Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

566results about How to "Burn evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

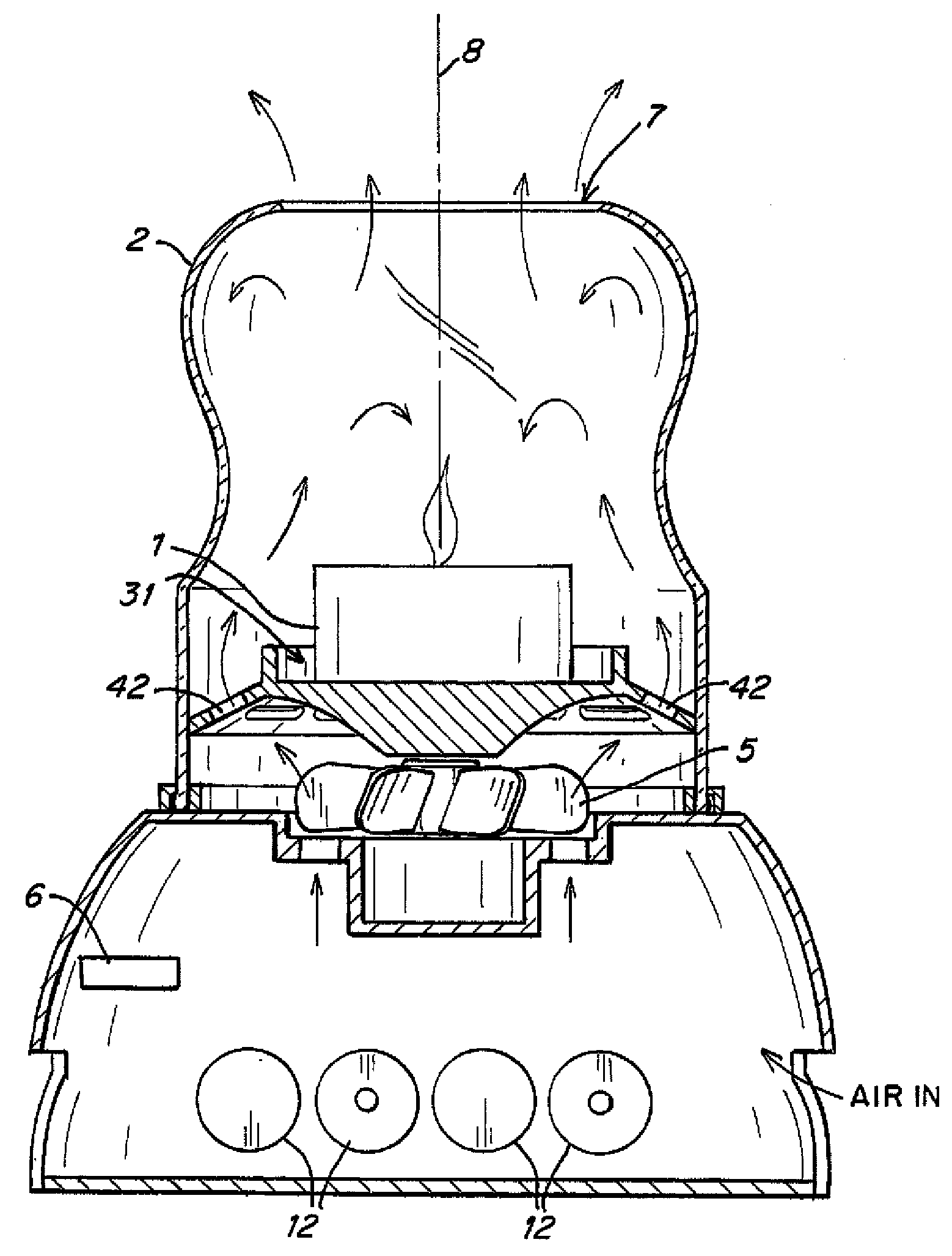

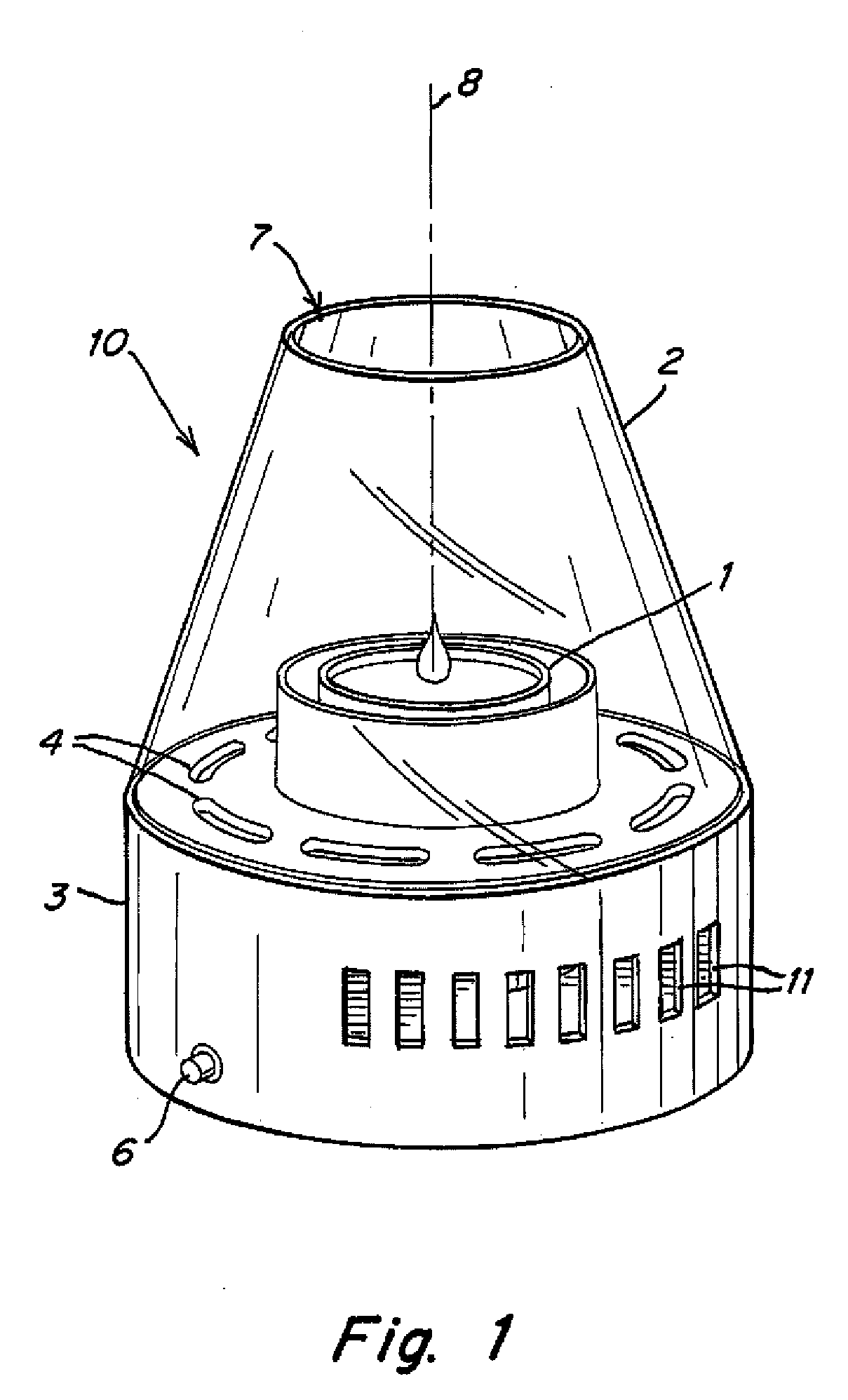

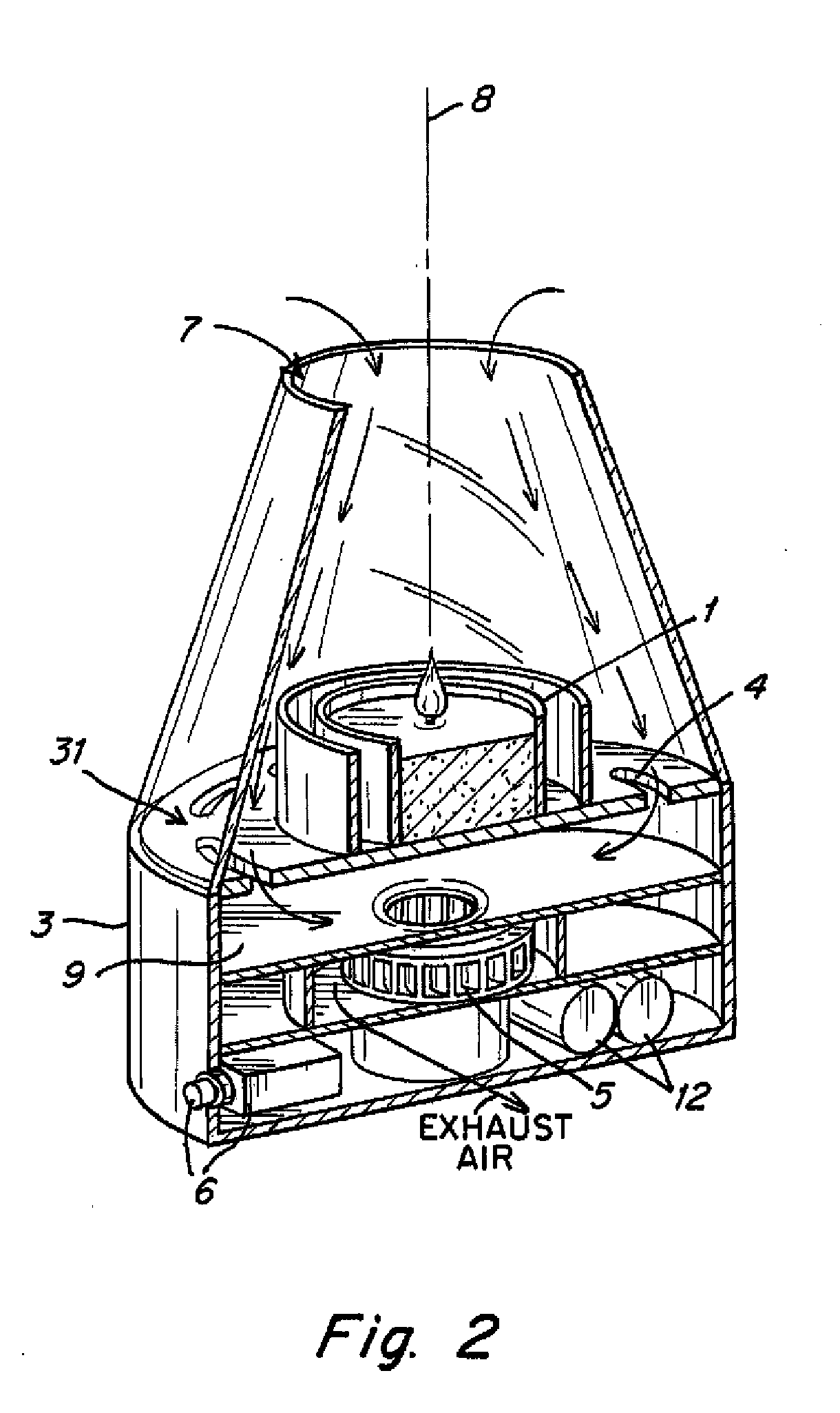

Method and apparatus for diffusing the fragrance of a burning candle

InactiveUS20090200393A1Create air turbulenceBurn more evenlyTobacco devicesCandle wicksFlavorAir movement

A method and apparatus for controlling a candle flame. A candle flame may be provided in a controllable environment, e.g., a semi-enclosed area formed at least in part by a cover. Air may be forced into the semi-enclosed area by an air movement device (e.g., a fan) to diffuse a candle's fragrance. The fragrance diffusion rate may be reduced by reducing (e.g., stopping) air flow into the semi-enclosed area.

