Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9514results about How to "High removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

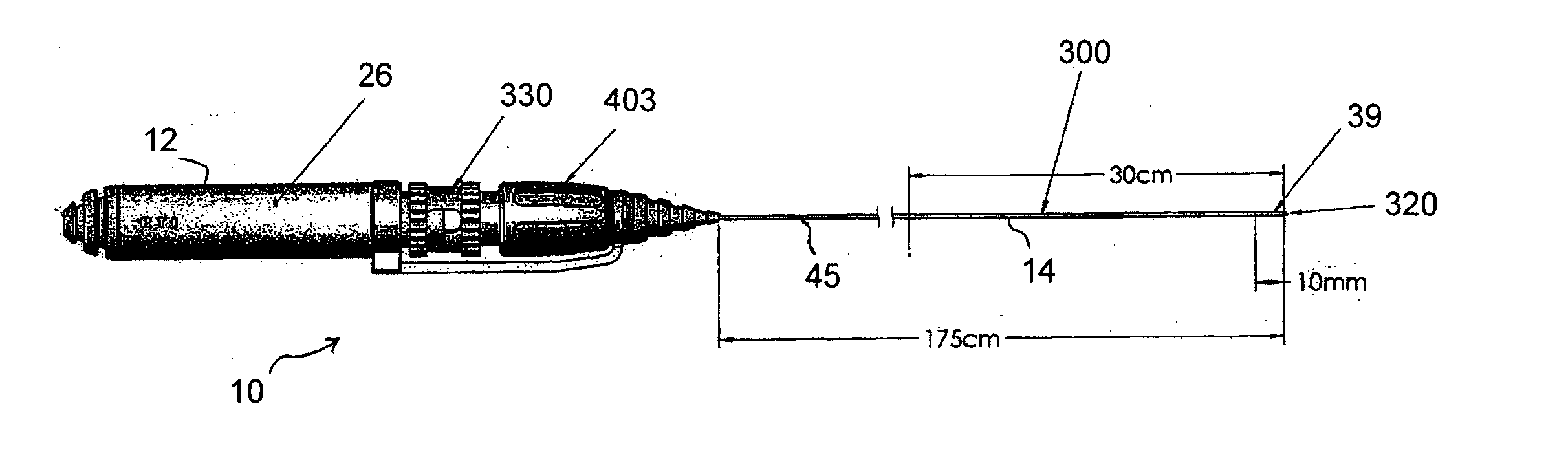

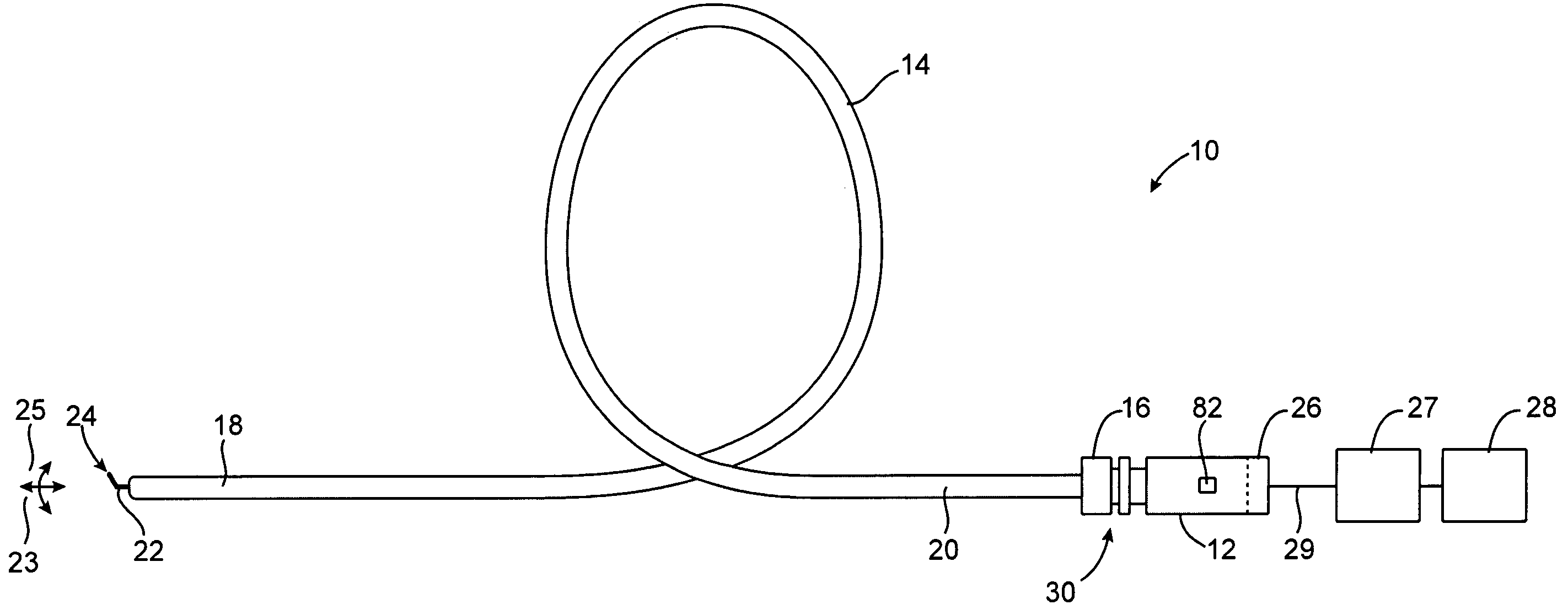

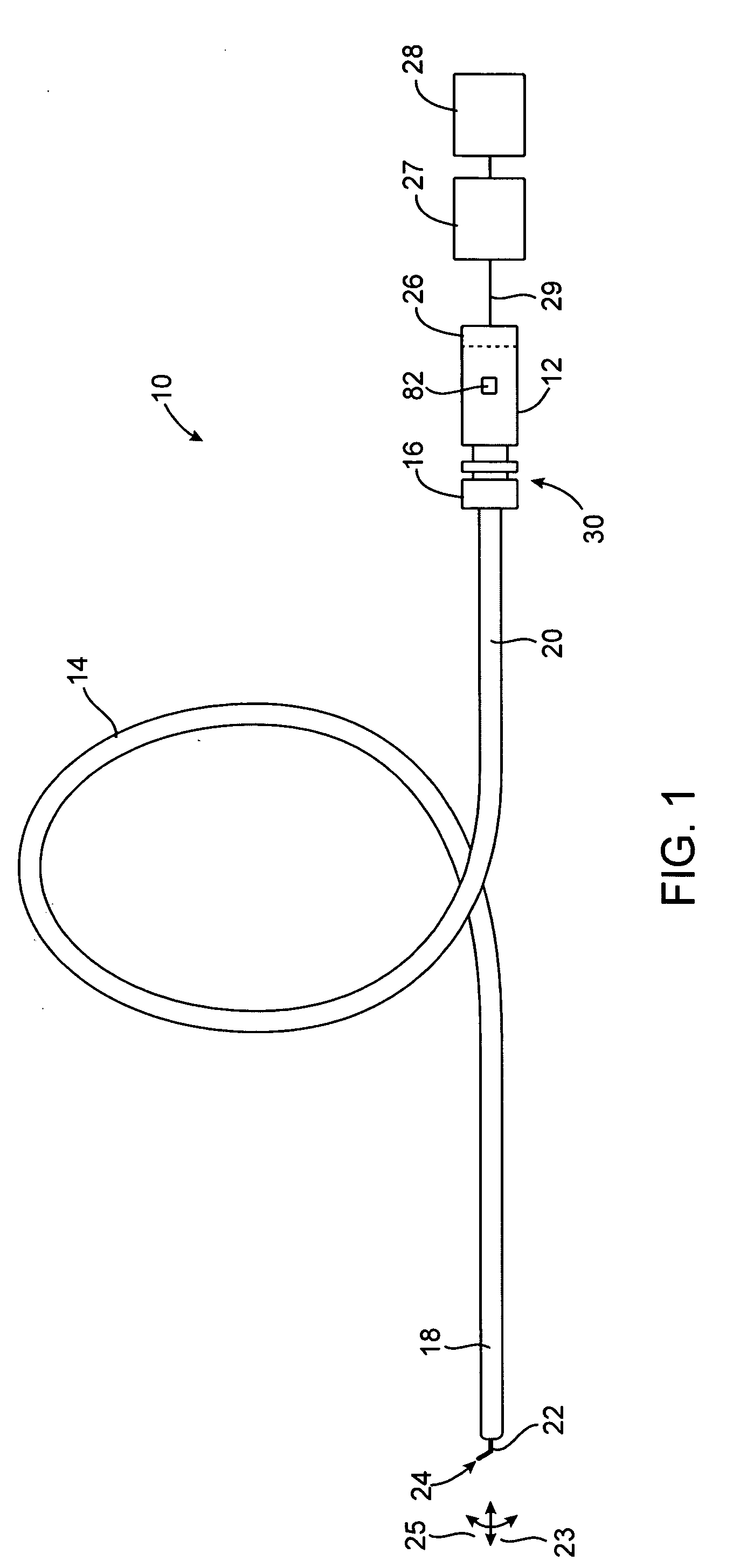

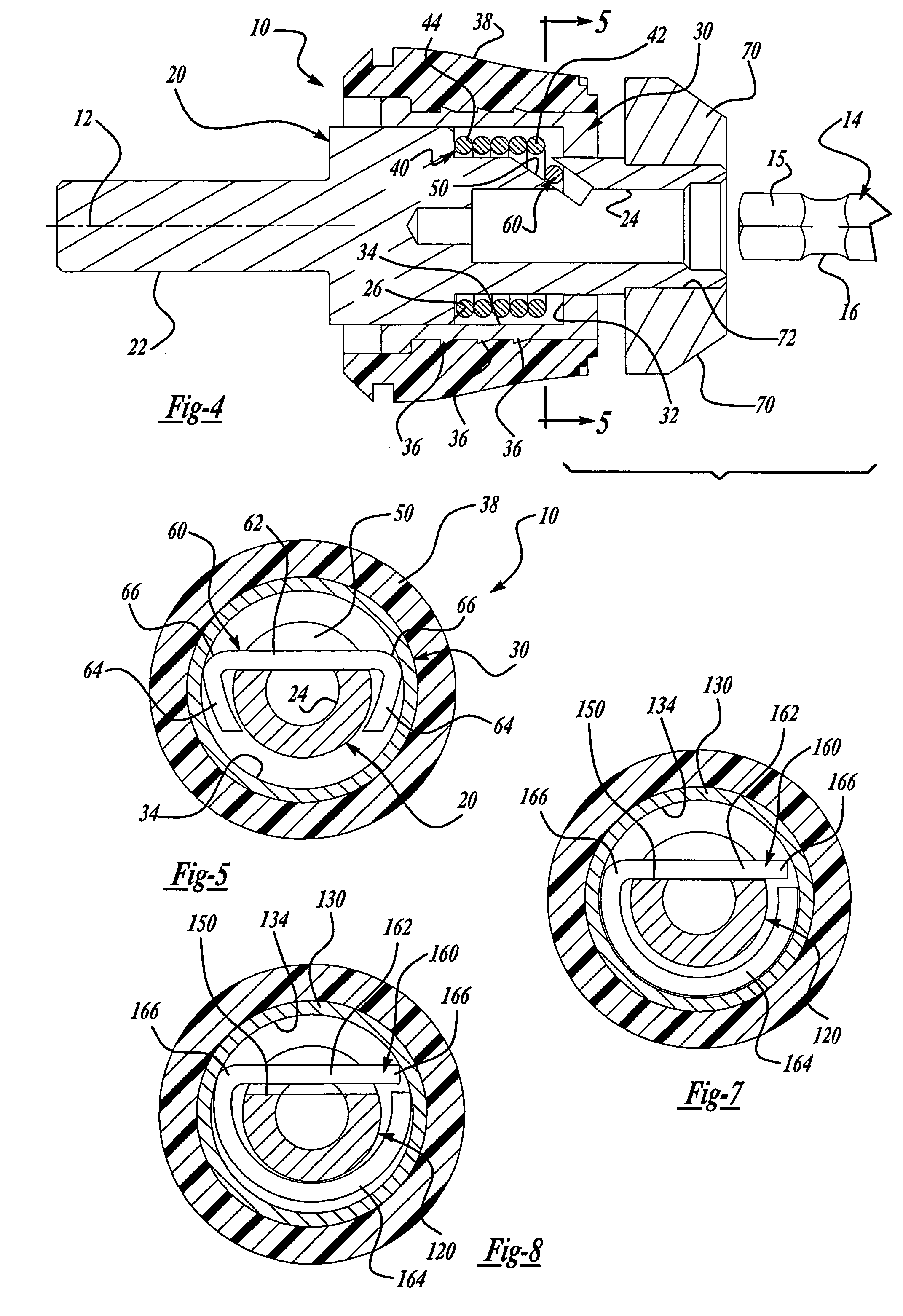

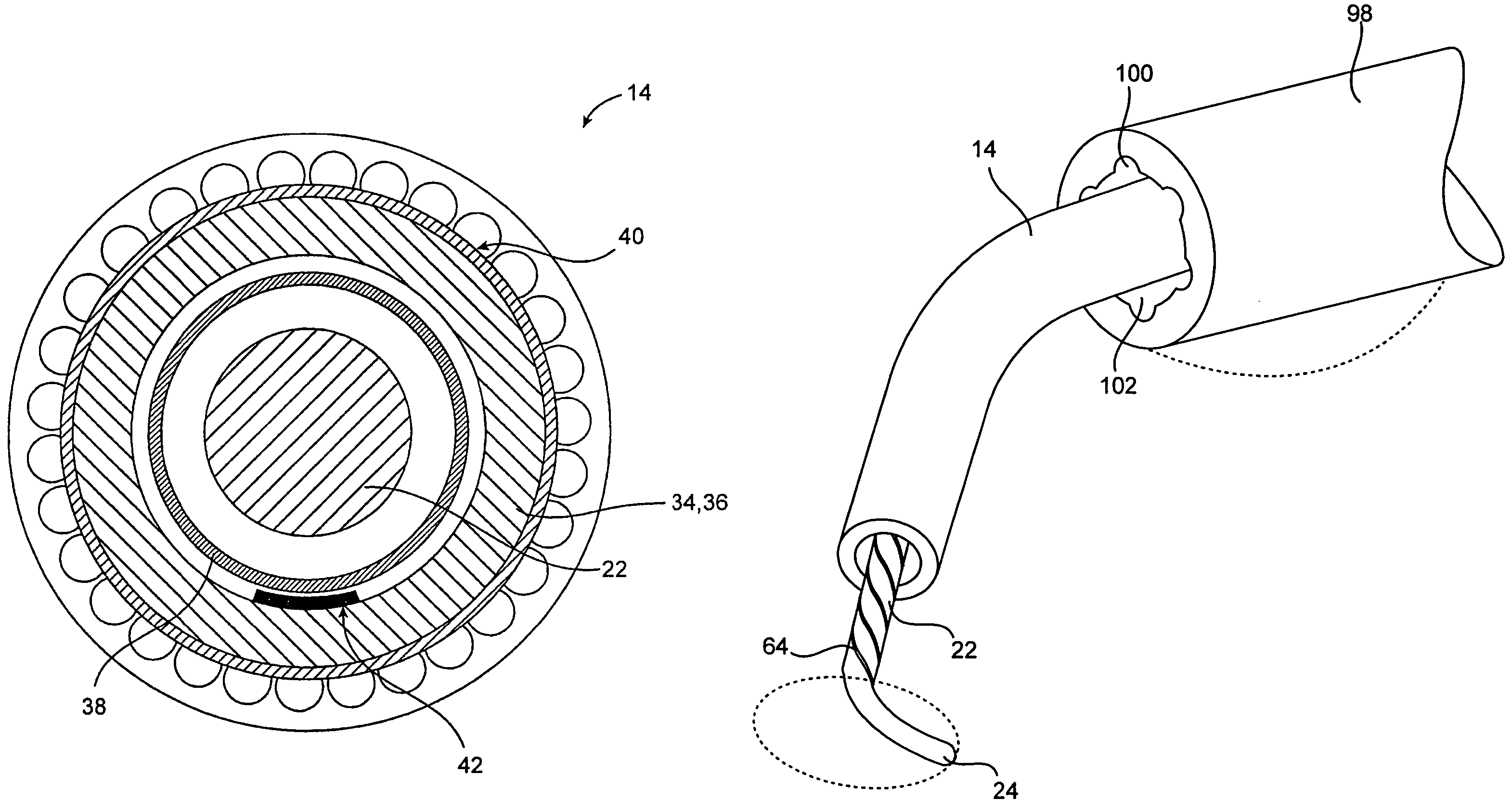

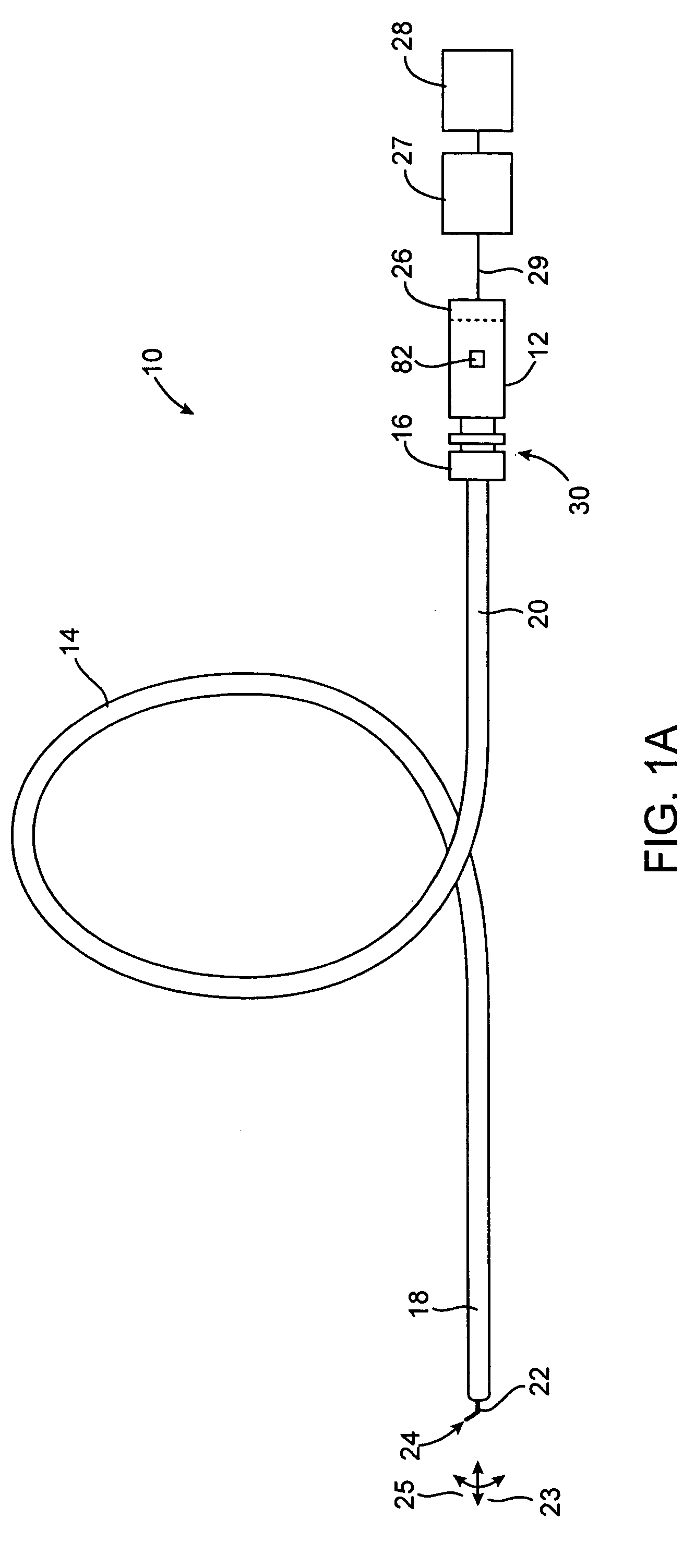

Guidewire for crossing occlusions or stenoses

InactiveUS20060074442A1Easy to controlFacilitate occlusionCannulasGuide wiresCoronary arteriesThrombus

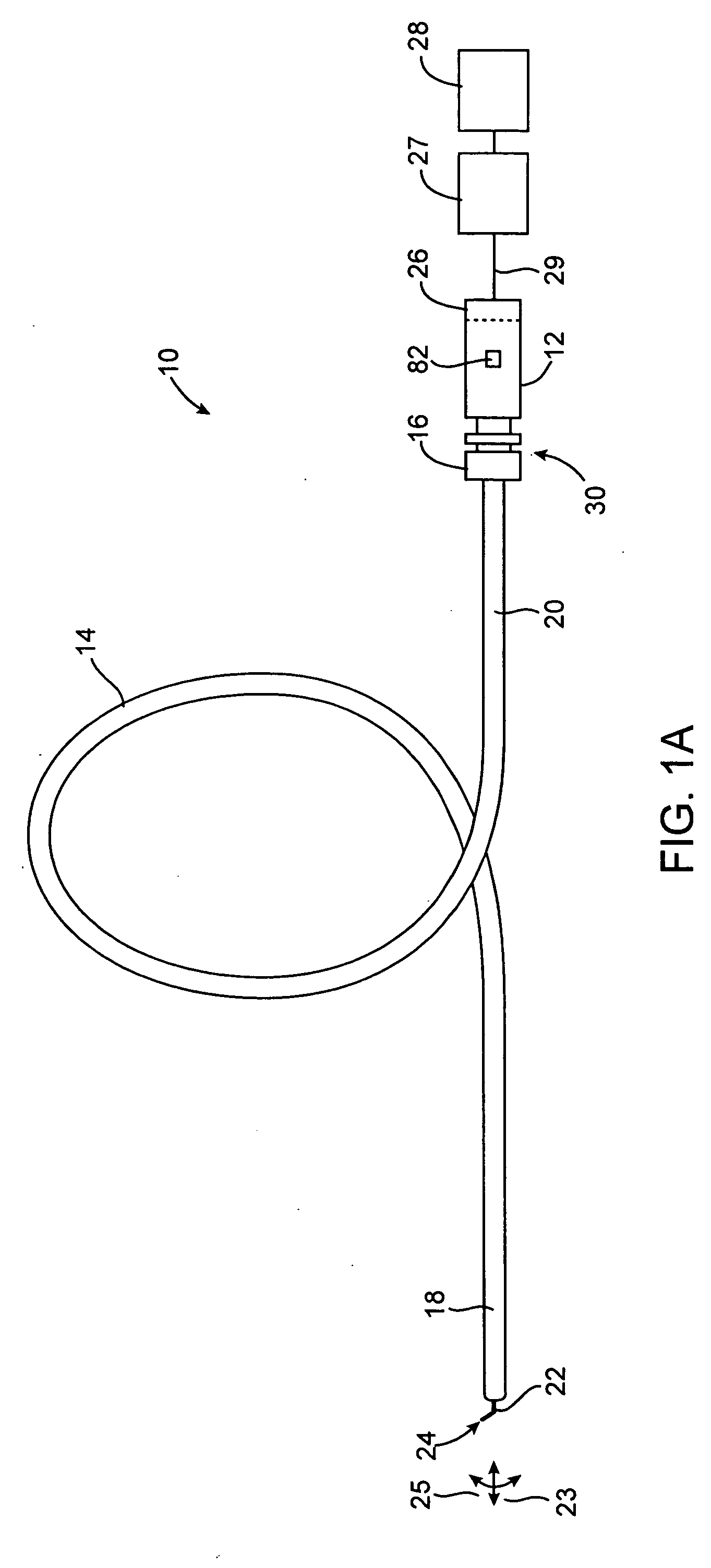

A deflectable and torqueable hollow guidewire device is disclosed for removing occlusive material and passing through occlusions, stenosis, thrombus, plaque, calcified material, and other materials in a body lumen, such as a coronary artery. The hollow guidewire generally comprises an elongate, tubular guidewire body that has an axial lumen. A mechanically moving core element is positioned at or near a distal end of the tubular guidewire body and extends through the axial lumen. Actuation of the core element (e.g., oscillation, reciprocation, and / or rotation) creates a passage through the occlusive or stenotic material in the body lumen.

