Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

640results about How to "Accelerate solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

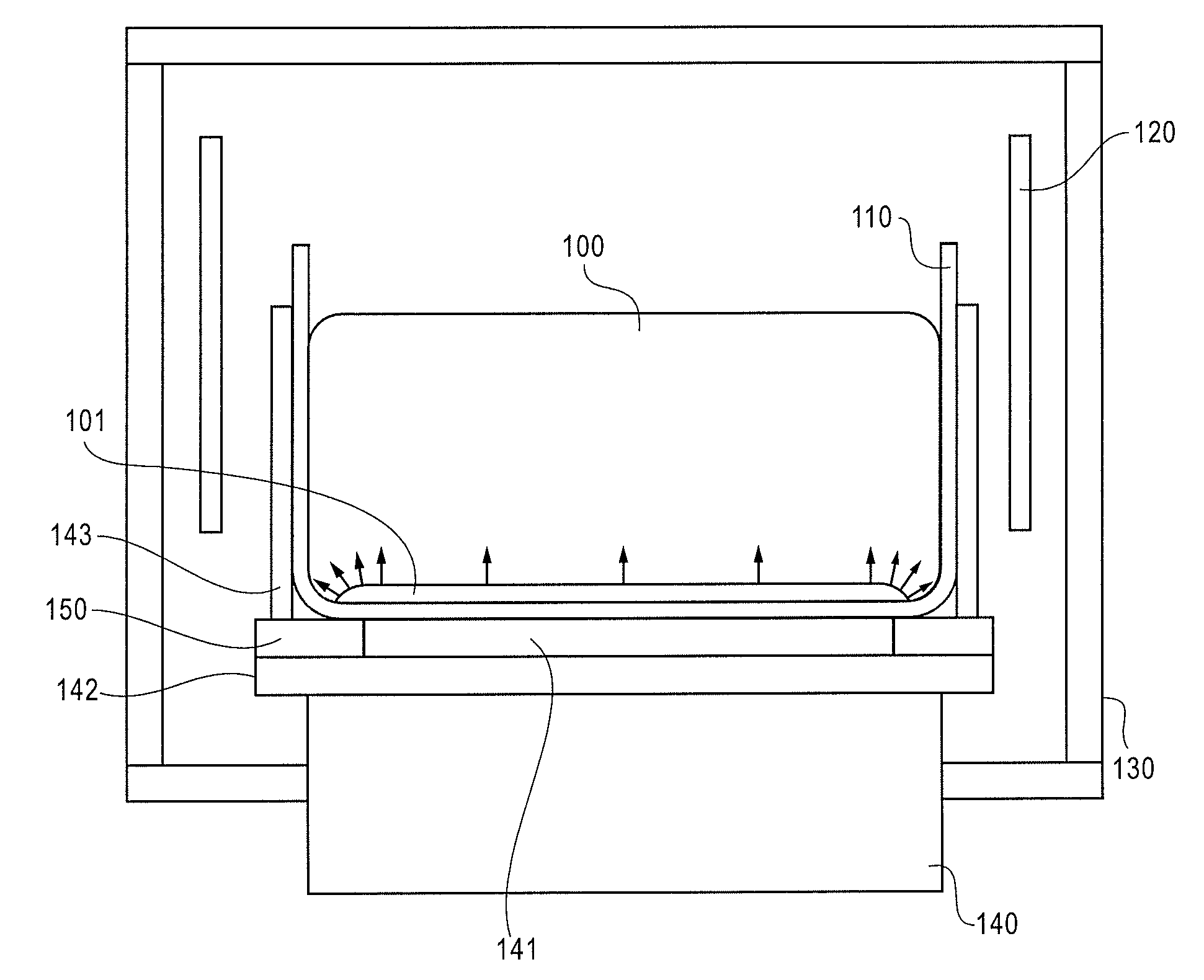

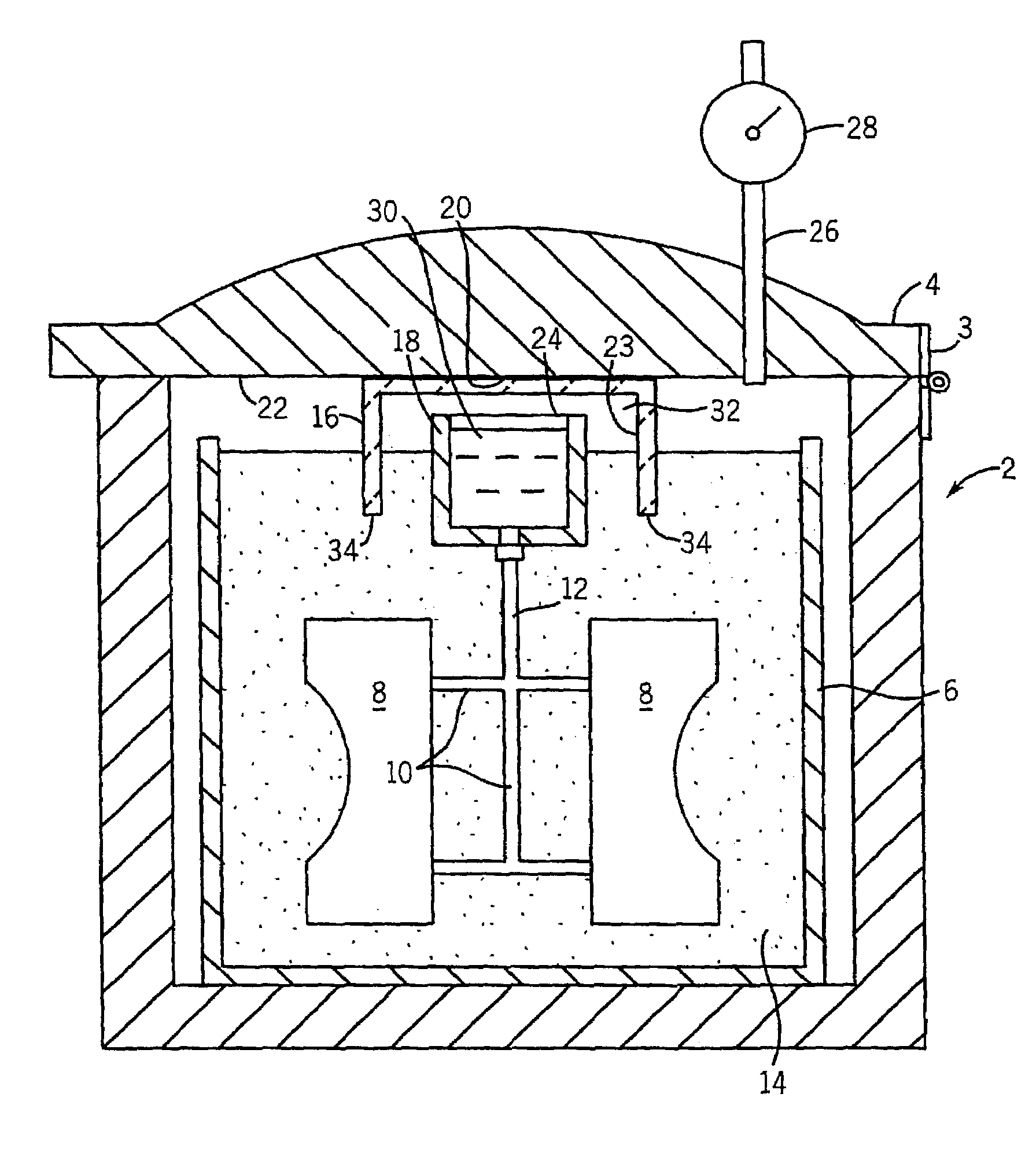

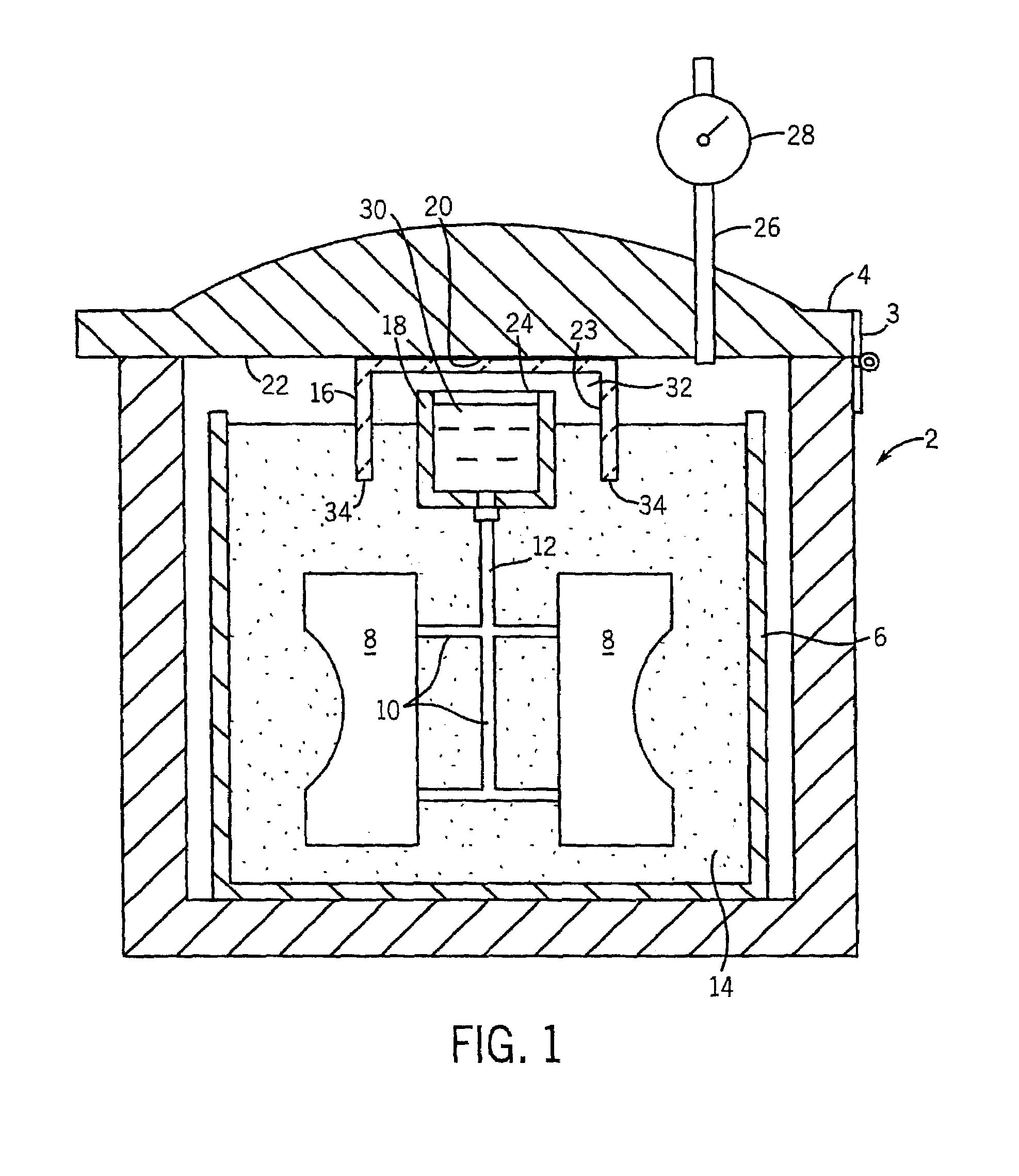

Method and system for providing a single-scan, continuous motion sequential lateral solidification

InactiveUS6908835B2Accelerate solidificationPolycrystalline material growthBy zone-melting liquidsPhysicsSeed crystal

