Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

805 results about "Measurement while drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

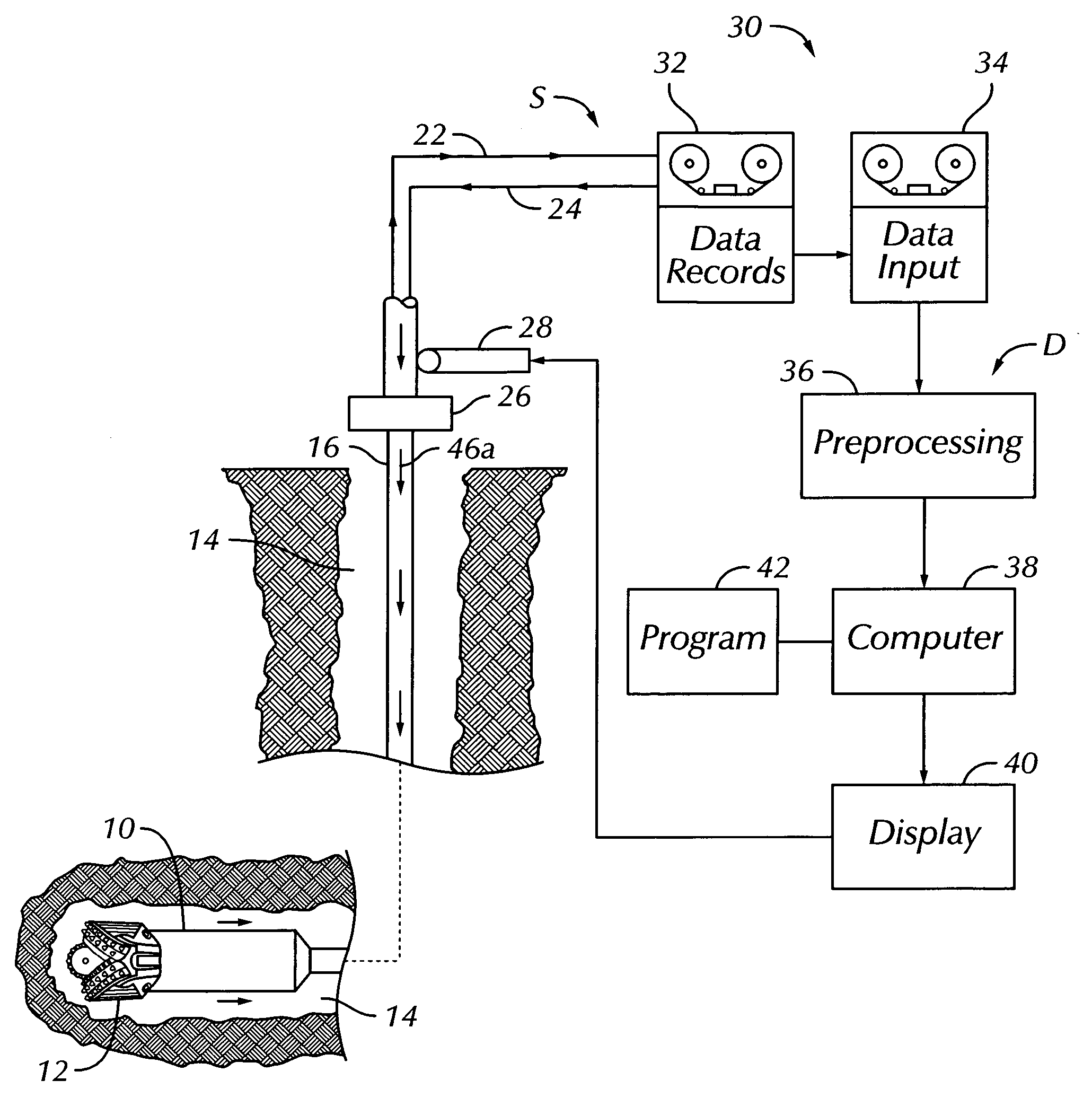

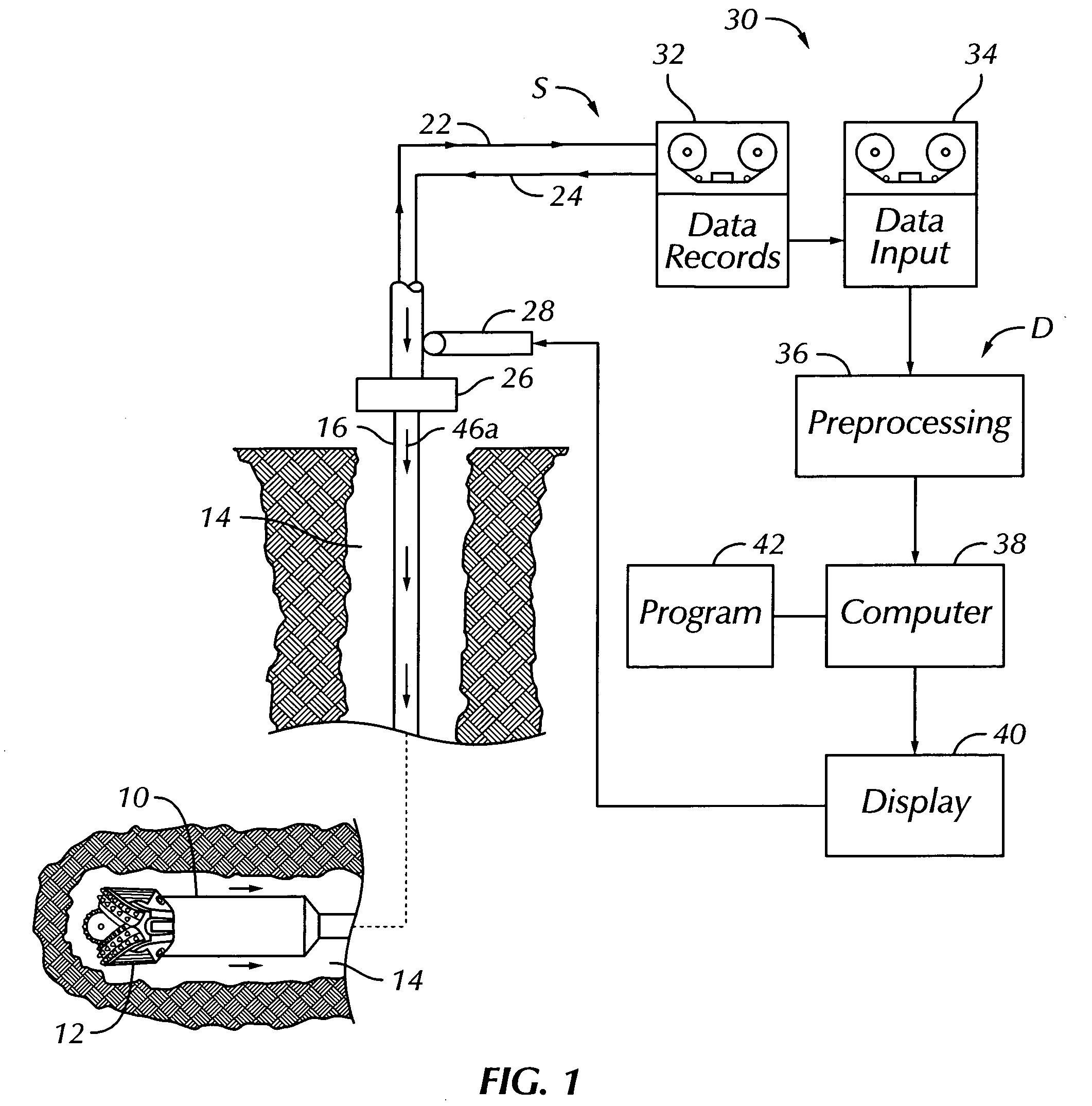

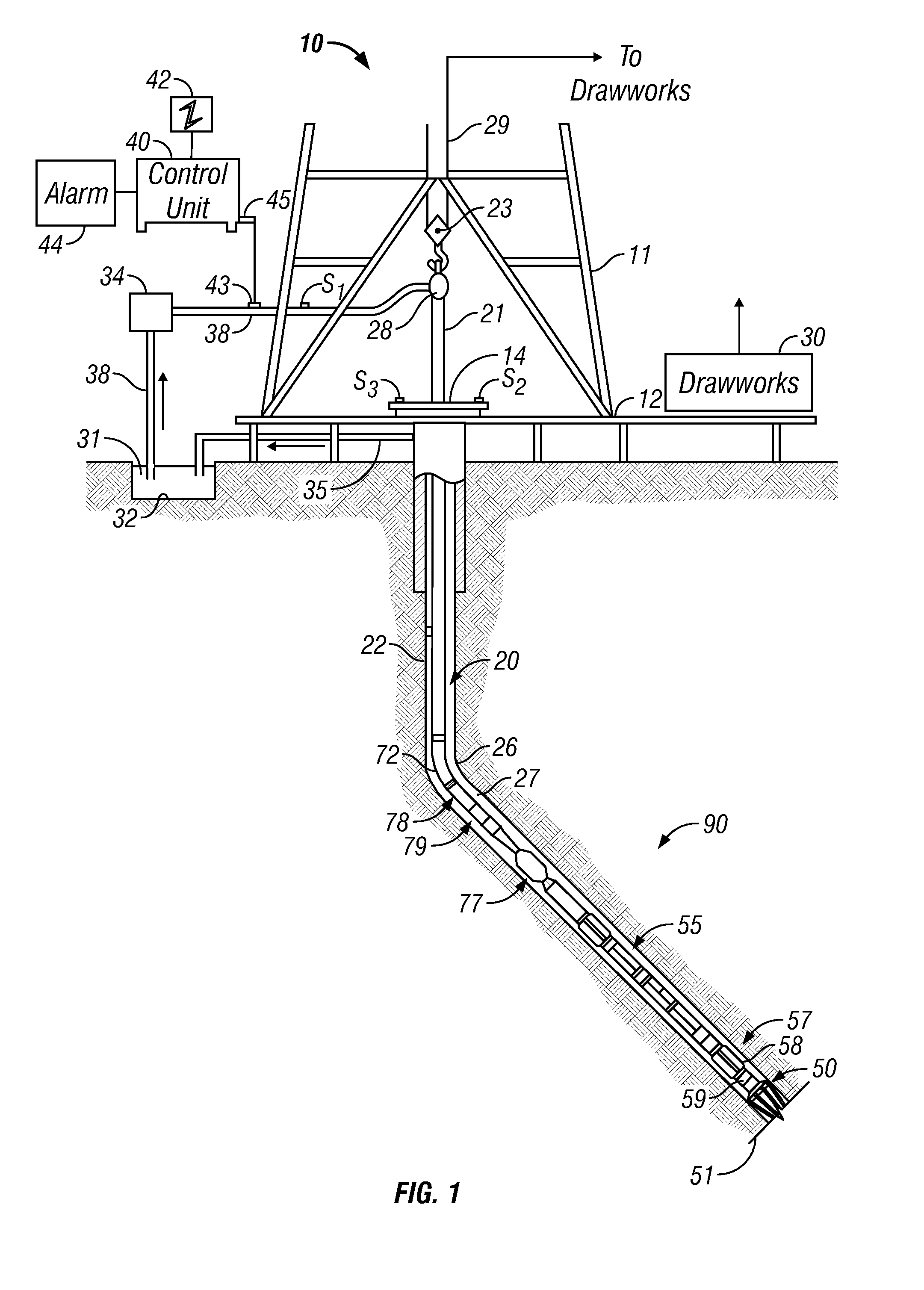

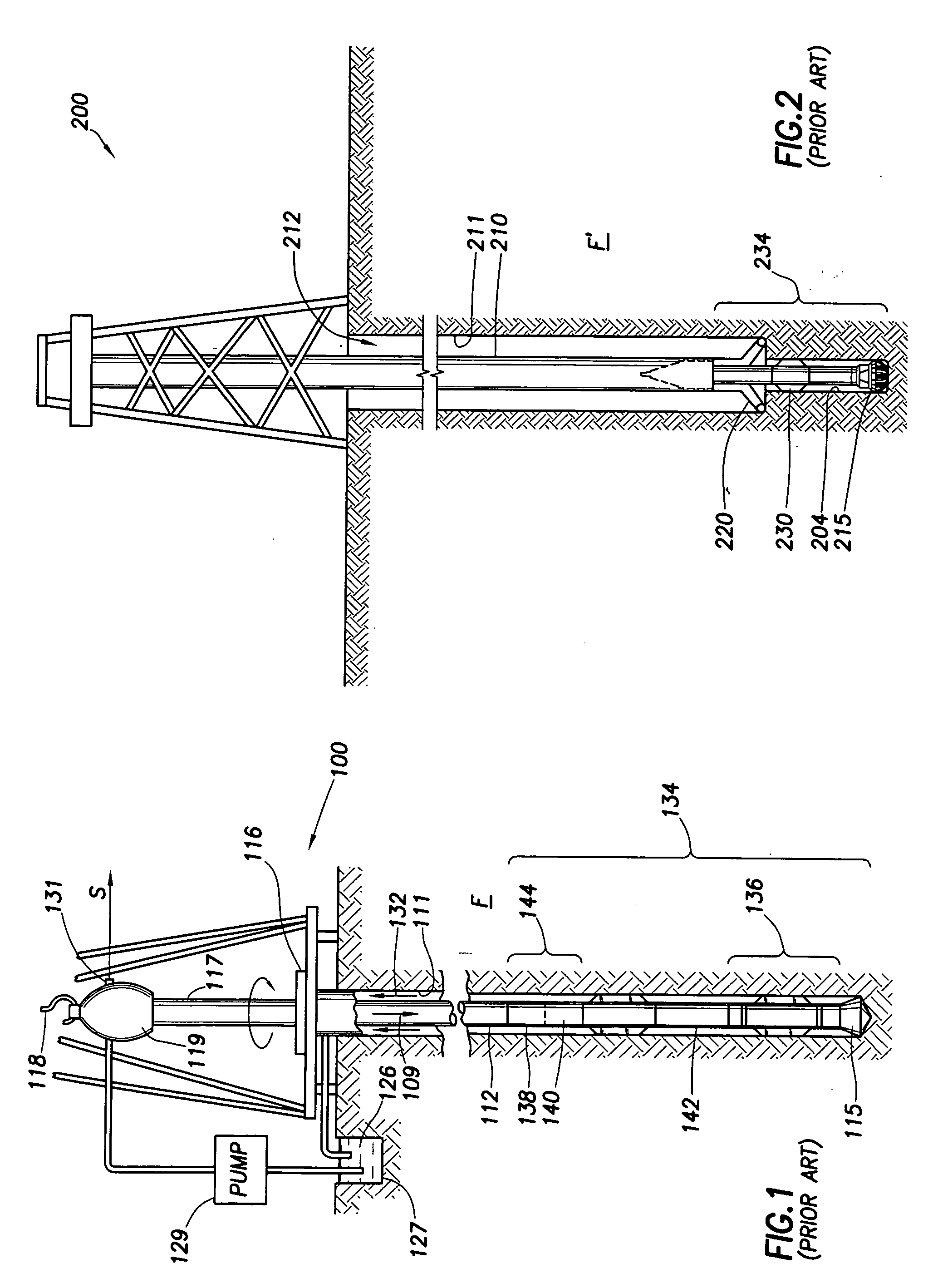

A drilling rig is used to create a borehole or well (also called a wellbore) in the earth's sub-surface, for example in order to extract natural resources such as gas or oil. During such drilling, data is acquired from the drilling rig sensors for a range of purposes such as: decision-support to monitor and manage the smooth operation of drilling; to make detailed records (or well log) of the geologic formations penetrated by a borehole; to generate operations statistics and performance benchmarks such that improvements can be identified, and to provide well planners with accurate historical operations-performance data with which to perform statistical risk analysis for future well operations. The terms measurement while drilling (MWD), and logging while drilling (LWD) are not used consistently throughout the industry. Although these terms are related, within the context of this section, the term MWD refers to directional-drilling measurements, e.g., for decision support for the smooth operation of the drilling, while LWD refers to measurements concerning the geological formation made while drilling.

