Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132 results about "Pulse combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

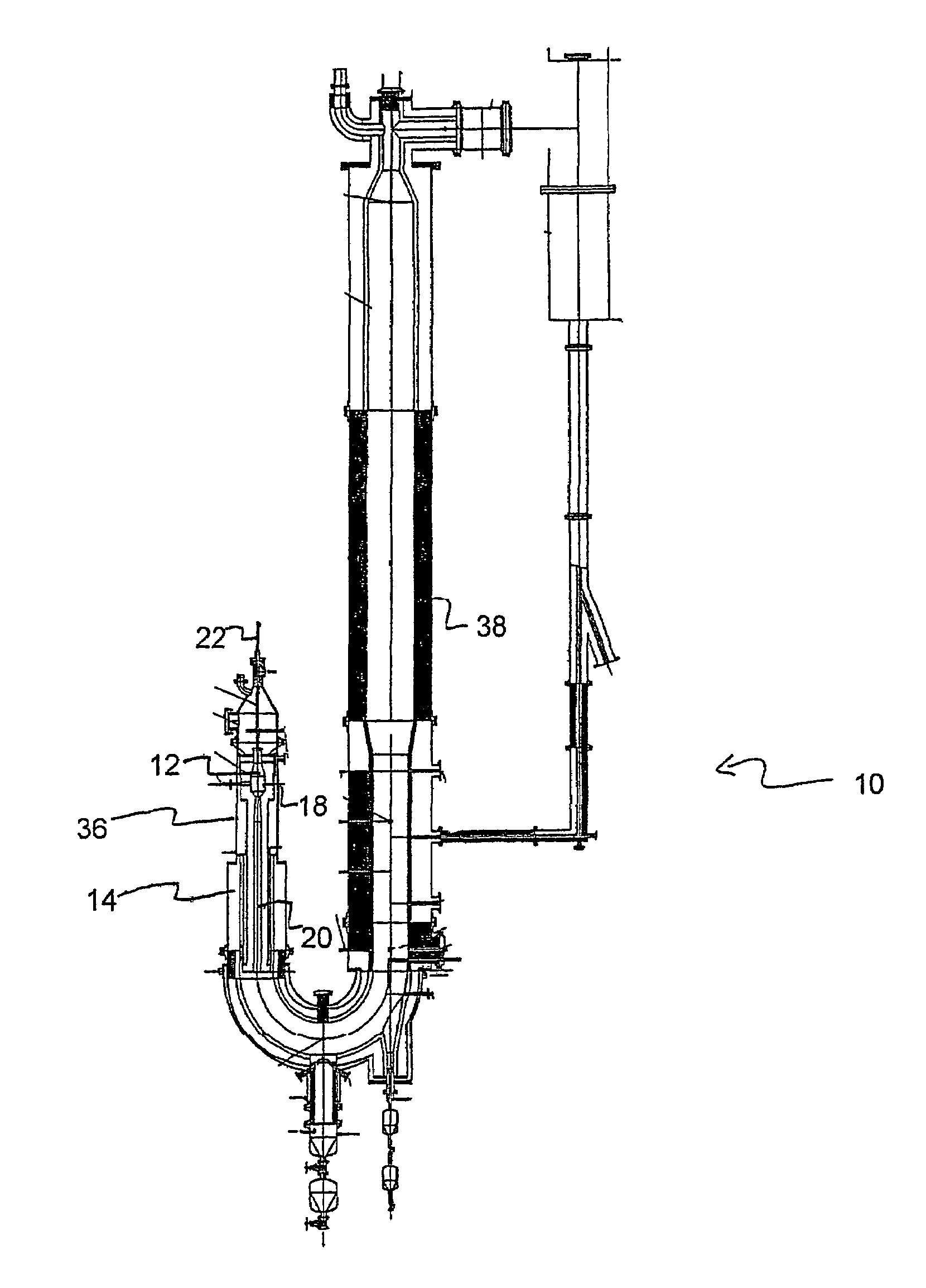

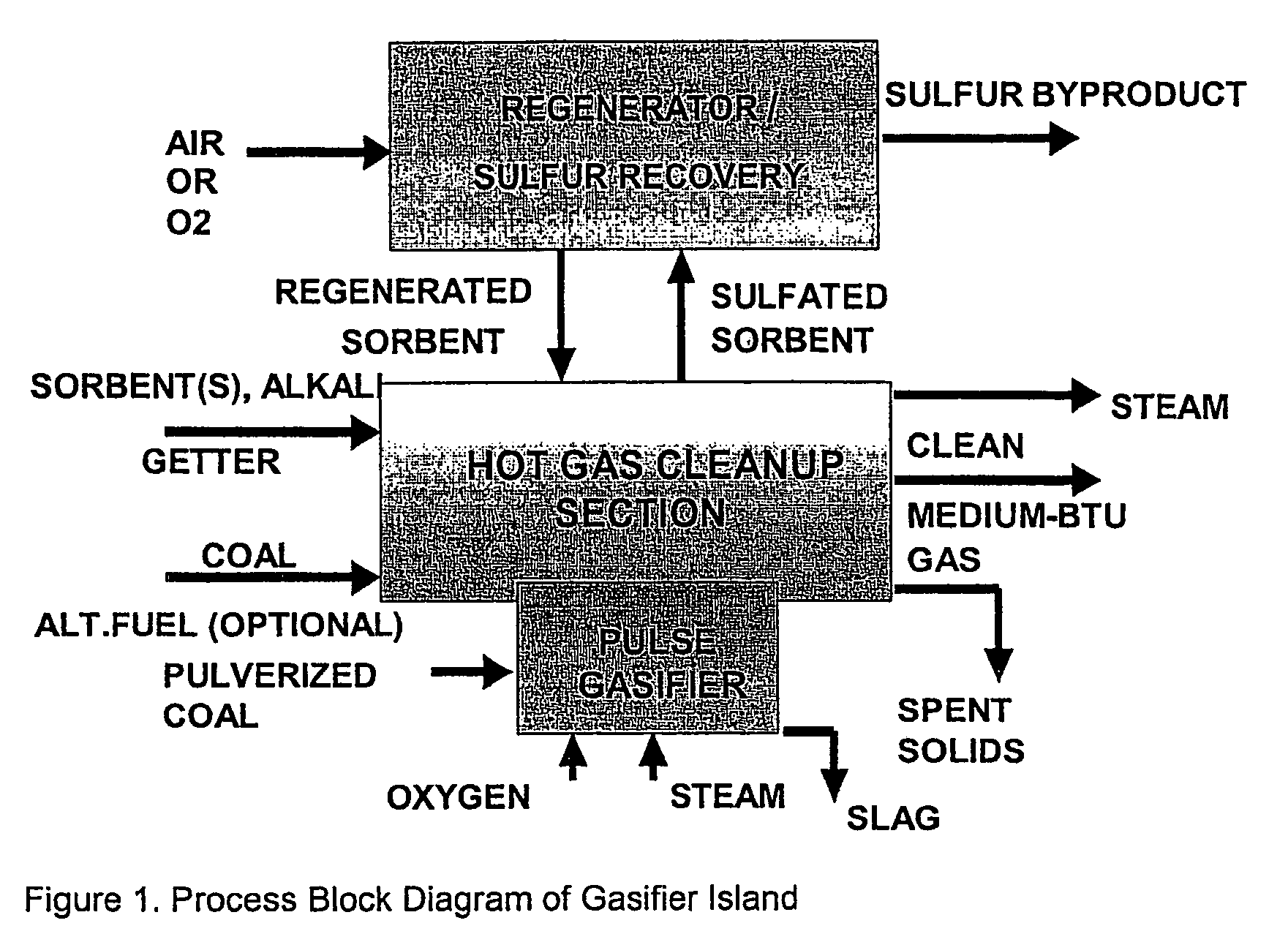

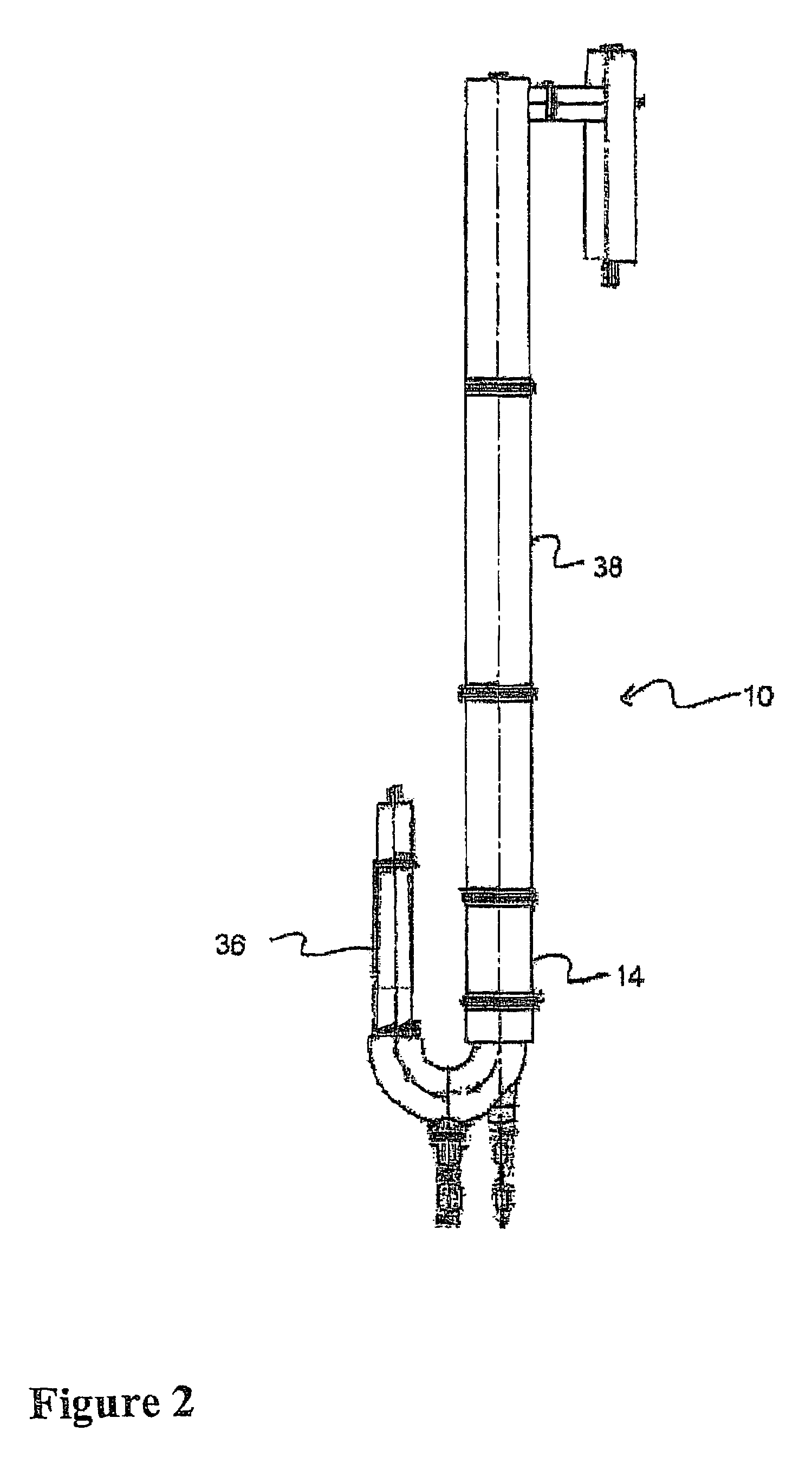

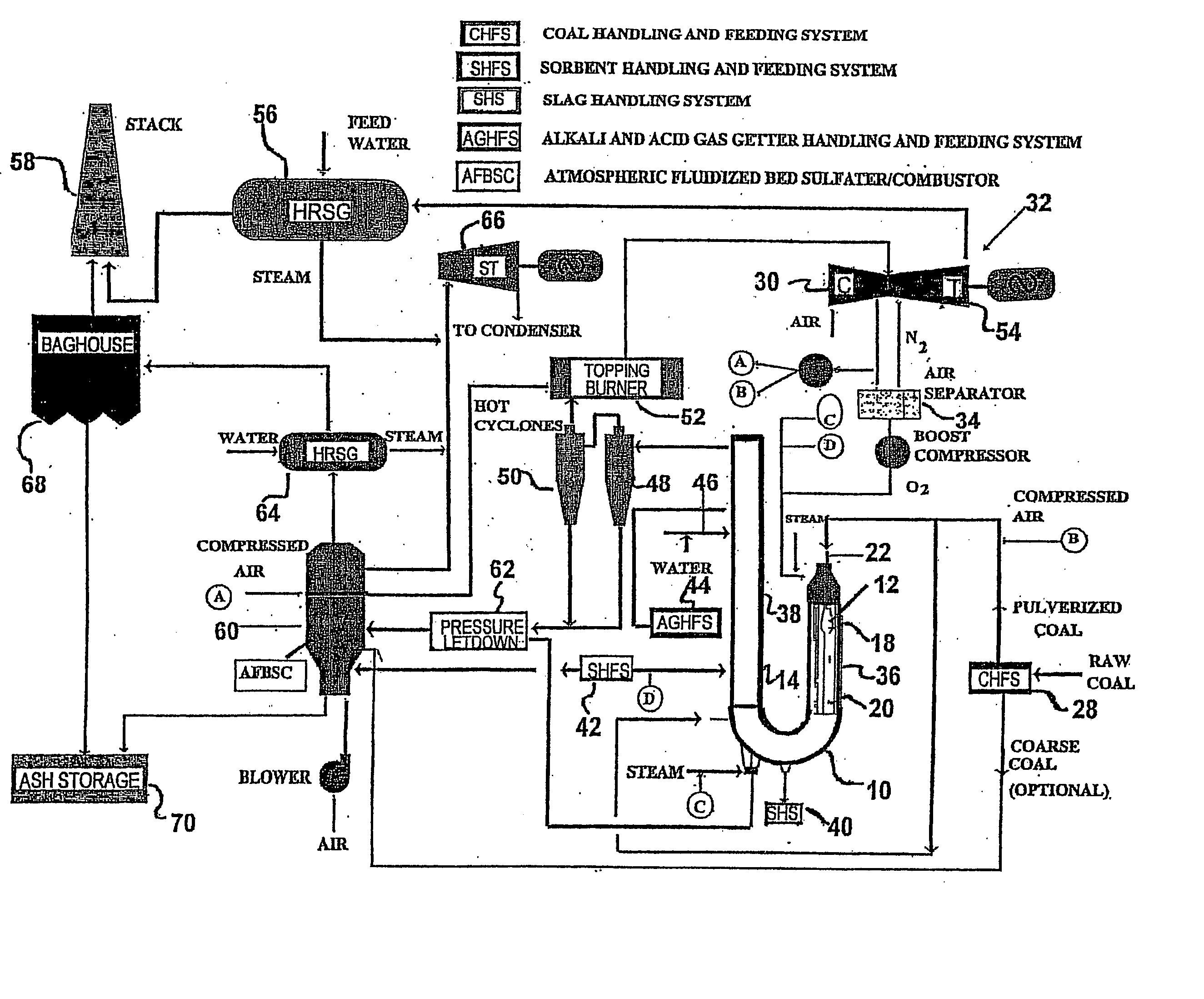

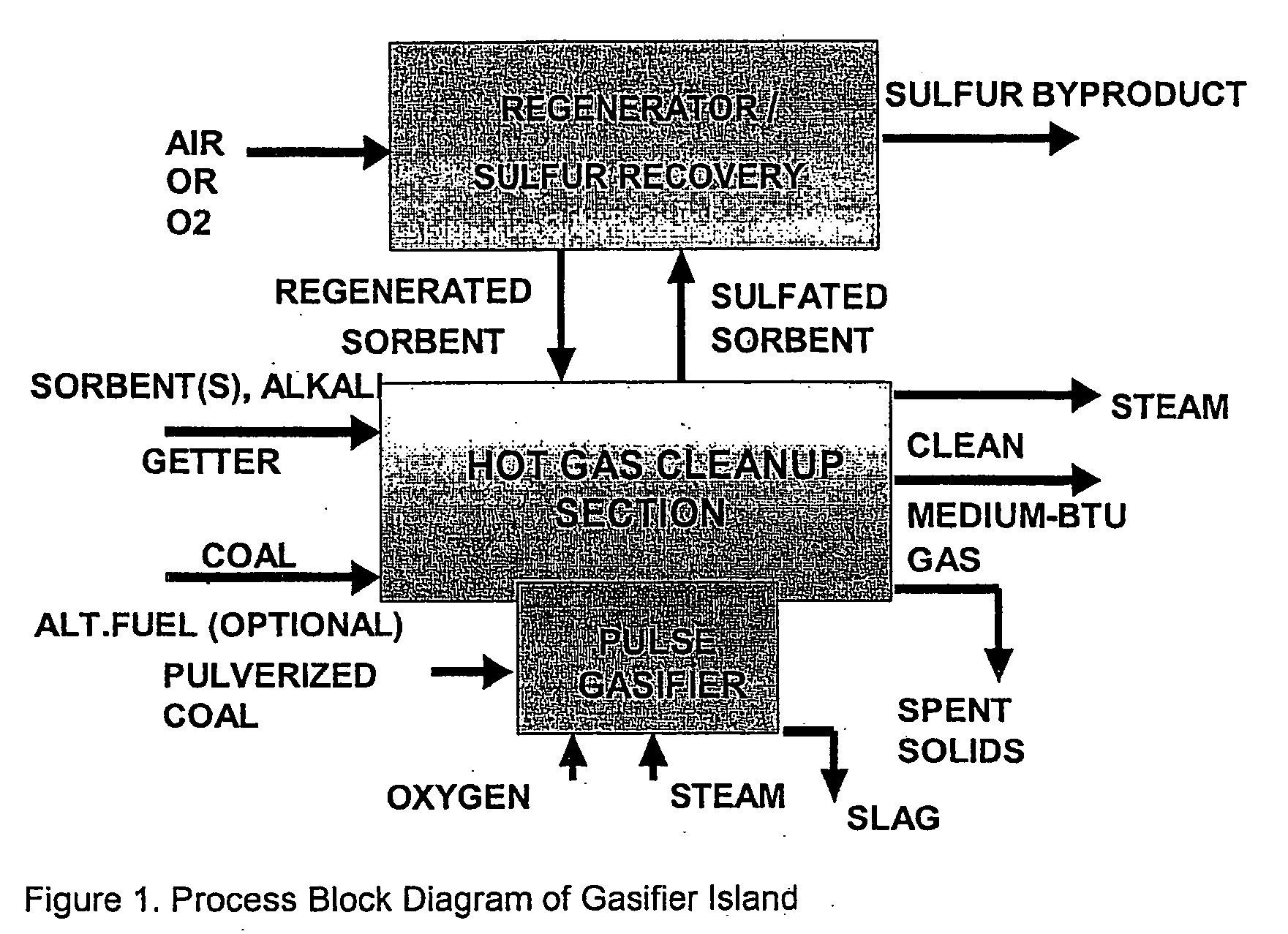

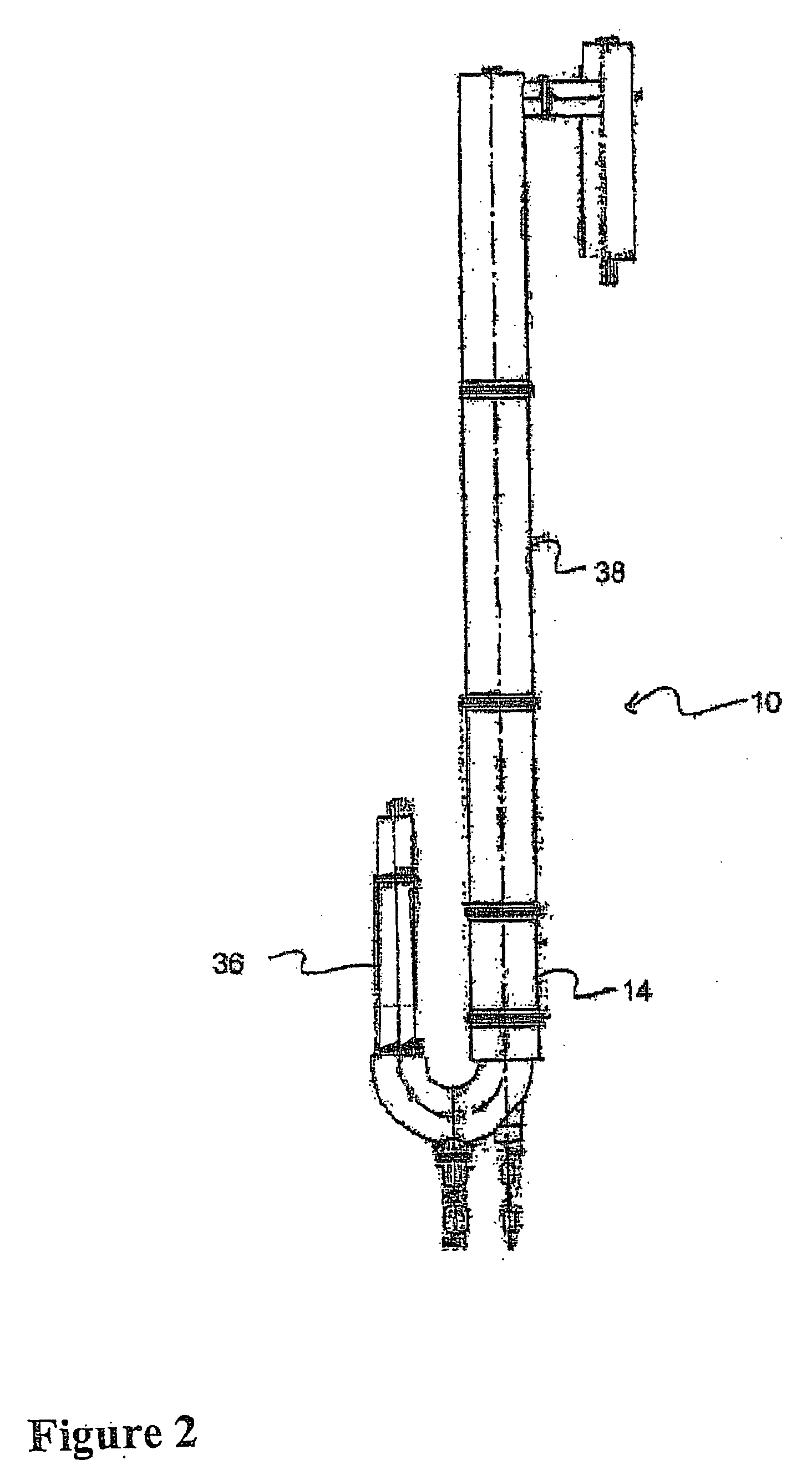

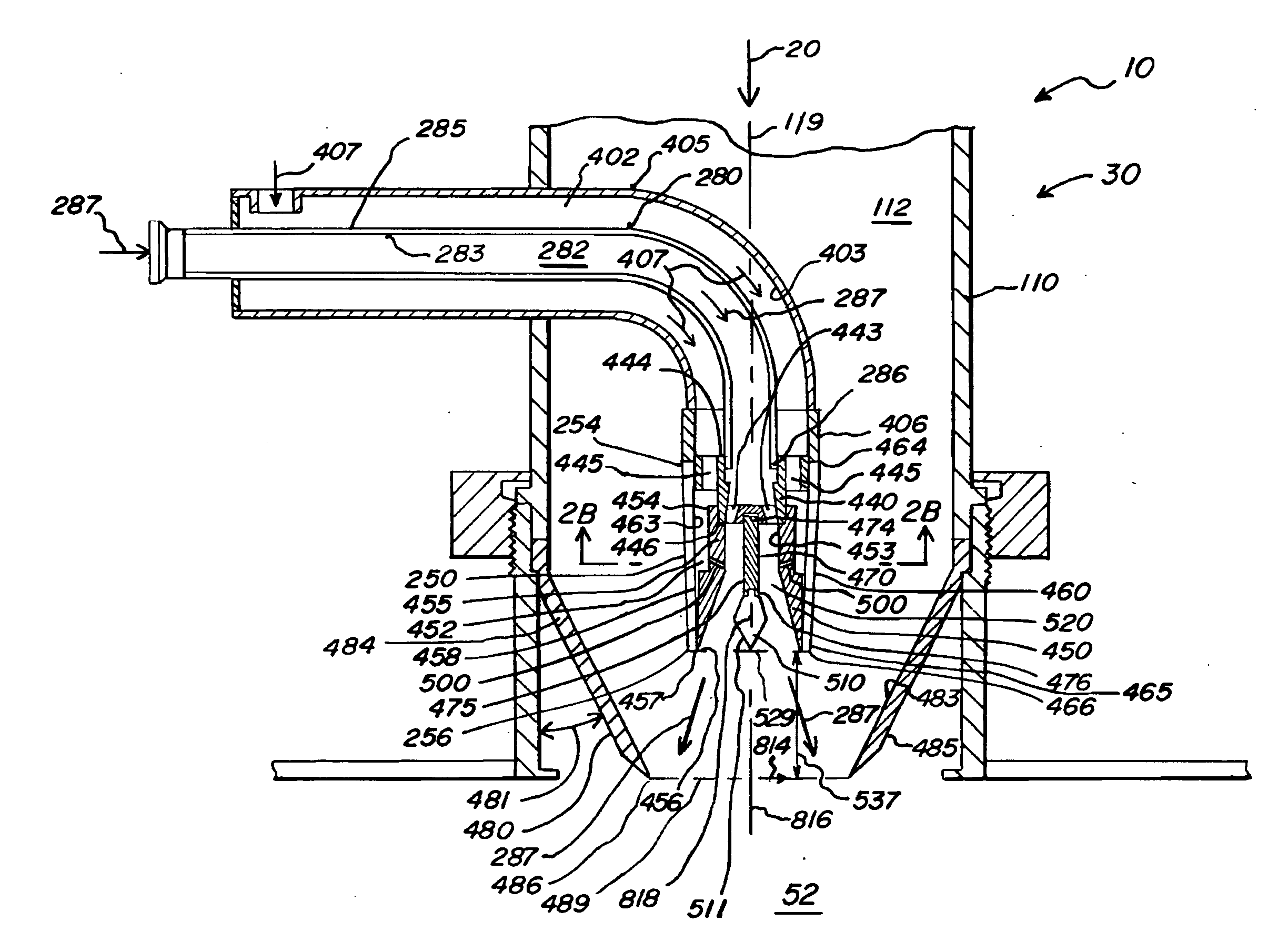

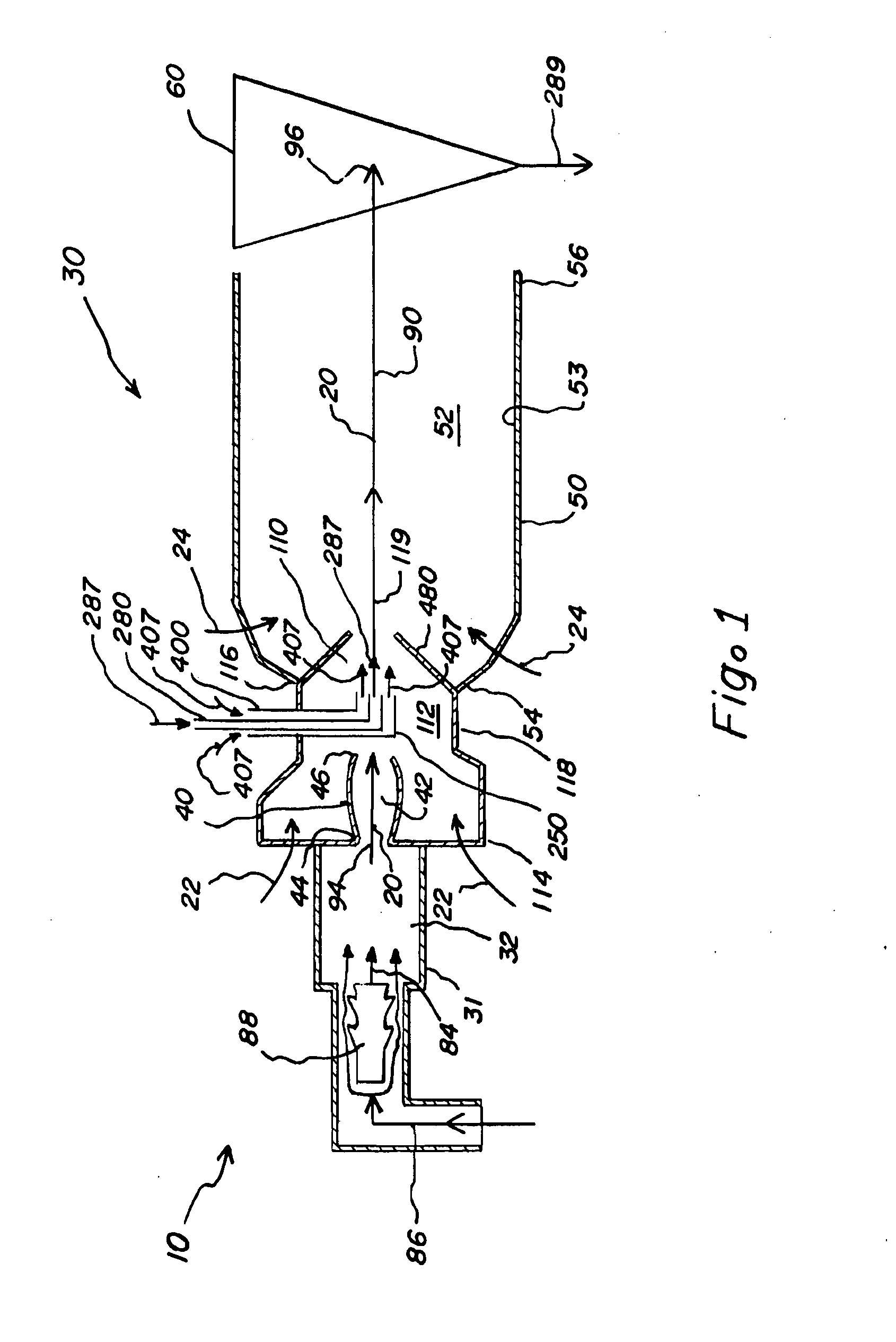

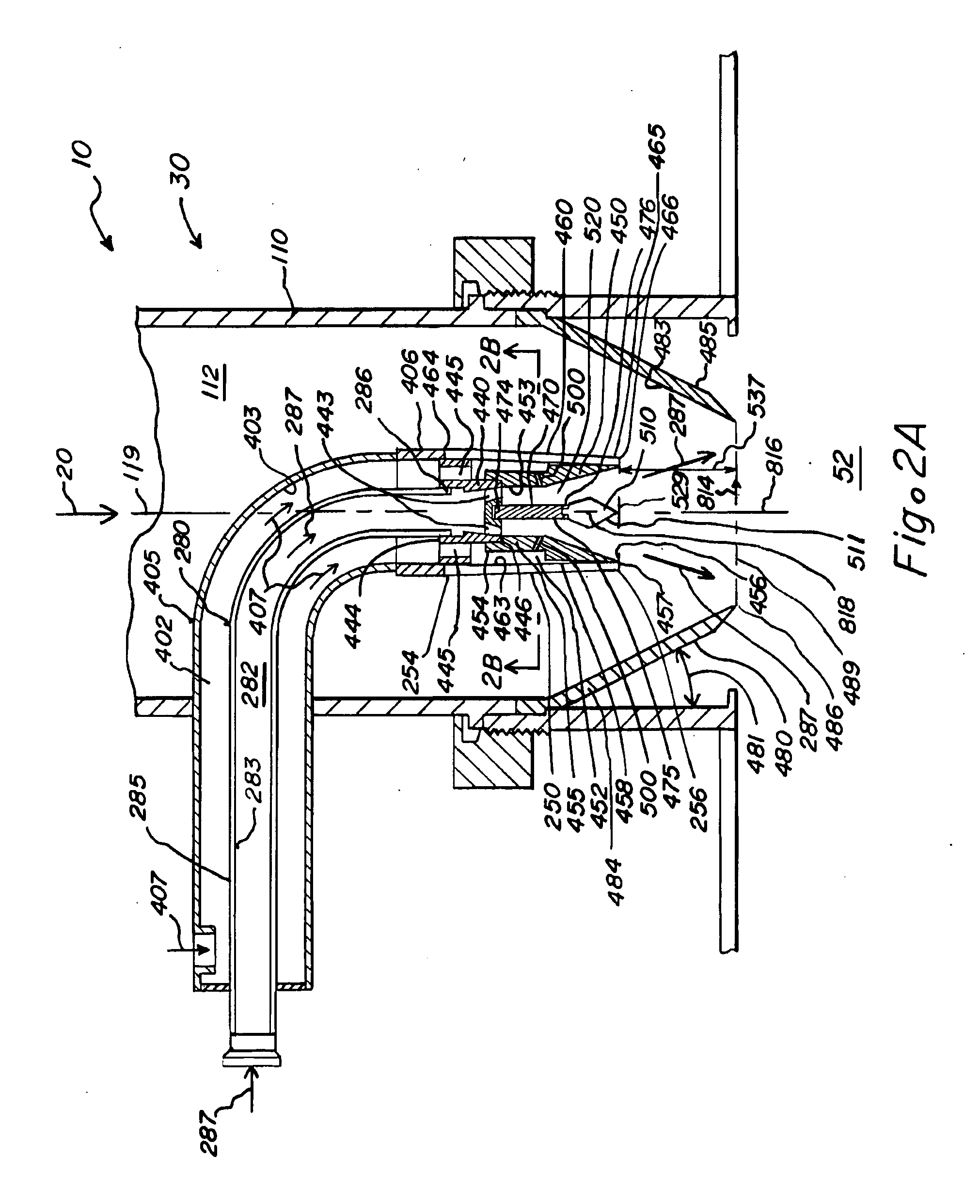

Pulse gasification and hot gas cleanup apparatus and process

InactiveUS6997118B2Easy to useConducive to agglomerationAuxillary pretreatmentGasifier mechanical detailsSteam reformingElectricity

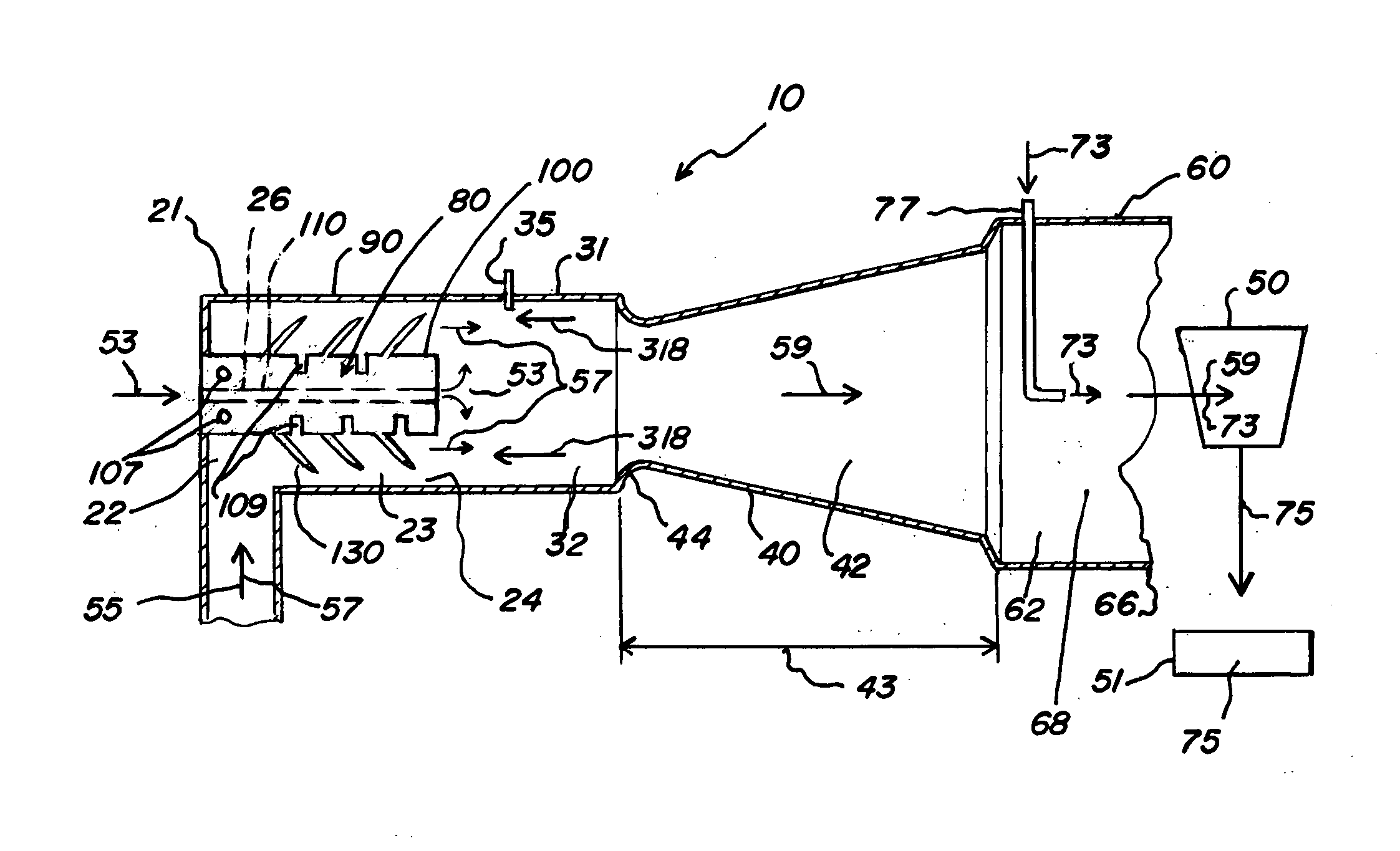

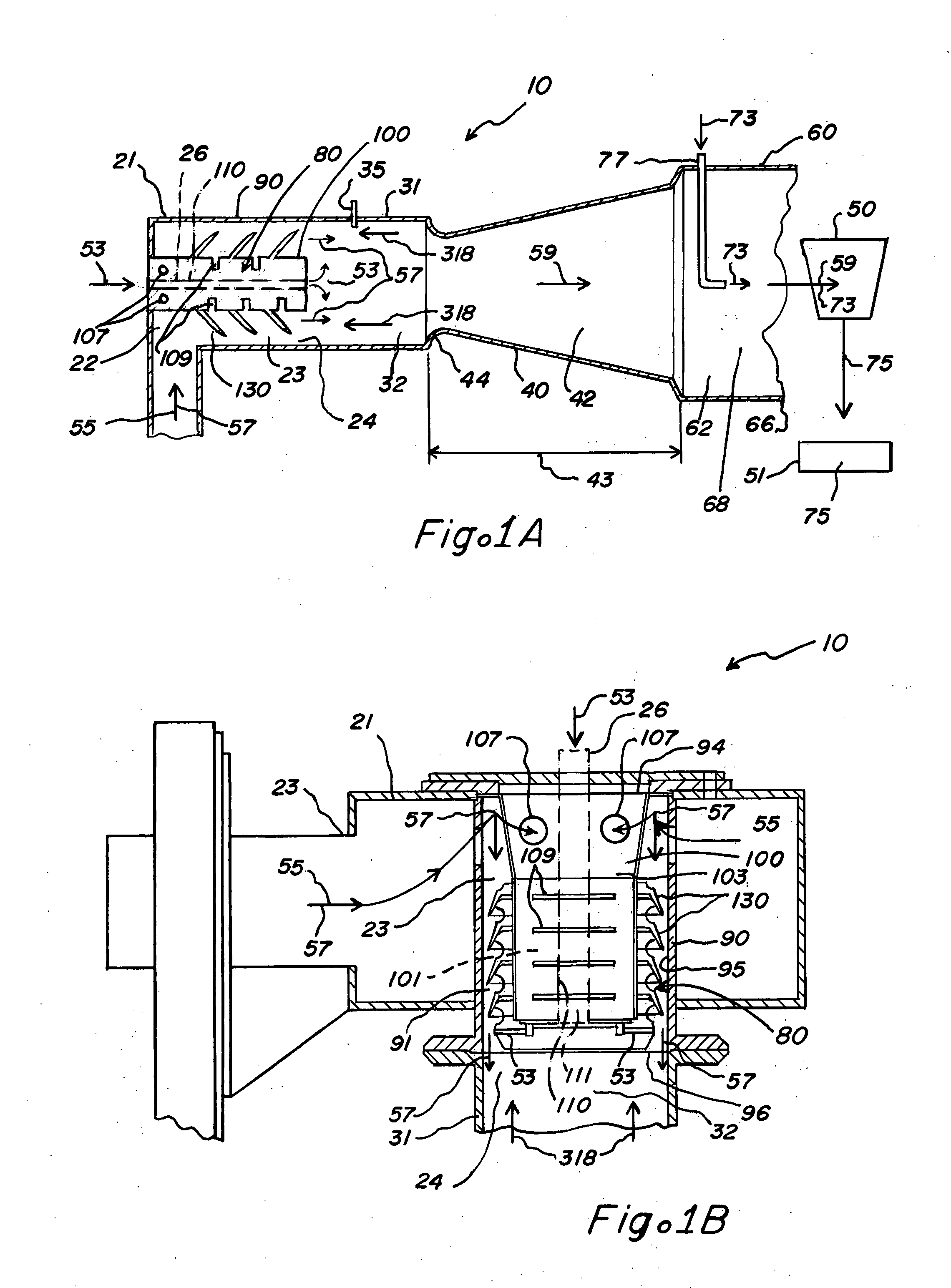

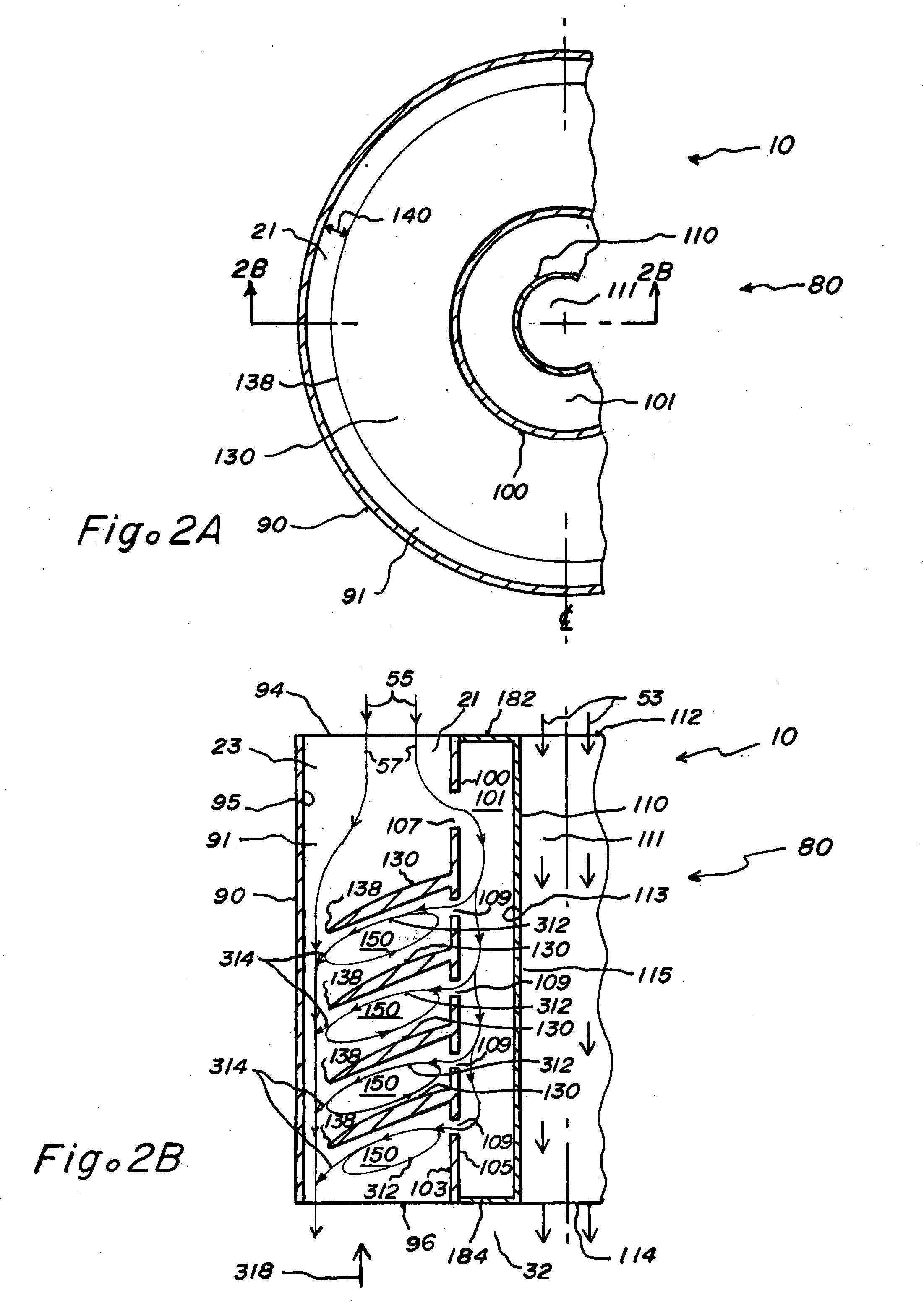

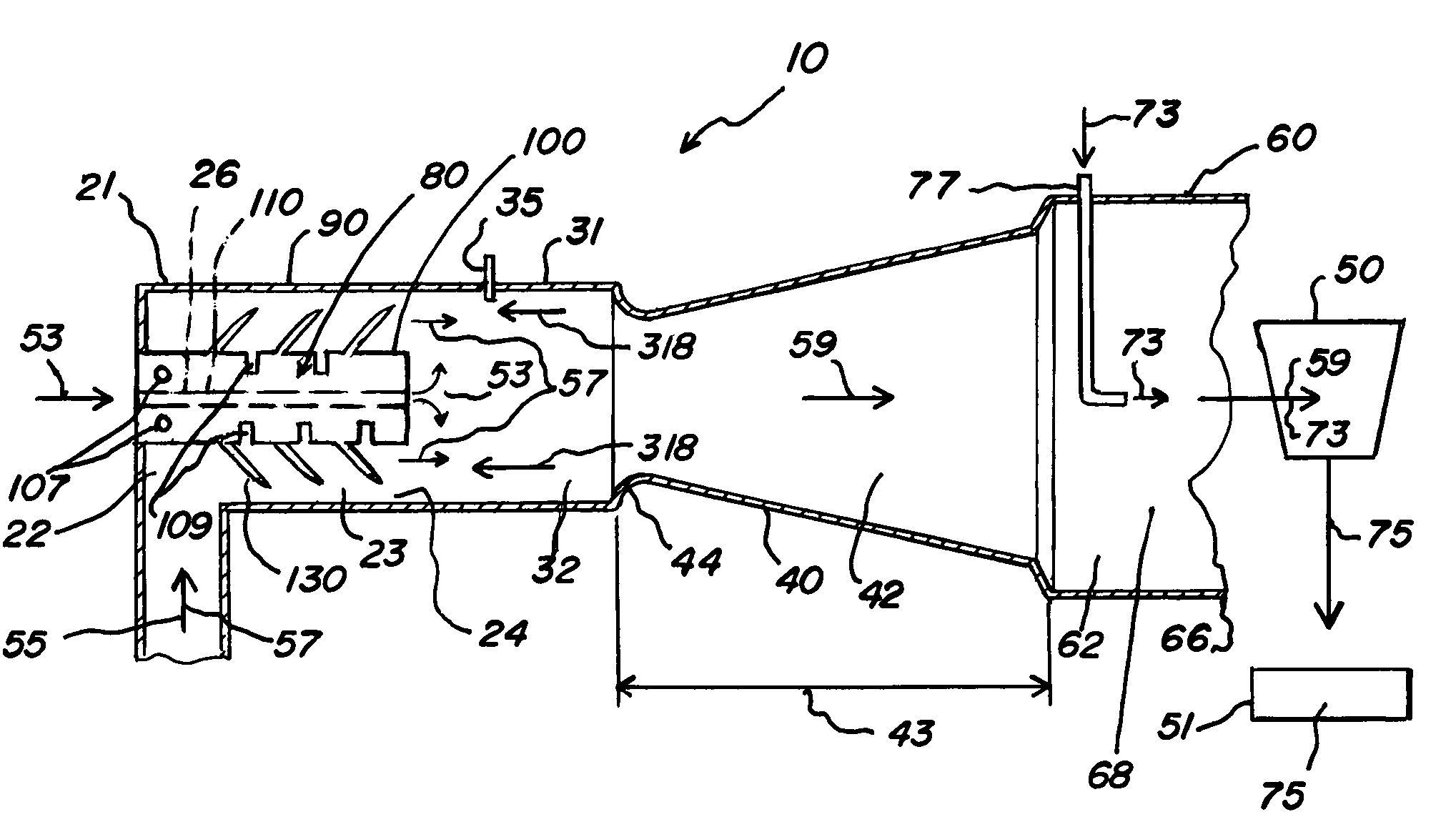

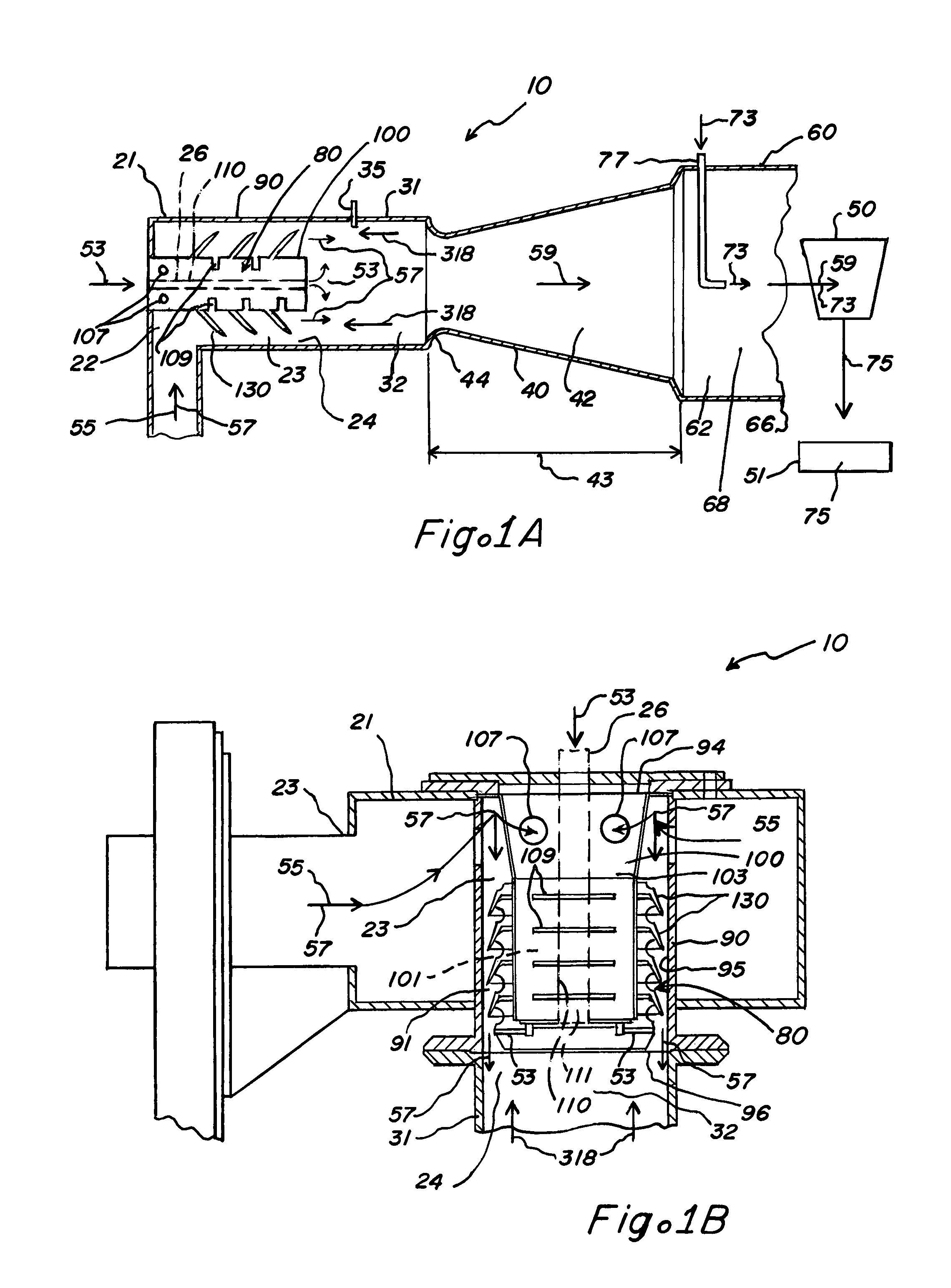

