Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "HEAD SPINNING" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

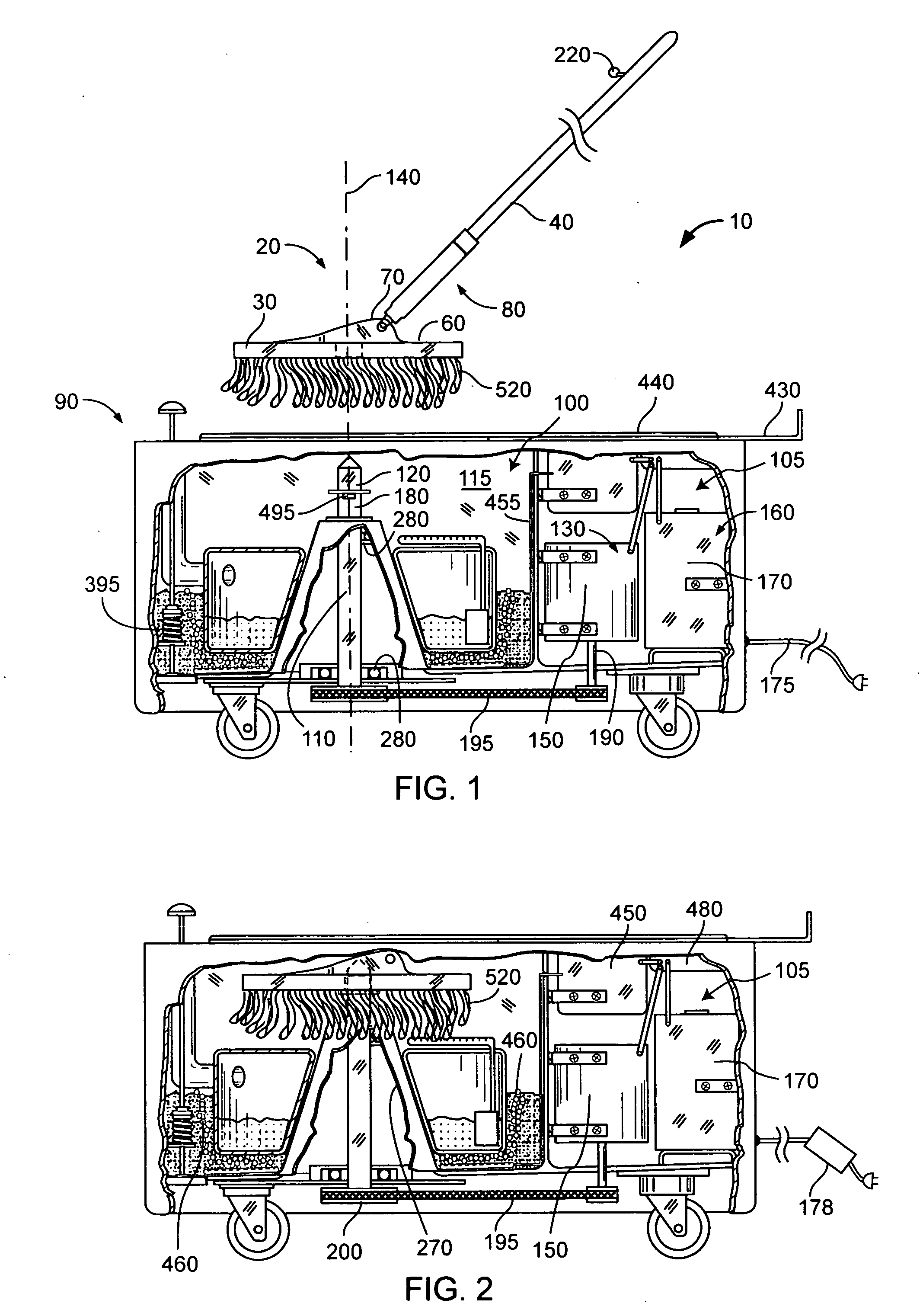

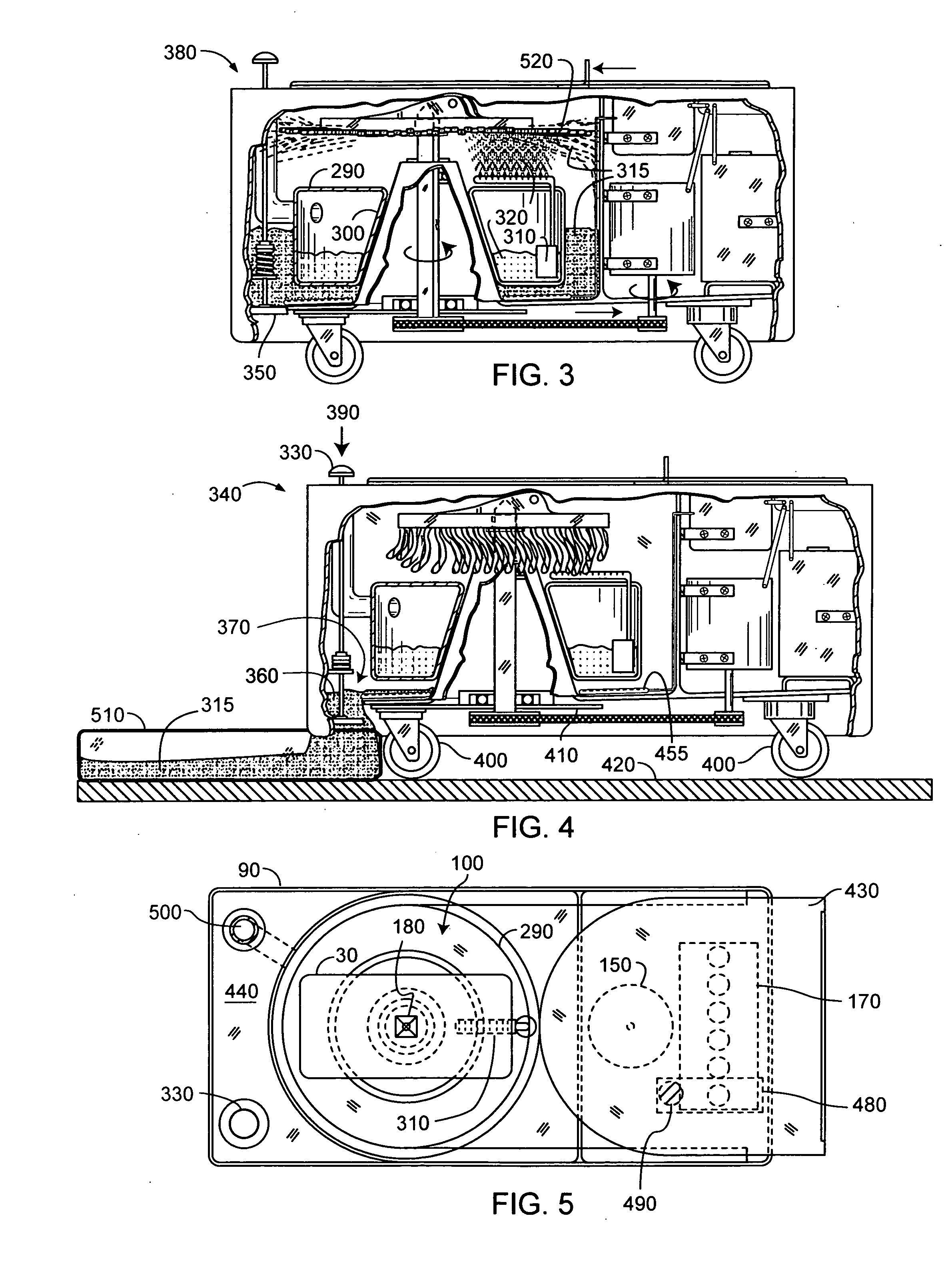

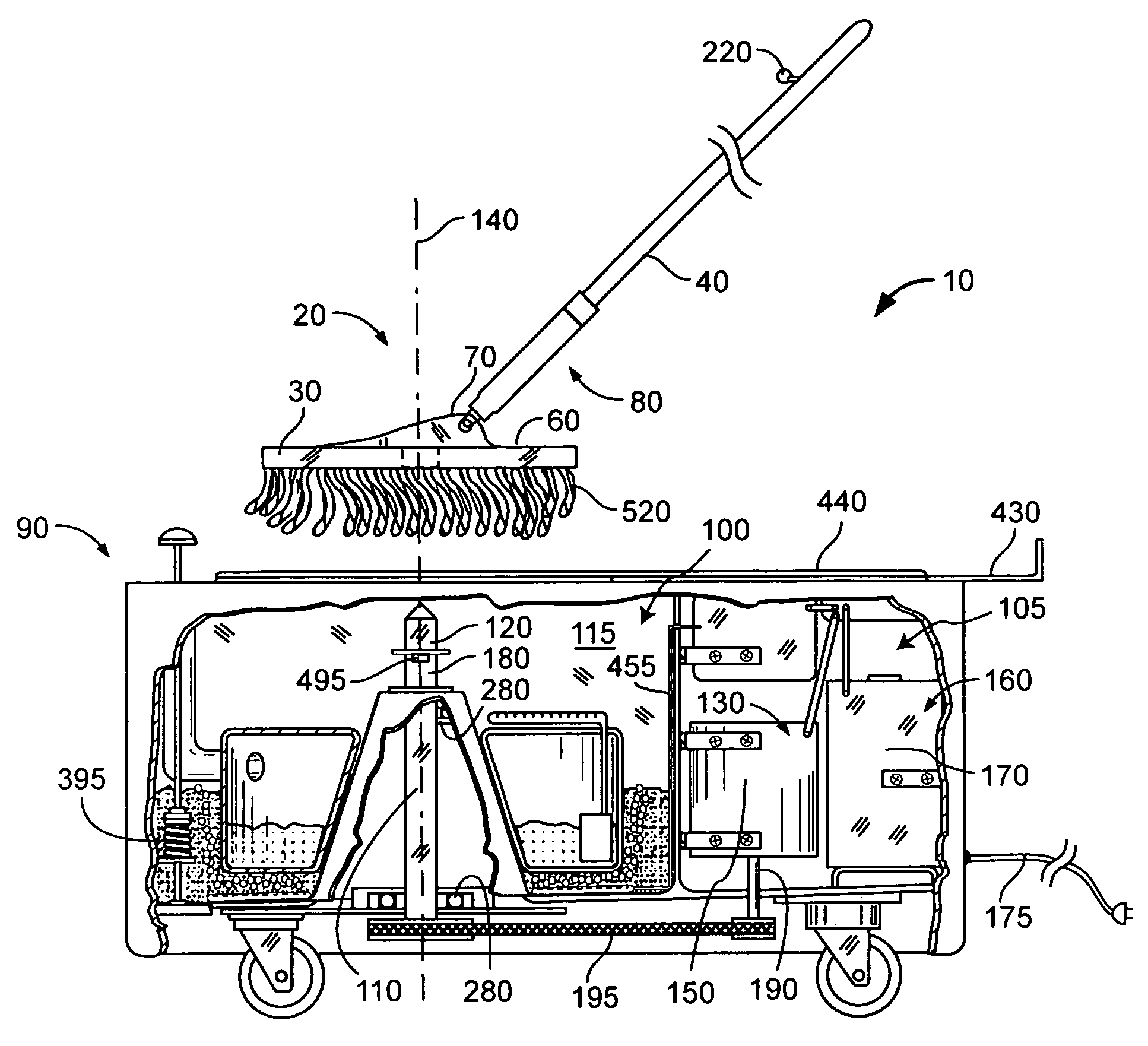

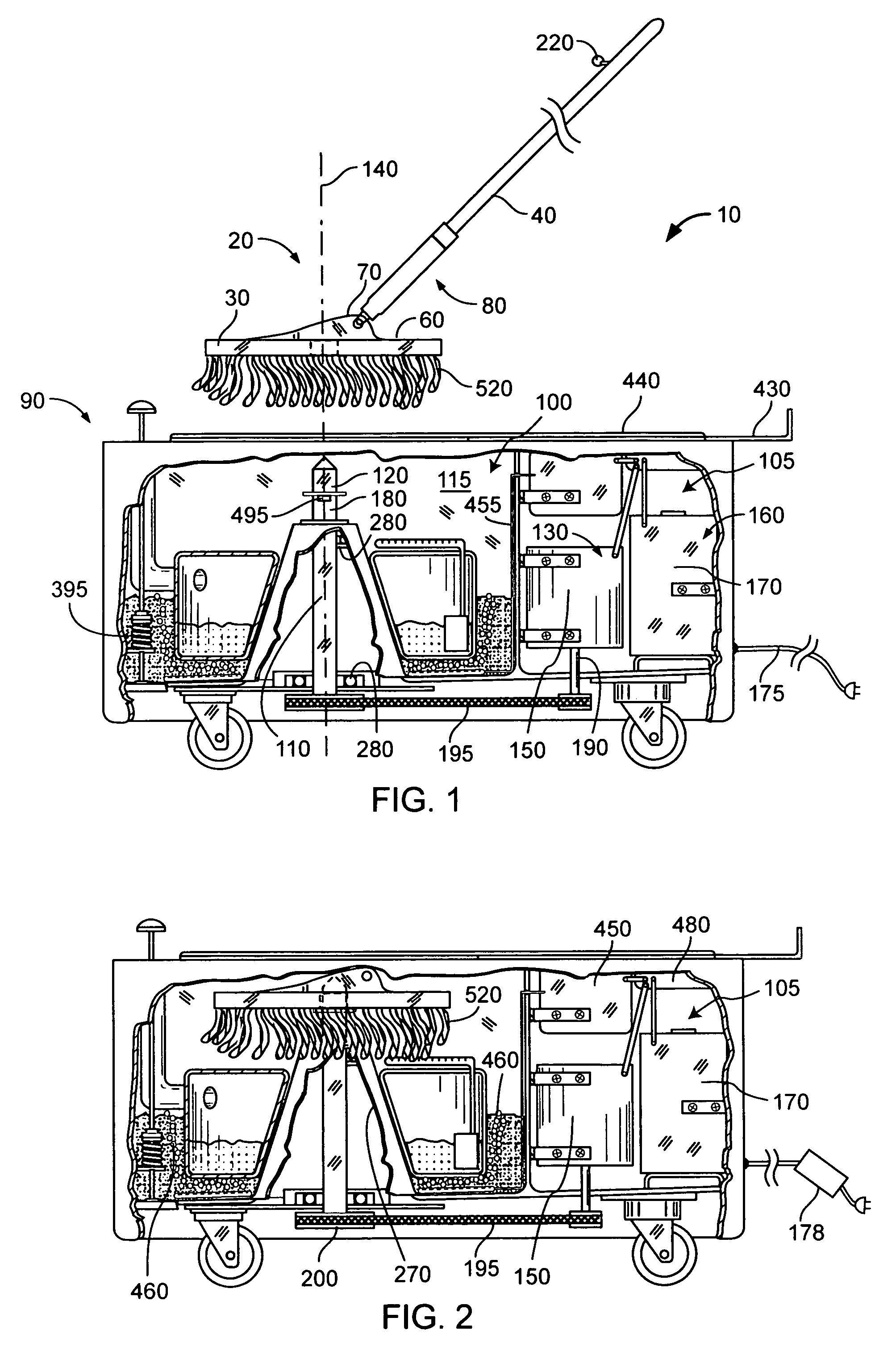

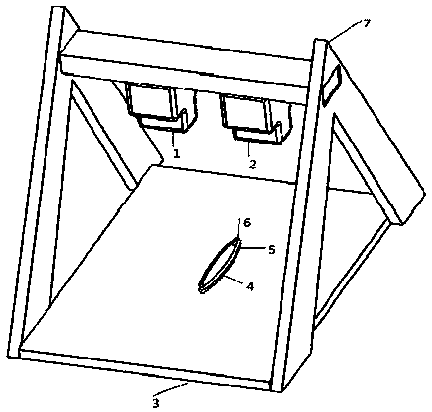

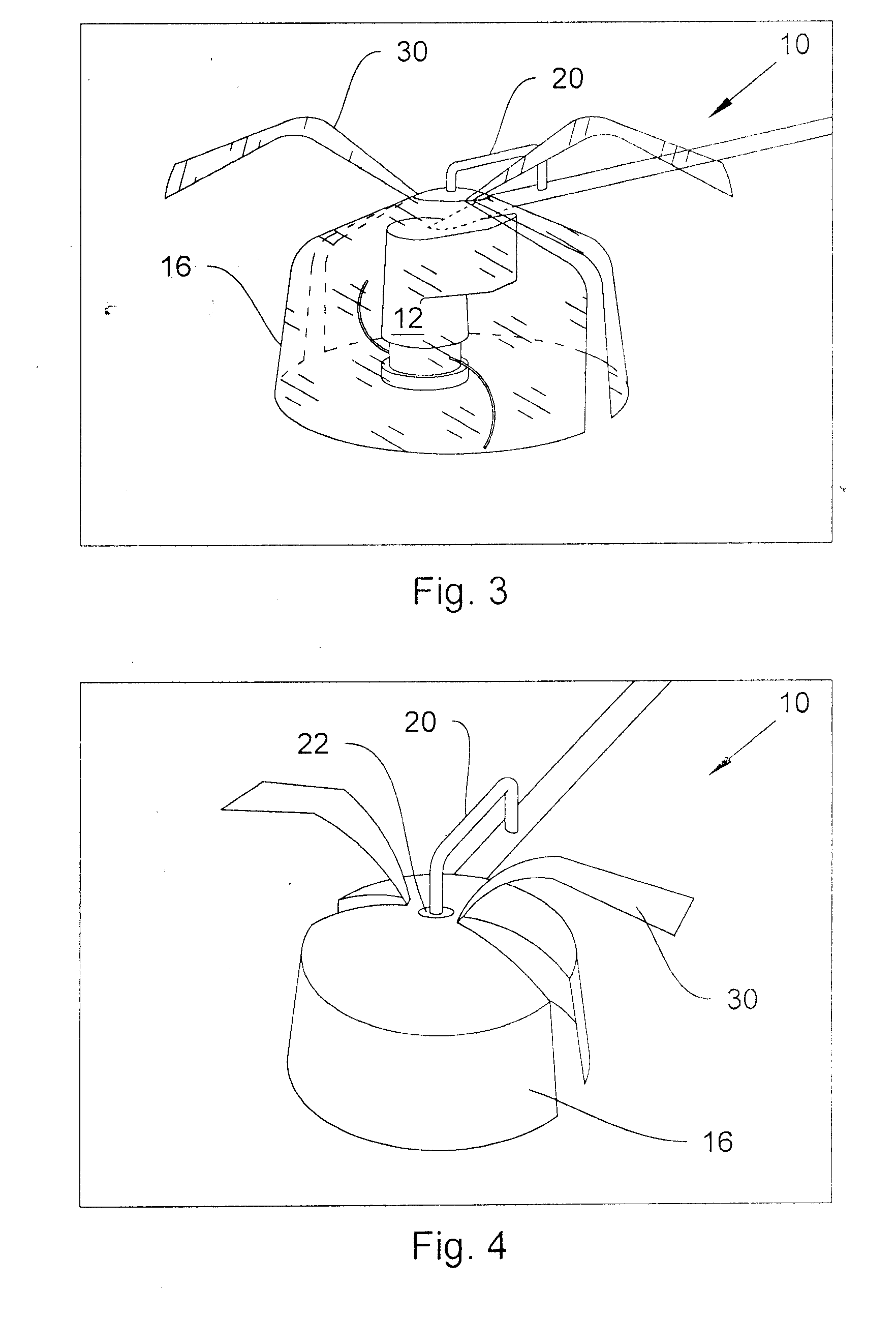

Mopping system and method of use

InactiveUS20070039117A1Avoid pollutionEasy to disinfectCarpet cleanersKitchenware cleanersRotational axisHEAD SPINNING

