Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Improve drilling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for evaluating and improving drilling operations

InactiveUS7020597B2Improve drilling performanceGeometric CADElectric/magnetic detection for well-loggingEngineeringDrill bit

Owner:SMITH INT INC

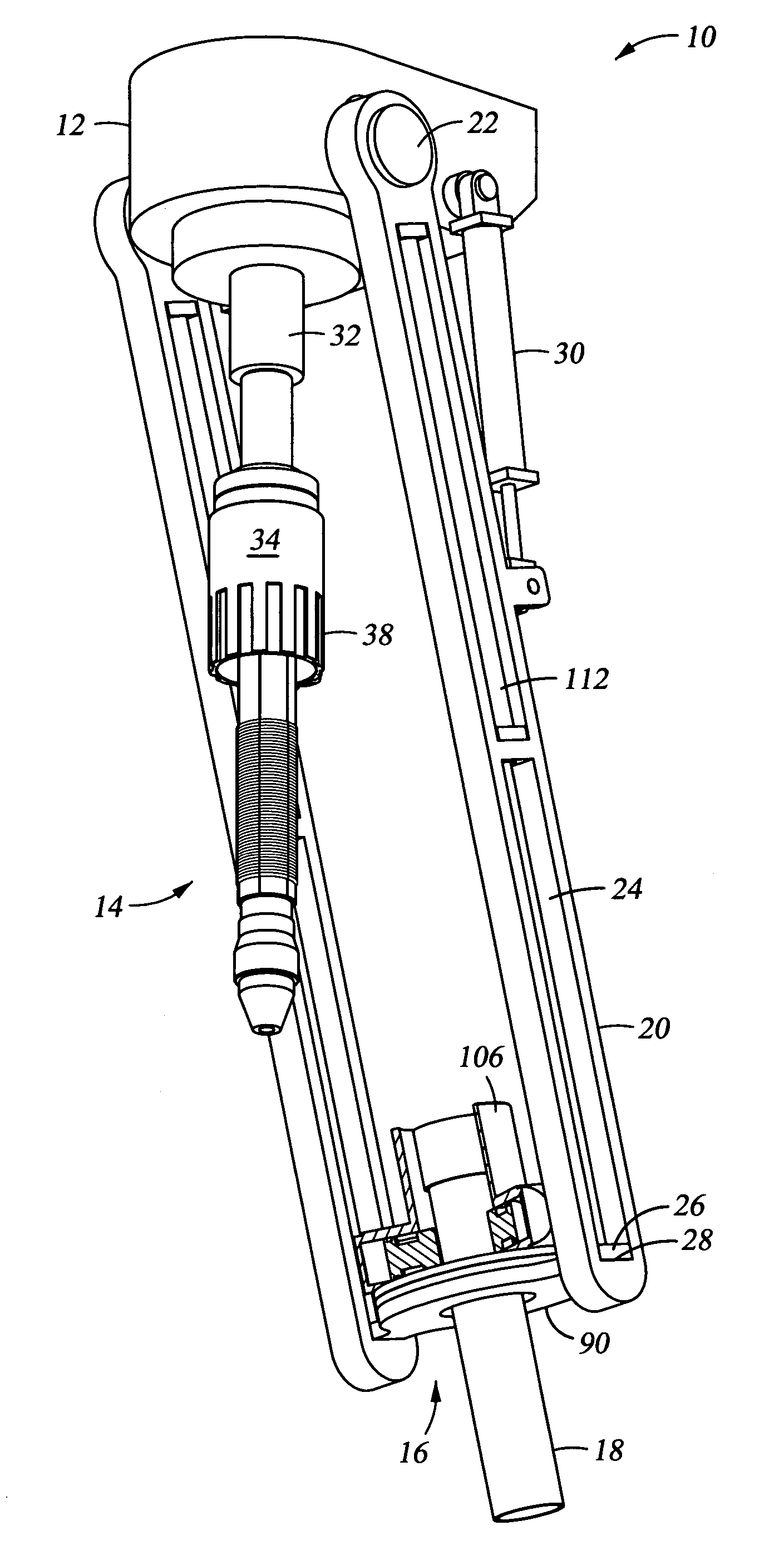

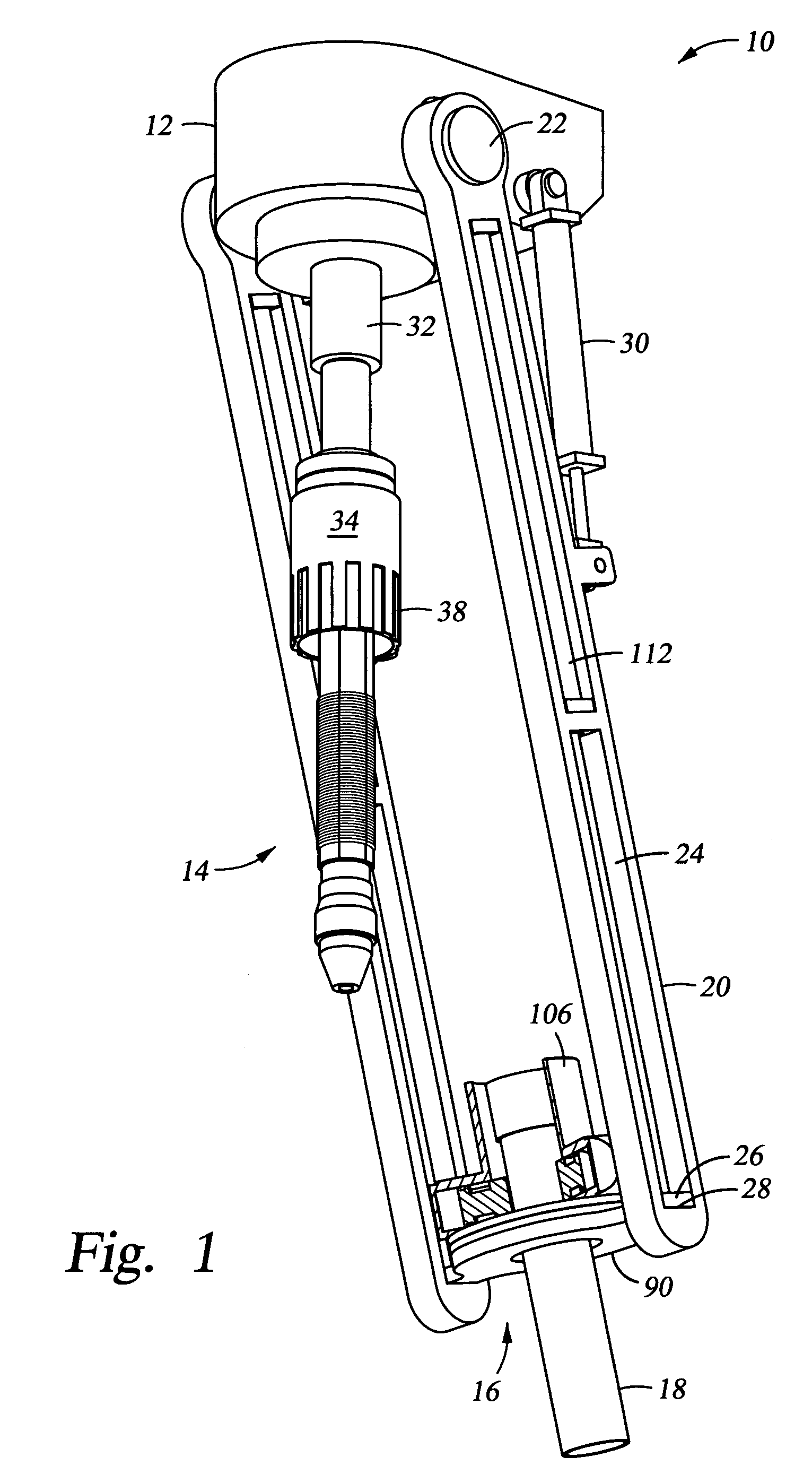

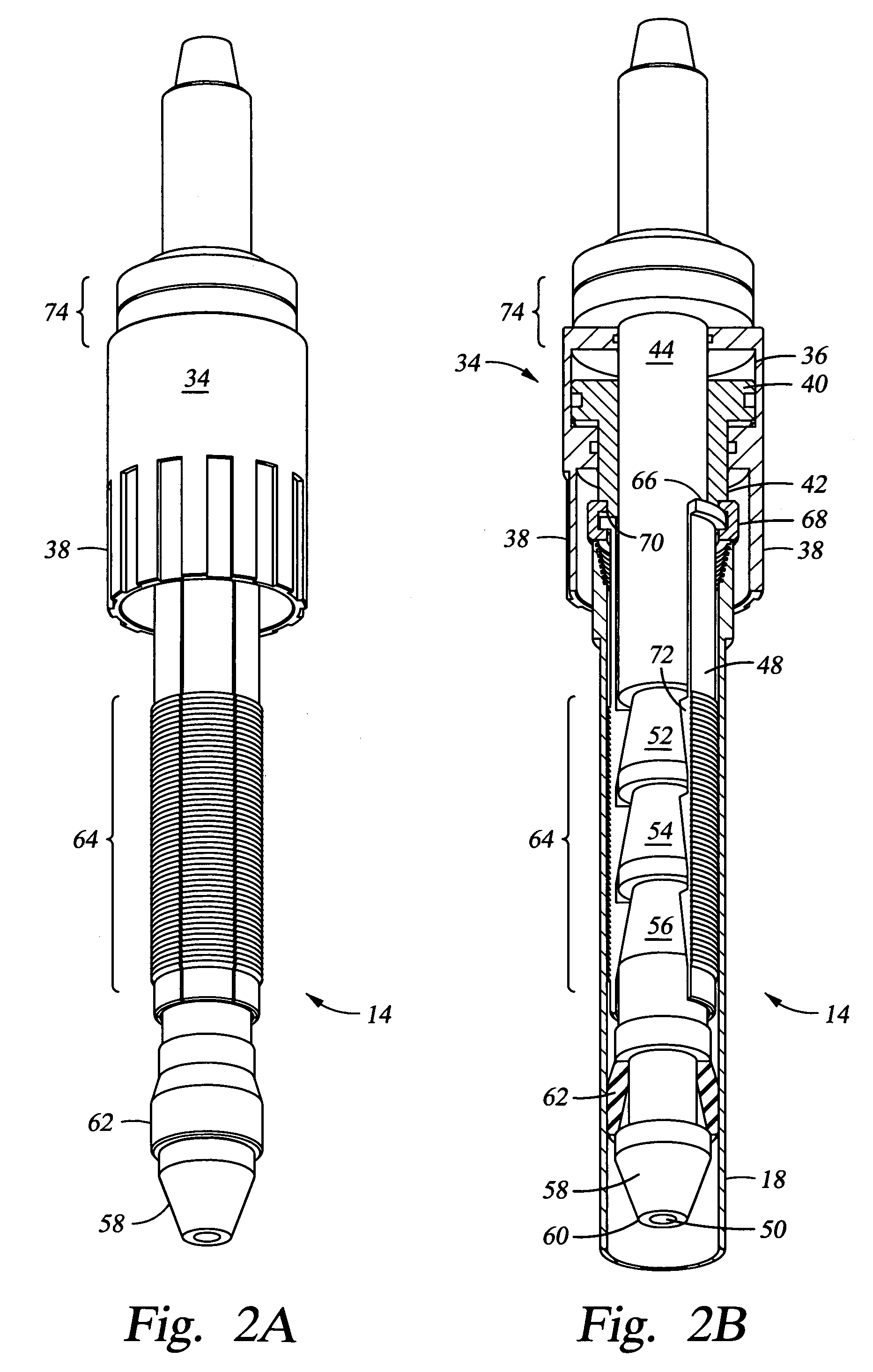

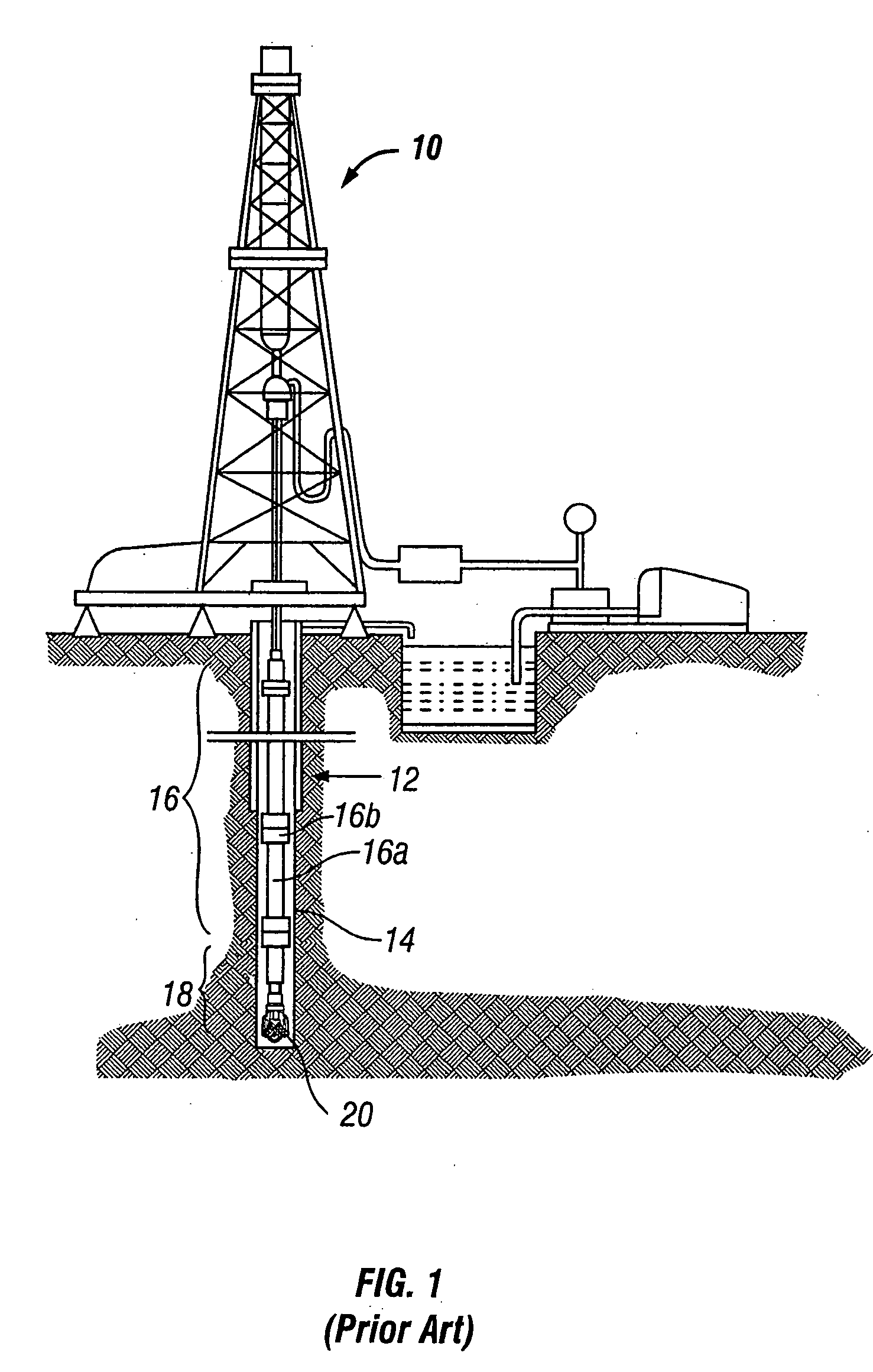

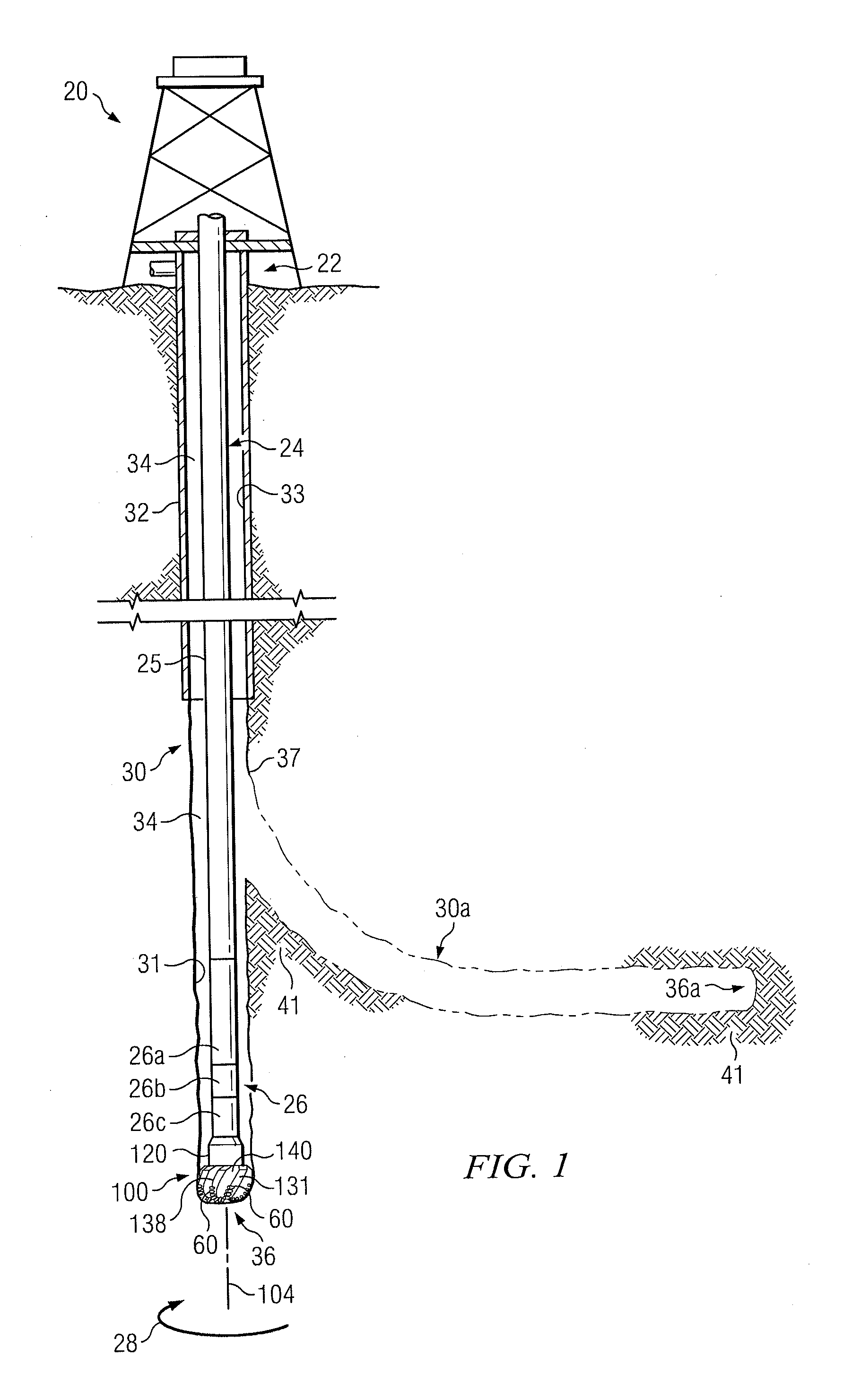

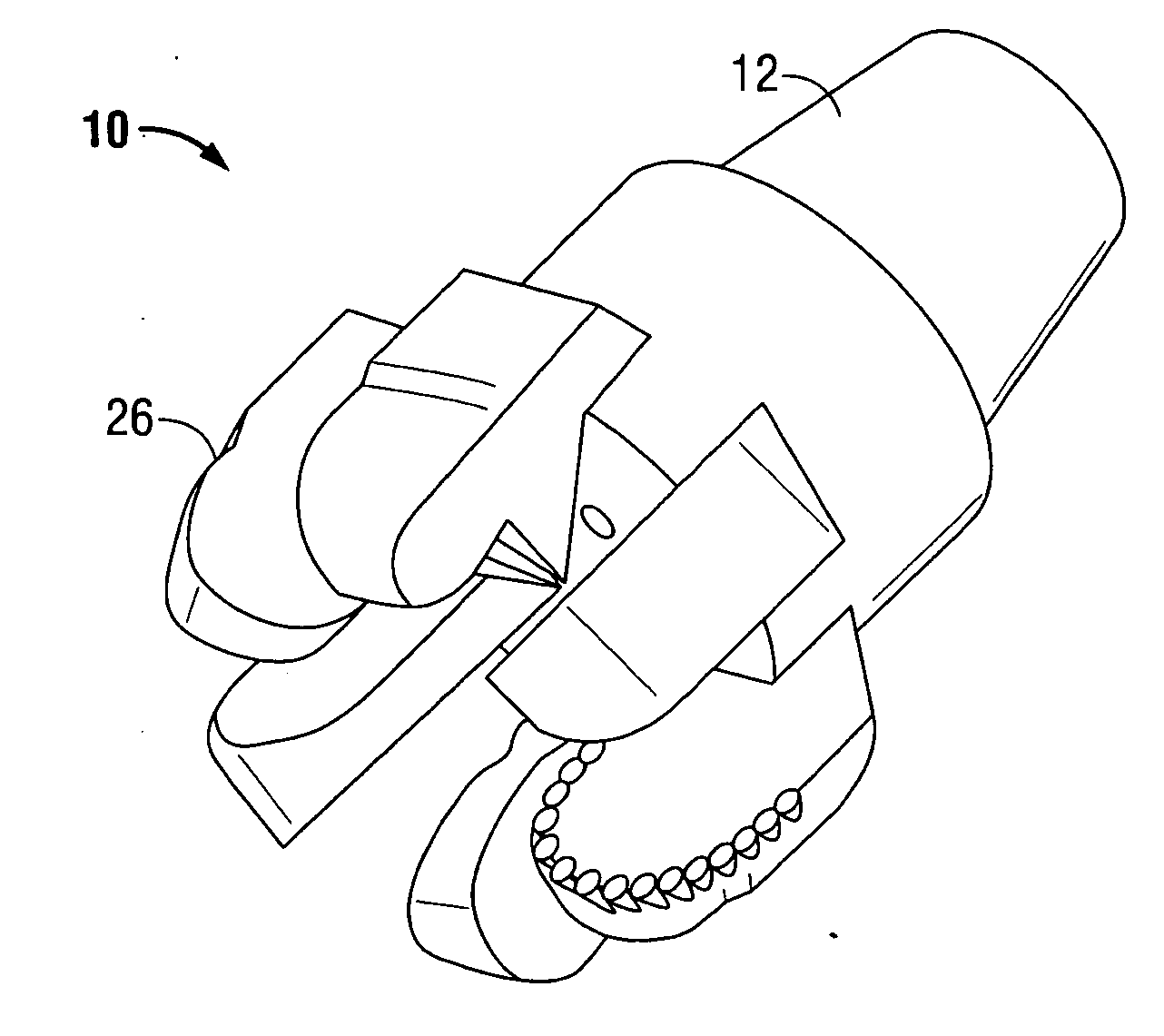

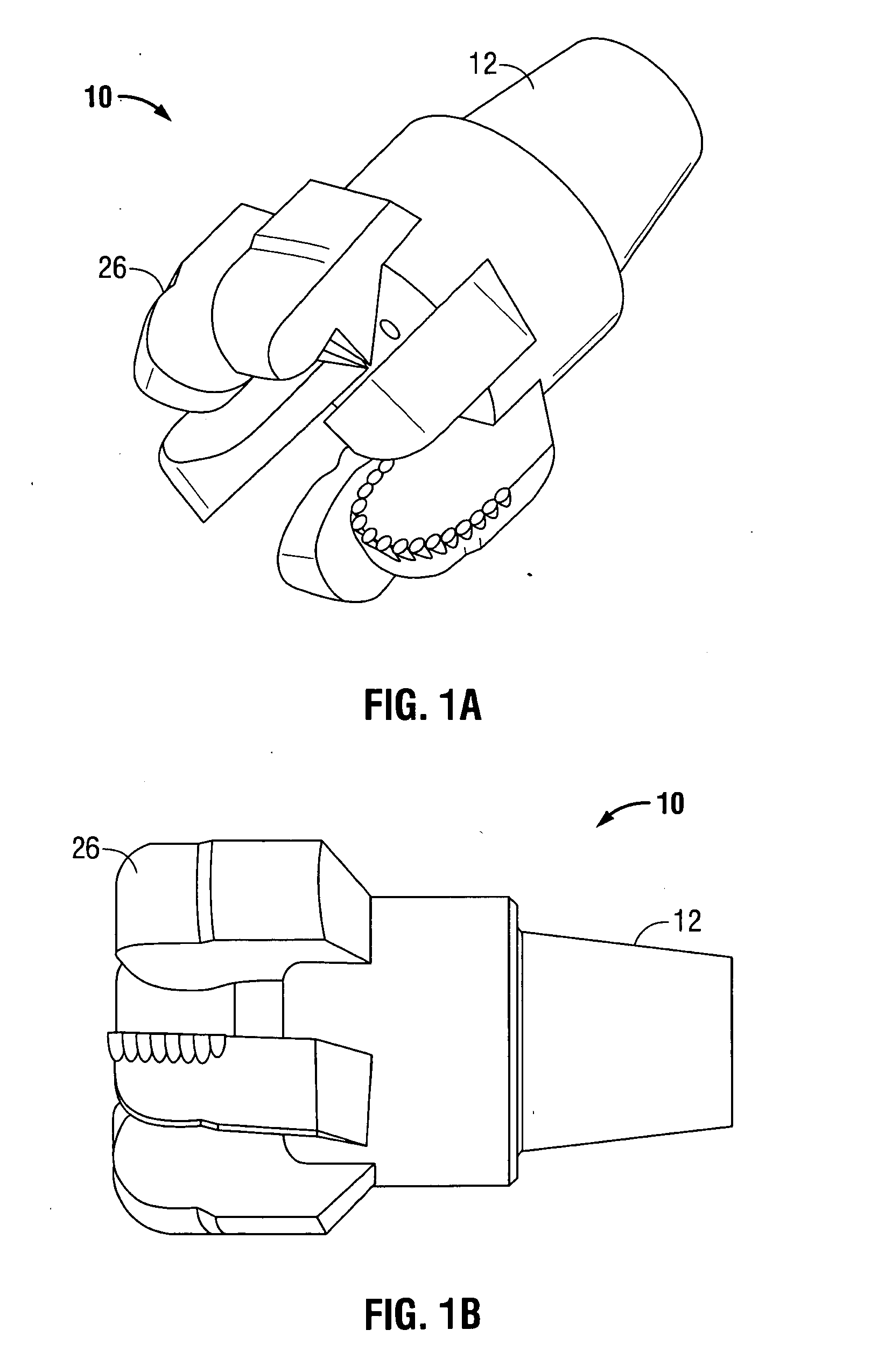

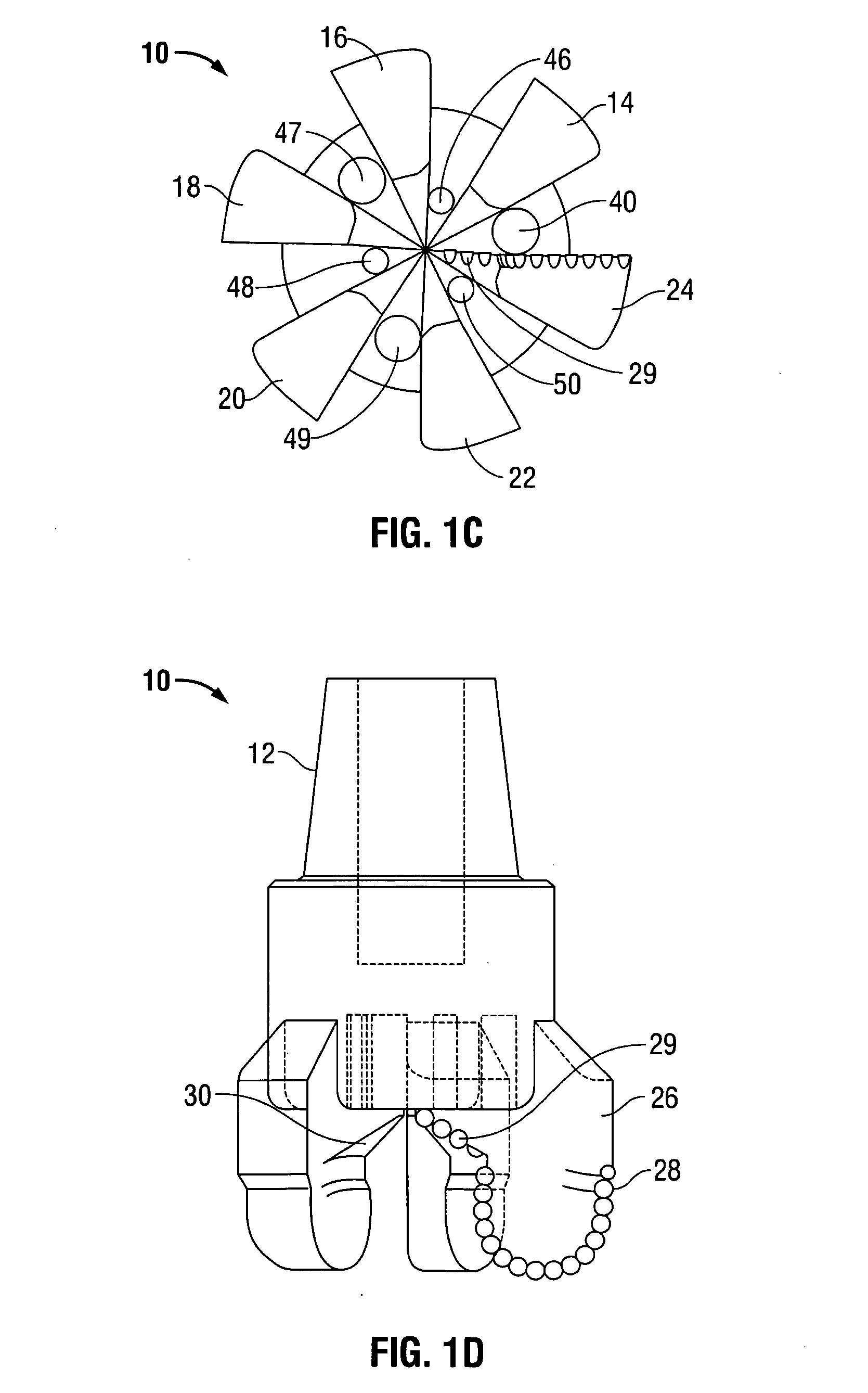

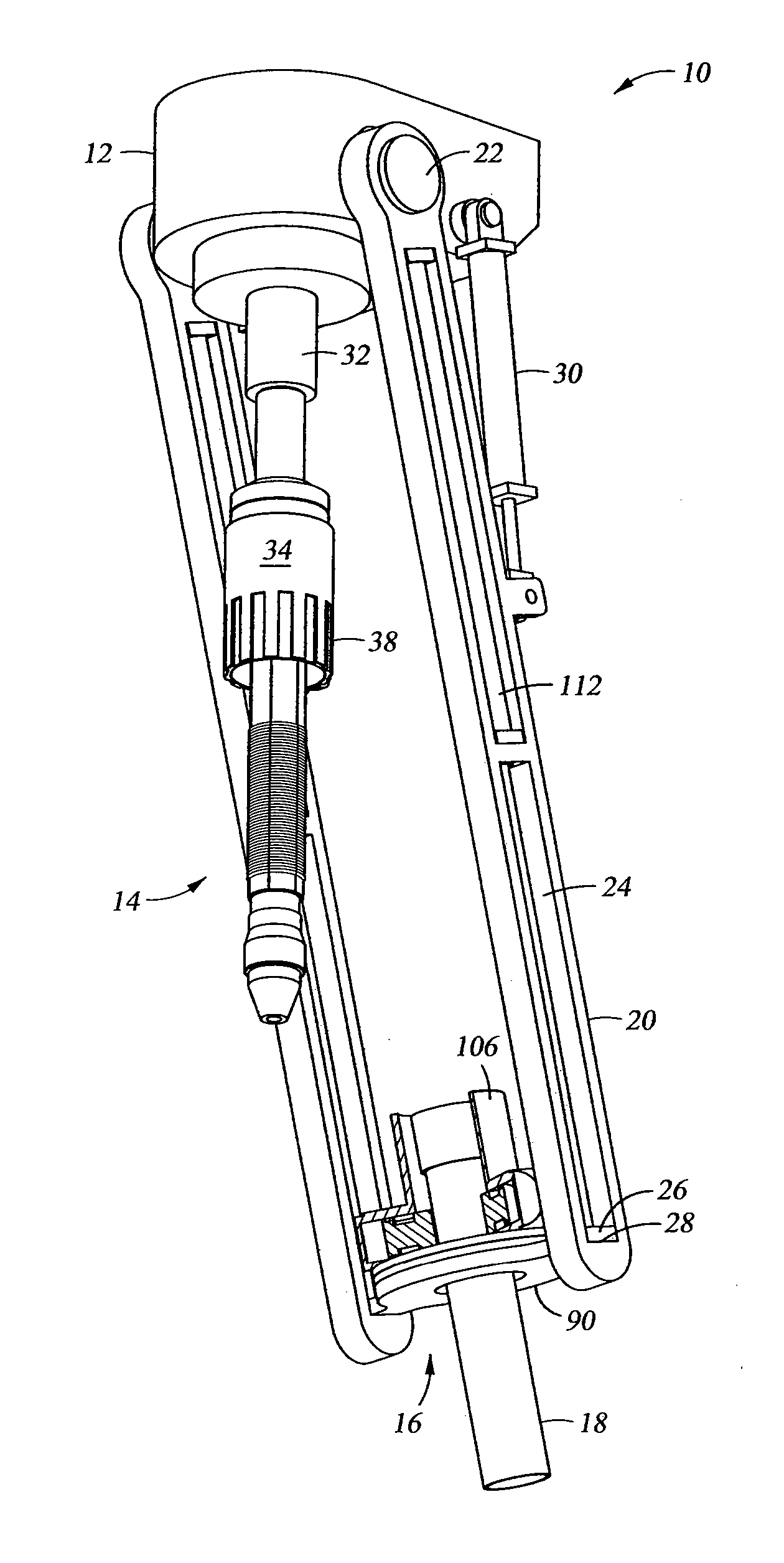

Casing running and drilling system

InactiveUS7191840B2Improve drilling performanceReduce morbidityDrilling rodsConstructionsTop driveEngineering

A method and apparatus for holding and turning a tubular and string of tubulars, such as casing, for make-up and drilling with the tubulars are disclosed. The apparatus generally includes a spear and a clamping head, both of which are mounted to a top drive. The spear and the clamping head can be engaged to transmit torque therebetween from the top drive. In addition, an aspect of the invention provides variable height wickers positioned on slips to enable use of the slips with variable inner diameter (ID) and weight casing without deformation or rupture of the casing. Still further, a casing collar is also provided to provide reinforcement to the casing in the area of slip contact with the casing ID.