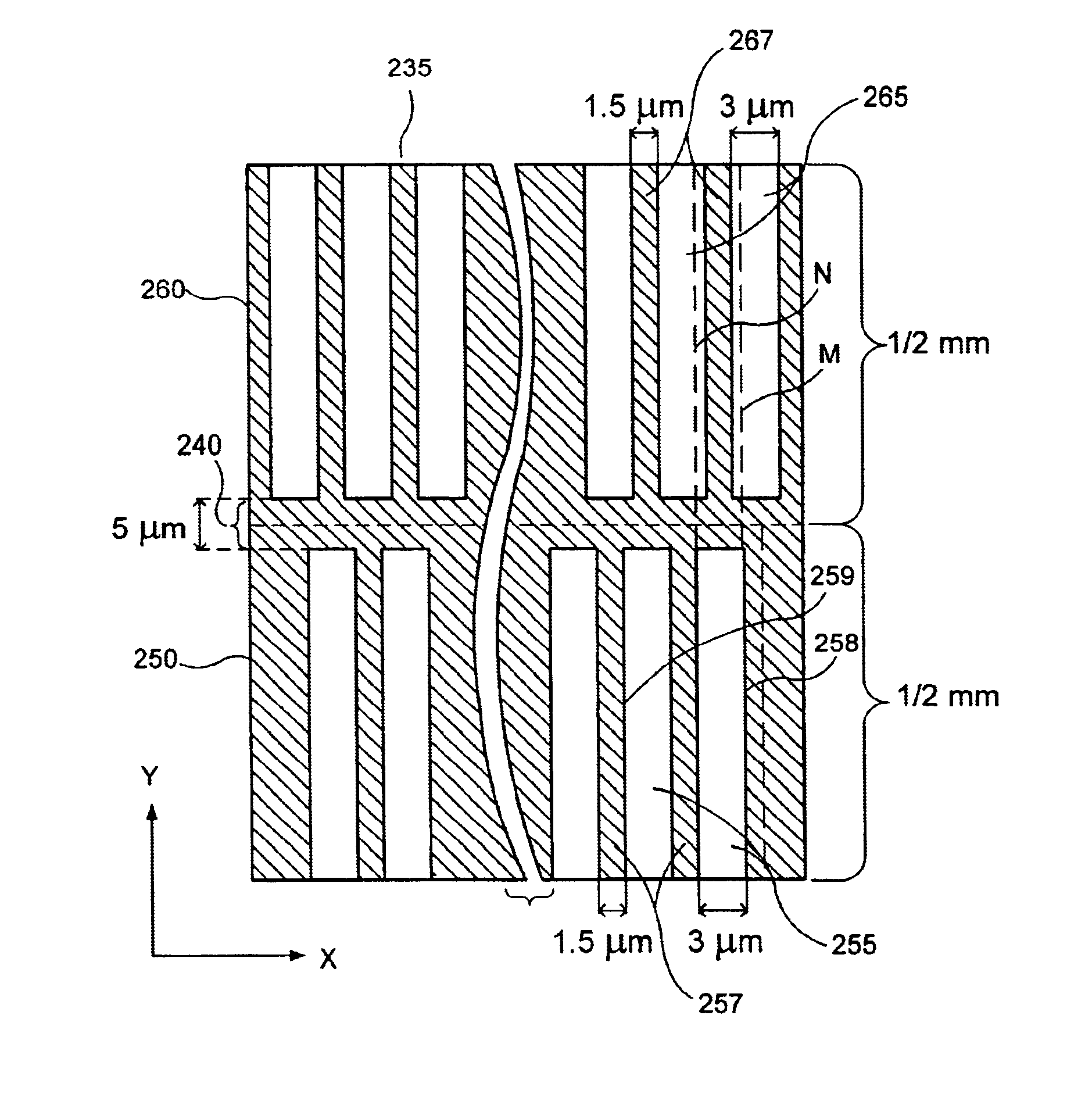

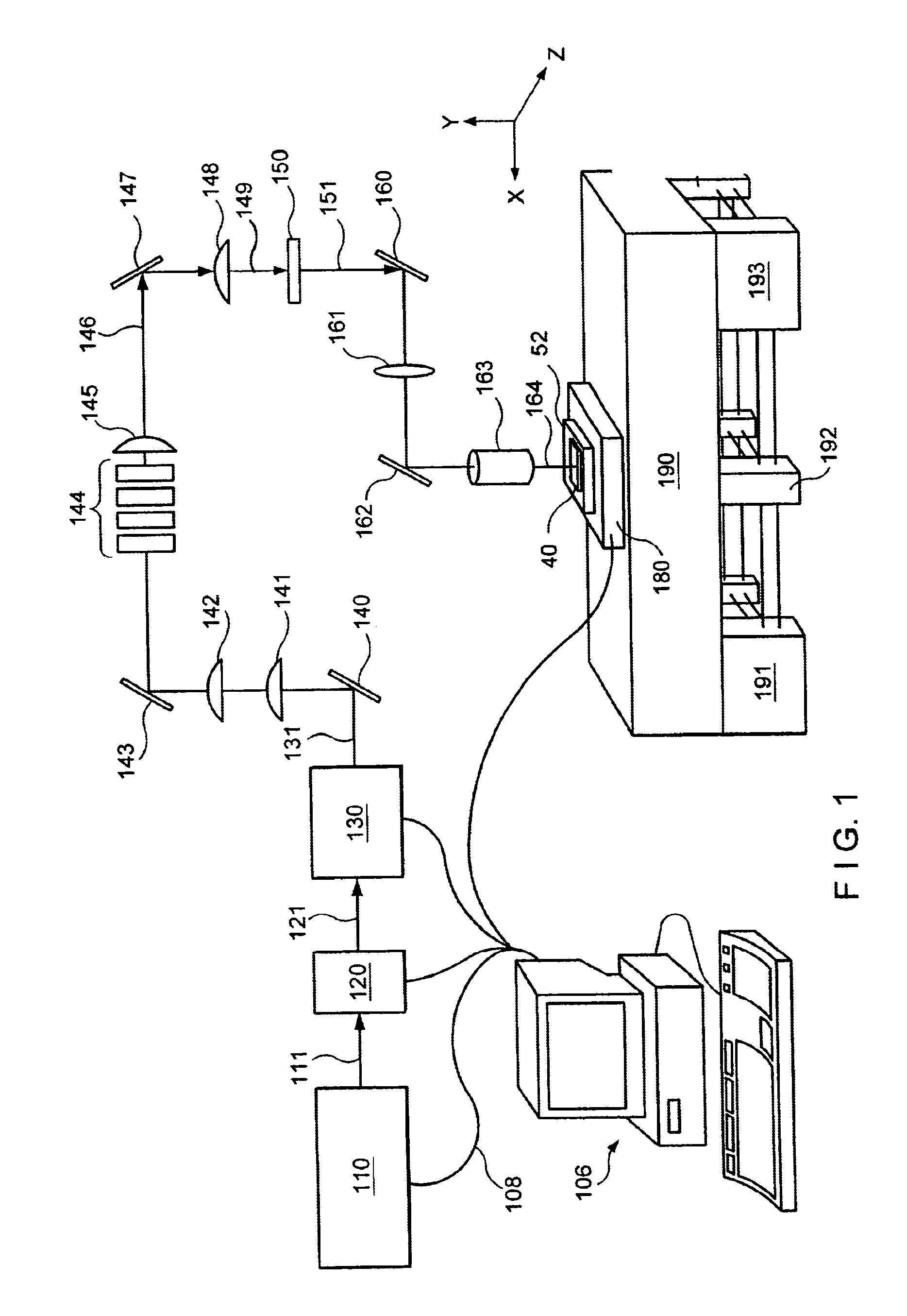

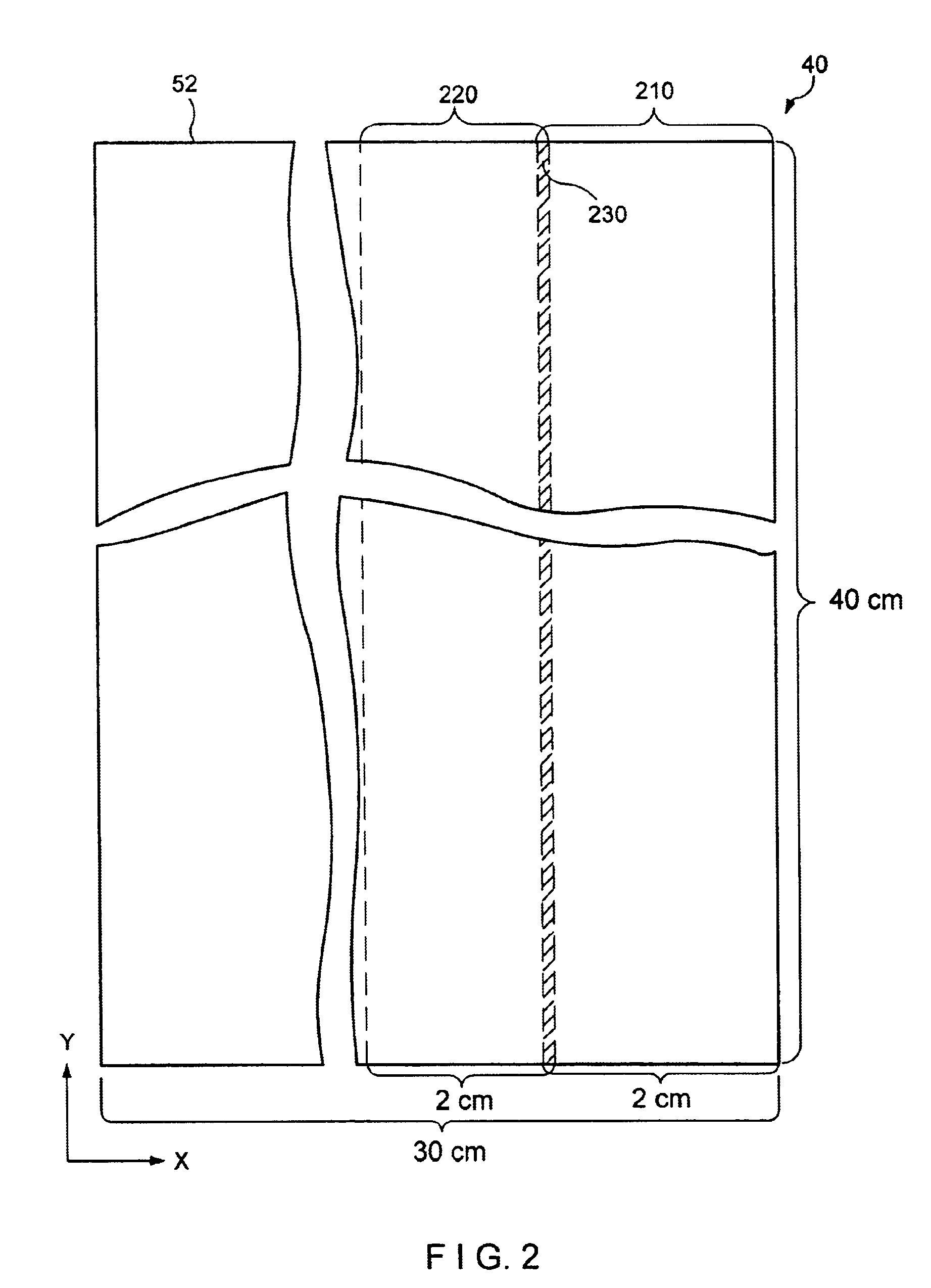

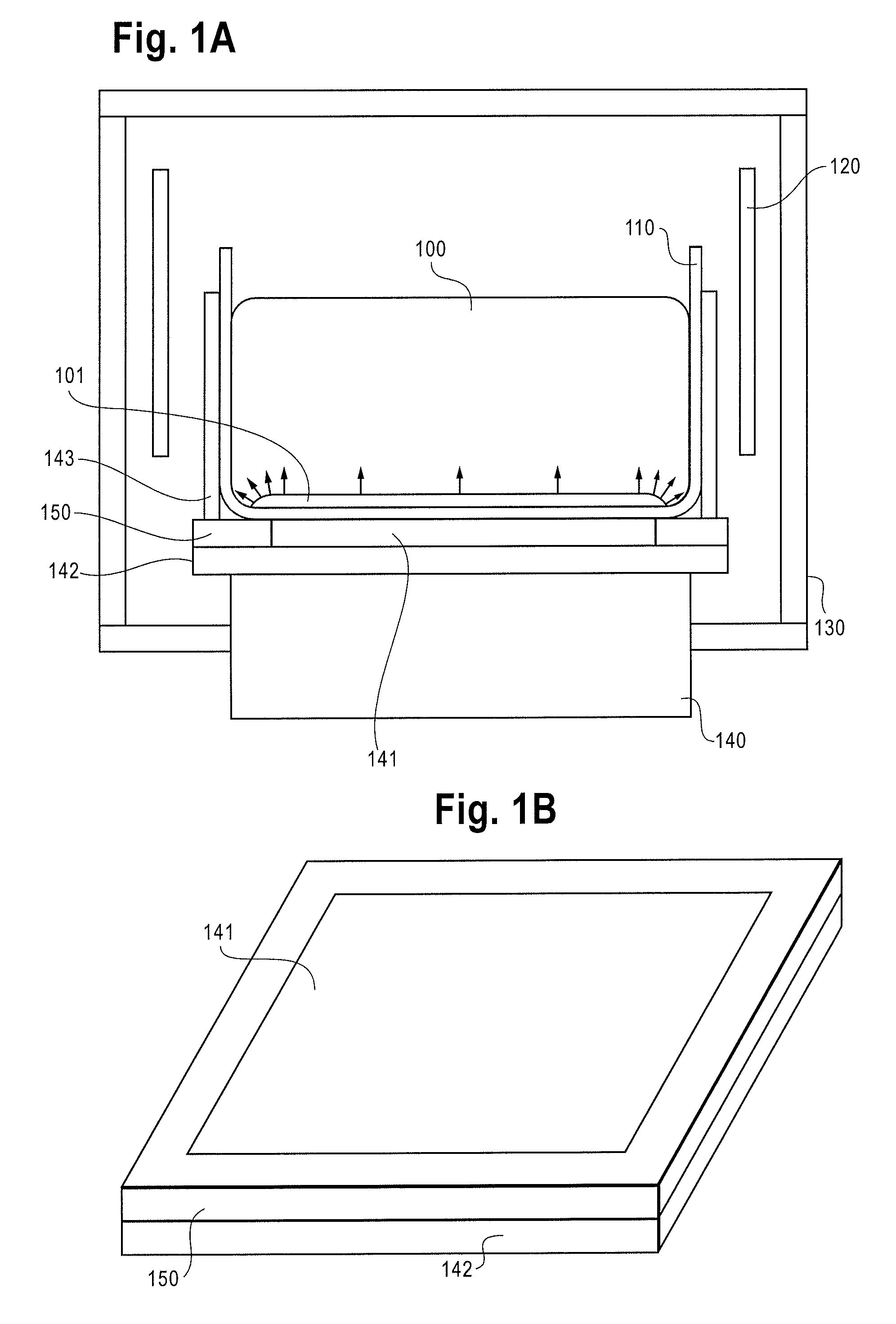

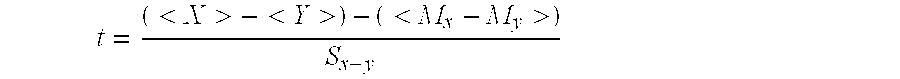

A method and system for processing a silicon thin film sample on a substrate. The substrate has a surface portion that does not seed crystal growth in the silicon thin film. The film sample has a first edge and a second edge. An irradiation beam generator is controlled to emit successive irradiation beam pulses at a predetermined repetition rate. Each of the irradiation beam pulses is masked to define a first plurality of beamlets and a second plurality of beamlets, the first and second plurality of beamlets of each of the irradiation pulses being provided for impinging the film sample and having an intensity which is sufficient to melt irradiated portions of the film sample throughout their entire thickness. The film sample is continuously scanned, at a constant predetermined speed, so that a successive impingement of the first and second beamlets of the irradiation beam pulses occurs in a scanning direction on the film sample between the first edge and the second edge. During the continuous scanning of the film sample, a plurality of first areas of the film sample are successively irradiated using the first beamlets of the irradiation beam pulses so that the first areas are melted throughout their thickness and leaving unirradiated regions between respective adjacent ones of the first areas. Also during the continuous scanning, each one of the first areas irradiated using the first beamlets of each of the irradiation beam pulses is allowed to re-solidify and crystalize. During resolidification and crystallization of the first areas, a plurality of second areas of the film sample are successively irradiated using the second beamlets of the irradiation beam pulses so that the second areas are melted throughout their thickness. Each of the second areas partially overlaps a respective pair of the re-solidified and crystalized first areas and the respective unirradiated region therebetween.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

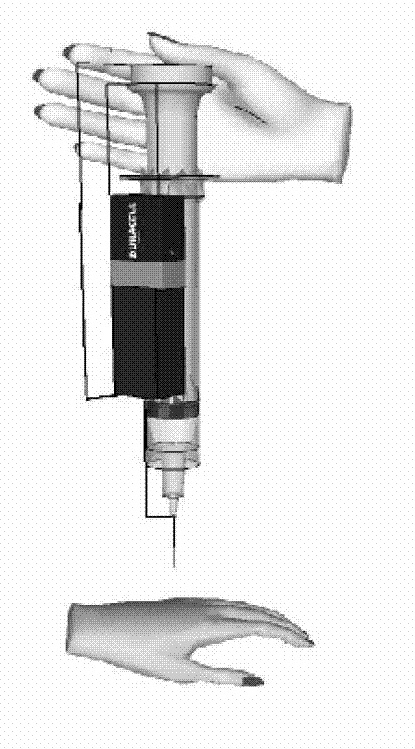

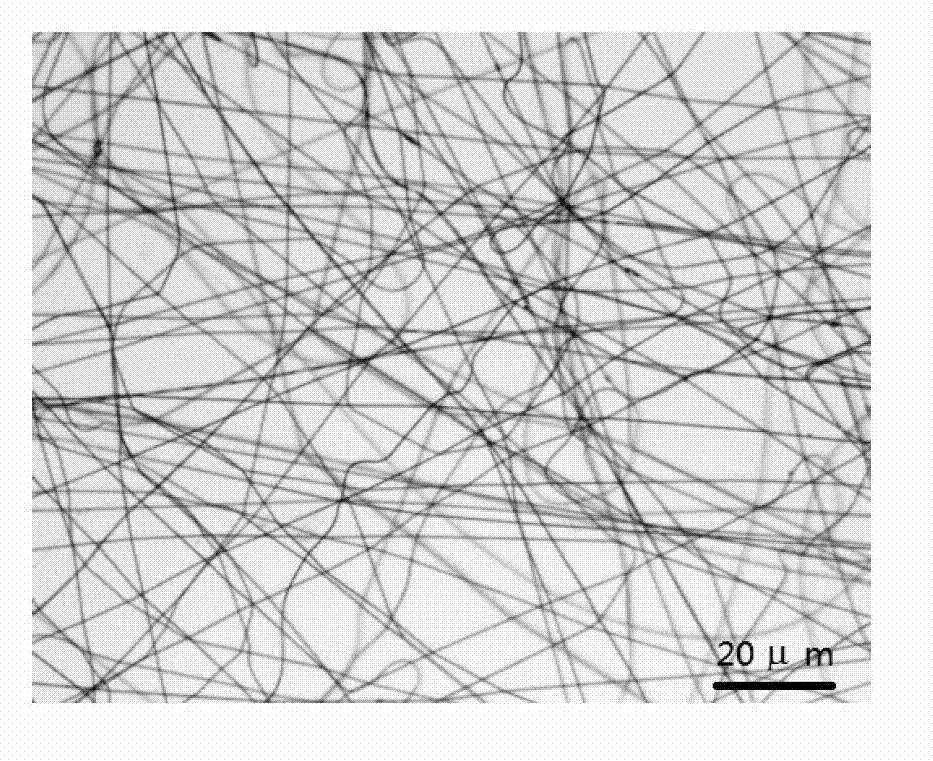

Portable handheld electrostatic spinning device

ActiveCN102776583AReduce fearTimely protectionFilament/thread formingEducational modelsElectricityElectrical battery

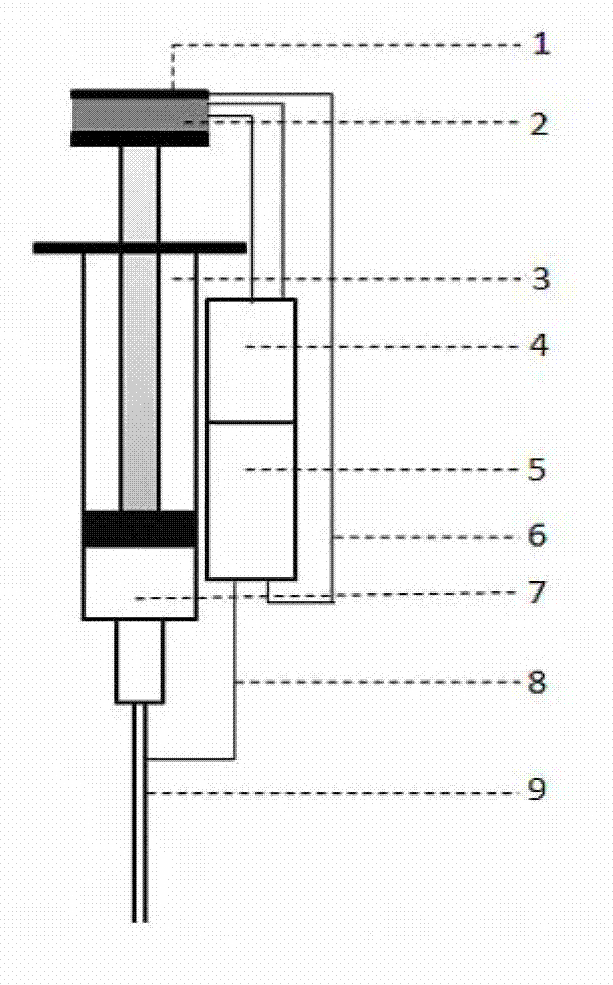

The invention belongs to the technical field of electrostatic spinning and relates to a portable handheld electrostatic spinning device. The top of a pushing rod of a medical syringe is provided with a pressure welding switch, a metal foil is arranged on the top side fixedly, a spinning solution is arranged in a front end inner cavity of the medical syringe, a square battery and a high-voltage direct-current inverter are arranged fixedly on the side wall of the syringe in a butt joint mode, and a stainless steel needle head which is used for spinning is arranged at the bottom end of the syringe in an inserting mode. A conventional medical syringe needle head structure and the syringe are combined and matched, the spinning solution is stored in the inner cavity of the medical syringe which is provided with the stainless steel needle head, the square battery provides a power supply for the high-voltage direct-current inverter, when the direct current voltage is inverted, the voltage in the unit of kilovolt, the positive pole of the high-voltage direct-current inverter is communicated electrically with the stainless steel needle head, and the negative pole of the high-voltage direct-current inverter is communicated electrically with the metal foils. The device is simple in overall structure, is convenient to carry, use and operate, applicable to occasions such as outdoor teaching and wounded rescue and high in economical value.

Owner:青岛中科凯尔科技有限公司

Low-aliquation high-speed steel roll and the preparing method

The invention discloses a low segregation centrifugal casting high speed steel roll and the method. The roll is constituted by high speed steel roll body and alloy ductile ion roll core. The roll is produced by electric furnace. The high speed steel roll body is cast on horizontal centrifuge. As the liquid steel is cast iron powder suspension concentrate with 4%-6% by weight of liquid steel is added. After the liquid steel is cast glass waste sludge is added and then it is cooled by spraying water to form the model. Meanwhile the rotate speed of casting model is changed continuously and finally the ductile ion roll core is cast at the top statically. There is no obvious element segregation in radial section of high speed steel roll manufactured in invention. The macro hardness of roll is high and can achieve 63-65HRC. The difference of roll face hardness is less than 2HRC. The hardness fall of roll along the radial direction is small. The tensile strength of roll body is more than 600MPa and the elongation of roll core is more than 3%. The service life is improved by 5-8 times than high chromium cast iron roll and is improved by 35%-48% than common high speed steel roll. It can decrease the producing cost of rolling steel and prolong roll changing period.

