Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

730results about How to "Achieve lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

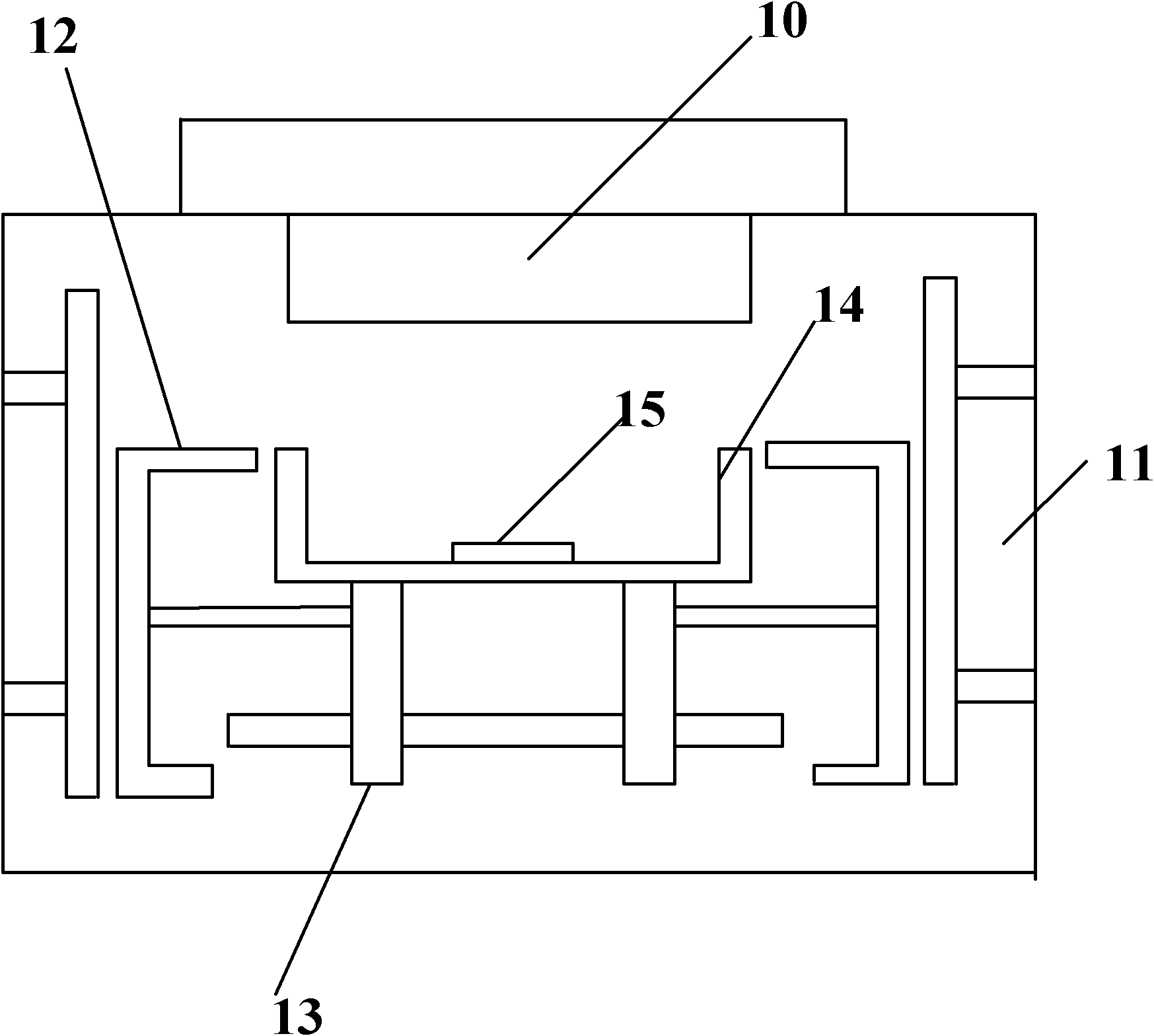

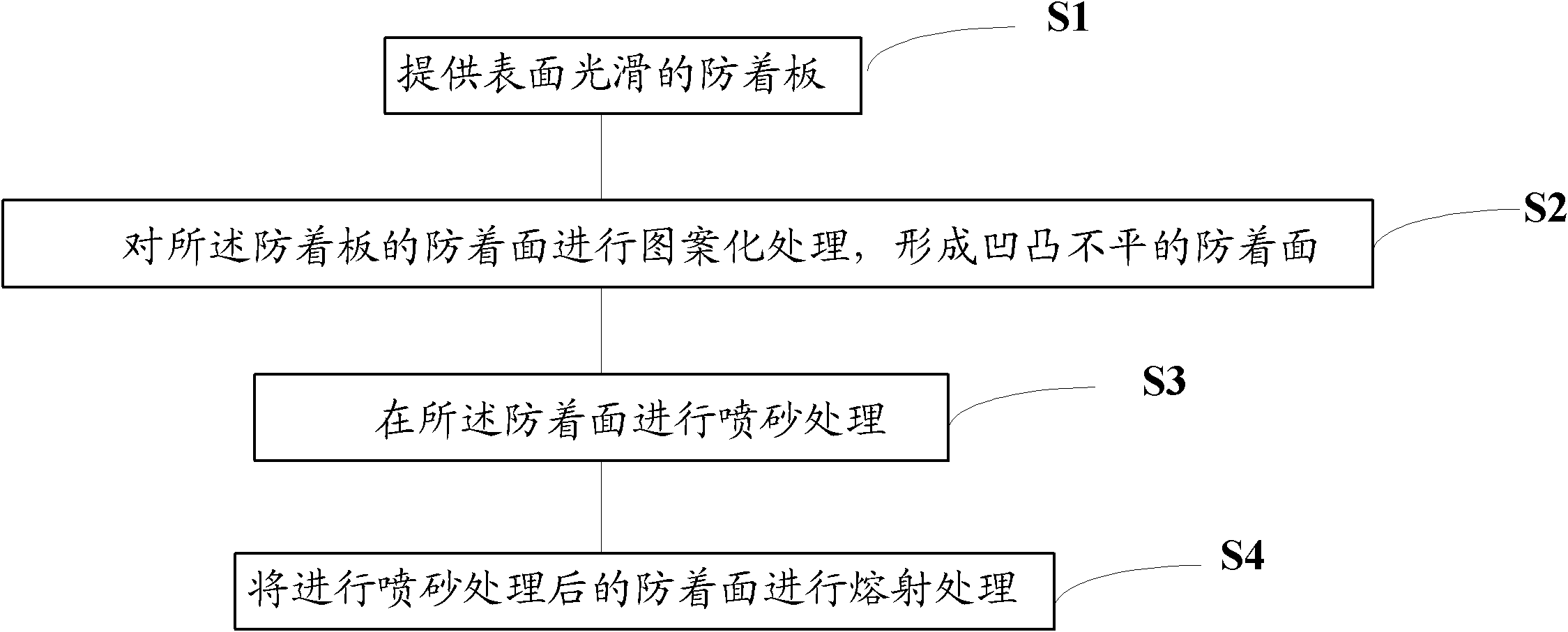

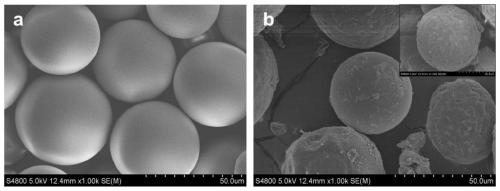

Method for processing surface of attachment-resisting plate

ActiveCN102011085AImprove corrosion resistanceImprove precipitation effectMolten spray coatingAbrasive blastingSputtering

The invention discloses a method for processing the surface of an attachment-resisting plate. The method comprises the following steps: providing an attachment-resisting plate with a smooth surface; patterning the attachment-resisting surface of the attachment-resisting plate with a smooth surface to form an uneven attachment-resisting surface; blasting the attachment-resisting surface; and meltallizing the attachment-resisting surface after blasting. The smooth surface of the attachment-resisting plate is subject to the patterning, the blasting and the meltallizing so that the surface of theattachment-resisting plate has corrosion resistance, rust prevention, abrasion resistance, lubrication, roughness, adsorption, insulation, heat insulation and other properties; the attachment-resisting surface of the attachment-resisting plate achieves even roughness; and the attachment-resisting plate can easily absorb target atoms or large-sized particles so that the target atoms or large-sizedparticles do not fall on a substrate, thereby increasing the sediment capability of the attachment-resisting plate, improving the cleanness of the inner wall of a sputtering machine, improving the filming rate of sputtering and prolonging the service life of the attachment-resisting plate.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