Owner:WEATHERFORD TECH HLDG LLC

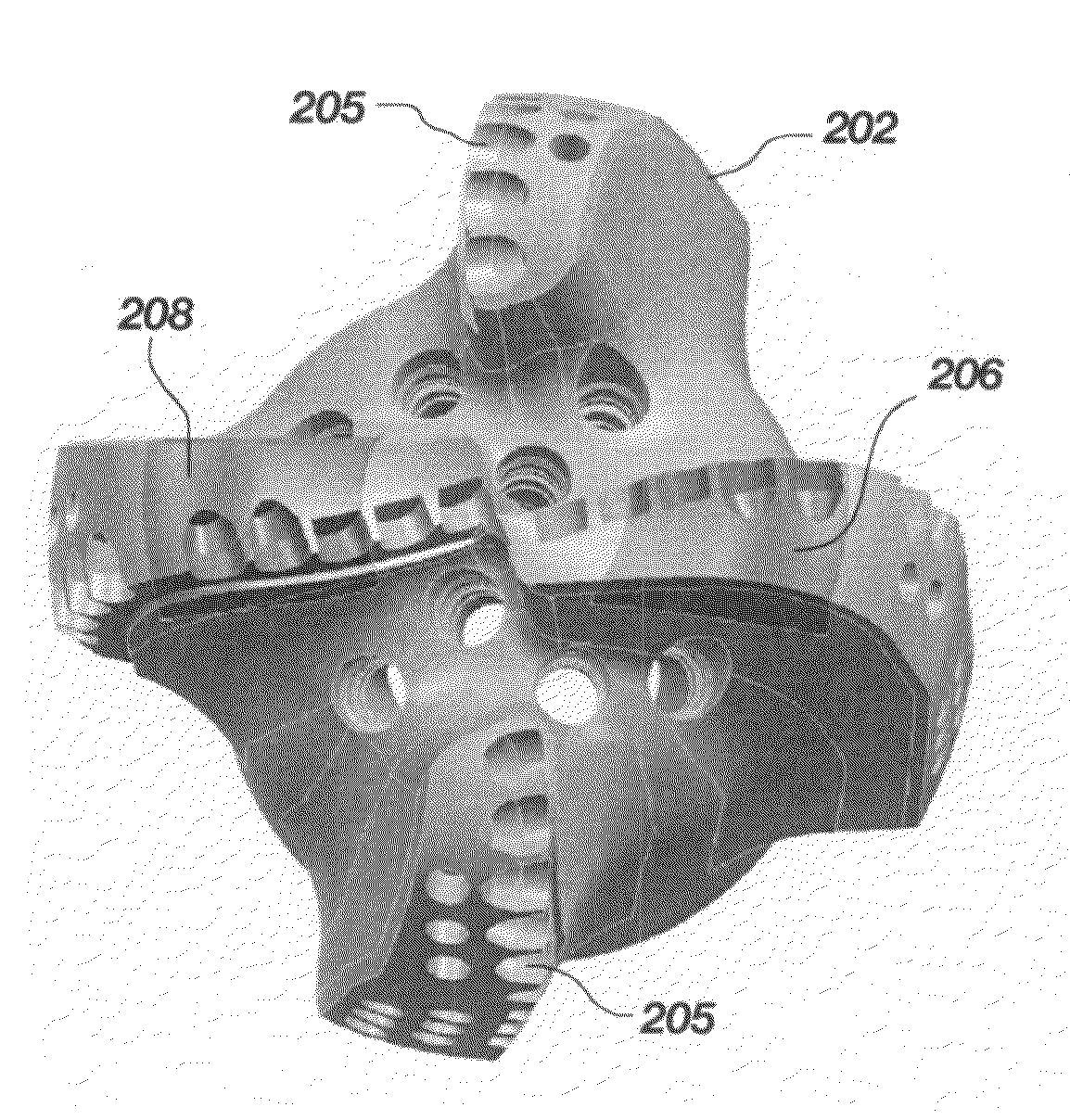

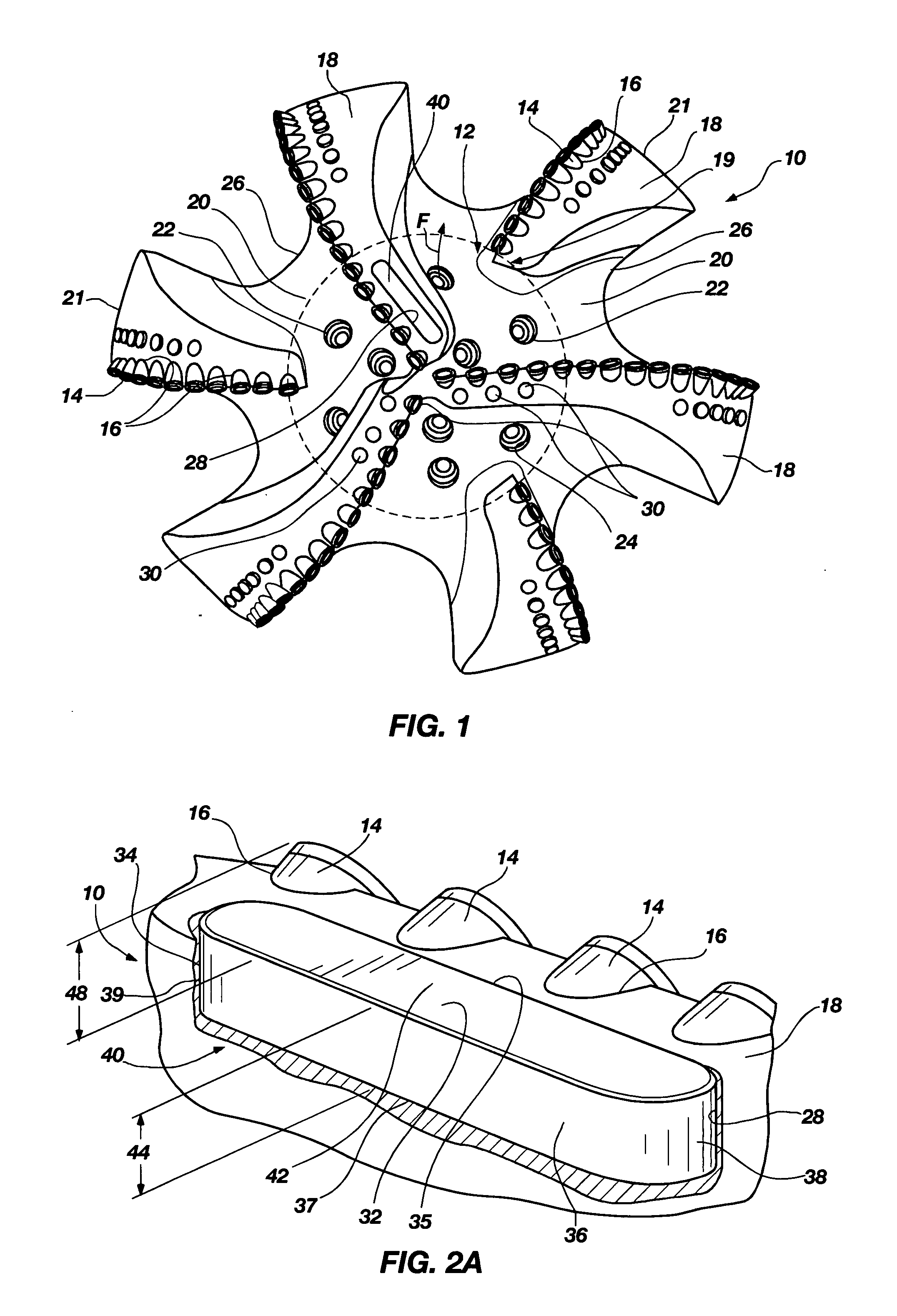

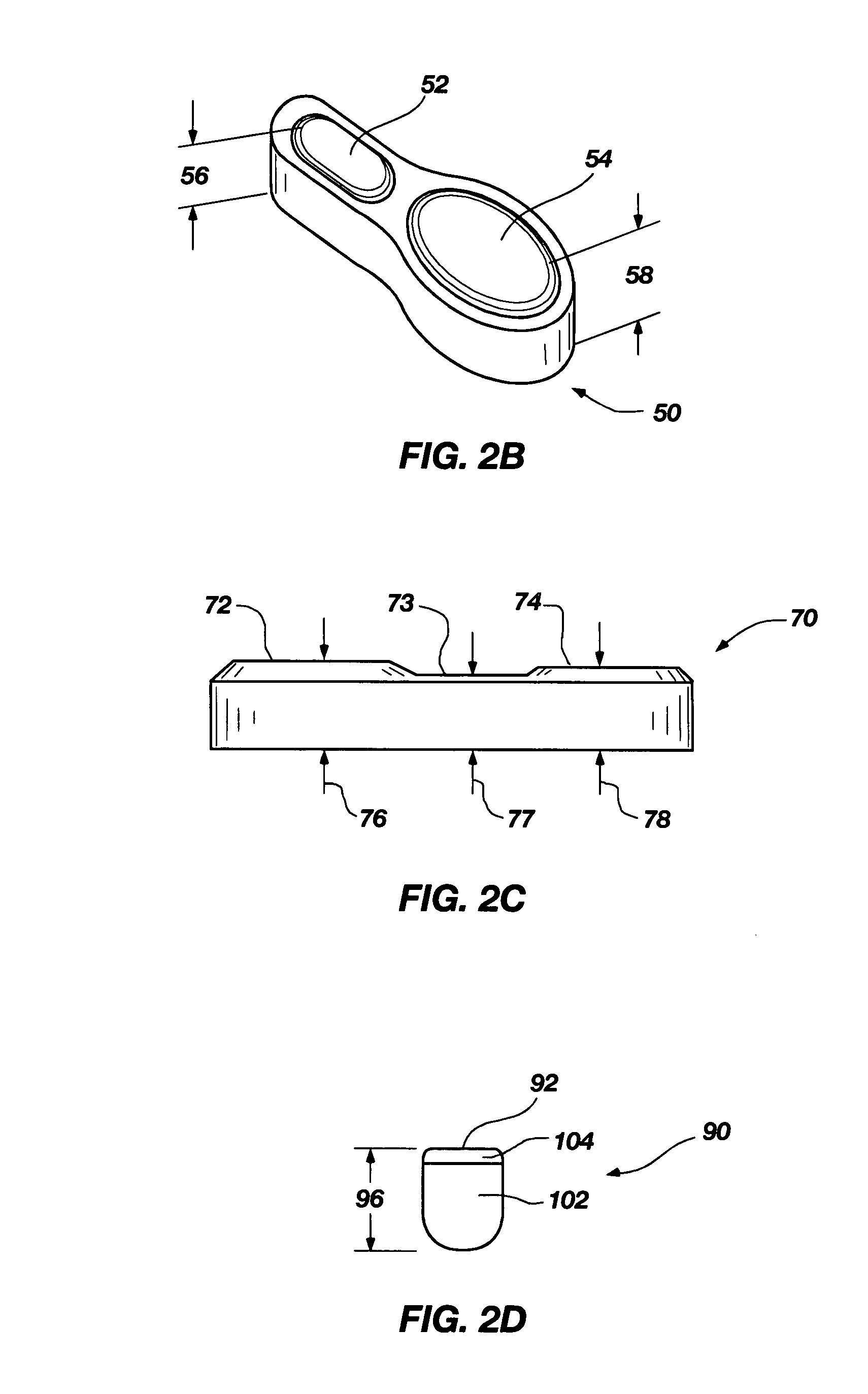

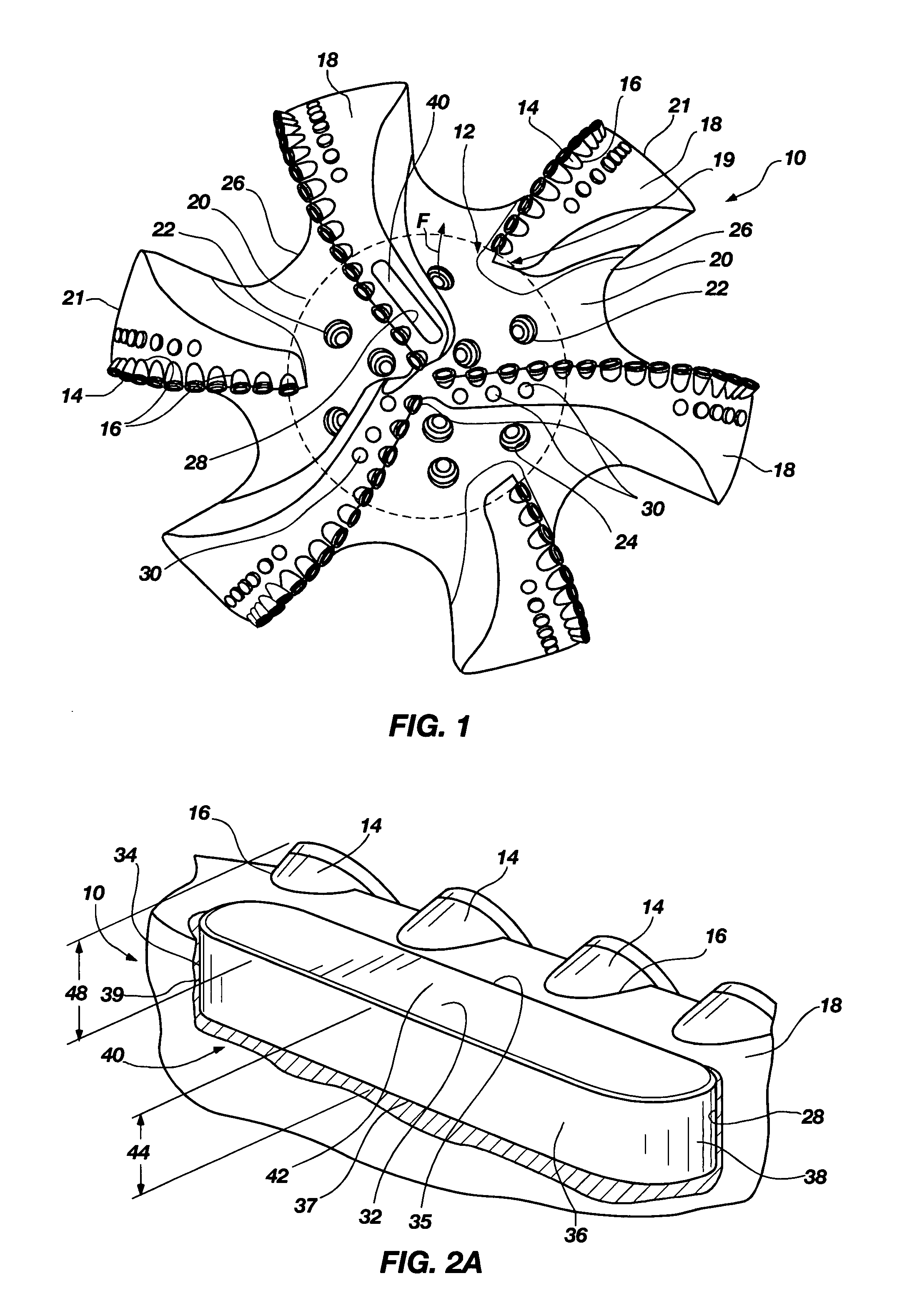

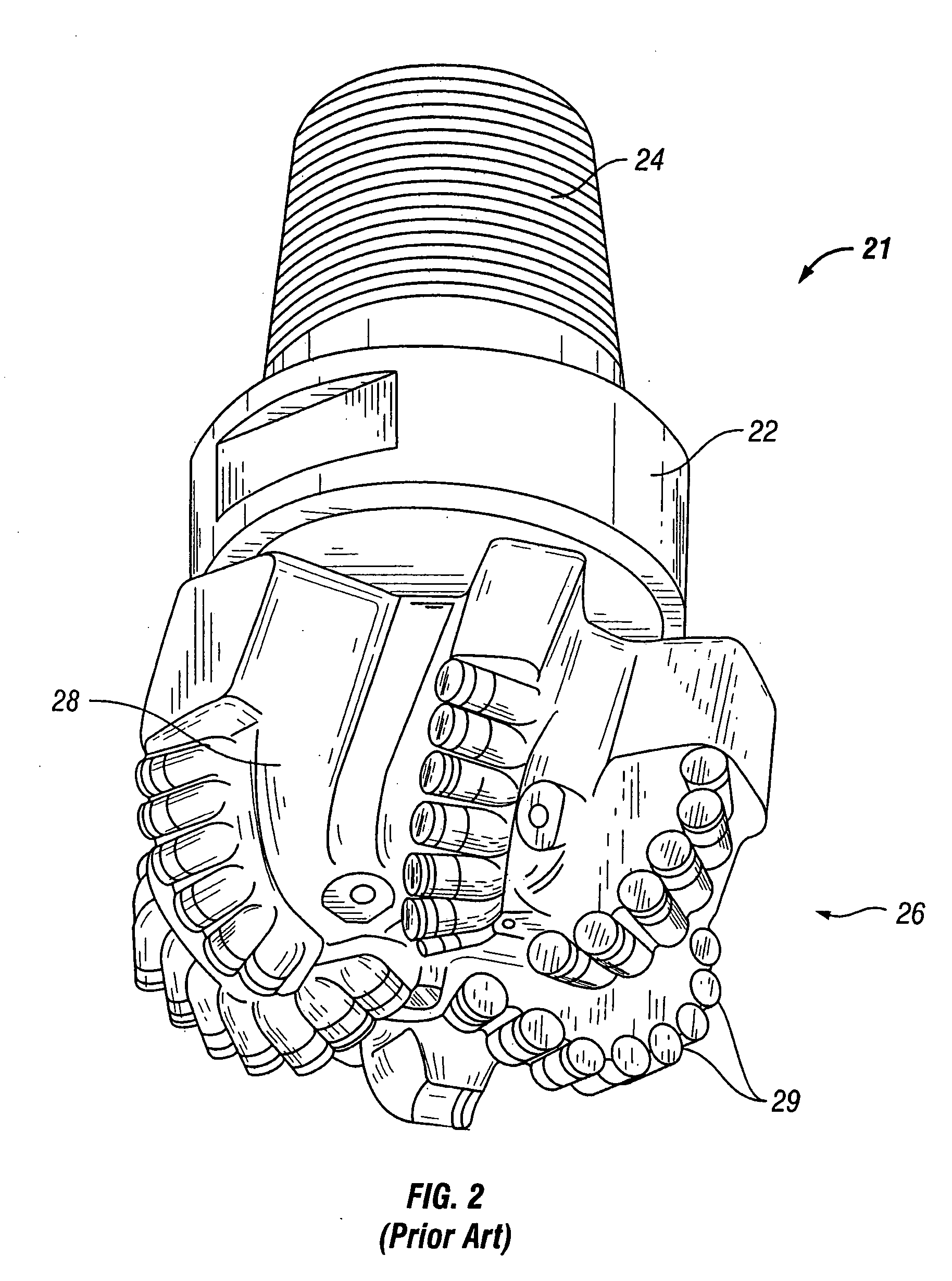

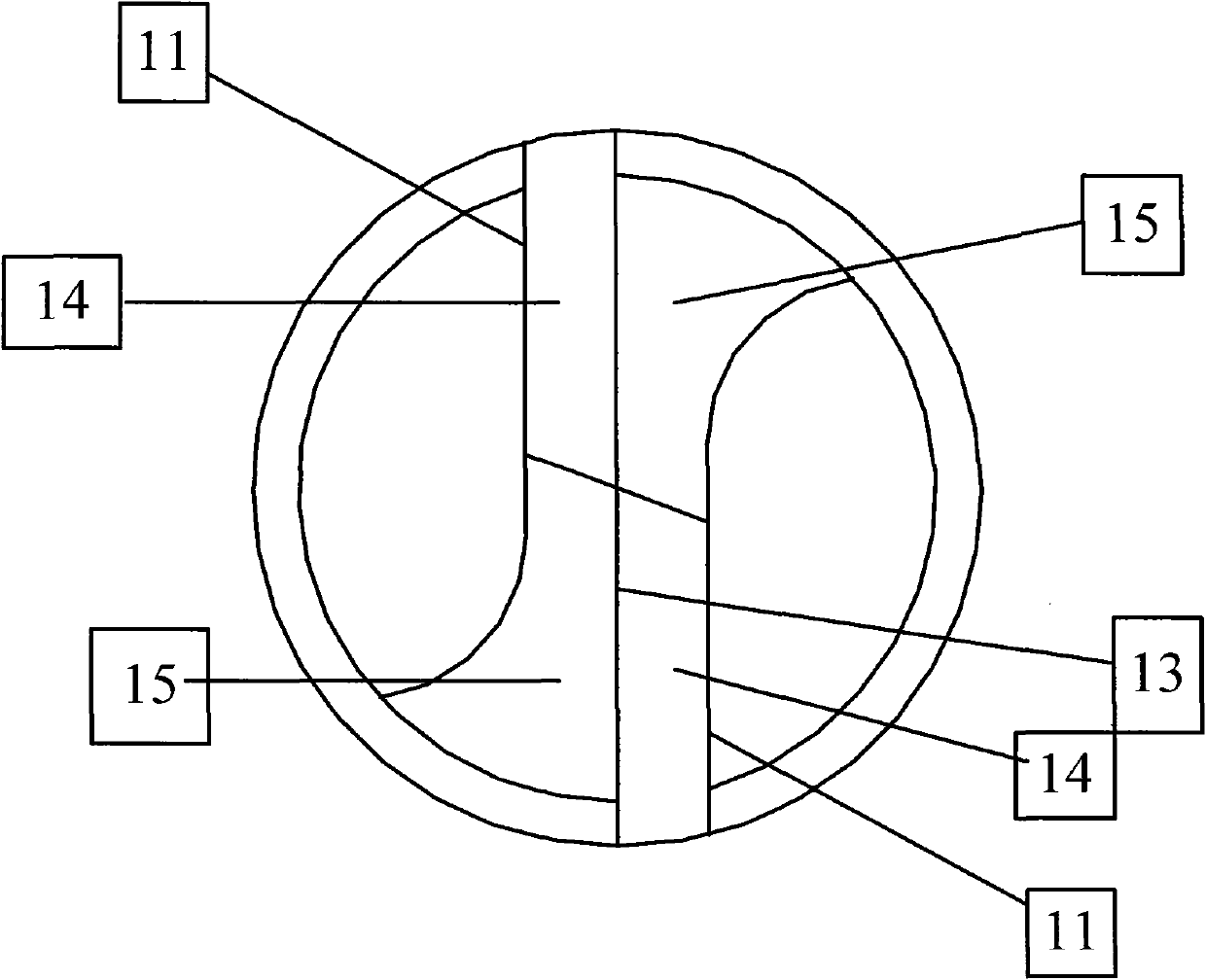

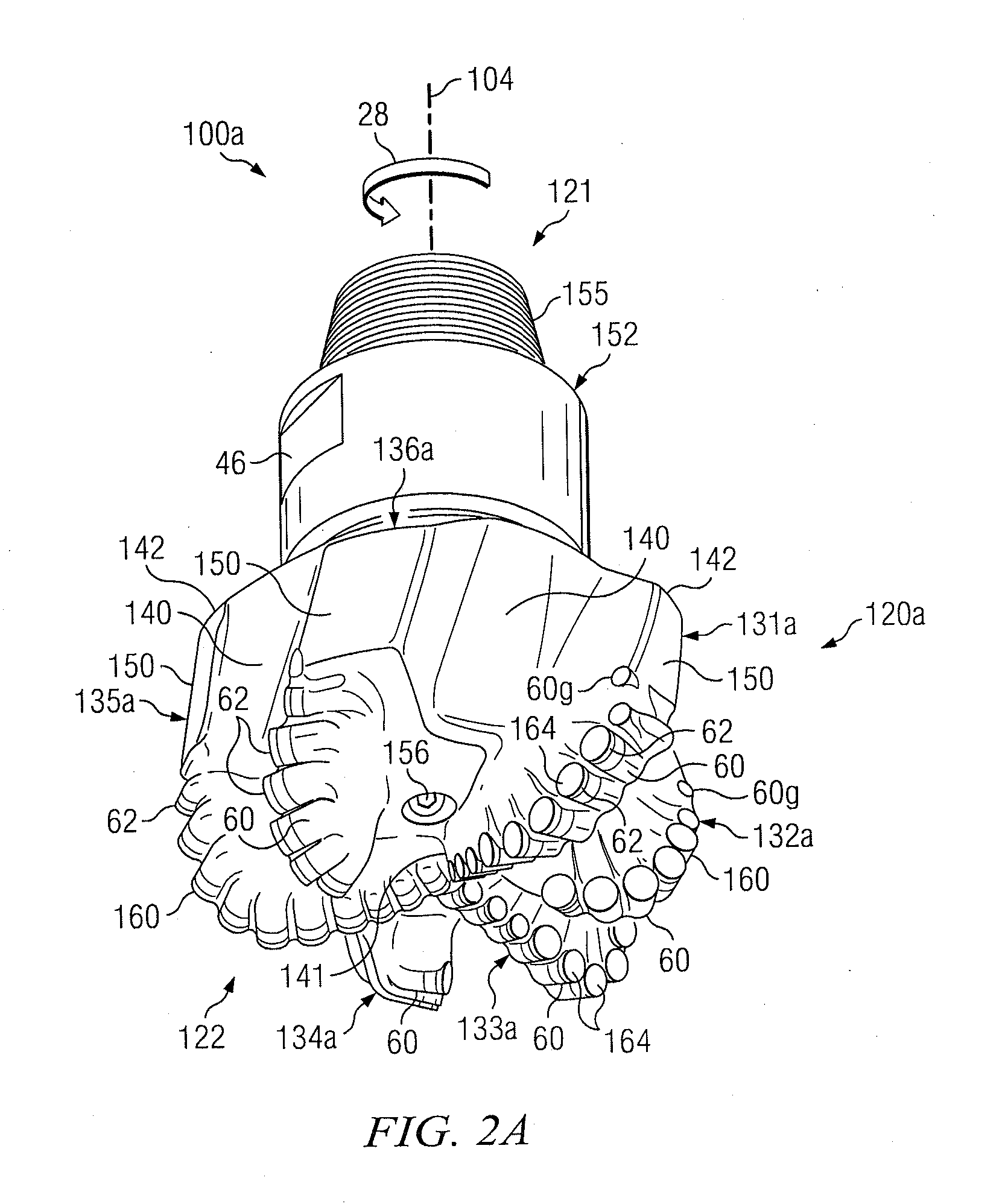

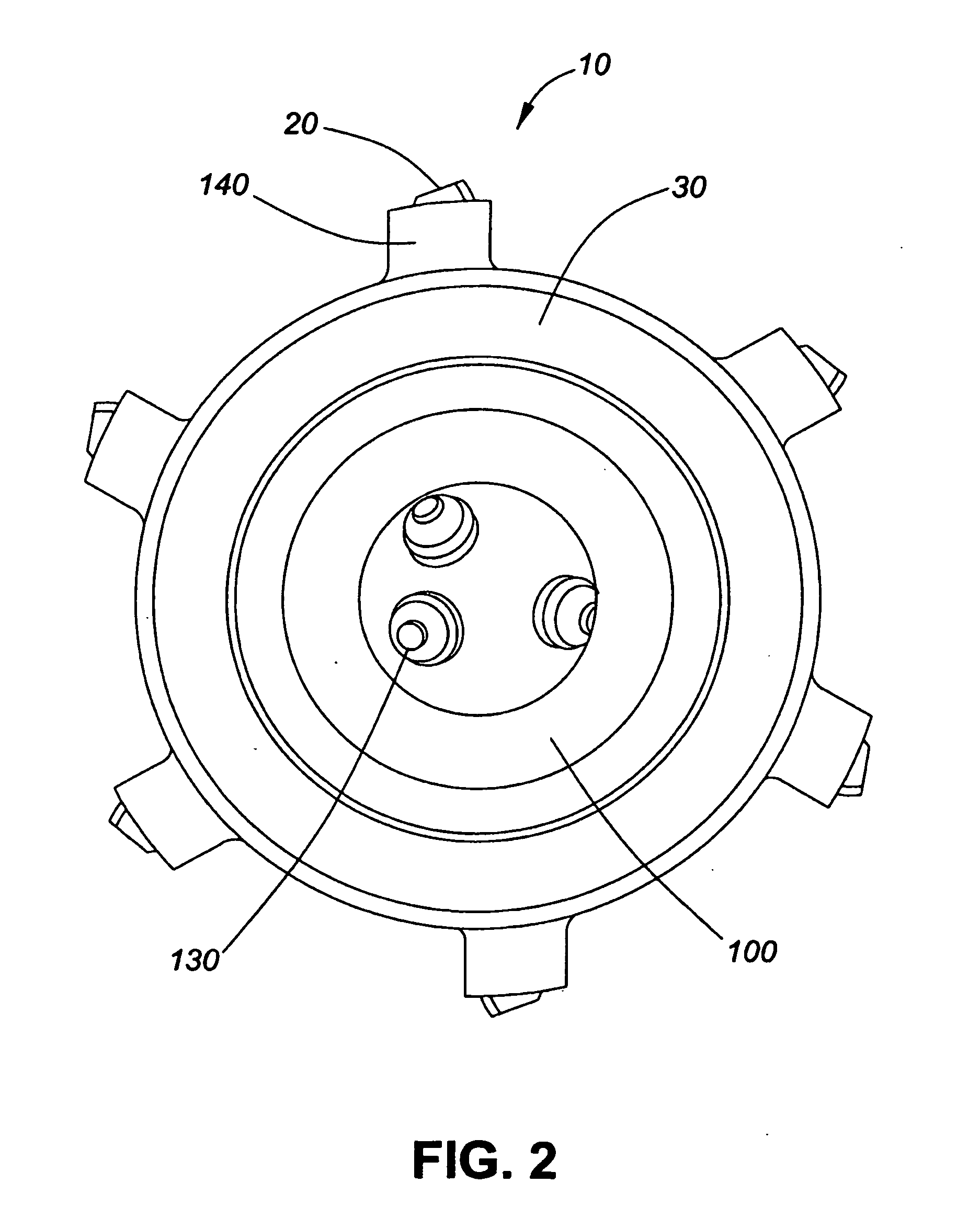

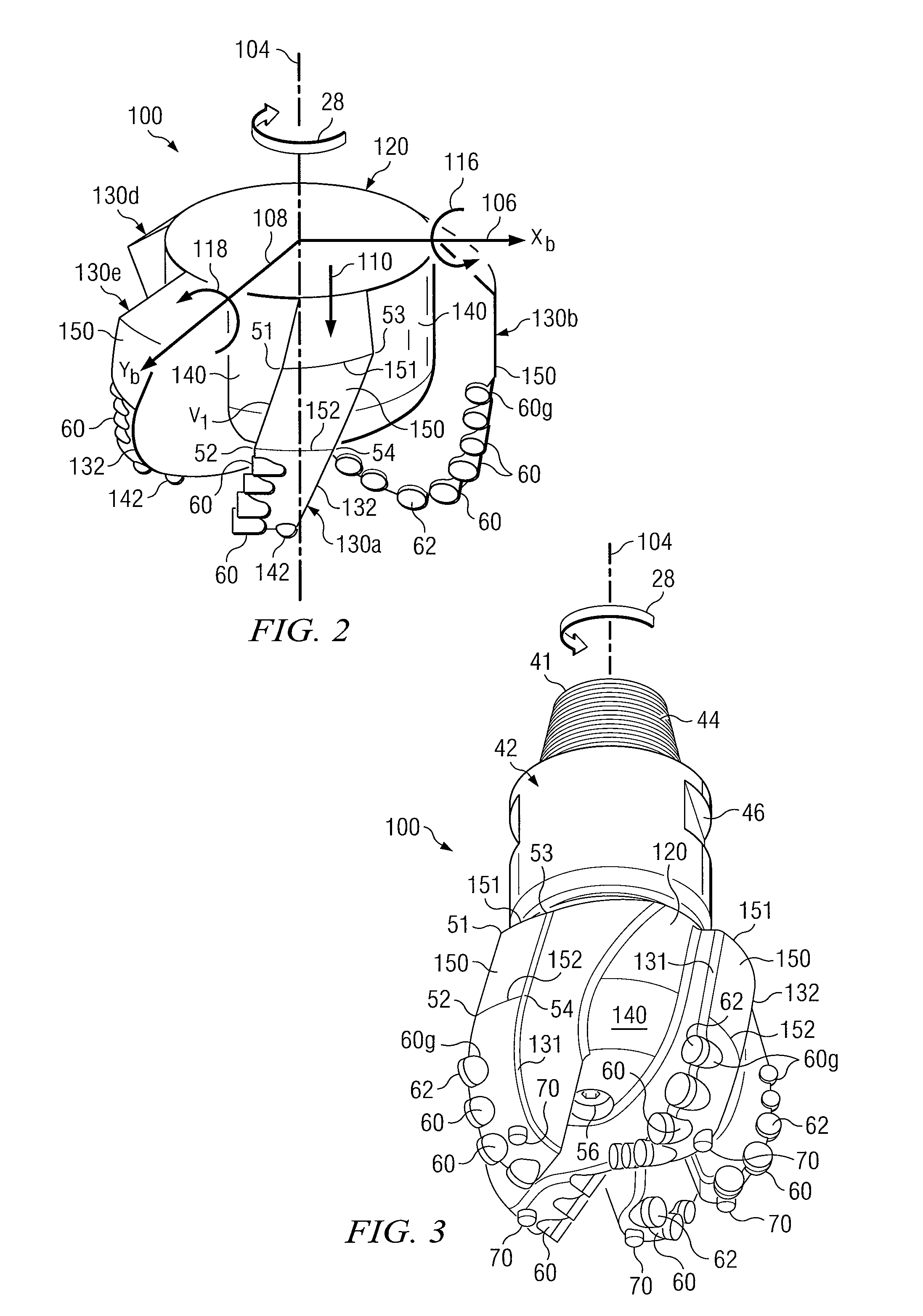

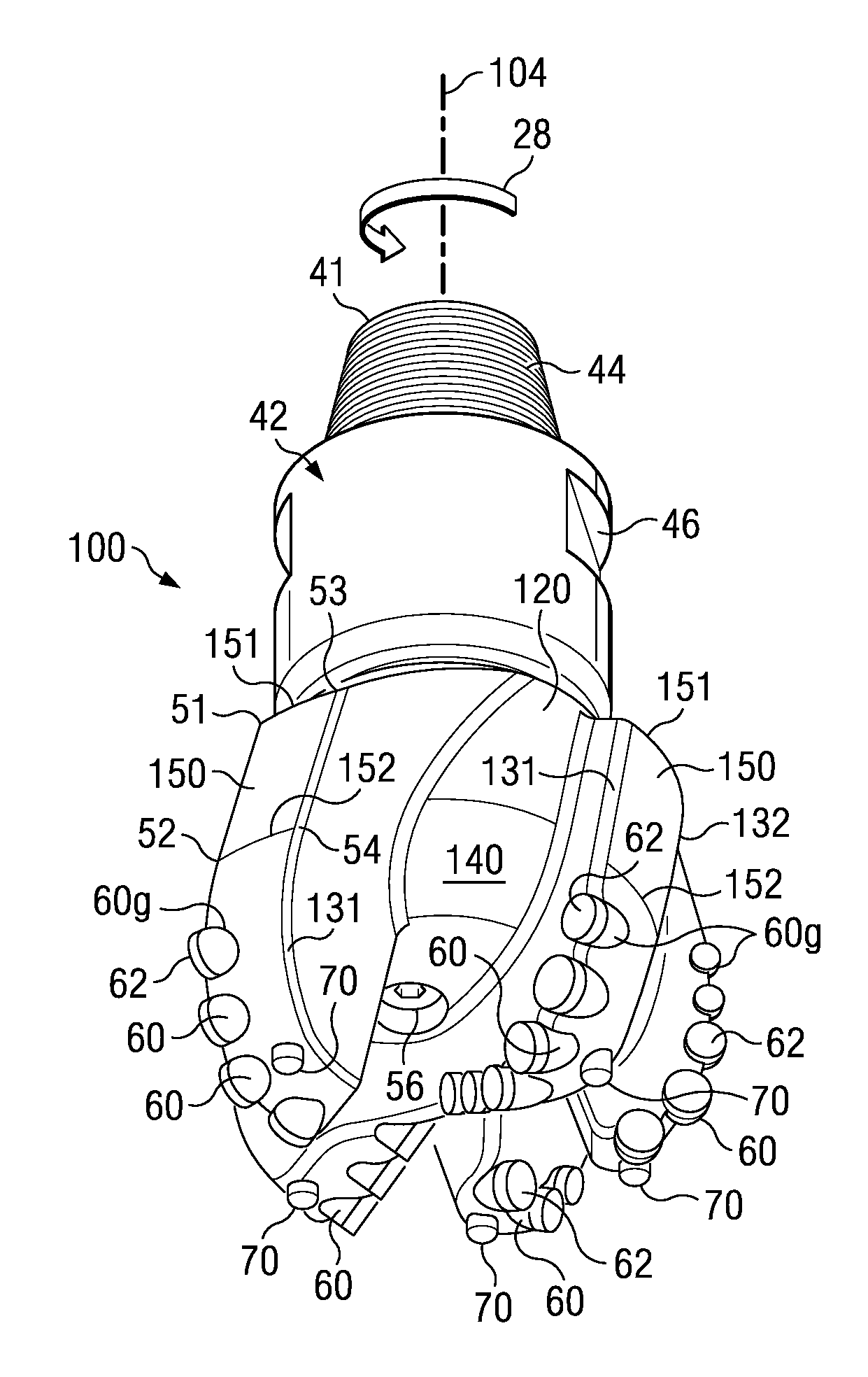

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS20080308321A1Minimize manufacturing tolerance uncertaintyReduce complexityEarth drilling toolsDrill bitsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES INC

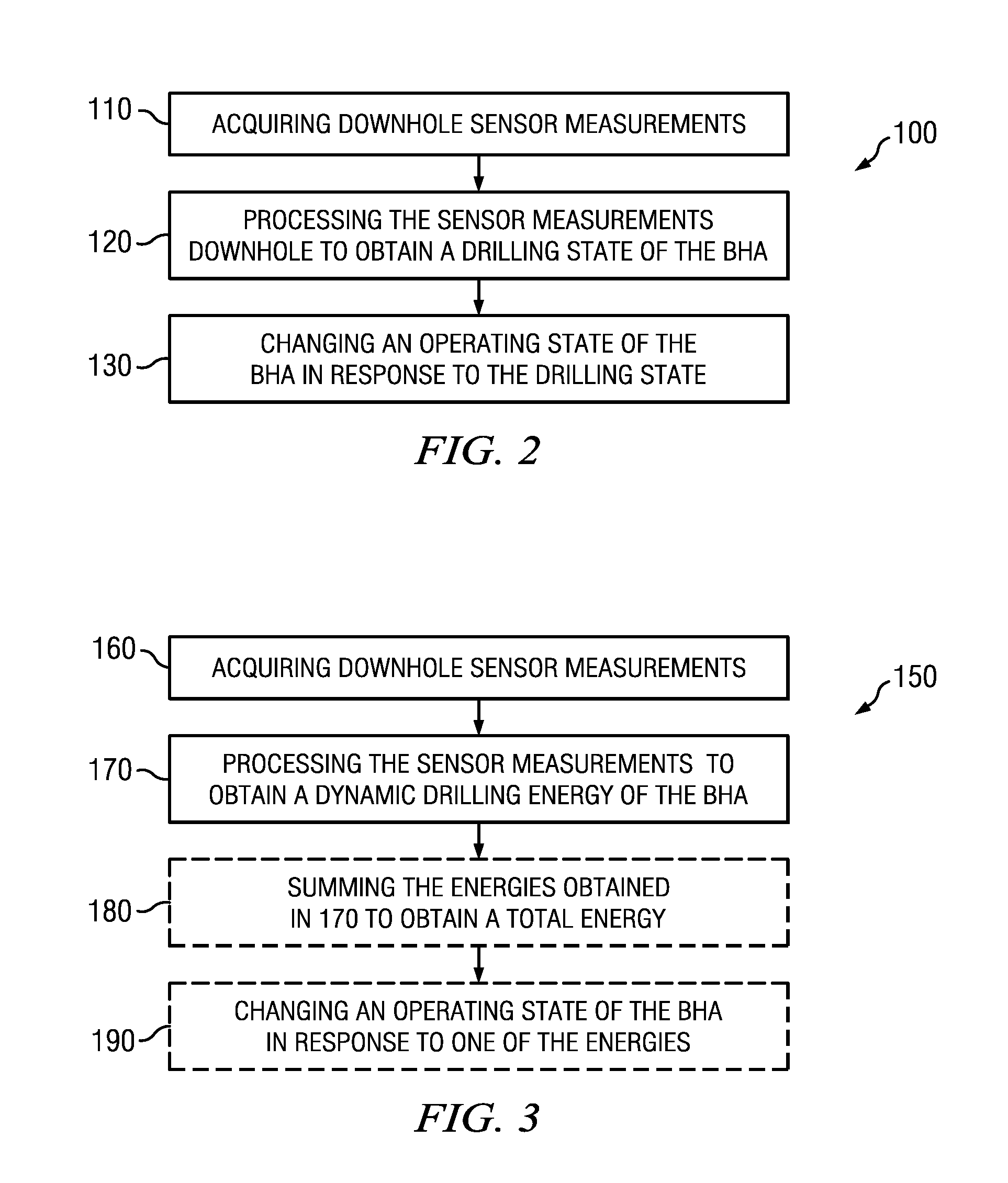

Downhole determination of drilling state

ActiveUS20140129148A1Valuable rig timeImprove drilling performanceElectric/magnetic detection for well-loggingSurveyWell drillingBottom hole assembly

A method for determining a drilling state of a bottom hole assembly in a wellbore includes acquiring one or more downhole sensor measurements and processing the sensor measurements using a downhole processor to determine a drilling state of the bottom hole assembly. An operating state of the bottom hole assembly may be automatically changed in response to the determined drilling state. A method for computing a dynamic drilling energy of a bottom hole assembly includes acquiring at least one sensor measurement and processing the sensor measurements to obtain at least one of (i) an energy of axial motion of the bottom hole assembly, (ii) an energy of rotational motion of the bottom hole assembly, and (iii) an energy of lateral motion of the bottom hole assembly.

Owner:SCHLUMBERGER TECH CORP

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS7814997B2Reduce complexityReduce inventory quantityDrill bitsDrilling rodsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES HLDG LLC

Methods for evaluating and improving drilling operations

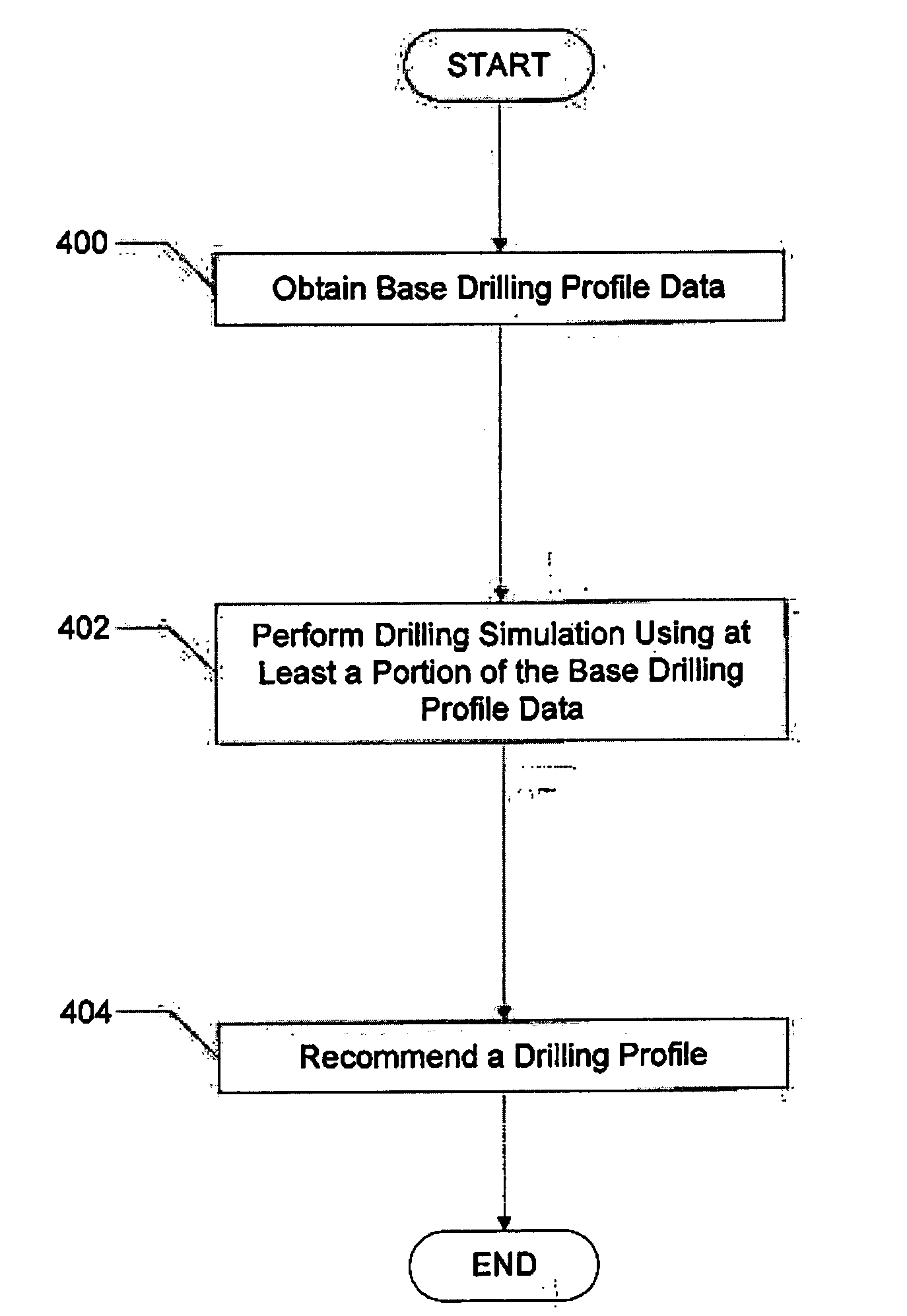