Owner:BOSTON SCI SCIMED INC

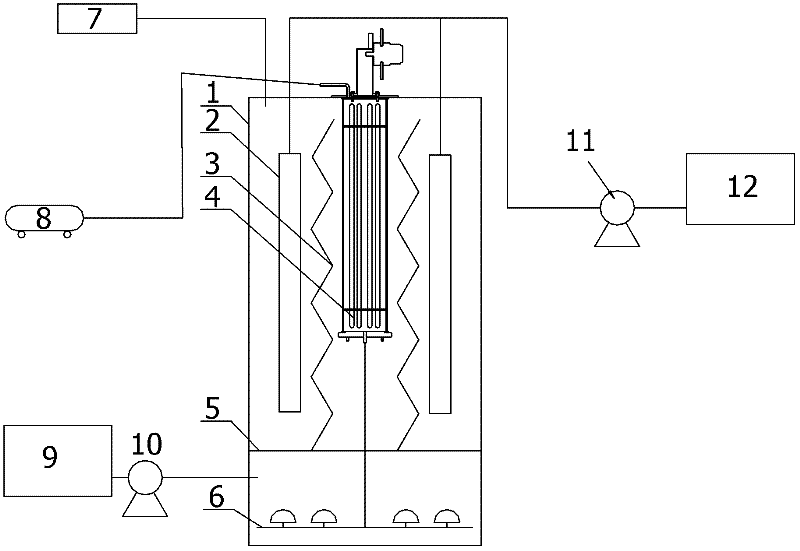

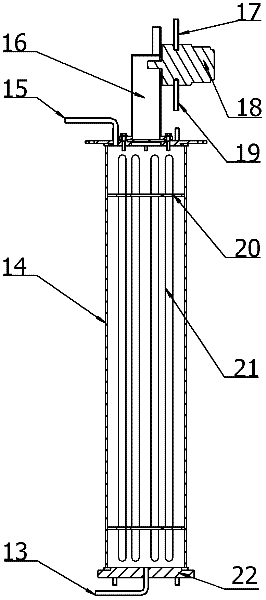

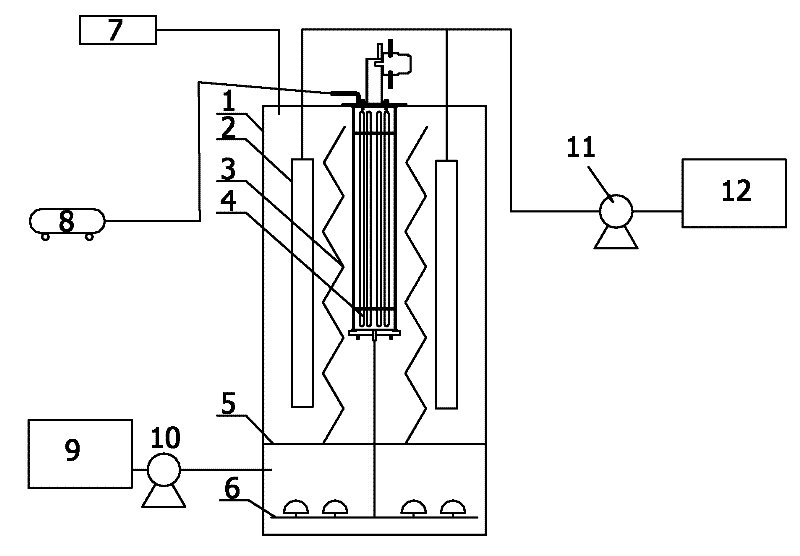

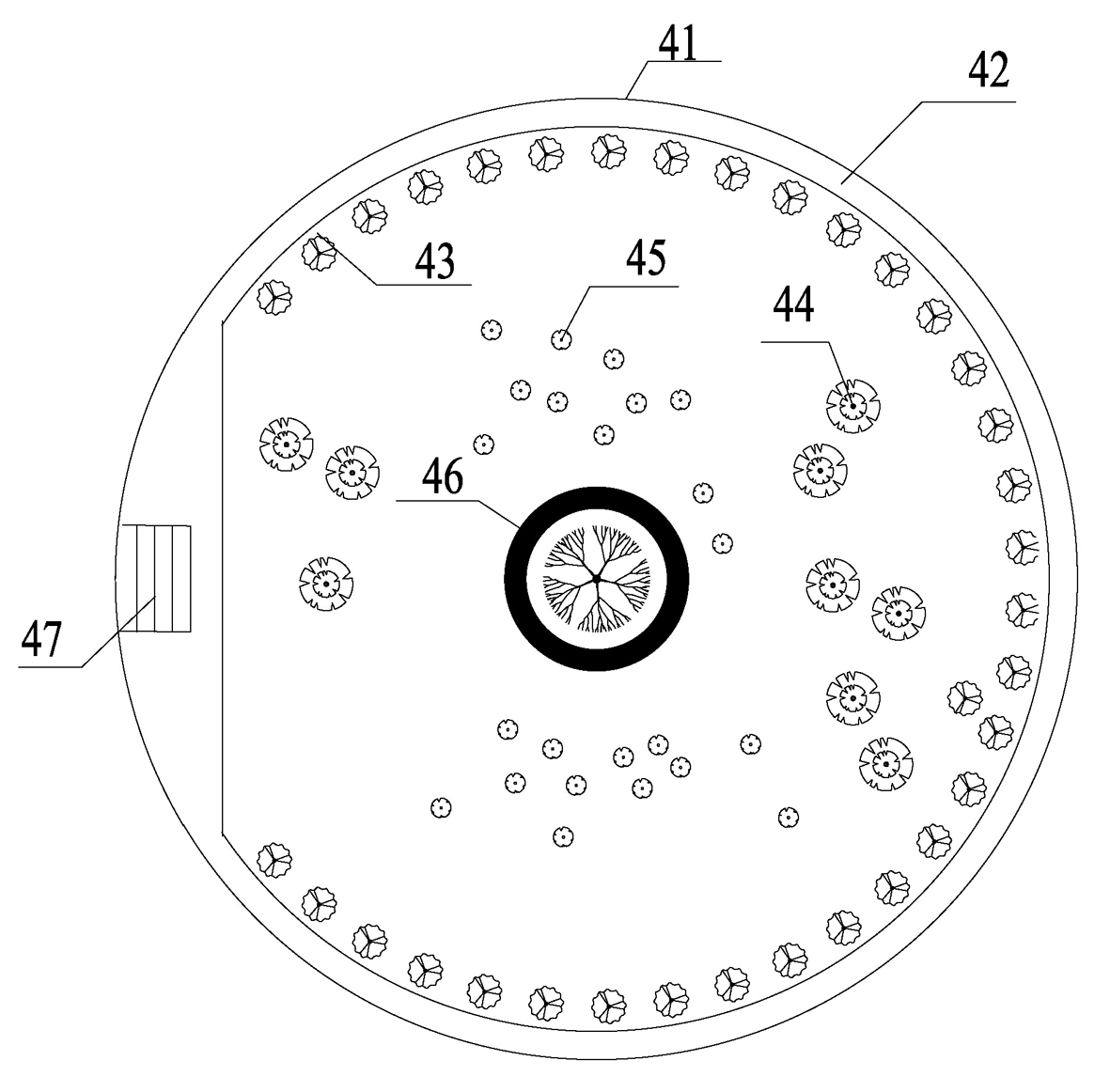

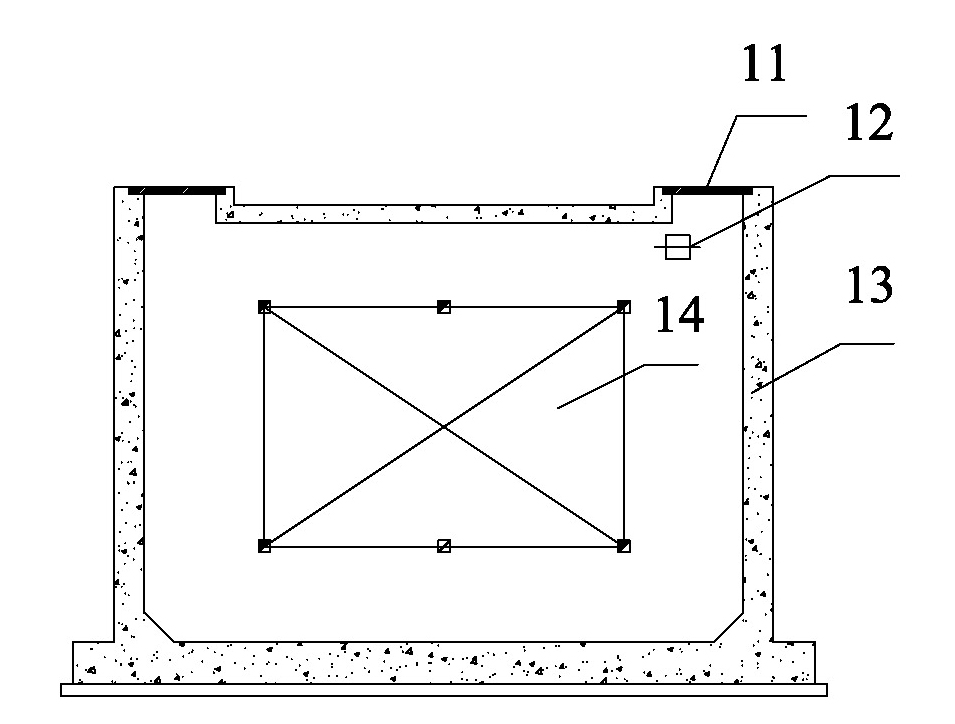

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

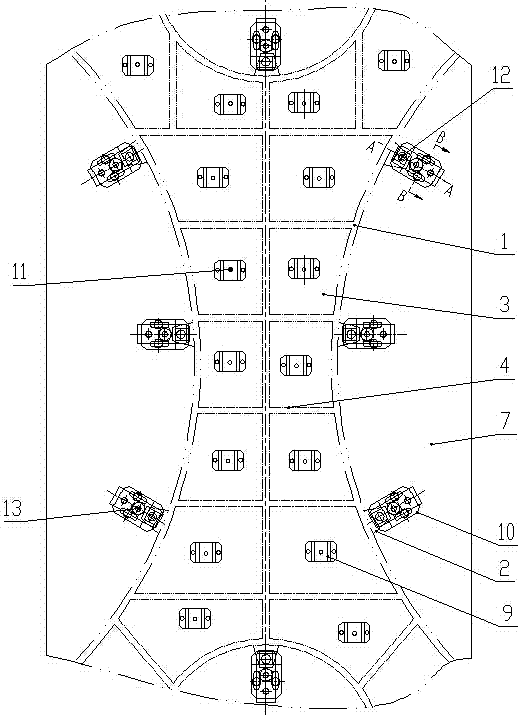

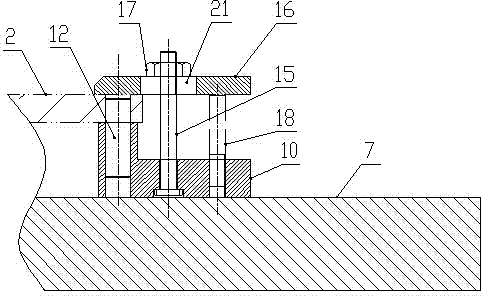

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

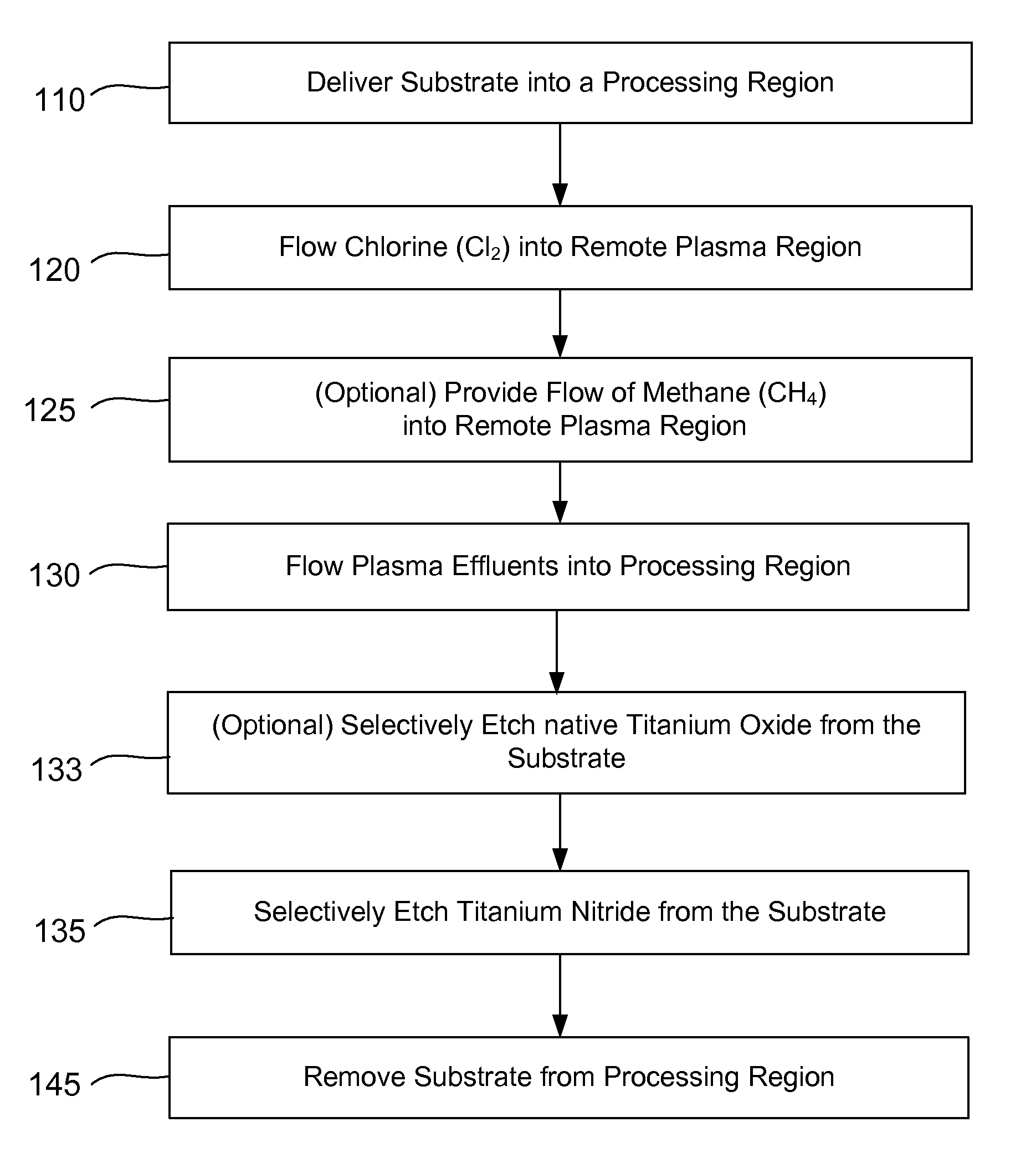

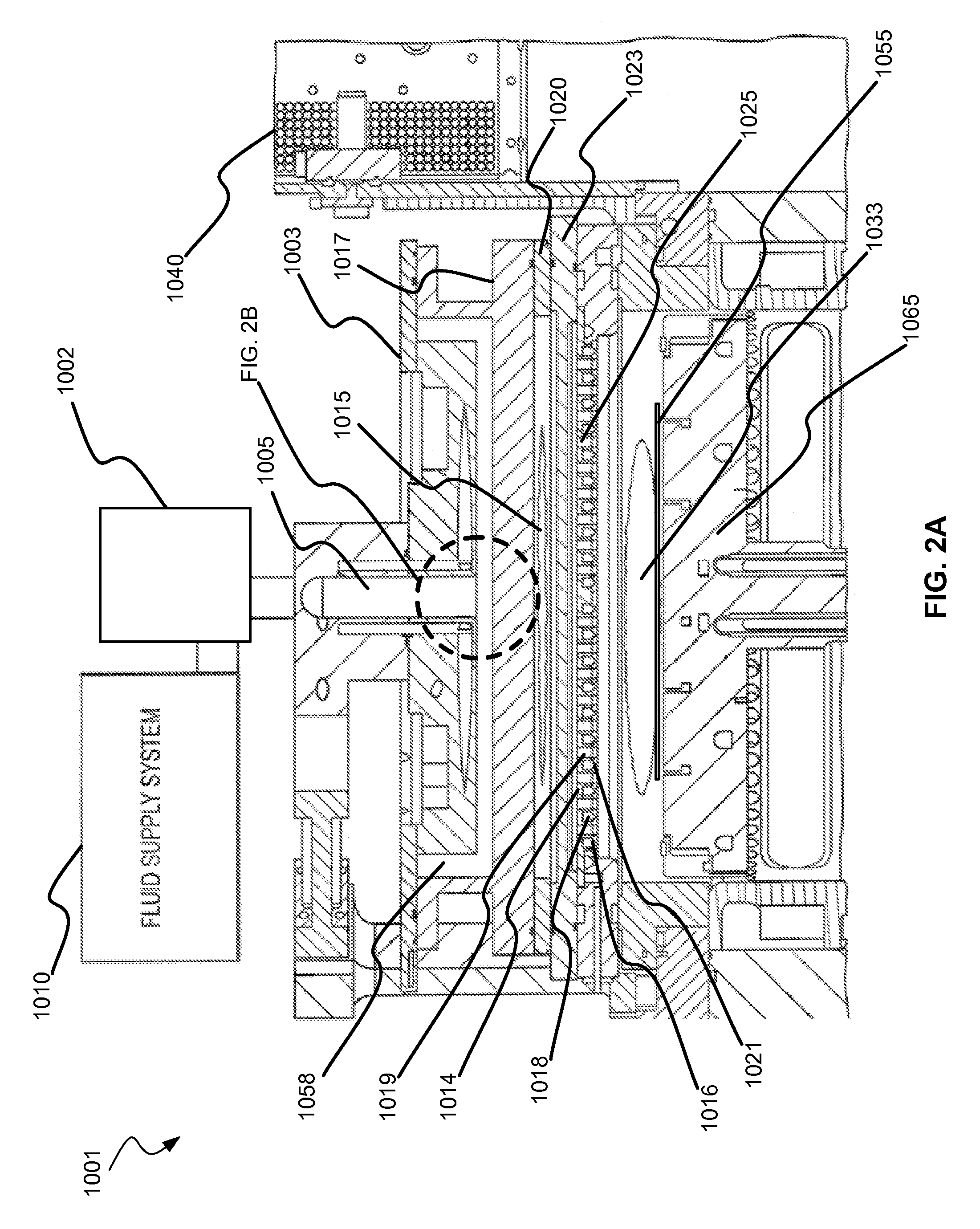

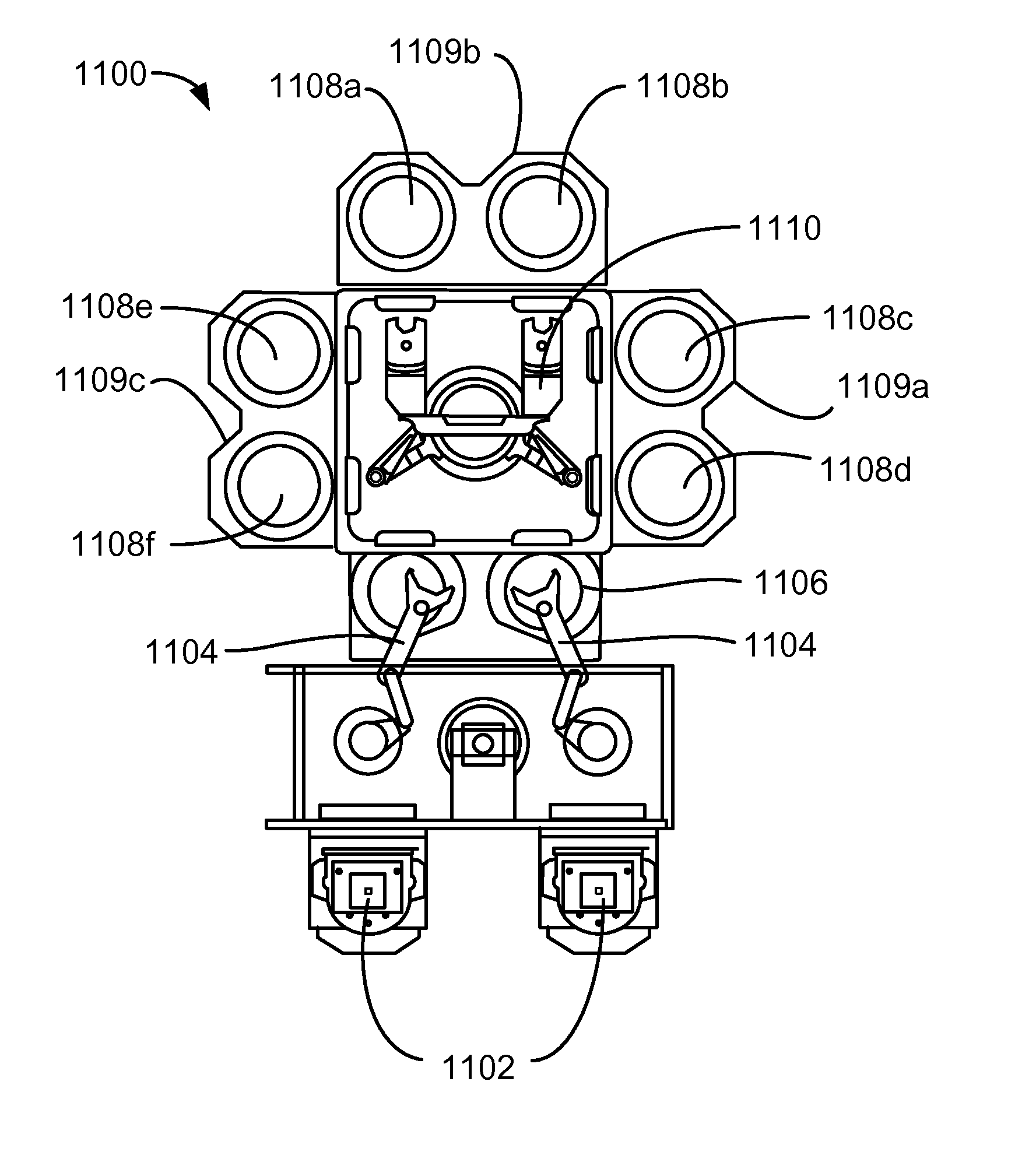

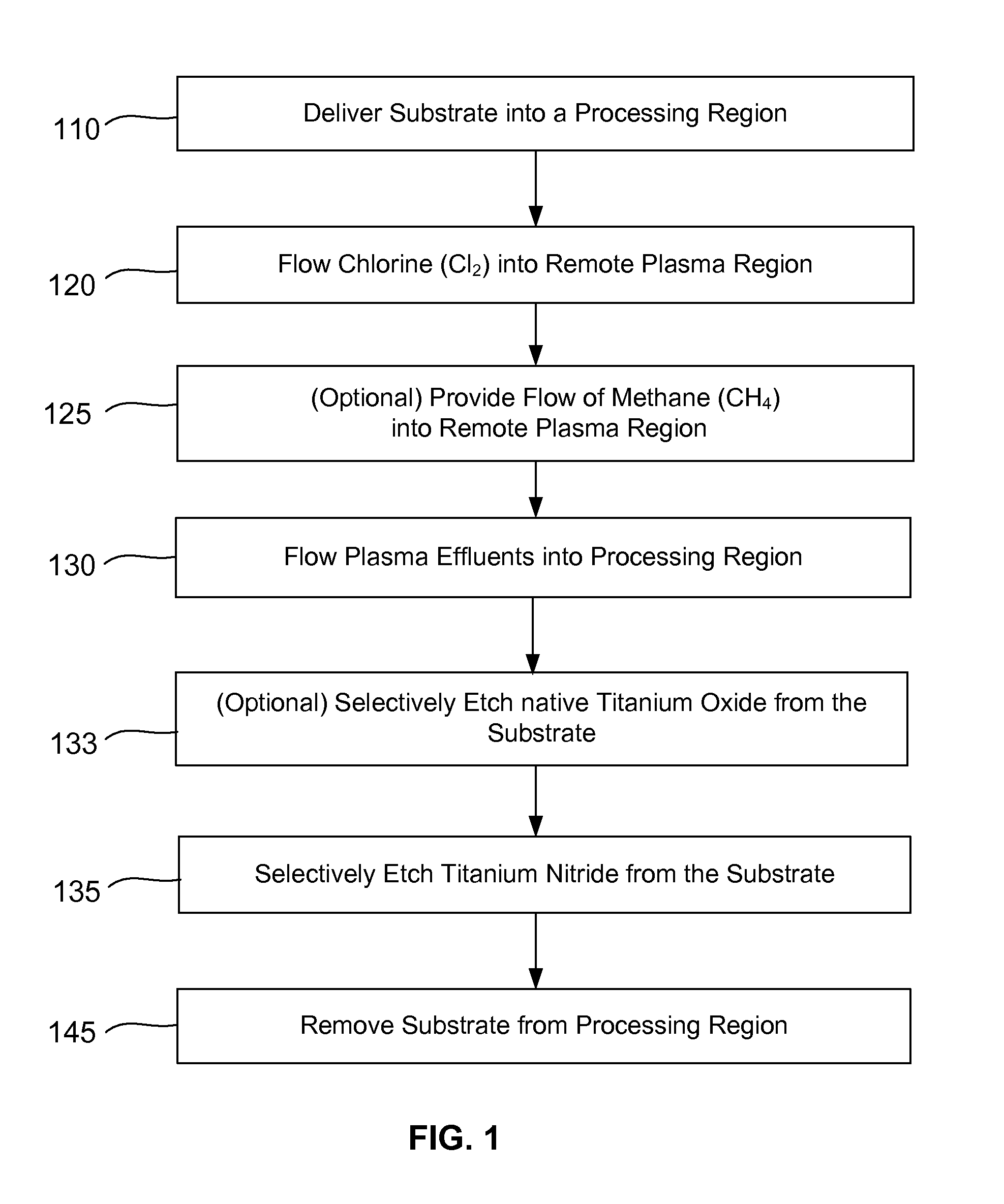

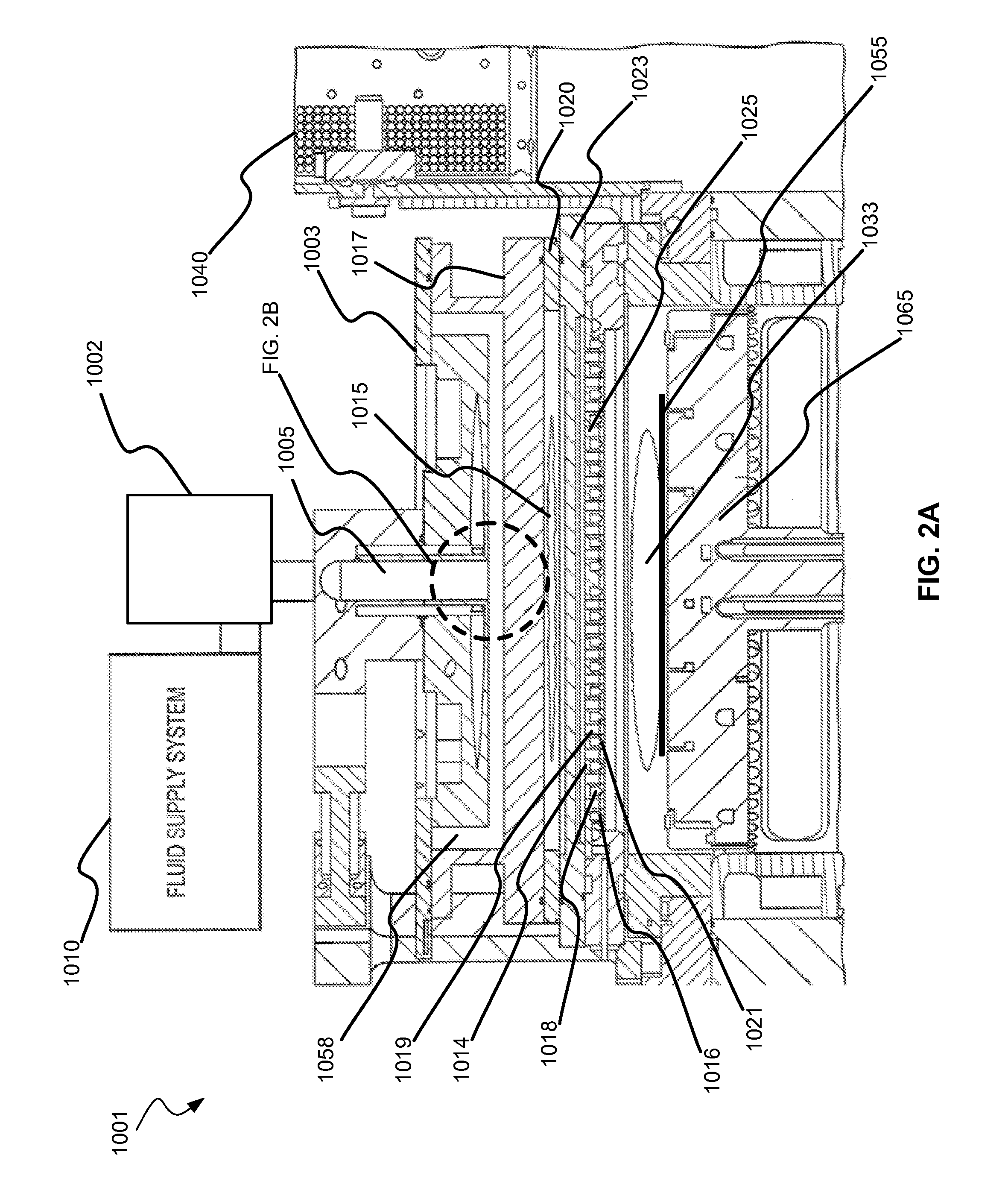

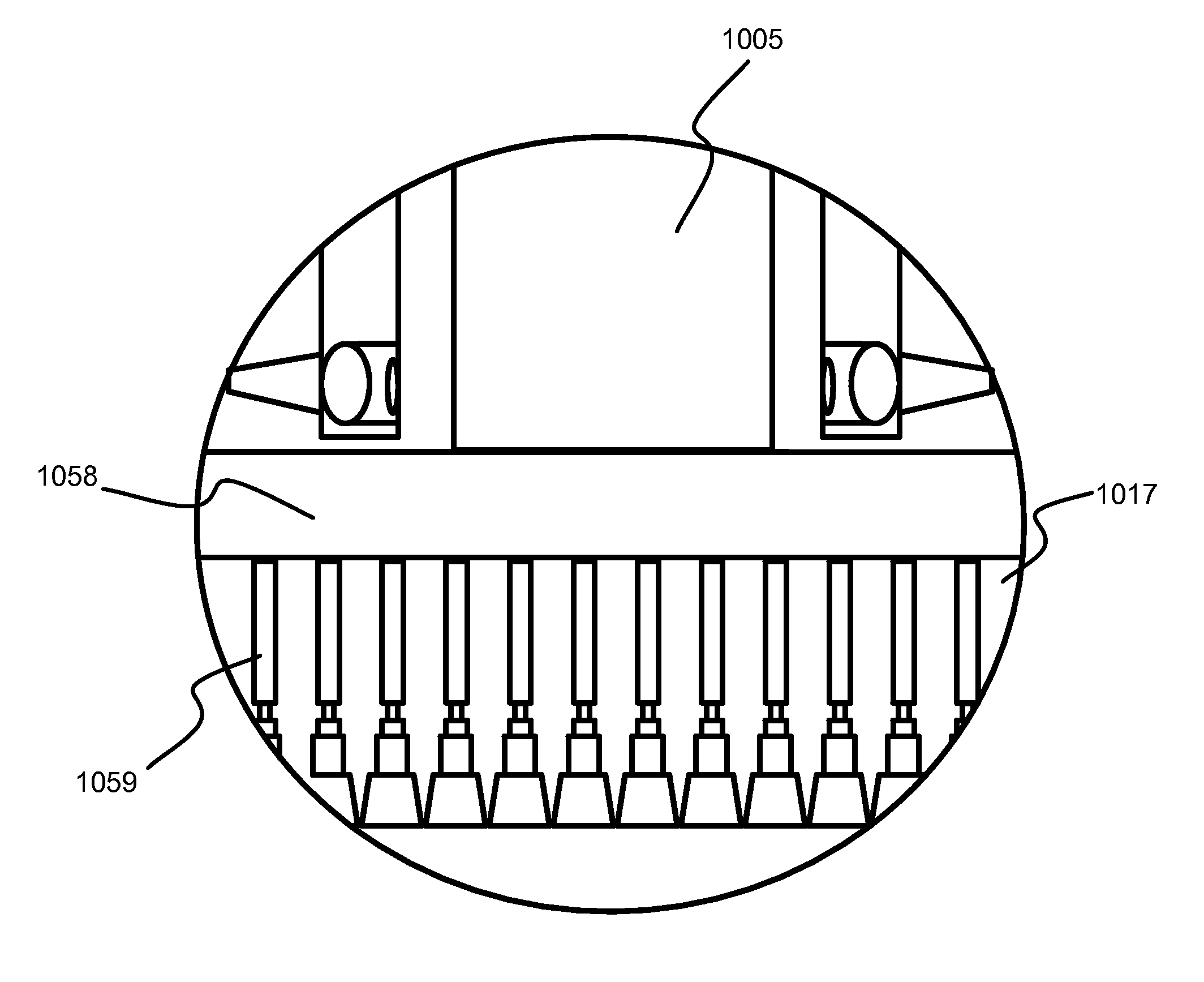

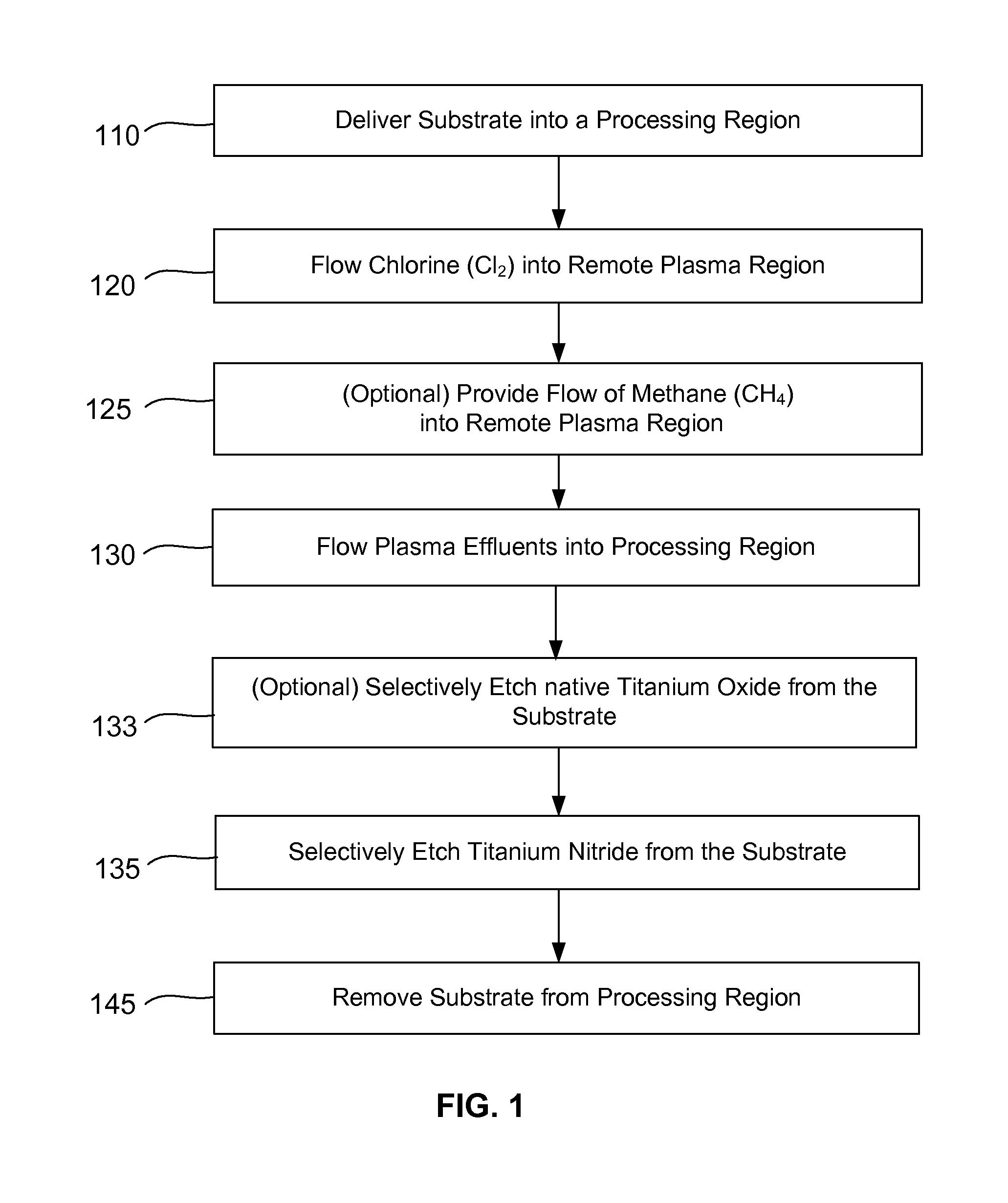

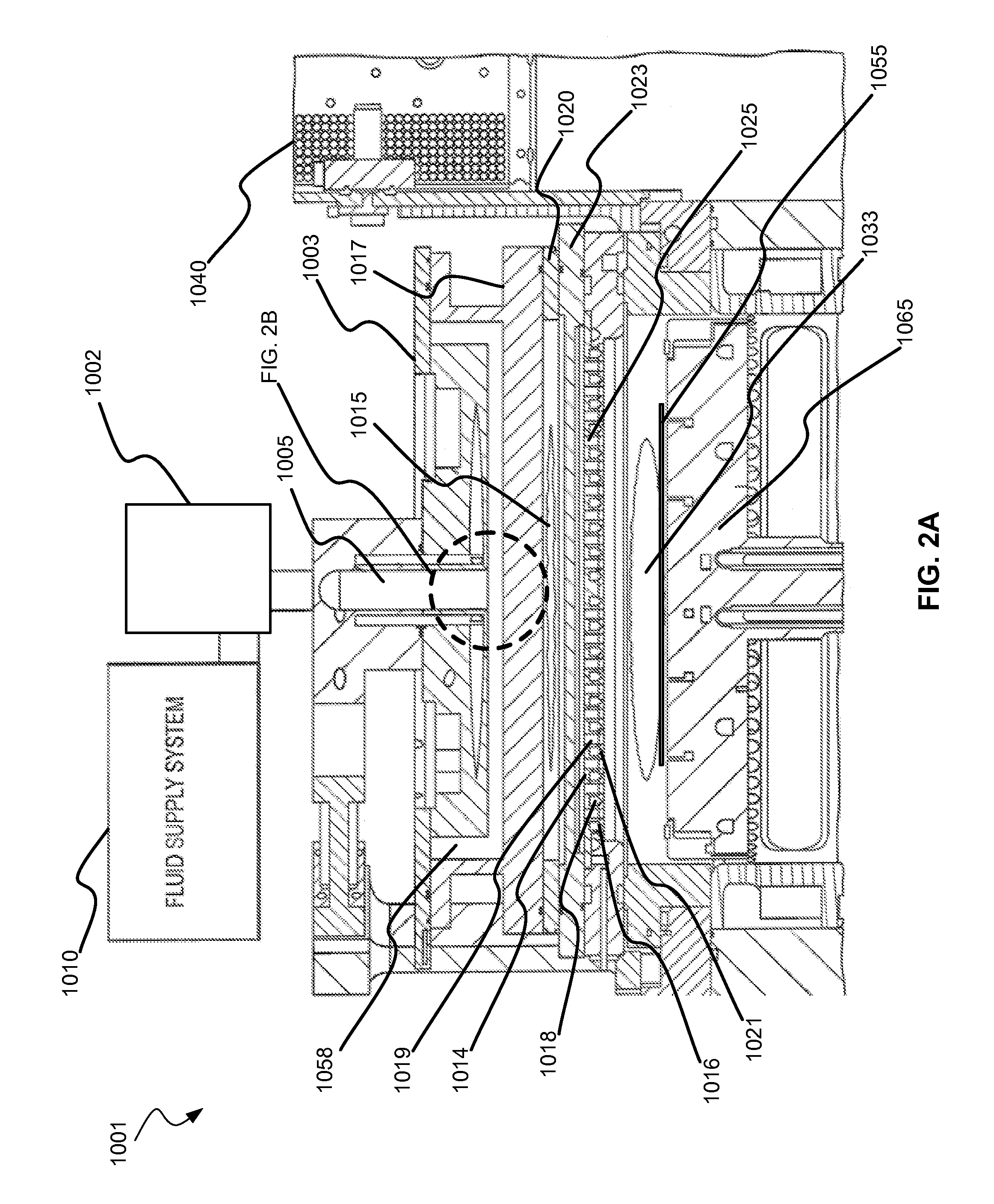

Selective titanium nitride removal

ActiveUS9040422B2Convenient restHigh removal rateElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaTitanium nitride

Methods are described herein for selectively etching titanium nitride relative to dielectric films, which may include, for example, alternative metals and metal oxides lacking in titanium and / or silicon-containing films (e.g. silicon oxide, silicon carbon nitride and low-K dielectric films). The methods include a remote plasma etch formed from a chlorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the titanium nitride. The plasma effluents react with exposed surfaces and selectively remove titanium nitride while very slowly removing the other exposed materials. The substrate processing region may also contain a plasma to facilitate breaking through any titanium oxide layer present on the titanium nitride. The plasma in the substrate processing region may be gently biased relative to the substrate to enhance removal rate of the titanium oxide layer.

Owner:APPLIED MATERIALS INC

Selective titanium nitride removal

ActiveUS20140256131A1Convenient restHigh removal rateElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaTitanium nitride

Methods are described herein for selectively etching titanium nitride relative to dielectric films, which may include, for example, alternative metals and metal oxides lacking in titanium and / or silicon-containing films (e.g. silicon oxide, silicon carbon nitride and low-K dielectric films). The methods include a remote plasma etch formed from a chlorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the titanium nitride. The plasma effluents react with exposed surfaces and selectively remove titanium nitride while very slowly removing the other exposed materials. The substrate processing region may also contain a plasma to facilitate breaking through any titanium oxide layer present on the titanium nitride. The plasma in the substrate processing region may be gently biased relative to the substrate to enhance removal rate of the titanium oxide layer.

Owner:APPLIED MATERIALS INC

Selective titanium nitride removal

