Full-automatic egg frying and vending machine

A vending machine, fully automatic technology, applied in egg cookers, instruments, handling coins or valuable banknotes, etc., can solve the problems of high labor cost, unsatisfactory, inability to fry and eat immediately, and achieve low production cost , low cost and high investment value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

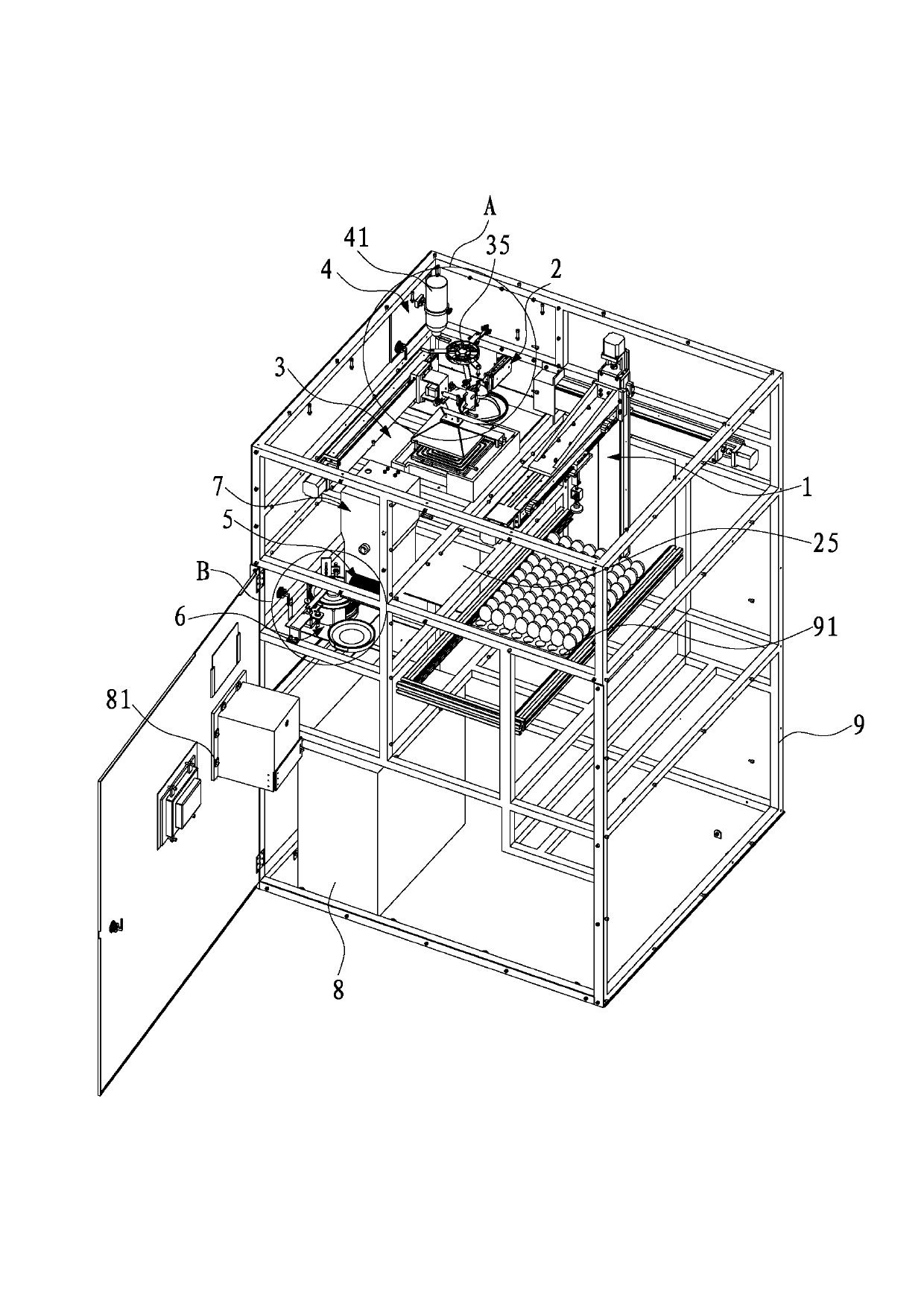

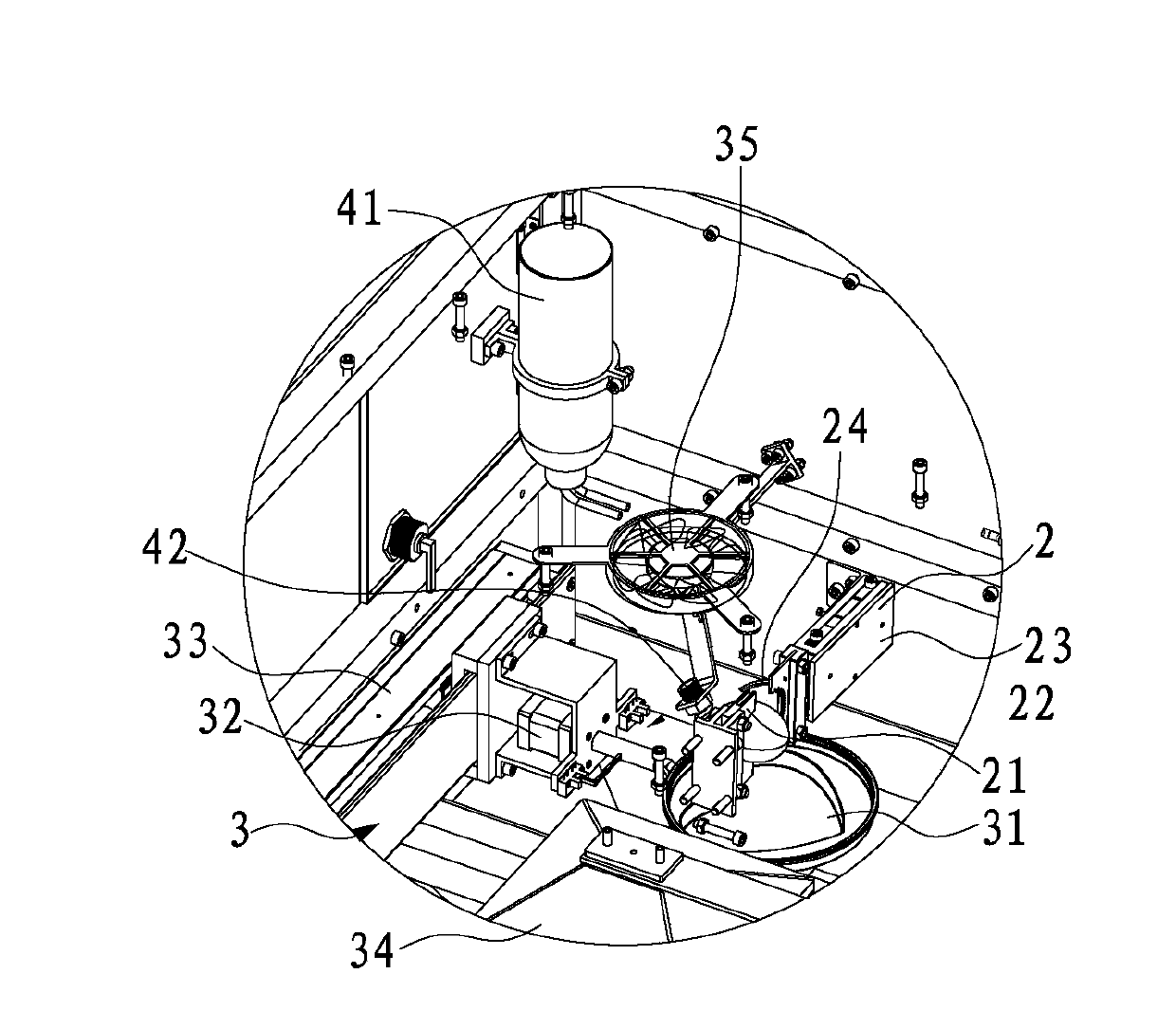

