Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3046results about How to "Achieve cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

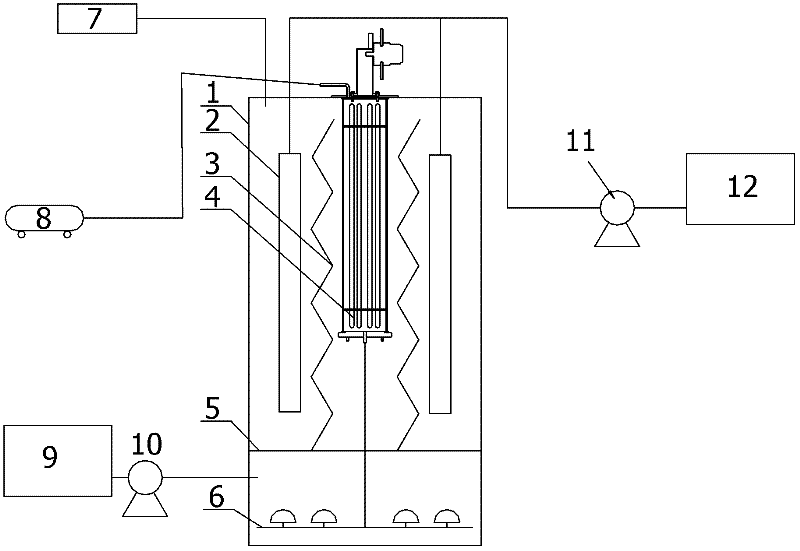

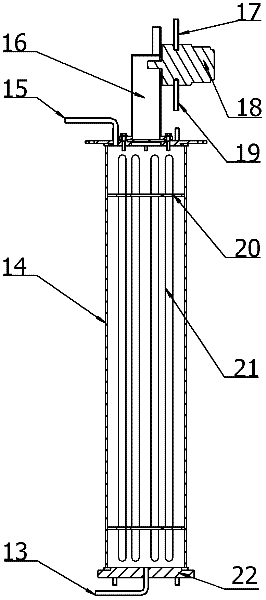

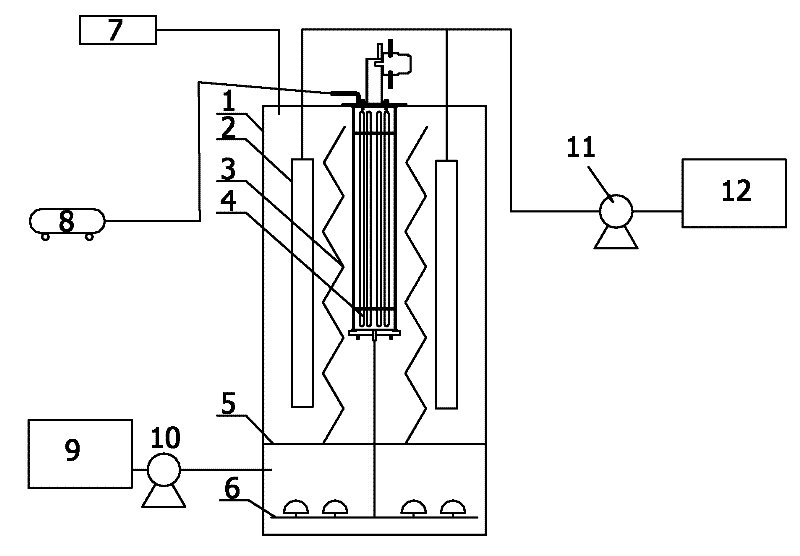

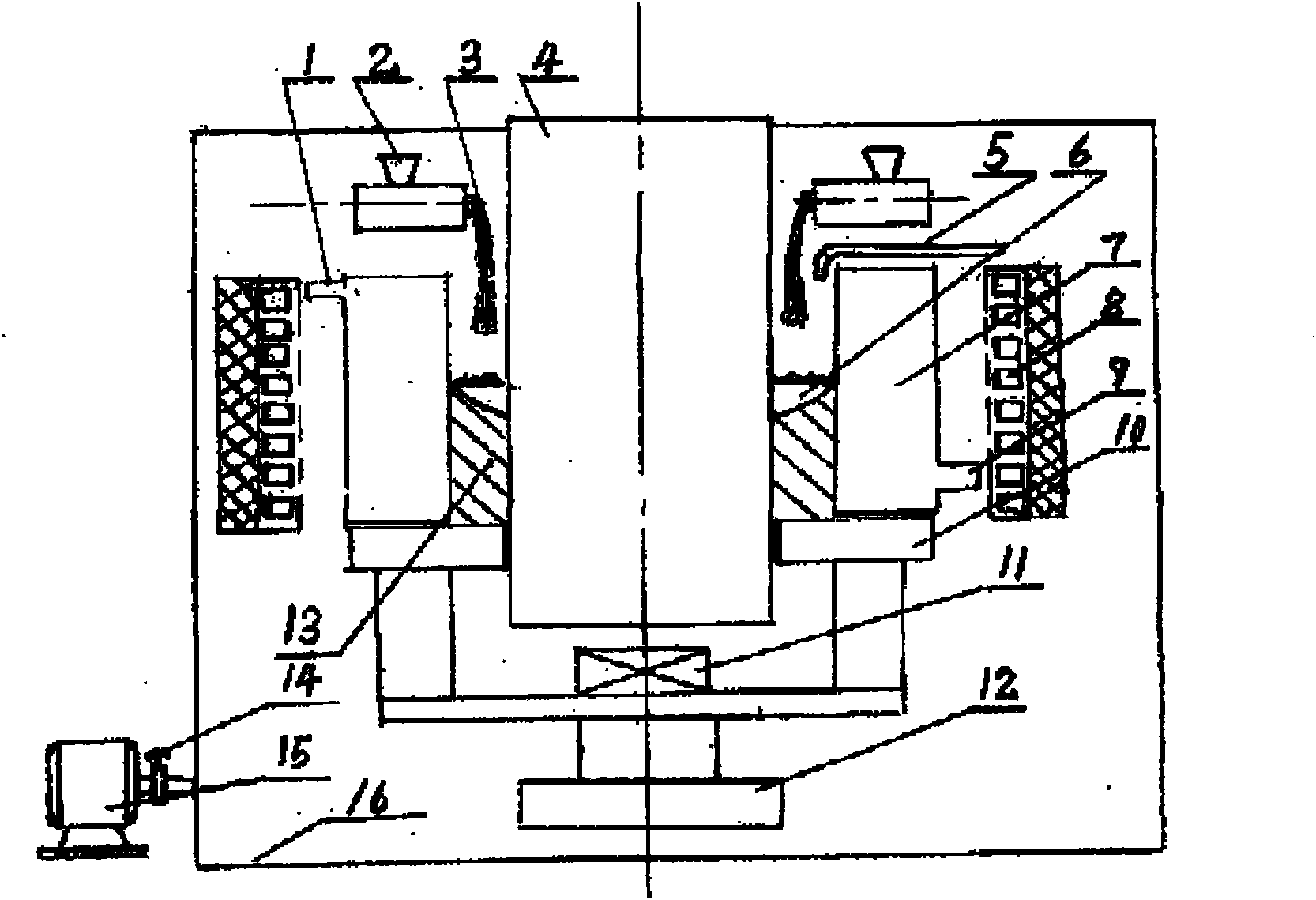

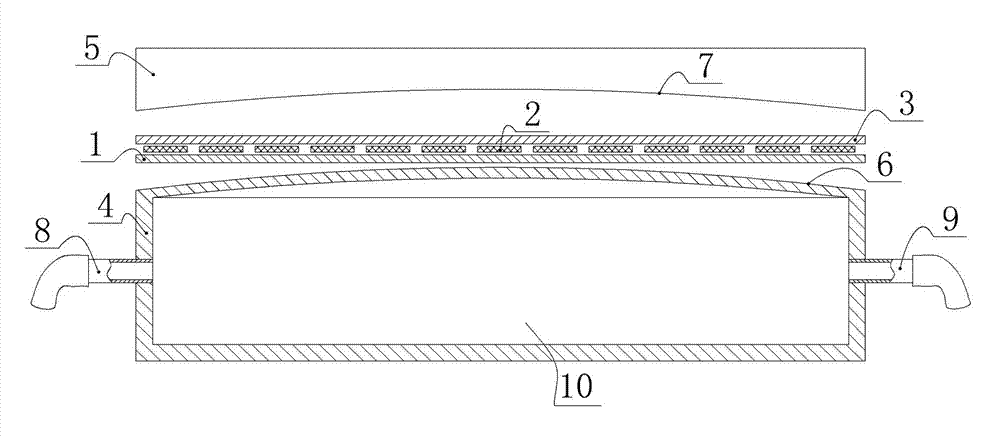

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

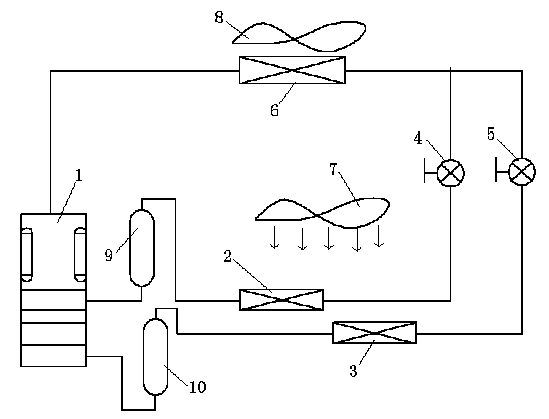

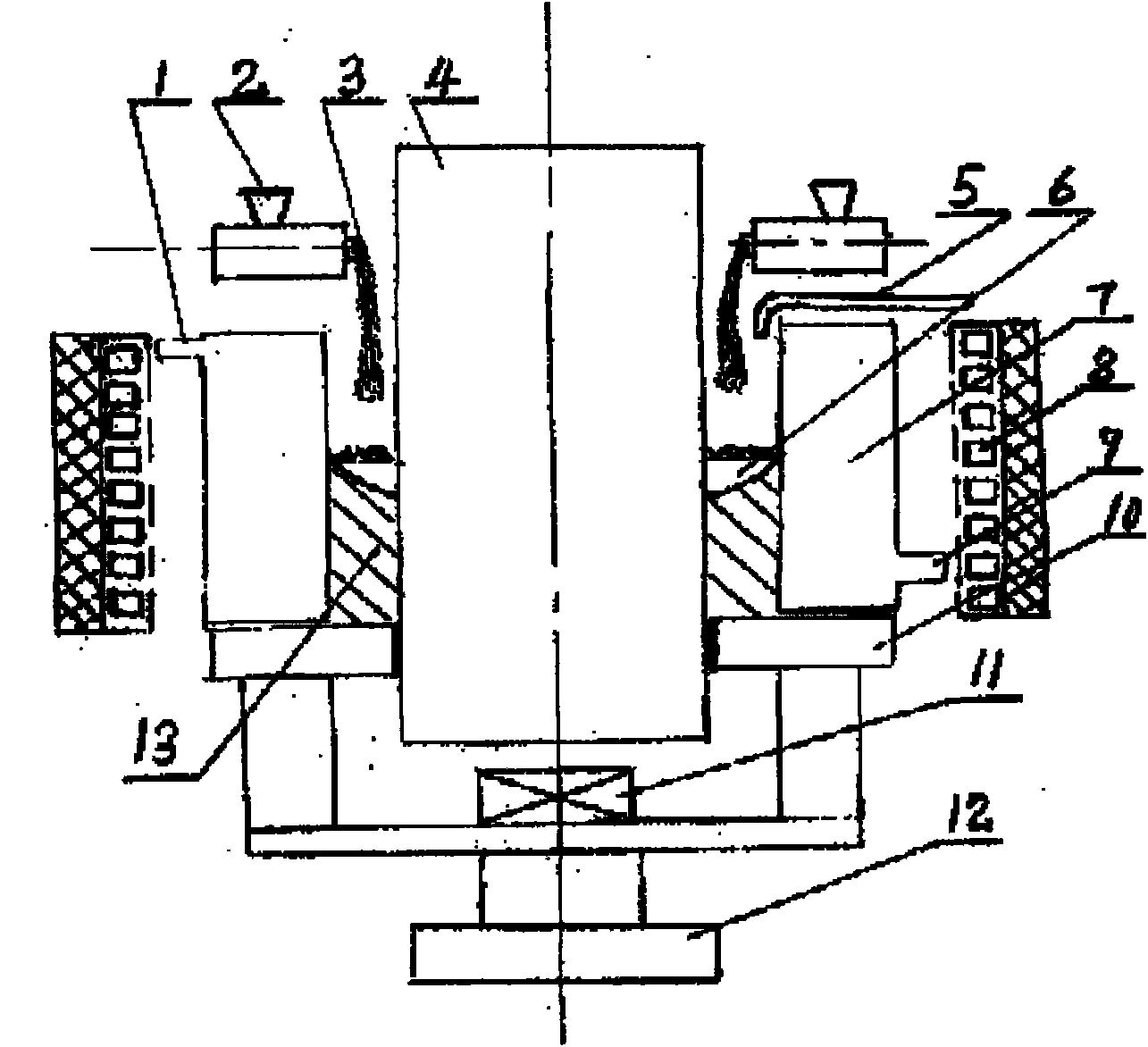

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

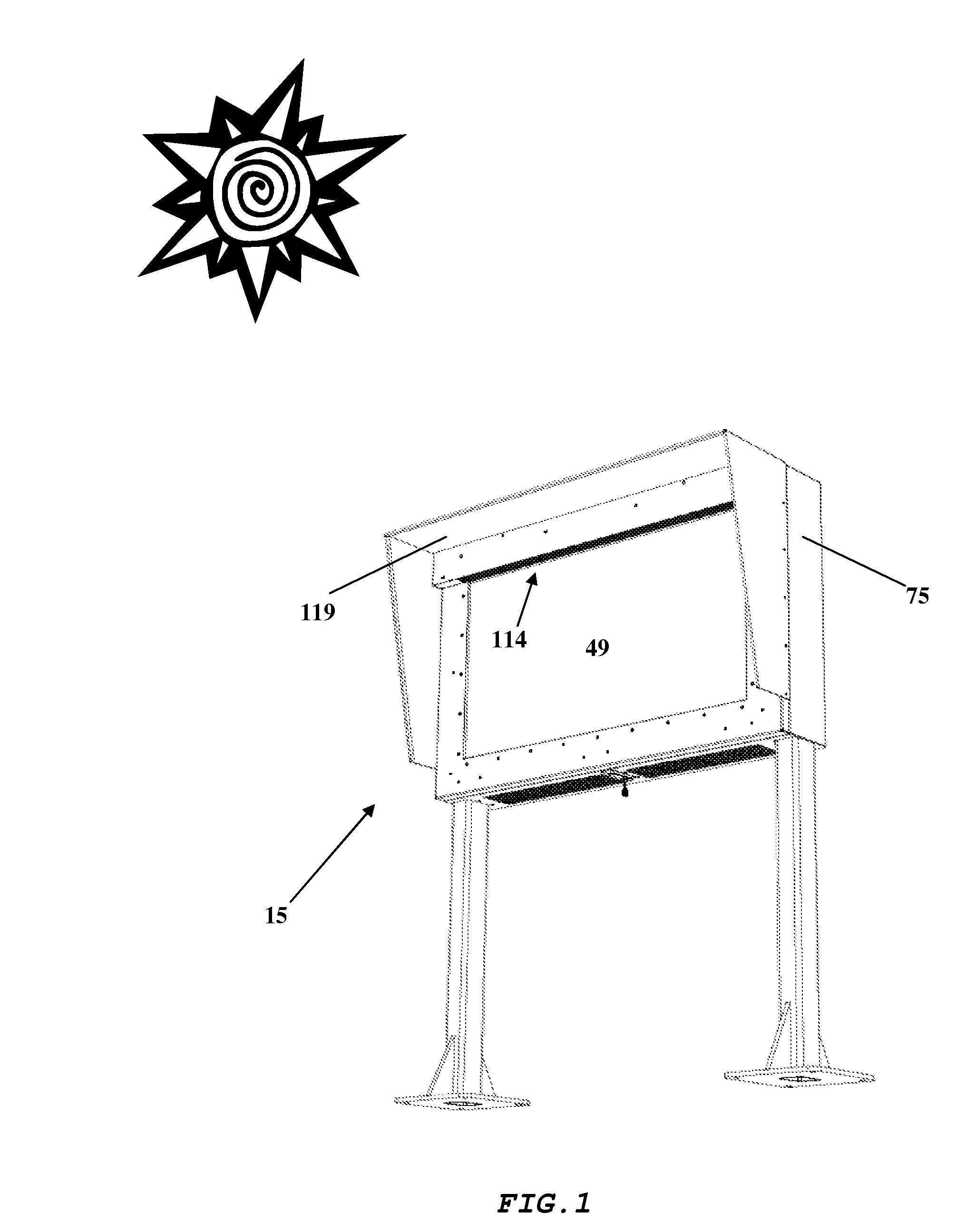

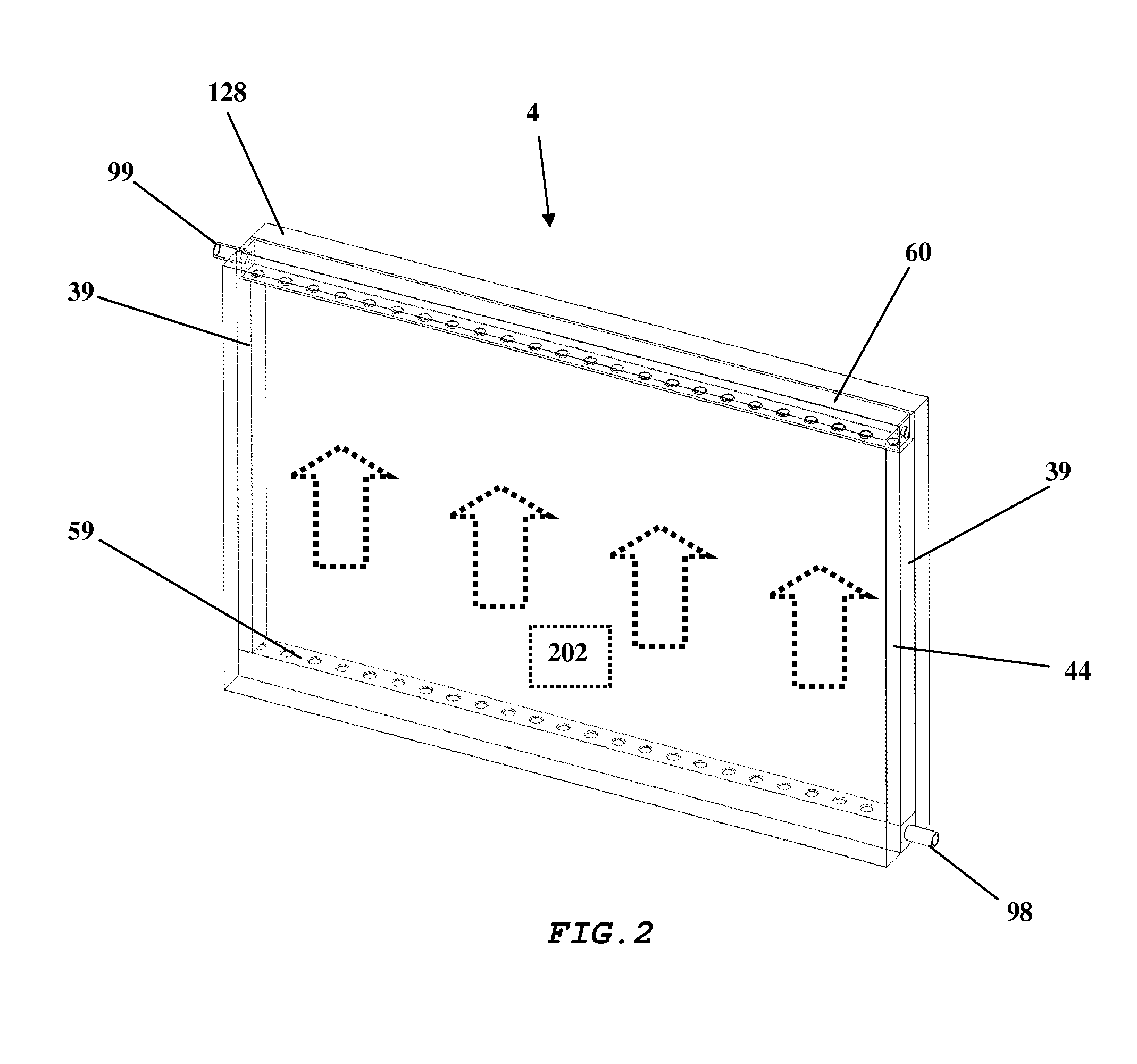

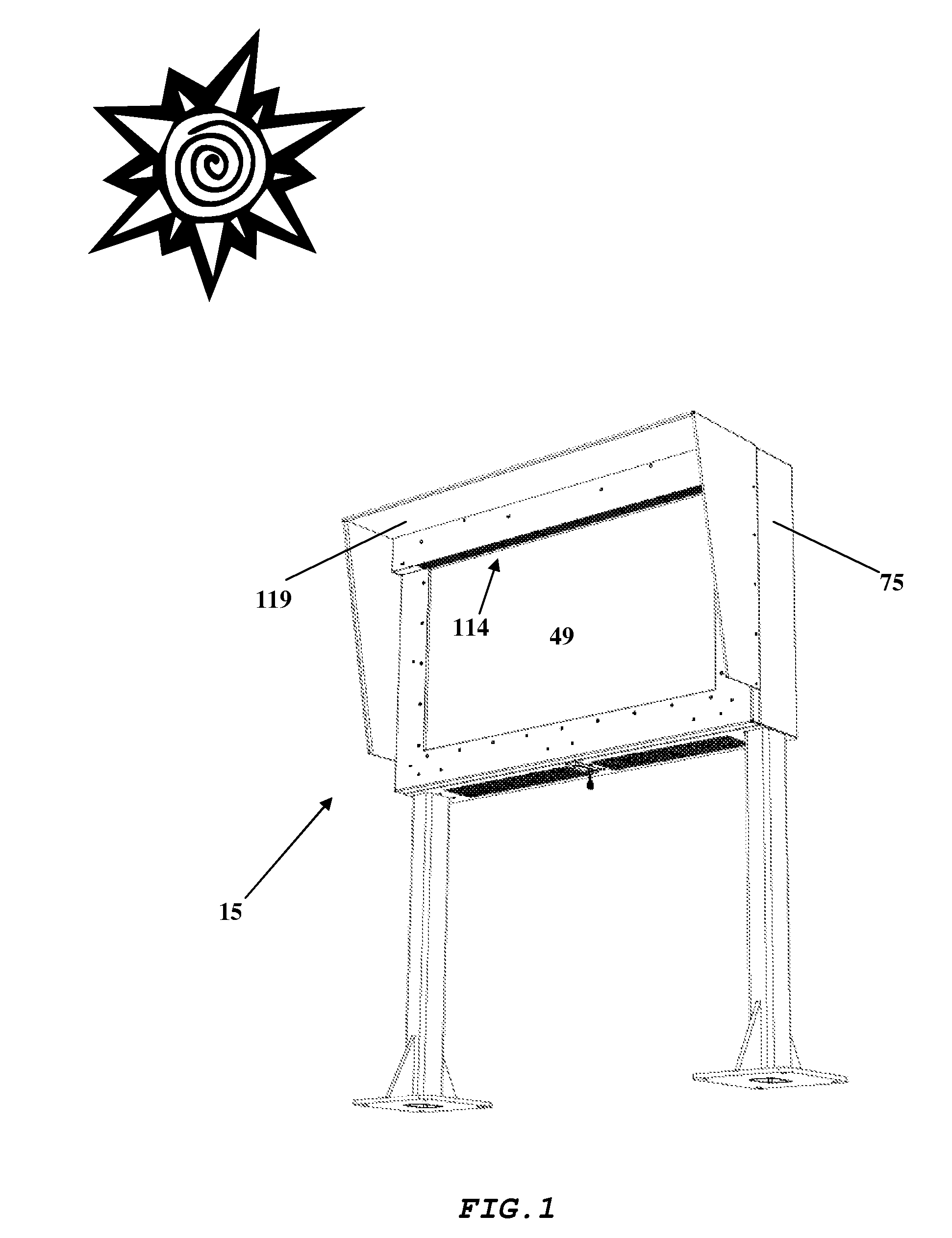

Gas station television

InactiveUS20090129021A1Reduce heatTemperature fluctuationNon-linear opticsCooling/ventilation/heating modificationsImaging qualityNuclear engineering

Preferred embodiments relates to a cooling system and a method for cooling an electronic display. Embodiments include a transparent liquid cooling chamber, a reservoir tank, and a pump. The components in the system are preferably housed within the electronic display housing. The cooling chamber defines a fluid compartment that is anterior to and coextensive with the electronic display surface. Circulating coolant removes heat directly from the electronic display surface by advection. In order to view the display, the coolant fluid is transparent or at least semi-transparent. The image quality of an exemplary embodiment remains essentially unchanged, even though coolant is flowing over the visible face of the electronic display surface.