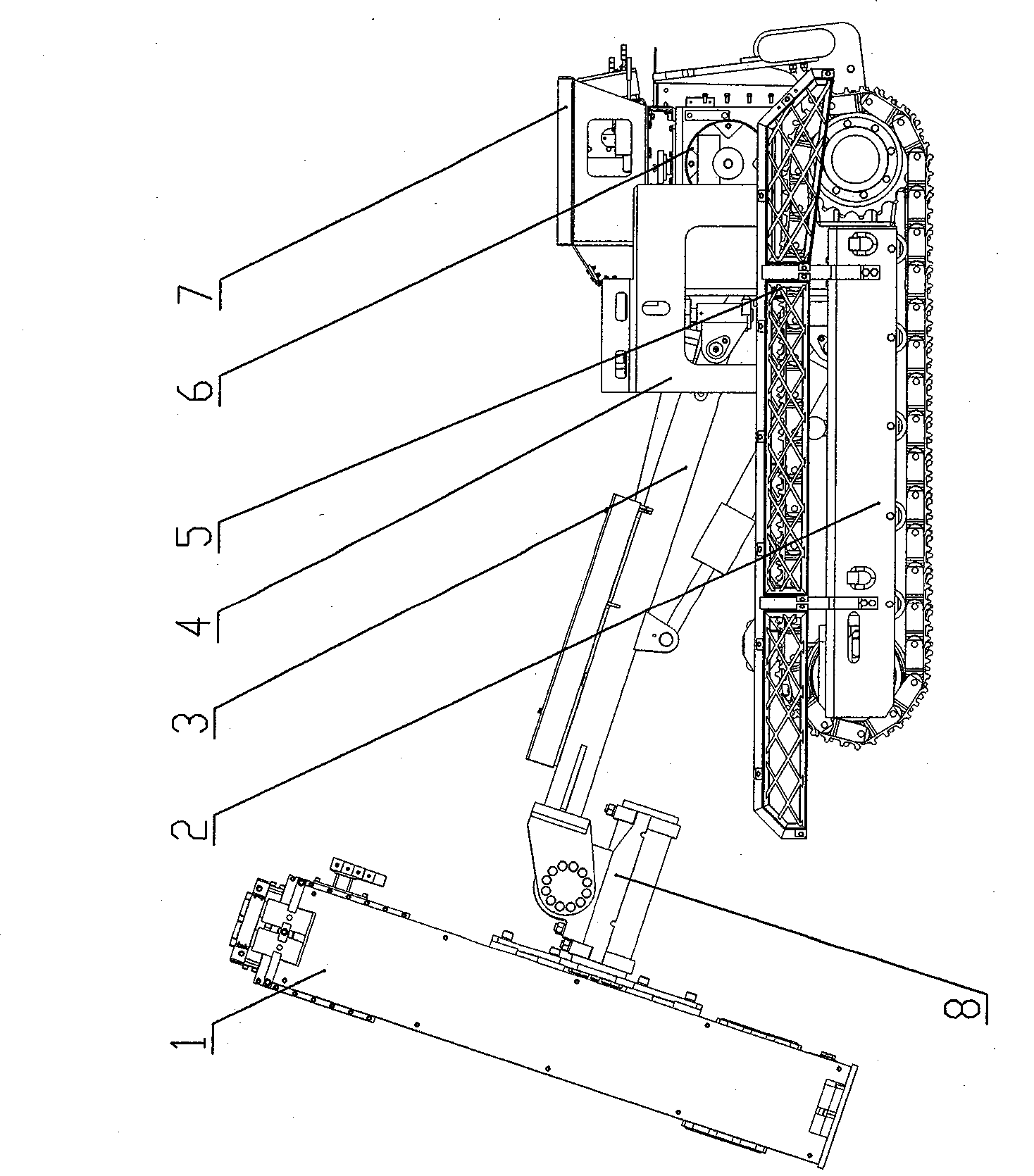

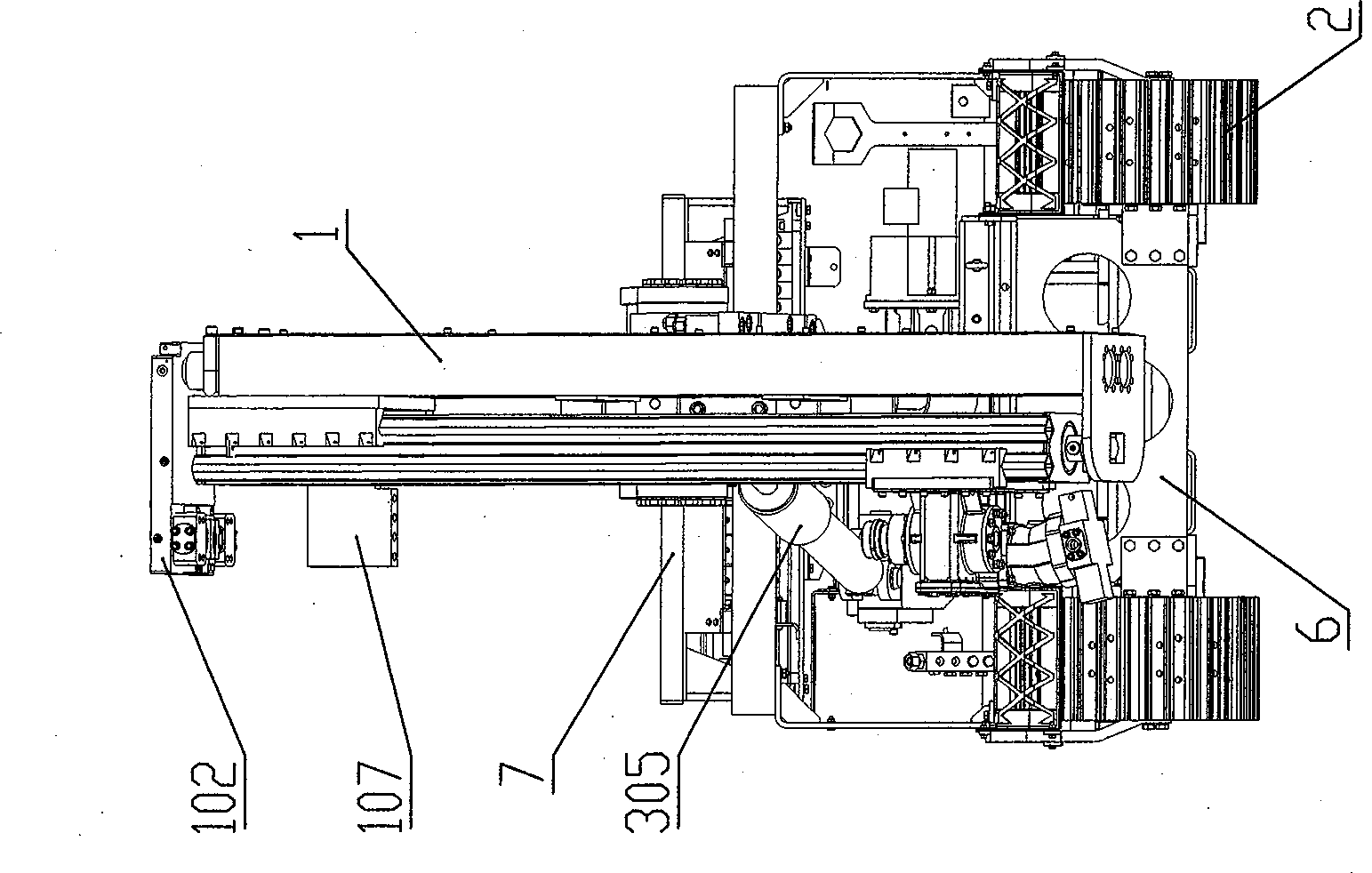

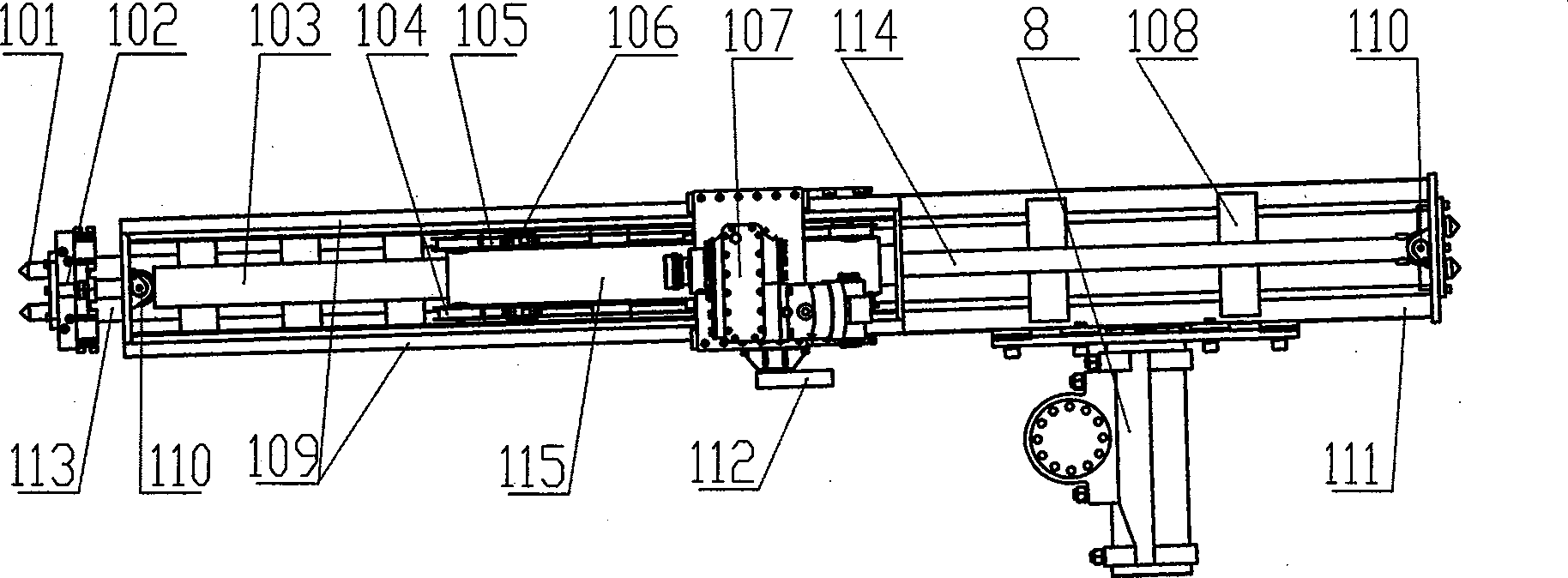

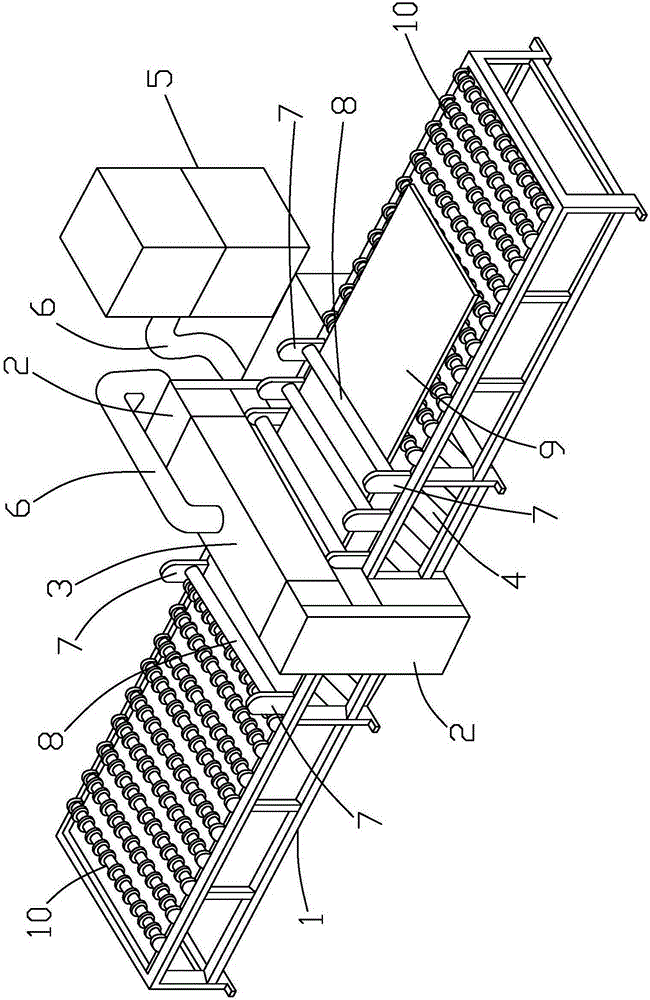

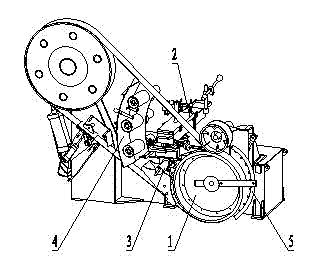

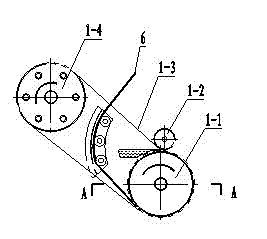

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

Novel corrosion-resistant alloy steel continuous casting powder and application thereof

The invention relates to novel corrosion-resistant alloy steel continuous casting powder and application thereof, and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises the following components in mass percentage: 17 to 25% of CaO, 23 to 31% of SiO2, 10 to 15% of Al2O3, 1 to 4% of MgO, 10 to 14% of (Na2O+Li2O), 1 to 8% of B2O3, 1 to 6% of TiO, 4 to 8% of BaO, and 10 to 13% of F<->. The casting powder has the characteristics that the melting point is small (865-988 DEG C), the viscosity is small (0.11-0.23Pa.s under 1,300 DEG C), the crystallizing rate is moderate (40-70%), etc. The casting powder can be applied well to the continuous casting of corrosion-resistant alloy steel (Fe-Cr-Ni system) containing 0 to 0.3% of Al and 0.8 to 1.1% of Ti in mass percentage.

Owner:CENT SOUTH UNIV

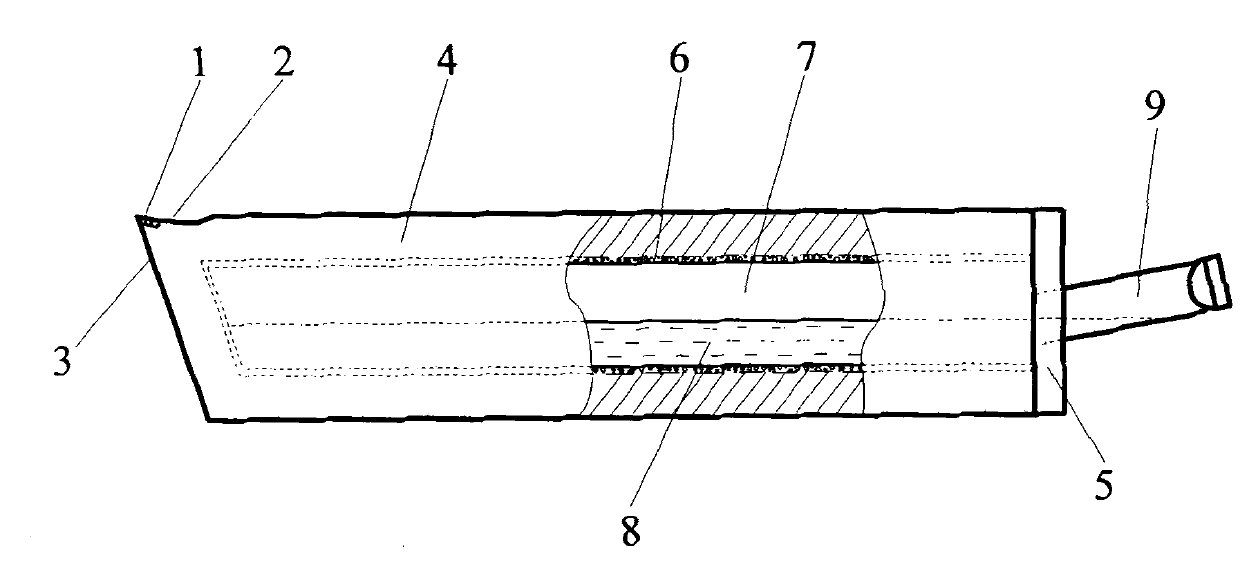

Self-lubricating and self-cooling dry cutter and manufacturing method thereof

InactiveCN102000841ARealize self-lubricating functionAchieve lubricationTurning toolsManufacturing technologyLiquid medium

The invention provides a manufacturing method of self-lubricating and self-cooling dry cutter, belonging to the technical field of mechanical cutter manufacturing. A cutter-scrap contact zone on a front cutter face of the cutter is provided with a plurality of miniature antifriction slots filled with solid lubricants, and the solid lubricants in the antifriction slots are coated on the front cutter face of the cutter in a towing way by the jointed action of cutting heat and scrap extrusion to form a continuous solid lubricating film so that the self-lubricating function of the cutter is realized; and a self-circulation cooling cavity is arranged in a cutter body, during cutting processing, a liquid medium in the cooling cavity absorbs heat transferred from the cutting part of the cutter so that the rapid heat radiation and cooling of the cutting part of the cutter can be effectively enhanced, thereby the self-cooling function of the cutter is realized. The cutter can reduce the frication of the cutting part with a workpiece and also lower the cutting temperature so that the friction of the cutter is reduced, the processing quality of the workpiece and the durability of the cutter are improved, and the cutter can be widely applied to dry cutting and cutting of materials difficult to process and realizes clean production.

Owner:SHANDONG UNIV

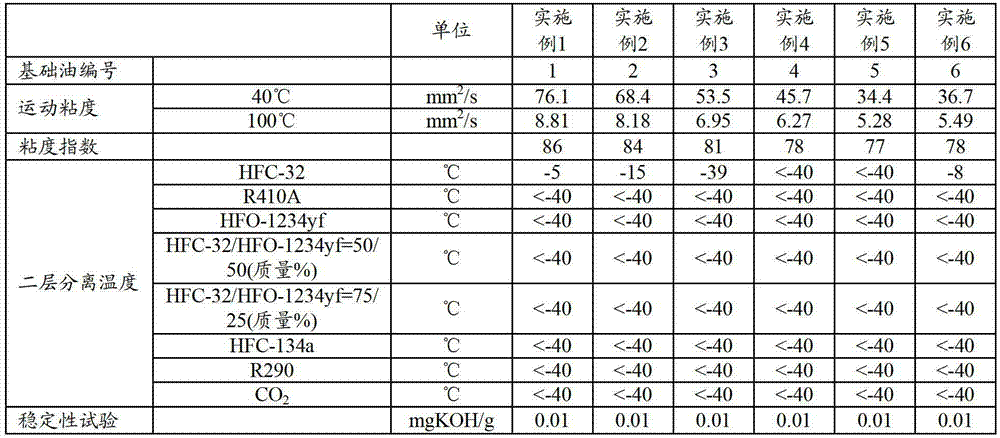

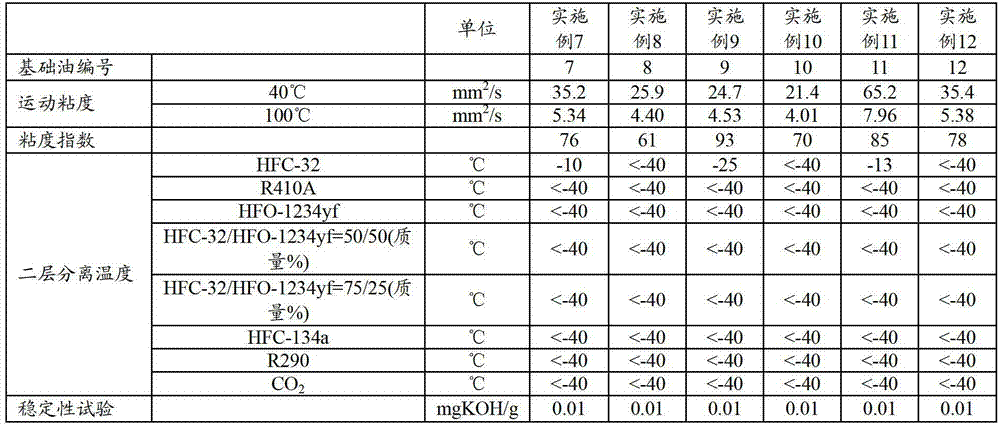

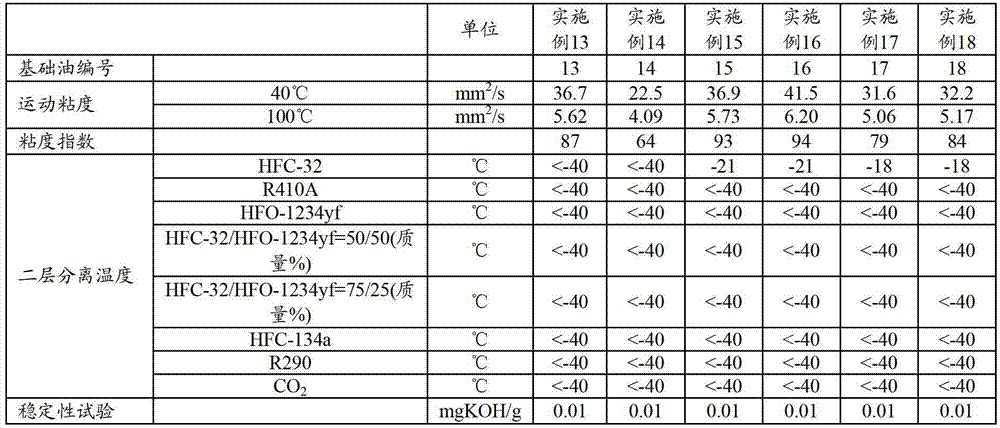

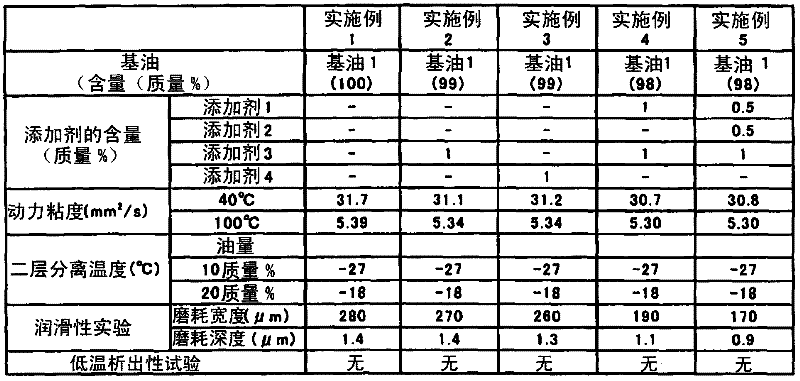

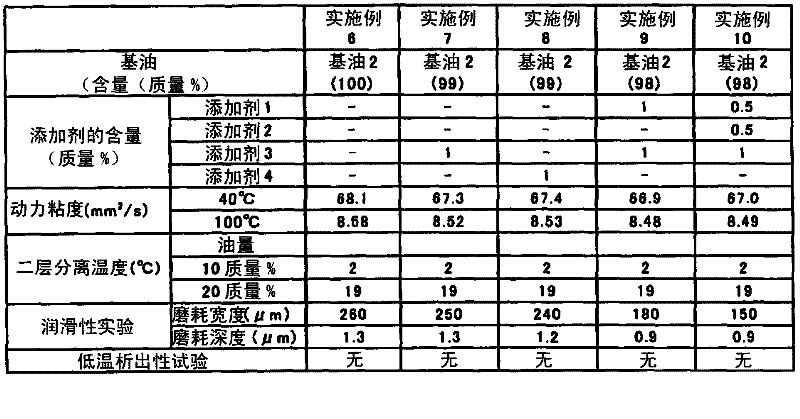

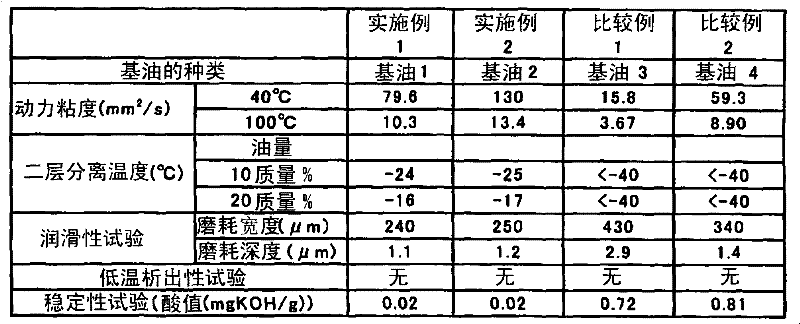

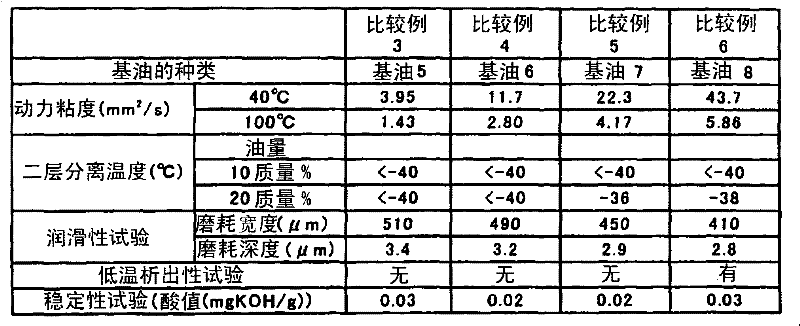

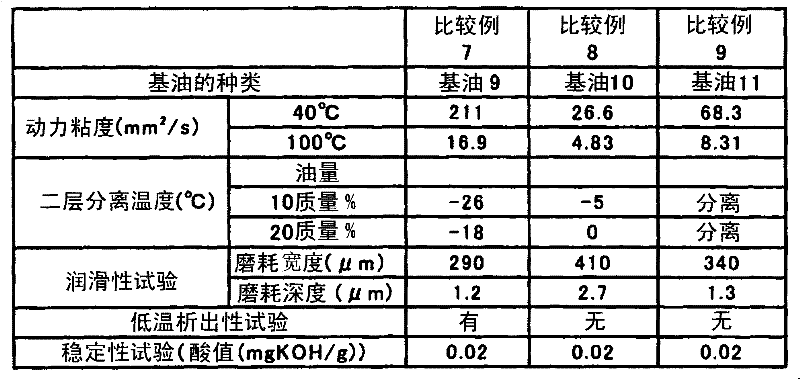

Refrigerating machine oil and working fluid composition for refrigerating machines

ActiveCN103097501AGood compatibilityAchieve lubricationHeat-exchange elementsBase-materialsBranched chain fatty acidsWorking fluid

This refrigerating machine oil comprises esters of a polyhydric alcohol with fatty acids. In the fatty acids, the molar ratio of C4-6 fatty acids to branched C7-9 fatty acids is 15:85 to 90:10, and the C4-6 fatty acids contain 2-methylpropanoic acid, with the sum total of the C4-6 fatty acids and the branched C7-9 fatty acids accounting for at least 20 mol% of the whole of the fatty acids constituting the esters. This working fluid composition for refrigerating machines comprises the refrigerating machine oil and a difluoromethane refrigerant and / or an unsaturated fluorinated hydrocarbon refrigerant.

