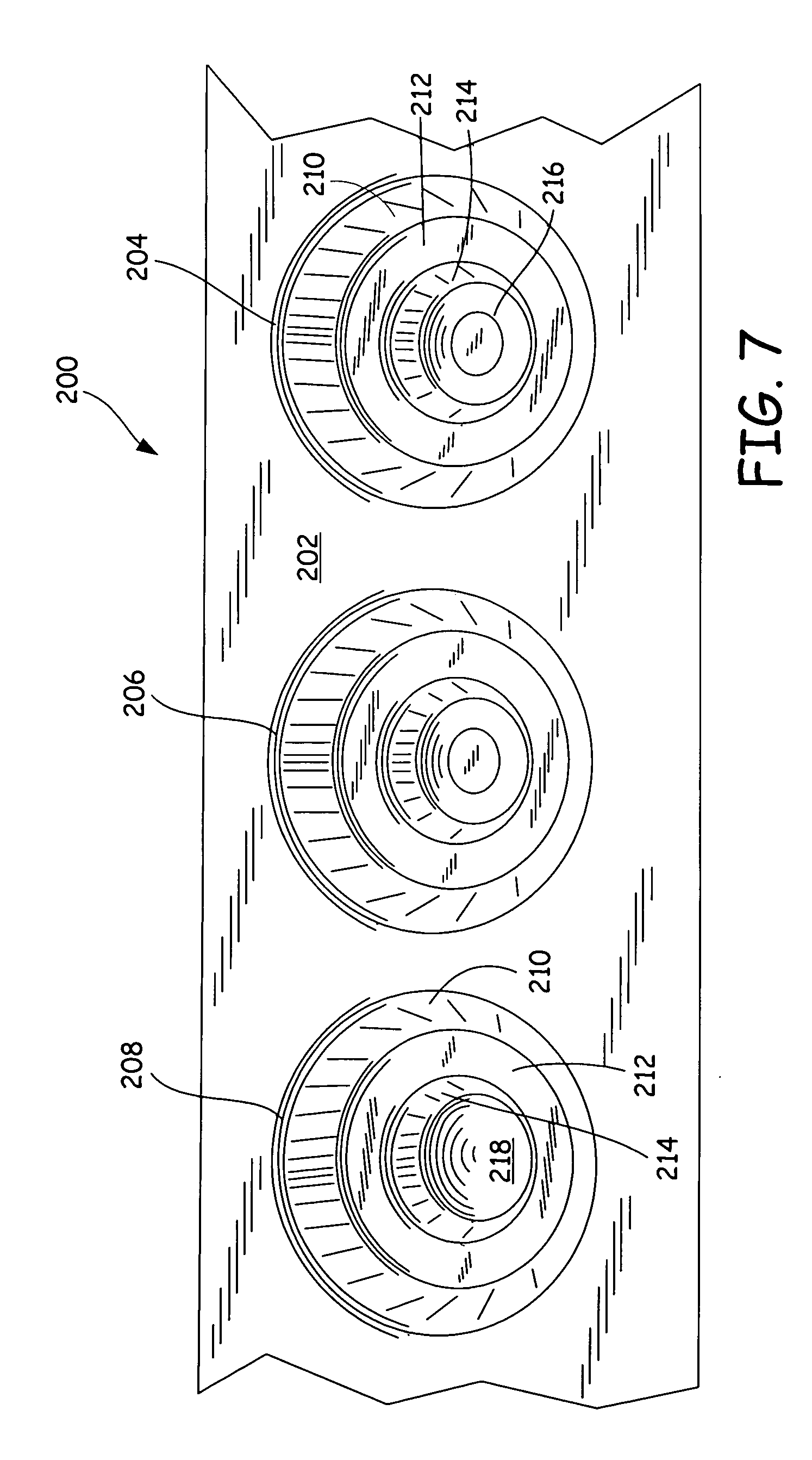

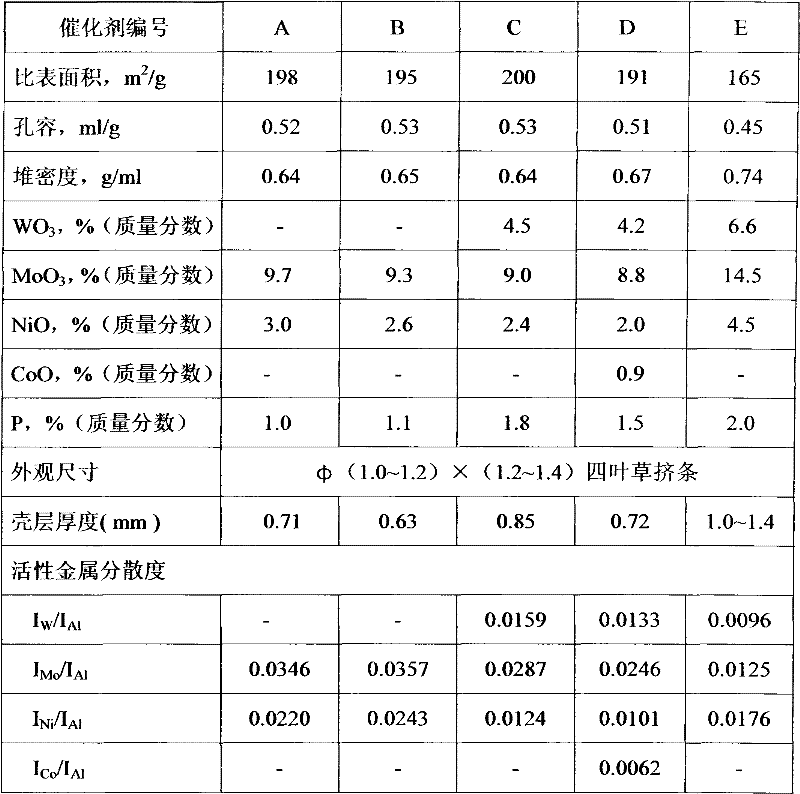

Preparation method of eggshell-type hydrogenation catalyst

ActiveCN102451722AEffectively adjust dispersionReduce churnPhysical/chemical process catalystsRefining to eliminate hetero atomsDispersityEggshell

The invention discloses a preparation method of an eggshell-type hydrogenation catalyst. The preparation method is characterized in that conventional carriers are dipped in an active metal dipping solution containing one or more thickening agents and one or more active metal dispersants under the condition of air bubbling and then are subjected to drying and calcination so that the eggshell-type hydrogenation catalyst is obtained. The preparation method can effectively adjust the thickness of a surface active metal shell layer of the eggshell-type hydrogenation catalyst and the dispersity of active metals, stabilize the active metals of the eggshell-type hydrogenation catalyst, reduce the loss of the active metals, and reduce an eggshell-type hydrogenation catalyst product cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic inorganic composite biologic medical fertilizer special for rice and preparation method of fertilizer

InactiveCN103524227ALow costPromote absorptionFertiliser formsFertilizer mixturesBiotechnologyEggshell

The invention discloses an organic inorganic composite biologic medical fertilizer special for rice. The fertilizer consists of the following raw materials in parts by weight: 15-25 parts of chicken manure, 8-14 parts of pig manure, 8-14 parts of sheep manure, 10-15 parts of rice chaff, 8-14 parts of straws, 6-12 parts of peat soil, 5-10 parts of animal born powder, 3-5 parts of animal fur powder, 5-7 parts of tree leaves, 4-6 parts of mushroom dregs, 13-16 parts of urea, 10-12 parts of superphosphate, 12-14 parts of calcium nitrate, 8-10 parts of potassium sulphate, 0.08-0.12 part of ammonium molybdate, 1.9-2.4 parts of copper sulfate, 0.8-1.2 parts of manganese sulfate, 3-5 parts of ferrous sulfate, 10-13 parts of potassium humate, 3-5 parts of eggshell powder, 0.4-0.6 part of glucose, 0.03-0.06 part of borax, 10-12 parts of animal fur and 3-4 parts of microorganism ferments. The fertilizer has the advantages that the fertilization and the sterilization are integrated, the cost is low, and has the environment-friendly and non-pollution effects.

Owner:合肥科友生物科技有限公司

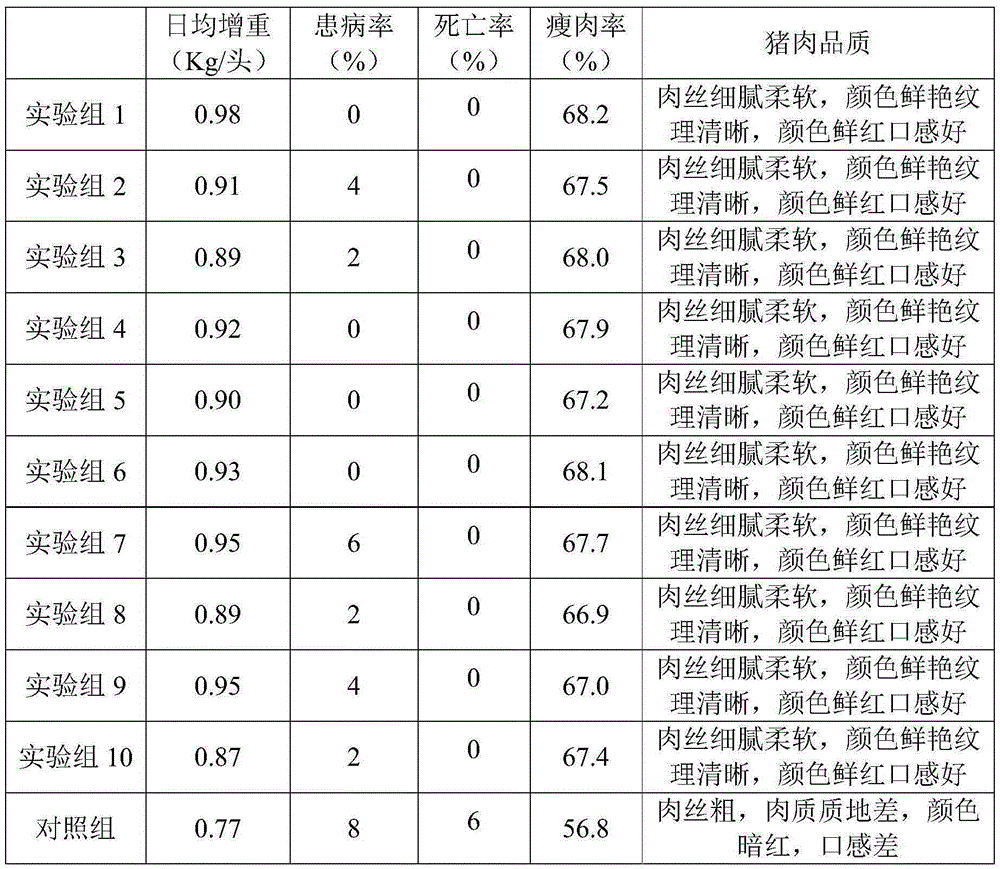

Pig feed and preparing method thereof

InactiveCN105394398AReasonable formulaNutritional balanceFood processingAnimal feeding stuffBiotechnologyLean meat

Pig feed is disclosed. The feed is prepared from following components by weight: 40-50 parts of corn, 30-40 parts of wheat, 15-25 parts of soybean meal, 20-35 parts of sweet potato residue, 2-6 parts of lactic acid bacteria, 3-10 parts of yeast, 10-15 parts of medical stone, 10-15 parts of eggshell, 10-15 parts of shell powder, 20-30 parts of silene conoidea, 10-20 parts of cottonsedge-like thistle herb, 10-15 parts of sweet potato vine, 10-20 parts of purslane herb, 3-10 parts of composite vitamin, 10-25 parts of vegetable oil, 5-15 parts of isatis root, 5-15 parts of liquorice root, 5-15 parts of milkvetch root, 5-15 parts of medicated leaven, 5-15 parts of malt, 5-15 parts of hawthorn fruit and 5-15 parts of dried tangerine peel. The feed is reasonable in formula, comprehensive in nutrition, good in taste and high in feed absorption rate. By adopting a plurality of the proper raw materials and adopting reasonable using amounts, comprehensive nutrition of the feed is optimized, and three functions, namely functions of regulating feed palatability, increasing the lean meat percentage and boosting pig immunity are achieved.

