Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

503results about "Drilling drives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite coating with nanoparticles for improved wear and lubricity in down hole tools

Owner:SMITH INT INC

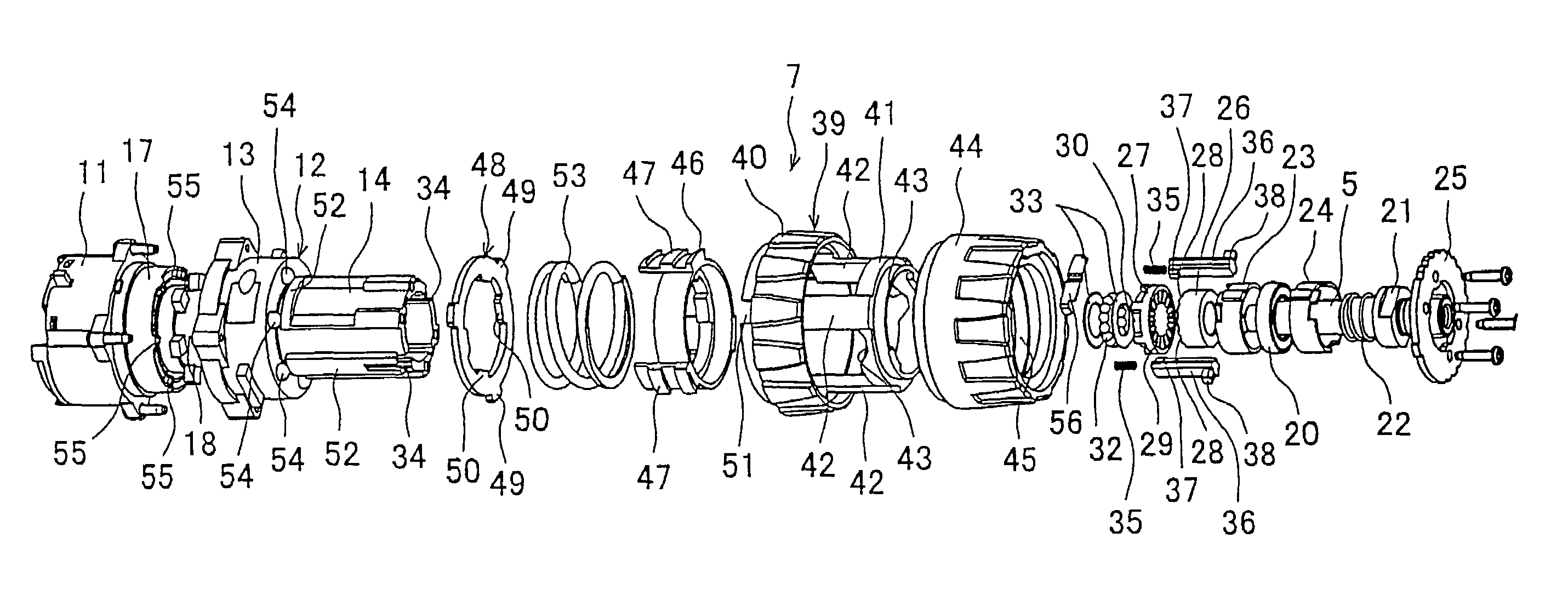

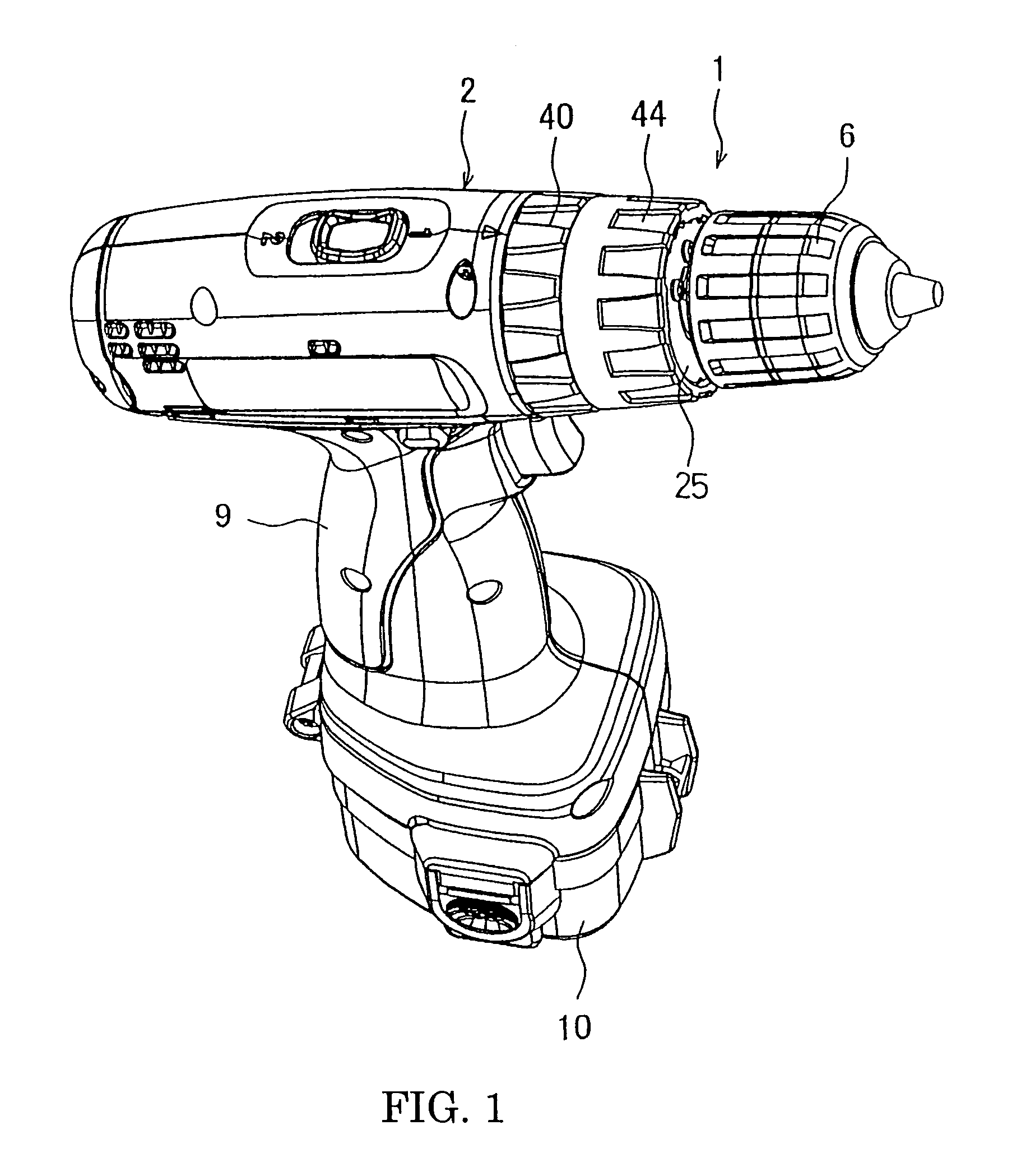

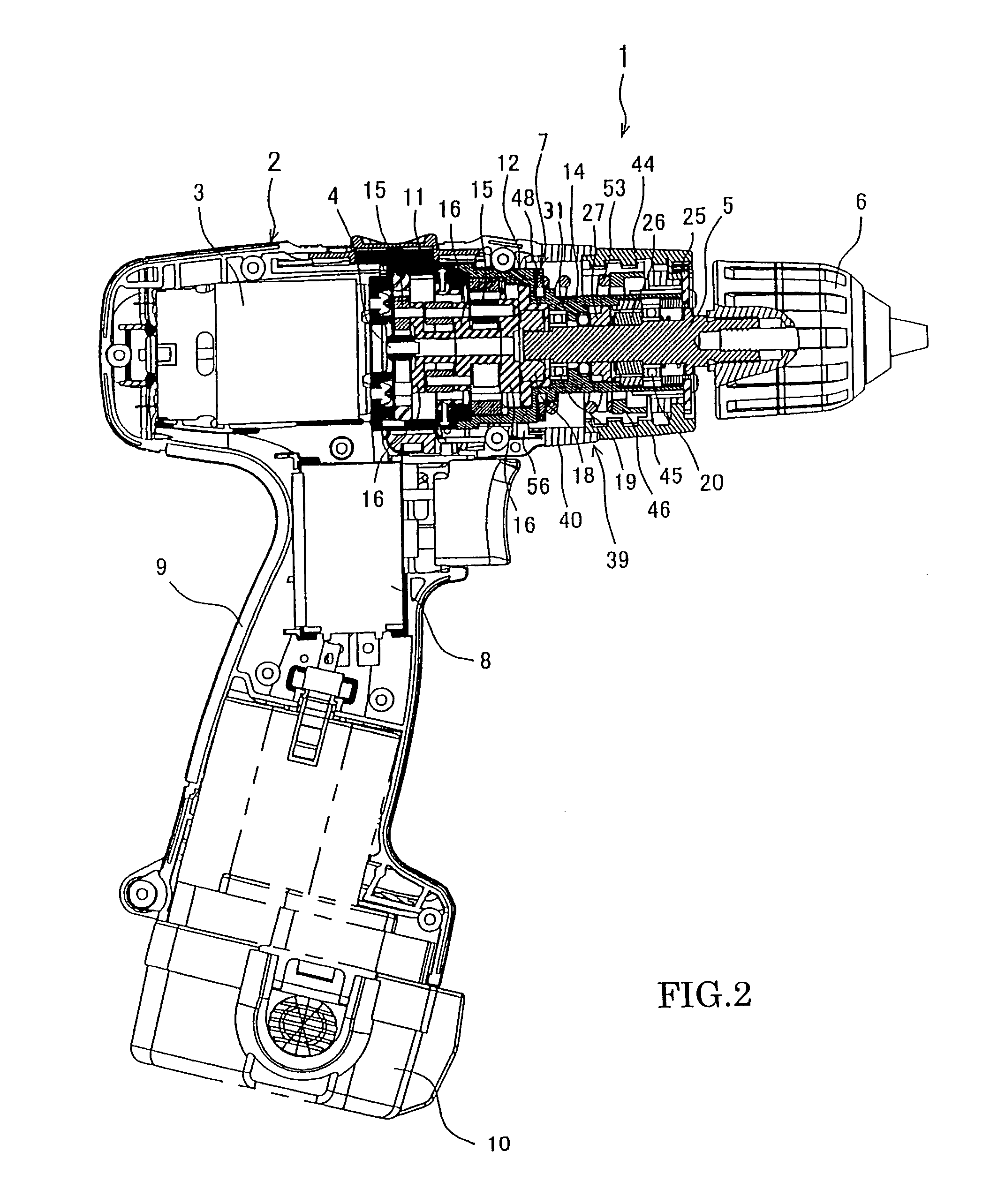

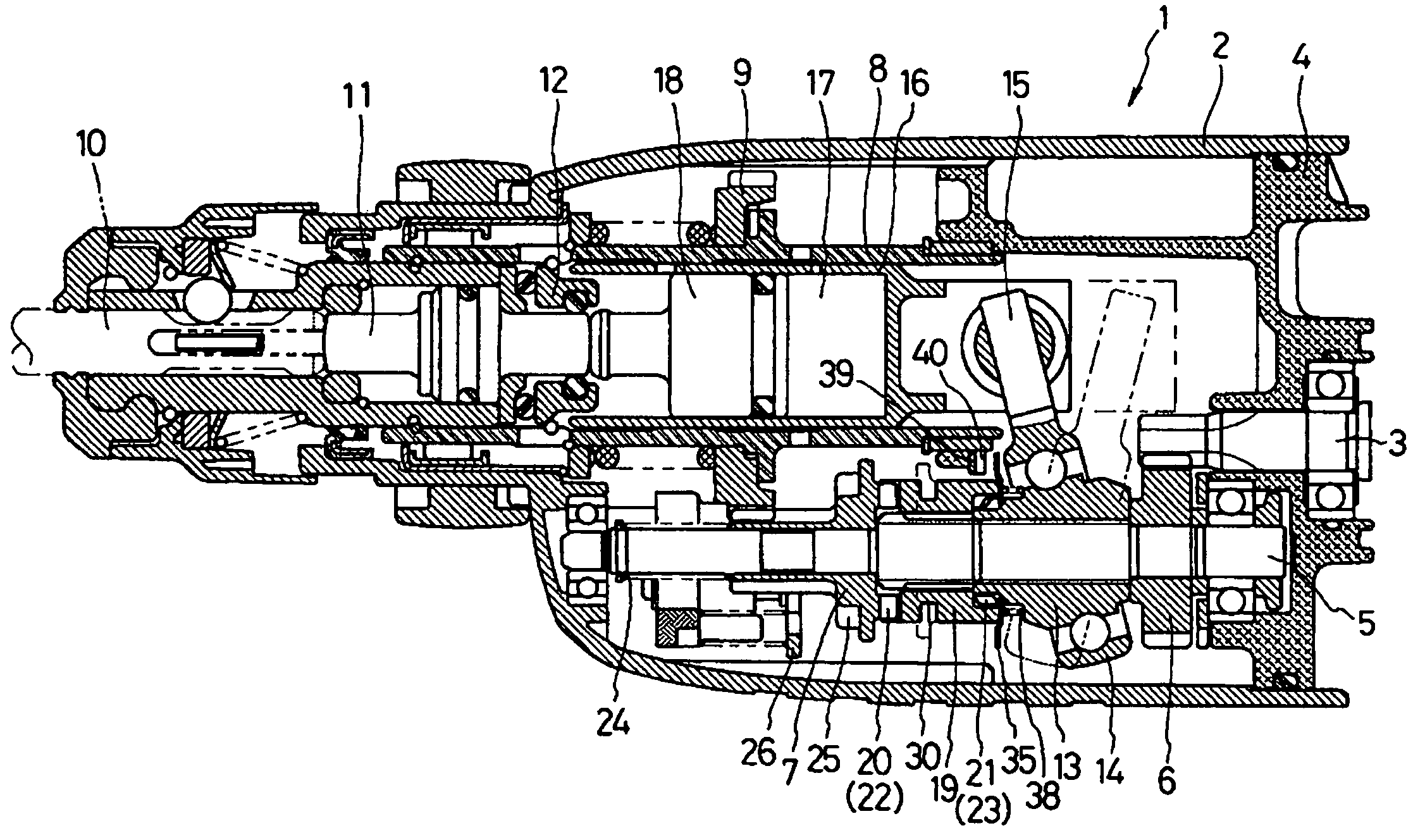

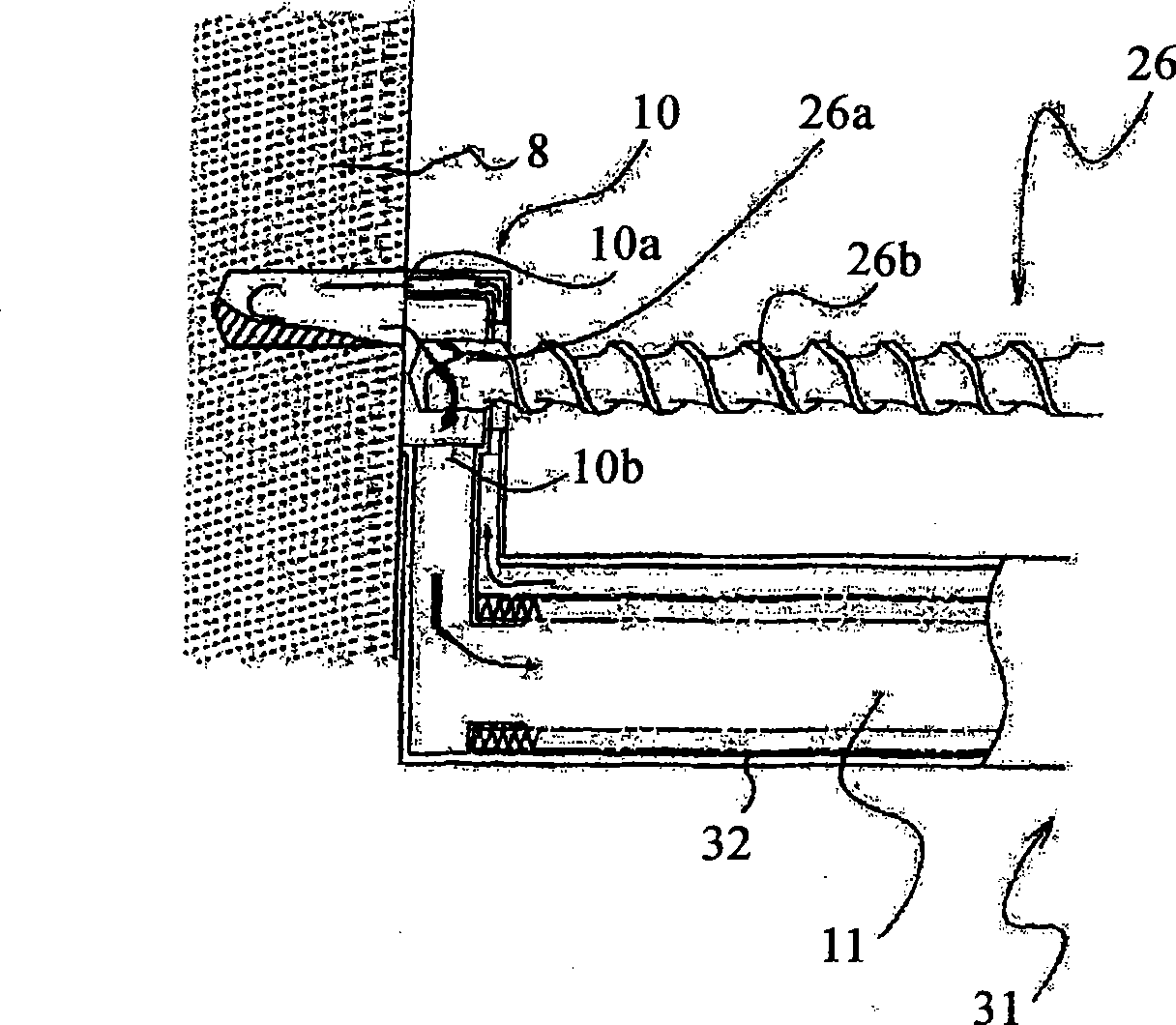

Driver drill

ActiveUS7201235B2Prevent erroneous clutch operationImprove reliabilityDrilling rodsConstructionsGear wheelCoil spring

A driver drill that can effectively prevent erroneous clutch operation in a drill mode is provided. A flat washer positioned between steel balls for locking an internal gear and a coil spring is rotatable by rotative operation of a mode-change ring. Also, protruding streaks are provided on a small-diameter unit of a second gear case around which a flat washer is externally mounted. The protruding streaks interfere with internal projections on an inner circumference of the flat washer at its predetermined rotating position to regulate a forward movement of the flat washer. When a drill mode is selected with the mode-change ring, the flat washer is locked by the protruding streaks.

Owner:MAKITA CORP

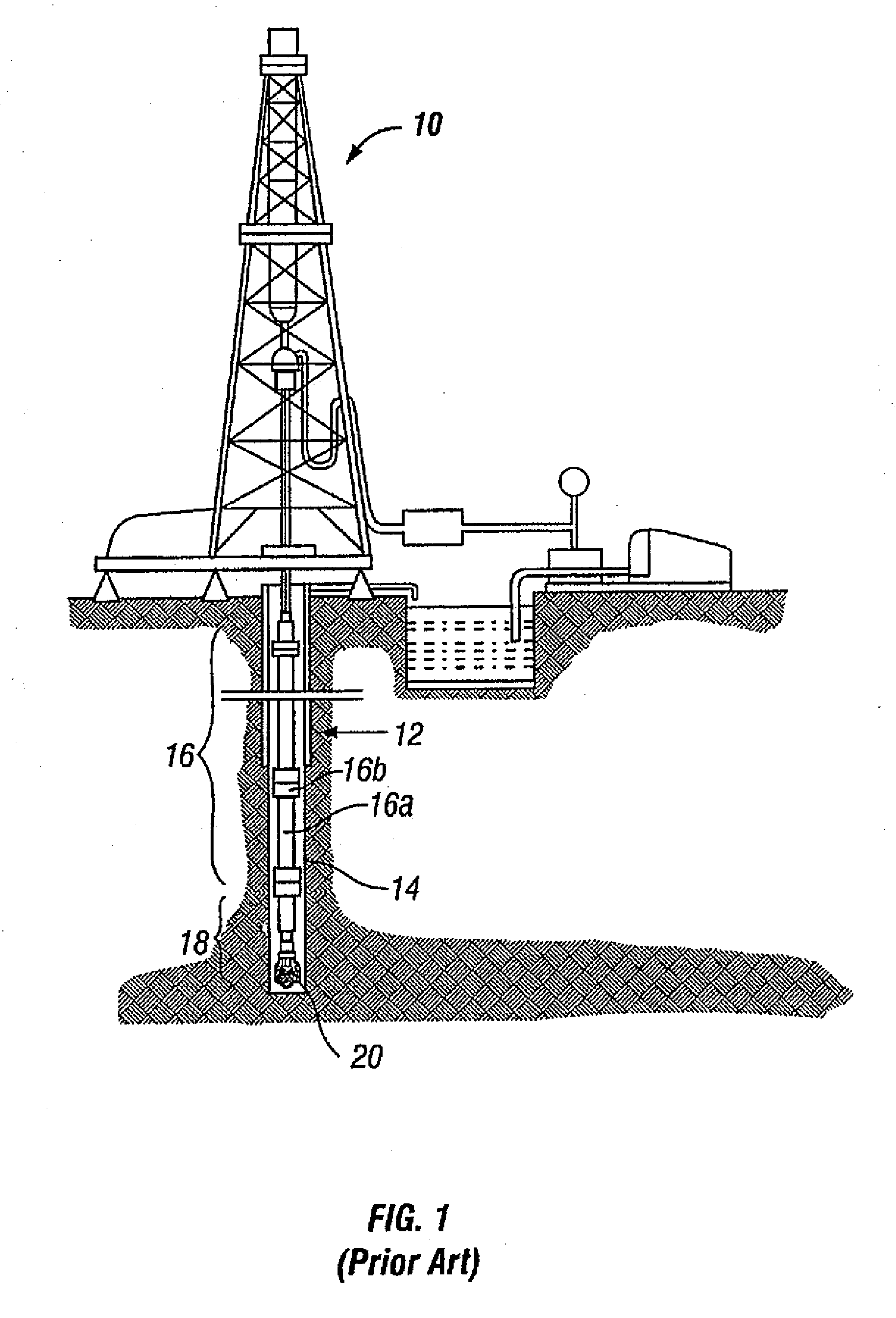

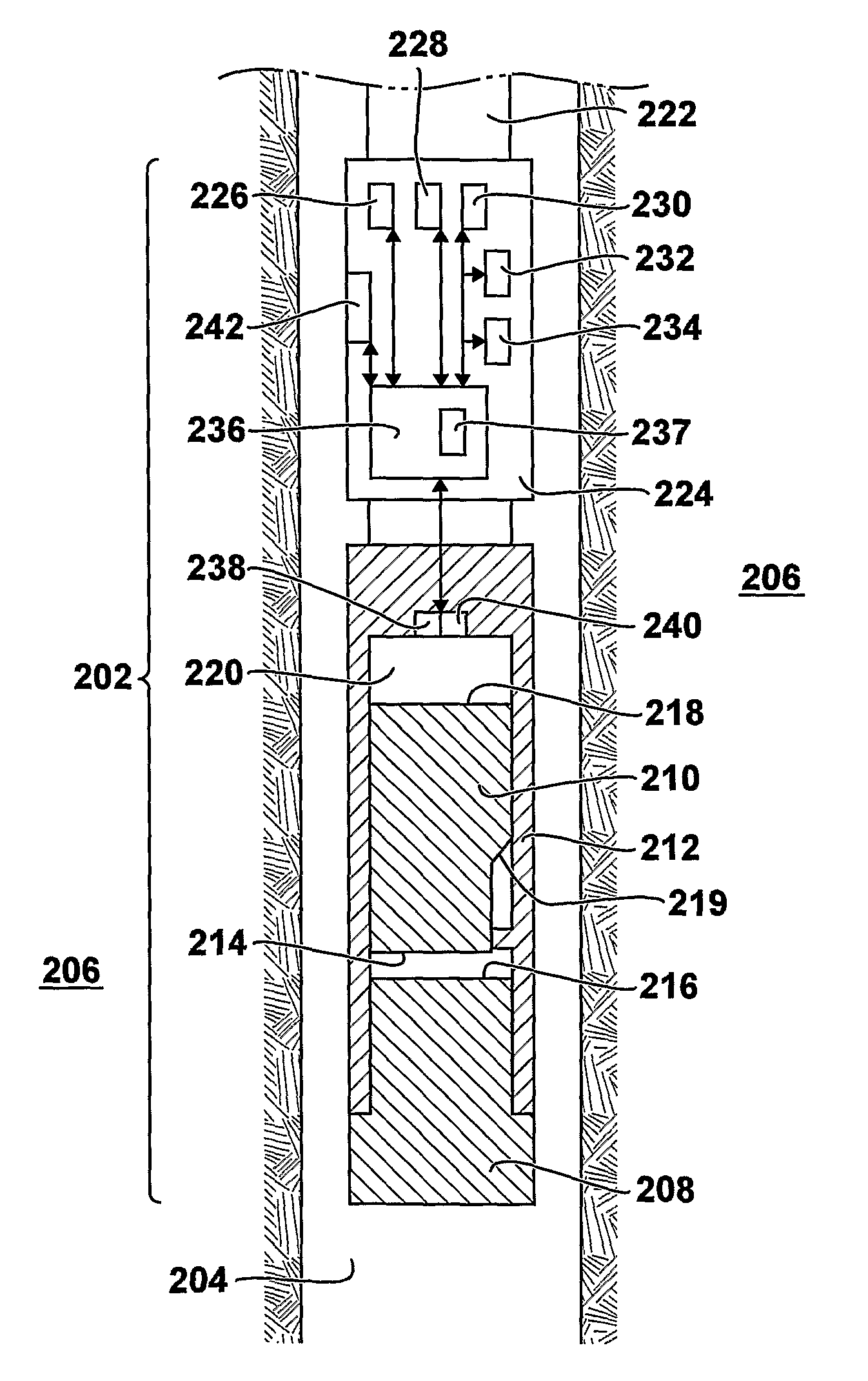

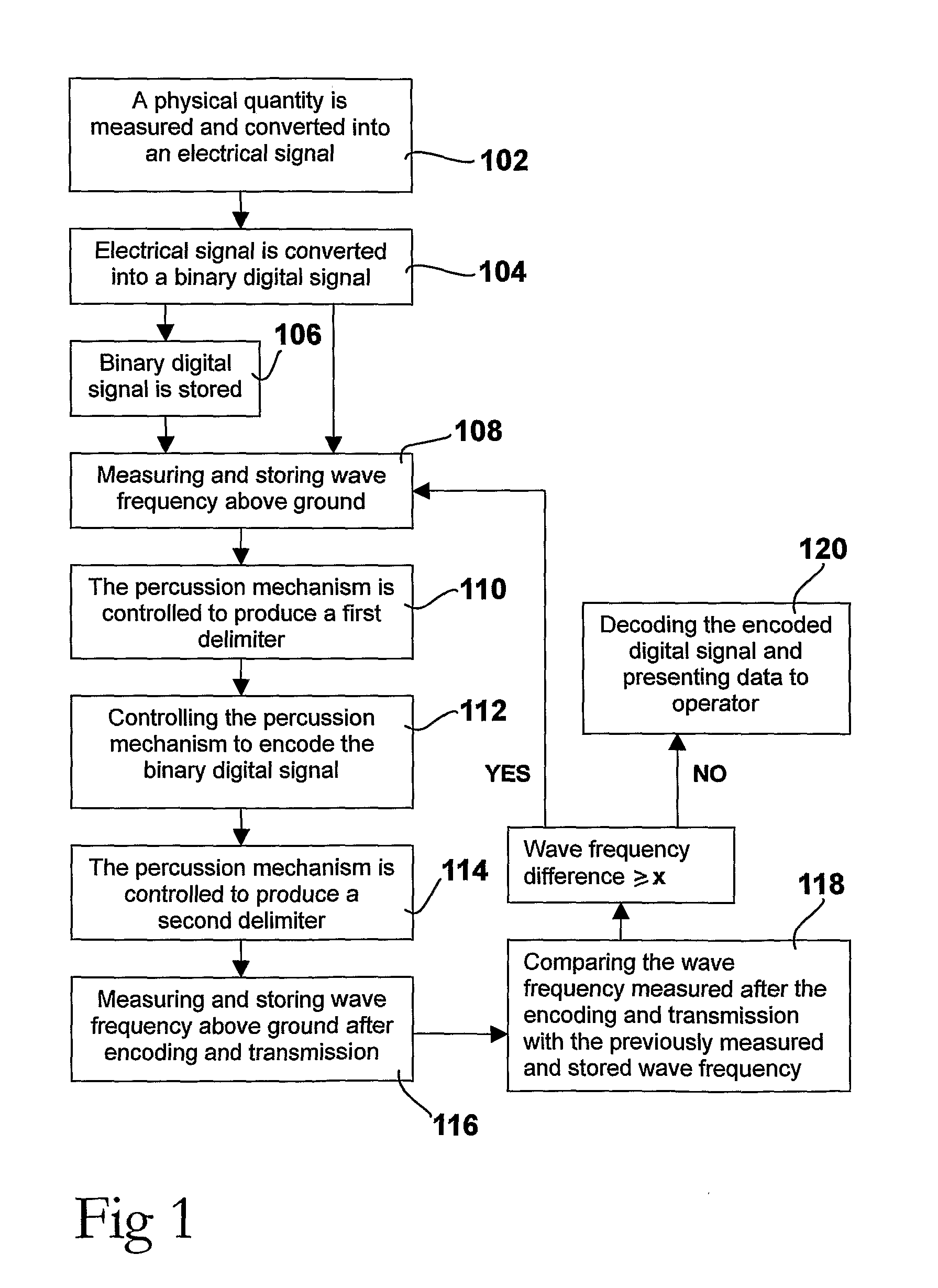

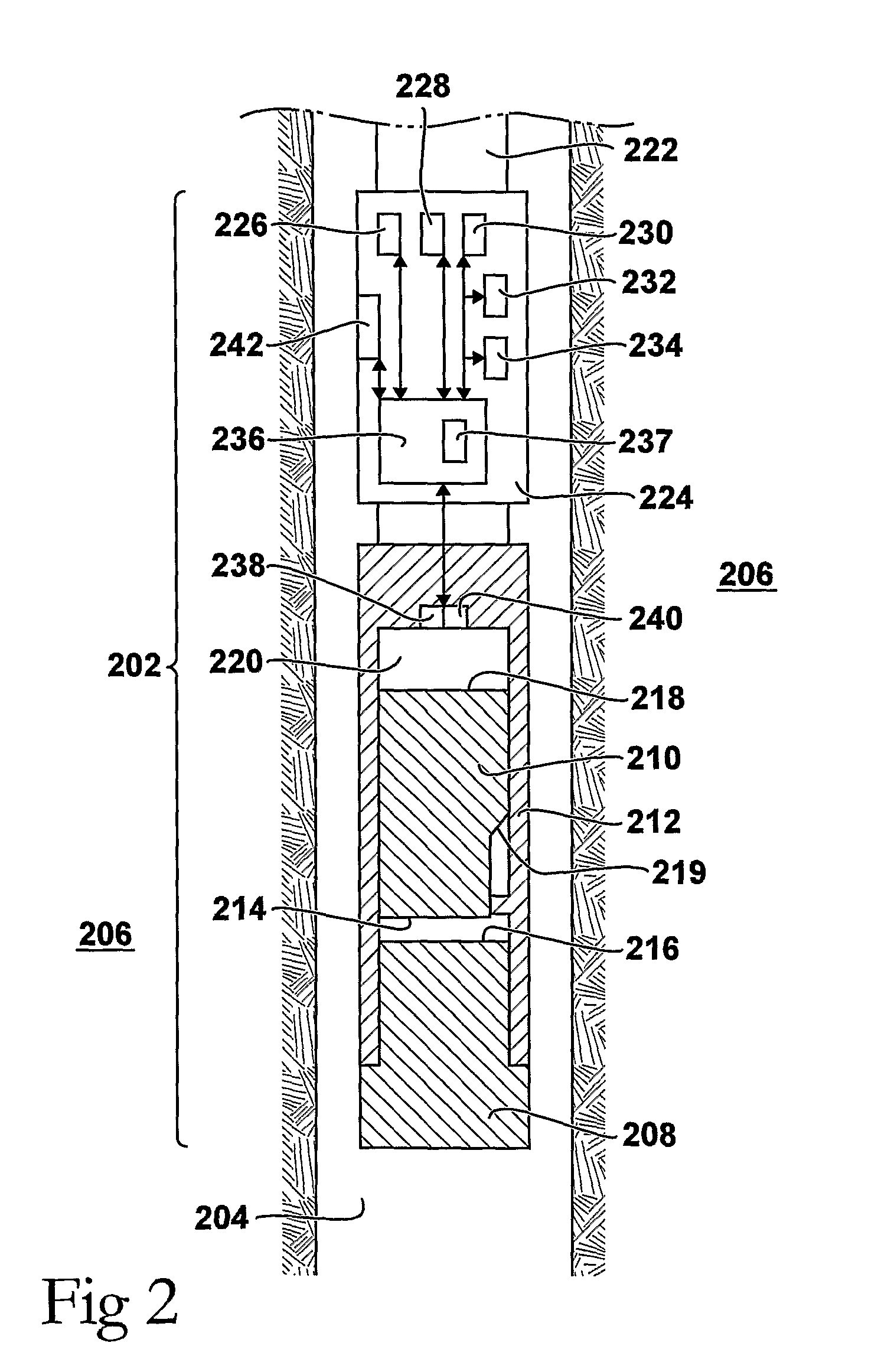

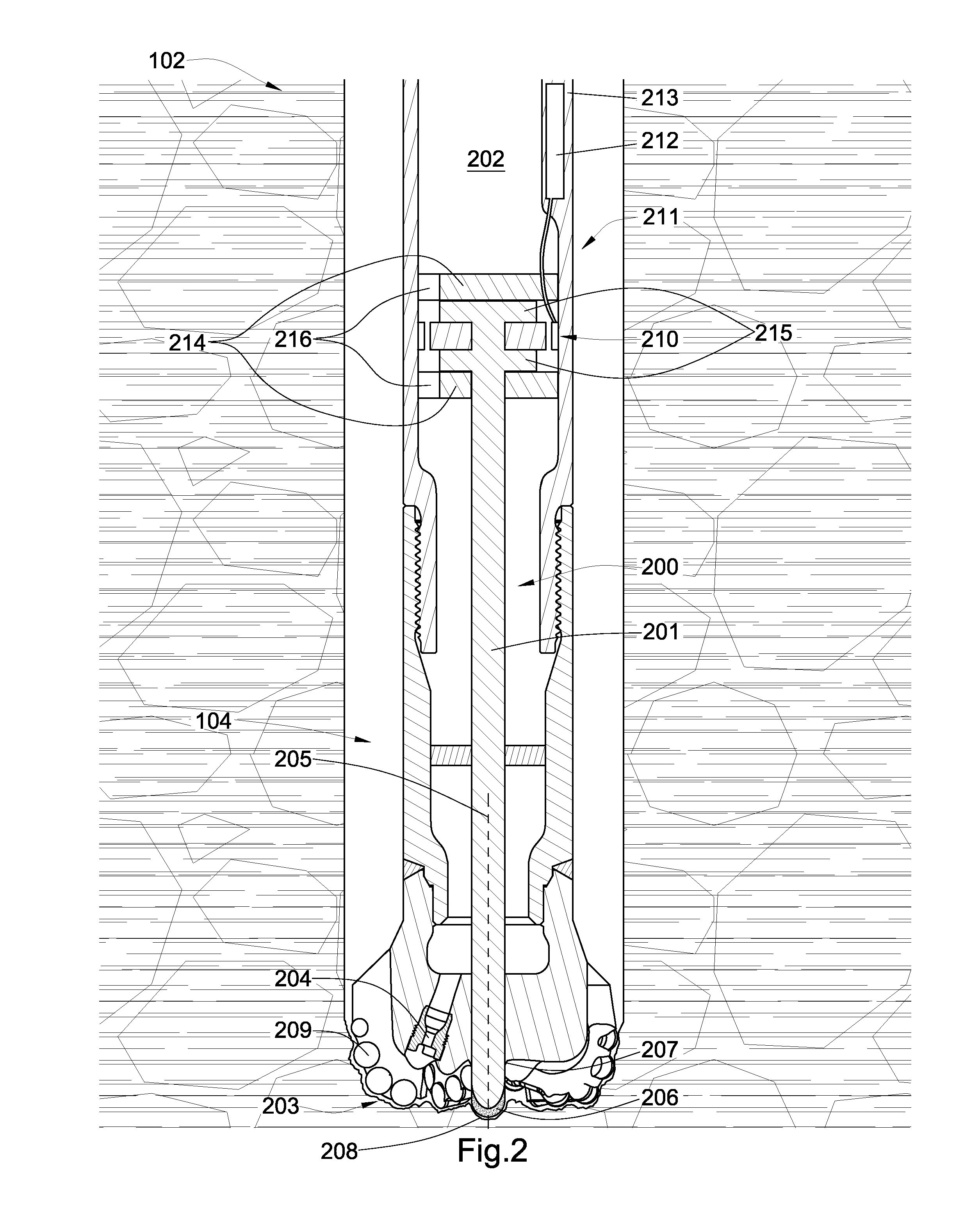

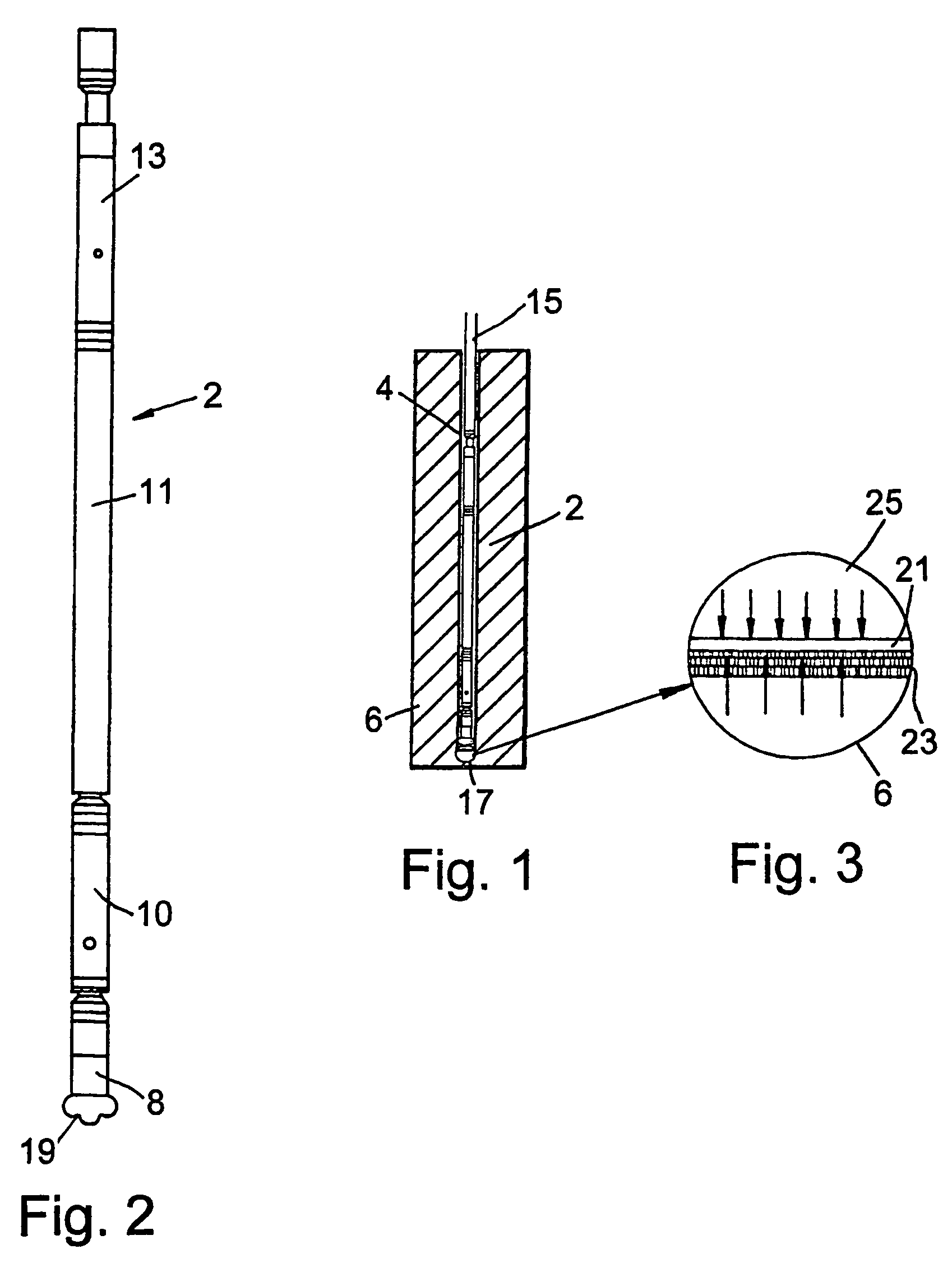

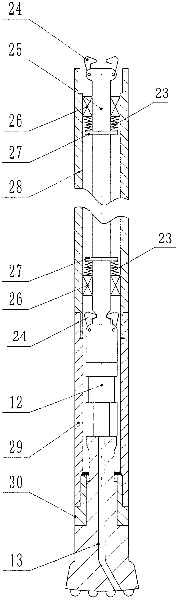

Bottom-hole assembly, and a method and system for transmitting data from a bottom-hole assembly