Owner:JX NIPPON OIL & ENERGY CORP

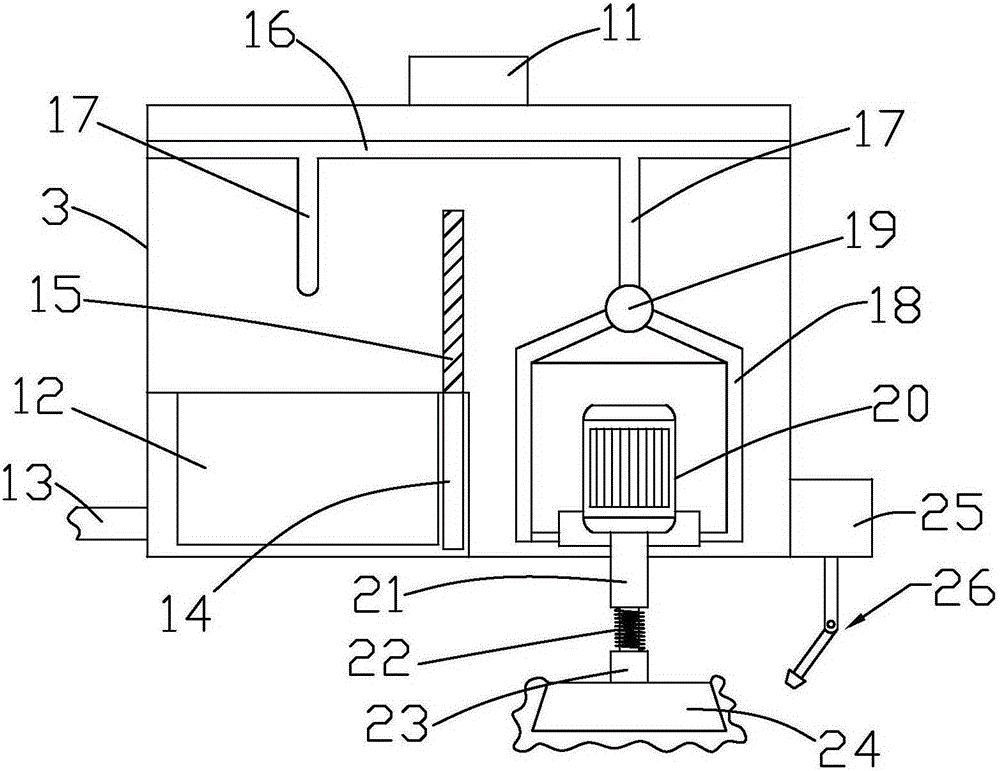

Multifunctional glass polishing machine

InactiveCN105215805ASatisfied with polishingImprove processing efficiencyGrinding drivesGrinding feedersEngineeringSewage treatment

The invention discloses a multifunctional glass polishing machine which comprises a feeding frame and a polishing device. The polishing device comprises moving control boxes, a cantilever, a bottom operating table and a water tank. A cleaning trough, a horizontal slide rail, vertical slide rails and upper polishing mechanisms are arranged in the cantilever. The upper polishing mechanisms are connected to a cantilever rod through supporting frames. The feeding frame horizontally penetrates through the moving control boxes. The bottom operating table is located below the feeding frame, and a lifting table, a supporting plate, a sewage disposal pool and a lower polishing mechanism are arranged in the bottom operating table. The lower polishing mechanism is arranged on the top face of the lifting table. Pressing mechanisms are arranged on the two sides of the cantilever. The water tank is located on one side of the feeding frame and connected with the cantilever through a conveying pipe. The multifunctional glass polishing machine is simple in structure and high in practicability, can be used for polishing both plain glass and curved glass, and improves the efficiency and quality of polishing.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Refrigerating machine oil and working fluid composition for refrigerator

ActiveCN102191114AGood compatibilityAchieve lubricationHeat-exchange elementsBase-materialsPentaerythritolWorking fluid

The invention discloses refrigerating machine oil and a working fluid composition for a refrigerator. The refrigerating machine oil of the invention contains ester which is above 10% of the total amount of the refrigerating machine oil by weight and used together with difluoromethane refrigerating medium. The ester is ester of pentaerythritol and fatty acid. Wherein in the fatty acid, the mol ratio of fatty acid with a branched chain and whose carbon atom number is 6 to 3,5,5-trimethyl caproic acid is (20:80)-(80:20); the sum of the fatty acid whose carbon atom number is 6 and the 3,5,5-trimethyl caproic acid is above 20 mol% in the fatty acid; furthermore, the working fluid composition for the refrigerator contains the refrigerating machine oil and the difluoromethane refrigerating medium in the invention.

Owner:JX NIPPON OIL & ENERGY CORP

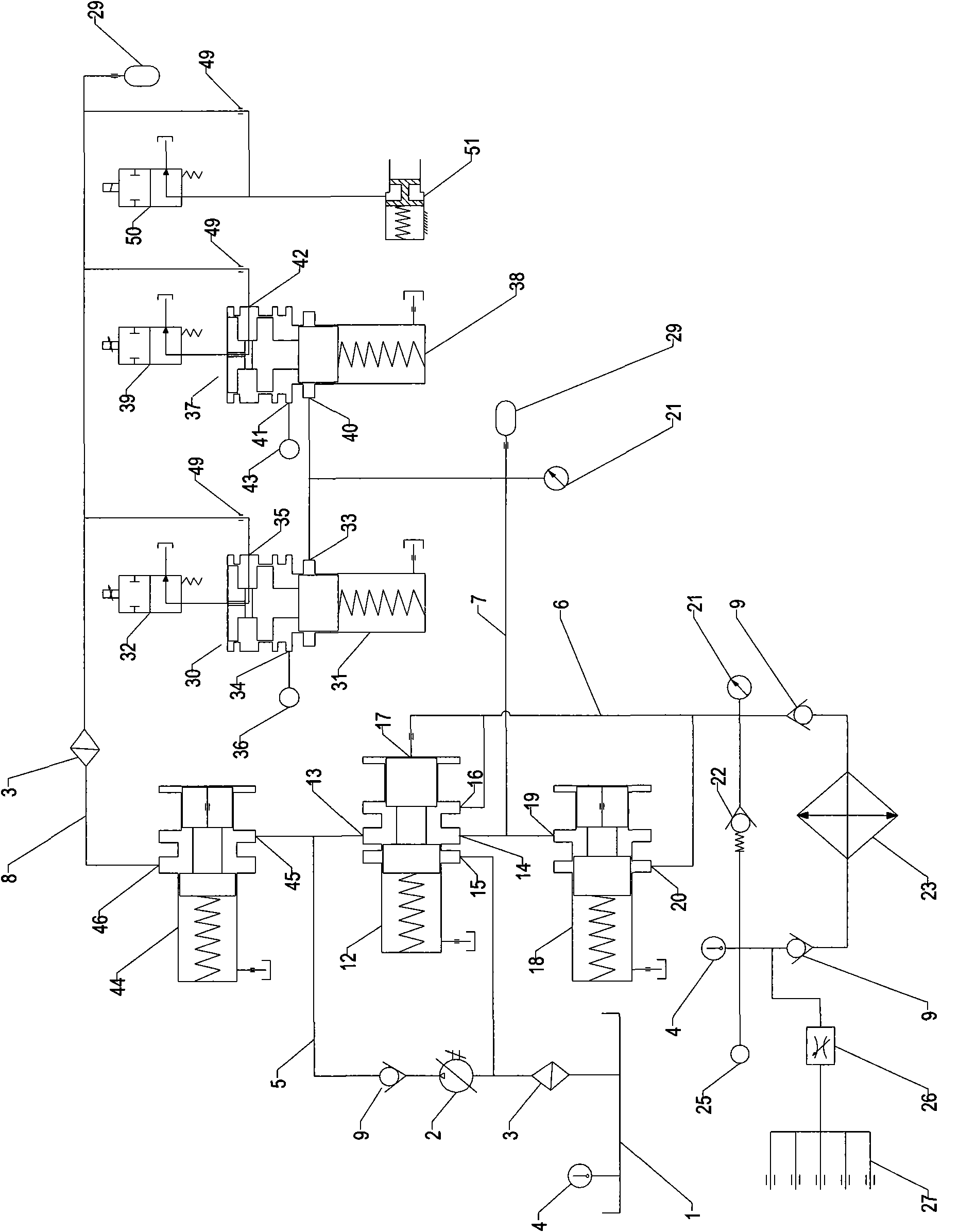

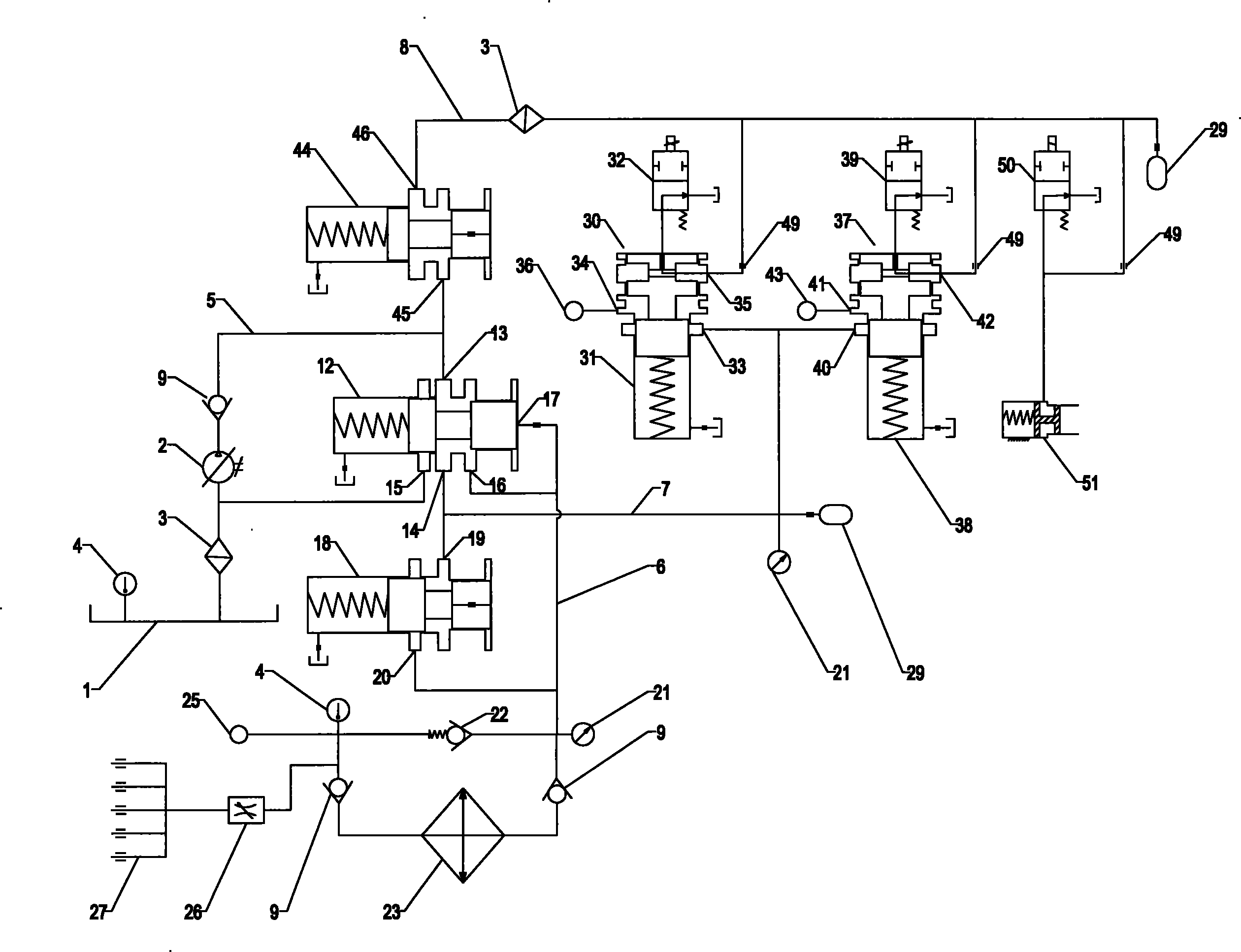

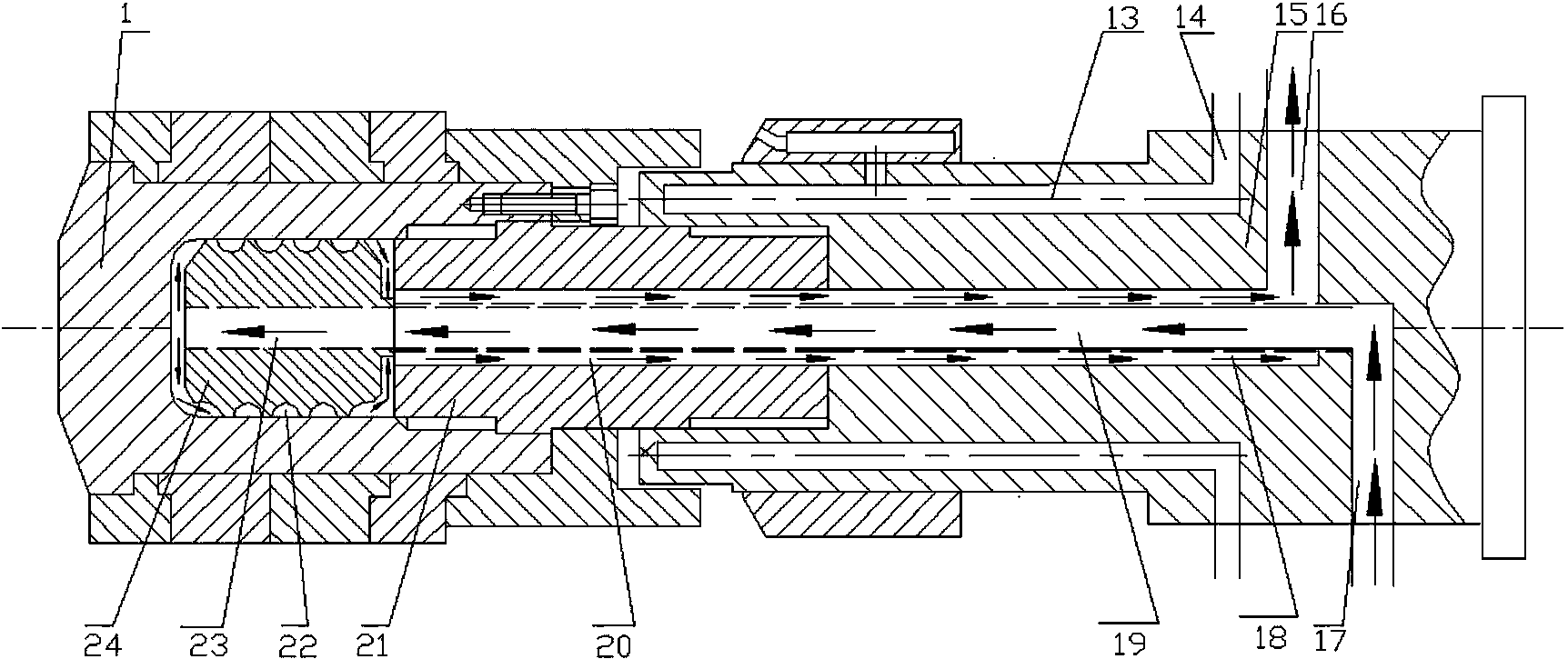

Hydraulic control device for hybrid power transmission

ActiveCN101994825AHigh transmission efficiencyImprove cooling effectGear lubrication/coolingGearing controlElectric power transmissionLubrication

The invention discloses a hydraulic control device for a hybrid power transmission, wherein a main oil-way is respectively connected with a lubricating oil-way, a clutch control oil-way and an electromagnetic valve control oil-way, the main oil-way is connected with a cooling and lubricating oil-way through an unloading valve, the cooling and lubrication oil-way is connected with a valve core control oil port of the unloading valve at the same time, the oil outlet of the unloading valve is respectively connected with an oil inlet of an overflow valve and the clutch control oil-way, the oil outlet of the overflow valve is connected with the lubricating oil-way, the clutch control oil-way is respectively connected with oil inlets of proportional reducing valves A and B, a reducing valve is arranged between the electromagnetic valve control oil-way and the main oil-way, the electromagnetic valve control oil-way is respectively connected with valve core control oil ports of the proportional reducing valves A and B through oil-saving holes, and is respectively connected with a switching electromagnetic valve and a halt locking hydraulic cylinder through the oil-saving holes. The hydraulic control device has simple structure, can rapidly lubricate the transmission, and is suitable for the hydraulic control of the hybrid power transmission.

