Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184results about How to "Uniform temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

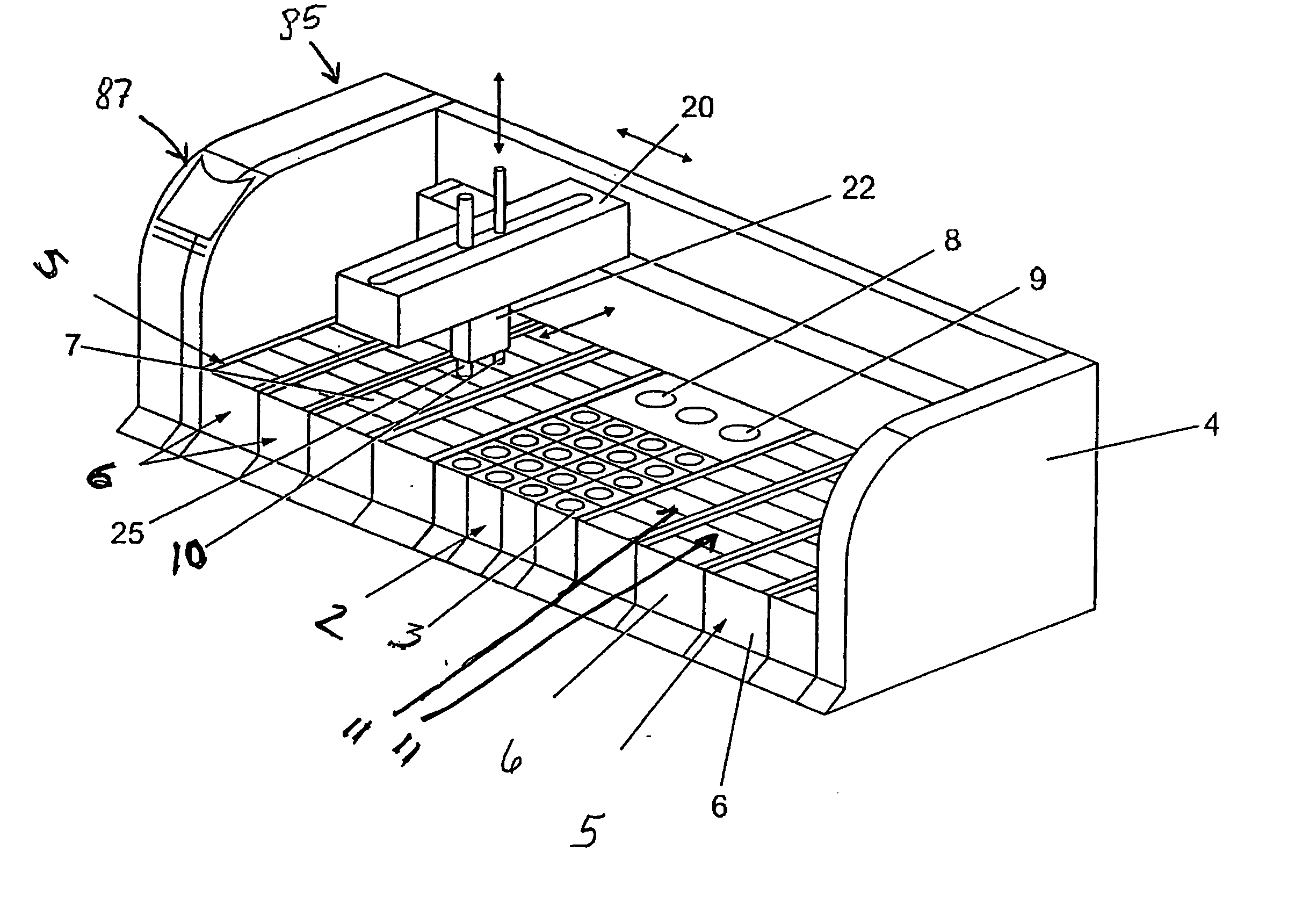

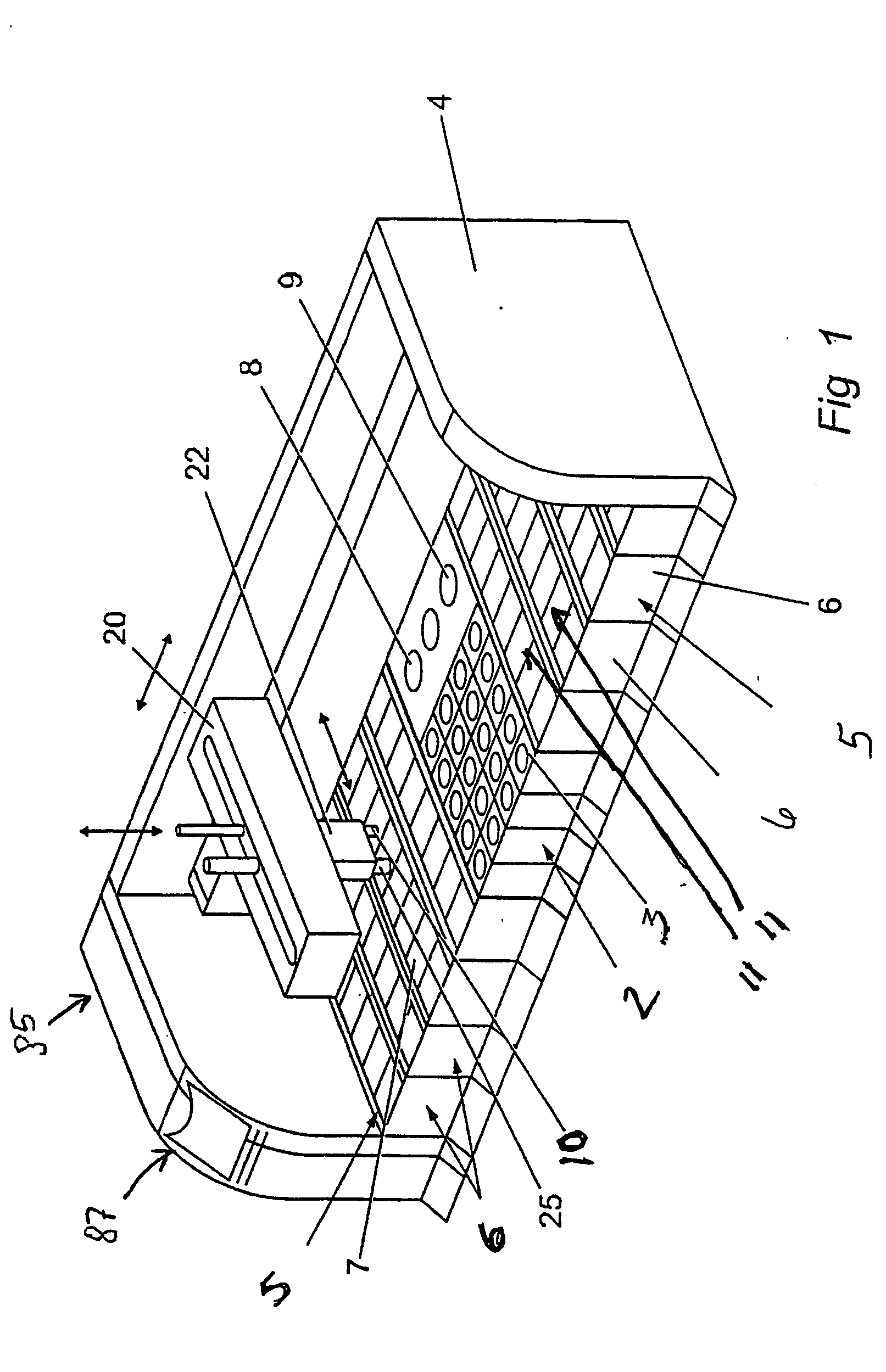

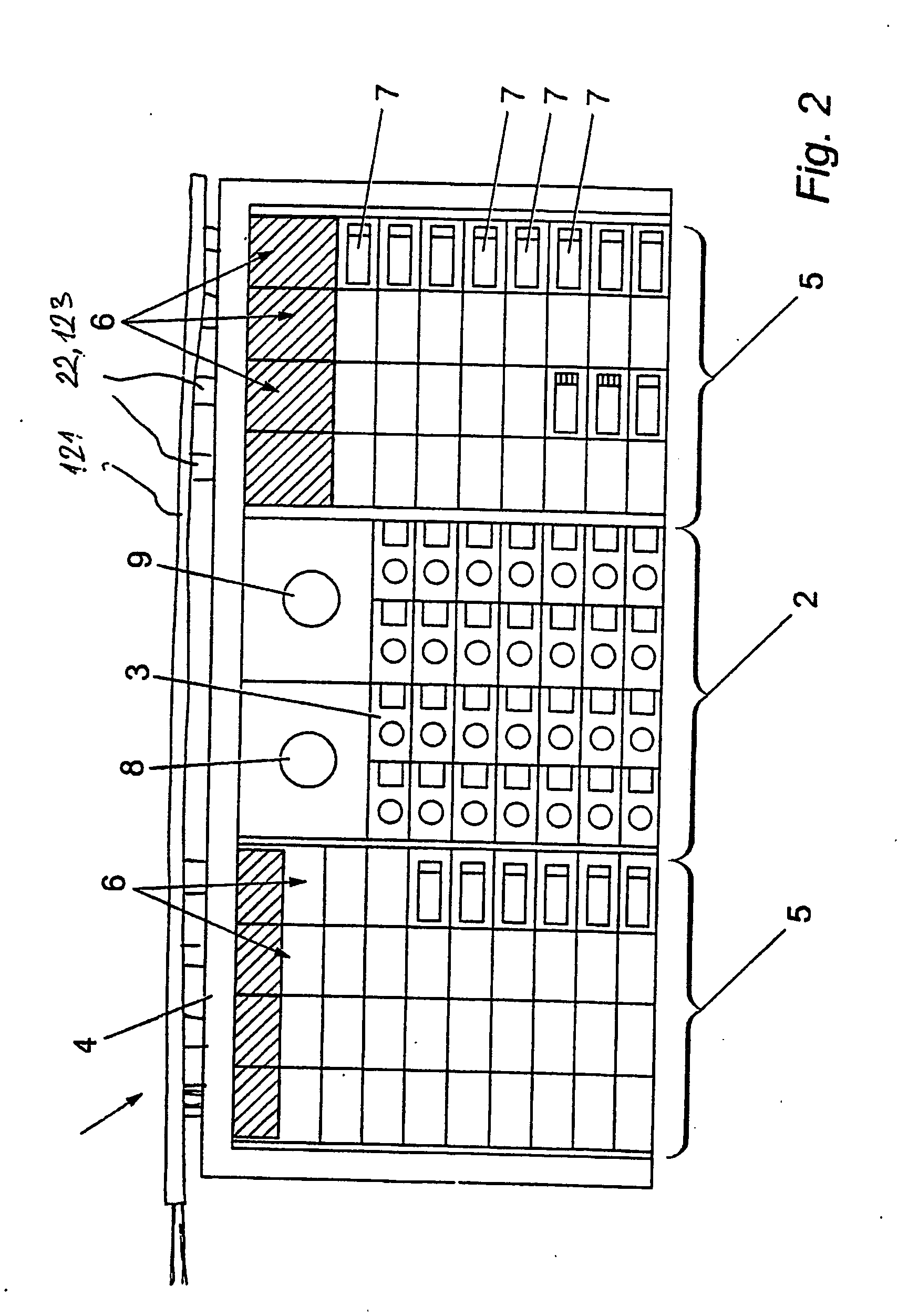

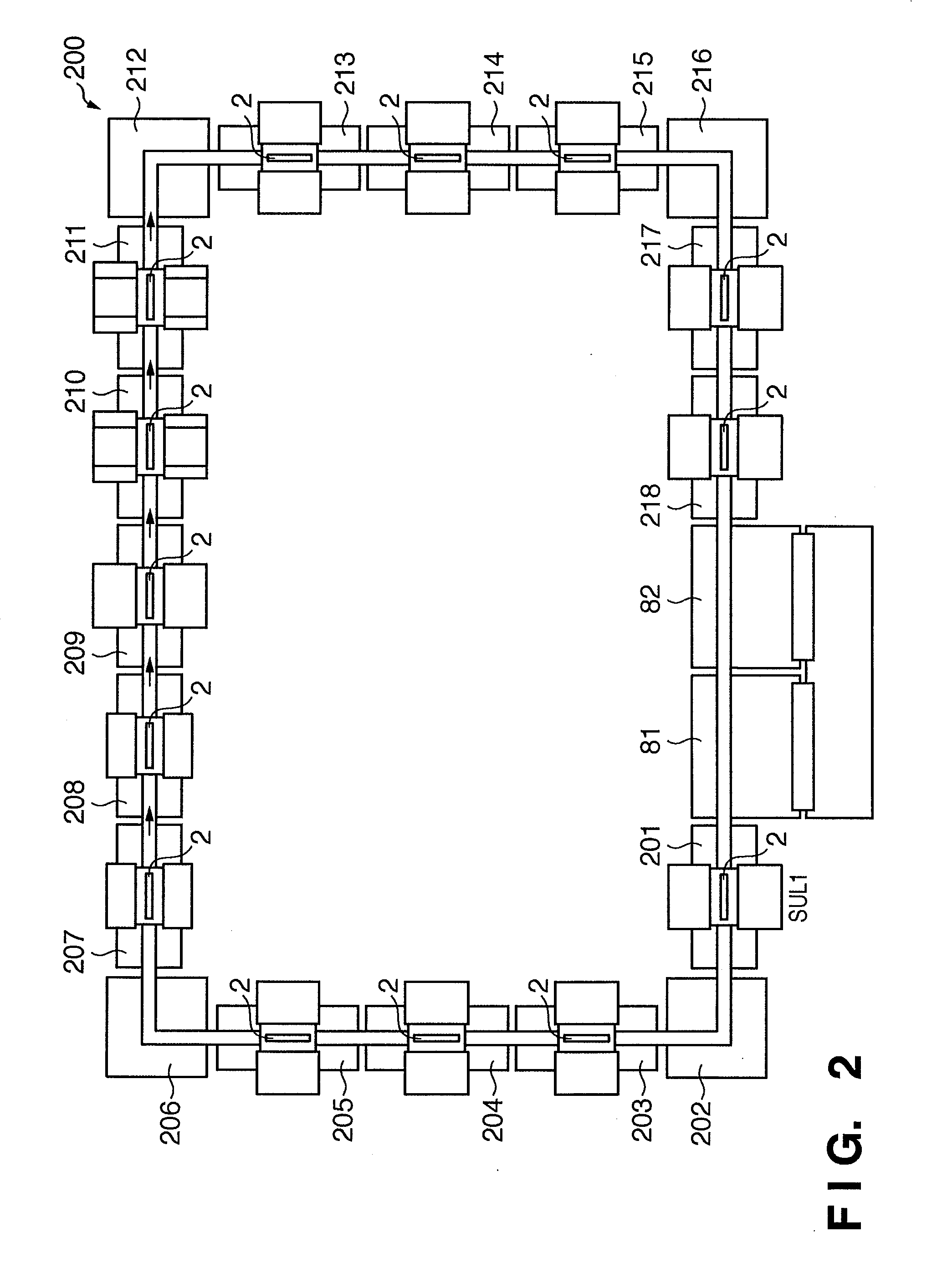

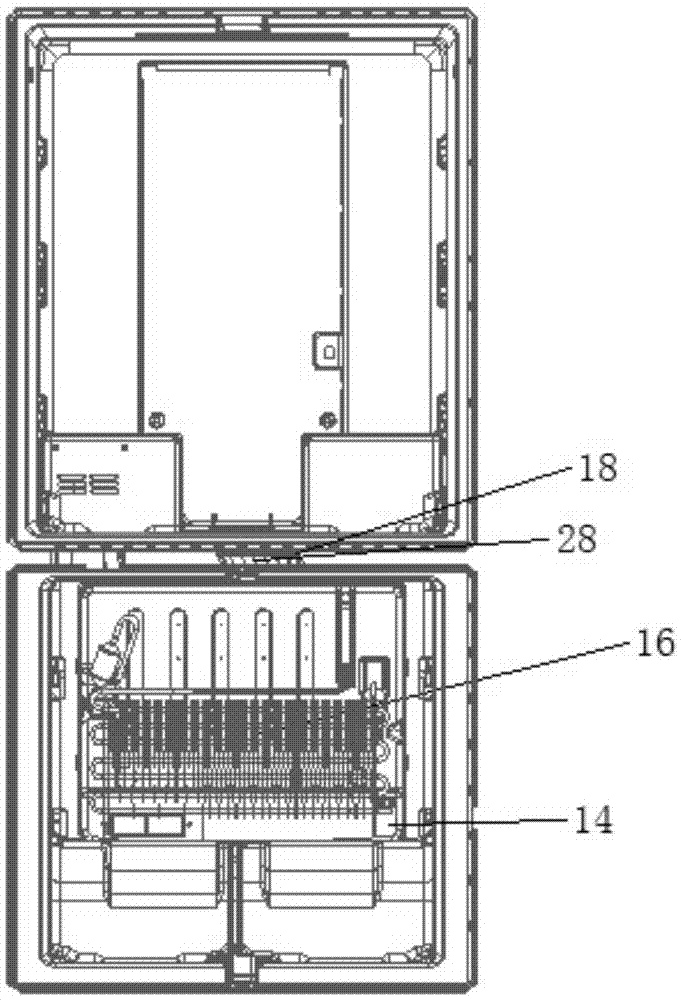

Apparatus for automated processing biological samples

ActiveUS20060045806A1Uniform temperature controlLayered productsStatic/dynamic balance measurementInterior spaceEngineering

The present invention concerns an apparatus for automatic processing at least one biological sample accommodated on a carrier member, such as a slide by applying a predetermined amount of reagents in a predetermined sequence according to a processing protocol, said apparatus comprising; a housing frame; at least one processing section for accommodating at least one slide, the at least one processing section is provided within the housing; a hood cover protecting the at least one processing section in said housing; wherein the hood cover completely encloses the processing section defining an interior space; and wherein the apparatus further comprises climate control device provided to control the environment within the interior space.