InactiveUS20110067928A1Efficient data transferData transmission rateSurveyDrill bitsElectricityEngineering

A bottom-hole assembly (202), BHA, for drilling a borehole (204, 301) in an earth formation (208, 300), comprising a percussion drill bit (208), a percussion mechanism adapted to strike the drill bit (208), at least one sensor (226, 228, 230, 232, 234) for measuring a physical quantity and converting it into an electrical signal, and converting means (237) for converting the electrical signal into a digital signal, and a method for transmitting data from such a bottom-hole assembly (202) positioned in a borehole (204, 301), the bottom-hole assembly (202) and the method being characterized by encoding the digital signal by controlling the percussion mechanism and time periods between two impacts delivered by the percussion mechanism on the drill bit (208) during drilling, and transmitting the encoded digital signal by waves generated by the impacts delivered by the percussion mechanism on the drill bit (208). A system which comprises said bottom-hole assembly (202).

Owner:SPC TECH

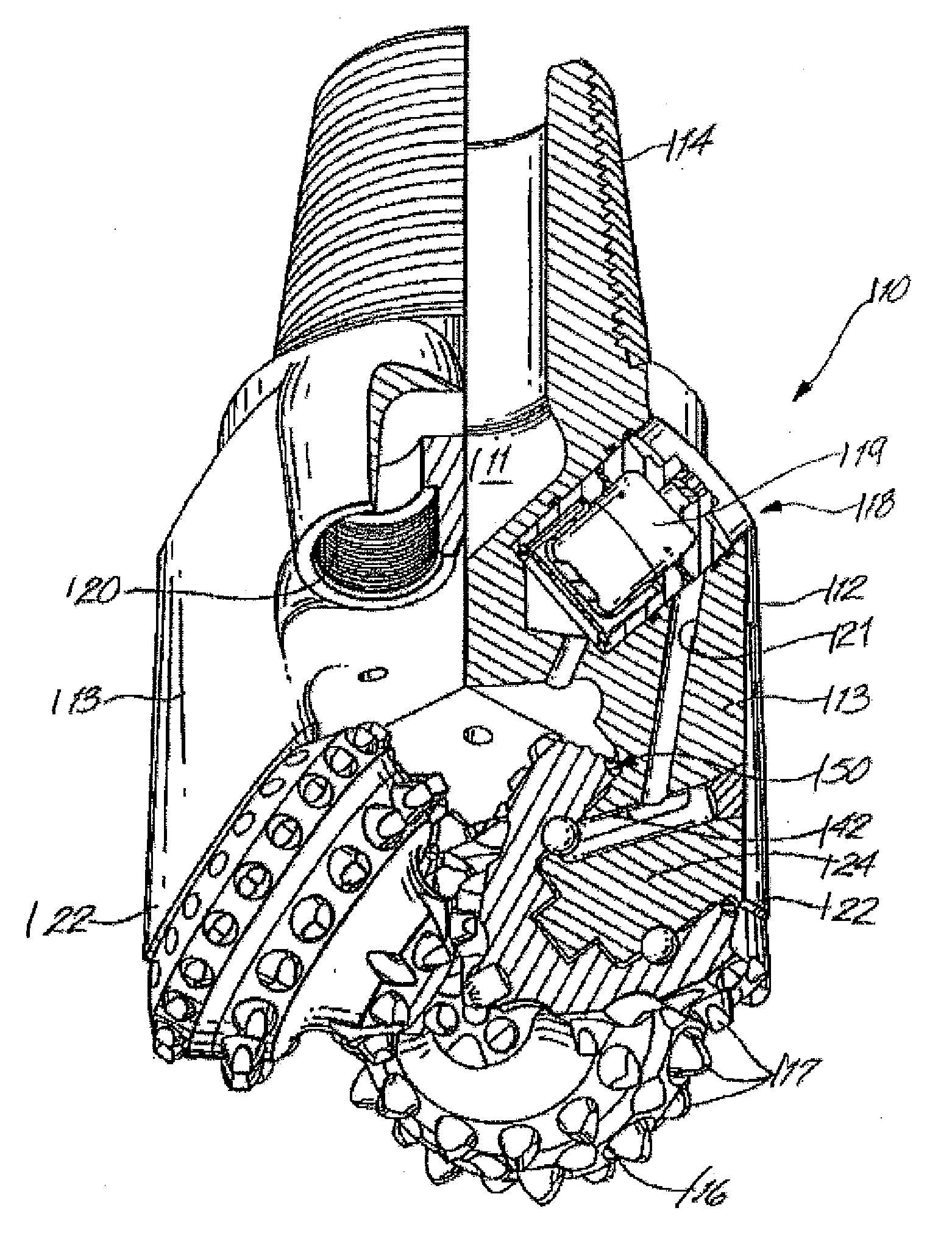

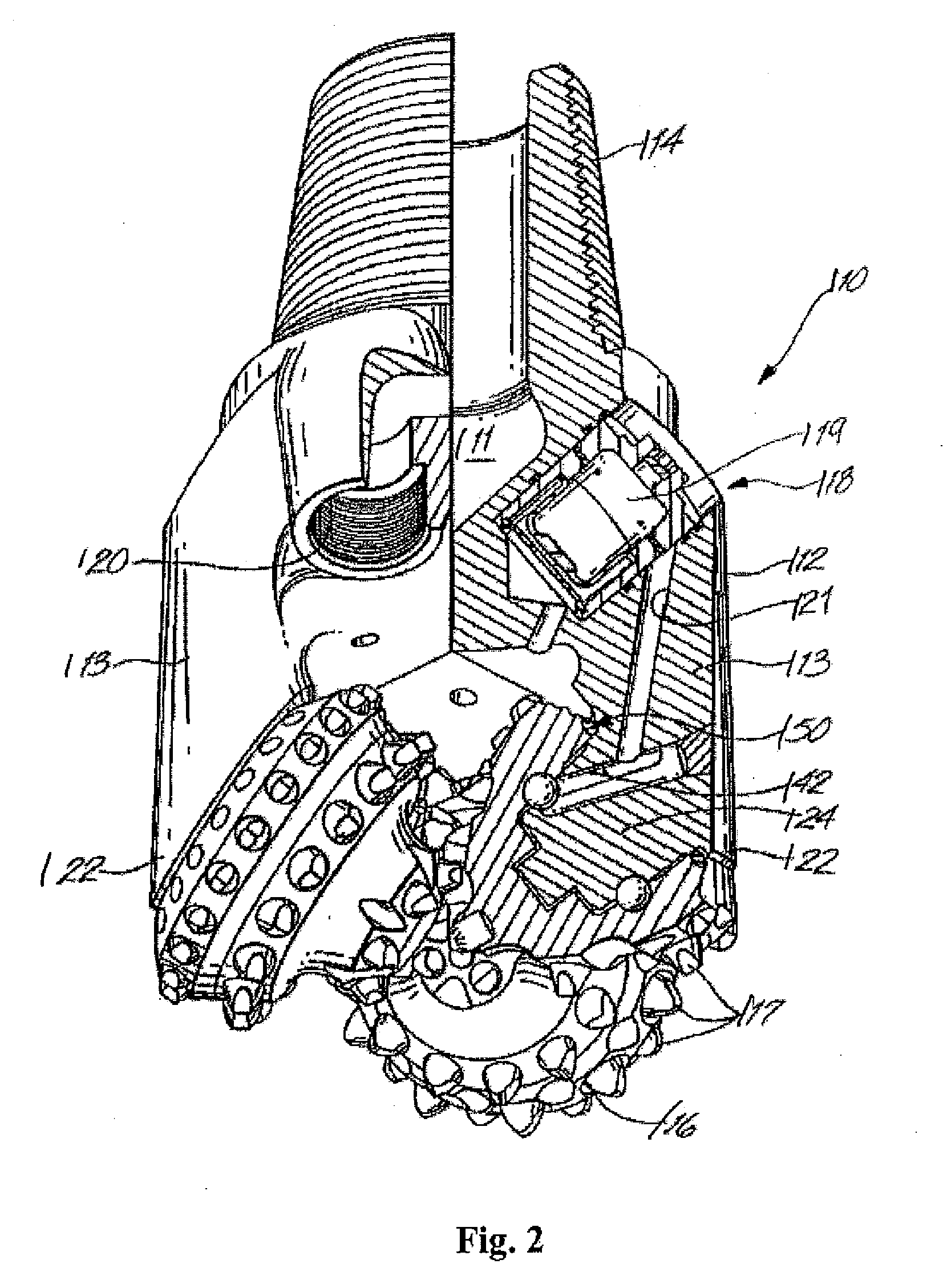

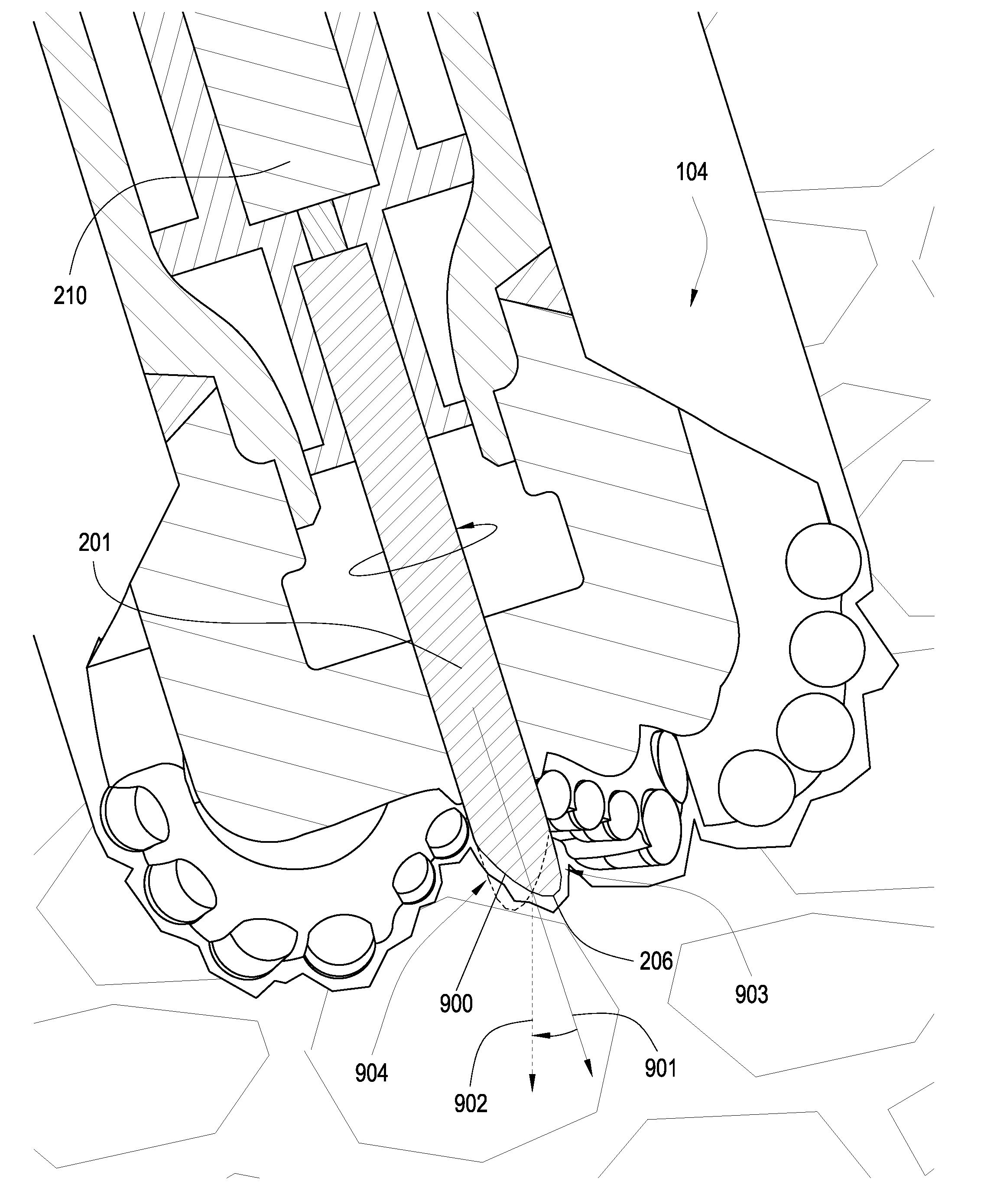

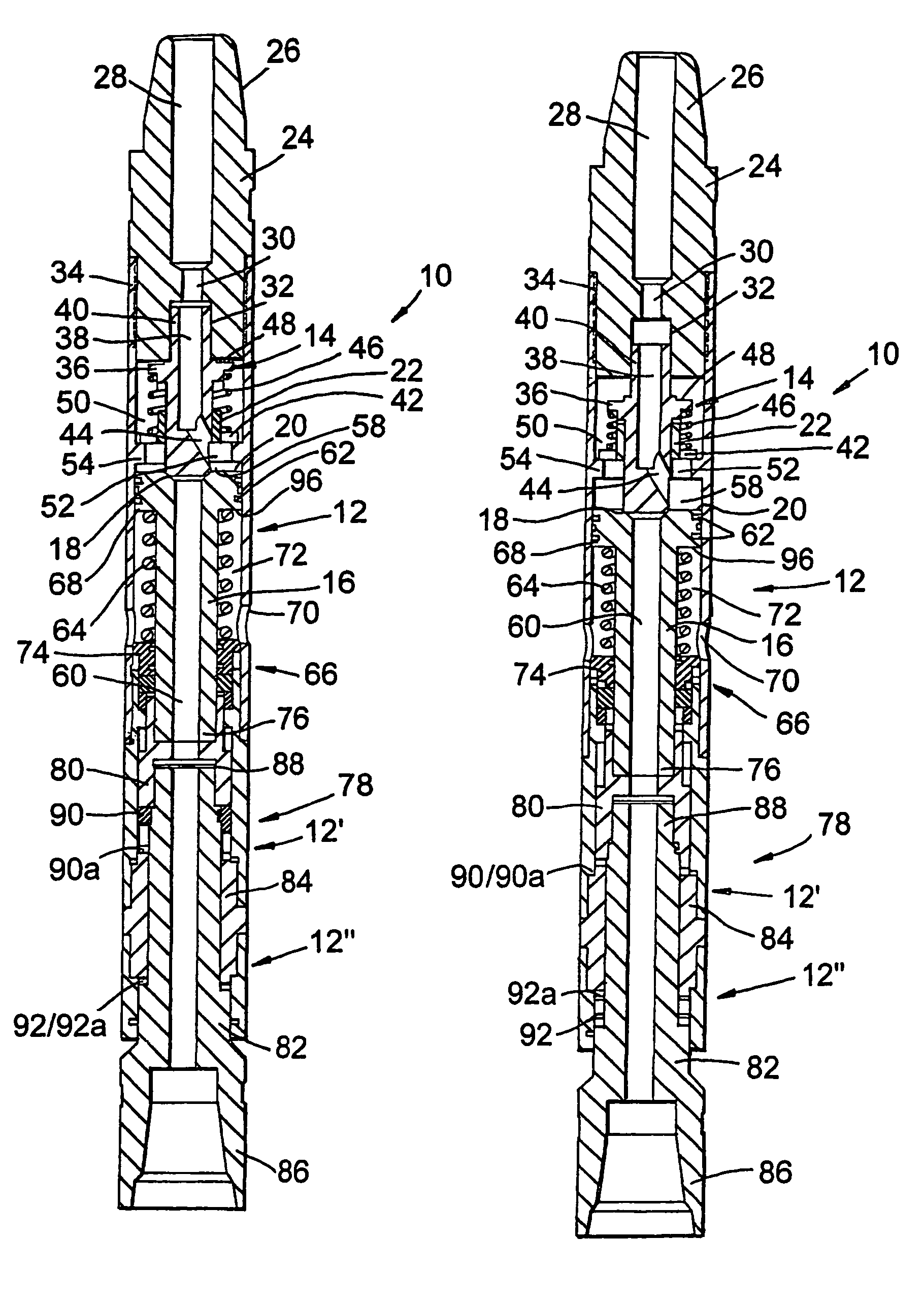

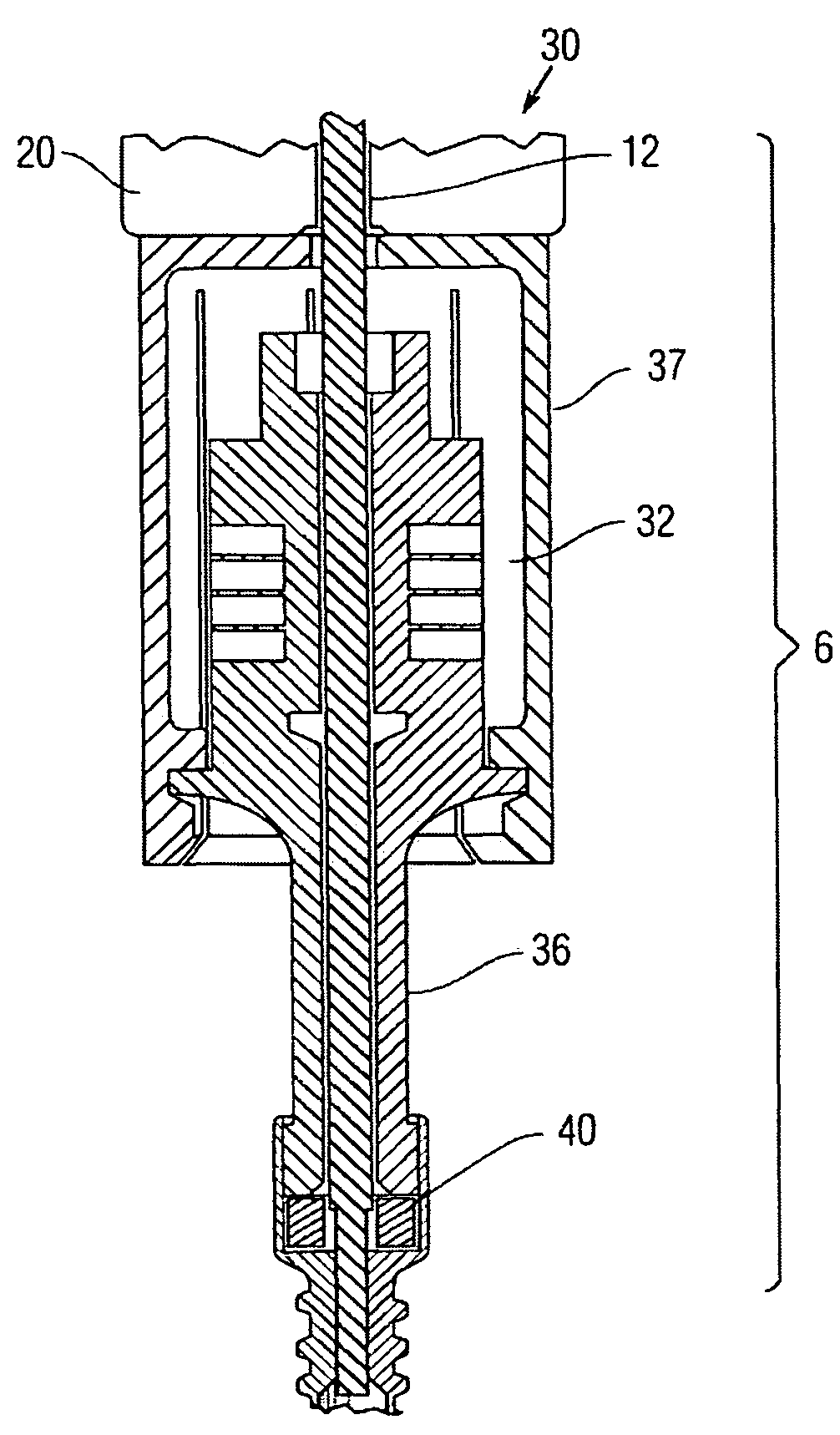

Jack Element in Communication with an Electric Motor and or Generator

A drill bit has a body intermediate a shank and a working face and has an axis of rotation. The working face has at least one cutting element and the body has at least a portion of a jack assembly. The jack assembly has at least a portion of a shaft disposed within a cavity formed in the body of the drill bit, the shaft having a distal end extending from an opening of the cavity formed in the working face. The jack assembly also has an electric motor and / or generator.

Owner:SCHLUMBERGER TECH CORP

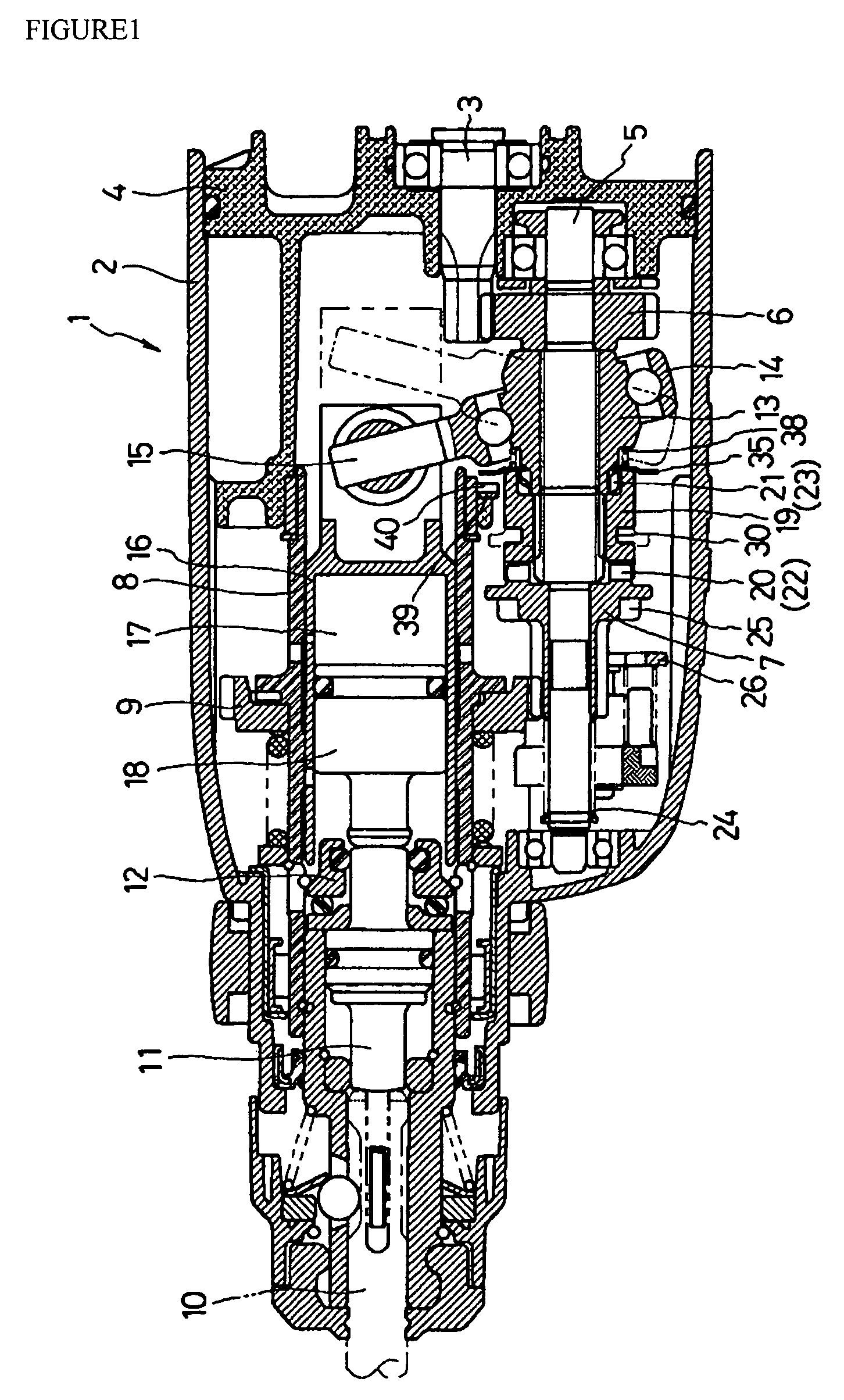

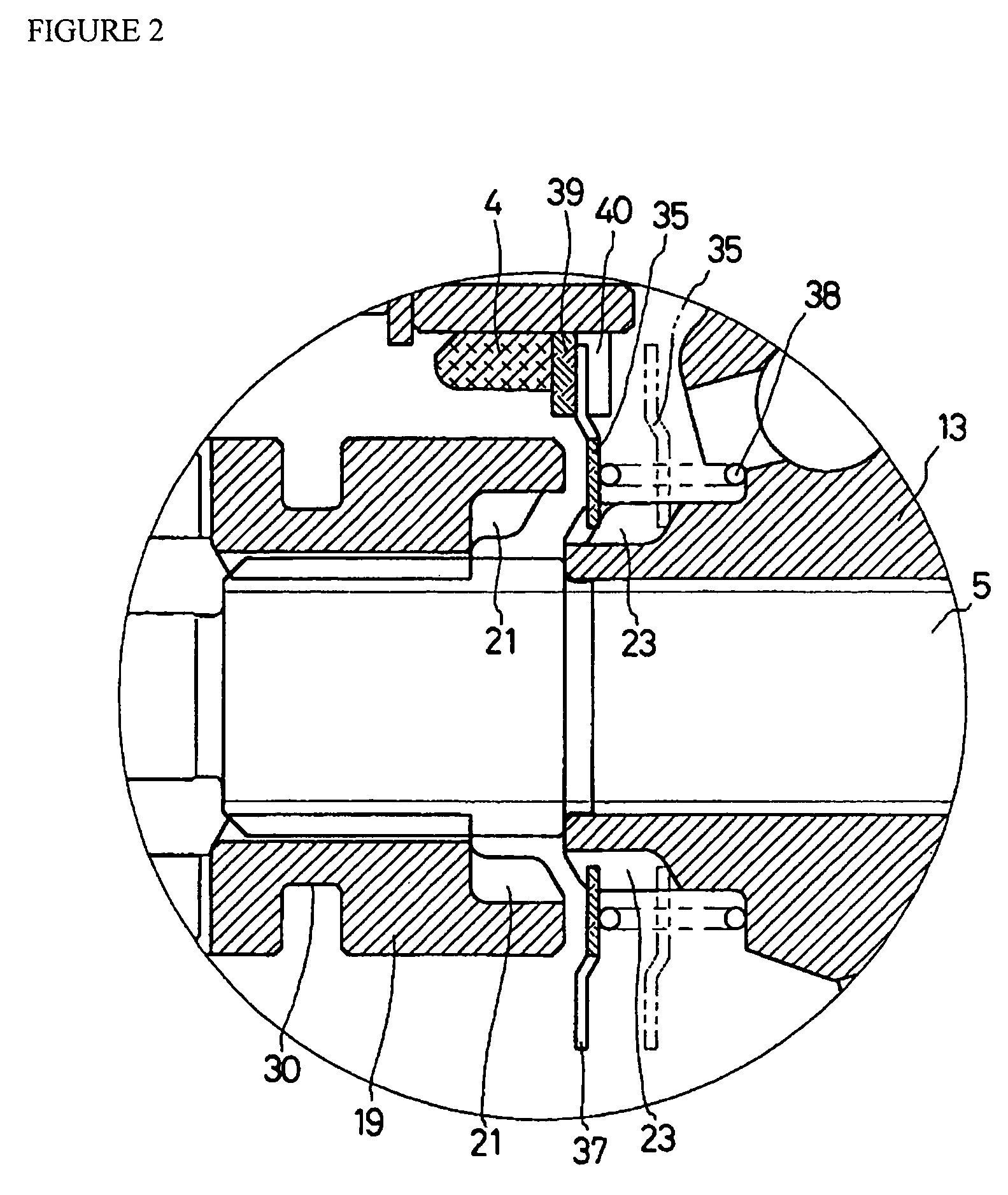

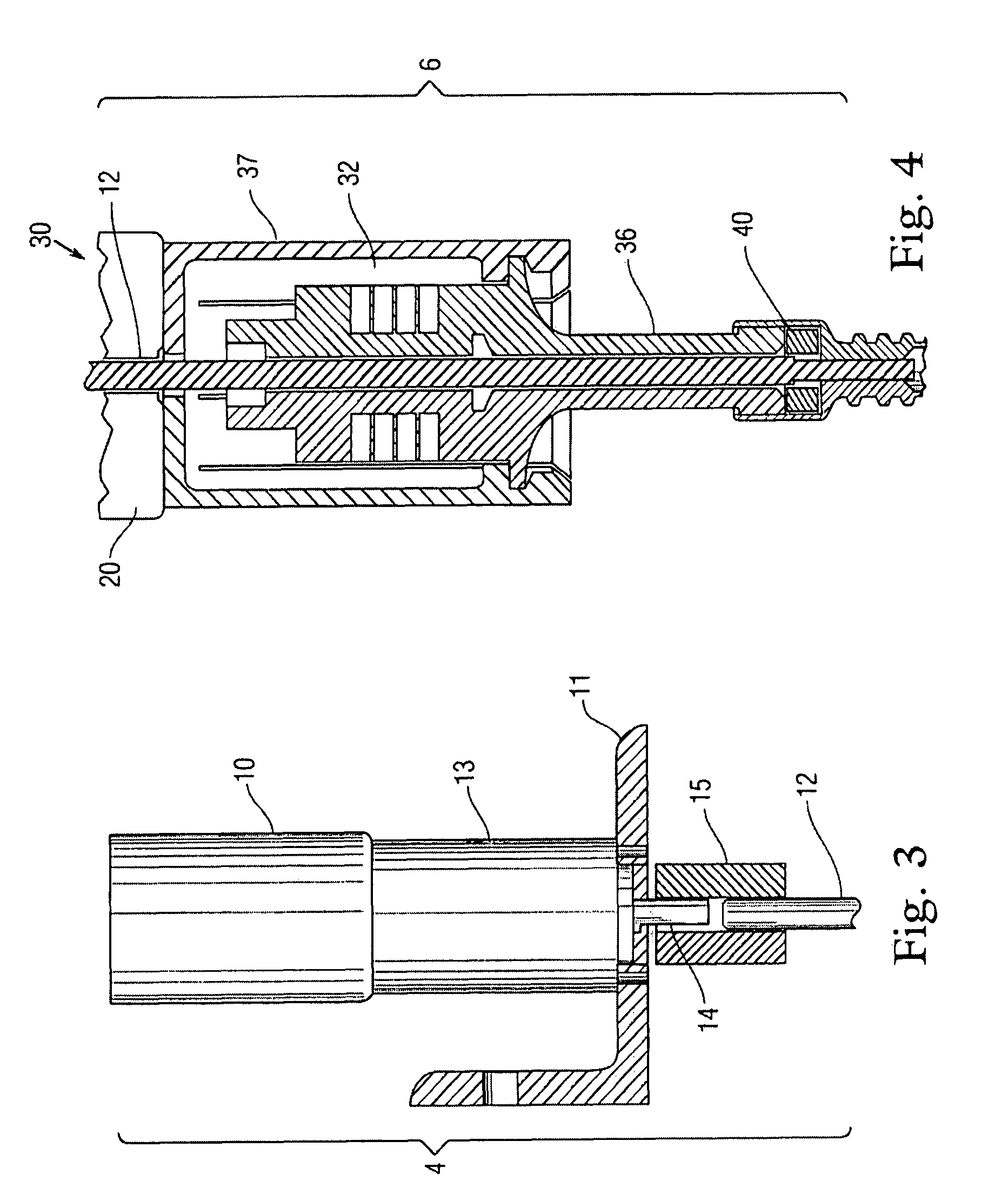

Hammer drill with a mechanism for preventing inadvertent hammer blows

InactiveUS6971455B2Reliably prevents inadvertent blows to the bitImprove reliabilityReciprocating drilling machinesPortable percussive toolsCoil springEngineering

A hammer drill (1) includes a lock plate (35) forward of a boss sleeve (13) and a swash bearing (14) which cooperates with the boss sleeve to convert the rotation of an intermediate shaft (5) on which the boss sleeve is mounted. The lock plate is mounted on the boss sleeve and selectively engages claws (23) of the boss sleeve (13) in a manner that permits its integral rotation with and axial slide with respect to the boss sleeve. The lock plate is additionally biased in the forward direction by a coil spring (38) so that when a clutch (19) is shifted forward in a drill mode, the lock plate also moves forward into engagement with a stopper (39) secured to an inner housing (4), preventing inadvertent rotation of the boss sleeve.

