Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

992 results about "Impact hammer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torsional impact drilling tool

ActiveCN101463709AReduce stick-slipReduce the possibility of failureVibration drillingRate of penetrationDrive shaft

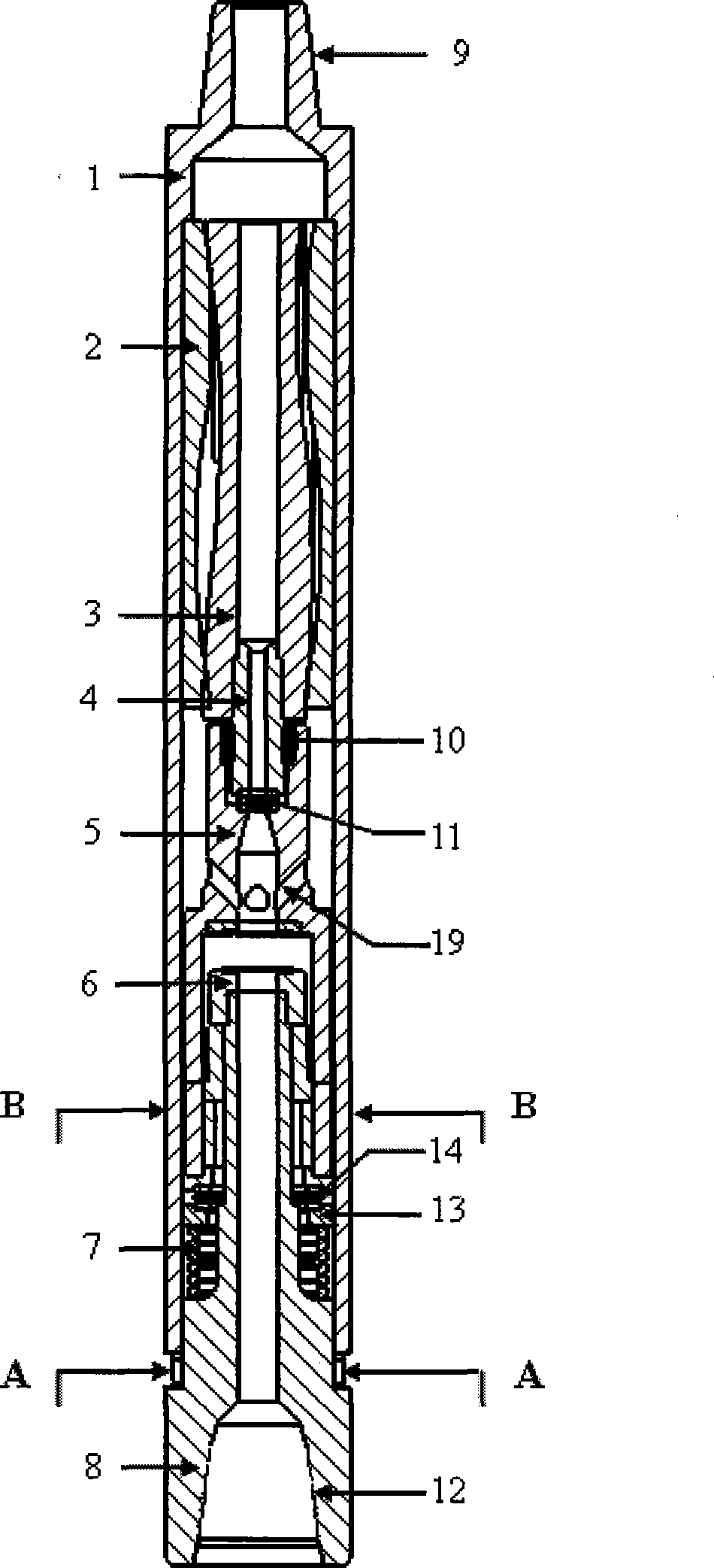

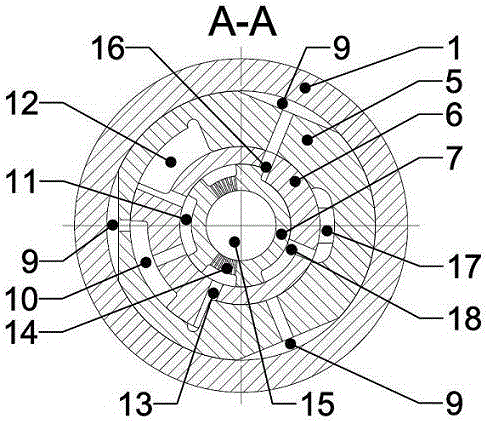

The invention relates to a torsional impact drilling tool used for applying low amplitude high frequency torsional impact to a drill bit during a drilling process, which can increase the drilling efficiency and the service life of the drill bit and lesson the tripping operation and the drilling cost. The technical scheme of the torsional impact drilling tool is as follows: a housing is connected with a short section of a drilling column led into the drill bit by a spline, and is positioned by a shaft shoulder; a screw motor rotor and a screw motor stator form a screw motor, the screw motor rotor is eccentrically connected to a transmission shaft by a universal shaft and two bearings, and four diversion holes are arranged on the transmission shaft; the lower end of the transmission shaft is connected with a carrier with a cavity; a sliding impactor is arranged in the cavity and is fixed by pins, and an impact hammer is arranged in the sliding impactor; a falling prevention ring is connected with the housing by screw threads; and the damping shaft shoulder on the short section of the drilling column led into the drill bit is matched with the impact hammer of the sliding impactor to form a ratchet wheel structure. The torsional impact drilling tool has simple structure, and can be used in hard strata of a deep well; and as being short, the tool is also applicable to the deflecting operation and can be used in crooked well holes, thereby reducing the phenomenon of stick-slip of the drill bit and improving the rate of penetration.

Owner:SOUTHWEST PETROLEUM UNIV

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

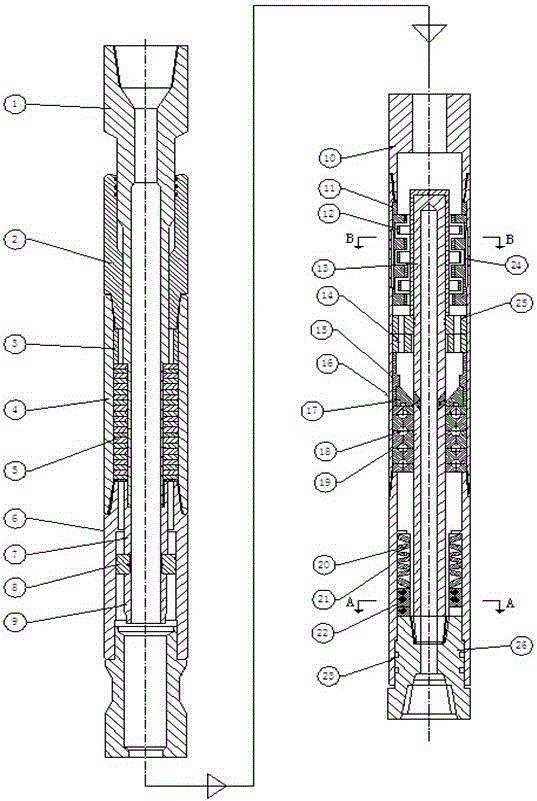

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

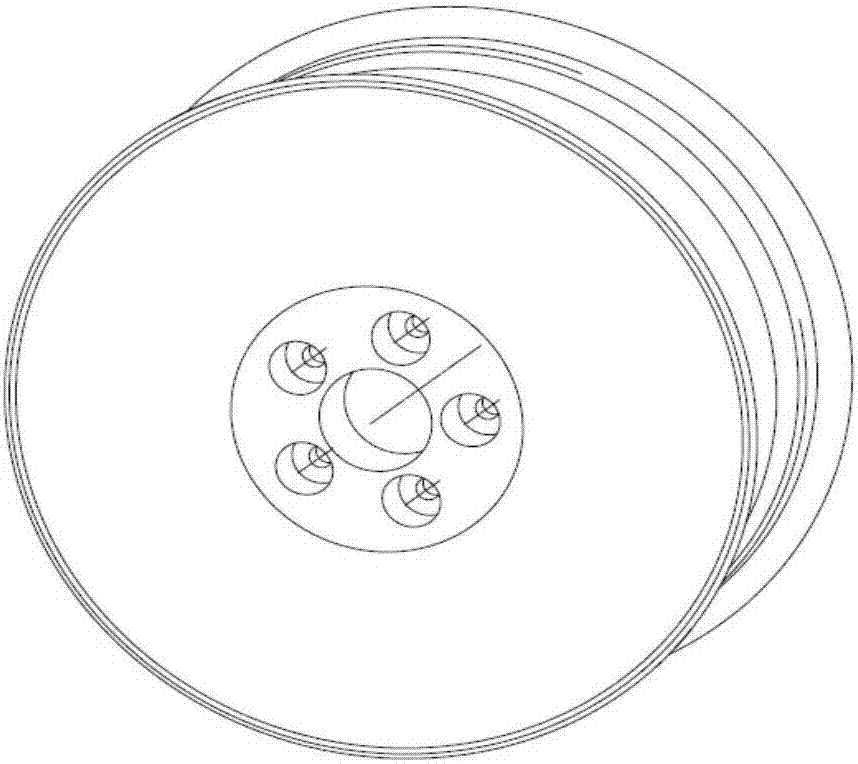

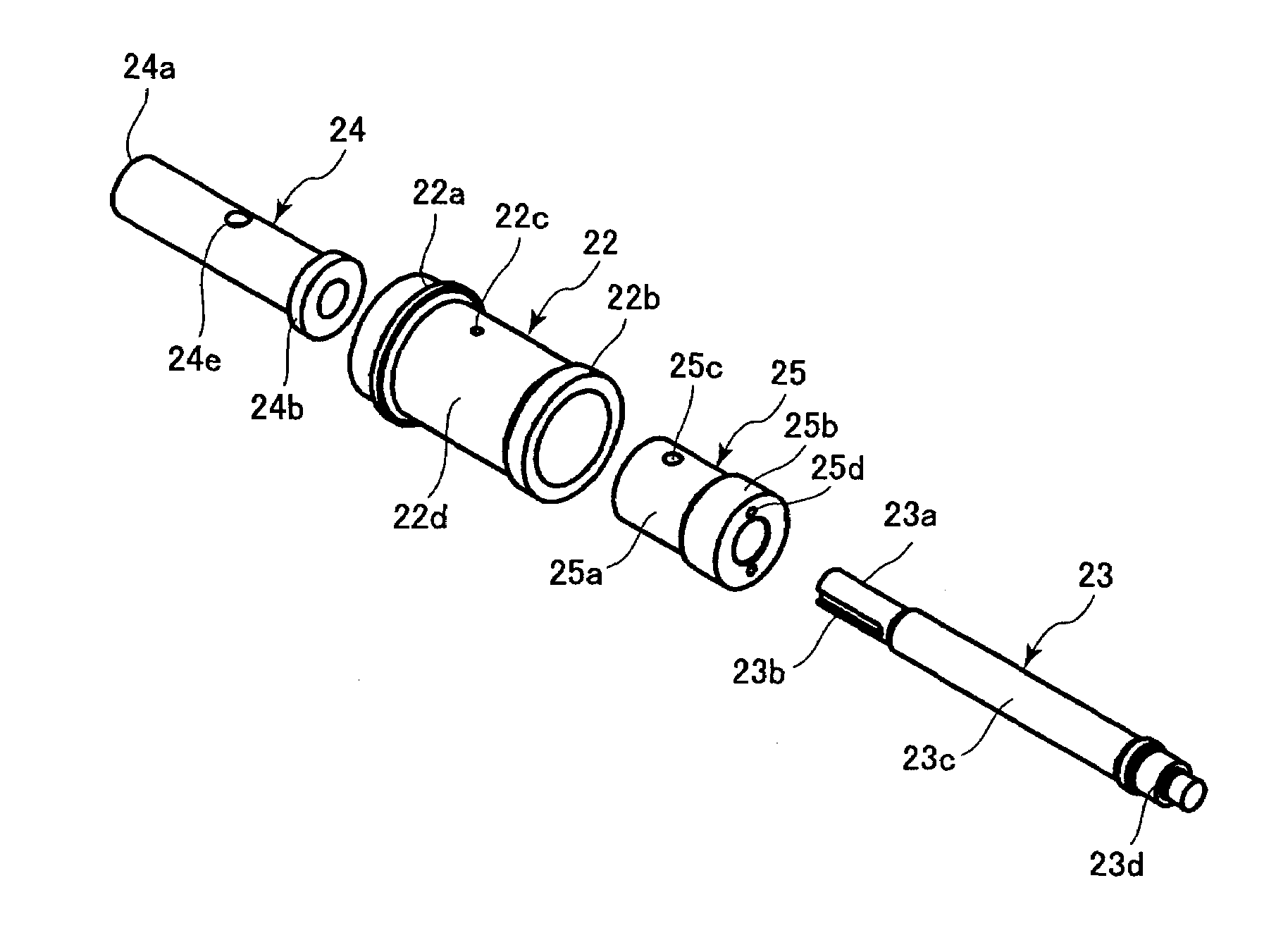

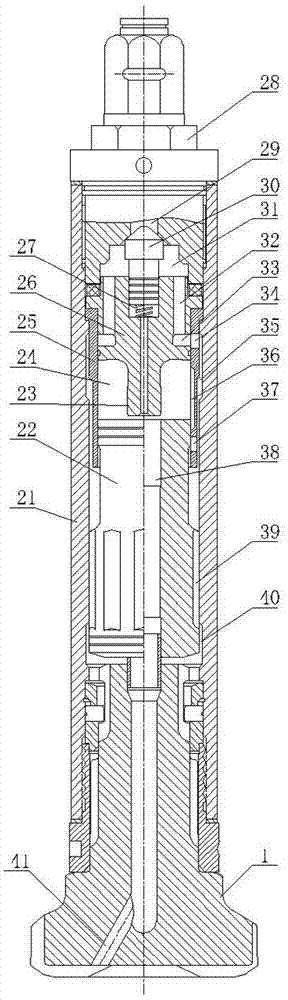

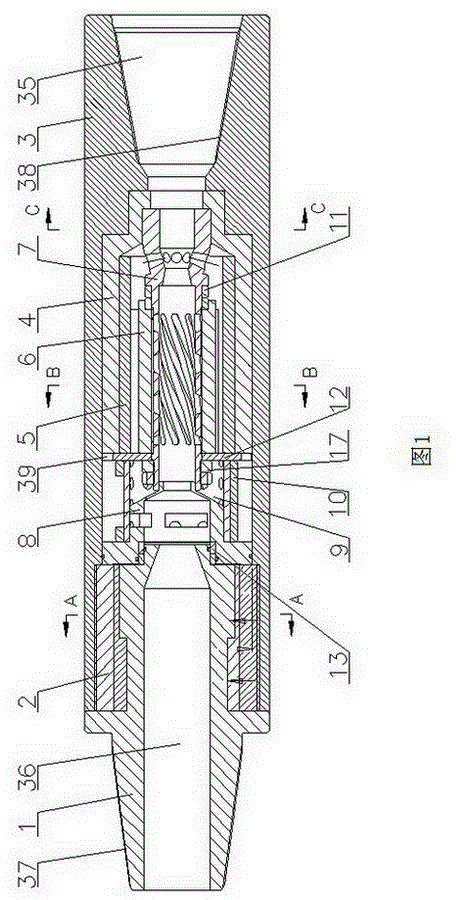

Torsional impact drilling tool

ActiveCN102454364ATorque stability and balanceReduce torsional oscillationsVibration drillingImpact hammerPetroleum engineering

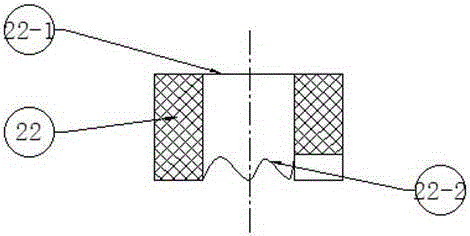

The invention discloses a torsional impact drilling tool which can apply high-frequency torsion impact to a drilling bit in the drilling engineering. The technical scheme of the torsional impact drilling tool is as follows: the torsional impact drilling tool mainly comprises a short section of a drill collar, a torsional impact generator and a connecting body, wherein the short section of the drill collar and the torsional impact generator are in clearance connection through the connecting body and are located by splines; a diversion cover is fixed on a hammer seat; a cavity is formed inside the diversion cover; a closure nozzle, a sieve tube, a locating sleeve and an impact hammer are sequentially arranged in the cavity from inside to outside; the sieve tube is fixed with the hammer seat; the impact hammer, the locating sleeve, the sieve tube and the hammer seat are provided with through holes in the circumferential direction; and an impact hammer head and a starting hammer head are processed on the impact hammer. The torsional impact drilling tool is arranged between the drill collar and the drilling bit; and the drilling bit receives the high-frequency torsional impact generated by the impact hammer under the driving of fluids while receiving the rotational torsion of a drill column. Compared with other drilling tools, the torsional impact drilling tool disclosed by the invention has the advantages that the high-frequency torsional impact can be generated, the sticking-sliding phenomenon of the drilling bit is eliminated, the mechanical drilling rate of harder or abrasive formation is increased, the service life of matched components, such as the drilling bit and the like of the drill column is prolonged, the drilling efficiency is improved and the drilling cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +3