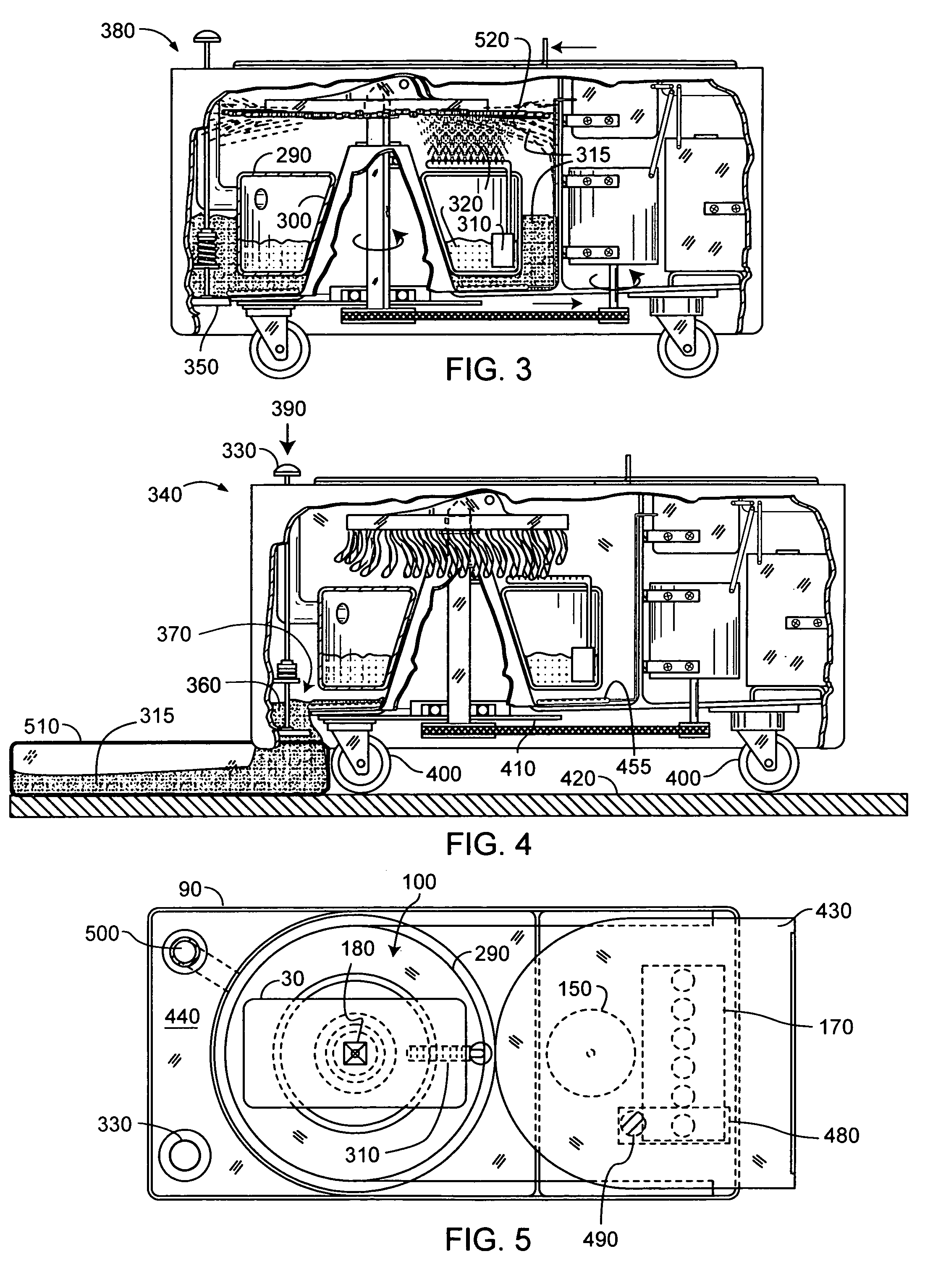

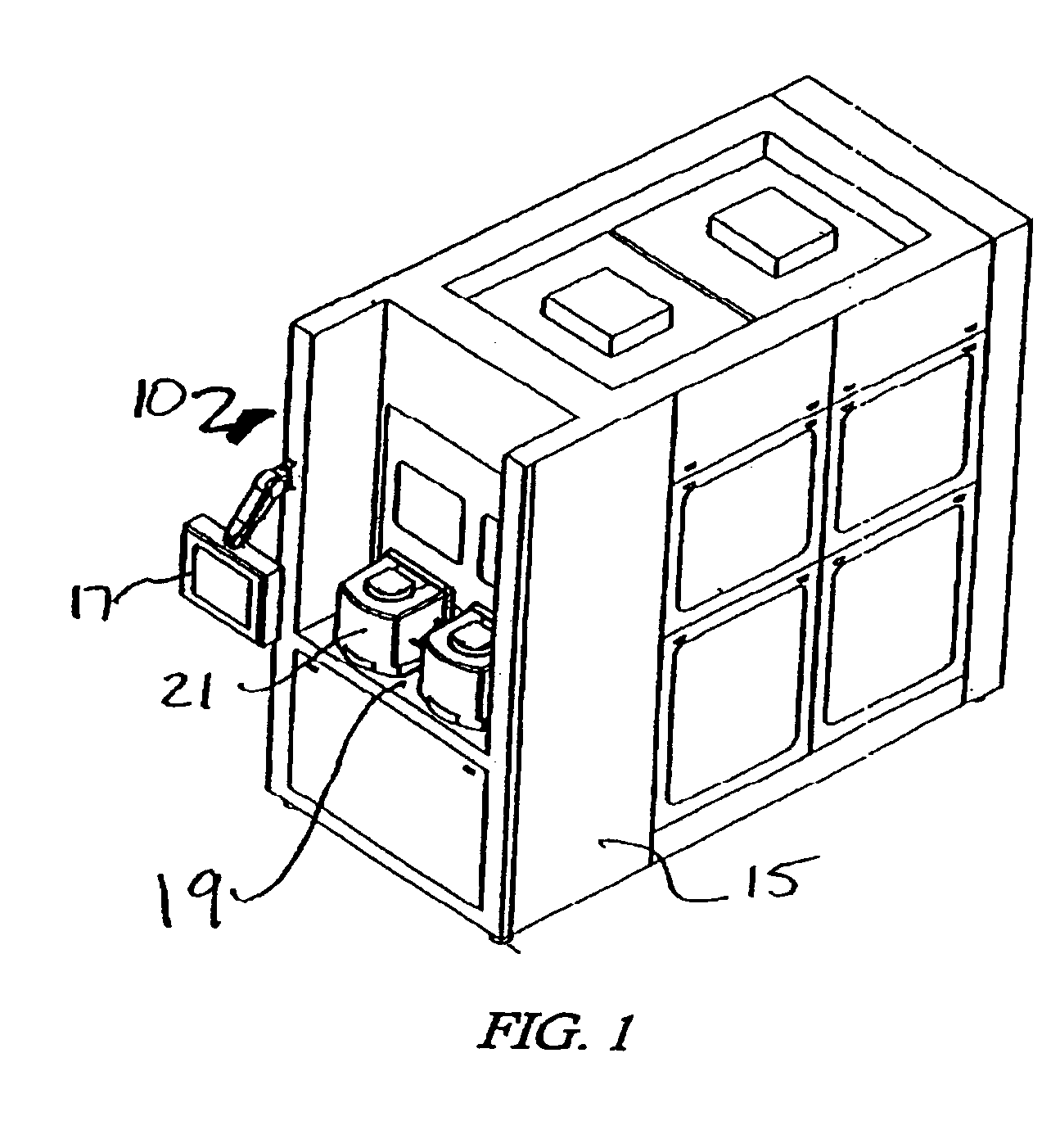

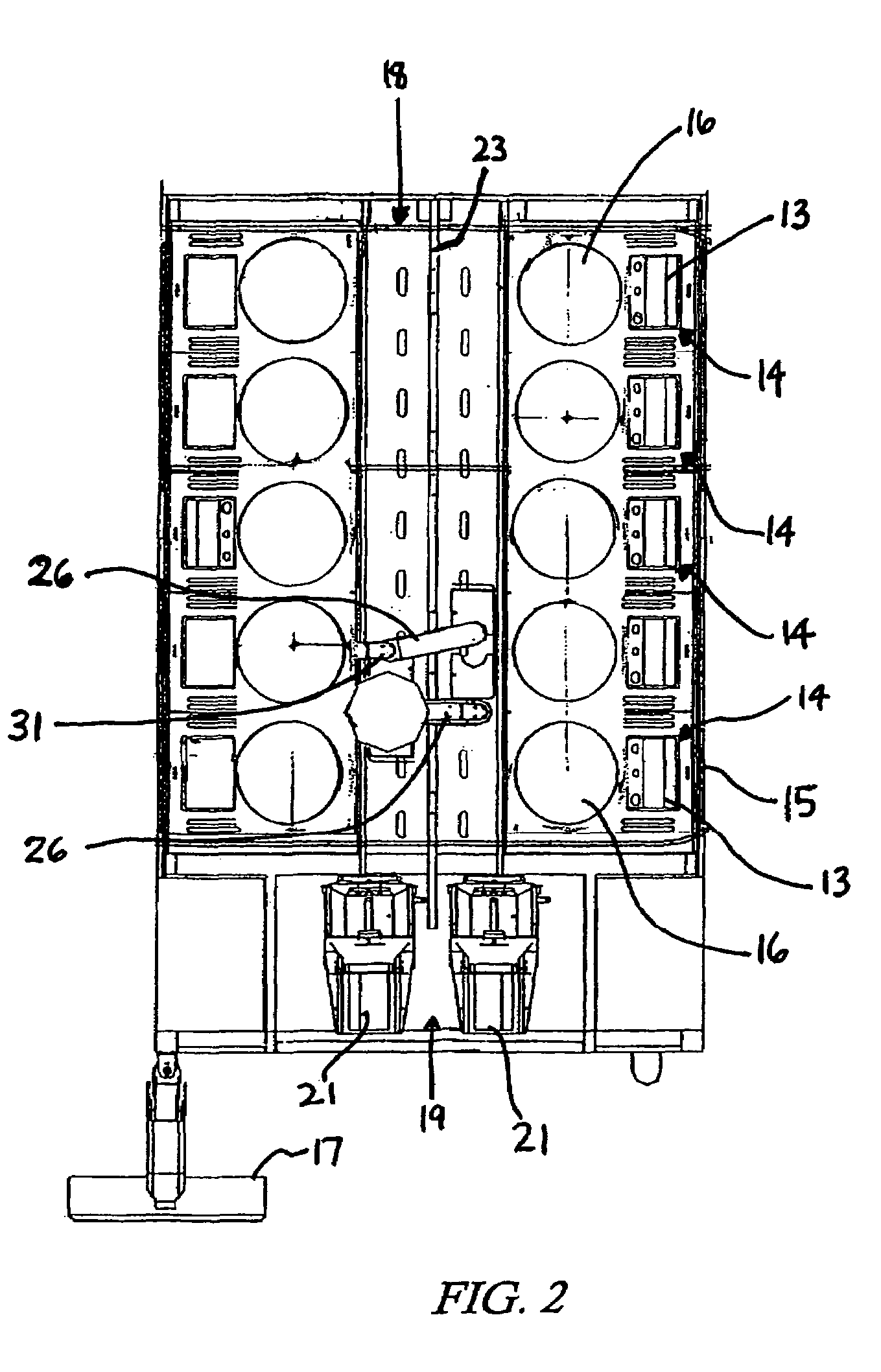

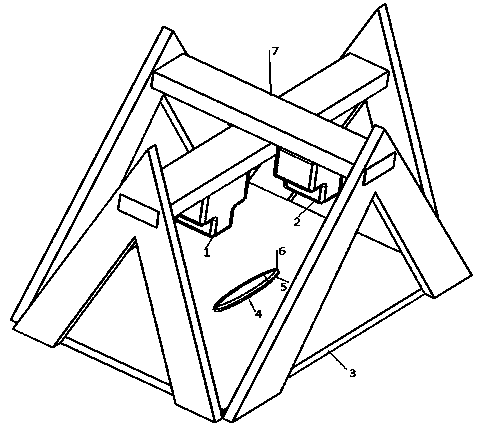

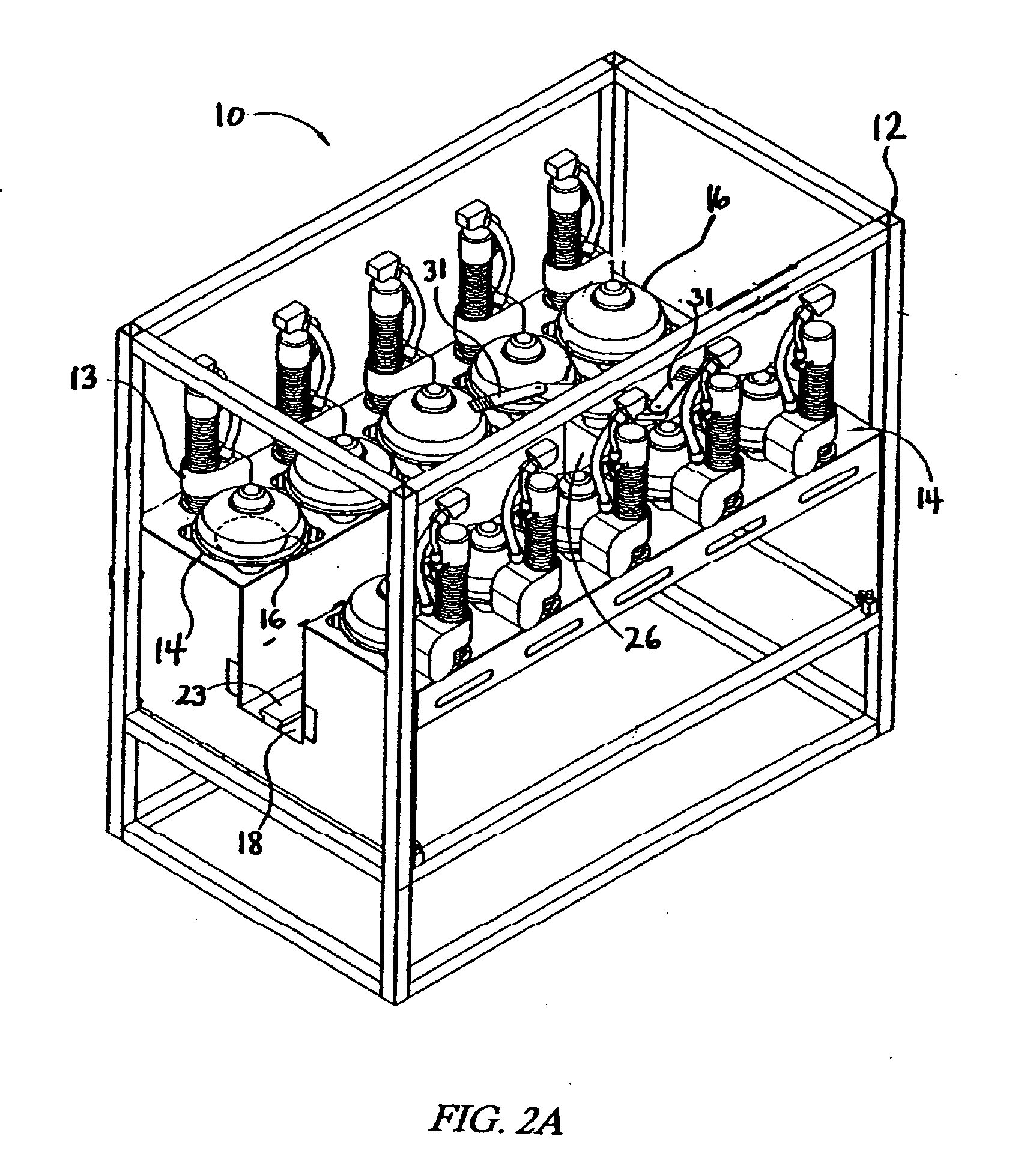

A mopping system and methods of its use are disclosed. A mop assembly includes a mop head that is adapted to be spun around a generally vertical rotational axis thereof when the mop head is fixed within a mop head spinning means of a bucket assembly. When the mop head is spun at a relatively high rate of rotational speed, water retained in the mop is forcefully dispelled from the mop by centrifugal force. The water leaves the mop and is retained within a spin chamber of the bucket assembly. A drain plunger is included to allow the collected water to be drained from the bucket assembly. An ozone generator may be included for introducing ozone gas into the collected fouled water in the spin chamber. A clean water tank with a pump and spraying means, mounted within the spin chamber just below the mop head when the mop head is engaged with the mop head spinning means, is preferably included to allow introduction of clean water to the moping surface of the mop head. The mop assembly may include a lever means for selectively detaching the mop head from the handle. A control circuit controls the spraying of clean water onto the mop head, the ozone generator, and the activation and speed of the mop head spinning means, such that various wash-dry cycles are available.

Owner:SPIN MOP

Production process of single-head spin high modulus low shrinkage polyester industrial filament

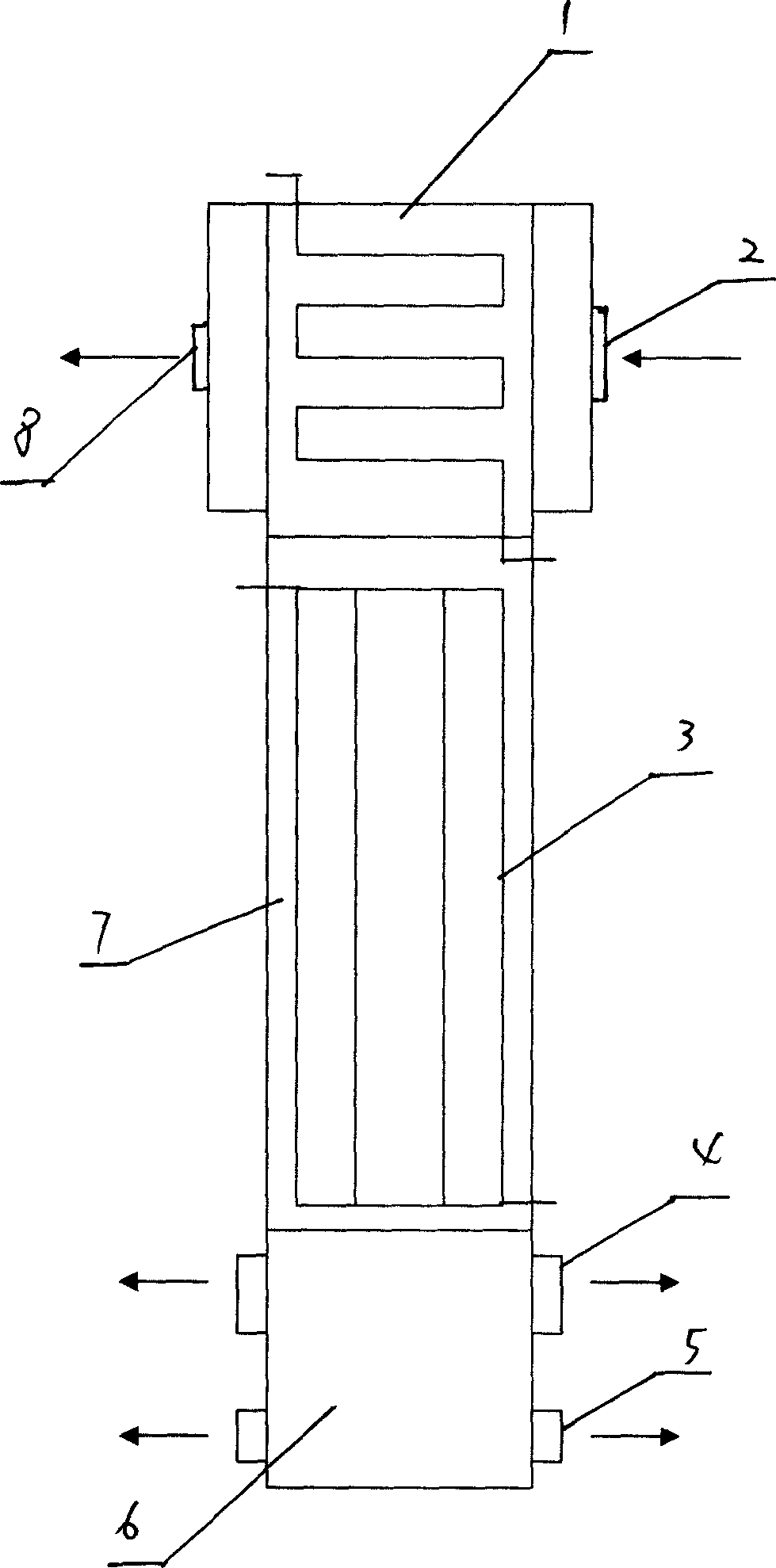

The invention relates to a production technique of a single-head spinned high modulus low-shrink industrial polyester filament. The technique includes the steps: 1. the processing of high-viscosity polyester slices: firstly pre-crystallizing is carried out for the polyester slice and then solid phase polymerization is carried out for polyester slice and then the viscosity of the polyester slice can reach 1.25 to 1.35 dl / g; 2. melt spinning: the polyester slice is transferred to a high-flow spinning screw extrusion machine with screw-diameter of 125 to 160mm, fused mass is extruded out from the spinning screw extrusion machine, then the fused mass is distributed to fused mass branch pipes through a fused mass header pipe, and the fused mass enters a spinning element through a measuring pump and then is extruded out from a spinneret plate with diameter of 220 to 240mm; the extruded filaments are heated by a slow-cooling heating ring, are cooled for forming through an annular air-blowing device and then enter spinning shafts; 3. stretch-wrap forming: the surfaces of filaments are oiled, filaments are stretched at a two-level high speed with total stretching-multiple of 1.8 to 2.2; then the filaments are loosely formed under high temperature between 230 and 260 DEG C and are wrapped with the technique speed of 5200 to 6500 meters / minute to obtain the finished product.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Mopping system and method of use

InactiveUS7174601B1Avoid pollutionEasy to disinfectCarpet cleanersKitchenware cleanersRotational axisOzone generator

A mopping system and methods of its use are disclosed. A mop assembly includes a mop head that is adapted to be spun around a generally vertical rotational axis thereof when the mop head is fixed within a mop head spinning means of a bucket assembly. When the mop head is spun at a relatively high rate of rotational speed, water retained in the mop is forcefully dispelled from the mop by centrifugal force. The water leaves the mop and is retained within a spin chamber of the bucket assembly. A drain plunger is included to allow the collected water to be drained from the bucket assembly. An ozone generator may be included for introducing ozone gas into the collected fouled water in the spin chamber. A clean water tank with a pump and spraying means, mounted within the spin chamber just below the mop head when the mop head is engaged with the mop head spinning means, is preferably included to allow introduction of clean water to the moping surface of the mop head. The mop assembly may include a lever means for selectively detaching the mop head from the handle. A control circuit controls the spraying of clean water onto the mop head, the ozone generator, and the activation and speed of the mop head spinning means, such that various wash-dry cycles are available.

Owner:SPIN MOP

Biodegradable electret melt-spurt filtering material and production method

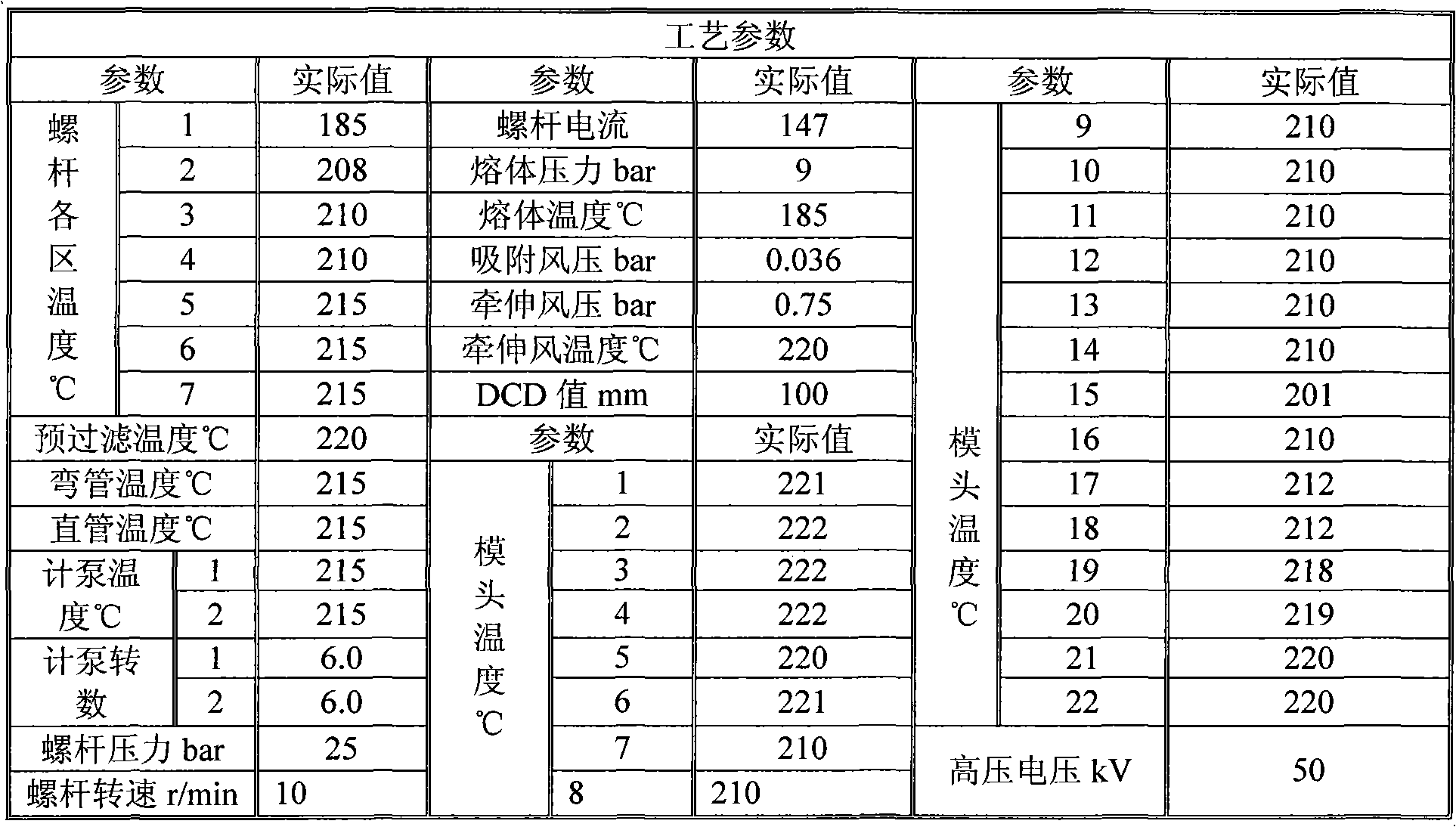

The invention discloses a biodegradable electret melt-spurt filtering material with the advantages of energy-saving, consumption reduction, 100 percent degradation in the natural environment and high filtering efficiency and a production method. The biodegradable electret melt-spurt filtering material is prepared form PLA slices with melting index of 500-800g / 10min (2.16kg, 230 DEG C) by the process steps of charging, screw rod melting extrusion, die head spinning, drawing, wet formation and high-voltage electric field electret. In the step of screw rod melting extrusion, the temperature of screw rods in each region is between 185 and 215 DEG C, the temperature of a filter is between 215 and 220 DEG C, the temperature of a metering pump is 215 DEG C and the pressure of the screw rod is 25bar; in the step of die head spinning, the temperature of the die head in each region is between 210 and 220 DEG C; in the step of drawing, the air pressure of the drawing is 0.75bar and the air temperature of the drawing is 220 DEG C; in the step of wet formation, the negative pressure of the absorption is 0.036bar, and the distance between a wet forming machine and a die head spinning jet plate is 100mm; and the step of high-voltage electric field electret is to enable a PLA fiber web to pass through a 50kV electric field.