Owner:AVELAR VICTOR

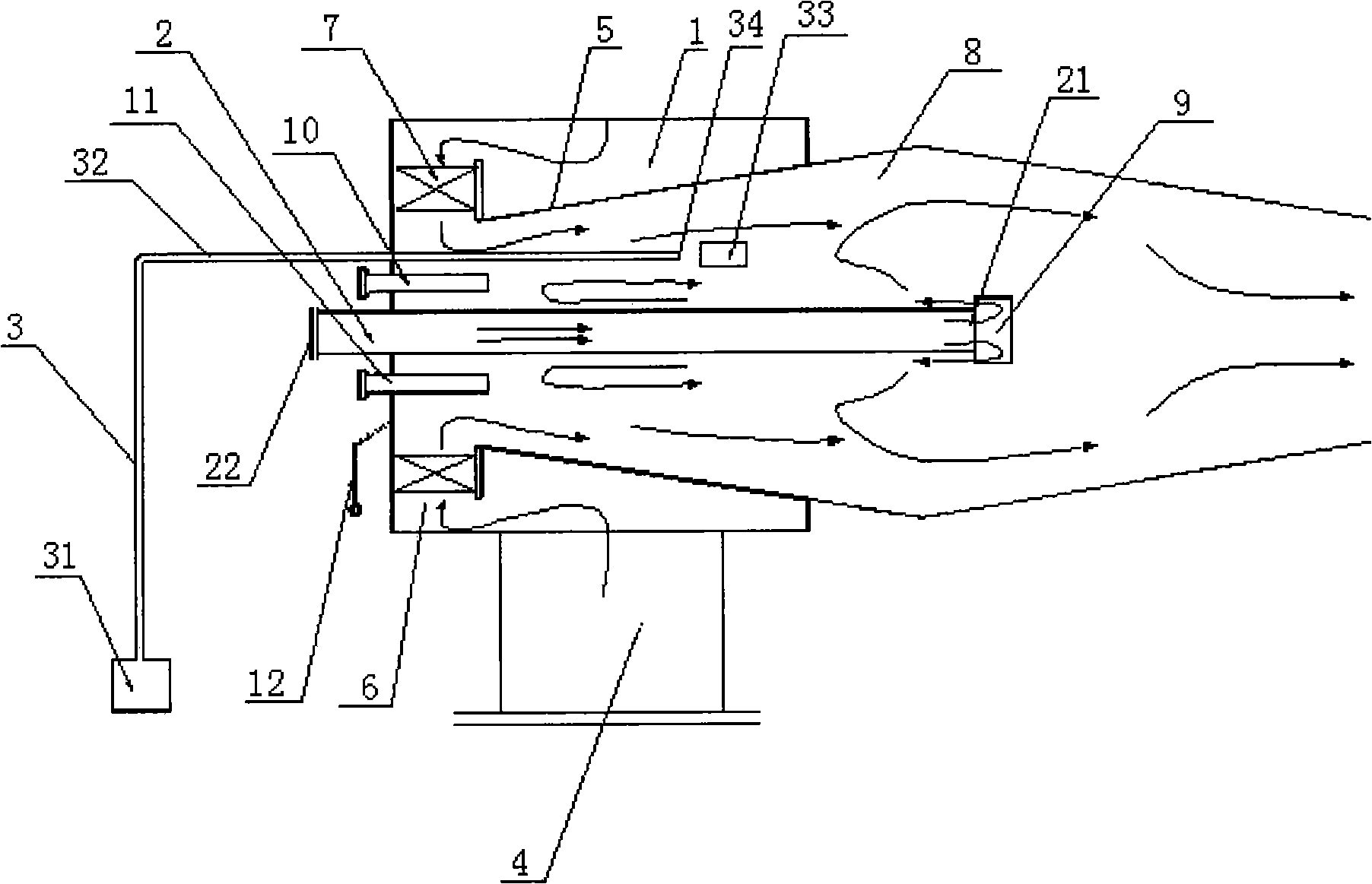

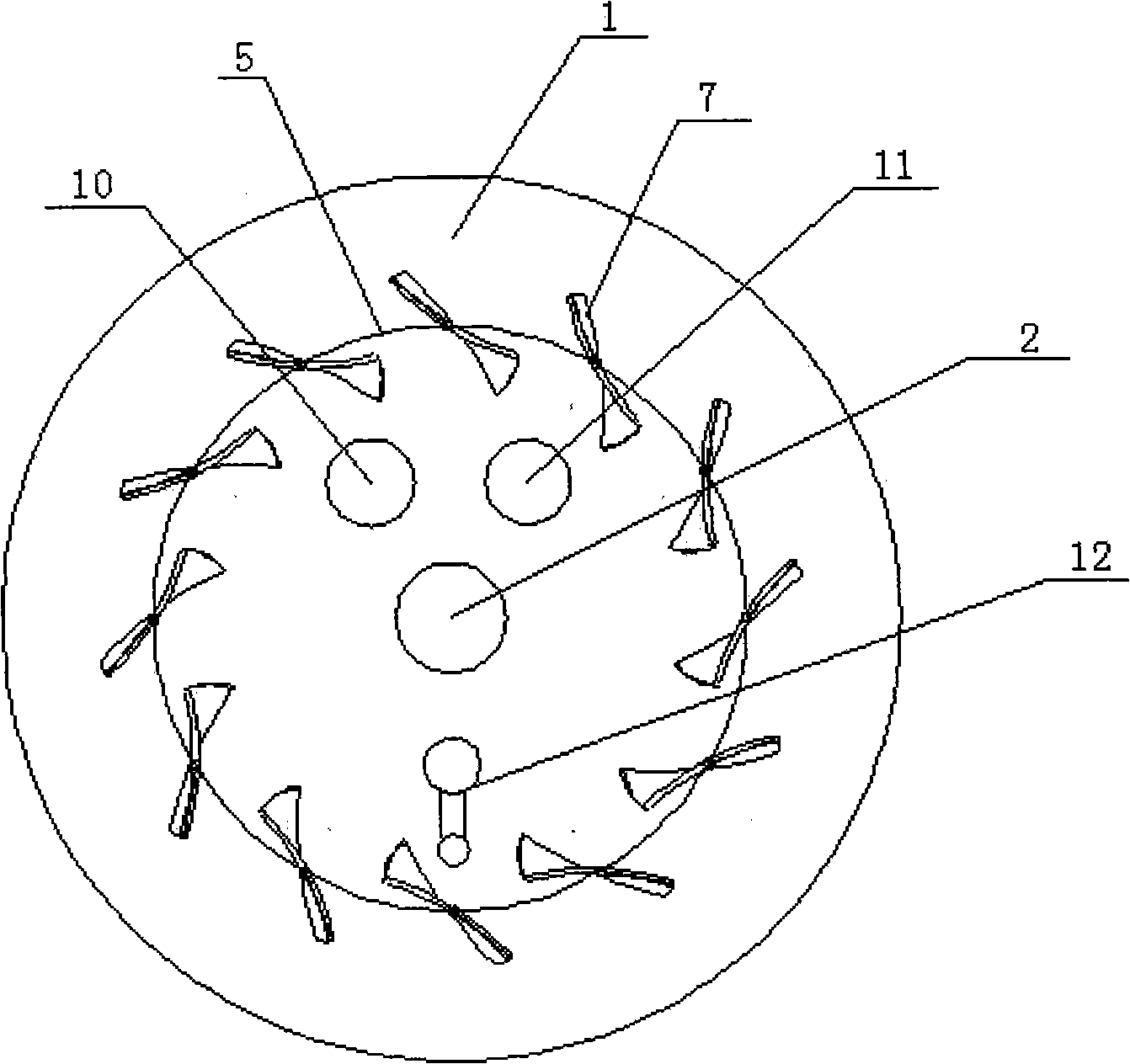

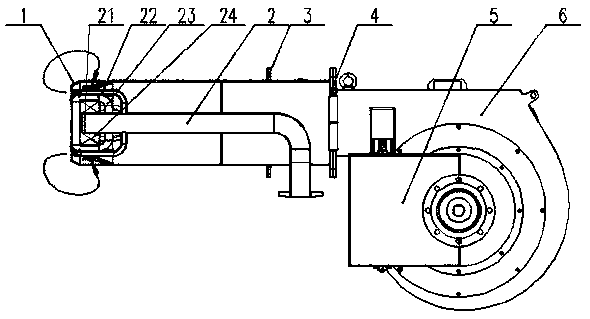

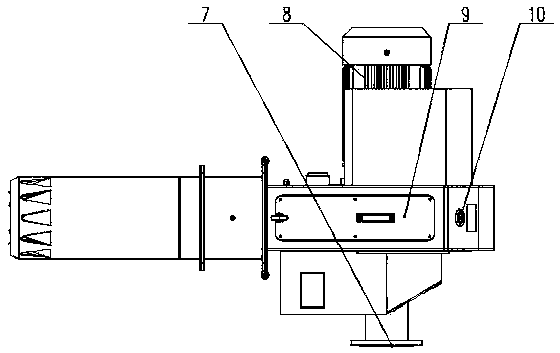

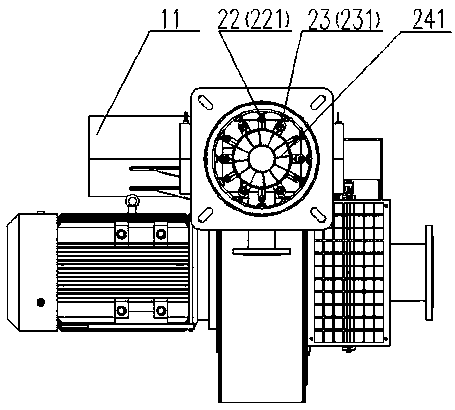

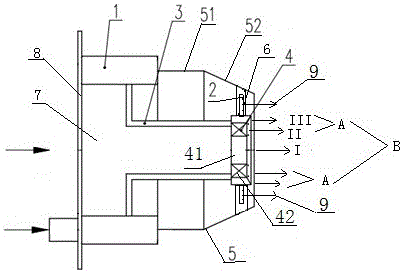

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

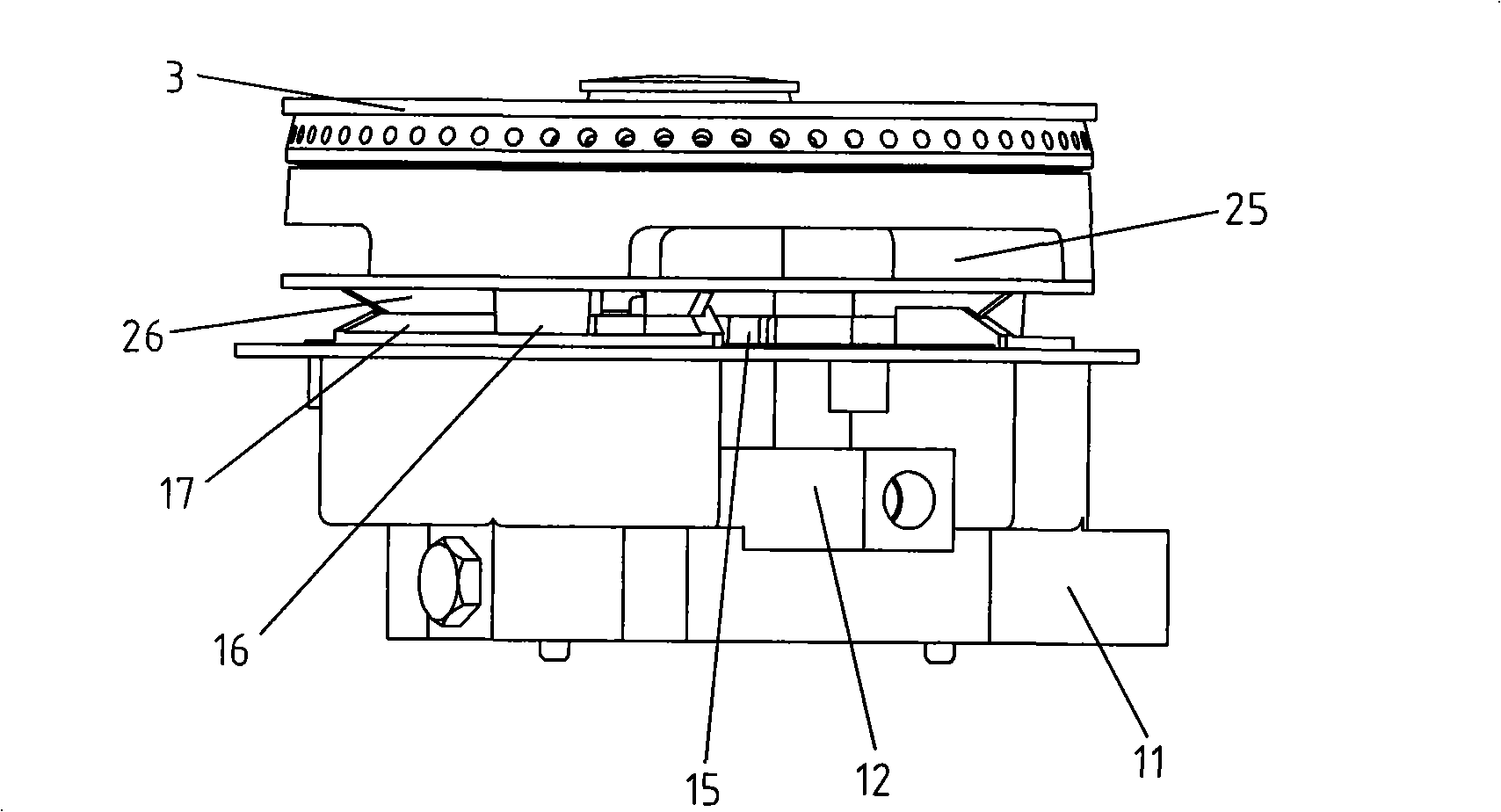

Household gas burner

The invention discloses a household gas burner, belonging to the part in the household gas kitchen range. The present household gas burner has the complex structure, poor processing precision and big accumulative error in assembling. The household gas burner comprises a nozzle, a gas distributing device, a gas mixing device and a fire lid, and characterized in that the gas distributing device and the gas mixing device are all the integrated structure, wherein the gas distributing device comprises a gas supplying pipe and a distributing chamber, a primary air inlet open is arranged on the distributing chamber, the nozzle is fixed on the orifice of the gas supplying pipe in the distributing chamber; the gas mixing device comprises a mixing pipe, a mixing chamber, a buffer baffle plate and a secondary air inlet slot, the mixing chamber is matched with the distributing chamber, the buffer baffle plate is arranged above the orifice of the mixing pipe in the mixing chamber, the secondary air inlet slot is arranged at the side surface of the gas mixing device. The gas distributing device and the gas mixing device in the invention have no accumulative error in assembling, simple assembling and safe and reliable use.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

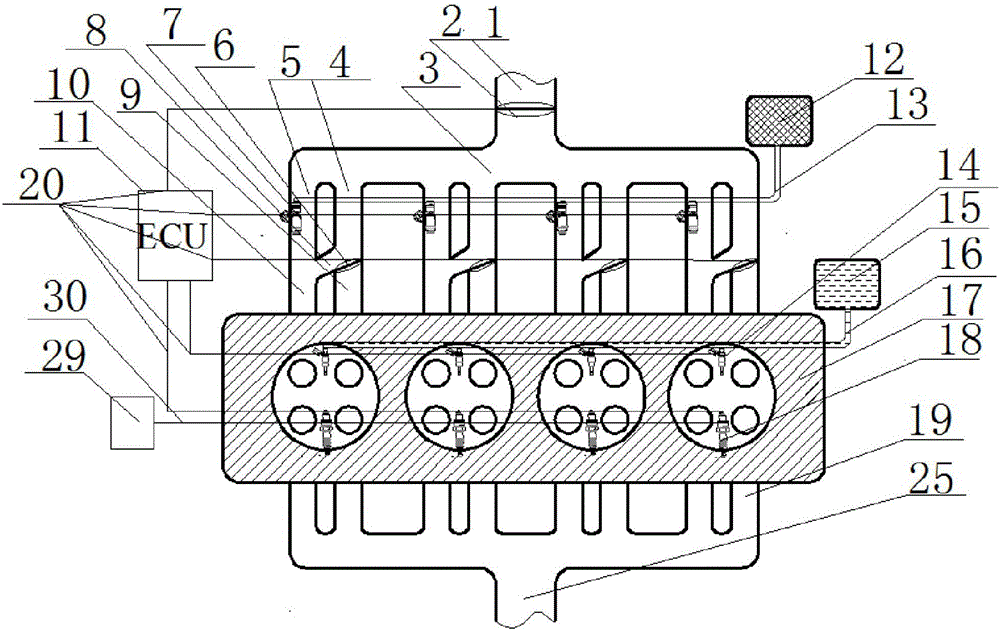

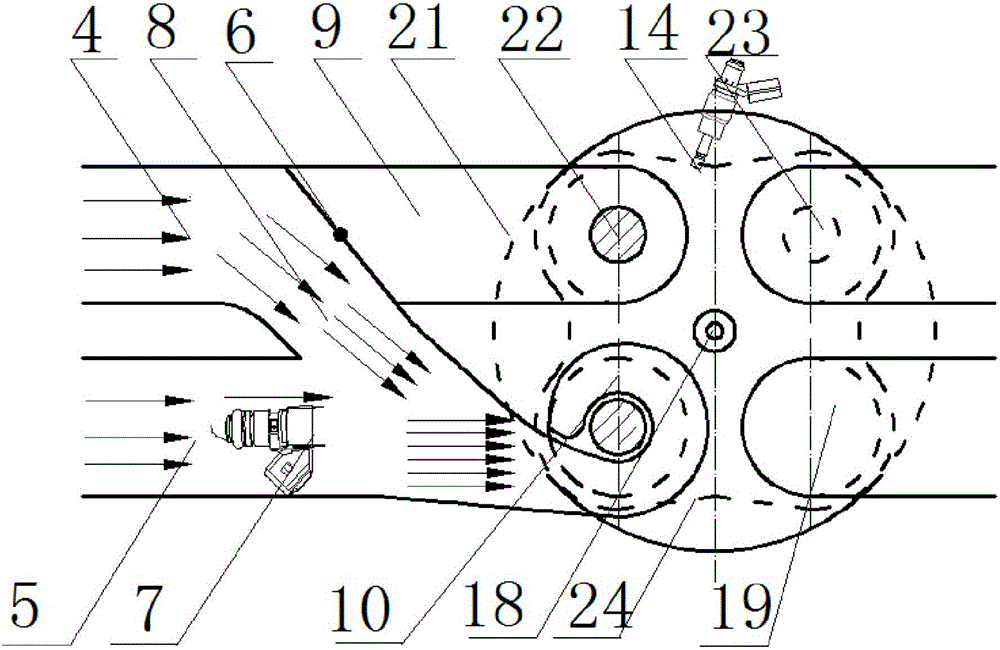

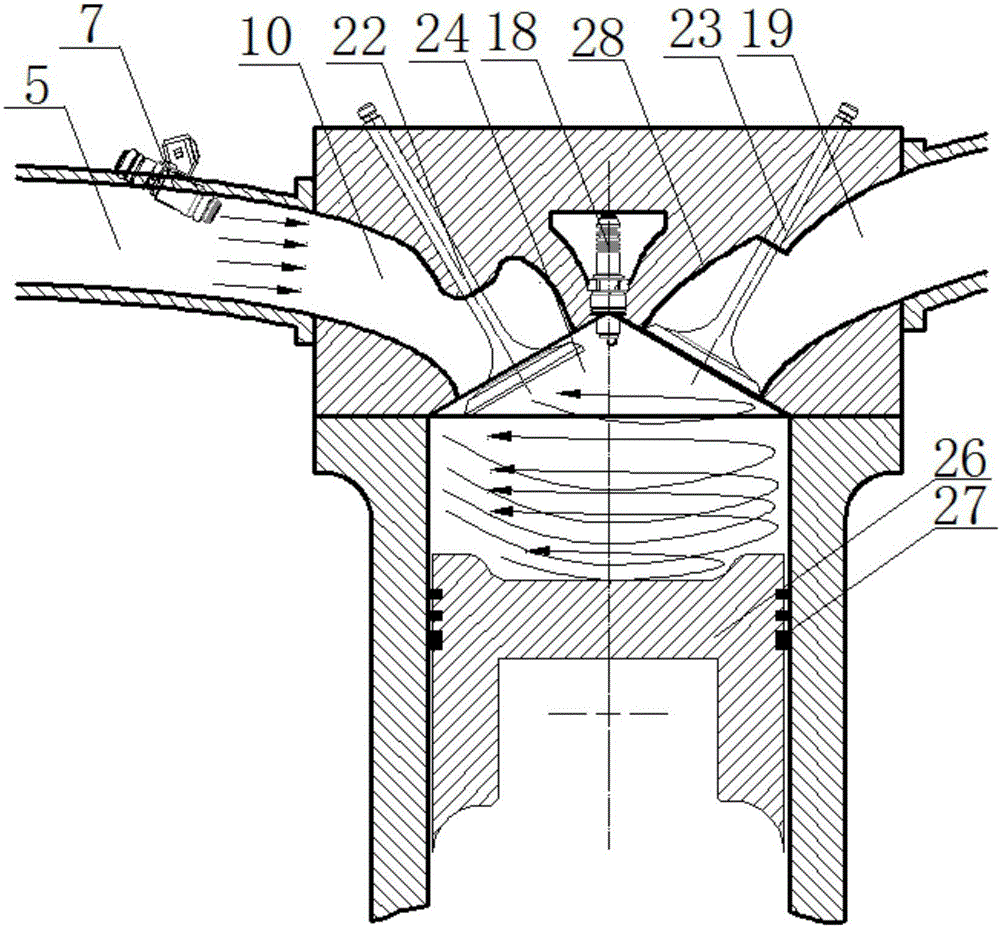

Dual-fuel spark-ignition internal combustion engine based on variable air channel, and control method

InactiveCN105715367ABurn fasterImprove economyInternal combustion piston enginesAir intakes for fuelCombustionInternal combustion engine

The invention designs a dual-fuel spark-ignition internal combustion engine based on a variable air channel, and a control method, aims at solving the problem that effective adjustment cannot be carried out on an intake flow and an airflow direction in an air channel, of an internal combustion engine adopting the traditional intake structure, and in particular, an internal combustion engine adopting a four-valve structure, and solving the problems of instable combustion, difficult ignition, fire and the like generated during lean combustion, and develops a dual-fuel