InactiveUS20050273304A1Improve drilling performanceBorehole/well accessoriesAnalogue processes for specific applicationsSection planeWell drilling

Methods and computer systems for performing and using drilling simulations. The drilling simulations can be used to improve drilling performance or demonstrate drilling performance of a drilling profile. One method for creating a drilling profile includes obtaining drilling profile data and performing a drilling simulation using at least a portion of the drilling profile data. Modifications are then recommended for the drilling profile data.

Owner:SMITH INT INC

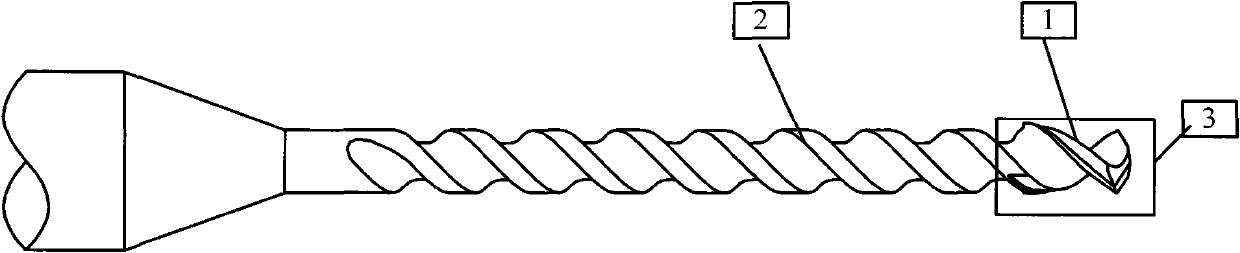

Minitype drill bit and processing method thereof

ActiveCN101791717AImprove wear resistanceAvoid affecting hole position accuracyTransportation and packagingTwist drillsFluteSeparated state

The invention discloses a minitype drill bit and a processing method thereof. The minitype drill bit comprises a drill point and a drill body, wherein the drill point comprises two main cutting edges which are symmetrical by the axle center of a minitype drill, two main cutter surfaces and two auxiliary cutter surfaces; and the drill body is provided with two spiral rising chip flutes, wherein the chip flutes are respectively a long chip flute and a short chip flute which have different helical angles so as to change the two chip flutes into a converging state from a separated state; and the short chip flute is finished at the joint part with the long chip flute. As the two chip flutes on the drill body of the minitype drill bit are set to be the long chip flute and the short chip flute which have the different helical angles, and the short chip flute is finished at the joint part with the long chip flute, most part of the drill body is the single long chip flute. Therefore, the rigid part of a flute body is increased, the core thickness thereof is thickened, and the rigidity of the drill body part of the minitype drill is better.