Owner:DALIAN RUIGUANG NONWOVEN GROUP

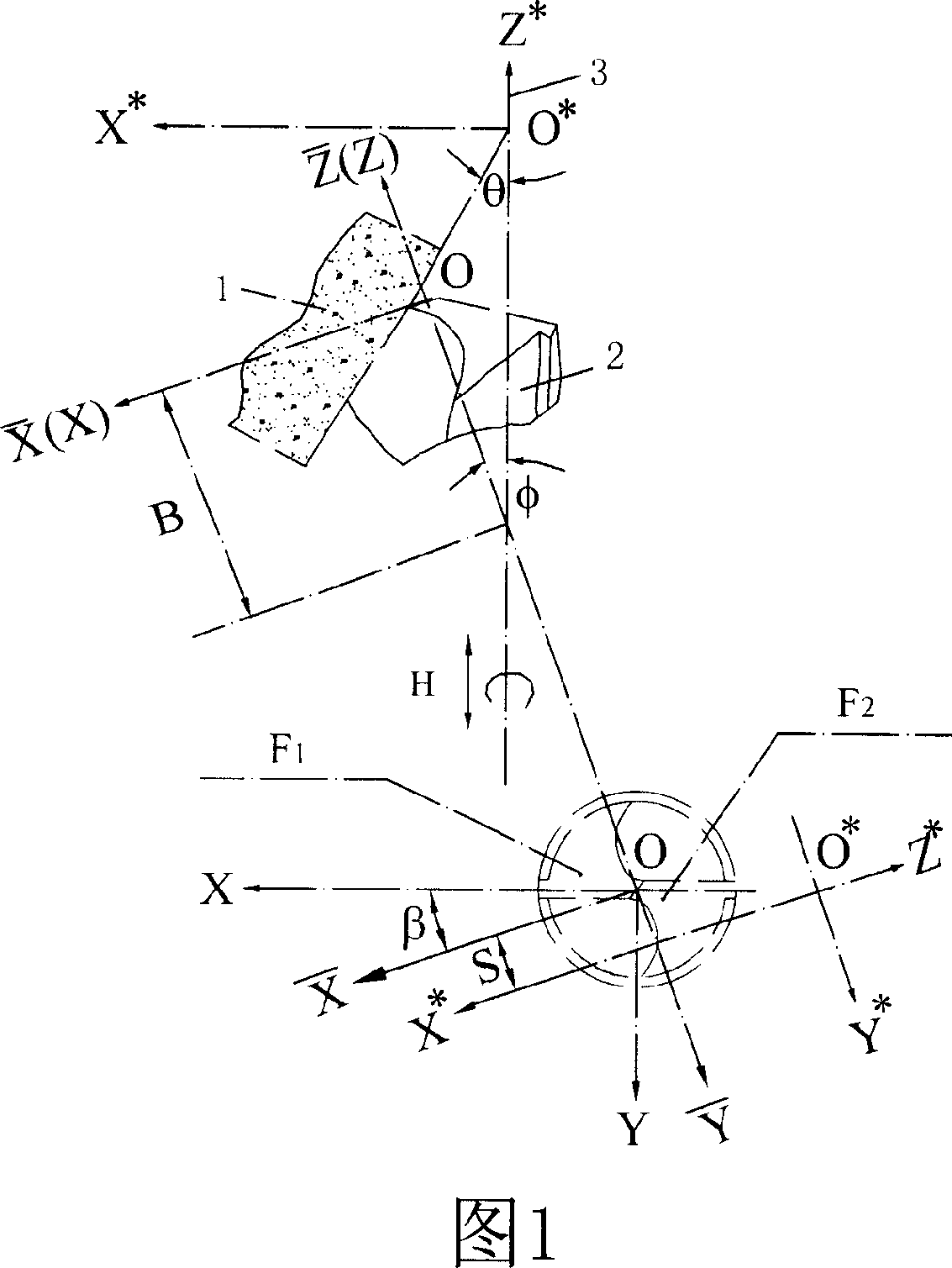

Sharpening method for drill tip back knife face of fully screw face drill

InactiveCN101053940AStrong ability to concentrateImprove drilling performanceTwist drillsHEAD SPINNINGGrinding wheel

The present invention relates to a tool sharpening method for the back tool face of drill head tip with a complete helical surface, wherein the back tool face is a continuous helical surface. In the tool sharpening process, the grinding wheel and the drill head execute a corresponding helix feeding movement, and the shaft line of the helical surface of the helix feeding movement intersects with the shaft line of the drill head to form an angle; the relative position of the grinding wheel and the drill head is adjusted according to the toll sharpening parameter of the back tool face; the grinding wheel is fixed, the drill head executes a helix feeding movement relative to the grinding wheel; alternatively, the drill head is fixed, the grinding wheel executes a helix feeding movement around the drill head. After the back tool face at one side is finished, the drill head spins by 180 degree relative to the initial position of the tool sharpening process and around the shaft line of the drill head, and the symmetrical back tool face is sharpened according to the same parameter. The present invention is adapted to the tool sharpening of drill tip of not only the big drill head but also the minitype drill head.

Owner:HUNAN UNIV

System for processing a workpiece

InactiveUS7217325B2Easy to manufactureFew defectLiquid surface applicatorsDecorative surface effectsHEAD SPINNINGEngineering

Owner:APPLIED MATERIALS INC

New technology of spandex fiber

InactiveCN1904152AStable temperature controlUniform temperature controlFilament/thread formingFiberFiltration

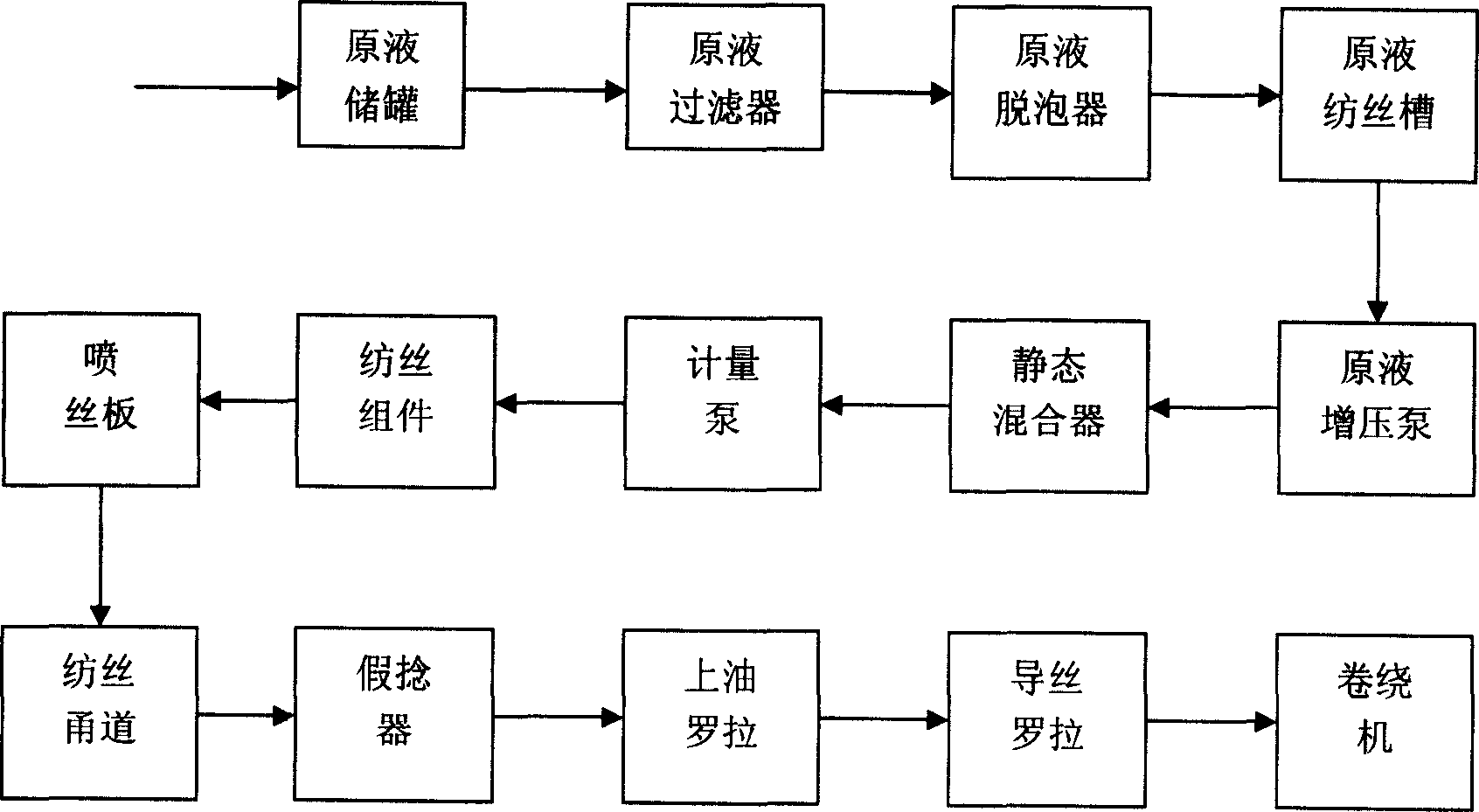

This invention relates to a new kind of spandex spinning technology. Send stock solution has undergone polymerization to storage jar for ripening, then through filtration, getting out of bubble, and entering spinning slot, pressing send by nitrogen gas and gear pump pressurize it into static mixer; Through the measuring pump to spit out stock solution and filtering it in spinning module, then allocate to spurt filament plate and spurt out from it; Evaporate out solvent in the spinning path and solidify it to spandex ammonia silk beam, then through false twisting, adding oil and rolling on the rolling machine to pack silk roll. This invention increase static mixer to suit 32 head spinning, reduce adverse effect caused by polymer which make gradient difference of temperature, residence time and viscosity along the radial of pipe; control the actuality temperature out of circulatory mediator in jar, spinning slot, static mixer and partner heat equipment, keep the homogenicity and stability after increasing the spinning air quantity and blast temperature, and increase volatilizing speed but not effect strand form.

Owner:连云港杜钟氨纶有限公司

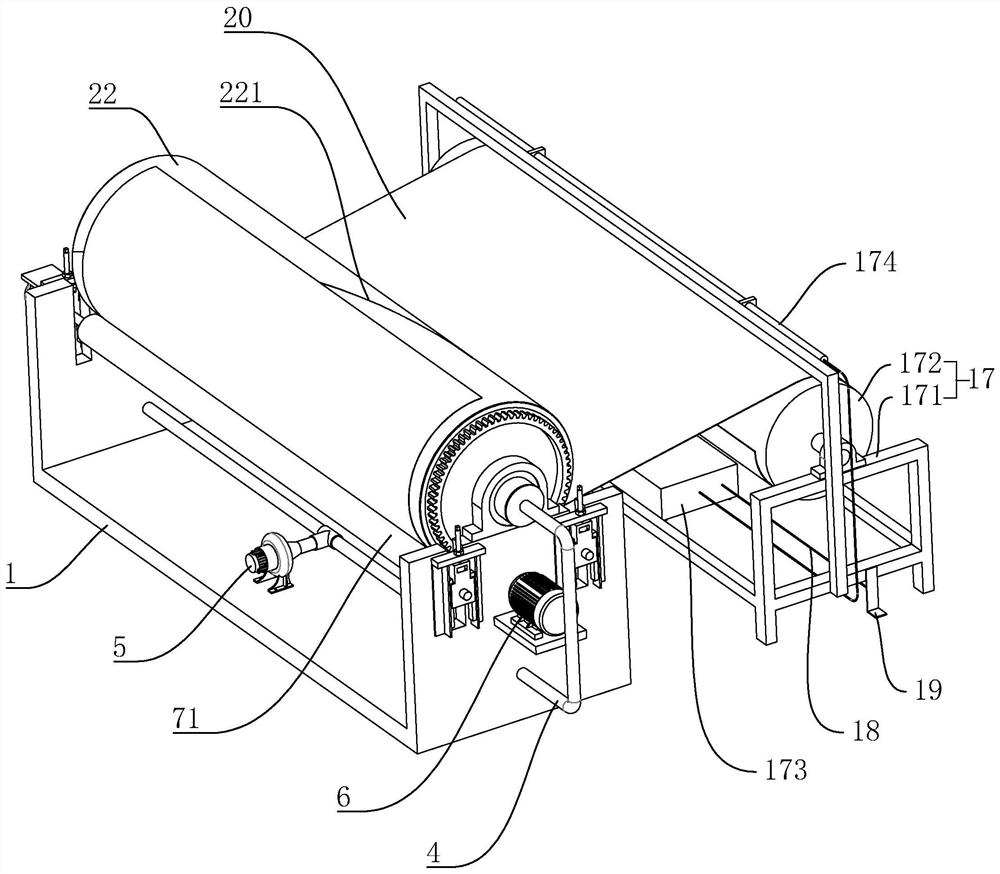

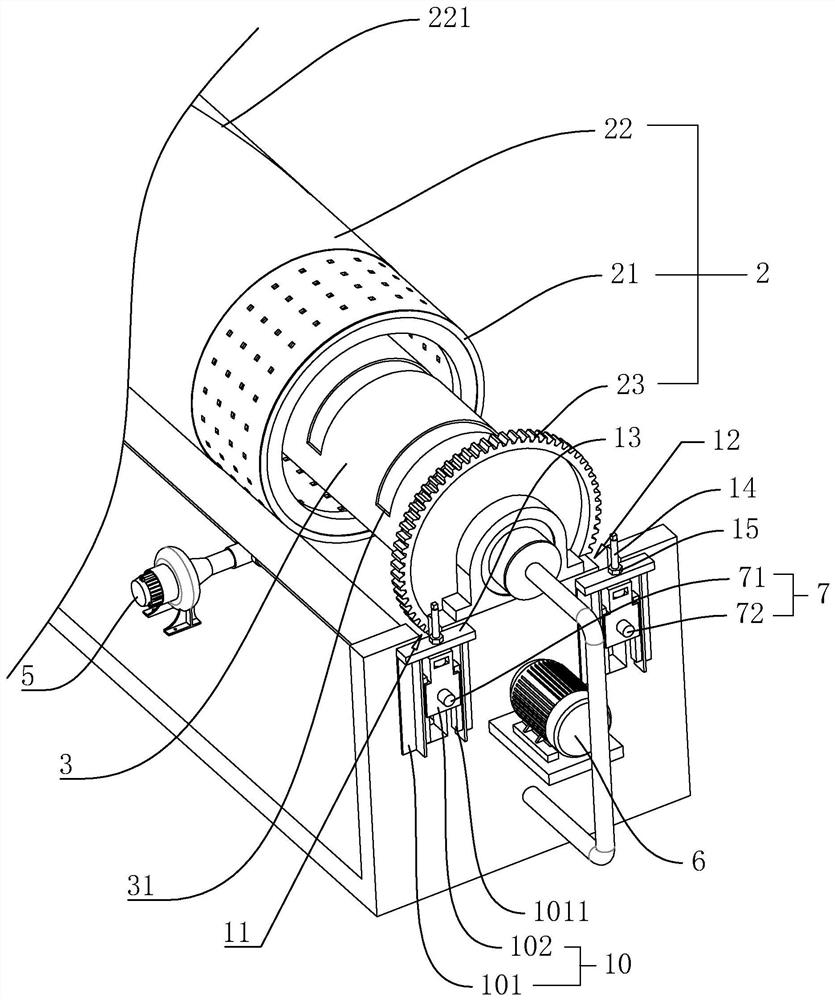

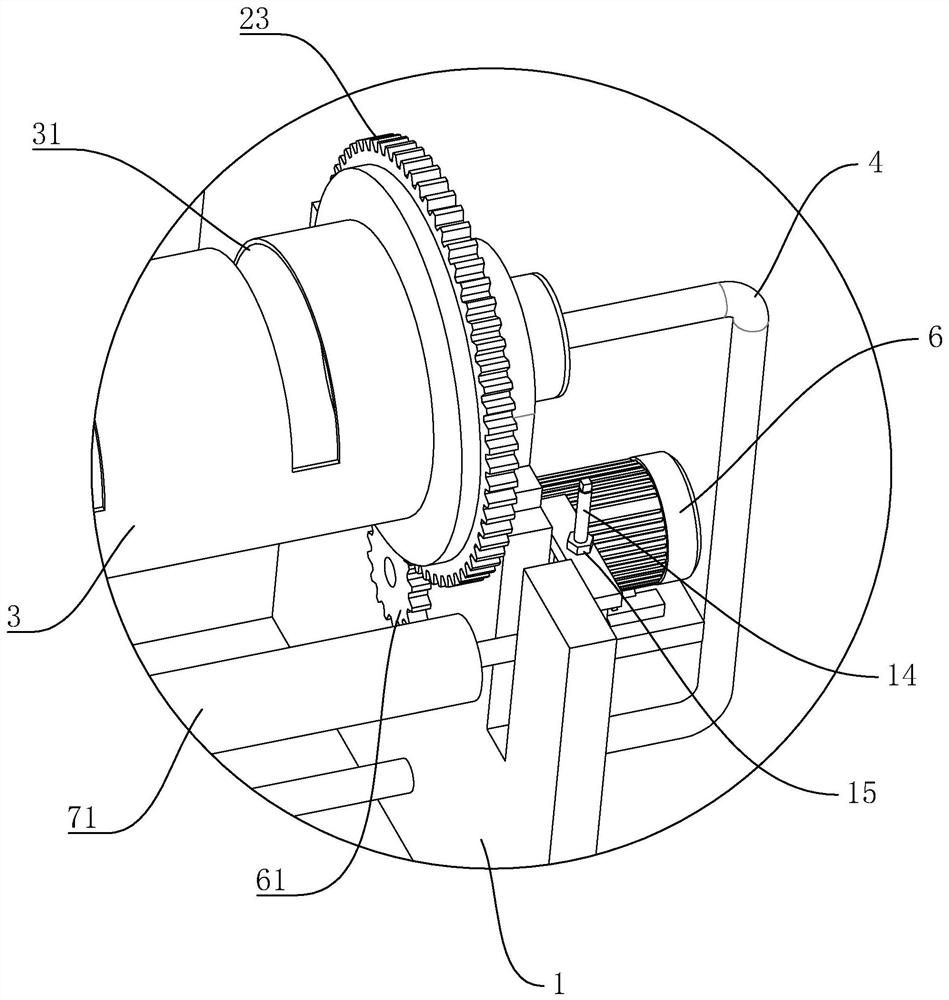

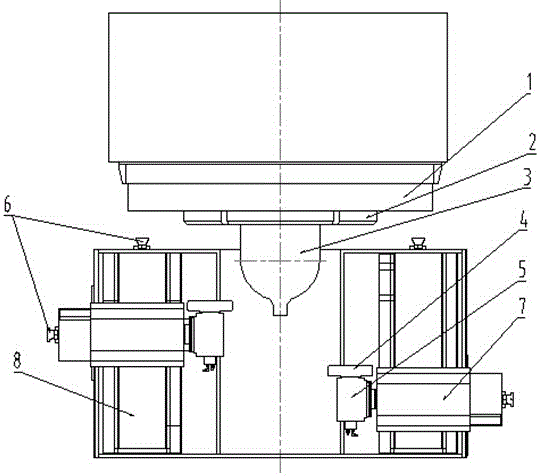

Uniform negative-pressure drum type web former of melt-blowing equipment and melt-blown fabric production process

The invention relates to the technical field of melt-blown fabric production, and aims at providing a uniform negative-pressure drum type web former of melt-blowing equipment and a melt-blown fabric production process. According to the technical scheme, the uniform negative-pressure drum type web former comprises a rack, a receiving drum arranged on the rack, and a winding mechanism located at theend, in the discharging direction, of the rack; the rack is provided with a first driving motor and a second driving motor, the first driving motor is used for driving the receiving drum to run, andthe second driving motor is used for driving the winding mechanism to run; the receiving drum comprises an inner barrel, and a filtering screen arranged on the outer layer of the inner barrel; a plurality of vent holes are evenly distributed in the barrel wall of the inner barrel, a negative-pressure flow guide barrel is arranged in the inner barrel in the axial direction, and the negative-pressure flow guide barrel communicates with a negative-pressure source; a pair of spreading roll sets parallel to the receiving drum is rotationally arranged below the receiving drum; and the traceless melt-blown fabric production process comprises the steps of raw material feeding, melt metering, die head spinning, yarn splitting and web paying, spreading and shaping and drafting and winding. The uniform negative-pressure drum type web former of melt-blowing equipment and the melt-blown fabric production process have the advantages of being uniform in melt-blowing web forming and homogeneous and traceless in fabric.

Owner:常州恒泓升机械有限公司

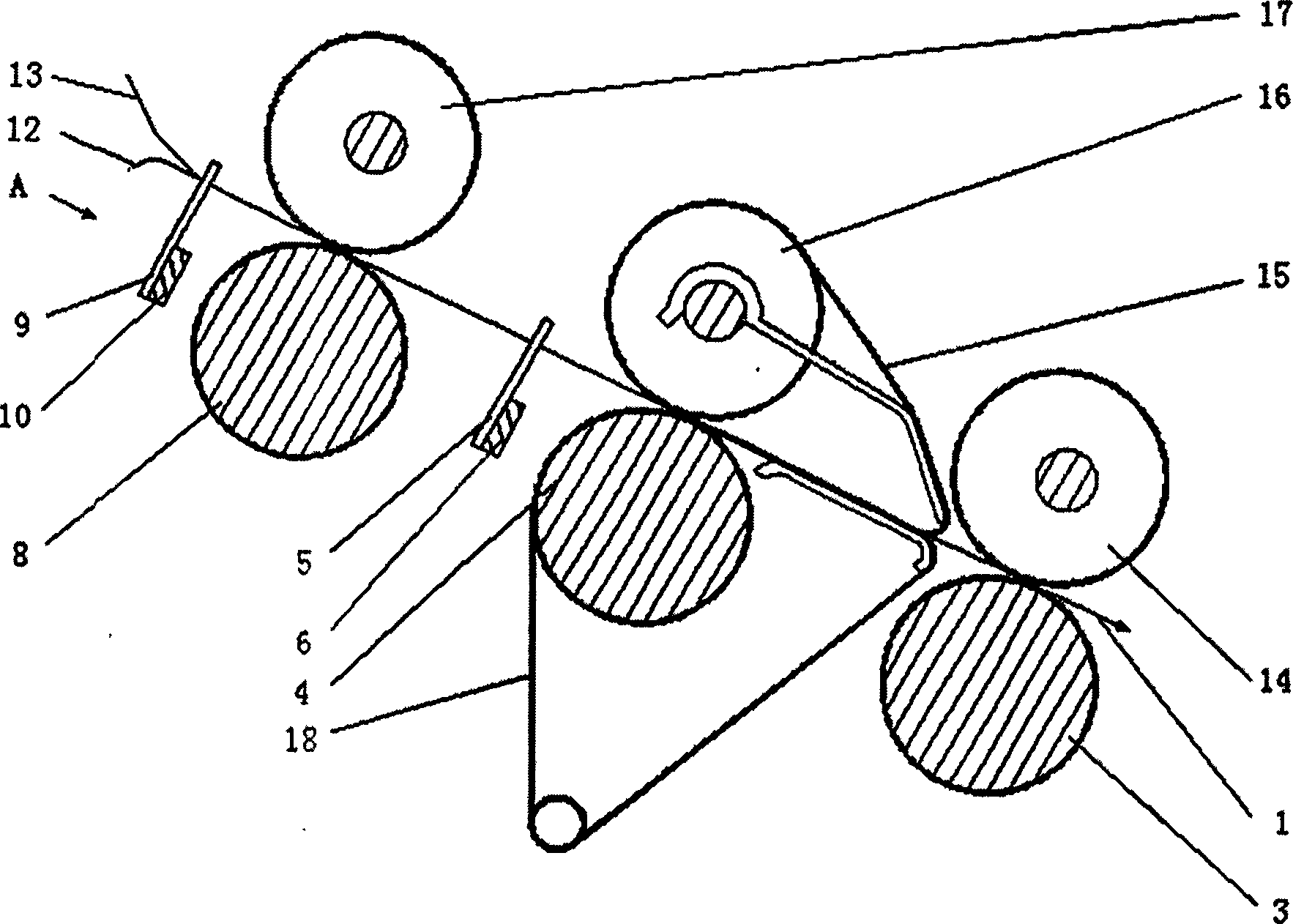

Method for preparing high-strength eight-head spinning polyamide-6 lower-middle denier full-drawn yarns

InactiveCN103409828AIncrease draft ratioIncrease productivityMelt spinning methodsStretch-spinning methodsYarnHEAD SPINNING

The invention relates to a method for preparing high-strength eight-head spinning polyamide-6 lower-middle denier full-drawn yarns. The method comprises the following steps that (1), a polyamide-6 slice enters a screw extruder through a stock bin, and the slice is made to be in a fusion state; (2), the slice in the fusion state is pressed into a spinning box through a fused material pipeline, is sprayed out through a spinneret plate, and forms tows in a small yarn chamber; (3), the tows are cooled in the small yarn chamber and pass a channel to be further cooled; (4), oil is fed to the cooled tows through an oil nozzle; (5), the oiled tows enter a feeding roller through a yarn guide and a yarn dividing bar, and then enter a coiler to be coiled after being drawn and shaped through a heat roller. The invention belongs to the spinning technology of chemical fibers. By means of the method, the production efficiency, the drawing multiplying power and the fiber strength are improved.