Owner:MFG RESOURCES INT INC

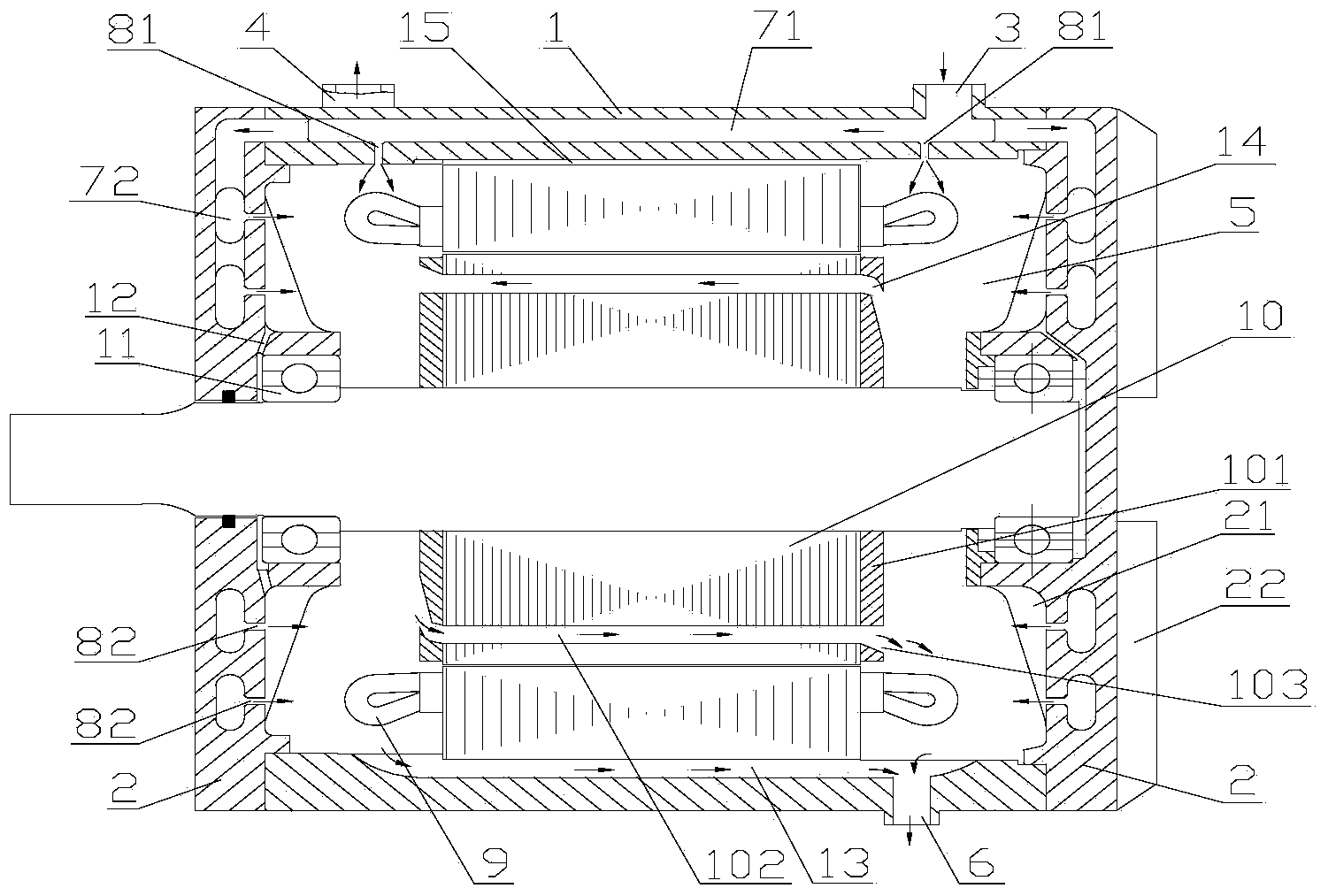

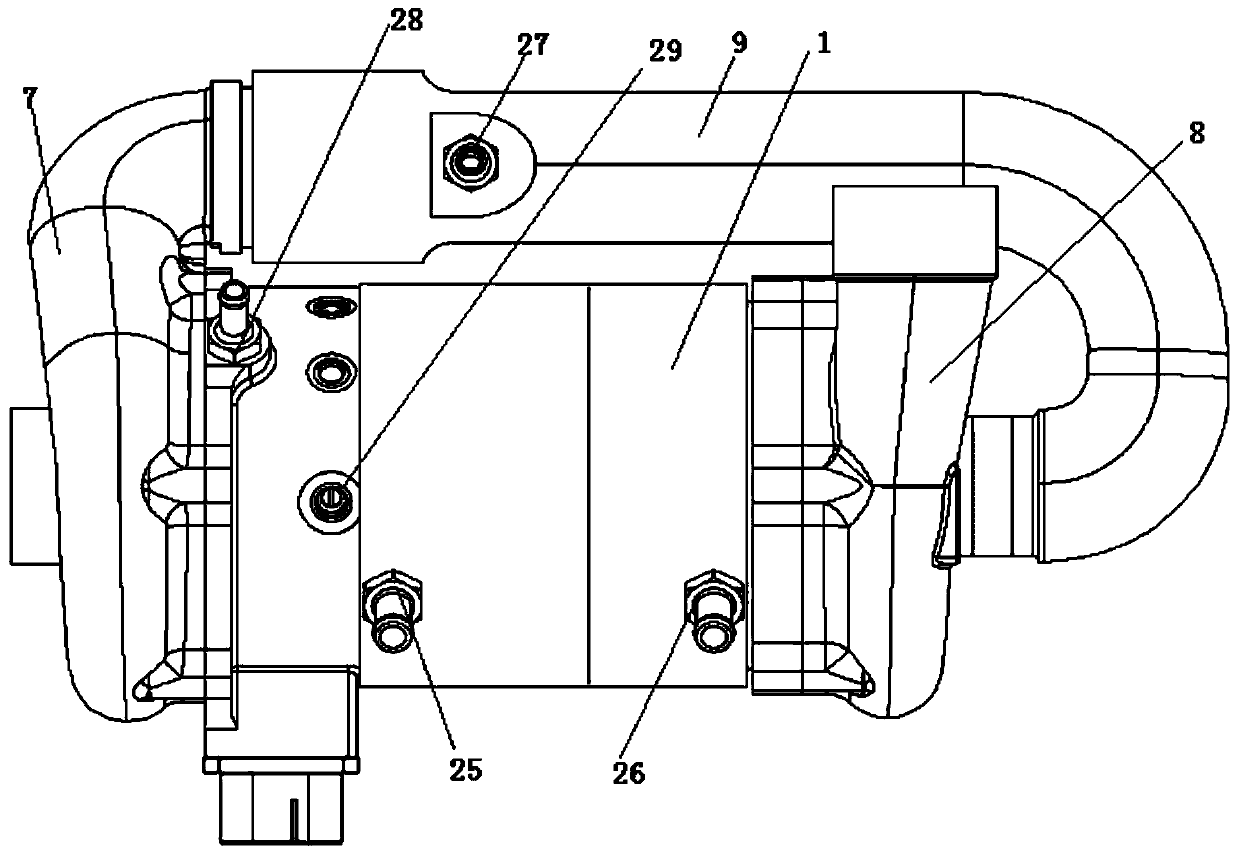

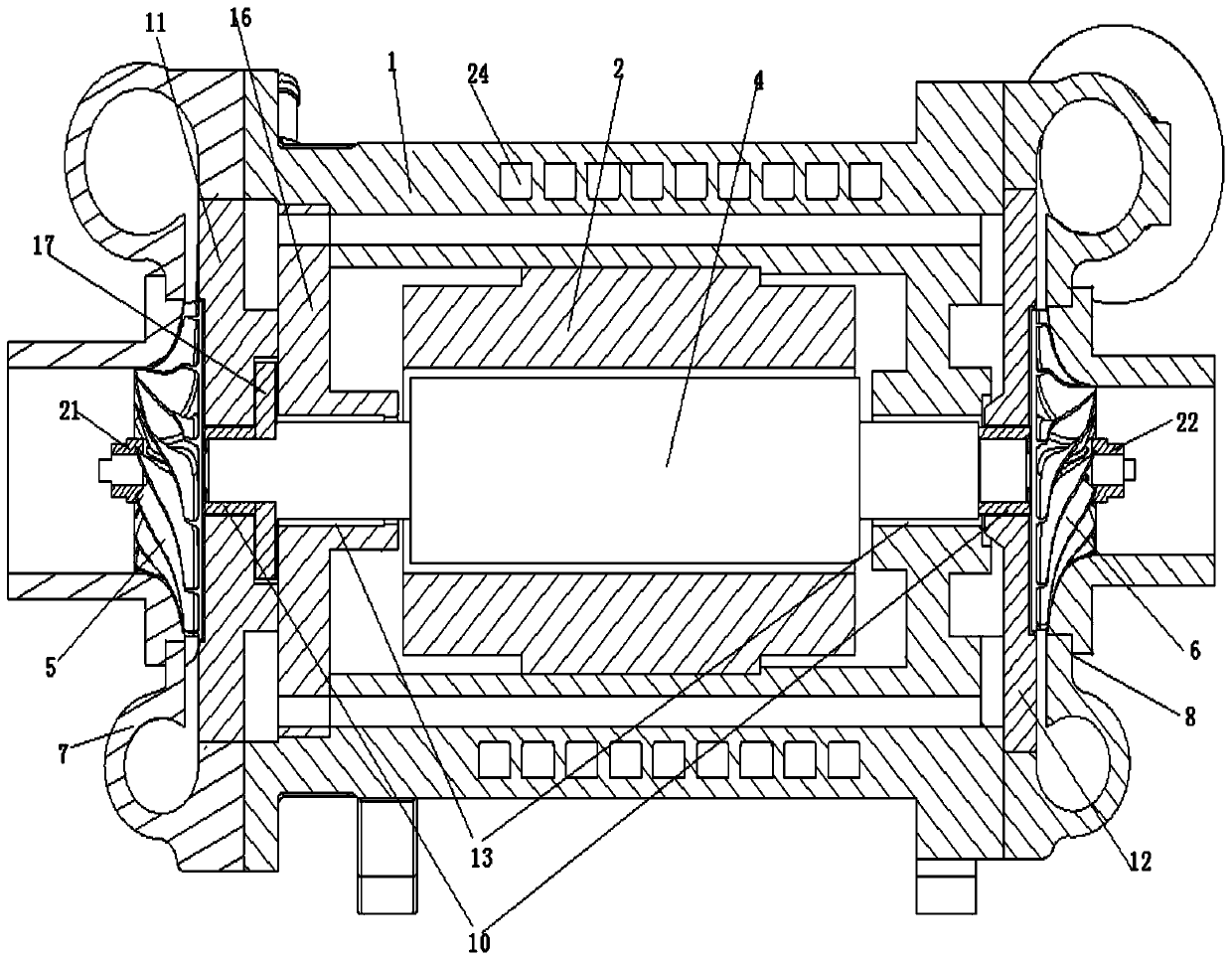

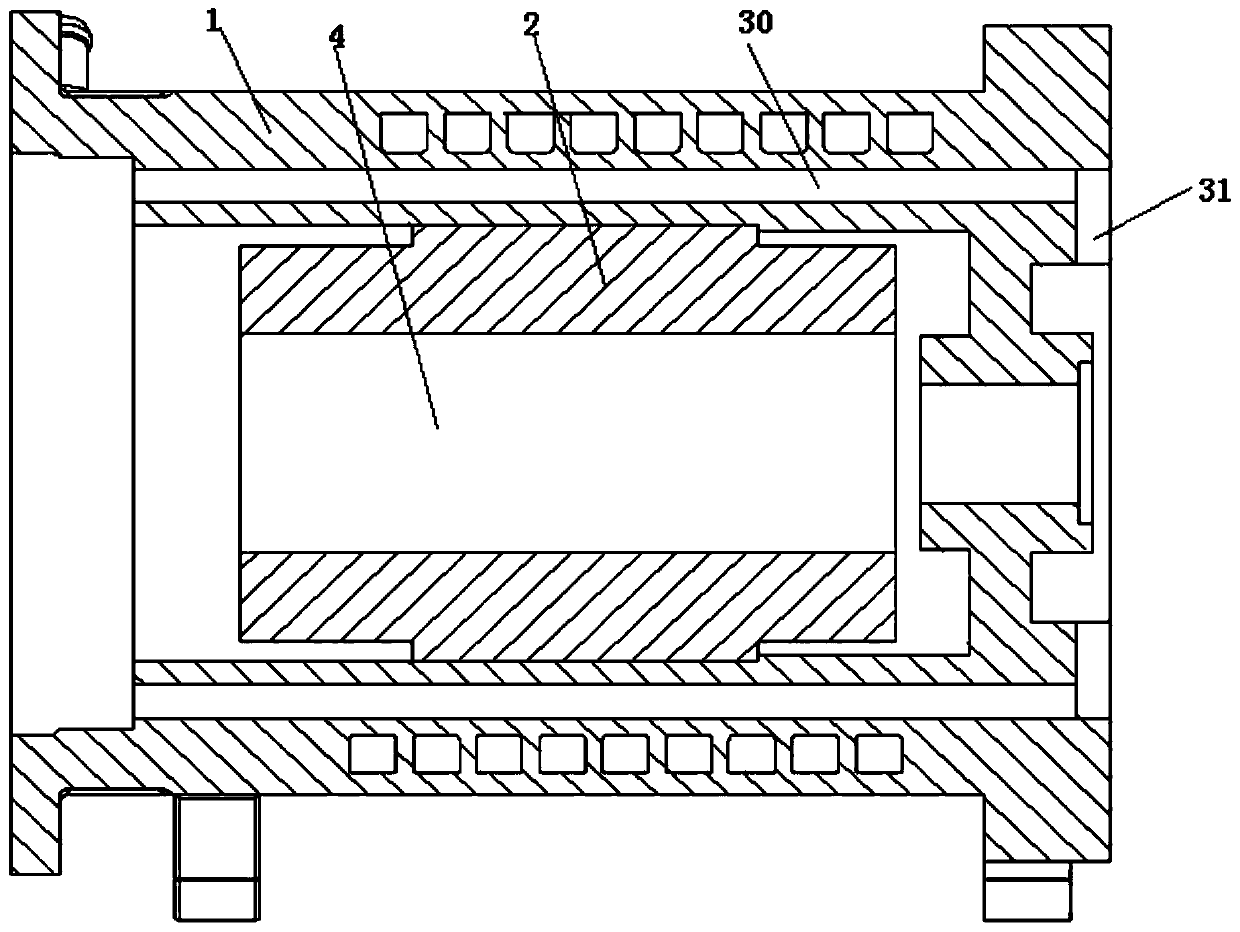

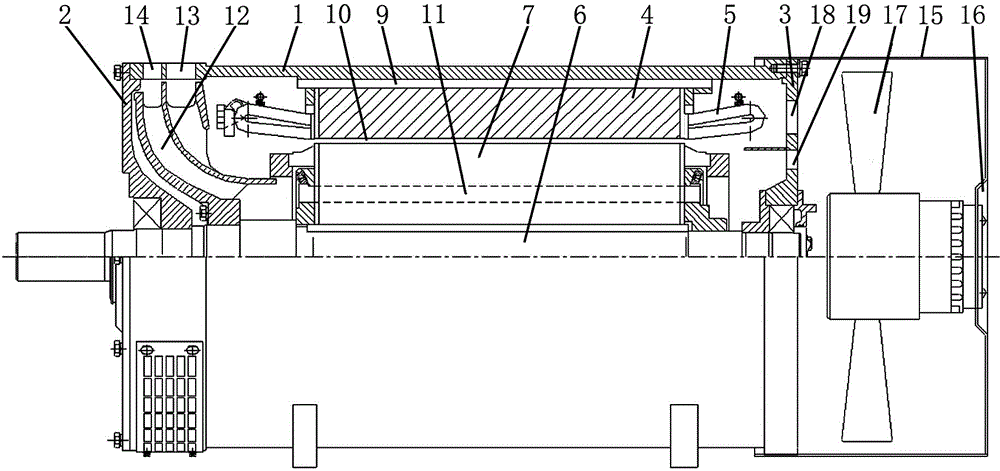

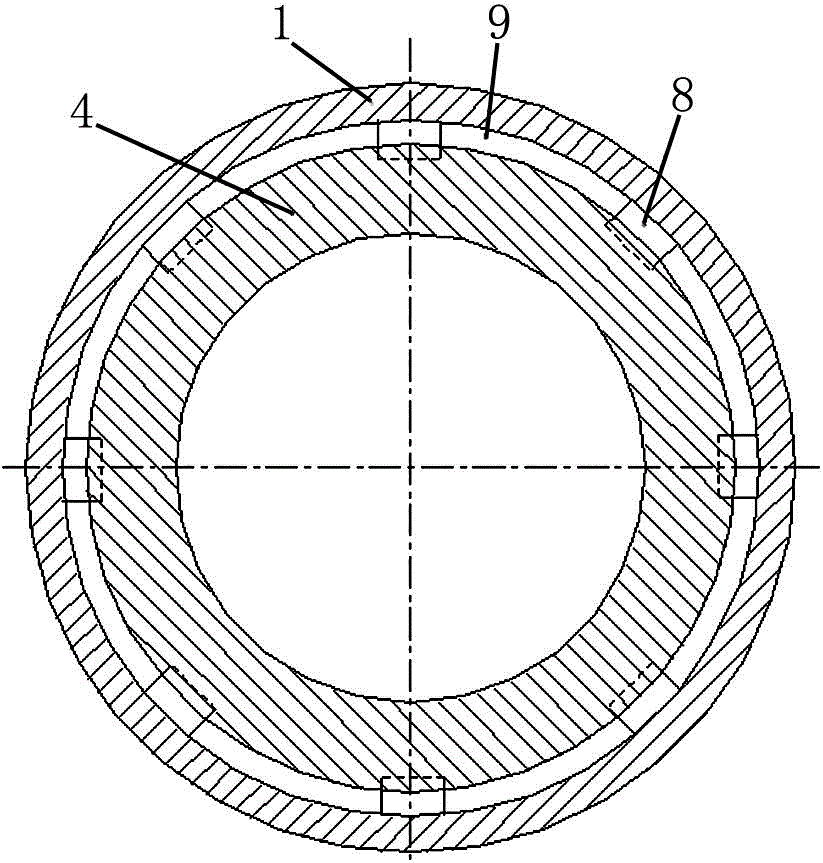

Permanent magnet synchronous traction motor and oil cooling device thereof

ActiveCN103532307AAchieve coolingImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsWork performanceOil cooling

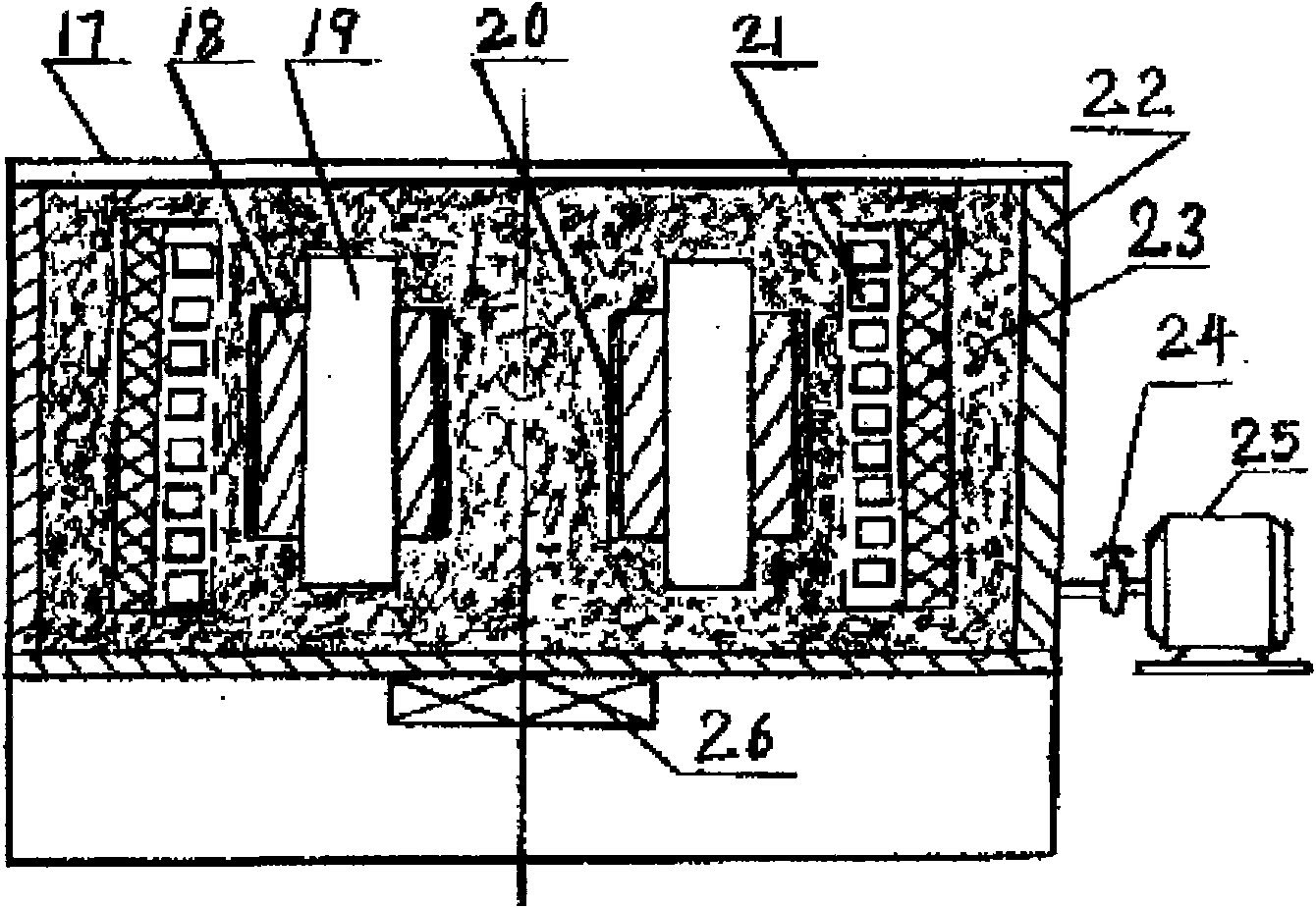

The invention discloses an oil cooling device used for a permanent magnet synchronous traction motor. The oil cooling device comprises a cooling channel formed in a shell and an end cover; the cooling channel is communicated with an external oil supplying pipeline by an oil inlet and is communicated with an external oil returning pipeline by a first oil outlet; an oil spraying port is formed in the shell and / or the end cover and is communicated with the cooling channel and an inner cavity of the permanent magnet synchronous traction motor; a second oil outlet is formed in the shell; the inner cavity is communicated with the external oil returning pipeline by the second oil outlet to guide cooling oil in the inner cavity. In such a mode, the oil cooling device can realize the direct cooling of the shell and the end cover, and meanwhile, the inner structure of the shell can be directly and effectively cooled by the cooling oil entering the inner cavity from the oil spraying port, so the cooling efficiency of the oil cooling device is improved, and the work performance of the oil cooling device is improved. The invention also discloses a permanent magnet synchronous traction motor comprising the oil cooling device.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST +1

