Device and method for measuring static characteristics of joint of rolling bearings

A technology of rolling bearings and measuring devices, which is applied in the direction of mechanical bearing testing, etc.

Pending Publication Date: 2018-11-16

SHAANXI UNIV OF SCI & TECH

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the stiffness of the rolling bearing junction can be obtained by using the analytical method,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

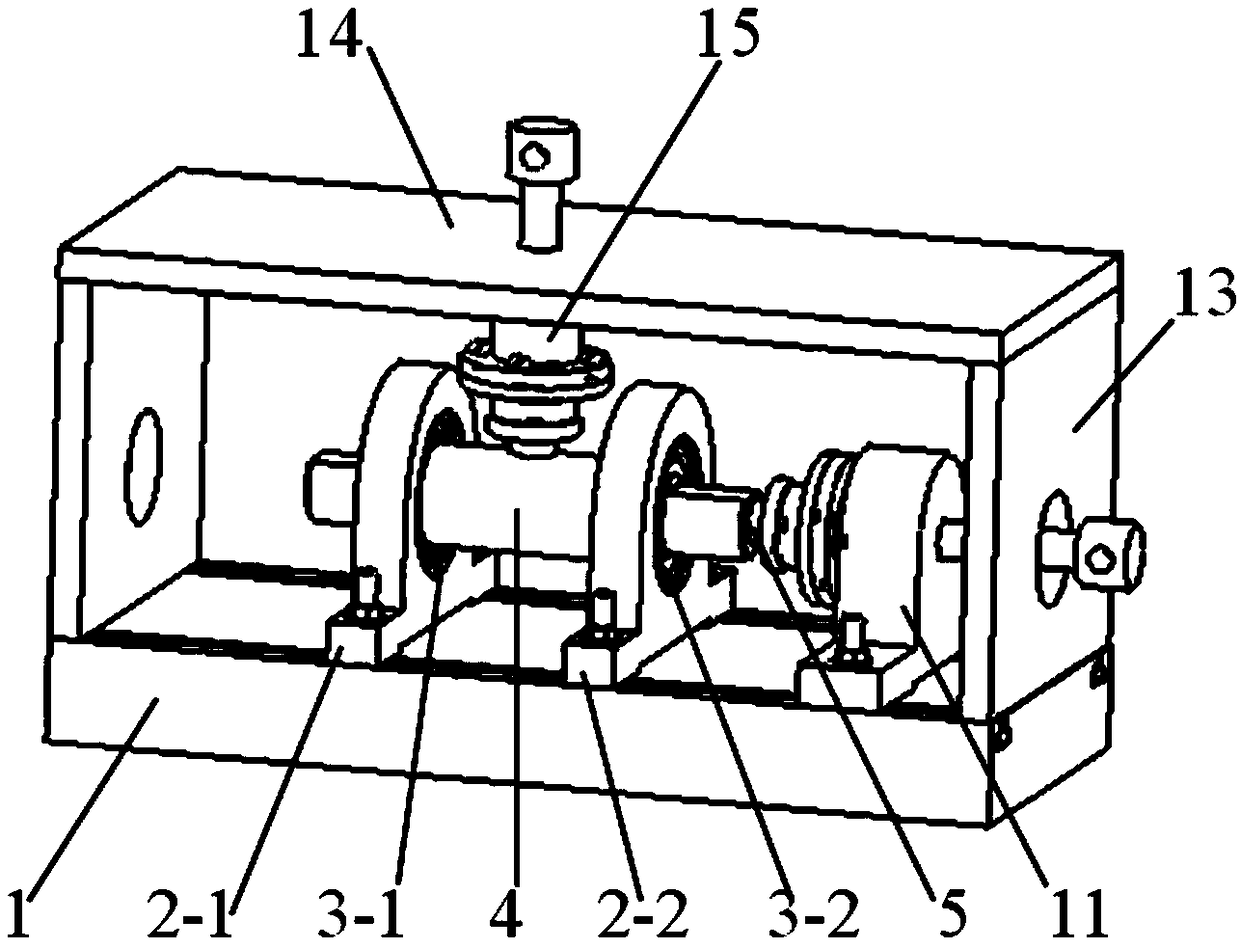

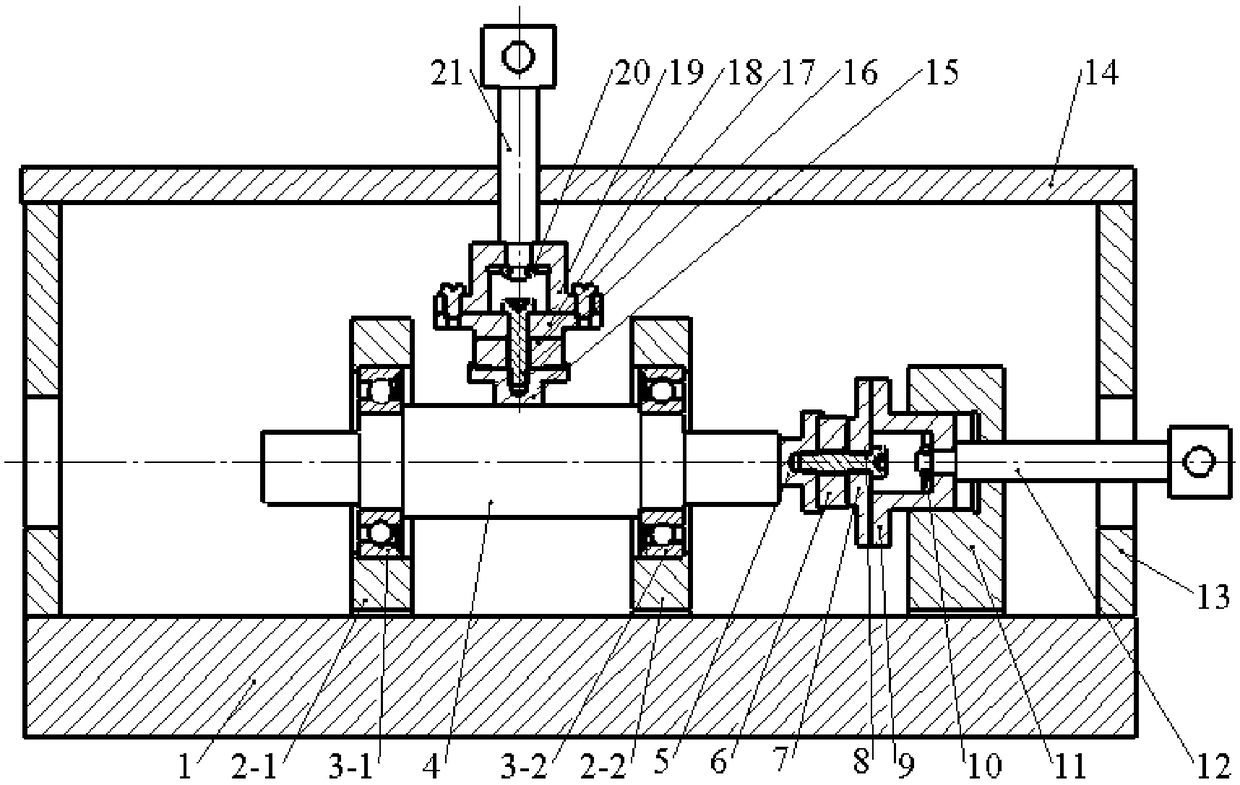

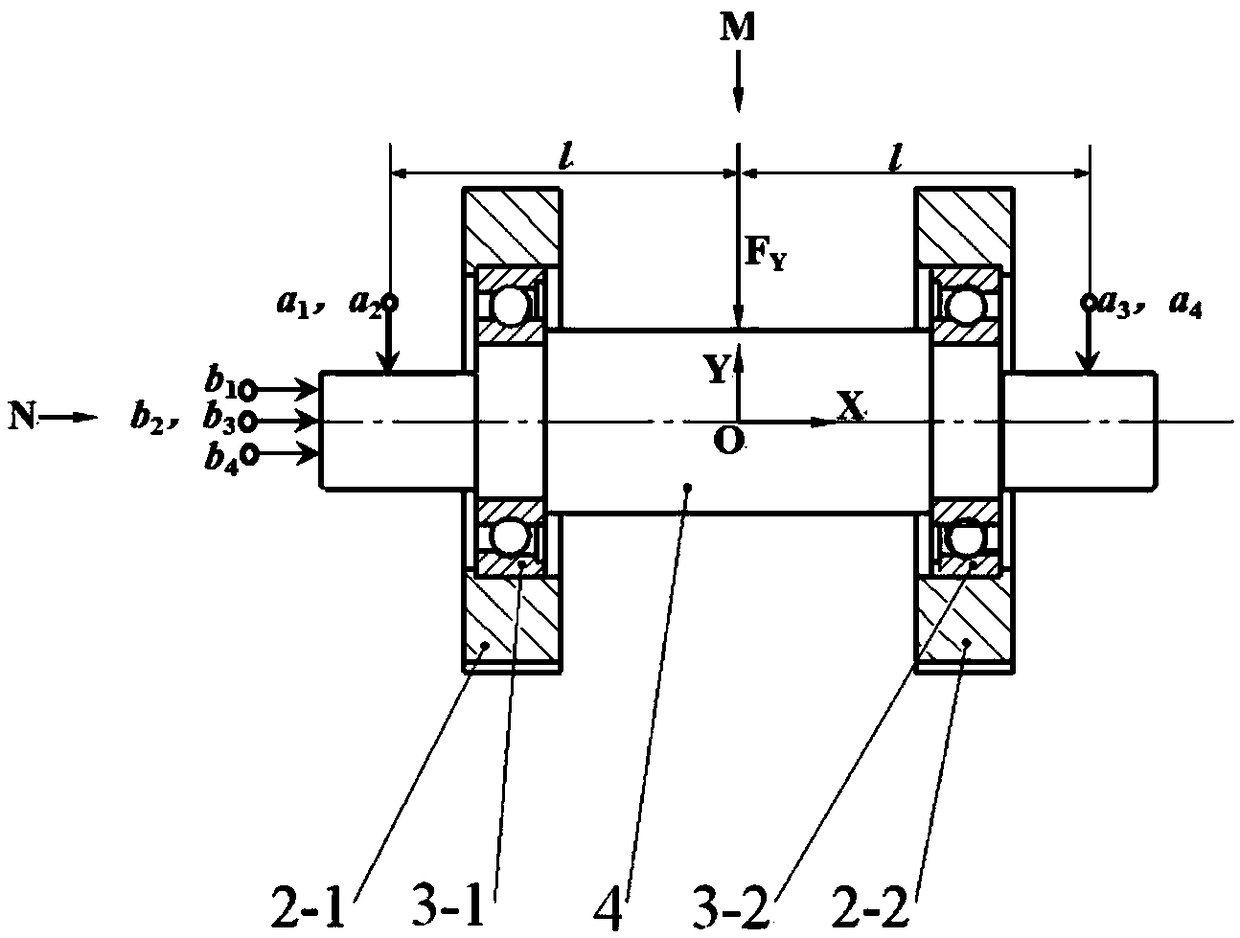

The invention discloses a device and method for measuring the static characteristics of the joint of rolling bearings, and the device comprises a substrate, and two sides of the substrate are connected with side vertical columns. The side vertical columns are connected with a top plate, and the substrate is provided with a T-shaped groove. The interior of the T-shaped groove is fixedly provided with a first bearing seat and a second