Owner:JIANGSU HAIYANG CHEM FIBERS

Preparation method of damping material used for installing draught fan

InactiveCN104987655ALight in massReduce thicknessPolyurea/polyurethane coatingsMelt spinning methodsPolymer scienceSilicon dioxide

The invention relates to a preparation method of a damping material used for installing a draught fan. The preparation method comprises the following steps: 1, putting nanometer carbon black, silica sol and addition agents into waterborne polyurethane latex, conducting ultrasonic treatment, and obtaining composite emulsion for standby application; 2, conducting mixing, grinding and dispersing on expanded vermiculite, cristobalite, bentonite and 3-phenyl-2-propyl acrylate for 2-2.5 h, mixing the obtained materials with other residual materials, stirring the mixture evenly and sufficiently, putting the mixture into a twin-screw extruder, conducting prilling by fusing and extrusion at the temperature ranging from 180 DEG C to 190 DEG C, and obtaining modified master batches; 3, putting the modified master batches into a screw extruder for being fused, spraying the flux out through a melting-spraying die head spinning orifice at the temperature ranging from 230 DEG C to 250 DEG C, stretching the flux under the effect of high-speed hot air flow, putting the flux into a receiving device, and after the composite emulsion is solidified and dried completely, obtaining the finished damping material. The phenolic resin damping material wrapped by expanded vermiculite-polyurethane composite emulsion which is obtained through preparation is low in mass, small in thickness and quite good in damping effect.

Owner:李平兰

Double-rotation wheel hot spinning necking method for large-diameter seamless gas cylinder

InactiveCN105728576AIncrease the outer diameterIncrease wall thicknessShaping toolsHEAD SPINNINGGas cylinder

The invention discloses a double-rotation wheel hot spinning necking method for a large-diameter seamless gas cylinder and relates to the technical field of metal formation. According to the double-rotation wheel hot spinning necking method, by sequentially carrying out processes including steel tube heating, hemisphere sealing head spinning, bottle mouth formation spinning and sealing head surface finishing spinning, the seamless gas cylinder with larger diameter and larger thickness can be produced, and in addition, double-wheel spinning reduces the spinning time and lowers the production cost.

Owner:YANGZHOU CHENGDE STEEL PIPE

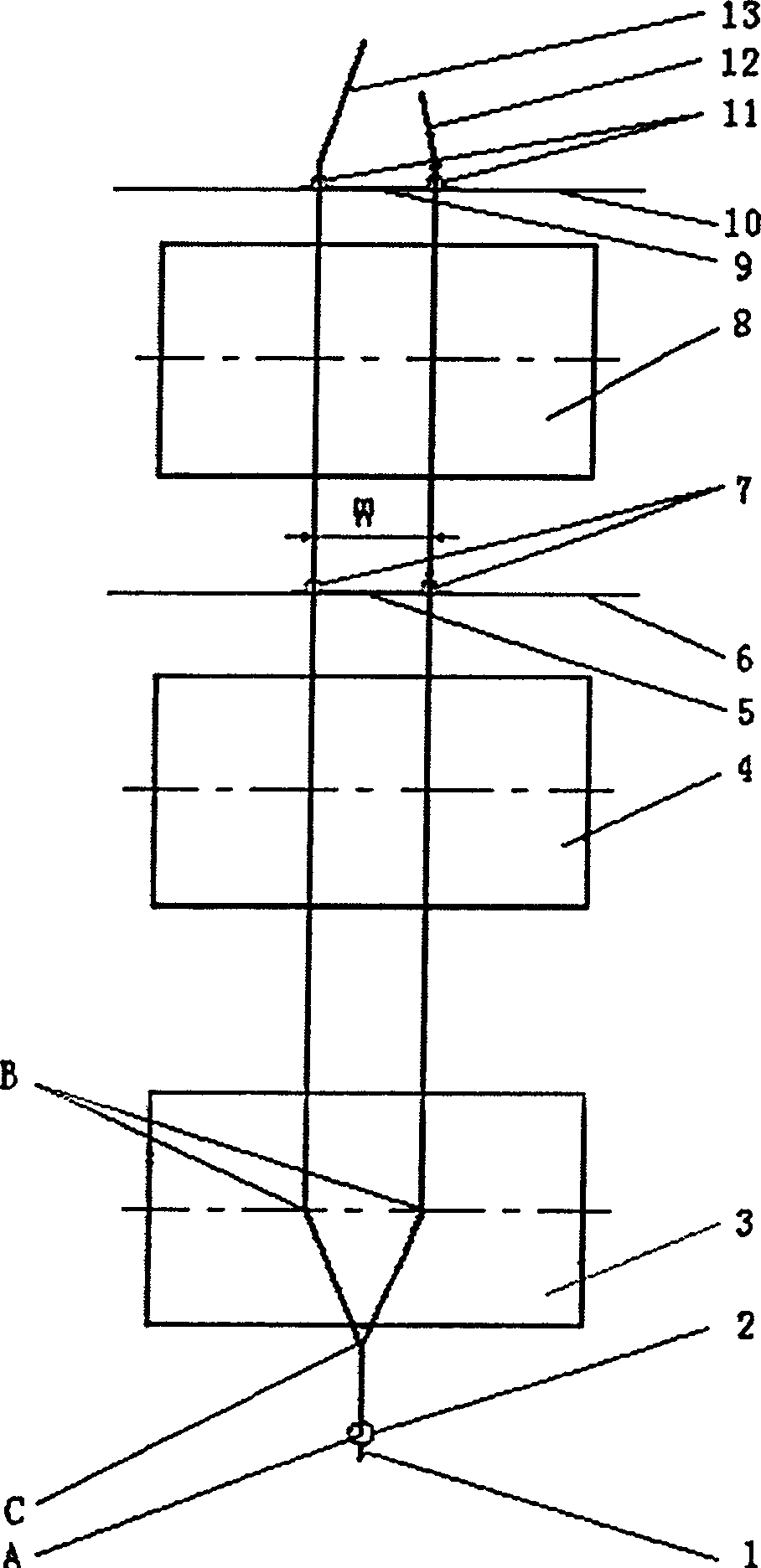

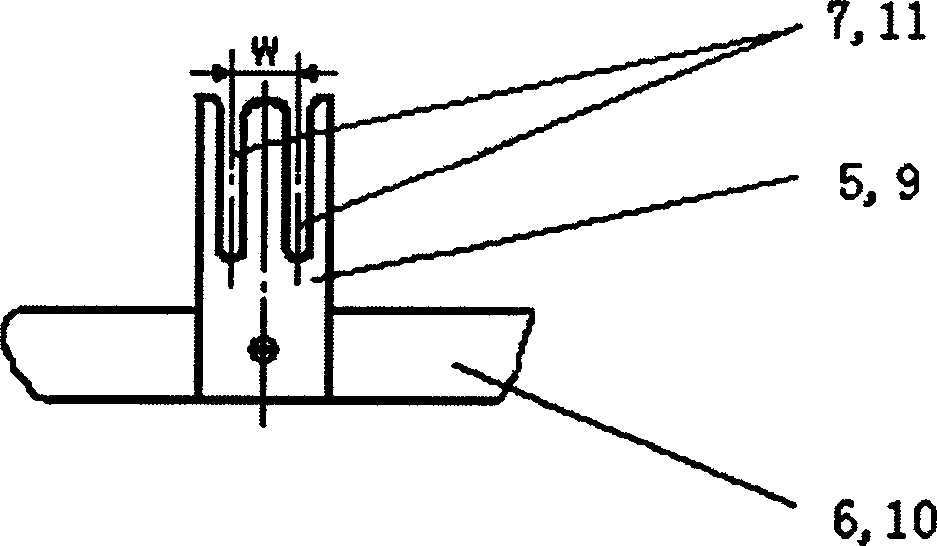

Method and its device for ring spindle yarn multiple head spinning

InactiveCN1587463AImprove friction resistanceImprove evennessContinuous wound-up machinesHEAD SPINNINGEngineering

The technological process of ring spindle yarn multiple-headed spinning includes multiple-headed roving feeding of two or more pieces of roving via yarn finger, back roller and leather roller, multiple-headed stretching via at least one middle yarn finger, front roller pairs, leather roller and leather ring, leading out from the front rollers and leather roller, twisting in the twisting area, and further twisting and winding via the front yarn finger. For realizing the said technological process, the ring spinning machine has corresponding improved mechanism, a multiple-headed feeding and yarn fingering unit. The present invention has the advantages of obtaining spun yarn with improved structure, effectively reduced spinning hairiness, improved friction performance of spun yarn in later processing steps, improved spun yarn homogeneity, raised single yarn strength, etc.

Owner:JIANGSU DANMAO TEXTILE

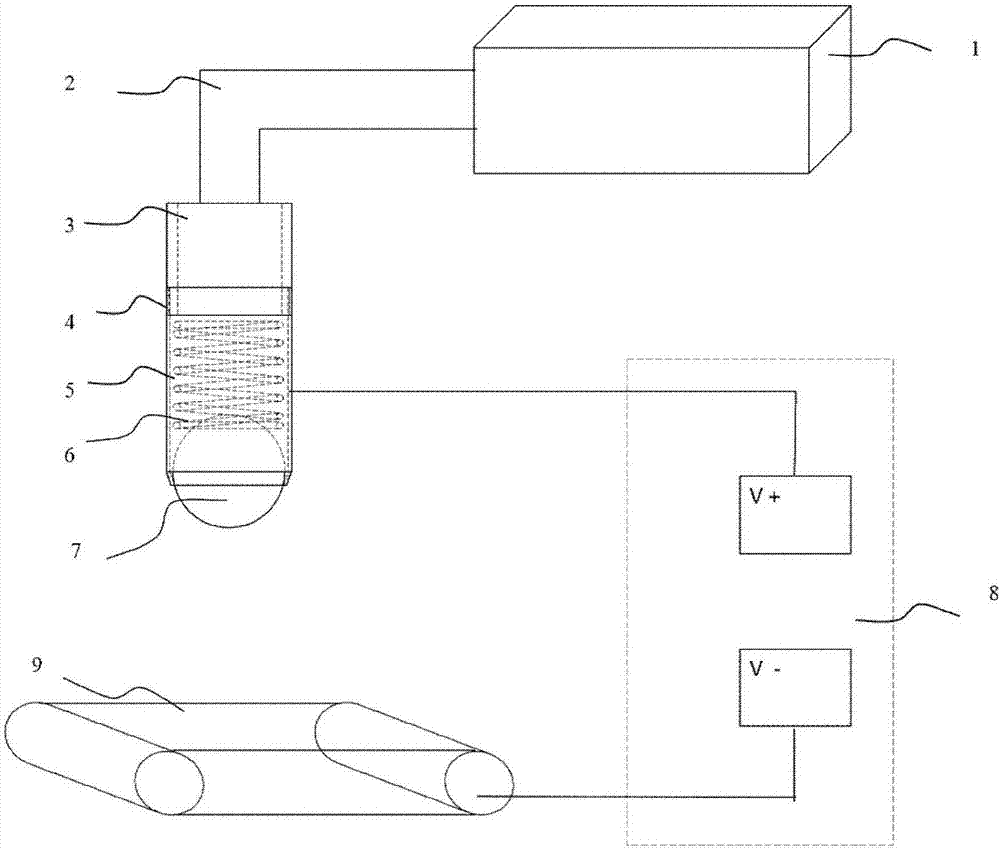

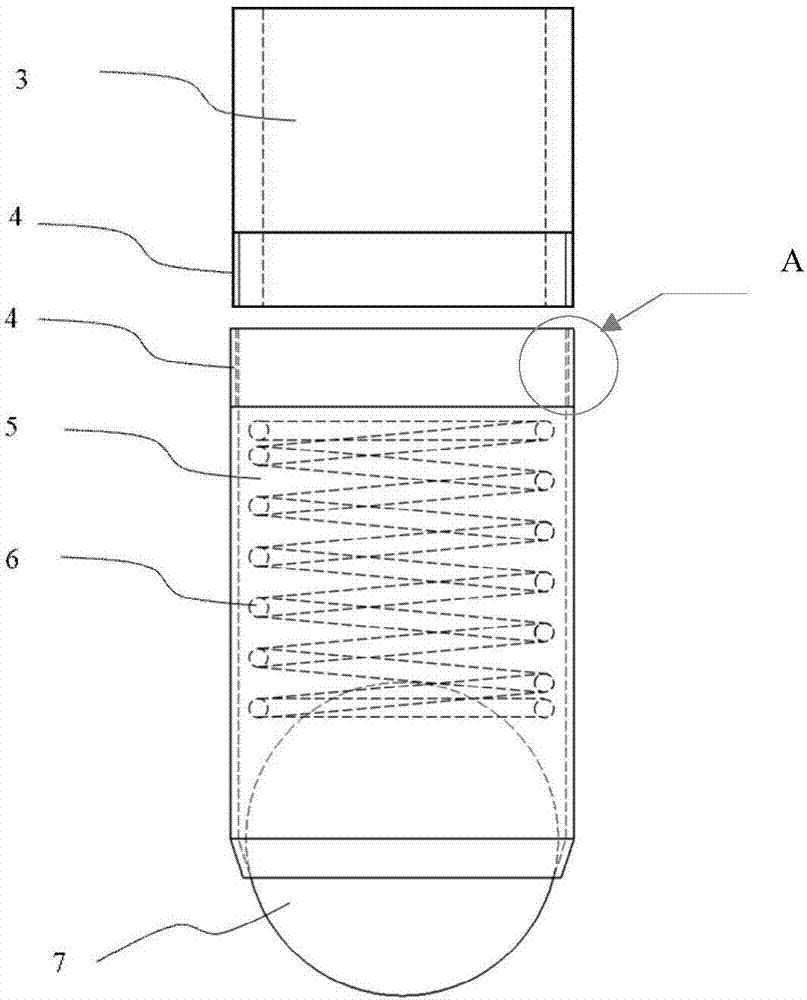

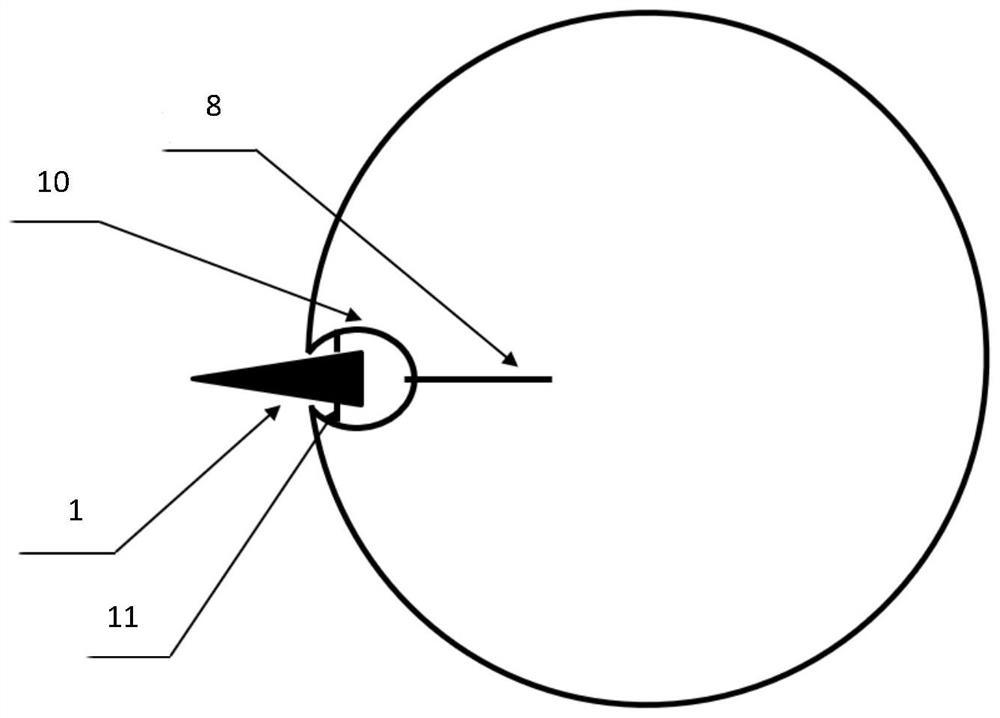

Bead head nozzle electrostatic spinning device

ActiveCN107201559AEasy to makeEasy to cleanFilament/thread formingTextile/flexible product manufactureHEAD SPINNINGCapillary Tubing

The invention discloses a bead head nozzle electrostatic spinning device and belongs to the field of electrostatic spinning. The bead head nozzle electrostatic spinning device comprises a liquid incoming propelling device, a bead head spinning system, a power supply system and a receiving system. A gap between a bead head and a liquid outgoing pipe cone closing portion is utilized to enable liquid to flow out, one or multiple Taylor cones are formed under excitation of a high-voltage electric field, and the problem of capillary needle type electrostatic spinning blockage can be solved effectively by rotating the bead head. The bead head can be demounted for cleaning after electrostatic spinning is finished. Solution spinnable range can be expanded by treating the liquid outgoing pipe cone closing portion to prepare uniform liquid leaking ports different in size according to different working conditions like viscosity of needed liquid, and the device can be used for melt spinning. Receiving distance can be adjusted by combining bead size with solution concentration so as to realize far-near field spinning.