Owner:钟景林

Method for rapidly making lead-free preserved duck egg by utilizing acid leaching pressurization method

ActiveCN102630972AShorten the production cycleImprove permeabilityFood preparationOrganic acidEggshell

The invention relates to a method for rapidly making lead-free preserved duck eggs by utilizing acid leaching pressurization method. The method comprises the following steps: duck eggs are subjected to pretreatment by 5% citric acid, and are then pickled under pressurized condition, the eggs shells are appropriately thinned by using the citric acid and pores are appropriately enlarged, so as to facilitate the infiltration of a material liquid, during the pressurized soaking process of the duck eggs, by increasing the static pressure of the material liquid, the infiltration of the material liquid is accelerated, so that high quality preserved duck eggs which are taken out of a vat after five to six days, and become completely mature after 30 days are made, and the production cycle of the preserved duck eggs is shortened. According to the method, the citric acid adopted in the invention is firstly used for the pretreatment process for pickling the eggs, as the citric acid is edible organic acid and can be accepted by consumers easily; pressurization technique is also used in the pickling process of the eggs for the first time, requirements on pressurizing equipment are not so high, so that the pressurization technique is suitable for being popularized by enterprises for large-scale production; by using the lead-free material liquid for pickling the eggs, the prepared preserved duck eggs are safe and harmless, so that the concerns of consumers on lead are eliminated; through using acid leaching pressurization method to rapidly make the lead-free preserved duck eggs, the infiltration process of the material liquid is greatly accelerated, the production cycle of the preserved duck eggs is shortened, the production efficiency is improved, and the material liquid can be recycled, and therefore, the method definitely can bring new innovations to the pickling technology in the egg pickling industry.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

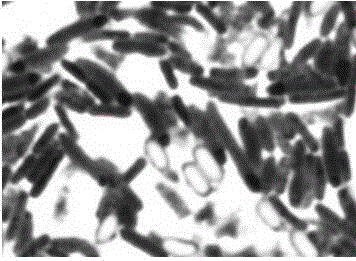

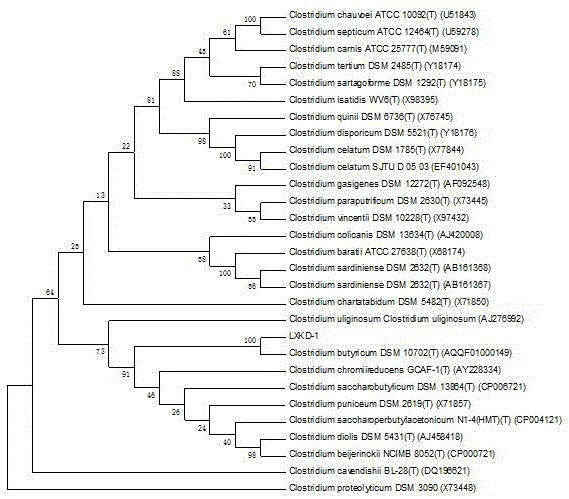

Preparation and application of Clostridium butyricum and live Clostridium butyricum preparation

ActiveCN106479924APromote growthPrevent diarrheaBacteriaMicroorganism based processesEscherichia coliEggshell

The invention discloses preparation and application of Clostridium butyricum and a live Clostridium butyricum preparation; Clostridium butyricum LXKJ-1 is collected in China Center for Type Culture Collection on 24 March, 2016 under CCTCC NO: M201613. A seed medium, fermentation medium formulation, culture conditions for Clostridium butyricum and a production of a preparation of live Clostridium butyricum are also disclosed. The Clostridium butyricum provided herein is tolerant to acids, bases and high temperature, is highly capable of producing butyric acid, can inhibit animal pathogens, such as Escherichia coli, Salmonella, Shigella, Staphylococcus aureus, Listeria monocytogenes, and Clostridium perfringens, and can prevent diarrhea in livestock and poultry due to Escherichia coli, Salmonella and Clostridium perfringens, improving intestinal flora balance, promoting the growth of livestock and poultry, relieving constipation in sows, improving egg weight for layers, improving eggshell quality for layers, and decreasing egg-feed ratio.

