Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduced boundary layer thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

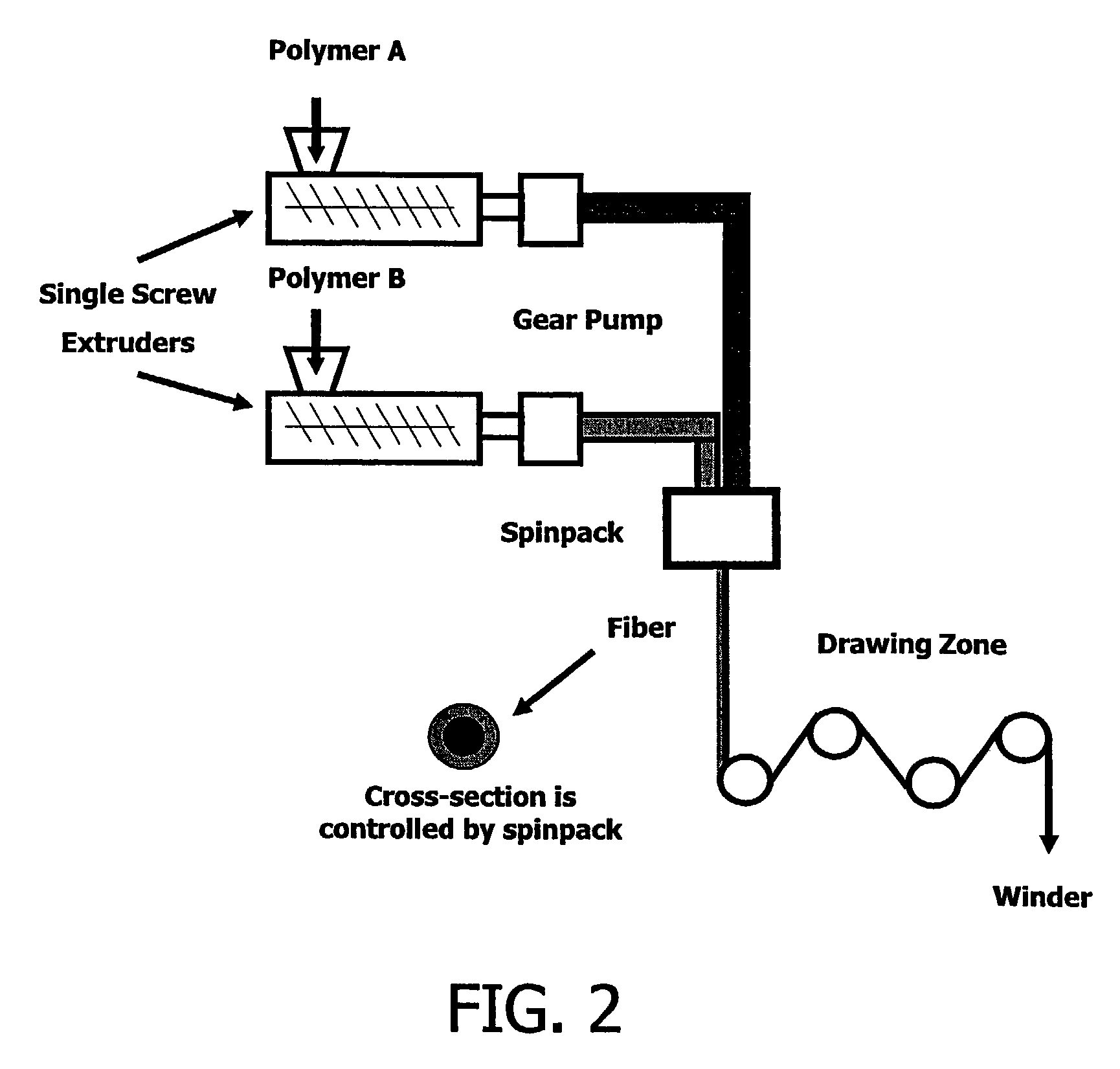

Fiber-based nano drug delivery systems (NDDS)

InactiveUS7491407B2High dissolution rateIncrease surface areaSynthetic resin layered productsWoven fabricsFiberDrug compound

A drug delivery system in the form of homo-component, bi-component or multi-component fibers wherein one of more of the components comprise a drug compounded with a polymer carrier. These fibers are packed to form a tablet directly, or are chopped and placed in a capsule.

Owner:NORTH CAROLINA STATE UNIV

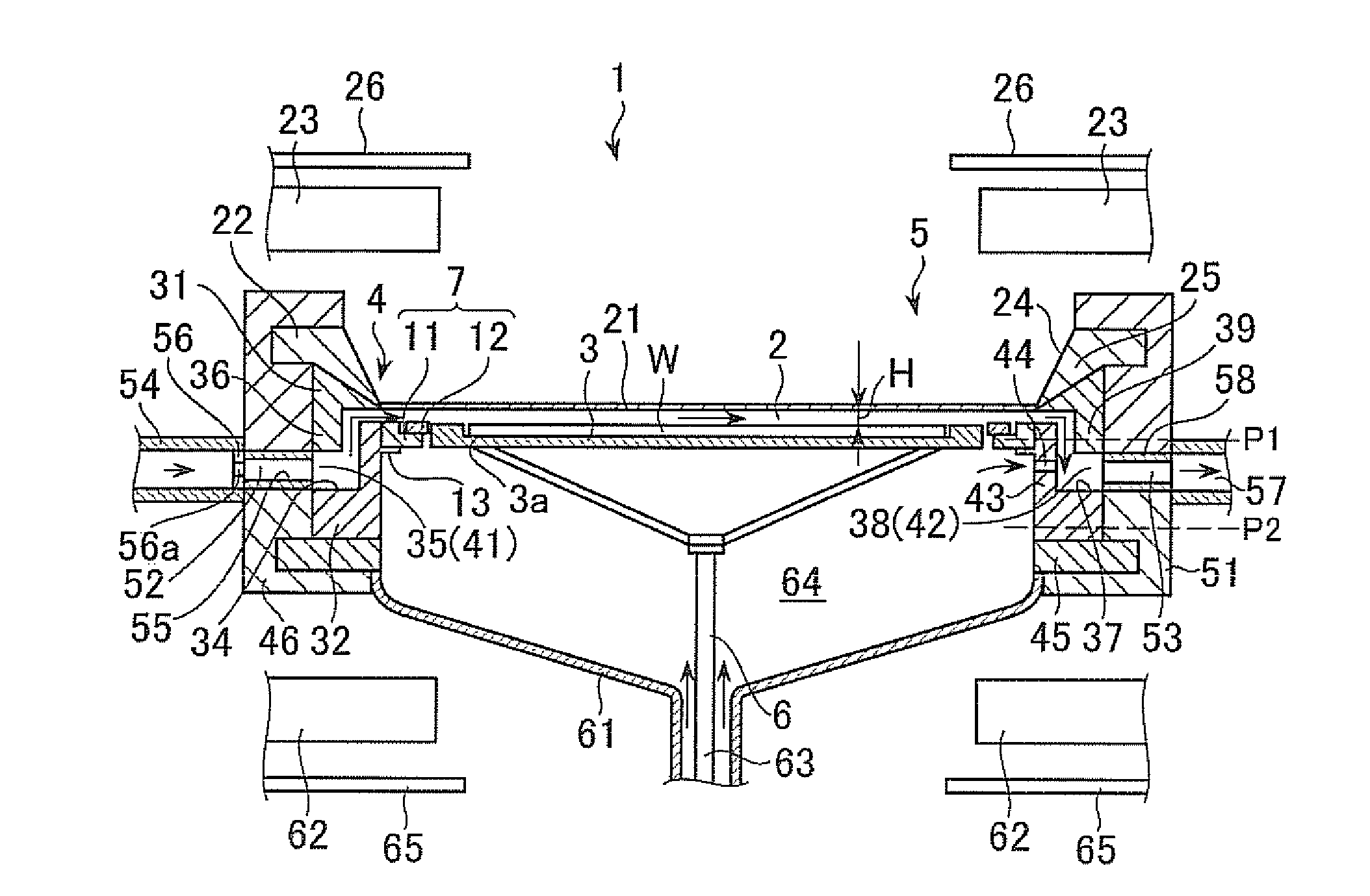

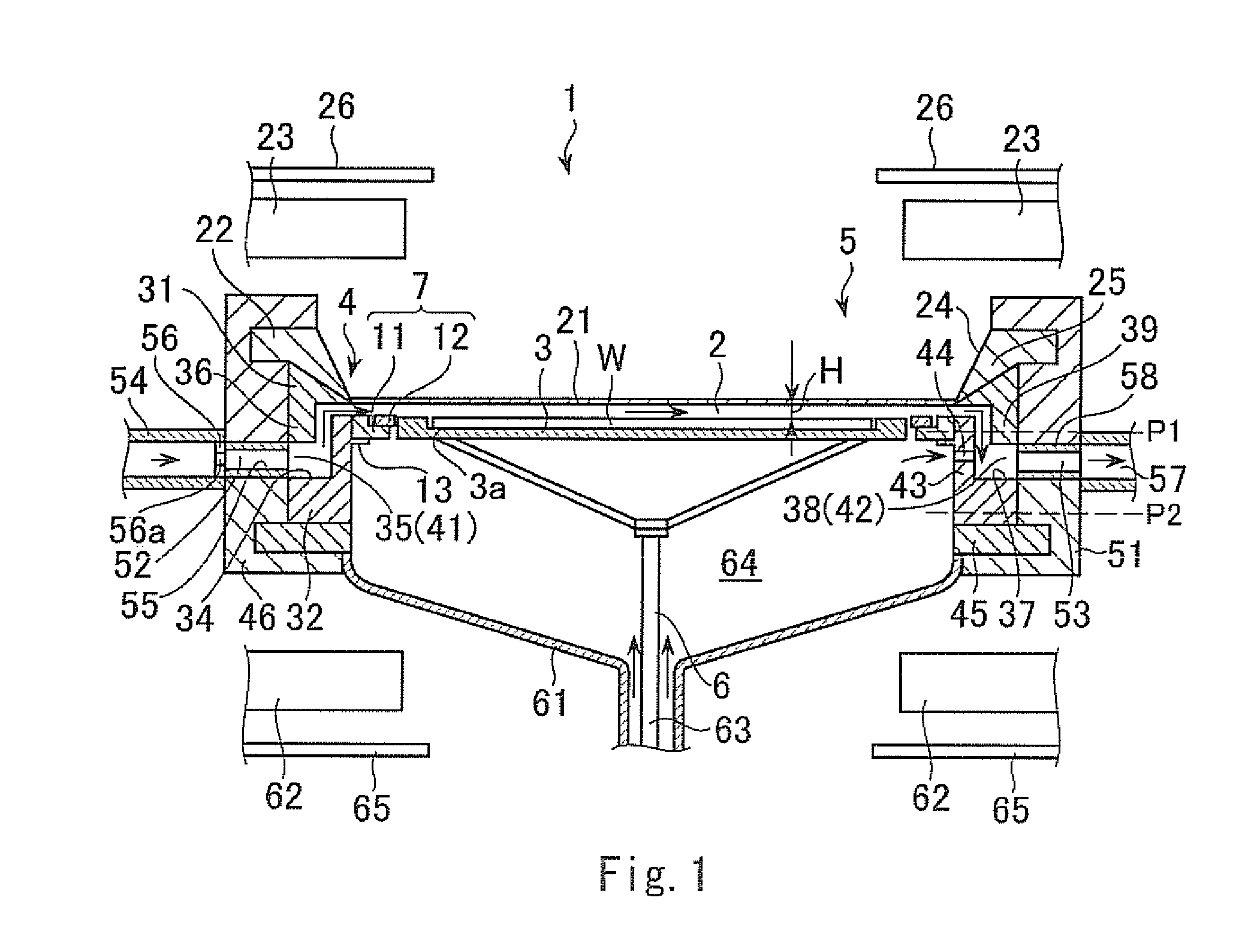

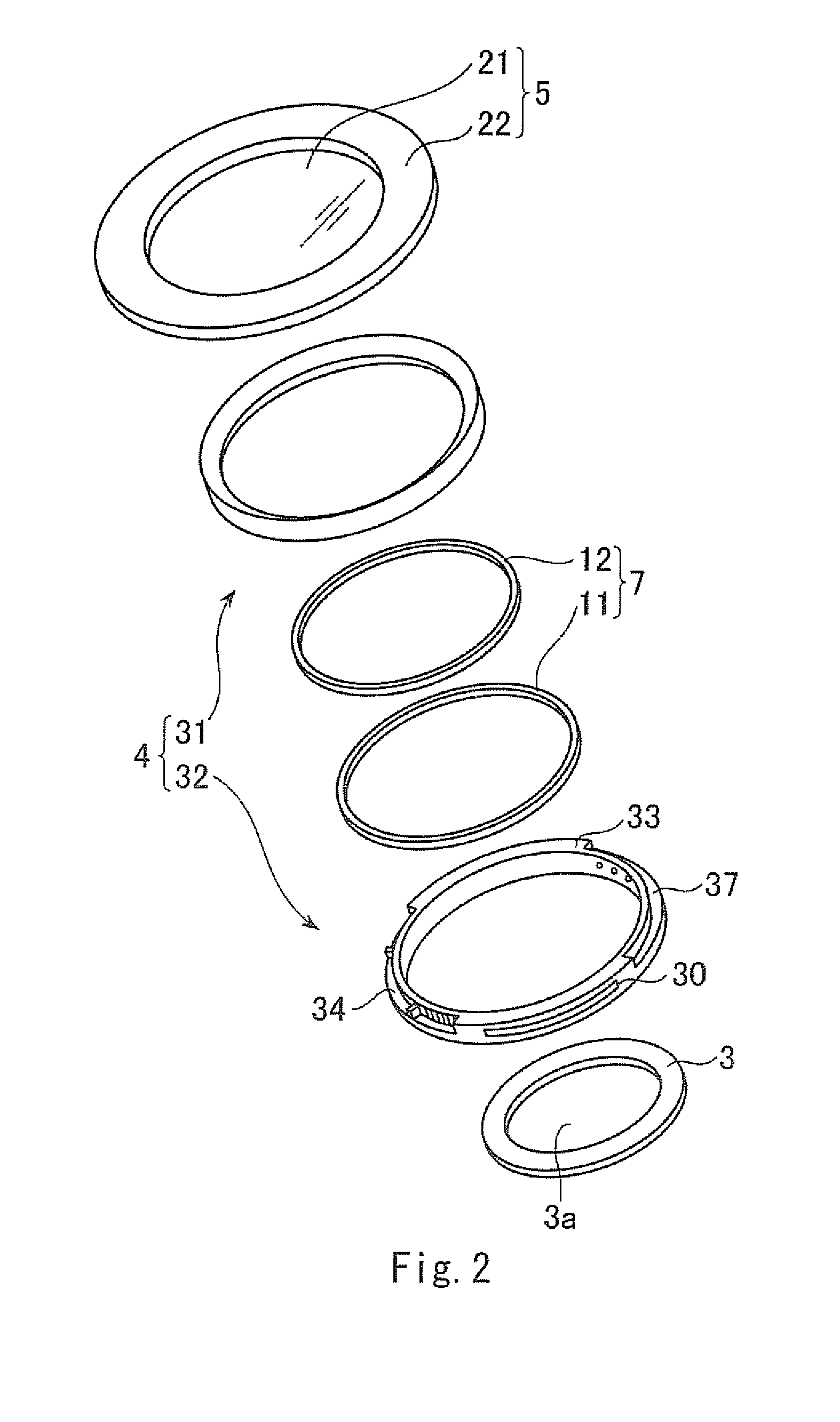

Film Forming Method Using Epitaxial Growth and Epitaxial Growth Apparatus

InactiveUS20140261159A1Reduce thicknessIncrease probabilityPolycrystalline material growthFrom chemically reactive gasesEngineeringGas supply

When a reaction chamber defined and formed by a ceiling plate as a top face, a substrate mounting portion as a bottom face, and a side wall as a lateral face is constructed, the ceiling plate is supported by a support at the circumferential edge of the ceiling plate from the upper side and the outer side of the circumferential edge, and the reactant gas is rectified in a reactant gas supply path disposed in the side wall so that a horizontal component in a flow direction of the reactant gas in the reaction chamber corresponds to a horizontal component in a direction extending from the center of an opening of the reactant gas supply path facing the reaction chamber to the center of the reaction chamber.

Owner:APPLIED MATERIALS INC

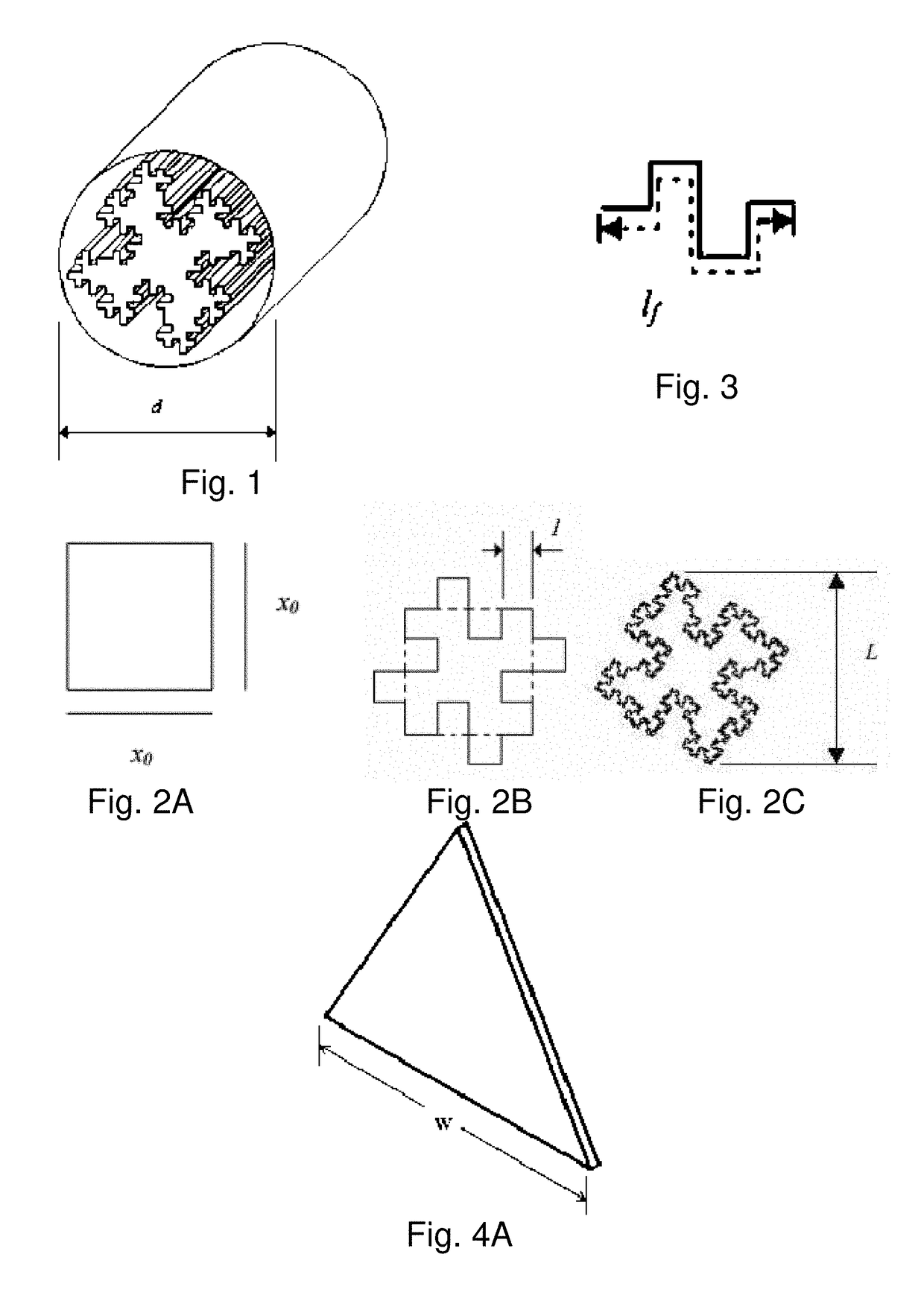

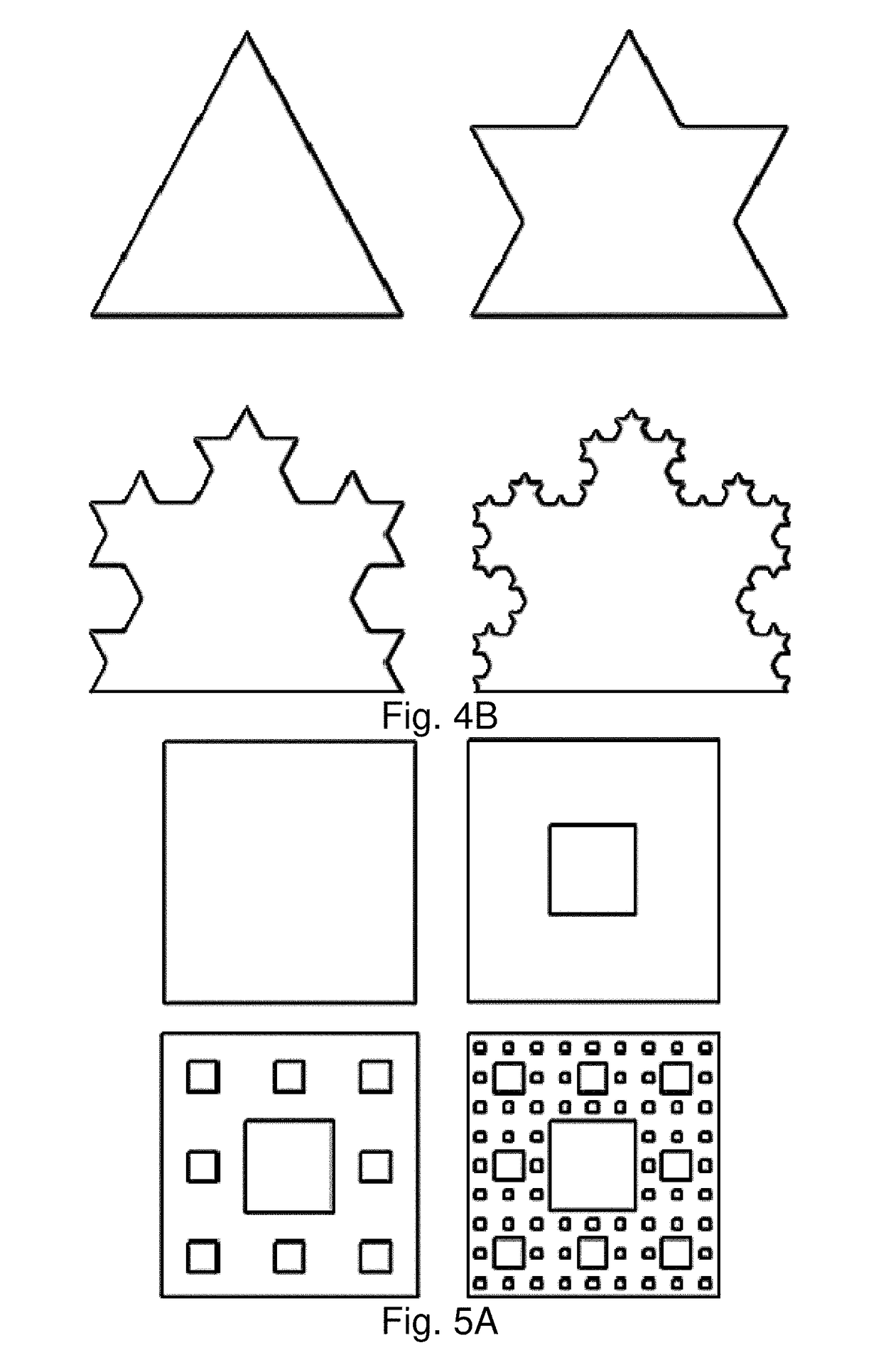

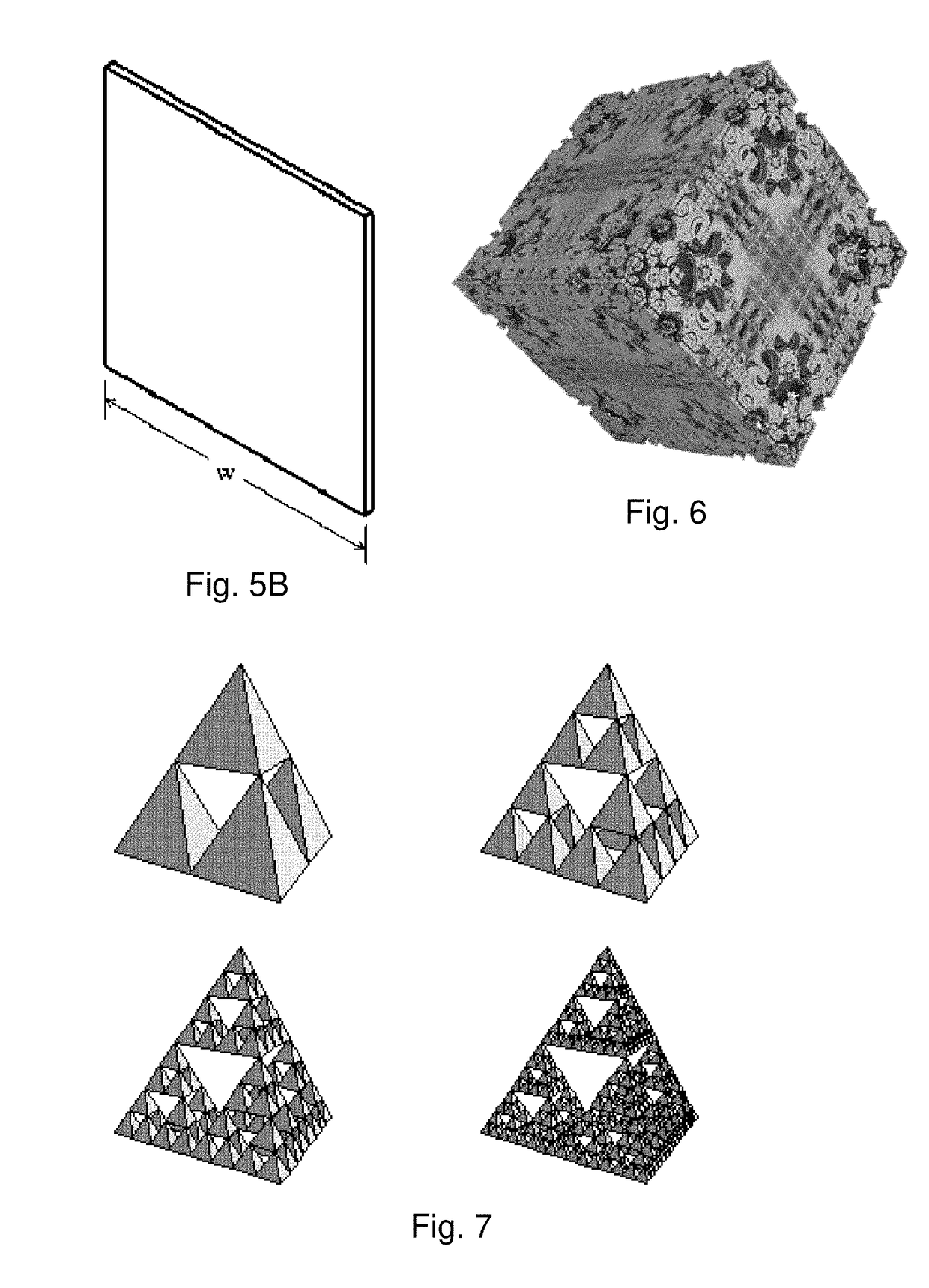

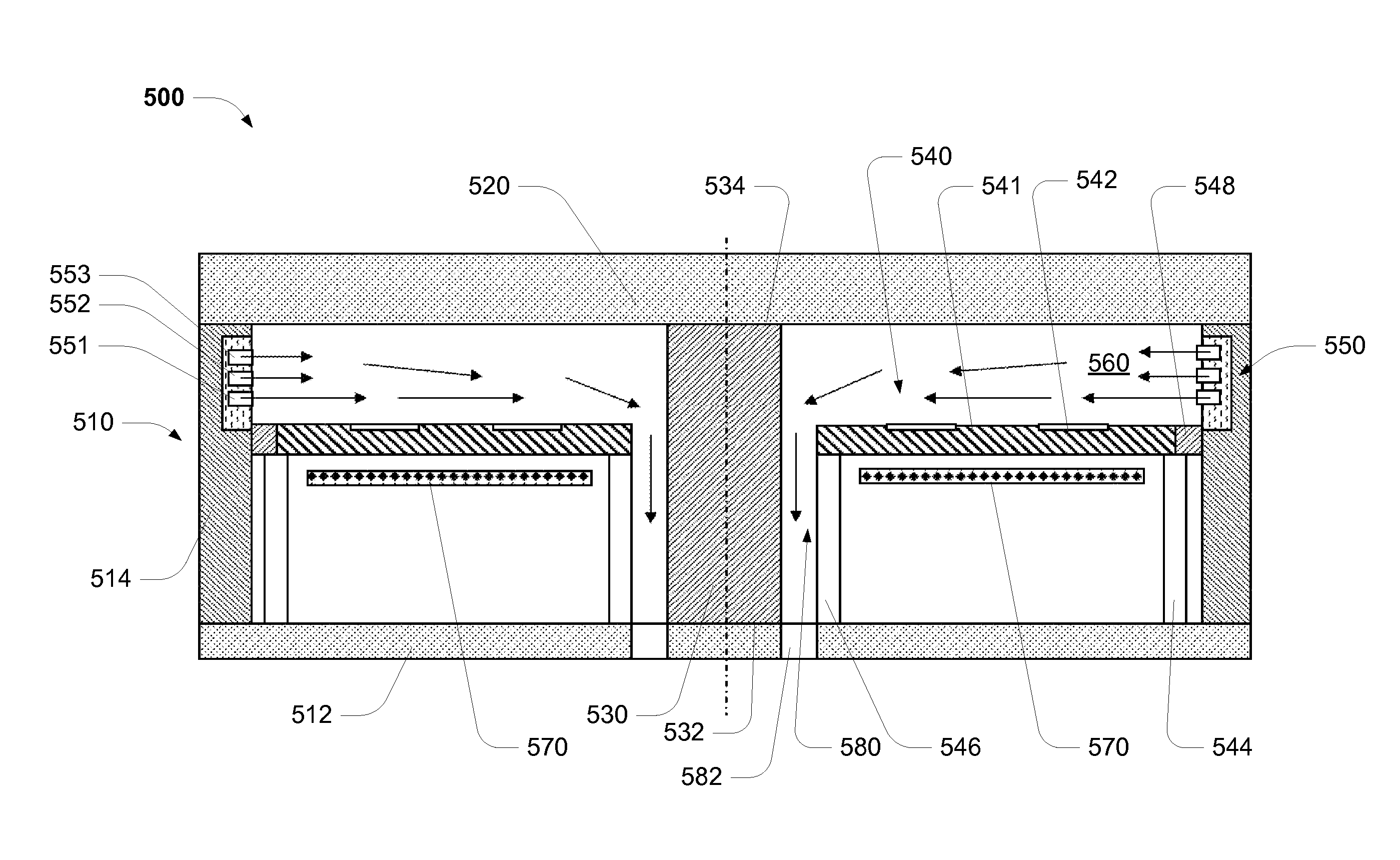

Multi-fractal heatsink system and method

ActiveUS20190021186A1Efficiently carries heat load awayReduce competitionComputer controlSemiconductor/solid-state device detailsHeat spreaderAerodynamics

A heat sink comprising a heat exchange device having a large scale morphology over a scale range and a small scale texture over a scale range, wherein at least one of the large scale morphology and the small scale texture has a fractal-like self-similarity over a scale range. The large scale morphology and small scale texture may be independently defined and implemented, or be provided with a transitional range. The large scale morphology may be algorithmically optimized according to a set of geometrically constraints. The small scale texture may be optimized according to aerodynamic parameters and constraints. The heat sink may be dynamically varying, and / or operated in conjunction with a dynamically varying heat transfer medium supply.