Owner:MAKITA CORP

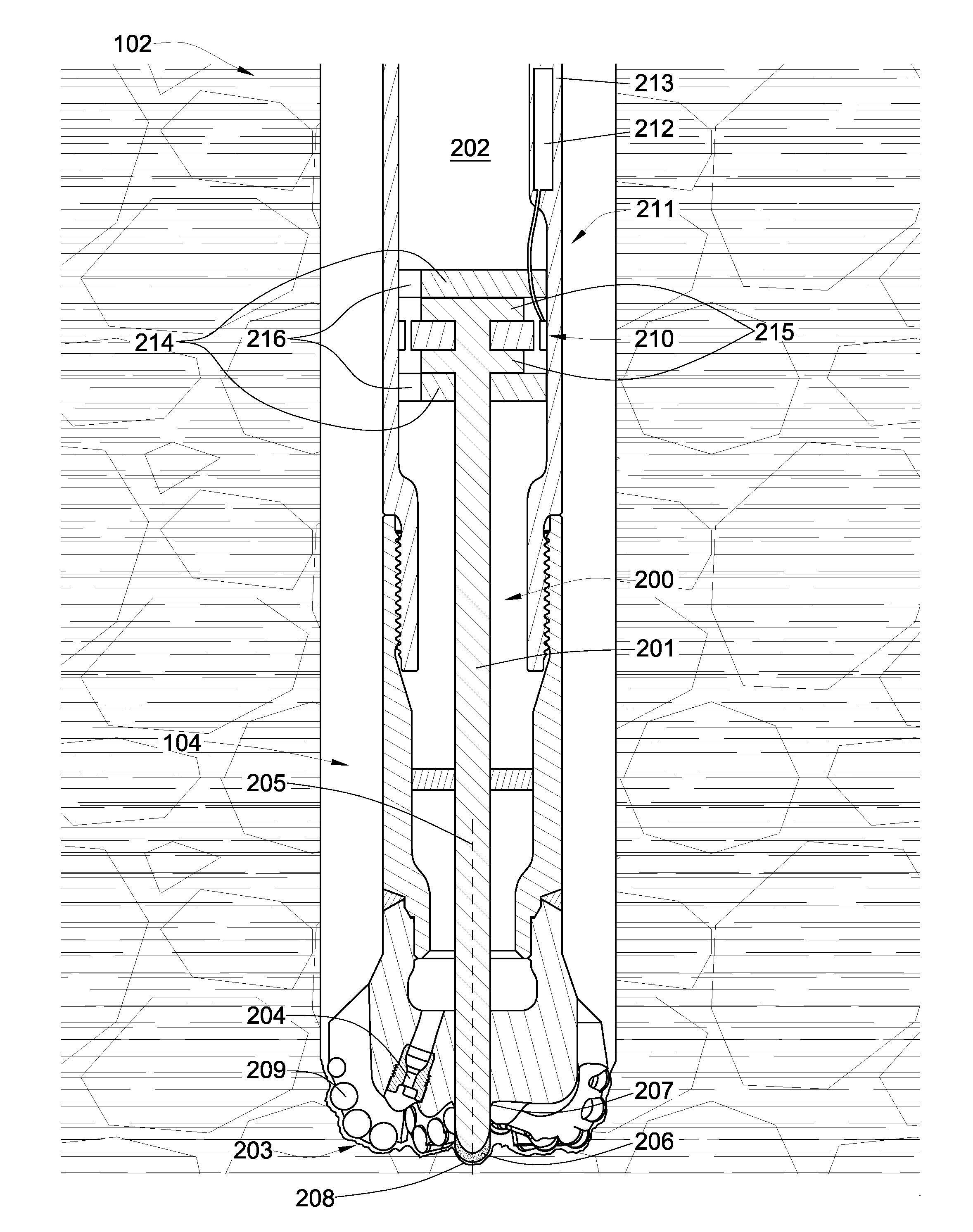

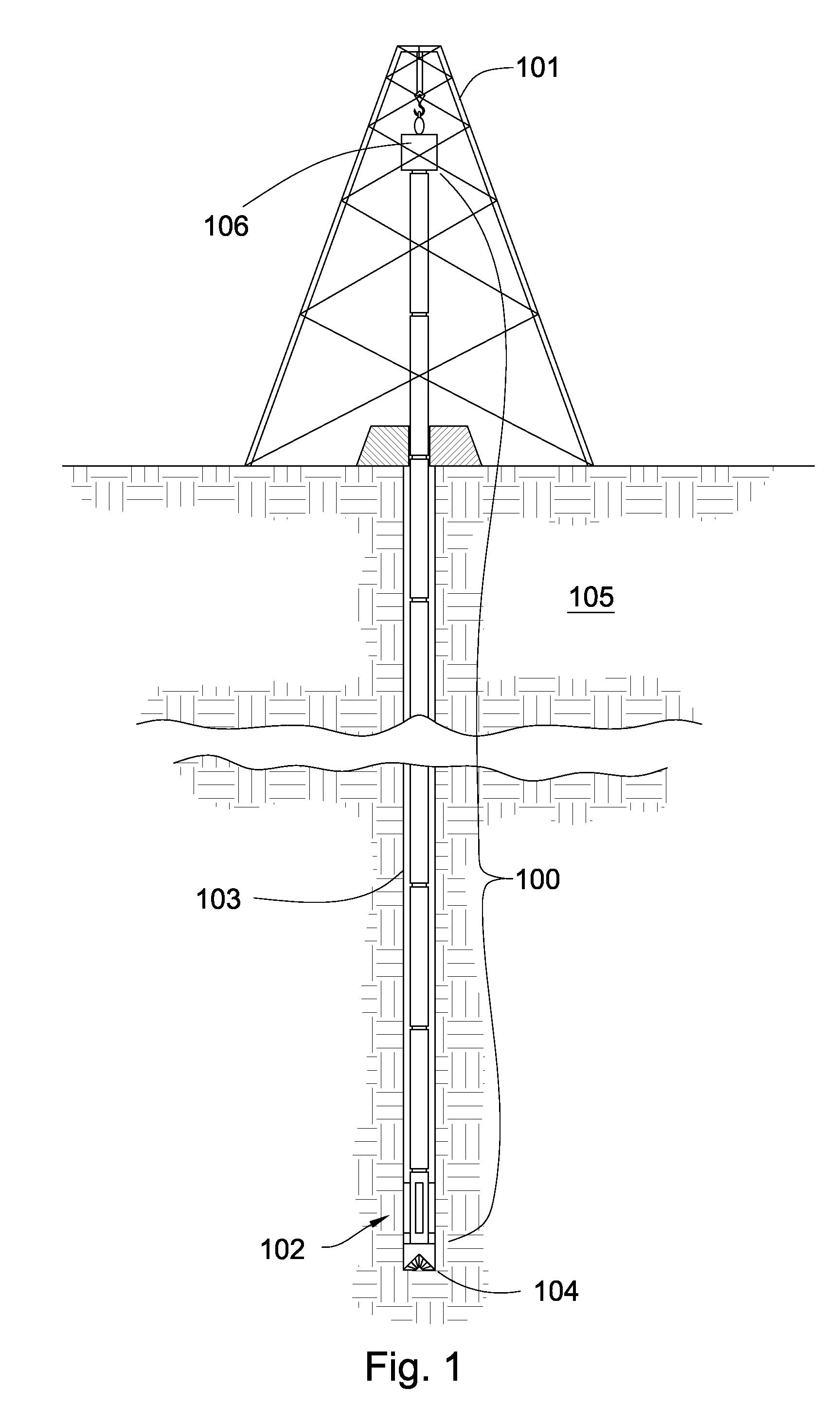

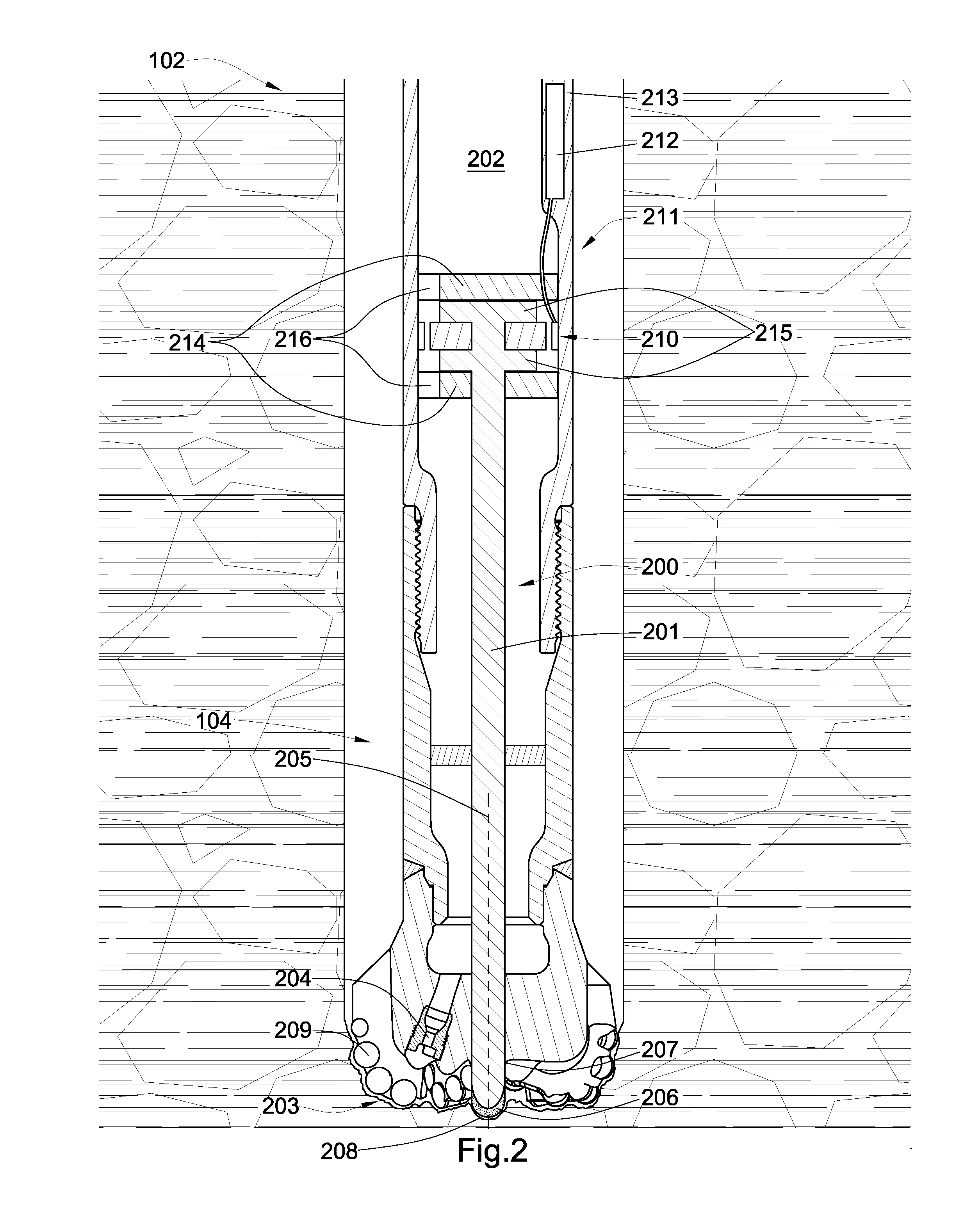

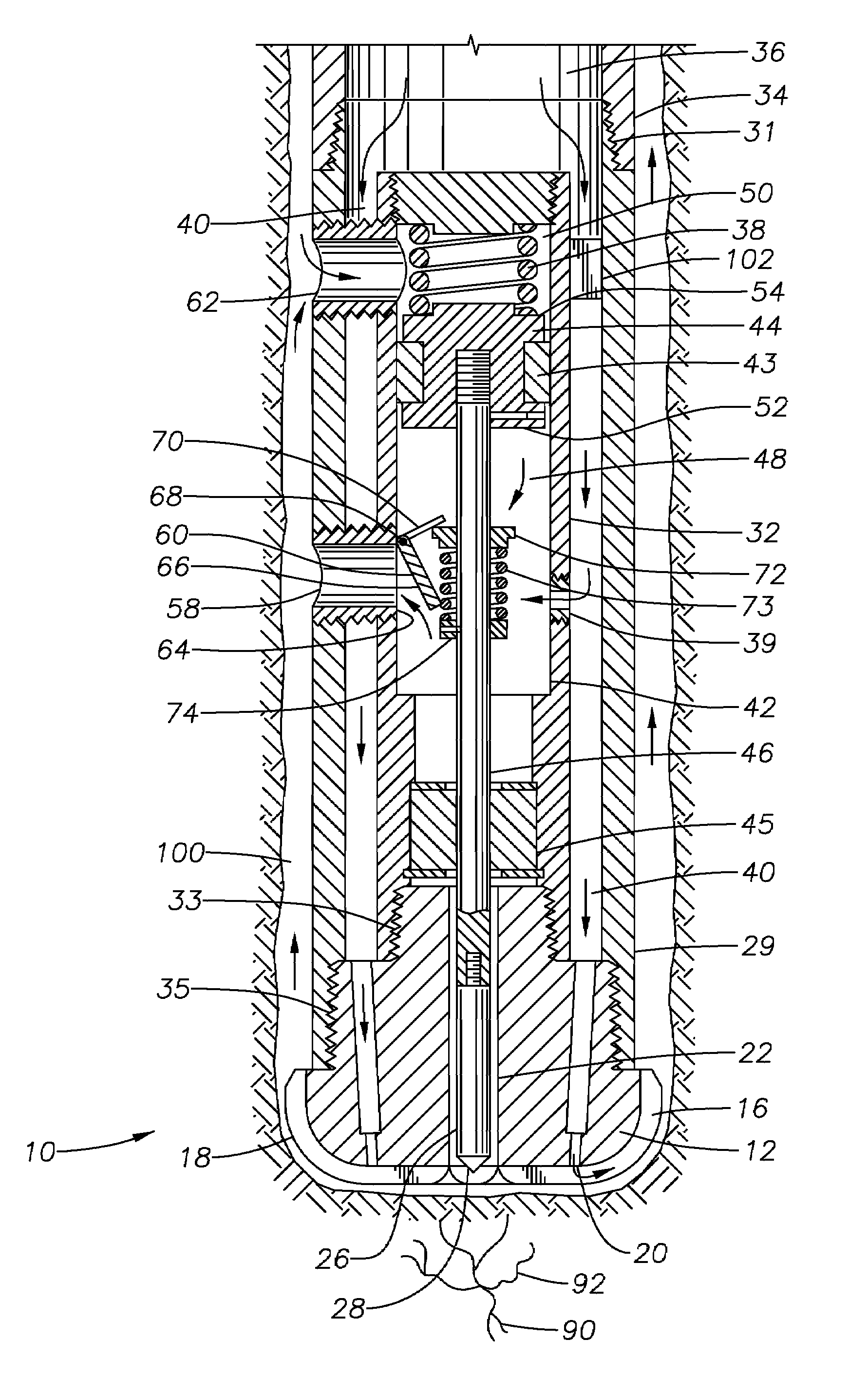

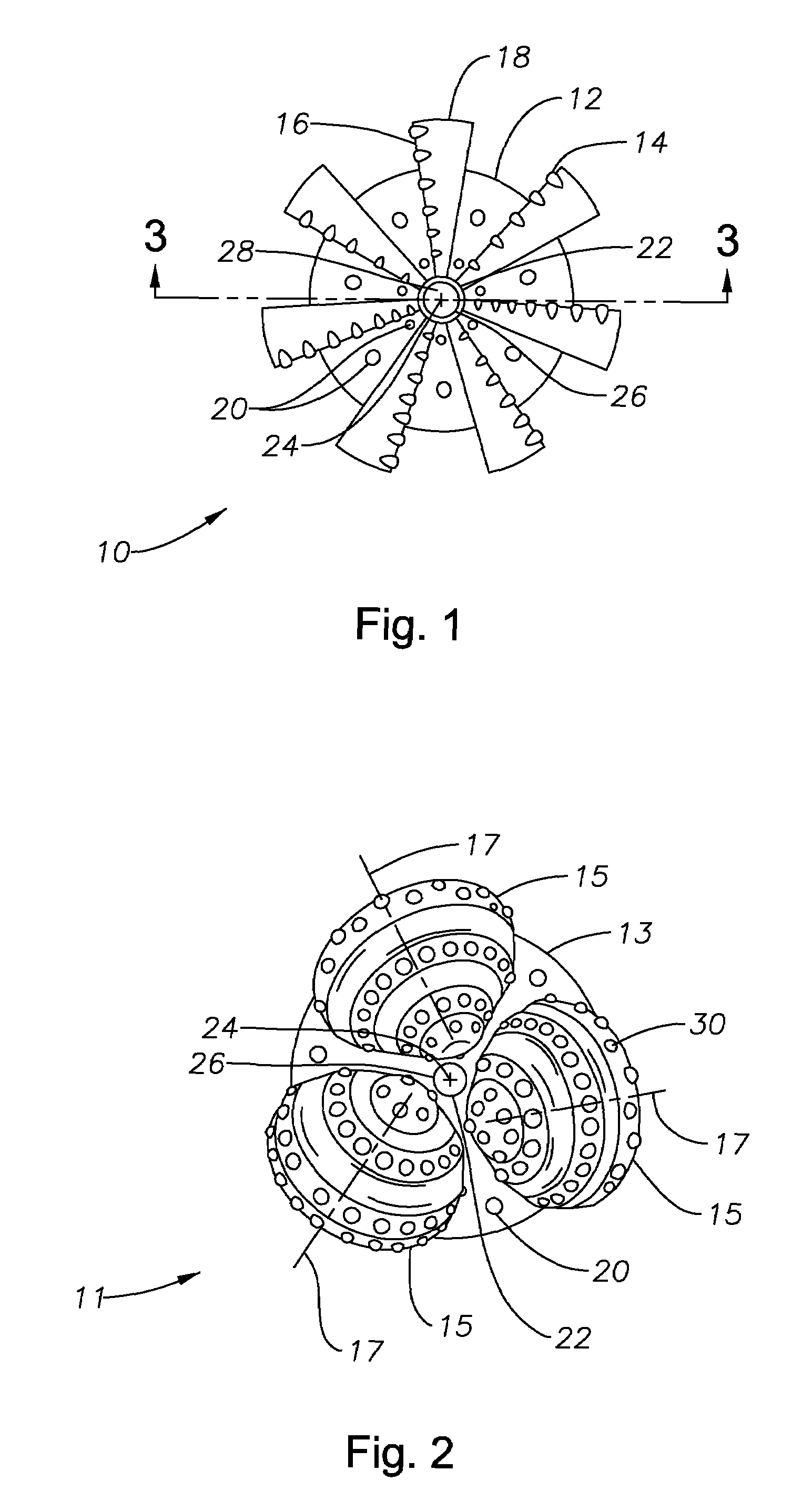

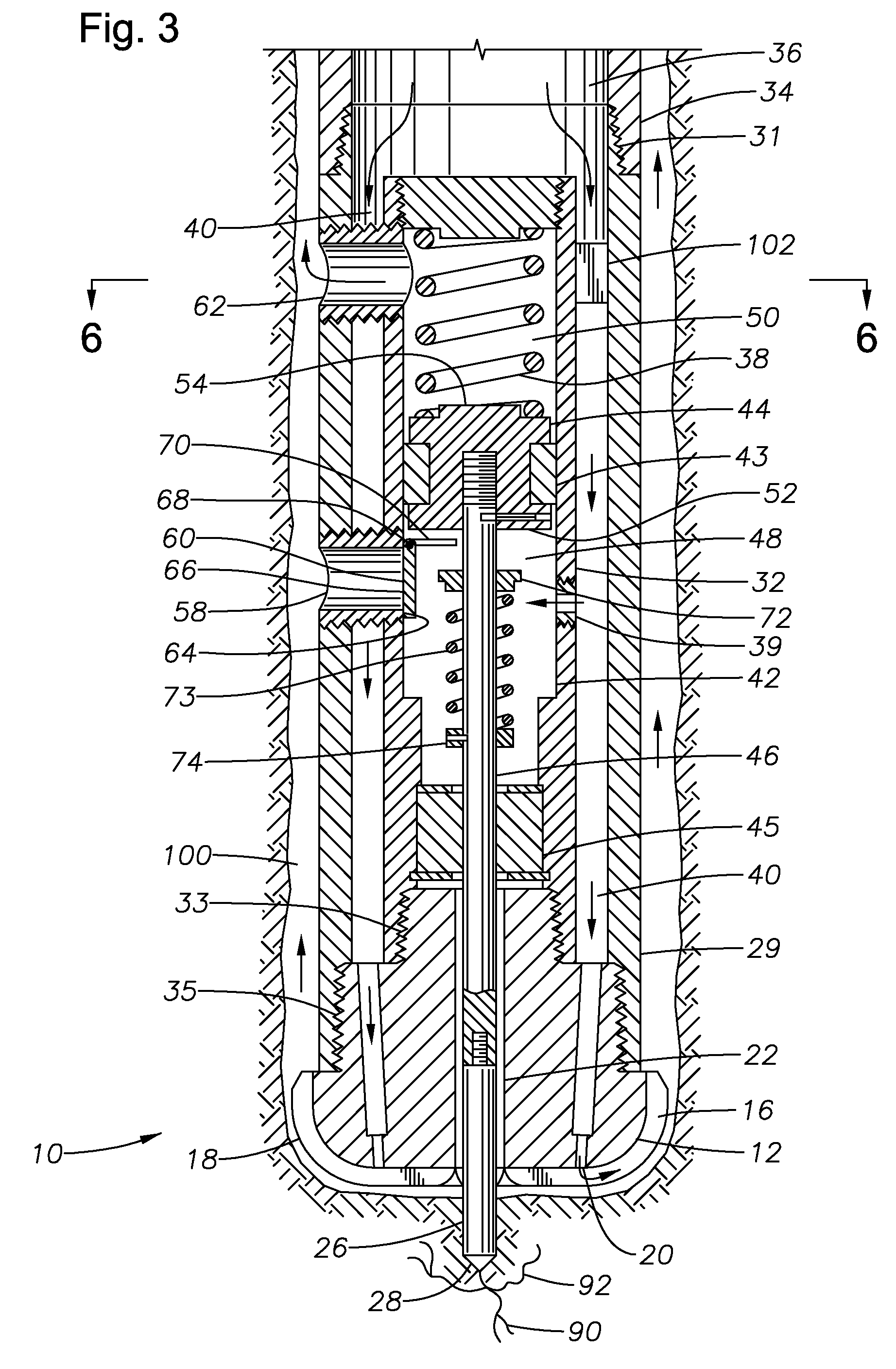

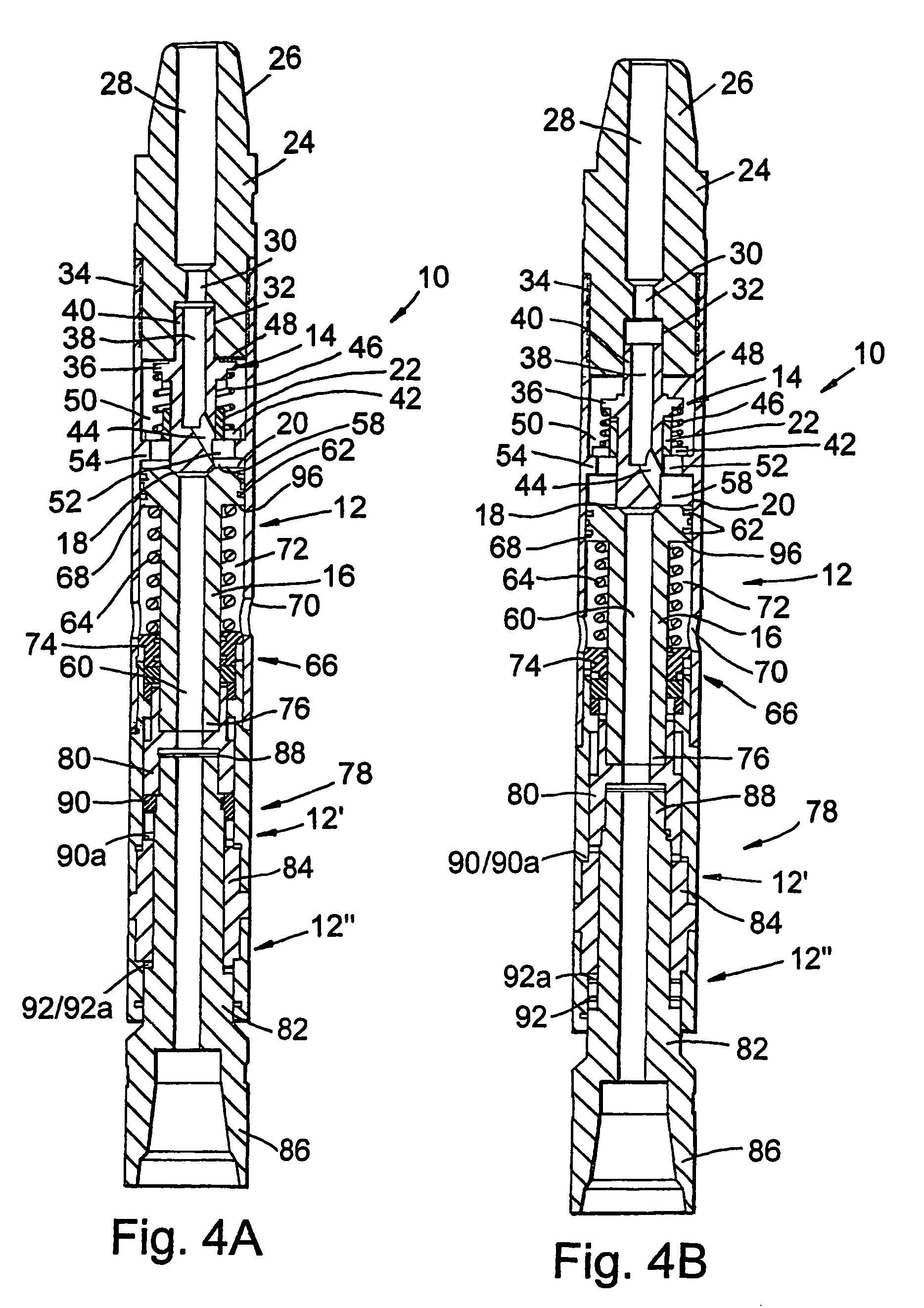

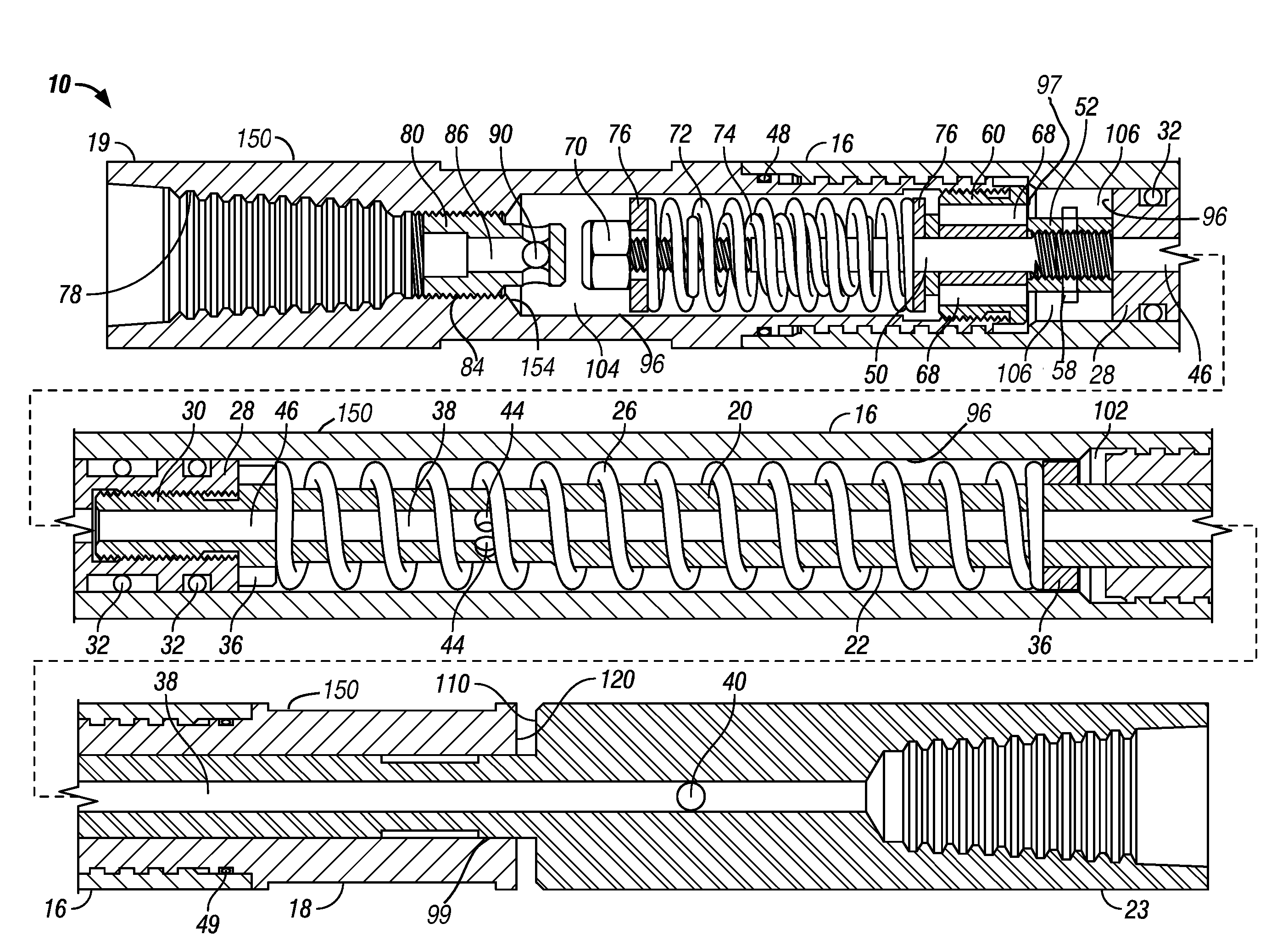

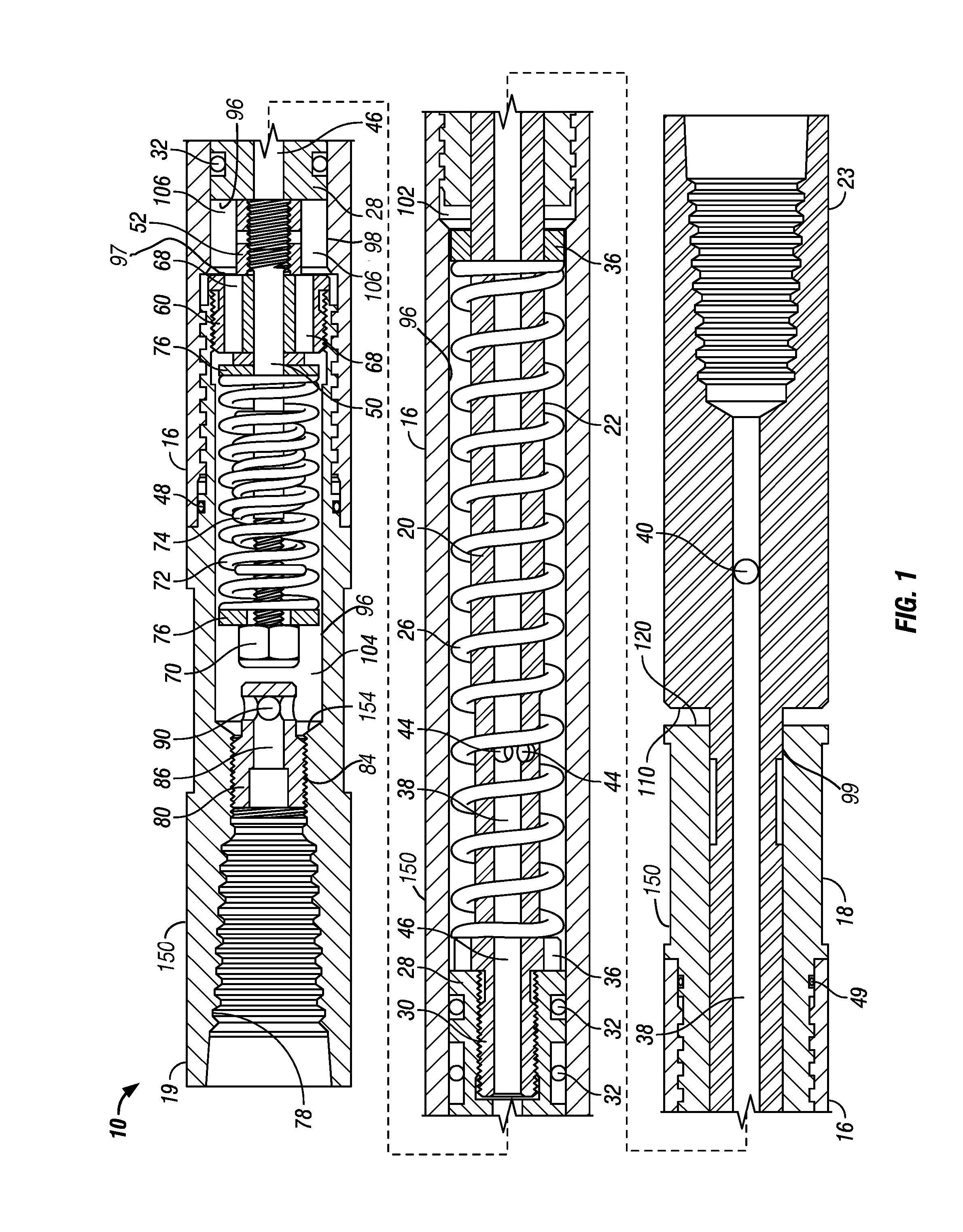

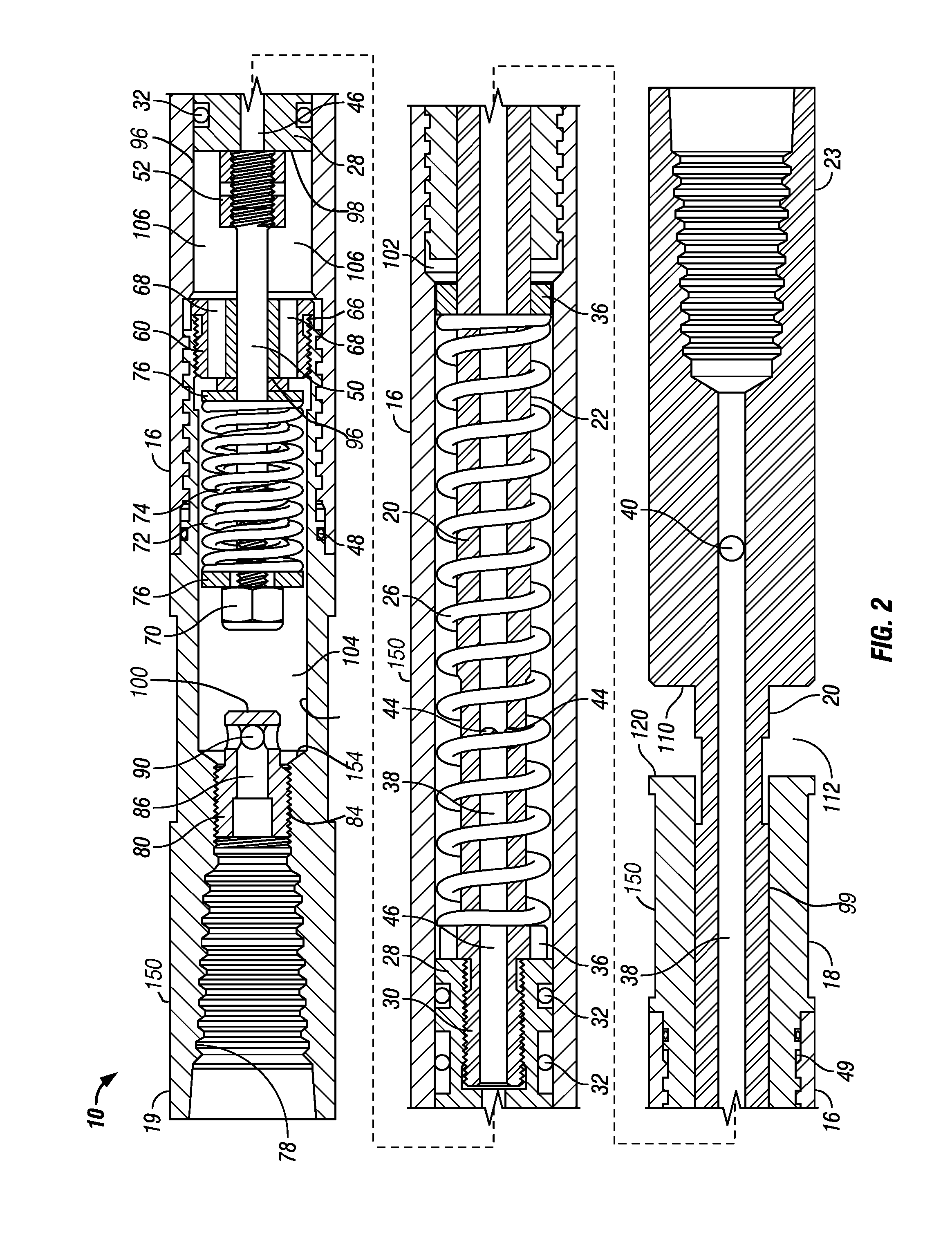

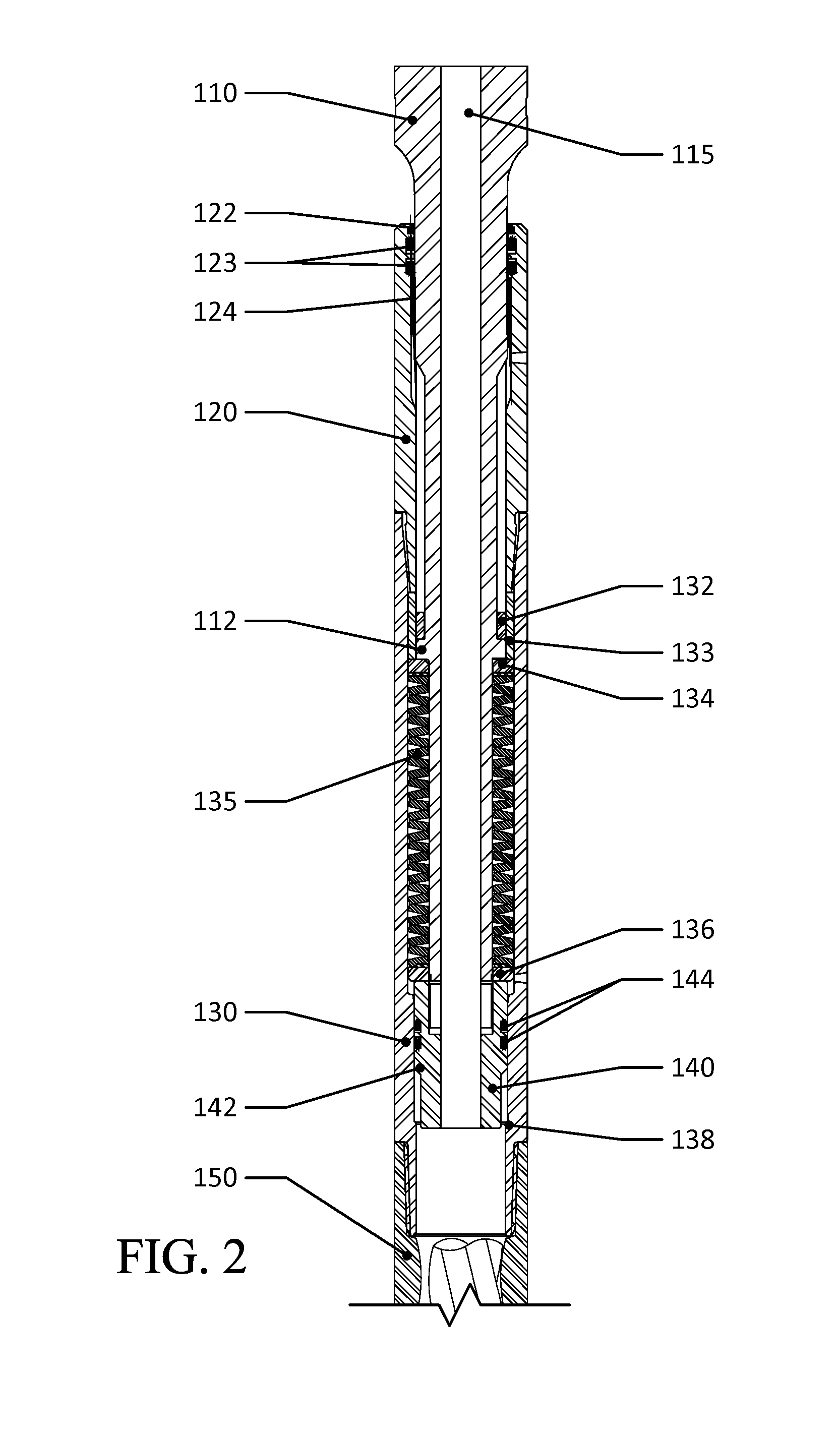

Rotary and mud-powered percussive drill bit assembly and method

InactiveUS7240744B1Increase drilling speedBest penetration rateDrill bitsConstructionsEnergy transferStored energy

A method and apparatus for boring a hole in the earth including a drill bit assembly including a fluid-powered impact engine contained within a drillpipe sub between an ordinary drillpipe and a modified conventional rotary drill bit. The impact engine is powered by pressurized drilling fluid delivered via the drillpipe which acts on a piston to charge an energy accumulator, preferably in the form of a spring. Periodically, the pressurized drilling fluid in the impact engine is vented, allowing the energy accumulator to rapidly transfer its stored energy to an impact bit which is slidingly housed in a rotary bit to strike and fracture the formation.

Owner:ENERGY TECH GROUP

Jack element in communication with an electric motor and or generator

A drill bit has a body intermediate a shank and a working face and has an axis of rotation. The working face has at least one cutting element and the body has at least a portion of a jack assembly. The jack assembly has at least a portion of a shaft disposed within a cavity formed in the body of the drill bit, the shaft having a distal end extending from an opening of the cavity formed in the working face. The jack assembly also has an electric motor and / or generator.

Owner:SCHLUMBERGER TECH CORP

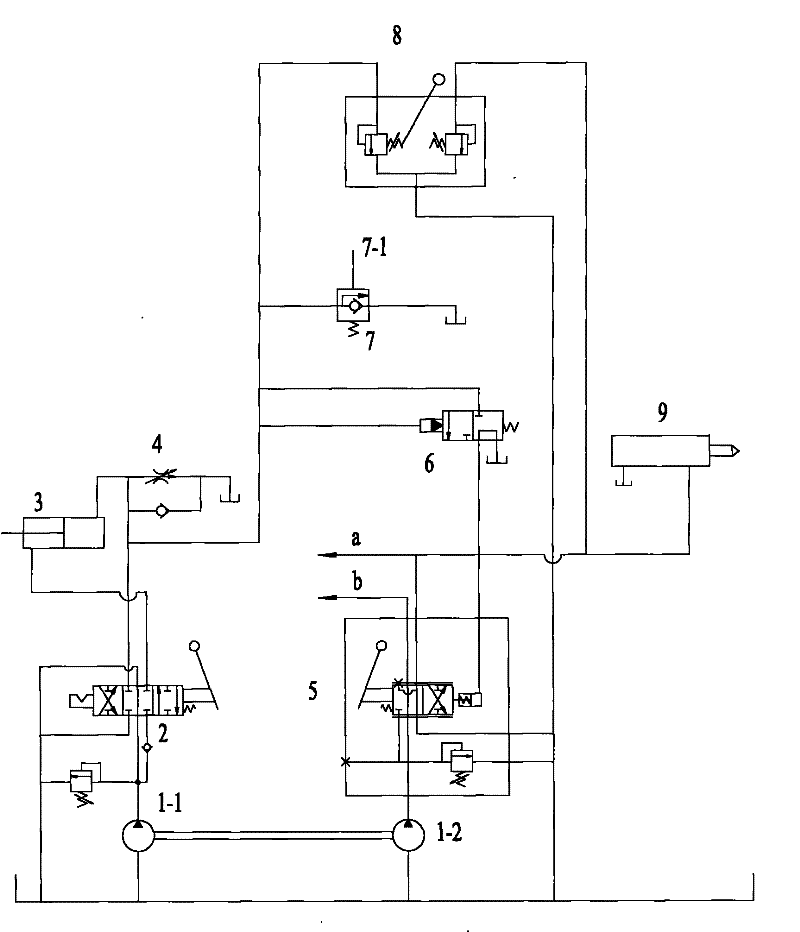

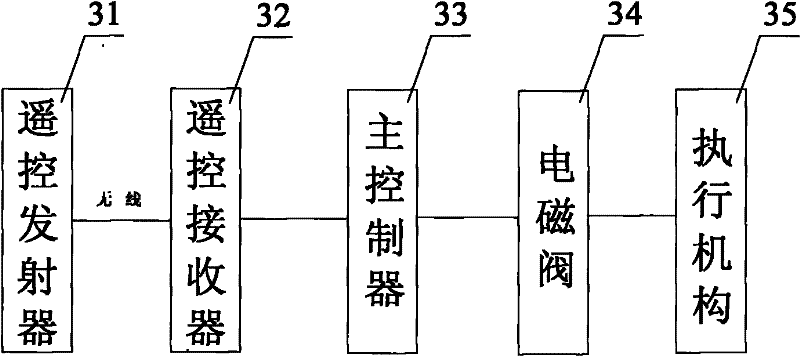

Hydraulic control loop used for jackdrill and control system thereof

InactiveCN101748969AReduce manufacturing costReduce labor intensityServomotorsDrilling drivesPunchingControl system

The invention relates to the technical field of jackdrill and discloses a hydraulic control loop used for jackdrill and control system thereof. The hydraulic control loop used for jackdrill includes a hydraulic pump, a drill rod thrust cylinder, a drill rod spin motor, a solenoid directional valve, a directional valve, an unloading valve and a sequence valve. In the hydraulic control loop used for jackdrill provided by the invention, control valves needing controlling all adopt solenoid valves, and the reversing or flux control of the control valves can be realized by transmitting solenoid control signals to the solenoid valves, and the operation staff do not heed to directly operate the control valves; therefore, the work intensity of the operation staff is smaller, the control performance is good and the defect of inaccurate locating and punching of manual operation can be overcome. One hydraulic pump can simultaneously supply oil to the drill rod thrust cylinder and the jackdrill, can simultaneously implement two motions including boosting and drilling, thus reducing the manufacture cost of the jackdrill. The invention also provides a control system for hydraulic control loop used for jackdrill.

Owner:SANY HEAVY EQUIP

Downhole tool

InactiveUS7073610B2Improve efficiencyIncrease ratingsDrill bitsReciprocating drilling machinesShuttle valveMechanical engineering

A downhole tool for generating a longitudinal mechanical load. In one embodiment, a downhole hammer is disclosed which is activated by applying a load on the hammer and supplying pressurizing fluid to the hammer. The hammer includes a shuttle valve and piston that are moveable between first and further position, seal faces of the shuttle valve and piston being released when the valve and the piston are in their respective further positions, to allow fluid flow through the tool. When the seal is releasing, the piston impacts a remainder of the tool to generate mechanical load. The mechanical load is cyclical by repeated movements of the shuttle valve and piston.