Owner:湖北绿雪生物科技有限公司

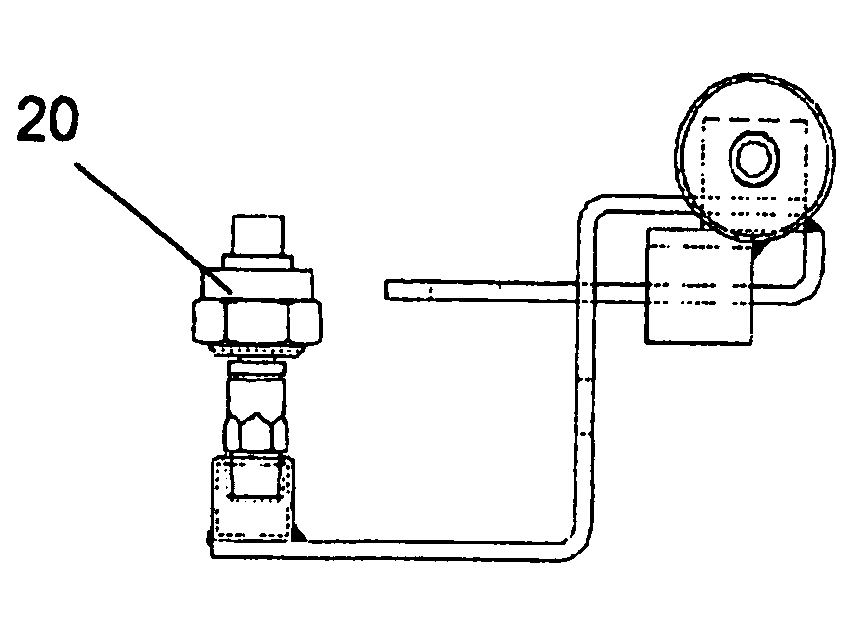

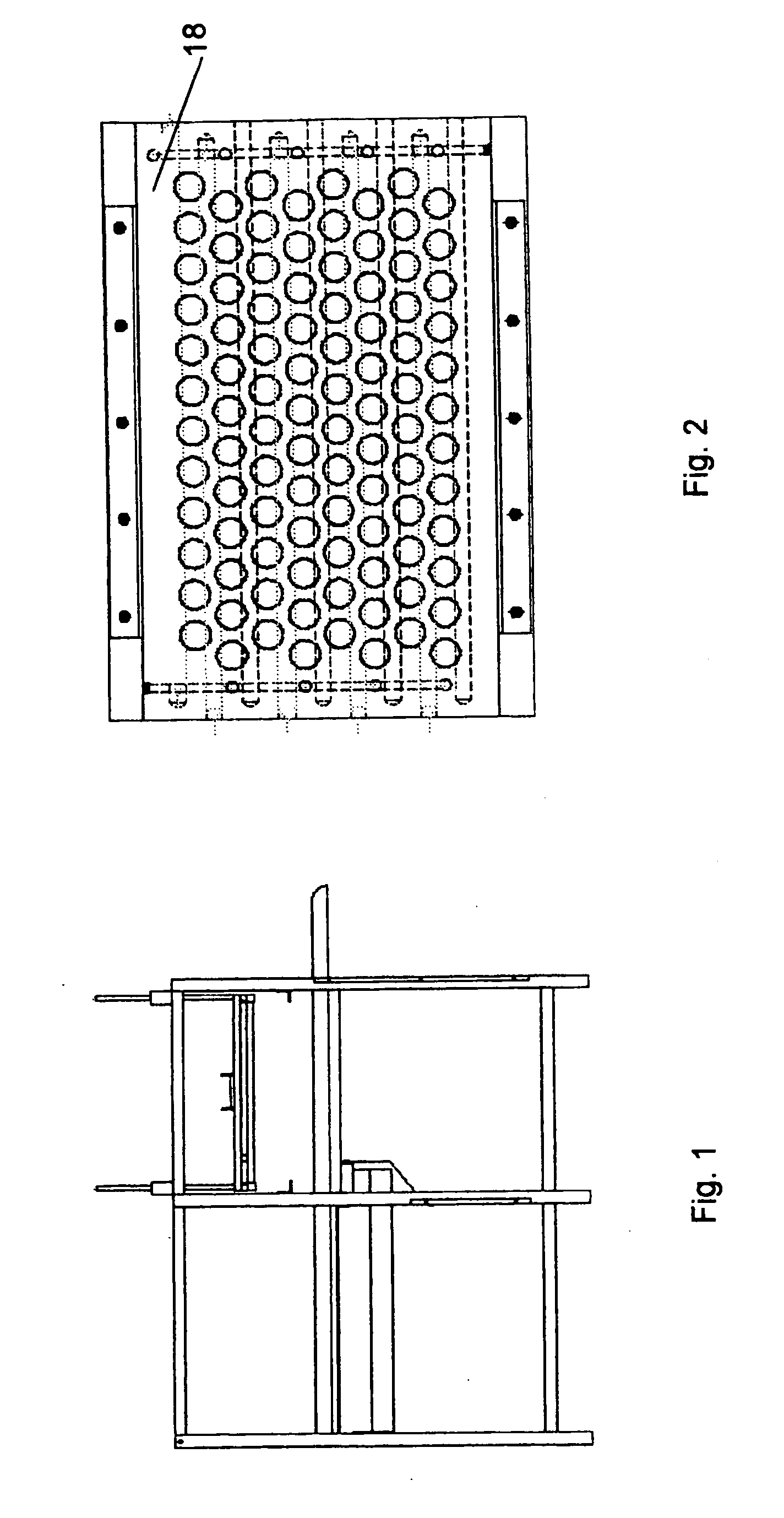

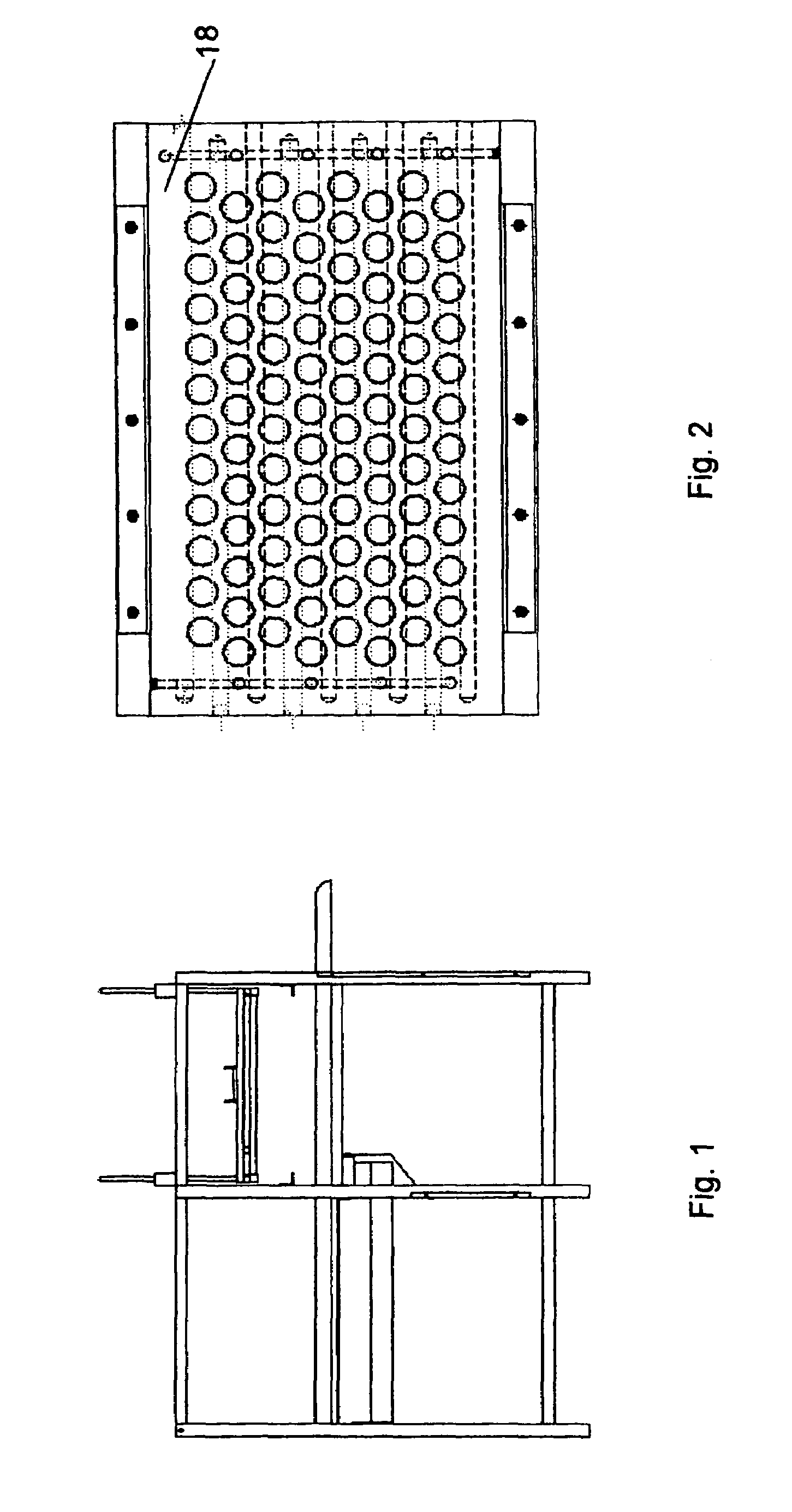

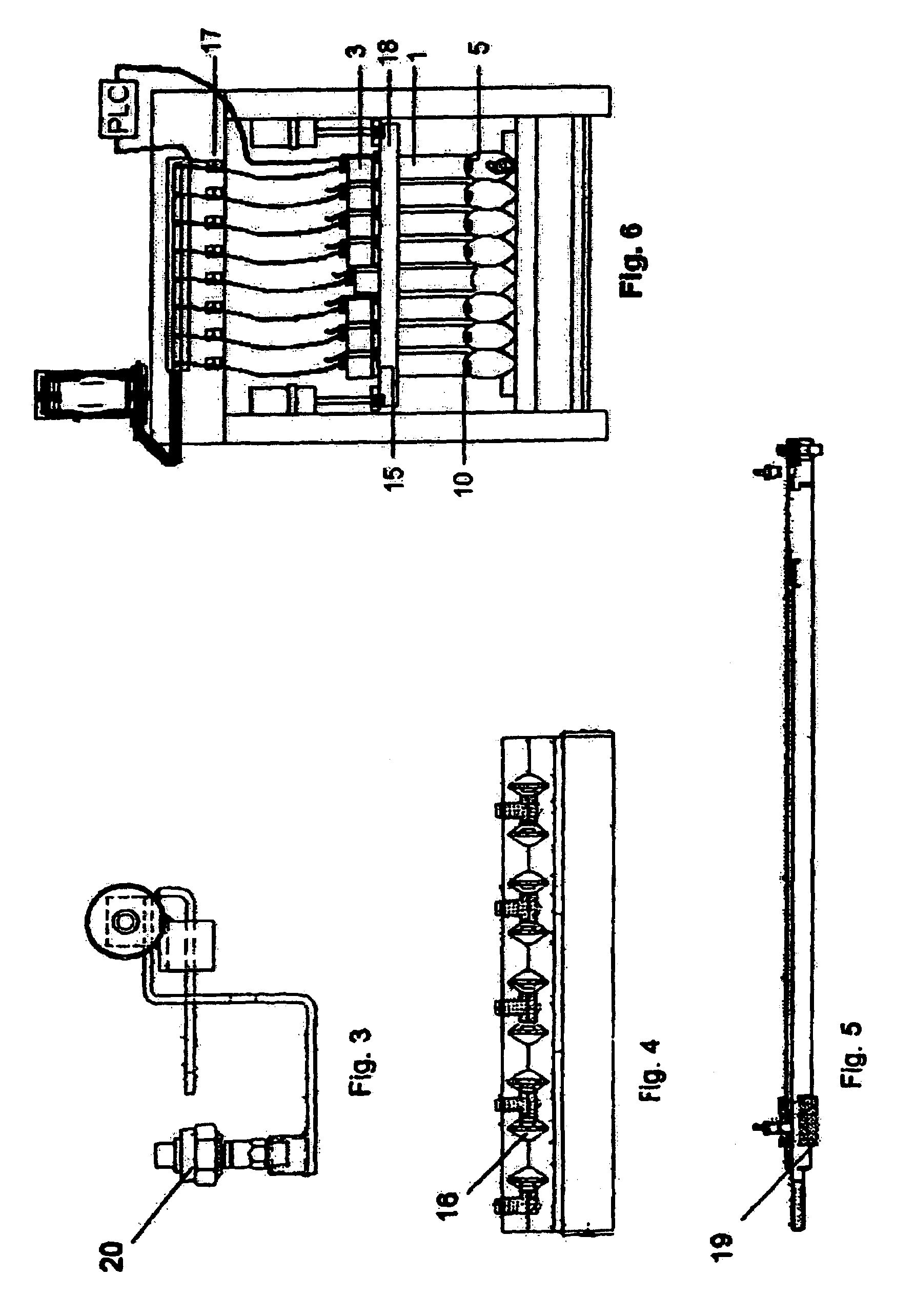

Automatic egg vaccinator

The invention relates to a system of automatic vaccination of eggs, developed for the purpose of vaccinating large quantities of fertile eggs in order to reduce the costs and labor involved, reduce embryonic mortality by increasing protection from diseases and reduce the stress in the first day of life of poultry chicks by eliminating the process of manually vaccinating each chick. The invention comprises an automatic system controlled by a PLC (programmable logic controller), using an injector that has a cylindrical body and cap made from high density non-corrosive plastic and together they form a pneumatic chamber, the cap containing an electronic contact sensor to signal empty egg spaces and avoiding wasting vaccine. The injector's pneumatic chamber contains a plasticized fiber sleeve to permit smooth movement of the pneumatic plunger. A needle passes through the plunger and a double acting spring in addition to securing the plunger in its starting position and returning it to the original position after the injection of vaccine, reduces the pressure on the needle after it breaks the egg shell to avoid harming the embryo. The injection platform that has conical holes for the injectors to permit lateral movements that allows the injectors to accommodate eggs that are tilted, with the injectors locked into position by a series of air bladders located within the platform and running parallel to the injectors. The sanitization system which disinfects the needle and the part of the injector in contact with the egg after every single injection is coupled with the removal of the incubator trays from the vaccination area to economize on production time.

Owner:MERIAL INC

Chinese medicinal herb additive for egg ducks and application thereof

InactiveCN101543260AImprove disease resistanceImprove qualityFood processingAnimal feeding stuffDiseaseEggshell

The invention discloses a Chinese medicinal herb additive for egg ducks and application thereof. The Chinese medicinal herb additive comprises amur corktree bark, eucommia bark, honeysuckle, szechwon tangshen root, sanguisorba, hawthorn, Indian Buead, officinal magnolia bark, Chinese pulsatilla root, giant knotweed rhizome, ricepaperplant pith, largehead atractylodes rhizome, tangerine peel, malt, indigowoad root, swordlike atractylodes rhizome, indigowoad leaf, three immortals, liquorice, cyrtomium fortune, nutgrass galingale rhizome, chatoyancy and calamus, and mixture of the compositions is added with calcium bicarbonate, phytase, vitamin E and methionine. The Chinese medicinal herb additive effectively promotes absorption of nutrient, can prevent and control diseases, strengthen quality of eggshells, reduce the broken egg rate and soft-shell eggs, abnormal eggs and sand shell eggs, can effectively prevent bird flu, prevent and control diseases such as laxness, feather pecking, hair shedding, anus pecking, salpingitis, respiratory disease and the like, can achieve good effect with a dosage of about 4 percent, cannot damage physiological functions of the egg ducks, and can prolong egg laying peak season, improve color of the eggshells and the laying rate by 9 to 20 percent, and increase weight of eggs.