Owner:FRACTAL HEATSINK TECH

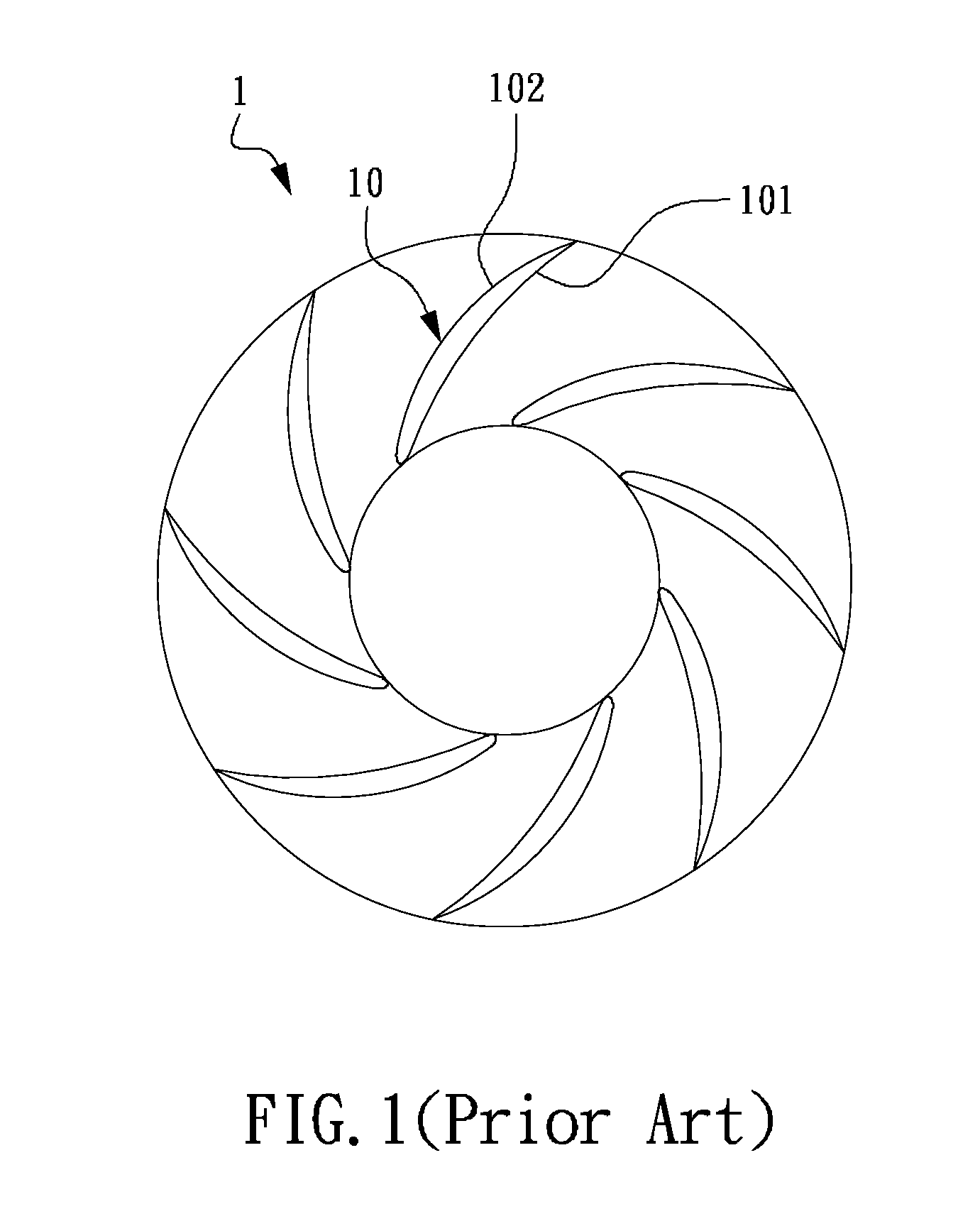

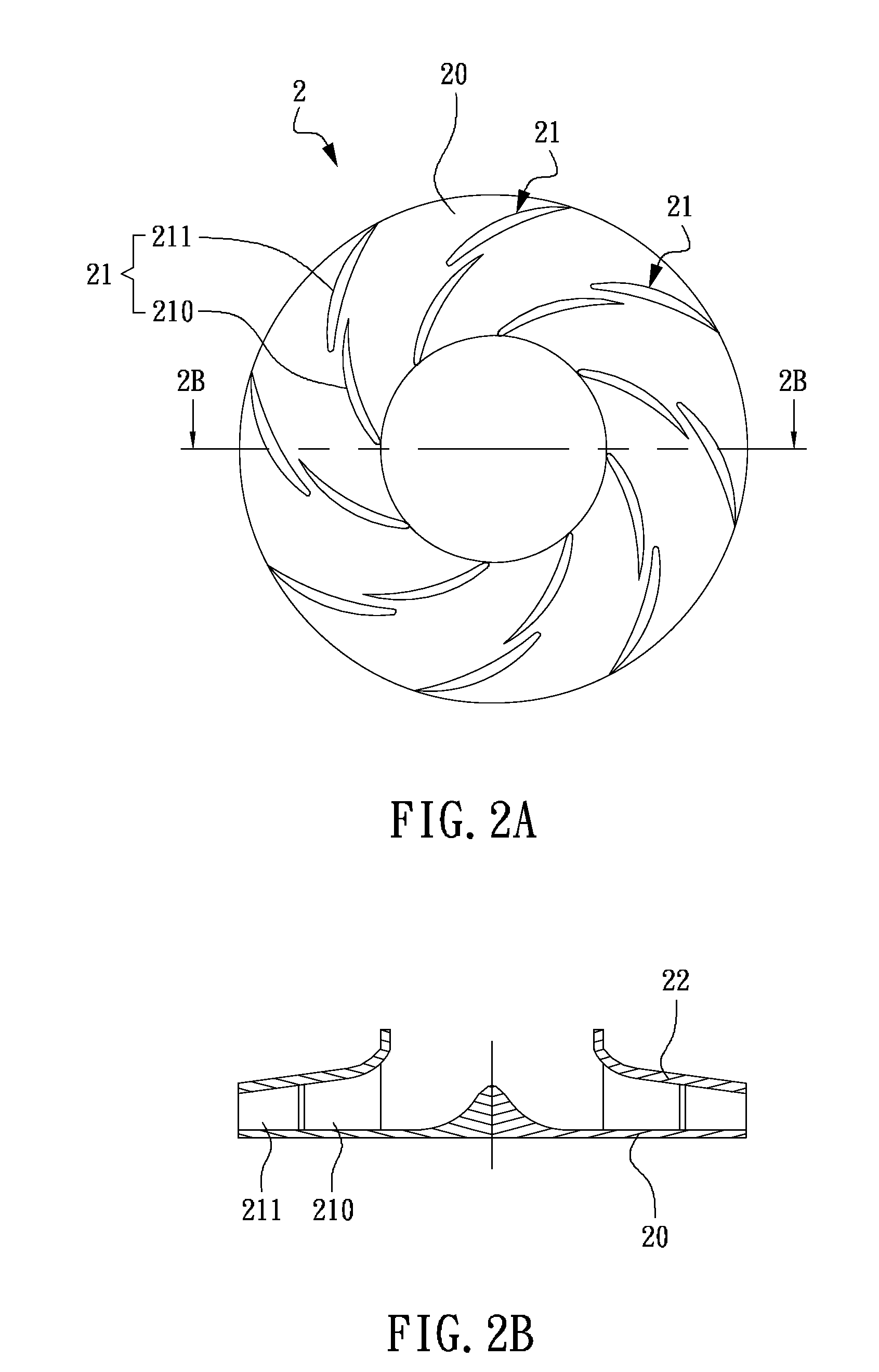

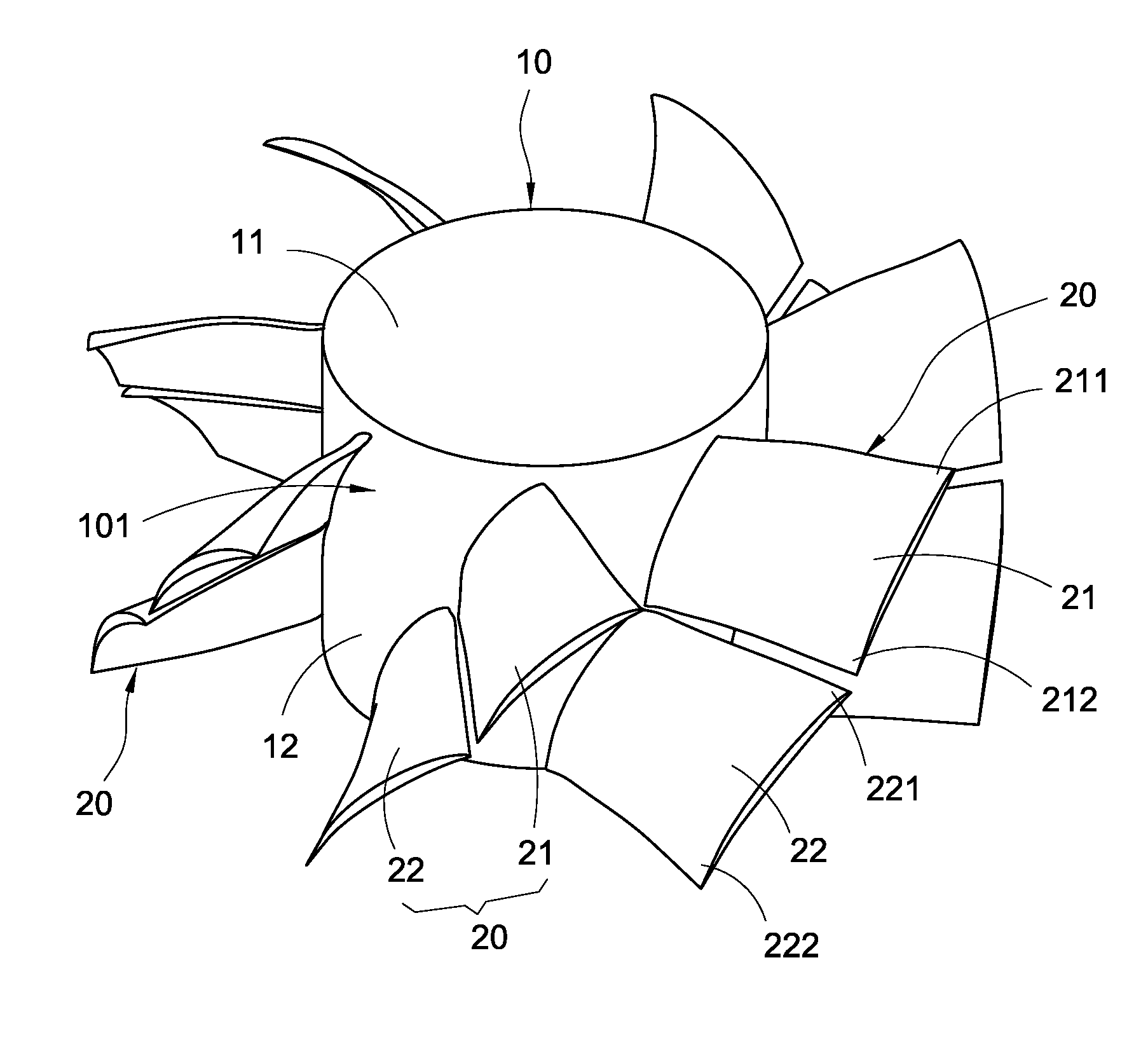

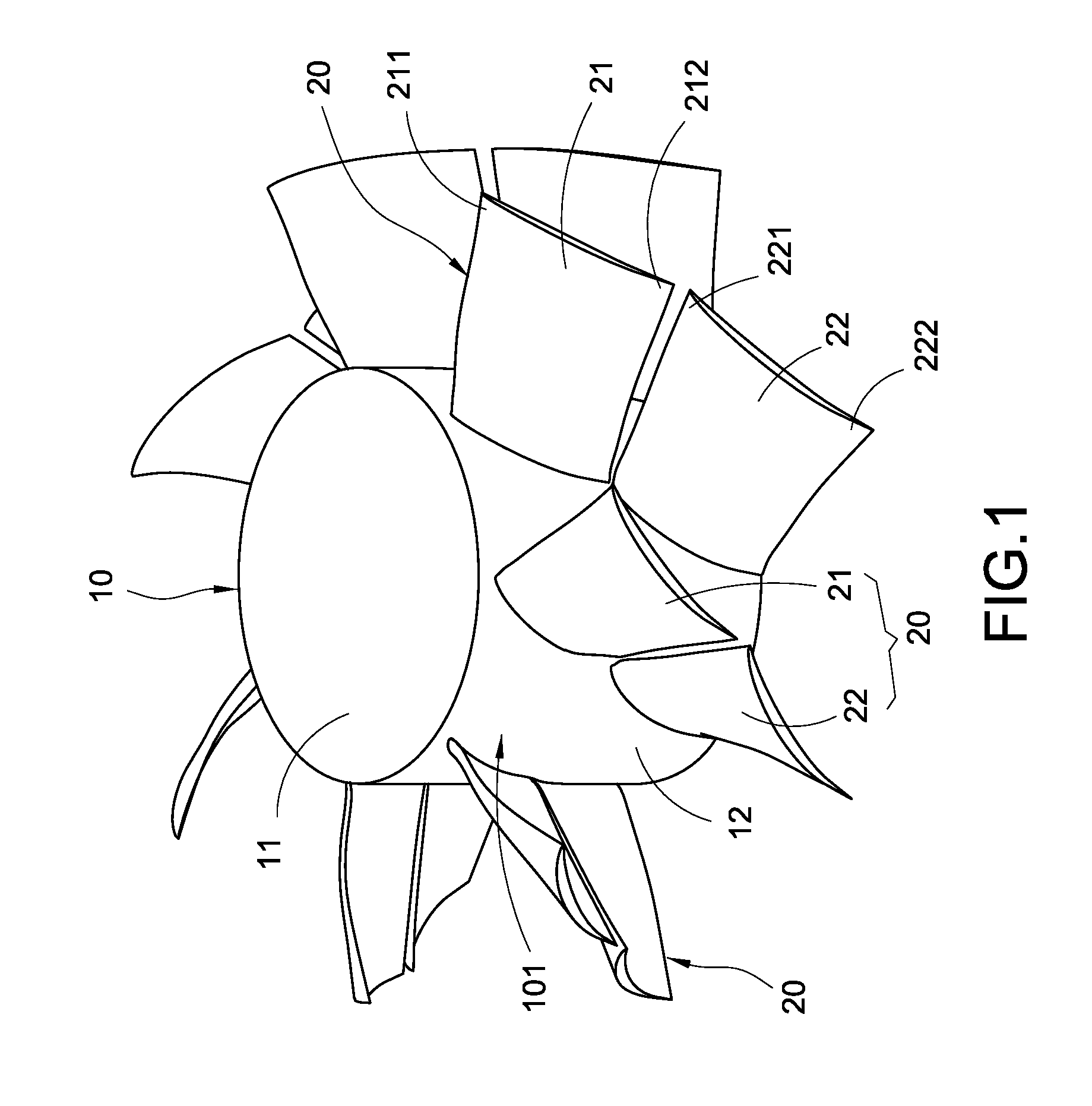

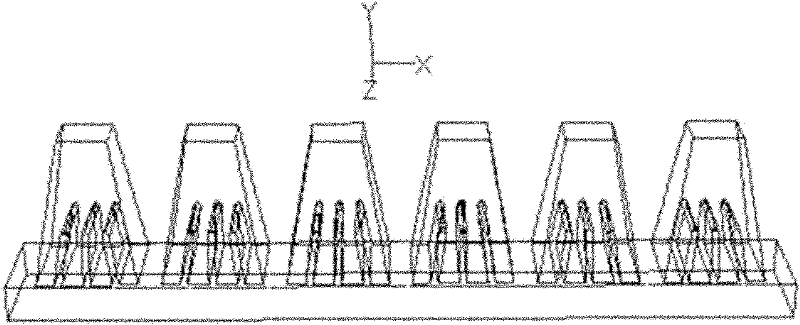

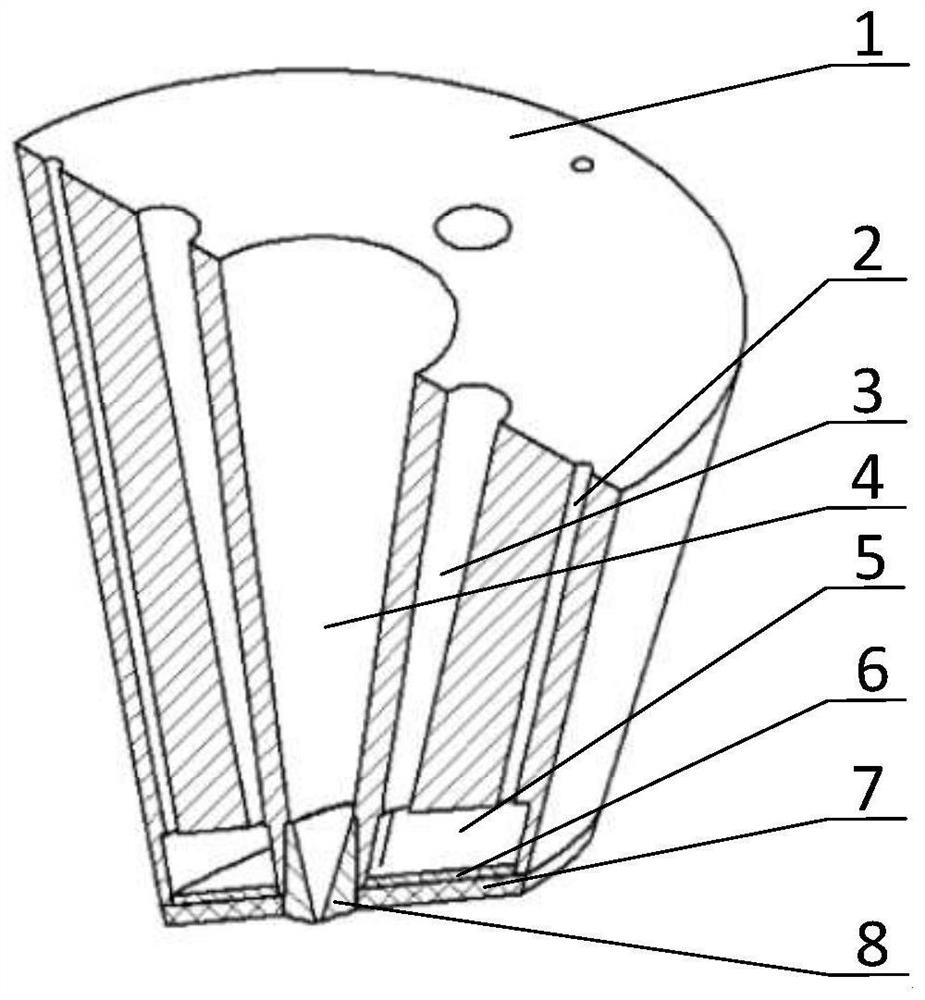

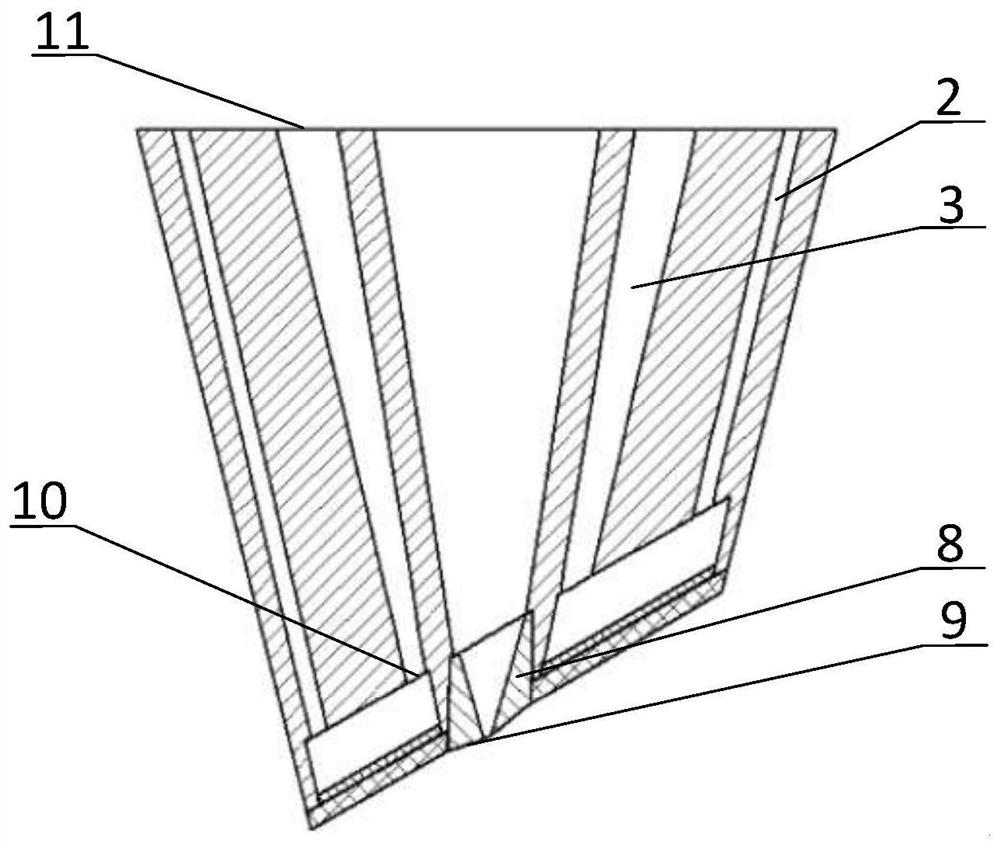

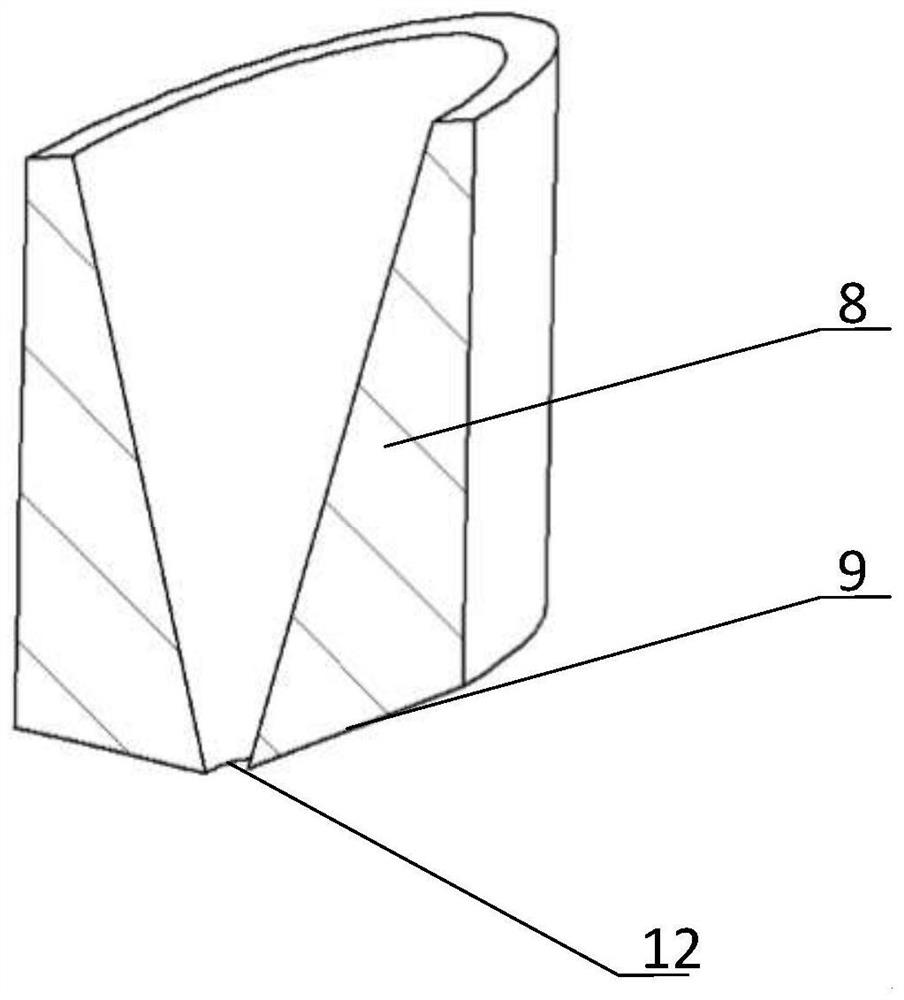

Impeller Structure and the Centrifugal Fan Device Using the Same

InactiveUS20080050228A1Reduced boundary layer thicknessGrowth can be interruptedPump componentsStatorsImpellerSuction stress

An impeller structure for a centrifugal fan device is disclosed, in which the impeller structure is primarily comprised of: a disc; and a plurality of blade structures, each being arranged on the disc; wherein, each blade structure further comprises: a first blade; and a second blade, arranged at a circumferential length away from a side of the first blade while radially overlapping with the radial of the first blade by a specific overlap area for forming a gap passage functioning as a nozzle. As a fluidic is flowing through and shooting out of the gap passage, not only the growth of the boundary layers on the suction surfaces of front blades are interrupted, but also as the fluidic with high kinetic energy is mixing with the low-kinetic fluidic flowing on the suction surfaces of rear blades, the thickness of the boundary layer is reduced while the separation point is delayed and thus separation can be prevented.

Owner:IND TECH RES INST

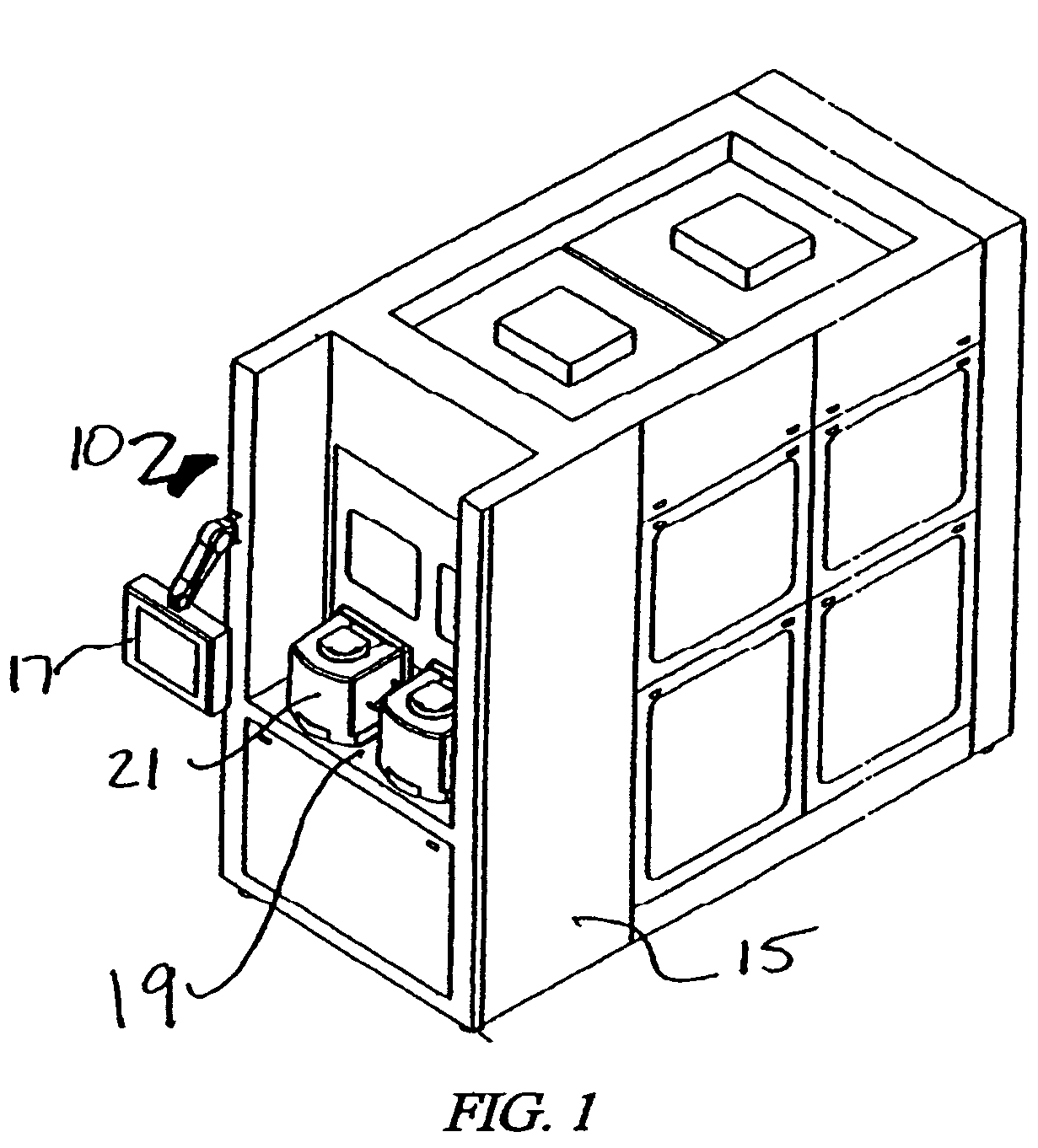

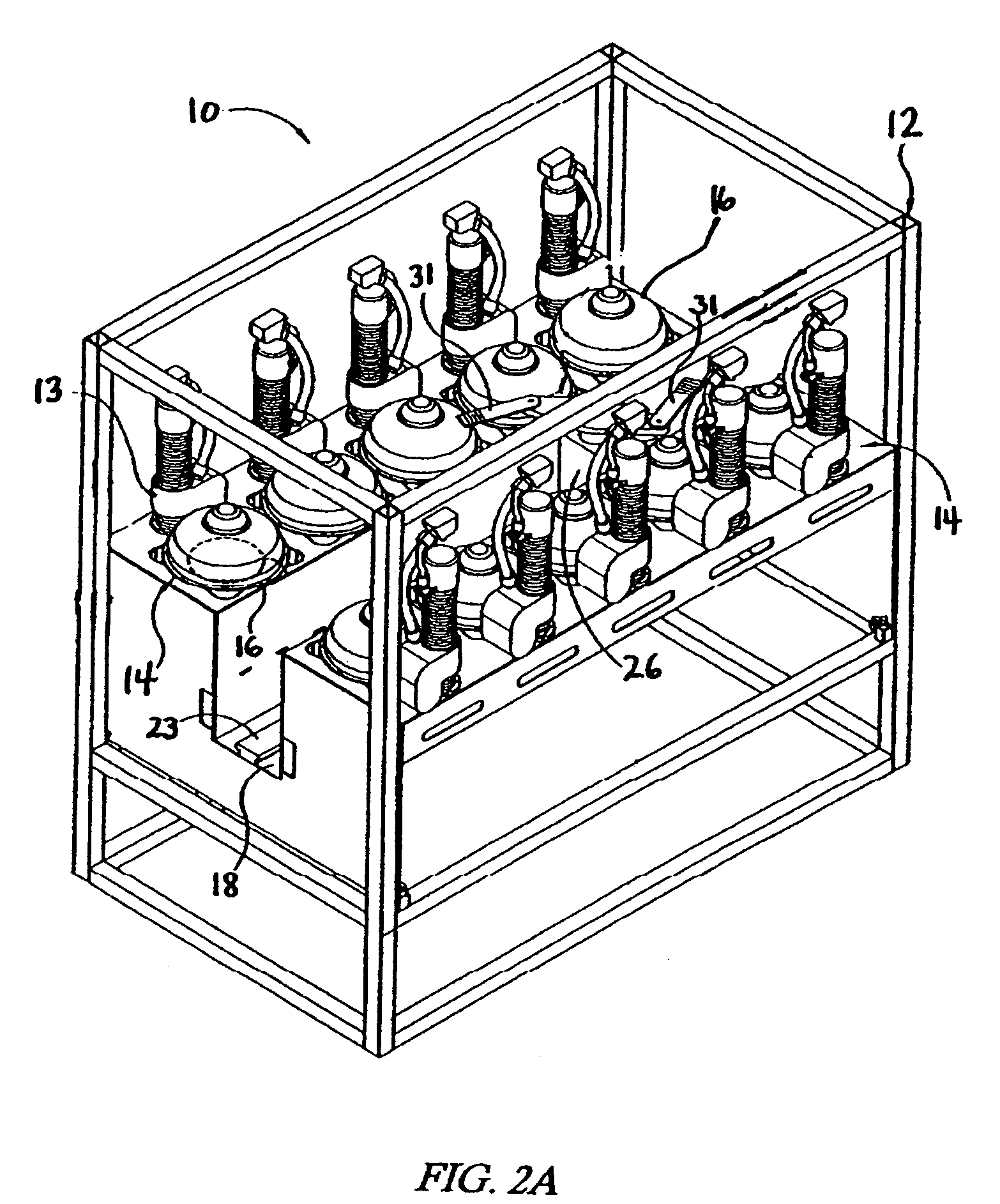

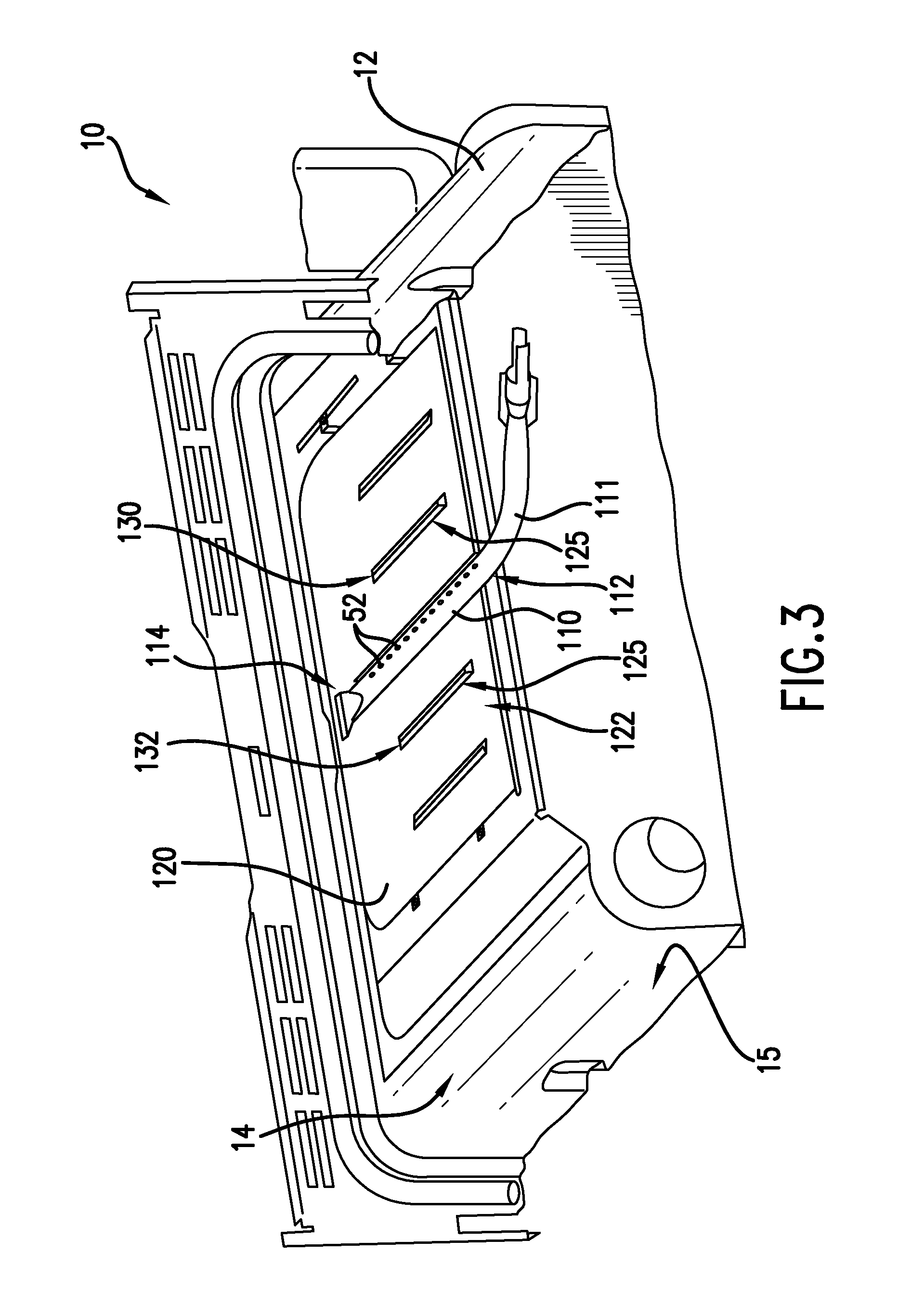

Active surface exchange catheter and method

InactiveUS7211066B1Increase exchange rateReduce fluid boundary layer thicknessTherapeutic coolingTherapeutic heatingDrug contentWorking fluid

Catheters for treating body fluids, particularly blood, include one or more tubes through which a working fluid is circulated. The fluid characteristics, e.g., temperature or drug content, interact with the body fluid by transfer through the tube walls. For enhancing the efficiency of such transfer, energy is added to the body fluid where it contacts the tube outer surfaces for reducing the thickness of thermal and concentration boundary layers at the tube surfaces. The energy adding is accomplished by causing pulsations in the walls of the tubes, or in the dimensions of a balloon parallel to the tubes, by means of pressure pulsations in the fluids circulated through the tubes and / or the balloon. Systems are disclosed for providing and controlling the circulation of various fluids and drugs through the catheter.

Owner:FOCALCOOL LLC

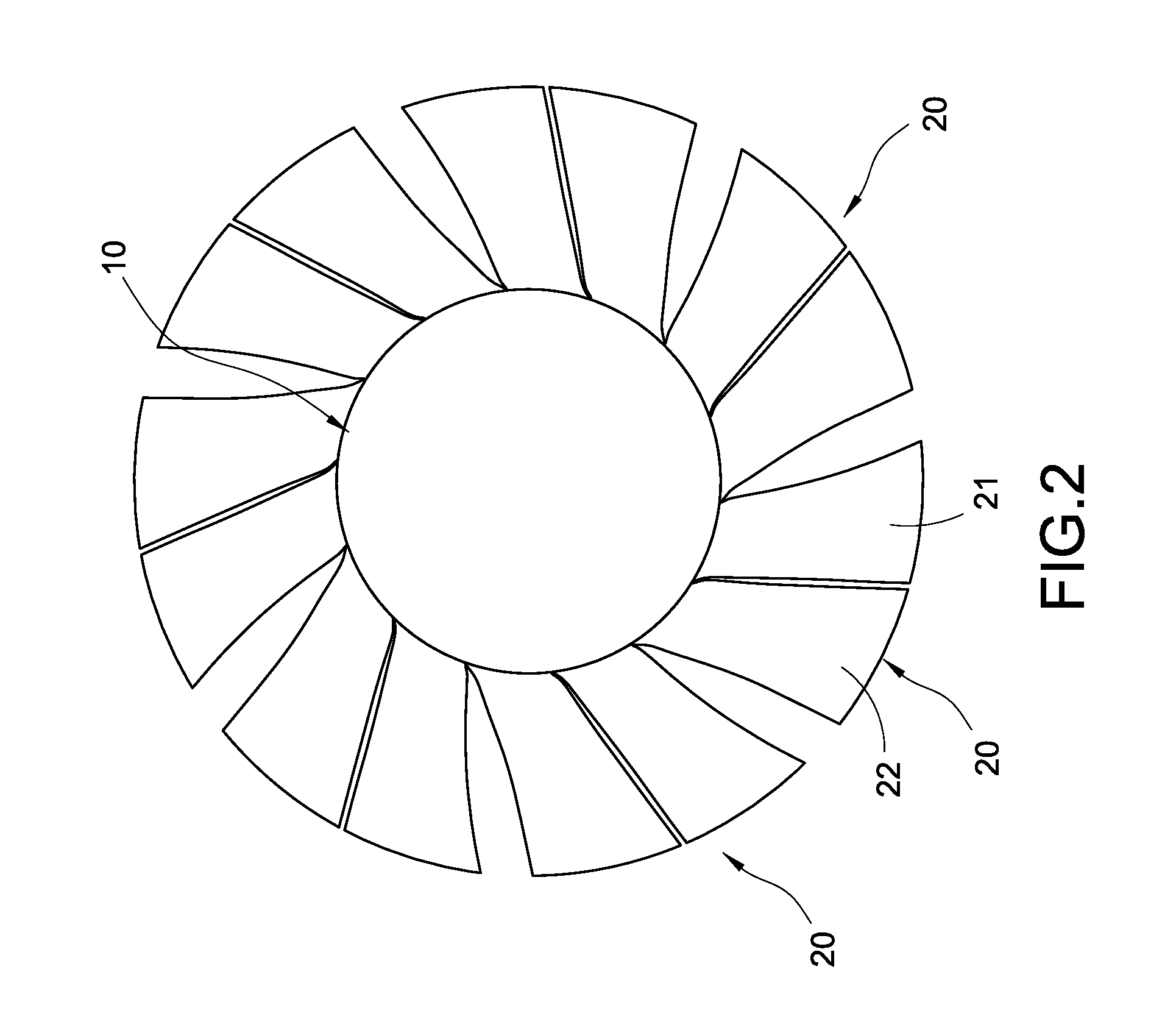

Blade structure of axial fan

InactiveUS20150152879A1Increase air flow rateExcellent characteristicsPropellersPump componentsLeading edgeFan blade

A blade structure of an axial fan is disclosed. The blade structure includes a hub and a plural of fan blades. The fan blades are disposed equidistantly on a periphery of the hub along a rotating direction of the hub. Each fan blade includes a first blade and a second blade. The first blade has a first leading edge and a first trailing edge, and the second blade having a second leading edge and a second trailing edge. A line connecting the first leading edge and the first trailing edge of each fan blade is a first chord line. The second leading edge is located at a line extended along the first chord line, and the separation between the first blade and the second blade is smaller than a distance of adjacent fan blades on the periphery of the hub.