Owner:AGILENT TECH INC

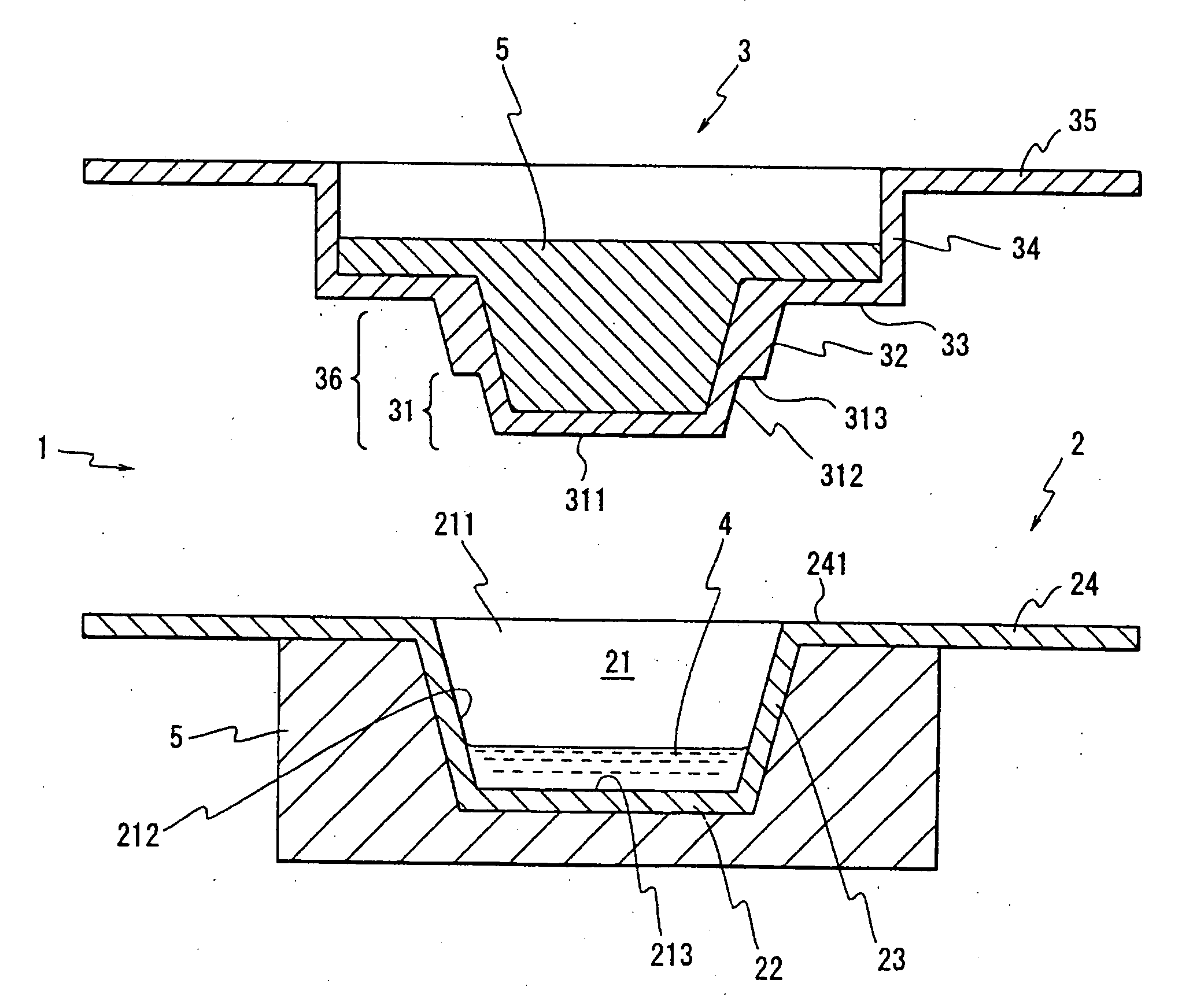

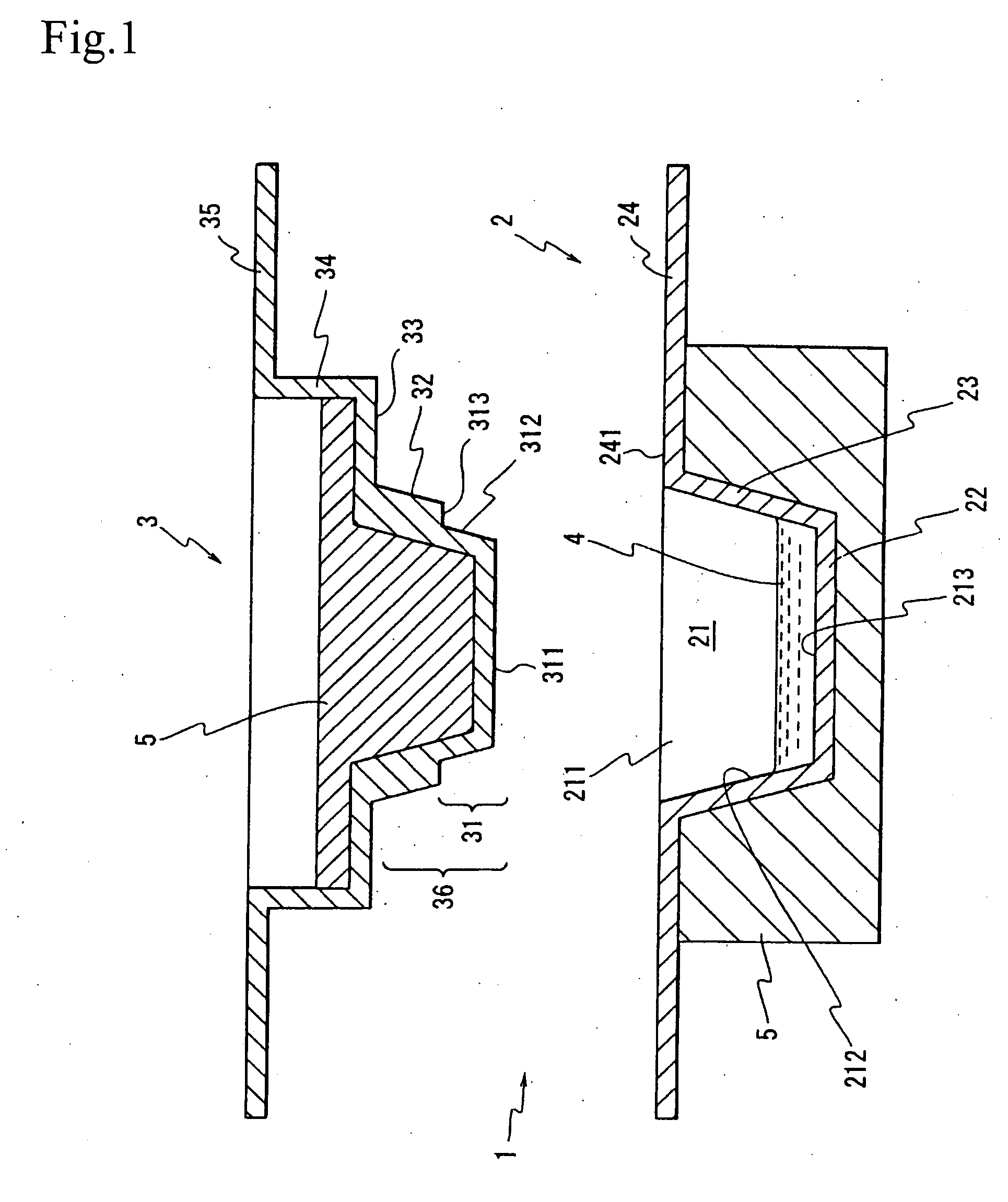

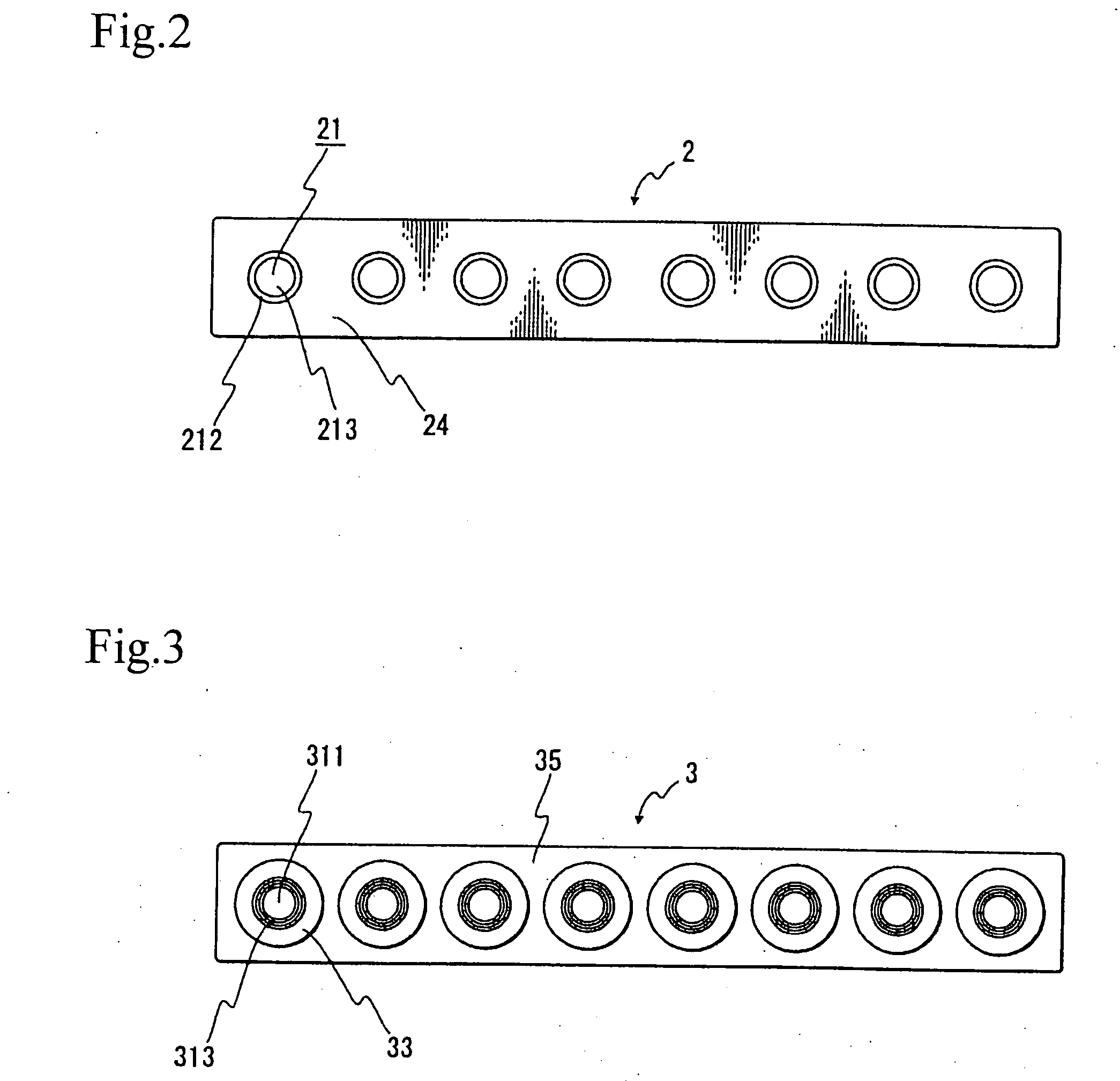

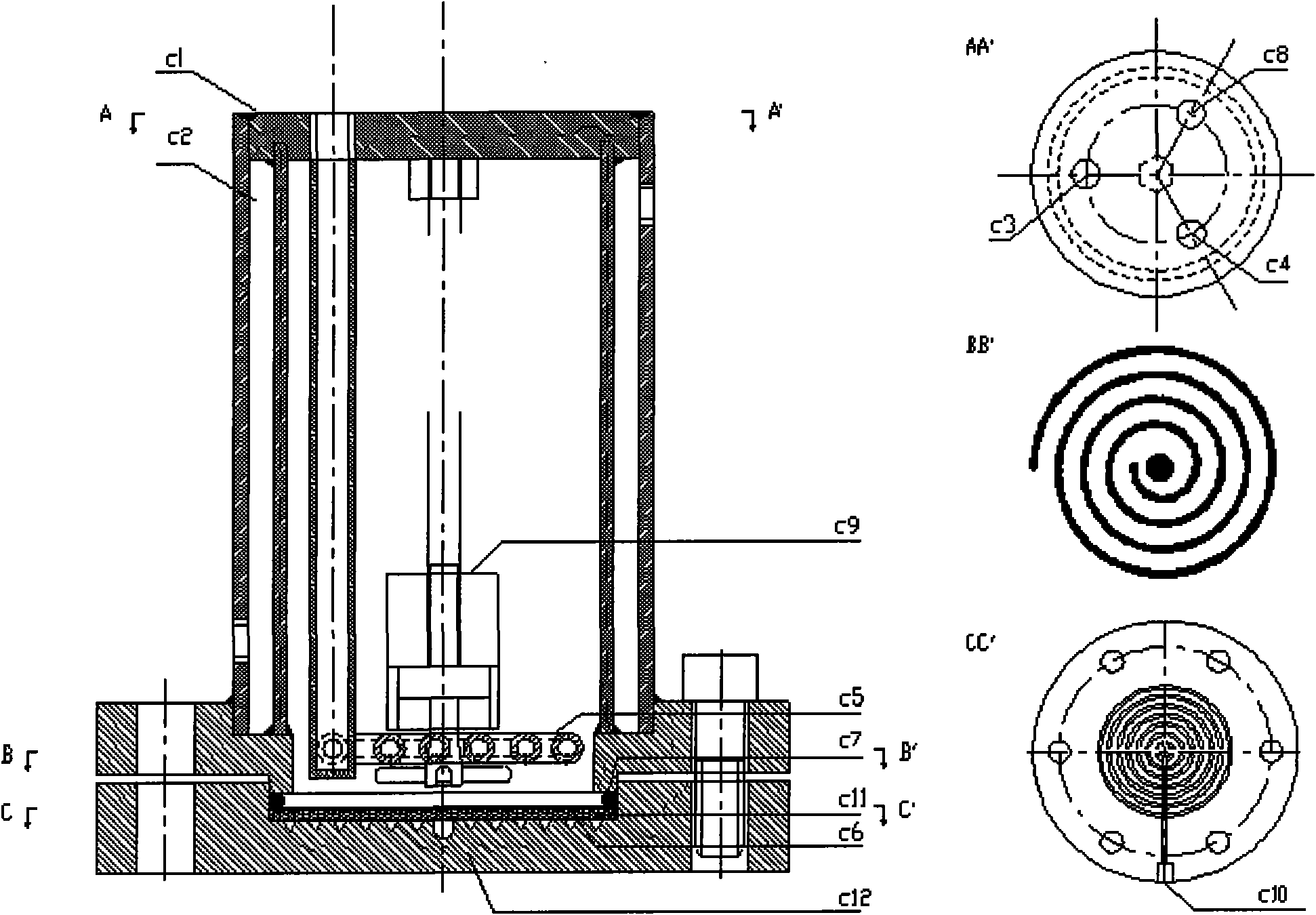

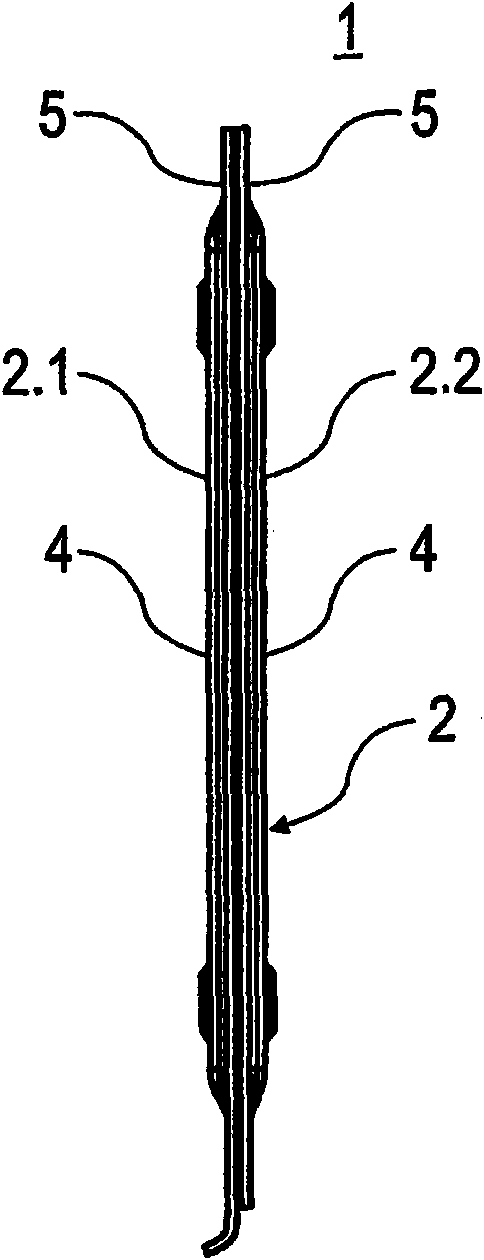

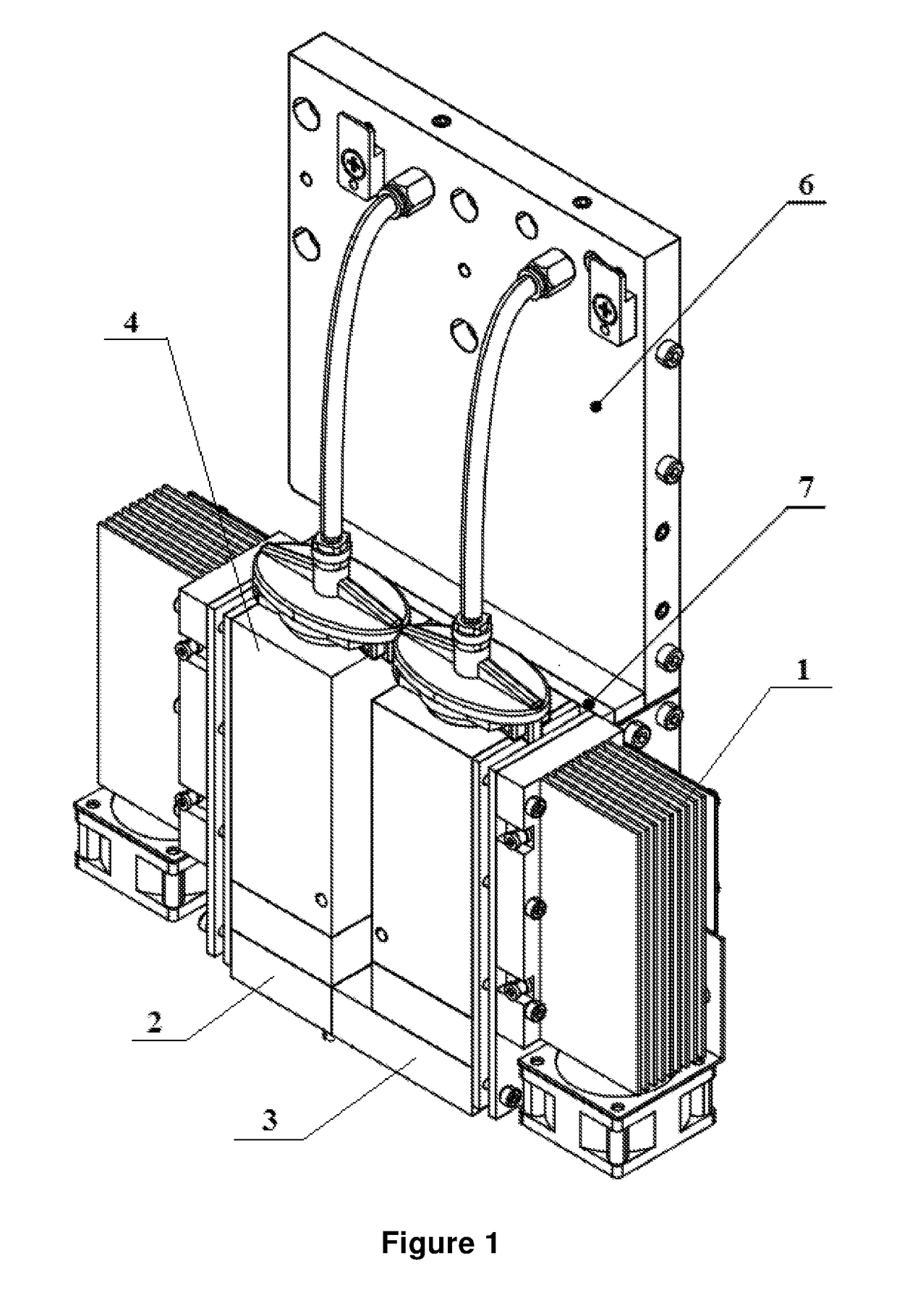

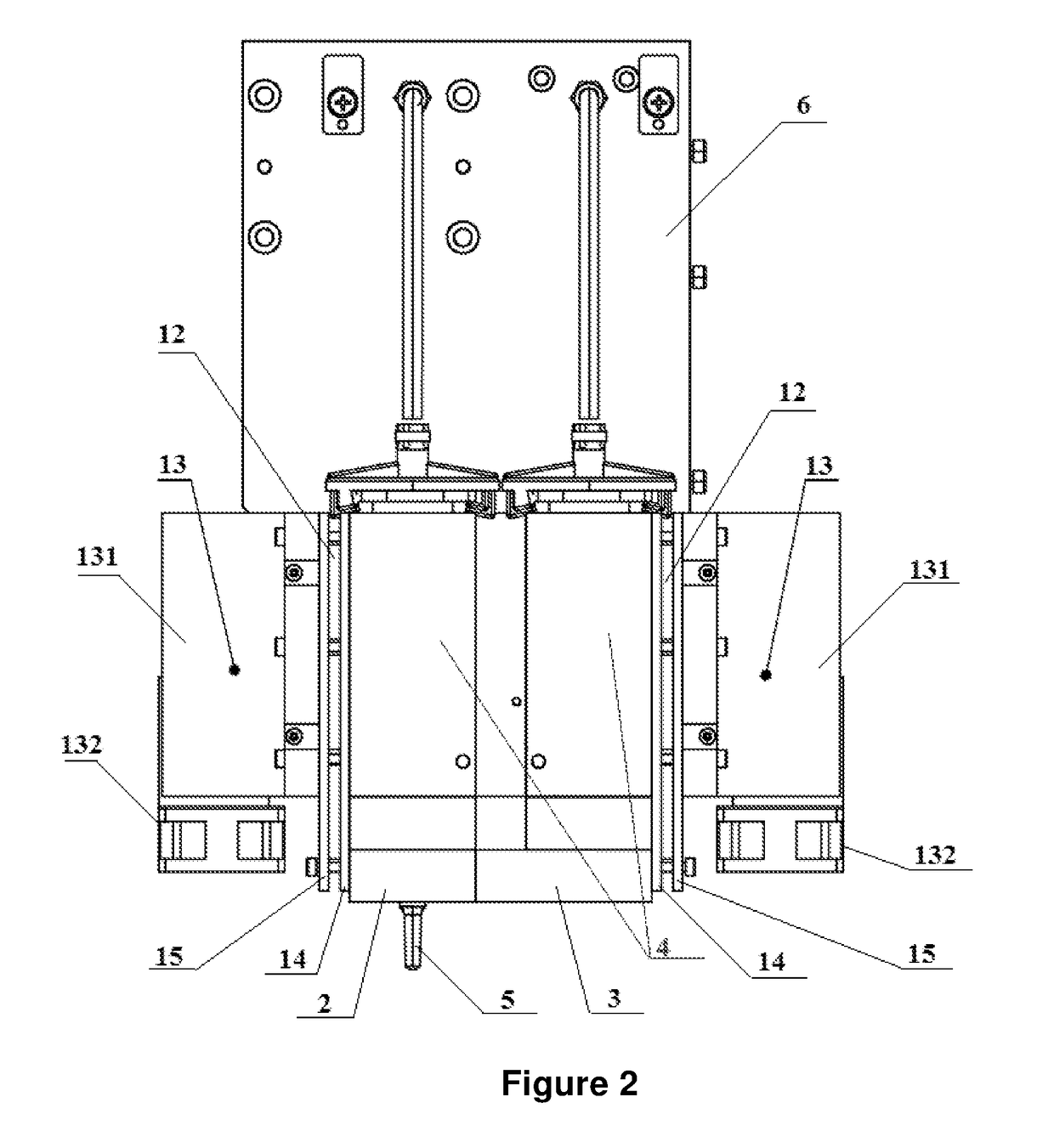

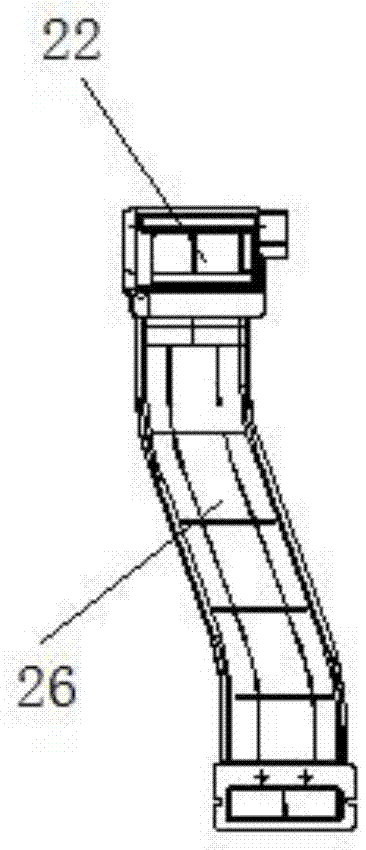

Reaction vessel, reaction apparatus and reaction solution temperature control method

InactiveUS20060205064A1Complete efficientlyIncrease contact areaProcess control/regulationBioreactor/fermenter combinationsTemperature controlOrganic chemistry

It is an object of the present invention to provide a reaction vessel which makes it possible to control the temperature of the reaction solution accommodated in the reaction chamber with a quick response, without any need for centrifuging when the reaction solution is accommodated in the reaction chamber, and which also makes it possible to cause the reaction to proceed even when the amount of reaction solution accommodated in the reaction chamber is extremely small. The present invention provides a reaction vessel comprising a reaction vessel main body which has a reaction chamber that has an opening part in the upper end and that can accommodate a reaction solution, and a cover member which can seal the opening part of the abovementioned reaction chamber, wherein the abovementioned cover member has a pressing part that can press the reaction solution accommodated in the abovementioned reaction chamber.

Owner:PRECISION SYST SCI

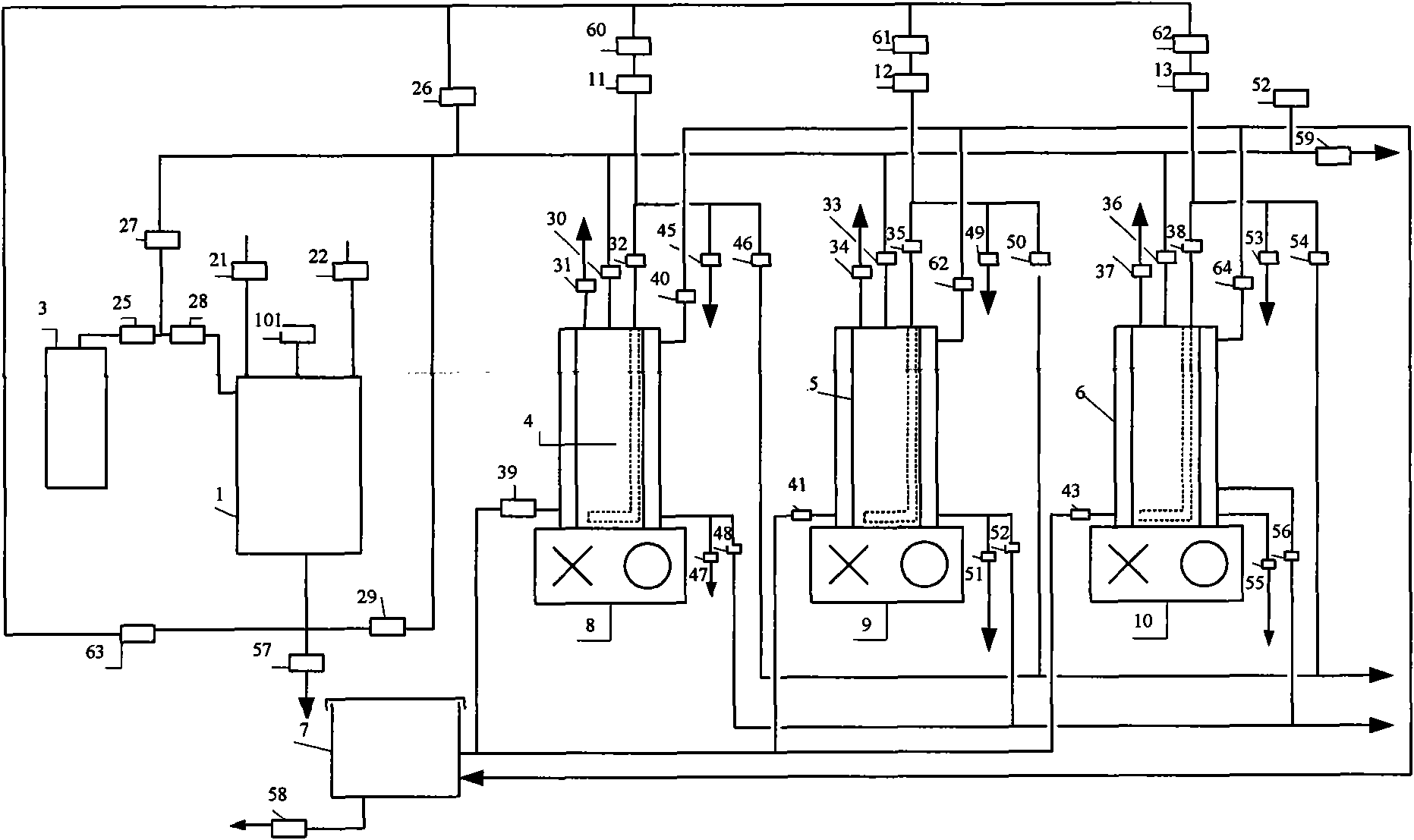

Membrane performance tester and application thereof

ActiveCN102049199AExtended stayStable temperature controlSemi-permeable membranesUltrasound attenuationWater baths

The invention provides a performance tester of a continuous flat ultrafiltration membrane and a reverse osmosis membrane and a use method thereof. The tester comprises a water supply unit, a drainage unit and a plurality of parallel infiltration ponds, wherein each infiltration pond comprises a substrate, a shell, a water inlet, a water outlet, an exhaust port, a bottom inserting tube, a stirrer and a constant-temperature water bath jacket. Produced water penetrating through a separation membrane to be measured is discharged out of the infiltration ponds via the water outlets. The tester can carry out constant-temperature and stable operation at higher temperature and can realize the functions of testing membrane separation performance and membrane flux attenuation, extracting key pollutants of the membrane, cleaning the membrane on line and testing membrane performance restore after cleaning.

Owner:CHINA PETROLEUM & CHEM CORP +1

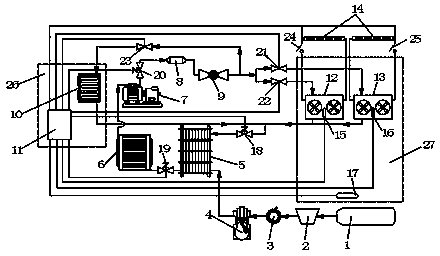

Energy-saving refrigeration transport cart

ActiveCN103507691AImprove preservation qualitySave fuelAir-treating devicesRefrigerated goods vehicleElectromagnetic valveWaste gas

The invention relates to an energy-saving refrigeration transport cart. The transport cart comprises a fuel gas system, a refrigerating system, a control system and an air feeding and returning system, wherein the fuel gas system is composed of a natural gas storage tank, a pressure reducer, an air mixer and an engine, the refrigerating system is composed of a plate-type heat exchanger, a condenser, a liquid pump, a drying filter, a throttling valve, an air cooler, an air conditioner, an electromagnetic valve and an electric valve in a connected mode, the control system is composed of a controller and a temperature sensor, the air feeding and returning system is composed of an uneven hole plate, an air feeding duct, an air returning baffle and an air returning duct, and a solar storage cell panel is connected with the controller through a control switch. Economical and safe natural gas low in pollution is adopted for the transport cart to be used as fuel, waste heat of exhaust gas is utilized to heat refrigerant when power is provided for the cart, and cooling capacity is provided for a refrigerating compartment and a cab; the solar storage cell panel is utilized to supply power to heat an electric heating wire to defrost the air cooler; airflow organization and a temperature field in the compartment can be controlled evenly, and the purposes of saving energy and protecting the environment are achieved.

Owner:SHANGHAI OCEAN UNIV

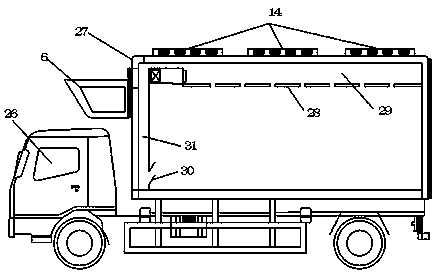

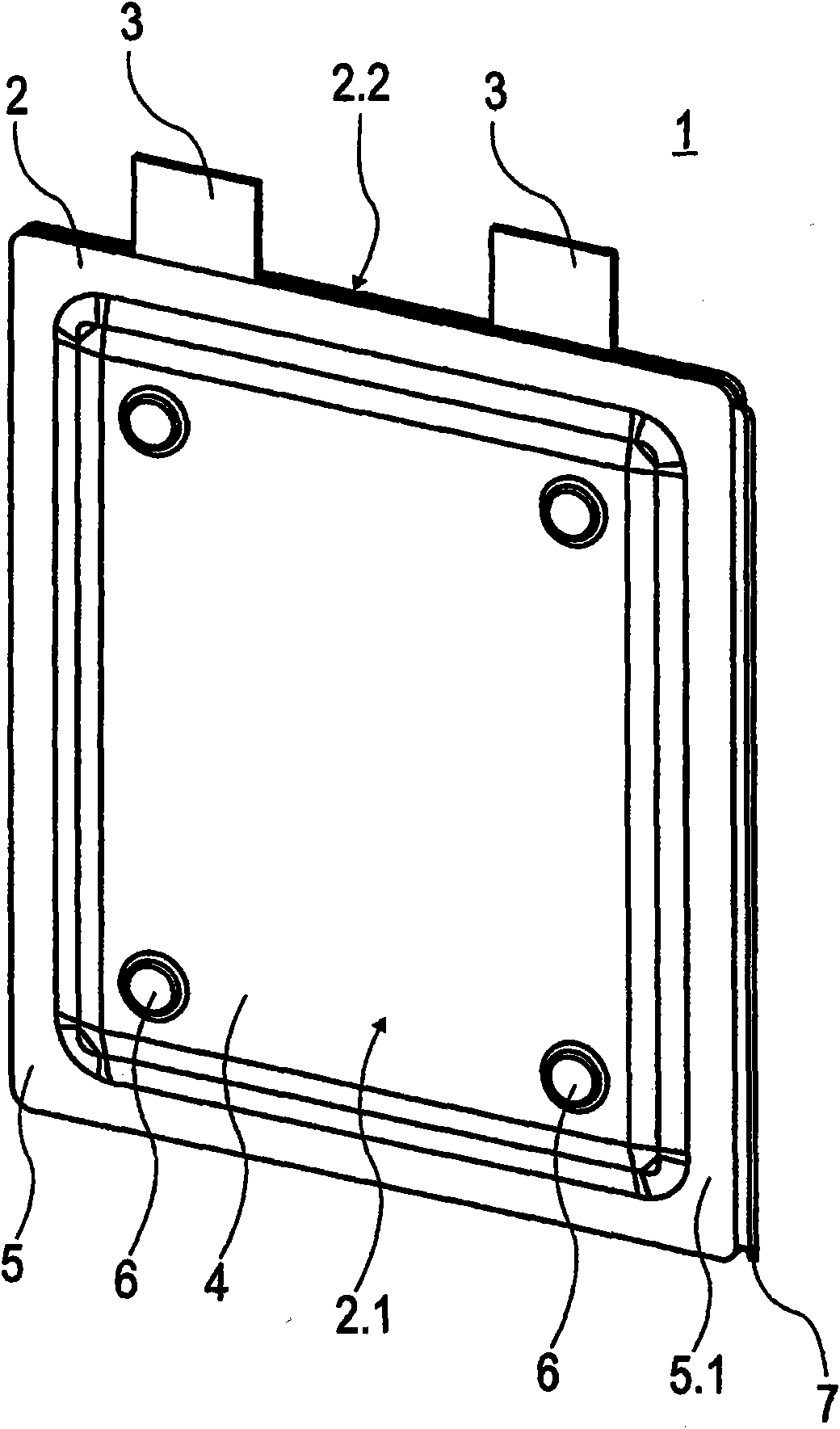

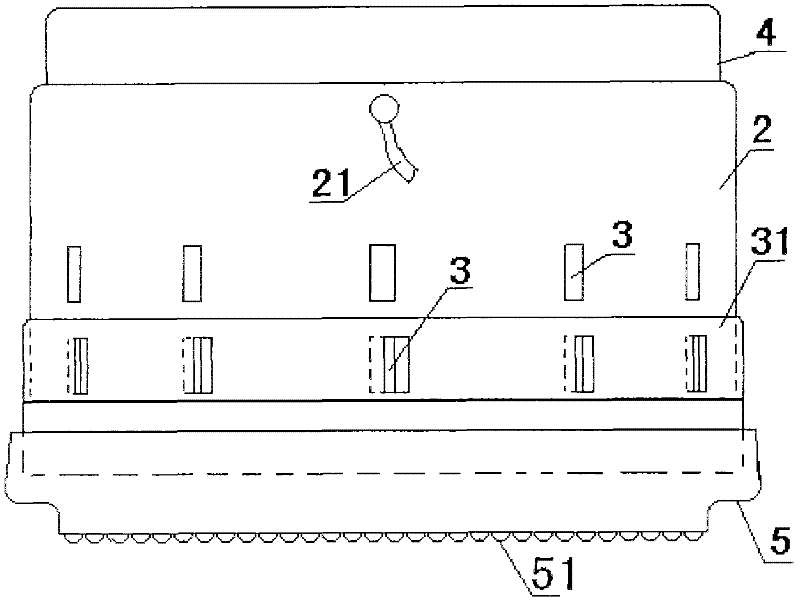

Battery, particularly for a hybrid drive

InactiveCN101772857ALow costSave installation spaceSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsTemperature controlMonomer

The invention relates to a battery (6) comprising at least one temperature control unit (7) that is configured as a cooling plate, and at least two galvanic individual cells (1), each having a metal housing (2), wherein the metal housing (2) has an extension (3), which can be accommodated at least partially in a respective recess (8) of the temperature control unit (7).