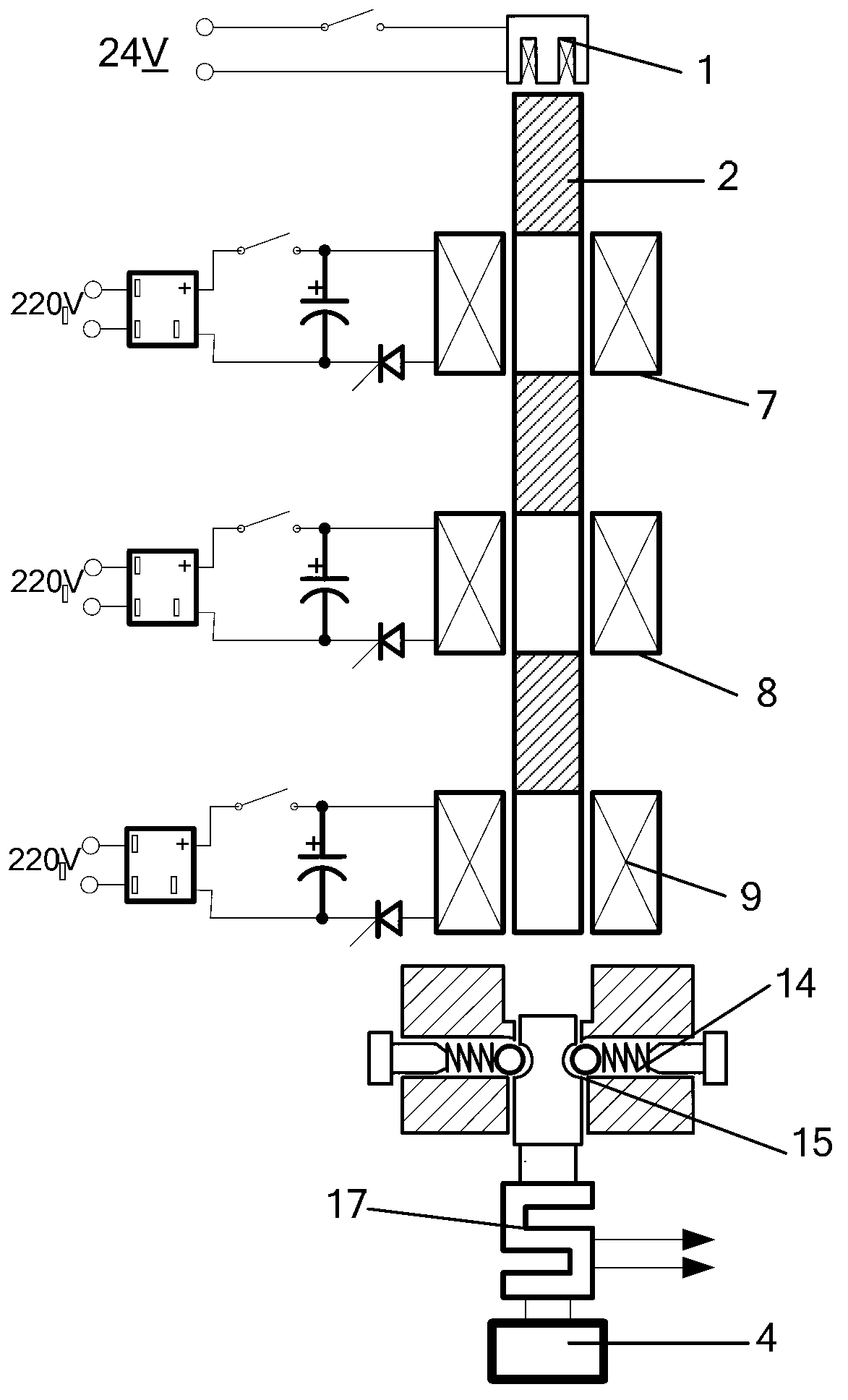

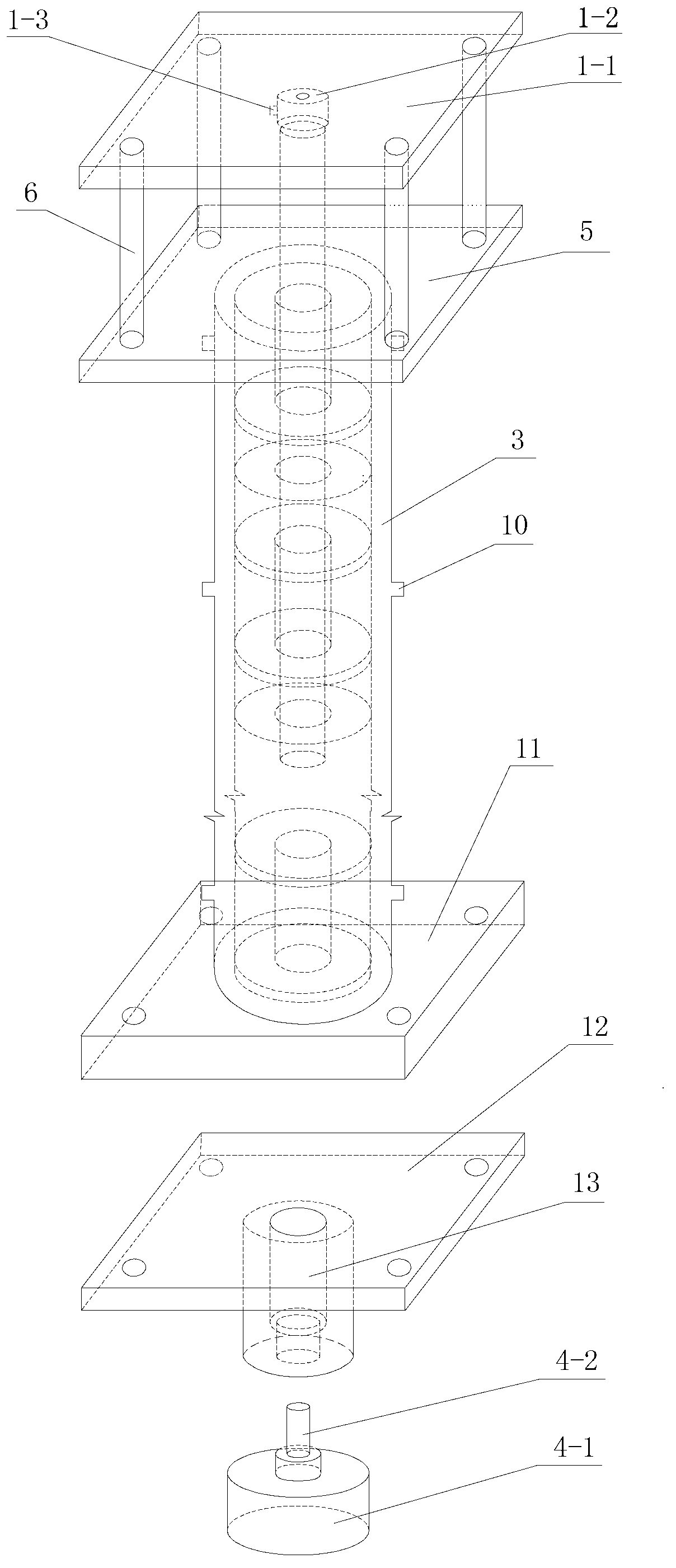

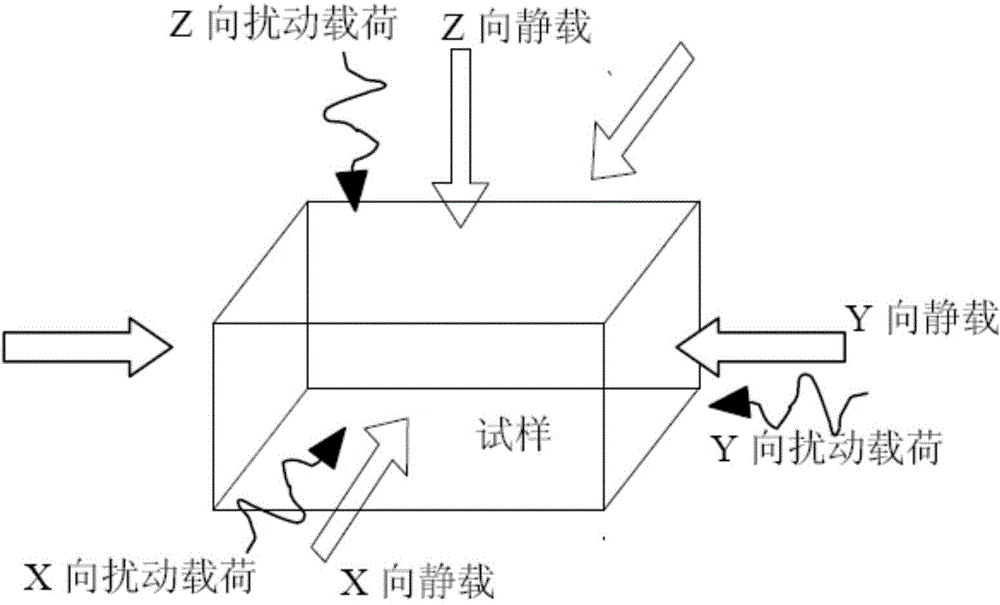

Multi-way high-energy high-speed electromagnetic force impact intelligent control testing device and method

InactiveCN103293069AIncrease impact speedImprove impact performanceShock testingStrength propertiesControl systemHigh energy

The invention discloses a multi-way high-energy high-speed electromagnetic force impact intelligent control testing device and method. The device comprises an electromagnet component, an impact rod, an outer sleeve, an electromagnetic acceleration coil group and an impact hammer, wherein the electromagnet component, the impact rod and the impact hammer are arranged above the outer sleeve, in the sleeve and below the sleeve, respectively; multi-stage electromagnetic acceleration coils arranged at the periphery of the impact rod are respectively and externally connected with a circuit control system. According to the method, acceleration is realized through sequential electromagnetic functions of the multi-stage electromagnetic acceleration coils in a moving process of the impact rod, and the impact energy and speed are increased and can be adjusted; the impact is set and limited in any direction through a base and the electromagnet component. According to the device and method, the electromagnetic stage acceleration impact rod is adopted, the impact speed and impact energy of the impact rod can be effectively increased and adjusted, the direction can be set according to the needs, the impact force is over 1000 times that of the weight of the impact hammer, the maximum times approximates to 3,000, a mains supply is used as a power source, and the device is well applied to a solid dielectric test in the field of civil engineering.

Owner:GUANGDONG UNIV OF TECH

Percussive down-the-hole hammer for rock drilling, and a drill bit used therein

InactiveUS6502650B1Easy to manufactureLow production costDrill bitsBorehole drivesPortion sizeReciprocating motion

A down-the-hole percussive hammer for rock drilling includes a cylindrical casing and a drill bit disposed at a front end of the casing. The drill bit includes a forwardly facing cutting surface and a center longitudinal passage extending forwardly through a rearwardly facing rearwardmost end surface of the drill bit. The passage includes a rearwardly facing impact surface. A piston is mounted in the casing longitudinally behind the drill bit for reciprocation in a longitudinal direction. The piston includes a front portion sized to enter the center passage of the drill bit and strike the impact surface of the drill bit during each forward stroke of the piston. The impact surface of the drill bit is spaced forwardly from the rearwardmost end surface of the drill bit by a distance of at least ten percent of a total longitudinal length of the drill bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Drilling hammer or impact hammer

InactiveUS6675908B1Reduce MechanismsReciprocating drilling machinesPortable percussive toolsAxial displacementEngineering

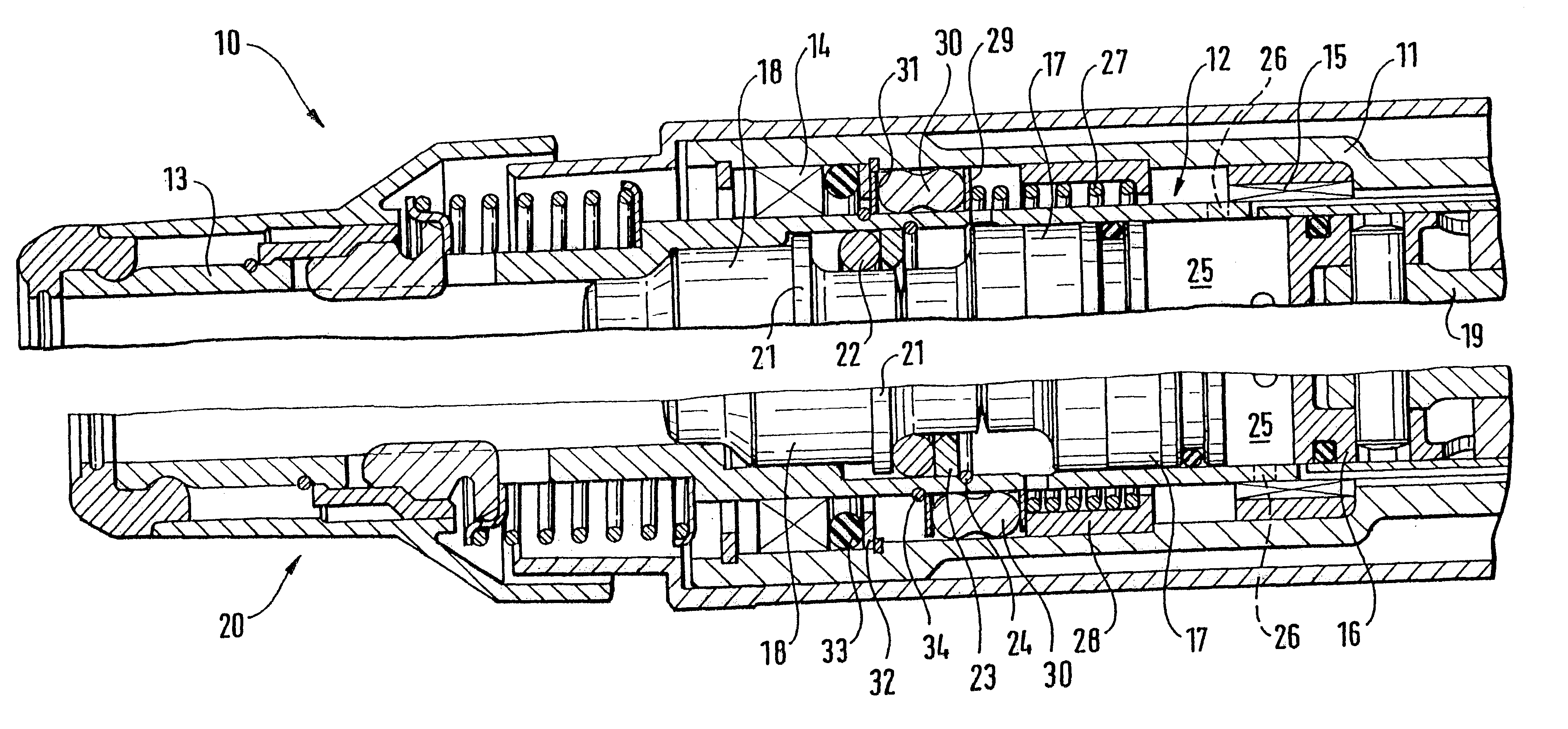

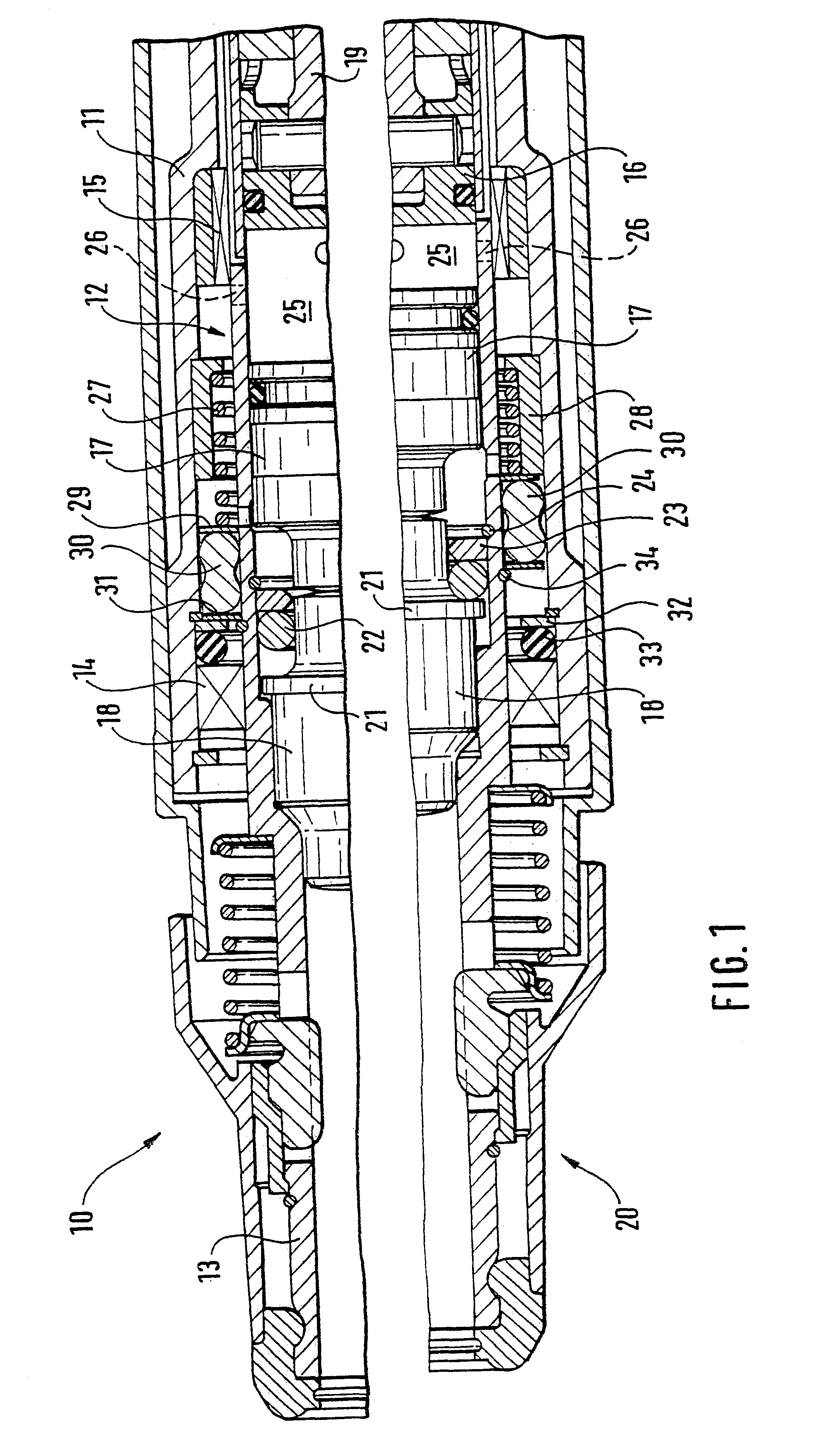

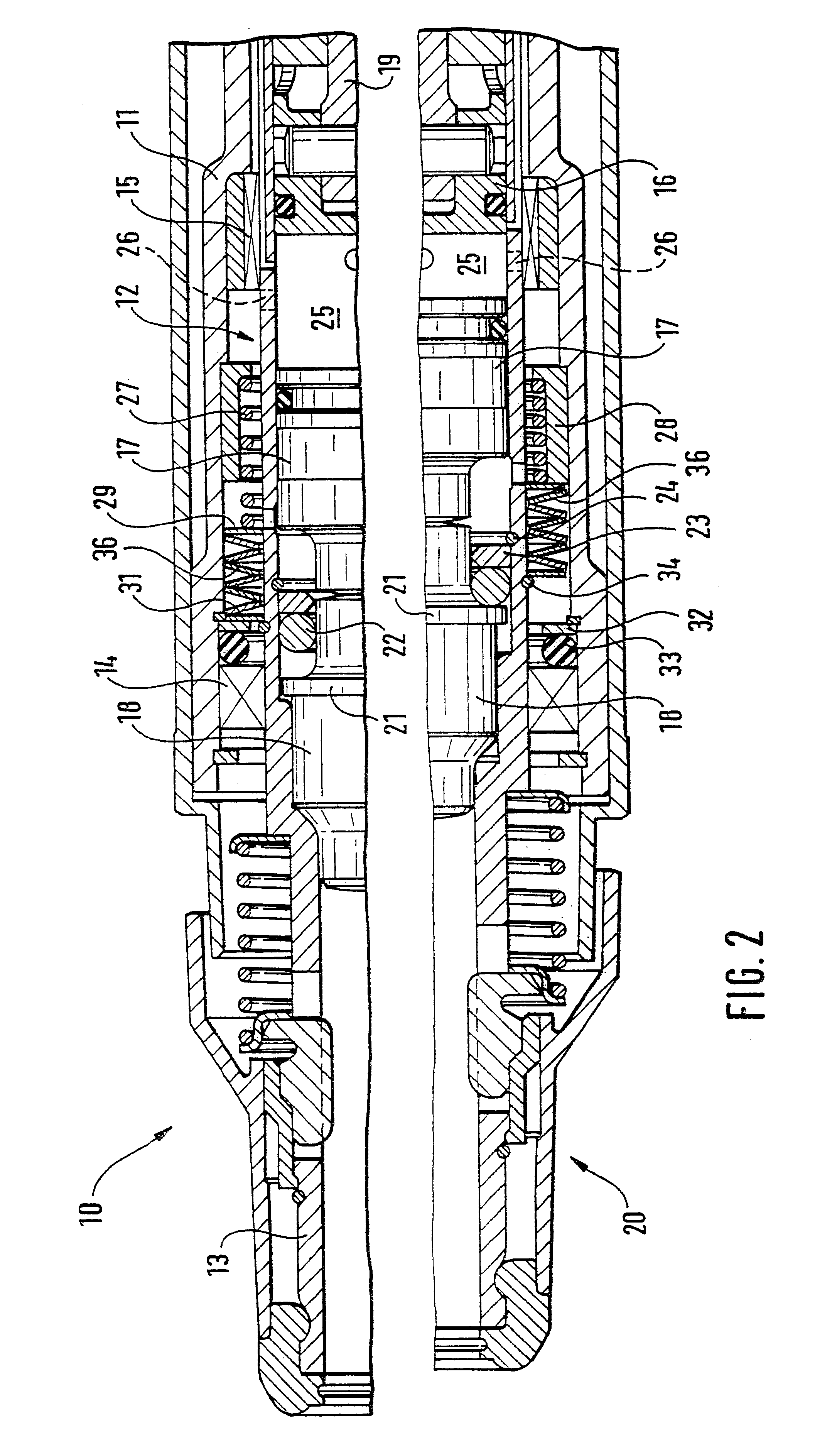

A drill hammer or riveter, includes a housing (11), in which a hammering mechanism (12) is accommodated that in an axially displaceably supported guide tube (13) has a reciprocating piston (16) and a striker (17), drivable by the piston (16) via an air cushion; the hammering mechanism (12) can be moved out of an idling position into a hammering position by an axial displacement of the guide tube (13); the guide tube (13) is urged by a restoring spring (27) in the direction of the idling position with a restoring force: and between the guide tube (13) and the housing (11), at least one damping and / or spring member (30, 36, 37) is provided, which in the hammering position of the guide tuber (13) has a spring or damping characteristic between the guide tube (13) and the housing (11) that deviates from the restoring spring (27) in the region of the idling position.