Owner:APPLIED THERMAL FLUID ANALYSIS CENT LIMITED LIABILITY

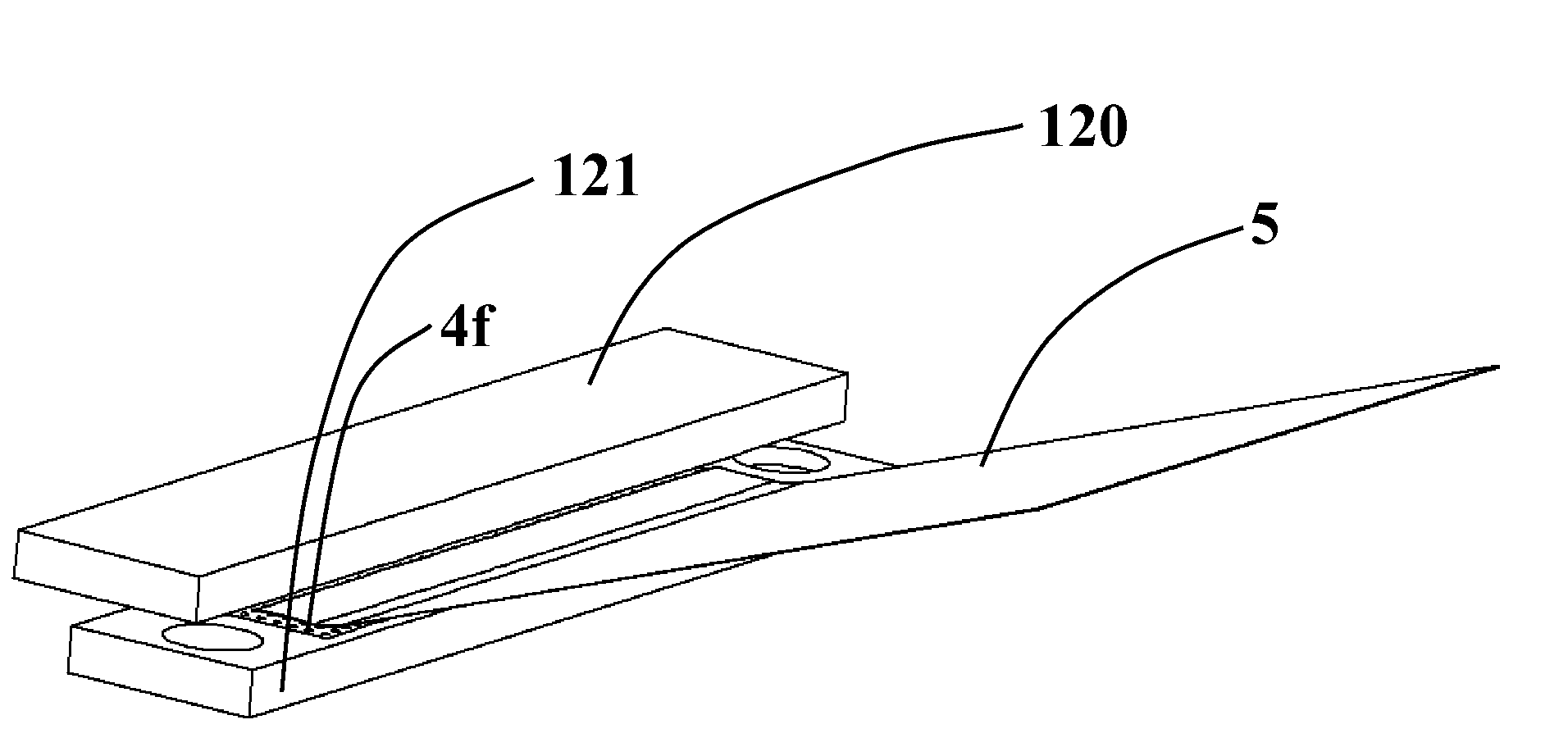

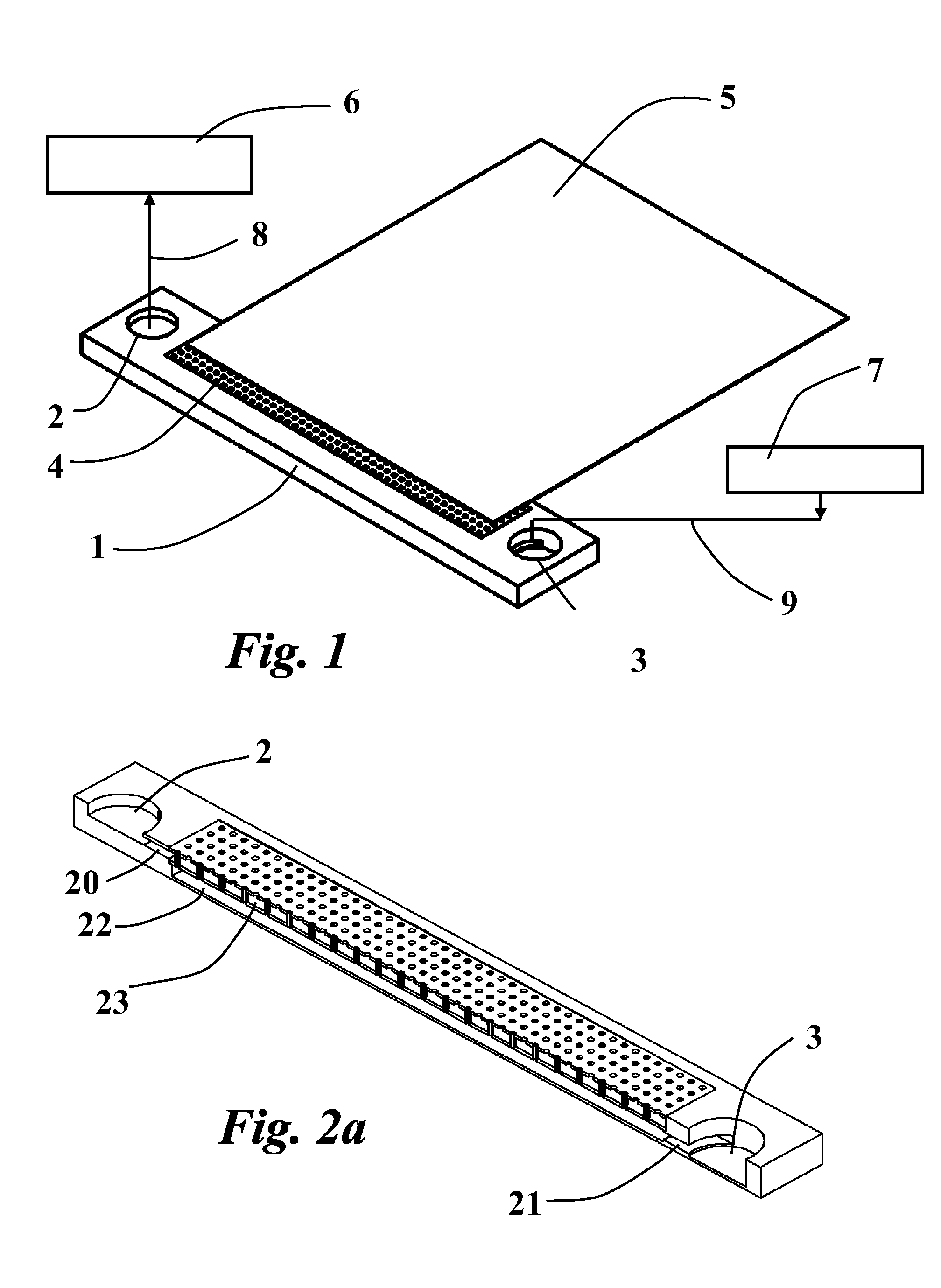

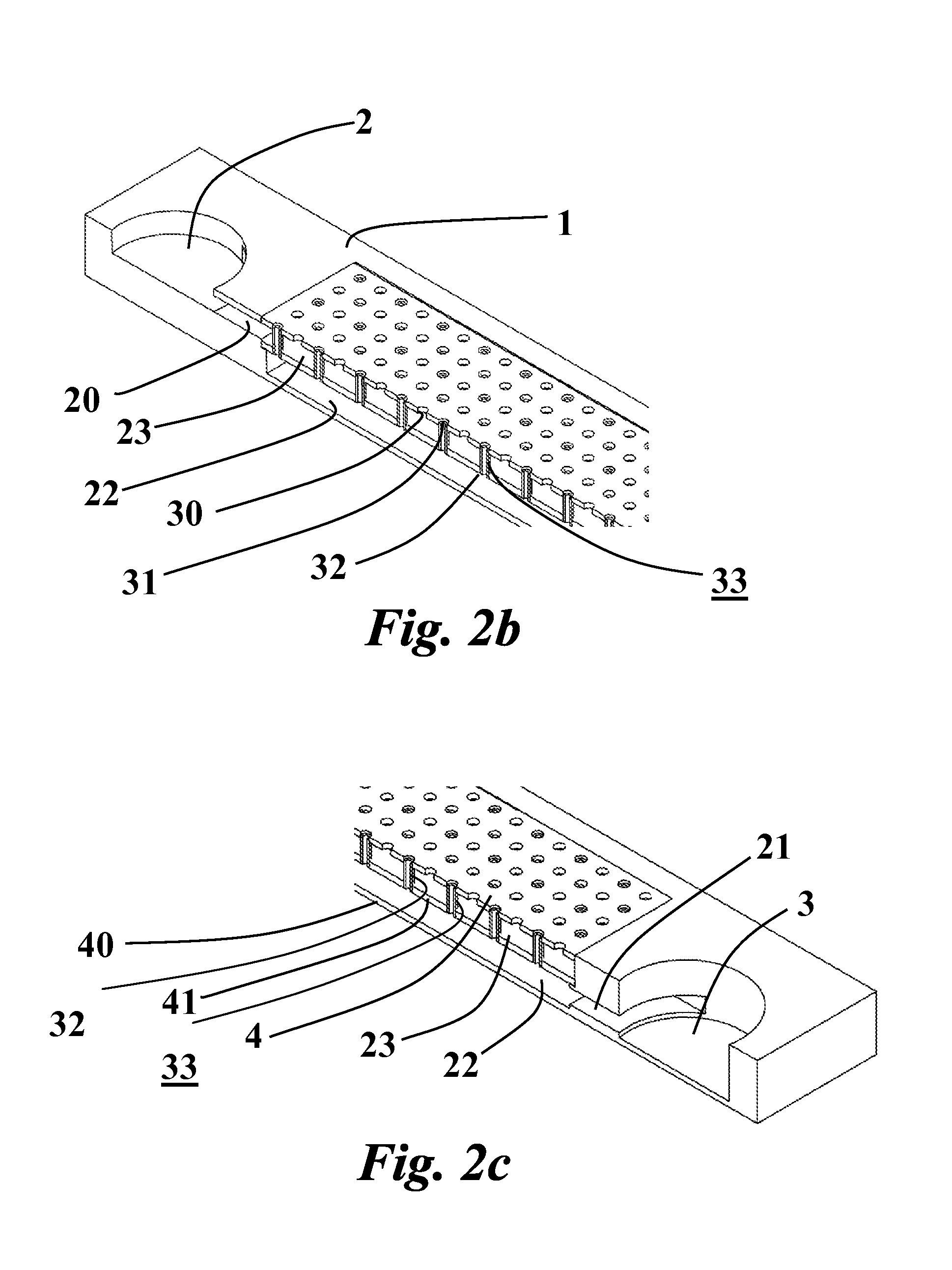

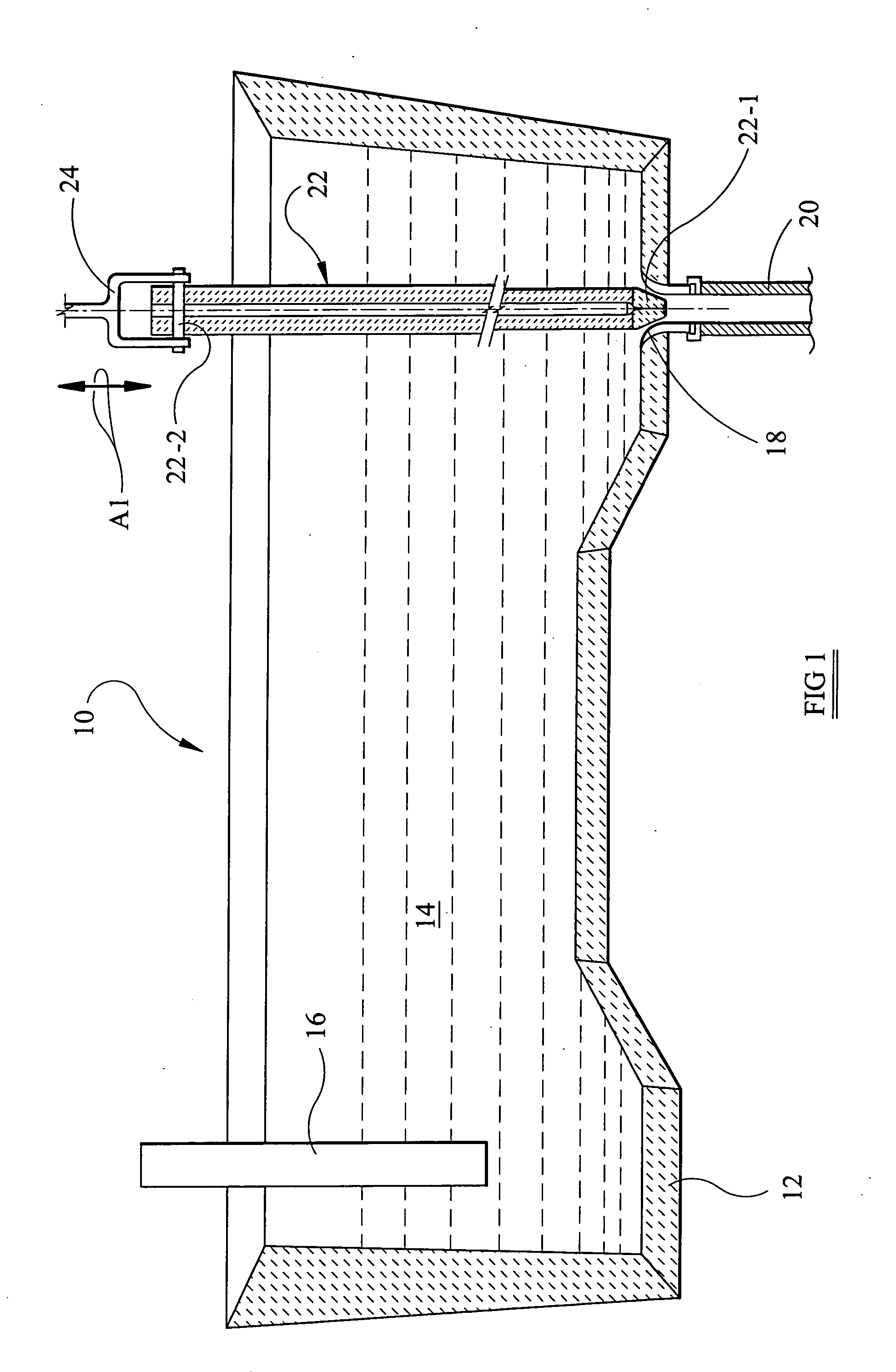

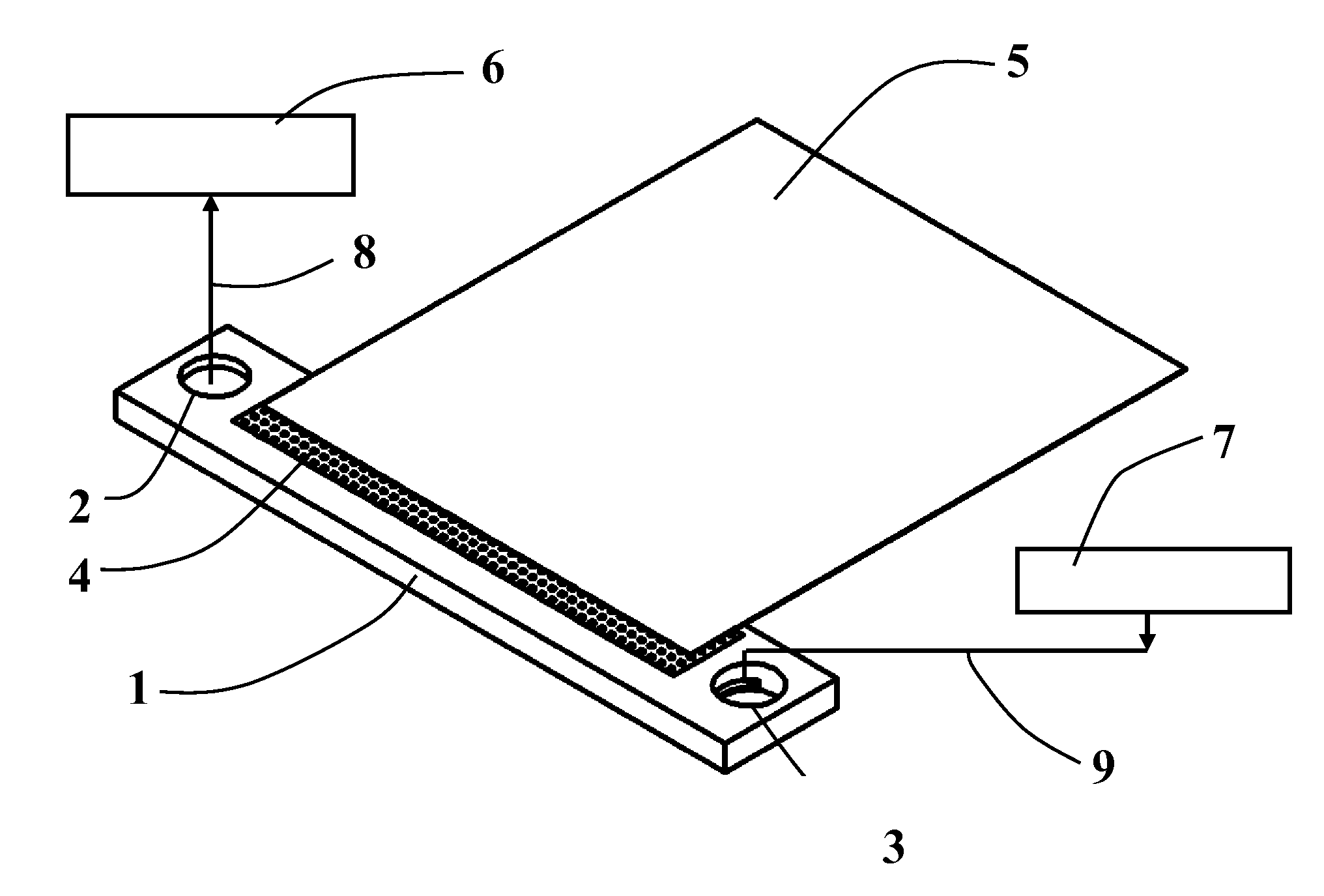

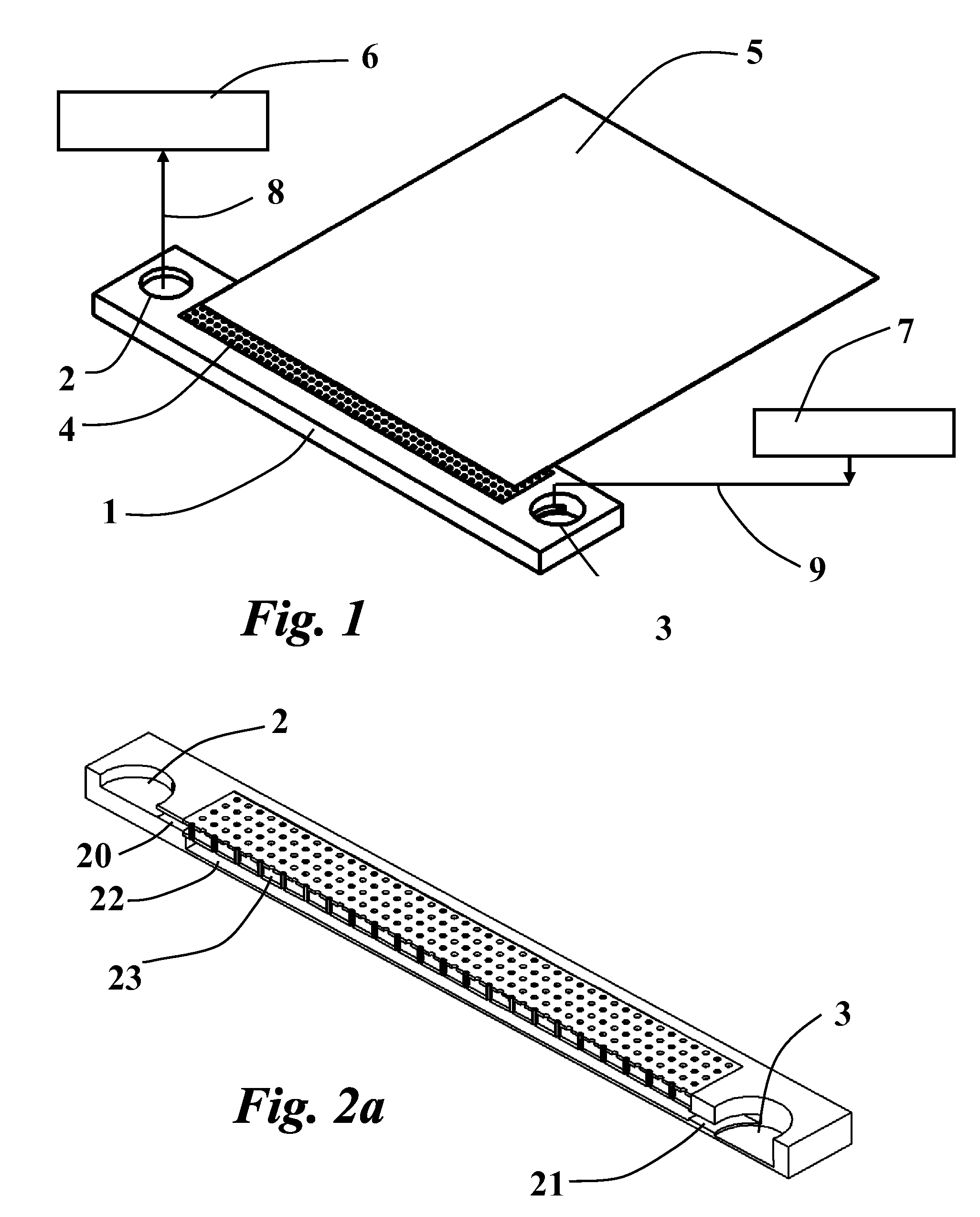

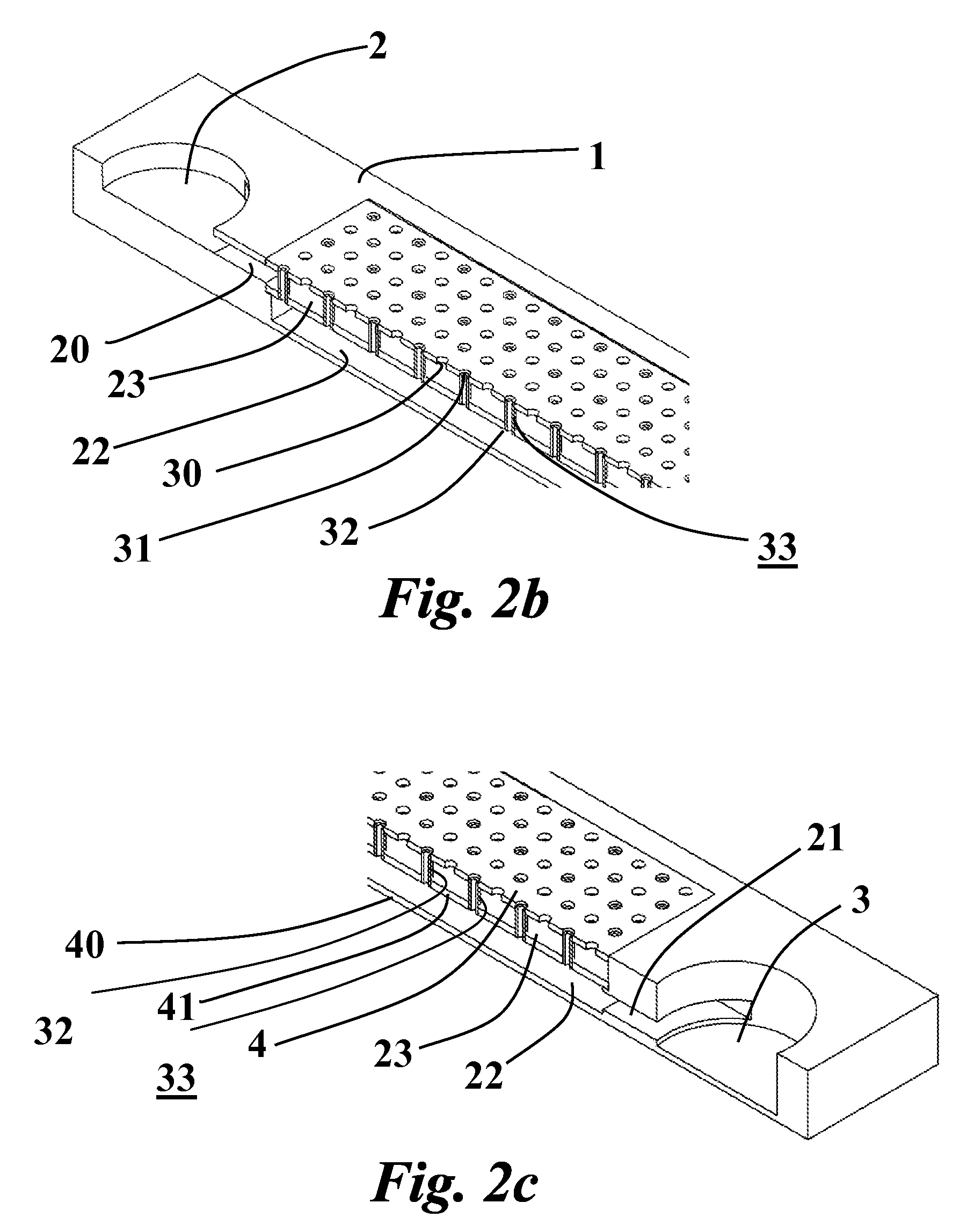

Permeation Device and Method for Reducing Aqueous Boundary Layer Thicknesses

ActiveUS20070251336A1Reduce thicknessReduced boundary layer thicknessSemi-permeable membranesWeather/light/corrosion resistanceRate limitingIntestinal structure

In many miniaturized high-throughput assays, effective stirring is difficult to achieve, and its consequences difficult to predict. Most microtitre plate-based in vitro assays of membrane permeability, such as Caco-2 and PAMPA, of sparingly soluble lipophilic test compounds in pharmaceutical research and development report permeability of water, and not of the intended membrane barrier. This is so because the aqueous boundary layer on both sides of the membrane barrier is rate limiting for these highly permeable molecules. The thickness of this water layer can be 1500-4000 μm in unstirred assays. Under in vivo conditions, however, the aqueous boundary layer is believed to be 30-100 μm thick in the intestine, and <1 μm at the blood-brain barrier. Using plate shakers to stir microtitre plates cannot lower the thickness of the water layer to match that found in vivo. We have discovered a high-throughput method and a simple, “robotics-friendly” device where individual-well stirring at speeds of about 600 rpm can lower the aqueous boundary layer thickness to <15 μm, which had not been previously achieved for plate-based permeability assays.

Owner:PION

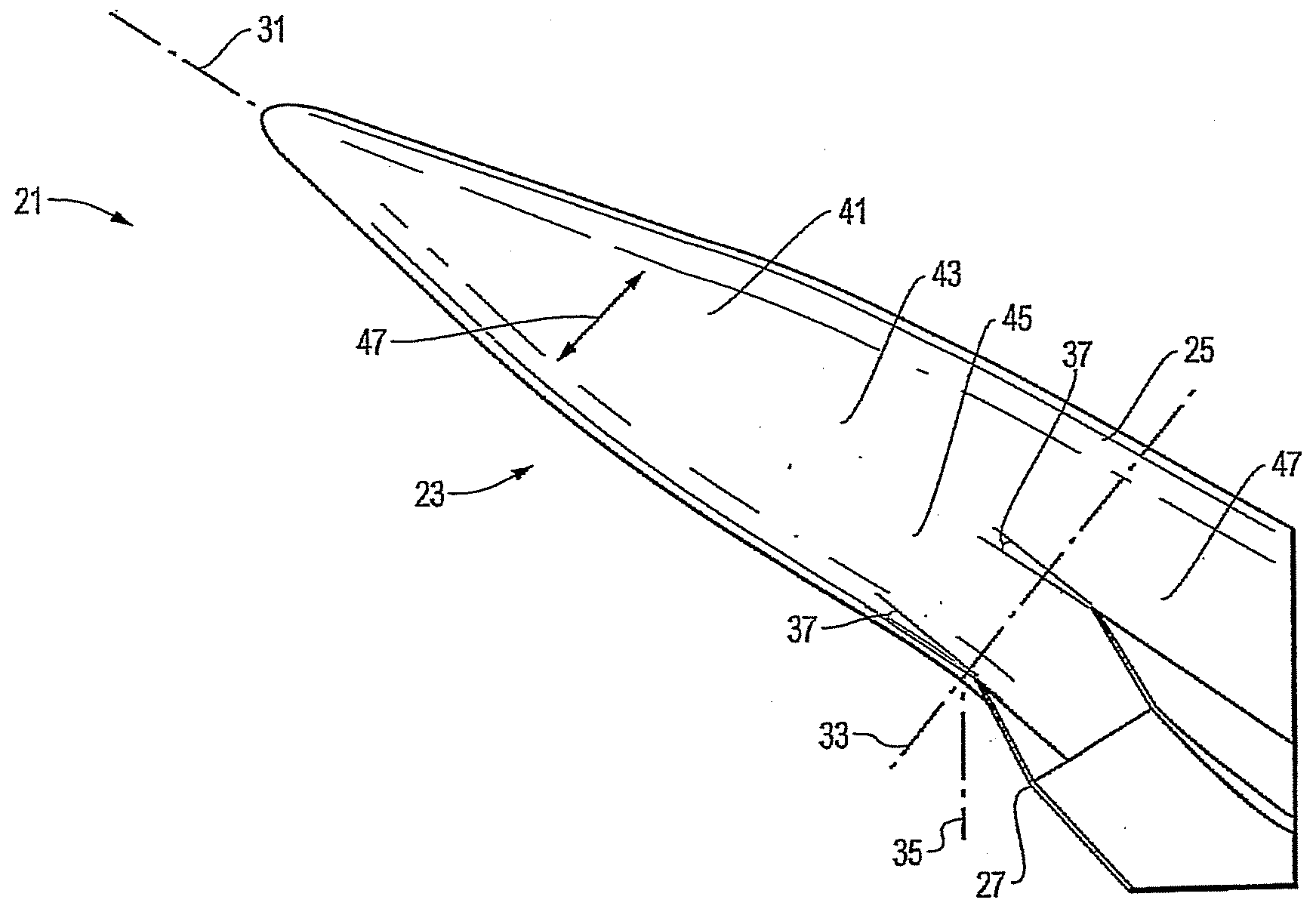

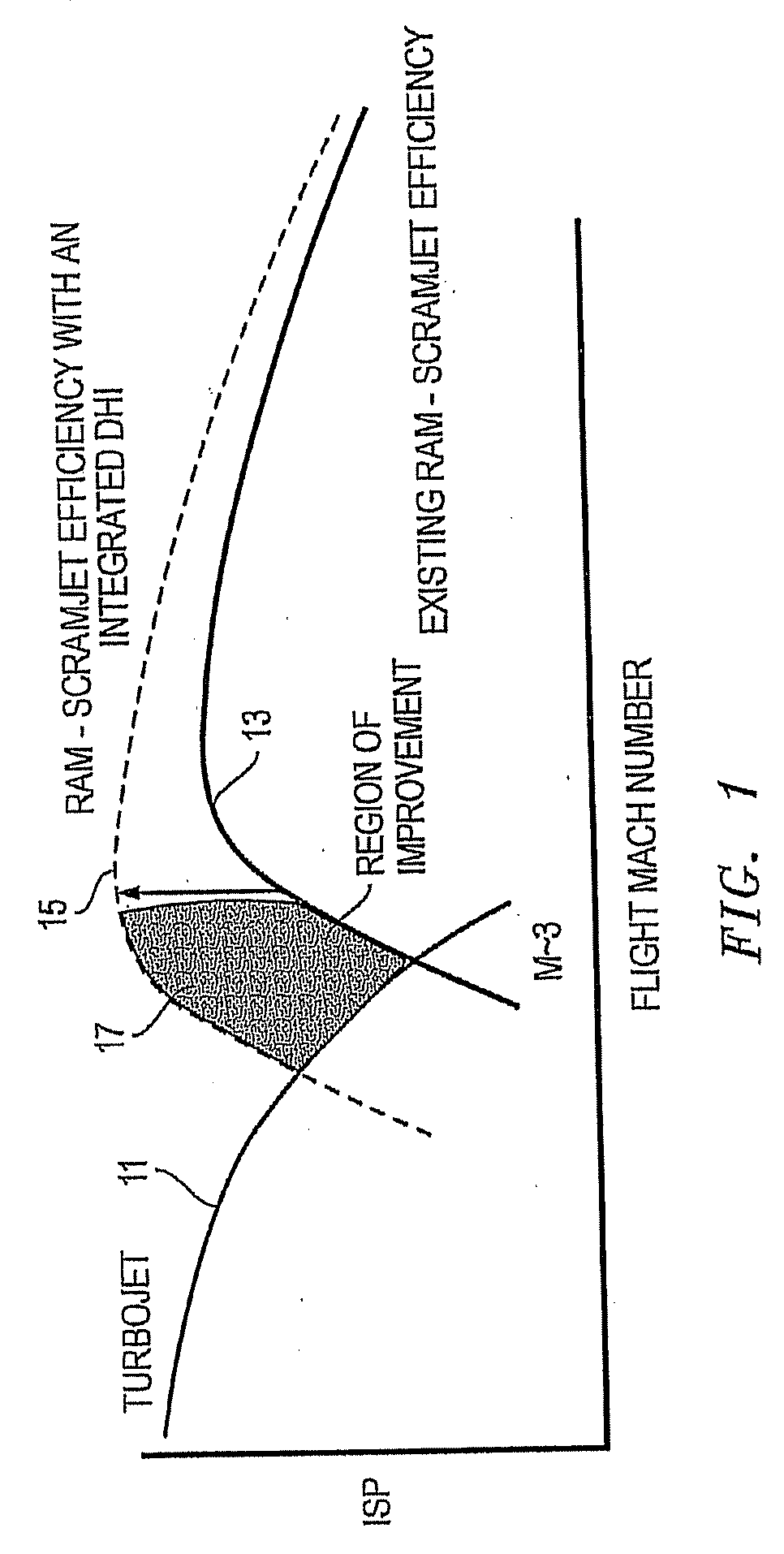

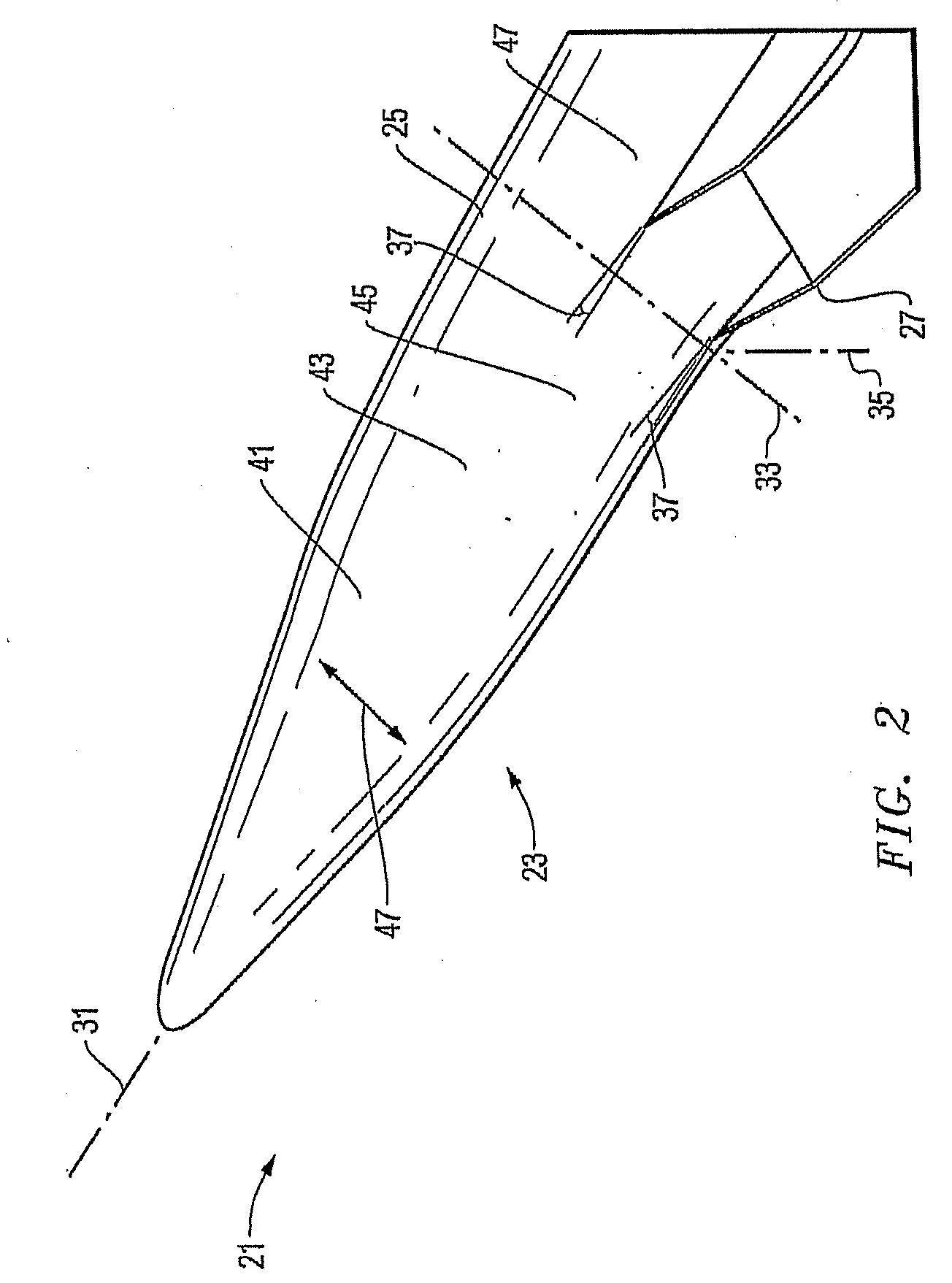

System, method, and apparatus for diverterless hypersonic inlet for integrated turbojet and ram-scramjet applications

ActiveUS20070136032A1Reduce penaltyFavorable air flow characteristicGeometric CADSustainable transportationAir breathingScramjet

A diverterless hypersonic inlet (DHI) for a high speed, air-breathing propulsion system reduces the ingested boundary layer flow, drag, and weight, and maintains a high capture area for hypersonic applications. The design enables high vehicle fineness ratios, low-observable features, and enhances ramjet operability limits. The DHI is optimized for a particular design flight Mach number. A forebody segment generates and focuses a system of multiple upstream shock waves at desired strengths and angles to facilitate required inlet and engine airflow conditions. The forebody contour diverts boundary layer flow to the inlet sides, effectively reducing the thickness of the boundary layer that is ingested by the inlet, while maintaining the capture area required by the hypersonic propulsion system. The cowl assembly is shaped to integrate with the forebody shock system and the thinned boundary layer region.

