Cooling Storage Cabinet and Method of Operating Thereof

a technology of cooling storage cabinet and cooling chamber, which is applied in the direction of domestic cooling apparatus, static/dynamic balance measurement, instruments, etc., can solve the problems of refrigerating compartment cooling, and achieve the effect of preventing local overcooling, reducing cooling capacity, and reducing rotational speed of inverter compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

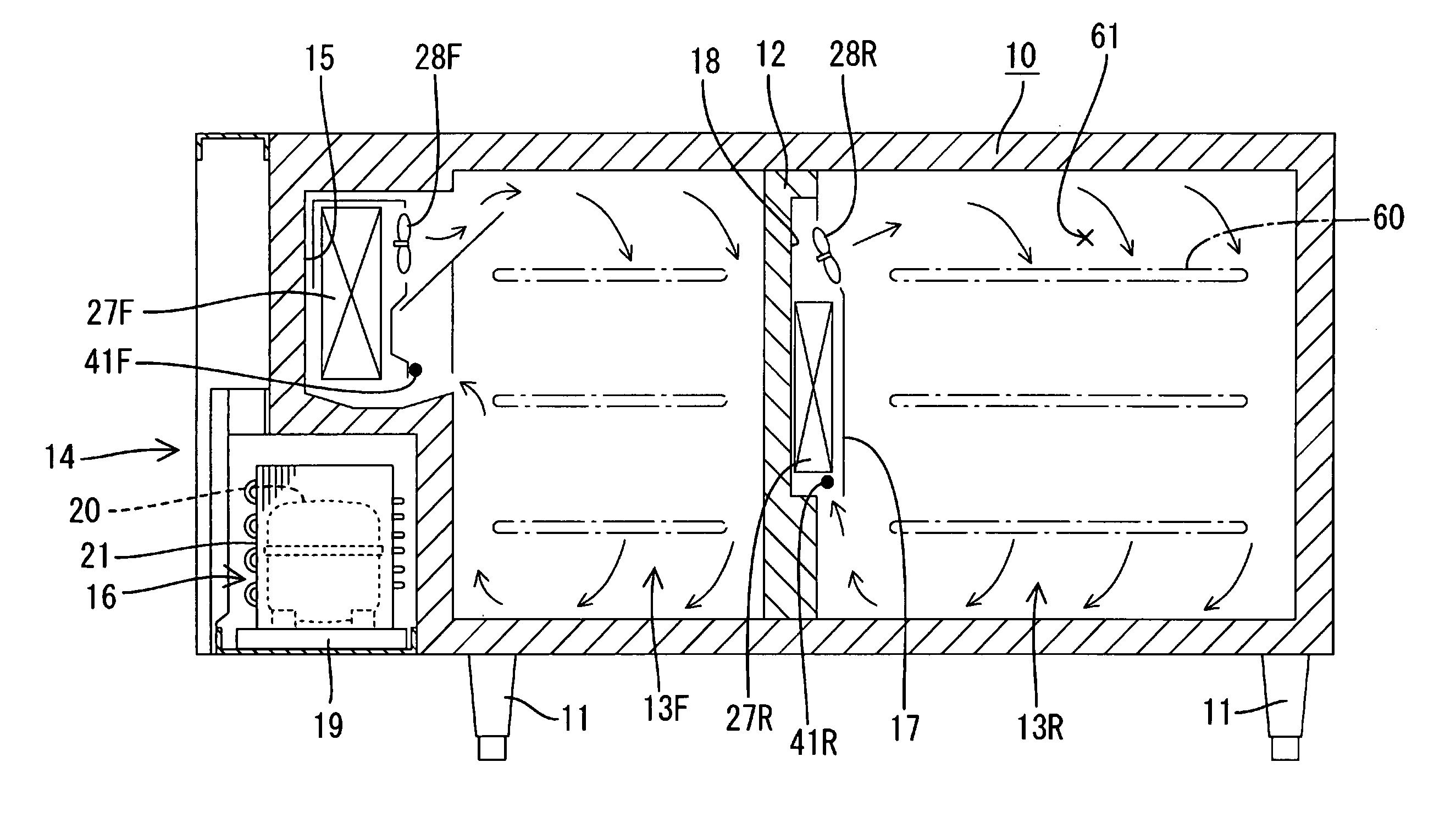

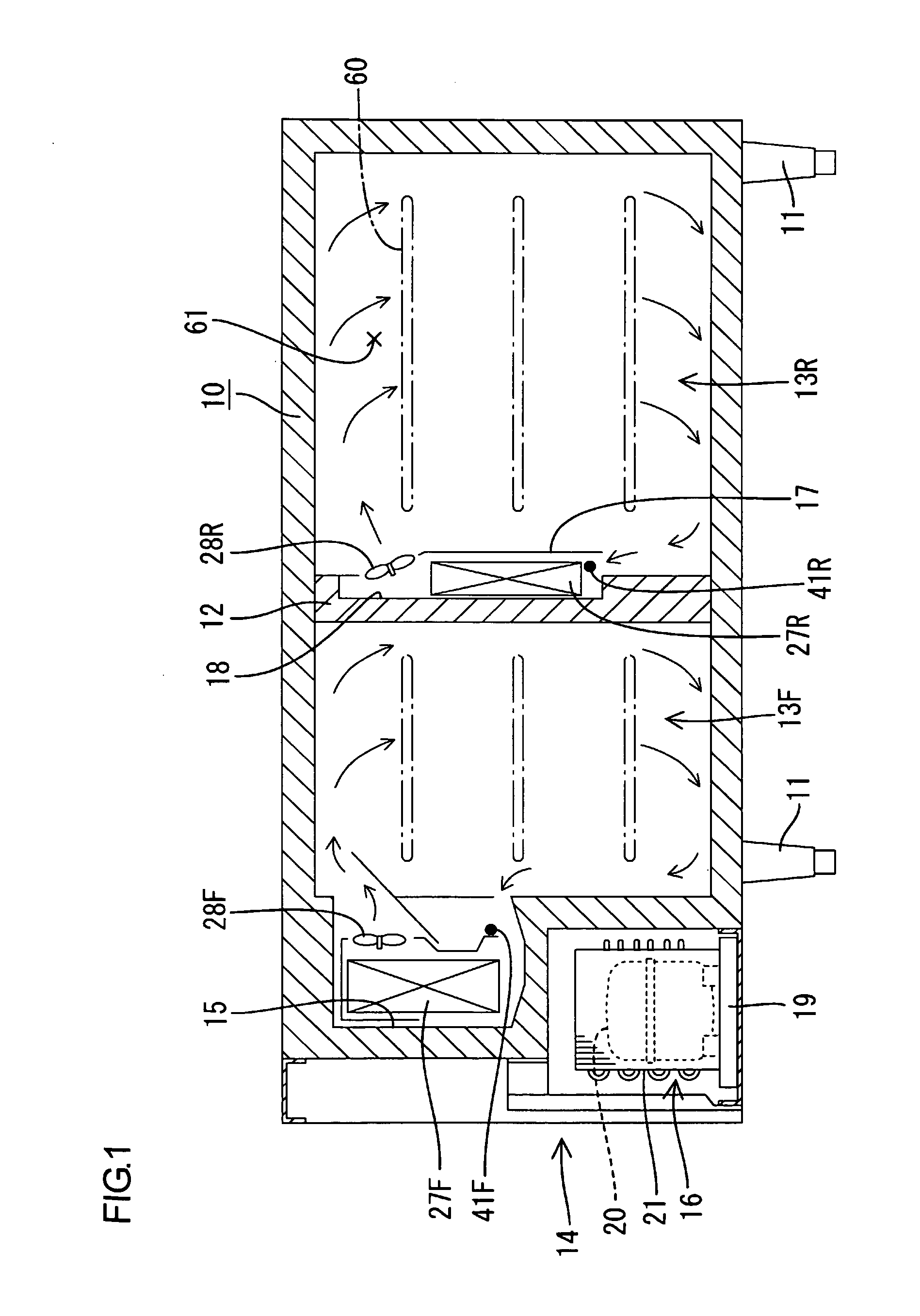