Owner:XI AN JIAOTONG UNIV

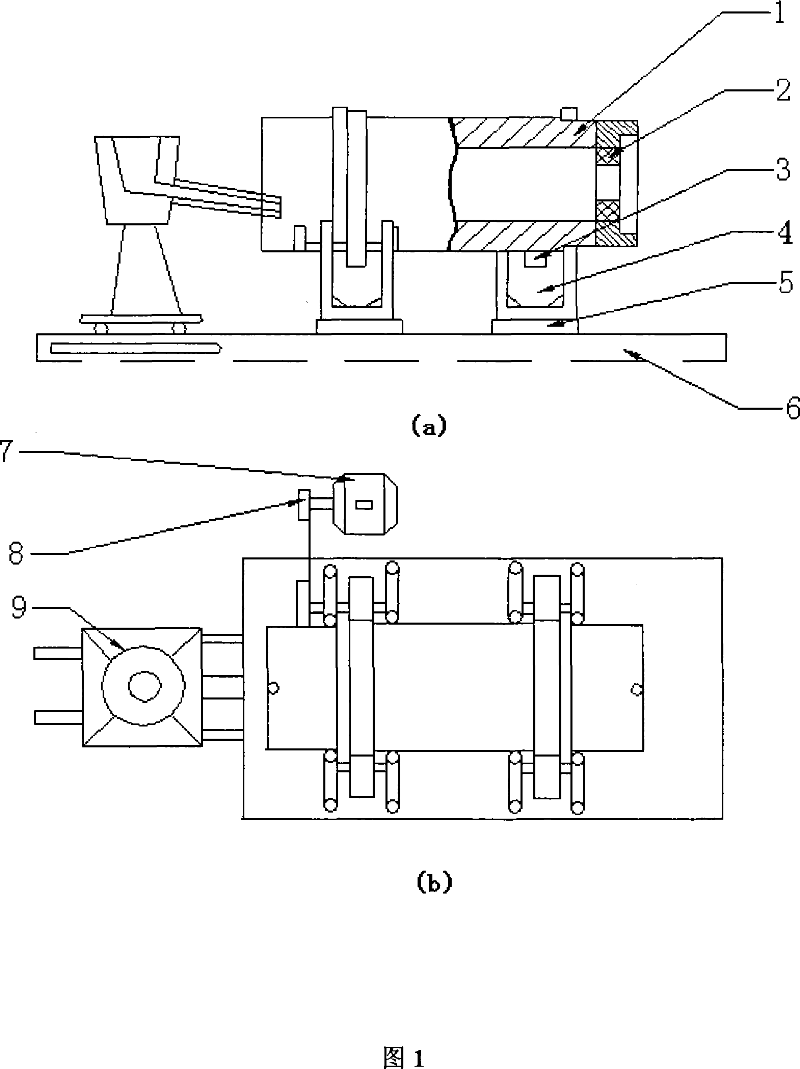

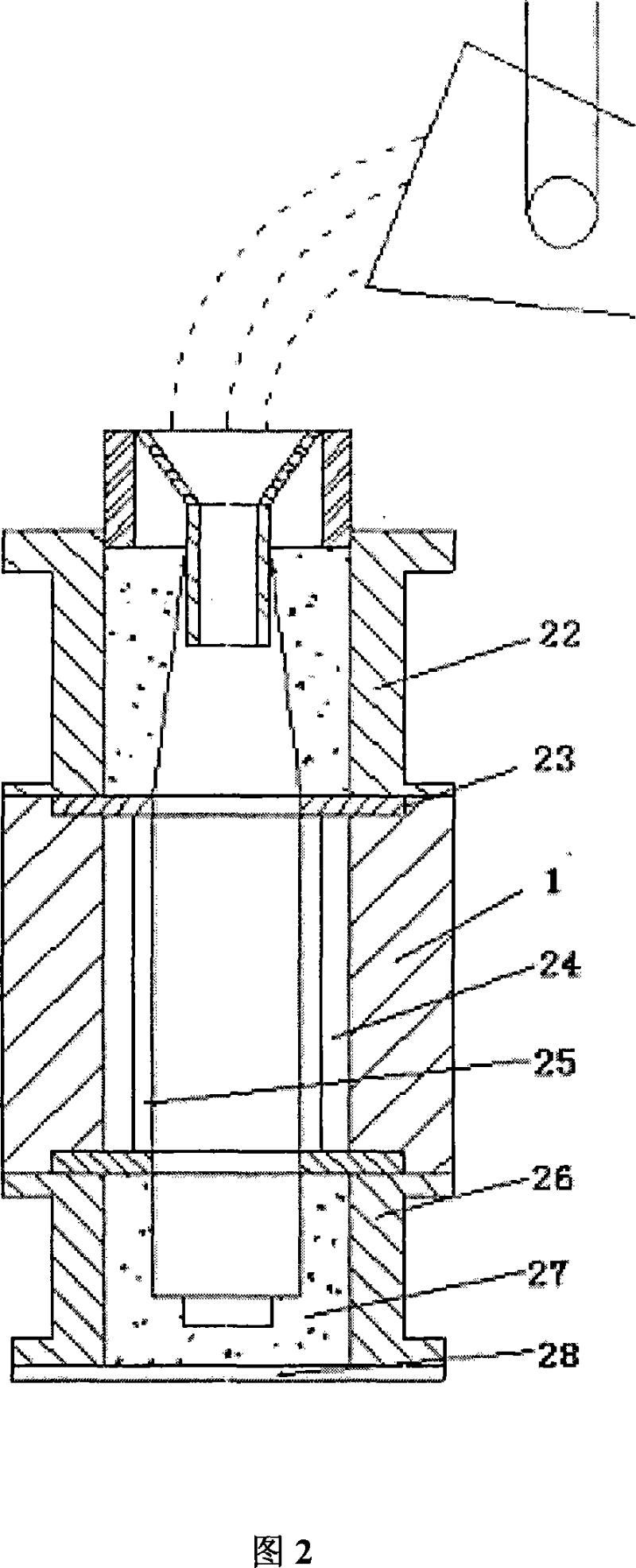

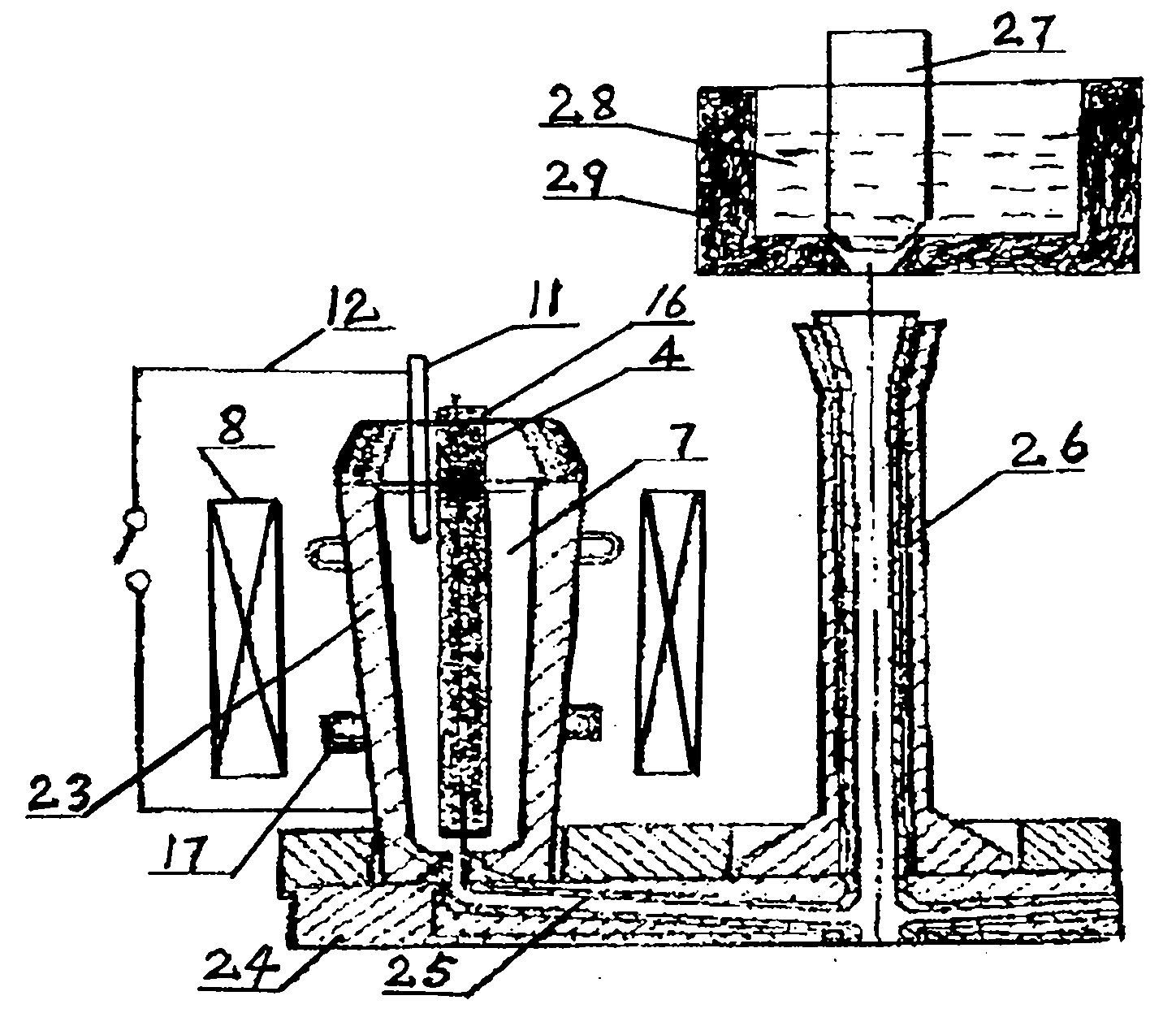

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

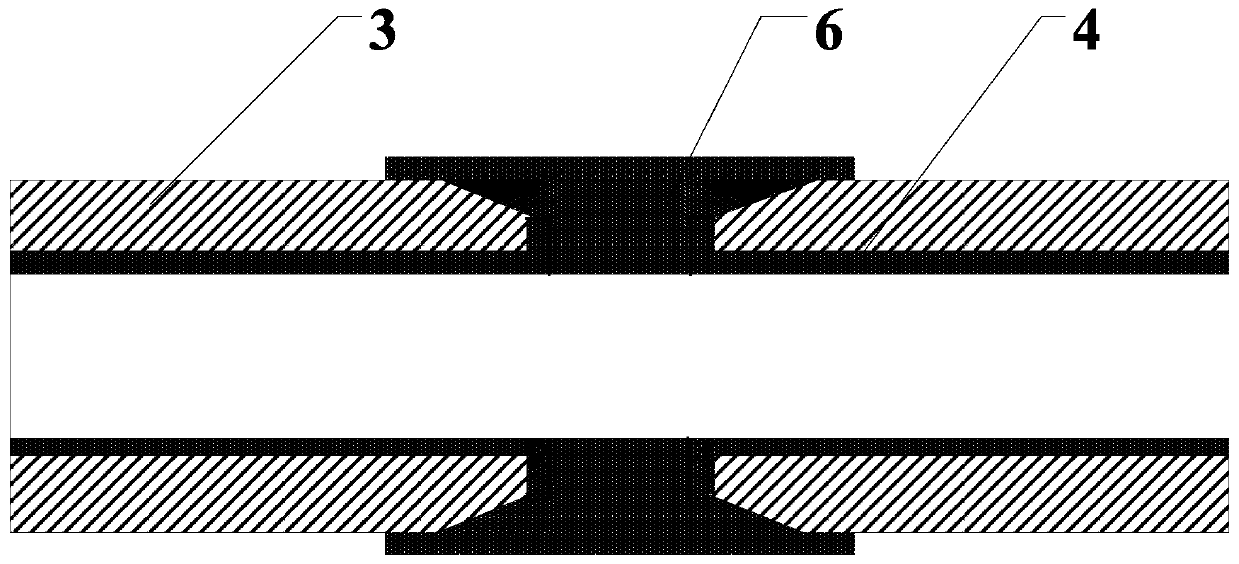

Methods and Apparatuses for Manufacturing Cast Silicon From Seed Crystals

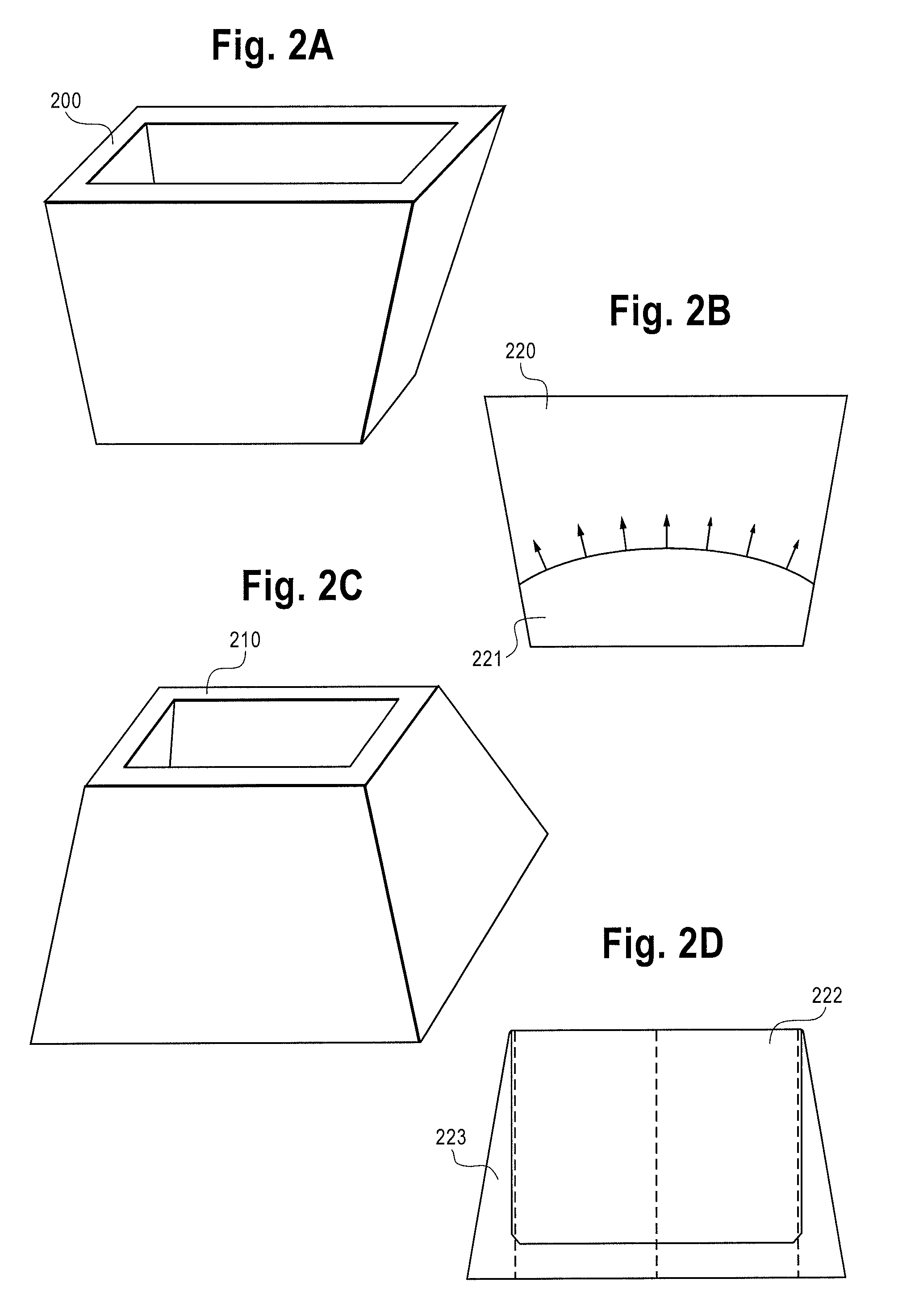

InactiveUS20100197070A1Reduce the cross-sectional areaIncrease the cross-sectional areaFinal product manufactureConfectioneryIngotCrystal growth