Owner:江西鼎盛新材料科技有限公司

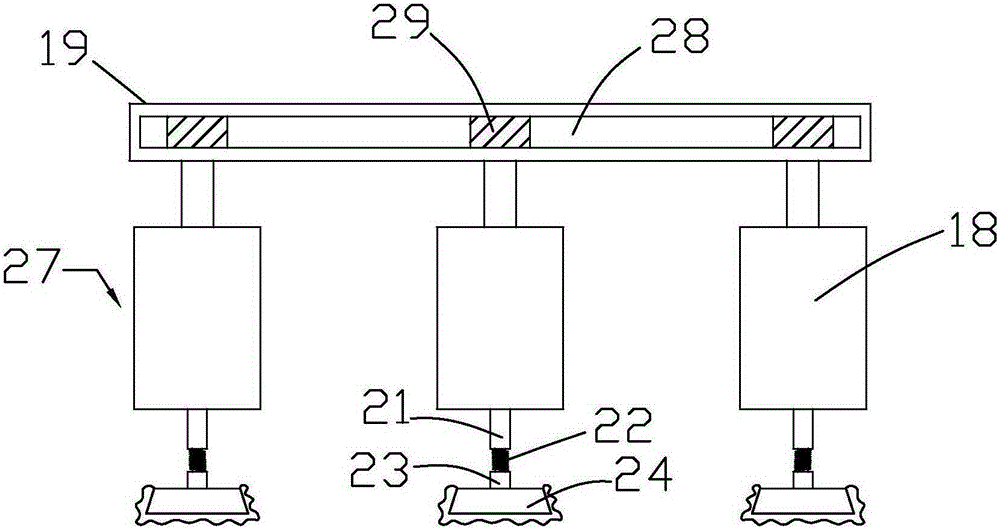

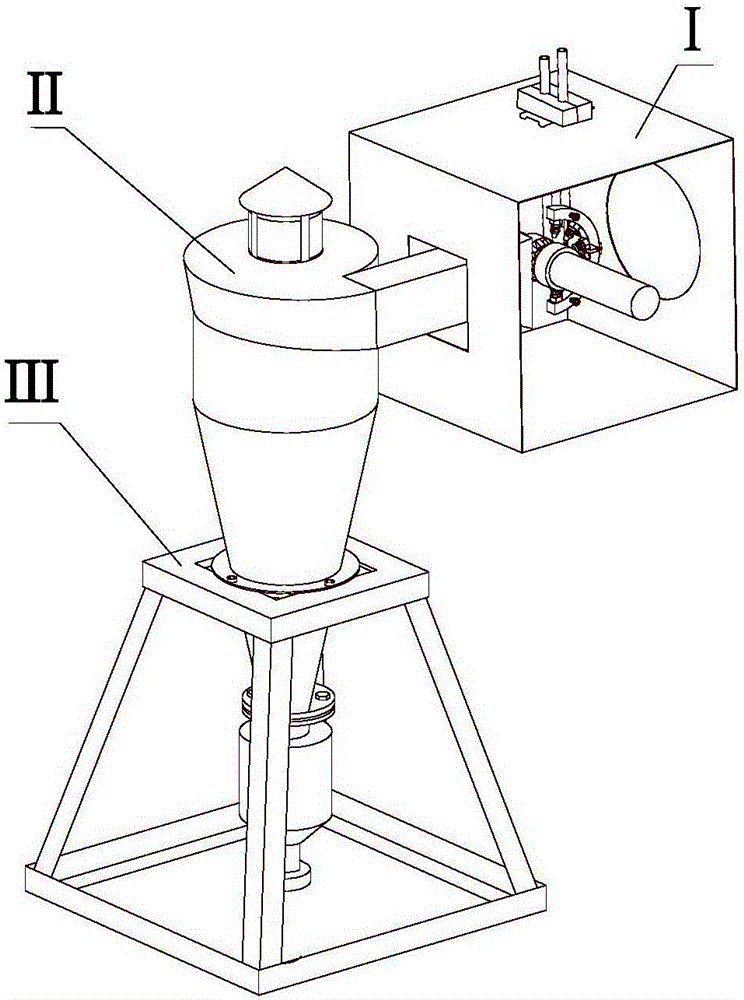

High-speed milling micro lubrication liquid supply nozzle structure and separation and recovery mechanism and system

ActiveCN106392764AAchieve lubricationAchieve coolingMaintainance and safety accessoriesSpray nozzleEngineering

The invention discloses a high-speed milling micro lubrication liquid supply nozzle structure and a separation and recovery mechanism and a system. The structure comprises at least two nozzle bodies; one ends of the nozzle bodies are connected with a pipeline shell, and the other ends of the nozzle bodies are spraying heads; mixing channels formed by internals of hollow pipes are arranged in the nozzle bodies; one ends of the mixing channels are communicated with at least two pipelines; gas is introduced in the first pipeline; lubricating oil is introduced in the second pipeline; a gas pipeline communicated with the first pipeline and a lubricating oil pipeline communicated with the second pipeline are arranged in the pipeline shell; the gas pipeline and the lubricating oil pipeline both surround the center point of the pipeline shell; through setting of the pipeline shell, the lubrication and the cooling of milled parts are realized, and the lubricating effect is good; and the structure can effectively prevent splashing of chips and fog drips through setting of a box body, reduces the harm to environments and operators in the machining process, meanwhile, can effectively realize separation of a lubricating agent, the chips and the gas, and reduces environmental pollution.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Freezer oil and work fluid composition for freezer

ActiveCN102191113AGood compatibilityAchieve lubricationHeat-exchange elementsBase-materialsPentaerythritolWorking fluid

The invention discloses freezer oil and work fluid composition for a freezer. Freezer oil of the invention comprises more than 10 mass percentage ester based on total amount of freezer oil and used with dichloromethane refrigerant, wherein the ester is ester of dipentaerythritol and fatty acid; the proportion of 2-methyl valeric acid in fatty acid is more than 20 mol%. Moreover, work fluid composition for the freezer of the invention comprises freezer oil of the invention and dichloromethane refrigerant.

Owner:JX NIPPON OIL & ENERGY CORP

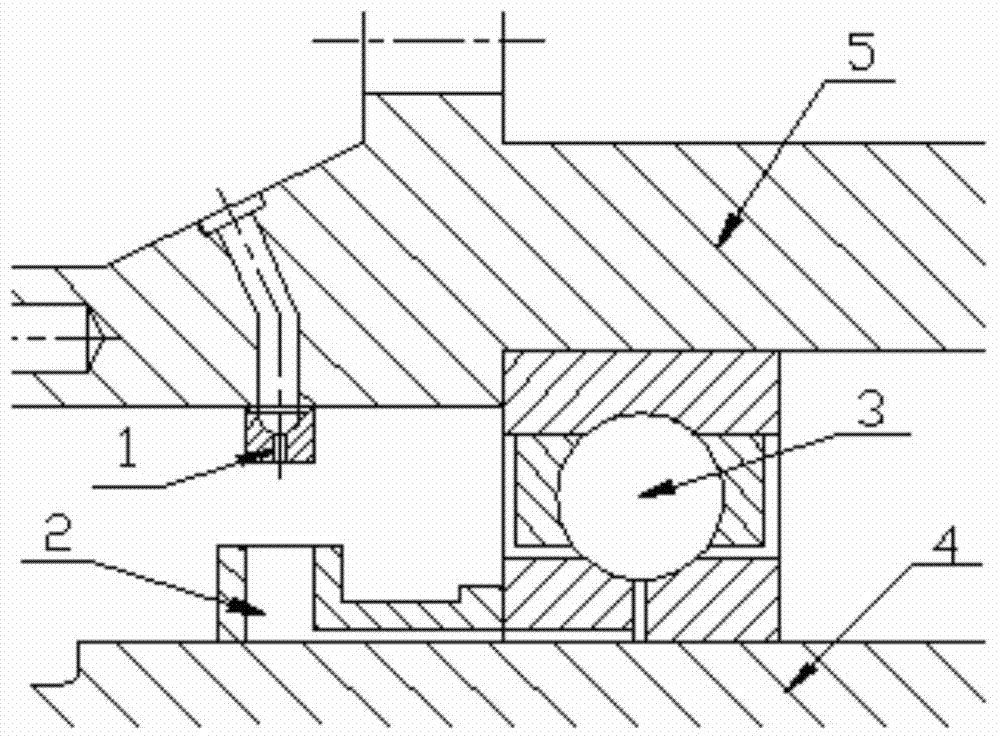

Inner gearing type gear rack power transmission mechanism

InactiveCN104832613AAchieve lubricationExtended service lifeGear vibration/noise dampingGear lubrication/coolingEngineeringRack and pinion

The invention relates to an inner gearing type gear rack power transmission mechanism, and radically solves such defects as short service life and weak stability in traditional half-gear shaft transmission mechanisms. The inner gearing type gear rack power transmission mechanism comprises a half-gear frame, a top piston arranged on the half-gear frame, a half-gear shaft, and a half gear arranged on the half-gear shaft, wherein racks are respectively arranged on the inner walls of the left and right sides of the half-gear frame; the half-gear shaft is positioned in the half-gear frame; and the half gear is engaged to the rack at the left side or the right side in the half-gear frame. The inner gearing type gear rack power transmission mechanism is characterized in that the half-gear frame is limited in a guide groove of a guide rail through the outer walls of the left and right sides; the top piston is mounted on the half-gear frame through a piston pin; a bottom piston is coaxially arranged at the bottom of the half-gear frame and the top piston, is limited in a damper cylinder rightly below the half-gear frame, and fits the inner wall of the damper cylinder; a damping spring immersed in lubricating oil is limited in the damper cylinder; and multiple oil leading holes are formed in the damper cylinder, and are respectively communicated with the guide groove and an inner frame of the half-gear frame.

Owner:潘济安

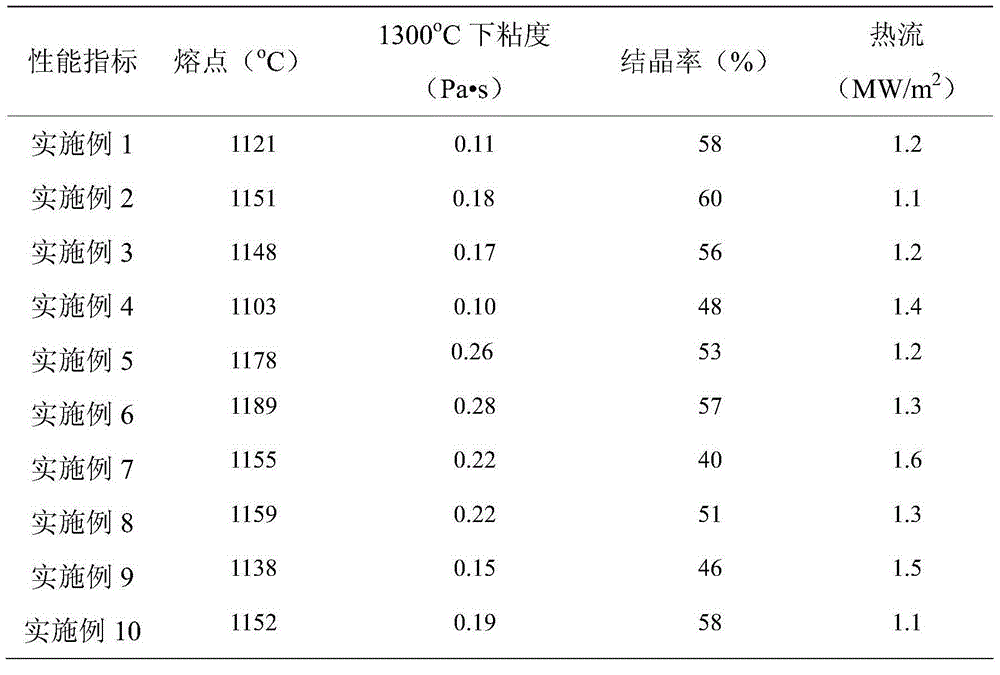

Novel medium manganese steel casting powder for automobile and application thereof

The invention relates to a novel medium manganese steel casting powder for an automobile and application of the novel medium manganese steel casting powder and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises, by mass, CaO 29%-37%, Al2O3 16%-25%, SiO2 11%-15%, MgO 2%-7%, Na2O 10%-14%, Li2O 1%-5%, MnO 1%-7% and F- 9%-13%. The melting point of the casting powder is 1,100-1,200 DEG C; at 1,300 DEG C, the viscosity of the casting powder is 0.10-0.30 Pa*s, and the crystallizing rate is 40%-70%; the heat flow is 1.1-1.6 MW / m<2> in the continuous casting process. The designed casting powder can be well used in the medium manganese steel continuous casting process for the automobile with the mass percentage of Mn being 3.0%-15.0%.