Owner:LOCKHEED MARTIN CORP

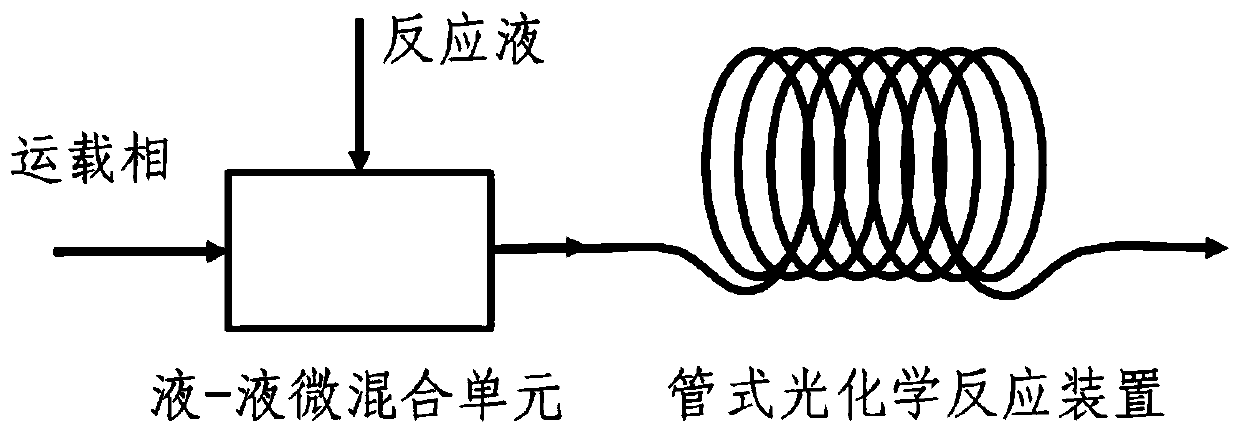

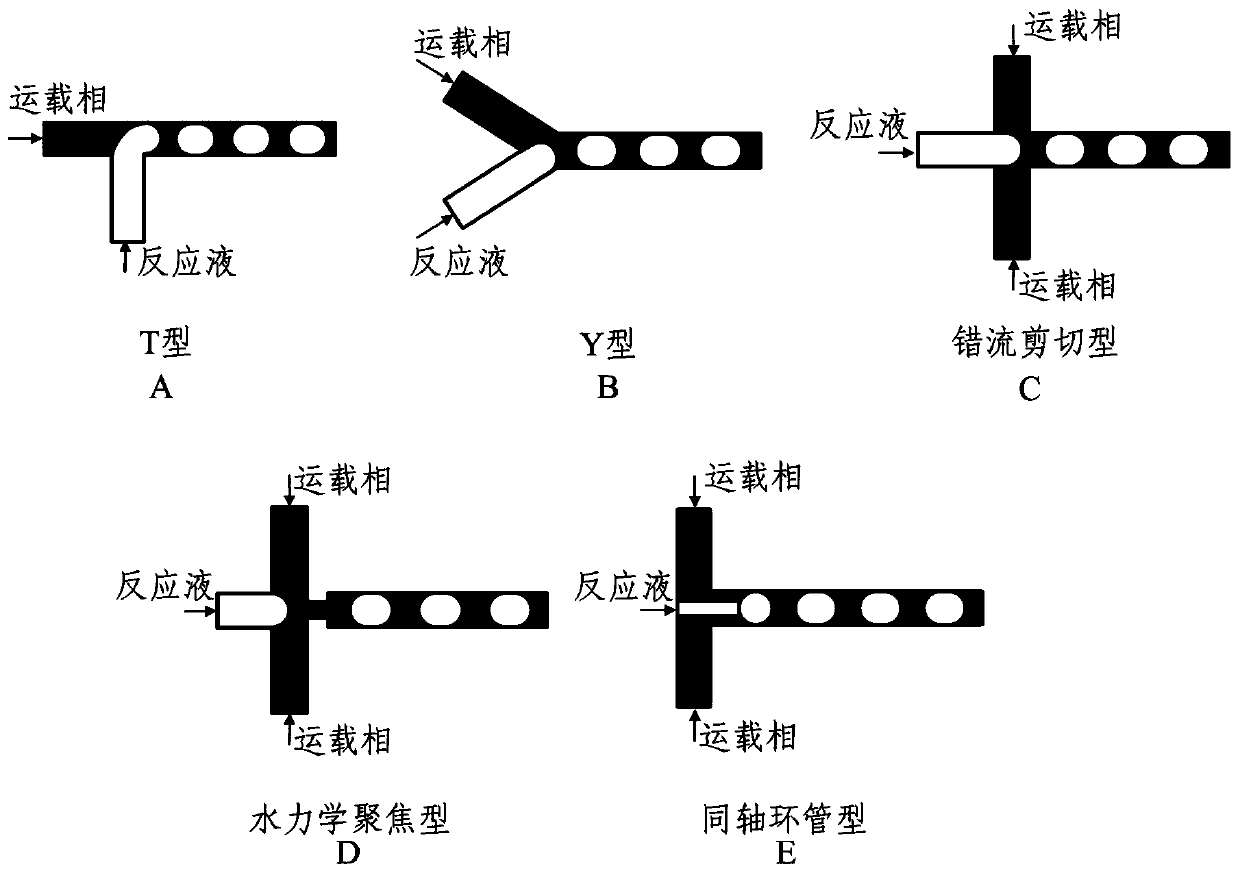

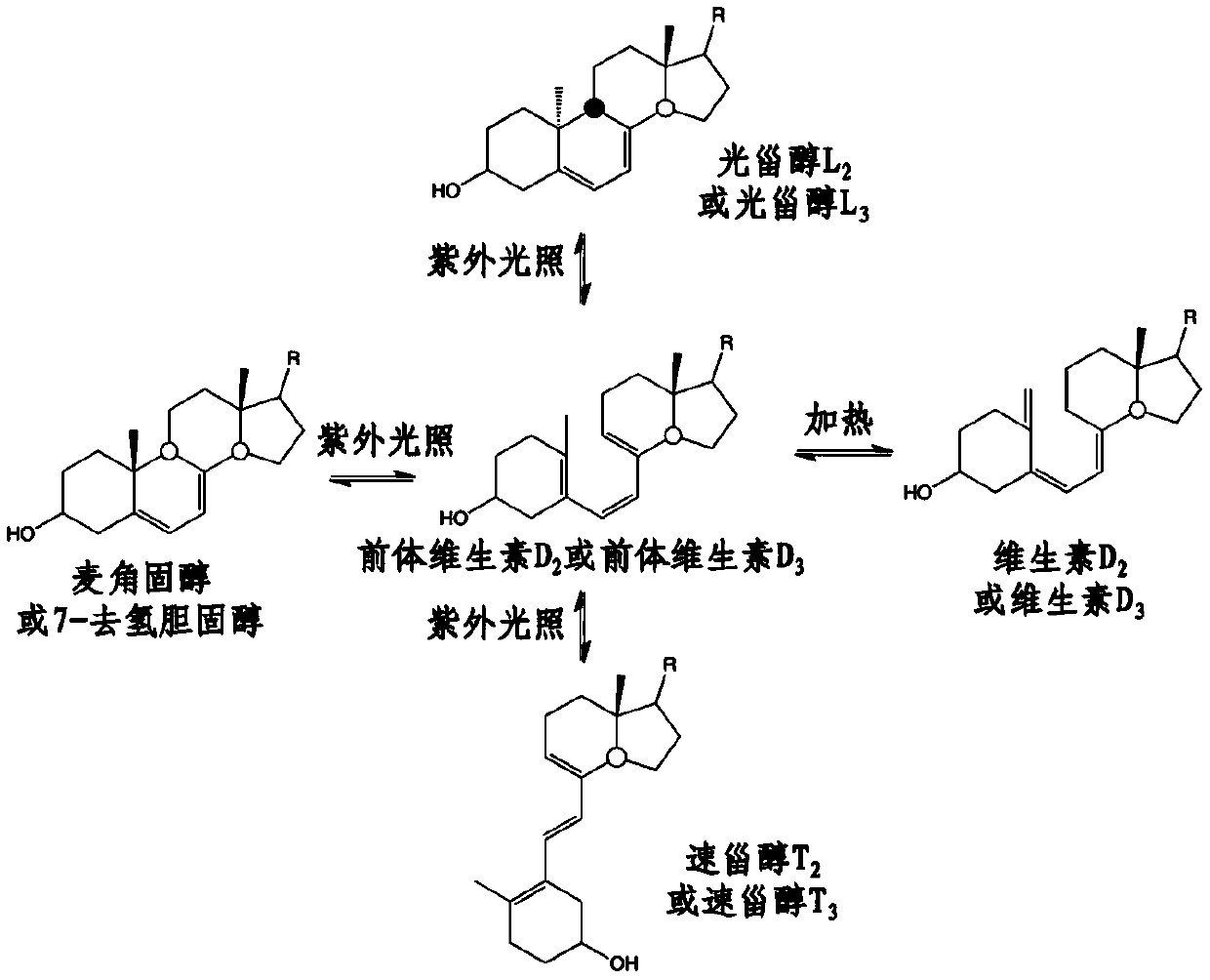

Method for photochemically synthesizing vitamin D2 and D3 in tubular reactor

The invention relates to a method for photochemically synthesizing vitamin D2 and D3 in a tubular reactor. The method is characterized in that the vitamin D2 and D3 are synthesized by ultraviolet light of different bands, the residence time of reaction liquid fed at different times in the tubular reactor is controlled to be the same by not dissolving with reaction liquid, not participating in reaction liquid separation and carrying ergosterol and 7-dehydrocholesterol reaction liquid and enhancing internal disturbance of the reaction liquid; the method has the advantages of continuous, stable and high efficiency of solar energy utilization, the operation is simple, and the process is controllable; the method has great prospect in the industrial production of the photochemically synthesizedvitamin D2 and D3.

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +1

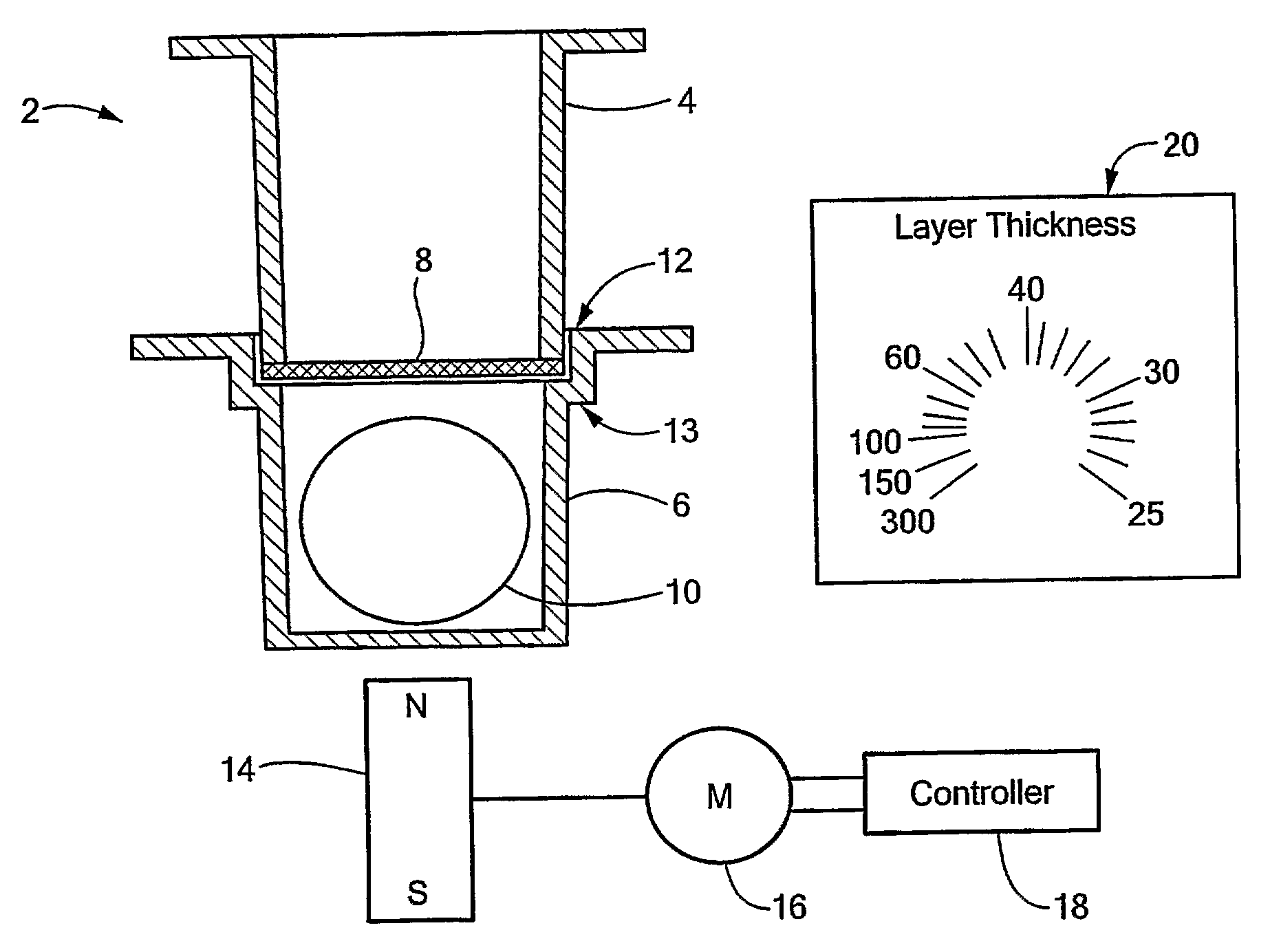

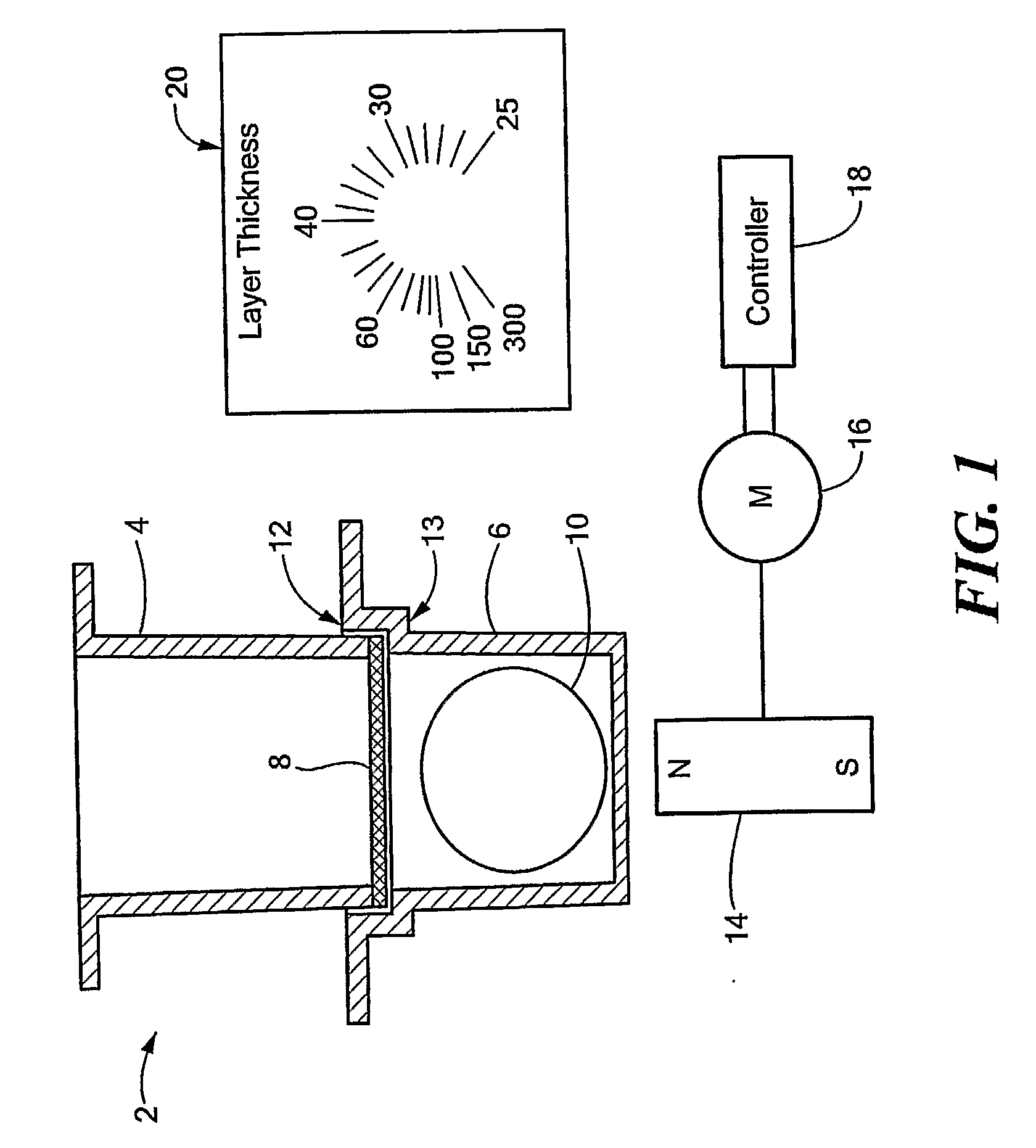

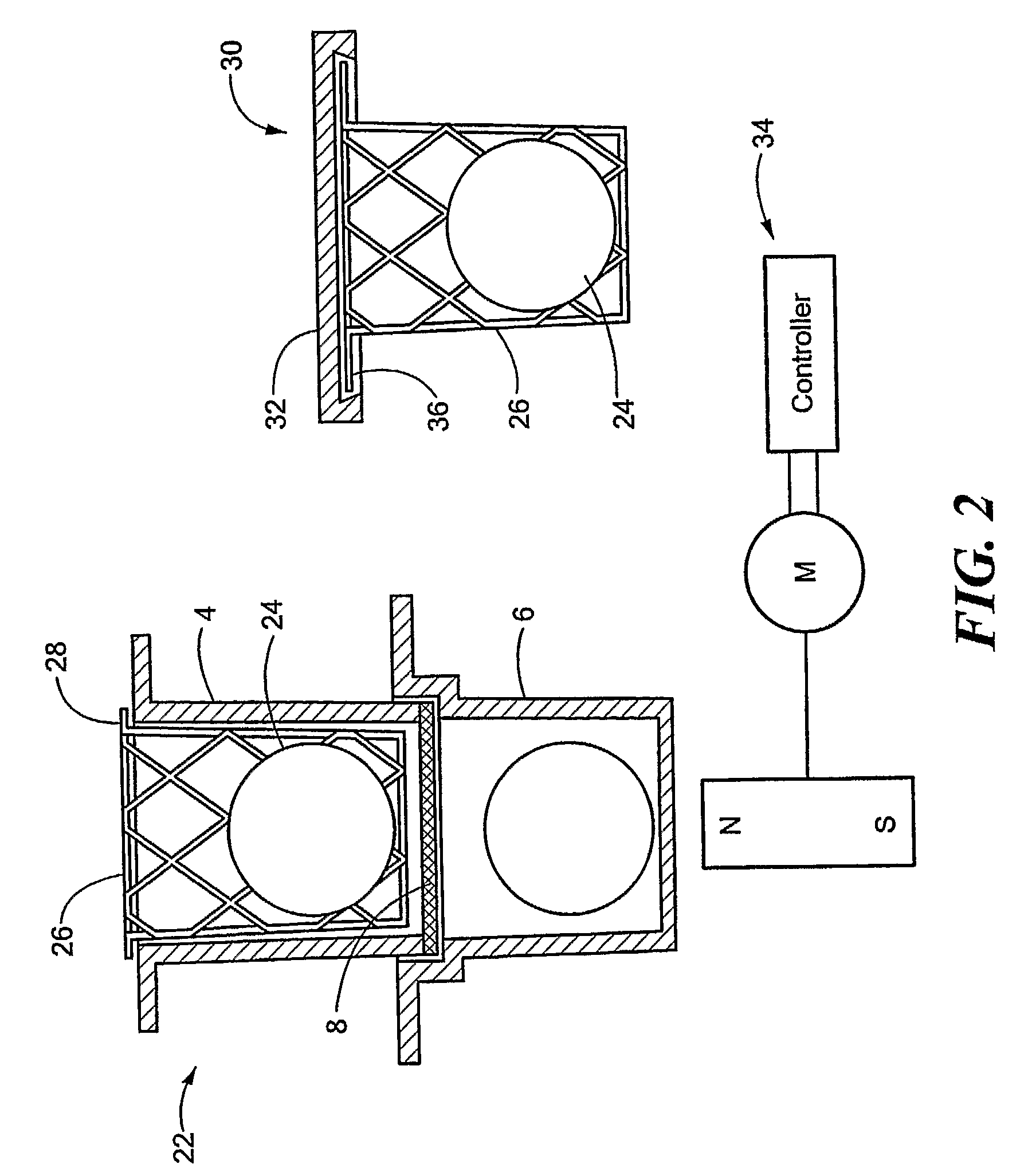

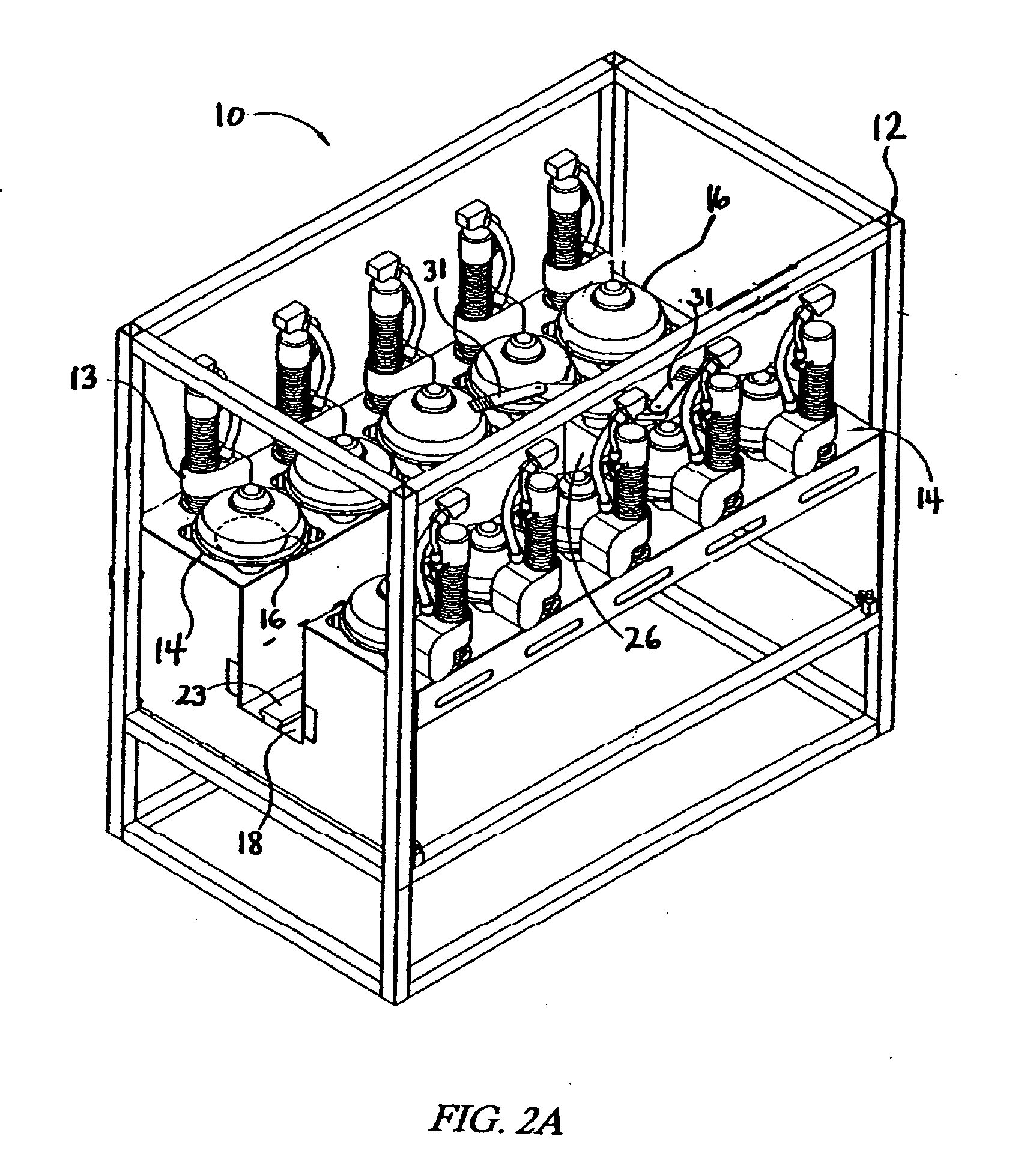

Method and apparatus for metal oxide chemical vapor deposition on a substrate surface

InactiveUS6231933B1Deposition rateReduced boundary layer thicknessPretreated surfacesSemiconductor/solid-state device manufacturingGas phaseAcoustic wave

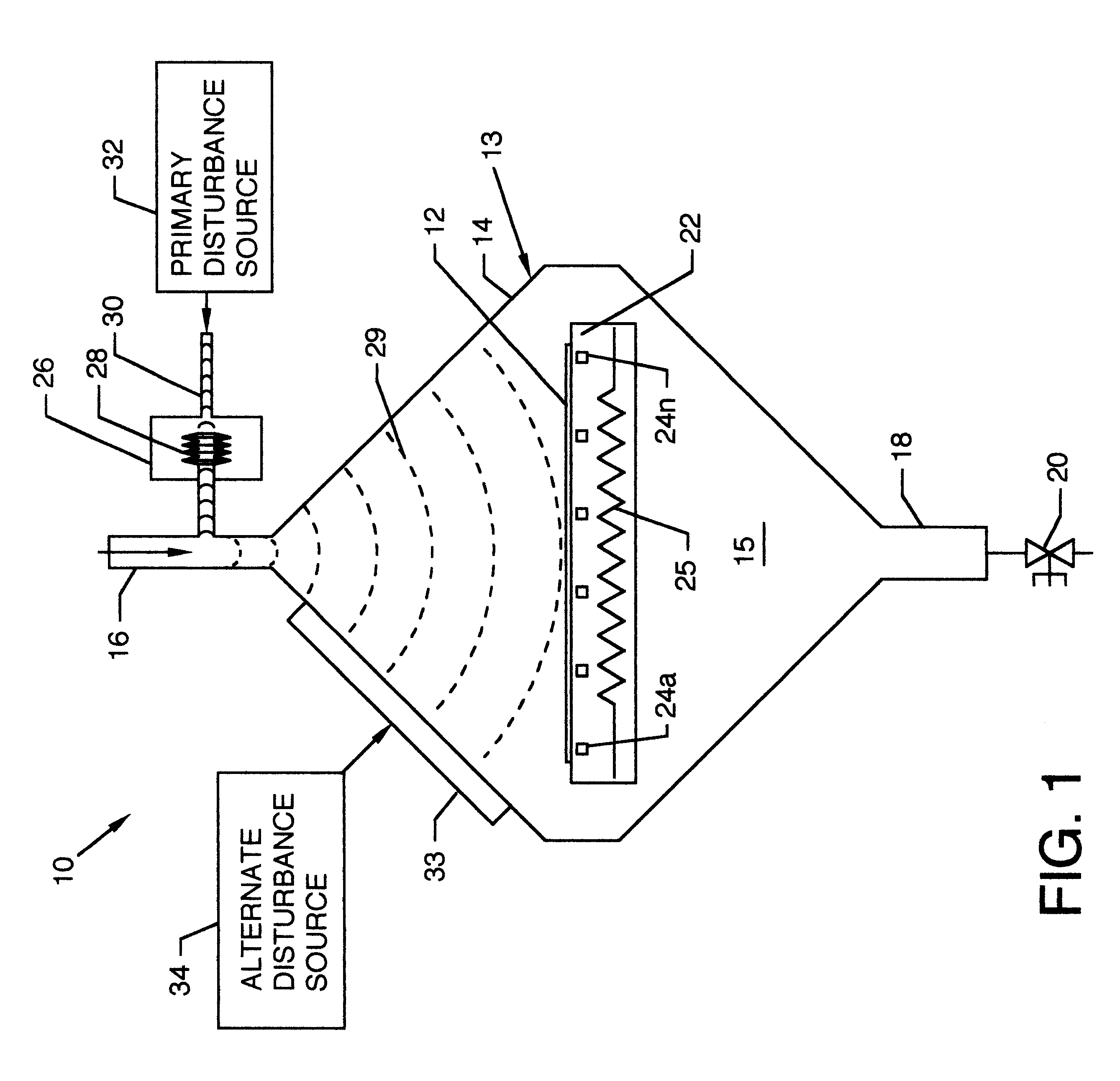

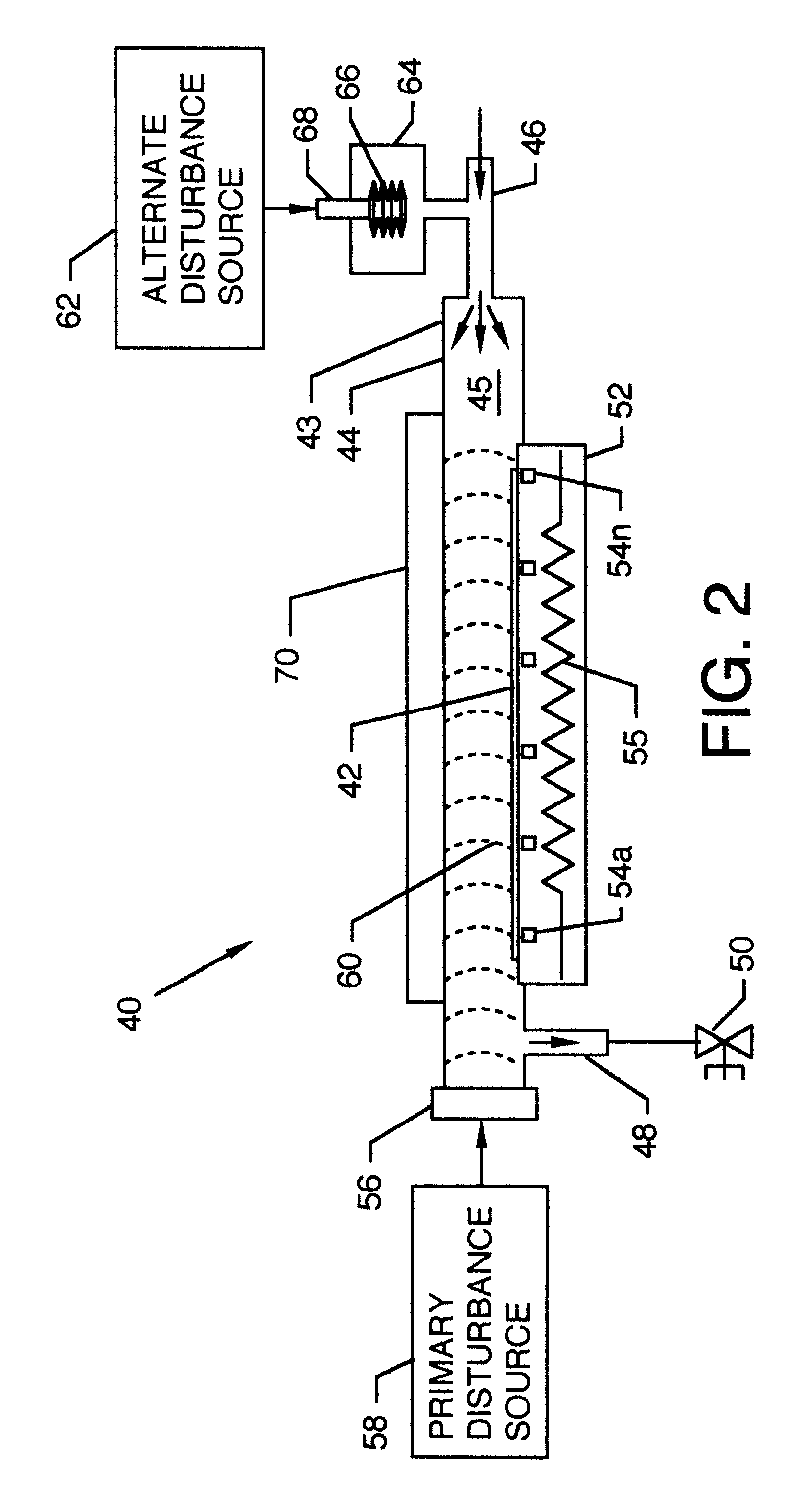

A method and apparatus for improved metal oxide chemical vapor deposition on a substrate surface where the application boundary layer is reduced and where the uniformity of the application boundary layer is greatly enhanced in a reactor. Primary and secondary sonic or other disturbance sources are incorporated for introducing disturbance into the interior chamber of the reactor, or an oscillating or vibrating chuck is incorporated within the interior chamber, to influence the boundary layer thickness and uniformity.