Owner:DAIMLER AG

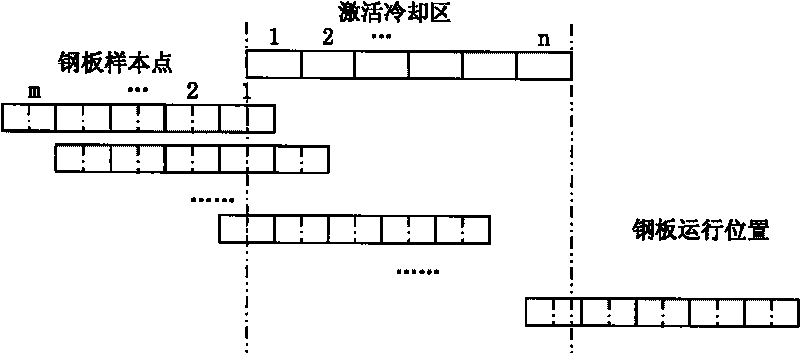

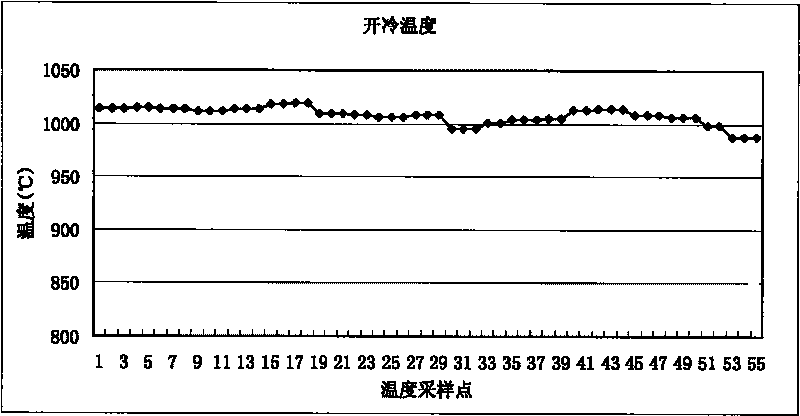

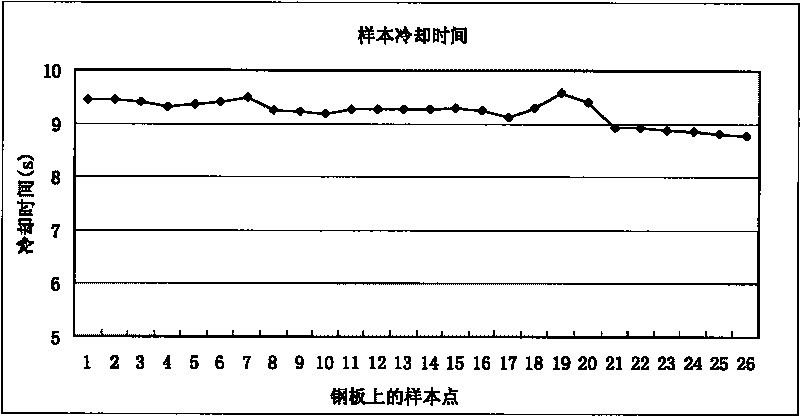

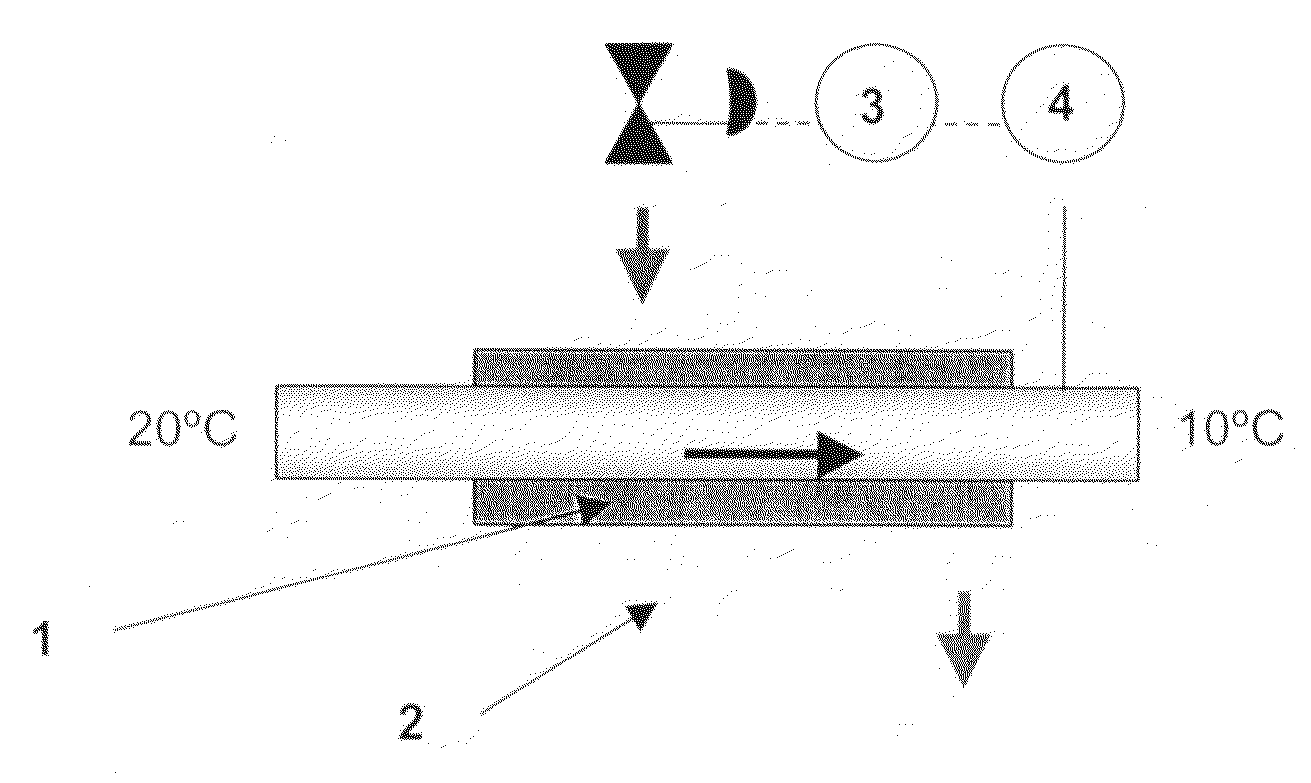

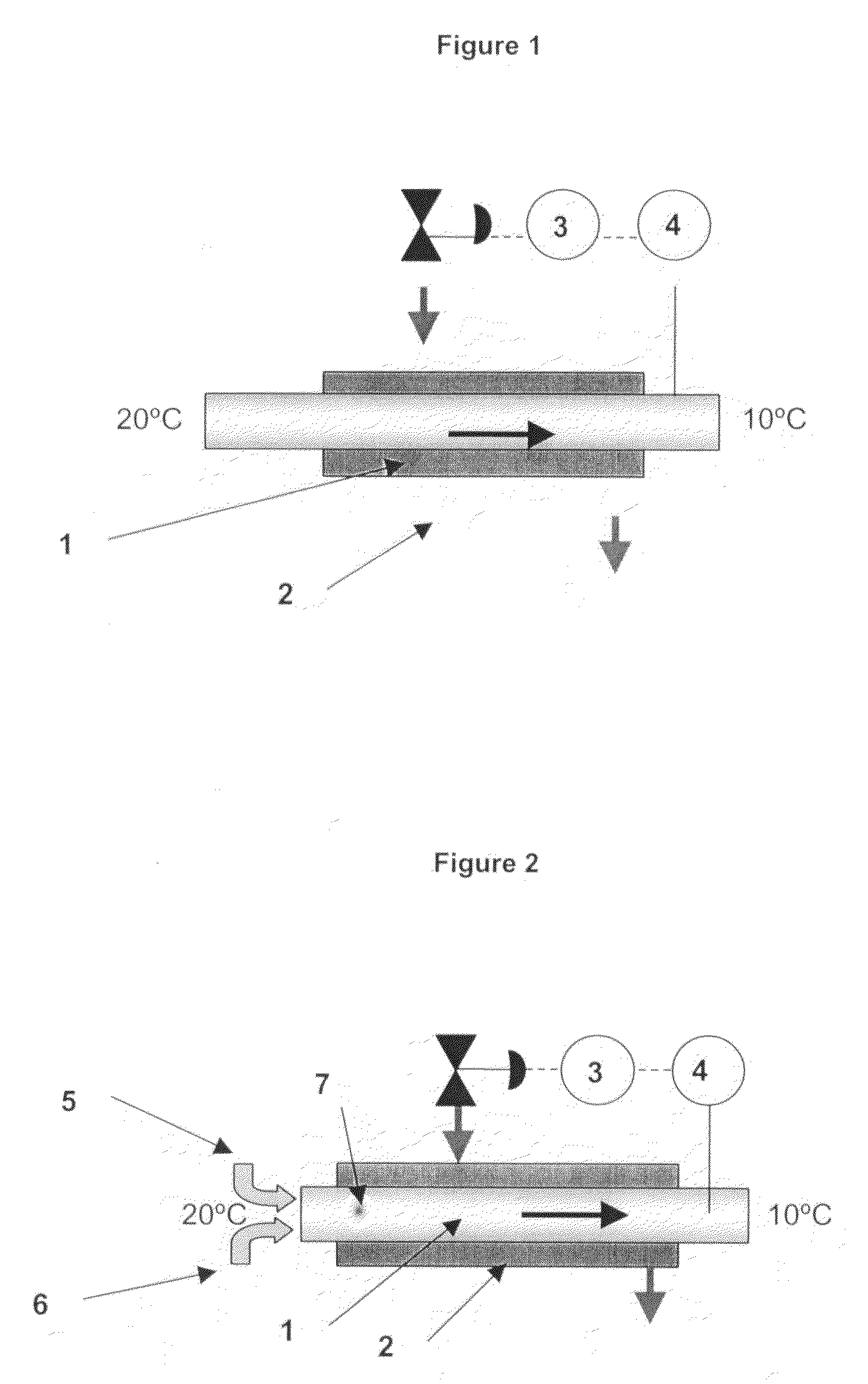

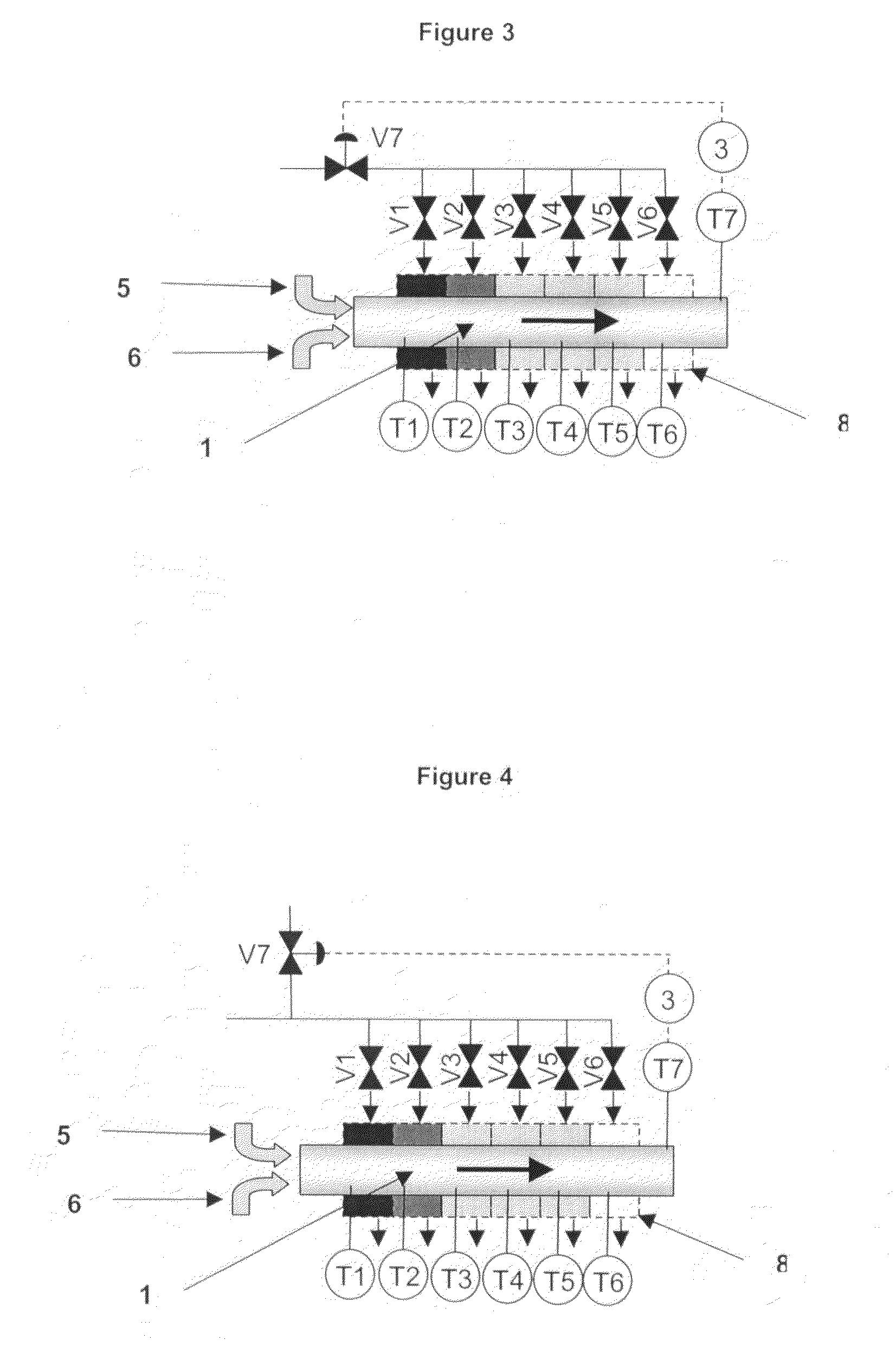

Method for controlling speed of cooling roller bed after rolling medium plate

InactiveCN101733291AGuaranteed cooling uniformityAvoid uneven tissue performanceTemperature control deviceAutomatic controlSheet steel

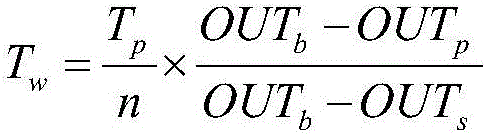

The invention discloses a method for controlling the speed of a cooling roller bed after rolling a medium plate, which belongs to the technical field of steel rolling automatic control, is mainly used in the process of cooling the medium plate after rolling, and realizes the control of the cooling uniformity of a steel plate in the length direction by controlling the speed of the roller bed. The invention provides the method for controlling the speed of the cooling roller bed after rolling the medium plate, which can ensure the cooling uniformity of the steel plate in the length direction. The method adopts a cooling control system after rolling and comprises the following steps: firstly, performing sample division on the steel plate in the length direction; secondly, before the steel plate enters an activation cooling zone, acquiring the actual temperature value of the steel plate in the length direction through a thermo-detector before cooling, and determining the speed of each sample of the steel plate to pass through the activation cooling zone; and thirdly, transmitting the speed, determined in the second step, of each sample of the steel plate to pass through the activation cooling zone to a basic automation unit of the cooling control system after cooling, and controlling the speed of the cooling roller bed by the basic automation unit of the cooling control system after cooling.

