Compound amino acid organic fertilizer and production method of compound amino acid organic fertilizer

A technology of compound amino acid and production method, which is applied in the field of compound amino acid organic fertilizer and its production, to achieve the effect of improving quality and yield, increasing aggregate structure, and improving soil ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

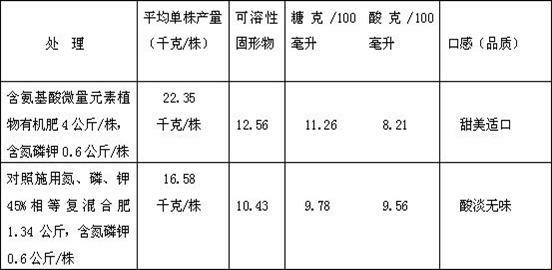

Examples

Embodiment 1

[0046] (1) Preparation of compound amino acid aqueous solution. First, animal hair, including human hair, pig hair, waste wool, rabbit hair, chicken feather, and duck feather mixed hair, is first hydrolyzed with edible hydrochloric acid with a mass content of 20-30%. Add 2-3 kg of dilute hydrochloric acid, heat to 60-100°C, wait for the hair to completely dissolve, then cool the hydrolyzate: transfer the above hydrolyzate to another alkali-resistant reaction kettle, and gradually add ammonium bicarbonate or sodium bicarbonate to carry out Neutralize until the pH value is 6-8 to obtain a complex amino acid aqueous solution.

[0047] (2) Microbial fermentation products are obtained by adding high-temperature cellulolytic enzymes, Trichoderma viride, Bacillus subtilis and Aspergillus oryzae to food industry waste residues for fermentation. High-temperature cellulolytic enzymes are obtained by taking 1 kg of fresh horse manure and soaking in 10 kg of water for 2 -24 hours, and the...

Embodiment 2

[0053] Example 2: Steps (1)-(6) are the same as in Example 1, (7) 2 kg of chelated amino acid salt, 6 kg of microbial fermentation product, 40 kg of inorganic fertilizer, and 20 kg of humic acid fertilizer are added to 2000 kg It is mixed with farmyard manure, and then placed in the warehouse to be naturally stacked and matured for more than 3-5 days before being packaged for delivery or dried at low temperature with a large air volume mixing cylinder, and then packed and packaged for delivery after granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com