Owner:JILIN AGRICULTURAL UNIV

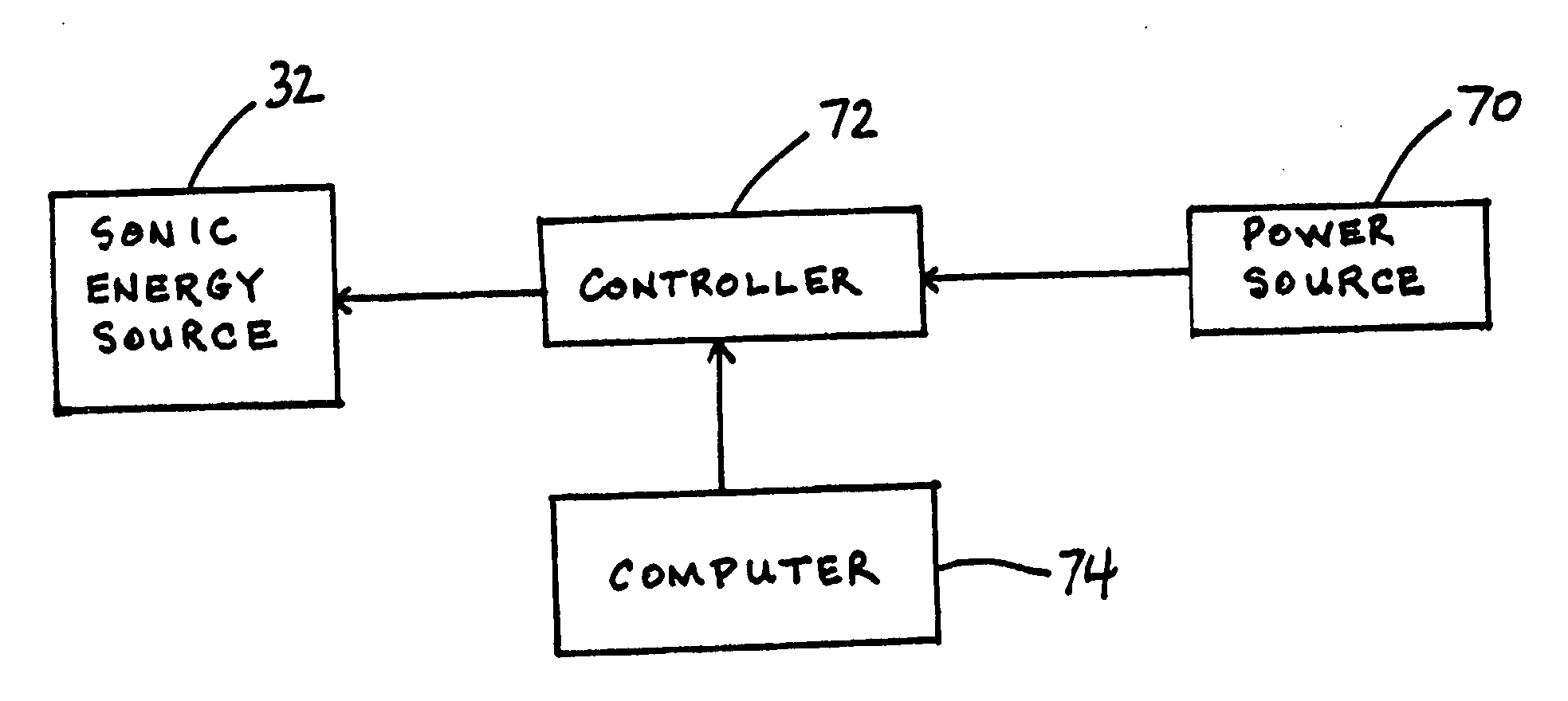

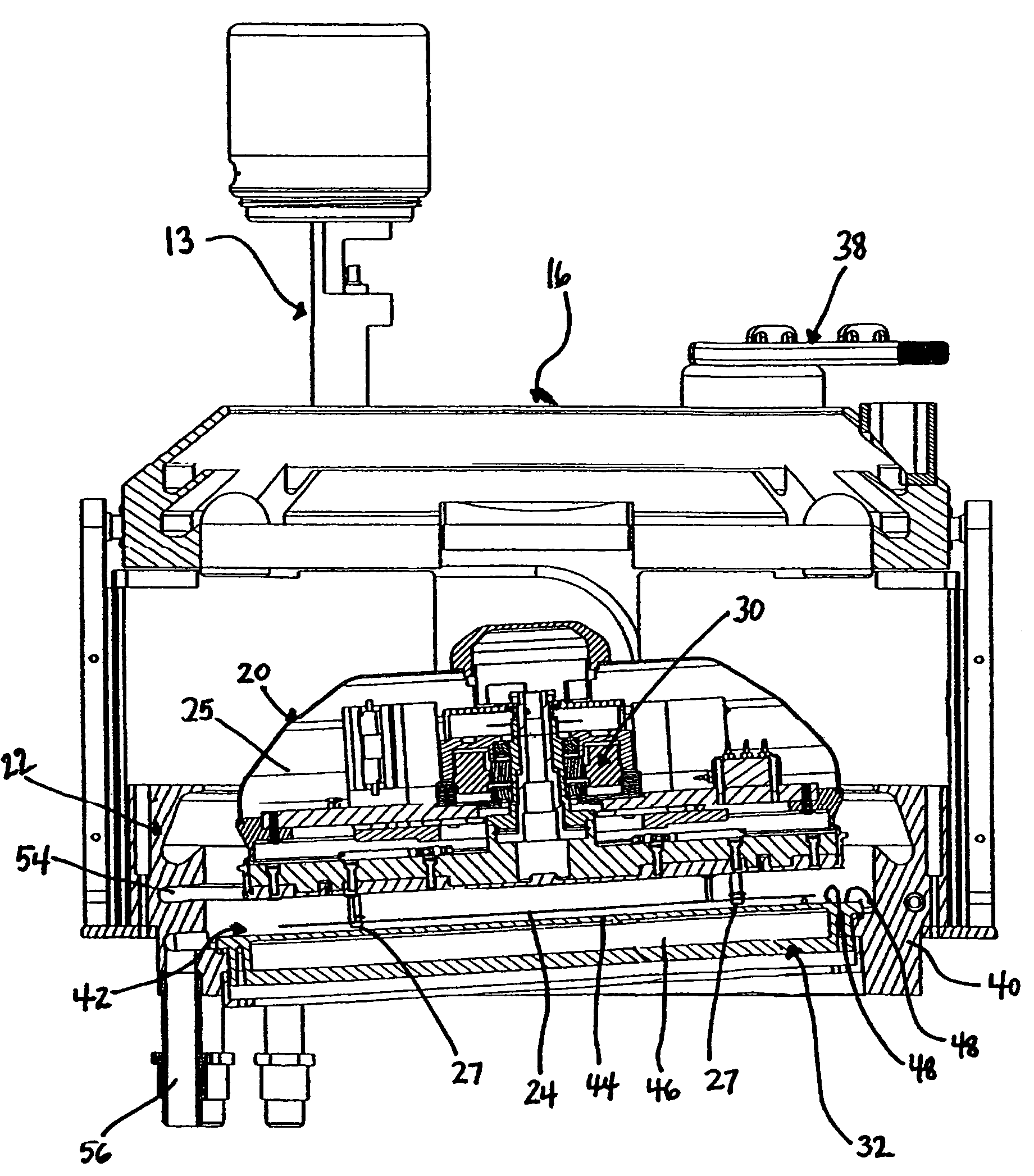

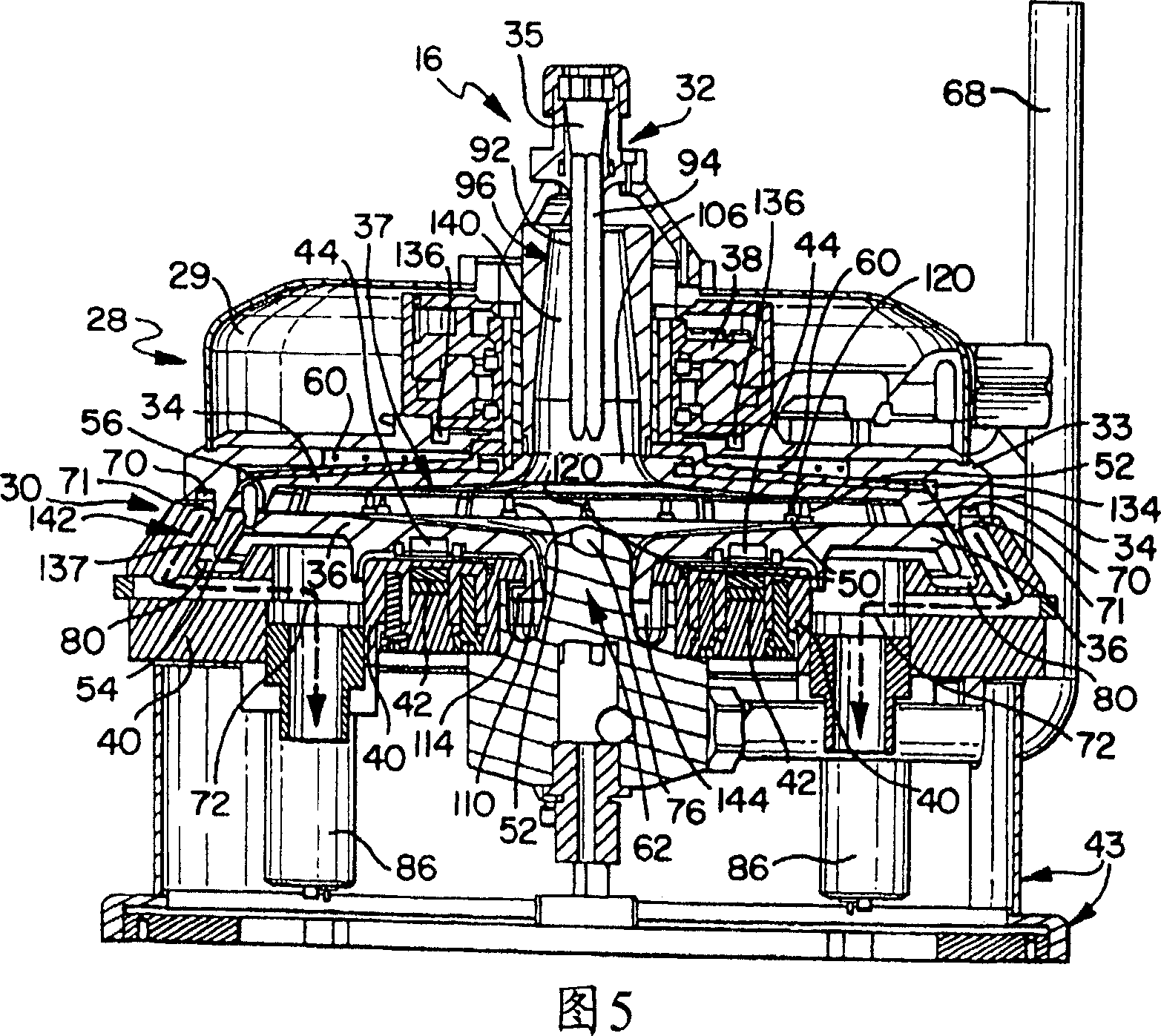

System for processing a workpiece

InactiveUS20070084829A1Easy to manufactureReduce particle pollutionDecorative surface effectsSemiconductor/solid-state device manufacturingHEAD SPINNINGEngineering

A system for processing a workpiece includes a process head assembly and a base assembly. The process head assembly has a process head and an upper rotor. The base assembly has a base and a lower rotor. The base and lower rotor have magnets wherein the upper rotor is engageable with the lower rotor via a magnetic force created by the magnets. The engaged upper and lower rotors form a process chamber where a semiconductor wafer is positioned for processing. Process fluids for treating the workpiece are introduced into the process chamber, optionally while the processing head spins the workpiece. Additionally, air flow around and through the process chamber is managed to reduce particle adders on the workpiece.

Owner:SEMITOOL INC

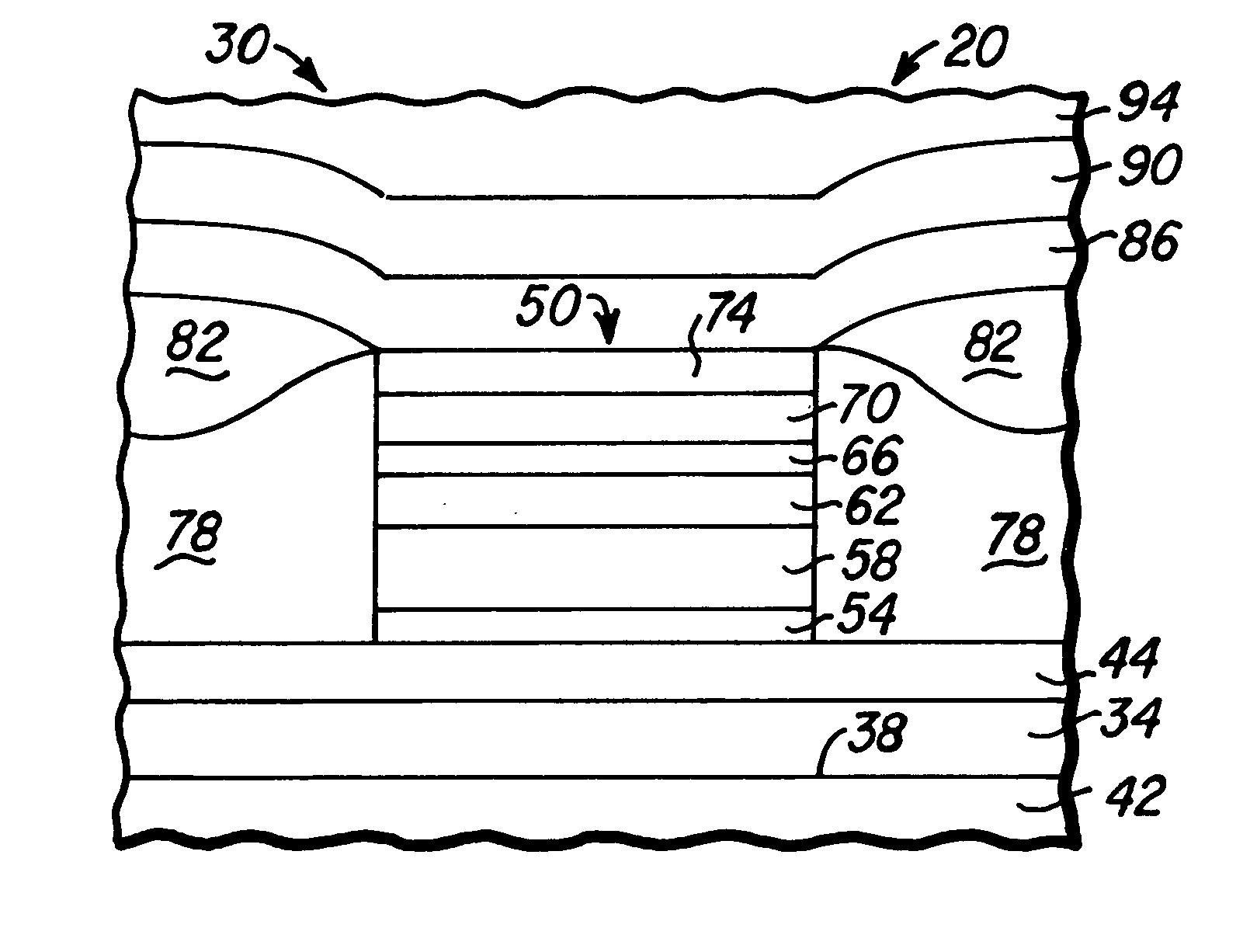

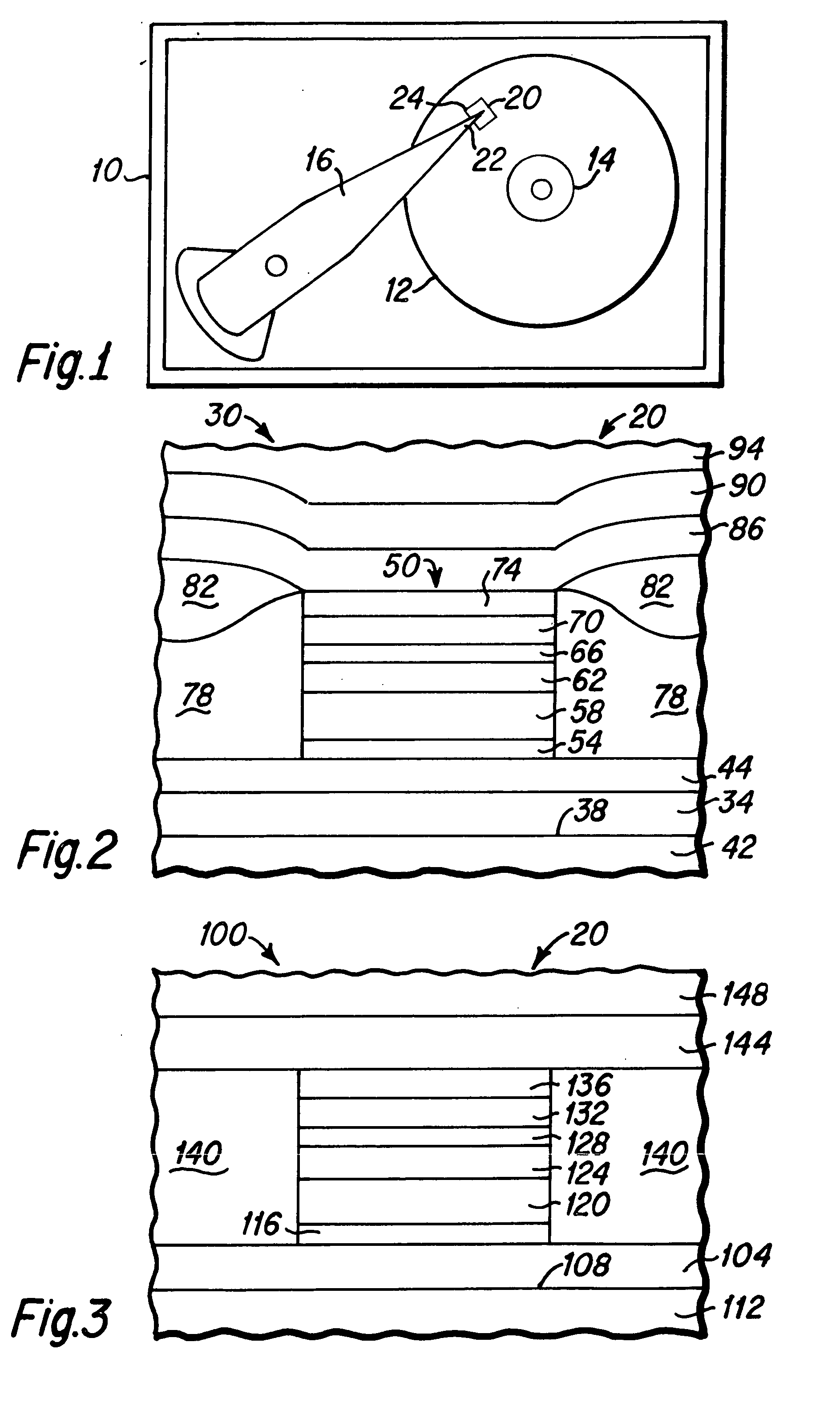

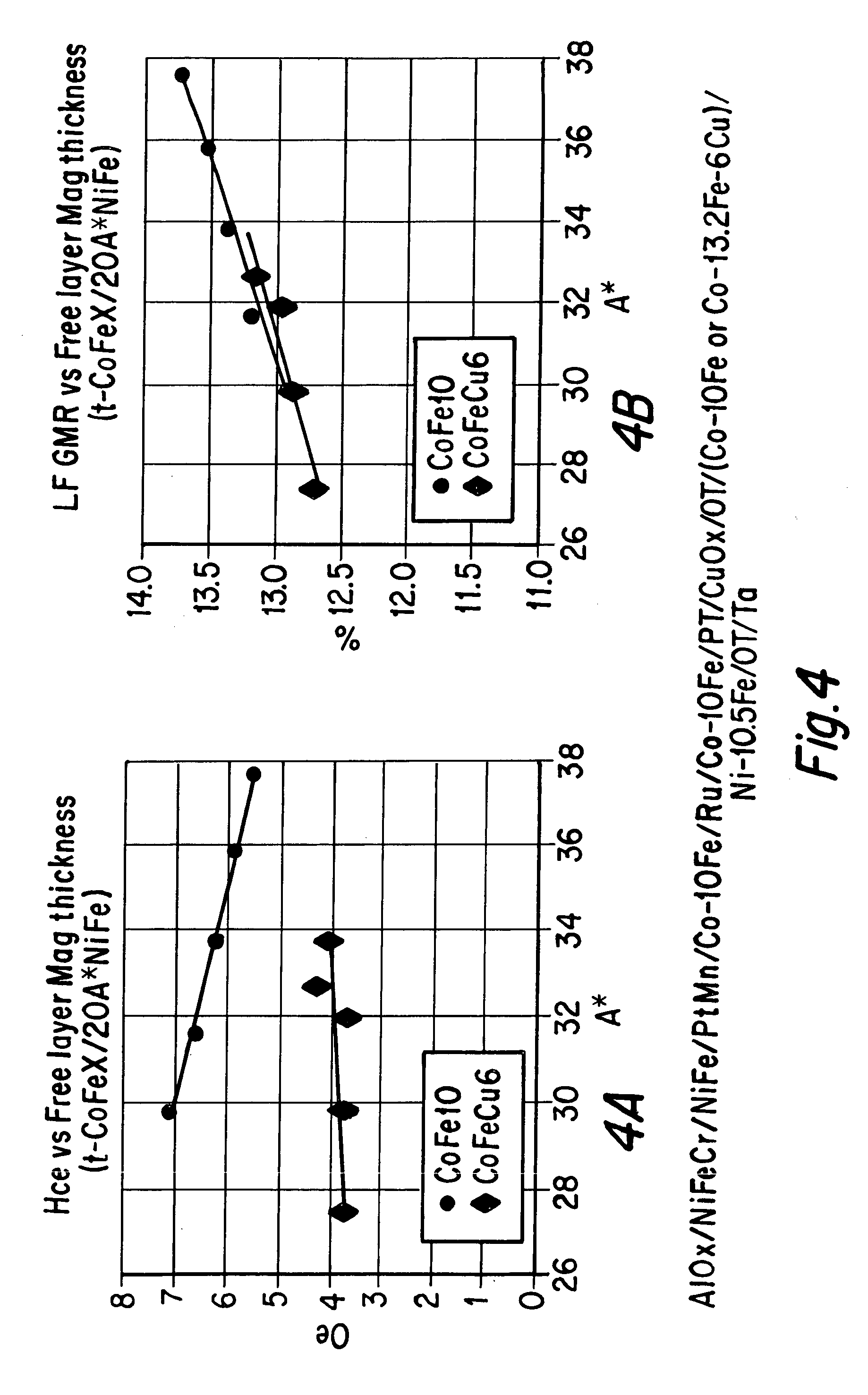

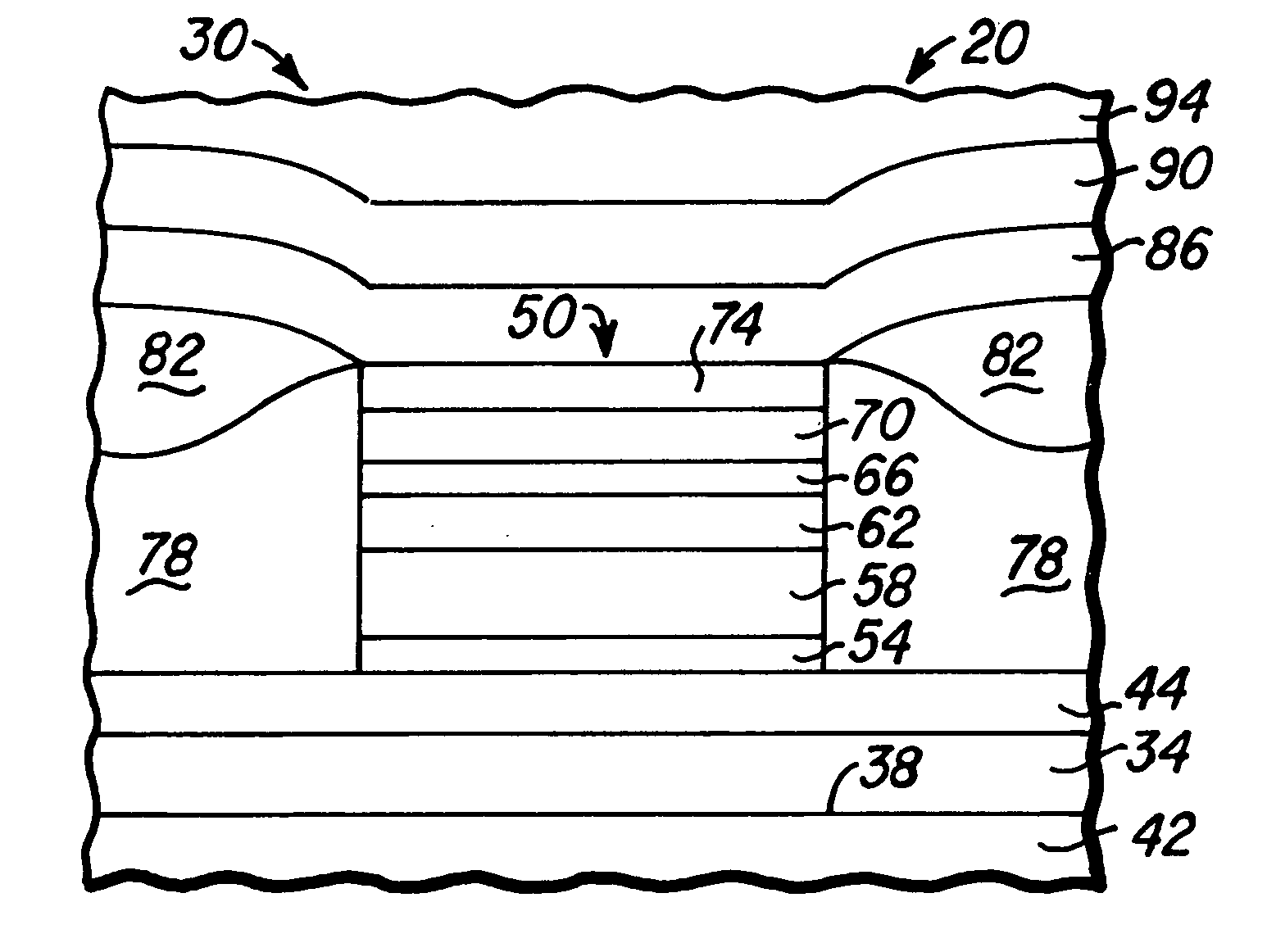

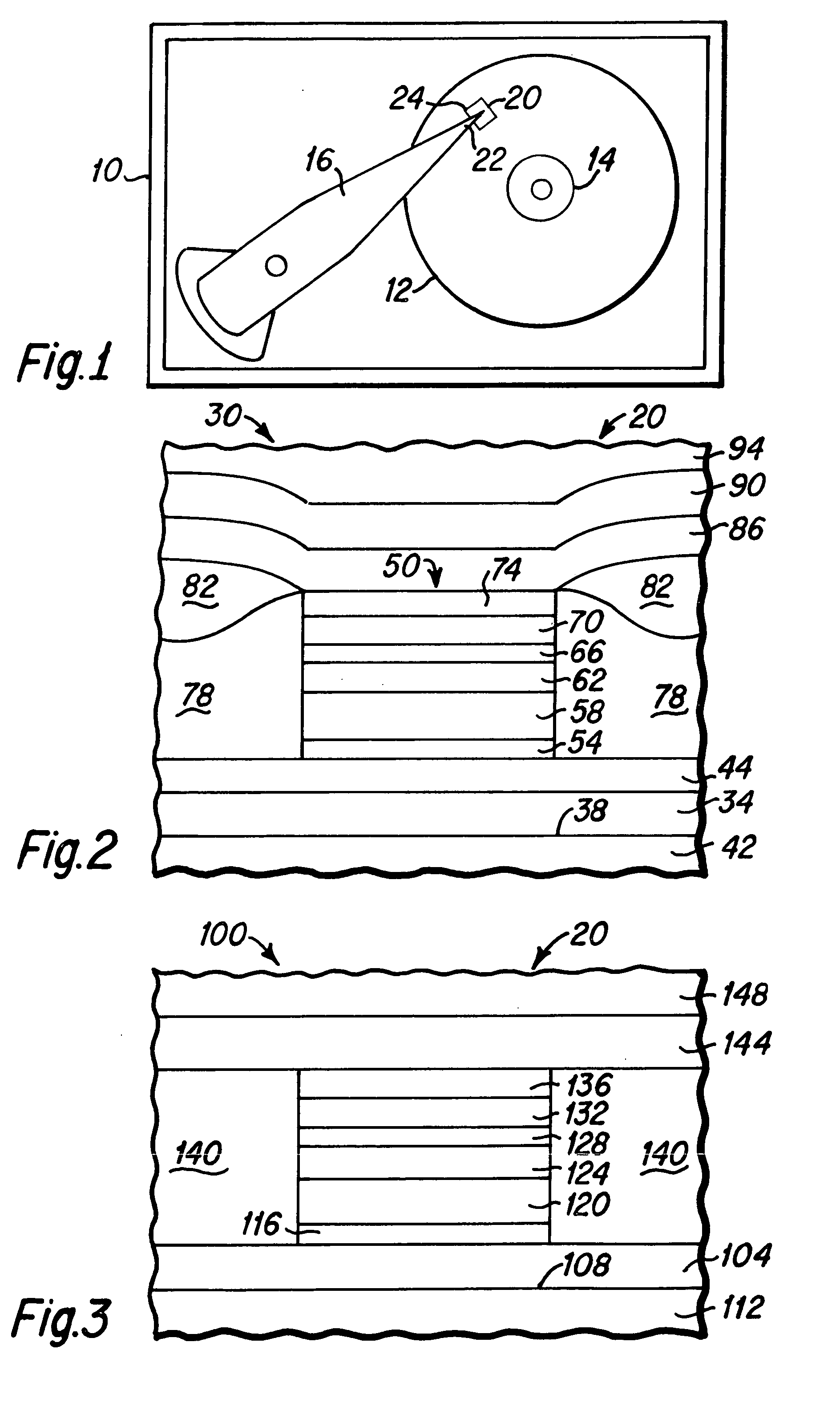

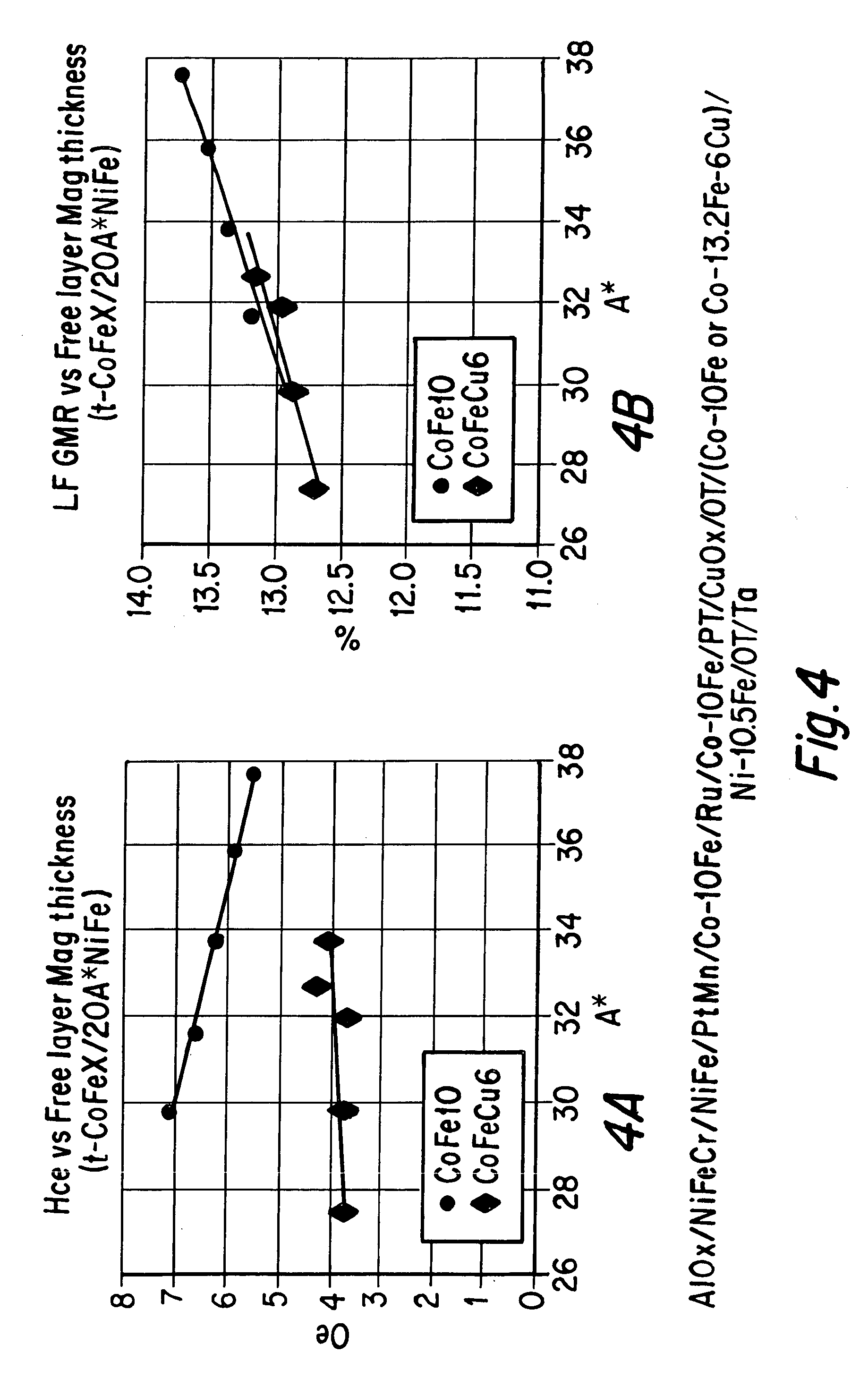

Magnetic head spin valve structure with CoFeCu magnetic layer and ZnOx/TaOx cap layer

InactiveUS20060061917A1Low coercivityIncreased ΔR/RNanomagnetismMagnetic measurementsHEAD SPINNINGSpin valve

A magnetic head that includes a spin valve sensor of the present invention which may be a CIP or CPP device. The sensor includes a free magnetic layer that is comprised of CoFeCu. In certain embodiments the free magnetic layer may also include a sublayer of NiFe. The CoFeCu free magnetic layer preferably includes Fe in a range of 5-20 at. % and Cu in a range of 1-10 at. %. The sensor may also include a cap layer of the present invention that is comprised of ZnOx / TaOx. The CoFeCu free magnetic layer of the present invention provides improved sensor performance characteristics of reduced coercivity and generally similar GMR as compared to the prior art. Where the ZnOx / TaOx cap layer is utilized, increased GMR is obtained. Thus a magnetic head of the present invention that includes both a CoFeCu free magnetic layer and a ZnOx / TaOx cap layer demonstrates reduced coercivity and increased GMR.