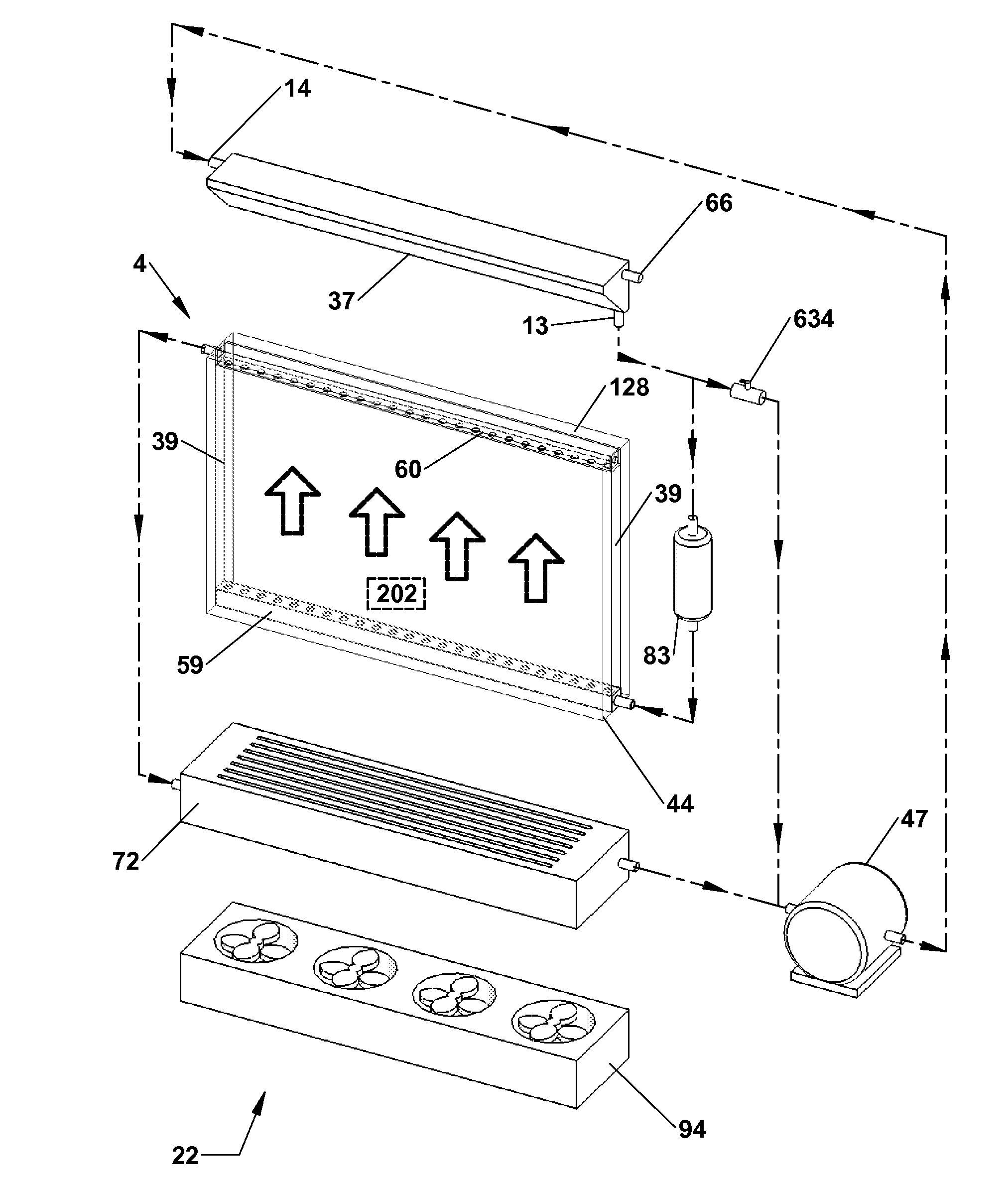

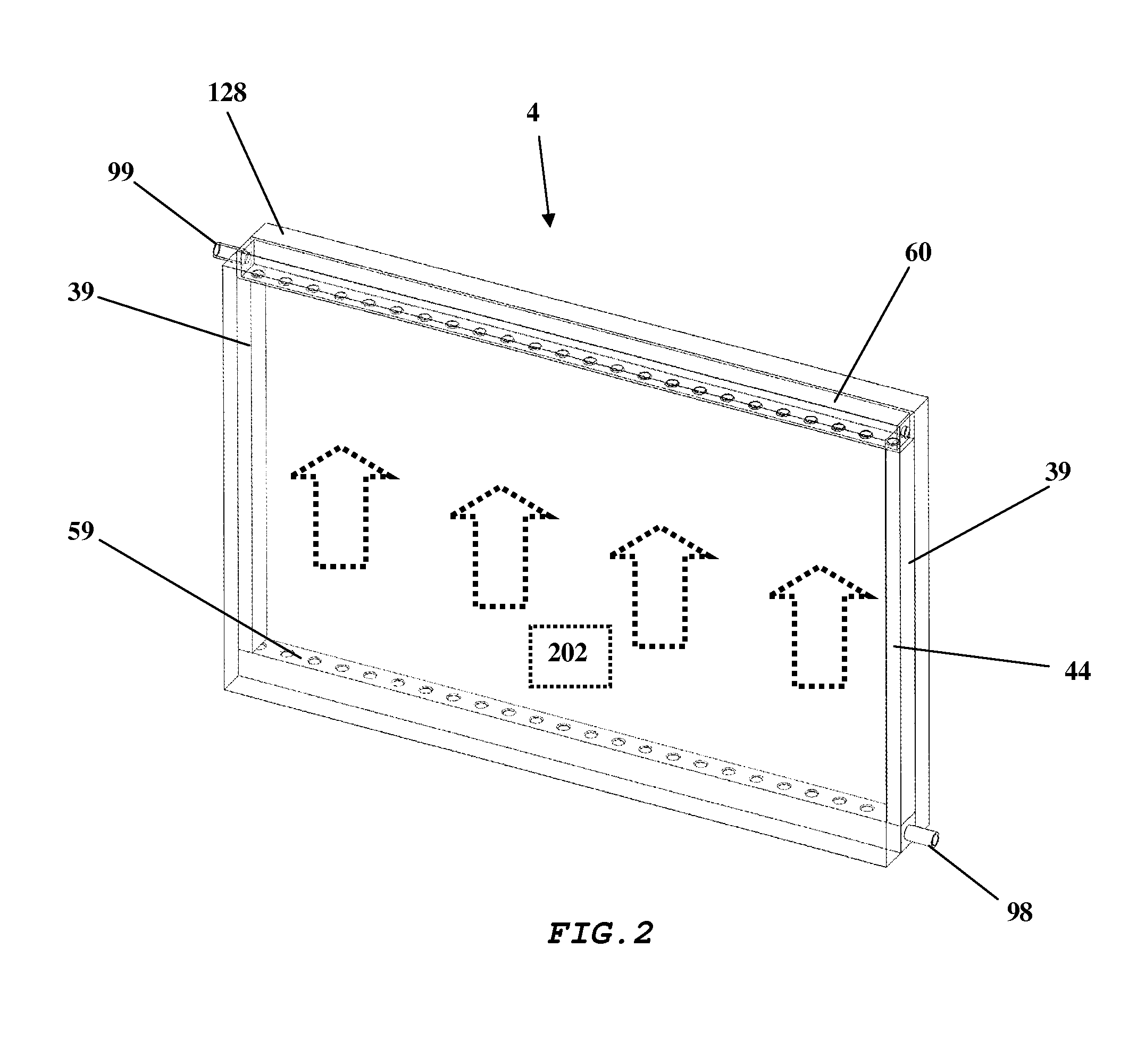

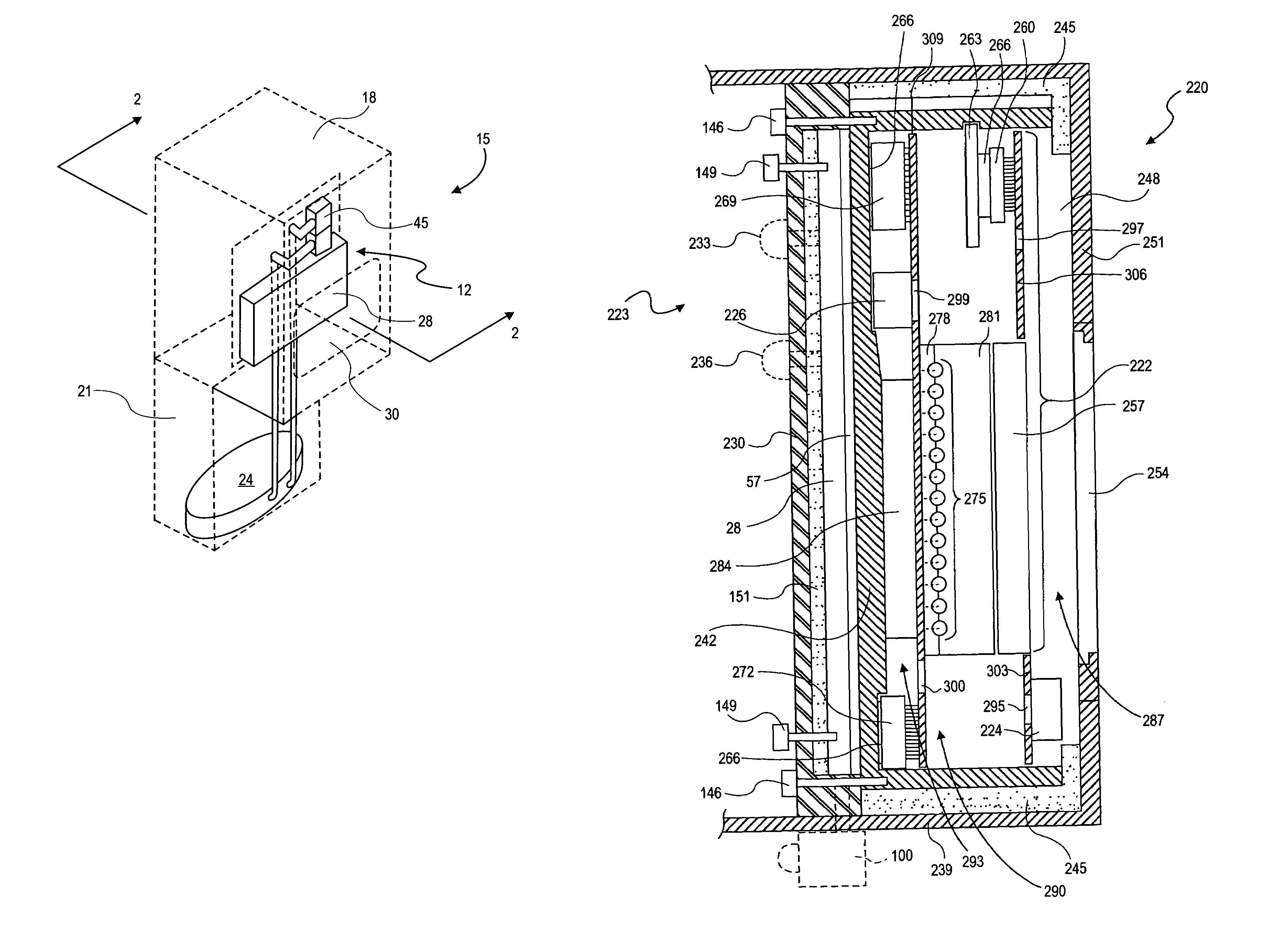

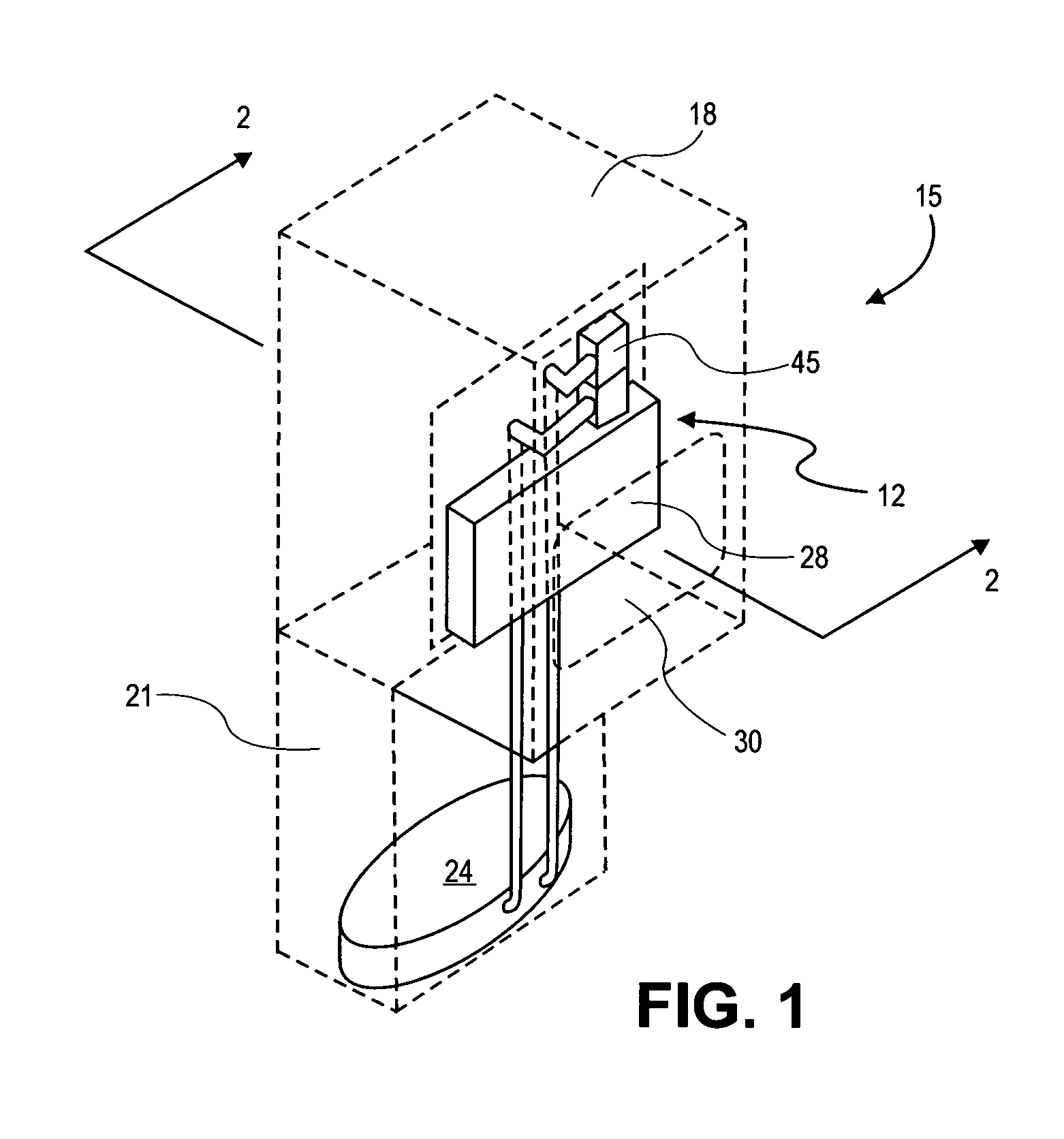

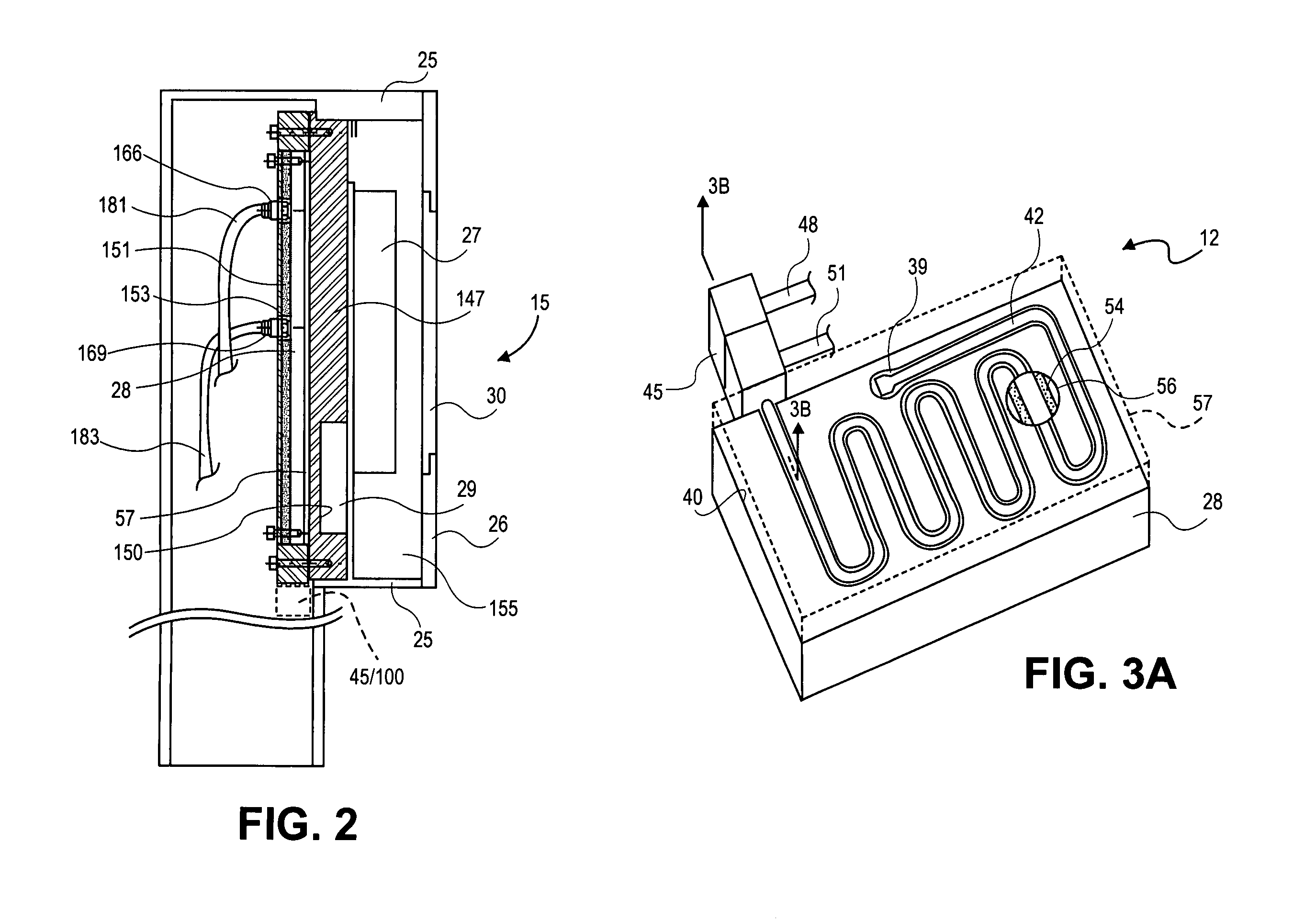

Fluid cooled display

InactiveUS8208115B2Temperature fluctuationImprove cooling effectNon-linear opticsCooling/ventilation/heating modificationsFluid compartmentsImaging quality

Preferred embodiments relates to a cooling system and a method for cooling an electronic display. Embodiments include a transparent liquid cooling chamber, a reservoir tank, and a pump. The components in the system are preferably housed within the electronic display housing. The cooling chamber defines a fluid compartment that is anterior to and coextensive with the electronic display surface. Circulating coolant removes heat directly from the electronic display surface by advection. In order to view the display, the coolant fluid is transparent or at least semi-transparent. The image quality of an exemplary embodiment remains essentially unchanged, even though coolant is flowing over the visible face of the electronic display surface.

Owner:MFG RESOURCES INT INC

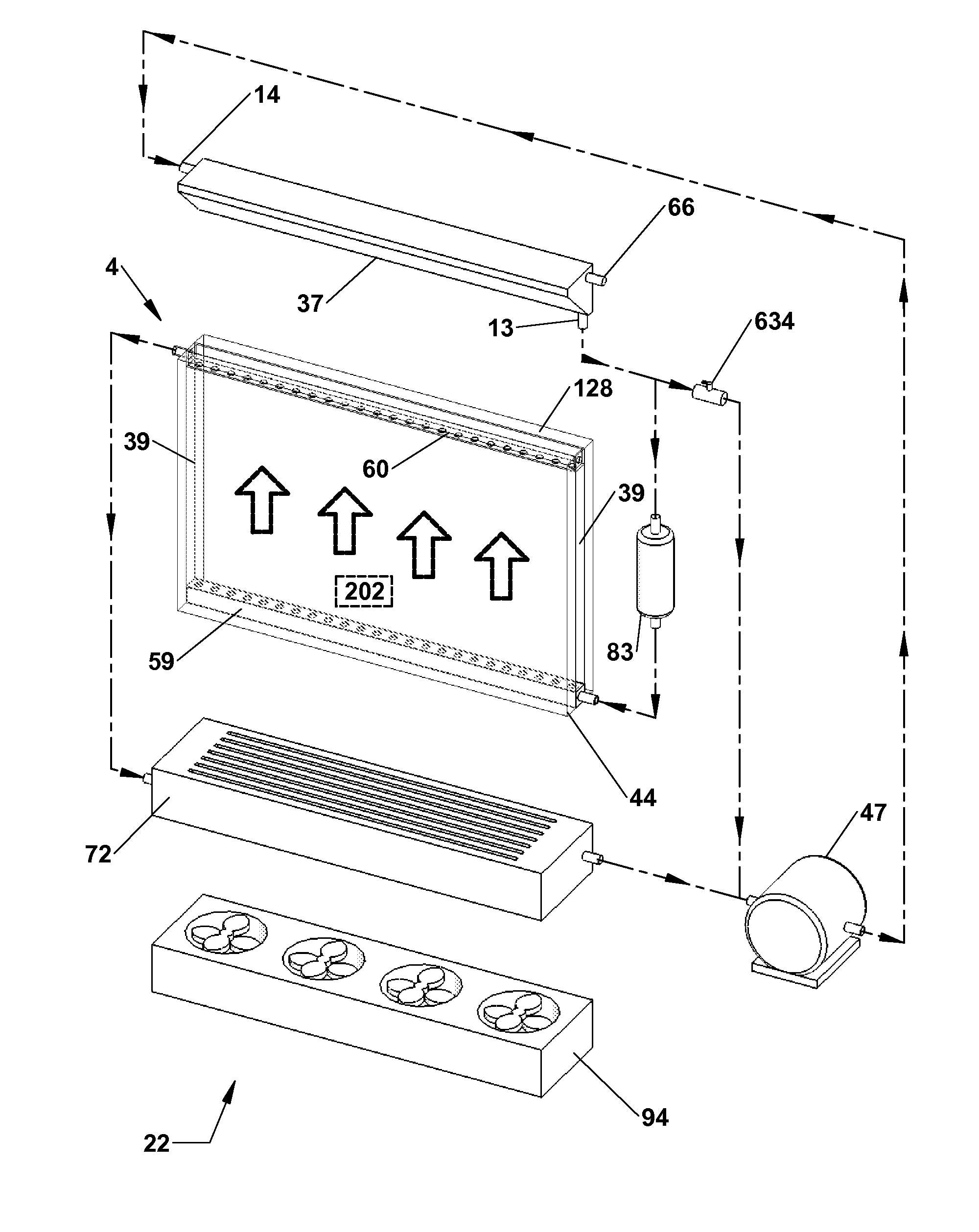

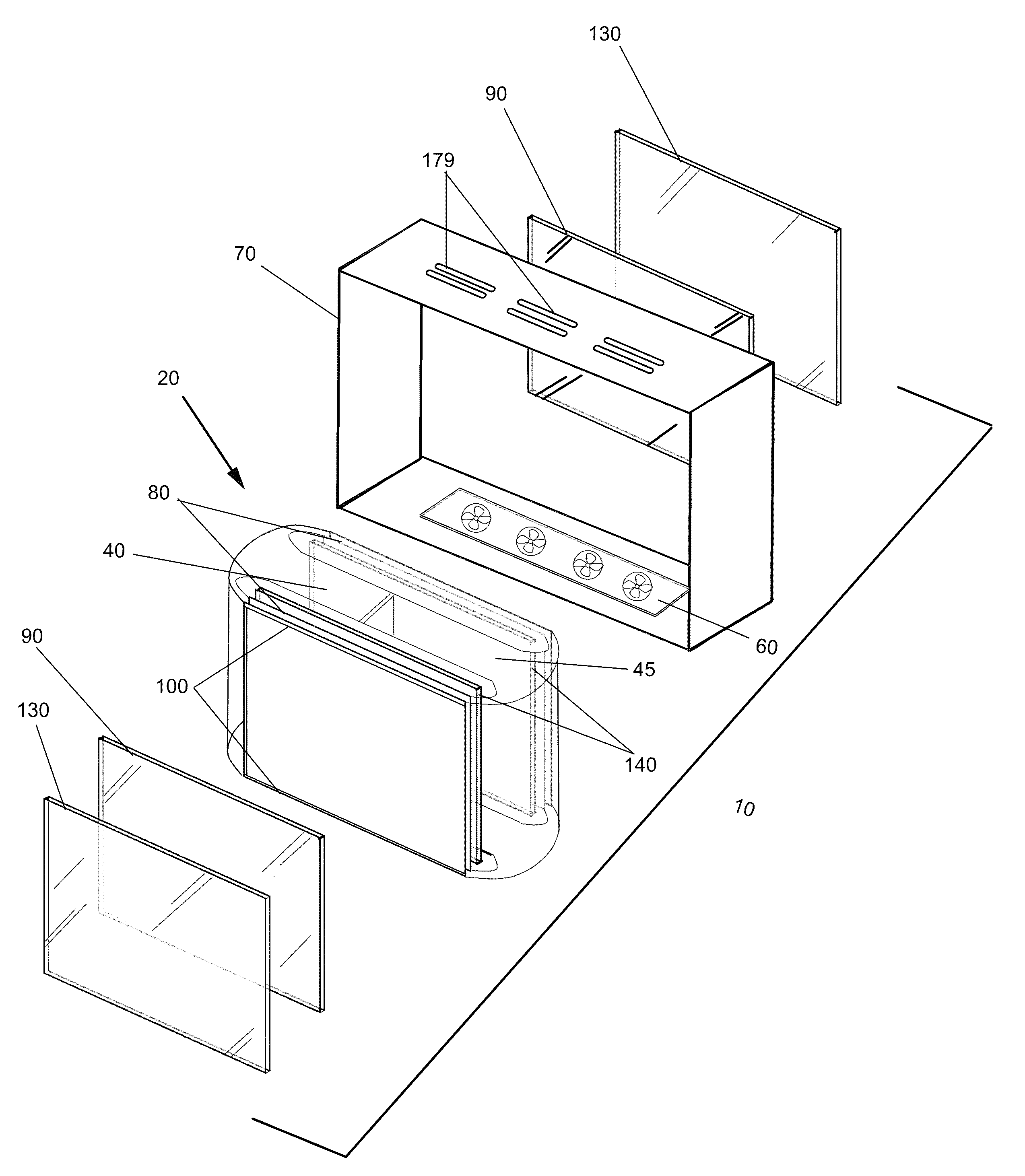

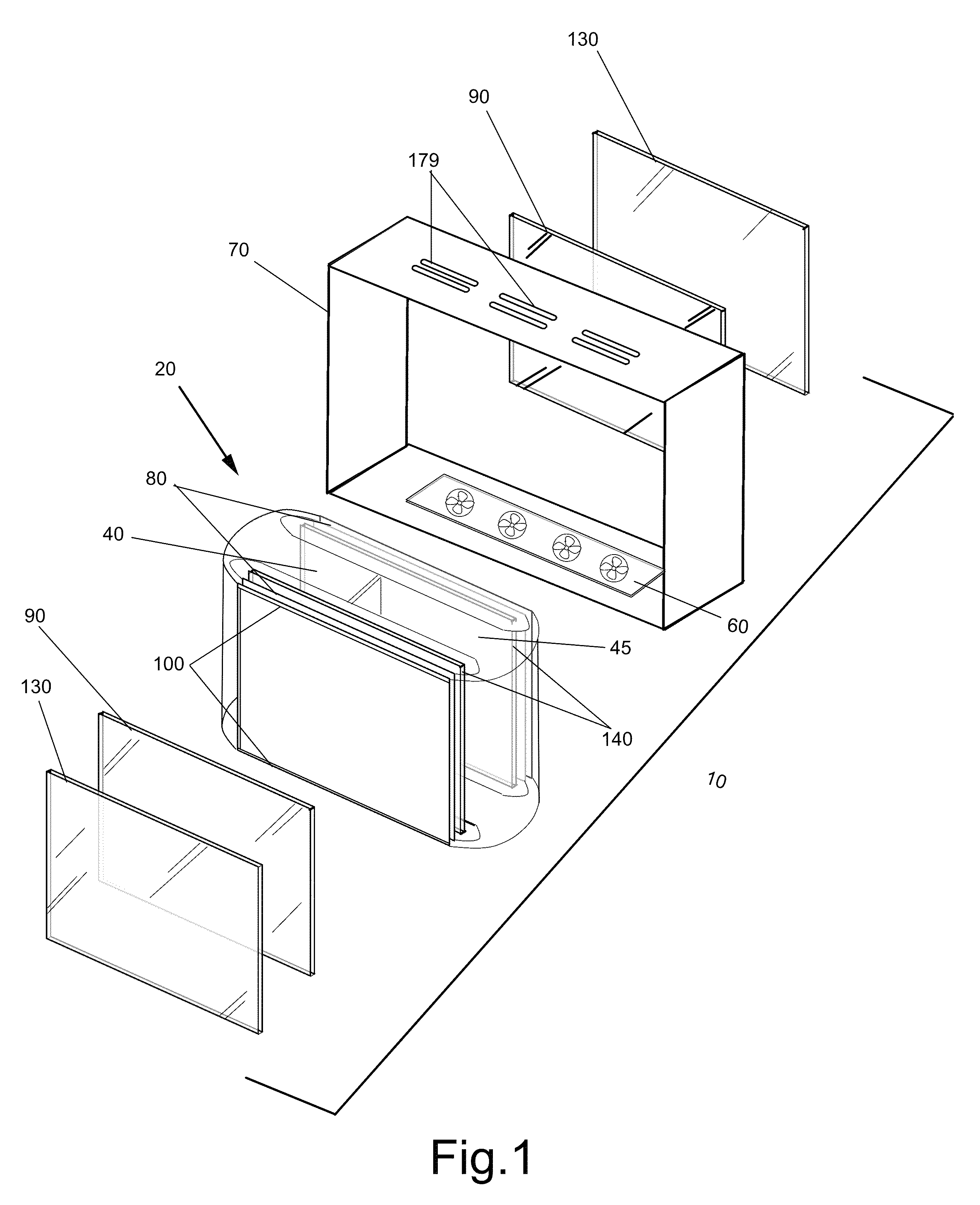

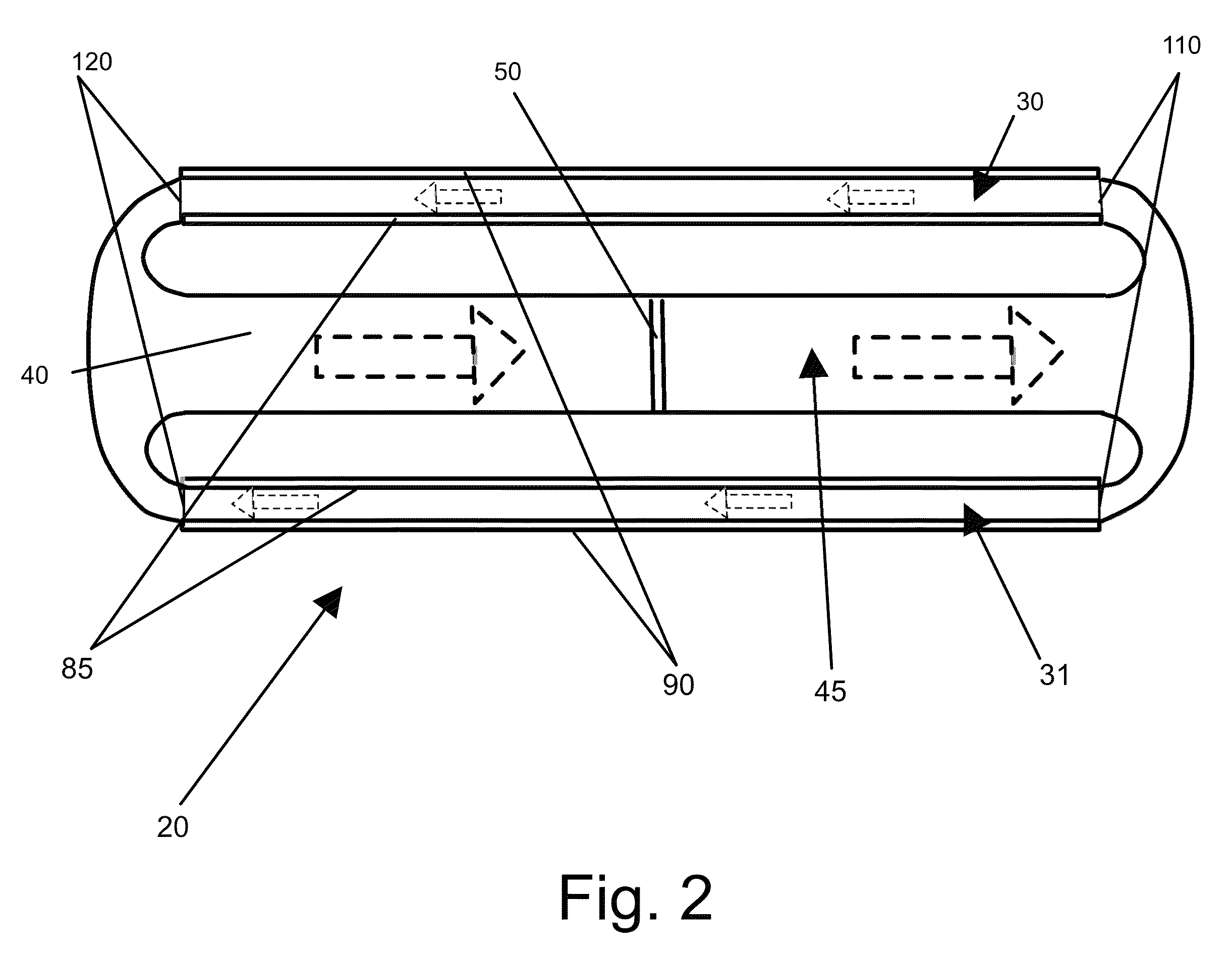

Shared isolated gas cooling system for oppositely facing electronic displays

ActiveUS8373841B2Temperature fluctuationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringImaging quality

A system and method for cooling back to back electronic displays. Transparent first and second gas chambers are co-existive with the front display surfaces of the first and second electronic displays. A closed loop of isolated gas enters the first and second gas chambers and contacts the front surfaces of the electronic displays, where it may extract heat from the front display surfaces. The isolated gas is then directed into a cooling chamber where it is cooled and re-introduced into the first and second gas chambers. Fans may be used to propel the isolated gas through the cooling chamber and the first and second gas chambers. The circulating gas removes heat directly from the electronic display surfaces. The isolated gas is transparent or at least semi-transparent to ensure that the image quality of the electronic displays is minimally impacted.

Owner:MFG RESOURCES INT INC

Cooling system for an electronic display

InactiveUS7161803B1Temperature fluctuationImprove life expectancyModifications for display panelsIndirect heat exchangersGas phaseCollector device

A cooling system for an electronic display may include a heat collector plate with internal gas and liquid phase lines. The cooling plate may be thermally isolated together with electronic components of the display within an enclosure of the display, while external lines carry liquid and gas phase refrigerant outside the enclosure to and from the heat collector plate. The external lines may be similar in size to each other and may be connected to the heat collector outside the heat collector plate by a manifold. The heat collector plate contacts a base plate of the electronic display in a thermally conductive relation to transfer heat from electronic components within the display to the gas phase refrigerant. Fans may be included for additional convective heat transfer. A single compressor may be fluidly connected to multiple heat collector plates in respective electronic displays.

Owner:FRONTLINE SYST

Building aluminum plate grinding device with cooling and dust removal function

InactiveCN107160246AImprove grinding efficiencyImprove sanding qualityPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftCooling effect

The invention discloses a building aluminum plate grinding device with the function of cooling and dust removal, which comprises a base and a top plate, a driving motor is connected to the right side of the lower end of the top plate, a driving shaft is connected to the lower end of the driving motor, and an upper driving belt is connected to the middle part of the upper end of the driving shaft The left end of the upper driving pulley is connected with the upper driven pulley through a belt, the upper end of the upper driven pulley is connected with a rotating cam at the coaxial position, the left end of the rotating cam is provided with a guide wheel, the left end of the guide wheel is connected with a guide rod, and the left end of the guide rod A wedge-shaped block is connected, the left end of the wedge-shaped block is in contact with a lifting wheel, the lower end of the lifting wheel is connected with a lifting shaft, the middle part of the lower end of the driving shaft is connected with a lower driving pulley, and the left end of the lower driving pulley is connected with a lower driven pulley through a belt. The middle part of the driven pulley is connected with a driven shaft. The invention realizes the synchronous rotation of the grinding wheel and the workbench, realizes the cooling effect on the grinding wheel, and takes away the aluminum dust produced during grinding.