Owner:ROBERT BOSCH GMBH +1

Percussive down-the-hole hammer for rock drilling, a top sub used therein and a method for adjusting air pressure

InactiveUS6454026B1Simple and inexpensive adjustabilityEasy to adjustDrill bitsReciprocating drilling machinesReciprocating motionEngineering

A down-the-hole percussive hammer includes a cylindrical casing adapted to carry a drill bit, and a piston mounted in the casing for reciprocal movement to repeatedly strike the drill bit. A top sub is mounted at a rear portion of the casing, the top sub including a front face facing the piston. A feed tube is mounted to the top sub and extends forwardly along a center axis of the casing and defines an air-conducting passage. The piston includes an axial through-hole which slidably receives the feed tube. The front face and the feed tube together define a recess opening toward the piston. A removable volume-changer is insertable into the recess to vary a volume of a space in which the piston slides, and thus control a pressure at which the piston operates.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Multi-objective optimization design method for wheel

ActiveCN107145663AImprove performanceAvoid defects where performance does not meet requirementsGeometric CADSustainable transportationTopology optimizationEngineering

The invention discloses a multi-objective optimization design method for a wheel, relates to the technical field of vehicle engineering and aims at solving the problems that the optimization space is limited and automatic optimization design is not carried out through joint transferring of calculation software with various properties due to the fact that only limited performance of the vehicle is analyzed and optimized and parametric modeling is lost at present. The method comprises the steps of topological optimization of a wheel fatigue test, combined topological optimization modeling, fatigue performance analysis, impact performance analysis, aerodynamic performance analysis and multi-objective optimization. Five working conditions of a dynamic bending fatigue test of the wheel, a dynamic radial fatigue test, an impact test of an impact hammer opposite to a spoke, an impact test of the impact hammer opposite to a window and air dynamics analysis of the wheel are set; the properties, such as the strength, the rigidity, the vibration characteristic, the fatigue life, the fatigue life security coefficient, the impact performance, the air dynamic property and the lightweight performance of the wheel are comprehensively considered; various performance parameters are calculated through finite element software emulation; and optimization design is carried out on the wheel by setting the performance parameters to be constraint conditions or objective functions.

Owner:JILIN UNIV

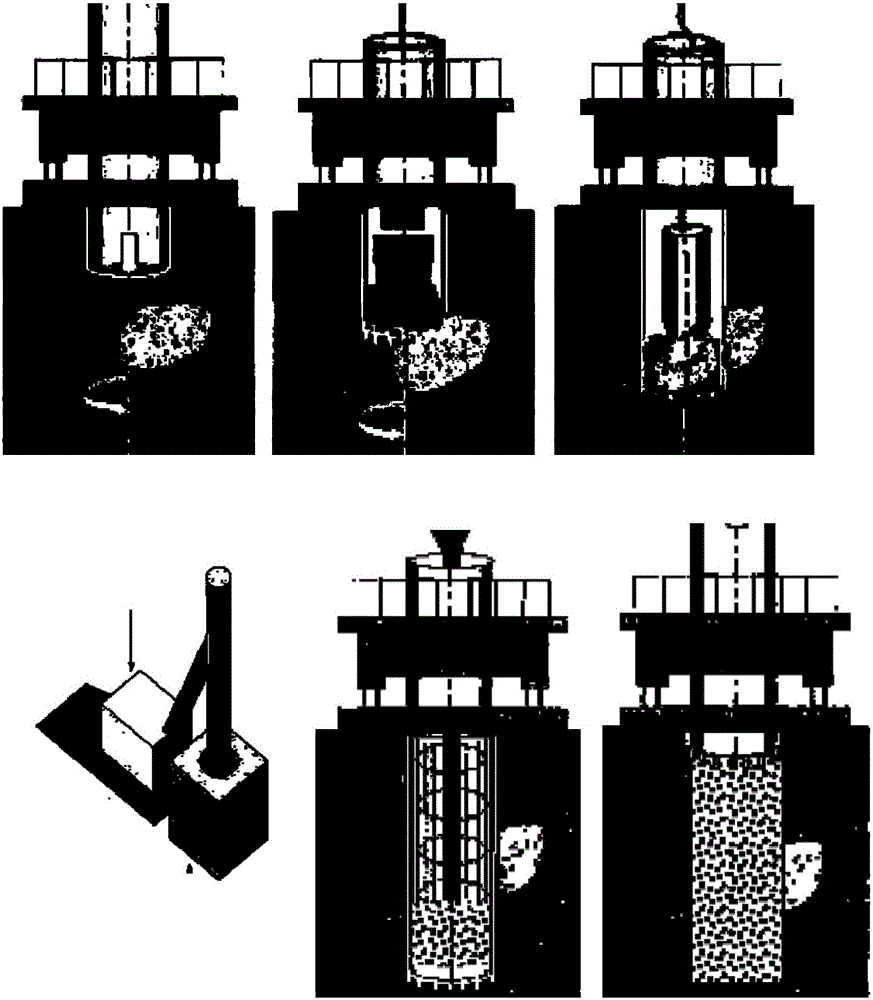

Large-diameter super-long pile construction method in karst area through full-casing pipe full rotating and rotary drilling

The invention belongs to the technical field of super-long pile construction of engineering construction, and discloses a large-diameter super-long pile construction method in the karst area through full-casing pipe full rotating and rotary drilling. The method comprises the steps of selecting the types of full casing pipes, rotating the installing casing pipes by 360 degrees, pressing the first casing pipe, checking the perpendicularity, alternately using a punching grab hand and an impact hammer, grabbing land rocks through a grab bucket, drilling the casing pipes to the hole bottoms, measuring the hole depth, carrying out hole cleaning for the first time, installing manufactured reinforcement cages, carrying out butt joint on the reinforcement cages, installing manufactured guide pipes subjected to pressure-bearing tests and sealing tests, arranging water isolation bolts, carrying out hole cleaning for the second time, pouring manufactured concrete, measuring the height of the concrete, pulling the guide pipes and the casing pipes sequentially, verifying the perpendicularity and pulling the casing pipes before initial setting of the concrete. According to the method, the pile driving efficiency of projects is improved, and the total cost of the projects is lowered.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD

Sleeve grouting compactness detection device and detection method

InactiveCN106596298AImprove reliabilityGuaranteed seismic performanceMaterial strength using single impulsive forceAudio power amplifierRebar

The invention discloses a sleeve grouting compactness detection device and a detection method. The device comprises an impact hammer, a guider, a grout outlet, a grout inlet, a grouting material, a sleeve, a steel bar, a sensor, a signal amplifier and a computer. The sleeve is internally provided with the steel bar and is grouted, the sensor is pasted on the surface of grout at the grout inlet of the detected sleeve, the guider is pasted on the surface of grout at the grout outlet of the sleeve, the impact hammer impacts the guider for whipping, the sensor receives a vibration reflected signal, the signal amplifier amplifies and stores the received reflected signal, and the computer reads the signal stored by the signal amplifier. The technology makes up the blank of existing sleeve grouting compactness detection technology, and improves the sleeve grouting quality and steel bar connection reliability, thus guaranteeing the seismic performance of a fabricated structure, enhancing the technological level of fabricated structure, and promoting the development of the construction industry modernization cause.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Drop hammer impact testing machine

InactiveCN101581646AShorten test timeReduce labor intensityStrength propertiesCatch and releaseChange positions

The invention discloses a drop hammer impact testing machine, which comprises an iron block, a drop hanger, a wire cable, a grapnel device and a rail holding device. The invention is characterized in that a beam, an upright post, a cross arm and a support are fixed to form a frame of the impact testing machine via screw bolts; a pulley is mounted on the beam and below the upright post; one end of the wire cable is arranged on the beam, and the other end thereof is connected with a power unit through the drop hanger and the pulley; the drop hanger is provided with a drop hanger device for catching and releasing an impact hammer; the rail holding device is fixed in the middle position below the upright post. By using the invention, automatically catching the hammer and automatically decoupling can be realized while the rail cannot change position to finish repeated impact tests, thus saving testing times, reducing labor strength and improving work efficiency greatly.

Owner:武汉凯盟机电工程有限公司

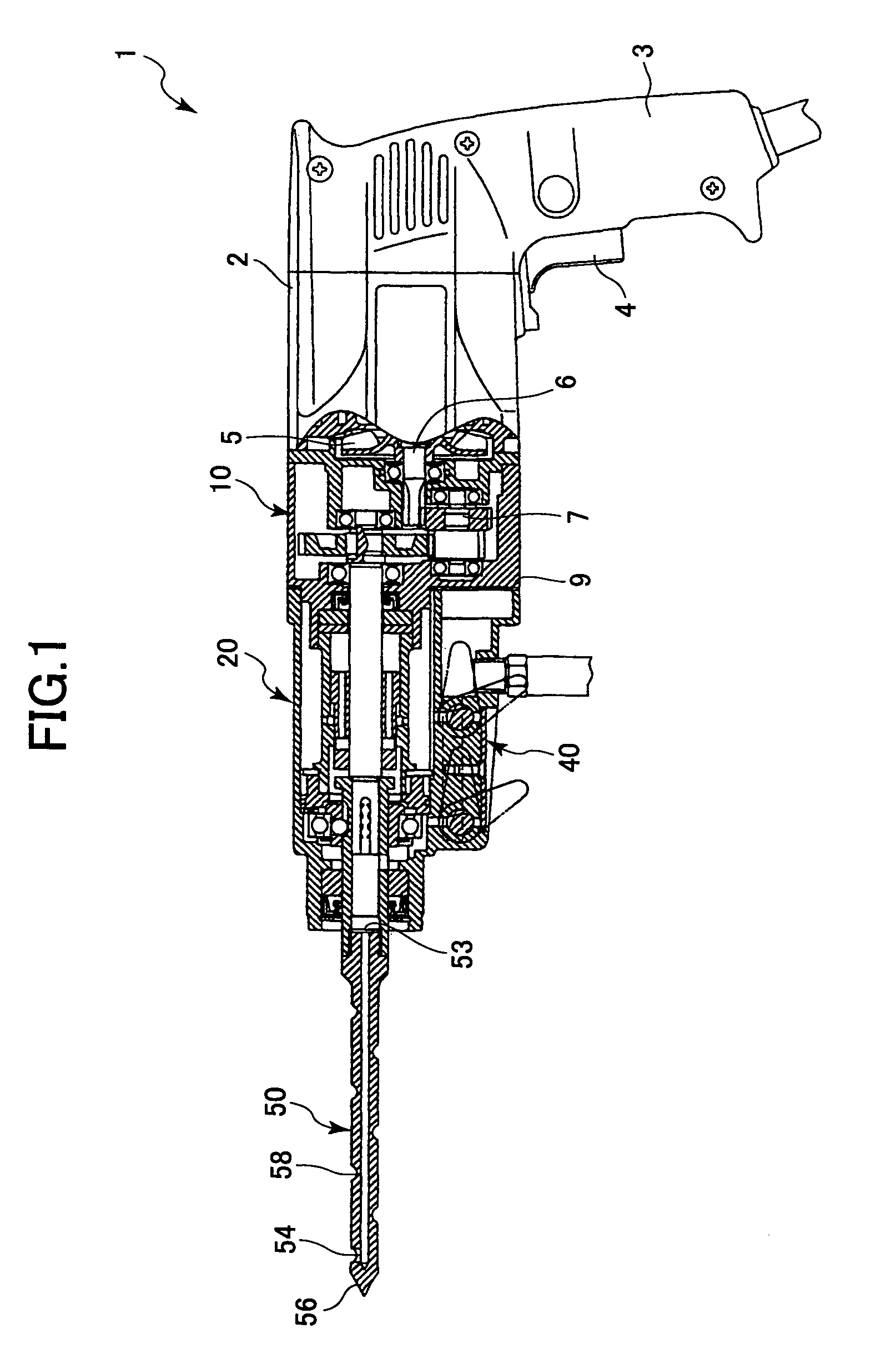

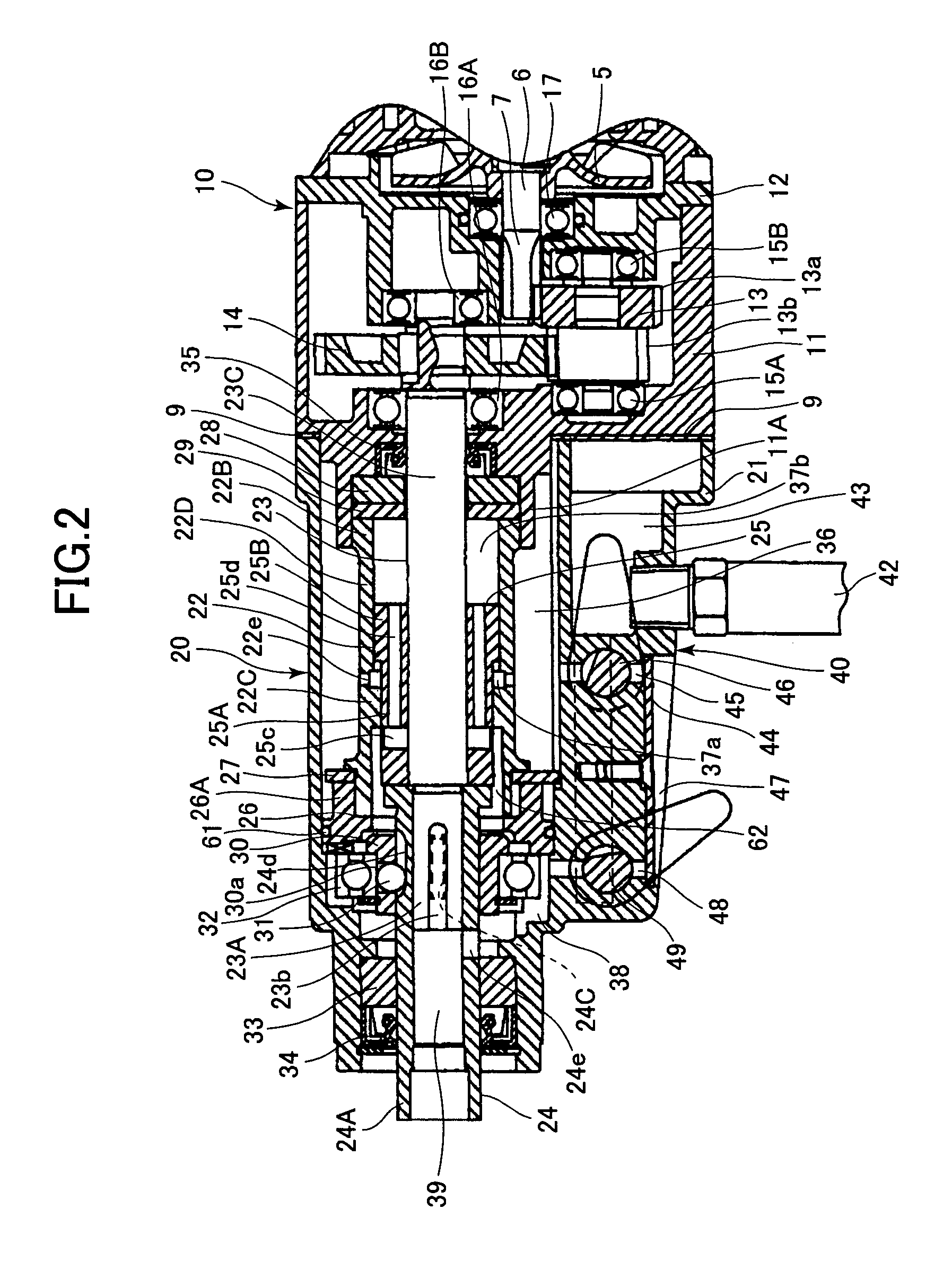

Impact hammer drill

InactiveUS7306047B2Increase speedReduce noiseReciprocating drilling machinesPortable percussive toolsLow noiseCompressed fluid

An impact hammer drill capable of performing drilling operation at a high speed with low noise and without requiring a large thrust. The drill includes a main shaft rotatable by an output shaft of a motor, and a spindle having an impact-receiving section and disposed over the main shaft slidably in its axial direction and rotatable together with the rotation of the main shaft. A piston is reciprocatingly slidably disposed over the main shaft for impacting against the impact-receiving section. A piston drive unit is disposed for driving the piston with a compressed fluid. A compressed fluid supplying unit is disposed for supplying the compressed fluid to the piston drive unit. A drill bit is attachable to the spindle. When performing drilling operation, the drill bit is imparted with a combined rotational motion and the reciprocal impact motion.

Owner:KOKI HLDG CO LTD

Pneumaticaly driven pipe swedging and flaring tools

InactiveUS7578161B1Forging/hammering/pressing machinesHeat exchange apparatusEngineeringMechanical engineering

Tools for expanding (i.e., flaring and swedging) the ends of metal tubes are configured for attachment to a powered impact hammer, such as an air hammer. A swedging tool for swedging an end of a metal tube has a swedging body with a die section for expanding the tube when driven thereinto and a flanged shank attached to the swedging body and configured for engagement by a powered impact hammer. A flaring tool for flaring an end of a metal tube includes a flaring body having a die section for flaring the tube when driven thereinto. A flanged shank is attached to the flaring body and configured for engagement by a powered impact hammer. A method for expanding an end of a metal tube entails attaching a die body for expanding the end of the metal tube to a powered impact hammer, aligning the die body with the inner diameter of the metal tube, activating the powered impact hammer, and urging the die body a determined distance into the metal tube.

Owner:SIZEMORE MARION M

Rotating impact acceleration device and method of power drilling tool

The invention relates to a rotating impact acceleration device and a method of a power drilling tool. The device is characterized in that a rotor transmission shaft, a driving tooth-shaped impact hammer and a driven impact transmission joint are mounted at the inner side of a stator outer cylinder; the lower end of the rotor transmission shaft is in threaded connection with the driven impact transmission joint; the middle part of the rotor transmission shaft and the middle part of the stator outer cylinder are formed to a cylindrical cavity; an impact force accumulating spring is mounted in the cavity; the lower end of the impact force accumulating spring fits the driving tooth-shaped impact hammer; a tooth-shaped curved surface is arranged at the lower end of the driving tooth-shaped impact hammer, and is engaged with a tooth-shaped curved surface at the upper end of the driven impact transmission joint; the driven impact transmission joint is driven by the rotor transmission shaft to generate a rotating motion corresponding to the driving tooth-shaped impact hammer; and the driving tooth-shaped hammer and the impact force accumulating spring generate axial reciprocating impact on the driven impact transmission joint to realize the rotation and the impact. The device is simple in structure and shorter in length, and dose not influence the operations of the power drilling tool and a measuring tool while drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

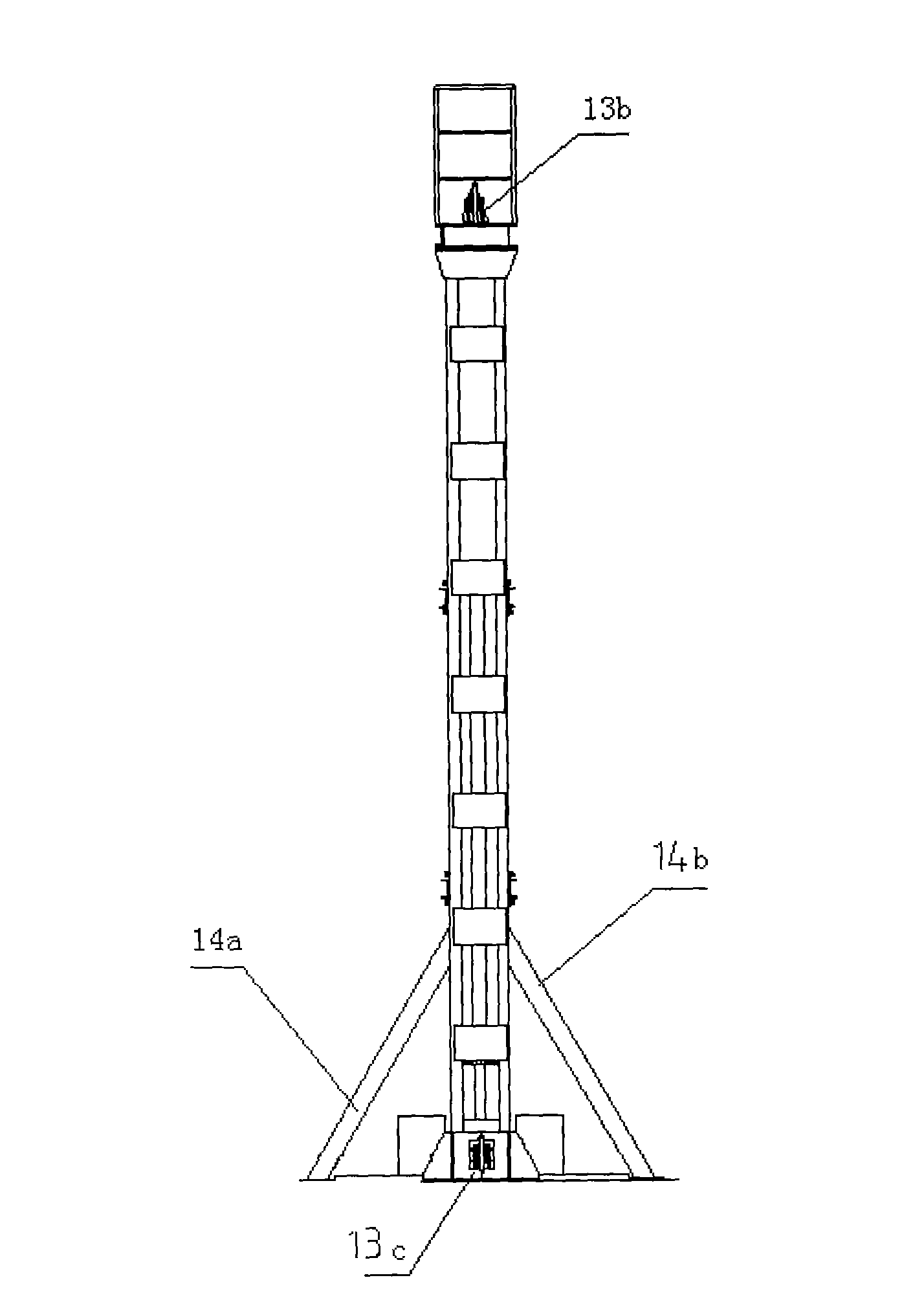

Walking dual-swing downhole drill

ActiveCN102828690AFully lubricatedOil Mist StabilizationConstructionsReciprocating drilling machinesEngineeringHigh pressure

The invention discloses a walking dual-swing downhole drill, which comprises a pile frame main body and a drilling main body, wherein the drilling main body comprises an upper power head, a lower power head, an outer sleeve, a spiral drill stem and a downhole hammer; the upper power head is connected with the top end of the spiral drill stem; the bottom end of the spiral drill stem is connected with the downhole hammer; the upper power head drives the spiral drill stem and the downhole hammer to rotate clockwise when working; the lower power head is connected with the outer sleeve and drives the outer sleeve to rotate anticlockwise when working; the downhole hammer comprises an impacter and an impact hammer; the hammer head of the impact hammer is exposed out of the lower opening of the outer sleeve; a high-pressure gas channel is arranged inside the drilling main body, and the high-pressure gas passes through the upper power head, a buffer, the spiral drill stem and the impacter and is finally blown outwards from the bottom part of the impact hammer. The walking dual-swing downhole drill has main characteristics of taking soil to form a hole by a dry method without pollution, and being adapted to various geologies and stratums, such as hard lithosphere, tundra, sand bed with abundant underground water, a rubble layer and boulder, which are difficult to drill by other pile drivers.