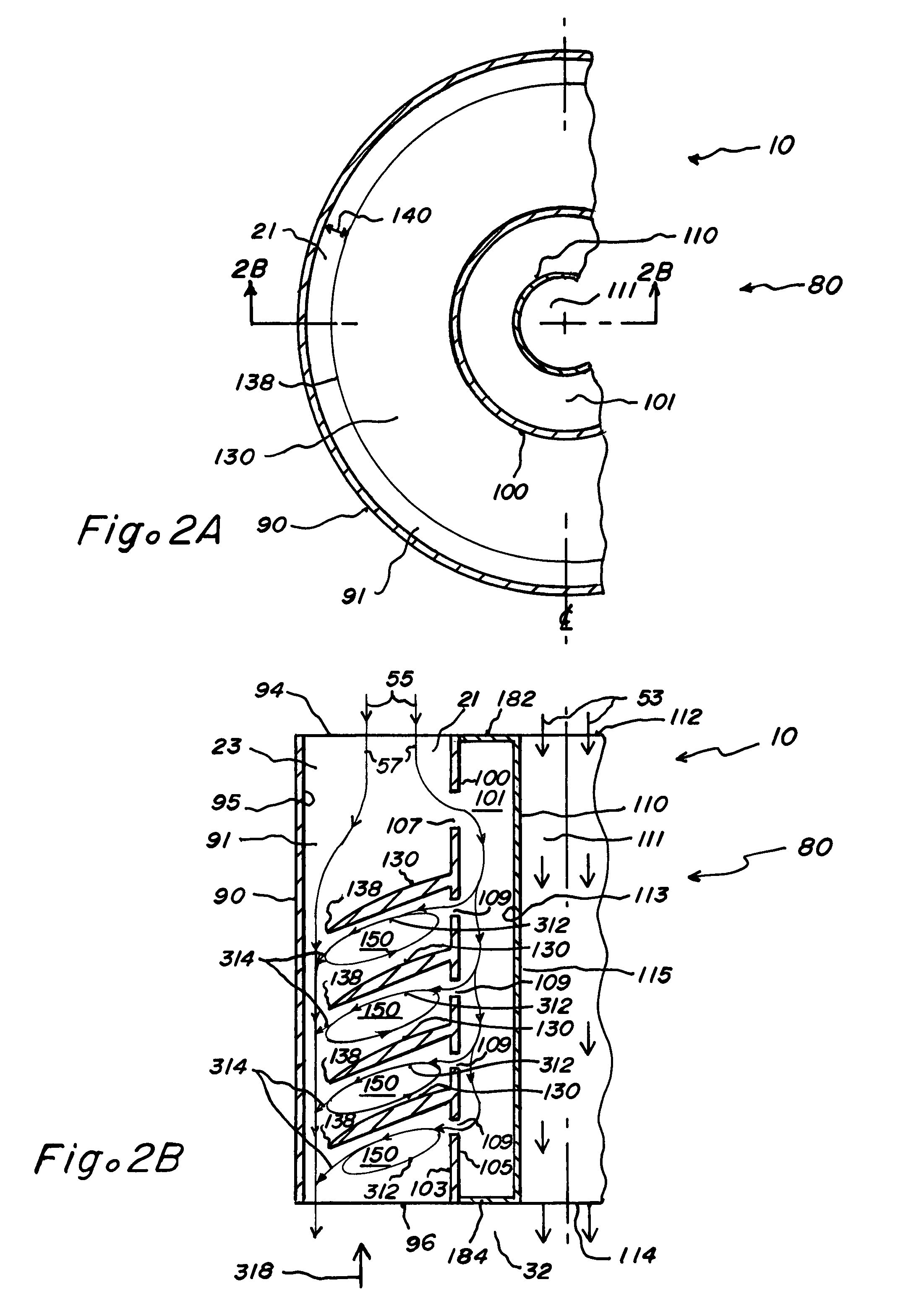

A gasifier system and process comprises a pulse combustion device in communication with a fluid channel for producing a gas stream having heat or fuel value. The pulse combustion device is operated under sub-stoichiometric conditions such that combustion and steam reforming both occur in the fluid channel. The pulse combustion device also produces a pulsating combustion product stream and an acoustic pressure wave. The acoustic pressure wave serves to cause agglomeration of particles contained within the combustion stream for easy removal. In one embodiment, a sulfur capturing agent is injected into the fluid channel for not only removing sulfur from the combustion product stream but for also facilitating particle agglomeration. Ultimately, a gas stream containing hydrogen is produced that may be used in various processes, such as in the production of electricity.