Owner:苏锦忠

Household air conditioner refrigerating system capable of separately controlling latent heat and sensible heat

InactiveCN104251515AAvoid defectsAchieve dehumidificationLighting and heating apparatusSpace heating and ventilation detailsPulp and paper industryAir conditioning

The invention discloses a household air conditioner refrigerating system capable of separately controlling latent heat and sensible heat. The household air conditioner refrigerating system comprises a double-cylinder compressor, two liquid reservoirs, two evaporators, two electronic expansion valves, a condenser, an indoor fan and an outdoor fan, wherein the double-cylinder compressor is respectively provided with an air exhaust port and two air suction ports; two air suction ports of the double-cylinder compressor are respectively connected with the two liquid reservoirs; the air suction ends of the two liquid reservoirs are respectively connected with one ends of the two evaporators; the other ends of the two evaporators are respectively connected with one end of the condenser through the two electronic expansion valves; the other end of the condenser is connected with the air exhaust port of the double-cylinder compressor; the indoor fan is arranged at the side close to the two evaporators; the outdoor fan is arranged at the side of the condenser. According to the household air conditioner refrigerating system, the disadvantages of the traditional commercial temperature-humidity independent control air conditioning system are overcome; the household air conditioner refrigerating system is simple in equipment and achieves the purpose of dehumidification and temperature reduction without adding special dehumidifying equipment, the energy consumption for system operation is effectively reduced, and the indoor comfortableness and air quality are improved.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

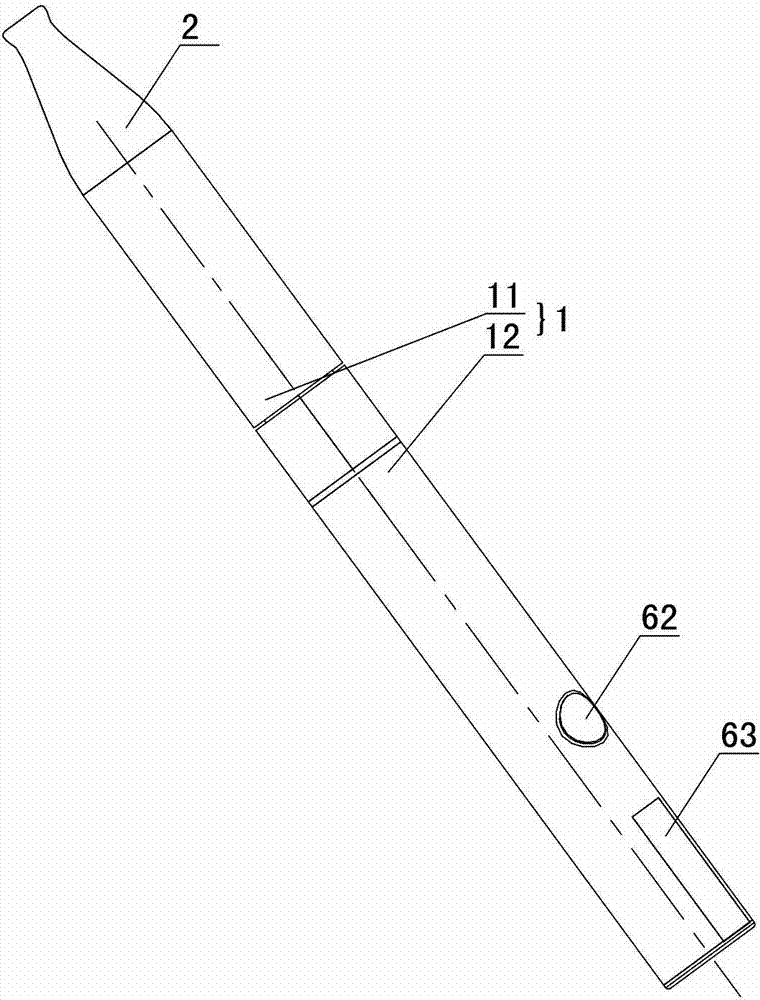

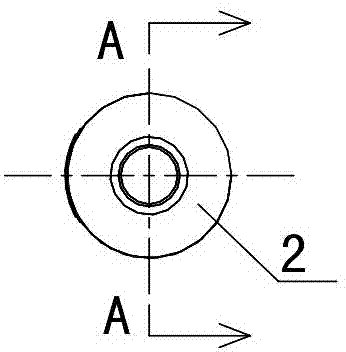

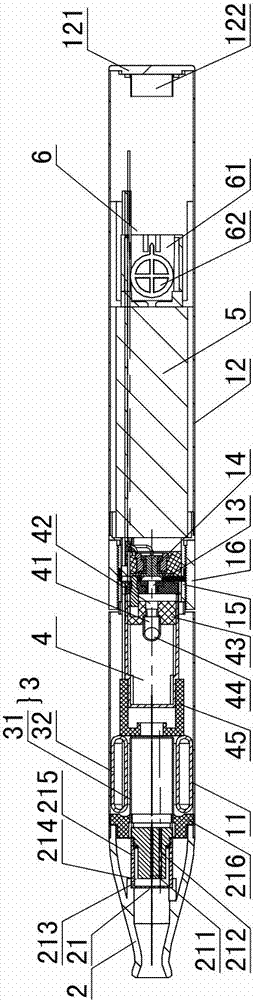

Baking type electronic cigarette with flavor adjusting function

The invention discloses a baking type electronic cigarette with a flavor adjusting function. The baking type electronic cigarette comprises an outer casing (1), wherein the outer casing (1) is provided with a cigarette nozzle (2), a baking unit (3), an oil cup (4), a battery (5) and a control unit (6) are sequentially arranged in the outer casing (1), the baking unit (3) comprises an electric heating baking cup (31), the two ends of the electric heating baking cup (31) are respectively provided with an opening, the opening end of the oil cup (4) is provided with an atomizer (41), one end of the electric heating baking cup (31) is communicated with the cigarette nozzle (2), the other end of the electric heating baking cup (31) is communicated with the atomizer (41), the outer wall of the electric heating baking cup (31) is provided with an electric heating sheet, and the electric heating sheet of the electric heating baking cup (31), an electric heating wire of the atomizer (41) and the battery (5) are respectively connected with the control unit (6). The baking type electronic cigarette has the advantages that the uniformity and shortage of smoke can be balanced when the ratio of smoke amount is not uniform or not enough during baking, the different cigarette flavors can be adjusted according to the mouth feel of a smoker, the selectable space is provided for the smoker, and the optimum mouth feel is realized.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

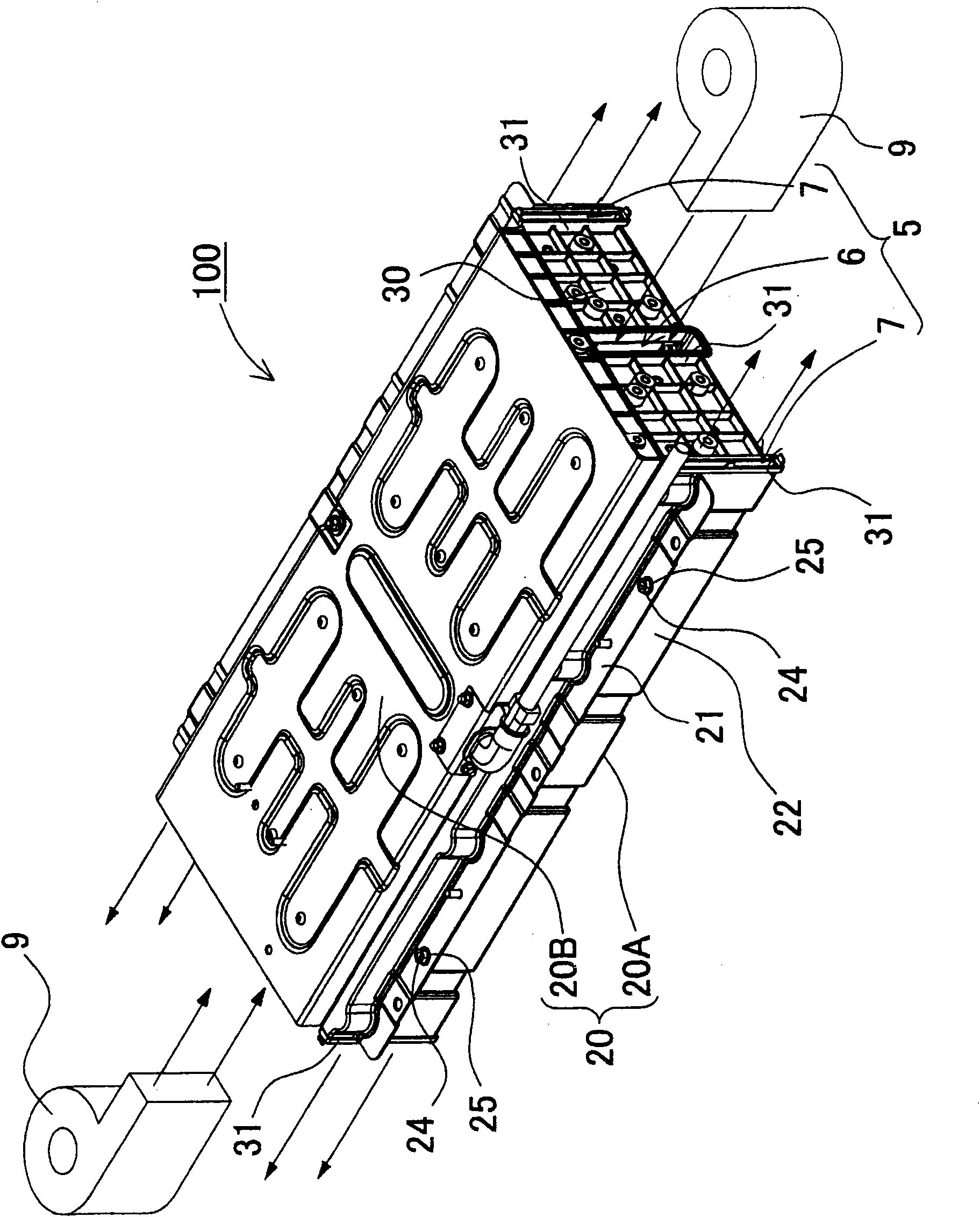

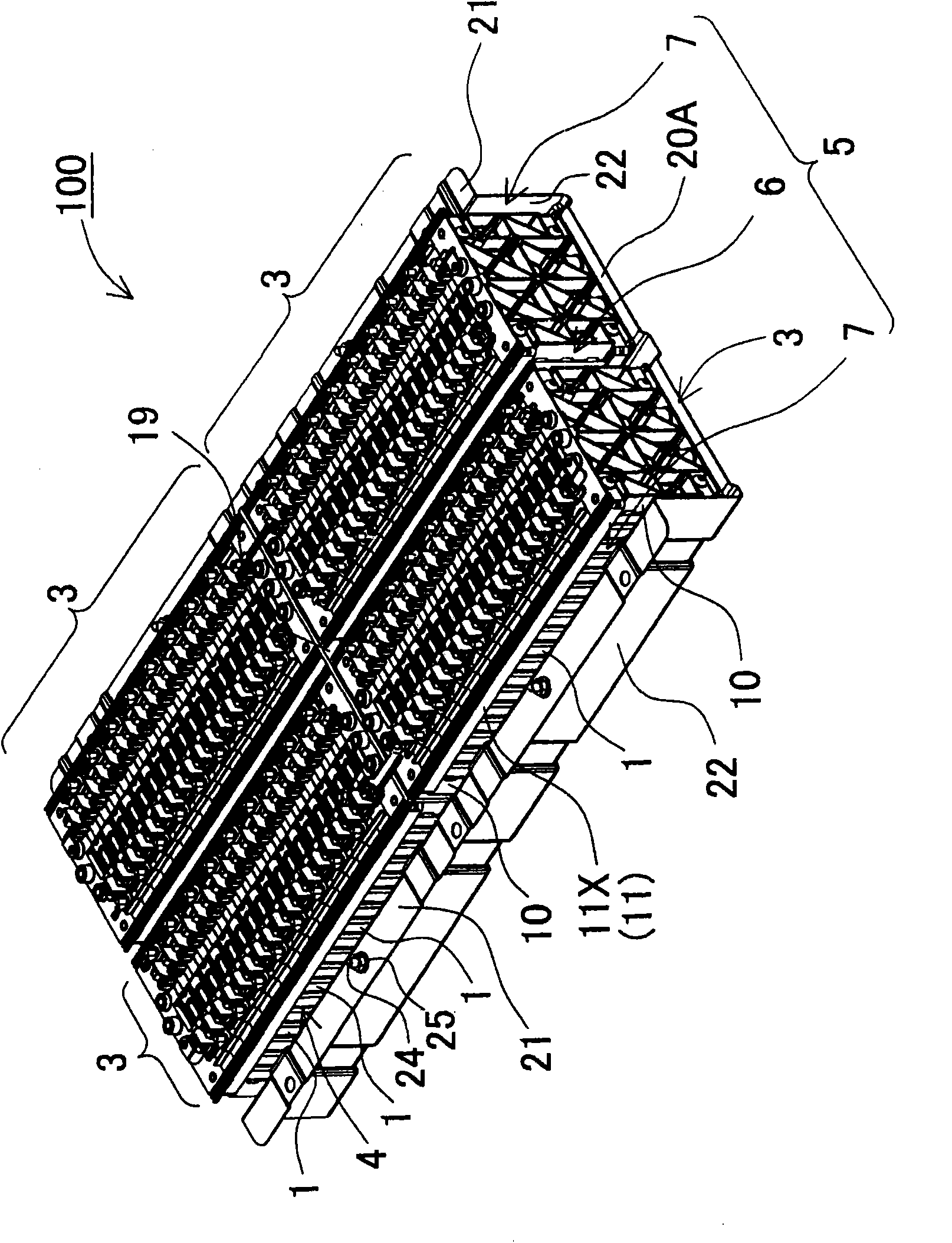

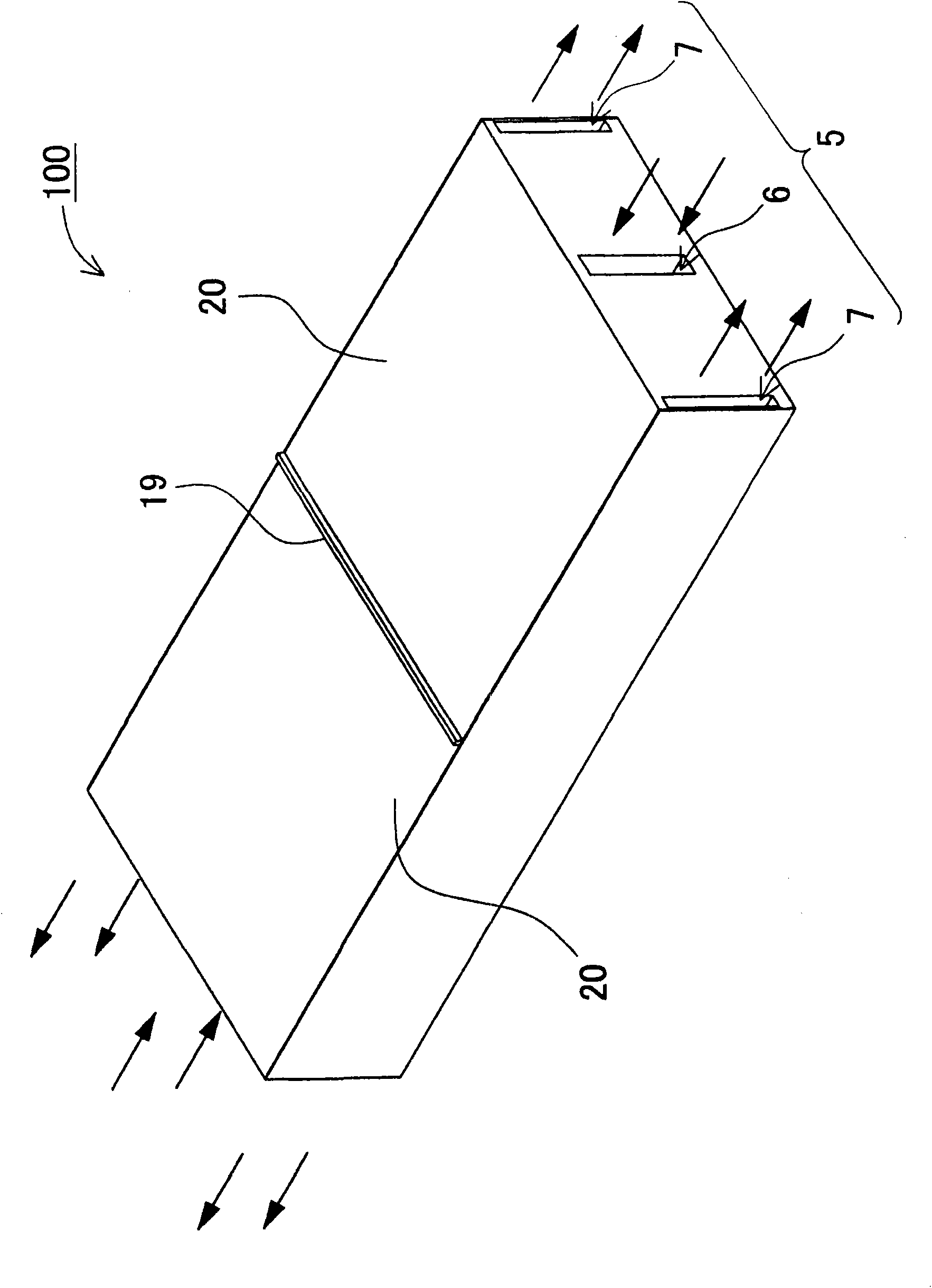

Power supply device and vehicle having the same

ActiveCN102054948AReduce manufacturing costEasy to set upPrimary cell to battery groupingLarge-sized flat cells/batteriesClosed chamberBinding state

The invention provides a power supply device capable of making the temperatures of the battery cells almost consistency at any position by reducing the temperature differences, and a vehicle having the same.A power supply device includes rectangular battery cells 1, resin separators 2, end spacers, thick metal end plates, and coupling members. The separator 2 is inserted between the cells 1 to insulate adjacent cells 1 from each other, and in thermal contact with the cells 1. The end spacers cover end battery cells on the opposed end surfaces of a battery block composed of the cells and the separators alternately arranged. The end plates cover the surfaces of the end spacers. The coupling members couple the end plates to each other. The separators form gaps for flowing air along the surfaces of the cells in contact with the separators. The end spacers have hollow layers on their surfaces in contact with the cells, and define closed chambers.

Owner:SANYO ELECTRIC CO LTD

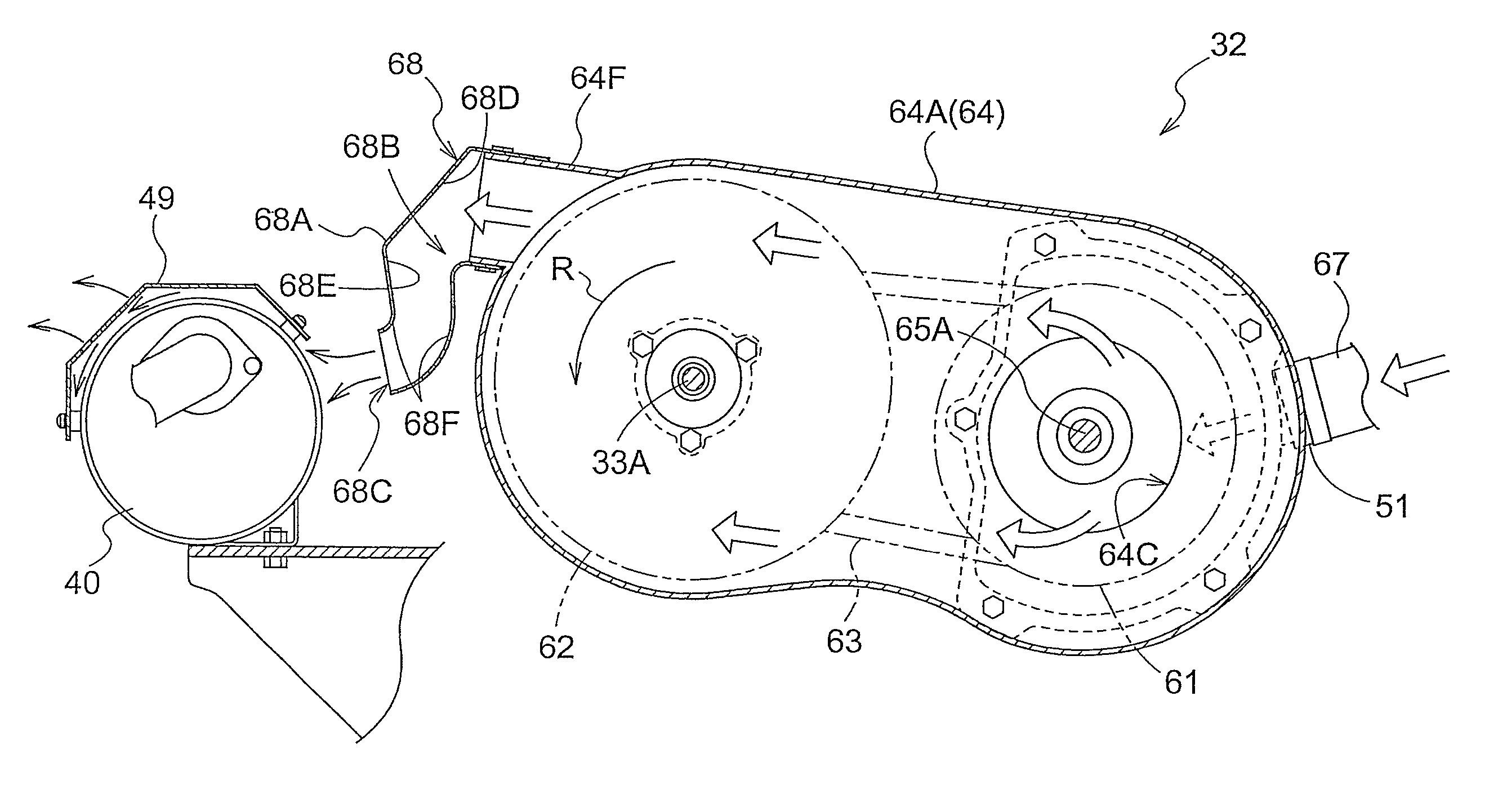

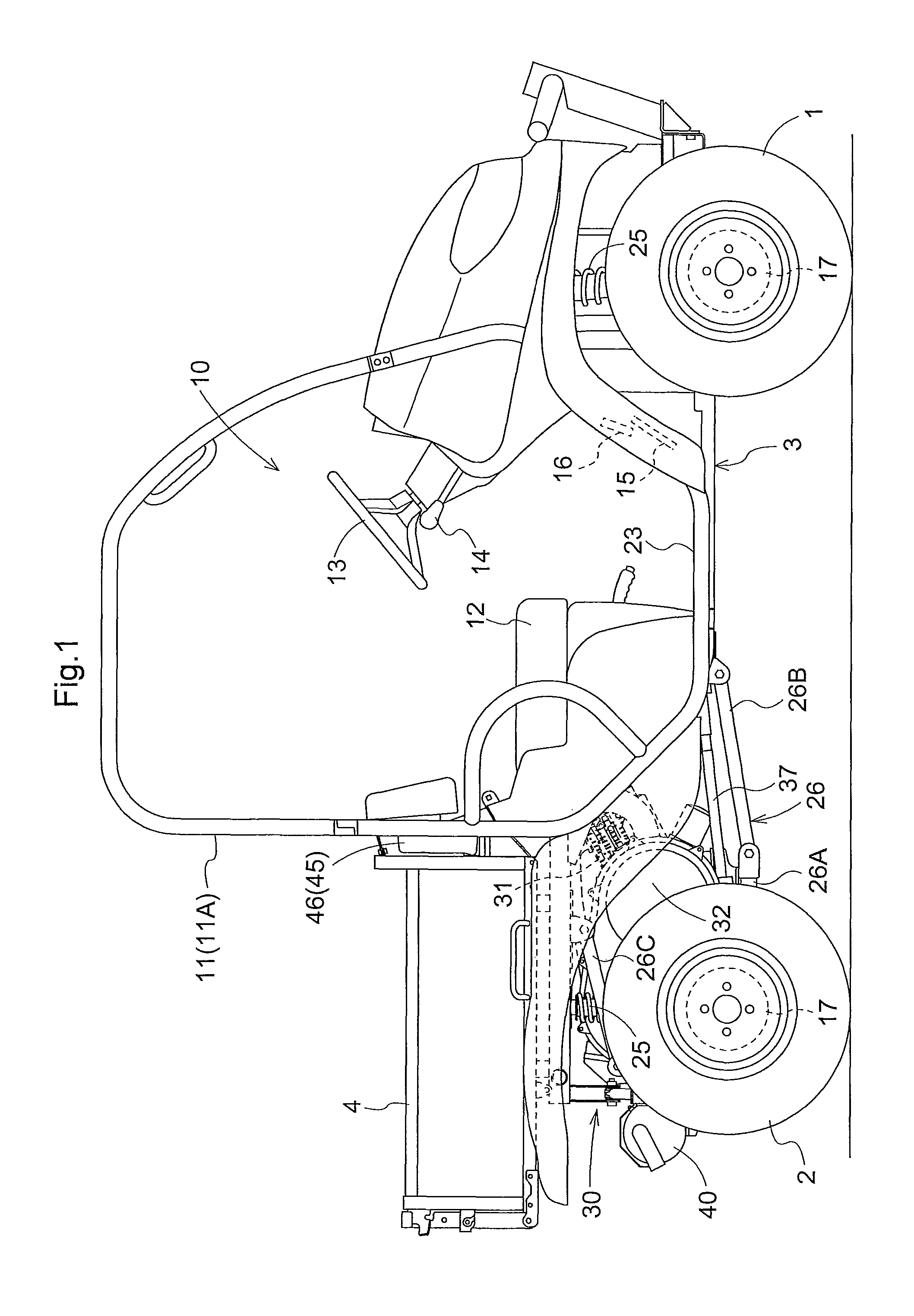

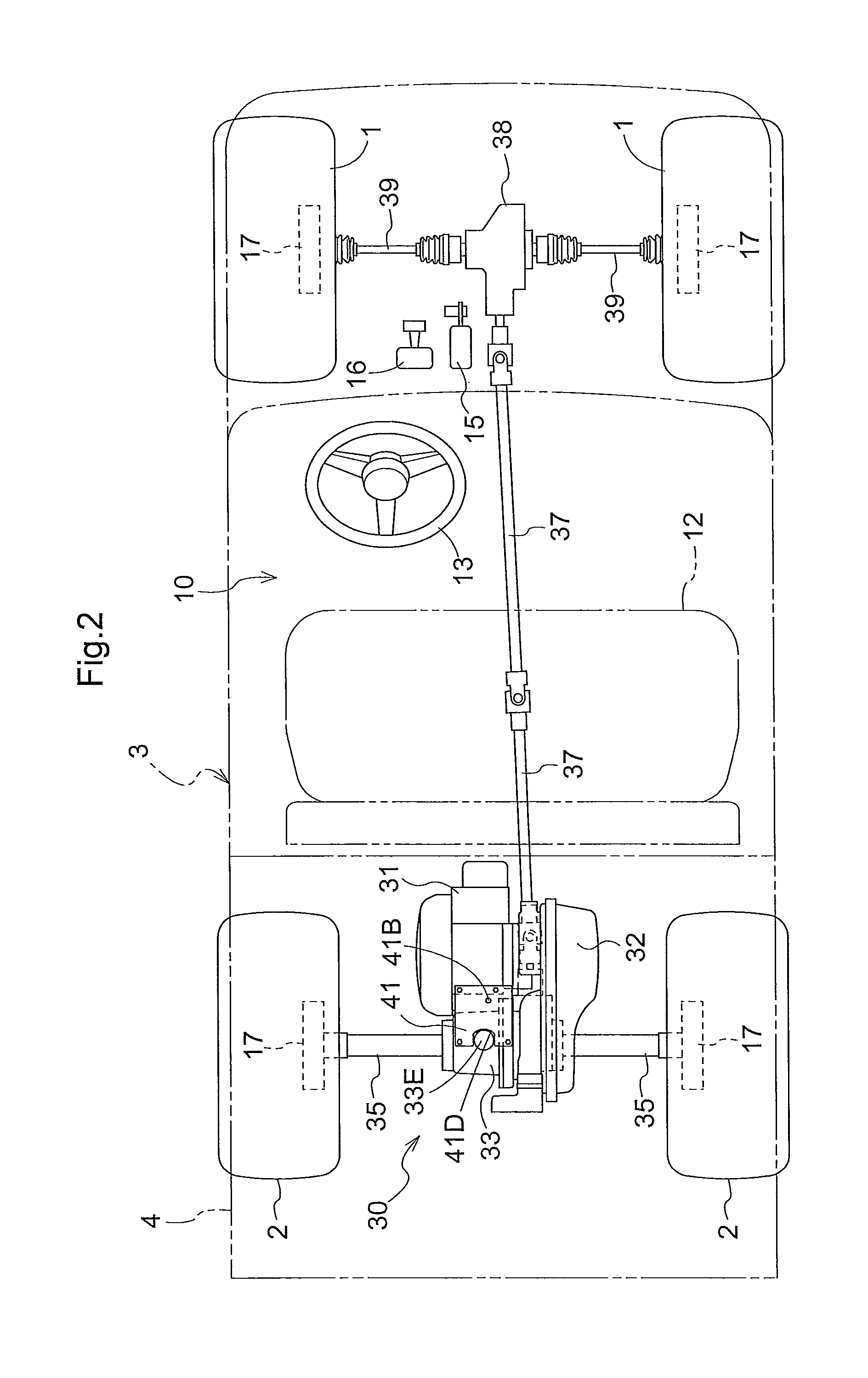

Work vehicle having engine and belt-type continuously variable transmission device

ActiveUS8439141B2Hitting is efficientSuppression temperatureAgricultural vehiclesJet propulsion mountingMufflerContinuously variable transmission

A work vehicle includes: a muffler which flows exhaust from an engine and extends in a transverse direction so as to allow the exhaust from the engine to flow in the transverse direction; and a CVT case for covering a belt-type CVT positioned frontward of the muffler in a longitudinal direction. The CVT case includes a cooling structure for introducing cooling air from outside, cooling the belt-type CVT, and discharging the cooling air from a discharge part. An exhaust duct includes an inflow opening to be connected to the discharge part for allowing the cooling air to flow into the exhaust duct, and an exhaust opening for allowing the cooling air to flow out rearward. The exhaust opening is elongated in an extending direction of the muffler and oriented in a direction that allows the cooling air flowing out to hit the muffler.