Owner:SHENZHEN JINZHOU PRECISION TECH

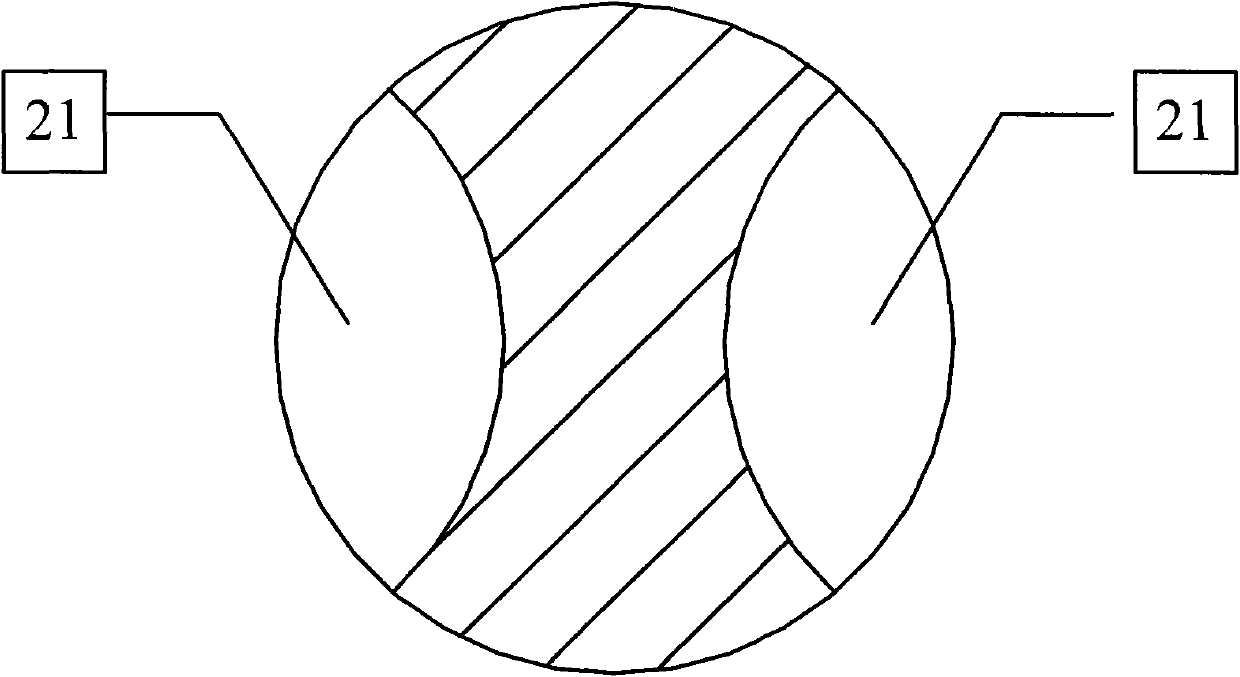

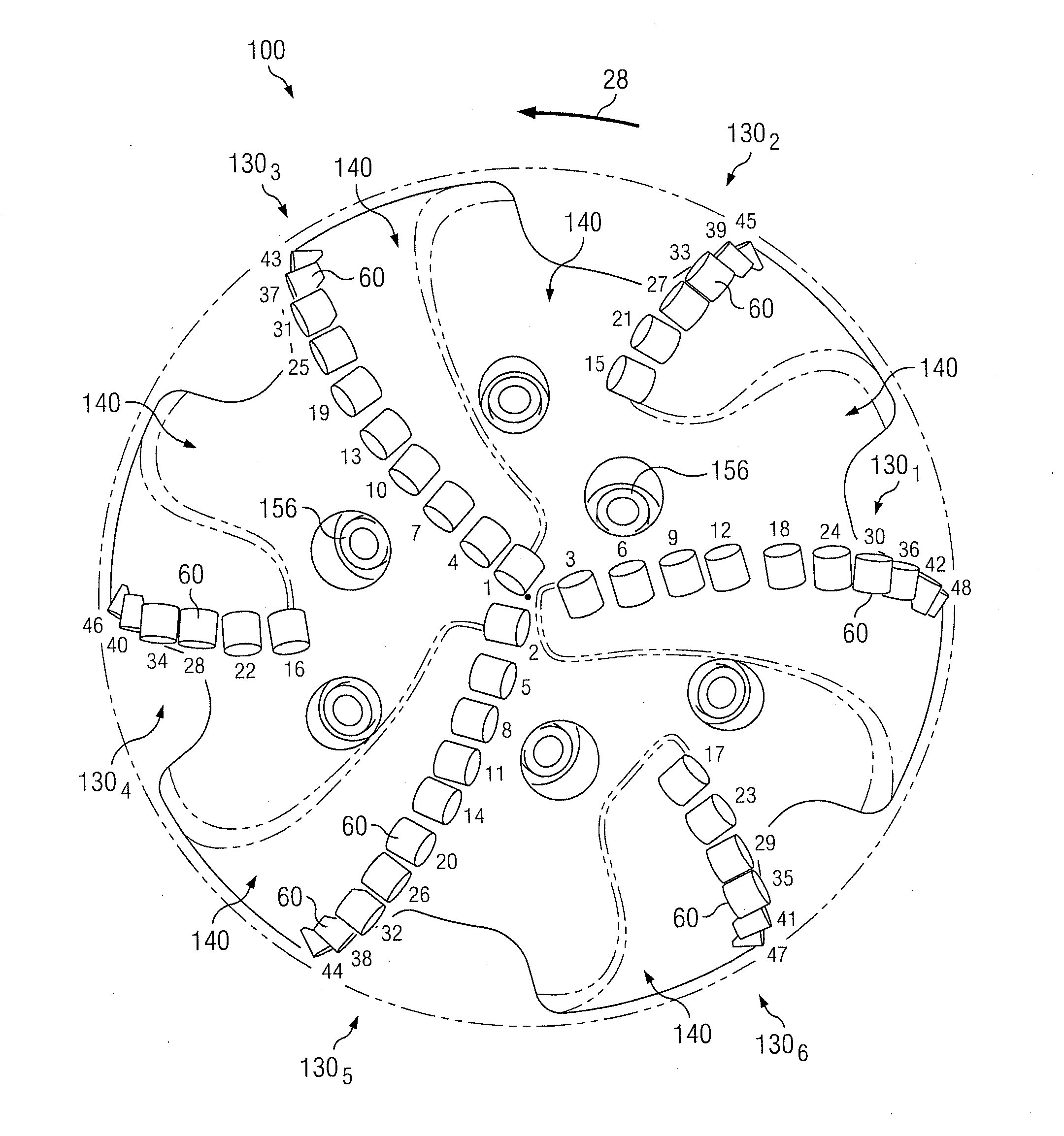

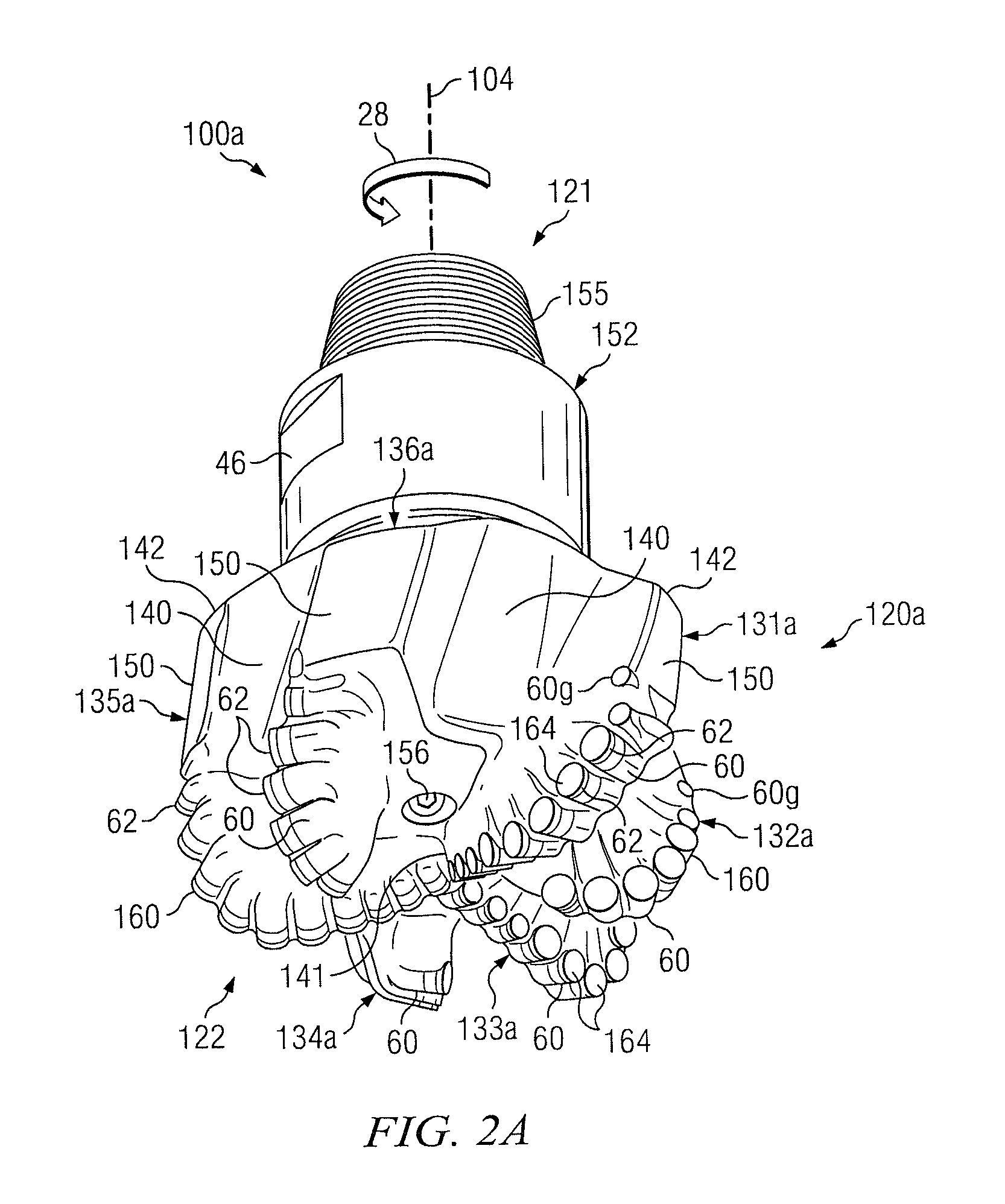

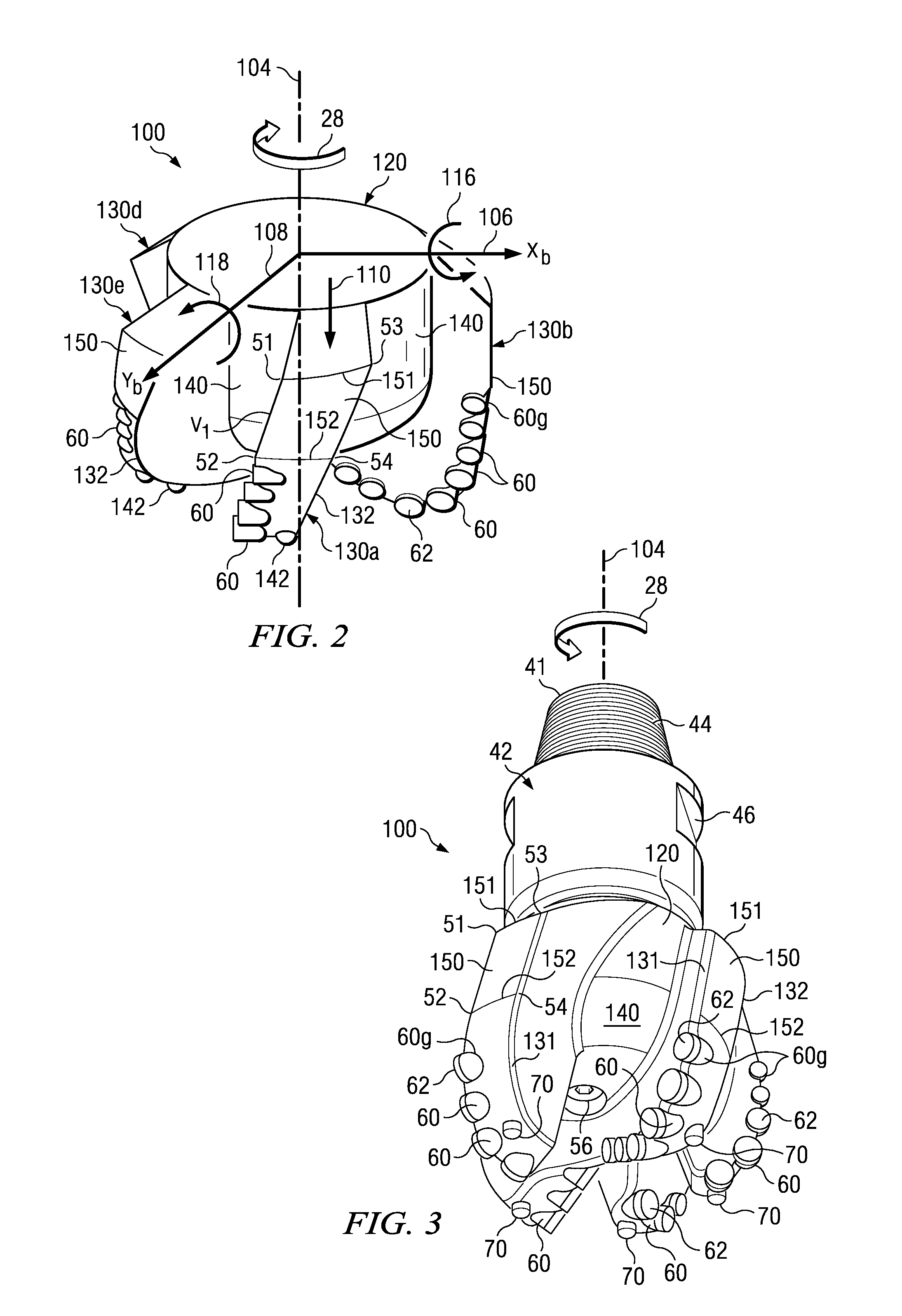

PDC Bits with Mixed Cutter Blades

ActiveUS20120152624A1Improve performanceHigh impact resistanceGeometric CADDrill bitsWear resistantDesign tool

Downhole drilling tools designed and manufactured to minimize or reduce imbalance forces and wear by disposing cutting elements in cutter groups and cutter sets in a level of force balance and by placing impact and / or wear resistant cutters on blades subject to high impact forces and / or large loadings. Manufacturing costs may be reduced by placing inexpensive cutters on blades not subject to high impact forces and / or loadings. Some embodiments comprise designing downhole tools with combinations of thicker blades to receive high impact forces and / or loadings with thinner blades. Some embodiments comprise designing downhole drilling tools with optimized fluid-flow properties. Designing methods may comprise performing simulations on a designed tool, evaluating respective forces acting on cutters during simulated engagement with a downhole (uniform and transitional) and / or evaluating wear on cutters and bit, and / or CFD simulations to evaluate fluid-flow optimization on a tool. Various cutter layout procedures and algorithms are described.