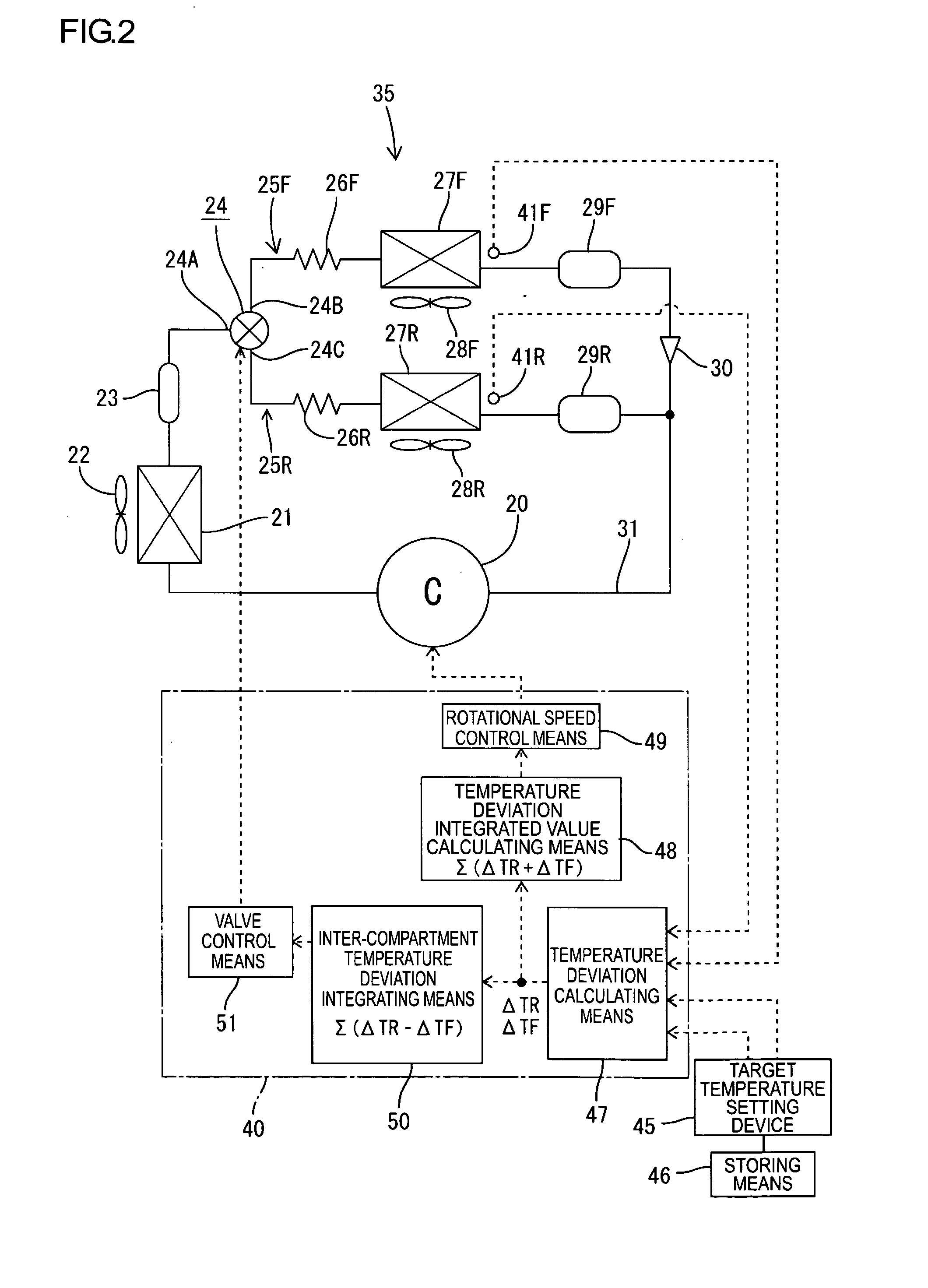

[0031]An embodiment in accordance with the present invention will hereinafter be explained with reference to FIGS. 1 through 11. Illustrated in this embodiment is a freezer-refrigerator of horizontal type (table type) for commercial use.

[0032]First, a general structure will be explained with reference to FIG. 1. Reference symbol 10 indicates a storage cabinet body, which is configured by a horizontally longer heat-insulating box body. The heat-insulating box body has an opening in front thereof. The storage cabinet body 10 is supported by legs 11. The legs 11 are provided in four corners on a bottom face of the storage cabinet body 10. The inside of the storage cabinet body 10 is separated into right and left sides by an additional heat-insulating partition wall 12. The left and relatively narrower side is defined as a freezing compartment 13F. The freezing compartment 13F corresponds to a first storage compartment. The right and wider side is defined as a refrigerating compartment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com