ActiveUS20150357205A1Convenient restHigh removal rateElectric discharge tubesSemiconductor/solid-state device manufacturingTitanium nitrideSilicon oxide

Methods are described herein for selectively etching titanium nitride relative to dielectric films, which may include, for example, alternative metals and metal oxides lacking in titanium and / or silicon-containing films (e.g. silicon oxide, silicon carbon nitride and low-K dielectric films). The methods include a remote plasma etch formed from a chlorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the titanium nitride. The plasma effluents react with exposed surfaces and selectively remove titanium nitride while very slowly removing the other exposed materials. The substrate processing region may also contain a plasma to facilitate breaking through any titanium oxide layer present on the titanium nitride. The plasma in the substrate processing region may be gently biased relative to the substrate to enhance removal rate of the titanium oxide layer.

Owner:APPLIED MATERIALS INC

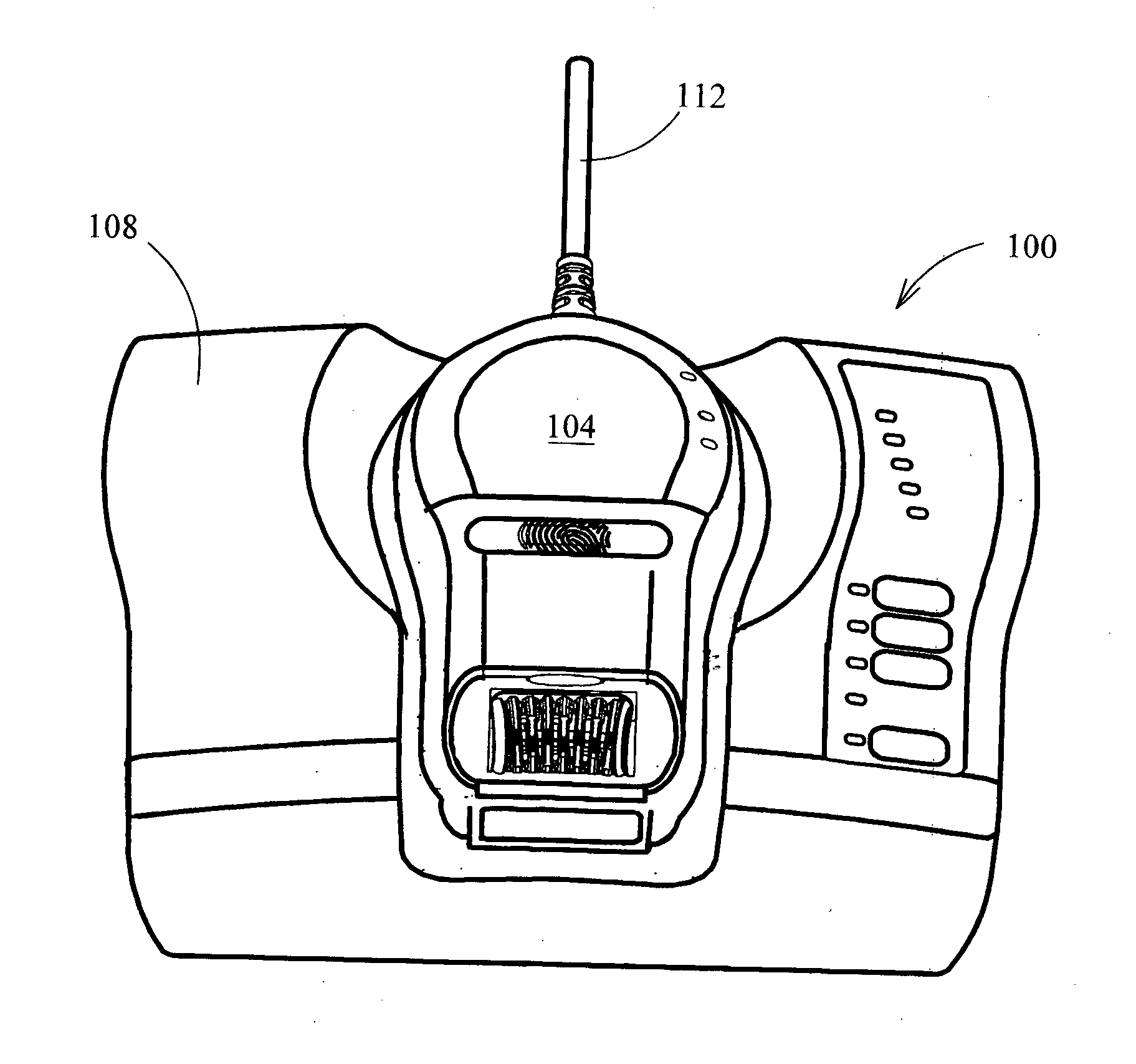

Method and apparatus for personal skin treatment

InactiveUS20130144280A1Effective dispersionEasy to disassembleHair-singeingDiagnosticsDocking stationHair removal

An apparatus enabling a casual user in a residential set-up to perform himself almost every skin treatment procedure by using a variety of modules that may be inserted into an infrastructure frame. The apparatus presents a docking station and an applicator. The applicator simultaneously receives only two types of skin treatment modules, these may be replaced after use for modules providing a different type of skin treatment. Such skin treatment modules like epilator, shaver, exfoliation or abrasive module, suction head, and massage head apply a mechanical action to the skin. Ultrasound module applies ultrasound waves to the skin. Intense pulsed light and RF apply electromagnetic radiation to the skin. A combination of these modules may be used to provide a variety of skin treatments such as hair removal, skin rejuvenation, skin exfoliation, acne treatment, circumference reduction, and other skin treatments.

Owner:SYNERON MEDICAL LTD

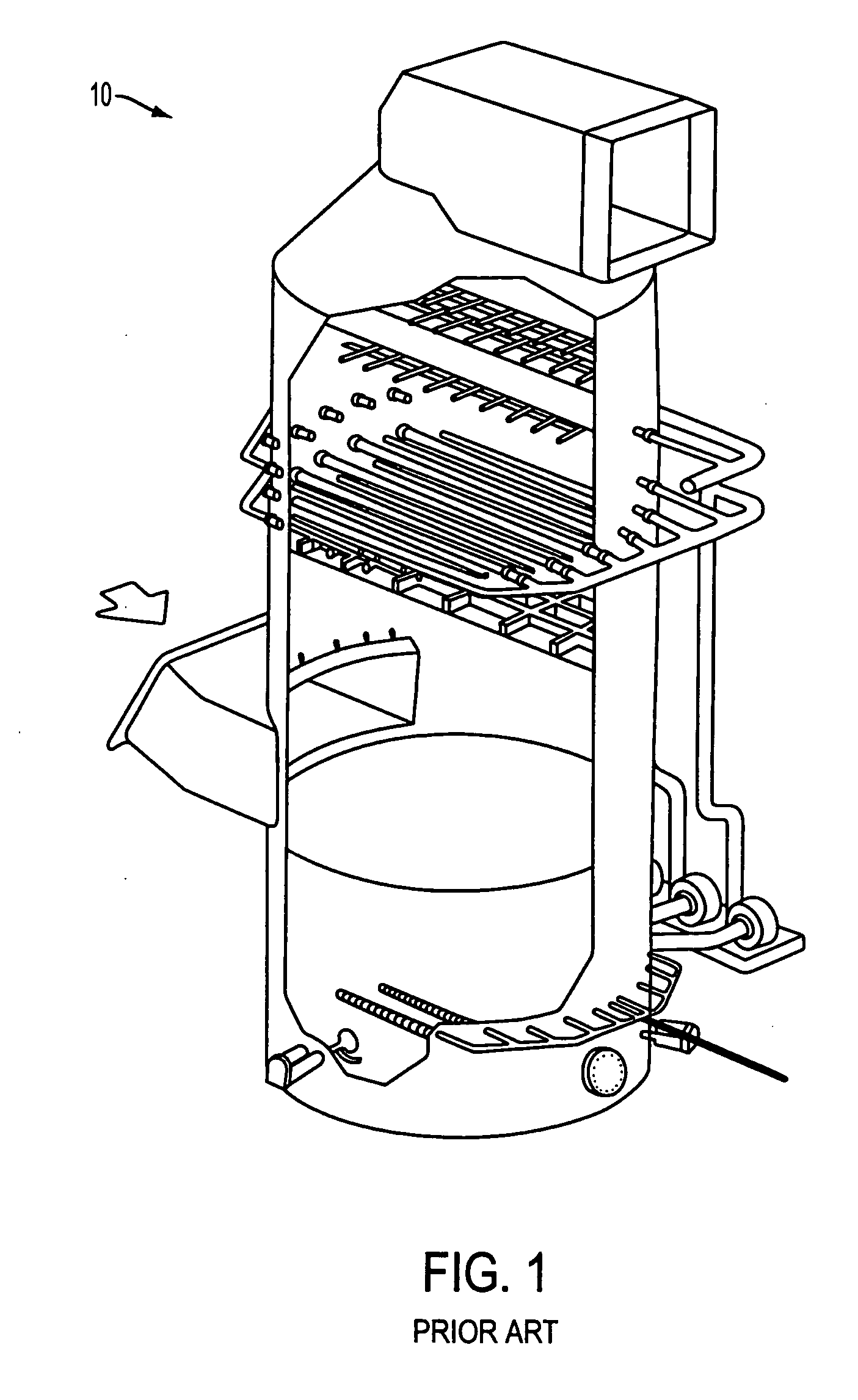

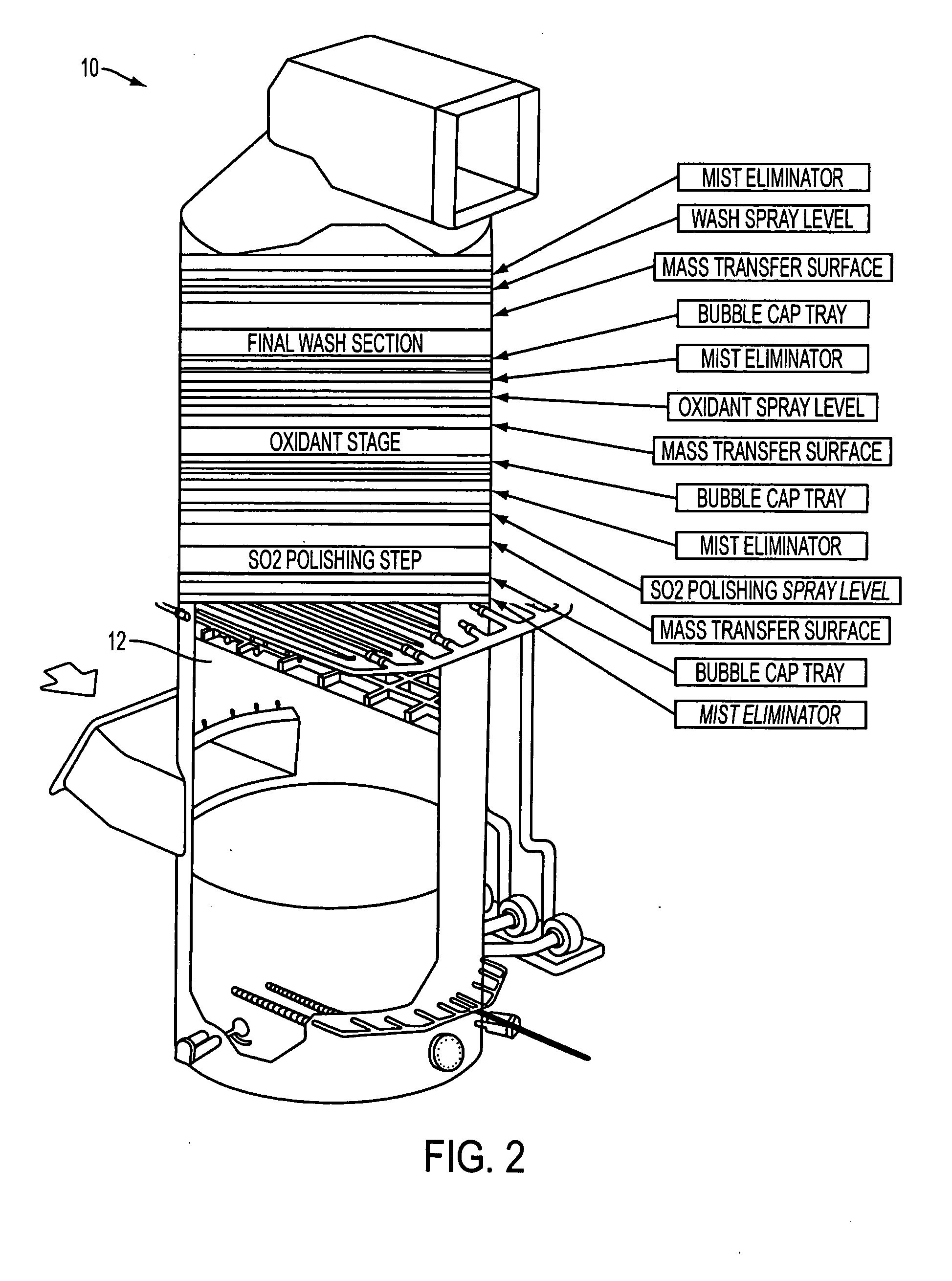

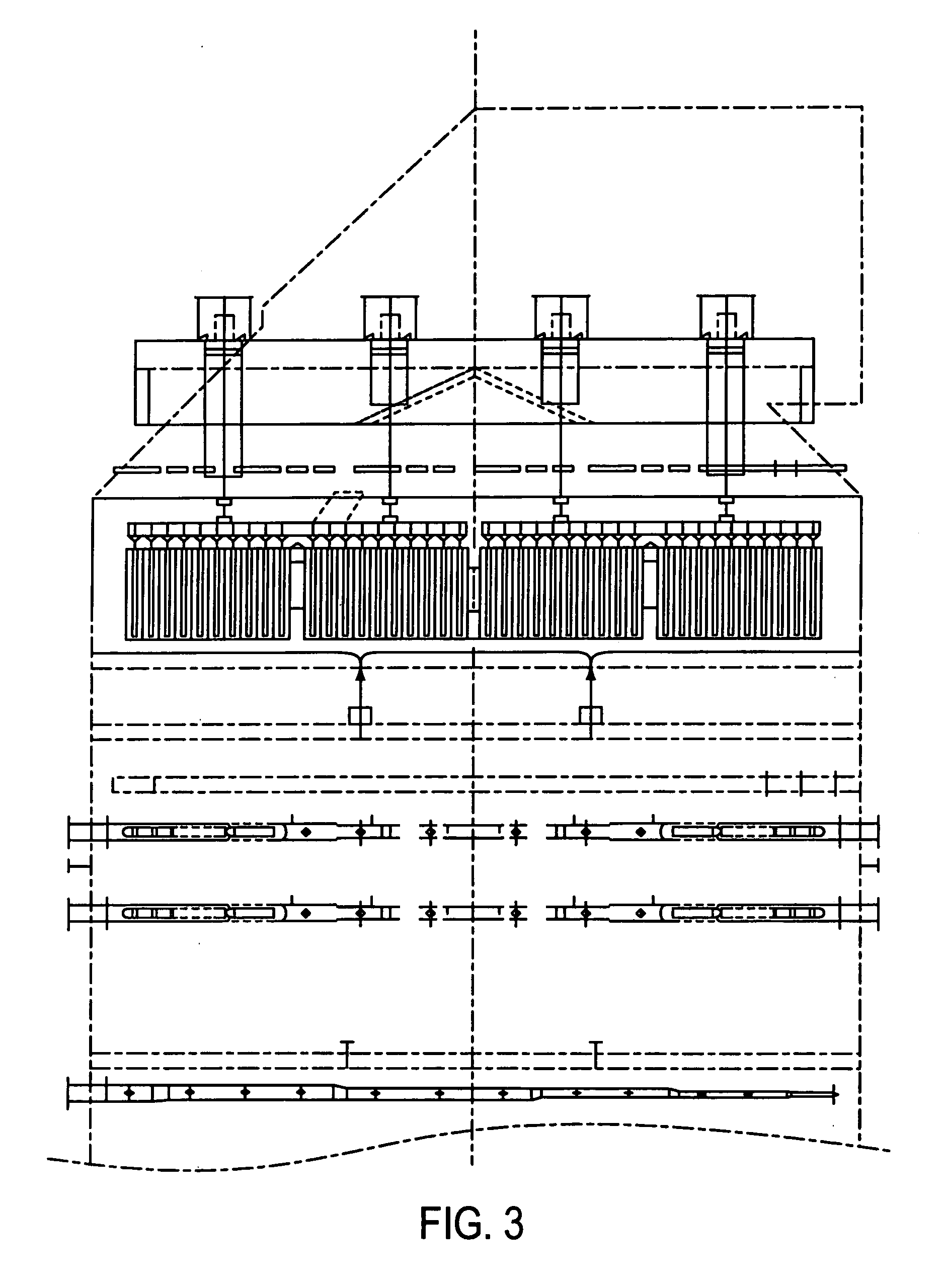

Removal of Hg, NOx, and SOx with using oxidants and staged gas/liquid contact

InactiveUS20050214187A1Simple methodHigh removal rateGas treatmentNitrogen compoundsNitrogen oxidesSorbent

A method of scrubbing mercury compounds and nitrogen oxides from a gas stream employing a scrubbing operation. The method involves the contact of the stream which contains mercury, SOx and NOx compounds with a sorbent to remove at least a portion of the latter compounds. This results in a partially cleaned stream. The method further involves contacting the latter stream with an oxidant to oxidize and remove substantially all residual nitrogen oxides, mercury and mercury compounds remaining in the stream.

