Drilling tool with dust collector

A drilling tool and dust collection device technology, which is applied in the field of drilling tools, can solve the problems of poor portability and rising costs, and achieve the effect of attractiveness, high efficiency, and prevention of external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

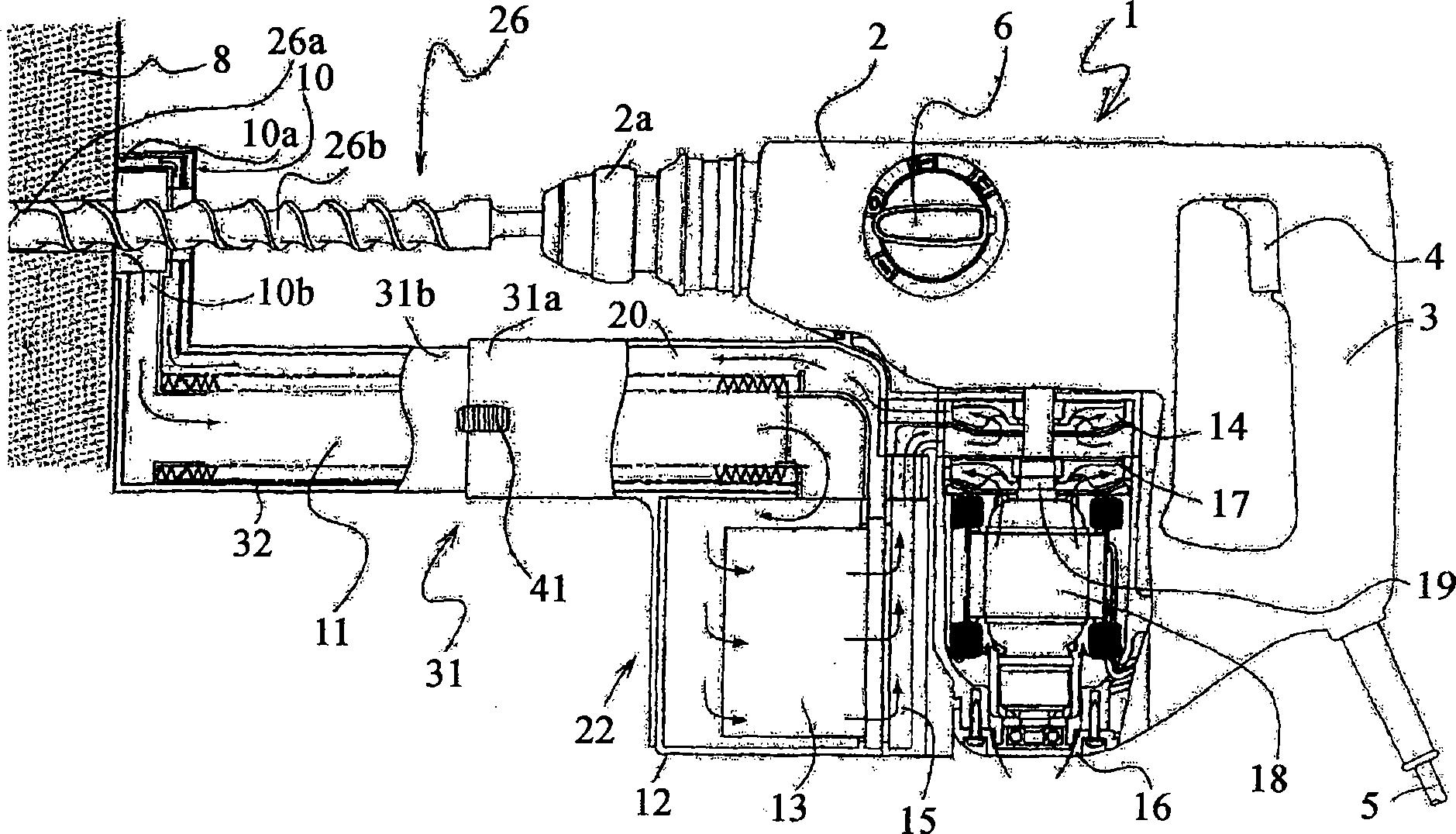

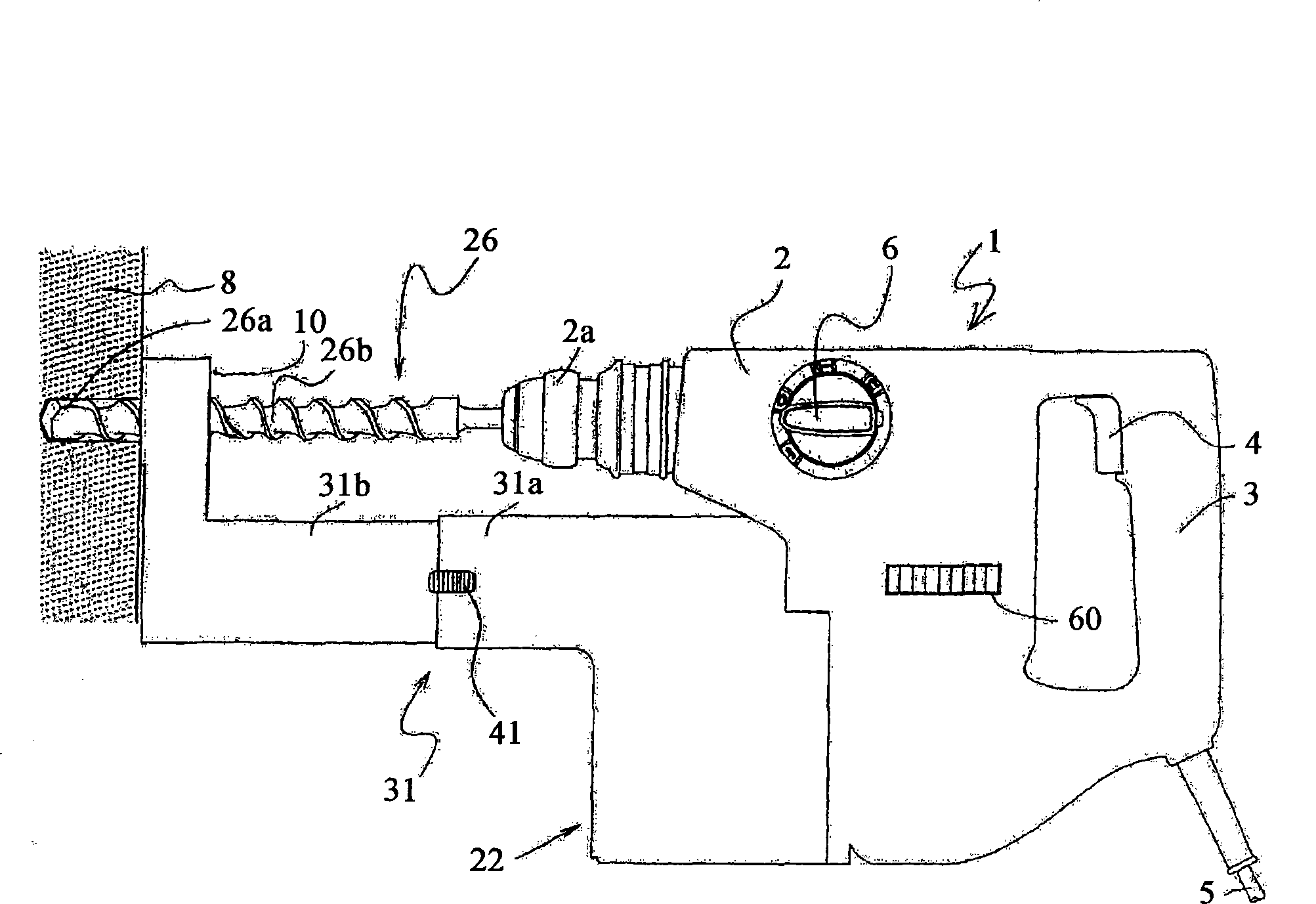

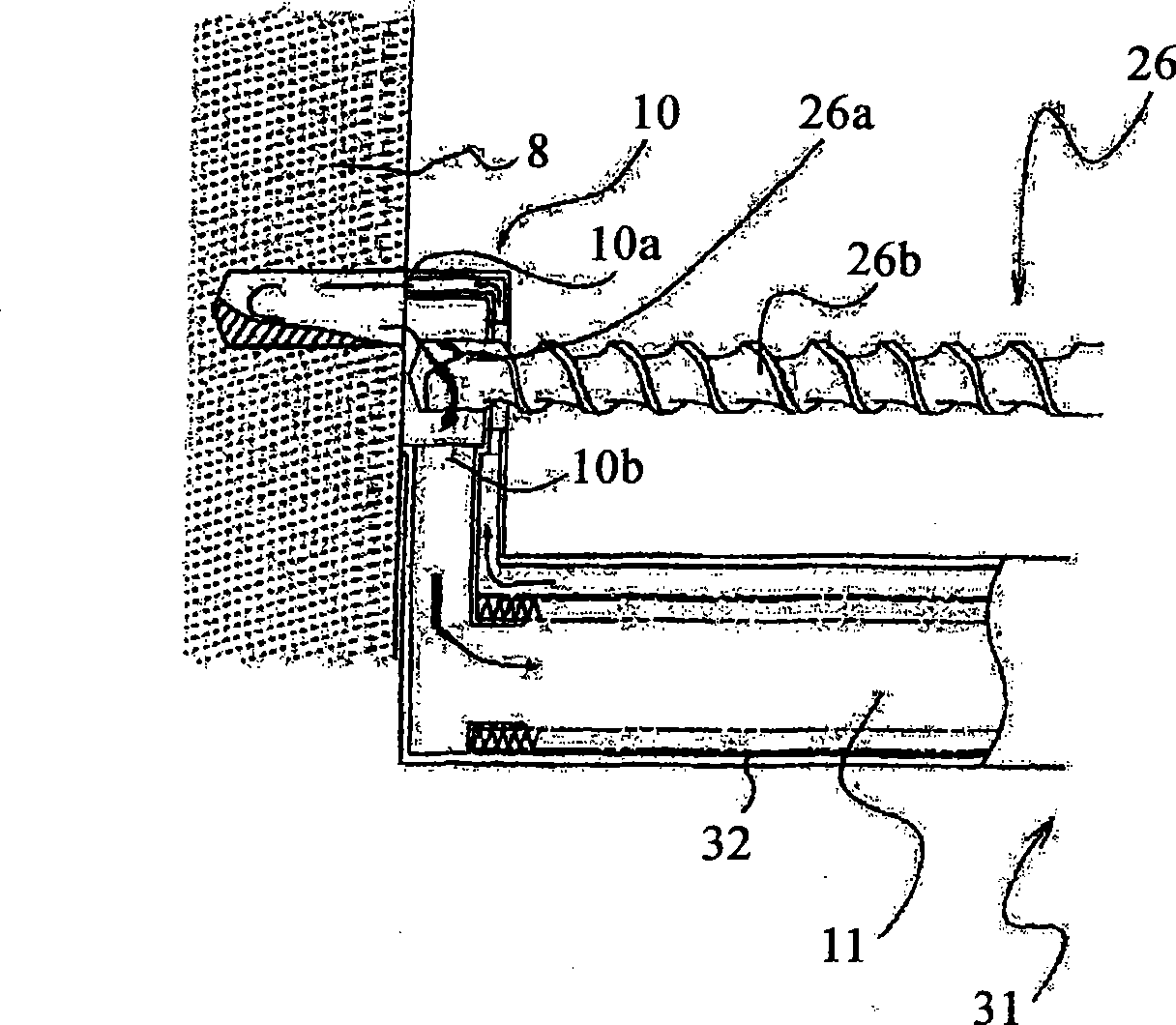

[0039] Below, refer to Figure 1 ~ Figure 2 , the drilling tool according to one embodiment of the present invention will be described. figure 1 is a partial cross-sectional view of the drilling tool, figure 2 is its appearance.

[0040] The hammer drill main body 1 has four modes as operation modes: rotation / impact mode, rotation mode, impact mode, and neutral (neutral) mode, and has an impact mechanism part, a rotation transmission mechanism part and Switch agency department. The rear end of the housing 2 ( figure 1 The right end of the handle 3) is provided with a handle 3, a switch 4 is provided on the handle 3, and an electric wire 5 for power supply is connected at the same time. A dial-shaped switch 6 for switching operation modes is provided on the side of the housing 2 . Utilize switch 6 can switch to above-mentioned four action modes. A tool holder 2a is provided at the front end of the housing, and a drill bit 26 is installed on the tool holder 2a. Homework ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com