Owner:HALLIBURTON ENERGY SERVICES INC

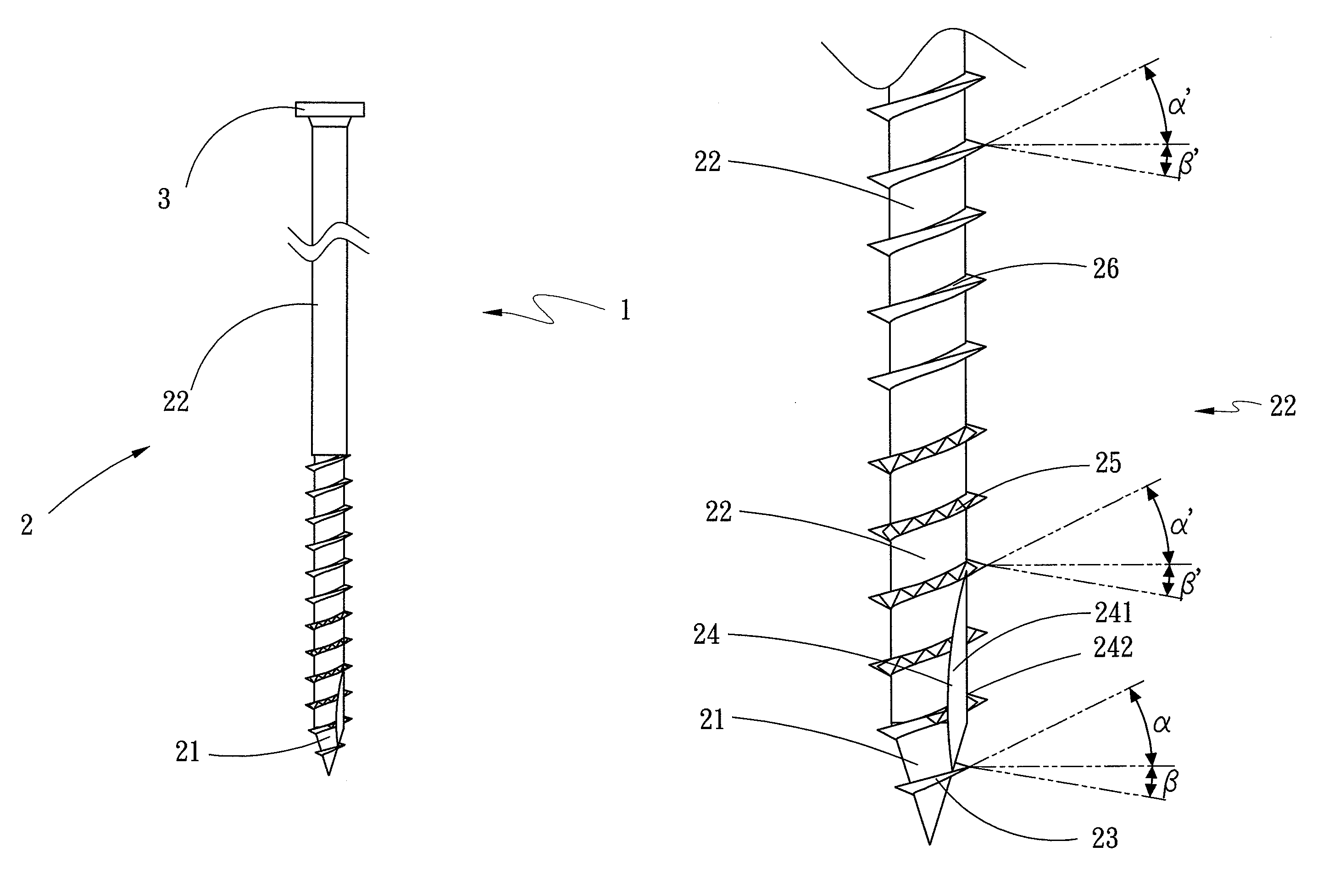

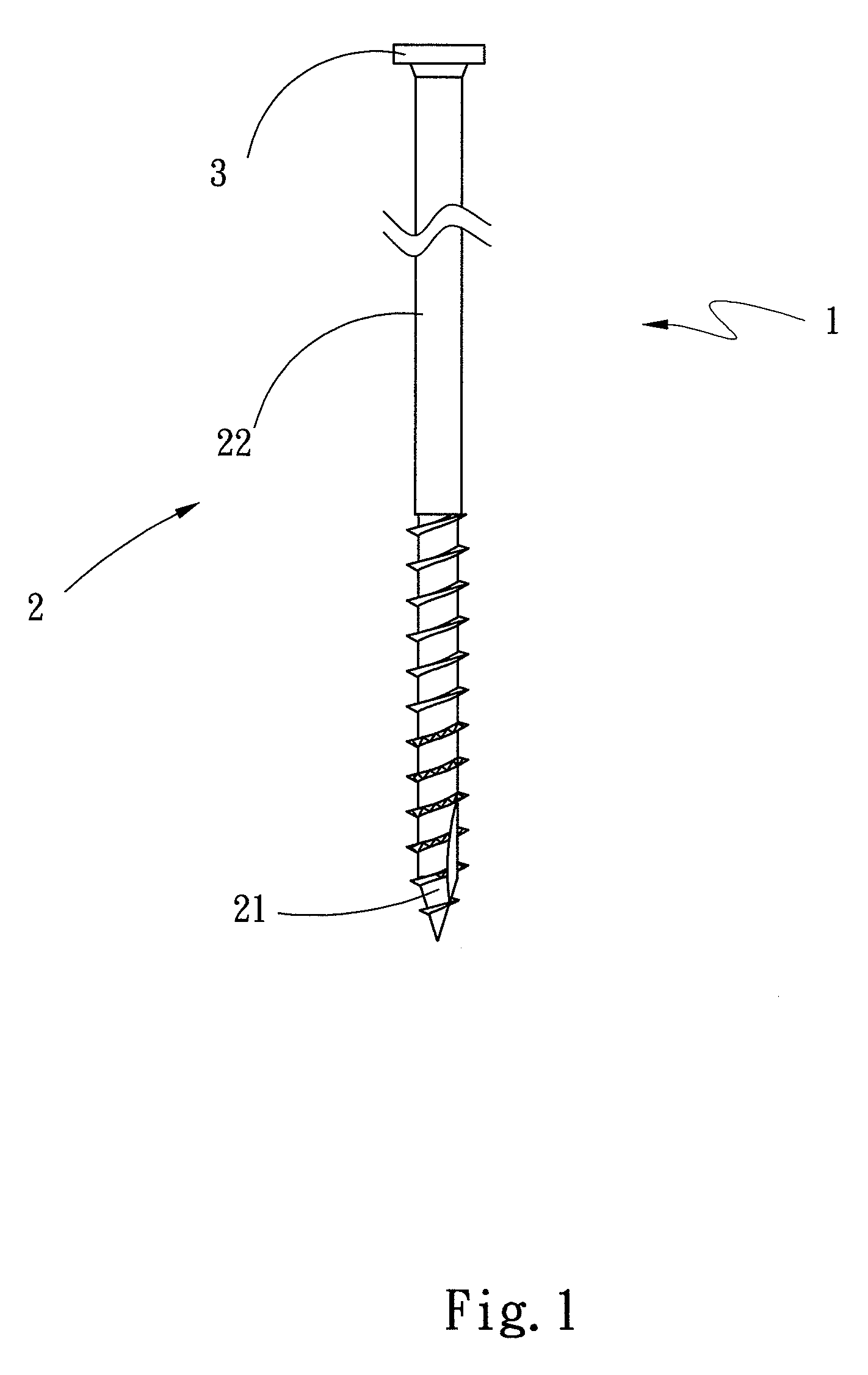

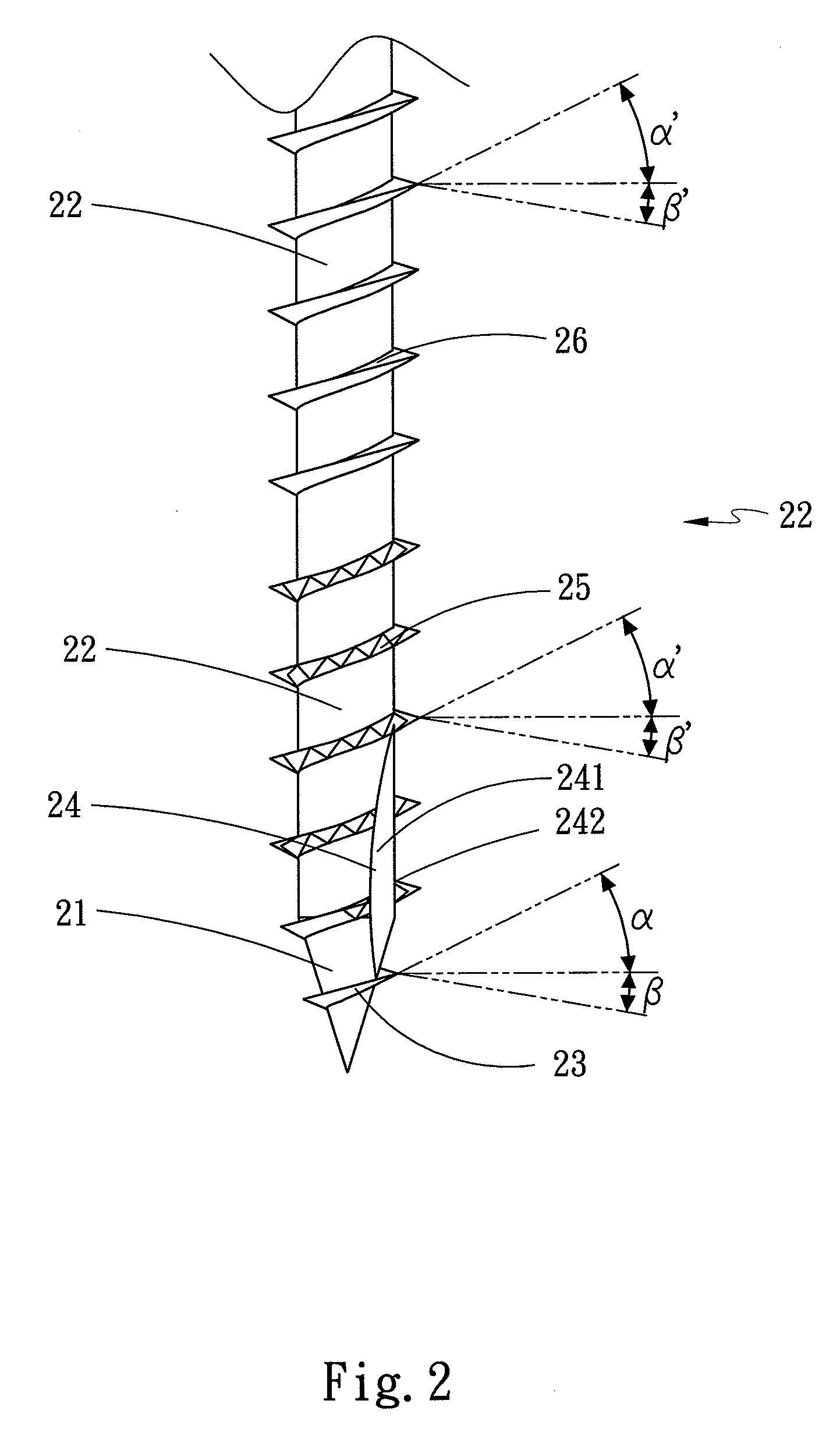

Screw

Owner:BI MIRTH CORP

Continuous oil pipe horizontal well drilling grinding and pumping type composite bridge plug process

ActiveCN105003220AImprove flexibilitySolve the problem of drilling and grindingBorehole/well accessoriesWell drillingCoiled tubing

The invention discloses a continuous oil pipe horizontal well drilling grinding and pumping type composite bridge plug process, which comprises the following steps of: (1) installing ground equipment; (2) connecting the ground equipment with a continuous oil pipe well pigging and washing tool string; (3) putting the continuous oil pipe well pigging and washing tool string into a well; (4) detecting the position of a fish top of a composite bridge plug, and performing well washing; (5) connecting the ground equipment with the continuous oil pipe well pigging and washing tool string; (6) putting the continuous oil pipe well pigging and washing tool string into the well; (7) performing drilling and grinding operation; (8) pumping three-side glue liquid into the well after the bridge plug is penetrated through drilling; and (9) putting down a continuous oil pipe (3) and performing the drilling grinding operation on the next bridge plug. The process has the advantages that the bridge plug drilling and grinding under pressure can be directly performed after the fracture without the pressure relieving; the construction period is short; the work intensity is low; and the stratum energy loss can be effectively prevented.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hard material head and rotary percussion drill bit

ActiveUS7559382B2Improve drilling performanceDrill bitsTool workpiece connectionEngineeringMechanical engineering

A hard material head (1) for a rotary percussion drill bit (2) having an elongated shaft (15) including at least three cutting edges (4) distributed circumferentially within a circumscribing circle, a bottom surface (6) located opposite the cutting edges (4) and fastened by a material bond to an end (8) of the drill bit shaft (15) of the rotary percussion drill bit (2), concave side surfaces (5) formed circumferentially between adjacent cutting edges (4), and a peripheral pocket (9) opening toward the bottom surface (6) and formed, respectively, in at least two concave side surfaces (5) located opposite one another, and in which a corresponding axial pin (10, 10′) formed on a shaft end (8) is form-locking engageable.

Owner:HILTI AG

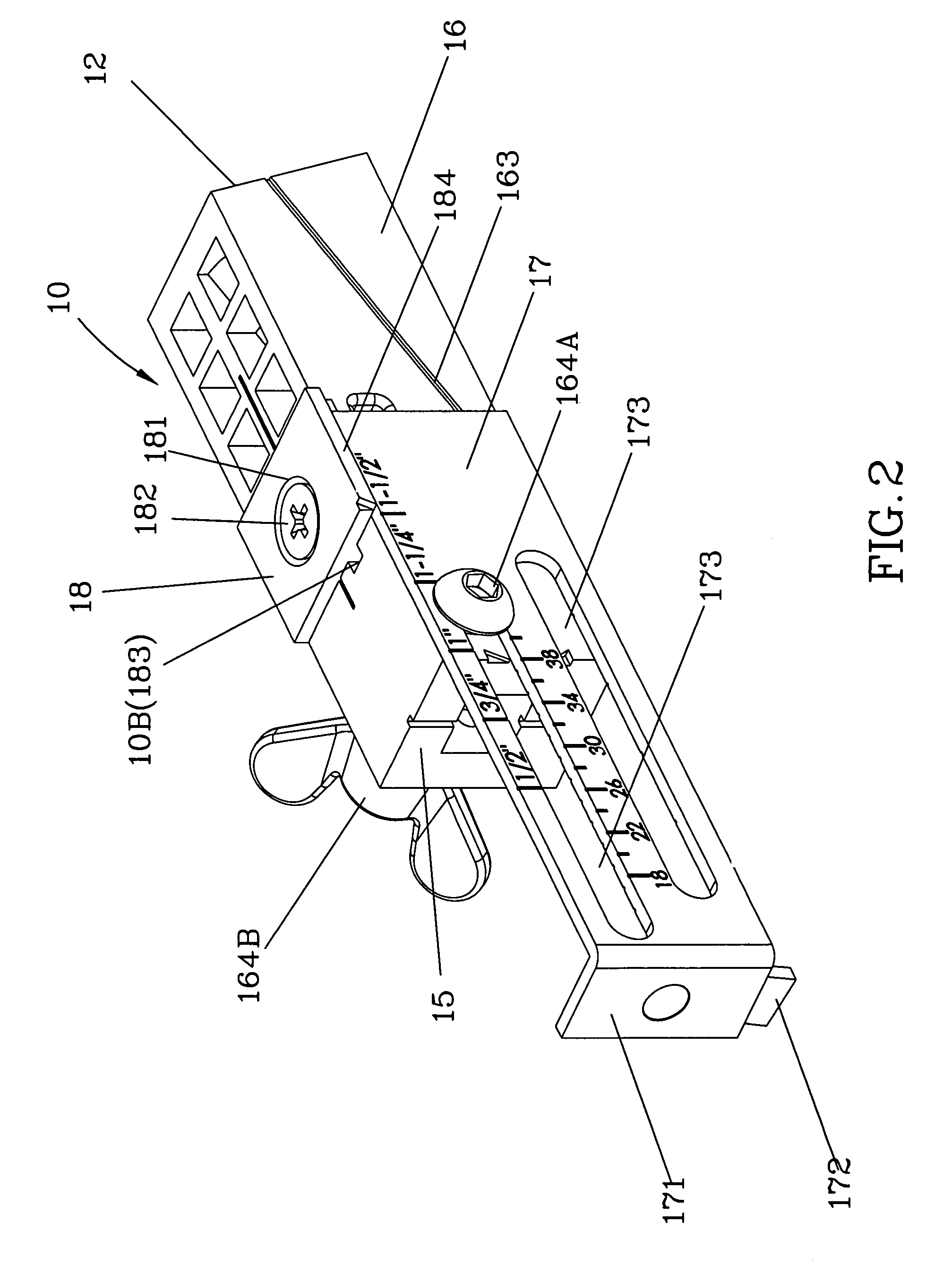

Simple inclined-hole drilling jig

InactiveUS7670089B2Easy to adjustProcess stabilityDrilling/boring measurement devicesThread cutting machinesAxial displacementEngineering

Owner:MICROSOFT CORP

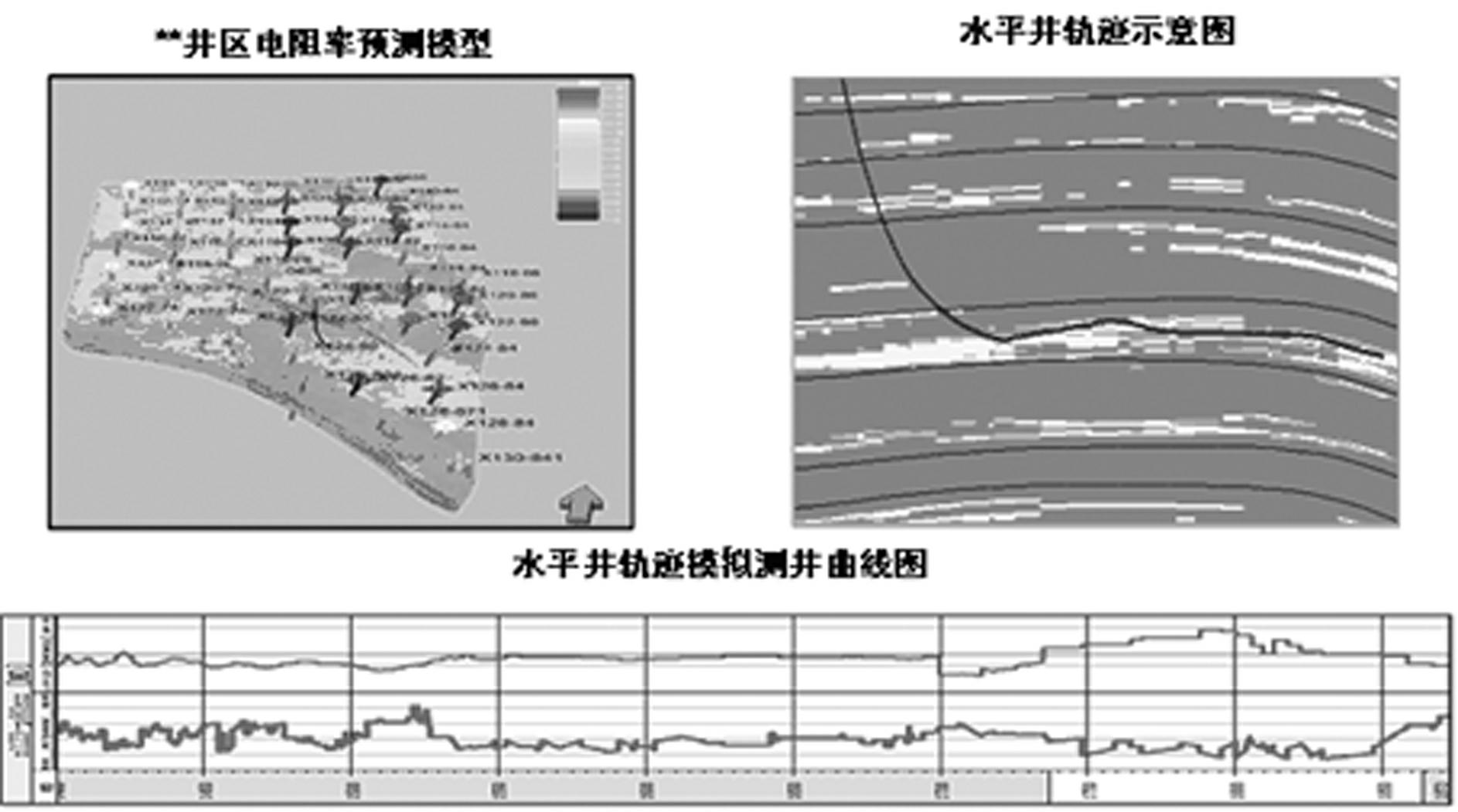

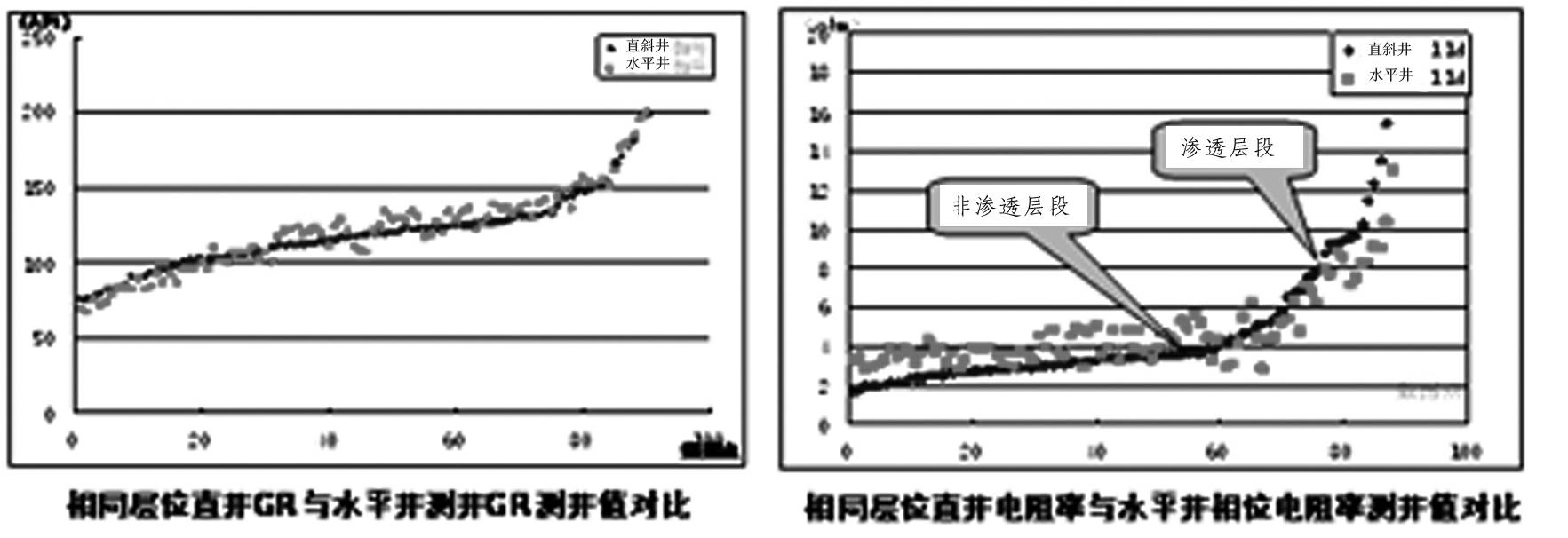

Horizontal well landing geosteering method

InactiveCN102322256AImprove landing accuracyTimelinessSurveyDirectional drillingGeosteeringHorizontal wells

The invention relates to a novel thin-interbedded horizontal well landing geosteering method. The horizontal well landing geosteering method includes the following steps: (1) constructing a horizontal well landing geosteering comparison model; (2) vertically correcting an LWD (Logging While Drilling) curve of a curve section; (3) carrying out error judgement and determining structure errors in real time by means of the fine comparison of the landing geosteering comparison model; and (4) determining a trajectory adjustment according to the structure errors scheme. The method realizes the transformation from conventional mark comparison to digitalized continuous comparison, and has the dual characteristics of real-timeliness and accuracy; and the digitized comparison profile of a landing section is established before drilling, the LWD curve is digitized in real time in the process of landing, and is finely compared with the profile after the vertical depth is corrected, the structure is corrected in real time, a result is judged according to the structure errors, the trajectory design is updated in real time, and thereby accurate landing can be realized.

Owner:PETROCHINA CO LTD +1

Reverse nozzle drill bit

InactiveUS20100147594A1Enhance performanceReduce pressureDrill bitsCutting machinesDrill cuttingsDrill bit

A drill bit design that employs reverse flow nozzles through which a portion of the drilling fluid is diverted. This reverse or upward flow of drilling fluid creates a condition by which the extraction of drilling sludge (combination of drilling fluid and drilling cuttings) in the cutting area of the drill bit is more efficient and has a greater amount of flow than designs of prior art. This increased flow has the effect of more efficiently removing damaging cuttings away from the drill cutters, lubricating the drill cutters more efficiently, and cooling the drill cutters more efficiently. The end result is increased drilling uptime, increased drilling speed, and less frequent drill bit catastrophic failures.

Owner:ND DOWNHOLE TECH

Screw

A screw has a screw head and a shank. The screw head has a square cavity, a hexagonal cavity or a hexagonal boss to be wedged by a screw driver for wrenching. The shank has four sections of threads on the periphery. A first thread is asymmetrical to facilitate drilling holes and spaced with a first threaded pitch. A second thread has a carved V-shaped tail end extended in a direction of the shank at a length larger than one of the first threaded. A third thread has asymmetrical saw-type threads, and a fourth tread is asymmetrical. The screw thus formed can rapidly perform thread tapping and debris dispelling, and reduce friction and expand drilling holes and achieve fast fastening.

Owner:BI MIRTH CORP

Combination coring bit and drill bit using fixed cutter PDC cutters

InactiveUS20100101870A1Improve drilling performanceLower the volumeArtificial islandsDrill bitsPolycrystalline diamondEngineering

A drill bit having fixed Polycrystalline Diamond Compact cutters is used to drill a borehole having a core stump therein. A plurality of additional fixed Polycrystalline Diamond Compact cutters are disposed in the dome of the bit and are usable to concentrate stresses in the top end of the core stump to facilitate the cutting down of the core stump.

Owner:DIAMANT DRILLING SERVICES

Casing running and drilling system

InactiveUS20070193751A1Improve drilling performanceReduce morbidityDrilling rodsConstructionsTop driveEngineering

Owner:WEATHERFORD TECH HLDG LLC

Screw with low drilling resistance

A screw with low drilling resistance comprises a head portion, a shank portion, a plurality of first threads, a drilling portion, and a plurality of second threads. Wherein, a plurality of opening slots are correspondingly defined on the second threads, and a first included angle of the first threads is smaller than a second included angle of the second threads. Thereby, the opening slots on the second threads efficiently provide the first threads with an auxiliary cutting effect and preferably offers a debris accommodating room. The first threads including the smaller first included angle favorably reinforce the bearing force of the second threads including the larger second included angle, thereby promoting the cutting effect of the screw and allowing a speedy screwing.

Owner:TAIWAN SHAN YIN INT CO LTD

Hard material head and rotary percussion drill bit

ActiveUS20070278016A1Improve drilling performanceDrill bitsTool workpiece connectionMechanical engineeringDrill bit

A hard material head (1) for a rotary percussion drill bit (2) having an elongated shaft (15) including at least three cutting edges (4) distributed circumferentially within a circumscribing circle, a bottom surface (6) located opposite the cutting edges (4) and fastened by a material bond to an end (8) of the drill bit shaft (15) of the rotary percussion drill bit (2), concave side surfaces (5) formed circumferentially between adjacent cutting edges (4), and a peripheral pocket (9) opening toward the bottom surface (6) and formed, respectively, in at least two concave side surfaces (5) located opposite one another, and in which a corresponding axial pin (10, 10′) formed on a shaft end (8) is form-locking engageable.