Owner:KUBOTA CORP

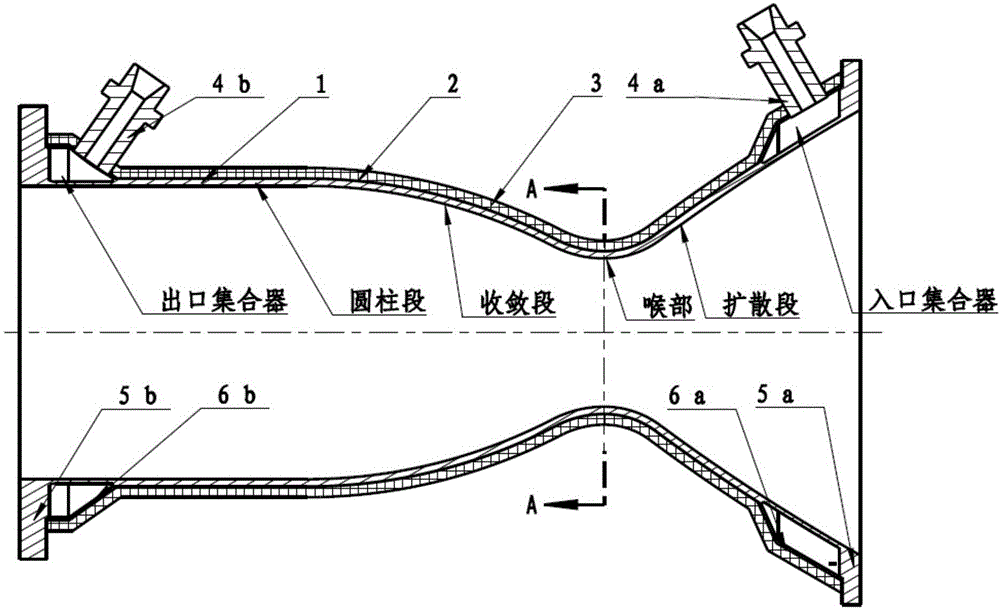

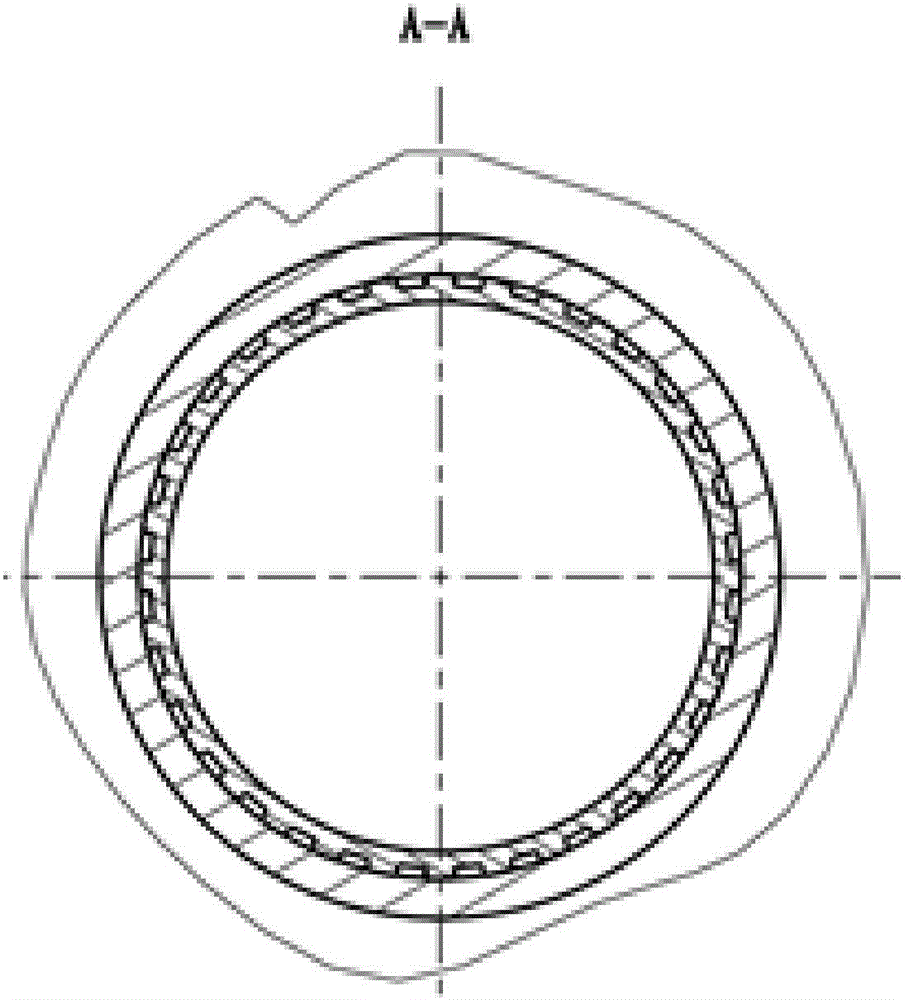

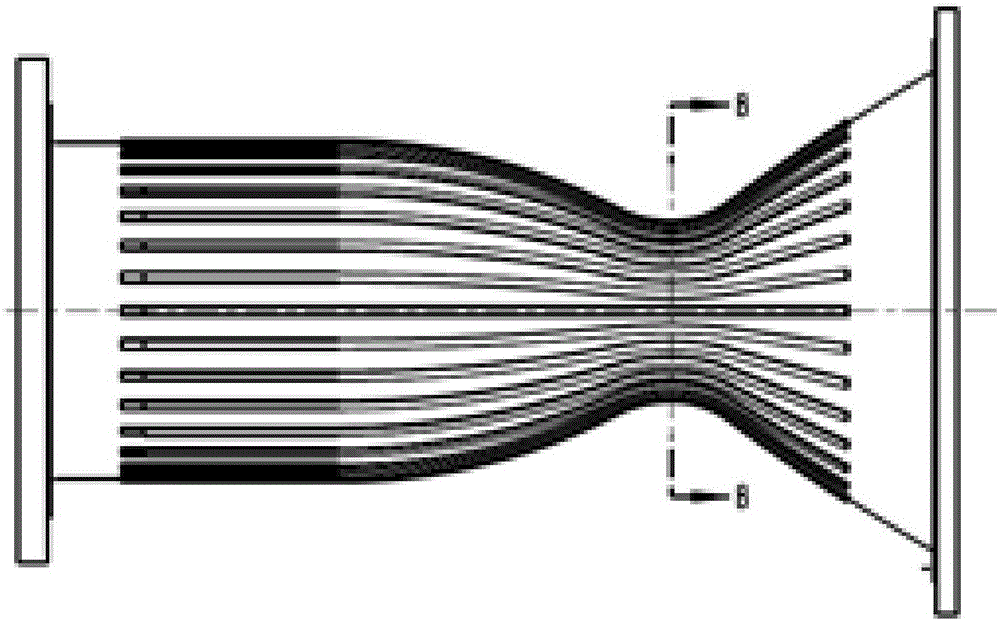

Combustion chamber of liquid rocket engine

InactiveCN106640424ASimple structure and molding processEasy to operateRocket engine plantsCombustion chamberClosed cavity

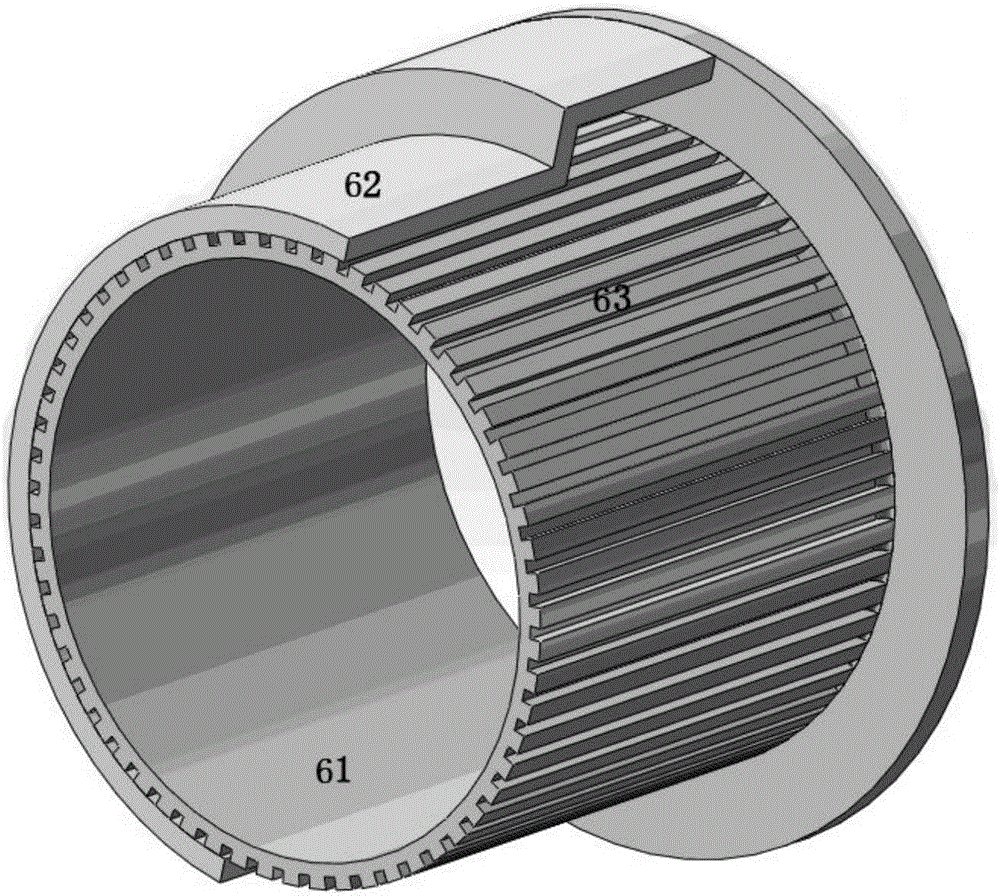

The invention discloses a combustion chamber of a liquid rocket engine. The combustion chamber comprises a metal inner wall, an adhesion layer, a non-metal outer wall, a propellant inlet connector, a propellant outlet connector, a rear-end flange, a front-end flange, a tail-end bearing plate and a front-end bearing plate, wherein the non-metal outer wall and the metal inner wall form one piece through the adhesion layer; a plurality of cooling grooves which are arranged in the peripheral direction are formed in the outer surface of the metal inner wall; the front-end bearing plate and the tail-end bearing plate form an outlet collector and an inlet collector which are in the shape of an annular cavity respectively with the front-end outer wall surface and the tail-end outer wall surface of the metal outer wall respectively; the front-end flange and the rear-end flange are fixed to the front-end bearing plate and the tail-end bearing plate respectively; the outlet collector and the inlet collector are made to form a closed cavity; and the propellant inlet connector and the propellant outlet connector are connected with the inlet collector and the outlet collector respectively. The combustion chamber disclosed by the invention has the advantages of being simple in structure and forming process, convenient to operate, low in manufacturing cost and short in manufacturing period.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

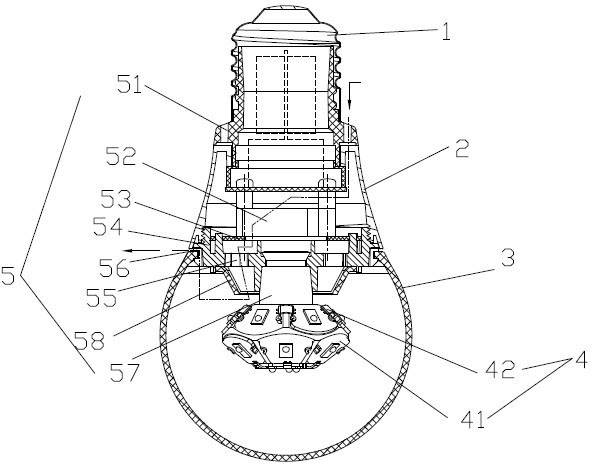

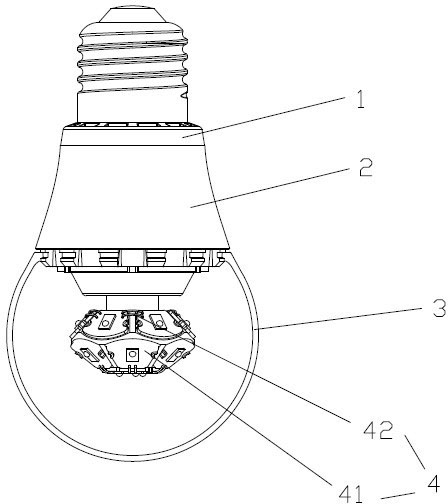

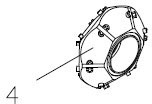

Large-luminosity-angle spherical bulb with diamond light-emitting surfaces

ActiveCN102128370AAchieve coolingIncrease the light transmission anglePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention provides a large-luminosity-angle spherical bulb with diamond light-emitting surfaces, comprising a lamp head insulating body, a lamp body, a lamp shade, a diamond polyhedron and LED (Light-Emitting Diode) light-emitting component and an in-bulb cooling device, wherein the lamp body connects the in-bulb cooling device and the lamp head insulating body; the lamp shade is matched with the in-bulb cooling device; the diamond polyhedron and LED light-emitting component is arranged near the center in the lamp shade and is combined by substrates, flexible connecting bridges, a diamond polyhedral heat-conducting installing body; the substrates are provided with LED light sources, and the front surfaces of the substrates are provided with welding points used for connecting; the flexible connecting bridges are connected among the substrates through circuits; the diamond polyhedral heat-conducting installing body is diamond-like and has N sides, can be used for fixing a light-emitting component and can be set into any angle and shape; and the in-bulb cooling device is communicated with the lamp head, the lamp body and the lamp shade to form an airflow inlet and outlet channel. In the large-luminosity-angle spherical bulb provided by the invention, the lamp shade is designed into a shape larger than a hemisphere, which can increase a light-transmitting angle, the LED light-emitting component is made into a diamond structure so as to realize multidirectional positive and negative surface irradiation, and the in-bulb cooling device can carry out forced air-cooling on the in-bulb radiating fins and radiating fins in the lamp body.

Owner:SICHUAN LIANKAI LIGHTING CO LTD

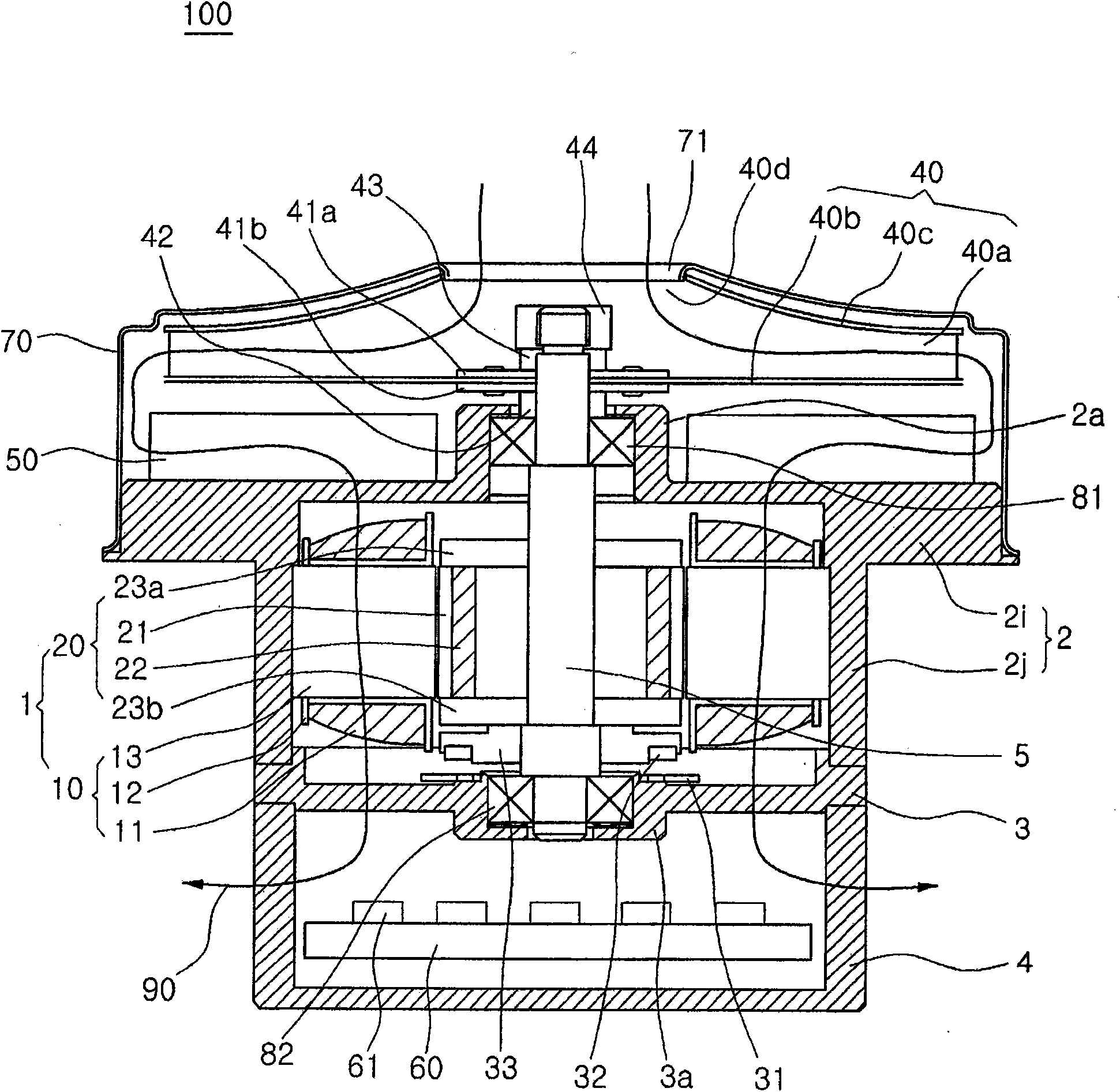

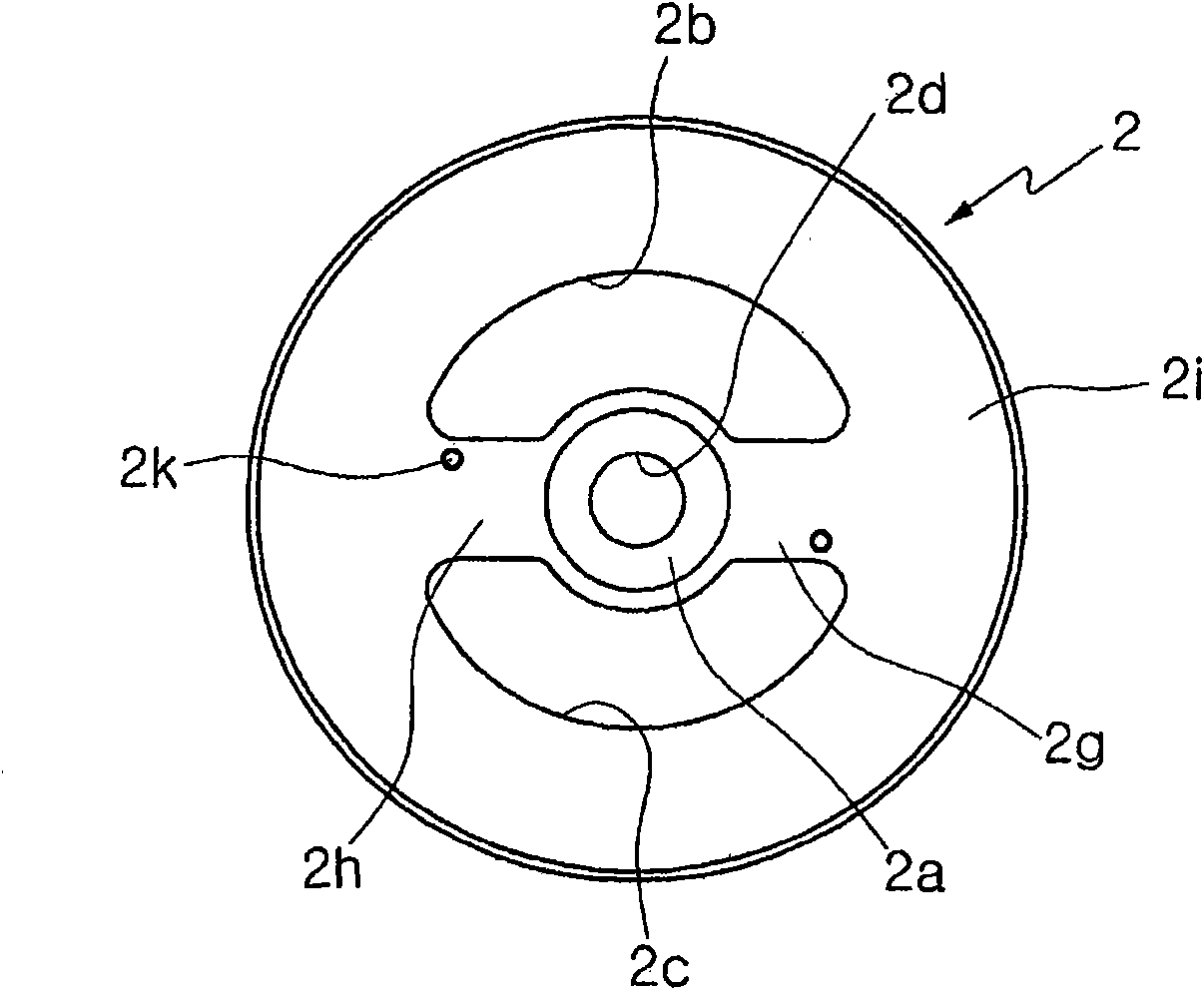

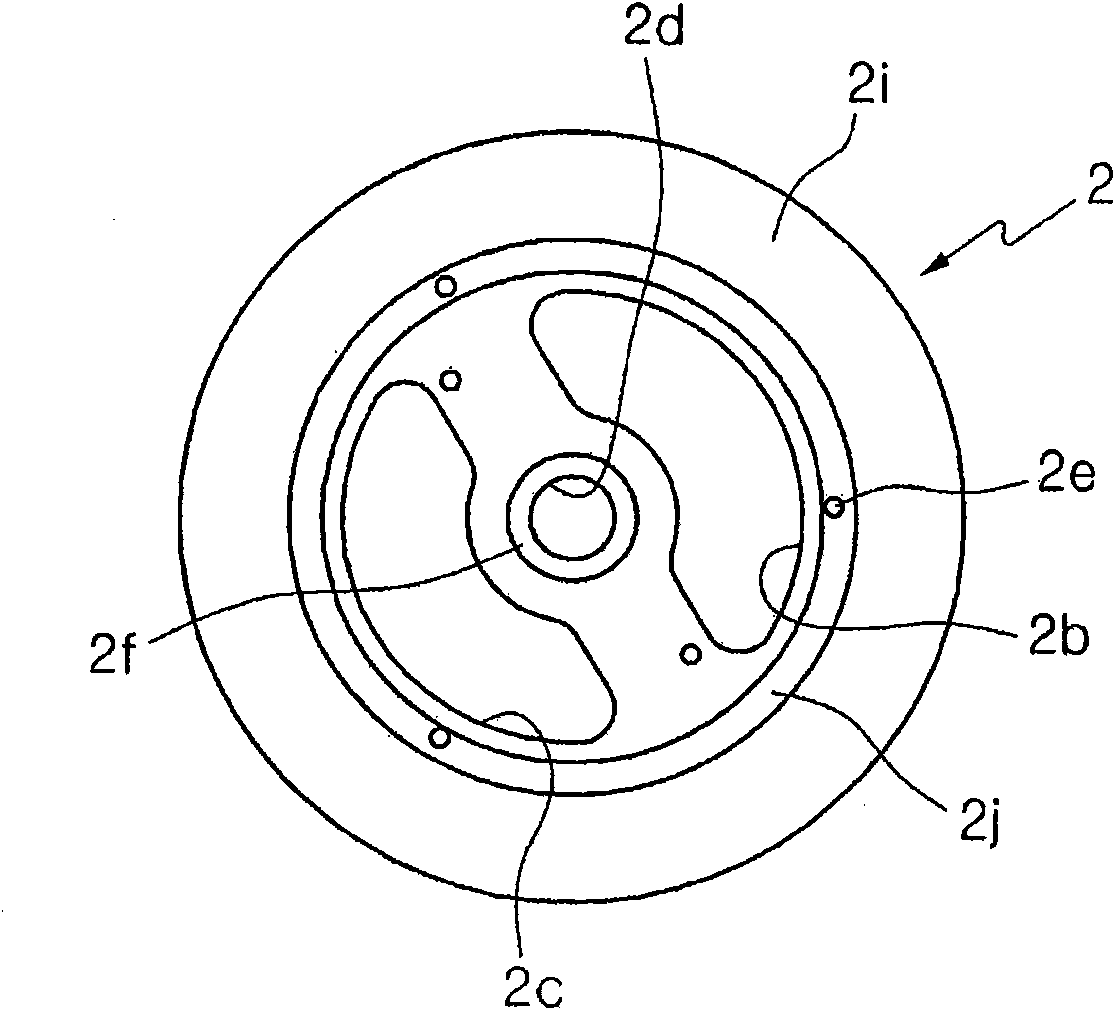

IPM motor and vacuum inhaling apparatus using the same

InactiveCN101802415AThe factor of frictional resistance is minimizedAchieve coolingPump componentsPiston pumpsRotational axisStator coil

Provided is a high speed and high efficiency IPM (Interior Permanent Magnet) motor and a slim type vacuum inhaling apparatus using the same, which establishes a passage path of introduced air into a path of air-cooling the inside of a stator and a circuit element to thus cool heat that is produced from the IPM motor without a special heat radiator. The IPM motor includes: a stator having a number of tees which are protruded so as to form a number of slots on the inner circumferential wall of a cylindrical body, and a stator coil which is partially wound around the slots; and an IPM type rotor having a rotor core at the central side of which a rotating shaft is mounted, and a number of permanent magnets which are fitted into a number of permanent magnet insertion holes which are formed on the identical circumference of the rotor core, and which is rotated by the stator. The permanent magnet includes a first group of permanent magnets and a second group of permanent magnets which wholly have two-pole magnetic pole structure and form a first spacer and a second spacer between the first group of permanent magnets and the second group of permanent magnets to prevent the leakage of magnetic flux in the circumference direction.

Owner:AMOTECH

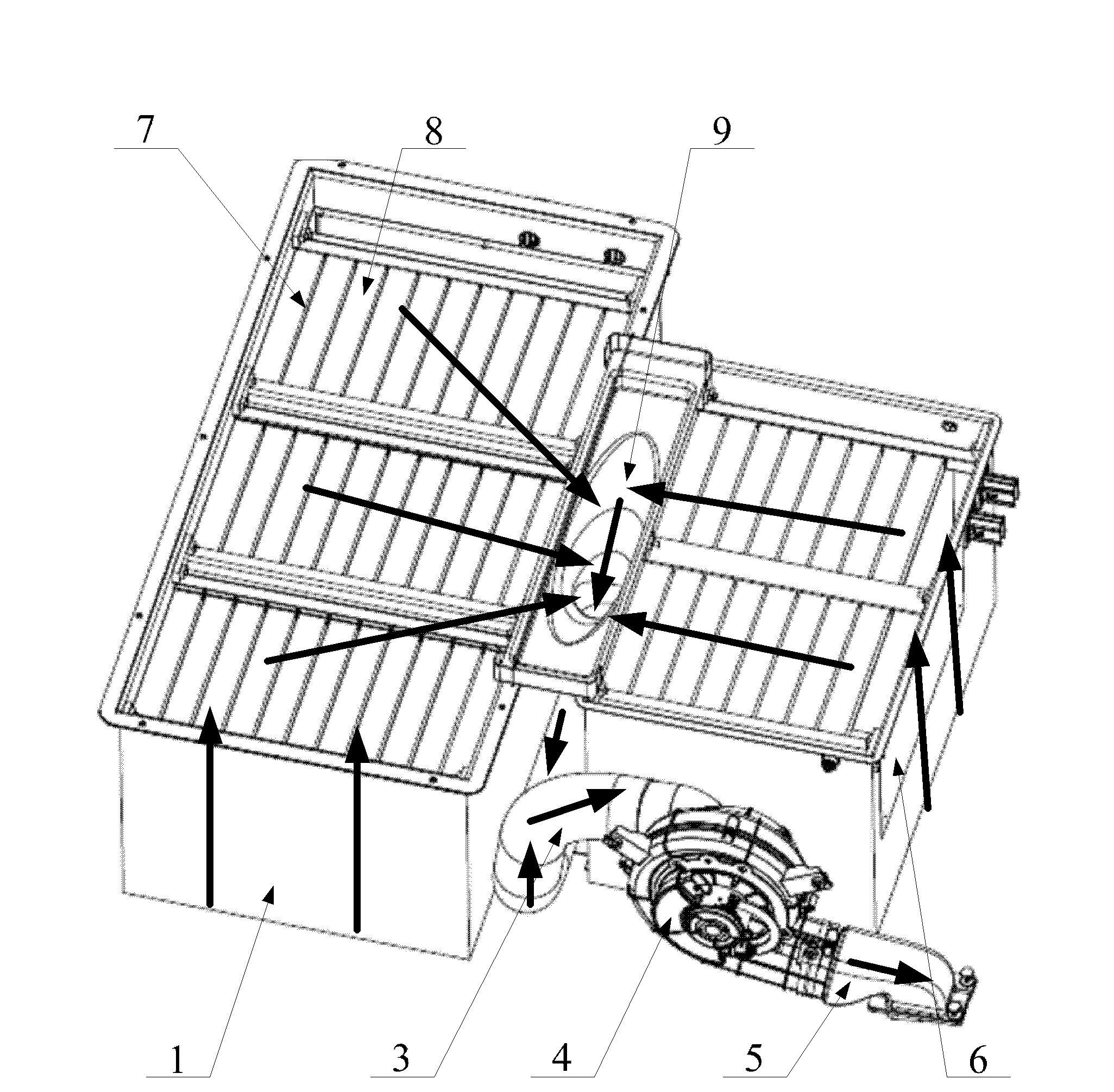

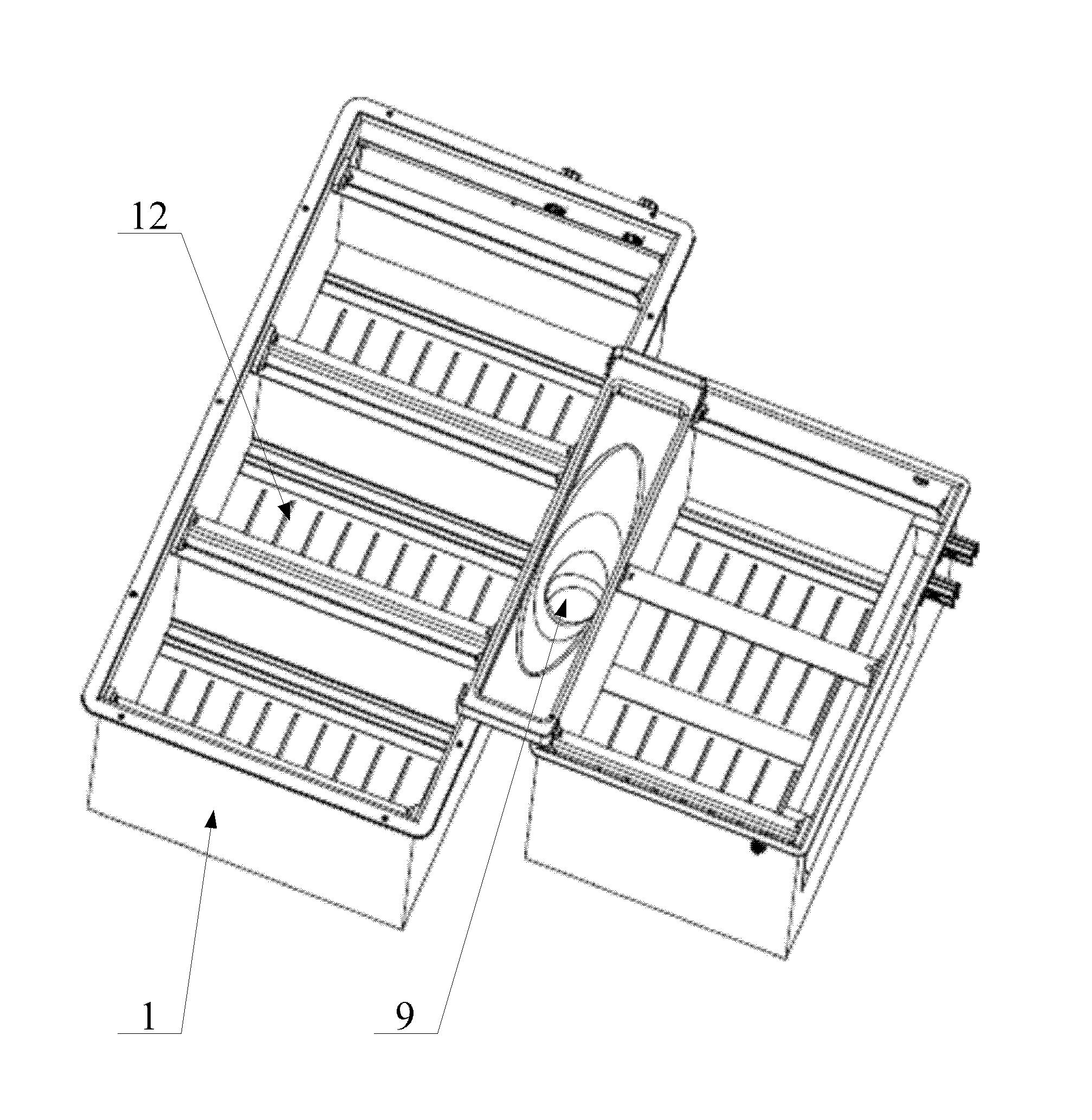

Electric vehicle and power battery assembly radiation system thereof

InactiveCN102437392ASmall footprintAchieve coolingElectric propulsion mountingSecondary cellsPower batteryElectrical battery

The invention provides a power battery assembly radiation system, which comprises a box body, a mounting bracket, a main air duct, an air outlet pipe, a fan and an exhaust pipe, wherein the bottom of the box body is provided with air inlet grids; parallel power battery packs are arranged in the box body; the top of the box body is provided with an upper cover; gaps between every two single power batteries in the power battery packs serve as air inlet passages which are communicated with air inlets of the air inlet grids; the mounting bracket supports the box body; an inlet of the main air duct is positioned at the top of the box body; the main air duct is communicated with the air inlet passages; the air outlet pipe is connected with an outlet of the main air duct; the fan is connected with the air outlet pipe; and the exhaust pipe is connected with the fan. In the power battery assembly radiation system, the gaps between every two single power batteries in the battery packs form the air inlet passages, and the mounting bracket, the air inlet grids, the main air duct, the air outlet pipe, the fan, the exhaust pipe and the upper cover realize cooling without an additional air duct, so that the problem that the parallel radiation system is limited by the arrangement space of the whole vehicle is solved, and the cooling efficiency of the parallel radiation system is improved. The invention also provides the electric vehicle.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

Two-stage air-suspending centrifugal electric direct drive air compressor

The invention discloses a two-stage air-suspending centrifugal electric direct drive air compressor. The two-stage air-suspending centrifugal electric direct drive air compressor comprises a shell, amotor stator, a spindle, impellers, lock nuts, volutes and a cooling system, wherein the shell, the motor stator and the spindle are sequentially arranged from outside to inside, the impellers, the lock nuts and the volutes are arranged on the two sides of the spindle, and the cooling system is arranged on the shell. The two-stage air-suspending centrifugal electric direct drive air compressor hasthe beneficial effects that the shell, the motor stator, the spindle, the impellers and the volutes are integrally designed, and the size and the weight of the whole machine are reduced. The two stages of impellers are connected in series through a middle pipeline, and small flow and the high-pressure ratio are achieved. Axial thrust of the two stages of impellers can be mutually offset, and axial force applied by thrust bearings is reduced. Radial and axial air bearings are adopted, gas films are formed through high-pressure gas generated by the bearings, friction between the bearings and arotor is reduced, air-suspending motor high-speed direct drive is formed, and mechanical losses are reduced. Part of compressed gas is introduced into a machine shell assembly through the middle pipeline, the motor stator, the spindle, the radial bearings and the thrust bearings are cooled, and the service life of the air compressor is prolonged.