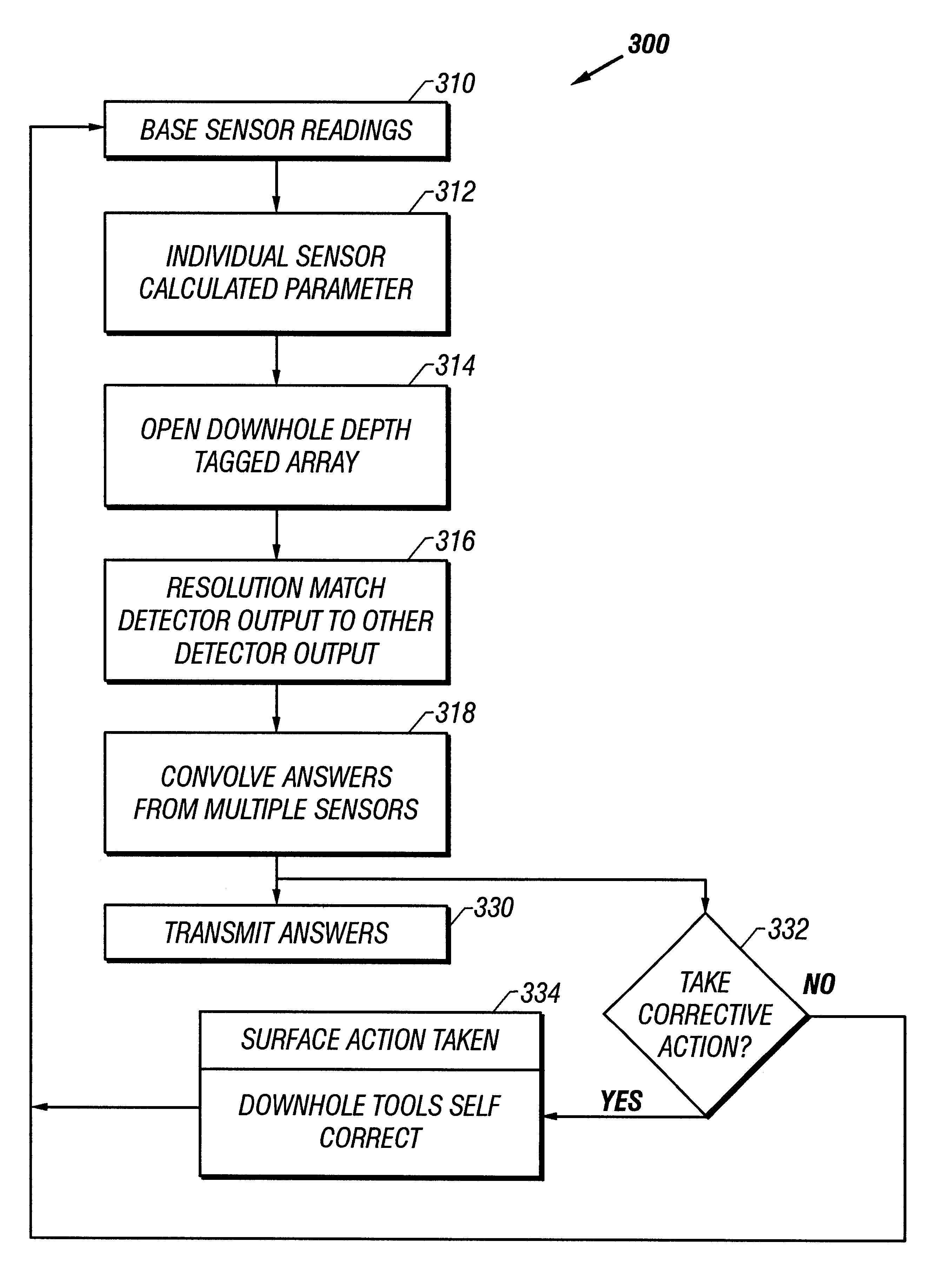

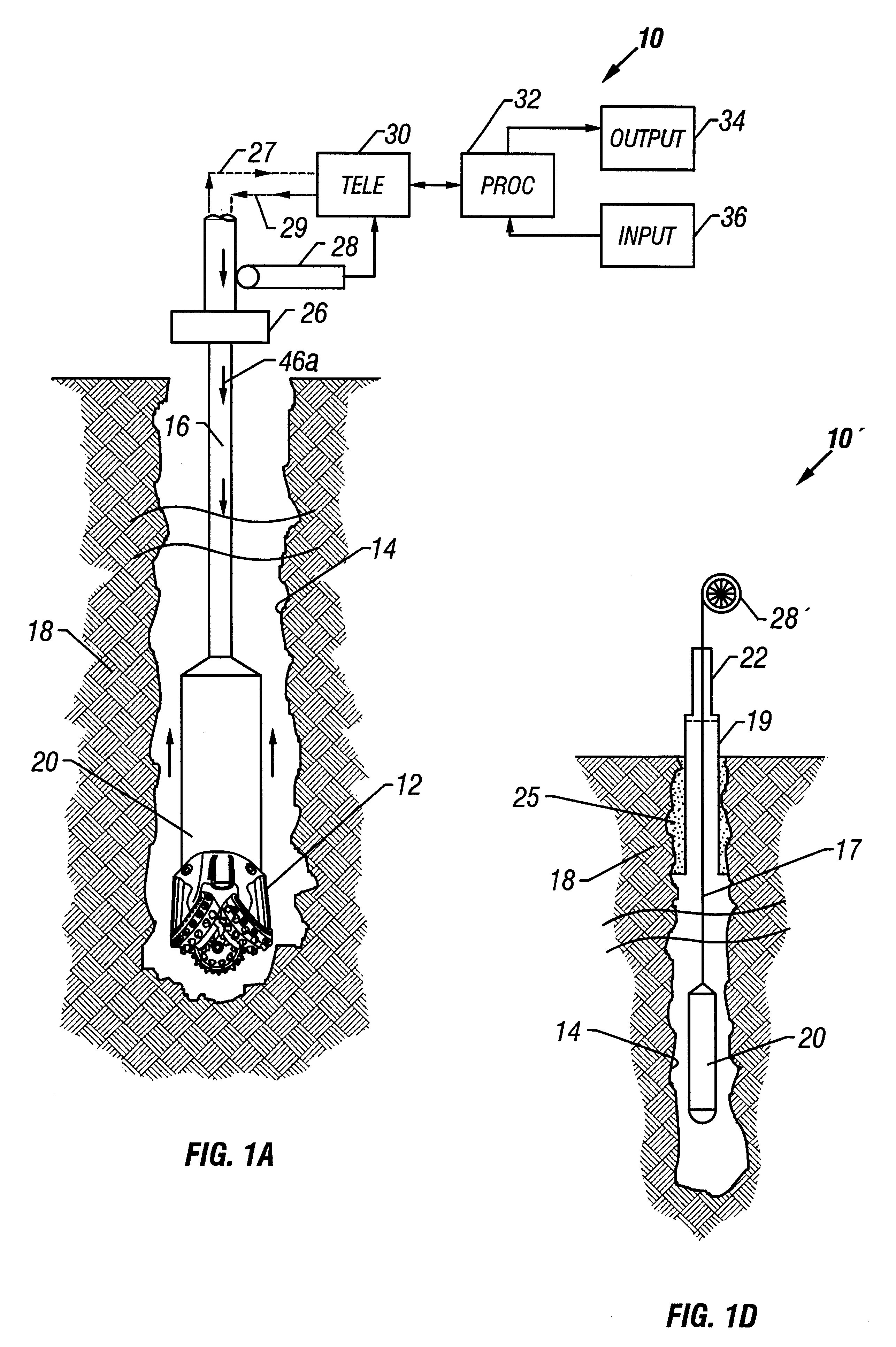

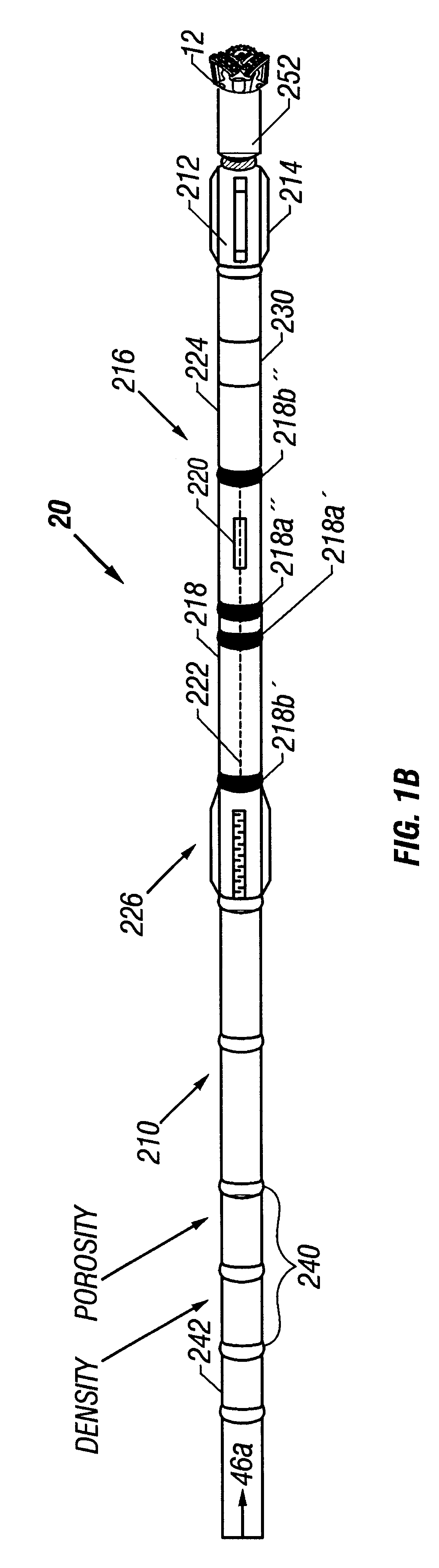

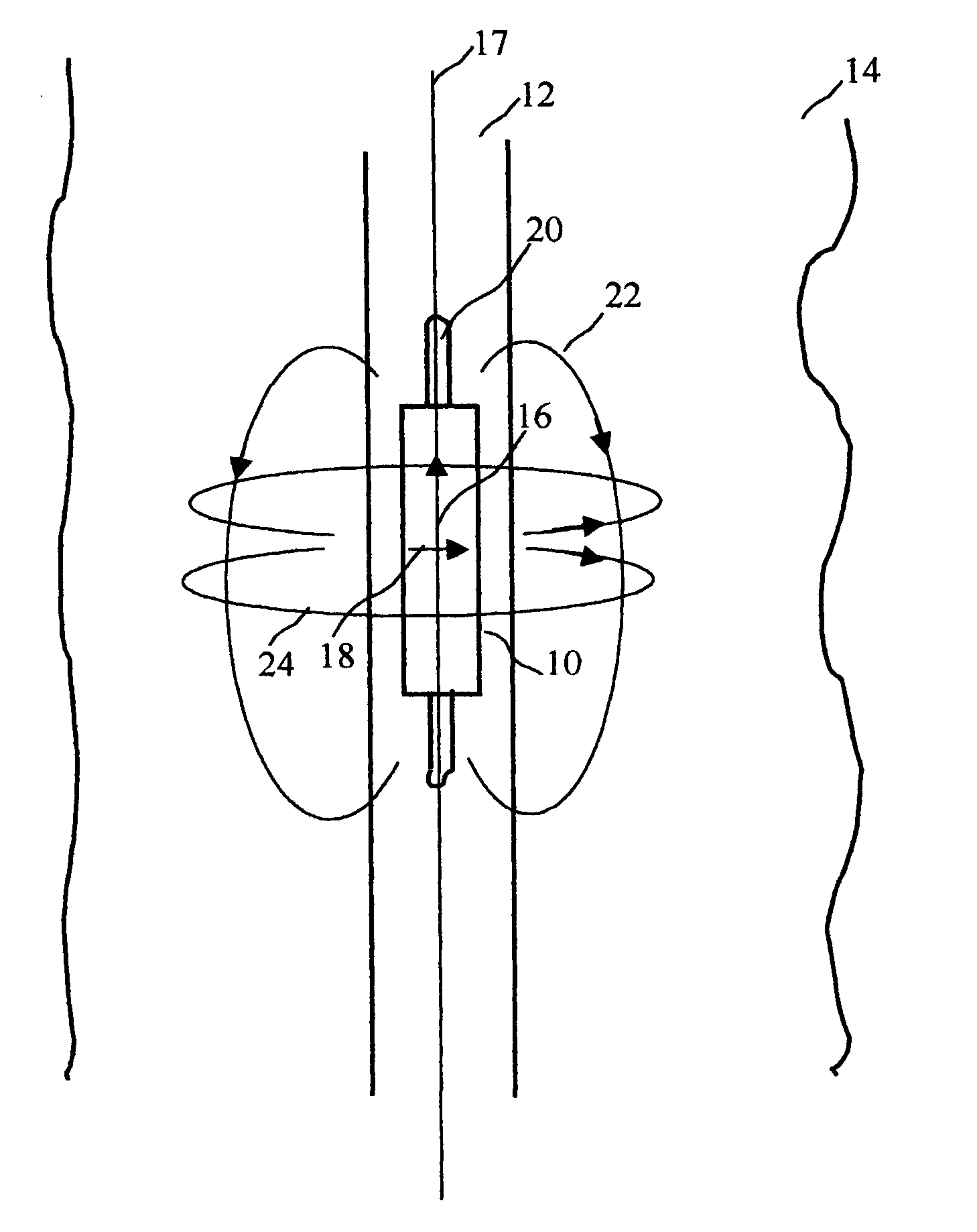

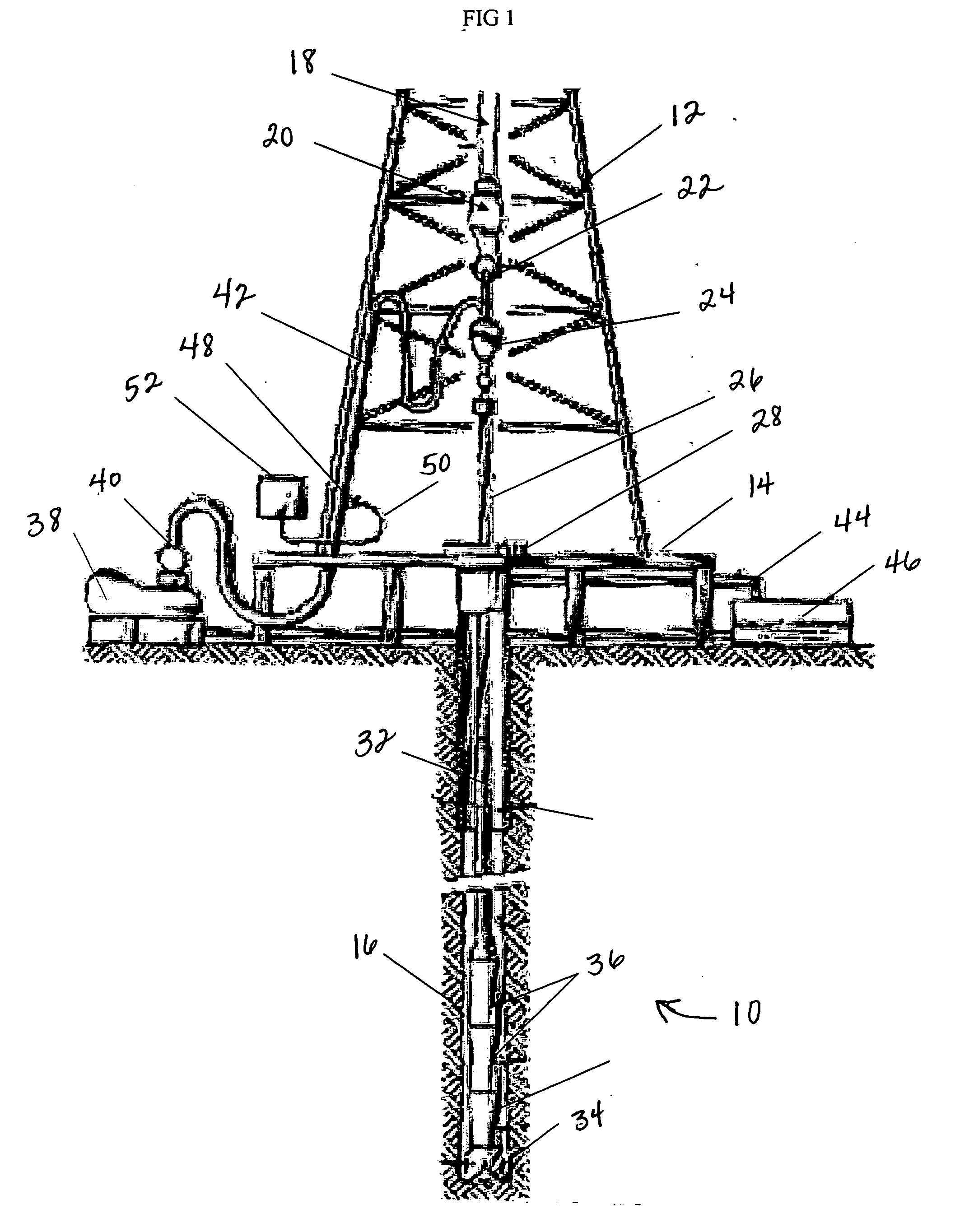

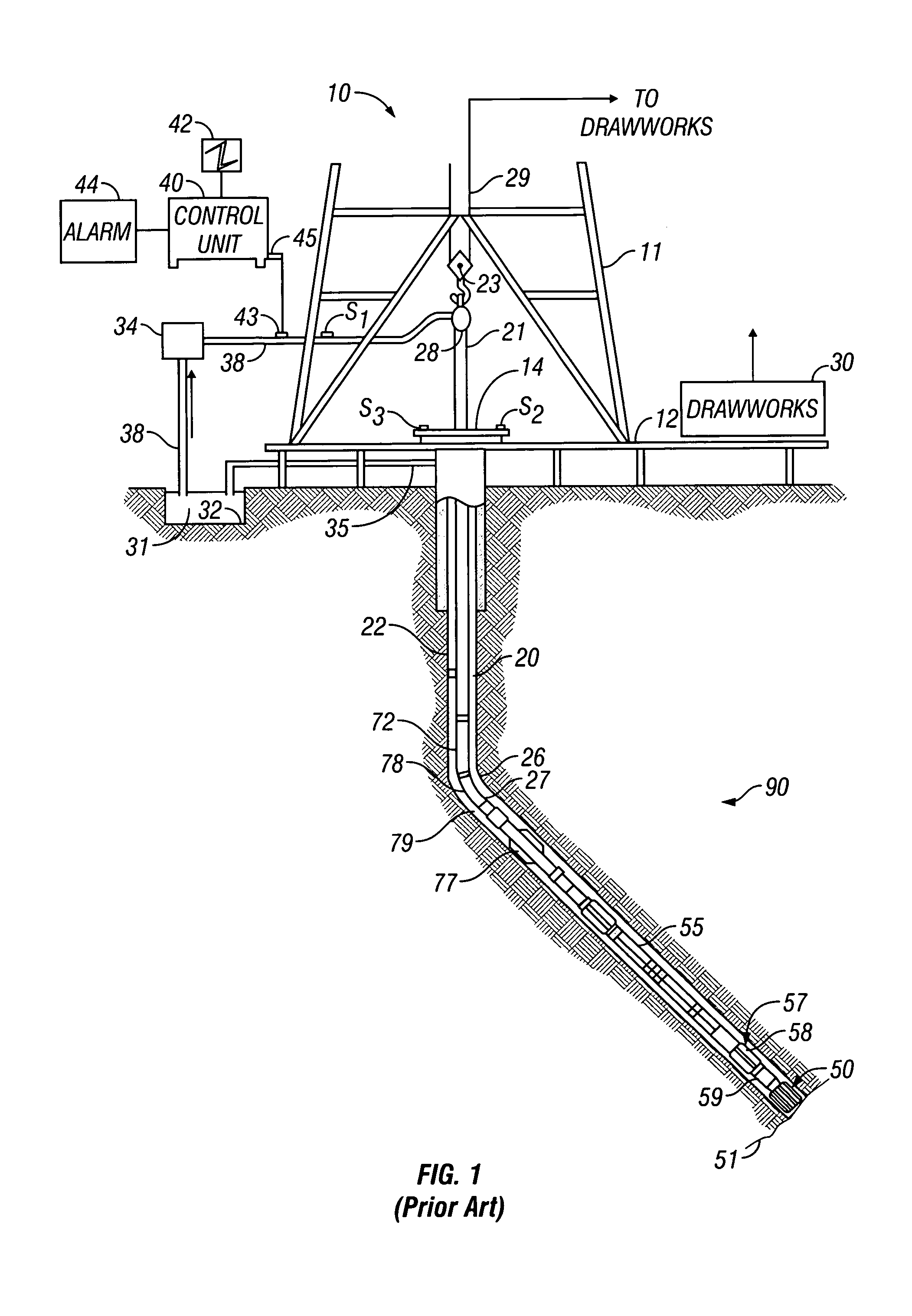

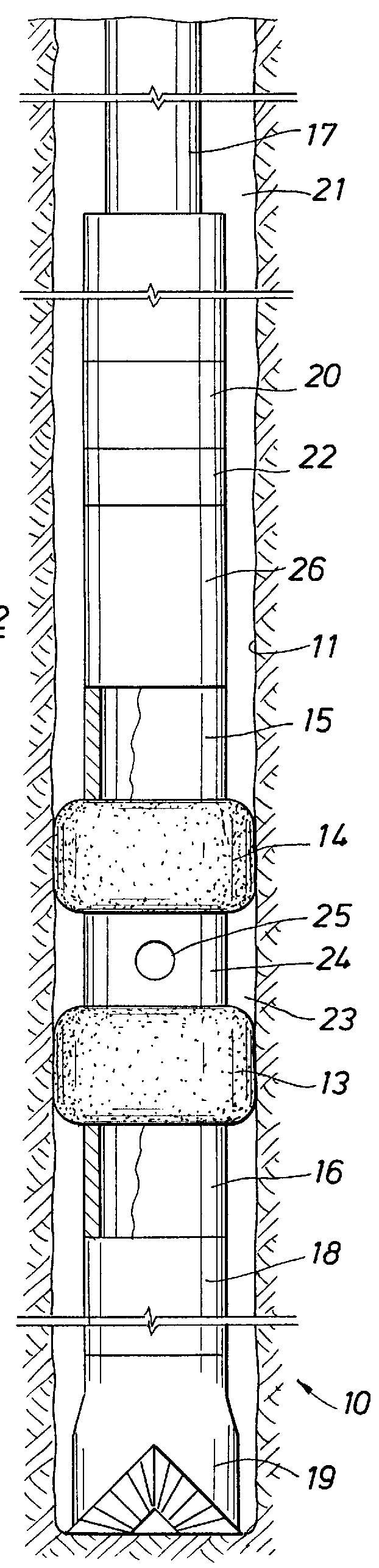

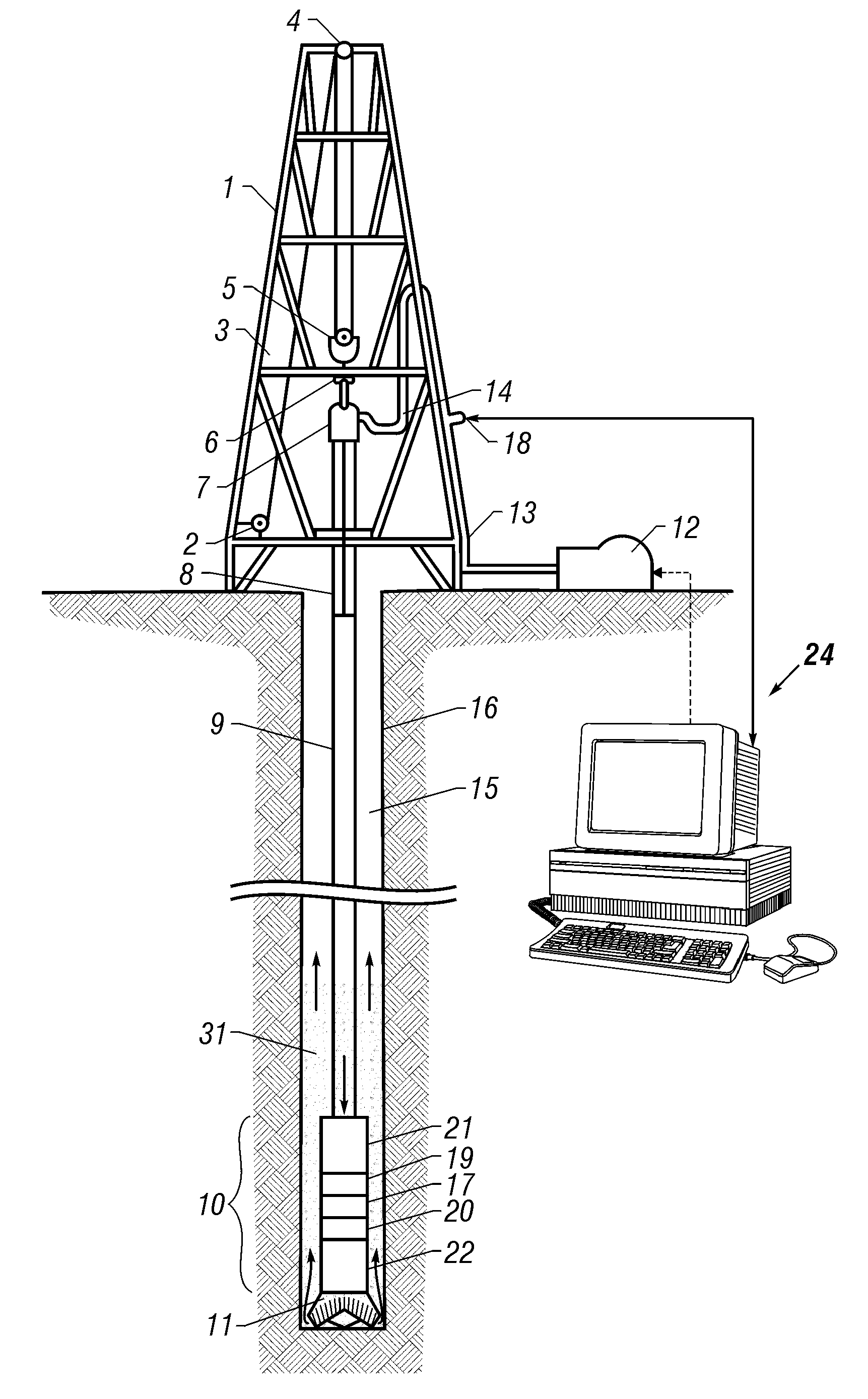

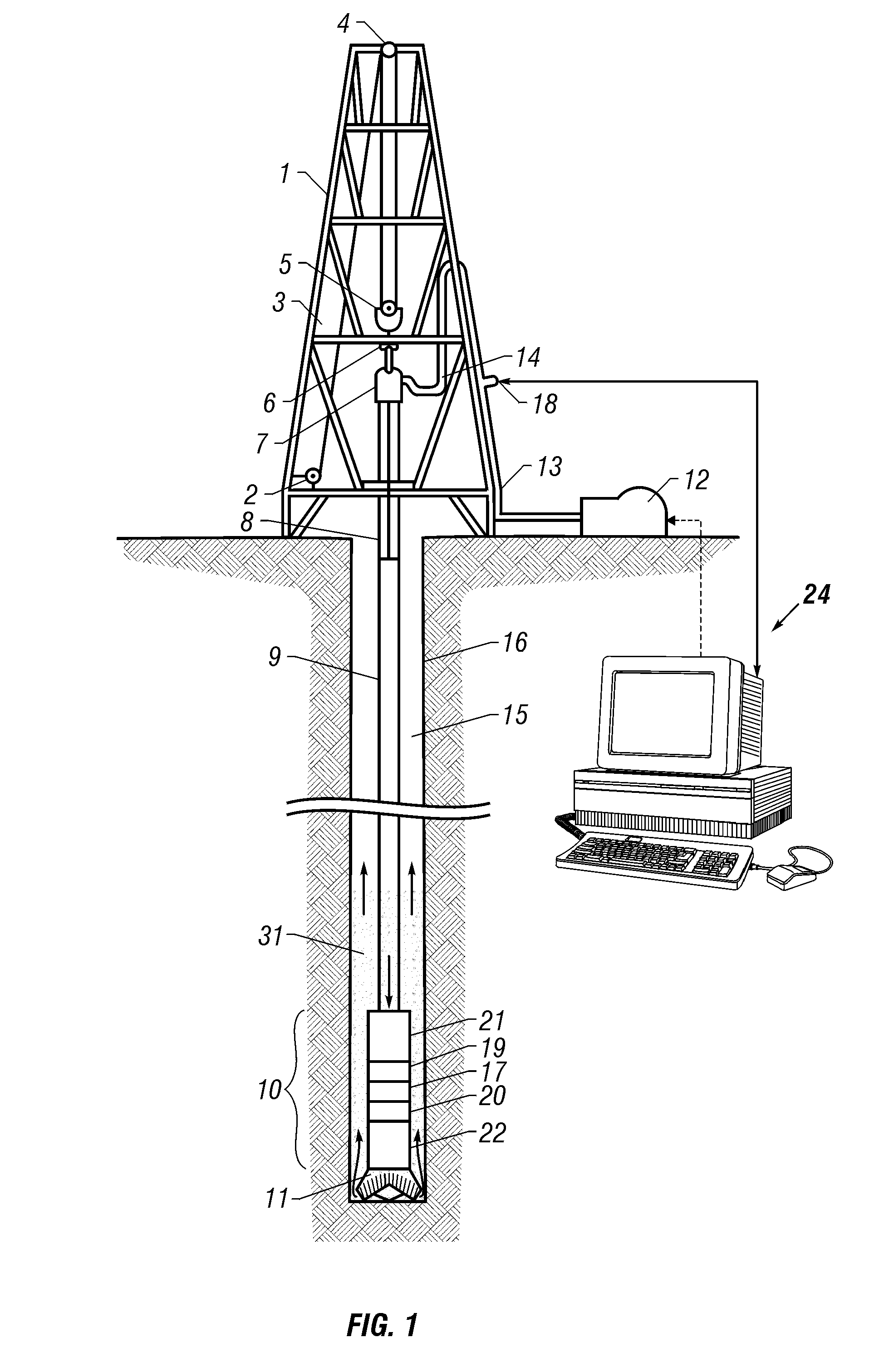

Drilling system with downhole apparatus for determining parameters of interest and for adjusting drilling direction in response thereto

The present invention provides a measurement-while-drilling (MWD) system having a downhole computer and multiple downhole sensors. Relatively large amounts of basic or "raw" data are measured by downhole sensors, and these data are processed within a downhole computer to be reduced to parameters of interest, which may be utilized to control the drilling operation by downhole devices, stored downhole, telemetered to the surface, or both. The measurements may be correlated downhole with stored reference data thereby providing additional information pertaining to the drilling operation. Downhole depth correlation between downhole measured parameters may be made by utilizing surface determined or downhole determined borehole depth.

Owner:BAKER HUGHES INC

Method and apparatus of using magnetic material with residual magnetization in transient electromagnetic measurement

ActiveUS20050189945A1Facilitates highly effective generationQuick switchElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingTransmitter antenna

Owner:BAKER HUGHES INC

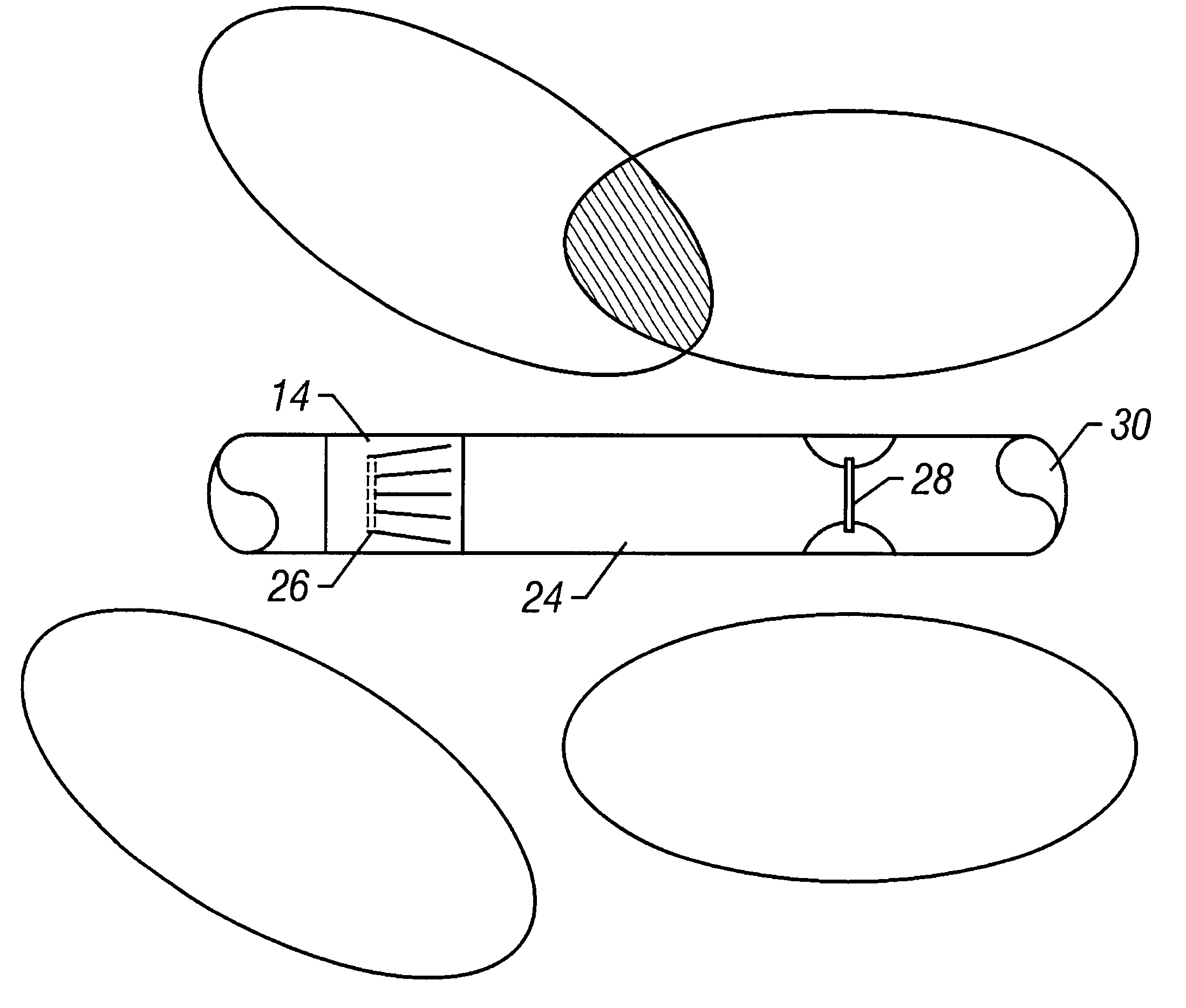

Method and apparatus for directional well logging with a shield having sloped slots

InactiveUS6297639B1Electric/magnetic detection for well-loggingDetection using electromagnetic wavesUltrasound attenuationDirectional well

Methods and apparatus for making directional measurements of earth formations surrounding a borehole. New antenna coil shield designs are utilized to provide selective attenuation of at least one electromagnetic energy field component as the component interacts with the shield. The new shields are implemented in several downhole tool configurations to provide azimuthally focused formation measurements. In effect, the new shield filters interacting electromagnetic energy field components to pass those components corresponding to a magnetic dipole oriented at an angle from the tool axis. The shields thereby alter a coil's envelope of influence to electromagnetic energy. The new shields also form part of a system for making directional measurements while drilling.

