Preparation method and application of bioactive factor loaded temperature-sensitive composite gel carrier

A bioactive factor and composite gel technology, applied in the field of bioactive factor sustained-release carrier preparation, can solve problems such as affecting patients' chewing function, facial aesthetics, and difficulty in denture repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

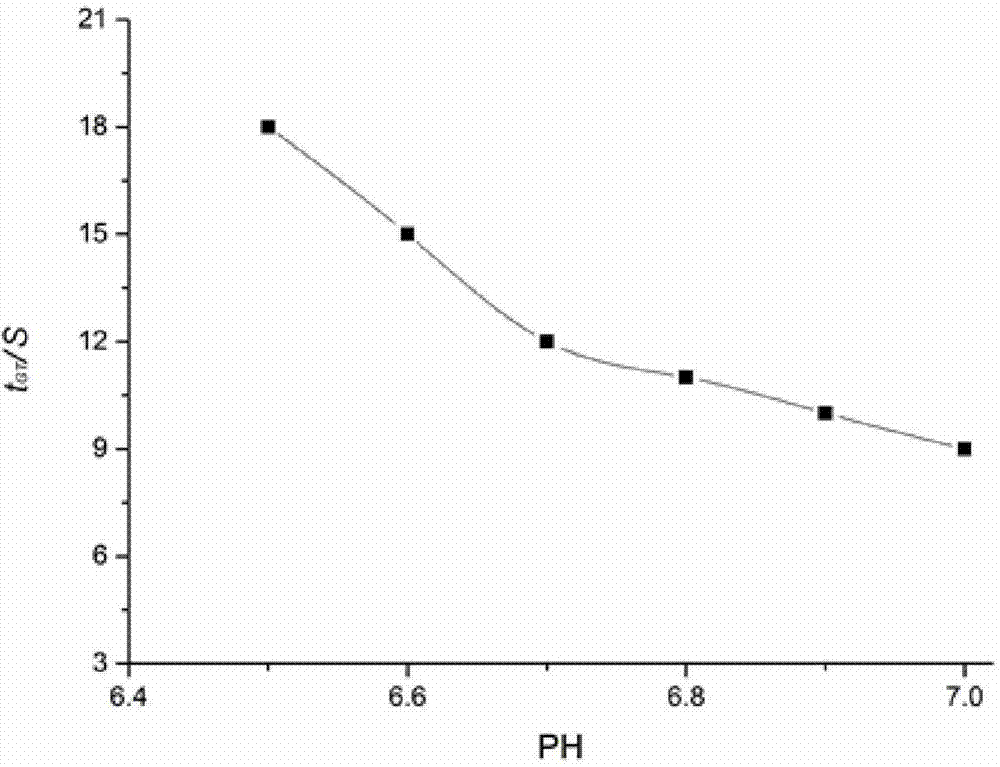

[0026] Step 1: Dissolve sodium alginate in 100 mL of distilled water at 60°C, mechanically stir for 10 minutes, ultrasonicate for 15 minutes, adjust the pH of the colloid to 4 with acetic acid, and make 2wt% sodium alginate hydrosol;

[0027] Step 2, take the sodium alginate hydrosol prepared in step 1 respectively, add chitosan under stirring conditions, mechanically stir at 60 ° C for 10 minutes, and ultrasonically 15 minutes, the sodium alginate / The relative weight ratio of chitosan is 0.2;