bearing seat through T-shaped bolts. A testing shaft is supported and installed in the first bearing seat and the second bearing seat through a first rolling bearing and a second rolling bearing. The interior of the T-shaped groove is also fixedly provided with a support seat through a T-shaped bolt. The support seat is provided with an axial loading assembly which applies an axial force to the testing shaft, and the axial loading assembly is set along the horizontal central line of the first and second rolling bearings. The center of the top plate is provided with a radial loading assembly which is used for applying a radial force to the testing shaft, and the radial loading assembly is set along the vertical central line of the first and second rolling bearings. The device and method can achieve the testing and verification of the static rigidity analysis of the joint of the rolling bearings.

Description

technical field [0001] The invention belongs to the technical field of mechanical structure joints, and in particular relates to a static characteristic measuring device and method for a rolling bearing joint. Background technique [0002] The machine tool is composed of components and the joints between the parts. The machine tool joints, such as rolling bearing joints, bolt joints, etc., contain a variety of nonlinear features. The existence of these complex joints makes it impossible to simply linearly superpose the analysis results of the characteristics of each component in the performance prediction analysis of the machine tool based on the design drawings. It is necessary to establish a model including the characteristics of the nonlinear joint so that the designer can analyze and accurately predict the overall performance of the machine tool. [0003] The rolling bearing joint is a kinematic joint, including the cylindrical surface contact between the inner ring and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/04

CPCG01M13/04

Inventor 惠烨李艳高峰

Owner SHAANXI UNIV OF SCI & TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com