Owner:ROTECH GROUP

Ultrasonic rotary-hammer drill

InactiveUS7740088B1Light weightConsume low amountDrill bitsPiezoelectric/electrostriction/magnetostriction machinesDrive shaftAcoustic wave

A mechanism for drilling or coring by a combination of sonic hammering and rotation. The drill includes a hammering section with a set of preload weights mounted atop a hammering actuator and an axial passage through the hammering section. In addition, a rotary section includes a motor coupled to a drive shaft that traverses the axial passage through the hammering section. A drill bit is coupled to the drive shaft for drilling by a combination of sonic hammering and rotation. The drill bit includes a fluted shaft leading to a distal crown cutter with teeth. The bit penetrates sampled media by repeated hammering action. In addition, the bit is rotated. As it rotates the fluted bit carries powdered cuttings helically upward along the side of the bit to the surface.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE

Jet Hammer

ActiveUS20090301744A1Less compressibleReciprocating drilling machinesConstructionsCompressibilityEngineering

An exemplary embodiment of the jet hammer includes an outer sleeve, impact assembly, and a valve assembly. The impact assembly is positioned in sliding relation to the outer sleeve to provide the impact of the jet hammer. The valve assembly generally comprises a cap screw, adjustment sleeve, valve port, inner compression spring, outer compression spring, and lock nut. The inner compression spring is relatively less compressible than the outer compression spring. In operation, fluid enters the valve assembly and acts on the compression springs forming an operational seal between the valve assembly and the impact assembly. In response, the outer sleeve is slidingly displaced from the impact assembly thereby compressing a main compression spring positioned along the mandrel shaft. Once the pressure acting on the valve assembly is released, the main compression spring decompresses forcefully causing the outer sleeve to impact a connection port, bit, tool, or other member attached to the upper end of the mandrel. This impact is translated onto the obstruction or item to be struck. The impact assembly may also be capable of rotational movement with respect to the outer sleeve wherein the mandrel shaft may contain at least one rotation nozzle thereon. The rotation nozzles allow for fluid communication from the mandrel's internal bore, through the nozzles, and against the proximate inner wall of the outer sleeve. This interaction causes the mandrel, and by connection the connection port, bit, tubing, or tool attached thereto, to rotate during the downward stroke of the hammer. Rotation nozzles may be located on the connection port and / or bit for additional rotational force.

Owner:SWINFORD JASON L +1

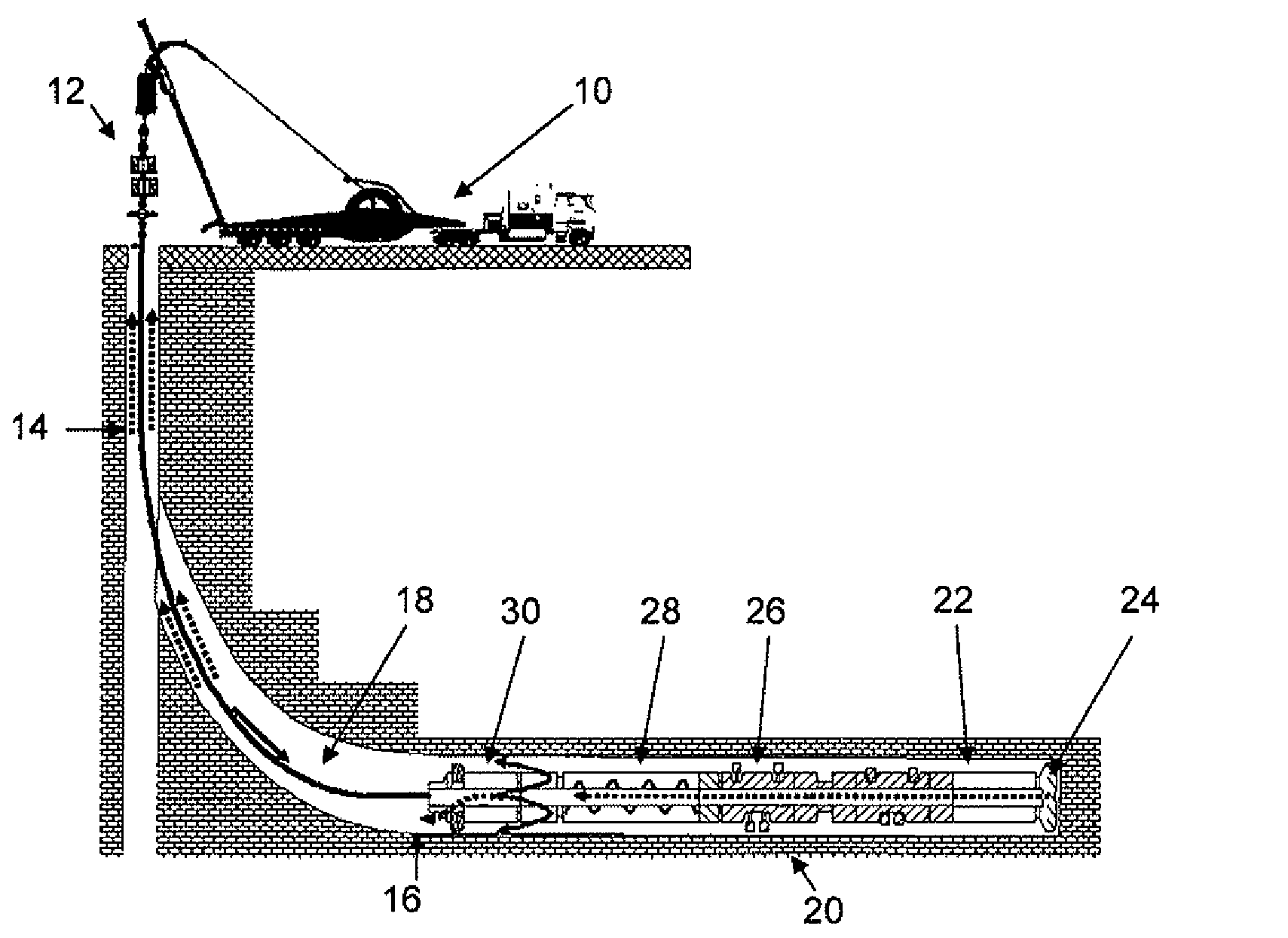

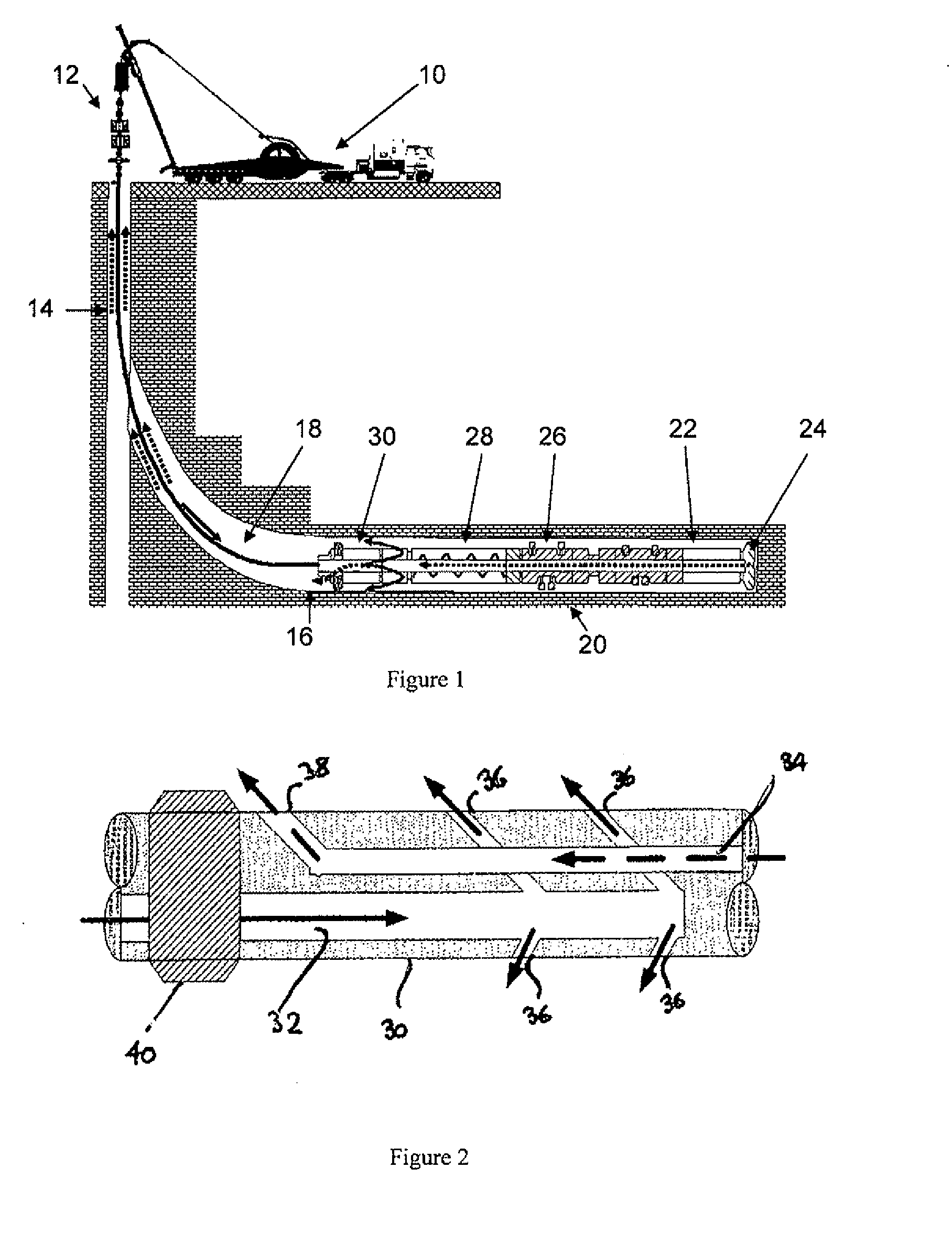

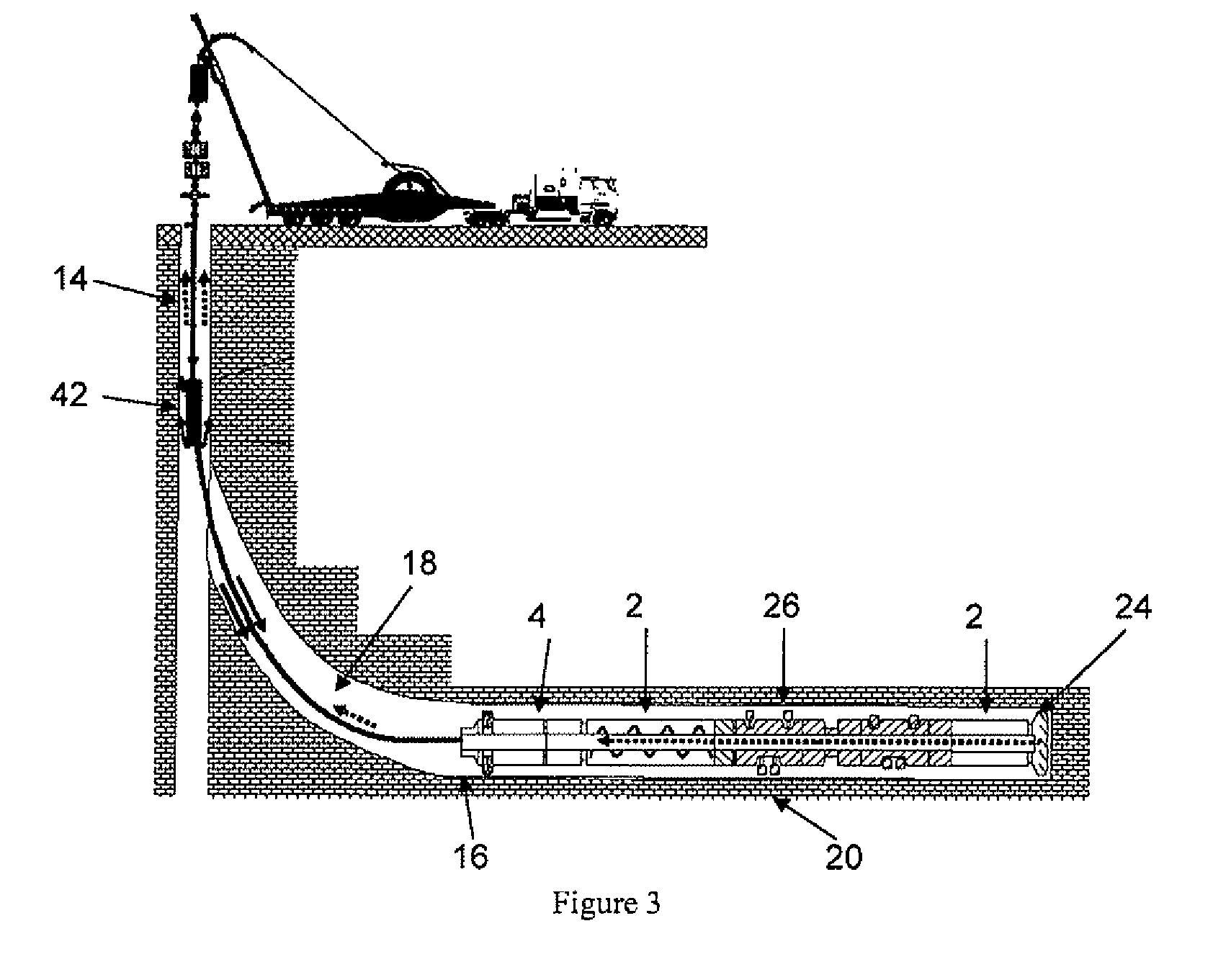

Methods and Apparatus for Wireline Drilling On Coiled Tubing

InactiveUS20090321141A1Improved cutting transportReduce riskDrilling rodsLiquid/gas jet drillingWell drillingElectric machine

Apparatus for drilling an underground borehole, comprising:a tubular conveyance system (18) including an electric cable and a supply of drilling fluid, the supply of drilling fluid being arranged in use to pump fluid from the surface down the inside of the tubular conveyance so as to return to the surface via the annulus between the outside of the tubular conveyance and the borehole;a drilling system comprising an electrically powered pump and a drilling motor, the pump being arranged in use to pump fluid from the borehole outside the drilling system up through the inside of the drilling system;a connector connecting the drilling system to the tubular conveyance system (18), through which the pump and motor are connected to the electric cable, anda flow diverter at which flow down the inside of the tubular conveyance system (18) is diverted into the annulus, and flow up the inside of the drilling system is diverted into the annulus.