Owner:瑞安市八达工程机械有限公司

Rotary Impact Mill

In one aspect of the invention, a rotary impact mill has a milling chamber defined by a housing with an inlet, an outlet, and at least one wall. A plurality of impact hammers located within the milling chamber are fastened to and longitudinally disposed along a rotor assembly that is connected to a rotary driving mechanism. At least one of the impact hammers has a plurality of inserts arranged adjacent one another in a row and attached to a body of the hammer, wherein a first end of at least one insert is complementary to a second end of an adjacent insert.

Owner:NOVATEK IP

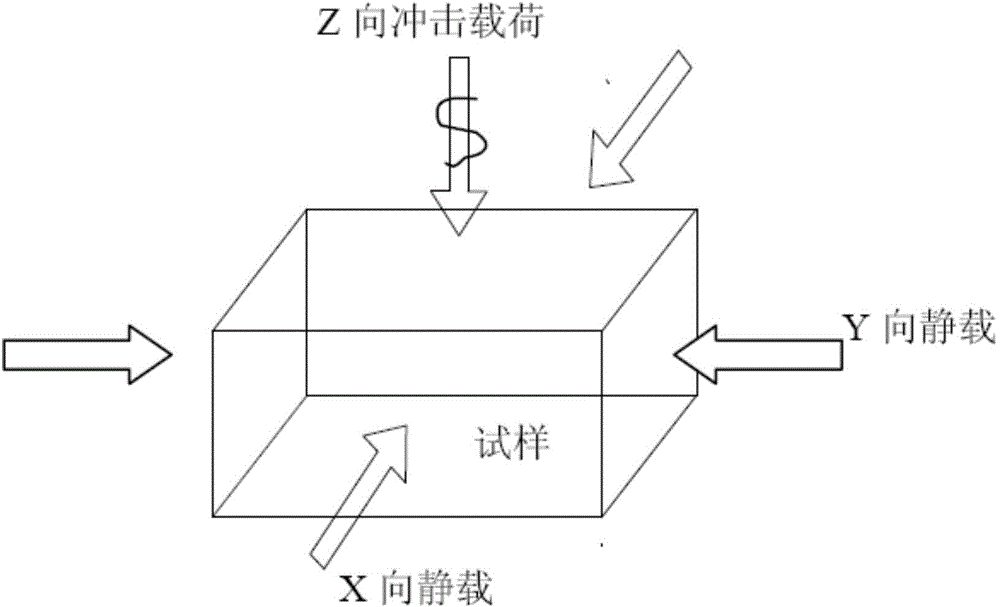

Impact disturbance surrounding rock testing equipment

The invention discloses impact disturbance surrounding rock testing equipment which comprises a top plate, a base, support standing columns, screw columns, a crossbeam, a crossbeam lifting motor and reducer part, a chain gear, an impact hammer, an impact hammer guide rod, a horizontal X-direction loading clamp plate, a horizontal Y-direction loading clamp plate, a horizontal X-direction servo hydraulic cylinder, a horizontal Y-direction servo hydraulic cylinder, a vertical Z-direction servo hydraulic cylinder, and an acceleration sensor. The impact disturbance surrounding rock testing equipment can apply static and dynamic loads to a large-size rock sample in three directions and apply certain waveform impact loads to the large-size rock samples along the vertical direction so as to simulate the disturbance response condition of the rock sample in a deep high stress environment.

Owner:HUNAN UNIV OF SCI & TECH

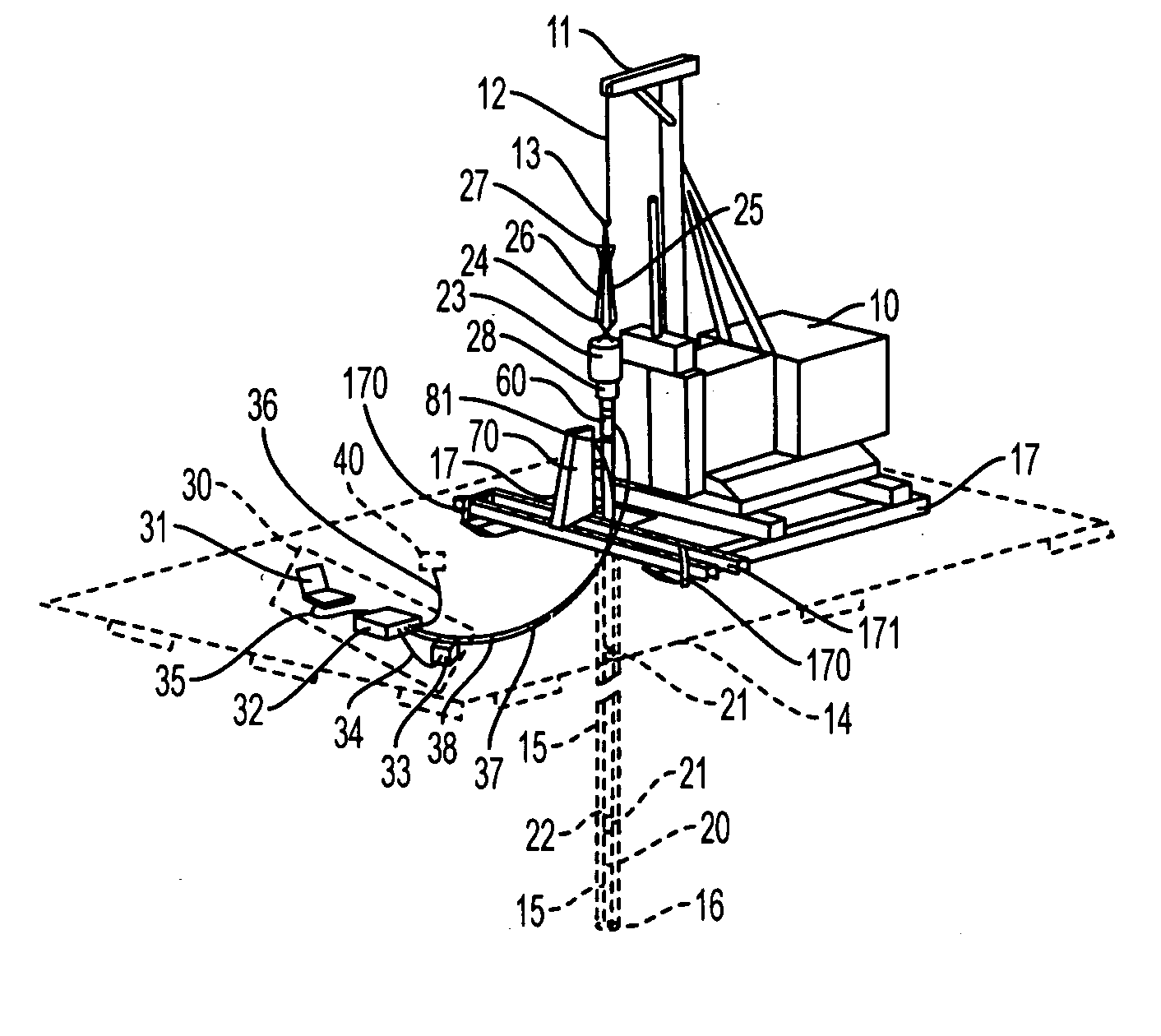

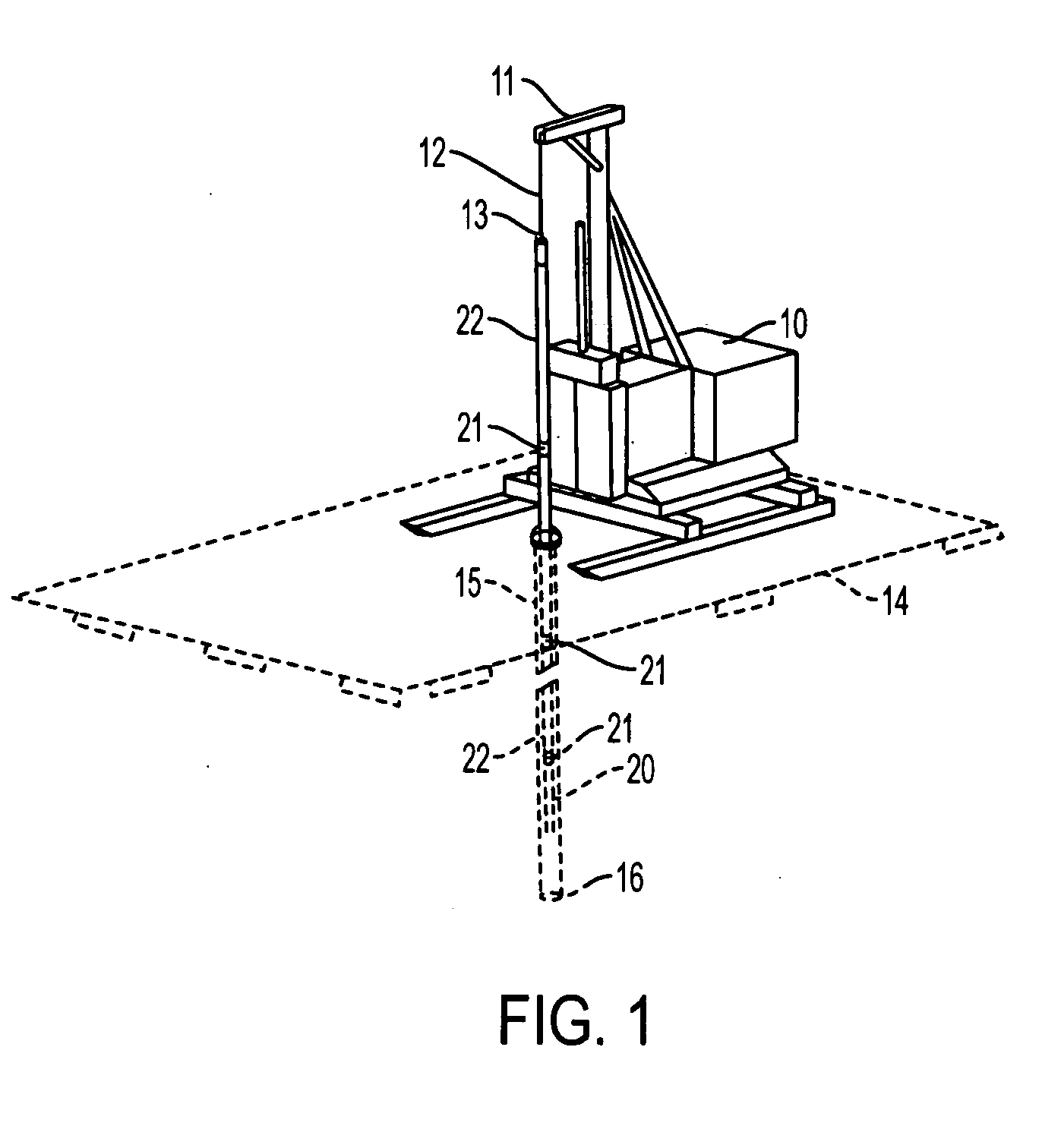

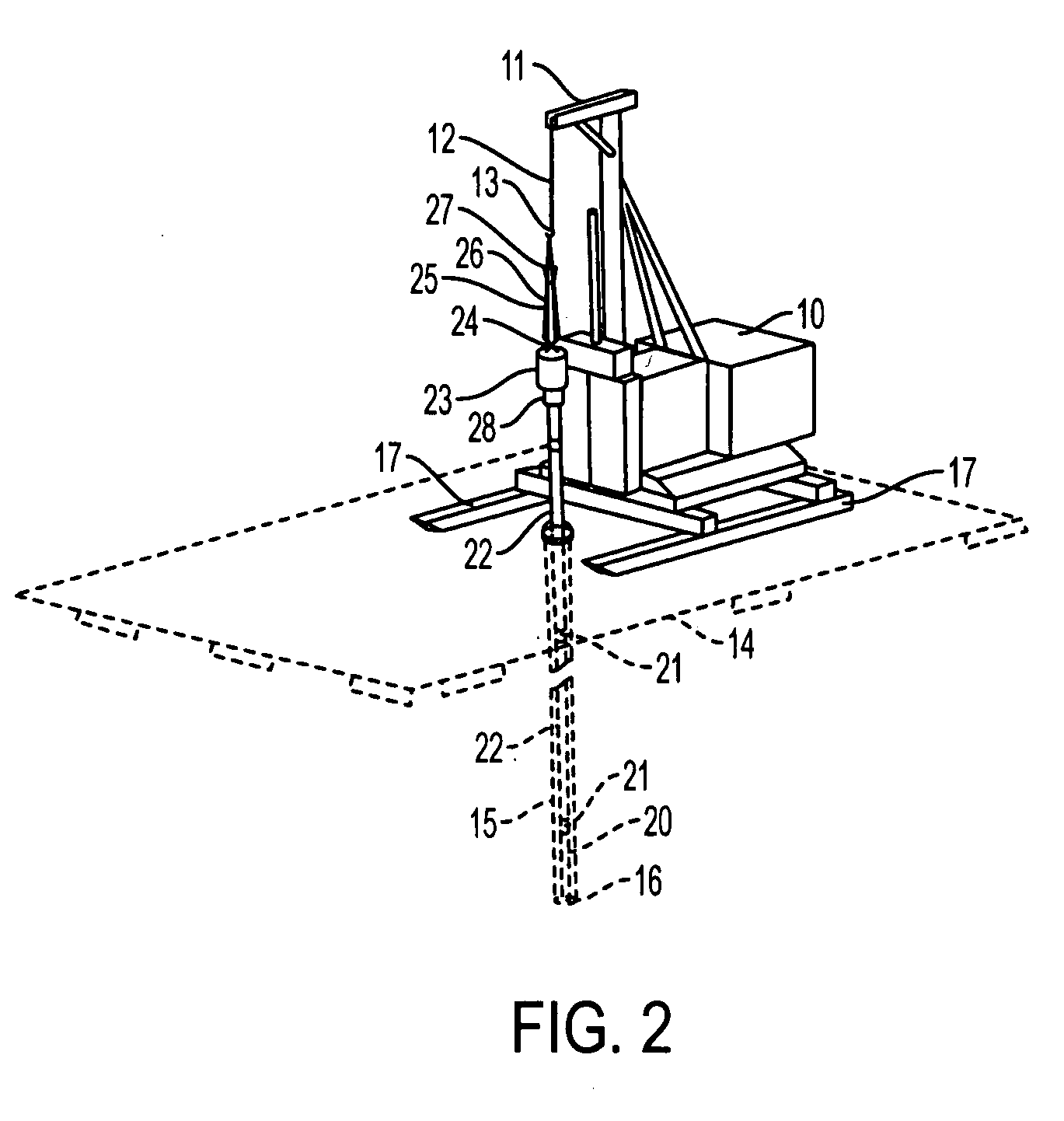

Automatic SPT monitor

An apparatus is used with an impact hammer penetration assemble such as standard penetration test (SPT) in geotechnical engineering. The impact hammer penetration assembly comprises a penetration sample, a series of rods coupled together and an impact hammer apparatus. The drop of the hammer from a constant height hits the coupled rods and sampler in series and forces the sampler deeper into the ground. The apparatus includes a tip depth transducer and sampler to output a first electrical signal that is a function of the sampler tip position. A shock force transducer communicates the axial shock force in the rod to output a second electrical signal that is a function of the rod shock force and hammer blows. A shock penetration transducer communicates the movement of the coupled rods and sampler to output a third electrical signal that is a function of the sampler penetration due to the hammer blows. A micro-process controller monitors and processes the first, second and third signals in real time.

Owner:HONG KONG THE UNIV OF

Hammer for rotary impact crusher

An impact hammer mountable to the drum of a rotary crusher employs an attachment bolt having a tapered head which is wedged into a tapered socket in the impact hammer body. A “supernut” is used to secure the bolt to the rotary drum. The supernut is tightened against the rotary shear head until it is snug. Then, threaded locking posts, which pass through the periphery of the supernut, are tightened repeatedly, thereby applying a great deal of tension the bolt shank and effectively stretching it. Any shocks applied to the impact hammer will drive the tapered head of the bolt deeper into the socket of the hammer body block, resulting in the maintenance of a secure hammer-to-drum union. The hammer body also has tungsten carbide chips embedded in a hardfacing material that is applied to the wear surfaces of the hammer.

Owner:KNOTTS BROOK H

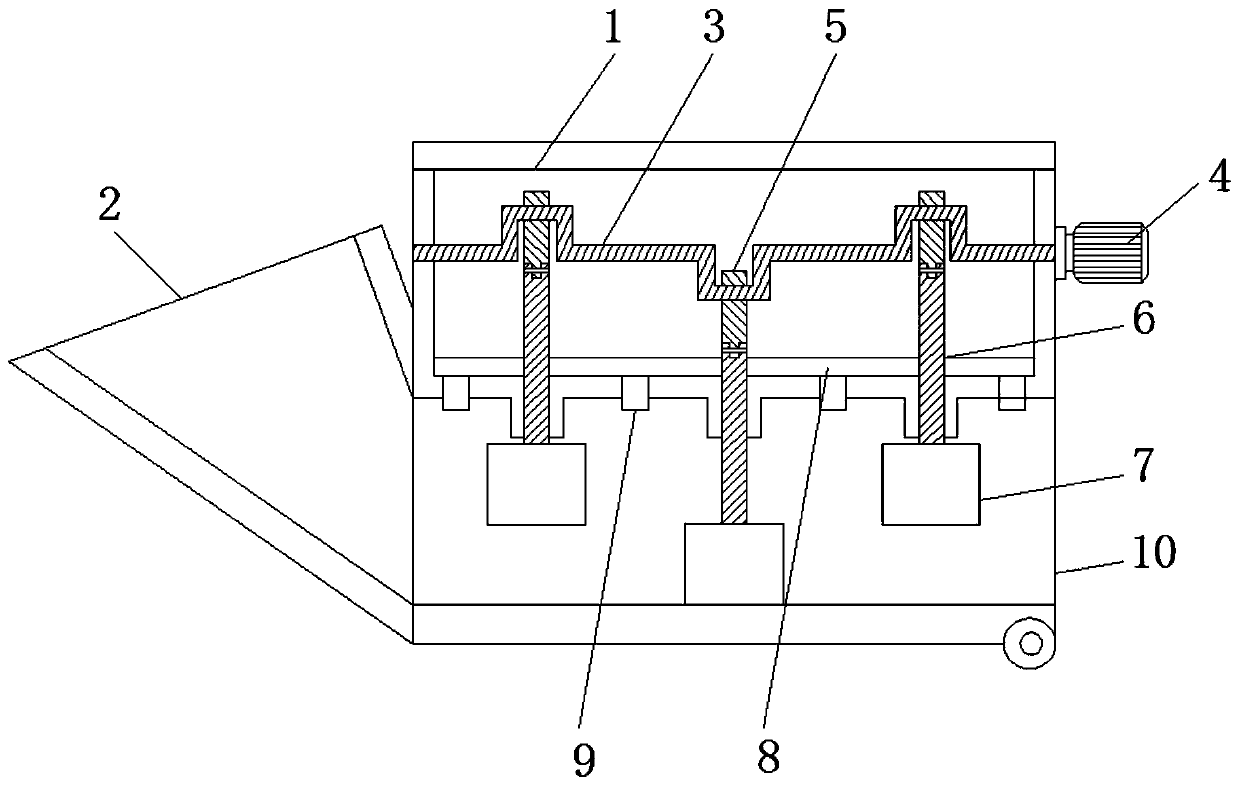

Construction waste crushing treatment device based on crank rocker principle

ActiveCN111085291APlay a pre-crushing effectExtended service lifeUsing liquid separation agentMagnetic separationCrankArchitectural engineering

The invention relates to the technical field of construction waste, and discloses a construction waste crushing treatment device based on a crank rocker principle. The construction waste crushing treatment device comprises a pre-crushing chamber, wherein a feeding opening is fixedly connected to the exterior of the pre-crushing chamber, a crank rocker is movably connected to the interior of the pre-crushing chamber, a pre-crushing motor is fixedly connected to the exterior of the crank rocker, a connecting rod is movably connected to the exterior of the crank rocker, an impact rod is hinged and connected to the exterior of the connecting rod, and an impact hammer is fixedly connected to the bottom of the impact rod. The pre-crushing motor and the impact hammer are used cooperatively, and the construction waste is impacted and crushed by the impact hammer, so that the pre-crushing effect of the construction waste is achieved; and meanwhile, the impact hammer impacts the bulk construction waste and enables the bulk construction waste to be subjected to fragmentation treatment, so that the subsequent use effect of crushing rollers is guaranteed, and the bulk construction waste is prevented from damaging the crushing rollers, and the service life of the crushing device is prolonged.