Owner:MFG & TECH CONVERSION INT

Combustion ignition

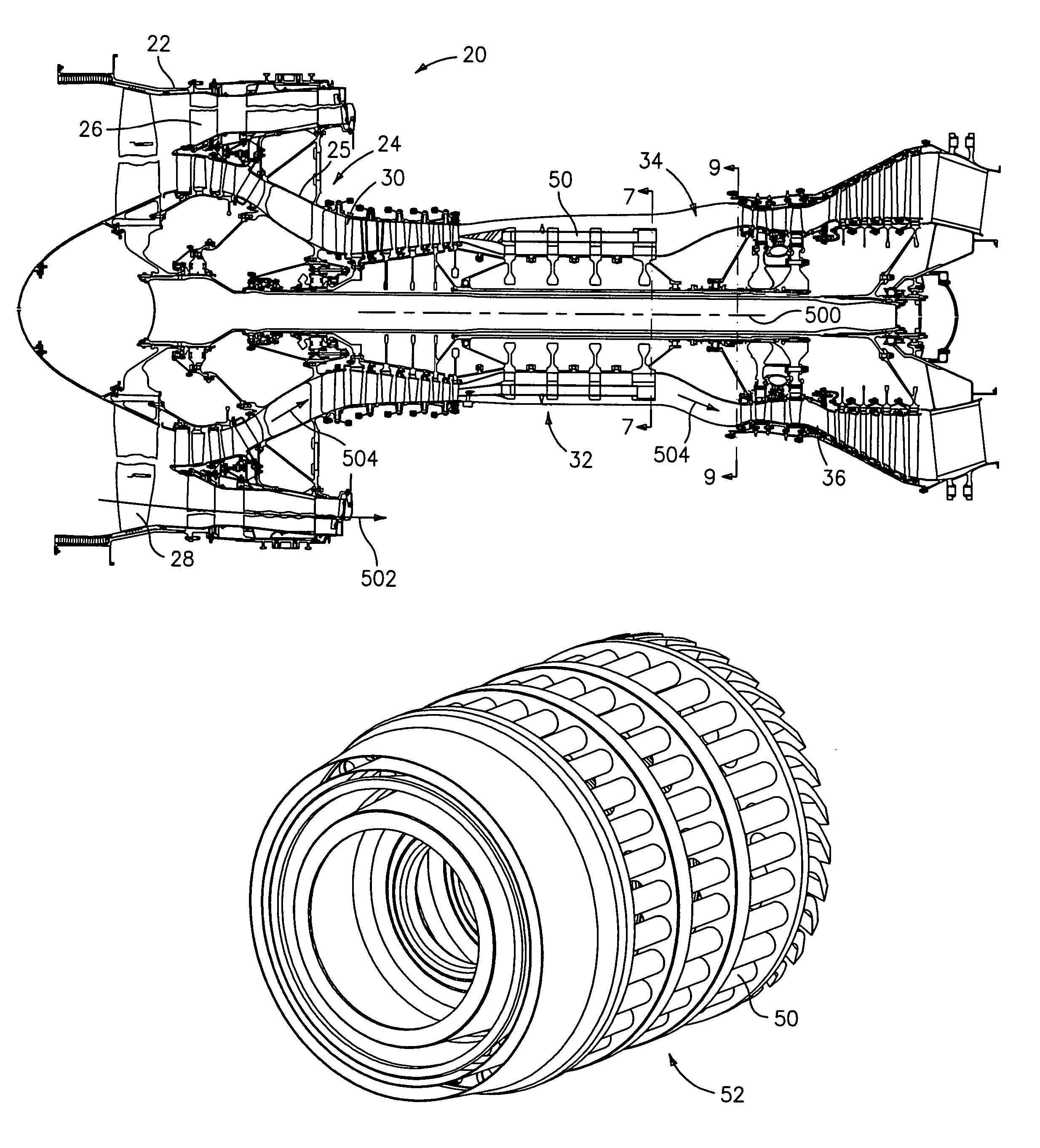

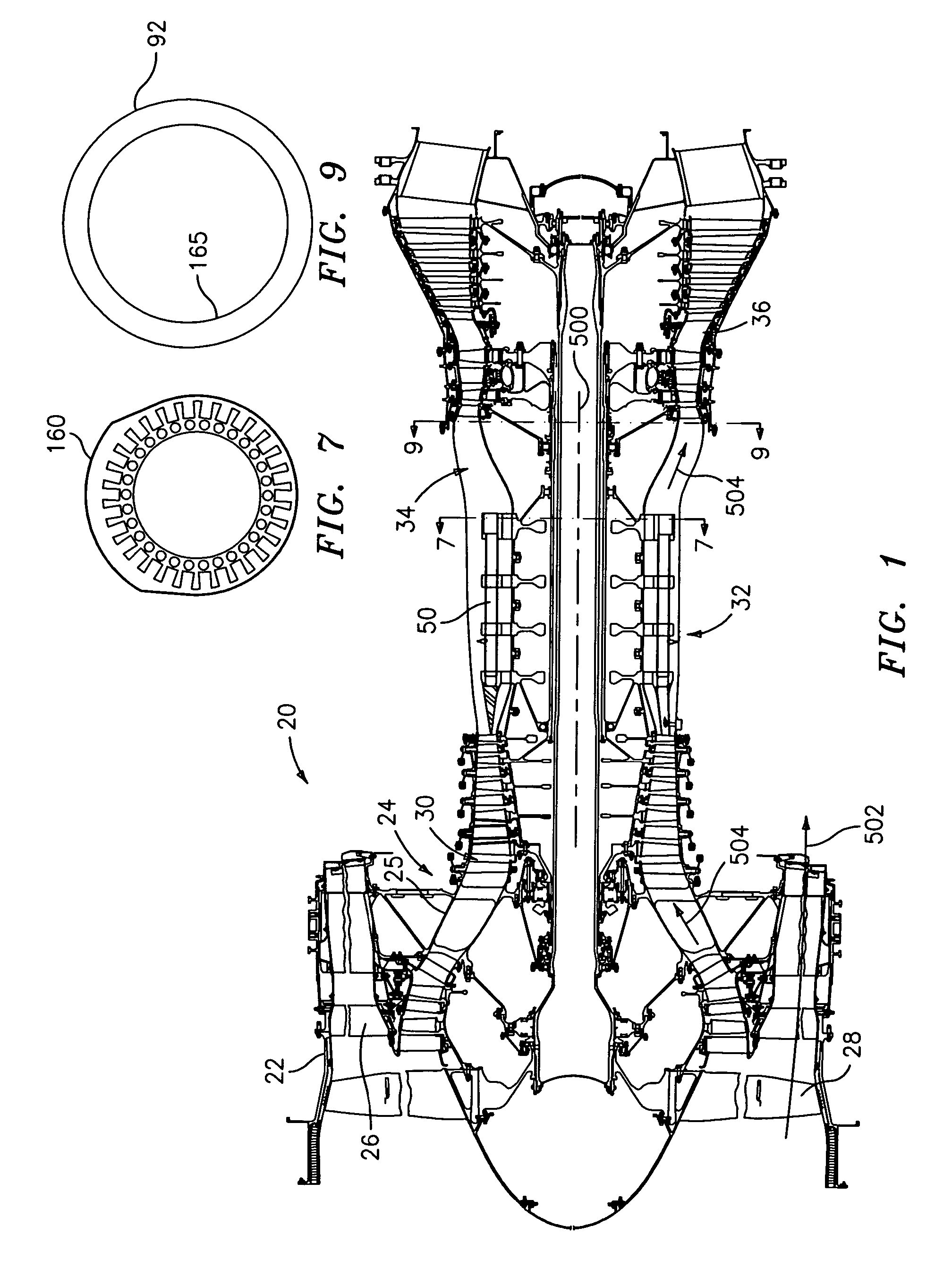

Distributed initiation (e.g., multipoint or continuous) is utilized to obtain constant volume-like combustion performance in a pulse combustion device in the absence of detonation. A number of such devices may be utilized as turbine engine combustors.

Owner:UNITED TECH CORP

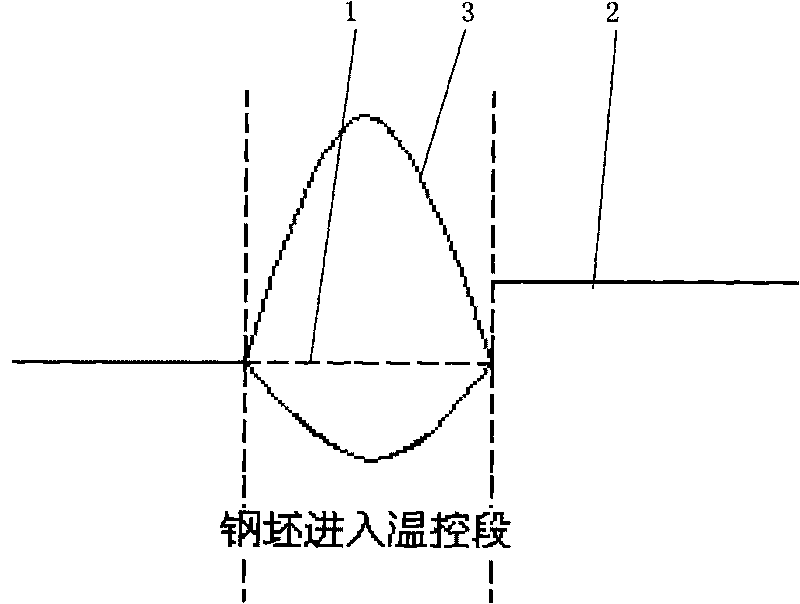

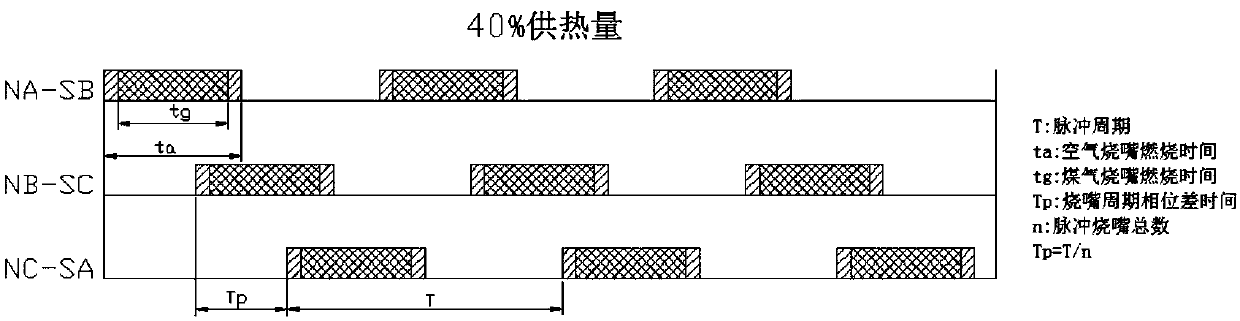

Pulse combustion temperature control method of heat treating furnace

ActiveCN101693945AGood temperature control accuracyQuick responseHeat treatment process controlTemperature controlThermal energy

The invention relates to the technical field of thermal treatment, in particular to a pulse combustion temperature control method of heat treating furnace, which is characterized by comprising the following steps: firstly, utilizing fuzzy self-adapting PID impulse adjustment to control temperature when a steel billet does not enter the temperature control segment of a heating zone, secondly, cutting the fuzzy self-adapting PID impulse adjustment control when understanding that steel billets enter the heating zone according to the material tracing information of the heat treating furnace, and conducing thermal energy balance control, thirdly, switching to fuzzy self-adapting PID impulse adjustment to control temperature when understanding that steel billets leave off according to the material tracing information of the heat treating furnace, fourthly, always adopting the conventional PID impulse adjustment to control temperature in a soaking zone. The pulse combustion temperature control method adopts the combination of fuzzy self-adapting PID impulse adjustment and thermal balanceheat supply to control heating segments, has better temperature control precision, can control overshoot within 10 DEG C, and plays the effects of accurate temperature control, fast dynamic response and energy saving.

Owner:WISDRI WUHAN AUTOMATION

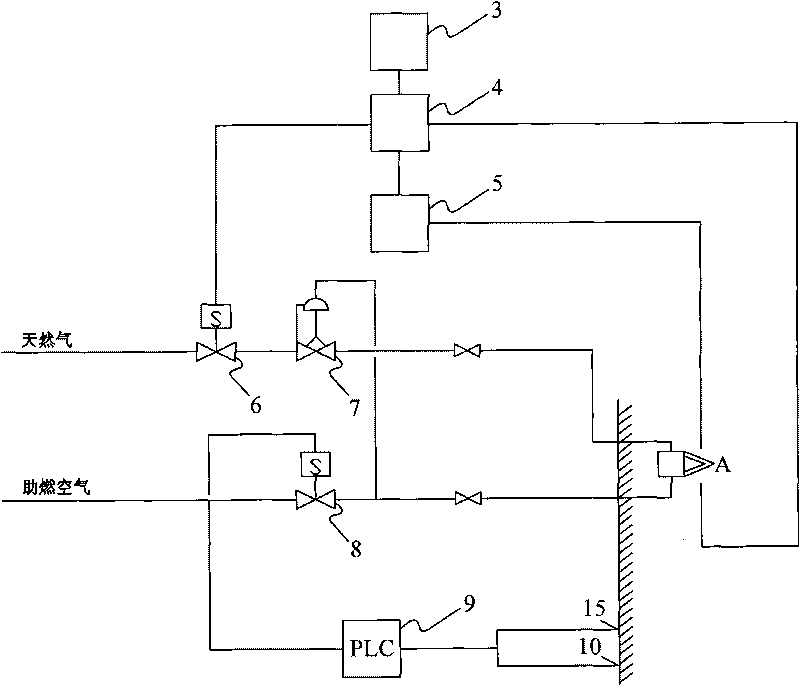

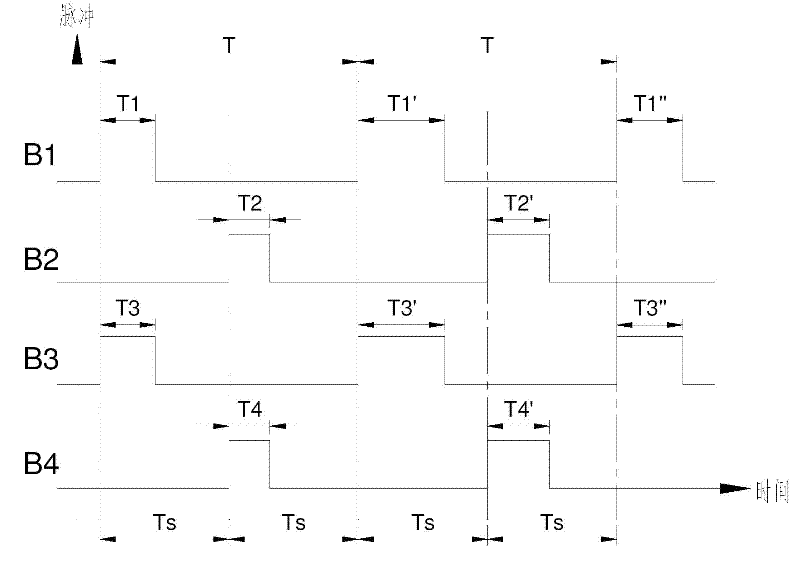

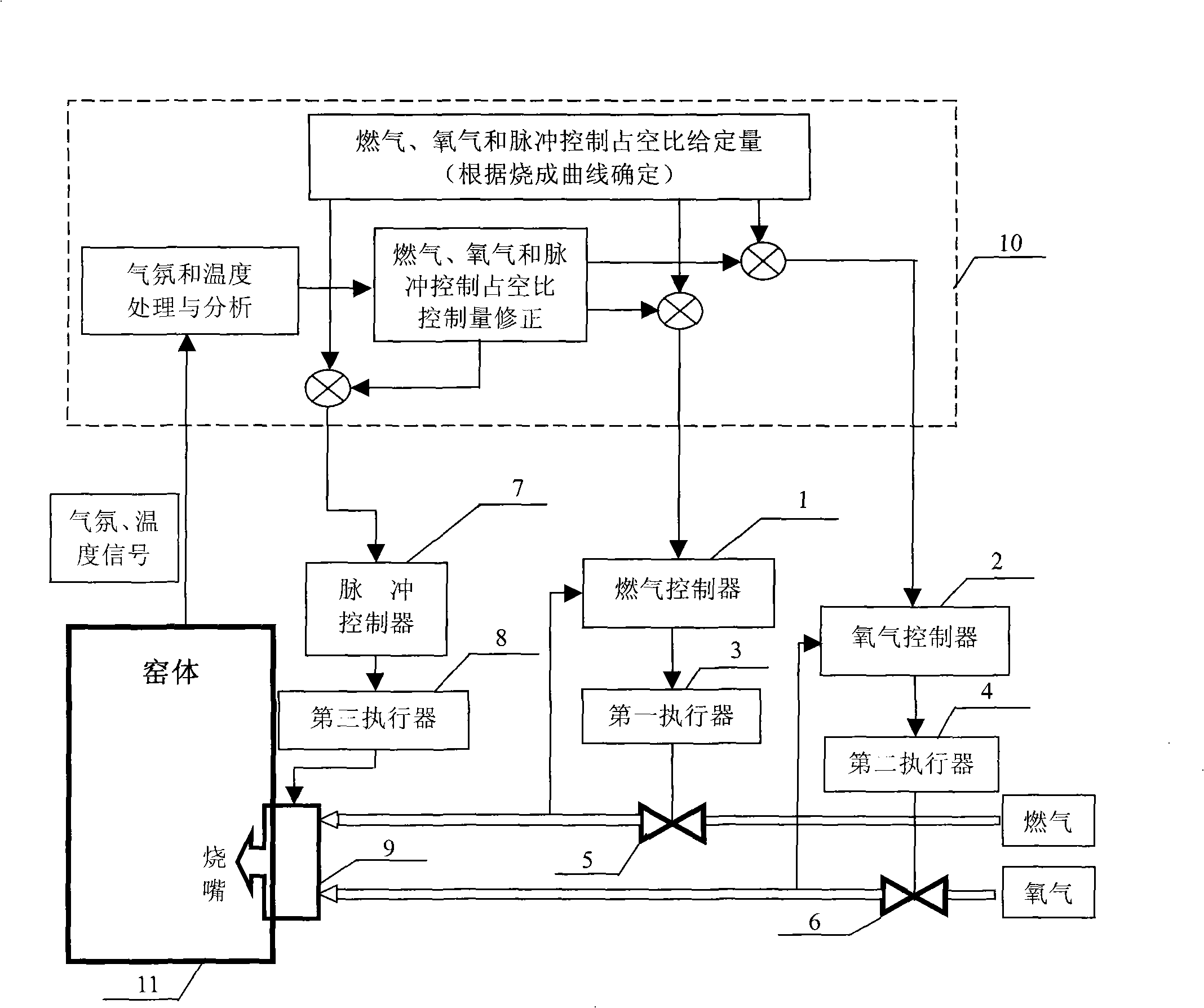

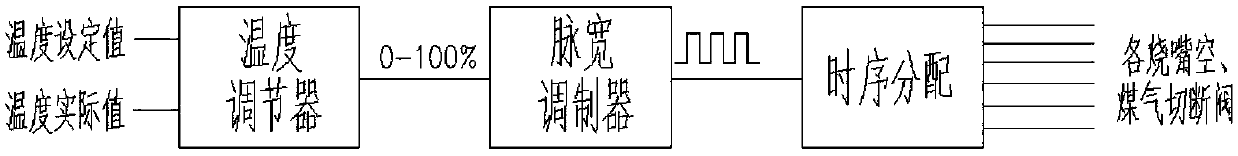

Pulse combustion control system and control method

ActiveCN101737797ALow costFlexible control abilityCombustion regulationTemperature controlControl system

The invention provides a method for controlling pulse combustion which uses a Programmable Logic Controller (PLC) programme to replace a pulse combustion controller to achieve the pulse combustion control, and mainly comprises an adjustment step, a nonlinear treatment step and an output step. The pulse combustion control is innovatively achieved through three steps of PLC programme, the nonlinear treatment step and the output. The method not only saves a large number of costs required for buying pulse controllers, but also has the control effect which is more flexible than the control effect of the pulse controllers, and the temperature control accuracy and the uniformity can well meet process requirements.