Owner:SCHLUMBERGER TECH CORP

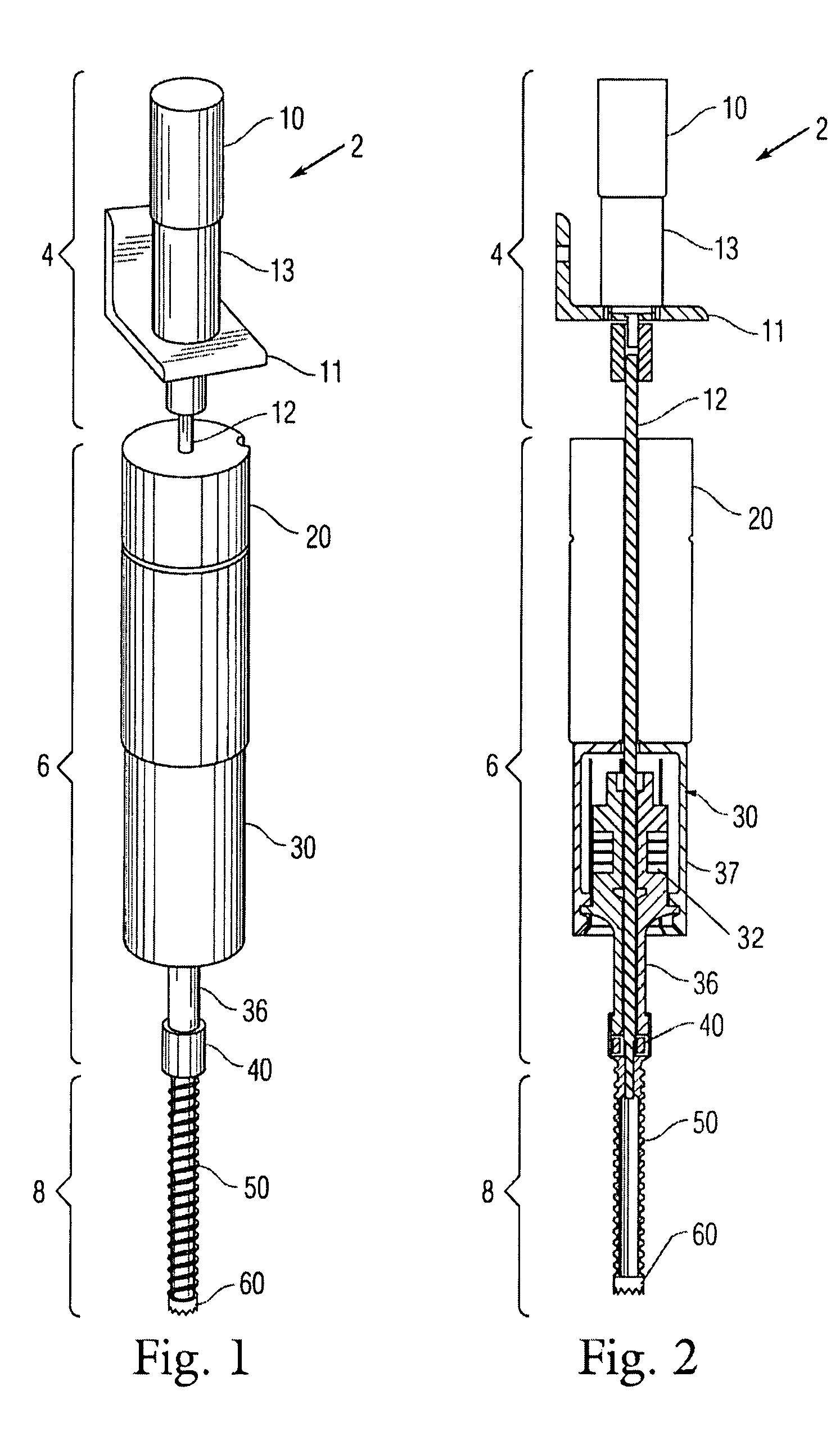

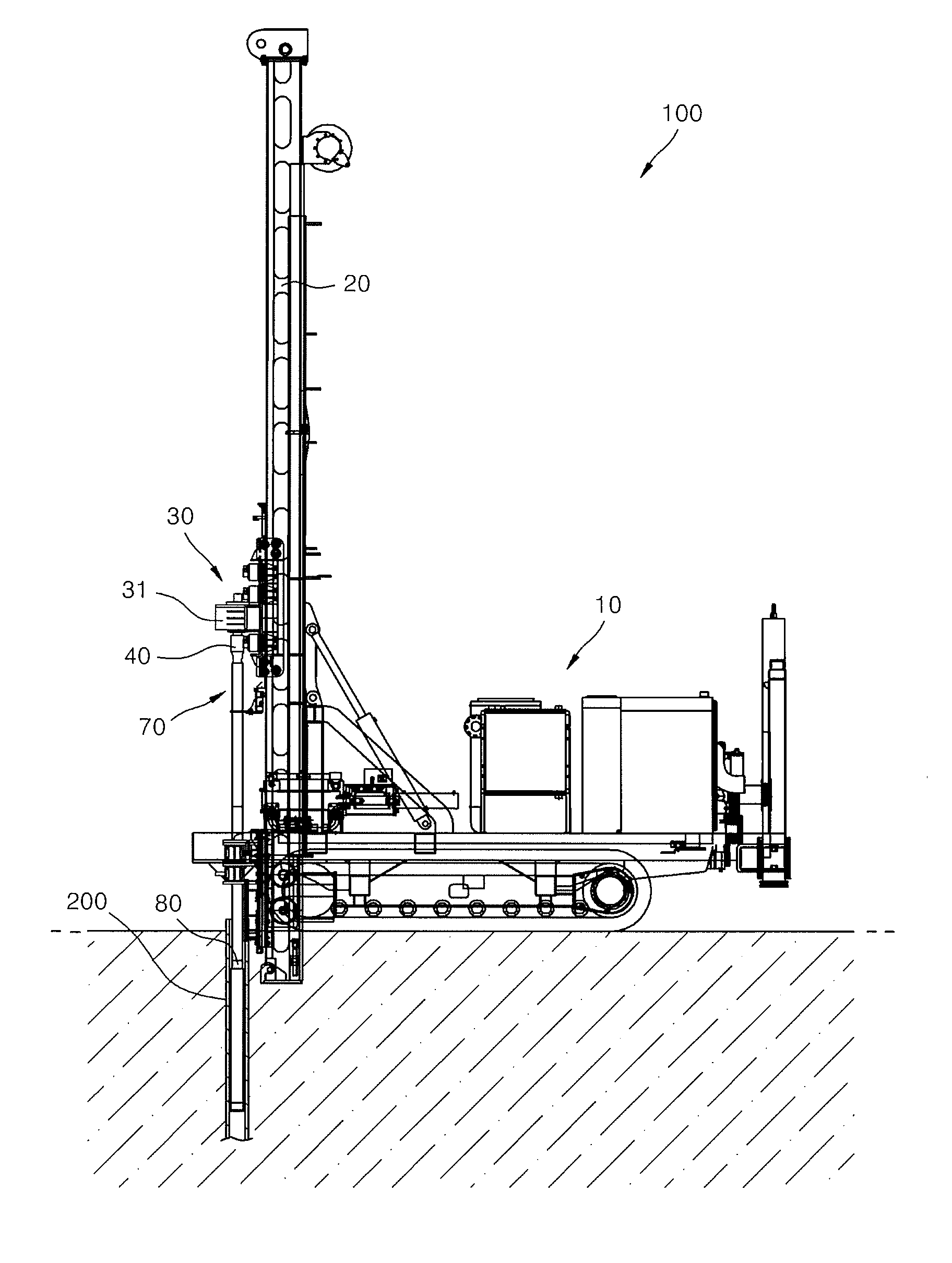

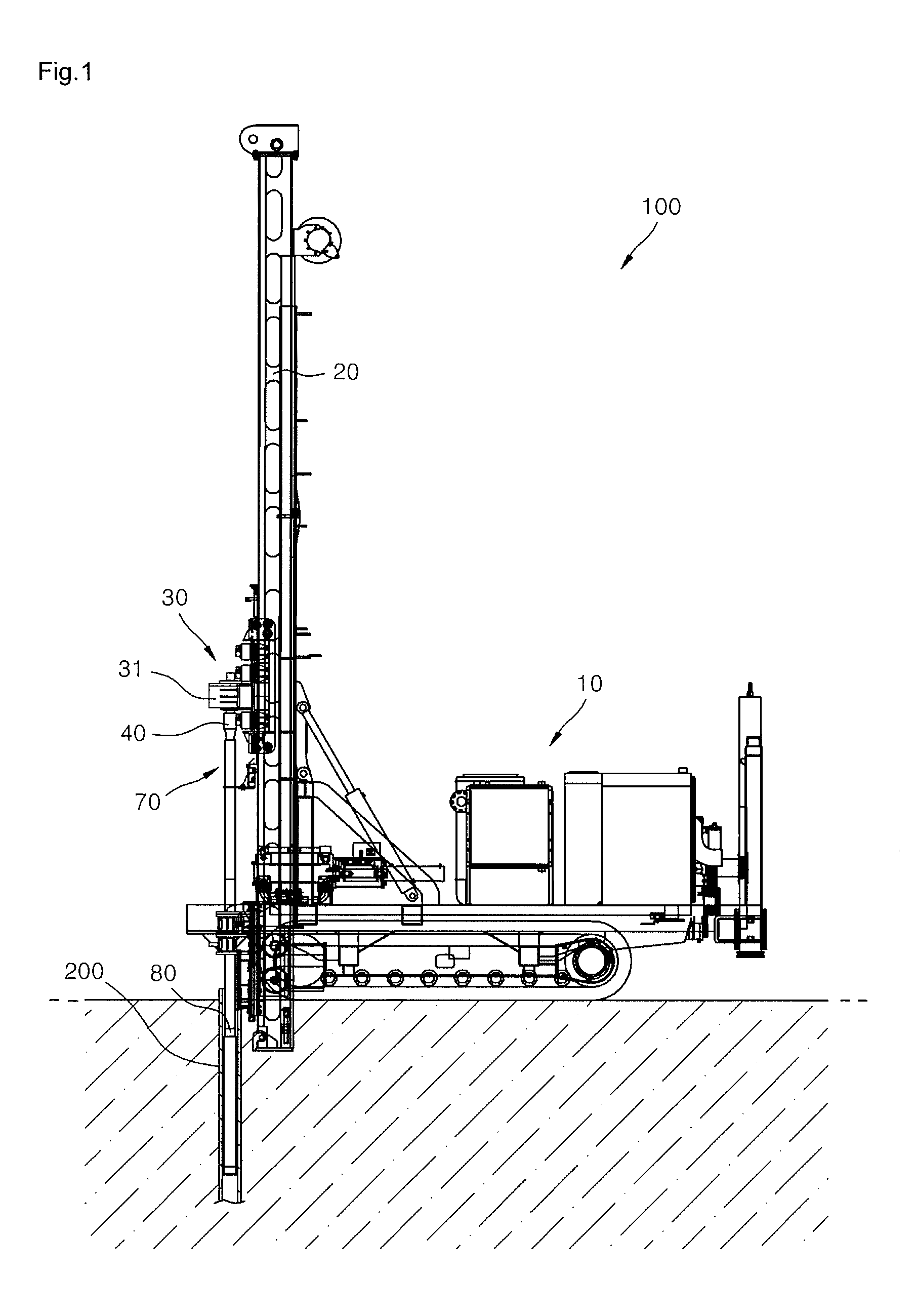

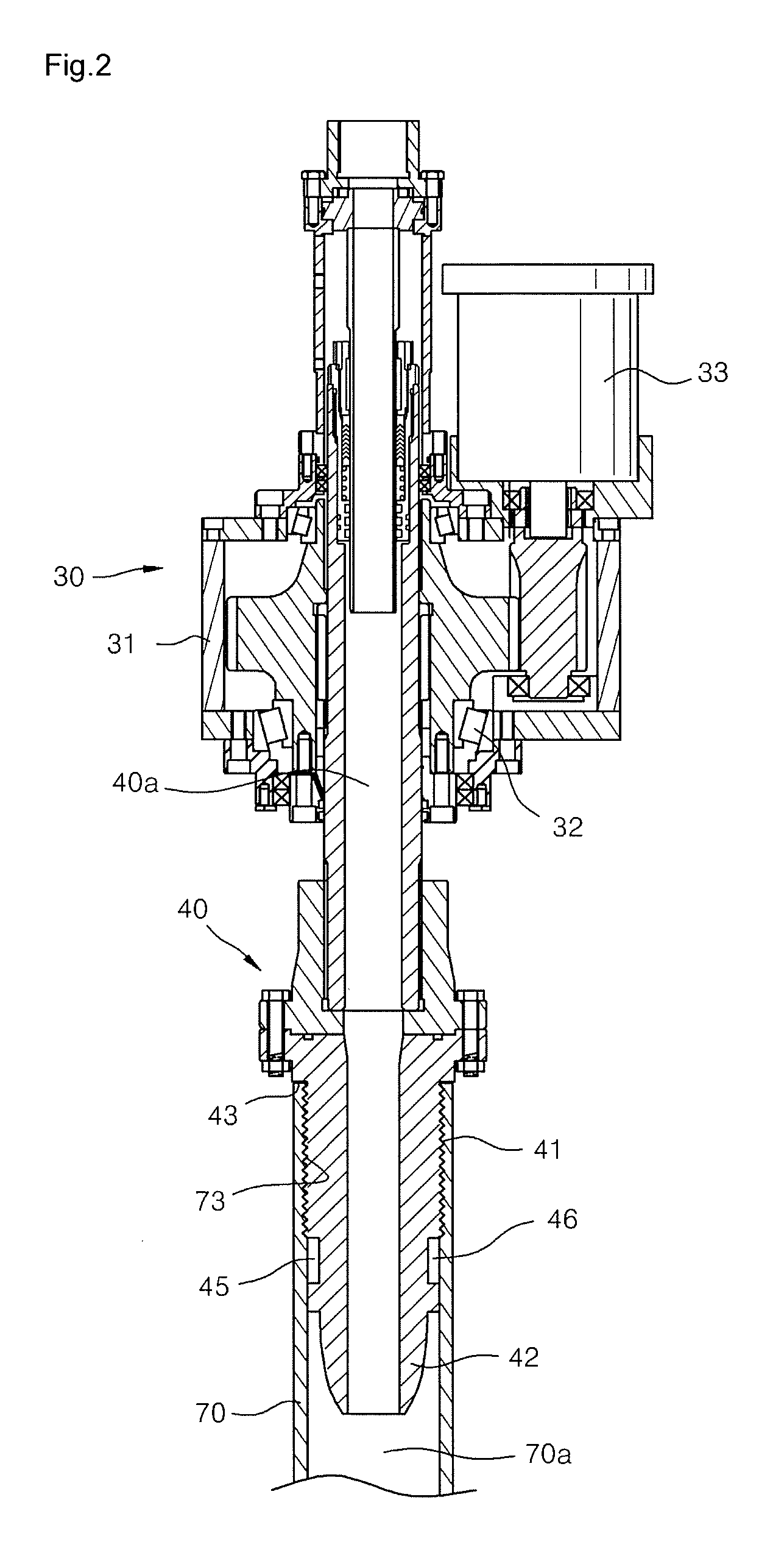

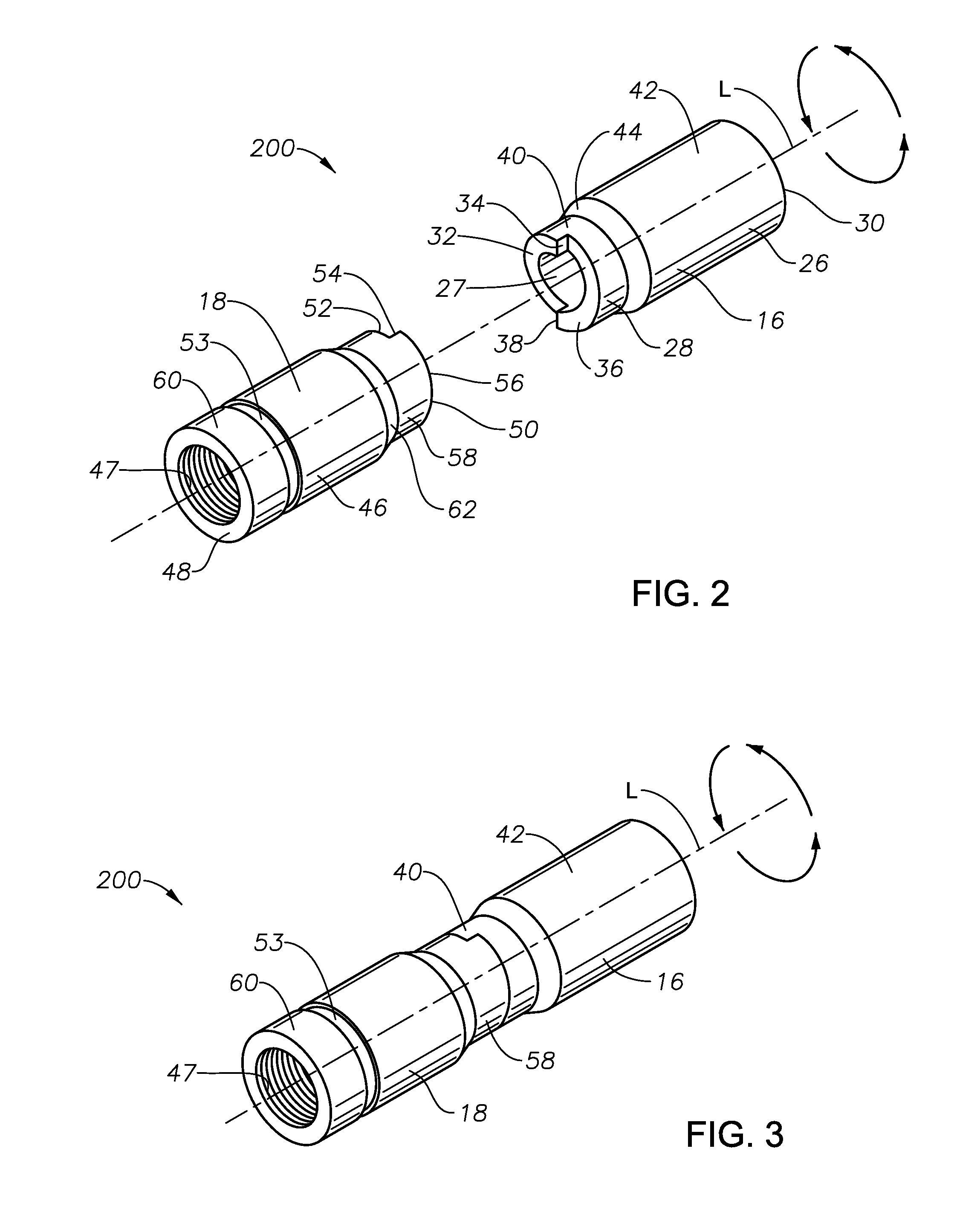

Drilling apparatus having head

InactiveUS20130233624A1Easy to engageImprove efficiencyDrilling rodsConstructionsDrive shaftCoupling

Disclosed is a drilling apparatus having a head. The drilling apparatus includes a main body, a lead supported by the main body of the drilling apparatus, a driving shaft slidably installed in the lead and having a unit rod connected thereto for performing a drilling work, and a head having an actuator for driving the driving shaft, wherein the driving shaft includes a screw coupling part formed on the outer circumferential surface of the driving shaft and screw-coupled with an end of the unit rod for performing the drilling work, and a screw coupling inducing part formed at a front end of the screw coupling part to induce screw coupling between the driving shaft and a rod screw coupling part formed at a hollow part formed at the end of the unit rod. The drilling apparatus can reduce the number of work numbers by combining the unit rod with the driving shaft, thereby increasing the efficiency of the drilling work.

Owner:IN SUK SHIN

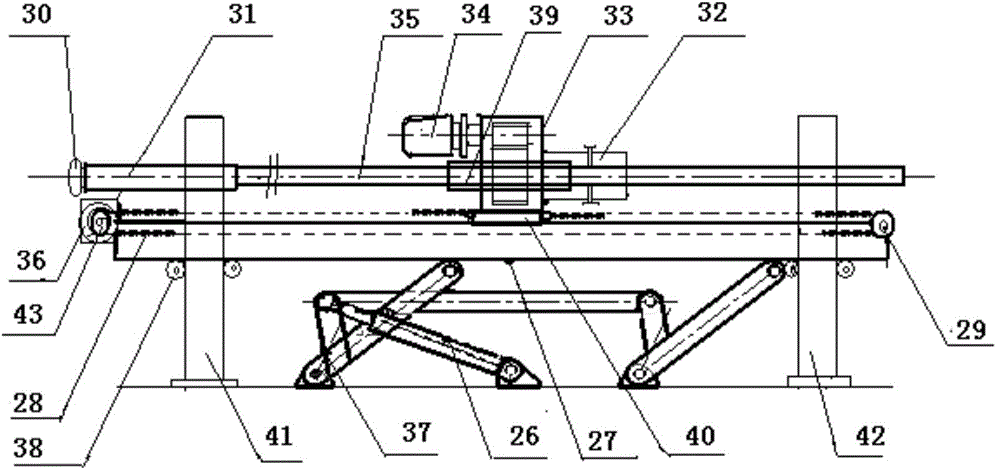

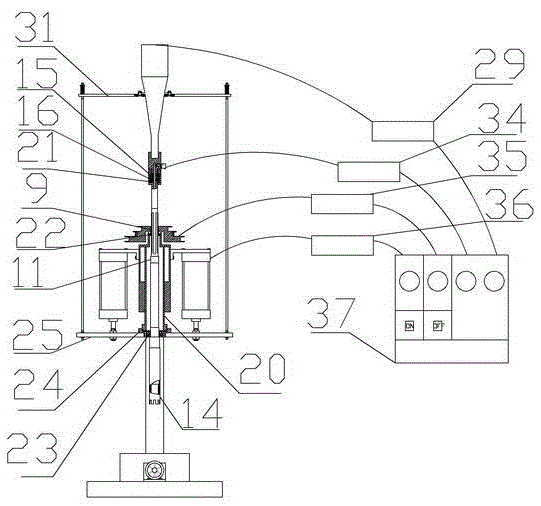

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

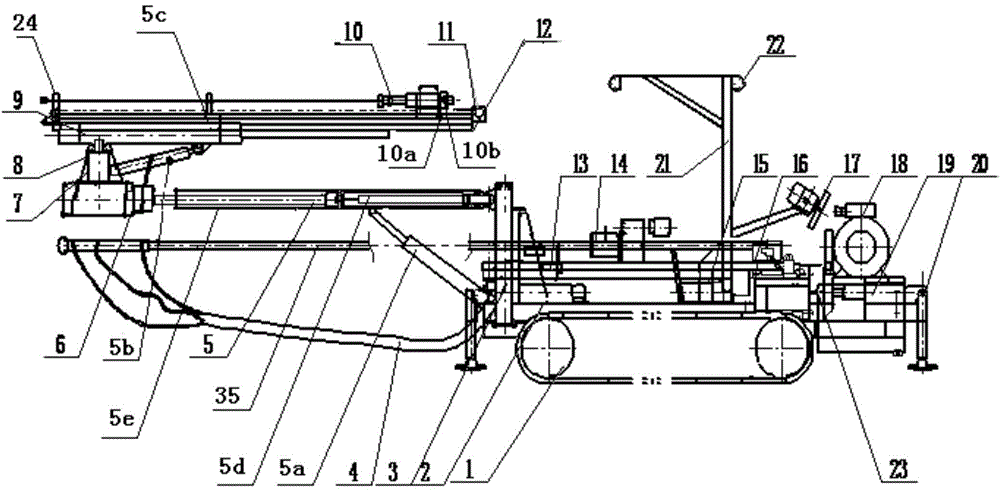

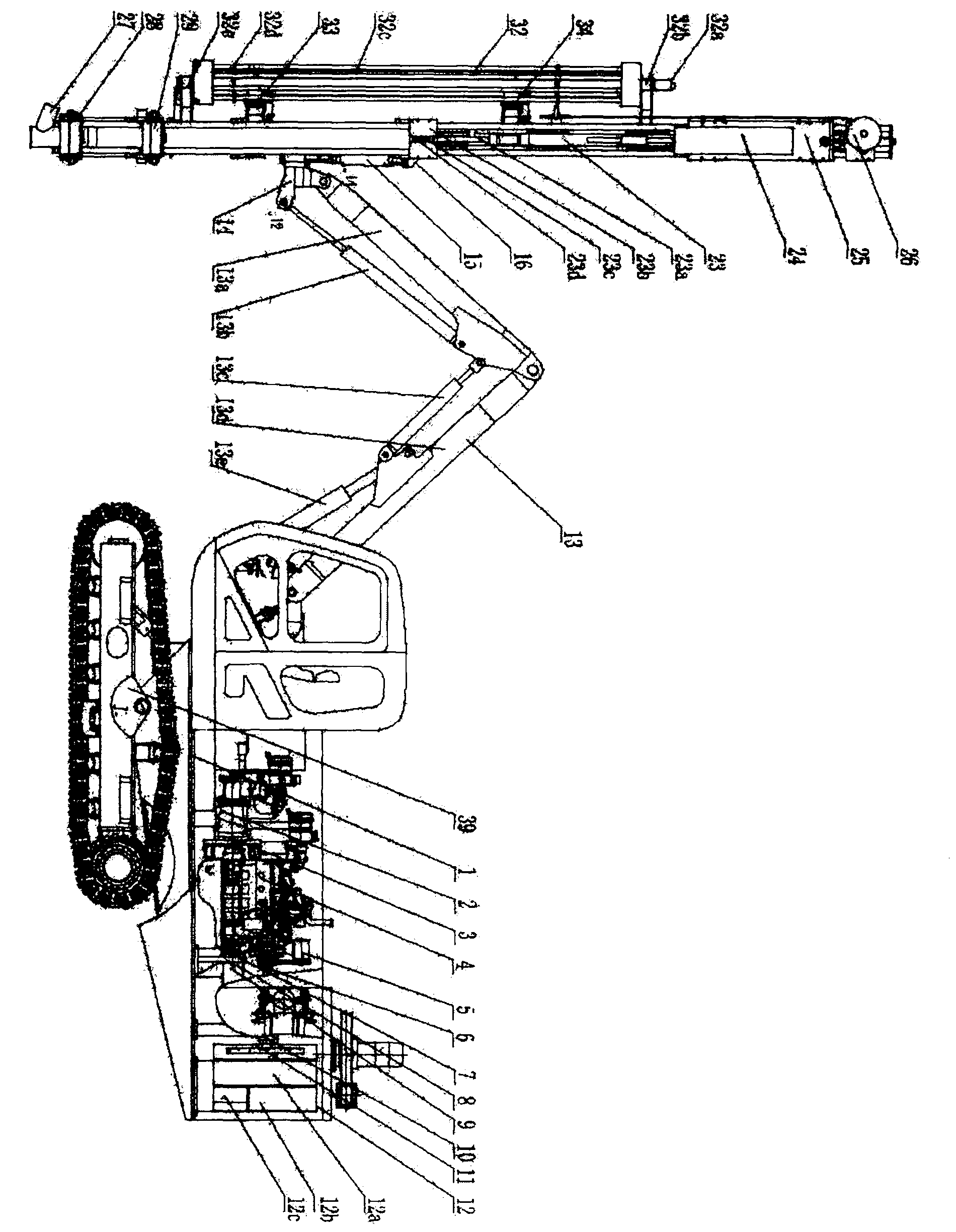

Whole-section quick-drilling drill carriage for parallel cut blasting of large empty holes in roadway

ActiveCN104612586ACompact chassisCompact structureDerricks/mastsDrilling drivesHydraulic motorReducer

The invention discloses a whole-section quick-drilling drill carriage specially used for parallel cut blasting of large empty holes in a roadway. The drill carriage is composed of a walking mechanism, a carriage frame, a hydraulic system, an electrical system and two drilling devices, wherein the first drilling device is used for drilling common blasting holes, and the second drilling device is used for drilling cut holes with the diameter of 100 mm or more. In the operating process of the drill carriage, a hydraulic motor drives a main chain wheel of a crawler-type walking chassis to rotate through a speed reducer; after a carriage body is stabilized, the first drilling device and the second drilling device are manipulated to select hole locations respectively; after the first drilling device and the second drilling device are located, the common blasting holes and the empty holes with the diameter of 100 mm or more can be drilled in rock simultaneously. The drill carriage is suitable for the roadway with the minimum section of 8 square meters and the maximum section of 23 square meters; by the adoption of a building block structural design, the drill carriage is convenient and fast to disassemble and assemble and convenient to transport; as a result, the drill carriage can be used when the length of the roadway under tunneling construction is seven meters or more, and accelerates tunneling mechanization and quick and efficient tunneling modernization.

Owner:SHANDONG UNIV OF SCI & TECH +1

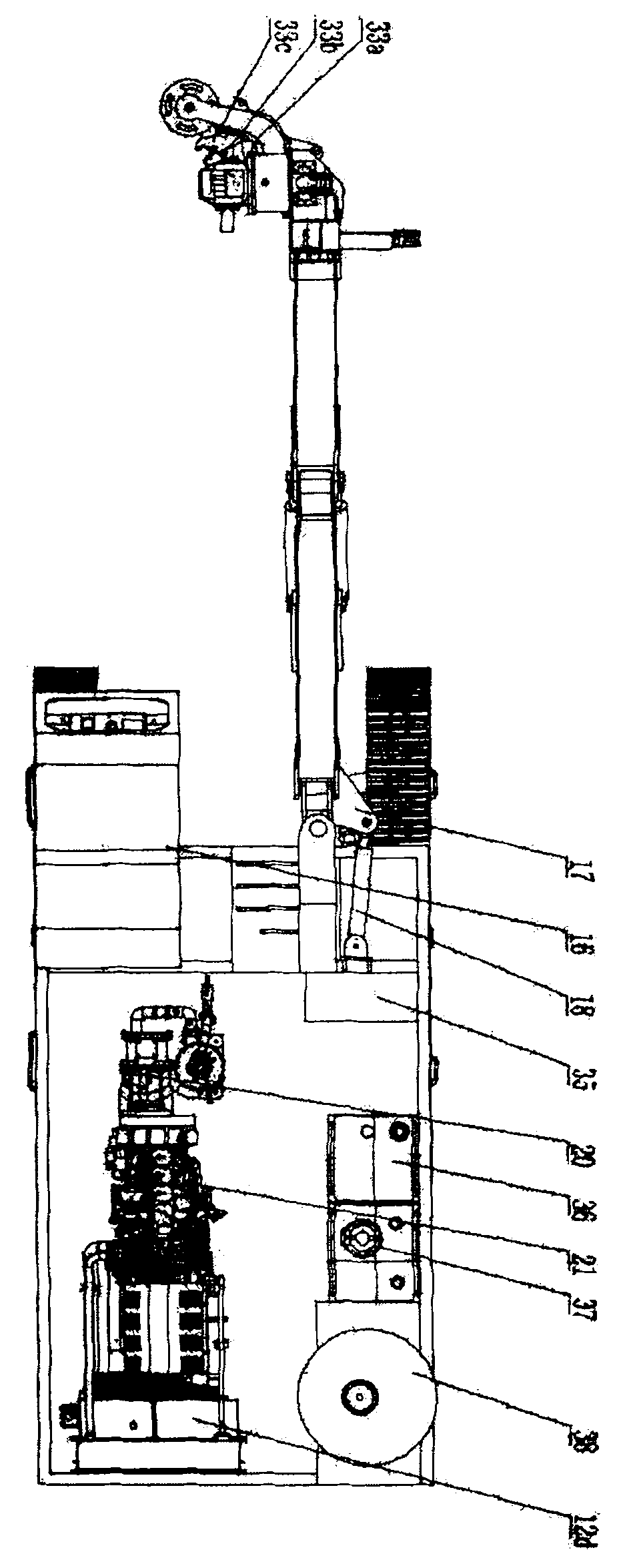

Multidirectional hydraulic rock drilling machine with integrated drives

InactiveCN102003143ACompact structureImprove energy efficiencyDrilling rodsDerricks/mastsElectronic control systemControl system

The invention relates to a multidirectional hydraulic rock drilling machine with integrated drives, and discloses multidirectional hydraulic rock drilling equipment with the integrated drives, which is composed of a rack, a drilling mechanism, a rod breaker mechanism, a drill hole angle adjustment mechanism, a crawler-type walking mechanism, an air compressor, an engine, a hydraulic system, an electronic control system, a dust removing system and the like, wherein, the crawler-type walking mechanism of a track frame the angle of which can be oscillated and is arranged below the rack; the air compressor, a hydraulic control system, an electrical apparatus control system, a power system and the dust removing system are arranged on the rack; the right front end of the rack is provided with afolded arm rack or a flexible arm rack; the front end of the arm rack is provided with a rotary head and the drilling mechanism; and the rod breaker mechanism, a pipe reeling mechanism, a propelling mechanism and a hydraulic rock drilling machine are arranged on a drilling rack of the drilling mechanism. The multidirectional hydraulic rock drilling machine integrating drive of the invention integrates the drives, can drill holes in multidirection, simultaneously has low energy consumption, high efficiency, compact structure and light and flexible operation, and is simple and convenient for maintenance.

Owner:吴亦舟

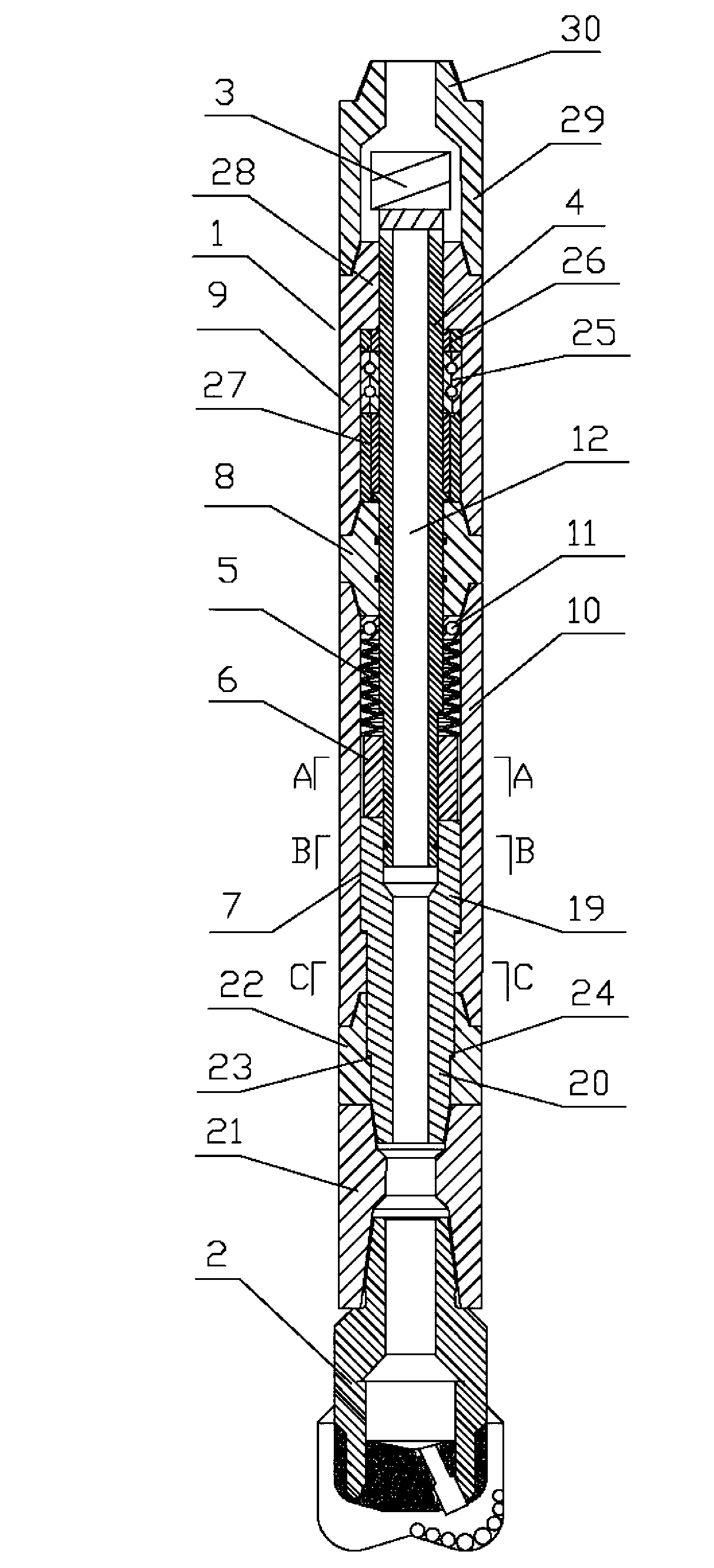

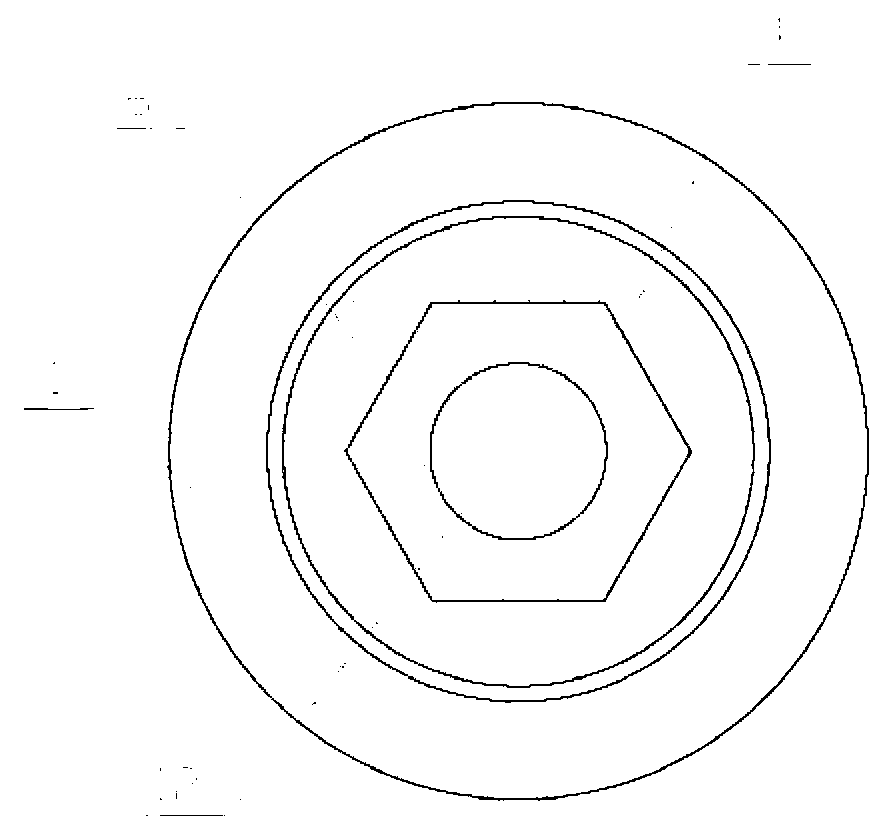

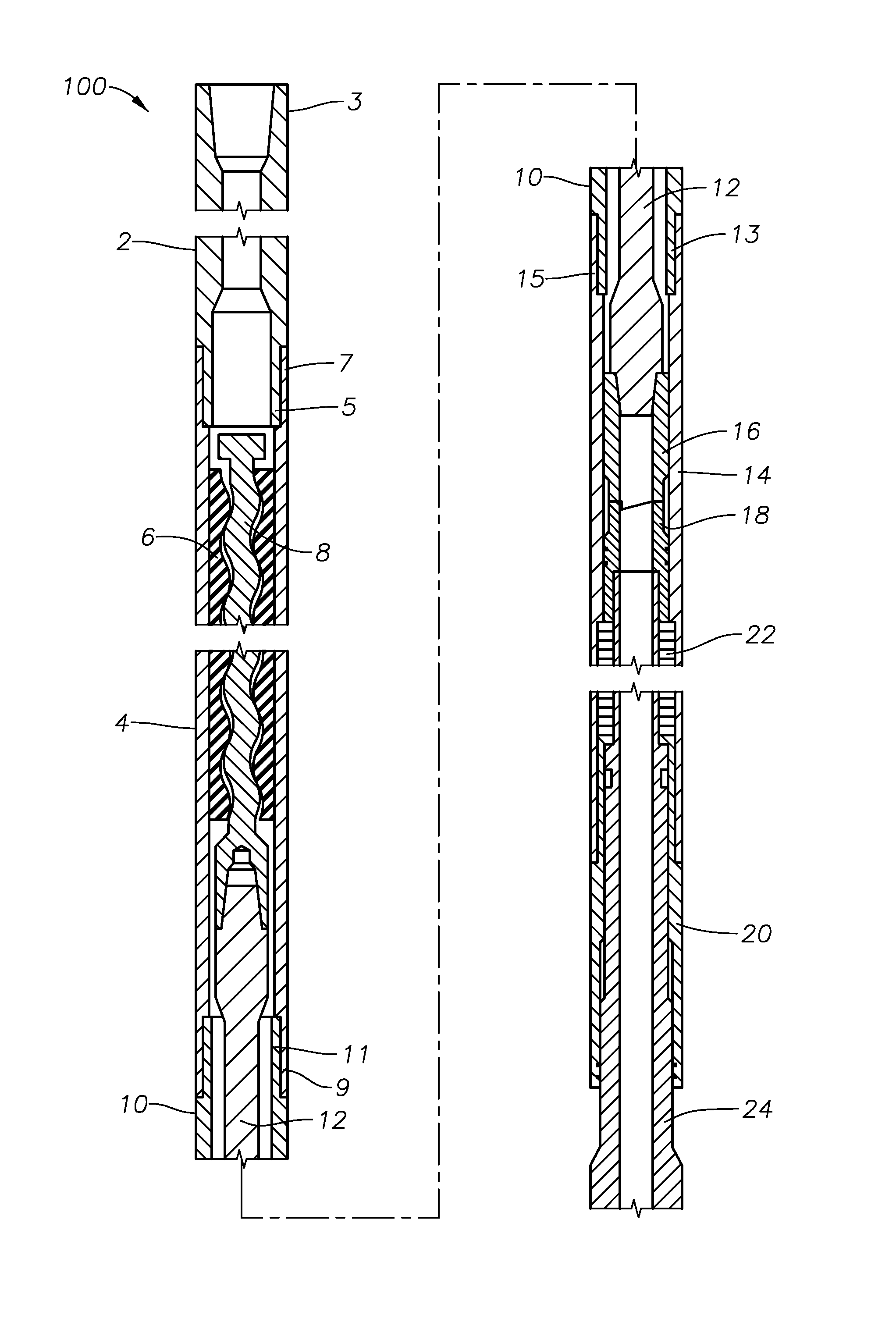

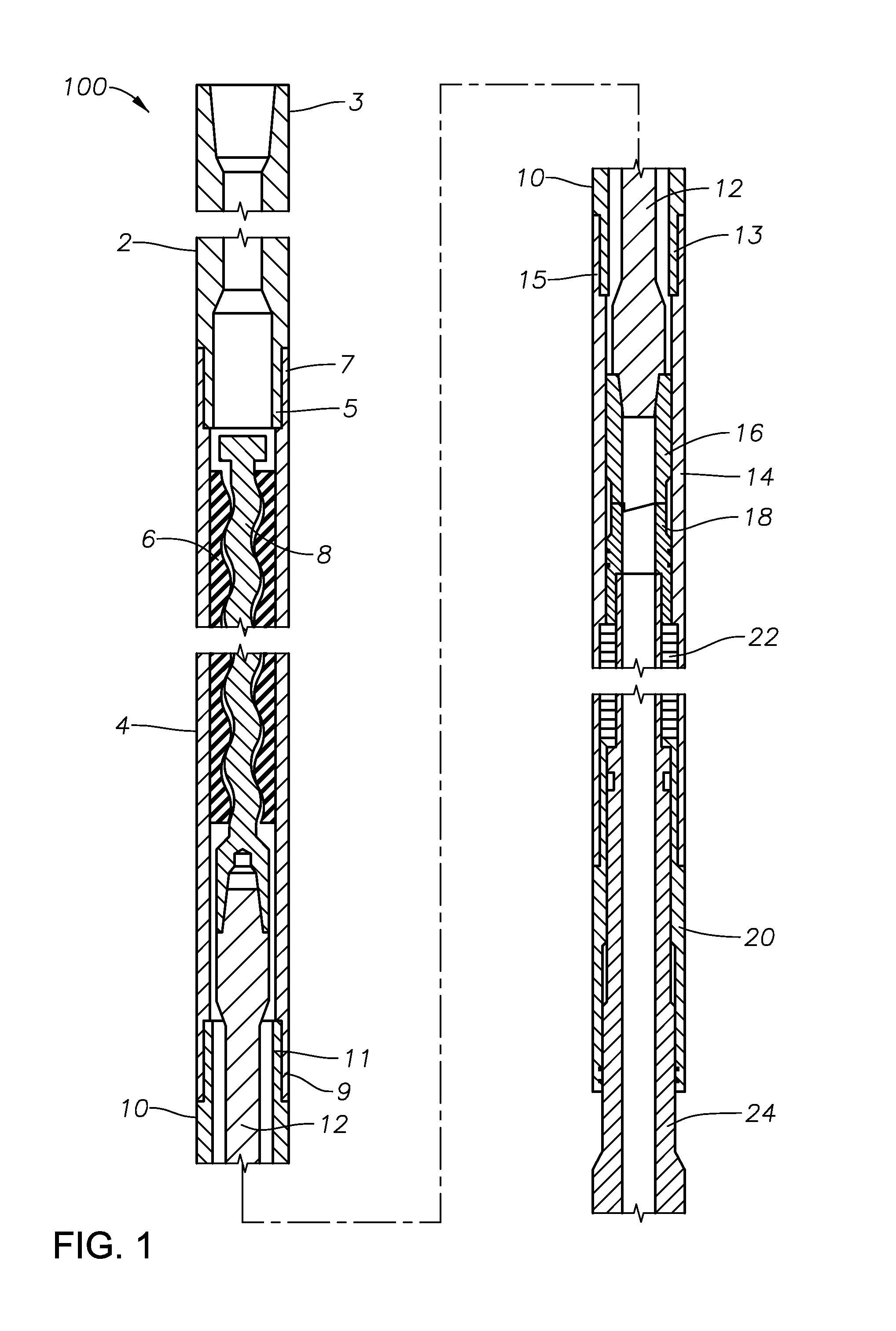

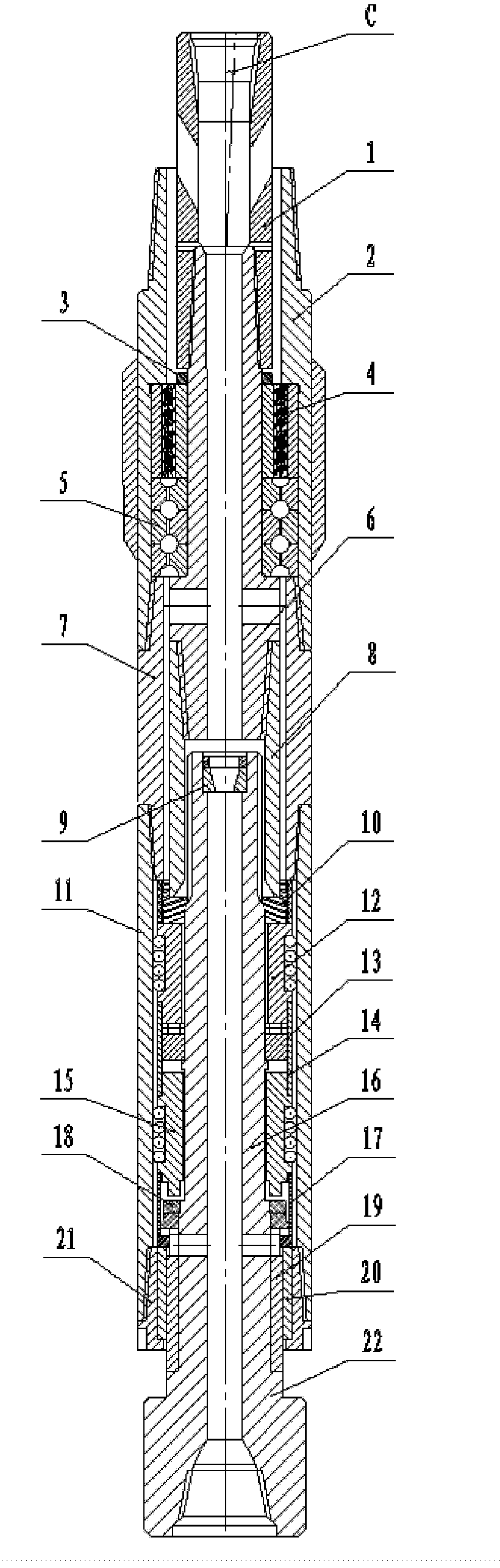

Impact screw drilling tool

InactiveCN102777122AIngenious designEasy to implementEarth drilling toolsDrilling drivesDrive shaftWell drilling

The invention discloses an impact screw drilling tool, and belongs to a well drilling technology and the impact screw drilling tool can be used for solving the problems that the screw drilling tool instantly produces an impact force and the cutting tooth of a drill bit is easy to damage in the prior art. The impact screw drilling tool comprises a bypass valve assembly, a motor assembly, a universal shaft assembly and a transmission shaft assembly which are sequentially connected, wherein the bypass valve assembly mainly consists of a valve body, a valve core, a spring and a sieve plate, the motor assembly mainly consists of a stator shell and a rotor, the universal shaft assembly mainly consists of a universal shaft shell and a universal shaft, and the transmission shaft assembly mainly consists of a transmission shaft shell, a hollow transmission shaft, a thrust bearing set and a radial bearing set; and a flow control assembly is arranged between the transmission shaft assembly and the universal shaft assembly. According to the screw drilling tool disclosed by the invention, on the basis of the original performance, the flow control assembly produces a flexible impact force, the rock-breaking efficiency of the drill bit is improved, the mechanical penetration rate is improved, the service life is greatly prolonged, and the application range of the screw drilling tool disclosed by the invention is widened by utilizing hydraulic power pressurizing assemblies at different positions.