Owner:江西太平洋宇洪建设有限公司

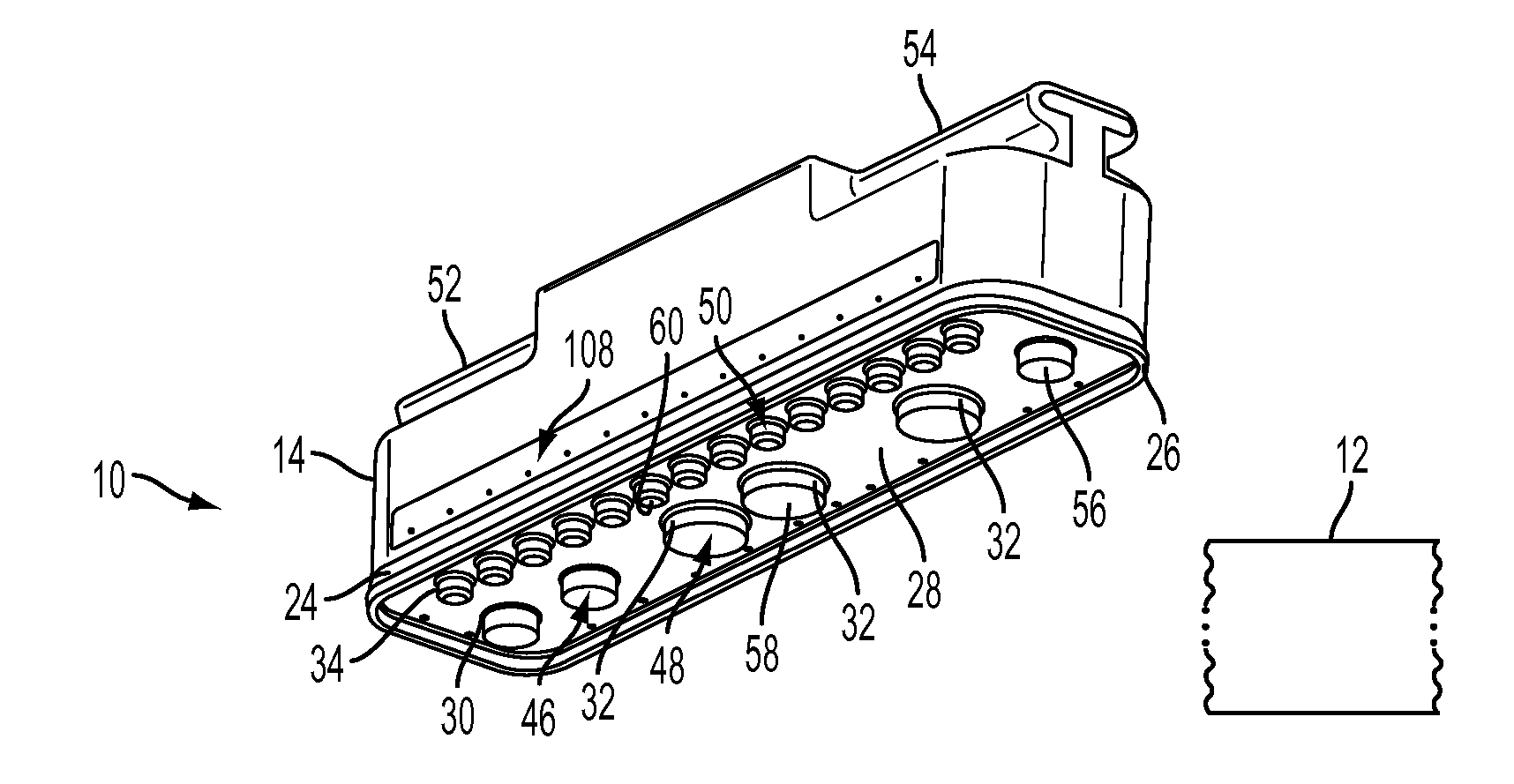

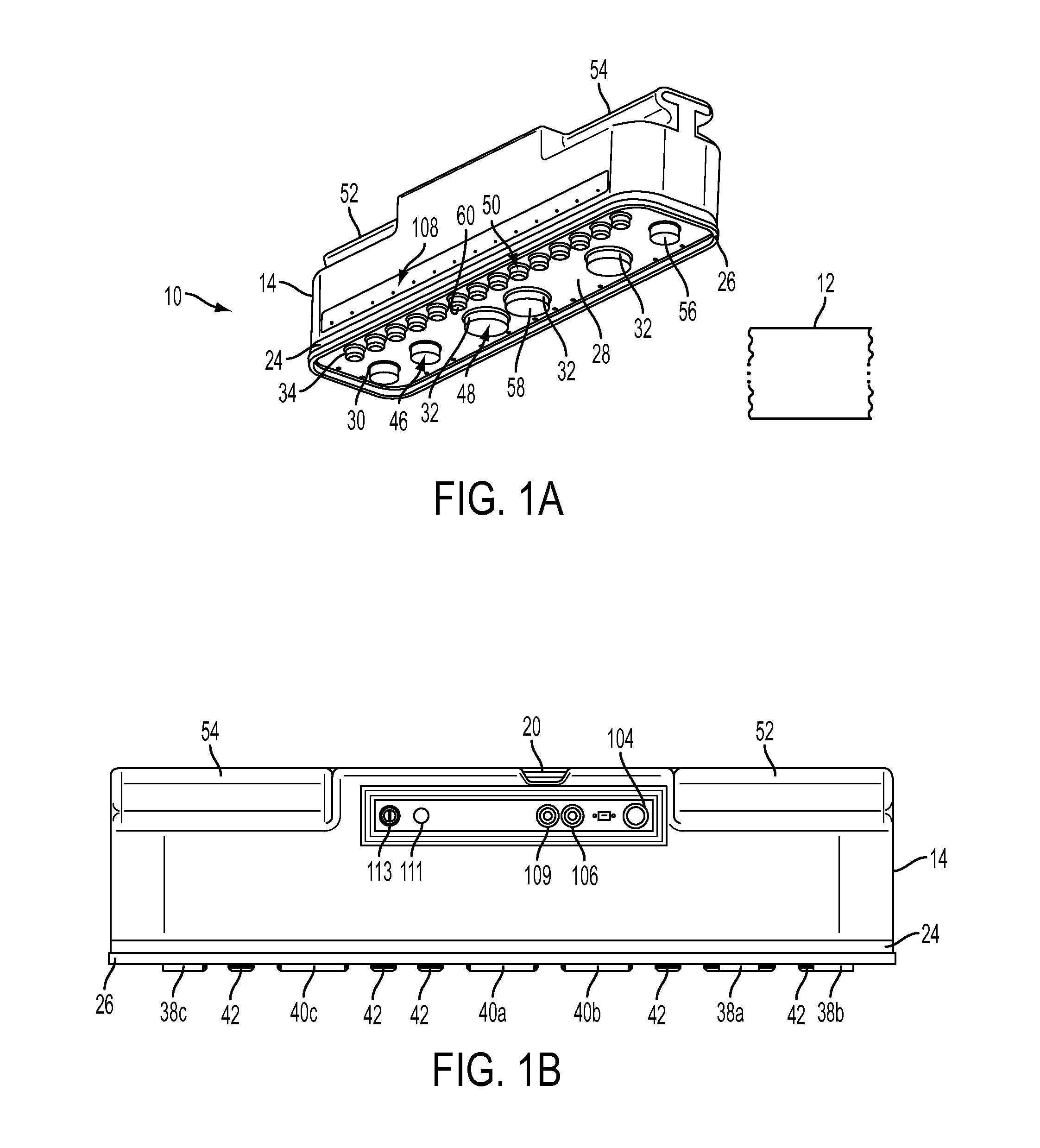

Apparatus and method for non-destructive testing of concrete

InactiveUS20150309007A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveTransducer

A device and method for determining characteristics of a concrete sample includes the use of multiple transducers at pre-determined positions with respect to each other. The transducers are coupled to the concrete surface so that they can impart and / or receive mechanical waves from the sample. Mechanical waves may be imparted to the sample by one or more transducers or by an impact hammer. A control device receives the output from receiving transducers and analyzes data there from to determine a desired characteristic of the sample.