Owner:AIRBORNE IND MINERALS INC CA

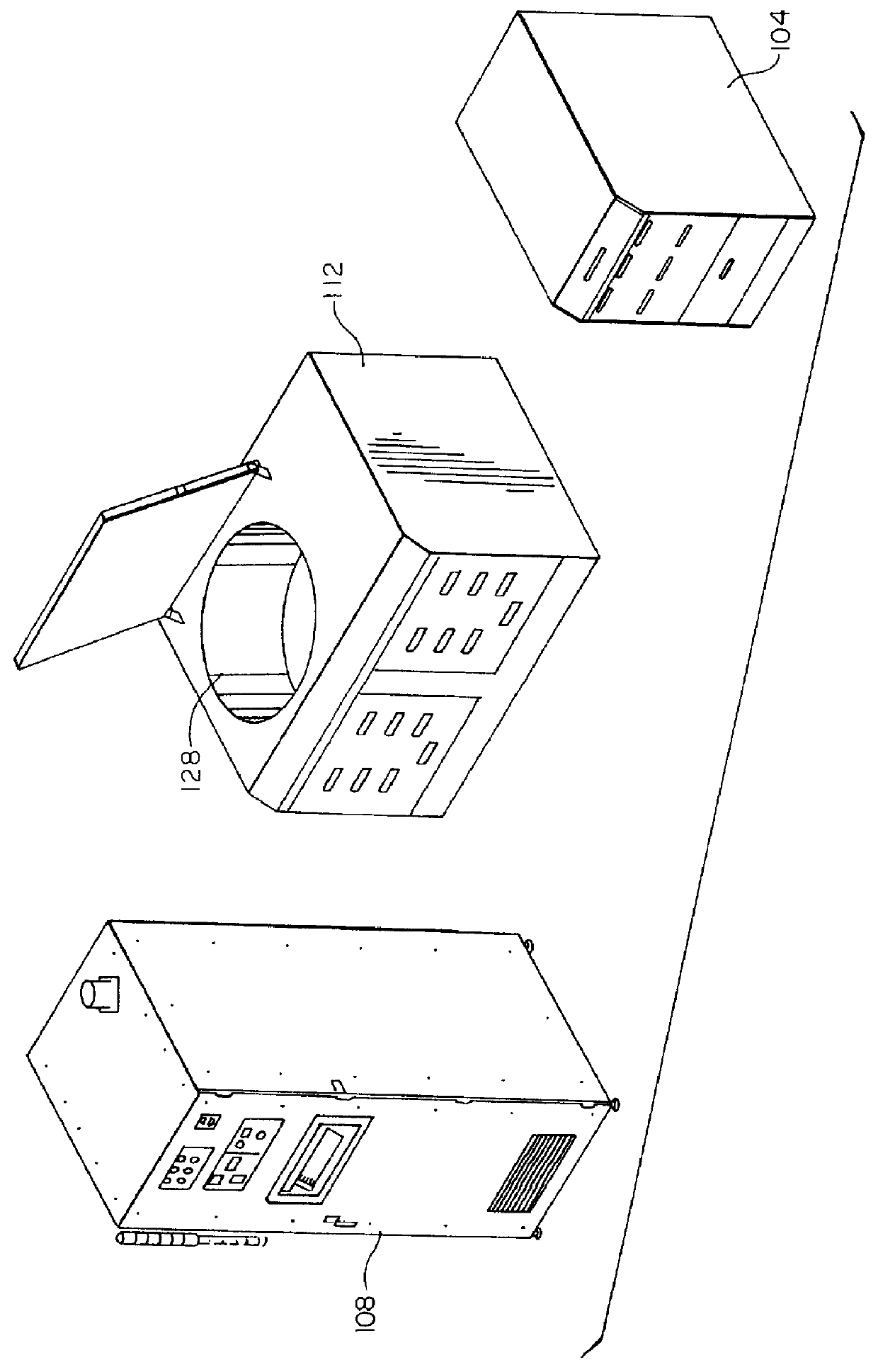

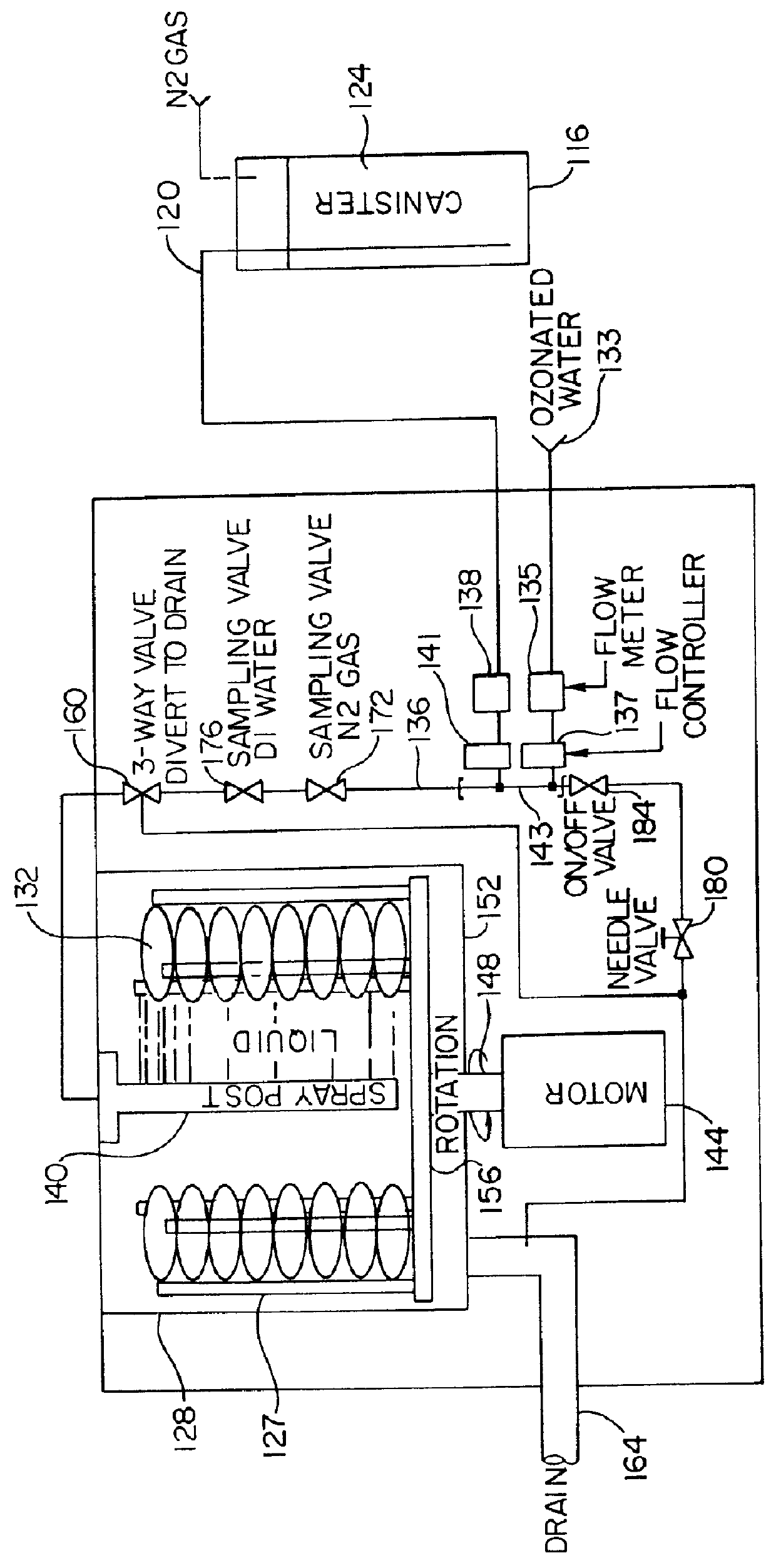

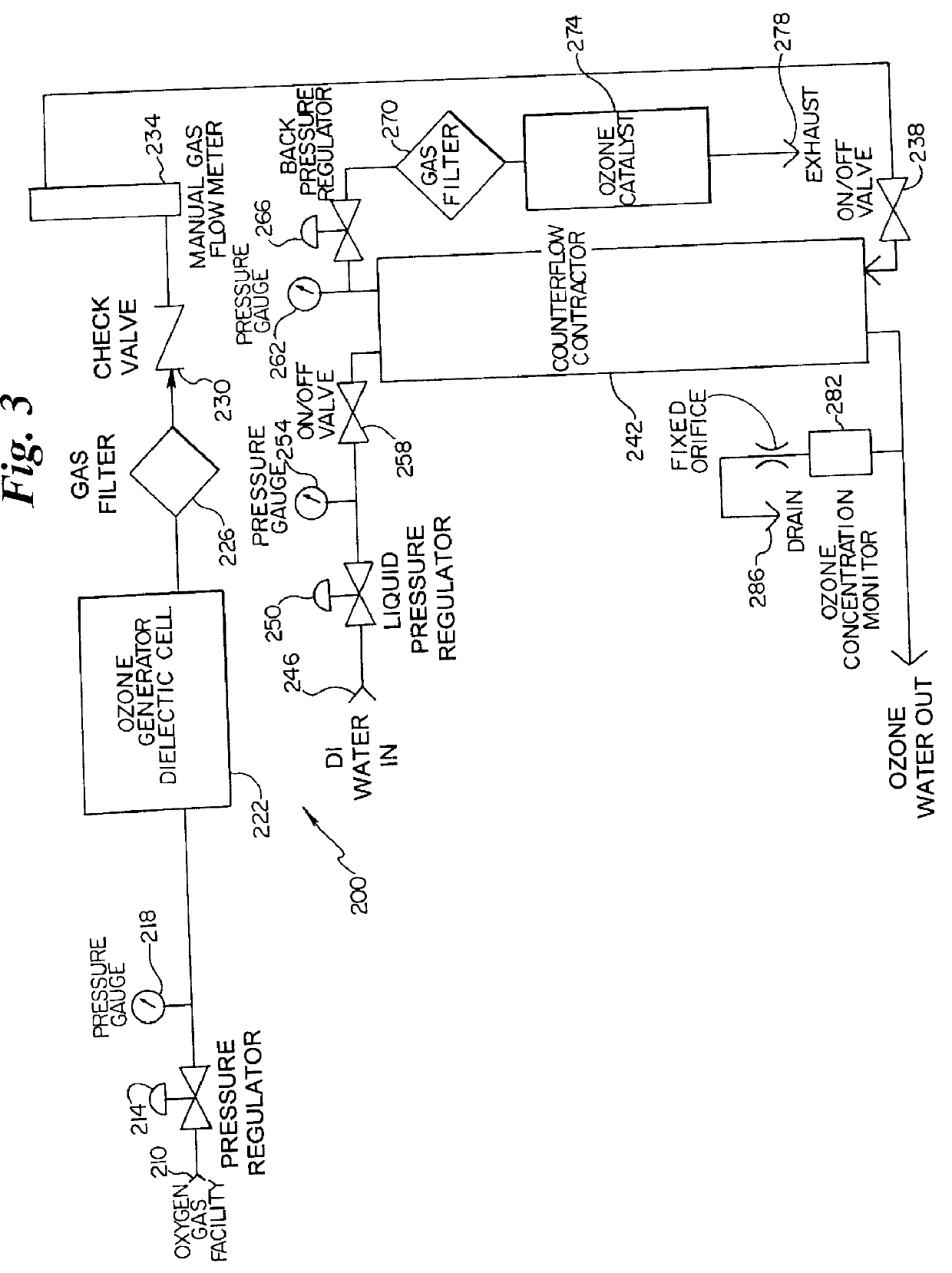

Organic removal process

InactiveUS6080531AEnhance removal rateEasy to removeSemiconductor/solid-state device manufacturingElectrostatic cleaningBicarbonateResist

An improved method of photoresist removal is disclosed in which a treating solution of ozone and bicarbonate or other suitable radical scavengers is used to treat a substrate for use in an electronic device. The method is particularly well suited to photoresist removal where certain metals such as aluminum, copper and oxides thereof are present on the surface of the substrate. The method is also well suited to the removal of other organic materials as well.

Owner:TEL FSI

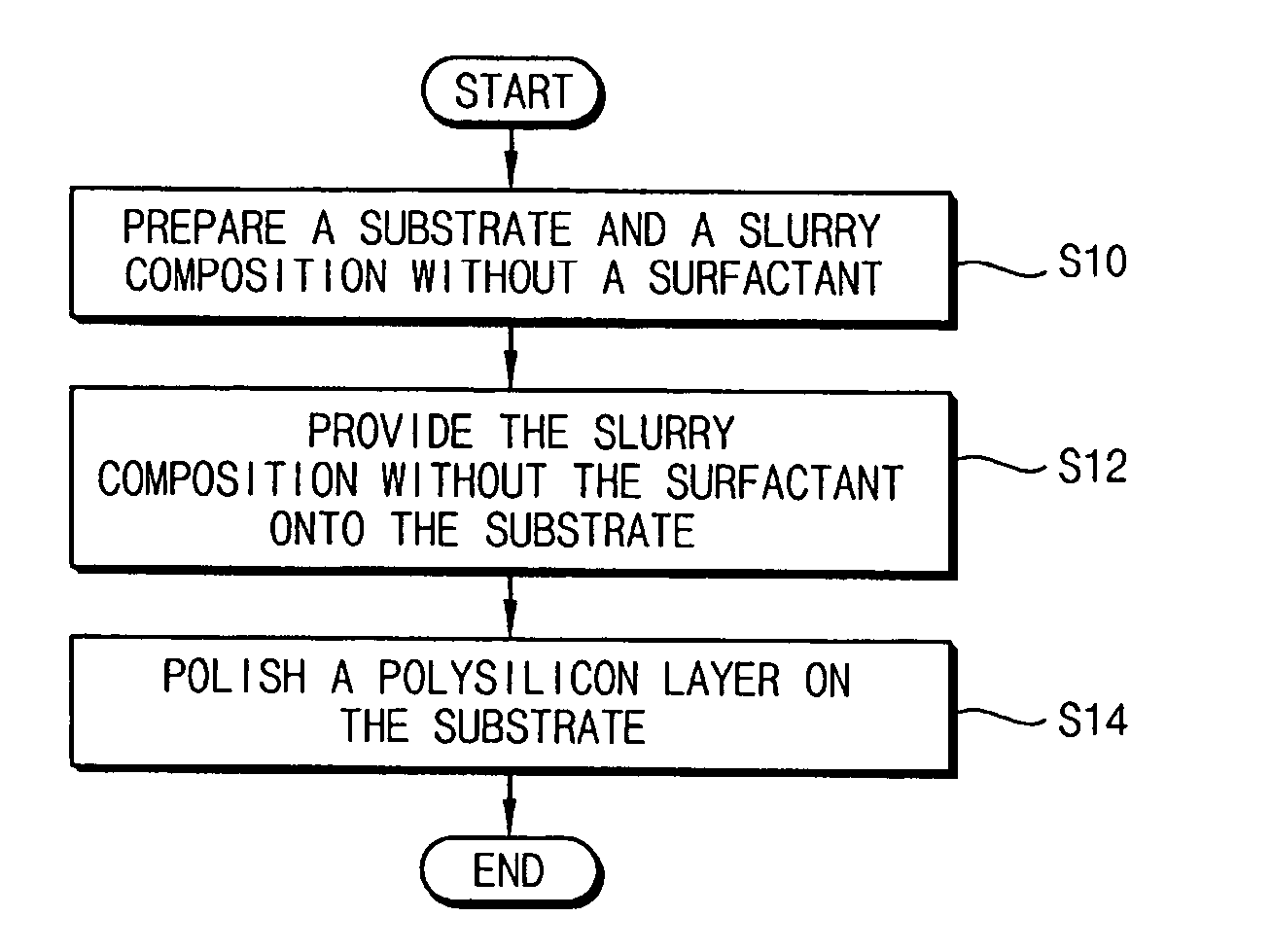

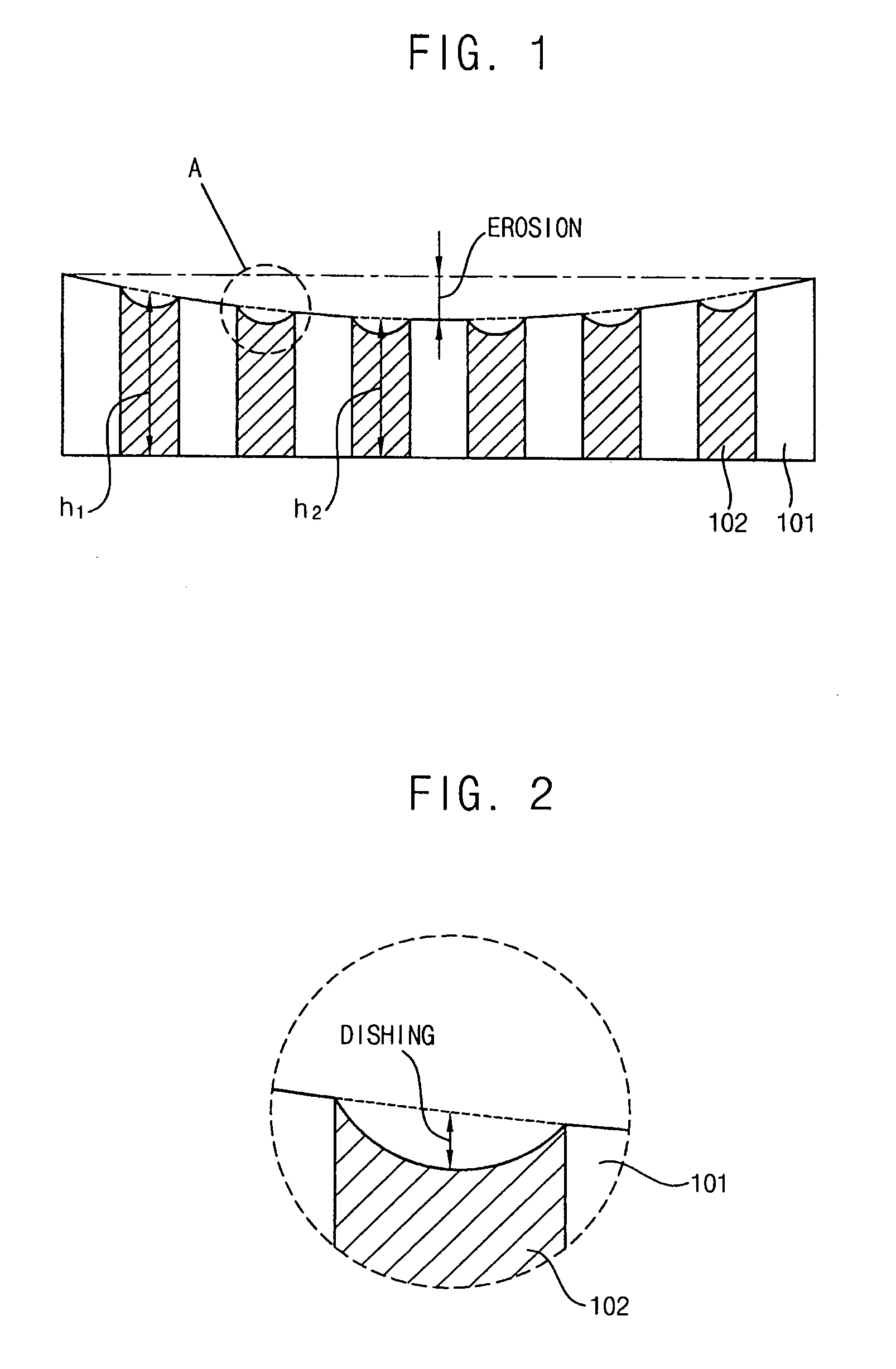

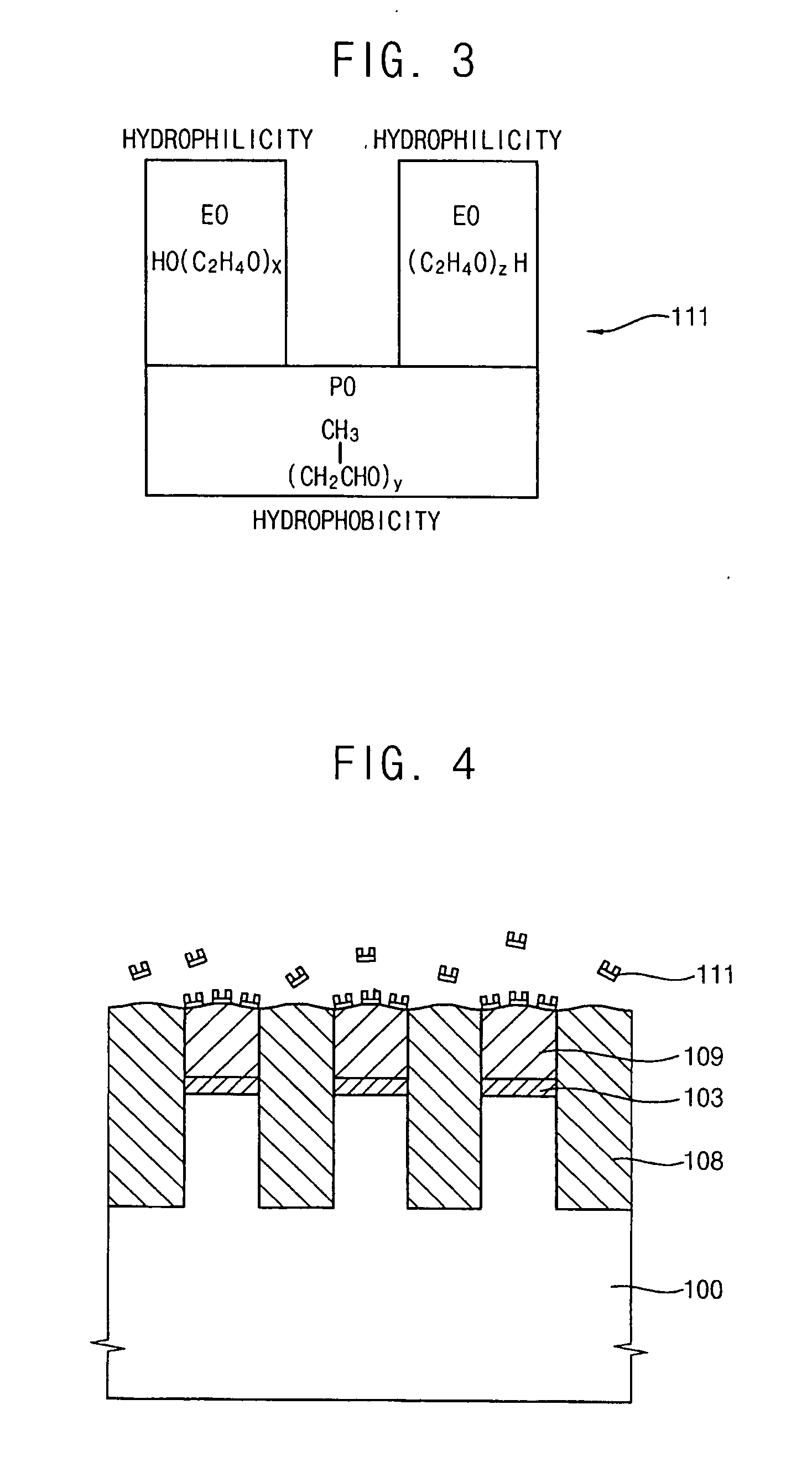

Slurry composition, polishing method using the slurry composition and method of forming a gate pattern using the slurry composition

InactiveUS20060014390A1High removal rateOther chemical processesSemiconductor/solid-state device manufacturingSlurrySURFACTANT BLEND

A slurry composition includes about 4.25 to about 18.5 weight percent of an abrasive, about 80 to about 95 weight percent of deionized water, and about 0.05 to about 1.5 weight percent of an additive. The slurry composition may further include a surfactant. In a polishing method using the slurry composition, a polysilicon layer may be rapidly polished, and also dishing and erosion of the polysilicon layer may be suppressed.

Owner:SAMSUNG ELECTRONICS CO LTD

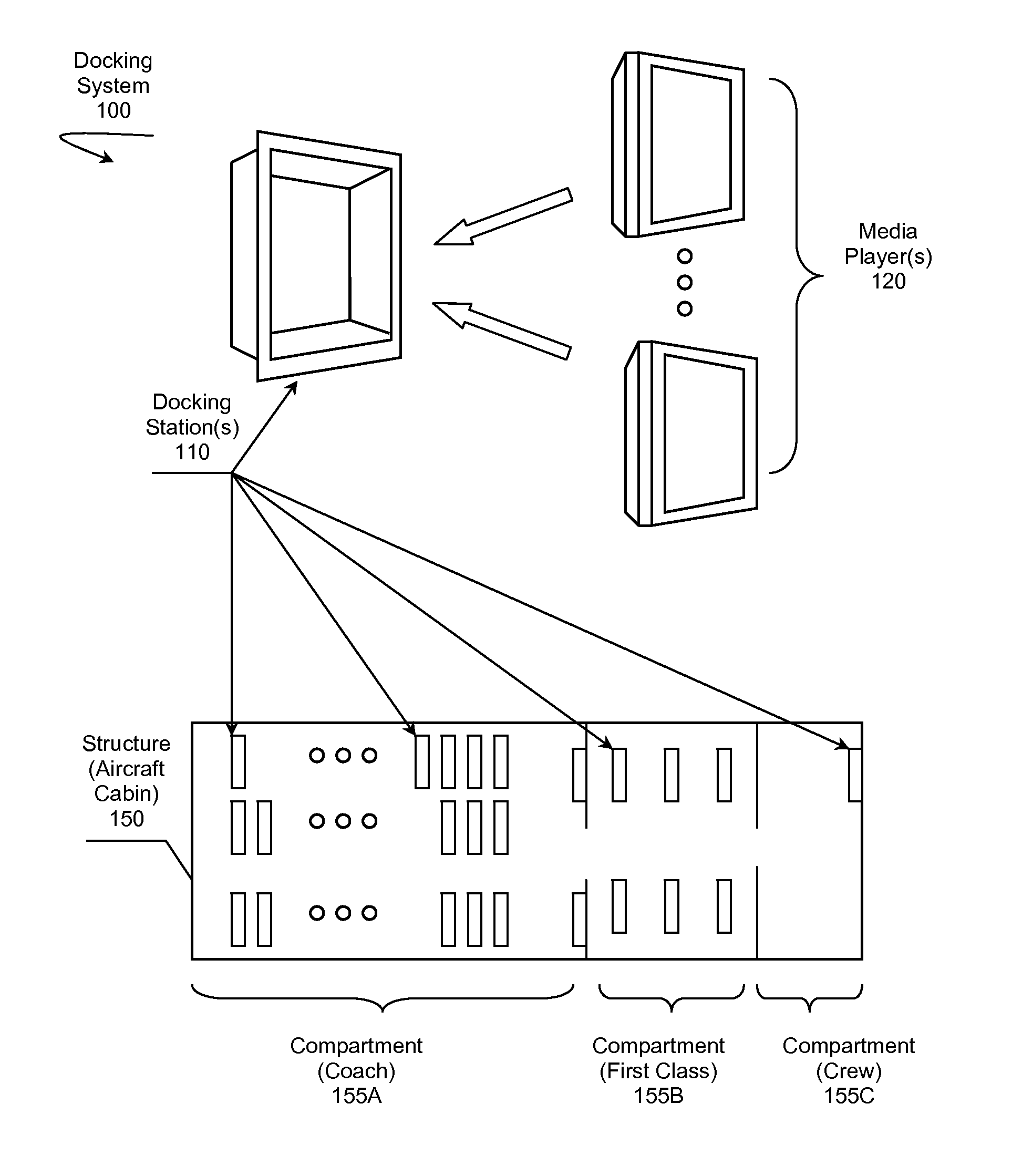

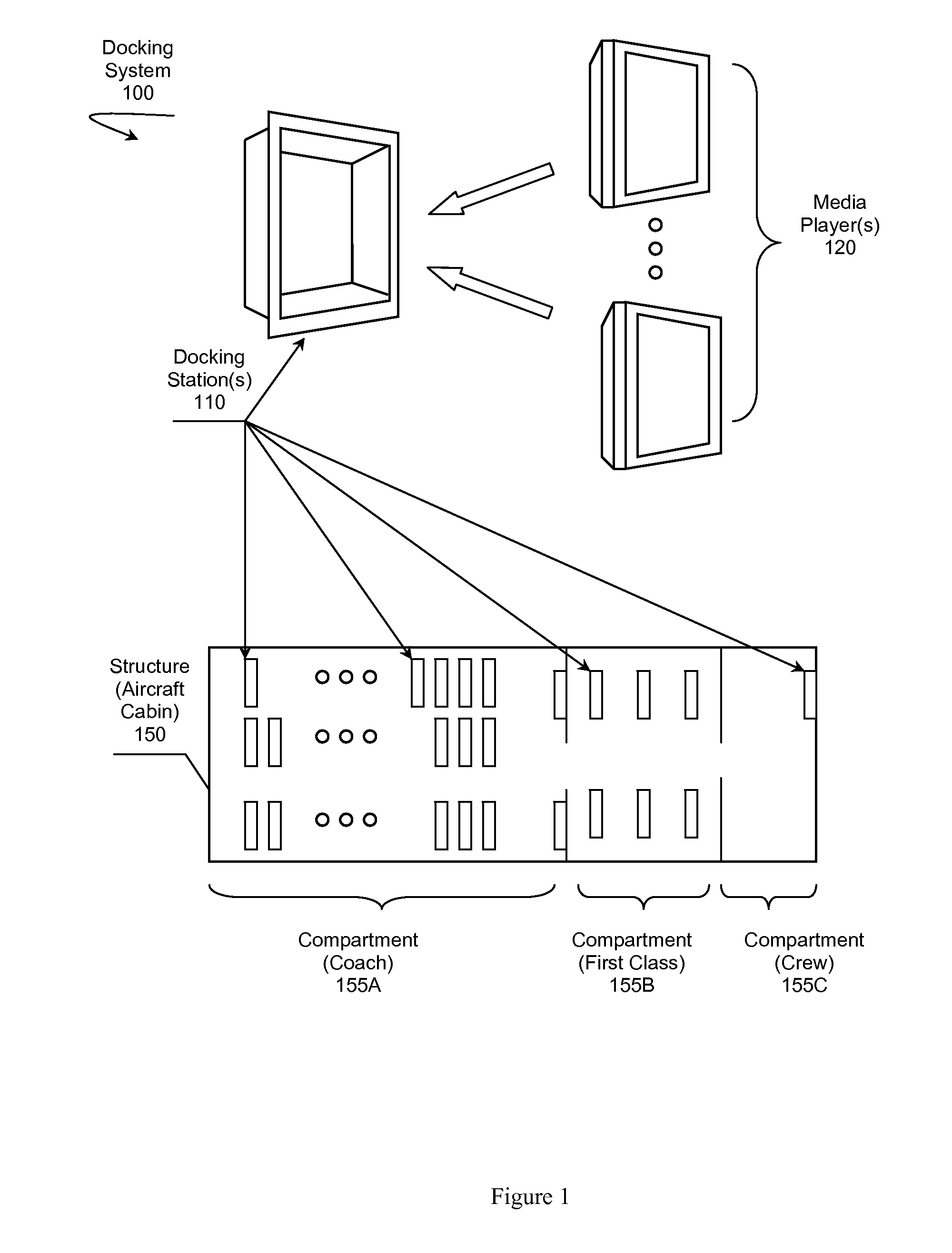

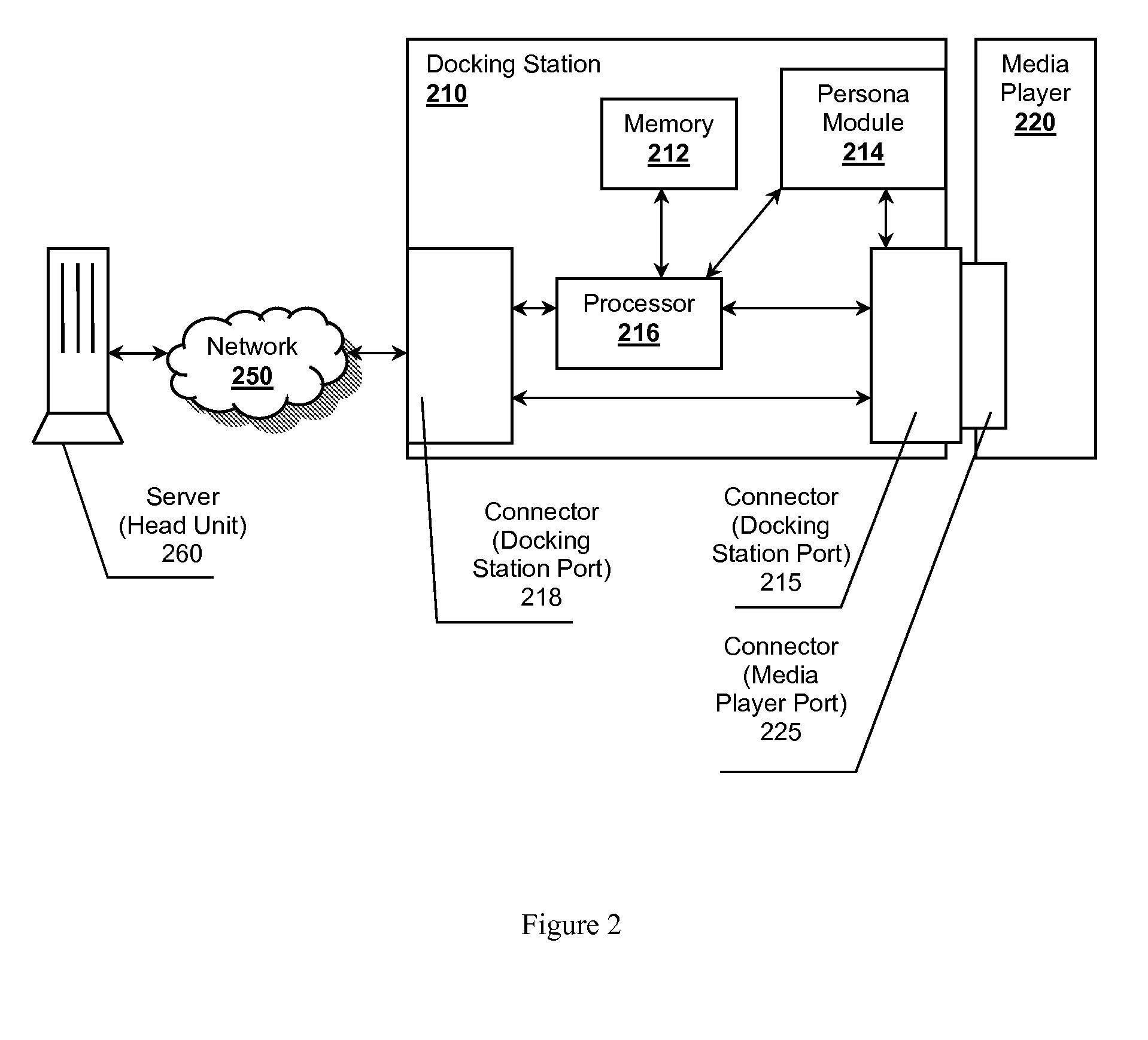

Universal Docking System

InactiveUS20100138581A1Solve the quick installationHigh removal rateBroadcast specific applicationsVehicle componentsDocking stationReal-time computing

A docking system is presented for an ecosystem where multiple media players provide functionality according to the location of corresponding docking stations. The docking stations have locally encoded media player persona information that depends on the location where the docking station is installed. Once a media player is docked with the docking station, the media player obtains the persona information and configures itself to provide the functionality required for the location. The media player can restrict content as necessary based on the obtained persona information. Other features also can be incorporated within the docking station and media player assemblies to provide for proper airflow, isolation from vibration, or installation by unskilled individuals. A preferred ecosystem employing the disclosed techniques includes an aircraft in-flight entertainment system.