Owner:SCHLUMBERGER TECH CORP

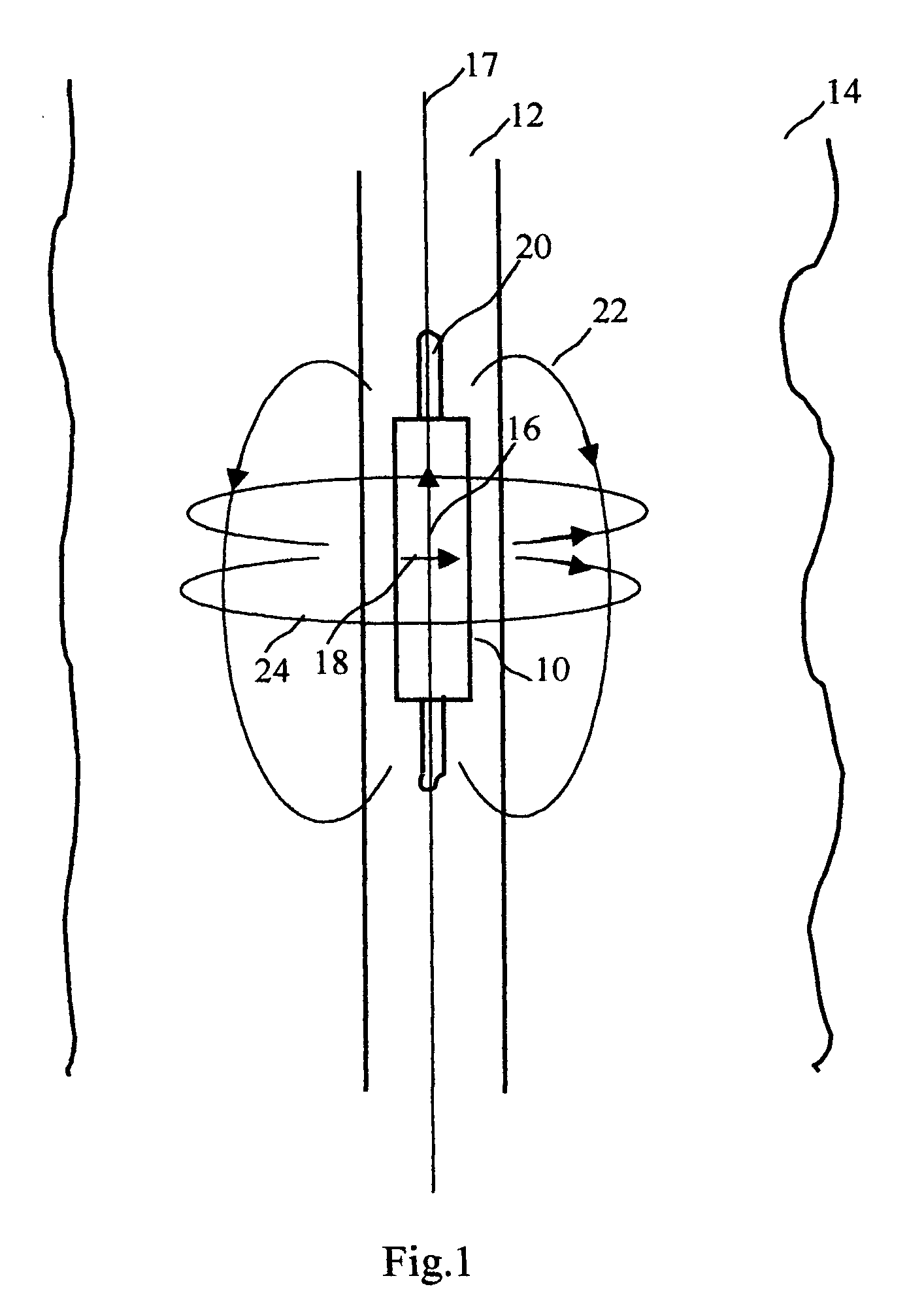

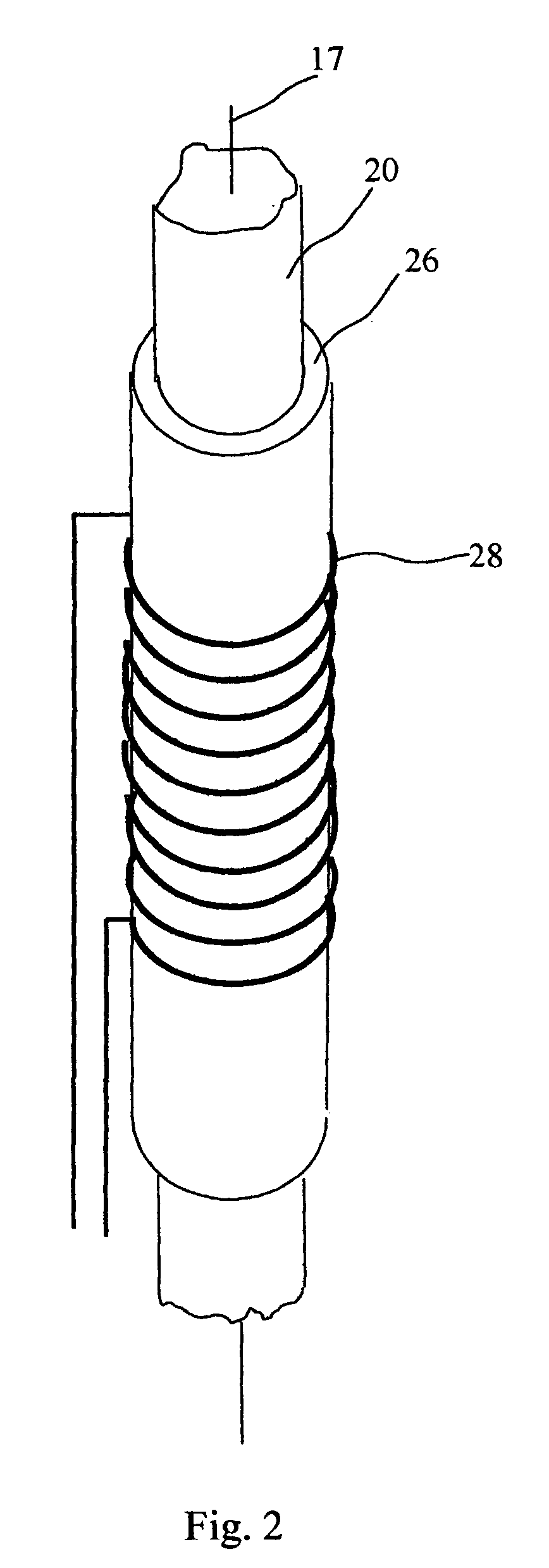

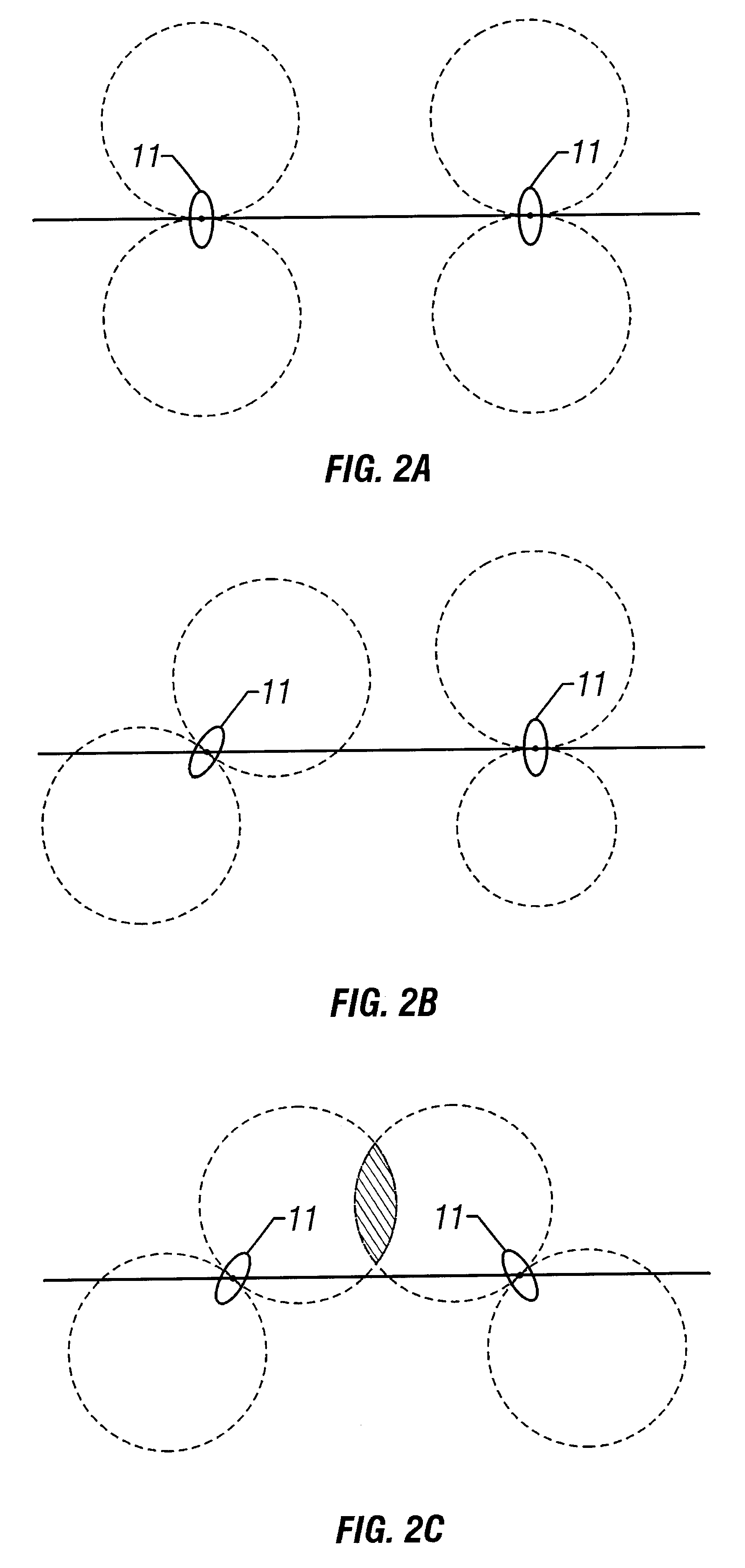

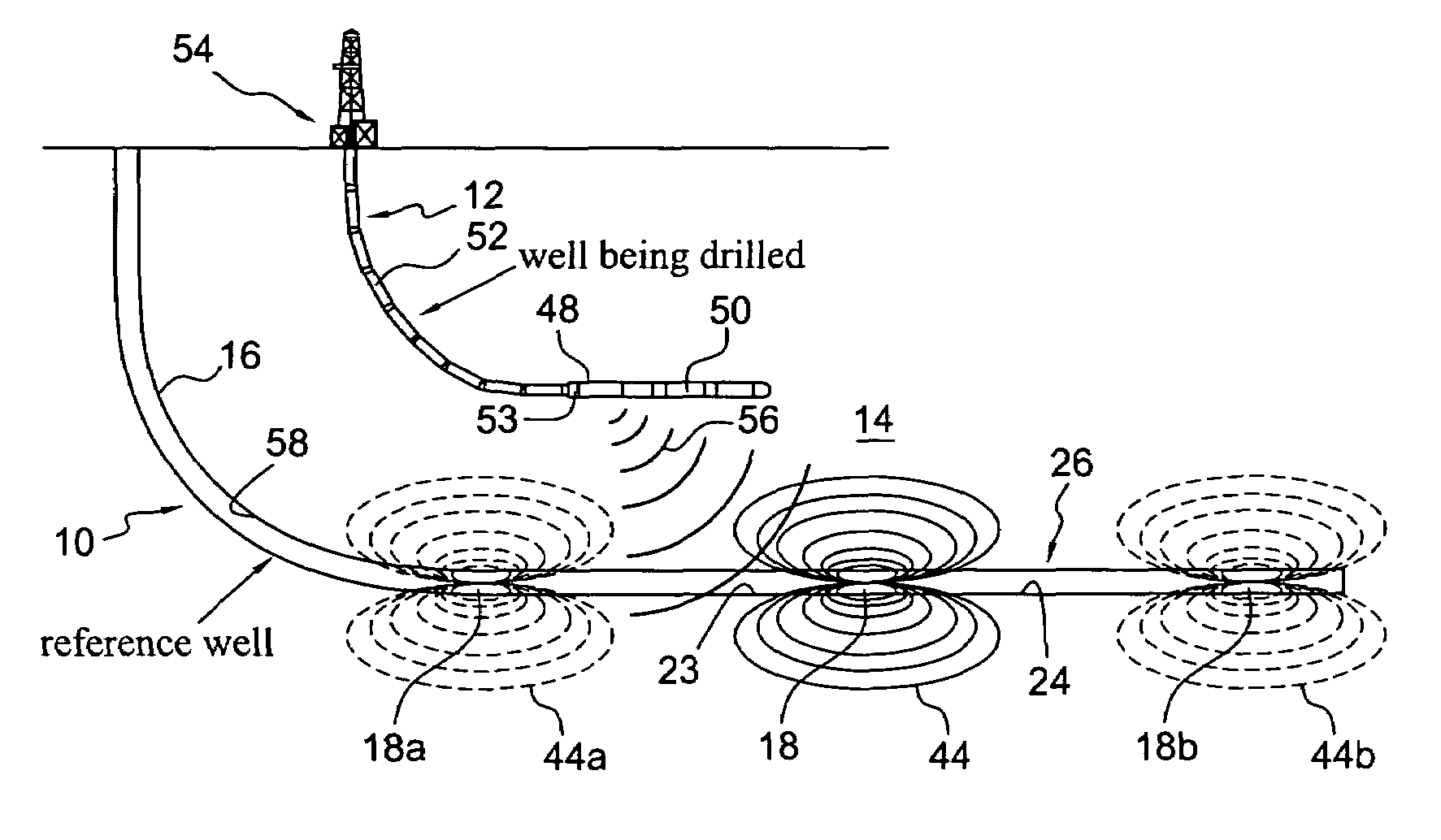

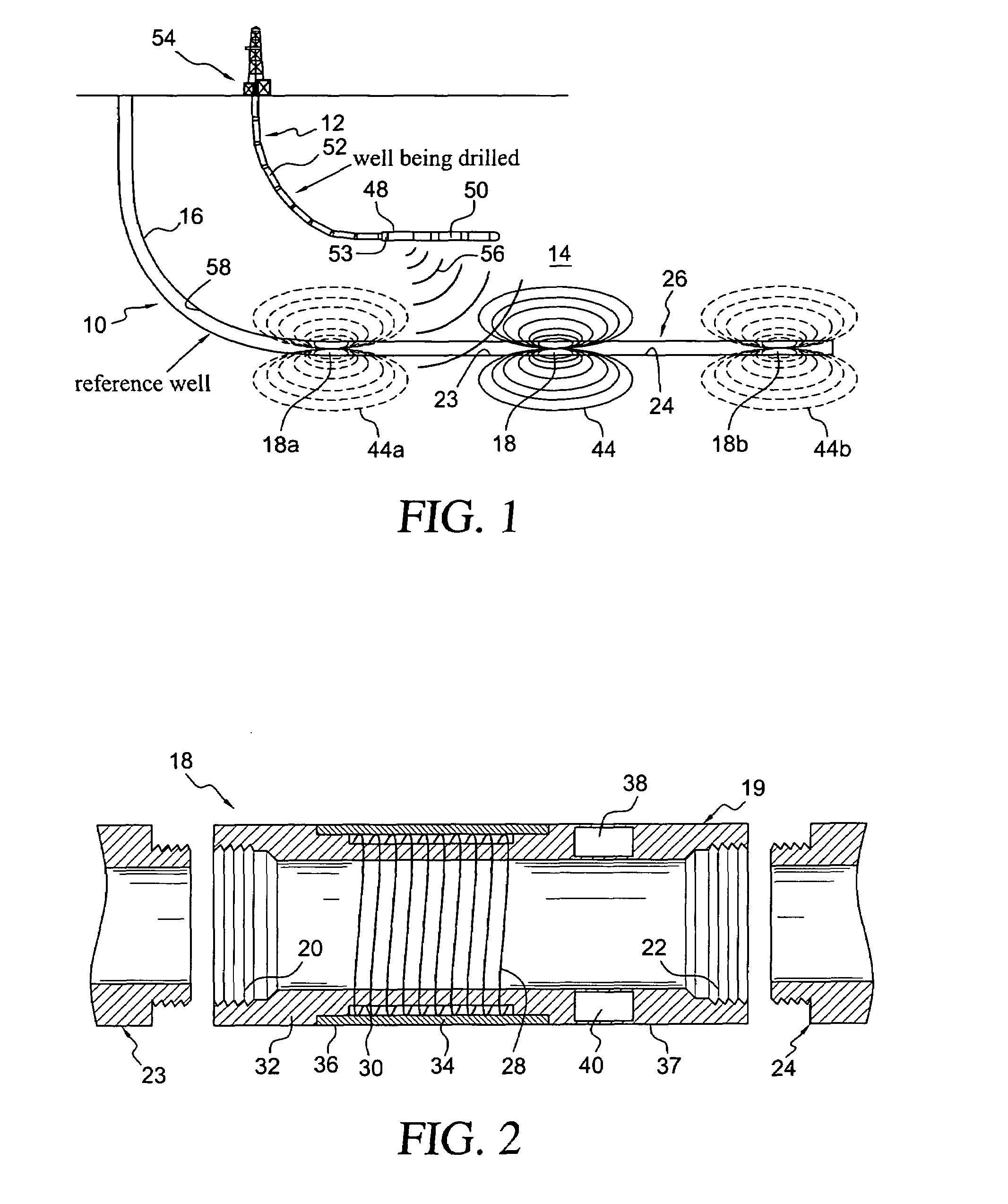

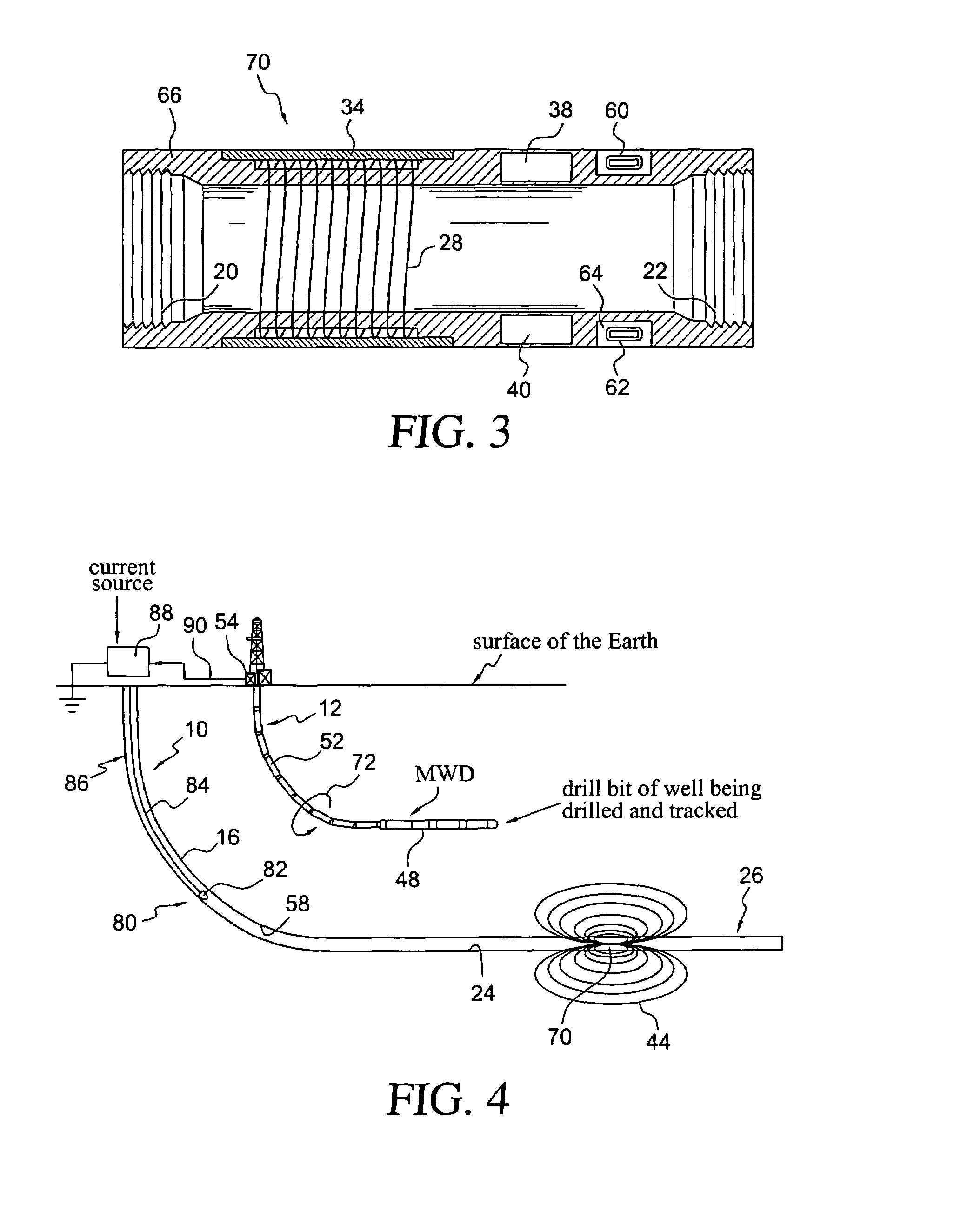

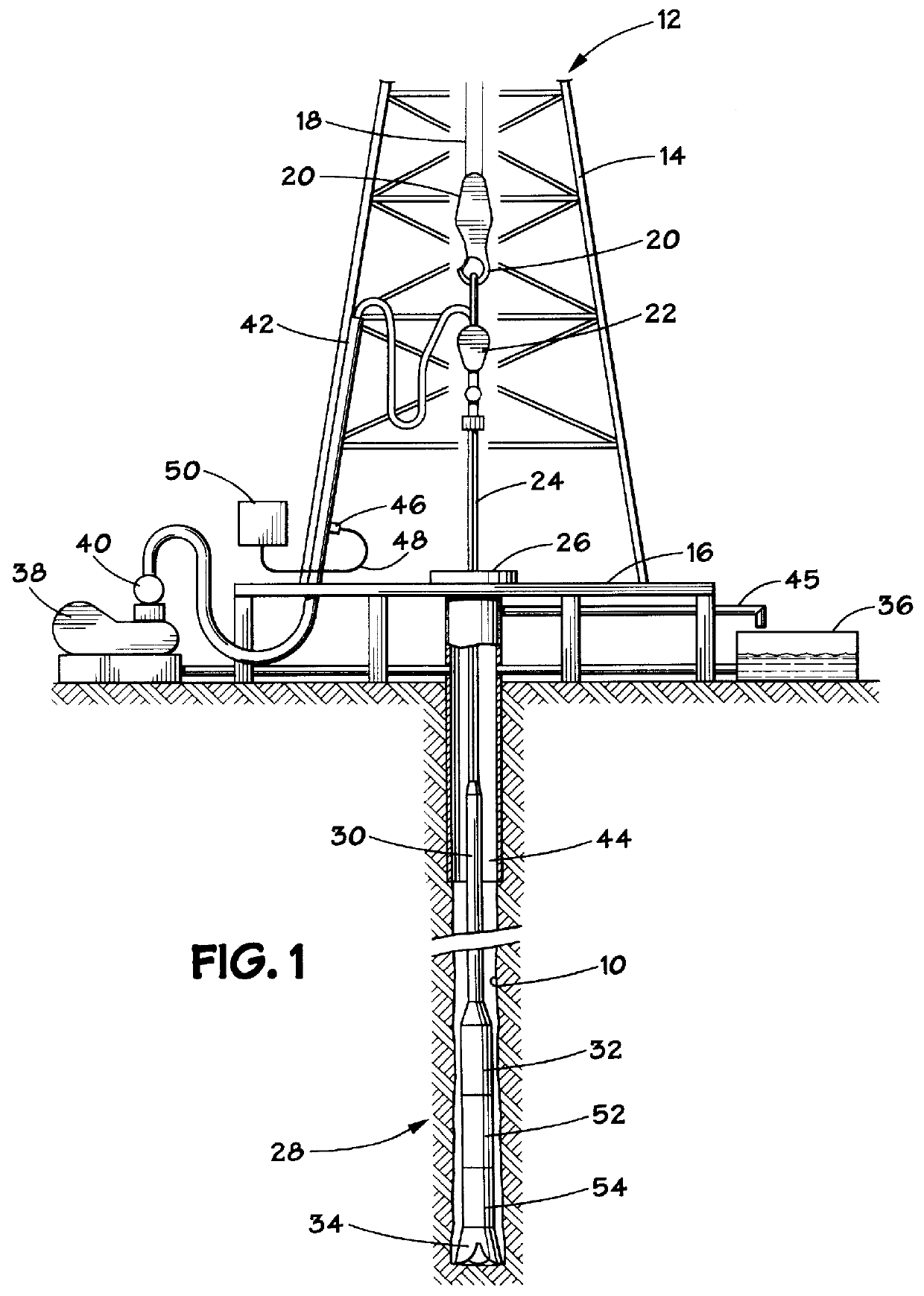

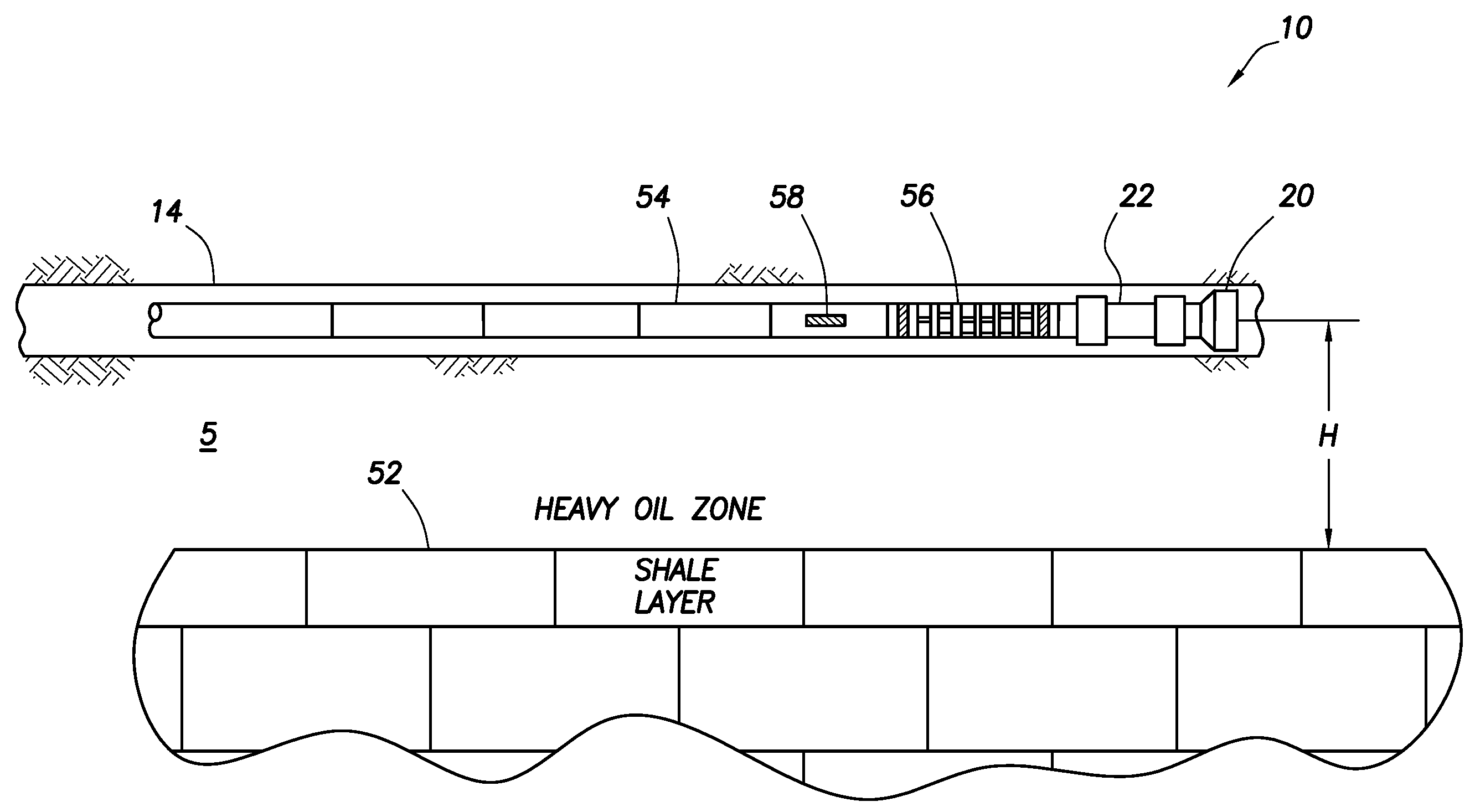

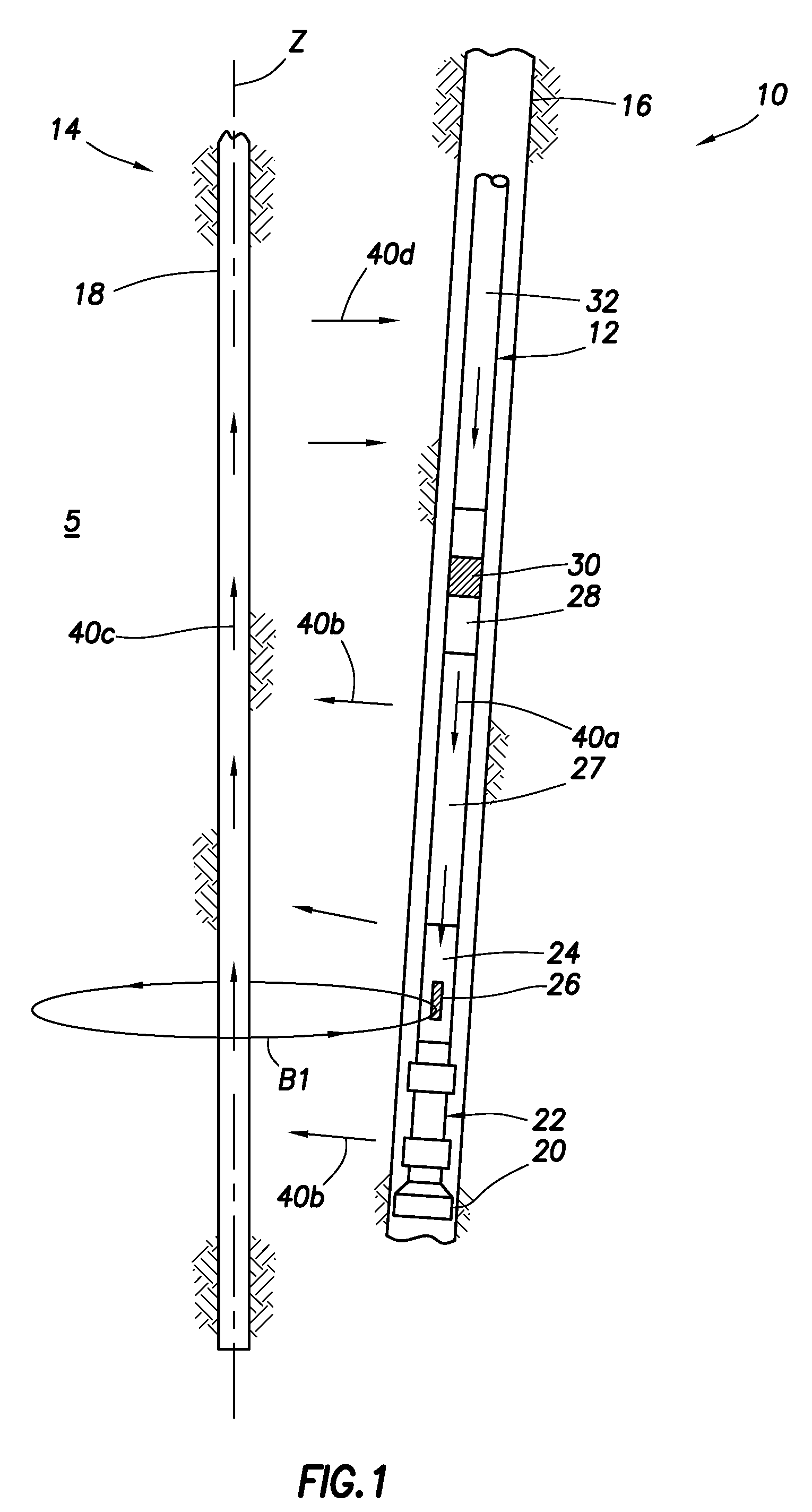

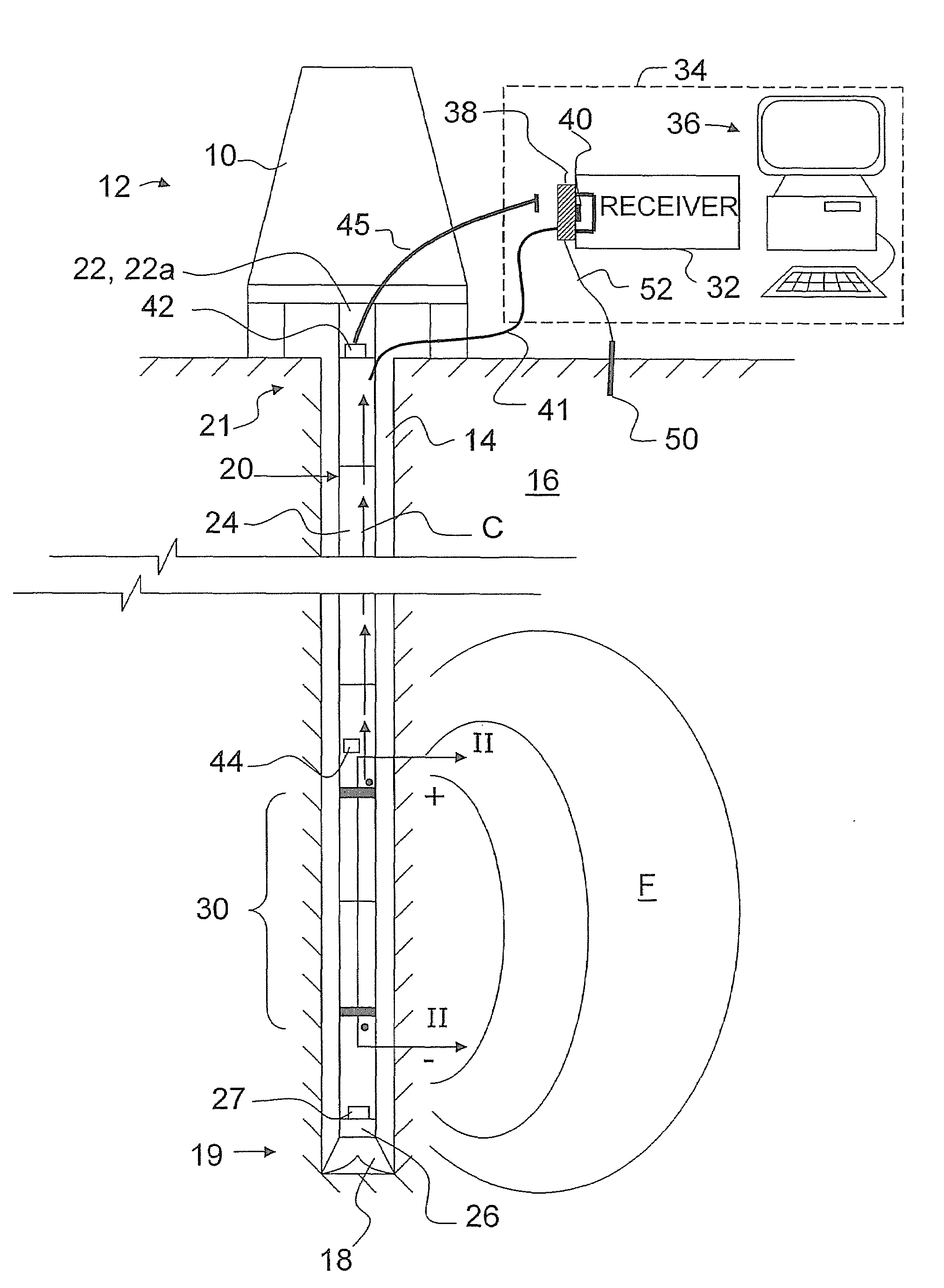

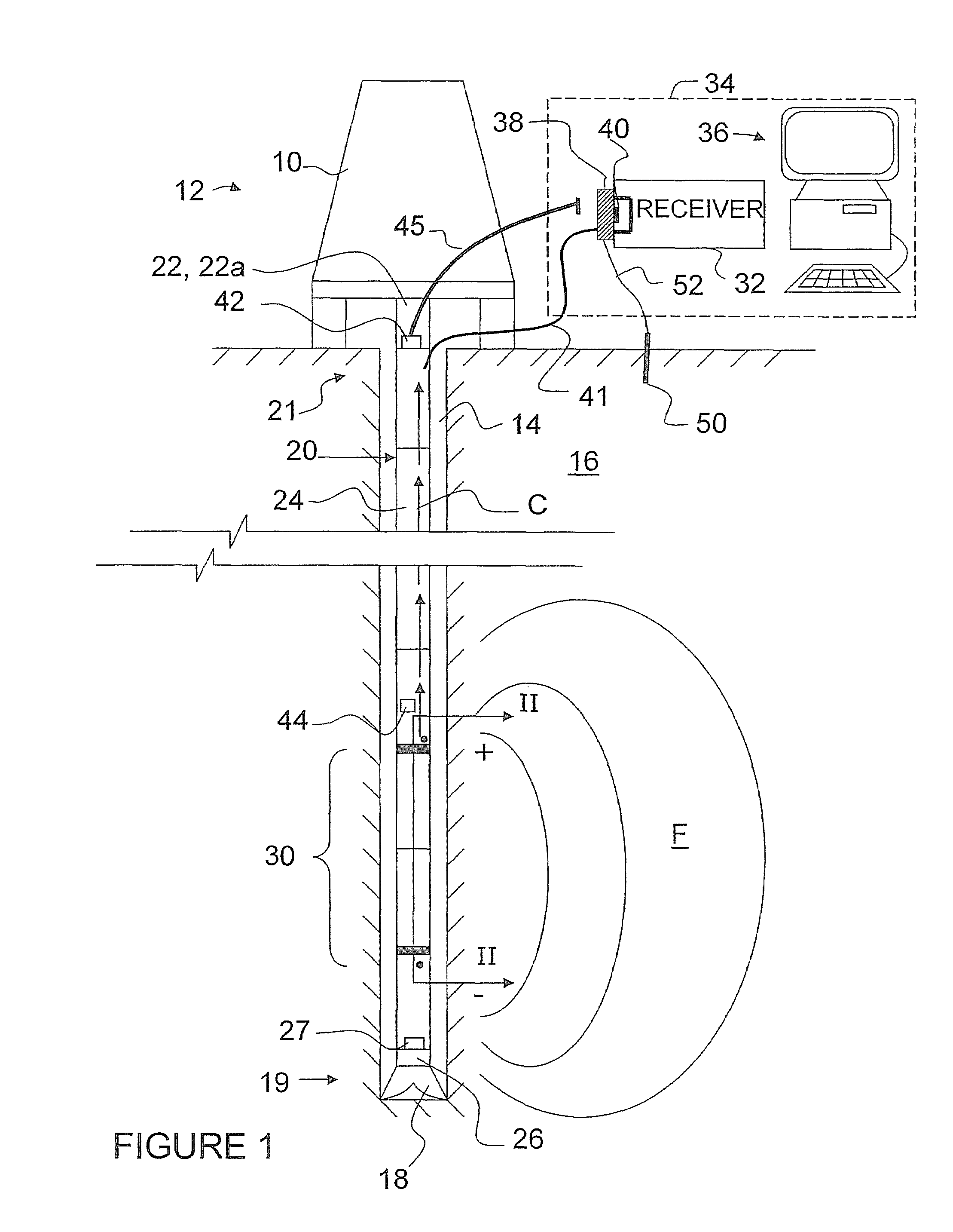

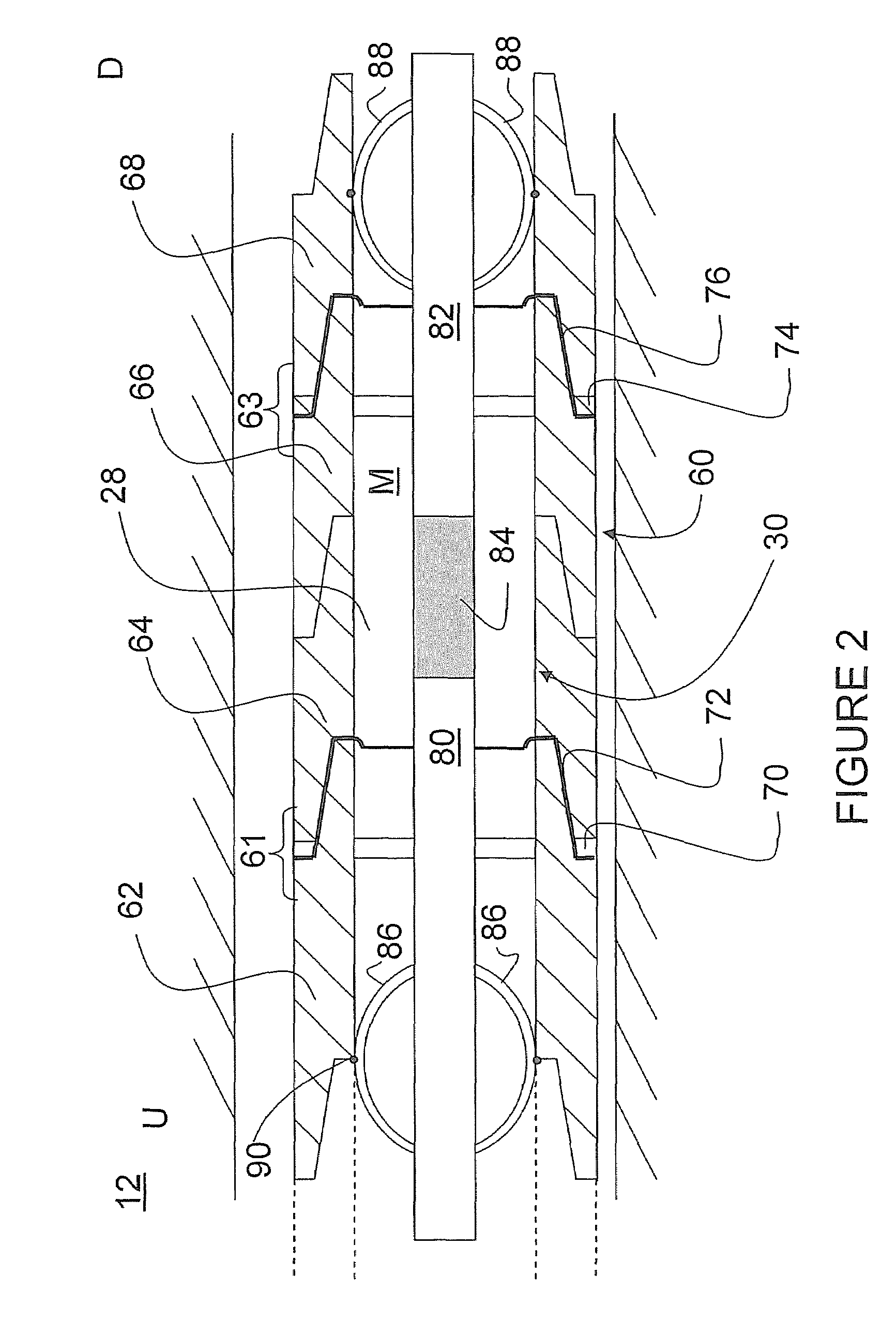

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

Electrically powered electromagnetic field source beacons installed in a reference well in combination with a down-hole measurement while drilling (MWD) electronic survey instrument near the drill bit in the borehole being drilled permit distance and direction measurements for drilling guidance. Each magnetic field source beacon consists of a coil of wire wound on a steel coupling between two lengths of steel tubing in the reference well, and powered by an electronic package. Control circuitry in the electronic package continuously “listens” for, and recognizes, a “start” signal that is initiated by the driller. After a “start” signal has been received, the beacon is energized for a short time interval during which an electromagnetic field is generated, which is measured by the MWD apparatus. The generated magnetic field may be an AC field, or switching circuitry can periodically reverse the direction of a generated DC electromagnetic field, and the measured vector components of the electromagnetic field are used to determine the relative location coordinates of the drilling bit and the beacon using well-known mathematical methods. The magnetic field source and powering electronic packages may be integral parts of the reference well casing or may be part of a temporary work string installed therein. Generally, numerous beacons will be installed along the length of the reference well, particularly in the important oil field application of drilling steam assisted gravity drainage (SAGD) well pairs.

Owner:HALLIBURTON ENERGY SERVICES INC

Measurement while drilling electromagnetic telemetry system using a fixed downhole receiver

InactiveUS6727827B1Electric/magnetic detection for well-loggingSurveyElectricityElectrical conductor

A system and method for enhancing the reception of electromagnetic (EM) waves in a fixed downhole receiver of an EM telemetry system is provided. In one embodiment, slots are formed in a portion of an outer casing and an EM receiver is positioned within the outer casing so as to be aligned with the slots formed therein. In another embodiment, an inductive coupling arrangement is provided to transfer signals from an EM receiver mounted on the outside surface of an outer casing to a wireline that is attached to the outer surface of an inner casing, which is disposed within the outer casing. In yet another embodiment, an insulated gap is formed in the surface of the outer casing. An EM receiver, mounted on the outer surface of the inner casing, is positioned above the insulated gap of the outer casing. An electrical coupling mechanism is further provided to electrically couple the inner and outer conductors at a point above the EM receiver.

Owner:SCHLUMBERGER TECH CORP

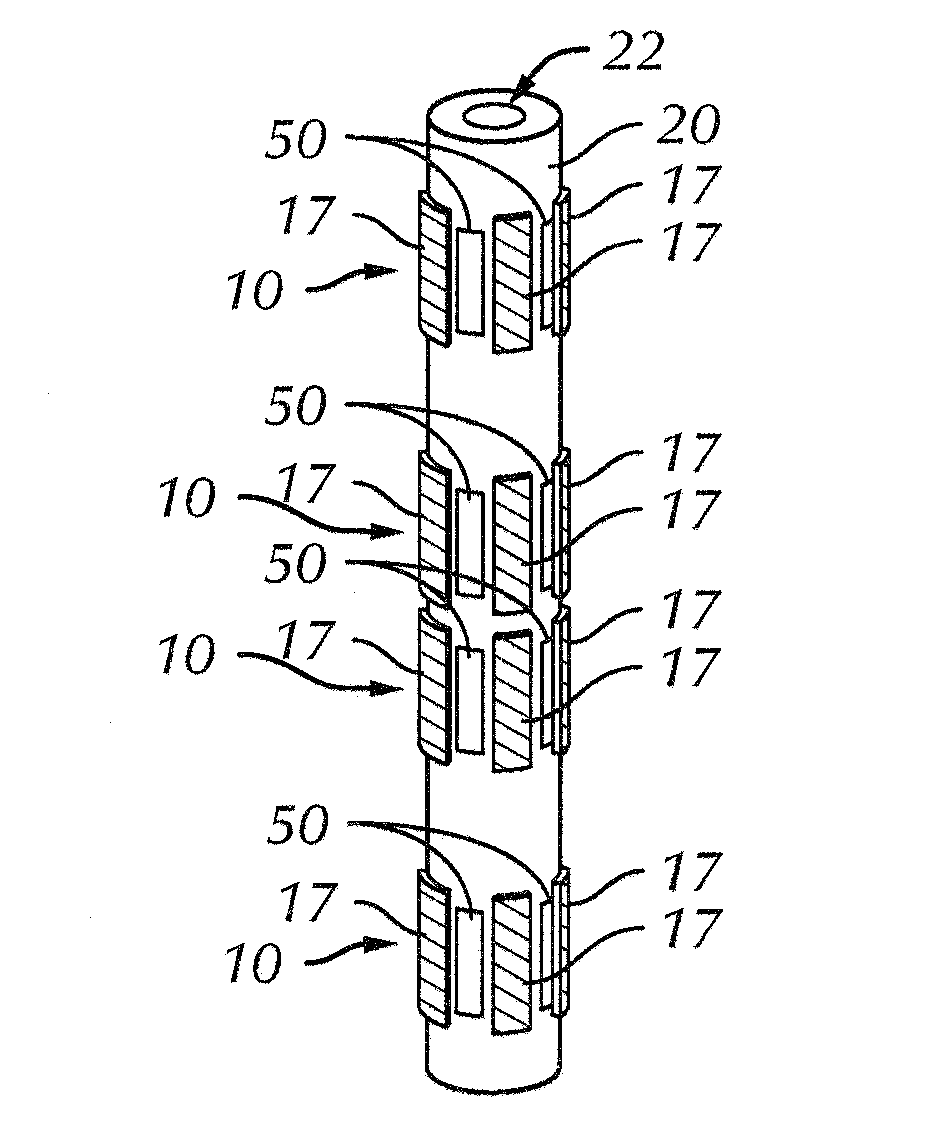

Array Antenna for Measurement-While-Drilling

ActiveUS20080224707A1Reduce their structural integrityProtection from damageLoop antennas with ferromagnetic coreElectric/magnetic detection for well-loggingElectrical conductorEngineering

An electromagnetic antenna for Measurement-While-Drilling (MWD) applications is disclosed. The antenna can include several array elements that can act alone or together in various measurement modes. The antenna elements can be disposed in tool body recesses to be protected from damage. The antenna elements can include a ferrite plate crossed or looped by independent current carrying conductors in two or more directions forming a bi-directional or crossed magnetic dipole. Although disclosed as a MWD system conveyed by a drill string, basic concepts of the system are applicable to other types of borehole conveyance.

Owner:WEATHERFORD TECH HLDG LLC

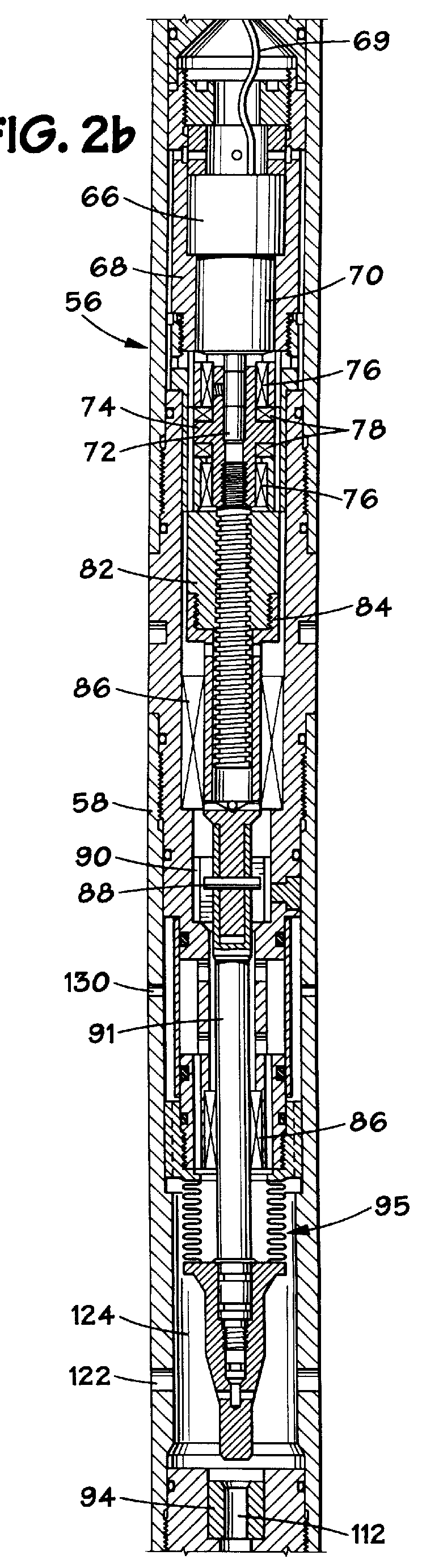

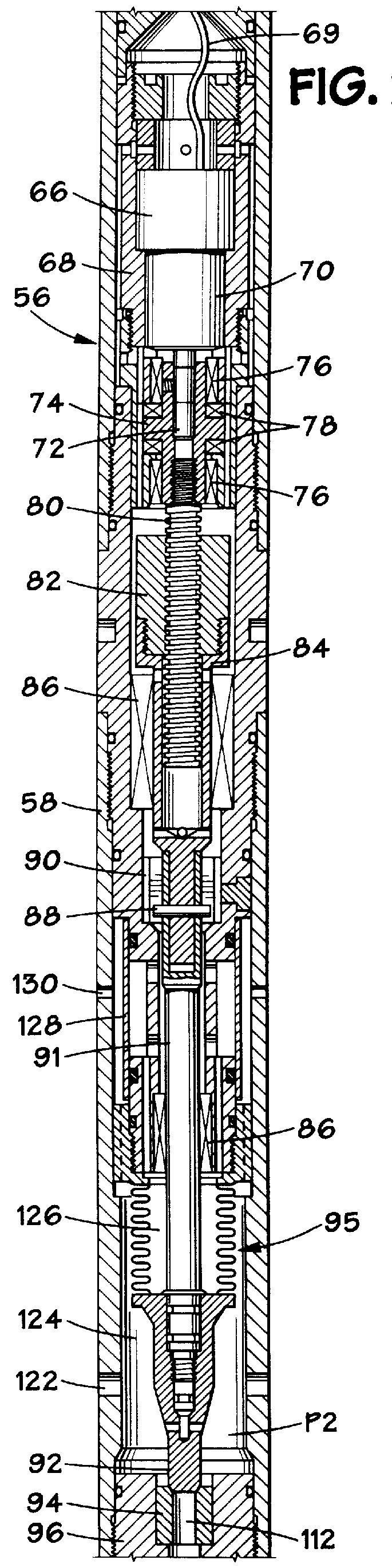

Servo-driven mud pulser

An improved servo-driven pulser is disclosed, for use in measurement while drilling applications. In the pulser, a battery powered on-board DC electric motor is used to operate a servo-valve, which in turn adjusts internal tool fluid pressures to cause operation of a main valve to substantially reduce mud flow to a drill bit, thereby creating a positive pressure pulse detectable at the surface. De-energizing the motor driving the pilot valve results in re-adjustment of internal fluid pressures, causing the main valve to reopen, thereby terminating the pressure pulse.