Owner:AMG IDEAL CAST SOLAR +1

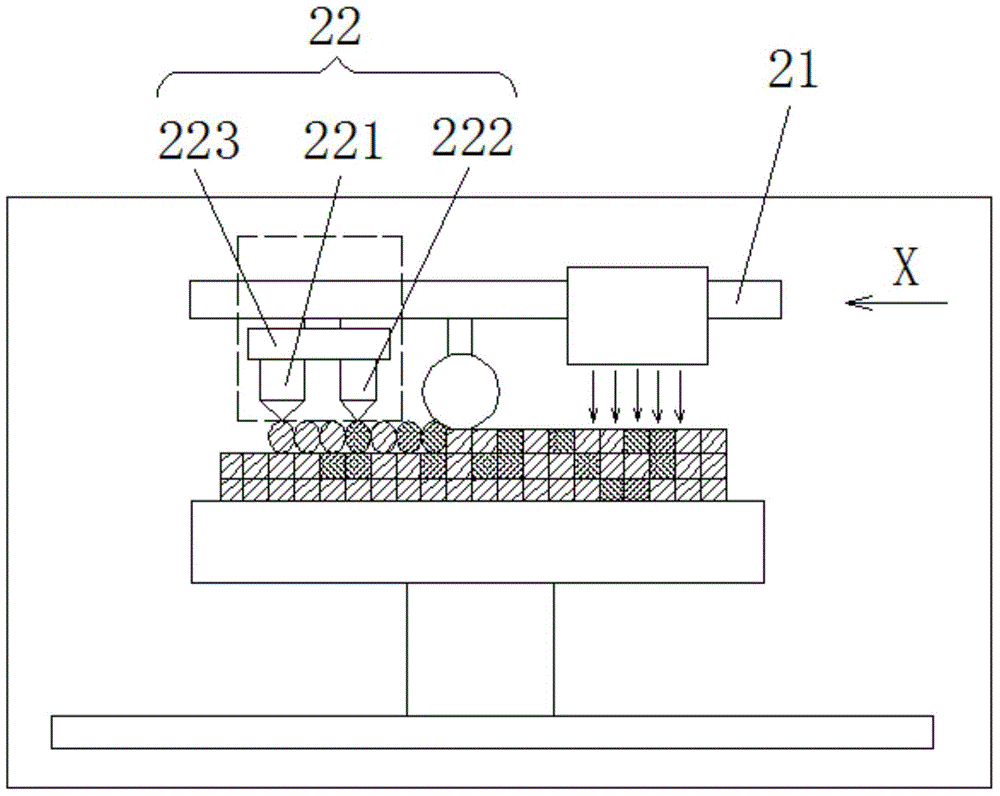

3D printing machine and 3D printing method

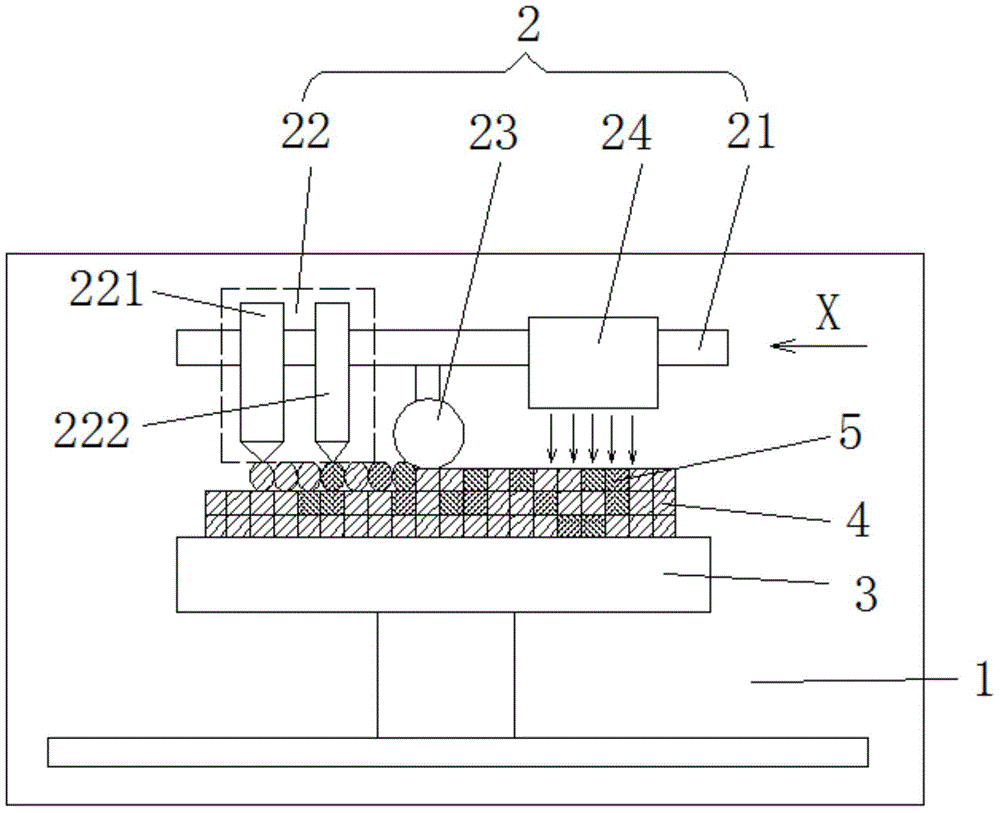

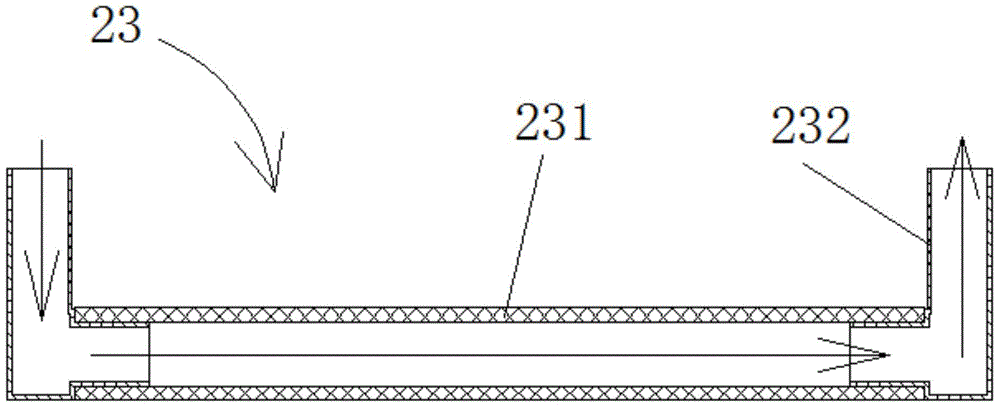

ActiveCN105172143AImprove printing efficiencyAchieve fixation3D object support structuresManufacturing data aquisition/processingHost materialEngineering

The invention discloses a 3D printing machine which comprises a printing chamber. A printing assembly and a bearing platform are arranged in the printing chamber. The printing assembly is arranged above the bearing platform. The printing assembly comprises a printing support, a printing head assembly and a curing lamp assembly, wherein the printing head assembly and the curing lamp assembly are connected to the printing support. The printing support moves in the printing direction. In the printing direction, the printing head assembly is located in front of the curing lamp assembly. The printing head assembly comprises a main printing head body of a printing model body and an auxiliary printing head body of a printing supporting material. The model main material is photosensitive resin. The printing temperature in the printing chamber is lower than the solidification temperature of the supporting material. The supporting material is solidified at the printing temperature. The invention further discloses a 3D printing method. By means of the 3D printing machine and the 3D printing method, the supporting material is removed easily.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

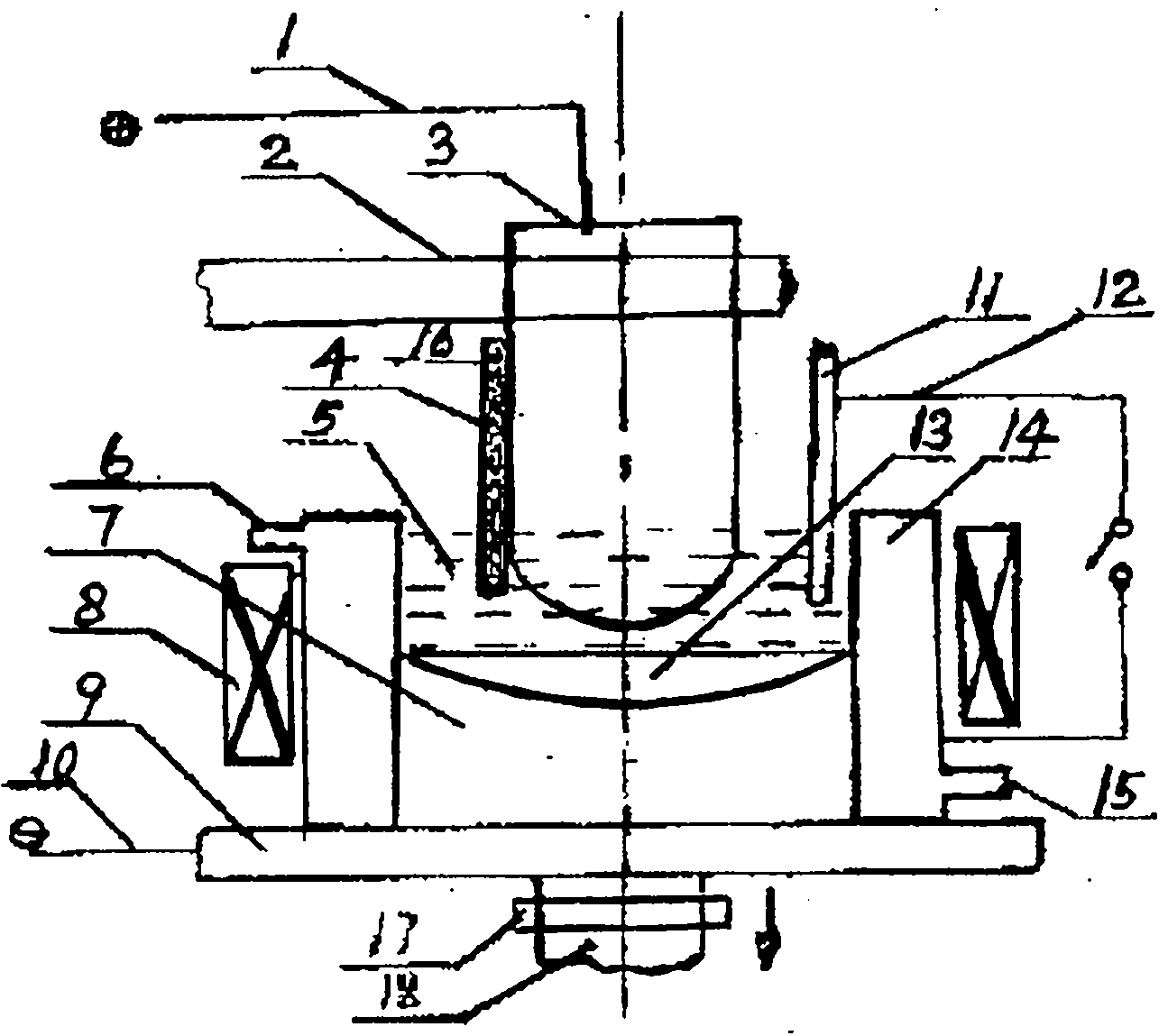

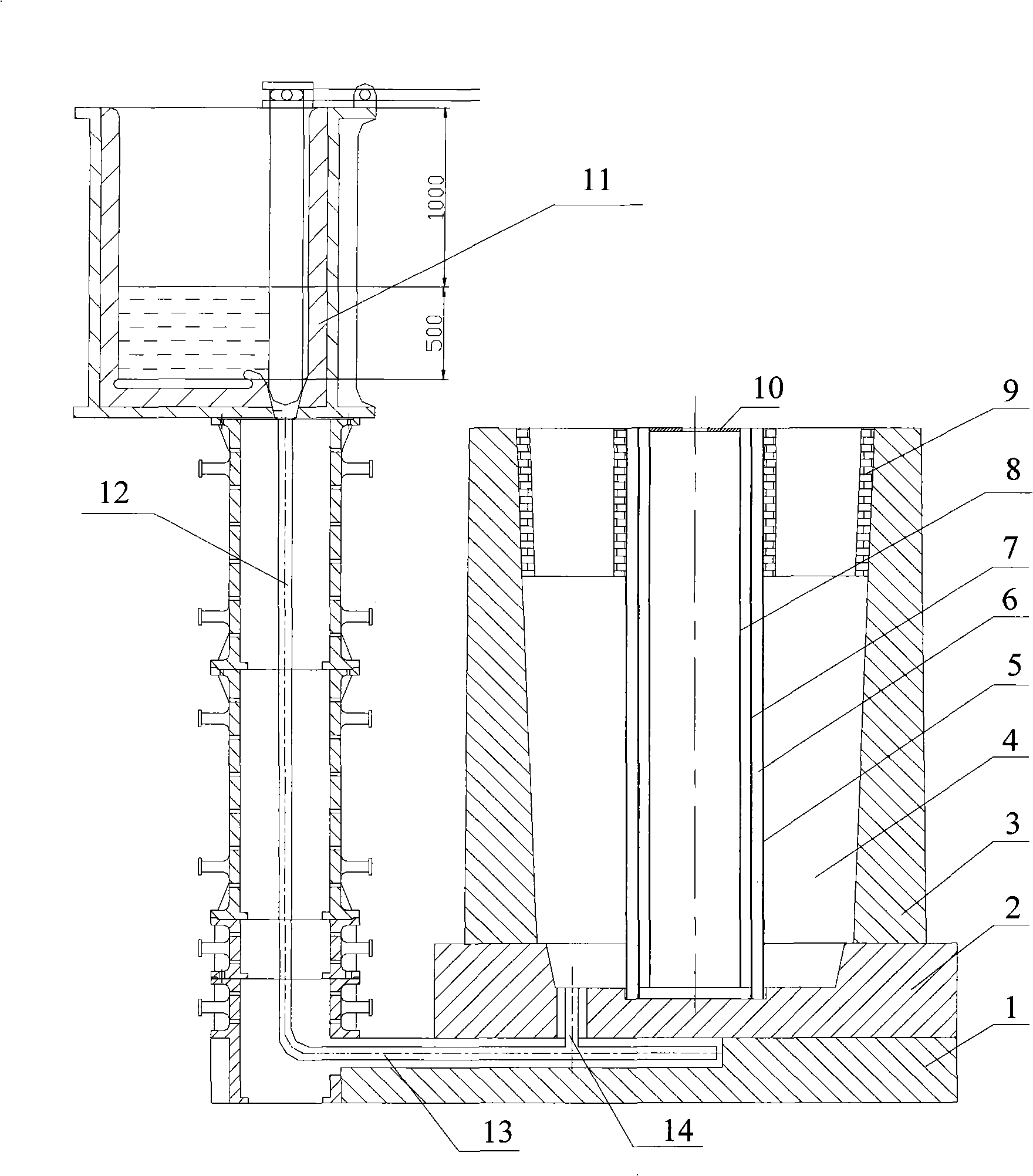

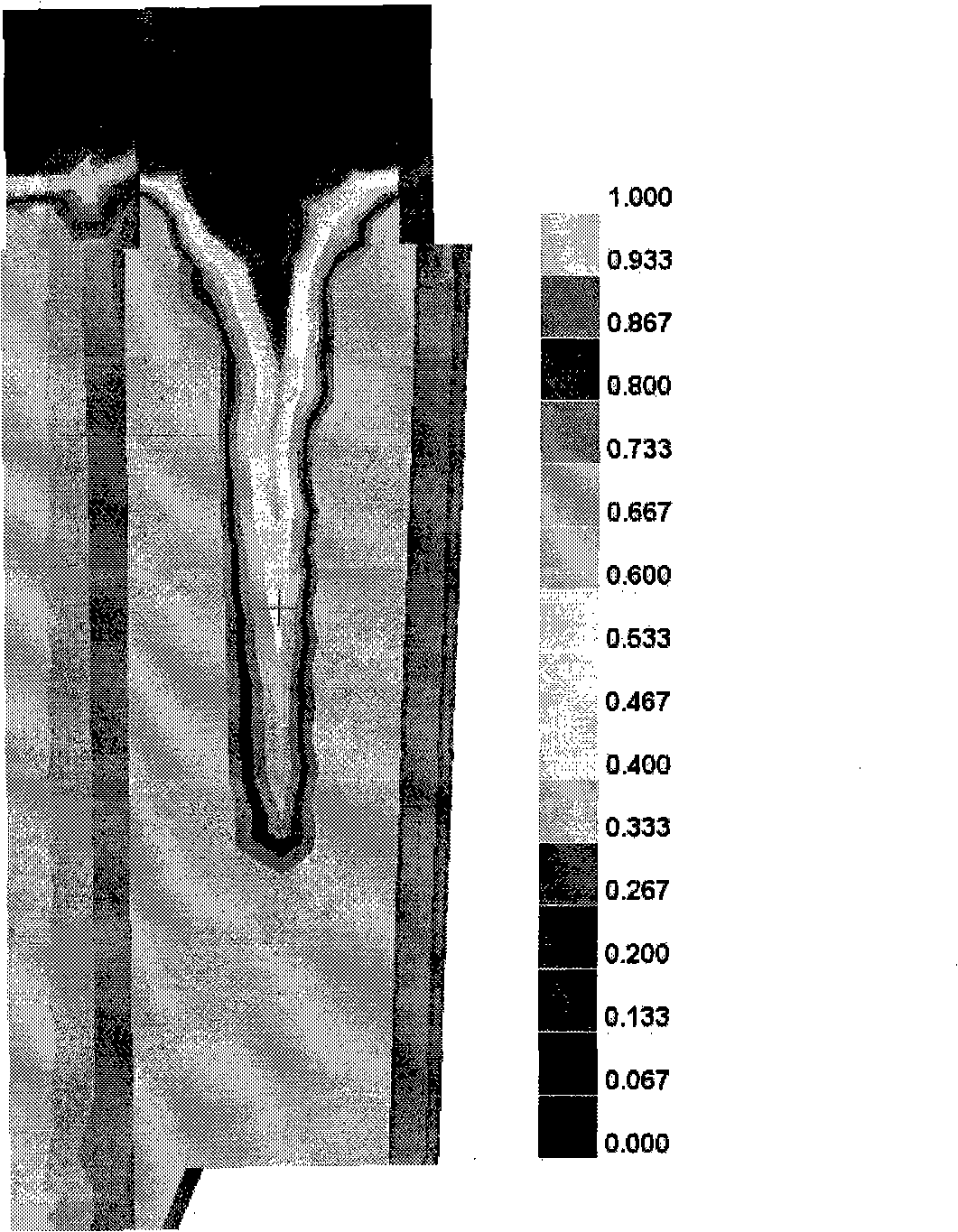

Method for manufacturing compound core low-segregation large-sized hollow steel ingot

InactiveCN101279359AGuaranteed sequential solidificationIncrease profitFoundry mouldsFoundry coresTemperature differenceIngot

The invention relates to a casting process of all levels of large-scale hollow ingots below 250-ton level, in particular to a manufacturing method of composite core low-segregation large-scale hollow ingots. The manufacturing method is applicable to the preparation process of all large-scale hollow ingots which adopt the composite core pouring, comprising the casting of the hollow ingots with various shapes, specifications and materials. In addition to the usage of the computer simulation means to reasonably design an ingot mold and a pouring system, the invention mainly adopts the composite core hole forming technology, the large temperature difference cooling technology, the narrow gap molding sand technology, the bottom pouring dispersible gate drainage technology, the thick and large chassis mandatory cooling technology and a liquid nitrogen ejector device etc., and the invention further designs the corresponding mold and the equipment, pours the steel water with the different materials and prepares the low-segregation hollow ingots. The invention can ensure the serial solidification of the hollow ingots, reduce the defects of shrinkage, loose and inclusion, control the segregation position, lead the segregation band of the hollow ingots to be positioned at the middle position and improve the utilization rate and the using range of the hollow ingots.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