Owner:BERIS ENG & RES CORP

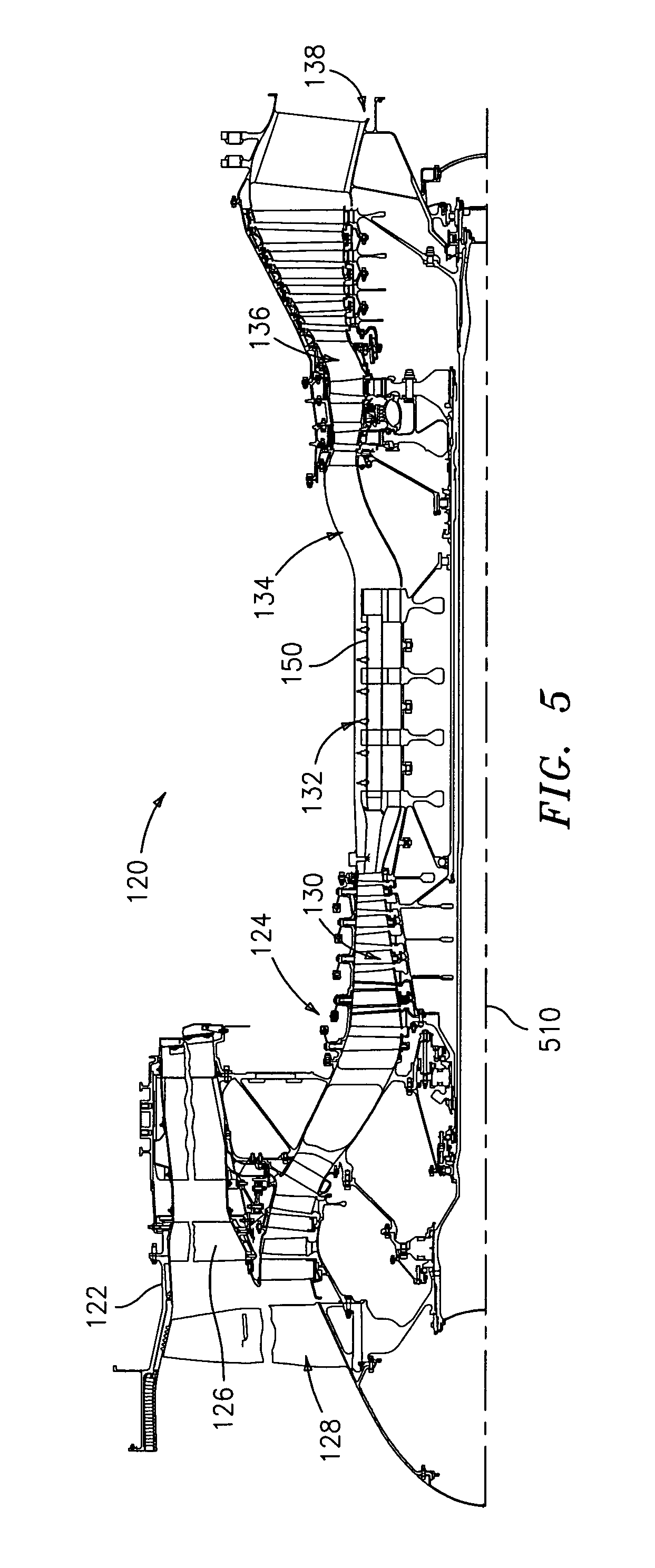

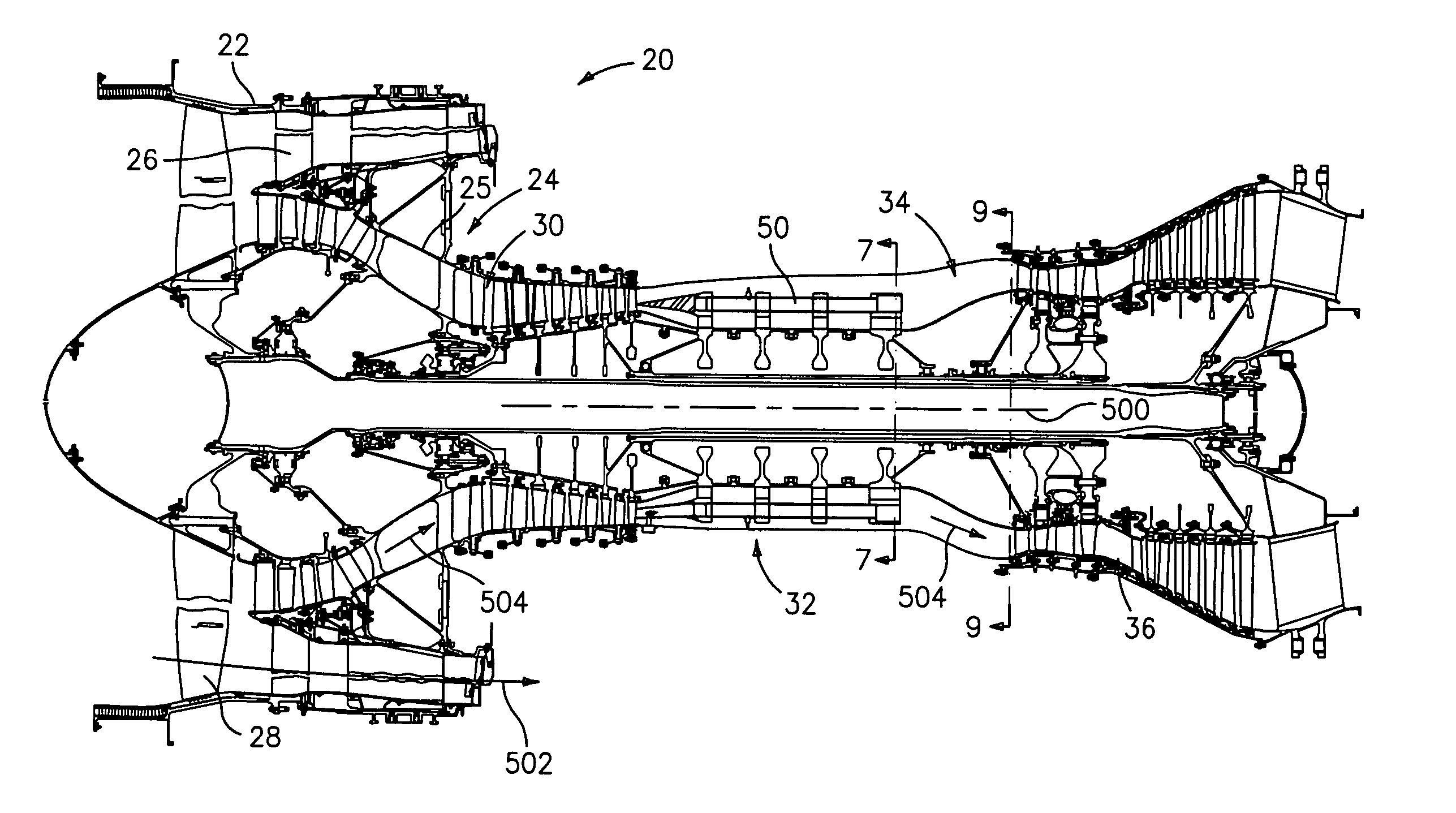

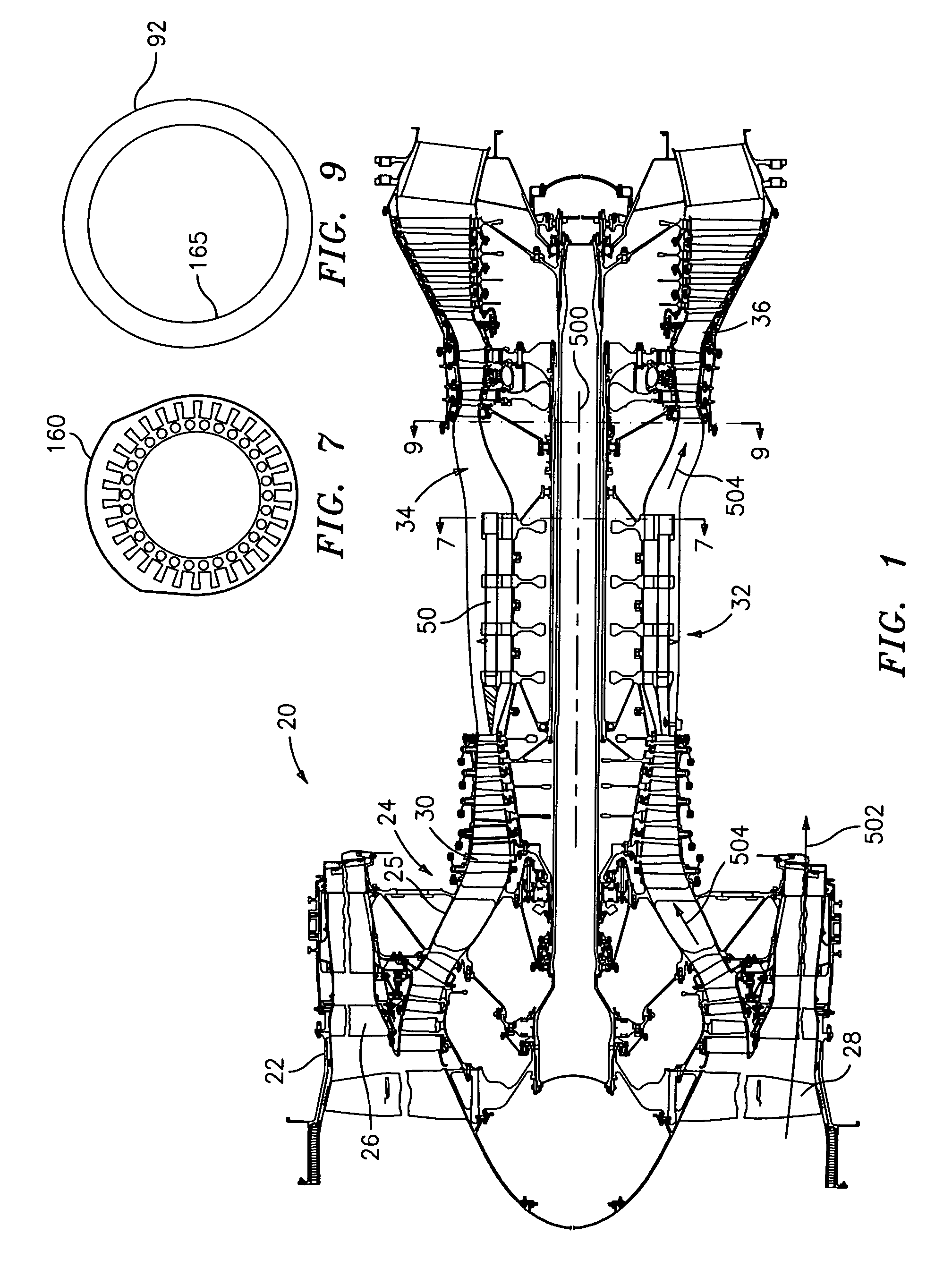

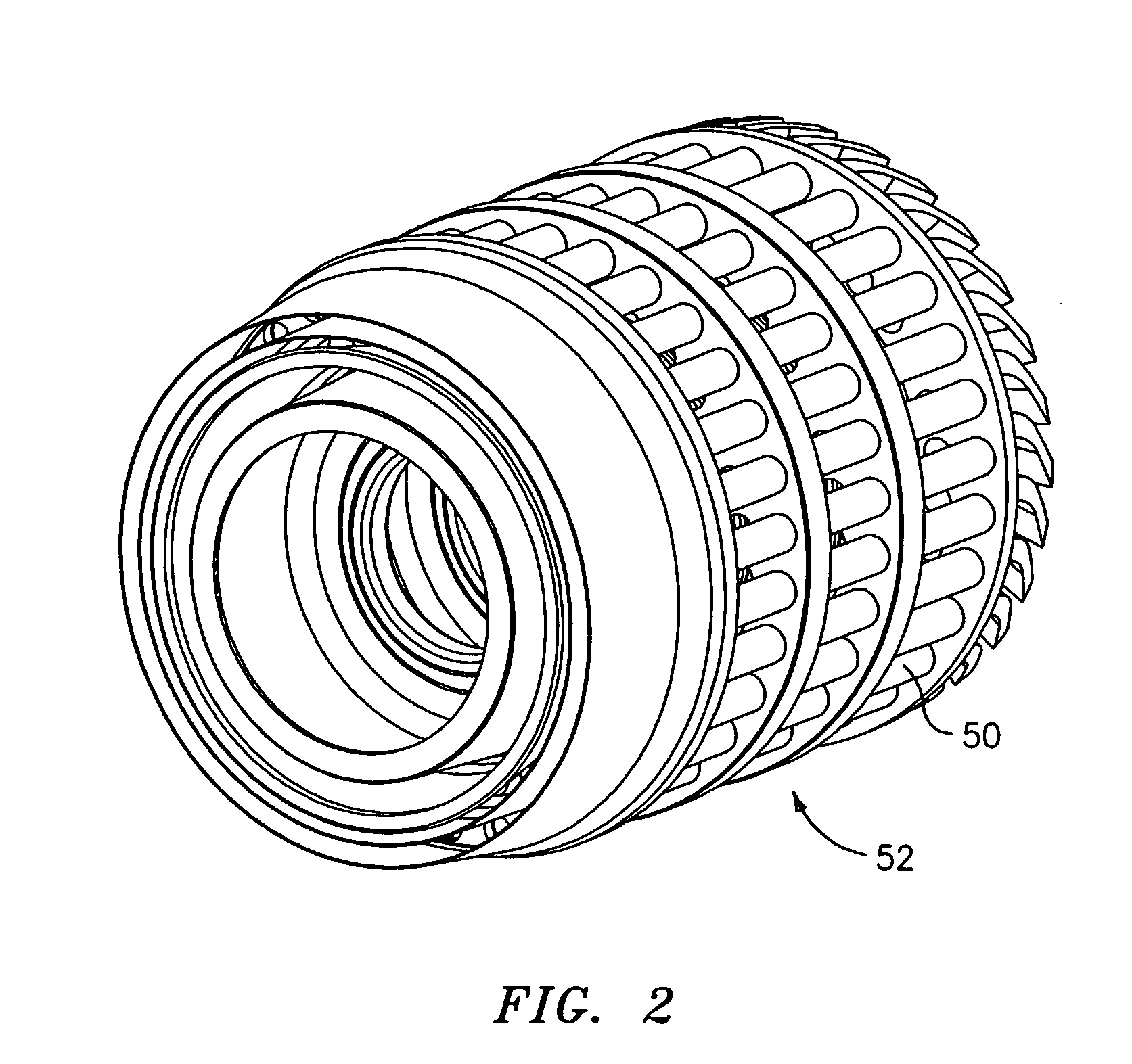

Pulsed combustion engine

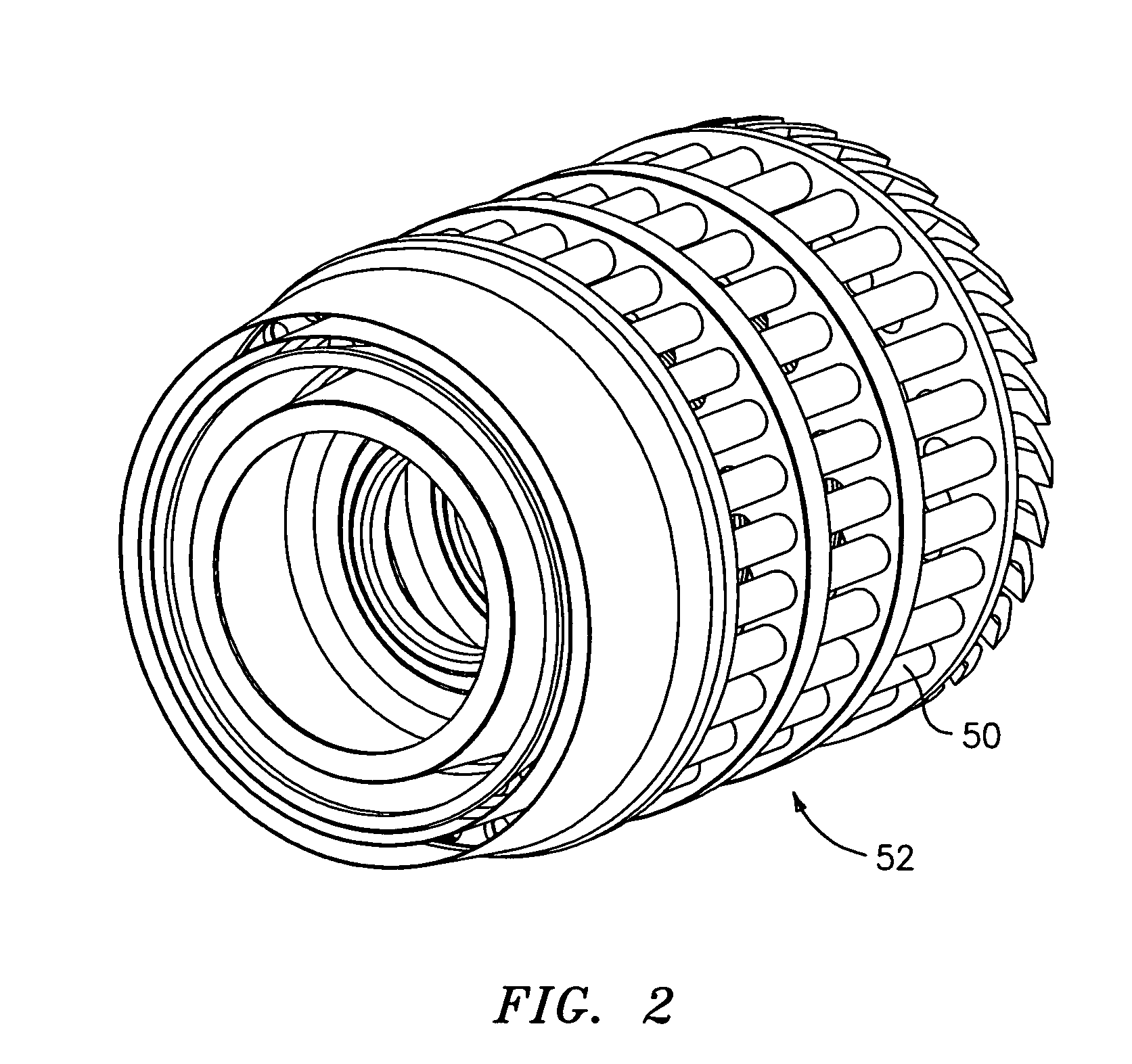

A pulsed combustion device includes a support structure and a combustor carousel supported by the support structure and rotating relative thereto about an axis. The carousel has a number of combustion conduits in a circumferential array. Each conduit cyclically receives a charge and discharges combustion products of the charge.

Owner:UNITED TECH CORP

Pulsed combustion engine

Owner:RTX CORP

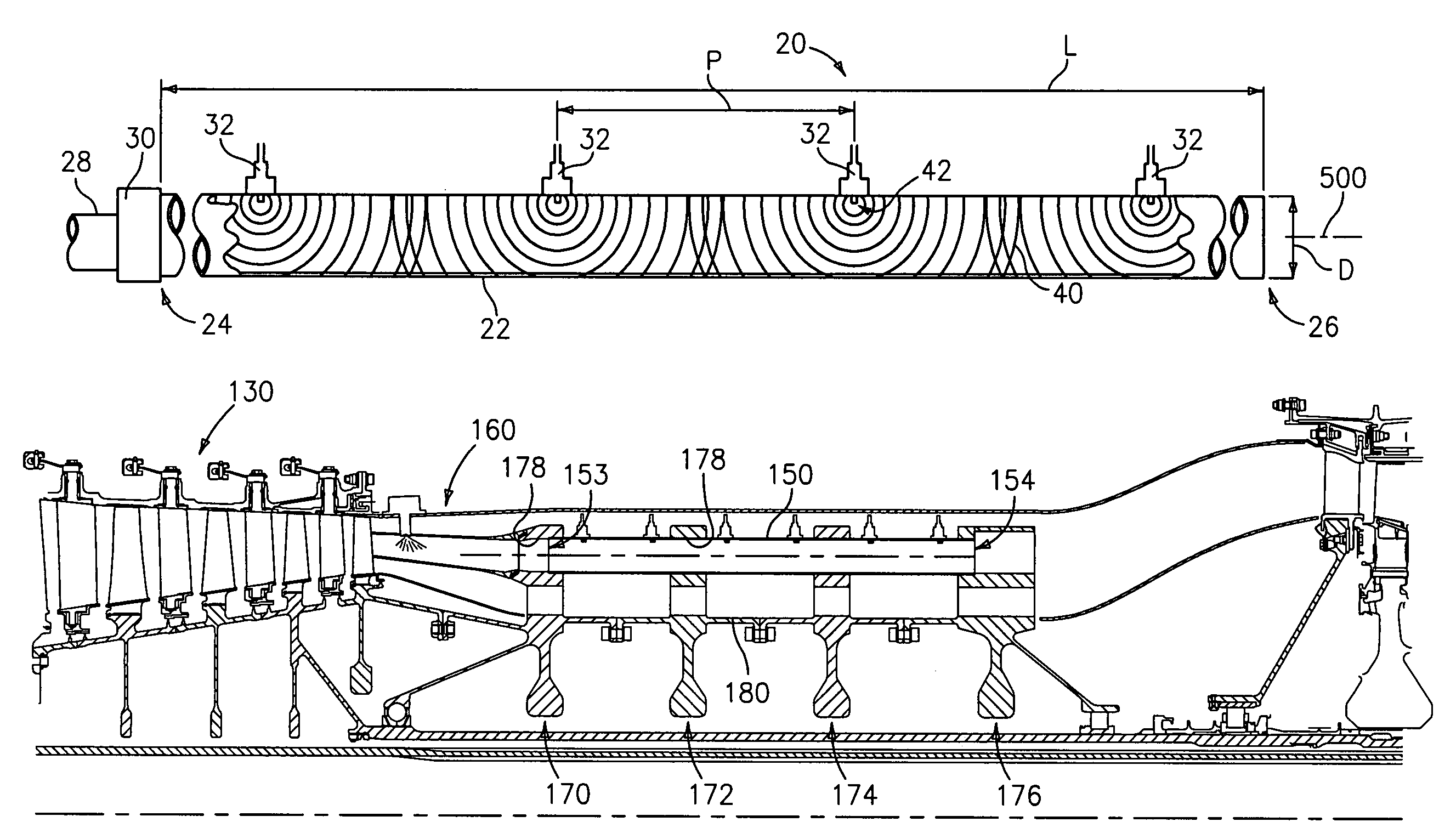

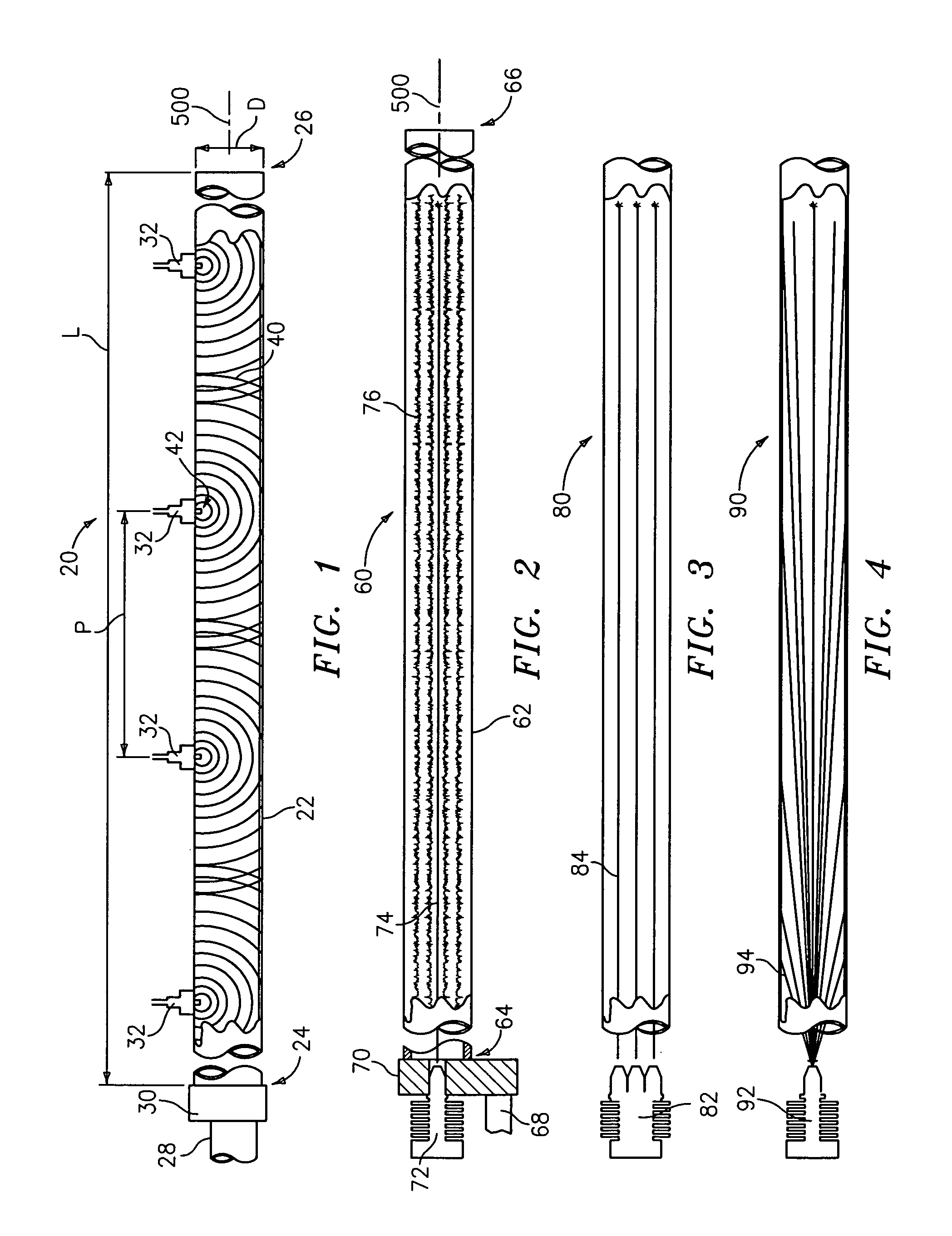

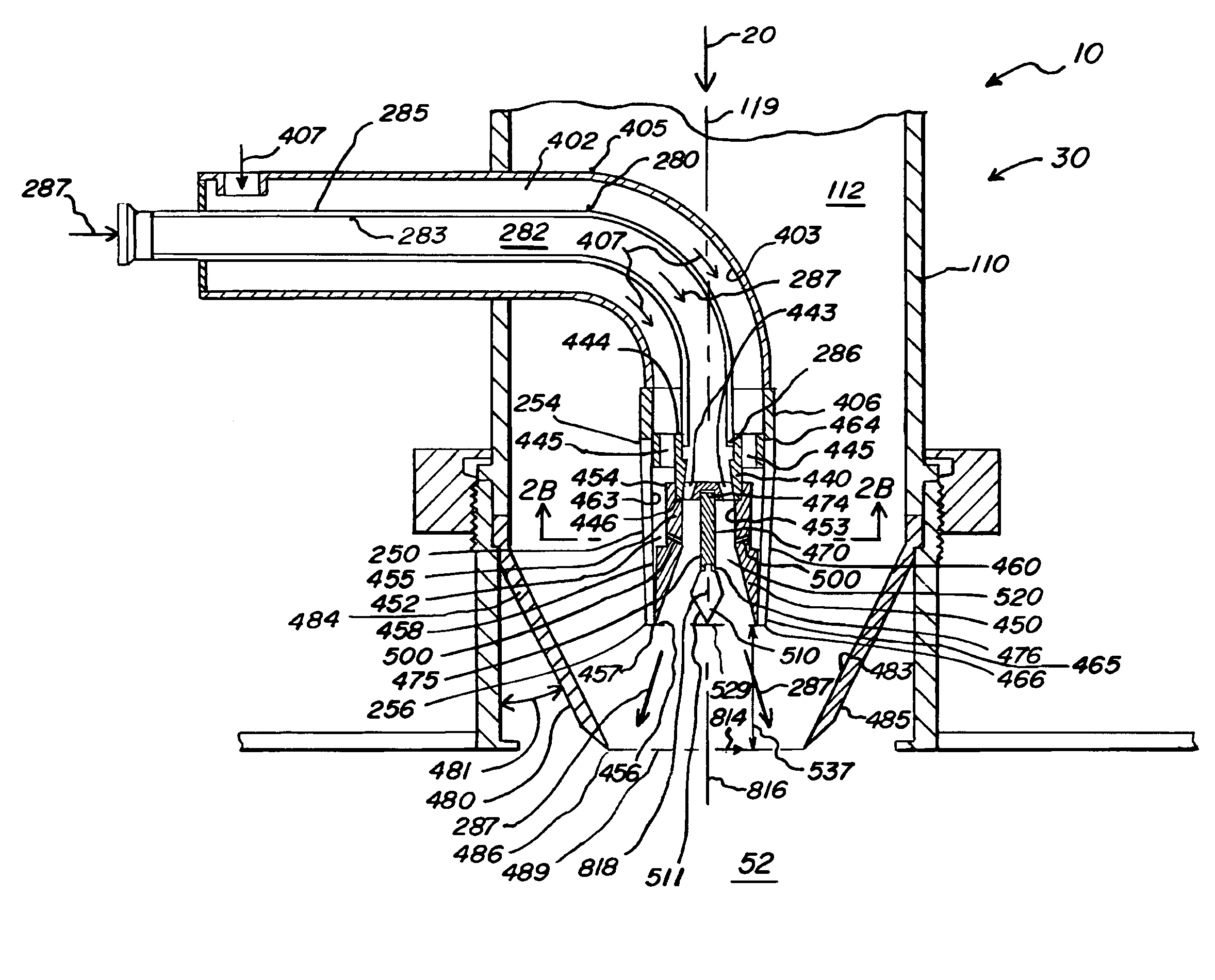

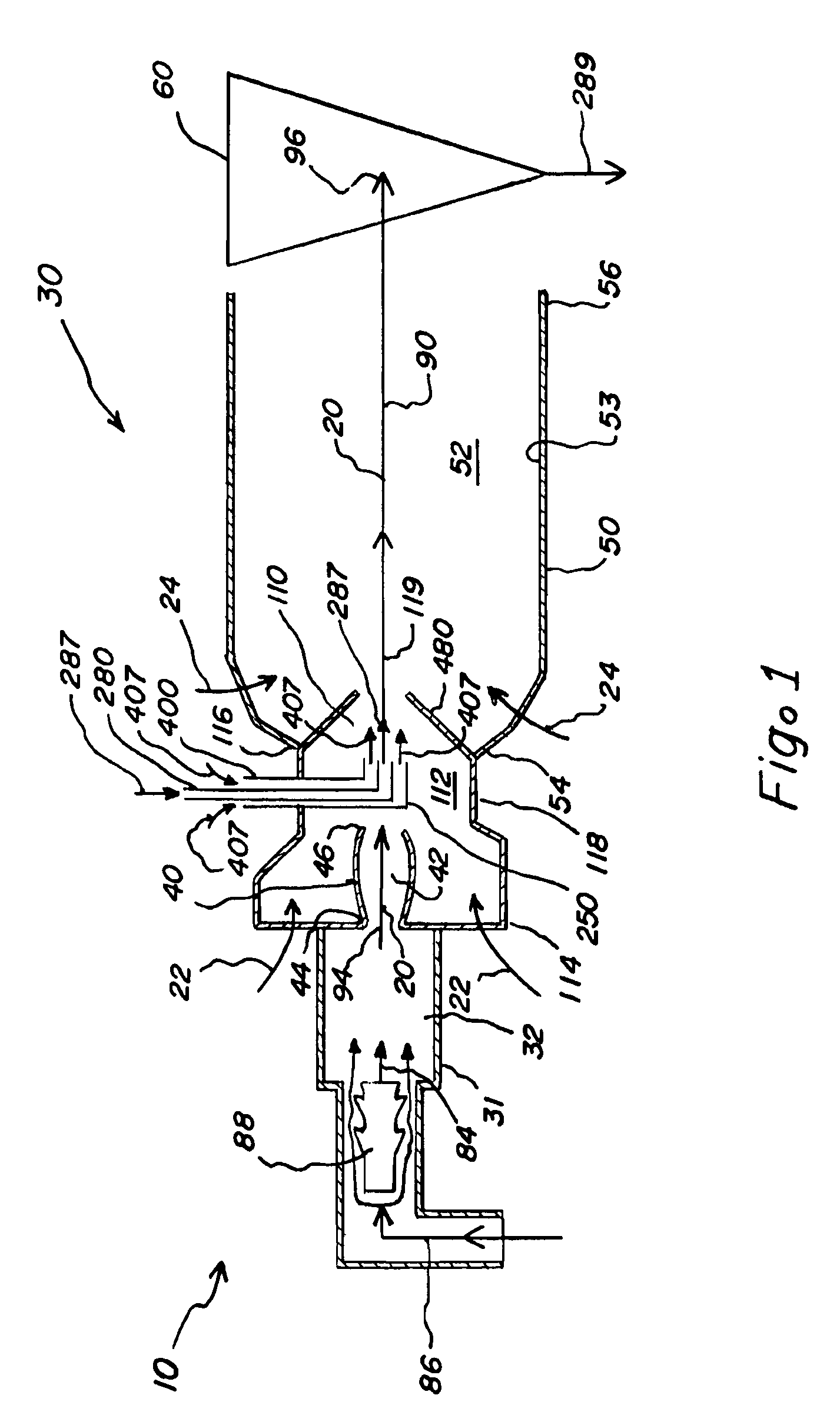

Pulse combustion dryer apparatus and methods

The present inventions relate to pulse combustion dryer apparatus and associated methods. The pulse combustion dryer apparatus may include a combustor that defines a combustion chamber that is in fluid communication with a tailpipe passage defined by a tailpipe. An air inlet communicates air into the combustion chamber through an air inlet passage. A fluid diode disposed within the air inlet passage allows airflow into the combustion chamber through the air inlet passage, and may generally prevent backflow of heated combustion products from the combustion chamber through the air inlet passage.