Owner:CHONGQING KAIZHOU JIUDING ANIMAL HUSBANDRY SCI & TECH DEV

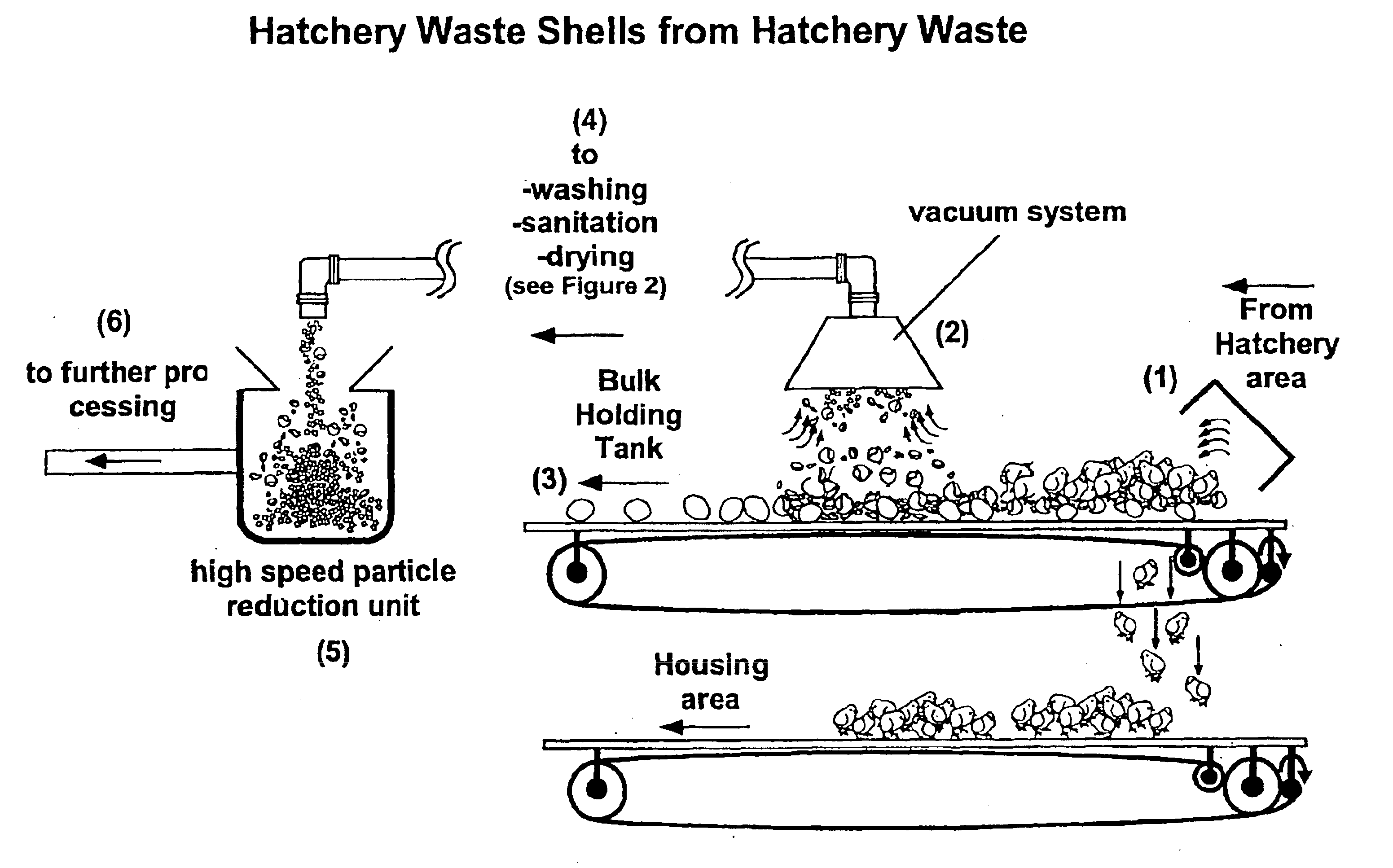

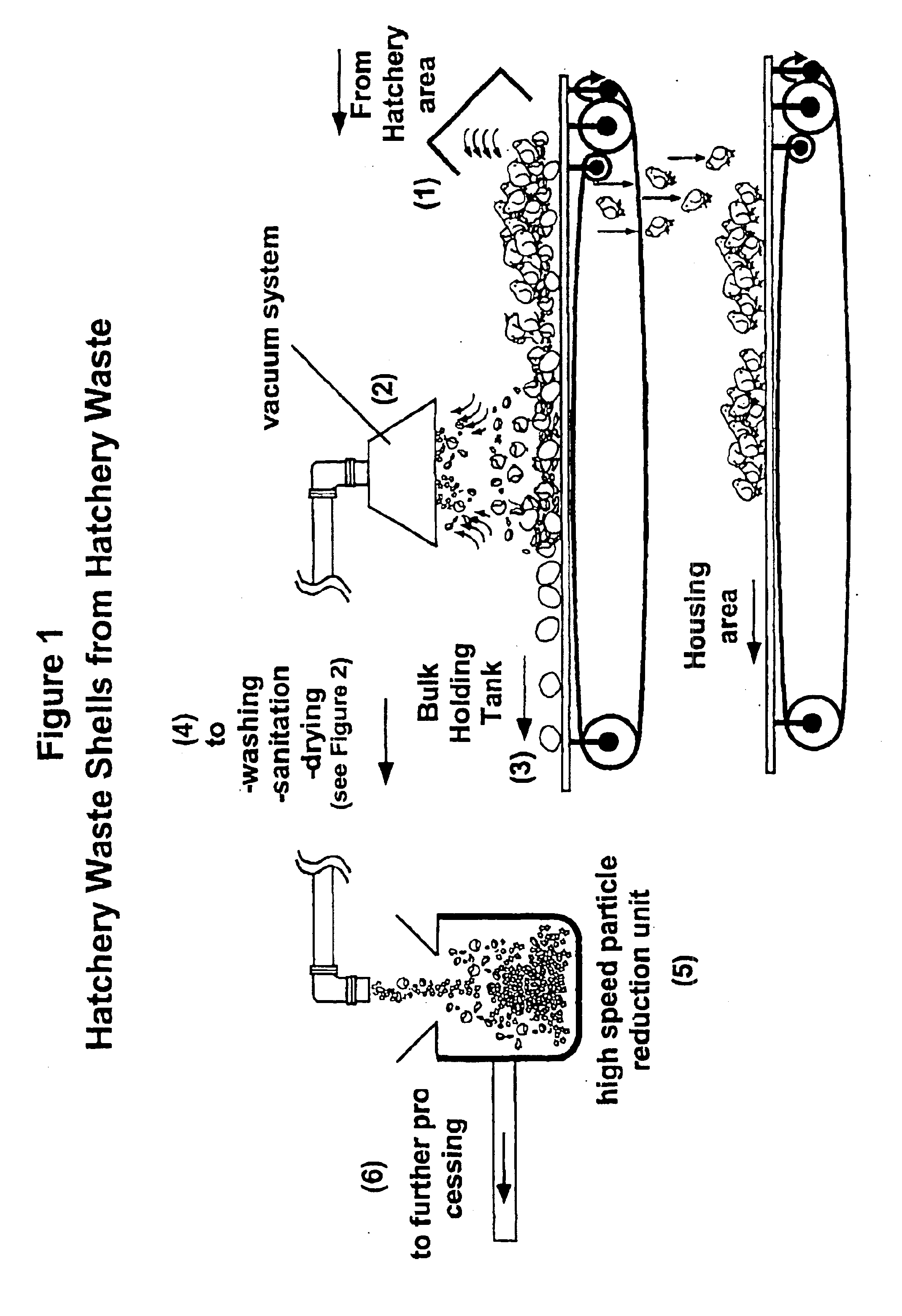

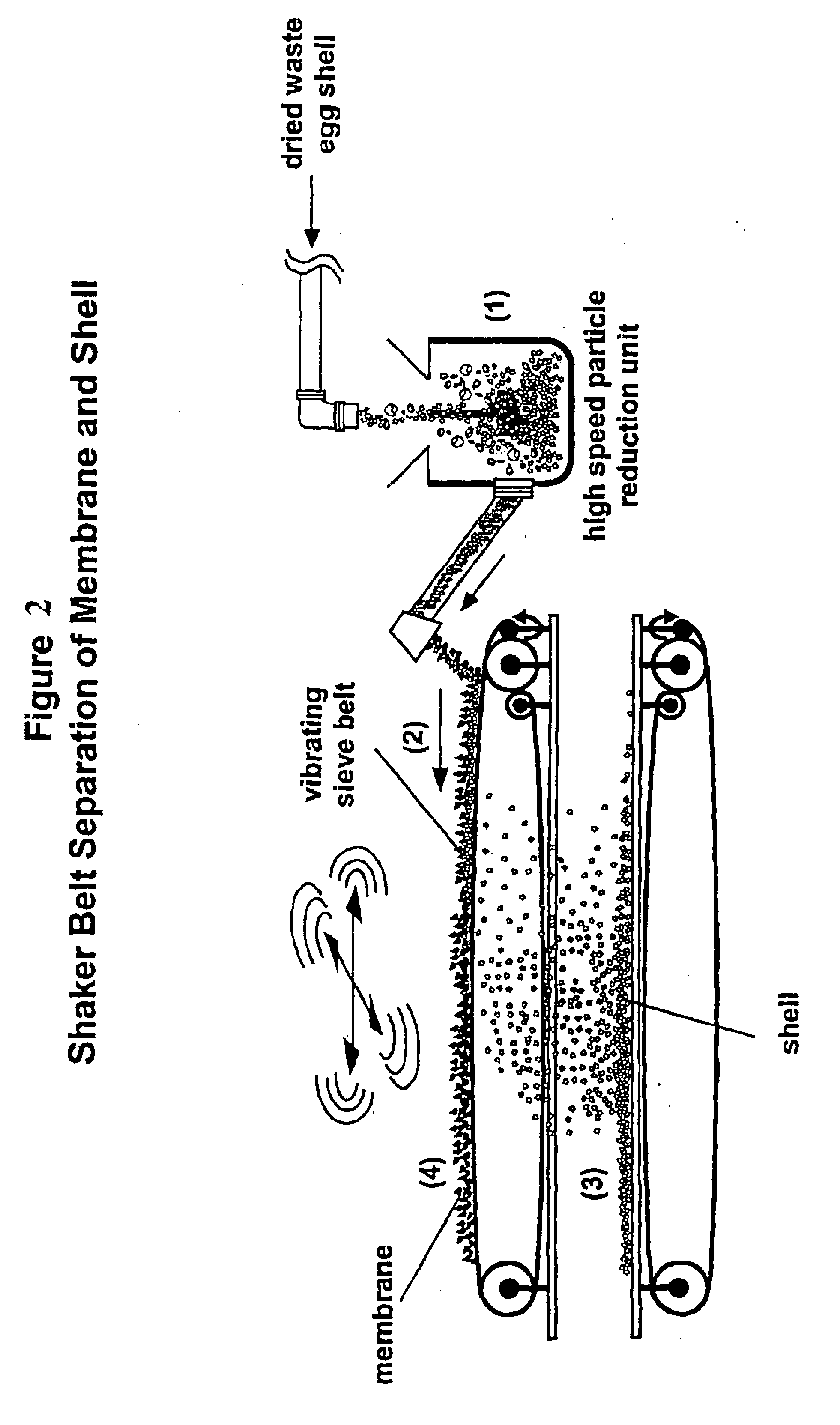

Hatchery eggshell waste processing method and device

InactiveUS6899294B2Reduce environmental impactEconomic benefitVitamin food ingredientsPeptide/protein ingredientsWaste processingEggshell

A method and apparatus for separating the organic membrane portion of waste egg shells from the hard inorganic mineral portion thereof, so that each can be used or further processed as desired, thereby addressing the environmental and economic issues associated with disposing of waste egg shells. The membrane and shell are separated by first processing waste eggshells so as to yield small waste eggshell particles. During this processing, the waste eggshell particles are at least slightly abraded, whereby the linking structure between the membrane and shell is at least partially disrupted. Thereafter, the waste eggshell particles are conveyed to a device, which isolates the two components based on their size and weight differences. The methods listed above can provide products from the eggshell waste including precipitated calcium carbonate, membrane, protein, amino acids, collagen and other important components.