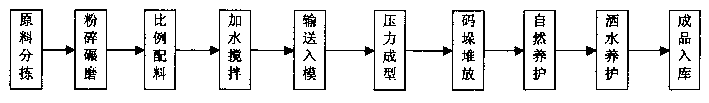

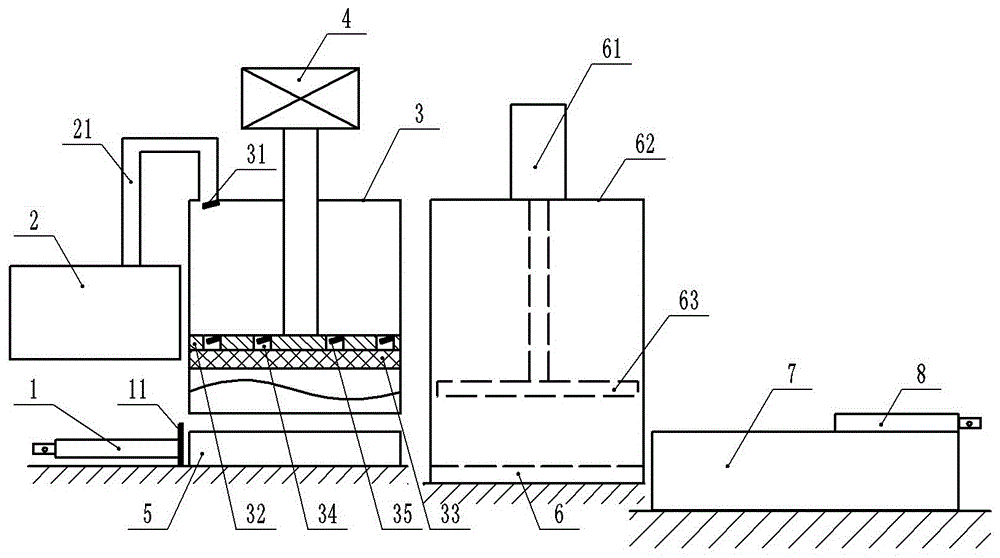

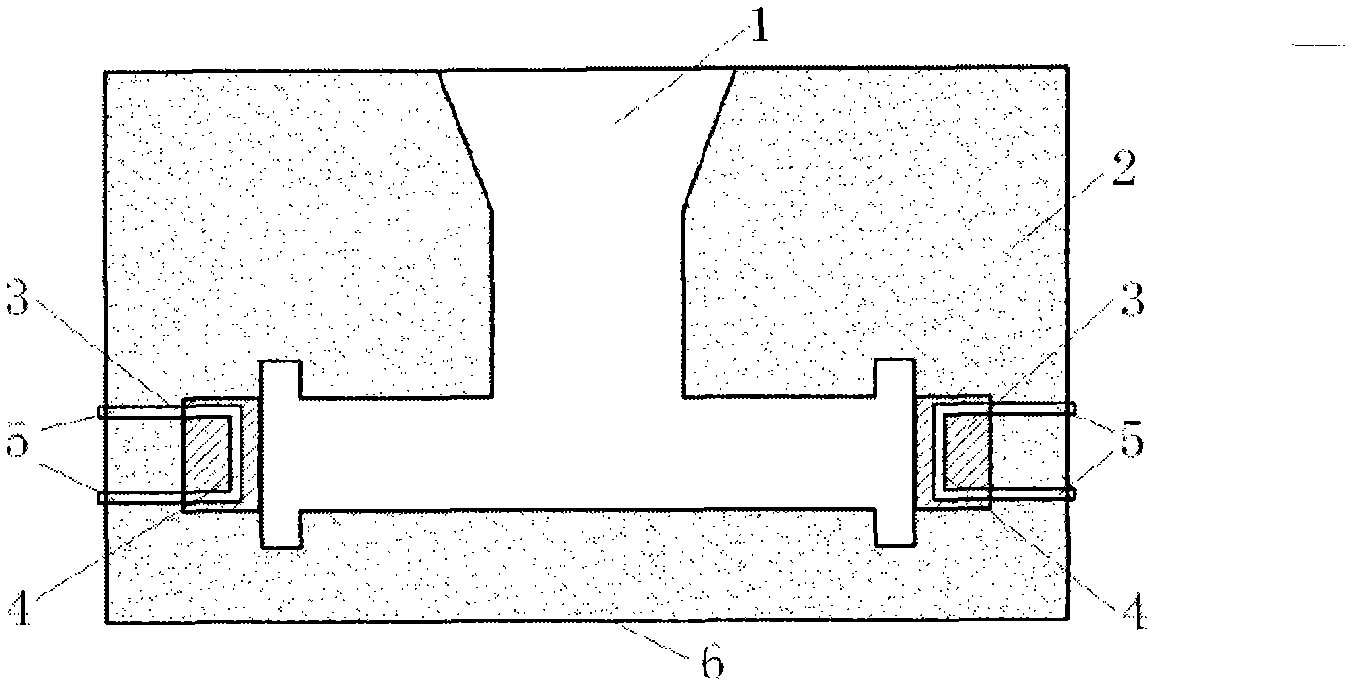

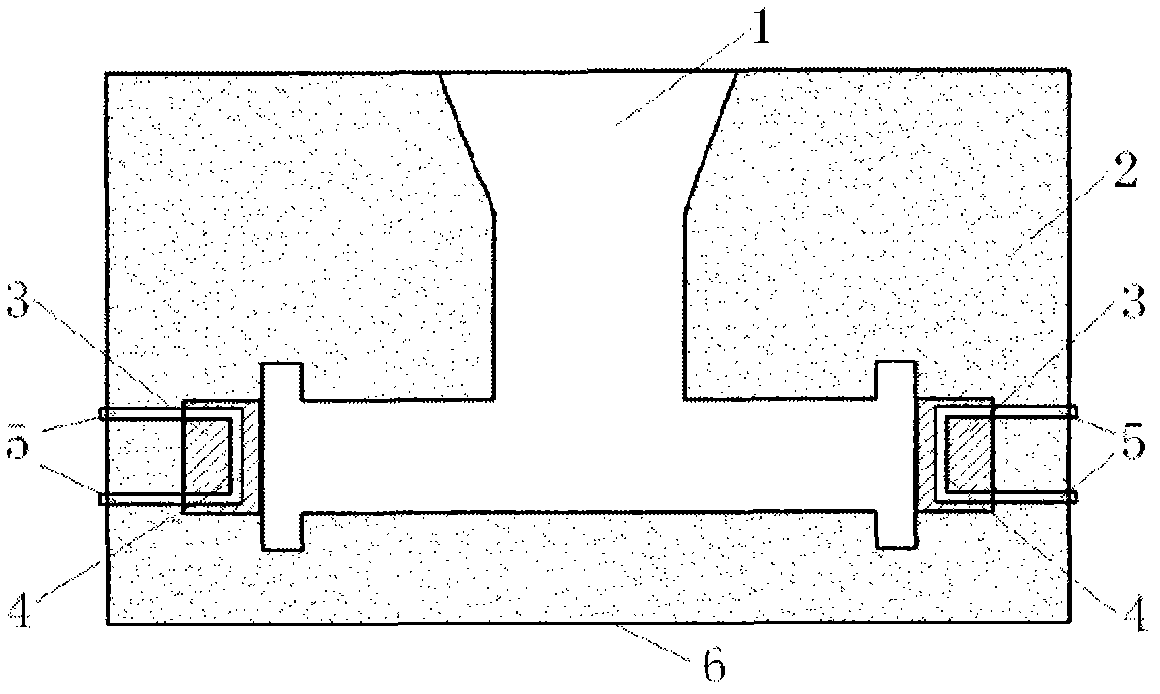

Baking-free slag brick and method of making same

InactiveCN1448360ALow raw material costSolve processing problemsSolid waste managementCeramic shaping apparatusBrickSlag

The baking-free slag brick is produced with building slag, inferior stone, cement with water-reducing agent in 1-2 % added, flash and lime. The production process includes the steps of: crushing andgrinding material, mixing, pressure molding at the pressure of 170-200 kg / sq cm to form adobe, and curing of the adobe at temperature over 0 deg.c for over 15 days. The utilization of building slag can reduce pollution and lower cost.

Owner:张庆军 +1

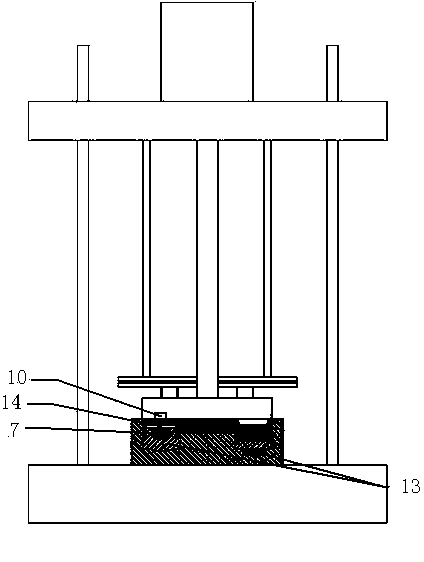

Plate press machine with glue coating function

ActiveCN106738100AAccelerate solidificationLighten the laborPlywood pressesMulti-purpose machinesWood machiningPulp and paper industry

The invention belongs to the technical field of wood working equipment, and particularly discloses a plate press machine with glue coating function. The plate press machine comprises a first horizontal push hydrocylinder, a glue coating device, a plate presser and a feeder from left to right, wherein the glue coating device comprises a bracket, a glue tank, an air cylinder and a glue supply tank; the glue supply tank is a tank body with an opening on the lower end; the glue supply tank is fixed to the bracket; a piston is arranged in the glue supply tank, and driven by the air cylinder; the air cylinder is positioned above the glue supply tank; the side wall of the glue supply tank communicates with a glue suction pipe; one end of the glue suction pipe is positioned in the glue tank; the joint between the glue suction pipe and glue supply tank is provided with a first one-way valve; the piston is provided with a through hole, and the through hole is provided with a one-way valve; the lower surface of the piston is provided with a sponge layer; the feeder comprises an elevating table and a second horizontal push hydrocylinder; and the second horizontal push hydrocylinder is positioned on the elevating table. By adopting the technical scheme, the wood plate can be pressed immediately after finishing glue coating, and the glue coating and pressing processes are continuous, so the production efficiency is high.

Owner:重庆汇升套装门有限公司

Method for controlling solidification and cooling of heavy castings

A method for controlling solidification and cooling of heavy castings improves a traditional chilling block, and a cooling channel is arranged inside the chilling block. A flowing cooling medium is led to the cooling channel inside the chilling block after the heavy castings are poured, so that cooling capacity of the chilling block cannot achieve saturation, and the chilling block can continuously have cooling effects. If the cooling medium is led to the cooling channel inside the chilling block, the hollow chilling block hinders heat of the castings from delivering from the chilling block to outside due to air-isolation effects. The method changes effects of the traditional chilling block, enables the chilling block to serve as a carrier for heat transferring and cooling, enables the cooling medium to continuously and indirectly cool the heavy castings, can quicken solidification and cooling of partial areas, better achieves progressive solidification, and improves feeding of the castings. After the heavy castings are solidified, the cooling capacity of the chilling block in different time can be adjusted by controlling the flow of the cooling medium, cooling with the castings is evenly quickened, and residual stress of the castings is reduced. The method is simple in chilling block manufacture, simple and convenient in operation and low in cost.

Owner:北京新方尊铸造科技有限责任公司

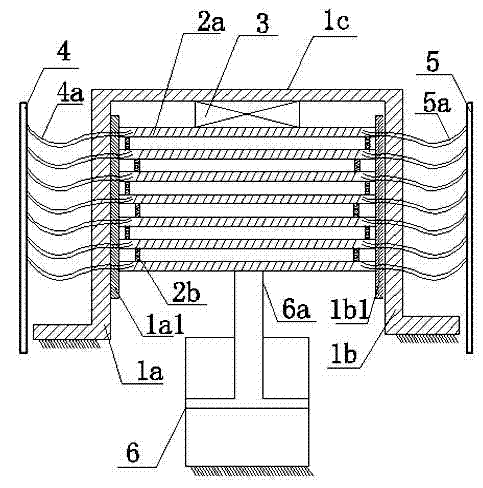

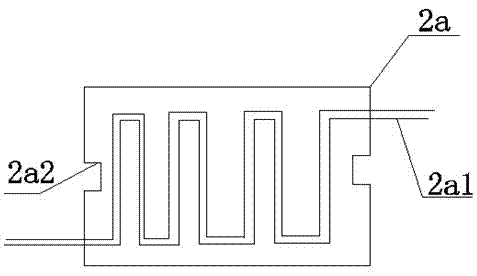

Platen machine

InactiveCN102922570AImprove pressing efficiencyHeating up fastPlywood pressesVeneer pressesEngineeringHeat exchanger

The invention discloses a platen machine which comprises a gantry frame and a compacting mould. The compacting mould is composed of multiply heating platens (2a), and an elastic connecting element (2b) is arranged between two adjacent heating platens. Each heating platen (2a) is hollow inside. A heat-exchanger tube (2a1) is arranged inside the platen machine, and the heat-exchanger tube (2a1) is connected with a heat transfer oil circulating system. Guide pillars (1a1, 1ab) used for guiding the multiply heating platens (2a) are arranged on the gantry frame. The platen machine also comprises a buffer device (3) which is fixedly connected on the bottom portion of the beam (1c) of the gantry frame, and is connected with the top layer heating platen of the multiply heating platens of the mould. The compacting mould is driven by a hydraulic cylinder (6) on the bottom portion of the compacting mould. A piston rod (6a) of the hydraulic cylinder is connected with the bottom layer heating platen. The platen machine can be used for compacting multiply wood plates each time, and compacting efficiency is high. Due to the fact heat transfer oil is adopted to transfer heat to the wood plates, the wood plates are heated up quickly, heat is distributed evenly, glue cement among the wood plates is enabled to solidify rapidly, compacting quality is high, and compacting speed is fast.