Owner:势加透博洁净动力如皋有限公司

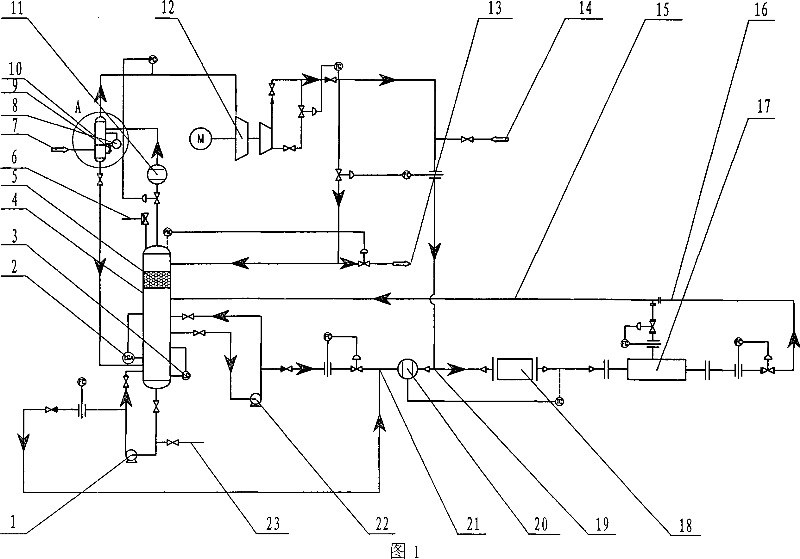

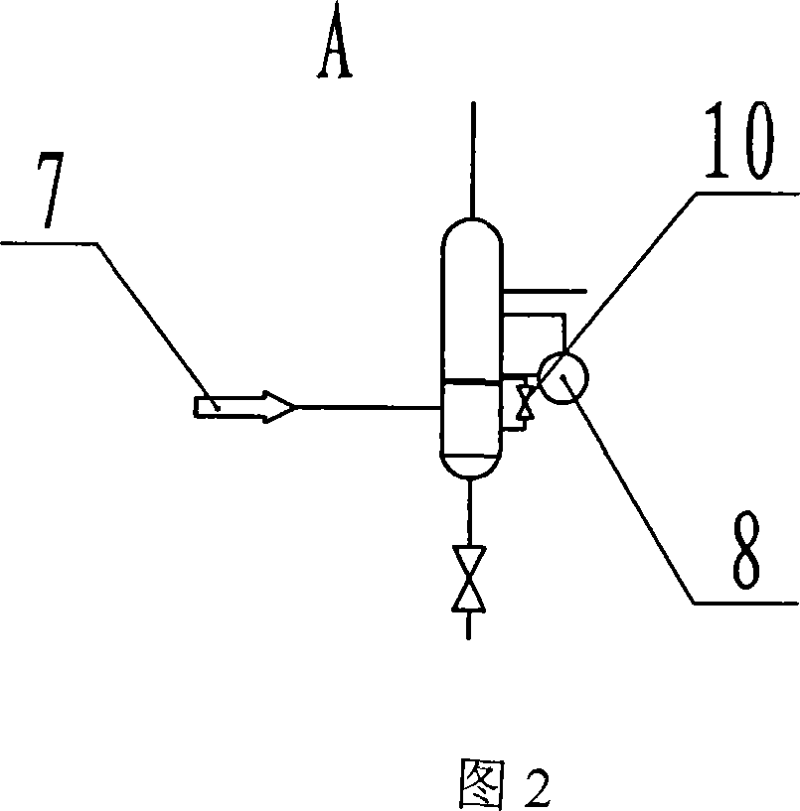

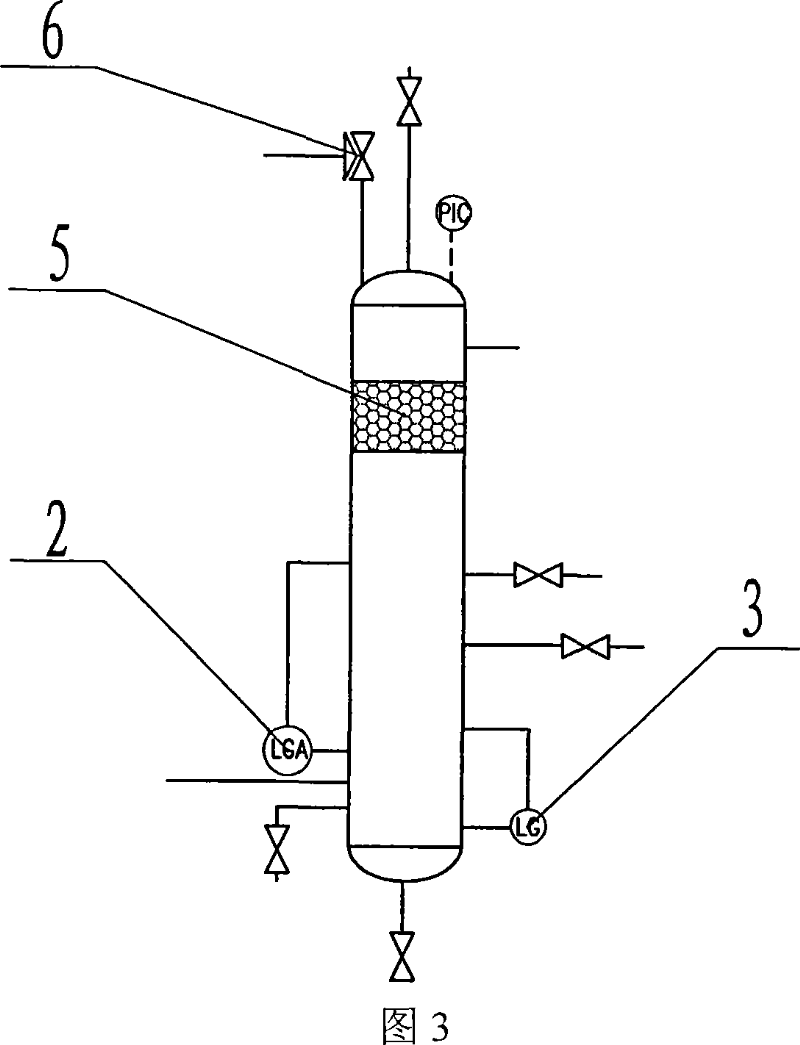

Loop-type multi-phase flow erosion test device

InactiveCN101038250AUniform atomizationEnsure balanceWeather/light/corrosion resistancePipeline systemsPipe fittingGas phase

The present invention discloses a ring-road type multi-phase flow erosion tester comprising a gas, oil and water three-phase separation tank and pipe circulating systems of said three phases including, in detail, a gassy system ranging from an export at the top part of the three-phase separation tank, a cooler and a cyclone separator, a circulating gas screw compressor to the pipe filter; an oil phase system ranging from an export at the middle part of the three-phase separation tank, a diesel magnetic drive pump, a heater to the pipe filter; and a water phase system ranging from an export at the bottom part of the three-phase separation tank, a wastewater metering pump, a heater to the pipe filter. After mixing, the three phases are connected to the three-phase separation tank through the pipe filter and a testing platform for pieced to be tested. The present invention is capable of simulating erosion study cases in practical pipe fittings such as tee joints, bend pipes, transition pipes and liner pipes to perform a transient characteristics prediction study of gas, oil and water multi-phase flow erosion destruction.

Owner:ZHEJIANG SCI-TECH UNIV

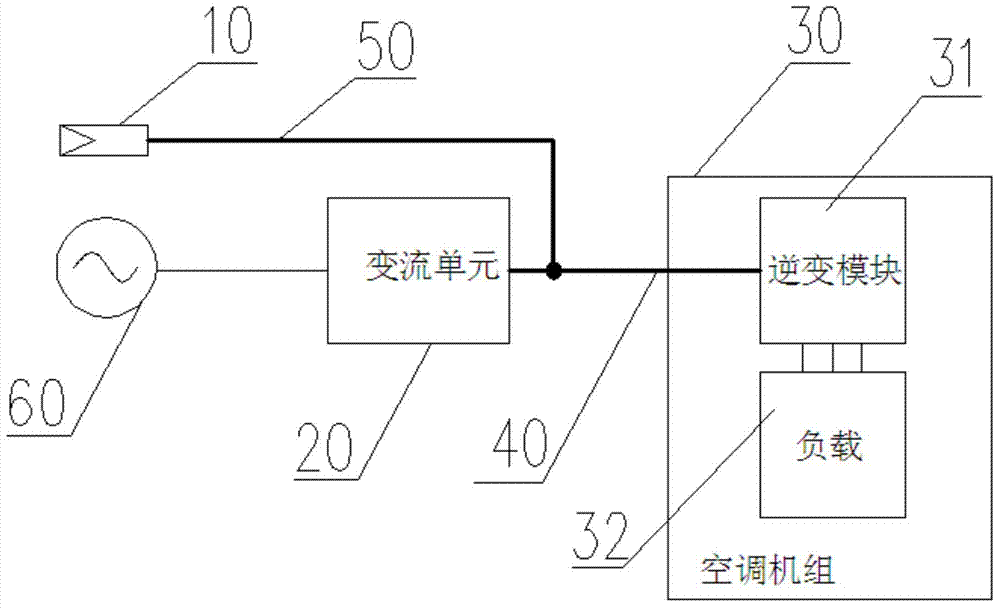

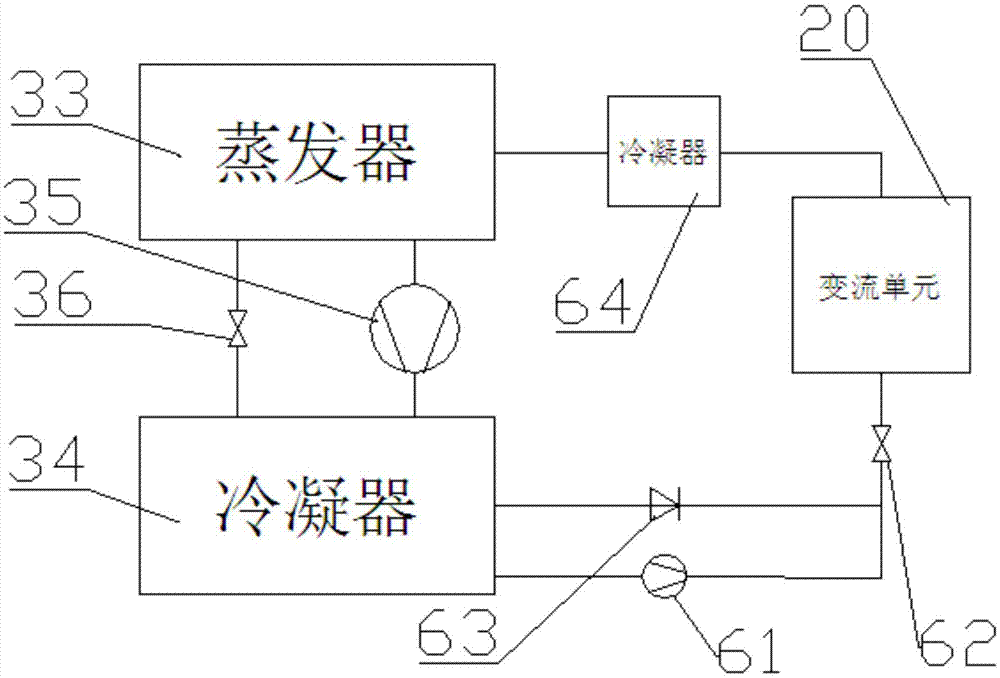

Photovoltaic air conditioning system

ActiveCN103486682ASeamless and efficient integrationAchieve coolingSpace heating and ventilation safety systemsLighting and heating apparatusPower gridPhotovoltaic power station

The invention discloses a photovoltaic air conditioning system which comprises a photovoltaic battery array, an air conditioning unit, a current transforming unit and a direct-current bus. The current transforming unit is disposed between a public power grid and an inversion module. The capacity of the current transforming unit is configured according to needs of the photovoltaic battery array or the public power grid. The inversion module serving a standard accessory of the unit is disposed on the air conditioning unit. Direct current emitted by the photovoltaic battery array and the direct current emitted after being rectified by the current transforming unit are supplied to the inversion module so as to power the air conditioning unit. By the system, the problem that the photovoltaic air conditioning systems are poor in adaptability in the prior art can be solved. The photovoltaic air conditioning system is capable of adapting to photovoltaic power stations of different capacities, and enabling the photovoltaic power stations to be seamlessly and efficiently combined with heating ventilation air conditioners.

Owner:GREE ELECTRIC APPLIANCES INC

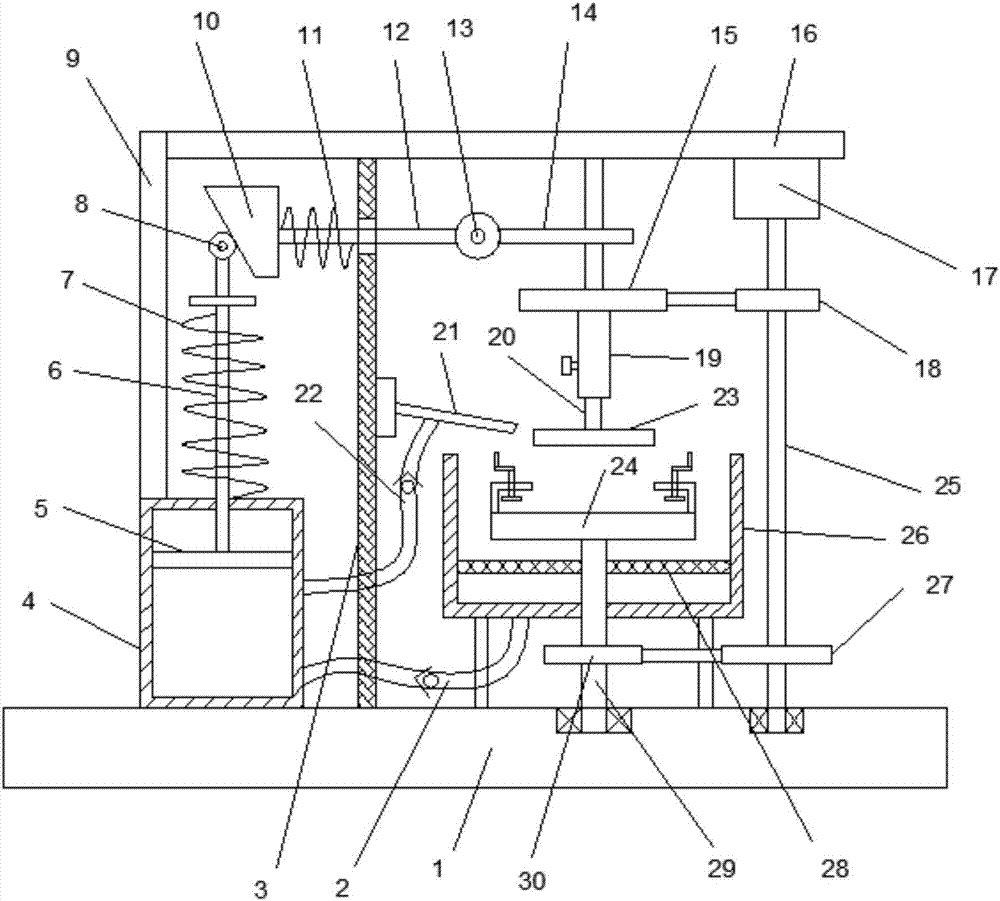

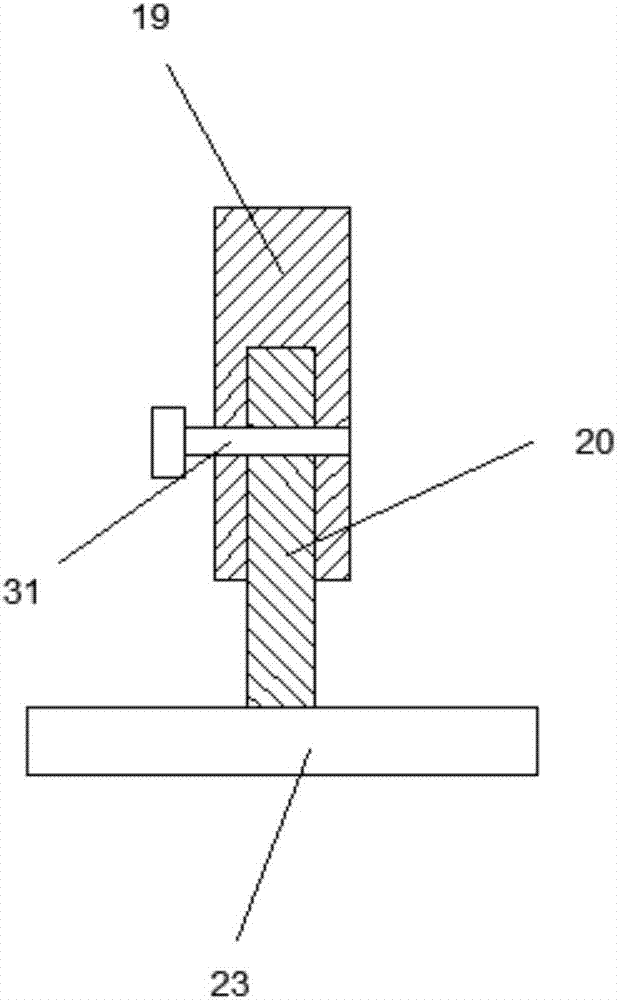

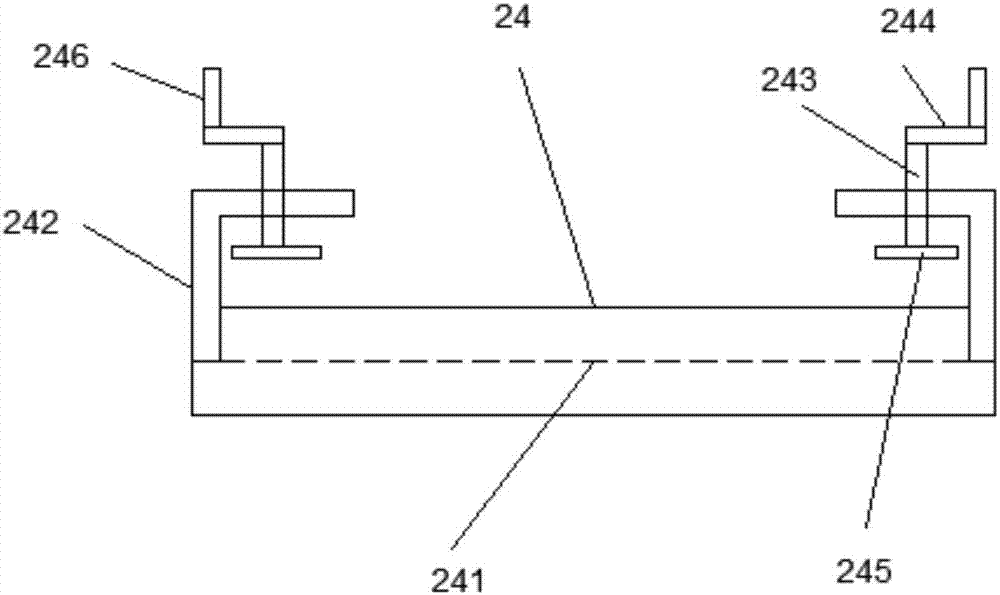

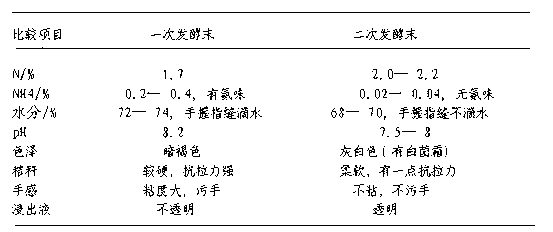

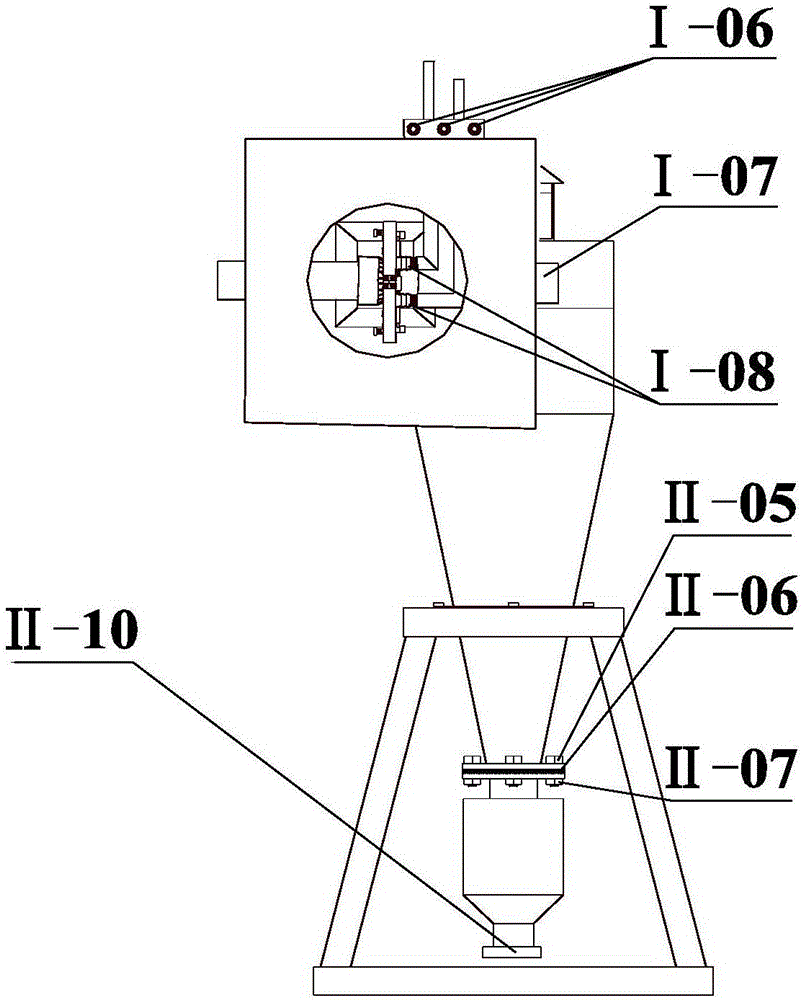

Novel normal-pressure room-temperature plasma induced mutation breeding device

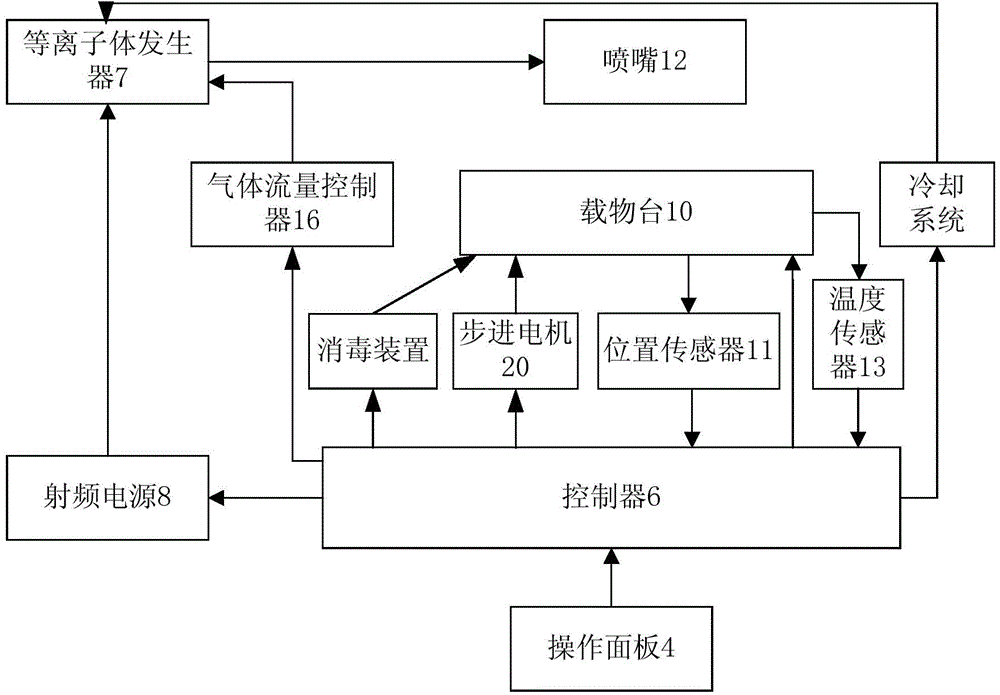

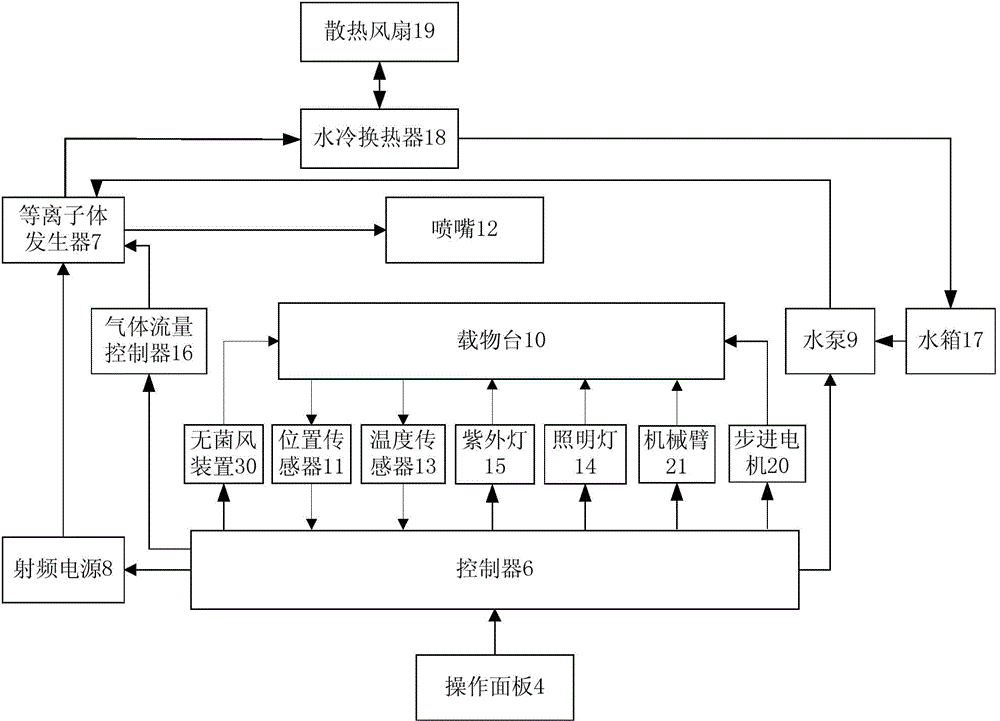

ActiveCN103981091ASmooth dischargeEnables continuous automated processingBioreactor/fermenter combinationsBiological substance pretreatmentsInduced mutationControl system

The invention relates to a novel normal-pressure room-temperature plasma induced mutation breeding device. The novel normal-pressure room-temperature plasma induced mutation breeding device comprises a sample processing system, a cooling system, a control system and a detection system; the sample processing system comprises a clean working chamber without bioactive contaminants; a step motor and an object stage are arranged in the clean working chamber; the object stage is arranged on the step motor; at least one sterilizing device mounting position is reserved in the inner cavity or on the wall of the clean working chamber; the detection system comprises a gas flow controller, a temperature sensor and a position sensor; and the control system comprises an operating panel and a controller, and the controller is used for controlling the step motor to realize rising and falling or horizontal rotation of the object stage so as to automatically process a plurality of samples. The novel normal-pressure room-temperature plasma induced mutation breeding device is capable of realizing the functions of continuous automatic processing, automatic sterilization, automatic monitoring and control on the samples, and also capable of completing the plasma induced mutation breeding in the normal pressure and room temperature environment at higher efficiency.