Owner:SYST & SOFTWARE ENTERPRISES LLC

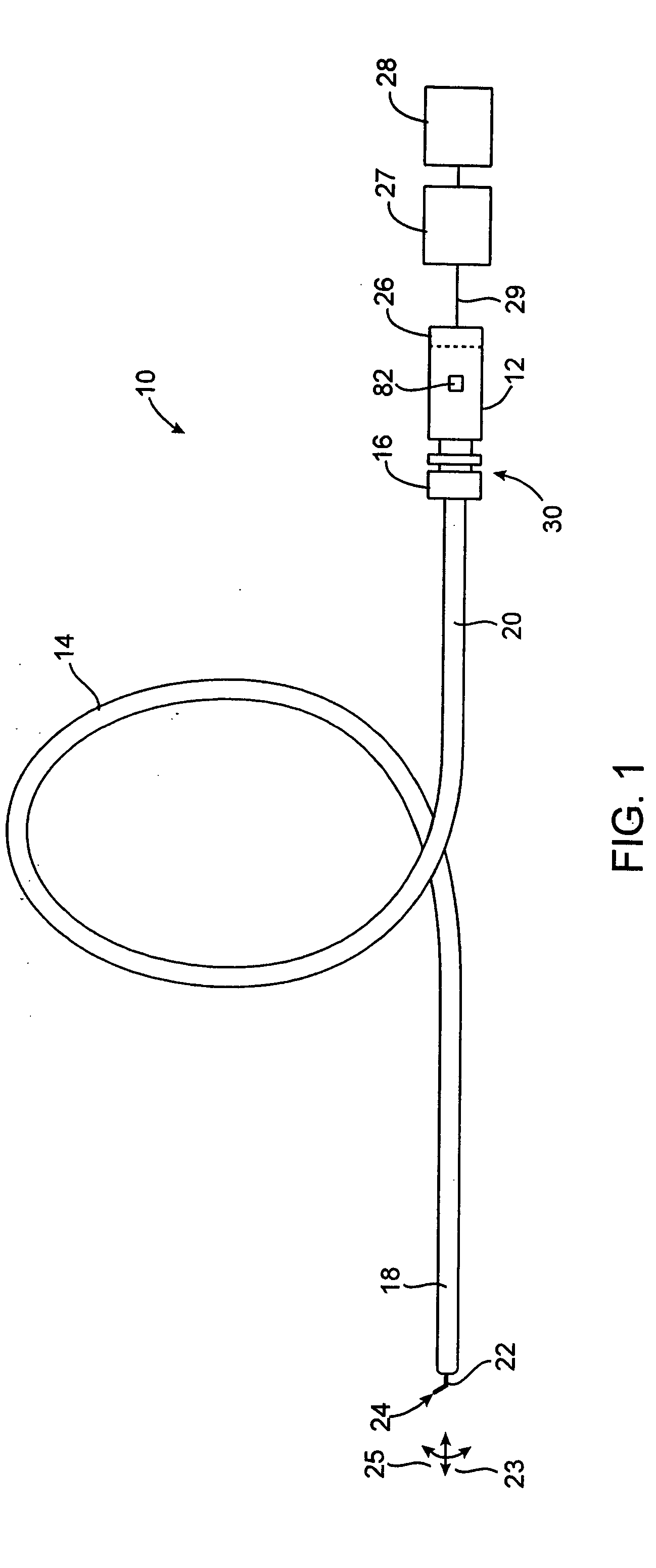

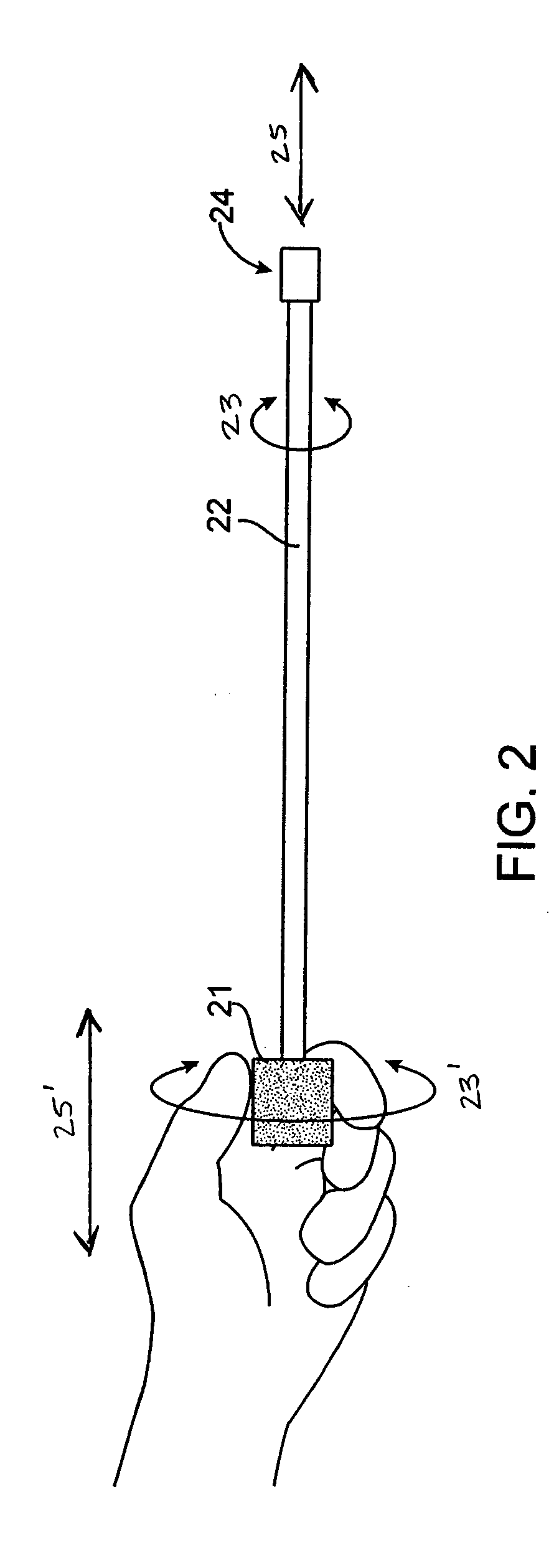

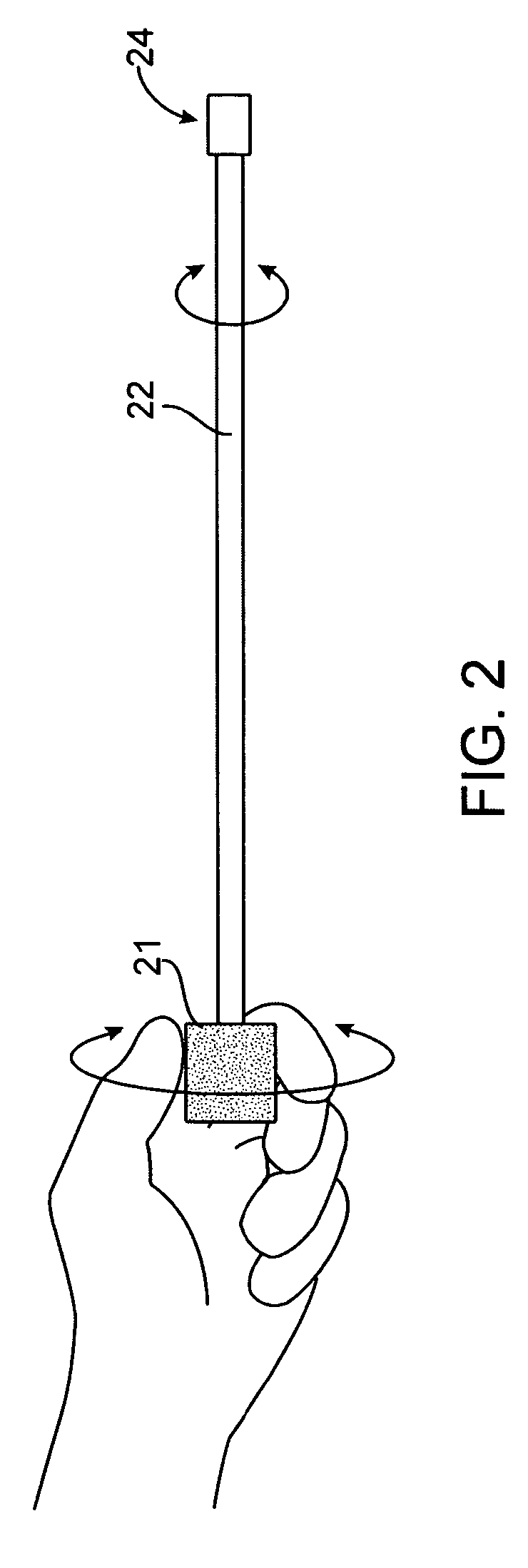

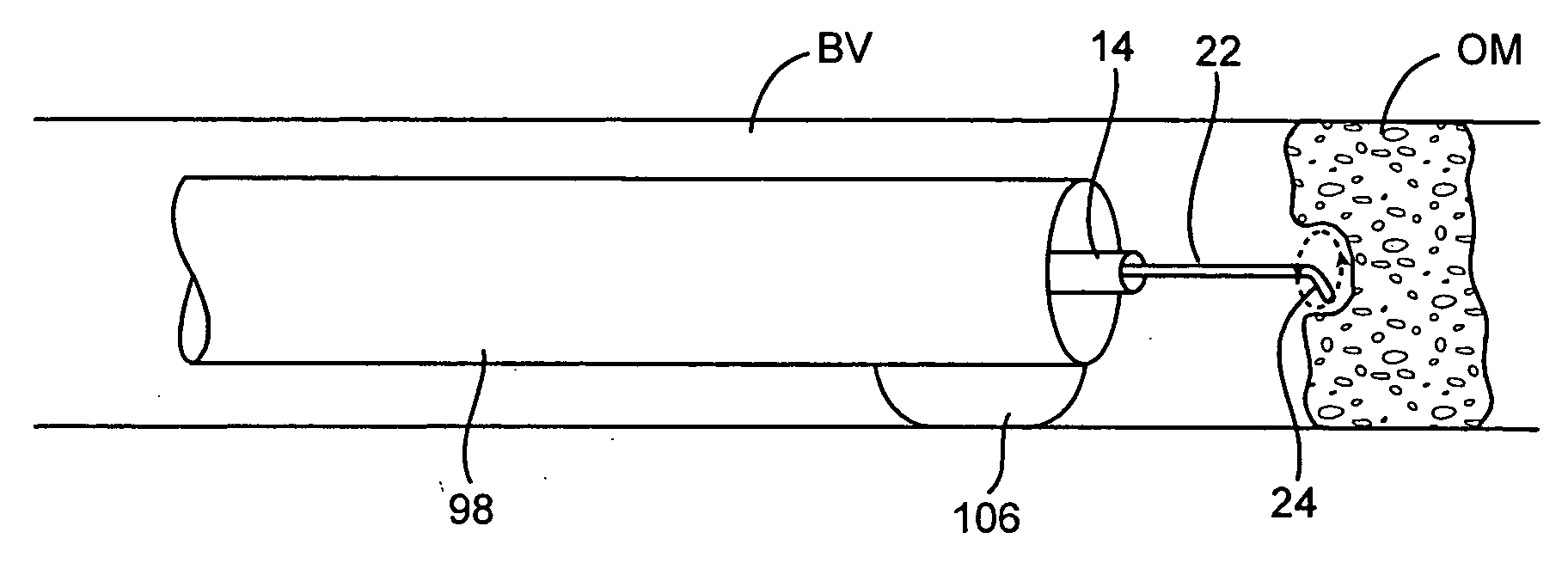

Guidewire for crossing occlusions or stenoses

InactiveUS20050119615A1Easy to controlFacilitate occlusionGuide wiresMedical devicesCoronary arteriesDrive shaft

A hollow guidewire for removing tissue from a body lumen, such as a coronary artery. The hollow guidewire comprises an elongate, tubular guidewire body that has an axial lumen. A tissue removal assembly, such as a rotating drive shaft, is positioned at or near a distal end of the tubular guidewire body and extends through the axial lumen. Actuation of the tissue removal assembly removes occlusive material in the body lumen.

Owner:BOSTON SCI SCIMED INC

Method for preparing magnetic filling with biological affinity, hydrophilicity and activity for water treatment

InactiveCN1522972AEasy to grow and compactGood compatibilitySustainable biological treatmentBiological water/sewage treatmentInjection molding machineInjection moulding

The present invention relates to a preparation method of biological affinity hydrophilic active magnetic seed filling material for treating water. It is characterized by that said method includes the following steps: mixing biological affinity substance, hydrophilic substance, magnetic powder and active carbon or magnetic powder and calcium carbonate in the high-molecular base material, and adding dispersion lubricating agent, uniformly stirring them, placing them into injection moulding machine, utilizing filling mould to make extrusion moulding and magnetizing, so as to obtain the invented filling material. It has biological affinity and hydrophilicity, at the same time can induce microbial activity and enzyme activity, and can raise oxygen utilization rate in water and water treatment efficiency.

Owner:SOUTH CHINA UNIV OF TECH

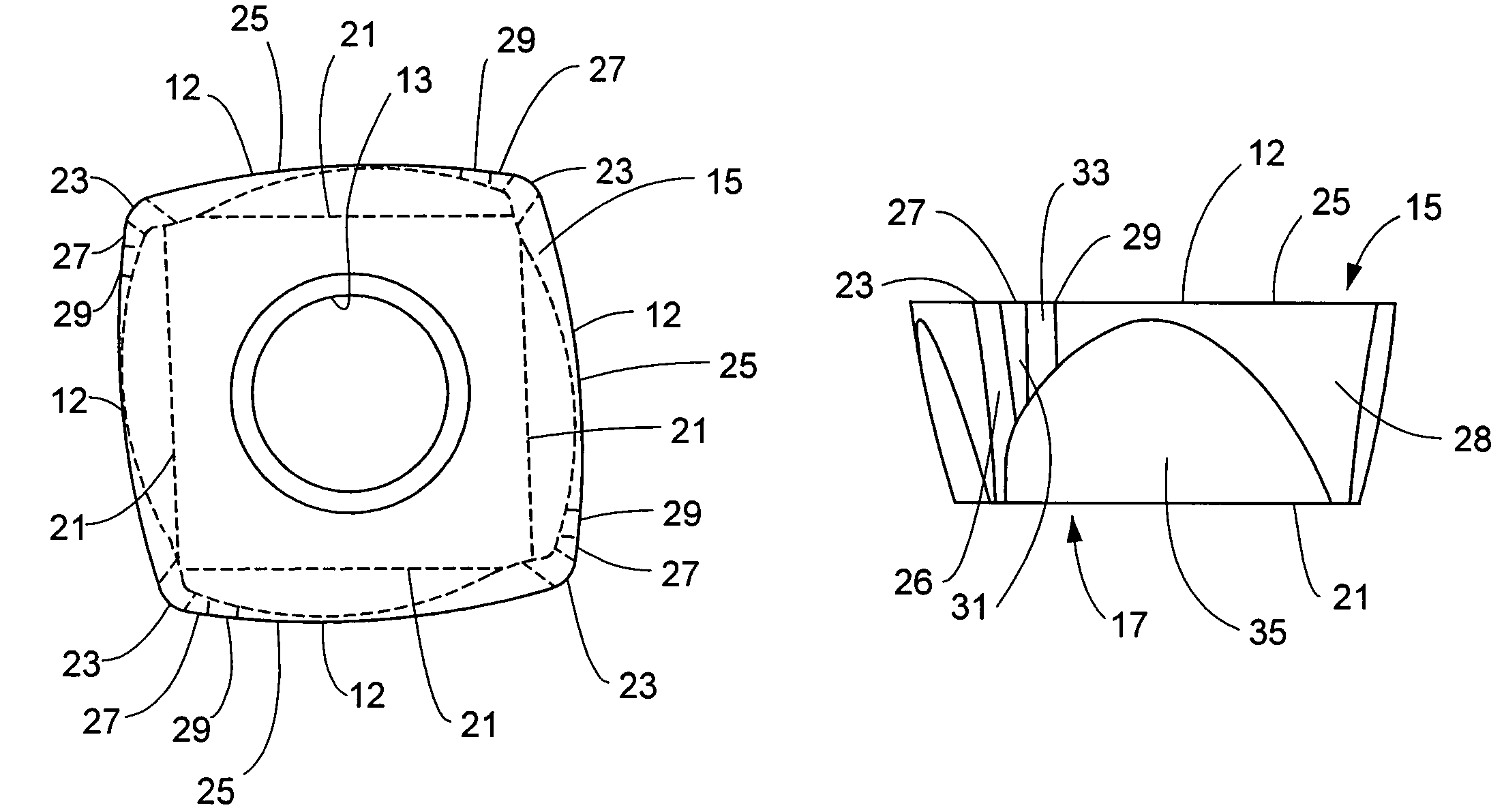

Cutting insert for high feed face milling

InactiveUS7220083B2Increase feed rateReduce forceTransportation and packagingMilling cuttersEllipseEdge strength

A cutting insert for milling operations, such as, face milling, slot milling, plunge milling, and ramping operations. The cutting insert exhibits a combination of favorable cutting edge strength, and unique cutting edge geometry, thus, allowing milling operations at relatively high feed rates. The cutting insert includes at least four cutting edges, wherein at least one of the cutting edges is a convex cutting edge. Certain embodiments of square cutting inserts will have four convex cutting edges which may be connected by nose corners. The convex cutting edge may comprise at least one of a circular arc, a portion of an ellipse, a portion of a parabola, a multi-segment spline curve, a straight line, or combinations of these. Wherein the convex cutting edge comprises a circular arc, the circular arc may have a radius greater than or equal to two times a radius of the largest circle that may be inscribed on the top surface.

Owner:KENNAMETAL INC

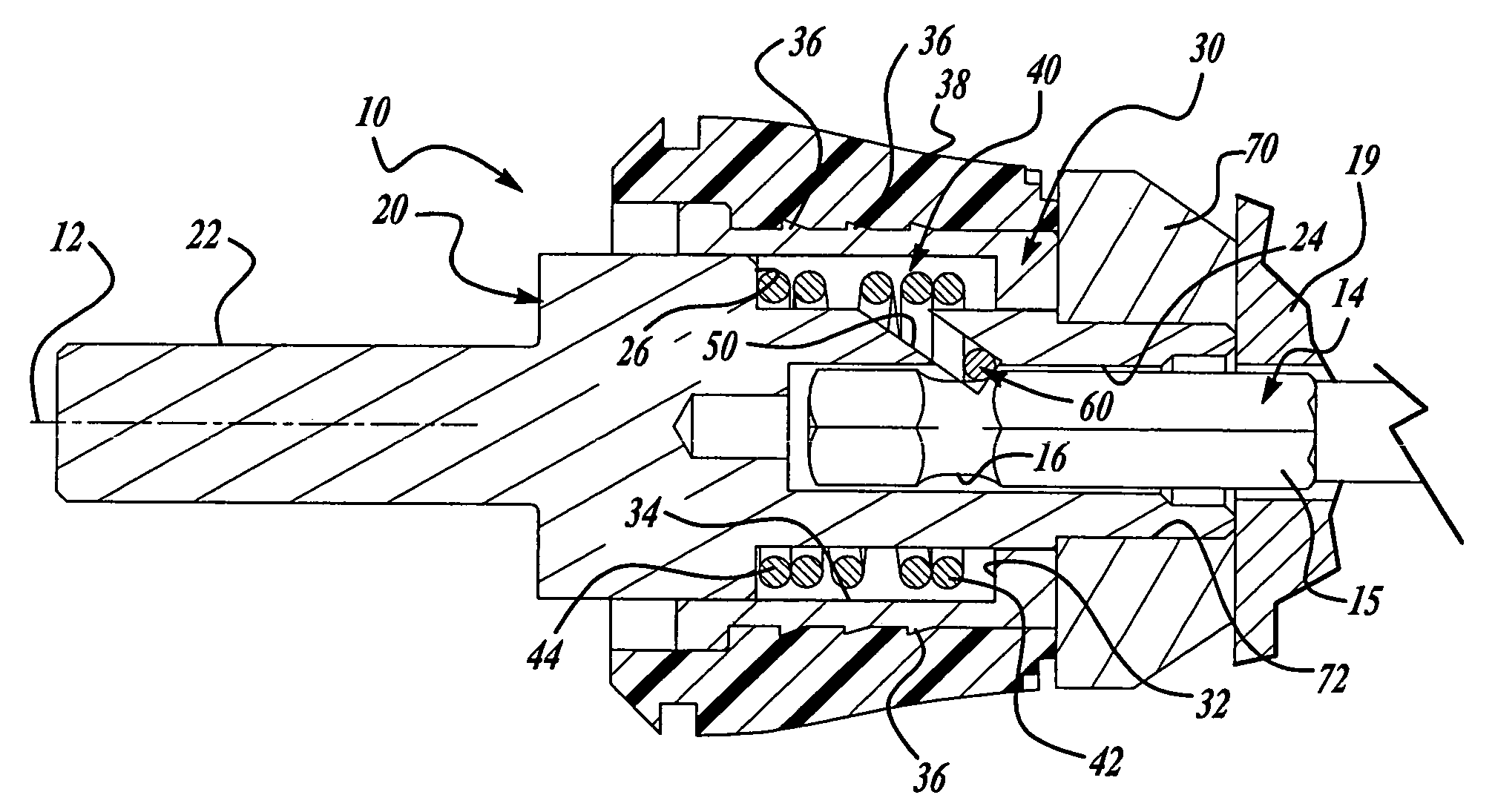

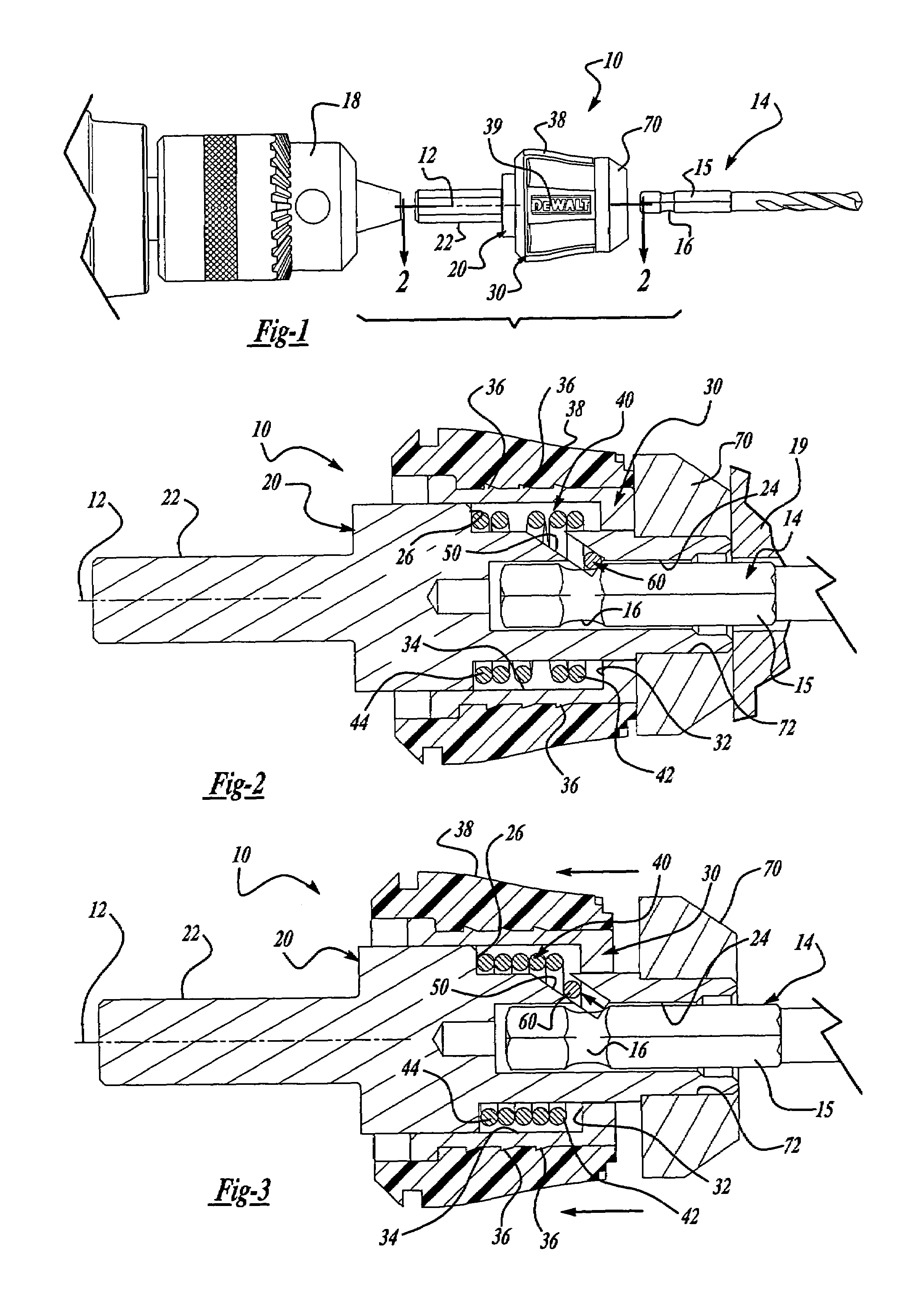

Quick-acting tool bit holder

InactiveUS7086813B1Minimize off-axis “ cocking ”Prevent over-retractionThread cutting machinesTransportation and packagingTool bitCoil spring

A “snap-in” bit chuck assembly for a rotary hand or powered tool, includes an elongated body having a hex shank at its rearward end, an elongated retraction collar slidably disposed on the body, and an outer retaining collar fixed to the forward end of the body. The body has a coaxial hex socket formed therein to allow a reversible tool to be inserted thereinto. A slot is formed in the body, between the outer surface of the body and the internal hex socket. A coil spring surrounds the body, inside the retraction collar, and normally biases the retraction collar forwardly and biases a retaining clip toward the bottom of the angular slot. The retaining clip slides outwardly in the angular slot, against the bias of the coil spring, as the reversible tool is inserted, where a recess on the reversible tool is engaged and retained by the clip. The tool is removed by sliding the retraction collar rearwardly, to compress the coil spring and allow the retaining clip to retract back up the slot. The clip is directly engaged by the coil spring and has two legs extending about the body so that the clip is self-retaining. The clip legs extend around the body such that the retraction force on the coil spring is directed through the center of the coil spring to keep it coaxially aligned with the body.