spark-ignition internal combustion engine based on a variable air channel, and a control method. The invention provides a variable intake system. According to the variable intake system, the optimal airflow movement under different working conditions is obtained through control for the opening and closing of a swirl control valve, and in combination with a piston top surface with a special shape. The invention discloses a combined internal combustion engine technology for carrying out in-cylinder direct injection and intake channel injection respectively on the basis of two fuels. The different combustion modes of an in-cylinder mixed gas are realized through control for an injection time and an injection pulse width, and in combination with an airflow movement, and then the working efficiency of the internal combustion engine under different working conditions is improved, and oil consumption and emission are reduced.

Owner:JILIN UNIV

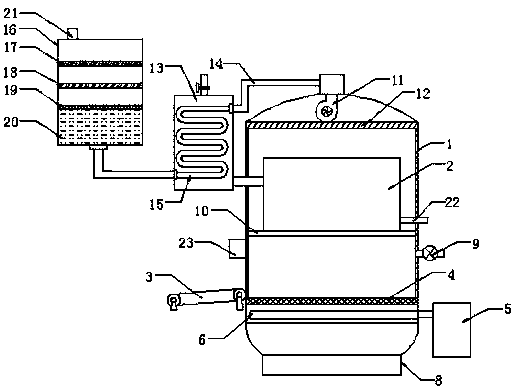

Environment friendly type industrial smoke overall treatment boiler and using method thereof

InactiveCN108645021ABurn evenlyBurn fullySolid fuel combustionCombustion technology mitigationCoalEngineering

The invention discloses an environment friendly type industrial smoke overall treatment boiler which comprises a boiler body, a heat exchange box and a purification box. A base is arranged at the bottom end of the boiler body, a burning cavity is arranged inside the boiler body, a burning separating plate is arranged at the lower end of the burning cavity, a fuel gas pipe is arranged below the burning separating plate, one end of the fuel gas pipe is connected with a fuel gas device, a feeding opening is formed in one side of the burning cavity, a conveying belt is arranged on the outer side of the feeding opening, a combustion-supporting pump is arranged on one side of the burning cavity, a supporting plate is arranged above the burning cavity and supports a water tank, and water in the water tank is heated to be discharged through a water discharging pipe; and the heat exchange box is arranged, heat of smoke in a smoke pipe is transferred to water in the heat exchange box, the waterin the heat exchange box is preheated, the water heating speed is increased, the heat energy is sufficiently used, the using amount of fire coal can be reduced, and energy conservation and emission reduction are achieved. The environment friendly type industrial smoke overall treatment boiler is reasonable in design, practical, feasible, more user-friendly and suitable for application and popularization.