Owner:PENN STATE RES FOUND

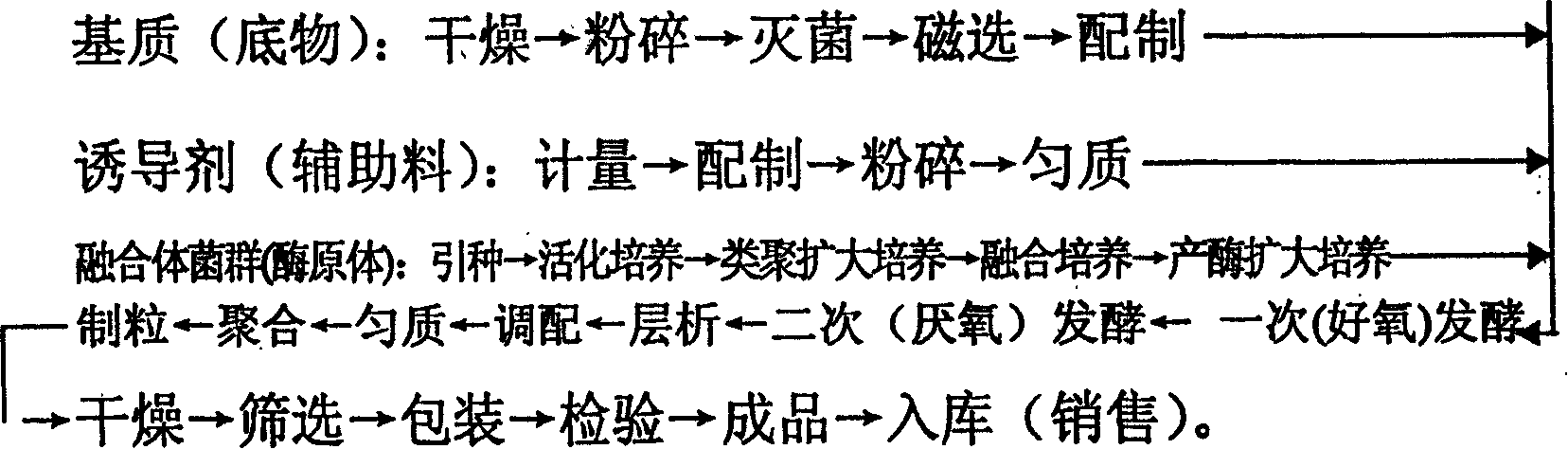

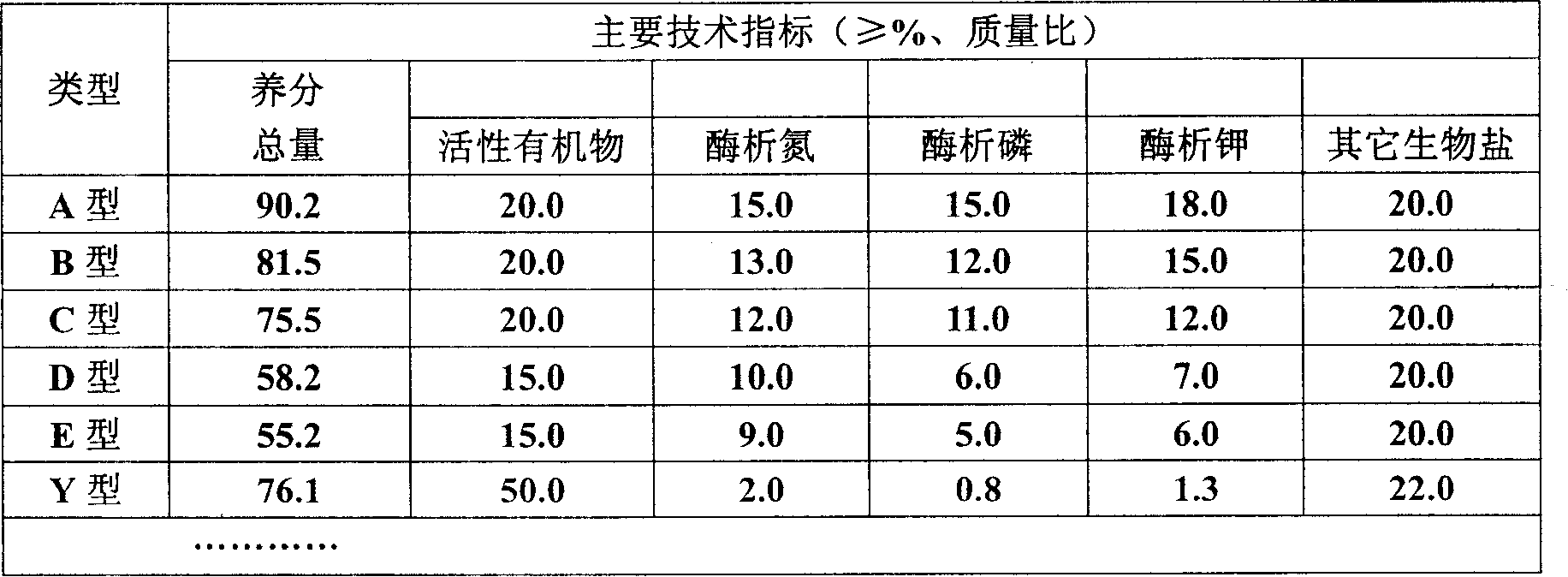

Nitrile ester phosphor potassium amine liveness fertilizer

InactiveCN101172895AIncrease proteinHigh fat contentBio-organic fraction processingClimate change adaptationEggshellSource function

The invention relates to nitrile ester phosphorus potassium and amine actively organic fertilizer. The invention is characterized in that the high quality, high effect and environmental protection fertilizer is produced through wastes such as city organic waste, crop stalk, weed, rice hull, residual bone, residual fur, residual fat, dry cake, chisel, shell and eggshell based on resource use and environmental protection. The invention has the beneficial effect that the reproducible waste comprises a mass of carbohydrates such as fibrin, lignose, starch, polysaccharide, aliphatic acid, ketone, alcohols, protein, nitrile fatty and aminopeptidase, and organically biogenic salts such as organic nitrogen, phosphor, kalium, silicon, sulfur, autunite, magnesium, iron, manganese, copper, boron, zinc and molybdenum. The organic materials are transformed into active nutrients of a plurality of organic enzyme source functions through solidoid fermentation and zymohydrolysis of a plurality of zymogenic combination floras, and the active nutrients can be completely absorbed by crops. Besides, the invention has the advantages of improving the environment of soil, increasing the antibody of plants, decreasing the environmental pollution, increasing the quality of agricultural products and promoting the healthy lives of human being.

Owner:彭辉照

Pickling method of multi-flavor marinated eggs

The invention relates to a food processing method, in particular to a pickling method of multi-flavor marinated eggs, which comprises the following steps: firstly, placing fresh eggs into a pickling salt solution after pretreatment; then, placing the pickling salt solution with the fresh eggs into a sealed container; introducing pulse pressure to the inside of the container at the normal temperature, wherein one pulse period of the pulse pressure is between 5 and 20 minutes, the ratio of the high pressure maintaining time to the low pressure maintaining time of the pulse pressure is 1 / 2, the time for raising the low pressure to the high pressure in one pulse period is 35 to 50 seconds, and the time for relieving the high pressure to the low pressure is 5 to 30 min; carrying out sampling verification on the picked marinated eggs; carrying out post maturation treatment; and steaming or boiling the marinated eggs after the post maturation to obtain finished products. The marinated eggs prepared by the invention have the advantages that the salinity of egg white and egg yolk are moderate, the appearance of the egg cases is good, the mouth feeling of the marinated eggs is good, in addition, the processing time of the finished eggs is short, and the storage period is long.

Owner:CHINA AGRI UNIV

Feed formula for egg-laying period of laying hen and preparation method

The invention relates to a formula and manufacturing method for feed used for laying hen in laying period. The formula has the components of: corn 25-45%, wheat 5-25%, full cream rice bran 6-25%, soybean meal 2-13%, residual forages%, adhesive 5-15%, cotton meal 5-10%, stone flour 8-11%, composite vitamin 0.2-0.5% and composite microelements 0.2-0.5%; wherein, the calcium granule can be substituted by same amount of eggshell powder, stone granule or shell powder; the adhesive and be substituted by secondary powder or flour; additionally, for maintaining the intestinal tract health of laying hen and the good culturing environment, 0.5% of micro-ecology preparation or traditional Chinese medicine health caring agent can be added. Feeding experiments prove: the feed in the invention can stabilize laying rate, prolong laying period, save one labor per 4000 eggs comparing with the traditional powder feed, reduces blending processes, avoid cross pollution, improve feed storage condition, purify culturing farm environment, reduce laying hen culturing risk effectively, and increase production of laying hen culturing substantially.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Automatic egg vaccinator

The invention relates to a system of automatic vaccination of eggs, developed for the purpose of vaccinating large quantities of fertile eggs in order to reduce the costs and labor involved, reduce embryonic mortality by increasing protection from diseases and reduce the stress in the first day of life of poultry chicks by eliminating the process of manually vaccinating each chick. The invention comprises an automatic system controlled by a PLC (programmable logic controller), using an injector that has a cylindrical body and cap made from high density non-corrosive plastic and together they form a pneumatic chamber, the cap containing an electronic contact sensor to signal empty egg spaces and avoiding wasting vaccine. The injector's pneumatic chamber contains a plasticized fiber sleeve to permit smooth movement of the pneumatic plunger. A needle passes through the plunger and a double acting spring in addition to securing the plunger in its starting position and returning it to the original position after the injection of vaccine, reduces the pressure on the needle after it breaks the egg shell to avoid harming the embryo. The injection platform that has conical holes for the injectors to permit lateral movements that allows the injectors to accommodate eggs that are tilted, with the injectors locked into position by a series of air bladders located within the platform and running parallel to the injectors. The sanitization system which disinfects the needle and the part of the injector in contact with the egg after every single injection is coupled with the removal of the incubator trays from the vaccination area to economize on production time.

