Distributed-flame combustion chamber head structure

A combustion chamber, distributed technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of uneven heat release, increase cooling consumption, and heat release concentration, achieve a wide range of fuel adaptation, suppress heat Sound oscillations, effects that dampen spawn rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

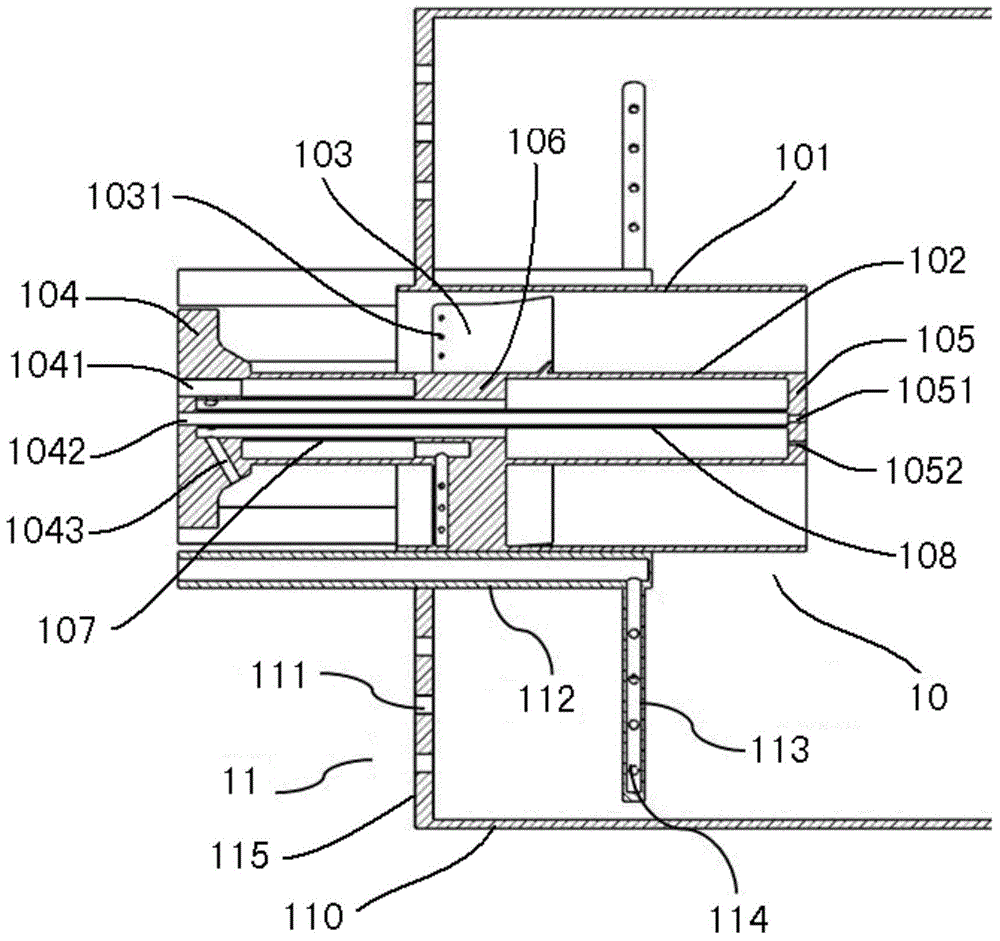

[0025] refer to figure 1 As shown, the combustion chamber head structure of the distributed flame of the present invention includes: a main nozzle 11 , a central duty nozzle 10 , a combustion outer wall 110 and a combustion end plate 115 , and the main nozzle 11 includes a plurality of main fuel pipes 112 . The combustion end plate 115 is fixed on the rear end of the combustion outer wall 110, and the combustion outer wall 110 and the combustion end plate 115 form a cylindrical structure with an open front end. The central duty nozzle 10 is arranged in the center of the combustion end plate 115 . One end of a plurality of main fuel pipes 112 is connected to the fuel gas passage hole on the fuel end plate 115, and the other end passes through the combustion end plate 115, extends into the outer wall of the combustion chamber 110, and is evenly arranged on the center duty nozzle 10. Around the outside, the portion of each main fuel pipe 112 protruding into the outer wall 110 of...