Owner:江苏福通木业有限公司

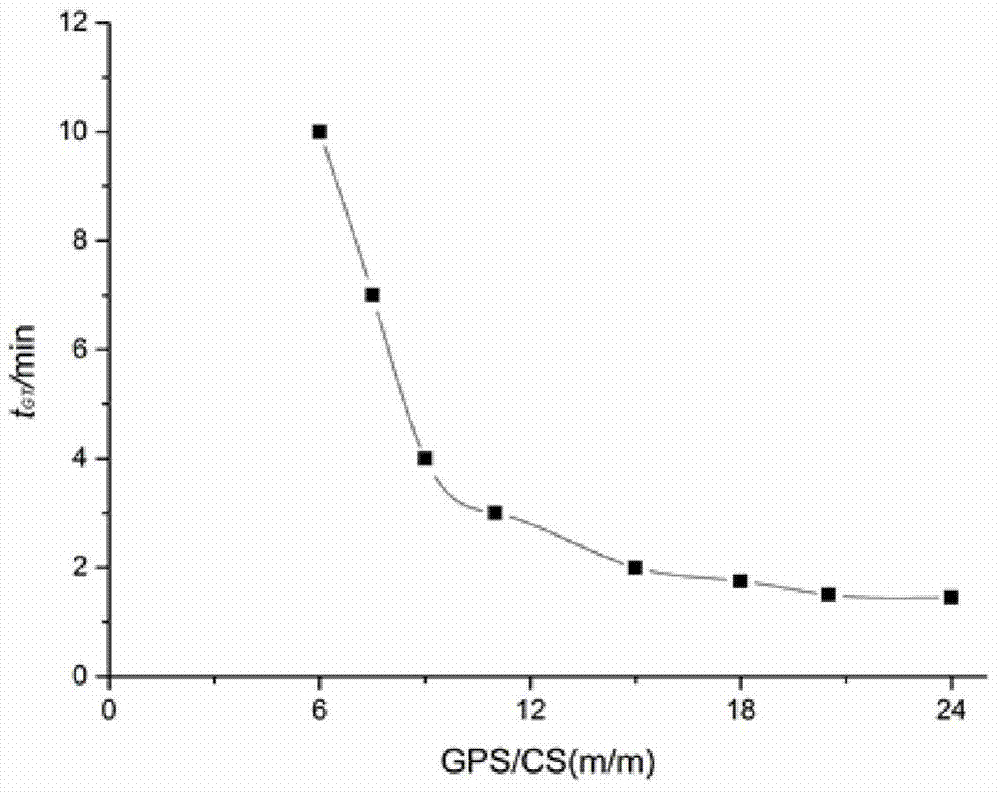

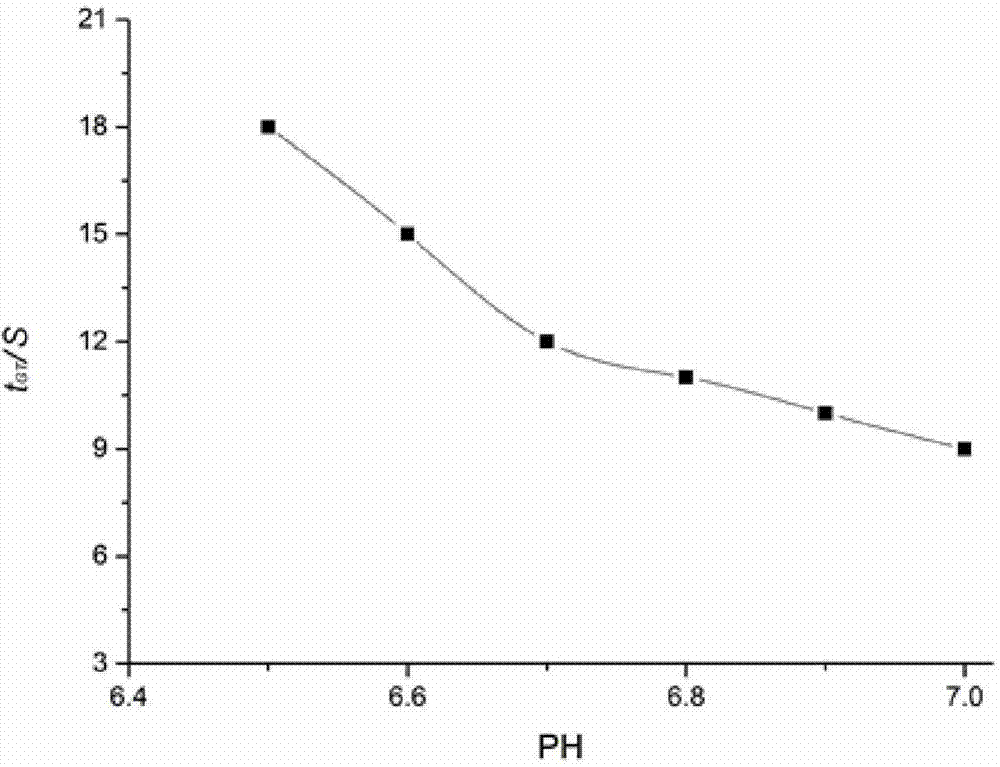

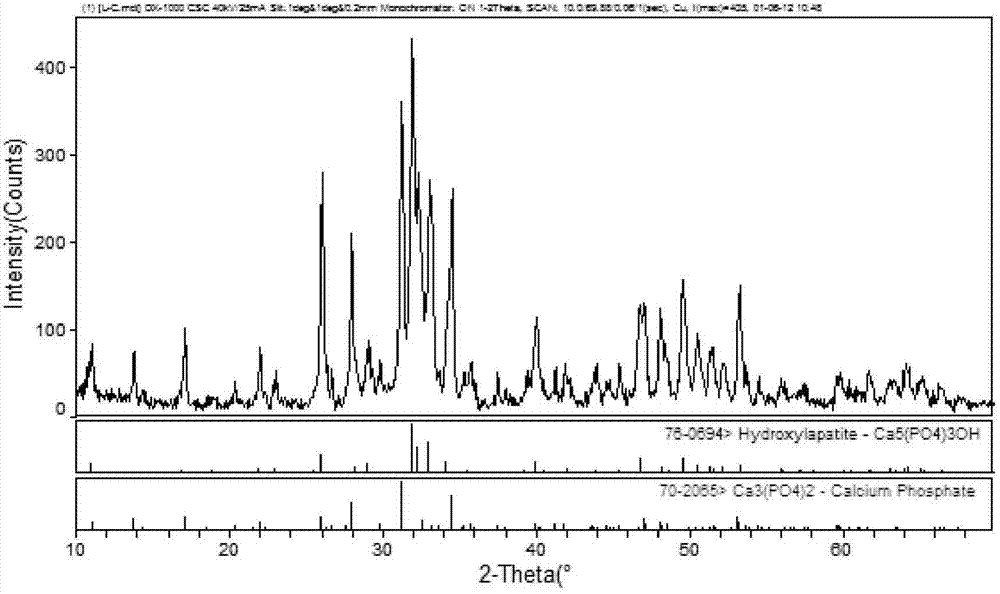

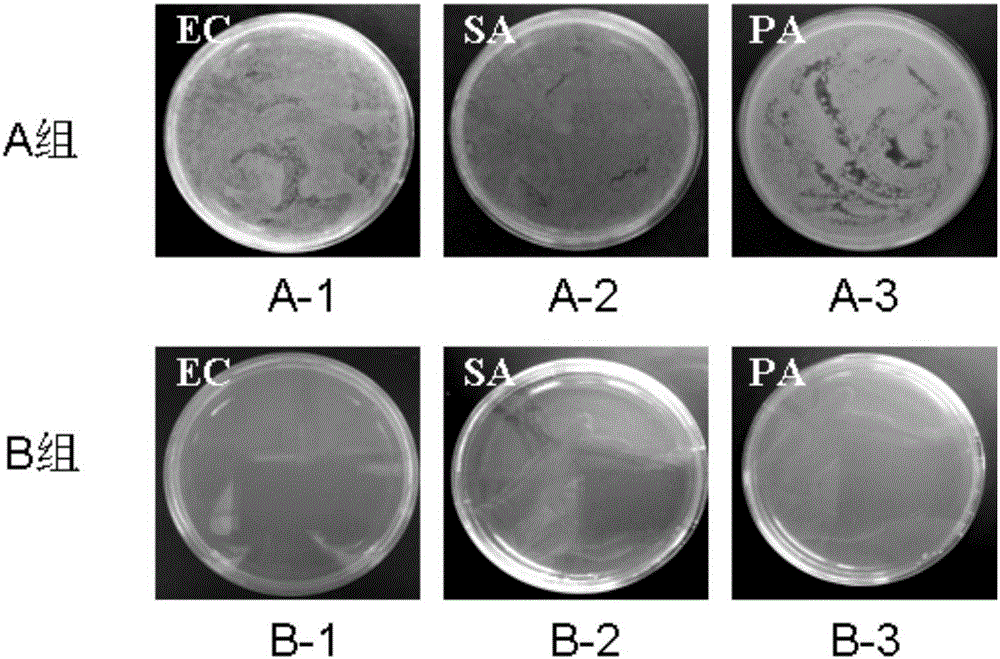

Preparation method and application of bioactive factor loaded temperature-sensitive composite gel carrier

ActiveCN103920192AImprove biological activityEasy to operateProsthesisBiocompatibility TestingSodium glycerophosphate

The invention relates to a preparation method and an application of a bioactive factor loaded temperature-sensitive composite gel carrier. The method comprises the following steps: 1. preparing a sodium alginate hydrosol; 2. preparing a sodium alginate-chitosan hydrosol through the hydrosol prepared by the step 1; 3. preparing a sodium glycerophosphate solution, adding the sodium alginate-chitosan hydrosol under a stirring condition to obtain a uniform sol; 4. adding adiponectin to the uniform sol prepared by the step 3, adding Ca<2+> and uniformly stirring; and 5. adding calcined bone powder to the sol prepared by the step 4 and uniformly mixing to obtain the bioactive factor loaded temperature-sensitive composite gel carrier. The preparation method, for shortcomings of the prior art of repairing missing and defects of an extraction socket wall, can greatly improve bioactivity, biocompatibility, mechanical tolerance and a slow release performance of a normal gel carrier, thus providing a novel repairing material for treatment of repairing missing and defects of the extraction socket wall.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Soybean protein casing colloid suitable for sausage coextrusion technology and preparation method thereof

The invention discloses soybean protein casing colloid suitable for the sausage coextrusion technology. The colloid comprises the following raw materials in parts by weight: 800-1200 parts of soybean protein colloid, 400-600 parts of collagen fiber colloid, 40-60 parts of high-strength long collagen fiber, 2-10 parts of crosslinking agent, 2-4 parts of transglutaminase and water, wherein the weight of water is 85%-95% of the weight of the final soybean protein casing colloid. After the casing colloid of the invention is extruded by a coextrusion system, the obtained casing has good elasticity and high compressive strength and packing strength, thus when the sausage with the obtained casing is cooked, the phenomenons that the casing shrinks excessively to burst and the casing fractures owning to high cooking temperature can not appear.

Owner:山东冠华蛋白肠衣有限公司

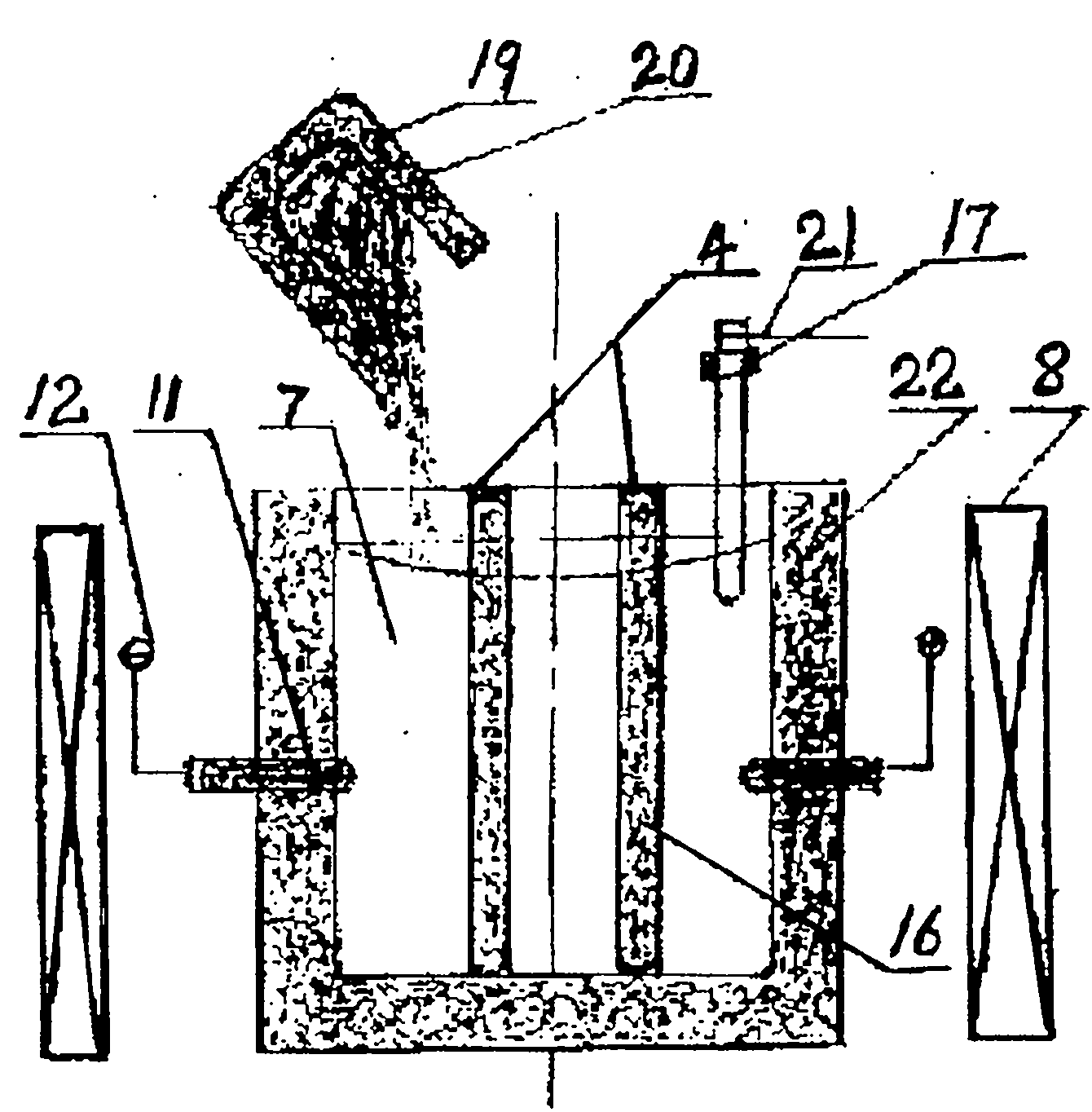

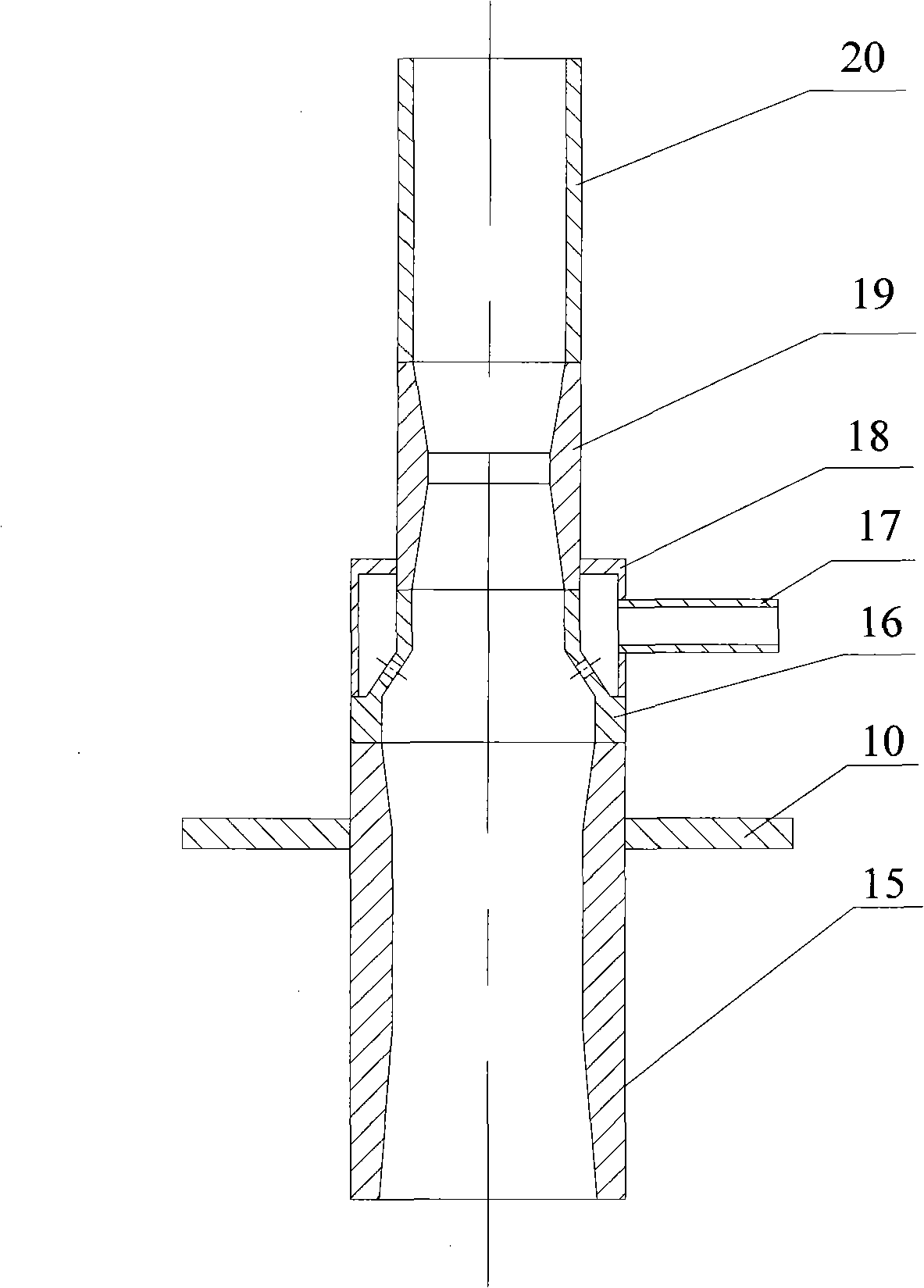

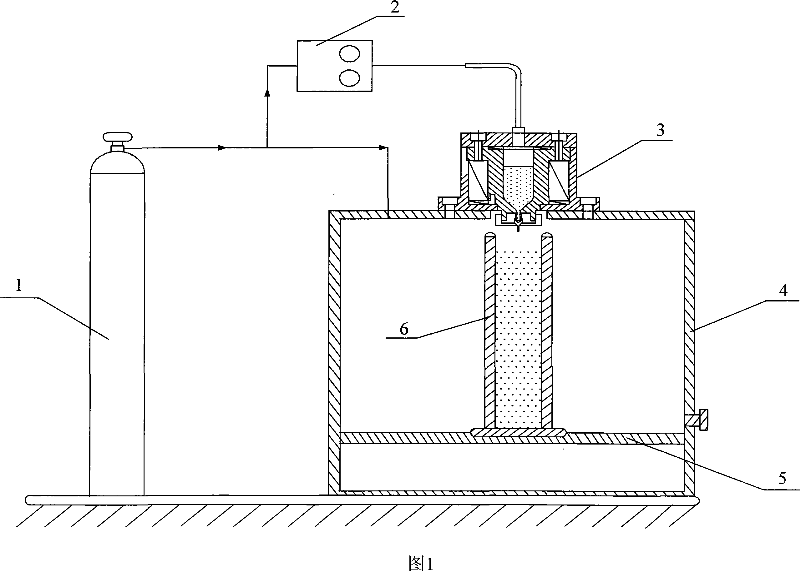

High-impurity molten silicon high-pressure gas-blow separation device and method

InactiveCN104131344AImprove cooling effectAccelerate solidificationPolycrystalline material growthSingle crystal growth detailsHigh densityShielding gas

The invention relates to a high-impurity molten silicon high-pressure gas-blow separation device and a high-impurity molten silicon high-pressure gas-blow separation method. According to the invention, a graphite pedestal is arranged in a furnace body on a lower part. A crucible accommodating polysilicon is arranged on the graphite pedestal. a heating body connected with a system control device is arranged on the periphery in the furnace body. Gas-blow pipes connected with an gas-supply device are arranged above the furnace body. Gas outlet ends of the gas-blow pipes are oriented towards the bottom surface inside the crucible, and are distributed between the crucible center and the crucible inner side surfaces. A polysilicon material is added into the crucible; the chamber of the furnace body is closed; high vacuum is pumped, wherein a vacuum degree is lower than 0.1Pa; heating is carried out such that polysilicon is molten; crystal growth is allowed; through the gas-supply device, hot and cold protective gases are sequentially blew to the top of silicon liquid by using the gas-blow pipes, such that molten silicon is focused to the center and edge of the crucible, and protrusions are formed; solidification is carried out; the material is cooled to a required fetching temperature, and is fetched from the furnace; and the high-density impurity part is removed. With the device and the method, yield can be improved, and cost can be reduced.