Owner:CENT SOUTH UNIV

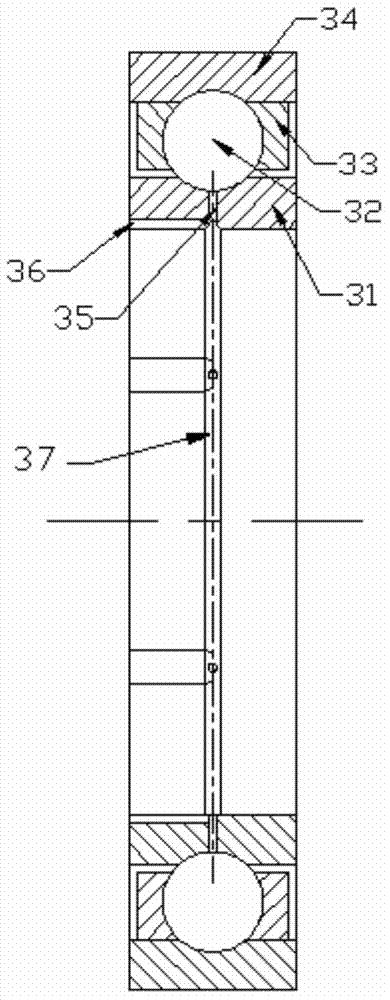

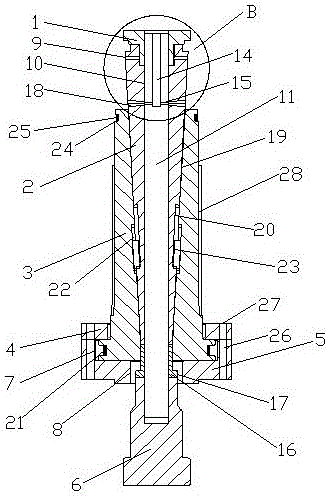

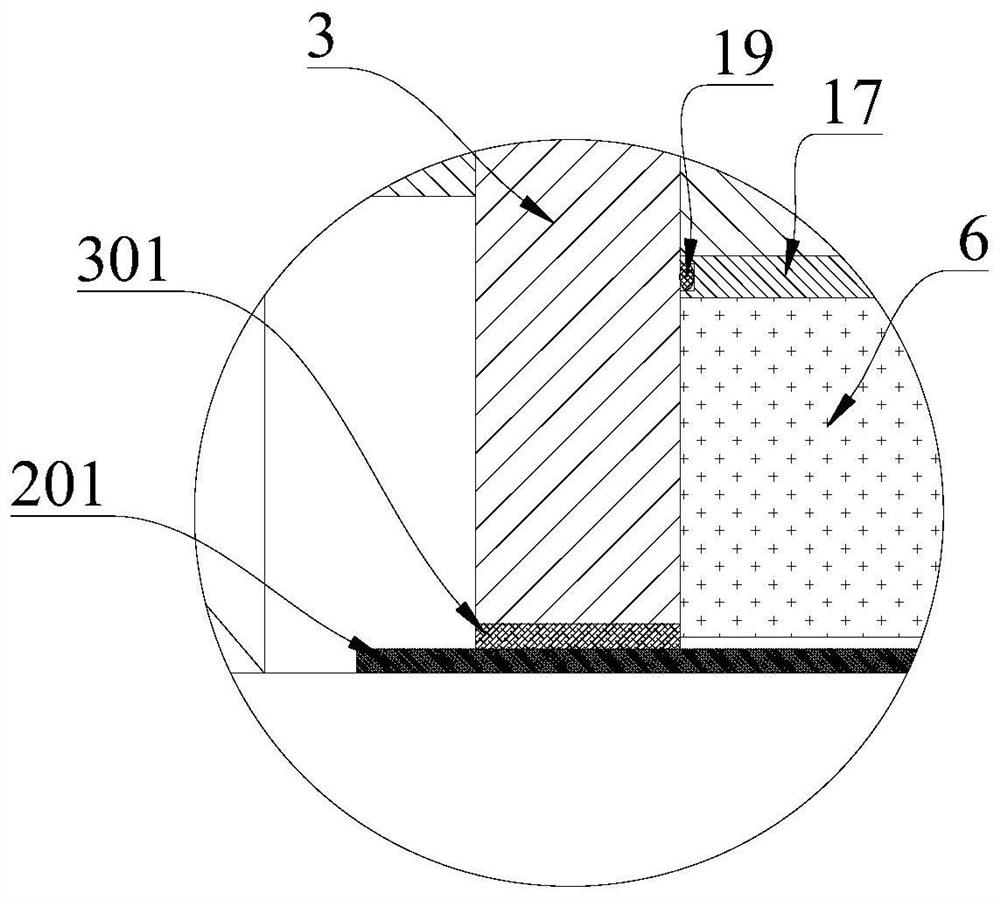

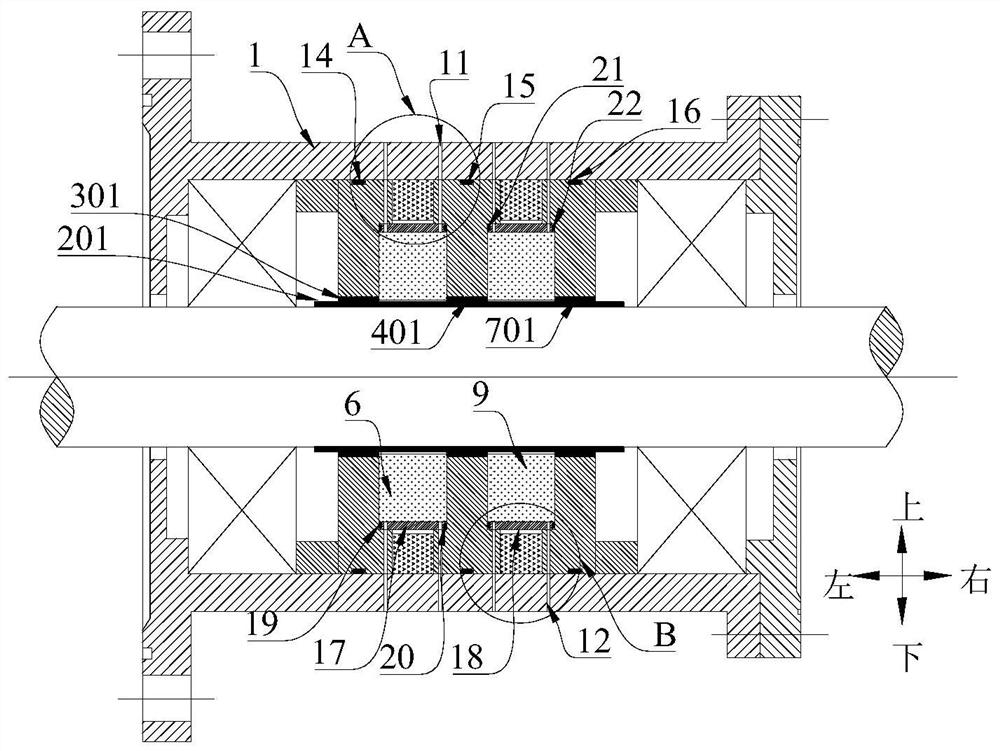

High-speed lower lubricating device for bearing ring

InactiveCN104747602ACause delay in deliveryEfficient collectionBearing componentsEngineeringPetroleum engineering

The invention discloses a high-speed lower lubricating device for a bearing ring. The high-speed lower lubricating device comprises an oil gathering sleeve, wherein an inner ring of a bearing and the oil gathering sleeve rotate synchronously; the inner wall of the inner ring of the bearing is respectively provided with a lubricating oil groove in an axial direction and a radial oil hole in a radial direction; one end of the radial oil hole is communicated with the lubricating oil groove, and the other end of the radial oil hole is communicated with a raceway of the inner ring of the bearing; the oil gathering sleeve and the inner ring of the bearing coaxially and fixedly sleeve a main shaft; the oil gathering sleeve is divided into two parts along the axial direction, the inner part of one part is provided with axial oil grooves butted with the lubricating oil groove, and the other part is radially provided with oil gathering passages which are in one-to-one butt joint with the axial oil grooves; the oil gathering passages are separated by a plurality of oil gathering blades distributed in the radial direction; an outer ring of the bearing is fixedly arranged on a shaft shell; the parts, which correspond to the oil gathering passages, of the shaft shell are provided with nozzles connected with a lubricating oil system. The high-speed lower lubricating device is capable of improving the bearing lubricating efficiency, reducing the lubricating oil quantity, further reducing the internal friction heat of the bearing and ensuring that sufficient oil film thickness exists in the raceway during high-speed rotation of the bearing.