Owner:王连会

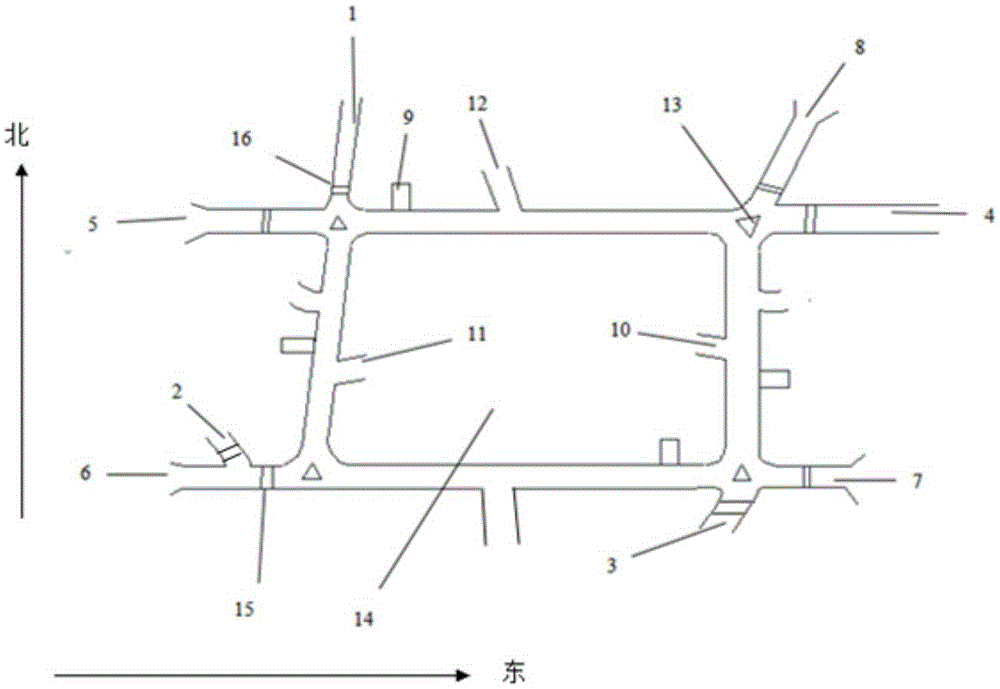

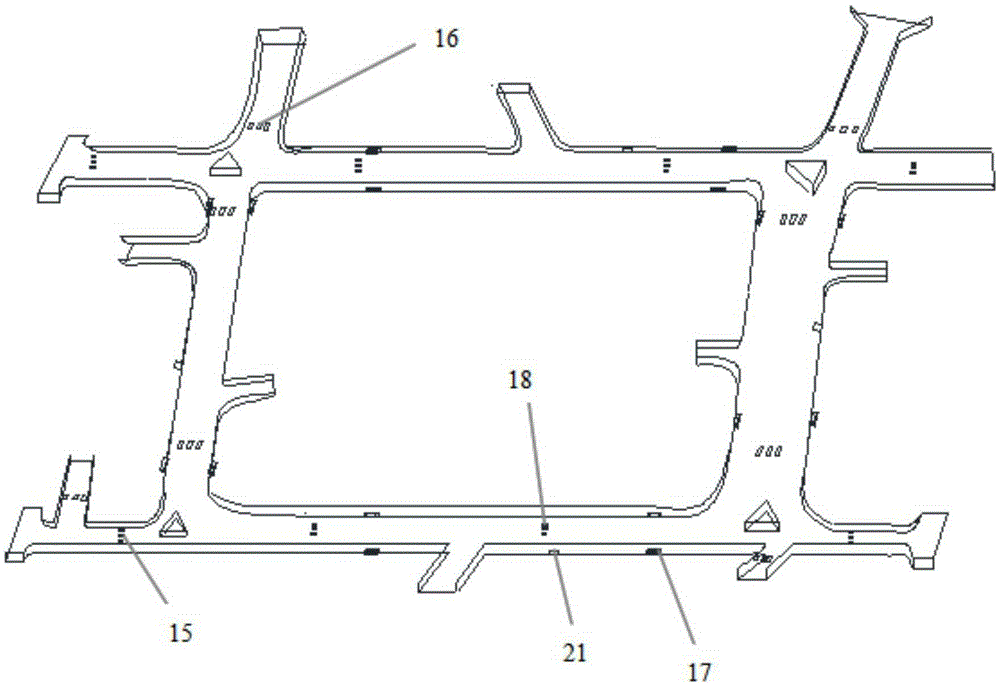

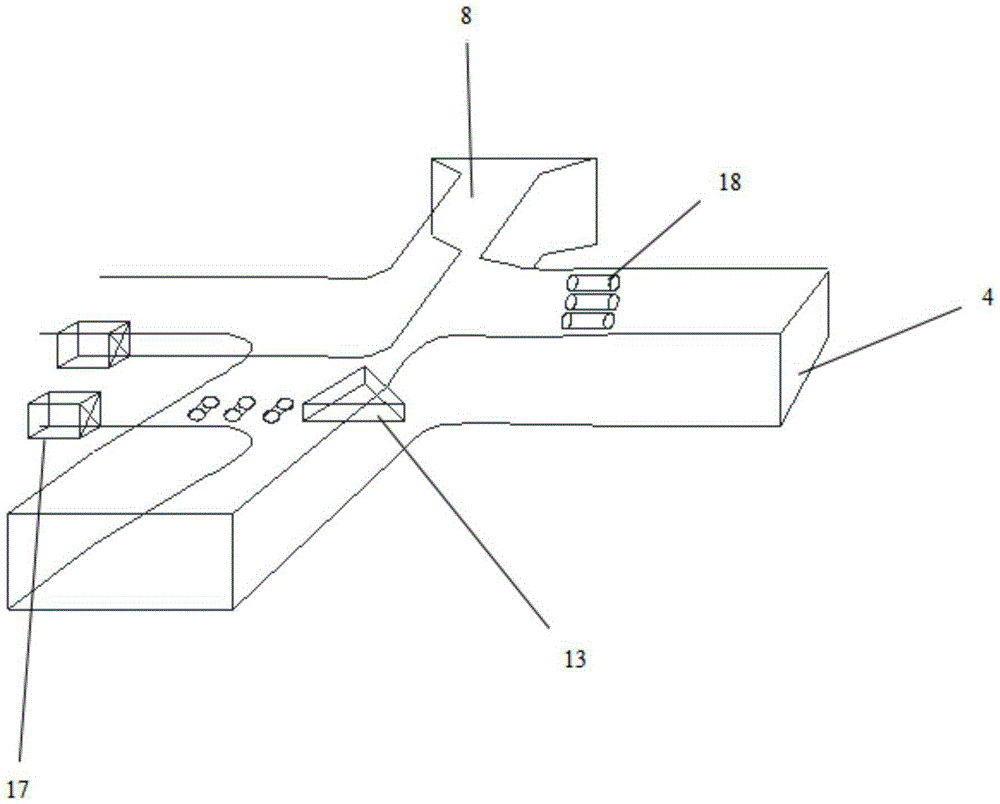

Fire ventilation and smoke exhaust experimental simulation device based on urban underground traffic linkage tunnel system

ActiveCN105243950AUnderstand and master the actual control effectBest way to openEducational modelsMeasurement deviceEngineering

The invention discloses a fire ventilation and smoke exhaust experimental simulation device based on an urban underground traffic linkage tunnel system. The fire ventilation and smoke exhaust experimental simulation device comprises a simulation fire source device, a tunnel longitudinal smoke exhaust control optimization device, a fire detection device, a multi-feature parameter measurement device and a tunnel slope adjustment device. The fire ventilation and smoke exhaust experimental simulation device consists of four single hole tunnels, the fire ventilation and smoke exhaust experimental simulation device is placed in directions of up-north, lower-south, left-west and right-east, and an underground parking garage is arranged in the center; the fire ventilation and smoke exhaust experimental simulation device is provided with an emergency escape door, model vehicles, an inlet jet blower, an outlet jet blower, axial flow fans, jet flow fans and smoke exhaust ports; a plurality of the axial flow fans and a plurality of the jet flow fans are respectively arranged on walls and upper ends of the tunnels of the simulation device; and the slope of the tunnel device can be adjusted. The fire ventilation and smoke exhaust experimental simulation device can simulate fire smoke characteristics and fire detection performance of the urban underground traffic linkage tunnels, and provides a research platform for acquiring reasonable fire smoke control schemes and smoke exhaust effect of the urban underground traffic linkage tunnels.

Owner:HEFEI UNIV OF TECH

Smokeless barbecue oven

ActiveCN104172942AEasy to useGreat tasteDomestic stoves or rangesLighting and heating apparatusEngineeringThermal efficiency

A smokeless barbecue oven comprises a base and a casing placed at the upper part of the base; the casing adopts a hollow structure; a bracket is placed at the upper part of the casing; a charcoal tray is place in the bracket; one or more fans are arranged on the base; one or more air passages corresponding to the fans are formed in the barbecue oven; the air passages are obliquely formed in a curved manner to form certain included angles with the barbecue oven in the vertical direction. Through the structural improvement, the problems in the prior art that the temperature of the barbecue oven in the working state is not even, the firepower is not adjustable and the heavy smoke is generated when the wood char is not burnt fully are solved effectively. The smokeless barbecue oven has the characteristics that the structure is simple and reasonable, the performance is reliable, the manufacturing cost is low, the firepower is even and adjustable, the operation is simple and convenient, the energy conservation and environmental protection are realized, the smokeless barbecue oven is clean and hygienic, the wood char is burnt fully and no smoke is generated and the heat efficiency is high and the like; the smokeless barbecue cuisine is realized for a user; as the major parts are made of stainless steel material, the durability is achieved and the practicability is high.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

Fired brick prepared from sludge

InactiveCN102491725AReduce contentReduce plasticitySolid waste managementFire brickProcess engineering

The invention relates to a fired brick prepared from sludge produced by a sewage treatment plant. The fired brick prepared from sludge comprises: by weight, 5 to 25 parts of sludge, 20 to 85 parts of shale and 0 to 70 parts of gangue, wherein the sludge is yellow shale. A preparation method of the fired brick prepared from sludge comprises the following steps of crushing the raw materials, mixing the crushed raw materials according to the ratios, adding water into the mixture, stirring, carrying out aging, drying and carrying out calcination. The preparation method utilizes sludge produced by a sewage treatment plant, changes the sludge into things of value, and realizes cyclic utilization of sludge, environment purification and resource saving. The fired brick prepared by the preparation method satisfies the national standard, and has good plasticity, high strength and a good color.

Owner:BAOFENG COUNTY RENHE NEW BUILDING MATERIAL

Coal fired boiler capable of controlling flue gas oxygen content

InactiveCN101545630AReduce flow rateImprove fresh air volumeSolid fuel combustionCombustion apparatusEngineeringHearth

The invention relates to a coal fired boiler capable of controlling flue gas oxygen content, which comprises a furnace body provided with a fire grate and a hearth, wherein the lower part of the fire grate is provided with a furnace bottom wind box; fuel gas in the hearth is exhausted from a chimney by a draught fan after passing through a venturi passage and a dust remover; an oxygen content analysis sensor is arranged between the hearth and the venturi passage and is connected with an oxygen content PLC; a fuel gas return pipe provided with a circulating fan is arranged between the draught fan and the chimney; the other end of the oxygen content analysis sensor is connected with an upper layer fuel gas return pipe with an upper layer fan and a wind box fuel gas return pipe respectively; the upper layer fuel gas return pipe is provided with an upper layer wind control valve, is controlled by the oxygen content PLC and is communicated with the hearth; the wind box fuel gas return pipe is provided with a wind box control valve and is controlled by a wind box temperature PLC; and the circulating fan and the upper layer fan are driven by an alternating current variable frequency speed control motor and are controlled by the wind box temperature PLC and the oxygen content PLC respectively. The coal fire boiler has the advantages that: firstly, the coal fire boiler can run under lower excess air and the hearth temperature is low during running so that the benefit of the boiler can be improved remarkably and the environmental pollution caused by the emission of NOx is reduced; and secondly, the coal fired boiler can adopt more extensive coal with low ash melting point to enlarge the serviceable range of the boiler and prolong the service life of the coal fired boiler.