Owner:NORTHEASTERN UNIV LIAONING

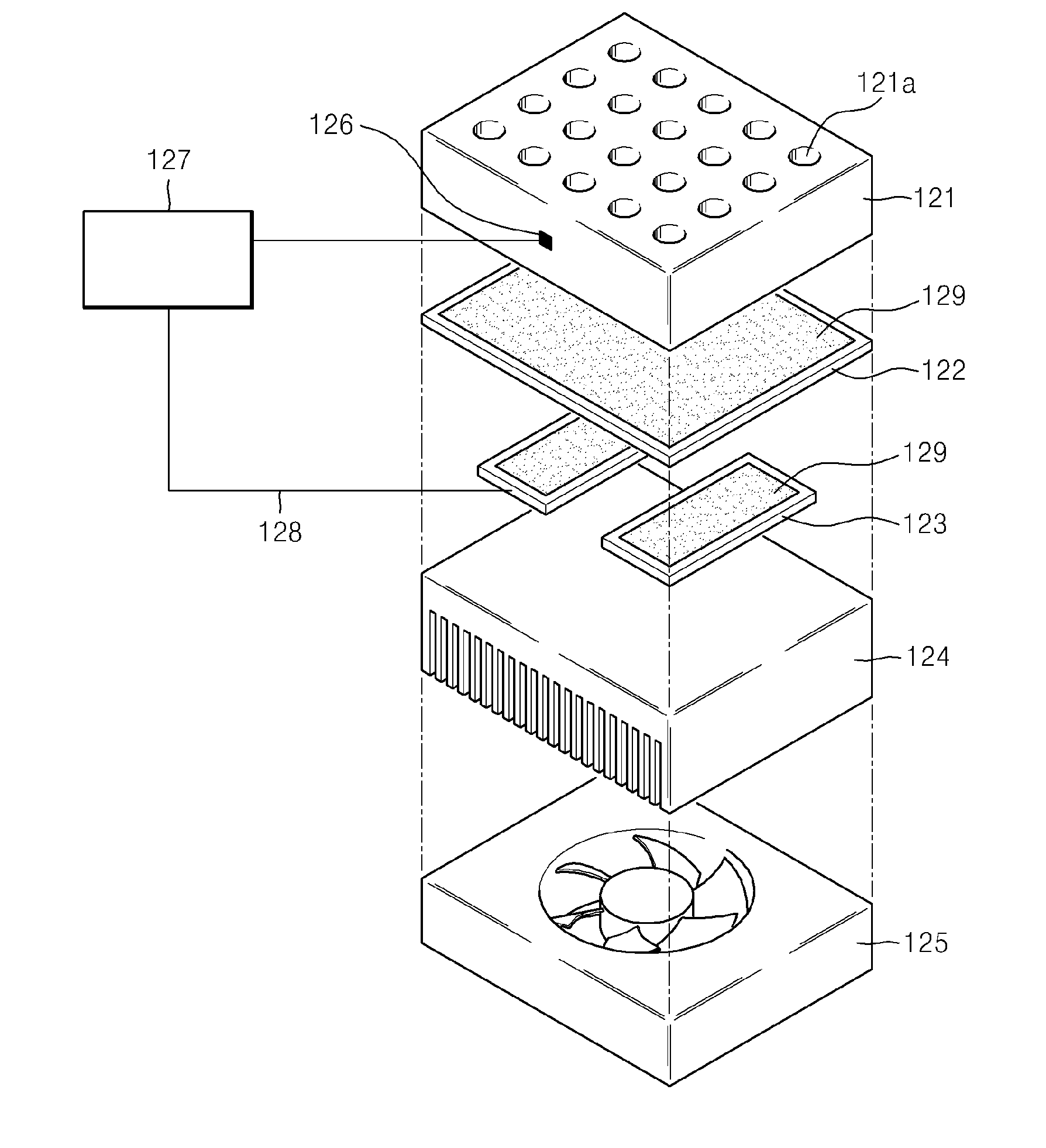

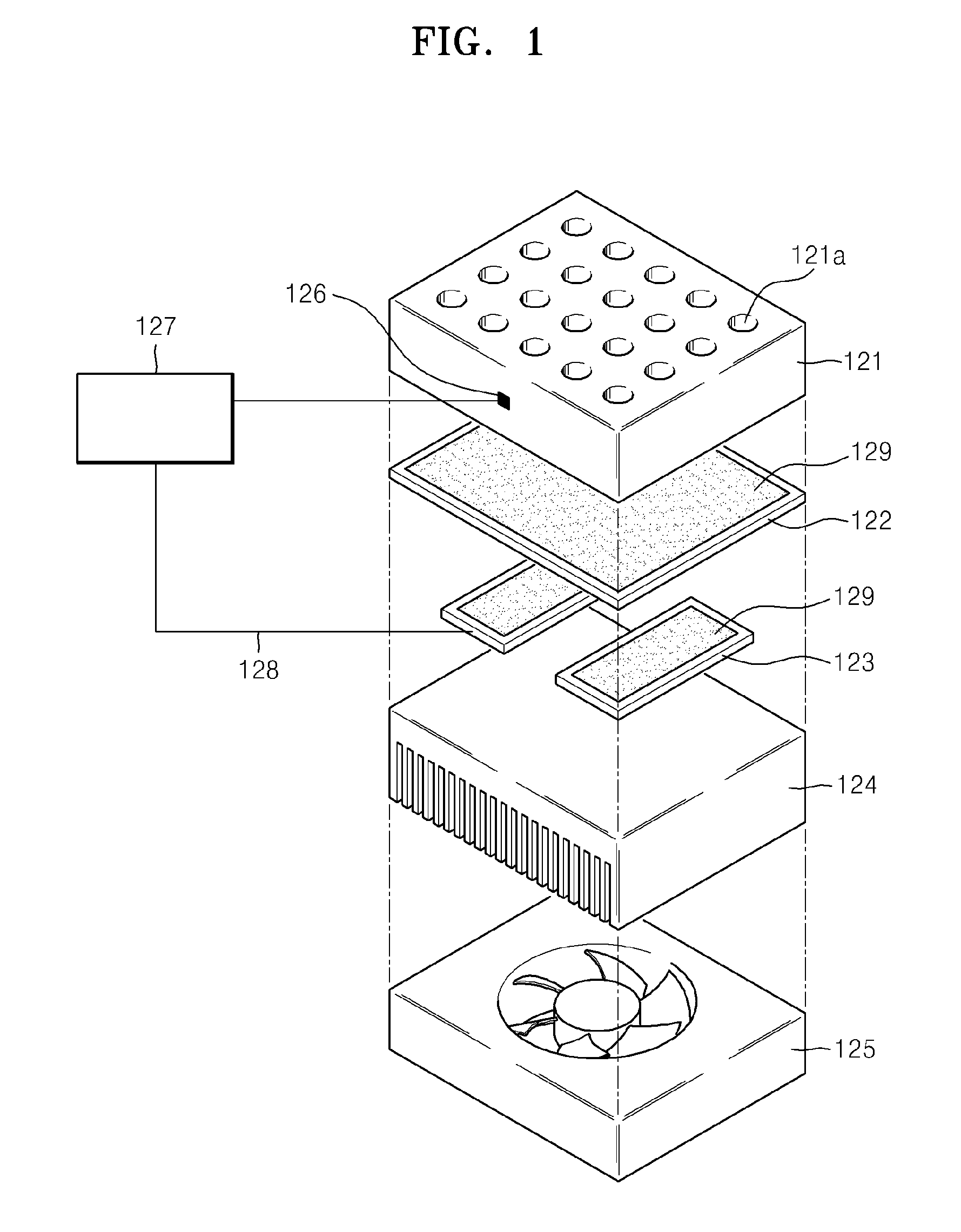

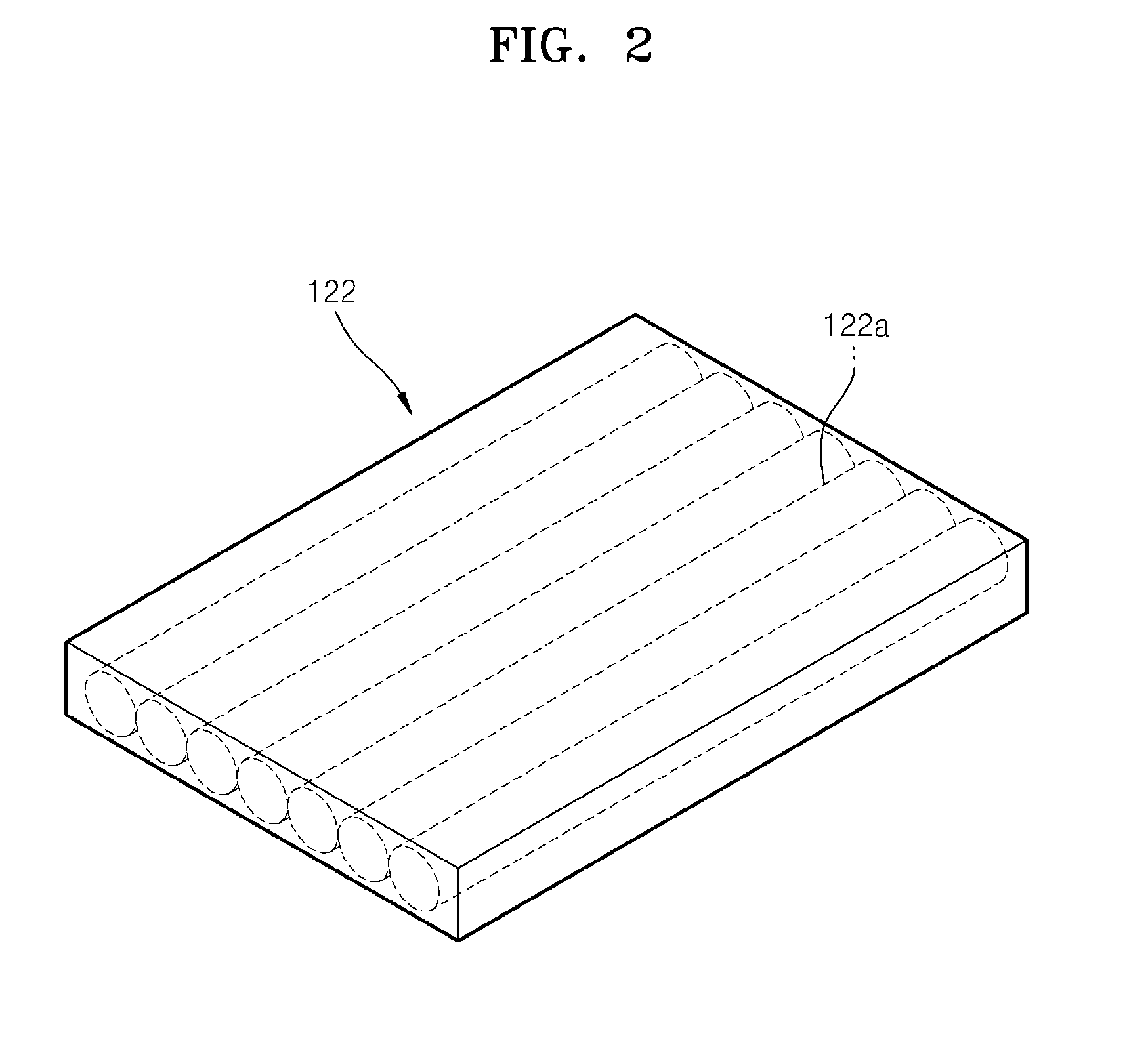

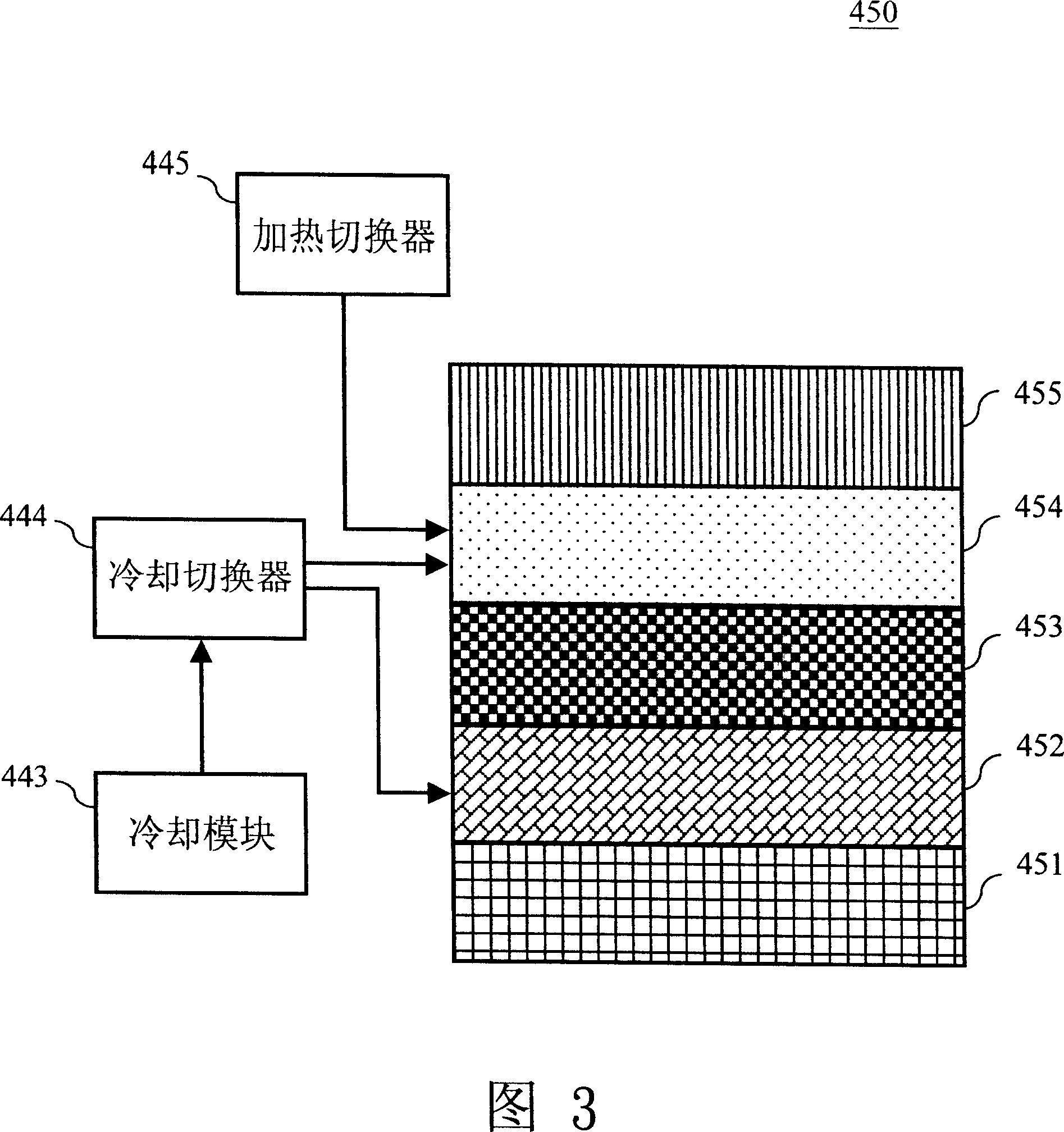

Temperature control apparatus for samples storage

InactiveUS20120240597A1Uniform temperature controlHeating or cooling apparatusTemperatue controlTemperature controlEngineering

A temperature control apparatus for sample storage includes: a well block comprising at least one accommodation groove accommodating at least one container for containing at least one sample therein, respectively; and a temperature control unit controlling a respective temperature of the at least one sample to be uniform, wherein the temperature control unit includes: a heat source portion generating heat or cold; and a heat transfer object transferring the heat or the cold of the heat source portion to the well block.

Owner:SAMSUNG TECHWIN CO LTD

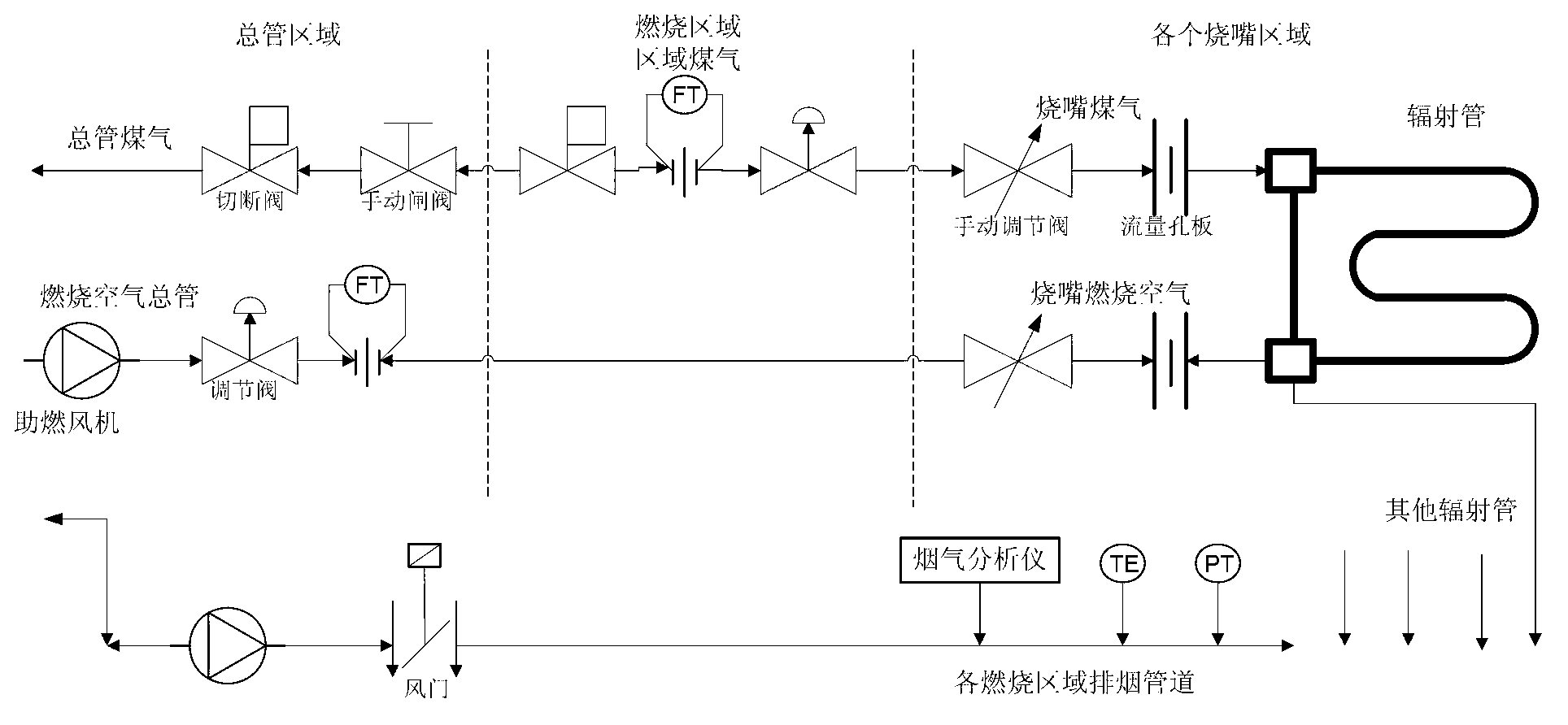

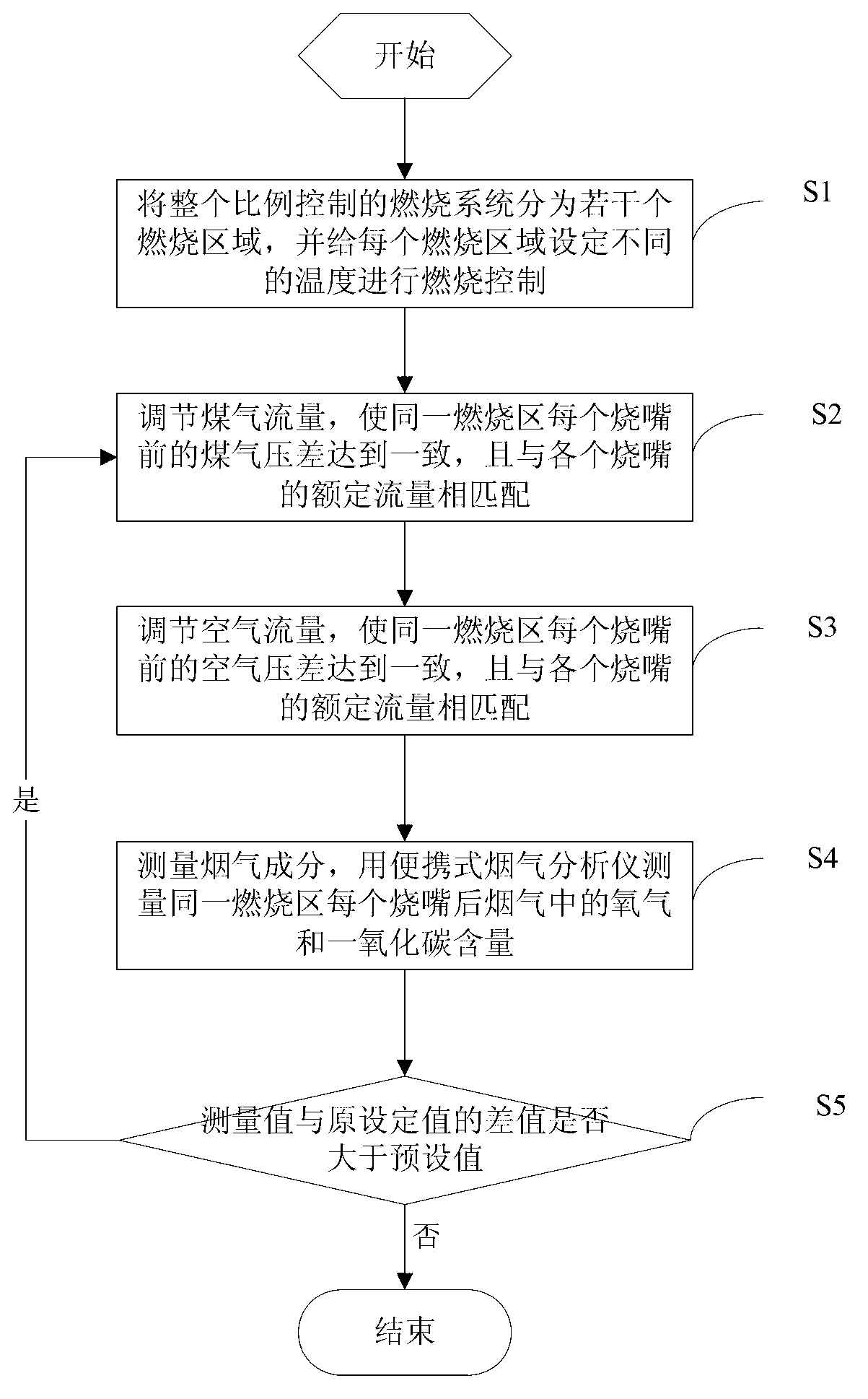

Adjusting and optimizing method of ratio-controlled combustion system

InactiveCN102937382AGuaranteed uptimeUniform temperature controlControl devices for furnacesGaseous fuel burnerCombustion systemTemperature control

The invention discloses an adjusting and optimizing method of a ratio-controlled combustion system. The adjusting and optimizing method includes the following steps: S1 the whole ratio-controlled combustion system is divided into a plurality of combustion areas, and different temperatures are set for the combustion areas for combustion control; S2 coal gas flow is adjusted; S3 air flow is adjusted; and S4 flue gas content is measured: a portable flue gas analyzer is adopted to measure contents of oxygen and carbonic oxide which are contained in flue gases of each burner arranged in the same combustion area, the coal gas flow and the air flow are readjusted if the difference value of the measurement valve and the originally set value is larger than the preset value, and adjusting and optimizing are completed if the measurement valve is identical to the originally set value. The adjusting and optimizing method especially aims at the ratio-controlled combustion system, and is simple and convenient to operate and convenient to popularize; and integrally adjusts and optimizes all the combustion areas, can ensure that the burners of all the combustion areas are identical in power and combustion state, enables temperature in a furnace to be uniformly controlled, and improves control accuracy in low load.

Owner:WISDRI WUHAN WIS IND FURNACE

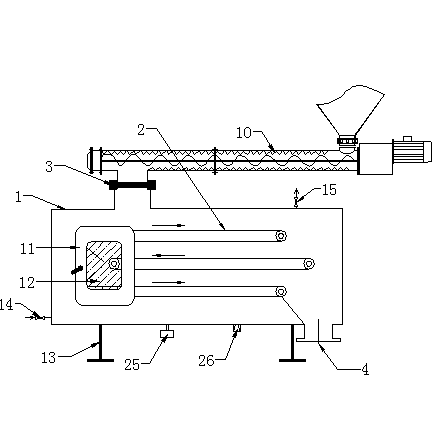

Solid state fermentation device

InactiveCN103122305AUniform evacuationGood evacuationBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSolid-state fermentation

The invention discloses a material fermentation device, and in particular relates to a solid state fermentation device, which comprises a fermentation box body, wherein a feeding port is arranged above the fermentation box, a discharging port is arranged below the fermentation box body, the fermentation box body is internally provided with more than two layers of parallel devices as well as staggered fermentation beds capable of undertaking materials falling off from an upper layer, a drive mechanism is arranged outside the fermentation box body, a spiral conveying device is arranged above the feeding port and is internally provided with spiral conveying blades, the fermentation box body is internally provided with more than one blank baffle which is respectively arranged between two adjacent fermentation beds, and a discharging baffle is arranged at the bottom of one side of the fermentation box body. Due to the adoption of the structure, the spiral conveying blades are used for conveying so that the material can be kept in a certain dispersing degree, therefore, the material is guaranteed to be uniform, zigzag teeth are arranged so as to enable the material to be better dispersed, an access door is arranged on the fermentation box body, and an inspection window arranged on the access door is convenient to overhaul the fermentation bed.

Owner:江苏麦客生物科技有限公司

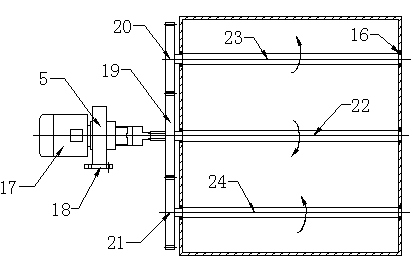

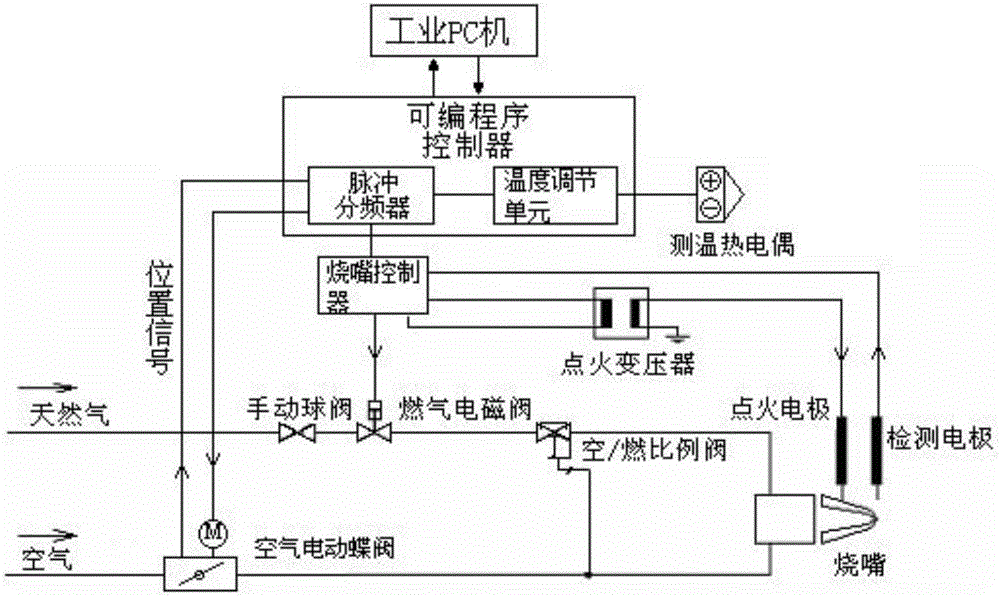

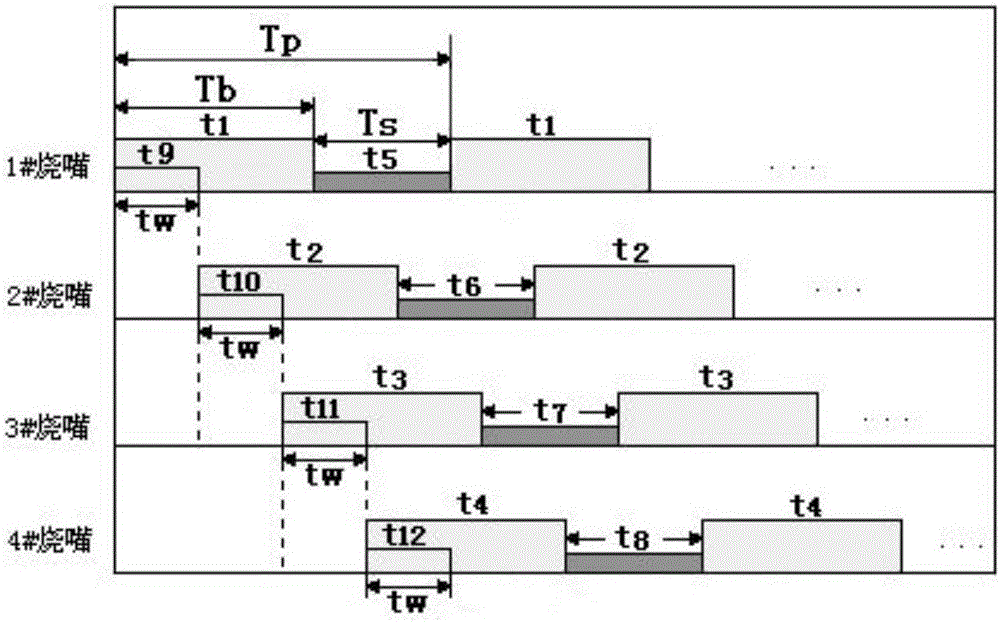

Multi-fragment pulse combustion control system and method

ActiveCN105864819AStable combustionHigh temperature control accuracyFuel supply regulationFurnace temperatureSolenoid valve

The invention discloses a multi-fragment pulse combustion control system and method. The multi-fragment pulse combustion control system comprises a temperature thermocouple, a programmable controller, a burner controller, an air electric butterfly valve, a fuel gas solenoid valve, a ratio valve of air to fuel, an ignition transformer and a burner, wherein the programmable controller is separately connected with the temperature thermocouple, the input end of the burner controller and the air electric butterfly valve; the output end of the burner controller is separately connected with the fuel gas solenoid valve, the ignition transformer and the burner; the burner is connected with the ignition transformer through an ignition electrode; and the ratio valve of air to fuel is separately connected with the air electric butterfly valve, the fuel gas solenoid valve and the burner through pipelines. The multi-fragment pulse combustion control system has the advantages that the furnace temperature is more uniform in distribution; the temperature control precision is high; the adjustment linear ratio is large; the design cost is low; and the like.

Owner:DALIAN UNIV

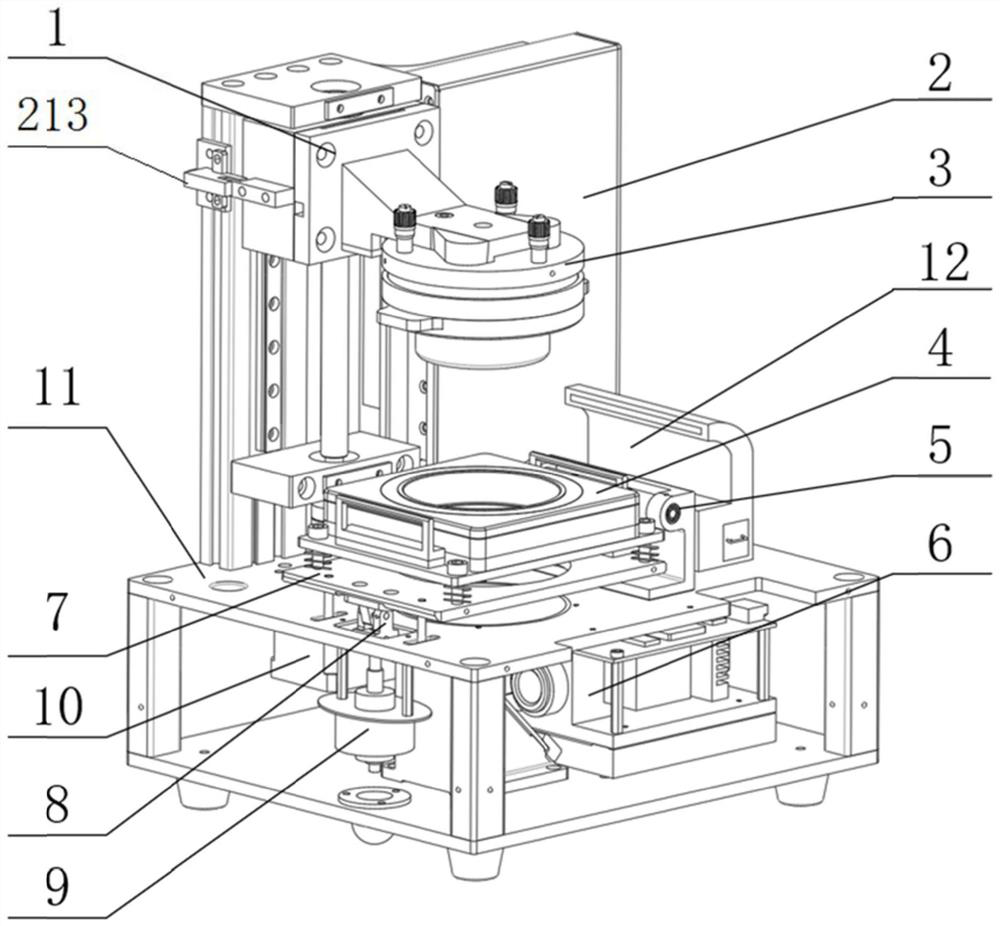

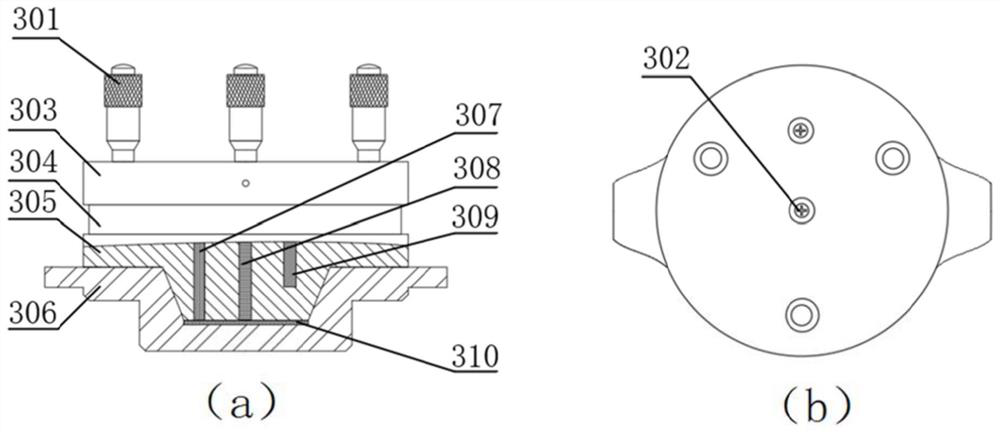

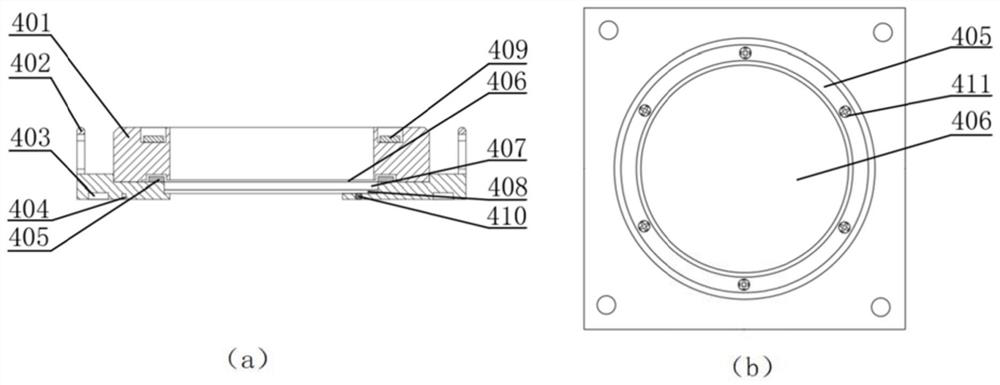

Projection type photocuring 3D printing device

InactiveCN111745958AReduce damageReduce capacityManufacturing platforms/substratesManufacturing driving means3d printMechanical engineering

The invention discloses a projection type photocuring 3D printing device. The projection type photocuring 3D printing device comprises a rack and further comprises a printing forming platform assembly, a trough assembly, a light source generator and a controller which are fixed in the rack. The trough assembly comprises a trough, a trough platform used for fixing and supporting the trough, and a drive mechanism I capable of driving the trough platform to conduct peeling overturning and return overturning. One side of the trough platform is hinged to the rack, and the other side of the trough platform is in shaft connection to the output end of the drive mechanism I. Under driving of the drive mechanism I, the trough platform conducts peeling overturning with the low speed and conducts return overturning with the high speed. The projection type photocuring 3D printing device meets the requirement for wide printing material coverage while the printing precision is ensured, and the forming performance and biology applicability of projection type photocuring 3D printing are improved.