Owner:DALIAN UNIV OF TECH

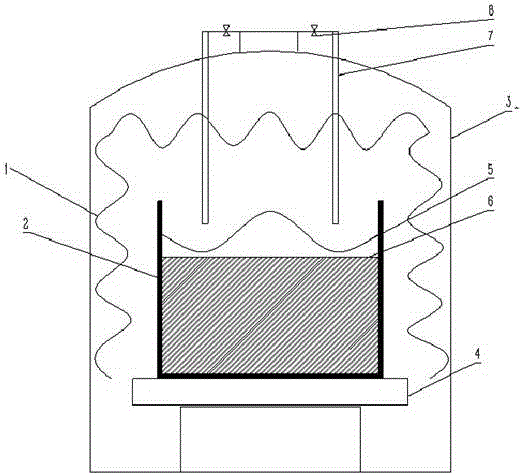

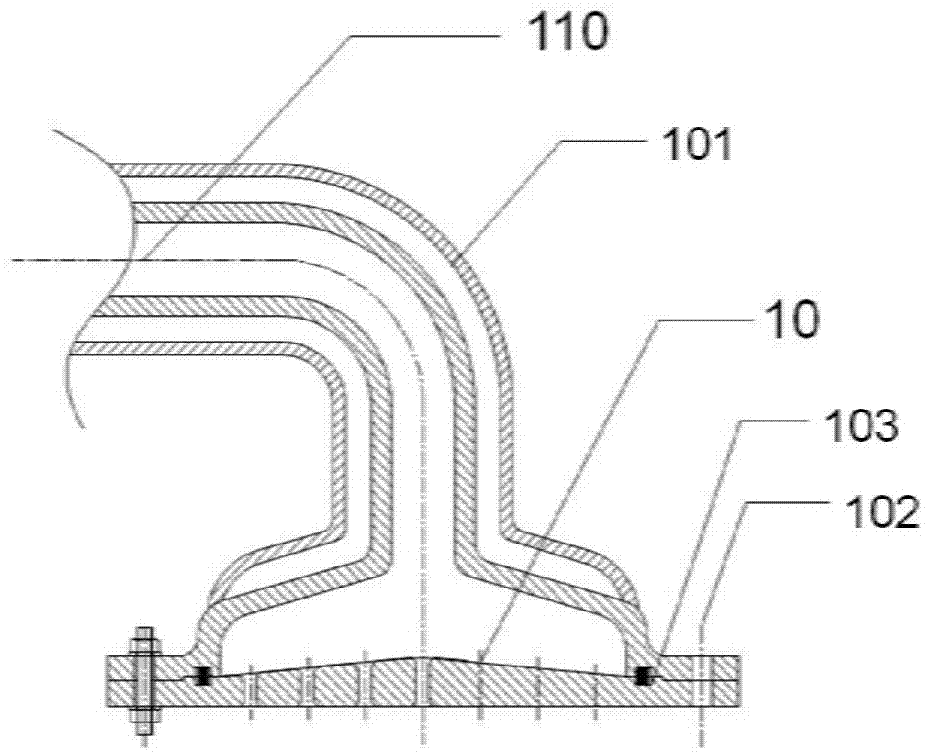

Internal pressure type fiber-reinforced filter membrane and preparation method thereof

ActiveCN103949166ASimple designEasy to operateSemi-permeable membranesInternal pressureWater production

The invention relates to an internal pressure type fiber-reinforced filter membrane and a preparation method thereof. The internal pressure type fiber-reinforced filter membrane is formed by coating the inner surface of a hollow braided tube with a layer of high-polymer membrane casting liquid and carrying out solidification and water washing under the action of internal and external coagulating bath solutions. By preparing the membrane by virtue of the hollow braided tube, the membrane casting liquid and a spinneret plate coextruded by internal coagulating core liquid, a continuous membrane preparation process is realized; the high-polymer membrane casting liquid contains a hydrophilic agent, and thus the prepared fiber-reinforced filter membrane is high in flux and strong in anti-pollution capacity. The internal pressure type fiber-reinforced filter membrane has the beneficial effects that the filter precision is high, a pore structure of the membrane can be controlled by virtue of process parameters of a membrane casting liquid preparation process and a membrane preparation process, the cross flow of inlet water is realized, the reflux ratio is low, and the water production rate is high; compared with an internal pressure type filter membrane, the internal pressure type fiber-reinforced filter membrane has the advantages that a runner is wide and is unlikely to be blocked, feed liquid with high content of suspended solids can be directly processed, and the pretreatment cost is lowered.

Owner:盐城海普润科技股份有限公司

Aluminum-silicon casting alloy having refined primary silicon due to pressure

InactiveUS7100669B1Decrease primary silicon particle sizeLower interfacial energyFoundry mouldsFoundry coresSilicon particleMachinability

Provided herein is a method for refining primary silicon present in a hypereutectic aluminum silicon alloy. The method contemplates the controlled application of pressure to refine the primary silicon during the casting of articles. The application of pressure decreases the primary silicon particle size to improve the machinability and wear resistance of the final cast articles.

Owner:BRUNSWICK CORPORATION

Gelatine-PCL (posterior cruciate ligament) dental hemostatic sponge and preparation method thereof

InactiveCN102247615AEasy to degradeImprove retention effectAbsorbent padsBandagesPosterior cruciate ligamentDental extraction

The invention provides gelatine-PCL (posterior cruciate ligament) dental hemostatic sponge and a preparation method thereof. The preparation method comprises the following steps of: firstly, stirring a gelatine solution with the mass fraction of 5-20% with a PCL solution with the mass fraction of 10-20% at the temperature of 25-60 DEG C to react for 1-5 hours so as to prepare a combined solution, then adding auxiliary additives to the combined solution, continuously stirring for 1-3 hours at the temperature of 25-60 DEG C to prepare a mixed solution, pouring the mixed solution into a mould, freezing for 0.5-4 hours at the temperature of minus 20 DEG C, and finally freeze drying and moulding in a freeze drying machine to obtain the gelatine-PCL hemostatic sponge. The gelatine-PCL hemostatic sponge prepared by the invention has good retention property, hemostatic property and anti-inflammatory bacteriostatic effect; the product is safe and effective without toxic or side effect; waste can be degraded without causing environmental pollution; and the gelatine-PCL hemostatic sponge can be widely applied as a postoperation hemostatic material for dental extraction and other oral surgeries and has a good market application prospect.

Owner:SICHUAN UNIV

Inorganic regenerated concrete mixture and its preparing method

InactiveCN1473787AQuality improvementExtend your lifeSolid waste managementSlagUltimate tensile strength

The present invention relates to a kind of inorganic regenerated concrete mixture and its preparation process. The inorganic regenerated concrete mixture is prepared with waste concrete regenerated aggregate and industrial waste slag as main material and through adding activating agent and water and through stirring. The mixture has the features of high strength, good hydraulicity and powerful deformation resistance. It is one ideal road base material and may be used widely in the road construction in soft soil foundation area.

Owner:TONGJI UNIV

Bimetal metallurgical composite pipe and manufacturing method thereof

The invention discloses a bimetal metallurgical composite pipe and a manufacturing method thereof. The manufacturing method comprises the following steps of manufacturing a pipe blank of the bimetal metallurgical composite pipe by adopting a vacuum water-cooling die casting technology, specifically inner metal and outer metal are metallurgically combined in a high-temperature diffusion mode, and the two ends of the pipe blank are covered by the inner metal; carrying out hot rolling forming on the obtained pipe blank of the bimetallic metallurgical composite pipe so as to enable the pipe diameter and the wall thickness of the bimetallic metallurgical composite pipe to meet the preset standard and make the inner metal meet the preset thickness requirement; and carrying out quenching and tempering treatment on the whole hot-rolled bimetallic metallurgical composite pipe to make the outer metal meet the preset strength requirement, and completing the manufacturing of the bimetallic metallurgical composite pipe. According to the method, the high strength of an oil pipe column is ensured, and meanwhile, the integrity of corrosion resistance of the inner wall is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

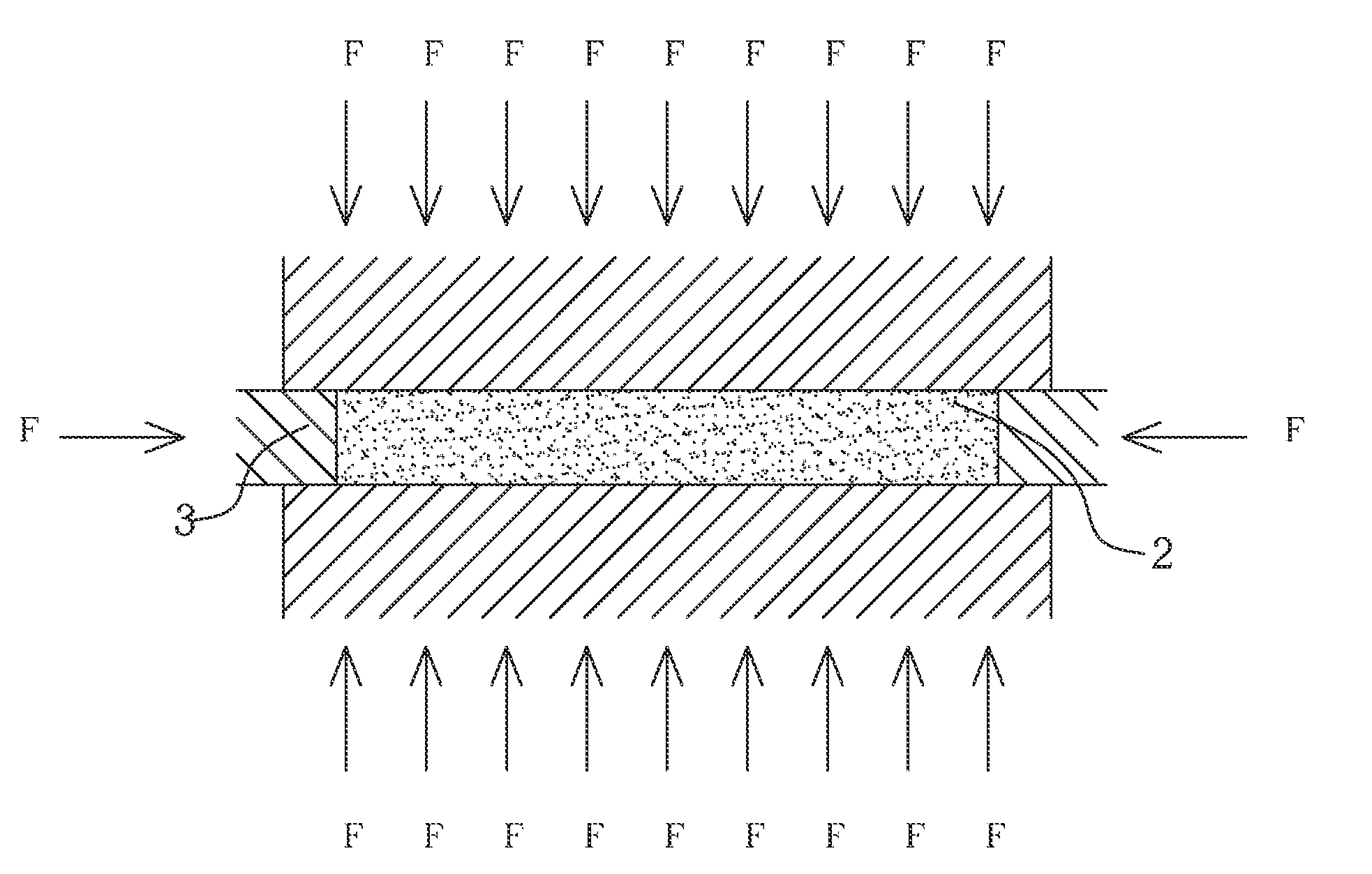

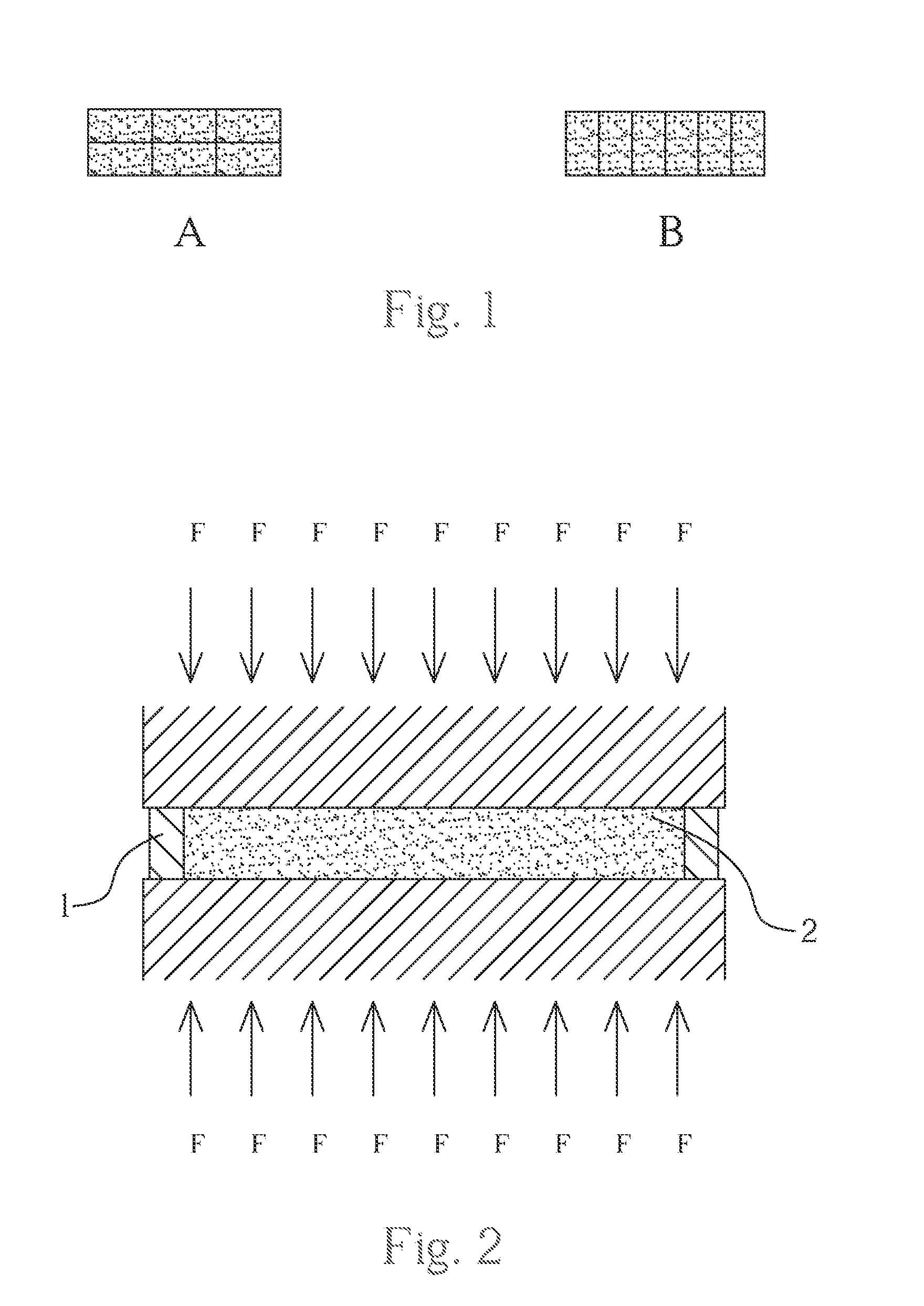

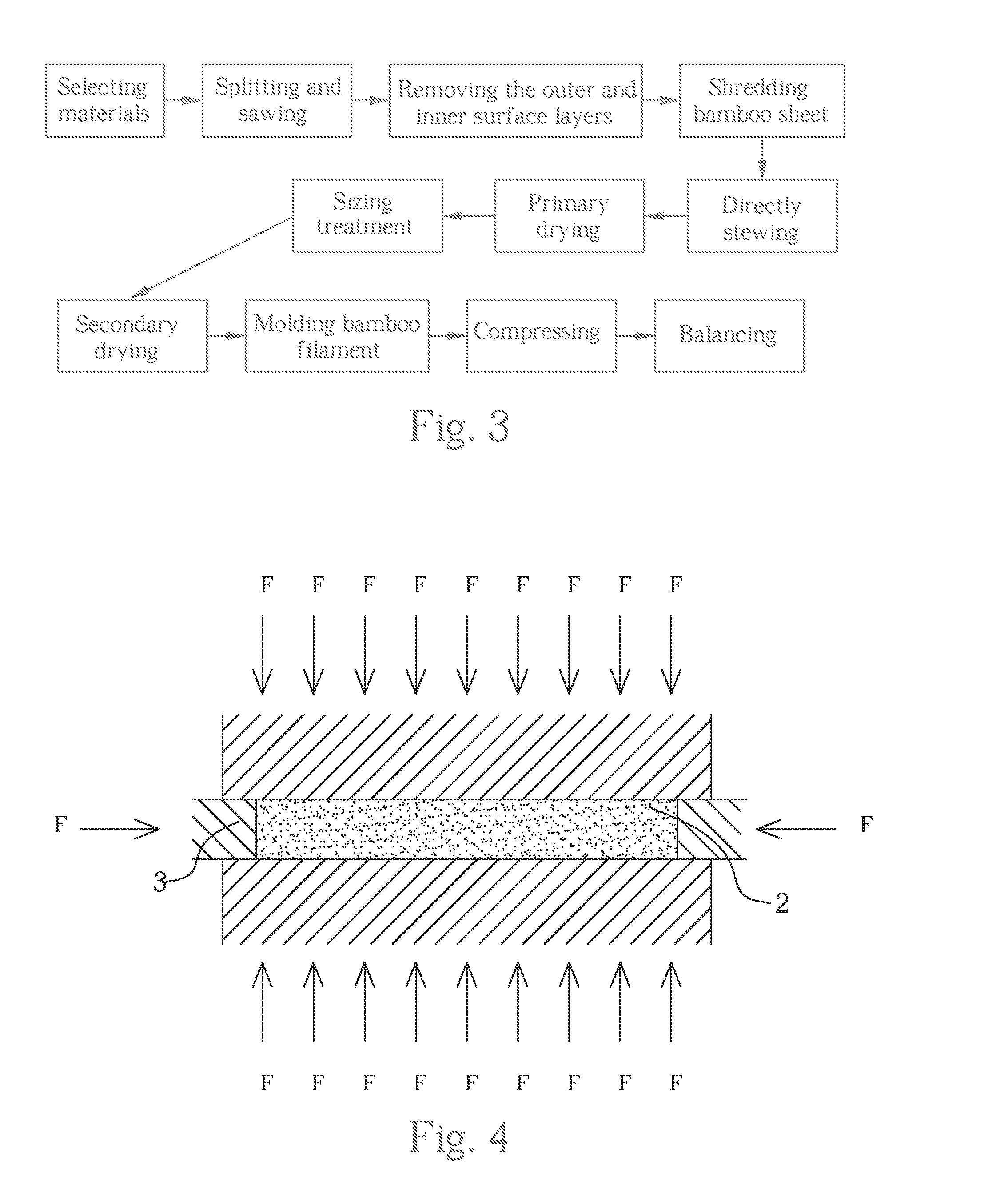

InactiveUS20080053570A1Stable qualityEasy to heat and coolStapling toolsWood compressionSizingHot press

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

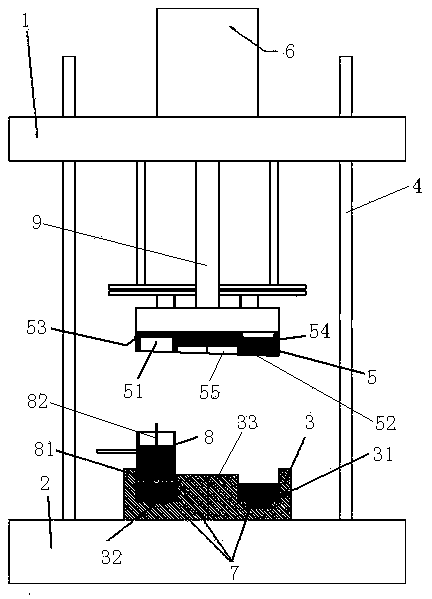

Casting and forging method and casting and forging device

The invention relates to a casting and forging method and a casting and forging device. The casting and forging device comprises a lower die and an upper die, wherein a cavity is formed in the upper end of the lower die; the upper die is connected with an oil cylinder capable of driving the upper die to move up and down; a punch which is in concave-convex fit with the cavity of the lower die and a riser which is arranged on the lower surface of the punch in an inwards concave manner are arranged at the lower end of the upper die; a sprue base which is located right below the riser and used for being matched with a casting ladle to accommodate a liquid is arranged on the bottom surface of the cavity of the lower die; the insertion travel of the upper die in the cavity comprises a feeding travel and a die forging travel with depths in the cavity increased; a pressure relief valve communicated with the riser is arranged at the upper end of the upper die. By the aid of the casting and forging method and the casting and forging device, the problem that bubbles can be formed on a casting due to the fact that exhausting cannot be performed during casting and forging in the prior art is solved.