Owner:PRIMAXX

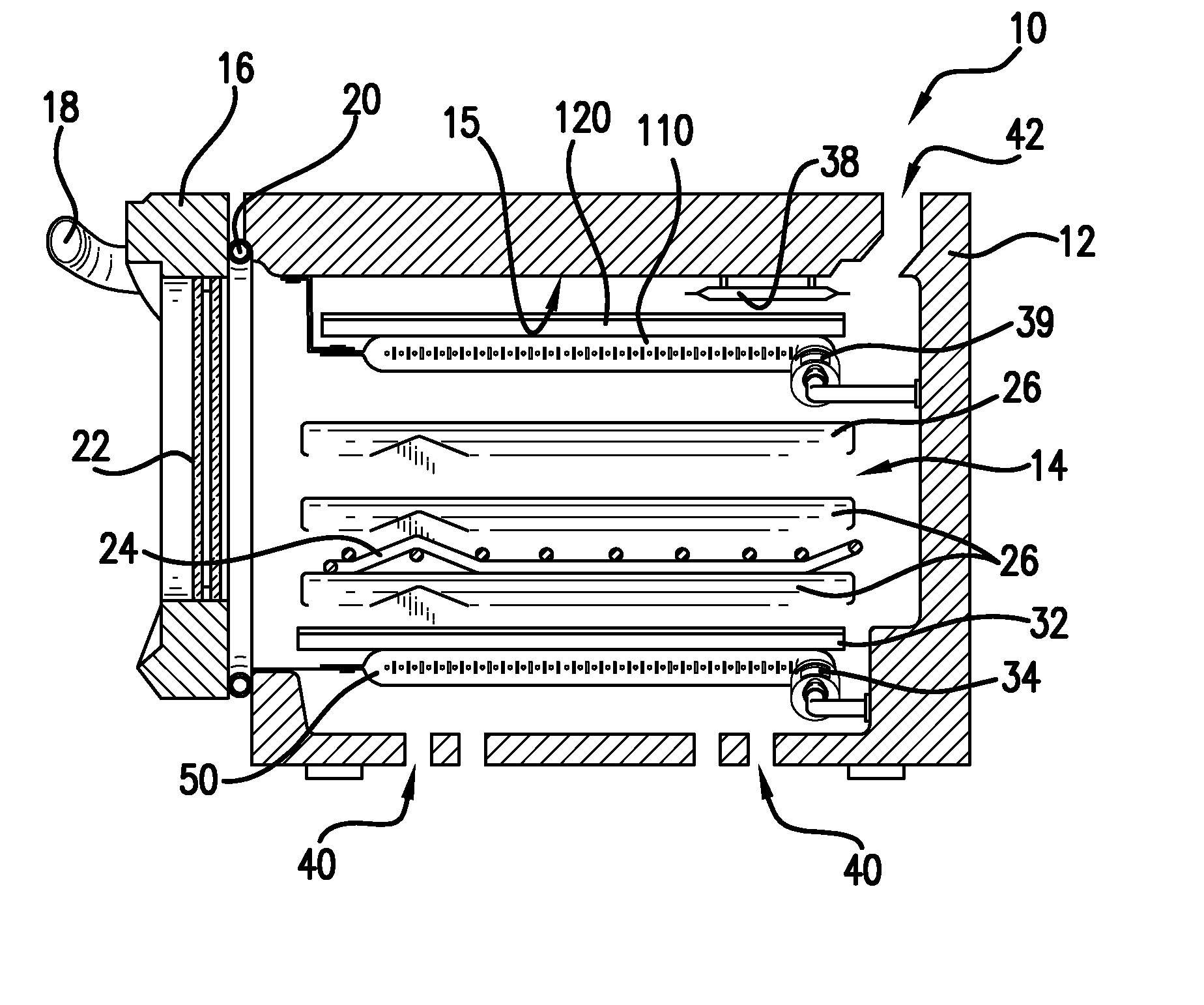

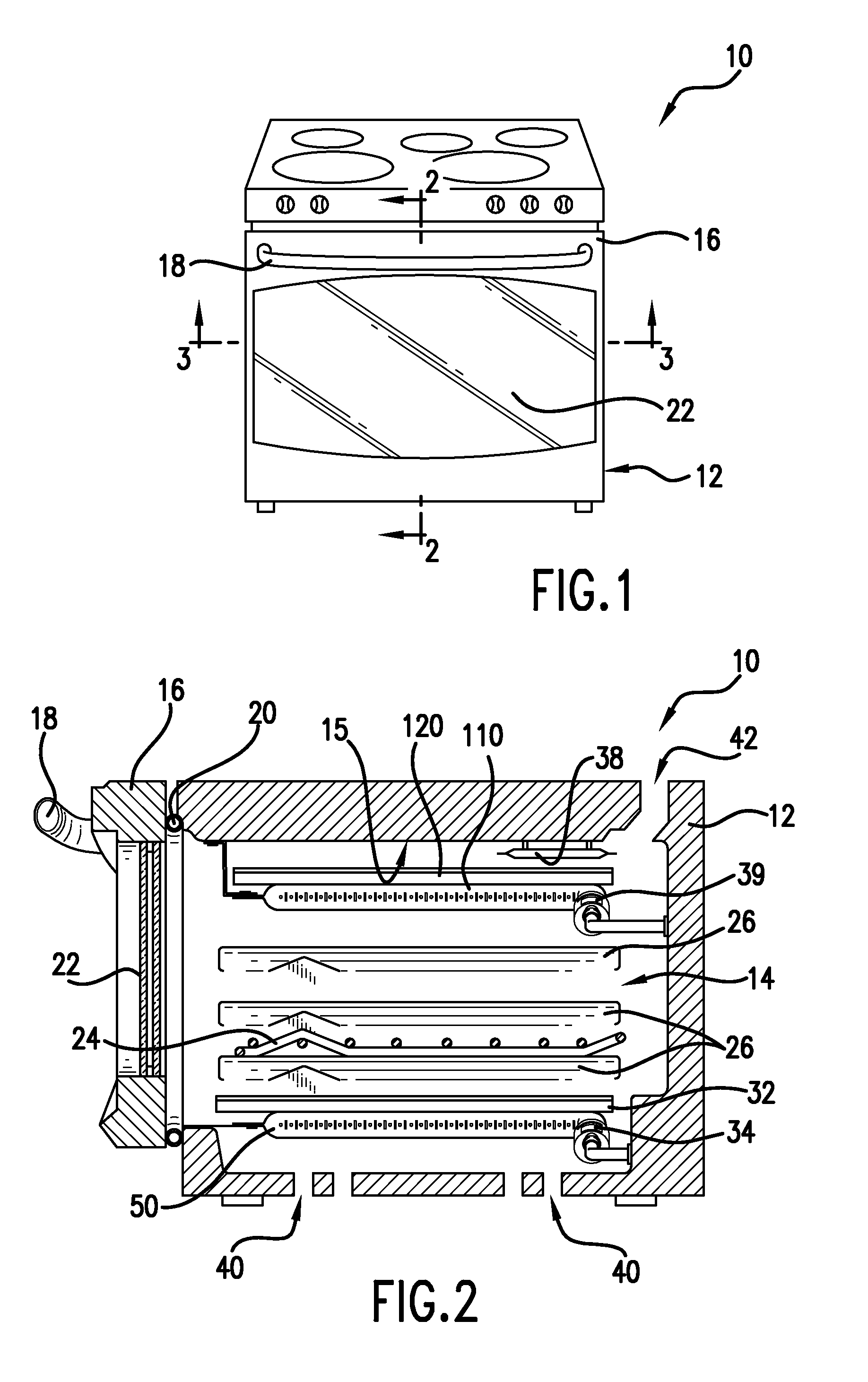

Burner assembly

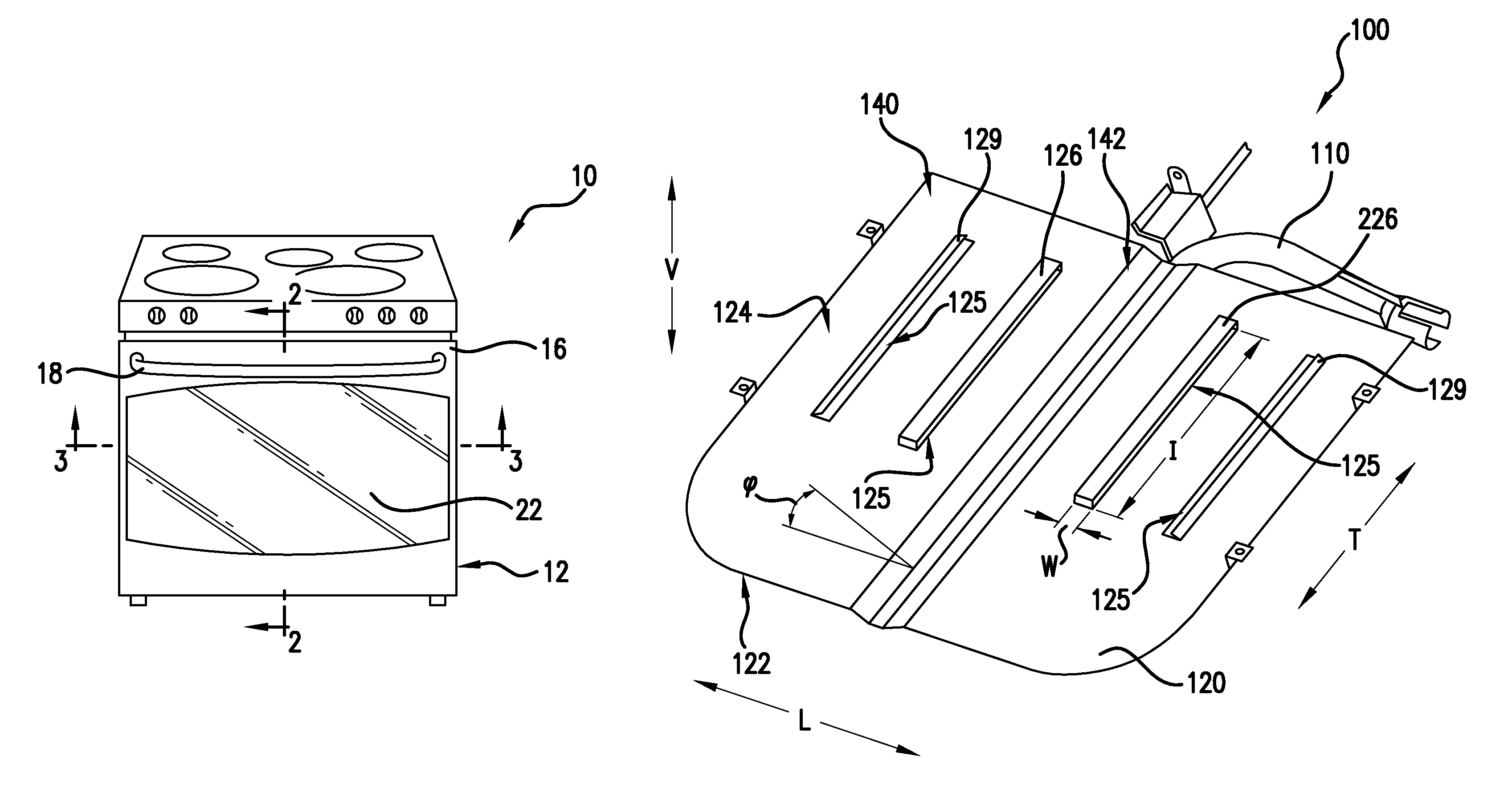

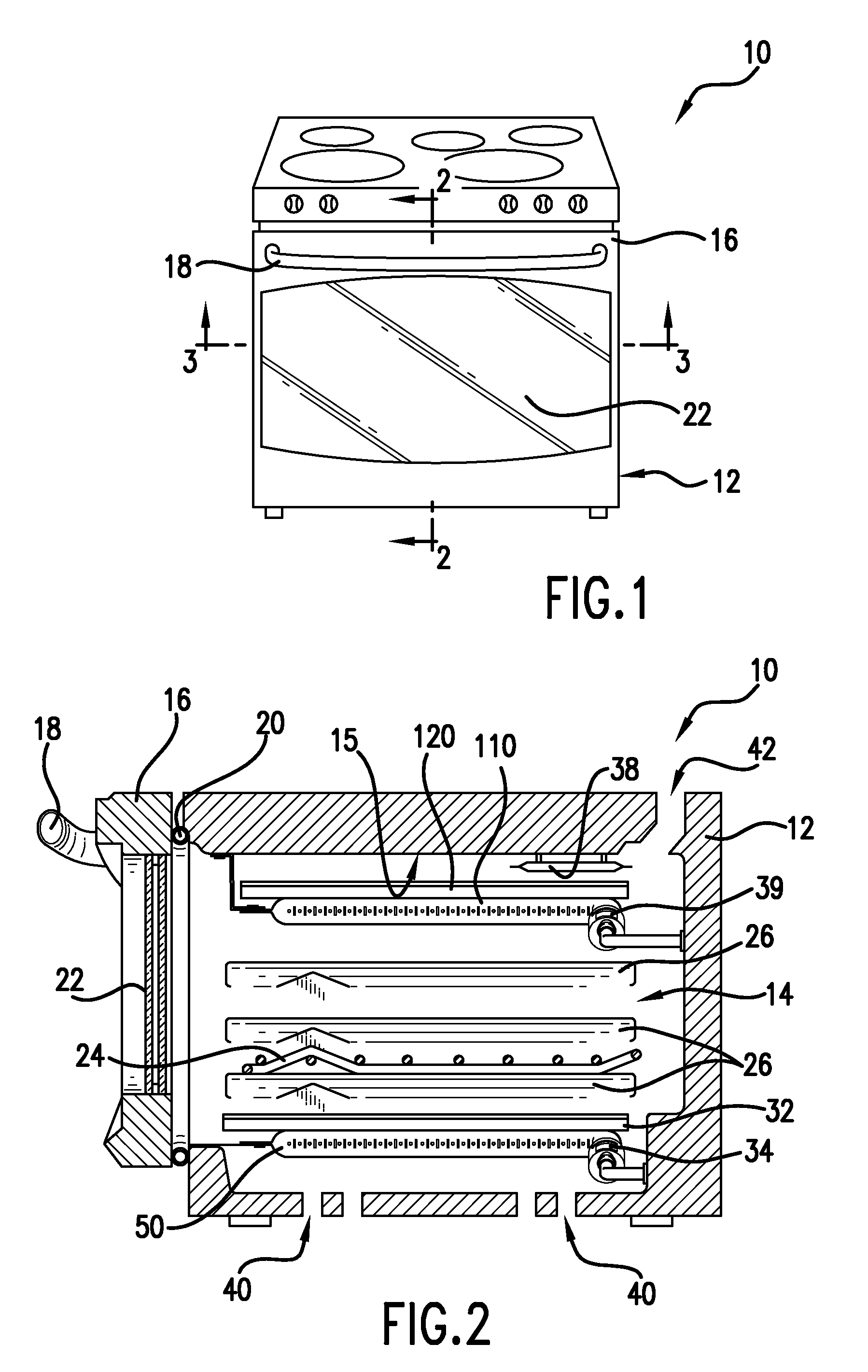

InactiveUS9175859B2Reduced boundary layer thicknessDomestic stoves or rangesCooking fumes removalEngineeringMechanical engineering

A burner assembly for an oven appliance is provided. The burner assembly includes a gas burner and a flame spreader. The flame spreader defines a slot or a series of apertures that is substantially parallel to the gas burner. The slot or series of apertures can decrease a thickness of a boundary layer positioned adjacent the flame spreader or increase a velocity or a temperature or both of the boundary layer.

