Film Forming Method Using Epitaxial Growth and Epitaxial Growth Apparatus

a technology of epitaxial growth and growth apparatus, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas growth process, etc., can solve the problems of difficult to adjust the thickness distribution or resistivity distribution, increase the number, etc., to reduce the thickness of the boundary layer, suppress the effect of flow increase, increase the growth ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

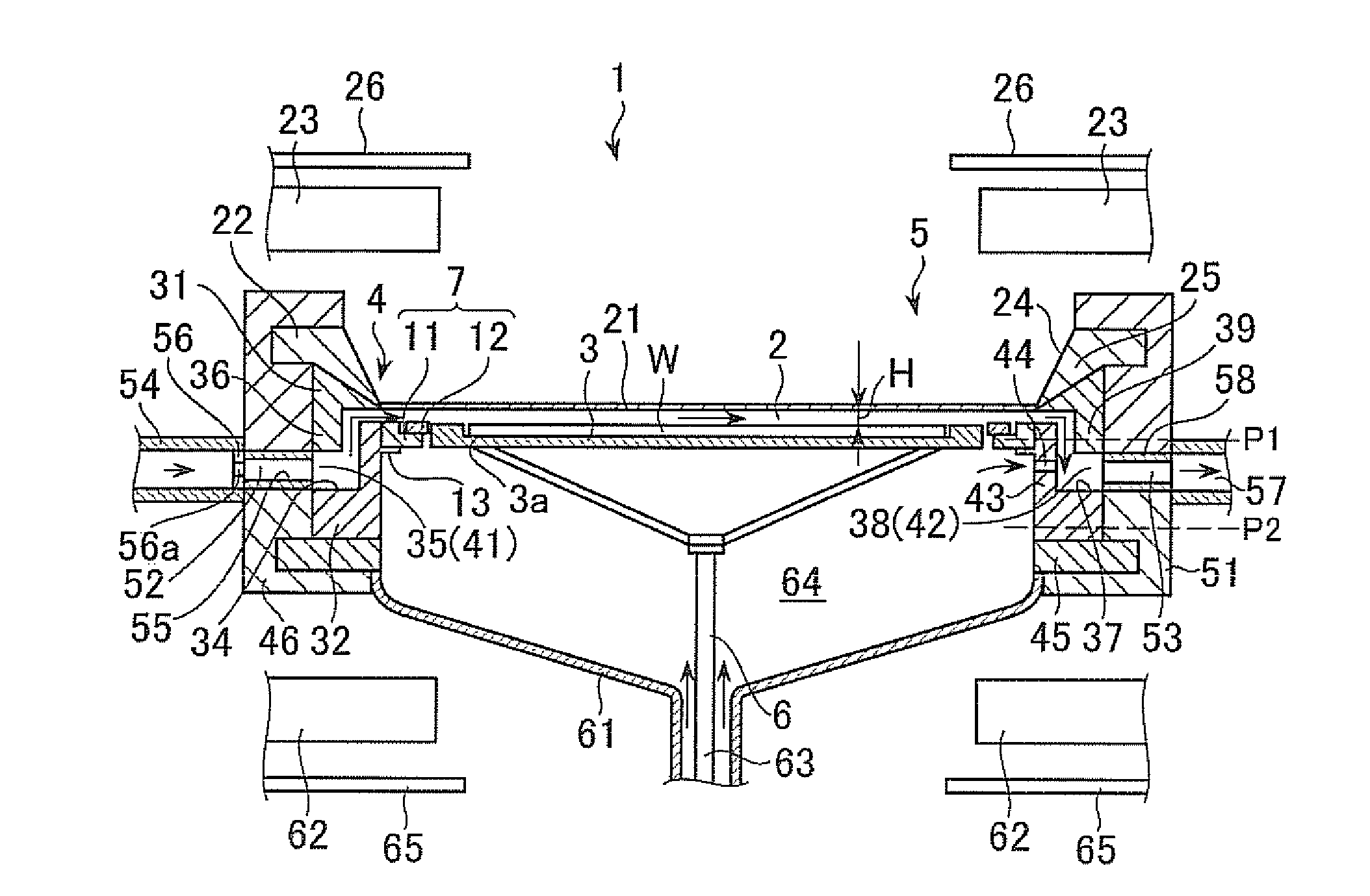

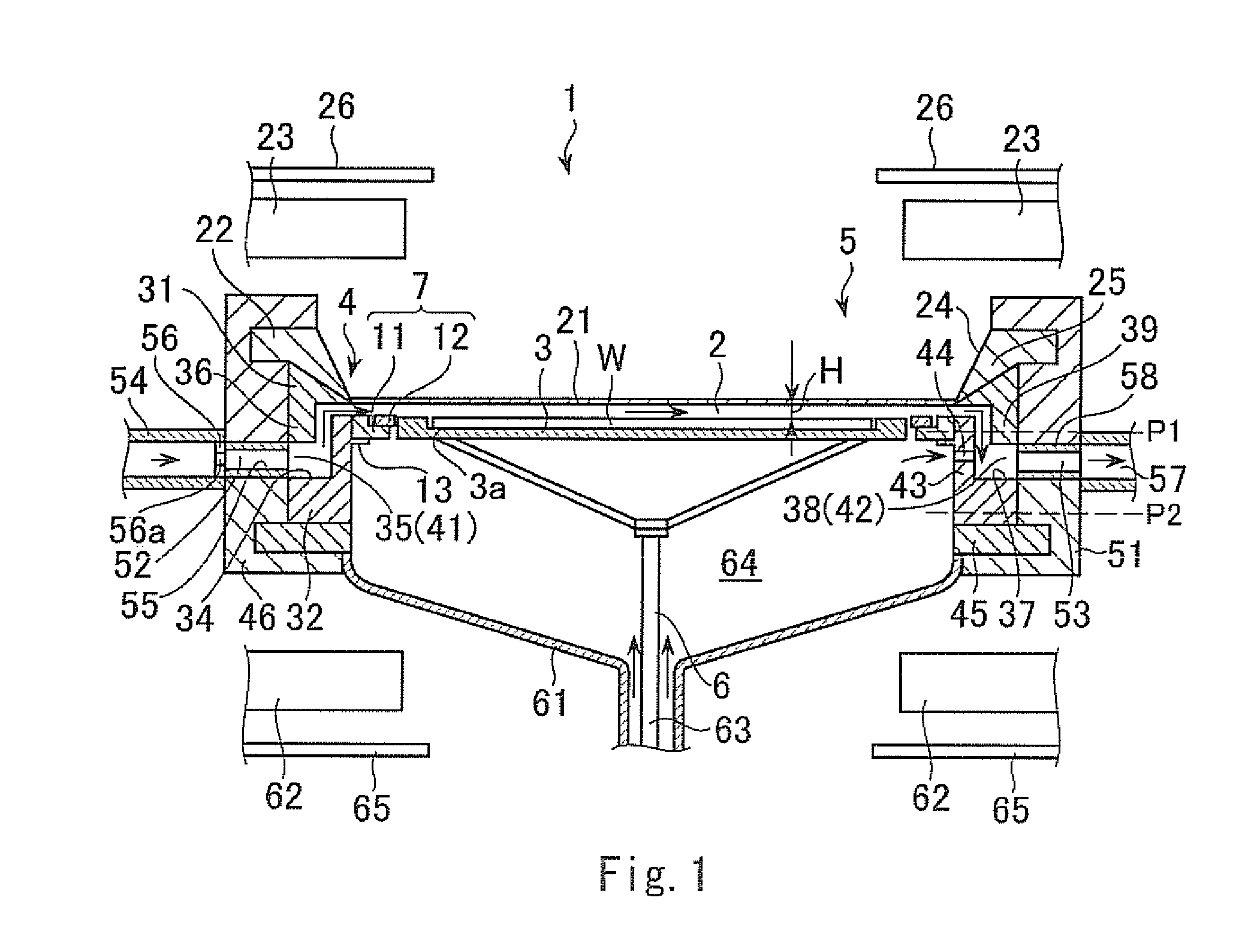

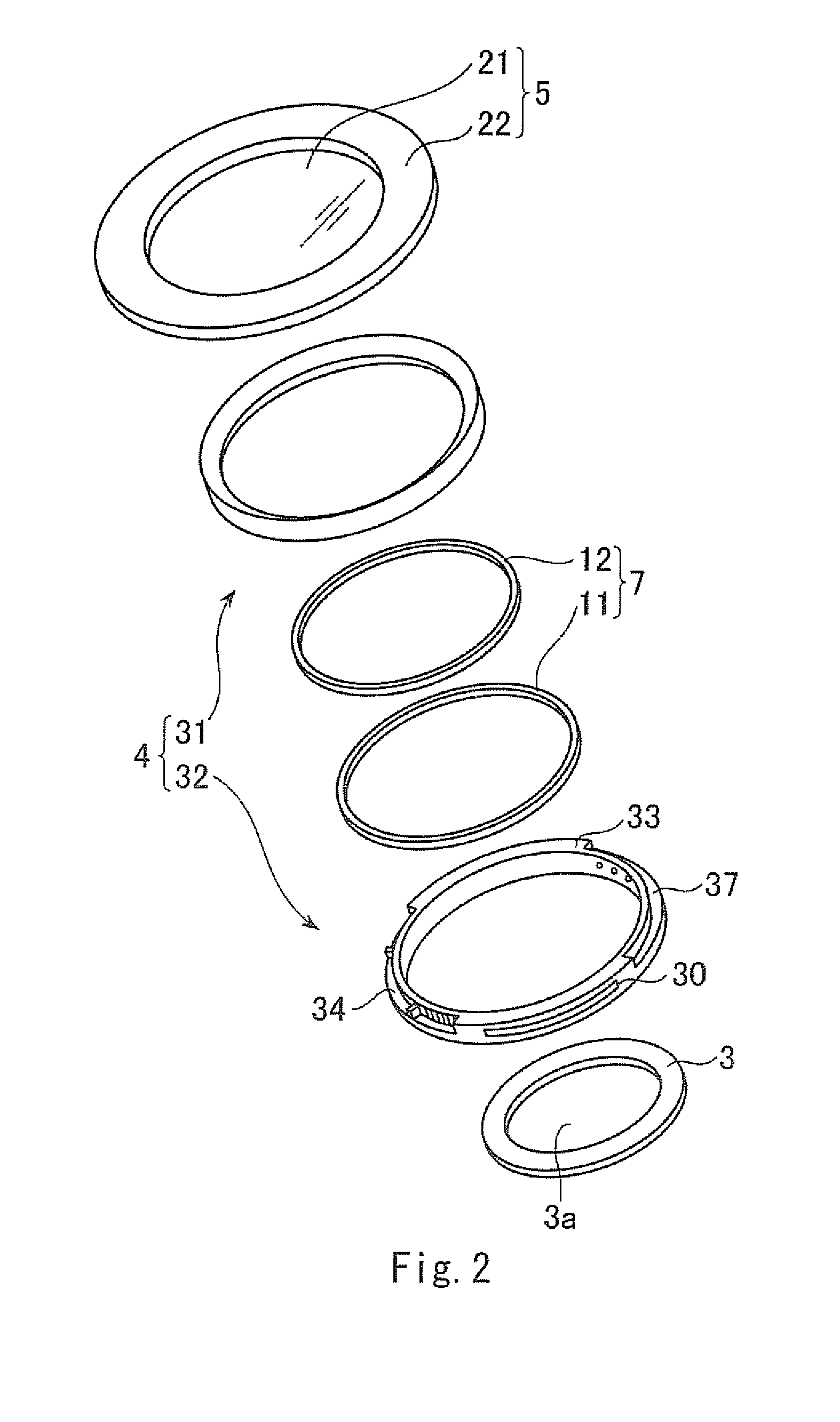

[0097]Epitaxial growth was carried out under the following growth conditions by the use of an epitaxial growth apparatus 1A (in which the distance H between the surface the substrate W and the ceiling plate 21 is 9.27 mm) employing the susceptor ring shown in FIG. 10.

[0098]Amount of first source gas (trichlorosilane): 8.5 SLM

[0099]Amount of purge gas (hydrogen): 15.0 SLM

[0100]Growth time: 600.0 seconds

[0101]Growth temperature: 1100.0° C.

[0102]Rotation speed: 20.0 RPM

example 2

[0103]Epitaxial growth was carried out under the same conditions as in Example 1, except that the amount of the first source gas was changed to 13.5 SLM.

example 3

[0104]Epitaxial growth was carried out under the same conditions as in Example 1, except that the amount of the first source gas was changed to 17.0 SLM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com