Owner:SMITH INT INC +1

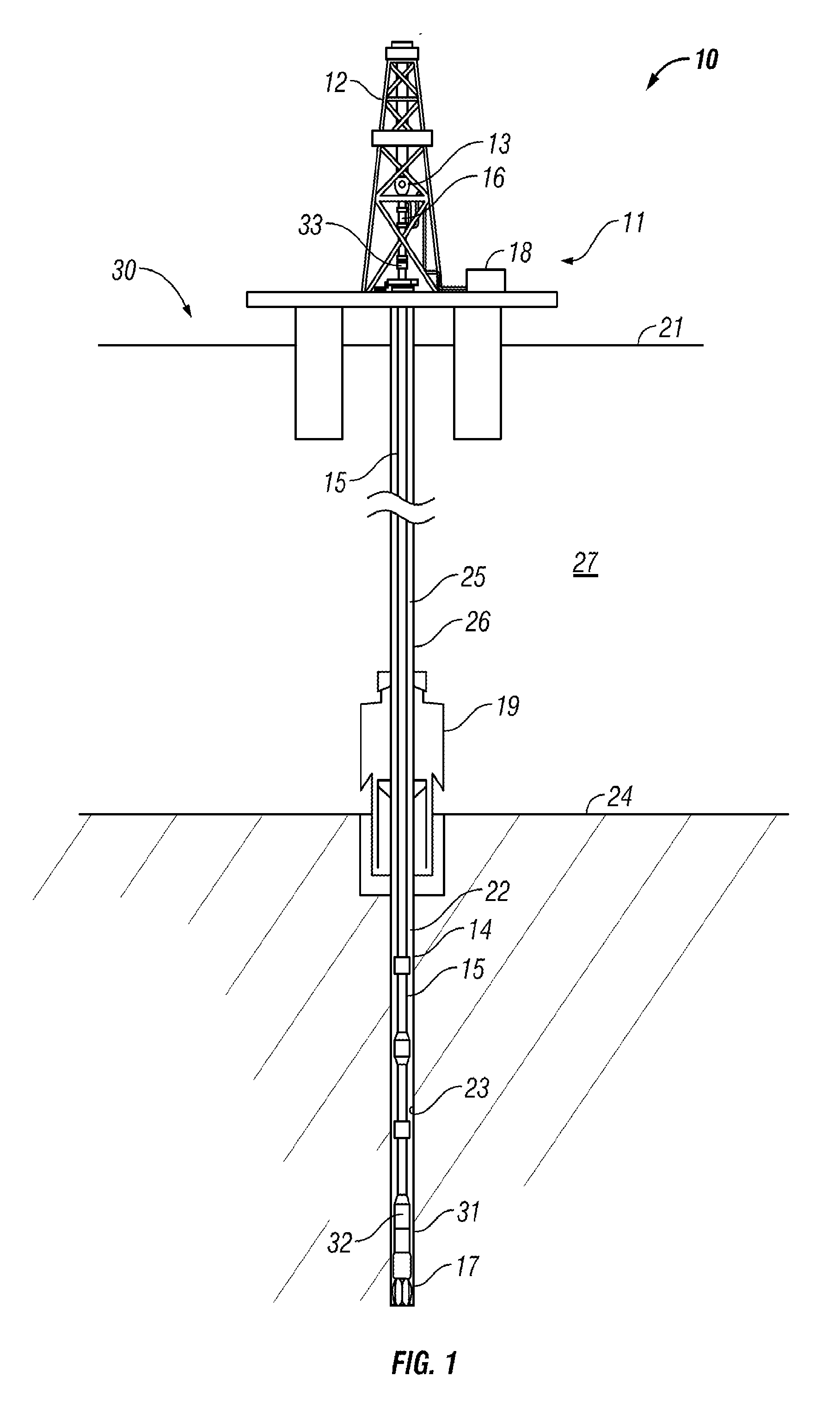

Drilling components and systems to dynamically control drilling dysfunctions and methods of drilling a well with same

Drilling tools that may detect and dynamically adjust drilling parameters to enhance the drilling performance of a drilling system used to drill a well. The tools may include sensors, such as RPM, axial force for measuring the weight on a drill bit, torque, vibration, and other sensors known in the art. A processor may compare the data measured by the sensors against various drilling models to determine whether a drilling dysfunction is occurring and what remedial actions, if any, ought to be taken. The processor may command various tools within the bottom hole assembly (BHA), including a bypass valve assembly and / or a hydraulic thruster to take actions that may eliminate drilling dysfunctions or improve overall drilling performance. The processor may communicate with a measurement while drilling (MWD) assembly, which may transmit the data measured by the sensors, the present status of the tools, and any remedial actions taken to the surface.

Owner:BAKER HUGHES INC

Method and apparatus for locating well casings from an adjacent wellbore

ActiveUS20070126426A1Electric/magnetic detection for well-loggingConstructionsEngineeringConductive materials

A wellbore tool for locating a target wellbore containing a conductive member from a second wellbore and directing the trajectory of the second wellbore relative to the target wellbore includes an electric current driver having an insulated gap; a three-axis magnetometer positioned within a non-magnetic housing that is disposed within a non-magnetic tubular, the three-axis magnetometer positioned below the electric current driver; a drill bit positioned below the three-axis magnetometer; a hollow tubular connected between the electric current driver and the three-axis magnetometer; and a measurement-while-drilling tool. The current driver generates an electric current across the gap to the portion of the tool below the insulated gap. In a method a current is generated across the insulated gap to the portion of the tool below the insulated gap to the conductive material in the target wellbore returning to a portion of the bottom hole assembly above the insulated gap thereby producing a target magnetic field. Measuring the target magnetic field at the bottom hole assembly and the earth's magnetic field; and determining the position of the second wellbore relative to the target wellbore. Then steering the bottom hole assembly to drill the second wellbore along a trajectory relative to the target wellbore.

Owner:SCHLUMBERGER TECH CORP

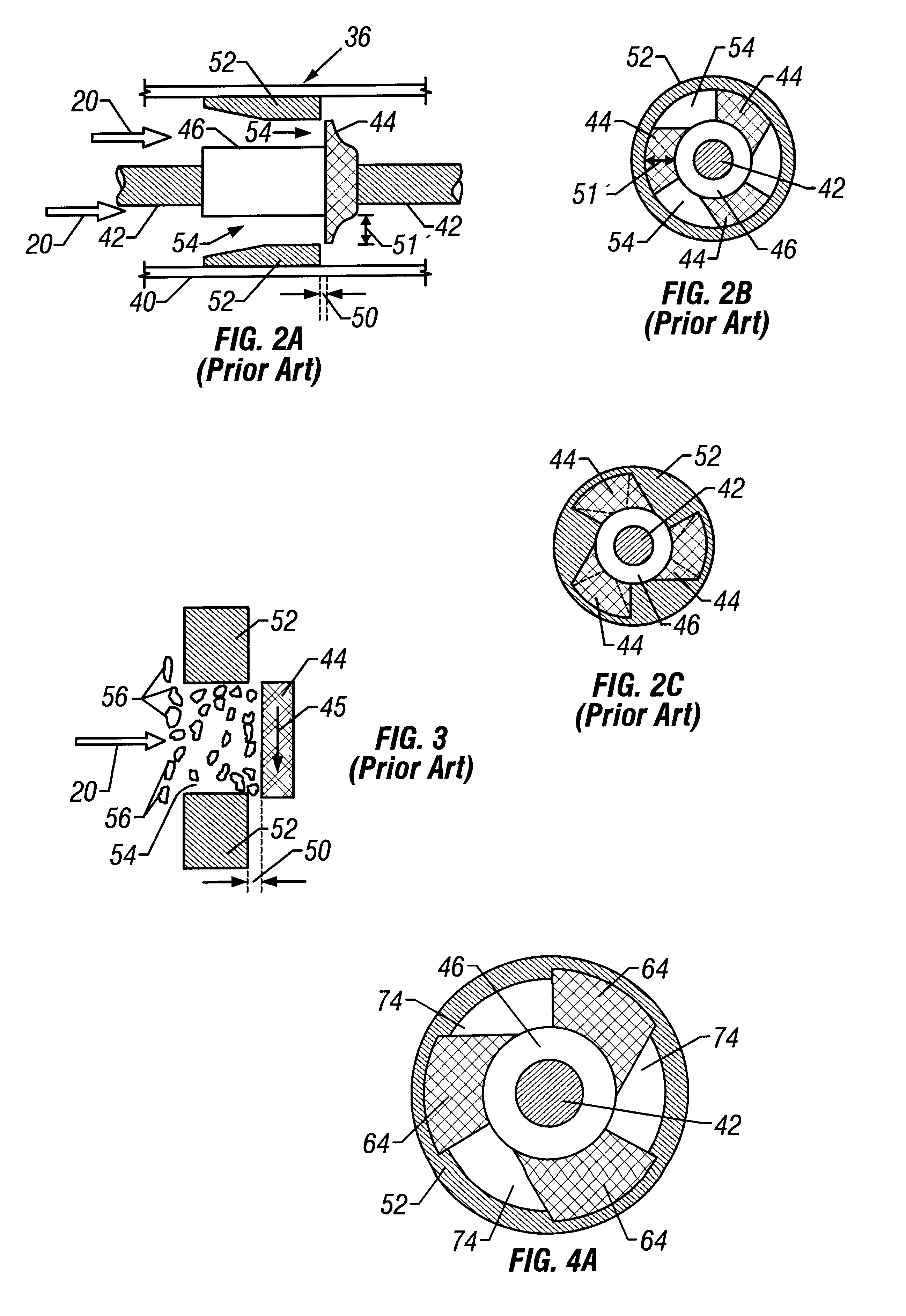

Pressure pulse generator for measurement-while-drilling systems which produces high signal strength and exhibits high resistance to jamming

InactiveUS6219301B1Easy to useIncrease signal strengthSurveyConstructionsHigh resistanceParticulates

A system is disclosed for generating and transmitting data signals to the surface of the earth while drilling a borehole, the system operating by generating pressure pulses in the drilling fluid filling the drill string. The system is designed to maximize signal strength while minimizing the probability of jamming by drilling fluid particulates. The system uses a rotary valve modulator consisting of a stator with flow orifices through which drilling fluid flows, and a rotor which rotates with respect to the stator thereby opening and restricting flow through the orifices and thereby generating pressure pulses. The flow orifices with the stator in a "closed" position are configured to reduce jamming, and to simultaneously minimize flow area in order to maximize signal strength. This is accomplished by imparting a shear to the fluid flow through the modulator, and minimizing the aspect ratio and maximizing the minimum principal dimension of the closed flow area. A preferred embodiment and three alternate embodiments of the modulator are disclosed.

Owner:SCHLUMBERGER TECH CORP

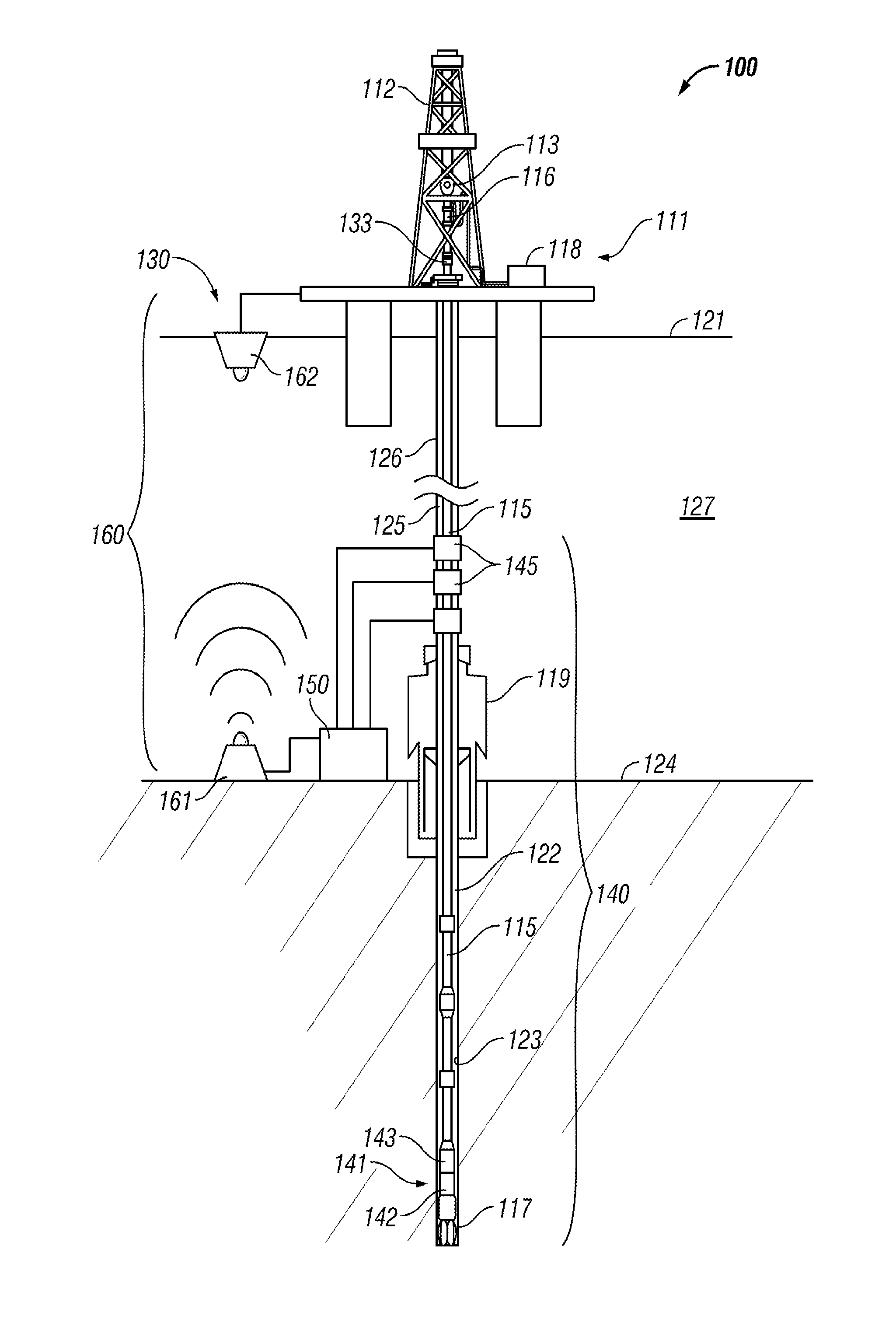

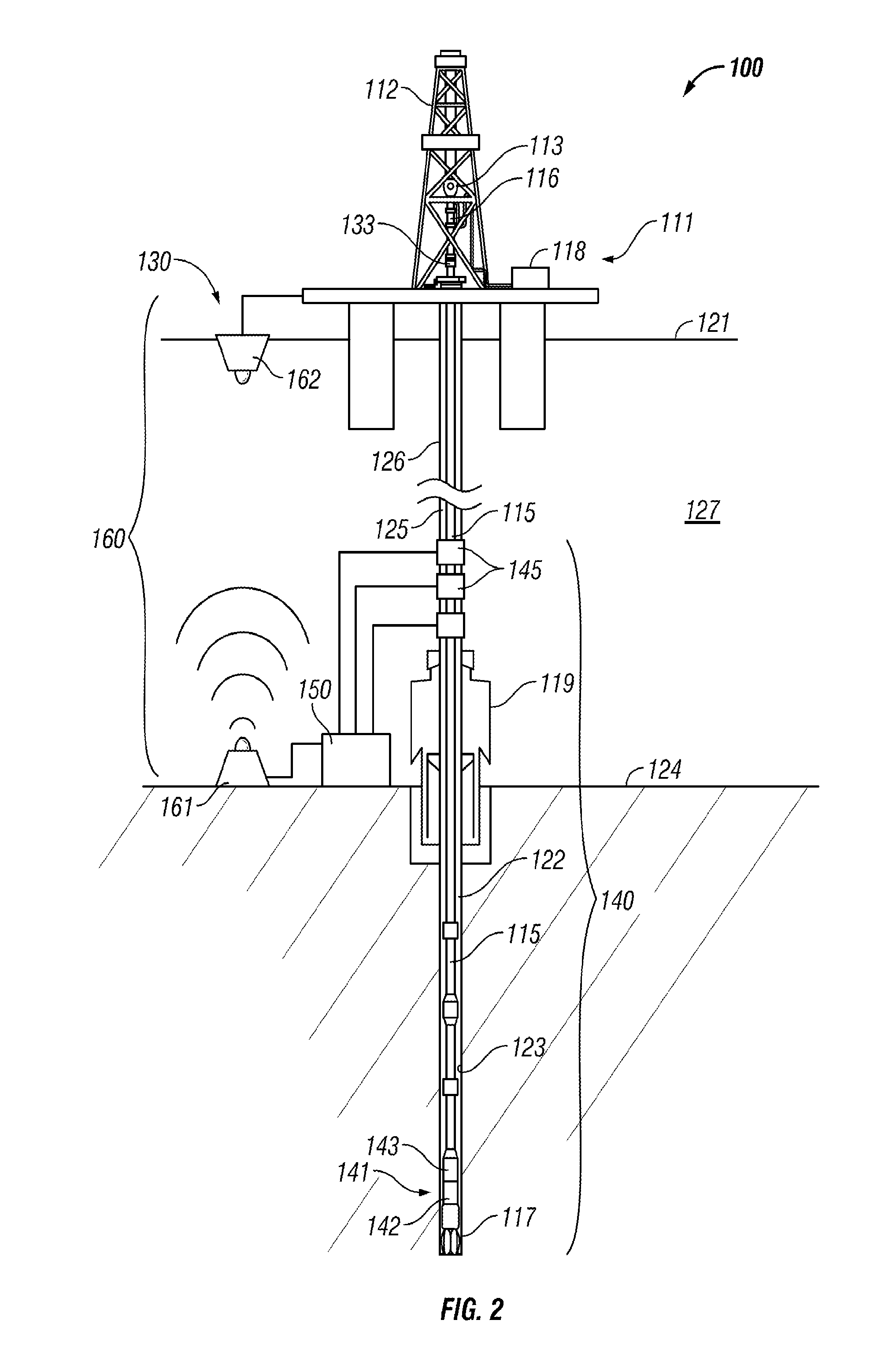

Exploitation Of Sea Floor Rig Structures To Enhance Measurement While Drilling Telemetry Data

ActiveUS20120126992A1Readily apparentWell/borehole valve arrangementsTransmissionOcean bottomCommunications system

A method for communicating data in an offshore data communication system comprises measuring L / MWD data with a sensor disposed in a bottomhole assembly positioned in a subsea borehole. The bottomhole assembly is disposed along a drillstring extending through the subsea borehole. In addition, the method comprises communicating the L / MWD data from the bottomhole assembly to the seafloor with a telemetry signal. Further, the method comprises receiving the telemetry signal with at least one telemetry transducer positioned proximal the sea floor. Still further, the method comprises processing the telemetry signal at the seafloor to produce a processed signal. Moreover, the method comprises transmitting the processed signal from the sea floor to the sea surface.

Owner:HALLIBURTON ENERGY SERVICES INC

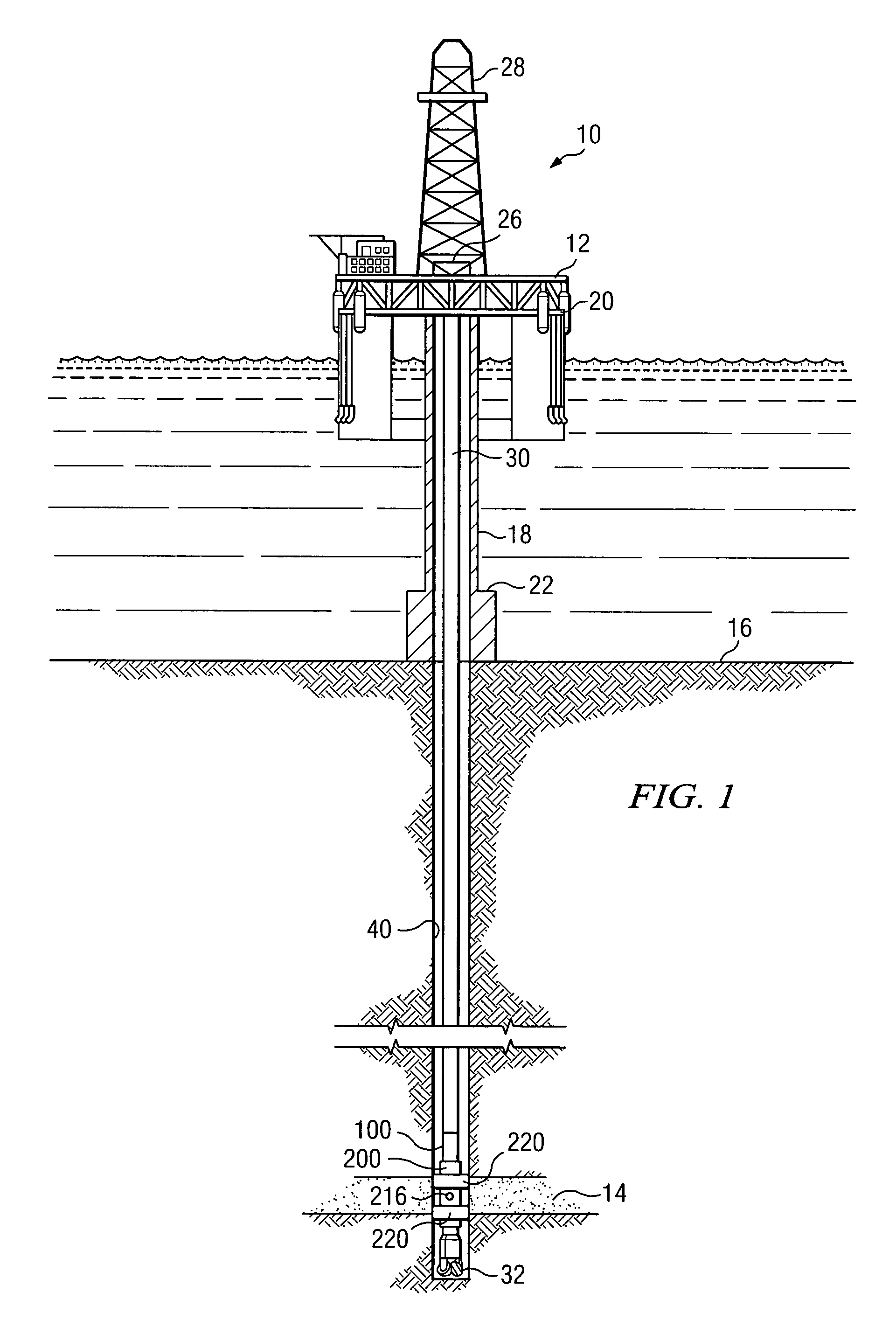

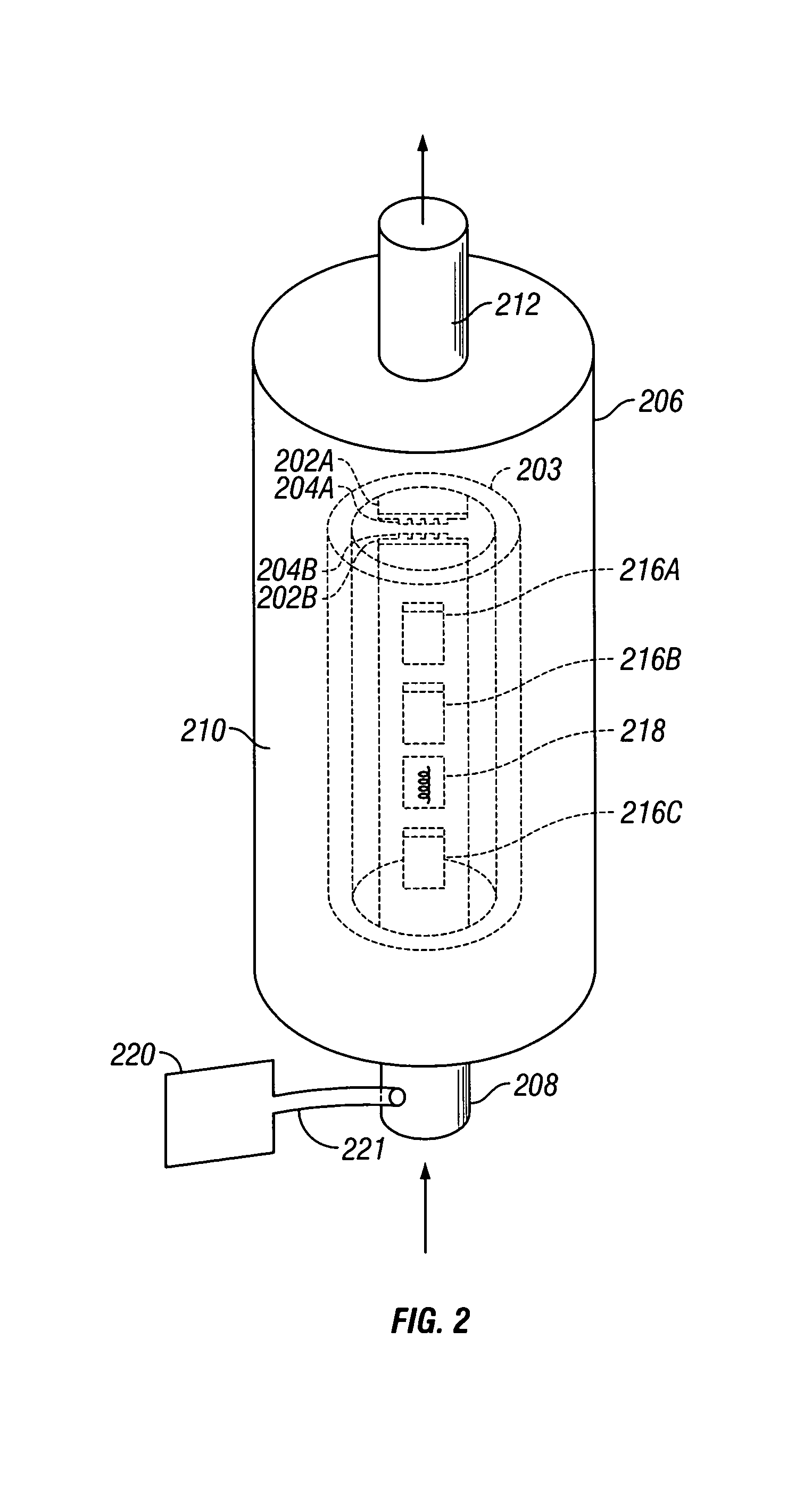

Apparatus for obtaining high quality formation fluid samples

InactiveUS20050028974A1Accurate measurementImprove assessmentSurveyInsulationEngineeringFormation fluid

A well fluid sampling tool is provided. The sampling tool includes at least one insulated sample chamber mounted in a tool collar. The tool collar may be coupled with a drill string such that, when the tool collar is deployed in a well bore, selected sample chambers may receive a fluid sample from outside the drill string without removing the drill string from the well bore (e.g., during measurement while drilling or logging while drilling operations). A heating module in thermal communication with at least one of the sample chambers is disposed to selectively heat the sample chambers in thermal communication therewith. The sampling tool may be particularly useful for acquiring and preserving substantially pristine formation fluid samples.

Owner:PATHFINDER ENERGY SERVICES

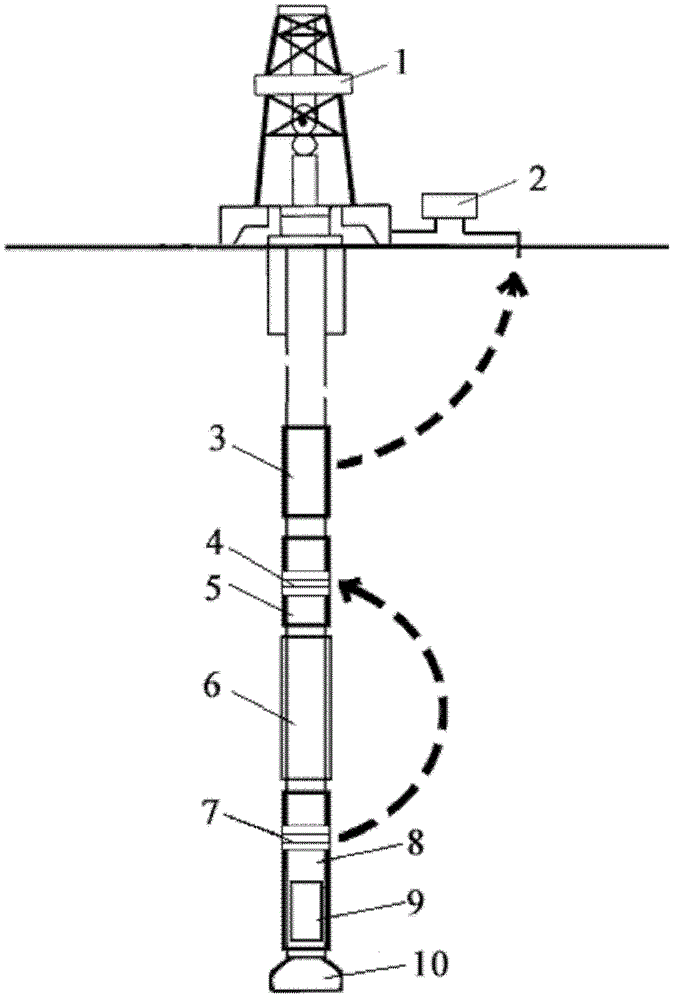

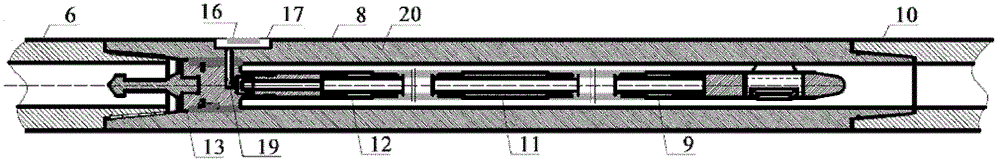

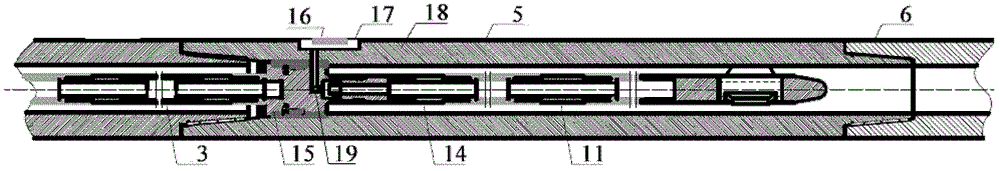

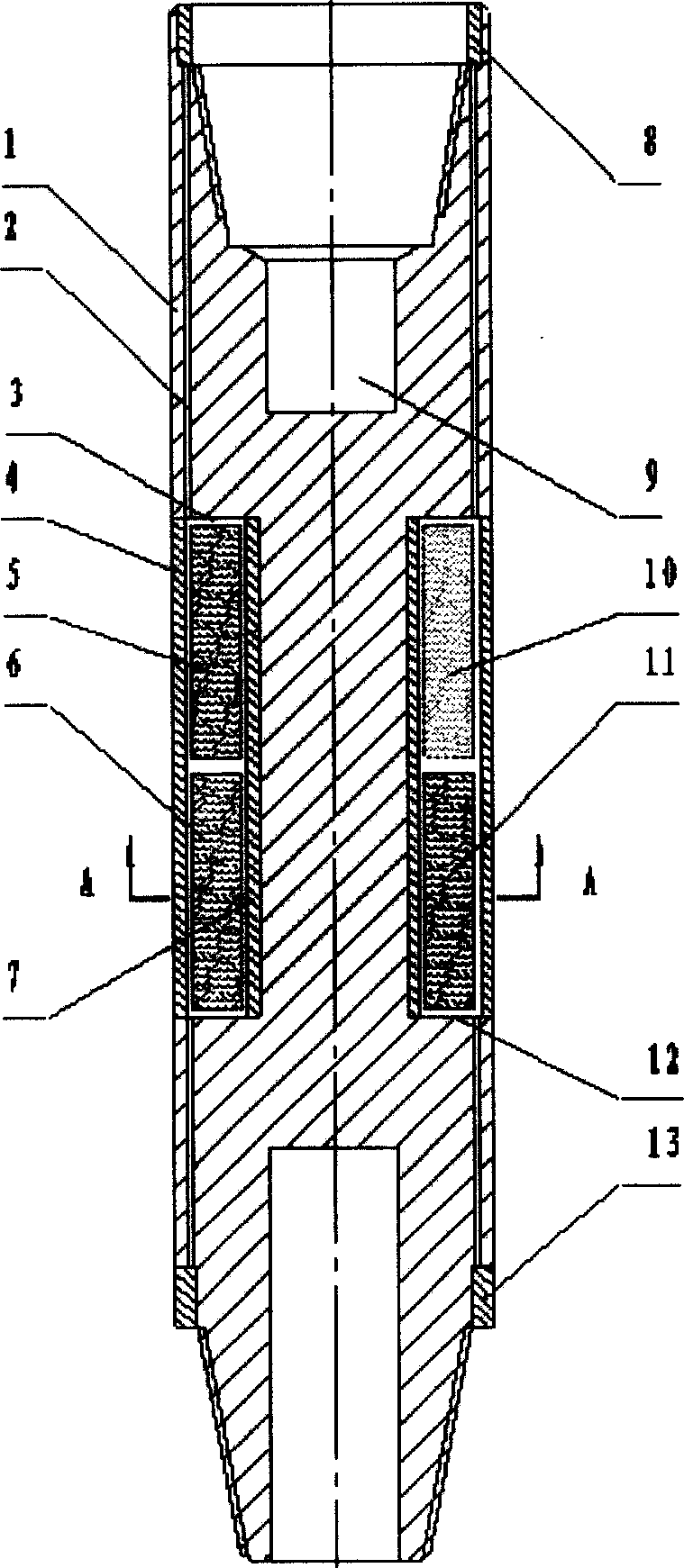

Short distance transmission system for wireless electromagnetic wave signals of downhole near bit and short distance transmission method

The invention provides a short distance transmission system for wireless electromagnetic wave signals of a downhole near bit and a short distance transmission method, and belongs to the field of geosteering systems and measurement while drilling instruments in industries such as petroleum, mines and geological prospecting. The automatic gain control technology is adopted in the short distance transmission system for realizing the automatic adjustment of enlargement factors of downhole weak signals. The short distance transmission system comprises a short section receiving assembly and a short section transmitting assembly, wherein the short section receiving assembly and the short section transmitting assembly are respectively provided with a receiving antenna and a transmitting antenna. Due to the fact that radial coupled antennas are adopted, the short distance transmission system is relatively simple in structure. Meanwhile, the short distance transmission system is high in arithmetic speed and can meet demands for real-time transmission of a large number of signals. Moreover, a front end processing module special for the downhole weak signals is utilized for carrying out the automatic gain adjustment to the collected signals, maintaining stable output of the signals and lowering processing difficulty of subsequent signals, and therefore the signal transmission quality is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Measurement while drilling apparatus and method of using the same

Owner:PNC BANK NAT ASSOC +2

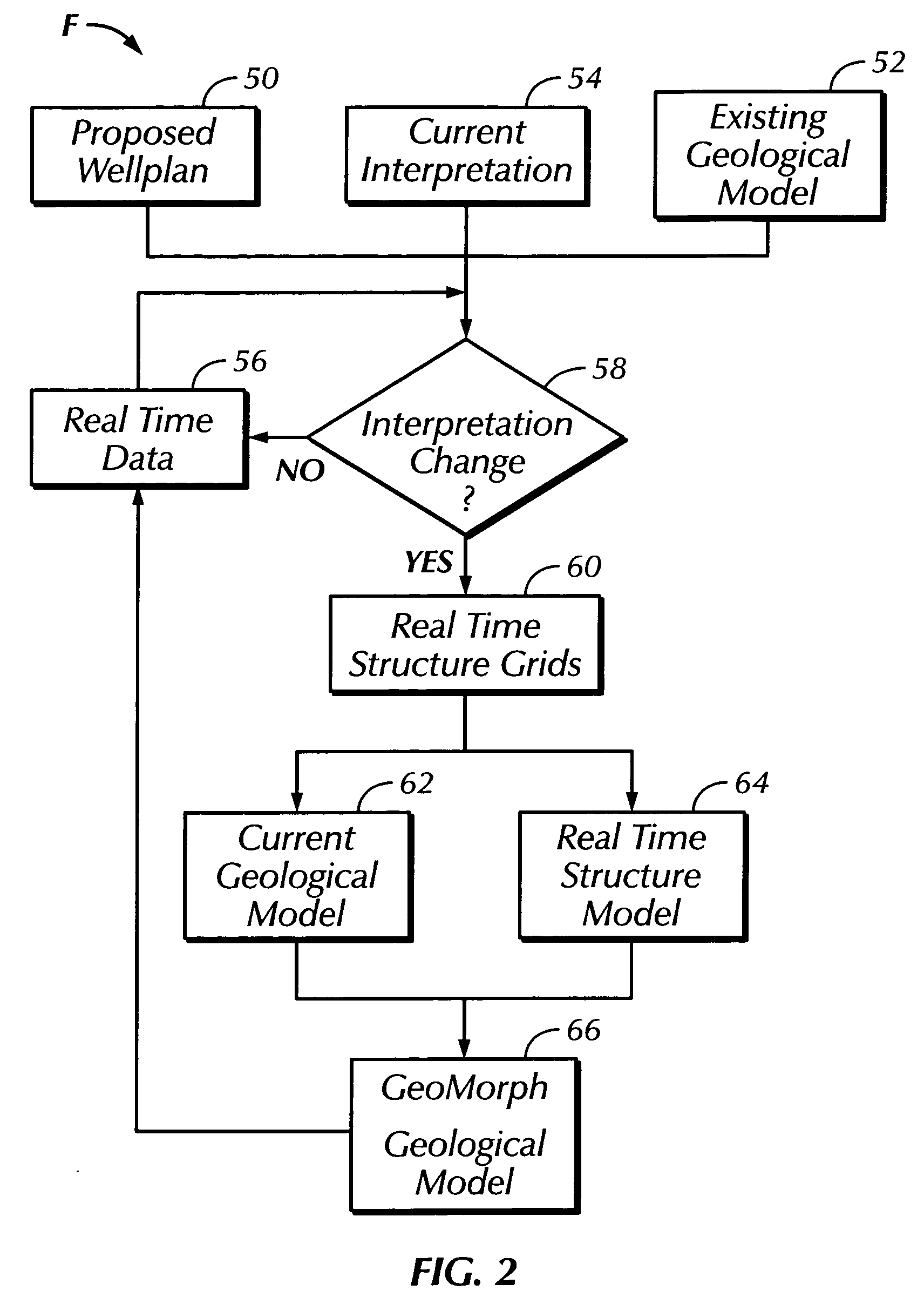

Real time earth model for collaborative geosteering

ActiveUS20050171698A1Improve drilling efficiencyImprove efficiencyElectric/magnetic detection for well-loggingSeismology for water-loggingGeosteeringWell drilling

An earth model is formed in real time during drilling of a well by incorporating up-to-the-minute knowledge derived from geology, seismic, drilling, and engineering data. The process of forming the model utilizes Logging-While-Drilling (LWD) or Measuring-While-Drilling (MWD) data directly from the drilling rig as the well is drilled. The LWD or MWD data is sent to visualization centers and compared with other data such as existing geological models, the proposed well plan and present interpretation of the subsurface stratigraphy. The results of the comparison enable experts to analyze anomalous results and update the geological model within minutes of penetration of a formation during drilling. Well drilling efficiency is improved, and an “on-the-spot” road map is provided for maximal reservoir contact and pinpoint accuracy.