Owner:WUXI TMAXTREE BIOTECHNOLOGY CO LTD

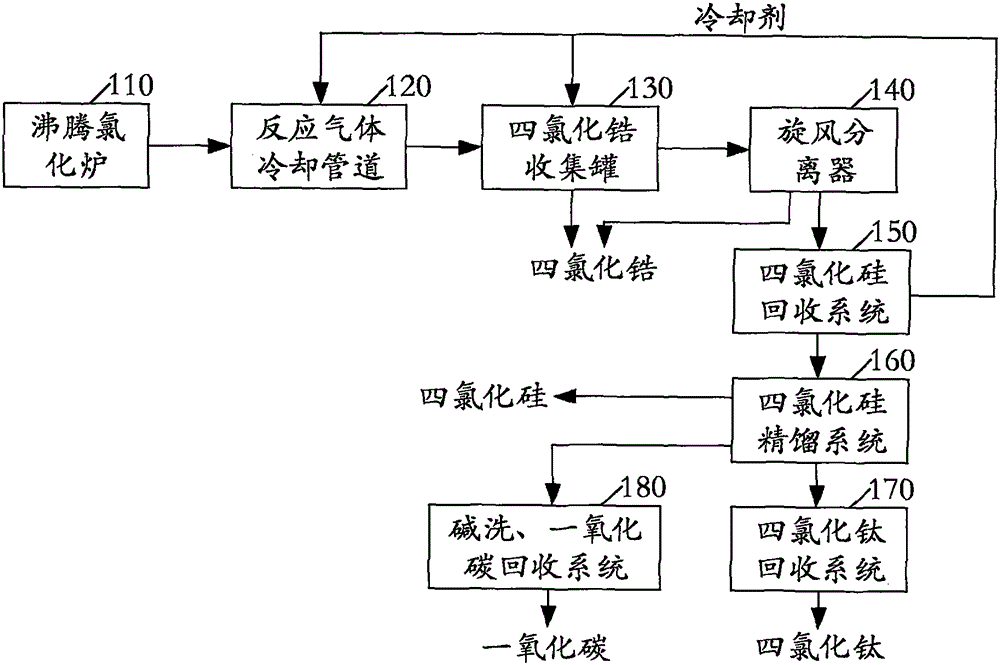

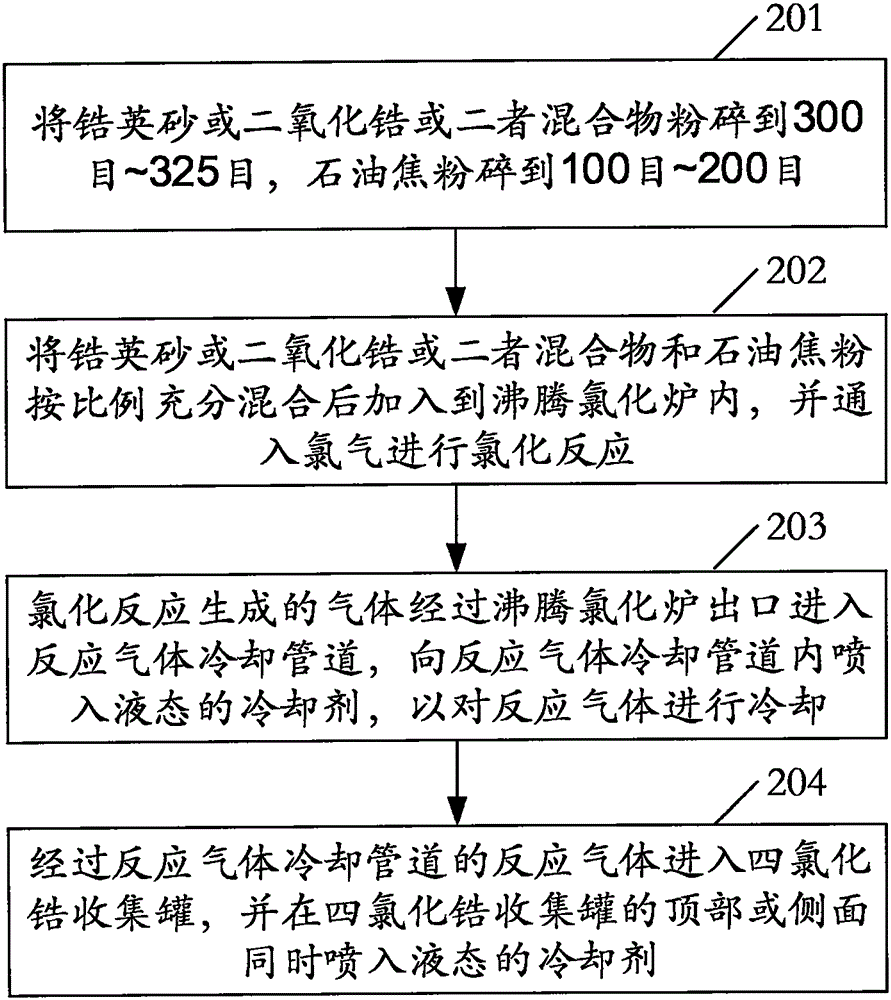

Method for cooling zirconium tetrachloride produced through fluidizing chlorination method

The invention relates to the field of chemical production, and discloses a method for cooling zirconium tetrachloride produced through a fluidizing chlorination method. The cooling method comprises the following steps: fully mixing zircon sand / zirconium dioxide / a mixture of zircon sand and zirconium dioxide with petroleum coke powder according to a certain ratio, adding the mixture into a fluidizing chlorination furnace, introducing chlorine gas into the furnace to carry out chlorination reactions; introducing the gas generated in the chlorination reactions into a reaction gas cooling channel from the outlet of the fluidizing chlorination furnace, spraying liquid coolant into the reaction gas cooling channel to cool the reaction gas; then introducing the cooled reaction gas into a zirconium tetrachloride collecting tank, at the same time, and spraying liquid coolant into the zirconium tetrachloride collecting tank from top part or lateral side of the zirconium tetrachloride collecting tank so as to cool the reaction gas, wherein zirconium tetrachloride in a gas state is cooled and converted into zirconium tetrachloride powder, and the powder falls on the bottom of the zirconium tetrachloride collecting tank. According to the cooling method, liquid coolant is sprayed to the reaction gas so as to cool the reaction gas, the cooling effect is improved, the yield of zirconium tetrachloride is increased, and the production cost is reduced.

Owner:王卓

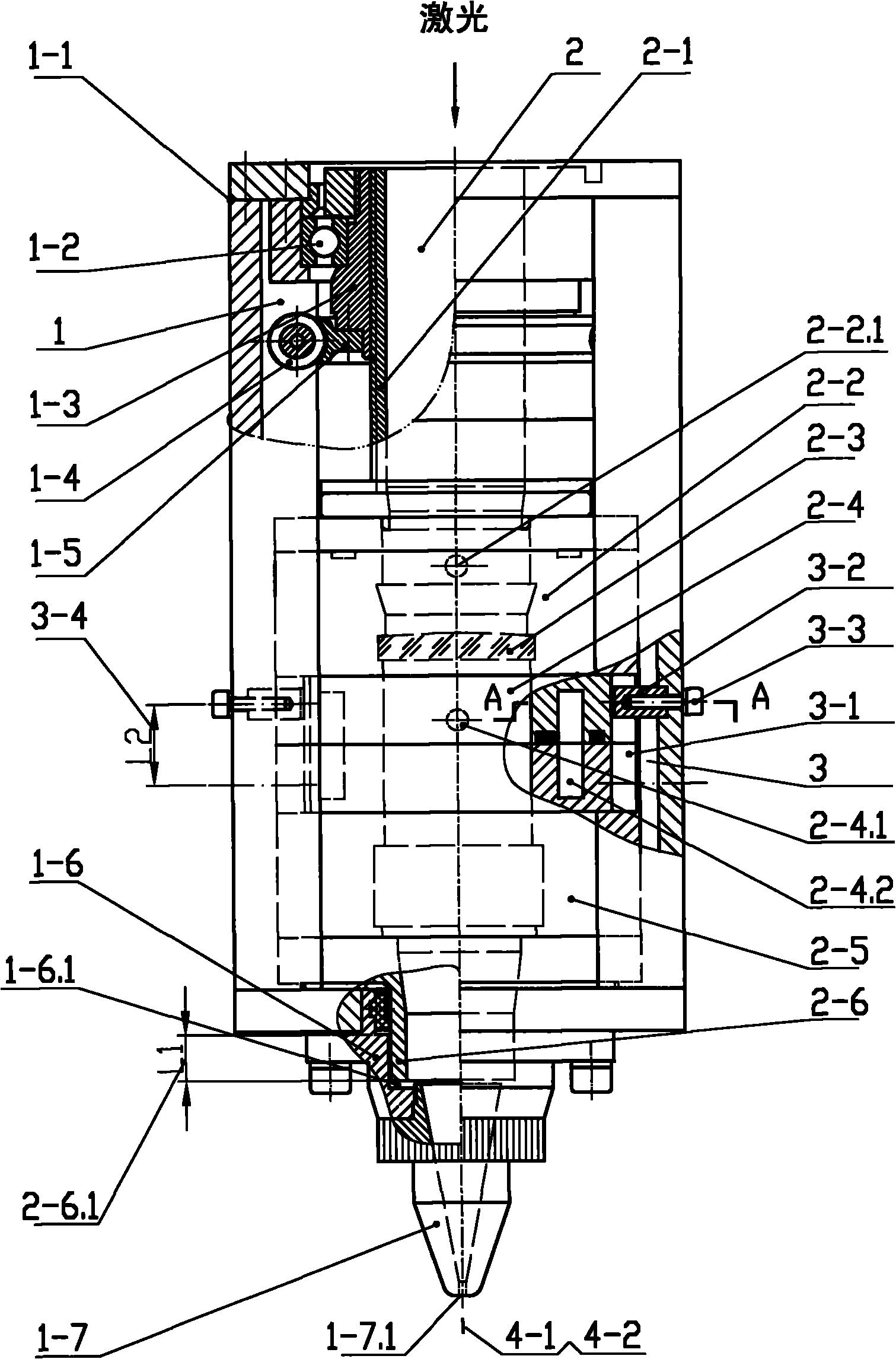

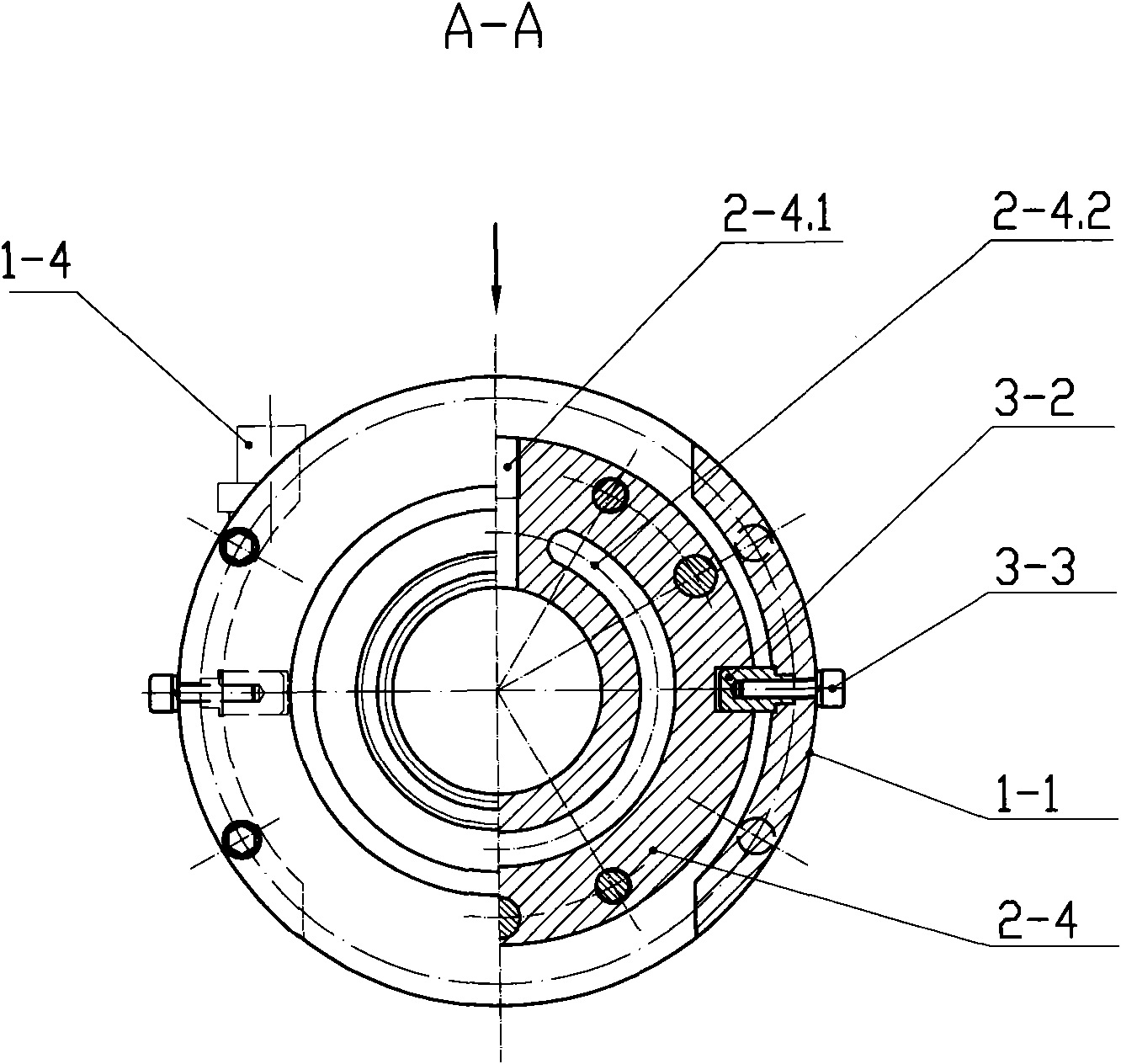

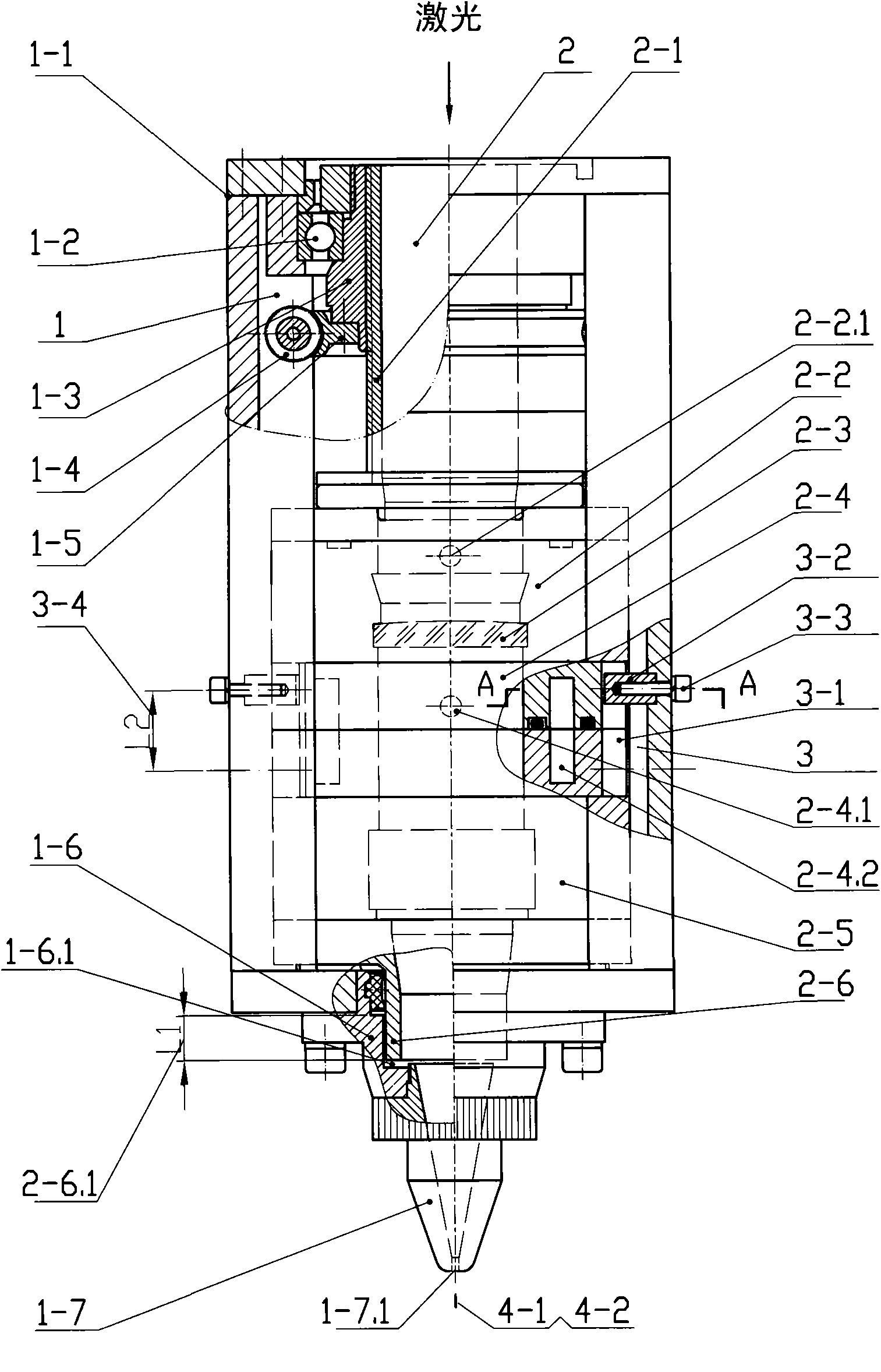

Automatic focus numerical control laser cutter

InactiveCN101837517AExpand the cutting rangeImprove stability and precisionLaser beam welding apparatusEngineeringWater tanks

The invention discloses an automatic focus numerical control laser cutter, which comprises a framework mechanism (1), a focusing mechanism (2), a lens seat mechanism and guide mechanisms (3) consisting of guide slots (3-1), guide keys (3-2) and locking screws (3-3). The framework mechanism comprises a fixed sleeve (1-1), a connecting seat (1-6) and a nozzle (1-7); the focusing mechanism comprises a worm (1-4), a worm gear (1-5), a bearing (1-2), a nut (1-3) and a trapezoidal thread sleeve (2-1); the lens seat mechanism comprises an upper lens seat (2-2) of a blow hole (2-2.1), a focusing lens (2-3) and an aqueous vapor seat (2-4) which consists of an upper part and a lower part and is provided with a blow hole (2-4.1) and an annular cooling water tank (2-4.2), a lower lens seat (2-5) and a ventilation seat (2-6); and the guide mechanisms are arranged in the aqueous vapor seat and bilaterally and symmetrically distributed by taking an axis of the cutter as a center. The cutter with the structure can realize high-precision, high-efficiency and smooth automatic focusing and has large focusing range and good focusing effects so as to expand the thickness range of plates to be cut.

Owner:LONGYAN LISHANG PRECISION MACHINERY

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

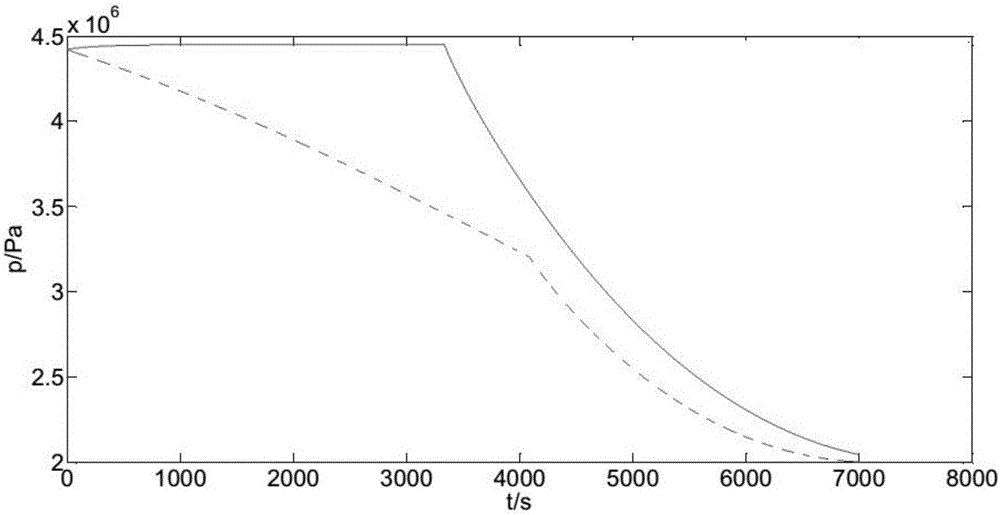

Self-pressurization supply system based on regenerative cooling

The invention belongs to the technical field of spacecraft systems and is mainly applied to liquid propulsion systems or solid-liquid mixing propulsion systems adopting high-saturated vapor pressure propulsive agents. In order to solve the problems that the temperature of propulsive agents and the pressure in a storage box are seriously reduced in the working process of a self-pressurization supply system, a self-pressurization scheme based on regenerative cooling is provided. The self-pressurization supply system is composed of a safety valve, a storage box, a filling pipeline, a filling valve, a one-way valve, a cooling channel, a liquid accumulating cavity, a main supply pipeline, a coolant pipeline, a burning agent pipeline, a main valve, a pressurization pipeline and the like. Propulsive agents cool the wall of a combustor and acquire heat at the same time. The propulsive agents subjected to heat exchange and vaporization return to the storage box to pressurize the storage box. According to the self-pressurization supply system based on regenerative cooling, the pressure intensity of the storage box can be basically maintained to be stable before the liquid propulsive agents in the storage box are completely discharged, and accordingly the effect that the thrust is basically stable is ensured.