Owner:苏州永沁泉智能设备有限公司

Battery housing having an attached fluid flow guiding unit

InactiveCN101772851ALow costSave installation spacePrimary cell to battery groupingLarge-sized flat cells/batteriesBattery packElectrical and Electronics engineering

Owner:DAIMLER AG

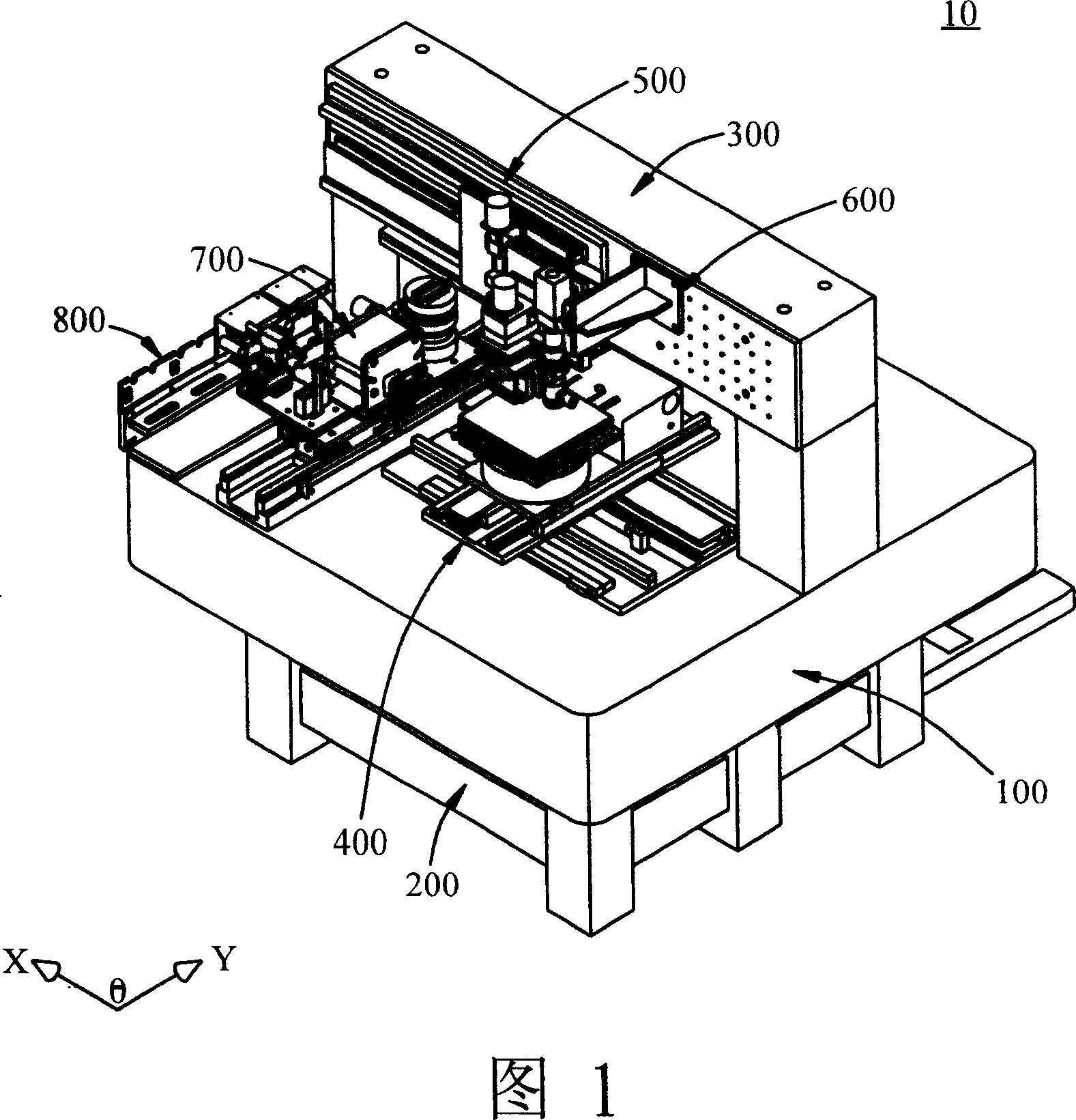

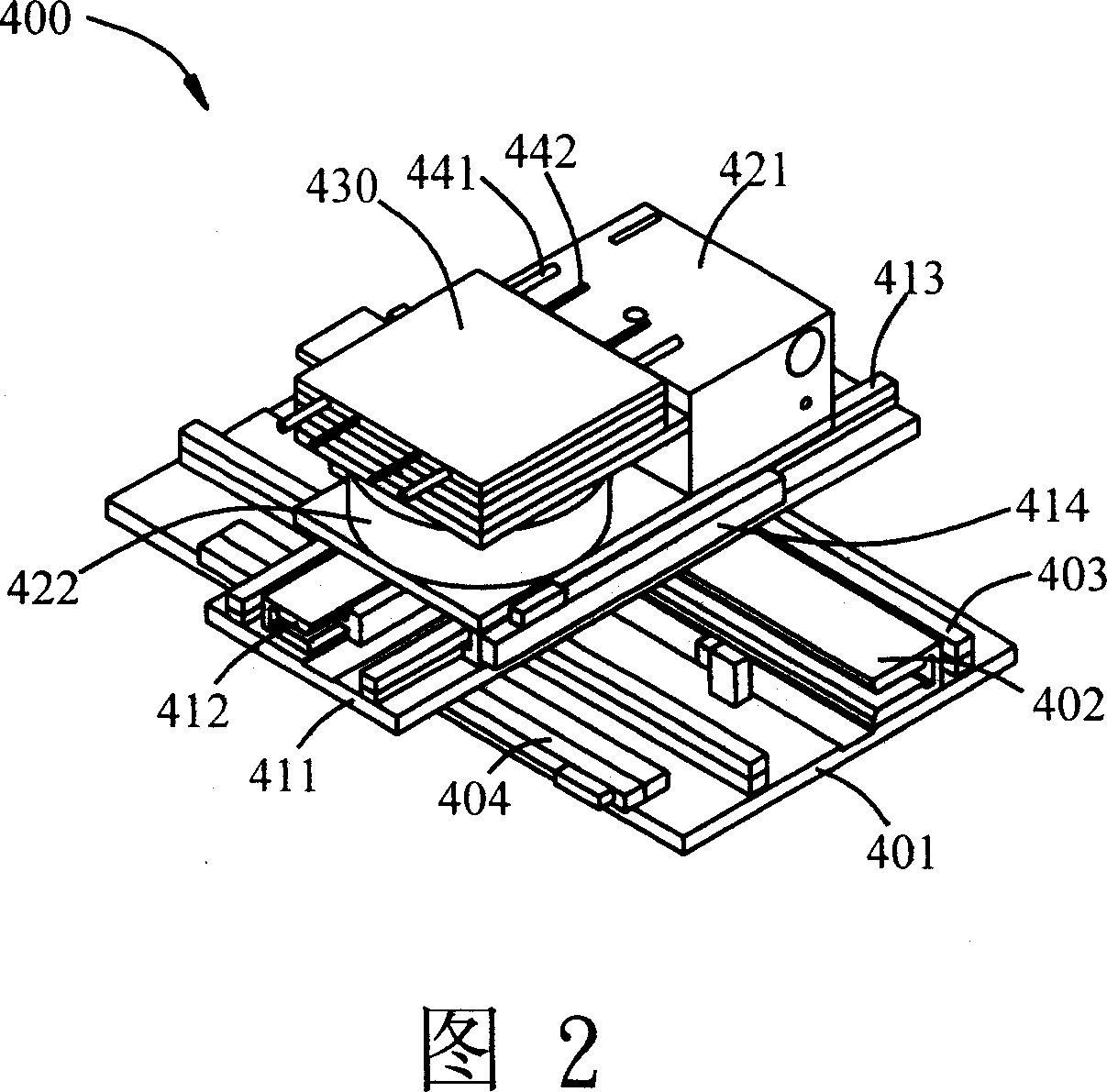

Method and apparatus for micro-droplet spray printing

ActiveCN1990238AAchieve functional consistencyReduced method timePower drive mechanismsOther printing apparatusTemperature control modeEngineering

The invention discloses a micro-drop spattering device and method, which comprises the following parts: spatter mode, mobile platform mode, image detecting mode, temperature control mode and spatter head maintaining mode, wherein the spatter head maintaining mode cleans spatter head; the spatter base carries the mobile platform mode, which detects the relative position and angle of spatter head and base; the temperature control mode modulates the surface temperature of base, which makes the temperature of base and micro-drop evenly, which improves flatness of moulded spatter film.

Owner:IND TECH RES INST

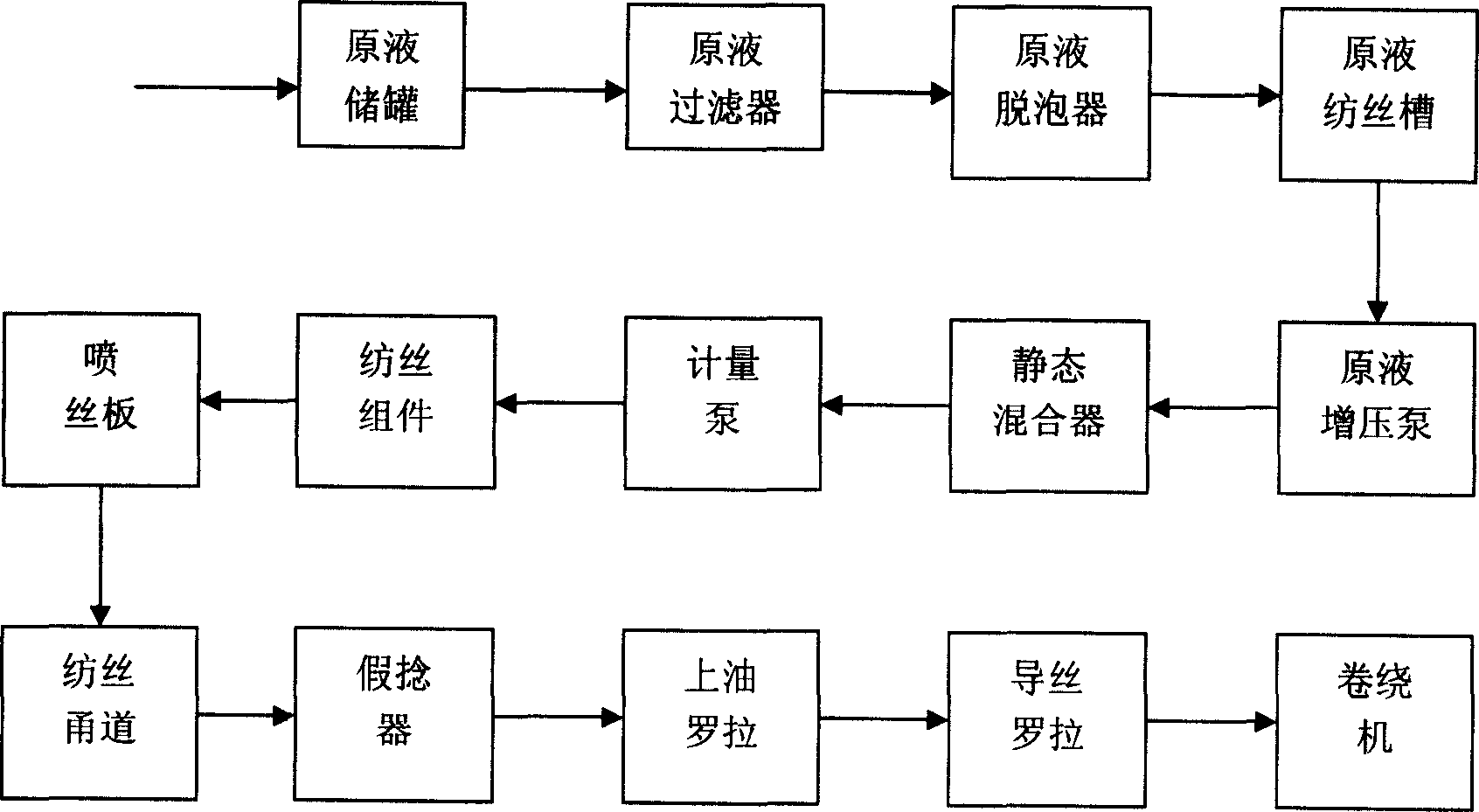

New technology of spandex fiber

InactiveCN1904152AStable temperature controlUniform temperature controlFilament/thread formingFiberFiltration

This invention relates to a new kind of spandex spinning technology. Send stock solution has undergone polymerization to storage jar for ripening, then through filtration, getting out of bubble, and entering spinning slot, pressing send by nitrogen gas and gear pump pressurize it into static mixer; Through the measuring pump to spit out stock solution and filtering it in spinning module, then allocate to spurt filament plate and spurt out from it; Evaporate out solvent in the spinning path and solidify it to spandex ammonia silk beam, then through false twisting, adding oil and rolling on the rolling machine to pack silk roll. This invention increase static mixer to suit 32 head spinning, reduce adverse effect caused by polymer which make gradient difference of temperature, residence time and viscosity along the radial of pipe; control the actuality temperature out of circulatory mediator in jar, spinning slot, static mixer and partner heat equipment, keep the homogenicity and stability after increasing the spinning air quantity and blast temperature, and increase volatilizing speed but not effect strand form.

Owner:连云港杜钟氨纶有限公司

Device for producing nanometer silicon dioxide through rice husk deep oxidation

The invention discloses a device for producing nanometer silicon dioxide through rice husk temperature control complete oxidation. The device comprises an oxidation cylindrical shell, a particle selector, a group of high speed air nozzles, a material inlet and a material outlet. The upper end of the material inlet is provided with two pneumatic gate valves and is connected to a spiral conveyer. The material outlet is connected to an external cyclone separator, a filter and a high temperature induced draught fan. The high temperature-resistant oxidation cylindrical shell utilizes wear-resistant high temperature-resistant alloy steel, ceramic or silicon carbide as a lining and is provided with a heat preservation jacket at the outer part. The particle selector is installed at the upper end in the oxidation cylindrical shell, is tightly connected to the oxidation cylindrical shell through a transmission shaft and a mechanical seal and is driven through a high speed variable frequency motor. The high speed air nozzles are arranged at the lower part of the oxidation cylindrical shell, comprise odd number of nozzles and are installed at a small dip angle. The high speed air nozzles utilize high temperature high pressure compressed air. The produced silica has an amorphous nanometer structure, impurity carbon is completely oxidized and product purity is very high. The product is crushed to form very fine granules.

Owner:王开辉

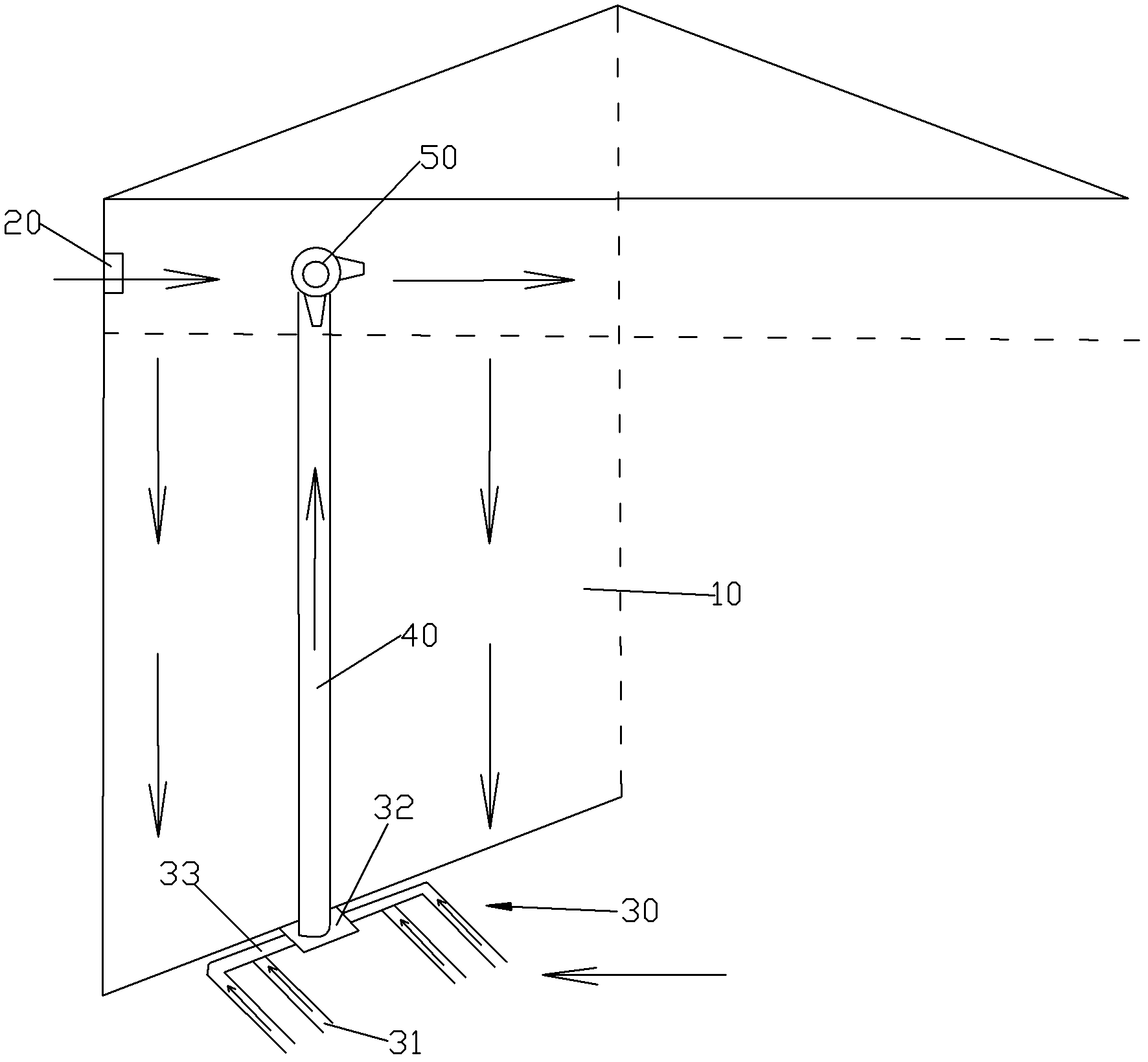

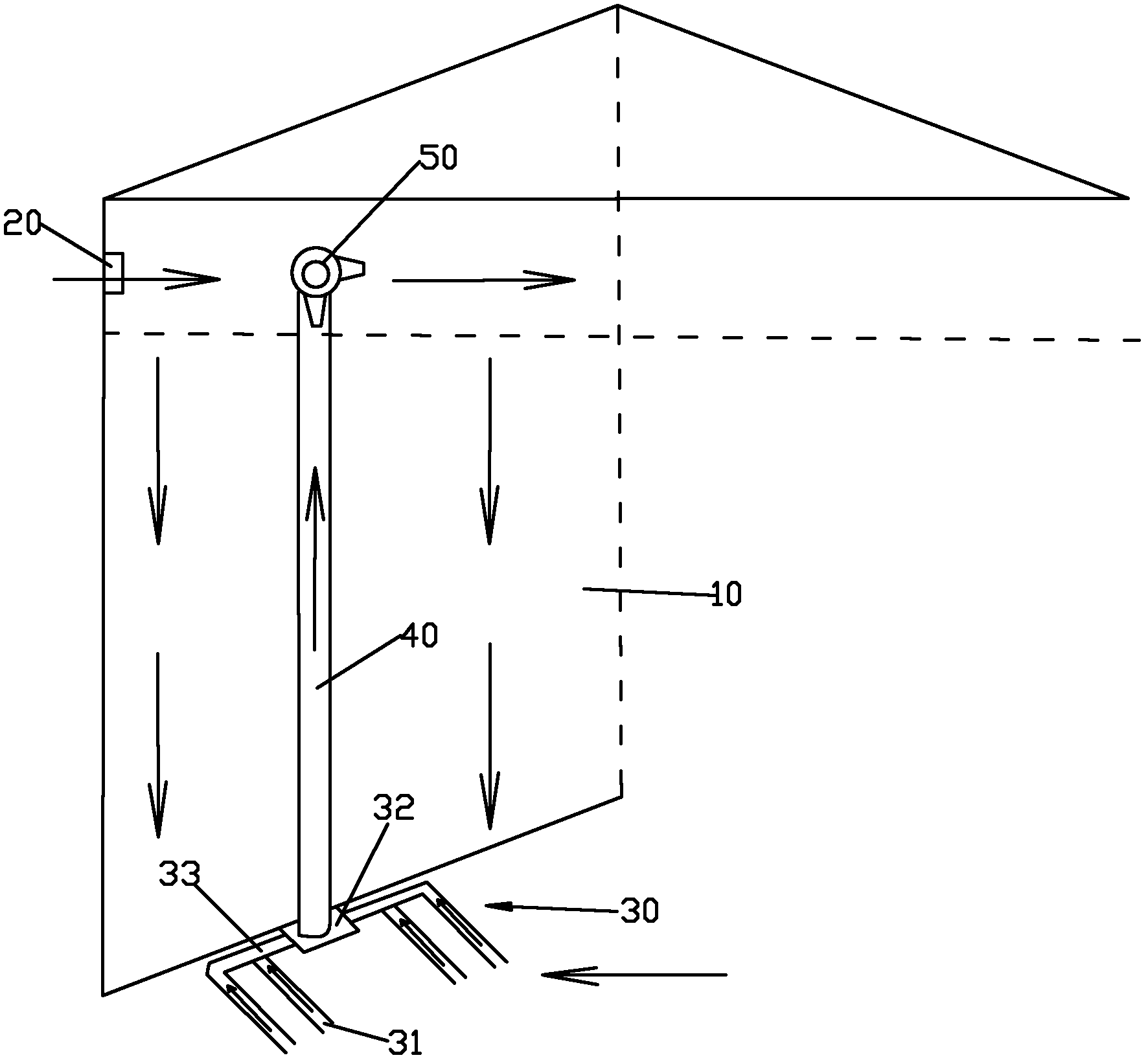

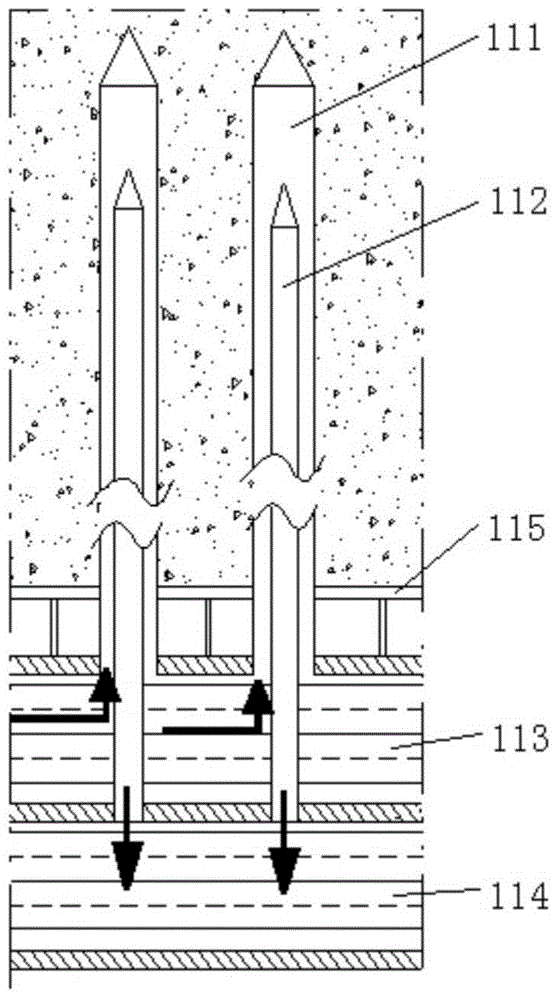

Supporting facility of technology of grain storage under circulation balanced temperature and humidity in bungaloid granary

InactiveCN102523847AAvoid mildew and heatReduce labor costsAgriculture tools and machinesHarvested fruit hanging devicesAirflowEngineering

The invention discloses a supporting facility of a technology of grain storage under circulation balanced temperature and humidity in a bungaloid granary. The facility comprises at least an air-conditioner, a ground ventiduct and at least an airflow pipeline, wherein the air-conditioners are installed on the upper part of a bungaloid granary; air blowing holes of the air-conditioners are downward so as to blow out airflow downward; the ground ventiduct is installed on the ground of the bungaloid granary and comprises a plurality of abreast air pipes and at least an air distribution box communicated with the air pipes; the air pipes are provided with through air holes so as to absorb airflow and ensure the airflow to flow into the air distribution boxes; airflow pipelines are vertically installed in the bungaloid granary; the lower ends of the airflow pipelines are communicated with the air distribution boxes; fans are arranged on the airflow pipelines and are used for exhausting the airflow from the upper ends of the airflow pipelines; and the air-conditioners, the ground ventiduct and the airflow pipelines are matched with the fans to form a circulation balanced temperature and humidity system. The facility has the following advantages that: the facility realizes balanced control of temperature and humidity in the granary, can effectively avoid the grain mildewing and heating temperature in the granary and can adapt to the high temperature and humidity environment in the southeast coastal areas in China; the labor cost and the electric cost are greatly lowered; and the grain losses are reduced.