Owner:SAUDI ARABIAN OIL CO

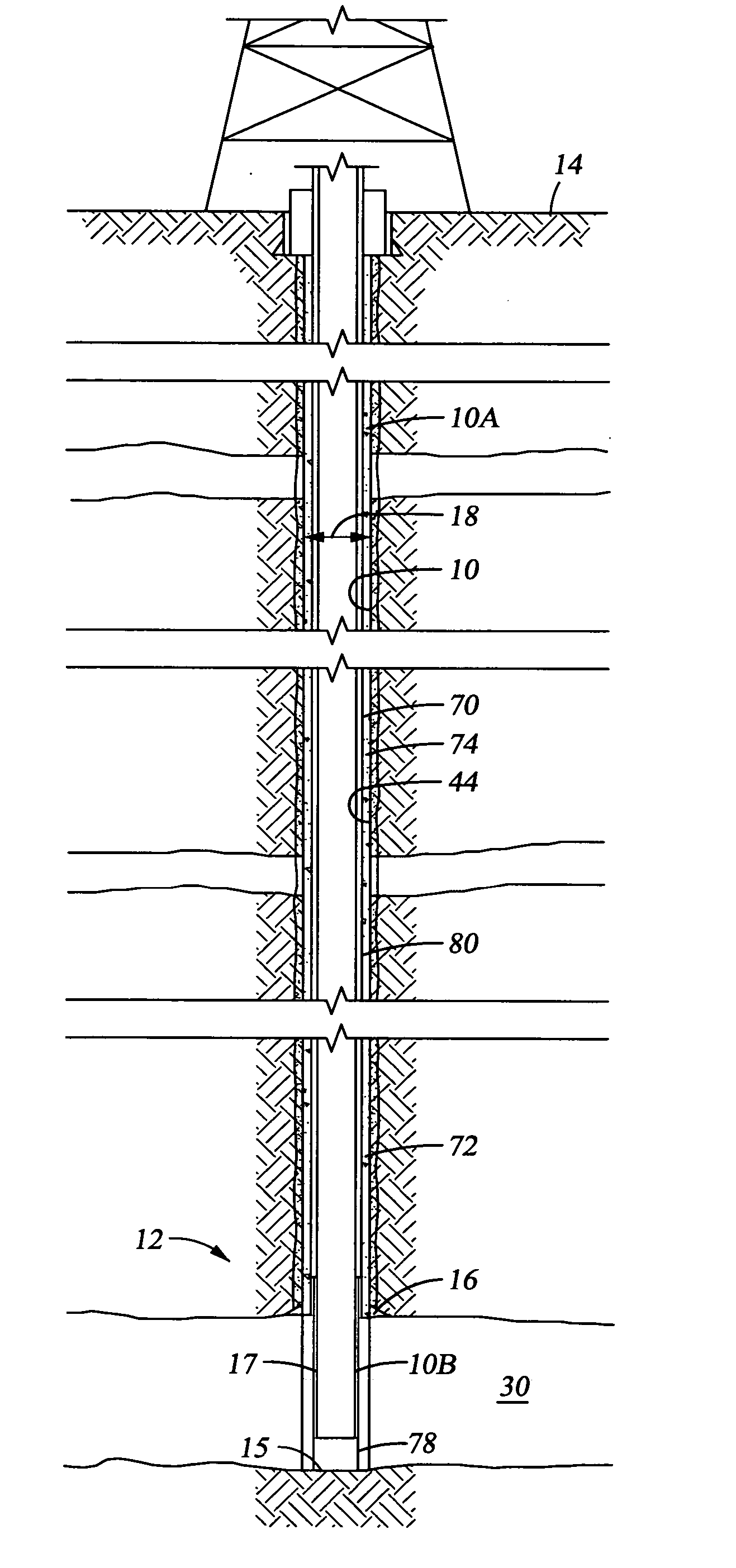

Method and apparatus for a monodiameter wellbore, monodiameter casing, monobore, and/or monowell

InactiveUS20050241855A1Design optimization and efficiencySmall sizeDrilling rodsConstructionsEngineeringLogging while drilling

An assembly and methods for constructing a MONOWELL includes a monodiameter casing disposed in a monodiameter wellbore having diametric efficiency with a monobore production delivery system disposed within the monodiameter casing. An assembly for constructing a monodiameter wellbore includes a bottomhole assembly having a overgauge hole drilling member, a directional steering assembly, a measurement while drilling tool, and a logging while drilling tool; a work string attached to the bottomhole assembly and extending to the surface; drilling fluids flowing through the work string and bottomhole assembly; chemical casing casing the borehole; expandable casing disposed in the wellbore; and a sealing composition disposed between the expandable casing and the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

System and method for downhole telemetry

A system and method are provided for providing electromagnetic (EM) measurement-while-drilling (MWD) telemetry capabilities using an existing mud-pulse MWD tool. An EM tool intercepts the output from the mud-pulse tool and generates an EM signal that mimics a mud-pulse pressure signal. The EM signal is intercepted at the surface by a receiver module that conditions the signal and inputs the signal into the existing pulse tool receiver. Since the EM signal mimics a mud-pulse signal, the pulse tool receiver does not require software or hardware modifications in order to process an EM telemetry mode. The EM tool can be adapted to also provide dual telemetry by incorporating a conventional pressure pulser that would normally be used with the pulse tool. A gap sub assembly for isolating the drill string is also provided that includes a pair of subs whose shoulders are separated by a non-conductive ceramic material and whose threads are separated by an insulative material, preferably a Kevlar™ cloth.

Owner:MOSTAR DIRECTIONAL TECH

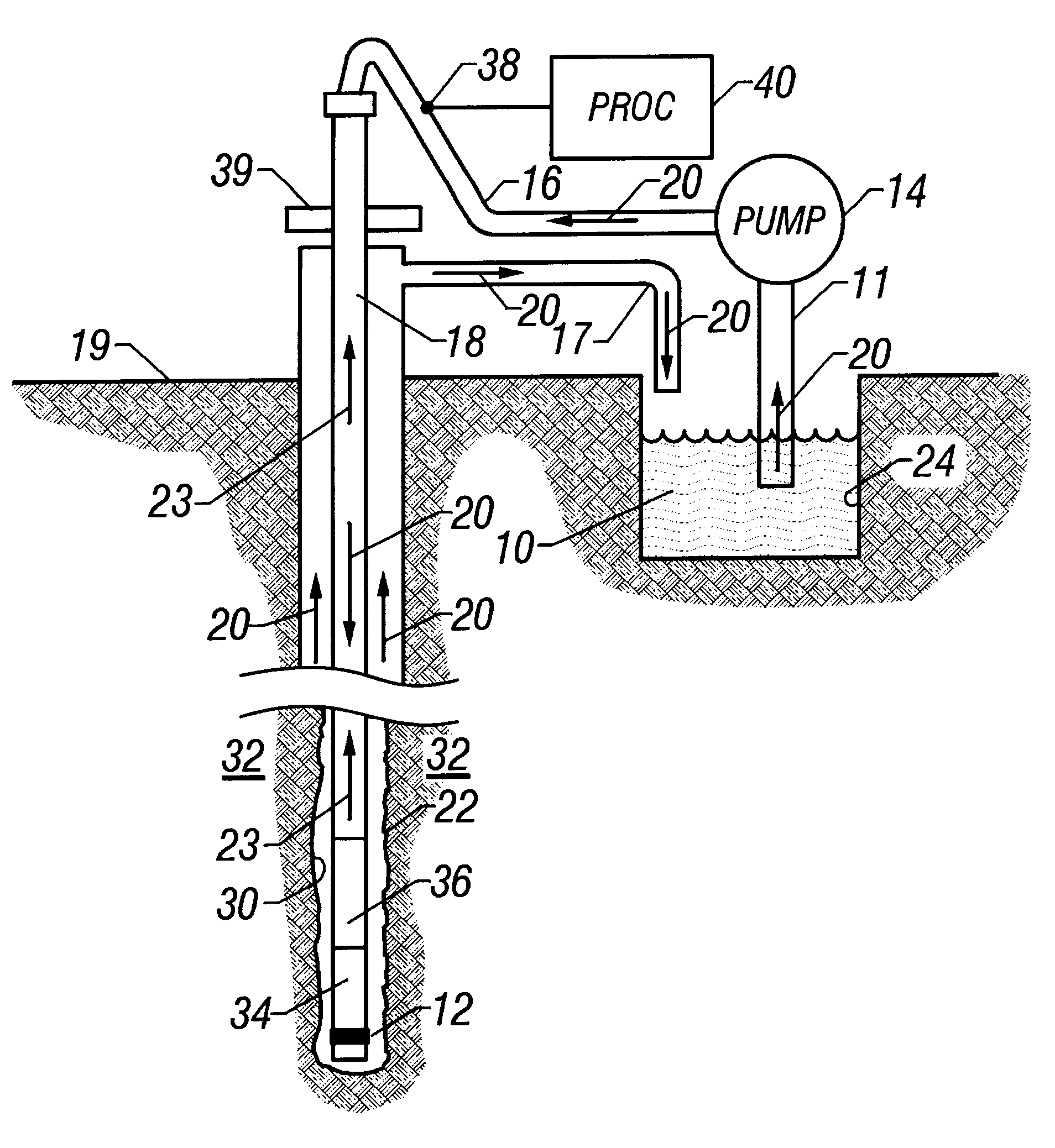

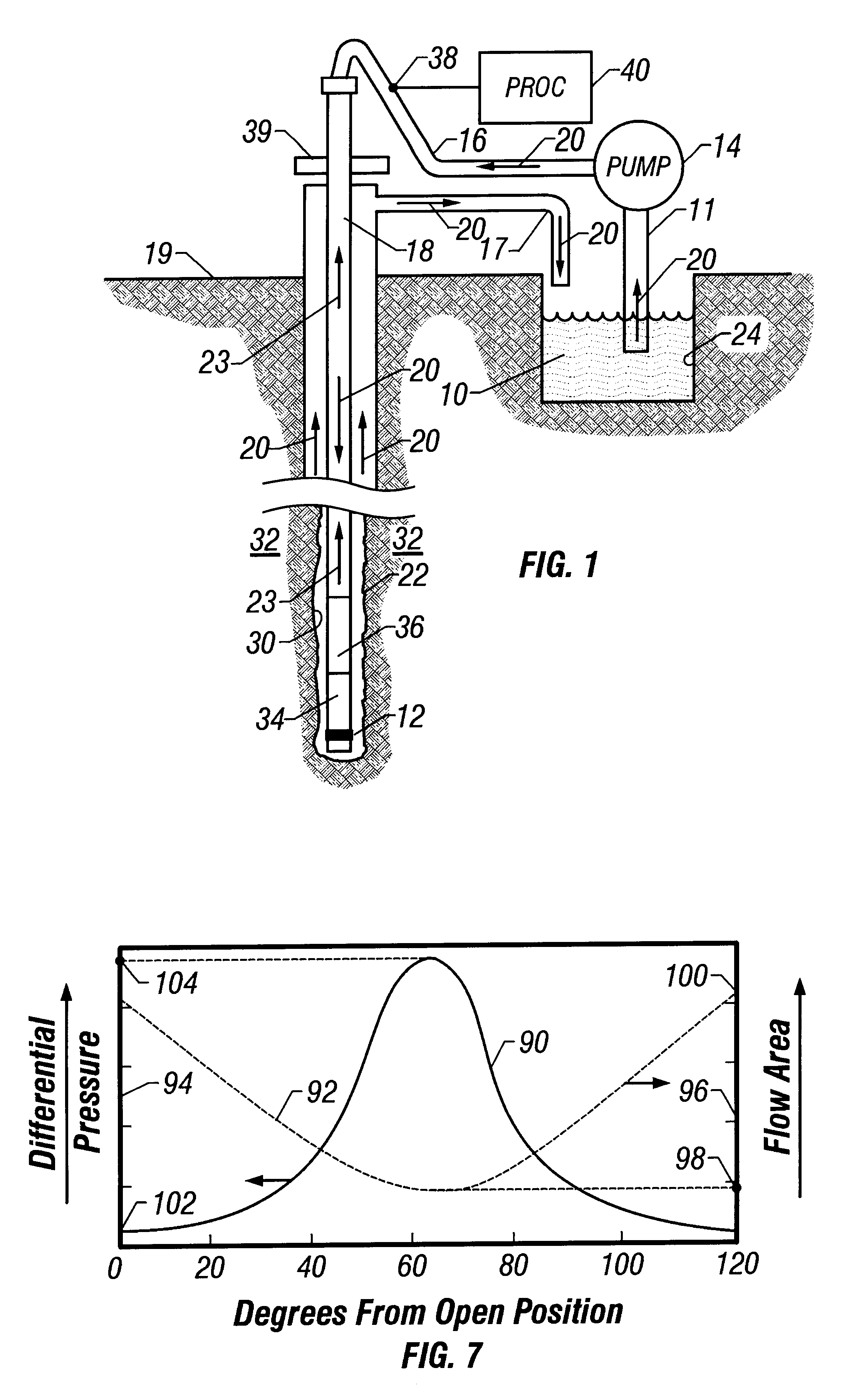

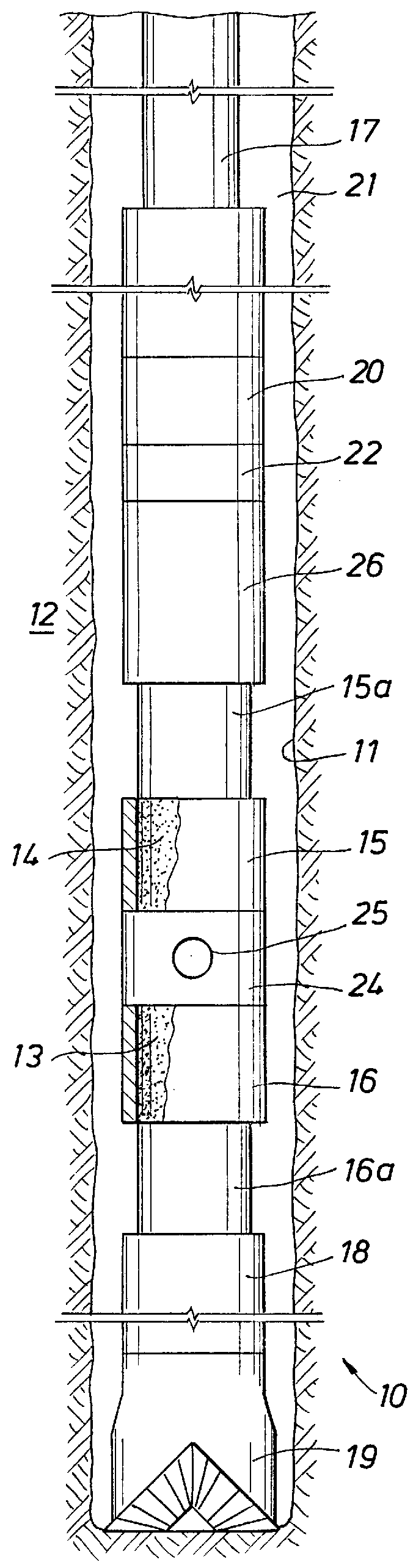

Subsurface measurement apparatus, system, and process for improved well drilling, control, and production

Subsurface wellbore conditions are measured directly in the wellbore while the fluid circulation system is not pumping. The measured values are recorded at the subsurface location and subsequently transmitted to the well surface when circulation is resumed using fluid pulse telemetry (FPT). Real-time measurements made when the fluids are circulating are transmitted real time using FPT. Axially spaced measurements are used to obtain differential values. The apparatus of the invention comprises an assembly carried by a drill string that is used to selectively isolate the area within the well that is to be evaluated. The apparatus includes an assembly having axially spaced inflatable well packers that are used to isolate an uncased section of the wellbore. The apparatus is equipped with self-contained measuring and recording equipment, a fluid receiving reservoir, circulation valving, measurement while drilling equipment, and automated controls. Measurements are made while the circulation is terminated or while the well packers are being used to isolate an area of the wellbore from the circulating fluid. The method is used to directly measure and evaluate conditions caused by pumping and drill string movement, such as swab and surge pressures. Other conditions such as the formation strength, formation pressure, the fluid density, and other subsurface conditions related to the well are also measured.

Owner:HALLIBURTON ENERGY SERVICES INC

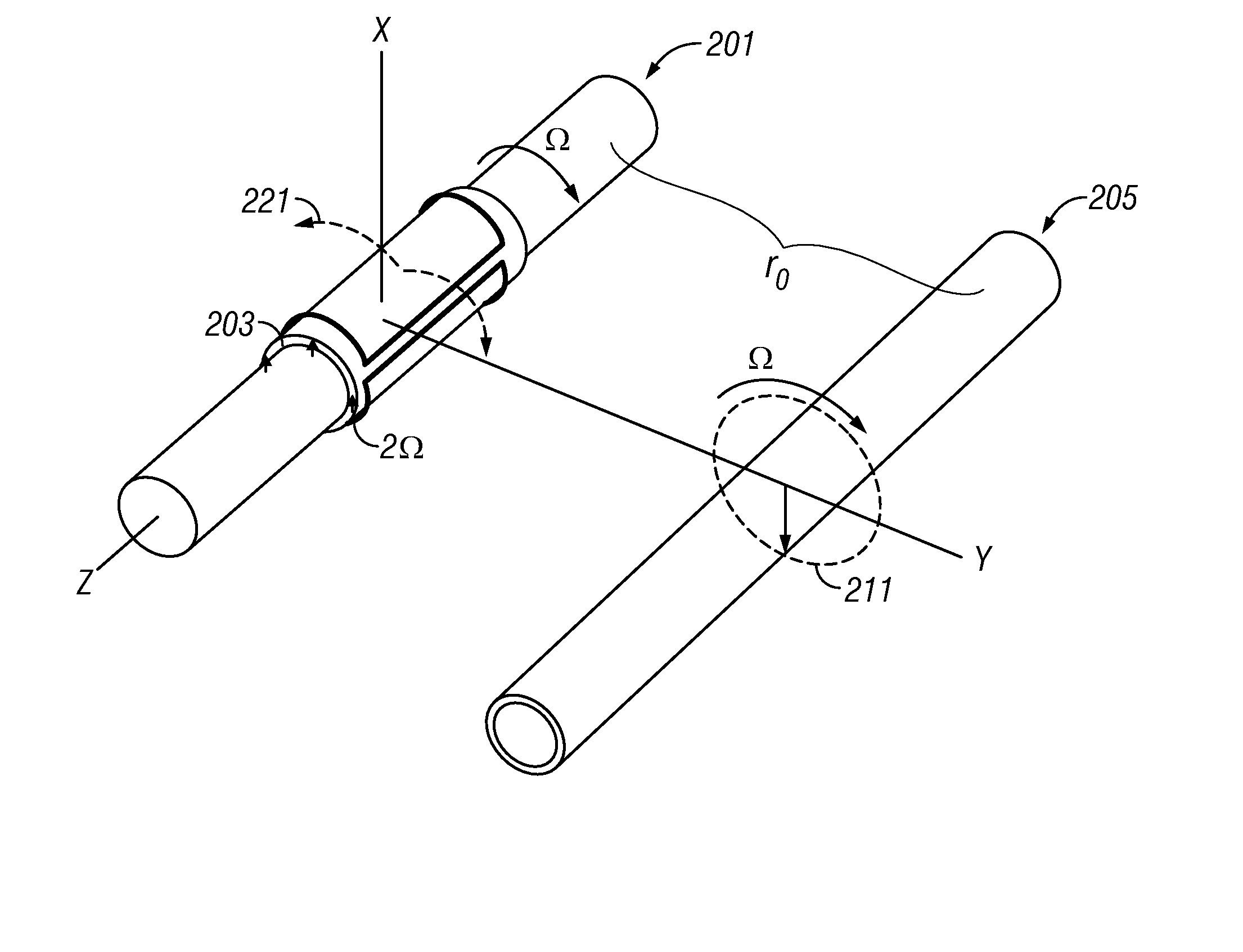

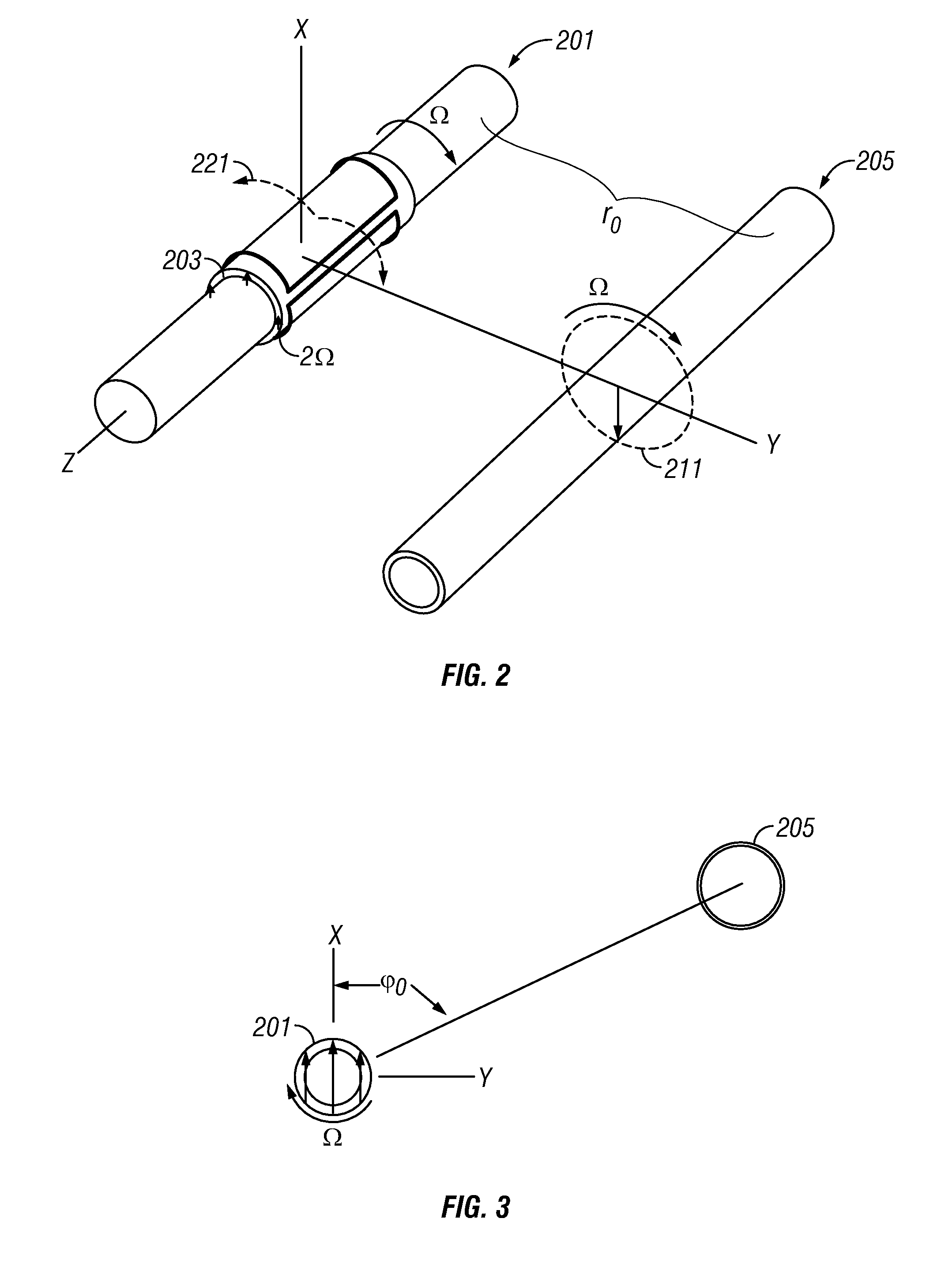

Method and Apparatus for Well-bore Proximity Measurement While Drilling

ActiveUS20080018334A1Eliminate the effects ofElectric/magnetic detection for well-loggingSurveyMagnetizationClassical mechanics

A rotating, transversely magnetized, magnet on a drill collar induces magnetization in a casing of a preexisting well. A coil rotating synchronously with the magnet produces a current at twice the frequency of rotation and having an amplitude that depends upon the distance from the magnet to the preexisting well. Alternatively, a variable magnetic field is produced in the casing using a switchable magnet. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:BAKER HUGHES INC

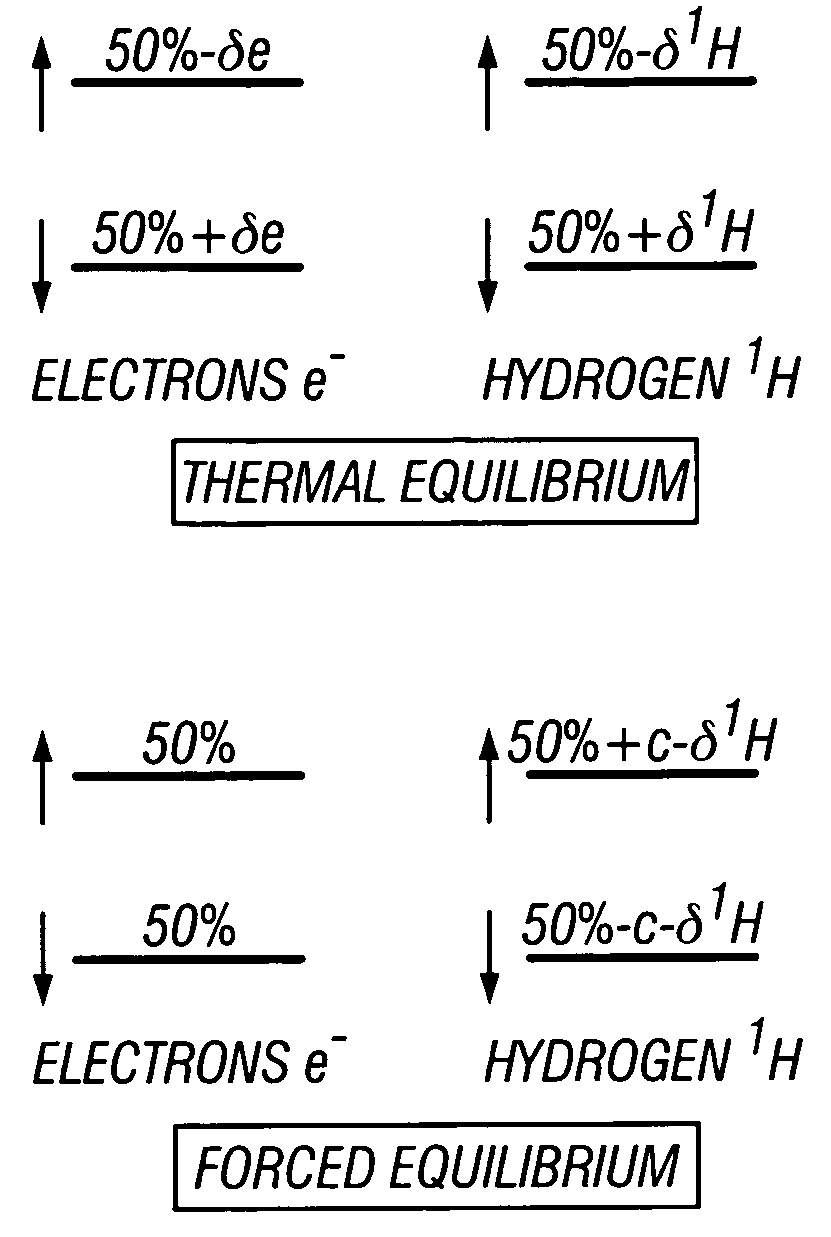

Downhole high resolution NMR spectroscopy with polarization enhancement

InactiveUS7126332B2Increase amplitudeElectric/magnetic detection for well-loggingMeasurements using double resonanceSignal onProton NMR

An apparatus and method is discussed for characterizing a fluid sample downhole of aliphatic hydrocarbon compounds, aromatic hydrocarbon compound, or connate mud filtrates containing carbon-13 isotopes using an enhanced nuclear magnetic resonance (NMR) signal on a measurement-while-drilling device. To enhance the carbon-13 NMR signal these nuclei are being hyperpolarized. Either the Overhauser Effect (OE) or the Nuclear Overhauser Effect or optical pumping and the Spin Polarization Induced Nuclear Overhauser Effect (SPINOE) can serve as a mechanism for hyperpolarization of the carbon-13 nuclei.

Owner:BAKER HUGHES HLDG LLC

Apparatus and method for seismic measurement-while-drilling

An apparatus and method for seismic measurement-while-drilling comprises at least one of a downhole seismic receiver or a downhole seismic source deployed in a telemetry drill string. Preferably both a downhole receiver and a downhole source are deployed in the drill string, the source and receiver being fixed at a pre-determined distance from each other. As drilling progresses into a subterranean formation, a first seismic shot is performed at a first level, producing a model characteristic of the subterranean formation, and at least one subsequent seismic shot is performed at at least one subsequent level, producing at least a second model characteristic of the subterranean formation. The first and at least the second model are used in combination to evaluate the subterranean formation and to evaluate the progress of the drill string relative to the formation.

Owner:NOVADRILL

Measurement while drilling bi-directional pulser operating in a near laminar annular flow channel

A device, method, and system for creating a pressure pulse from drilling fluid within a drill string in a down hole drill collar for enabling measurement-while drilling. The device and system are designed such that primarily laminar flow exists in the area surrounding the pulser apparatus. The method associated with the reproducible and essentially noise-free pulses occurs when a pulser bell is manipulated in an upward and downward direction by a combination of the solenoid activation of a bi-directional poppet to redirect the fluid flow from the pressure reservoir to and from a sliding pressure chamber and associated upper and lower flow connecting channels. The pulse or non-pulse is converted into a digital signal uphole by a pressure transducer in conjunction with a decoding algorithm. It is then displayed to the driller and oilfield operators as useful directional and formation information that help the oilfield operator for uphole decision making regarding directional drilling. Additional pulsers can be added to the tool so that higher data bit rates can be accomplished. These higher data bit rates will provide for more comprehensive data collection thereby reducing drilling costs and optimizing oil field yields. The higher bit rate allows for more sensors that can send additional and improved information uphole without the use of open hole wire line logging which is impossible to accommodate while drilling horizontally.

Owner:TELEDRILL

Subsurface measurement apparatus, system, and process for improved well drilling control and production

Subsurface wellbore conditions are measured directly in the wellbore while the fluid circulation system is not pumping. The measured values are recorded at the subsurface location and subsequently transmitted to the well surface when circulation is resumed using fluid pulse telemetry (FPT). Real-time measurements made when the fluids are circulating are transmitted real time using FPT. Axially spaced measurements are used to obtain differential values. The apparatus of the invention comprises an assembly carried by a drill string that is used to selectively isolate the area within the well that is to be evaluated. The apparatus includes an assembly having axially spaced inflatable well packers that are used to isolate an uncased section of the wellbore. The apparatus is equipped with self-contained measuring and recording equipment, a fluid receiving reservoir, circulation valving, measurement while drilling equipment, and automated controls. Measurements are made while the circulation is terminated or while the well packers are being used to isolate an area of the wellbore from the circulating fluid. The method is used to directly measure and evaluate conditions caused by pumping and drill string movement, such as swab and surge pressures. Other conditions such as the formation strength, formation pressure, the fluid density, and other subsurface conditions related to the well are also measured.