Owner:STATE GRID CORP OF CHINA +2

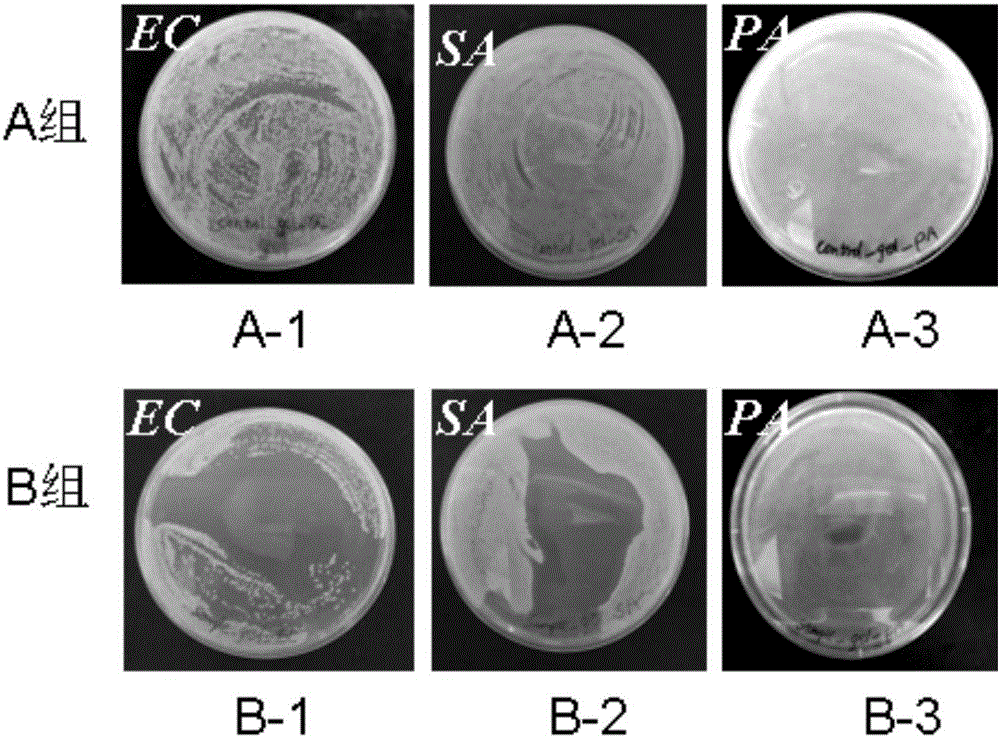

Sustained antibacterial hemostatic powder and preparation method thereof

InactiveCN106512076AAccelerate solidificationIncrease concentrationSurgical adhesivesMicrocapsulesHEMOSTATIC POWDERCarboxymethyl cellulose

The invention belongs to the field of medical equipment, particularly relates to the field of medical biopolymer materials and provides sustained antibacterial hemostatic powder and a preparation method of the sustained antibacterial hemostatic powder. The sustained antibacterial hemostatic powder is prepared from nanometer silver, sodium carboxymethyl cellulose and alginate, and by weight, 1-3 parts of the nanometer silver, 10-20 parts of the sodium carboxymethyl cellulose and 5-10 parts of the alginate are included. According to the sustained antibacterial hemostatic powder, the nanometer silver, the sodium carboxymethyl cellulose and the alginate are used as the raw materials, and the sustained antibacterial hemostatic powder is obtained through a spray drying method; and the hemostatic powder not only has the hemostatic function, but also has the excellent antibacterial function, as degradation of the sodium carboxymethyl cellulose and the alginate after the hemostatic powder is in contact with the blood or diffusate, the contained nanometer silver is released slowly, and thus the sustained antibacterial purpose is achieved.

Owner:GUANGDONG TAIBAO MEDICAL DEVICE TECH RES INST CO LTD

Method and device for producing small solder alloys welding balls

InactiveCN101036946AUniform sizeChange sizeWelding/cutting media/materialsSoldering mediaNitrogen gasElectron

A making device and method of subtilis solder alloy solderball, which relates to a making device and method of the alloy solderball for electronic packaging industry, in order to settle the problems that the making device of existing solderball is large with complicated structure and high making cost and the making process of the solderball is miscellaneous with low efficiency and low precision of the made solderball. The gas output ends of gas supply device of the invention respectively connect to the input end of the pressure controller and the top end of the gas protection installation, a lifting work platform is provided on the lower part of the gas protection installation and can move vertically, a cooling solidification device is mounted on the lifting work platform in the gas protection installation; the method of the invention is that: adding the solder with solid state to the liquid droplet maker; filling argon gas or nitrogen in the gas protection installation; melting the solder; dispersing the melt drip; forming the solderball; completing the steps of collecting, cleaning, drying, packaging. The device of the invention has advantages of simple structure and low cost, the method of the invention has characteristic of good process flexibility.

Owner:HARBIN INST OF TECH

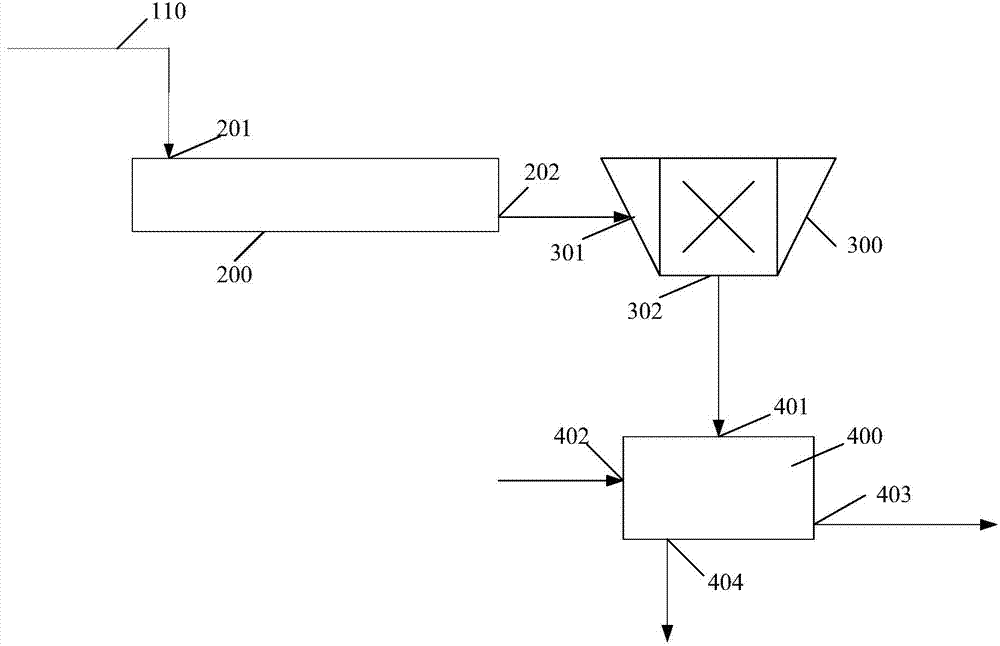

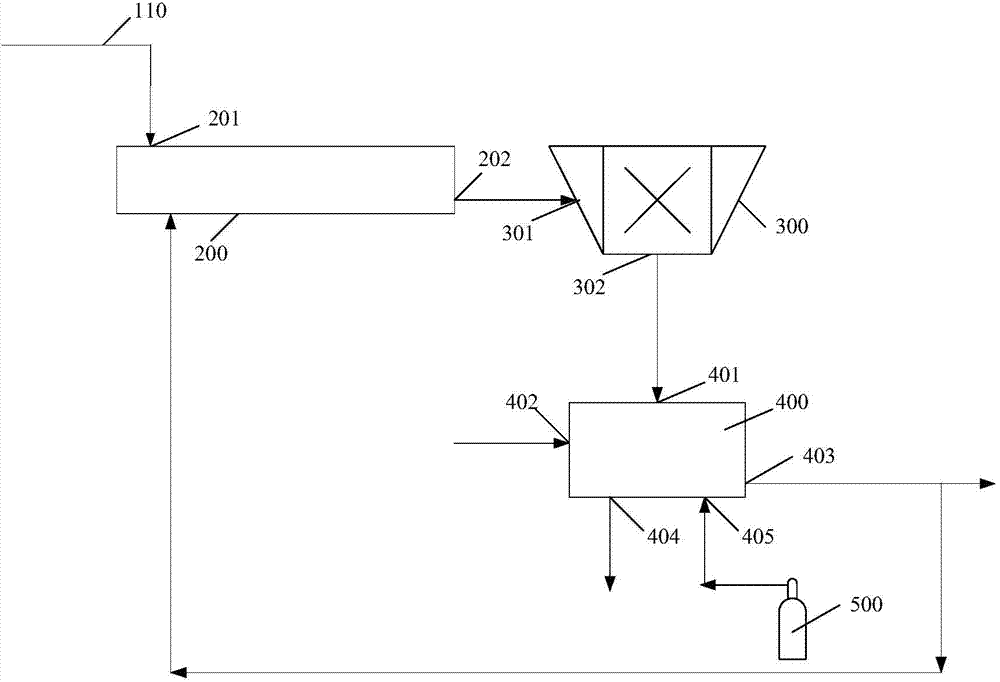

Lyocell fiber spinning solution waste recycling device and recycling method thereof

ActiveCN104711706ASmall sizeLarge specific surface areaArtificial filament recoveryTextile/flexible product manufactureManufacturing cost reductionSlag

The invention provides a lyocell fiber spinning solution waste recycling device and a recycling method thereof. The recycling device comprises a waste pipeline, a cooling device, a breaking device and a leaching device, wherein the waste pipeline is provided with a spinning solution waste inlet and a spinning solution waste outlet; the spinning solution waste inlet is connected to a spinning solution waste output device; the cooling device is provided with a cooling material inlet and a cooling material outlet; the cooling material inlet is communicated with the spinning solution waste outlet; the breaking device is provided with a breaking material inlet and a breaking material outlet; the breaking material inlet is communicated with the cooling material outlet; the leaching device is provided with a leaching material inlet, an NMMO leaching solvent inlet, a leaching liquid outlet and a leaching slag outlet; the leaching material inlet is communicated with the breaking material outlet; a plurality of extrusion holes are formed in the spinning solution waste outlet of the waste pipeline. By virtue of the application of the recycling device, the NMMO solvent in the lyocell fiber spinning solution waste is effectively recycled, so that the manufacturing cost is reduced.

Owner:CHINESE TEXTILE ACAD

Pollen pini tooth cleaning agent and preparation method thereof

InactiveCN102451118APrevent bleeding gumsPromote blood clottingCosmetic preparationsToilet preparationsBiomedical engineeringPennyroyal

The invention relates to a pollen pini tooth cleaning agent and a preparation method thereof, and specifically relates to a mouthwash using pollen pini as a main raw material and a preparation method thereof. Main raw materials comprise 30-55 parts of pollen pini, 12-35 parts of chitosan, 10-20 parts of sodium aluminum carbonate, 5-10 parts of zinc chloride and 10-25 parts of pennyroyal. The cleaning agent provided by the invention can be used as a mouthwash for everyday tooth brushing and gargling before and after meals; the cleaning agent can clean teeth and oral cavity, prevent carious tooth, treat gingival bleeding and periodontitis, is convenient for usage and has a lasting effect.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

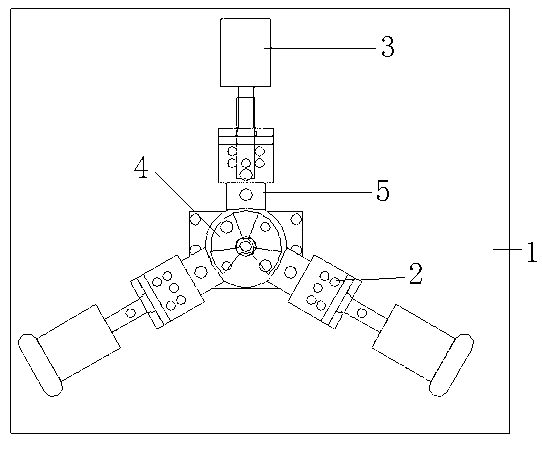

Automatic welding machine

InactiveCN102794555AHigh degree of automationImprove welding efficiencyResistance electrode holdersControl systemAutomation

The invention relates to an automatic welding machine. The automatic welding machine comprises a working platform, one or more welding mechanisms arranged on the working platform and a control system for controlling the welding mechanisms. The automatic welding machine is characterized in that the welding mechanism comprises a central electrode and a plurality of moving electrodes arranged at the periphery of the central electrode, wherein each moving electrode comprises a sliding rail, a moving electrode block and a moving electrode cylinder; the moving electrode block can be arranged on the sliding rail in a sliding manner; the moving electrode cylinder is used for driving the electrode block to slide upwards; the central electrode and the moving electrodes are respectively connected with two electrodes of a power supply; and the moving electrode cylinder is connected with the control system. The automatic welding machine has the advantages that a plurality of workpieces or a plurality of welding parts of the same workpiece can be welded automatically and simultaneously, the automation degree is high, the use is convenient and the welding efficiency is high.

Owner:伟业精密科技(惠州)有限公司

Method for improving self-feeding capacity of high and thick large-cross section casting blank

ActiveCN102161090AAchieving radial self-feedingImprove the interface heat transfer coefficientState of artDiameter ratio

The invention relates to the field of casting blank manufacturing, in particular to a method for improving the self-feeding capacity of a high and thick large-cross section casting blank, and can solve the problems that the center quality of the thick large-cross section casting blank is poor, cracks are generated on the surface of the thick large-cross section casting blank, and the rejection rate is high in the prior art. The method comprises the following steps of: controlling external cooling conditions of different solidification stages of the casting blank to quickly solidify the outer surface of the casting blank to form a shell, establish strength and prevent surface cracks from being generated; performing heat preservation and slow cooling on the surface of the casting blank to keep a large area of a core part in a pasty area, wherein a solidification layer on the outer surface of the casting blank is kept at a higher temperature so that plastic deformation is realized; and performing simultaneous solidification and solid-phase movement in the subsequent solidifying and shrinking process of the casting blank to fulfill the aim of radial self-feeding of a deformable metal at a high temperature so as to eliminate the internal shrinkage cavities and surface cracks of the casting blank and obviously improve the looseness until the internal looseness of the casting blank is eliminated. The method is applicable to the high and thick large-cross section casting blank, particularly to a thick large-cross section casting round blank and a thick large-cross section casting square blank of which the height-diameter ratio is high and the axial looseness cannot be improved through riser feeding.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Antimicrobial disinfectant with good biocompatibility

InactiveCN106491633AGood biocompatibilityPromote regenerationOrganic active ingredientsAntiinfectivesHuman bodySide effect

The invention discloses an antimicrobial disinfectant with good biocompatibility. The antimicrobial disinfectant includes: 0.001wt%-100wt% of an antimicrobial macromolecule; 0wt%-99.999wt% of an assistant; and 0wt%-99.999wt% of a solvent. The antimicrobial disinfectant provided by the invention has the characteristics of simple components and easy preparation; long-acting and rapid killing and inhibiting effect on gram positive pathogenic bacteria, gram negative pathogenic bacteria, moulds, fungi, viruses and other microorganisms selectively; no toxic or side effect on normal animal body cells and tissues; no irritation on the human body; auxiliary hemostasis and coagulation, and promotion of cell tissue regeneration, acceleration of wound healing, and no drug resistance; and no pollution to the environment, thus being a widely applicable, economical, environment-friendly and safe antimicrobial disinfectant.

Owner:克灵美(天津)生物科技有限公司

Mint coconut fragrant low-salt duck egg and preparation method thereof

The present invention discloses a mint coconut fragrant low-salt duck egg prepared from the following parts by weight of raw materials: 70-80 parts of fresh duck eggs, 10-12 parts of mint leaves, 6-8 parts of strawberries, 8-10 parts of green olives, 4-5 parts of broadleaf holly leaf, 2-3 parts of radix isatidis, 4-5 parts of achene of great burdock, 1-2 parts of calyx seu fructus physalis, 3-4 parts of gotu kola, 2-3 parts of Indian Kalimeris herb, 4-5 parts of loquat flower, 20-30 parts of high-degree Chinese liquor, 40-50 parts of coconut milk, and proper amount of yellow sand, white vinegar and table salt; the duck eggs are soaked with the white vinegar for formation of small holes on eggshell to facilitate the exchange of substances such as salt and the like, then duck eggs are first pickled with a pickle liquid and then pickled with a pickle wine with same salt content with that of the pickle liquid, the osmotic pressure of egg white and the osmotic pressure outside the shell are consistent, so that salt permeates into egg yolk for dehydration of the egg yolk, salt content of the egg white may not rise, the first phase is quickly completed by vacuum pickling, by addition of the Chinese liquor, the coagulation of protein is accelerated, the egg yolk releases oil quickly, the egg white of cooked salted duck eggs tastes appropriate, the egg yolk is loose, oily and smooth, and the mint coconut fragrant low-salt duck egg is overflowed in liquor aroma, rich in coconut flavor, and rich in mint flavor.

Owner:柳培健

Curing agent for treatment of electroplating sludge, and preparation method and application method thereof

The invention relates to a curing agent for treatment of electroplating sludge. The curing agent comprises the following raw materials in percentage by weight: 75%-79% of cement, 10%-15% of sands, 5%-8% of sodium silicate and 6%-10% of activated aluminium oxide; the invention further discloses a preparation method and an application method of the curing agent. The curing agent has a wide application range, and overcomes potential hazards due to secondary environmental pollution of electroplating heavy metal sludge.

Owner:湖南中车环境工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com