Owner:NINGBO YINUO ENERGY TECH

Preprocessing method for incineration of industry peril waste

InactiveCN101255990AChange the status quo of incinerationBurn evenlyIncinerator apparatusPretreatment methodSlag

The invention discloses a preprocessing method for industrial dangerous waste incineration, wherein the industrial dangerous waste comprises liquid organic waste, slag waste, heating diluted waste, inorganic hard waste, soft waste, high-water pasty waste, and is preprocessed by one or more technique steps selected according to classification from digestion, neutralization, isolation, dying, thermal dissolving dilution, dip-washing and crushing. The invented method is provided with stability, a good processing effect and low processing cost.

Owner:刘正华

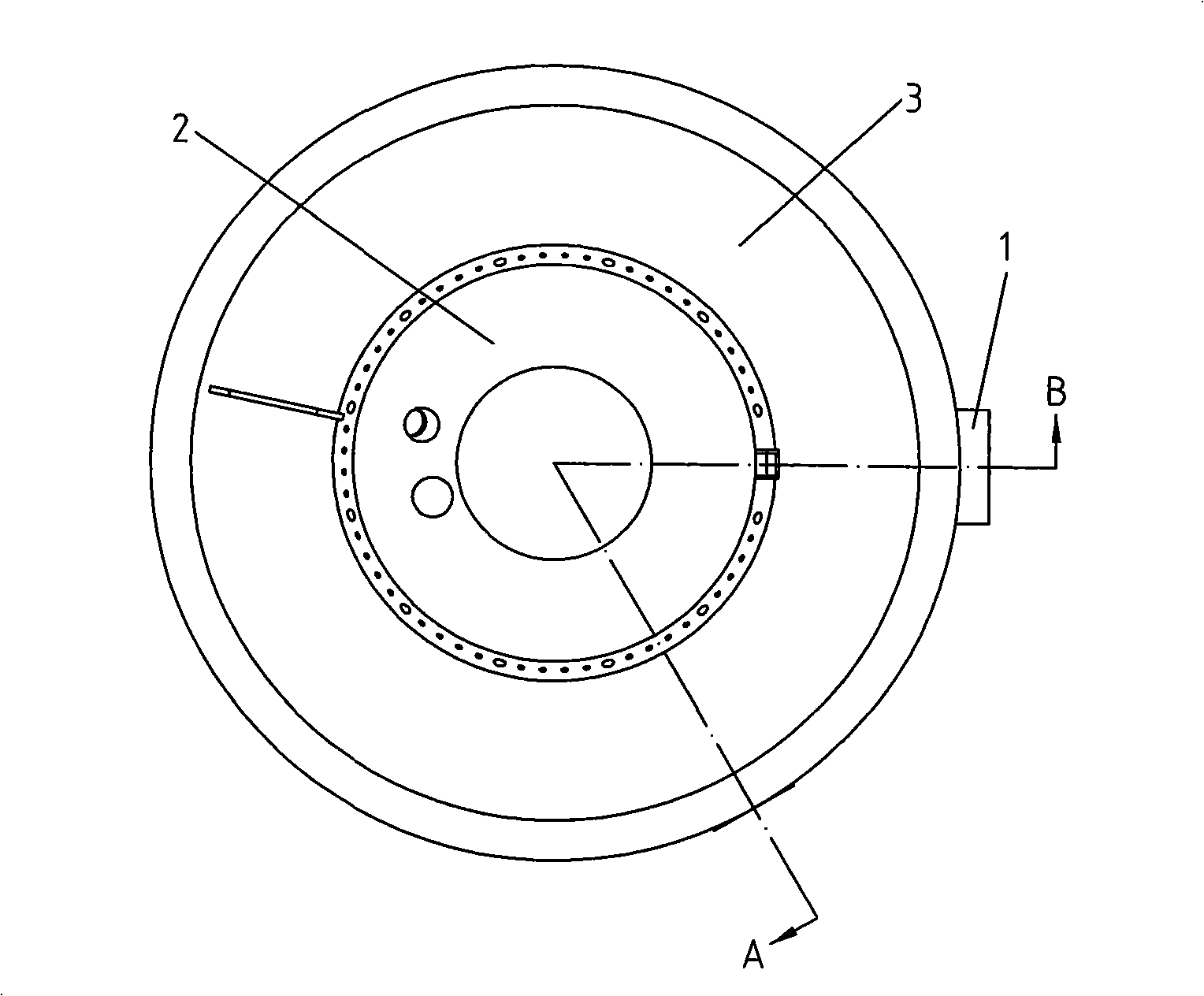

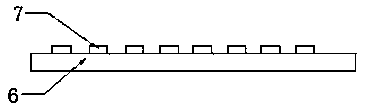

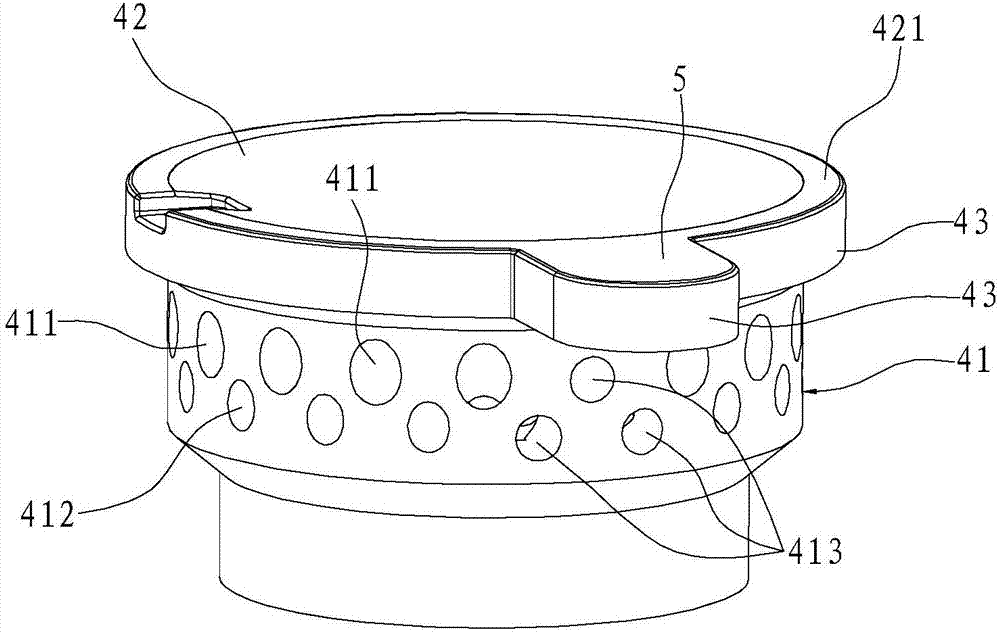

Inner ring fire cover of gas combustor

The invention relates to an inner ring fire cover of a gas combustor. The inner ring fire cover of the gas combustor comprises a fire cover body with an opened upper part, and a cover body covering amouth part of the fire cover body; an inner ring gas mixing cavity is formed between an inner peripheral surface of the fire cover body and the cover body; fire outlet holes are distributed in the peripheral direction of the side wall of the fire cover body; all the fire outlet holes communicate with the inner ring gas mixing cavity; the peripheral edge of the cover body is outwards projected on the fire cover body in the horizontal direction; and the bottom of at least part of the peripheral edge downwards extends to form a waterproof edge. Compared with the prior art, when overflowing liquidflows to the peripheral edge of the cover body, the overflowing liquid can flow and drip along with the waterproof edge, so that the overflowing liquid is prevented from flowing into the fire outletholes, the flame extinction is prevented, the overflowing liquid is prevented from blocking the fire outlet holes, and stable, efficient and uniform combustion is guaranteed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Ultra-low nitrogen gas burner

PendingCN109539253AStructural requirementsStable emissionsGaseous fuel burnerNitrogen oxidesFlue gas

The invention discloses an ultra-low nitrogen gas burner, which comprises a combustion cylinder, a shell and a motor, wherein the combustion cylinder is connected through a rotary positioning pin, thecombustion cylinder is a necking combustion cylinder, the front end of the combustion cylinder is provided with a flue gas internal circulation channel, the flue gas is sucked into the channel to bemixed with combustion-supporting air, a fuel pipe is arranged in the combustion cylinder along the central axis, a plurality of primary fuel spray guns and secondary fuel spray guns which are arrangedaround the circumference of the fuel pipe are also arranged in the combustion cylinder, the ring layer of the primary fuel spray guns is arranged outside the ring layer of the secondary fuel spray guns, and the primary fuel spray guns and the secondary fuel spray guns are arranged at intervals around the inner ring layer and the outer ring layer of the circumference of the fuel pipe, a combustionstabilizing cover is arranged between the fuel pipe and the combustion cylinder, a plurality of blades are arranged in the combustion stabilizing cover; and after passing through the combustion stabilizing cover, the combustion-supporting air is changed into rotational flow air from direct flow air. The ultra-low nitrogen gas burner can achieve balanced combustion, reduce the yield of nitrogen oxides and meet the requirements of energy conservation and environmental protection.

Owner:徐州科能燃烧控制科技有限公司

U-shaped internal-combustion rotating limekiln capable of recovering CO2

The invention belongs to the field of kiln, and provides a u-shaped internal-combustion rotating limekiln capable of recovering CO2. The limekiln is characterized in that the rotary kiln is horizontal, a u-shaped muffle heating furnace and a u-shaped calcining chamber are adjacently arranged inside the rotary kiln, blades are arranged on the inner wall of the muffle heating furnace and the inner wall of the calcining chamber, and a carbon dioxide collector is arranged through a limestone feeding inlet to communicate with the calcining chamber. Compared with present muffle rotary limekilns, the u-shaped internal-combustion rotating limekiln capable of recovering CO2 has significant advantages of reasonable structure, energy conservation, and emission reduction, and can recover and utilize materials and improve product quality.

Owner:赵光辉

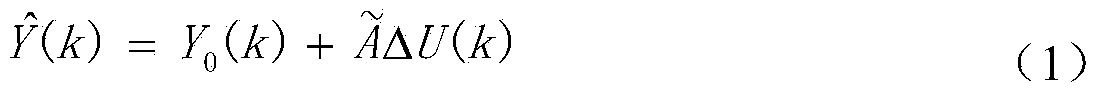

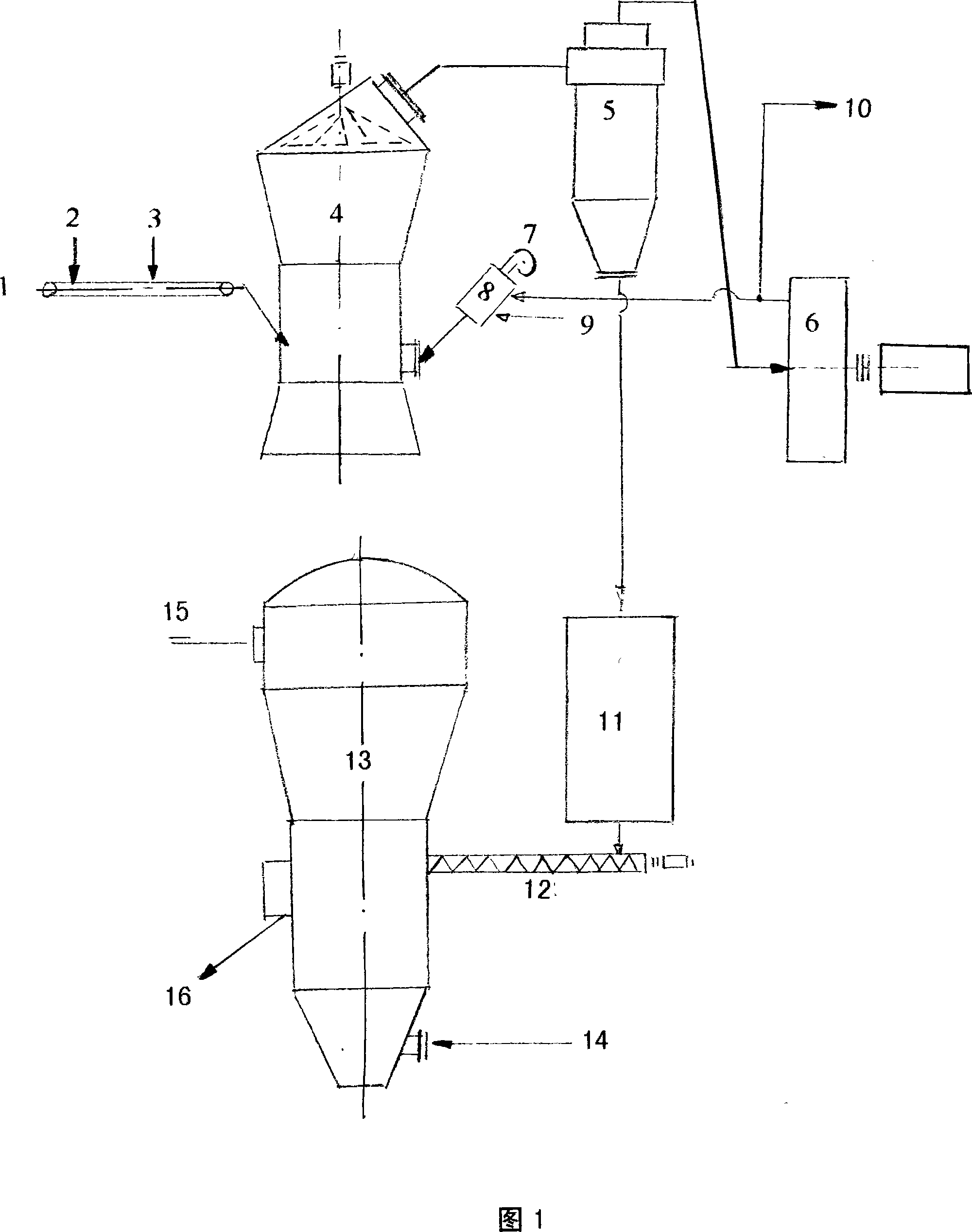

Multivariable cooperative control method for double-hearth circulating fluidized bed unit