Owner:HALLIBURTON ENERGY SERVICES INC

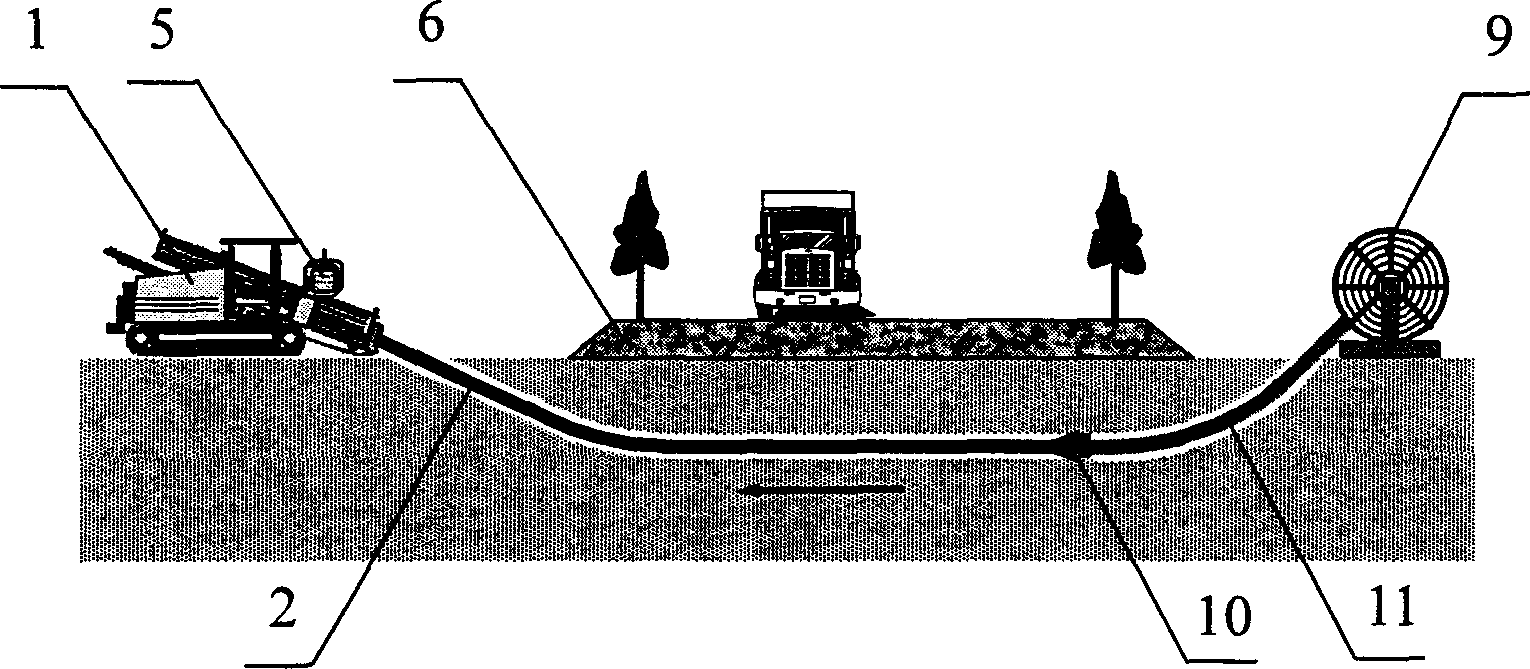

Guide positioning method and positioning instrument for horizontal directional drilling

The invention discloses a horizontal directional drilling guiding position method and position indicator, which comprises the following parts: sensing emission probe in the guiding drilling tool, walking type position follower and driller monitor on the drill, wherein the sensing emission probe is composed of angle sensor, signal disposing and transmitting unit, solenoid coil and battery, which sends the measured the incidence, facing angle, temperature and other parameters to the follower through wireless electromagnetic wave; the position follower calls the parameter of underground probe to measure position and depth according to the signal relative strength distribution, whose final result is sent to the driller display through wireless pattern. The invention is convenient to operate for the driller personnel.

Owner:ZOOMLION HEAVY IND CO LTD +1

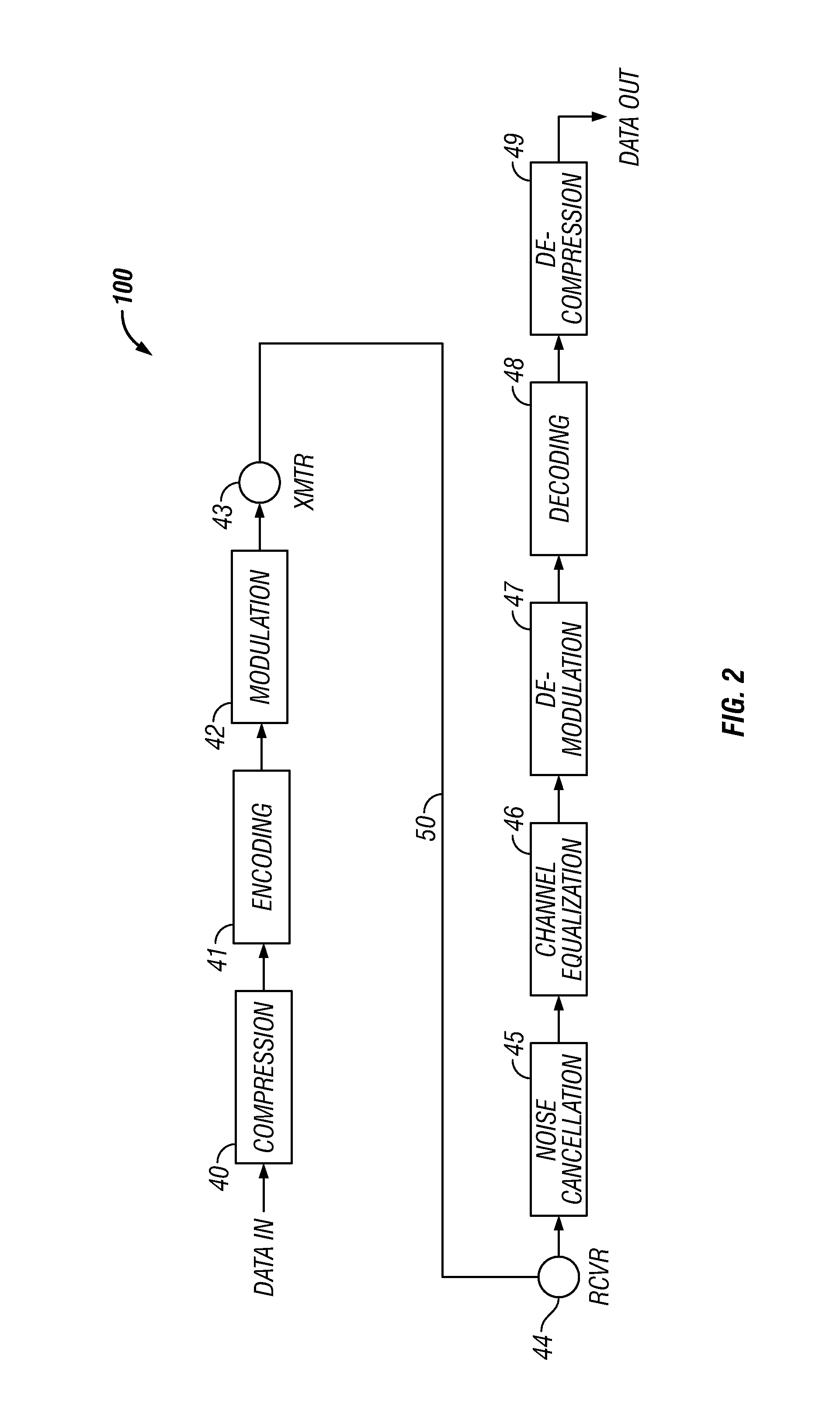

System and Method for Measurement While Drilling Telemetry

InactiveUS20070189119A1Remove distortionCancel noiseSurveyBroadcast information monitoringEngineeringPulse synchronization

A system for transmitting information in a well comprises a tubular string disposed in the well and having a drilling fluid flowing therethrough. A pulser is disposed in the tubular string and transmits a pulse synchronization marker comprising a chirp signal. A surface controller, acting under programmed instructions, detects the chirp signal adjusts a signal decoding technique based on the detected chirp signal.

Owner:BAKER HUGHES INC

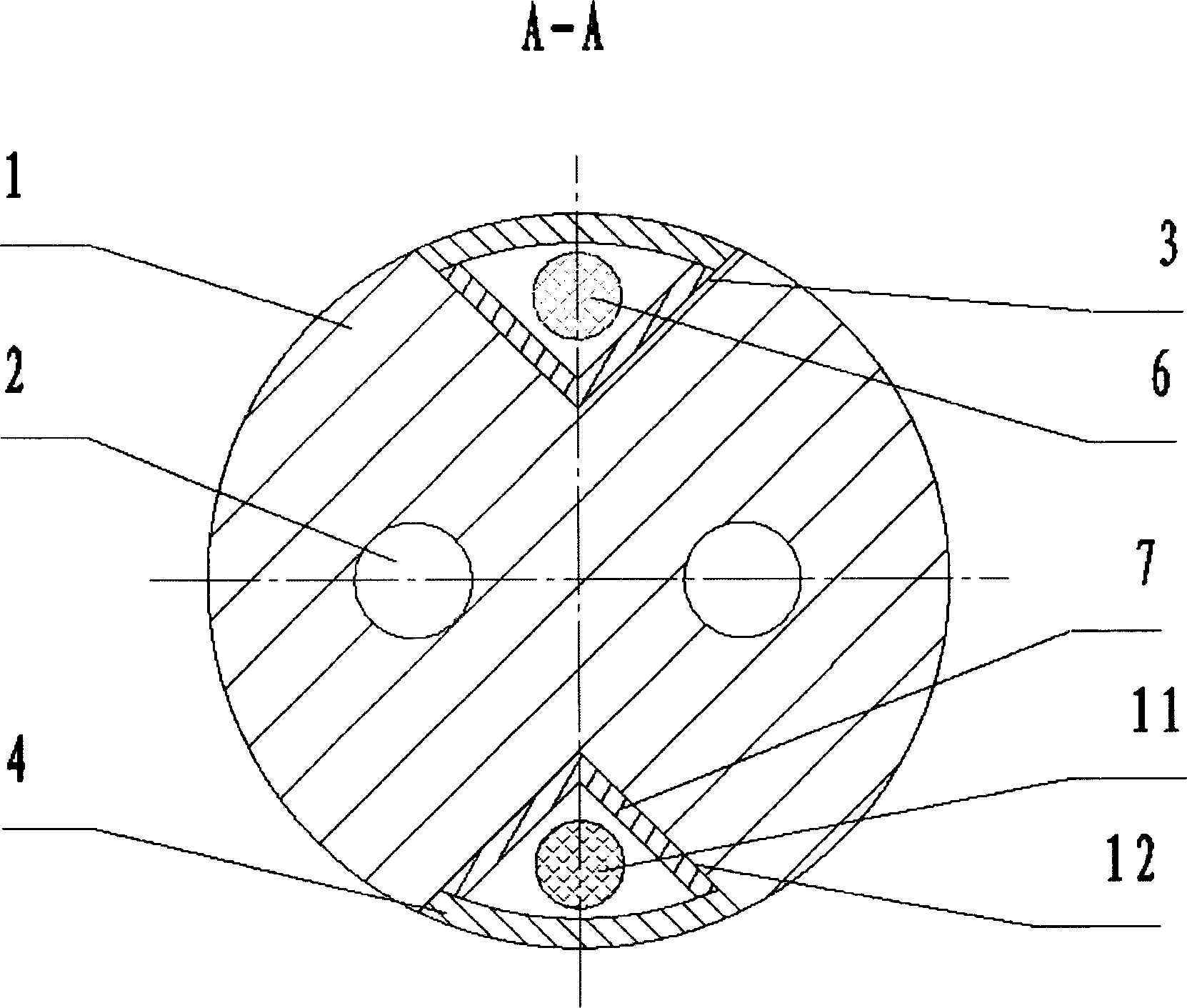

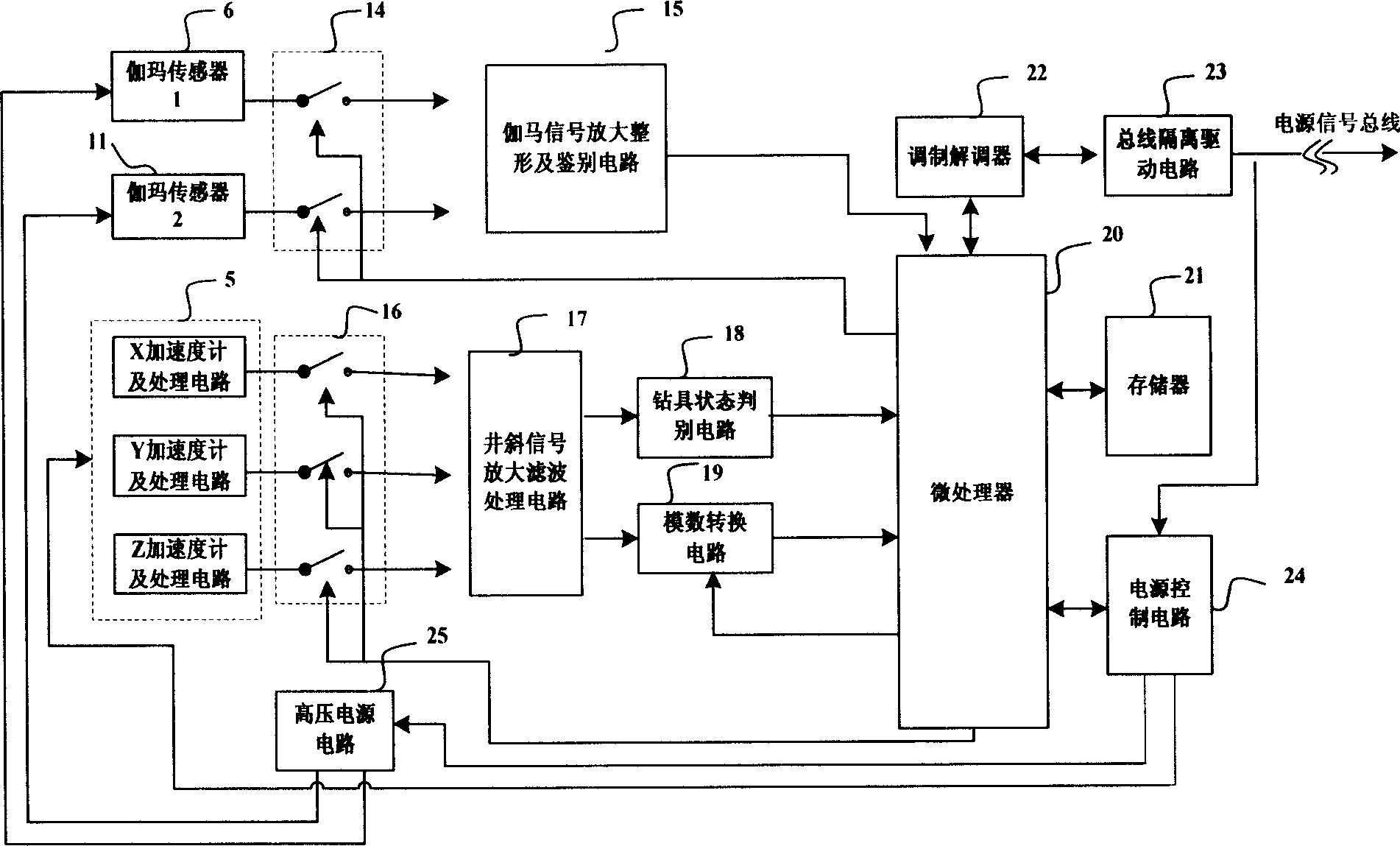

Well deflection and position gamma measuring nistrument during drilling

ActiveCN1676874AControl walkAchieve geosteeringSurveyNuclear radiation detectionLithologySignal processing circuits

The invention is direction and position drill-following survey apparatus comprising a drill collar, two V slots, metal shielding layer, tow gamma sensor, three-axis acceleration sensor, signal processing circuit module, high pressure sealing cover board, boring liquor conducting channel, upper slip ring connector, lower slip ring connector, wire hole. The invention integrated gamma survey and directional survey in just a short section which enables the drill not only survey the rock properties real-timely, but also tell the upper and lower rock characteristics when boring well., so to effectively find out the upper cover layer of the storage layer and seize the best timing entering the oil storage layer. Moreover, meanwhile assorting the upper and lower rock properties, the direction and drill status also can be obtained without any delay, which, facilitating adjusting the well boring track according to the geographic data and manage the drill travels a best track underground among the oil storage. The invention is suitable for geological guiding in fossil engineering.