Owner:CENT SOUTH UNIV

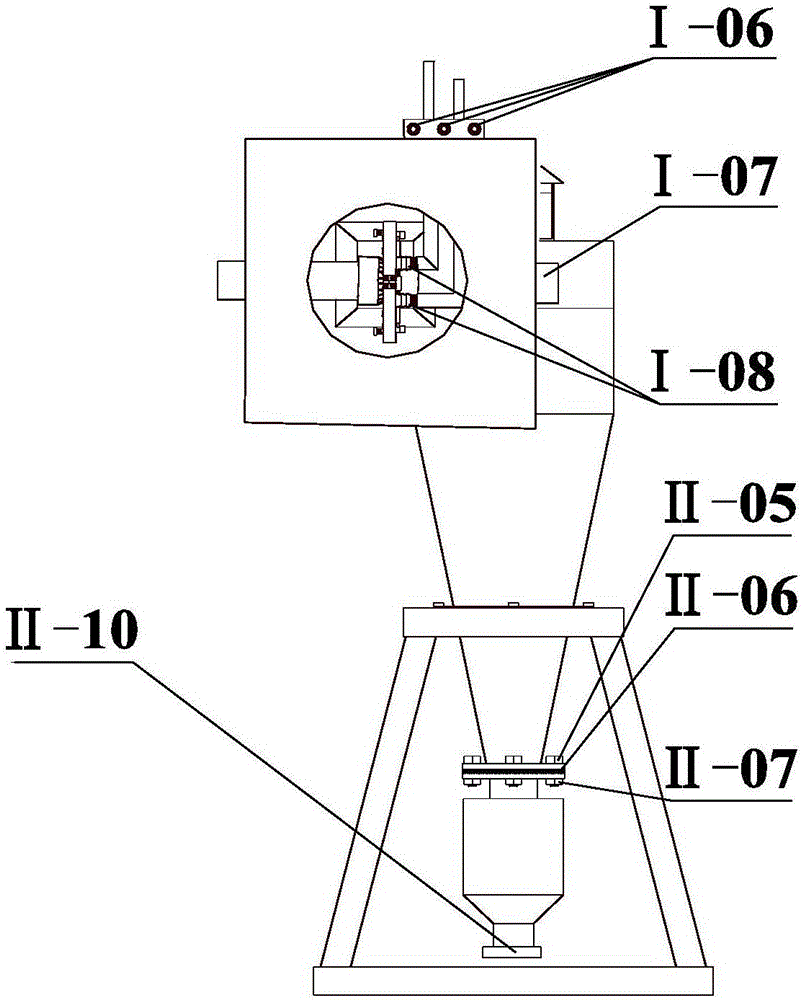

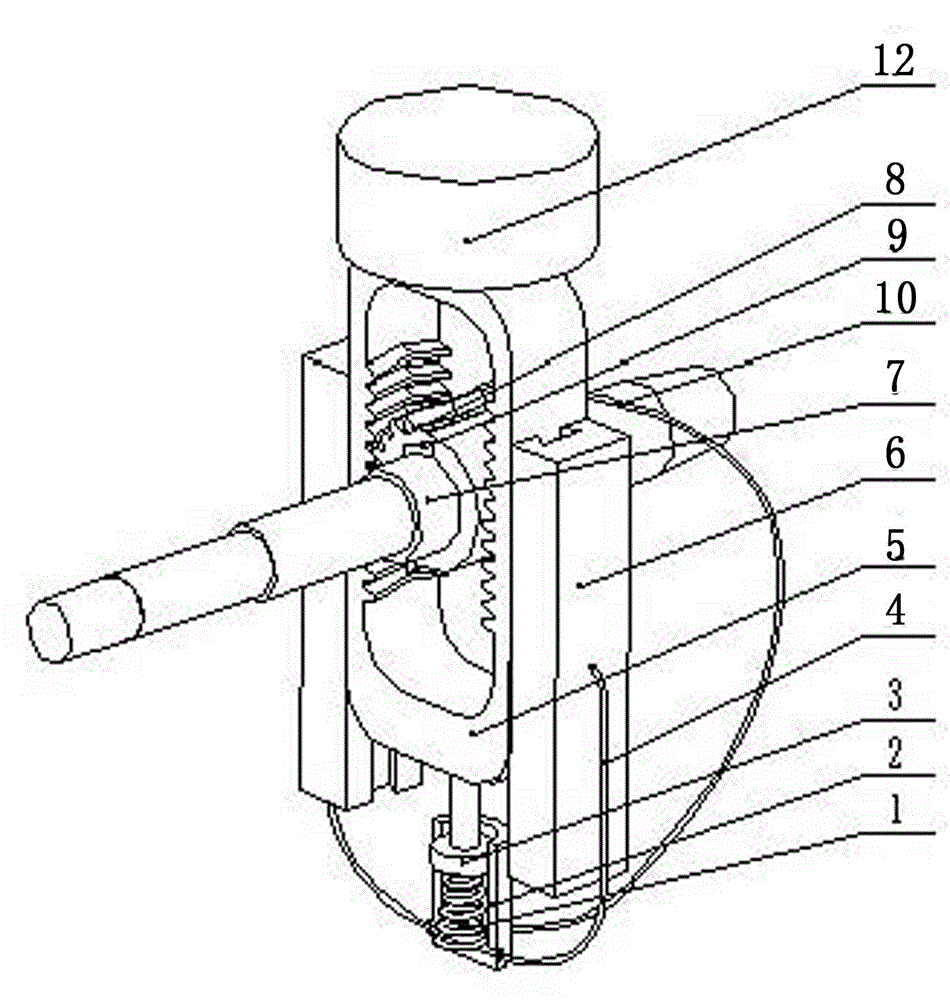

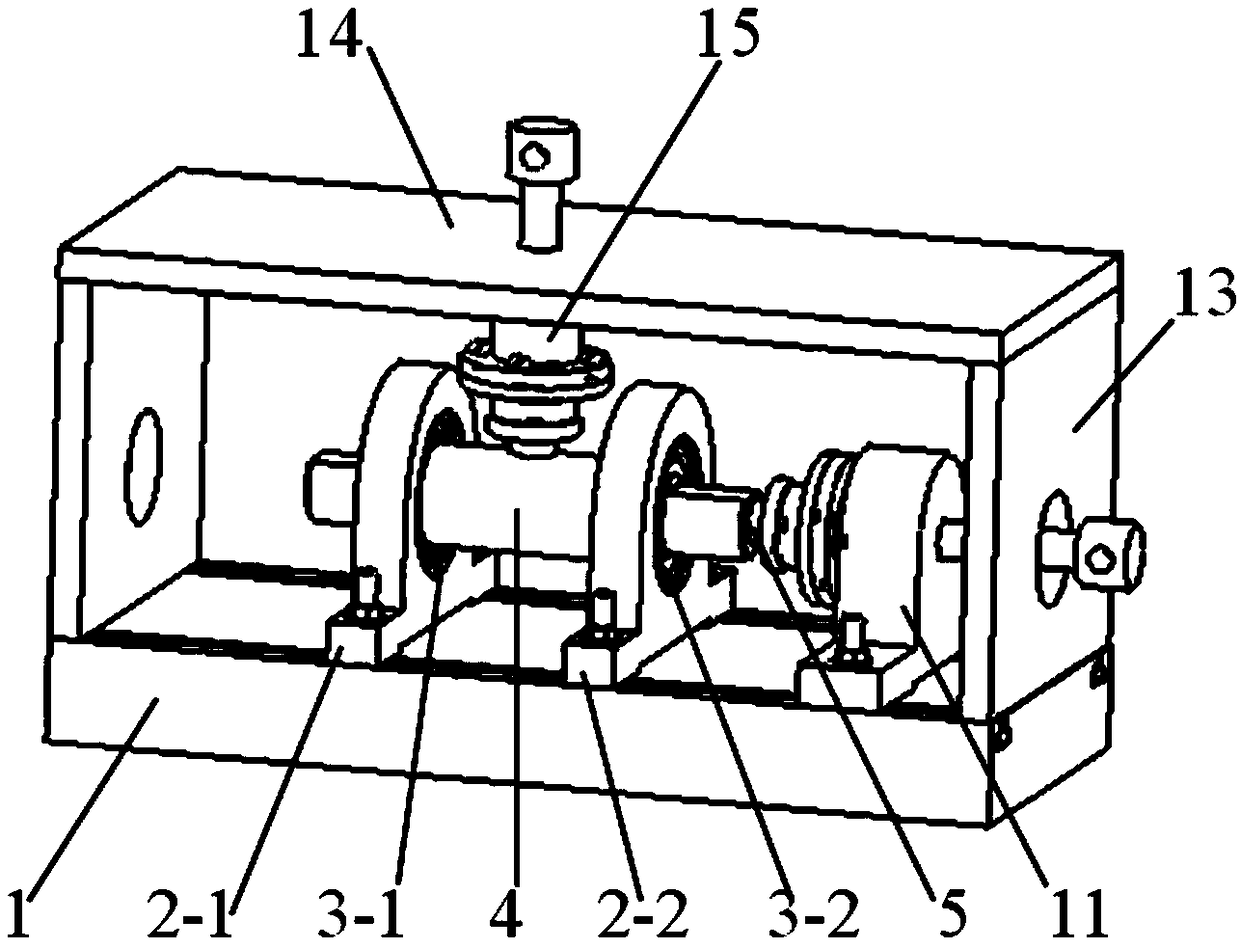

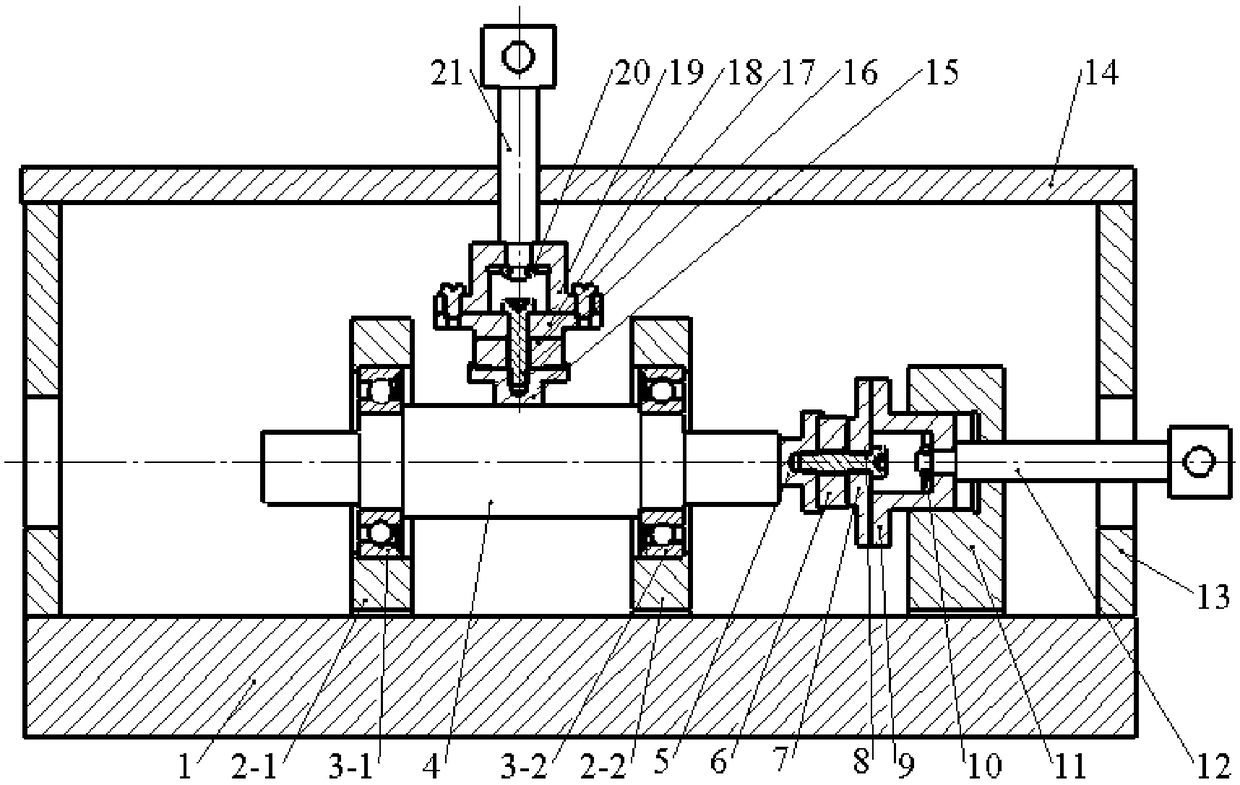

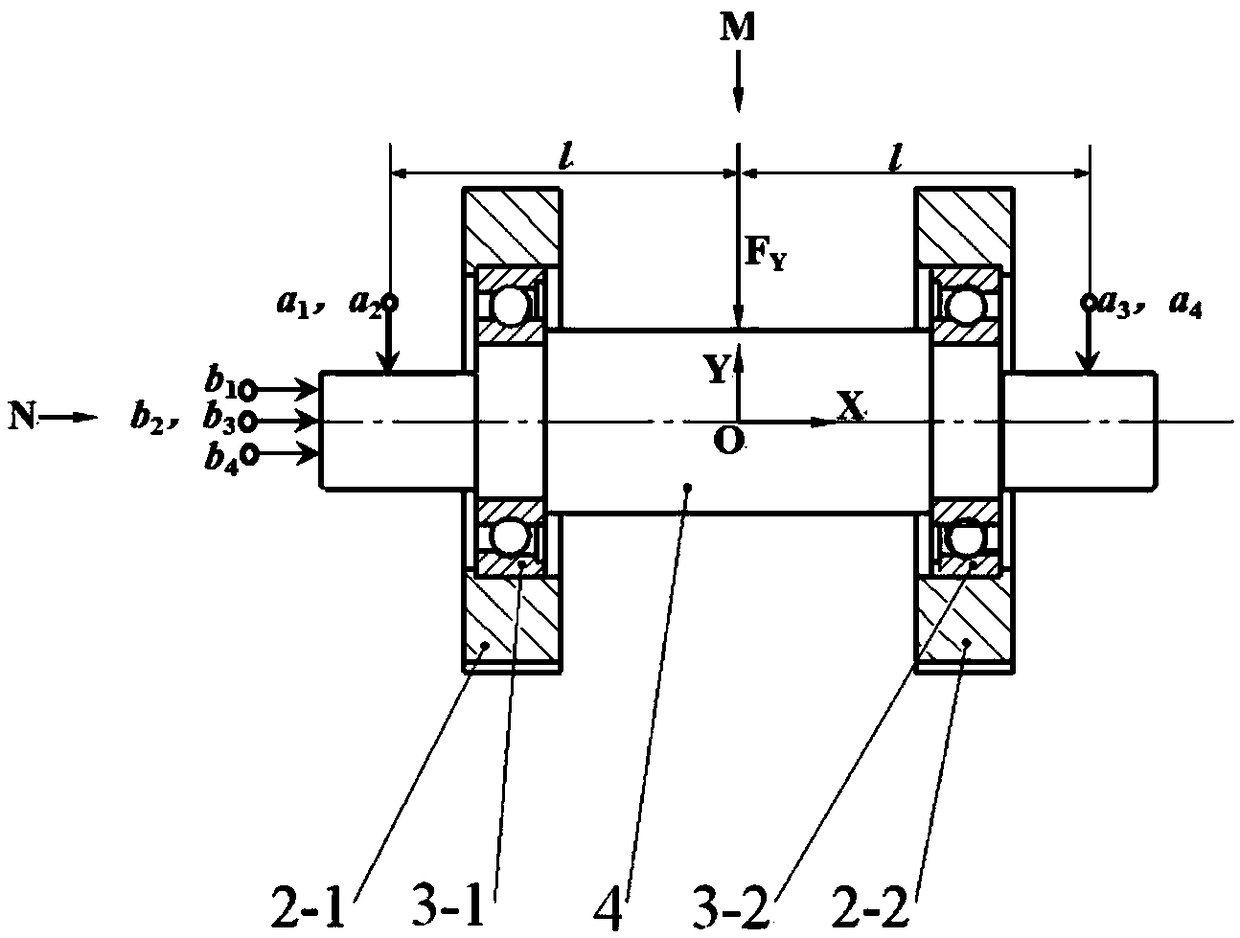

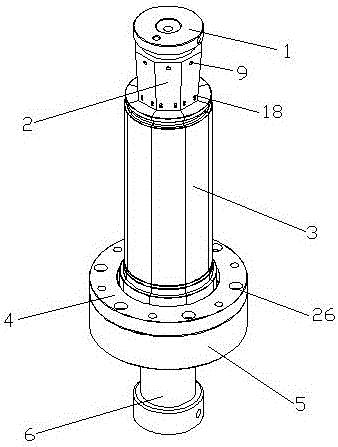

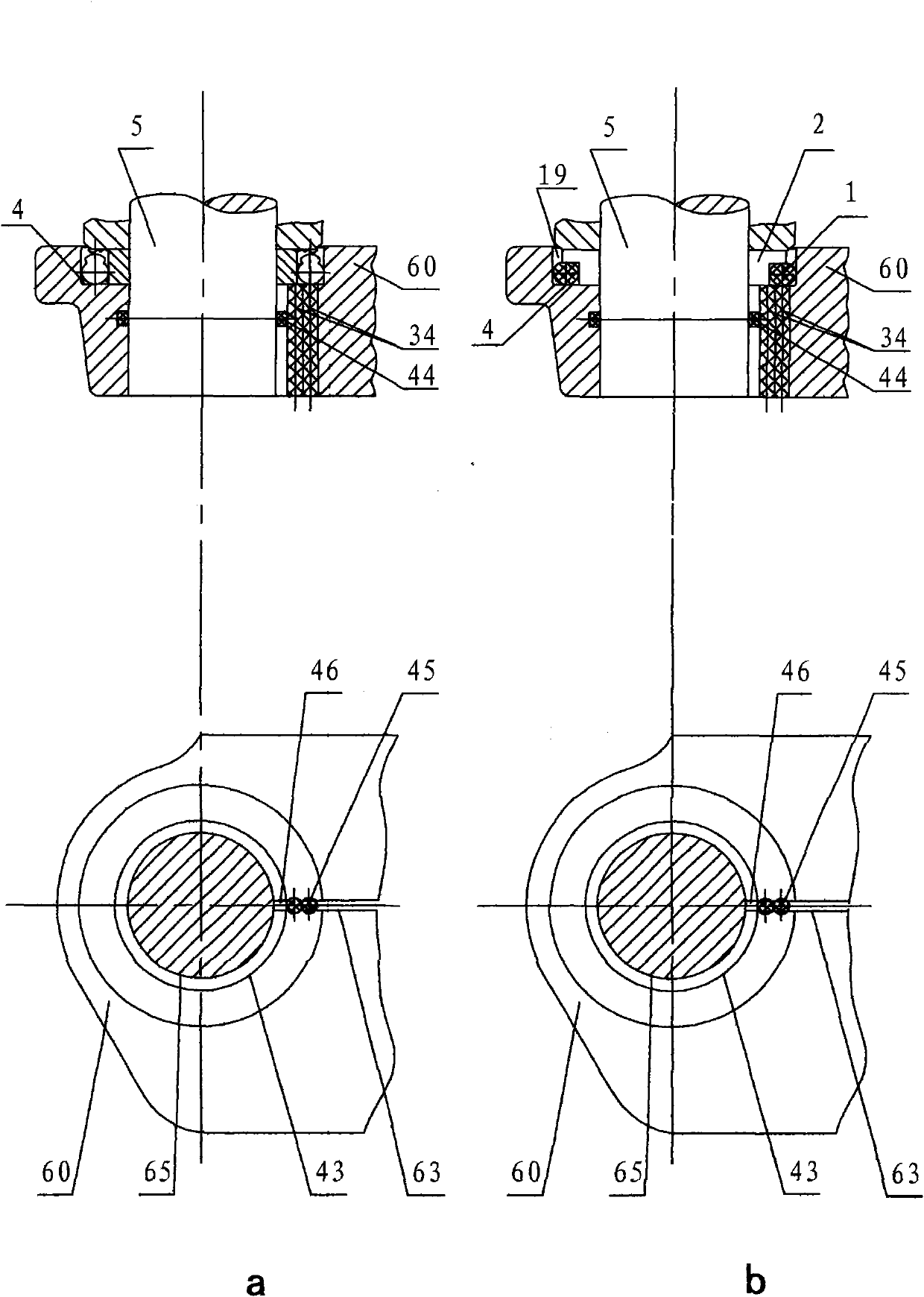

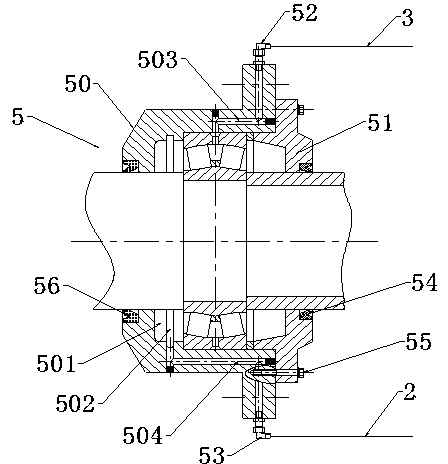

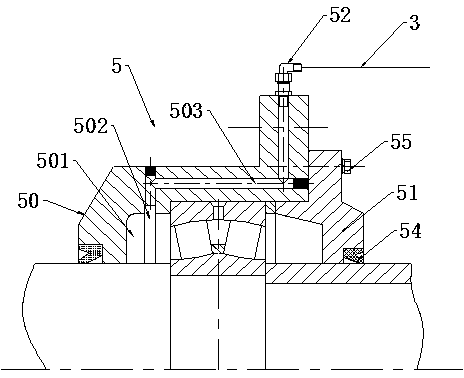

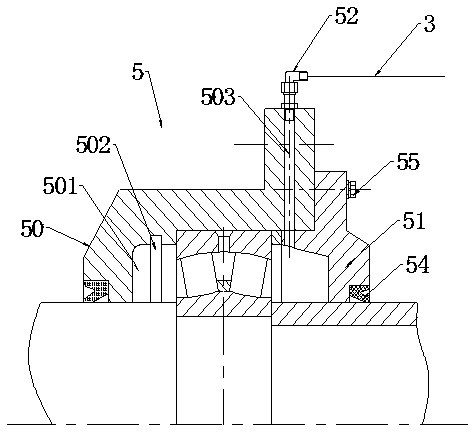

Device and method for measuring static characteristics of joint of rolling bearings

PendingCN108827635ARadial loads onlyUniform force distributionMachine bearings testingRolling-element bearingAxial force

Owner:SHAANXI UNIV OF SCI & TECH

Rounding and sizing processing mould for pipe fittings

The invention relates to a rounding and sizing processing mould for pipe fittings. The rounding and sizing processing mould comprises a cap, an expanding core, mould pieces, a cover plate, a mould base and an expanding core base, wherein a ring-shaped cavity is arranged on the top of the mould base; a mounting slot is formed in the bottom of the mould base; through holes are formed inside the cap and the expanding core; a drawbar is arranged in the through holes; an oil injecting hole is formed in the top of the drawbar; a regulating gasket is arranged in front of the expanding core base and the expanding core; edges of cross sections of the plurality of mould pieces are arc-shaped, and are on the same circle D; a first elastic ring is arranged between the outer walls of the mould pieces and the mould base; the inner walls of the mould pieces are in clearance fit with conical surfaces of the expanding core; second limiting slots are formed in the inner walls of the mould pieces; limiting slide blocks are arranged between the second limiting slots and first limiting slots; and second elastic rings are arranged in grooves of the plurality of the mould pieces. The rounding and sizing processing mould is precise in structure, is reasonable in design, is convenient to dismount and maintain, can be used for simultaneously carrying out sizing, rounding and processing on pipe fittings, is stable in sizing, rounding and processing quality, is convenient and quick in oil injecting and lubricating, and is beneficial for improving processing efficiency and prolonging the service life of the mould.

Owner:ZHENJIANG HENGYUAN AUTOMOBILE COMPONENTS

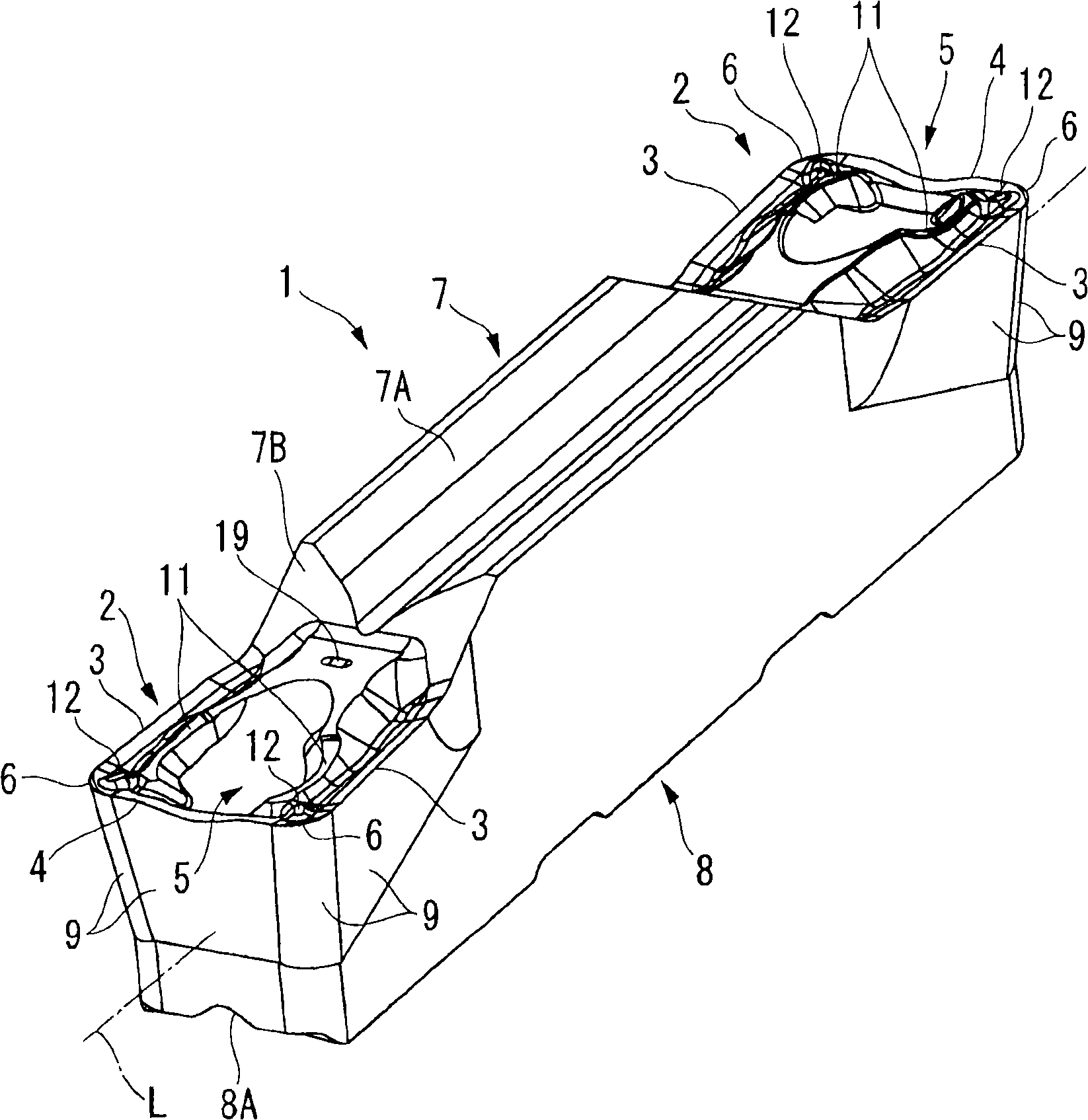

Sliding part

Provided is a sliding part providing functionality for both leak prevention and lubrication with no relation to the magnitude of the pressure difference between the inner and outer circumference of a sliding face by drawing in a fluid with a cavitation region on the upstream side of a depressed portion, such as a dimple formed on the sliding face, and generating positive pressure between the sliding faces on the downstream side of the dimple. A sliding part is characterized in that: dimples are provided on the sliding face on one of a pair of sliding parts that slide relative to each other; a cavitation forming region on the upstream side of each dimple is disposed near a low pressure fluid side and a positive pressure generating region on the downstream side is disposed near a high pressure fluid side; and the fluid drawn in with the cavitation forming region of the dimple is returned to the high pressure fluid side from the positive pressure generating region by passing through the inside of the dimple.