Owner:HILTI AG

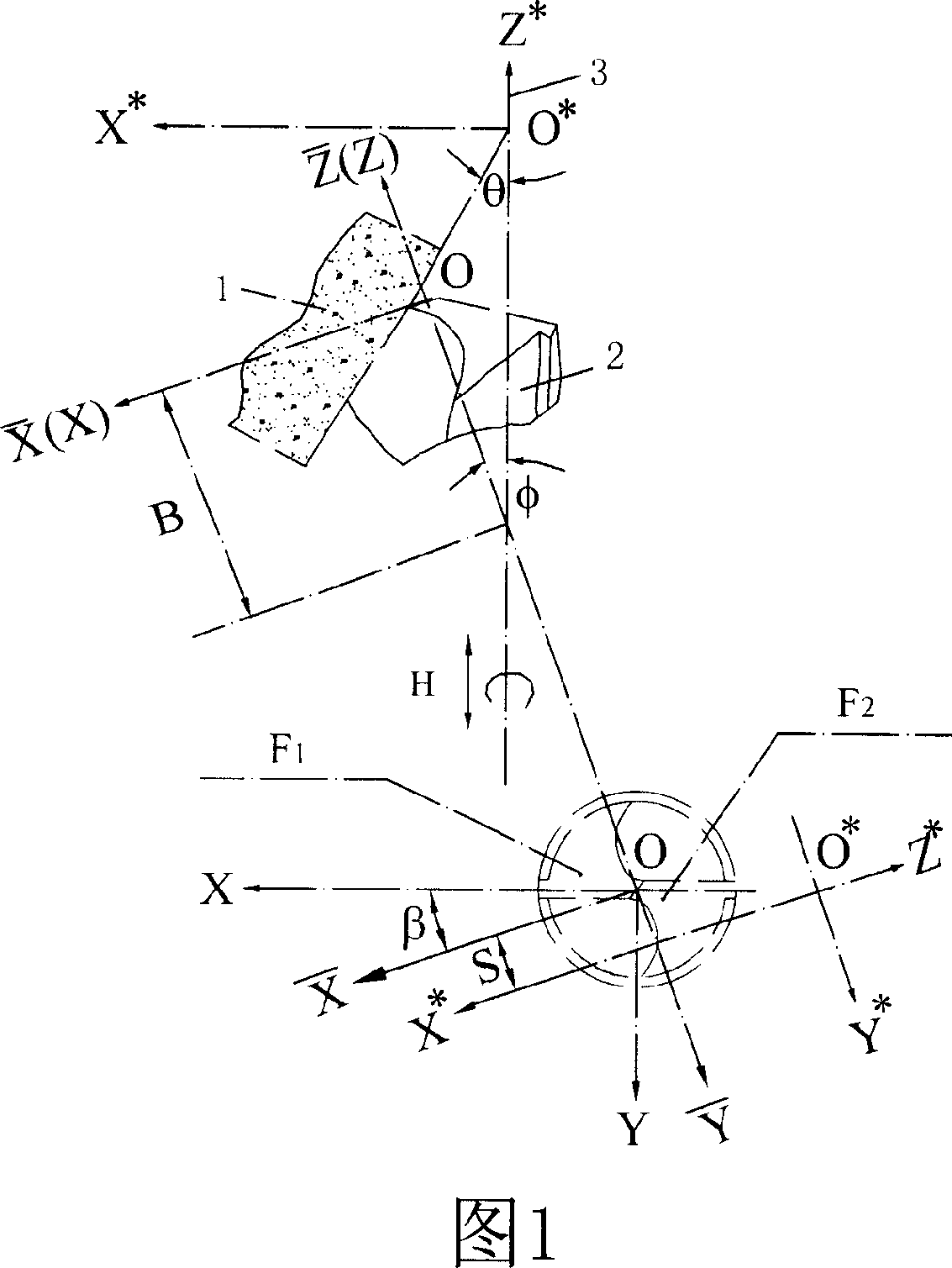

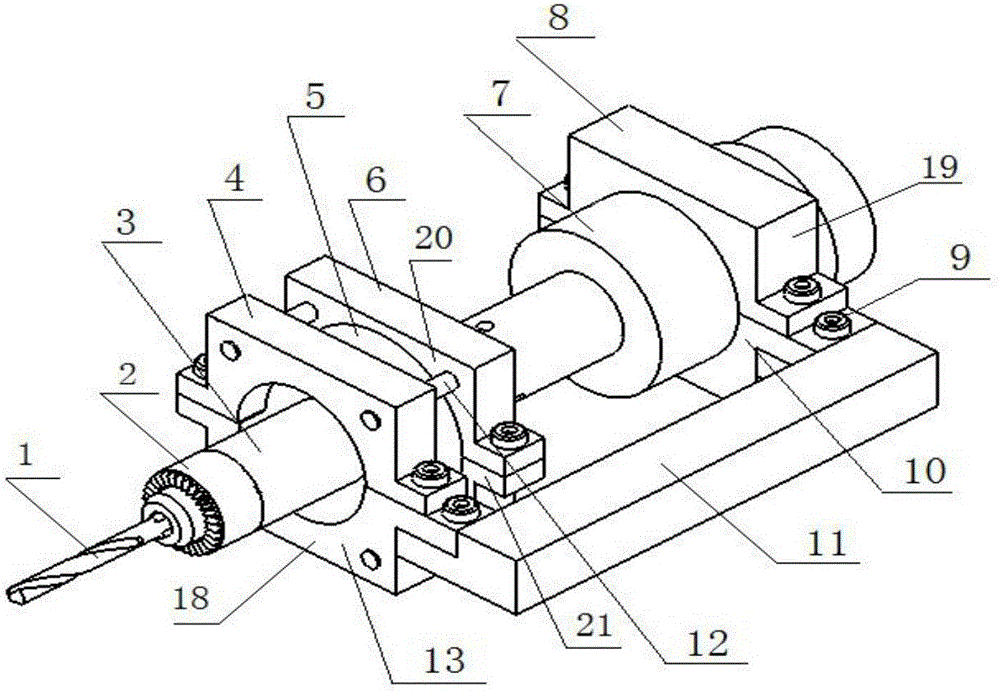

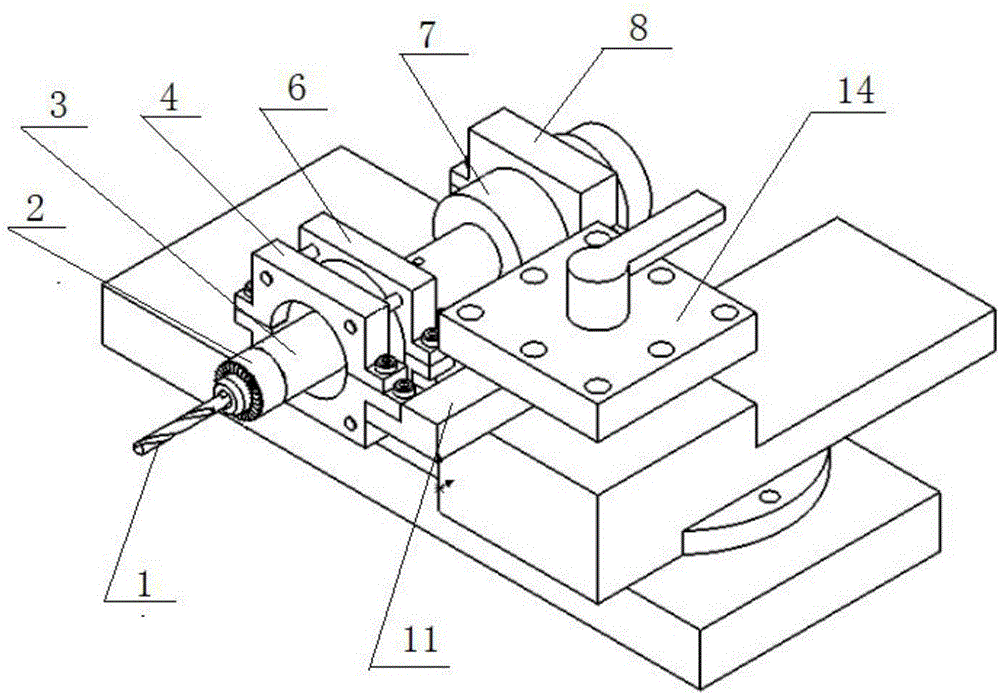

Variable dimension vibrating auxiliary drilling device and track generation method

InactiveCN106925809AImprove drilling performanceAxial amplitude increasesWorkpiecesTurning toolsTransducerMachine tool

The invention discloses a variable dimension vibrating auxiliary drilling device and a track generation method, and belongs to the field of numerical control machining. The device is composed of an amplitude-change pole, a piezoelectric transducer, a connecting sleeve, a cutter mounting structure, a machine tool mounting cutter handle and a sliding ring. The device is connected with a machine tool spindle through the machine tool mounting cutter handle; the amplitude-change pole adopts a one fourth wavelength conical step type composite amplitude change mode; the piezoelectric transducer adopts a longitudinal bending vibration sandwiching mode and is composed of piezoelectric ceramic pieces, electrode plates, a rear end cover (a reflex housing), insulation spacers and a pretightening force bolt which are connected through the pretightening force bolt in a fastened mode; the amplitude-change pole is connected with the piezoelectric transducer through a pretightening force bolt and connected with the cutter handle through the sleeve; and the sliding ring is connected with the sleeve through a catch bolt, and thus the whole structure of the device is formed. A cutter is fixed to the cutter mounting structure, one-dimensional, two-dimensional and three-dimensional elliptic track output is generated in the position of a cutter nose under control of drive signals of the piezoelectric transducer. The device is simple, stable three dimensional elliptic motion tracks can be generated conveniently, and the device can be directly integrated with numerical control machining machine tools for auxiliary precision drilling machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sharpening method for drill tip back knife face of fully screw face drill

InactiveCN101053940AStrong ability to concentrateImprove drilling performanceTwist drillsHEAD SPINNINGGrinding wheel

The present invention relates to a tool sharpening method for the back tool face of drill head tip with a complete helical surface, wherein the back tool face is a continuous helical surface. In the tool sharpening process, the grinding wheel and the drill head execute a corresponding helix feeding movement, and the shaft line of the helical surface of the helix feeding movement intersects with the shaft line of the drill head to form an angle; the relative position of the grinding wheel and the drill head is adjusted according to the toll sharpening parameter of the back tool face; the grinding wheel is fixed, the drill head executes a helix feeding movement relative to the grinding wheel; alternatively, the drill head is fixed, the grinding wheel executes a helix feeding movement around the drill head. After the back tool face at one side is finished, the drill head spins by 180 degree relative to the initial position of the tool sharpening process and around the shaft line of the drill head, and the symmetrical back tool face is sharpened according to the same parameter. The present invention is adapted to the tool sharpening of drill tip of not only the big drill head but also the minitype drill head.

Owner:HUNAN UNIV

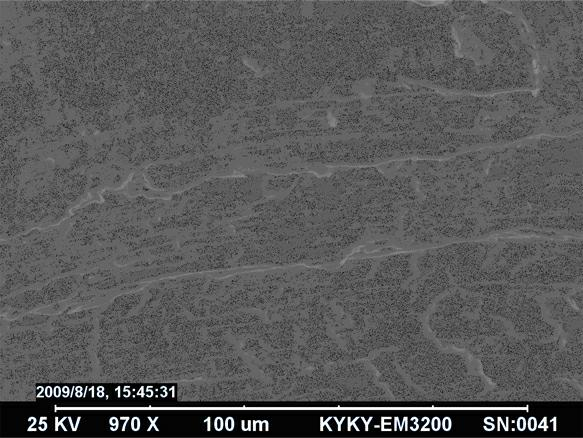

Micropore forming method

InactiveCN102601406AImprove machining accuracySatisfies the requirements of machining accuracy of extremely small holes for suctionEngineeringMaterials science

A micropore forming method includes the steps: firstly, fixing a molybdenum sheet on a worktable of machining equipment; and secondly, forming a micropore with the diameter of phi 0.38mm, the roundness of 0.01mm and the surface roughness of Ra 0.1 at a preset position of the molybdenum sheet. The micropore forming step particularly includes positioning, pre-drilling and expanding. An expanding drill with the diameter of phi 0.38mm is used for expanding on the basis of pre-drilling during expanding, cutting fluid is used for washing the expanding drill and the molybdenum sheet during expanding, the rotation speed of the expanding drill is 5000-10000 revolutions per minute, the feed speed of the expanding drill is 1-5mm / min, drilling is repeated for 8-12 times, and grease lubricant is smeared on the surface of a drill bit of the expanding drill. The micropore forming method adopts a machining mode, and the formed micropore can meet the requirement of an extremely small suction hole on machining precision.

Owner:KYKY TECH

Method of finishing cutting elements

ActiveUS7549912B2Improve drilling performanceImprove performanceEdge grinding machinesDrill bitsHigh energyMechanical engineering

A method for manufacturing drill bit inserts in which the inserts are finished in a centrifugal disc finishing machine. The centrifugal disc finishing machine comprises a configured surface rotating relative to a stationary receptacle, and the inserts may be finished with a mass of materials comprising at least one of a group of media, parts, detergent, and solution. Also, a method of increasing drill bit insert performance comprising accelerating a plurality of inserts in a high-energy finishing machine, wherein the acceleration results in a generally toroidal interaction between the inserts and at least one of the group comprising media, parts, detergent, and solution.

Owner:SMITH INT INC

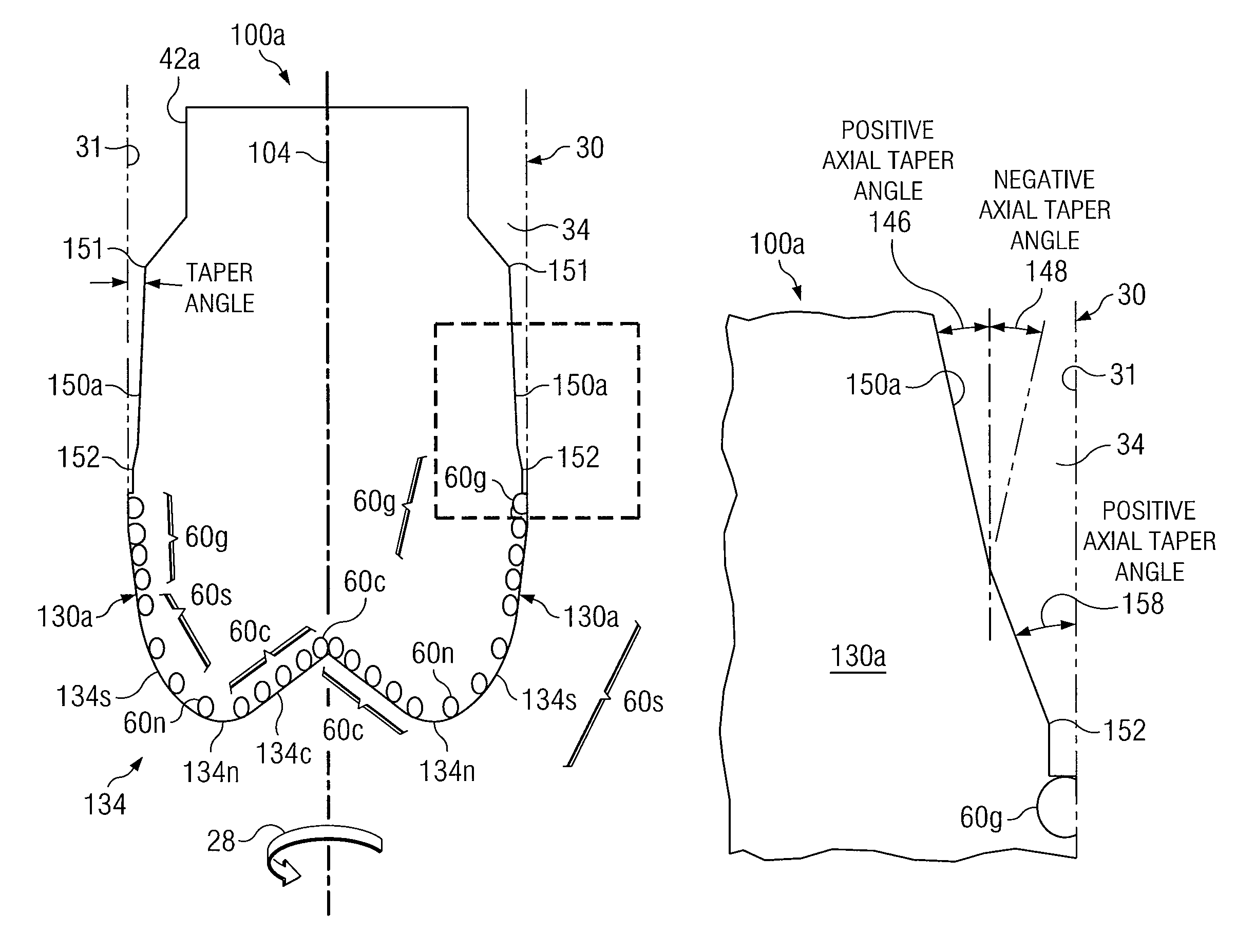

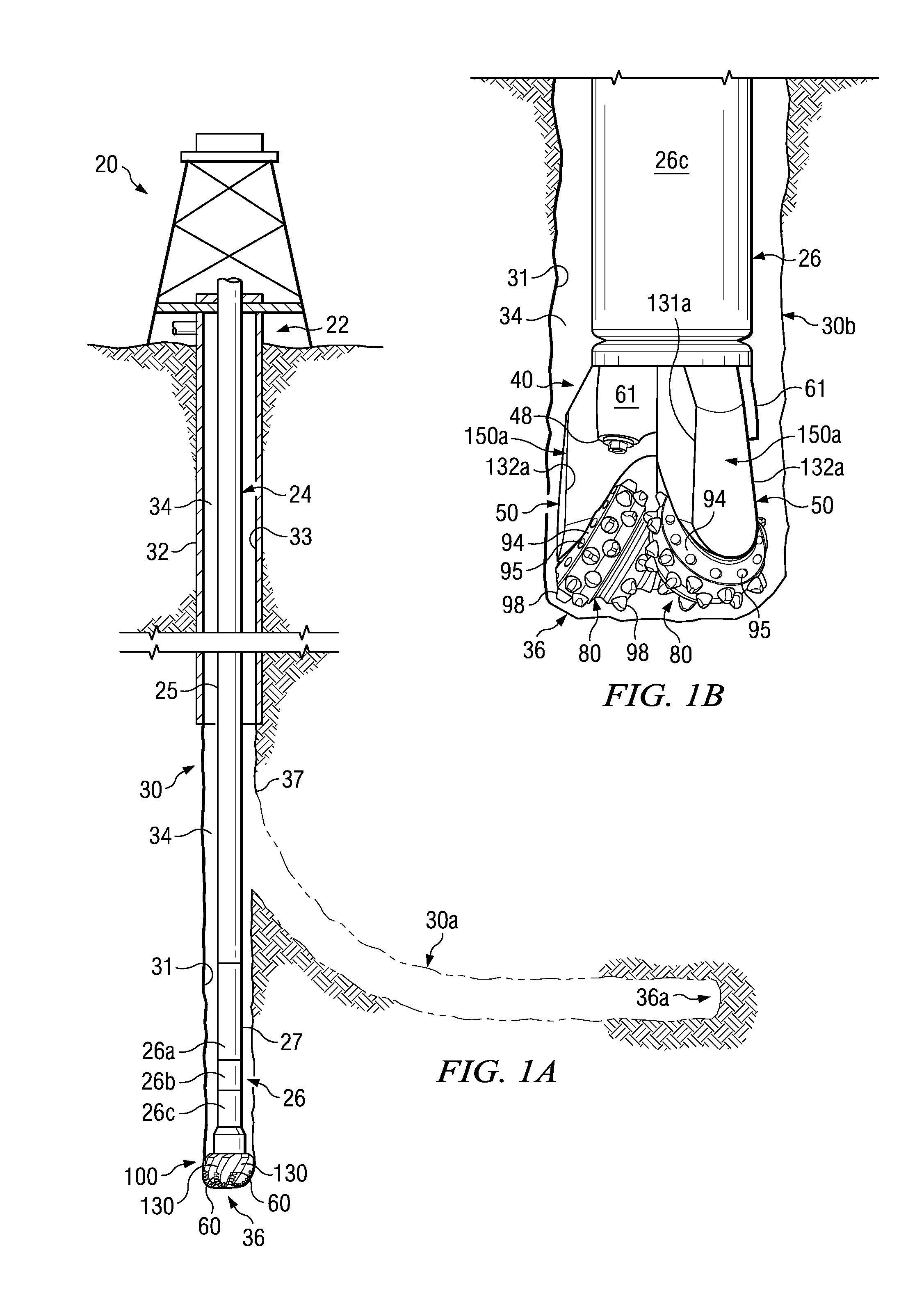

Rotary drill bits with gage pads having improved steerability and reduced wear

Owner:HALLIBURTON ENERGY SERVICES INC

PDC bits with mixed cutter blades

ActiveUS9115552B2Reduce and eliminate wear related damageImprove impact resistanceGeometric CADDrill bitsManufacturing cost reductionWear resistant

Owner:HALLIBURTON ENERGY SERVICES INC

Combination coring bit and drill bit using fixed cutter PDC cutters

InactiveUS8820441B2Improve drilling performanceLower the volumeArtificial islandsDrill bitsPolycrystalline diamondEngineering

A drill bit having fixed Polycrystalline Diamond Compact cutters is used to drill a borehole having a core stump therein. A plurality of additional fixed Polycrystalline Diamond Compact cutters are disposed in the dome of the bit and are usable to concentrate stresses in the top end of the core stump to facilitate the cutting down of the core stump.