Owner:中石化石油工程技术服务有限公司 +3

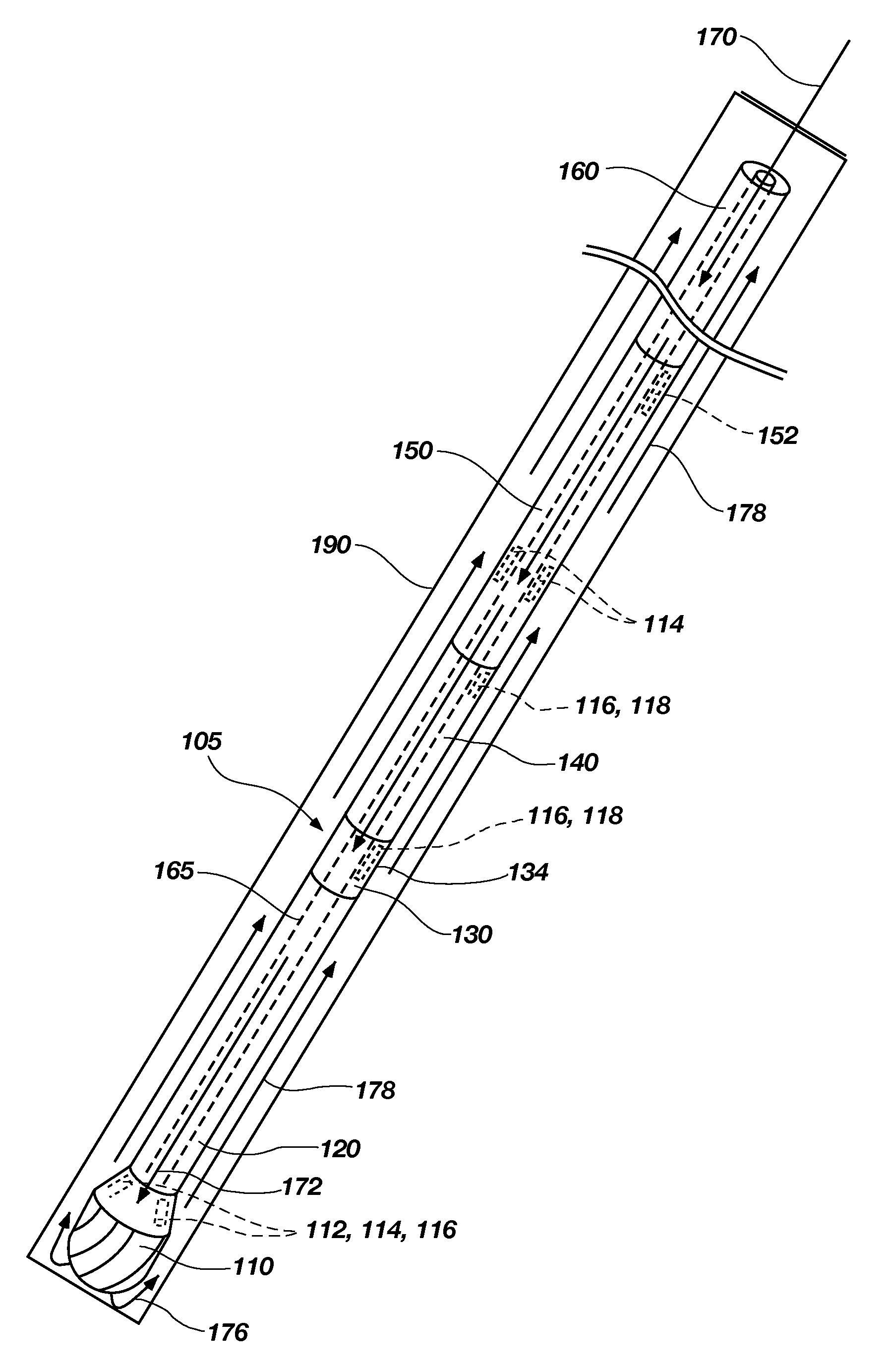

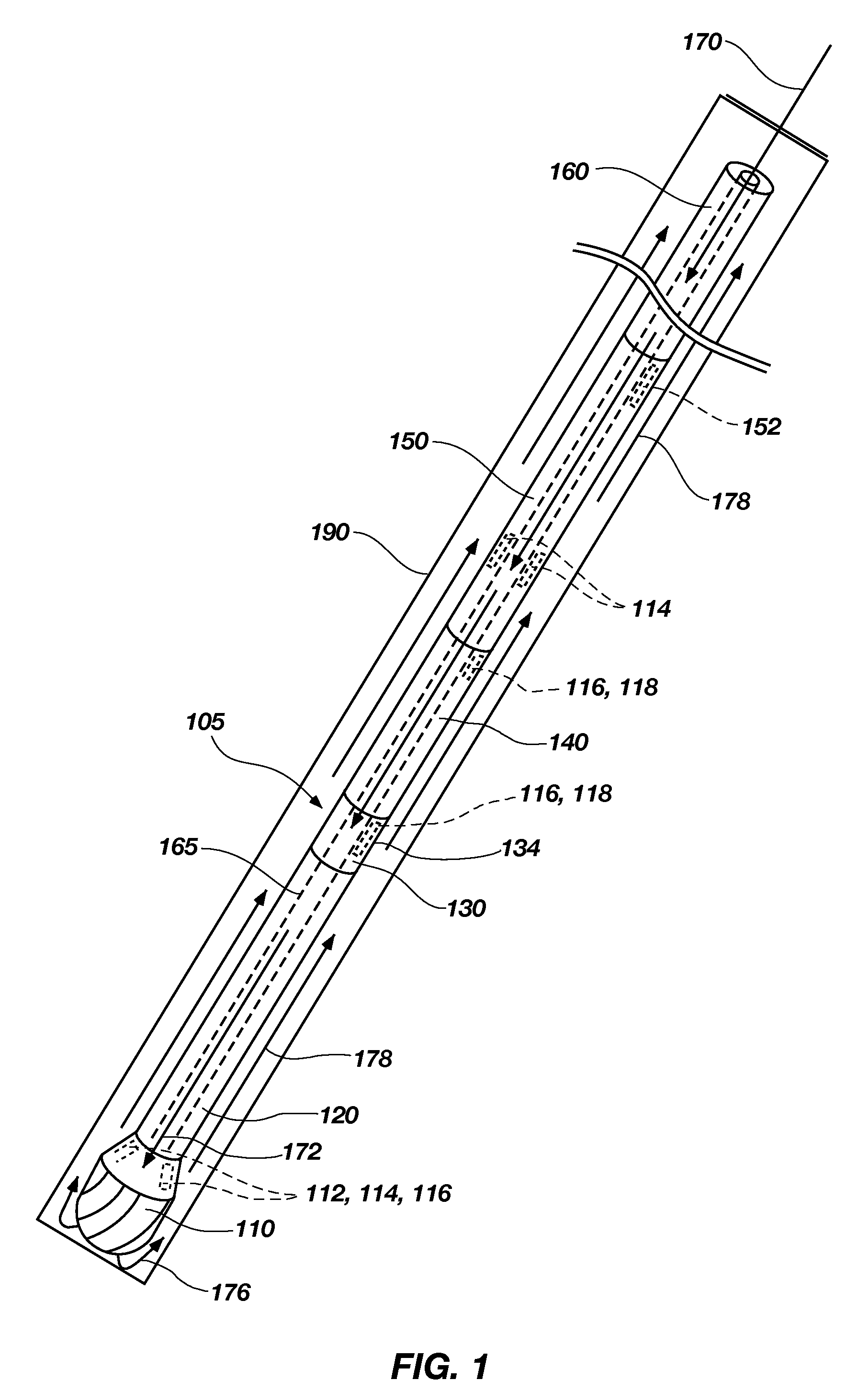

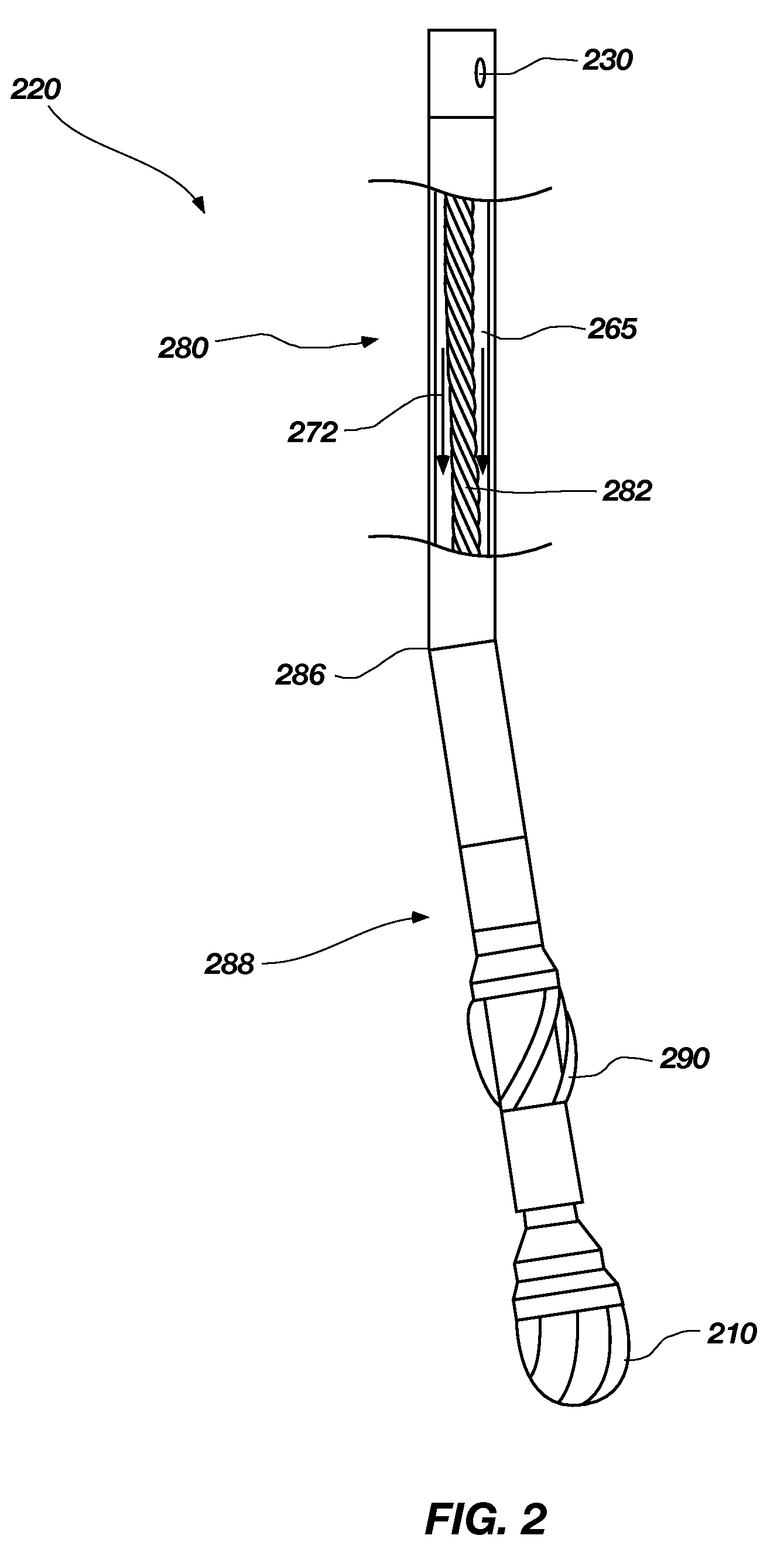

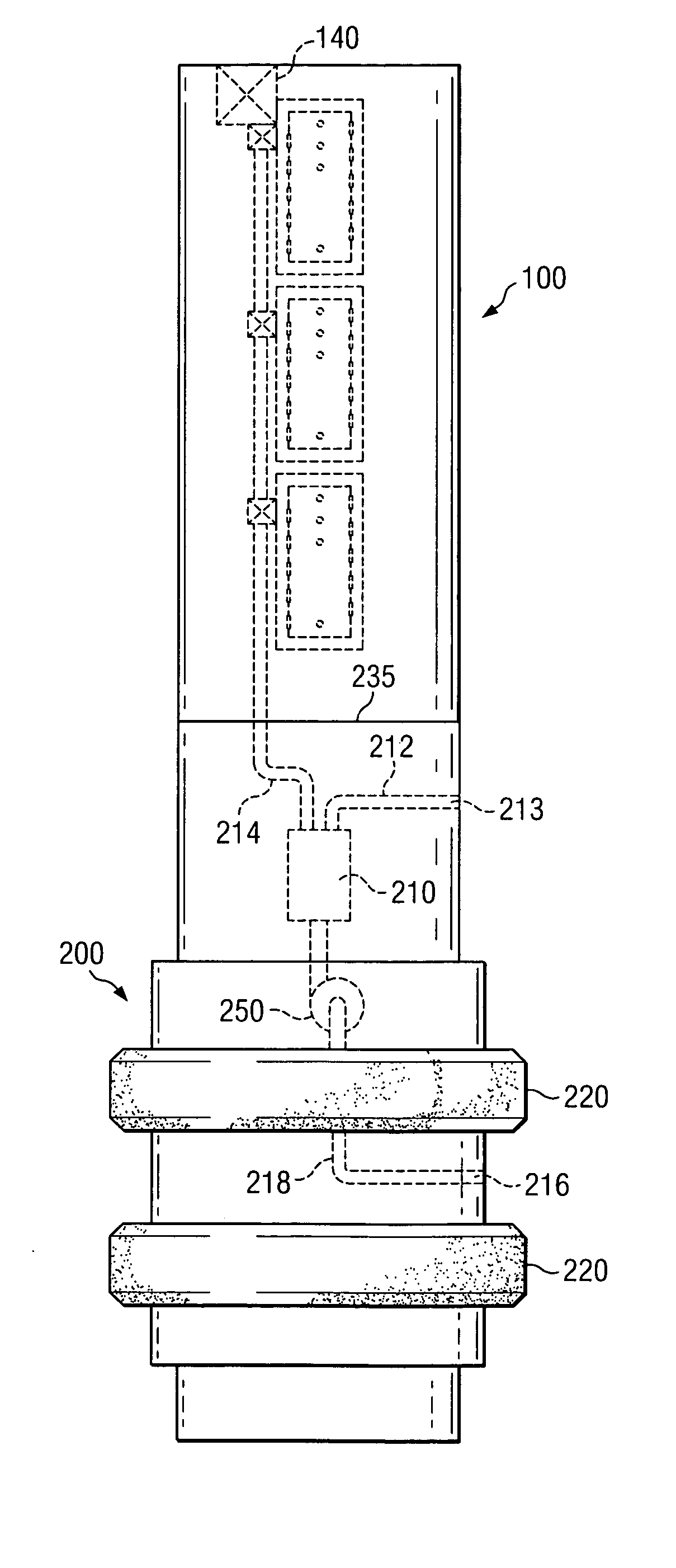

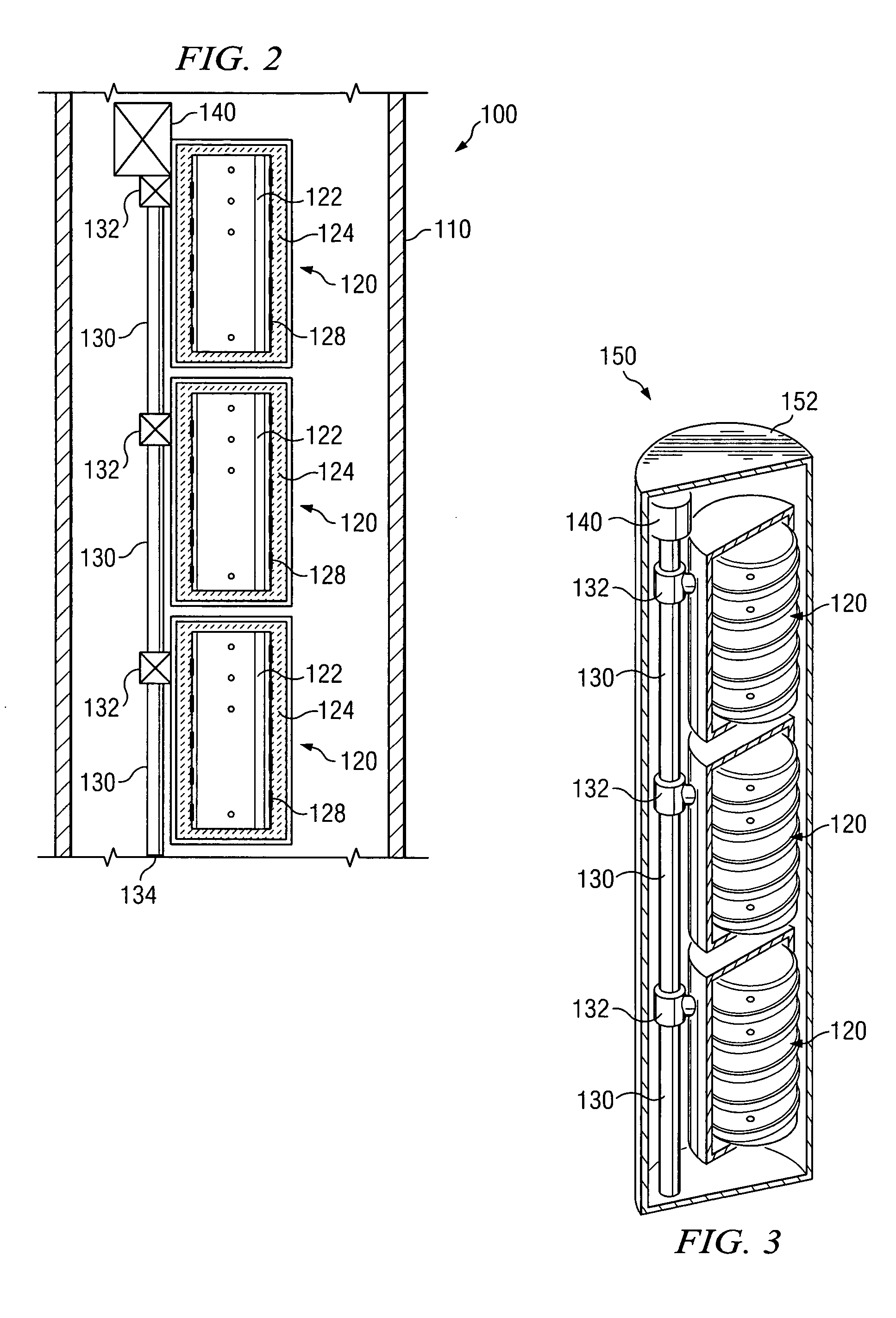

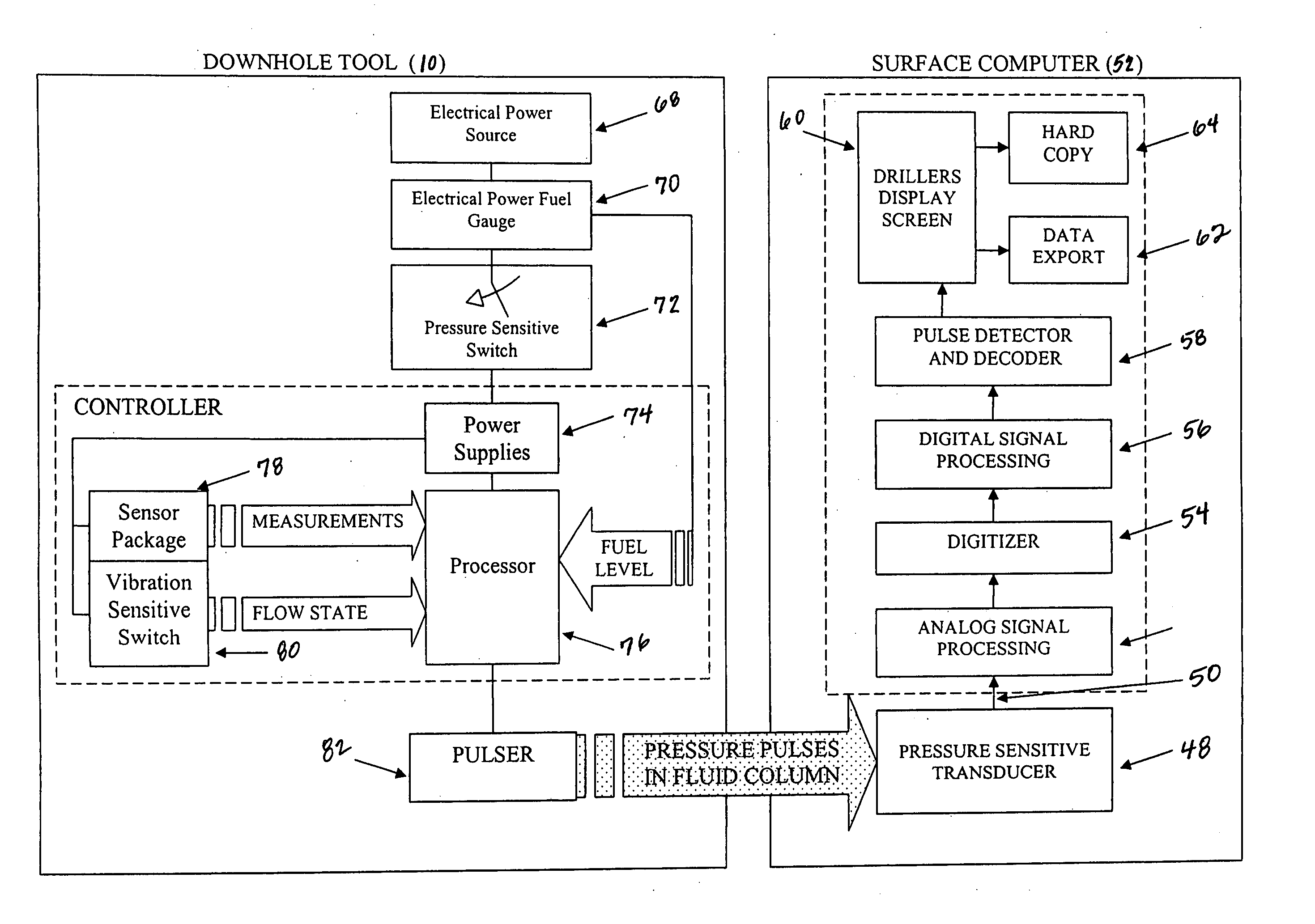

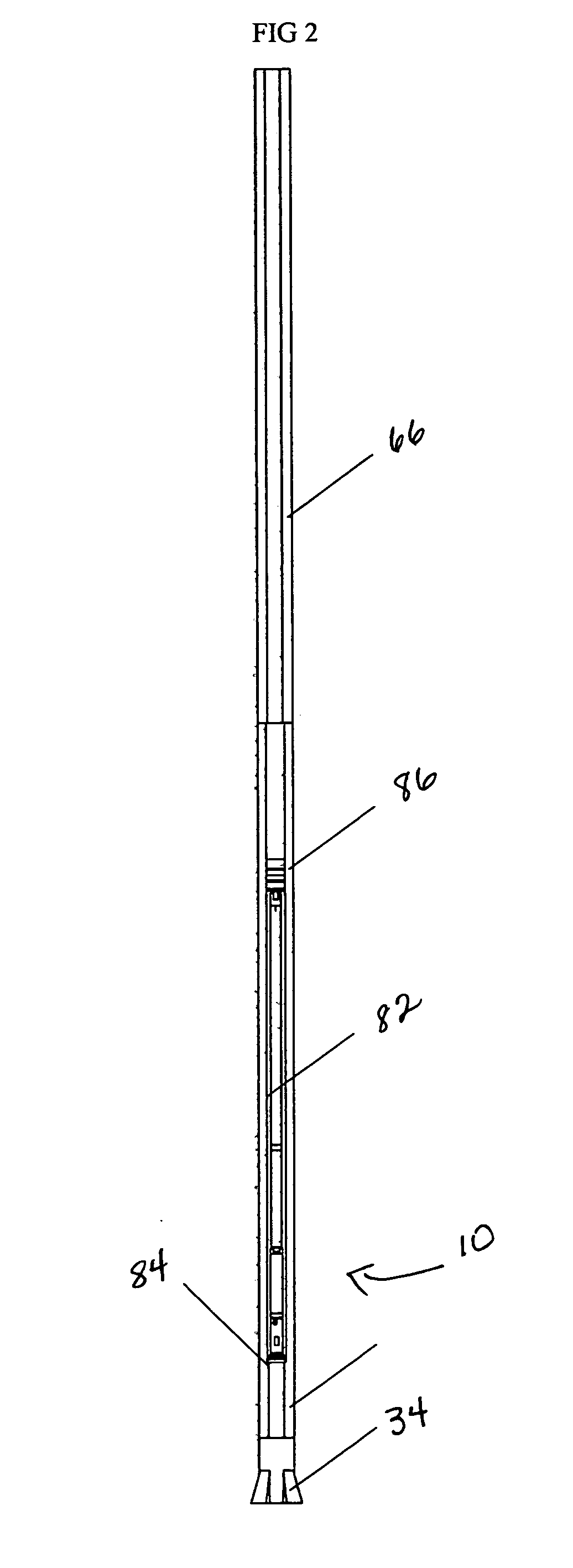

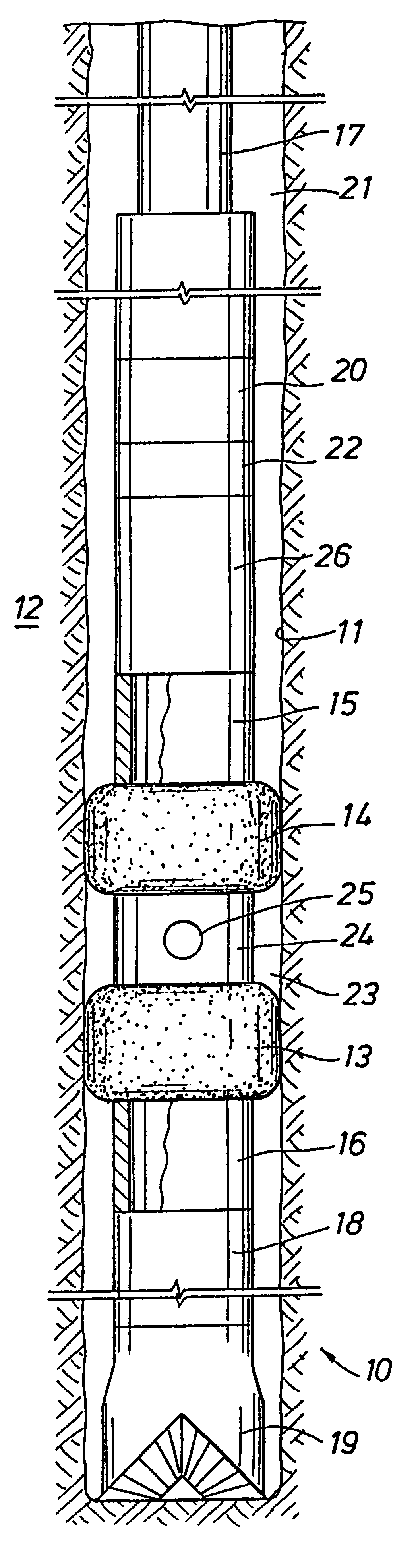

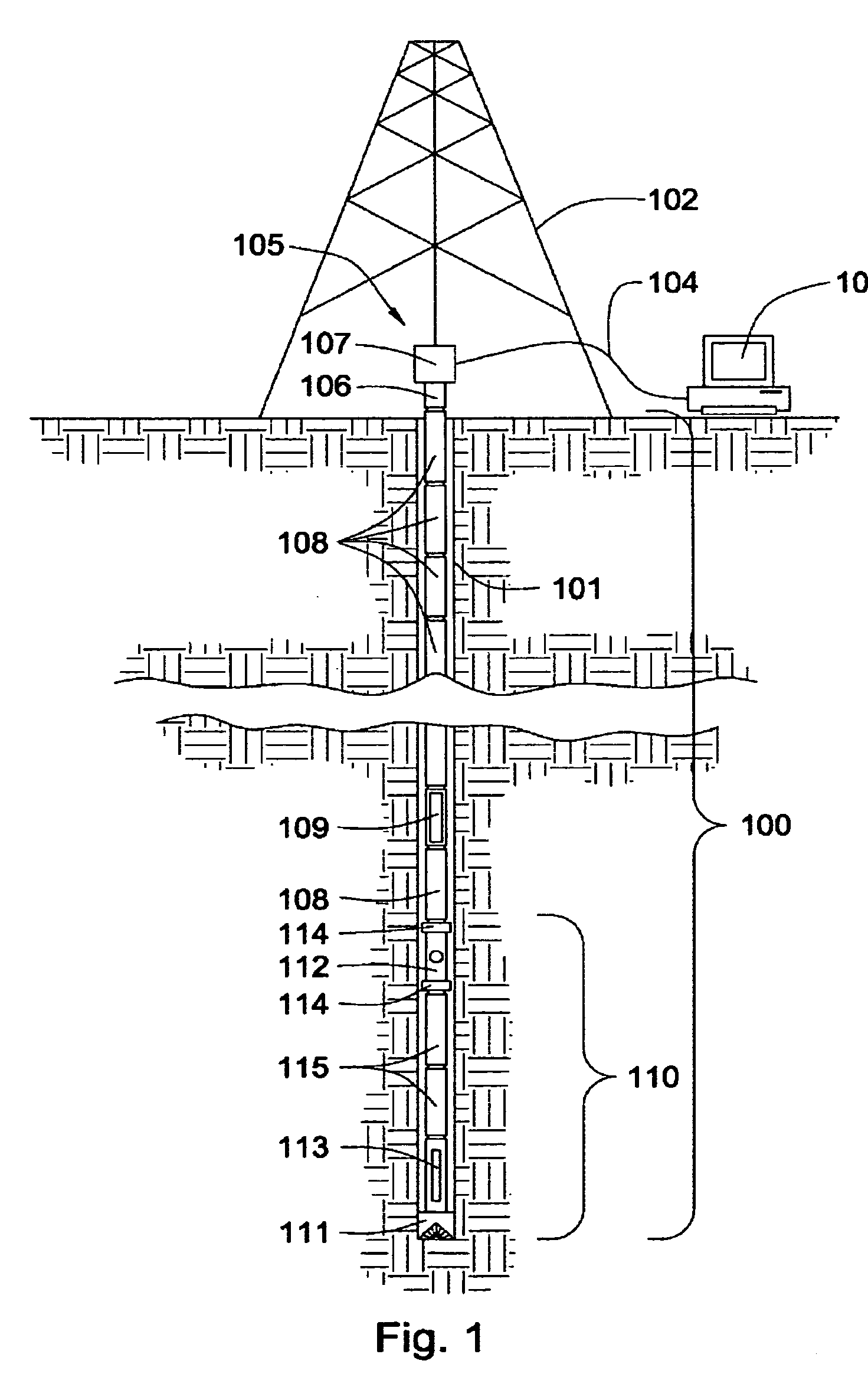

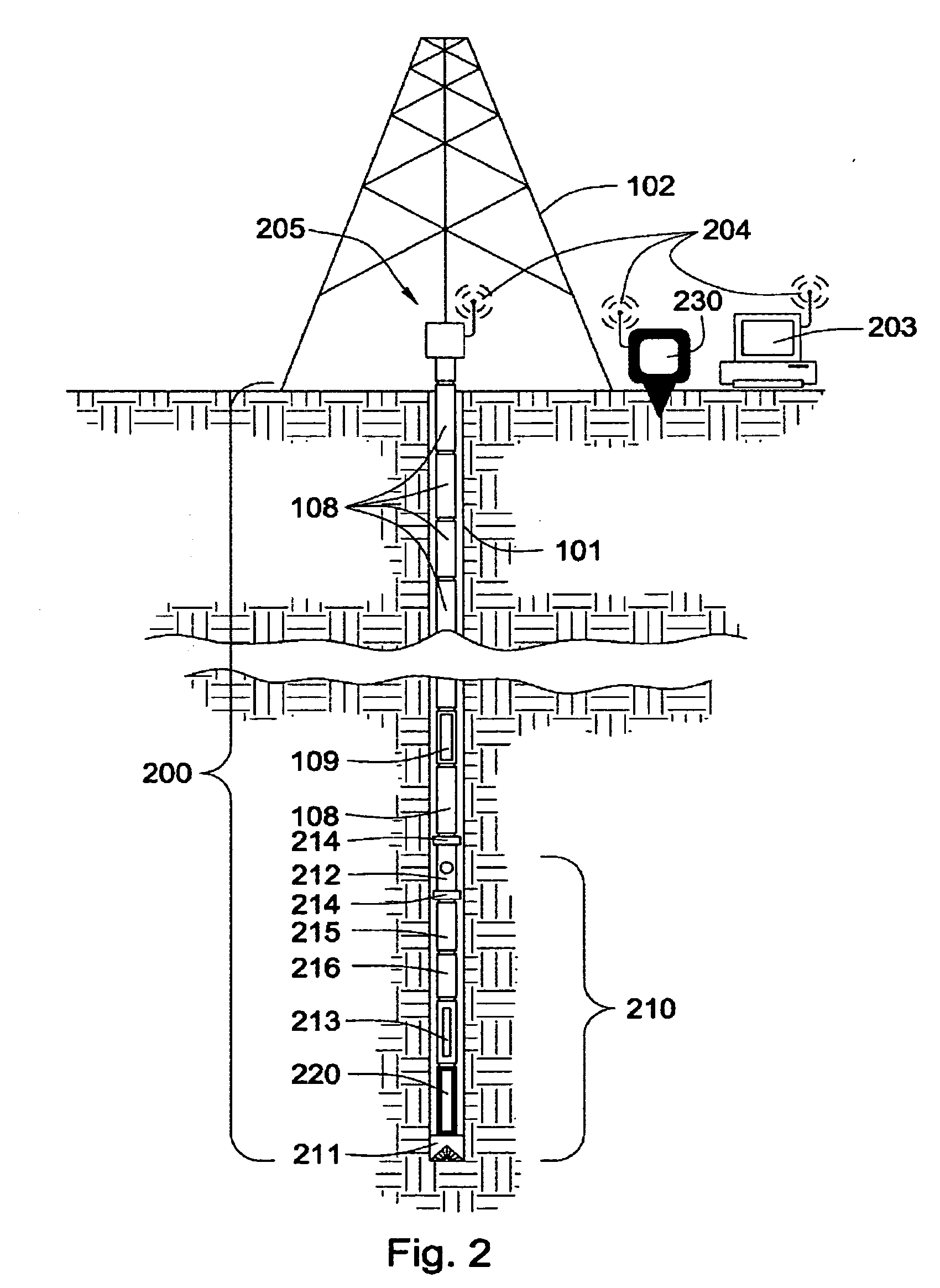

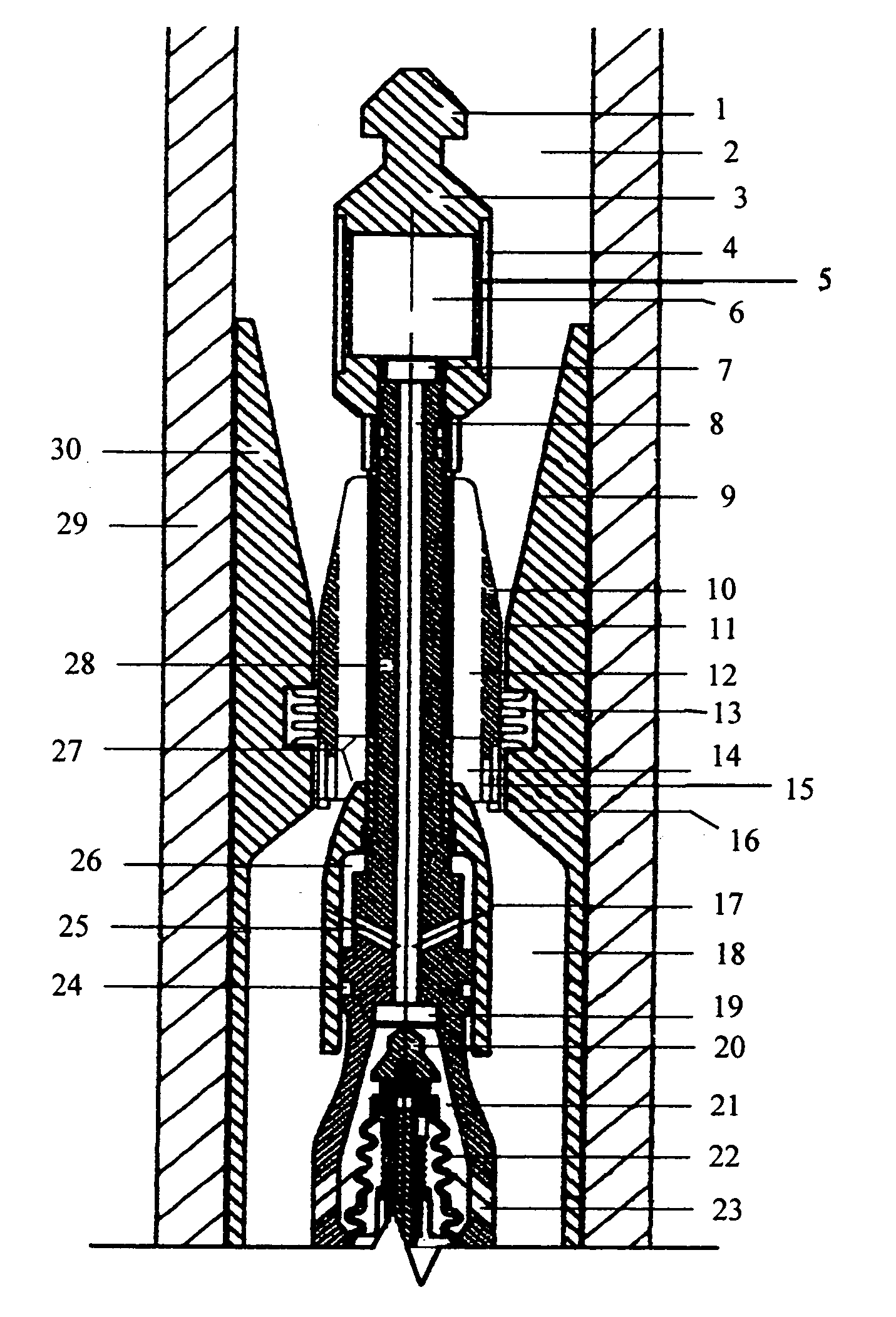

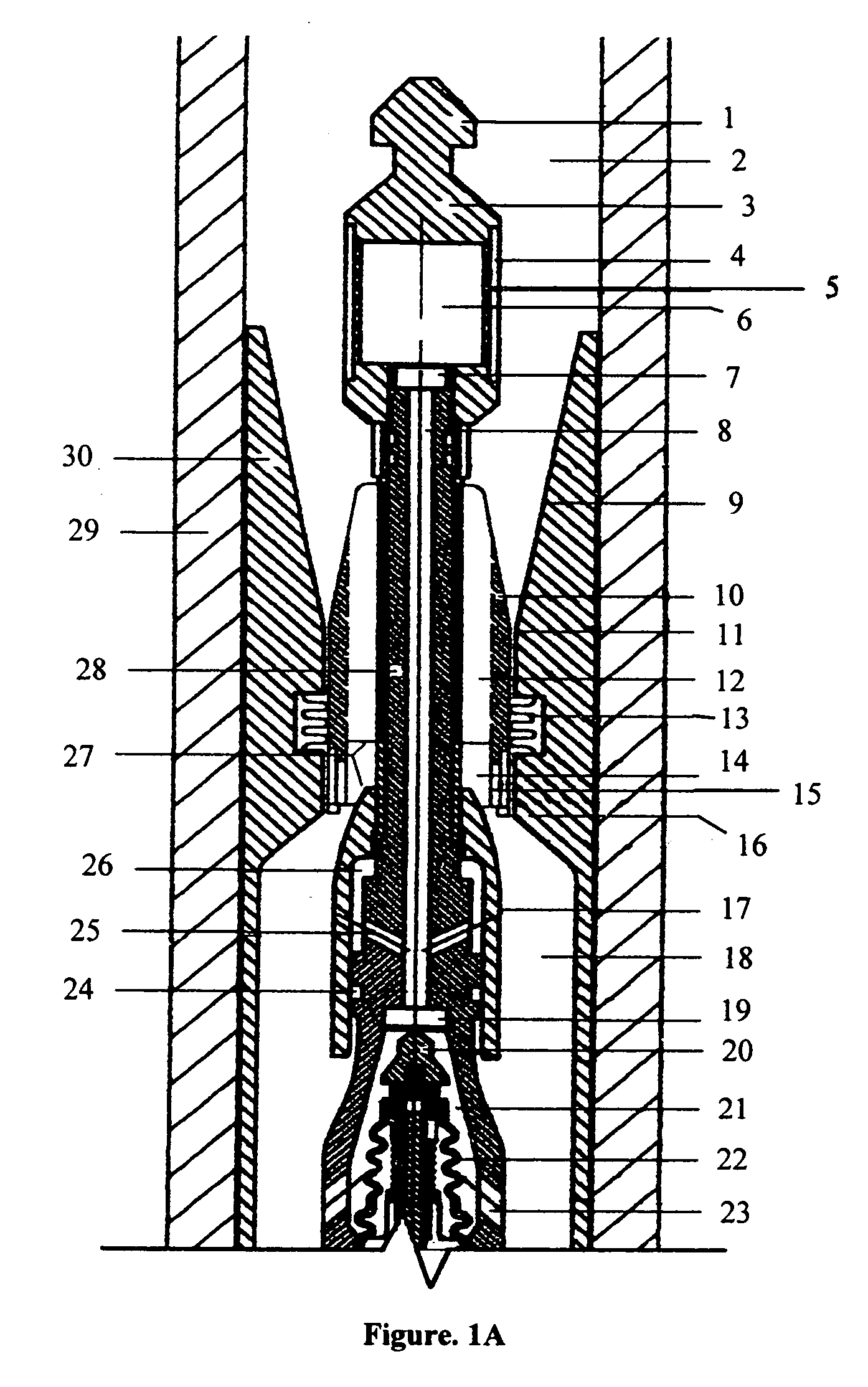

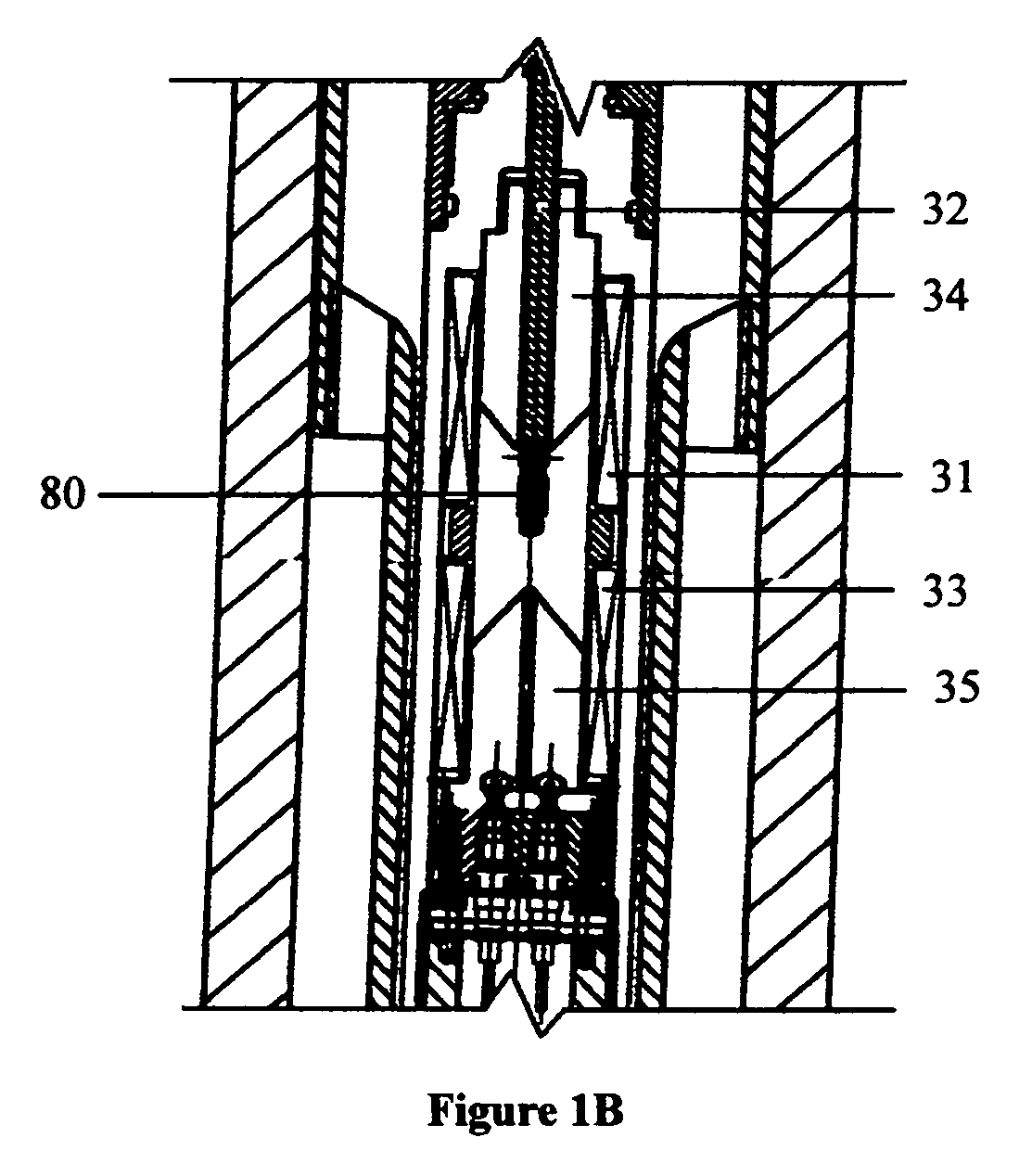

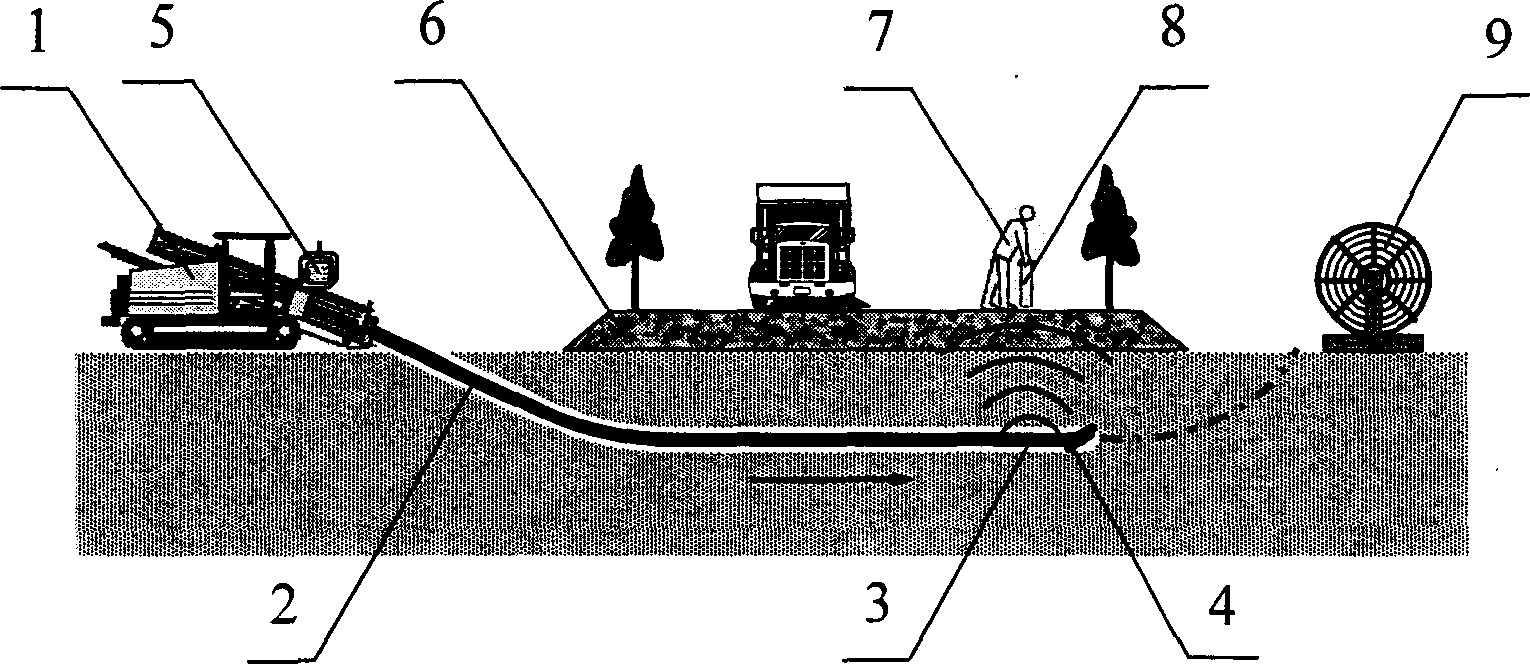

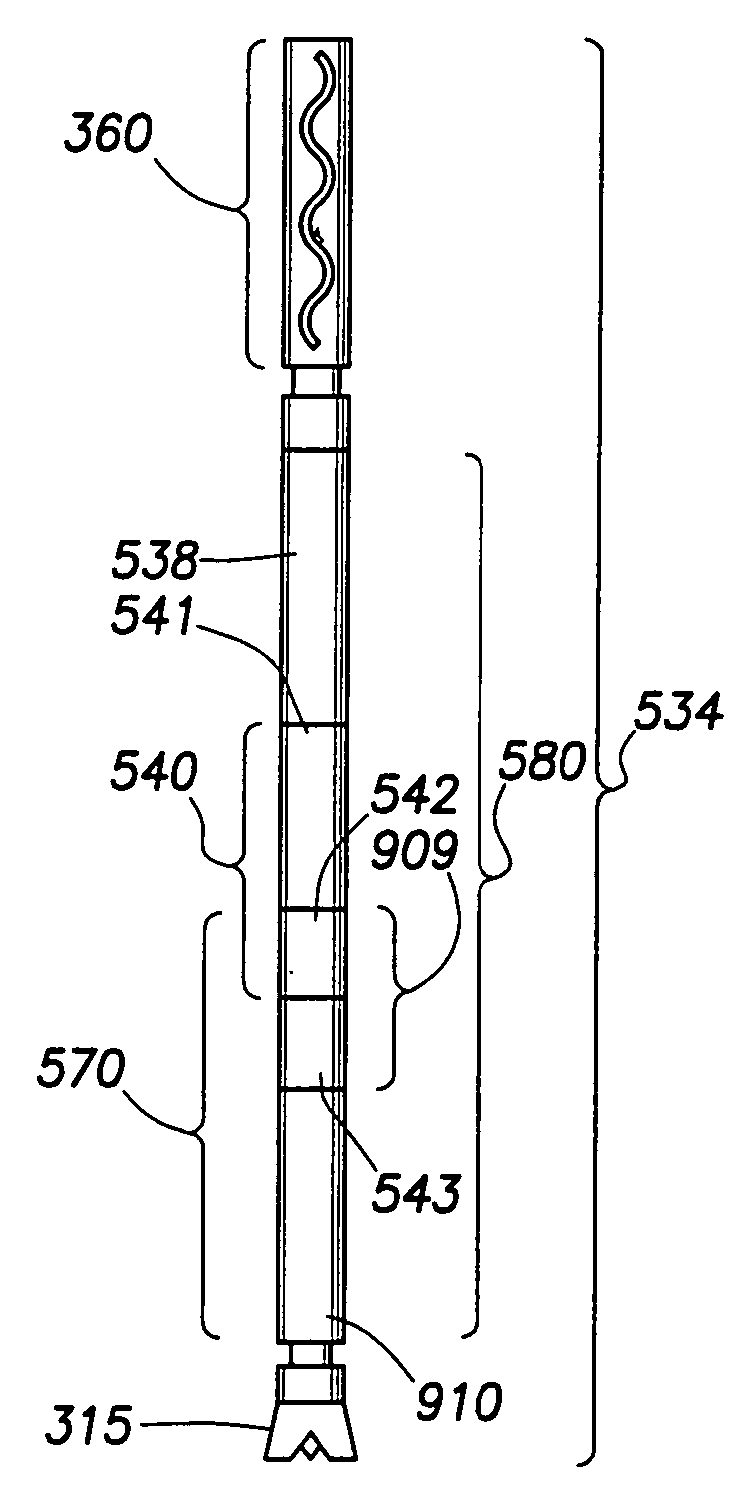

Measurement while drilling apparatus and method of using the same

ActiveUS7735579B2Effectively strainingExtend your lifeSurveyConstructionsData transmissionMechanical engineering

A method and apparatus used to transmit information to the surface from a subsurface location during the process of drilling a bore hole is described. A novel pressure pulse generator or “pulser” is coupled to a sensor package, a controller and a battery power source all of which reside inside a short section of drill pipe close to the bit at the bottom of the bore hole being drilled. The assembled apparatus or “MWD Tool” can be commanded from the surface to make a measurement of desired parameters and transmit this information to the surface by encoding data in pressure pulses generated by a pulser valve that includes a stator and a rotor which may be open and closed to create pressure pulses.

Owner:PNC BANK NAT ASSOC +2

Apparatus and method for measuring while drilling

InactiveUS20060254819A1Improve cost efficiencyImprove drilling performanceSurveyConstructionsWell drillingMud motor

An apparatus, system, and method for transmitting measurements while drilling are adapted for use with a drill string equipped with a mud motor. The drill string may comprise a plurality of interconnected drill pipe joints or a plurality of interconnected casing joints. The apparatus comprises a measurement-while-drilling tool adapted for placement in the drill string beneath the mud motor. The measurement-while-drilling tool has a system for transmitting telemetry signals, such as mud-pulse telemetry signals, upwardly through the mud motor and the drill string. In particular embodiments, the measurement-while-drilling tool has a system for transmitting mud-pulse telemetry signals upwardly through the mud motor and the drill string at frequencies below approximately 1 Hz, although other frequencies may be employed to advantage. The apparatus may further comprise a rotary steerable system for placement in the drill string beneath the mud motor. The rotary steerable system may be a point-the-bit system or a push-the-bit system. In particular embodiments, the rotary steerable system and the measurement-while-drilling tool are integrated.