Owner:PULSE HLDG

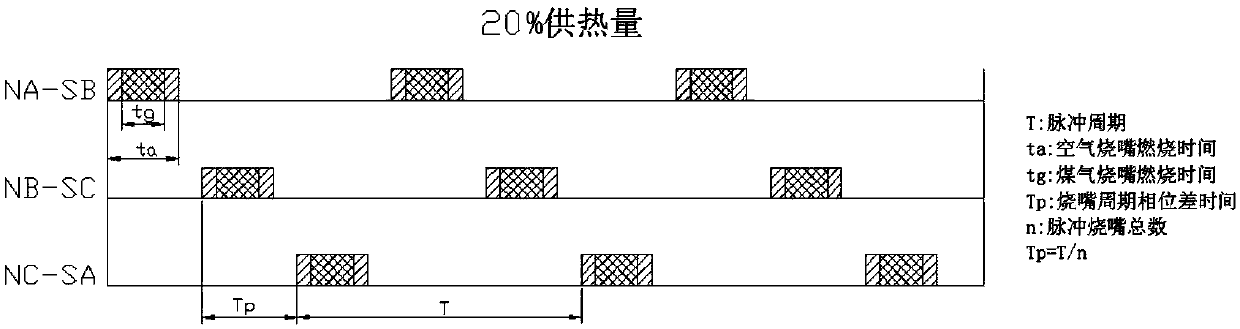

Pulse-combustion control method of steel rolling heating furnace

InactiveCN102221220AEven workloadImprove heat transfer efficiencyFurnace typesHeat treatment furnacesFurnace temperaturePulse cycle

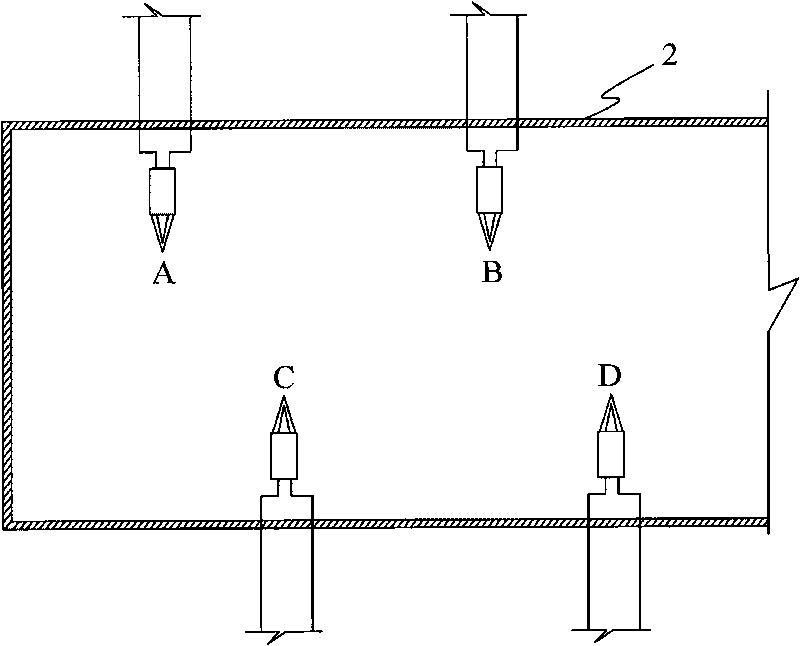

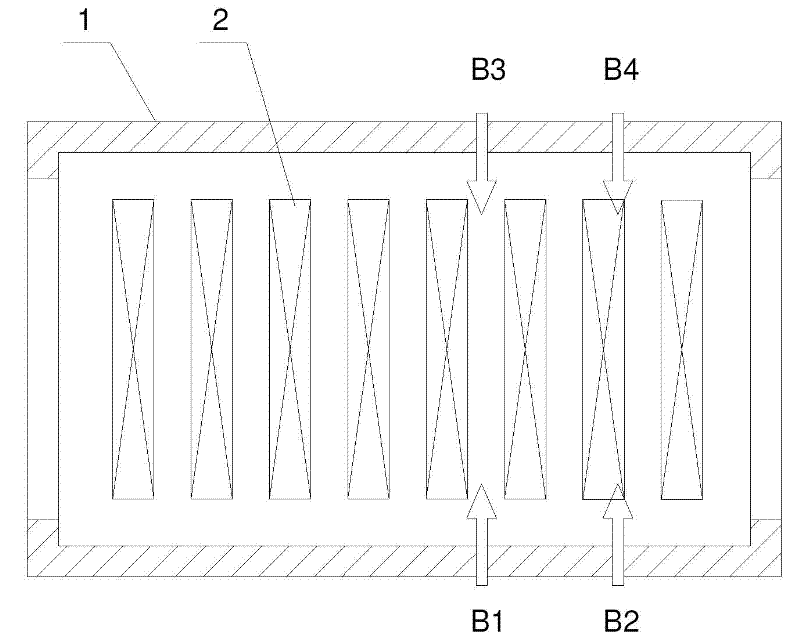

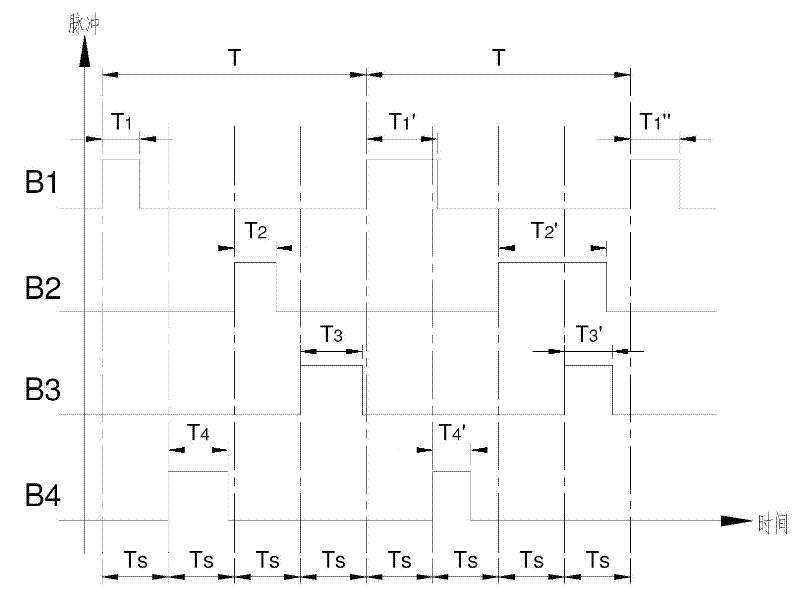

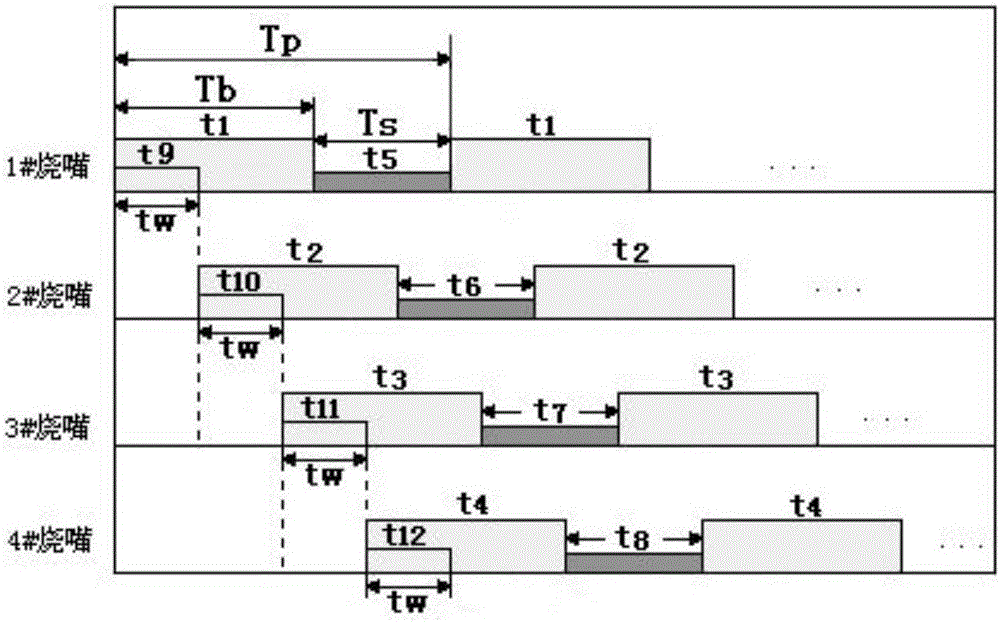

The invention discloses a pulse-combustion control method of a steel rolling heating furnace, namely at least four gas nozzles are arranged at the two sides of the heating furnace and located at the upper and lower parts of blanks in the blank along the length direction of the oven, thus whole-side-burning is formed for the heating furnace, the pulse of opening and closing of the whole gas nozzles is finished in T time and T is taken as a cycle period, each gas nozzle is opened at Ts interval successively, the quantity of the gas nozzles is N, thus in a pulse cycle period Ts=T / N, each gas nozzle open pulse order is set as required and opened by rated heating efficiency, each gas nozzle open pulse time is T1, T2...TQ, and the each gas nozzle open pulse time T1, T2... and TQ are calculated by the PID controller of the heating furnace control system according to the set value and the measured value of the furnace temperature. The pulse-combustion control method provided by the invention has the advantages of improving the furnace-shape, balancing the workload of the gas nozzle, improving fuel burn-off rate, strengthening the heat transfer efficiency of the blank, saving the fuel loss and improving control accuracy and flexibility of the furnace temperature, and is convenient in maintain and operation.

Owner:BAOSTEEL IND FURNACE ENG TECH

Pulsed combustion engine

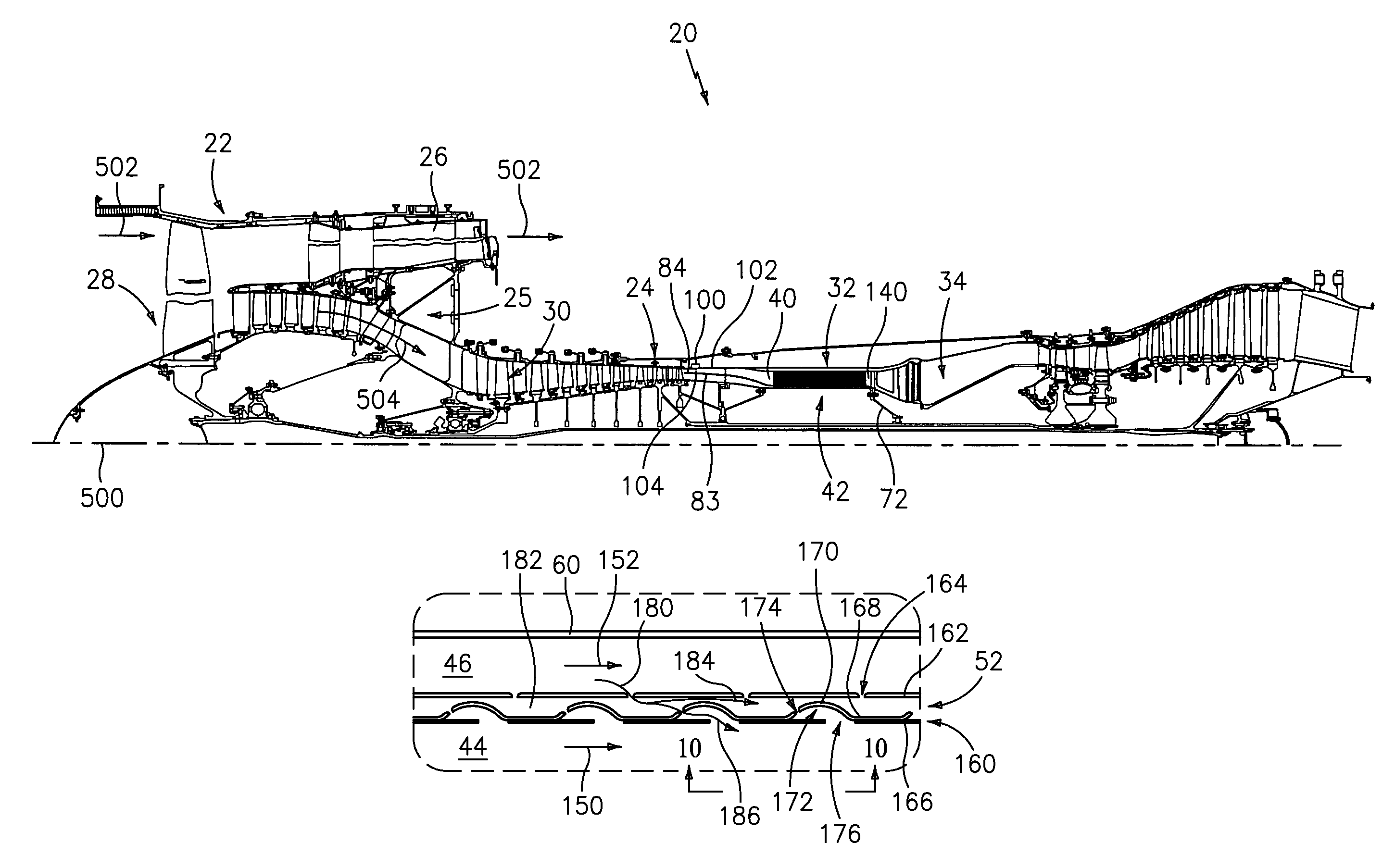

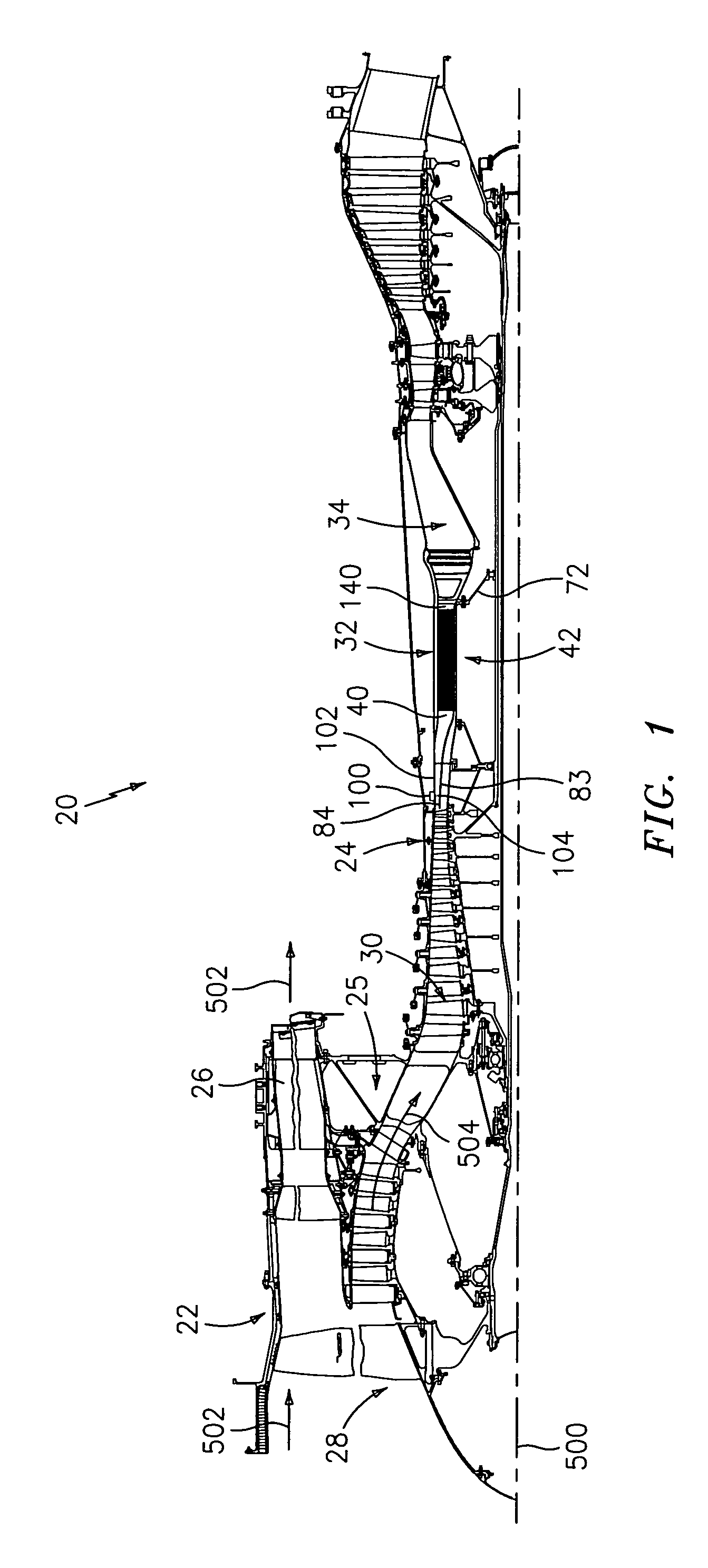

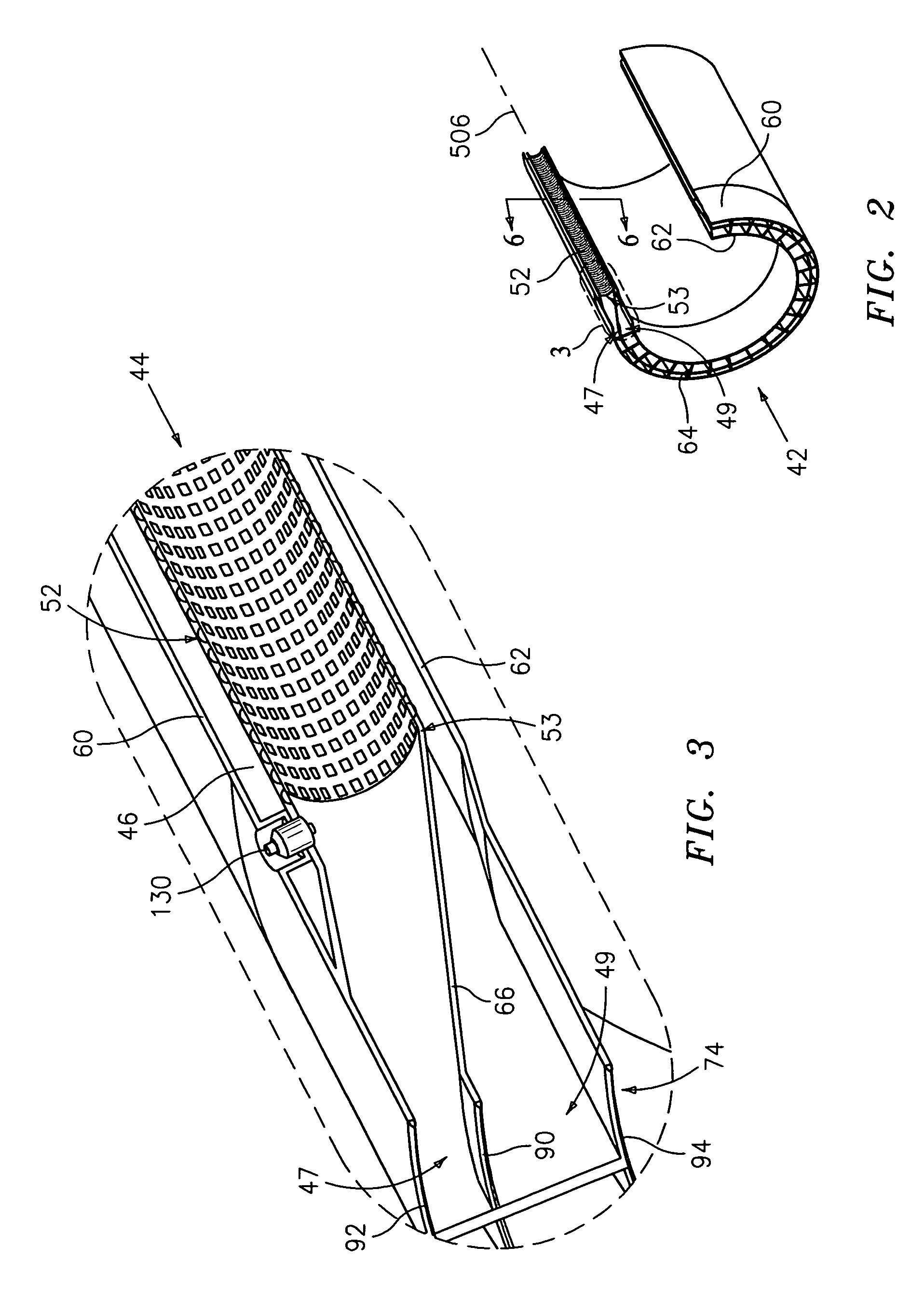

InactiveUS20050000205A1Gas turbine plantsIntermittent jet plantsMechanical engineeringCharge and discharge

A pulsed combustion device includes a support structure and a combustor carousel supported by the support structure and rotating relative thereto about an axis. The carousel has a number of combustion conduits in a circumferential array. Each conduit cyclically receives a charge and discharges combustion products of the charge.

Owner:UNITED TECH CORP

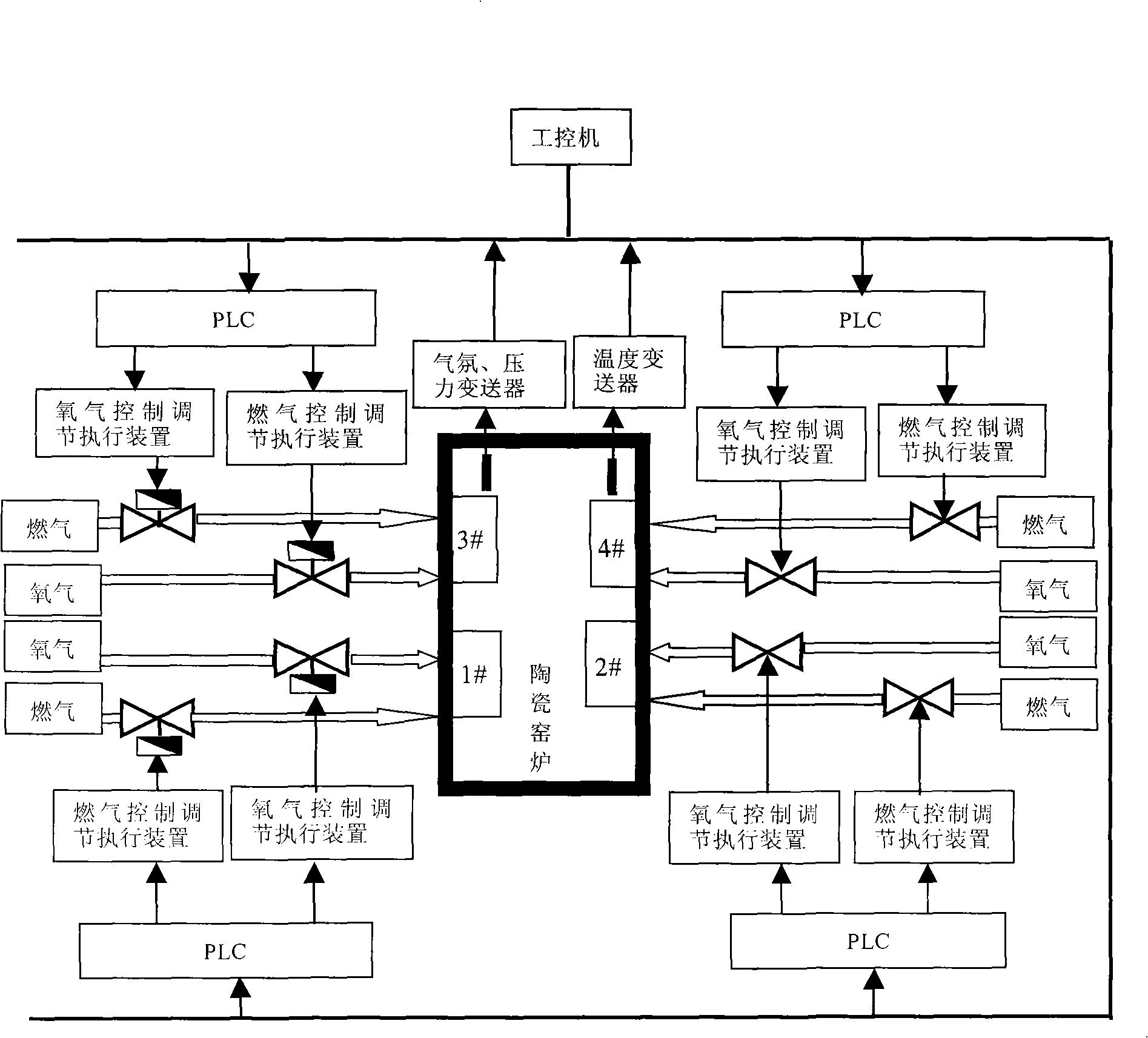

Oxygen-enriched and all-oxygen combustion roller kiln combustion control method

InactiveCN101338910ABurn fullySave energyFuel supply regulationIndirect carbon-dioxide mitigationClosed loop feedbackActuator

The invention discloses a method for controlling the combustion of an oxygen-enriched and full-oxygen combustion roller kiln, a pulse-combustion control method. The mixture ratio of the oxygen and the fuel gas is automatically adjusted by the separate closed-loop feedback control of oxygen and fuel gas, and meanwhile, the mixture ratio is corrected by real-time controlled variable according to the burnt curve; subsequently, under the action of the two signals, the fuel gas and the oxygen actuator adjusts in real-time the fuel gas valve and the oxygen valve, and realize and maintain the preset optimal combustion control ratio; a supervisory computer is used to sample and process the kiln in real-time, then the given quantity of pulse duty-ratio confirmed by the burnt curve is corrected to achieve the real-time controlled variable; and finally, the actuator is controlled and adjusted by the pulse manipulator in real-time to achieve optimal combustion control. The invention is highly efficient, energy-saving, environment-friendly, etc. The oxygen in the combustion atmosphere in the kiln can be kept at more than 21 percent of the volume content and is mixed with fuel gas for combustion; in addition, the proportions of the oxygen and the fuel gas as well as the combustion time are adjusted automatically.

Owner:WUHAN UNIV OF TECH

Pulse gasification and hot gas cleanup apparatus and process

InactiveUS20050120924A1Easy to useConducive to agglomerationAuxillary pretreatmentGasifier mechanical detailsSteam reformingElectricity

A gasifier system and process comprises a pulse combustion device in communication with a fluid channel for producing a gas stream having heat or fuel value. The pulse combustion device is operated under sub-stoichiometric conditions such that combustion and steam reforming both occur in the fluid channel. The pulse combustion device also produces a pulsating combustion product stream and an acoustic pressure wave. The acoustic pressure wave serves to cause agglomeration of particles contained within the combustion stream for easy removal. In one embodiment, a sulfur capturing agent is injected into the fluid channel for not only removing sulfur from the combustion product stream but for also facilitating particle agglomeration. Ultimately, a gas stream containing hydrogen is produced that may be used in various processes, such as in the production of electricity.