Owner:BLACK & DECKER INC

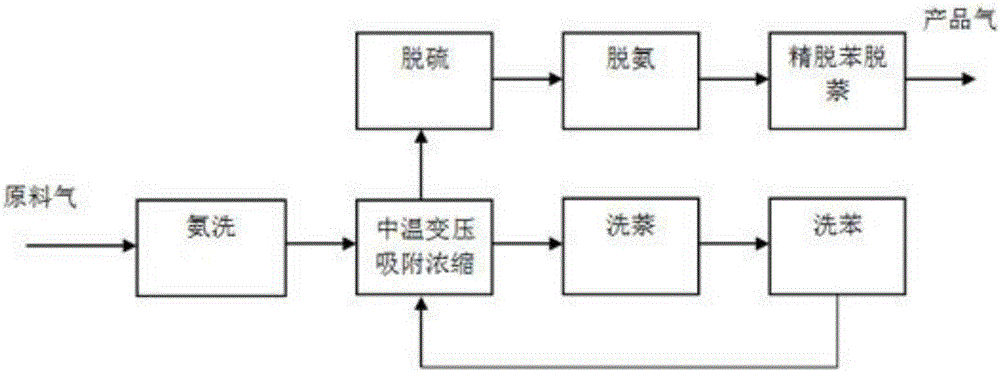

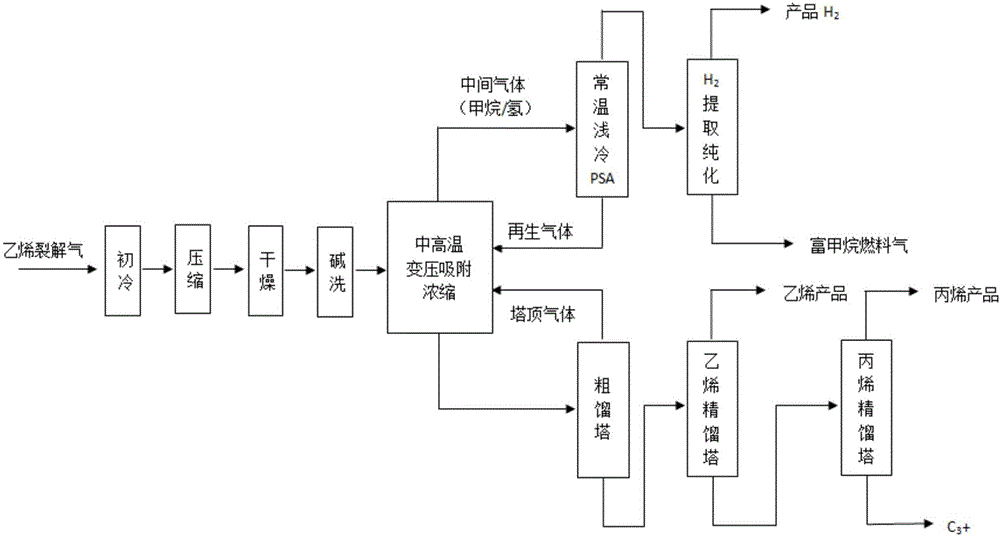

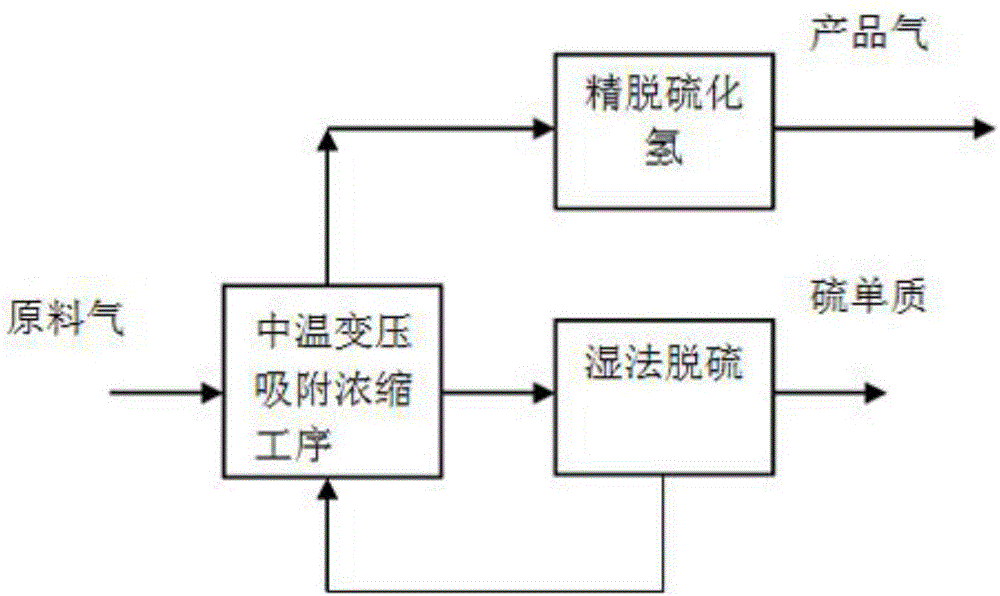

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

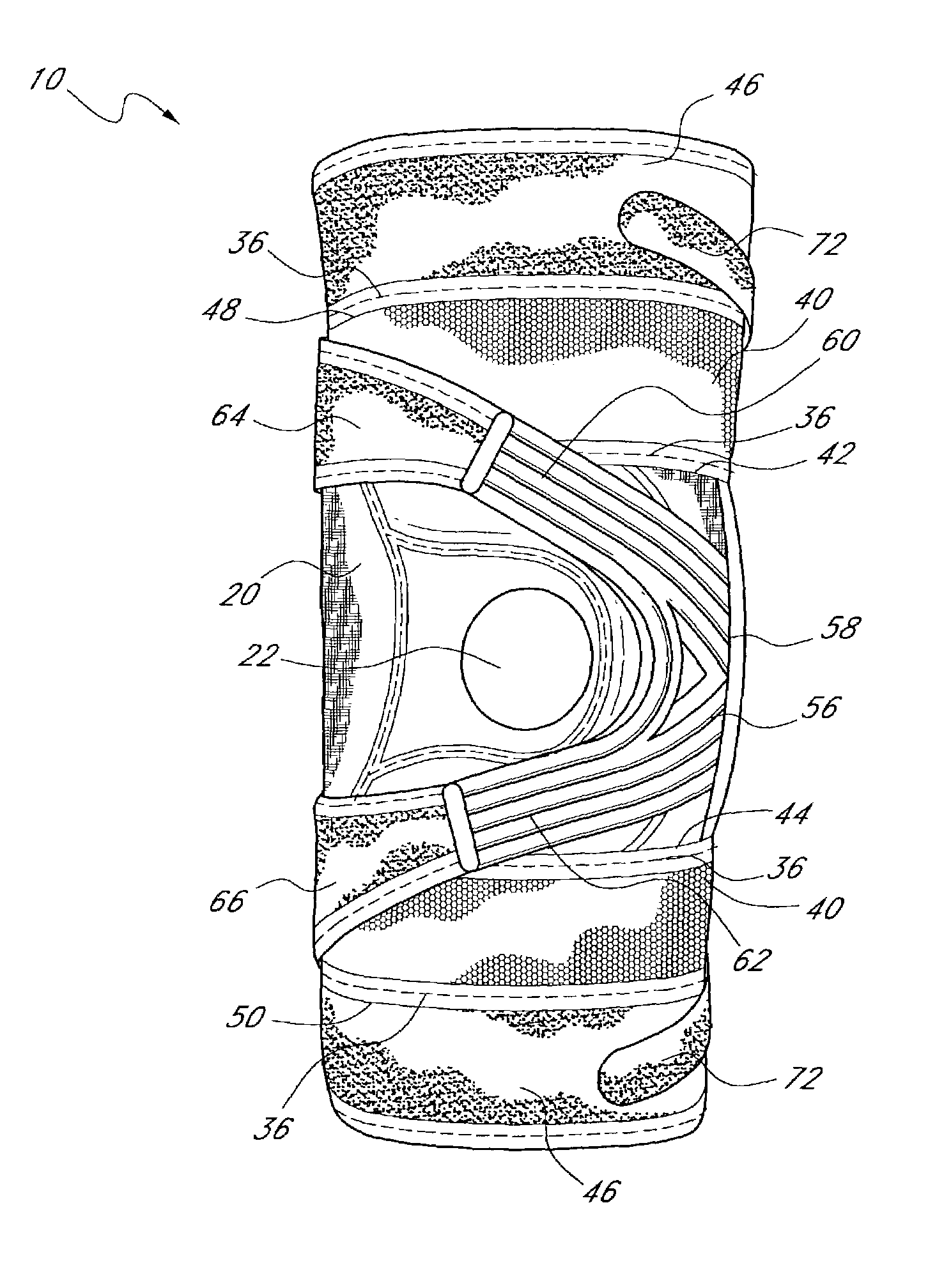

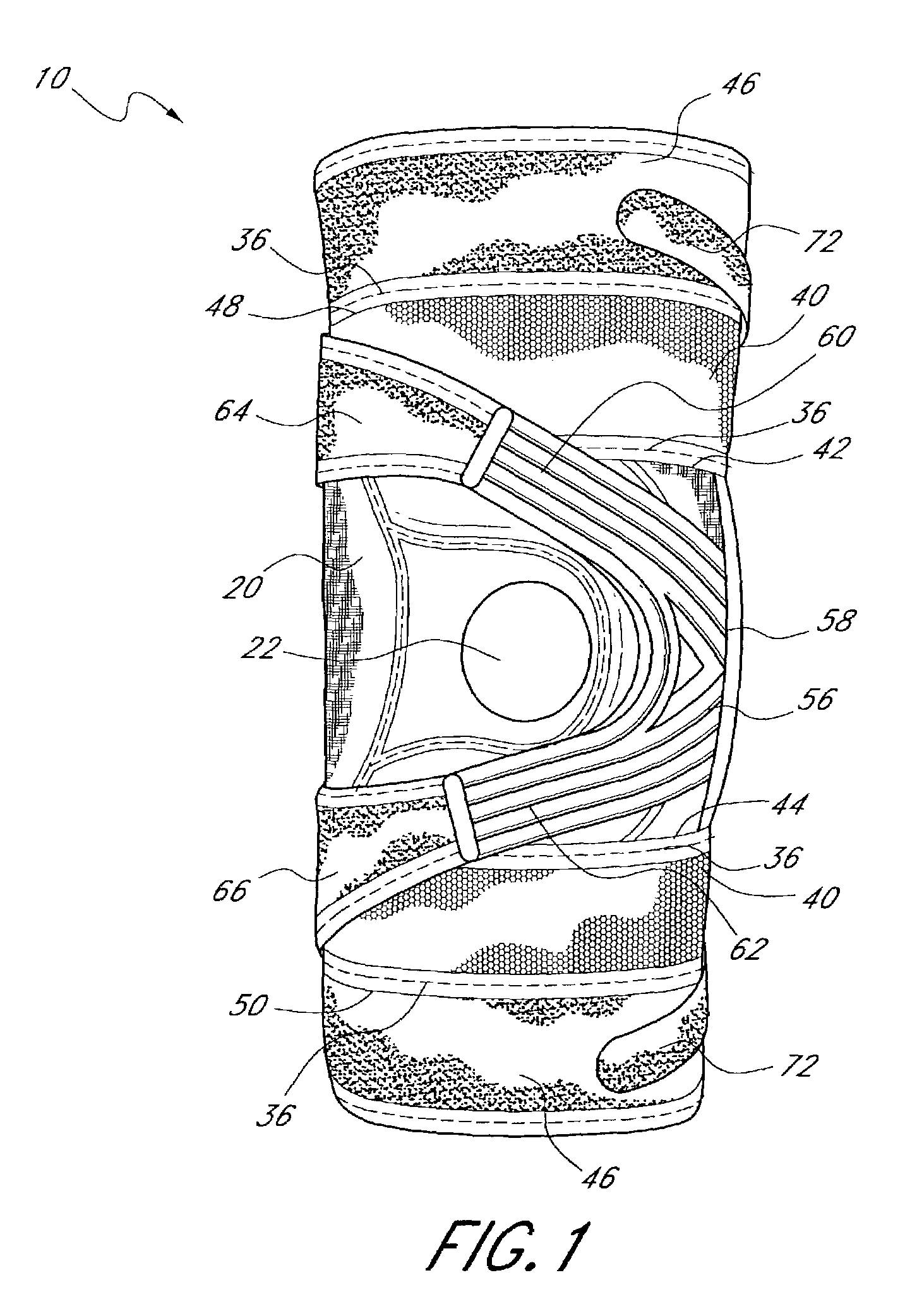

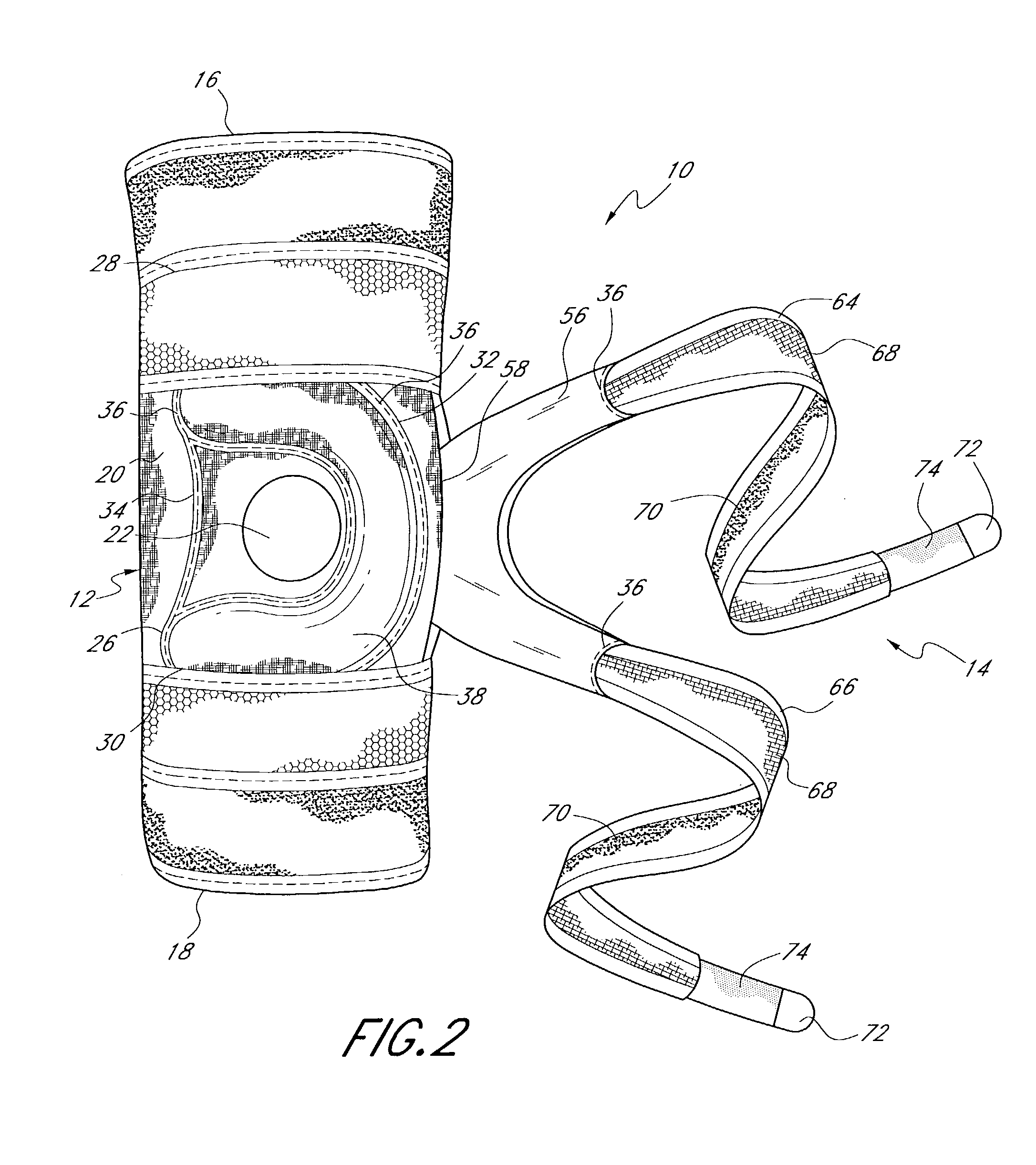

Patellofemoral brace

ActiveUS7083586B2Maintain adequate and consistentAdequate and consistent tensionNon-surgical orthopedic devicesButtressThermoplastic elastomer

A patellofemoral brace including a buttress for supporting a wearer's patella is provided. The patellofemoral brace includes an elastic sleeve that is easy to apply to the wearer's leg and easy to remove from the wearer's leg. The sleeve includes distinct bands of material so that end bands are substantially rotationally independent of a central band. The end bands resist translation along and rotation about the wearer's leg. The brace further includes a tensioning strap that lies across the buttress to further support the buttress and the wearer's patella. A portion of the tensioning strap is constructed of a thermoplastic elastomer, so that the strap provides firmer support to the buttress than a fabric strap, but is more comfortable and more evenly supports the buttress than a hard, inelastic strap.

Owner:DJO

Guidewire for crossing occlusions or stenoses

Systems and methods for crossing stenosis, partial occlusions, or complete occlusions within a body lumen. The systems generally include an elongate member such as a hollow guidewire that houses a rotatable and translatable drive shaft. The drive shaft typically has a distal portion that is advanced to create a path in the occlusive material that is large enough to allow the hollow guidewire to cross the occlusive material.

Owner:REVASCULAR THERAPEUTICS

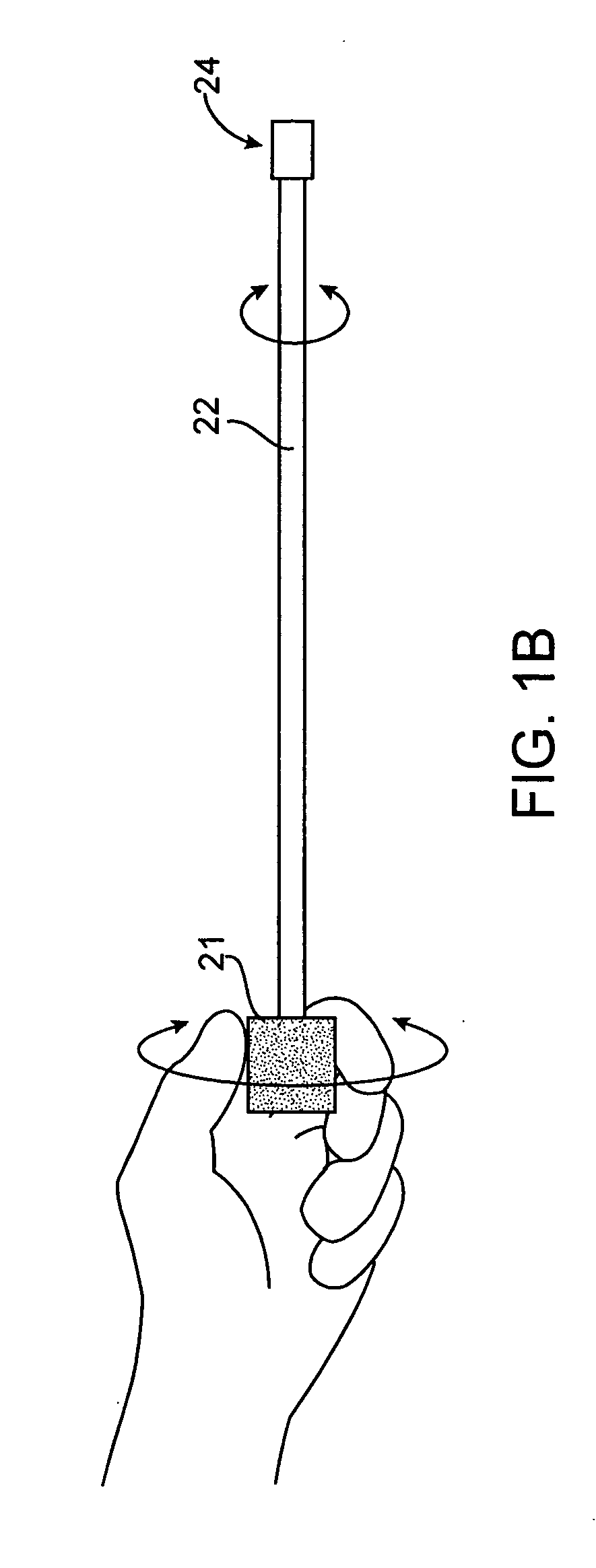

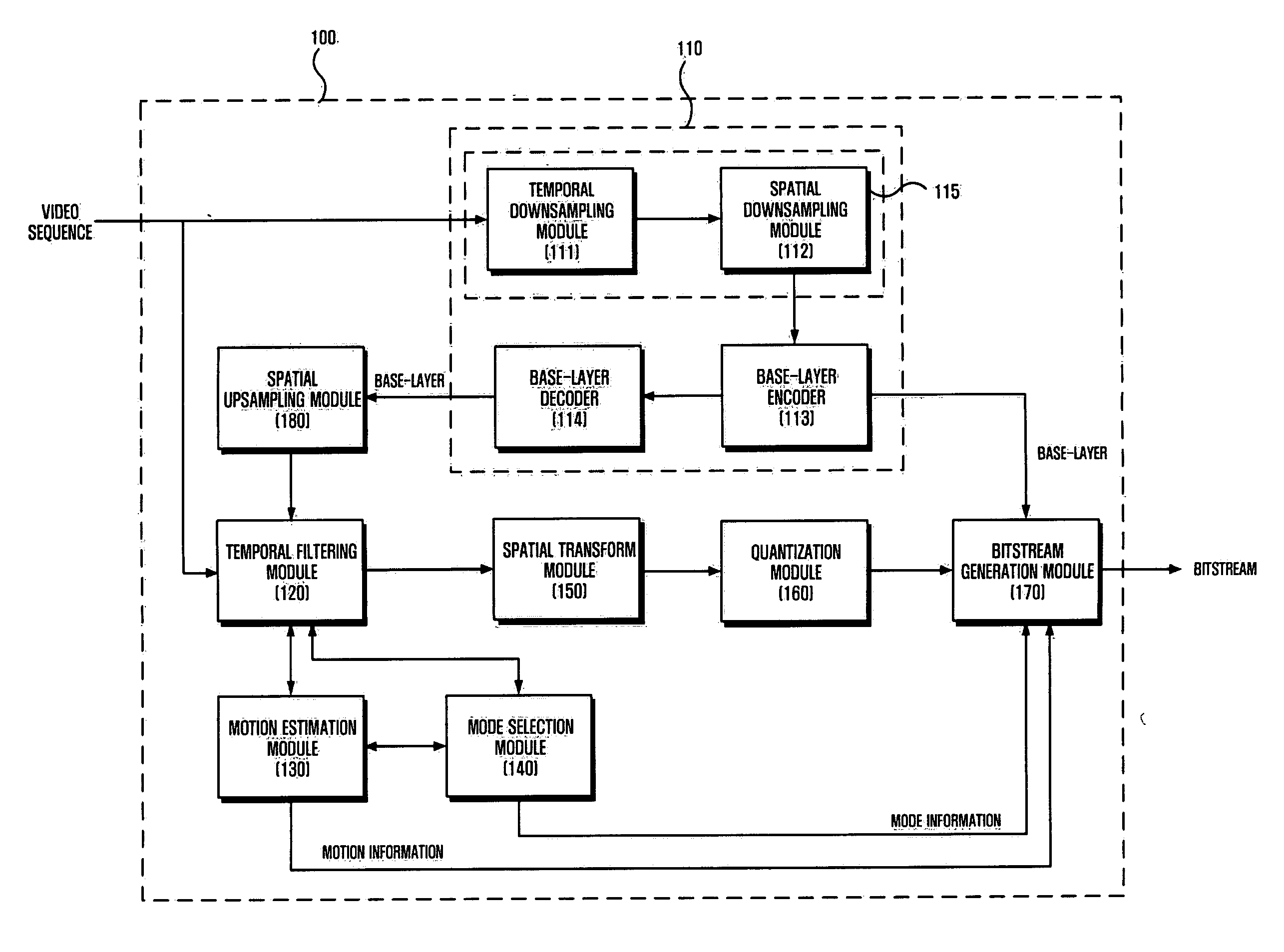

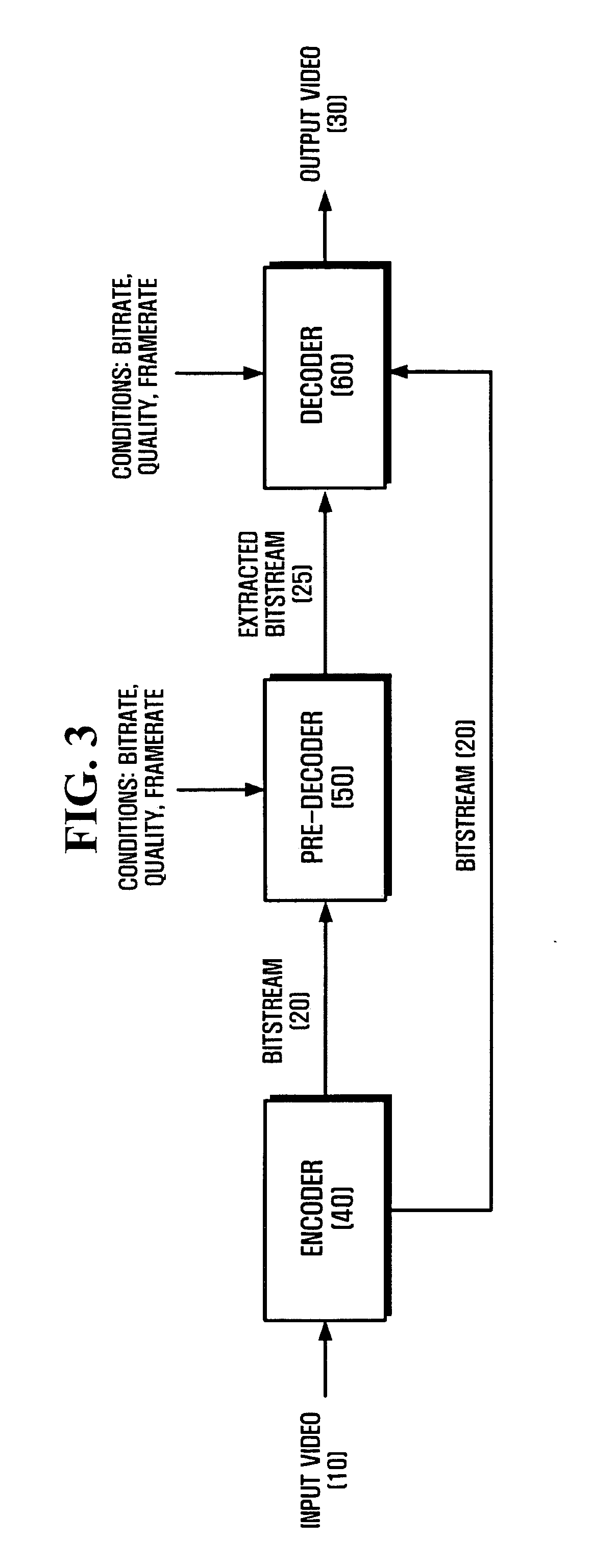

Scalable video coding method and apparatus using base-layer

InactiveUS20060013313A1Low rateIncrease bitrateColor television with pulse code modulationColor television with bandwidth reductionComputer graphics (images)Video encoding

A method of more efficiently conducting temporal filtering in a scalable video codec by use of a base-layer is provided. The method of efficiently compressing frames at higher layers by use of a base-layer in a multilayer-based video coding method includes (a) generating a base-layer frame from an input original video sequence, having the same temporal position as a first higher layer frame, (b) upsampling the base-layer frame to have the resolution of a higher layer frame, and (c) removing redundancy of the first higher layer frame on a block basis by referencing a second higher layer frame having a different temporal position from the first higher layer frame and the upsampled base-layer frame.