Owner:SCHLUMBERGER TECH CORP

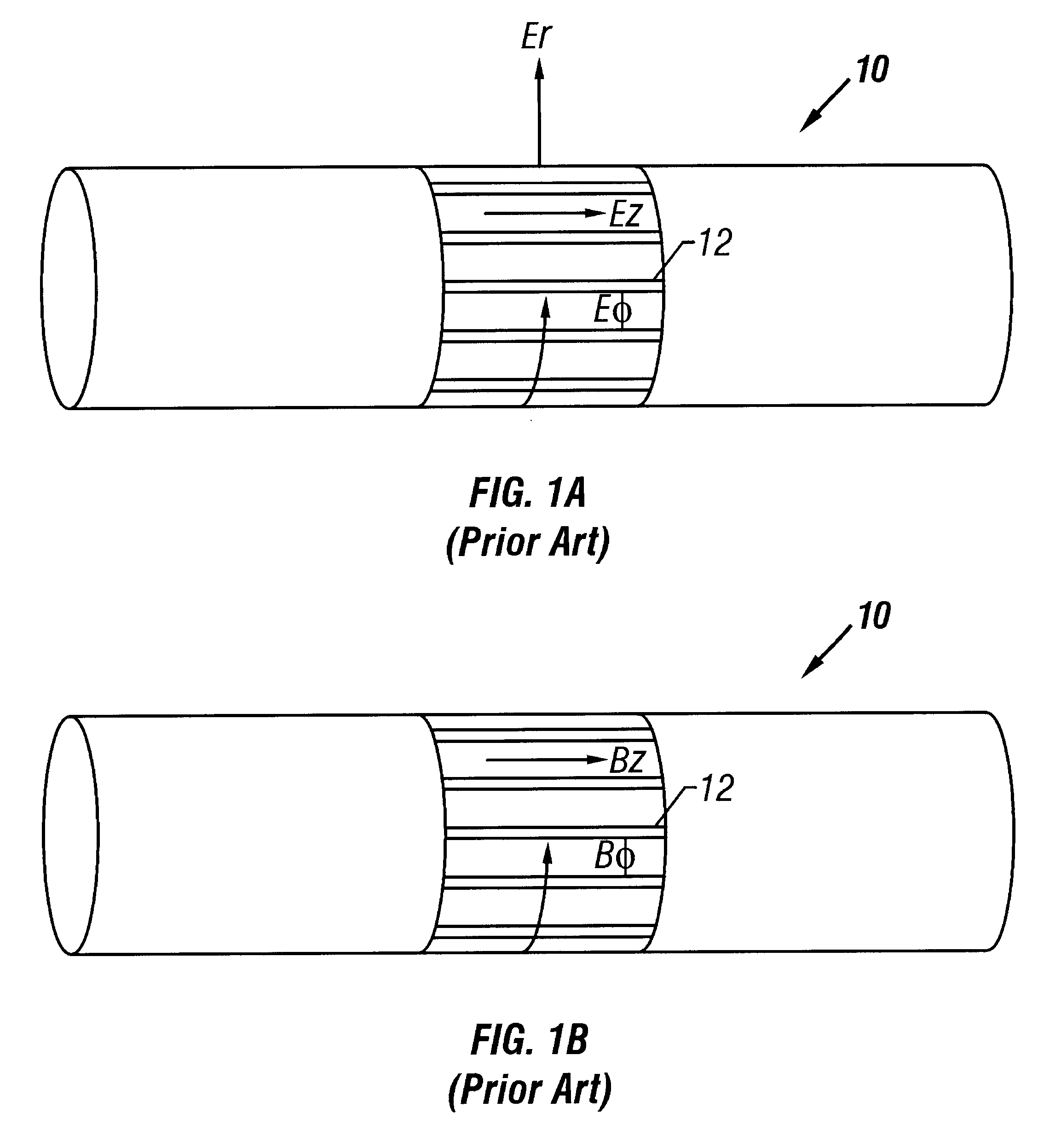

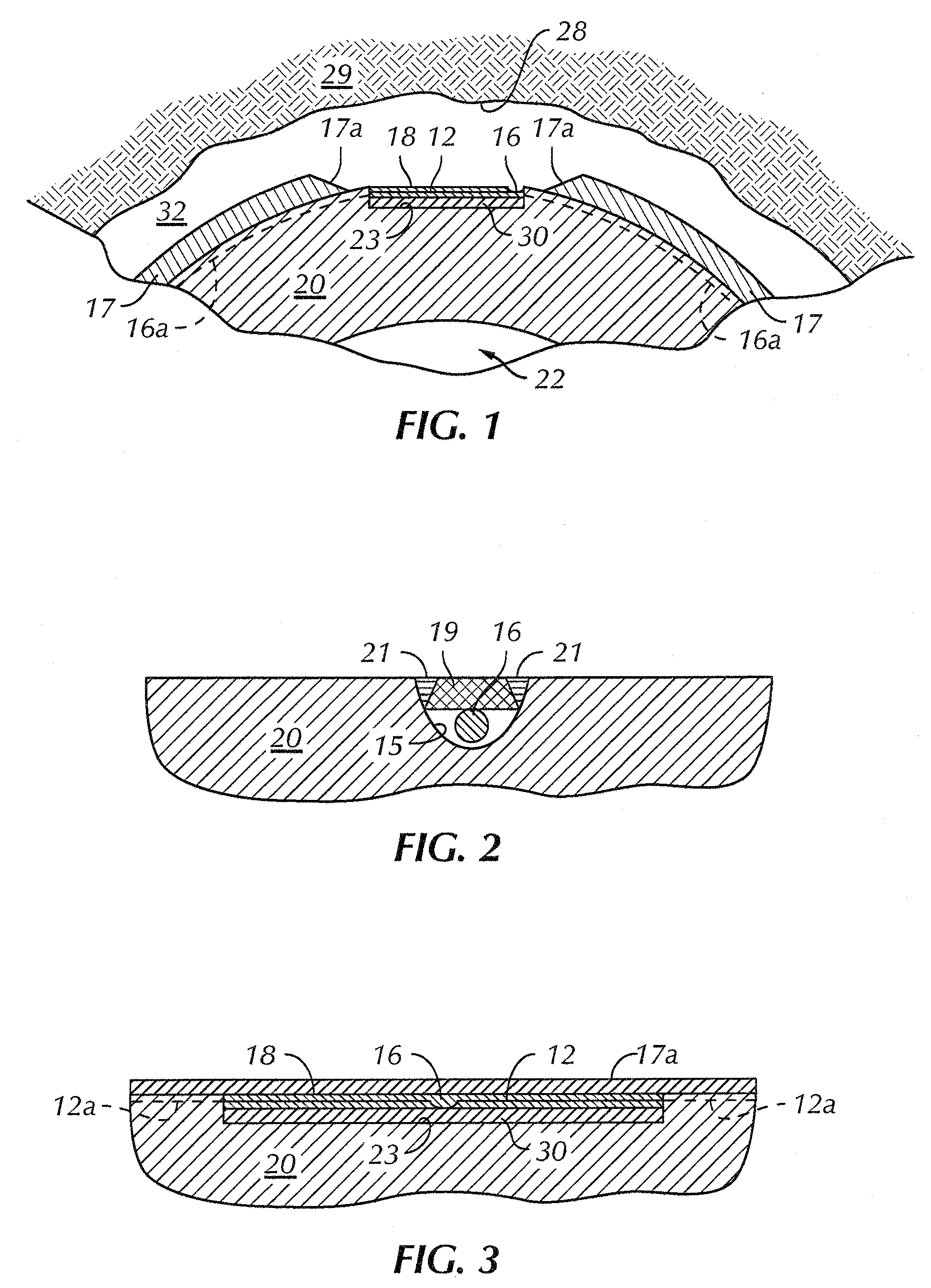

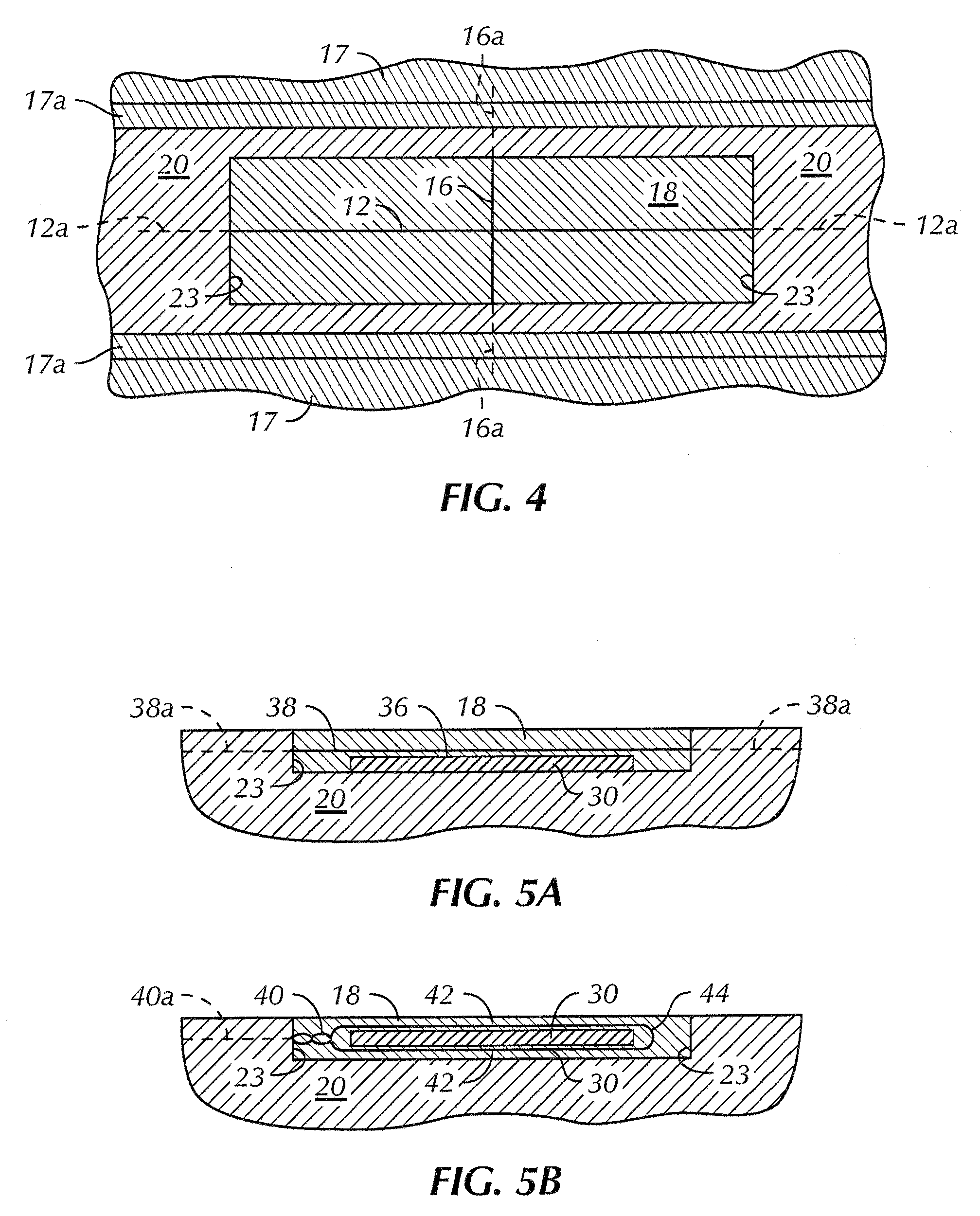

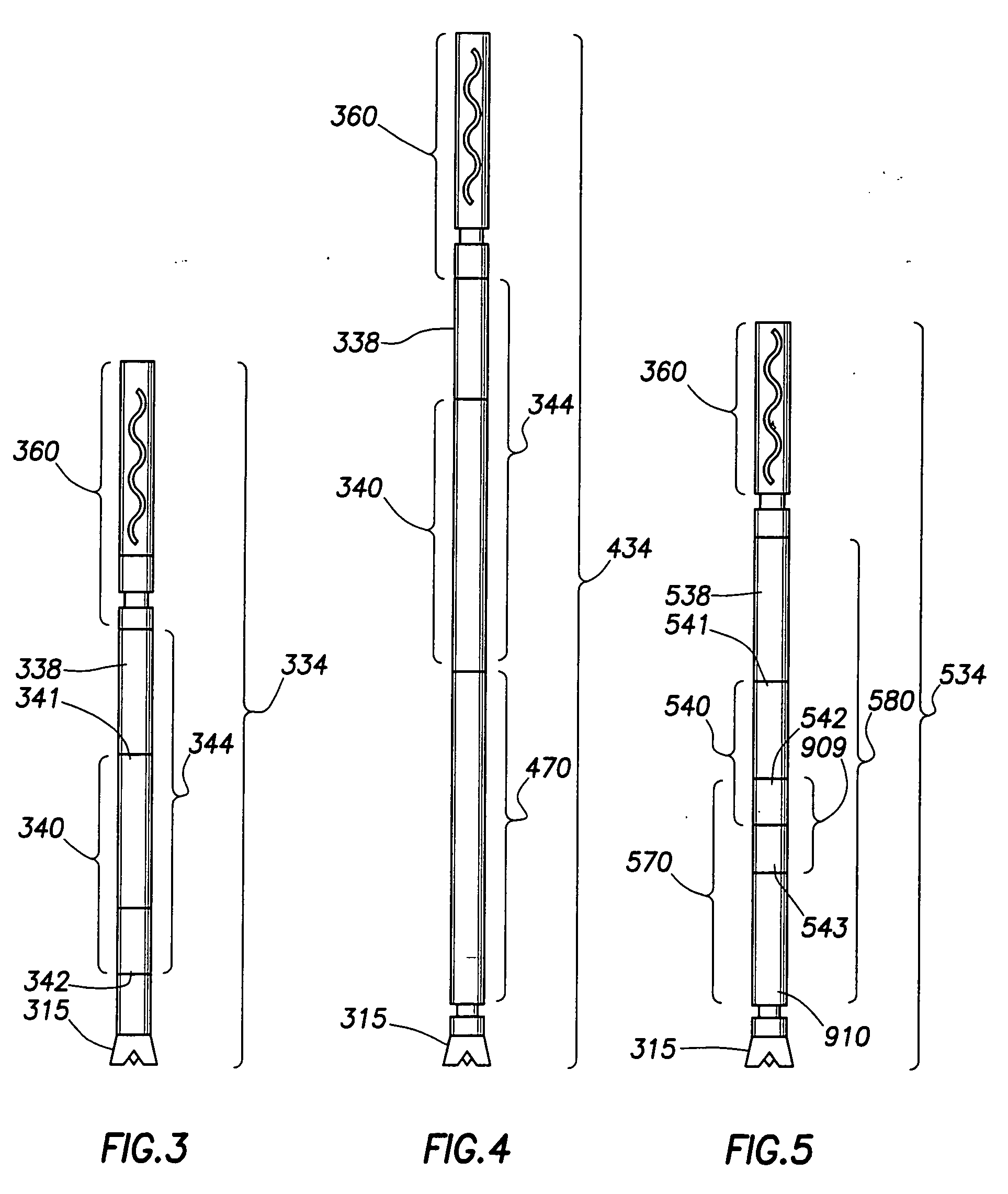

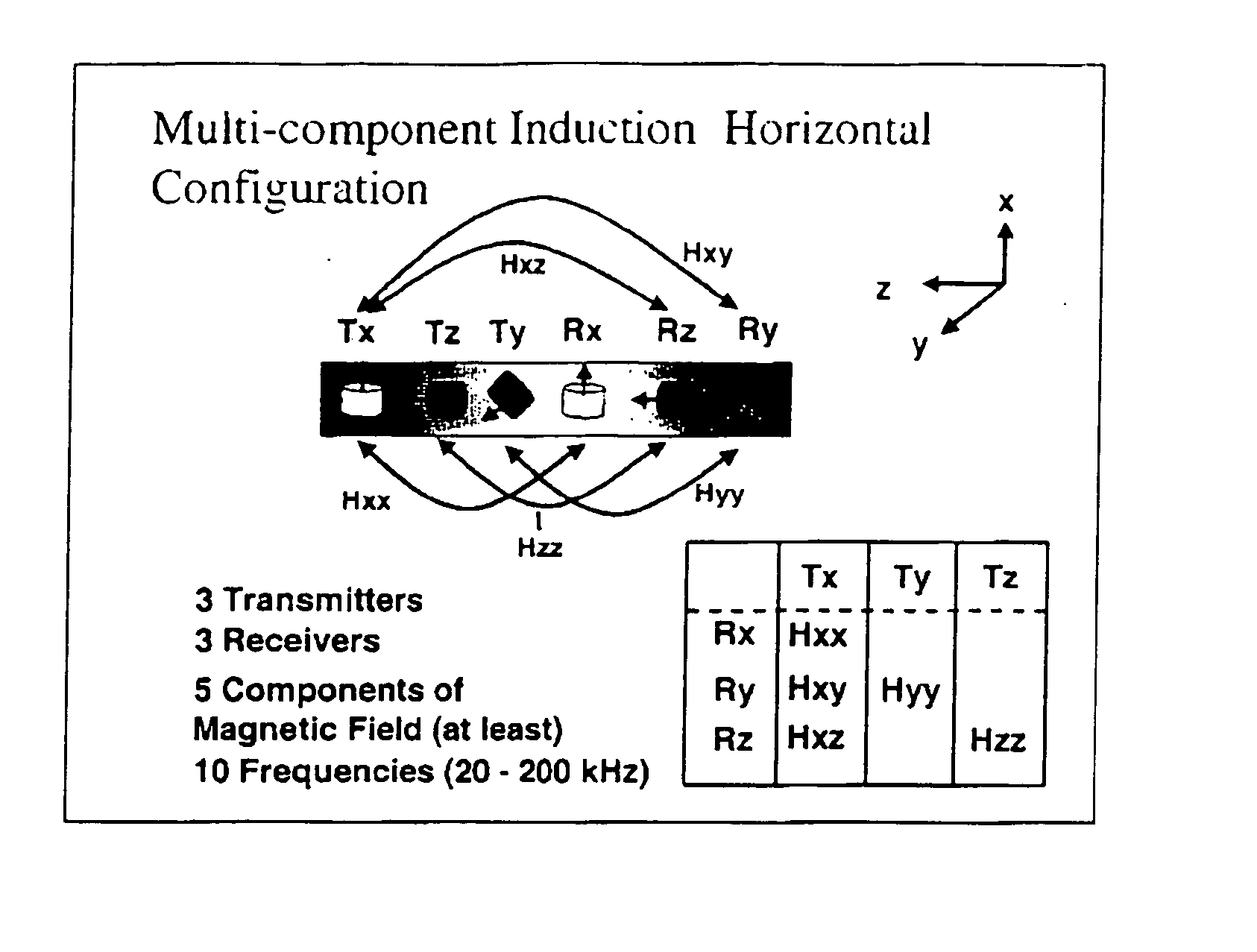

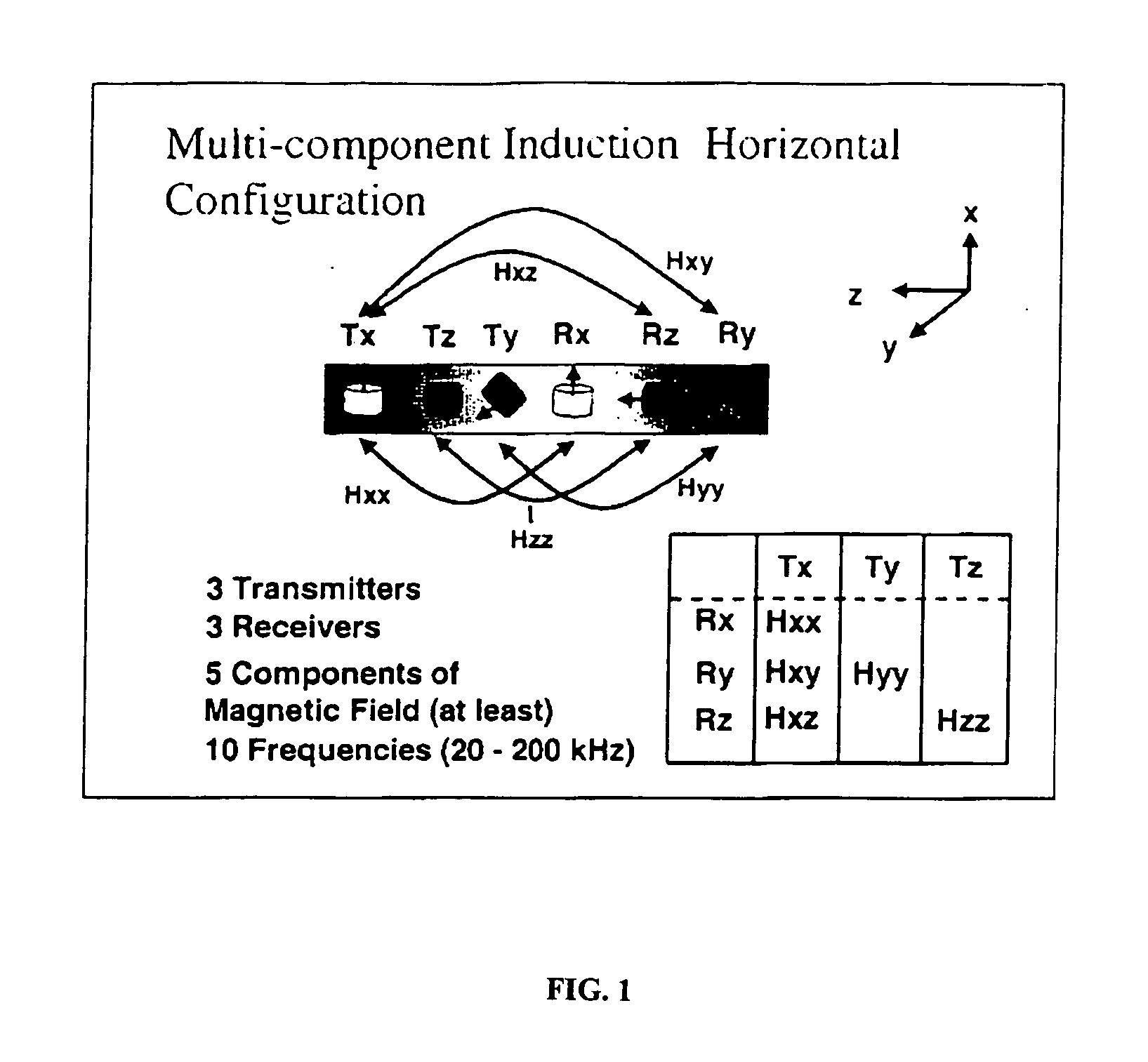

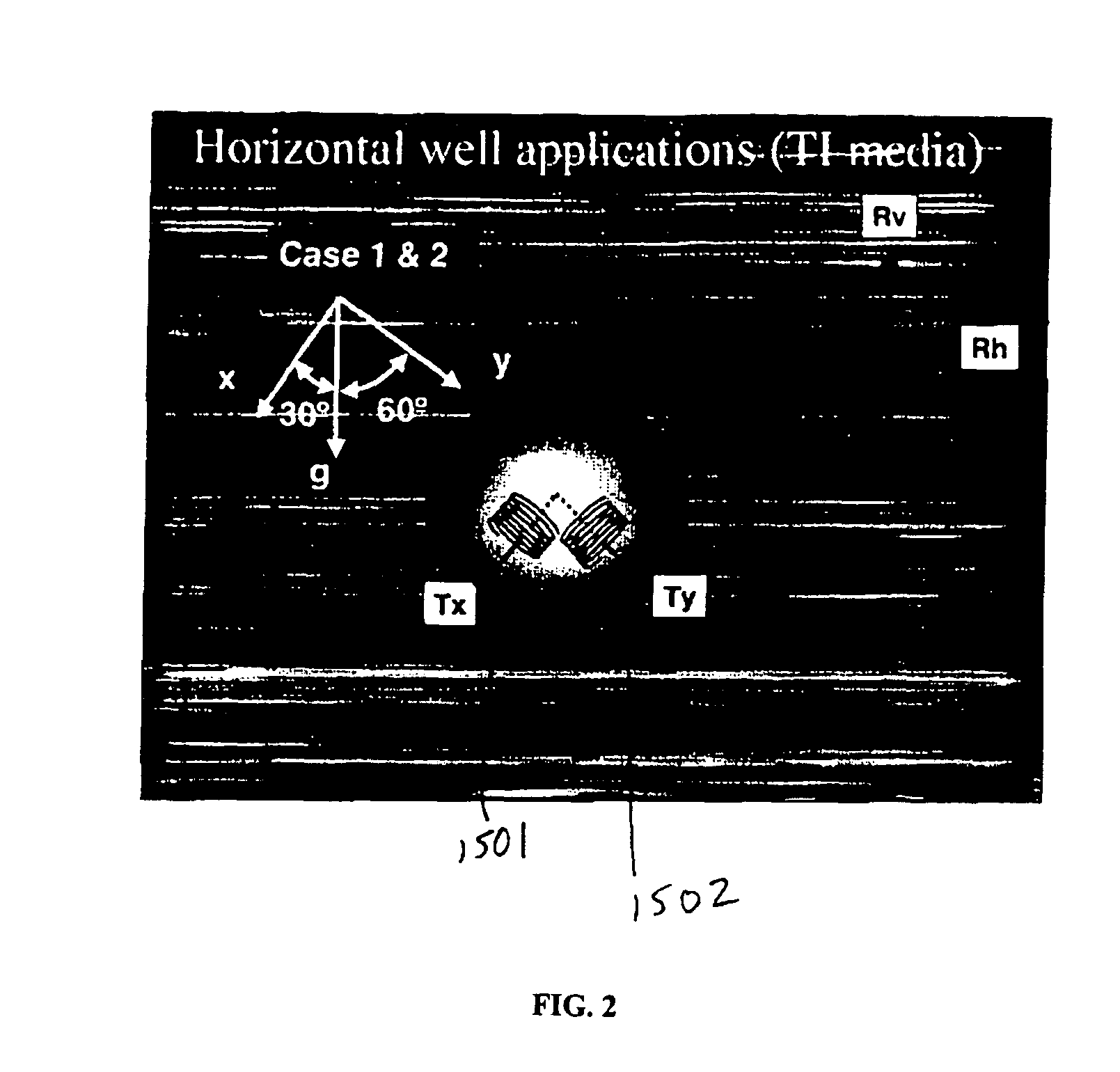

Method and apparatus for directional resistivity measurement while drilling

ActiveUS20040113626A1Electric/magnetic detection for well-loggingAcoustic wave reradiationWell drillingTransverse magnetic field

A measurement-while-drilling or logging while drilling method and apparatus for determining the azimuth of providing magnetic field in a remote formation layer in the vicinity of a down hole resistivity tool. A cross-component magnetic field with substantially orthogonal transmitter and receiver coils is provided. The coil planes are either substantially orthogonal (coaxial coils) or parallel (transverse coils) with respect to, the longitudinal axis of the tool body. The coils are placed on the tool body having a external surface and a plurality of grooves are cut in the external surface of the tool body and oriented substantially horizontally with respect to the longitudinal axis of the tool body for the coils and oriented vertically with respect to the longitudinal axis of the tool body for the coaxial coils. A transverse and coaxial coil are placed in the grooves for transmission or reception of a cross-component transverse magnetic field. Ferrite materials may be inserted in the grooves in between the coil wire and the bottom of the grooves. Multiple receivers, transmitters and frequencies may be used to obtain the maximum possible signal-to-noise ratio. The in-phase or quadrature part of a magnetic field, or a combination of the two, or alternatively, the amplitude and / or phase, of the cross-component magnetic field may be measured and processed to indicate the azimuth of a remote layer boundary, provided that the layer boundary is within the depth of investigation of the tool. Measurements may also be made at continuous or multiple tool azimuths.

Owner:BAKER HUGHES HLDG LLC

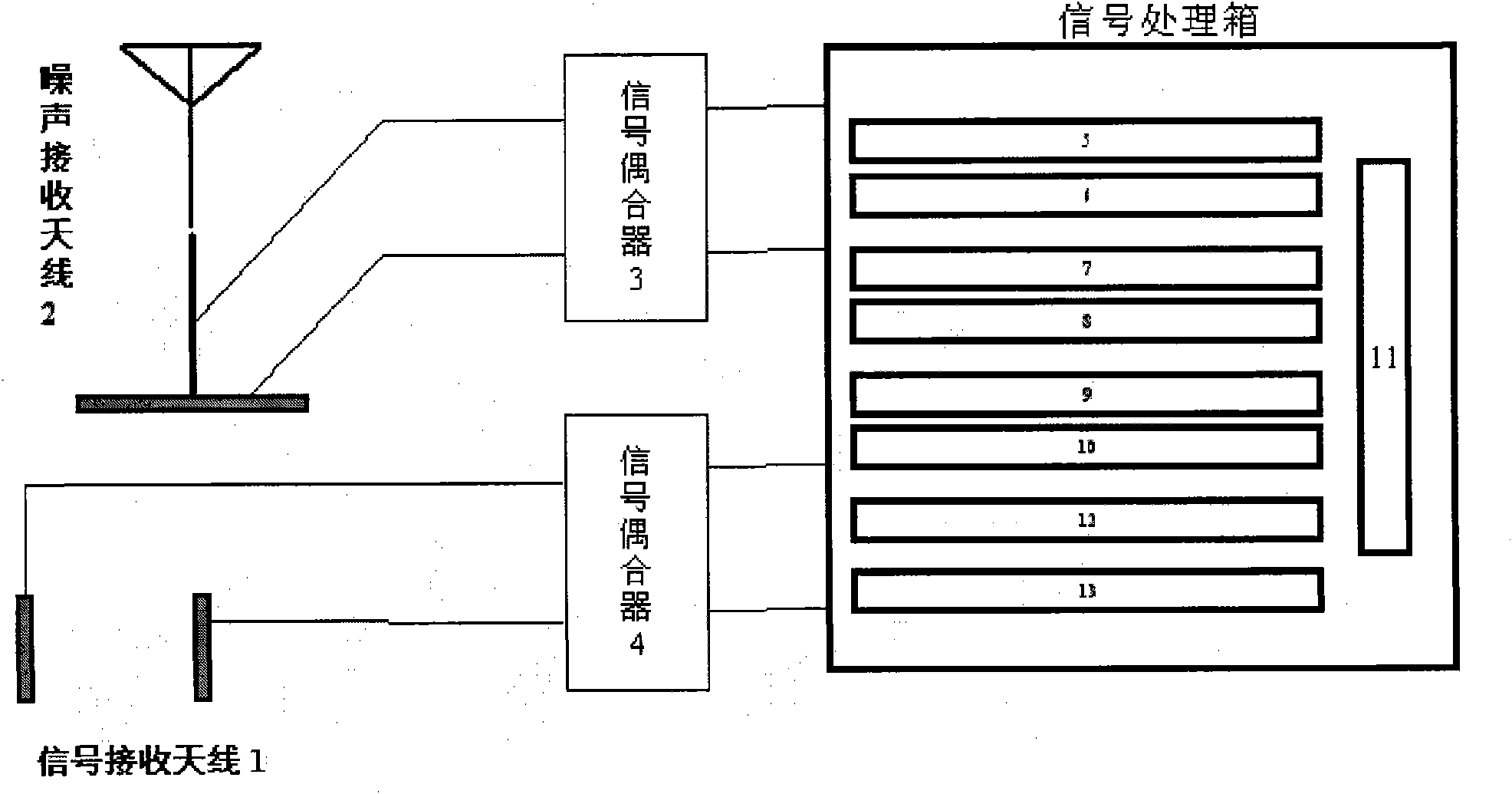

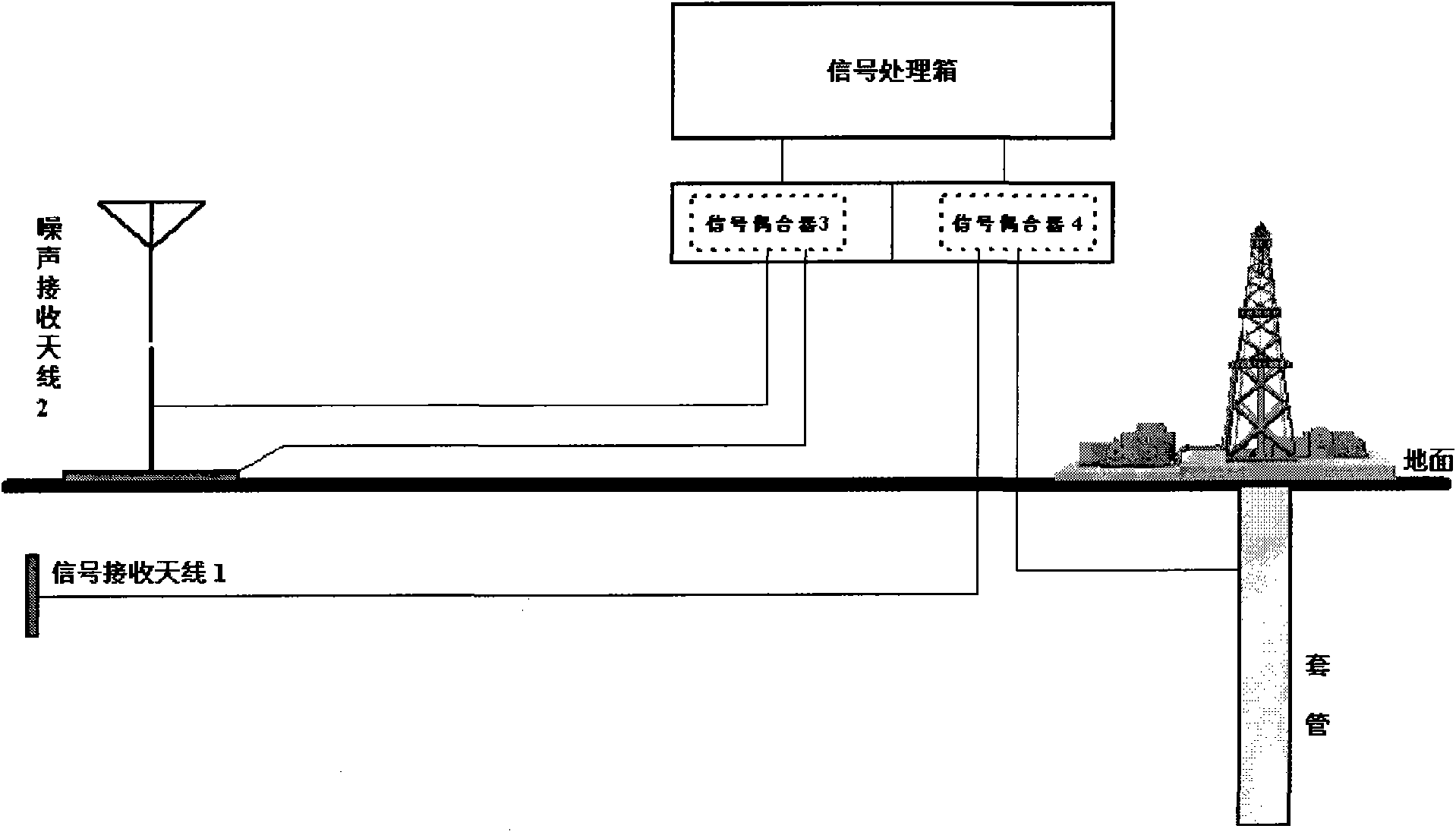

Ground signal receiving device for electromagnetic measurement while drilling system and receiving method thereof

ActiveCN101525998AImprove reception performanceIncreased depth of measurementSurveyConstructionsDigital signal processingLow noise

The invention relates to a device in an electromagnetic measurement while drilling system for receiving an electromagnetic signal with measurement data information sent underground on the ground and transmitting the signal to a data processing computer, and a method thereof. The device uses two antennas in a well field to receive an electromagnetic signal sent underground and a well field noise signal respectively; and the two signals enter a program controlled low noise preamplifier to be amplified through the coupling of an impedance converter, then enter a signal conditioning module for processing, and then enter a digital signal processing module through analog-to-digital conversion, and finally data is transmitted to a computer terminal through an interface module. The device is matched with a downhole electromagnetic signal transmitter to form the electromagnetic measurement while drilling system to form the information communication between underground and ground. The electromagnetic measurement while drilling system is not affected by drilling fluid medium, can perform data transmission without circulating a drilling fluid under any working condition, and can solve the measurement while drilling problem in gas drilling and aerated drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com