Owner:WESTERN DIGITAL TECH INC

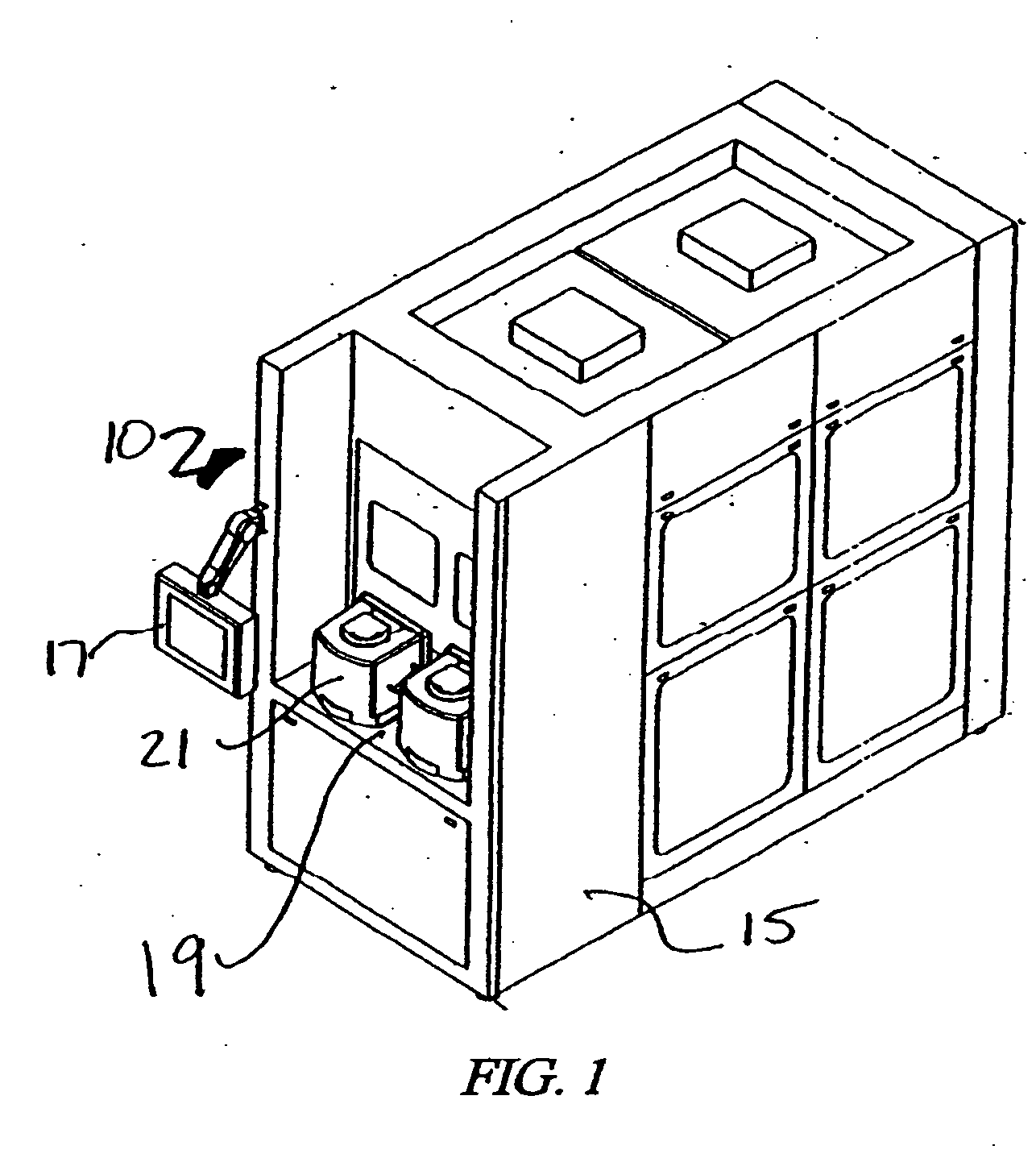

Automatic collection method for spinning behavior data of silkworms

ActiveCN103808308AImprove efficiencyImprove data accuracyPicture taking arrangementsPicture interpretationHEAD SPINNINGComputer graphics (images)

The invention discloses an automatic collection method for spinning behavior data of silkworms. According to the method, a binocular vision technology is used; two cameras are fixed in the same direction or different directions to automatically collect the spinning behavior data of the silkworms. The behavior data mainly comprises kinematic velocity and track of the silkworm head spinning mouths in the spinning process. The method comprises the steps of collecting image sequences of movement of silkworm heads in the spinning process of the silkworms by using the cameras, then solving three-dimensional coordinates of the movement of the silkworm spinning mouths according to the collected image sequences to analyze the behavior data comprising spinning velocity and track of the silkworms and store the behavior data. Through the method, manual labor for collecting spinning behavior data of silkworms is reduced and the precision of the data collection is improved.

Owner:SOUTHWEST UNIVERSITY

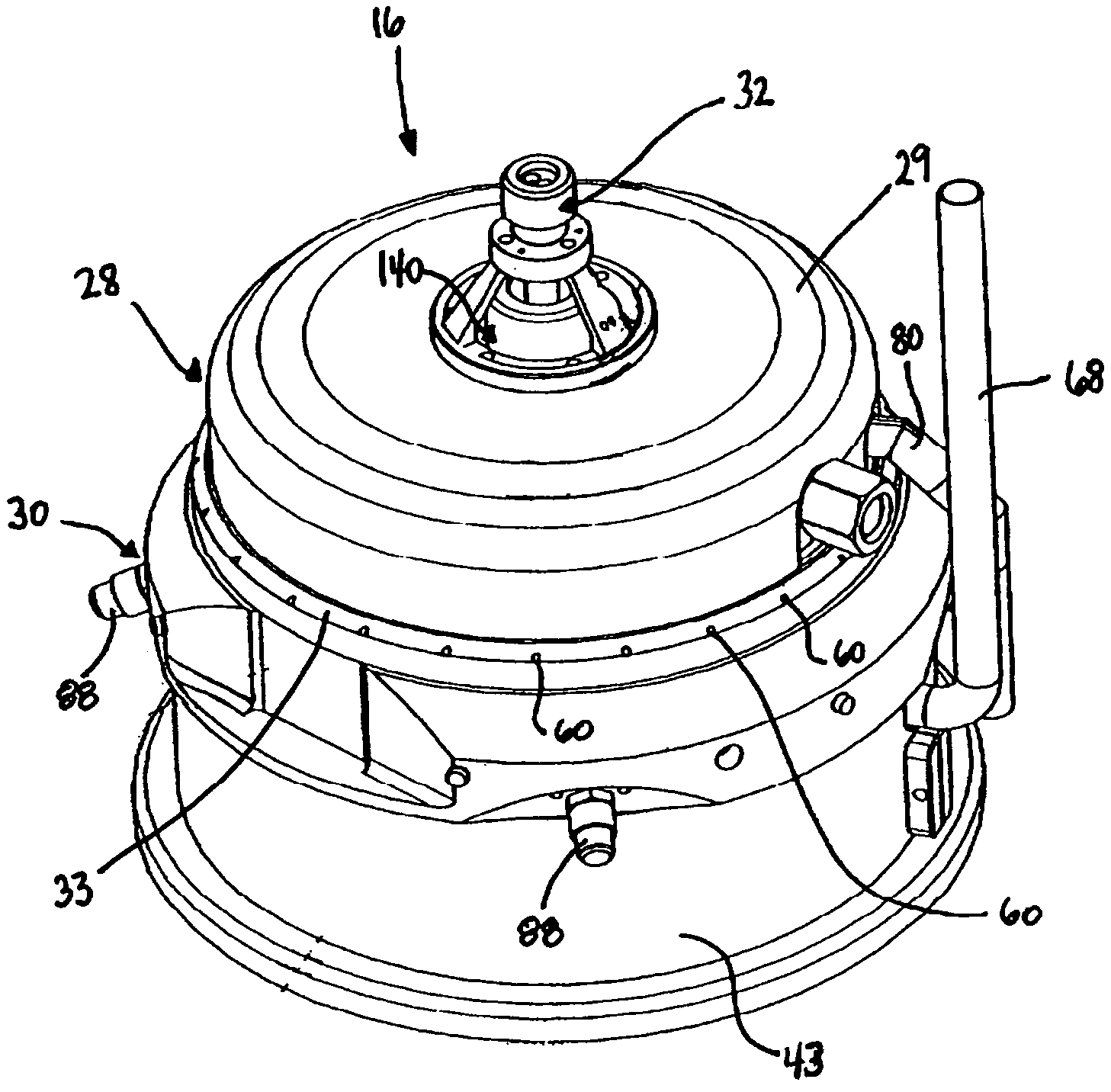

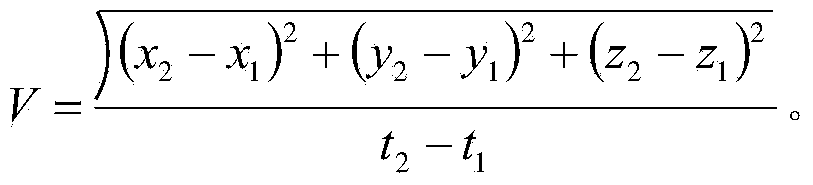

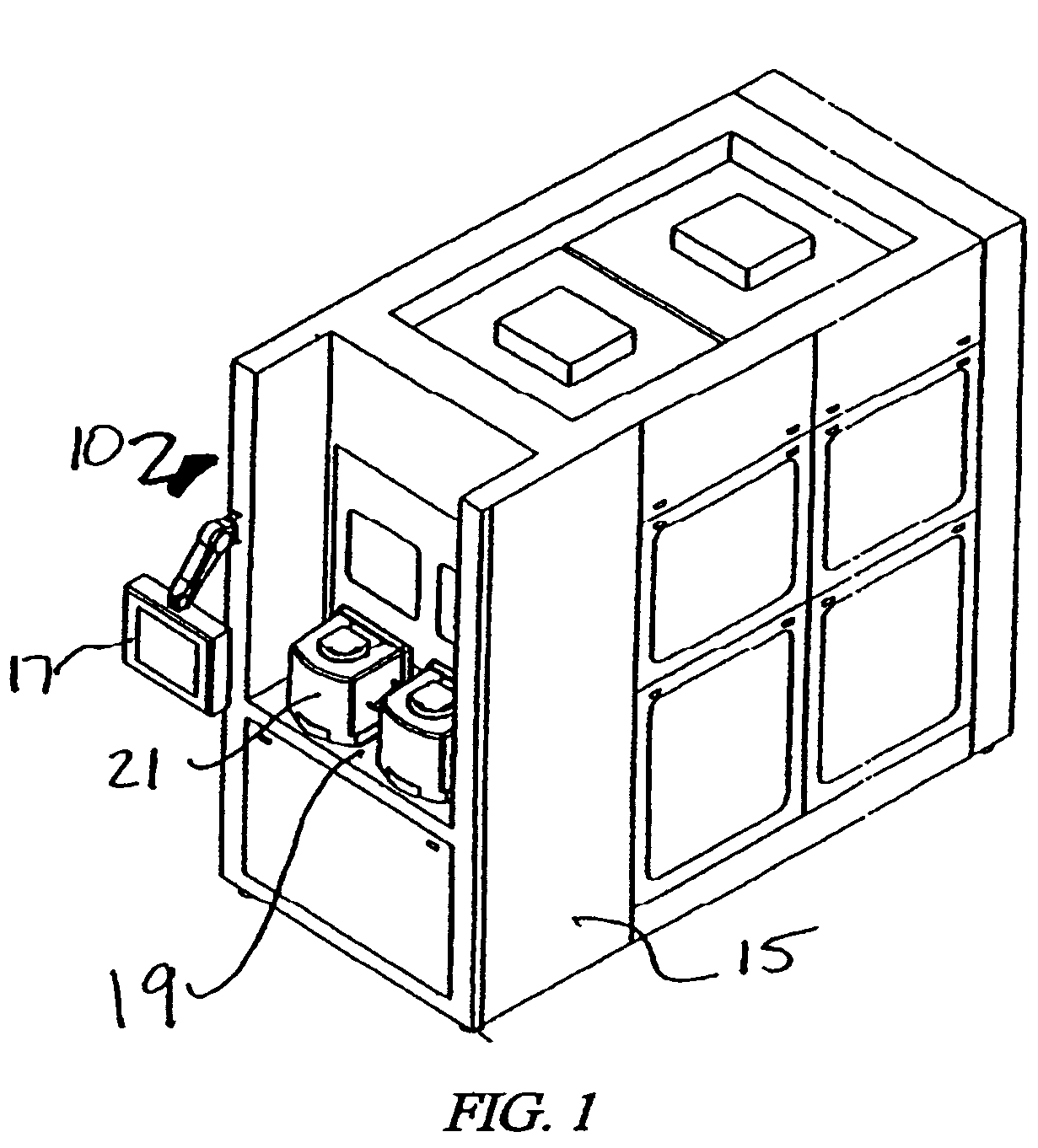

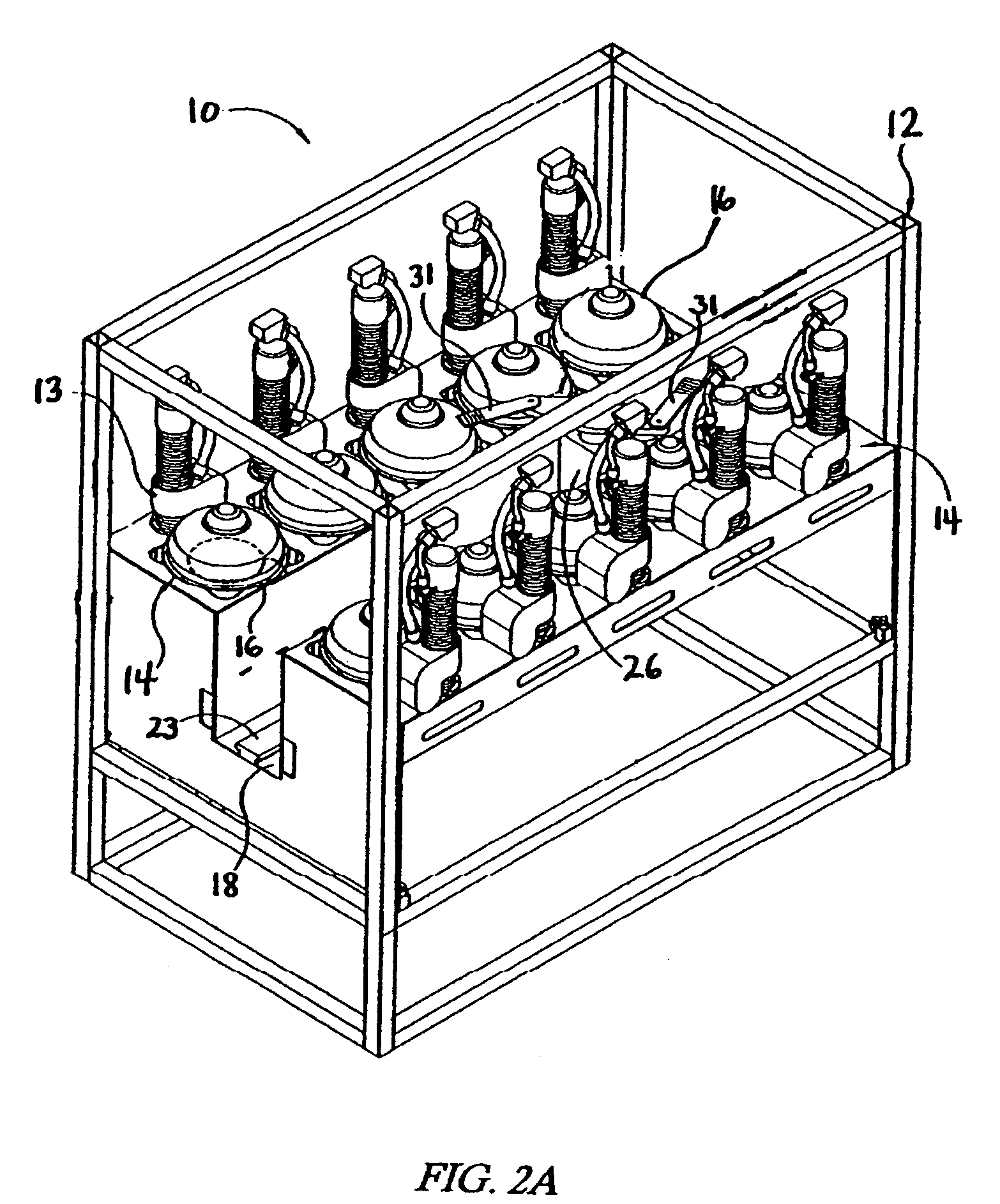

Sonic energy process chamber

InactiveUS20050199066A1Reduced boundary layer thicknessUniform processingRadiation pyrometryAnalysing solids using sonic/ultrasonic/infrasonic wavesHEAD SPINNINGTransducer

A system for processing a workpiece includes a base having a bowl or recess for holding a processing fluid. A sonic energy source, such as a megasonic transducer, provides sonic energy into a processing fluid in the bowl. A process head holds a workpiece. A process head lifter lowers the head holding the workpiece into the processing fluid in the bowl. Sonic energy is provided to the workpiece through the processing fluid, optionally while the processing head spins the workpiece. The processing fluid may include de-ionized water and an etchant.