Owner:MERIAL INC

Feed for chickens

InactiveCN101703173AIncrease sedimentationImprove immunityFood processingAnimal feeding stuffDiseaseYolk

A feed for chickens takes yellow mealworms as a new resource of animal protein, takes lutein as a feed additive, and is formed by matching sweet corns, yellow mealworms, bean pulp, lutein, dibasic calcium phosphate, premix compound, salt, fine aggregate and wheat barn, wherein the metabolizable energy is 2850-2900 kcal / kg, the protein is more than or equal to 19.5%, Ca accounts for 0.9-1.2%, total phosphorus accounts for 0.6-0.8 %, methionine is more than or equal to 0.48%, and lysine is more than or equal to 1.15%. In the invention, compared with the feed taking the bean pulp as a main material, the immunity of poultry and the function of the immune system are improved, the immune cells are activated overall, the generation of the antibody is promoted, the occurrence rate of diseases is decreased, and the precipitation capacity of the lutein in the egg yolk is improved greatly, the mouthfeel of eggs, the laying rate and egg quality of the chickens are improved, the egg laying peak season is prolonged, the single egg weight is increased, the color of the egg shell is bright, the nutritional value is higher, the laying rate is improved by 4%, the mortality and elimination rate is reduced by 4.5%, the feed is saved by 14%, and the economic benefit is improved by 4.3%.

Owner:CHANGZHI TIANHE ANIMAL HUSBANDRY DEV

Livestock feed

InactiveCN105285318ANutritional diversityPromote digestion and absorptionAnimal feeding stuffFeed conversion ratioEggshell

The present invention relates to an animal feed, in particular relates to a livestock feed, and belongs to the technical field of preparing feed from plant materials such as potatoes or non-silage root tuber plants. The present invention discloses a livestock feed which is safe to livestock animals, and has low costs, complete nutrition, good palatability and a high feed conversion rate. The livestock feed comprises the following raw materials in parts by weight: 10-15 parts of rice bran, 10-15 parts of wheat bran, 5-10 parts of sweet potato vine bran, 5-10 parts of broad bean leaf bran, 5-10 parts of soy stalk bran, 20 to 25 parts of rapeseed cake, 5-10 parts of cottonseed cake, 20-25 parts of soybean cake, 5-10 parts of broad beans, 10-15 parts of peas, 5-10 parts of bean dregs, 5-10 parts of silkworm pupa, 7-10 parts of fish meal, 7-10 parts of bone meal, 5-10 parts of blood meal, 5-10 parts of stone powder, 7-10 parts of eggshell powder, 0.5-1 part of calcium hydrogen phosphate, 0.5-1 part of calcium carbonate, 0.5 part of salt, 3-5 parts of Lactobacillus acidophilus, 3-5 parts of Bnfillus licheniformis, 5-10 parts of licorice root, 5-10 parts of indigowoad root, 5-10 parts of tuber fleeceflower stem and leaves, 1-3 parts of organoselenium, 5-8parts of active dry yeast, 2-4 parts of nigecose syrup and 1-3 parts of biuret.