Owner:HAIER US APPLIANCE SOLUTIONS INC

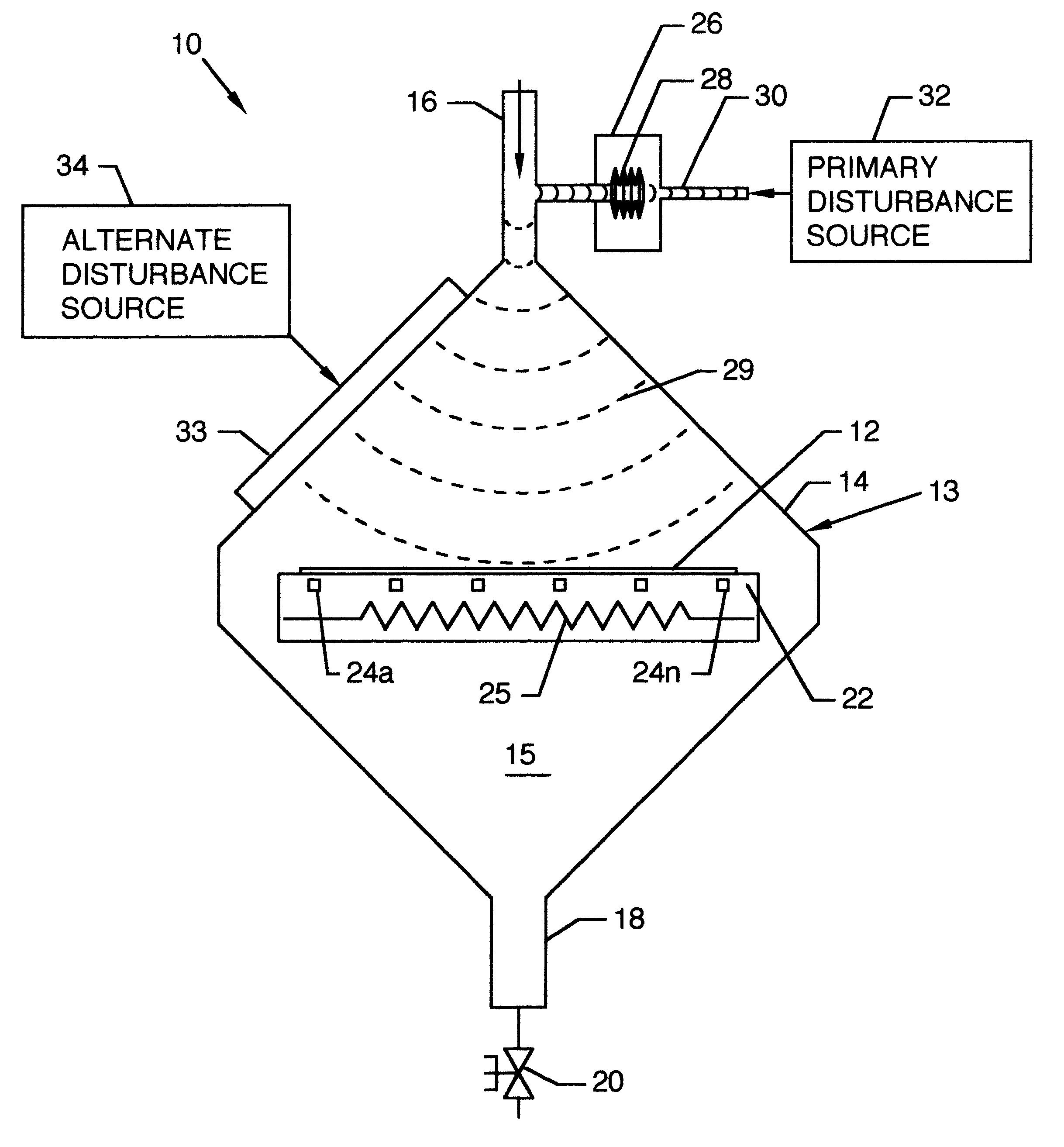

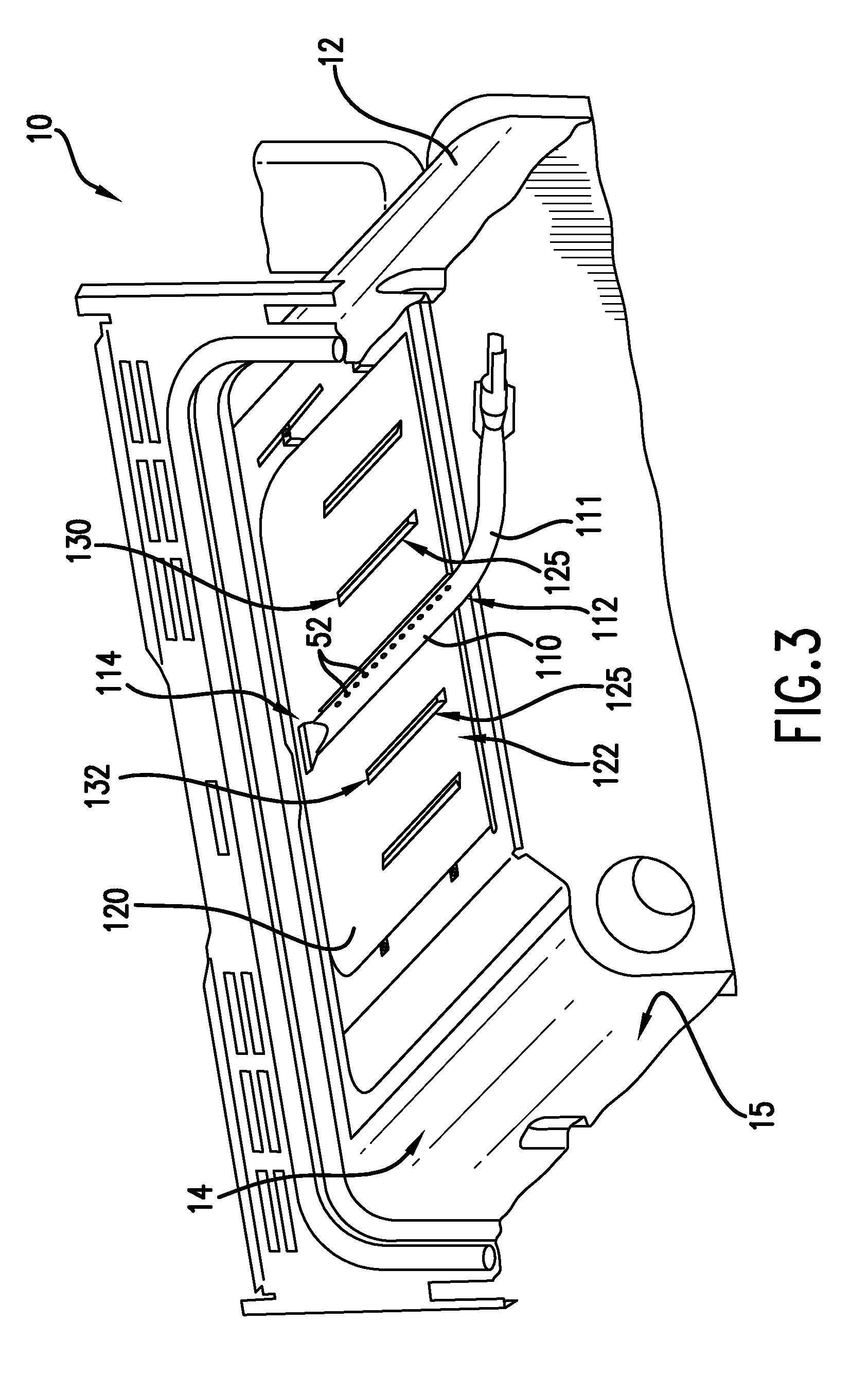

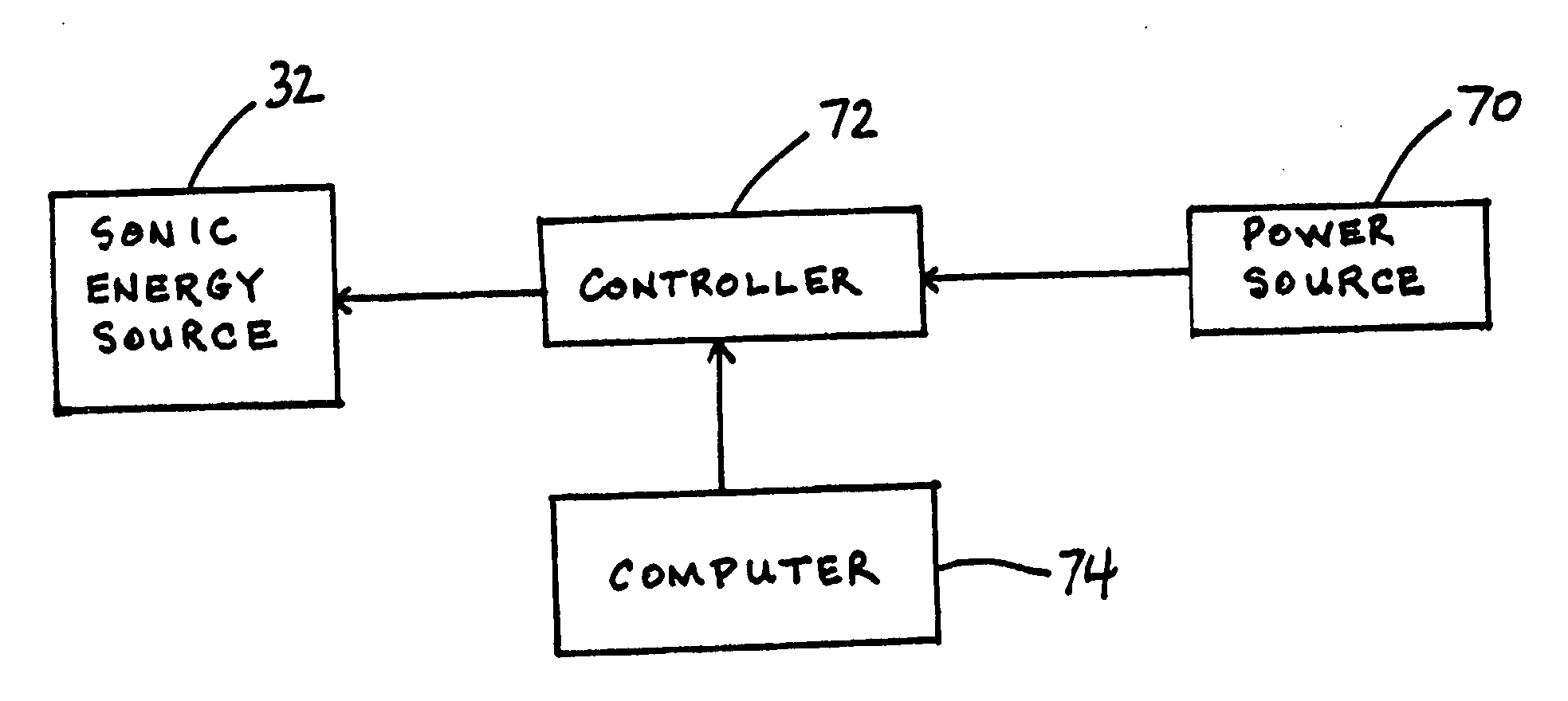

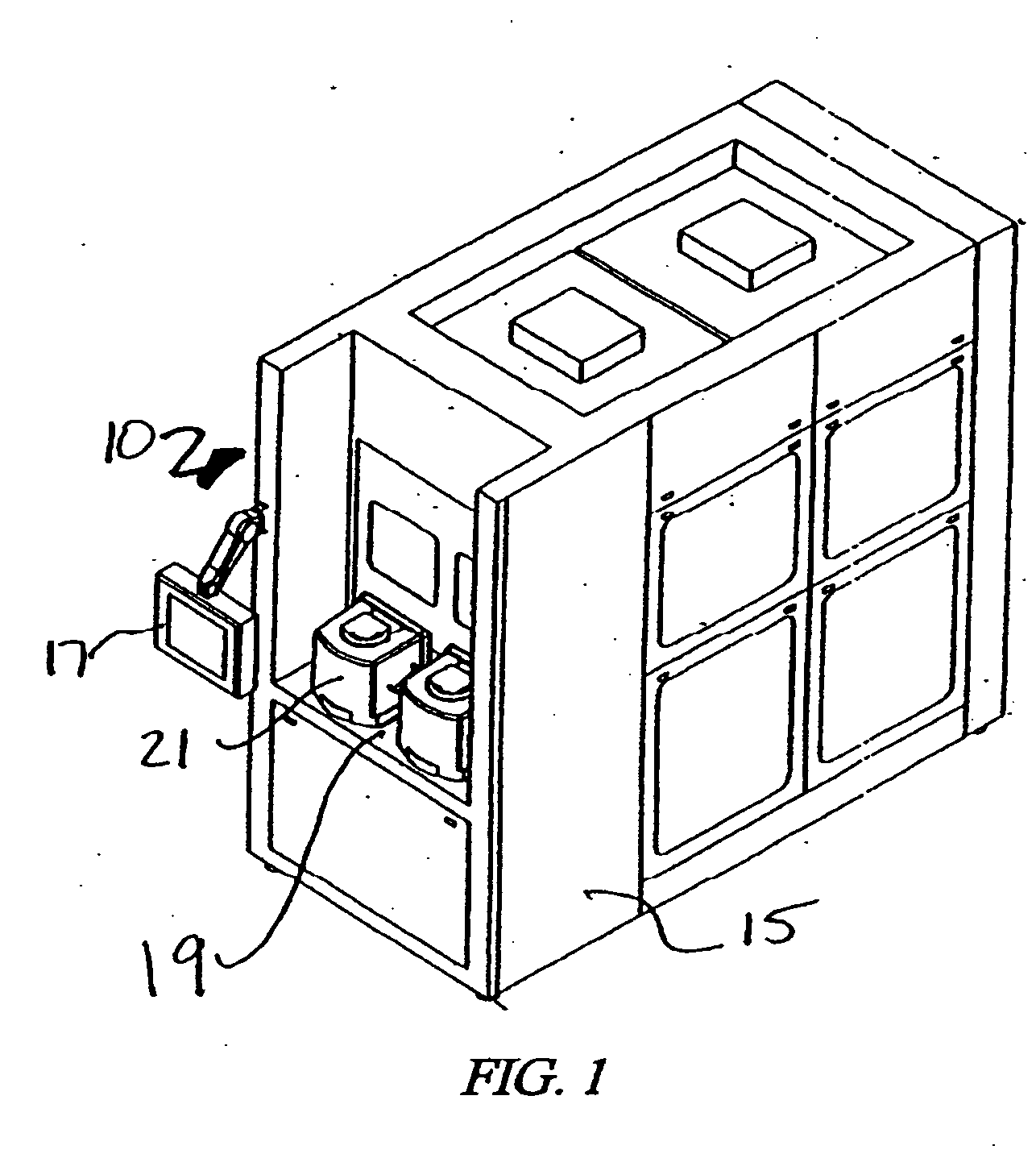

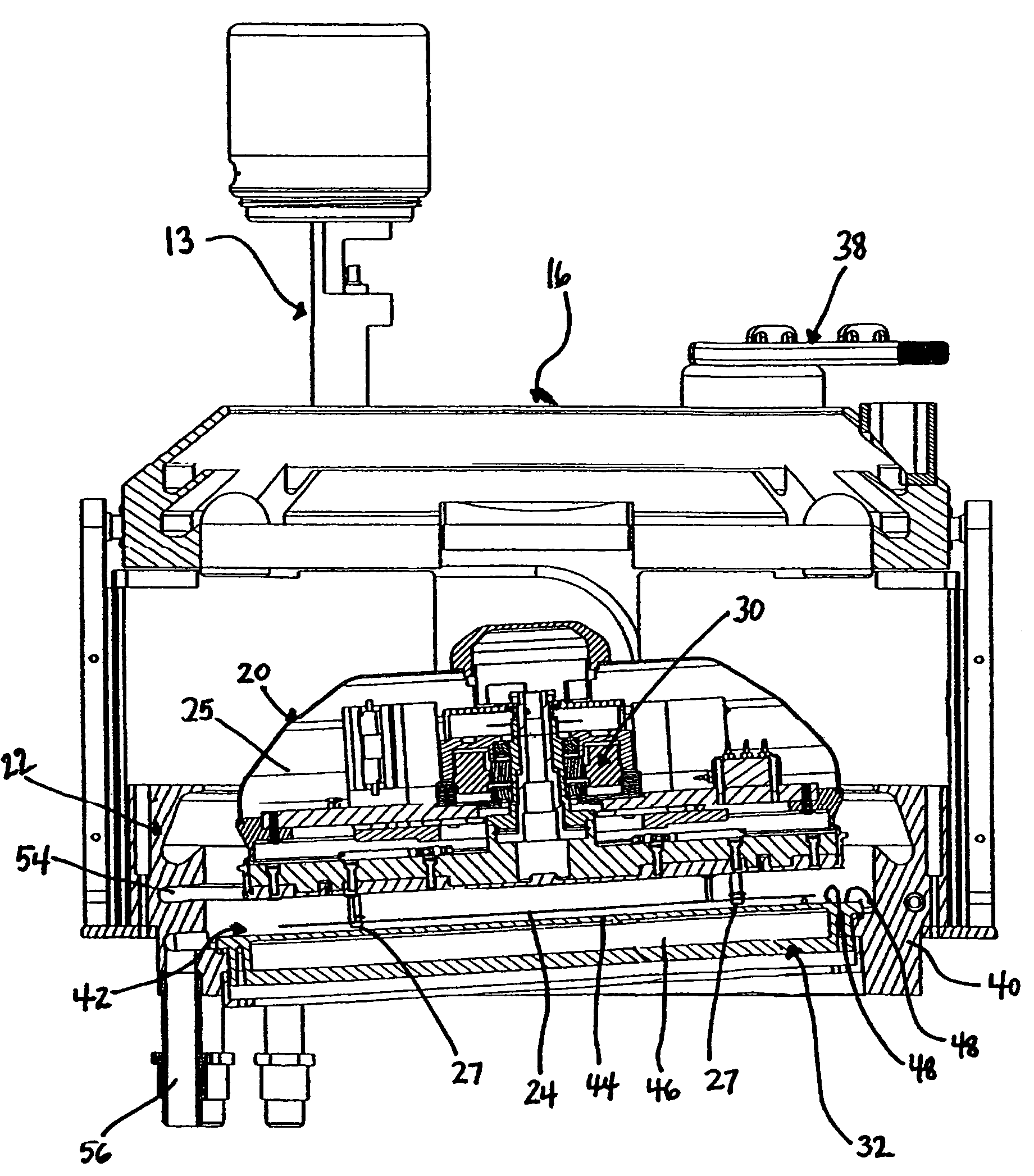

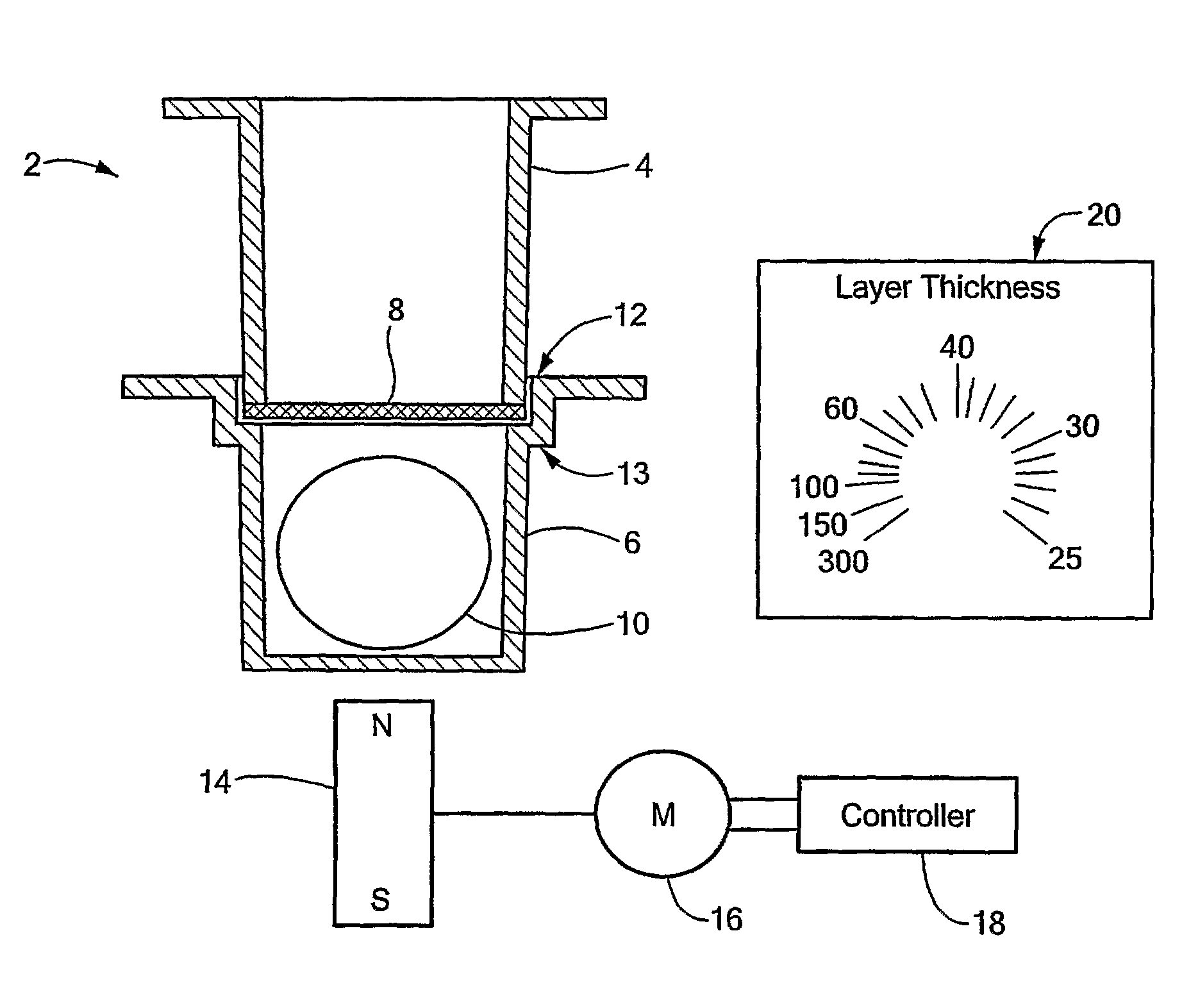

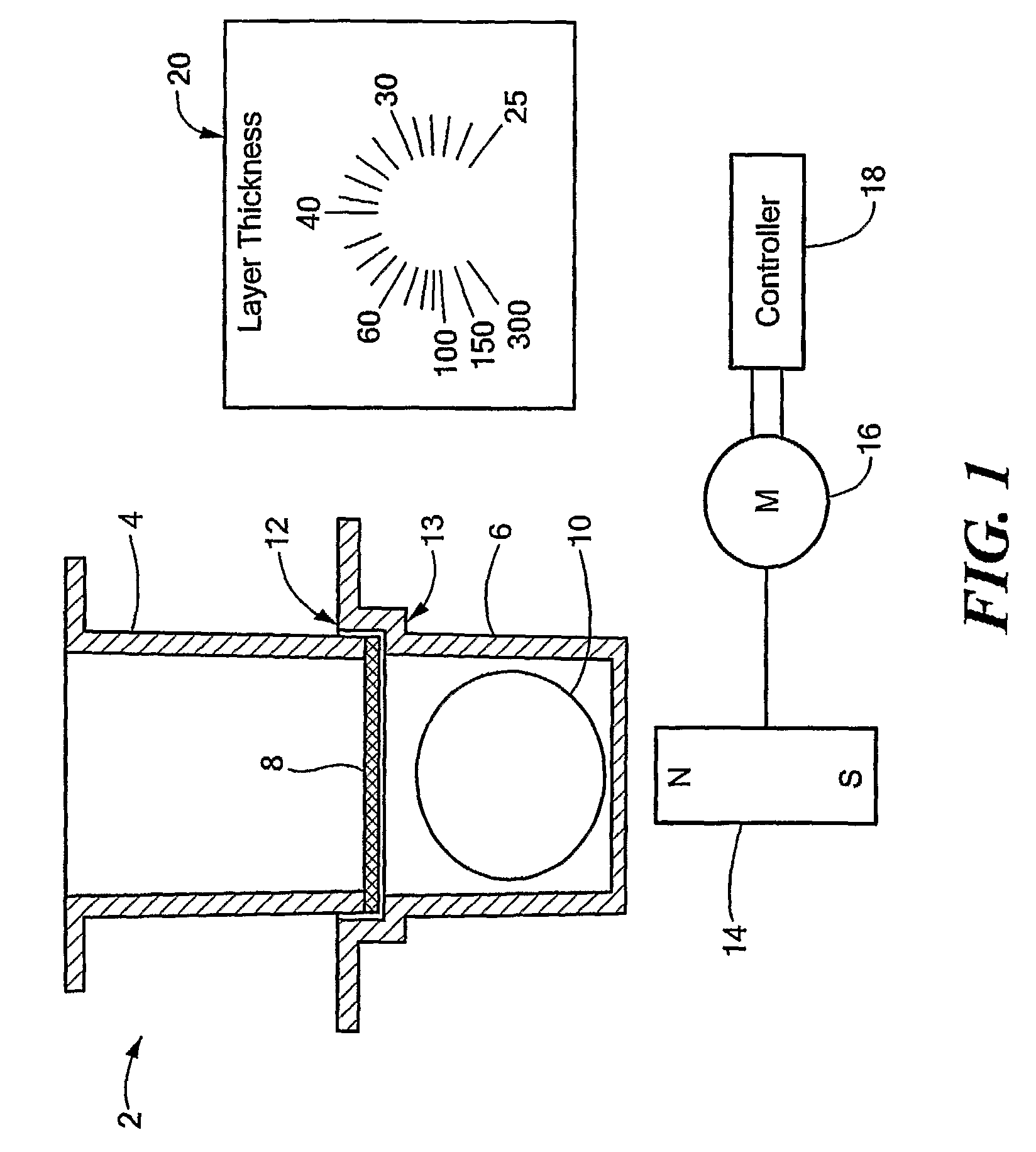

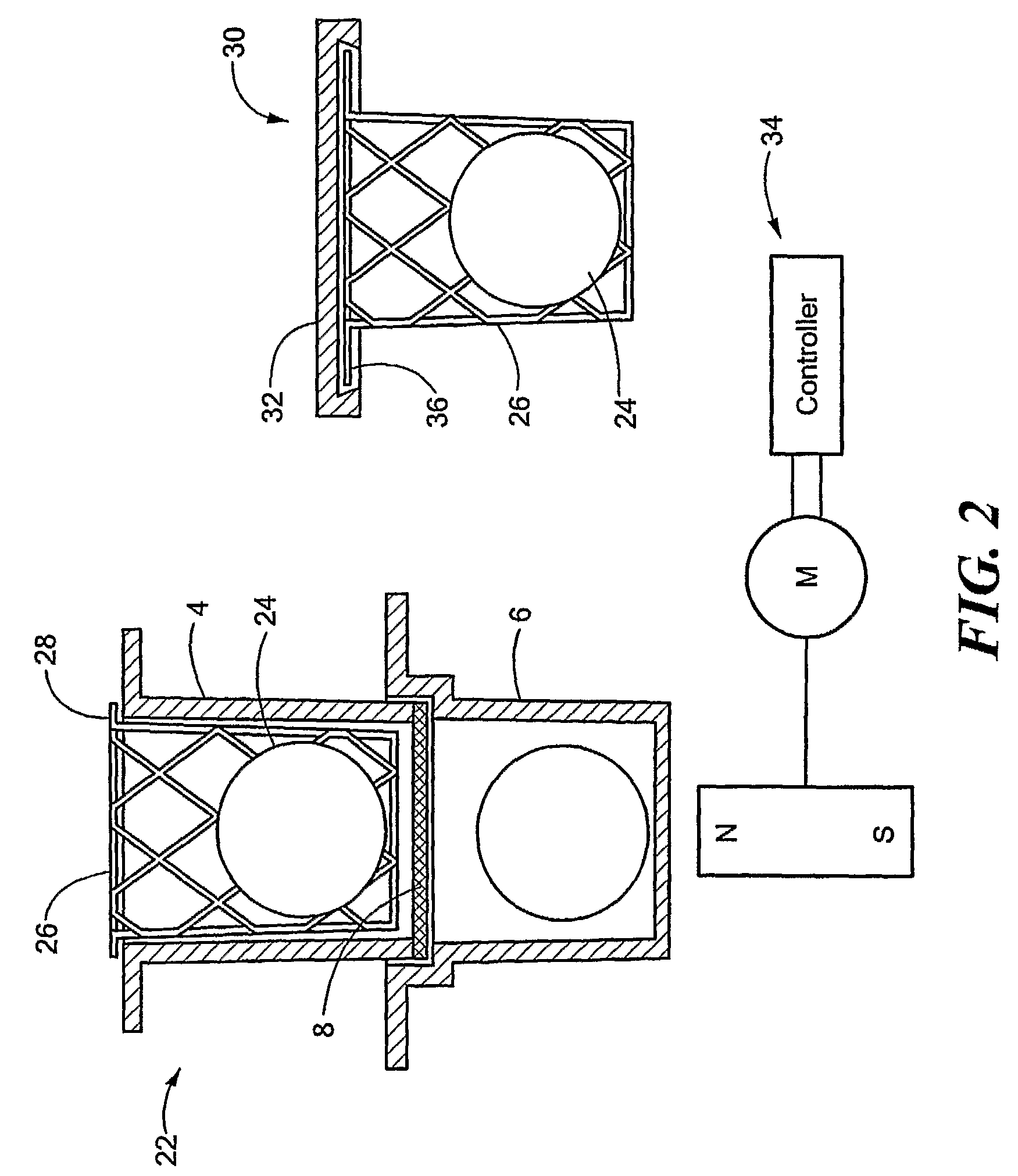

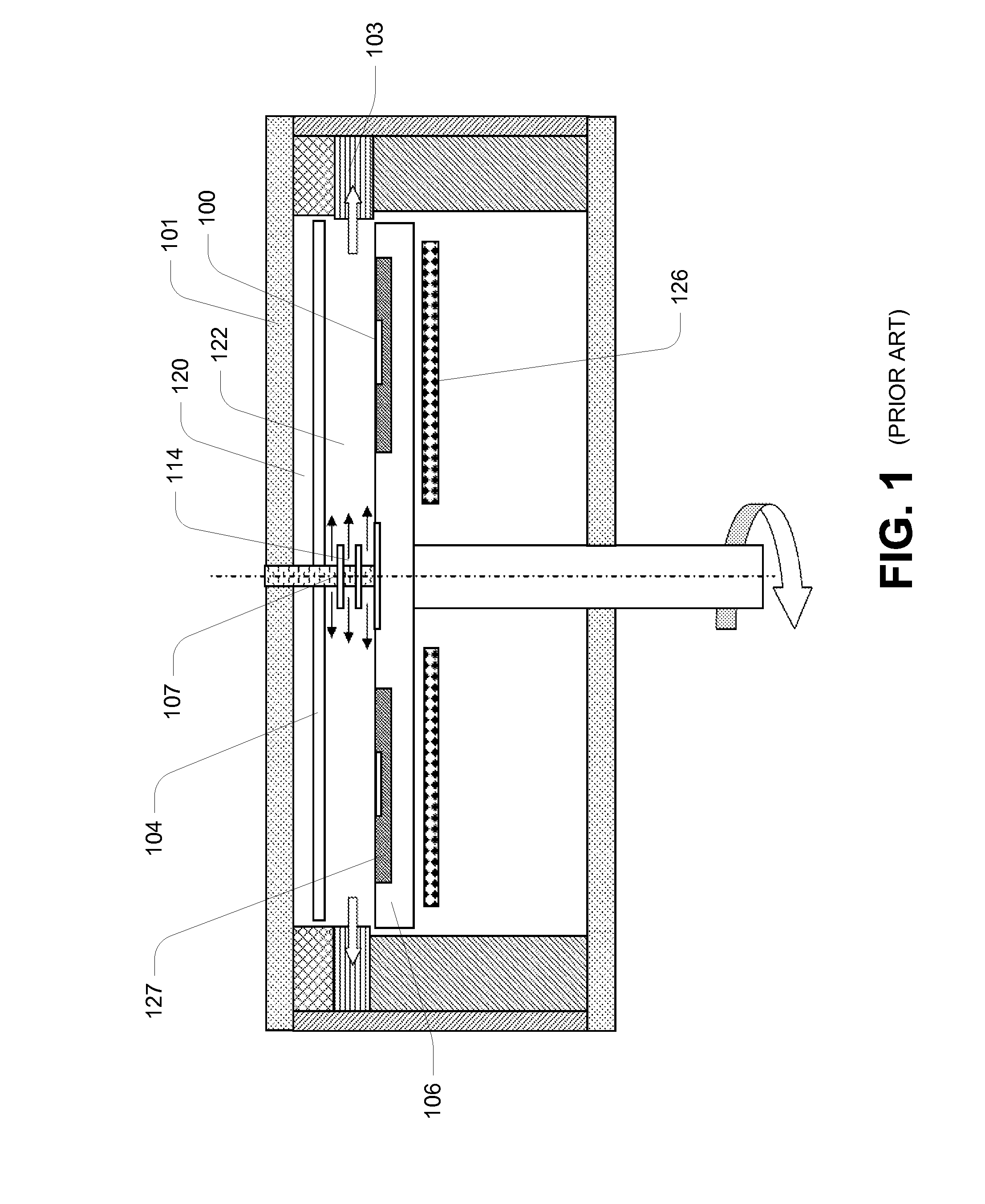

Sonic energy process chamber

InactiveUS20050199066A1Reduced boundary layer thicknessUniform processingRadiation pyrometryAnalysing solids using sonic/ultrasonic/infrasonic wavesHEAD SPINNINGTransducer

A system for processing a workpiece includes a base having a bowl or recess for holding a processing fluid. A sonic energy source, such as a megasonic transducer, provides sonic energy into a processing fluid in the bowl. A process head holds a workpiece. A process head lifter lowers the head holding the workpiece into the processing fluid in the bowl. Sonic energy is provided to the workpiece through the processing fluid, optionally while the processing head spins the workpiece. The processing fluid may include de-ionized water and an etchant.

Owner:APPLIED MATERIALS INC

Apparatus and method for non-contact manipulation, conditioning, shaping and drying of surfaces

ActiveUS20140245950A1High enough heat transfer rateLow costLiquid surface applicatorsTypewritersContact methodProcess engineering

Non-contact method and apparatus for Drying, Conditioning, Shaping and Manipulating of sheet fed Media. These functions are performed either on one side, or simultaneously or delayed one from the other on both sides, of the Media. For Drying, the energy applied is minimized to that necessary to supply latent heat of vaporization permitting use in, for example, low cost printers. No friction is introduced in the transport path enabling high speed, reliable Media transport. A region is established between Media and Platen wherein heat, support, and chemical or other processing may occur in a controlled way. Relatively few, inexpensive, and small parts are needed lowering the cost, energy, and space requirements for performing the various functions allowing for new applications in many fields. Media is supported a specific distance from a Platen by a balance of Fluid forces. The Media and the Platen bound a region in which forced convection greatly enhances process rates otherwise be limited by diffusion. The method and apparatus described is particularly suitable for high speed, low cost, inkjet printing.

Owner:SECCOMBE S DANA

Sonic energy process chamber

InactiveUS7337663B2Reduced boundary layer thicknessUniform processingRadiation pyrometryAnalysing solids using sonic/ultrasonic/infrasonic wavesHEAD SPINNINGTransducer

A system for processing a workpiece includes a base having a bowl or recess for holding a processing fluid. A sonic energy source, such as a megasonic transducer, provides sonic energy into a processing fluid in the bowl. A process head holds a workpiece. A process head lifter lowers the head holding the workpiece into the processing fluid in the bowl. Sonic energy is provided to the workpiece through the processing fluid, optionally while the processing head spins the workpiece. The processing fluid may include de-ionized water and an etchant.

Owner:APPLIED MATERIALS INC

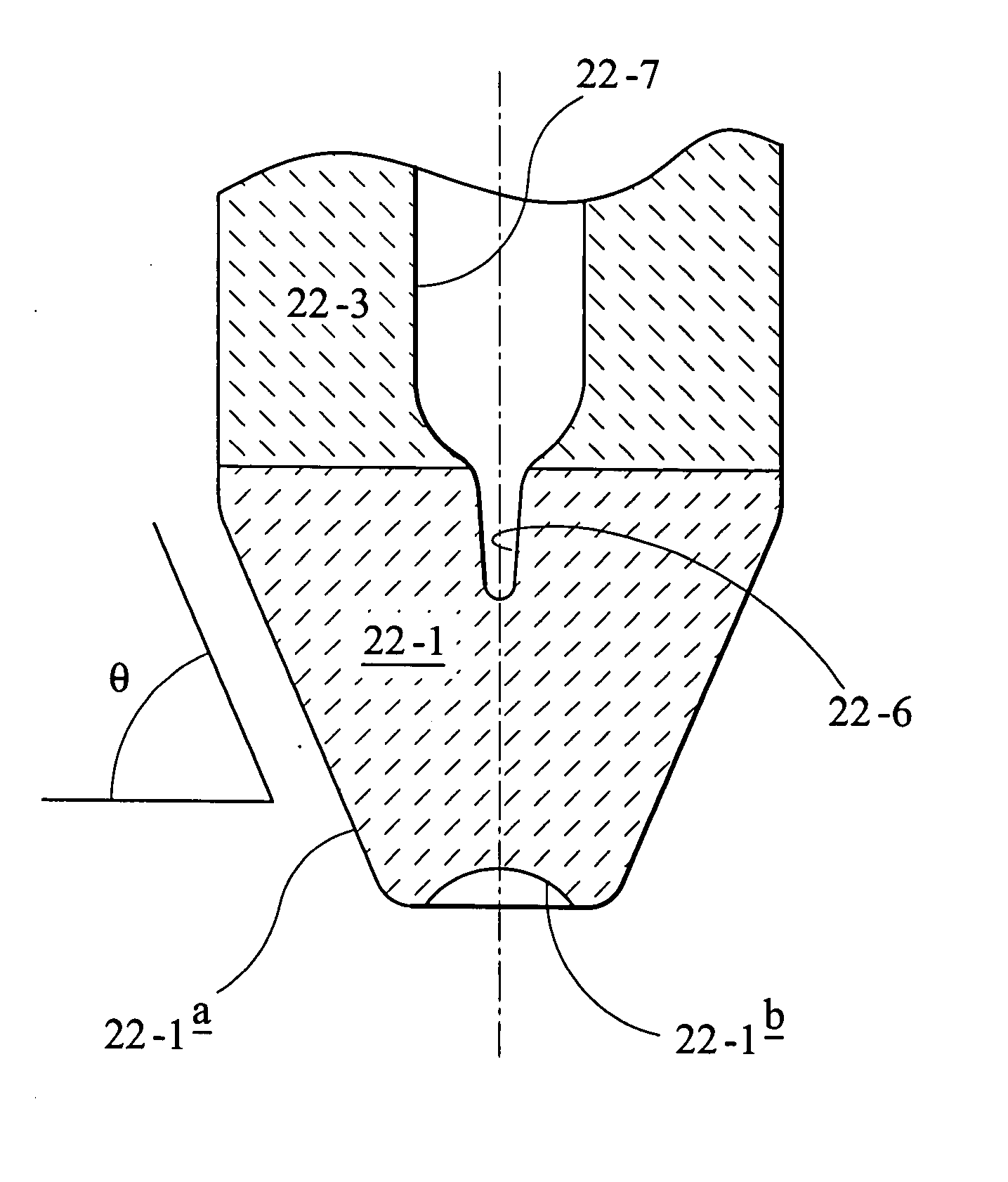

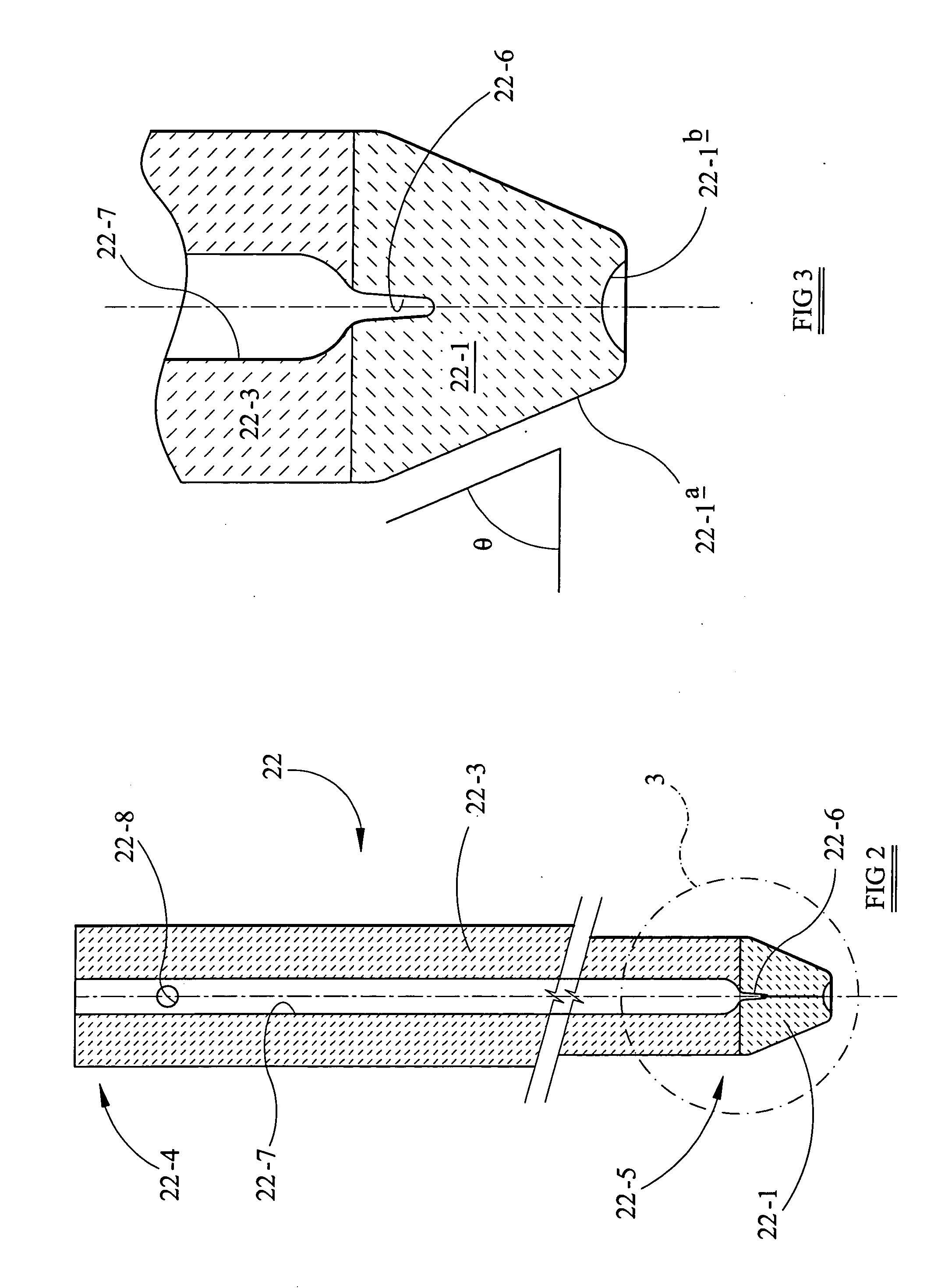

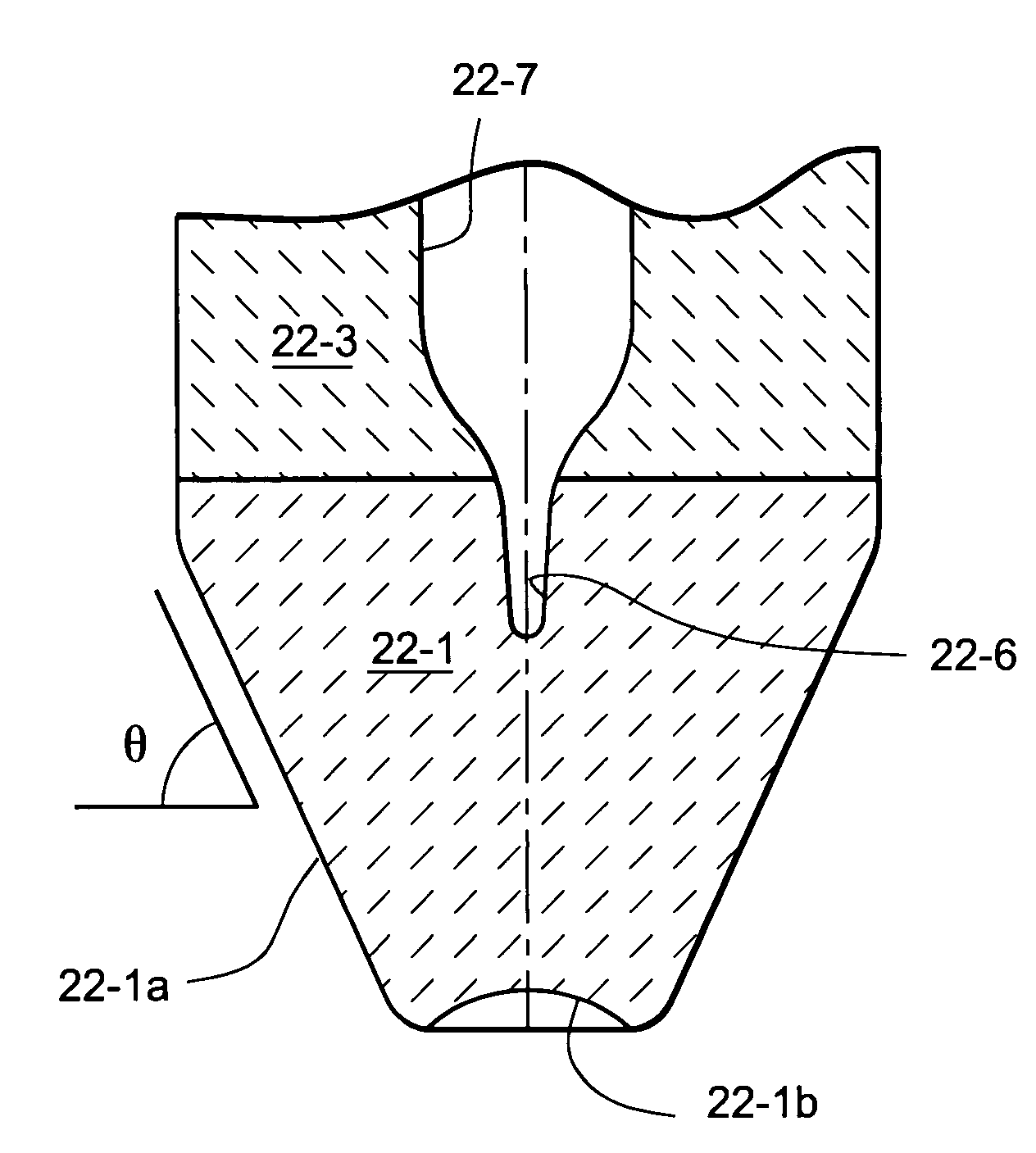

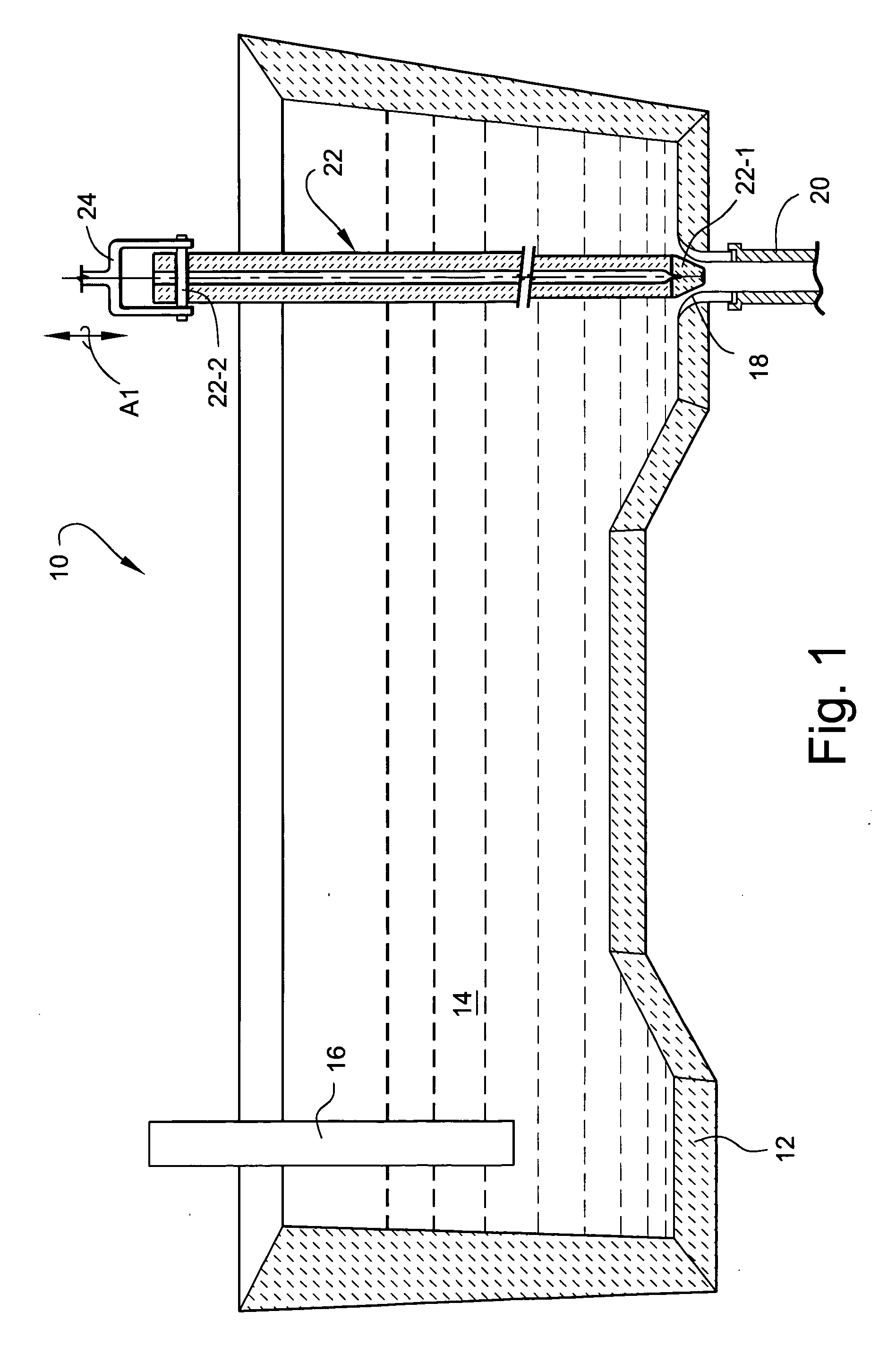

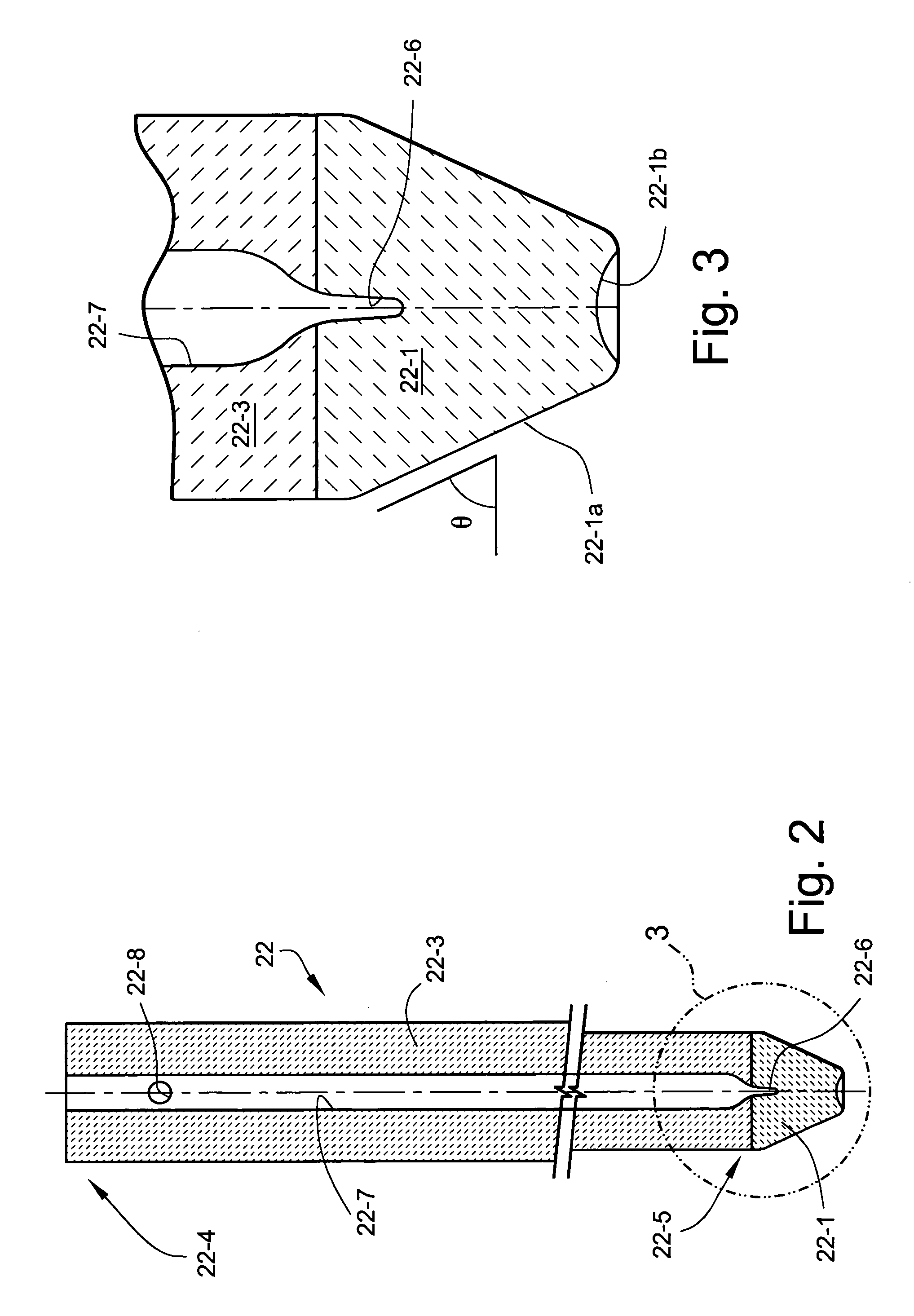

Tundish stopper rod for continuous molten metal casting

InactiveUS20060261100A1Increasing the thicknessIncreased riskMelt-holding vesselsLiquid flow controllersLayer thicknessSpherical form

Stopper rods (22) for the continuous casting of molten metal have a stopper rod body (22-3), and a stopper rod tip (22-1) at a lower end of the stopper rod body. The stopper rod tip defines a frustoconically shaped exterior surface (22-1a) which terminates in a recessed nose (22-1b). The recessed nose is most preferably a curvilinear surface (e.g., a spherical segment), but non-curvilinear surfaces (e.g., prismatic, pyramidal, triangular, and quadrangular surfaces) may alternatively be employed. The frustoconically shaped exterior surface (22-1a) of the stopper rod tip most preferably forms an angle θ with respect to a horizontal plane which is sufficiently great so as to increase the velocity of the flowing molten metal to reduce the boundary layer thickness thereof adjacent the nozzle and stopper rod tip surfaces so as to minimize the deposition of inclusions thereon. Preferably the angle θ is greater than 70°.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

Apparatus and method for processing airflow with flowfield molded hypersonic inlet

ActiveUS20090094987A1Reducing penaltyImproved airflow characteristicsGeometric CADCosmonautic vehiclesShock waveJet engine

Owner:LOCKHEED MARTIN CORP

Method for removal of photoresist using sparger

InactiveUS6863836B2Fast wayIncrease ratingsDecorative surface effectsElectrostatic cleaningEnvironmental engineeringPhotoresist

A method of removing photoresist from semiconductor wafers through the use of a sparger plate. According to the inventive method, at least one semiconductor wafer is positioned in a process tank above the sparger plate. A mixture of ozone and deionized water is introduced into the process tank at a position below the sparger plate. The mixture of ozone and deionized water is then introduced across the wafer via the sparger plate at an increased flow velocity while the wafer is submerged in the mixture of deionized water and ozone.