Owner:APPLIED MATERIALS INC

Polypropylene spunbond nonwoven fabric and preparation process for improving softness of polypropylene spunbond nonwoven fabric

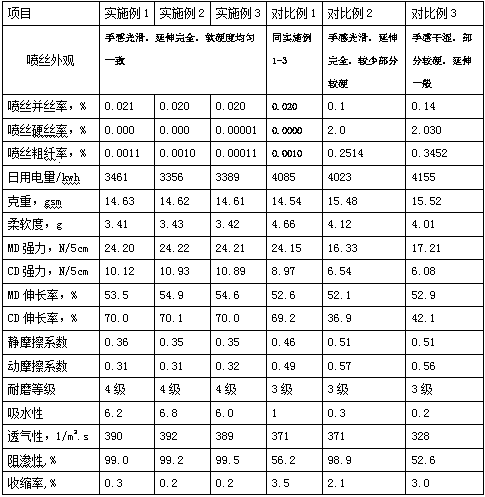

The invention provides polypropylene spunbond nonwoven fabric. According to the polypropylene spunbond nonwoven fabric, the softness is 3.41-3.43, the MD strength is 24.20-24.22 N / 5cm, and the CD strength is 10.12-10.93 N / 5cm; the invention further provides a preparation process for improving the softness of the polypropylene spunbond nonwoven fabric; the preparation process comprises pretreatment, die head spinning and hot rolling treatment, wherein during the hot rolling treatment, the mesh belt speed is 630-645 m / min and the hot rolling pressure is 80-90 daN / cm; the adding quantity of pretreated melt-blown materials is 3-10% of the gross raw materials, the melt-blown materials are high-melt-index PP melt-blown materials, and the melt index is 800-1500 g / 10 min; and during the die head spinning, the pressure of an air bellow is 2900-4000 pa, the temperature of the upper and lower cold air is 18-22 DEG C, and the single suction air volume is 1300 cubic meters per hour.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

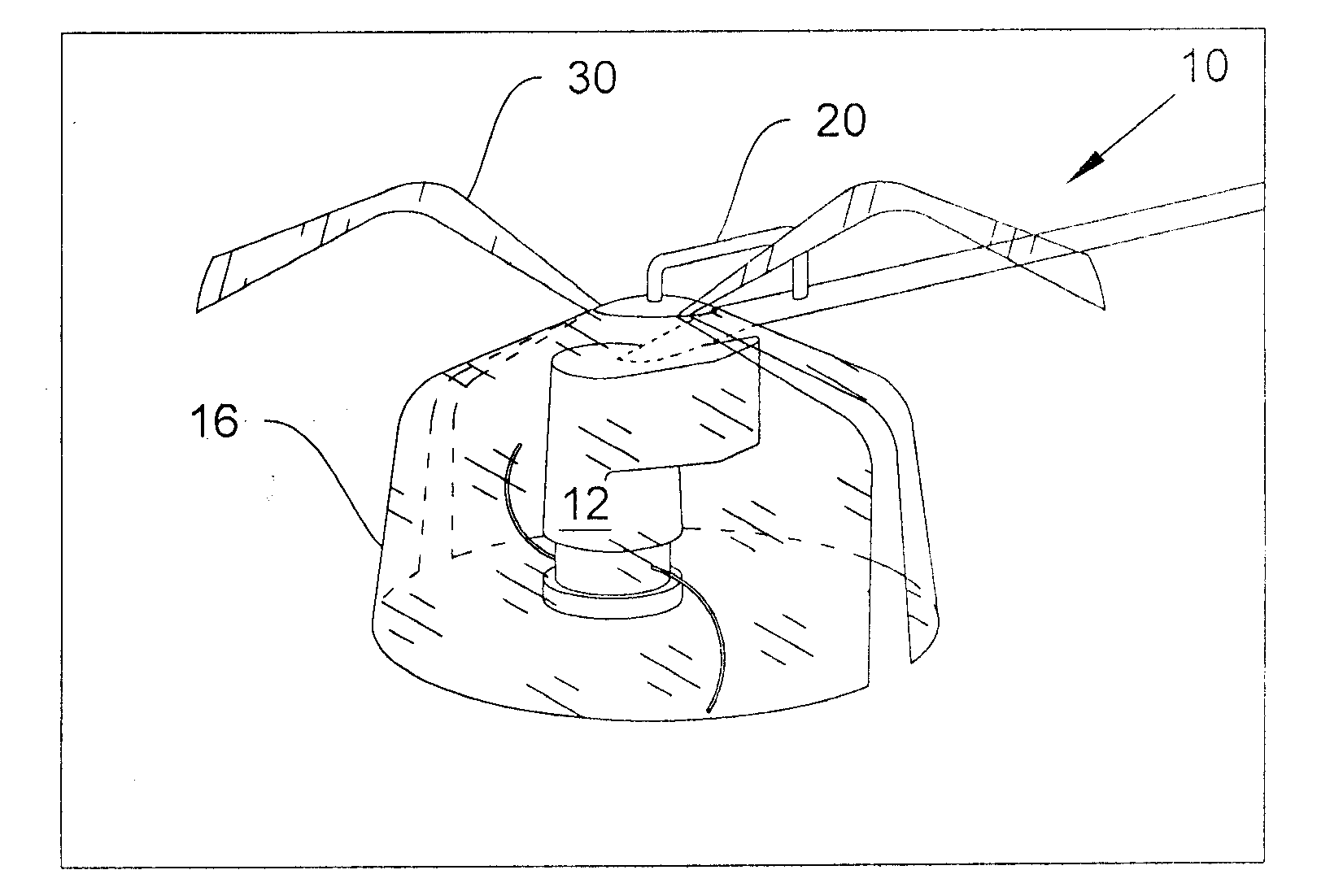

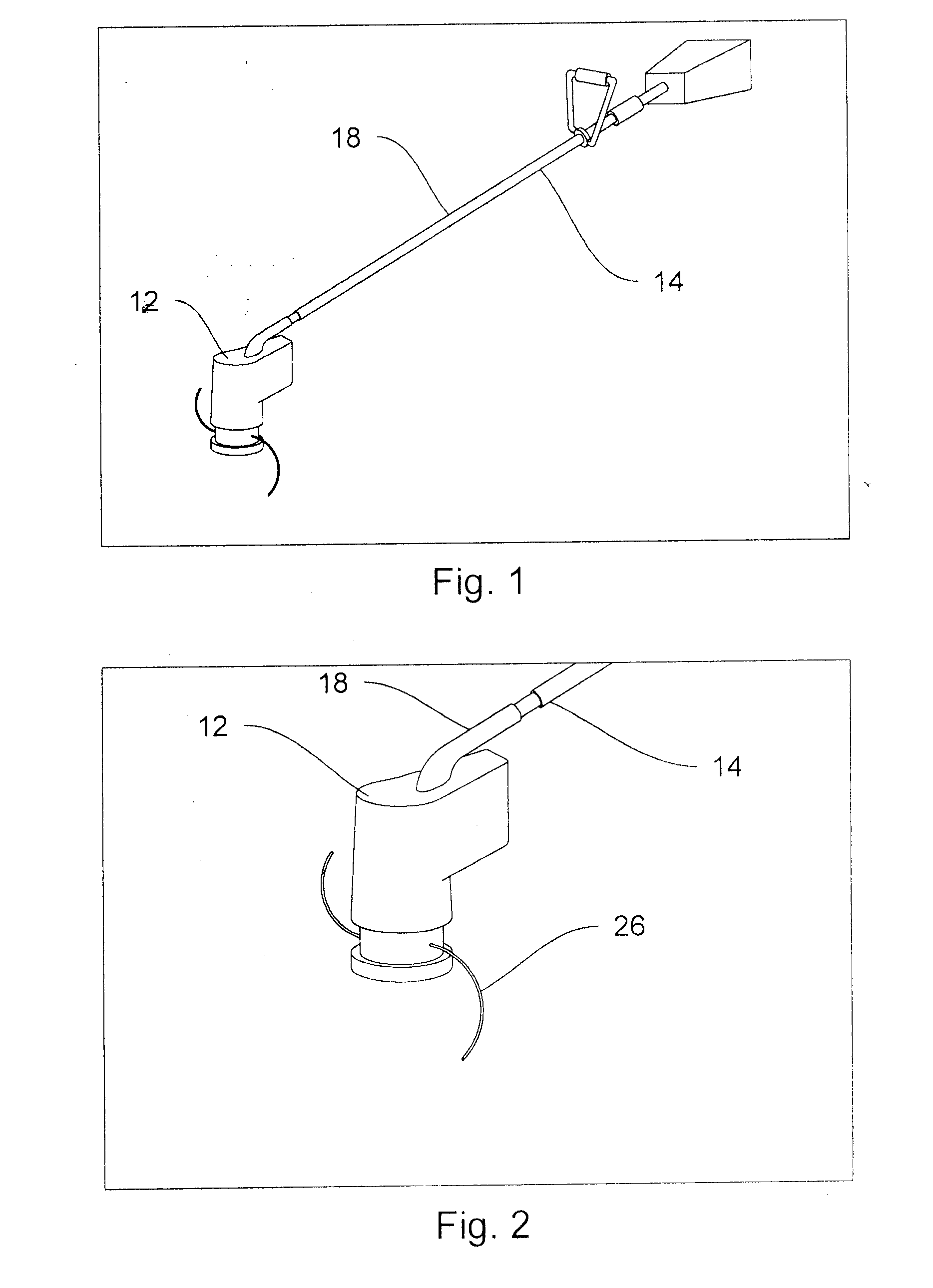

Protective Shield Apparatus

A protective shield apparatus for a power trimmer is provided. The power trimmer has a lower shaft with a trimmer head attached thereto with the trimmer head spinning a trimmer wire. The protective shield apparatus comprises a telescopic adjusting rod having a first end and a second end with the first end of the rod capable of being secured to the lower shaft of the power trimmer. A dome cover is secured to the second end of the telescopic adjusting rod by a gimbal bearing. The dome cover remains at a horizontal position, parallel with a ground surface and above the trimmer head, even when the trimmer head is being used at an angle with the dome cover reducing the power trimmer's hazardous tendency to “throw” debris out as it trims.

Owner:MACEDONIO JOHN +1

Device and method for catching and knotting head yarn and tail yarn of yarn spools

ActiveCN111498610ASimple and clear design structureImprove reliabilityFilament handlingSteroscopic systemsYarnHEAD SPINNING

The invention discloses a device and method for catching and knotting a head yarn and a tail yarn of yarn spools. The device for catching and knotting the head yarn and the tail yarn of the yarn spools consists of a controller, a binocular vision sensor, a truss robot and other parts; the designed structure is clear, and the reliability is good; the binocular vision sensor is used for capturing the head yarn and tail yarn of A and B yarn spools on the same layer of creel; the image processing, recognition technology and three-dimensional detection method are used for determining the coordinatepositions of the head yarn and tail yarn of the yarn spools; then a yarn capture mechanism is used for accurately capturing the head yarn and tail yarn to be knotted according to the identified positioning information; and the head yarn and tail yarn to be knotted are rotated into a bell mouth of a knotting machine to realize connection, so that the functions of automatic capture, knotting, and continuation are completed.

Owner:ZHEJIANG SCI-TECH UNIV

Sonic energy process chamber

InactiveUS7337663B2Reduced boundary layer thicknessUniform processingRadiation pyrometryAnalysing solids using sonic/ultrasonic/infrasonic wavesHEAD SPINNINGTransducer

A system for processing a workpiece includes a base having a bowl or recess for holding a processing fluid. A sonic energy source, such as a megasonic transducer, provides sonic energy into a processing fluid in the bowl. A process head holds a workpiece. A process head lifter lowers the head holding the workpiece into the processing fluid in the bowl. Sonic energy is provided to the workpiece through the processing fluid, optionally while the processing head spins the workpiece. The processing fluid may include de-ionized water and an etchant.

Owner:APPLIED MATERIALS INC

High-modulus and low-extension polyester industrial yarns used for geofabric and production method thereof

InactiveCN108914228AEnsure breaking strengthMeet needsArtificial filament heat treatmentMelt spinning methodsYarnBreaking strength

The invention discloses high-modulus and low-extension polyester industrial yarns used for geofabric and a production method thereof. The high-modulus and low-extension polyester industrial yarns comprise the following raw material such as 50-70 parts by weight of terephthalic acid, 20-30 parts by weight of glycol, 0.018-0.035 parts by weight of catalysts and 0.35-0.75 parts by weight of oil agents. A solid phase polymerization reactor is used for performing tackifying operation and used in conjunction with multi-head spinning technology and two-level drafting and one-level relaxation and heatsetting operation. Additionally, a twin-type winding machine is used for high-speed winding operation such that high-modulus and low-extension polyester industrial yarns used for solid-phase tackifying multi-head direct-spinning geofabric are achieved. During the above processing operation, drafting ration, relaxation ratio, drafting temperature and relaxation temperature help ensure breaking strength at the constant extension ratio of 5% during processing of polyester industrial yarns. During the application process, requirements for strength, drafting and anti-aging and other performance parameters are met.

Owner:浙江金汇特材料有限公司

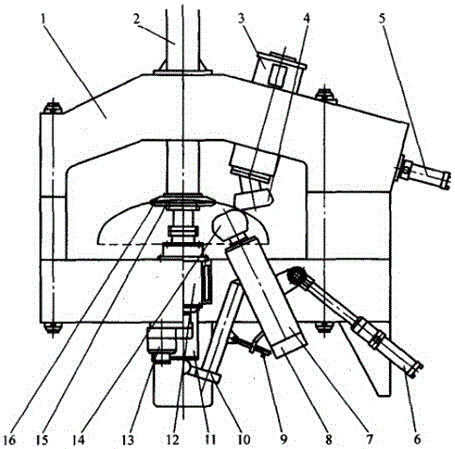

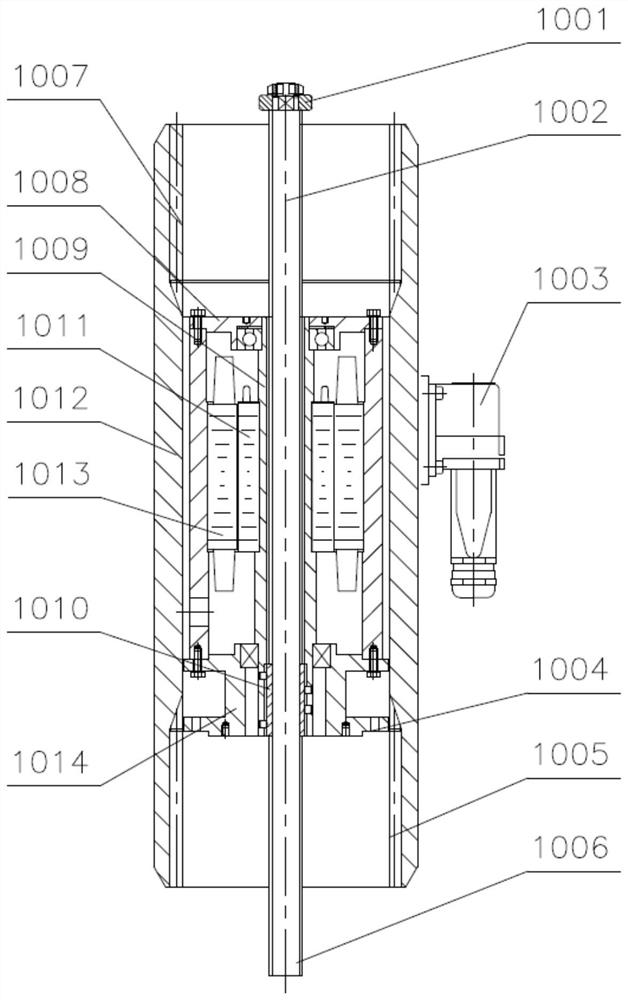

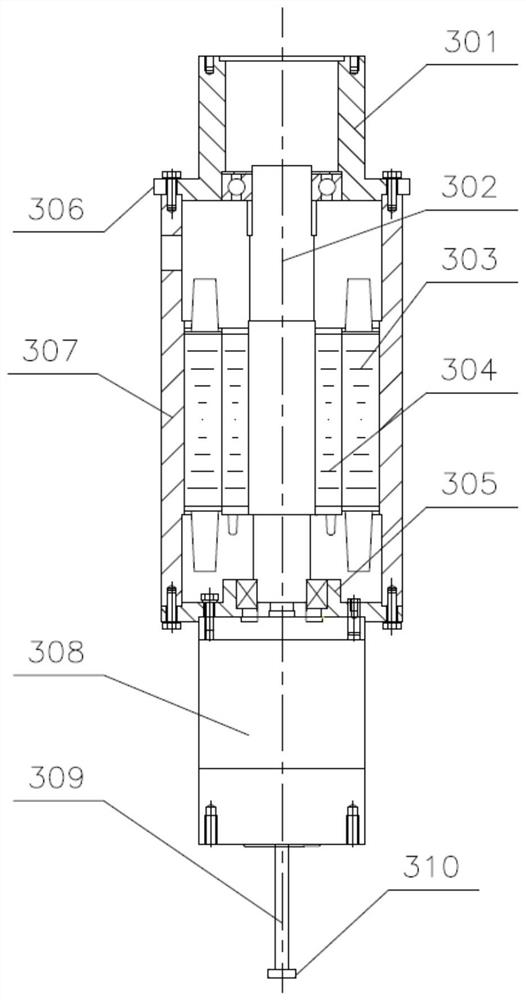

Numerical control sealing head spinning machine

The invention relates to a numerical control sealing head spinning machine and belongs to the technical field of machinery. The numerical control sealing head spinning machine comprises a main shaft, a lathe bed, a rotary wheel and a connecting rod. A rotary wheel base is installed on the upper portion of the lathe bed. The rotary wheel is installed on the inner wall of the rotary wheel base. A hydraulic cylinder is installed on the side wall of the outside of the rotary wheel base. The lathe bed is internally provided with the main shaft. A forming mold is installed on the upper portion of the main shaft. A main shaft speed change mechanism is arranged in the middle of the main shaft. The bottom of the main shaft is connected with a connecting rod bracket. The connecting rod is installed between the bracket and the lathe bed. By means of the designed numerical control sealing head spinning machine, the technical problems that existing spinning machines are complex in structure, poor in safety performance, high in price and the like can be solved.

Owner:安庆康为模具制造有限公司

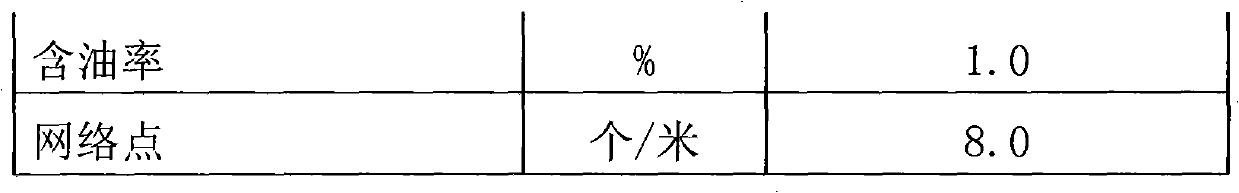

Hyperfine polyester drawn yarn and production technique thereof

The invention relates to a hyperfine polyester drawn yarn produced by continuous polyesters, and is characterized in that the standard is 20D / 12F; the hyperfine polyester drawn yarn is produced by using s coiler with 18 head spinning positions and side-blown cooling technology; the product performance is excellent; the production processing technique comprises the following steps: processing performing esterification of the phthalic acid and the glycol with raw material; then preparing the polyester melt by prepolycondensation and final polycondensation to directly spin; and using spinning-drawing one-step method technique route. The technique is reasonable, and the fiber has excellent spinnability, excellent physical property index, less broken filament, high switching success rate, more than 99% of dying uniformity rate and more than 98% of full coiling rate; and the yarn is smooth in weaving, light and soft in fabric quality, excellent in fabric style, and satisfied with the weaving requirement of shell and lining fabrics of superior quality clothing, thereby improving the level and the additional value of the product.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

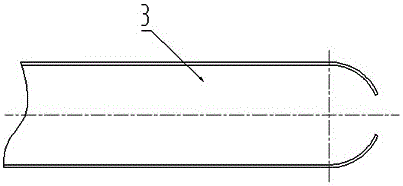

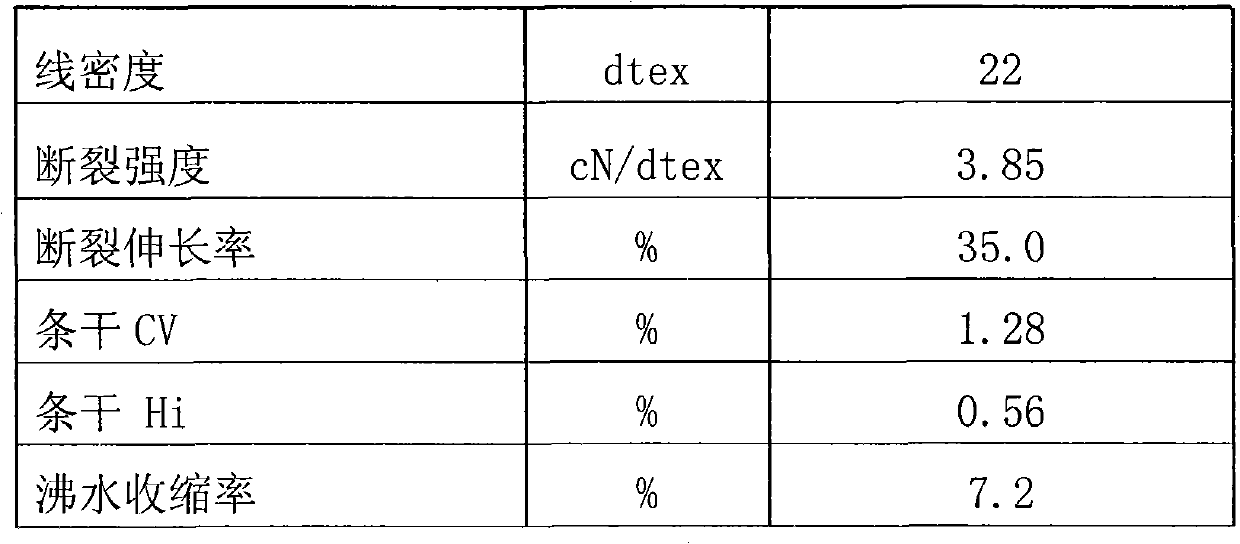

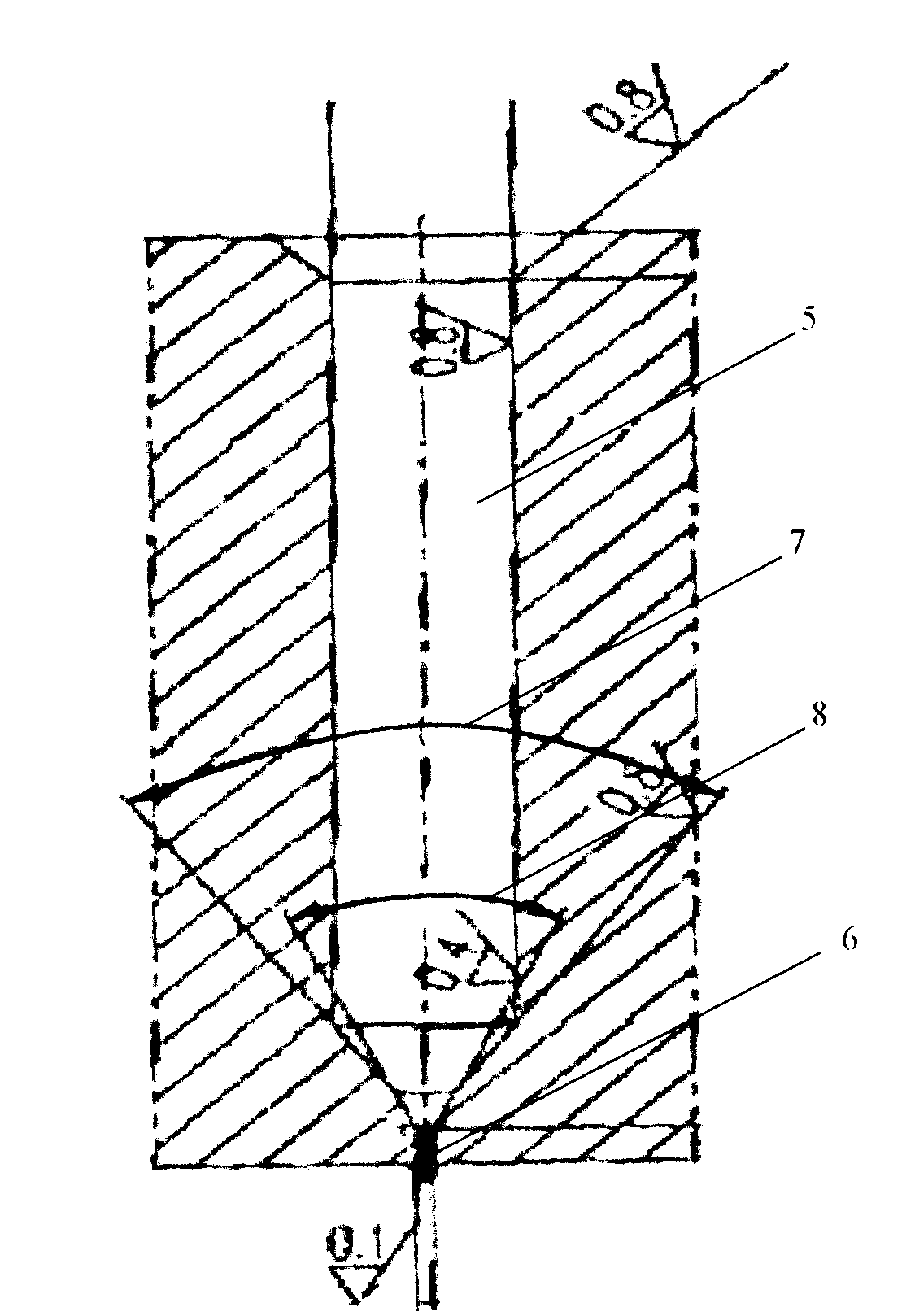

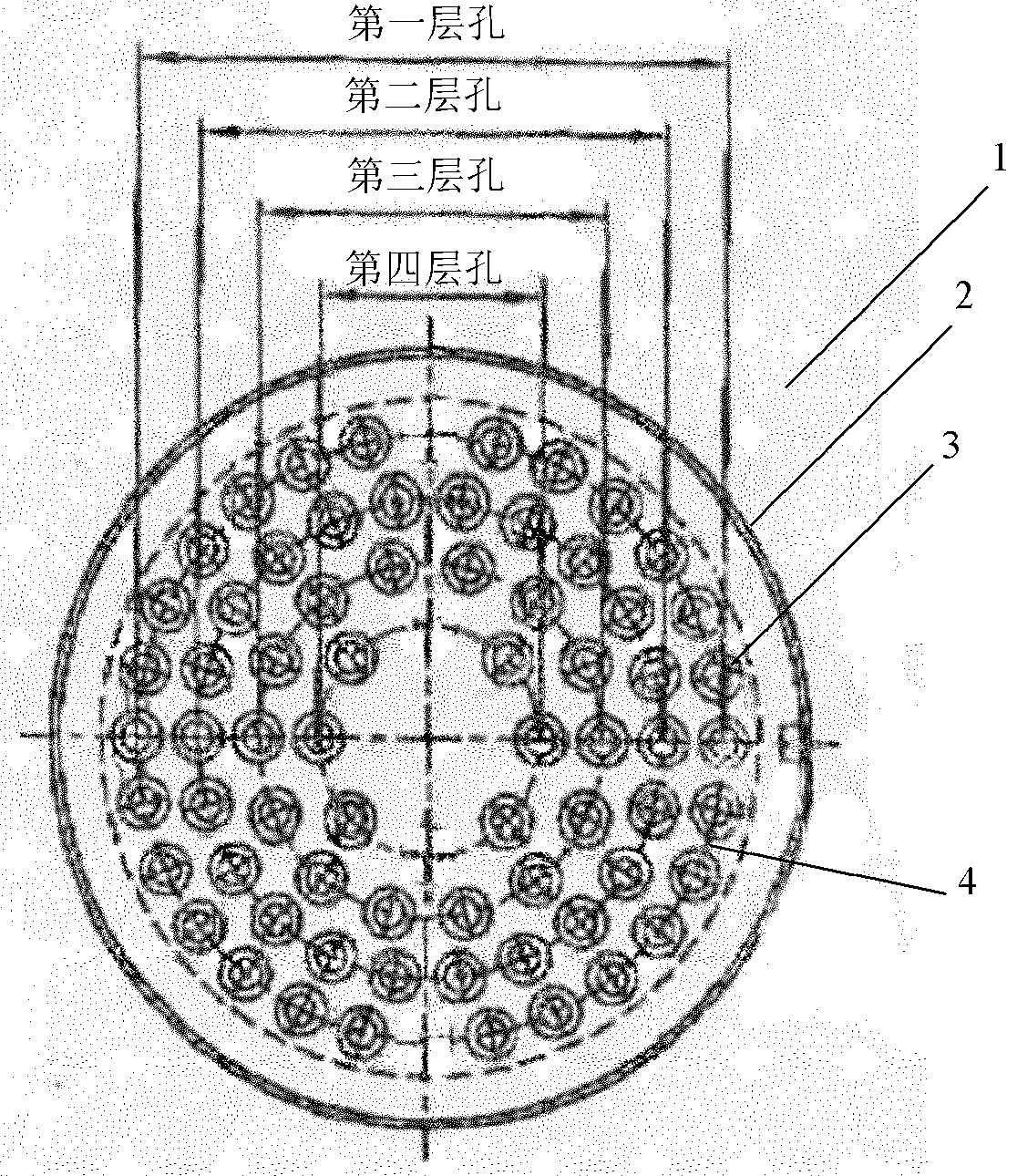

Device for producing fine denier POY (polyester pre-orientated yarn) by head spinning method