Owner:NLA DIAGNOSTICS

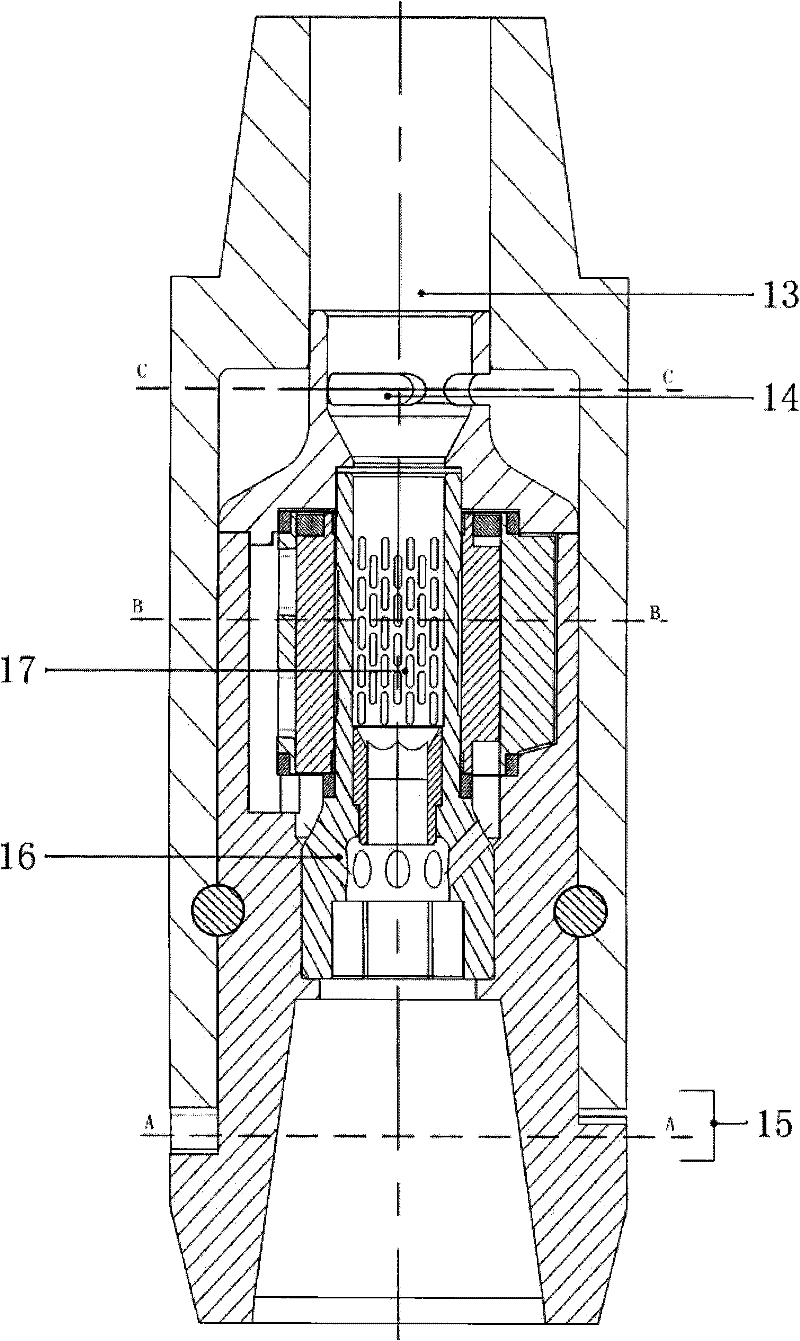

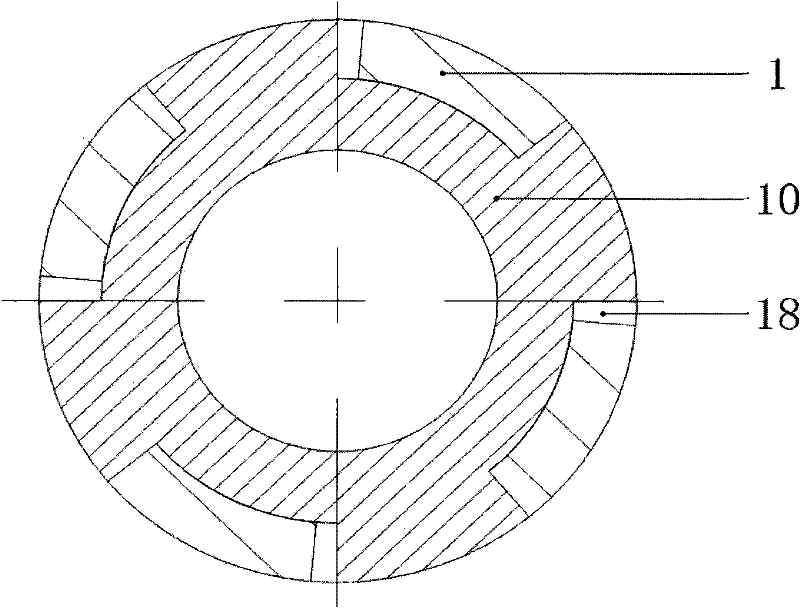

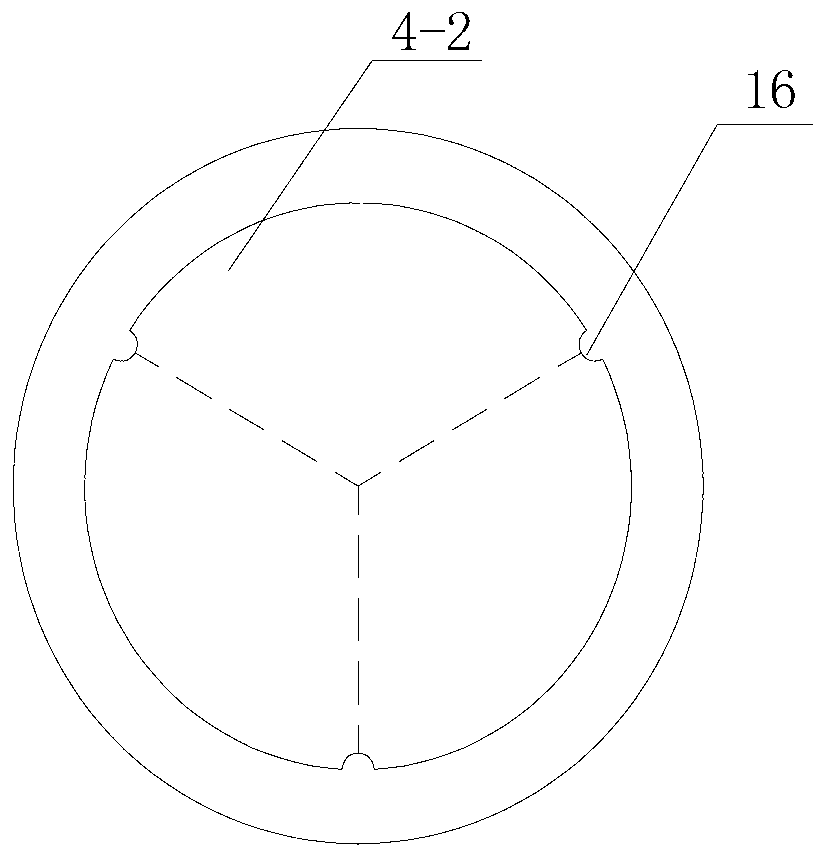

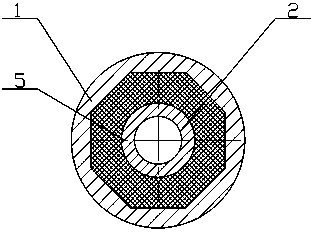

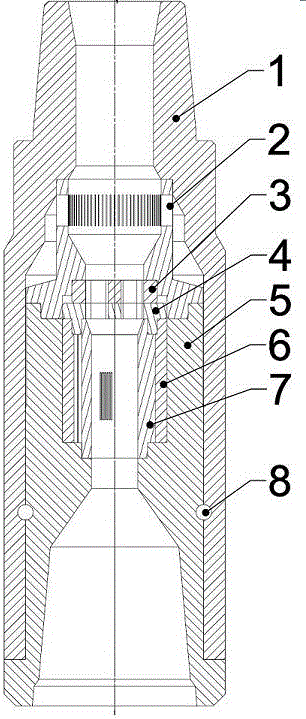

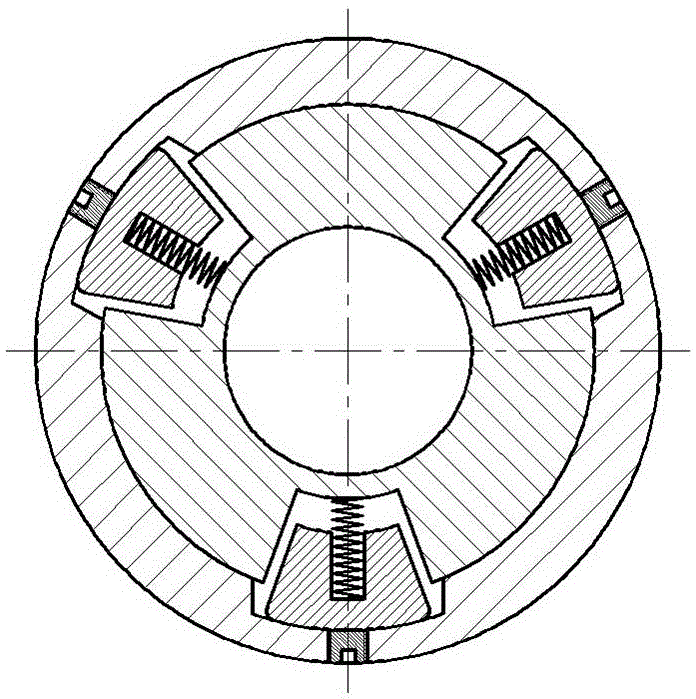

Hydraulic circumferential torque impact generator

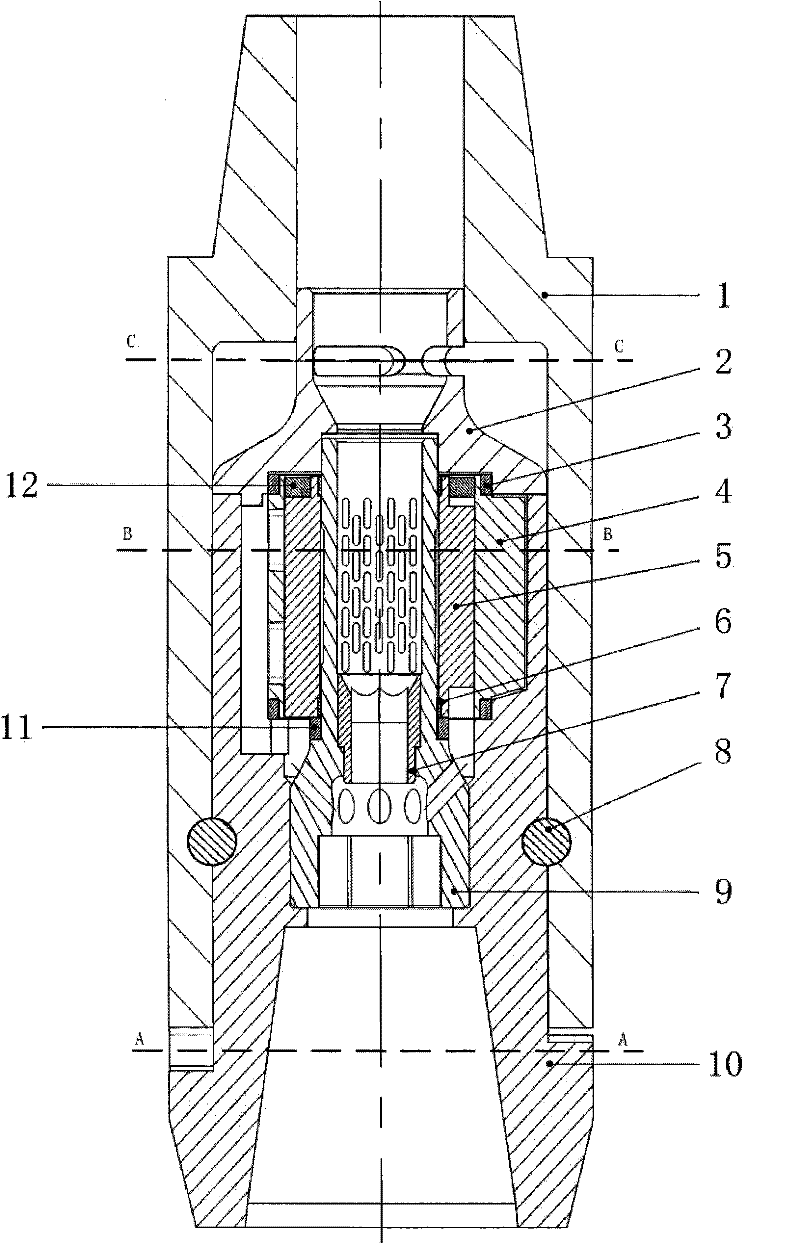

The invention relates to a hydraulic circumferential torque impact generator and belongs to the field of underground drilling speed-improving tools in the petroleum drilling process. The impact generator comprises a housing head, a housing, a screen pipe, a circulation starter and an orifice plug. An assembly sleeve is arranged in the housing, an impact hammer is assembled in the assembly sleeve, the screen pipe is arranged in the impact hammer, the circulation starter is installed on the screen pipe through a screen pipe sliding bearing, and a seal piece is installed on one side of the impact hammer and a port of the circulation starter and is tightly fit with the impact hammer and the port of the circulation starter. A sand removal sleeve is installed in the housing between the seal piece and an anti-drop block through a positioning sleeve, and the orifice plug is installed in the positioning sleeve on one side of the sand removal sleeve through a housing head sliding bearing. The impact generator produces high-frequency low-amplitude torque impact through the impact hammer to improve mechanical drilling speed, and the service life of a well drilling tool is prolonged. The problem that an existing torque impact device is unreasonable in structural design and accordingly the service life of the drilling tool is short is solved. The hydraulic circumferential torque impact generator is especially suitable for petroleum drilling.

Owner:YANGTZE UNIVERSITY

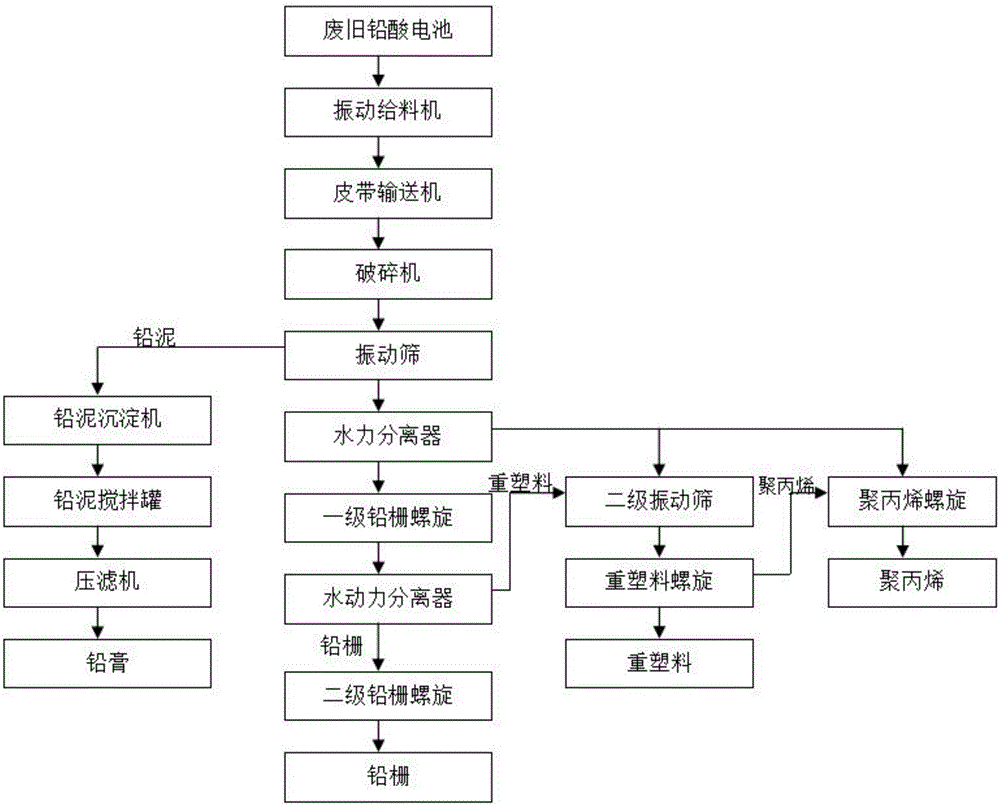

Waste lead-acid storage battery crushing-and-separation one-step energy-saving recycling process

ActiveCN105846005ALow costLess investment in infrastructureWaste accumulators reclaimingBattery recyclingCrusherScrew conveyor

A waste lead-acid storage battery crushing-and-separation one-step energy-saving recycling process. According to work principle of a system in the process, an impact hammer crusher crushes a waste storage battery, and the crushed material is cleaned and separated through a vibration sieve to obtain lead plaster, and according to the physical characters of the crushed materials of the storage battery, wherein the specific gravities of the materials are different, the materials are separated through water buoyant force and compressed air, and finally, the materials are separately conveyed into different stores for storage through a spiral conveyor.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

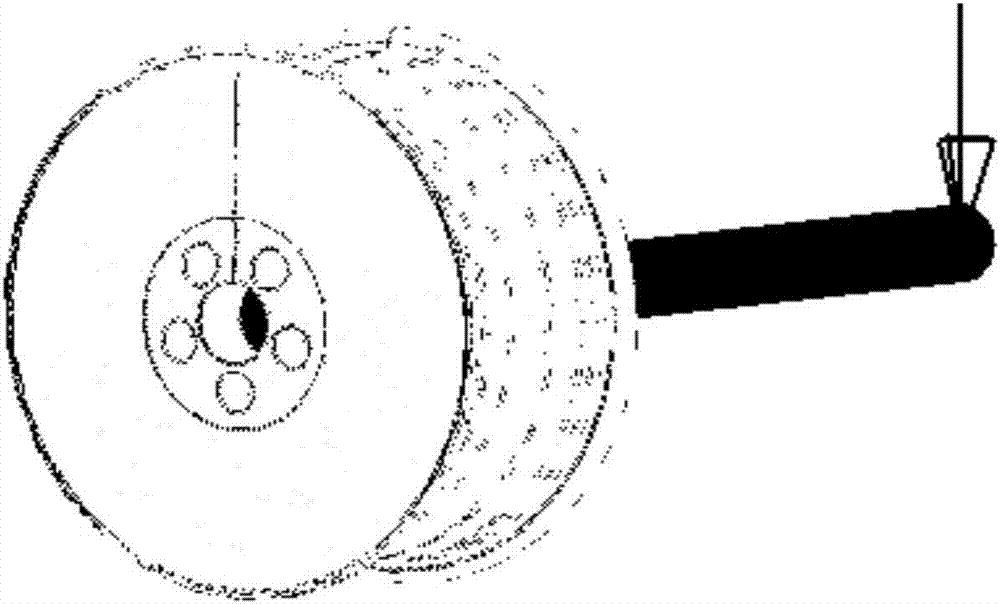

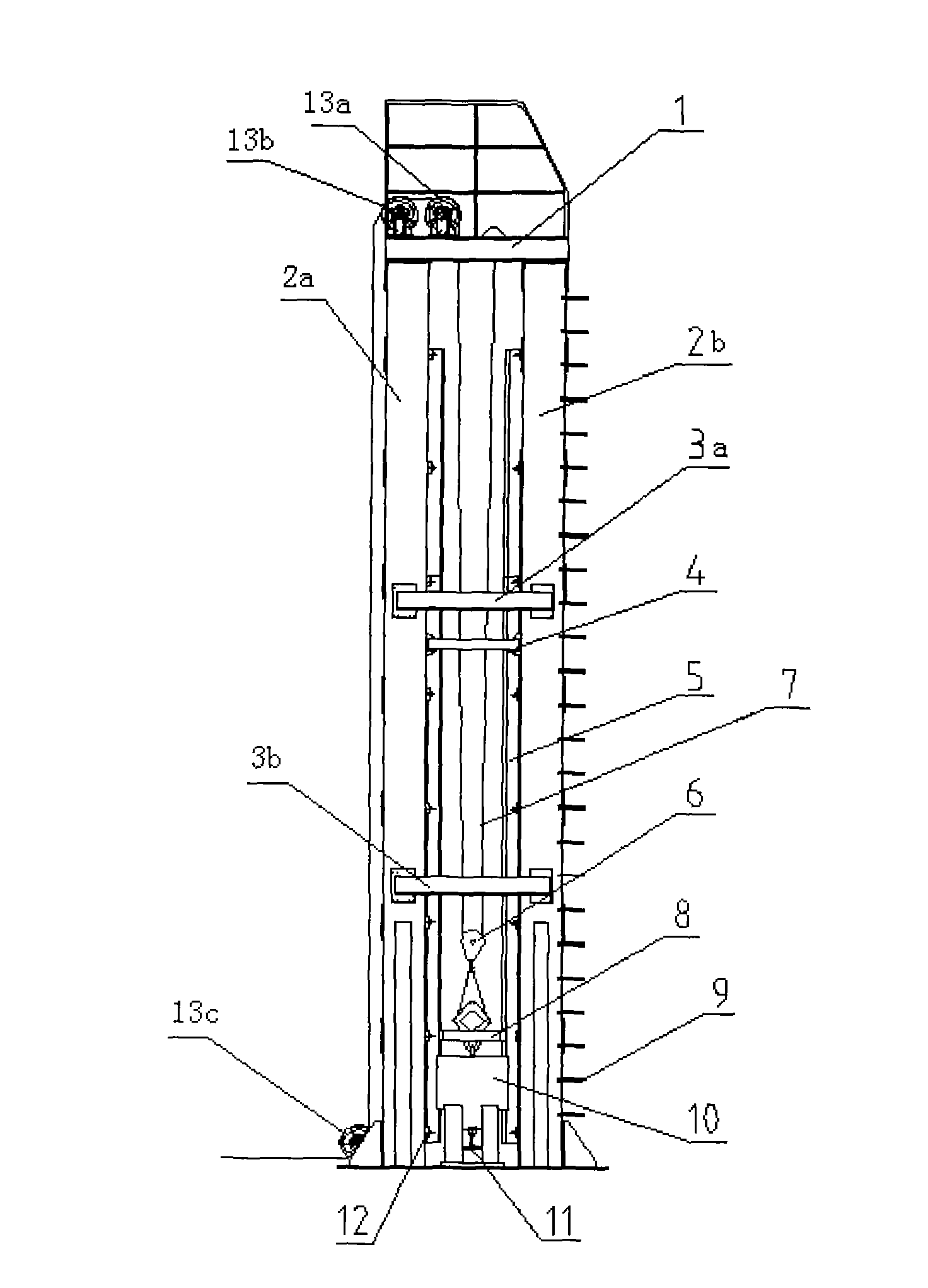

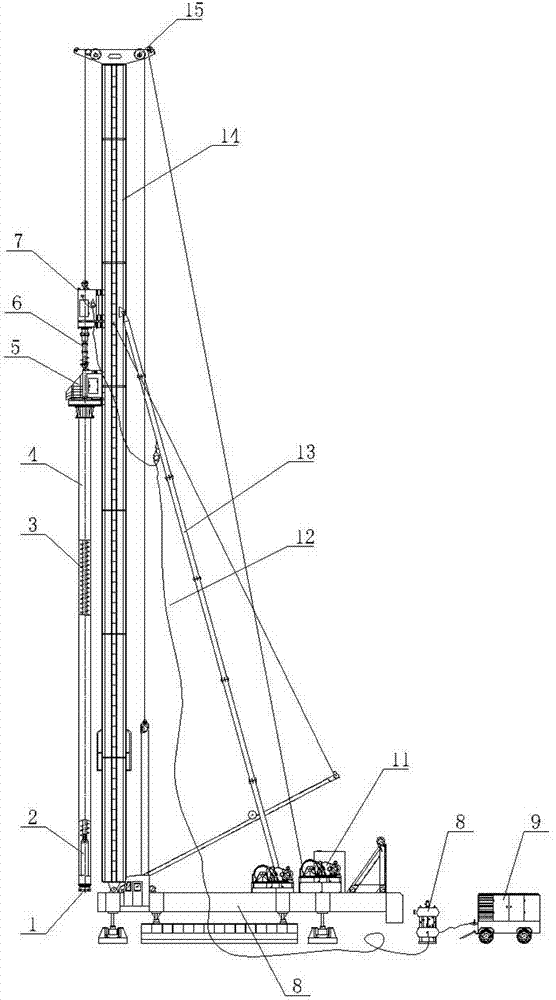

Hydraulic combined impact hammer drilling machine

ActiveCN104594802AChange the problem of difficult constructionImprove construction efficiencyDrilling rodsConstructionsControl engineeringWinch

The invention provides a hydraulic combined impact hammer drilling machine and relates to the field of engineering pile driver devices. The hydraulic combined impact hammer drilling machine comprises a power source, an integrated machine frame, a walking mechanism, a posture mechanism, a liftable reel pipe mechanism, an upper power head, a lower power head, a winch, a drilling rig clamper and a hydraulic combined impact hammer drilling bit. Track walking is adopted by the walking mechanism. The walking mechanism is driven by a hydraulic reducer. The integrated machine frame is installed on a body of the walking mechanism. The power source, the posture mechanism, the power heads, the liftable reel pipe mechanism and the hydraulic combined impact hammer drilling bit are installed on the integrated machine frame. The hydraulic combined impact hammer drilling machine can complete construction operation independently, solves the problems that during traditional construction, a pile foundation is in contact with a rock stratum, and construction is difficult and is high in construction efficiency and low in cost, the practicability and the flexibility of the hydraulic combined impact hammer drilling machine are greatly improved, and the application range of the hydraulic combined impact hammer drilling machine is greatly widened.

Owner:陶德明

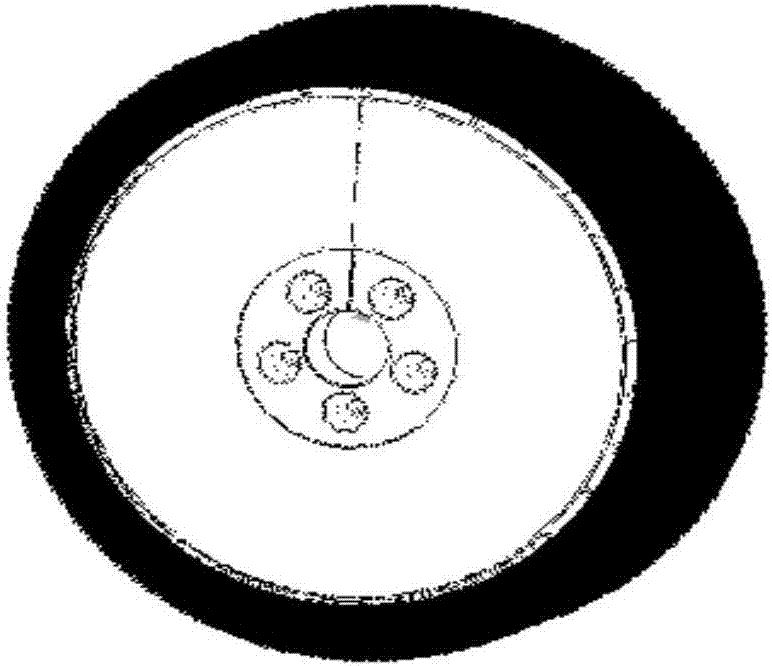

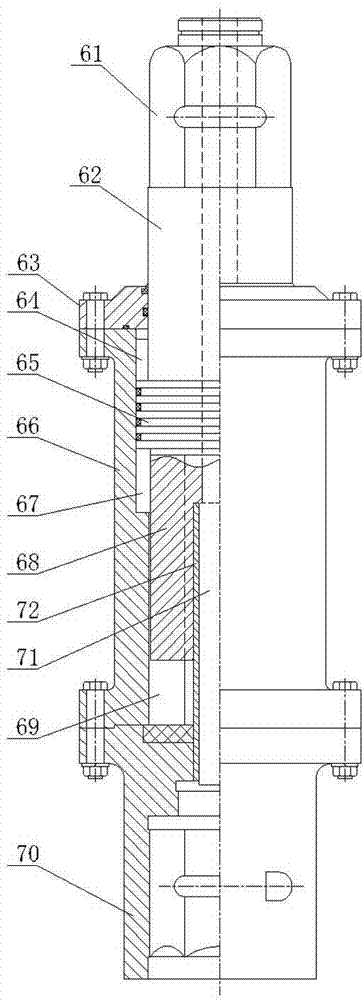

Circumferential axial negative pressure impact speeding-up tool

ActiveCN106150349AAchieve openAchieve closureConstructionsLiquid/gas jet drillingImpact hammerDrill bit

The invention provides a circumferential axial negative pressure impact speeding-up tool. The speeding-up tool comprises an outer barrel, a fixed valve seat, a fixed valve block, a movable valve block, an impact barrel, an impact hammer, a reversing valve and a ball bearing, wherein a main valve and a control valve which are mutually in reversing control are arranged in the tool, the inner wall surface of the impact barrel and the outer wall surface of the impact hammer form the main valve, the inner wall surface of the impact hammer and the outer wall surface of the reversing valve form the control valve, the impact hammer and the reversing valve reciprocate when being driven by drilling fluid, a movable-fixed valve group is also arranged in the tool, a movable valve is fixedly connected with the impact hammer, and the movable-fixed valve realizes opening and closing of a central runner by virtue of swinging of the impact hammer. By adopting the structure, the speeding-up tool provided by the invention has the beneficial effects that one circumferential and high-frequency impact is applied to a drill bit by virtue of reciprocating impact of the impact hammer, and stick-slip vibration phenomenon of the drill bit is obviously improved; a drilling column runner is periodically opened and closed by virtue of the movable-fixed valve group, an instant negative pressure pulse is formed at shaft bottom, chip hold down and repeated breaking are reduced, negative pressure pulse well drilling is realized, and mechanical drilling rate is improved.