Owner:NAT UNIV OF DEFENSE TECH

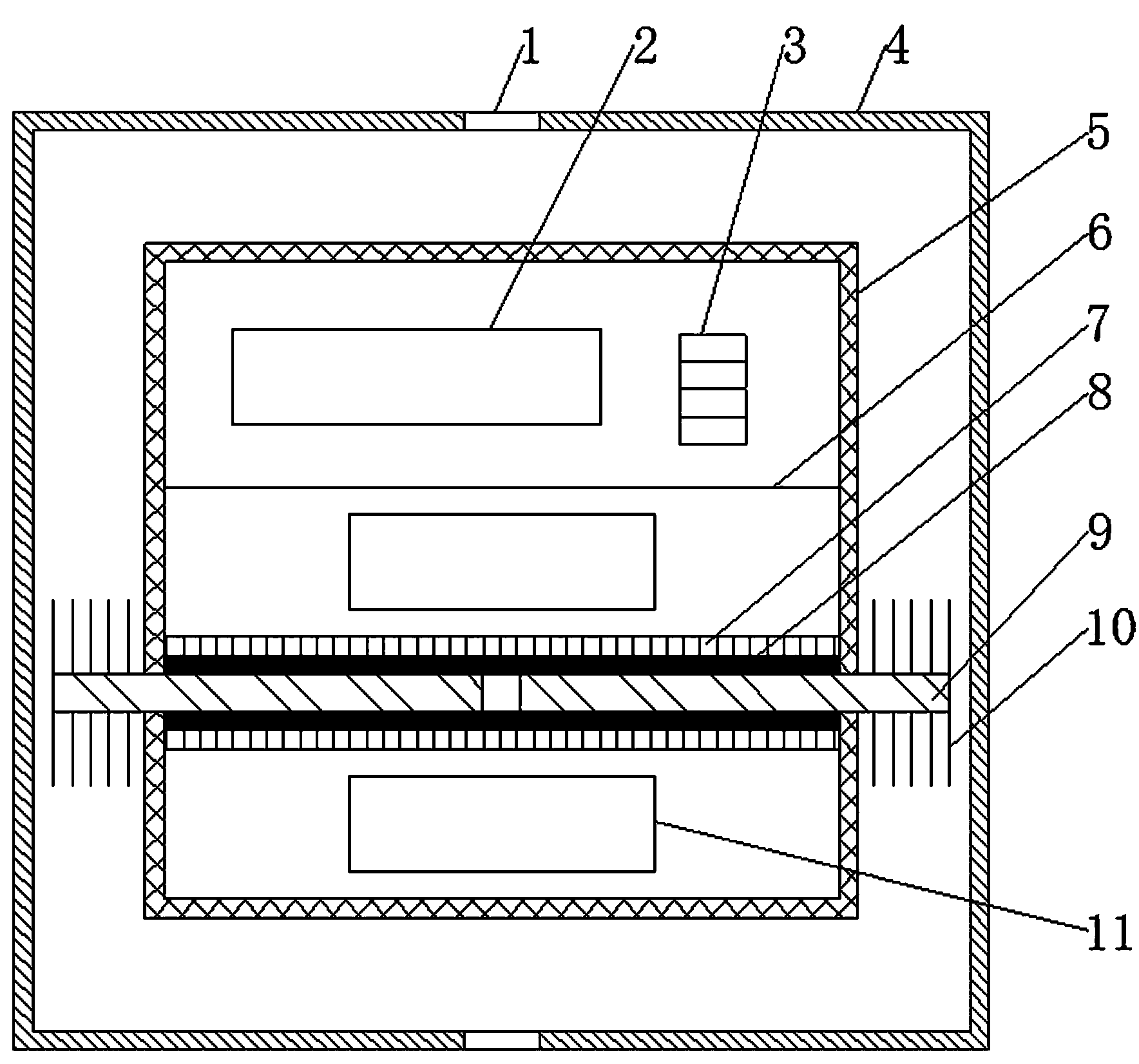

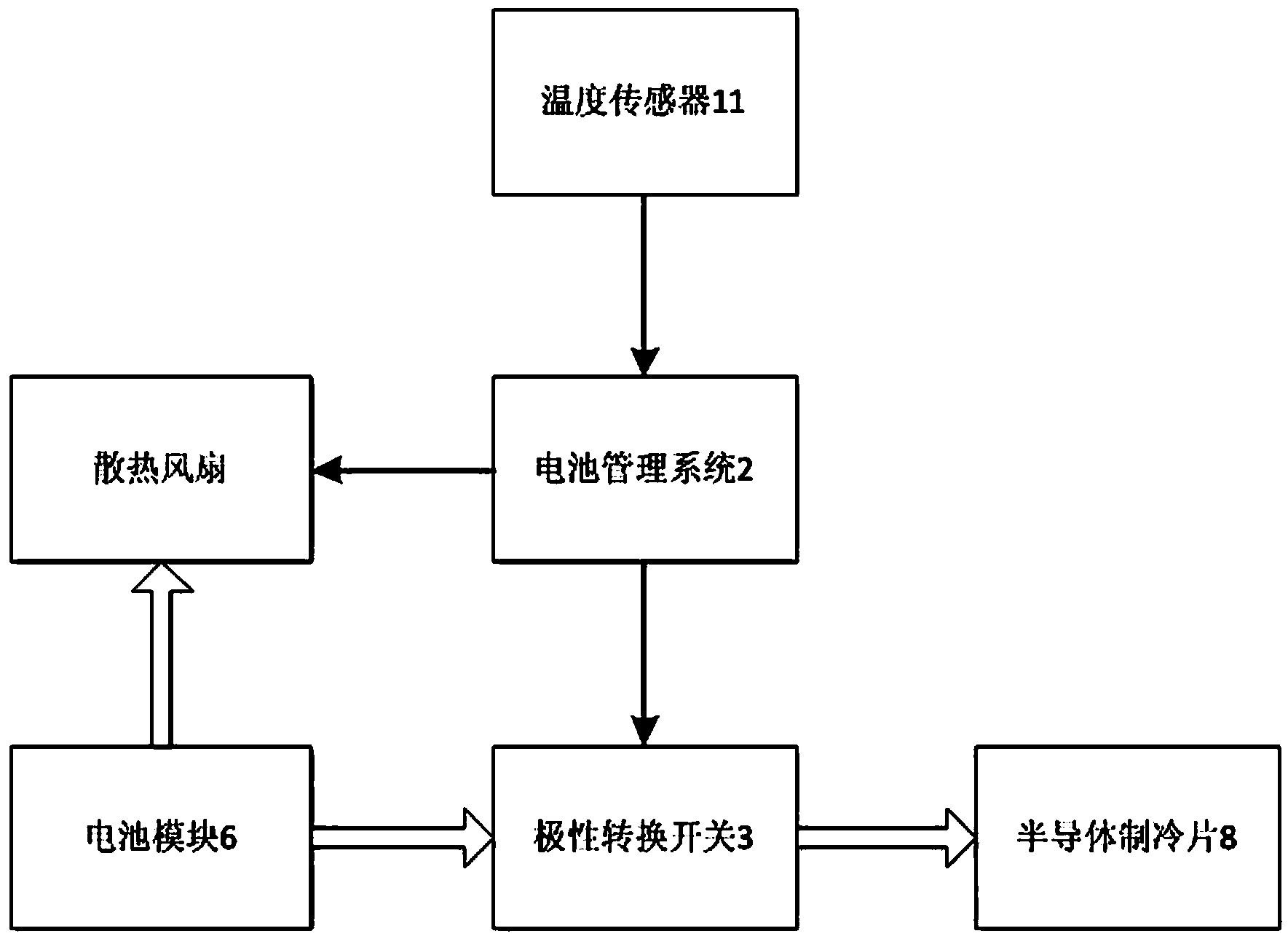

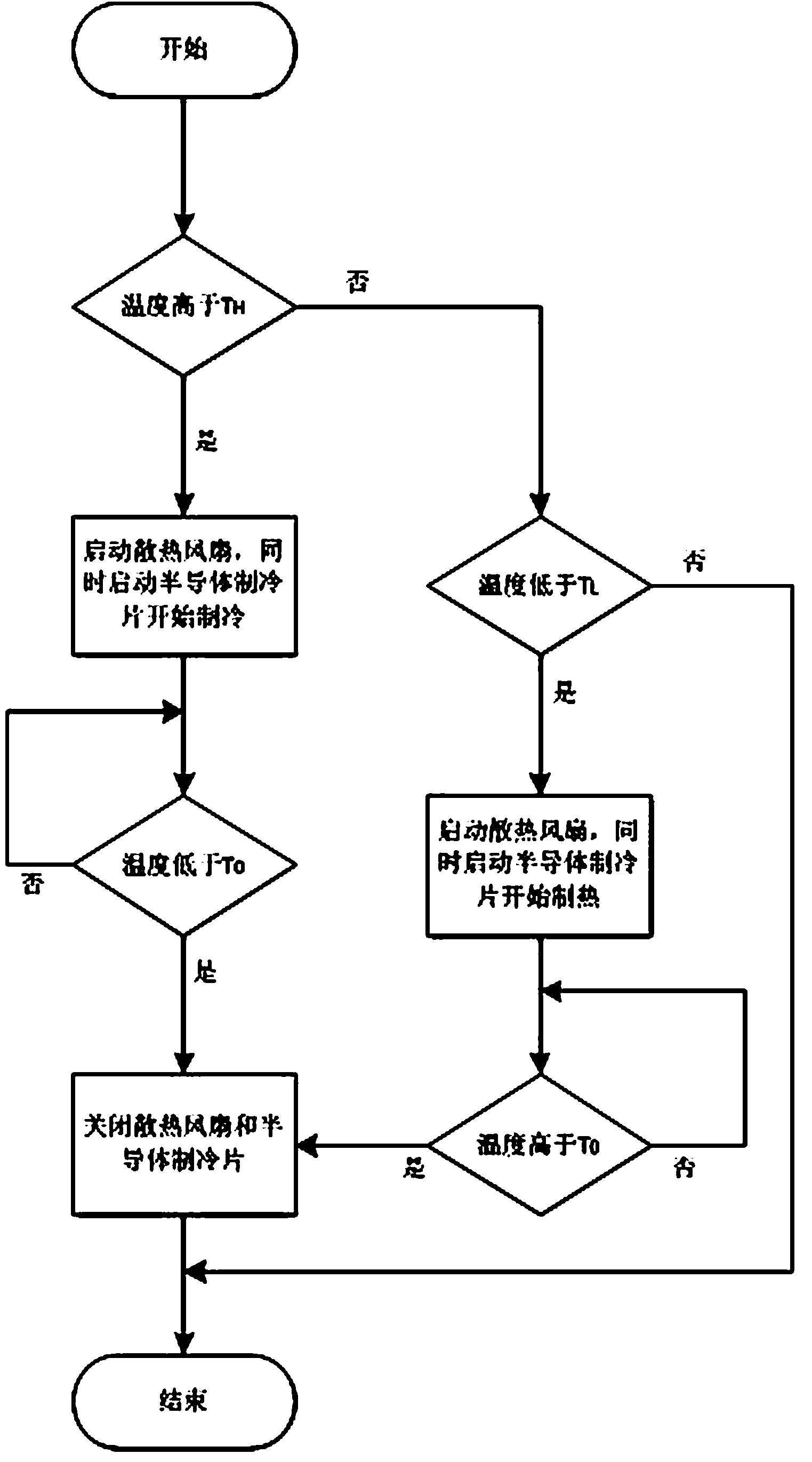

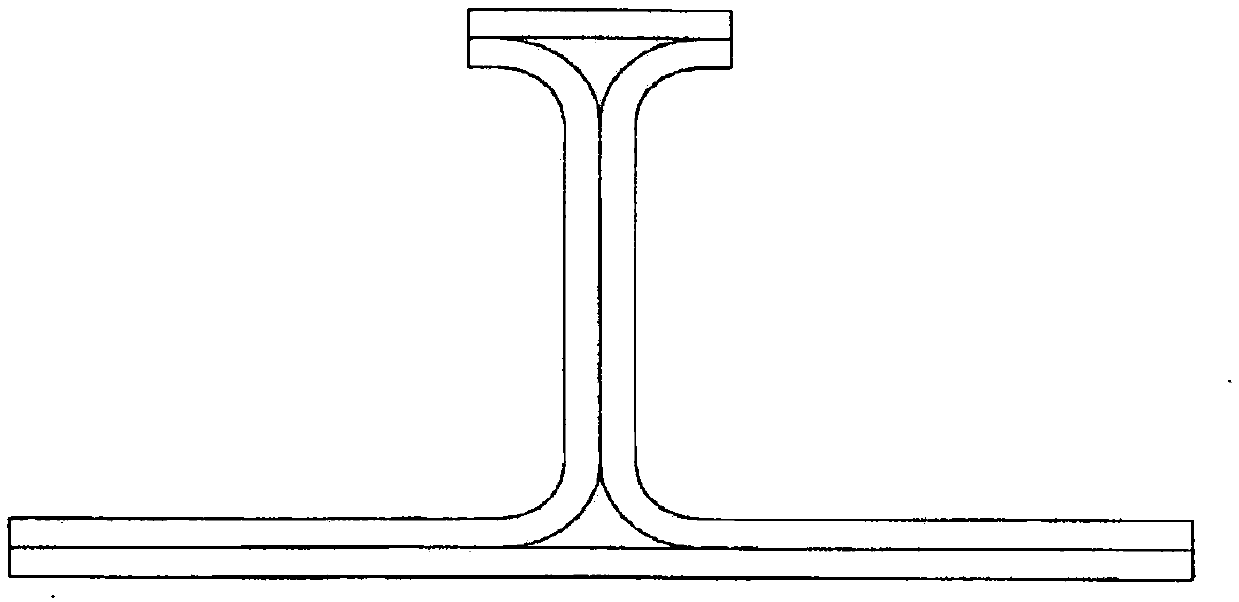

Battery box heat management system and method for electric automobile

InactiveCN103531864AAchieve coolingAchieve heatingCell temperature controlBattery isolationThermodynamicsHeat management

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

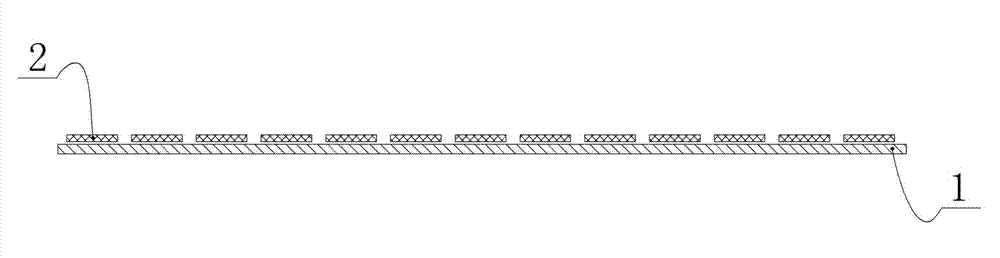

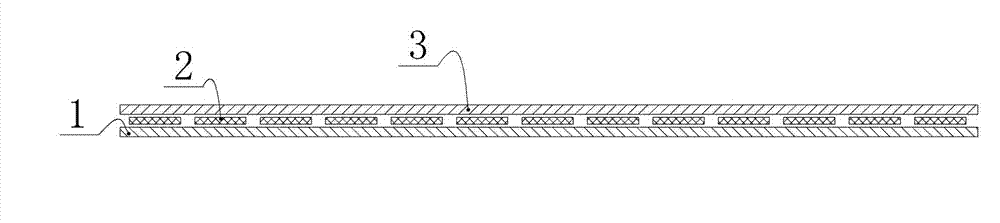

Filled 0-degree carbon fiber prepreg preforming tooling and preforming process

The invention discloses a filled 0-degree carbon fiber prepreg preforming tooling and a preforming process. The tooling comprises a forming pressure plate, forming mandrels, a base plate and limit stops, wherein multiple forming mandrels are closely and parallelly arranged on the base plate, the chamfers of the forming mandrels are consistent with an R angle of a long joist, filled 0-degree carbon fiber prepregs are located at the chamfers of the forming mandrels, the pressure plate is arranged above the mandrels, and the outer sides of the mandrels at the two ends are respectively provided with a limit stop. The preforming process comprises the following steps: (1) manufacturing a preforming tooling; (2) calculating the theoretic application amount of filled 0-degree carbon fiber prepregs; and (3) filling the 0-degree carbon fiber prepregs: weighting the 0-degree carbon fiber prepregs, cutting the 0-degree carbon fiber prepregs into fiber bundles with a size of 3-4mm, feeding the cut 0-degree carbon fiber prepregs into the preforming tooling, slightly compacting the prepregs by using a scraping plate, and after the prepregs are subjected to vacuum compaction on a heating platform at temperature of 70-80 DEG C for 15 min, transferring the prepregs to a normal-temperature workbench for cooling, and then taking out the obtained products. According to the invention, the forming quality of long joists is improved, and a situation that the shape of long joists after being manufactured is irregular is greatly improved.

Owner:SHENYANG AIRCRAFT CORP

Efficient cooling motor with three independent wind-path structures

ActiveCN103607073ASolve the cooling problemSolve power problemsMagnetic circuit rotating partsElectric machinesElectric vehicleConductor Coil

The invention relates to a motor, in particular to an efficient cooling motor with three independent wind-path structures. The problems that an existing electric vehicle traction motor is poor in cooling capability, low in output power, small in output torque, weak in overload capacity, large in size, high in weight and high in cost are solved. The efficient cooling motor with the three independent wind-path structures comprises a base, a front end cover, a rear end cover, a stator assembly and a rotor assembly. The stator assembly comprises a stator iron core and a stator winding. The rotor assembly comprises a rotary shaft and a rotor iron core. An outer-layer axial air gap is reserved between the surface of the inner circle of the base and the surface of the outer circle of the stator iron core, and an inner-layer axial air gap is reserved between the surface of the inner circle of the stator iron core and the surface of the outer circle of the rotor iron core. An axial air duct is formed in the end face of the rotor iron core in a penetrating through mode, a centrifugal fan is installed in an inner cavity in the front portion of the base, an air channel is installed on the surface of the outer circle of the rear portion of the base, and an axial flow fan is installed in an inner cavity of the air channel. The efficient cooling motor with the three independent wind-path structures is suitable for electric vehicles.

Owner:CRRC YONGJI ELECTRIC CO LTD

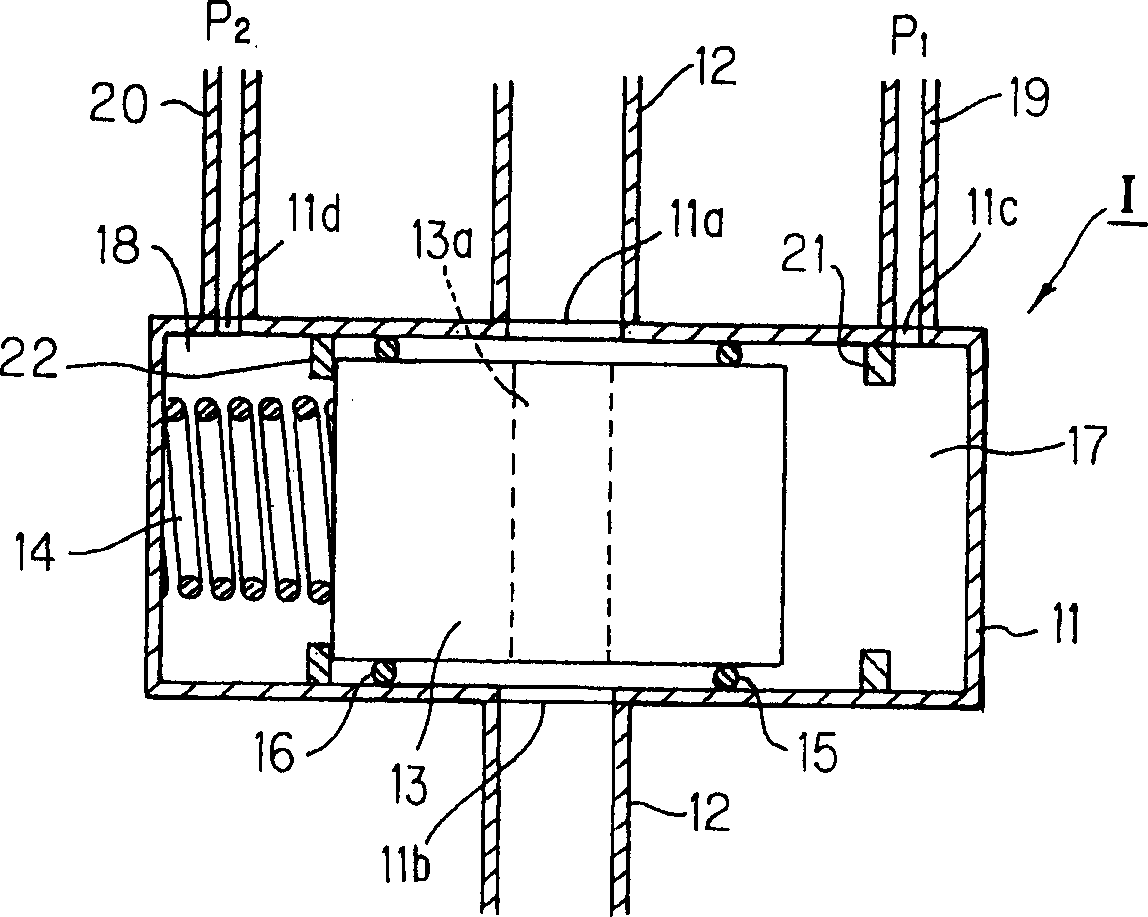

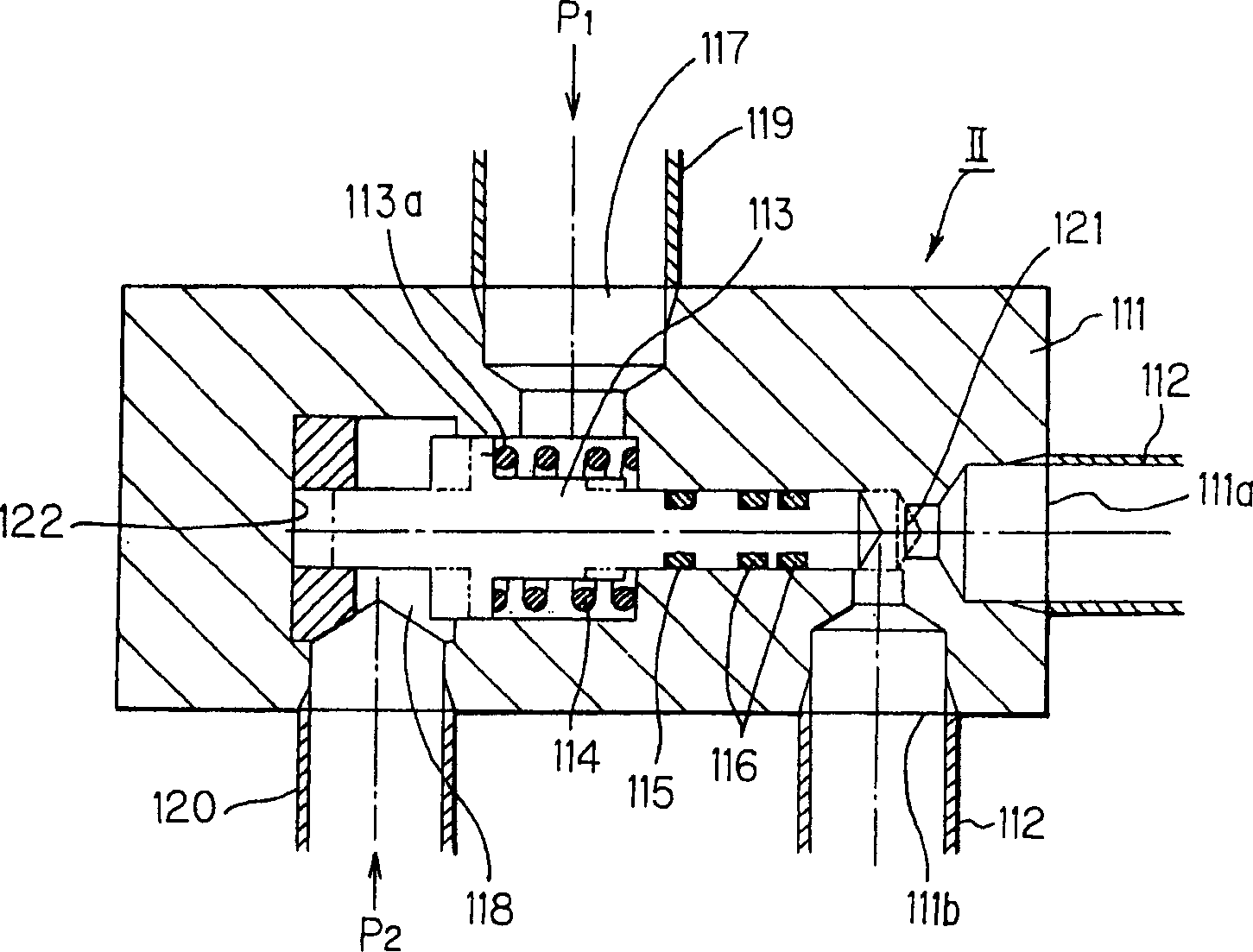

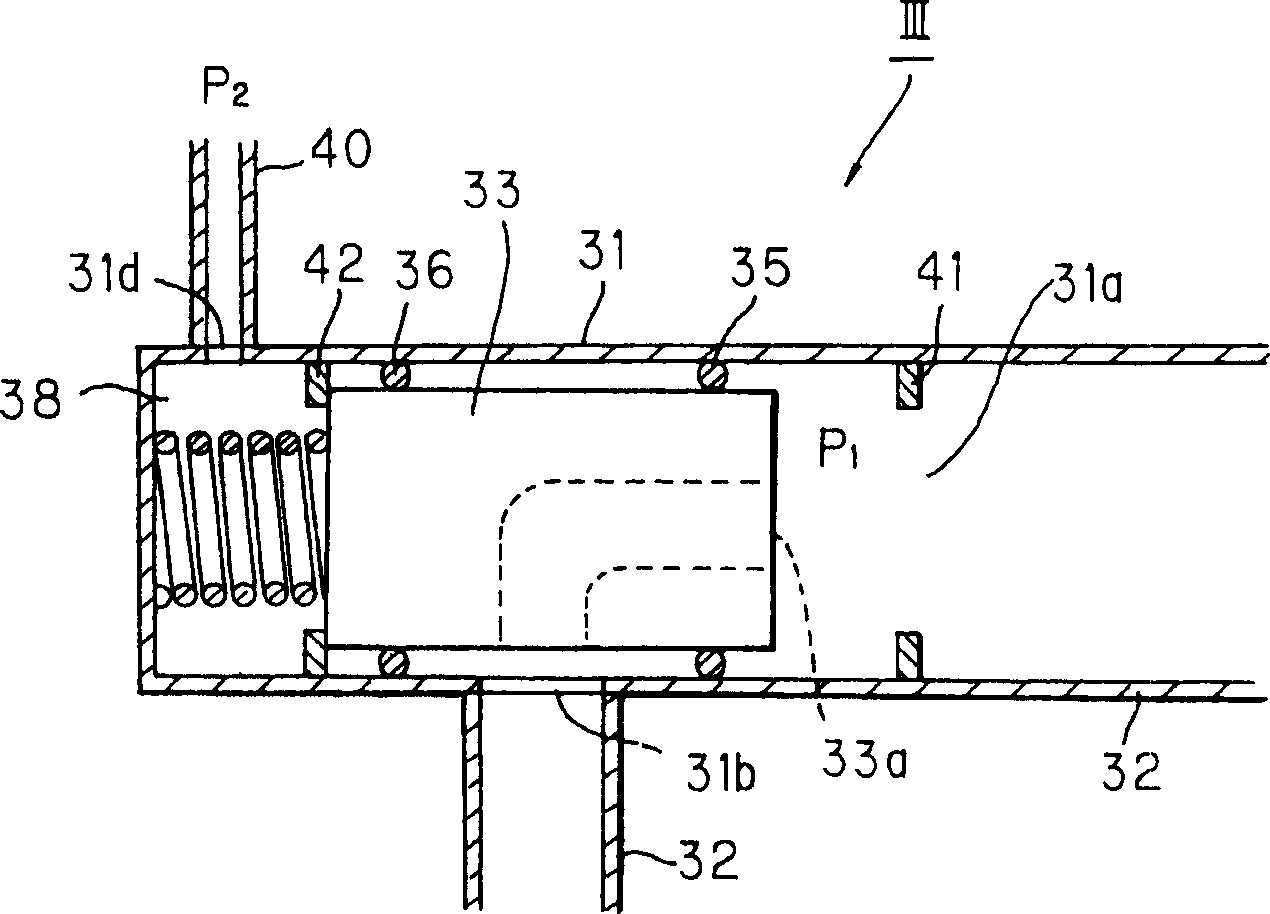

Self-contained regulating valve, and compression type refrigerating machine having the same

InactiveCN1422367ASimple structureLow priceOperating means/releasing devices for valvesCompression machines with non-reversible cycleInterior spaceDifferential pressure

A self-contained regulating valve having a spool, axially movable in the internal space of a cylindrical valve main body, wherein one pressure (P1) is applied to one end surface of the spool while the other pressure (P2) is applied to the other end surface, the spool being formed with a through-hole, so that when the difference between one pressure (P1) and the other present (P2) exceeds a set value, the through-hole communicates with a pipe line connected to the valve main body, thus establishing the open state.

Owner:MITSUBISHI HEAVY IND LTD

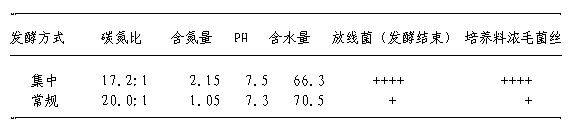

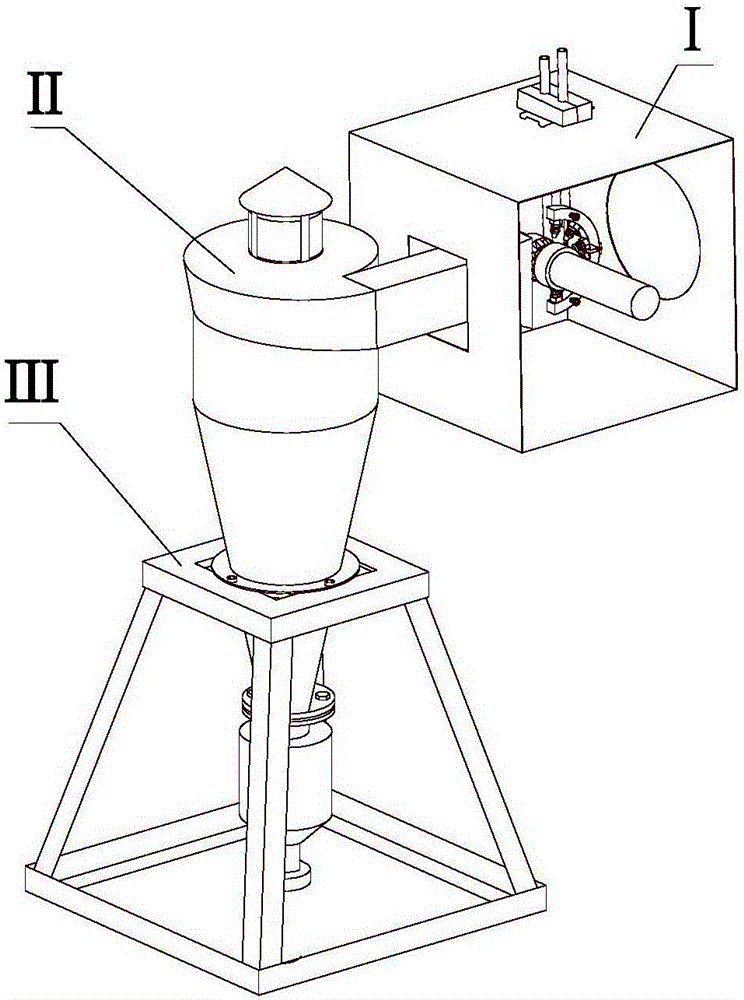

Centralized secondary fermentation method for agaricus bisporus

InactiveCN103319219AQuality productionHigh yield productionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal Foraging

The invention discloses a centralized secondary fermentation method for agaricus bisporus. The culture medium comprises the following raw materials in parts by weight: 45-60 parts of forage, 35-50 parts of chicken manure, 2-8 parts of gypsum and 3-10 parts of oil cakes. The method comprises the following steps of: uniformly spreading forage in a pre-wetting pool for pre-wetting for 2-5 days; adding chicken manure, gypsum and oil cakes and uniformly and adequately mixing; filling the mixed fermentation material in a ventilating floor in a primary fermentation tunnel, and conveying fresh air to the fermentation material through a fan; fermenting for 4-6 days and transferring the fermentation material to another primary fermentation tunnel. The base material of the primary tunnel fermentation is uniformly stacked on the ventilating floor in a secondary fermentation tunnel, and the temperature of the fermentation material is controlled by operation of the fan. Secondary fermentation comprises the following steps: a balancing stage, a heating stage, pasteurization, cultivation at constant temperature and discharge at low temperature. According to the method, local wheat straw hoods, straws, chicken manure and the like are used as main raw materials to form the culture medium. Centralized scaled production cultivation materials are formed by the technology of pre-treatment of the raw materials, primary fermentation and secondary fermentation.

Owner:SICHUAN MAOSEN BIOLOGICAL SCI & TECH

High-speed milling micro lubrication liquid supply nozzle structure and separation and recovery mechanism and system

ActiveCN106392764AAchieve lubricationAchieve coolingMaintainance and safety accessoriesSpray nozzleEngineering

The invention discloses a high-speed milling micro lubrication liquid supply nozzle structure and a separation and recovery mechanism and a system. The structure comprises at least two nozzle bodies; one ends of the nozzle bodies are connected with a pipeline shell, and the other ends of the nozzle bodies are spraying heads; mixing channels formed by internals of hollow pipes are arranged in the nozzle bodies; one ends of the mixing channels are communicated with at least two pipelines; gas is introduced in the first pipeline; lubricating oil is introduced in the second pipeline; a gas pipeline communicated with the first pipeline and a lubricating oil pipeline communicated with the second pipeline are arranged in the pipeline shell; the gas pipeline and the lubricating oil pipeline both surround the center point of the pipeline shell; through setting of the pipeline shell, the lubrication and the cooling of milled parts are realized, and the lubricating effect is good; and the structure can effectively prevent splashing of chips and fog drips through setting of a box body, reduces the harm to environments and operators in the machining process, meanwhile, can effectively realize separation of a lubricating agent, the chips and the gas, and reduces environmental pollution.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Arc solar panel and processing technology

InactiveCN102856410AExtended service lifeStable in natureFinal product manufacturePhotovoltaic energy generationTransmittancePolyester resin

The invention relates to an arc solar panel which comprises a plastic substrate and a plurality of solar silicon crystal boards regularly arranged on the plastic substrate. The solar silicon crystal boards are used for photovoltaic power generation. The arc solar panel is characterized in that polyester resin layers with light transmittance performance are attached to the upper surfaces of the solar silicon crystal boards; and the lower surface of the plastic substrate is of the same curved surface shape with the outer surface of an automobile top plate. A processing technology of the arc solar panel, which is disclosed by the invention, comprises the following steps of: c, adhering the solar silicon crystal boards; d, arranging the polyester resin layers; 3, loading a die; f, filling a heating medium; g, carrying out hot embossing; and h, carrying out cooling sizing. According to the arc solar panel disclosed by the invention, the firmness of the integral arc solar panel is effectively ensured and the capacity of receiving the sunlight is ensured. The technology for manufacturing the arc solar panel, which is disclosed by the invention, has simple and reasonable steps and can be used for effectively ensuring the quality of the manufactured arc solar panel.

Owner:张正泉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com