ActiveCN104296131AOvercome the defect of difficult decoupling by adjusting separatelyImprove tracking performanceFluidized bed combustionApparatus for fluidised bed combustionCombustionFluidized bed

The invention discloses a multivariable cooperative control method for a double-hearth circulating fluidized bed unit, belongs to a multivariable system for constructing a circulating fluidized bedboiler and a turbo-set, and adopts a multivariable constraint DMC algorithm based on tracking error gradient. The adopted algorithm makes improvement on the traditional DMC algorithm, specifically, the tracking error gradient is introduced in an objective function, so that the tracking effect for the set value is improved, and constraint is attached to input and output, so that the controlled variable of a solution is within the physical scope. According to the invention, as the bed temperature and the bed pressure of hearths on left and right sides are considered simultaneously, during variable working condition regulation, the load tracking capacity is guaranteed, and the bed temperature and bed pressure of the two hearths are balanced and stable, and balanced combustion is realized.

Owner:SOUTHEAST UNIV +1

Process for dry type ore grinding employing vertical roller mill

The invention relates to a process of drying-grinding by using vertical roller mill, belonging to fluidizing roasting technique. It comprises following steps: coarse crushing, middle crushing coal and ore exploited from well, conveying crushed coal and ore to high-pressure vertical grinding roller through belt conveyer for drying grinding; the high-pressure vertical grinding roller drying coal and ore by using hot wind got from cyclic induced draft fan, the water content of dried ore is less than 2%; dried grinding coal and core in vertical grinding roller, classifying grinded material, discharging qualified material, feeding it into cyclone dust collector; returning unqualified material into roller for grinding; discharging cyanide leached hot calcine from discharge port of boiling calcining furnace. The invention is characterized by simplified process, saved area and investment, good coal distribution, homogenous burning, good baking effect in equilibrium temperature furnace, increased leaching ratio for goal materials and adequate utilization of excess heat resources.

Owner:CHANGCHUN GOLD RES INST

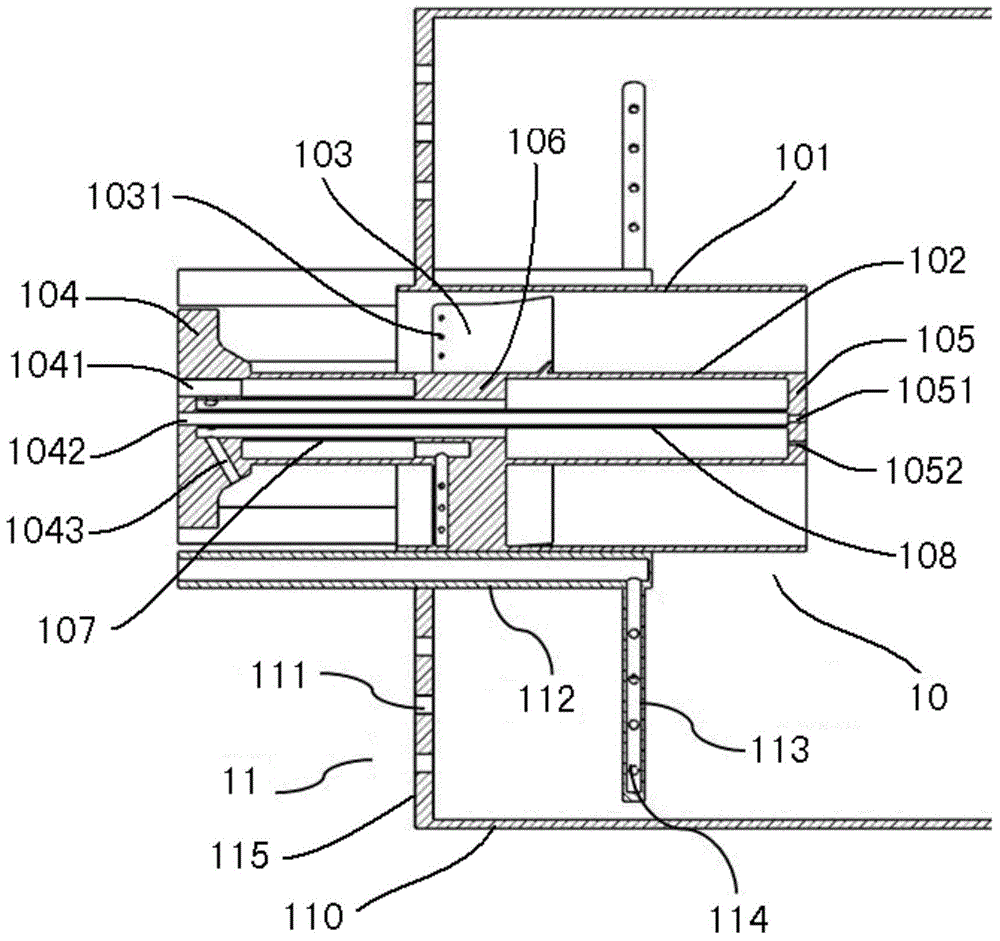

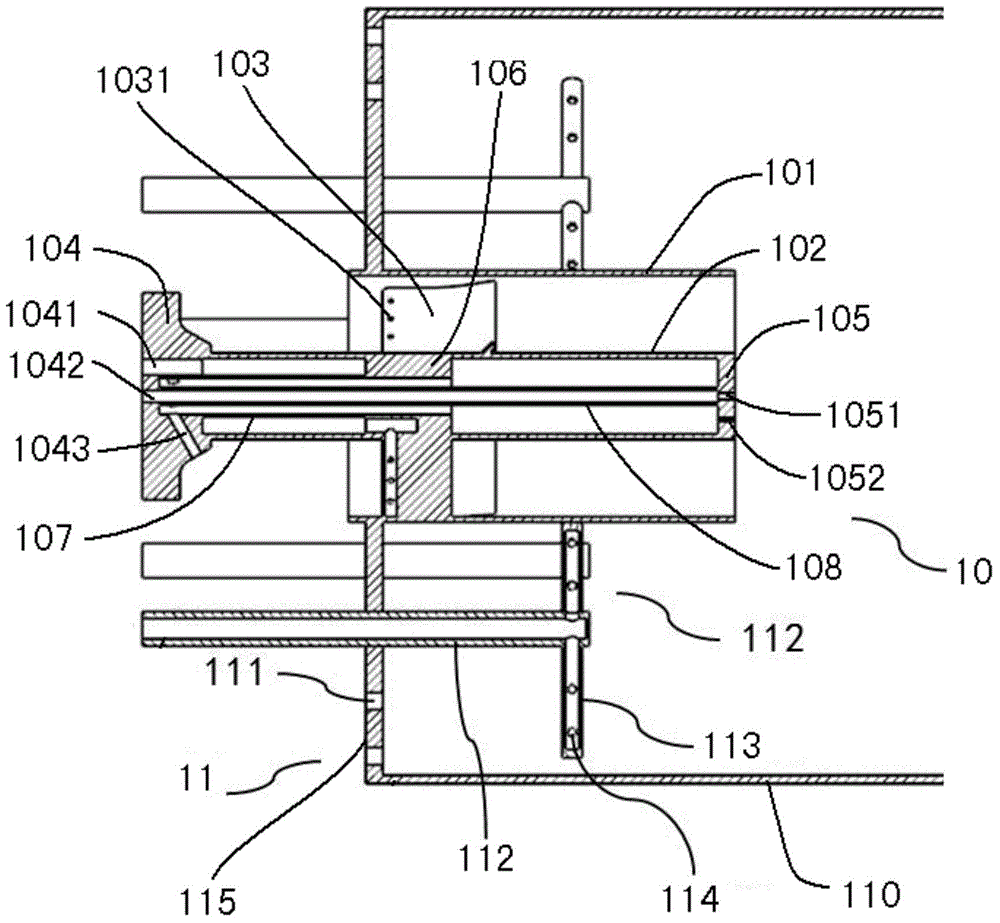

Unit modular large household refuse incineration furnace

The invention discloses a unit modular large household refuse incineration furnace and relates to household refuse incineration treatment equipment. The unit modular large household refuse incineration furnace comprises an incineration grate mechanism, air chambers and air supply systems, wherein the incineration grate mechanism comprises a drying section grate, a burning section grate, a burnout section grate and a rack; the drying section grate, the burning section grate and the burnout section grate respectively comprise two groups of grate units; each group of grate units comprises a spindle, a partition plate, a front wall plate, a rear wall plate and a grate with stepped drop; each grate comprises two groups of edge modules and at least one group of middle modules; each edge module and each middle module respectively consist of a plurality of grate sheets; each group of edge modules is fixed on the corresponding rack through a sidewall protection plate device; each air chamber is formed below each middle module and each edge module; an air inlet is formed at the lower end of each air chamber and connected with the corresponding air supply system; and each air supply system comprises a drying section air supply system, a burning section air supply system and a burnout section air supply system. The unit modular large household refuse incineration furnace is stable in operation, low in energy consumption and long in service life.

Owner:江苏楹能环保科技发展有限公司

Pre-mixing and pre-evaporation low-pollution combustion chamber with double-oil-way four-rotational-flow pre-film type main combustion stage

ActiveCN103697500AEasy to adjustReduce pollutionContinuous combustion chamberCombustion chamberEvaporation

The invention relates to a pre-mixing and pre-evaporation low-pollution combustion chamber with a double-oil-way four-rotational-flow pre-film type main combustion stage. The combustion chamber is of a single-ring-cavity structure, and adopts a central staged combustion mode, wherein the head of the combustion chamber is divided into a preliminary combustion stage and a main combustion stage, the preliminary combustion stage adopts a mode of combining diffusive combustion with rotational-flow pre-mixing combustion, and is capable of reducing pollutant discharge under low-flow working conditions while ensuring combustion stability; the main combustion stage adopts a mode of pre-mixing and pre-evaporation combustion, and is capable of effectively reducing combustion pollutants. The oil way of the main combustion stage is divided into two stages, fuel oil in each stage forms an oil film on a pre-film plate, and the oil films are atomized, evaporated and blended under the action of two rotational flows to form a uniform oil-gas mixture, thus facilitating reduction for the combustion pollutants; due to the double-oil-way design, the one-stage working of the main combustion stage under low-flow and medium-flow working conditions such as entrance, and the two-stage working of the main combustion stage under high-flow working conditions such as take-off can be met, thus facilitating the oil-gas matching of the combustion chamber under different working conditions, and further reducing the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aeroengine.