Owner:MFG & TECH CONVERSION INT

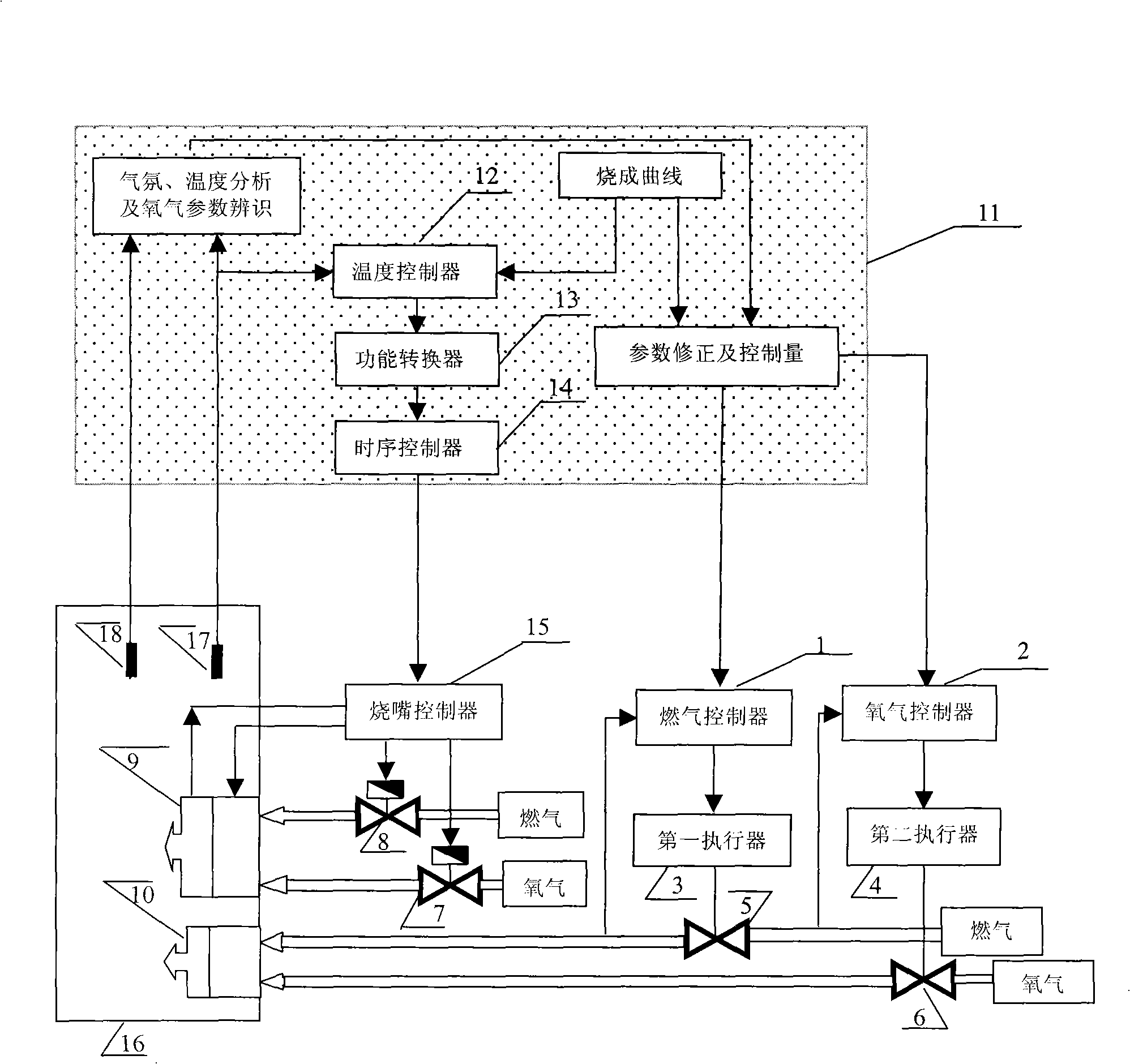

Mixed combustion control system of oxygen-enriched and full-oxygen combustion ceramic roller kiln

InactiveCN101344264AOvercoming the Shortcomings of Continuous CombustionImprove thermal effectFuel supply regulationIndirect carbon-dioxide mitigationAutomatic controlOxygen controller

The invention relates to a mixed combustion control system of an oxygen-rich and total-oxygen combustion ceramic roller kiln, which is composed of a pulse combustion control subsystem and a proportion combustion automatic control subsystem, and a firing curve which is determined by an upper computer (11) is simultaneously implemented; the pulse combustion control subsystem is composed of a temperature measurement sensor (17), a temperature controller (12), a function converter (13), a time sequence controller (14), a burner controller (15), an oxygen electromagnetic valve (7), a gas electromagnetic valve (8) and a pulse combustion burner (9); and the proportion combustion control subsystem is composed of an atmosphere pressure sensor (18), the upper computer (11), a gas controller (1), an oxygen controller (2), a first actuator, a second actuator, a gas valve (5) and an oxygen valve (6). The mixed combustion control system of the invention is applicable to being used in the ceramic roller kiln, can better enhance the combustion performance of the ceramic roller kiln on the whole, save the energy, reduce the emission, improve the product quality, simplify the structure and facilitate the operation simultaneously.

Owner:WUHAN UNIV OF TECH

Precipitated silicas having a narrow particle size distribution

InactiveUS6902715B2Narrow particle size distributionMaterial nanotechnologyPigmenting treatmentSilica particleChemical physics

The present invention provides silica particles, which include the following physical properties: BET surface area: 100-700 m2 / g; DBP absorption: 100-500 g / 100 g; tamped density: 100-250 g / l; ALPINE sieve residue>63μ: <5%; and particle sizes (cumulative volume distribution): d95<40 μm; d50<20 μm; and d5<10 μm. The present invention also provides a process for producing silica having a narrow particle size distribution, which includes drying a silica suspension in a pulse combustion dryer to produce silica particles having the following particle size distribution (cumulative volume distribution): d5<10 μm; d50<20 μm; and d95<40 μm.

Owner:EVONIK DEGUSSA GMBH

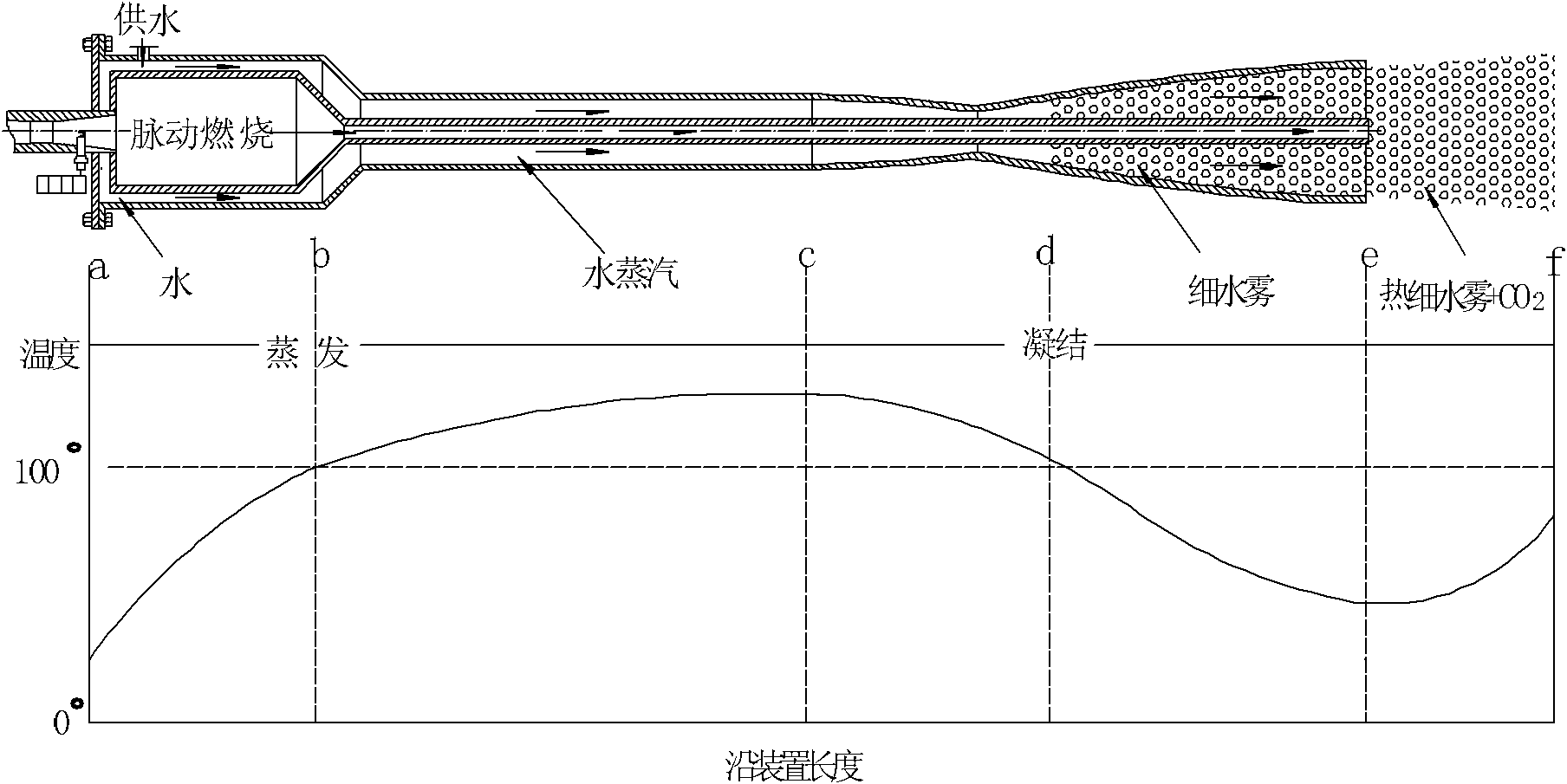

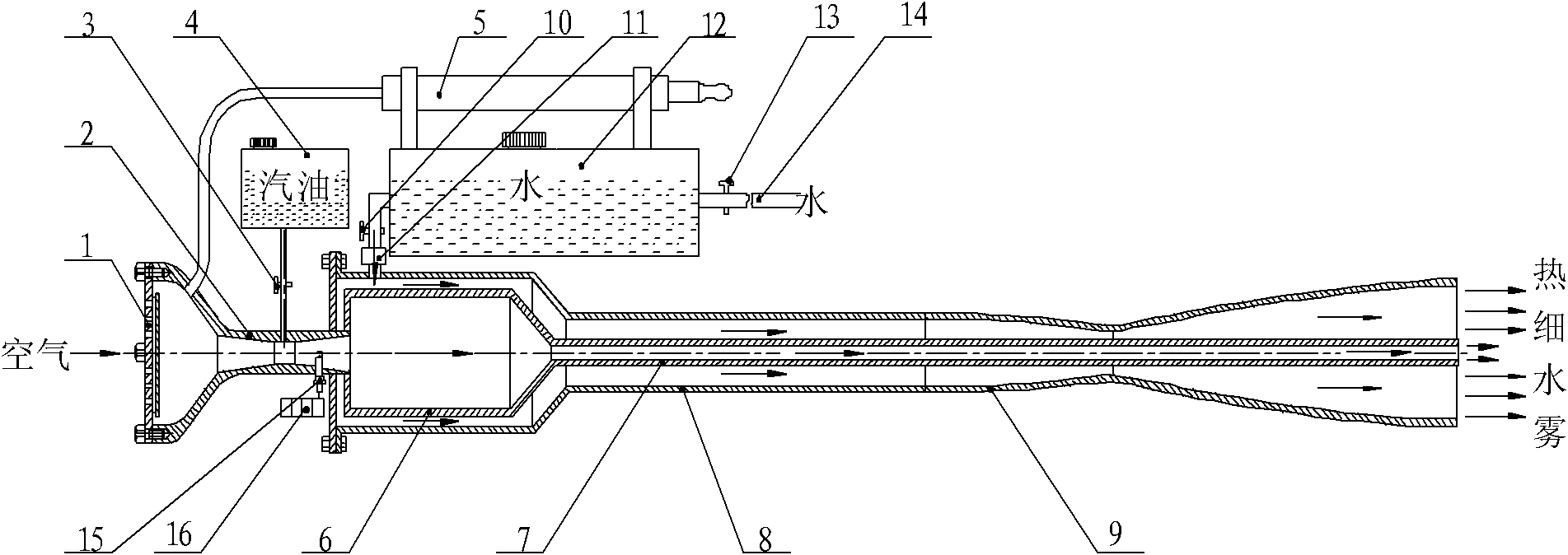

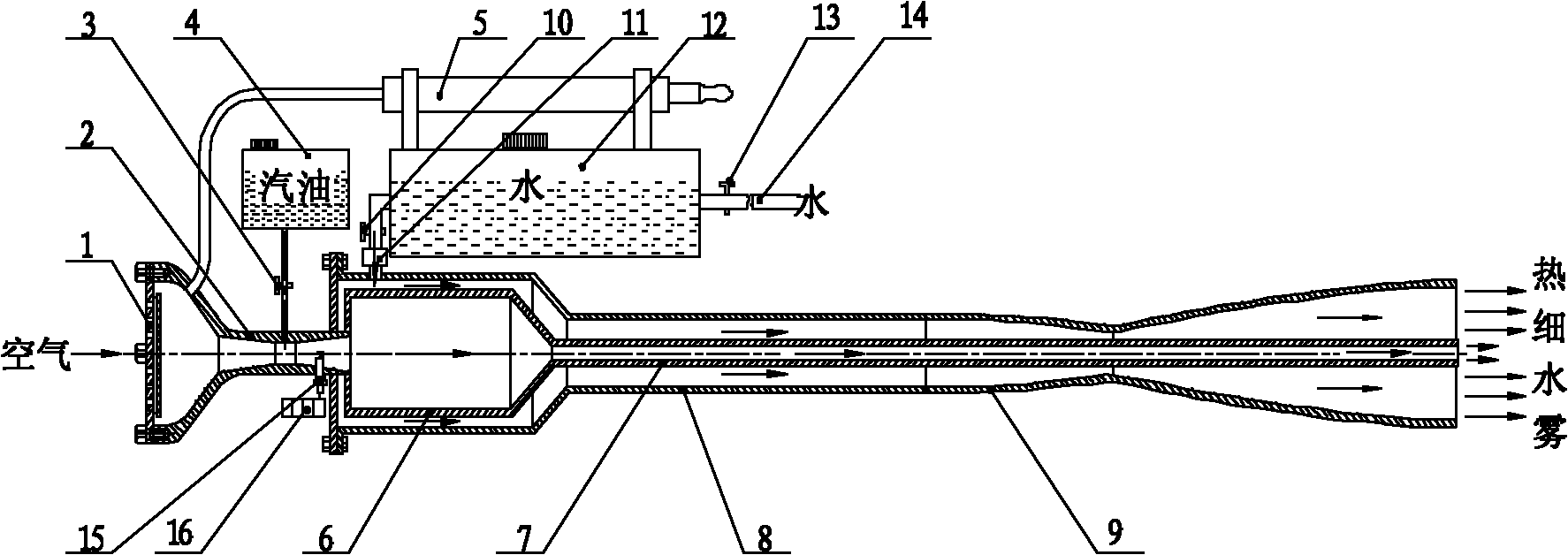

Pulse combustion-driven hot fine water mist generation method and device

ActiveCN102151629AIncrease jet speedNo pollution in the processLiquid spraying apparatusWater vaporEngineering

The invention relates to a pulse combustion-driven hot fine water mist generation method and a pulse combustion-driven hot fine water mist generation device. The hot fine water mist generation method consists of two phase change processes of water, wherein the first phase change is accomplished by vaporizing water into water vapor with a pulse combustion heating device; and the second phase change is accomplished by accelerating the water vapor in a Laval nozzle to convert heat energy into kinetic energy and lowering the temperature of the water vapor in an acceleration process to condense the water vapor into liquid drops with a very small diameter and into fine water mist. The liquid drops are mixed with fuel gas (which is mainly CO2) generated by pulse combustion at the position of the outlet of a spray pipe, and at the same time, the fuel gas heats the fine water mist to 60 to 80 DEG C to form hot fine water mist; and the fuel gas and the hot fine water mist are sprayed to fire sites to extinguish fires. A corresponding portable amplification device consists of three parts, namely, a pulse combustor, a clamping sleeve and a water supply system. The corresponding portable amplification device has the advantages of high extinguishing efficiency, high extinguishing speed, long extinguishing lasting time and the like. The device is mainly used in the field of fire fighting and can also be used in the field of pesticide spraying, mist production and the like.

Owner:BEIHANG UNIV

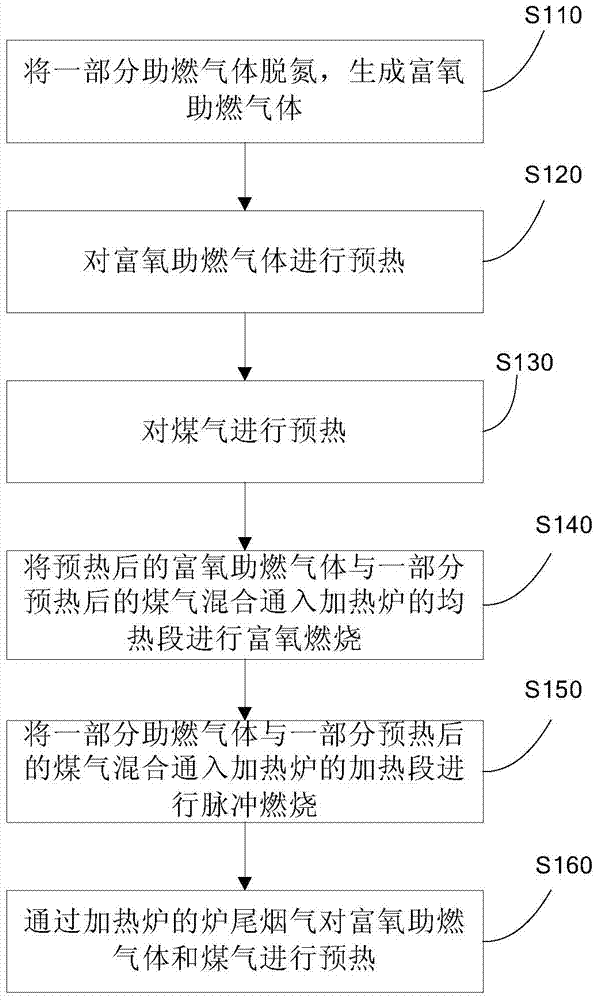

Heating method and system based on steel rolling heating furnace

InactiveCN104748568AReduce furnace unit consumptionHigh heat intensityIndirect carbon-dioxide mitigationGaseous fuel burnerFlue gasCoupling

The invention relates to the field of a metallurgical technology, and discloses a heating method and a heating system based on a steel rolling heating furnace. The method comprises the steps of denitrifying a part of combustion-supporting gas to generate oxygen-enriched combustion-supporting gas; preheating the oxygen-enriched combustion-supporting gas; preheating coal gas; mixing and feeding the oxygen-enriched combustion-supporting gas and the preheated coal gas to a soaking zone of the heating furnace to carry out oxygen-enriched combustion; mixing and feeding a part of oxygen-enriched combustion-supporting gas and the preheated coal gas into a heating section of the heating furnace to carry out pulse-combustion; and preheating the oxygen-enriched combustion-supporting gas and the coal gas through furnace tail flue gas. According to the method provided by the invention, an oxygen-enriched combustion technology, a pulse combustion technology and a heat accumulating type combustion technology can be combined to realize coupling application on the oxygen-enriched combustion technology and the heat accumulating type combustion technology on the steel rolling heating furnace, the technical advantages of heat accumulating type combustion, oxygen-enriched combustion and pulse combustion can be integrated, and the heat transfer speed and heating speed in the steel rolling and heating process can be accelerated to finally realize the energy-saving and cost-reducing of the steel rolling heating furnace.

Owner:SHOUGANG CORPORATION

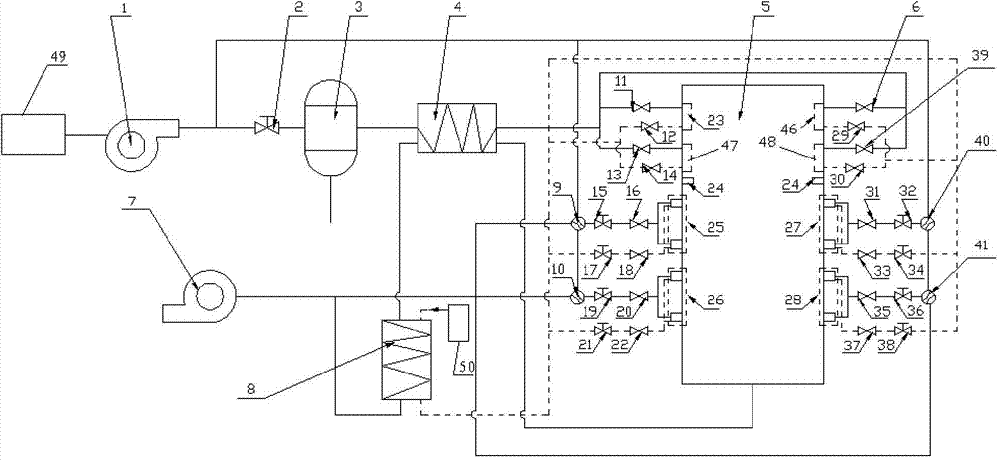

Multi-fragment pulse combustion control system and method

ActiveCN105864819AStable combustionHigh temperature control accuracyFuel supply regulationFurnace temperatureSolenoid valve

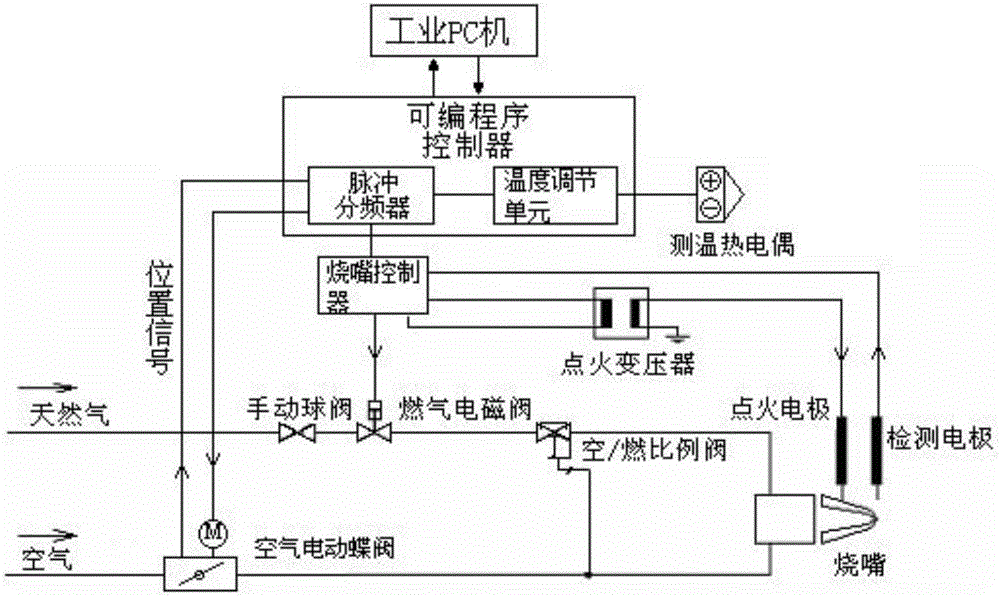

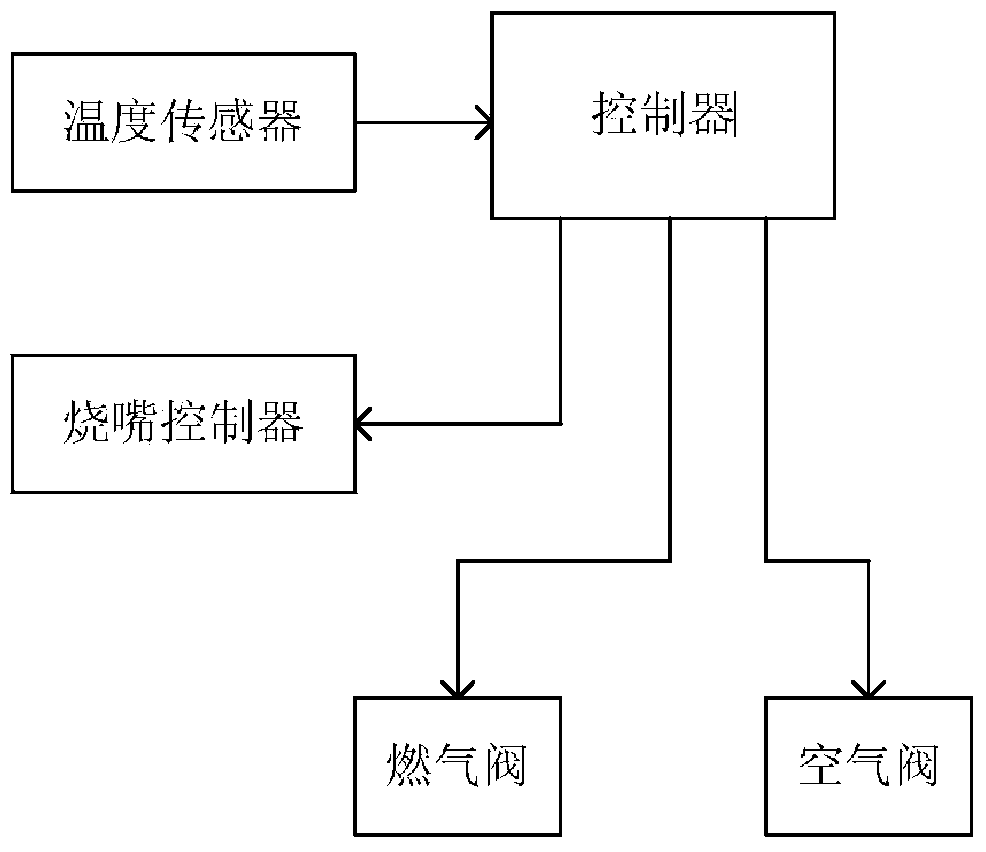

The invention discloses a multi-fragment pulse combustion control system and method. The multi-fragment pulse combustion control system comprises a temperature thermocouple, a programmable controller, a burner controller, an air electric butterfly valve, a fuel gas solenoid valve, a ratio valve of air to fuel, an ignition transformer and a burner, wherein the programmable controller is separately connected with the temperature thermocouple, the input end of the burner controller and the air electric butterfly valve; the output end of the burner controller is separately connected with the fuel gas solenoid valve, the ignition transformer and the burner; the burner is connected with the ignition transformer through an ignition electrode; and the ratio valve of air to fuel is separately connected with the air electric butterfly valve, the fuel gas solenoid valve and the burner through pipelines. The multi-fragment pulse combustion control system has the advantages that the furnace temperature is more uniform in distribution; the temperature control precision is high; the adjustment linear ratio is large; the design cost is low; and the like.

Owner:DALIAN UNIV

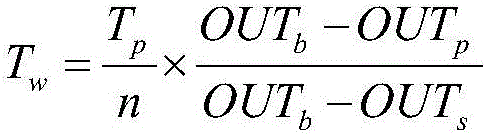

Method for controlling pulse combustion of multiple burners of fuel gas furnace

The invention provides a method for controlling pulse combustion of multiple burners of a fuel gas furnace. According to the method, the differential value between a set temperature and the actual temperature inside the fuel gas furnace is calculated through a controller, a temperature difference signal is calculated through a PID, is converted into a multi-time-sequence variable pulse signal by combining the maximum work period of working of the burners, and is output as a control signal, the multi-time-sequence variable pulse signal controls the opening and closing states of an air valve and a fuel gas valve according to different heating modes and controls the work period of the burner controller. The method enables the burners to burn according to a certain rule, thereby effectively controlling the combustion temperature, guaranteeing temperature uniformity inside the fuel gas furnace and improving combustion efficiency.

Owner:JIANGNAN UNIV

Pulse combustion dryer apparatus and methods

The present inventions relate to pulse combustion dryer apparatus and associated methods. The pulse combustion dryer apparatus may include a combustor that defines a combustion chamber that is in fluid communication with a tailpipe passage defined by a tailpipe. An air inlet communicates air into the combustion chamber through an air inlet passage. A fluid diode disposed within the air inlet passage allows airflow into the combustion chamber through the air inlet passage, and may generally prevent backflow of heated combustion products from the combustion chamber through the air inlet passage.