Owner:SHANDONG DADONGLIAN PETROLEUM EQUIP

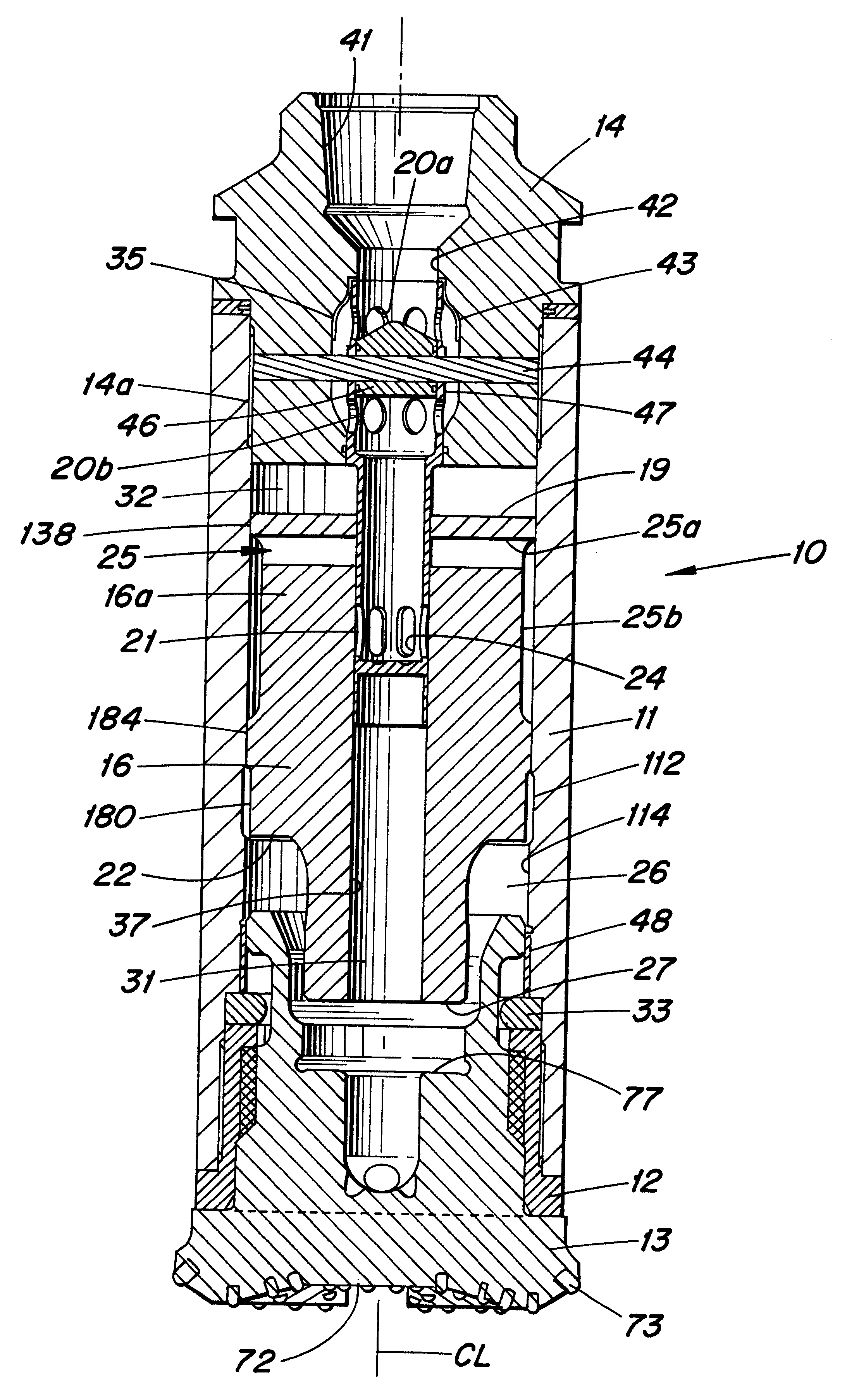

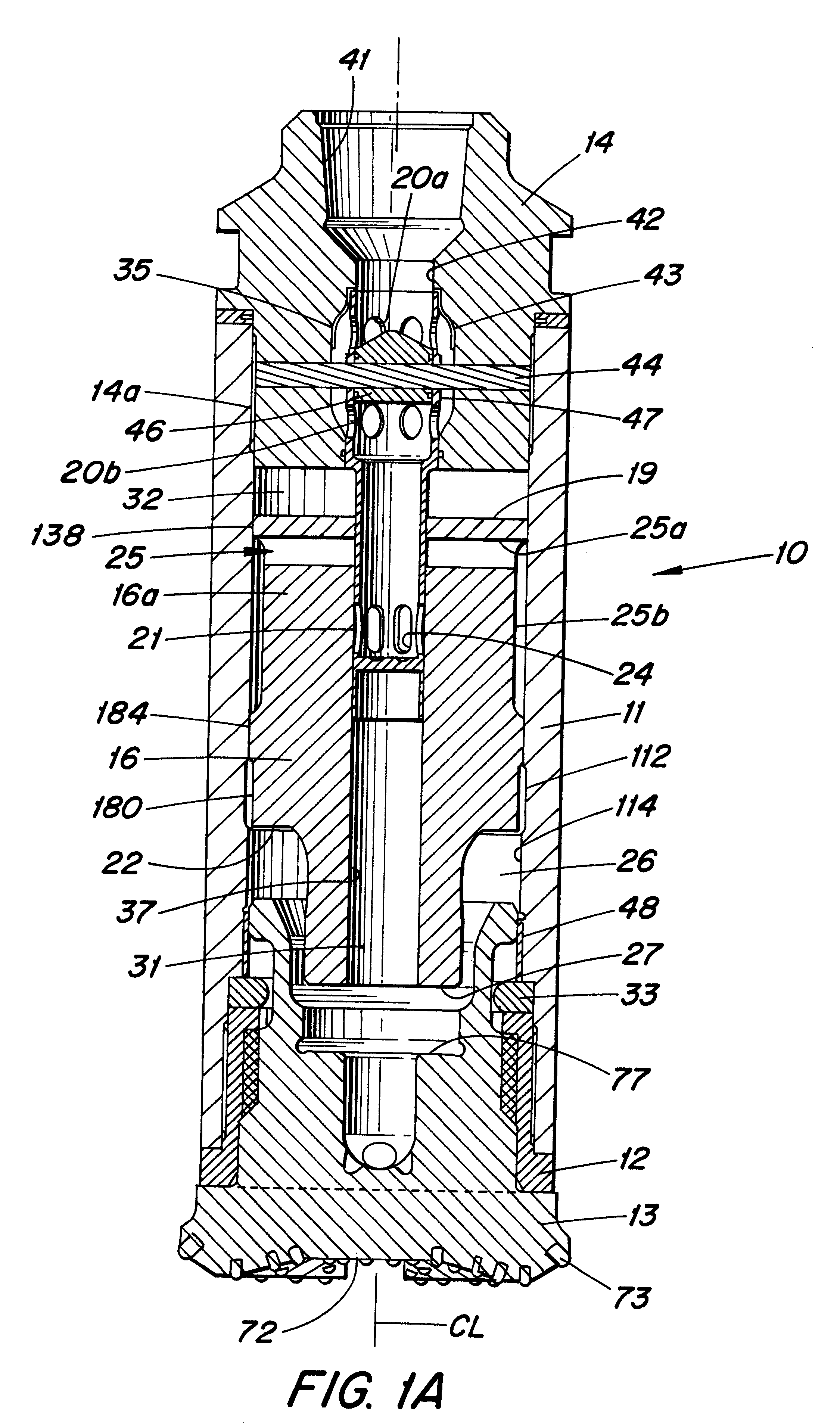

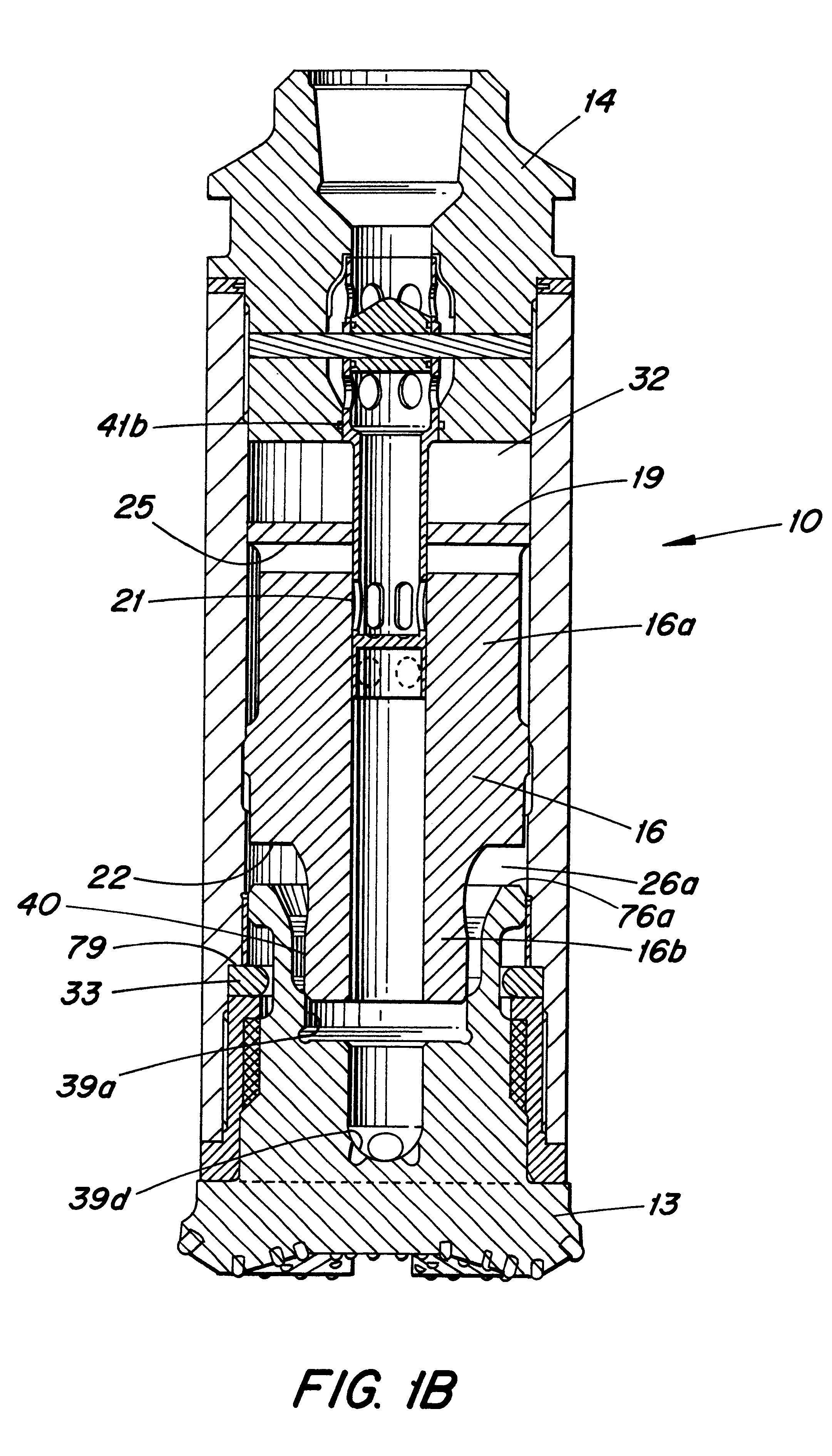

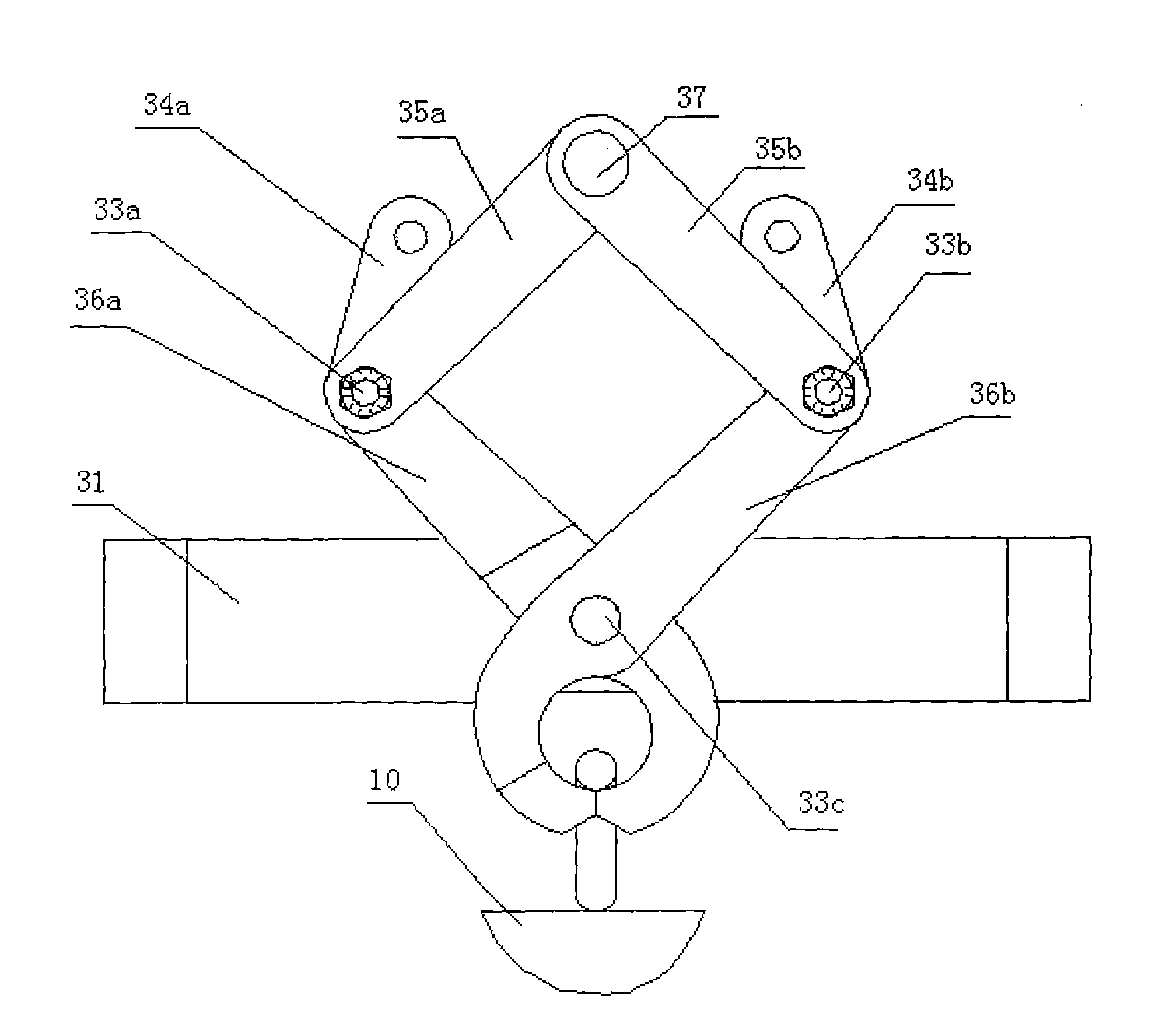

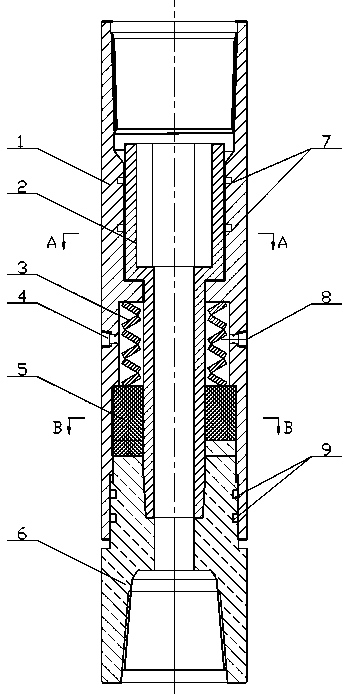

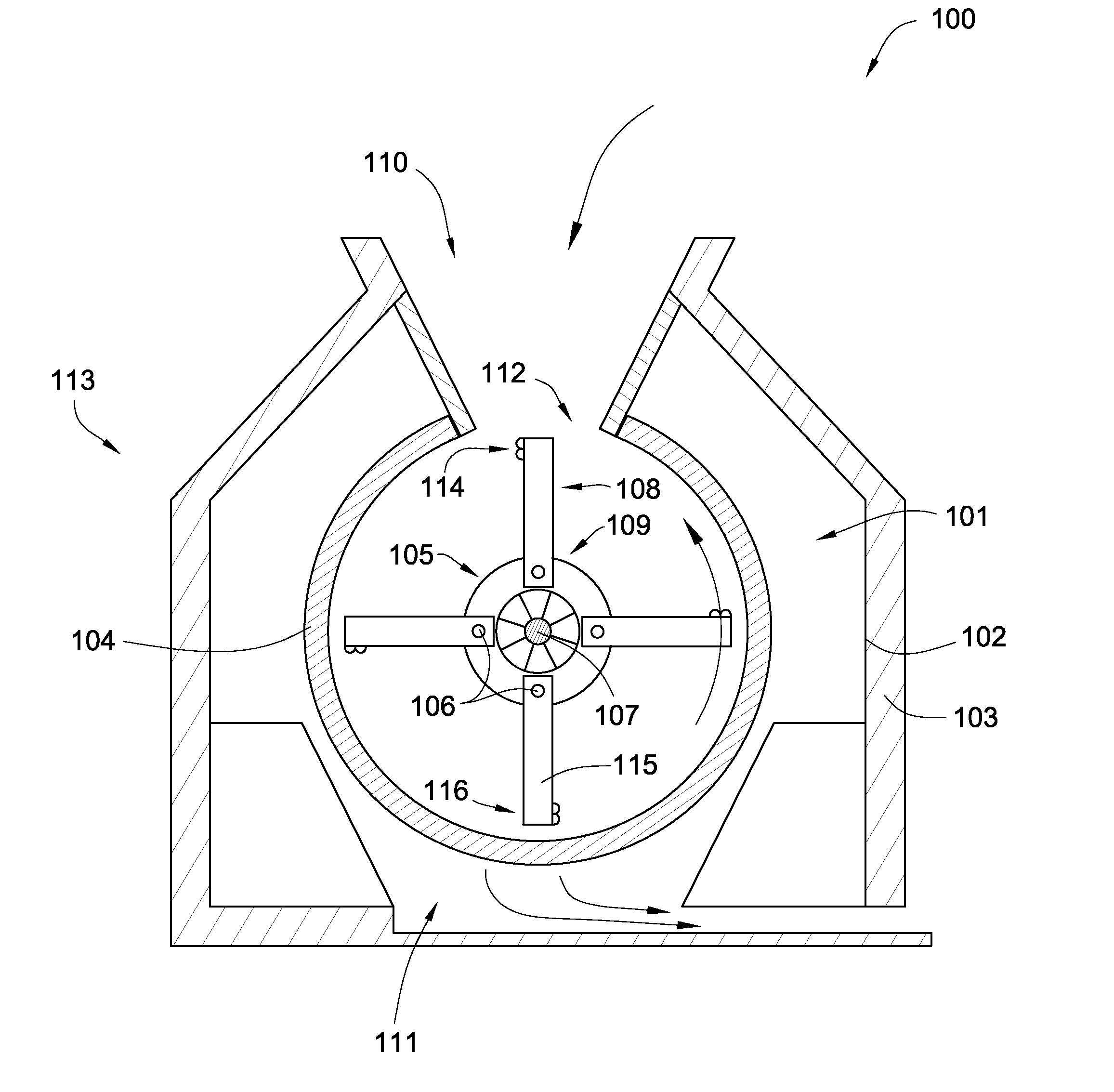

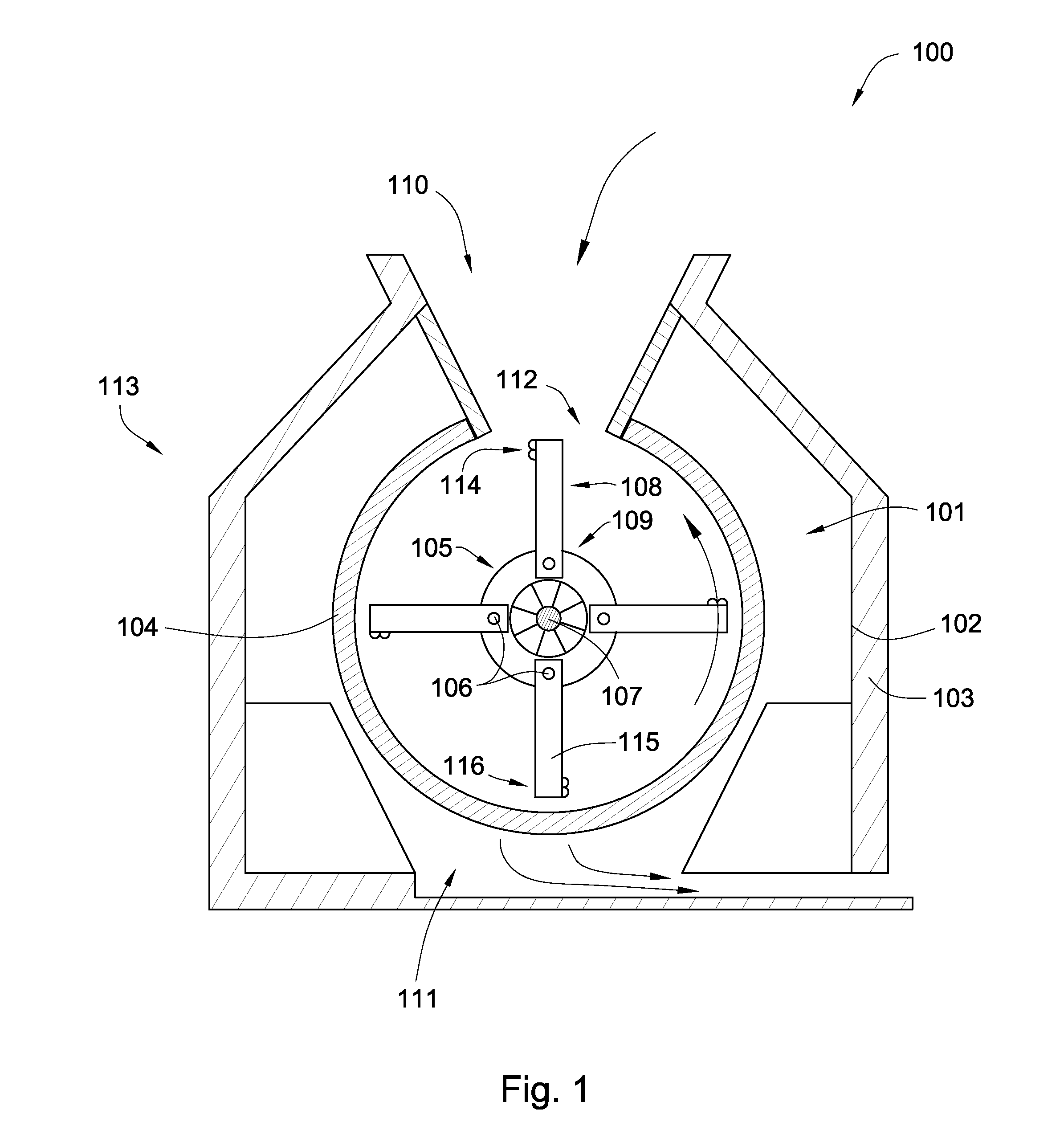

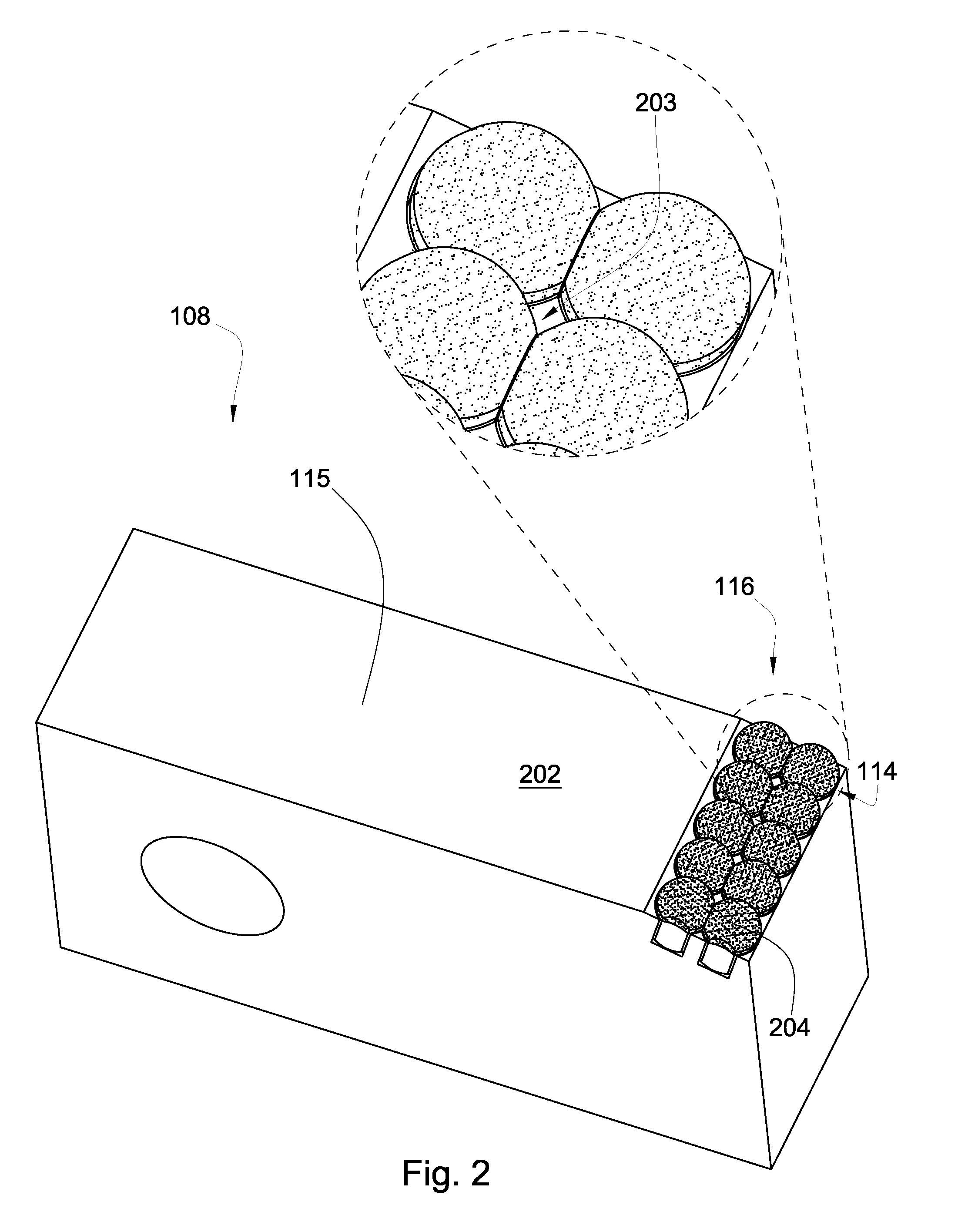

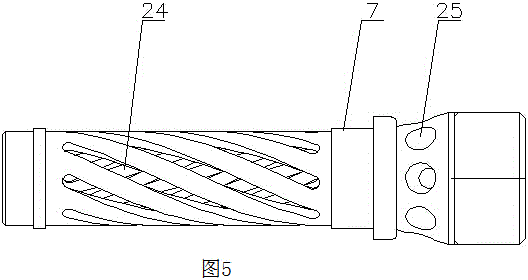

Reciprocable impact hammer

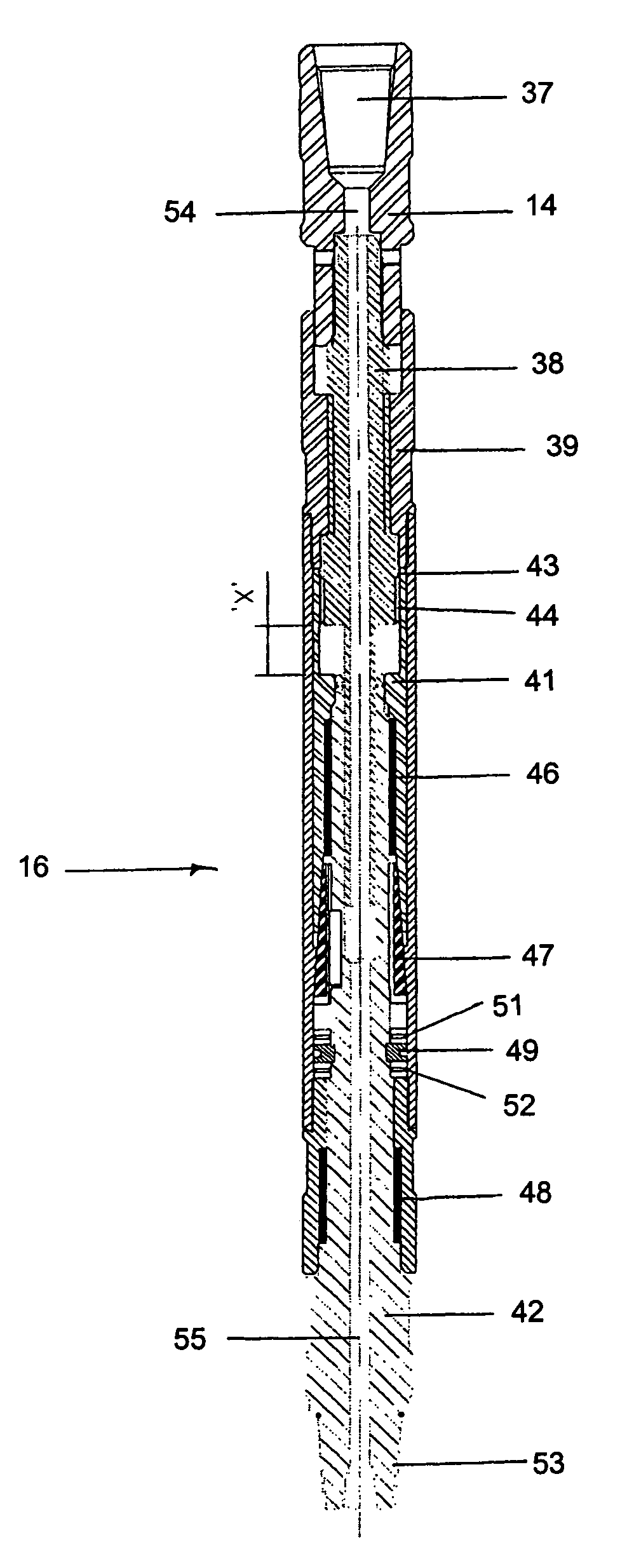

ActiveUS6986394B2Without excessive wearGuaranteed normal transmissionBorehole drivesDriving apparatusEngineeringMechanical engineering

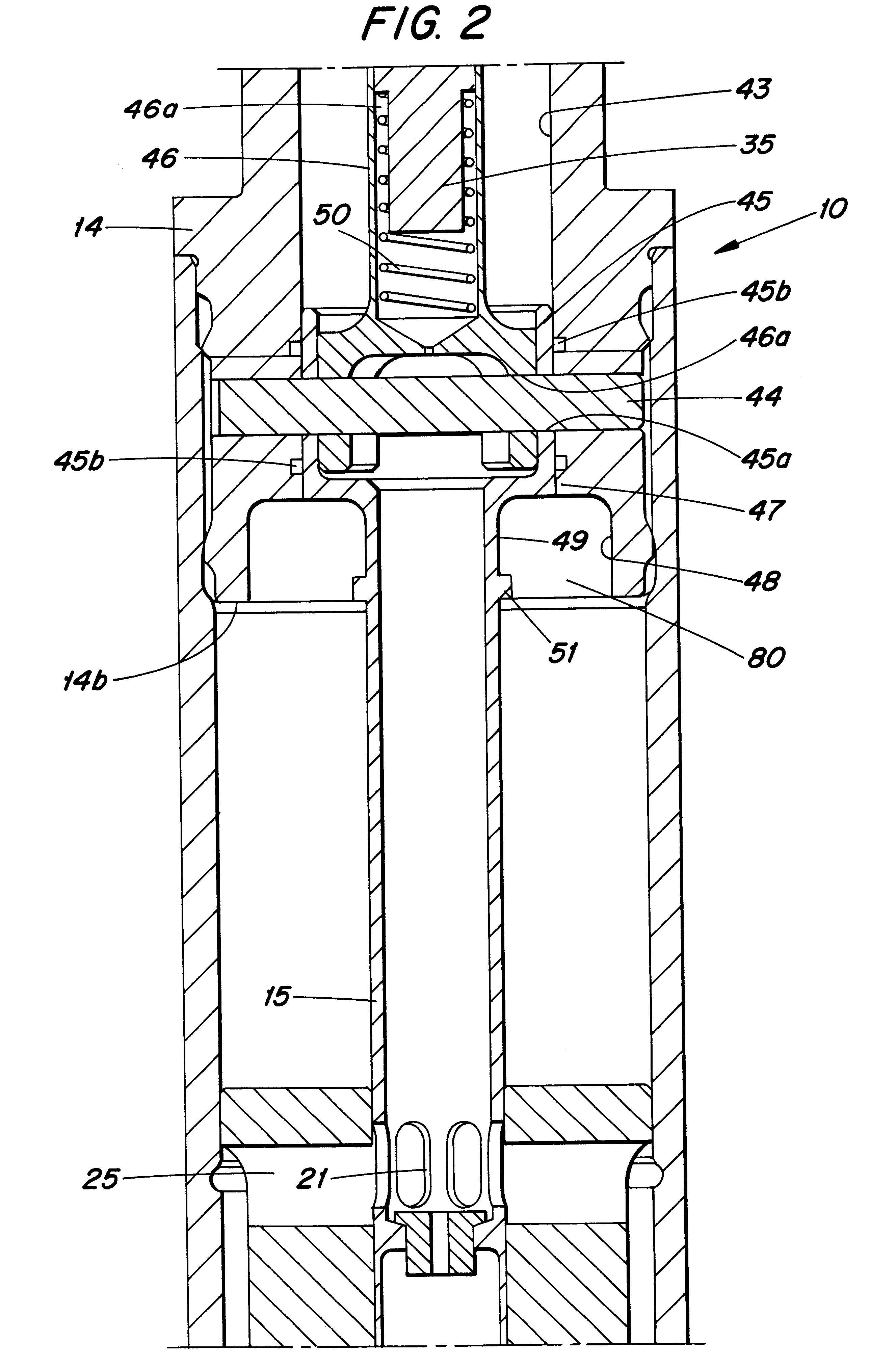

In the field of borehole creation there is a need for a reciprocable impact hammer with a tool that is rotatable while under load. A reciprocable impact hammer (10) for use in a downhole location comprises a tool support member (11); a hammer member (12); a jack mechanism (13); a connector member (14); and a transmission (16). The transmission (16) converts linear motion of the connector member (14) to rotary motion of the hammer member (12) whereby when a force acts on the connector member (14) via the hammer member (12) and the tool support member (11) operation of the jack mechanism (13) causes initial elongation of the impact hammer (10) followed in succession by:(i) collapsing of the hammer member (12) and the tool support member (11) together such that the hammer member (12) separates from the connector member (14) and imparts an impulse to the tool support member (11); and(ii) movement of the connector member (14) towards the hammer member (12) under the influence of the force whereby the transmission (16) causes rotation of the remainder of the impact hammer (10).

Owner:GENERAL MOTORS COMPANY +1

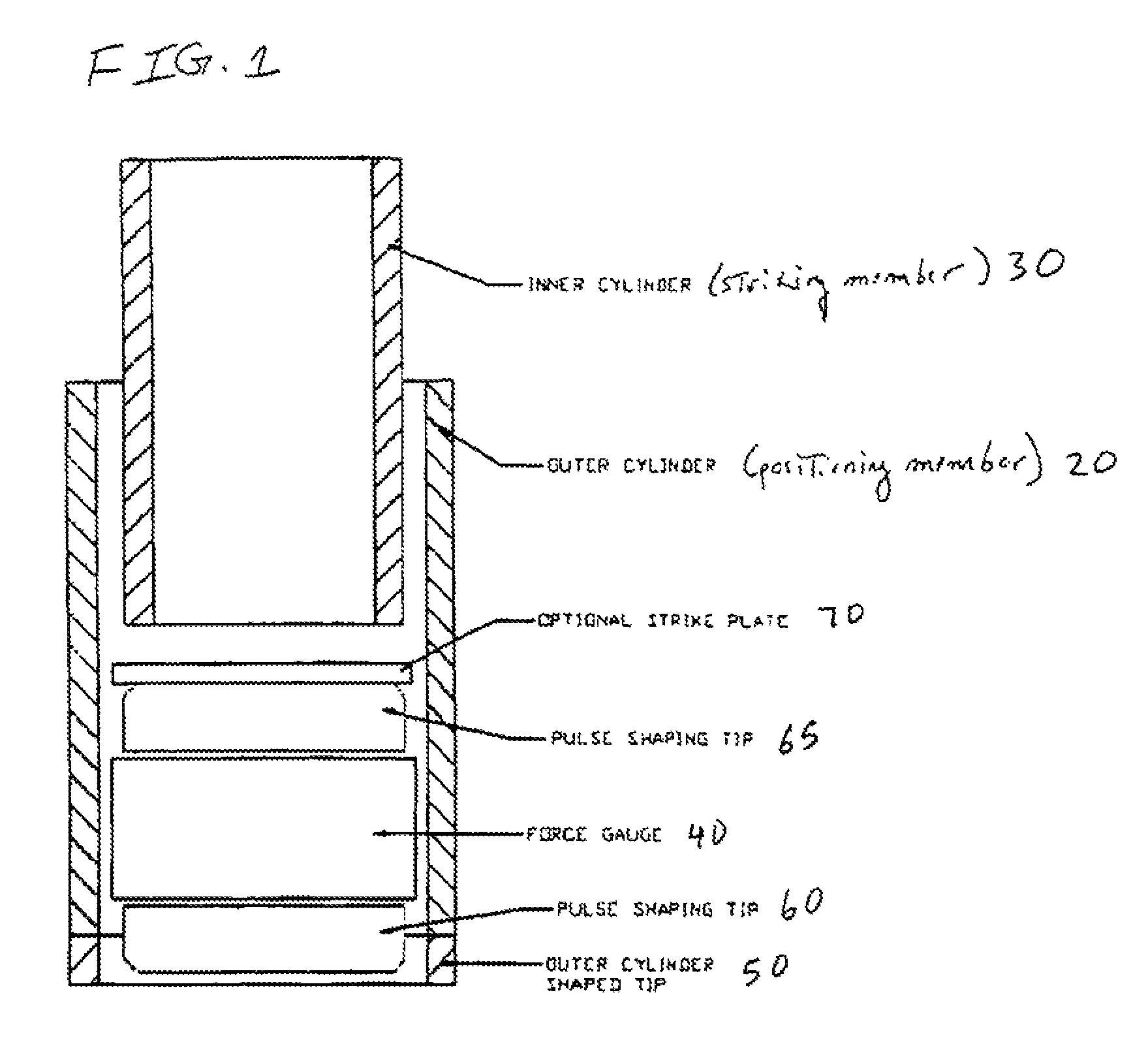

Calibrated impact hammer

InactiveUS7900498B1Easy to useMinimal effortAcceleration measurement using interia forcesAnalysing solids using sonic/ultrasonic/infrasonic wavesDetentEngineering

An apparatus includes a positioner. The apparatus includes a striker axially movable in the positioner. The striker includes a striker inner end. The apparatus includes a force gauge axially movable in the positioner. The force gauge includes a force gauge inner end. The force gauge inner end is in communication with the striker inner end. Optionally, the striker defines at least one fluid passage axially therethrough.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

Percussion Unit

ActiveUS20150136433A1Avoid settingAvoid stimulationDerricks/mastsPortable percussive toolsLoop controlControl cell

Percussion unit, especially for a rotary hammer and / or percussion hammer, comprising a control unit which is designed for open-loop and / or closed loop control of a pneumatic percussion mechanism, and at least one operating condition sensor unit. According to the disclosure, the control unit is designed to detect at least one percussion mechanism parameter depending on measurement values of the operating condition sensor unit.

Owner:ROBERT BOSCH GMBH

Composite impact drilling tool