Owner:中央储备粮漳州直属库有限公司

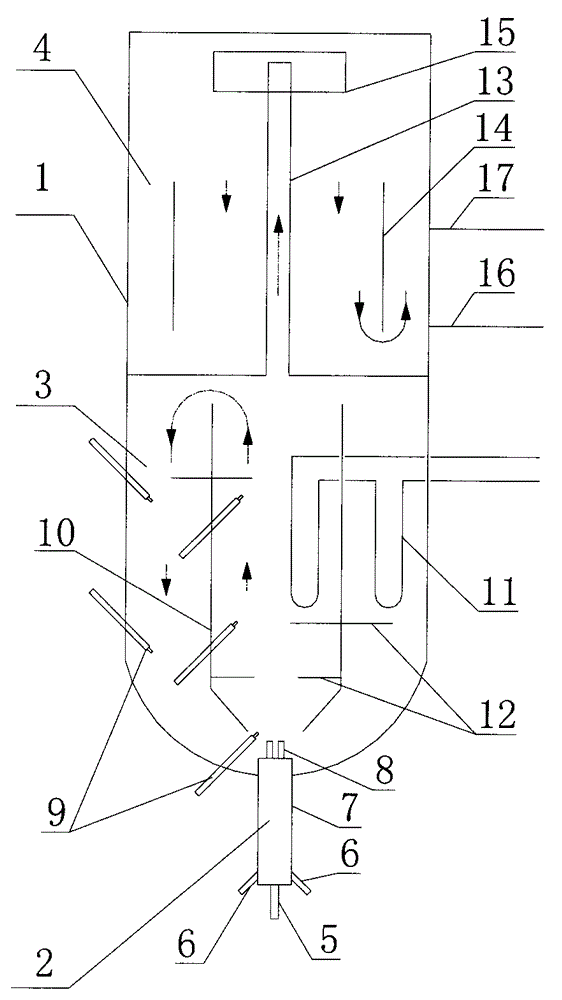

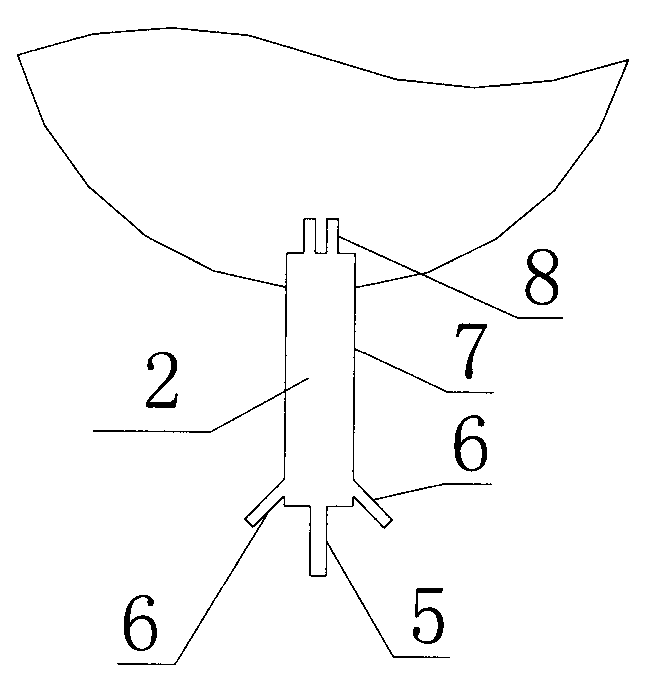

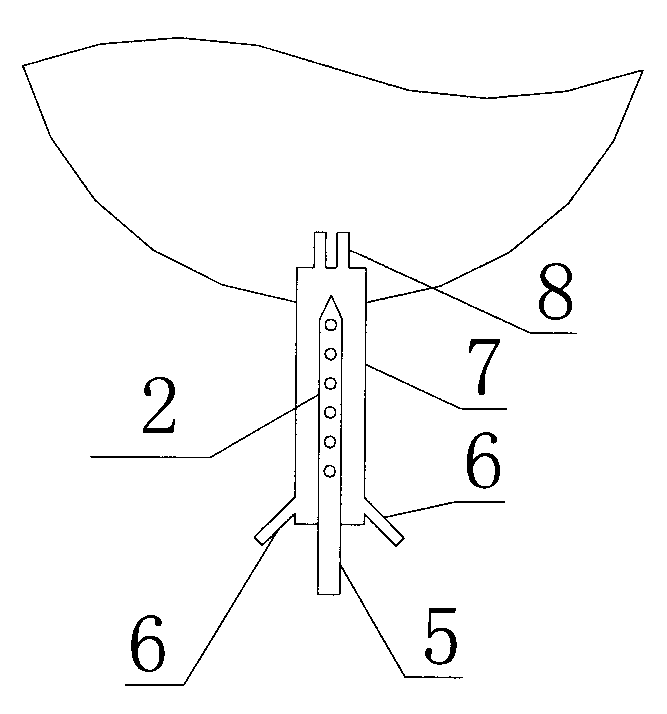

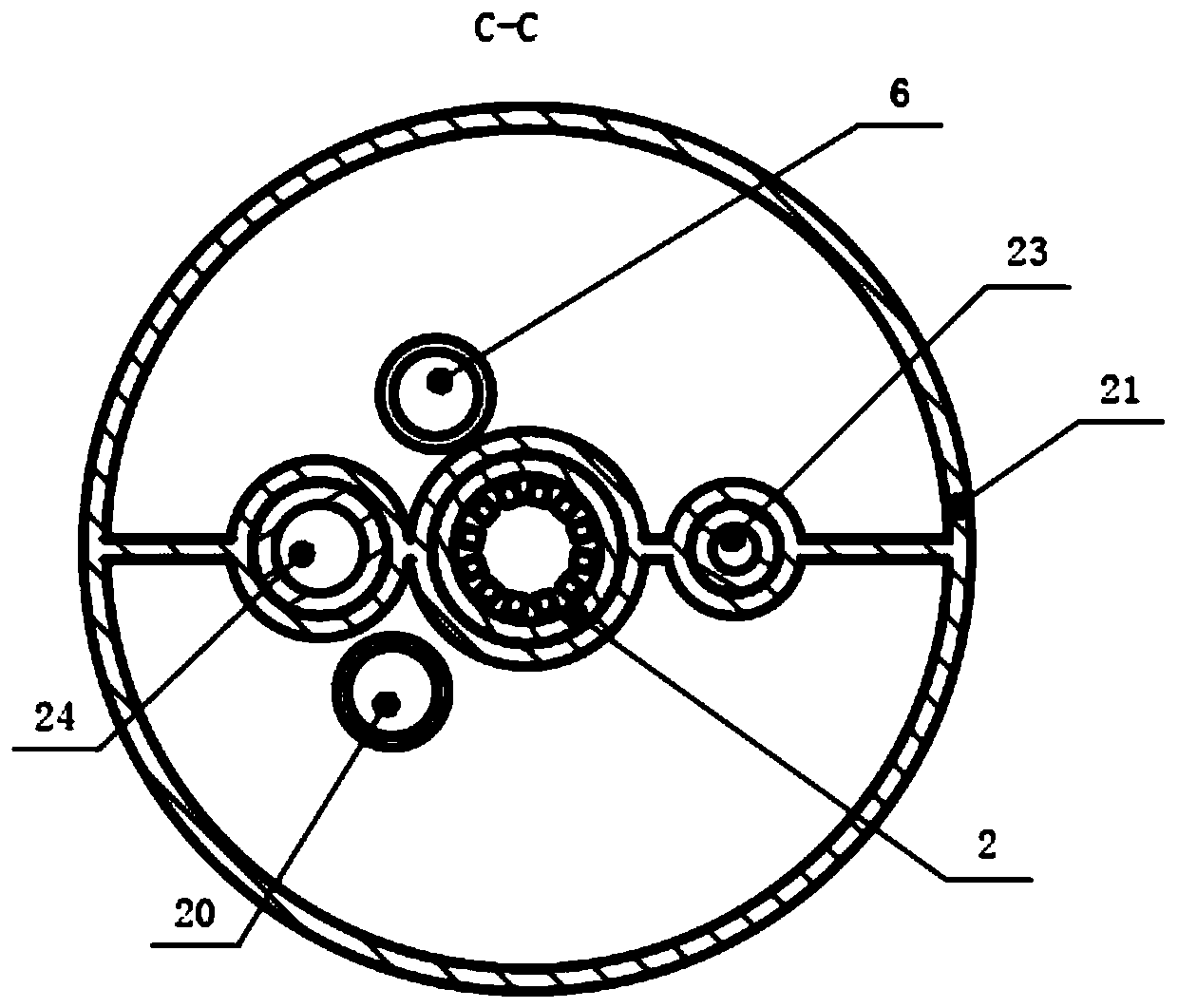

Alkylation reactor and alkylation method

ActiveCN105233784AIngenious structural designIngenious designLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferHydrocarbon mixtures

The invention discloses an alkylation reactor and an alkylation method. The alkylation reactor comprises a settling area, a reaction area and a mixing area, wherein the mixing area consists of a cylindrical mixing chamber, charging pipes and outlet nozzles, the mixing area communicates with the reaction area through the outlet nozzles, the reaction area is provided with alkene charging pipes, a cylindrical partition plate, a heat exchange pipe bundle and deflection baffles and is divided into two portions by the cylindrical partition plate, a central cylindrical space serves as a fluid rising zone, an external annular space serves as a fluid backflow zone, the rising zone and the backflow zone communicate with each other at the top parts and the bottom parts, the settling area is provided with a liquid rising pipe, a swirling component and a cylindrical baffle and is divided into two portions, i.e., a central cylindrical space and an external annular space by the cylindrical baffle, the spaces of the two portions communicate with each other at the top parts and the bottom parts, the liquid rising pipe and the swirling component are located in the central cylindrical space of the settling area, the bottom of the liquid rising pipe communicates with the rising zone of the reaction area, the top of the liquid rising pipe is connected with the swirling component, and the external annular space of the settling area is connected with a liquid acid outlet pipe and a hydrocarbon mixture outlet pipe. By using the alkylation reactor and the alkylation method, a liquid acid catalyst and alkane can be adequately mixed in the mixing area of the reactor, and polymerization among alkenes is reduced; and the reaction temperature is low, the acid-hydrocarbon separation is rapid, and the acid consumption is low.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

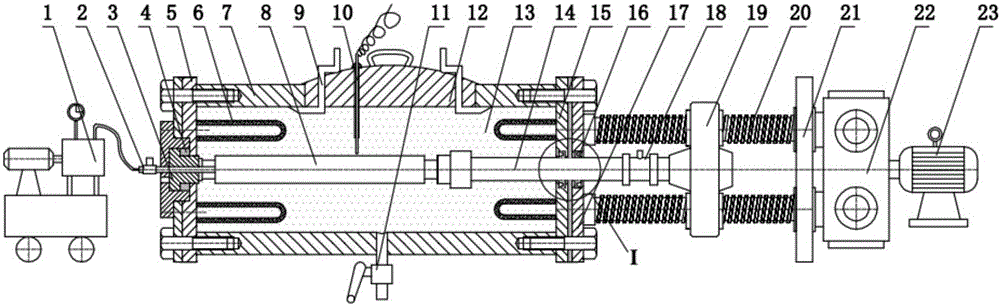

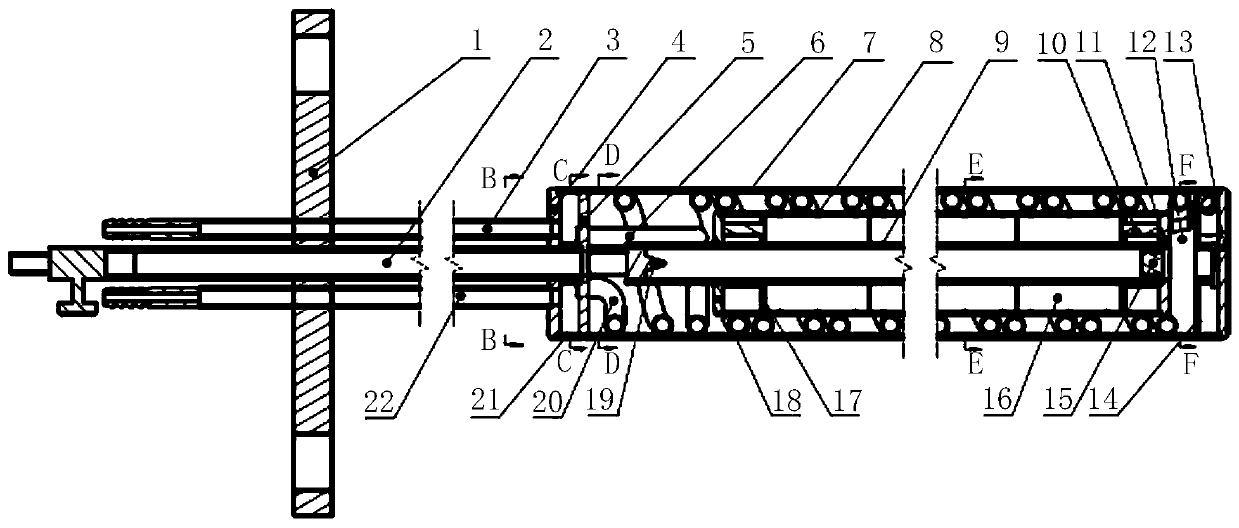

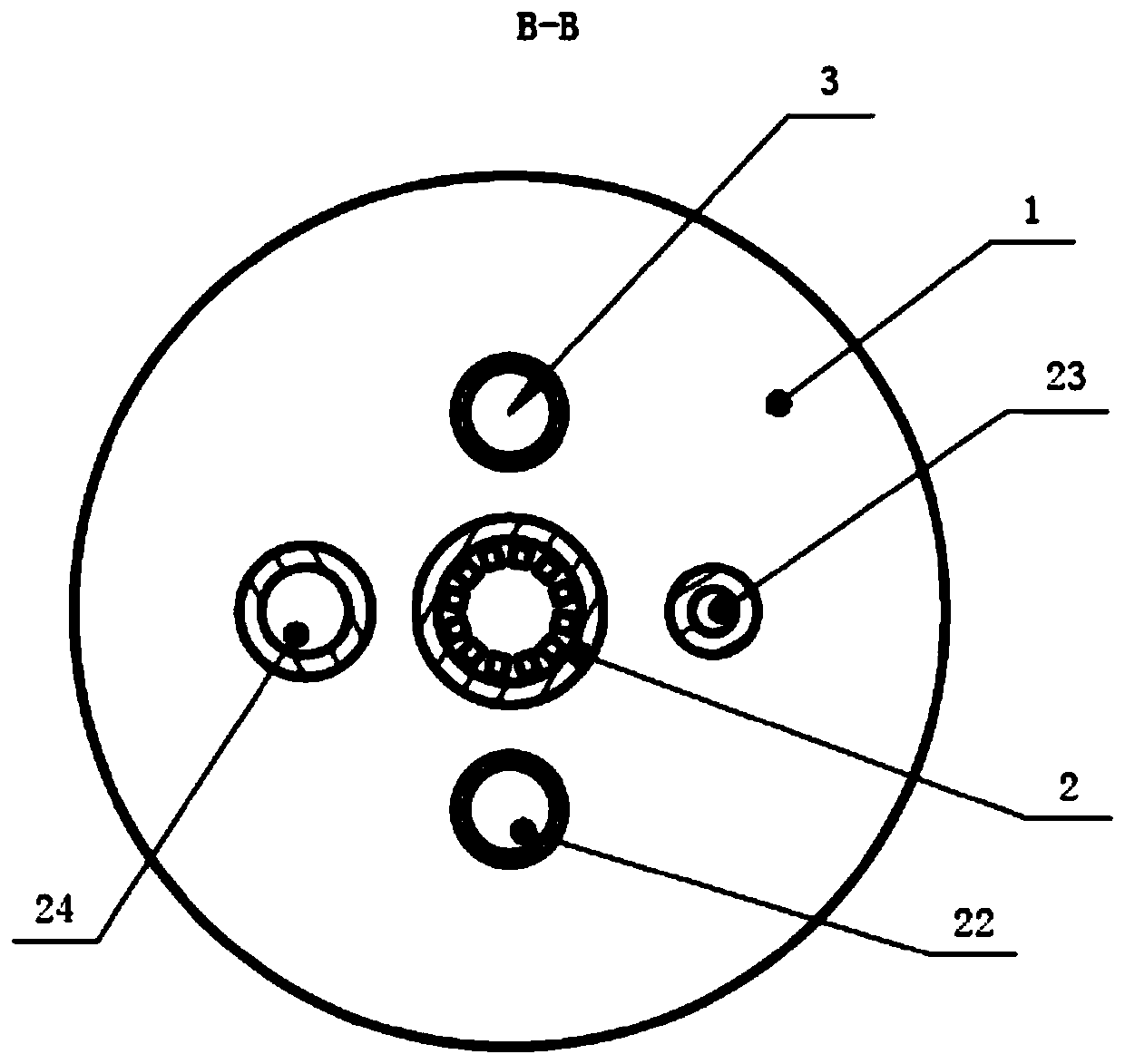

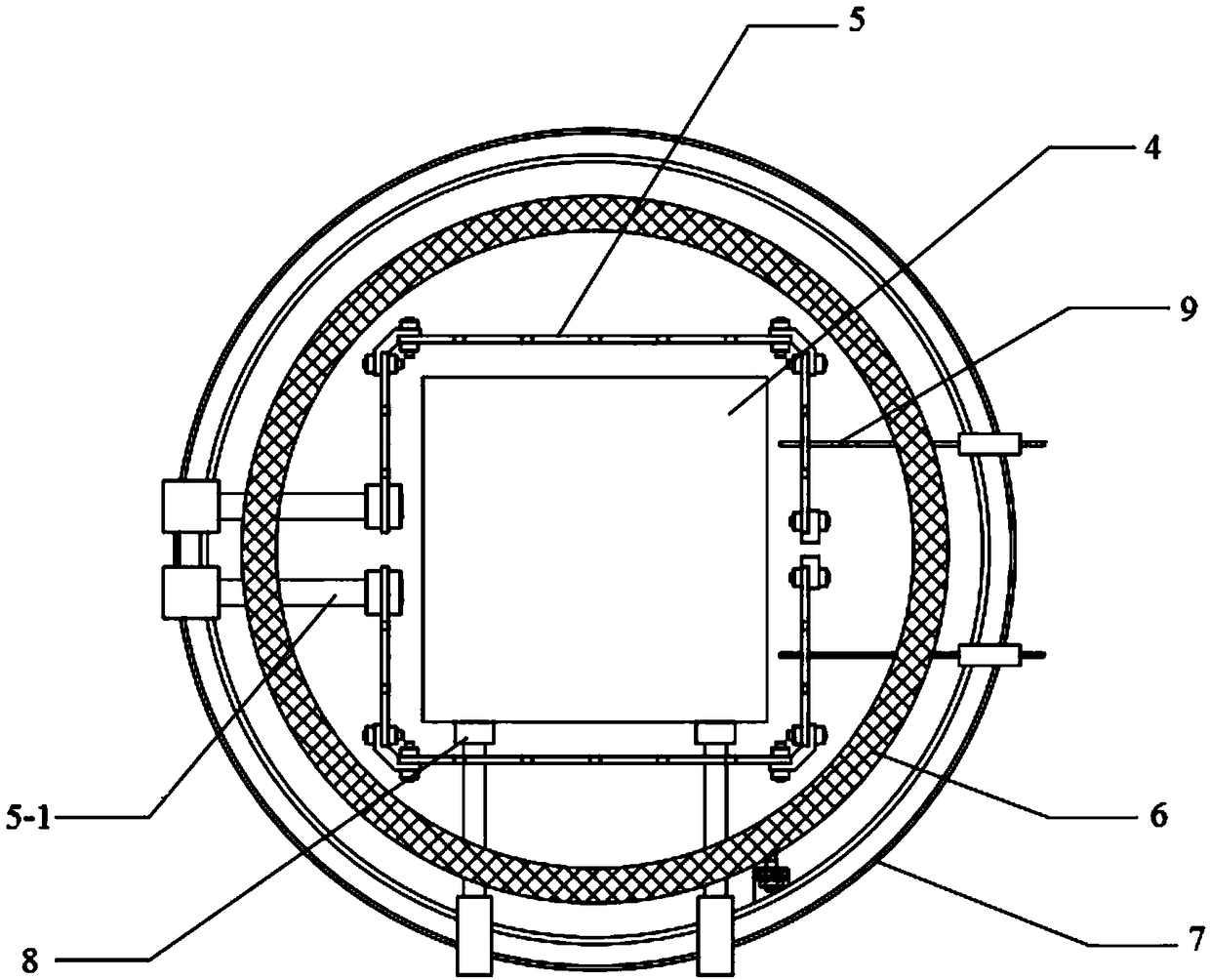

Axial hot stretch flexible composite plastic high-pressure delivery pipe testing device

ActiveCN106053228AGet axial forceGet axial elongationMaterial strength using tensile/compressive forcesManufacturing cost reductionHydraulic pump

The invention discloses an axial hot stretch flexible composite plastic high-pressure delivery pipe testing device, and belongs to the technical field of nonmetallic composite pipe hot stretch testing. A flexible composite pipe is prepared through the procedures of composite pipe blank discharging, pipe joint locking, surface processing and the like. The composite pipe is fixed to a clamp of a stretch device; a cylindrical cylinder wrapping the composite pipe is filled with water, and water in the cylinder is heated; a certain amount of water is injected into the composite pipe through a hydraulic pump station, and certain pressure is kept in the pipe. Due to the heat transfer effect of a medium in the cylinder, the surface temperature of the composite pipe reaches a certain fixed value; finally, the composite pressed inside and heated outside is mechanically stretched, and performance parameters of the composite pipe in the hot stretch process is tested with the aid of various sensors on the stretch device. The testing device has the advantages that the structure is compact; due to the cylinder and beam integrated design of the testing device, manufacturing cost can be reduced, and pressurization testing safety can be improved; meanwhile, various performance parameters of pipe blanks with different diameters can be obtained, and the testing device has certain universality.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

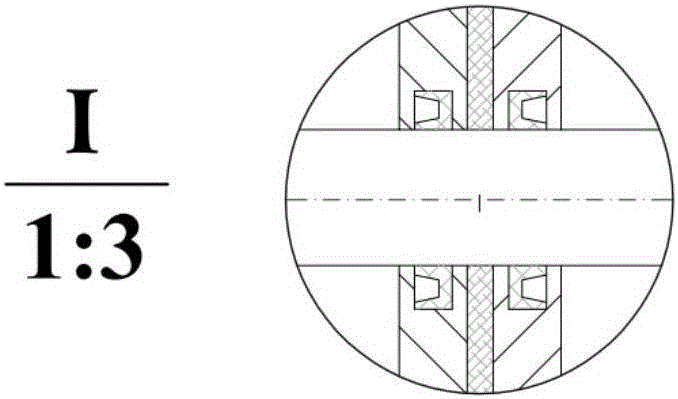

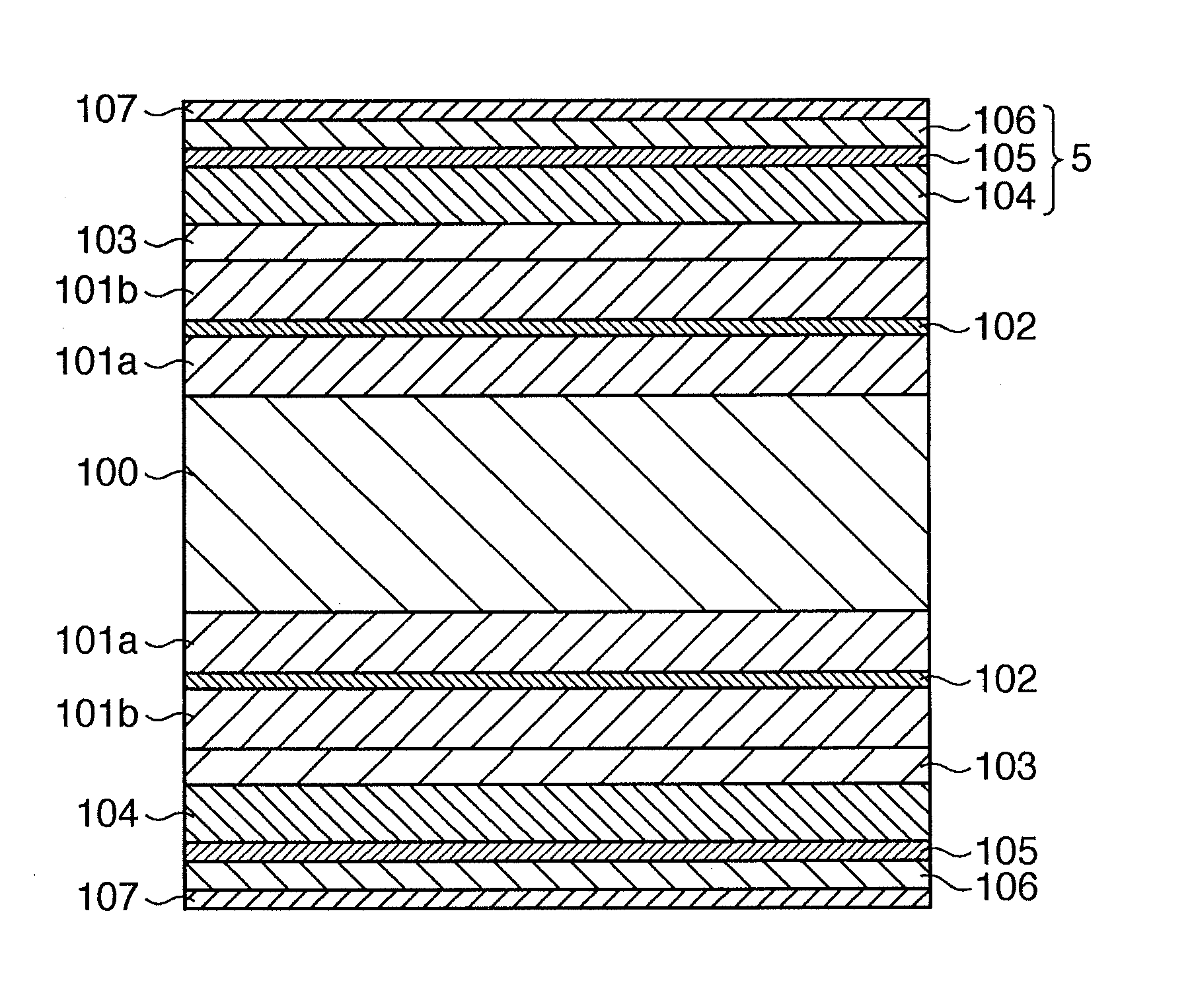

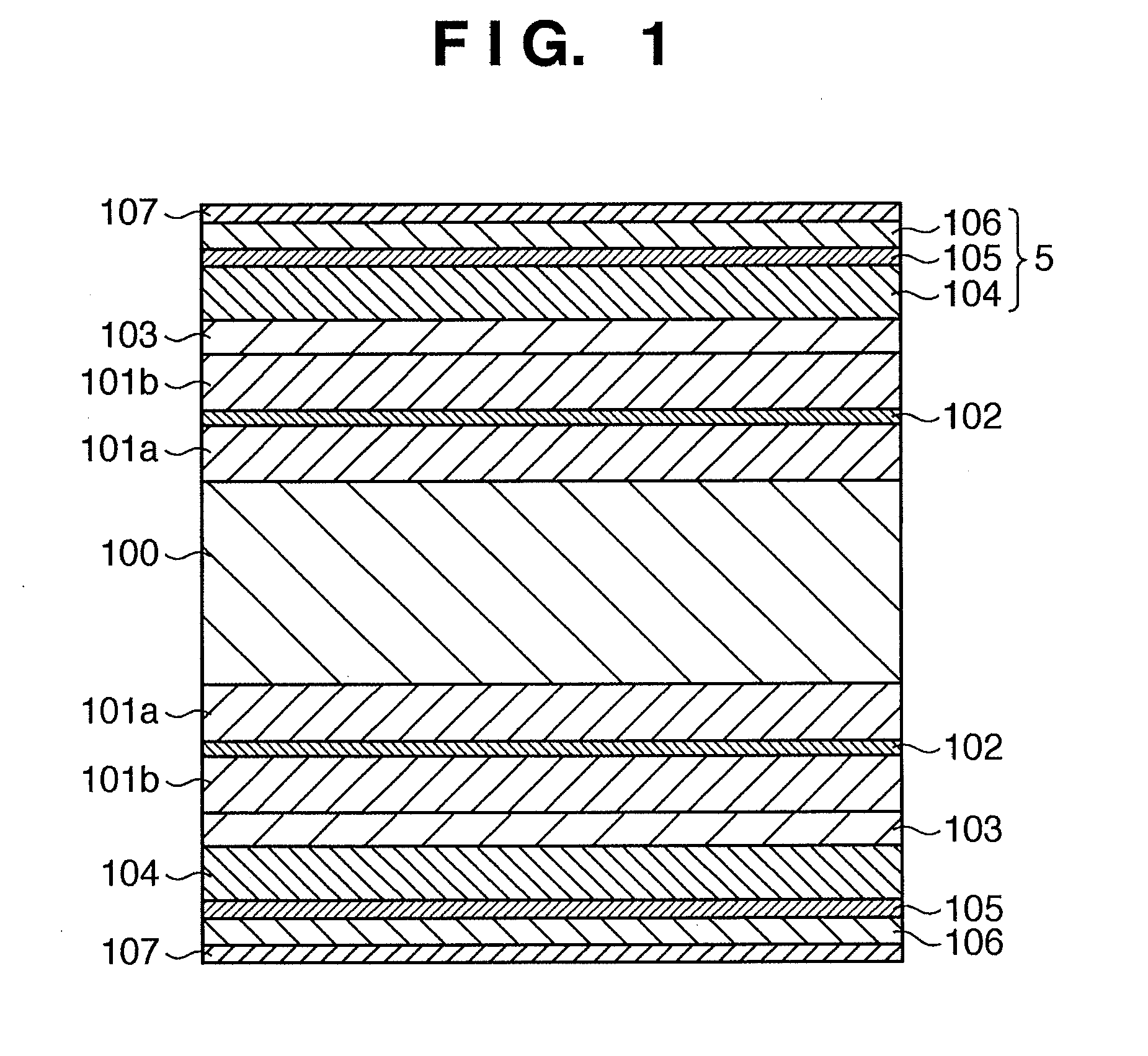

Sputtering apparatus, thin film formation apparatus, and magnetic recording medium manufacturing method

InactiveUS20100108496A1Uniform temperature controlCellsVacuum evaporation coatingEngineeringRecording media

A sputtering apparatus includes a first target accommodating unit to accommodate a first target for film formation on a substrate; a first heater, arranged to surround the first target, for heating the substrate; and a second target accommodating unit arranged to surround the first heater to accommodate a second target for film formation on the substrate.