Owner:NAURA AKRION INC

Burner assembly

ActiveUS20140144424A1Reduced boundary layer thicknessDomestic stoves or rangesCooking fumes removalEngineeringMechanical engineering

A burner assembly for an oven appliance is provided. The burner assembly includes a gas burner and a flame spreader. The flame spreader defines a slot or a series of apertures that is substantially parallel to the gas burner. The slot or series of apertures can decrease a thickness of a boundary layer positioned adjacent the flame spreader or increase a velocity or a temperature or both of the boundary layer.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Apparatus and method for non-contact manipulation, conditioning, shaping and drying of surfaces

ActiveUS9272301B2Low costReduce energy consumptionLiquid surface applicatorsTypewritersContact methodCompound (substance)

Owner:SECCOMBE S DANA

Tundish stopper rod for continuous molten metal casting

InactiveUS20060249546A1Improving steel cleanlinessReduce depositionMelt-holding vesselsLiquid flow controllersLayer thicknessConoid

Stopper rods for the continuous casting of molten metal have a stopper rod body, and a stopper rod tip at a lower end of the stopper rod body. The stopper rod tip defines a frustroconically shaped exterior surface which terminates in a recessed nose. The recessed nose is most preferably a curvilinear surface (e.g., a spherical segment), but non-curvilinear surfaces (e.g., prismatic, pyramidal, triangular, and quadrangular surfaces) may alternatively be employed. The frustroconically shaped exterior surface of the stopper rod tip most preferably forms an angle θ with respect to a horizontal plane which is sufficiently great so as to increase the velocity of the flowing molten metal to reduce the boundary layer thickness thereof adjacent the nozzle and stopper rod tip surfaces so as to minimize the deposition of inclusions thereon. In addition, the angle θ formed by the frustroconically shaped exterior surface is also most preferably sufficiently small so as to not detrimentally affect the lifting force sensitivities of the stopper rod.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

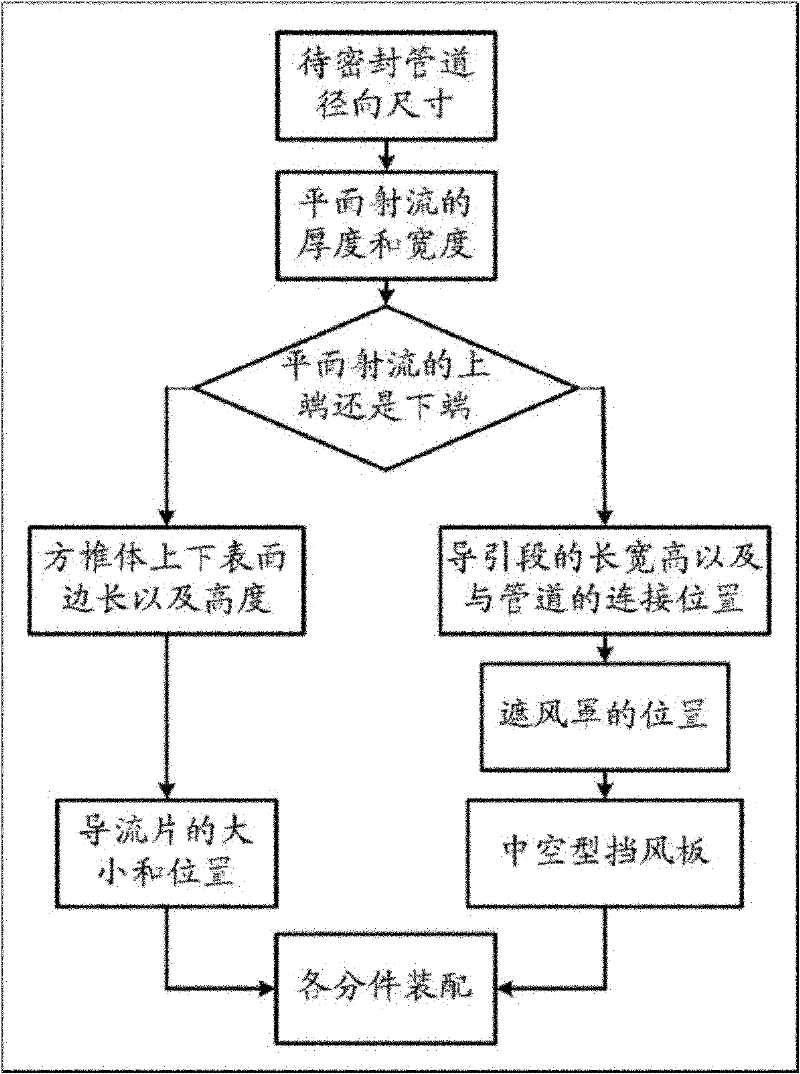

Air curtain design method for sealing transmission channel in laser

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

A Composite Thermal Aperture Cooling Device for a Solar Telescope

ActiveCN108986600BIncrease the Reynolds numberImprove heat transfer effectEducational modelsEngineeringStray light

The invention discloses a composite thermal diaphragm cooling device for a solar telescope. In a large-aperture solar telescope system, the sunlight cut off by a thermal diaphragm will not only causetemperature rise but also bring a stray light source. The composite thermal diaphragm cooling device comprises a thermal diaphragm base body, a jet impingement plate, a reflecting plate and a thermaldiaphragm plug-in, wherein the thermal diaphragm base body is provided with an optical path channel at the central position; a reflecting surface of the thermal diaphragm base body is provided with adiaphragm placement groove and a jet cavity; the reflecting surface of the thermal diaphragm base body is fixed with a reflecting plate; the inner side surface of the reflecting plate is fixed with the jet impingement plate; the thermal diaphragm base body is internally provided with n liquid inlet flow channels and n liquid outlet flow channels; the thermal diaphragm plug-in is plugged in the diaphragm placement groove of the thermal diaphragm base body; the middle part of the thermal diaphragm plug-in is provided with a light inlet channel; and the edge of the outer side surface of the thermal diaphragm plug-in is flush with the inner contour of the reflecting plate, and the middle part is set in an outward protruding manner. The composite thermal diaphragm cooling device can increase the Reynolds number of a cooling liquid in the liquid inlet flow channels through a gradual-shrinking hole design, and thus enhances the heat exchange performance.

Owner:HANGZHOU DIANZI UNIV

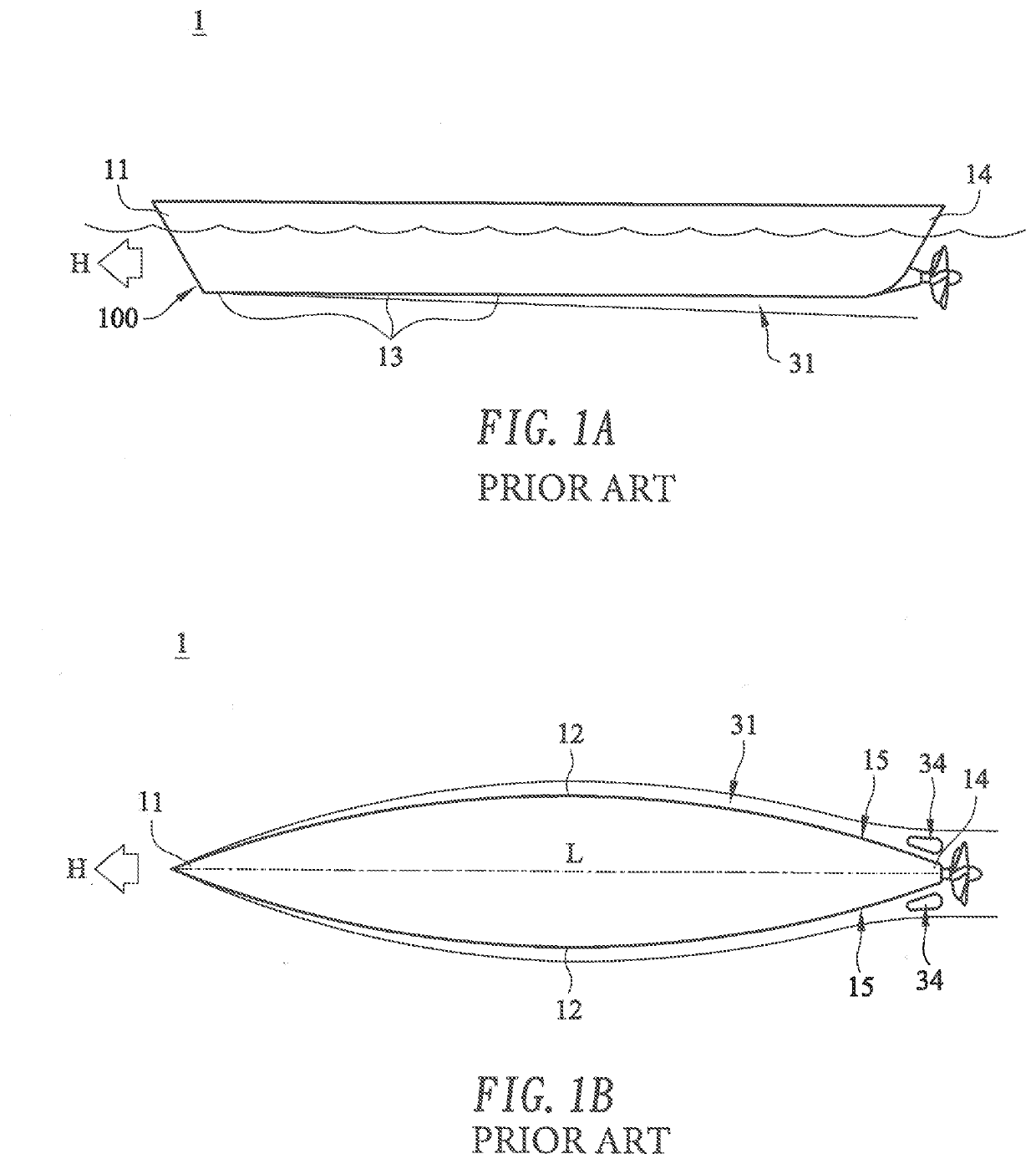

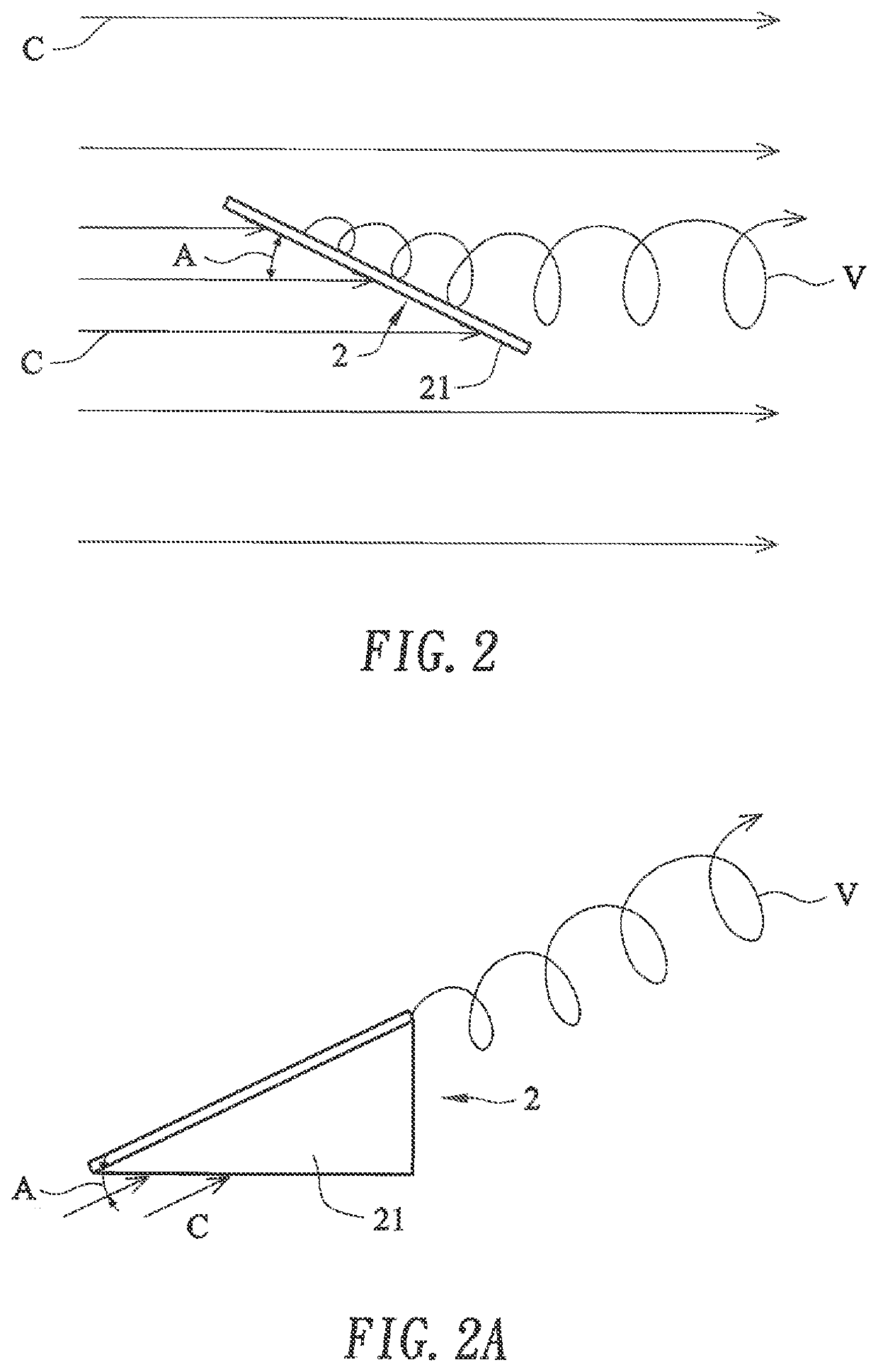

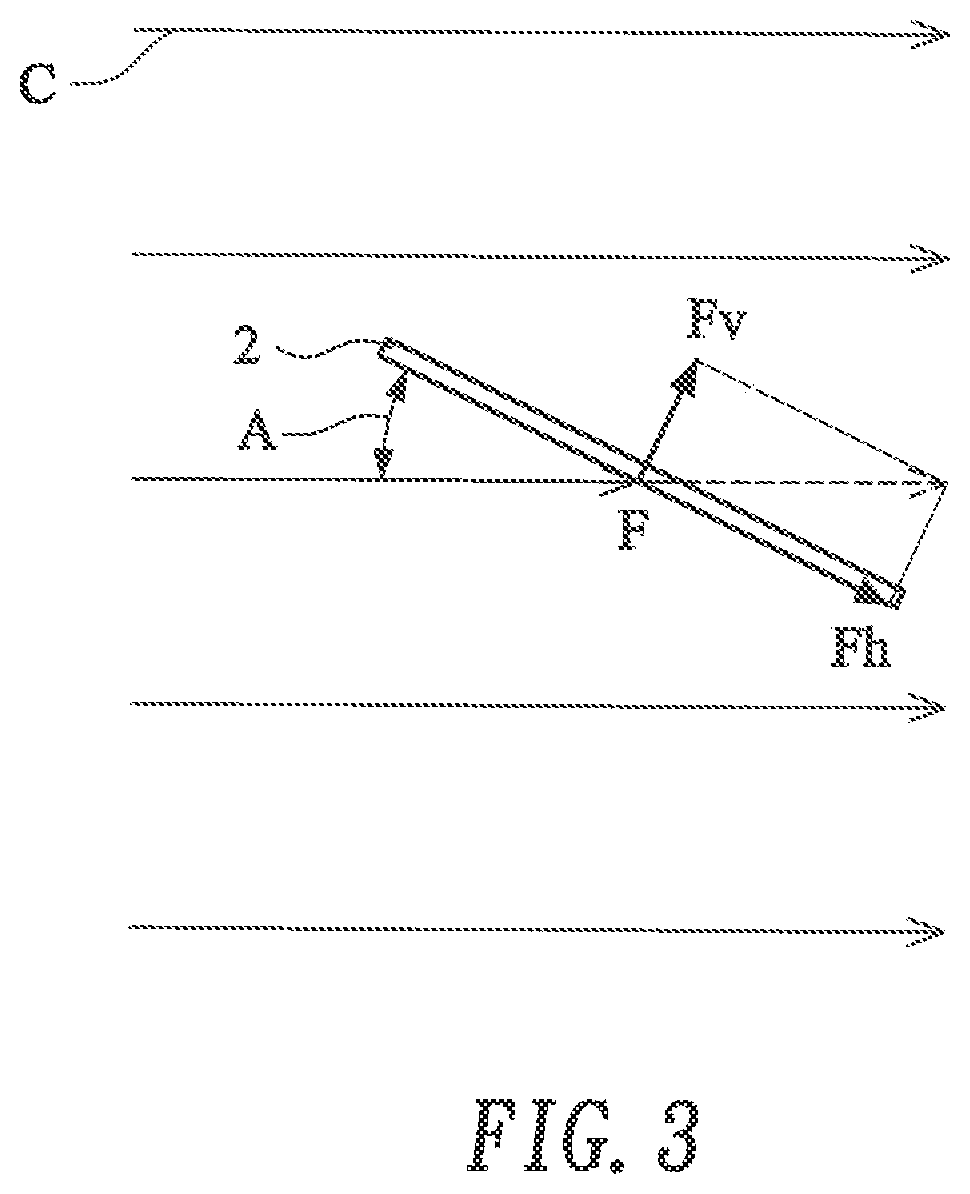

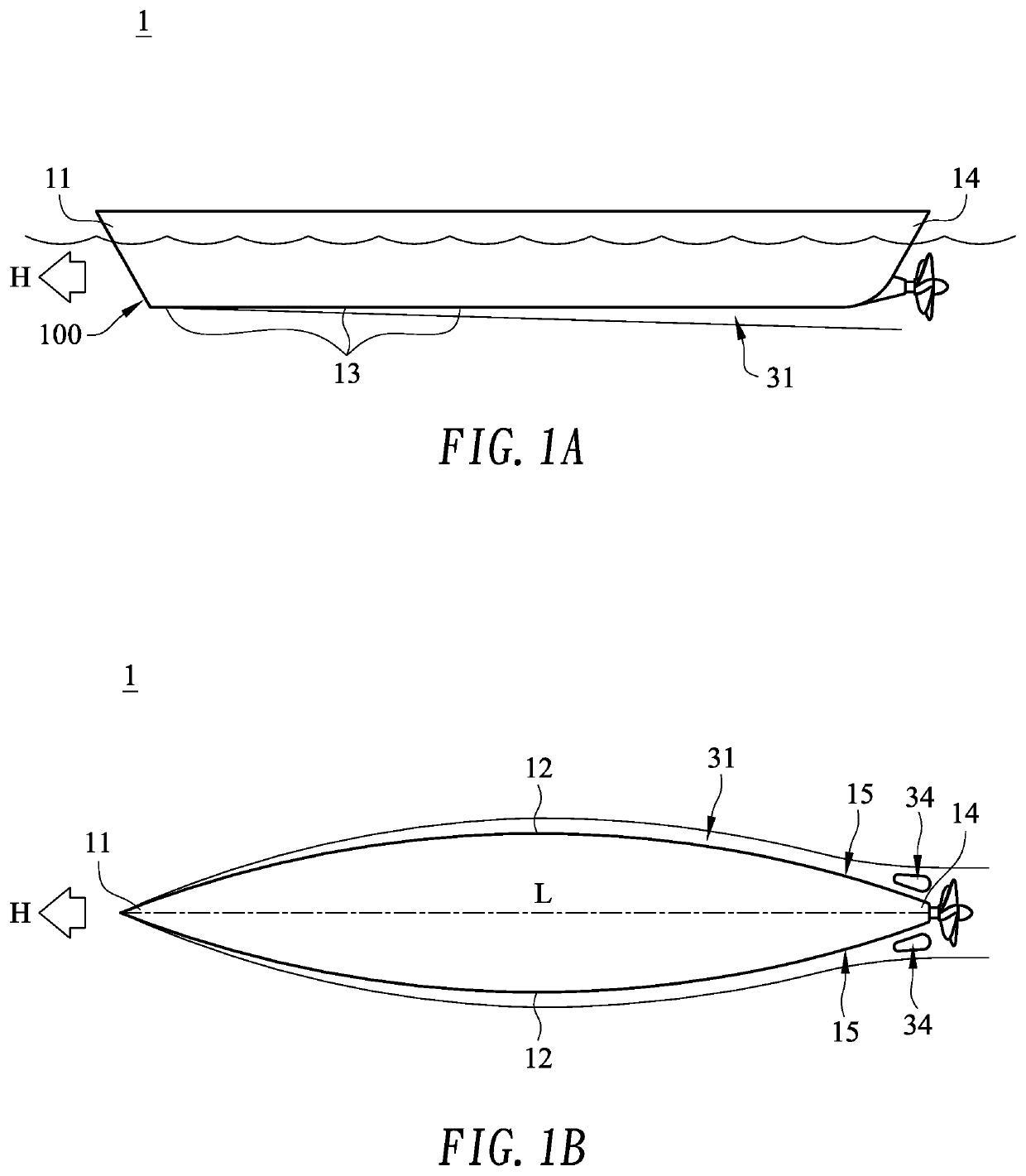

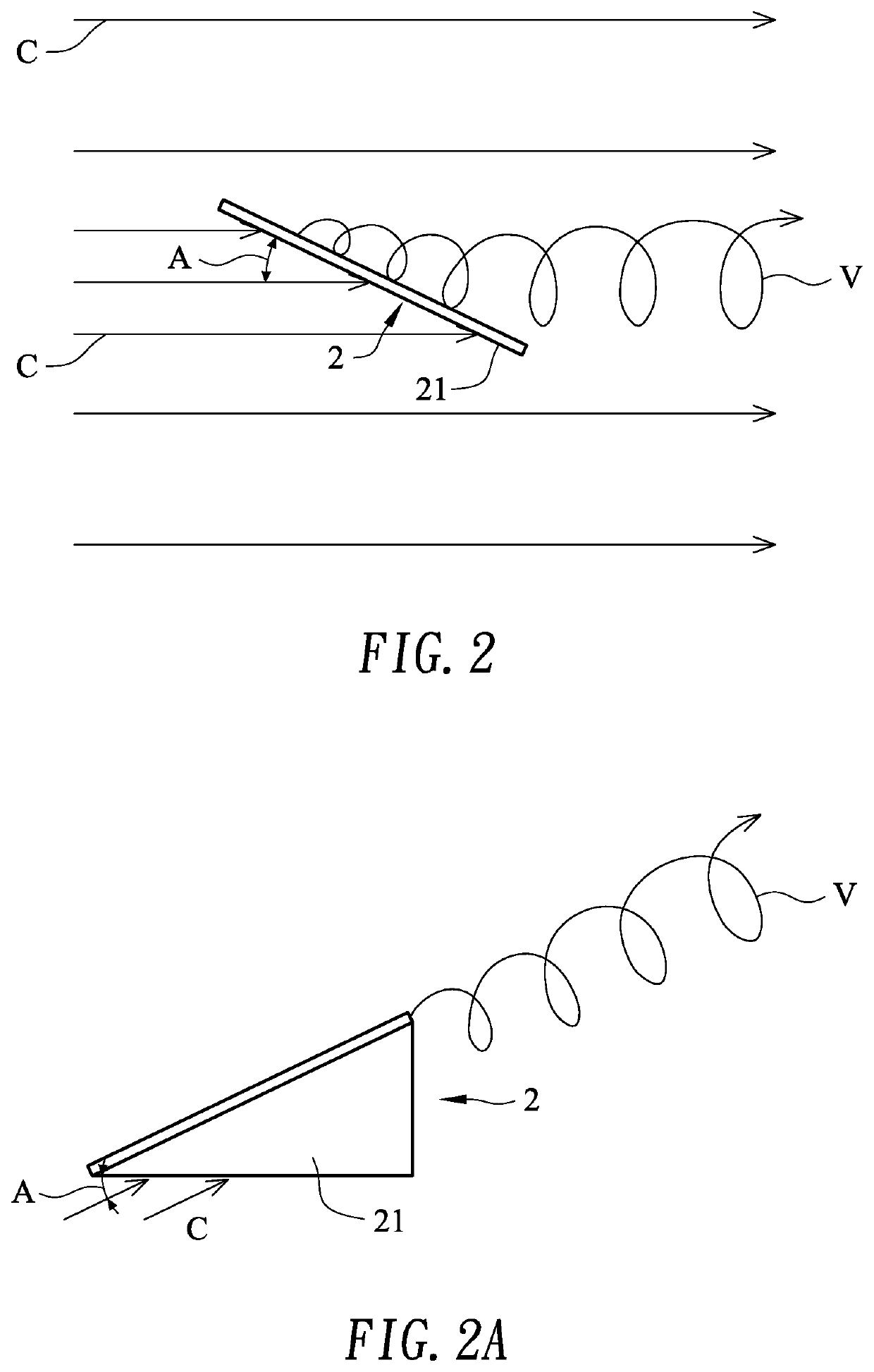

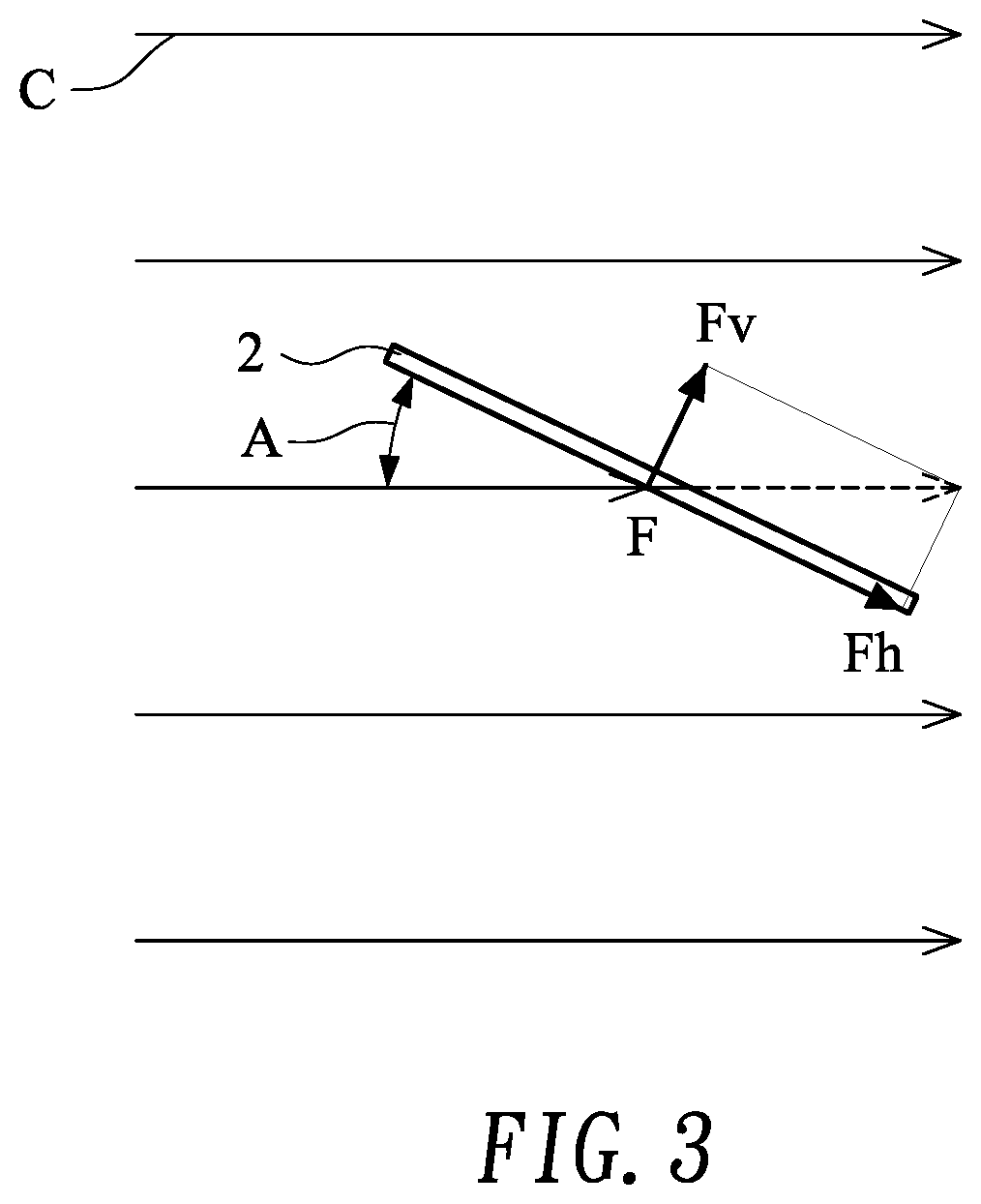

Structure for reducing the drag of a ship and its application

InactiveUS20190389539A1Reduced boundary layer thicknessIncrease pressureWatercraft hull designHydrodynamic/hydrostatic featuresMarine engineeringClassical mechanics

Owner:MEI CHEN HSIN

Photochemical synthesis of vitamin D in a tubular reactor 2 、d 3 Methods

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +1

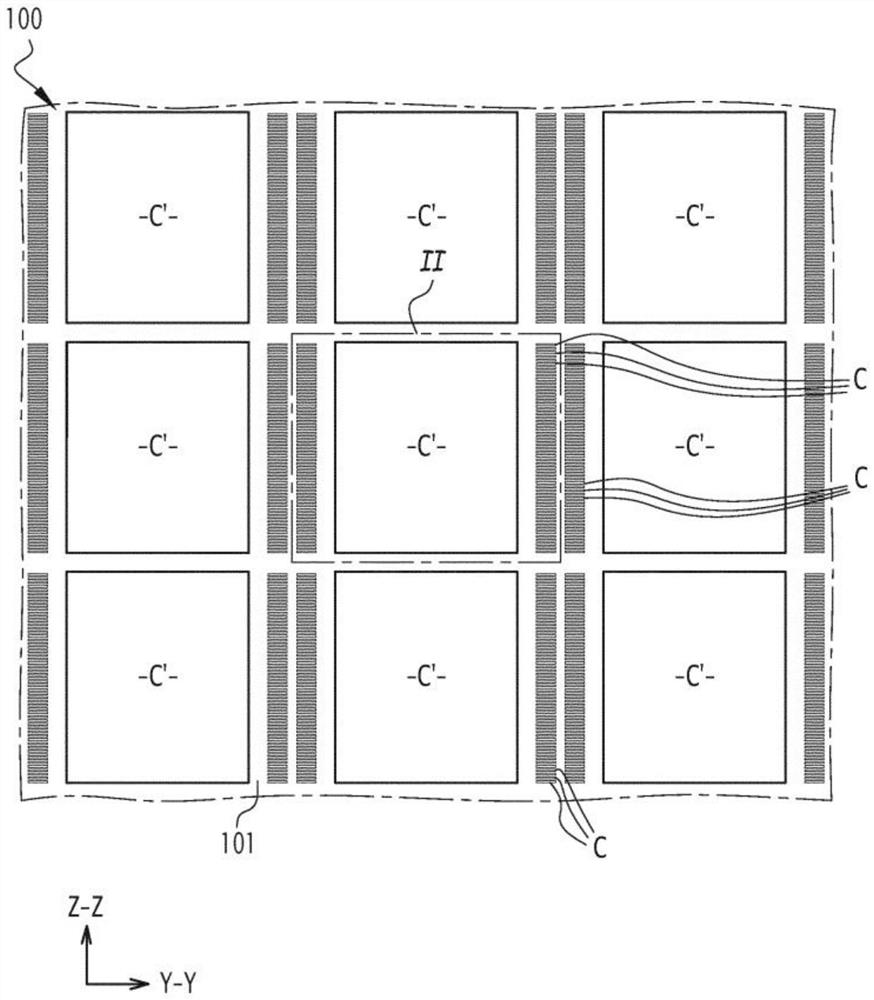

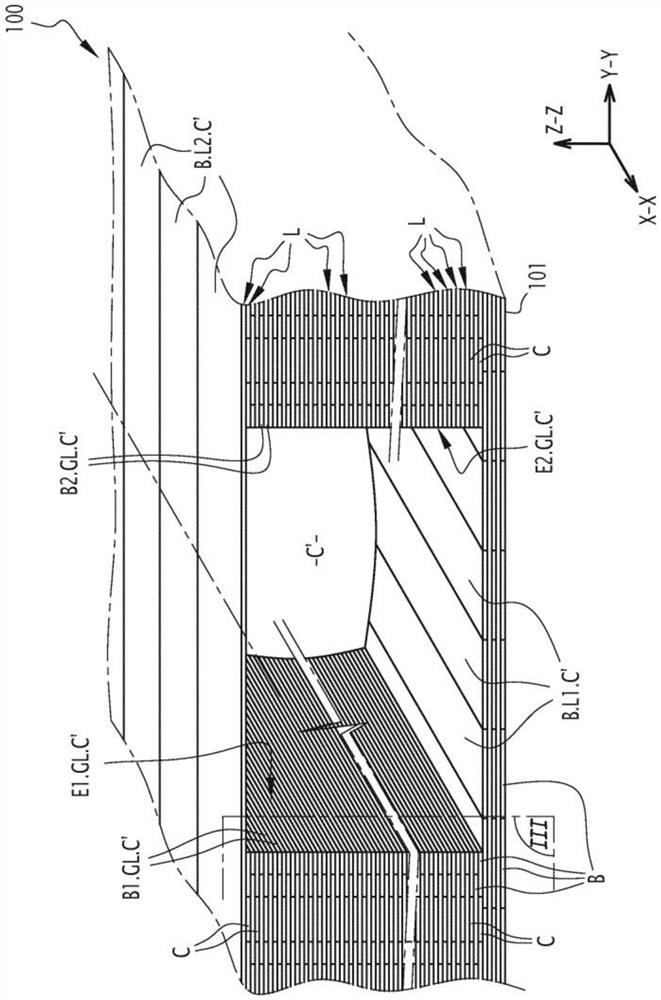

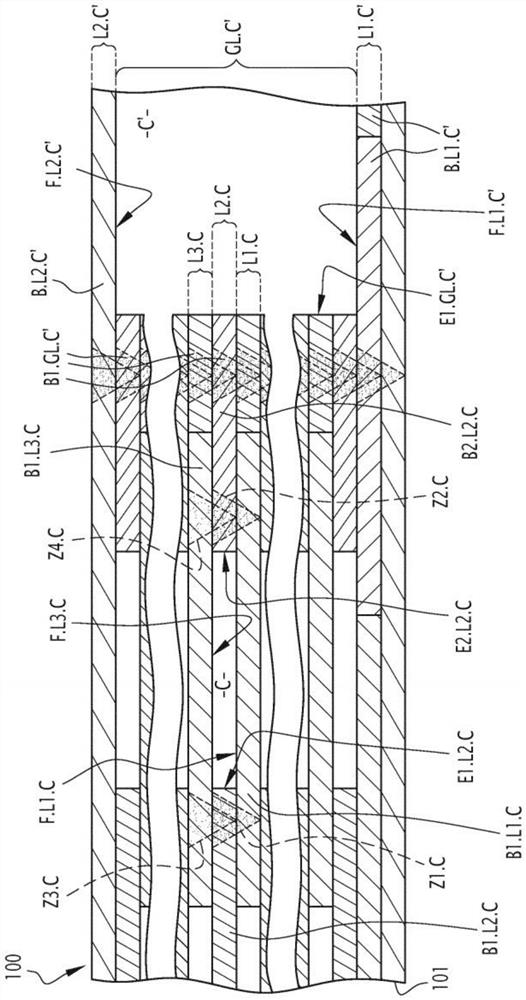

Heat exchanger and method for manufacturing such heat exchanger

ActiveCN111936814ALimited exchange volumeDoes not affect thermodynamic performance levelAdditive manufacturing apparatusRecuperative heat exchangersMetal stripsEngineering

A heat exchanger (100) comprises fluid circulation channels (C) extending lengthwise along a first axis (X-X), and a plurality of layers (L) that are flat and superposed on one another along a secondaxis (Z-Z). In order to improve the performance of this exchanger, each layer is made up of metal strips (B) such that the strips of the one same layer all extend lengthwise in a direction perpendicular to the second axis and adjacent to one another, without necessarily touching, in the plane of the relevant layer. In addition, each of the channels is jointly defined by first, second and third layers, the second layer being intercalated, along the second axis, directly between the first and third layers so that each channel is delimited by a one face of the first layer, one face of the third layer and edges of the second layer which run parallel to the first axis and transversely to the plane of this second layer, these edges being formed by strips of this second layer which are fusion-welded to the first and third layers in fusion zones which extend continuously along the entire length of the channel and which are situated, along a third axis (Y-Y), on either side of the channel.