InactiveCN106121513AReduce the impactImprove drilling efficiencyBorehole drivesWell drillingThrust bearing

The invention discloses a composite impact drilling tool. The drilling tool is mainly composed of an impact short joint, a shell, an anti-falling block, a nut, a radial spring, a seal ring, an impact hammer, an axial spring, an impact shaft, a thrust bearing, a fixed shaft, a turbine stator, a turbine rotor, a stator pressing cap, a rotor pressing cap and a conversion joint. The composite impact drilling tool is characterized in that a collision bearing block is arranged at the top end of the impact short joint, and an inclined face used for bearing the collision of the impact hammer is arranged on the collision bearing block; an impact block is arranged at the bottom end of the impact hammer, an inclined face used for colliding the collision bearing block of the impact short joint is arranged on the impact block, a through hole is formed in the top end of the impact hammer, and a rectangular spline groove is formed in the through hole; a rectangular spline is arranged on the impact shaft, and a disc-shaped step is arranged at the lower end of the impact shaft; and a step is arranged in the middle of the shell, and the axial spring is arranged between the lower end face of the step of the shell and the upper end face of the impact hammer. Circumferential torque pulses and axial force pulses in the axial direction can be generated by the composite impact drilling tool at the same time, the drilling tool can be used on a drilling bit to assist rock breaking, and therefore the drilling efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Digital fatigue impact test instrument and test method

InactiveCN107941447APower-off position controllableAchieve fatigue shockMaterial strength using repeated/pulsating forcesShock testingData acquisitionContact force

The invention discloses a digital fatigue impact test instrument and a test method, comprising a guide rail, a guide rail support frame, a specimen fixture, an impact hammer head, a light shield, an acceleration sensor, a force sensor, a photoelectric sensor, a cylinder control valve, a cylinder, and an electromagnet , travel switch and computer. When the impact hammer head descends from a height along the linear guide rail to impact the test specimen, the data acquisition card records the experimental data of the impact process, and under the action of the cylinder and the electromagnet, the impact hammer head can rise to the set position to prepare for the next impact. The instrument can not only control the number of impacts and collect sensor data during the impact process, but also obtain the impact contact force, impact energy, impact time, acceleration, displacement, and velocity in each impact process. The relationship between the changes in the physical quantities involved , to realize the automation, continuous and full digitalization of the fatigue impact process, which is of great significance to the accurate simulation, design and failure mechanism exploration of the material impact resistance process.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com