Owner:CANON ANELVA CORP

Diketene preparation device and diketene preparation method

ActiveCN104592172AEasy to condense and separateDowngradeOrganic chemistryAcetic acidAcetic anhydride

The invention relates to a diketene preparation device and a diketene preparation method. The diketene preparation device comprises an acetic acid evaporator, a mixer, a cracking furnace, a quenching condenser and an absorption tower. The outlets of the acetic acid evaporator and the mixer are connected with the cracking furnace; the cracking furnace is then connected with the multi-level quenching condenser; the quenching condenser is then connected with the absorption tower; one branch of the absorption tower is connected with a polymerization tank, and the other branch of the absorption tower is connected with a water absorption tower; and the outlet of the third-level quenching condenser is connected with the quenching condenser behind through a liquid ring pump. The diketene preparation device and diketene preparation method provided by the invention have the beneficial effects that when the cracked gas is pressurized, the impurities such as acetic acid, water and acetic anhydride in the cracked gas can be condensed out more sufficiently, and thus the quality of the cracked gas before entering the absorption tower is improved while the freezing level is lowered; and compared with the traditional technology in which the energy consumption accounts for 45% of the total cost of diketene, the device and method provided by the invention have the advantage that the energy consumption only accounts for 25% of the total cost of diketene through improvement.

Owner:QINGDAO UNIV OF SCI & TECH

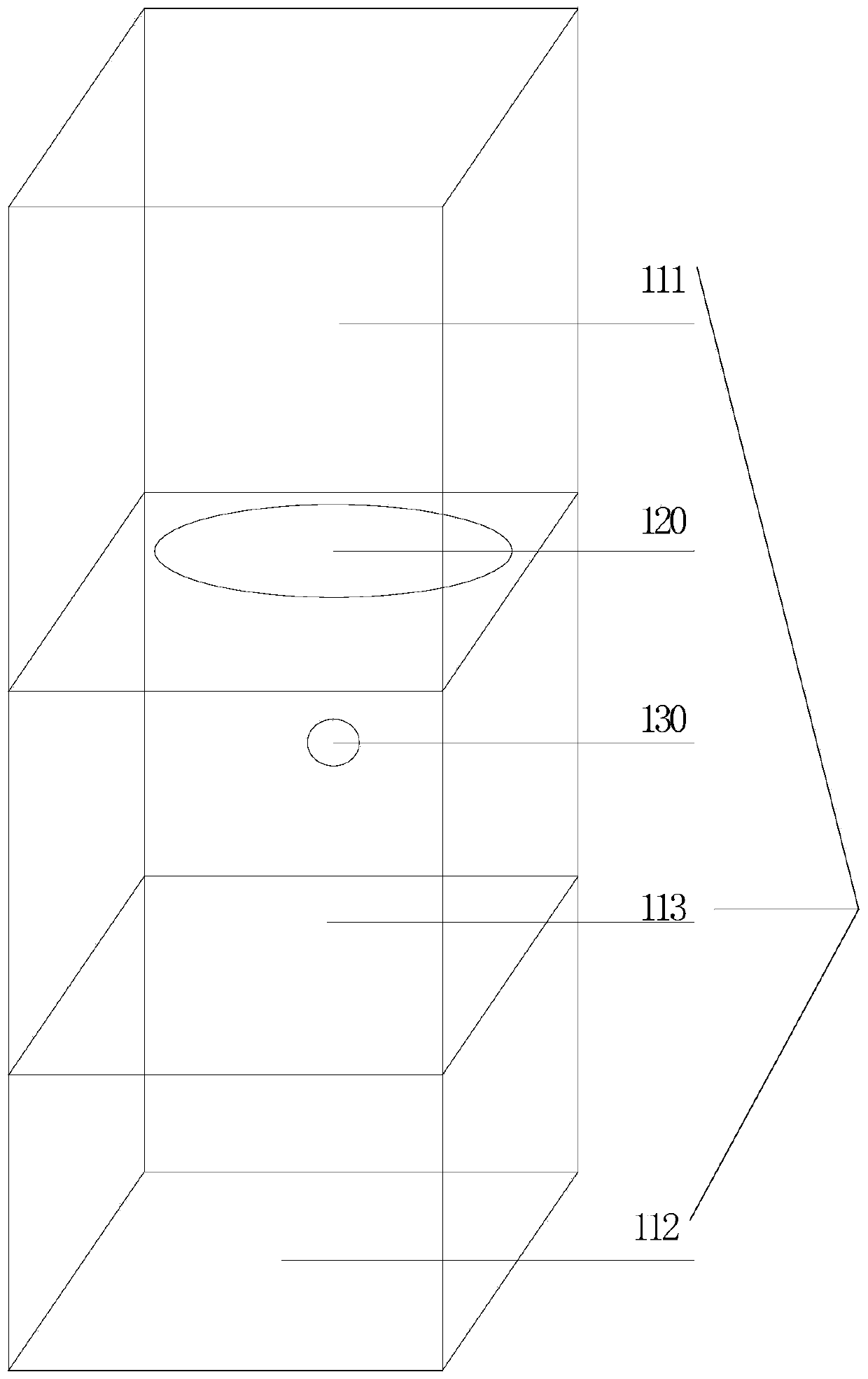

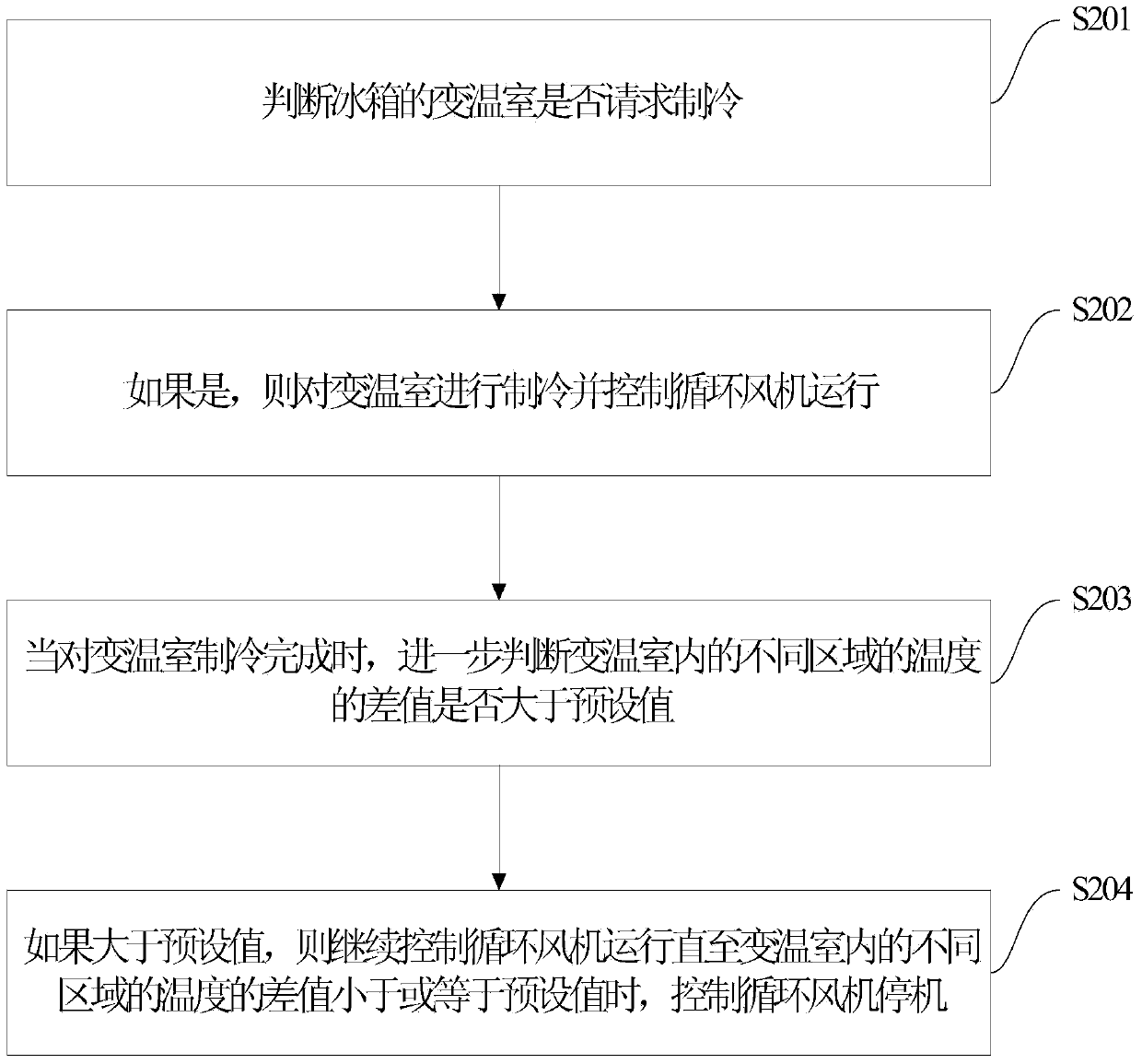

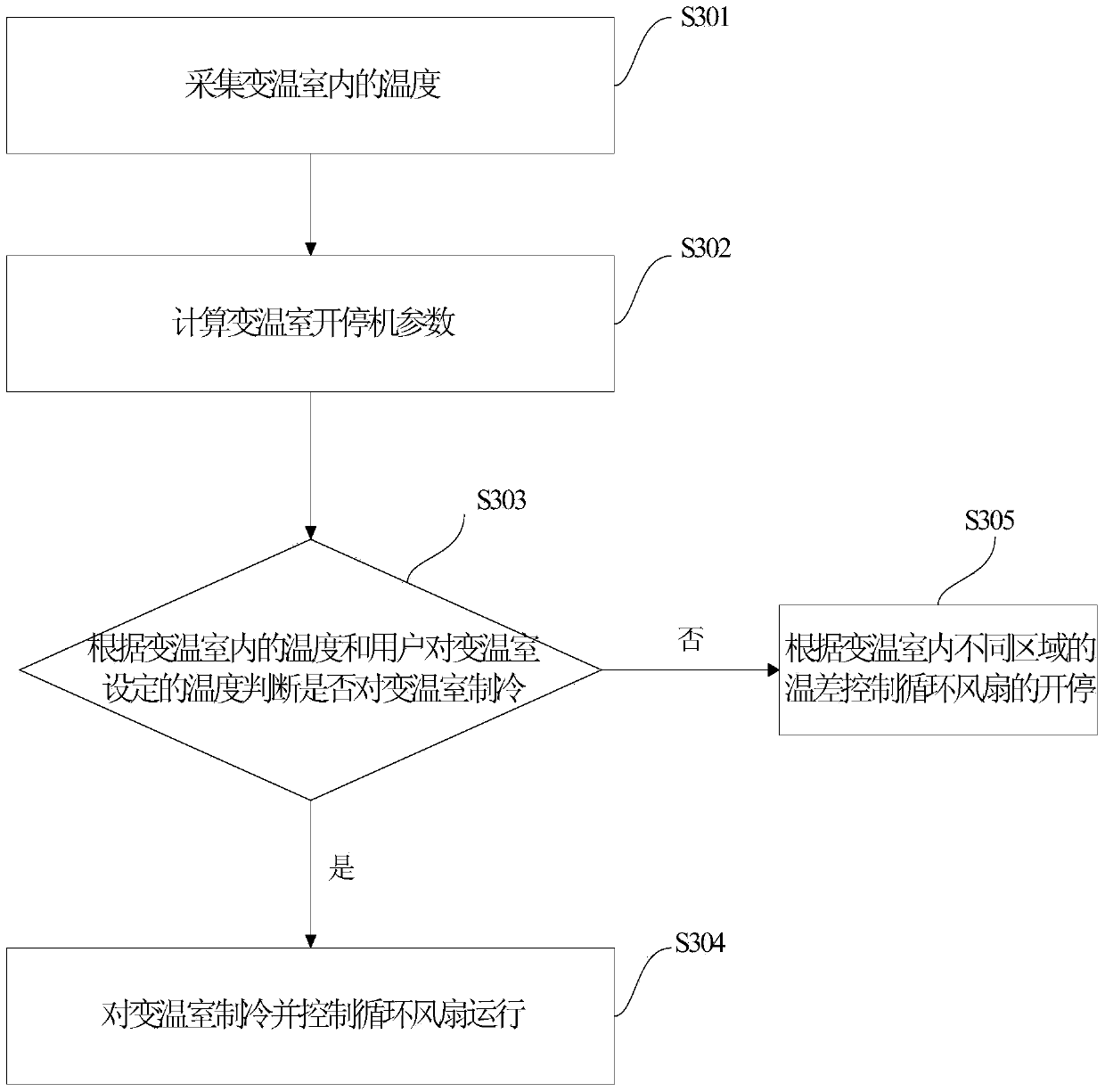

Control method of refrigerator and refrigerator

ActiveCN103423960AUniform temperatureAccurate temperatureDomestic cooling apparatusLighting and heating apparatusEngineeringTemperature difference

The invention provides a refrigerator, which comprises a door body, a refrigerator body, a circulating fan, temperature sensors, a refrigerating system and a controller, wherein chambers are defined in the interior of the refrigerator body; the chambers comprise a refrigerating chamber, a freezing chamber and a temperature-variable chamber; the circulating fan is arranged in the temperature-variable chamber, and runs when temperature differences of different areas in the temperature-variable chamber are bigger than a preset value or runs during the refrigerating process of the temperature-variable chamber; the temperature sensors are respectively arranged in the chambers so as to acquire the temperature of each chamber; the refrigerating system is used for refrigerating the chambers; the controller is used for controlling the refrigerating system to be started and stopped and the circulating fan to be started and stopped according to the acquired temperature. The refrigerator provided by the embodiment of the invention has the advantages that the temperature of the temperature-variable chamber can be accurately controlled, and the temperature fluctuation of the temperature-variable chamber is smaller, and therefore, the market competitiveness of the refrigerator is promoted. The invention also provides a control method of the refrigerator.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

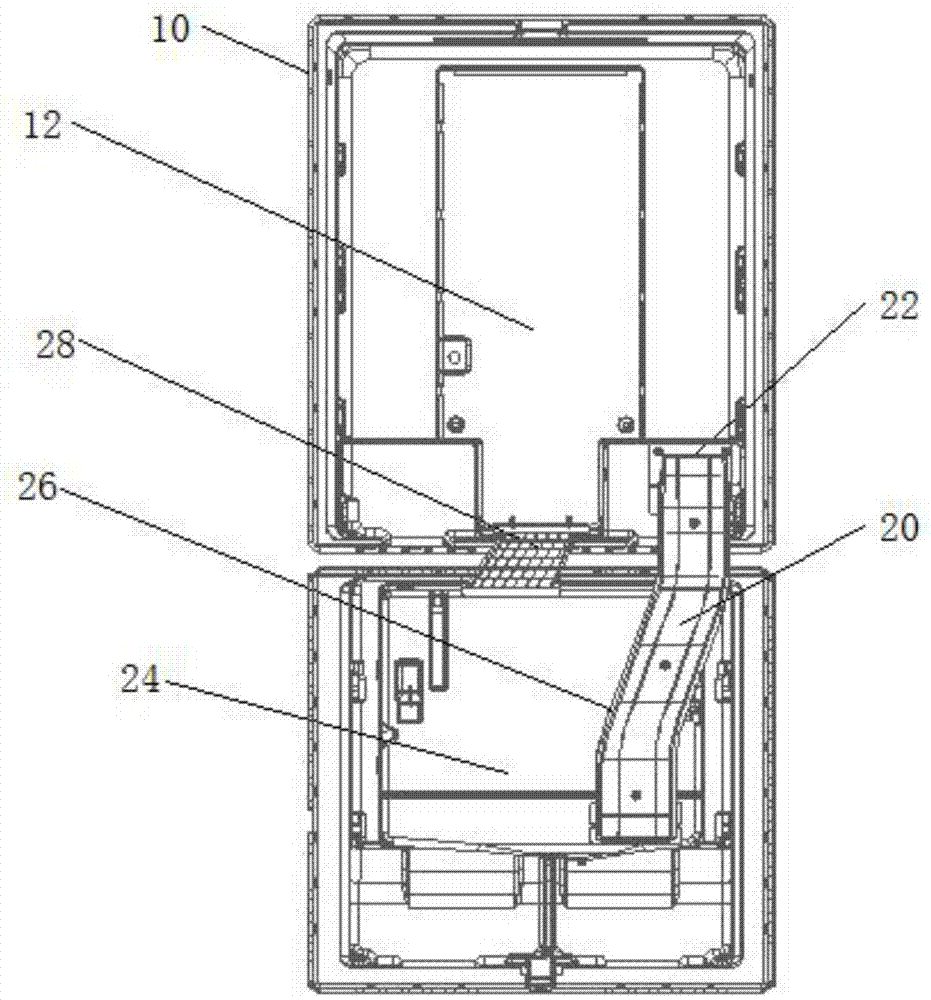

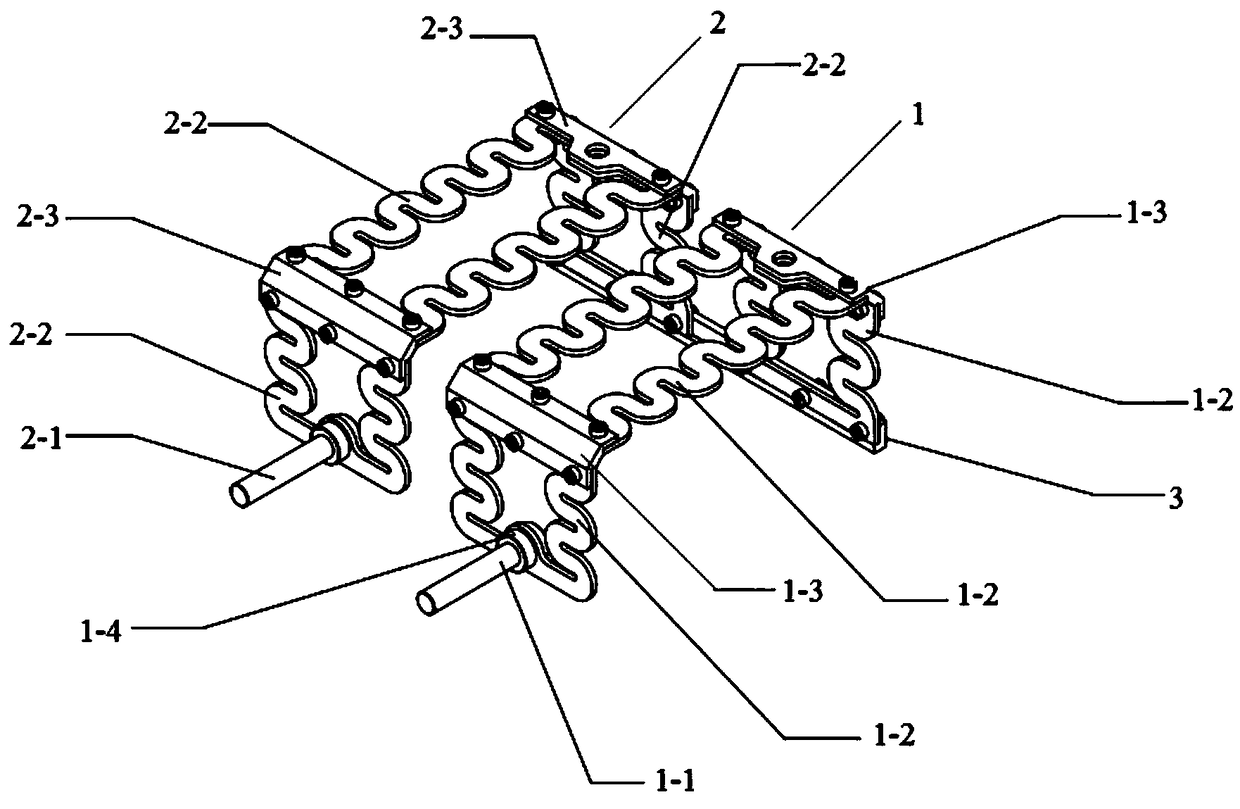

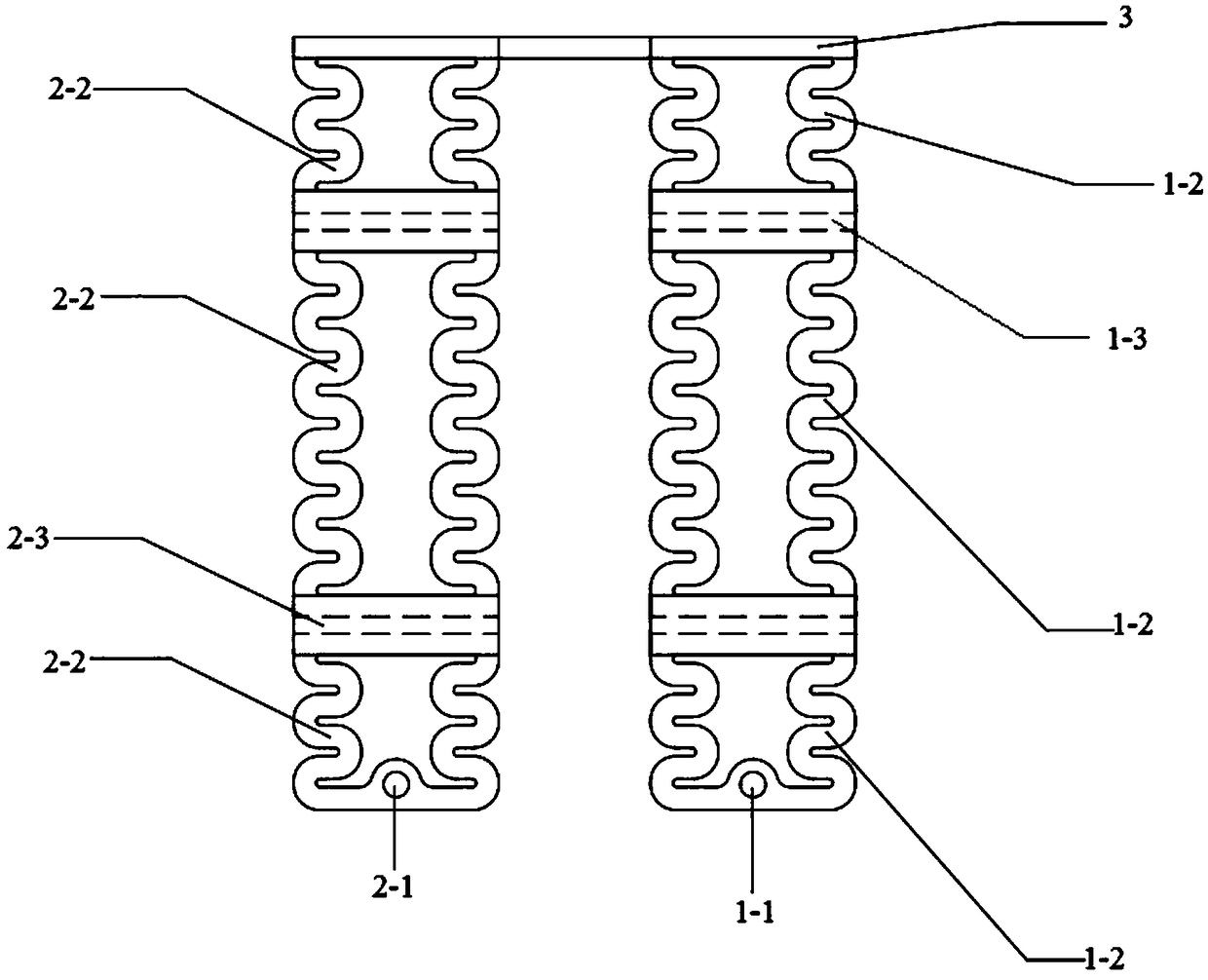

Bioprinter temperature control system and bioprinter

ActiveUS20190009474A1Solve the real problemImprove printing efficiencyManufacturing enclosuresAuxillary controllers with auxillary heating devicesTemperature controlControl system

The present invention relates to the technical field of a bioprinter, and in particular relates to a bioprinter temperature control system and a bioprinter. The bioprinter temperature control system provided by the present invention, comprises a flow channel temperature control system, for controlling a temperature of a flow channel between an outlet of a bioprinting material container of a bioprinter and a nozzle of the bioprinter, such that the temperature of the flow channel conforms to a desired temperature of a biological printing material. The temperature control system of the present invention can realize the temperature control of the biological printing material, improving the survival rate of the printing material, and ensuring the biological function of the printing material.

Owner:SICHUAN REVOTEK CO LTD

Control method for environment in refrigerating chamber of refrigerator

InactiveCN105444519AReduce energy consumptionReduce percentageLighting and heating apparatusCooling fluid circulationEngineeringCold store

The invention discloses a control method for the environment in the refrigerating chamber of a refrigerator. The refrigerator comprises a box body and a refrigerating system, the box body comprises the refrigerating chamber and an evaporator cavity, the refrigerating system comprises a compressor, an evaporator arranged inside the evaporator cavity, an air inlet air passage for communicating the refrigerating chamber and the evaporator cavity, and an air return air passage; an air return air door is arranged between the air return air passage and the refrigerating chamber; the control method comprises the following steps: a, detecting the temperature of the refrigerating chamber repeatedly until the temperature of the refrigerating chamber is lower than or equal to a first preset temperature threshold value; b, detecting the humidity of the refrigerating chamber repeatedly until the humidity of the refrigerating chamber is smaller than or equal to a first preset humidity threshold value; and c, closing the air return air door. The control method provided by the invention ensures that energy consumption of the refrigerator is low, even refrigeration is achieved, and the freshness of foods in the refrigerating chamber can be effectively kept.