Owner:INETYX

Permeation device and method for reducing aqueous boundary layer thicknesses

ActiveUS8840849B2Reduce thicknessReduced boundary layer thicknessSemi-permeable membranesWeather/light/corrosion resistanceIn vivo absorptionMolecular entity

Owner:PION

Structure for reducing the drag of a ship and its application

InactiveUS20190351974A1Reduce resistanceIncreased speed and efficiencyWatercraft hull designHydrodynamic/hydrostatic featuresMarine engineering

Owner:MEI CHEN HSIN

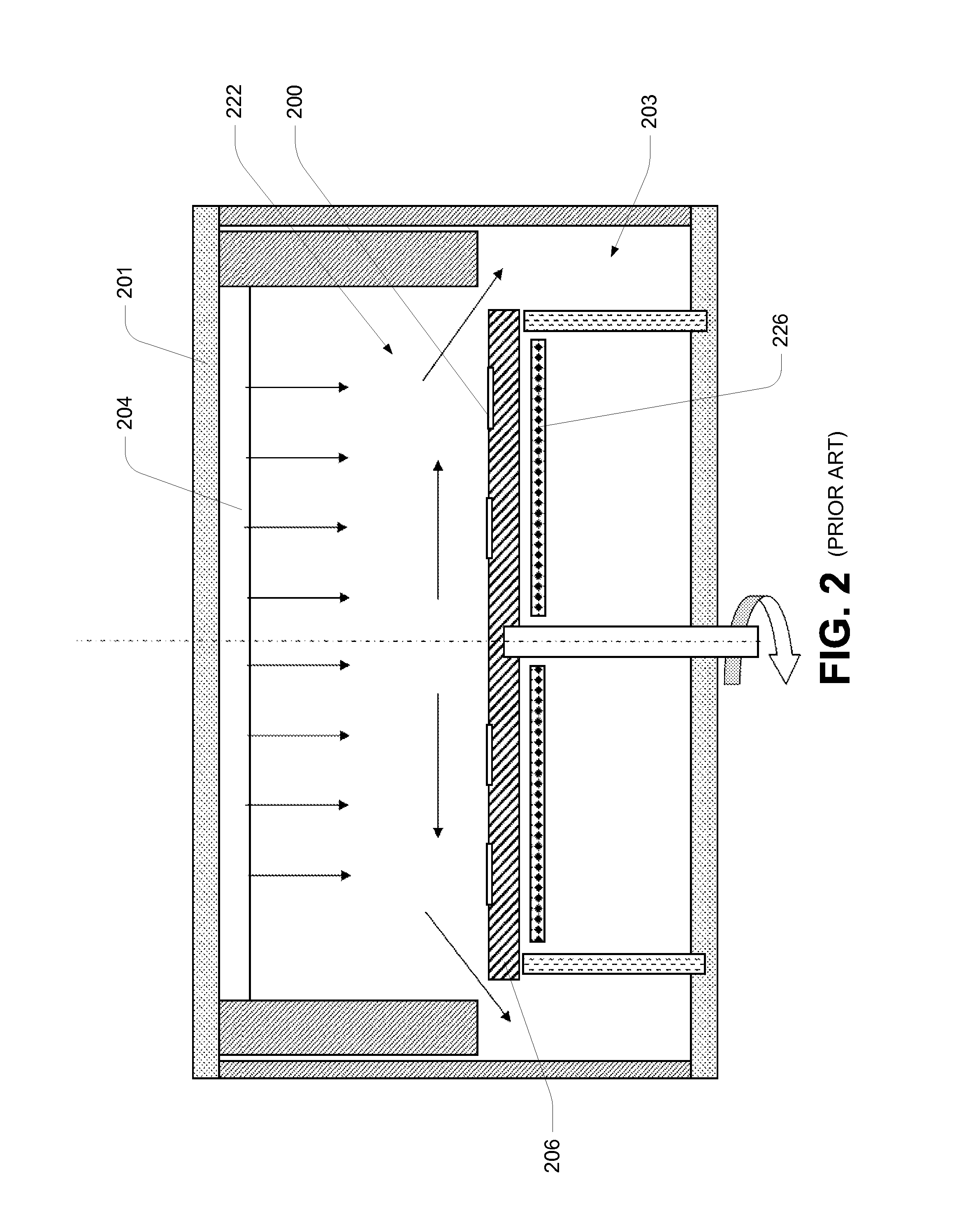

Chemical vapor deposition reactor and method

InactiveUS8465802B2Eliminate disadvantagesIncreases mass transportPolycrystalline material growthFrom chemically reactive gasesGas phaseProcess engineering

A reactor and method for performing chemical vapor deposition are disclosed. A chemical vapor deposition reactor can have a cylindrical chamber that comprises a cylindrical lid support and an annular gas distribution plate. Said chamber can be configured to have a horizontal laminar flow of at least one gas stream in the radial direction and a vertical downward flow of another gas stream over wafers. A large capacity of a CVD reactor with simple structures, easy maintenance and low consumption of reactants can be achieved. High uniformity, repeatability, reproducibility and consistency of depositing layers on wafers can be obtained.

Owner:LI GANG

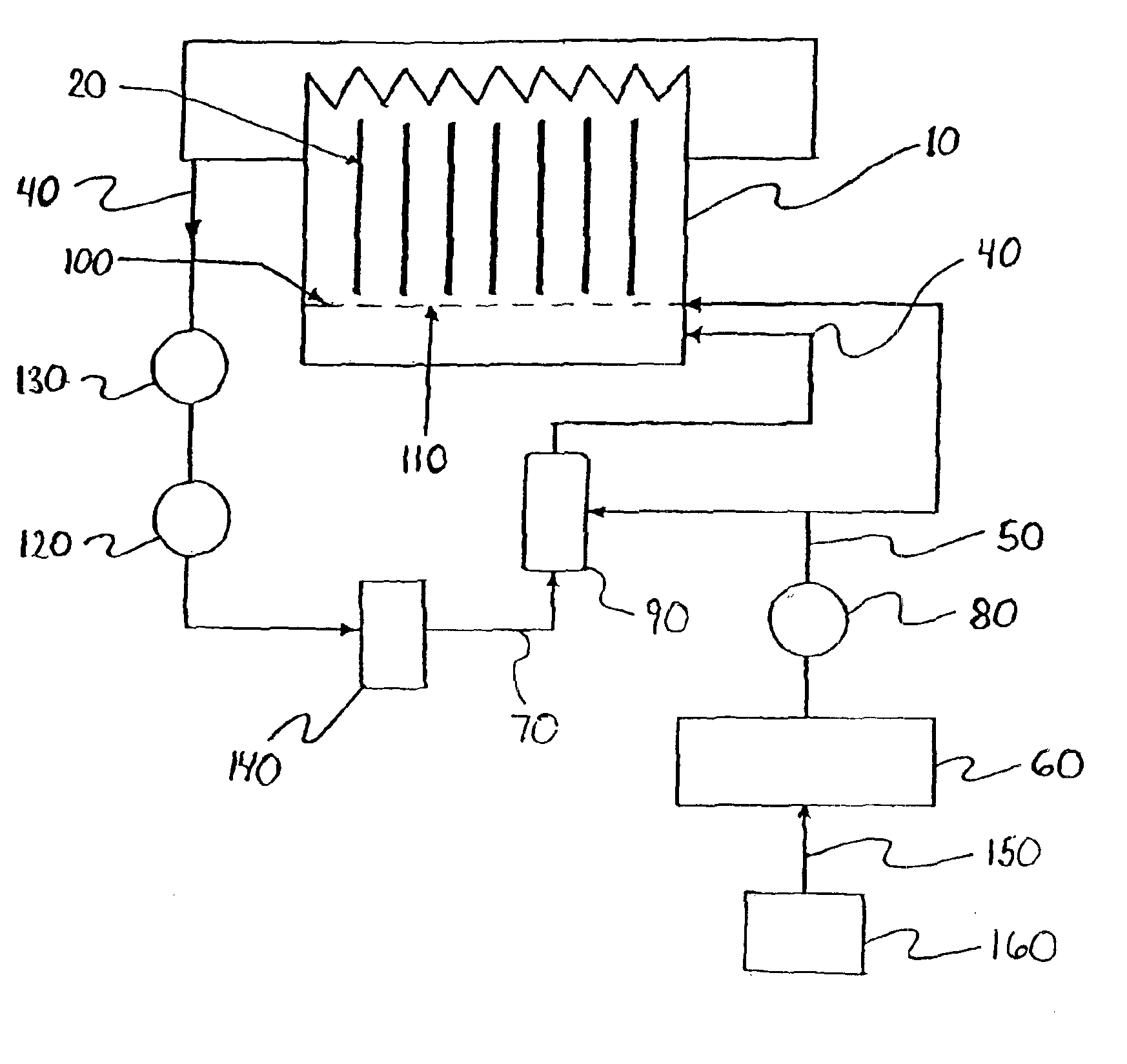

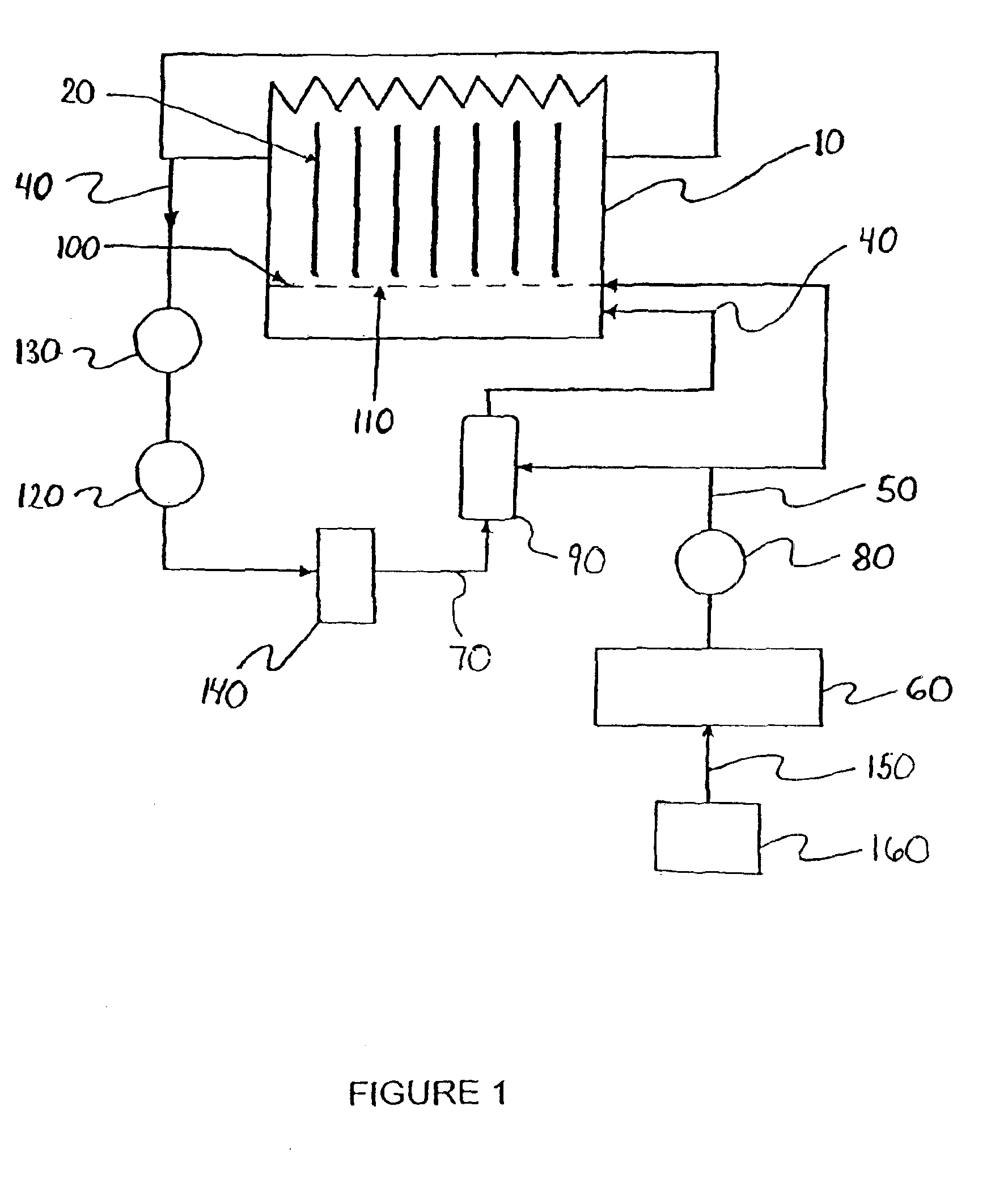

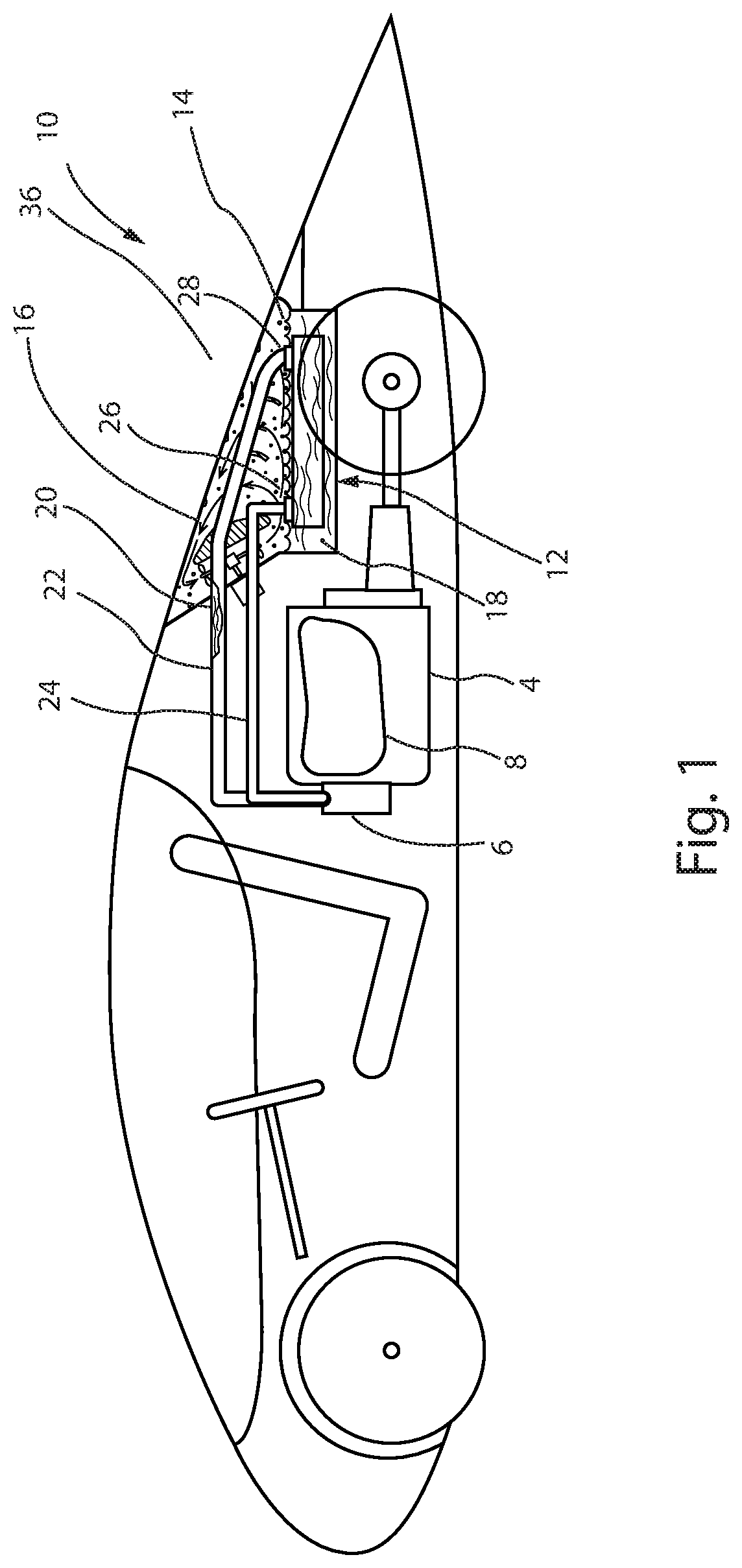

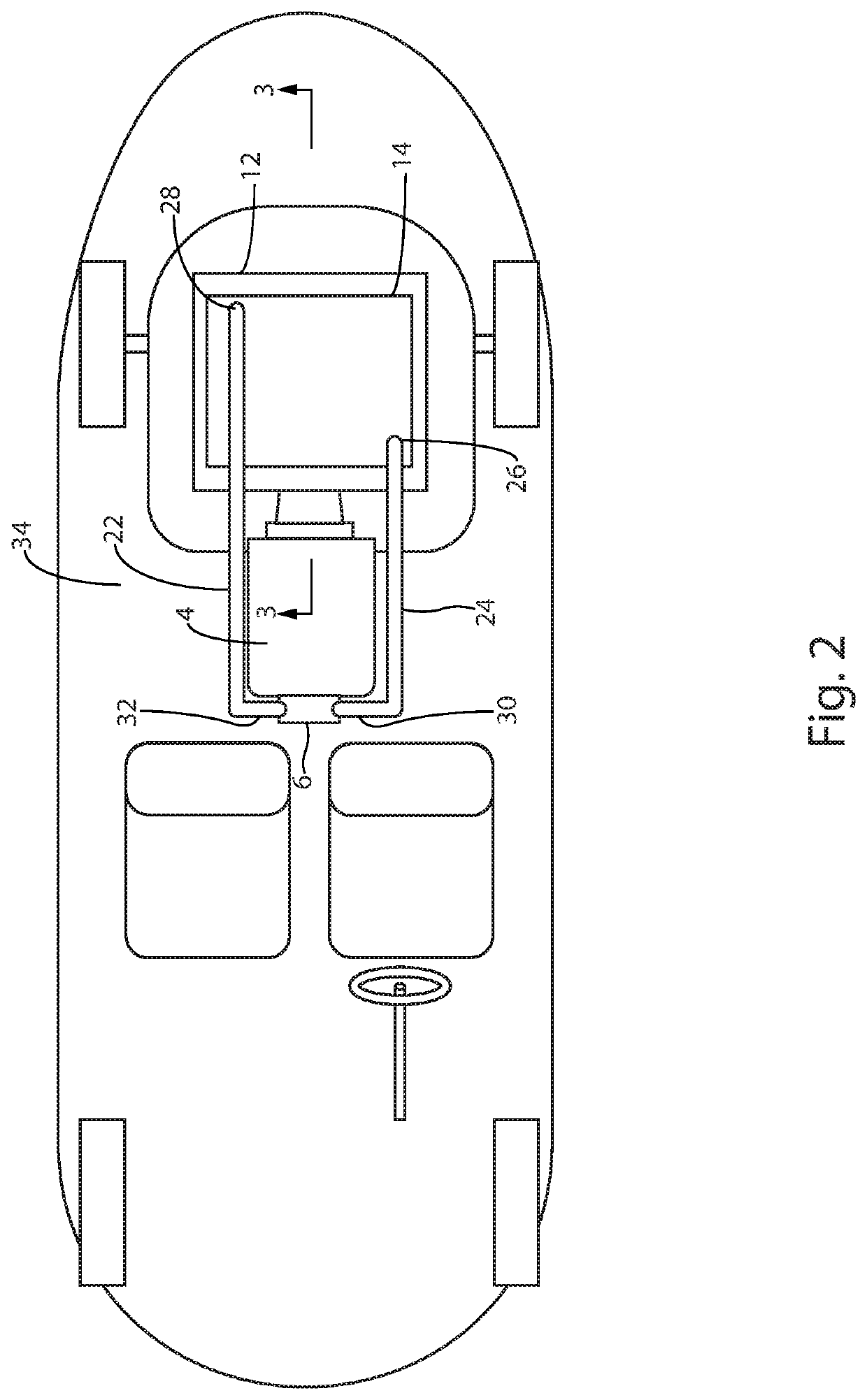

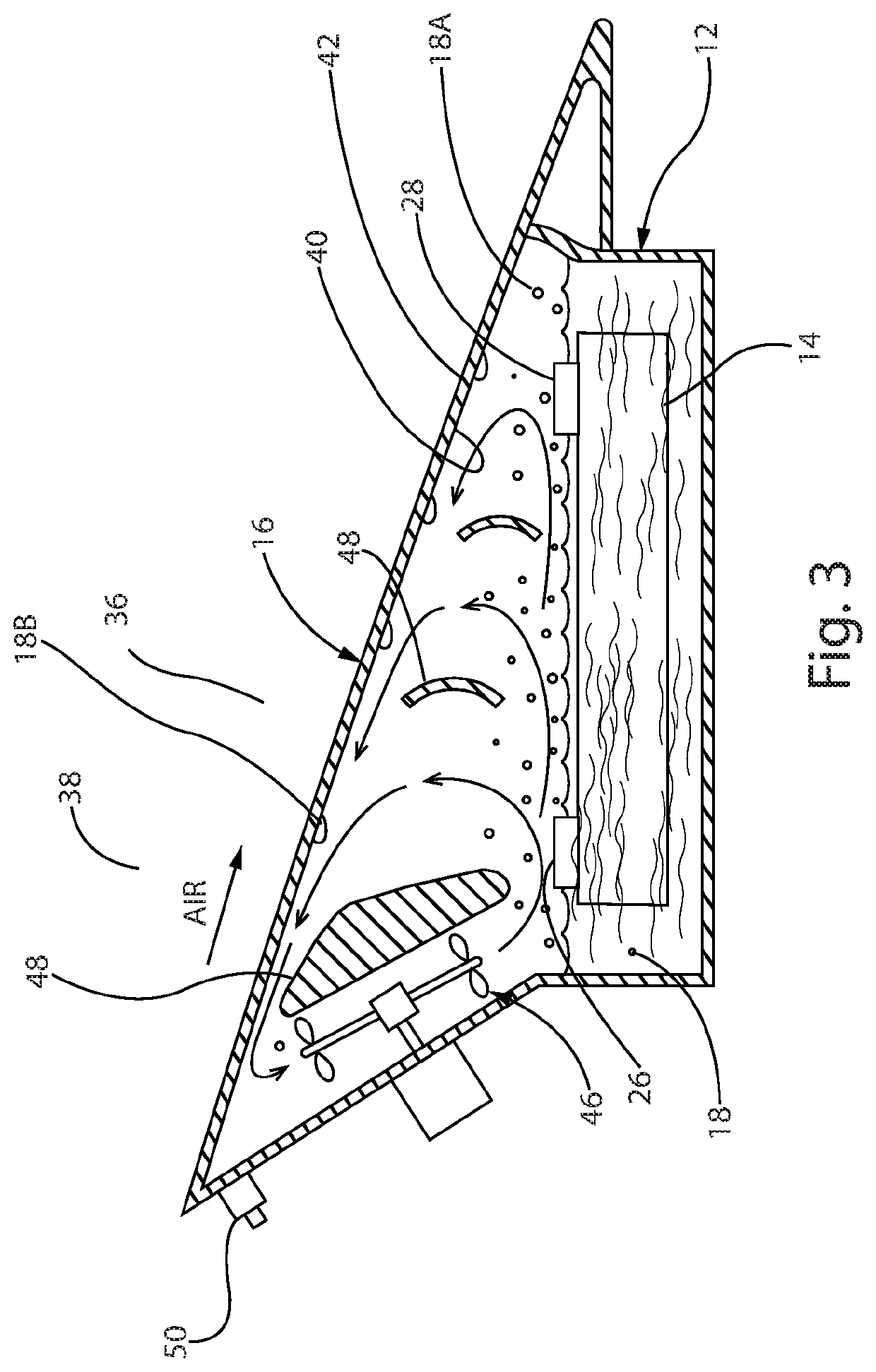

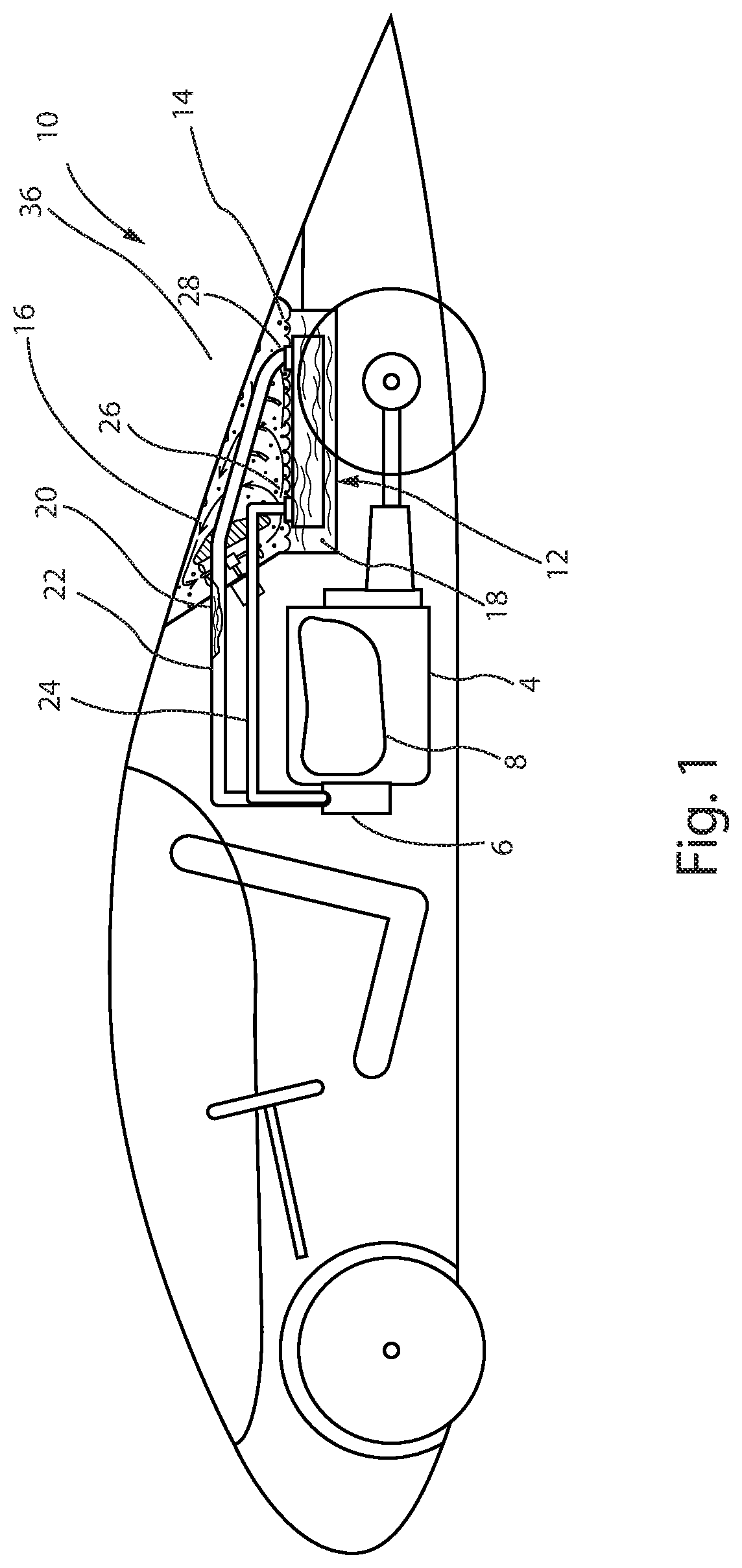

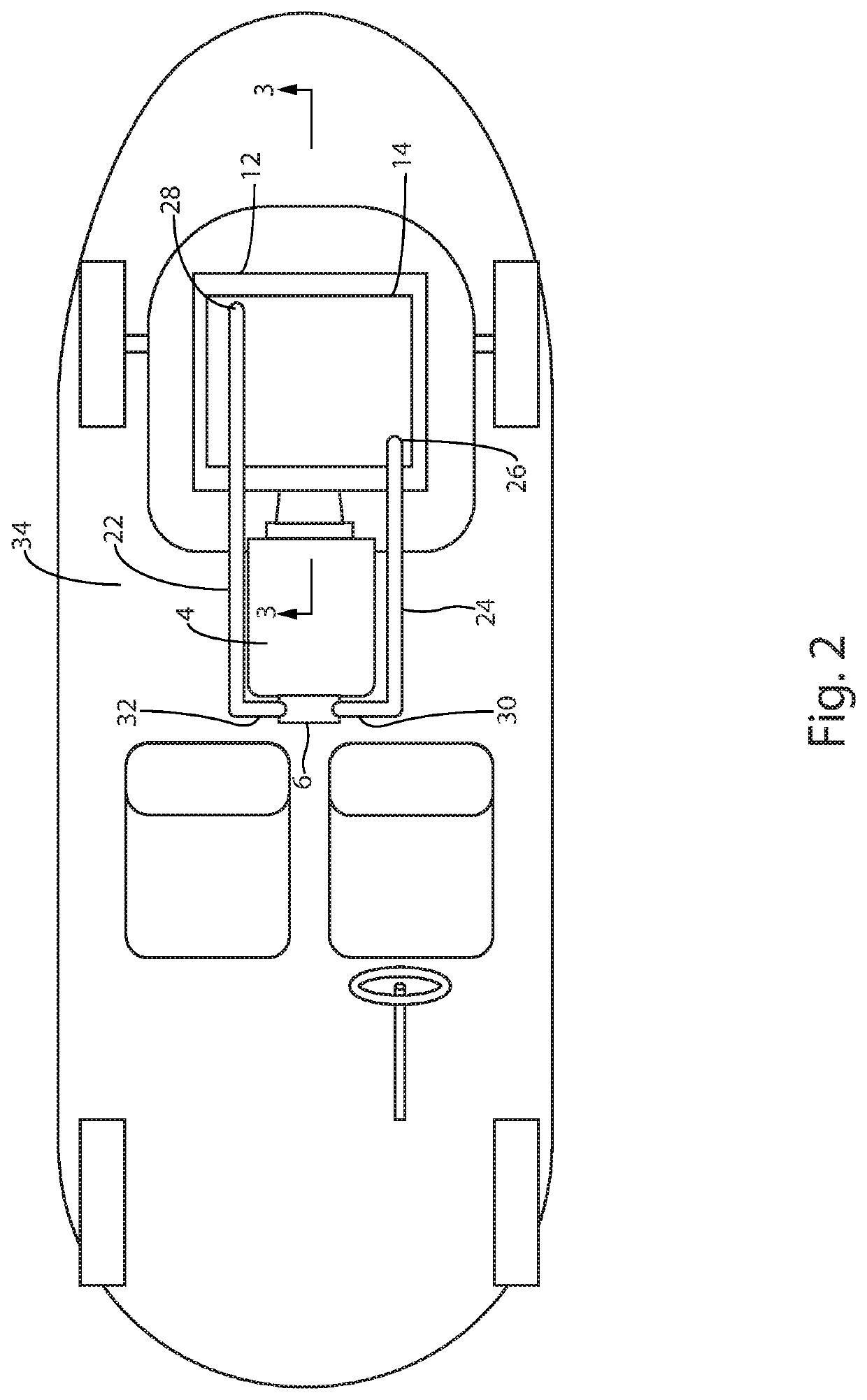

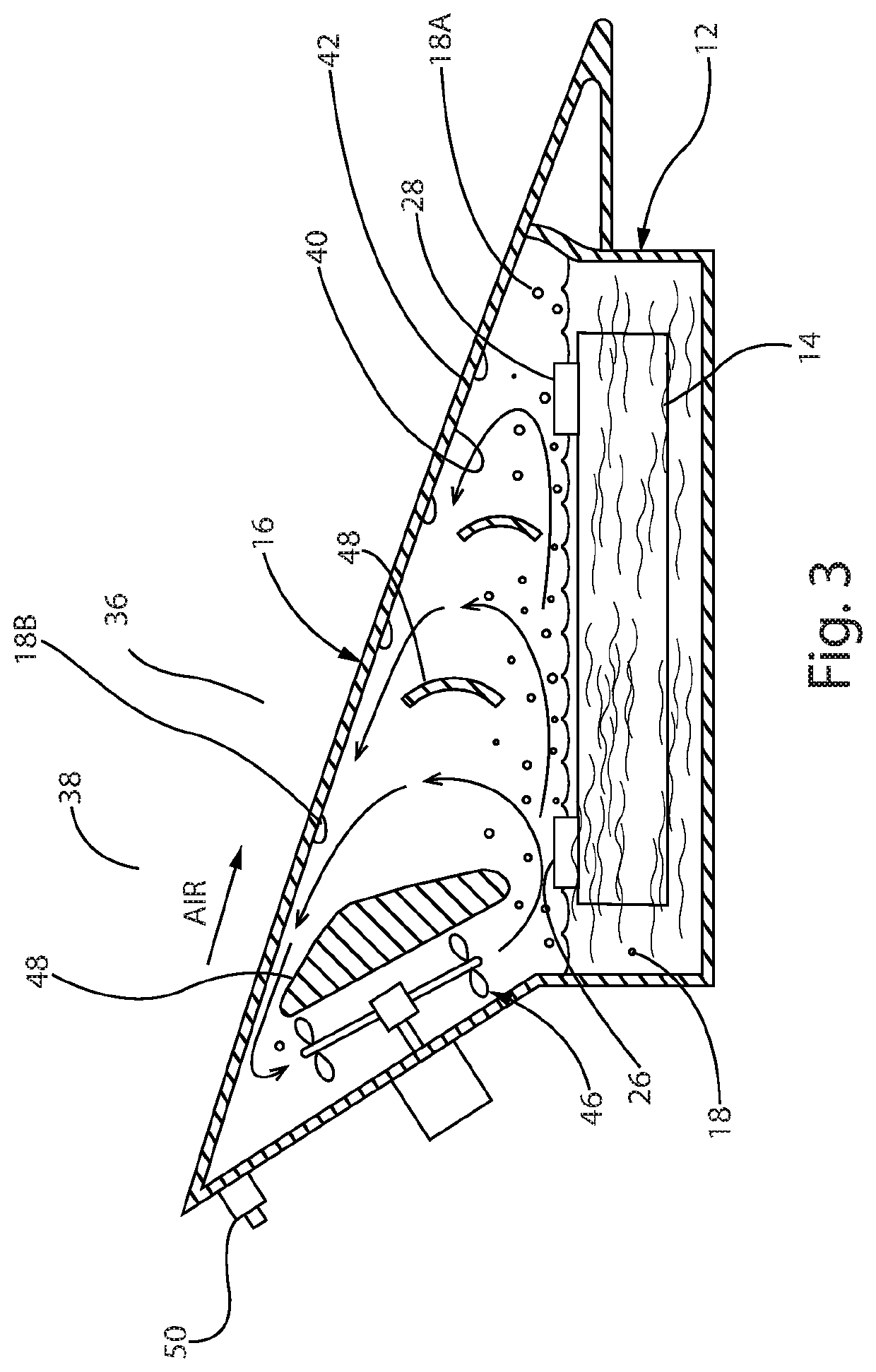

Alternative method of heat removal from an internal combustion engine

ActiveUS20200325813A1Great aerodynamic efficiencyImprove vehicle performanceLiquid coolingMachines/enginesProcess engineeringEngineering

A condensation cooling system for motor vehicles is presented. The system, in principal pan, comprises a liquid-to-liquid heat exchanger for circulating a first coolant, a coolant tank for circulating a second coolant, and a condensing panel or surface, where the condensing panel is pan of the coolant tank and also functions as a vehicle body panel. These components are arranged in two circuits, i.e. an engine cooling circuit in which a first coolant is circulated and a vapor condensing circuit in which a second coolant is circulated. The two cooling circuits are interconnected by the coolant tank where the heat exchanger is positioned within the coolant tank such that it is immersed in the second coolant. The coolant tank may also be equipped with pressure release valves, electric fans and diffuser plates to control pressure and manage air and vapor flow internally within the tank.

Owner:MOORE JAMES

Alternative method of heat removal from an internal combustion engine

ActiveUS11008927B2Improve aerodynamic efficiencyImprove vehicle performanceLiquid coolingMachines/enginesProcess engineeringInternal combustion engine

A condensation cooling system for motor vehicles is presented. The system, in principal part, comprises a liquid-to-liquid heat exchanger for circulating a first coolant, a coolant tank for circulating a second coolant, and a condensing panel or surface, where the condensing panel is part of the coolant tank and also functions as a vehicle body panel. These components are arranged in two circuits, i.e. an engine cooling circuit in which a first coolant is circulated and a vapor condensing circuit in which a second coolant is circulated. The two cooling circuits are interconnected by the coolant tank where the heat exchanger is positioned within the coolant tank such that it is immersed in the second coolant. The coolant tank may also be equipped with pressure release valves, electric fans and diffuser plates to control pressure and manage air and vapor flow internally within the tank.

Owner:MOORE JAMES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com