Owner:刘铮

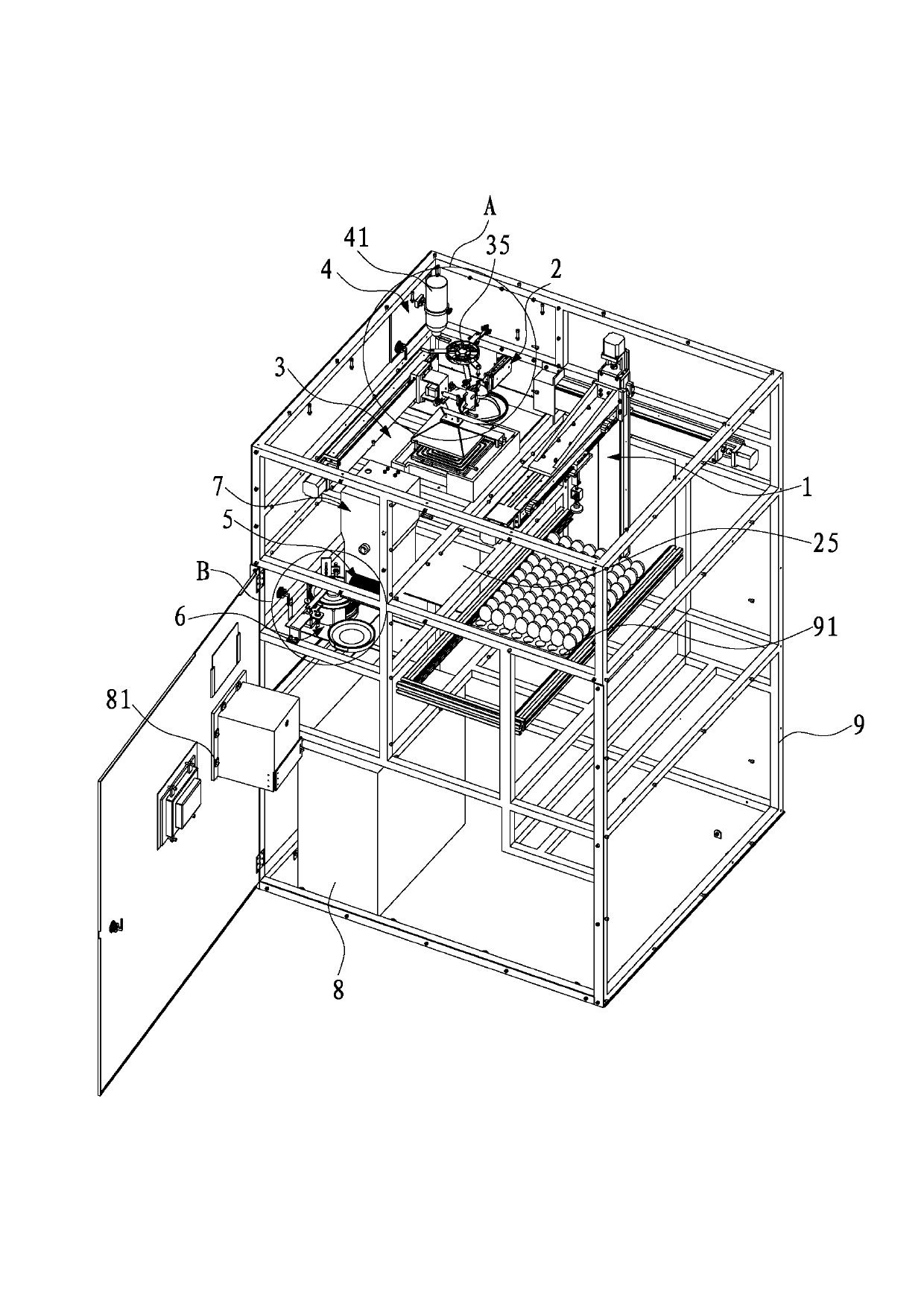

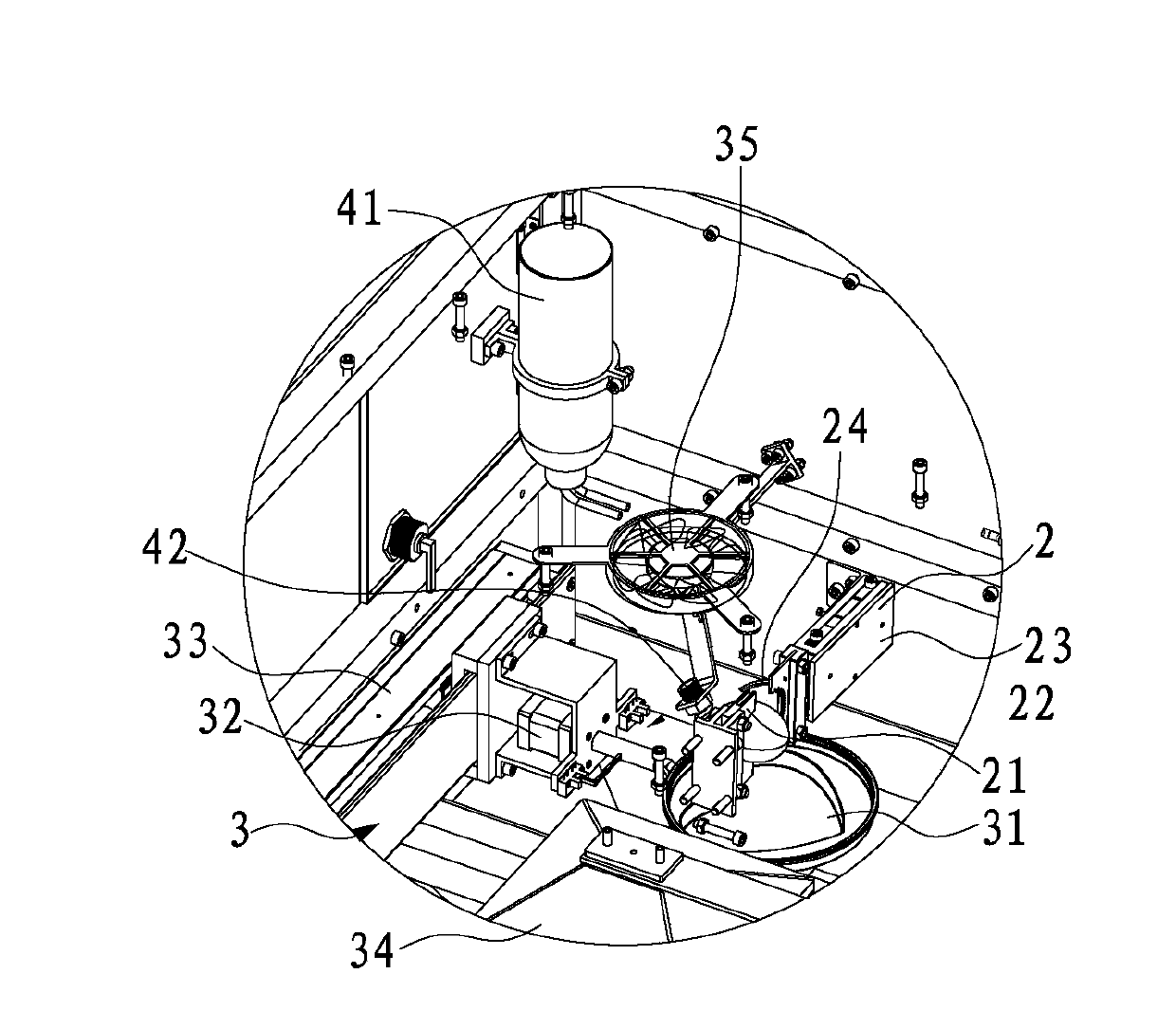

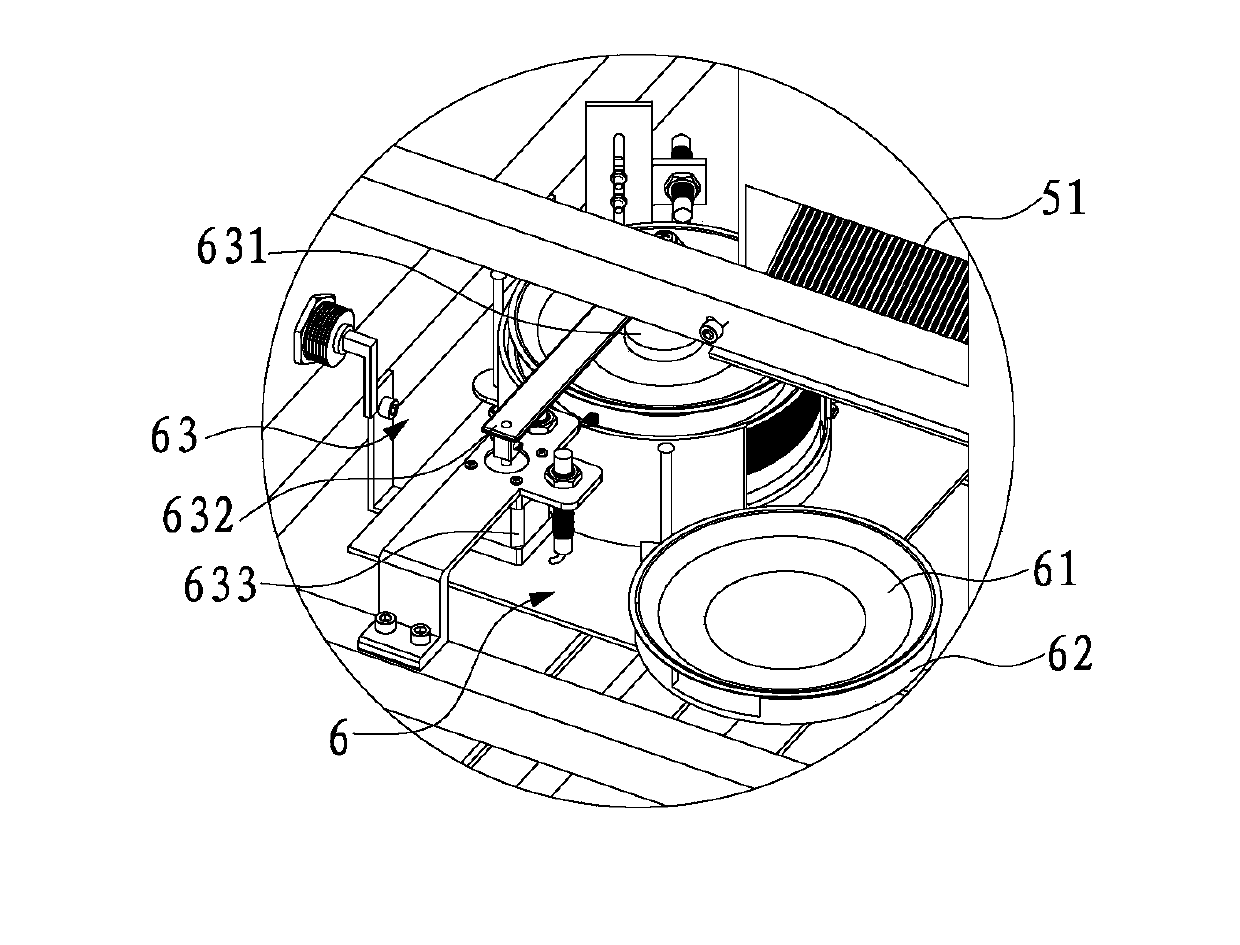

Full-automatic egg frying and vending machine

The invention discloses a full-automatic egg frying and vending machine. The full-automatic egg frying and vending machine comprises an egg taking mechanism, an egg liquid separation mechanism, an egg frying and conveying mechanism, an oil addition mechanism and a control mechanism, wherein the egg liquid separation mechanism is used for cracking an eggshell in a clamping mode to enable egg liquid to flow out, the mechanisms are fixedly installed on a rack, and the rack is provided with an egg rack; the egg taking mechanism comprises an egg taking device and a moving device, wherein the egg taking device is used for taking raw eggs down from the egg rack, and the moving device is used for moving the egg taking device to the egg liquid separation mechanism; the egg frying and conveying mechanism comprises a frying pan, a horizontal movement device and a heating and egg frying device, wherein the horizontal movement device can drive the frying pan to move; the oil addition mechanism is used for adding oil to the frying pan. According to the full-automatic egg frying and vending machine, the process from raw egg taking operation, egg cracking operation, processing to vending operation can be automatically accomplished, manual intervention is not needed, the defect that in the traditional egg frying process, a worker needs to be on site is overcome, convenience and rapidness are achieved, the cost is low, the eggs can be fried immediately, it is ensured that fried eggs are fresh and delicious, the market prospect is wide, and the full-automatic egg frying and vending machine has quite high investment value.

Owner:XIAMEN UNIV OF TECH

Thin-walled body strengthen porcelain and production technique thereof

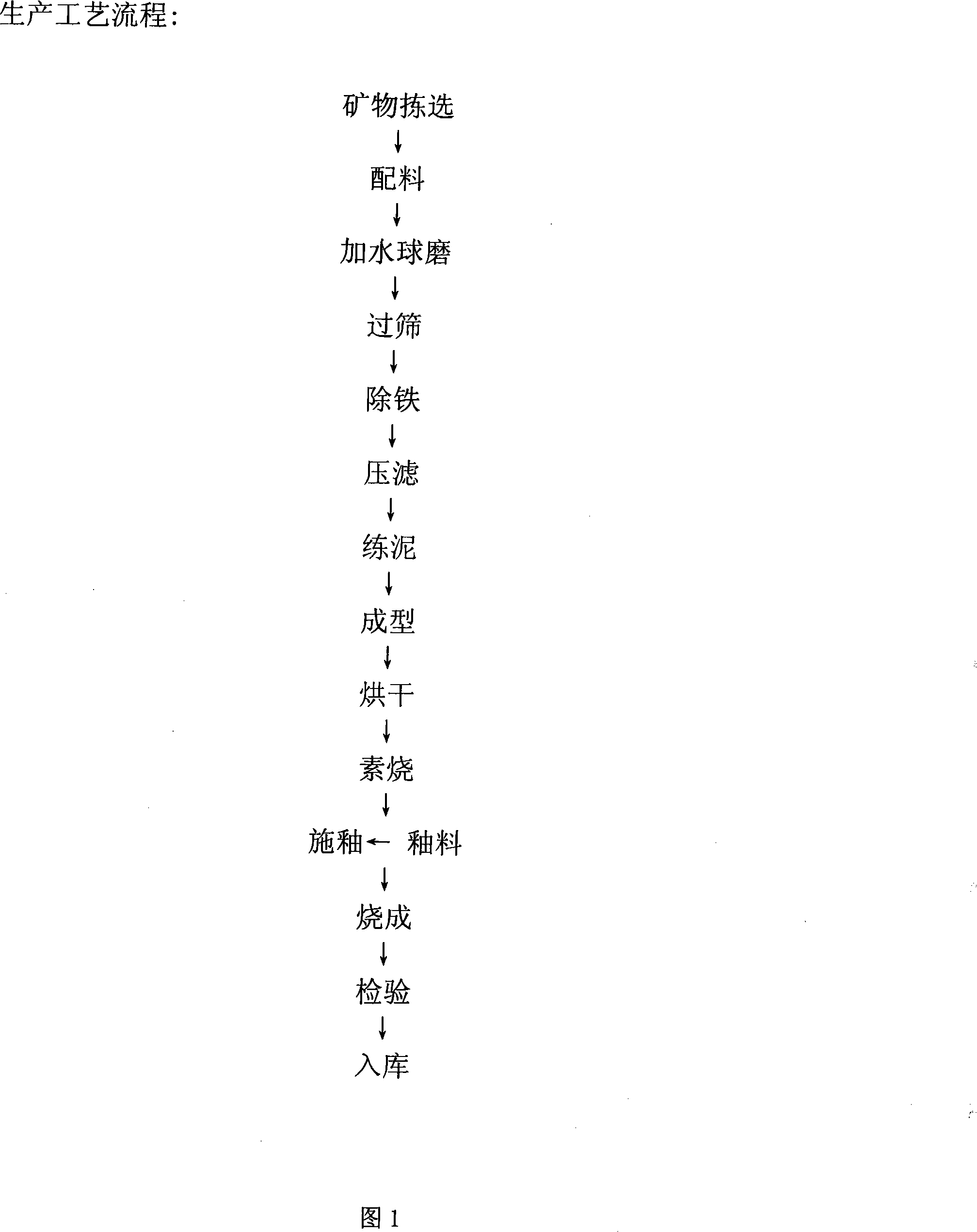

The invention relates to a strengthen porcelain and a production process thereof, which more particularly relates to an eggshell strengthen porcelain and the corresponding production process. A body of the eggshell strengthen porcelain comprises kaolin, weathered potash feldspar, quartz, Alpha oxidized aluminum single crystal, zirconia single crystal, bentonite and talc. The production process of the eggshell strengthen porcelain comprises steps of ore sorting, batching, ball milling by adding water, sieving, removing iron, pressure filtering, clay preparation, forming, baking, biscuit firing, glazing, sintering to finish. The product of the invention has good whiteness, transmittance and thermo stability, high mechanical strength, smooth glaze, light instrument; the thickness of the product is approximately one half of the traditional strengthen porcelain only.

Owner:林伟河

Concentrated feed for laying hen in egg-laying peak period

InactiveCN102084939AHas the effect of disease prevention and health careImprove immunityFood processingAnimal feeding stuffYolkEggshell

The invention discloses a concentrated feed for laying hens in egg-laying peak period. The feed comprises a laying hen dietary feed with main components of soybean meal, cottonseed meal, rapeseed meal, corn germ cake, corn germ meal, enzyme hydrolyzed feather meal, stone powder, calcium hydrogen phosphate, medical stone, salt, and methionine; a health care agent combination pack and a premix are added into the laying hen dietary feed; the health care agent combination pack comprises ovary protecting elements, microecological preparations, enzyme preparations, diluents, and Chinese herbal medicine health care agents; and the premix comprises coated vitamins, mineral elements, methionine, and carriers. The feed can prolong the egg-laying peak period of laying hens, improve the body immunity of laying hens, improve the quality of the eggs, allow the eggshell to have a good texture and a pure color, allow the yolk to have a dark color, and allow the eliminated hens to be full-fledged and have good quality.