Owner:PULSE HLDG

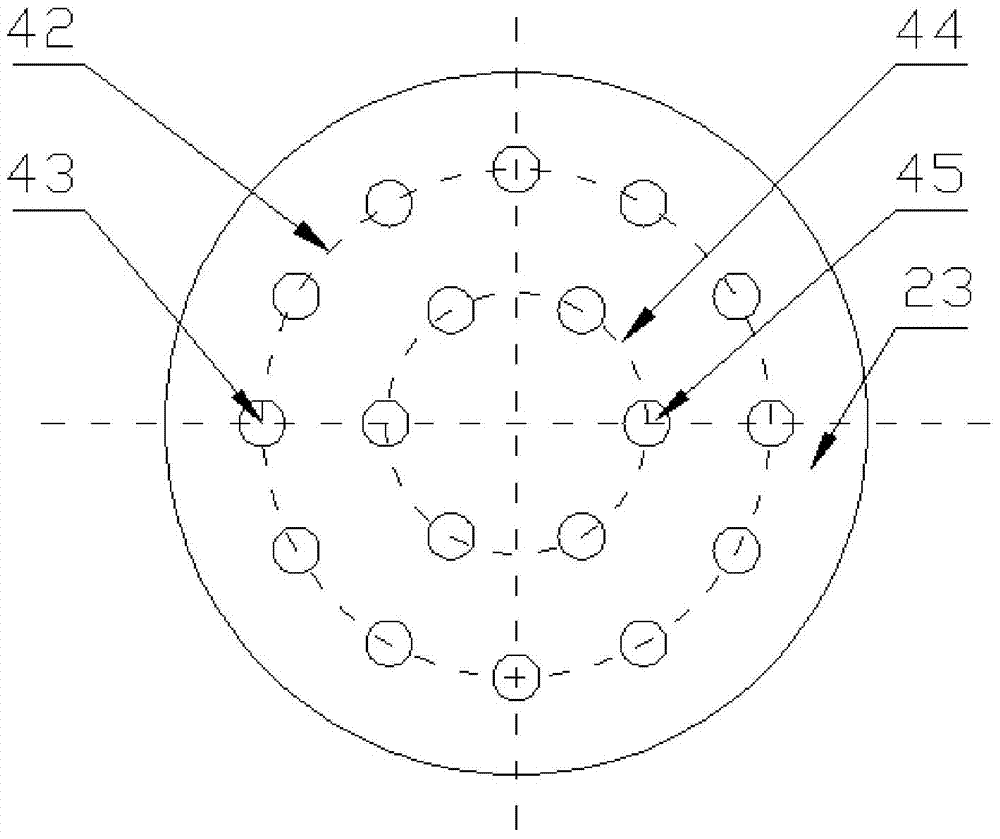

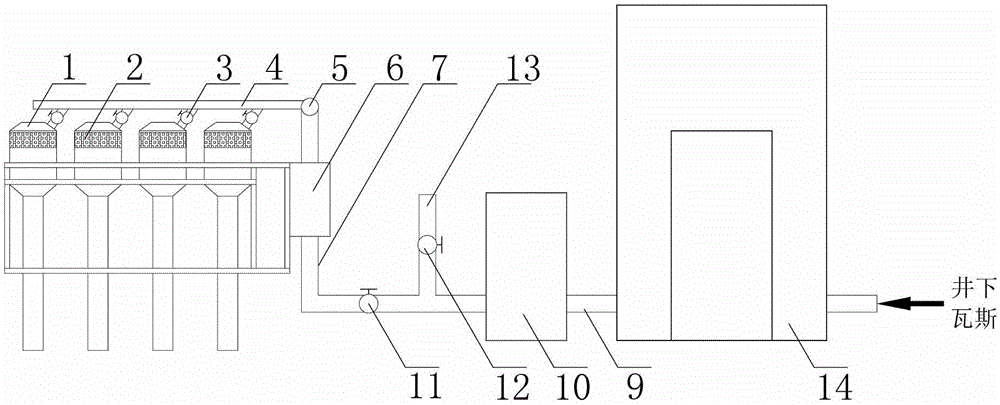

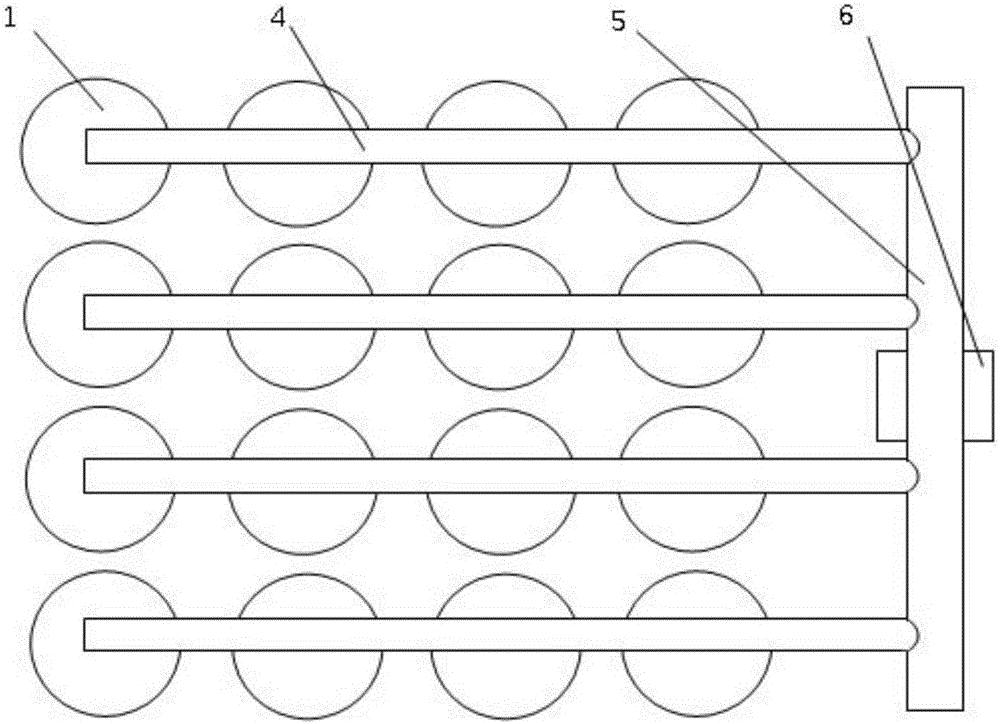

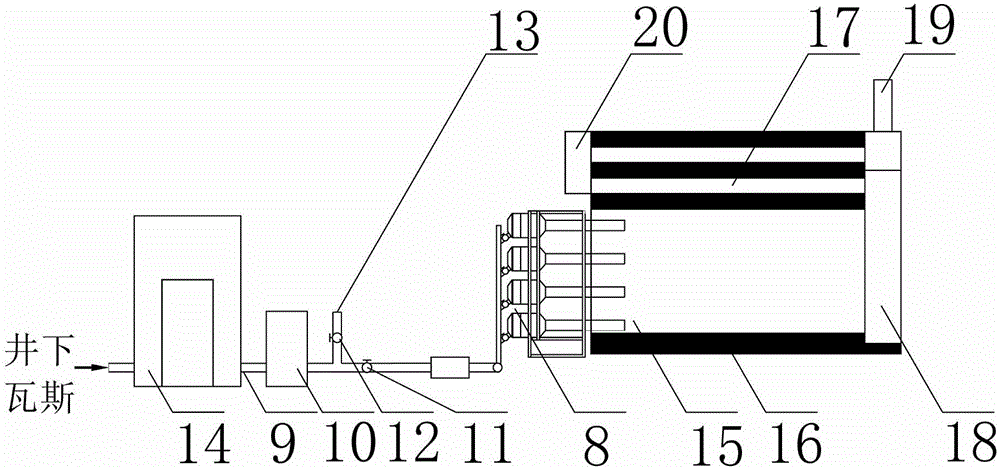

High-power array low-concentration gas pulse combustion method and device

ActiveCN107525066AReduced use rangeCompact structureGaseous fuel feeder/distributionPulsating combustionCombustionDetonation

The invention belongs to the technical field of gas combustion, and relates to a high-power array low-concentration gas pulse combustion method and a device. 2-16 pulse combustion units with porous medium chambers and damping adjusting valves are arranged to form an independent subarray in an array manner; all units in the subarray share one intake branch pipe; each subarray is connected with a distribution mother pipe through the intake branch pipe to form an array system; and the distribution mother pipe is connected with a supply main pipe with a combustion controller. The porous medium chambers can effectively prevent detonation or explosion; and the damping adjusting valves guarantee balanced intake flows among all the pulse combustion units in the array system. The low-concentration gas utilization range can be narrowed by above 5%, so that the problems of difficult ignition and explosion in the low-concentration gas pulse combustion process are solved, and the stable combustion is guaranteed; and as the number of the pulse combustion units is flexibly combined, the total power of the device can be changed, and low-concentration gas is used more reasonably according to the gas extracting conditions.

Owner:CHINA UNIV OF MINING & TECH +1

Heating furnace pulse control system and method

InactiveCN108317866AReduce distractionsFully disturbedWork heating devicesControl devices for furnacesPulse controlControl system

The invention provides a heating furnace pulse control system and method and belongs to the technical field of metallurgy. The upper section of the system conducts heat supply through flat flame burners, and the lower section of the system conducts heat supply through NOx burners. The three burners are arranged at the south end of the lower section, and the three burners are arranged at the northend of the lower section. The heating furnace pulse control system integrates the double-cross amplitude limit technology and the pulse control technology. Every two crossed burners of the six burnersof the lower section serve as a group, and the three groups of the burners work in sequence. According to the heating furnace pulse control system, the pulse combustion technology is adopted; as allthe burners work under high-load conditions, extrusive flames are long, and the thermal radiation capacity is high; thus, steel blanks can be heated uniformly, and the burners can be protected againstbackfire; moreover, through periodic switching of the pulse burners, the furnace atmosphere can be blended sufficiently, the gas thermal convection capability is enhanced at high radiation, and the heating uniformity of the plate blanks is further improved.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

Nozzle apparatus for material dispersion in a dryer and methods for drying materials

Apparatus and methods for the dispersion of material into a drying gas stream are disclosed. The material dispersion apparatus can have a nozzle and a venturi positioned downstream of the nozzle. The drying gas stream can be generated by pulse combustion dryer or by spray dryer and pass over at least a portion of the nozzle.

Owner:PULSE HLDG

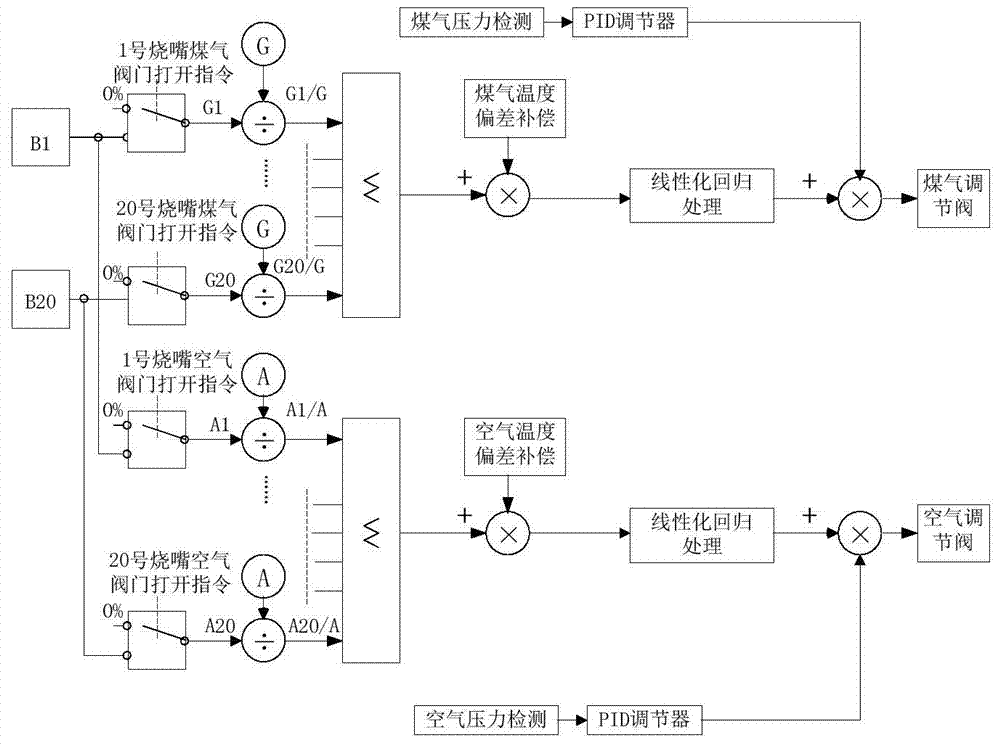

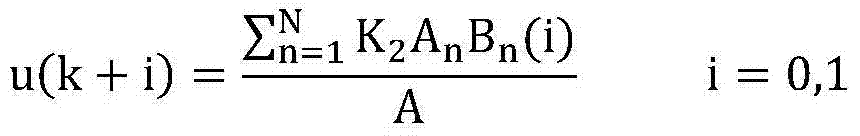

Pulse-combustion type feed-forward optimal control method for fuel gas and combustion-supporting gas pressure

ActiveCN103939938AReduce consumptionReduce oxidation burnFuel supply regulationControl signalOptimal control

The invention provides a pulse-combustion type feed-forward optimal control method for fuel gas and combustion-supporting gas pressure. The method includes the steps that step A, two control signals are obtained, wherein the first control signal is processed to be a digital signal by polynomial calculation through a PID adjustor to serve as a feedback variable source signal, and the second control signal serves as a feed-forward signal after temperature compensation is performed on the percentage of the accumulatively added fuel gas or the combustion-supporting gas, accounting for the total flow, of a combustion nozzle in an open state; step B, the first control signal and the second control signal are added to obtain a feed-forward optimal control signal. Fuel consumption is reduced, oxidation burning losses of a casting blank are reduced, the utilization rate of fuel is increased, heating quality of the casting blank is improved, and uniformity of heating temperature is improved. The unit consumption of coal gas of a large-scale plate blank heating furnace is reduced to 1.06GJ / t. The temperature difference between the upper surface and the lower surface of a plate blank out of the furnace is smaller than or equal to 10 DEG C. The temperature difference between the middle and the two ends in the length direction of the casting blank is smaller than or equal to 20 DEG C, and therefore the heating quality of the casting blank is stable and reliable.

Owner:上海策立工程技术有限公司

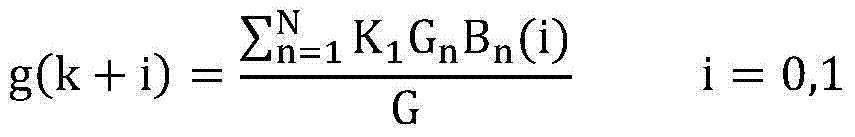

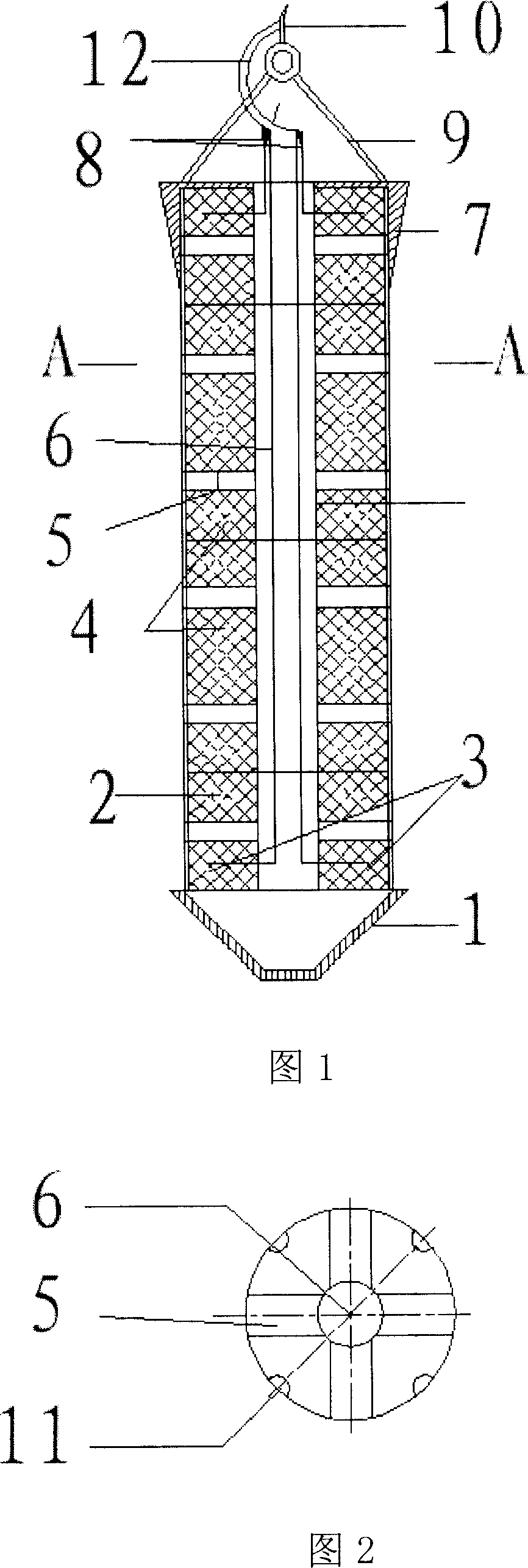

Biomass fuel pulse combustion hot blast device and use method thereof

The invention discloses a biomass fuel pulse combustion hot blast device and a use method thereof. The biomass fuel pulse combustion hot blast device adopts the technical scheme by including a base (20), wherein a Rijke pulse combustor main body is mounted on the base (20); the Rijke pulse combustor main body includes a furnace chamber barrel body (16), a lower air pipe (4) and an upper air outlet pipe (9) from bottom to top; a grate (17) is mounted at the L position x=(0.12 to 0.26) away from the lower end of the Rijke pulse combustor main body; a rotary distributing rod (6) is arranged on the grate (17); and a feeding device including a feeding and speed regulating motor (7) and a spiral feeder (8) is arranged on the side wall of the furnace chamber barrel body (16). When the biomass fuel pulse combustion hot blast device is in use, the temperature in the combustion chamber is kept between 800 to 950 degrees. The biomass fuel pulse combustion hot blast device and the use method thereof solve the problems of insufficient combustion, caking and slag bonding during the biomass fuel combusting process, and provide a heat source with simple structure, efficiency in combustion and low manufacturing and use costs for drying agricultural products and the like.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

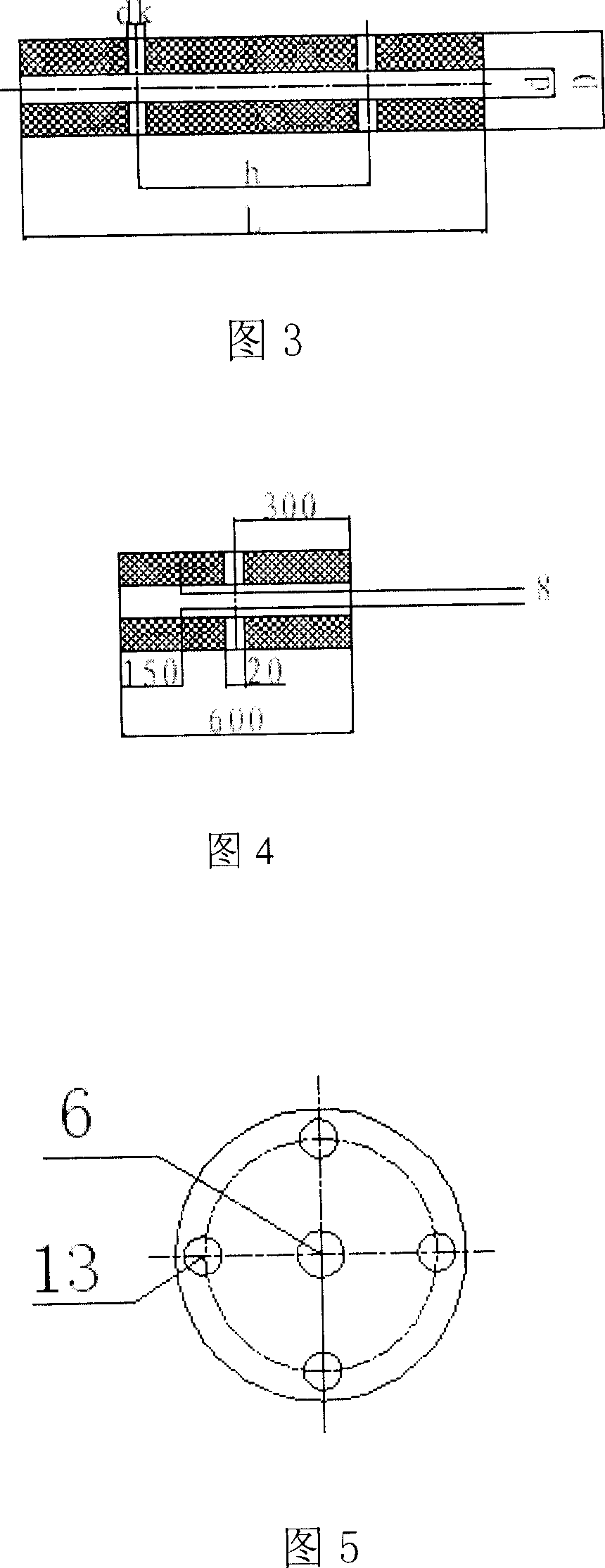

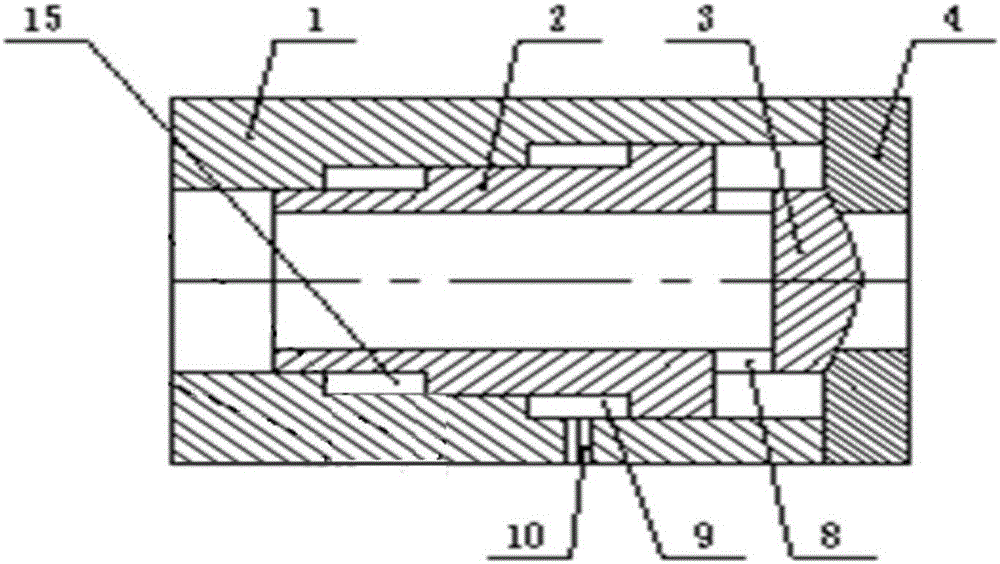

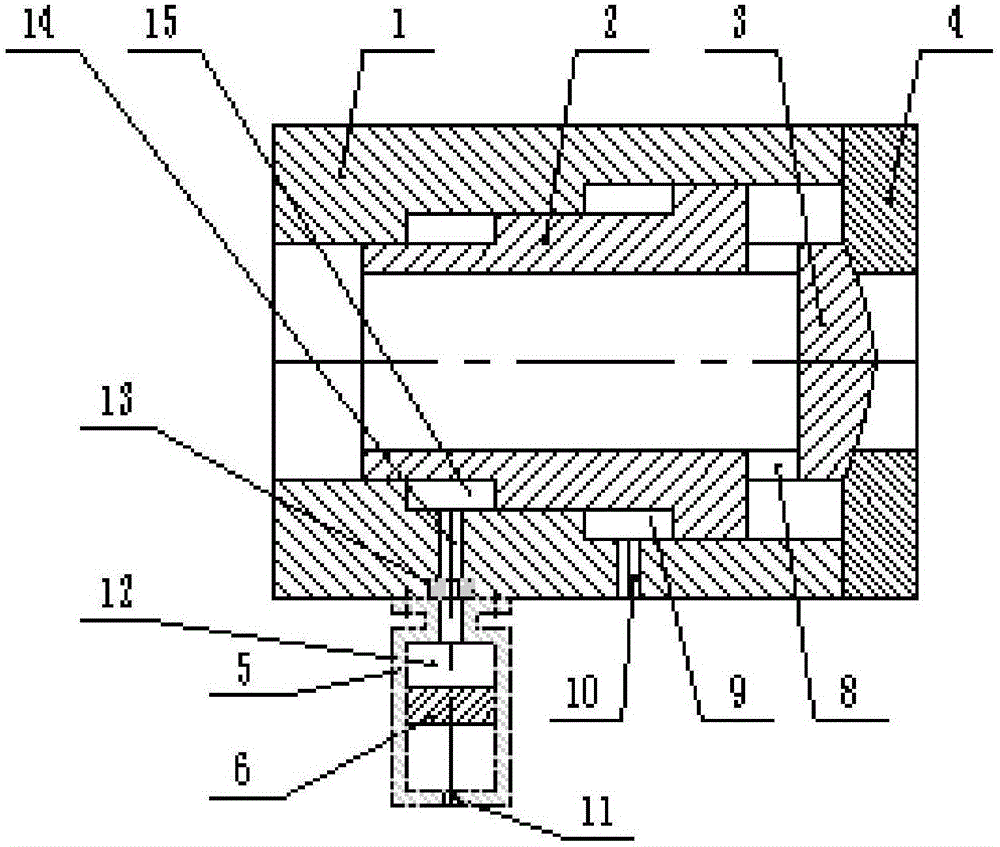

Control method for multiple tail tube pulsating combustor and apparatus

InactiveCN101493229AConvenient pressure adjustment and controlStable jobCombustion regulationInternal pressureControl engineering

The invention discloses a method and a device for controlling a multi-tailpipe pulse combustor. A valve opening in front of a draft fan is regulated to change the pressure in a decoupling chamber, namely the tailpipe exit pressure; acoustic characteristics in the pulse combustor are changed to ensure the pulse combustion and heat release of the tailpipe section; at the same time, the connecting pipe section can experience heat exchange as a steady-state heating surface. The pulse combustor in the device of the invention can adopt the basic structure of the Helmholtz pulse combustor, consists of a mixing chamber, an air feeder, an ignition device, a combustor, a tailpipe and a decoupling chamber and applies the multi-tailpipe structure. The device for controlling the combustor is arranged at the back of the decoupling chamber and consists of a connecting pipe, a valve, an exhaust pipe, a draft fan and a motor. The controlling method of the invention features convenient operation, stable working and high efficiency.

Owner:HARBIN INST OF TECH

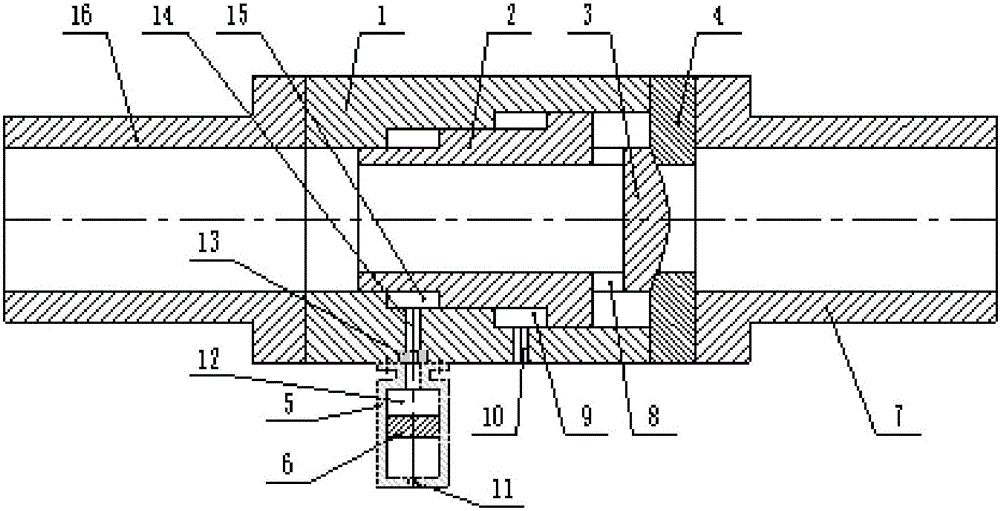

Sound wave shock and pulse combustion type pressing crack apparatus

ActiveCN101004133ANo pollution in the processEliminate seal designFluid removalType fracturePolysulfide rubber

The present invention discloses a sonic oscillation and pulsed combustion type fracturing device. It is a powder column string made up by using two igniter columns and several main powder-charged columns and making them be overlapped together. Every igniter column and main powder-charged column are characterized by respectively adopting cylindrical powder column made up by adopting solid propellant containing ammonium perchlorate oxidant and polysulfide rubber combustion agent, on said igniter columns and main powder-charged columns are set axial central holes and radial through holes which are mutually communicated, in the lower end portion of igniter column an electric igniter is set.