Owner:HAIER SMART HOME CO LTD

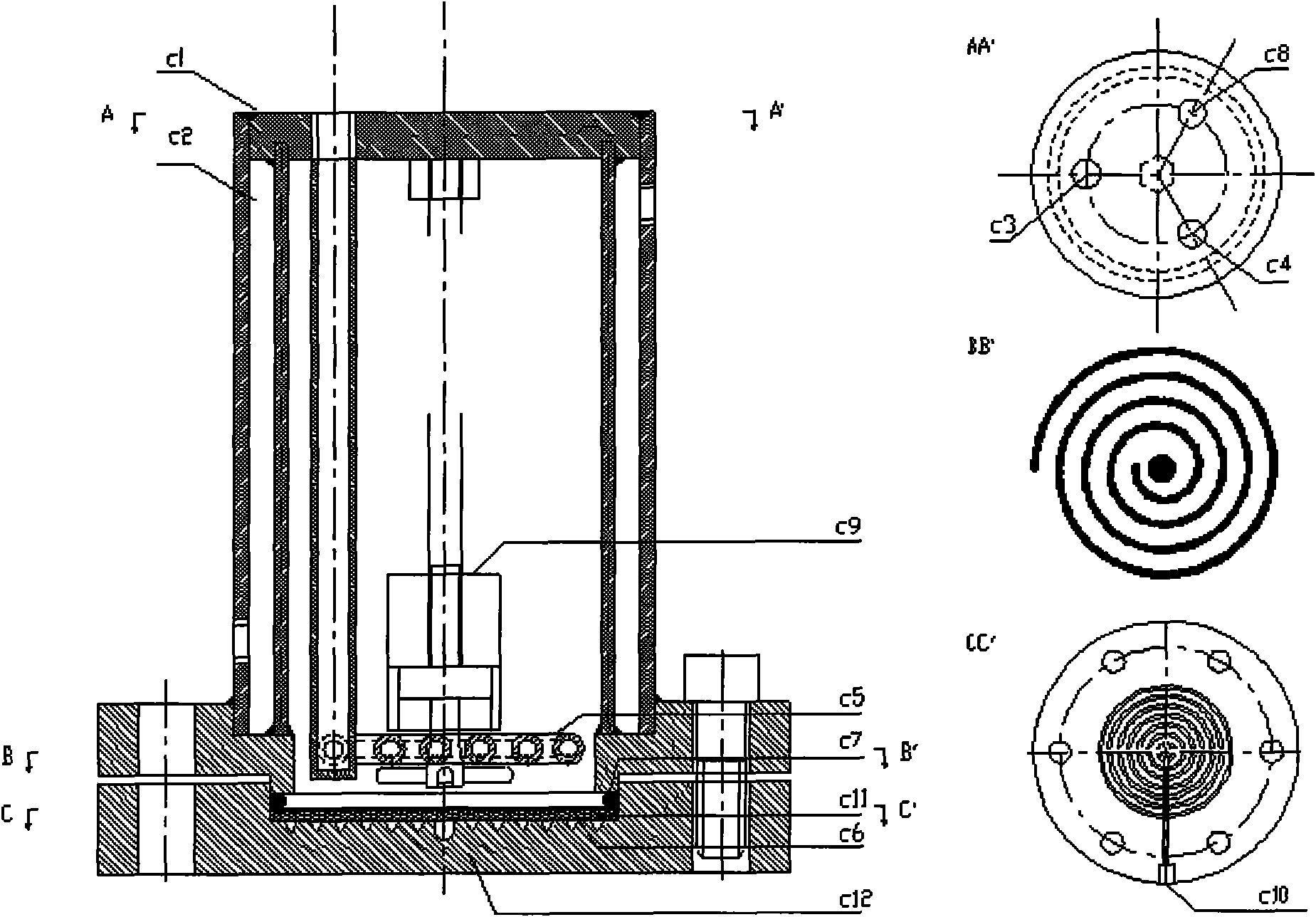

Spiral ultra-long cooling loop irradiation device

ActiveCN110853793ASolve the problem of uneven axial temperatureTemperature close toIrradiation devicesOutfallEngineering

The invention discloses a spiral ultra-long cooling loop irradiation device, which is characterized in that an inner-layer annular space is formed between an inner-layer irradiation tank and a middle-layer irradiation tank, and an outer-layer annular space is formed between the middle-layer irradiation tank and an outer-layer irradiation tank; a sample is arranged on a clamping block, and the clamping block is arranged in the inner-layer annular space; an outer-layer cooling pipe and an inner-layer cooling pipe are both wound on the outer wall of the middle-layer irradiation tank; a water outlet of the outer-layer cooling pipe is communicated with the outer-layer annular space at the bottom of the outer-layer irradiation tank; a water outlet of the inner-layer cooling pipe is communicatedwith the bottom of the inner-layer irradiation tank; the inner-layer irradiation tank is communicated with the outer-layer annular space through a one-way valve; a circulating water outlet pipe is arranged at the top of the outer-layer irradiation tank and is communicated with the outer-layer annular space. According to the spiral ultra-long cooling loop irradiation device, the problem that the axial temperature of an irradiation device is not uniform is solved, the inner spiral cooling circulation loop and the outer spiral cooling circulation loop are arranged to control the temperature in the irradiation device, and it is guaranteed that the temperatures of all material samples in the irradiation device are close.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

High-efficiency reliable thermal moxibustion device

InactiveCN102475629AUniform temperature controlReduce irritation and pollutionDevices for heating/cooling reflex pointsElectrotherapyEngineeringSmoke

The invention relates to a high-efficiency reliable thermal moxibustion device, which solves the problem of inconvenience in use of the conventional thermal moxibustion device. The device comprises a barrel-shaped inner box and a barrel-shaped outer box, wherein the inner box and the outer box are sleeved with each other, vent holes are formed on upper openings of the inner and outer boxes; a moxa stick fixing mechanism is arranged at the inner bottom of the inner box, and an annular end cover is arranged on the upper part of the outer box; radial distributed vent heat-conducting holes are formed at the bottom of the inner box and the bottom of the outer box; a heat-insulating protective gasket is sleeved at one end of each heat-conducting hole of the outer box; vent hole control rings for regulating throughput are sleeved on the periphery of the outer box in a circumferential sliding assembly way; and medical five-element materials are fixedly arranged on the end face of the opening of the heat-insulating protective gasket. The device has the advantages of large moxibustion area, centralized energy, convenience and balance in temperature control, small smoke stimulation and pollution, safe and high-efficiency moxibustion, five-element medical health care, and capability of improving comfort.

Owner:李建书

Heating body and vacuum sintering furnace capable of achieving multi-region temperature control

ActiveCN108458589AUniform temperature controlReduce temperature differenceMuffle furnacesCharge treatment typeTemperature controlTransformer

The invention discloses a heating body and a vacuum sintering furnace capable of achieving multi-region temperature control. The vacuum sintering furnace comprises an airtight box, a heating device and a heat-insulation cylinder. The heating device comprises a plurality of heating body sets which are evenly distributed outside the airtight box. Each heating body set comprises two heating bodies which are of the same structure and surround the side face of the airtight box. Each heating body comprises a first heating structure and a second heating structure, wherein the head end of the first heating structure and the head end of the second heating structure are connected with the output end of a single-phase transformer, the tail end of the first heating structure and the tail end of the second heating structure are connected with a long connecting piece, and the single-phase transformer, the first heating structure and the second heating structure form a current circuit. According to the heating body and the vacuum sintering furnace, each heating body heats a corresponding region, and the heating temperature of each heating body is regulated automatically; and the heating device formed by the multiple heating bodies is used for heating the multiple regions of the vacuum sintering furnace, so that the temperature in the vacuum sintering furnace is controlled to be uniform.

Owner:NINGBO HIPER VACUUM TECH CO LTD

Heat Exhanger with Varying Cross Sectional Area of Conduits

InactiveUS20090101319A1Uniform temperature controlPeak heat transfer capacityCorrosion preventionIndirect heat exchangersTemperature controlPath length

A process involving heat exchange that employs heat exchangers where the process material flows over a heat transfer surface in which a process material passes through the process conduit of a heat exchanger wherein the desired velocity profile of the process material passing through the process conduit is achieved by varying the cross sectional area of the process conduit in 3 or more locations along the path length of the process conduit which allows better regulation of heating or cooling within the system which, for some processes, will result in improved temperature control.

Owner:ASHE MORRIS LTD

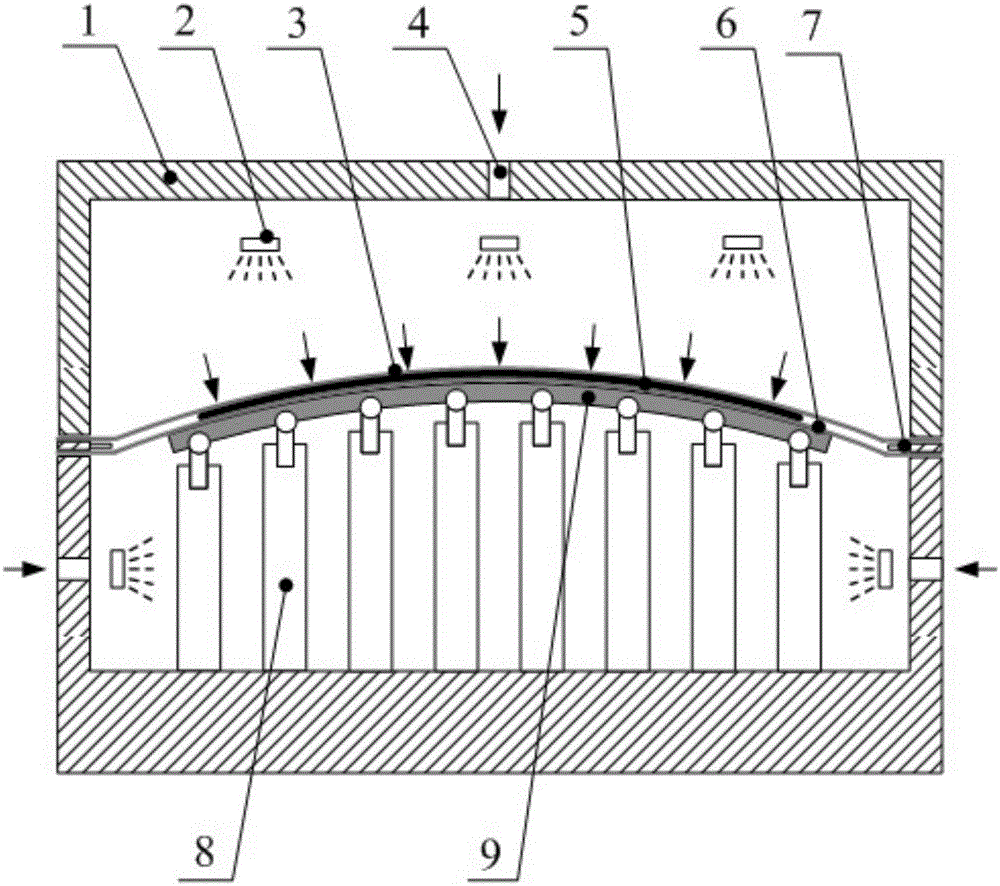

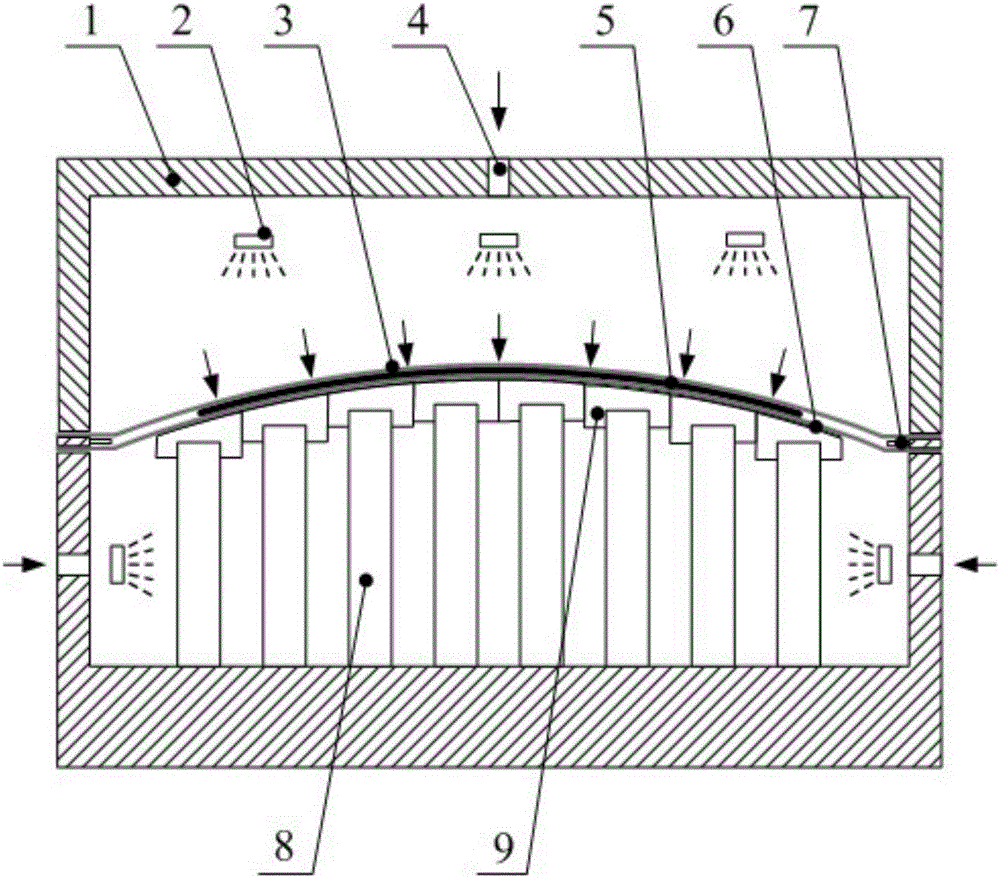

Resin plate multi-point hot forming uniform temperature controlling and loading method

The invention provides a resin plate multi-point hot forming uniform temperature controlling and loading method. The resin plate multi-point hot forming uniform temperature controlling and loading method comprises the following steps that (1) the height of a multi-point base body die is adjusted through multi-point forming CAD / CAE / CAM software, and a target part profile is formed; (2) a resin plate is placed above the multi-point base body die; (3) the resin plate to be formed is heated to the target forming temperature through heaters which are arranged inside a hot-bulging box and on the periphery of the multi-point base body die; (4) a gap between the hot-bulging box and a multi-point base body is filled with compressed air so that a silica membrane can expand and deform, the resin plate and a polyurethane membrane are driven to be slowly attached to the die profile, and formation is achieved; (5) the heaters in the hot-bulging box and on the periphery of the multi-point base body are turned off after formation, gas continues to be injected into the gap between the hot-bulging box and the multi-point base body, and the laminated resin plate is subjected to pressure maintaining treatment; and (6) gas is not injected into the gap between the hot-bulging box and the multi-point base body, and the resin plate is cooled to the room temperature slowly.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

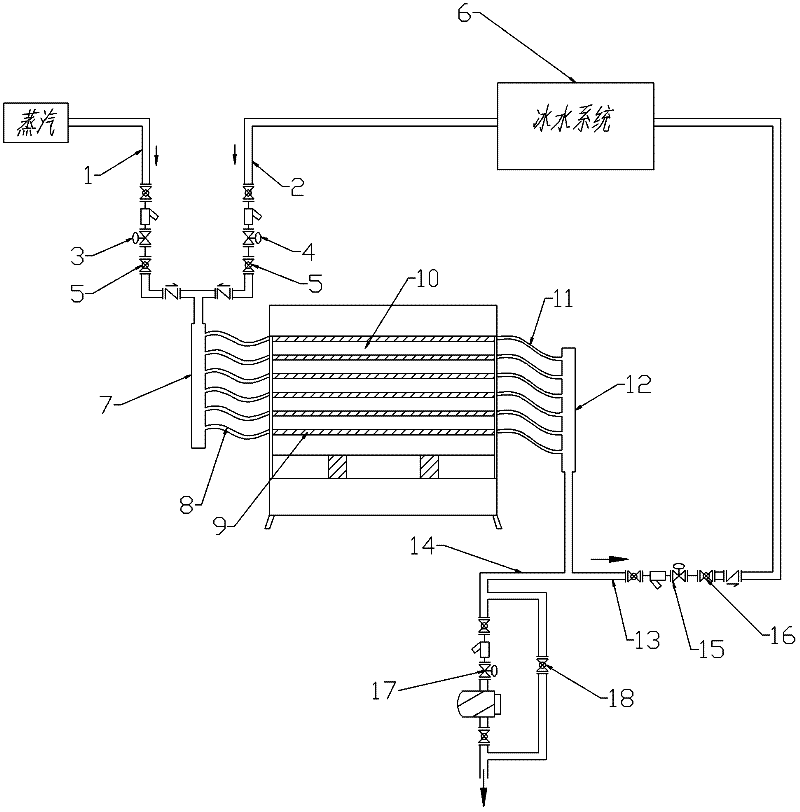

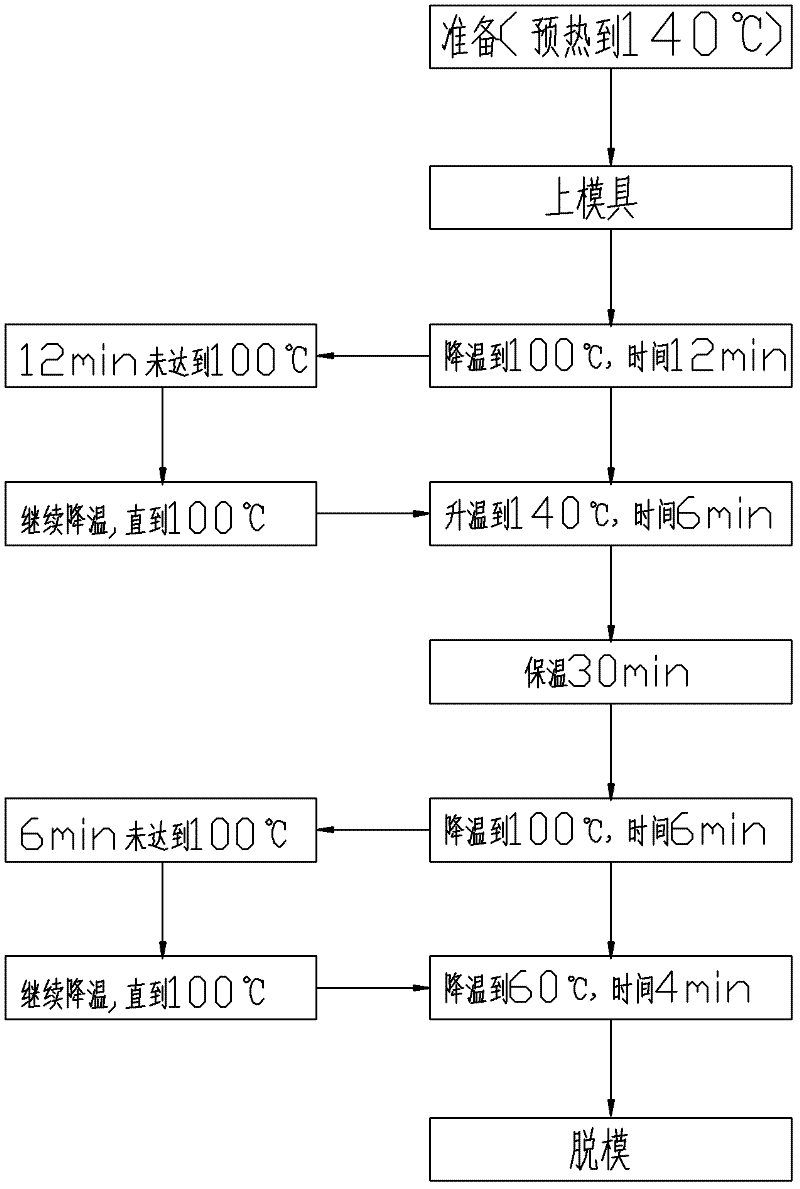

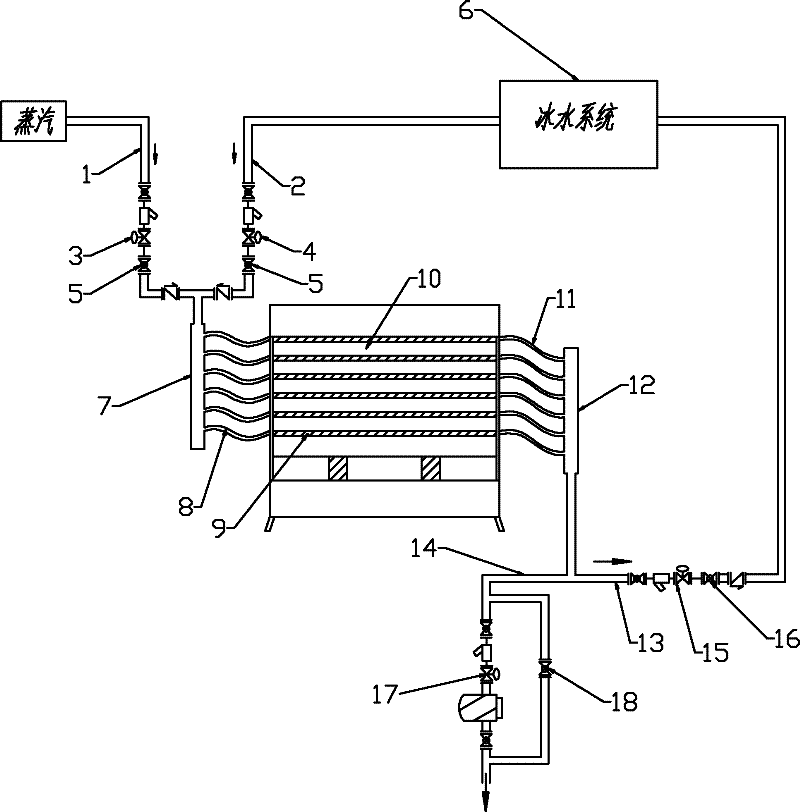

Novel carbon fiber ice hockey rod thermal forming furnace and thermal forming method thereof

The invention relates to a novel carbon fiber ice hockey rod thermal forming furnace, which comprises a furnace frame, a plurality of cold-hot plates and a cold water / steam circulating system. Molds are arranged between the cold-hot plates. The cold-hot plates are communicated with the cold water / steam circulating system. The cold water / steam circulating system comprises water inlet branch pipes and water outlet branch pipes, wherein the water inlet branch pipes and the water outlet branch pipes are respectively connected with various heat dissipation pipes, the water inlet branch pipes are connected with a water inlet main pipe, and the water outlet branch pipes are connected with a water outlet main pipe. The water inlet main pipe is respectively connected with a steam pipe and a cold water pipe. The steam pipe is provided with a steam electromagnetic valve. The cold water pipe is provided with a cold water electromagnetic valve. The water outlet main pipe is respectively connected with a steam backwater pipe and a cold water backwater pipe. The steam backwater pipe is provided with a steam backwater electromagnetic valve. The cold water backwater pipe is provided with a cold water backwater electromagnetic valve. According to the present invention, the following characteristics of the novel carbon fiber ice hockey rod are achieved: the cold and the hot are integrated, the control is automatic, the temperature control is uniform, the strength of the prepared ice hockey rod is high, and the toughness is good.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE +1

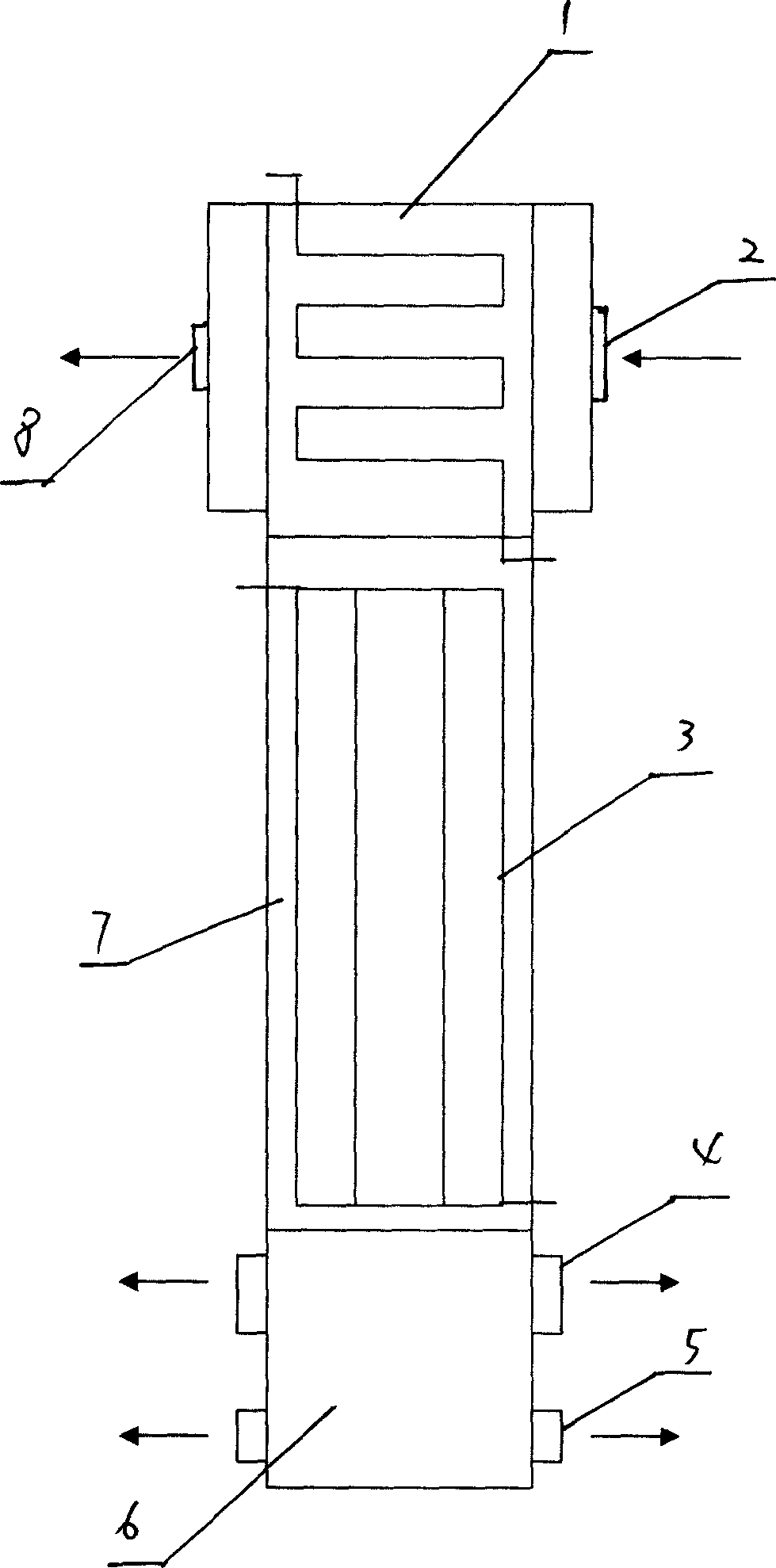

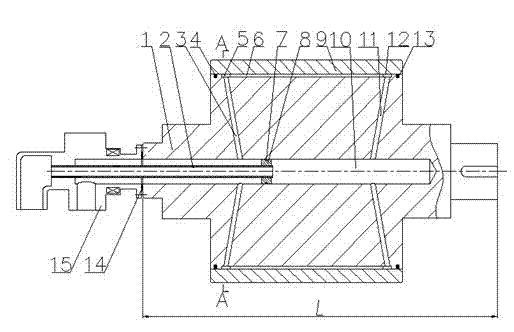

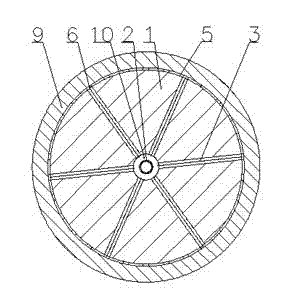

Roller shell roller capable of heating with heat conducting oil

ActiveCN103785687AReduce processing difficultyReduce processing costsRollsMetal rolling arrangementsEngineeringMechanics

The invention relates to a roller shell roller capable of heating with heat conducting oil. According to the technological scheme, a center oil channel (10) is machined in the driven end of a roller body (1), and a left annular oil groove (5) and a right annular oil groove (12) are symmetrically machined in the cylindrical face of the roller body (1). Oil conducting grooves (6) are evenly machined between the left annular oil groove (5) and the right annular oil groove (12). Left slant oil channels (3) are evenly formed in the bottom of the left annular oil groove (5) and right slant oil channels (11) and the left slant oil channels (3) are symmetrically formed. The cylindrical face of the roller body is fixedly sleeved with a roller sleeve (9). The driven end of the roller body (1) is fixedly provided with a double-path rotation adapter (15). An oil conducting pipe (2) is arranged in the center oil channel (10). One end of the oil conducting pipe (2) is installed in the double-path rotation adapter (15). The other end of the oil conducting pipe (2) is fixedly provided with an oil blocking ring (8) which is arranged between the left slant oil channels (3) and the right slant oil channels (11). The roller shell roller capable of heating with the heat conducting oil has the advantages of being capable of evenly controlling the temperature of a rolled face, easy to machine and low in cost.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com