Embodiment 2

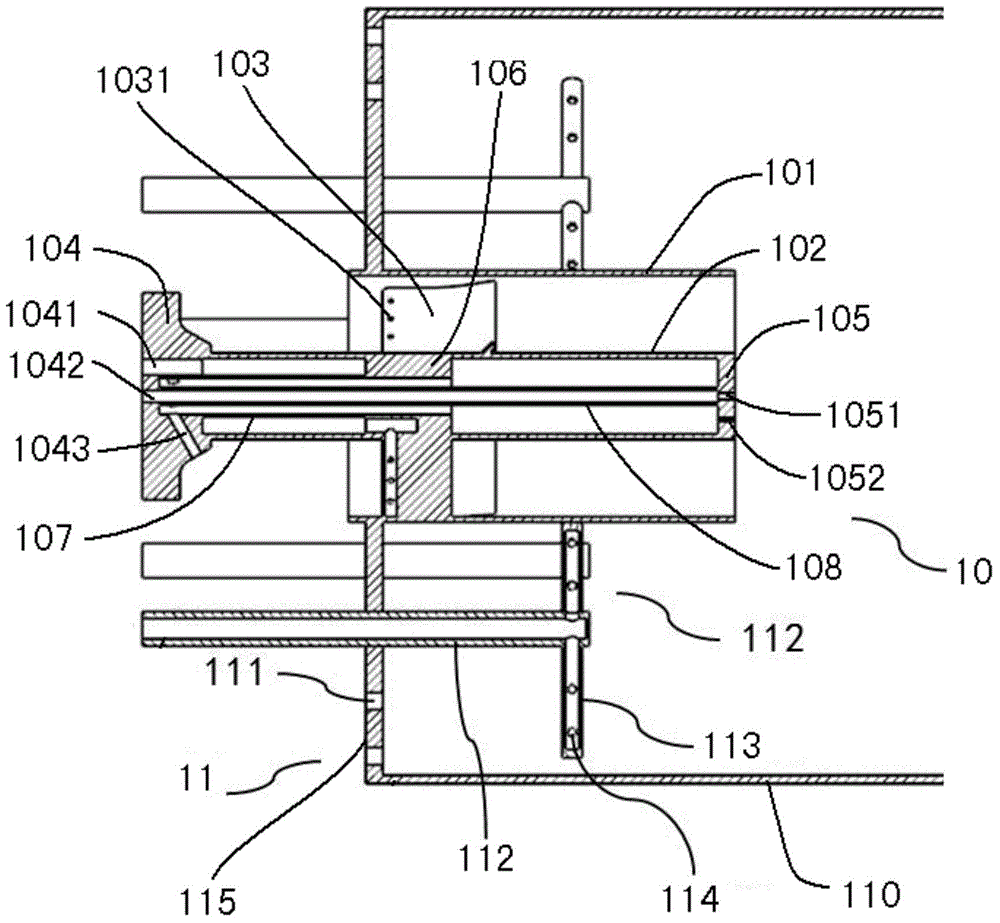

[0034] This embodiment is basically the same as Embodiment 1, the difference is: refer to figure 2 As shown, in this embodiment, there are two radial fuel pipes 113 on each main fuel pipe 112, and the two radial fuel pipes 113 are located on the same radial section. In addition, three or more radial fuel pipes 113 may be used.

[0035] The working process of the present invention is as follows: part of the air fuel enters the central duty nozzle 10 to form a central diffusion flame and a central premixed flame to provide ignition energy for the main nozzle fuel-air mixture, and part of the air enters the outer wall of the combustion chamber 110 at a high speed from the main air inlet 111 , forming a high-speed jet air, part of the fuel enters the main fuel pipe 112 from the end cover, and is ejected from the main fuel injection hole 114 of the radial fuel pipe 113, and is mixed with the high-speed jet air to form a high-speed jet mixture, which is discharged downstream of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com