Owner:SAMSUNG ELECTRONICS CO LTD

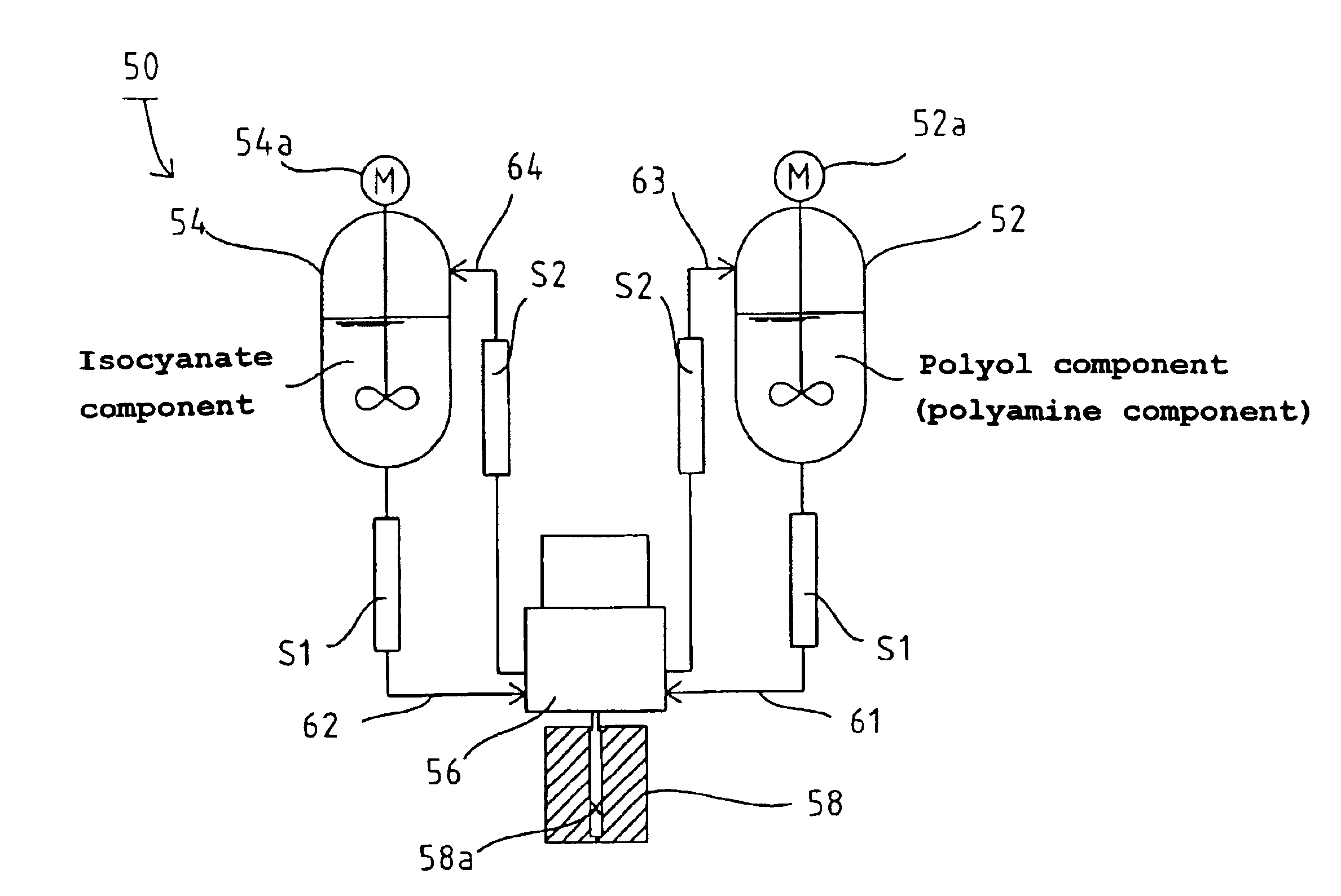

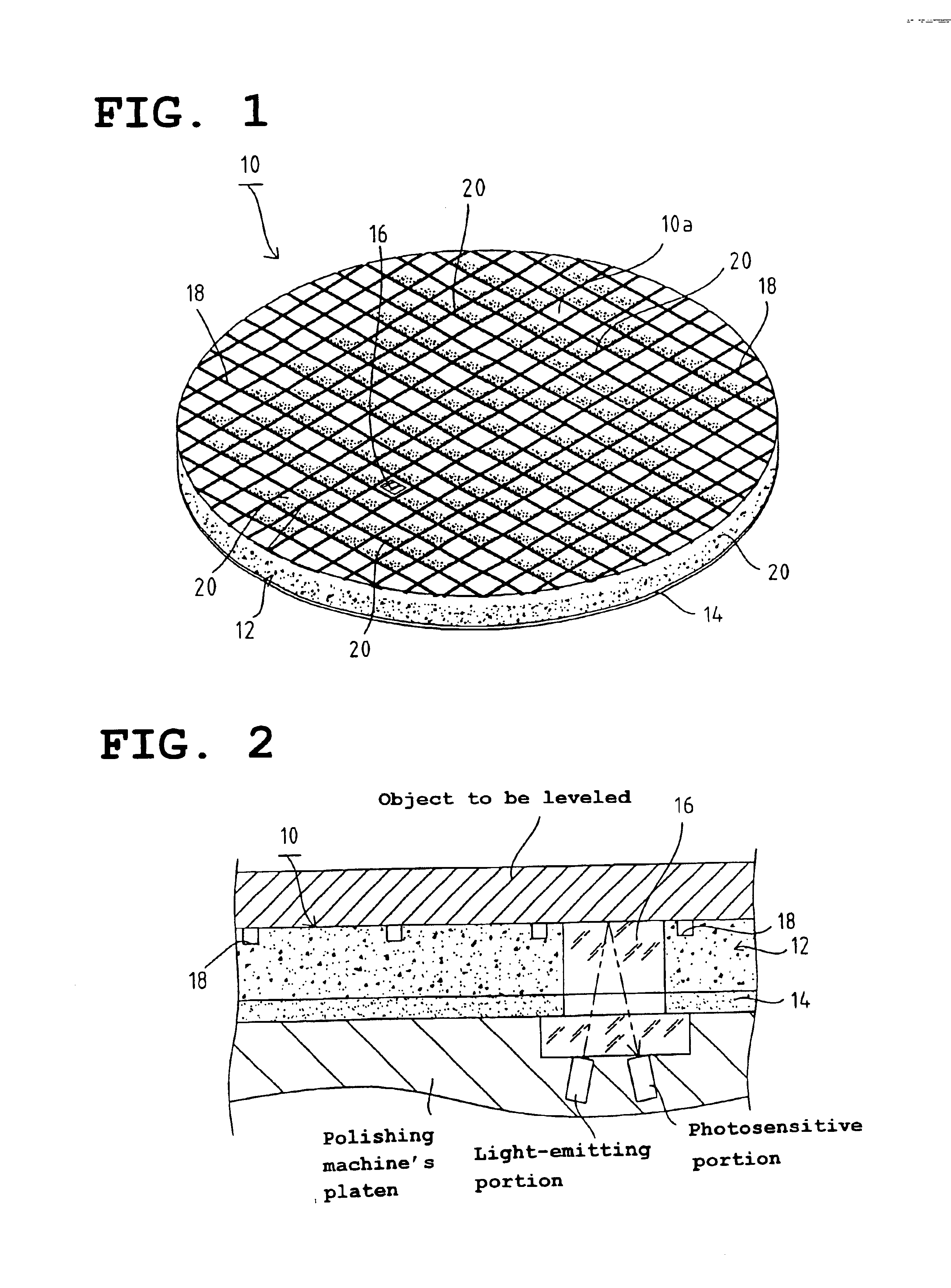

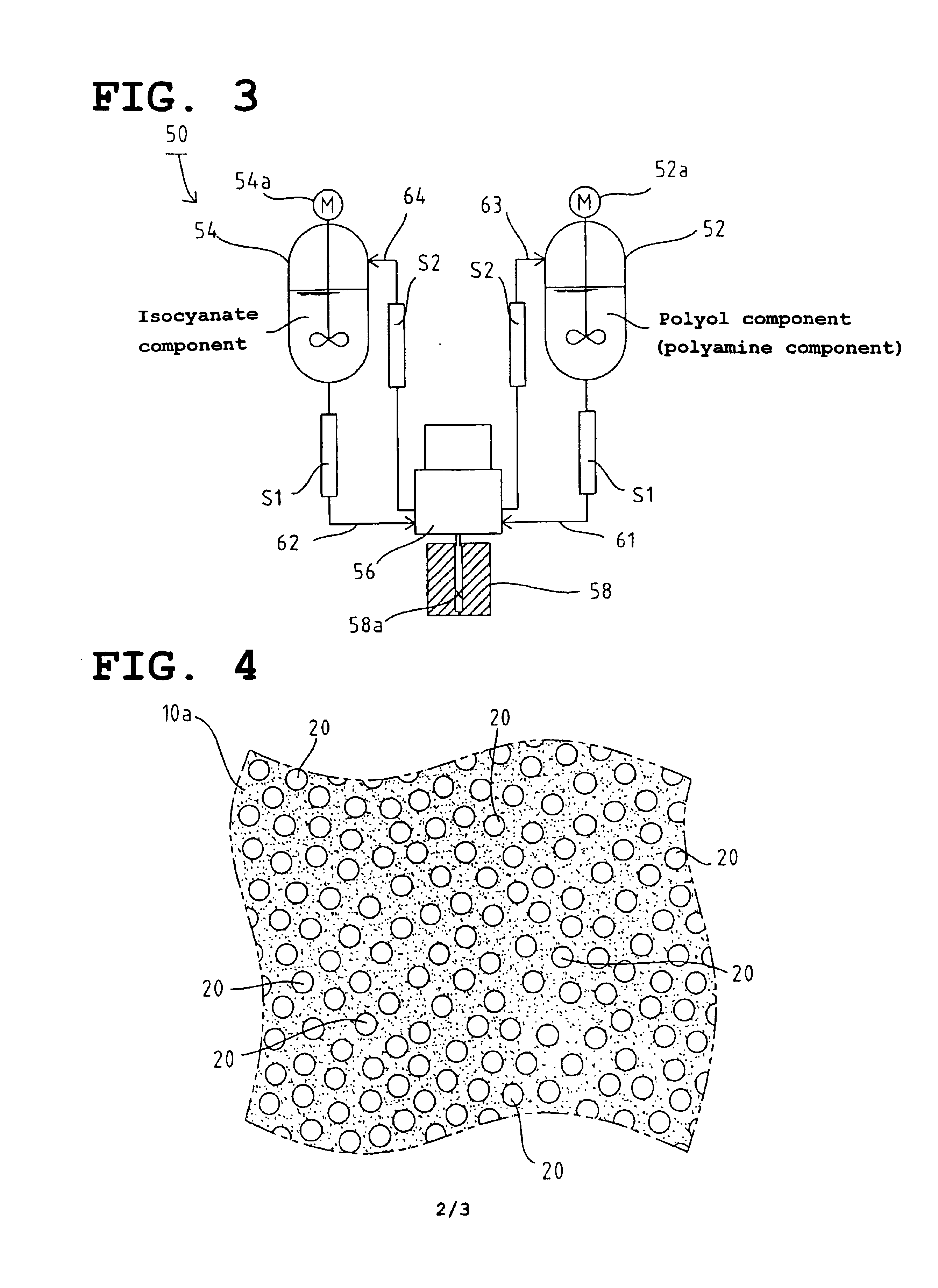

Polishing pad

InactiveUS6837781B2Excellent removal rateHigh qualitySemiconductor/solid-state device manufacturingLapping machinesPolyureaEngineering

A high quality polishing pad suitable for chemical mechanical polishing (CMP) of semiconductor wafer, etc. which is not affected by the change of polishing conditions during polishing and can attain excellent removal rate, capacity of step height reduction and uniformity is described, wherein a polyurethane-based foam 12 having fine and uniform cells 20 suitable for polishing of semiconductor material, etc. obtained by reaction-injection molding a gas-dissolved raw material prepared by dissolving an inert gas in a mixture of a polyurethane or polyurea as a main raw material and various subsidiary raw materials under pressure is used.

Owner:ROGERS INOAC CORP

Guidewire for crossing occlusions or stenoses

Systems and methods for crossing stenosis, partial occlusions, or complete occlusions within a body lumen. The systems generally include an elongate member such as a hollow guidewire that houses a rotatable and translatable drive shaft. The drive shaft typically has a distal portion that is advanced to create a path in the occlusive material that is large enough to allow the hollow guidewire to cross the occlusive material.

Owner:REVASCULAR THERAPEUTICS

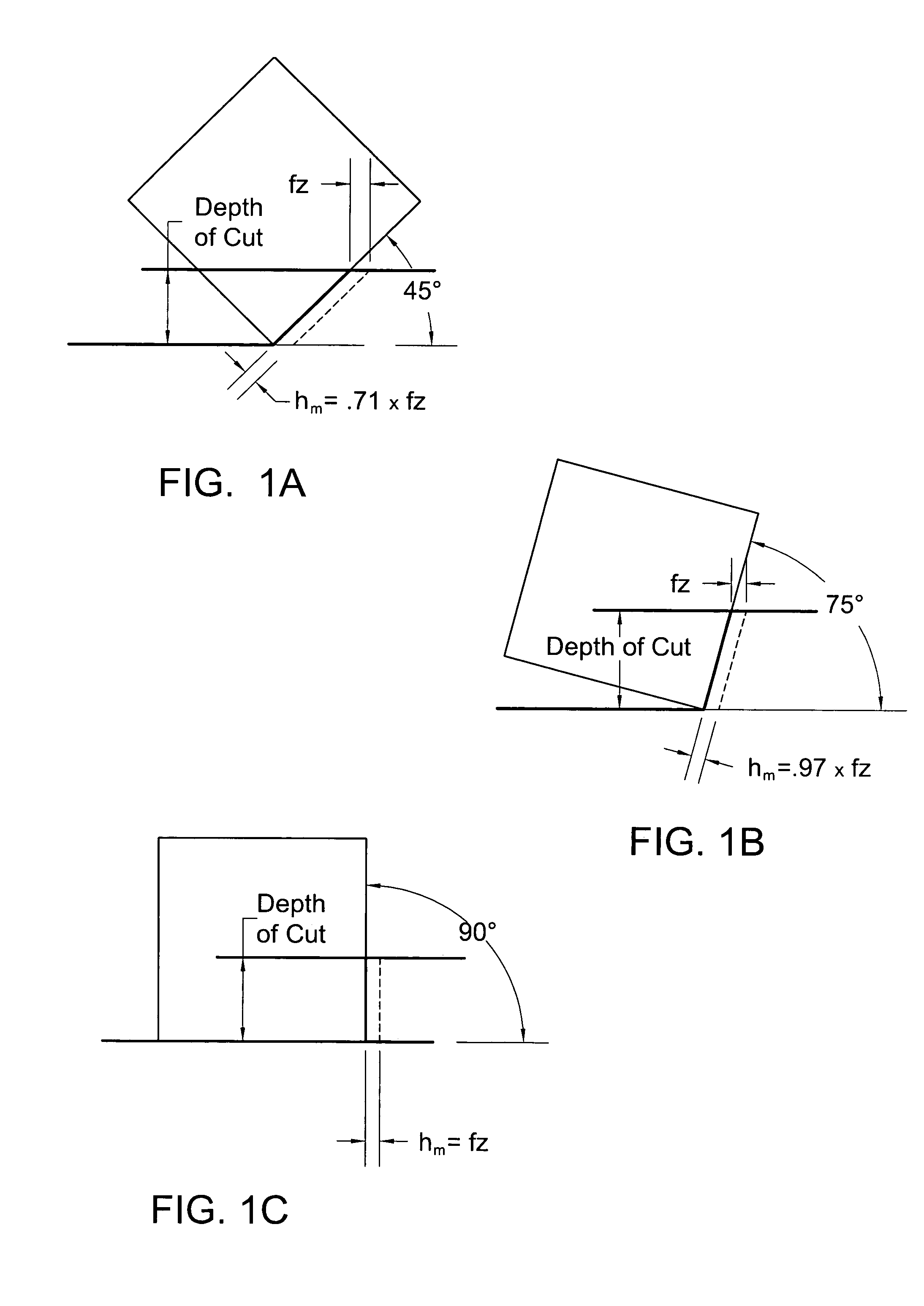

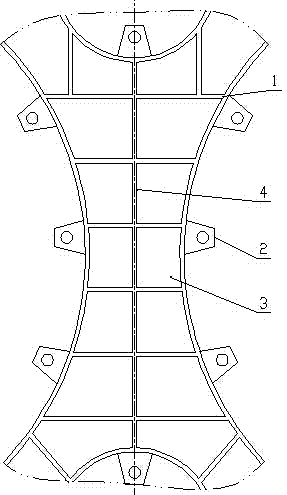

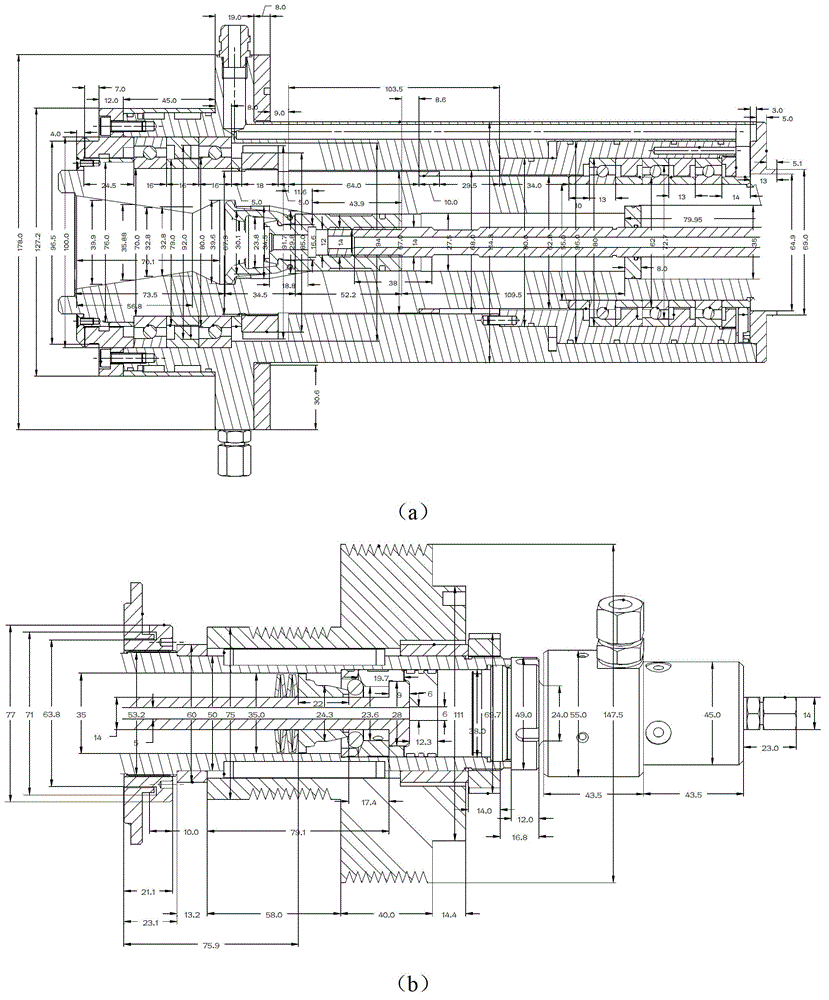

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

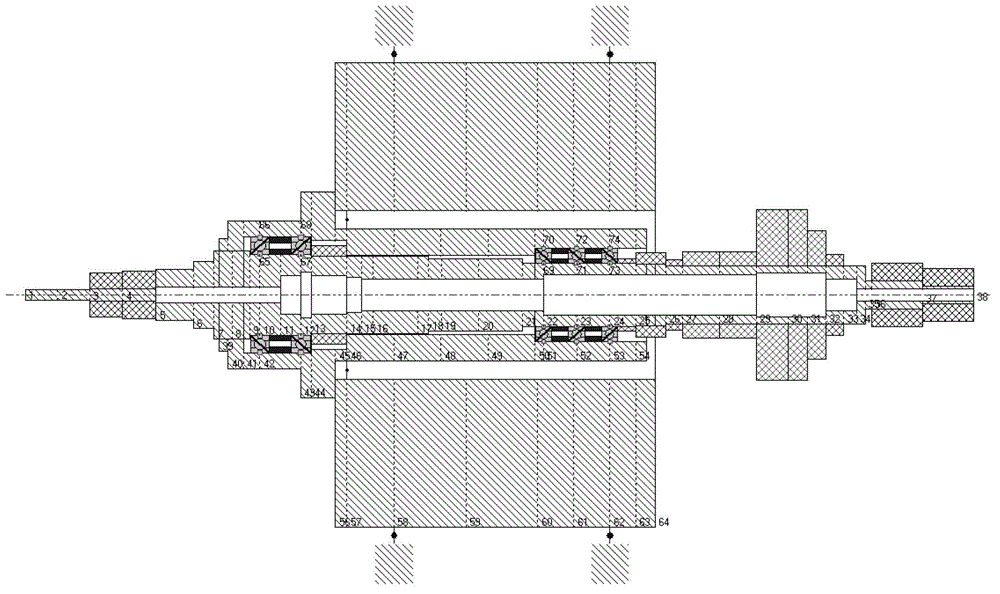

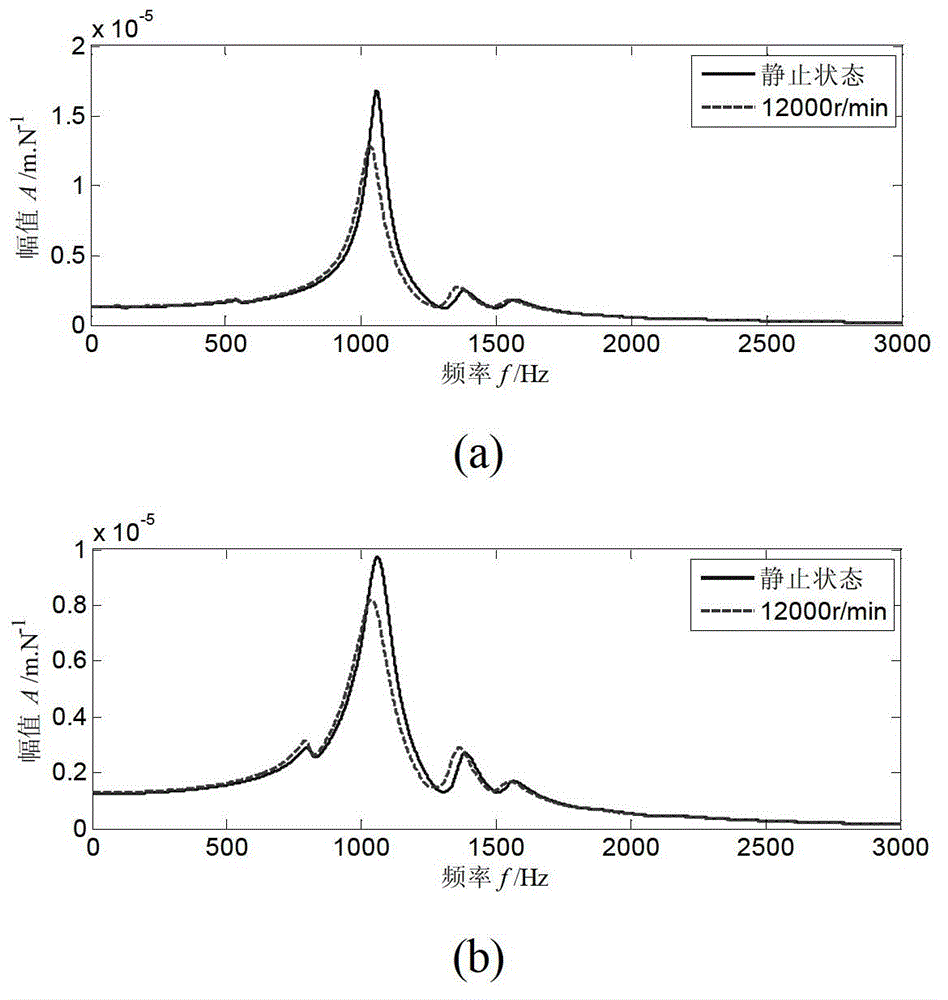

High-speed milling process parameter optimizing method based on dynamic model

ActiveCN102873381AImprove accuracyHigh removal rateMilling machinesSpecial data processing applicationsDynamic modelsSystem dynamics model

The invention relates to a high-speed milling process parameter optimizing method based on a dynamic model. The optimizing method includes 1) inputting structure parameter and initial cutting condition of a spindle-cutter system; 2) building a dynamic model of the spindle-cutter system, calculating a frequency response function of the cutter nose position according to the model and determining cutting force coefficient; 3) building a high speed spindle-cutter dynamic characteristic and milling interaction process model to obtain the characteristic equation of a closed loop dynamic milling system; 4) calculating a high-speed milling machining shimmy stability leaf picture; 5) selecting lathe spindle rotating speed and cutting depth to achieve high-speed milling parameter optimization with the lower bound curve of the high-speed milling machining shimmy stability leaf picture as the constraint condition and with maximum material removing rate as the optimization target. The method considers centrifugal force and gyroscopic couple effect of the cutter-cutter system in the high-speed rotating state, approaches actual work condition, improves accuracy of stability prediction, and provides effective technology for optimization of high-speed milling process parameter optimization.

Owner:XI AN JIAOTONG UNIV

Composition and method for polishing a sapphire surface

InactiveUS20060196849A1Simple compositionImprove methodOther chemical processesDecorative surface effectsColloidal silicaSlurry

An improved composition and method for polishing a sapphire surface is disclosed. The method comprises abrading a sapphire surface, such as a C-plane or R-plane surface of a sapphire wafer, with a polishing slurry comprising an abrasive amount of an inorganic abrasive material such as colloidal silica suspended in an aqueous medium having a salt compound dissolved therein. The aqueous medium has a basic pH and includes the salt compound in an amount sufficient to enhance the sapphire removal rate relative to the rate achievable under the same polishing conditions using a the same inorganic abrasive in the absence of the salt compound.