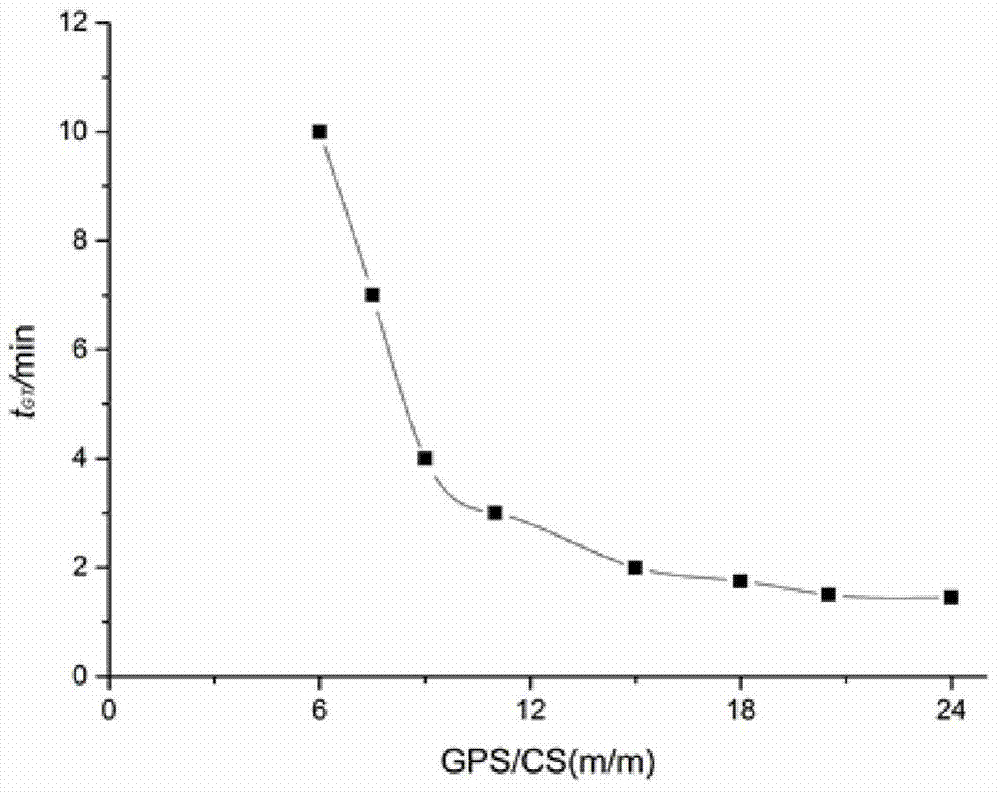

[0028] Step 3, prepare a sodium glycerophosphate aqueous solution with a mass concentration of 50%: add sodium alginate-chitosan hydrosol under the condition of stirring the sodium glycerophosphate aqueous solution, and control the sodium glycerophosphate / chitosan hydrosol because the pH of the sol is 4 to 5. The mass ratio is 18, forming a homogeneous sol;

[0029] Step 4, add adiponectin at 0.1% to 0.3% by weight of the homogeneous sol to the homogeneous sol prepared in step 3 unde...

Embodiment 2

[0035] Step 1: Dissolve sodium alginate in 100 mL of distilled water at 60°C, mechanically stir for 10 minutes, ultrasonicate for 15 minutes, adjust the pH of the colloid to 4 with acetic acid, and make 2wt% sodium alginate hydrosol;

[0036] Step 2, take the sodium alginate hydrosol prepared in step 1 respectively, add chitosan under stirring conditions, mechanically stir at 60 ° C for 10 minutes, and ultrasonically 15 minutes, the sodium alginate / The relative weight ratio of chitosan is 0.4;

[0037] Step 3, prepare a sodium glycerophosphate aqueous solution with a mass concentration of 50%: add sodium alginate-chitosan hydrosol under the condition of stirring the sodium glycerophosphate aqueous solution, and control the sodium glycerophosphate / chitosan hydrosol because the pH of the sol is 4 to 5. The mass ratio is 22.4, forming a homogeneous sol;

[0038] Step 4, add adiponectin at 0.1% to 0.3% by weight of the homogeneous sol to the homogeneous sol prepared in step 3 unde...

Embodiment 3

[0043] Step 1: Dissolve sodium alginate in 100 mL of distilled water at 60°C, mechanically stir for 10 minutes, ultrasonicate for 15 minutes, adjust the pH of the colloid to 5 with hydrochloric acid, and make 3wt% sodium alginate hydrosol;

[0044] Step 2, take the sodium alginate hydrosol prepared in step 1 respectively, add chitosan under stirring conditions, mechanically stir at 60 ° C for 10 minutes, and ultrasonically 15 minutes, the sodium alginate / The relative weight ratio of chitosan is 0.8;

[0045] Step 3, prepare a sodium glycerophosphate aqueous solution with a mass concentration of 50%: add sodium alginate-chitosan hydrosol under the condition of stirring the sodium glycerophosphate aqueous solution, and control the sodium glycerophosphate / chitosan hydrosol because the pH of the sol is 4 to 5. The mass ratio is 15, forming a homogeneous sol;

[0046] Step 4, add adiponectin at 0.1% to 0.3% by weight of the homogeneous sol to the homogeneous sol prepared in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com