Owner:WUHUA ENERGY TECH CO LTD

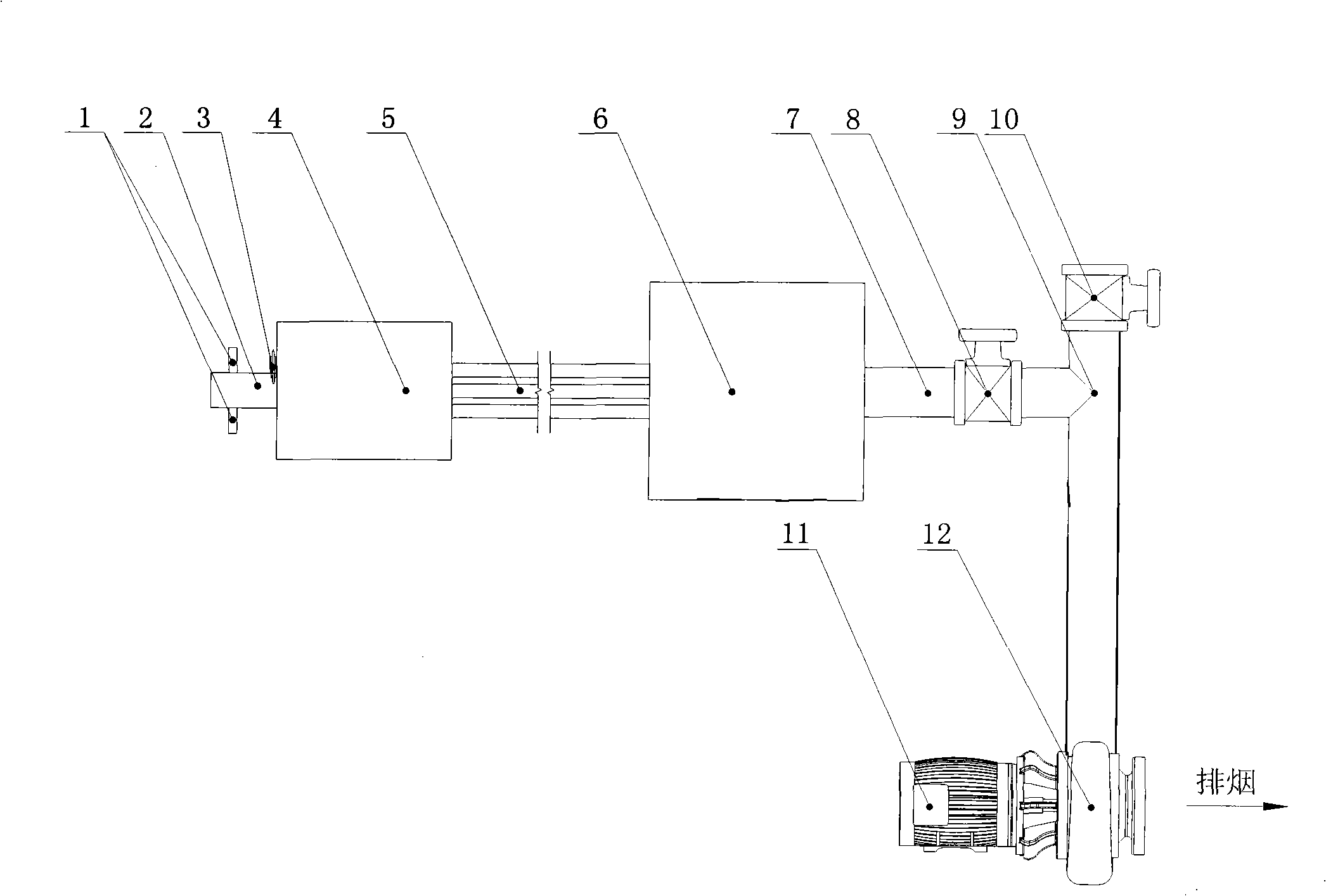

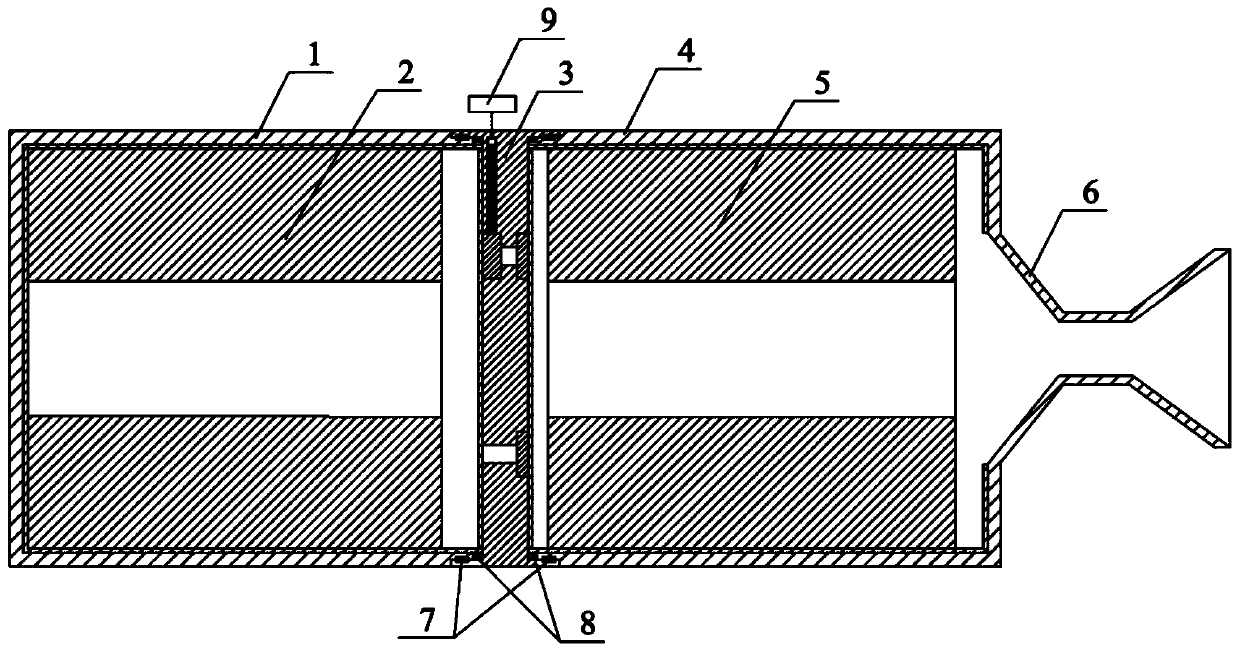

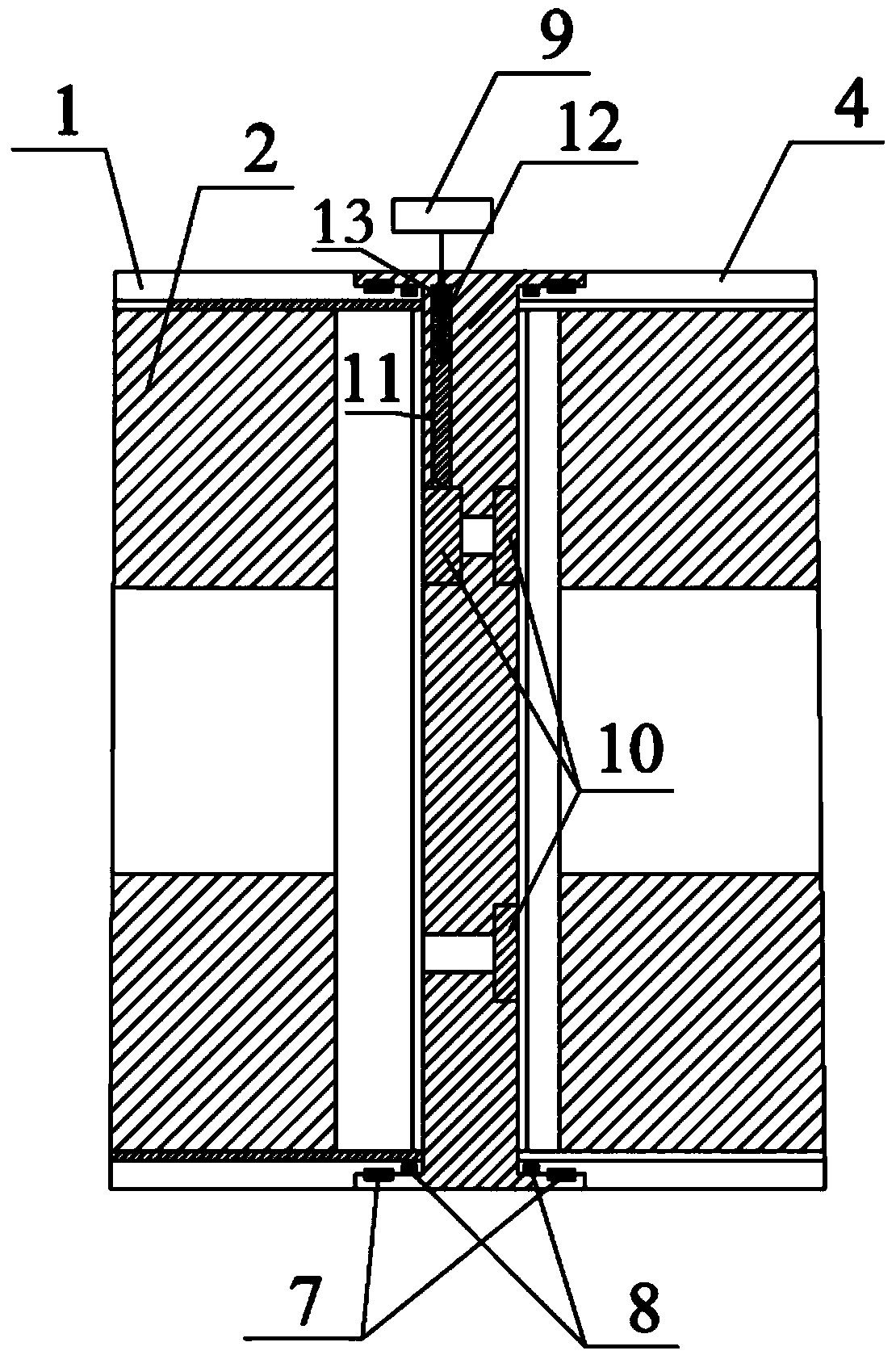

High-power pulse combustion steam boiler with multi-combustor parallel heating

The invention discloses a high-power pulse combustion steam boiler with multi-combustor parallel heating, belonging to the technical field of advanced energy sources. In the invention, the heat is supplied for the steam boiler by adopting a linkage mode of a plurality of groups of pulse combustors, that is to say, the plurality of pulse combustors are soaked in a boiler shell in parallel; safety ignition and control of the parallel pulse combustors are set by an electric control system program, therefore, independent ignition-flameout protection-restarting of each pulse combustor in the plurality of parallel pulse combustors can be realized, and the safe and automatic control function can be achieved; and a pipe network is added as a waste heat recovery device in a decoupling chamber so as to fully utilize the heat and improve the heat efficiency of the steam boiler. The high-power pulse combustion steam boiler realizes the high-power steam boiler design on the premise of ensuring the stable operation of the pulse combustors; the automatic control program of safety ignition-flameout protection-starting of the combustor groups ensures the ignition safety and reliability of the pulse combustors; and the waste heat recovery device ensures that the flue gas temperature is reduced to 180 DEG C and the heat loss is reduced.

Owner:CHINA AGRI UNIV

Nozzle apparatus for material dispersion in a dryer and methods for drying materials

Owner:PULSE HLDG

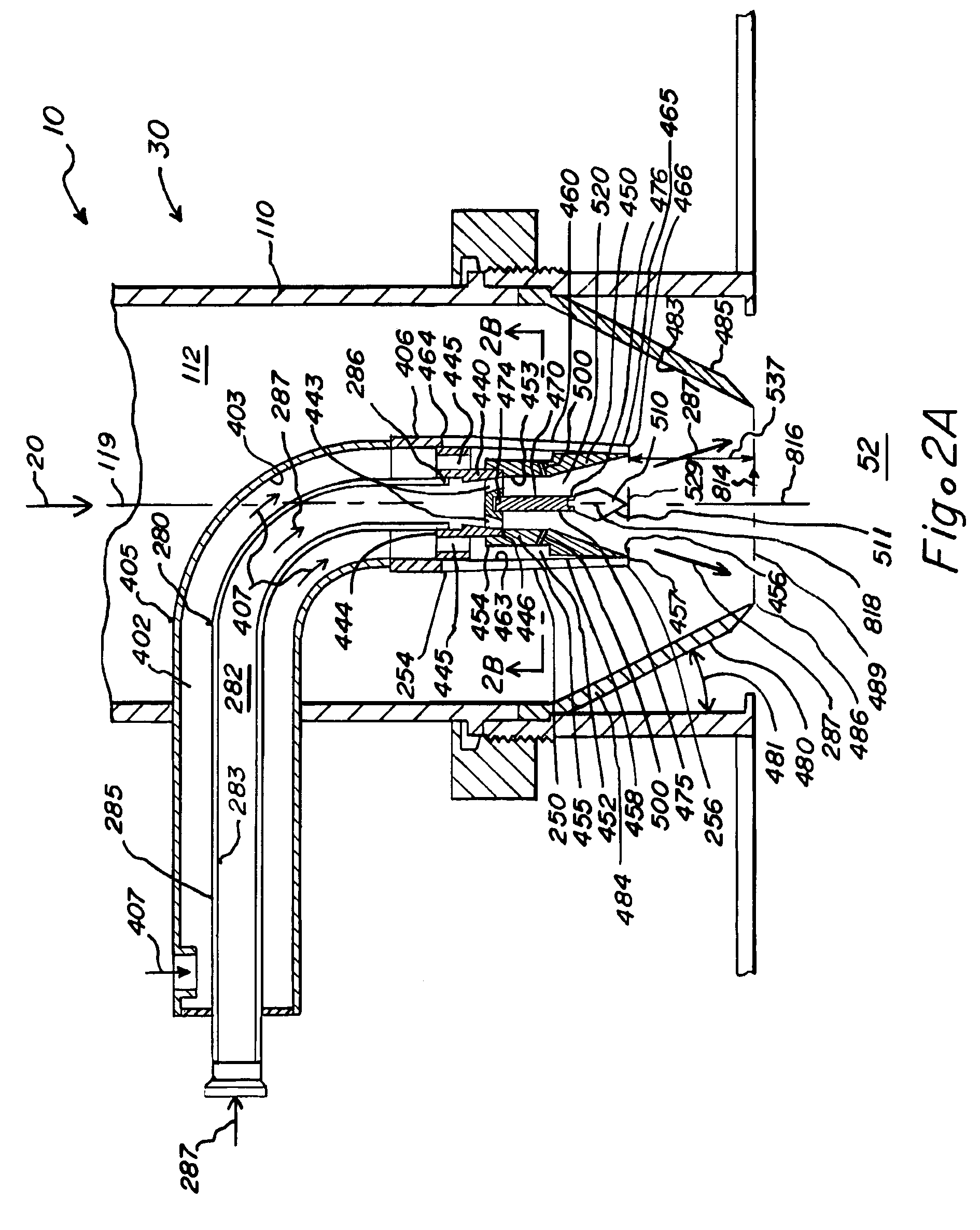

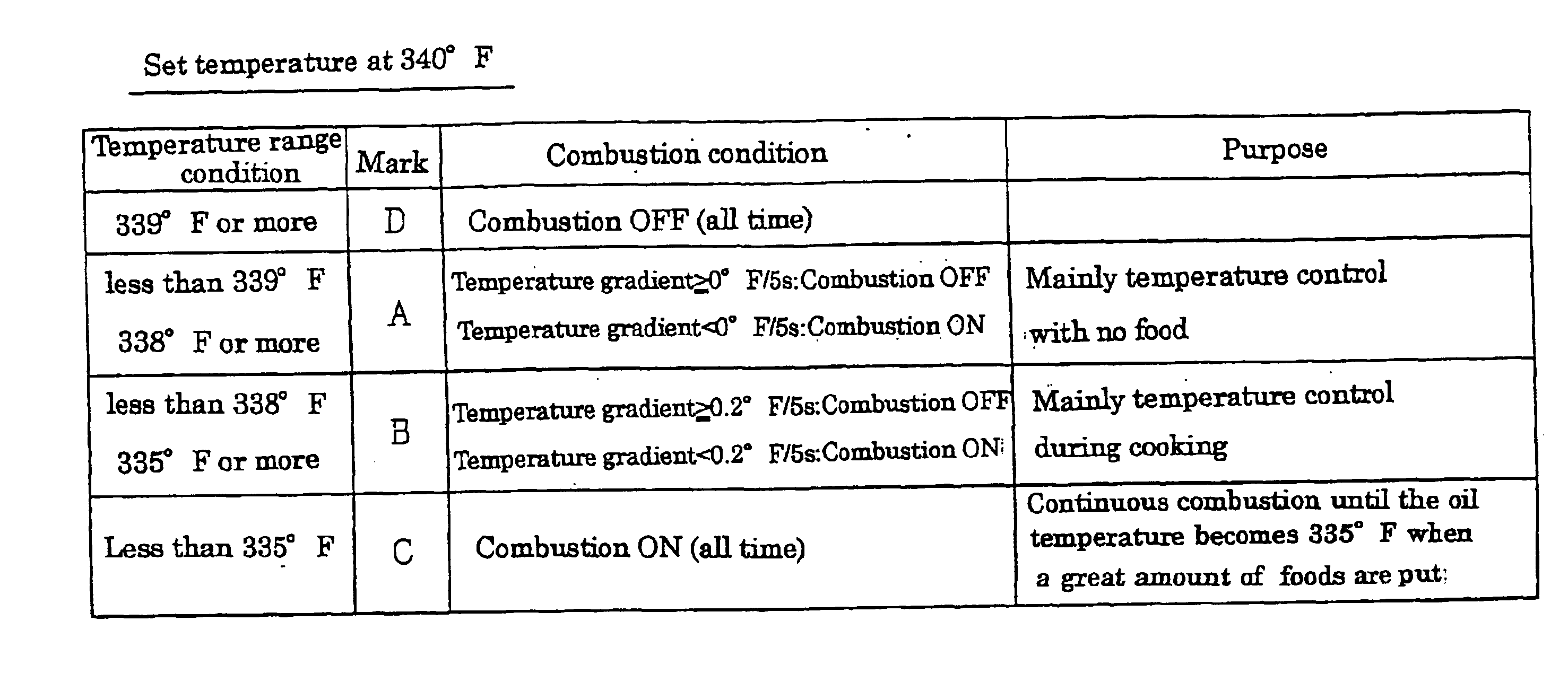

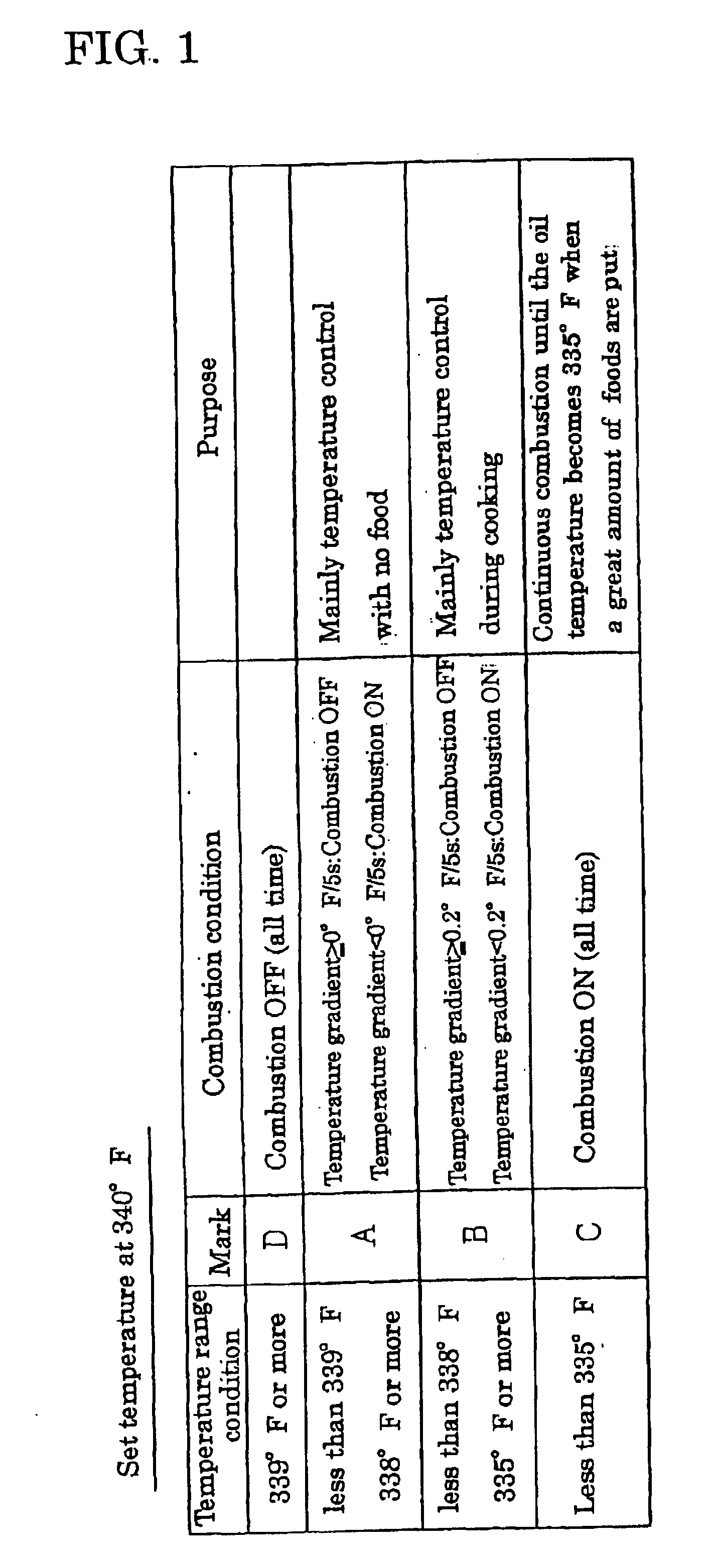

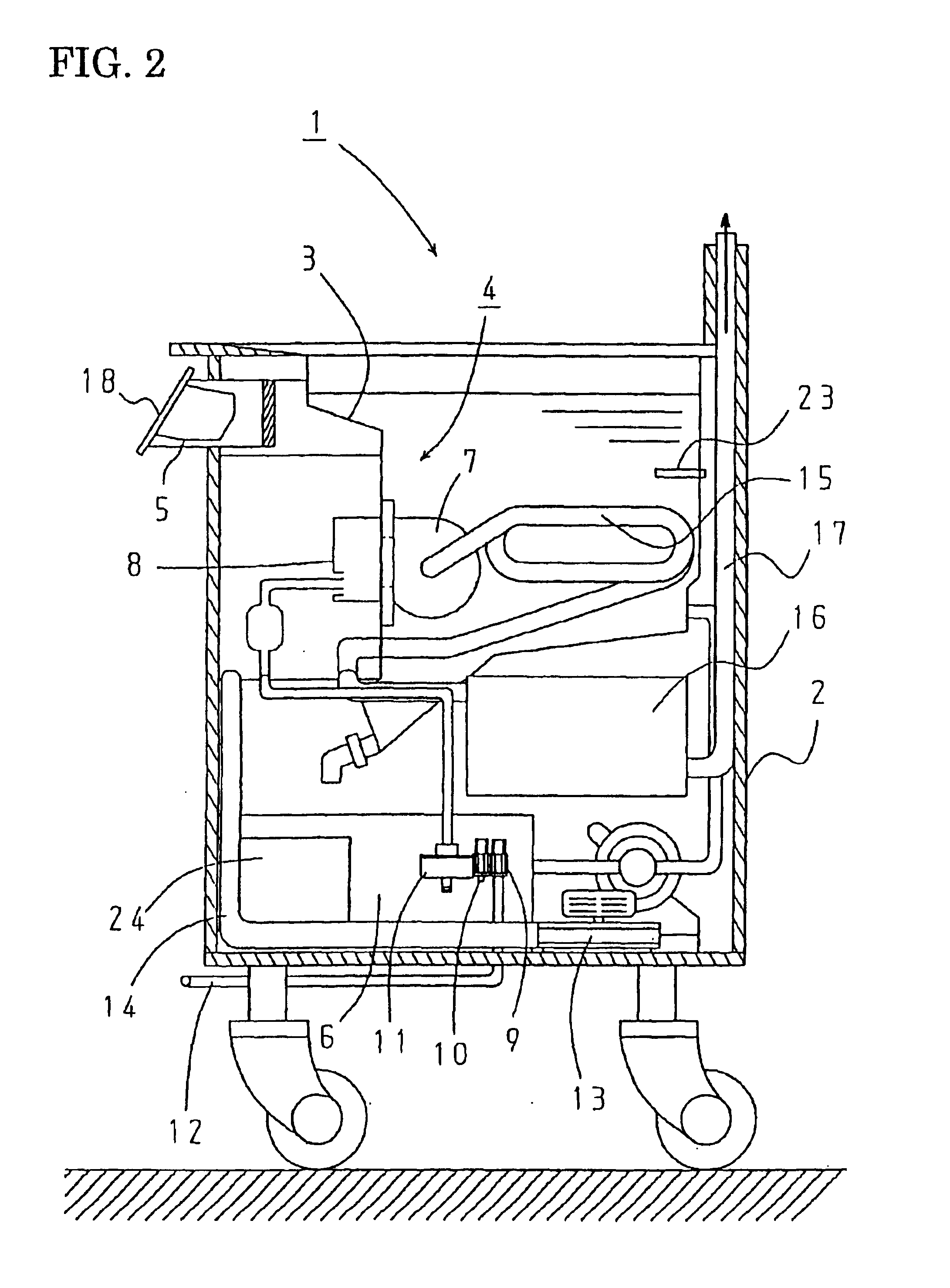

Fryer

InactiveUS6883419B2Precise temperature controlAvoid switchingFluid heatersBoiling over preventionThermodynamicsEngineering

A fryer in which an overshoot is prevented by an accurate oil temperature control is disclosed. A pulse burner (4) is controlled to be switched ON / OFF based on a condition which is different by each temperature range. This enables to control the pulse burner (4) in accordance with factors which effect on the oil temperature such as an amount and heat capacity of foods and heat quantity of a utensil. Whereby, the oil temperature control in an excellent level is performed under various conditions. Moreover, as the condition to perform ON / OFF control of the pulse burner (4) is simple, for example, which is whether or not the temperature gradient of cooking oil exceeds the standard value, it needs no complicated control and reliability is improved.

Owner:PALOMA

Thrust-adjustable multistage pulse solid rocket engine

Owner:北京灵动飞天动力科技有限公司

Fast valve with controllable damping structure

InactiveCN105952952AWith controllable damping structureAdjustable opening speedOperating means/releasing devices for valvesValve members for absorbing fluid energyPistonPulse combustion

The invention provides a fast valve with a controllable damping structure, which belongs to the technical field of pulse combustion wind tunnels. The present invention adds a controllable damping structure on the basis of the existing fast valve, and the controllable damping structure includes a throttle orifice, a damping liquid cylinder and a damping liquid cylinder piston; the damping liquid cylinder piston divides the damping liquid cylinder into an upper damping liquid cavity and the lower driving air chamber, the lower driving air chamber is connected to the driving air source through a filling and discharging hole, the upper damping liquid chamber communicates with the damping chamber through the throttling hole on the throttle orifice plate, and the damping liquid through hole; the damping chamber and the upper damping chamber The liquid cavity is filled with damping liquid. The present invention realizes the adjustment of the opening speed of the entire fast valve by adjusting the aperture size of the throttle hole on the throttle orifice 13 in the controllable damping structure, and at the same time adopts the liquid damping method to more effectively buffer the piston during the valve opening process. The impact on the valve body can meet the application requirements of building a larger pulse combustion wind tunnel project.

Owner:INHALE HYPERSONIC TECH RES CENT UNIT 63820 OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com