Owner:DIAMANT DRILLING SERVICES

Full helicoidal surface Micro-drill web thinning method

InactiveCN101081483AGood centering effectImprove drilling performanceTwist drillsEngineeringThinning

The process of grinding the chisel edge of small spiral bit includes the following steps: regulating the relative locations of grinding wheel and bit based on the chisel edge grinding coefficient to make the tail gap of the back face in the bit aligned to the grinding wheel, fixing one of the bit and the grinding wheel and making the other move linearly along the axis of the spiral back face until the grinding wheel grinds to the center of the bit to form the second back plane in the tail gap; and turning the bit around its axis by 180 deg to grind one other symmetrical back plane. The process can decrease the sharp chisel edge angle in the bit center, raise the centering capacity of the bit, improve the drilling capacity and drilling performance of the bit.

Owner:HUNAN UNIV

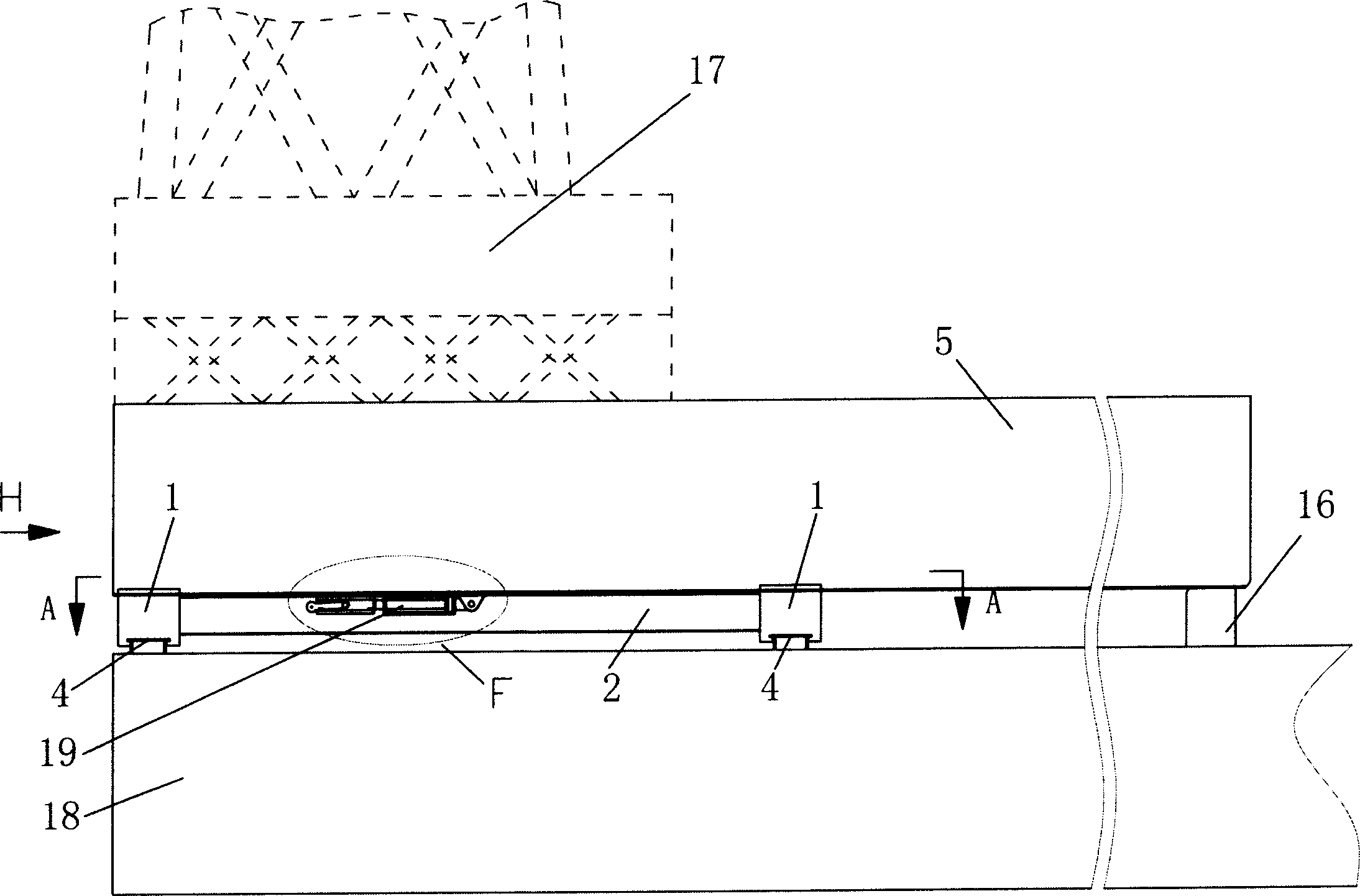

Movable bracket of cantilever beam on platform of drilling for oil

InactiveCN1687533AImprove stress conditionImprove carrying capacityArtificial islandsUnderwater structuresCantilevered beamTower

This is a kind of cantilever moving bracket of petroleum artesian well platform belonging to petroleum artesian well platform equipment field. This kind of ancon moving bracket of petroleum artesian well platform adopts the square framework structure comprising of four bracket pedestals, two bracket longerons and two crossbeams. The lower part of the four corners of the bracket of the square framework equips sliding trough making the moving bracket have transverse movement on the slideway under bracket, and the upper of which equips the sliding trough making ancon and bracket have lengthways movement together on the slideway. The boring tower is fixed at the rump of ancon. Inside the moving bracket there equips driving device having transverse and lengthways movement, making that moving bracket can conveniently make boring tower exactly locate in the position need artesian. Besides its structure is simple, and its work is dependable. Especially it improves the carrying situation of ancon, enhances the hole-making capability of artesian platform, increases artesian depth, and makes the hole-making efficiency and economy performance ulteriorly improved.

Owner:DALIAN UNIV OF TECH

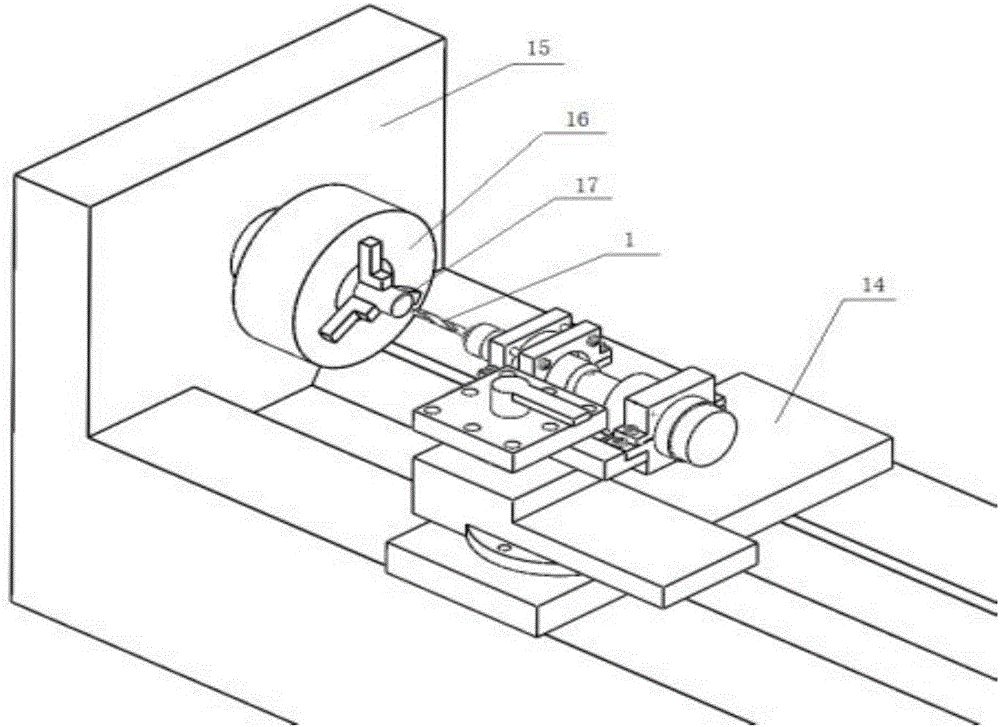

Axial ultrasonic vibration drilling device fixed by lathe carriage

InactiveCN106424836ASimple structureEasy to installMechanical vibrations separationBoring/drilling componentsTransducerEngineering

Provided is an axial ultrasonic vibration drilling device fixed by a lathe carriage. The axial ultrasonic vibration drilling device fixed by the lathe carriage comprises a drill, an amplitude-change pole, a transducer, a beam hanging type fixed device and an ultrasonic generator electrically connected to the transducer. The beam hanging type fixed device comprises a hanging beam fixed on the lathe carriage and a front pressing plate and a rear pressing plate, wherein the front pressing plate and the rear pressing plate are fixedly connected to the hanging beam, the front pressing plate fixes the front end of the amplitude-change pole, the rear pressing plate fixes the transducer, a fixed pressing plate fixes the middle part of the amplitude-change pole, and the front pressing plate, the rear pressing plate and the fixed pressing plate are all divided into upper and lower two parts and are assembled through bolts. Compared with a drilling device achieved on a drilling machine, there is no need to conduct any special refit on a machine tool; in addition, a method of workpiece revolution is adopted, there is no need to use assembly units such as a ring manifold or a carbon brush, thus the structure is simplified, the cost is saved, and the axial ultrasonic vibration drilling device fixed by the lathe carriage is convenient to disassemble and assemble and is beneficial to a proceeding of ultrasonic vibration drilling.

Owner:NORTHEASTERN UNIV

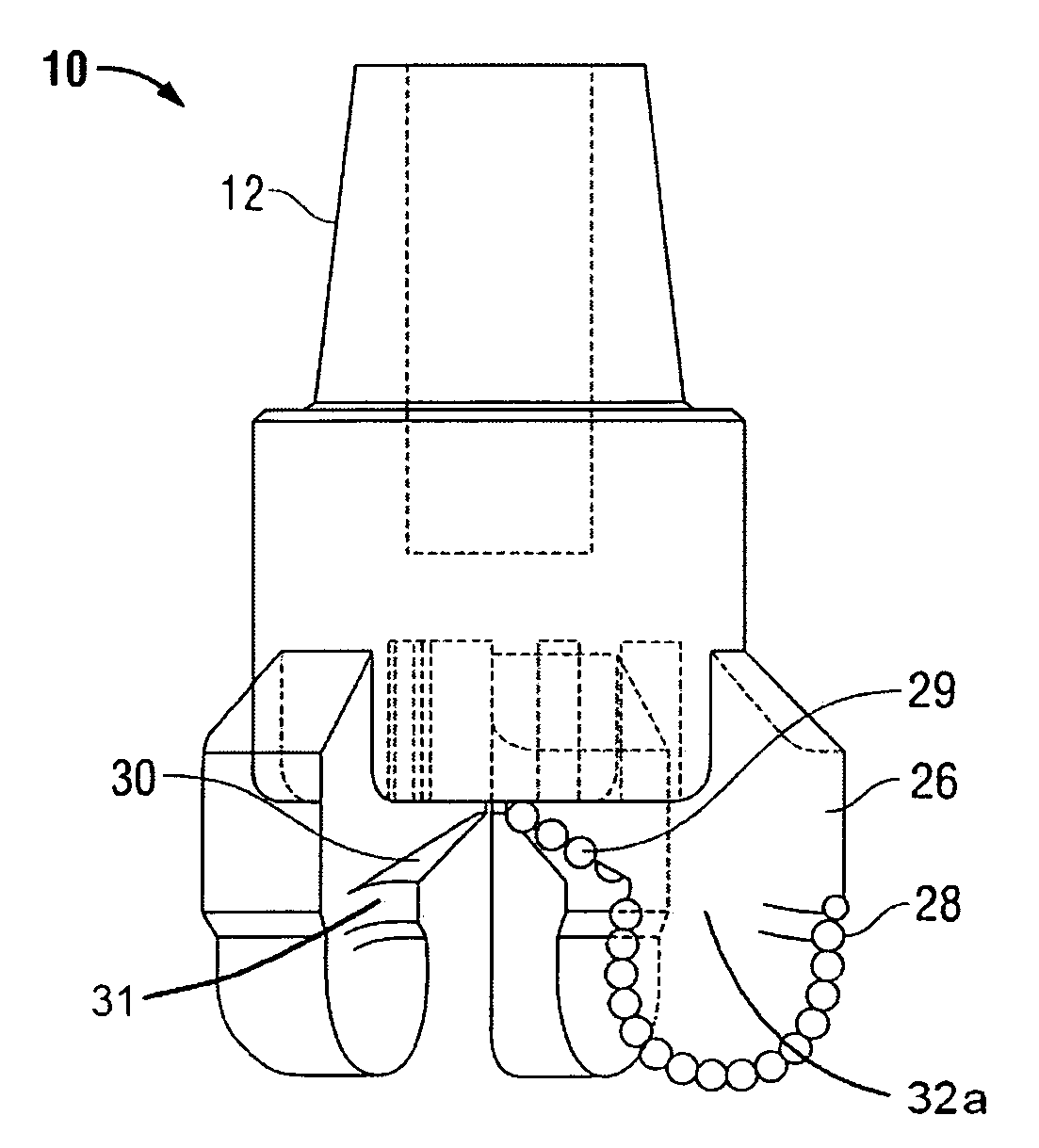

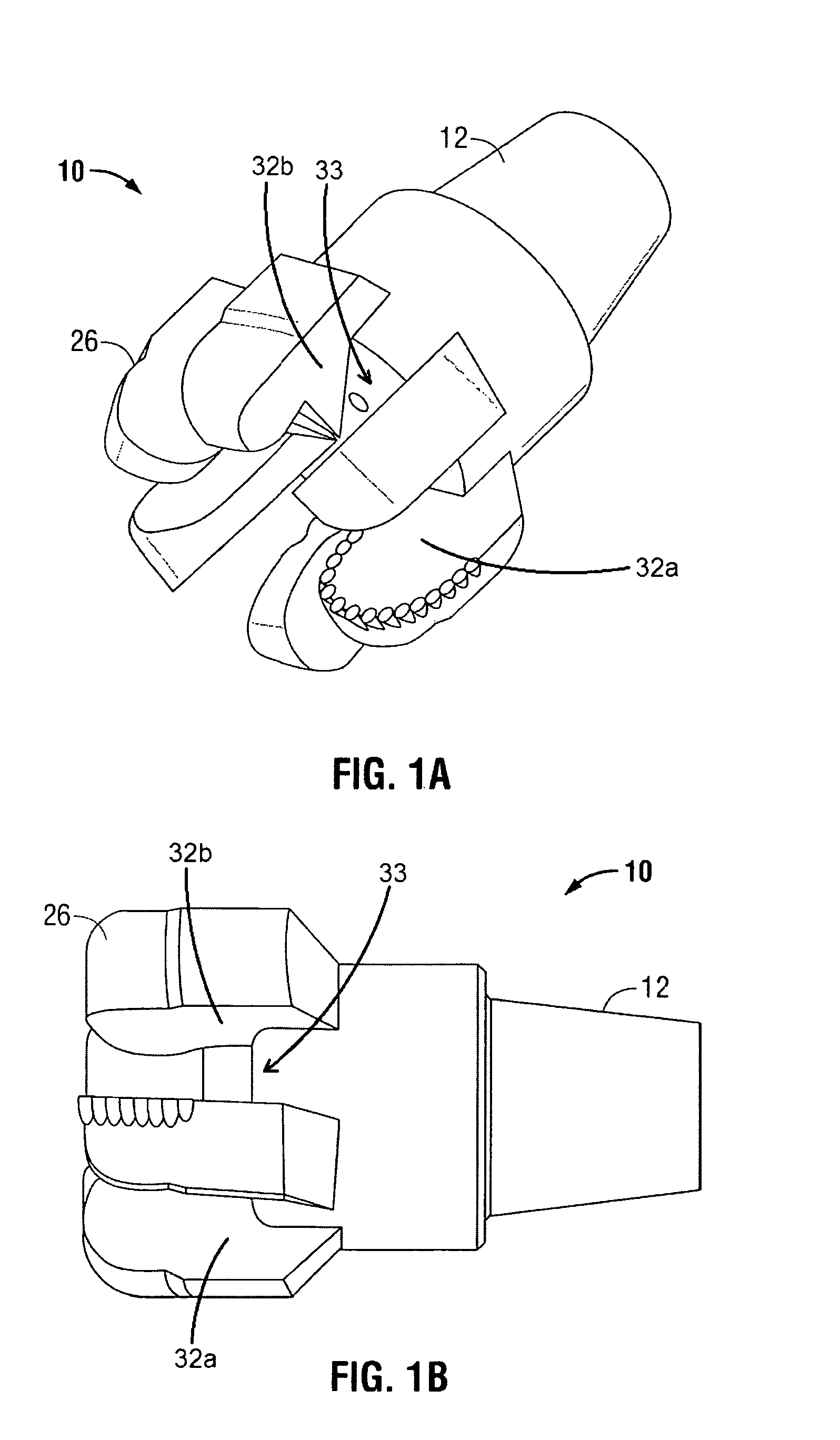

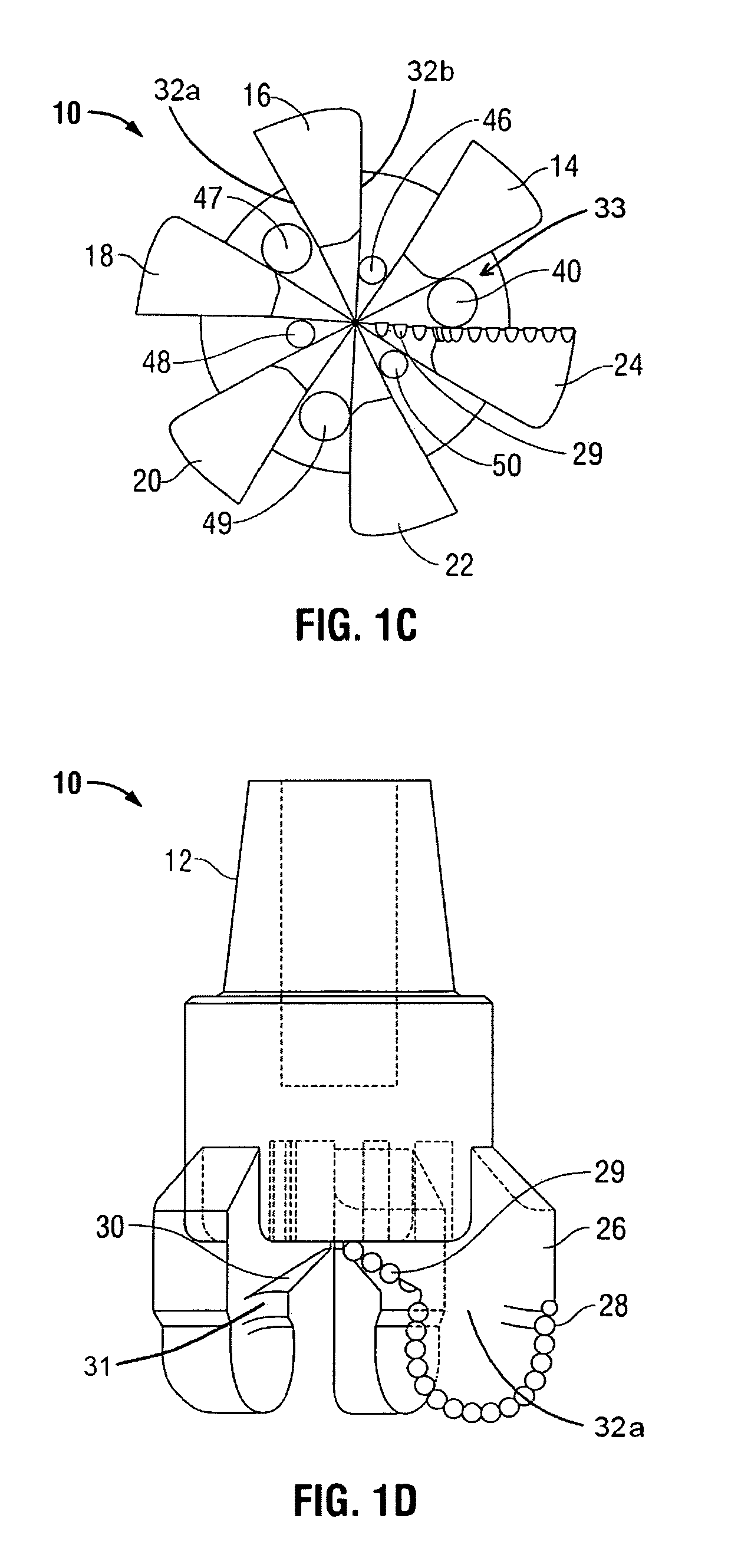

Rotary drill bit with gage pads having improved steerability and reduced wear

A rotary drill bit having blades with gage pads disposed on exterior portions thereof to improve steerability of the rotary drill bit during formation of a directional wellbore without sacrifice of lateral stability. One or more of the gage pads may include radially tapered exterior portions and / or cut out portions to assist with reducing wear of the associated gage pad. For some applications, a rotary drill bit may be formed having blades with gage pads having a relatively uniform exterior surface. Hard facing material and / or buttons may be disposed on exterior portions of the gage pad to form a radially tapered portion to improve steerability, reduce wear of the gage pad and / or improve ability of the rotary drill to form a wellbore having a generally uniform inside diameter, particularly during directional drilling of the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com