Owner:熊继有 +1

Flow controlling downhole tool

A downhole tool assembly for use in a drilling string includes a motor, a flow head, and a flow restrictor. The flow head is coupled to the motor and comprises a plurality of ports permitting fluid communication therethrough. The flow restrictor is in fluid communication with the flow head and comprises a plurality of ports permitting fluid communication therethrough. The flow restrictor is stationary with respect to the flow head, which rotates. As the flow head rotates, one or more of the plurality of ports of the flow head enters into and out of alignment with one or more of the plurality of ports of the flow restrictor such that fluid flow through the ports of the flow head and the flow restrictor is constrained to a cyclic, polyrhythmic pattern optionally including at least one interval where the fluid flow is substantially blocked by the flow restrictor.

Owner:IMPULSE DOWNHOLE SOLUTIONS LTD

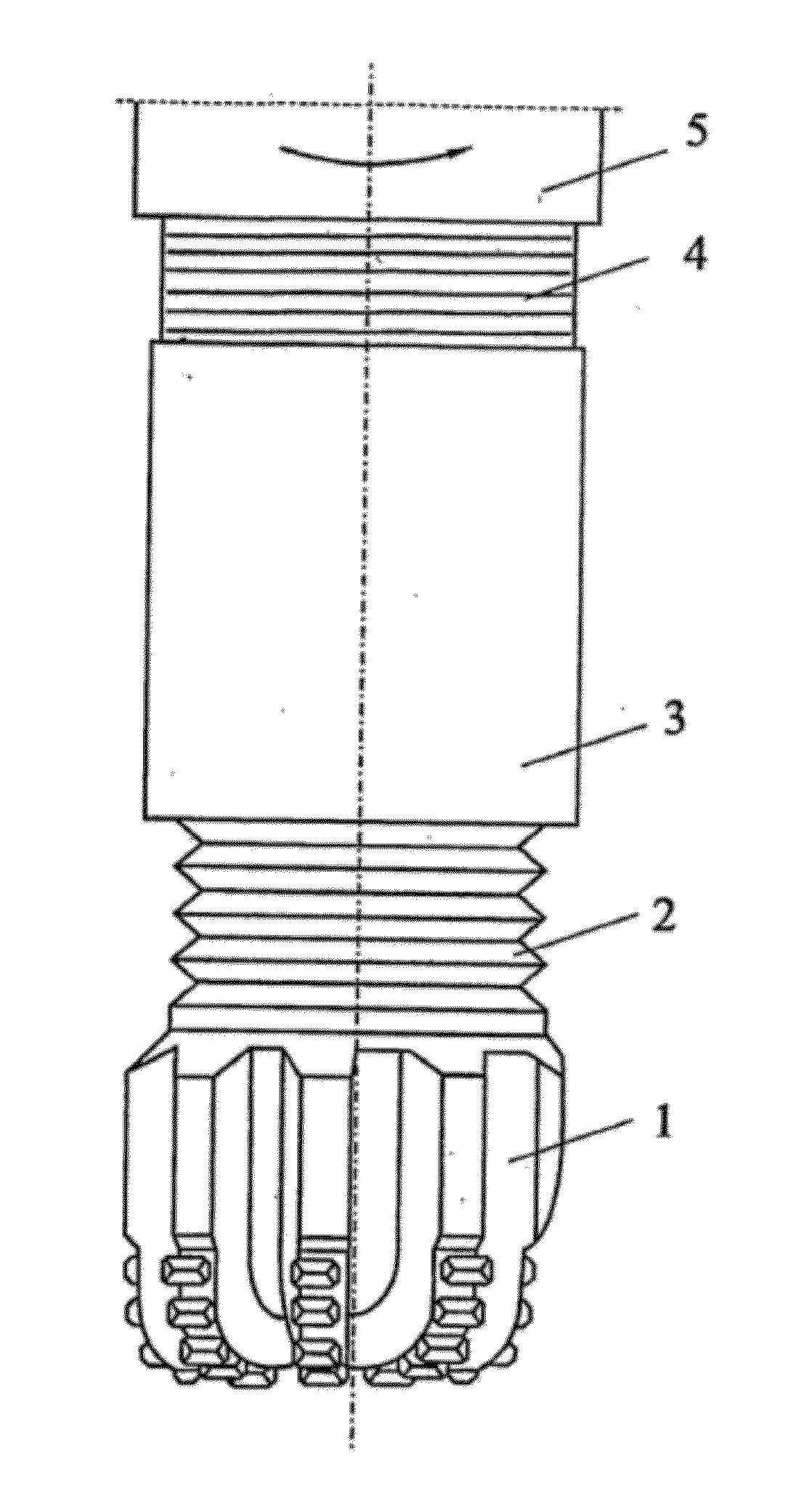

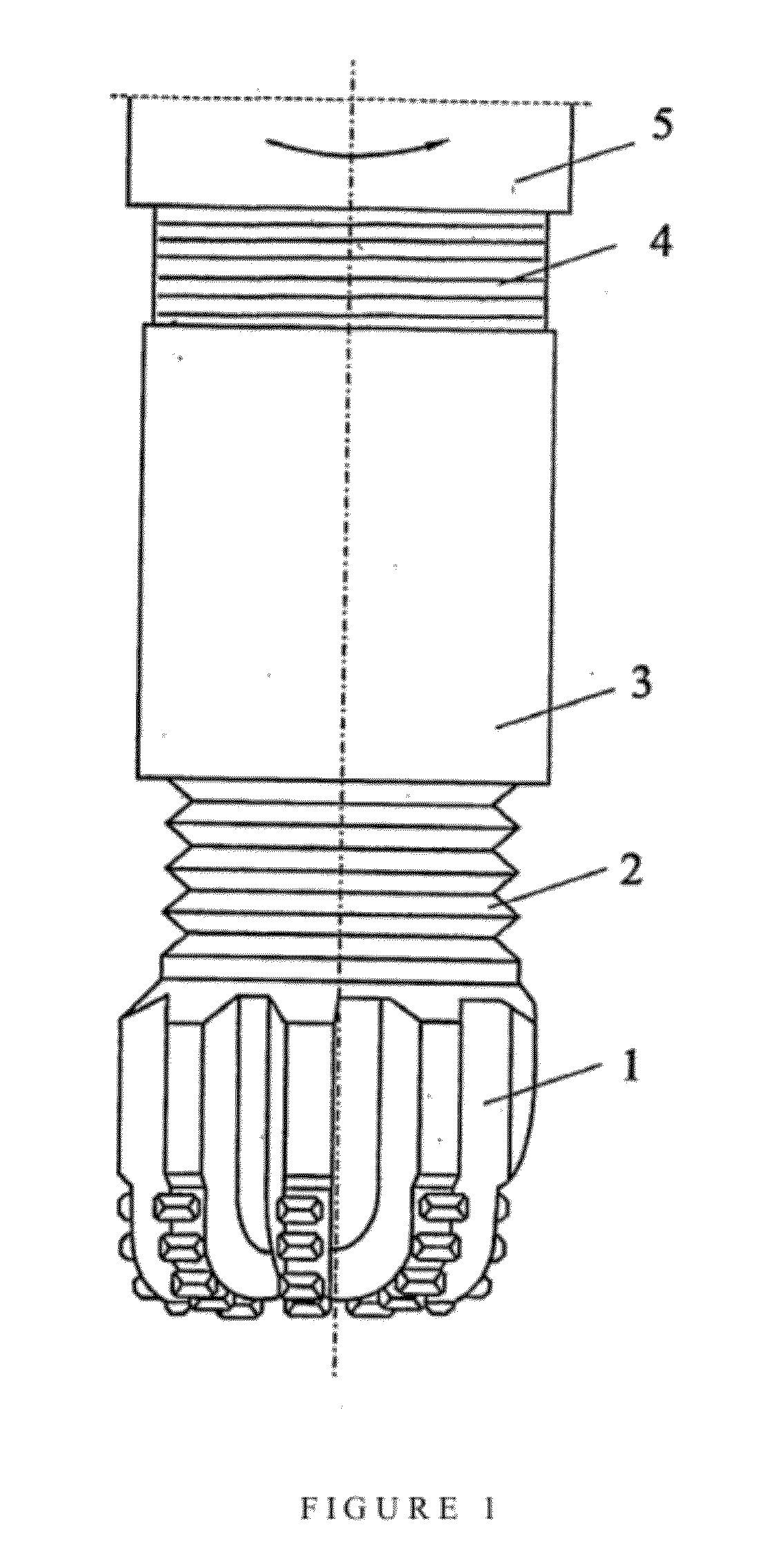

Spring energy-storage inspiring type rotary percussive drill device

ActiveCN103174380AReasonable installationCompact installationDrilling drivesEngineeringEnergy storage

The invention relates to a spring energy-storage inspiring type rotary percussive drill device, in particular to the spring energy-storage inspiring type rotary percussive drill device which produces quick continuous impact due to the fact that a down-hole motor, a rotating shaft and an impact vibration kit match with each other. The spring energy-storage inspiring type rotary percussive drill device comprises the down-hole motor and a drill pipe which is connected with the down-hole motor, wherein a drill is arranged at the lower end of the drill pipe. The spring energy-storage inspiring type rotary percussive drill device is characterized in that an impact mechanism is arranged inside the drill pipe, and the impact mechanism comprises the down-hole motor, the rotating shaft which is arranged at the lower end of the down-hole motor and the impact vibration kit which is arranged at the lower portion of the rotating shaft in a sleeved mode. Due to the design of the impact mechanism, and the down-hole motor, the rotating shaft and the impact vibration kit match with each other, the quick continuous impact is produced, bit pressure high-frequently vibrates by a large margin in the drilling process, the drilling process is quickened and drilling efficiency is improved with the cooperation of torque-on-bit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

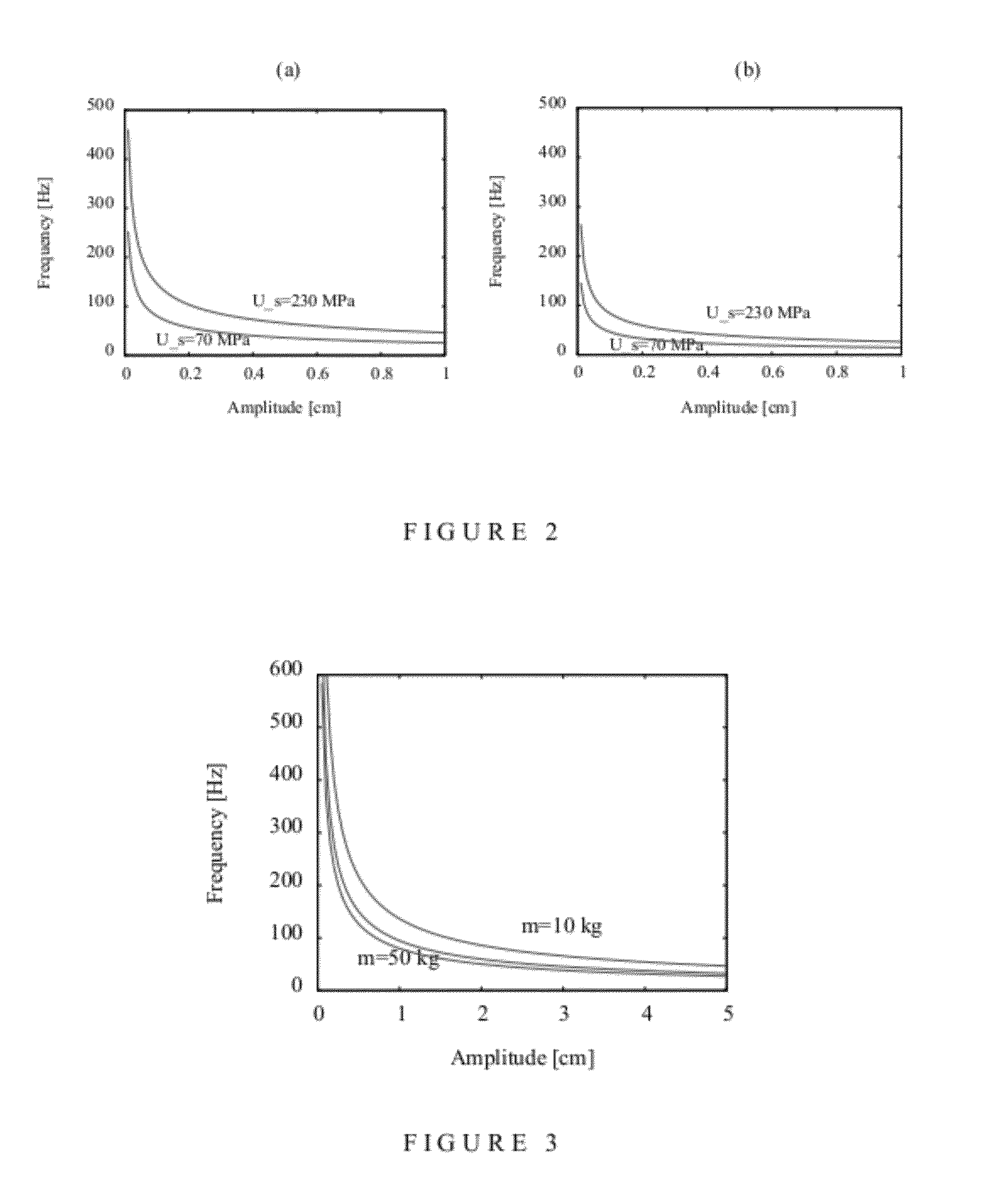

Resonance enhanced rotary drilling

ActiveUS20120241219A1Improve high performanceHigh drilling performanceDirectional drillingVibration devicesEffective diameterDrill bit

A method for controlling a resonance enhanced rotary drill comprising a rotary drill bit and an oscillator for applying axial oscillatory loading to the rotary drill bit, the method comprising:controlling frequency (f) of the oscillator in the resonance enhanced rotary drill whereby the frequency (f) is maintained in the range(D2 Us / (8000 πAm))1 / 2≦f≦Sf(D2 Us / (8000 πAm))1 / 2 where D is diameter of the rotary drill bit, Us is compressive strength of material being drilled, A is amplitude of vibration, m is vibrating mass, and Sf is a scaling factor greater than 1; andcontrolling dynamic force (Fd) of the oscillator in the resonance enhanced rotary drill whereby the dynamic force (Fd) is maintained in the range[(π / 4)D2effUs]≦Fd≦SFd[(π / 4)D2effUs]where Deff is an effective diameter of the rotary drill bit, Us is a compressive strength of material being drilled, and SFd is a scaling factor greater than 1,wherein the frequency (f) and the dynamic force (Fd) of the oscillator are controlled by monitoring signals representing the compressive strength (Us) of the material being drilled and adjusting the frequency (f) and the dynamic force (Fd) of the oscillator using a closed loop real-time feedback mechanism according to changes in the compressive strength (Us) of the material being drilled.

Owner:ITI SCOTLAND

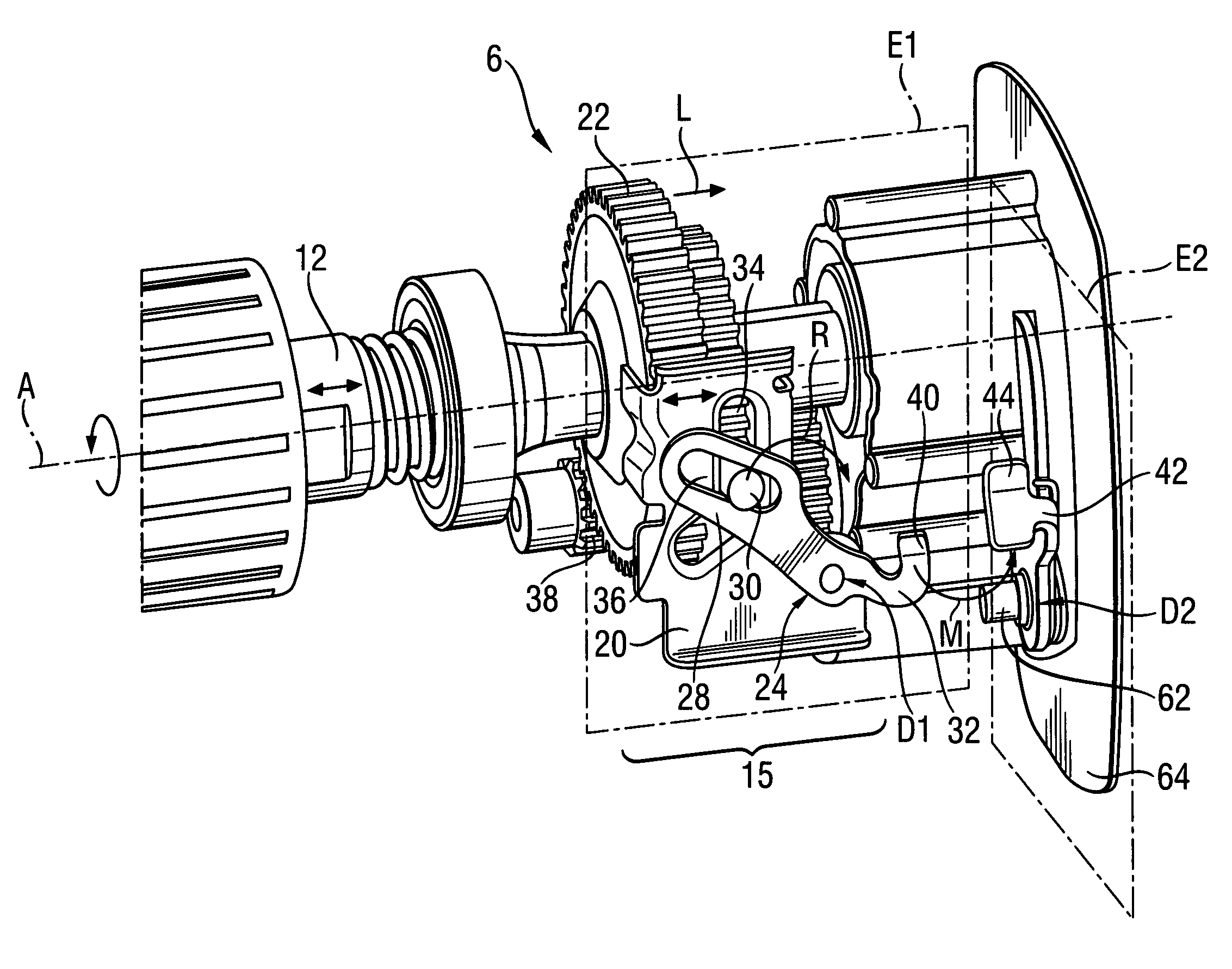

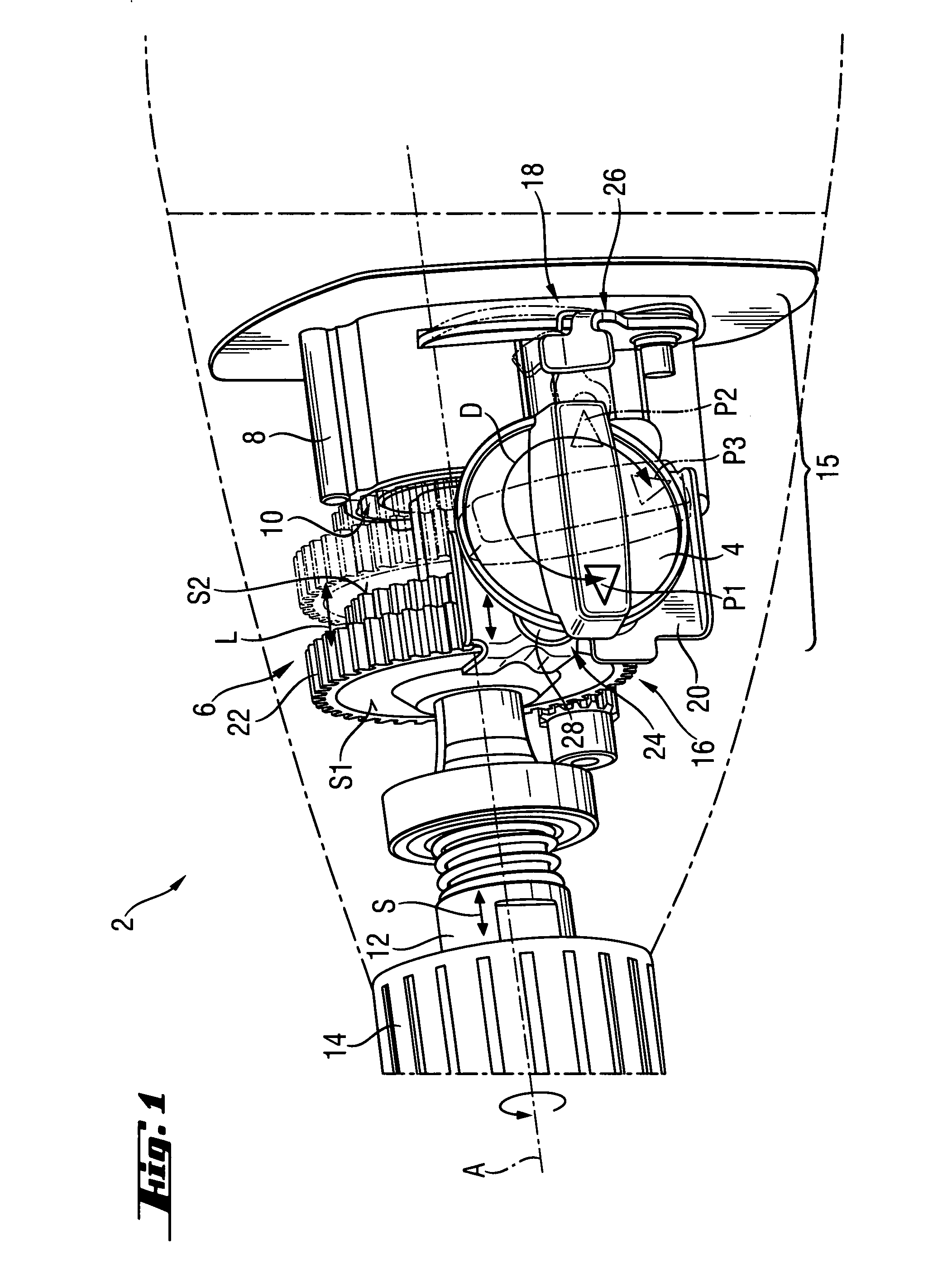

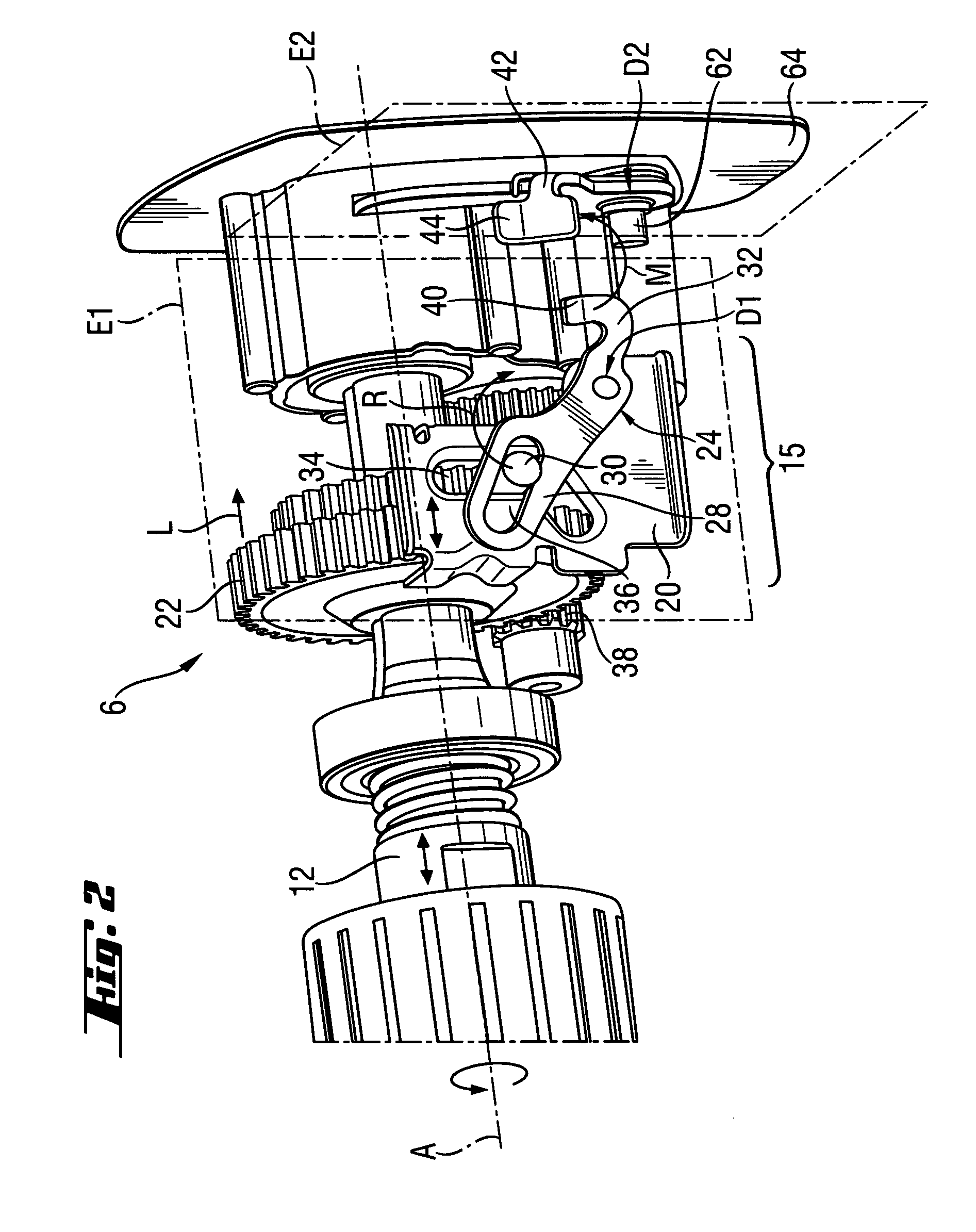

Hand-held electric power tool

A hand-held electric power tool (2) includes a switching gear unit (6) which has at least two switching stages, including an impact mechanism (10) which can be switched on, and a mode switch (4) with which the switching gear unit (6) can be switched back and forth between the switching stages. The impact mechanism (10) can be switched on and off, and the mode switch (4) is movement-coupled with a gear unit switching mechanism (16) of the switching gear unit (6) and with an impact mechanism switching mechanism (18) of the impact mechanism (10). The impact mechanism switching mechanism (18) has a swiveling mechanism which can be swiveled by the mode switch (4) between an active position, in which the impact mechanism (10) can be activated, and a passive position in which the impact mechanism (10) is deactivated.

Owner:HILTI AG

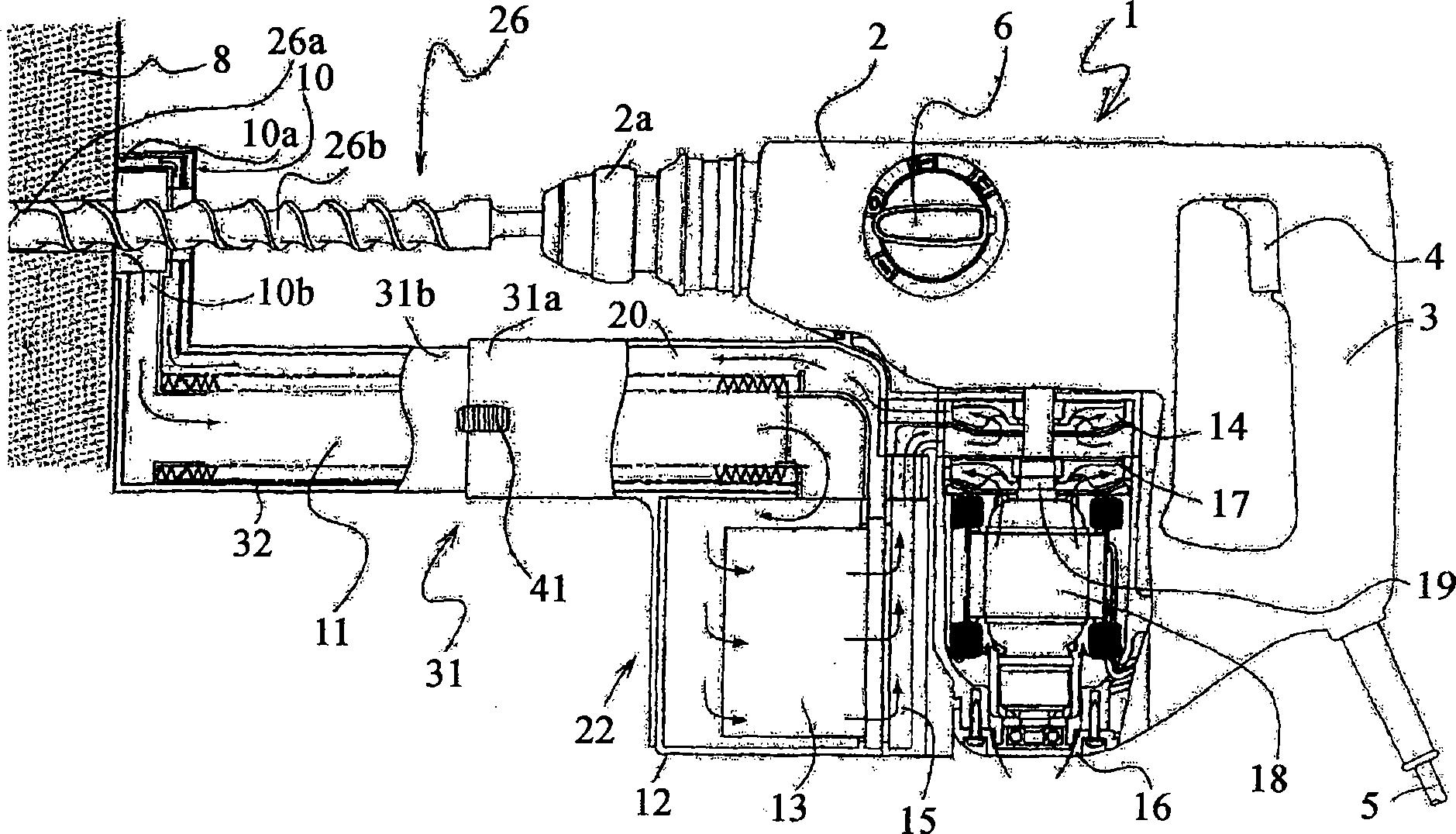

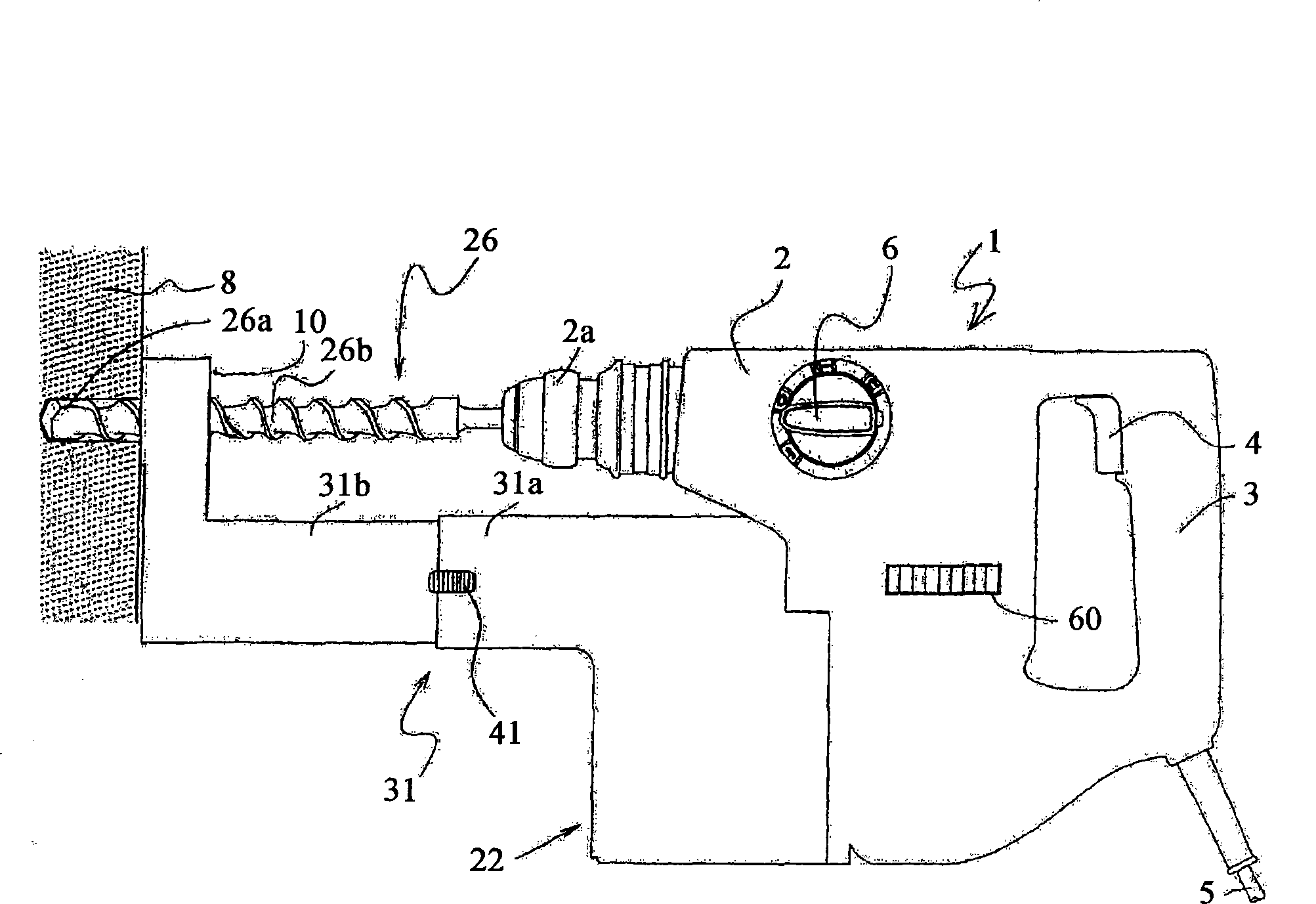

Drilling tool with dust collector

InactiveCN101451423APrevent leakageLess attractivePortable percussive toolsDrilling drivesEngineeringDust collector

The invention provides a drilling tool having a miniaturized dust collection device, which improves the working efficiency while improving the dust collecting efficiency. The drilling tool uses the rotary force of an electric motor to rotate the drill bit. The dust collection device is installed near the front end of the drill bit. The dust collection device collects the dust caused by drilled material of drilling. The dust collection device is provided with: a penetrating portion configured to penetrate the drill bit; a dust collection nozzle that absorbs mill dust produced near the front end of the drill bit; and an ejection opening that ejects air. Absorbed air enters, passes through a dust collection filter and reaches the path of a fan connected with the electric motor, and a currentof air is formed by using the rotary force of the fan. The current of air is the current of air for absorption from the dust collection nozzle and the current of air for ejection from the ejection opening. The amount of the absorbed air is larger than that of the air ejected from the ejection opening.

