Rotating impact acceleration device and method of power drilling tool

A technology of power drilling tools and impact hammers, which can be applied to the driving device for drilling in boreholes, drilling equipment, earthwork drilling and production, etc. It can solve the problems of inability to match power drilling tools, unaffordable speed-up tools, and failure to cause downhole accidents, etc. , it is easy to adjust the impact amplitude, it is beneficial to work for a long time, and it is beneficial to transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

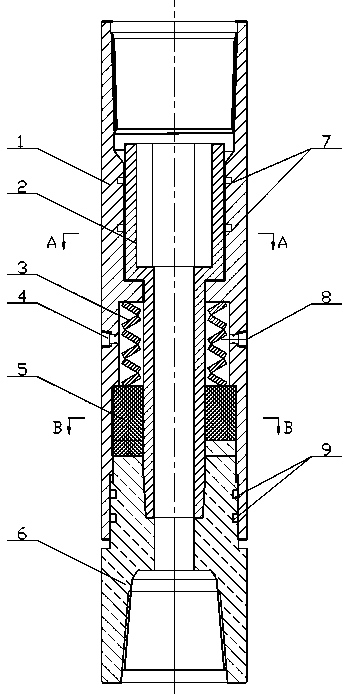

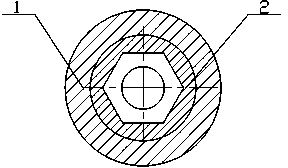

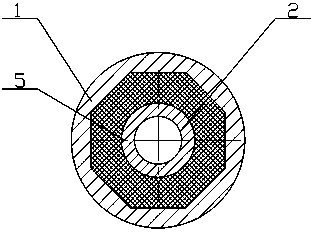

[0032] Such as figure 1 , figure 2 , image 3 As shown, the rotary impact acceleration device for power drilling tools mentioned in the present invention includes a stator outer cylinder 1, a rotor transmission shaft 2, an impact storage spring 3, an active toothed impact hammer 5, and a passive impact transmission joint 6.

[0033] Such as Figure 4 As shown, the outside of the stator outer cylinder 1 is a cylindrical surface of equal diameter, and the inside is sequentially from top to bottom a power drilling tool casing connecting buckle 101, a transmission shaft support surface 102, a transmission shaft anti-off end surface 103, and a transmission shaft support surface. 104, the spring supporting surface 105, the spring outer cylinder 106, the twisting surface 107, the rotating sealing end surface 108; the power drilling tool casing connecting buckle 101 is used to connect the power drilling tool casing; the outer diameter of the transmission shaft supporting surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com