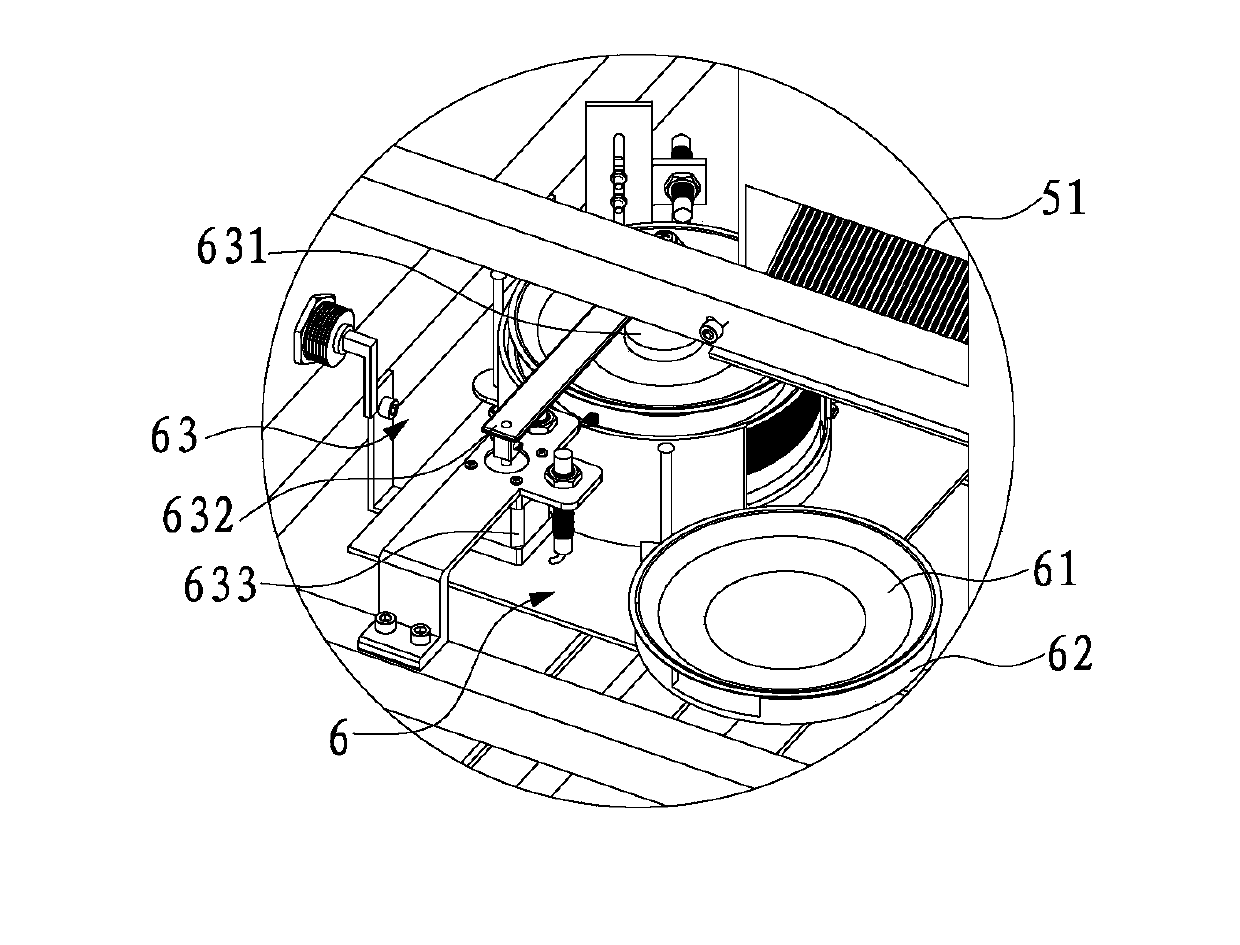

[0037] The present invention discloses a fully automatic fried egg vending machine, such as Figure 1 to Figure 9 Shown is a preferred embodiment of the present invention. The omelette machine includes an egg fetching mechanism 1, an egg liquid separation mechanism 2, an fried egg and a transmission mechanism 3, a refueling mechanism 4, an egg oil separation mechanism 5, a pan mechanism 6, a cleaning mechanism 7 and a control mechanism 8, and the Each mechanism is fixedly installed on the frame 9, and the frame 9 is provided with an egg rack 91 for storing raw eggs. in:

[0038] The egg fetching mechanism 1 is used to remove the eggs on the egg rack 91 and transfer them to the egg liquid separating mechanism 2 . Such as Figure 4 As shown, the egg fetching mechanism 1 includes an egg fetching device 11 for removing eggs from the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com