Owner:BEIHANG UNIV +1

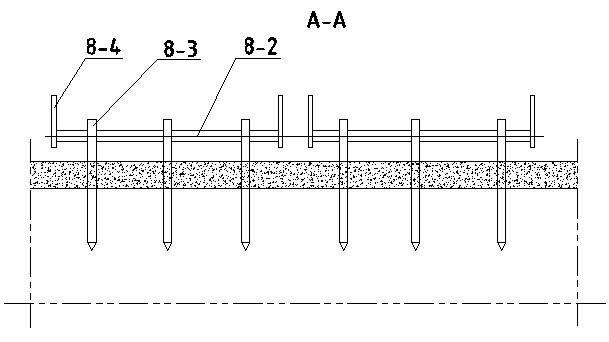

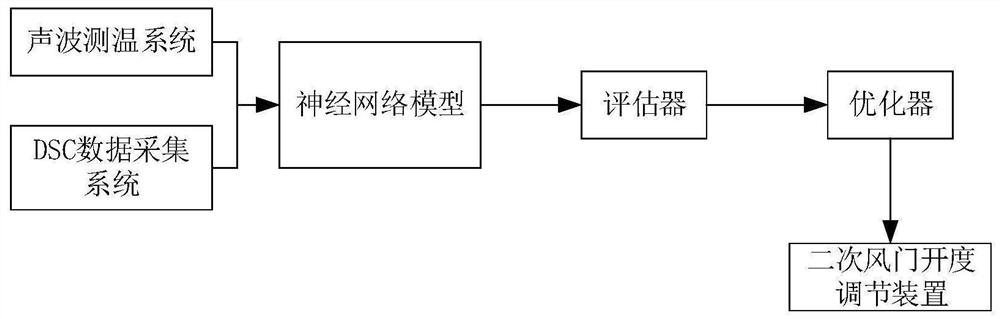

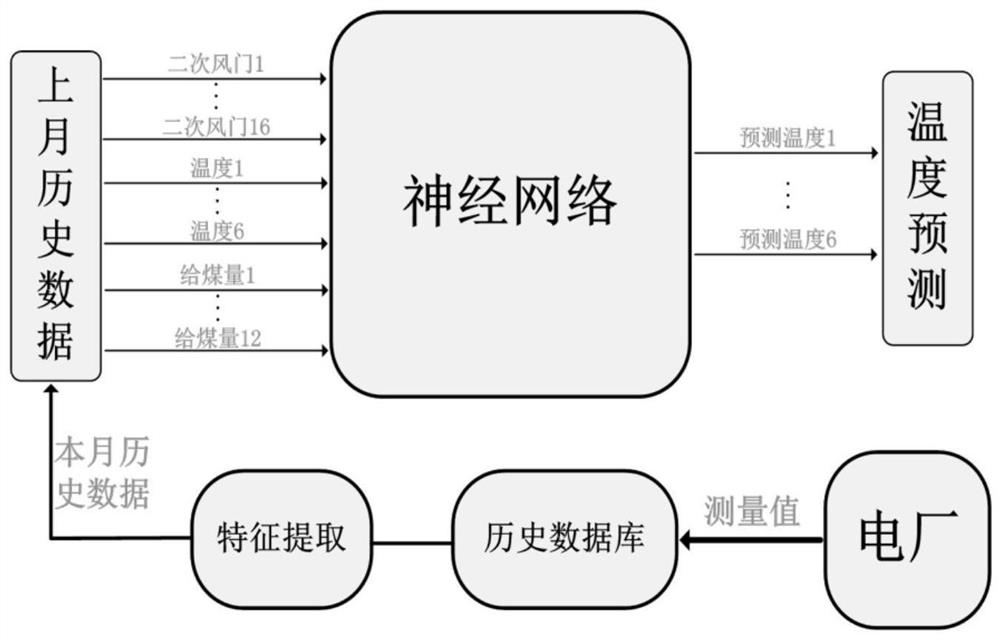

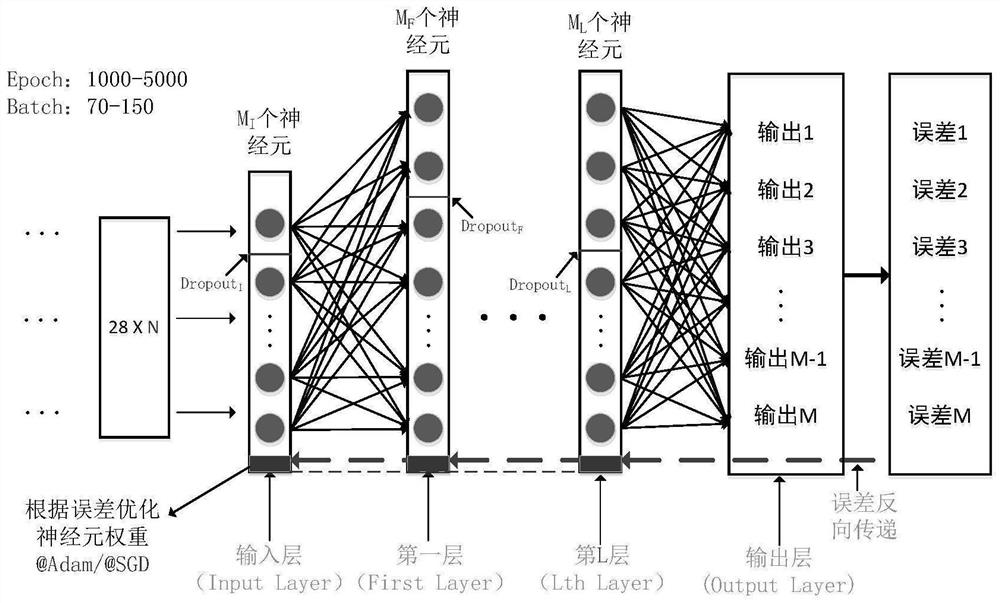

Combustion control system and control method for power plant

ActiveCN111829003AImprove generalization abilityReduce mistakesAir supply regulationTotal factory controlData acquisitionNetwork model

The invention discloses a combustion control system for a power plant. The combustion control system comprises a data acquisition part, a control part and an execution part. The data acquisition partcomprises a sound wave temperature measurement system and a DCS data acquisition system. The control part comprises a neural network model module, an evaluator and an optimizer. The execution part comprises a secondary air door opening degree adjusting device. The invention further discloses a combustion control method for the power plant. According to the system and the method, a neural network is adopted to construct a model, and extremely high universality and transportability are achieved. According to the system and the method, stable, long-term and manual intervention-free combustion canbe achieved for the power plant, and the purposes of reducing coal consumption and NOx and CO emissions as much as possible, reducing the combustion temperature of a hearth, uniform combusting and reducing the smoke temperature under the condition of a given load can be achieved.

Owner:嘉兴汇智诚电子科技有限公司

Distributed-flame combustion chamber head structure

ActiveCN104566470AReduce cooling effectReduce consumptionContinuous combustion chamberNitrogen oxidesGeneration rate

The invention relates to the technical field of gas turbine combustion chambers, and discloses a distributed-flame combustion chamber head structure. The distributed-flame combustion chamber head structure comprises a main spray nozzle, a central on-duty spray nozzle, a combustion chamber outer wall and a combustion end plate, wherein the main spray nozzle comprises a plurality of main combustion pipes; the combustion end plate is fixed at the back end of the combustion chamber outer wall; the central on-duty spray nozzle is arranged in the center of the combustion end plate; the main combustion pipes pass through the combustion end plate, extend into the combustion chamber outer wall, and are arranged around the outer side of the central on-duty spray nozzle; at least one radial combustion pipe is arranged on a part, which extends into the combustion chamber outer wall, of each main combustion pipe; the radial combustion pipes are positioned on the upstream of the front end of the central on-duty spray nozzle; each radial combustion pipe is provided with a main fuel spray nozzle; the combustion end plate is provided with a plurality of main air inlets. Distributed flame is established, so that defects caused by non-uniform heat release are overcome, and the generation rate of nitrogen oxides is restrained.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

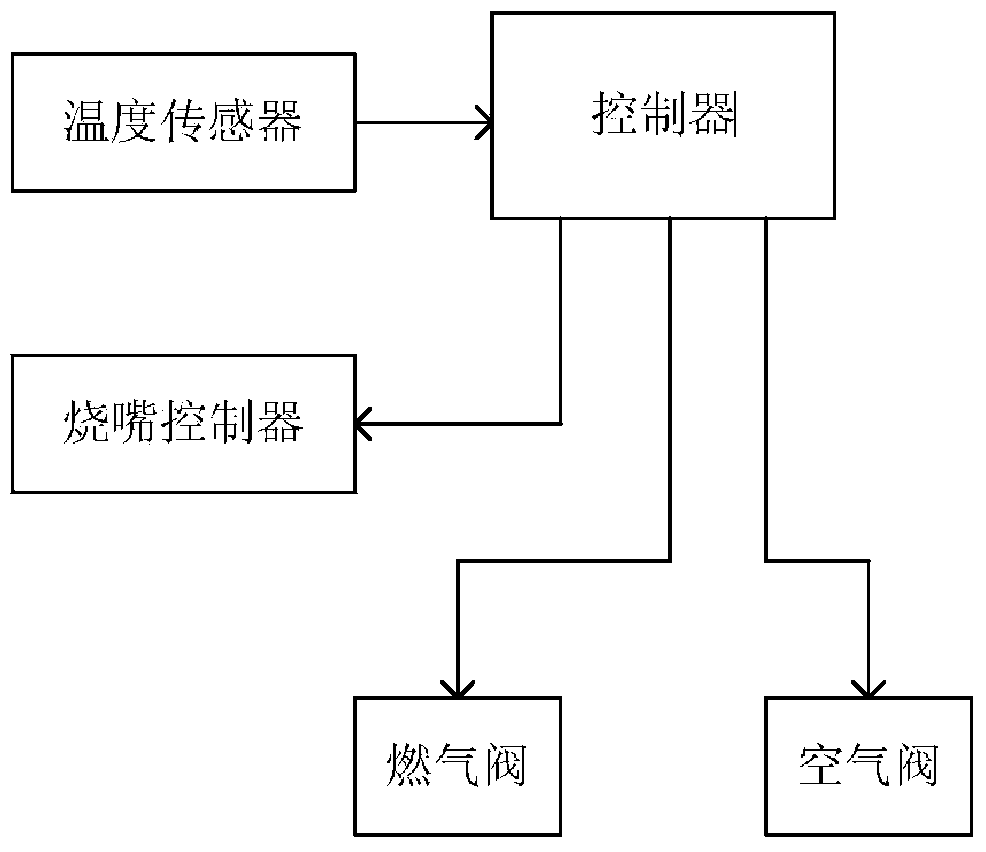

Method for controlling pulse combustion of multiple burners of fuel gas furnace

The invention provides a method for controlling pulse combustion of multiple burners of a fuel gas furnace. According to the method, the differential value between a set temperature and the actual temperature inside the fuel gas furnace is calculated through a controller, a temperature difference signal is calculated through a PID, is converted into a multi-time-sequence variable pulse signal by combining the maximum work period of working of the burners, and is output as a control signal, the multi-time-sequence variable pulse signal controls the opening and closing states of an air valve and a fuel gas valve according to different heating modes and controls the work period of the burner controller. The method enables the burners to burn according to a certain rule, thereby effectively controlling the combustion temperature, guaranteeing temperature uniformity inside the fuel gas furnace and improving combustion efficiency.