InactiveCN102418154AOvercome the defect of uneven denierReduce the deviation value of denier uneven linear densitySpinnerette packsPolyesterHEAD SPINNING

The invention discloses a device for producing fine denier POY (polyester pre-orientated yarn) by a head spinning method, which comprises a spinneret plate with a spinneret plate distribution plate, wherein the spinneret plate distribution plate comprises a first part positioned at the left side and a second part positioned at the right side, and the first part and the second part are separated from each other; the spinneret plate comprises four rings of radially distributed spinneret holes, and the spinneret holes in each ring of spinneret holes are communicated by shallow grooves; each spinneret hole comprises a pilot hole groove and a microhole, and the pilot hole groove comprises a cavity, a first-stage cone and a second-stage cone which are sequentially arranged, so that two-stage cone angle transition is formed; and the microhole is arranged at the lower end of the second-stage cone. Therefore, the defect of size unevenness of products can be overcome, and the size unevenness linear density deviation value of the products can be reduced.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

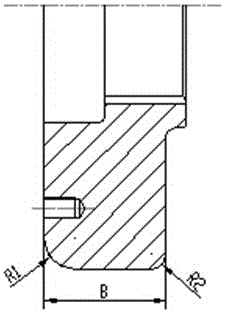

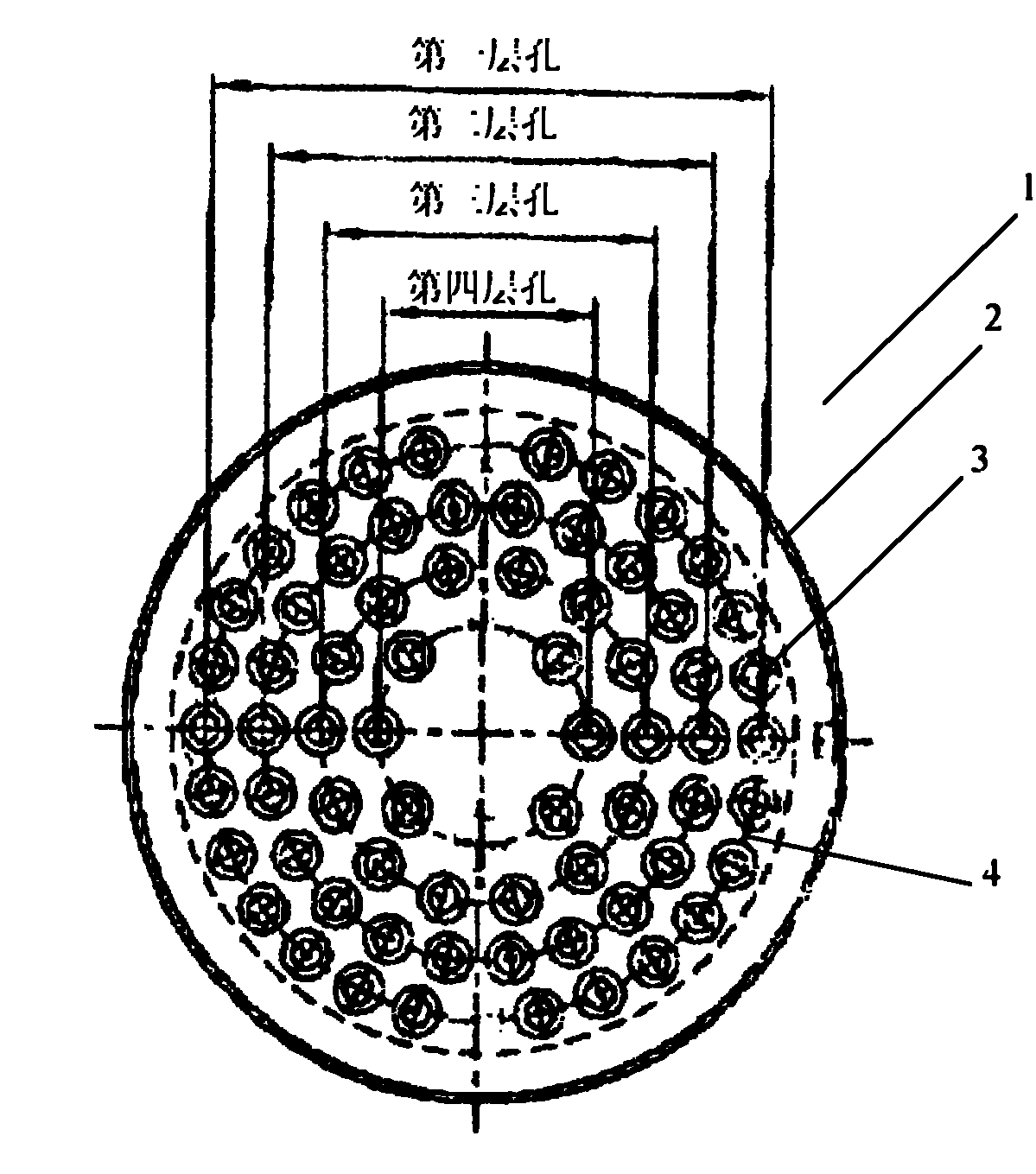

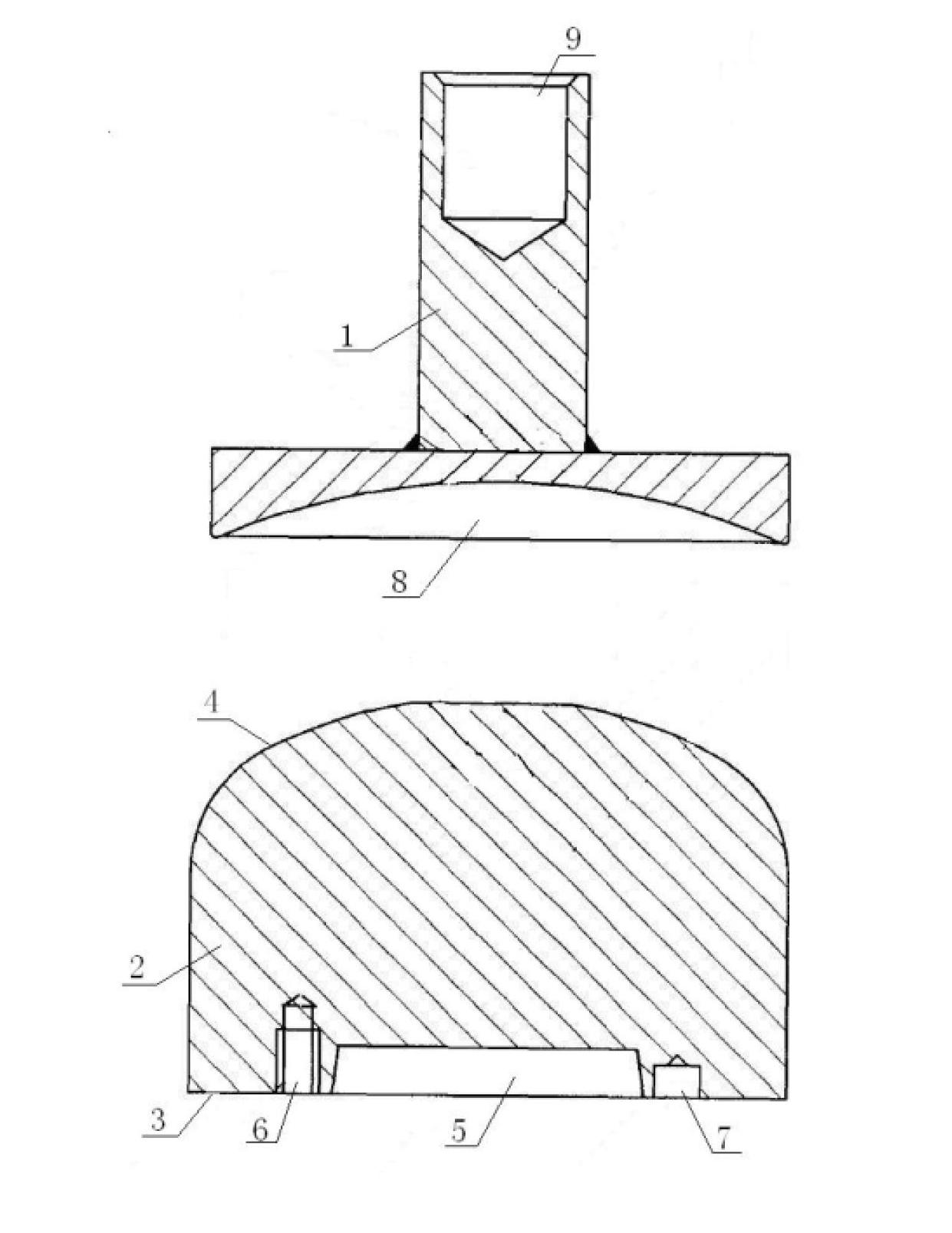

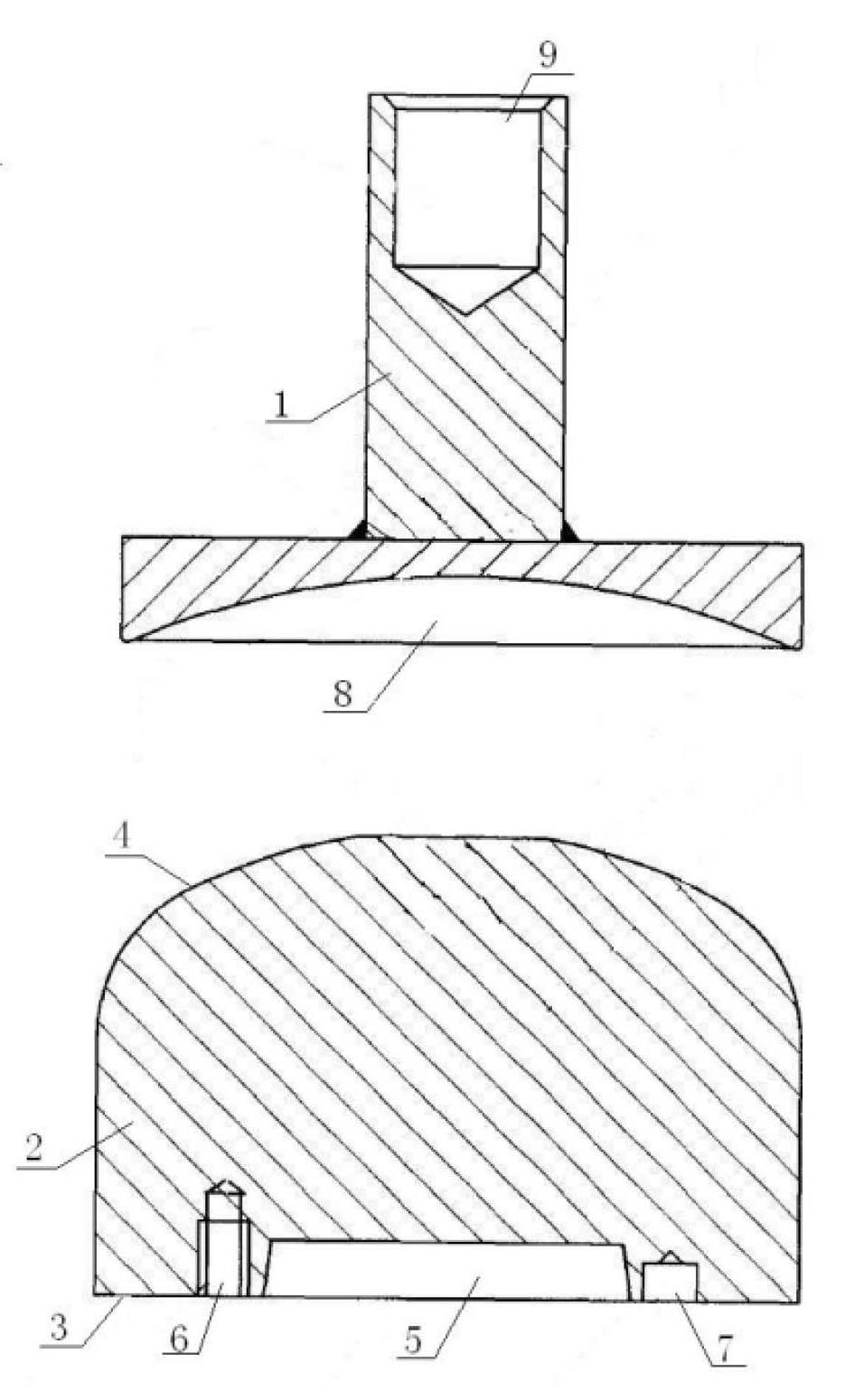

Large-caliber head spinning die

InactiveCN102632140AQuality improvementReduce manufacturing costShaping toolsHollow articlesHEAD SPINNINGEngineering

The invention relates to a large-caliber head spinning die comprising an upper die and a lower die, wherein one end of the lower die is a flat surface while the other end is a big radial arc-shaped surface; a cone-shaped blind hole is arranged at the flat surface end of the lower die; a threaded blind hole is arranged at one side of the cone-shaped blind hole while an avoiding blind hole is arranged at the other side; the lower part of the upper die is a concave cambered surface; and a big blind hole is arranged at the upper part of the upper die. The large-caliber head spinning die disclosed by the invention has the advantages of lower cost, high quality and high accuracy.

Owner:宜兴市联丰化工机械有限公司

Magnetic head spin valve structure with CoFeCu magnetic layer and ZnOx/TaOx cap layer

InactiveUS7277260B2Improve performanceLow coercivityNanomagnetismMagnetic measurementsHEAD SPINNINGSpin valve

Owner:WESTERN DIGITAL TECH INC

Workpiece processing system

InactiveCN1943007AReduce pollutionShorten the timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingHEAD SPINNINGEngineering

A system for processing a workpiece includes a process head assembly and a base assembly. The process head assembly has a process head and an upper rotor. The base assembly has a base and a lower rotor. The base and lower rotor have magnets wherein the upper rotor is engageable with the lower rotor via a magnetic force created by the magnets. The engaged upper and lower rotors form a process chamber where a semiconductor wafer is positioned for processing. Process fluids for treating the workpiece are introduced into the process chamber, optionally while the processing head spins the workpiece. Additionally, air flow around and through the process chamber is managed to reduce particle adders on the workpiece.

Owner:APPLIED MATERIALS INC

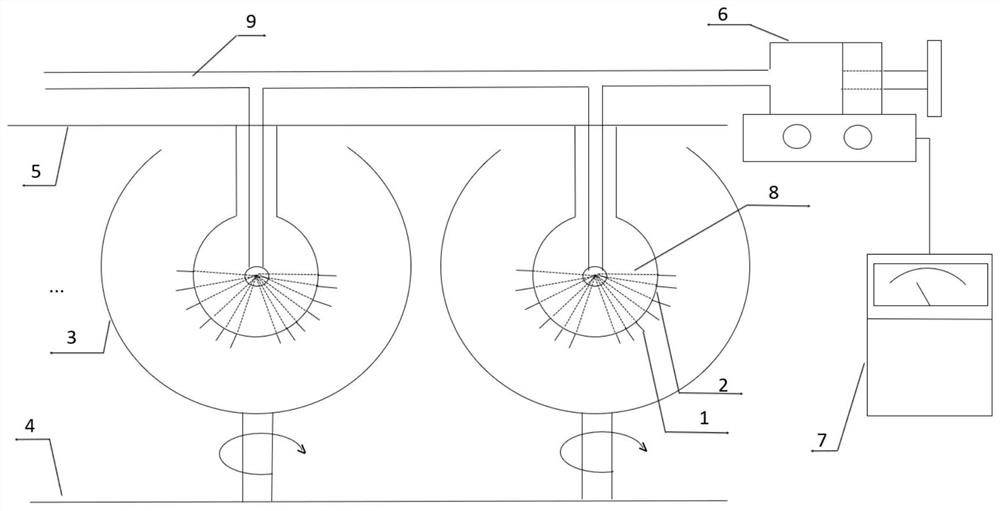

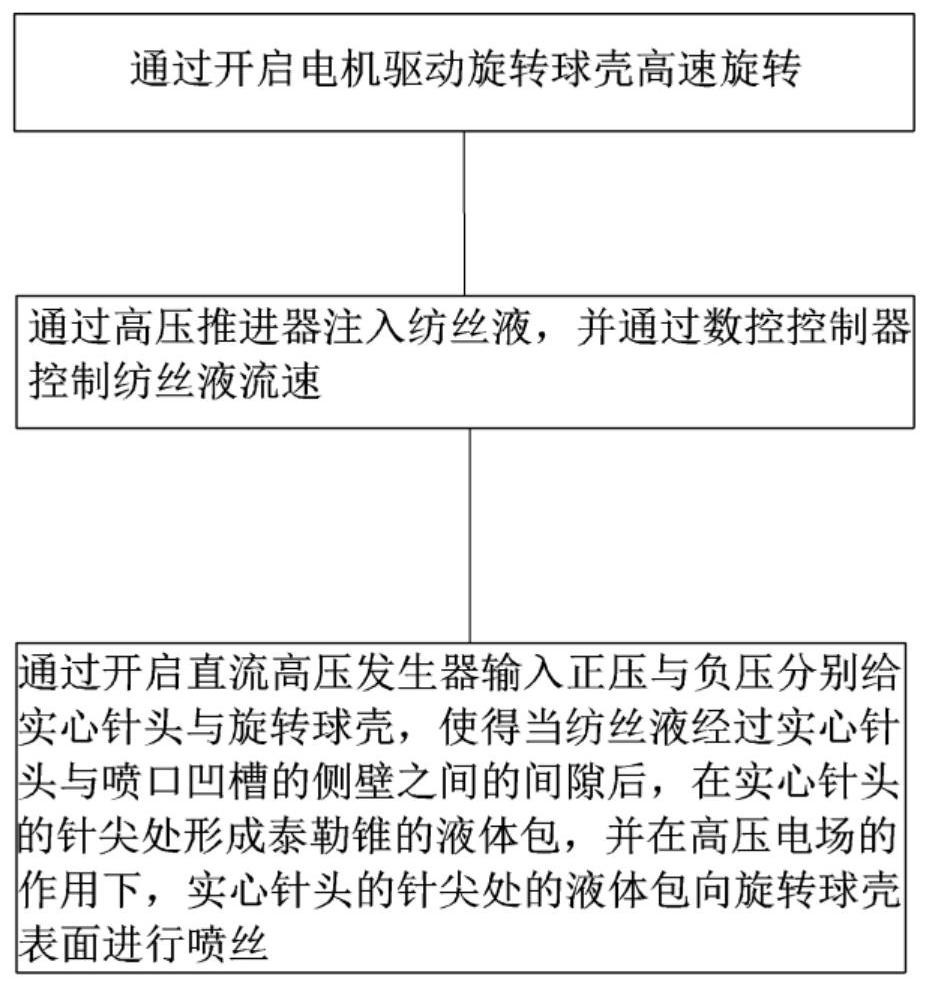

Multi-needle-head spinning fiber preparation device and method based on online algorithm

PendingCN111647959AGood orientationAvoid changeFilament/thread formingTextile/flexible product manufactureHEAD SPINNINGEngineering

The invention discloses a multi-needle-head spinning fiber preparation device and method based on an online algorithm. A high-pressure liquid delivering device is arranged to drive a spinning solutionto flow to a gap between a solid needle head and a nozzle groove, an electric field is formed between the solid needle head and a rotating spherical shell through a direct-current high-pressure generator, under drainage of the solid needle head, the spinning solution can form a Taylor cone liquid bag at the needle point of the solid needle head, under stretching of the electric field effect, thespinning solution at the needle point of the solid needle head is used for spraying spinning fibers and is deposited on the surface of the rotating spherical shell, the rotating spherical shell rotates at a high speed, so that the spinning fibers are regularly distributed under the action of mechanical force, the diameter of the fibers is smaller, and the orientation degree of the spinning fibersis improved. The multiple spraying grooves and the corresponding solid needle head are arranged, meanwhile, the high-pressure liquid delivering device is used for driving the flow speed of the spinning solution to accelerate spinning, and thus, the spinning efficiency is higher.

Owner:GUANGDONG UNIV OF TECH

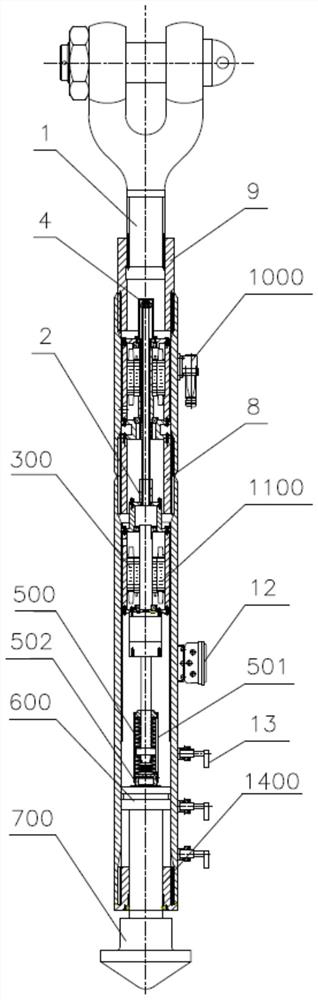

Electric telescopic and spin-locked windproof pull rod

ActiveCN112707313AChange the manual operation modeTravelling gearTrolleysComputer hardwareHEAD SPINNING

The invention provides an electric telescopic and spin-locked windproof pull rod, and particularly relates to a windproof device technology of container wharf large machinery. The electric telescopic and spin-locked windproof pull rod comprises a shackle, an upper rod, a lock head shaft telescopic motor, a motor transition joint, a lock head rotating motor, a transition rod, a lower rod, a buffer coupler, a lock head shaft, a lock head shaft upper sliding seat and a lock head shaft lower sliding seat. For the electric telescopic and spin-locked windproof pull rod, double motors are adopted for driving, the lock head shaft telescopic motor drives a lead screw, then a pull rod lock head shaft moves up and down, and the lock head shaft is matched with a ground anchor base in height position; and the lock head rotating motor directly drives the lock head shaft to rotate, so that automatic spin-locked hook anchor is realized. The position of a lock head spin-locked hook anchor face of the lock head shaft is collected through a plurality of position sensors, intelligent cooperative automatic control for the windproof pull rod and the whole large machine can be efficiently and accurately realized, thus the traditional manual operation mode is changed, the manual intervention through one-by-one adjustment on site is not needed, and anchoring and releasing of anchoring of the windproof pull rod are automatically completed.

Owner:上海久能机电制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com