Owner:HENAN MUHE GROUP FEED

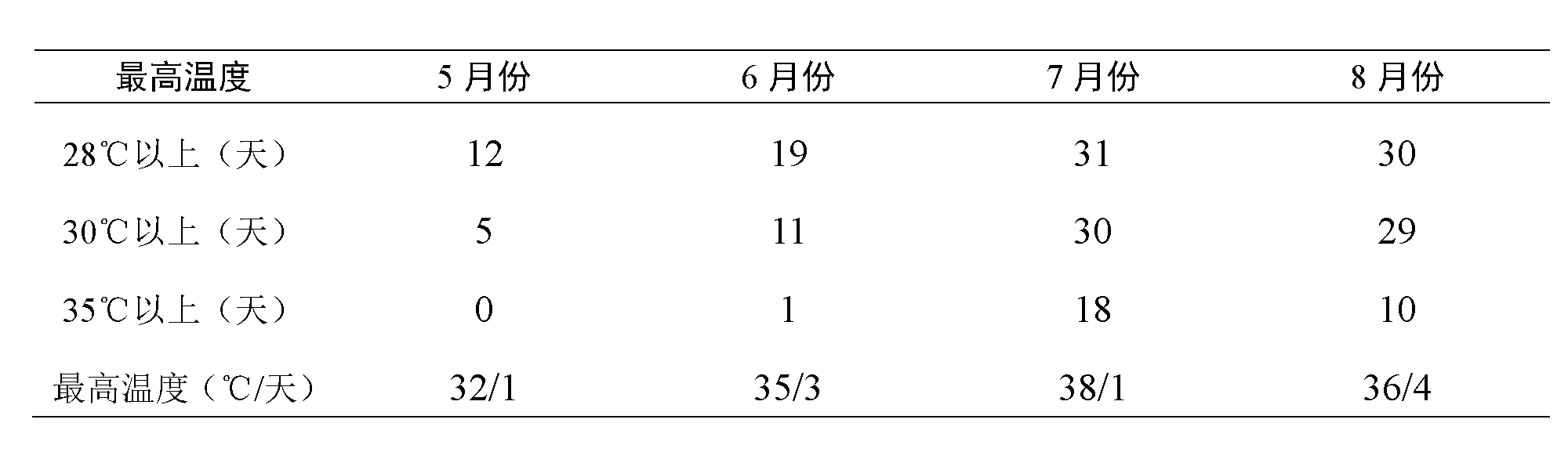

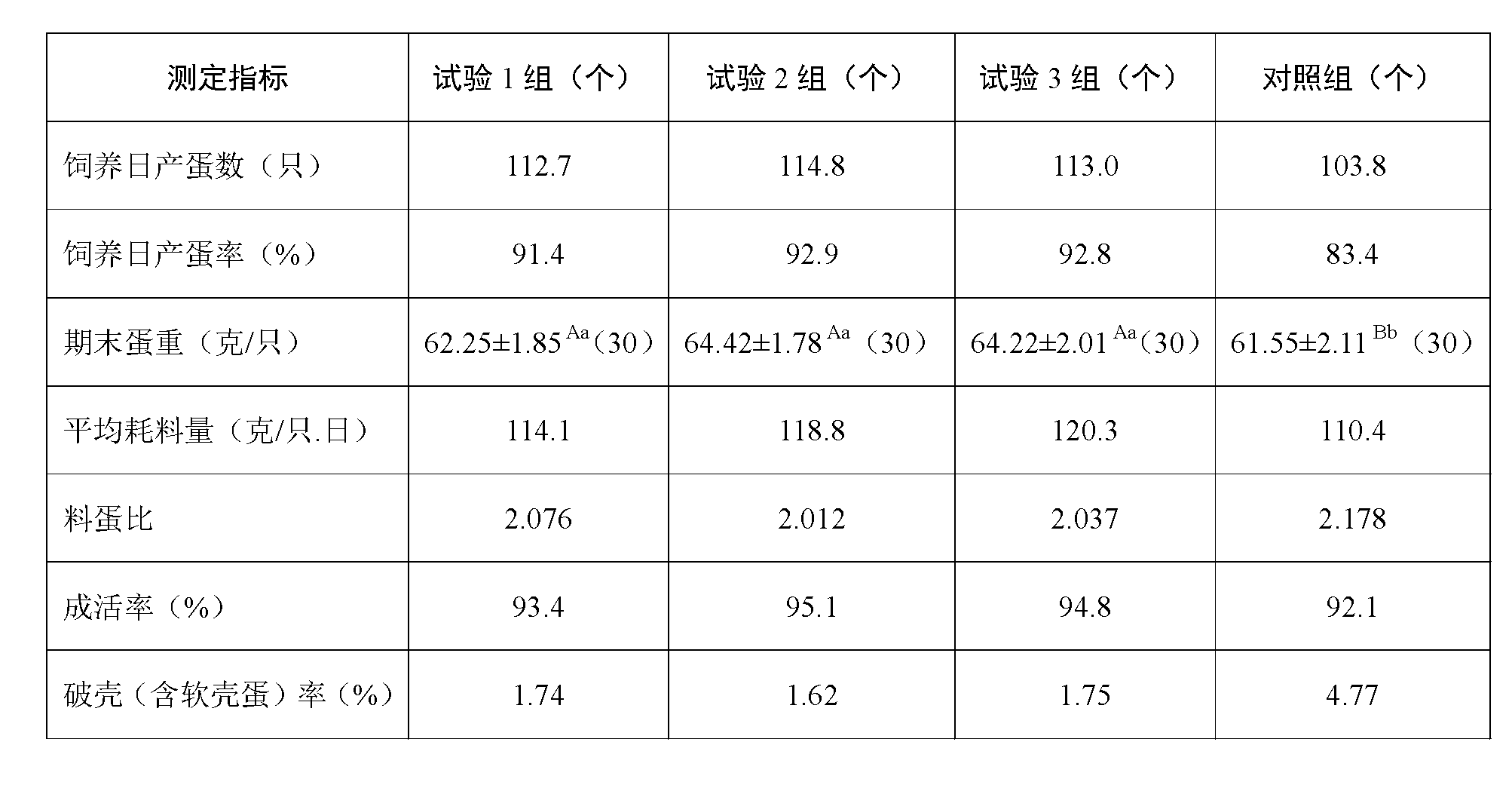

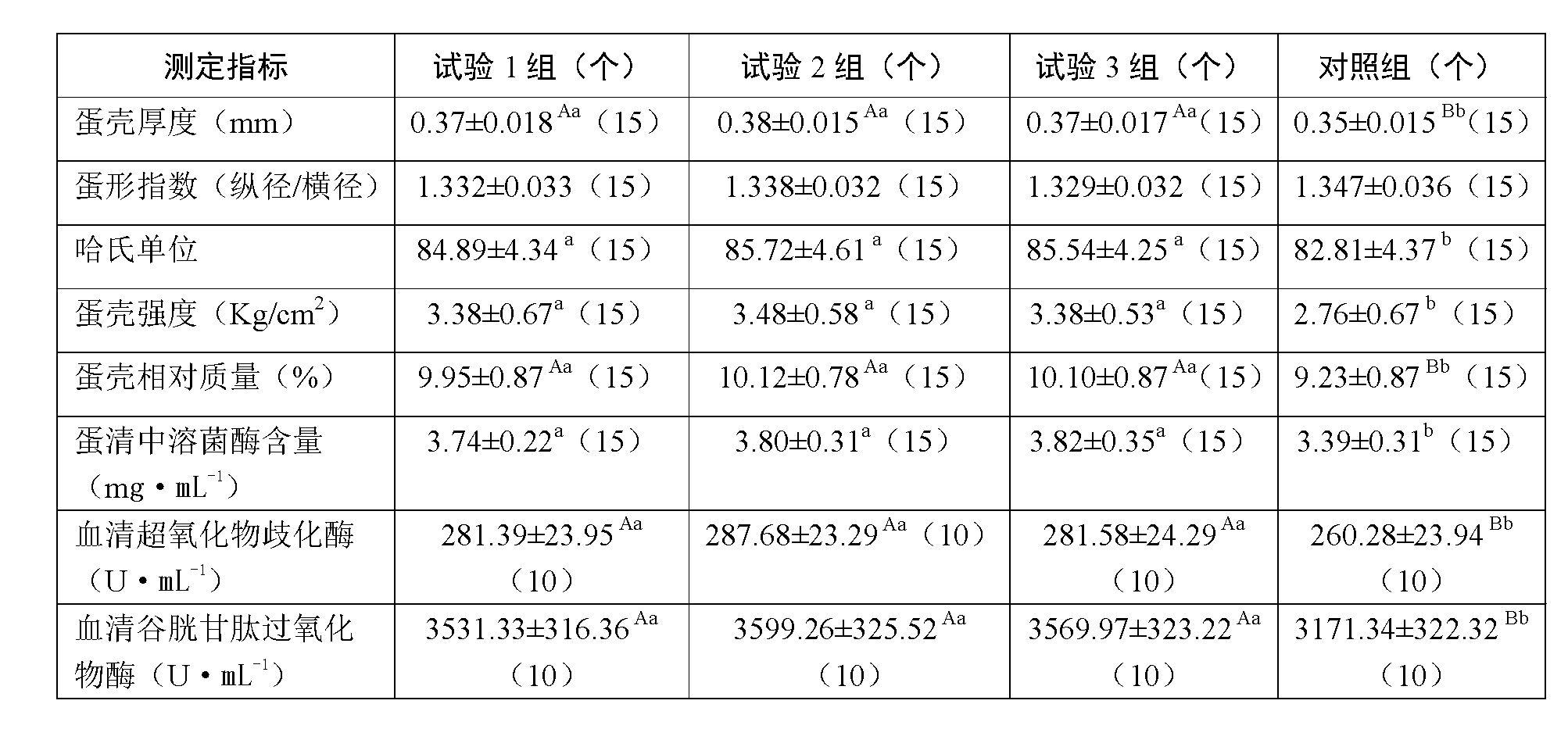

Feed for improving production performance of laying hens in high temperature season and breeding method

InactiveCN103211116AIncrease feed intakeIncrease production capacityAnimal watering devicesAnimal feeding stuffAnimal scienceEggshell

The invention discloses feed for improving production performance of laying hens in a high temperature season and a breeding method. The method comprises the following steps of: adding 0.5-2.5 percent of soybean oil into a formula of normal laying hen feed for performing equivalent replacement on corn in the formula of normal laying hen feed, adding 50-200mg of Chinese herbal medicine mixed additive subjected to superfine grinding into the feed per kg, wherein the Chinese herbal medicine mixed additive comprises astragalus, Chinese angelica, herba epimedii, glossy privet fruit, wolfberry, hawthorn, motherwort, mint and liquorice. Therefore, the eggshell thickness of the laying hen can be increased by 8.3-8.6 percent, the Haugh unit is improved by 3.2-3.5 percent, the eggshell strength is improved by 22.1-32.9 percent, the egg breakage rate is reduced by 3-4 percent, the feed utilization rate is improved by 7-8 percent, the high-temperature period death rate of the laying hen is reduced by 1-3 percent, and the laying hen is bright in feather color and gloss.

Owner:YIXING HUAFENG CULTURE PROFESSIONAL COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com