Owner:JIANGNAN UNIV

Petal-shaped staged combustion gas low-nitrogen combustor

The invention discloses a petal-shaped staged combustion gas low-nitrogen combustor. The combustor comprises a fuel gas collection tank, a combustion stabilizing disc, a nozzle and a combustion supporting channel; the nozzle is connected to one end of the fuel gas collection tank, and the combustion supporting channel extends to the tail end of the nozzle from an inlet of the fuel gas collection tank; the combustion stabilizing disc is arranged in the nozzle, and a gas chamber is arranged between the combustion stabilizing disc and the inner wall of the nozzle; the air chamber is connected to the fuel gas collection tank through a plurality of fuel conveying pipes, and a plurality of sector-shaped grooves which are evenly formed in the circumferential direction of the nozzle are formed in the tail end of the nozzle; a spray gun is formed in the position, in the circumferential direction of each sector-shaped groove, in each sector-shaped groove, and is connected with the gas chamber to obtain gas; and the combustion stabilizing disc comprises a center channel and a bending blade channel. The low-nitrogen combustor achieves staged combustion, nitric oxides are reduced, the combustion efficiency is not reduced, the current environment-friendly requirement is met, and meanwhile emissions of the nitric oxides are reduced to a greater extent.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD +1

Blowing burner and gas stove

ActiveCN104791793ABurn fullyAvoid ignition failureDomestic stoves or rangesGaseous fuel burnerGas stovesFuel gas

The invention provides a blowing burner and a gas stove. The blowing burner comprises a burner assembly and a blower assembly, wherein the burner assembly comprises burner heads and gas distribution discs, the gas distribution discs are located above the burner heads and connected with the burner heads, each gas distribution disc is provided with multiple gas distribution channels, the cross sectional areas of at least two gas distribution channels of the multiple gas distribution channels are not the same, and the blower assembly is connected with the burner heads and used for leading air into the burner heads. According to the technical scheme, the gas flow of all the channels can be the same by changing the cross sectional areas of the channels on the gas distribution discs, therefore, gas can be fully burnt, and even heating can be achieved; meanwhile, air doors are arranged between the blower assembly and the burner heads, and the air which enters the burner heads can be accurately controlled, so that the proportion of the gas amount and the air amount of the burner heads can be moderate, and the sufficient burning of the gas can be guaranteed; in addition, the air amount in a blower can be controlled by using a stepless speed regulation device, and therefore the air amount can be changed continuously and evenly.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

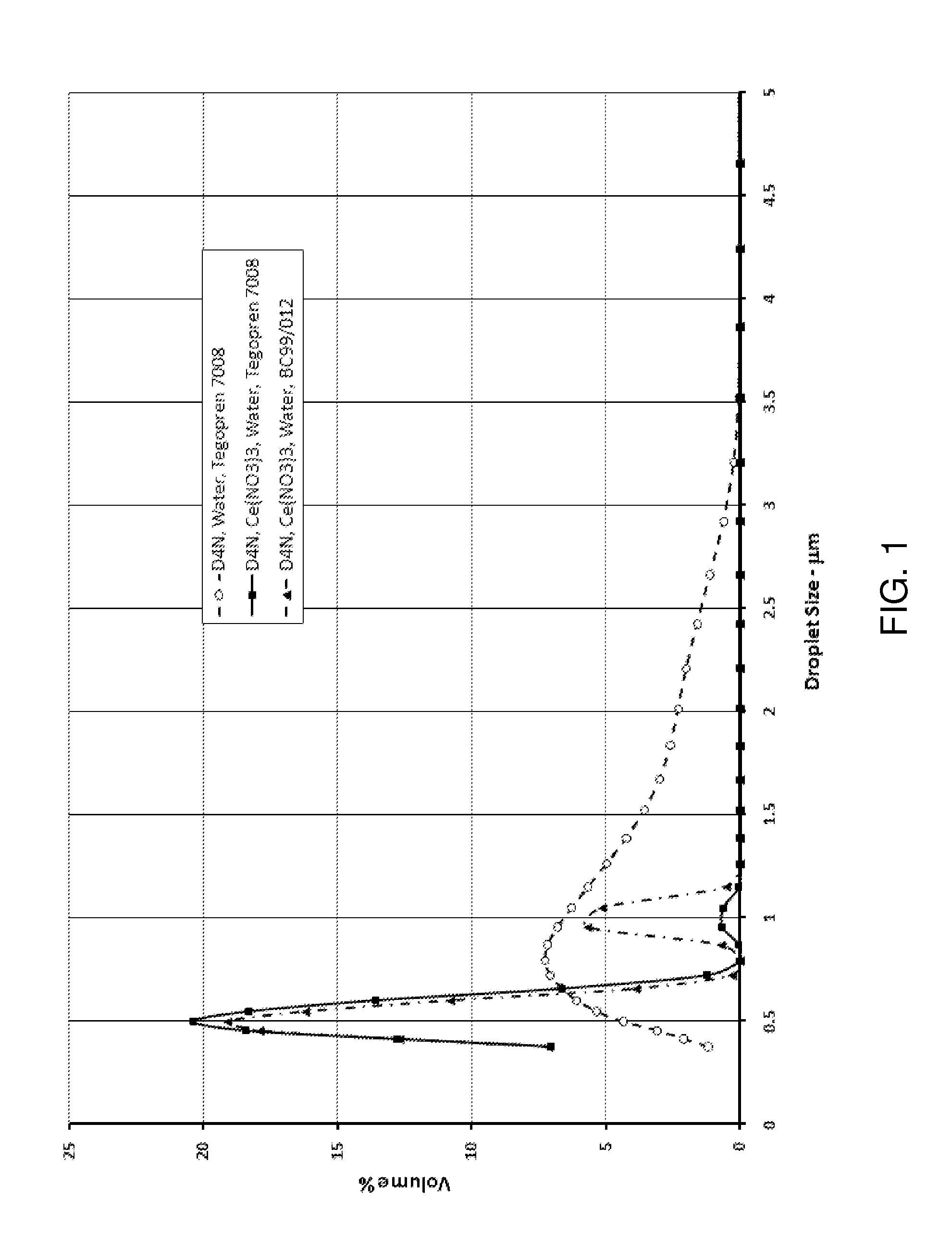

Manufacture of synthetic silica glass

InactiveUS20130045854A1Reduce nitrogen oxide emissionsLower Level RequirementsSilicaGlass shaping apparatusEmulsionSilicon dioxide

Methods are described for manufacturing silica-based glass, in which silica precursor material is supplied to a synthesis flame in the form of an emulsion. The methods involve the steps of: forming an emulsion of an aqueous phase in a non-aqueous liquid silica precursor material; supplying the emulsion as a spray of droplets into a synthesis flame, whereby the precursor material is converted in the flame into a silica-containing soot; and collecting the soot on a substrate, either as a porous soot body for subsequent consolidation to glass or directly as a substantially pore-free glass.

Owner:HERAEUS QUARTZ UK

Modified grate furnace waste incineration device

ActiveCN105351944AAdjust the temperature reasonablyReasonable adjustment of oxygen contentIncinerator apparatusThermal energyFlue gas

The invention discloses a modified grate furnace waste incineration device. An air vent is formed in the rear arch of a hearth of a waste incineration furnace, is connected with the air chamber of a fire grate at the drying section of an incinerator through a pipeline, and is also connected with an outlet flue of the hearth of the incinerator through the pipeline; the coal economizer outlet of a waste heat boiler joins the pipeline connected with the air vent of the rear arch of the hearth through the pipeline; a circulating fan is further arranged on the pipeline; an air conditioning bypass is arranged at the inlet of the circulating fan. According to the invention, partial hot smoke containing certain content of oxygen at the tail part of the hearth and the partial hot smoke at the outlet of the coal economizer are recycled, so that drying and preheating of waste and disturbance and combustion support of smoke are met, the fed combustion air amount and the total smoke amount can be effectively reduced, the oxygen content of a combustion area is reasonably controlled, improvement of the waste combustion quality is facilitated, improvement of the utilization efficiency of combustion thermal energy is also facilitated, and the content of pollutants in the discharged flue gas is decreased.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Fuel additive

InactiveCN101353602APromote catalysisEasy to crackLiquid carbonaceous fuelsFuel additivesNitrobenzeneOil additive

The invention relates to a fuel oil additive, in particular to a fuel oil additive which can be added into gasoline and diesel. The fuel oil additive consists of the following raw materials by weight percentage: 2 to 3 percent of octanol, 10 to 13 percent of isopropyl alcohol, 1.5 to 3.5 percent of nitrobenzene, 1.5 to 3.5 percent of methenamine, 0.3 to 0.5 percent of ferrocene, and the rest is methyl alcohol. The fuel oil additive of the invention adopts the liquid phase catalysis technology to promote the catalysis and cracking of the fuel oil, and enhance the physical activity, thereby causing the combustion to be more full, even and thorough. The fuel oil additive of the invention has the following functions of: 1. saving the fuel oil; 2. eliminating carbon in exhaust gases; and 3. reducing exhaust gas discharge to satisfy the European III standard.

Owner:施孝豪

Continuous ultrafine glass fibre and centrifugation manufacturing method thereof

The invention discloses continuous ultrafine glass fibre. The glass fibre comprises following components by weight: 60-67 parts of SiO2, 2-6 parts of Al2O3, 3-7 parts of CaO, 1.5-4.5 parts of MgO, 0.1-2 parts of K2O, 14-18 parts of Na2O and 3-8 parts of B2O3. The diameter of the glass fibre is 1-5 [mu]m and the length of the glass fiber is 150-50000 mm. A method of manufacturing the continuous ultrafine glass fibre includes: selecting a certain amount of borax, quartz sand, potassium feldspar powder, albite powder, dolomite, sodium carbonate and calcite, mixing and smelting to obtain a glass liquid; feeding the glass liquid into a centrifugation disk having a revolving speed of 3800-4500 r / min and centrifuging to form glass trickle; and finally jetting and blowing to stretch the glass trickle by utilization of high-temperature fuel gas to form a finished product of the glass fibre. The diameter of the glass fibre is 1-5 [mu]m and the length of the glass fiber is 150-50000 mm. The glass fiber is high in strength.

Owner:宣汉正原微玻纤有限公司

Garbage incinerator and incineration method

InactiveCN104566388ABurn evenlyFully burnt outIndirect carbon-dioxide mitigationAir/fuel supply for combustionReduction rateLitter

The invention relates to a garbage incinerator and an incineration method. The garbage incinerator comprises a plurality of grate plates and further comprises a plurality of independent air chambers located below the grate plates, each independent air chamber is provided with a primary air inlet pipe and an oxygen inlet pipe, and each oxygen inlet pipe is further provided with an electric air door for controlling oxygen inlet. Through regulating an independent oxygen supply unit, garbage can be uniformly burnt on the grate, the garbage is burnt out completely, and accordingly the garbage heat energy is completely used, the thermal reduction rate is lowered, and the grate plate protection is realized.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA +2

Vertical coke oven

InactiveCN1490379ACompact and reasonable structureSmall footprintVertical chamber coke ovensEnergy inputCombustion chamberMarine engineering

A vertical mechanical coke oven is composed of upper and lower layers. Said upper layer is composed of pairs of carbonizing chamber and combustion chamber, air preheating chamber, and flue. Said lower layer has the water sealing trough, delivering mechanism and water. It features that the coke is discharged from carbonizing, chambers into water-sealing trough for quenching it, greatly, lowering the environmental pollution.

Owner:李成福 +3

Burning system for directly burning low-volatilization powder carbocoal by using high-temperature air

InactiveCN101666490AEmission reductionPromote fireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterCombustion system

The invention discloses a burning system for directly burning low-volatilization powder carbocoal by using high-temperature air, relating to a burning system for directly burning low-volatilization powder carbocoal, and solving the problems of low burning efficiency and high pollutant discharge in the prior burning device for the low-volatilization powder carbocoal. A hearth is communicated with ahigh-temperature air pre-heating device through a high-temperature flue gas channel; two ends of a flue gas residual heat recycling device are communicated with the flue gas flow parts of the high-temperature air pre-heating device and a low-temperature air pre-heater through a low-temperature flue gas channel; an outlet flue of the low-temperature air pre-heater is communicated with a gas mixerthrough a tail flue gas channel; the gas mixer is communicated with an air flow part of the low-temperature air pre-heater through an inlet air flow channel; the air flow part of the low-temperature air pre-heater is communicated with the high-temperature air pre-heating device through a secondary air flow channel; and the high-temperature air pre-heating device is communicated with a rotary flowburner through a primary air flow channel. The invention has advantages of high burning efficiency and low pollutant discharge rate.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

Thermal desorption device for soil restoration and method thereof

ActiveCN108746177AHeating is smooth and evenEasy temperature controlContaminated soil reclamationTemperature controlCombustion

The invention discloses a thermal desorption device for soil restoration. The thermal desorption device comprises a hot oil heating furnace unit and a thermal desorption unit. A heat absorption spiralpipe is arranged in the hot oil heating furnace unit. A heat release spiral pipe is arranged in the thermal desorption unit. The hot oil outlet end of the heat absorption spiral pipe is connected with the hot oil inlet end of the heat release spiral pipe through a first oil guide pipe in a communicating mode. The cold oil outlet end of the heat release spiral pipe is connected with the oil inletend of the heat absorption spiral pipe through a second oil guide pipe in a communicating mode. A circulation pump is arranged on the second oil guide pipe. The thermal desorption device is simple instructure, combustion in a furnace cavity is even, meanwhile, the heat release spiral pipe is adopted for heating a soil source stably and evenly, temperature control is convenient, and the mode thatflames are directly adopted for intense high-temperature heating on the soil source in the soil thermal desorption cavity is avoided.

Owner:广东禹航环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com