Owner:EAGLE INDS

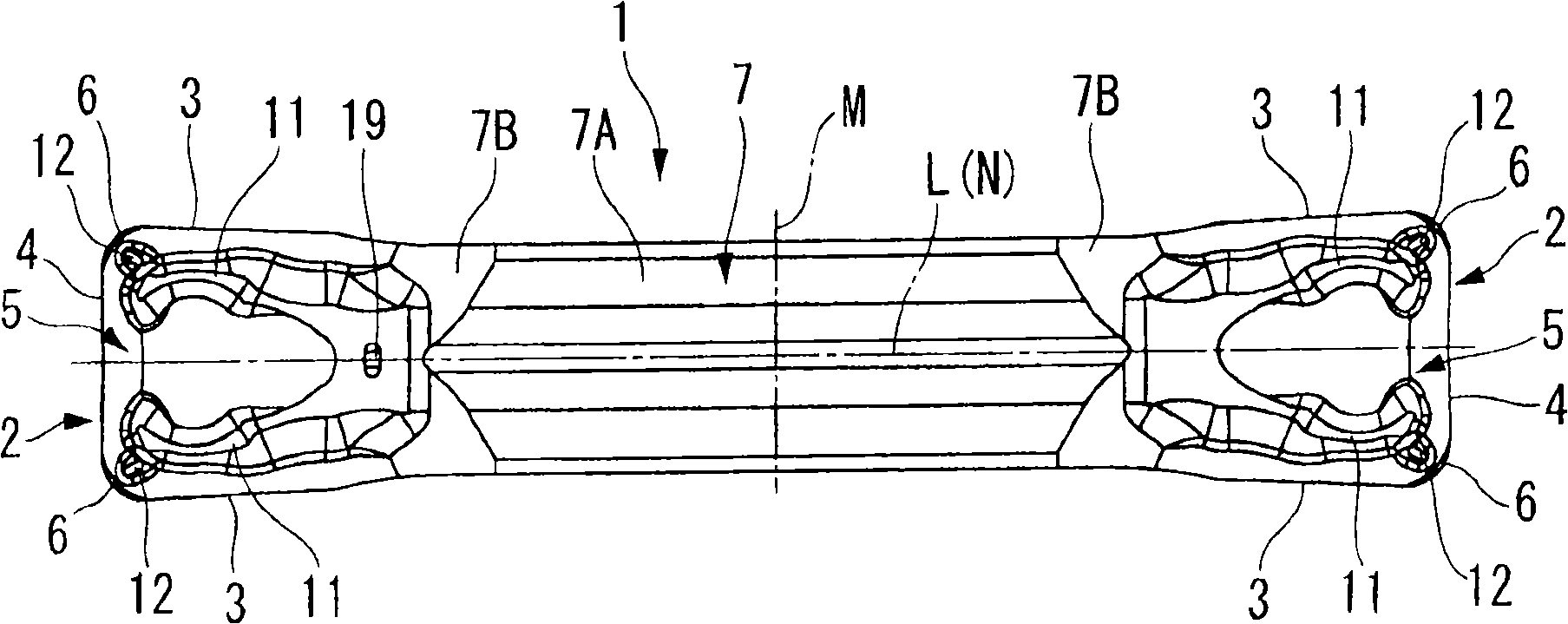

Cutting insert

A cutting insert having an insert body formed in a shaft-shape, wherein a cutting edge portion having a square rake face is formed on an end portion of the insert body, and wherein the rake face includes: a pair of side cutting edges extending in a longitudinal direction of the insert body; a front cutting edge extending in a transverse direction perpendicular to the longitudinal direction between each front end of the side cutting edges; a pair of protruded streaks extending toward each of corner portions at which each of the side cutting edges intersect the front cutting edge, and a projection which protrudes and is separated from the protruded streaks between front ends of the protruded streaks in the vicinity of the corner portion and the corner portion.

Owner:MITSUBISHI MATERIALS CORP

Manufacturing process and equipment for storage battery hauling net lead strip or net punching plate gate lead strip

ActiveCN102931416AReduce lead fume pollutionReduce lossElectrode carriers/collectorsMetal rolling arrangementsPunchingPollutant emissions

The invention discloses a manufacturing process for a storage battery hauling net lead strip or a punching net plate gate lead strip. The manufacturing process comprises the steps of melting electrolytic lead and adding alloy elements, conveying to the mixture to a continuous lead strip casting machine, and casting the mixture to a coarse alloy lead strip, then taking the coarse alloy lead strip as the raw materials and directly conducting cold rolling on the coarse alloy lead strip to be refined lead strip used for the hauling net or a punching net by the continuous lead strip casting machine. The manufacturing process comprises the steps of a. melting the electrolytic lead; b. conveying lead liquid; c. continuously casting to from the coarse alloy lead strip; d. continuously rolling to form the refined alloy lead strip; and e. rolling and storing. In addition, the invention also provides special manufacturing equipment. According to the manufacturing process and the manufacturing equipment, not only the discharging amount of pollutants such as lead fume can be obviously reduced, the energy consumption and the material loss also can be reduced, and the product quality and the production efficiency of the lead acid storage battery plate gate hauling net or the punching net lead strip can be improved.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

Track component and assembly method for constituting track

ActiveCN101947982AStructural changes are scientific and practicalAchieving tightnessEndless track vehiclesFastenerForce direction

Owner:董明国

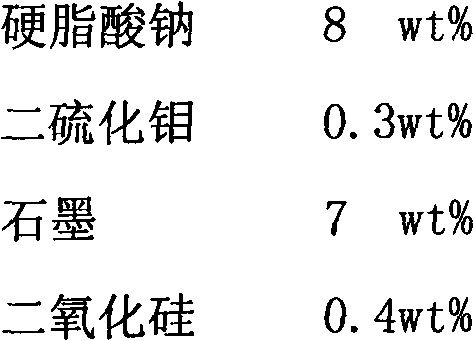

High temperature resistance lubrication mold release agent for glassware molding

The invention relates to a high temperature resistance mold release agent composition for glassware molding. The composition comprises: (a) a refined plant lubrication oil or a refined mineral lubrication oil, (b) at least a viscosity index improver selected from a styrene-isoprene copolymer or a polyisoprene copolymer, (c) at least a thickener selected from zinc stearate, sodium stearate or magnesium stearate, (d) at least an anti-wear agent selected from molybdenum disulfide or silica, and (e) at least an inorganic lubricant selected from graphite, boron nitride or talc powder. The composition has multiple effects of excellent oxidation stability, excellent lubricity, high temperature resistance and the like, and can meet requirements of high temperature resistance mold release agents for molding of glassware with different viscosity grades.

Owner:天津市硅酸盐研究所有限公司

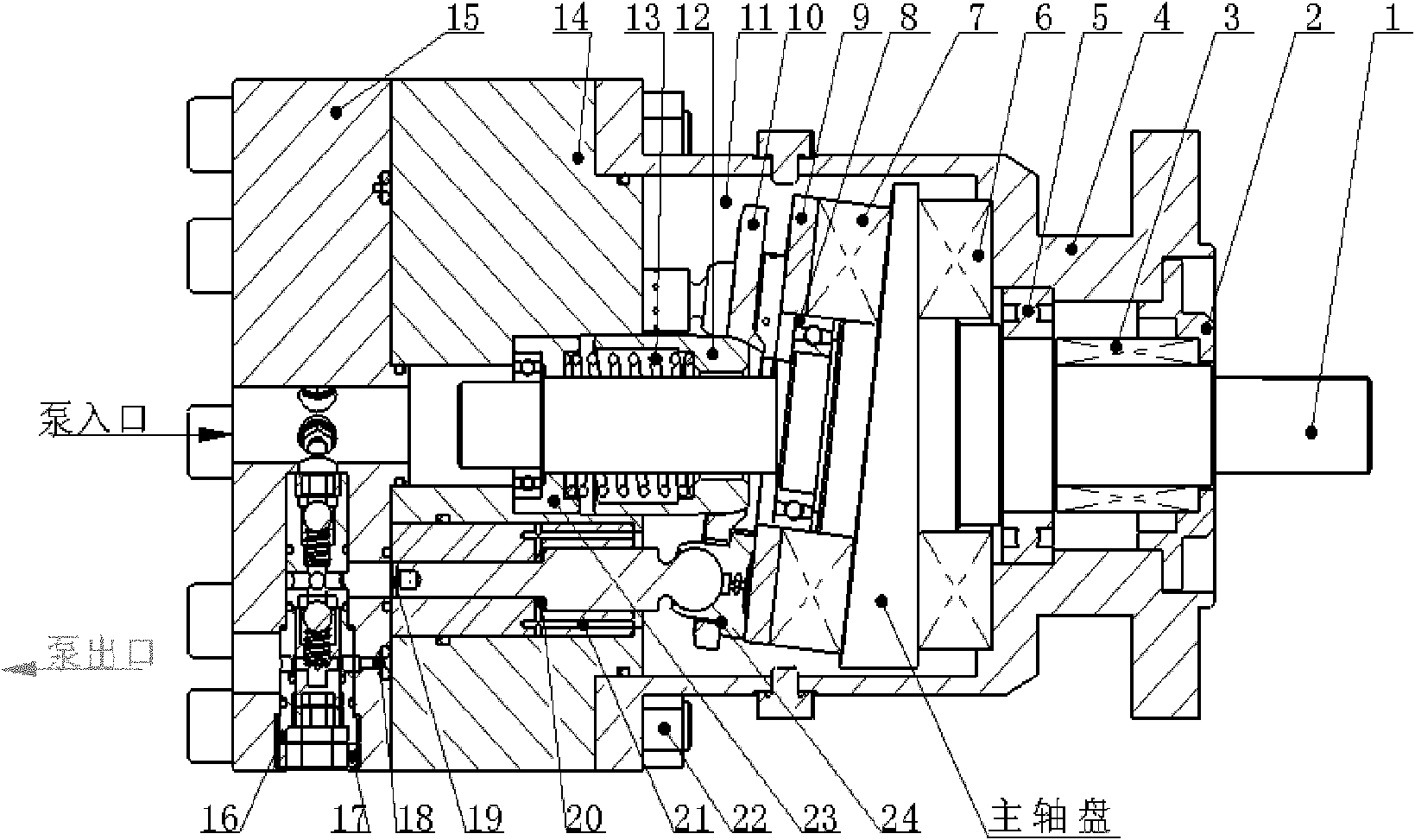

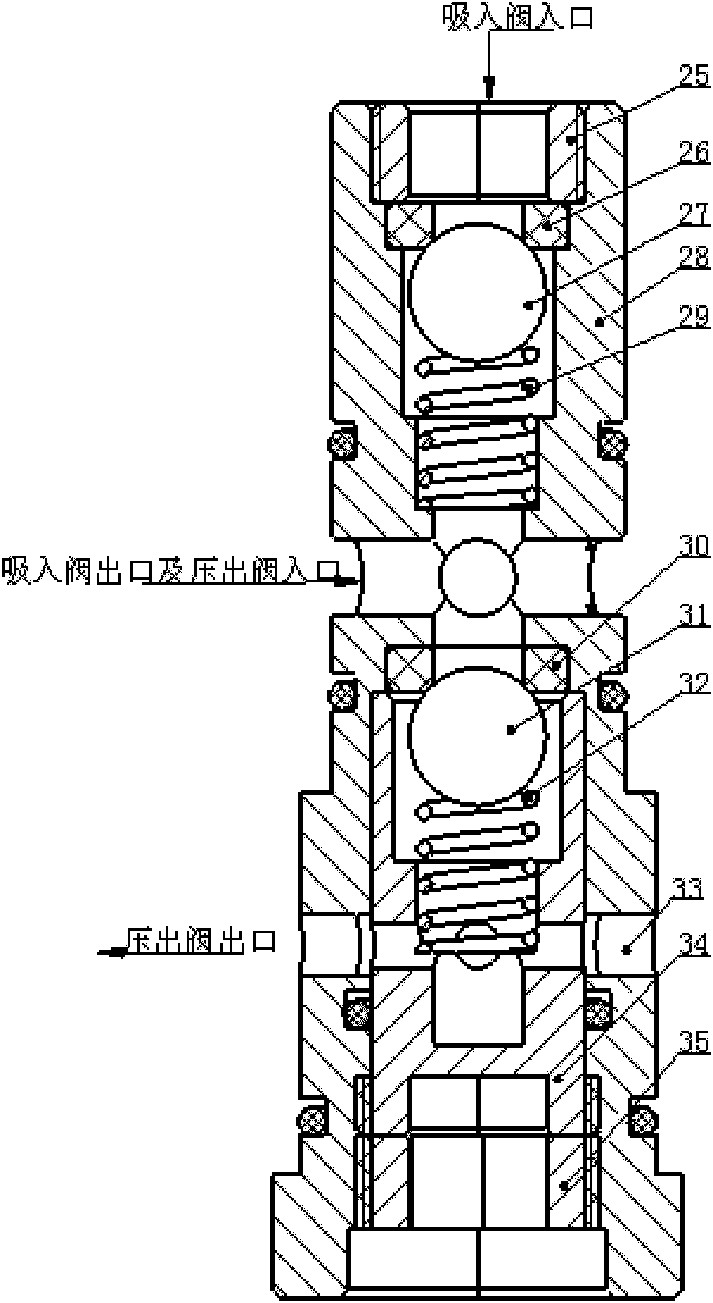

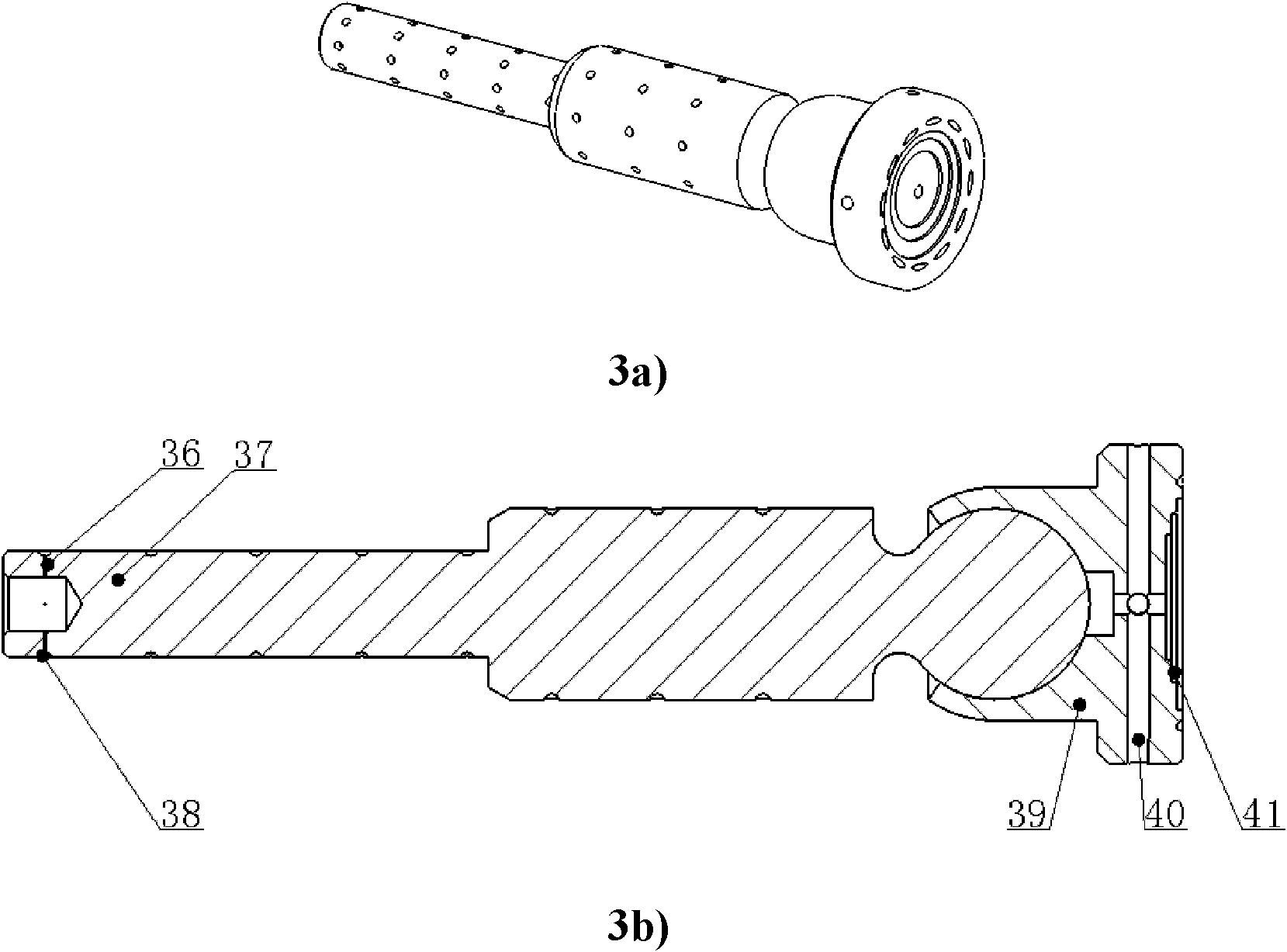

Fully water-lubricated super-pressure plunger water pump

InactiveCN101956685AReduce contact stressSolve friction and wear problemsPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionEngineering

The invention provides a fully water-lubricated super-pressure plunger water pump, mainly comprising a cavity, a live spindle and a plunger flow-distribution unit; the plunger flow-distribution unit comprises a flat valve assembly and a plunger slipper assembly; the plunger slipper assembly is used for dividing the cavity into a pressure cavity and a lubricating cavity which are independent from each other; the plunger slipper assembly carries out reciprocating motion by the driving of the live spindle so that the flat valve assembly sucks in water and discharges water through a water pump inlet and a water pump outlet, and water is simultaneously conveyed to the lubricating cavity through the water pump inlet so as to provide fluid to the rotating unit for lubricating and realizing full water lubrication. The flat valve assembly is designed integrally, and the assembly can be replaced quickly when maintenance so as to shorten maintenance time; the plunger is a stepped structure, the cylindrical surface thereof is provided with recesses, and the bottom of the slipper is provided with a stepped support cavity, thereby solving the wearing and friction problem of the plunger / plunger sleeve pair and slipper / sloping cam plate pair under high-speed heavy-duty condition, and prolonging the service life of the water pump.

