Heating furnace pulse control system and method

A pulse control and heating furnace technology, applied in the field of metallurgy, can solve the problems of weak heat radiation ability, inability to guarantee the high-load combustion state of the burner, and high energy consumption per ton of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A heating furnace pulse control system provided by an embodiment of the present invention, the upper section of the system uses a flat flame burner for heating, the lower section uses a low NOx burner, and three burners are respectively installed at the north and south ends of the lower section ;

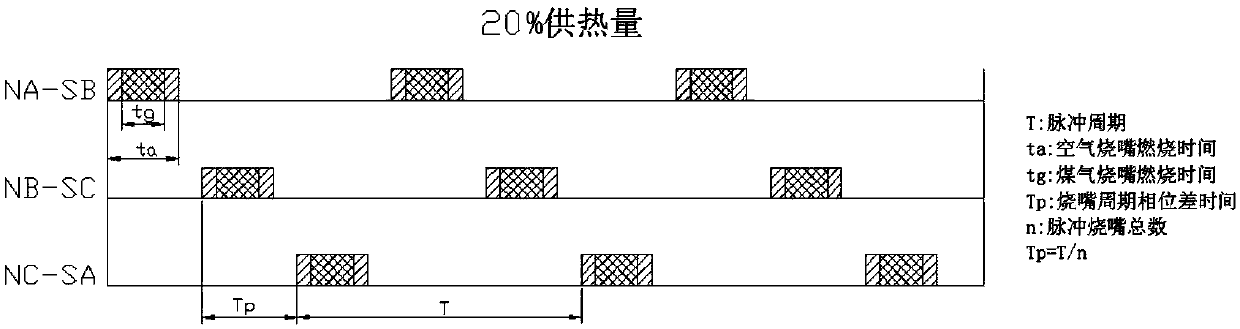

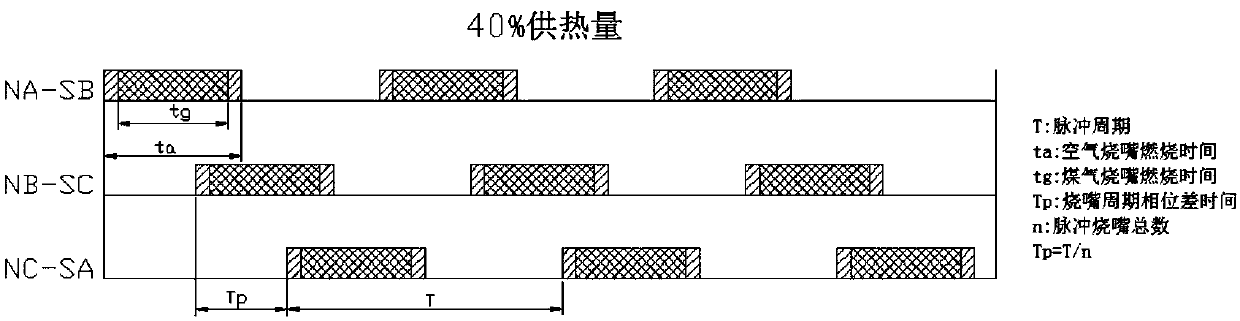

[0026] The pulse control system of the heating furnace adopts double-crossing limit and pulse control technology, and the six burners in the lower section work in sequence with two crossed burners as a group.

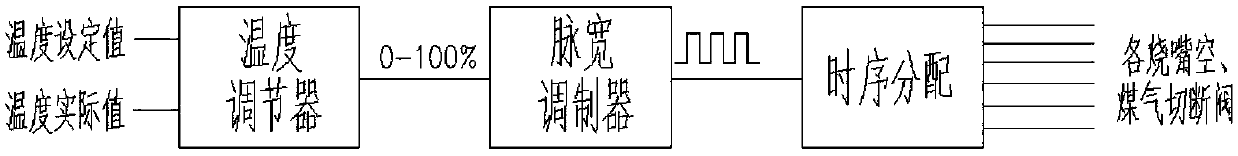

[0027] The control system of this scheme is based on the original double-crossing limiter, adding pulse control technology. The difference from conventional pulse control is that the 6 burners in the lower section no longer use a single burner cycle switch mode, but use 2 burners that are crossed. The mouth is a group and moves sequentially, such as figure 2 shown.

[0028] Taking the pulse period of 60s and heating demand of 20% as an example, analyze the status of...

Embodiment 2

[0044] Based on the same inventive concept, this embodiment provides a heating furnace pulse control method. The problem-solving principle of the heating furnace pulse control method is similar to a heating furnace pulse control system. Therefore, the implementation of the heating furnace pulse control method can be found in the heating furnace pulse The implementation of the control system will not be repeated here.

[0045] see Figure 5 The heating furnace pulse control method provided by this program is applied to any heating furnace pulse control system proposed in the first embodiment above. The upper section of the heating furnace pulse control system uses flat flame burners for heating, and the lower section uses low NOx burners. mouth, three burners are respectively arranged at the north and south ends of the lower section; the method includes:

[0046] Step 201: Send the pulse duty ratio of the output of the temperature regulator to a pulse width modulator, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com