Owner:CABOT MICROELECTRONICS CORP

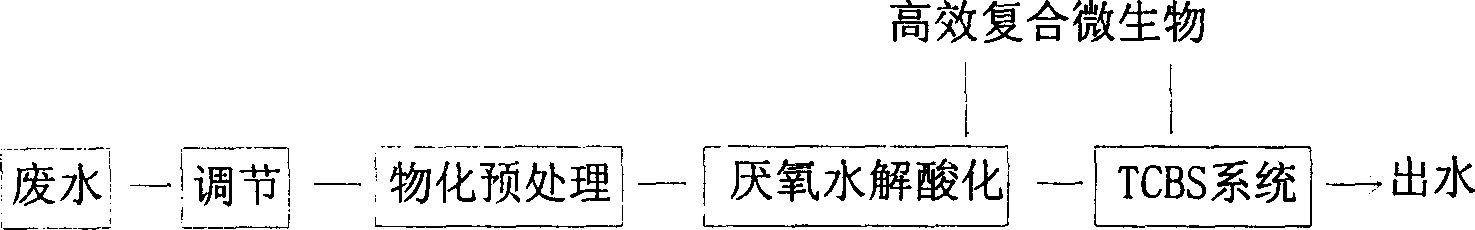

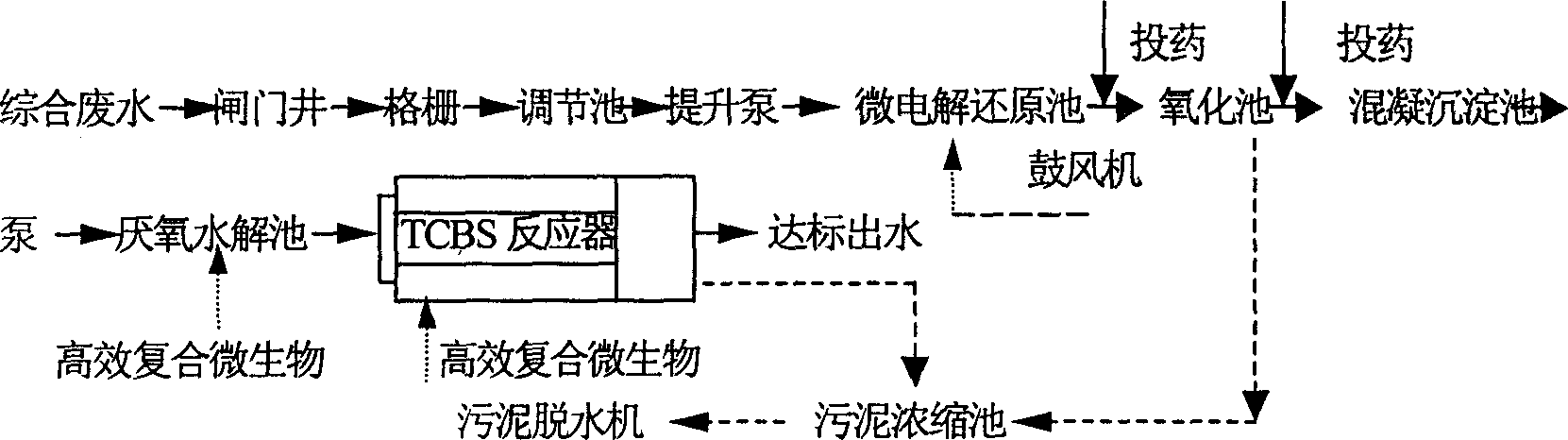

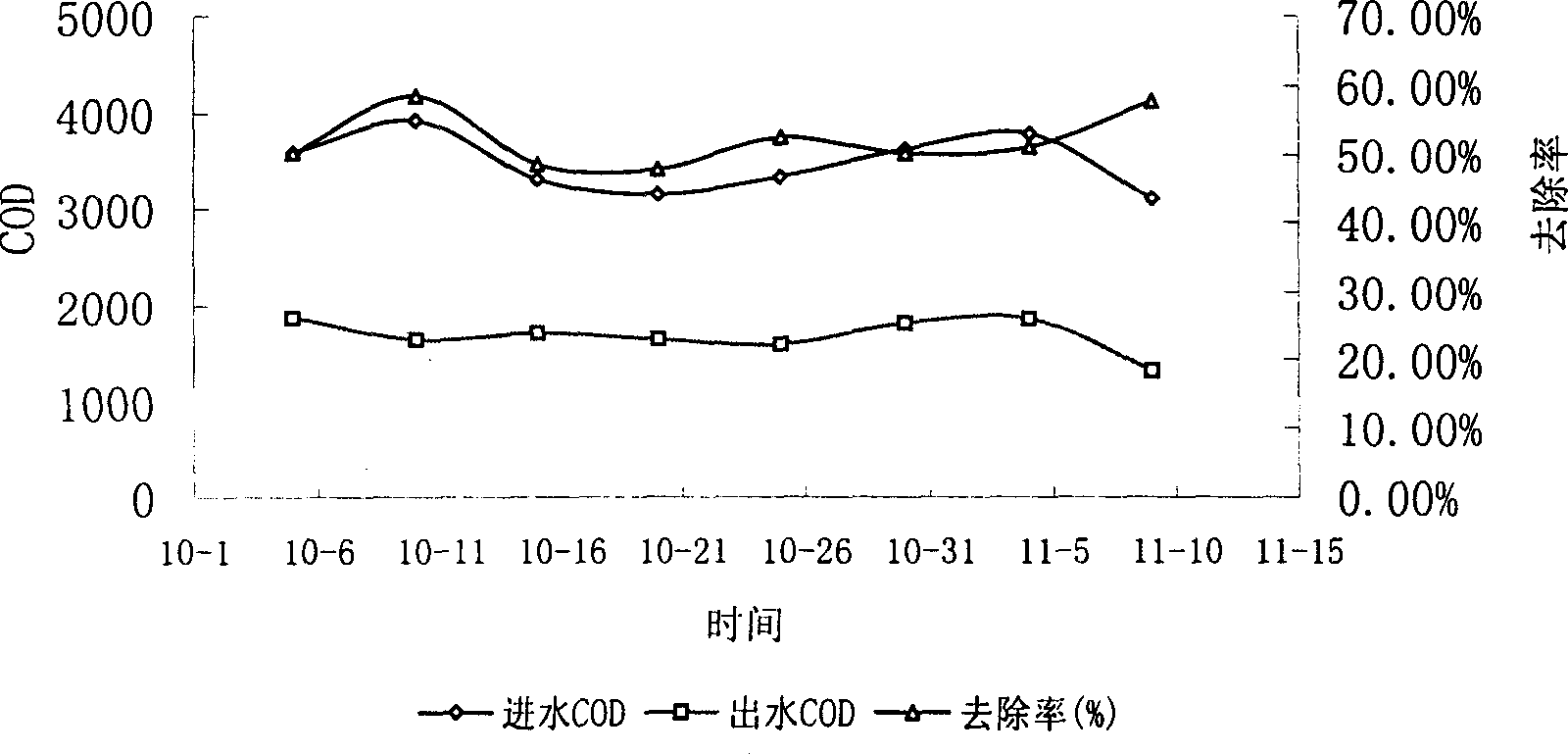

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

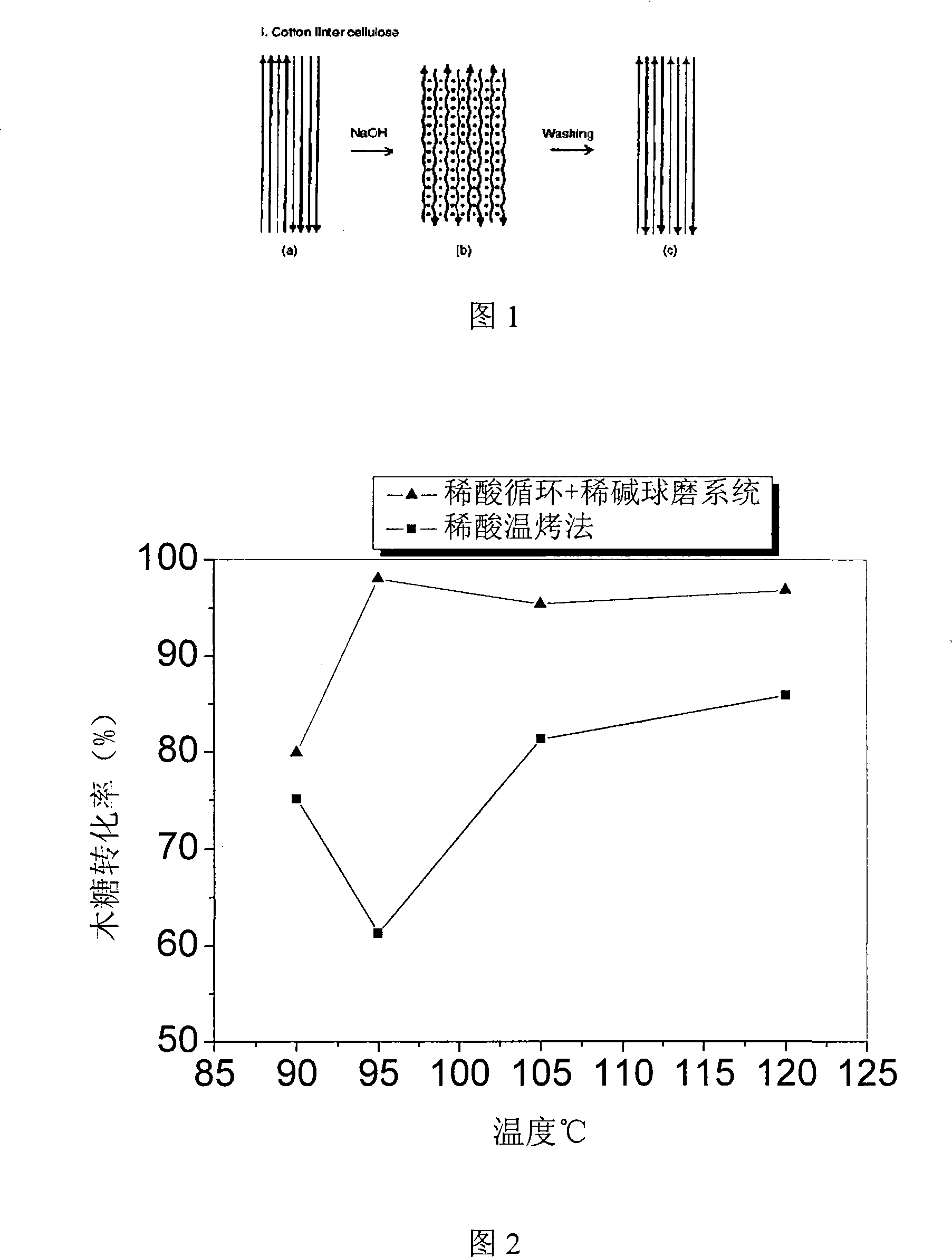

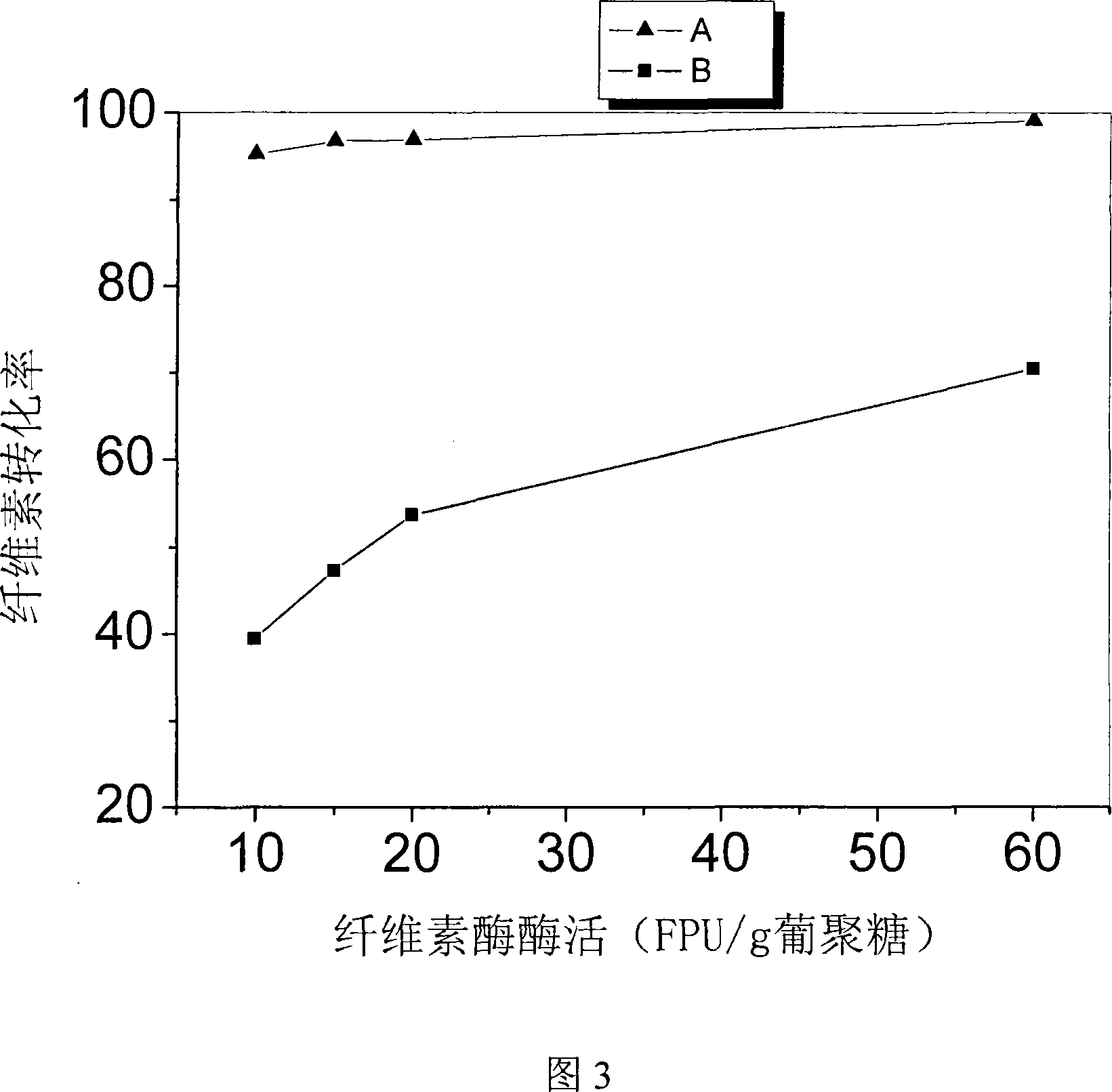

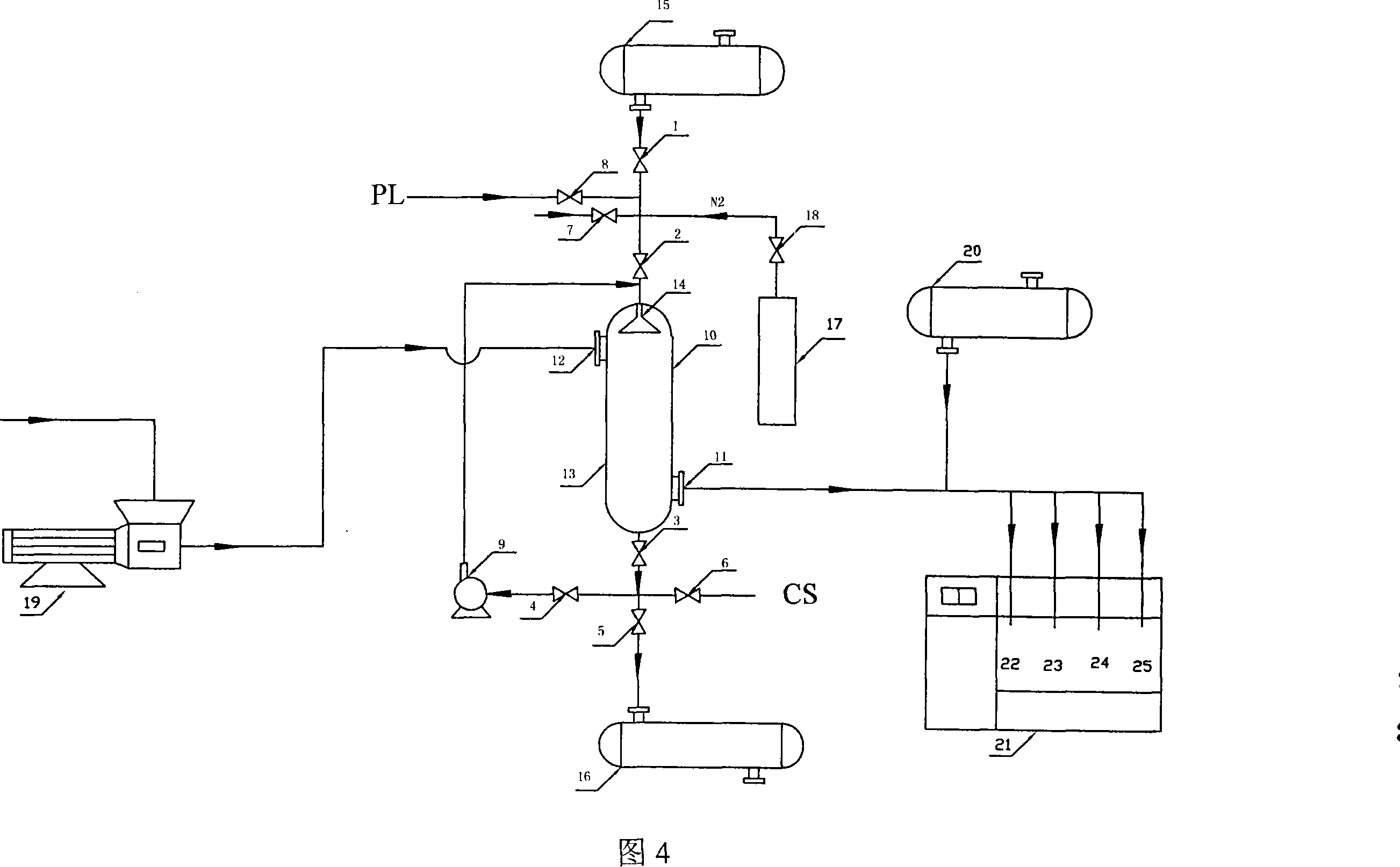

Combined pretreatment method of wood cellulose and system thereof

InactiveCN101230546AImprove hemicellulose conversion rateCellulose enzymatic conversion rate decreasedPaper material treatmentChemistryStart up

The invention discloses a combined preprocessing method of lignocellulose. The lignocellulose is arranged in a recycle reactor after being crushed, and dilute acid is injected; a recycle pump starts up, the circular reaction is acted under the temperature ranging from 50 DEG C to 200 DEG C, and the obtained hydrolysate is disacidified and then is used for ferment after the reaction is finished; the surplus lignocellulose in the recycle reactor is put in a globe mill for ball milling through adding lye after the surplus lignocellulose is washed, and the surplus lignocellulose is used in subsequent zymohydrolysis after ball milling and alkali removing. The invention effectively increases the hemicellulose percent conversion, the lignin removal rate and the cellulose zymohydrolysis percent conversion in the lignocellulose, reduces fermentation inhibition products, and reduces the enzyme usage when in zymohydrolysis, shortens the reaction time and increases the sugar consistence at the same time; in addition, the invention can set the water consumption during the preprocessing according to the needs of subsequent ferment consistence.

Owner:CHINA PETROLEUM & CHEM CORP +1

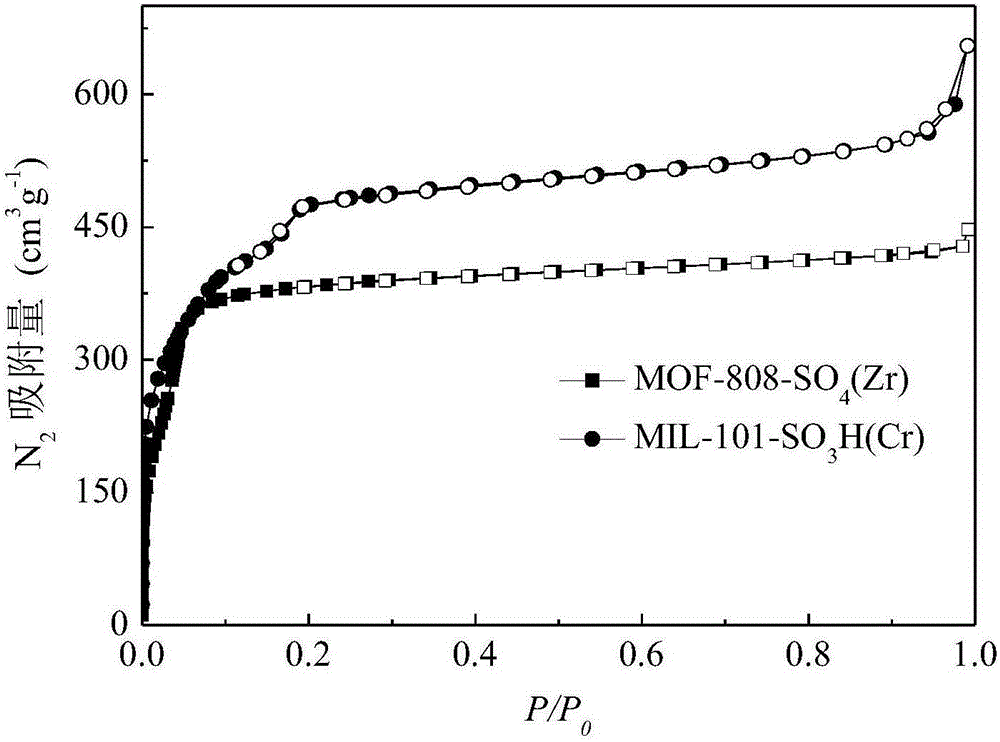

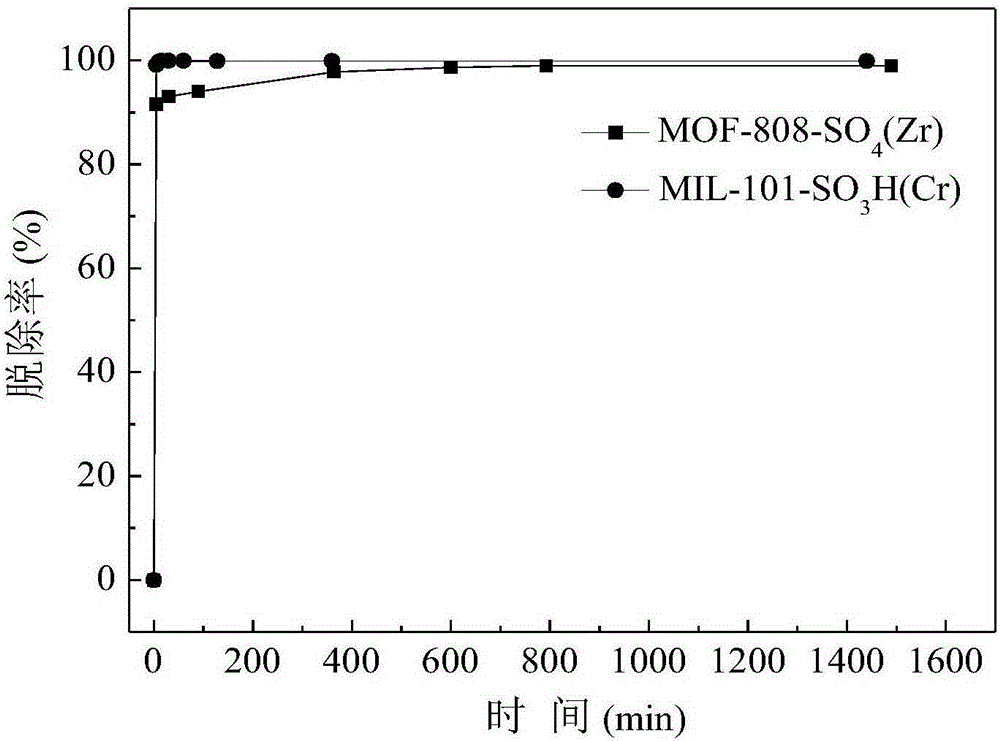

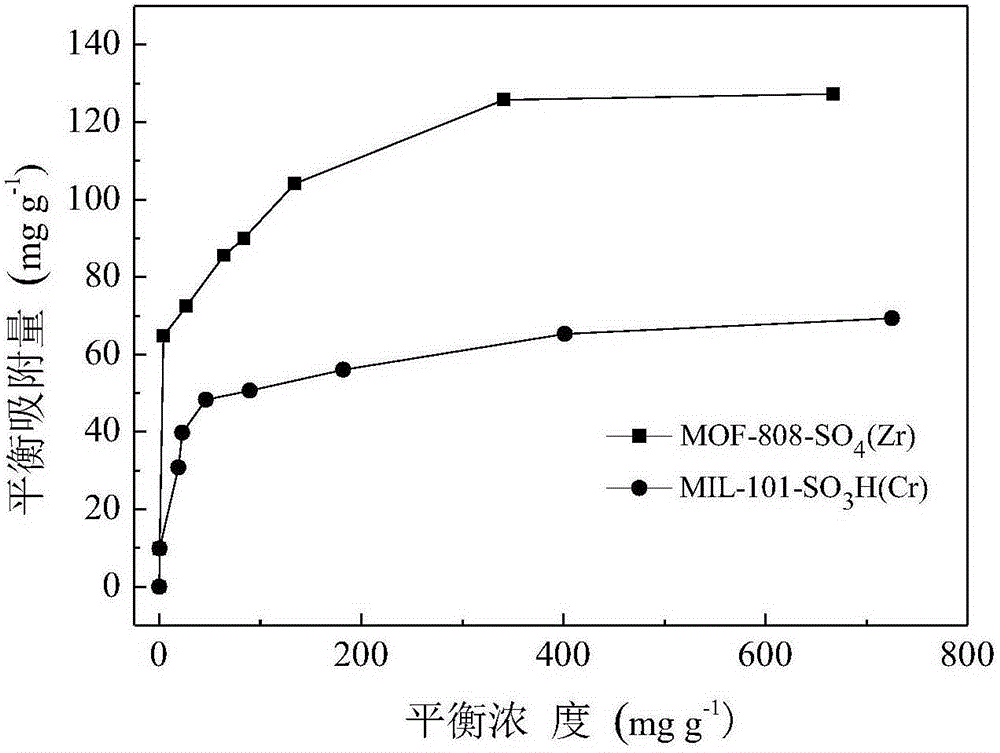

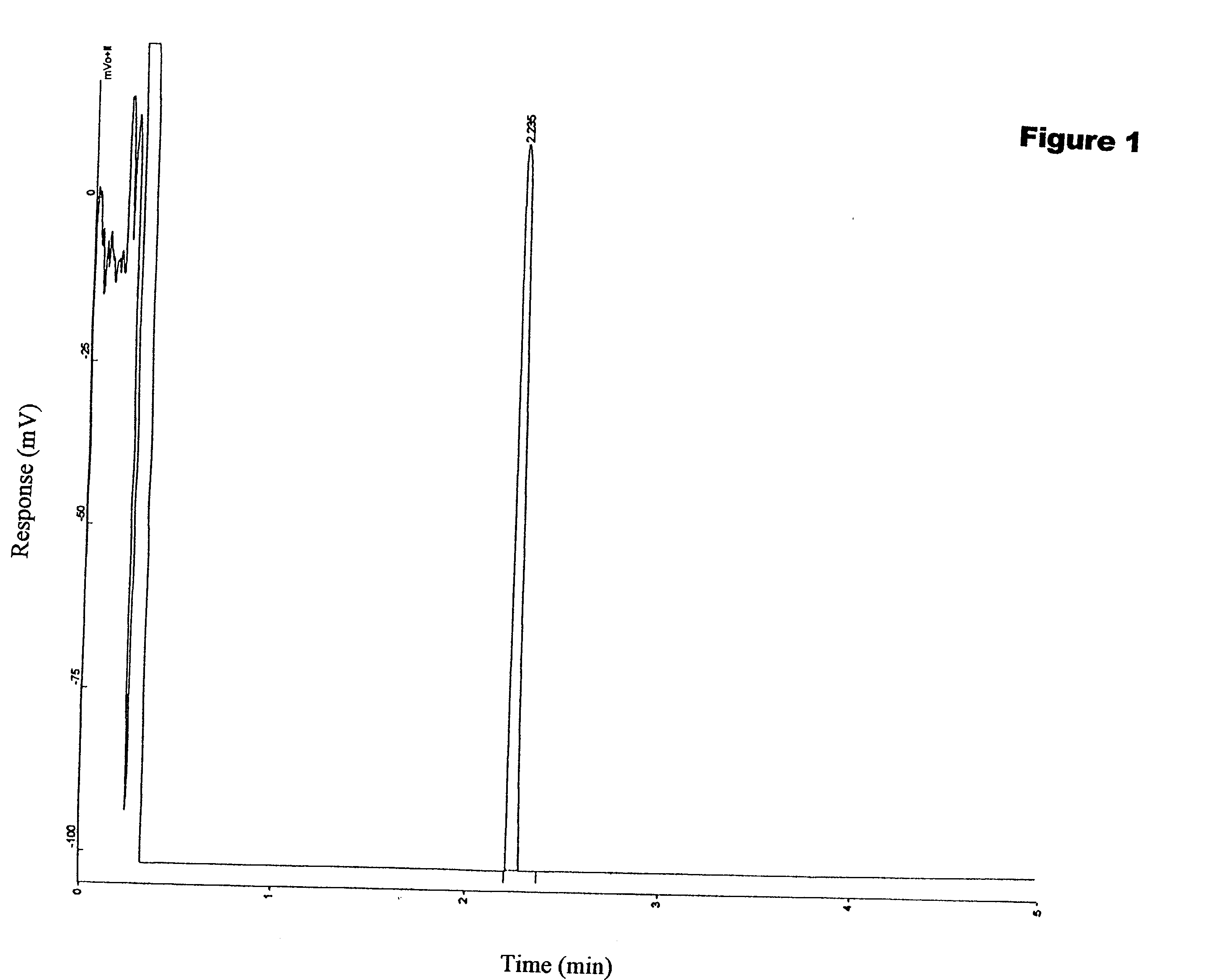

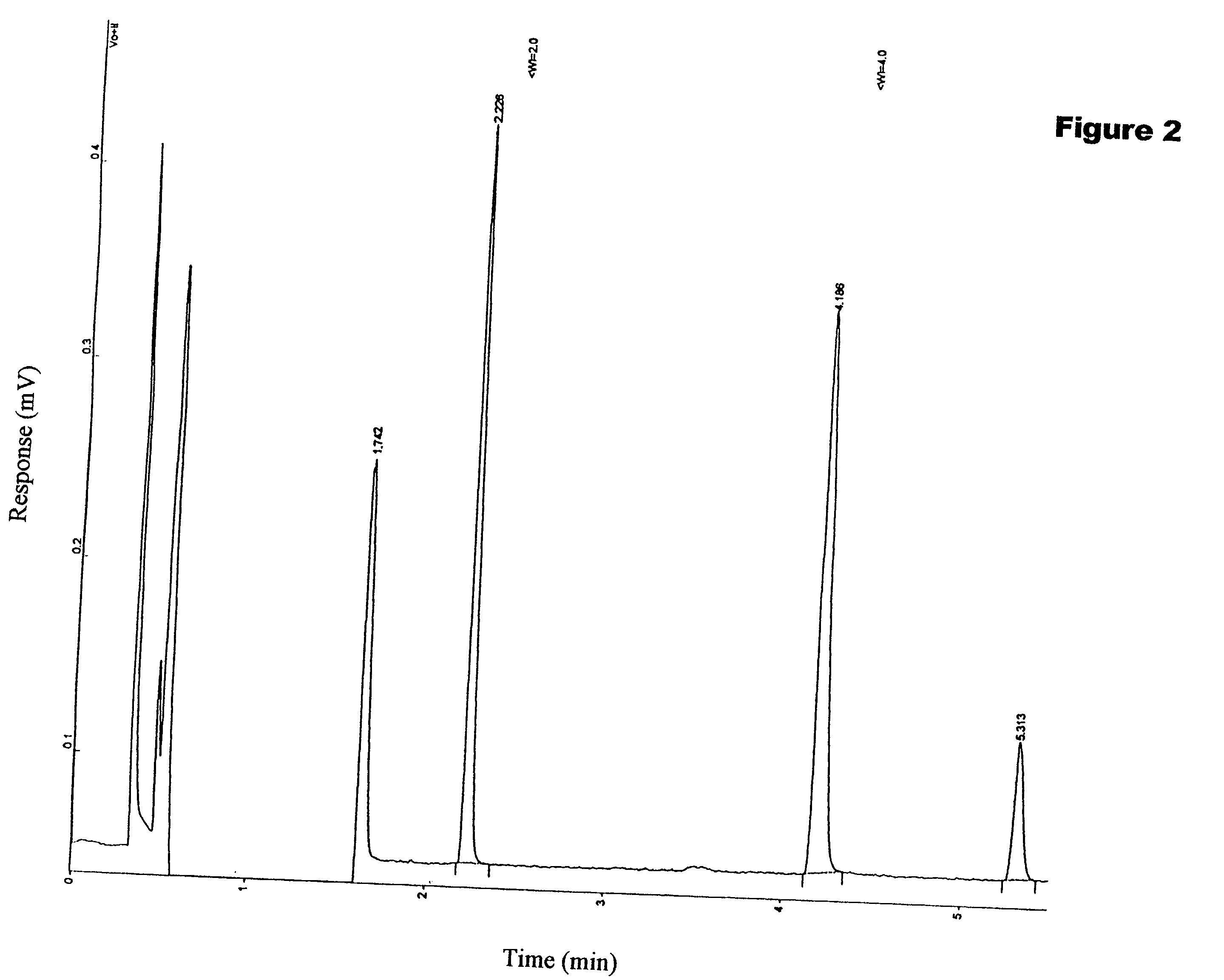

Application of metal-organic framework functional material

ActiveCN105214612AImprove adsorption capacityHigh removal rateOther chemical processesRadioactive decontaminationIonMetal-organic framework

The invention discloses an application of a metal-organic framework functional material, and belongs to the technical field of water processing. A metal-organic framework material is subjected to pre-modification and post-modification, and a series of different functional groups are introduced to an organic ligand or an inorganic metal cluster of the material. The metal-organic framework functional material is used as an adsorbent for removing radioactive ions from nuclear waste. The metal-organic framework material containing sulfate radicals and sulfonate radicals has a preferable adsorption effect on 133Ba<2+>; the maximum removal rate can reach 99.9%; and adsorption equilibrium can be achieved in 5min. By using the functionalized metal-organic framework material, a simple, easy, efficient, and fast novel method is provided for removing 133Ba<2+> from the nuclear waste. The metal-organic framework functional material has significant industrial application value with respect to nuclear pollution management.

Owner:BEIJING UNIV OF CHEM TECH

Molecular sieve adsorbent-catalyst for sulfur compound contaminated gas and liquid streams and process for its use

InactiveUS20020009404A1Enhanced level of sulfur purificationImprove adsorption capacityMolecular sieve catalystsOther chemical processesMolecular sieveAlkaline earth metal

An adsorbent-catalyst for removal of sulphur compounds from sulfur compound contaminated gas and liquid feed streams, wherein the adsorbent-catalyst is a synthetic X or Y faujasite with a silica to alumina ratio from 1.8:1 to about 5:1 and wherein 40 to 90% of the cations of the faujasite include transition metals of Groups IB, IIB and VIIB with the balance of the cations being alkali or alkaline earth metals.

Owner:ZEOCHEM LLC

Ecological greenbelt treatment process and system for treating rural domestic sewage

ActiveCN101948214AEasy to handleLess investmentTreatment using aerobic processesWaste based fuelConstructed wetlandReclaimed water

The invention relates to an ecological greenbelt treatment process for treating rural domestic sewage, which mainly comprises the steps of: (1) anaerobic pretreatment: performing anaerobic hydrolysis pretreatment to domestic sewage; (2) artificial wetland treatment: performing artificial wetland treatment to pretreated domestic sewage; and (3) shallow ecological pond aerobic biotreatment: further performing shallow ecological pond aerobic biotreatment to outlet water treated by the artificial wetland, degrading and converting organic matters and nutrients entering the pond, and recycling purified sewage as a regenerated water resource. The invention adopts an ecological greenbelt treatment system comprising the anaerobic pretreatment, the artificial wetland and the shallow ecological pond to treat the rural domestic sewage, and has the characteristics of good treatment effect, recycling on site, low investment, low system operating cost, simple maintenance, obvious ecological benefit and the like.

Owner:浙江博世华环保科技有限公司

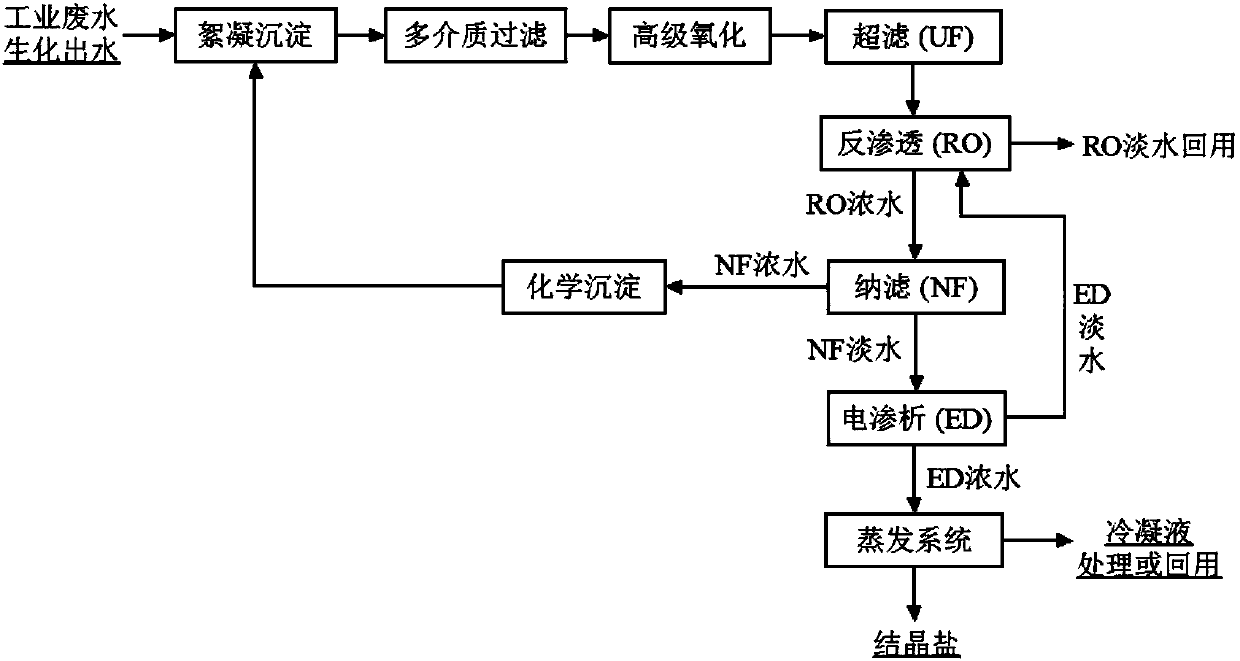

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Treatment method of waste water containing organic phosphorus

ActiveCN101704606AHigh removal rateEasy to operateWater contaminantsMultistage water/sewage treatmentElectrochemical responseElectrolysis

The invention relates to a treatment method of waste water containing organic phosphorus, comprising the following steps: leading process waste water containing organic phosphorus to pass through a sand filtration tank for removing suspended matter and then adjusting the pH value thereof to 3-4; leading the process waste water to pass through a high-efficient catalytic oxidation apparatus, adding hydrogen peroxide for conducting oxidative degradation of the process waste water; then introducing the process waste water to a catalytic micro-electrolysis device, adding scrap iron and activated carbon and stirring, conducting electrochemical reaction, blasting air into the lower part of the catalytic micro-electrolysis device, and removing hard-degradable organic matter in the process waste water; and introducing the effluent of the catalytic micro-electrolysis device into an oxidation kettle, adding hydrogen peroxide for conducting multistage oxidation treatment, later adding lime, adjusting the pH value of the process waste water to 8-9, then adding flocculant for conducting precipitation, and forming ironic phosphate and calcium phosphate precipitate, thus removing phosphorus in the waste water. Compared with the prior art, the treatment method transforms the organic phosphorus into inorganic phosphorus for removal and has high removal rate of total phosphorus and low running cost, and the formed phosphate can be recycled and reused.

Owner:CAC NANTONG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com