Owner:HUAZHONG UNIV OF SCI & TECH

Self-lubricated microcapsule/bismaleimide friction composite material and preparation method thereof

ActiveCN110330941AImprove carrying capacityAvoid gatheringOther chemical processesDiphenylmethaneThermoplastic

The invention provides a self-lubricated microcapsule / bismaleimide friction composite material and a preparation method thereof. The preparation method comprises the following steps: (1) by taking anionic liquid as a core material, and a composite material of graphene oxide and a thermoplastic resin as a wall material, preparing an ionic liquid @ graphene oxide / thermoplastic resin self-lubricatedmicrocapsules with a solid-liquid system lubricating filler; (2) mixing and heating the ionic liquid @ graphene oxide / thermoplastic resin, diphenylmethane type bismaleimide and diallyl bisphenol A, completely melting the components, pouring the components into a mold, performing sectional heating curing, and further performing aftertreatment on the components, thereby obtaining an ionic liquid @graphene oxide / thermoplastic resin self-lubricated microcapsule / bismaleimide resin composite material. The material has self lubrication in the friction process, the service life of the material can be prolonged, the application range of the material can be widened, and the material can be used under conditions of oil-sensitive materials and no oil pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Manual jacking technology of long-distance heavy-caliber concrete pipe for complex stratums

InactiveCN109798396AImprove penetration efficiencyImprove construction accuracyPipe laying and repairRoad surfaceLubrication

The invention relates to the technical field of pipeline project construction, in particular to a manual jacking technology of a long-distance heavy-caliber concrete pipe for complex stratums. The manual jacking technology of the long-distance heavy-caliber concrete pipe for the complex stratums comprises the following steps of (1) construction preparation, (2) pipeline axis measurement and location, (3) pipe jacking work well construction, (4) guiding rail mounting, (5) tool pipe cap mounting, (6) mounting and debugging of pipe jacking equipment, (7) pipeline jacking construction, (8) inspection well construction, and (9) trench backfilling and pavement recovering. The manual jacking technology of the long-distance heavy-caliber concrete pipe for the complex stratums is applied to the manual jacking construction of the long-distance heavy-caliber concrete pipe in the complex stratums, the damage degree of pavements can be reduced, the construction process is simple, the construction cost is low, the construction period is short, lubrication and drag reduction are conducted on the pipeline, construction accuracy is high, the pushing force of pipeline jacking is small, the jacking distance is long, the progress of works is greatly improved, and working efficiency is improved.

Owner:青岛瑞源工程集团有限公司

Bearing block, oil cavity cleaning and lubricating system and method for bearing block, and mineral engineering machinery

ActiveCN103867581AAchieve cleaningImprove cleaning efficiencyHollow article cleaningLubrication elementsSystem structureScrew thread

The invention discloses a bearing block, which comprises a bearing sleeve and a bearing cap, wherein a flange is arranged at one end of the bearing sleeve, and a through shaft hole is formed in the other end of the bearing sleeve; a threaded hole is also formed in the flange, is connected with an oil inlet hole passage, and is communicated with a bearing hole through the oil inlet hole passage; an oil outlet threaded hole and an oil outlet hole passage are also formed in the flange, and the oil outlet hole passage is communicated with a transition section of the bearing sleeve to form a loop, so that an oil cavity of the bearing block is cleaned; the oil inlet hole passage and the oil outlet hole passage can be flexibly formed, so that the universality of the bearing block is improved, and the application range of the bearing block is widened. In addition, the invention discloses a bearing-block-based bearing block cleaning and lubricating system and a bearing-block-based bearing block cleaning and lubricating method. The system has the advantages of simple structure, safety, reliability, good cleaning and lubricating effects, capability of automatically cleaning and lubricating the bearing block and high applicability. Moreover, the invention provides mineral engineering machinery based on the bearing block and the bearing block oil cavity cleaning and lubricating system.

Owner:江苏京冶海上风电轴承制造有限公司

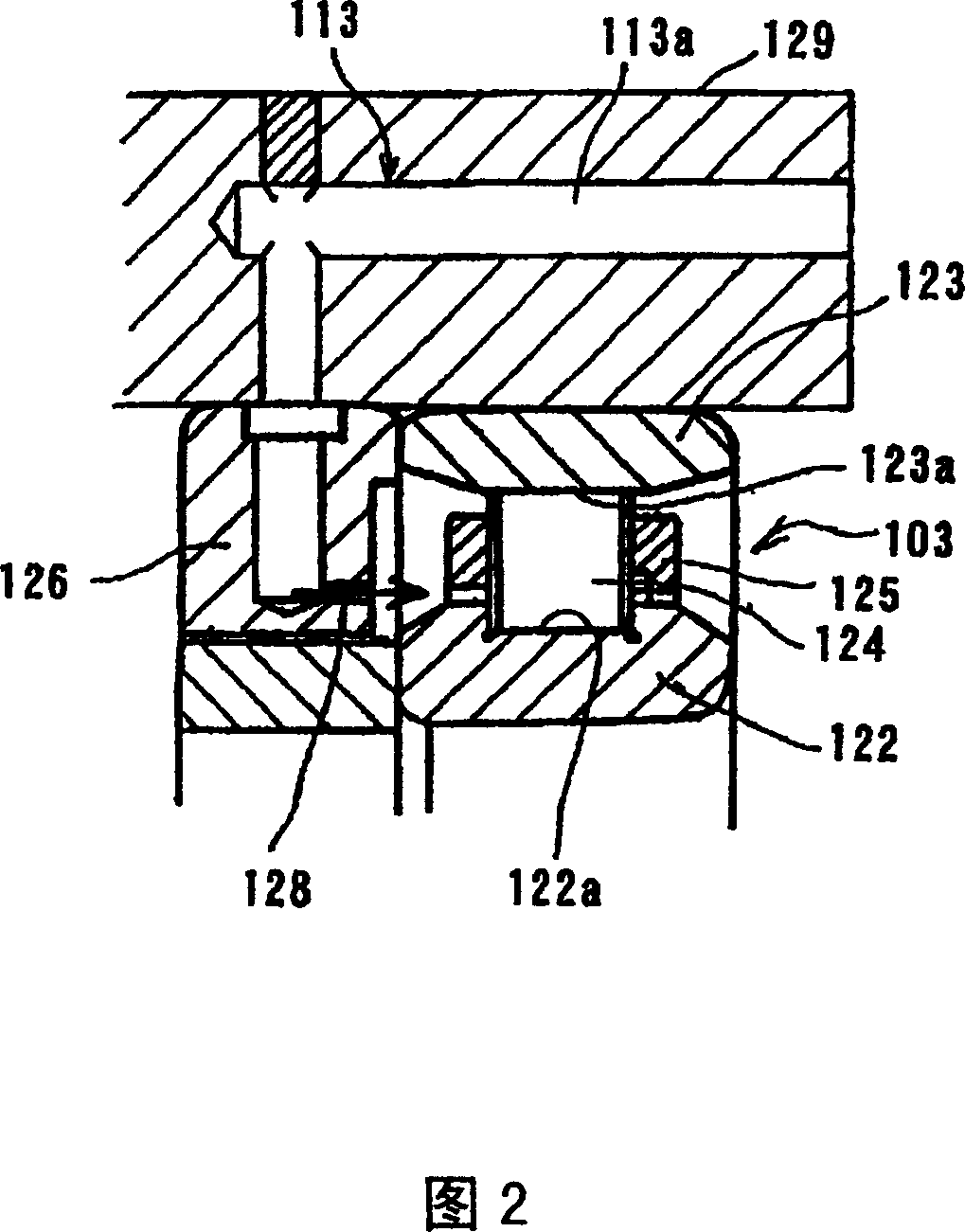

Rolling bearing lubricating method and device

There is provided a lubricating method for a rolling bearing assembly capable of achieving a reliable lubrication and exhibiting a stable temperature rise. The method is for supplying a lubricant oil to the rolling bearing assembly during the operation thereof, in which in order to keep the temperature of a rolling bearing assembly ( 103 ) within a predetermined tolerance, the amount of the lubricant oil to be supplied during the operation is automatically or manually adjusted by means of a supply adjusting unit ( 102 ). Supply of the lubricant oil is performed in the form of an air / oil mixture by the use of a lubricant supply unit ( 101 ).

Owner:NTN CORP

Multifunctional door

ActiveCN106930661APrevent hard to lockIngenious structureDoor/window applicationsAlarm locksEngineeringLubrication

The invention belongs to the field of doors and windows of fixed buildings, and particularly discloses a multifunctional door. The multifunctional door comprises a door body, a door frame, a door lock, a lubrication mechanism and a prompting mechanism. The door lock comprises a lock tongue, a lock groove and a sliding groove, and a through hole is formed in the lock tongue; the lubrication mechanism comprises an oil outlet unit matched with the through hole and a reflow unit matched with the sliding groove, and the oil outlet unit and the reflow unit are communicated; and the prompting mechanism comprises a flow alarm which can alarm automatically when no liquid flows, and the flow alarm is mounted in the oil outlet unit. The scheme can lubricate the lock tongue and prevent that the door is too difficult to lock due to rust of the lock tongue; according to the flow of lubricants, the multifunctional door can issue a corresponding prompt, and prompt the users whether the door is locked; and the multifunctional door is ingenious in structure and good in prompting effect.

Owner:重庆市浩源门业有限公司

Special continuous casting crystallizer casting powder for carbon steel in ESP

ActiveCN107931552AMeet the requirements of slag consumptionMeet the process requirementsSlagCarbon steel

The invention belongs to the technical field of steel making, and particularly relates to special continuous casting crystallizer casting powder for carbon steel in ESP. The special continuous castingcrystallizer casting powder for carbon steel in ESP comprises the following chemical components in percentages by mass: 29%-33% of CaO, 23%-27% of SiO2, 6.5%-8% of MgO, 3.5%-6% of of Al2O3, 6%-8% ofNa2O, 7.5%-9.5% of F<->, 1%-3% of MnO2, 0.4%-0.7% of Li2O and 2.5%-4.0% of C. The slagging speed is high, uniform slagging is implemented, the thickness of a slag film is suitable, consumption is moderate, and quality defects on the surface of a casting blank can be prevented.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Double-coating magnetic liquid sealing device

The invention discloses a double-coating magnetic liquid sealing device. The sealing device comprises a shell, a rotating shaft, a first pole shoe, a second pole shoe and a first permanent magnet, wherein a shaft chamber is formed in the shell; the rotating shaft is rotationally arranged in the shaft chamber; a first non-magnetic coating is arranged on the outer circumferential surface of the rotating shaft; the first pole shoe and the second pole shoe are arranged on the rotating shaft in a sleeving mode and are arranged at intervals in the axial direction of the rotating shaft; second non-magnetic coatings are arranged on the inner circumferential surface of the first pole shoe and the inner circumferential surface of the second pole shoe; the first permanent magnet is arranged on the rotating shaft in a sleeving mode; the first permanent magnet is located between the first pole shoe and the second pole shoe; a first liquid cavity is formed among the first pole shoe, the second poleshoe, the first permanent magnet and the first non-magnetic coating; and the first liquid cavity is used for storing magnetic liquid. According to the double-coating magnetic liquid sealing device, the machining difficulty and cost are reduced, the magnetic liquid can be supplemented in time, the pressure resistance of the magnetic liquid sealing is maintained, the magnetic liquid further has a lubricating effect, and the torsion moment of the magnetic liquid sealing is reduced.

Owner:TSINGHUA UNIV

Seamless inner surface treatment self-lubricating sliding bearing

The invention discloses a self-lubricating sliding bearing with seamless inner surface treatment, belonging to the technical field of bearings, comprising a support seat; balls are sleeved inside the fixed frame; the outer wall of the ball and the inner wall of the outer ring body are attached to each other; There is an oil storage chamber; the side wall of the support seat is provided with a protective tube; the inside of the protective tube is penetrated with cotton thread; the inside of the protective tube is respectively provided with a first limit sleeve and a second limit sleeve; the outer wall of the second limit sleeve There is an adjustment knob in the screw connection; the cotton thread runs through the inside of the first limit sleeve and the second limit sleeve; the top of the cotton thread extends into the inside of the fixing plate; the outer wall of the fixing plate is provided with a sponge pad; the side wall of the support seat and the storage A filling cap is provided at the opposite position of the oil chamber. The self-lubricating sliding bearing of the present invention can stably and evenly apply lubricating oil to each ball to realize self-lubricating of the bearing.

Owner:江苏持华科技有限公司

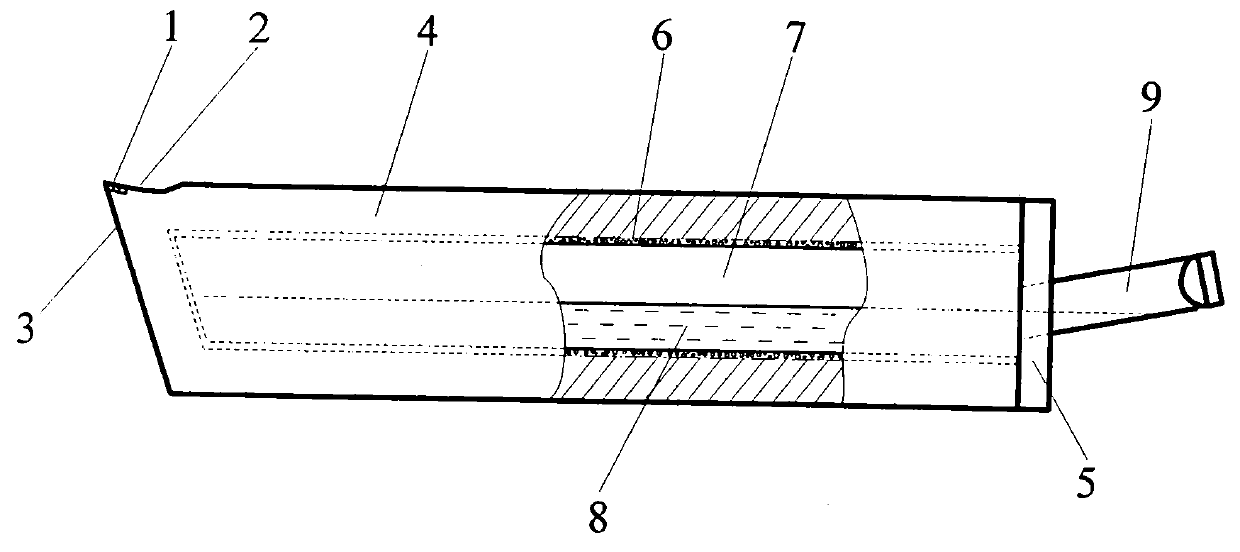

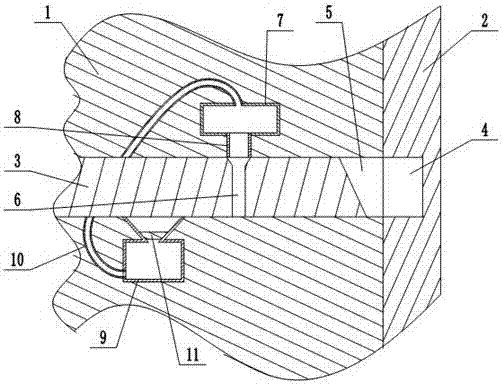

Punch for high-vacuum die casting and lubrication device for punch

The invention discloses a punch for high-vacuum die casting. The punch for high-vacuum die casting comprises a punch body, an ejection rod provided with an axial through hole and a punch ejection rod threaded connecting piece provided with an axial center through hole, wherein an axial center through hole in a certain depth is formed in one end of the punch body and serves as a cooling chamber, the ejection rod is arranged coaxial with the punch body in an opposite mode, the other opposite end is connected with a driving component, the punch ejection rod threaded connecting piece is arranged between the punch body and the ejection rod, the two ends of the punch ejection rod threaded connecting piece are fixedly connected with the end of the punch body and the end of the ejection rod respectively, and a water cooling pipe used for providing cooling water penetrates through the center through hole of the ejection rod and the center through hole of the punch ejection rod threaded connecting piece and is communicated with a center through whole of a threaded water groove piece. The invention further discloses a lubrication device for the punch. According to the lubrication device, the punch and a pressure chamber can be effectively sealed, and the punch can be well lubricated and cooled through spraying lubrication of the ejection rod and a water cooling circulation system, so that the service life of the punch and the service life of the pressure chamber are prolonged, the frequency for replacement of punches is reduced, and the production efficiency is improved.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com