Owner:KOKI HLDG CO LTD

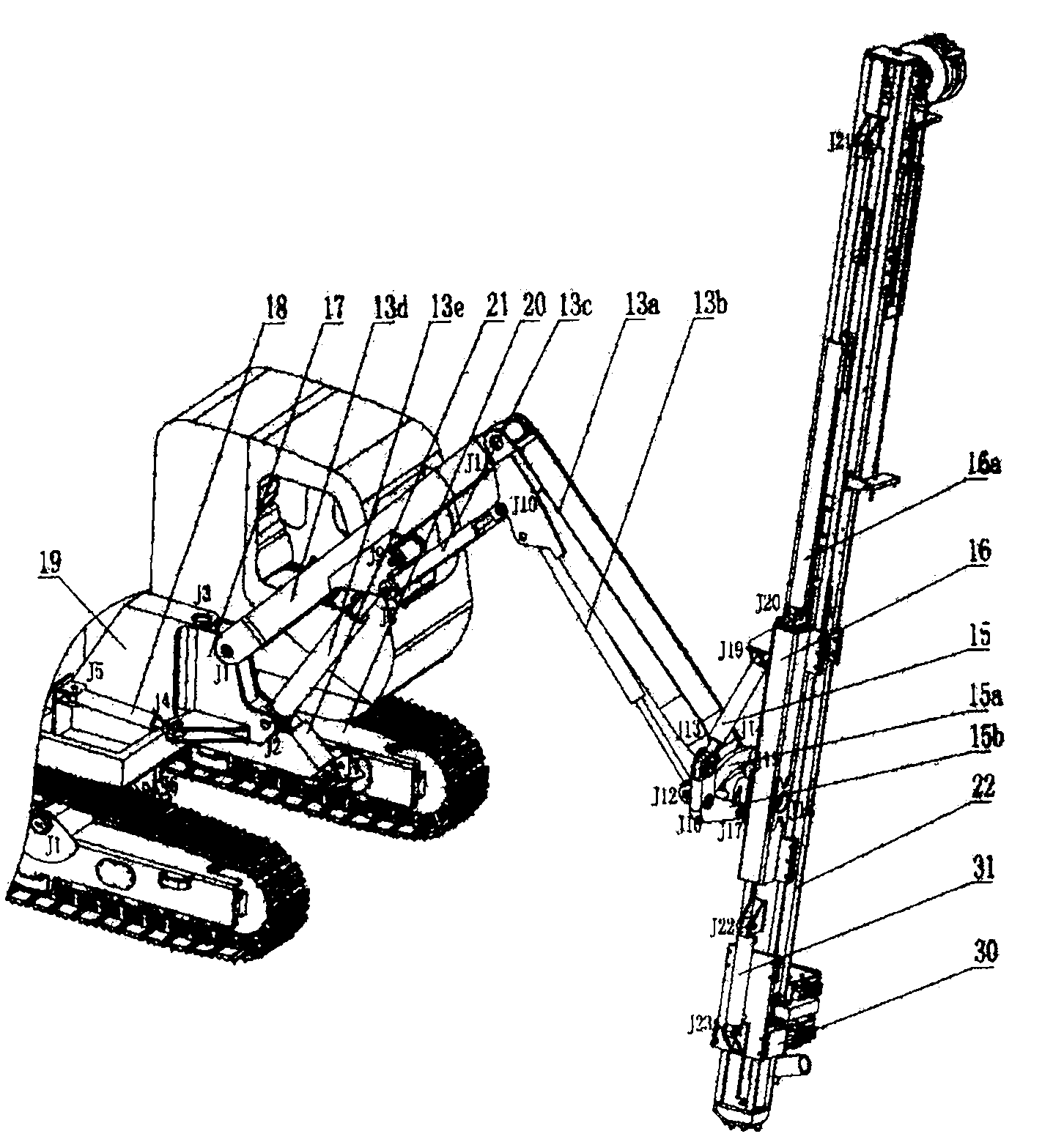

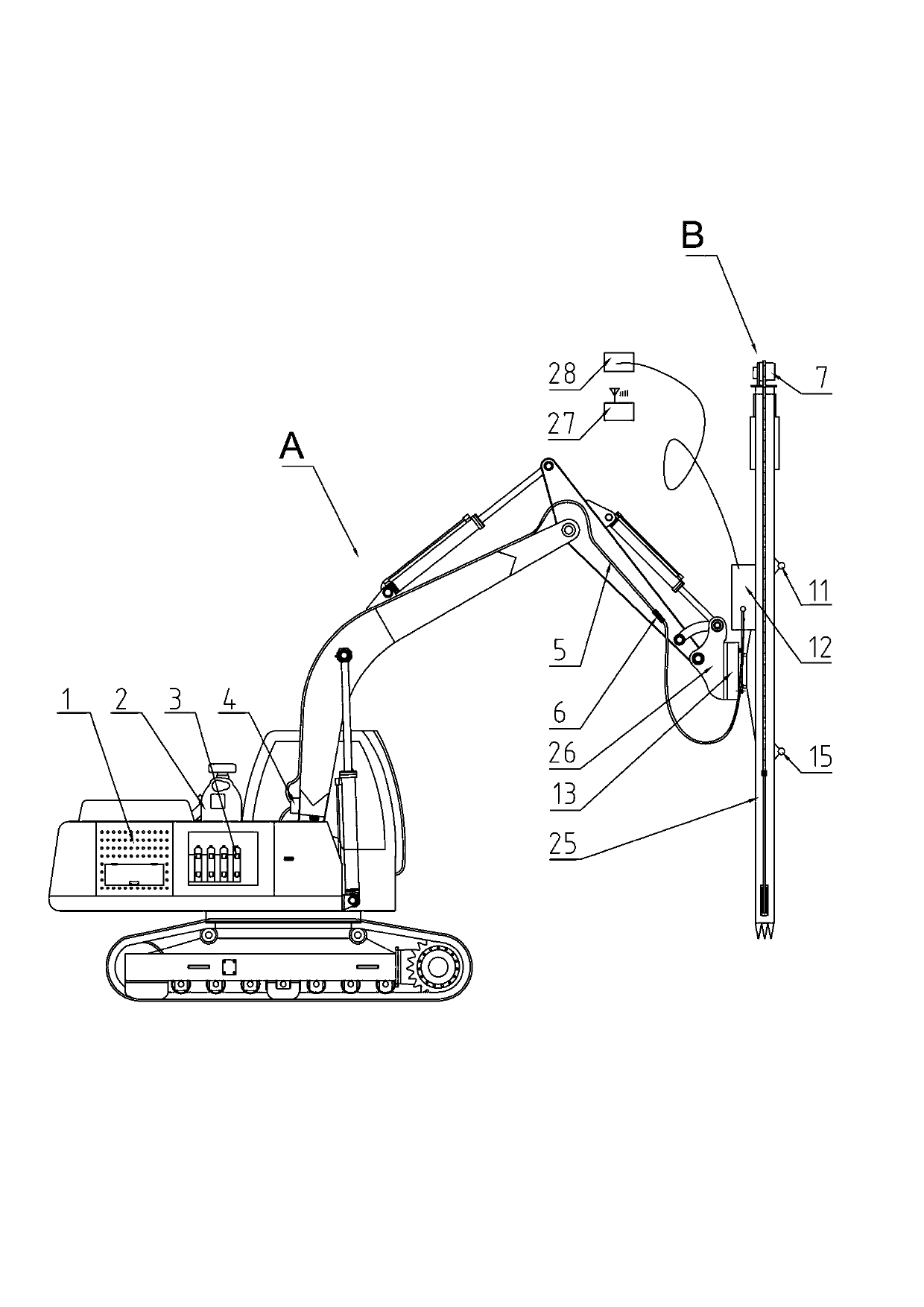

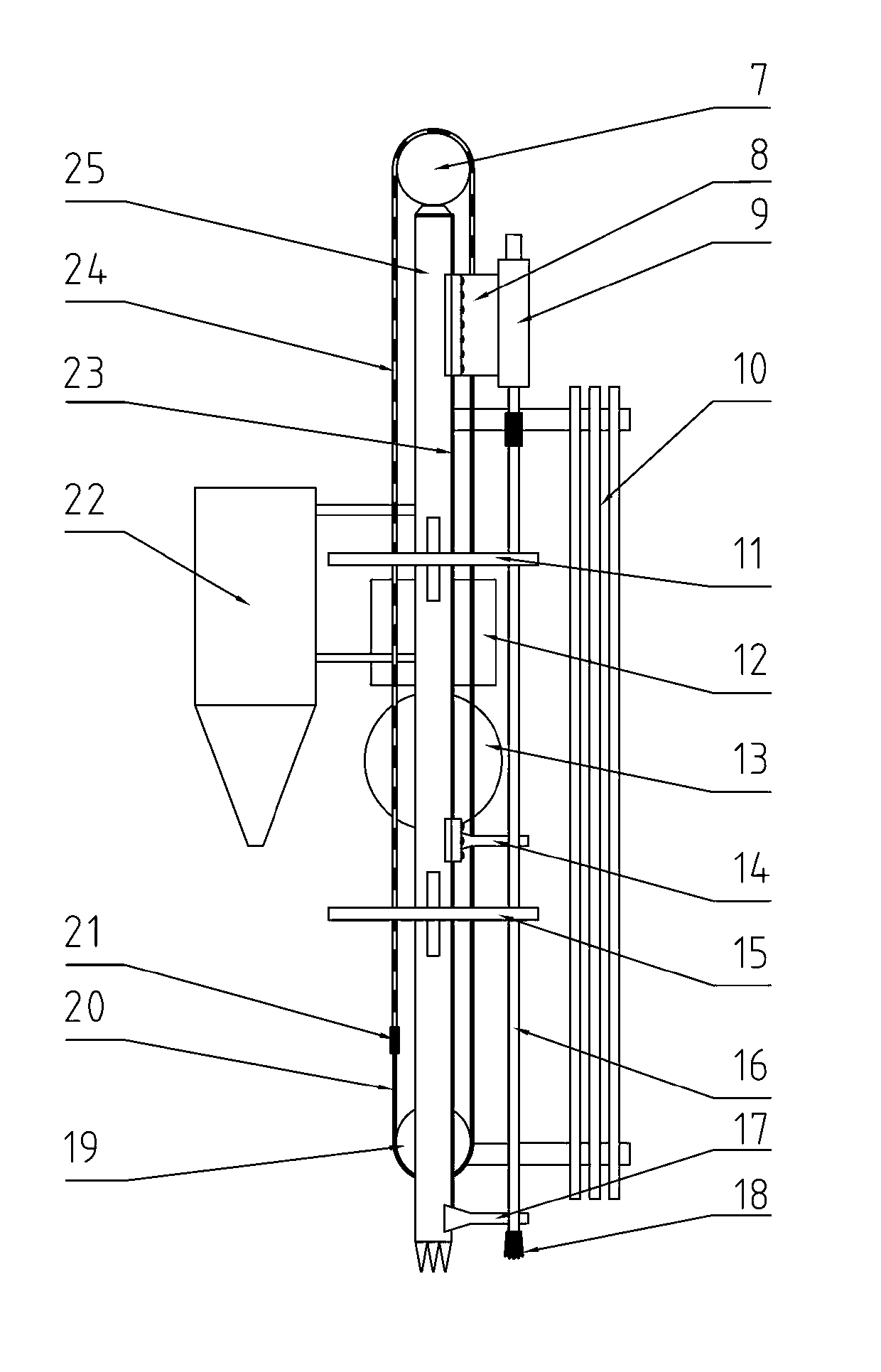

Full-hydraulic rock-drilling excavator using hydraulic excavator for production

ActiveCN102913130ACompact structureEasy to convertConstructionsDerricks/mastsEngineeringHigh pressure

The invention discloses a full-hydraulic rock-drilling excavator using a hydraulic excavator for production. The full-hydraulic rock-drilling excavator is an engineering machine which combines functions of a full-hydraulic rock-drilling drilling machine and a conventional excavator and comprises a hydraulic excavator (A) and a full-hydraulic drilling machine (B), wherein a helical-lobe compressor(2) and a power regulation device (4) are arranged on a conventional hydraulic excavator top form the hydraulic excavator (A), confluence of two groups of high-pressure oil pumps of the hydraulic excavator, which are in parallel connection is achieved, output from stand-by valve sets is achieved, and the helical-lobe compressor (2) and the full-hydraulic drilling machine (B) are driven respectively through the power regulation device (4); the helical-lobe compressor (2) provides required compressed air for the full-hydraulic drilling machine (B); and the full-hydraulic drilling machine (B) is installed at a bucket position of the hydraulic excavator (A). The full-hydraulic rock-drilling excavator can maintain original functions of the hydraulic excavator and can be connected with other accessories which require hydraulic drive conveniently, functions of the full-hydraulic rock-drilling excavator can be replaced in a few minutes, and multiple purposes are achieved.

Owner:丁佑民

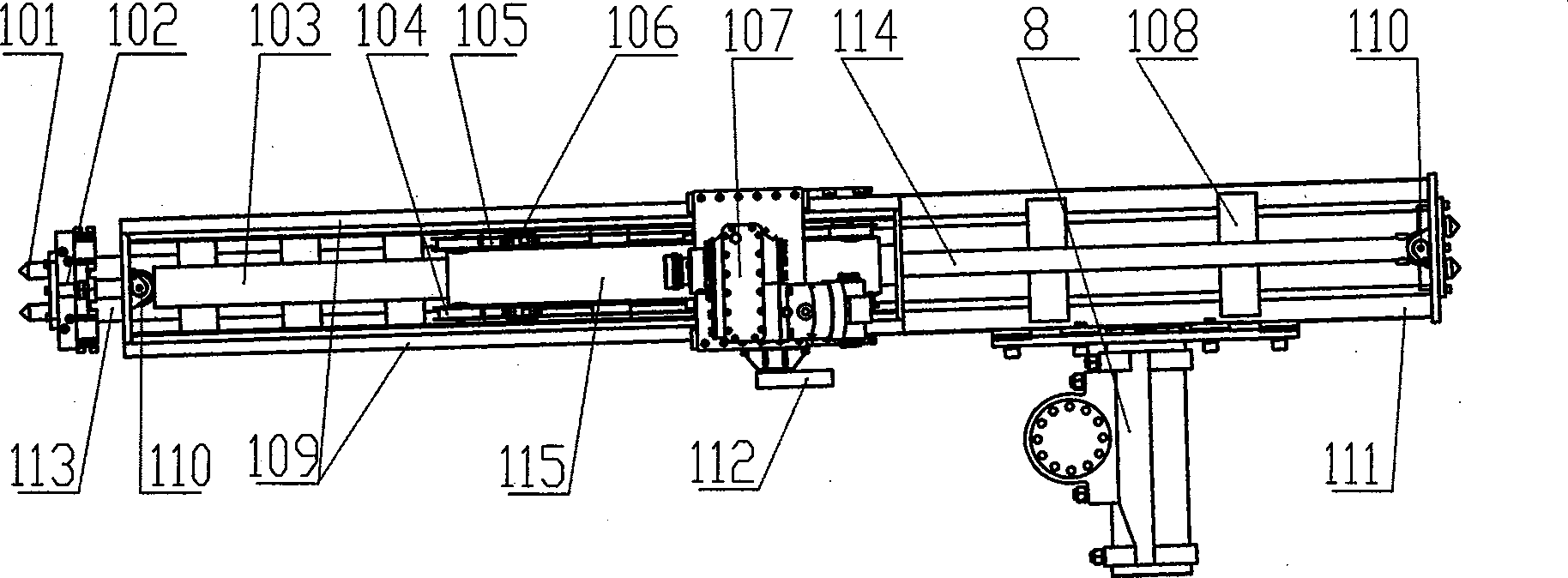

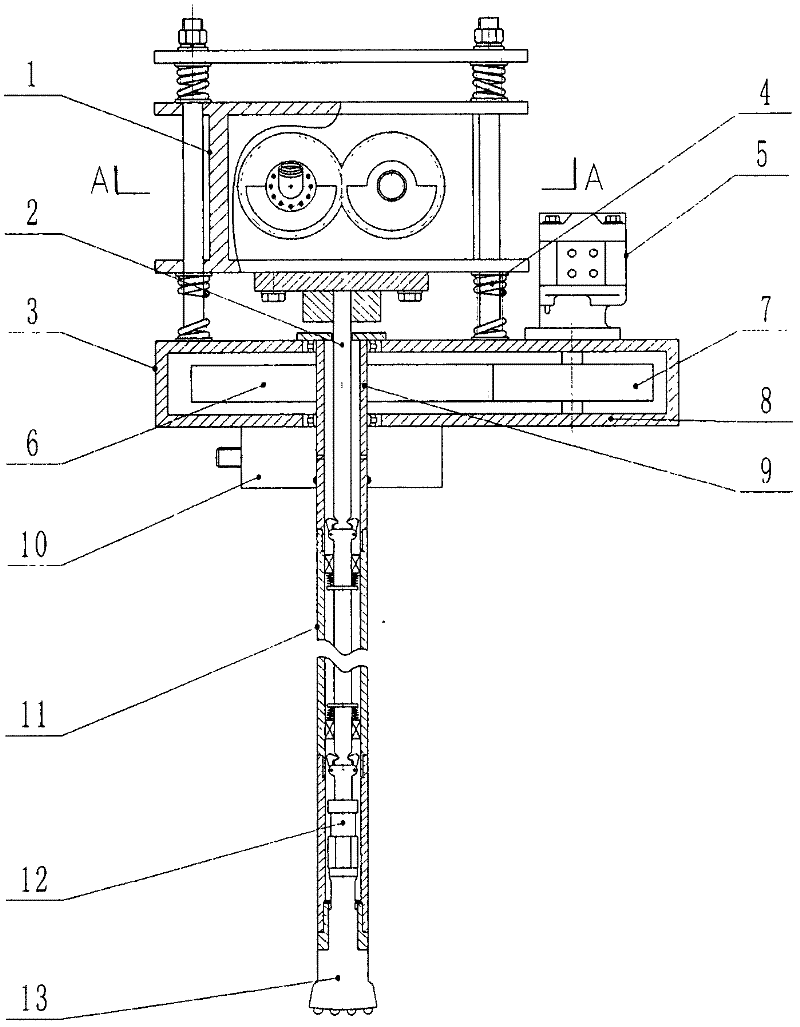

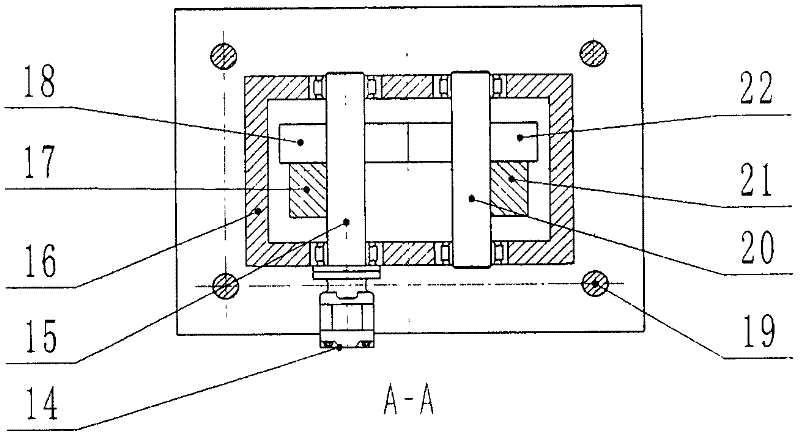

Rotary impact type rock drilling machine and double-layer drilling rod mechanism

InactiveCN102213074AImpact can be transmitted wellReduce impact energyDrilling rodsConstructionsCouplingDrilling machines

The invention discloses a rotary impact type rock drilling machine and a double-layer drilling rod mechanism. The rotary impact type rock drilling machine comprises an excitation mechanism, a rotating mechanism and a flushing mechanism, wherein the rotating mechanism comprises a rotary box body, a driving gear, a rotary gear and a rotary coupling sleeve; the rotary gear is tightly sheathed on the rotary coupling sleeve and meshed with the driving gear; a coupling link is arranged in the rotary coupling sleeve, the rotary coupling sleeve is connected with the double-layer drilling rod mechanism, an impact drilling column which is positioned by a guide shaft bushing is arranged in an outer-layer rotating drilling pipe of the double-layer drilling rod mechanism, a clamping lock for connecting the coupling link is arranged at the top of the inner-layer impact drilling column, an impact head connected with the impact drilling column is arranged in a drilling bit coupling sleeve, and a drilling bit positioned below the impact head is connected with the drilling bit coupling sleeve through front coupling. As the impact head is positioned at the bottom of the double-layer drilling rod mechanism and acts on the drilling bit directly, the impact energy generated by the rotary impact type rock drilling machine can not be weakened along with the increase of the length of a drilling rod, the rotary impact type rock drilling machine has high efficiency of a hydraulic rock drilling machine and also has the advantages of good transfer of impact energy and straight drilling of a downhole drill; furthermore, the high impact energy can be easy to generate, and large-aperture drilling and deep hole rock drilling can be realized.

Owner:HENR TECH GUANGXI CO LTD

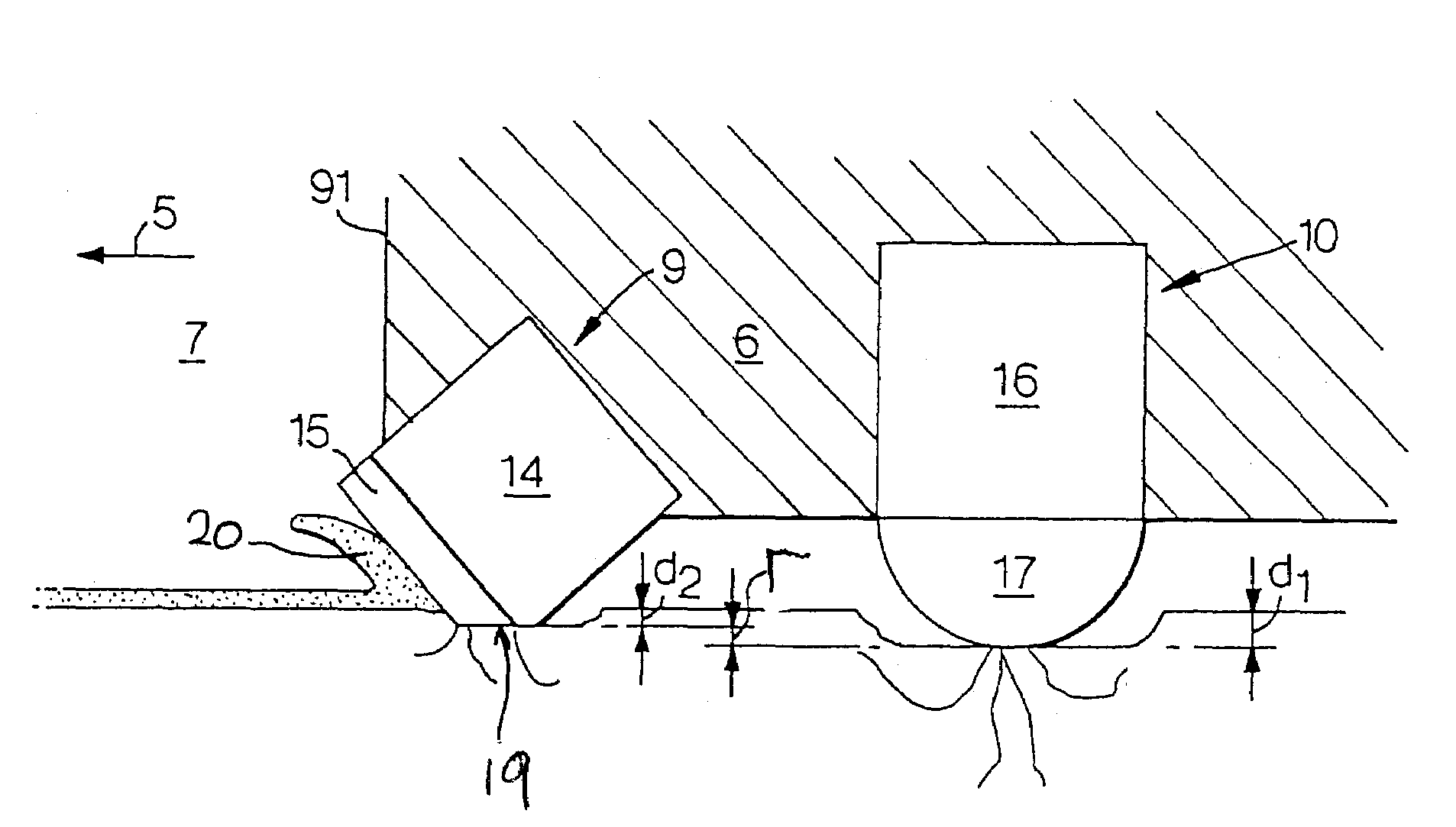

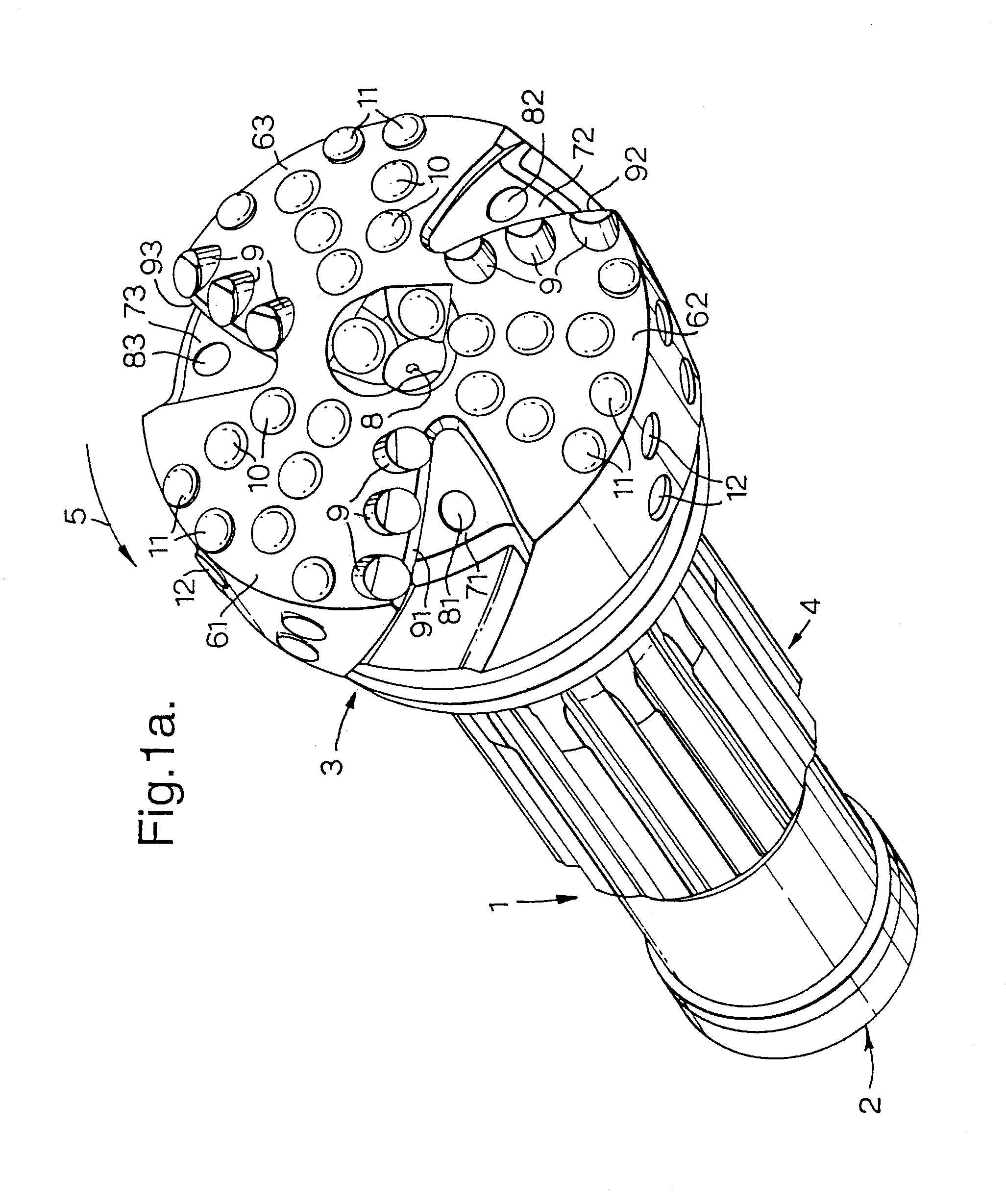

Percussive drill bit

A percussion drill bit for drilling into a subterranean earth formation. The drill bit has a central longitudinal axis and is operable by applying repetitive axial percussive impacts on the drill bit in a direction having a component along the axis and by applying rotary motion about the axis relative to the earth formation. The drill bit is provided with one or more axial cutters for predominantly axially cutting the subterranean earth formation in response to the axial percussive impacts and one or more shear cutters for predominantly shear cutting the subterranean earth formation in response to the rotary motion. There is a first shear cutter of the one or more shear cutters, and one or more of the axial cutters are arranged with respect to the first shear cutter to engage with the subterranean earth formation earlier during a percussive impact than the first shear cutter.

Owner:SHELL OIL CO

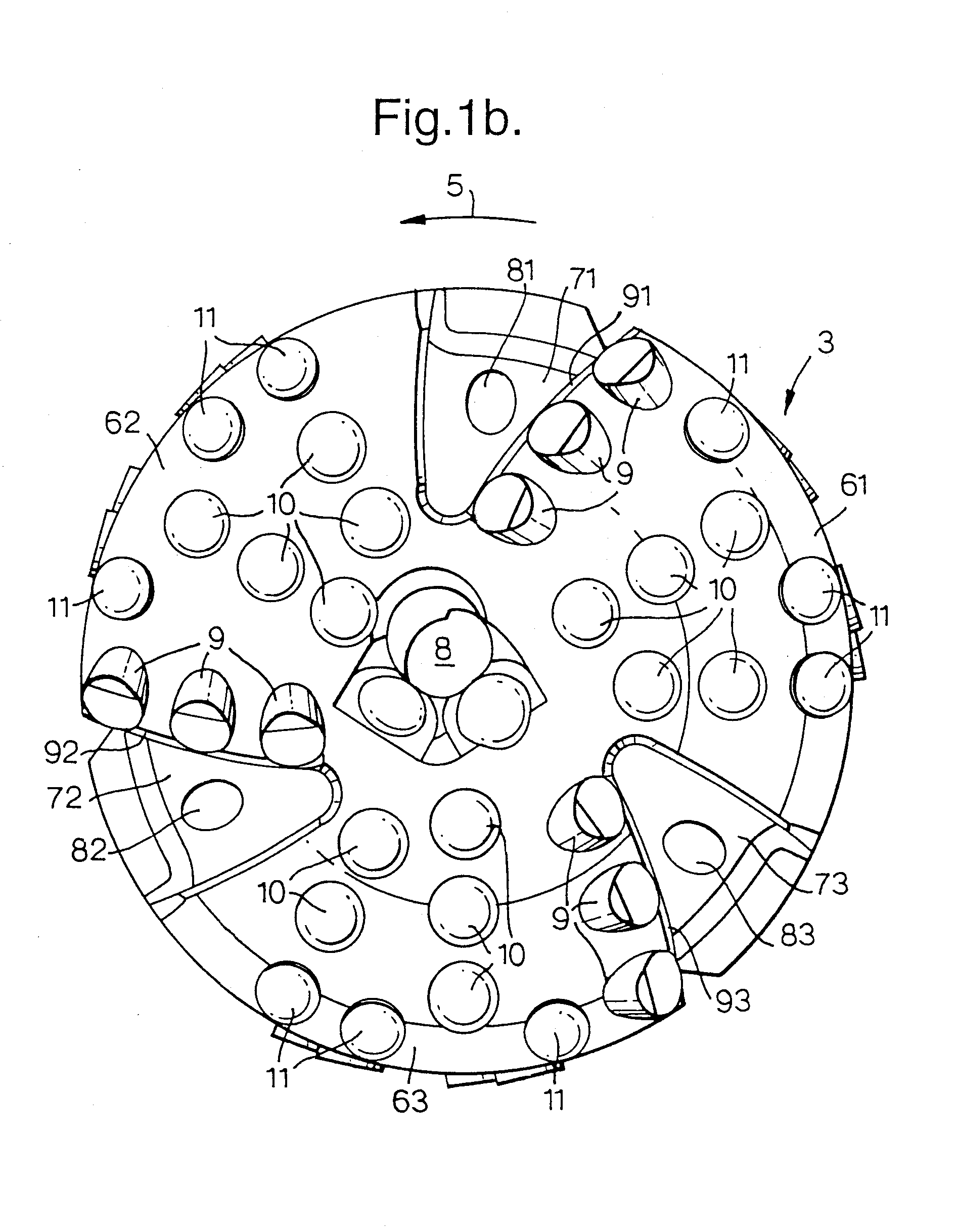

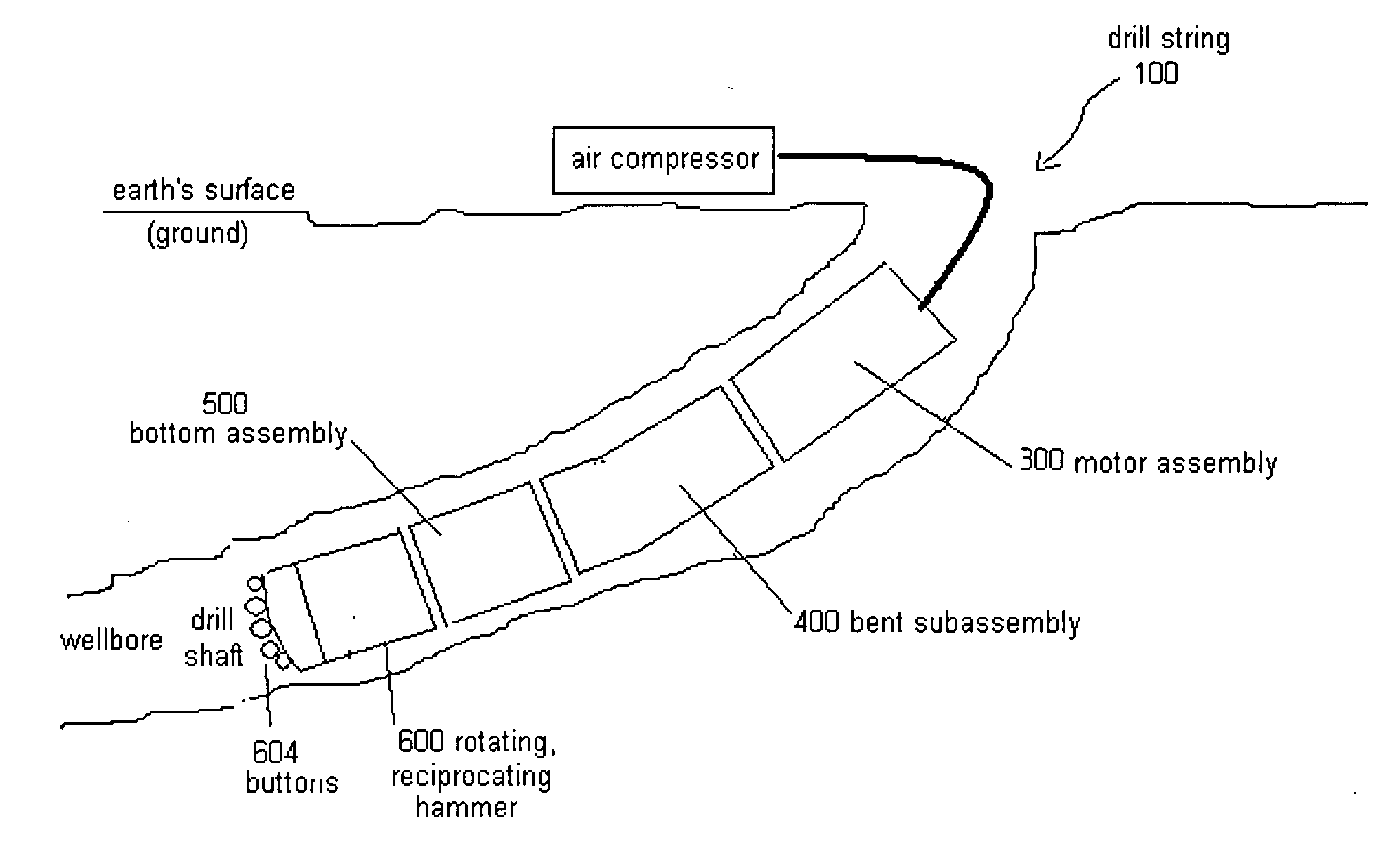

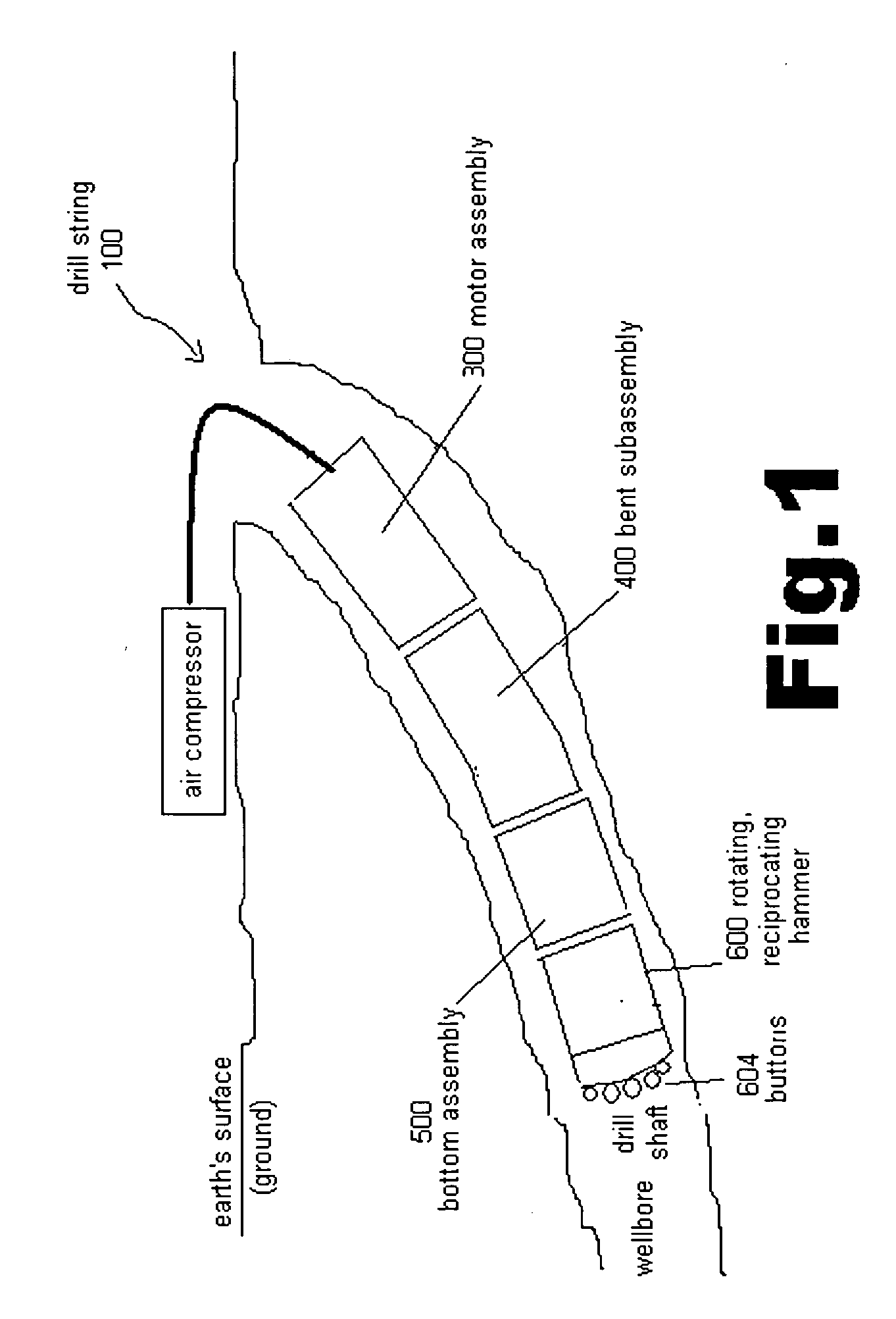

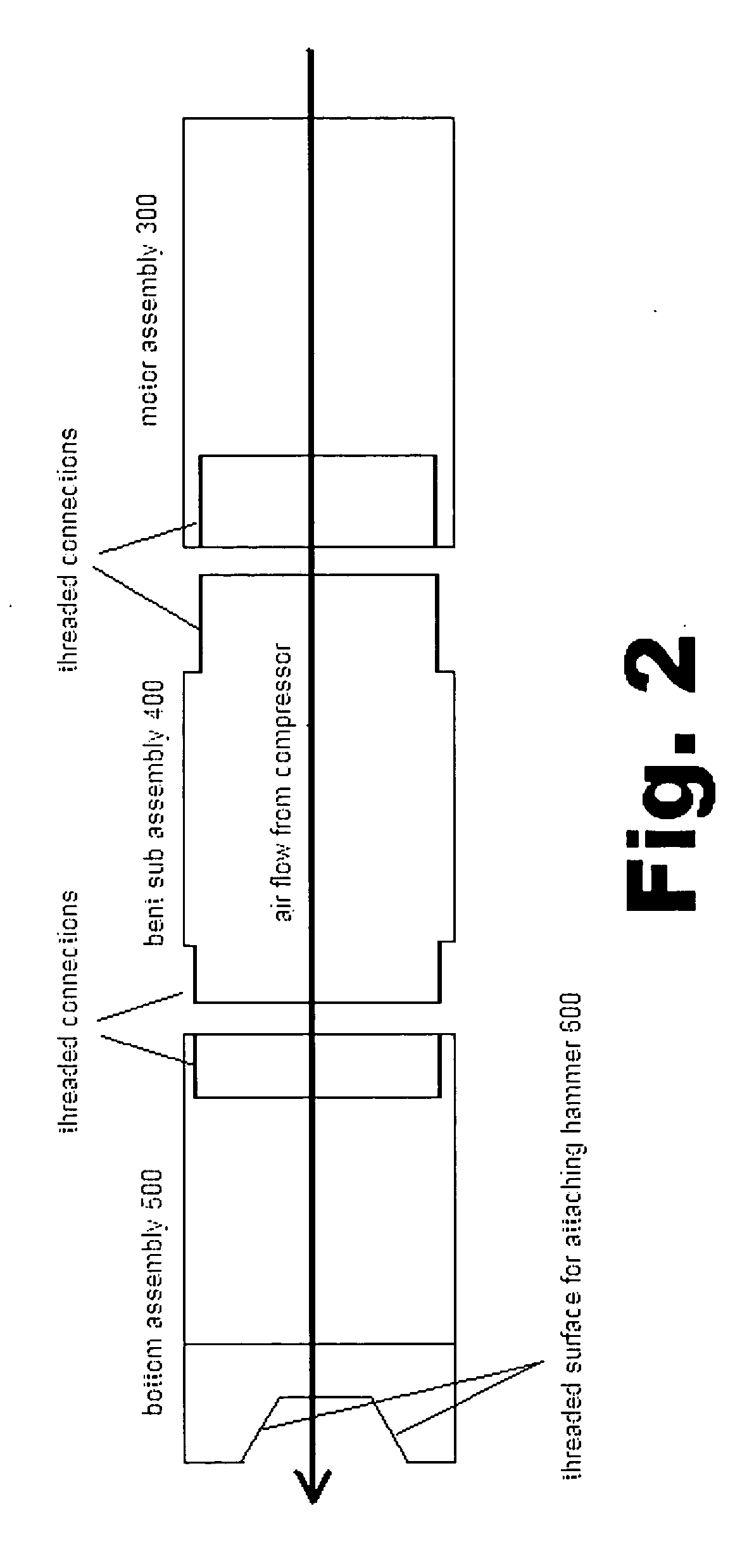

Combined directional and impact drilling motor

Owner:KENTUCKY AIR DRILLING SYST

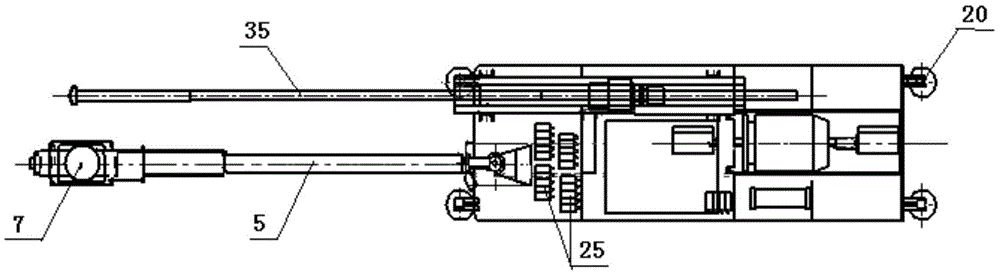

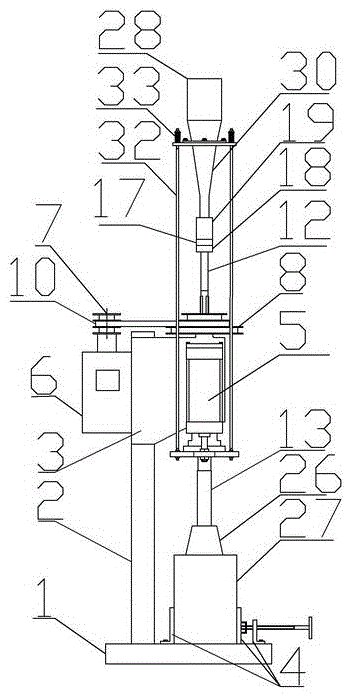

Ultrasonic vibration rock crushing experimental device and experimental method

The invention discloses an ultrasonic vibration rock crushing experimental device and experimental method. The experimental device is composed of a drilling mechanism, an ultrasonic vibration mechanism and a drilling parameter control system. A clamping device is installed on a drilling machine base, a rock is fixed on the clamping device, and two cylinders are fixed on the two sides of a drilling machine rack. A motor, a driving wheel and a driven wheel are fixed on the drilling machine rack, the lower end of a drilling machine column is fixedly connected with the drilling machine base, and the upper end of the drilling machine column is fixedly connected with the drilling machine rack. A vibration transmission rod and a faucet are connected to the upper end of a driven rod, and a drill pipe and a drill bit are connected to the lower end of the driven rod. An ultrasonic transducer and the drilling mechanism are connected together through a connecting rod mechanism. A control cabinet composed of a flow regulator, a frequency converter, a driving power supply, a pressure regulating valve and an ultrasonic generator is connected with a water pump, the motor, the cylinders and the ultrasonic transducer. By means of the ultrasonic vibration rock crushing experimental device and experimental method, the whole process of crushing the rock during comprehensive drilling and core drilling under different drilling parameters can be simulated, and rock grindability tests and evaluation of the performance and quality of a micro drill bit can also be achieved.

Owner:JILIN UNIV

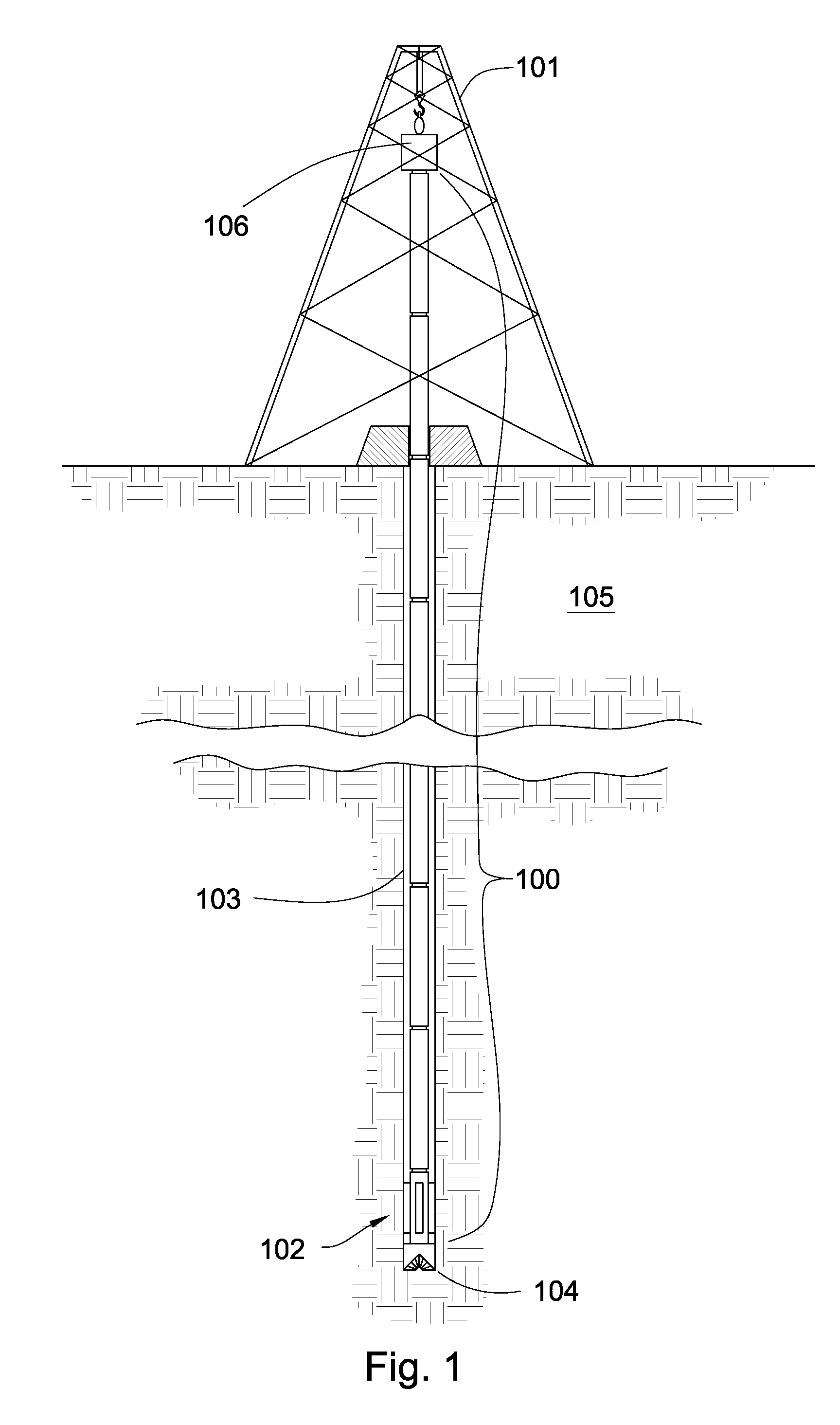

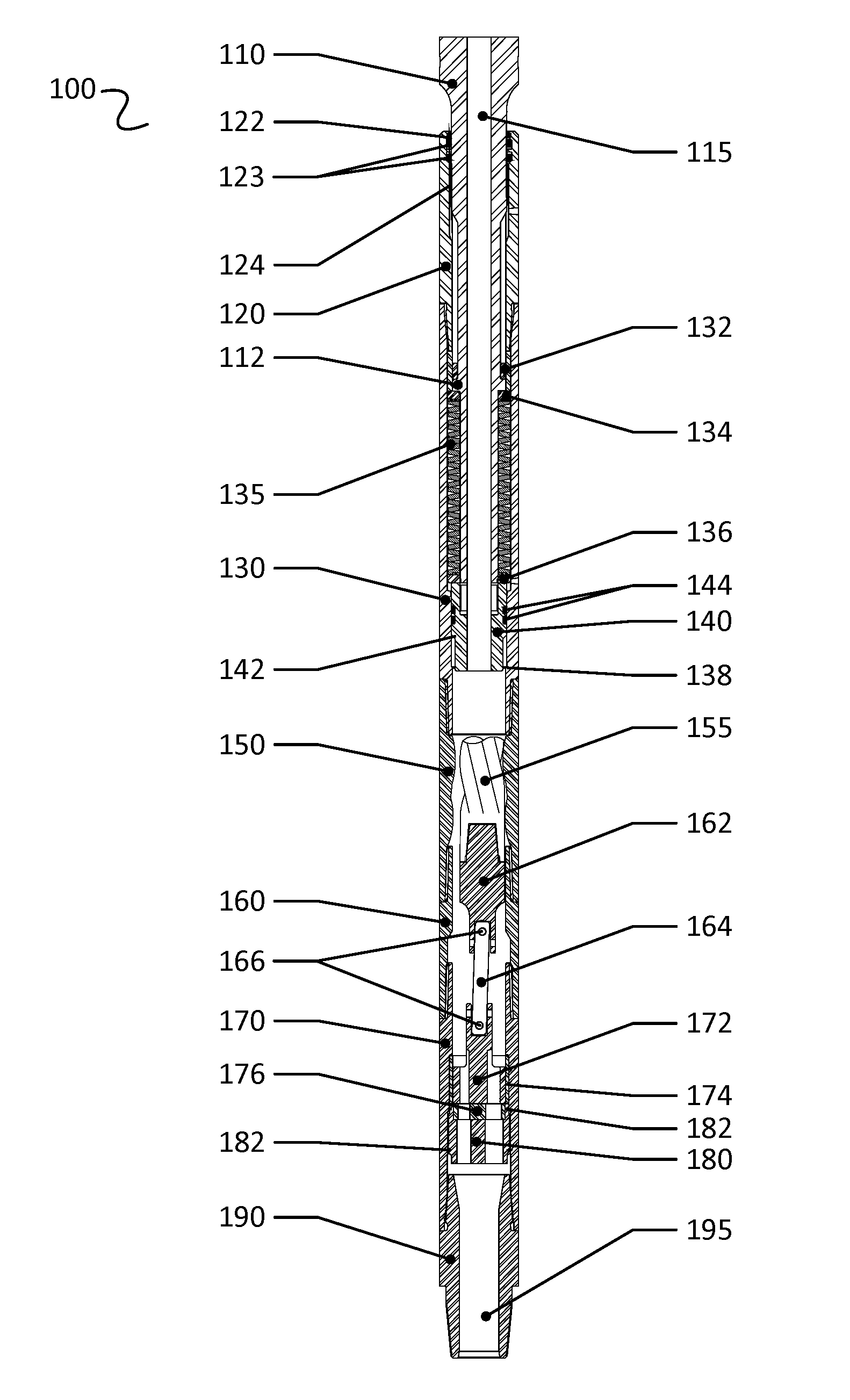

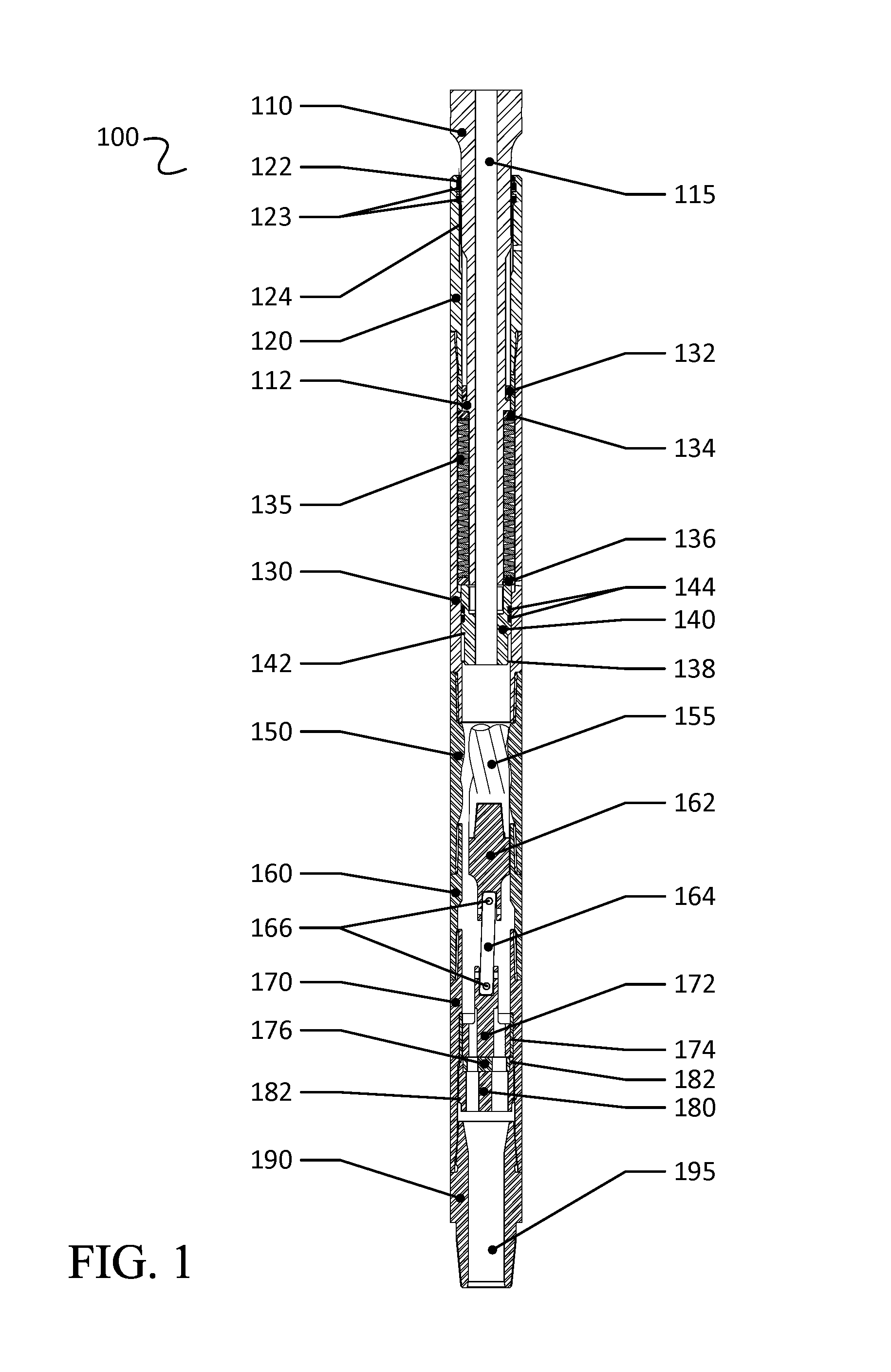

Systems and methods for producing forced axial vibration of a drillstring

Systems and methods for producing forced axial vibration of a drillstring. Systems include a cam housing positioned above a drill bit in a drillstring, a rotatable cam positioned internal of the cam housing, the rotatable cam having at least one cam surface exhibiting reciprocating axial movement upon rotation of the rotatable cam, and a non-rotatable cam follower positioned internal surface of the cam housing and having at least one cam follower surface engaging the cam surface. The cam follower transfers the reciprocating axial movement to the drill bit. The rotatable cam is rotated by a fluid-powered positive displacement power section positioned above and mechanically attached to the rotatable cam in the drillstring to effect the rotation of the rotatable cam, and thus effect the reciprocating axial movement of the drill bit.

Owner:LAGUNA OIL TOOLS

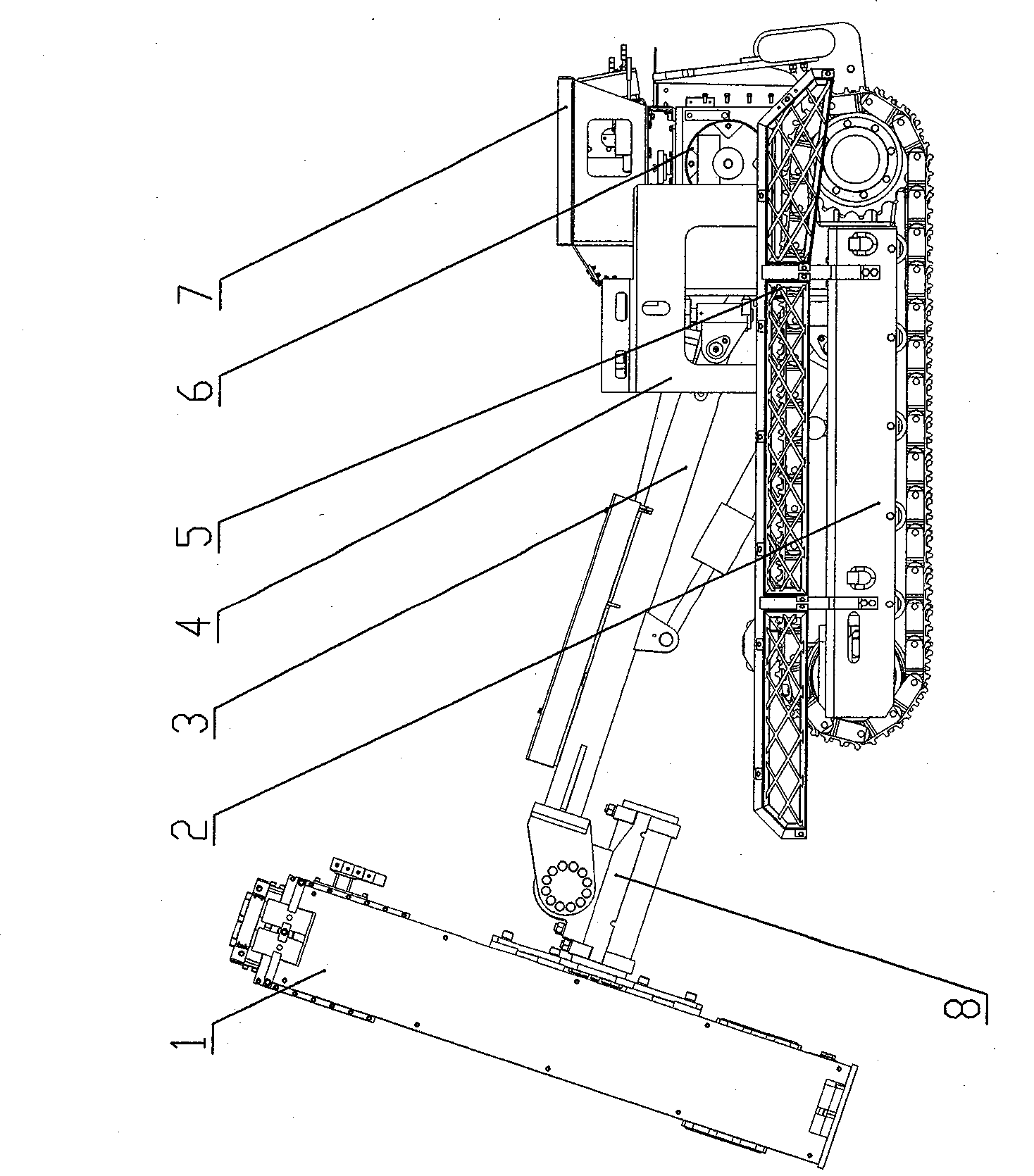

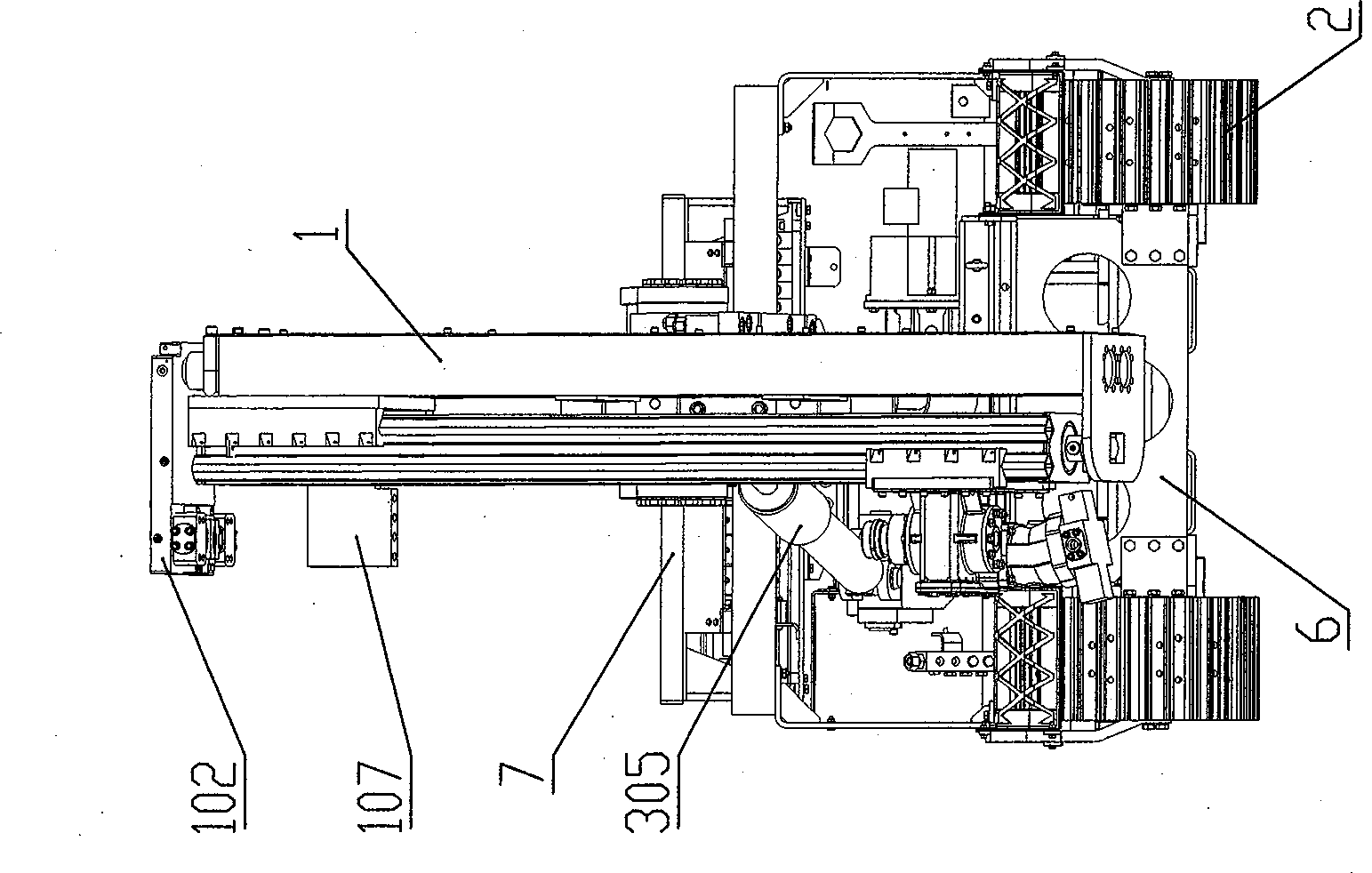

Hydraulic combined impact hammer drilling machine

ActiveCN104594802AChange the problem of difficult constructionImprove construction efficiencyDrilling rodsConstructionsControl engineeringWinch

The invention provides a hydraulic combined impact hammer drilling machine and relates to the field of engineering pile driver devices. The hydraulic combined impact hammer drilling machine comprises a power source, an integrated machine frame, a walking mechanism, a posture mechanism, a liftable reel pipe mechanism, an upper power head, a lower power head, a winch, a drilling rig clamper and a hydraulic combined impact hammer drilling bit. Track walking is adopted by the walking mechanism. The walking mechanism is driven by a hydraulic reducer. The integrated machine frame is installed on a body of the walking mechanism. The power source, the posture mechanism, the power heads, the liftable reel pipe mechanism and the hydraulic combined impact hammer drilling bit are installed on the integrated machine frame. The hydraulic combined impact hammer drilling machine can complete construction operation independently, solves the problems that during traditional construction, a pile foundation is in contact with a rock stratum, and construction is difficult and is high in construction efficiency and low in cost, the practicability and the flexibility of the hydraulic combined impact hammer drilling machine are greatly improved, and the application range of the hydraulic combined impact hammer drilling machine is greatly widened.

Owner:陶德明

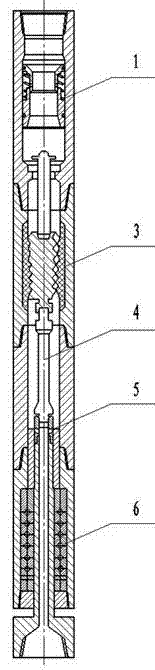

Down-hole rotary impact type drilling tool

InactiveCN103375132AReduce stick-slipReduce the possibility of failureDrilling drivesAxial displacementBall bearing

The invention relates to a down-hole rotary impact type drilling tool. The drilling tool is characterized in that an overflowing sleeve (1), an upper transmission spindle (6), a splined hub (8), an impact bearing seat (16) and a lower transmission spindle (22) are sequentially installed in a casing; an upper TC transverse bearing (4) and a rolling ball bearing pack (5) are sequentially installed outside the upper transmission spindle (6); a belleville spring (10), a vibration sleeve (12), a vibration starting seat (13), an impact heat (15), a PDC bearing (18), a lower TC transverse bearing moving ring (19) and a lower TC transverse bearing static ring (20) are sequentially mounted outside the impact bearing seat (16) and the lower transmission spindle (22); the impact heat (15) and the impact bearing seat (16) are connected through a flat key, the lower end face of the vibration sleeve (12) is connected with the upper end face of the vibration starting seat (13) through a flat key, and the vibration starting seat (13) is used for generating axial displacement and transmitting the axial displacement to the vibration sleeve (12) and the impact bearing seat (16). According to the down-hole rotary impact type drilling tool, low-amplitude high-frequency impact force is exerted on a drill, so that rock can be broken by the joint action of high-frequency periodical impact force with static-pressure rotation, the rate of penetration of hard stratums is effectively increased, drilling costs are reduced, and comprehensive technological and economic benefits of the drilling engineering are improved.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com